Patents

Literature

43results about How to "Guaranteed center distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

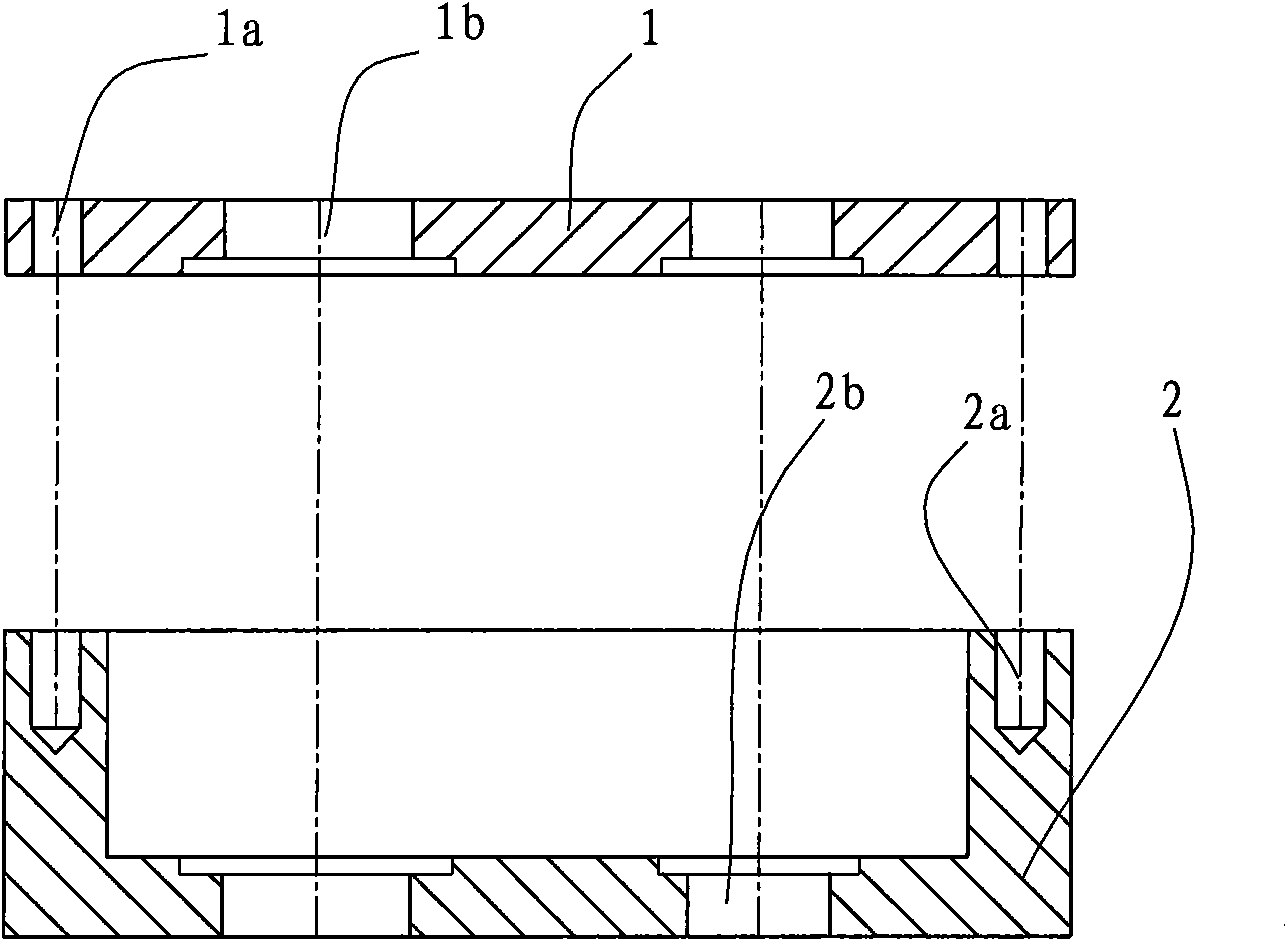

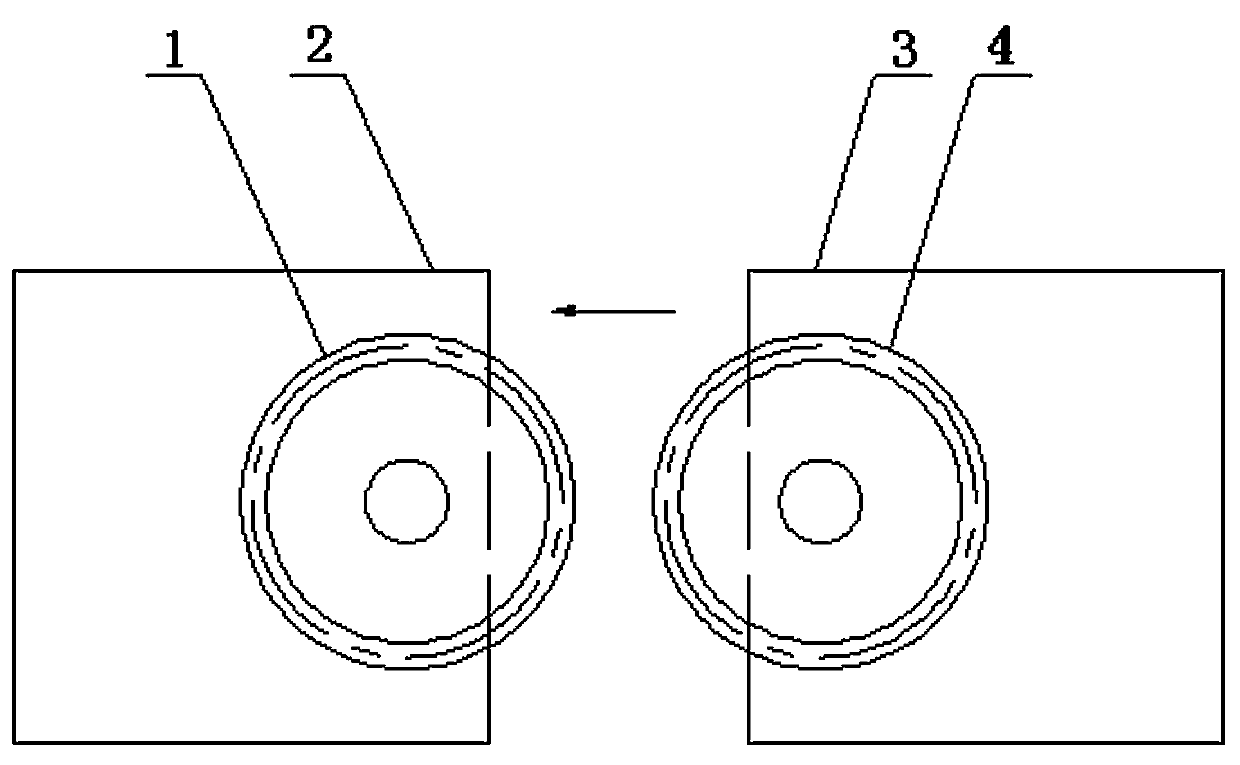

Processing method of case body and case cover of gear case

The invention discloses a processing method of a gear case, which comprises the following steps: a. processing a case cover; b. processing a case body; c. assembling, and fixing by pin bolts. The processing method of the gear case has the beneficial effects of: 1. respectively processing the case body and the case cover into finished products according to drawing requirements, and then assemblingthe case body and the case cover, thus being capable of guaranteeing the coaxiality and good interchangeability of two bearing holes, guaranteeing the quality, and simultaneously being applicable to be produced in batch without pairing or marking, and having low scrap rate; 2. adopting a novel technique for positioning, drilling and boring of a center drill, thus guaranteeing the center distance;and 3. leading the coaxiality of the assembled S1 and S2 to be 0.1 to 0.30, thus completely meeting the requirements of users.

Owner:CHONGQING QINGPING MACHINERY

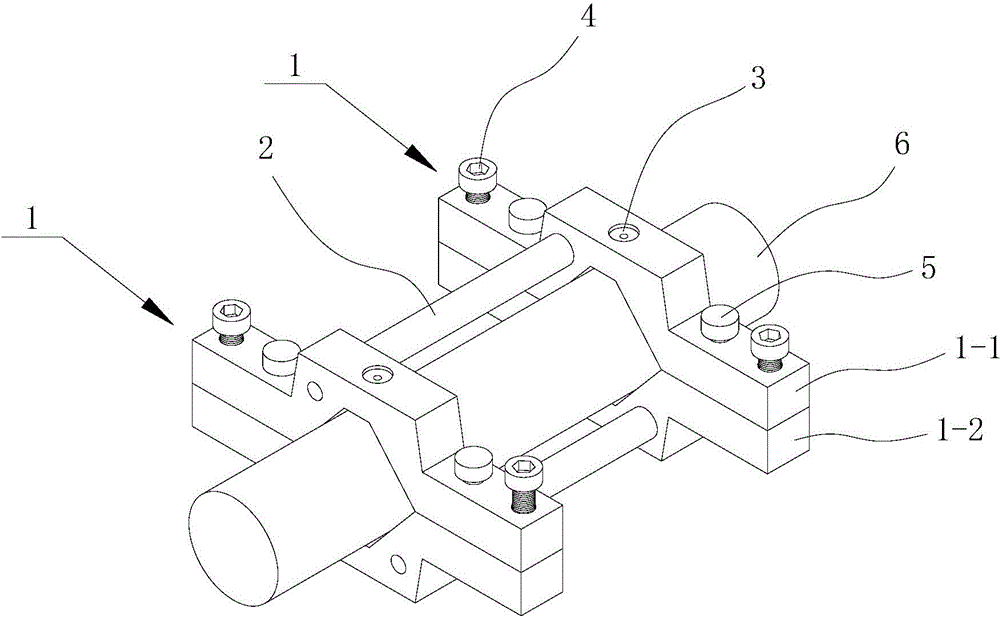

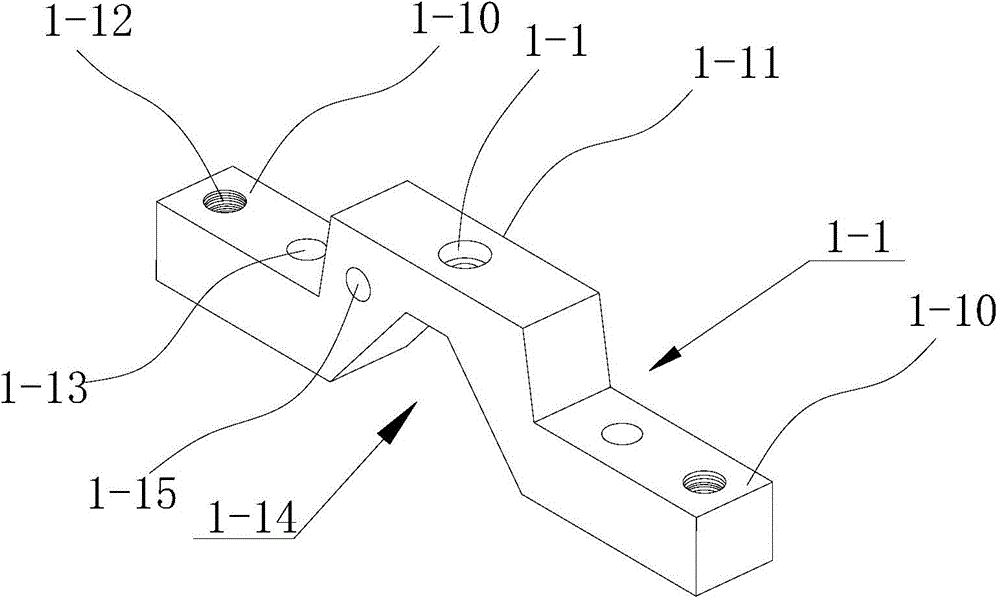

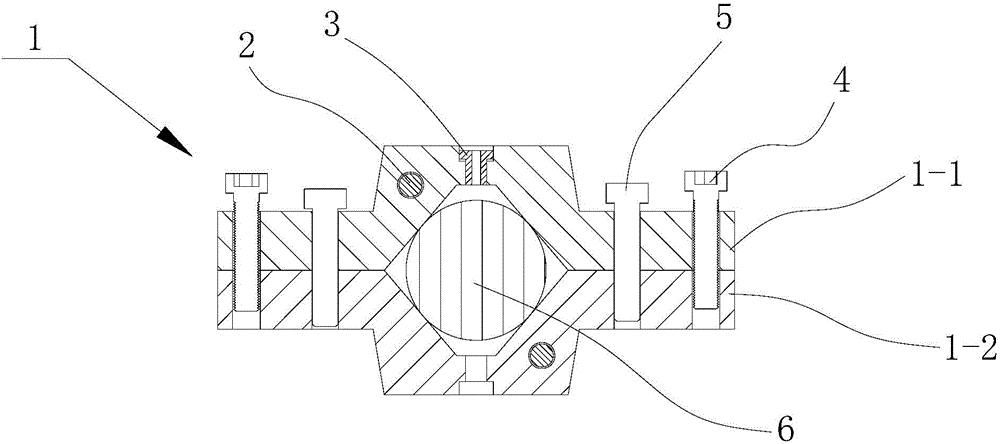

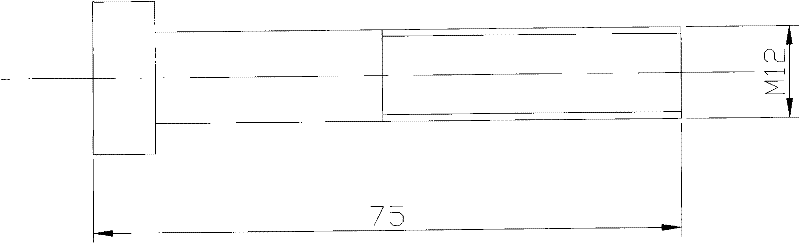

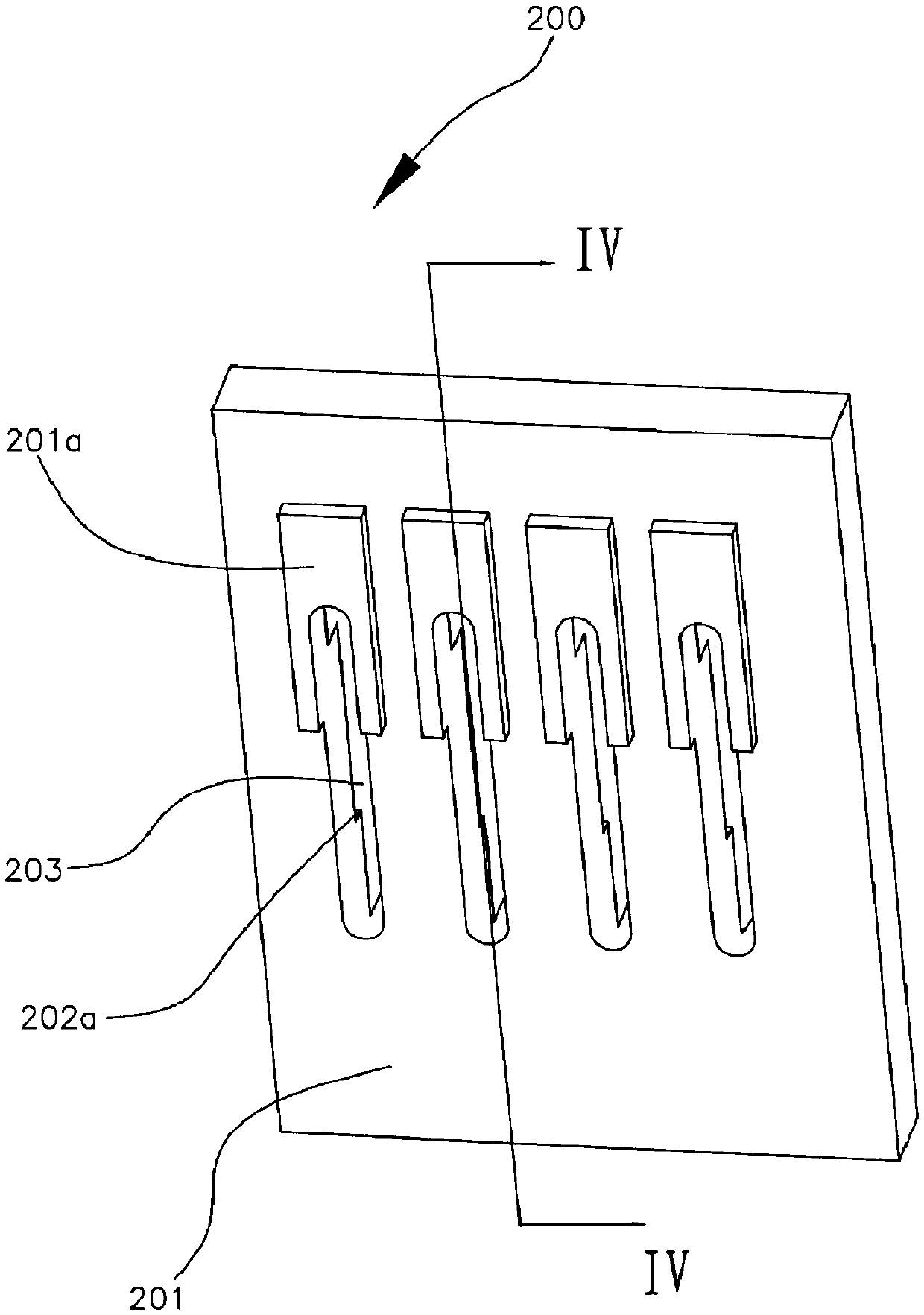

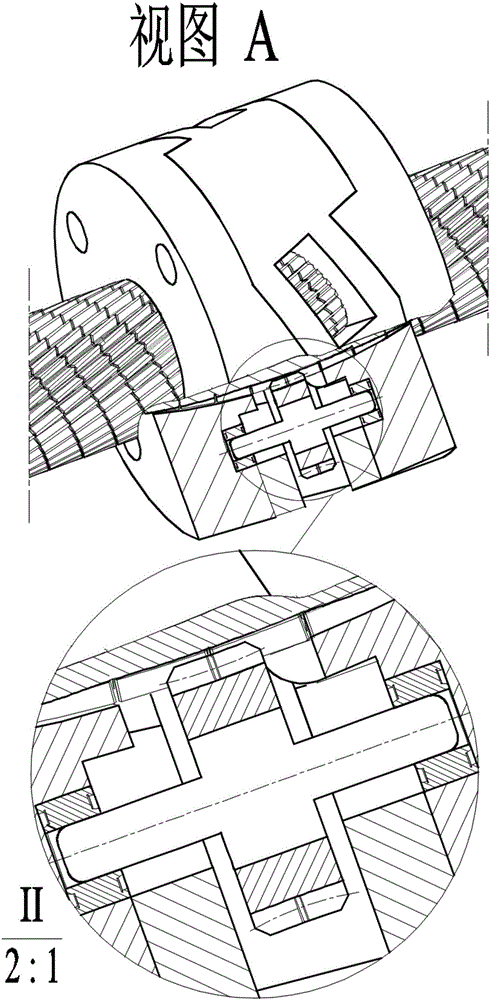

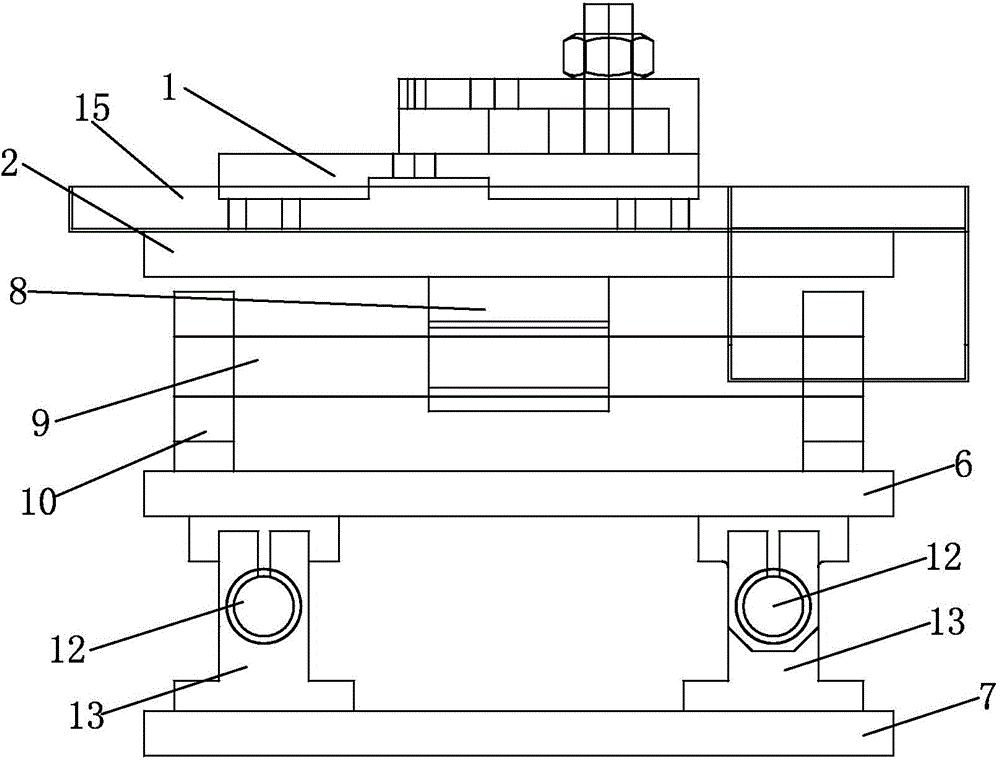

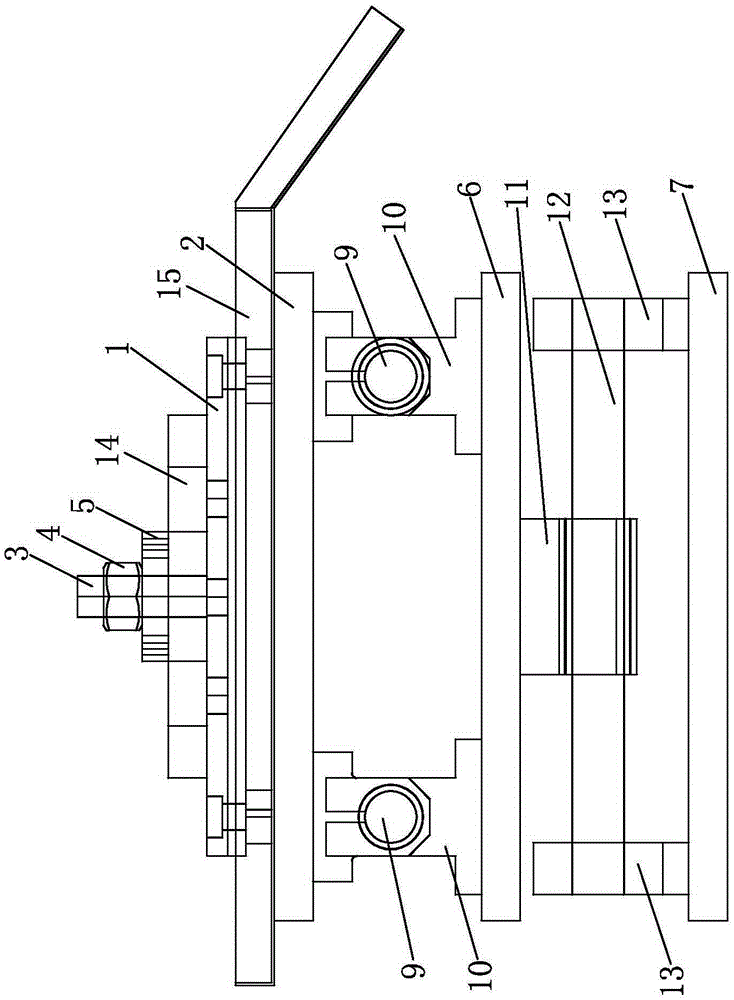

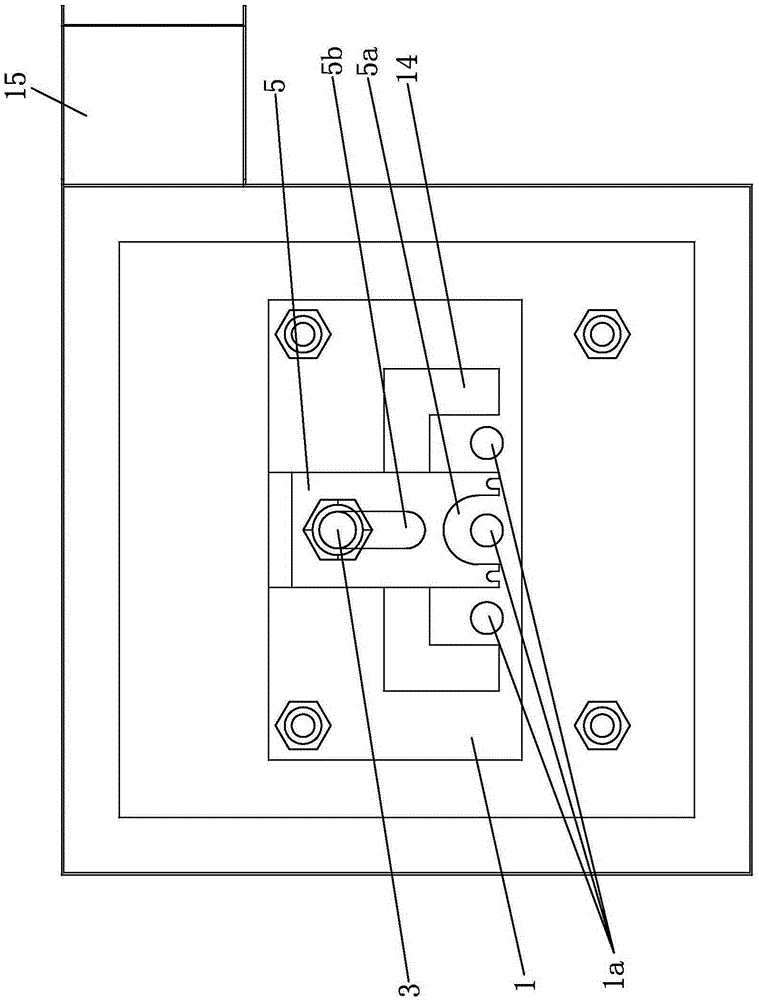

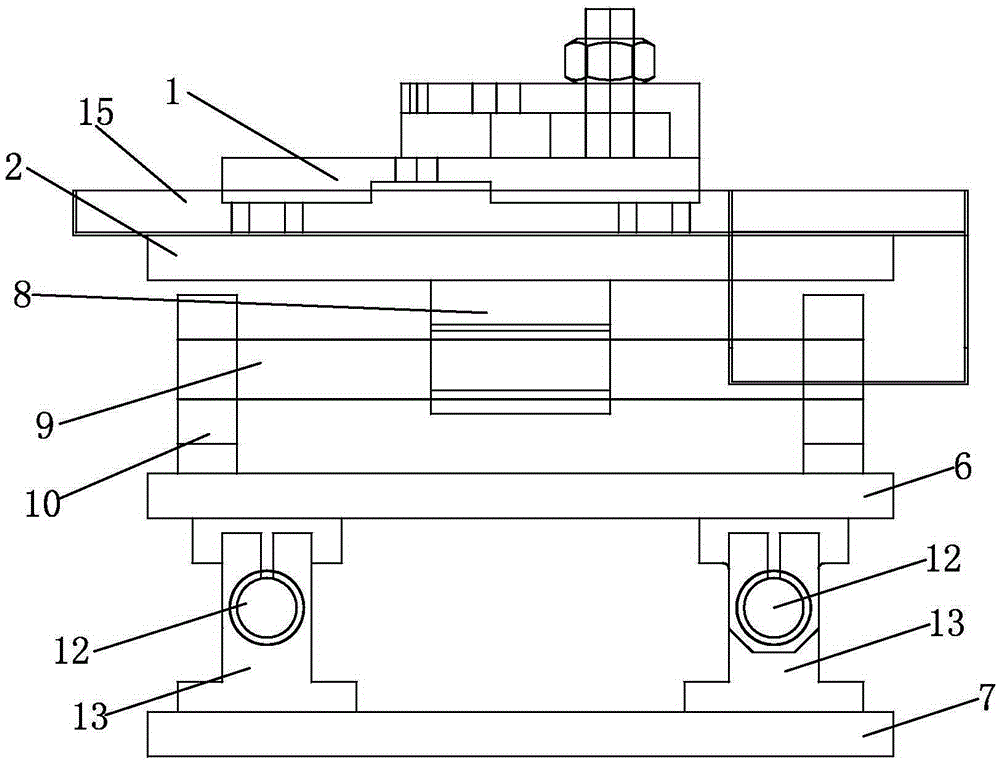

Rapid clamping and drilling mould for machining of side hole of round steel

The invention relates to a rapid clamping and drilling mould for machining of a side hole of round steel. The rapid clamping and drilling mould for machining of the side hole of the round steel comprises two clamping assemblies and a positioning rod, wherein the two clamping assemblies are used for clamping the round steel, each clamping assembly comprises an upper clamping body and a lower clamping body, each upper clamping body comprises a connecting part and a clamping part, a connecting screw hole and a positioning pin hole are formed in each connecting part, an isosceles-trapezoid-shaped opening is formed in each clamping part, a through drill hole is formed in the top of each opening, and a drill jig sleeve is arranged in each drill hole; the upper clamping body and the lower clamping body of each clamping assembly are of the same structure and are combined together, the screw hole and the positioning pin hole of each upper clamping body correspond to a screw hole and a positioning pin hole of the corresponding lower clamping body, connecting bolts are arranged in the screw holes in a screwed mode, and positioning pins are inserted in the positioning pin holes; a round steel clamping cavity is formed after the upper clamping bodies and the lower clamping bodies are combined together. According to the rapid clamping and drilling mould for machining of the side hole of the round steel, the round steel is clamped in a one-time mode through the drilling mold, machining of the whole hole is achieved, drilling efficiency and drilling quality are improved, and the coaxiality of drilled holes and the distances between adjacent holes are guaranteed; deflected holes and eccentric holes are avoided, and product quality is improved.

