Patents

Literature

270results about How to "Improve slotting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mechanical excavation method for hard-rock tunnel with medium-short length

The invention discloses a mechanical excavation method for a hard-rock tunnel with the medium-short length and belongs to the field of construction methods. The mechanical excavation method comprises the steps that first, a plurality of parallel and vertical grooves are cut on a tunnel face in a tunnel profile at certain intervals, and each vertical groove enables rock on the two sides of the vertical groove to form a free face with the certain depth; and then crushing equipment is utilized to apply extruding stress to each free face of the two sides of the corresponding vertical groove, so that the rock of the two sides of the vertical grooves is crushed, and excavation of the tunnel is achieved. Compared with the prior art, the requirement of the construction, limited in blasting vibration, of the new built rock tunnel with the medium-short length for the aspects such as the economy, efficiency and the safety risk can be met; and meanwhile the construction efficiency is greatly improved compared with the prior art.

Owner:张华 +1

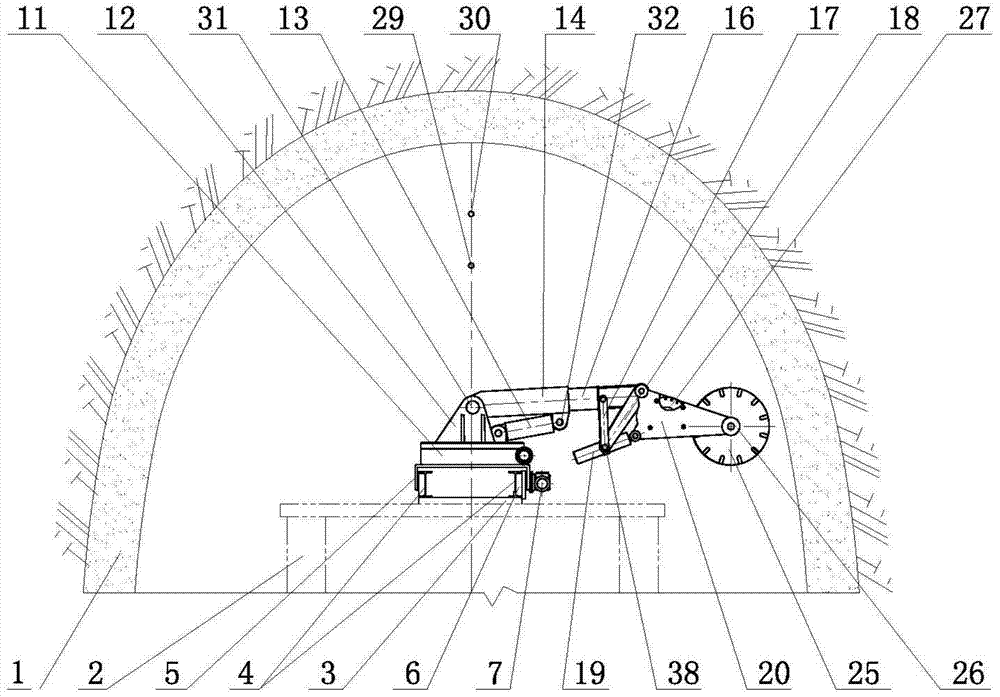

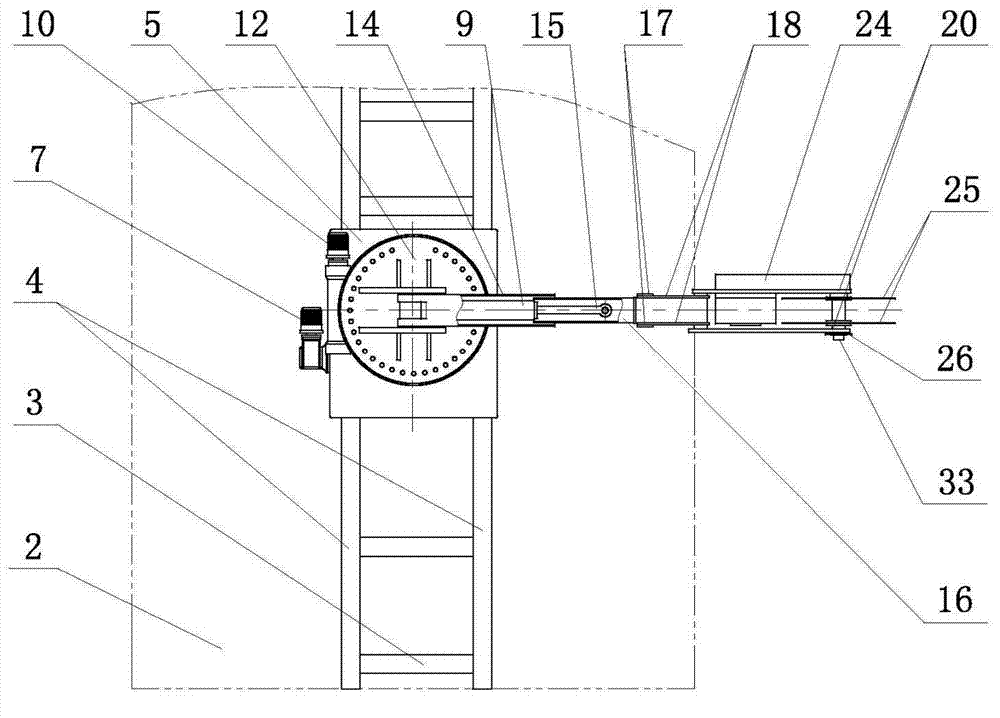

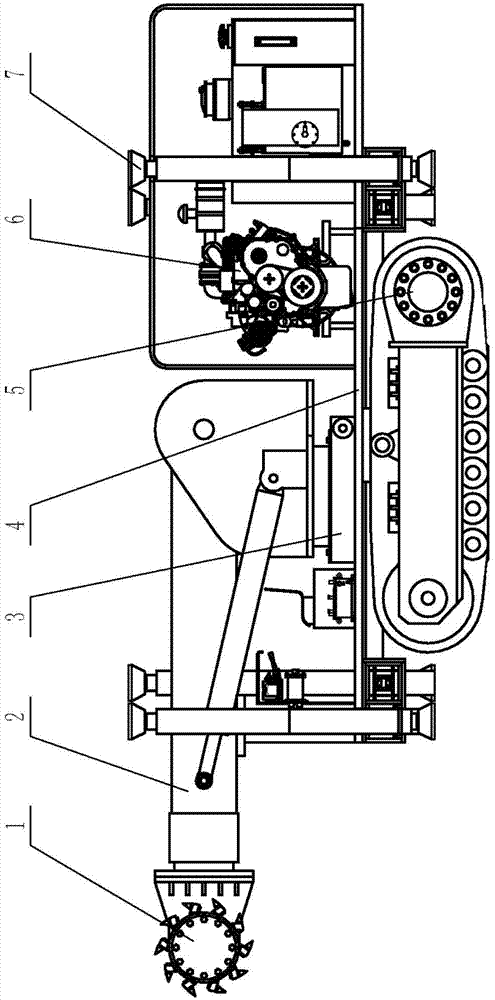

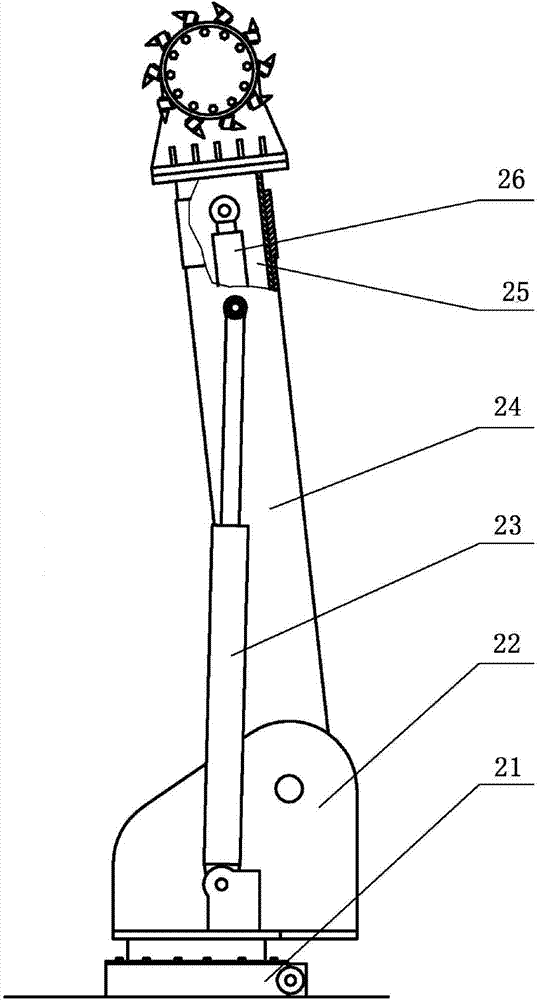

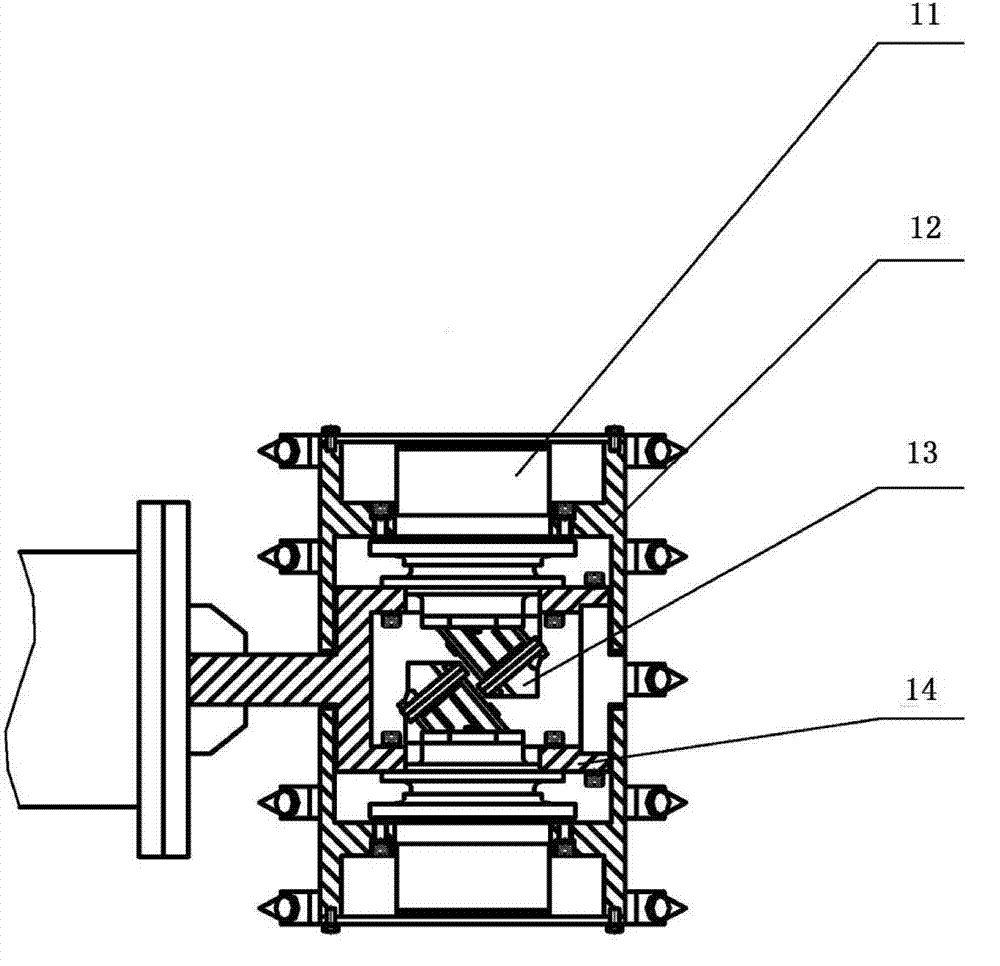

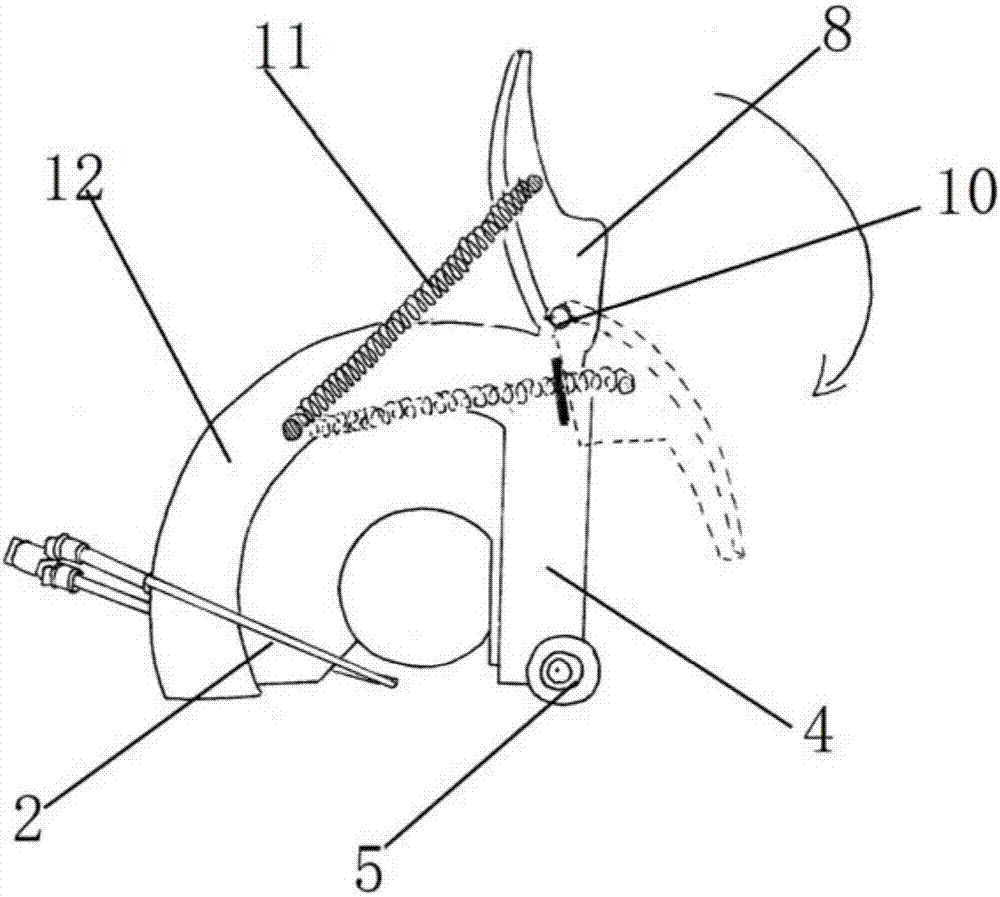

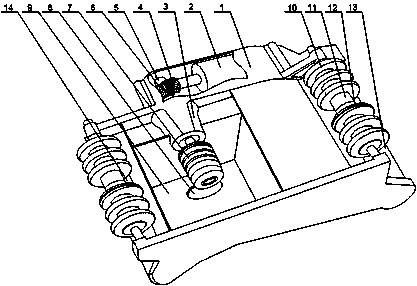

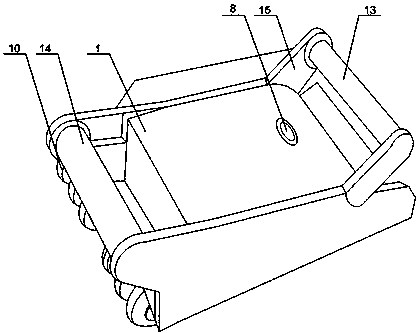

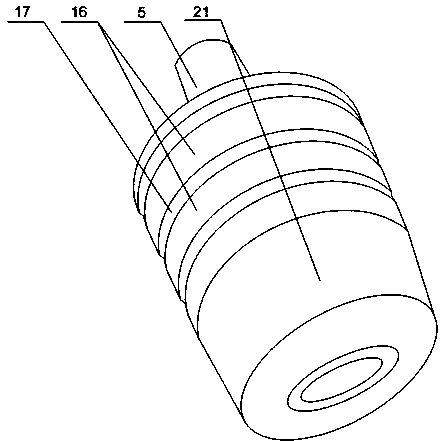

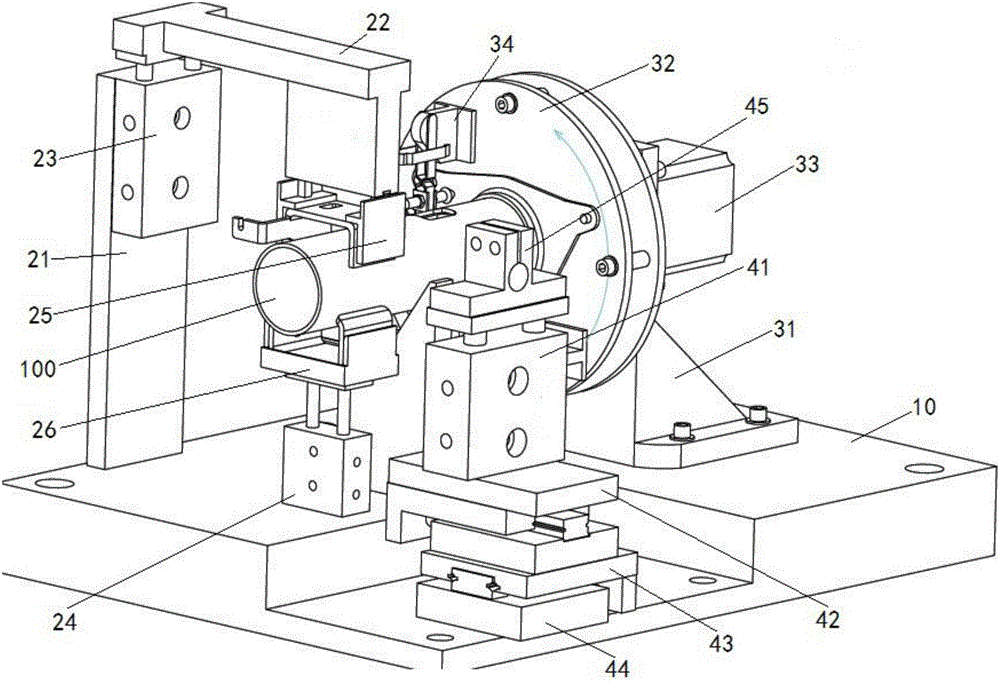

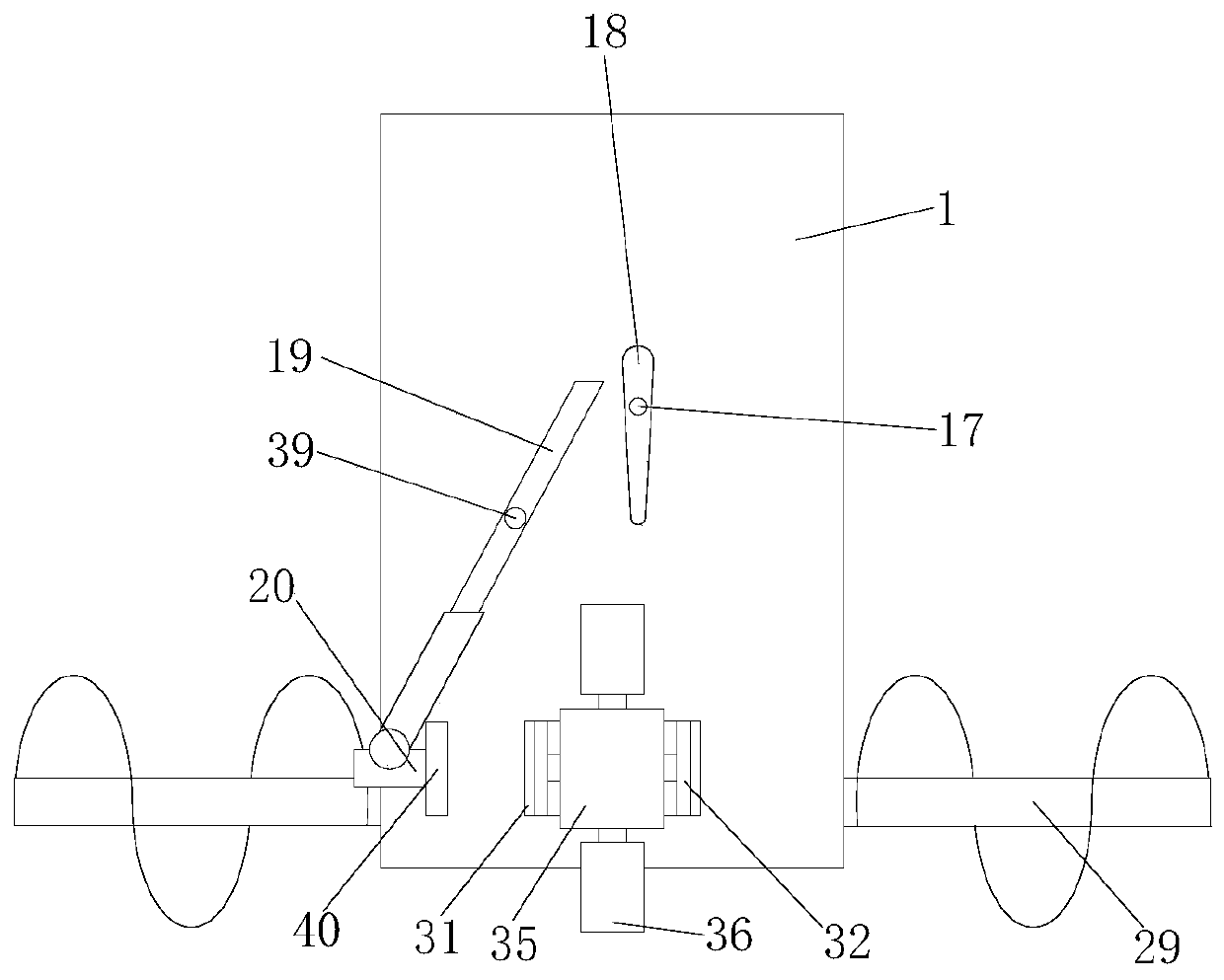

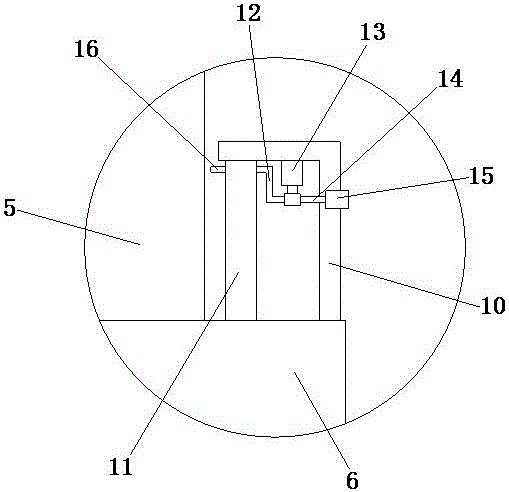

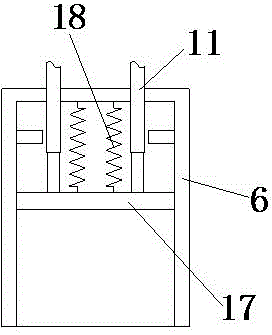

Lining steel arch frame installing groove grooving machine for treating existing railway tunnel defects

ActiveCN104500107ARealize fully mechanized slotting operationImprove slotting efficiencyUnderground chambersTunnel liningHydraulic cylinderRailway tunnel

The invention relates to a lining steel arch frame installing groove grooving machine for treating existing railway tunnel defects, and belongs to the technical field of railway tunnel defect treatment equipment. The lining steel arch frame installing groove grooving machine consists of a machine seat, a telescopic arm and a cutting head, wherein the telescopic arm is arranged on the machine seat and is provided with a pitch hydraulic cylinder, and the cutting head is arranged at the front end of the telescopic arm and can swing relative to the telescopic arm. The lining steel arch frame installing groove grooving machine has the advantages that the fully mechanical grooving operation of railway tunnel lining steel arch frame installing grooves can be realized, in addition, contact nets and load bearing cables of the existing railway tunnel can be safely avoided, the grooving efficiency is high, and the safety is high. Through a defect treatment trolley, the grooving machine can complete the grooving operation of a plurality of steel arch frame installing grooves in one trolley station.

