Device capable of being positioned and used for conducting slotting on middle of wood board

A kind of equipment and wood board technology, which is applied in the field of equipment for slotting in the middle of wood boards, can solve problems such as product errors, waste products, hand shake slotting, etc., and achieve the effect of improving slotting efficiency, ensuring accuracy, and ensuring slotting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

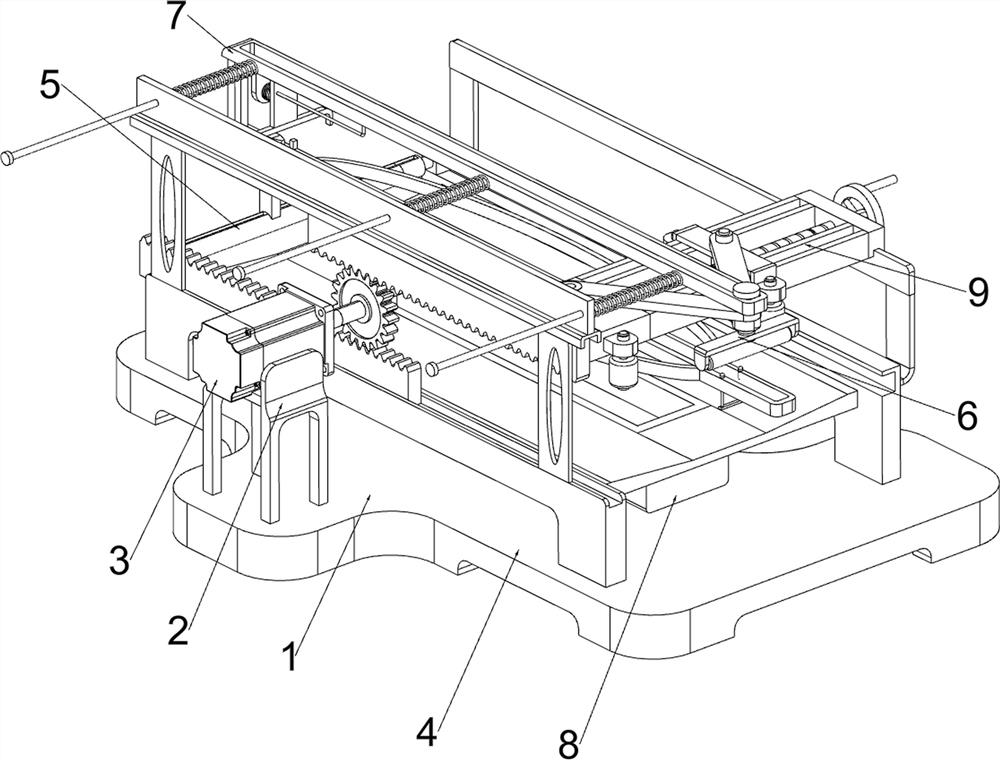

[0078] A device that can be positioned for slotting in the middle of a plank, such as figure 1 As shown, it includes a base 1, a support frame 2, a servo motor 3, a moving mechanism 4 and a slotting mechanism 5, a support frame 2 is provided on the front side of the top of the base 1, a servo motor 3 is provided on the top of the support frame 2, and a servo motor 3 is provided on the top of the base 1. There is a moving mechanism 4, and the left side of the moving mechanism 4 is provided with a slotting mechanism 5.

[0079] The staff puts the wooden board in the equipment, and then starts the servo motor 3 to work in the forward direction. The servo motor 3 drives the slotting mechanism 5 to move to the right through the moving mechanism 4, so as to slot the wooden board. After the slotting is completed, the servo motor 3 is started in reverse. The motor 3 works, thereby driving the slotting mechanism 5 to reset, and finally the servo motor 3 is closed, and the staff takes o...

Embodiment 2

[0081] On the basis of Example 1, such as Figure 2-4 As shown, the moving mechanism 4 includes a first guide rail 40, a first connecting plate 41, a second guide rail 42, a first rack 43, a second rack 44, a gear 45, a first guide plate 46 and a third guide rail 47, The front side of the top of the base 1 is provided with a first guide rail 40, the first guide rail 40 is symmetrically provided with a first connecting plate 41, and a second guide rail 42 is arranged between the tops of the first connecting plate 41, and a sliding type is provided in the first guide rail 40. The first rack 43, the second guide rail 42 is provided with a second rack 44, the output shaft of the servo motor 3 is provided with a gear 45, the gear 45 is meshed with the first rack 43 and the second rack 44, and the base 1 A third guide rail 47 is provided on the rear side of the top, and a first guide plate 46 is provided on the top of the third guide rail 47 .

