Patents

Literature

62results about How to "Solving Concentricity Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

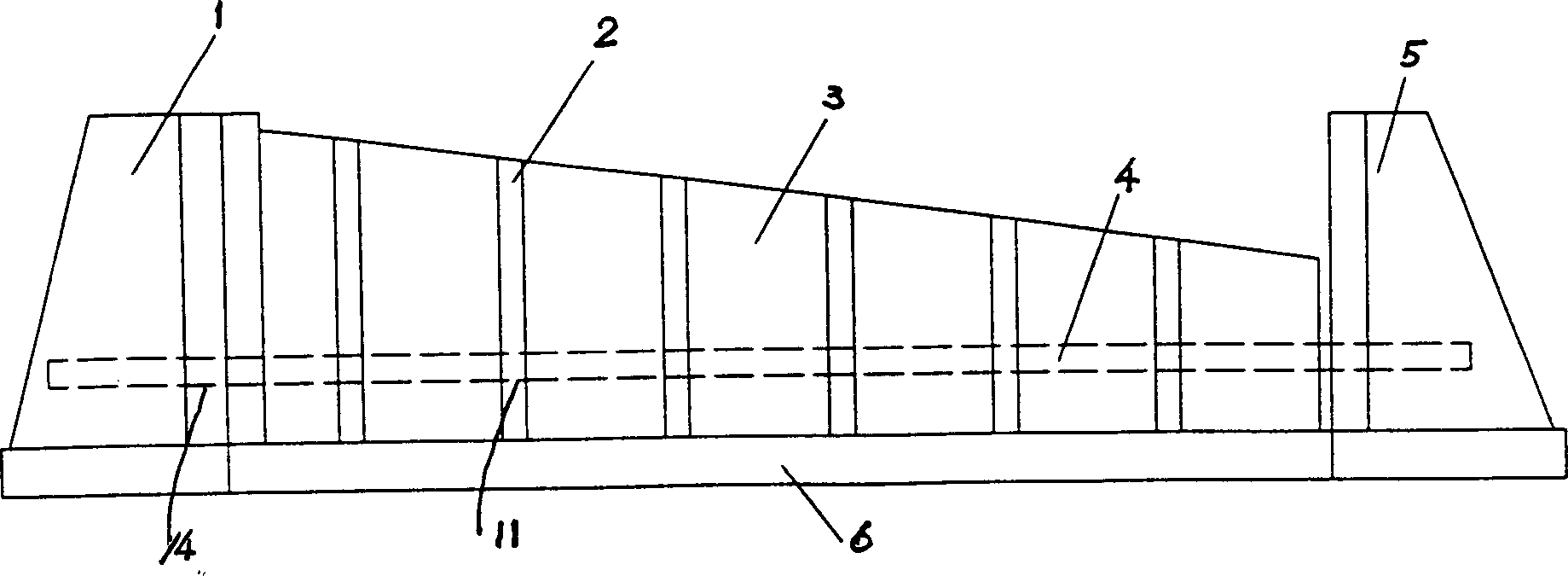

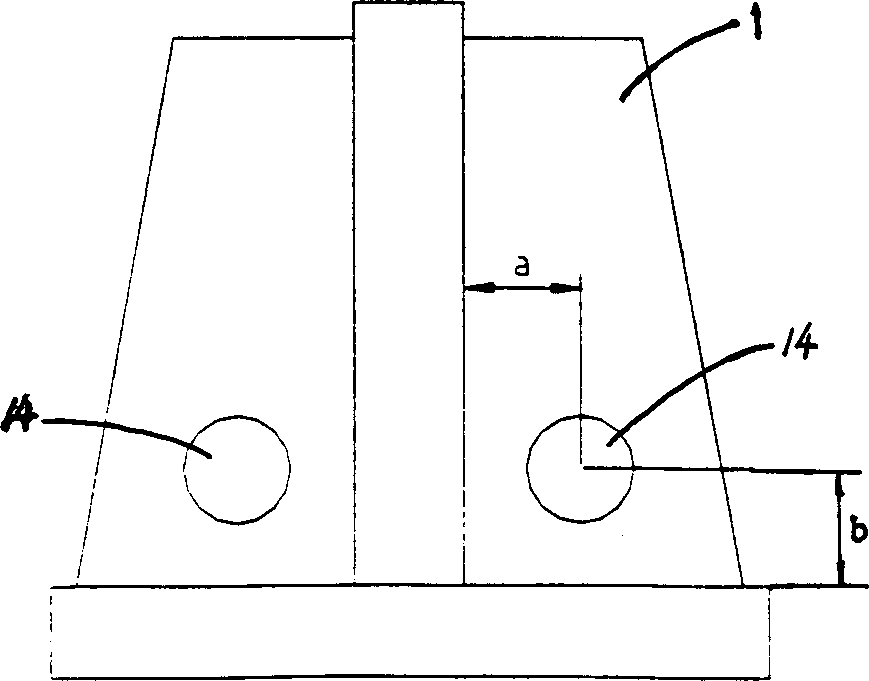

Low-speed diesel engine frame welding method

InactiveCN1405482ASolving Concentricity ProblemsSolve the deformationMachine framesWelding apparatusLow speedEngineering

A method for welding the frame of a low speed diesel engine. It includes the following steps: 1) By passing locating iron pipes through the screw holes in small iron plates, a number of small iron paltes are located between two bed-jigs according to the requirements of design, and spot welded on a guide plate and a triangle plate to form guide plate components. 2) The bilateral symmetric and located guide plate components are put symmetrically side by side and located by butt strap welding. 3) The welded and located bilateral guide plate component are welded in symmetry. 4) After welding, butt straps are removed, and the bila-teral guide plate components are separated. 5) with the help of the bed-jig, the bilateral guide plate components and a division plate are located on a cast-iron platform.

Owner:HUDONG HEAVY MACHINERY +1

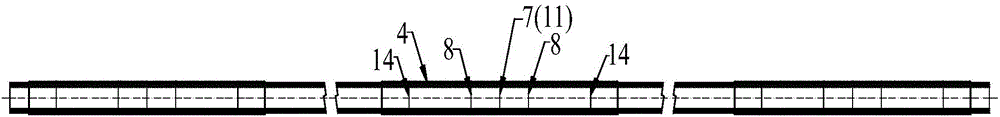

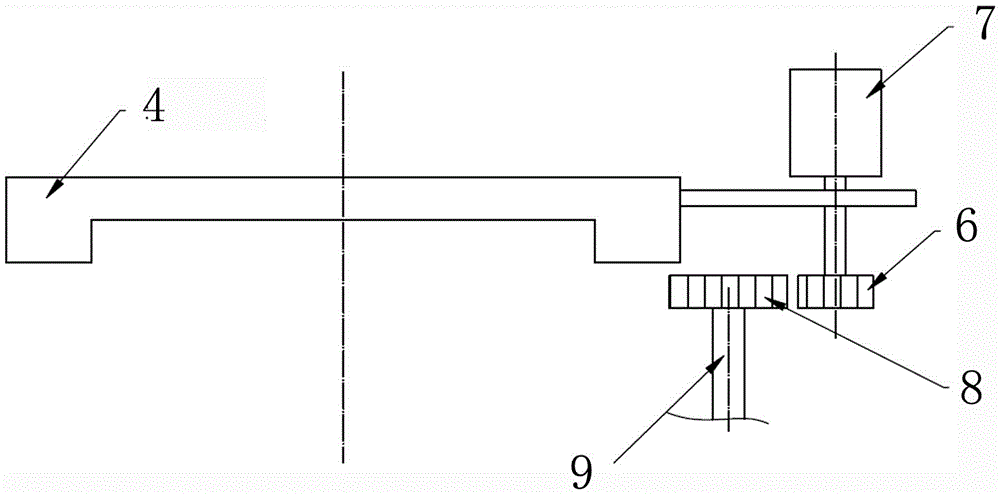

Marine opening and closing hinge installation tool and method

ActiveCN106628009ABreak through the technical problem of difficult construction in assembly and weldingResolve parallelismCargo handling apparatusPassenger handling apparatusSternReference line

The invention provides a marine opening and closing hinge installation tool and method. The installation tool comprises a positioning shaft (4) and positioning reinforcing plates (5), positioning holes (6) are formed in the positioning reinforcing plates (5), and positioning shafts (4) penetrate through the positioning holes (6) in the positioning reinforcing plates (5) and pin holes (2) in a plurality of hinge components (1). The installation method comprises the steps that reference lines are marked on the bow or stern and a gangplank (3) of a ship, accurate positioning during opening and closing hinge installation can be achieved according to the corresponding relation between reference lines on the tool and the reference lines on the ship, the phenomenon that different shrinkages and stresses generated in the construction process, and vertical and front-back size shrinkage malposition are avoided, hinge perpendicularity and center line parallelism can be ensured, the precision is effectively controlled, and installation pairing of the hinge is achieved finally.

Owner:JIANGNAN SHIPYARD GRP CO LTD

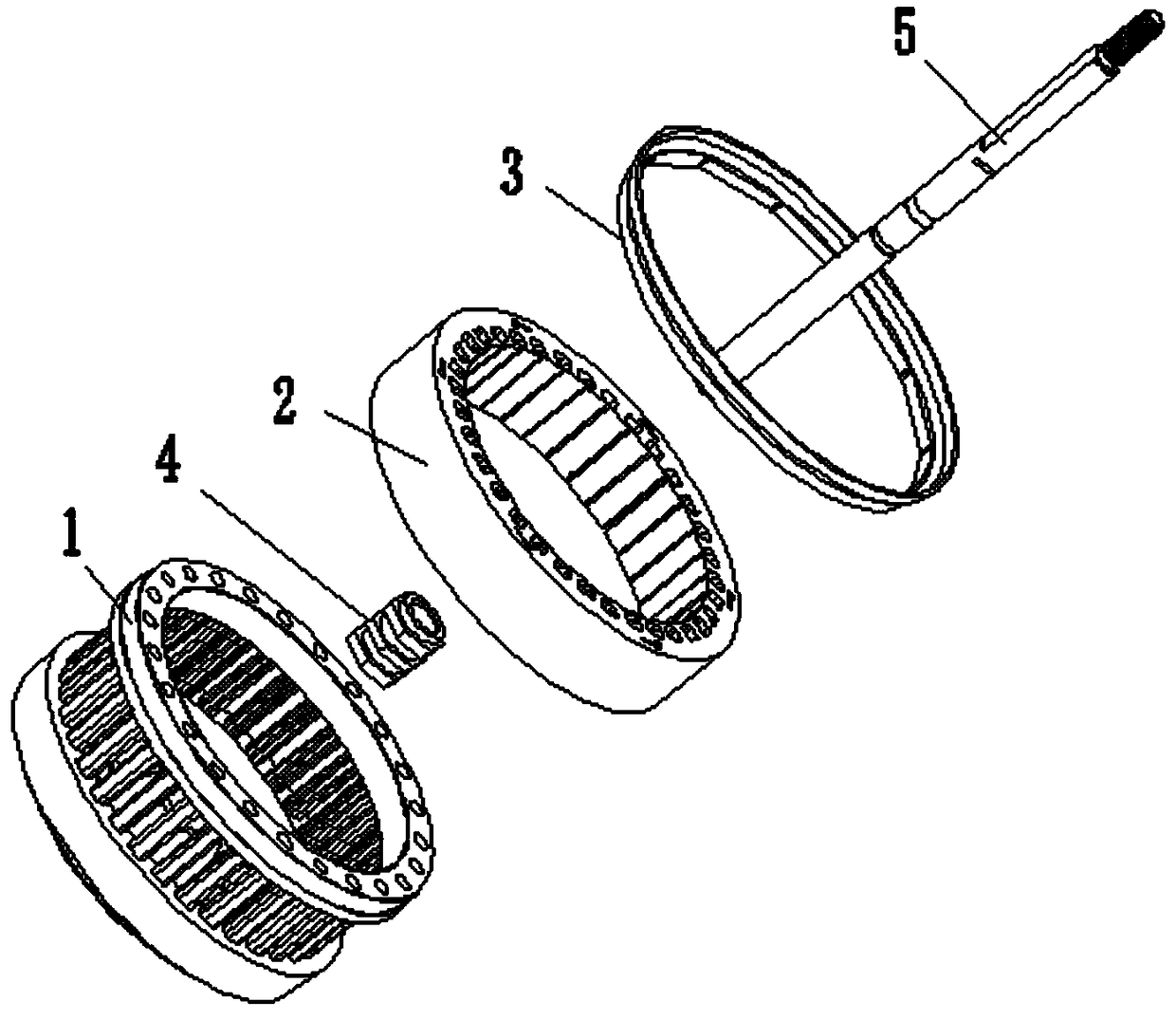

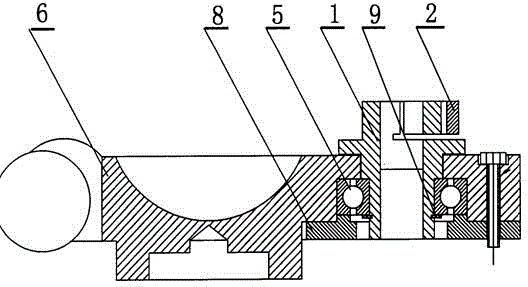

Tool used for machining blade holes of axial flow pump impeller body

ActiveCN103707106ASolving Concentricity ProblemsSolve the measurement datum problem of key dimensionsPositioning apparatusMetal-working holdersAxial-flow pumpImpeller

The invention relates to a tool used for machining blade holes of an axial flow pump impeller body. The tool comprises a rotary body fixed to a lathe spindle, wherein a scale dividing block is fixed on the rotary body, a fastening device used for fixing a workpiece on the scale dividing block is arranged above the scale dividing block, a first layer of positioning pin holes, a second layer of positioning pin holes and a third layer of positioning pine holes are formed in the outer side of the scale dividing block in the circumferential direction from inside to outside, and positioning pins matched with the positioning pin holes are arranged on the scale dividing block. According to the technical scheme, an installation method with the tool directly connected with a lathe is adopted, a rotating center in the direction same as the rotating direction of the lathe spindle is generated for each blade hole to be machined, and concentricity is achieved between the blade holes to be machined and the lathe spindle; by means of the cooperation between the scale dividing block and the rotary body and the utilization of a scale dividing mechanism, fast and accurate scale division is achieved easily when the blade holes rotate along with the scale dividing block during machining; a cylindrical section arranged on a pull rod enables the measuring basis of the critical dimension to be available during lathe machining.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

Borehole processing method of long-range parts

InactiveCN101337285AGuaranteed verticalityGuaranteed center distanceBoring/drilling machinesEngineeringMachine tool

The invention discloses a method for processing an internal boring for a long-distance part, which comprises the following steps: clamping two bent plates provided with central holes on the front and the back side surfaces of a bored part, passing a spotting spindle through the central holes of the part and the bent plates to cause the center of the part and the centers of the bent plates to coincide, and pressing and fixing the bent plates; rounding the four main shaft of a boring lathe by using a dial test indicator after detaching the part and the spotting spindle, adjusting the four main shafts of the lathe to be coaxial with the central holes of the two bent plates, and tightly fixing the four main shafts; placing a part to be bored on the boring lathe and positioning through the bent plates, using a second spotting spindle to pass through the bent plates and the part, pressing the part tightly after positioning the part, removing the spotting spindle, and starting boring. The front hole and the back hole of a processed part are coaxial, the hole distance is consistent, the functions of the four shafts of the lathe are brought into full play, the product quality is improved, the boring time is saved, and the production efficiency is improved.

Owner:四川航天神坤装备有限公司

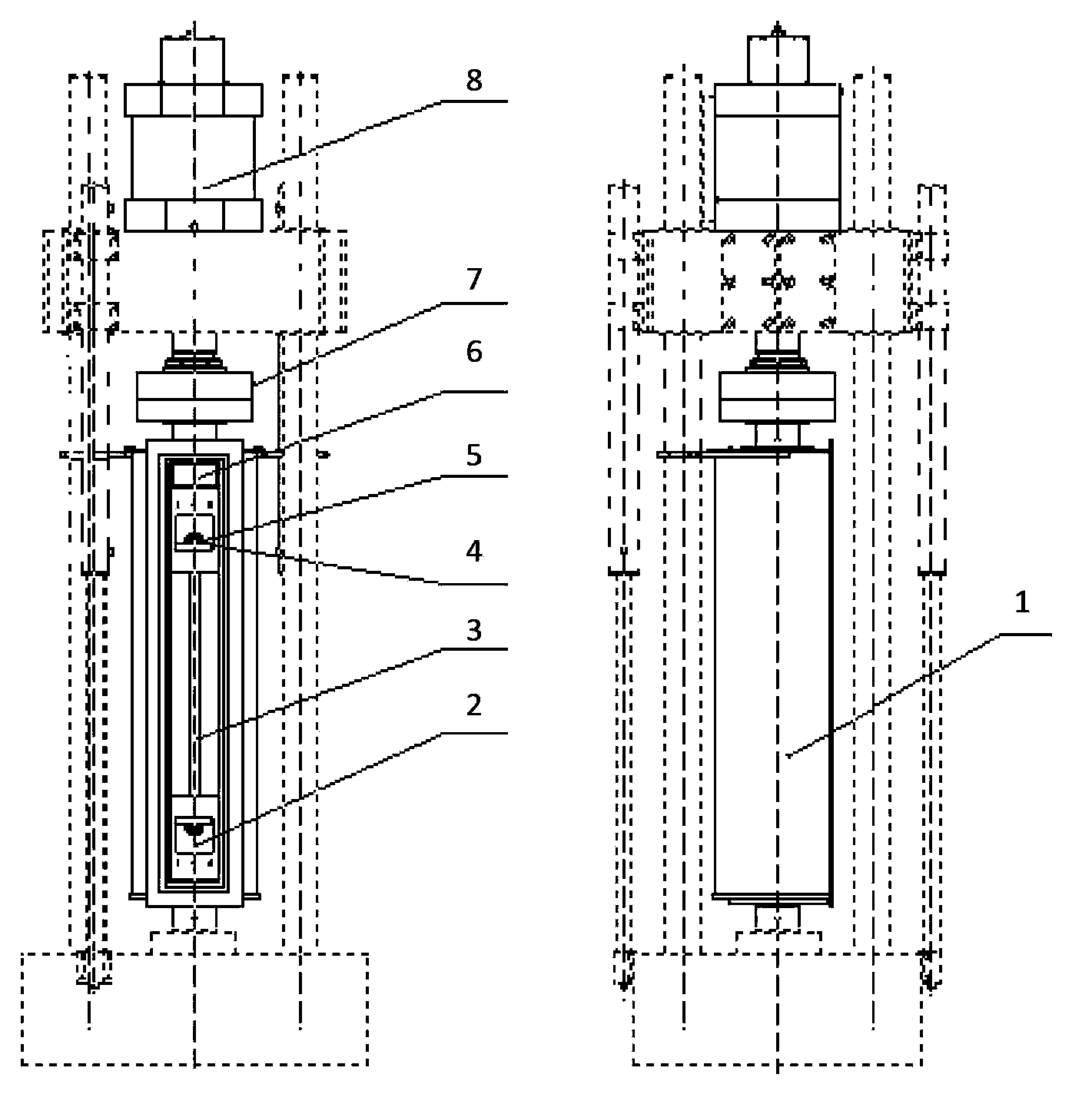

Large low-temperature fatigue experimental device for bolt

InactiveCN103884600AEasy loadingEasy to replaceMaterial strength using tensile/compressive forcesEngineeringHigh intensity

The invention belongs to an experimental device, and particularly relates to a large low-temperature fatigue experimental device for a bolt. The large low-temperature fatigue experimental device comprises a low-temperature environmental box, wherein the low-temperature environmental box consists of a hollow cylindrical-special-vertical Dewar flask, and the upper end and the lower end of the low-temperature environmental box are respectively provided with a coaxial through hole; an upper pulling rod and a lower pulling rod are connected with a clamp system arranged in the low-temperature environmental box by the two through holes; the clamp system is used for clamping a tested experimental bolt; and the upper pulling rod and the lower pulling rod are connected with an external power source. The large low-temperature fatigue experimental device has the beneficial effect of being capable of being suitable for carrying out high-strength and large-size (the length is more than 1000mm and the diameter is more than phi40mm) bolt fatigue test under the environment with the ultralow temperature of being minus 196 DEG C.

Owner:SOUTHWESTERN INST OF PHYSICS +1

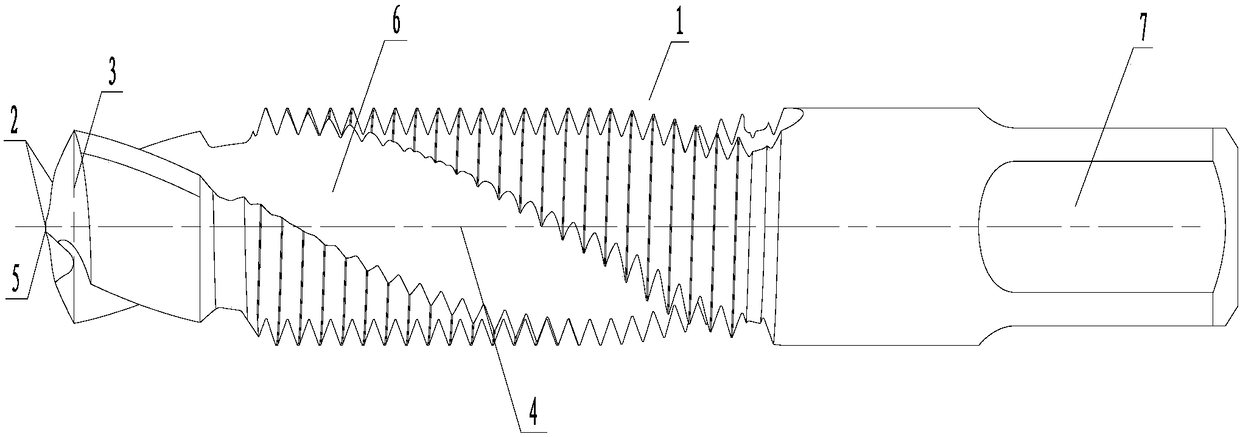

Combined tap and drill

InactiveCN108098083AAvoid frequent replacementQuality assuranceThread cutting toolsMachine toolMachining

The invention discloses a combined tap and drill, belongs to the technical field of machining tool design and manufacture and provides a drilling and tapping integrated combined tap and drill which can ensure internal thread machining quality. The combined tap and drill comprises a tap and drill body, a guide drill hole cutting edge is arranged at the tip end of the tap and drill body, and a bottom hole before tapping is drilled in the tapping process by the tap and drill body under cooperation of the guide drill hole cutting edge.