Owner:中铁西南科学研究院有限公司

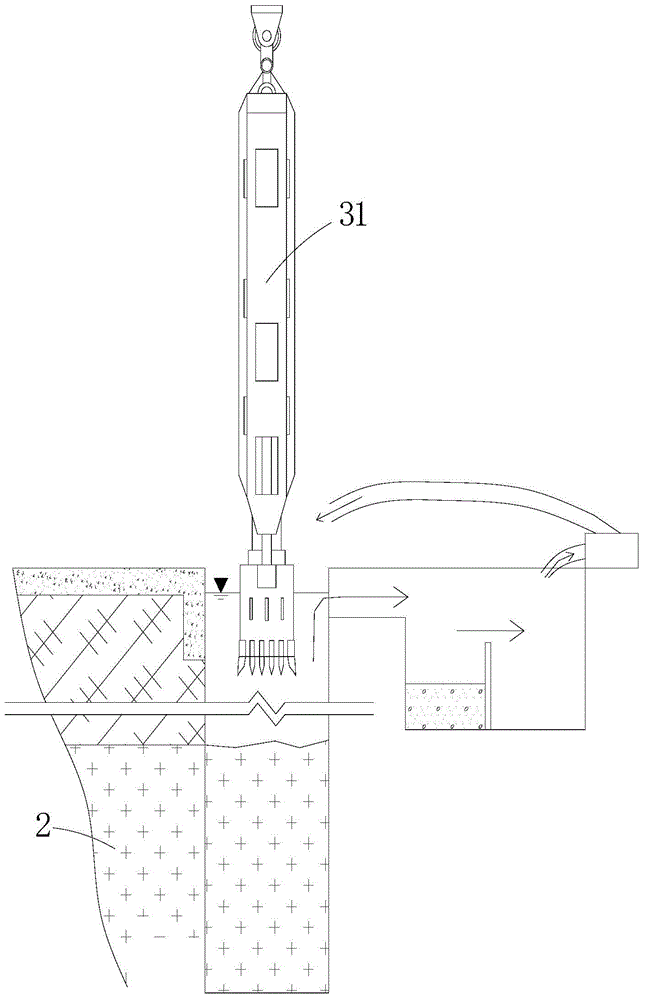

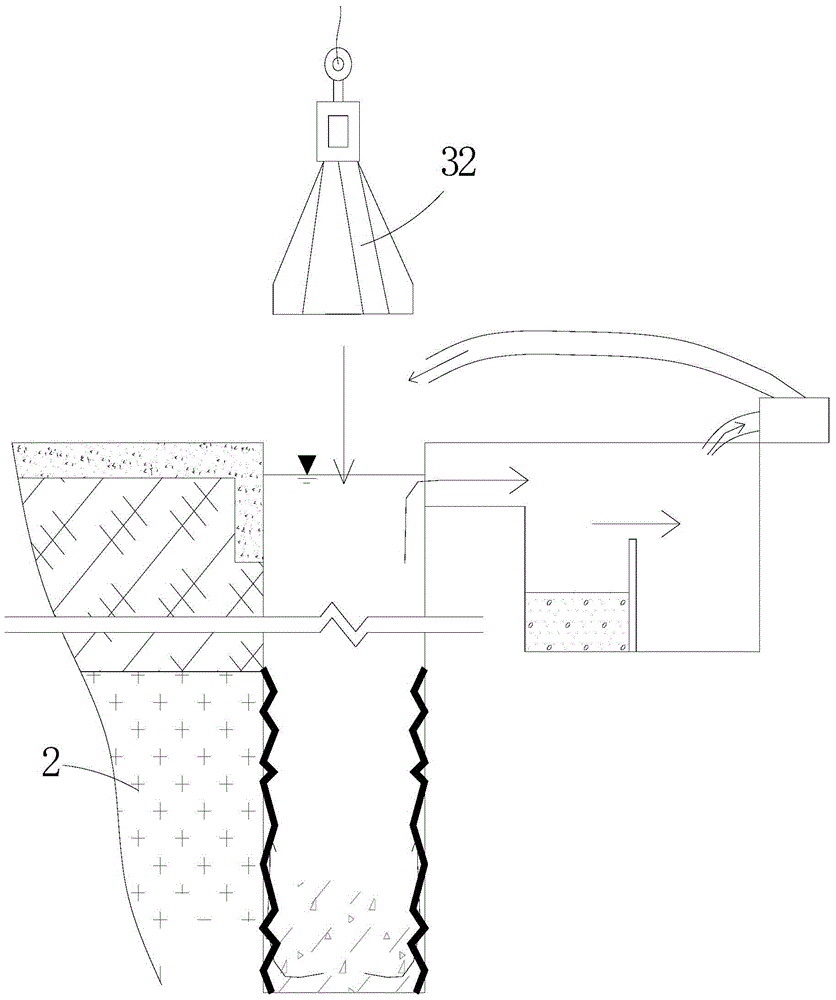

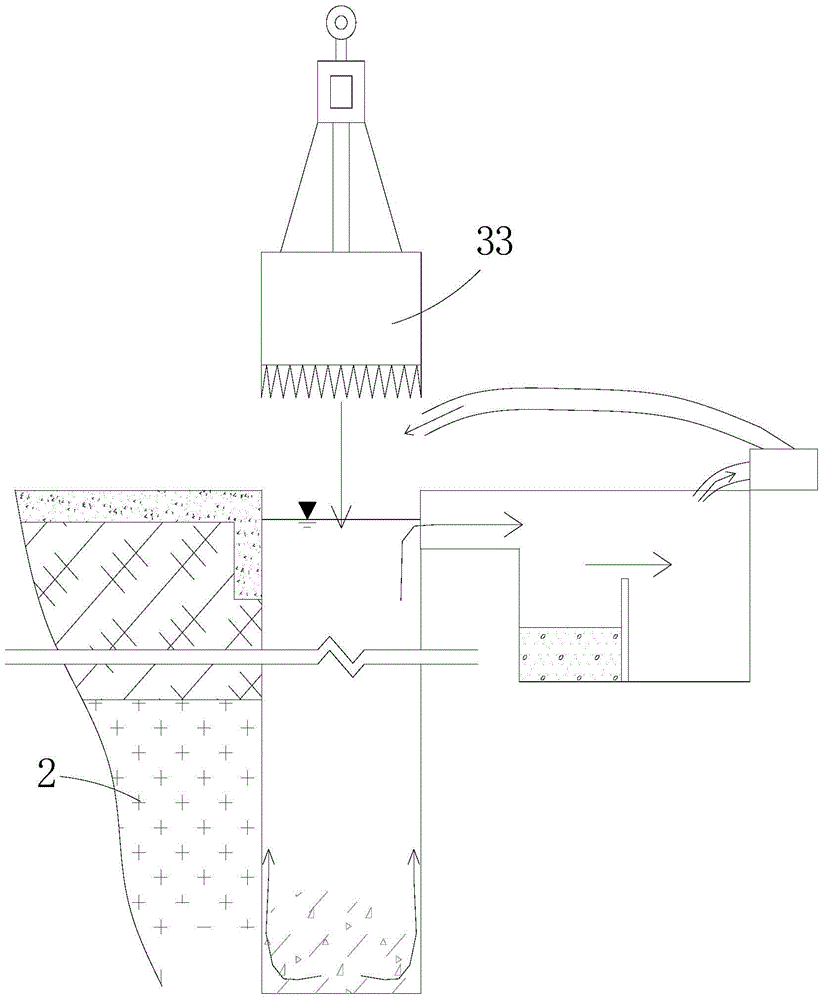

Grooving construction method for embedding underground continuous wall into rock

The invention relates to the technical field of embedding underground continuous walls into rock and grooving of the underground continuous walls and discloses a grooving construction method for embedding an underground continuous wall into rock. The method includes the steps that firstly, a grab bucket is used for excavating soil so that a groove can be formed, and a residual soil layer is reserved between the groove bottom and a rock face; secondly, a rotary excavating drilling tube is used for drilling holes in the residual soil layer and a seriously-weathered layer, a cutting-tooth drilling tube is used for drilling medium-weathered rock and micro-weathered rock, and rock entering holes in bed rock are formed; thirdly, the second step is repeated, and a plurality of rock entering holes are formed in the length extension direction of a groove segment; fourthly, a plane set-hammer is used for clearing away hard rock tooth edges. According to the construction method, the grooving speed is high, and on-site general layout and civilized construction are facilitated; meanwhile, the cutting-tooth drilling tube is used for performing rotary excavation and entering the rock to take a core, and impacting vibration is avoided; due to the fact that the grooving construction period is short, the exposing time of the groove wall is relatively short, the risk that groove wall soil collapses is reduced, the groove wall is stable, and construction cost is indirectly reduced; the residual soil layer is reserved on the rock face of the bed rock, the rotary excavating drilling tube plays a guiding role in the hole forming process, and the situation that because the inner rock face of the groove segment is inclined, hole drilling deflects is prevented.

Owner:SHENZHEN SUNHUI MECHANICAL CO LTD

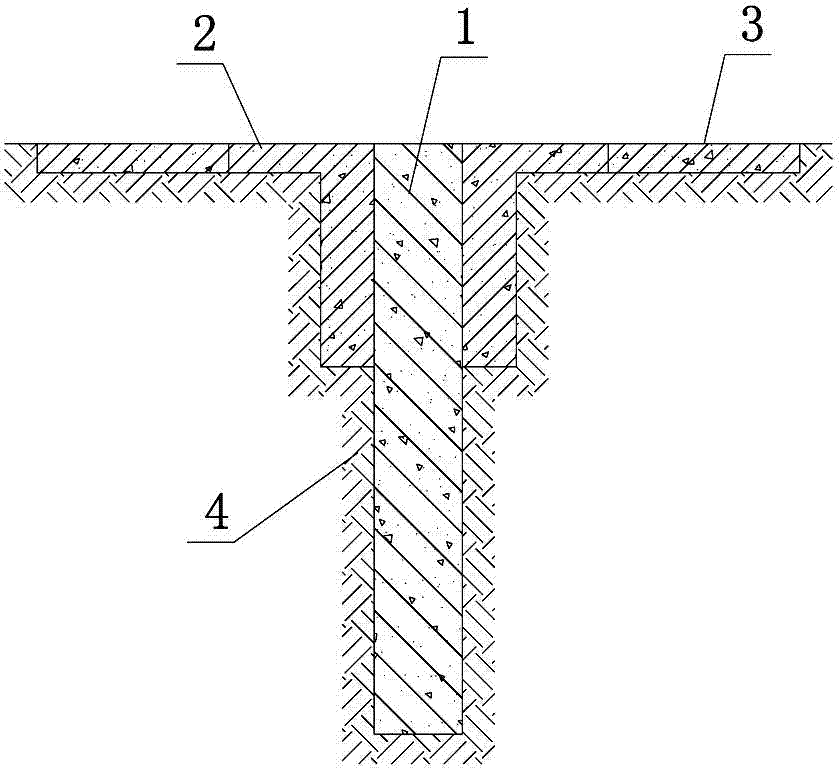

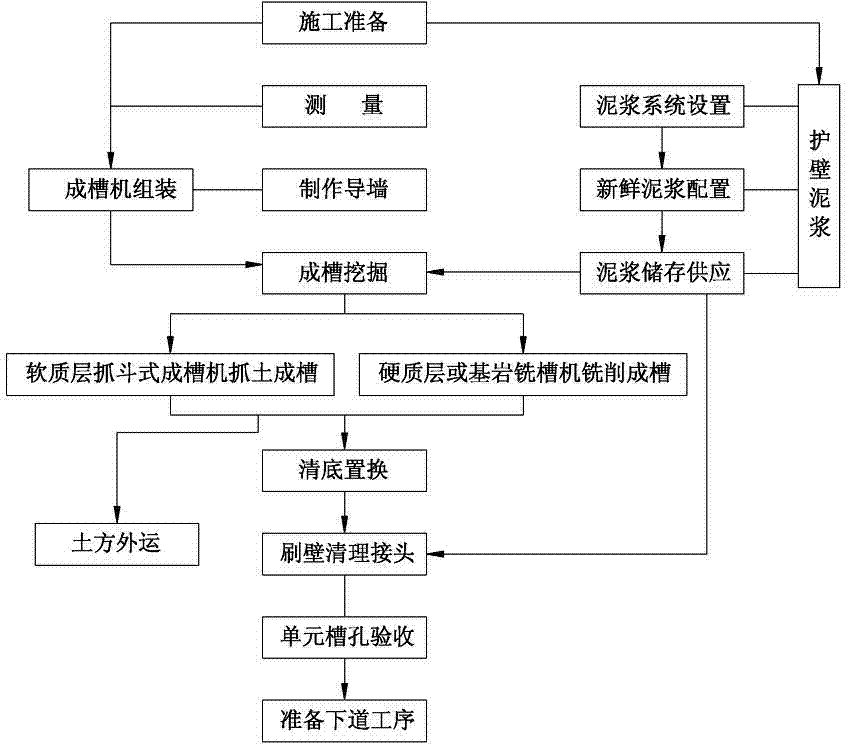

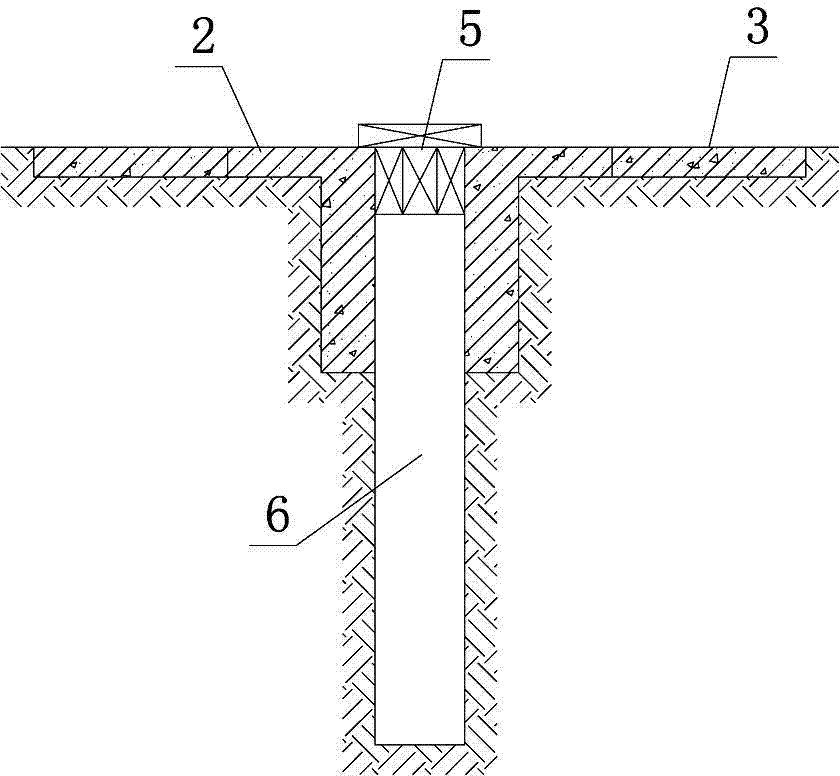

Super-deep underground continuous wall and construction method thereof

The invention relates to a super-deep underground continuous wall which comprises an underground continuous wall body. Guide walls are symmetrically arranged on the two sides of the wall body, the cross sections of the guide walls are in the shape of an L, the lower ends of the guide walls are located on underground rock-soil, and the lug edges of the guide walls are connected with a concrete pavement. The invention further discloses a construction method of the super-deep underground continuous wall. The method includes the following steps of construction preparation, measuring, guide wall manufacturing, wall protection slurry manufacturing, grooving construction, bottom-clearing replacement, connector cleaning through wall brushing and unit slot section inspection, wherein a grabbing-milling integrated grooving method is used in the grooving construction. The method is high in grooving efficiency, short in construction time and short in groove wall soaking time, the grabbing-milling integrated grooving method is used in the grooving construction, technologies can be changed timely according to different stratum hardness situations, the characteristics that a grab bucket is high in digging speed at the soft soil layer and milling wheel can achieve rapid milling and digging footage at a hard soil layer or bed rod with standard penetration test blow count exceeding 45 are fully used, and therefore rapid and efficient grooving of the whole wall can be achieved.

Owner:ZHONGDING INT ENG

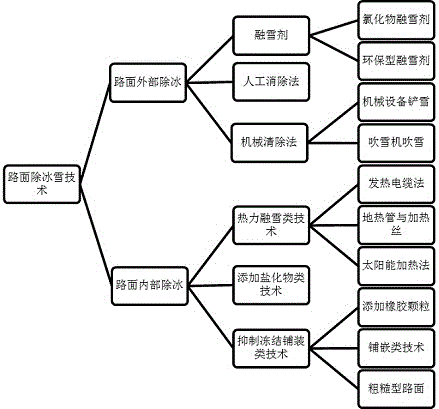

Integrated pavement deicing equipment

InactiveCN106012943ASolve the deicing and cleaning rateSolve protection problemsSnow cleaningThermal energyRoad surface

The invention relates to comprehensive road surface deicing equipment. Comprehensive road surface deicing equipment, including a mechanical deicing device, a deicing margin control device for controlling the amount of ice removed by the mechanical deicing device to leave a residual ice layer on the road surface, and a device for dissolving the ice layer by heat energy The thermal deicing device that melts the remaining ice layer defines that the comprehensive road surface deicing equipment moves forward when in use, and the thermal deicing device is arranged behind the mechanical deicing device. The deicing margin control device can be used to control the amount of ice removed by the mechanical deicing device, so as to leave a residual ice layer with a set thickness on the road surface, so as to prevent the mechanical deicing device from directly contacting the road surface and causing damage to the road surface or the device Self-damage; and the remaining ice layer can be melted by the thermal deicing device arranged at the rear of the mechanical deicing device, so as to achieve the purpose of no ice layer remaining. The contradiction between high deicing efficiency and energy saving.

Owner:中国人民解放军防空兵学院

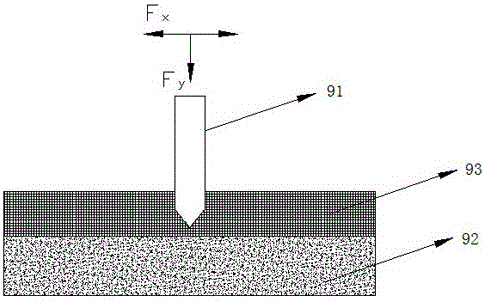

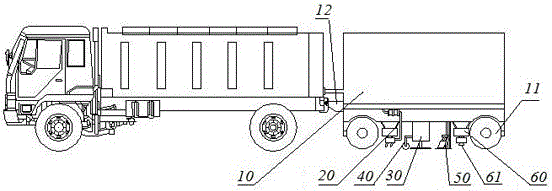

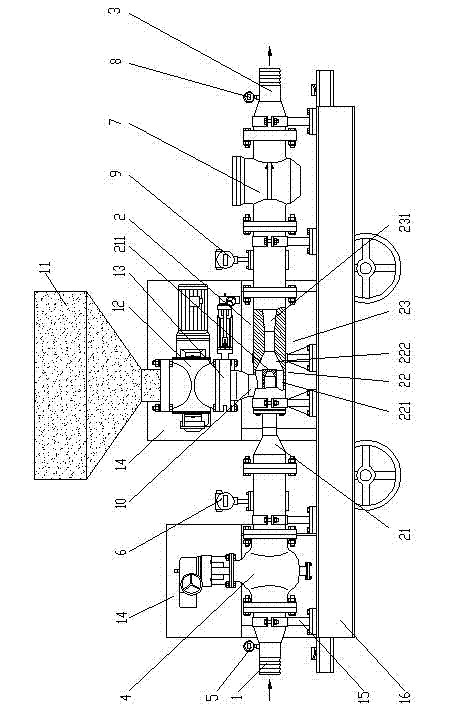

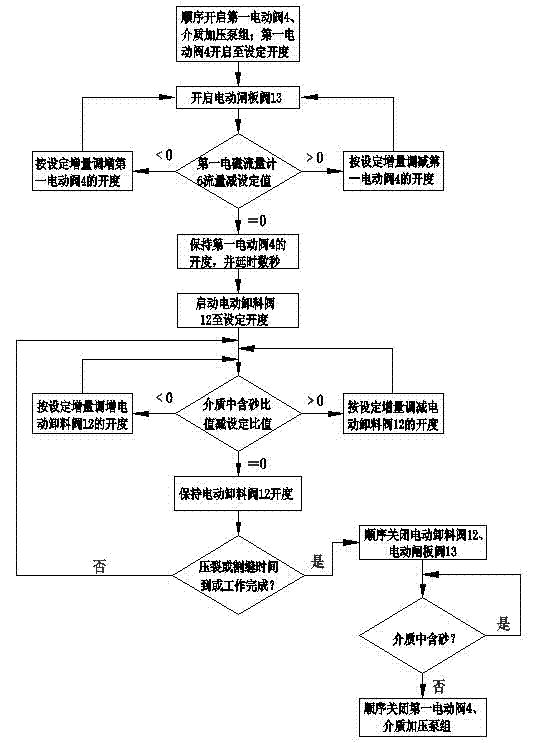

Sand charging device used during fracturing or slotting under coal mine and sand charging control method

InactiveCN102900417AGuaranteed tightnessImprove stabilityFluid removalGas removalMining engineeringCharge control

The invention discloses a sand charging device used during fracturing or slotting under a coal mine and a sand charging control method. The device comprises a water inlet pipe, a mixing pipe and a water outlet pipe which are sequentially connected, wherein a first electric valve, a first digital pressure meter, a first electromagnetic flowmeter are arranged on a pipeline of the water inlet pipe; an outlet end of the water outlet pipe is connected with a medium inlet of a medium booster pump; a check valve, a second digital pressure meter and a second electromagnetic flowmeter are arranged on a pipeline of the water outlet pipe; a hopper for accommodating sand is communicated with the upper part of the mixing pipe through a sand feeding pipe, and an electric unloading valve and an electric gate valve are arranged on a pipeline of the sand feeding pipe; the first electric valve, the electric unloading valve and the electric gate valve are anti-explosive; and the water inlet pipe, the mixing pipe and the water outlet pipe are respectively fixed on a flat mine vehicle. By the device, the sand charging time and sand charging amount are controlled by the conventional control technology. The sand charging device is simple in structure, small in size and safely used; and by the method, the coal seam cracking efficiency can be improved, and an anti-reflection effect of cracked coal and rock mass is guaranteed.

Owner:重庆市能源投资集团科技有限责任公司

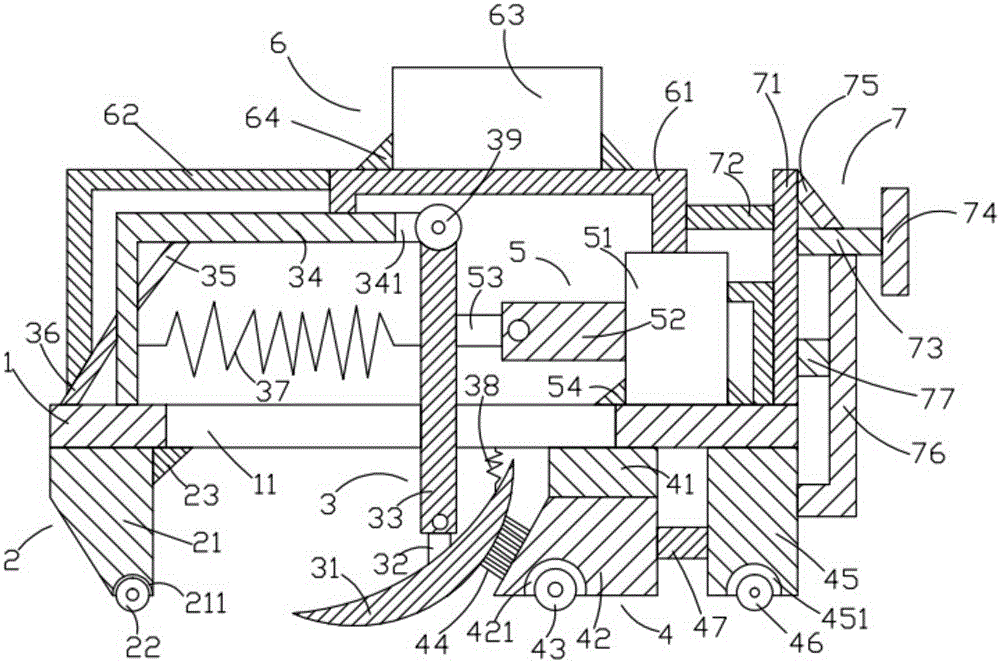

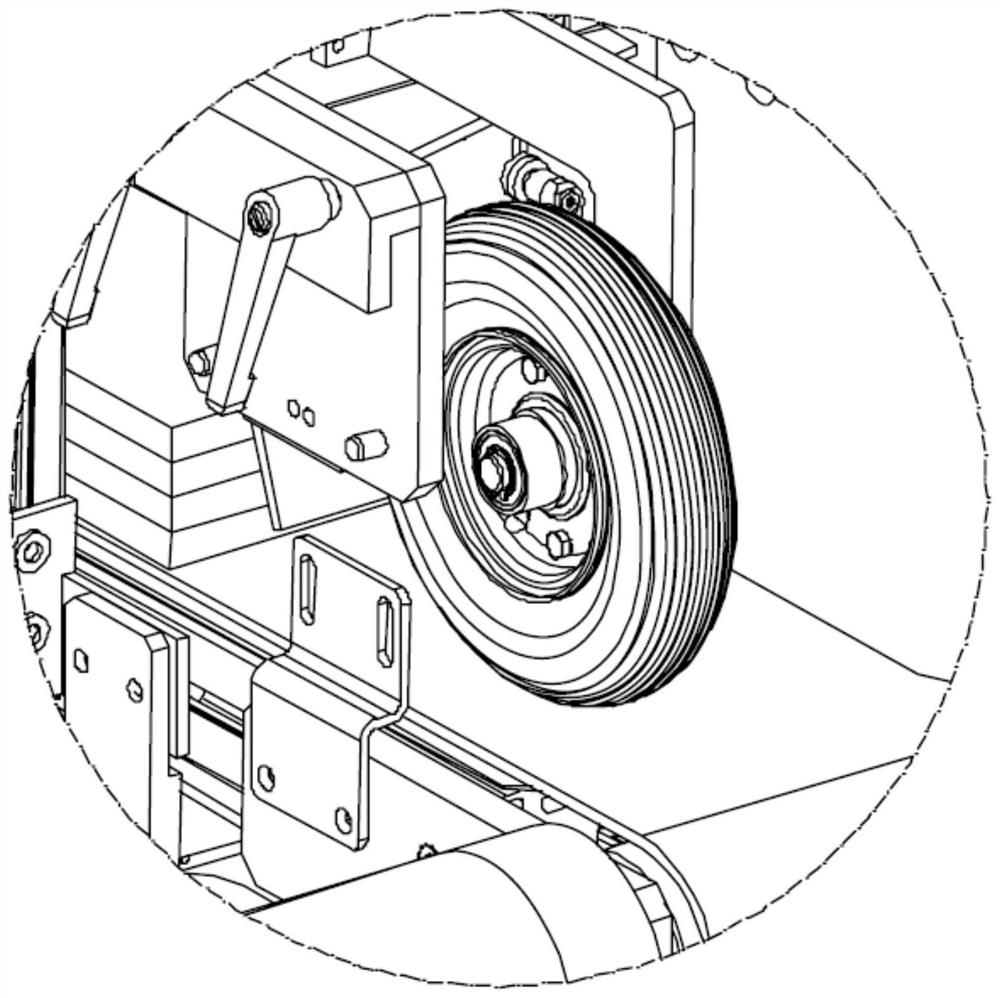

Grooving machine

The invention discloses a grooving machine, which comprises a self-walking mechanism, a working arm rotating mechanism, a working arm mechanism, a cutting mechanism, and a power and control mechanism, wherein the self-walking mechanism is arranged at the bottom of the grooving machine; a mounting platform is arranged at the upper part of the self-walking mechanism; the working arm rotating mechanism and the power and control mechanism are arranged on the mounting platform; the working arm rotating mechanism comprises a turbo-worm reducer and a working arm mounting holder connected with an output shaft of the turbo-worm reducer; the turbo-worm reducer is fixed on the mounting platform; the working arm mechanism is rotatably connected onto the working arm mounting holder and is connected with the cutting mechanism; the power and control mechanism is connected with and controls actions of the self-walking mechanism, the working arm mechanism, the working arm rotating mechanism and the cutting mechanism. A grooving working arm can rotate freely for 360 degrees; the stability coefficient of the grooving machine can be increased through an expendable stabilizing support leg mechanism; the mechanical grooving operation is realized; the grooving efficiency is improved; the labor intensity is alleviated and the safety coefficient is increased.