Owner:TIANJIN ANSHUNCHENG METAL PROD

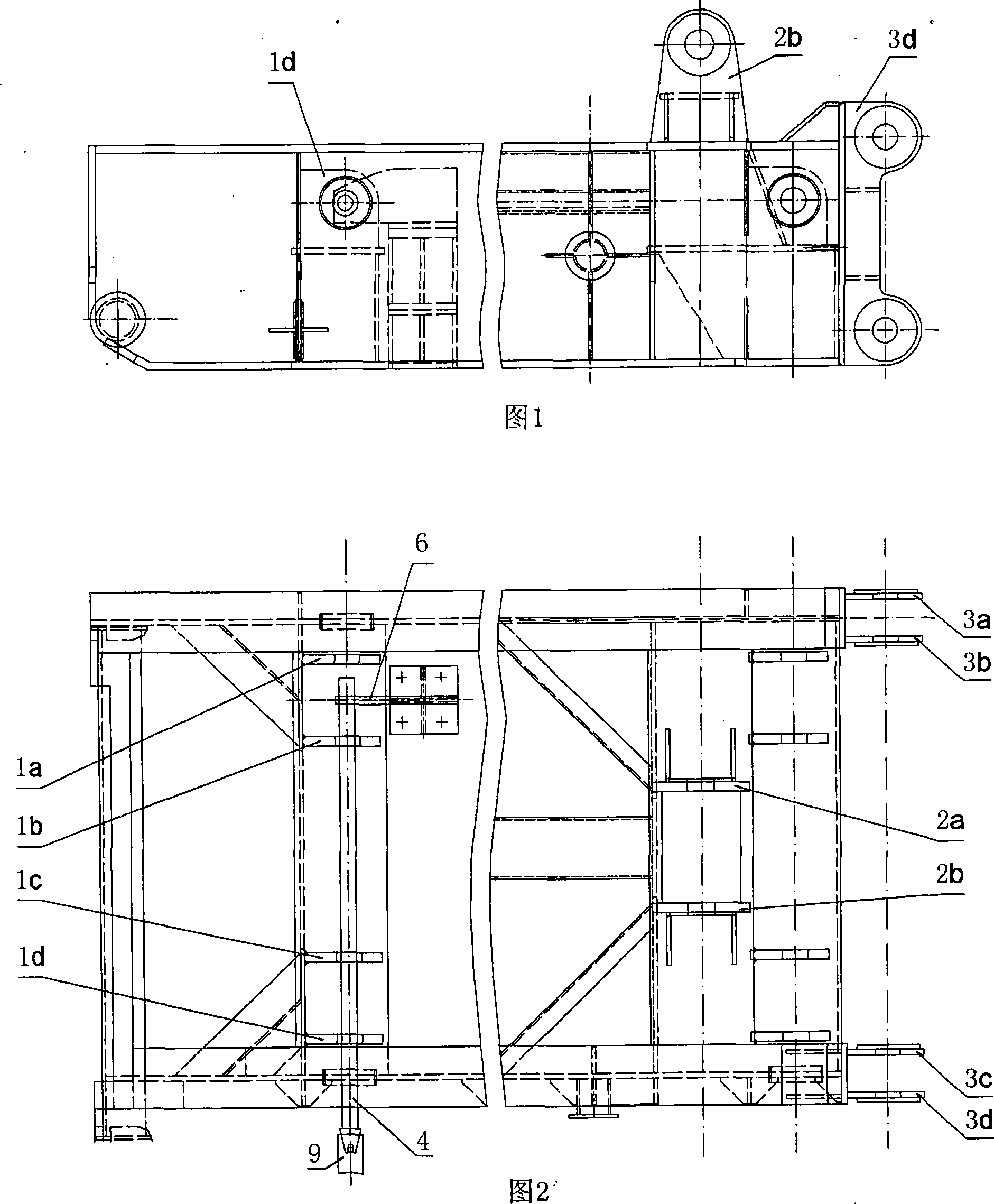

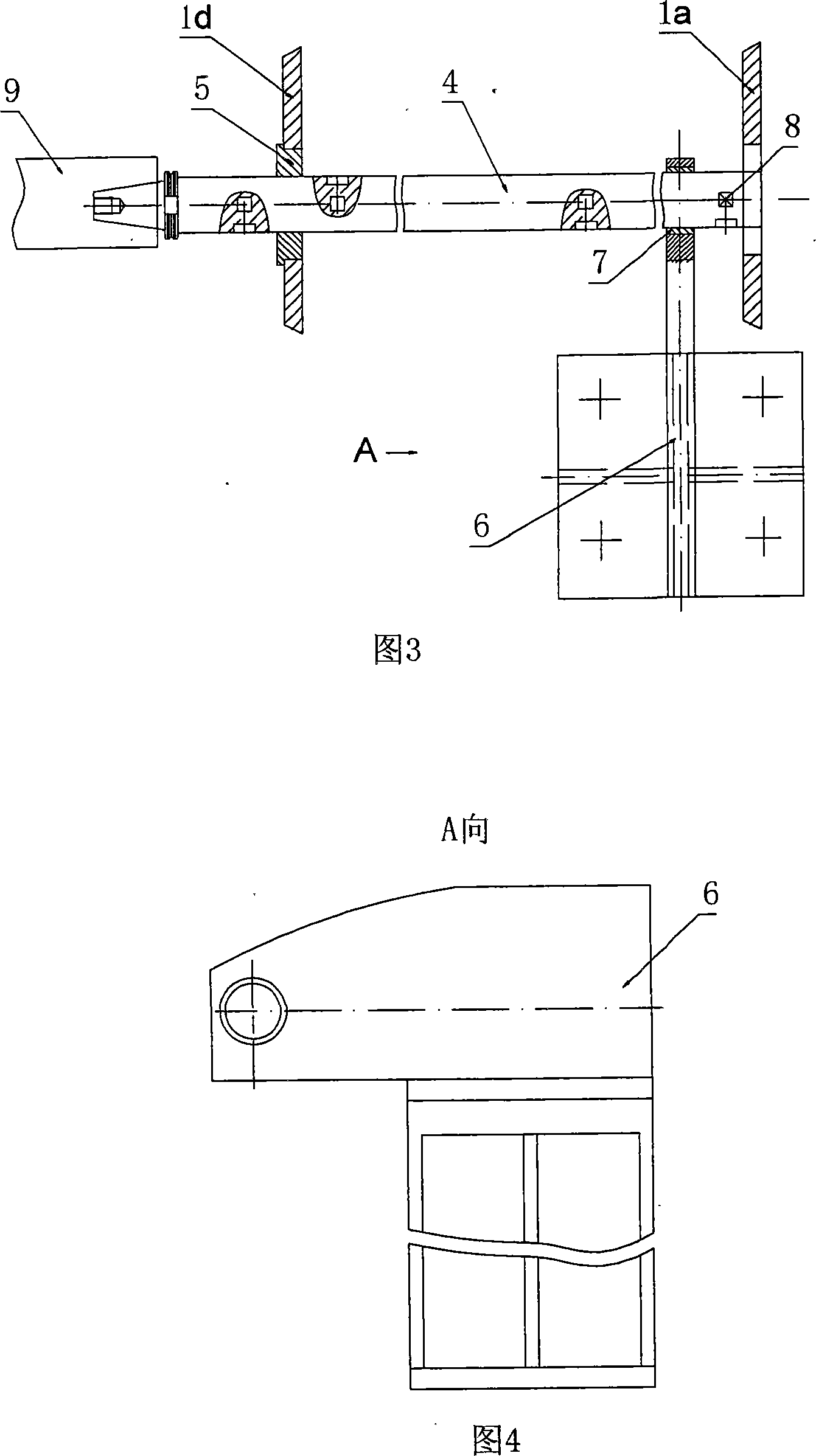

Coaxial large strided distance ear base hole boring auxiliary device and boring process method

InactiveCN101195175AGuaranteed coaxialityReduce runoutBoring/drilling machinesEngineeringMachine tool

The invention relates to an auxiliary device for borings of coaxial large span length ear base holes and a method for manufacturing the borings. The auxiliary device comprises an extending knife bar, a transitional supporting sleeve and a support, wherein the transitional supporting sleeve is inserted in an ear base hole which is manufactured through a common short knife bar and near a constructional element of the end surface of a machine tool main axle, a support supporting sleeve is inserted in a round hole on the support, and the extending knife bar is passed respectively through the transitional supporting sleeve and the support supporting sleeve and supported in auxiliary by the transitional supporting sleeve and the support supporting sleeve. The method for manufacturing the borings adopts the auxiliary device to manufacture the coaxial long center ear base holes on a large scale boring and milling machine. The coaxiality of coaxial ear base holes and center distance and the depth of parallelism between central lines of different axis ear base holes can be guaranteed, a derrick and a drill floor are connected on a basal seat after adopting the method to manufacture the borings of coaxial long center ear-seat holes on large scale structural elements as a driller, which has high assembly preciseness, little cooperating gap, and is stable while in use, installing working amount can be decreased greatly, and installing working efficiency can be increased.

Owner:RG PETRO MACHINERY GROUP

Clamp for turning irregular sleeve and machining method for same

InactiveCN102528478AImprove processing efficiencyGuaranteed center distancePositioning apparatusMetal-working holdersMachine toolMachining

The invention discloses a device for rapidly clamping and precisely positioning an irregular sleeve part. The device comprises a datum positioning plate, a large gasket, a screw, a double-headed screw rod, a cover plate and a nut. The part is attached to a large end face of the datum positioning plate through a boss of the datum positioning plate and the bottom of the part, thereby being precisely positioned, and the part is rapidly clamped by the large gasket, the screw, the double-headed screw rod, the cover plate and the nut. An internal machining element and an external machining element of the part are successfully clamped and turned once, so that turning of the sleeve part is greatly simplified and facilitated. By the aid of the device for turning and clamping the irregular internal sleeve, the part can be rapidly, simply and conveniently mounted on a turning machine tool, conformity of the axis of the part and the axis of a machine tool spindle is ensured, part machining efficiency is greatly improved, and the quality of the part is stable.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Borehole processing method of long-range parts

InactiveCN101337285AGuaranteed verticalityGuaranteed center distanceBoring/drilling machinesEngineeringMachine tool

The invention discloses a method for processing an internal boring for a long-distance part, which comprises the following steps: clamping two bent plates provided with central holes on the front and the back side surfaces of a bored part, passing a spotting spindle through the central holes of the part and the bent plates to cause the center of the part and the centers of the bent plates to coincide, and pressing and fixing the bent plates; rounding the four main shaft of a boring lathe by using a dial test indicator after detaching the part and the spotting spindle, adjusting the four main shafts of the lathe to be coaxial with the central holes of the two bent plates, and tightly fixing the four main shafts; placing a part to be bored on the boring lathe and positioning through the bent plates, using a second spotting spindle to pass through the bent plates and the part, pressing the part tightly after positioning the part, removing the spotting spindle, and starting boring. The front hole and the back hole of a processed part are coaxial, the hole distance is consistent, the functions of the four shafts of the lathe are brought into full play, the product quality is improved, the boring time is saved, and the production efficiency is improved.