Owner:SICHUAN GUOXIN MACHINERY MFG CO LTD

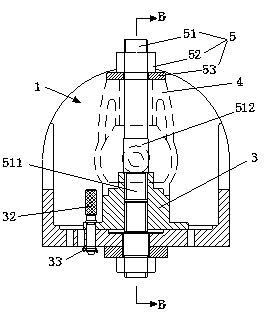

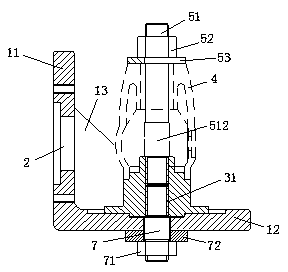

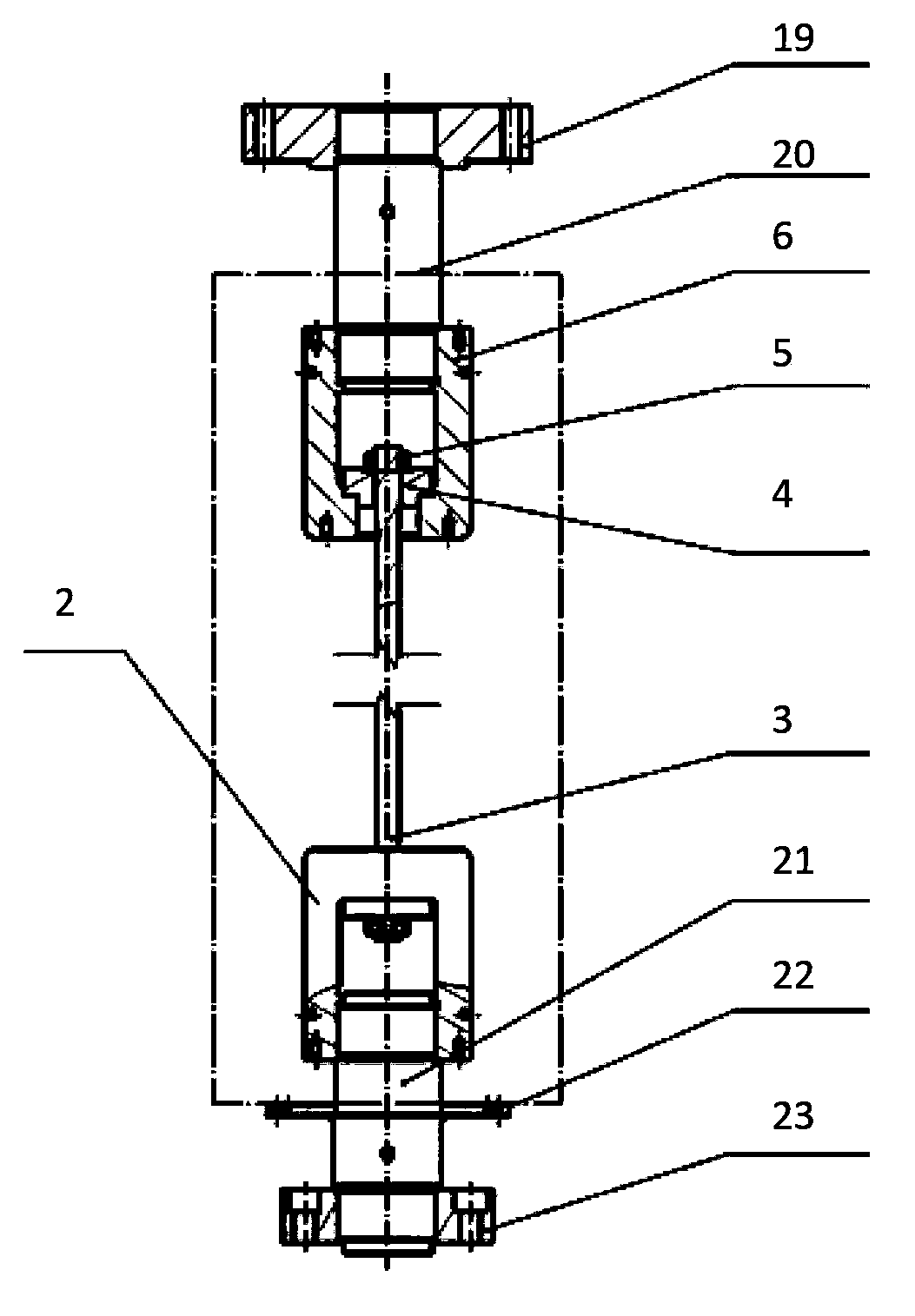

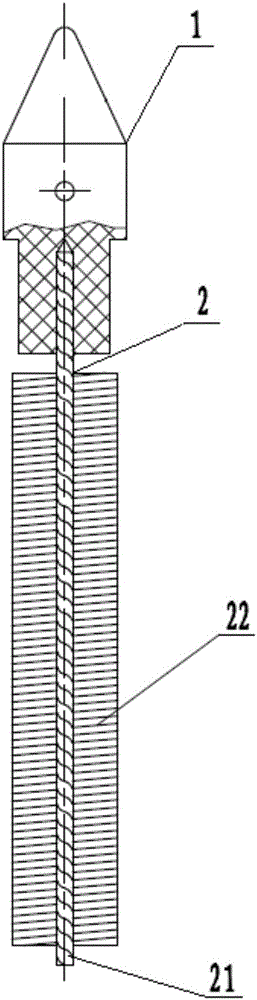

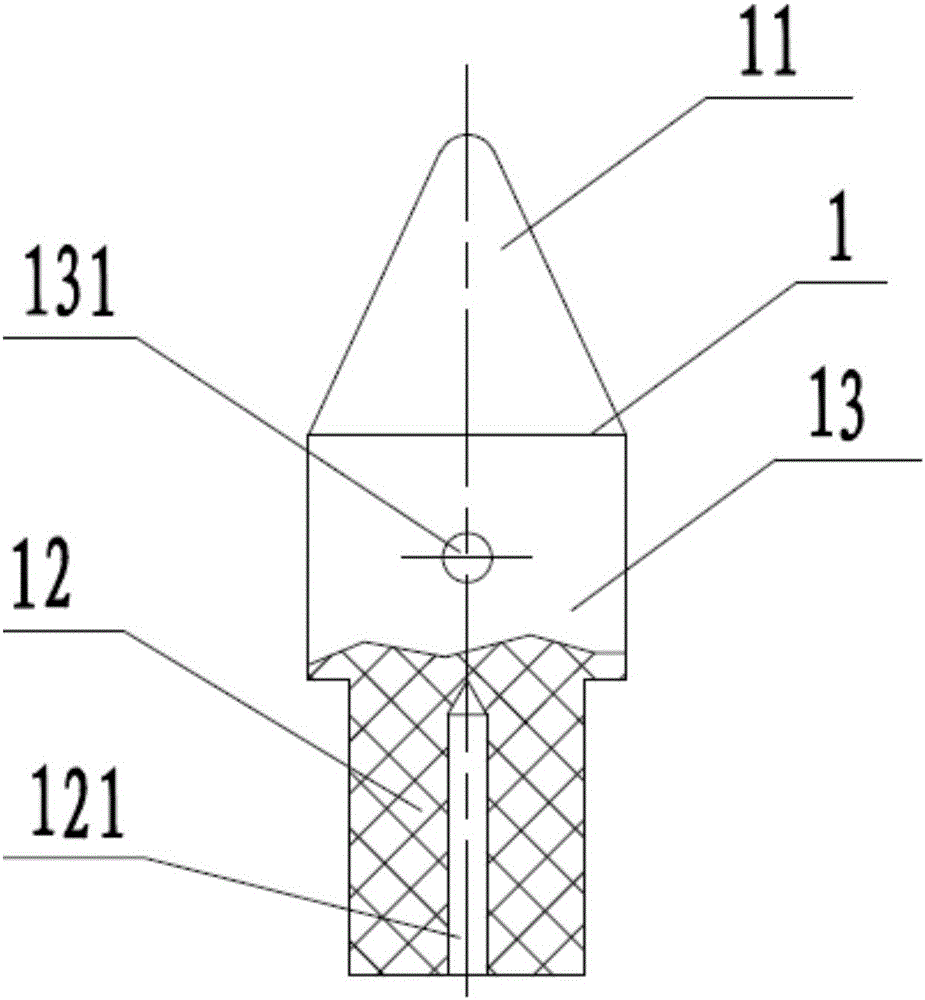

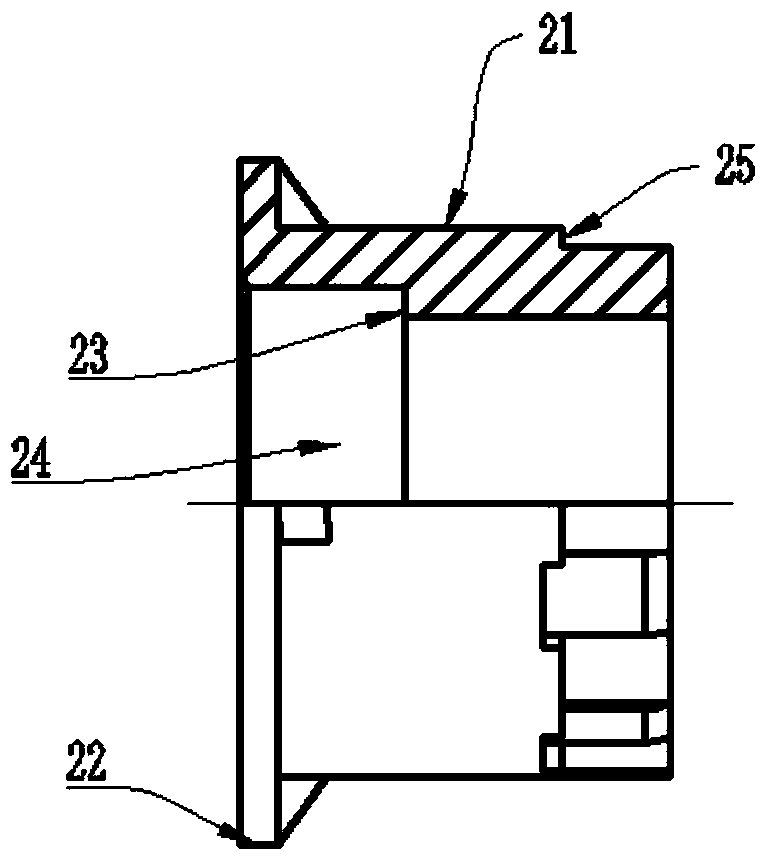

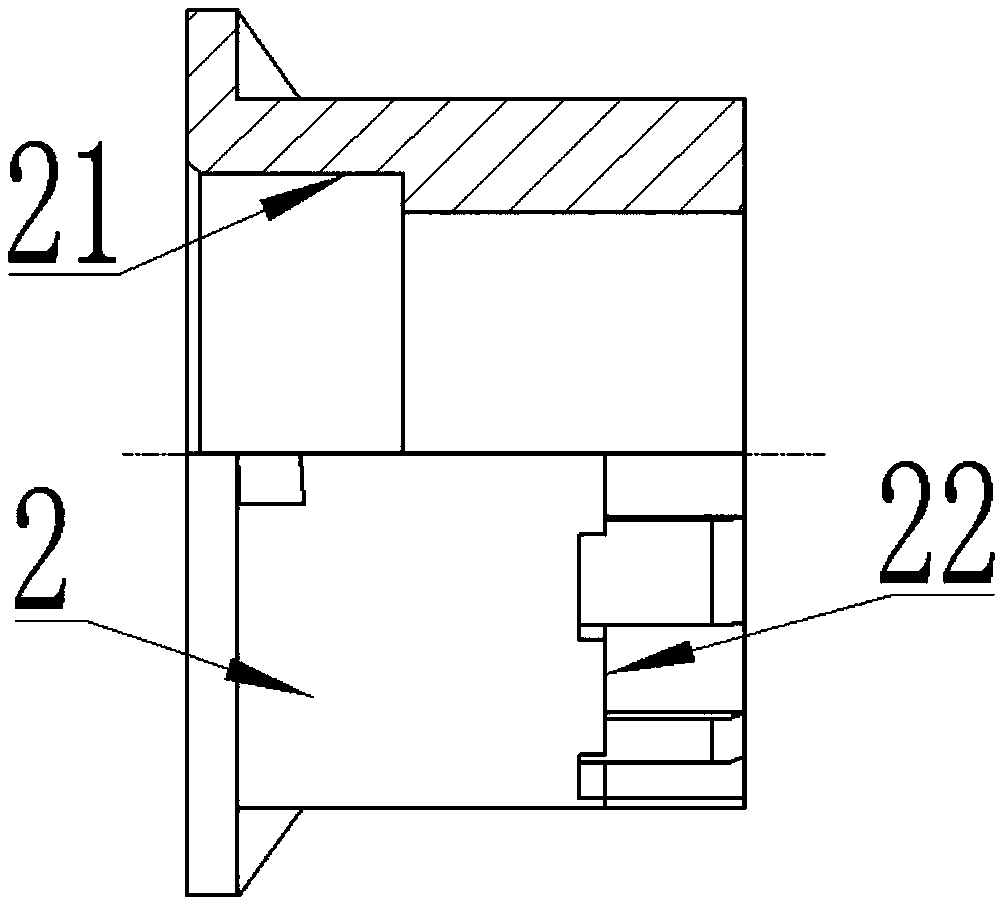

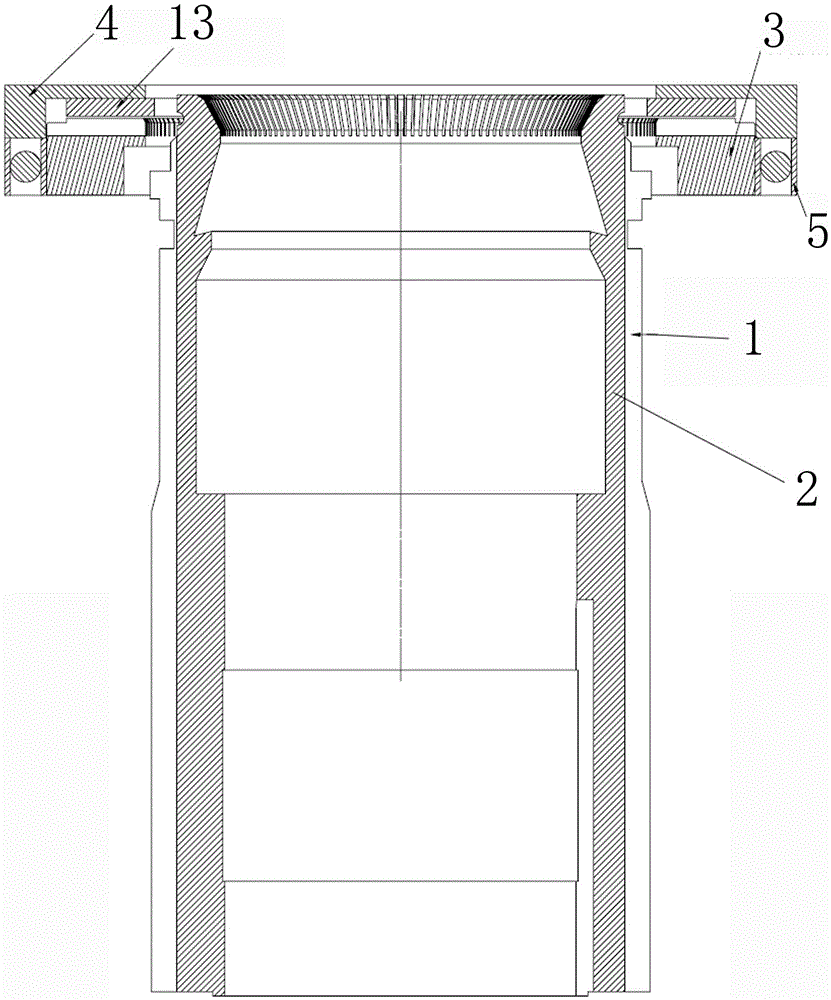

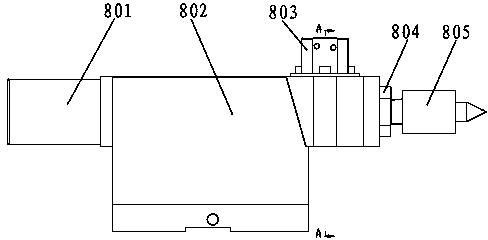

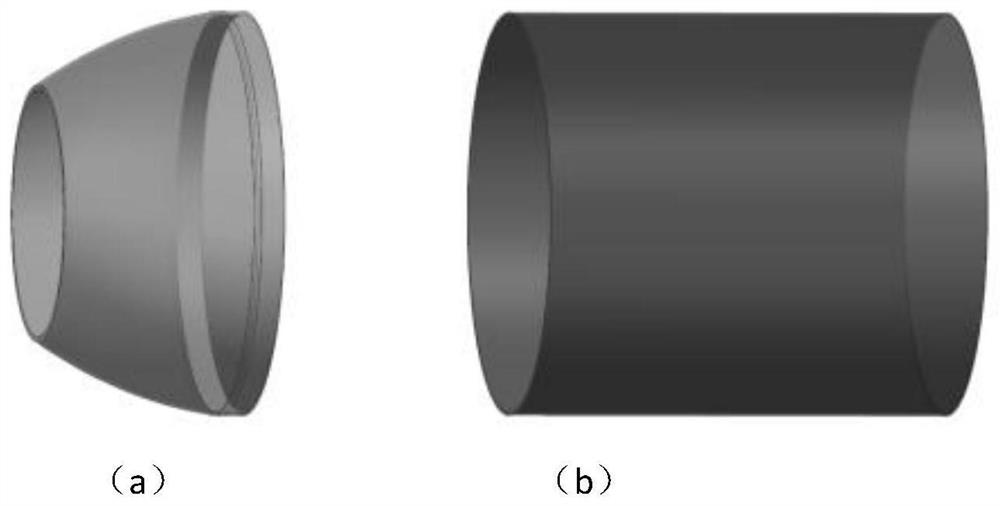

Flexible internal supporting type guide head for pipe penetration of heat exchanger

The invention provides a flexible internal supporting type guide head for pipe penetration of a heat exchanger. The guide head comprises a guide piece (1) and an elastic supporting piece (2) which is located below the guide piece (1) and fixedly connected with the guide piece (1), wherein the guide piece (1) comprises a guide head body (11), a connecting part (12) and any transition part (13); the outer diameter of the guide head body (11), the outer diameter of the connecting part (12) and the outer diameter of the transition part (13) are decreased gradually; and the elastic supporting piece (2) comprises a connecting shaft (21) and an elastic supporting strip (22). The invention further provides a method for conducting pipe penetration of the heat exchanger by using the flexible internal supporting type guide head. The flexible internal supporting type guide head has good rigidity and high precision, and the problem that guiding and concentricity cannot be achieved in the pipe penetration process of the heat exchanger is effectively solved; installation is easy, guiding is reliable, firmness and stability are achieved, and using is easy and convenient; and the success rate is high, the pipe penetration time is shortened, the pipe penetration precision is improved, and the breakage rate of heat exchange pipes, pipe plates and baffle plates in the pipe penetration process is decreased.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

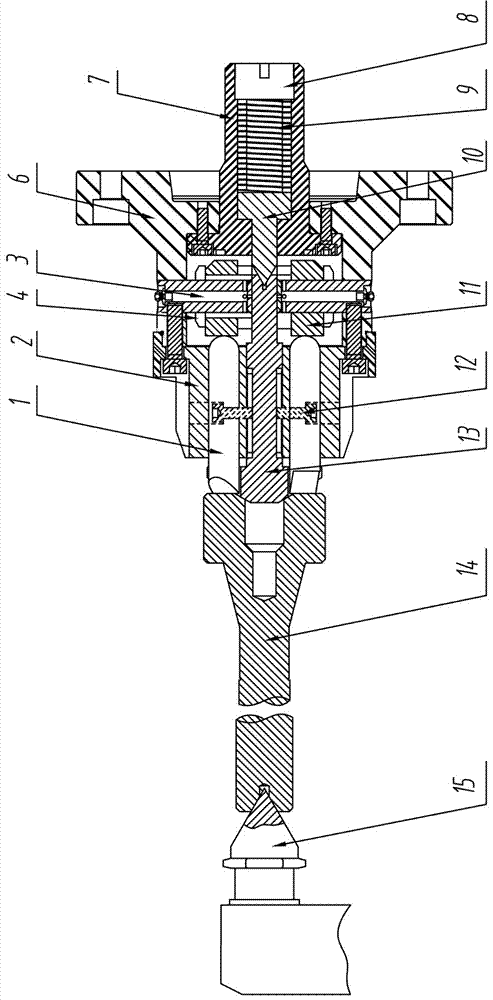

Self-tightening end surface driving chuck

PendingCN107309694AImprove stabilitySolving Concentricity ProblemsLarge fixed membersPositioning apparatusPilot holeMachine tool

The invention relates to a driving clamping chuck, in particular to a driving device without a hydraulic station or a pneumatic room used as a power source, is used for high-precision and high-coaxiality non-circular curve and complex shape machining of rotary parts, and specifically relates to a self-tightening end surface driving chuck. The chuck comprises a tailstock tip, a chuck tip, a guide seat, a spring tip seat and a connecting disk; the tailstock tip is opposite to the chuck tip; a guide hole is formed in the guide seat; the connecting disk is fixedly connected with the output end of an oil cylinder of a machine tool; and the central axis of the tailstock tip is overlapped with the central axis of the chuck tip. The chuck tip is used for centering, the tailstock tip clamps a workpiece for matching with forwards pushing and guarantees the concentricity of two ends of the workpiece, the problem about coaxiality of a precision part due to secondary clamping in a traditional process scheme can be effectively solved, the chuck is simple in structure, free of auxiliary devices and simple and convenient to maintain.

Owner:西安铁路职业技术学院

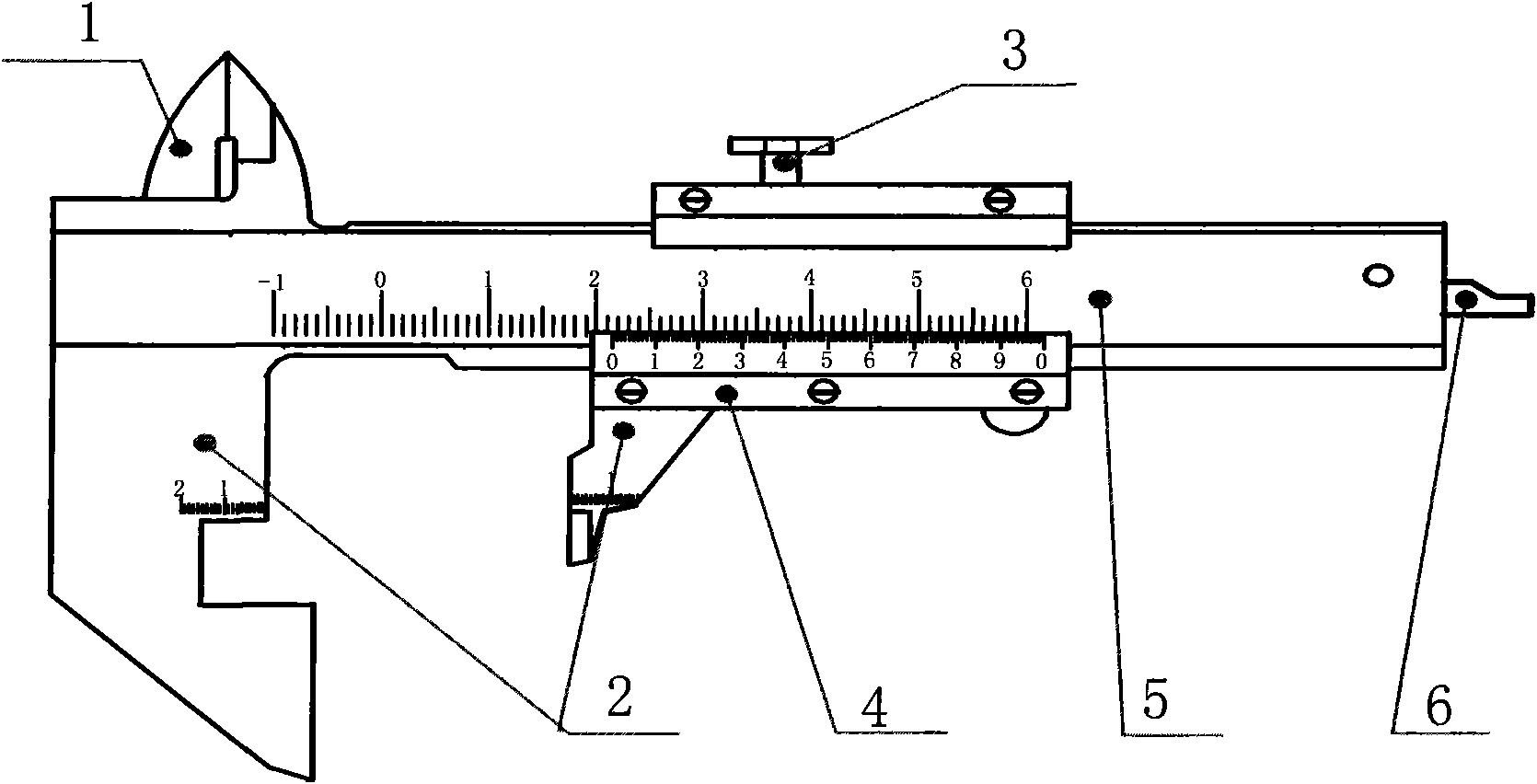

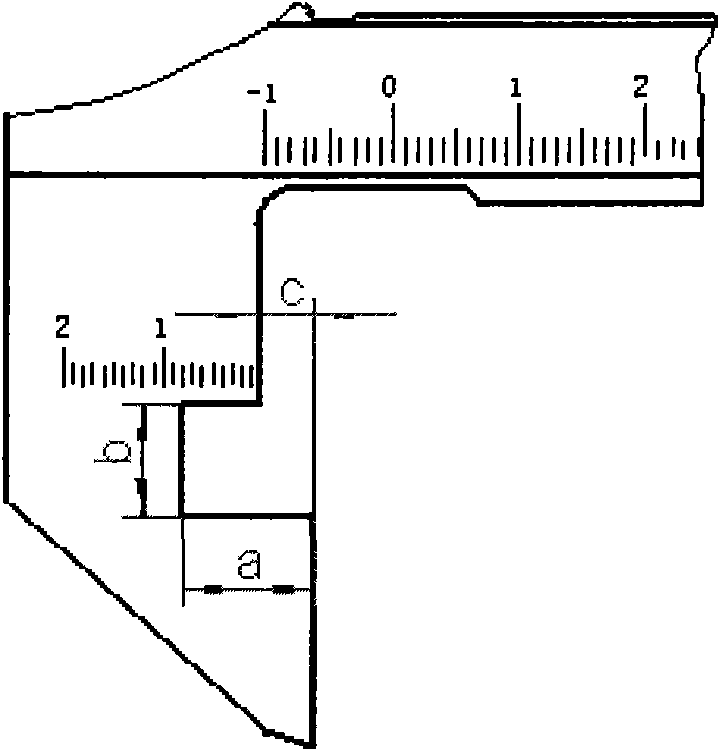

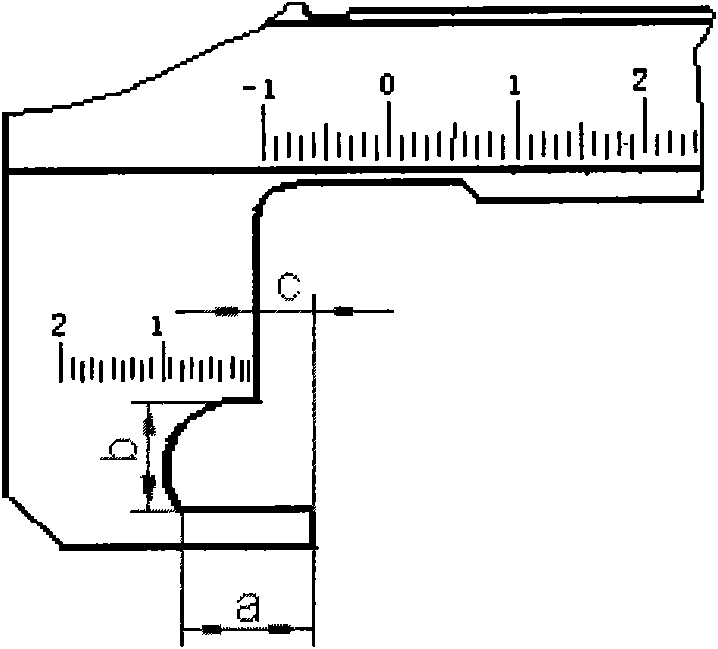

Coaxiality caliper

ActiveCN101858716ARealize measurementEasy to measureAngles/taper measurementsSlide gaugesVernier scaleEngineering

The invention provides a coaxiality vernier caliper with multifunctional measurement, which comprises an inner measure-hand pair (1), an outer measure-hand pair (2), a fastening screw (3), a vernier (4), a caliper frame (5) and a depth caliper rod (6). The structure improvement is in relation to the outer measure-hand pair (2) mainly; scales for measuring coaxiality and symmetry of products are marked on the same end surface of the big hand and the small hand of the outer measure-hand pair (2); the big hand of the outer measure-hand pair (2) is provided with a groove; the steps width at the low part and the upper part of the groove is c, the depth of the groove is b, and the width of the groove is a; the small hand of the outer measure-hand pair is used for measuring a trapezoidal section; a measuring head is positioned at the bottom of the trapezoidal section; the height of a measuring surface is E, and the width of the measuring surface is F; when the height E of the measuring surface has a big size and the width F of the measuring surface has a small size, the caliper is used for measuring the coaxiality of the inner hole and the excircle of a part; and when the height E of the measuring surface has a small size and the width F of the measuring surface has a large size, the caliper is used for measuring the excircle of the part and the coaxiality of an excircle groove and the excircle.