Owner:蒲长晏

Ground trough digging device for agriculture

A ground trough digging device for agriculture comprises a support plate, a first rolling wheel device, a trough digging device, a second rolling wheel device, a cylinder device, a counterweight device and a pushing device; the support plate is provided with a rectangular hole, and the first rolling wheel device comprises a first supporting block, a first rolling wheel and a first triangular block; the trough digging device comprises a hook, a first fixing block, a first rotating rod, a rotating shaft, a first support, a first oblique rod, a first spring, a second oblique rod and a second spring; the second rolling wheel device comprises a second supporting block, a third supporting block, a second rolling wheel, bristles, a fourth supporting block, a third rolling wheel and a first connecting rod; the cylinder device comprises a cylinder, a pushing rod, a second connecting rod, second triangular blocks and a second support; the counterweight device comprises a first fixing frame, a second fixing frame, a counterweight and third triangular blocks; the pushing device comprises a first vertical rod, a first cross rod and a second cross rod. By means of the ground trough digging device for the agriculture, small trough digging operation can be conducted during agricultural sowing, operation is easy, and the trough digging efficiency is high.

Owner:谭家湾遗址公园运营管理(桐乡乌镇)有限公司

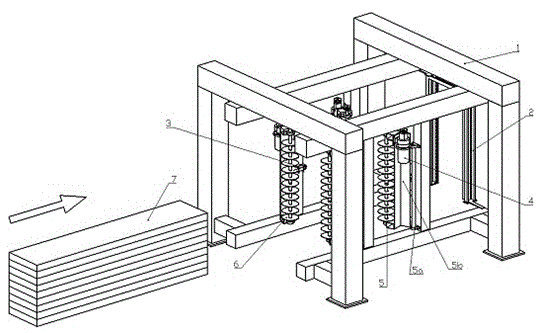

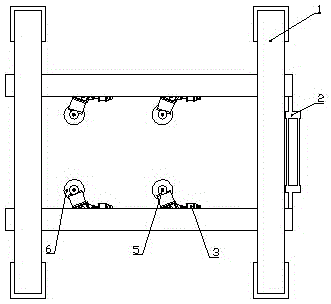

Spliced wood board grooving machine

ActiveCN109434976AConvenience to the leftReduce workloadWood mortising machinesBark-zones/chip/dust/waste removalPhysical healthPulp and paper industry

The invention relates to a grooving machine, in particular to a spliced wood board grooving machine. The spliced wood board grooving machine aims at achieving the technical effects that the physical health can be protected, and grooving efficiency can be improved. According to the technical scheme, the spliced wood board grooving machine comprises a holder, a delivery motor, a delivery wheel, an extending-and-contracting device, a first support, first rolling wheels, a first hollow sleeve, an arc-shaped sliding block and the like. The delivery motor which can drive the delivery wheel to rotateis mounted at the top of the holder. The delivery wheel is fixed to an output shaft of the delivery motor, wherein wood boards can be conveyed through the delivery wheel. The extending-and-contracting device capable of fixing the wood boards is mounted on the lower portion of the front side face of the holder. According to the spliced wood board grooving machine, by means of the extending-and-contracting device, a user can groove the wood boards of different thicknesses conveniently; a cutting wheel rotates, and the wood boards are conveyed leftwards, so that the wood boards can be grooved; by means of a rotating guide sleeve, grooving can be conducted on different positions of the wood boards, and thus, the grooving efficiency can be improved; and the work amount of the user can be reduced.

Owner:湖南高鹏木艺有限公司

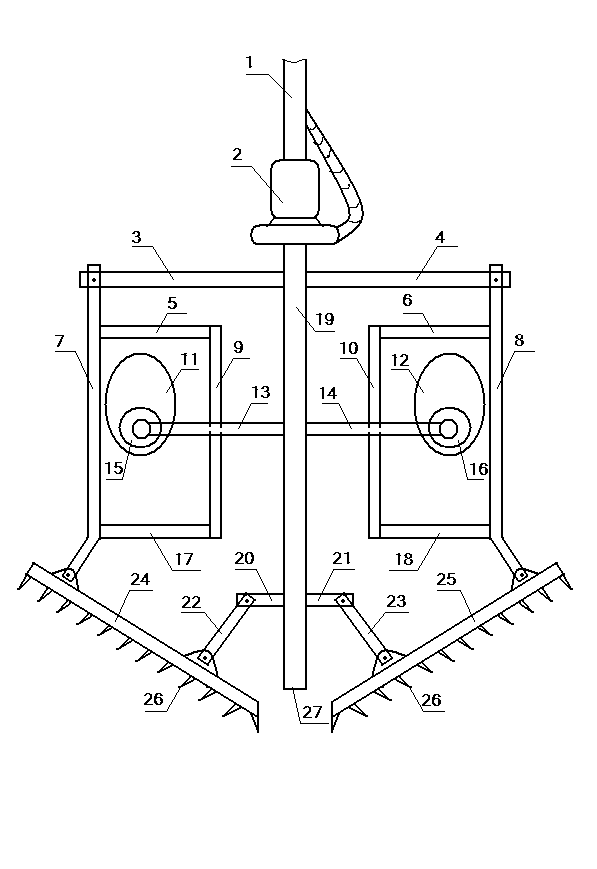

Ellipsoidal groover

ActiveCN103243758AHigh slotting efficiencyLow equipment costSoil-shifting machines/dredgersEllipsoidEngineering

Provided is an ellipsoidal groover. A water outlet pipe is arranged on the upper portion of the groover, a mud pump is arranged at the lower end of the water outlet pipe, a water suction pipe is arranged at the lower end of the mud pump, and an upper arm A and an upper arm B are respectively fixed on the left side and the right side on the upper portion of the water suction pipe. The left end of the upper arm A is hinged to the upper end of a crank arm A, the lower end of the crank arm A is hinged to the left end of an arm lever A, the right end of the upper arm B is hinged to the upper end of a crank arm B, and the lower end of the crank arm B is hinged to the right end of an arm lever B. A middle arm A and a middle arm B are respectively fixed on the left side and the right side on the middle portion of the water suction pipe, a hydraulic driving machine A is arranged at the left end of the middle arm A, an ellipsoid A is fixed outside the hydraulic driving machine A, a hydraulic driving machine B is arranged at the right end of the middle arm B, and an ellipsoid B is fixed outside the hydraulic driving machine B. A lower arm A and a lower arm B are fixed on the lower portion of the water suction pipe, the left end of the lower arm A is hinged to the upper end of a rocker A, the lower end of the rocker A is hinged to the right end of the arm lever A, the right end of the lower arm B is hinged to the upper end of a rocker B, and the lower end of the rocker B is hinged to the left end of the arm lever B. A rectangular frame A is arranged outside the ellipsoid A, and a rectangular frame B is arranged outside the ellipsoid B.

Owner:泰州市海通资产管理有限公司

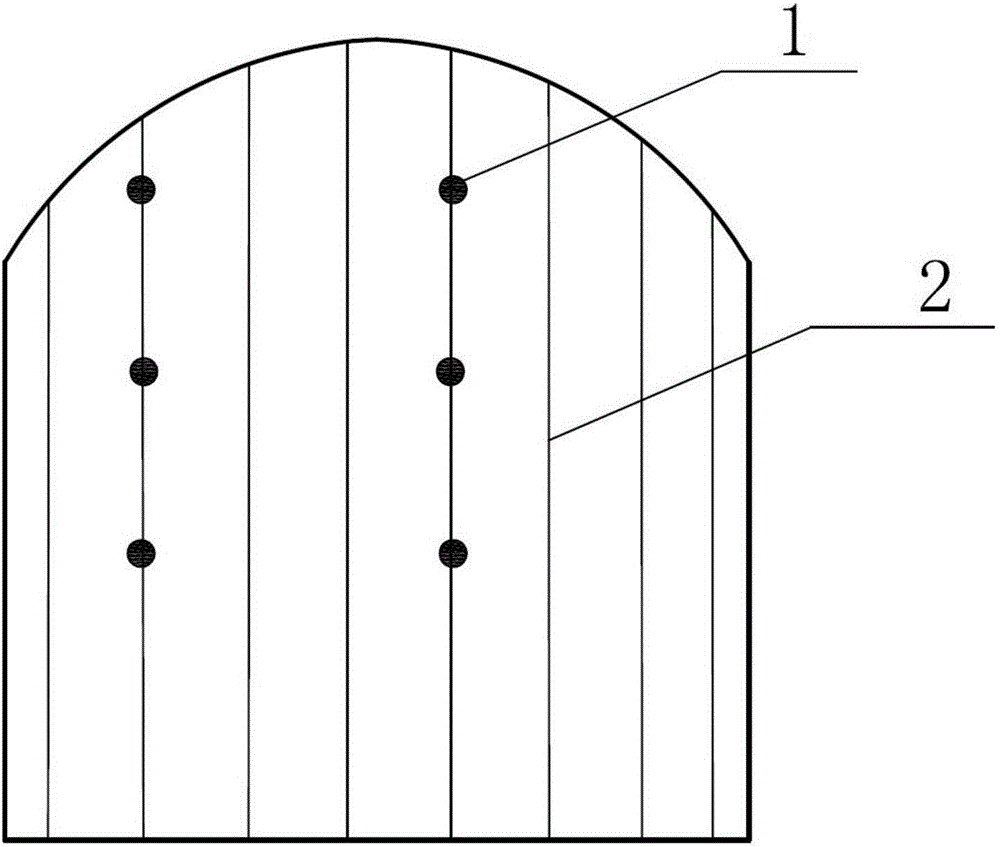

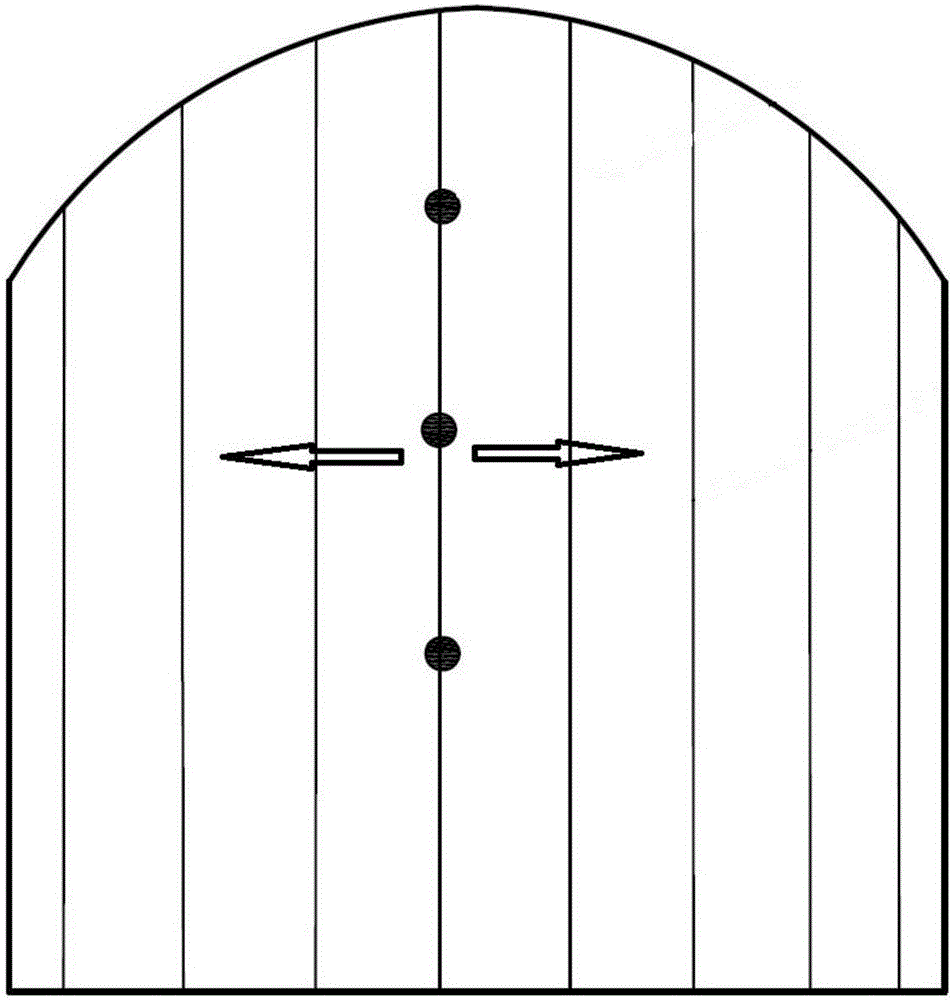

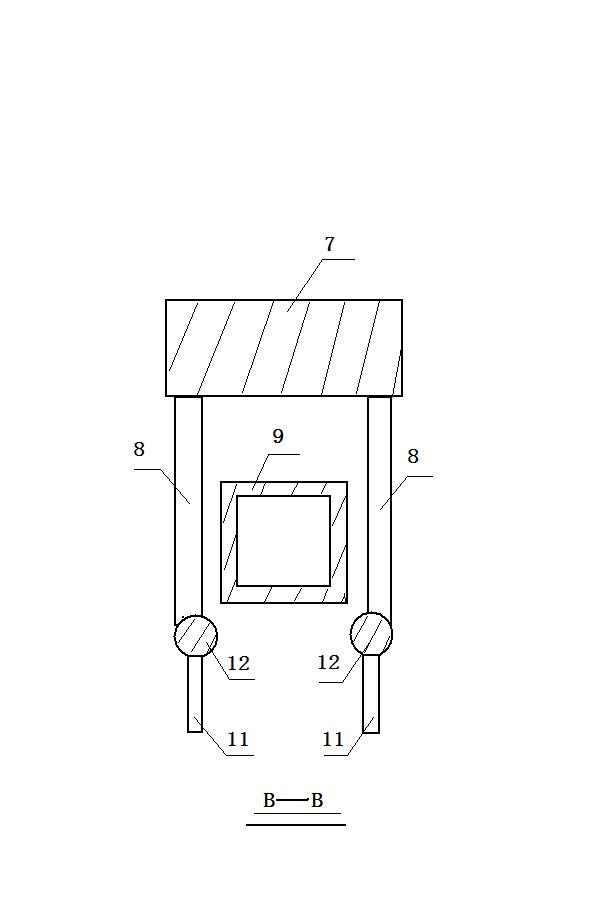

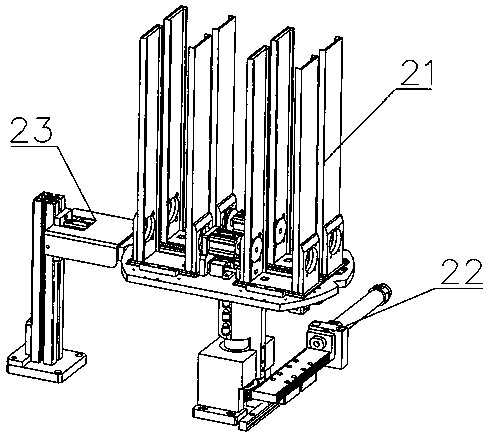

Concrete block slotting equipment

InactiveCN104786375AImprove slotting efficiencyImprove processing efficiencyStone-like material working toolsTextileMechanical engineering

The invention discloses concrete block slotting equipment. According to the technical scheme, the concrete block slotting equipment comprises a vertical rack, a channel allowing a green body to pass through is arranged in the rack, multiple cutter shafts which are vertically arranged are symmetrically arranged on the two sides of the channel, and multiple disc-shaped blades are installed on each cutter shaft at certain intervals; cutter seats which can adjust feeding distance of the cutter shafts are connected with the cutter shafts and the rack, the cutter shafts are rotatably connected with the cutter seats through power devices, and a door-frame-shaped purging frame is arranged on the portion, located at the tail end of the channel, of the rack. The concrete block slotting equipment has the advantages that after cutting of an aerated concrete wallboard green body is completed, secondary cutting can be conducted on a cutting crack, a gridding cloth installation groove can be formed, the slotting efficiency is high, and the machining efficiency is improved.

Owner:山东阳光众泰机械工程有限公司

Multifunctional groove box cutting machine and using method thereof

PendingCN107877713AGood orientationReduce or avoid harmWorking accessoriesStone-like material working toolsEngineeringMechanical engineering

The invention relates to the field of cutting machine equipment, in particular to a multifunctional groove box cutting machine and a using method thereof. The cutting machine comprises a machine body;a motor is arranged in the machine body, is connected with a cutting saw blade through a transmission mechanism and drives the cutting saw blade to rotate to work through the transmission mechanism;and a protective cover used for wrapping the cutting saw blade is arranged on the machine body and is provided with a guide assembly used for feeding and guiding the cutting machine. According to thecutting machine and the using method thereof, the guide assembly is arranged so that the feeding smoothness of the cutting machine can be guaranteed to a certain degree, meanwhile, the guide assemblyhas a good guiding function so that the grooving efficiency can be improved to a certain degree, by means of the guiding function of a guide mechanism, the grooving straightness can be ensured, and the grooving quality can be improved.

Owner:胡才春

Multi-blade trench cutting machine

The invention discloses a multi-blade trench cutting machine. The multi-blade trench cutting machine comprises a shell and a motor, a movable chamber with an open bottom is formed in the middle of the shell, a saw blade clamping head is arranged in the movable chamber and comprises a nut, a plurality of clamping blocks and movable blocks, a bevel gear B matched with a bevel gear A is mounted at the other end of a rotating shaft, the clamping blocks are arranged on the rotating shaft slidably, a gap is reserved between each two adjacent clamping blocks, annular grooves are formed in each two adjacent clamping blocks oppositely, the movable blocks are capable of moving in the annular grooves freely and connected with the bottoms of the annular grooves through springs, a thread is formed in the outer wall at the end of the rotating shaft, and the nut is in thread fit with the rotating shaft. The multi-blade trench cutting machine has the advantages that since the clamping blocks and the movable blocks are used for clamping and fixing saw blades, when the saw blades vibrate, the springs at the bottoms of the annular grooves restore by means of elastic deformation and are capable of counteracting a stress effect produced by vibration effectively, idling of the rotating shaft is avoided and trench cutting efficiency is improved while stable rotation of the saw blades is guaranteed.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

