Patents

Literature

125 results about "Elliptical recess" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

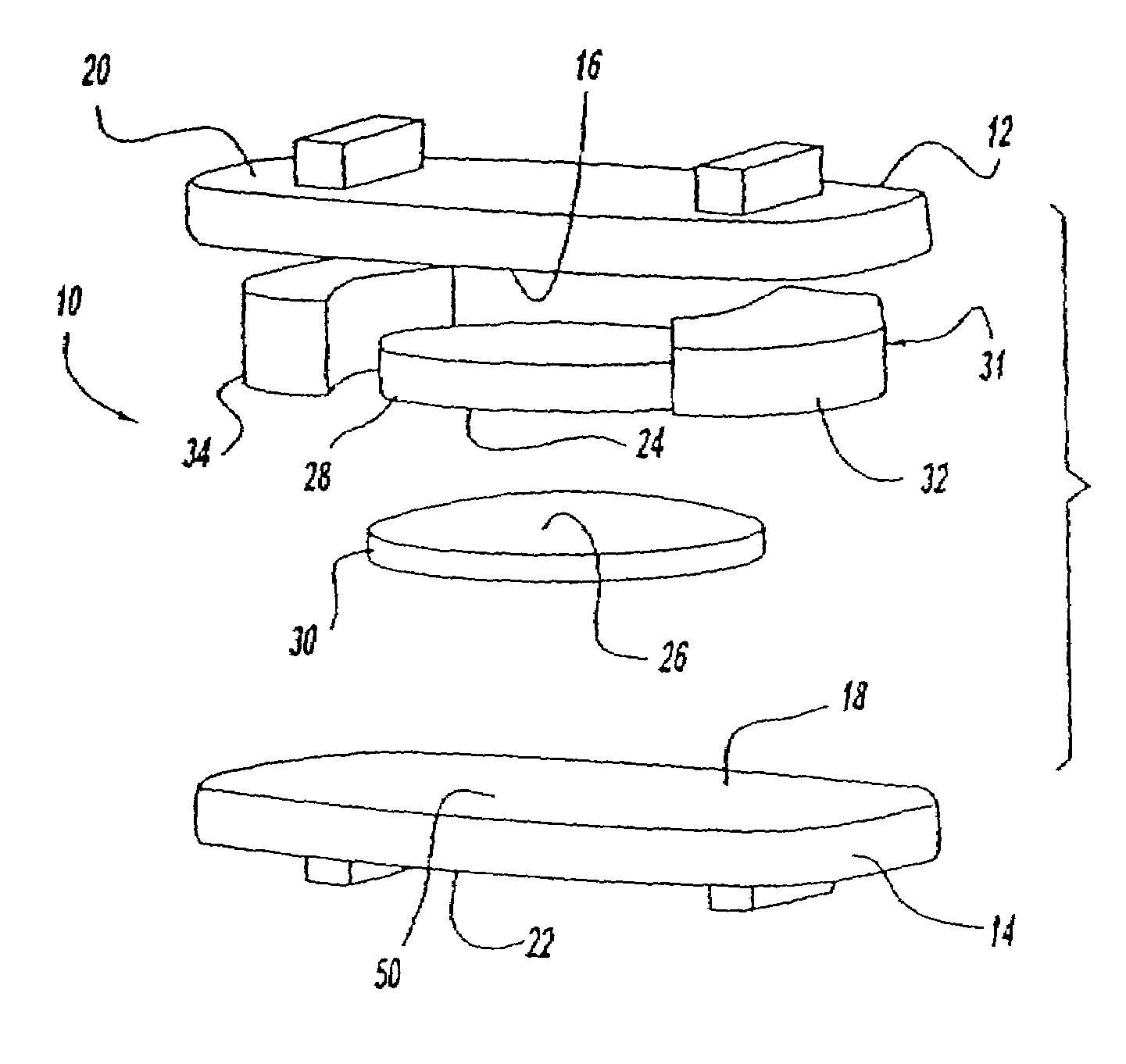

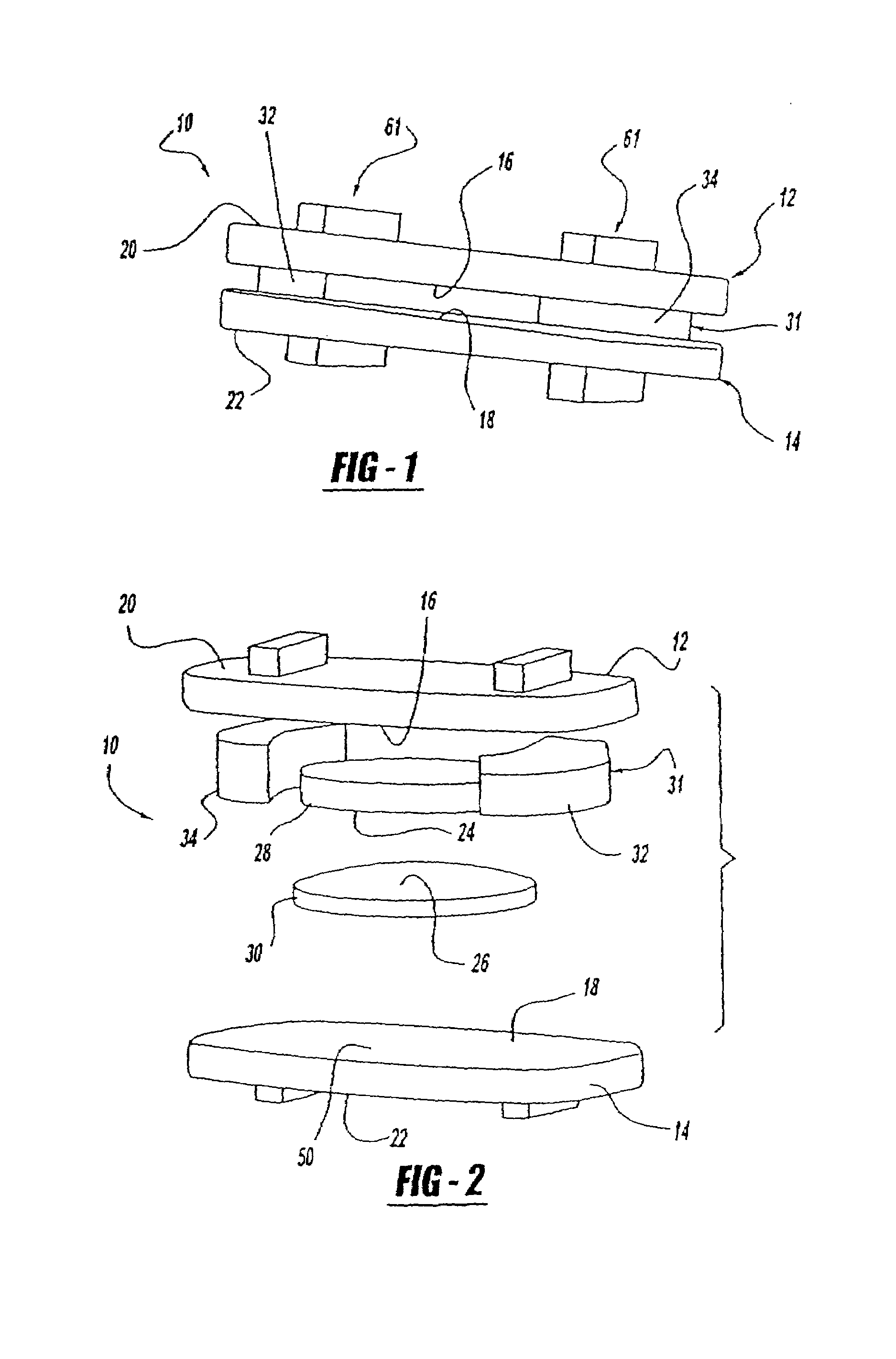

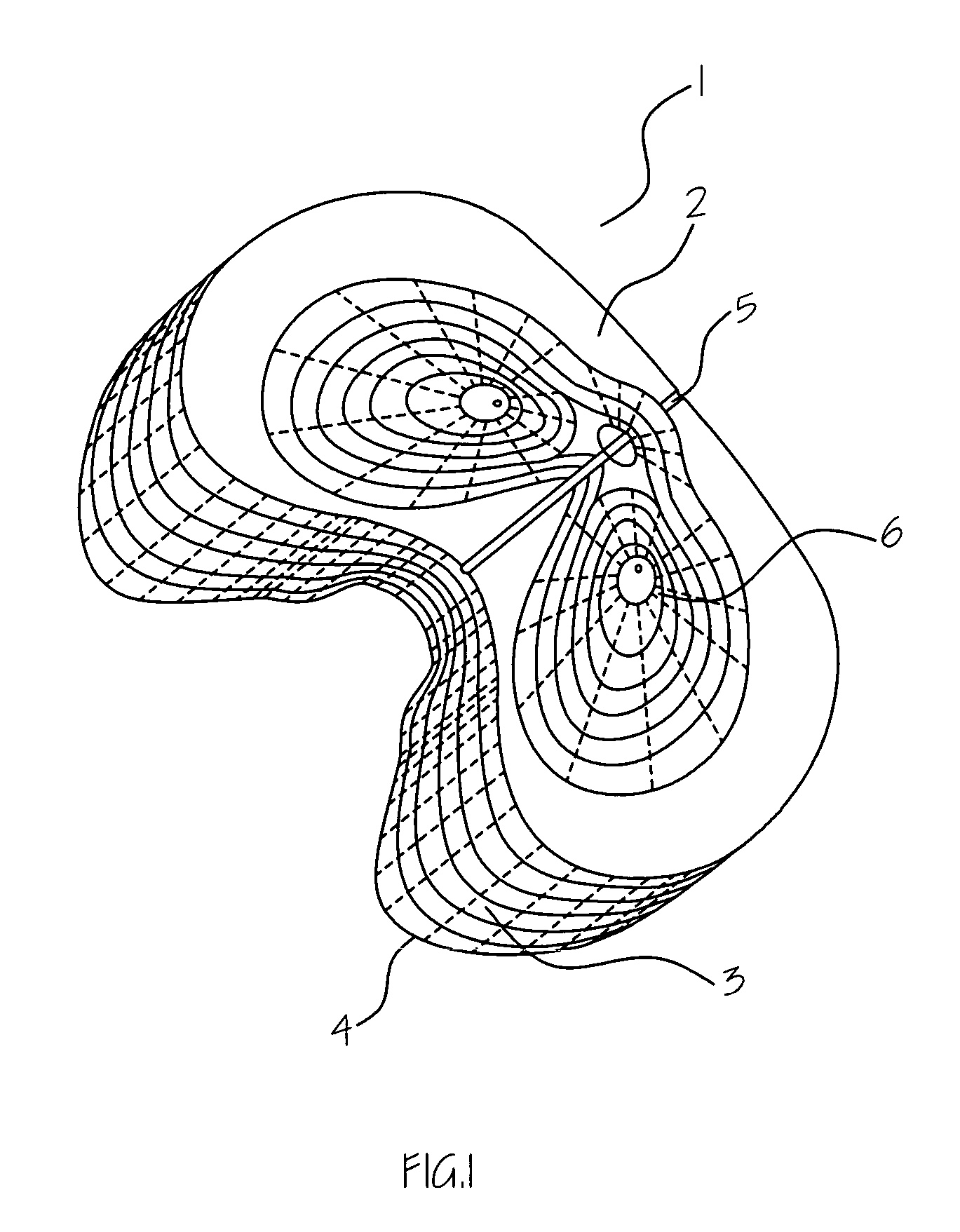

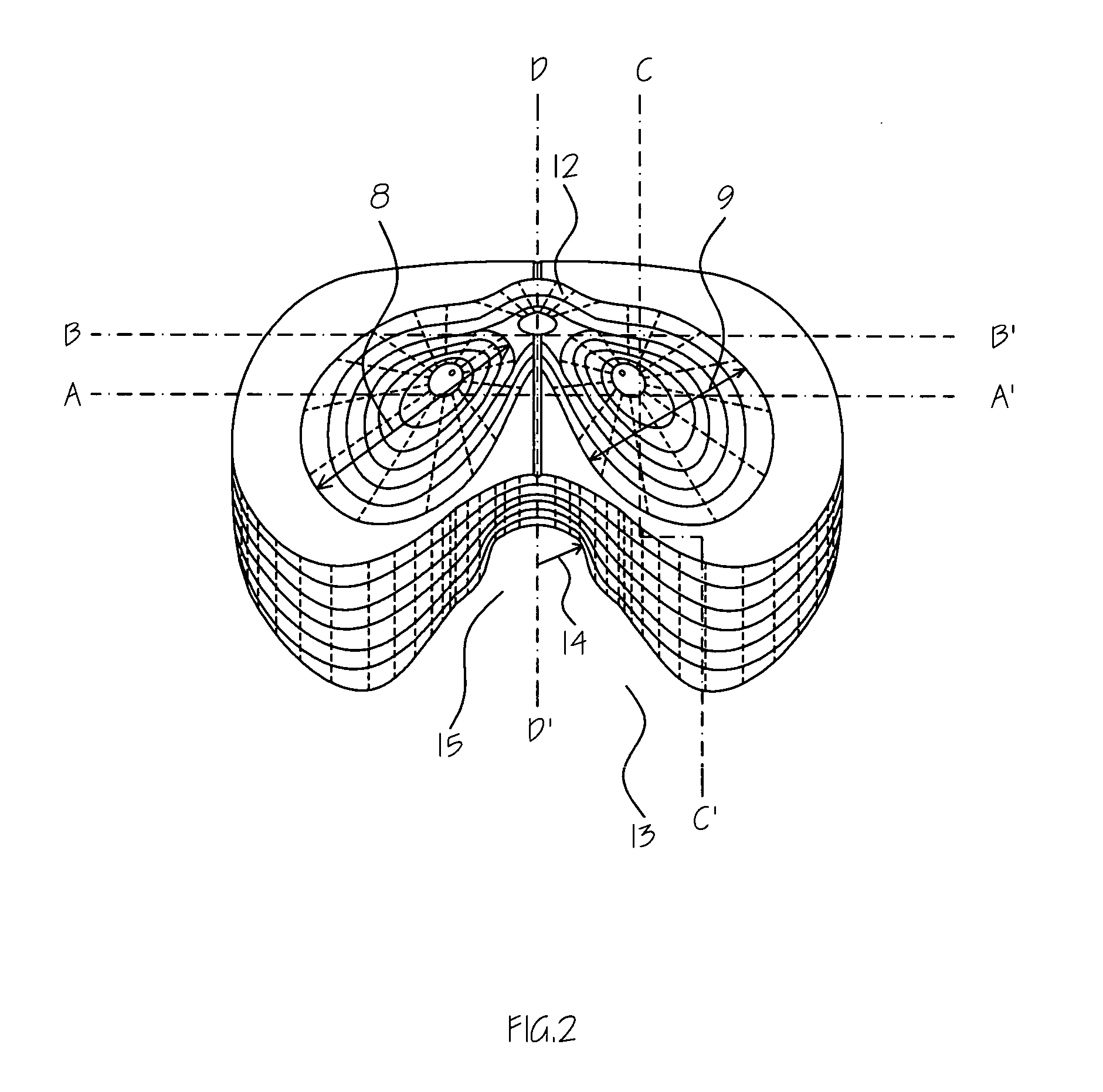

Artificial intervertebral disc

An artificial intervertebral disc including housing members including spaced inner surfaces facing each other and oppositely facing outer surfaces for engaging spaced apart intervertebral surfaces; self-adjusting bearing mechanisms operatively disposed between the inner surfaces for moving relative to the housing members to adjust and compensate for vertebral disc motion; and positioning ring for controlling motion and position of the bearing mechanisms and for absorption of compressive loads. An artificial intervertebral disc including housing members having an oval recess on the inner surfaces; oval bearing mechanisms operatively disposed within the oval recess between the inner surfaces for moving relative to the housing members to adjust and compensate for vertebral disc motion; and oval positioning ring. A spring member for an artificial intervertebral disc including a substantially annular body having an axially extended bore therethrough defining a passageway.