Owner:四川航天神坤装备有限公司

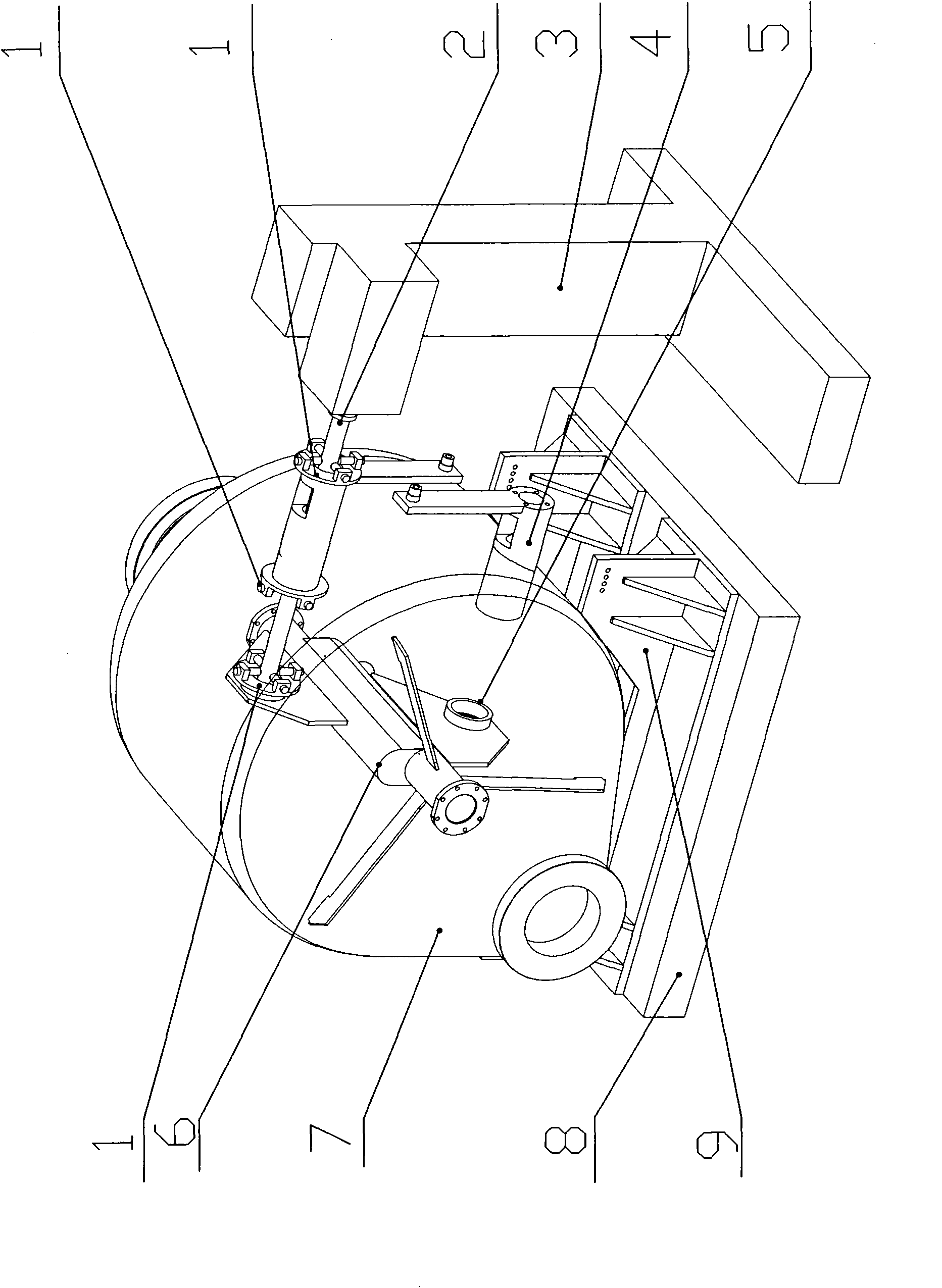

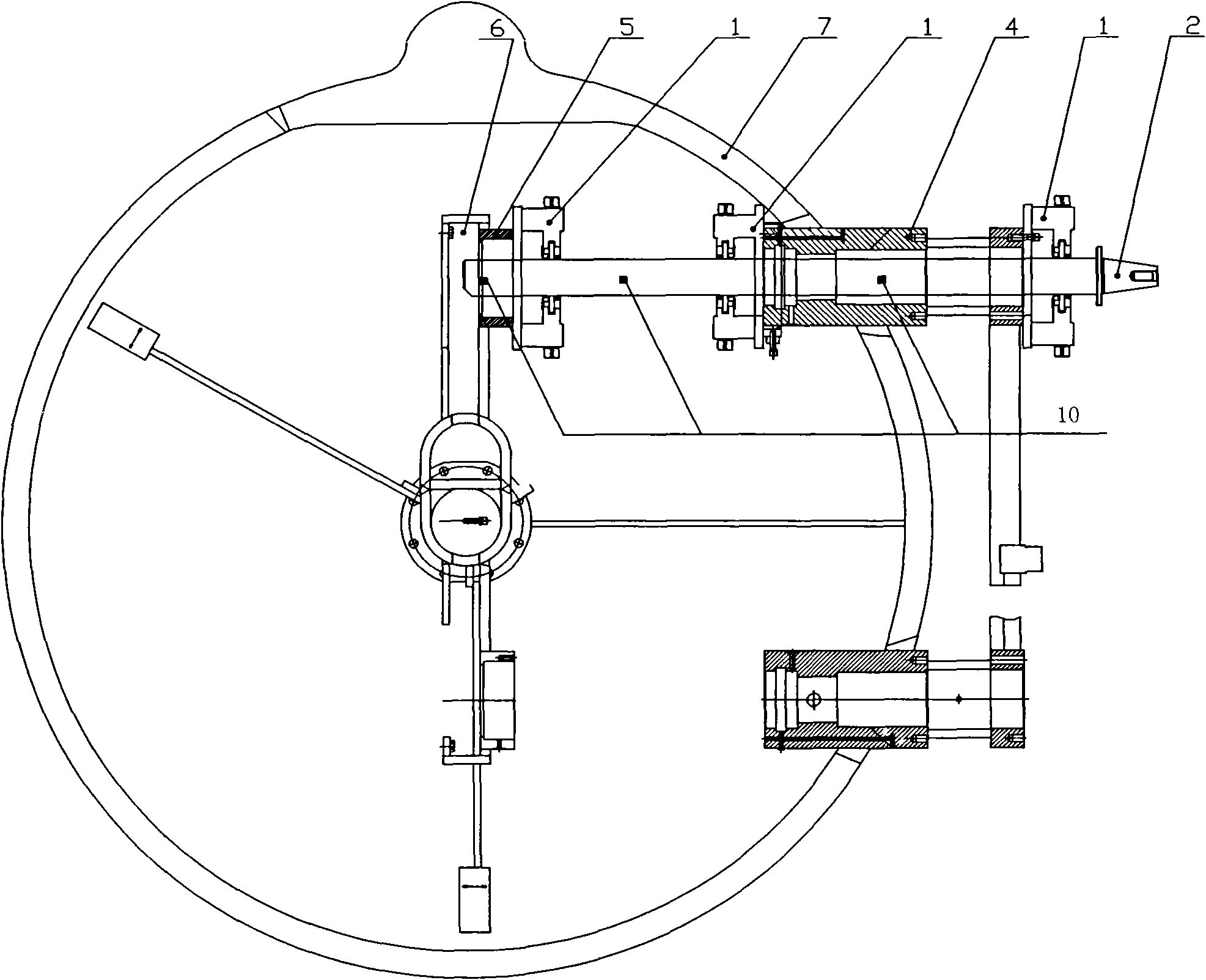

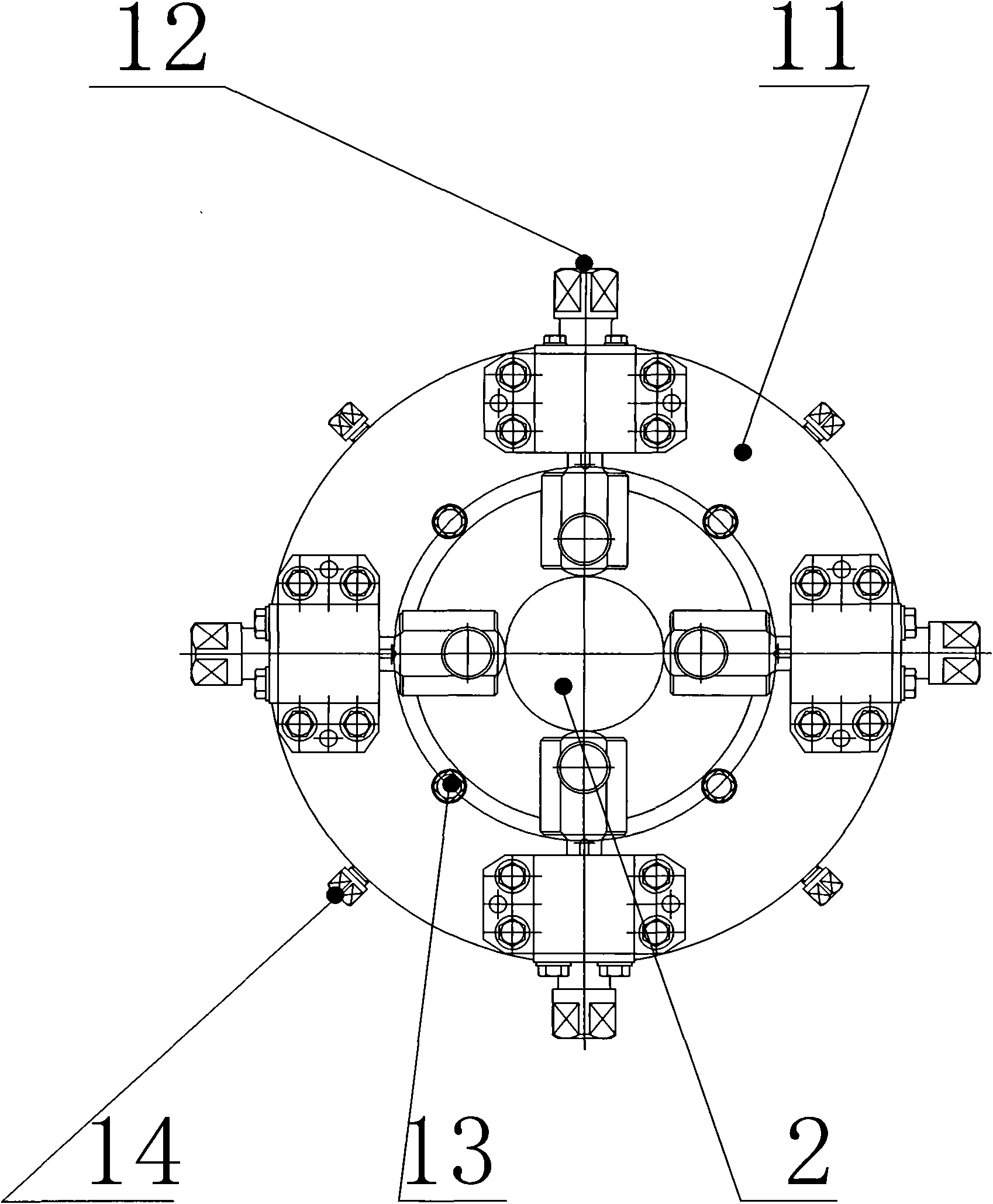

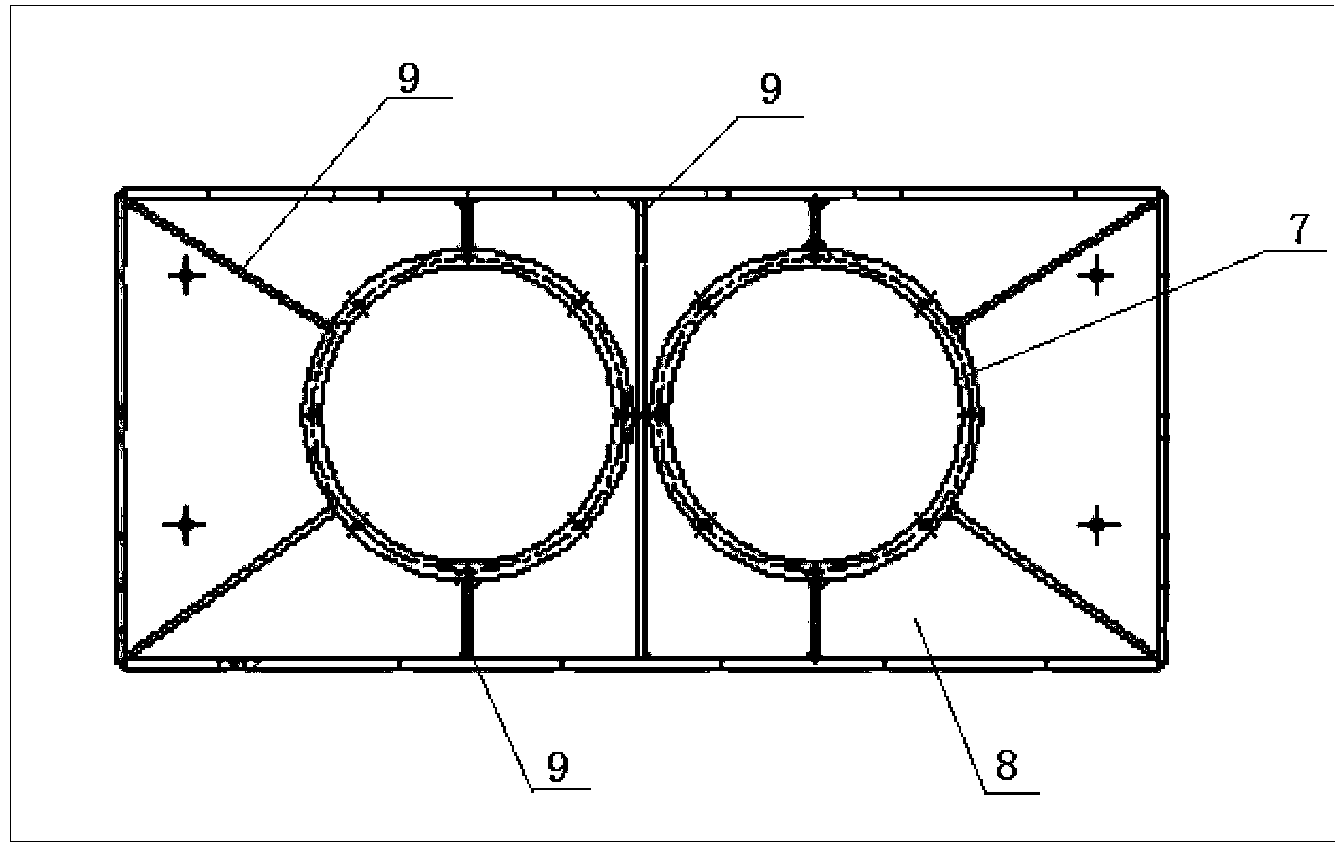

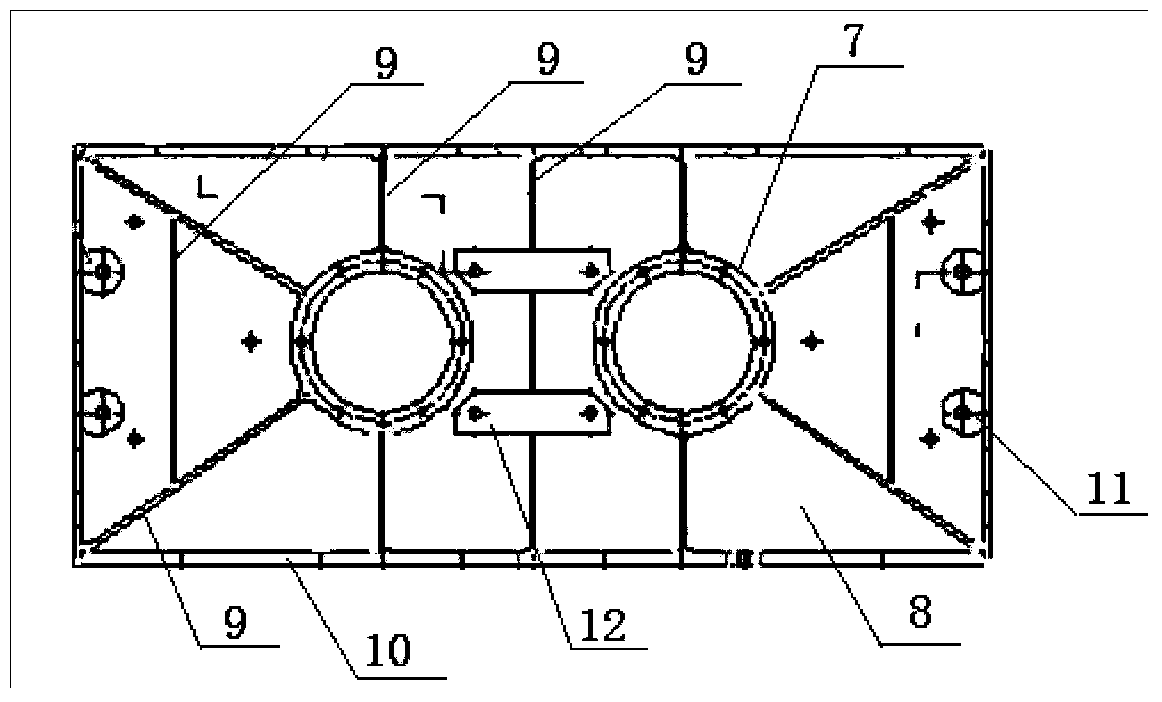

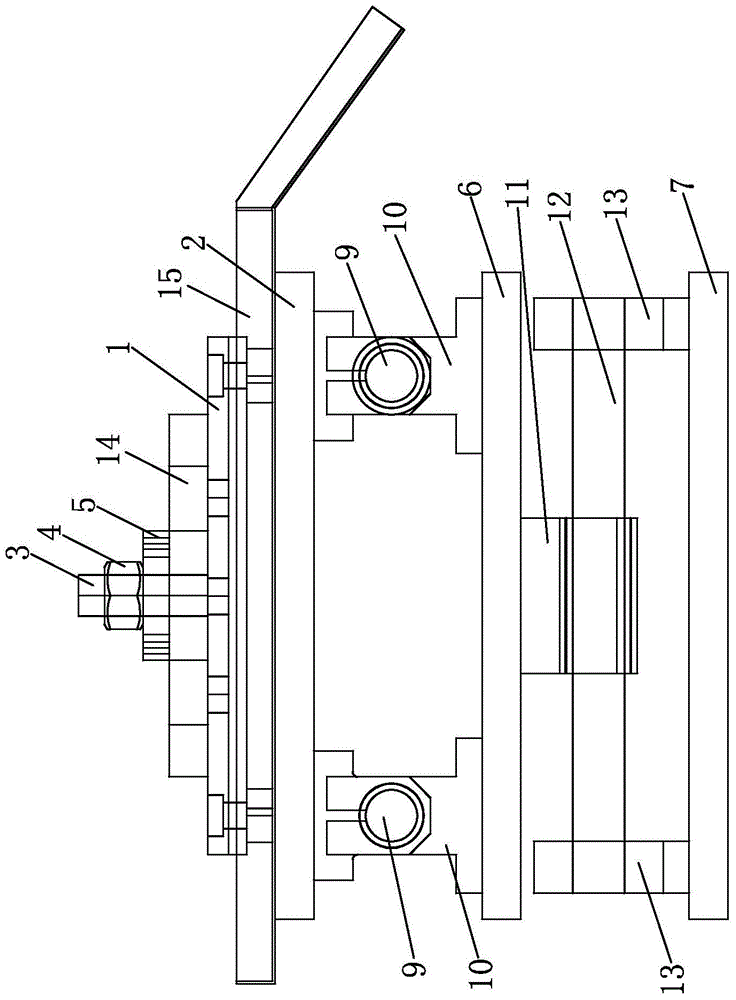

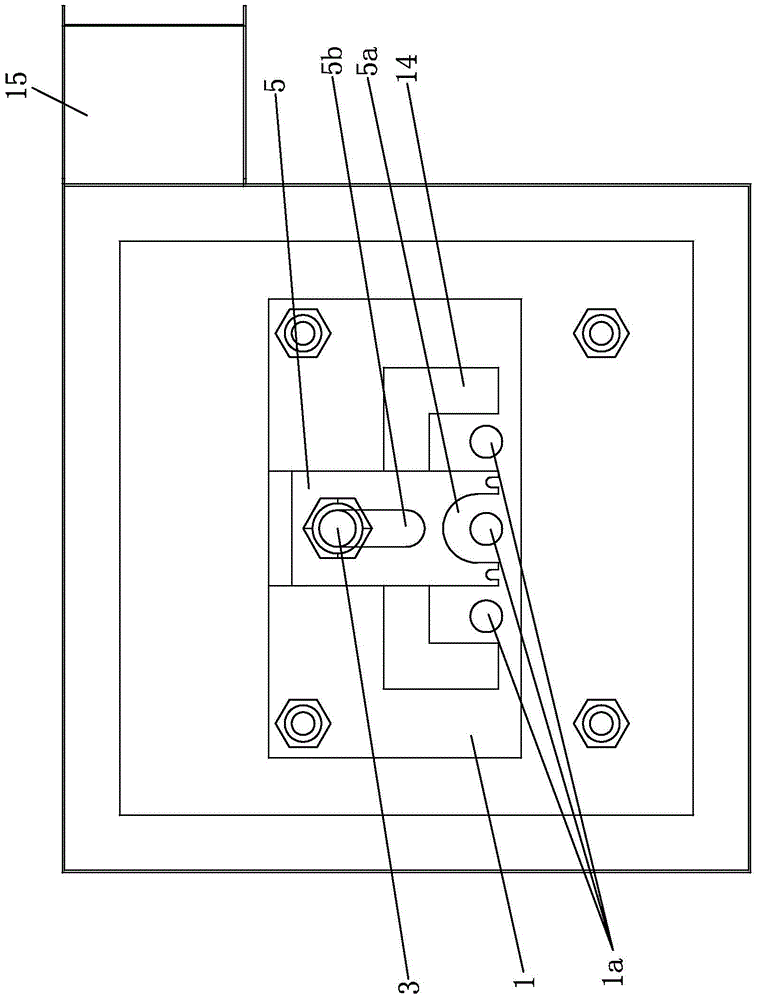

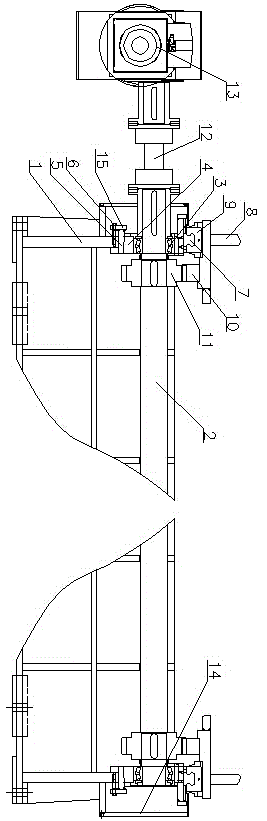

Split overlength shaft sleeve and bearing ring inner bore processing auxiliary device and processing method

ActiveCN102059373AReduce deflectionVersatilityLarge fixed membersBoring/drilling componentsDigital controlRing cutter

The invention relates to a split overlength shaft sleeve and bearing ring inner bore processing auxiliary device and a processing method. The processing auxiliary device comprises a V-shaped support (9), wherein the V-shaped support (9) is connected to an ash lock shell (7) which is connected with an inner oscillating bar shield (6), the inner oscillating bar shield (6) is connected with a bearing ring (5), a shaft sleeve (4) is connected to the ash lock shell, the shaft sleeve and the bearing ring are arranged on the same axes, the inner end face and the outer end face of the shaft sleeve and the end face of the bearing ring are respectively used for fixing an auxiliary supporting device (1) by using bolts, a lengthening cutter bar (2) penetrates through the auxiliary supporting device and is finally connected with a main shaft of a floor digital control boring and milling machine (3), the lengthening cutter bar is provided with a group of boring cutter installing square grooves (10), and boring cutters are arranged in the boring cutter installing square grooves. The invention is used for boring and milling inner bores with large length, big span and high requirement for concentricity.

Owner:HARBIN BOILER

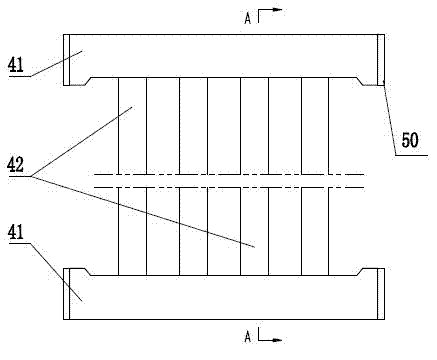

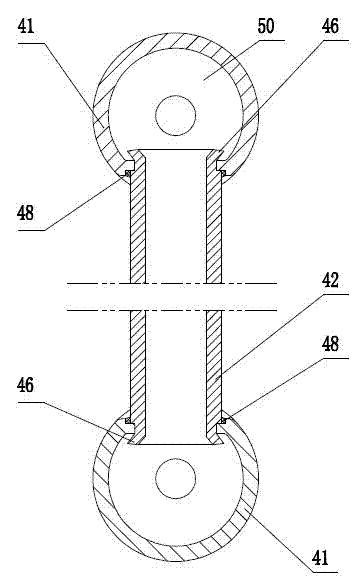

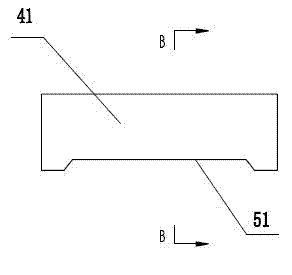

Processing method of heating radiator

InactiveCN102161152AImprove connection strengthShorten insertionSoldering apparatusEngineeringHeat spreader

The invention discloses a processing method of a heating radiator. The processing method comprises the following steps of: (1) processing a plurality of radiating pipe installation holes respectively on two header tubes, and processing thread connector installation holes respectively at the two ends of the two header tubes; (2) processing splicing sections respectively at the two ends of the plurality of radiating pipes, and forming a positioning platform respectively at the transition positions of the splicing sections and radiating pipe bodies; (3) inserting the two ends of the plurality of radiating pipes respectively and sequentially into the radiating pipe installation holes of the two header tubes and then connecting the radiating pipes and the header tubes into a whole in a riveting manner; (4) after the riveting is finished, brazing the header tubes and the radiating pipes into a whole in a weld area formed among the outer hole walls of the radiating pipe installation holes and the radiating pipes, and welding; and (5) after brazing is finished, welding thread connectors in the thread connector installation holes. The processing method has the advantages of small deformation after welding, less processing steps, low energy consumption and low production cost, less environmental pollution, and good production environment; and a radiator prepared by the processing method has long service life and good radiating effect is good.

Owner:山东沃利森机械科技有限公司

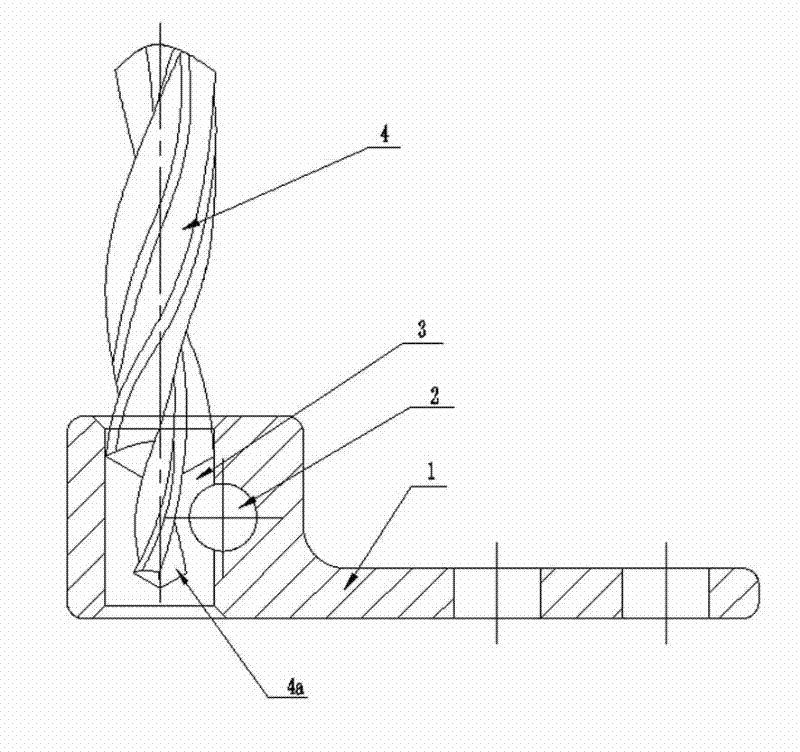

Crossed hole processing method

The invention provides a crossed hole processing method, which comprises the steps that: firstly, a small hole is processed, the small holes is used for prepositioning, a step drill is adopted during large hole processing, the radius of the minor diameter of the step drill is smaller than the center distance from an outer bus of the small hole to a large hole, and when the major diameter of the step drill is cut into the small hole, the minor diameter of the step drill passes through the small hole, so the distance from the large hole center and the small hole center is ensured. The crossed hole processing method has the advantages that the center distance of the two crossed holes can be ensured, a filling shaft is omitted, the manufacture cost is saved, and the process operability is simple.

Owner:湖北华阳汽车变速系统股份有限公司

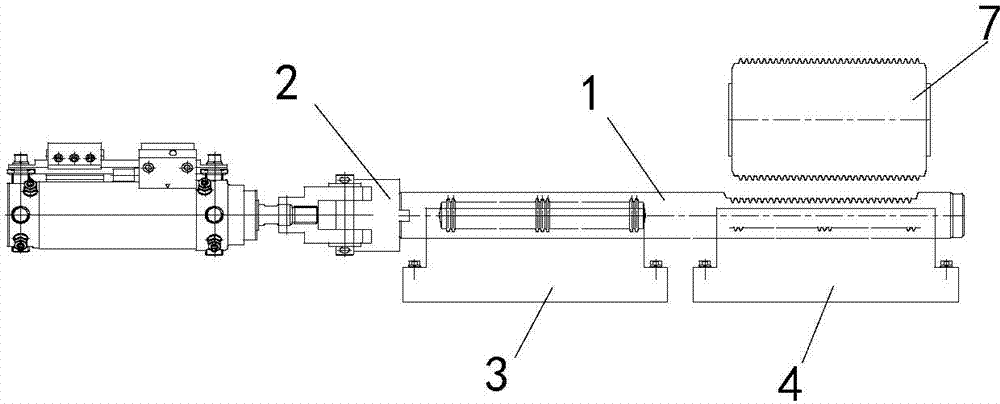

Machining method for rack of electric steering gear

The invention provides a machining method for a rack of an electric steering gear. According to the method, the process of stress relieving tempering, natural aging, one-time clamping and combined grinding is adopted, the requirements for the tolerance of the tooth surface of each driving tooth and the tooth surface of each driven tooth being + / - 5', the OPD variation of the tooth profile of each whole driving gear and the OPD variation of the tooth profile of each whole driven gear being 0.04 mm, the linearity being 0.05 and the roughness being Ra 0.8 are met, and the requirement for the high-precision tolerance of Max0.04 is guaranteed. By means of the method, the machining efficiency is improved, and the product precision is guaranteed.

Owner:上海格尔汽车科技发展有限公司

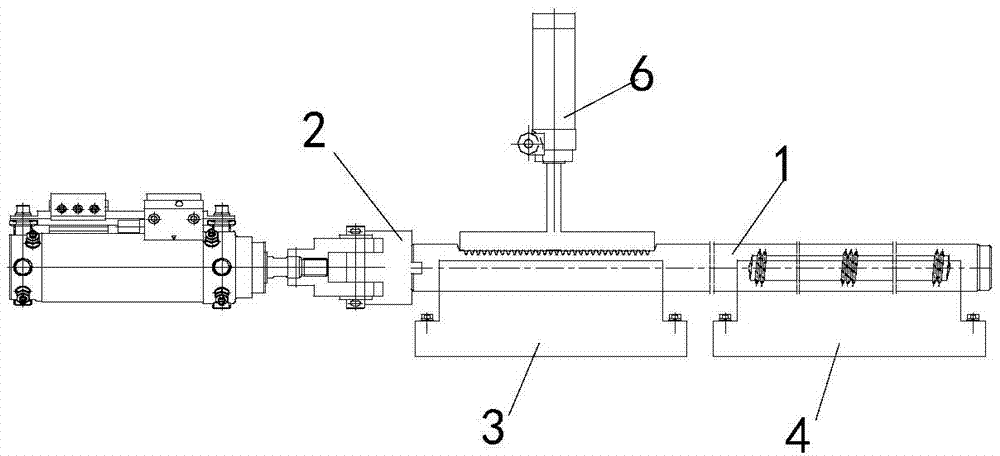

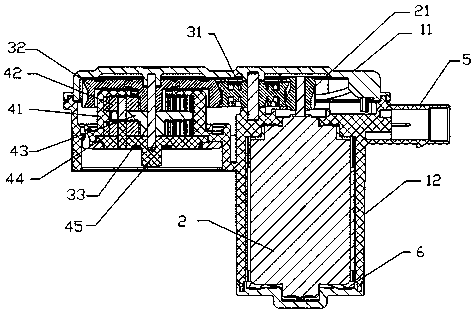

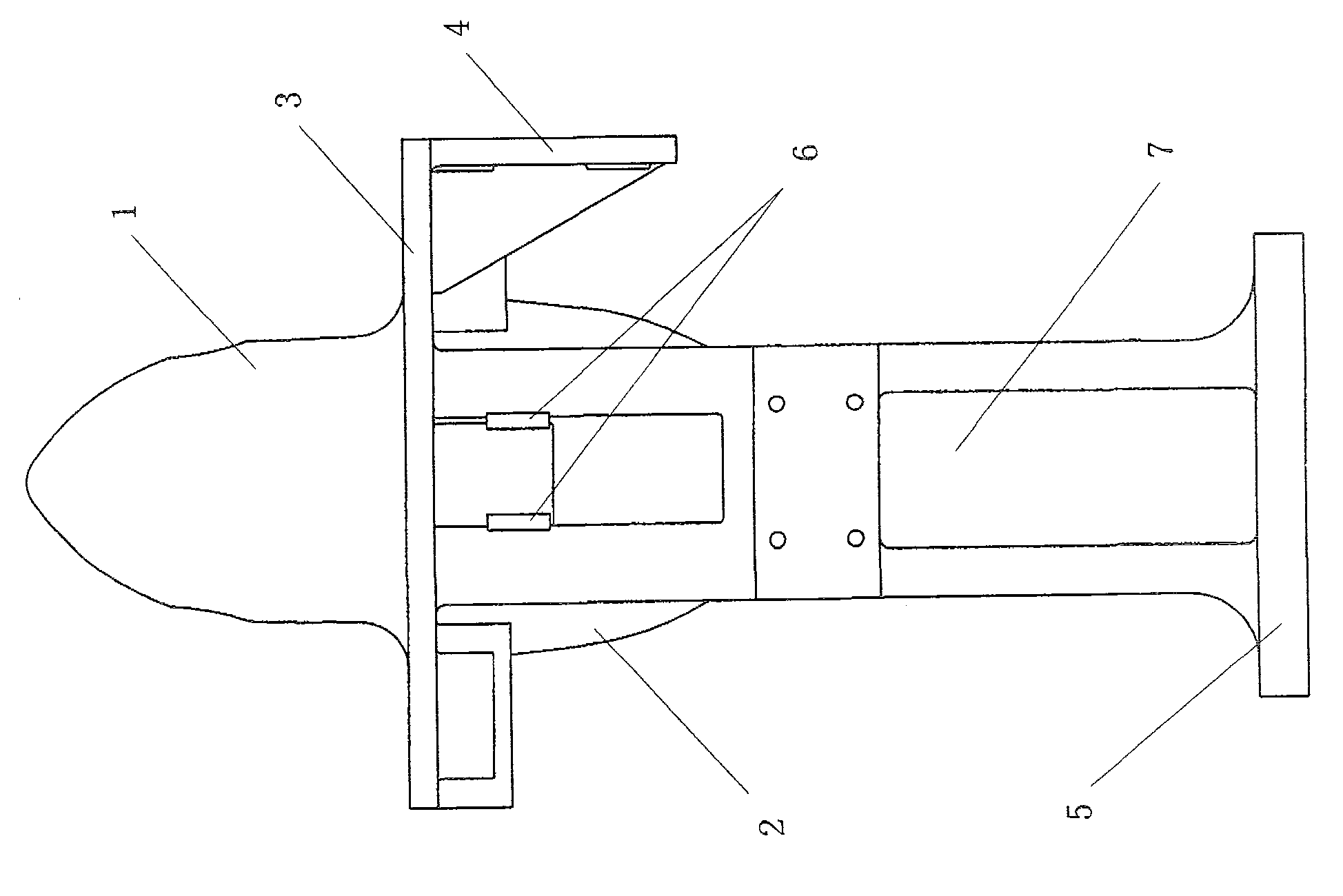

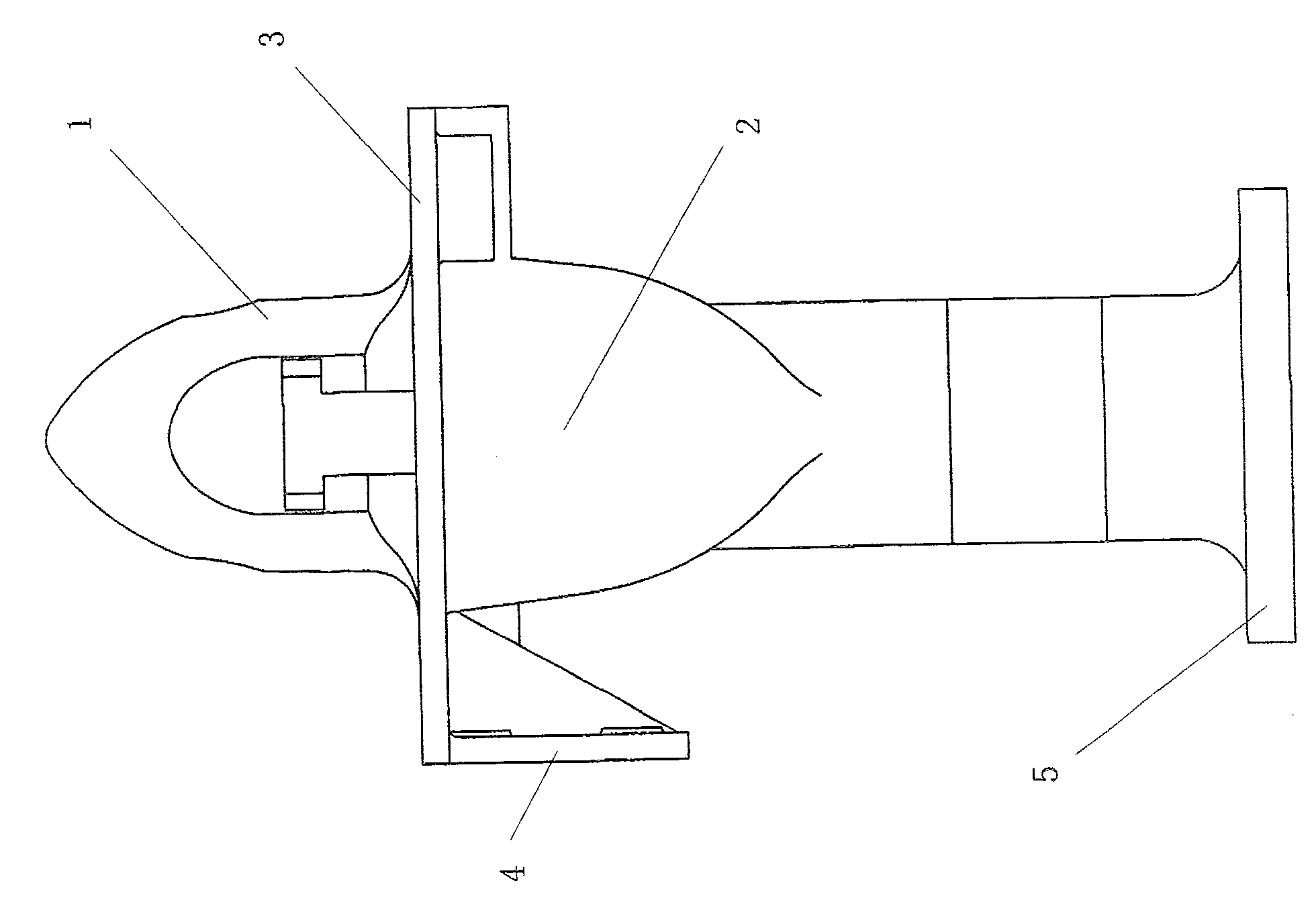

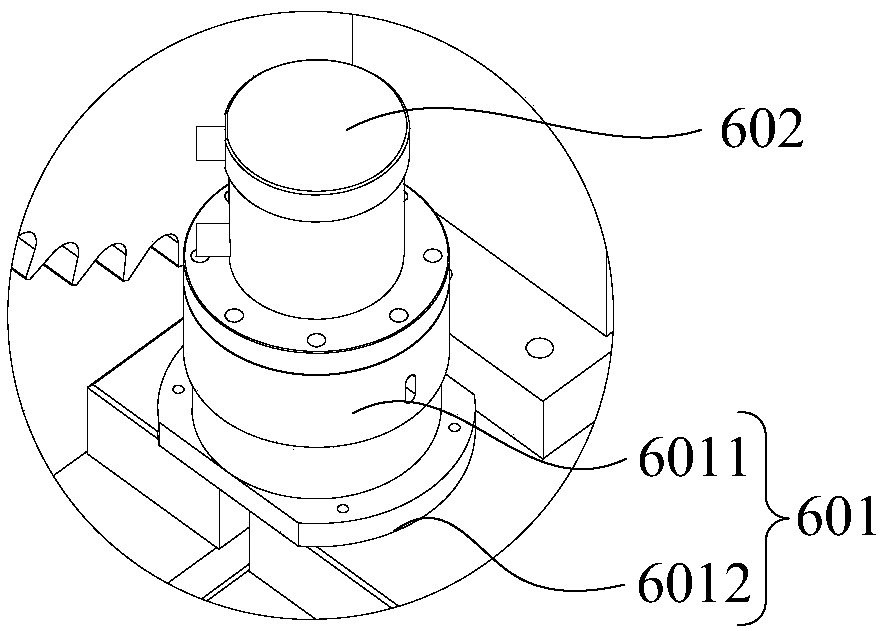

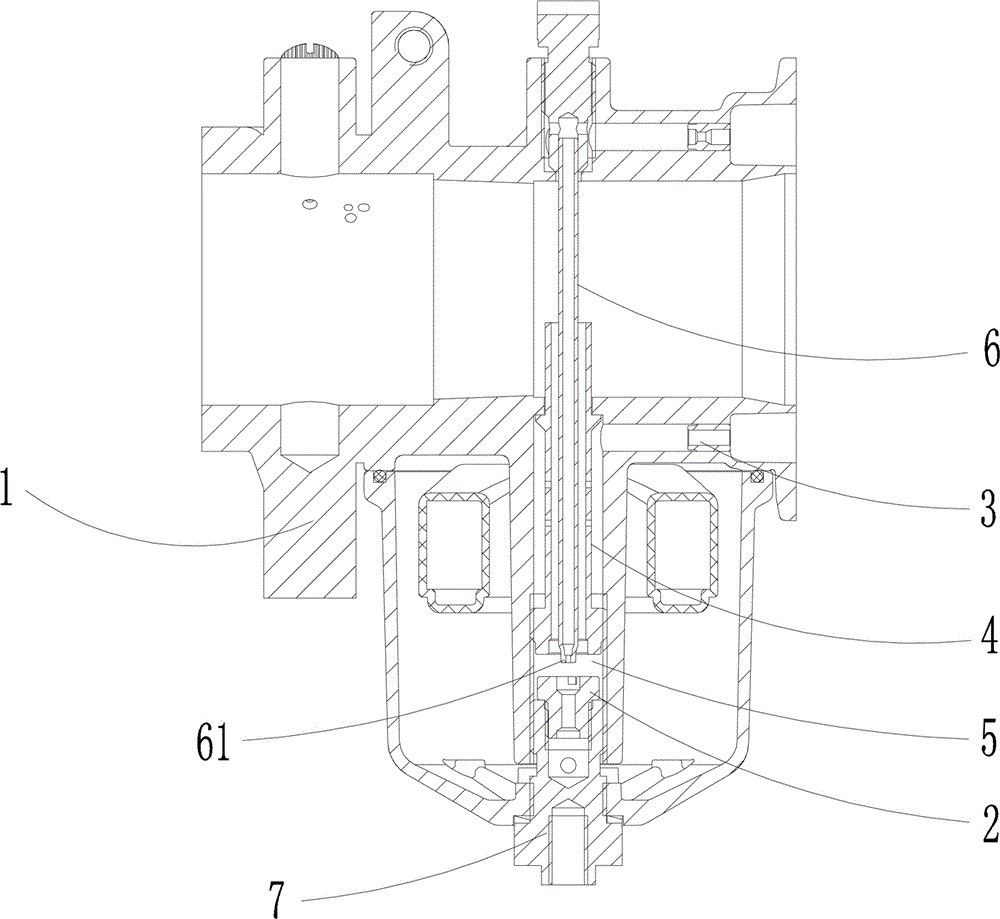

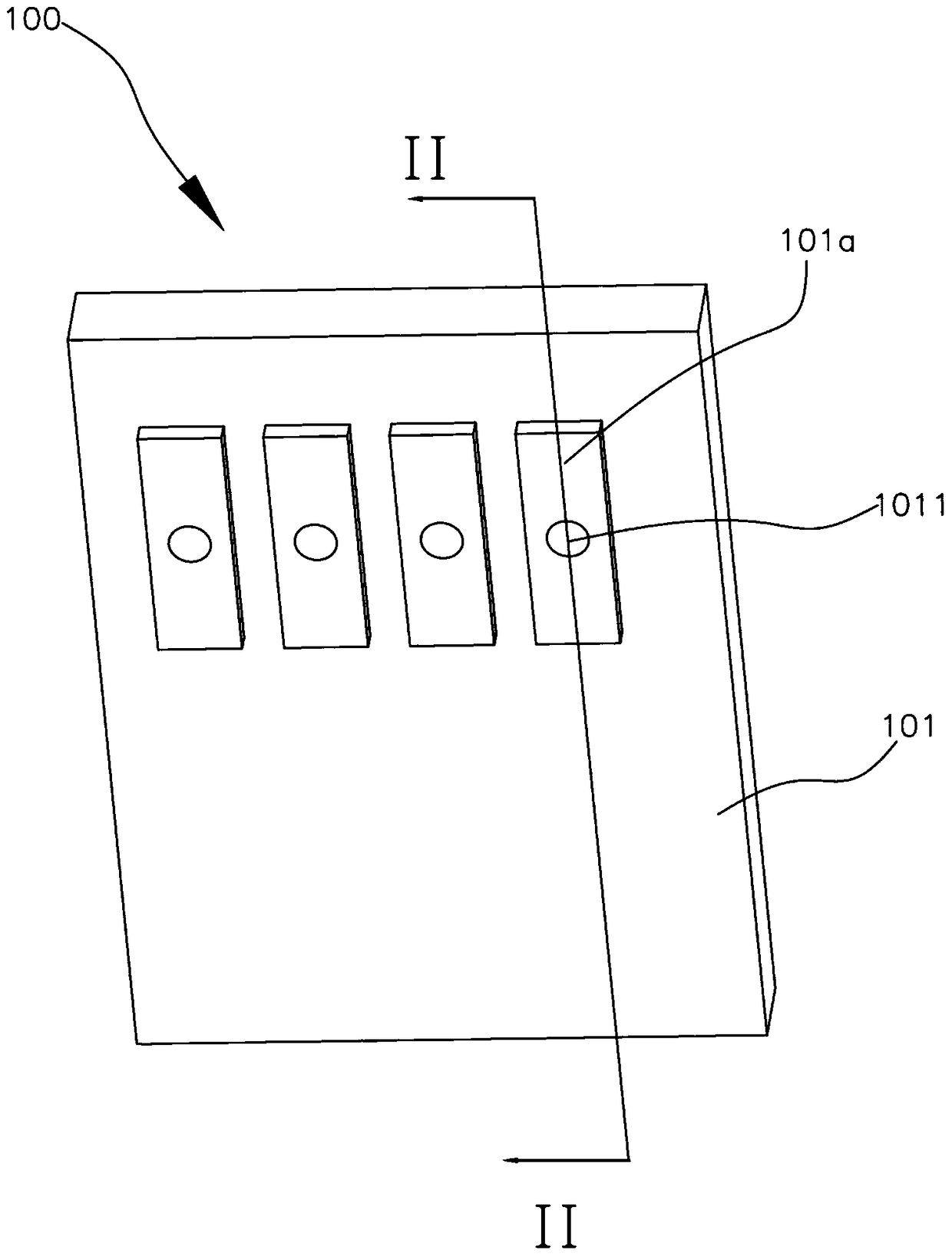

Compact actuator for vehicle electronic parking system

PendingCN111284468ASame structureGuaranteed center distanceBraking action transmissionGear driveGear wheel