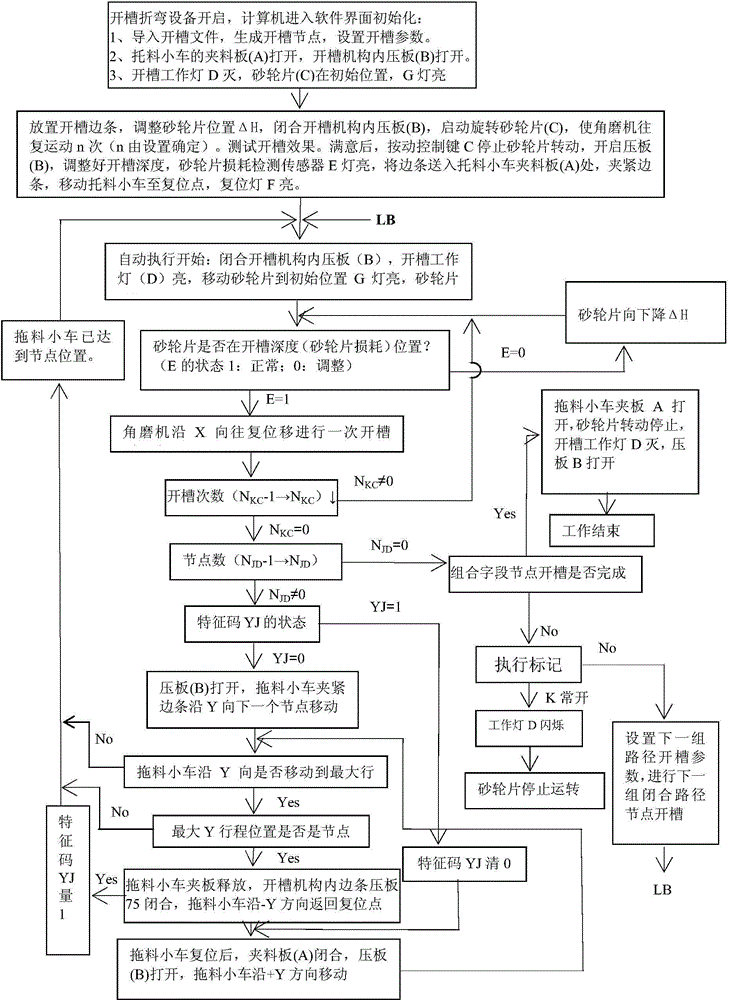

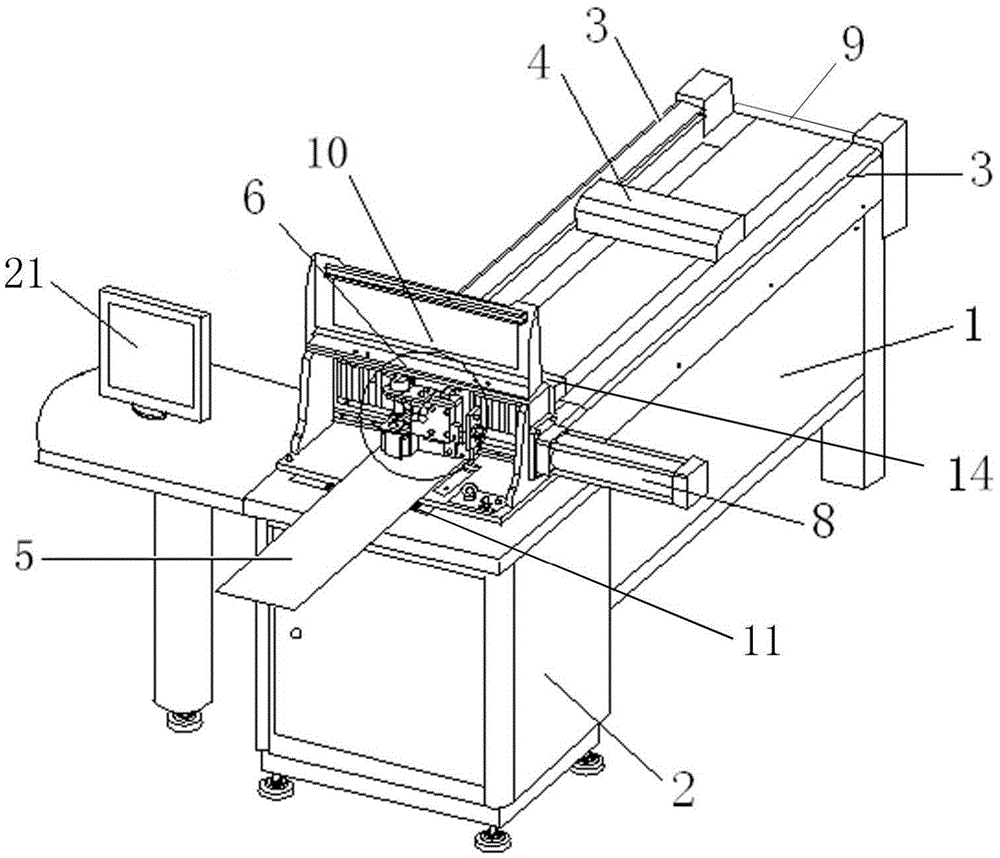

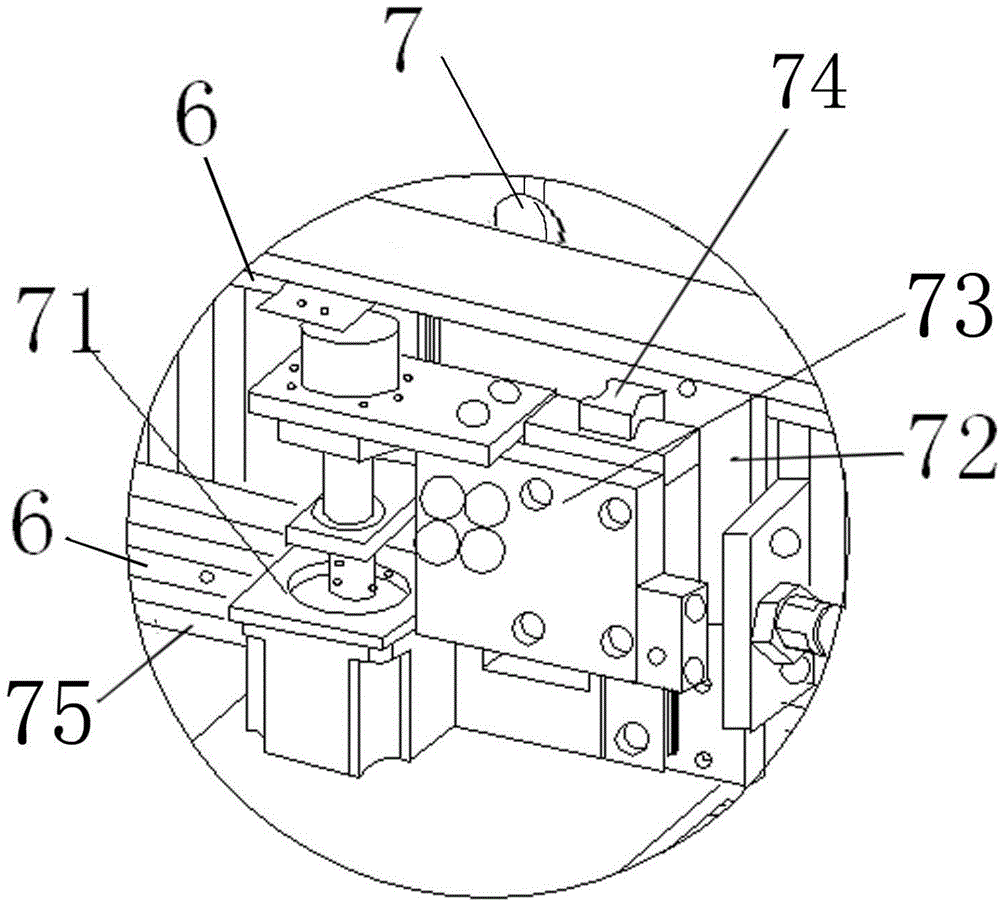

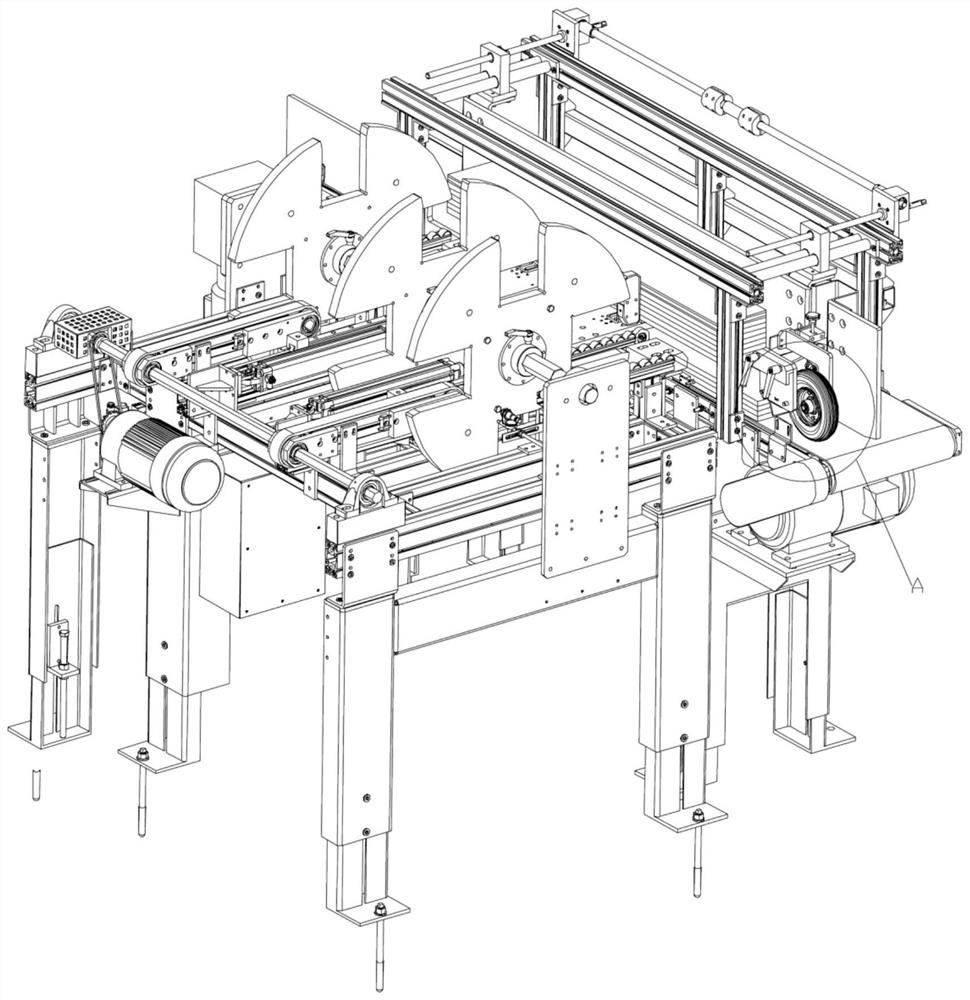

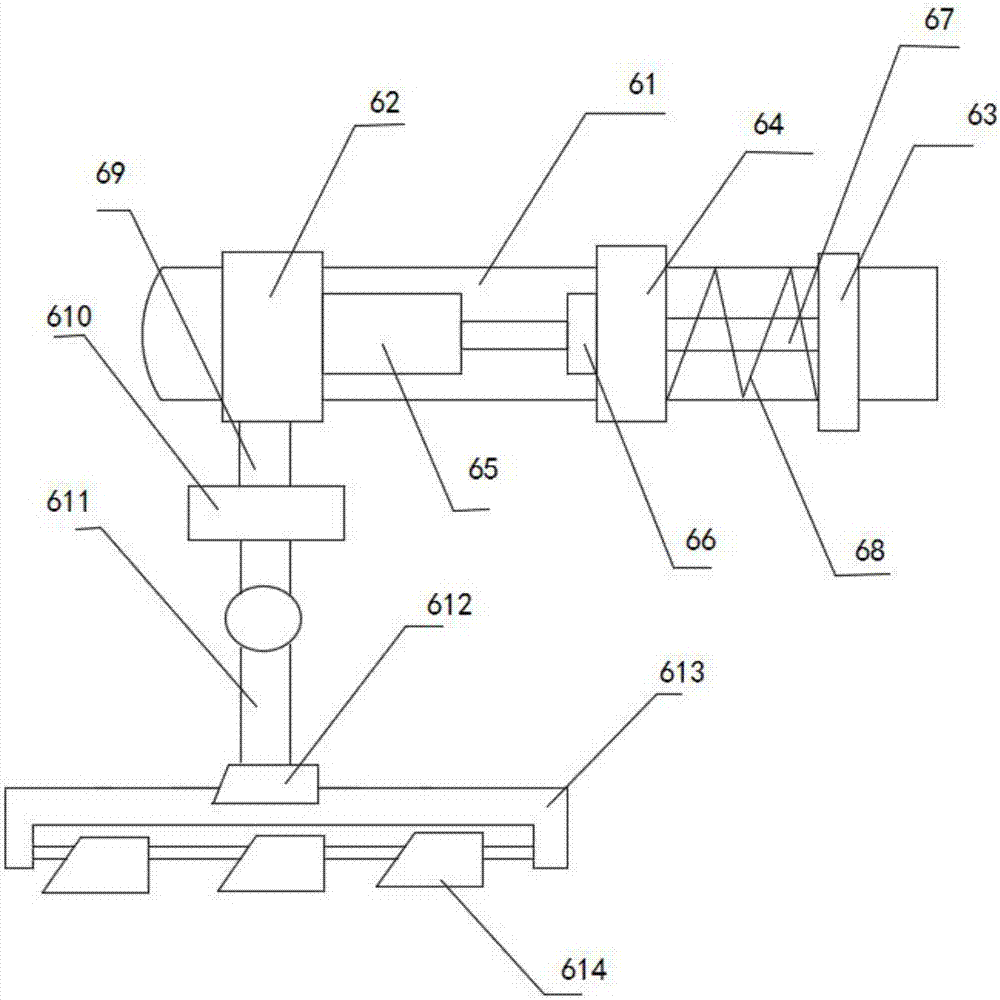

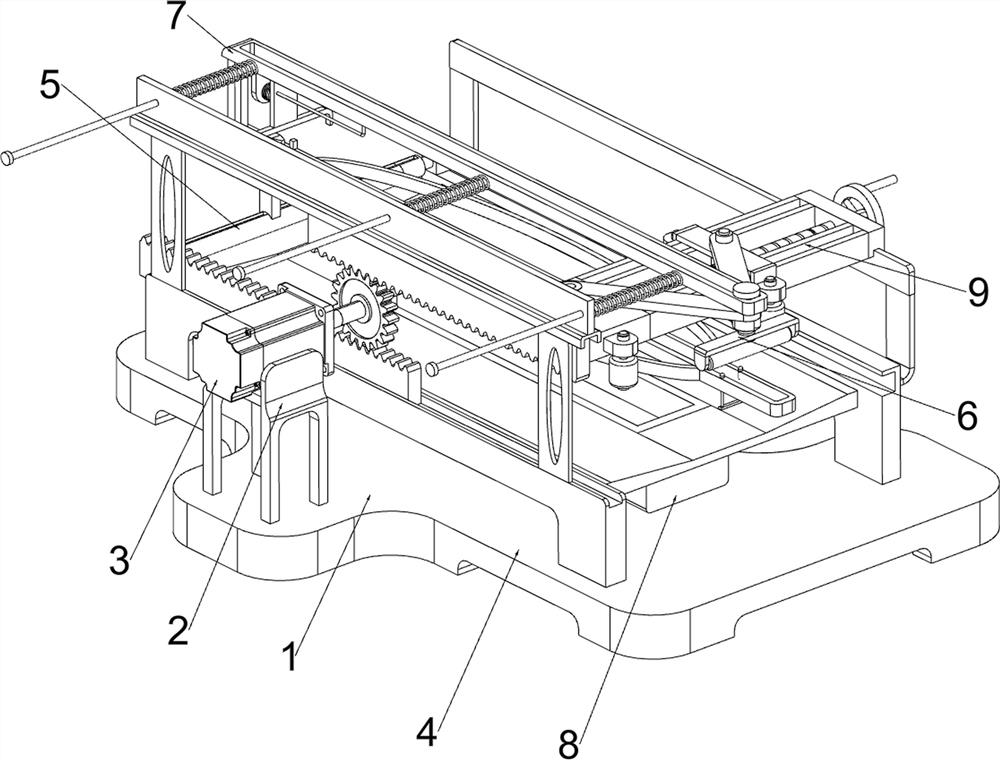

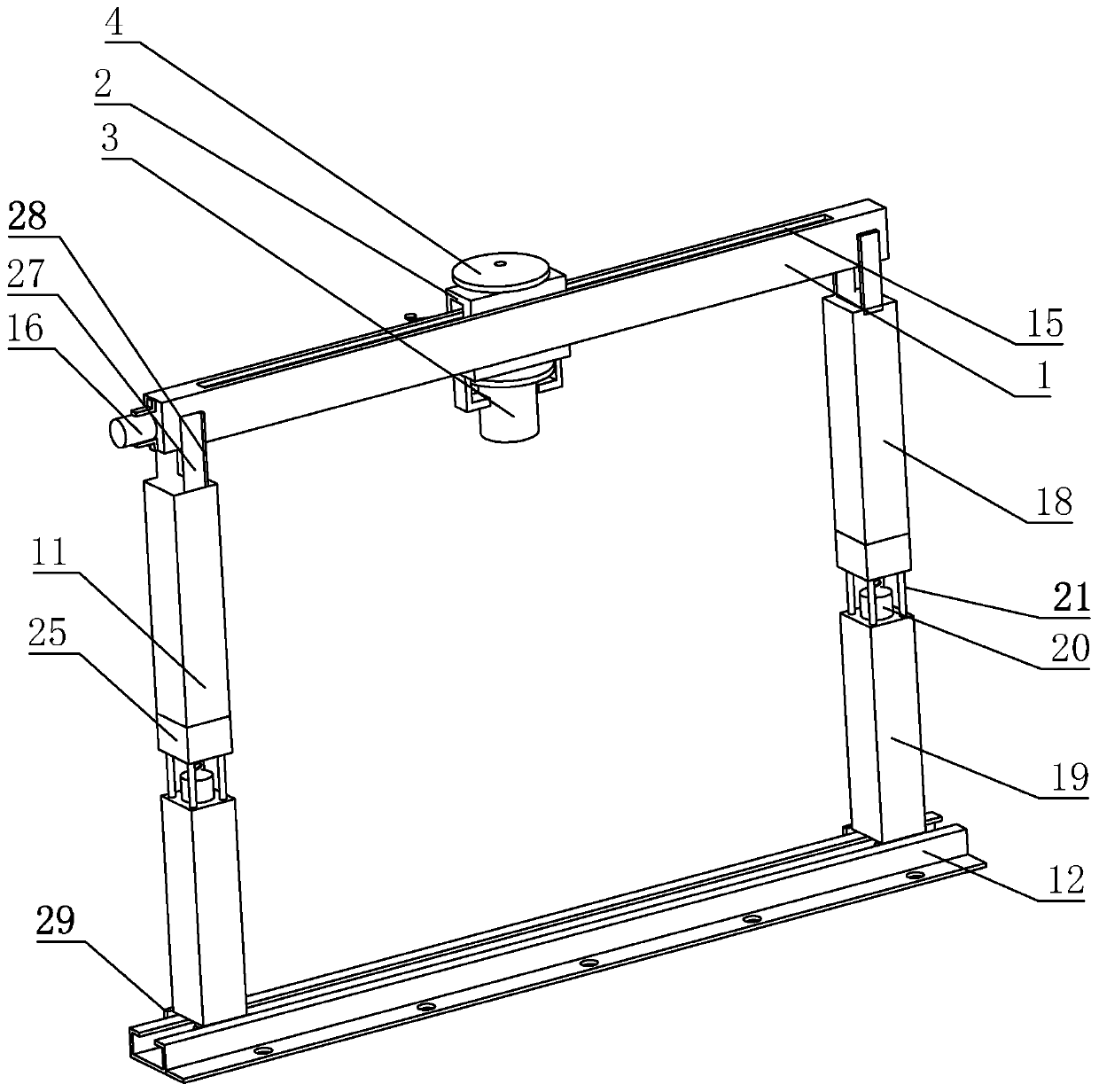

Advertisement typeface side trip full automatic numerical control grooving bending machine and grooving method

InactiveCN104551931AGuaranteed smooth progressLength is not limitedGrinding drivesGrinding feed controlNumerical controlGrinding wheel

The invention provides an advertisement typeface side trip full automatic numerical control grooving bending machine and a grooving method. The machine comprises a support table, a material dragging mechanism located on the support table, a grooving mechanism located at the one end of the material dragging mechanism and a control device. The bending machine adopts the electromechanical structure feeding transmission mode of 'reciprocating material clamping and pulling', ensures accuracy and stability of the size of the grooving node, and enables the length of the machine strip not to be constrained. By means of an automatic marking mechanism arranged at the grooving cut position, operation of manual measurement and marking is avoided, and the grooving efficiency and accuracy are improved. By means of a grinding wheel loss detection sensor, the grooving loss of the grinding wheel is compensated automatically, and consistency of the grooving effect and the side strip grooving depth is ensured. The material dragging device achieves the way of multi-strip parallel arrangement and simultaneous grooving, and is high in grooving efficiency for characters in large batch and repeat rate. The grooving process is set and controlled to operate by the special computer software program, the automation degree is high, and stability and reliability are achieved.

Owner:LASER TECH INST TIANJIN CITY

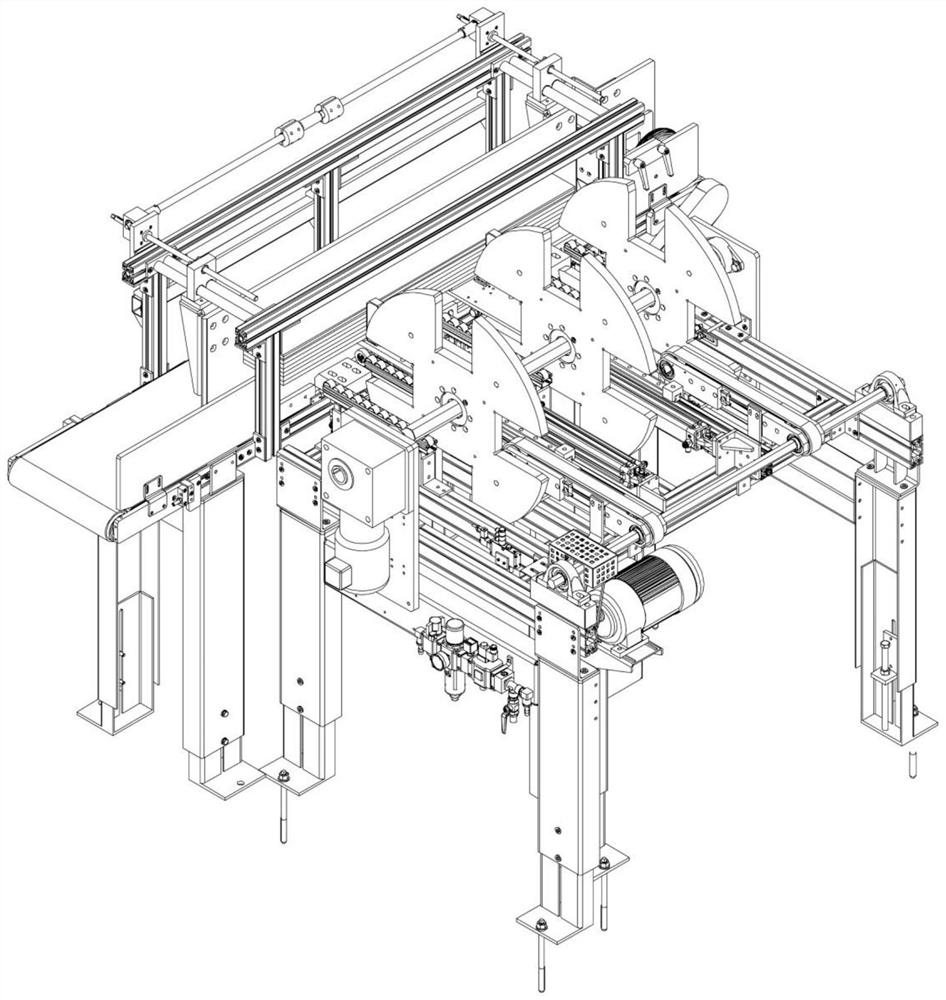

Plate turnover machine

ActiveCN111646168AAvoid efficiencyAvoid quality problemsConveyorsConveyor partsStructural engineeringMechanical engineering

The invention discloses a plate turnover machine, which performs plate turnover with the minimum unit of plate pile. The plate turnover machine comprises a plate pile turnover device, a plate pile feeding and conveying device and a plate pile discharging conveying device, wherein the plate pile turnover device comprises a plurality of receiving mechanisms; the receiving mechanism is provided witha bayonet for accommodating a plate pile; the receiving mechanism can rotate around the own axis to drive the bayonet to rotate from a first position to a second position; the plate pile feeding conveying device is arranged at an upstream station of the plate pile turnover device, and can be used for conveying the plate pile into a bayonet in the first position; and the plate pile discharging conveying device is arranged at a downstream station of the plate pile turnover device, and can be used for taking the plate pile out of a bayonet at the second position. Through adoption of the plate turnover machine, the plate turnover efficiency is improved.

Owner:豪德机械(上海)有限公司

Construction method of granite geological underground continuous wall trench

InactiveCN110528498AShorten the construction periodLow costSoil-shifting machines/dredgersBulkheads/pilesSlurry wallGranolithic

The embodiment of the invention provides a construction method of a granite geological underground continuous wall trench. Through a hole position placing step, a step of using a down-the-hole drill to construct a guide hole, a step of using a hydraulic grab bucket grooving machine to grab a soil layer, a step of using a pile washing machine to wash rocks and a step of using a double wheel trenchmilling machine to directly mill the rock to form a trench, construction operation is carried out; by using the down-the-hole drill to construct the guide hole first and then using the hydraulic grabbucket grooving machine to clean the soil layer, a novel underground continuous wall combined trench forming process is created on the basis of a traditional construction method; and therefore, on theone hand, difficult problems of hammer deviation, drilling tool jamming, low trench forming efficiency and the like of high-strength inclined plane granite formation underground continuous wall construction are solved; and meanwhile, the safety, quality and progress of the underground continuous wall construction are guaranteed; and the effect is improved, and the cost is saved.

Owner:中铁七局集团西安铁路工程有限公司

Wood plate grooving machine for furniture

ActiveCN107042554AQuality improvementImprove slotting efficiencyMulti-purpose machinesWood mortising machinesEngineeringSlide plate

The invention discloses a wood plate grooving machine for furniture. The wood plate grooving machine comprises a rack, a motor and a rotary tool, wherein the rack is provided with a clamp for fixing a wood plate, the clamp comprises a thread hole, the thread hole is formed in the rack, and a screw rod is in threaded connection into the thread hole; a slide plate is slidably connected to the rack, the motor is fixedly connected to the slide plate, the motor is connected with a rotary shaft, a groove is formed in the rack, the rotary tool is driven to rotate by the rotary shaft, a plurality of rolling wheels are further fixedly connected to the rotary shaft, and a sector gear is fixedly connected to the rotary shaft between the rotary tool and the motor; and a slide rod is further slidably connected to the rack, one end of the slide rod is slidably connected into the groove, the slide rod is parallel to the rotary shaft, a planing tool in the shape of a U-shaped groove is installed on the slide rod, a rack is further slidably connected to the slide plate, the rack is fixedly connected to the lower part of the slide rod, the sector gear is engaged with the rack, a boss is further arranged on the slide plate, and an elastic element is connected between the boss and the rack. Compared with the prior art, the wood plate grooving machine disclosed by the invention is high in grooving quality and higher in grooving efficiency.