Owner:AVIC STANDARD PARTS MFG

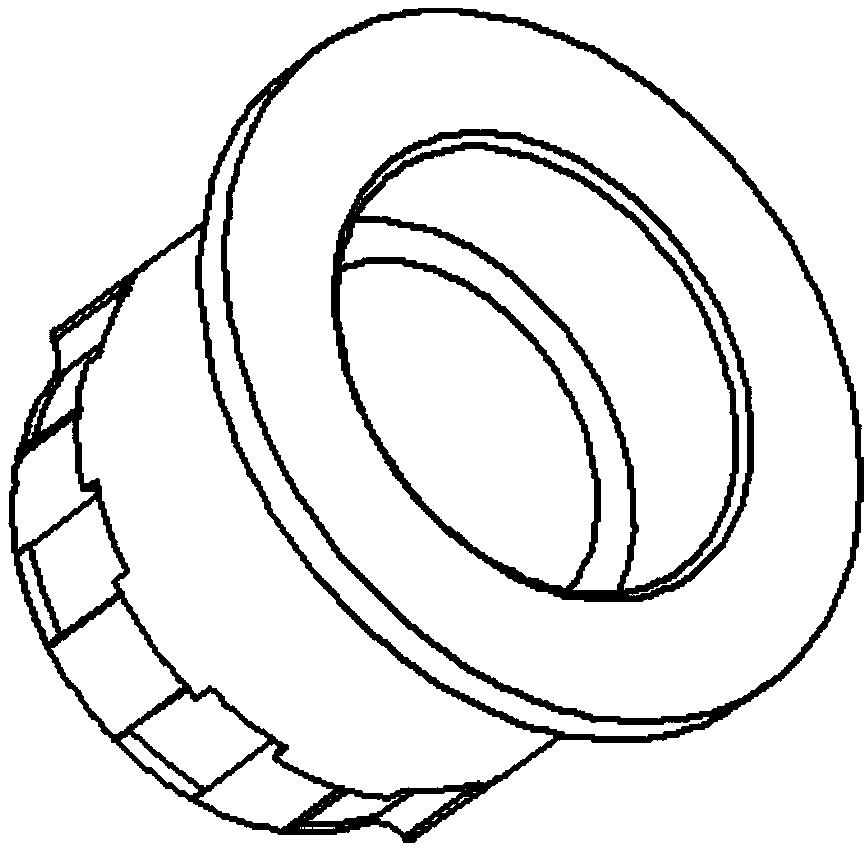

Plastic packaging stator module

InactiveCN108832734AAvoid circular jumping phenomenonSolving Concentricity ProblemsMagnetic circuit stationary partsSupports/enclosures/casingsPlastic packagingEngineering

The invention relates to the technical field of outer rotor motors, and specifically relates to a plastic packaging stator module. Bearing supports nested onto the inner circle of a stator iron core are arranged on two sides of the stator iron core respectively; a bearing used for being in transition fit with a rotating shaft is arranged in each bearing support respectively; the stator iron core and the bearing supports are plastically packaged through a thermosetting plastic to form the integral plastic packaging stator module; and the stator iron core and the bearing supports are formed intoone body through injection molding in an integral injection molding manner. A unified assembling standard is adopted, the phenomenon of circular run-out existing between relative bearings during theoperation of the rotating shaft due to different assembling standards in components are assembled in the prior art is avoided, and the problem of concentricity between the rotating shaft and the stator iron core is solved effectively.

Owner:合肥市通得力电气制造有限公司

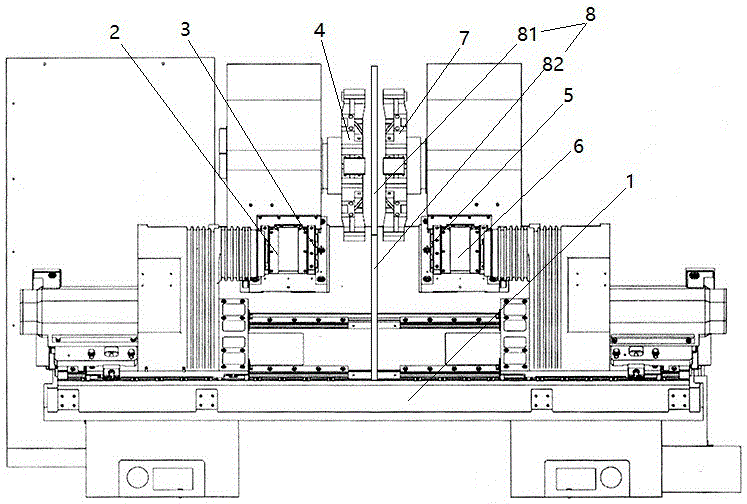

One-time clamping symmetrical turning method and device for glass die

The invention discloses a one-time clamping symmetrical turning method for a glass die. The method includes the following steps that the glass die is clamped by a first clamping disc, the first clamping disc is driven by a first drive shaft to rotate, and turning is conducted on one end of the glass die; after turning of one end is completed, the glass die is driven by the first clamping disc to move towards a second clamping disc, the turned end of the glass die is clamped by the second clamping disc, the first clamping disc releases the glass die, the second clamping disc is driven by a second drive shaft to rotate and conducts turning on the end, clamped by the first clamping disc, of the glass die, a rotary shaft of the first clamping disc and a rotary shaft of the second clamping disc are concentric and oppositely arranged along the rotary shafts, and the movement direction of the first clamping disc is parallel to the rotating shaft direction. The invention further discloses a machining device suitable for the machining method. By the adoption of the method, the coaxiality problem generated in the two-time clamping process can be solved, and machining efficiency is high.

Owner:CHANGSHU JINGGONG MOLD MFG

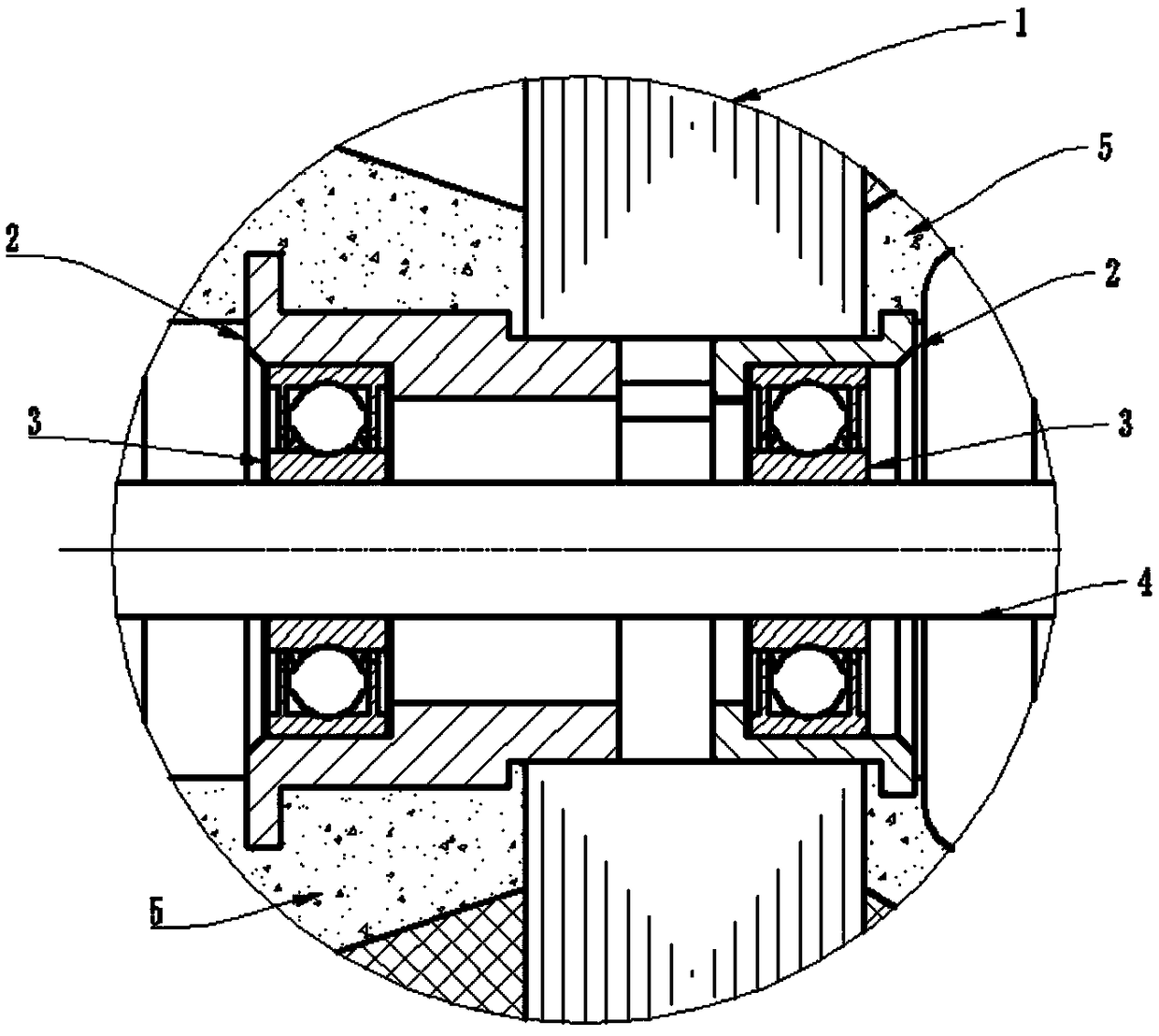

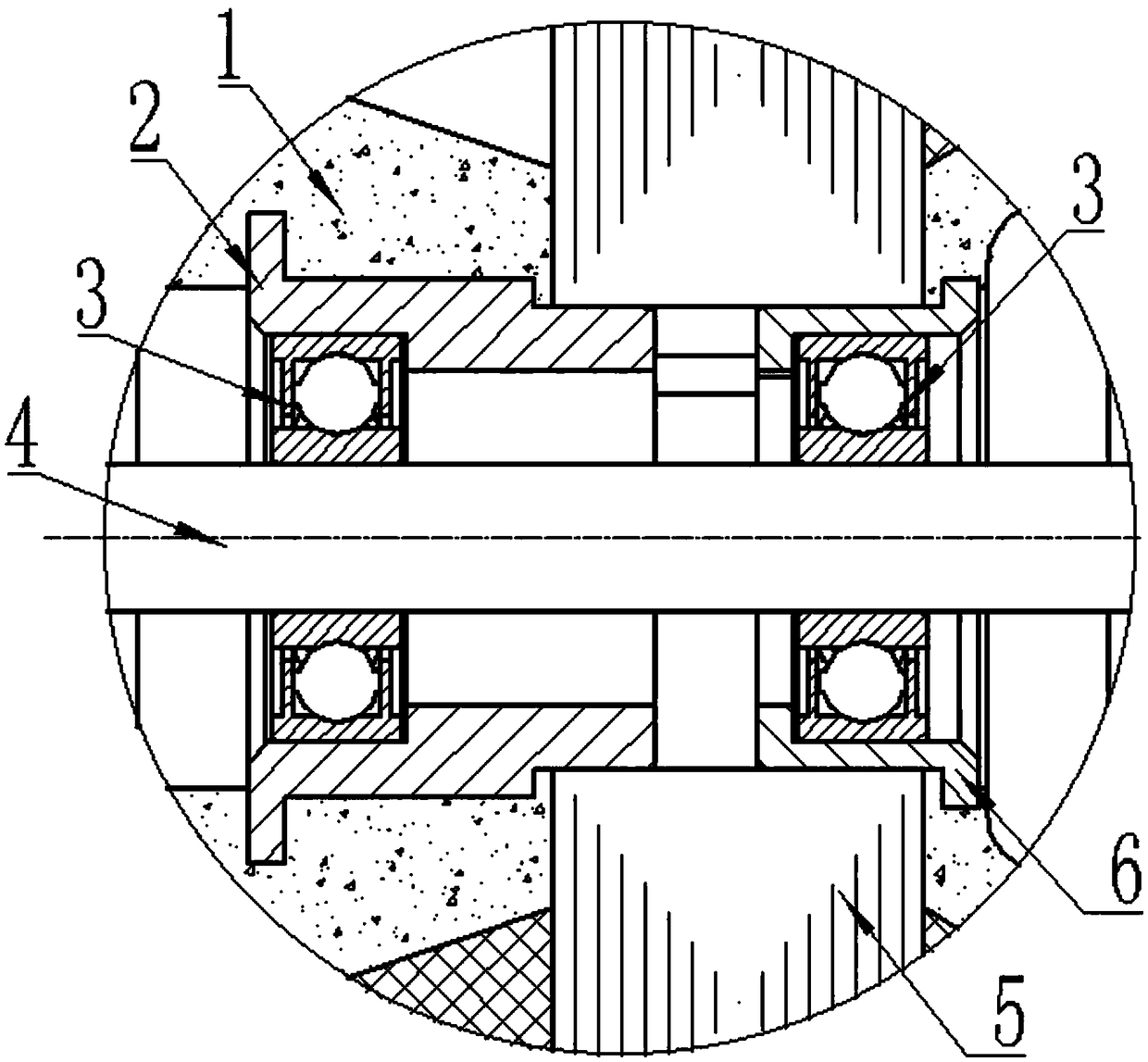

Bearing bracket structure for outer rotor motor

InactiveCN108768051AExtended service lifeAddressing the effects of lifespan damageMagnetic circuit stationary partsSupports/enclosures/casingsEngineeringMechanical engineering

The invention relates to the technical field of the outer rotor motor, especially a bearing bracket structure for the outer rotor motor. The bearing bracket structure comprises a stator iron core anda rotating shaft; a first bearing bracket is arranged at one side of the stator iron core, a first bracket limiting end is arranged at one end of the first bearing bracket, and the first bracket limiting end is coaxially fixed in the stator iron core; a second bearing bracket is arranged at the other side of the stator iron core, a second bracket limiting end is arranged at one end of the second bearing bracket, and the second bracket limiting end is coaxially fixed in the stator iron core; a second bearing chamber is arranged in the second bearing bracket, a bearing is arranged in the secondbearing chamber, and the rotating shaft penetrates two bearings; the external of each of the first bearing bracket, the bearing, the rotating shaft, the stator iron core, and the second bearing bracket is plastic-packaged to form the stator plastic-packaged body. The bearing bracket structure disclosed by the invention effectively solves the influence of damaging the bearing life in the operationof the rotating shaft, solves the defect of circle run-out when the bearing and the rotating shaft are in operation, and effectively prolongs the service life of the motor.