The invention relates to a compact actuator for a vehicle electronic parking system. The compact actuator is characterized by comprising an outer shell, a driving motor, a transmission gear set and aplanetary gear set, a full-gear transmission mode is adopted, a belt transmission mode adopted by traditional transmission is canceled, a middle idle wheel is adopted, the transmission center distancecan be better guaranteed. The system assembly has lower transmission noise and higher transmission efficiency; the planetary gears have the same structure, so that the assembly process is optimized,the transmission structure is simpler and more compact, and the cost is lower; the gear ring structure and the middle shell are integrally formed, and the problem that the output shaft is broken due to the fact that the coaxiality of the middle shell of the planetary gear set is poor and gears bear large lateral force is solved; Meanwhile, all parts in the planetary gear set are simultaneously mounted in the gear ring of the outer shell at a time in the same assembling procedure, and the driving motor can be mounted in the middle shell in the same procedure under the condition that the outer shell is not needed.

Owner:GELUBO TECH CO LTD

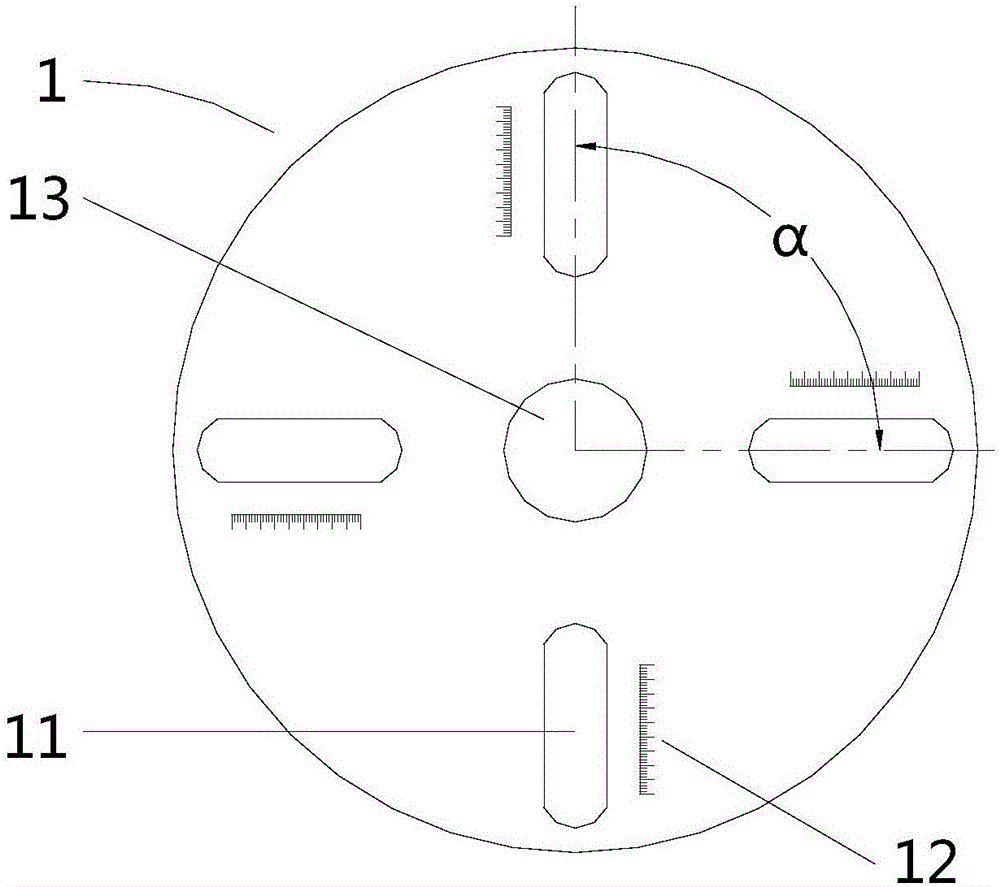

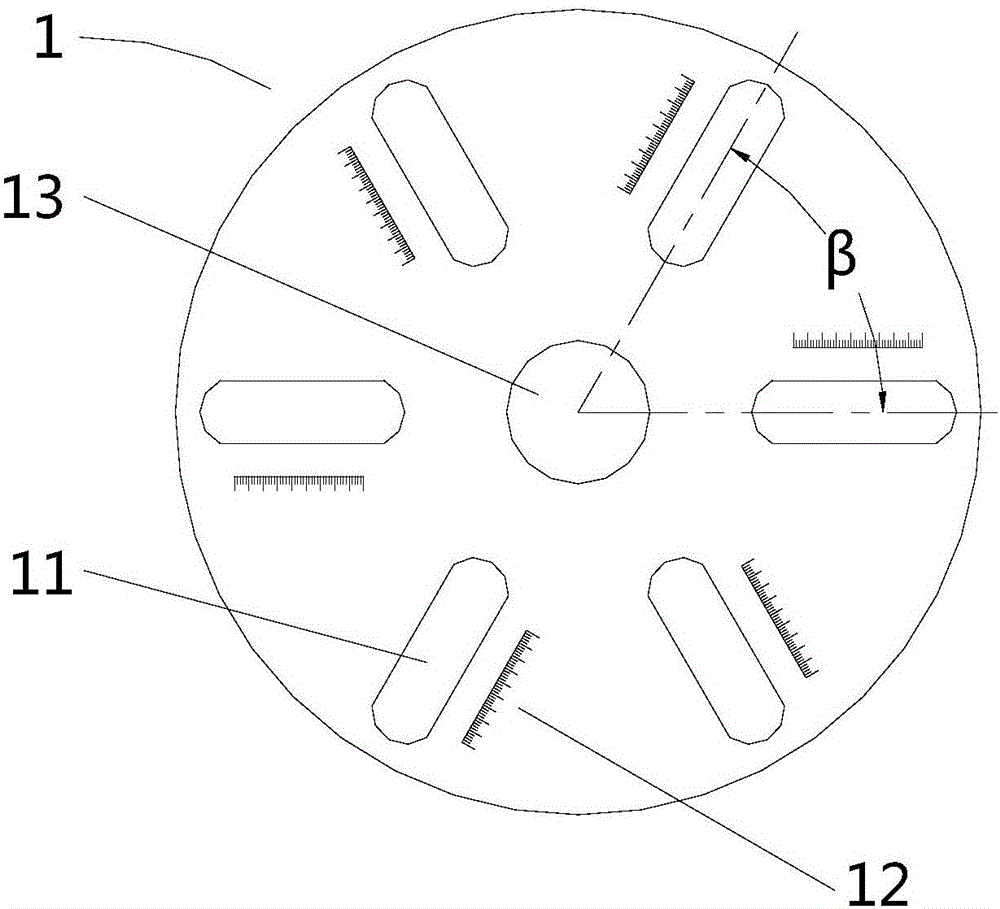

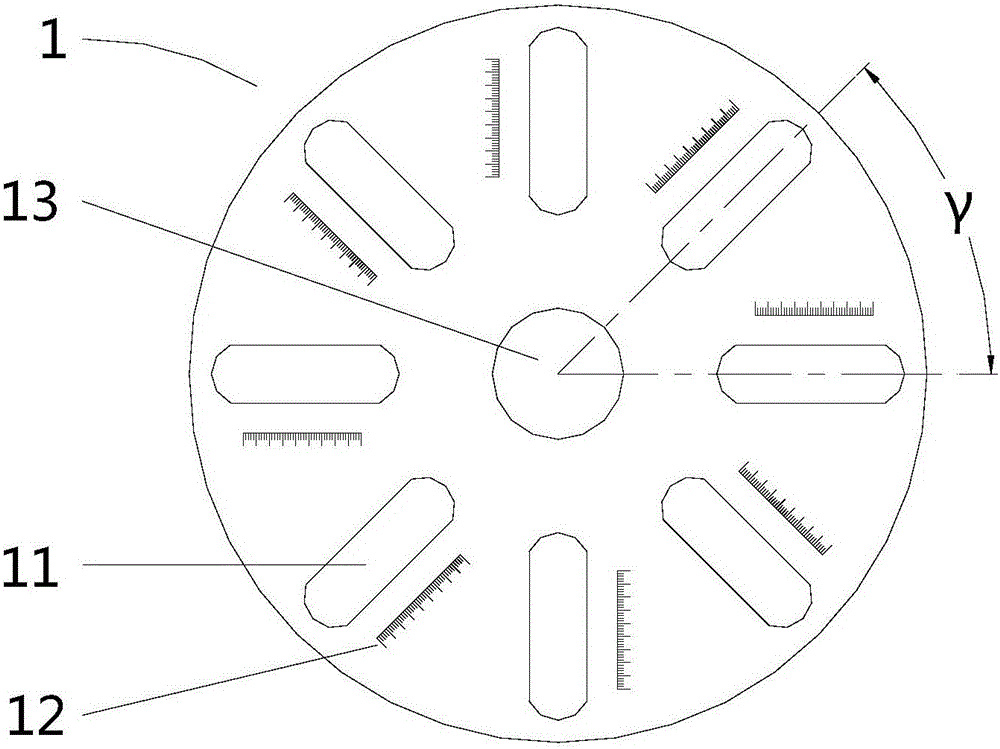

Foundation bolt pre-burying auxiliary welding device

ActiveCN105750798AThe overall structure is simpleImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAnchor bolt

The invention discloses a foundation bolt pre-burying auxiliary welding device, and belongs to the technical field of electric auxiliary tools. The foundation bolt pre-burying auxiliary welding device comprises a bottom plate, a positioning sleeve, a sliding block and a locking part, wherein sliding grooves are formed in the bottom plate radially by taking the central point of the bottom plate as a circle center; central included angles in a length direction among adjacent sliding grooves are equal; scales corresponding to lengths of the sliding grooves are formed in one side in the length direction of the sliding grooves in the bottom plate; a positioning hole is formed in the axial direction of the positioning sleeve; an opening is formed in one end of the positioning sleeve; the end, where the opening is formed, of the positioning sleeve serves as an open end; the bottom wall of the positioning hole serves as a positioning surface; the open end penetrates through the sliding grooves in the bottom plate and is then connected with the sliding block; a positioning boss is arranged, or a clamping plate is connected, onto the outer wall, adjacent to the open end, of the positioning sleeve; a connecting hole matched with the open end is formed in the sliding block; a locking hole matched with the locking part is formed in the sliding block; a calibration device is arranged on the sliding block. By adopting the foundation bolt pre-burying auxiliary welding device, a foundation bolt can be welded by only one person, the working efficiency is high, and the welding quality is good.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JINHUA POWER SUPPLY CO +2

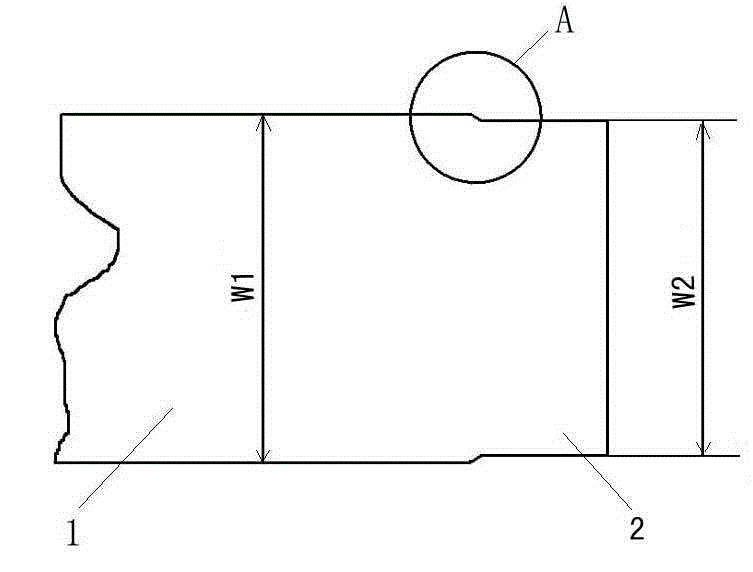

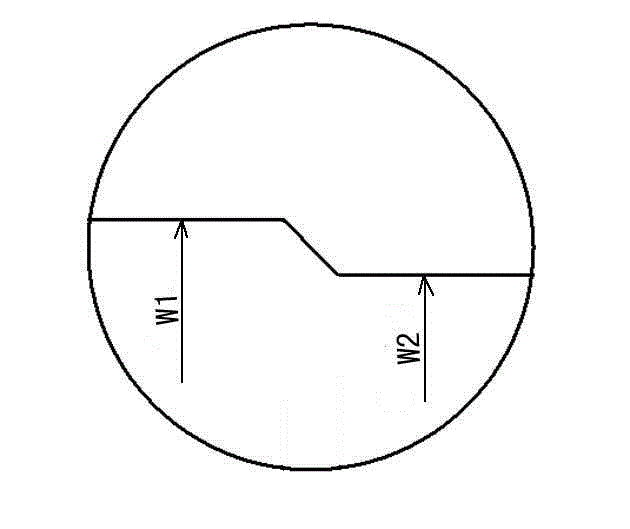

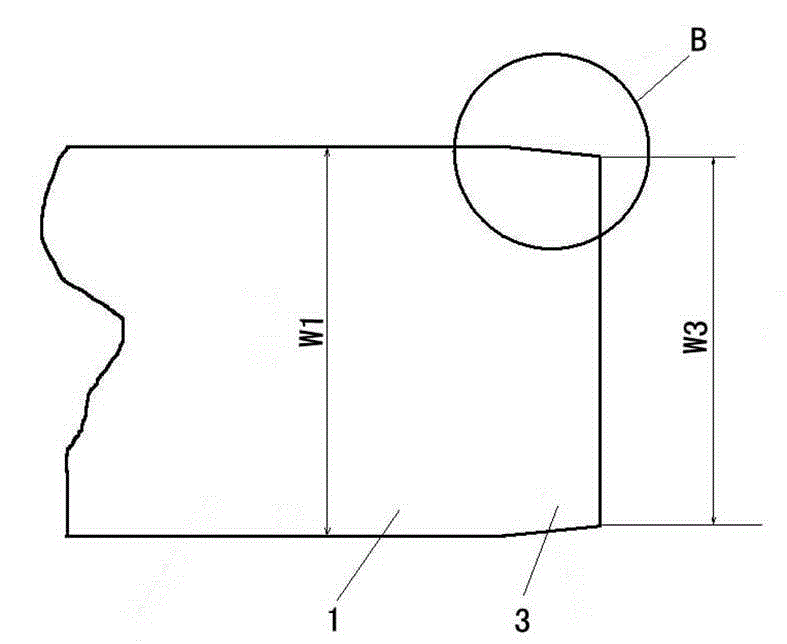

Closing structure for flat tube of condenser of automobile air-conditioner

InactiveCN103557644AEnsure welding reliabilityImprove appearance qualityEvaporators/condensersHeat exchanger casingsEngineeringWedge shape

The invention provides a closing structure for a flat tube of a condenser of an automobile air-conditioner, in order to solve the problems of a present flat tube structure that the inserting and positioning are difficult, the correcting for the center distance of collecting mains is required before brazing, the invariableness cannot be ensured during a brazing process after the correcting, the appearance effect is inferior, and the like, during a core manufacturing process. A joint of an end of the flat tube and the collecting main is arranged in a wedge form, namely, the size of an outer edge on one side of the port of the end of the flat tube is smaller than the size of an inner edge of an assembling hole of the collecting main, and then, is linearly increased to be consistent with the size of the outer edge of a tube body, so that a wedge-shaped transitional zone is formed between the tube body of the flat tube and the port. The closing structure provided by the invention has the beneficial effects that the flat tube can be conveniently inserted into the assembling hole on the collecting main and can be accurately positioned, the center distance between the collecting mains at two ends meets a design demand, and meanwhile, the welding reliability (zero leakage) is ensured. Besides, after the welding is finished, no closing trace of the flat tube can be seen and the appearance quality is increased.

Owner:CHONGQING CHAOLI HI TECH

Flexible printed circuit board and mobile terminal

ActiveCN105578744AImprove adhesionInhibit sheddingPrinted circuit aspectsElectrical connection printed elementsFlexible circuitsEngineering

The invention provides a flexible printed circuit board, comprising a first side and a second side which are arranged face to face, wherein the first side is provided with at least one first bonding pad; the second side is provided with at least one second bonding pad corresponding to the at least one first bonding pad; a tin guiding channel is formed between each first bonding pad and the corresponding second bonding pad, the tin guiding channel is formed in the flexible printed circuit board and communicates the first bonding pad and the corresponding second bonding pad, and the center distance between the first bonding pad and the corresponding second bonding pad which are communicated by the tin guiding channel is a preset numerical value. According to the flexible printed circuit board provided by the invention, the tin guiding channel is used for connecting each first bonding pad and the corresponding second bonding pad together; by virtue of the circulating function of the tin guiding channel, soldering tin can flow from the first bonding pad to the surface of the second bonding pad and therefore a lot of soldering tin can be attached to the surfaces of the first bonding pad and the second bonding pad and further the first bonding pad or the second bonding pad can be prevented from falling off from the flexible printed circuit board. In addition, the invention further provides a mobile terminal comprising the flexible printed circuit board.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

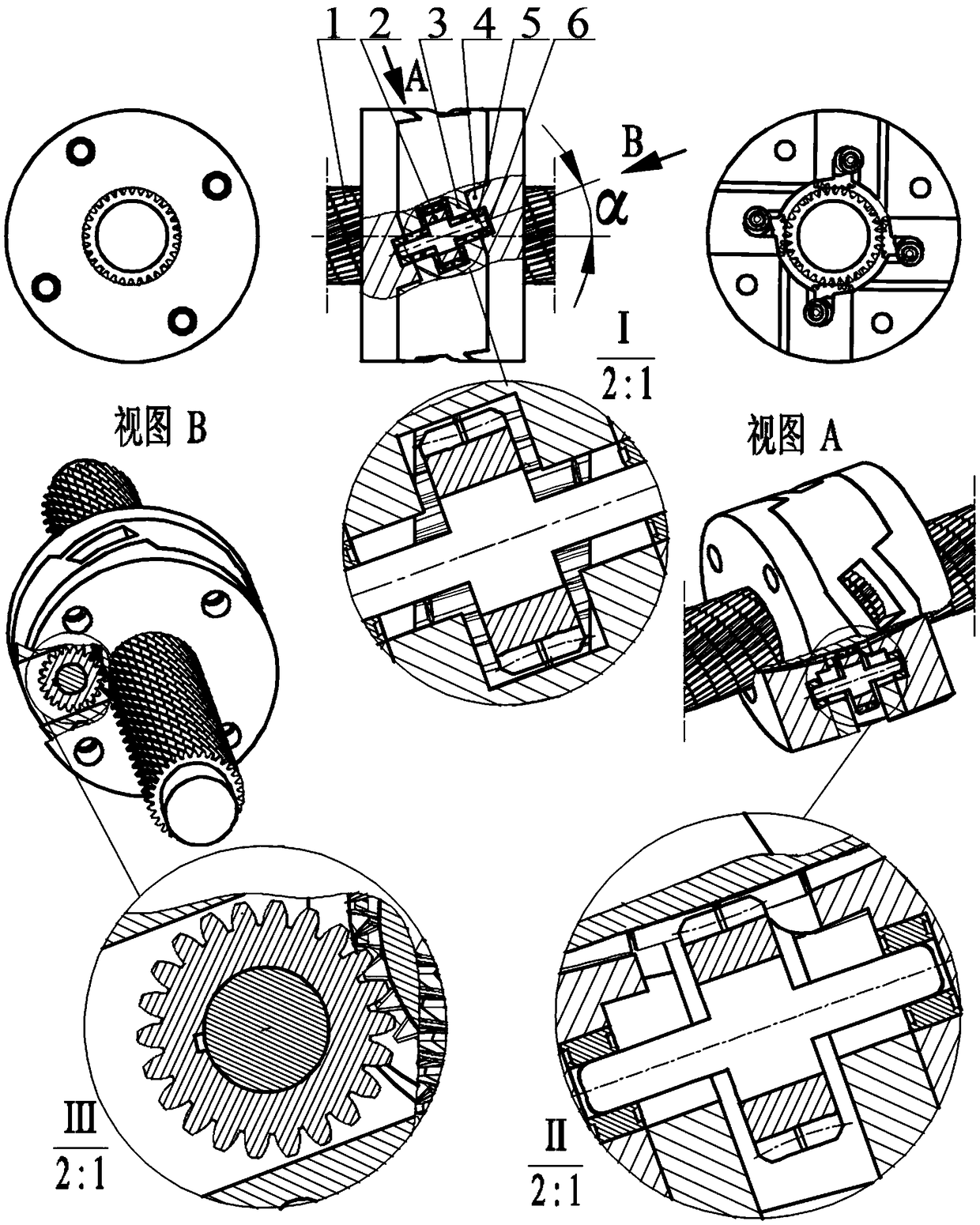

Worm gear screw rod

ActiveCN106224447AGuaranteed center distanceReliable transmissionToothed gearingsPortable liftingHelical lineRolling-element bearing

The invention discloses a worm gear screw rod which comprises a novel helical tooth shaft, novel worm gears, a sleeve, an end cover, a worm gear shaft, a bearing and the like; the novel helical tooth shaft is a long shaft with helical teeth and is provided with a straight groove cut along a helical line which has the helical angle to be 90 degrees-alpha and is perpendicular to the direction of turning of the helical teeth and a cut with a chamfer to be 60 degrees; the helical teeth have the helical angle of alpha; as for each novel worm gear, a boss with the same section size as the cut is point-processed in a worm gear tooth surface; each worm gear tooth surface is in contact with a tooth surface line of the helical teeth; each boss is aligned at and matched with the cut; the worm gear shaft penetrates through a U-shaped groove formed in the sleeve and is installed on blind holes formed in the end cover through a rolling bearing; and under driving of a motor, the novel worm gears roll on the novel helical tooth shaft along the helical line, and helical transmission is realized by depending on the mechanical biting force. According to the worm gear screw rod, compared with the traditional screw rod, sliding friction is very small and unrelated to the driving force and the axial load, the kinetic helix rise angle can be more greatly increased, the transmission efficiency is higher, and transmission is smoother and more reliable.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