Owner:AESCULAP IMPLANT SYST

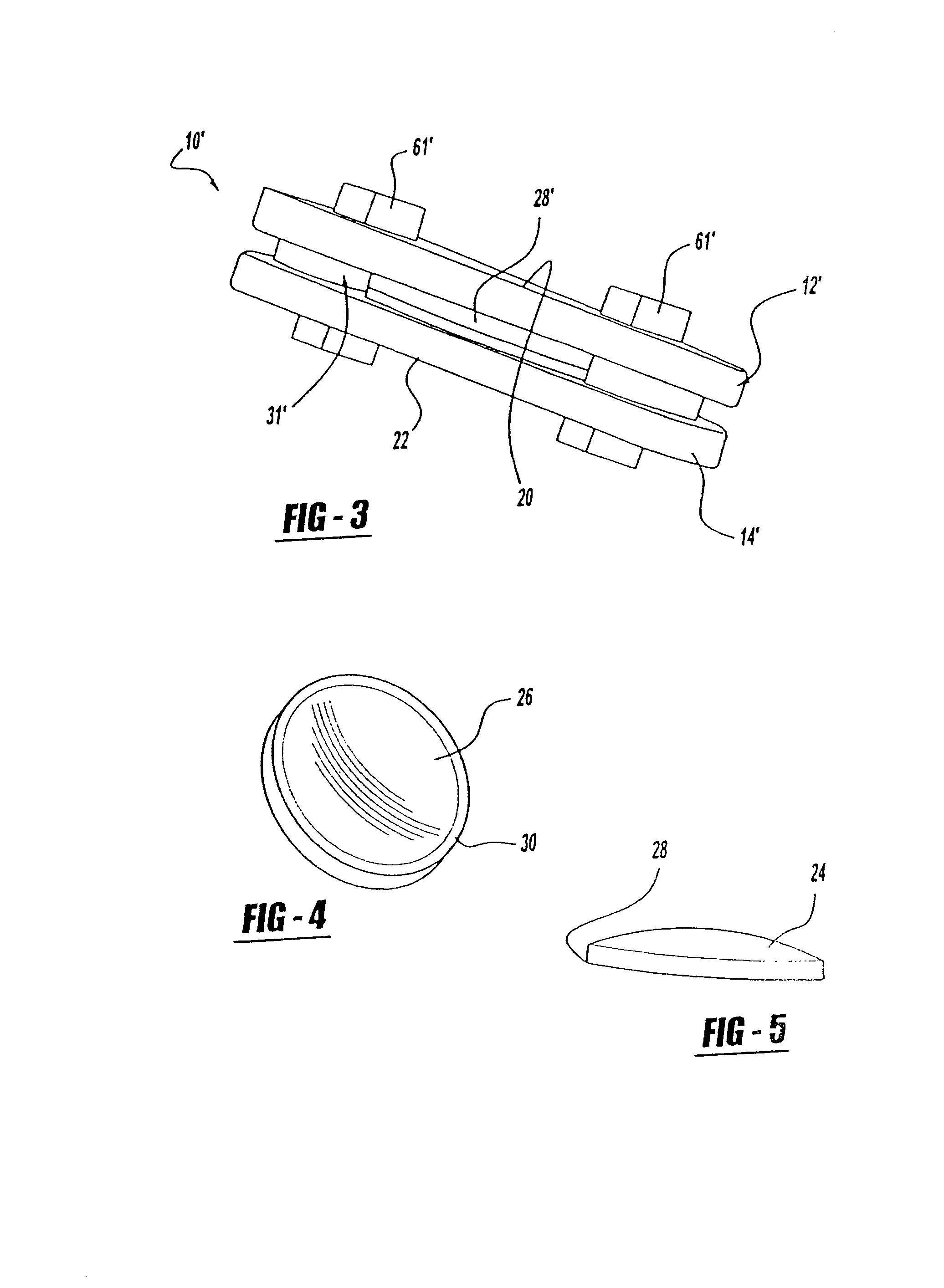

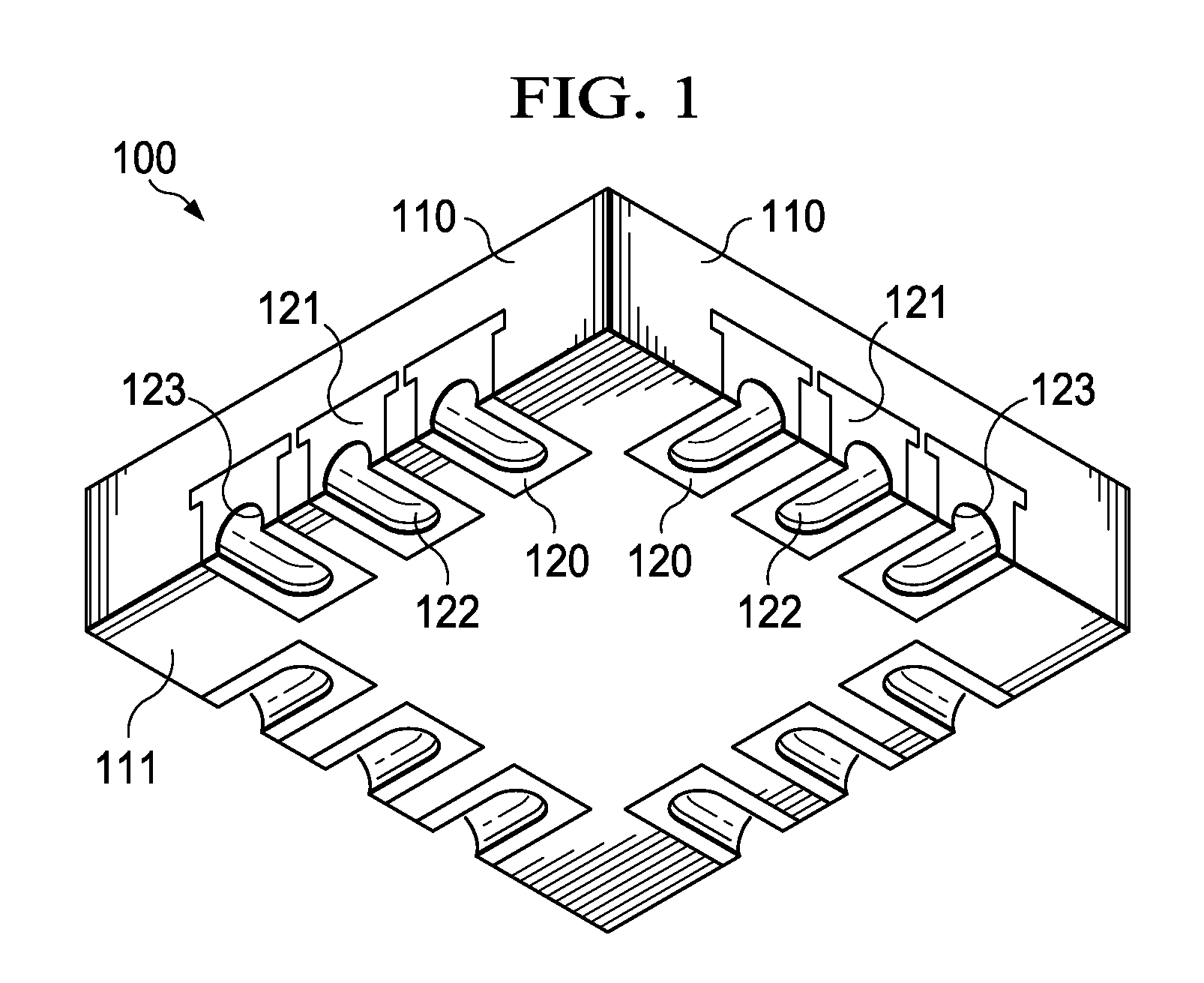