Owner:合肥市通得力电气制造有限公司 +1

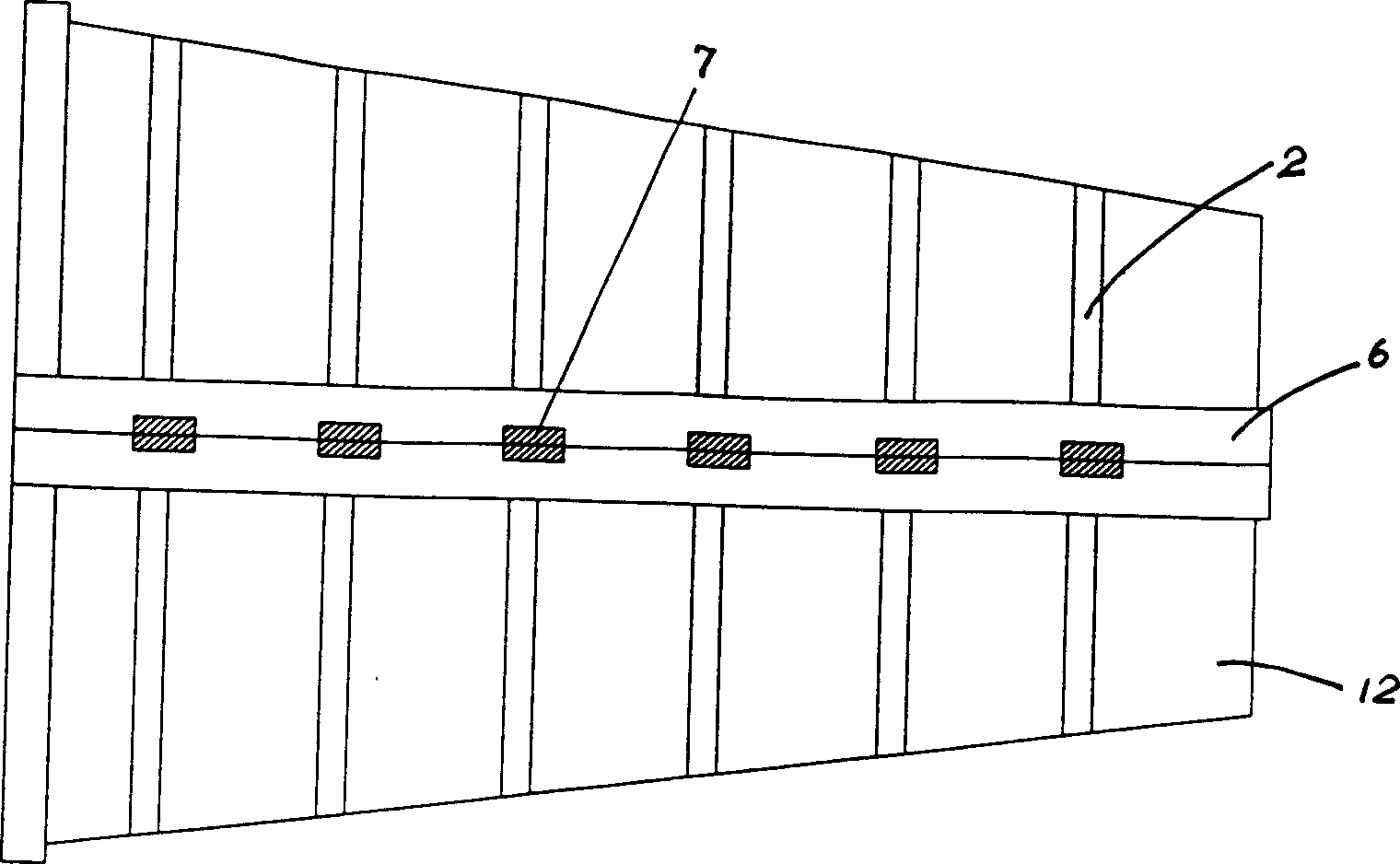

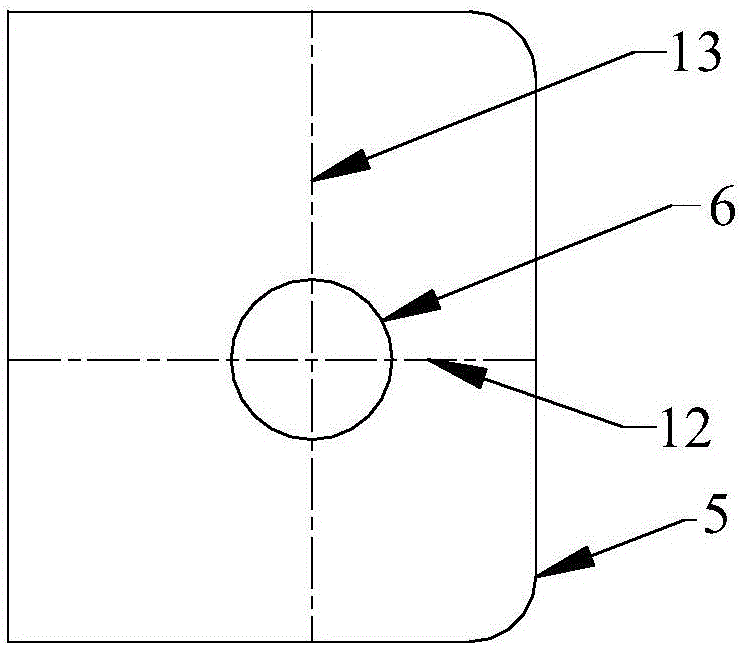

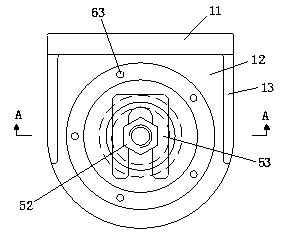

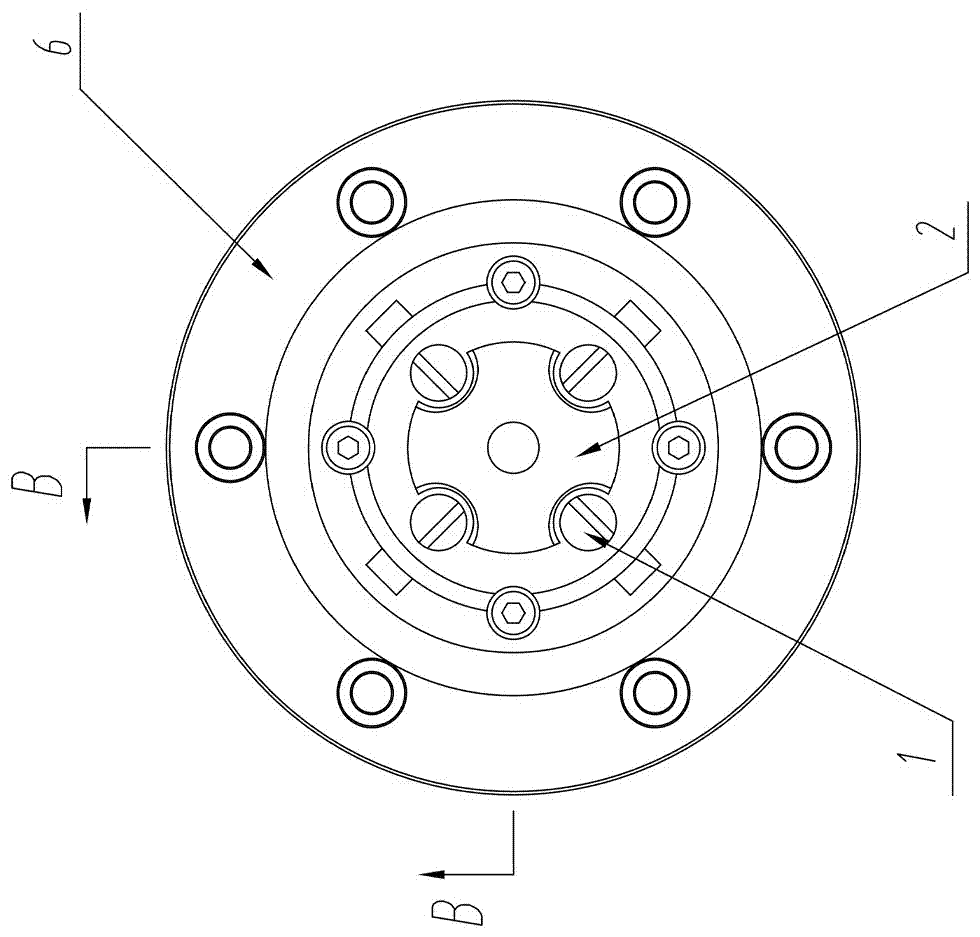

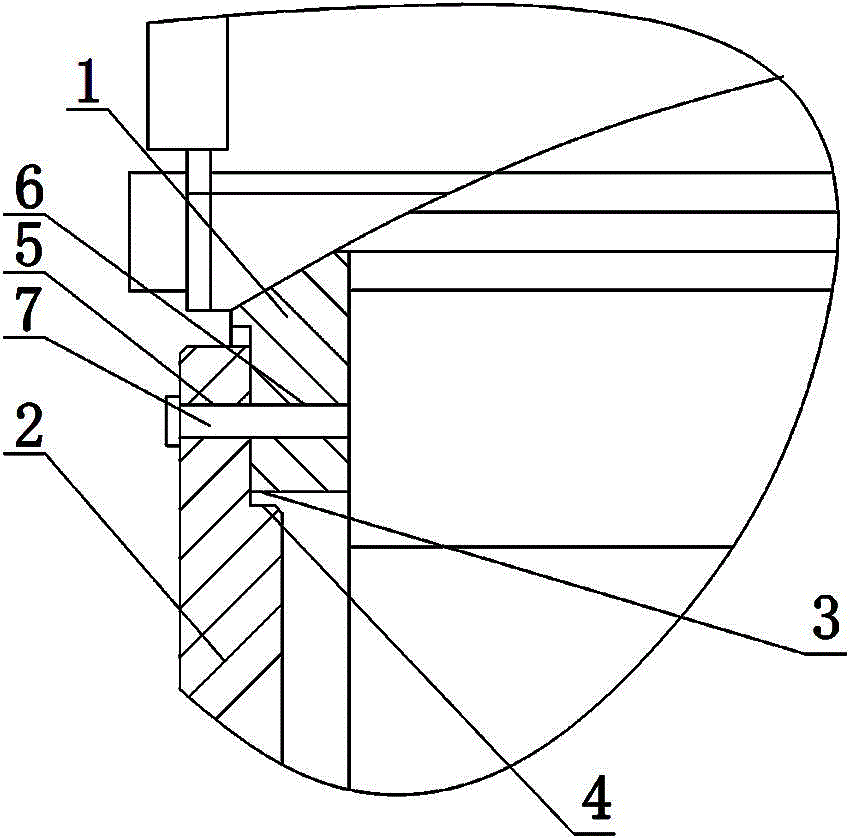

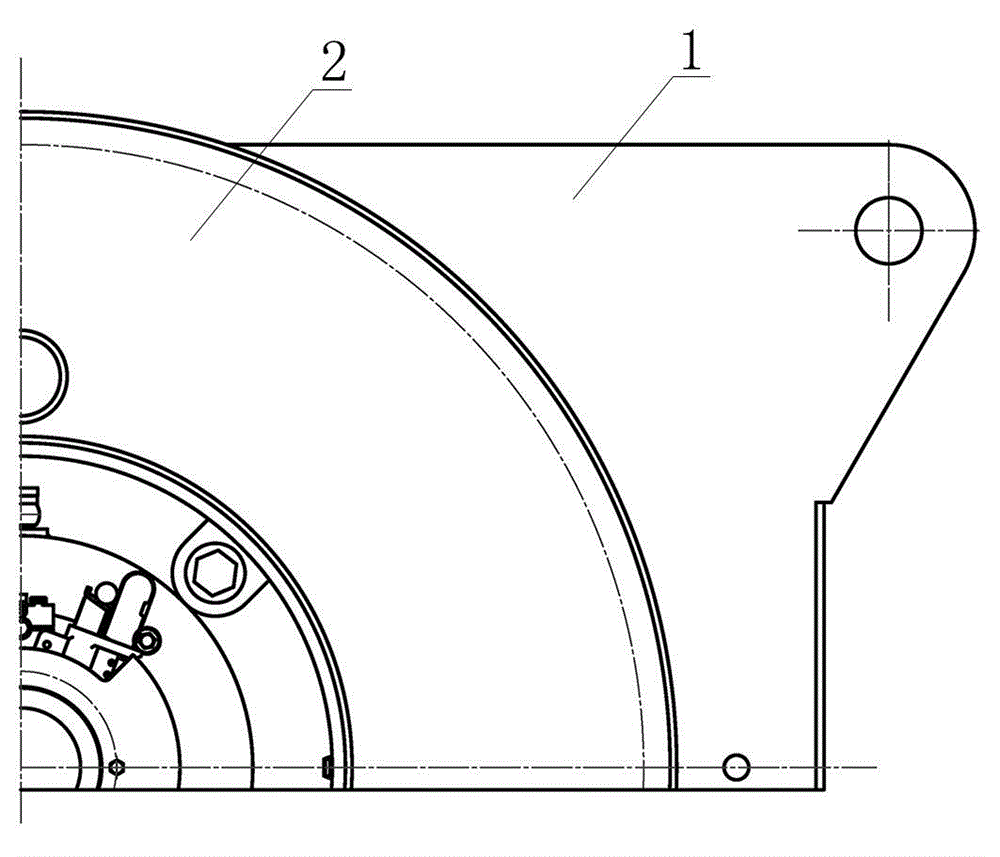

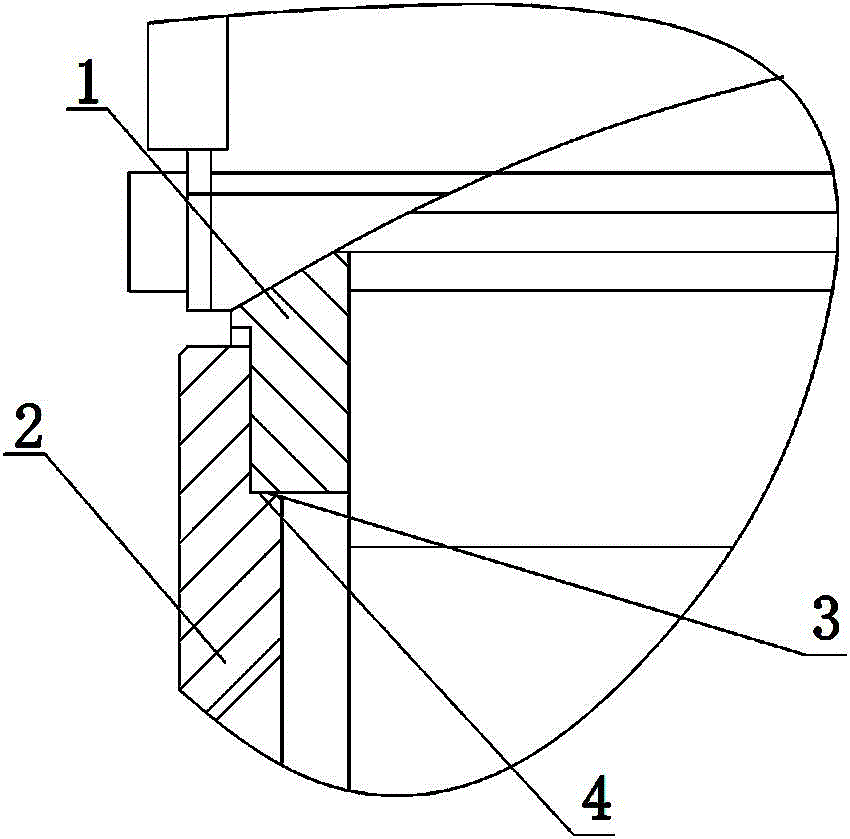

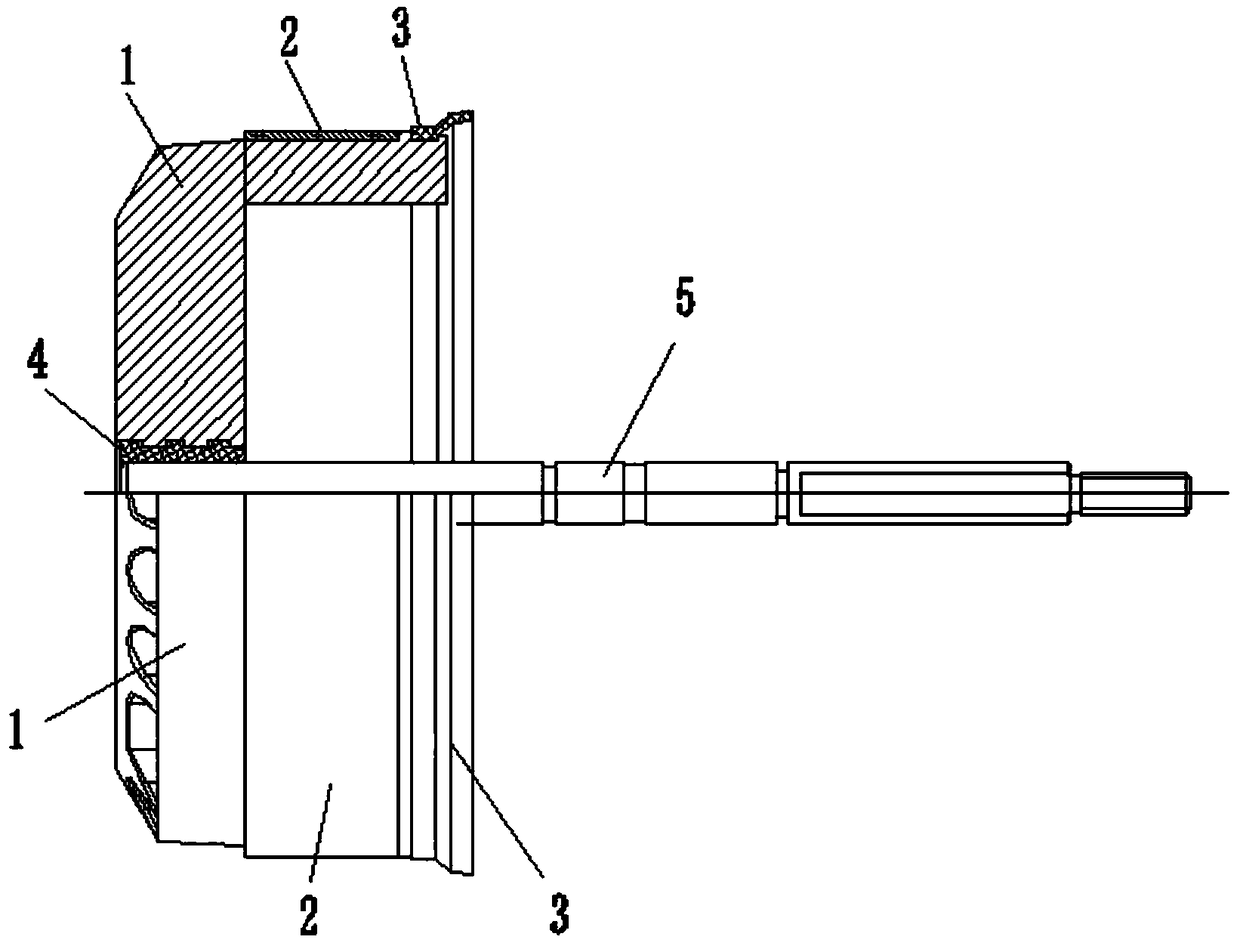

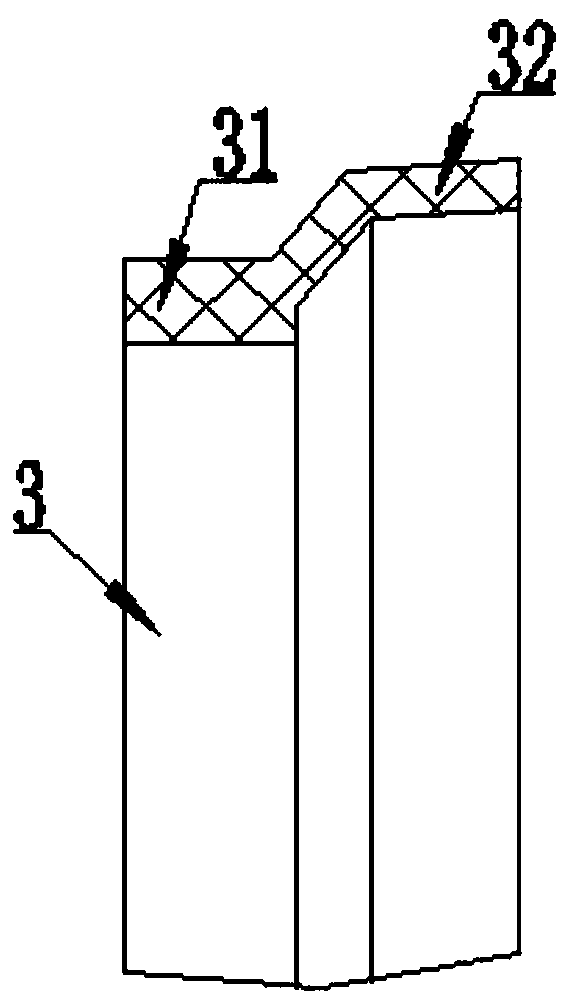

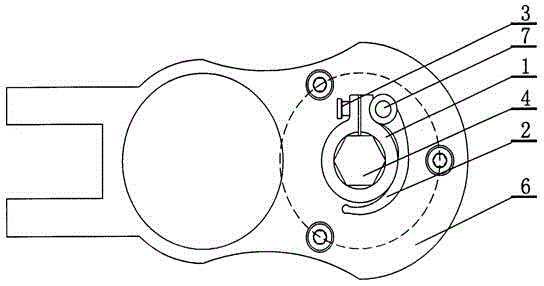

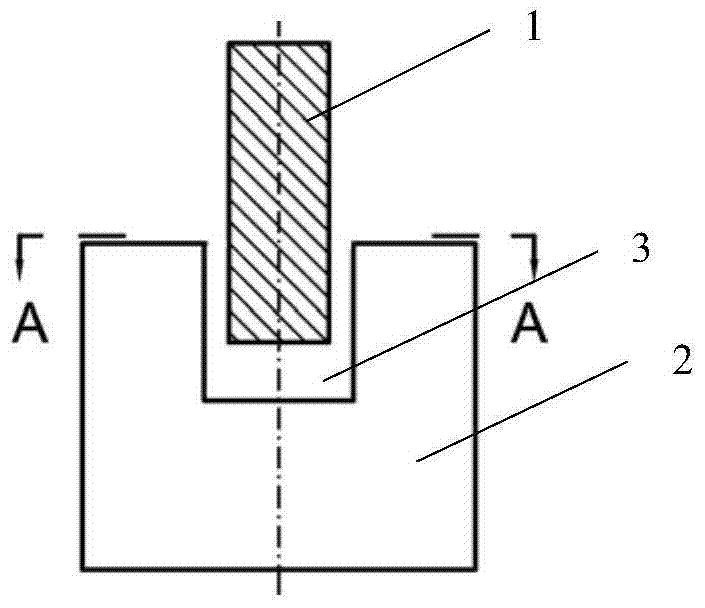

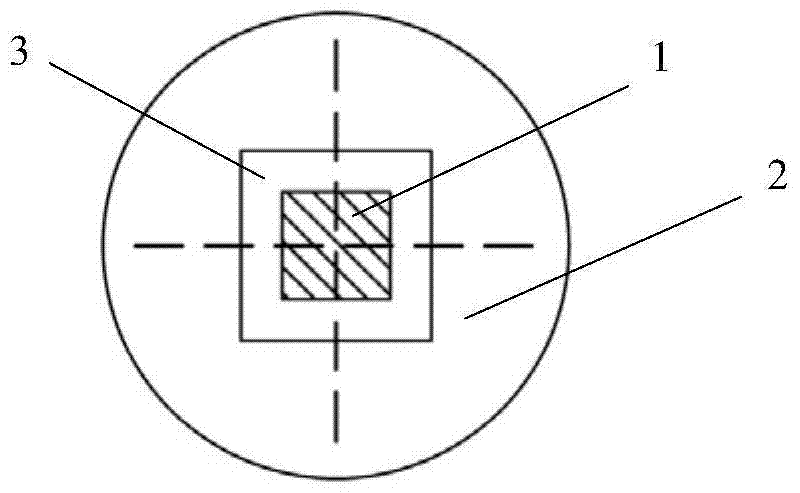

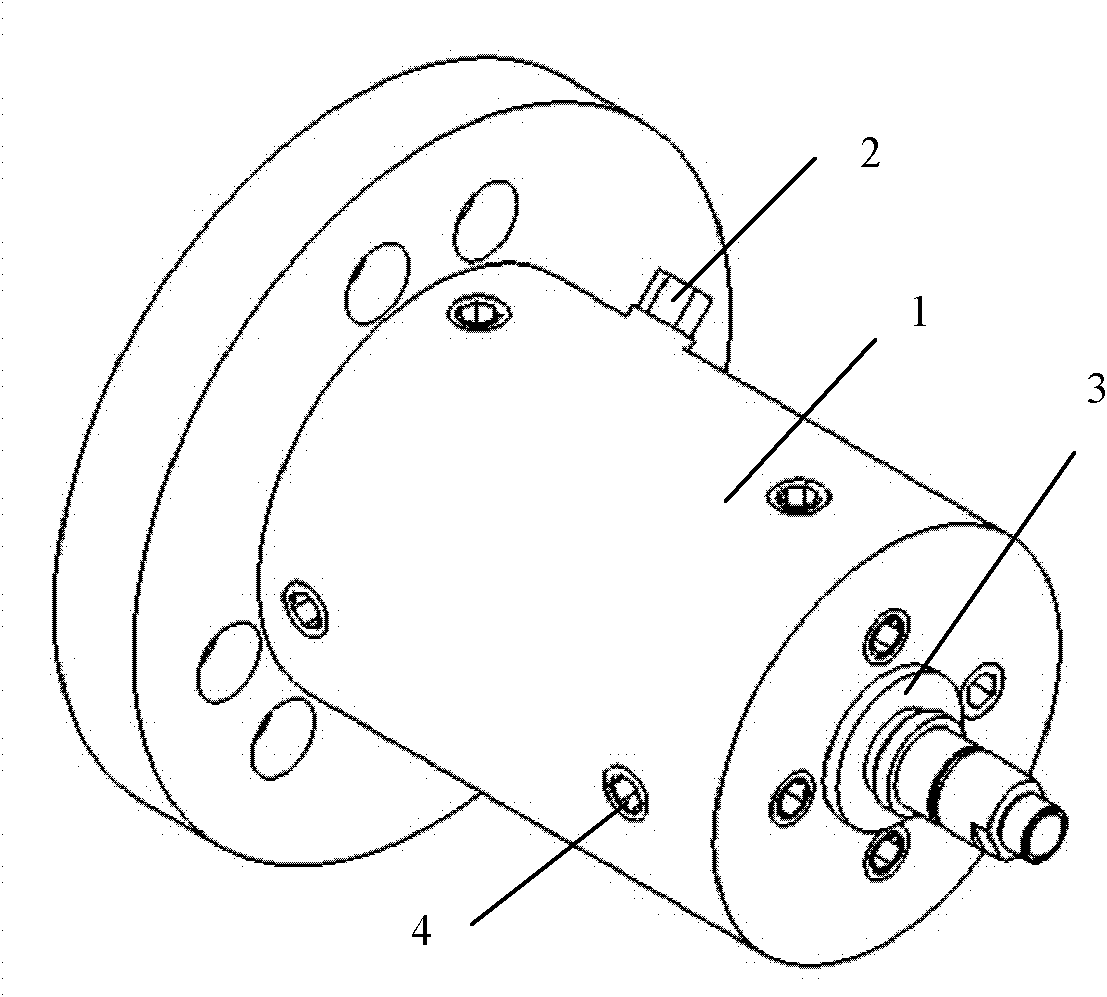

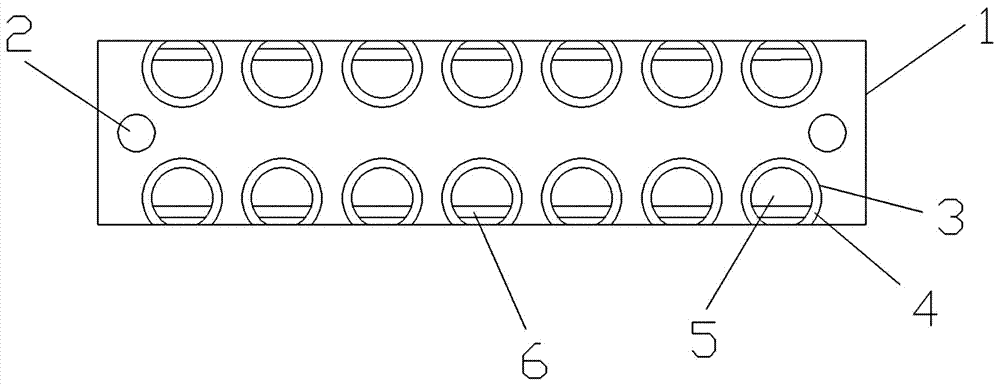

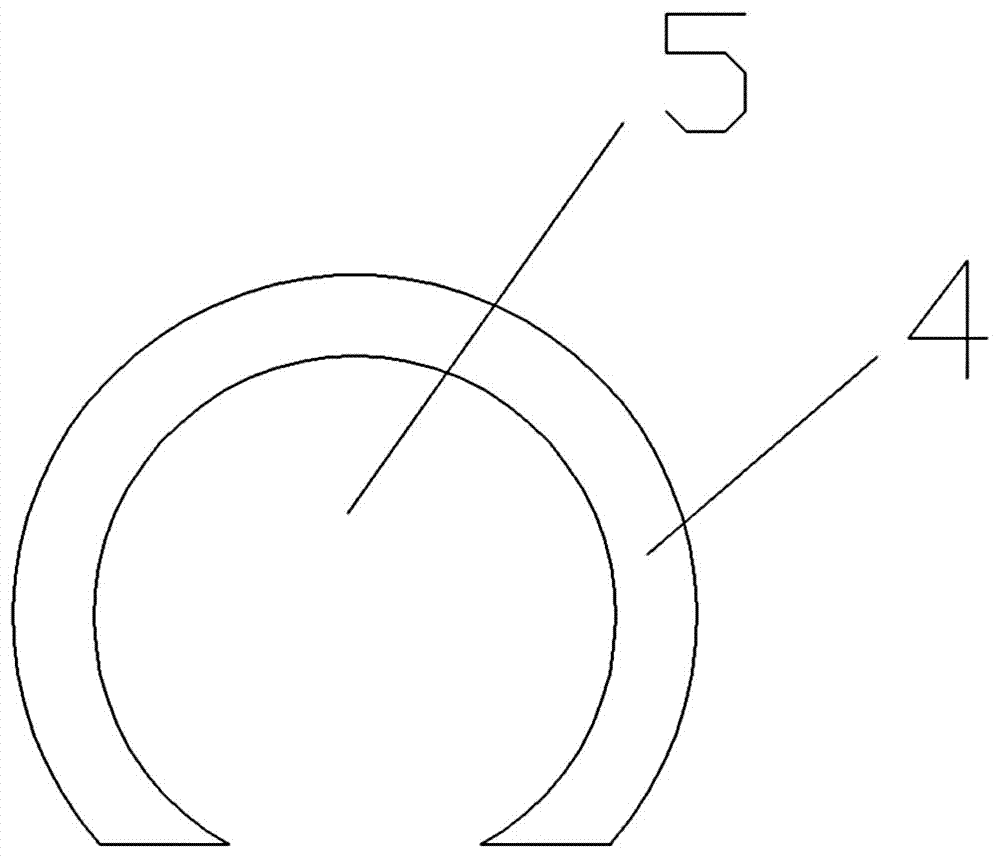

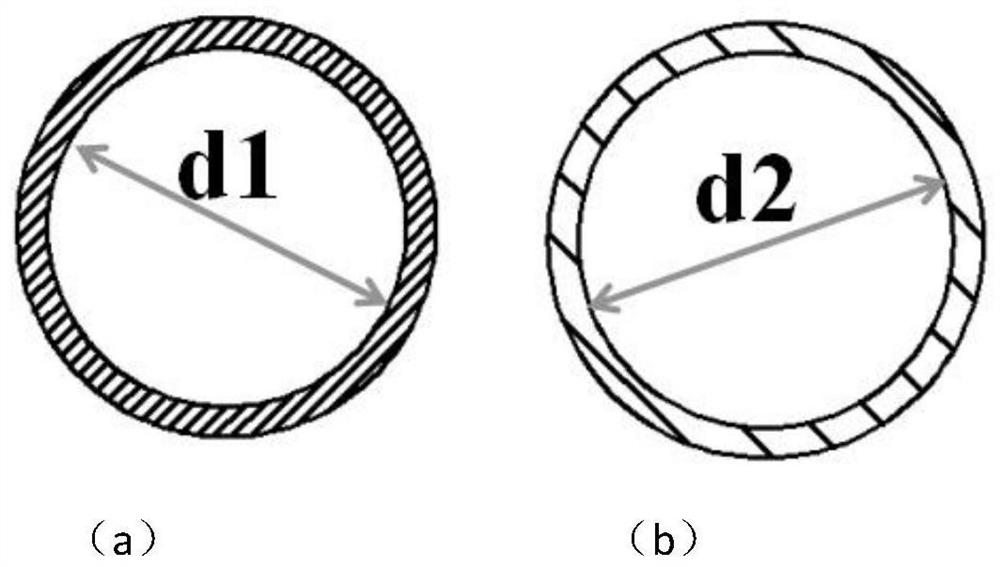

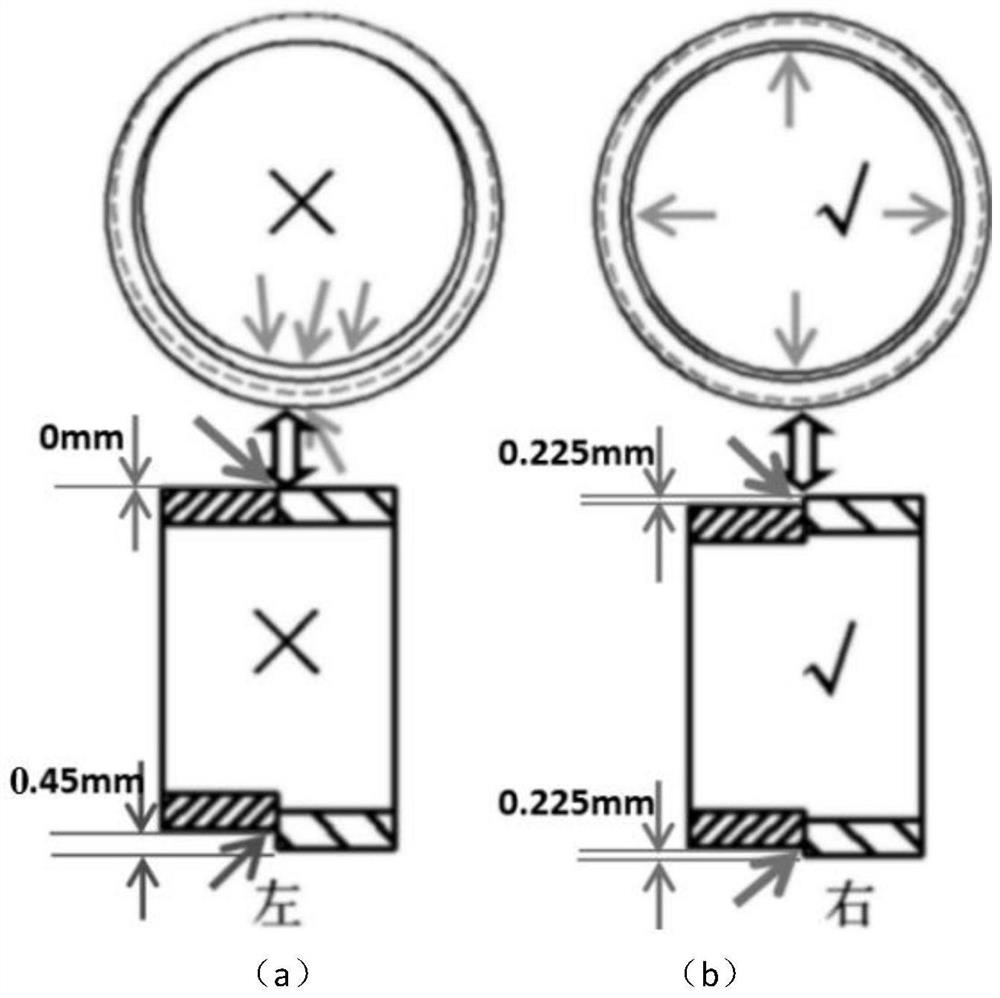

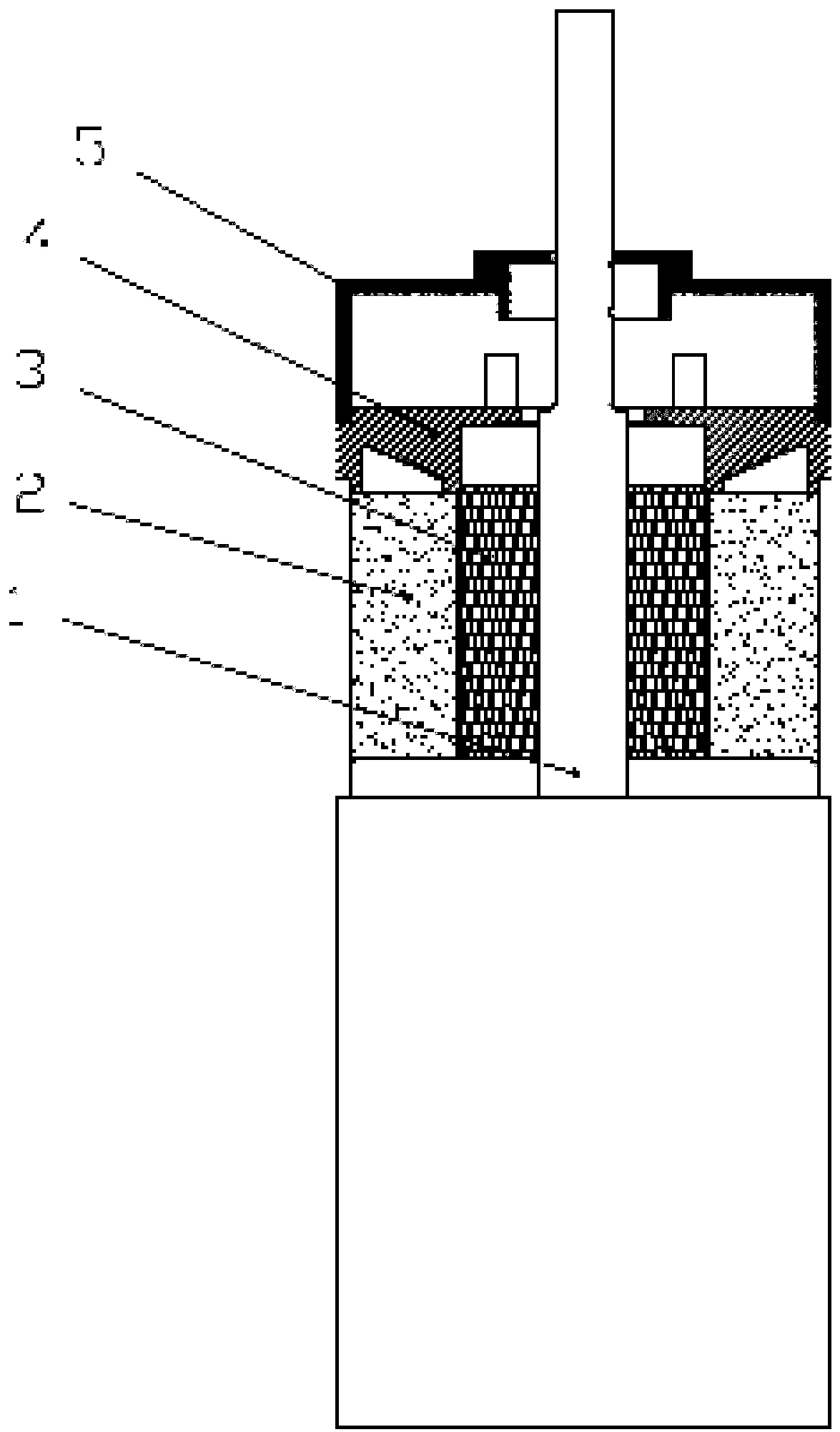

A double-fed wind driven generator novel seam allowance assembling structure and an assembling method

ActiveCN103607063ASolving Concentricity ProblemsSolve the problem of air gap uniformityManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringWind field

The invention discloses a double-fed wind driven generator novel seam allowance assembling structure comprising a machine support (1) and an end cap (2). The machine support (1) is provided with an inner seam allowance (3). The end cap is provided with an outer seam allowance (4). A gap exists between an outer circumference surface of the outer seam allowance (4) of the end cap (2) and an inner circumference surface of the inner seam allowance (3) of the machine support (1). A plurality of positioning holes A (5) are arranged uniformly along a circumferential direction on the end cap (2). The machine support (1) is provided with positioning holes B (6) matched with the positioning holes A (5). Positioning pins (7) are arranged inside the positioning holes A (5) and the positioning holes B (6). The invention also discloses an assembling method for the assembling structure. The beneficial effects of the present invention are that: problems of air gap uniformity and concentricity of front and back end cap bearing chambers are solved; the consistency of the double-fed wind driven generator novel seam allowance assembling structure is good, so that smooth bearing maintenance in wind fields is possible; the structure is more stable, and scratches do not easily occur; long-term operation is facilitated; and the economical efficiency is good.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

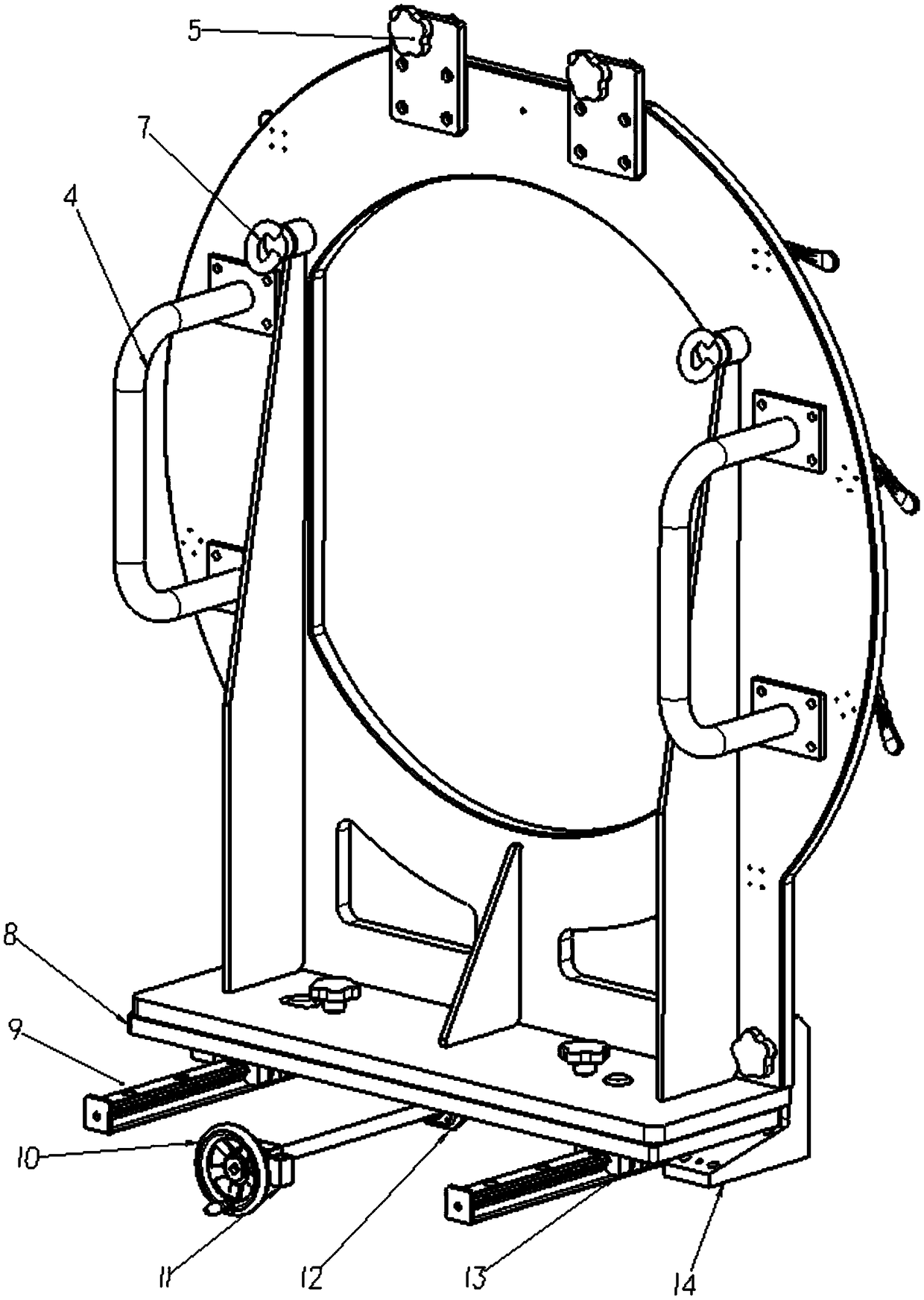

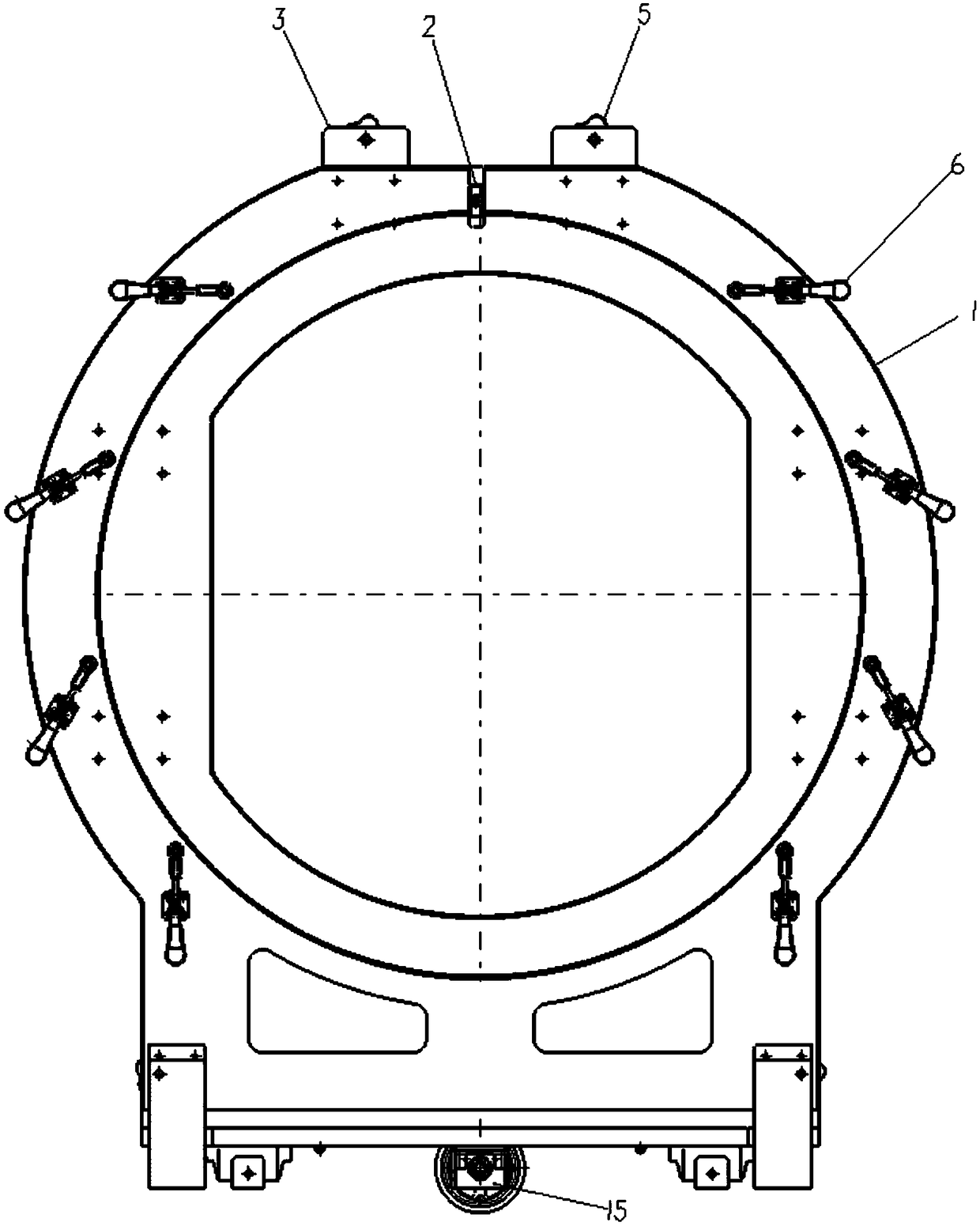

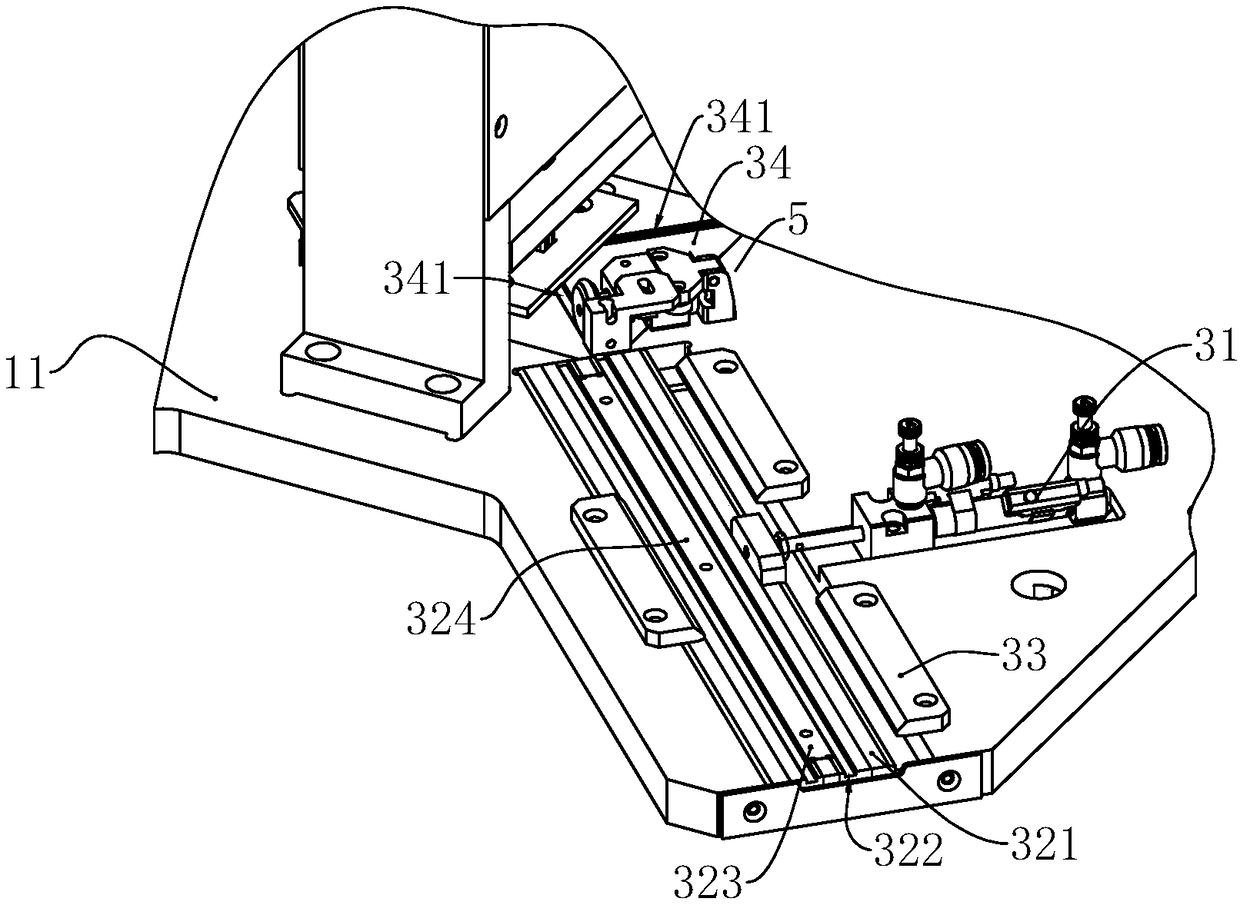

Device for installing cylindrical flange

ActiveCN109436367ASolving Concentricity ProblemsSolve the poor verticality of the planeWork holdersAircraft assemblyBall screwForceps