Owner:重庆市永川区植成家俱厂

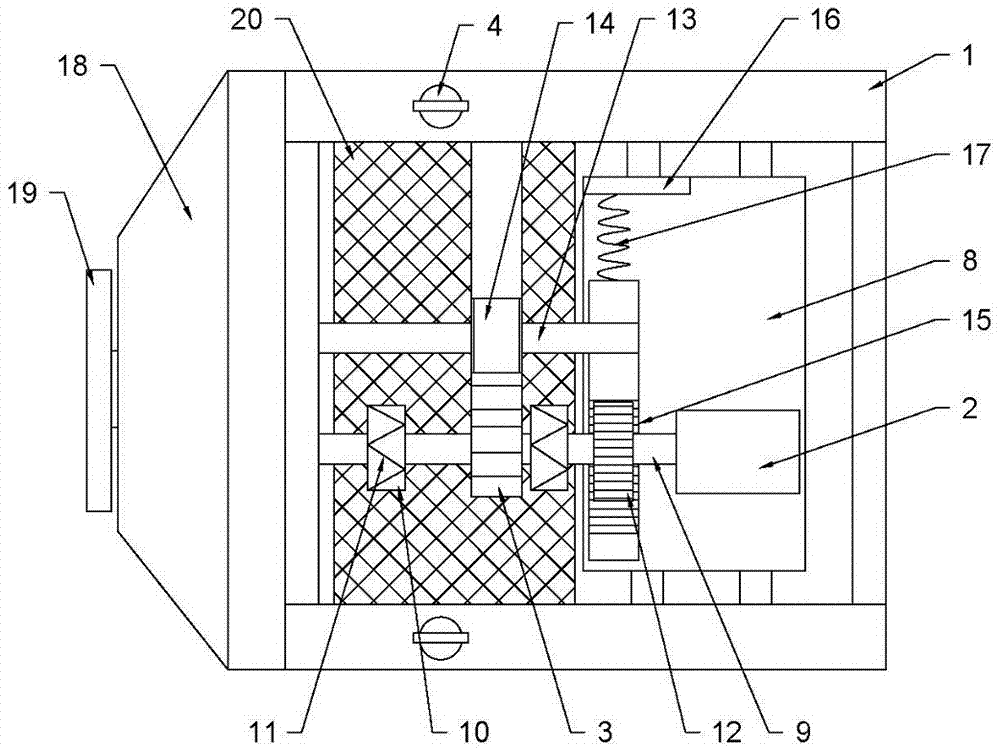

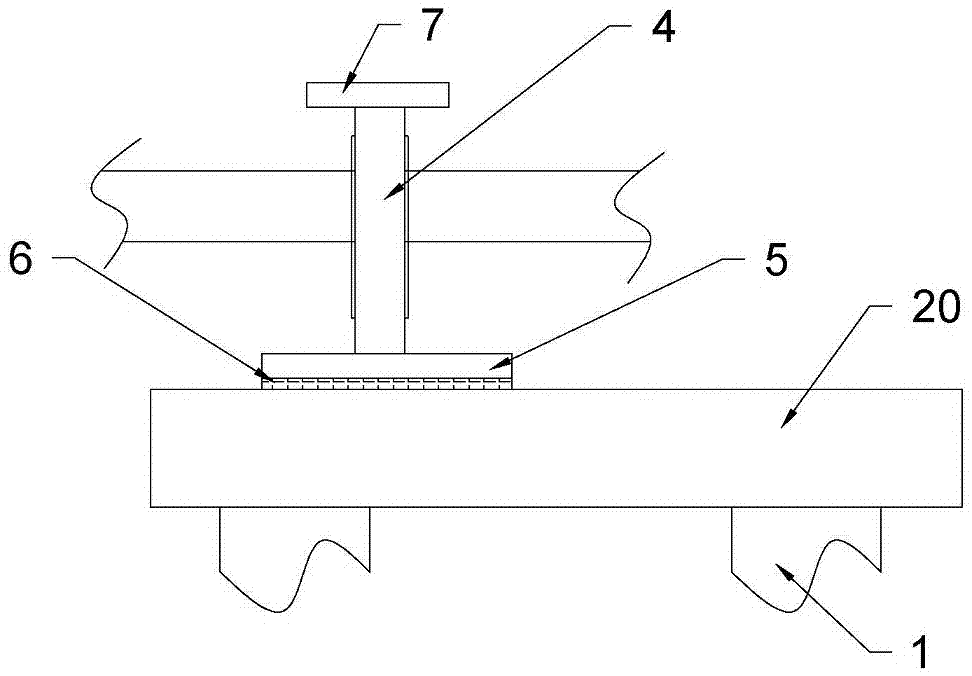

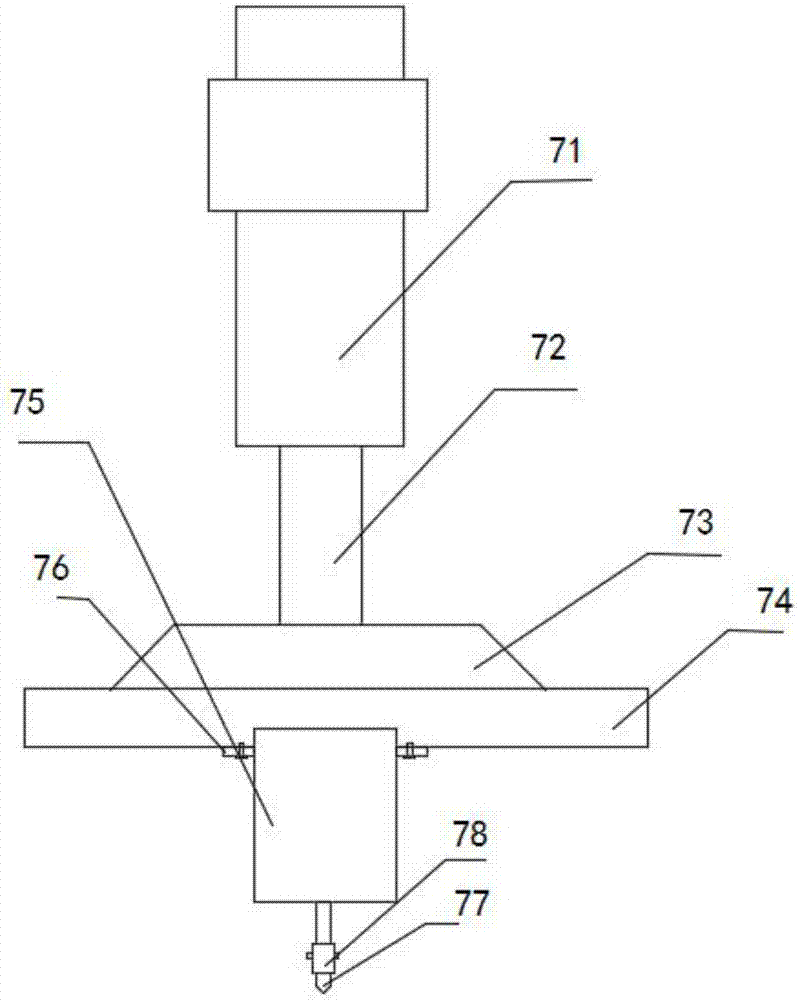

Automatic processing machine for manufacturing shaving board

ActiveCN110480463ANo need for manual grindingImprove slotting efficiencyGrinding drivesMulti-purpose machinesAutomatic processing

The invention relates to an automatic processing machine for manufacturing a shaving board. The automatic processing machine comprises a mounting table, a driving device, a cutting and polishing device and a limiting mechanism, wherein the driving device is arranged at the upper end of the mounting table, the cutting and polishing device is arranged at the lower end of the driving device, and thelimiting mechanism is arranged in the middle of the mounting table. The automatic processing machine for manufacturing the shaving board can solve the problems that when an existing shaving board machining device is used for machining the shaving board, the shape of grooves machined by a grooving cutter is mostly single, and one grooving cutter can only open one groove; when the grooves of different shapes need to be machined in the shaving board, various cutters need to be prepared, and the replacement process of the cutter is complex; the inner walls of the formed grooves are rough, and theinner walls of the grooves are usually required to be polished manually; and however, manual polishing is inconvenient due to the fact that the inner spaces of the formed groove are small, and the like.

Owner:江苏汇丰木业有限公司

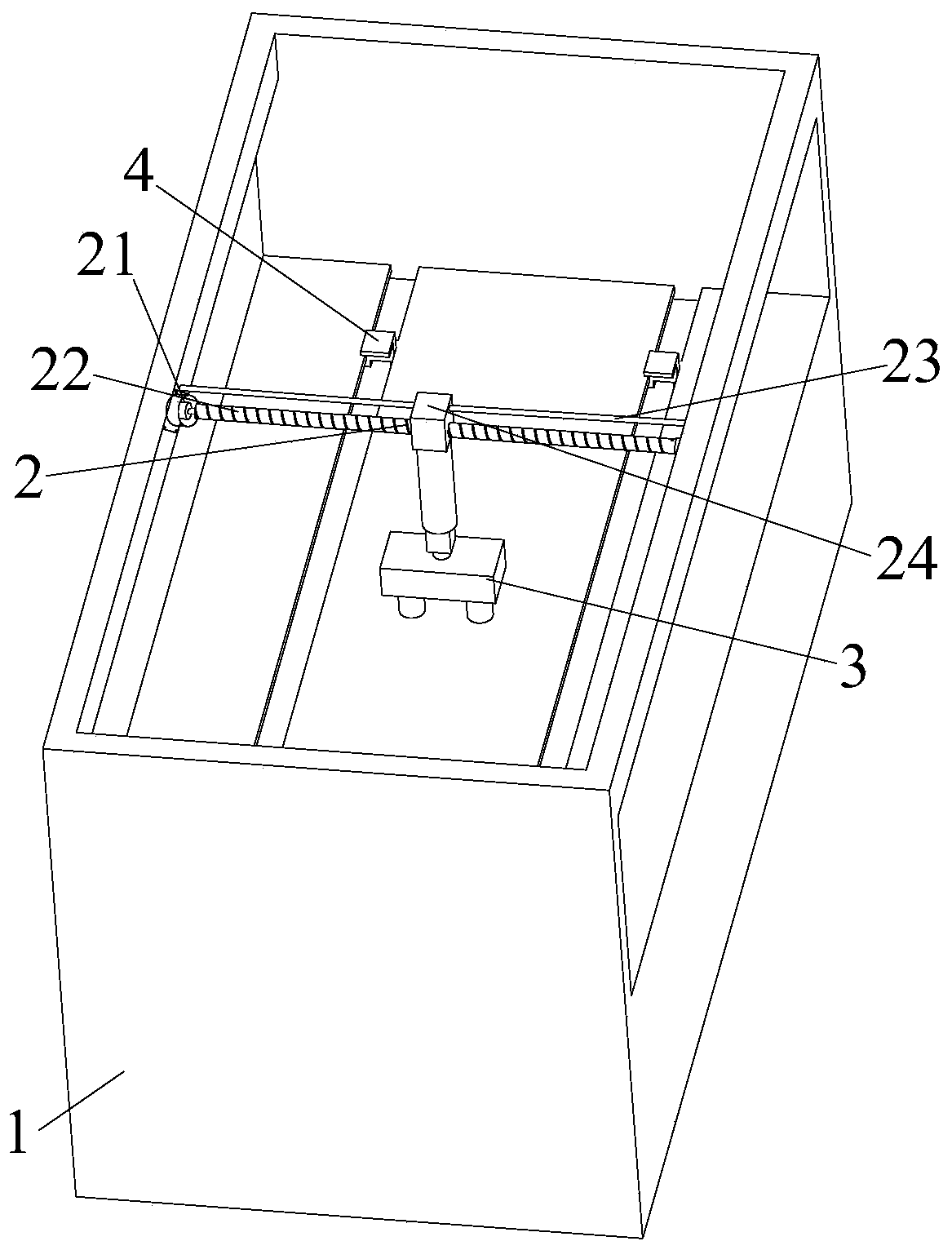

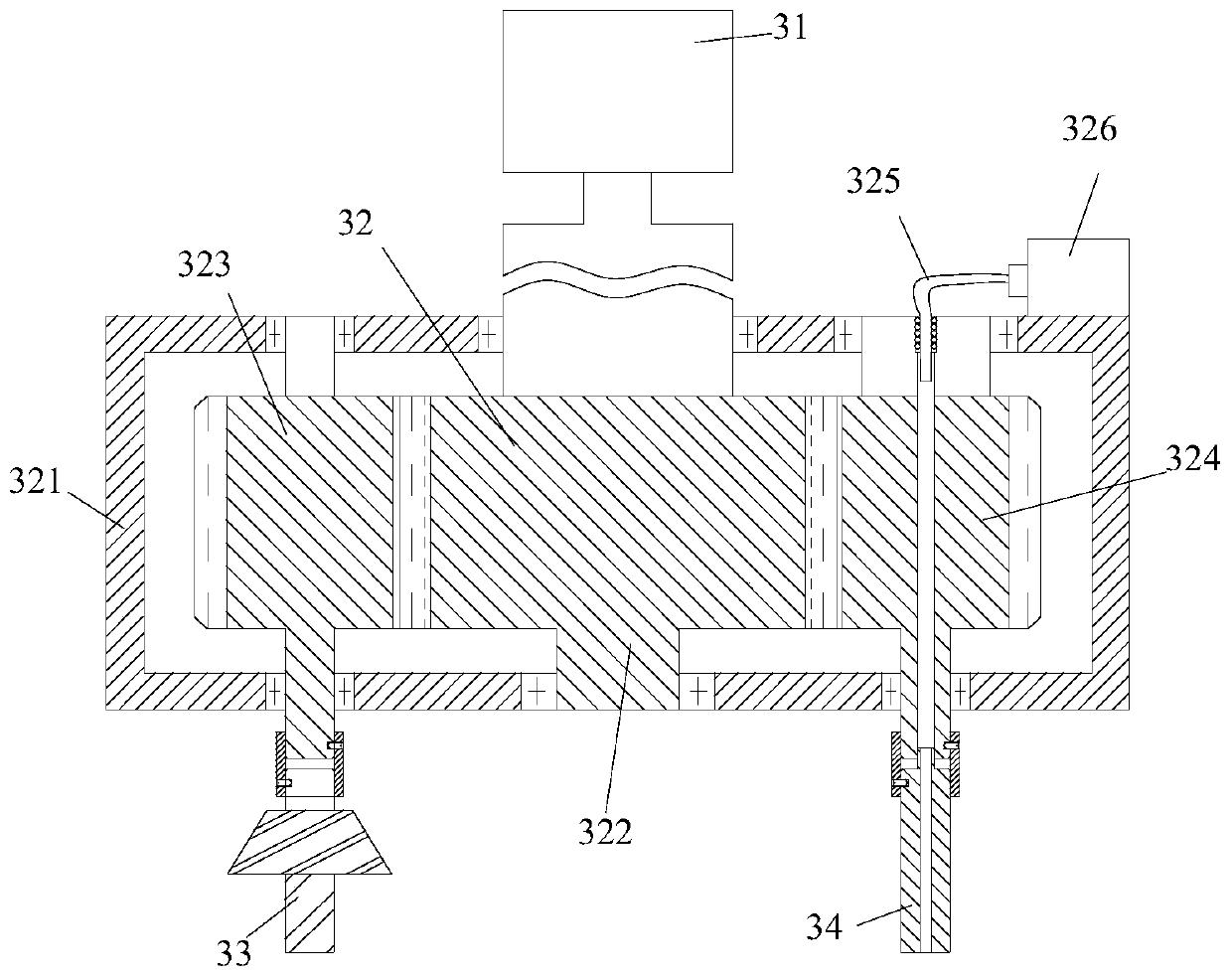

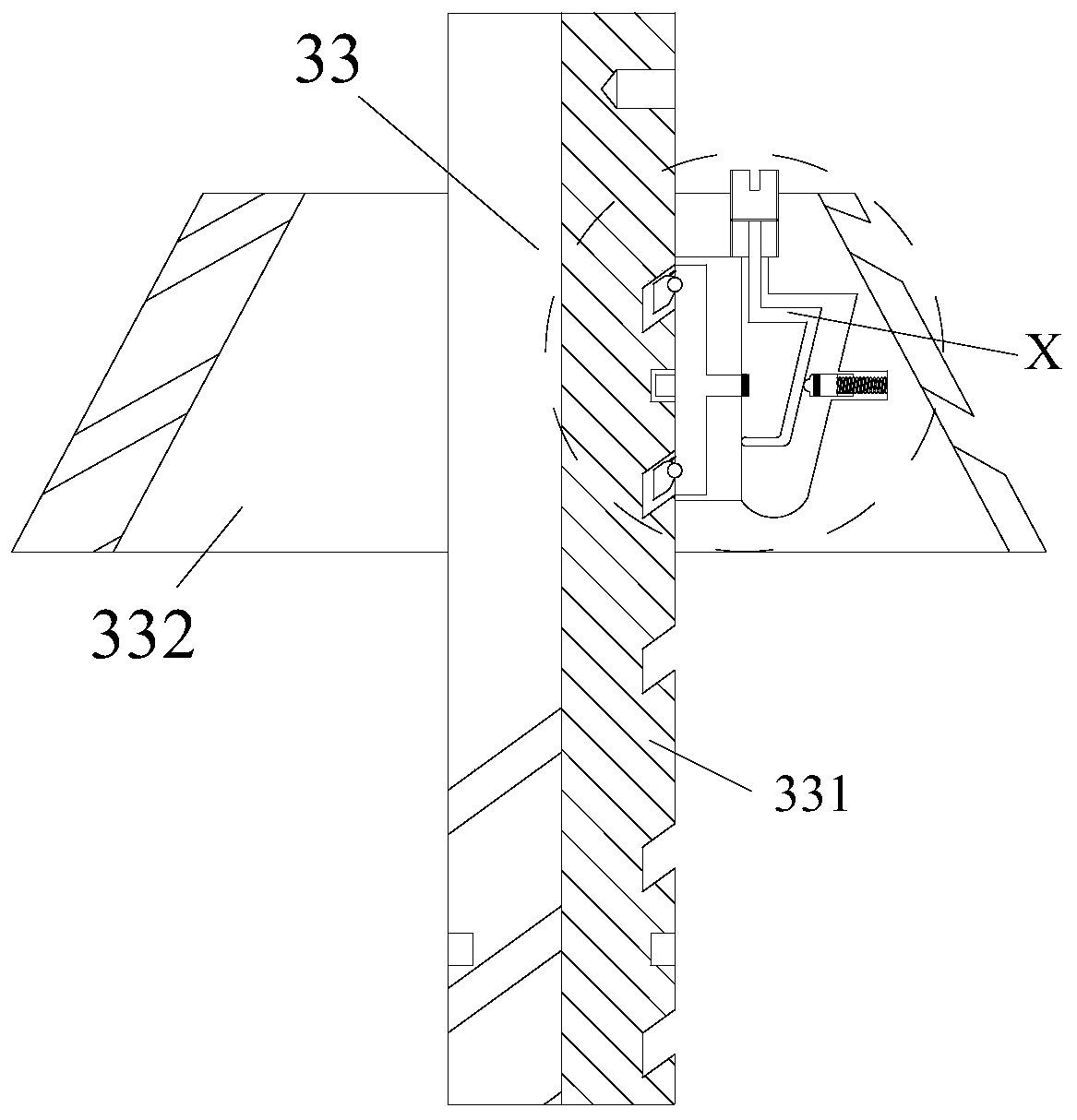

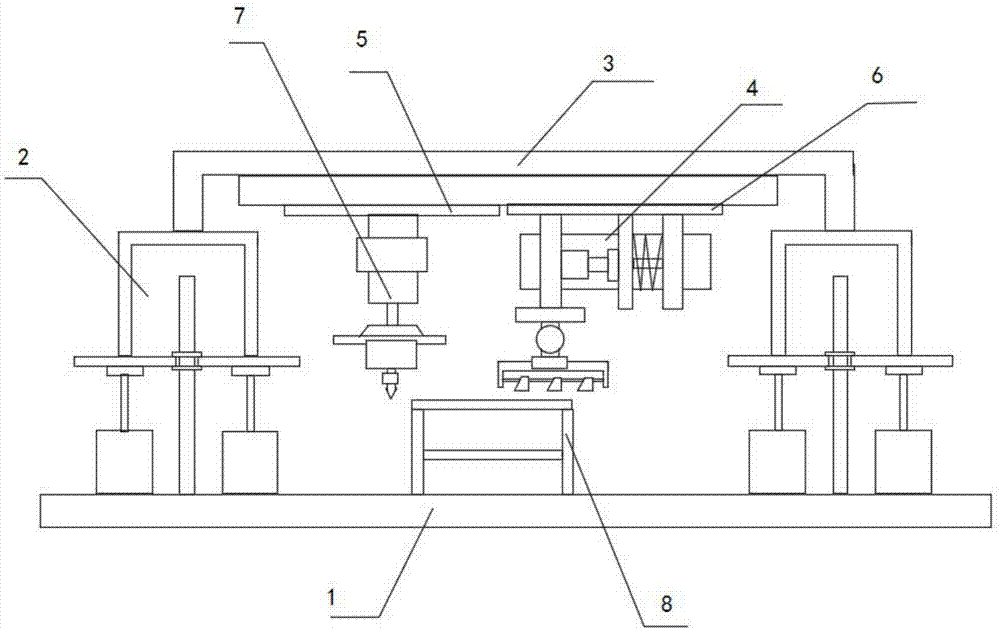

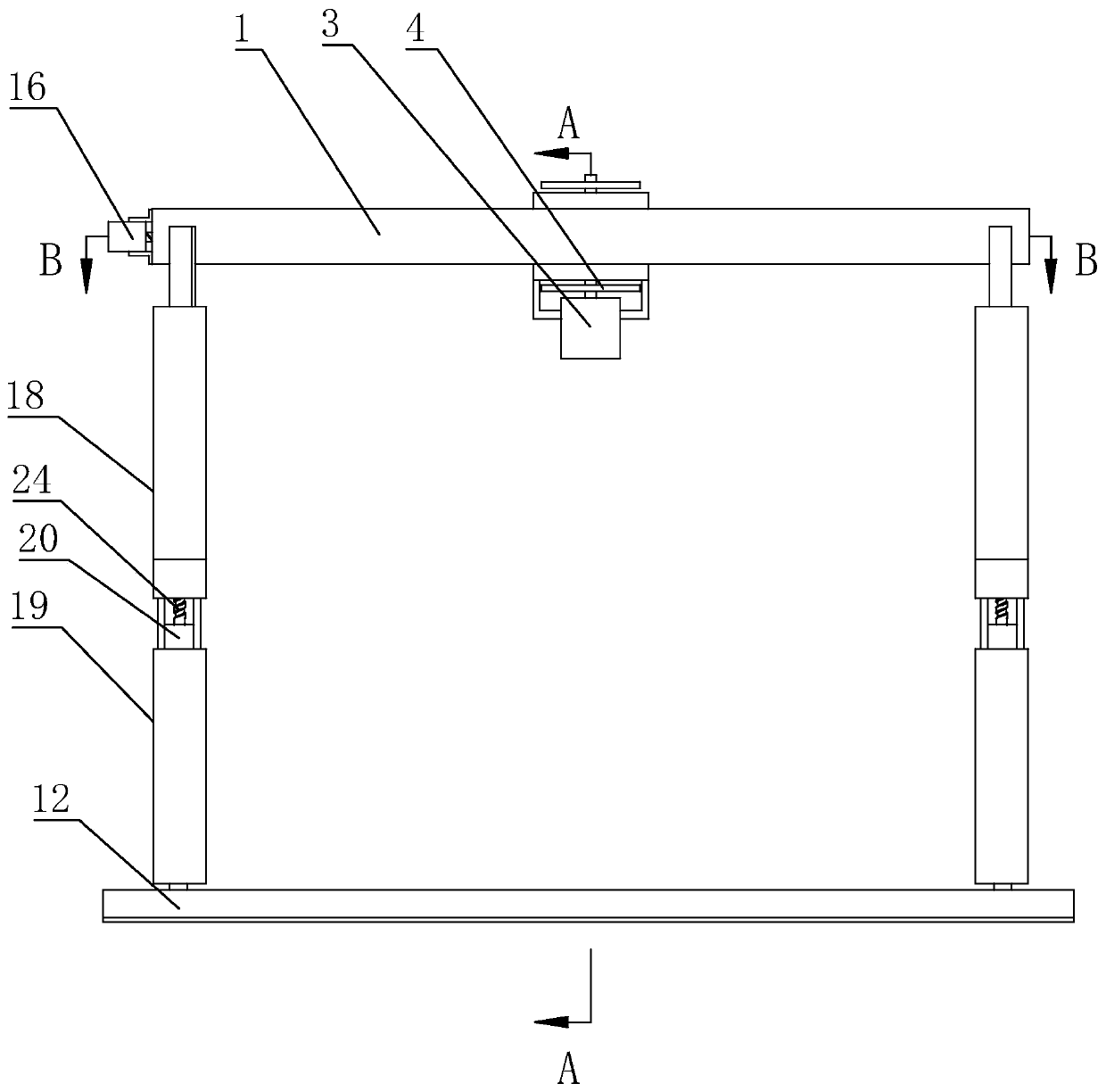

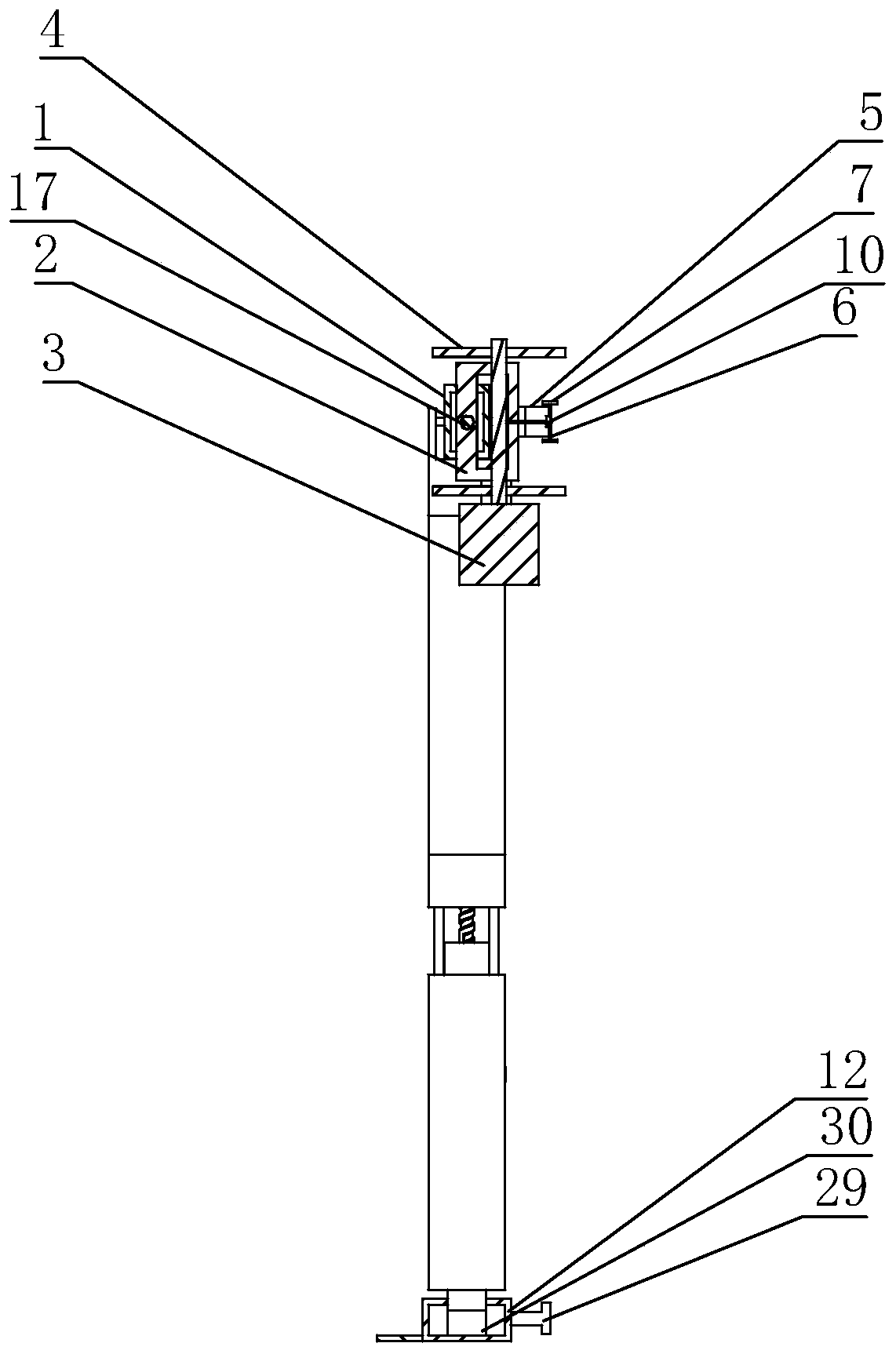

Double-station surface treatment equipment

InactiveCN107511878AHigh degree of automation integrationIncrease productivityMetal working apparatusFace sheetSurface finishing

The invention provides double-station surface treatment equipment comprising a base, lifting assemblies, a top face plate, a first displacement assembly and a second displacement assembly. The lifting assemblies are arranged on the left and right sides of the base correspondingly; the top face plate is arranged at the upper ends of the lifting assemblies; and the first displacement assembly and the second displacement assembly are arranged on the lower surface of the top face plate. The double-station surface treatment equipment further comprises a slotting assembly arranged at the lower end of the first displacement assembly, a perforating assembly arranged at the lower end of the second displacement assembly, and a conveying assembly fixed to the upper end of the middle of the surface of the base. The double-station surface treatment equipment is novel in structure, ingenious in design, high in slotting and perforating efficiency, capable of increasing the finished product rate greatly and beneficial for saving the manpower resource.