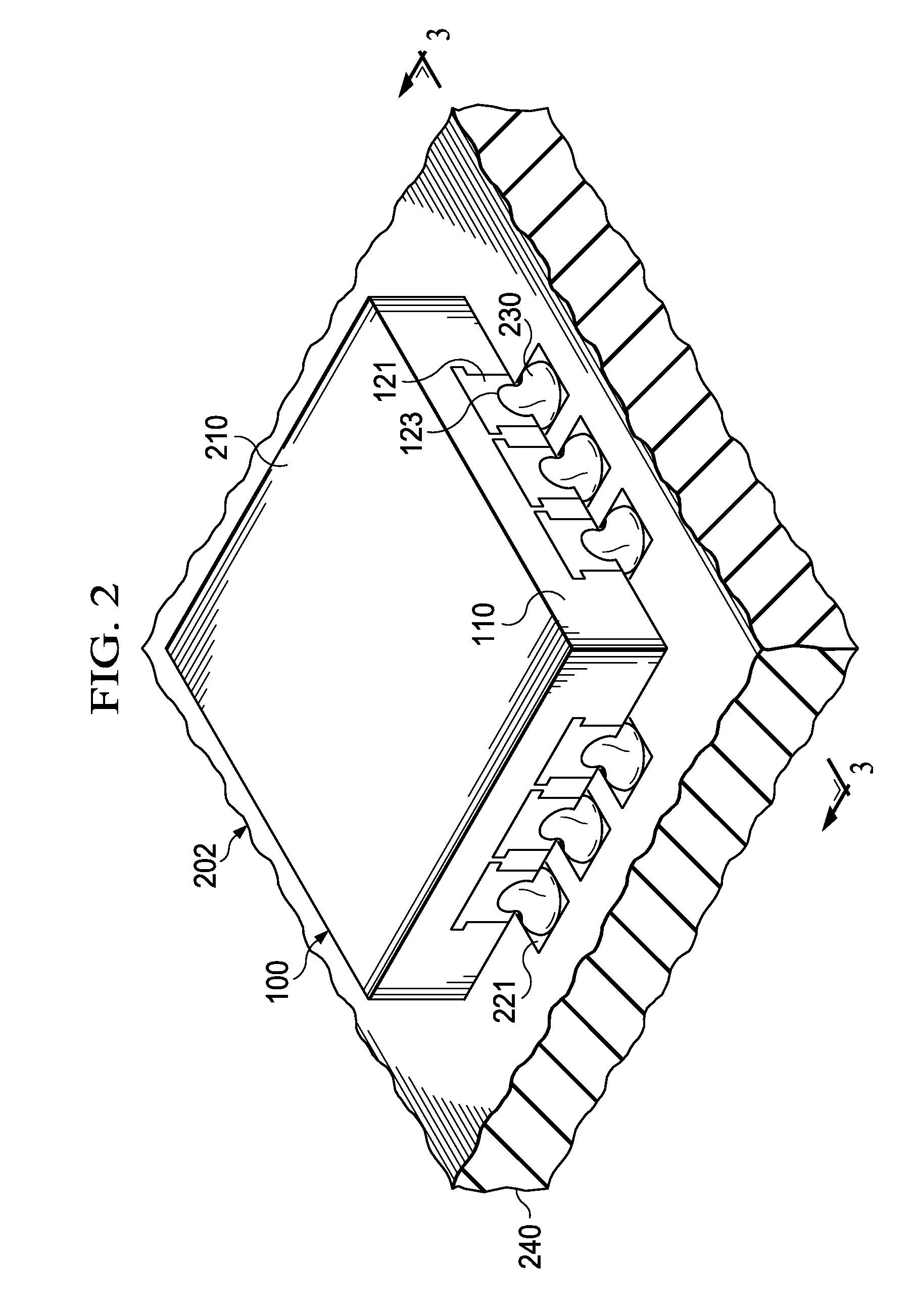

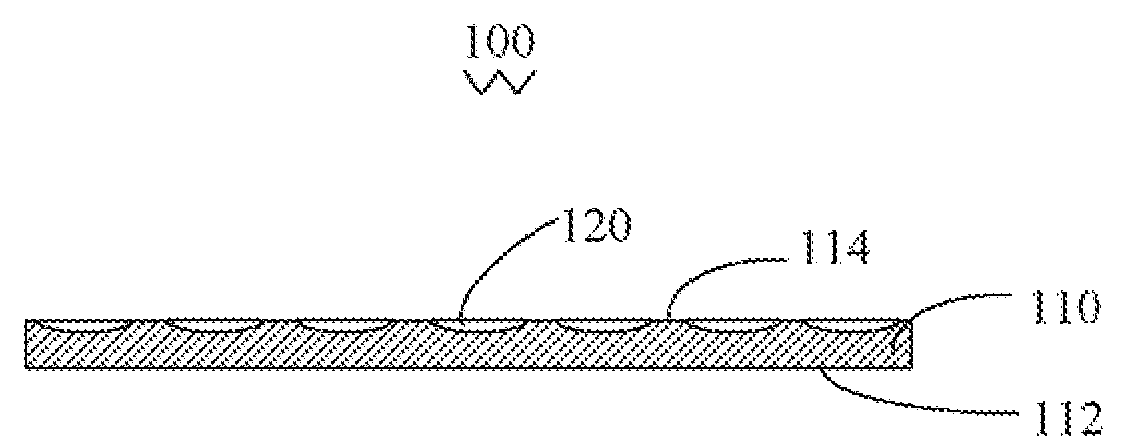

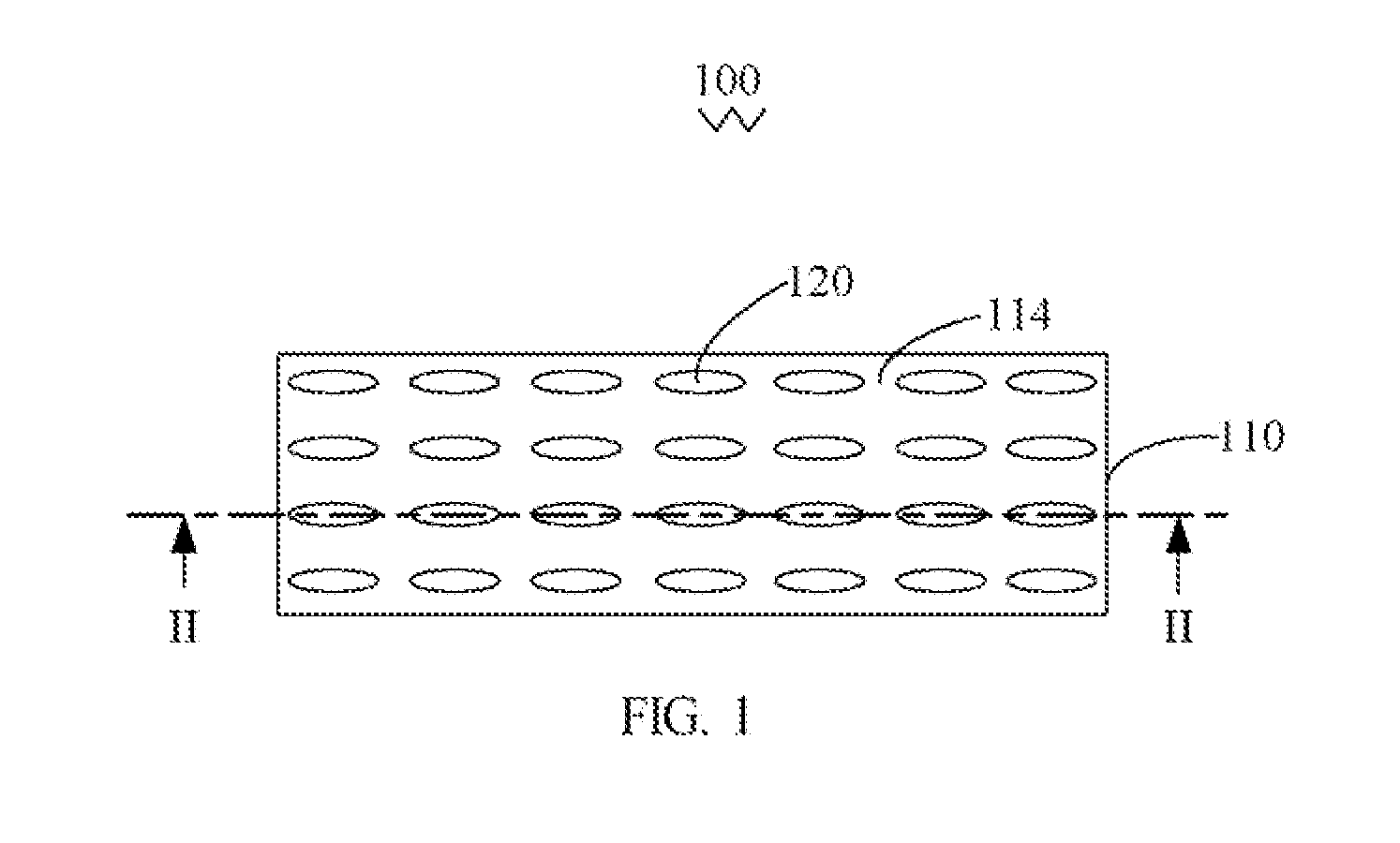