The invention provides a device for installing a cylindrical flange. The device comprises a mounting mechanism and a transmission mechanism, wherein the mounting mechanism comprises a mounting angle seat, a positioning block, a positioning plate, a handle, a handle screw, horizontal clamp forceps and a lifting ring, wherein the mounting angle seat serves as a mounting platform, the handle and thepositioning plate are fixed at the side, provided with a rib, of the mounting angle seat, the positioning block and the horizontal clamp forceps are fixed at the other side of the mounting angle seat,the positioning block is located in the vertical center line of the mounting angle seat, and the horizontal clamp forceps are uniformly distributed on the left and right sides of the mounting angle seat by taking the center of the mounting angle seat as the center of a circle and taking a fixed radius as a datum; the transmission mechanism comprises an angle seat supporting plate, a guide rail, ahand wheel, a ball screw, a drive sliding block, a guide rail sliding block, a limiting angle bracket and a bearing base, wherein the guide rail and the limiting angle bracket are arranged on a workbench, the guide rail sliding block is embedded in the guide rail and moves front and back along the back and rear of the guide rail, the angle seat supporting plate is fixed on the guide rail slidingblock, the drive sliding block is fixed on the angle seat supporting plate, and the whole mounting mechanism is vertically placed on the angle seat supporting plate of the transmission mechanism.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

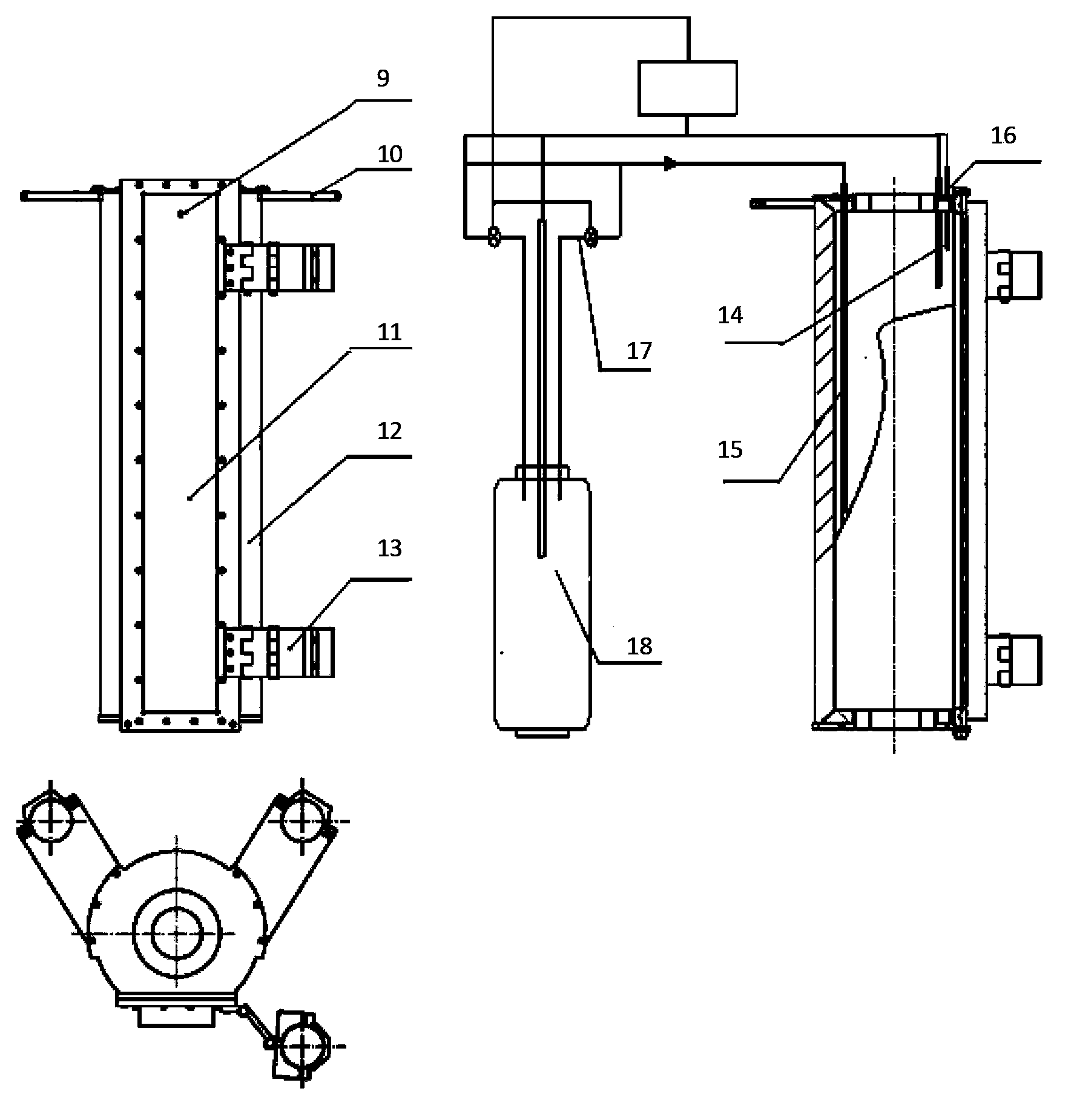

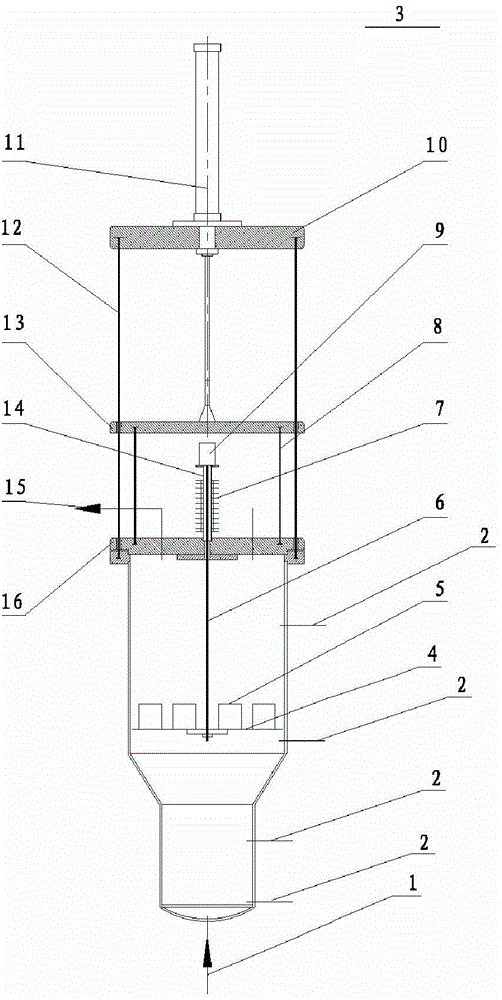

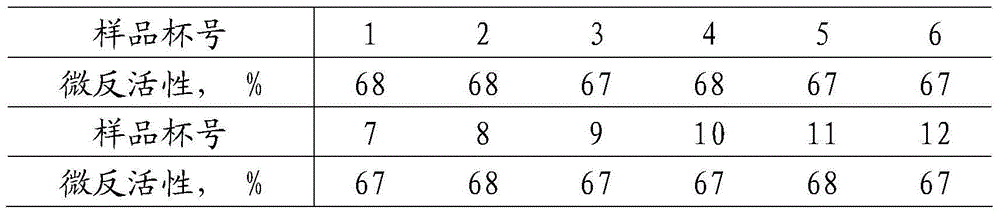

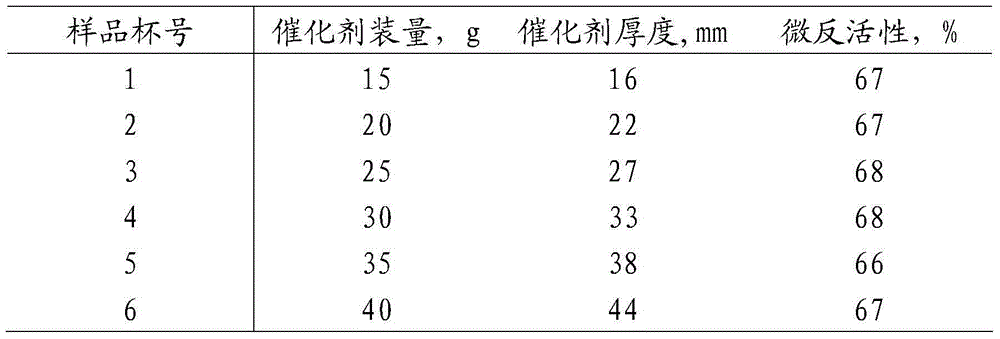

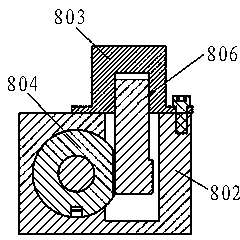

Suspended rotary catalyst ageing oven

InactiveCN104007004AWidely used valueGood repeatability of spin agingPreparing sample for investigationEngineeringFlange

The invention relates to a suspended rotary catalyst ageing oven, comprising a feeding pipe, temperature measuring pipes, an ageing oven, a sample cup bracket, a sample cup, a rotating shaft, a radiator, supporting rods, a motor, a cylinder fixing plate, a lifting cylinder, lifting guide rails, a connecting plate, a motor support frame, a steam outlet pipe and a flange, wherein the upper end of the rotating shaft is connected with the motor and then passes through the center of the flange, the lower end of the rotating shaft is connected with the center of the sample cup bracket, the sample cup is arranged on the sample cup bracket, the motor is supported and fixed by the motor support frame which is fixed on the flange, the flange is fixed on the connecting plate through the two supporting rods, the lifting cylinder is fixed on the cylinder fixing plate, the upper ends of the lifting guide rails are fixed on the cylinder fixing plate, the lower ends of the lifting guide rails are fixed on the flange, the feeding pipe is located at the bottom end of the aging oven, the steam outlet pipe in located between the connecting plate and the flange, the radiator is arranged on the rotating shaft, and the temperature measuring pipes are arranged between the bottom end of the aging oven and the flange.