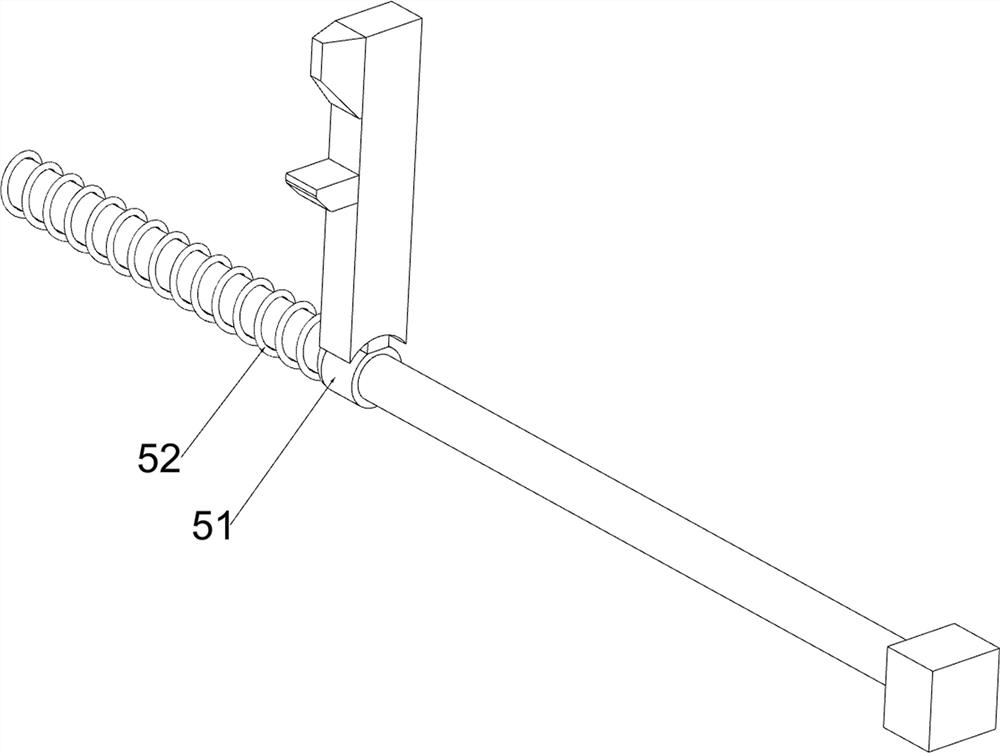

[0082] Grooving mechanism 5 comprise...

Embodiment 3

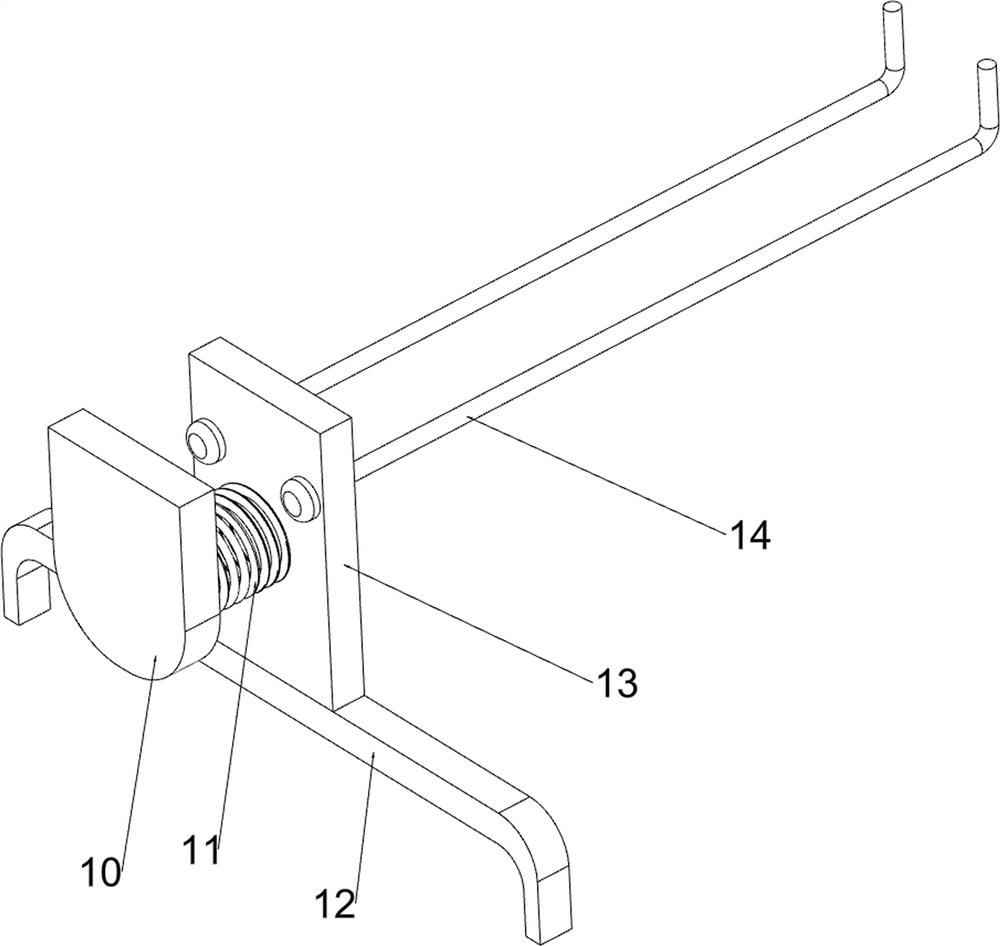

[0085] On the basis of Example 2, such as Figure 5-9 As shown, a guide mechanism 7 is also included, and the guide mechanism 7 includes a support rod 70, a second connecting rod 71, a second guide plate 72, a limit block 73, a block 74, a third spring 75, and a third guide plate 76 , the second connecting frame 77, the fourth spring 78 and the first guide rod 79, the second guide rail 42 upper sliding type is provided with three first guide rods 79, the third guide plate 76 is arranged between the first guide rods 79, the second Three fourth springs 78 are arranged between a guide rod 79 and the third guide plate 76, and the fourth springs 78 are all sleeved on the first guide rod 79, and a second connecting rod 71 is arranged symmetrically on the left side of the third guide plate 76. , a second guide plate 72 is provided between the bottom of the second connecting rod 71, a support rod 70 is provided on both sides of the second guide plate 72, a limit block 73 is arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com