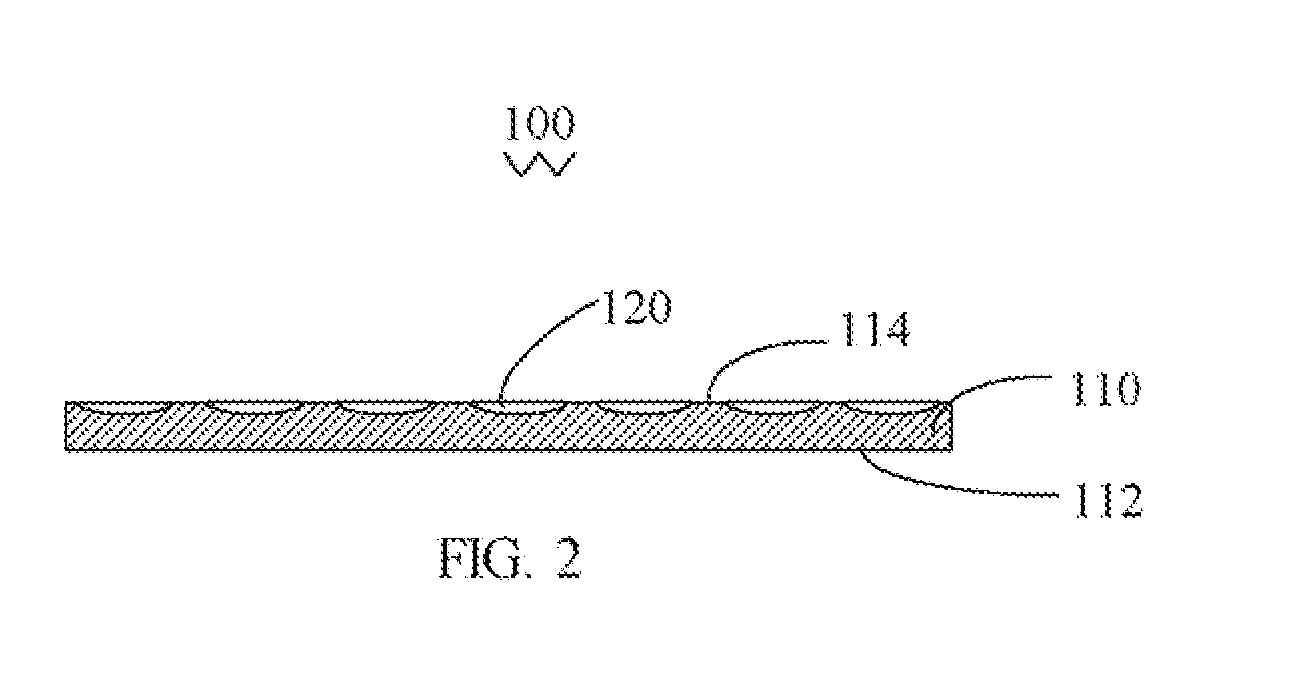

Semiconductor Package Leads Having Grooved Contact Areas

InactiveUS20100133693A1Big impactReliability of significantFinal product manufactureSemiconductor/solid-state device detailsSemiconductor packageElliptical recess

