Pipeline slotter for wall

A groover and wall pipe technology, which is applied in construction, building structure and other directions, can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing labor intensity and improving groove efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

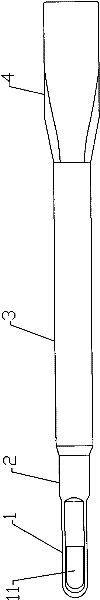

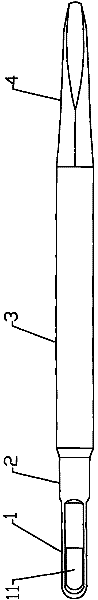

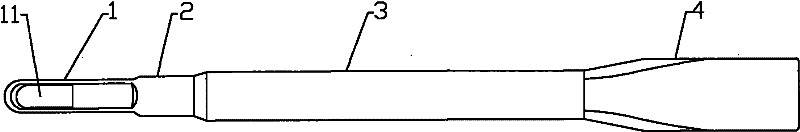

[0013] see figure 1 , 2 As shown, the present invention includes a fixed section 1, a transition section 2, an extension section 3 and a terminal 4; the fixed section 1, the transition section 2, the extension section 3 and the terminal 4 are sequentially fixedly connected as an integral structure; the described The fixed section 1 is in the shape of a square column, and each surface of the square column is provided with an elliptical groove 11 for fixing on an electric hammer; the diameter of the transition section 2 is 3 to 8 mm thicker than that of the fixed section 1 The diameter of the extension section 3 is 4 to 6 millimeters thicker than that of the transition section, and is also cylindrical; the end is double-edged, and the width is 3 to 8 millimeters larger than the diameter of the extension section.

[0014] Apparently, the above-mentioned embodiments of the present invention are only examples for clearly illustrating the present invention, rather than limiting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com