Rapid clamping and drilling mould for machining of side hole of round steel

A round steel, fast technology, applied in the direction of the drilling mold used for the workpiece, etc., can solve the problems of difficult to ensure the concentricity of the hole, prolong the processing time of parts, exhaust gas and other problems, and achieve the effect of improving drilling efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

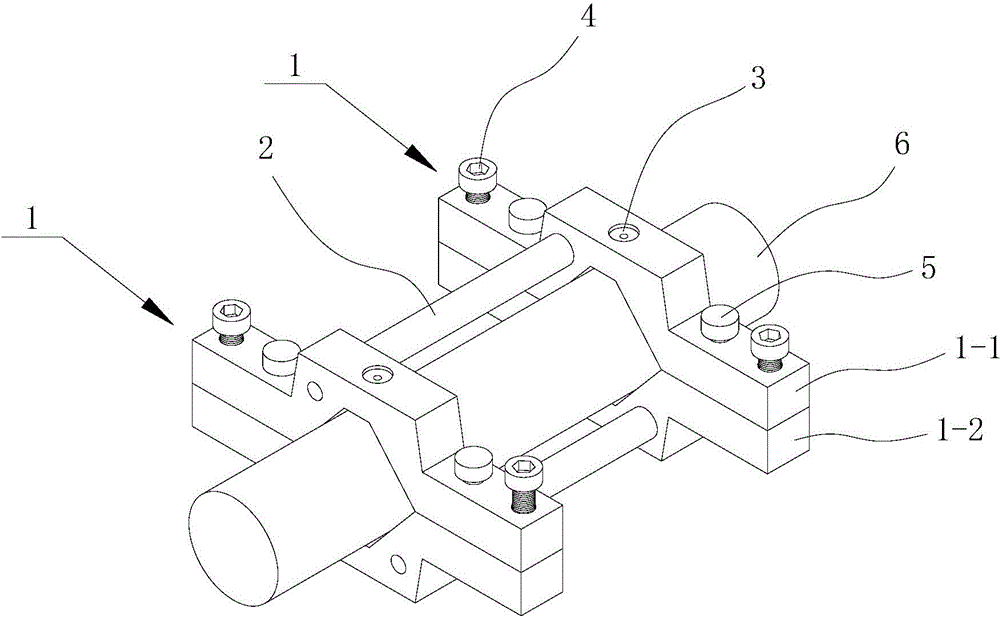

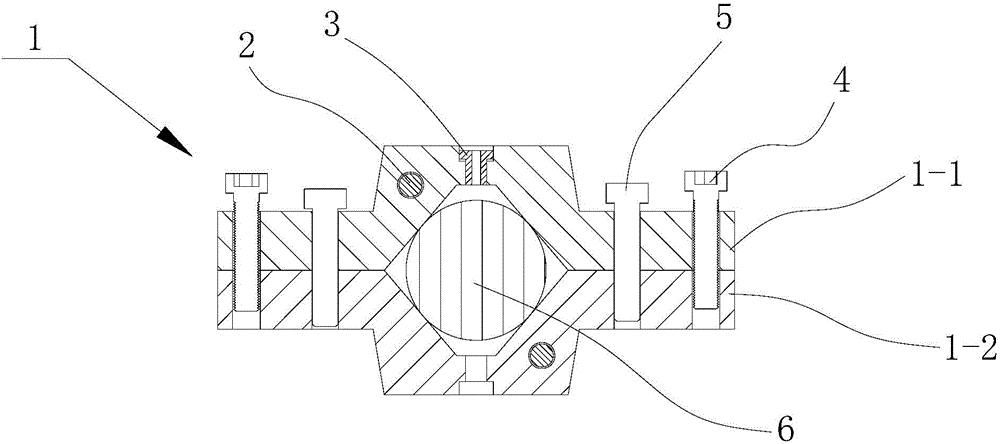

[0012] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

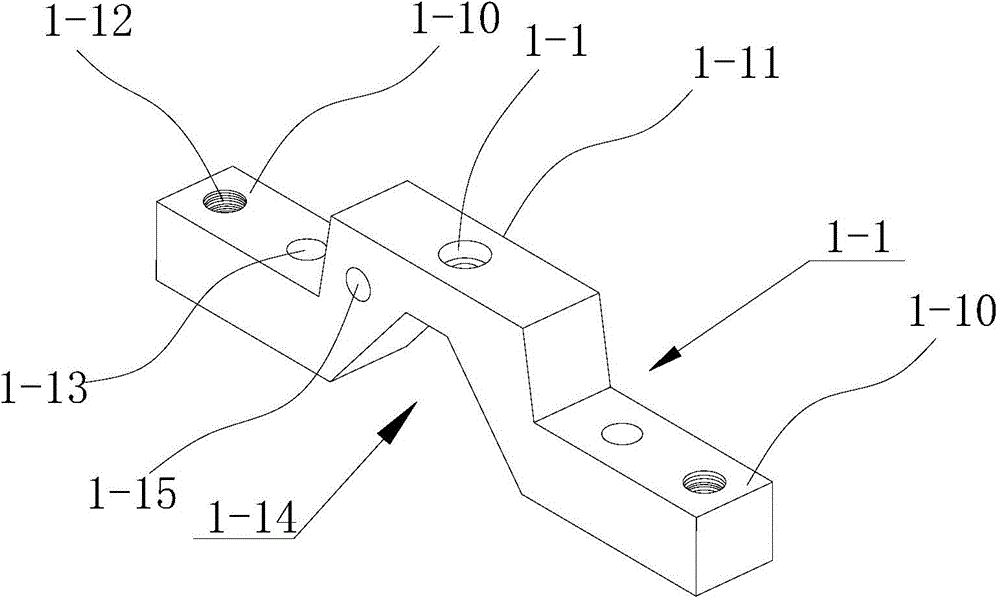

[0013] See Figure 1 to Figure 3 , A quick clamping drilling mold for processing round steel side holes, comprising two clamping components 1 for clamping round steel, a positioning rod 2 is inserted between the two clamping components, positioning rod The center distance between adjacent holes can be ensured. Each of the above-mentioned clamping components is provided with a drill sleeve 3; the above-mentioned clamping component 1 includes an upper clamping body 1-1 and a lower clamping body 1-2, The upper clamping body includes a connecting portion 1-10 and a clamping portion 1-11, wherein the connecting portion is provided with a connecting screw hole 1-12 and a positioning pin hole 1-13, and the clamping portion 1-11 There are isosceles trapezoidal openings 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com