Coal seam gas adsorption and desorption deformation and deformation force dynamic test system

A technology of dynamic testing and coal seam gas, which is applied in the direction of measuring devices and instruments, can solve the problems of inability to effectively monitor acoustic emission signals, inability to test internal damage evolution laws, adsorption, desorption deformation, or single influencing factors of deformation force, etc., to achieve Simple structure, good sealing performance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

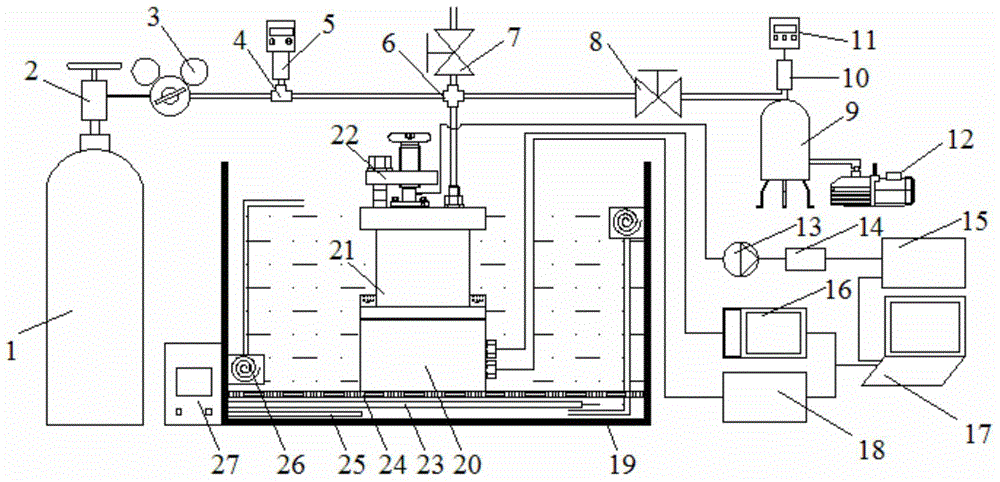

[0061] A coal seam gas adsorption / desorption deformation and deformation force dynamic testing system is characterized in that it includes a test tank system, a constant temperature system, an air pressure system and a measurement system.