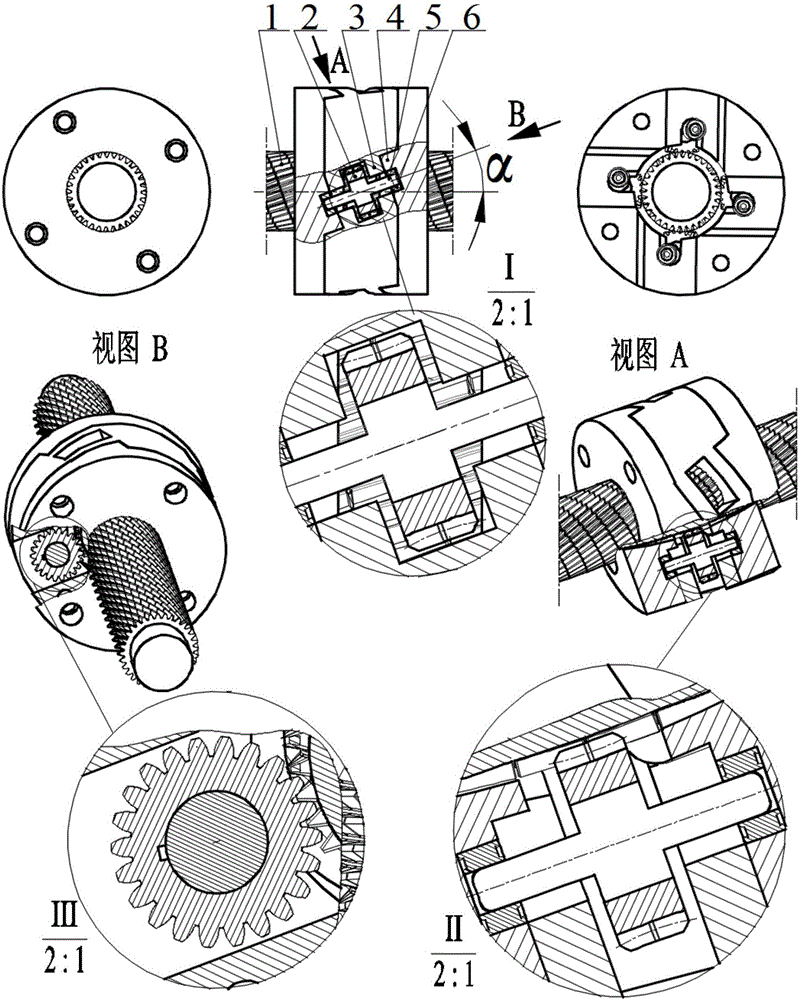

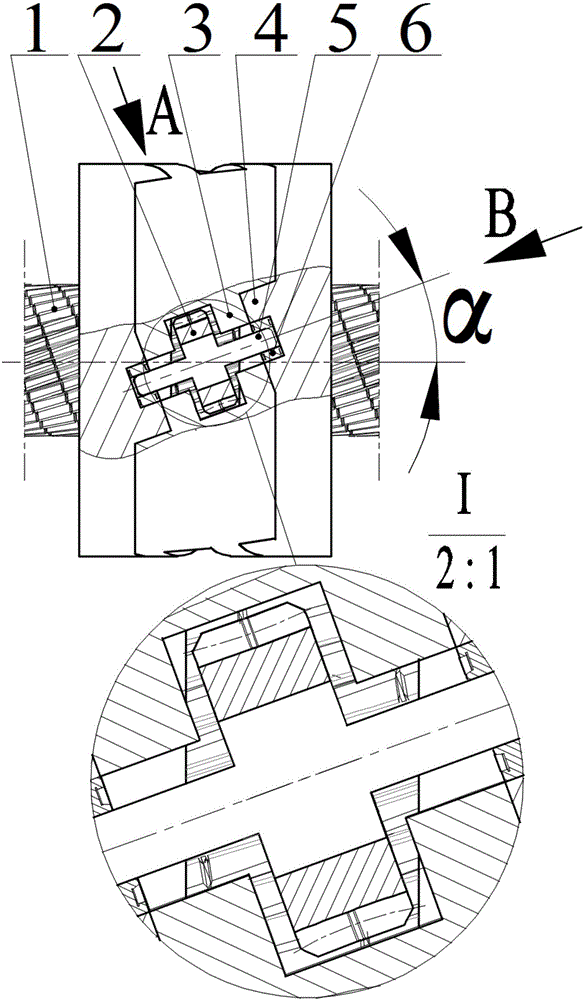

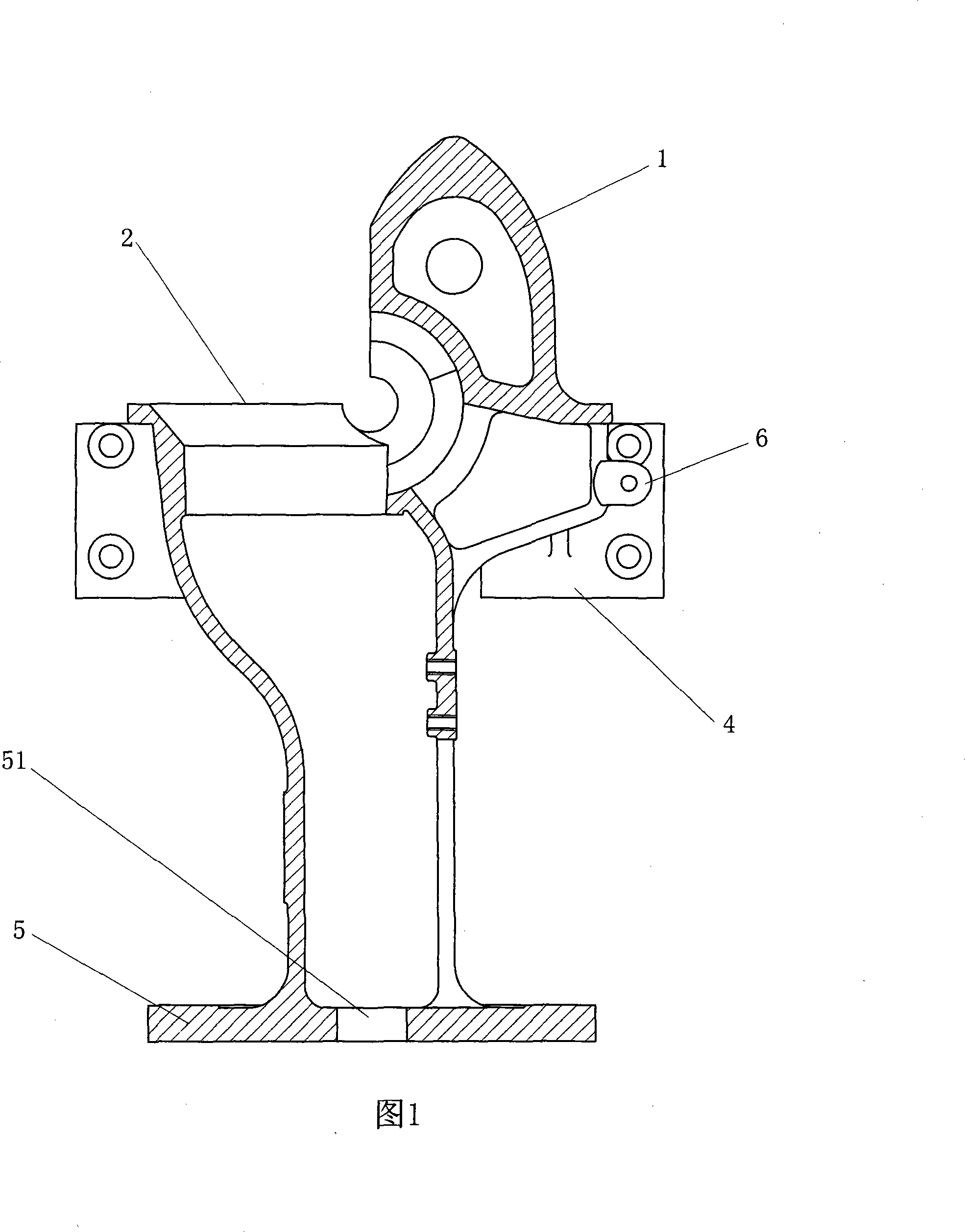

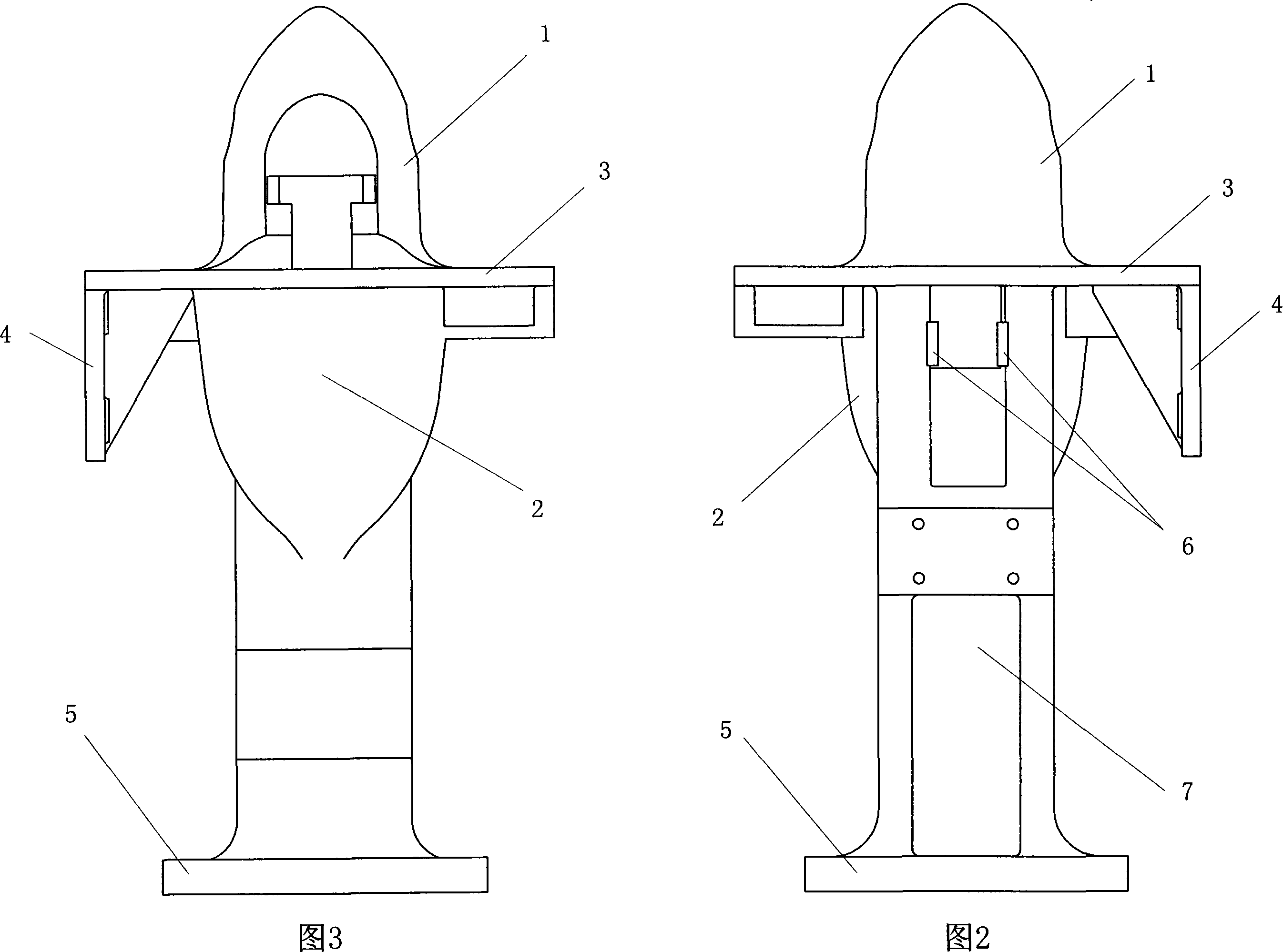

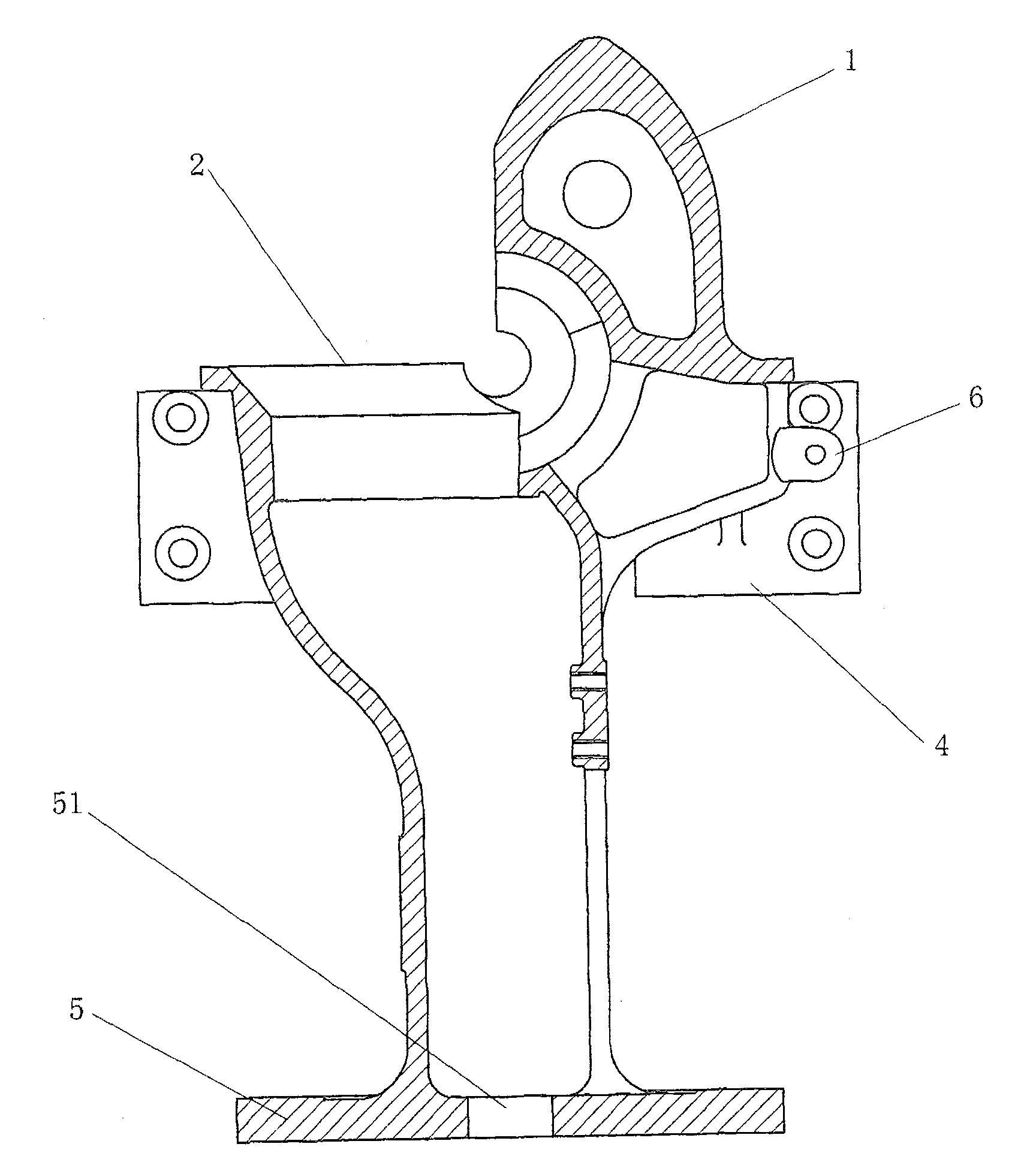

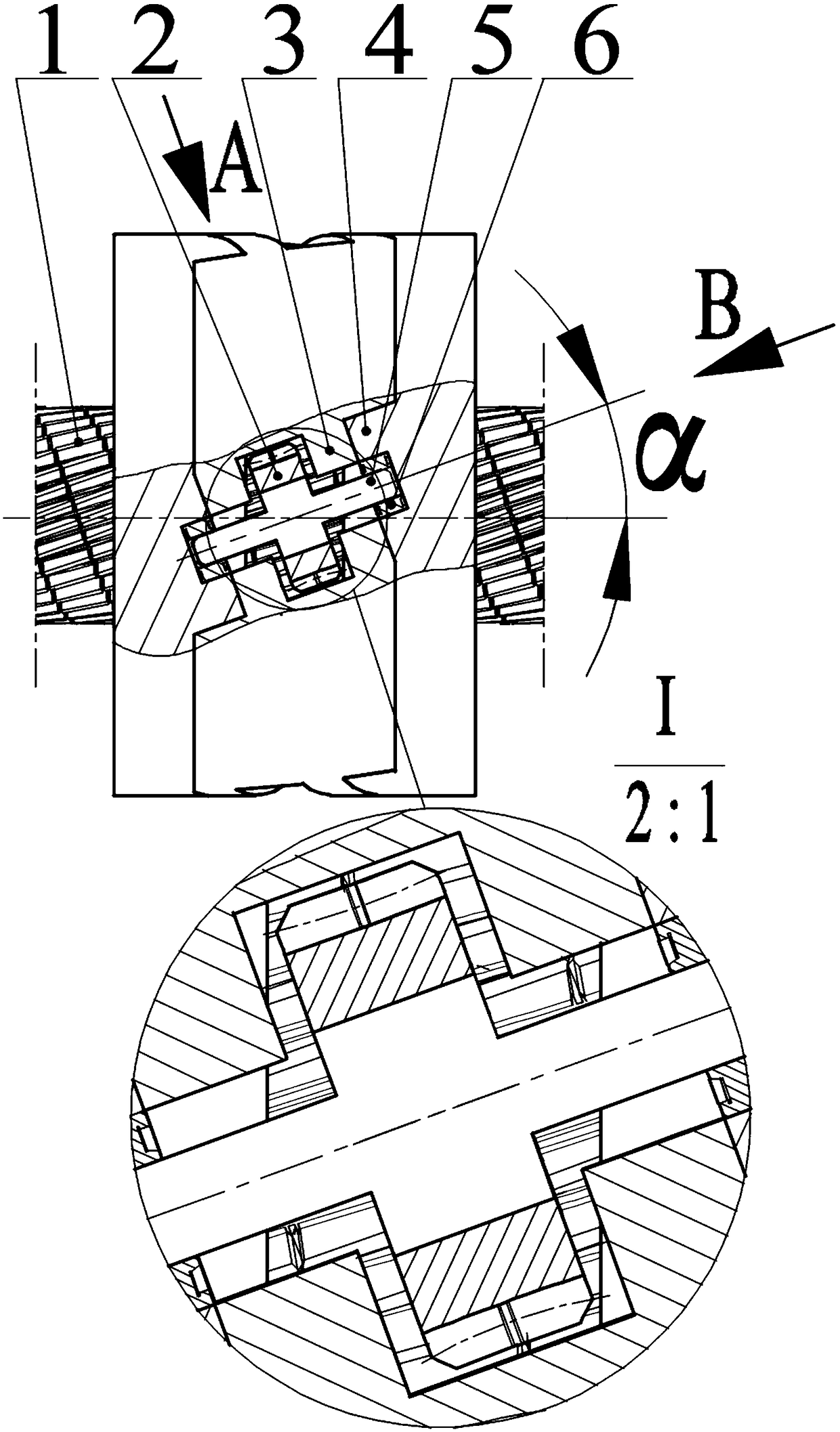

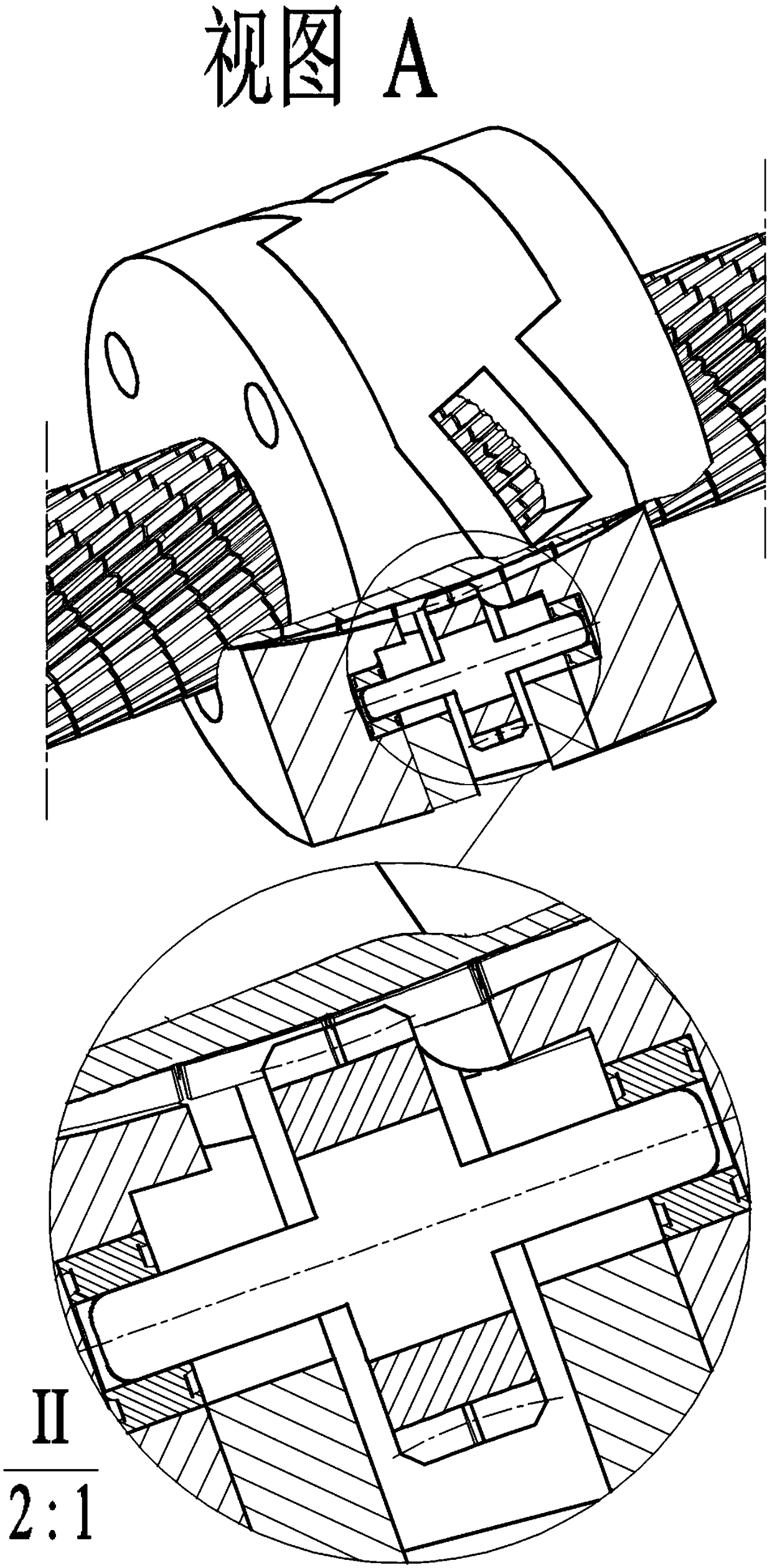

Tight-lock coupler body mechanical manufacturing processes

InactiveCN101229613AGuaranteed accuracyGuaranteed center distanceRailway couplingsHardnessEngineering

The invention relates to a machining process for a tight-lock coupler body. A rough blank is cast by E-class steel with the thermal treatment hardness of HB241-291. When in machining, a bottom face of a bracket is milled and four installing holes on the bracket are drilled and two of the four installing holes are drilling-hinging position holes; meanwhile, the bottom face of the bracket and the two holes are adopted as a reference, namely, the positioning of one face and two pins, to fulfill the post processing procedures. By adopting the positioning of one face and two pins at the front end, the invention eliminates positioning errors and guarantees the correctness of each positioning and clamping as well as guarantees the center distance of a convex taper hole and a concave taper hole at the front end. In addition, the adoption of the positioning of one face and two pins can also ensures that all the post procedures conduct the positioning on the same reference without calibration of workpieces, which substantially shortens the time for the fixture, improves the efficiency and guarantees the product quality.

Owner:CHANGZHOU KEXING RAILWAY EQUIP

Tight-lock coupler body mechanical manufacturing processes

InactiveCN100569433CGuaranteed accuracyGuaranteed center distanceRailway couplingsHardnessEngineering

The invention relates to a machining process for a tight-lock coupler body. A rough blank is cast by E-class steel with the thermal treatment hardness of HB241-291. When in machining, a bottom face of a bracket is milled and four installing holes on the bracket are drilled and two of the four installing holes are drilling-hinging position holes; meanwhile, the bottom face of the bracket and the two holes are adopted as a reference, namely, the positioning of one face and two pins, to fulfill the post processing procedures. By adopting the positioning of one face and two pins at the front end, the invention eliminates positioning errors and guarantees the correctness of each positioning and clamping as well as guarantees the center distance of a convex taper hole and a concave taper hole at the front end. In addition, the adoption of the positioning of one face and two pins can also ensures that all the post procedures conduct the positioning on the same reference without calibration of workpieces, which substantially shortens the time for the fixture, improves the efficiency and guarantees the product quality.

Owner:CHANGZHOU KEXING RAILWAY EQUIP

Worm gear screw

ActiveCN106224447BGuaranteed center distanceReliable transmissionPortable liftingToothed gearingsHelical lineHelical scan

The invention discloses a worm gear screw rod which comprises a novel helical tooth shaft, novel worm gears, a sleeve, an end cover, a worm gear shaft, a bearing and the like; the novel helical tooth shaft is a long shaft with helical teeth and is provided with a straight groove cut along a helical line which has the helical angle to be 90 degrees-alpha and is perpendicular to the direction of turning of the helical teeth and a cut with a chamfer to be 60 degrees; the helical teeth have the helical angle of alpha; as for each novel worm gear, a boss with the same section size as the cut is point-processed in a worm gear tooth surface; each worm gear tooth surface is in contact with a tooth surface line of the helical teeth; each boss is aligned at and matched with the cut; the worm gear shaft penetrates through a U-shaped groove formed in the sleeve and is installed on blind holes formed in the end cover through a rolling bearing; and under driving of a motor, the novel worm gears roll on the novel helical tooth shaft along the helical line, and helical transmission is realized by depending on the mechanical biting force. According to the worm gear screw rod, compared with the traditional screw rod, sliding friction is very small and unrelated to the driving force and the axial load, the kinetic helix rise angle can be more greatly increased, the transmission efficiency is higher, and transmission is smoother and more reliable.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