Owner:KYMSON LUOYANG PETROCHEM EQUIP

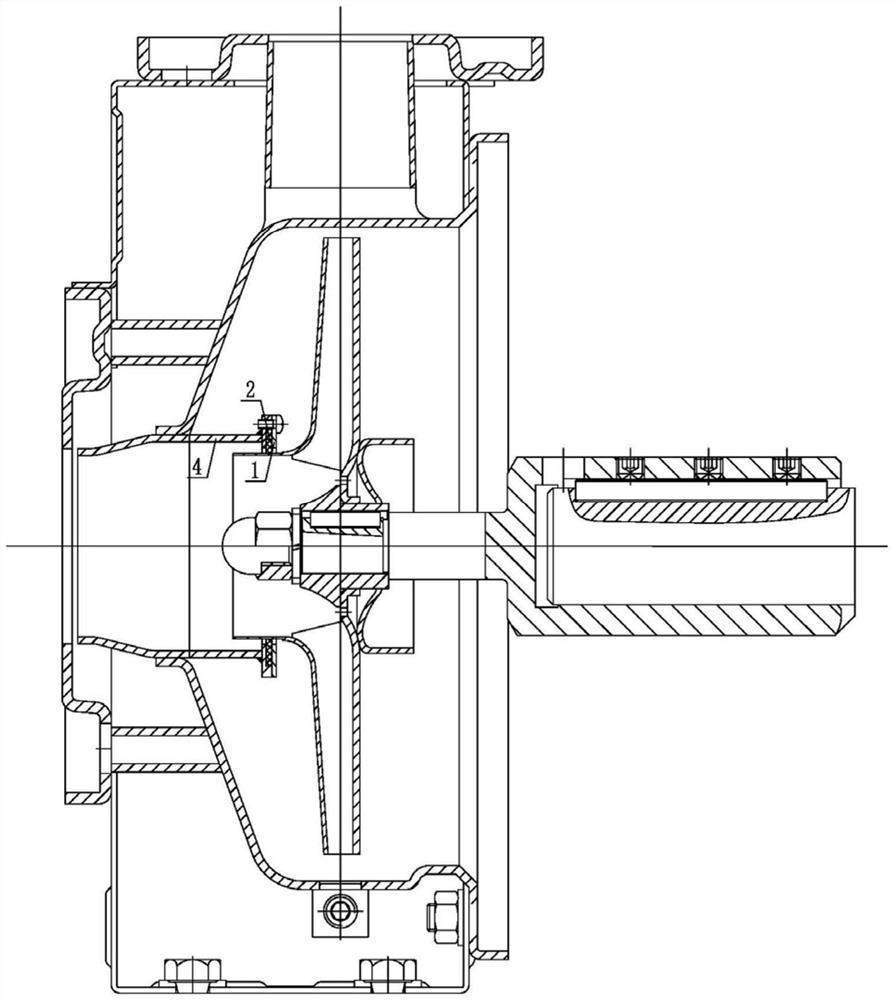

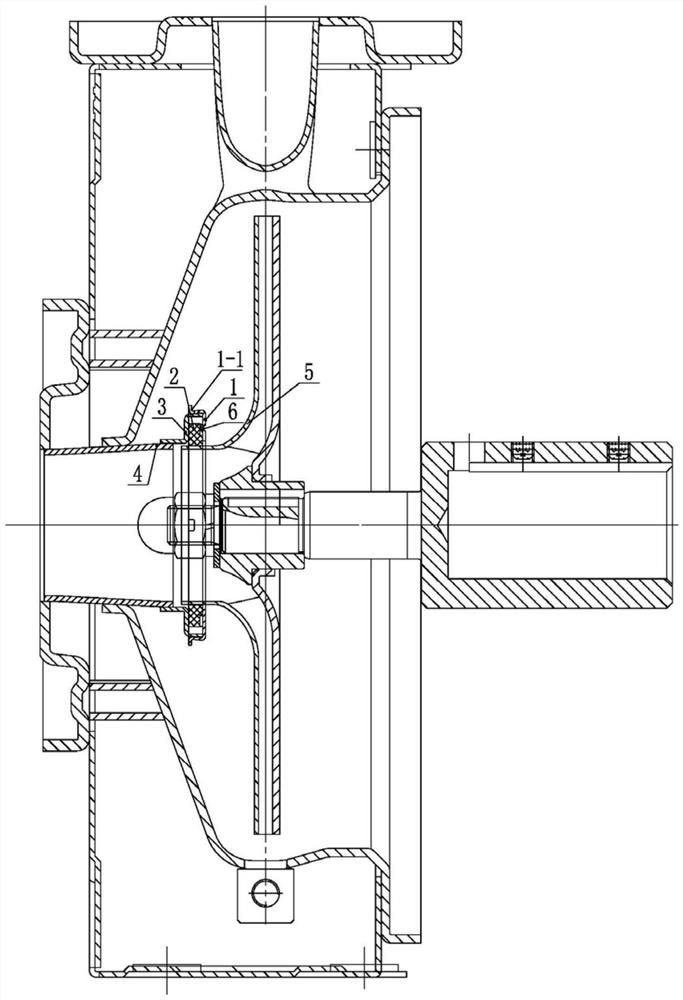

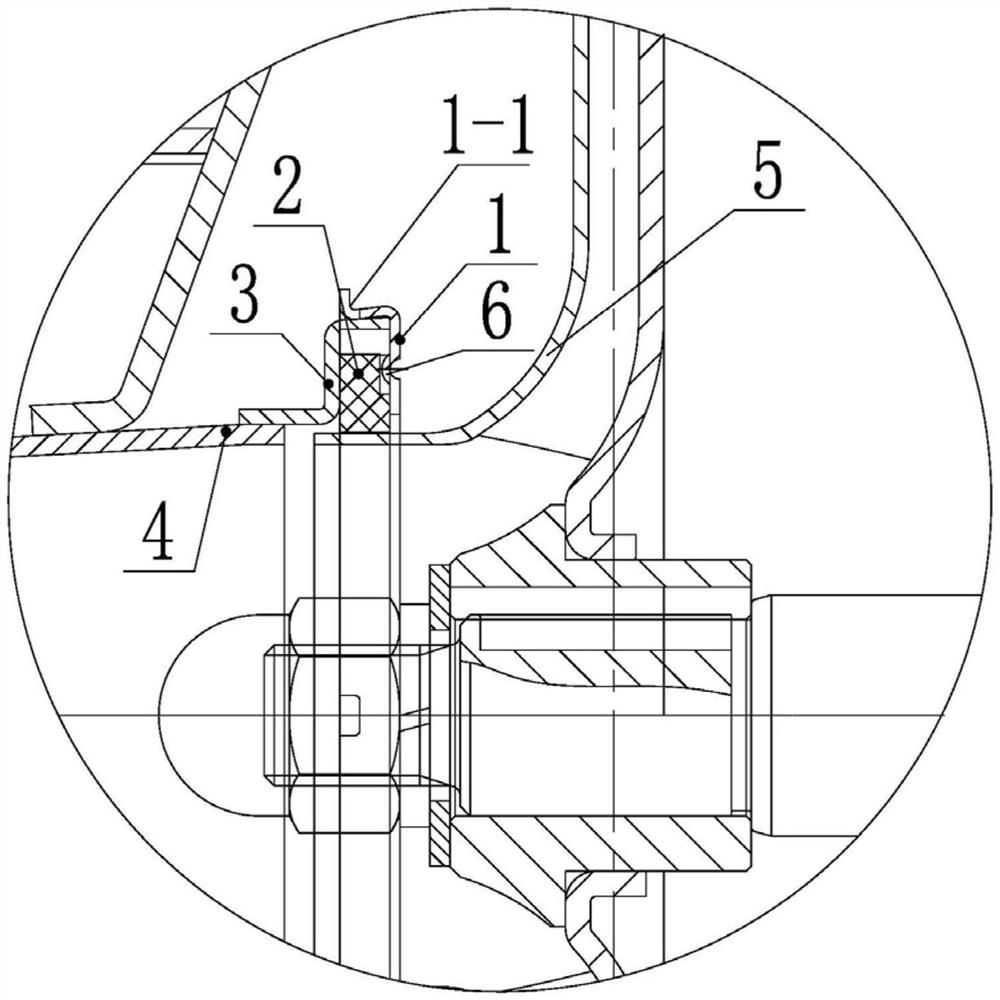

Stamping centrifugal pump sealing structure

PendingCN113915170ASolving Concentricity ProblemsGuaranteed concentricityPump componentsPumpsInterference fitPhysics

The invention discloses a stamping centrifugal pump sealing structure. The stamping centrifugal pump sealing structure comprises an impeller ring, an impeller ring seat, a water inlet pipe and an impeller ring cover, one end of the water inlet pipe is connected with an inner circle of the impeller ring seat in an inserted interference fit mode, the impeller ring cover is arranged on an outer circle of the impeller ring seat in a sleeving mode, a cavity is defined by the outer circle and the inner wall of the impeller ring seat and the bottom surface of the impeller ring cover, an impeller is sleeved with the impeller ring, and the impeller ring is arranged in the cavity; convex points are arranged on the bottom surface of the impeller ring cover and are used for being clamped with clamping grooves in the impeller ring. The structure has the beneficial effects that (1) the problem about concentricity is solved, and the impeller ring seat is directly in interference fit with the water inlet pipe, so that the concentricity is ensured through matching; (2) machining steps of the new structure are omitted, procedures are reduced, and the cost is reduced; and (3) the convenience of assembly is improved, and the impeller ring cover is directly pressed on the impeller ring seat without being fixed by screws.

Owner:NANFANG PUMP IND

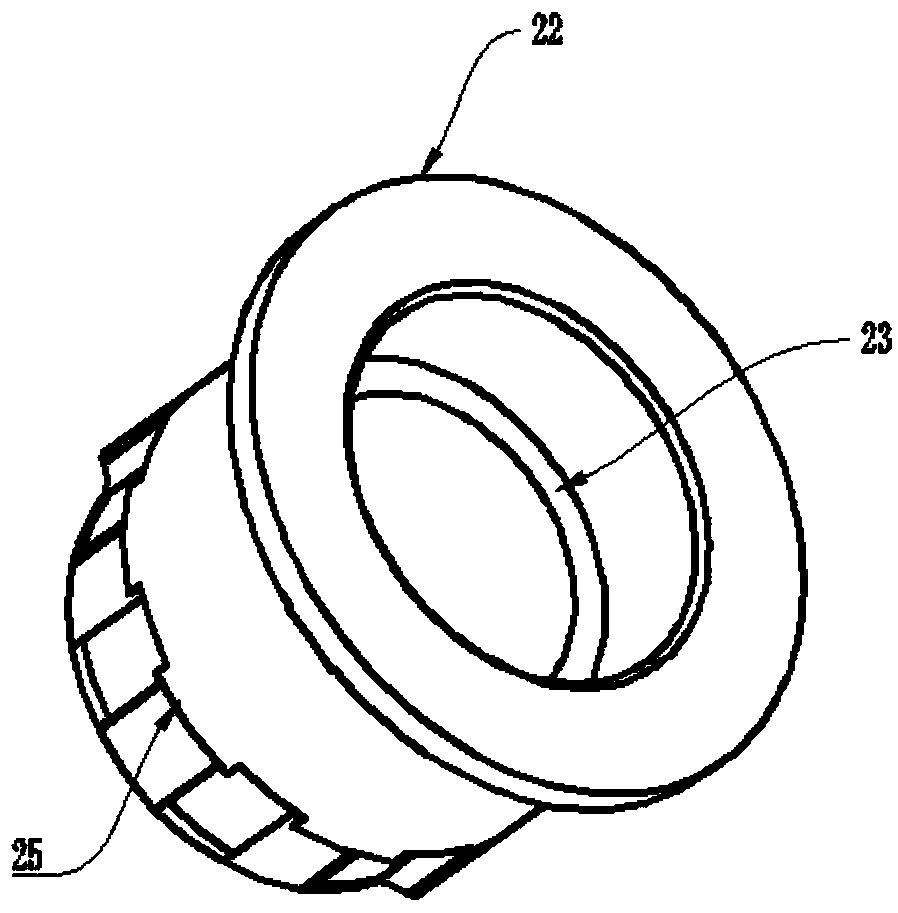

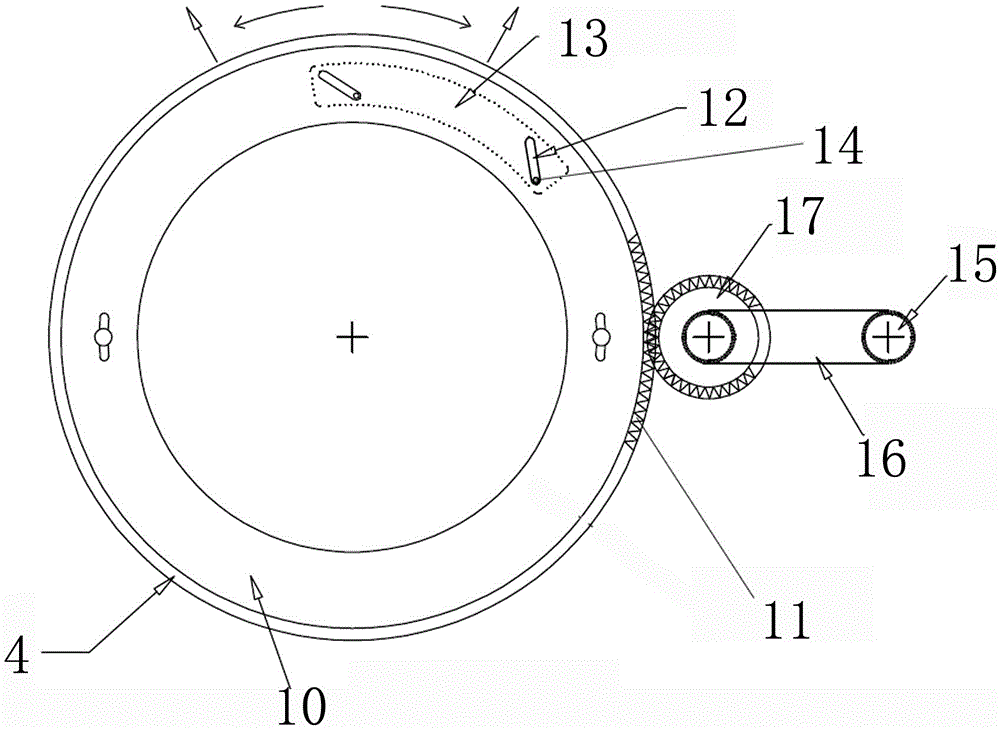

Novel needle cylinder, inner and outer sinker cam-cap and sinker cap structure of computer-controlled hosiery machine

InactiveCN105483925ASolving Concentricity ProblemsSolving synchronicityWeft knittingMachine partsRadial position

The invention discloses a novel needle cylinder, inner and outer sinker cam-caps and a sinker cap structure of a computer-controlled hosiery machine. The structure comprises a needle cylinder, an inner sinker cam-cap, an outer sinker cam-cap and a sinker cap, wherein the needle cylinder and the inner sinker cam-cap are overall or integrally formed, the outer sinker cam-cap is arranged at the upper part of the needle cylinder and sleeved with a bearing, and the sinker cap is fixed on an outer ring of the bearing. Original two single pieces, namely, the needle cylinder and the inner sinker cam-cap are replaced with an integrated part, and concentricity and synchronism are realized; the bearing is added to the outer sinker cam-cap, the sinker cap is directly fixed with the outer sinker cam-cap through the bearing, concentricity and synchronism of a machine part are ensured, and the problem of face runout of the sinker cap is solved; the mutually matching position of the sinker cap and a stitch cam can be changed; an original adjustable and invariable sinker cam is changed in the mode that the radial position of the sinker cam is variable under the action of curved slots due to the fact that a moving disc with curved slots can be moved on the sinker cap and performs forward or backward motion with the circle center under the action of a stepping motor.

Owner:XINCHANG ZHENXING TEXTILE MACHINERY CO LTD

Rotor aluminum casting structure of outer rotor motor

InactiveCN108718126AExtended service lifeSolve the jumpMagnetic circuit rotating partsSupports/enclosures/casingsEngineeringLiquid circulation

The invention relates to the technical field of outer rotor motors, and particularly relates to a rotor aluminum casting structure of an outer rotor motor. The rotor aluminum casting structure comprises an injection mold main body, a rotor core is fixedly arranged in the injection mold main body, a plurality of liquid circulation holes are formed in the circumferential direction of the rotor core,the liquid circulation holes are arranged along the axial direction of the rotor core, a waterproof ring is arranged on one side of the rotor core, the waterproof ring is fixed in the injection moldmain body, a rotating shaft is coaxially arranged in the rotor core, a shaft seat is fixedly sleeved at the tail of the rotating shaft, the shaft seat is fixed in the injection mold main body, and therotor core, the waterproof ring, the shaft seat and the rotating shaft are packaged together through injection molding equipment to form a plastic package main body. The rotor aluminum casting structure provided by the invention effectively eliminates the assembly error caused by the conversion, and effectively solves the problem of the circular rotation of the rotating shaft, and as the rotor core, the waterproof ring, the shaft seat and the rotating shaft are packaged together, the problem of concentricity of the rotating shaft with the plastic package main body and the rotor core is effectively solved, and the service life of the motor is effectively prolonged.

Owner:合肥市通得力电气制造有限公司 +1

Automatic locked centering dustproof mechanism for drilling machine

InactiveCN105715216AGuaranteed uptimeExtended service lifeDrilling rodsDrilling casingsEngineeringMechanical engineering

The invention relates to an automatic locked centering dustproof mechanism for a drilling machine. According to the structure of the automatic locked centering dustproof mechanism, two cracks which are perpendicular to each other are formed in the upper end of an anchor rod sleeve of the drilling machine; an automatic locked centering device is arranged at the vertical crack of the anchor rod sleeve; a hexagon guide sleeve is arranged inside the anchor rod sleeve; the anchor rod sleeve is mounted on a bearing seat through a centering bearing in a linked manner; a dustproof ring is arranged below the centering bearing and is fixed on the anchor rod sleeve; the bearing seat is fixed on the upper end cover of the drilling machine. The automatic locked centering dustproof mechanism has functions of automatic locking, centering, dust prevention and the like, and the service life of the drilling machine can be prolonged.

Owner:CHANGZHOU ZHONGLI MACHINERY MFG CO LTD

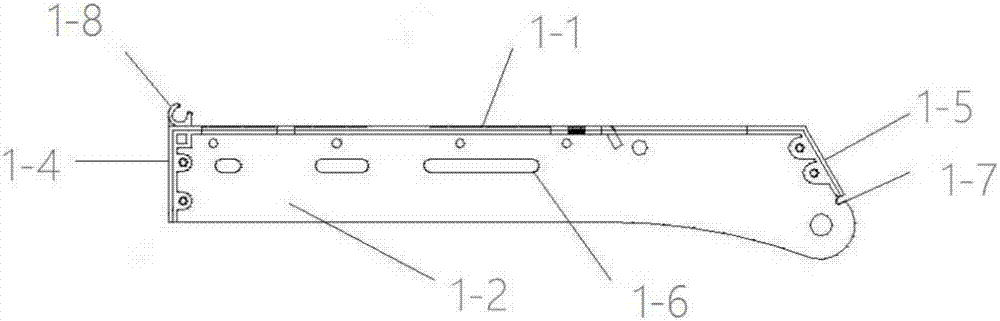

Novel spinning cradle

The invention relates to a novel spinning cradle. The novel spinning cradle comprises a handle, a casing, an upper fixing clamp and a lower fixing clamp, and is characterized in that any one or more of the casing, the upper fixing clamp and the lower fixing clamp are not integrally formed. The novel spinning cradle has the beneficial effects as follows: the technology for the casing, the upper fixing clamp and the lower fixing clamp is simple, concentricity is high, and batch production can be realized.

Owner:ZHANGJIAGANG GUANGDA TEXTILE MACHINERY

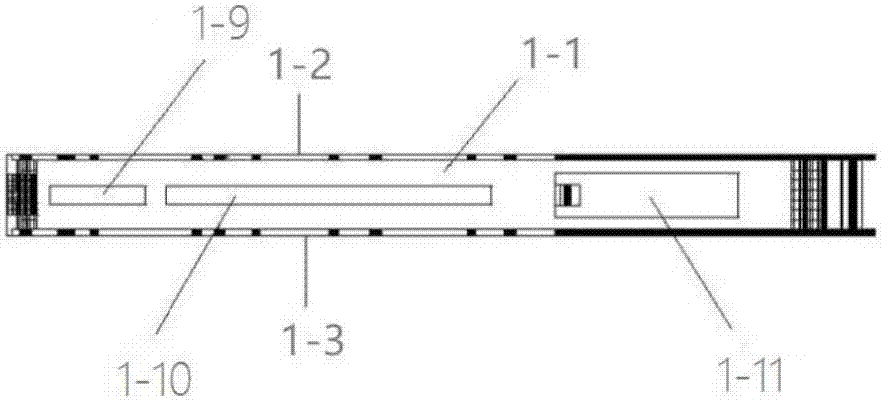

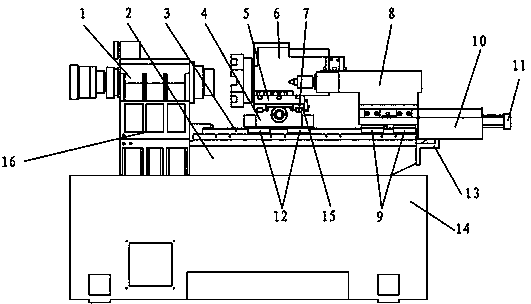

Precision gang tool level bed numerically controlled lathe with tailstock

InactiveCN104493202ASimple structureReasonable designAutomatic/semiautomatic turning machinesTailstocks/centresAgricultural engineeringMachine tool

The invention relates to a precision gang tool level bed numerically controlled lathe with a tailstock and belongs to the technical field of metal cutting machine tools. The lathe comprises a base, wherein a headstock seat and a bed are fixedly arranged on the base; a headstock unit is fixedly arranged on the headstock seat; a Z-axis linear rail and a Z-axis lead screw are fixedly arranged on the bed; a first Z-axis linear rail slide block is arranged on the Z-axis linear rail in a sliding fit manner; a middle planker is fixedly arranged on the first Z-axis linear rail slide block and connected with the Z-axis lead screw; an X-axis linear rail and an X-axis lead screw are fixedly arranged on the middle planker; an X-axis linear rail slide block is arranged on the X-axis linear rail in a sliding fit manner; a small planker is fixedly arranged on the X-axis linear rail slide block and connected with the X-axis lead screw; a multistation cutter turret is fixedly arranged on the small planker; a second Z-axis linear rail slide block is arranged on the Z-axis linear rail in a sliding fit manner; a tailstock unit is fixedly arranged on the second Z-axis linear rail slide block; and the bottom of the tailstock unit is connected with a hydraulic tailstock push cylinder. The lathe has positive significance for popularization of the numerically controlled machine tools.