Owner:嘉善中正电子科技有限公司

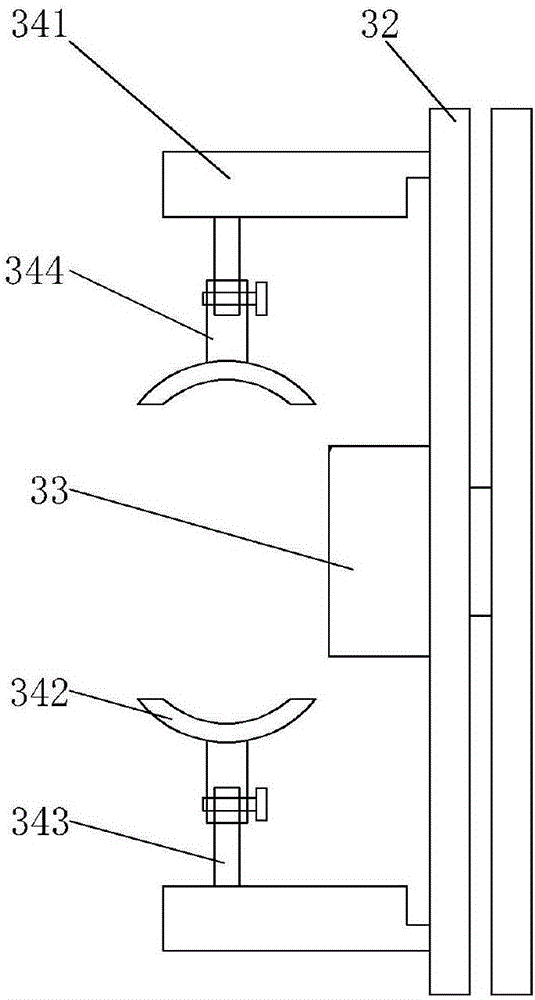

Fixing device for steel pipe grooving

The invention discloses a fixing device for steel pipe grooving. The fixing device comprises a base, a first fixing mechanism, a second fixing mechanism and a guiding mechanism. The first fixing mechanism comprises a stand column, a beam, a first lifting air cylinder, a second lifting air cylinder, a first clamp head and a second clamp head. The second fixing mechanism comprises a fixing base, a rotating disc and a rotating motor. An annular positioning protrusion and three annular positioning clamps are arranged on the rotating disc. The three annular positioning clamps are arranged on the outer side of the annular positioning protrusion and uniformly distributed around the axis of the rotating disc. The guiding mechanism comprises a third lifting air cylinder, a Y-axis sliding block, an X-axis sliding block and a bottom block which are sequentially arranged from top to bottom, and the movable end of the third lifting air cylinder is provided with a placement base for positioning a grooving machine. The fixing device is compact in structure, convenient to use and capable of effectively fixing a steel pipe, rapidly and accurately performing grooving in the axial direction and the radial direction of the steel pipe conveniently, and greatly improving the grooving efficiency and the grooving quality.

Owner:ZHEJIANG CHANKONG STEEL PIPE

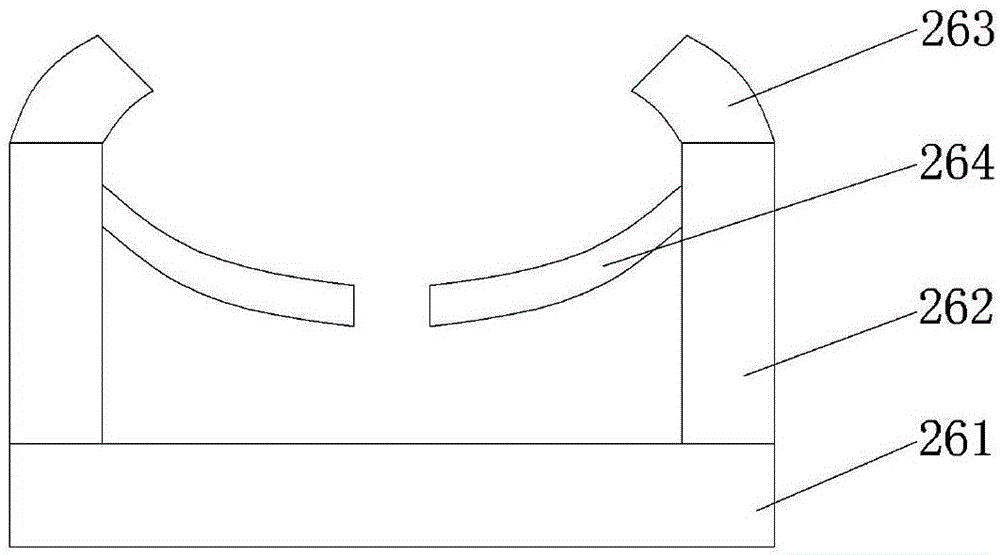

Double-faced slotting device for bearing production

ActiveCN109079209ACompact structureEasy to useMilling equipment detailsMetal working apparatusRotary stageEngineering

The invention discloses a double-faced slotting device for bearing production. The device comprises a workbench, a slotting mechanism and a positioning mechanism, wherein the slotting mechanism comprises a rotating table, a rotating arm and slotting components; the slotting components comprise slotting motors, fine adjustment air cylinders, movement screw rods, movement motors, sliding plates, guide rails and longitudinal frame blocks; the positioning mechanism comprises a positioning transverse plate, a left positioning stand plate, a right positioning stand plate, a position adjustment sliding plate, a position adjustment motor, a position adjustment screw rod, a left positioning component and a right positioning component; the left positioning component comprises a left lifting air cylinder, a left lifting plate and a left positioning head; and the right positioning component comprises a right lifting air cylinder, a right lifting plate, a right telescopic air cylinder and a right positioning head. The device is compact in structure, convenient to use and high in automation degree, and can perform automatic positioning on an object to be drilled and single-faced or double-facedslotting; slotted holes of the double-faced slotting are symmetrical; the slotting quality is good; and the device can form the slotted holes at different inclination angles and is very convenient touse.