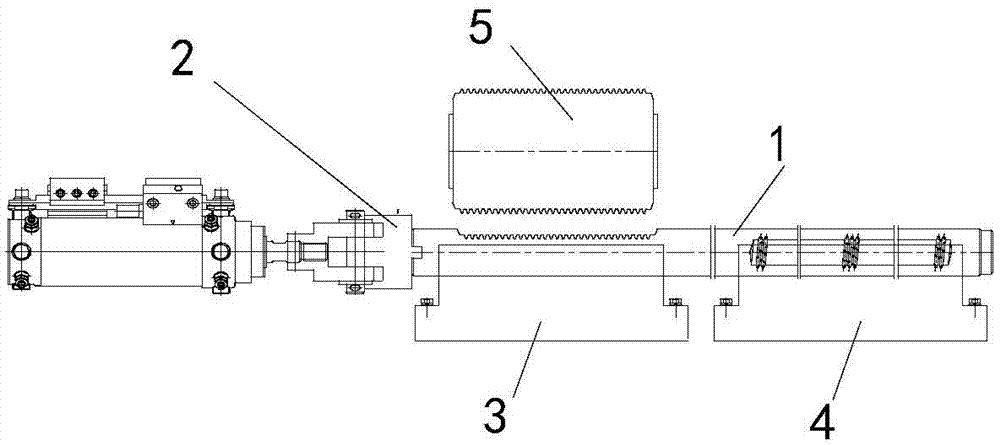

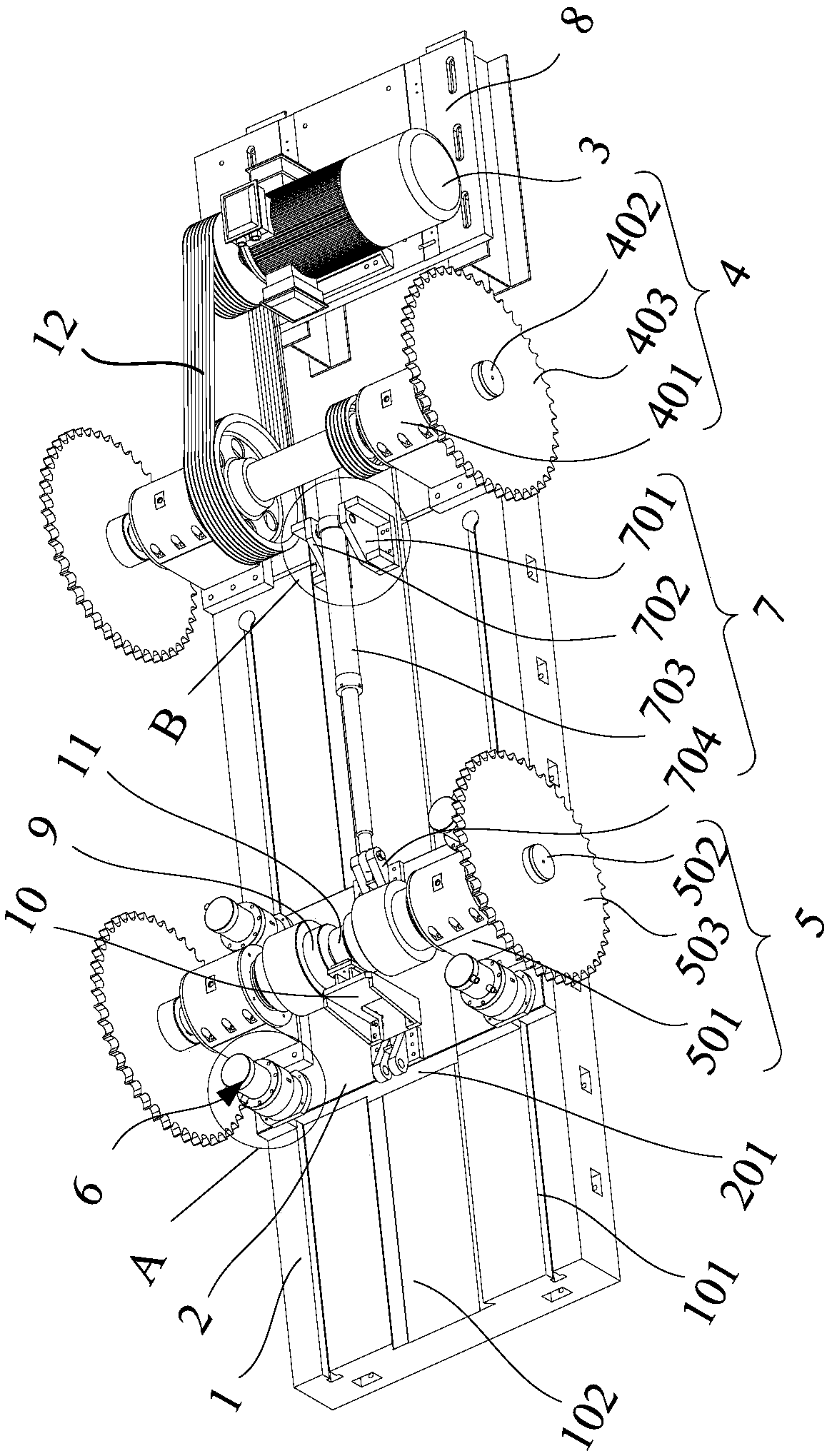

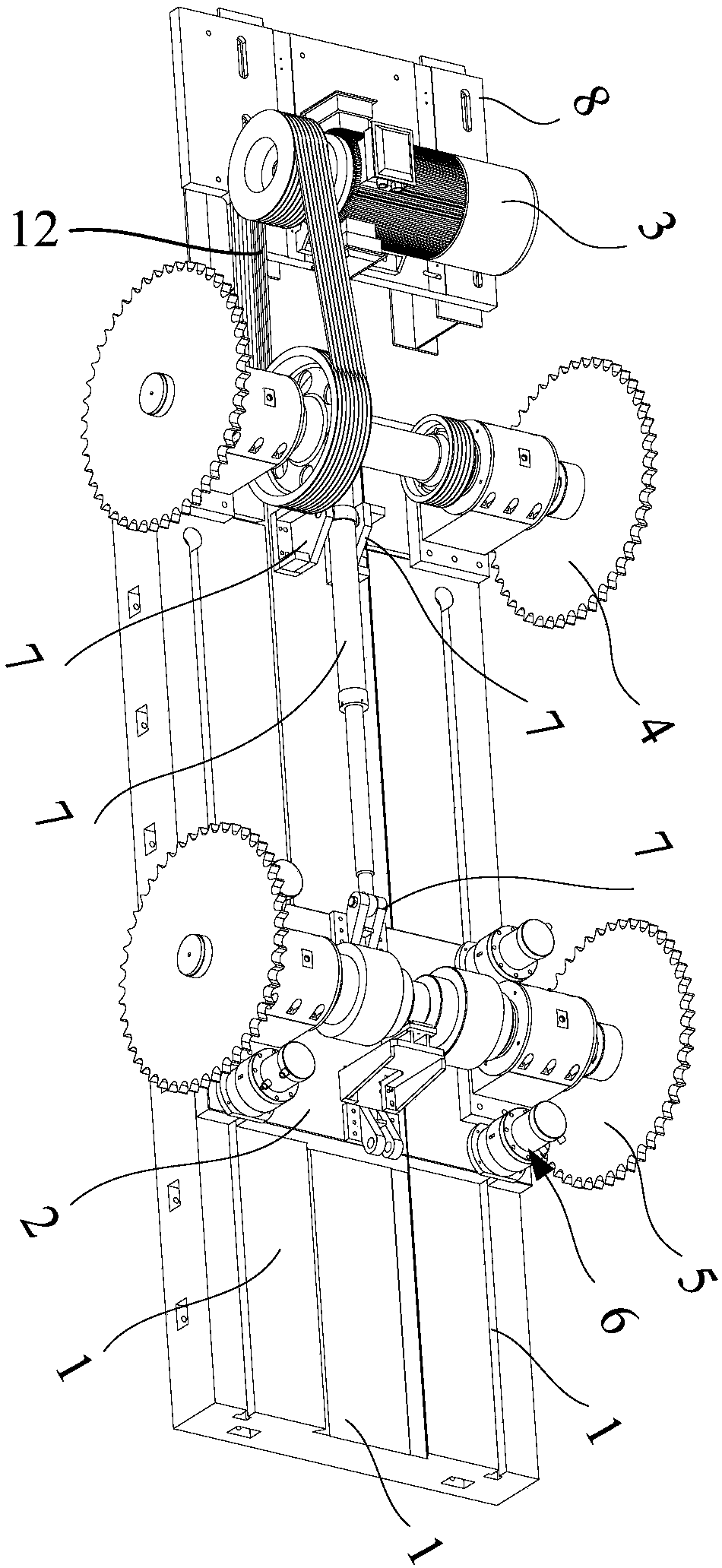

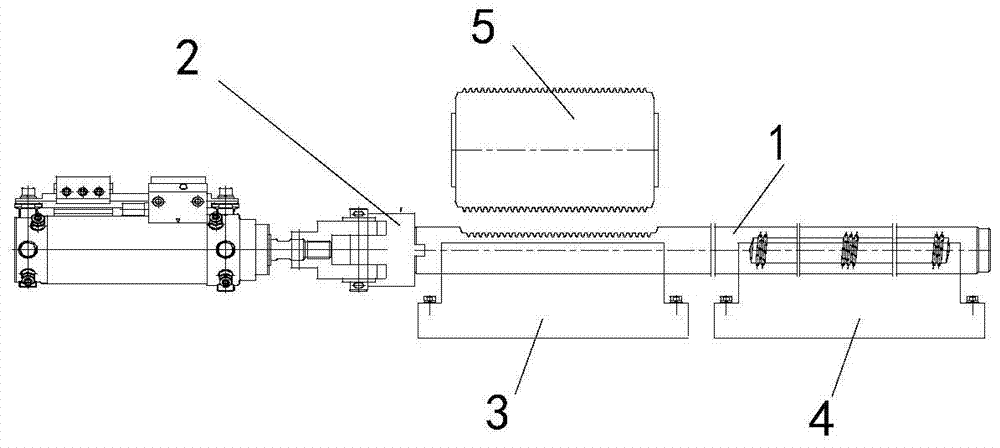

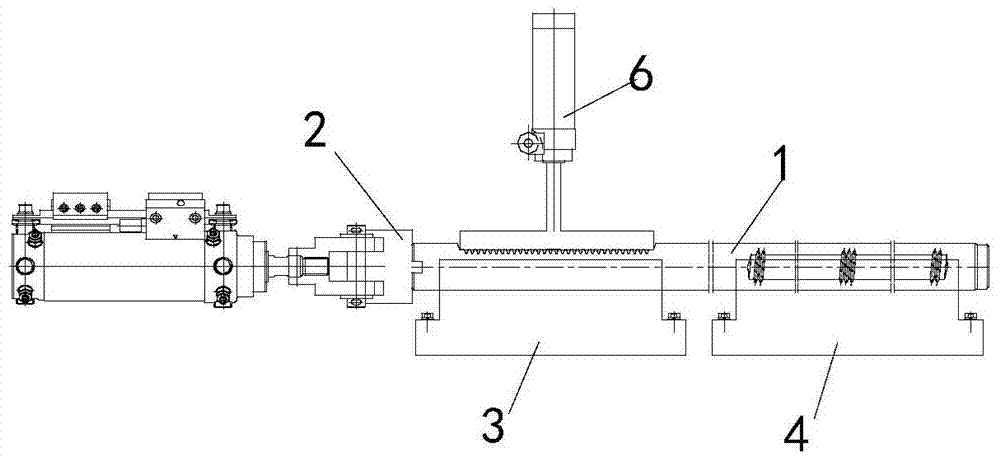

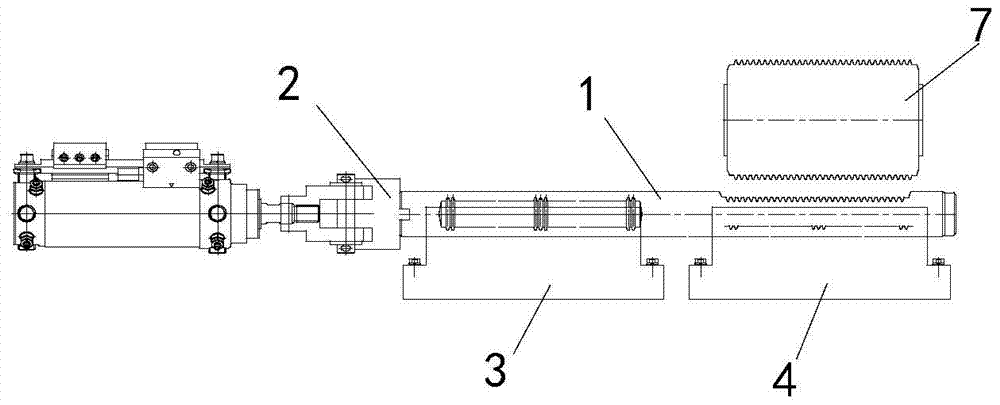

Chain wear test device and chain wear test method

PendingCN109387447AConform to the running stateSimulation test results are accurateInvestigating abrasion/wear resistanceDrive shaftEngineering

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

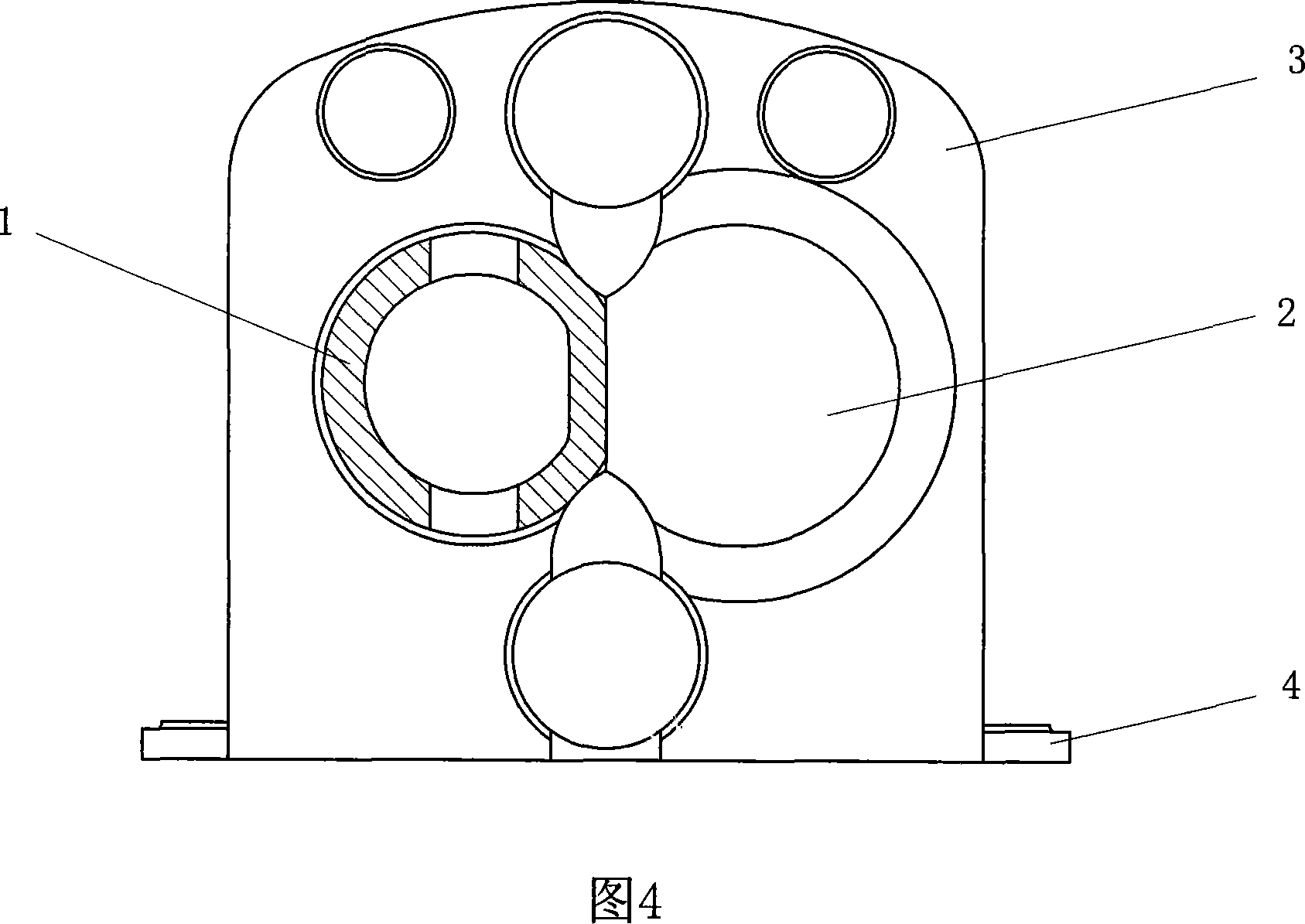

Gear pair for preventing collision and ensuring center distance

ActiveCN103775618AAvoid damageGuaranteed center distanceGear vibration/noise dampingToothed gearingsGear wheelClassical mechanics

The invention relates to a gear pair for preventing collision and ensuring center distance, which solves the problems that the cost for ensuring the center distance through the base processing precision and the assembly is high, the collision between gears cannot be prevented, and the noise is high. A first gear (4) is mounted on a slide gear shaft (6), and a second gear (1) is mounted on a fixed gear shaft (7); the slide gear shaft (6) is in movable fit with a groove (3a) in a first base (3); the fixed gear shaft (7) is mounted on a second base (2), and the second base (2) is fixed with the first base (3); one end of a gear jacking spring (5) is connected with the groove (3a) in the first base (3), and the other end of the gear jacking spring (5) is propped against the slide gear shaft (6); the first gear (4) and the second gear (1) are meshed through the pre-tightening force of the gear jacking spring (5). During meshing, a second cylinder (1a) which is connected with the side surface of the second gear (1) is in contact with a first cylinder (4a) which is connected with the side surface of the first gear (4), the reference diameter of the second cylinder (1a) is equal to that of the second gear, and the reference diameter of the first cylinder (1a) is equal to that of the first gear.

Owner:CHENGDU JIAYITONG INFORMATION TECH CO LTD

Coaxial large strided distance ear base hole boring auxiliary device and boring process method

InactiveCN100551592CGuaranteed coaxialityReduce runoutBoring/drilling machinesEngineeringMachine tool

The invention relates to an auxiliary device for borings of coaxial large span length ear base holes and a method for manufacturing the borings. The auxiliary device comprises an extending knife bar, a transitional supporting sleeve and a support, wherein the transitional supporting sleeve is inserted in an ear base hole which is manufactured through a common short knife bar and near a constructional element of the end surface of a machine tool main axle, a support supporting sleeve is inserted in a round hole on the support, and the extending knife bar is passed respectively through the transitional supporting sleeve and the support supporting sleeve and supported in auxiliary by the transitional supporting sleeve and the support supporting sleeve. The method for manufacturing the borings adopts the auxiliary device to manufacture the coaxial long center ear base holes on a large scale boring and milling machine. The coaxiality of coaxial ear base holes and center distance and the depth of parallelism between central lines of different axis ear base holes can be guaranteed, a derrick and a drill floor are connected on a basal seat after adopting the method to manufacture the borings of coaxial long center ear-seat holes on large scale structural elements as a driller, which has high assembly preciseness, little cooperating gap, and is stable while in use, installing working amount can be decreased greatly, and installing working efficiency can be increased.