Owner:杭州万宝数控机床有限公司

Adapter for transferring torque between square and square bore shafts

ActiveCN104948596BFlexible fillingEfficient fillingYielding couplingWork measurementFatigue damageControl theory

The invention discloses an adapter piece for transmitting torque between a square shaft and a square hole shaft, which belongs to the technical field of measurement and the field of mechanical assembly accessories. The adapter for transmitting torque between a square shaft and a square hole shaft according to the present invention includes a square cylinder, the inner and outer radial surfaces of the square cylinder are adapted to the square shaft and the square hole respectively, and the square cylinder is a split type , which is composed of two symmetrical right-angle gaskets. Under the torsion state, the two right-angle gaskets open to the surroundings and fit with the inner wall of the square hole; the upper ends of the right-angle gaskets are respectively provided with mounting pieces. The mounting tabs are perpendicular to the right-angle spacers. The adapter of the present invention can be tightly attached to the inner wall of the square hole when in use, is only subjected to pressure, transmits torque through force without being subjected to torque, is not damaged by torsion, and is not easily damaged by fatigue. The adapter of the present invention can be automatically centered when it is twisted, so that the rotation centerlines of the two right-angled gaskets coincide with the axes of the square shaft and the square hole.

Owner:刘军

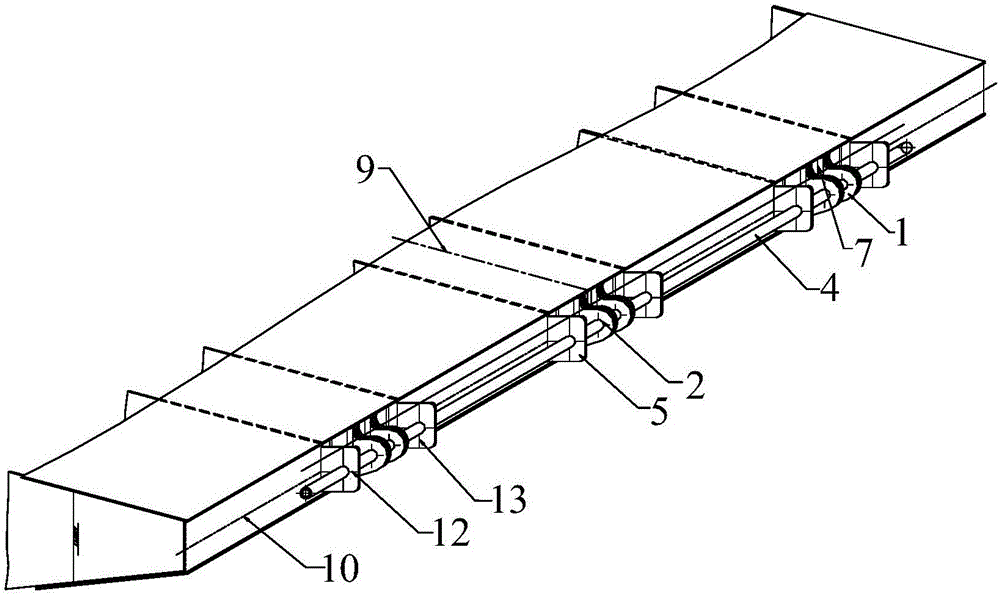

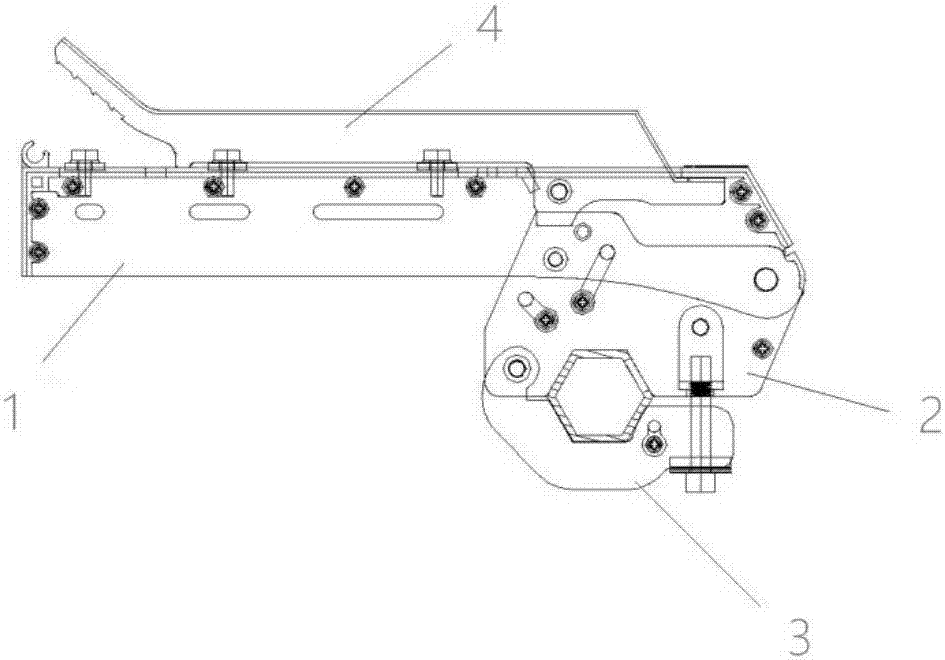

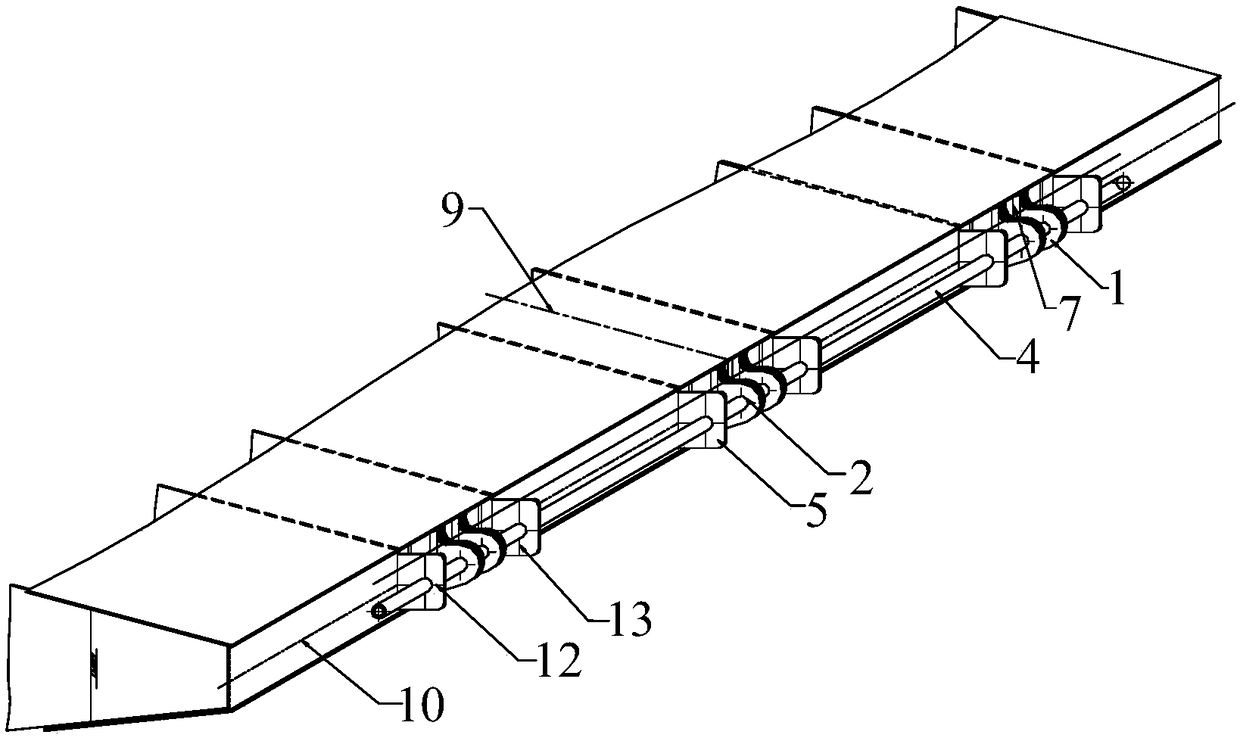

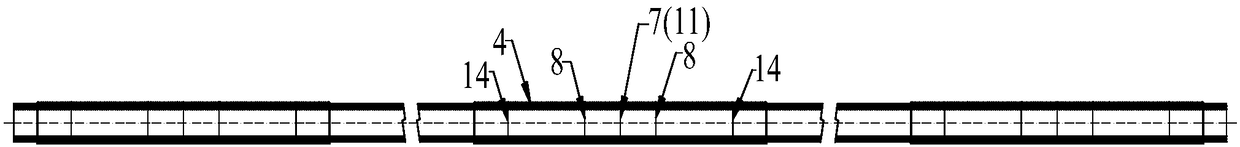

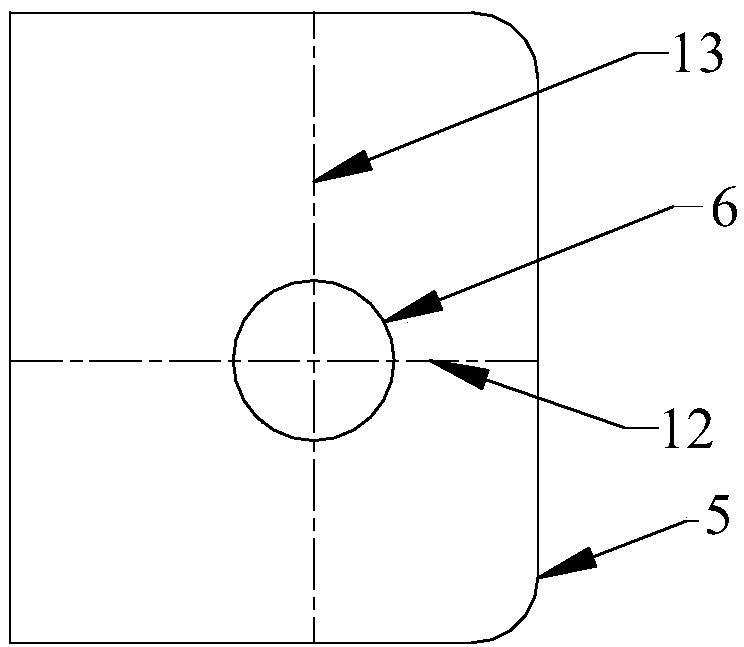

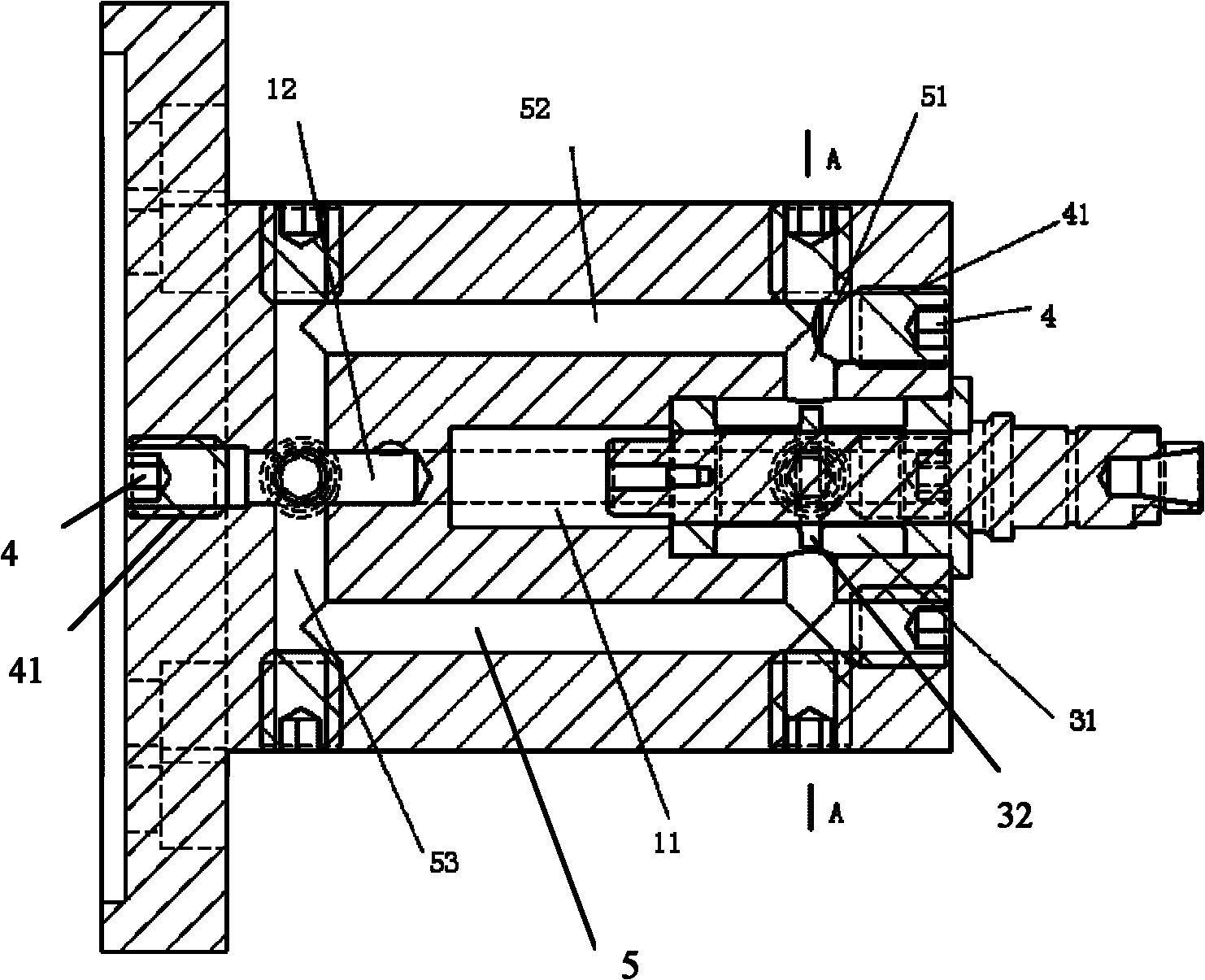

Installation tooling and installation method of opening and closing hinge for ships

ActiveCN106628009BBreak through the technical problem of difficult construction in assembly and weldingResolve parallelismCargo handling apparatusPassenger handling apparatusReference lineStern

The invention provides a marine opening and closing hinge installation tool and method. The installation tool comprises a positioning shaft (4) and positioning reinforcing plates (5), positioning holes (6) are formed in the positioning reinforcing plates (5), and positioning shafts (4) penetrate through the positioning holes (6) in the positioning reinforcing plates (5) and pin holes (2) in a plurality of hinge components (1). The installation method comprises the steps that reference lines are marked on the bow or stern and a gangplank (3) of a ship, accurate positioning during opening and closing hinge installation can be achieved according to the corresponding relation between reference lines on the tool and the reference lines on the ship, the phenomenon that different shrinkages and stresses generated in the construction process, and vertical and front-back size shrinkage malposition are avoided, hinge perpendicularity and center line parallelism can be ensured, the precision is effectively controlled, and installation pairing of the hinge is achieved finally.

Owner:JIANGNAN SHIPYARD GRP CO LTD

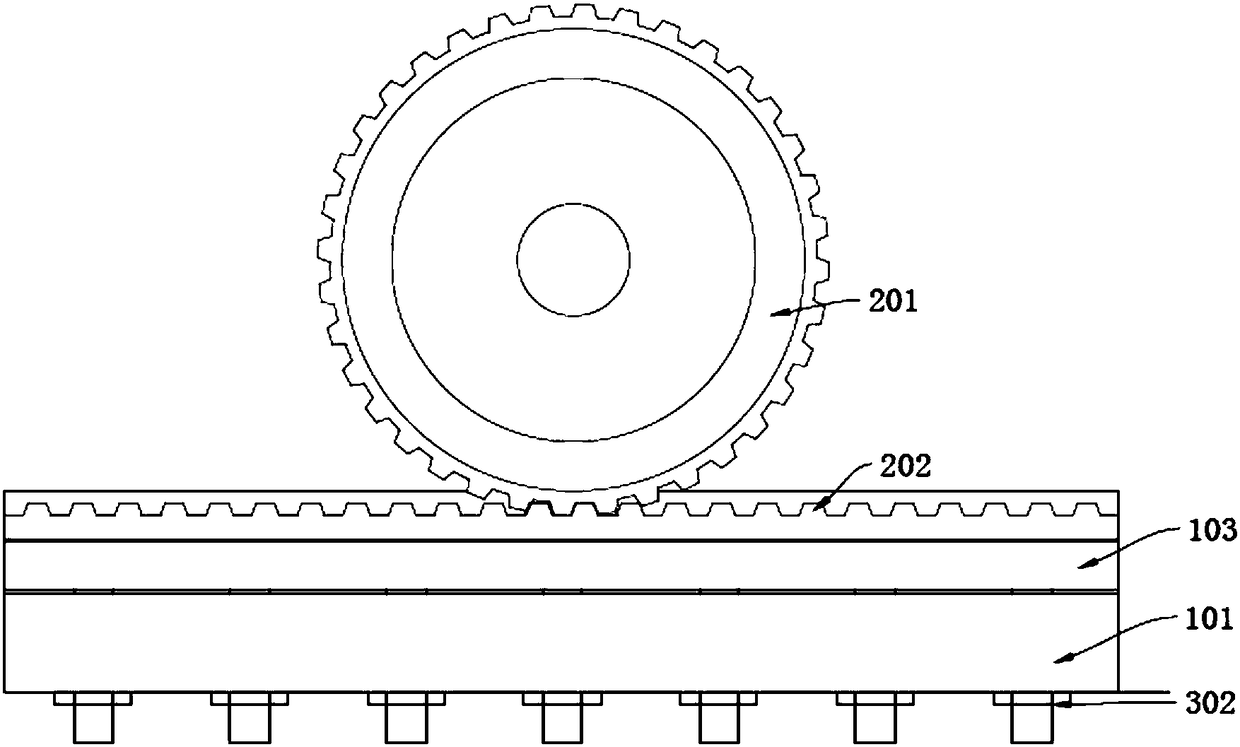

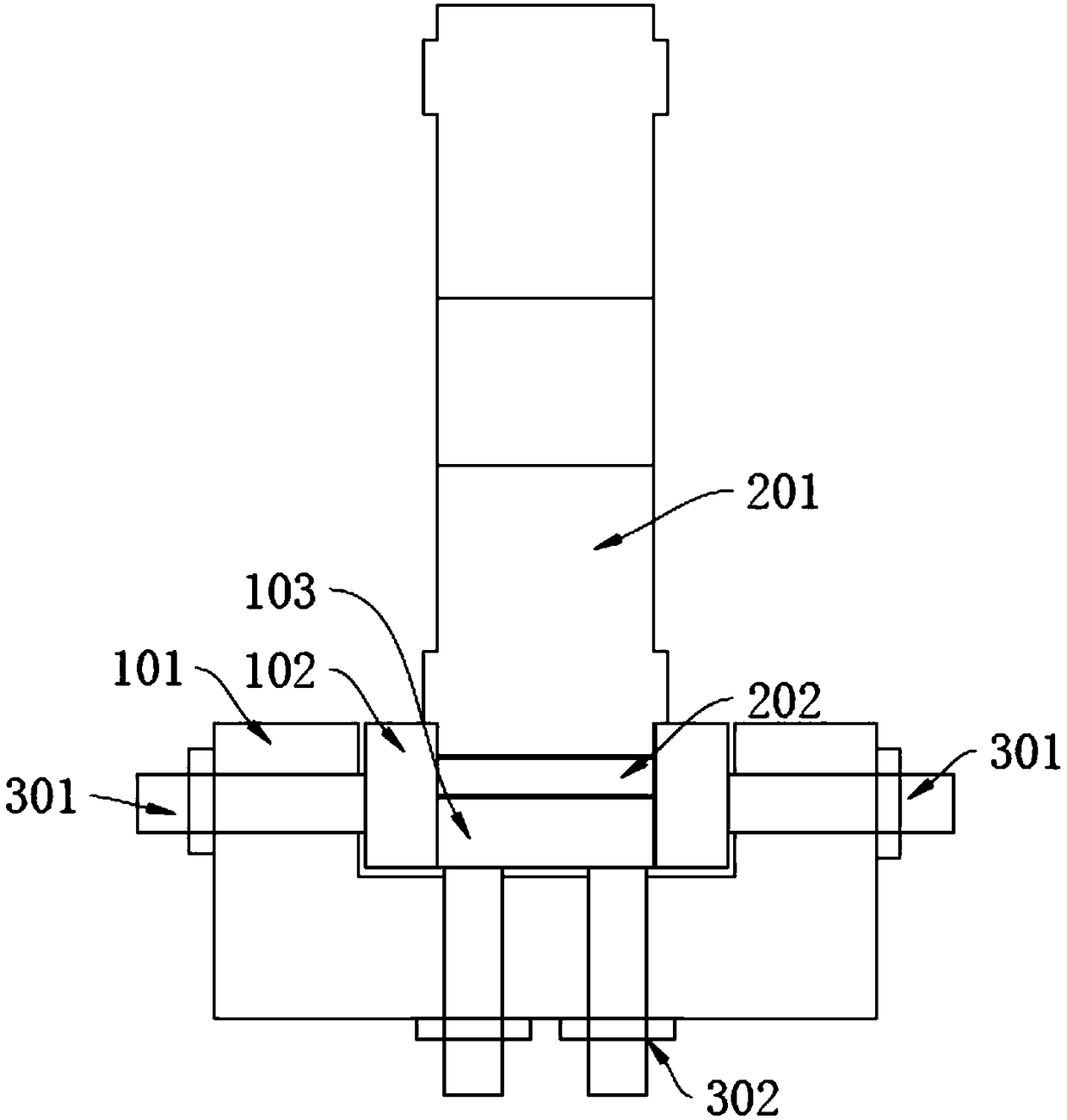

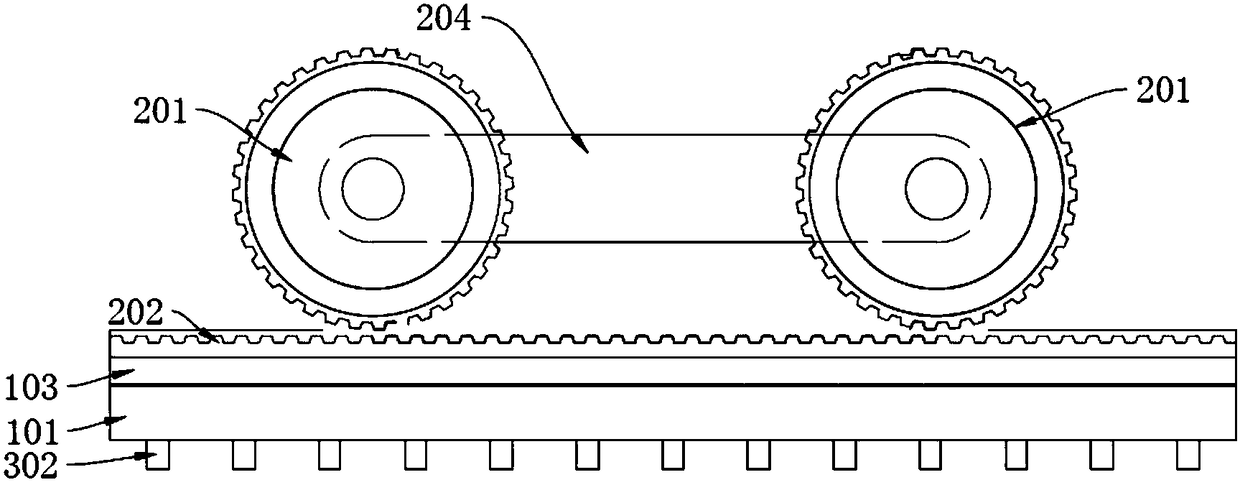

Linear motion mechanism

PendingCN108518459AGuaranteed motion accuracySolve the problem of short transmission distanceFriction gearingsLinear motionEngineering

The invention discloses a linear motion mechanism. The linear motion mechanism comprises a first U-shaped guide rail supporting plate, a plane synchronous belt, a synchronous belt wheel, a first rigidbottom plate and first rigid side plates, wherein the first rigid bottom plate and the two first rigid side plates are mounted in a first groove in the first U-shaped guide rail supporting plate; theplane synchronous belt is arranged on the first rigid bottom plate and is engaged with the synchronous belt wheel. The mounting accuracy of the synchronous belt wheel is ensured through the first rigid bottom plate and the first rigid side plates jointly; the first rigid bottom plate and the first rigid side plates are simple and regular in shape, the mounting accuracy is ensured simply by ensuring the parallelism and planeness of a mounting surface, and the machining cost is much lower than that of a traditional sliding rail, therefore, the machining cost is lowered on the whole; and the synchronous belt wheel and the plane synchronous belt cooperate with the moving accuracy of the linear motion system, a locating mechanism or a locating function based servo system is not required to beconfigured independently, so that the economic cost is further reduced.