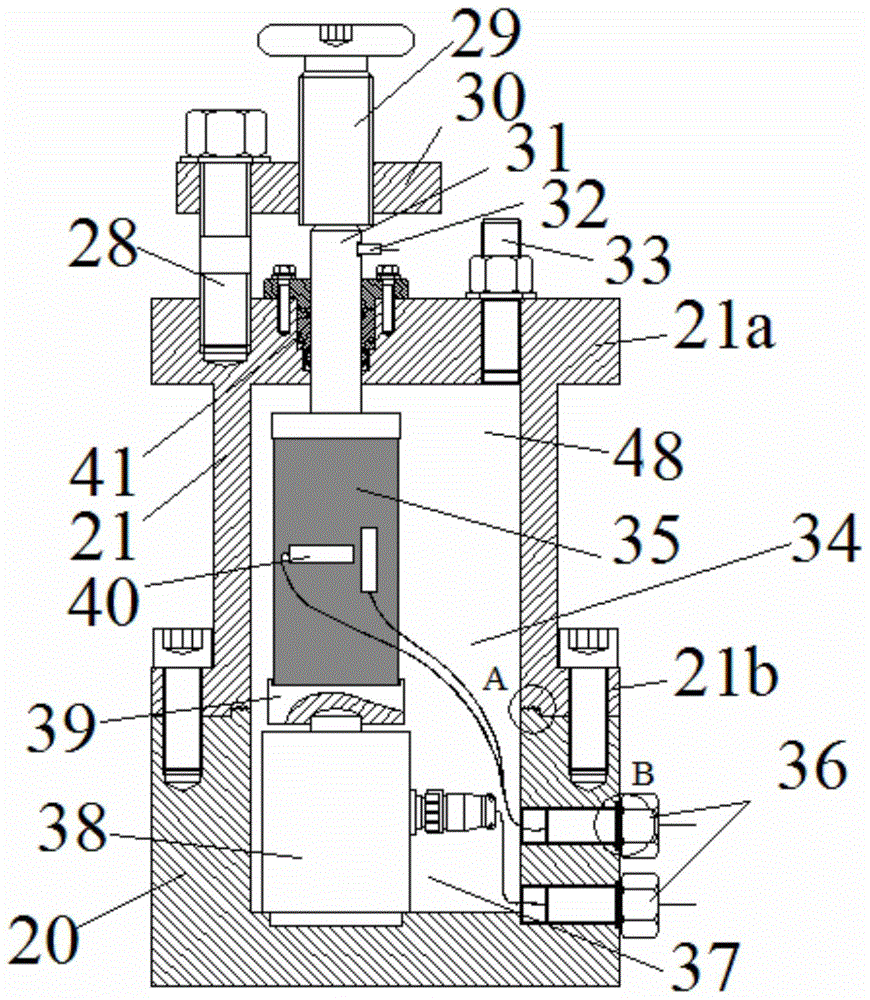

[0062] The test tank system includes a base 20, a tank body 21, a limit pressure rod 31, a load cell 38 and a limit mechanism. The base 20 is a hollow body with an open upper end and a closed lower end, and the tank body 21 is a hollow body with a closed upper end and an open lower end.

[0063] During the test, the lower end of the tank body 21 is fastened to the upper end of the base 20 , so that the inner cavity of the base 20 and the inner cavity of the tank body 21 together form an airtight test cavity 34 . see figure 2 , the inner cavity 48 of the tank is located on the upper part of the inner cavity 37 of the base, and the two together form the test cavity 34 . In this embodiment, the base 20 and the tank body 21 can be separated,...

Embodiment 2

[0071] The main structure of this embodiment is the same as that of Embodiment 1. Furthermore, a heating pipe 23 , a separator 24 , a temperature sensor 25 and a circulating water pump 26 are installed in the tank body 19 . The partition 24 is suspended in the tank body 19 , and the lower end of the base 20 is placed on the upper surface of the partition 24 . The heating pipe 23 is located below the partition 24 . The heating tube 23 is controlled by a temperature controller 27 installed outside the tank body 19 . The constant temperature water in the tank body 19 is driven to circulate by the circulating water pump 26 . The temperature sensor 25 is located outside the tank body 19, and is connected with the heating pipe 23 and the temperature sensor 25 through wires to control the water temperature.

[0072] During the test, the tank body 19 was filled with constant temperature water, and the base 20 and the tank body 21 were immersed in the constant temperature water. The...

Embodiment 3

[0074] The main structure of this embodiment is the same as that of Embodiment 1. Further, the limit mechanism of the test tank system is composed of a column 28 , a loading hand wheel 29 and a limit plate 30 .

[0075] The limiting plate 30 is located above the tank body 21 .

[0076] The lower end of the column 28 is fixed on the upper end of the tank body 21 . The upper end of the column 28 supports the limiting plate 30 .

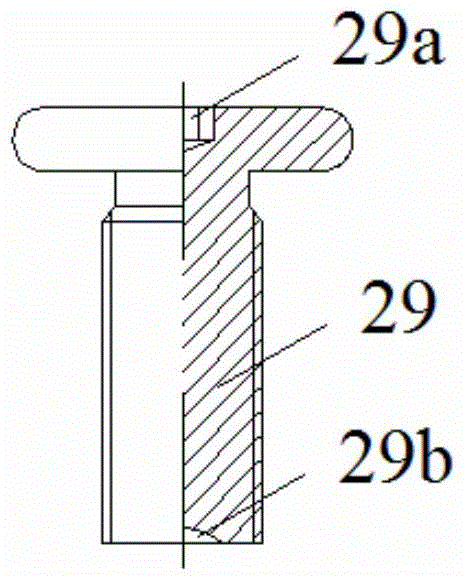

[0077] The loading hand wheel 29 is installed above the limiting plate 30 . The lower end of the loading hand wheel 29 is connected with a telescopic rod. In the embodiment, the loading hand wheel 29 and the telescopic rod are integrally formed, and its section is "T" shape. The limiting plate 30 has a screw hole through which the telescopic rod passes. After the lower end of the telescoping rod is screwed into the screw hole on the limiting plate 30 , it contacts with the upper end of the limiting pressing rod 31 . Further, an inner hexagonal groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com