Owner:浙江德诺智能配件科技股份有限公司

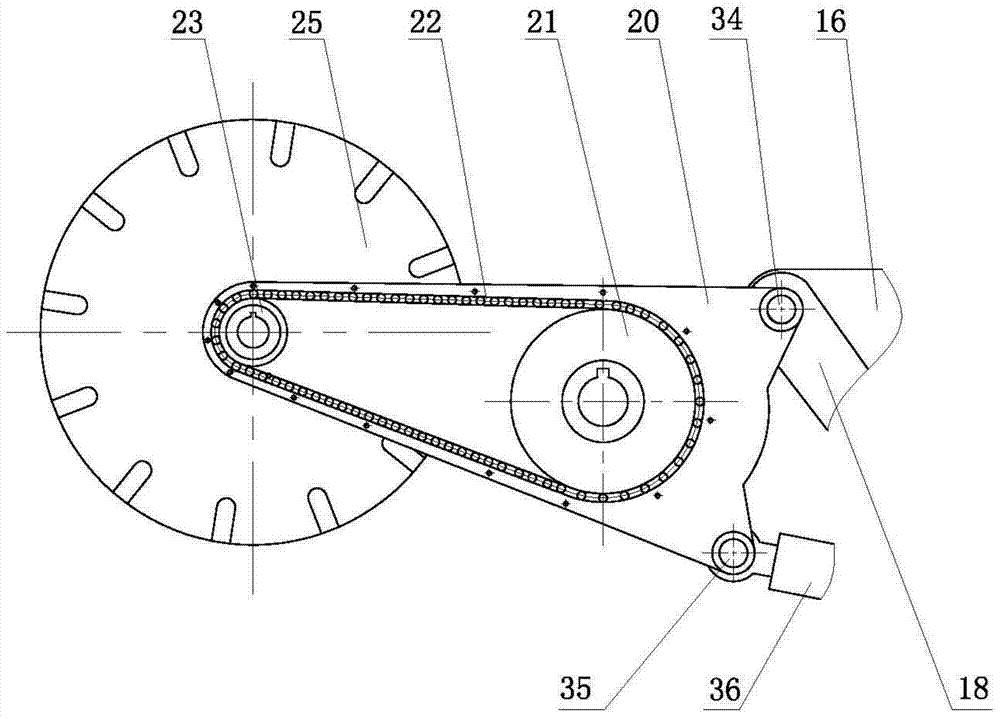

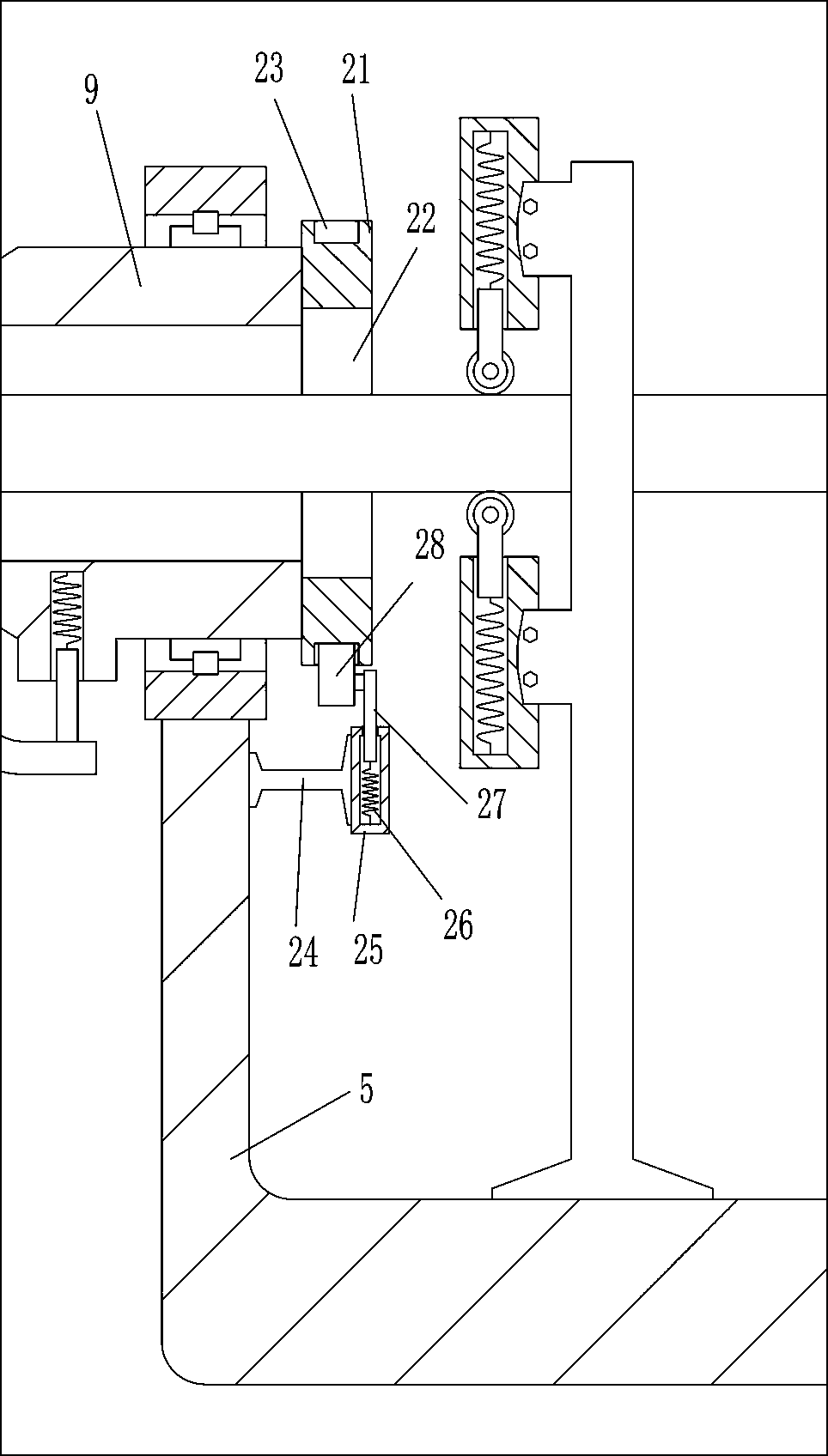

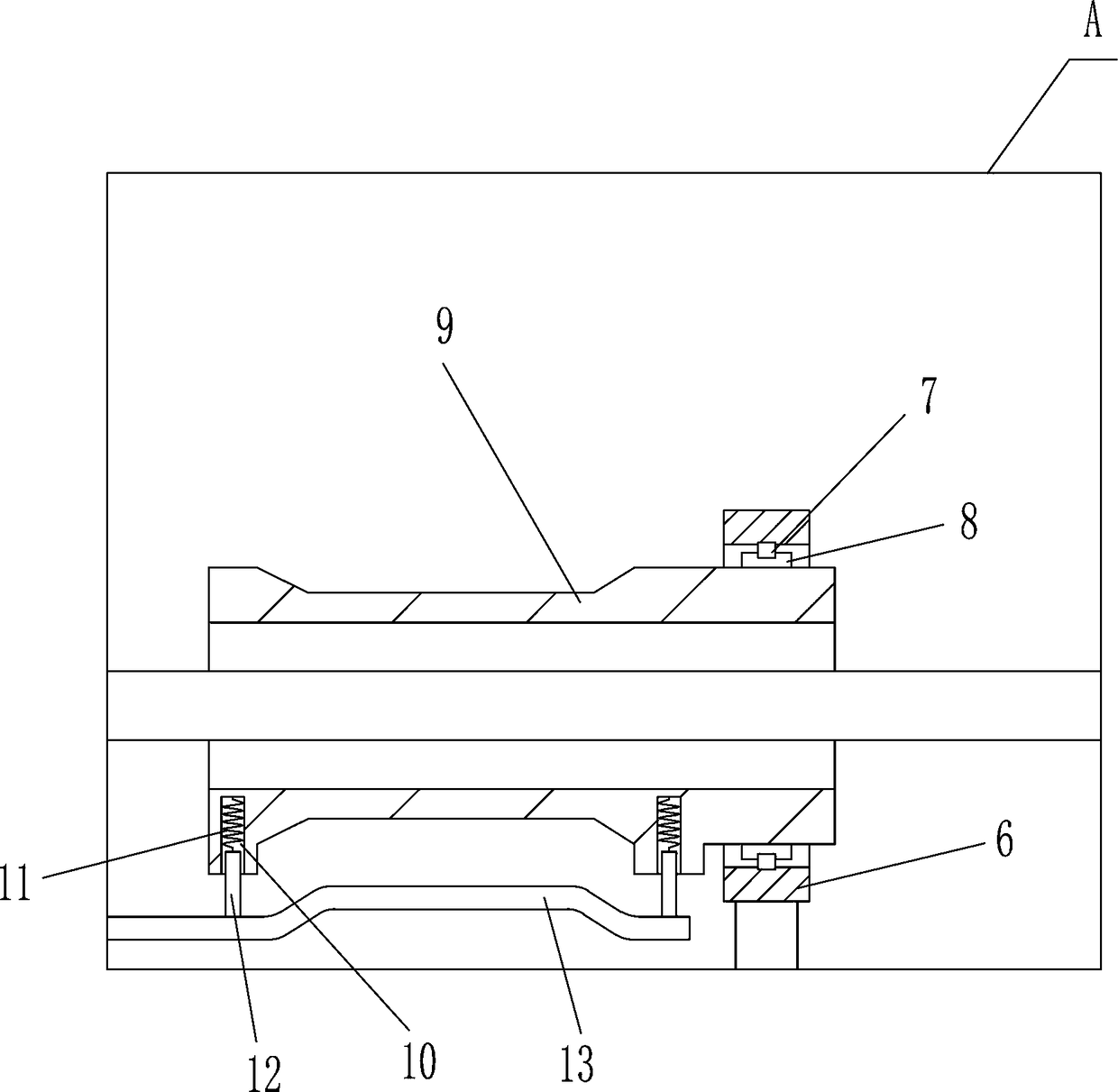

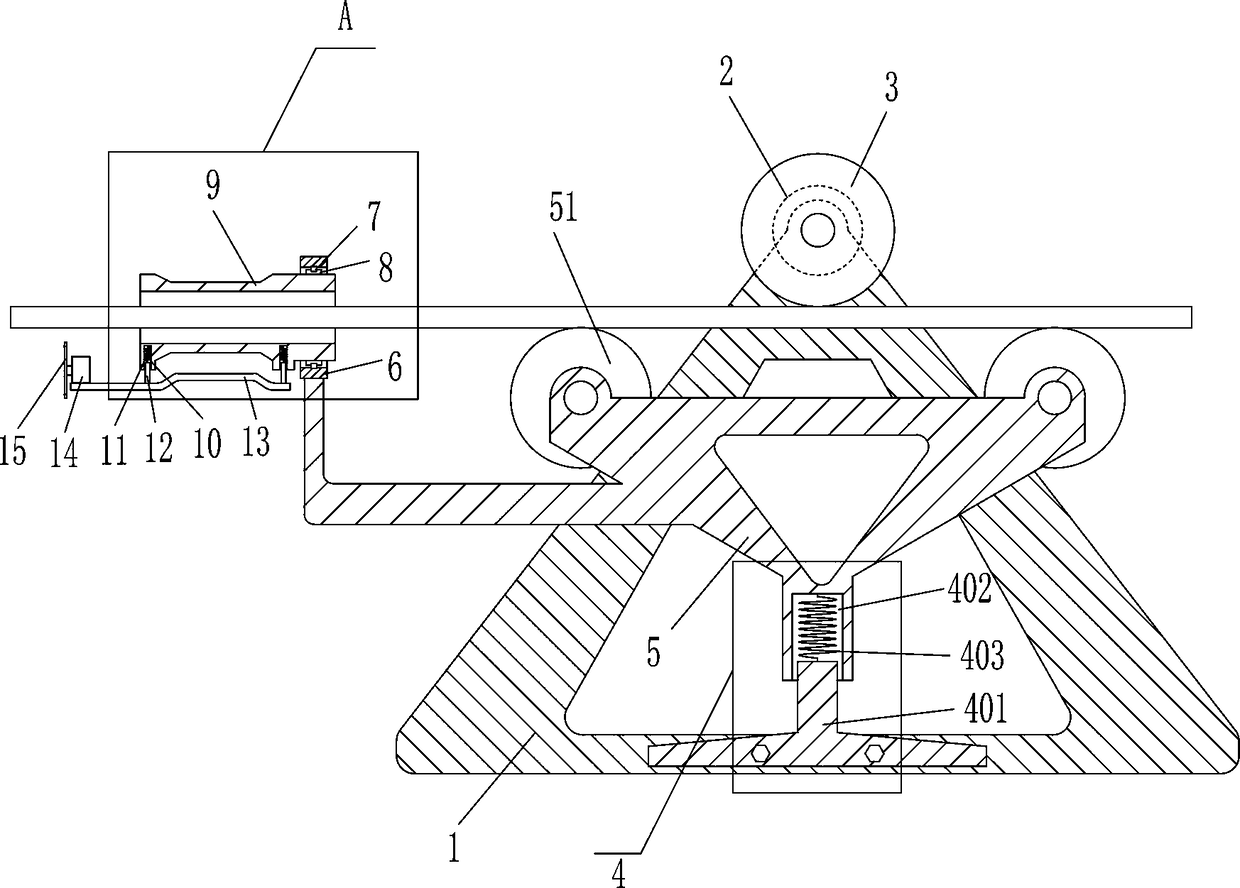

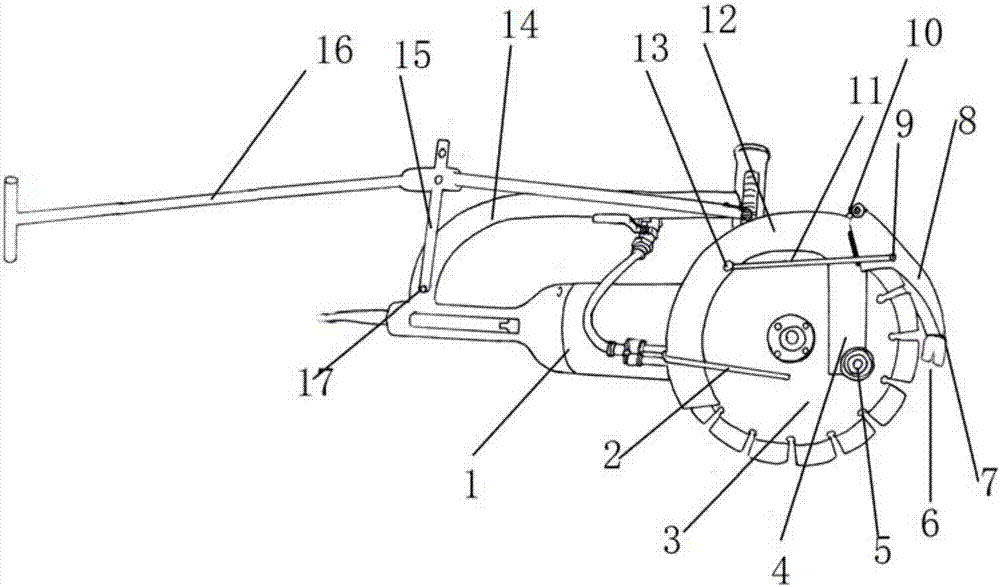

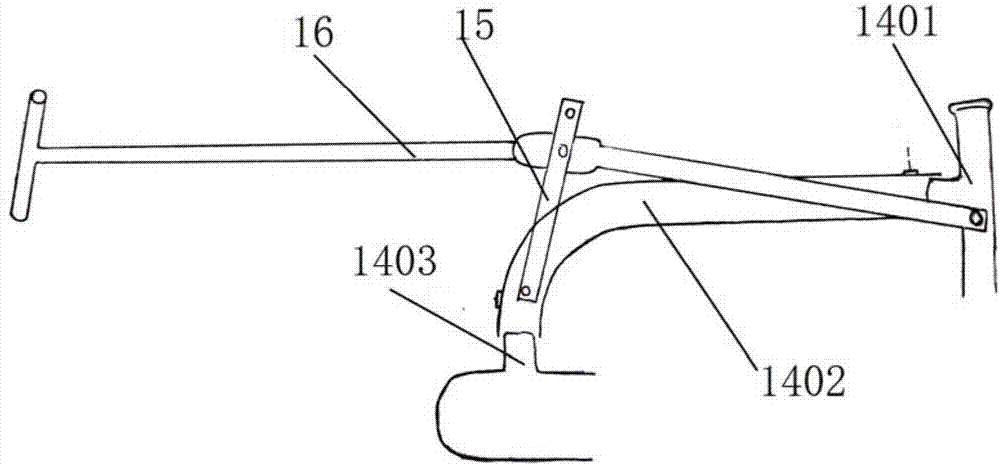

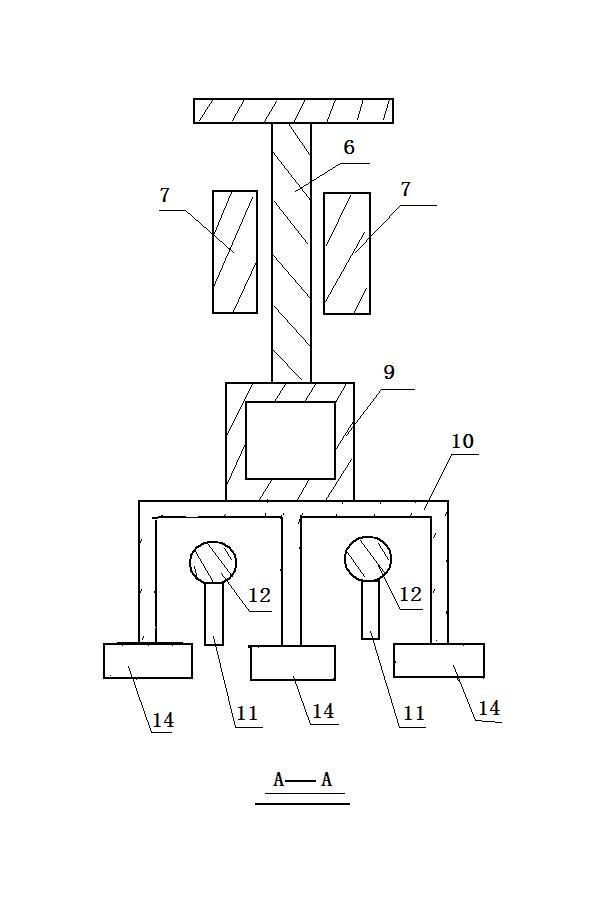

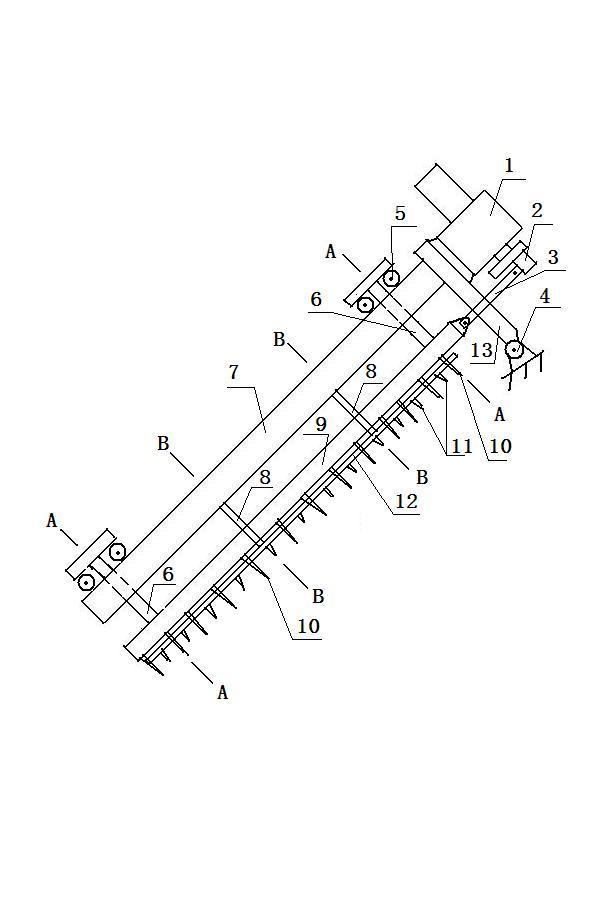

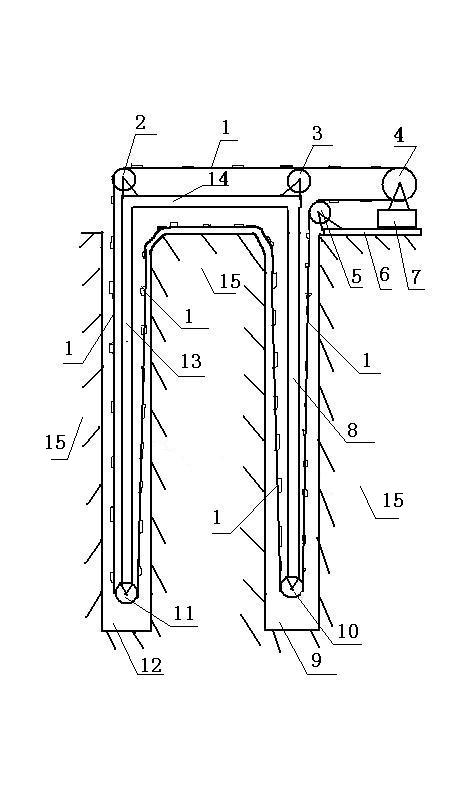

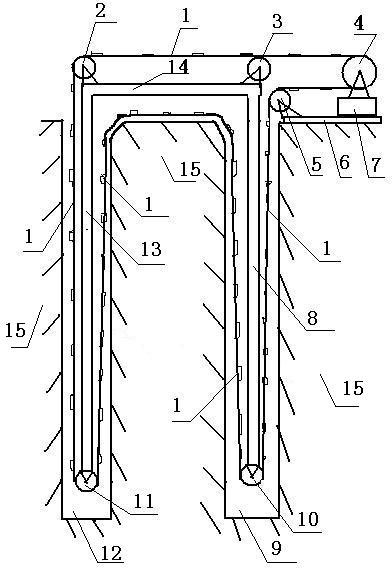

Dragging-saw grooving machine without sticking drill

ActiveCN102677719AImprove slotting efficiencySoil-shifting machines/dredgersArchitectural engineeringReducer

The invention relates to a dragging-saw grooving machine without sticking a drill, which is used for grooving an underground diaphragm wall. A reducer is fixedly arranged at the right end of a vertical arm, and the lower end of the reducer is provided with a crank. The crank is hinged at the right end of a support arm through a connecting rod, and the left end of the vertical arm is fixedly arranged at the support arm A. The lower ends of two pull rods are fixedly arranged at a support rod B, and the upper ends of the pull rods are hung on the support arm A through two idler wheels. The lower part of the support rod B is provided with two support rods C, and each support rod C is fixedly arranged on the support arm A through two connecting rods. The lower ends of the support rods C are provided with a plurality of cutter teeth B, and the lower end of the support rod B is provided with a plurality of cutter teeth A. The cutter teeth A adopt a reverse hill substructure, and the lower ends of the cutter teeth A are provided with blades. The cutter teeth A of the grooving machine move back and forth, and the cutter teeth B do not move among the cutter teeth A, so that the cutter teeth A and the cutter teeth B form relative movement, and soil cut by the cutter teeth A is removed by the cutter teeth B. The grooving efficiency is high, and a soil body with large stickiness can also be grooved.

Owner:中阳建设集团有限公司

Device capable of being positioned and used for conducting slotting on middle of wood board

PendingCN113263564AImprove slotting efficiencyMake sure to slotProfiling/shaping machinesWood mortising machinesServoEngineering

The invention relates to equipment for conducting slotting on the middle of a wood board, in particular to a device capable of being positioned and used for conducting slotting on the middle of the wood board. The device which does not need manual slotting, is high in machining efficiency and good in machining quality and is capable of being positioned and used for conducting slotting on the middle of the wood board is provided. The device capable of being positioned and used for conducting slotting on the middle of the wood board comprises a base, a supporting frame, a servo motor, a moving mechanism and a slotting mechanism, and the base is used for installing the whole device. The supporting frame is arranged on one side of the top of the base. The servo motor is arranged at the top of the supporting frame. The moving mechanism is arranged at the top of the base. The grooving mechanism is arranged on one side of the moving mechanism. Cooperation between a pressing mechanism and a positioning mechanism is adopted, the width of the wood board is adjusted by rotating the positioning mechanism, and meanwhile the wood board in the slotting process is pressed and fixed through cooperation with the pressing mechanism.

Owner:邱显斌

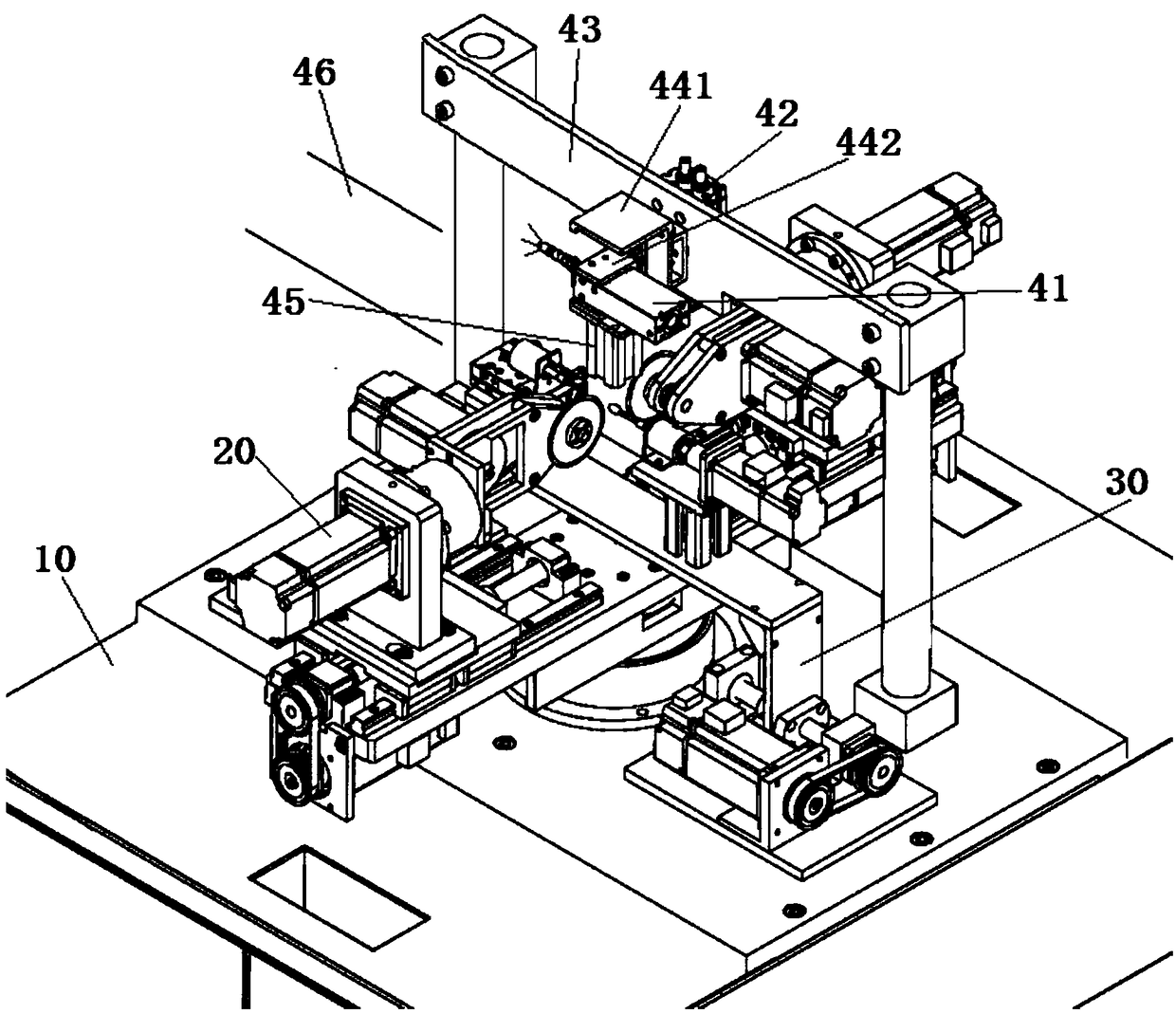

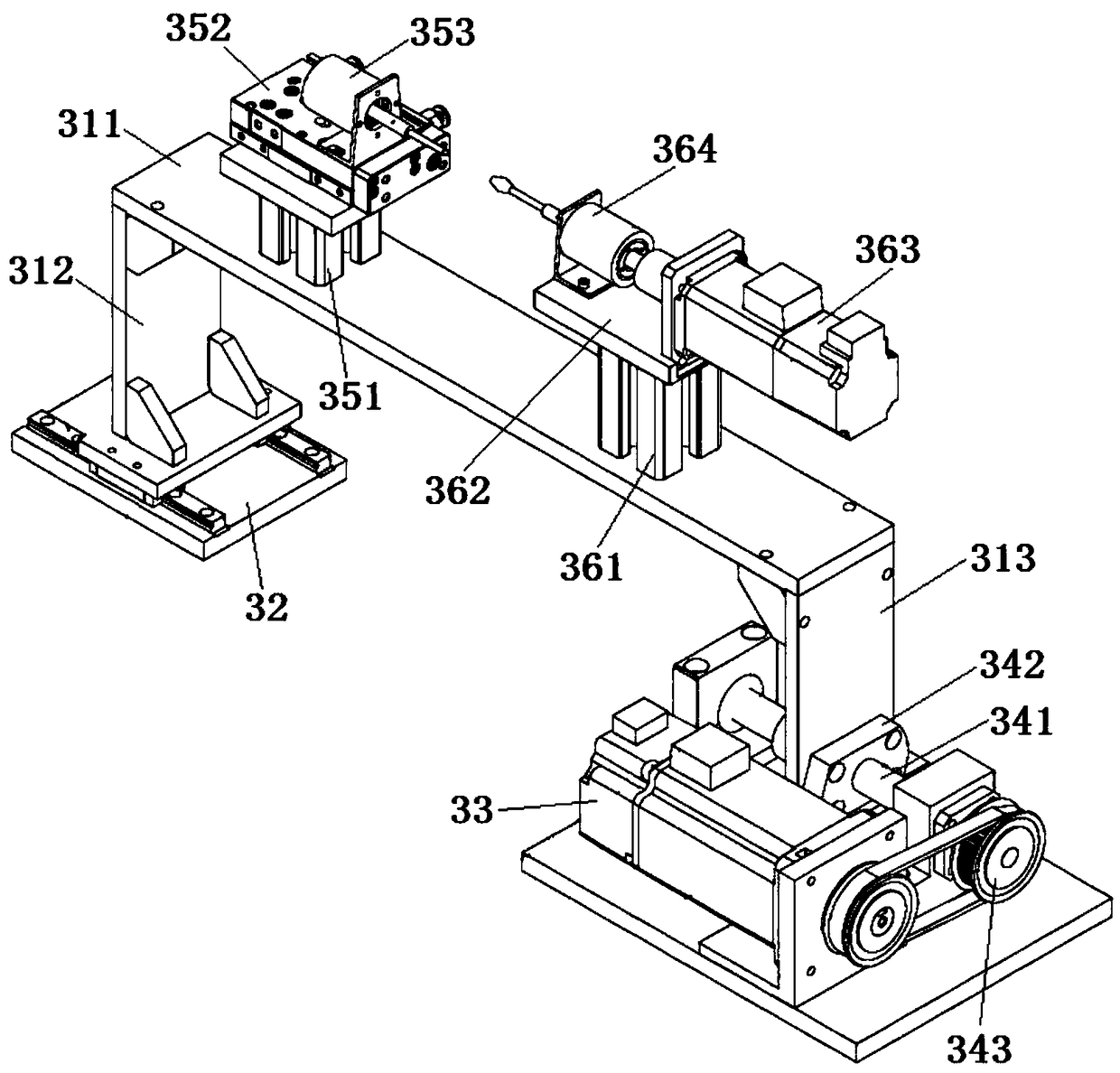

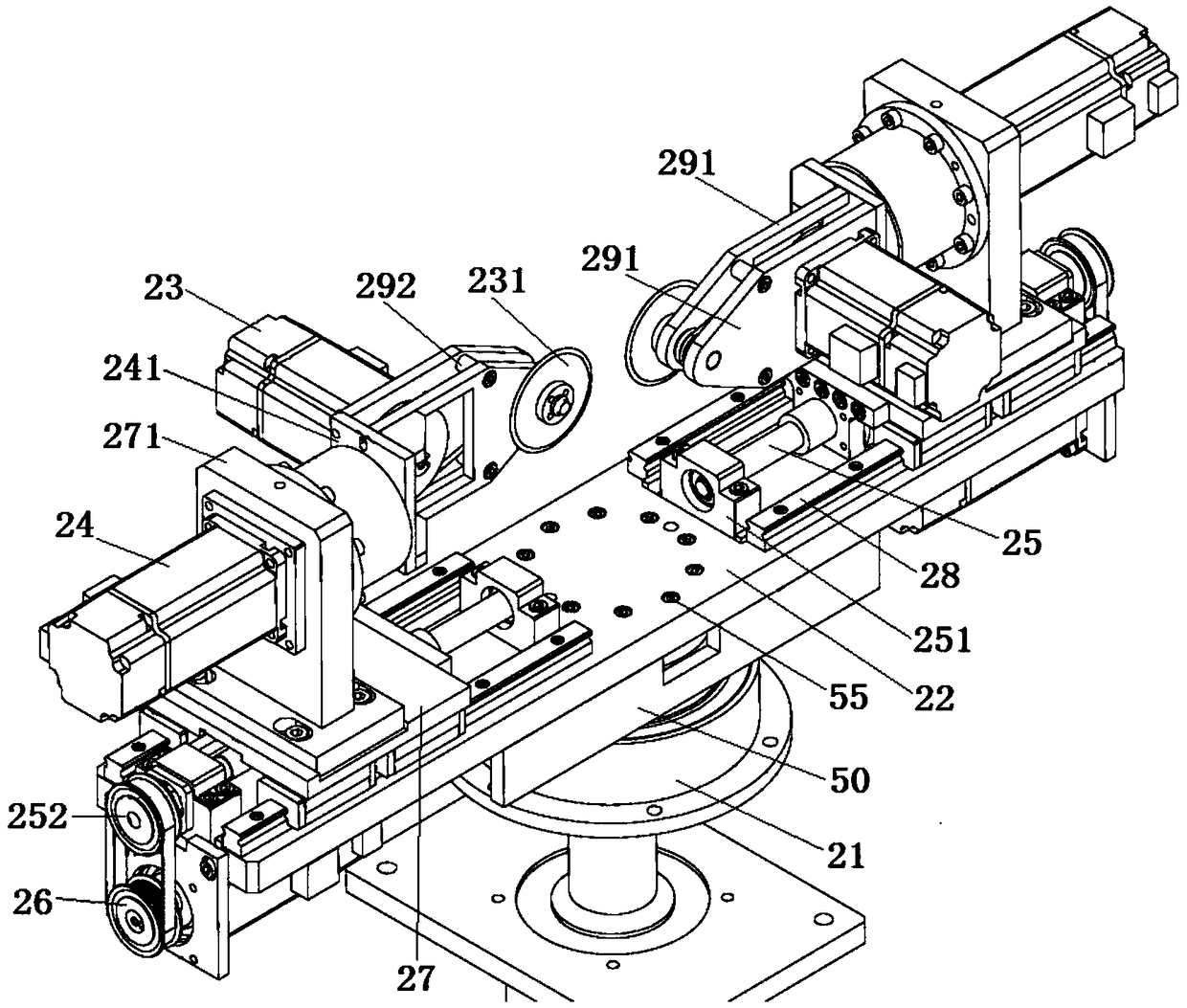

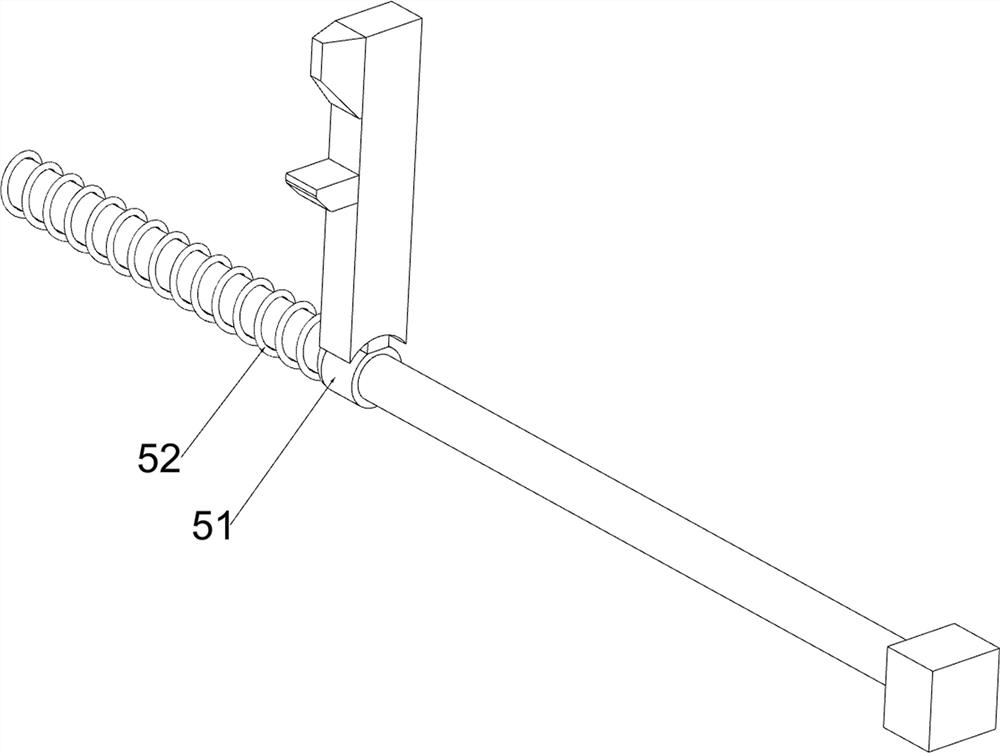

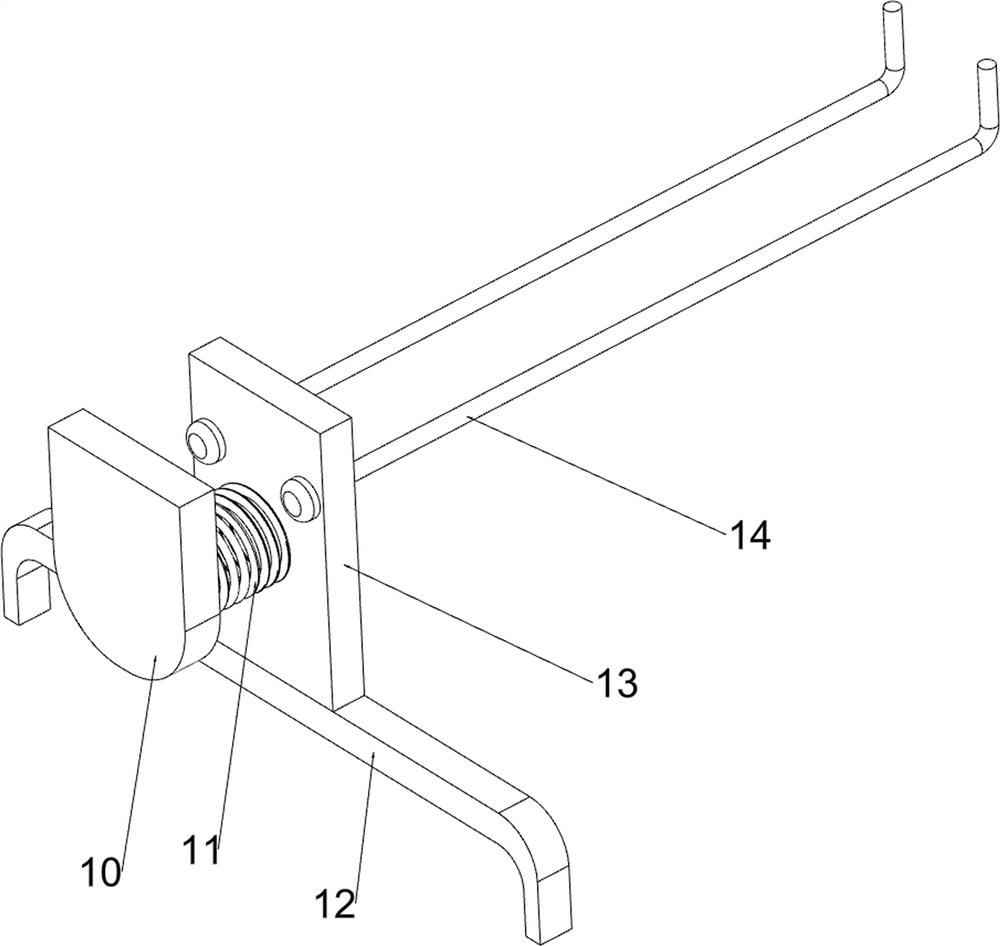

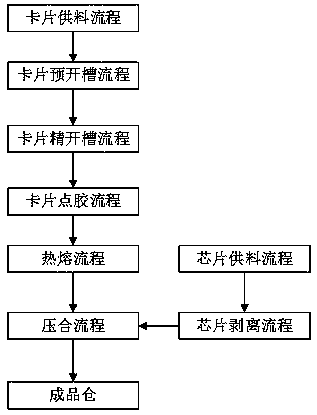

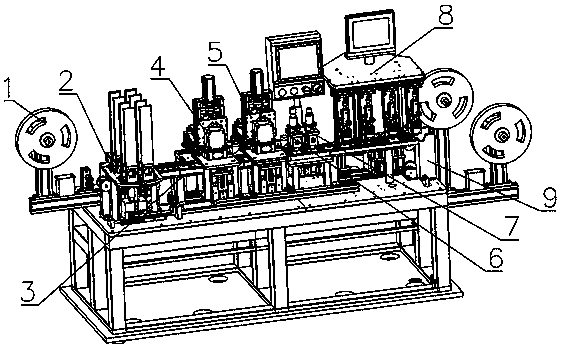

Production method for hot-melting implanting of IC card slotting chip

InactiveCN108960394AImprove efficiencyHigh precisionSemiconductor/solid-state device manufacturingRecord carriers used with machinesHot meltEngineering

The invention discloses a production method for hot-melting implanting of an IC card slotting chip. The production method comprises a card feeding flow, a conveying line flow, a chip feeding flow, a chip stripping flow, a card pre-slotting flow, a card pre-slotting flow, a card fine-slotting flow, a card dispersing flow, a hot melting flow, and a pressing flow. The conveying line flow is implemented all the time during the card feeding flow, the card pre-slotting flow, the card fine-slotting flow, the card dispersing flow, the hot melting flow, and the pressing flow. The chip stripping flow iscarried out continuously from the chip feeding flow; the card pre-slotting flow is carried out continuously after the card feeding flow; the card fine-slotting flow is carried out continuously afterthe card pre-slotting flow; the card dispersing flow is carried out continuously after the card fine-slotting flow; the hot melting flow is carried out continuously after the card dispersing flow; andthe pressing flow is carried out after the chip stripping flow and the hot melting flow. According to the invention, the production method has advantages of having the high automation degree, havinghigh stability, realizing continuous card production, improving the production efficiency, reducing the product reject ration, and saving the production costs and thus has the great market applicationvalue.