Owner:RG PETRO MACHINERY GROUP

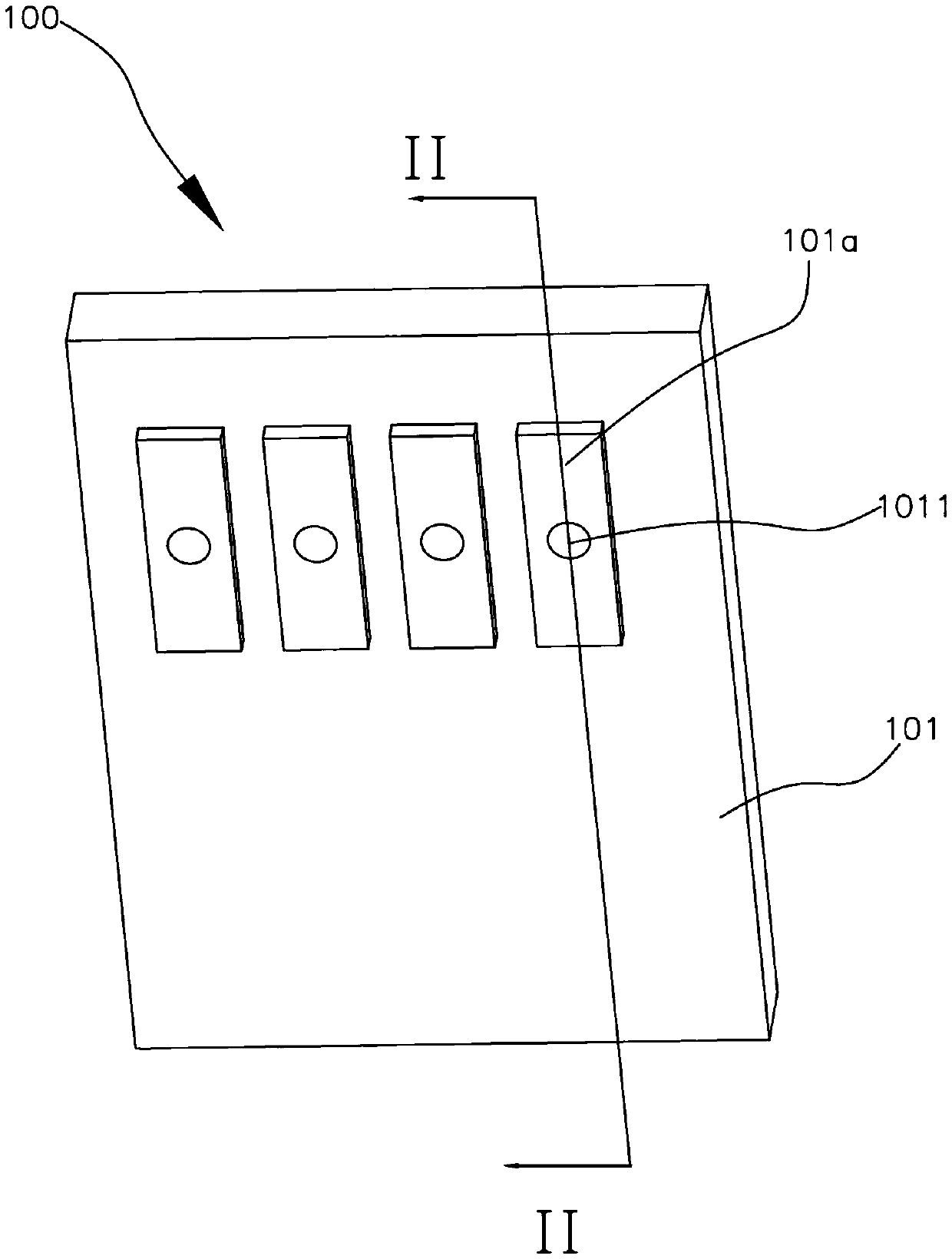

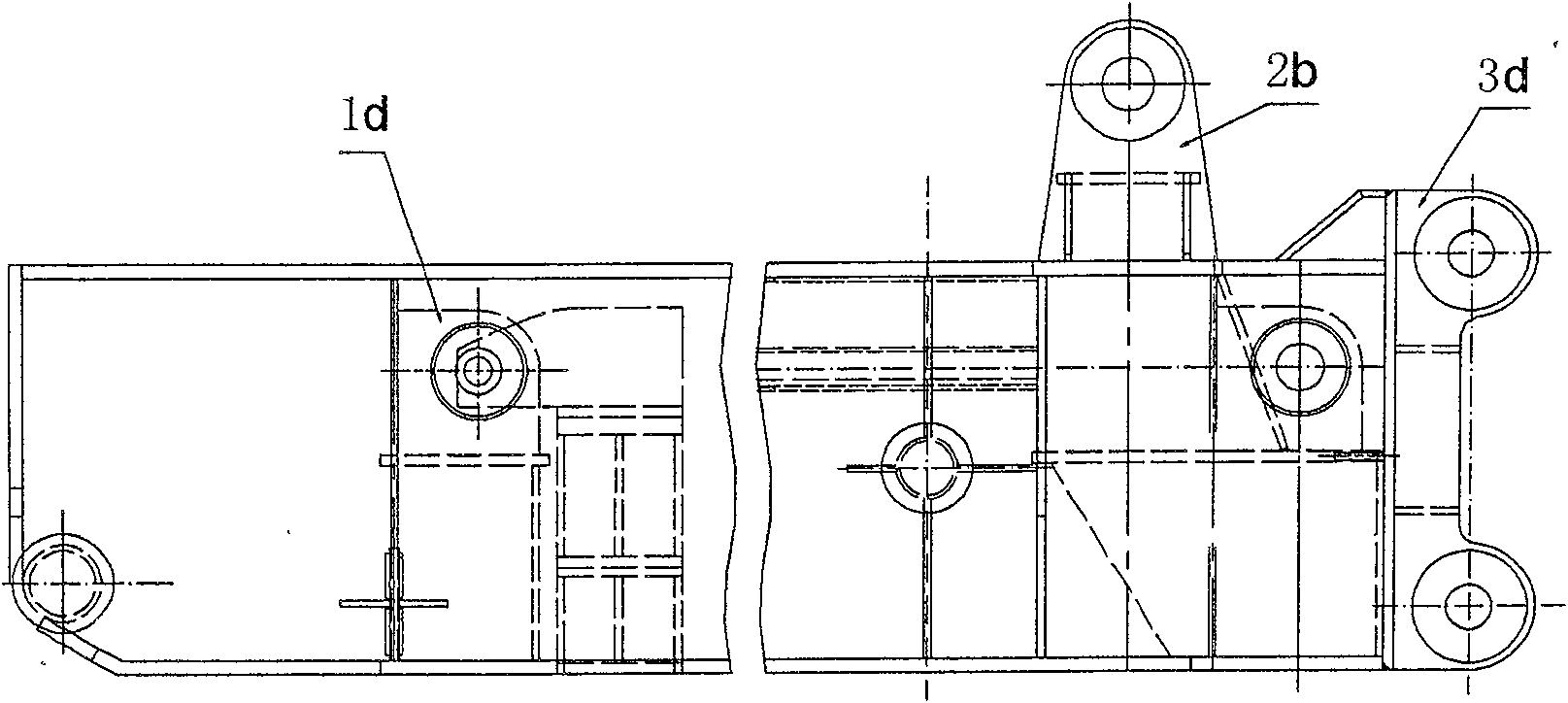

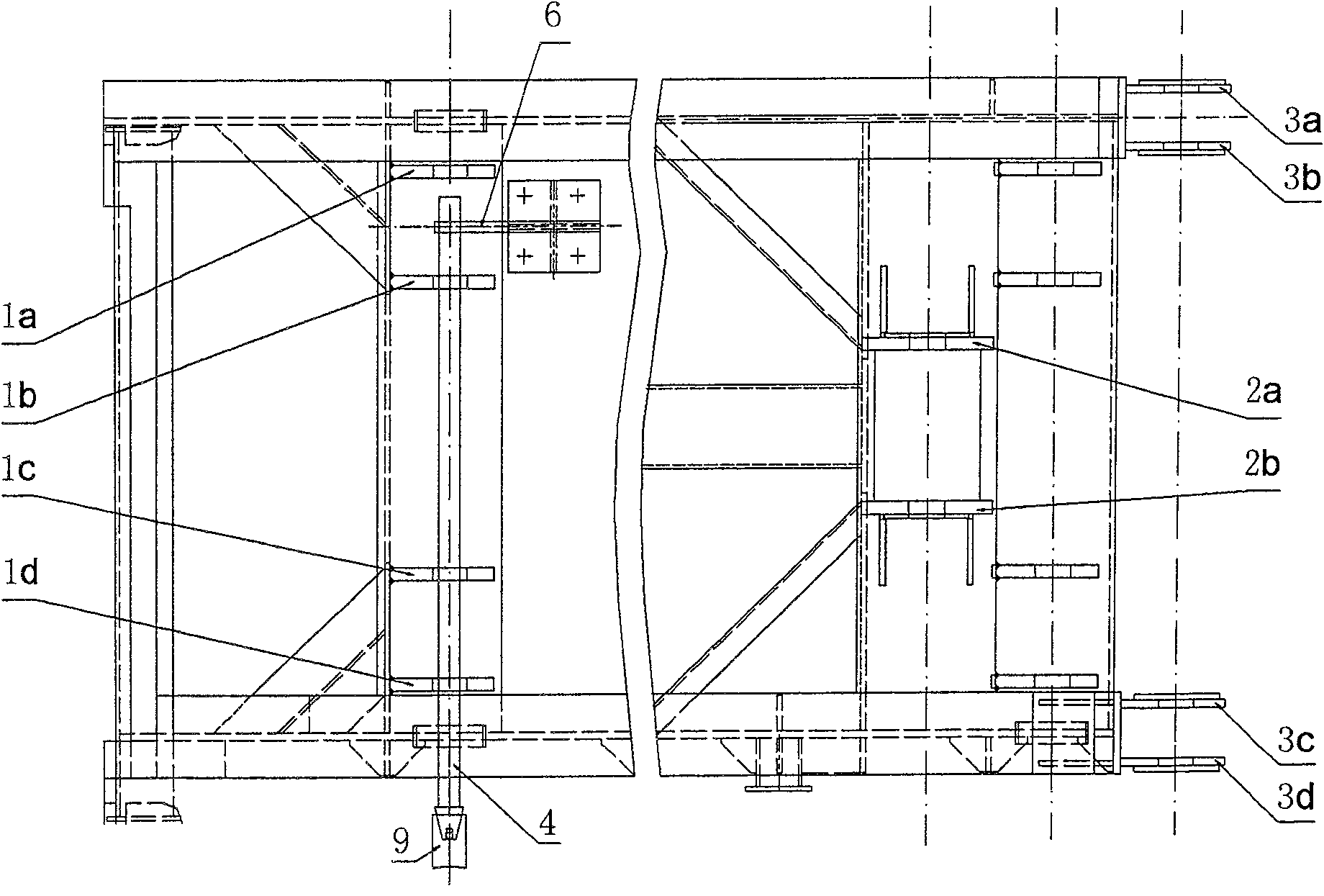

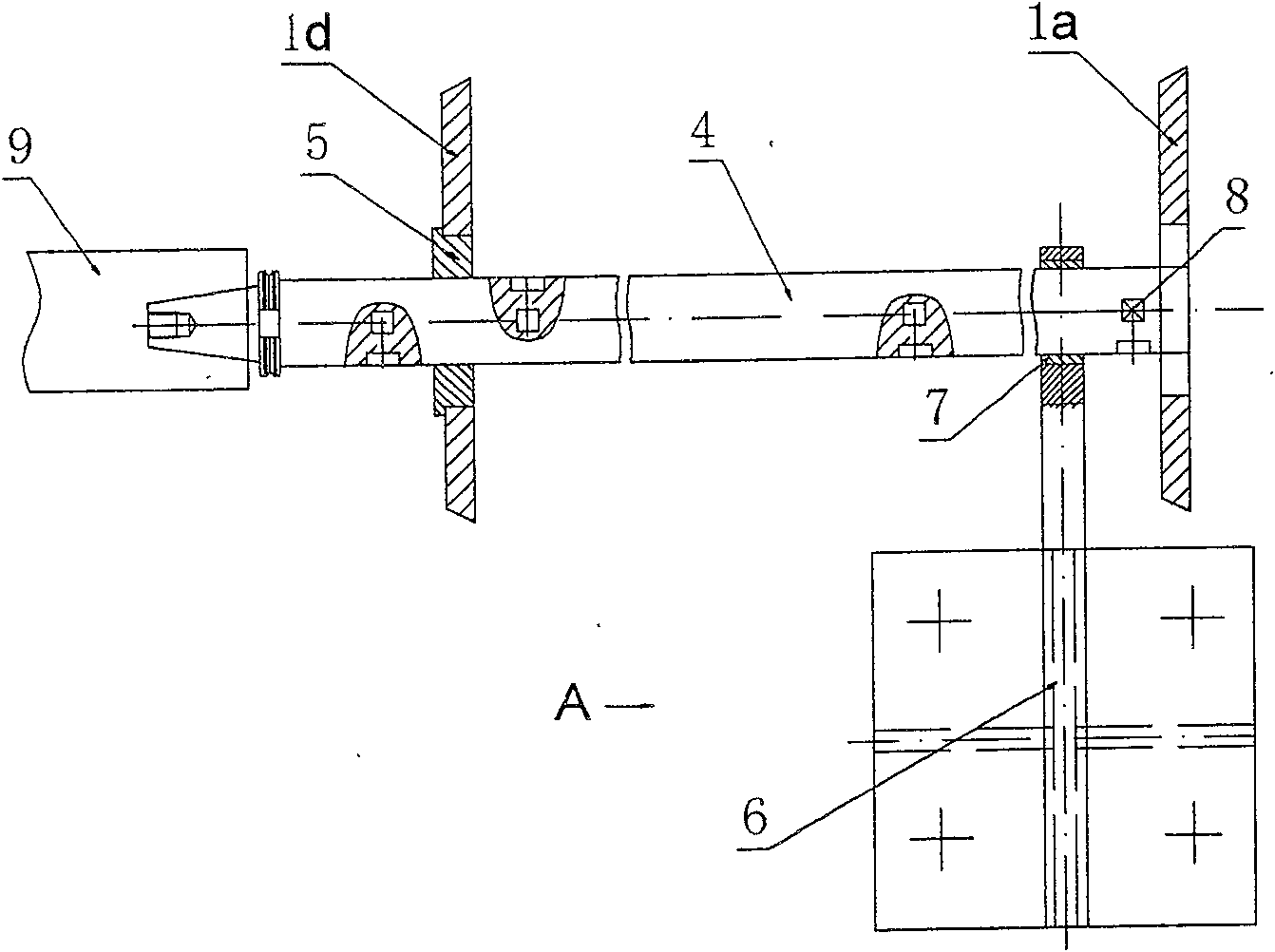

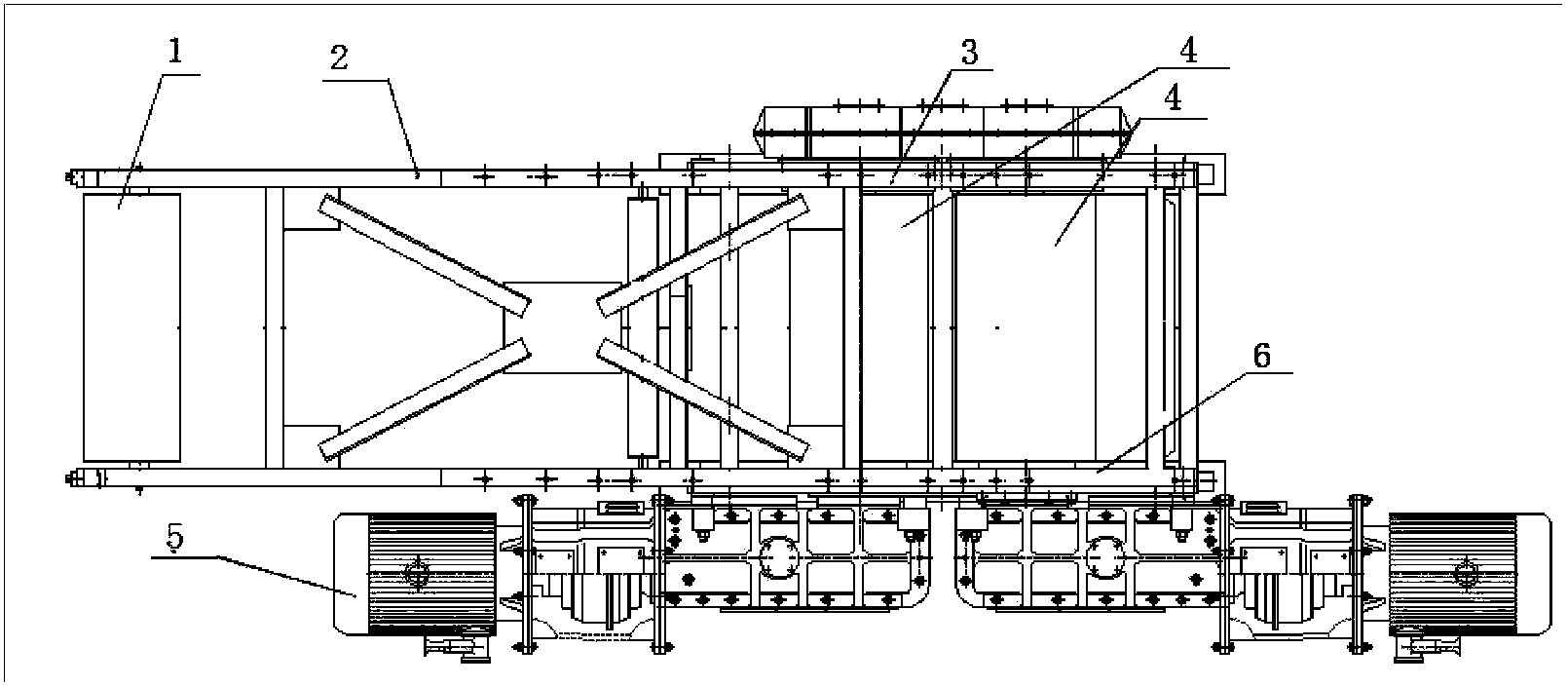

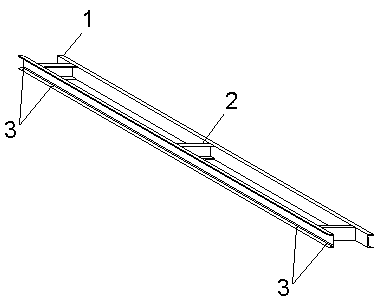

Belt conveyor headstock and manufacturing method thereof

The invention relates to the technical field of conveyor racks, in particular to a belt conveyor headstock and a manufacturing method of the belt conveyor headstock. A left side plate and a right side plate on the belt conveyor headstock are machined by the adoption of the same tool, in this way, positions and center distances of sleeves are effectively ensured, so that the center distance of the sleeve on the left side plate is in accordance with the center distance of the sleeve on the right side plate, then the coaxiality of main rollers is ensured when the main transmission rollers are installed, the transmission efficiency is ensured, belt off tracking is avoided, and working efficiency is improved.

Owner:GUIZHOU HONGSHI COAL MACHINE MFG

Tapping tooling of automobile engine support

InactiveCN103551882ASimple structureEasy to implementThread cutting machinesLarge fixed membersEngineeringKidney

The invention discloses a tapping tooling of an automobile engine support. The bottom surface of a horizontal supporting plate and the top surface of a workbench are fixed through columns; the horizontal supporting plate is provided with three screw tap abdicating holes; a screw is vertically fixed on the rear portion of the top surface of the horizontal supporting plate; the top end of the screw is connected with a nut; the front portion of a pressing plate is provided with a semicircular gap; the rear portion of the pressing plate is provided with a kidney-shaped hole along the front and back direction; the screw penetrates the kidney-shaped hole; the workbench is supported on the top surface of a sliding table through two first sliding assemblies which are side by side left and right; the sliding table is supported on the top surface of a horizontal base plate through two second sliding assemblies which are side by side front and back; the workbench can slide in the front and back direction and the left and right direction. According to the tapping tooling of the automobile engine support, a user can move the workbench to move the support, so that the support can move to the position which needs to be drilled conveniently and rapidly and accordingly the operation is convenient and the center distance between three threaded holes which need to be machined and are formed in the support can be effectively guaranteed.

Owner:HENAN POLYTECHNIC

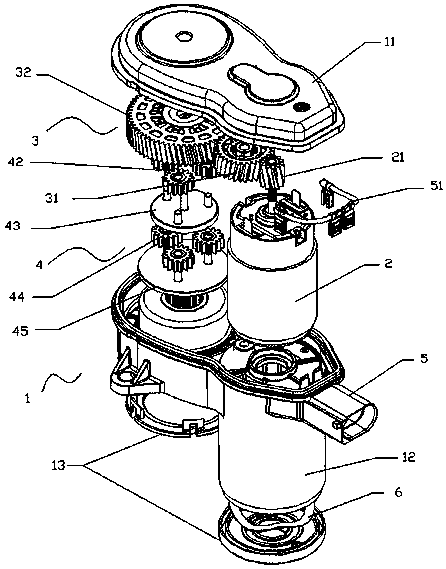

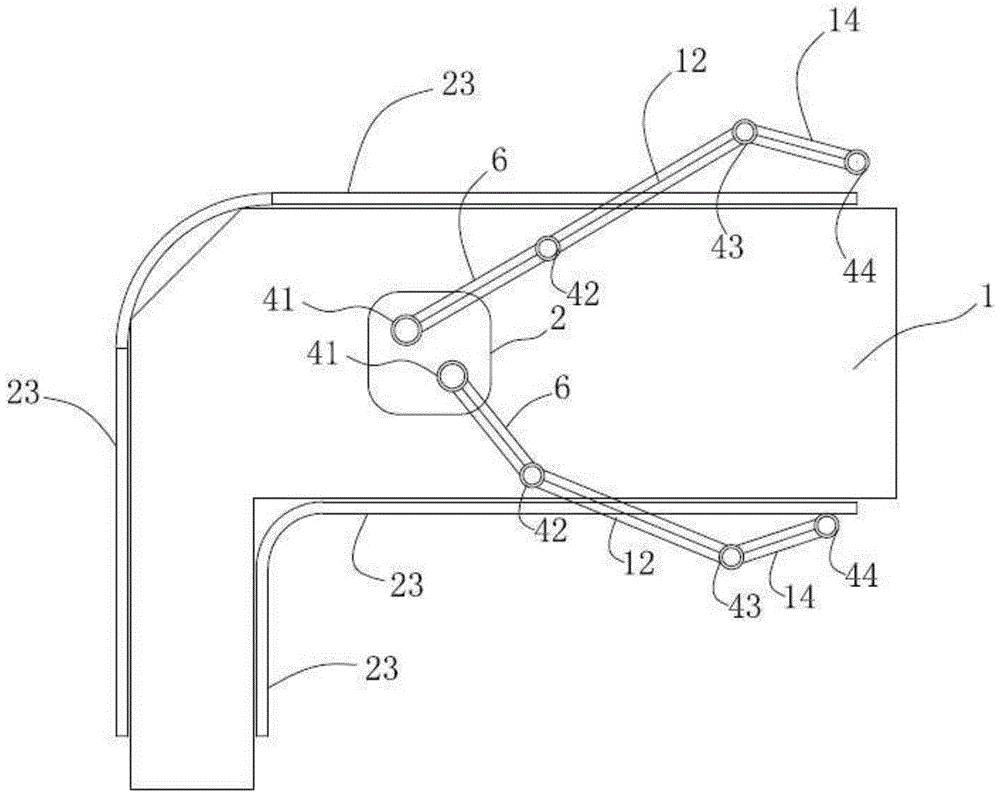

Gear rack center distance adjusting mechanism

InactiveCN105156613AGuaranteed center distanceQuality assuranceGearing detailsFriction gearingsCouplingEngineering

The invention relates to a gear rack center distance adjusting mechanism, which comprises frames which are mounted on a base, wherein a synchronization rotating shaft is mounted in the width direction of the frames; two ends of the synchronization rotating shaft are mounted in bearing seats of two sides of the frames by bearings; upper wedge blocks are arranged under the bearing seats; the lower ends of the upper wedge blocks are provided with lower wedge blocks which are matched with the upper wedge blocks; the outer ends of the lower wedge blocks are connected with adjusting screws; the upper ends of two sides of the frames are provided with linear guide rails; sliding blocks which are mounted on the lower ends of tool rests are arranged on the linear guide rails; racks are mounted at two sides of the lower end faces of the tool rests; two synchronization gears are arranged on the synchronization rotating shaft in a sleeving way; the two synchronization gears are respectively meshed with the racks; and one end of the synchronization rotating shaft is connected with an output shaft of a servo motor by a coupler. The gear rack center distance adjusting mechanism has the advantages that the structure is simple; two ends of the synchronization rotating shaft do synchronous movement, and the movement is stable, so that the positioning precision of the tool rests is high, and the quality of a processed workpiece is ensured.

Owner:JIANGSU YAWEI MACHINE TOOL

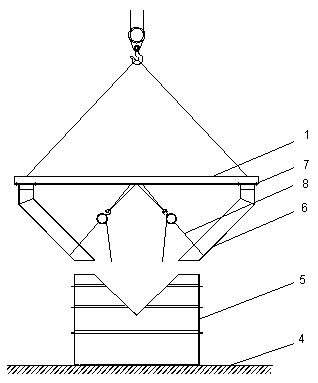

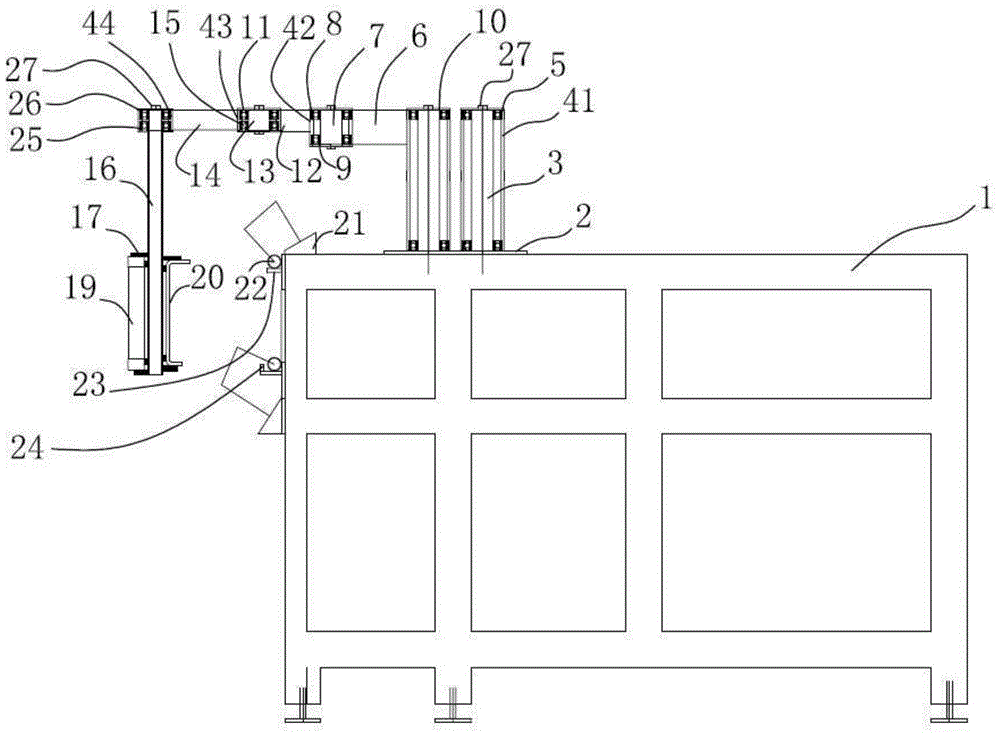

Ground assembly and installation method for air box and ash discharge pipes of chain grate

InactiveCN111521028AGuaranteed levelnessGuaranteed center distanceFurnace typesHandling discharged materialButt jointStress point

The invention discloses a ground assembly and installation method for an air box and ash discharge pipes of a chain grate. The ground assembly and installation method is characterized by comprising the steps that a lifting appliance is manufactured and bolt holes are opened according to the design sizes of flanges of the ash discharge pipes; a platform is arranged, and an air box body is invertedon the platform with a large opening facing downwards; the two horizontally placed ash discharge pipes are connected with the lifting appliance on the ground; the lifting appliance and the two ash discharge pipes are erected and lifted, and the ash discharge pipes are in butt joint with connecting ports of the inverted air box; after the butt joint of the connecting ports, the stressed points of the connecting ports are firmly welded through electric welding, the lifting appliance is dismantled, and then the butt joint of next group of ash discharge pipes is carried out; and after the connecting ports are fully welded, the air box and the ash discharge pipes which are connected together are turned over and lifted to the chain grate for installation in place. According to the ground assembly and installation method, the installation precision and efficiency of the air box and ash discharge pipes of the chain grate can be improved, the operability of the method is high, channel steel formanufacturing the lifting appliance is easy to find, used inverted chains are common tools, the flanges do not need to be measured by a steel ruler and a level gauge, the butt joint is in place in one step, and the method is convenient and accurate.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

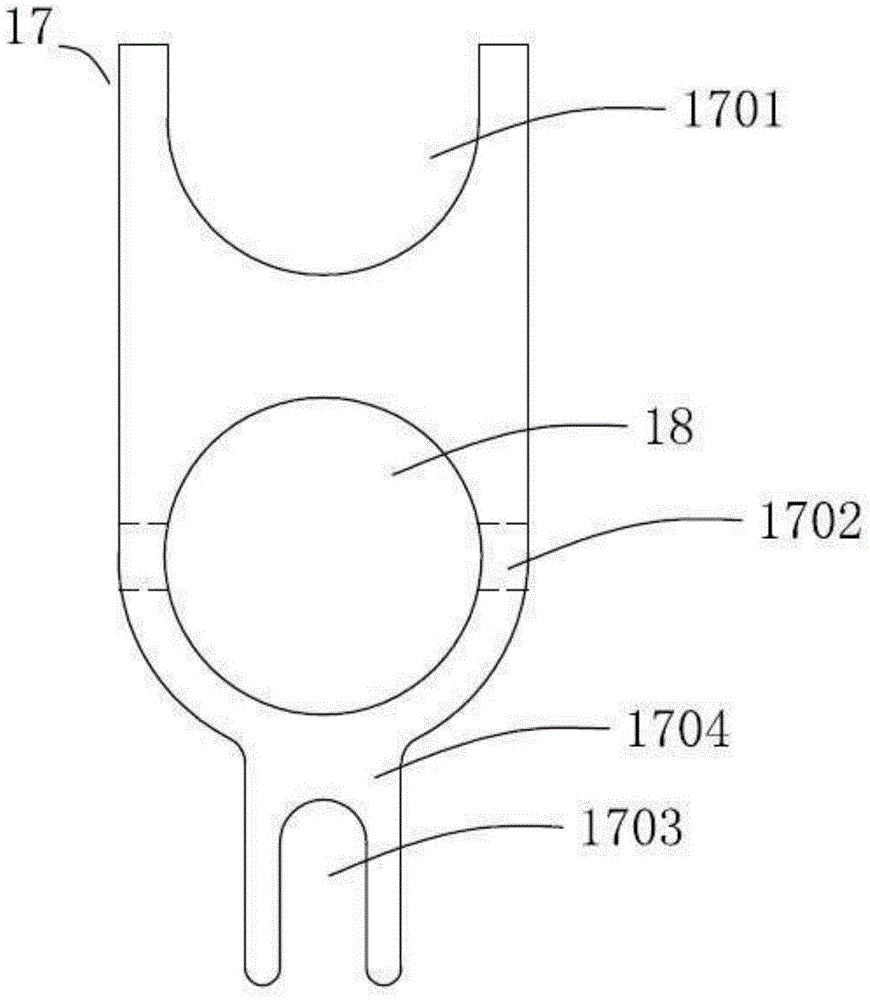

A tooling structure that can ensure the verticality of welding of reinforcement ribs, support columns and guide rails

ActiveCN105215603BGuaranteed center distanceEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCantilever

The invention relates to a tool structure capable of guaranteeing welding perpendicularity of reinforcing ribs, supporting columns and guide rails. The tool structure comprises a working frame, a first rotary shaft, a second rotary shaft, a third rotary shaft and a fourth rotary shaft, and further comprises a cantilever, wherein each rotary shaft is mounted in each rotary drum and capable of realizing rotary motion; the other end of the cantilever is provided with a pair of mounting plates; and one surface, opposite to the cantilever, of the working frame is further connected with a pair of tool plates. The tool structure is simple in structure and convenient in use; during welding operation, the supporting columns, the reinforcing ribs and the guide rails are opposite to an operator, so that the operation of the operator is convenient. The guide rails are arranged on each tool plate, and the tool plates are parallel to one another, so that a distance between the guide rails on the tool plates is fixed, and a central distance between the guide rails is guaranteed; the cantilever is perpendicular to the ground, and the mounting plates are additionally arranged on the cantilever, so that the reinforcing ribs and the supporting columns are also perpendicular to the ground, thereby guaranteeing the welding perpendicularity of the guide rails, the supporting columns and the reinforcing ribs and improving the production efficiency.

Owner:SYMAX ELEVATOR CHINA

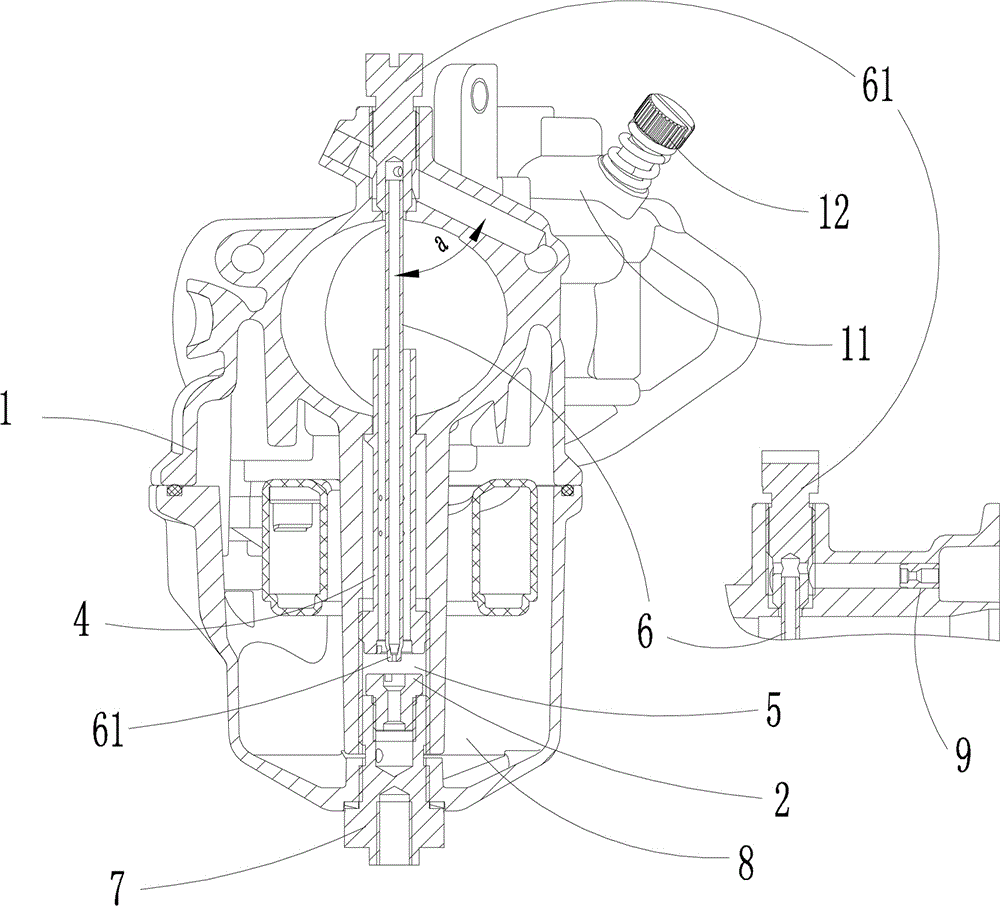

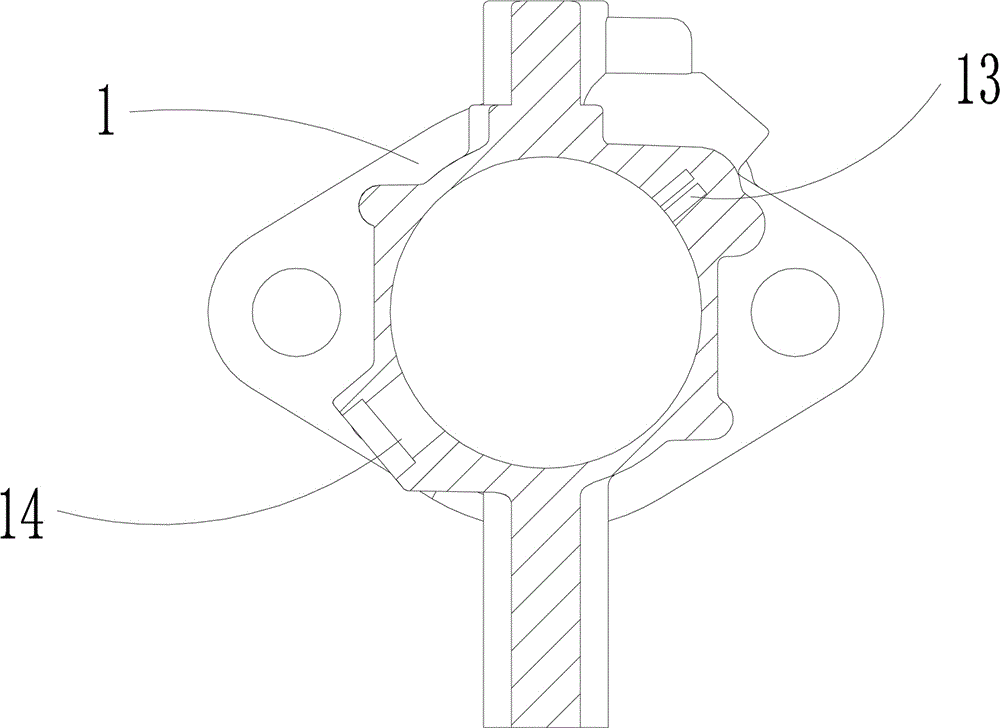

outboard carburetor

ActiveCN102644524BReduce resistanceEmission reductionIdling devicesMachines/enginesPollutant emissionsIdle speed

The invention relates to a carburetor, in particular to a carburetor for an outboard motor, which comprises a carburetor body, and the carburetor body is respectively provided with an independent main oil circuit system and an idle oil supply system. The invention provides an improved carburetor for outboard motors with more stable idle speed, smaller speed fluctuation, acceleration sensitivity, lower fuel consumption, less difficult processing technology, lower cost, smaller pollutant discharge and lighter weight .

Owner:福鼎市佳磐通用部件有限公司

An automobile engine bracket tapping tooling

InactiveCN103551882BSimple structureEasy to implementThread cutting machinesLarge fixed membersEngineeringKidney

Owner:HENAN POLYTECHNIC

A processing method for electric steering gear rack

The invention provides a machining method for a rack of an electric steering gear. According to the method, the process of stress relieving tempering, natural aging, one-time clamping and combined grinding is adopted, the requirements for the tolerance of the tooth surface of each driving tooth and the tooth surface of each driven tooth being + / - 5', the OPD variation of the tooth profile of each whole driving gear and the OPD variation of the tooth profile of each whole driven gear being 0.04 mm, the linearity being 0.05 and the roughness being Ra 0.8 are met, and the requirement for the high-precision tolerance of Max0.04 is guaranteed. By means of the method, the machining efficiency is improved, and the product precision is guaranteed.