Owner:SHANGHAI LIONSTEK CO LTD

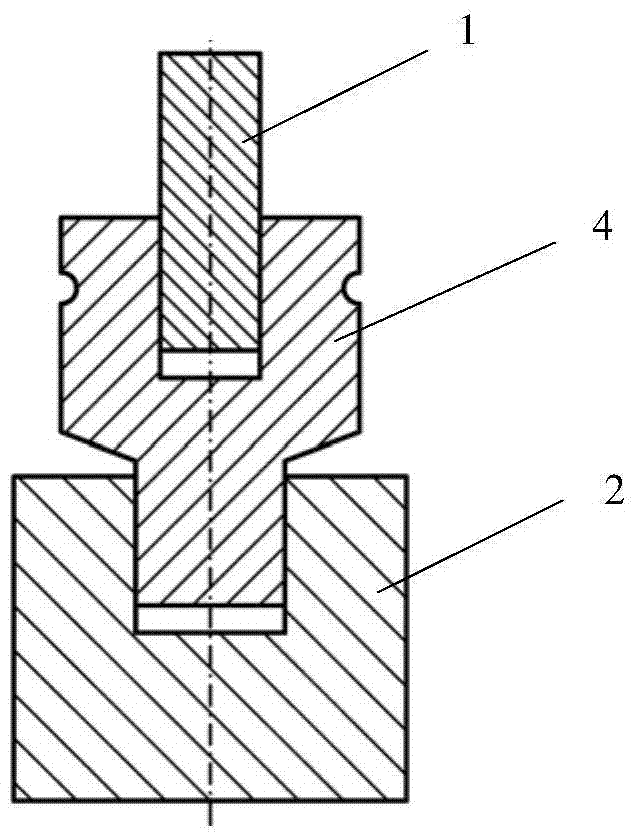

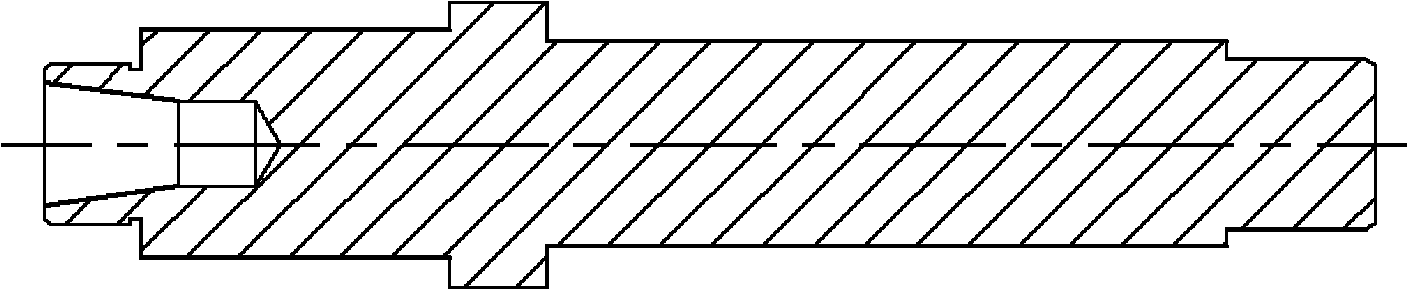

Hydraulic clamp for processing spindle taper hole

InactiveCN102161162BReduce distortionHigh clamping accuracyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a hydraulic clamp for processing spindle taper hole, which realizes grinding instead of milling, solves the problem of coaxiality between a spindle bearing shift of a core part spindle on the high-speed electrical spindle of the core part of a high-speed numerically controlled machine tool and a spindle taper hole, and improves the manufacturing precision of the core part spindle on the high-spindle electrical spindle. The hydraulic clamp comprises a clamp body, wherein the rear end of the clamp body is coaxially connected to the spindle of the precise numerically controlled machine tool; the front end of the clamp and the clamp are coaxially sleeved with an outer expansion sleeve for clamping parts to be processed; the clamp body comprises an inner radiate hydraulic pipeline system which uniformly pressures the inner wall of the outer expansion sleeve; and the radiate hydraulic pipeline system comprises a plurality of radiate hydraulic pipelines with the same aperture, which radiate the later wall of the clamp body uniformly by taking a central axis of the outer expansion sleeve as the centre.

Owner:常州合泰电机电器股份有限公司

Clamping die used for sensor base drilling

The invention discloses a clamping die used for sensor base drilling. The clamping die comprises a die body of a single-layer structure. A set of workpiece holes are formed in the die body. A positioning block in interference fit with the corresponding workpiece hole is arranged in each workpiece hole. A positioning hole is formed in the center of each positioning block. The positioning holes areconcentric with the workpiece holes. The positioning blocks are used for achieving height positioning on sensor bases placed in the workpiece holes. The two rows workpiece holes are arranged in parallel. Two fixing pins are arranged in the die body in a penetrating manner and are used for fixing the positioning blocks in the two rows of workpieces correspondingly in a penetrating and inserting manner. The single-layer die body is adopted, the thickness of the die body is the same as that of an original double-layer die plate, and the die body is not likely to deform in the machining process when being heated; and the height positioning problem and the concentric problem are solved at the same time through the annular positioning blocks, on one hand, the positioning blocks are in interference fit with the workpiece holes, on the other hand, the positioning blocks are firmly fixed through the fixing pins, the phenomenon that the positioning holes of the positioning blocks and the workpiece holes are dislocated cannot occur, it is ensured that the workpiece holes and the positioning holes can be accurately concentric in the use process, and the product quality is ensured.

Owner:BENGBU CHUANGYE ELECTRONICS

Stepped annular part high-precision butt joint circular welding inner supporting tool and design method and welding method thereof

PendingCN113732609ASolve local serious wrong edgeSolving Concentricity ProblemsWelding/cutting auxillary devicesAuxillary welding devicesButt weldingButt joint

The invention provides a stepped annular part high-precision butt joint circular welding inner supporting tool and a design method and welding method thereof. Two sets of supporting petals are designed for two parts, and the outer diameter of each set of supporting petals is the same as the inner diameter of the corresponding supporting part; two sets of staggered wedge-shaped transmission shafts are designed, and a main shaft is sleeved with the wedge-shaped transmission shafts and used for driving the supporting petals to support outwards; and two flanges with locking bottoms are designed at the two ends and can be inserted into the inner sides of the ends of two parts for clamping and fixing, and finally welding of butt joint circular welds is completed. The stepped annular part high-precision butt joint circular welding inner supporting tool solves the problems of easy misalignment, substandard coaxiality and roundness and the like after welding of stepped circular welds with butt joint interface size differences, is suitable for high-precision butt joint circular welding and auxiliary post-welding fine machining of stepped variable-diameter annular (cylindrical or non-cylindrical) parts with butt joint welded junctions with size differences, can guarantee the weld quality and the post-welding shape and position size effectively and can improve the welding efficiency remarkably.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

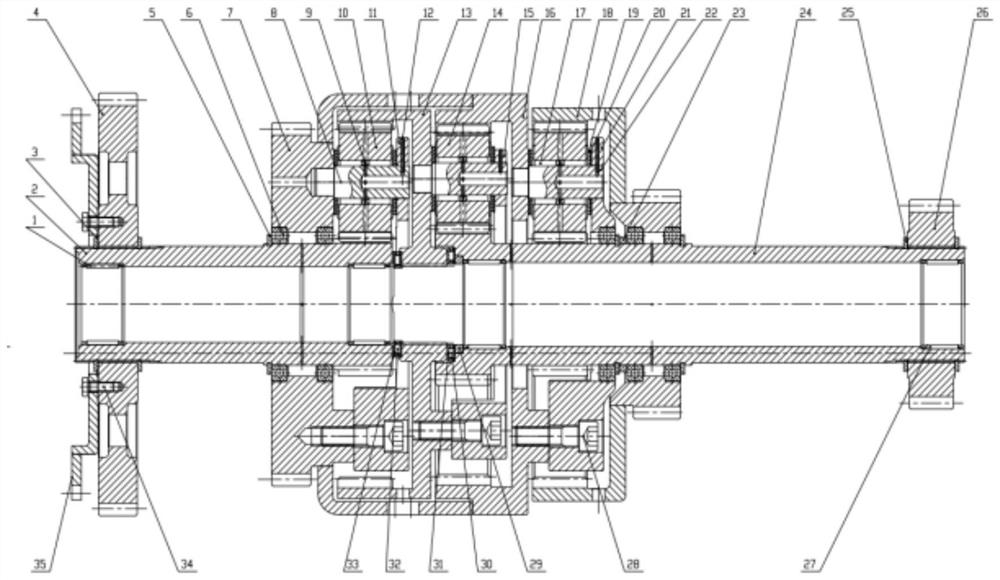

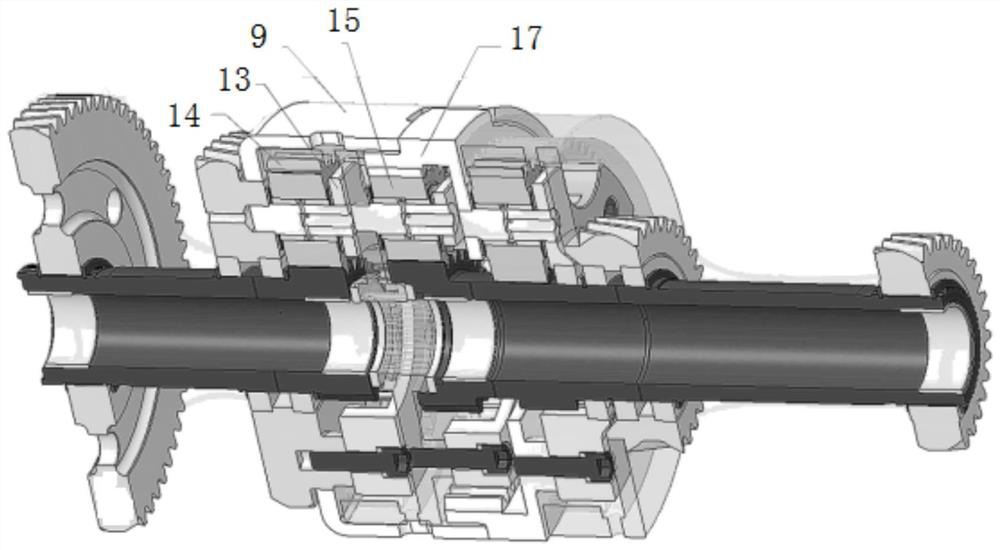

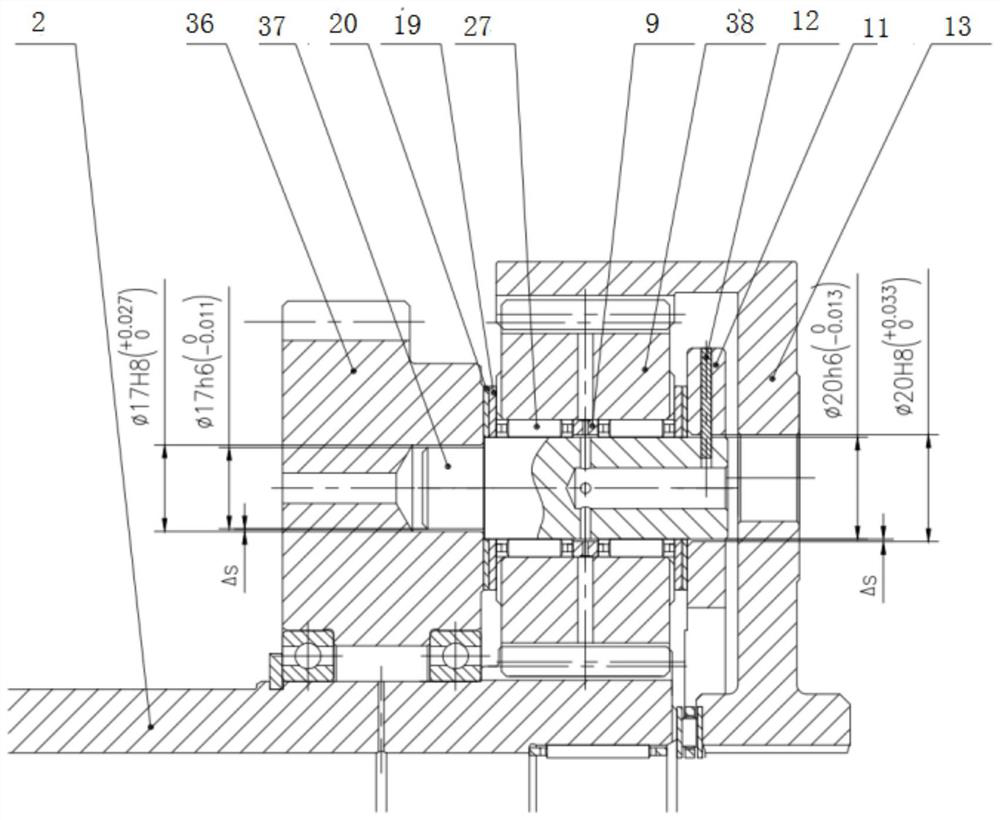

HMCVT three-planet-row converging mechanism of high-power tractor

InactiveCN113958666ALarge transmission torqueConfluence implementationToothed gearingsGearing detailsDrive wheelBall bearing

The invention relates to an HMCVT three-planet-row converging mechanism of a high-power tractor. The mechanism comprises a three-planet-row converging mechanism body, a tooth-embedded connection further-optimized planet gear mechanism and a tooth-embedded connection further-optimized planet gear mechanism. The three-planet-row converging mechanism body comprises a needle bearing, a sun gear P1, a shaft elastic check ring, a motor shaft driven wheel, a shaft elastic check ring, a deep groove ball bearing, a driving wheel sleeve welding part C3, planetary gear shafts P1P2 , a needle bearing spacer bush, planetary gears P1P3, a planetary carrier P1, an elastic pin, a gear ring P1, a planetary gear P2, a planetary carrier P2, a gear ring P2, a needle bearing, a driving wheel gear ring welding part C1 and a thrust copper gasket. The device solves the problem that a single-stage planetary gear transmission system cannot meet the engineering operation requirements of low speed, heavy load and large torque, the problem of concentricity of the sun gear, the planetary carrier and the gear ring of the HMCVT converging mechanism of the high-power tractor is solved, and the problems of uneven load and stress unbalance loading in the meshing process of the planetary row gears are solved.

Owner:NANJING AGRICULTURAL UNIVERSITY

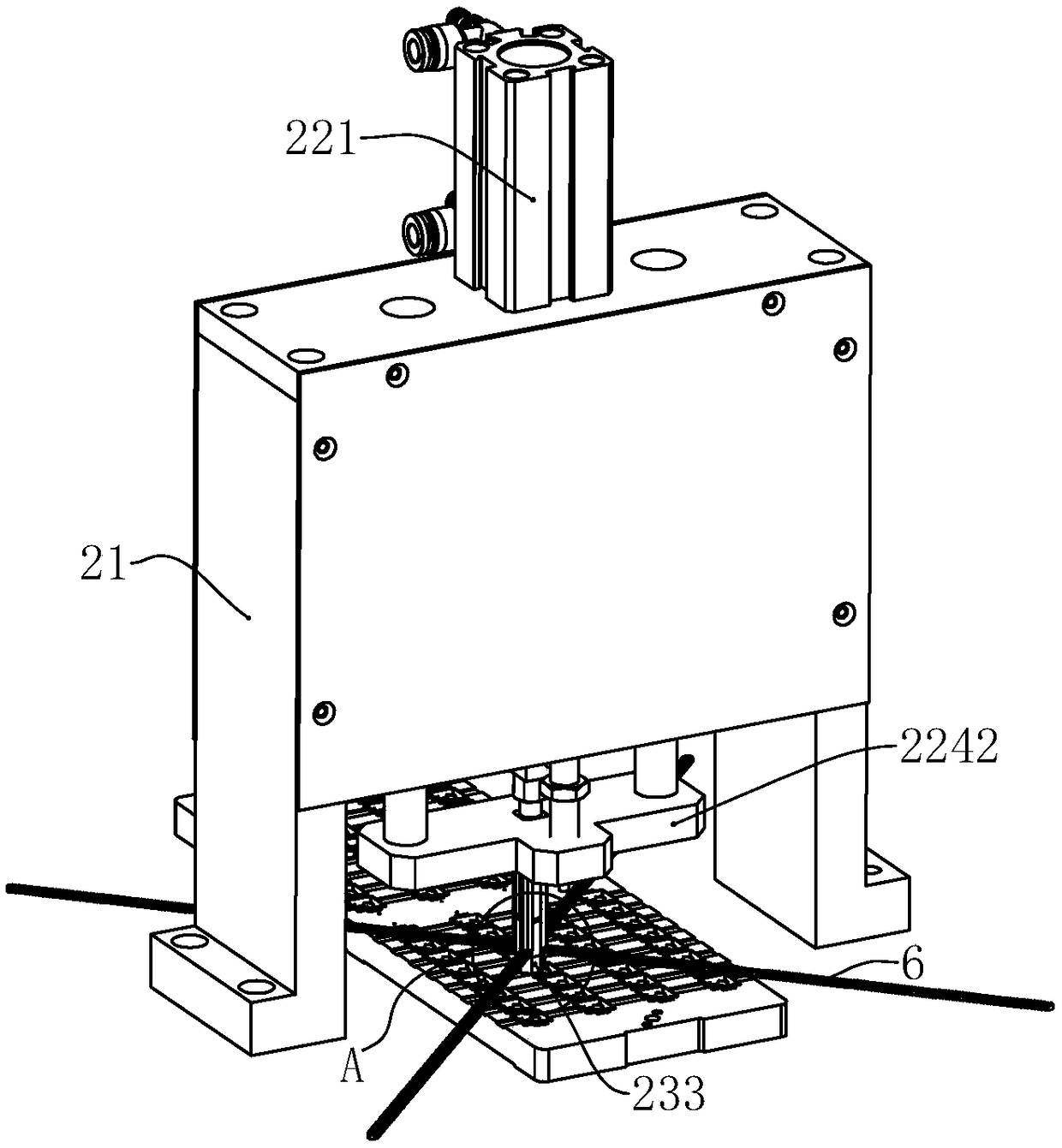

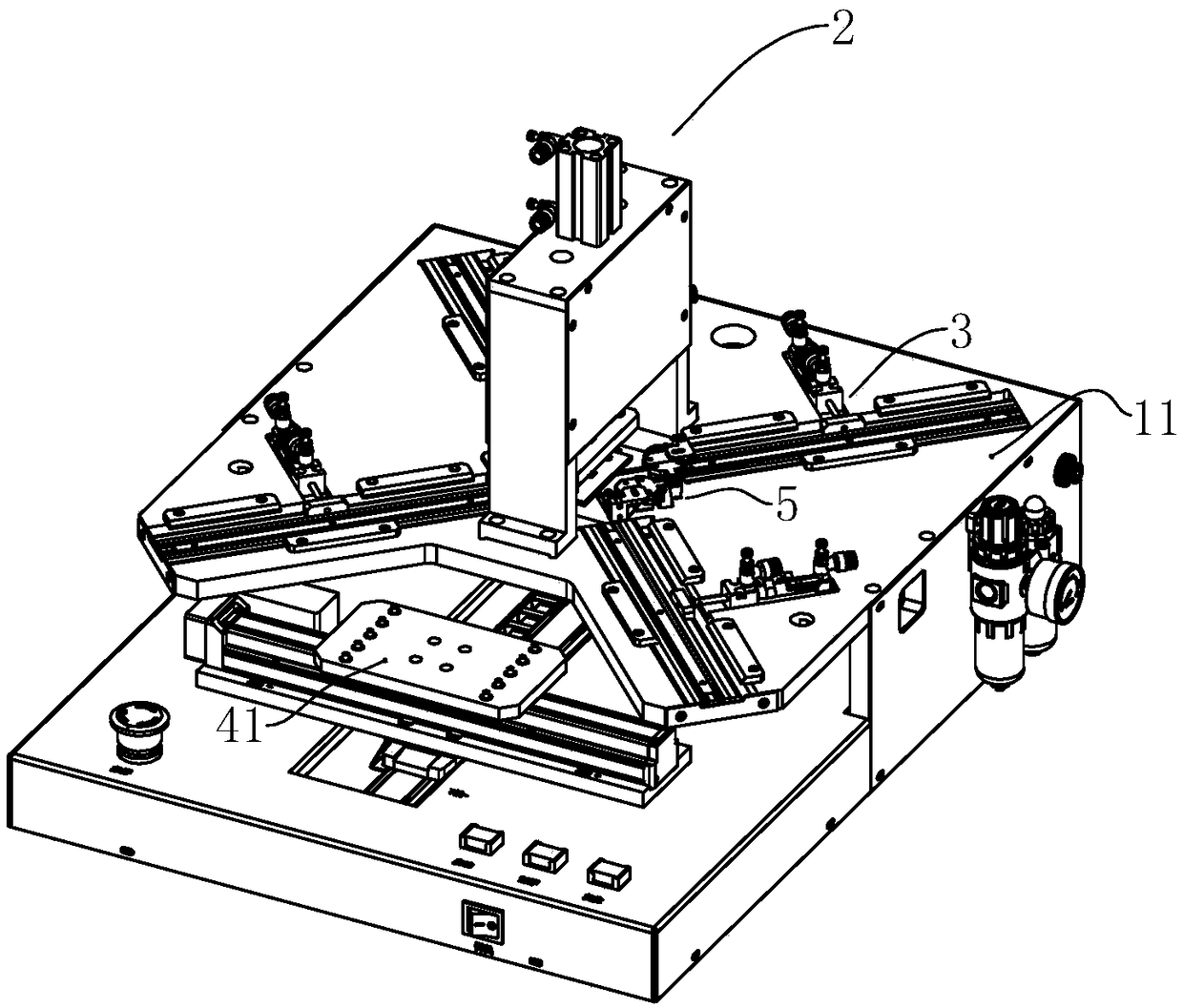

Stable pressing cutter mechanism, high-precision magnet loading device and operating method thereof

PendingCN108964381AExtended service lifeReduce magnetismManufacturing stator/rotor bodiesMagnetMotion direction

The invention relates to a stable pressing cutter mechanism, a high-precision magnet loading device and an operating method thereof. The stable pressing cutter mechanism comprises a lower cross beam,a second driving mechanism, a pressing cutter assembly, an iron core and an elastic recovery mechanism, wherein the elastic recovery mechanism comprises second guide shafts and a compression spring, the two second guide shafts are provided with a pressing block in a threaded manner; the upper end of the iron core is fixed on the pressing block after passing through the pressing cutter assembly; and the second driving mechanism is positioned above the pressing block, and the second driving mechanism downwardly drives the pressing block and the iron core to move downwards. According to the stable pressing cutter mechanism, the high-precision magnet loading device and the operating method thereof, the upper end of the iron core is connected and fixed to the pressing block, the joint is flatlymilled so as to prevent rotation of the iron core; the pressing block is arranged and driven by means of the second driving mechanism so as to drive the iron core, the second guide shafts are arranged on two sides of the center of the pressing block to ensure that stress and motion directions of the iron core are vertically downward in the downward moving process driven by means of the second driving mechanism, the coaxiality problem of the iron core and the pressing cutter is solved, the service life of the iron core and the pressing cutter is prolonged, and the probability of occurrence ofthe magnet jamming phenomenon is reduced.

Owner:ZHEJIANG DESIGN ELECTRONICS TECH

Control device of gateway

PendingCN109235322AAvoid transmission failureSolving Concentricity ProblemsTraffic restrictionsCouplingReducer

The invention discloses a control device of a gateway, and belongs to the technical field of gateways, which comprises a reducer and a bearingless motor. The bearingless motor includes a motor statorand a motor rotor, wherein the output shaft of the bearingless motor and the input shaft of the reducer share the same shaft, the input shaft of the reducer extends from its flange oil seal to the outside, A motor rotor is sleeved and fixed at the middle section of the input shaft of the speed reducer, a motor stator is arranged on the motor rotor sleeve, the motor stator is fixed on the speed reducer and kept fixed, one end of the input shaft of the speed reducer is connected with a gateway which is driven through a speed reduction unit, and the other end of the input shaft of the speed reducer is idle. The device of the invention can overcome the coaxiality problem of the traditional device and thoroughly solve the abrasion problem of the coupling.

Owner:武汉宝久电科电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com