Owner:深圳市阿尓法智慧科技有限公司

Rock trenching machine and trenching method

InactiveCN102619248ASimple structureEasy to operateSoil-shifting machines/dredgersDrive wheelEngineering

The invention relates to a rock trenching machine and a trenching method for seepage resistance of rock cracks. The rock trenching machine comprises a trenching machine track and a trolley on the track, wherein a driving wheel is arranged on the trolley; a vertical rod A is arranged at the lower left end of a cross bar; a rotating wheel E is arranged at the lower end of the vertical rod A; a rotating wheel A is arranged at the upper end of the vertical rod A; a vertical rod B is arranged at the lower right end of the cross bar; a rotating wheel D is arranged at the lower end of the vertical rod B; a rotating wheel B is arranged at the upper end of the vertical rod B; a rotating wheel C is arranged at the left end of the track and the upper right end of a hole B; and a steel wire starts from the driving wheel, rounds the rotating wheel B, the rotating wheel A and the rotating wheel E, is cut into rocks and then enters the rotating wheel D and finally rounds the rotating wheel C and enters the driving wheel. When the rock trenching machine works, two holes are drilled in a rock to be trenched and then the vertical rod A and the vertical rod B of the trenching machine are implanted into the holes; the steel wire winds around the rotating wheels and the driving wheel; and the driving wheel is driven to drive the steel wire to rotate and cut the rocks to form a trench.

Owner:海力控股集团有限公司

Wall slotting device for interior decoration

ActiveCN111469286ASimple structureEasy to implementWorking accessoriesStone-like material working toolsClassical mechanicsElectric machinery

The invention discloses a wall slotting device for interior decoration, and mainly relates to the field of interior decoration. The wall slotting device for interior decoration comprises a sliding frame, wherein a slotting support is slidably connected onto the sliding frame; a slotting motor is arranged on the slotting support; and a slotting blade is fixed onto an output shaft of the slotting motor. The wall slotting device for interior decoration is characterized in that connecting plates are symmetrically and rotatably connected to one side of the sliding frame; fixed shafts are arranged at one ends of the connecting plates; guide pulleys are symmetrically and rotatably connected to two ends of the fixed shafts; a connecting rod is rotatably connected onto one fixed shaft; a sleeve pipe is rotatably connected onto the other fixed shaft; one end of the sleeve pipe is slidably connected to the outer part of the connecting rod in a sleeving way; a limiting block is movably connected onto the slotting support; one end of the limiting block is located on a motion path of the sleeve pipe; and telescopic support rods are symmetrically and rotatably connected to two ends of the slidingframe. The wall slotting device for interior decoration provided by the invention has the beneficial effects that the control on the wall slotting depth quantization is improved, the slotting qualityis improved, and the protection on an inner pipeline is improved.

Owner:SHANDONG JIAOTONG UNIV

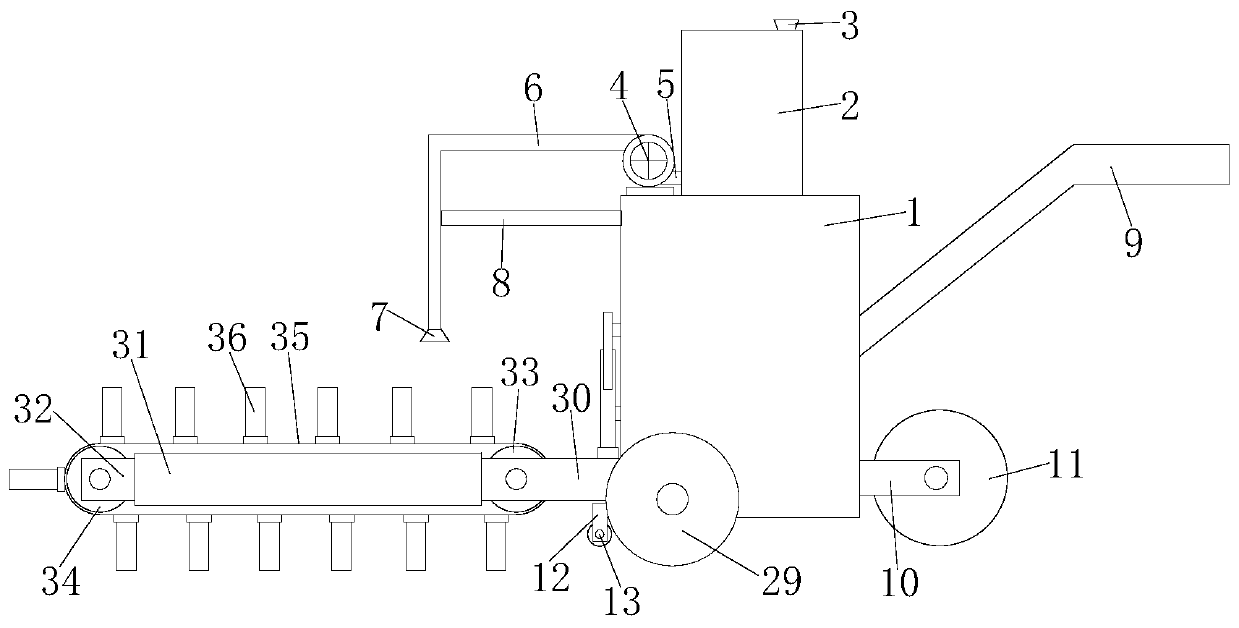

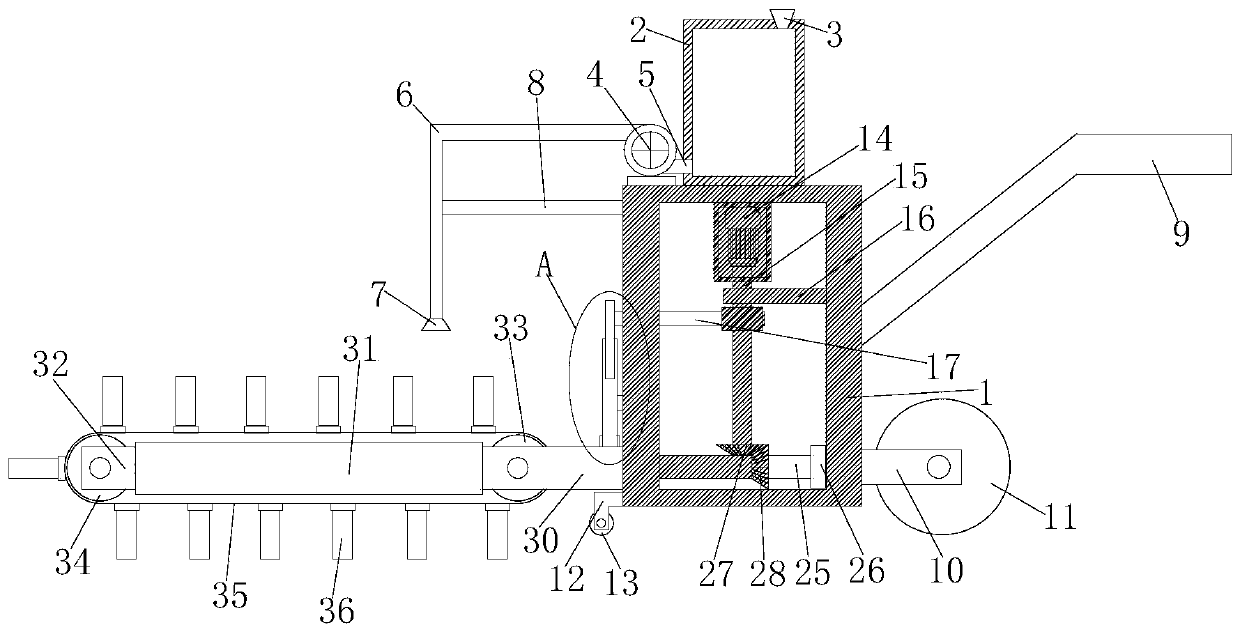

Irrigation and water conservancy construction slotting equipment

InactiveCN111364542AReduce hardnessAvoid damageSoil-shifting machines/dredgersIrrigation ditchesSprayerWater spray

The invention belongs to the technical field of irrigation and water conservancy equipment, and particularly relates to irrigation and water conservancy construction slotting equipment. The irrigationand water conservancy construction slotting equipment comprises a box body. A water tank is fixedly installed on the top of the box body. A water inlet is formed in the top of the water tank. A waterpump is fixedly installed on the top of the box body. A water pumping pipe and one end of a water outlet pipe are fixedly installed on the water pump. The water outlet pipe is fixedly installed on one side of the box body, and a sprayer is fixedly installed at the other end of the water outlet pipe. A handle is fixedly installed on one side of the box body. A first mounting plate is fixedly installed on one side of the box body, and a first guide pulley is installed on the first mounting plate in a rotating mode. A second mounting plate is fixedly installed on the other side of the box body,and a second guide pulley is fixedly installed on the second mounting plate. According to the irrigation and water conservancy construction slotting equipment, manual slotting is avoided, and time andlabor are saved; moreover, a vibration device is arranged, soil bonding is effectively prevented, and slotting efficiency and quality are greatly improved; and a water spraying device is further arranged, soil is made humid and softened, the phenomenon that the soil is too hard to damage a slotting rod is prevented and the service life of the slotting equipment is prolonged.

Owner:王小珍

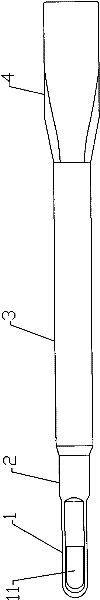

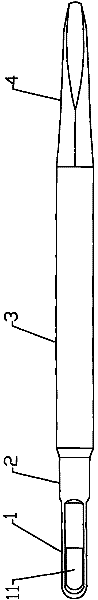

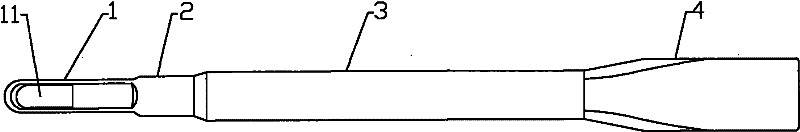

Pipeline slotter for wall

InactiveCN102191850AReduce labor intensityImprove slotting efficiencyBuilding constructionsElliptical recessBiomedical engineering

The invention provides a pipe slotter for a wall. The pipeline slotter comprises a fixed section, a transition section, an extension section and an end which are fixedly connected into a whole in sequence, wherein the fixed section is in the shape of a square column; an oval groove is arranged on each surface of the square column so as to fix the square column on an electric hammer; the diameter of the transition section is larger than that of the fixed section and the transition section is cylindrical; the diameter of the extension section is larger than that of the transition section and the extension section is also cylindrical; and the end is provided with double blades and the width of the end is larger than the diameter of the extension section. The pipeline slotter has the beneficial effects of improving the slotting efficiency by more than 5 times and reducing the labor intensity of workers.

Owner:山东金柱集团有限公司

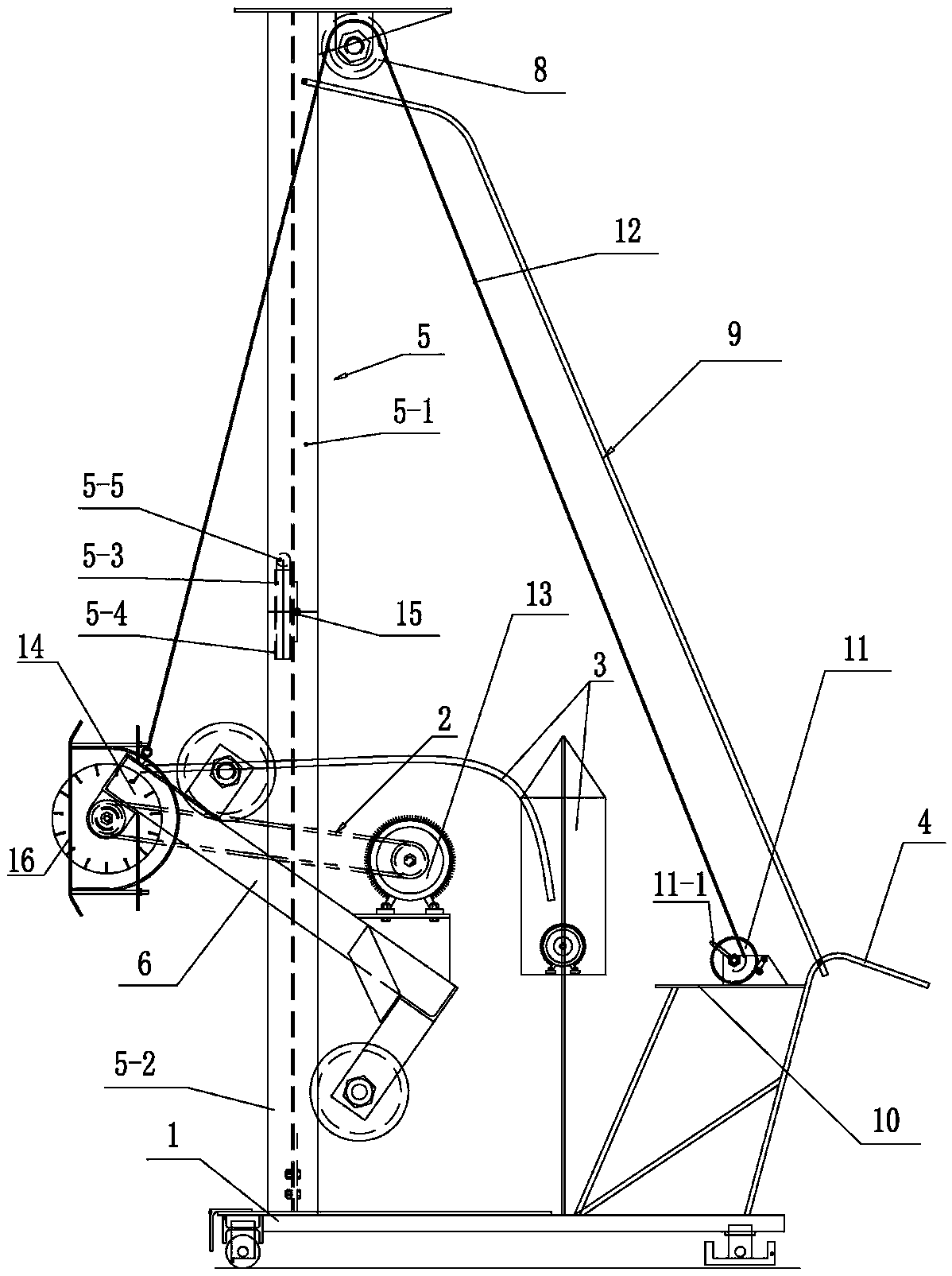

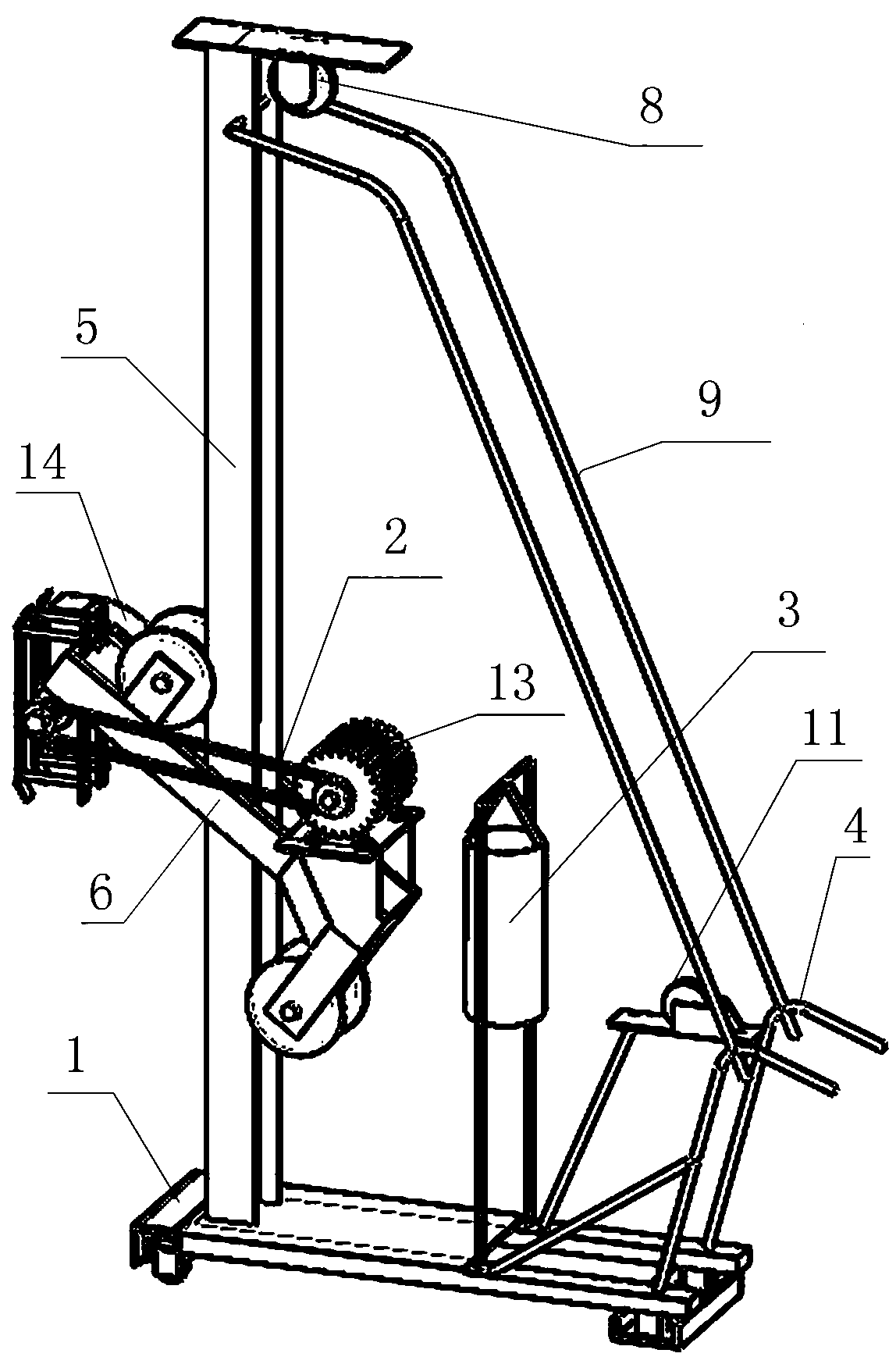

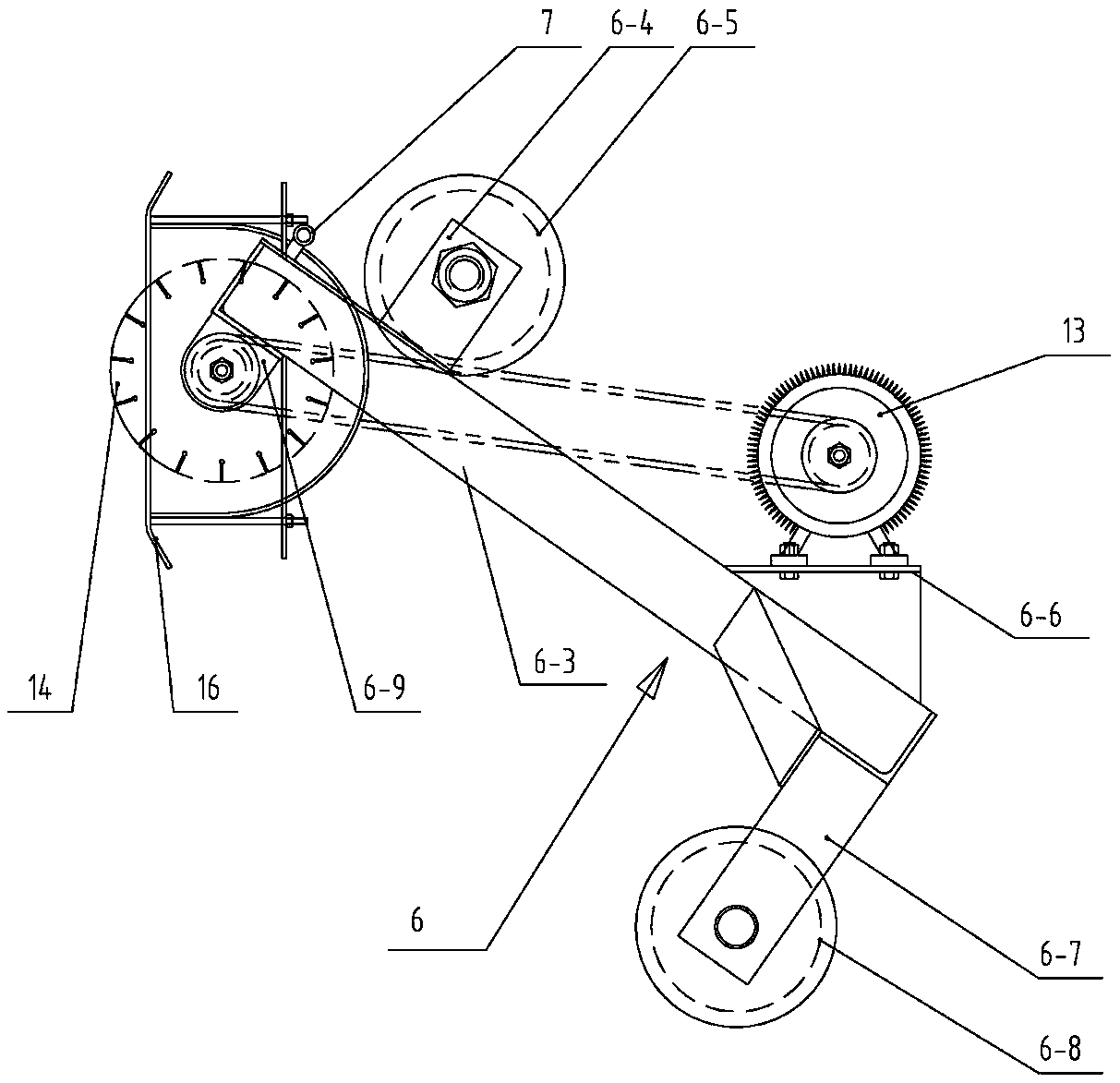

Wall pipeline slotting machine

The invention relates to a wall pipeline grooving machine which comprises a moving vehicle body, a grooving work part and a water spraying and dust removing device. The wall pipeline grooving machine further comprises a moving mechanism formed by an I-shaped steel climbing column, a climbing frame, a ratchet mechanism, a steel cable and a fixed pulley together. The grooving work part is mounted on the climbing frame, and the climbing frame can vertically move on the I-shaped steel climbing column through the traction of the ratchet mechanism and the steel cable. The I-shaped steel climbing column can be stretched or folded for use. The I-shaped steel climbing column is well fixed according to the floor height of a room, a switch on an equipment and switch mounting panel is turned on, the grooving work part works while the water spraying and dust removing device makes a wall body moist, the ratchet mechanism is operated to drive the climbing frame to move upwards along the I-shaped steel climbing column, and a blade of the grooving work part cuts along the wall body to carry out wall grooving operation under the situation of no environmental pollution. The wall pipeline grooving machine provided by the invention is reasonable in structure, stable in overall work, simple to operate, high in grooving efficiency, orderly and standard in grooving, straight and attractive in grooving, and consistent in groove depth; by using the wall pipeline grooving machine provided by the invention, both time and labor are saved, and the project progress is quick.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

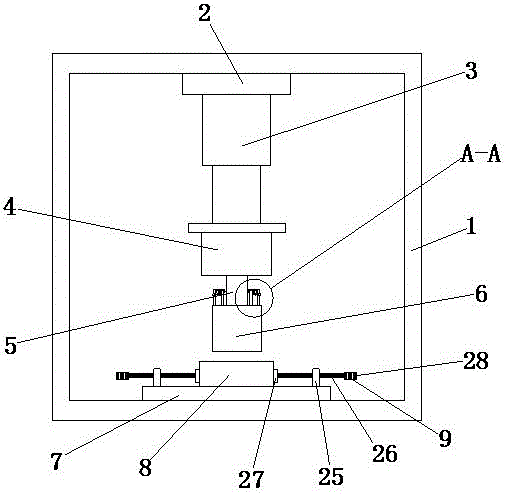

Grooving device for mold

The invention discloses a grooving device for a mold. The grooving device comprises a shell body. A pedestal is arranged at the top of the inner wall of the shell body. The bottom of the pedestal is fixedly connected with an electric pushing rod. The free end of the electric pushing rod is fixedly connected with a rotating motor through a connecting plate. A rotating shaft is arranged on the side, away from the connecting plate, of the rotating motor. The side, away from the rotating motor, of the rotating shaft is fixedly connected with a grooving box. A base is fixedly connected to the bottom of the inner wall of the shell body. A mold embryo body used cooperatively with the grooving box is fixedly installed at the top of the base, and clamping devices are symmetrically arranged on the two sides of the mold embryo body. According to the grooving device for the mold, a telescopic rod pushes a pushing plate to move downwards through the thrust produced by gas, accordingly, residues on the inner wall of the grooving box are removed, manual cleaning is not needed, the operation difficulty and the operation quantity of workers are reduced, the time and effort are saved, the grooving efficiency is improved, the grooving amount is increased, the applicability is high, and using of the grooving device by people is convenient.

Owner:CHANGZHOU JINCHENGYU HARDWARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com