Owner:上海格尔汽车科技发展有限公司

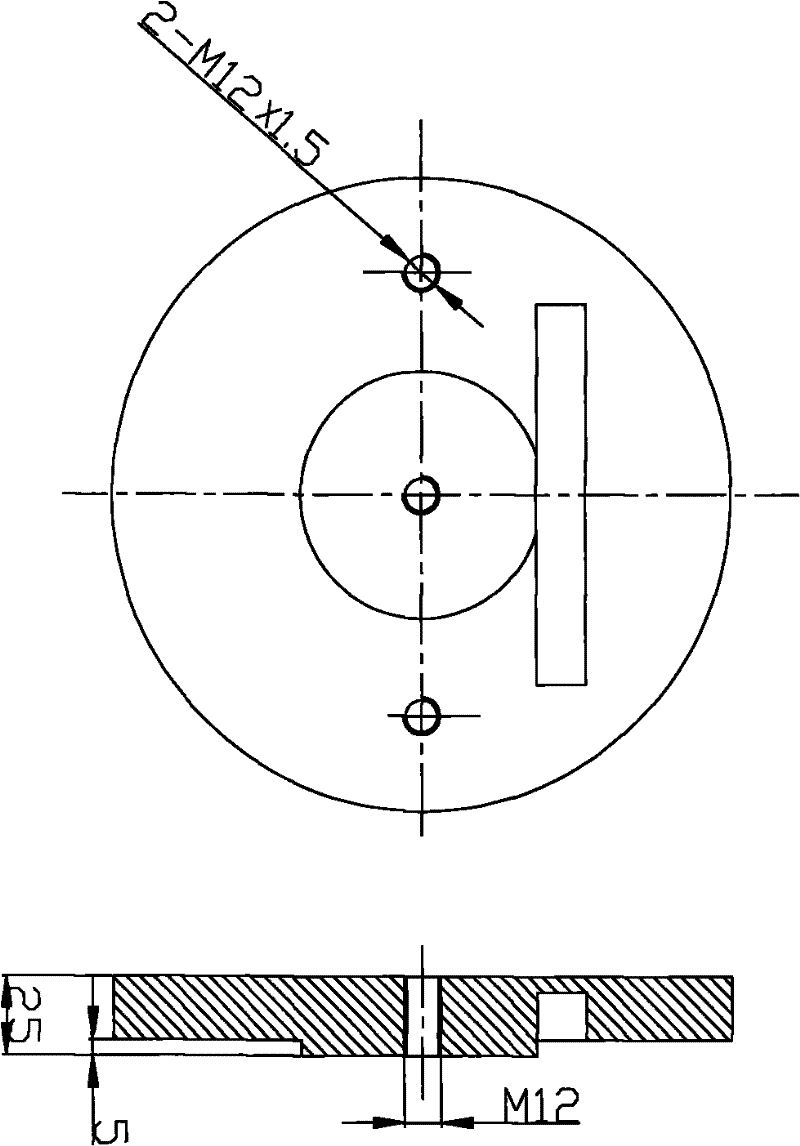

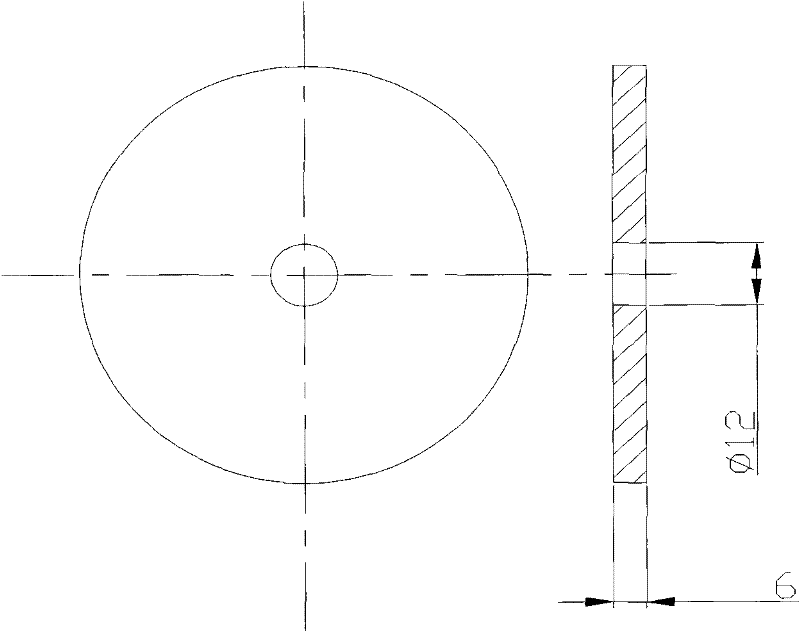

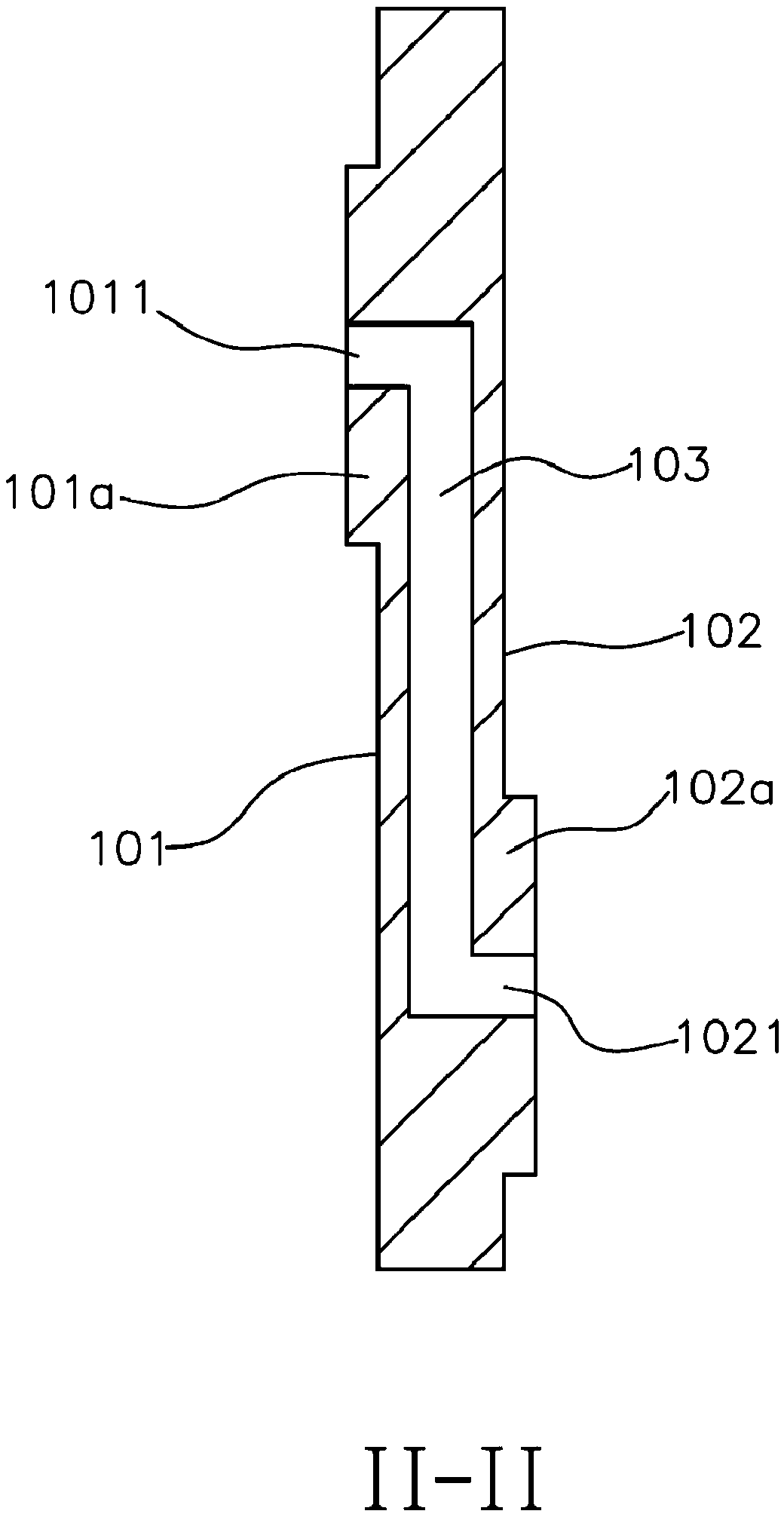

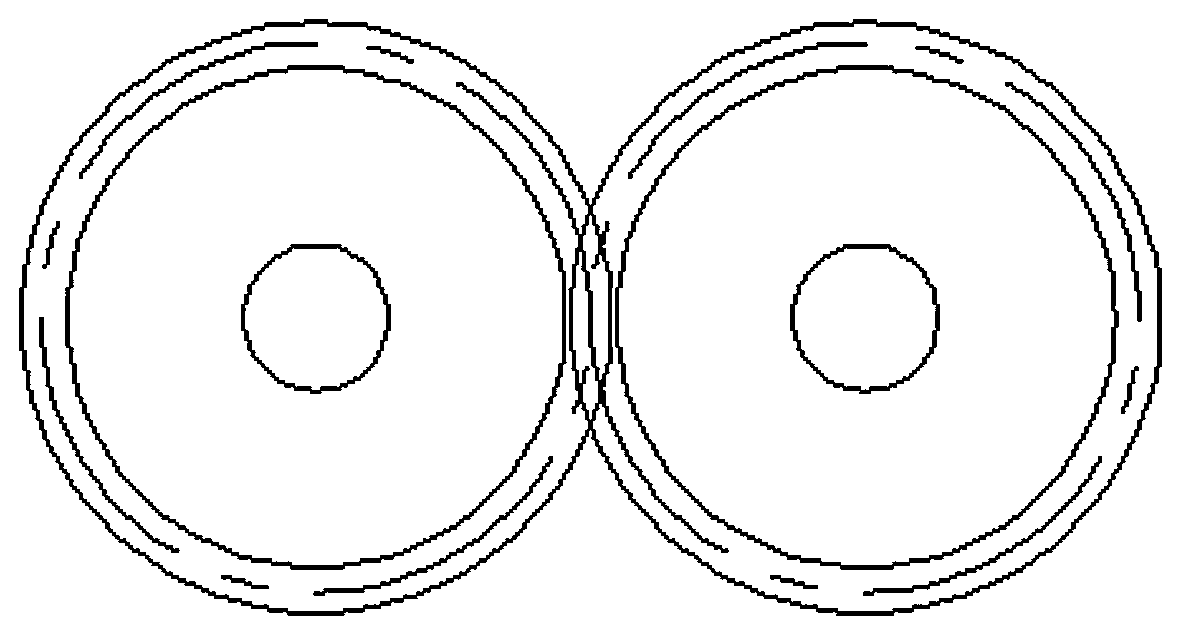

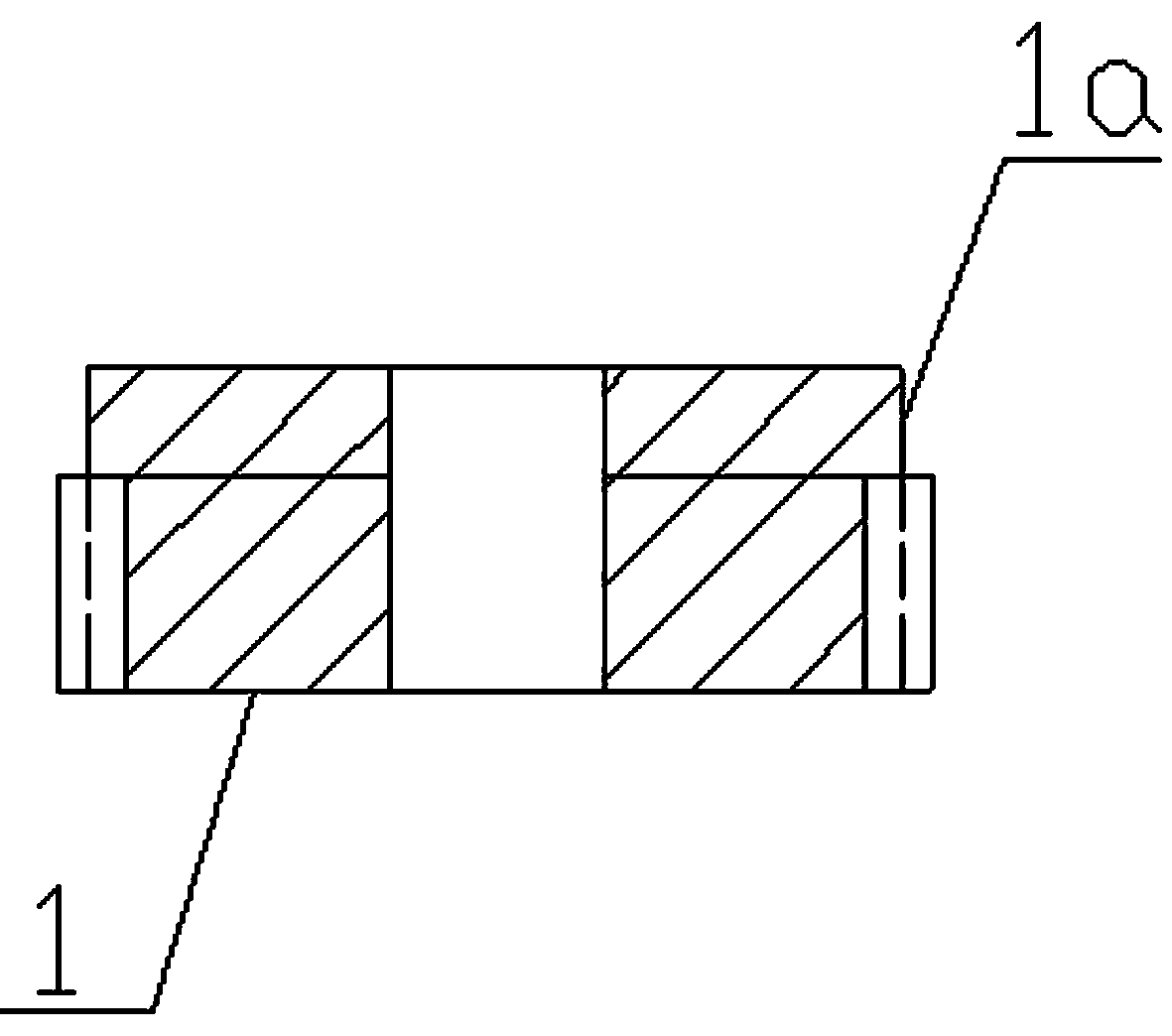

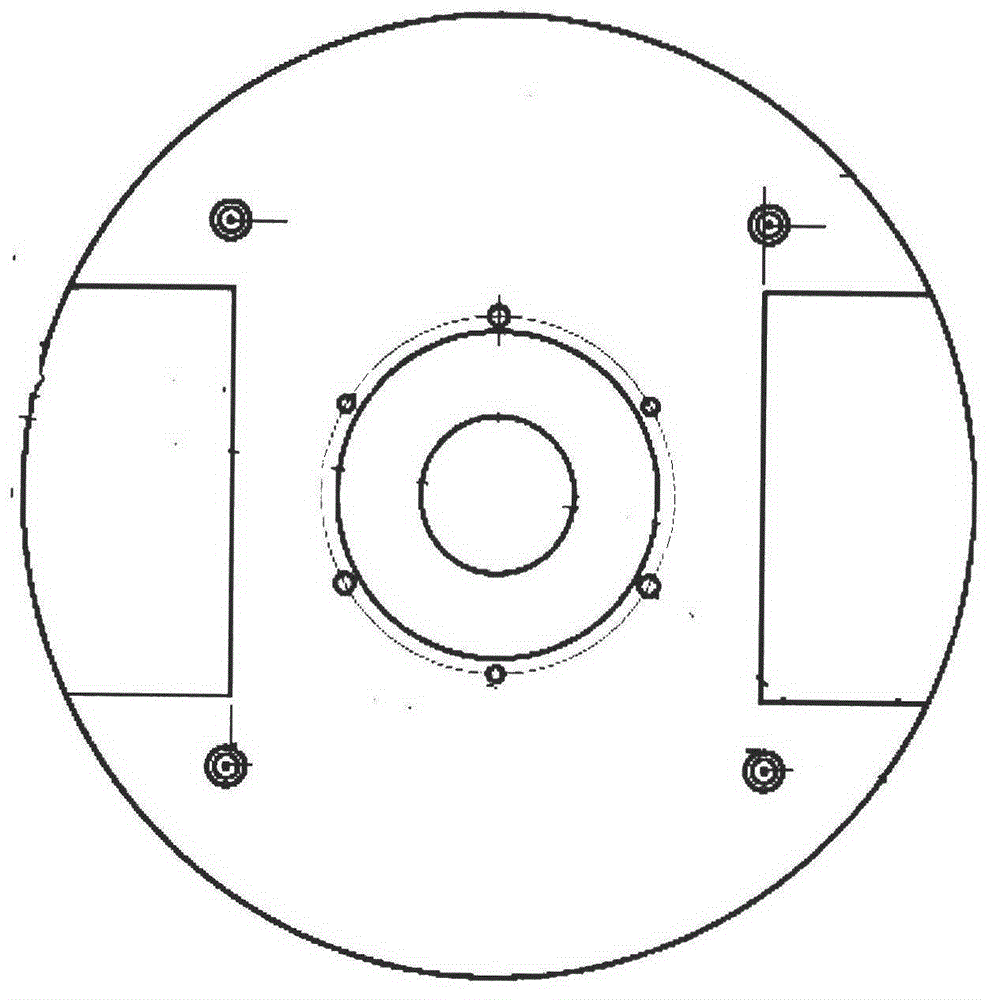

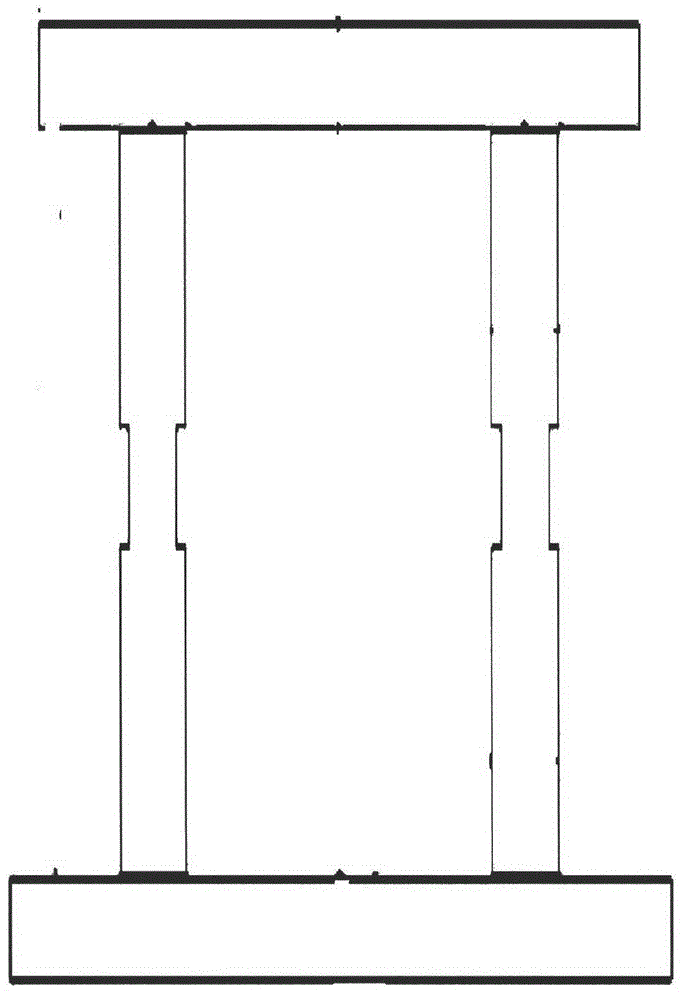

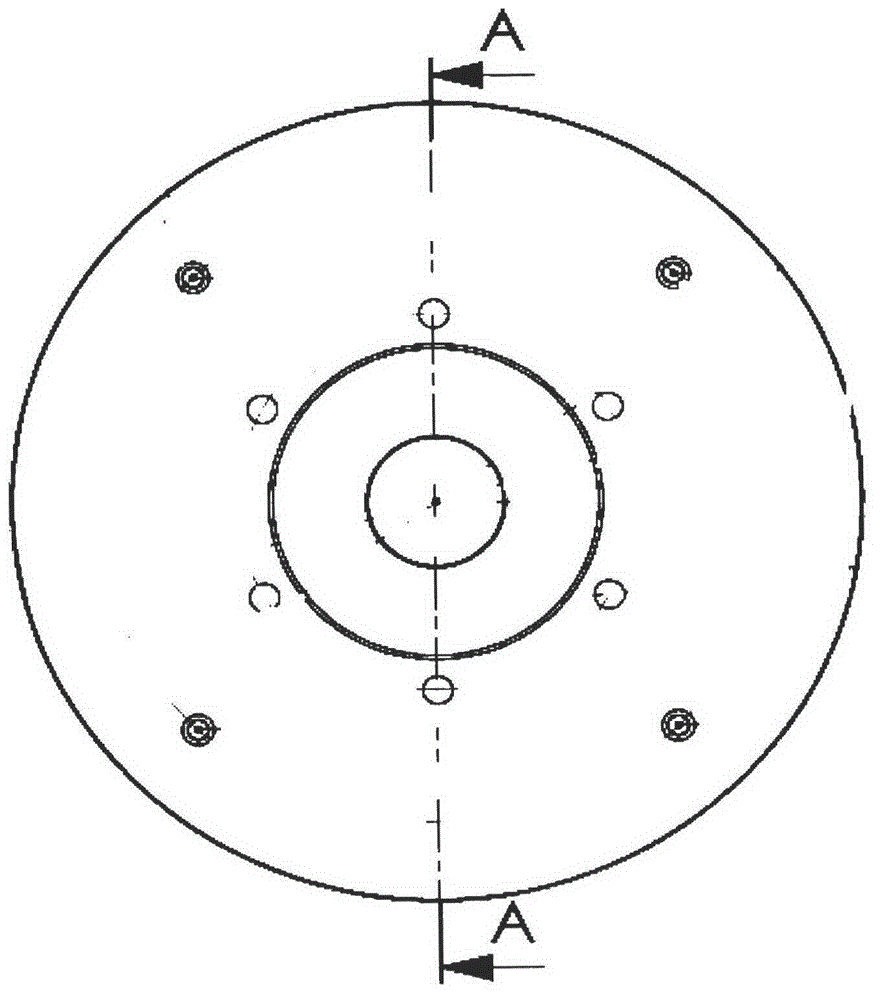

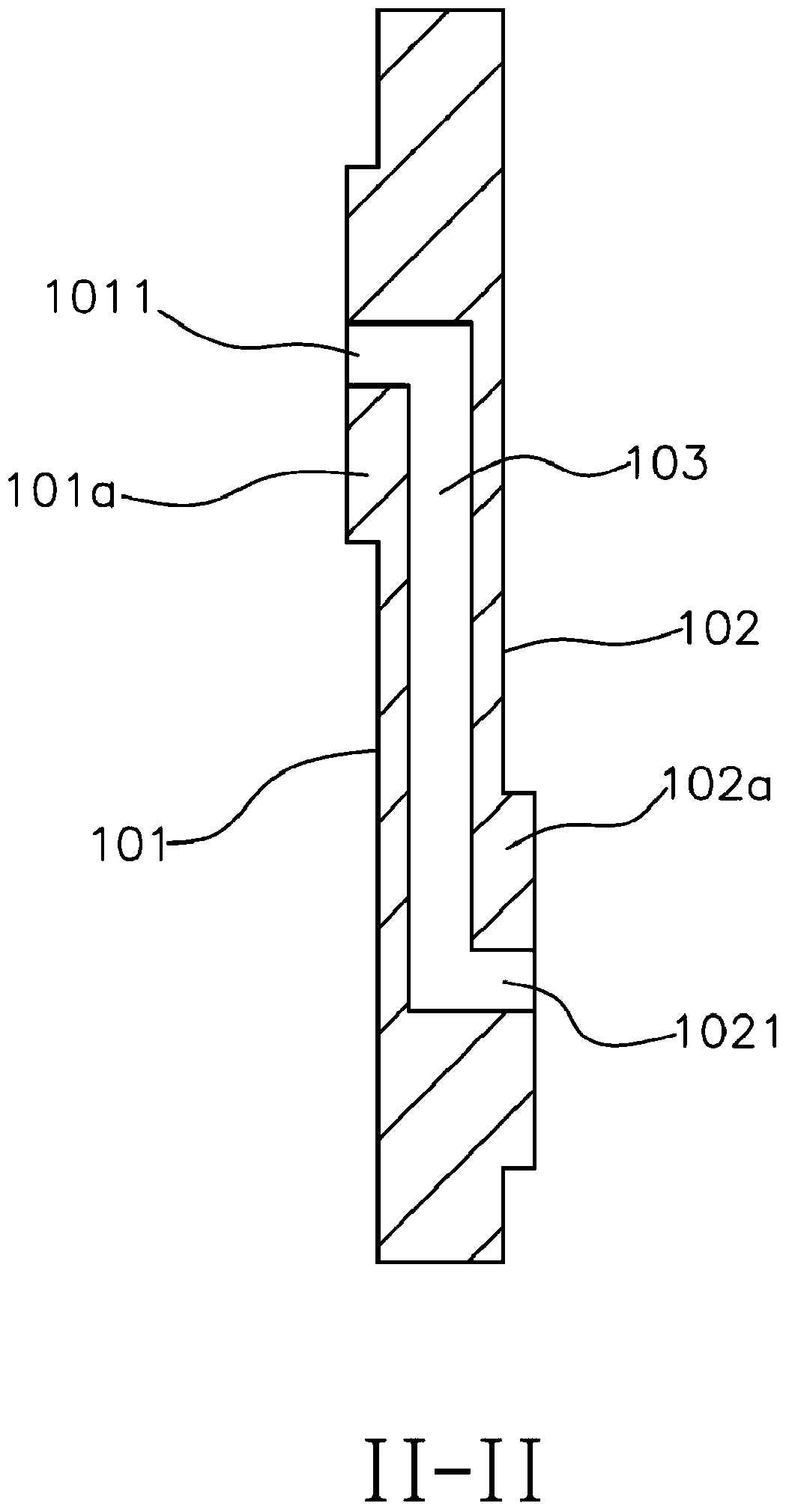

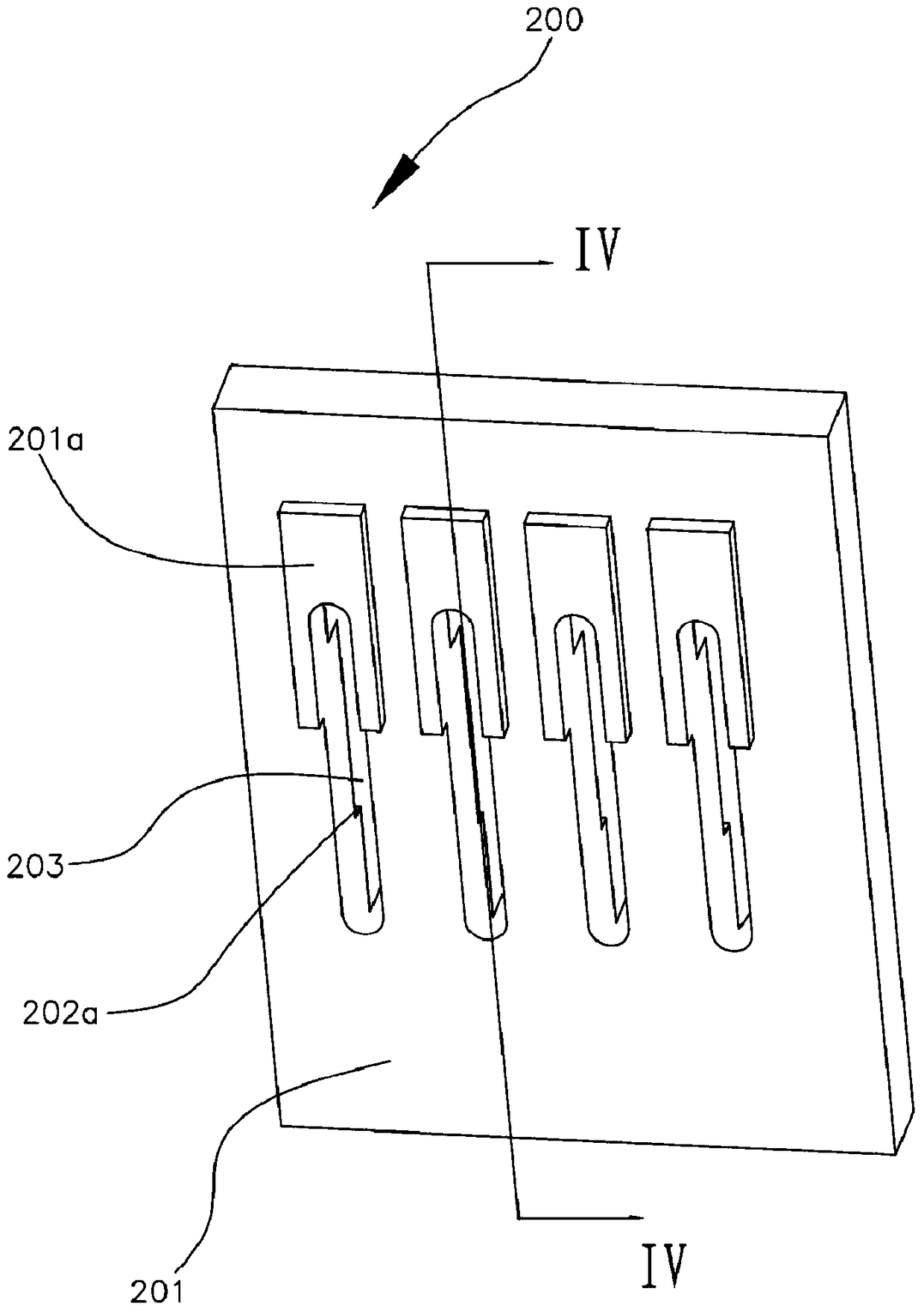

Positioning fixture for turning inner hole in casting

InactiveCN105881064APrecise positioningHigh concentricityPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to a positioning fixture for turning an inner hole in a casting, and belongs to the technical field of mechanical processing. The positioning fixture for turning an inner hole in the casting is characterized in that a pair of ring flanges is configured in parallel and is fixedly connected through 3-4 pin columns (3); a first through hole (101) is formed in the center of the first ring flange (1), a second through hole (201) is formed in the center of the second ring flange (2), the first through hole and the second through hole are coaxial, and the hole diameter of the second through hole (201) is larger than that of the first through hole (101); a first group of pin holes (103) are formed in the first ring flange (1), and the hole centers of the first group of pin holes (103) are uniformly distributed in a circumference which uses the circle center of the first ring flange as the center; a second group of pin holes (202) are formed in the second ring flange (2), and the hole centers of the second group of pin holes (202) are uniformly distributed in a circumference which uses the circle center of the second ring flange as the center.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

Flexible circuit board and mobile terminal

ActiveCN105578744BImprove adhesionInhibit sheddingPrinted circuit aspectsElectrical connection printed elementsFlexible circuitsComputer terminal

The invention provides a flexible printed circuit board, comprising a first side and a second side which are arranged face to face, wherein the first side is provided with at least one first bonding pad; the second side is provided with at least one second bonding pad corresponding to the at least one first bonding pad; a tin guiding channel is formed between each first bonding pad and the corresponding second bonding pad, the tin guiding channel is formed in the flexible printed circuit board and communicates the first bonding pad and the corresponding second bonding pad, and the center distance between the first bonding pad and the corresponding second bonding pad which are communicated by the tin guiding channel is a preset numerical value. According to the flexible printed circuit board provided by the invention, the tin guiding channel is used for connecting each first bonding pad and the corresponding second bonding pad together; by virtue of the circulating function of the tin guiding channel, soldering tin can flow from the first bonding pad to the surface of the second bonding pad and therefore a lot of soldering tin can be attached to the surfaces of the first bonding pad and the second bonding pad and further the first bonding pad or the second bonding pad can be prevented from falling off from the flexible printed circuit board. In addition, the invention further provides a mobile terminal comprising the flexible printed circuit board.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com