Depressurized extraction method for cutting through roof or floor of coal seam by abrasive water jet

A coal seam roof and abrasive jet technology, which is applied in mining fluids, mining equipment, earthwork drilling, etc., can solve the problems of affecting drilling efficiency, material waste, and not revealing the safety of gas extraction, so as to reduce the cost of gas drainage and increase The effect of air permeability and shortening the extraction standard time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of implementation.

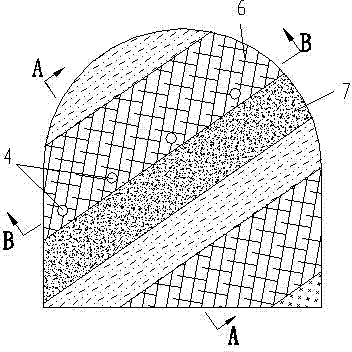

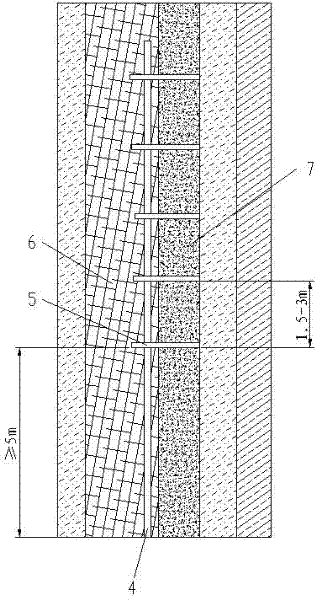

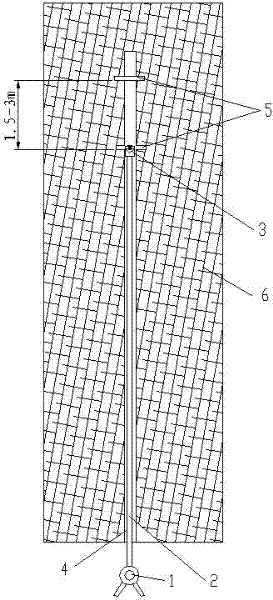

[0024] see figure 1 , figure 2 , image 3 , a pressure relief extraction method in which an abrasive jet cuts through a coal seam roof or floor, the method comprises the following steps:

[0025] a, use drilling rig 1 to drill a layer-by-layer drilling 4 to the set depth on the coal rock mass top plate, bottom plate or hard layer 6 excavated in the half-coal roadway through the drill pipe 2 and the slotted drill bit 3;

[0026] b. Input a high-pressure abrasive water jet with a pressure of 25-30Mpa to the slotted drill bit 3 through the drill pipe 2, and the drill pipe 2 rotates in situ, and a radial cut is formed on the wall of the bedding drilling 4 through the high-pressure abrasive water jet. Seam 5, slot 5 penetrates the roof, floor or hard layer 6 and soft layer 7 of the coal rock mass; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com