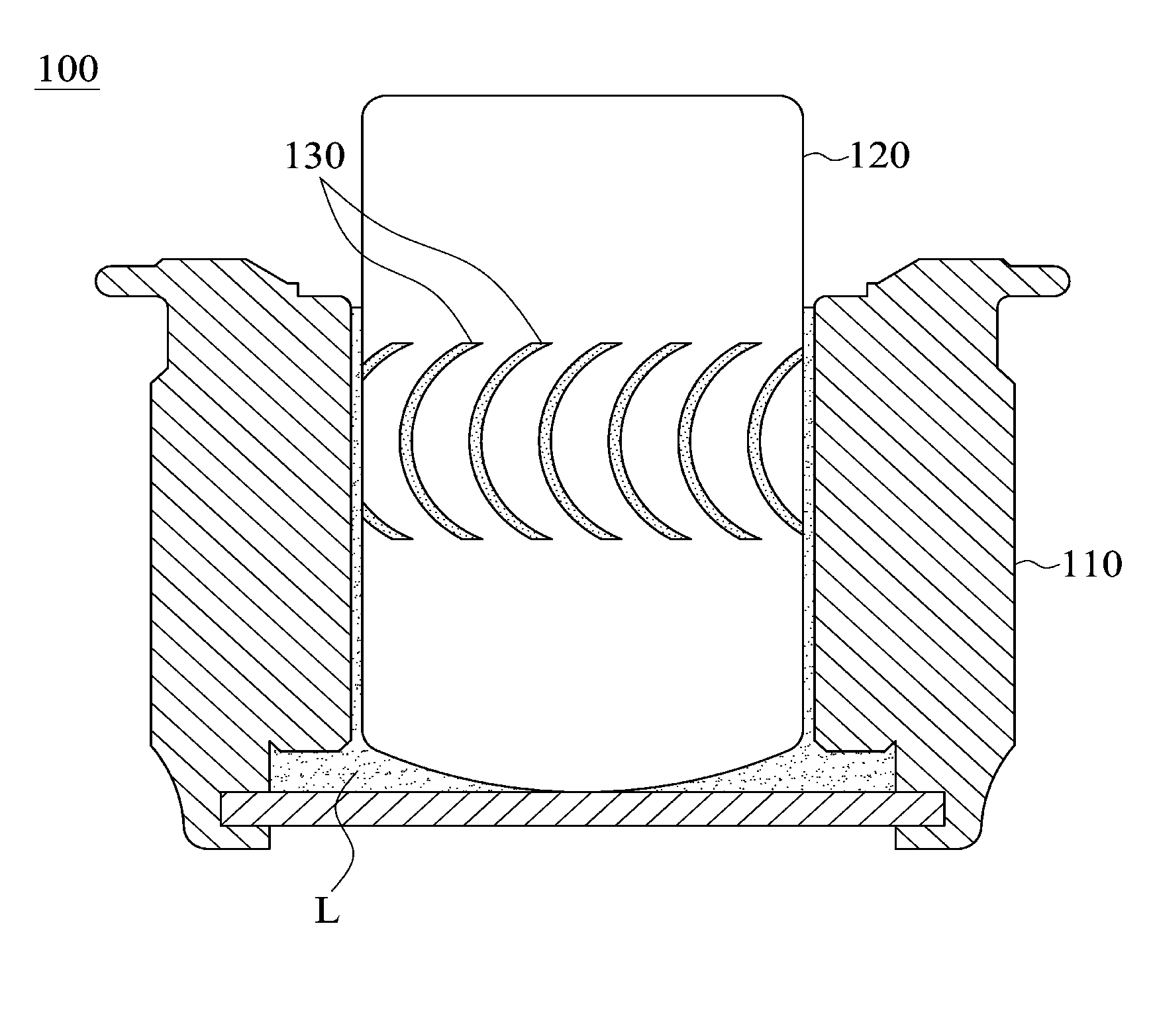

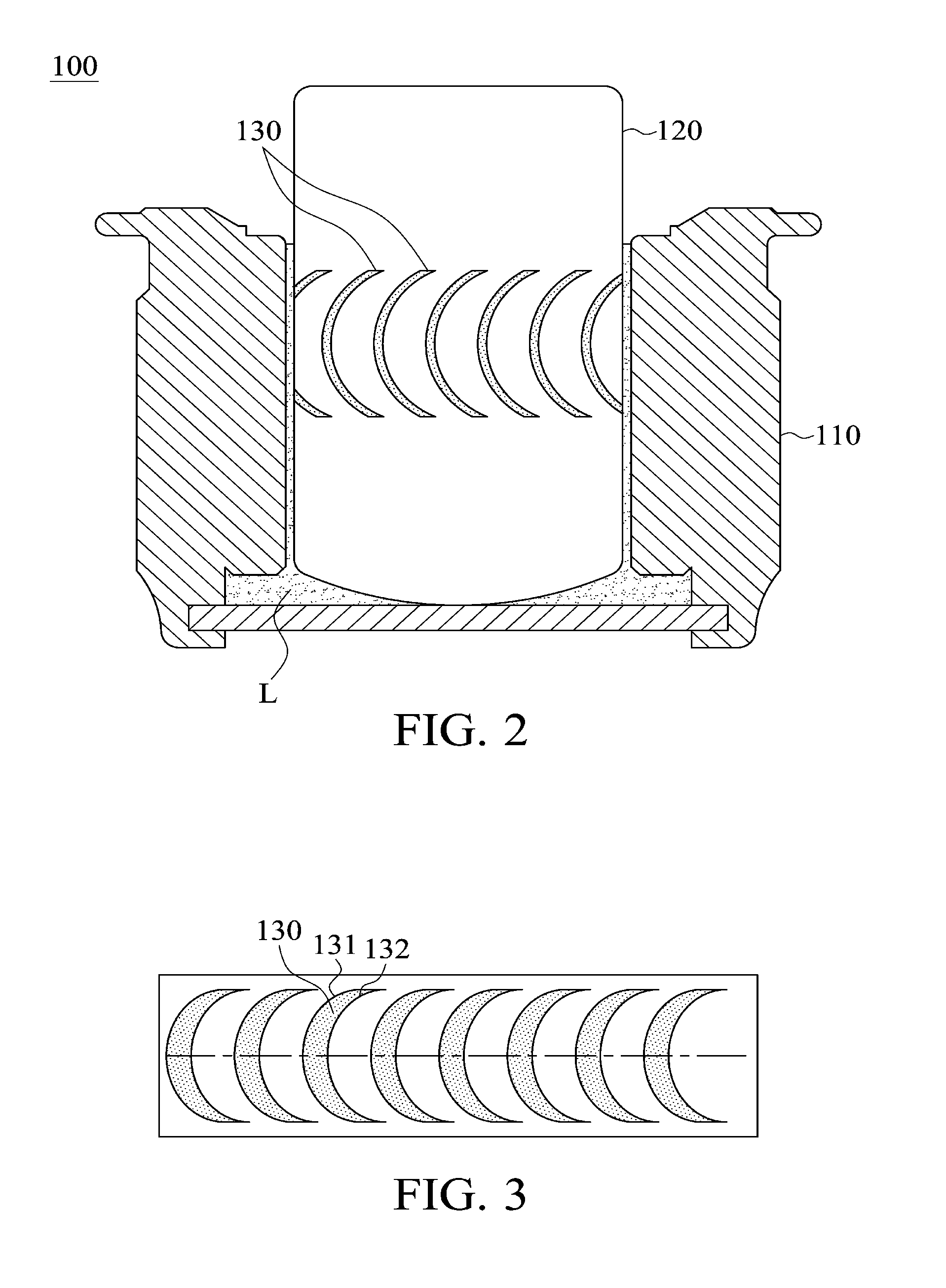

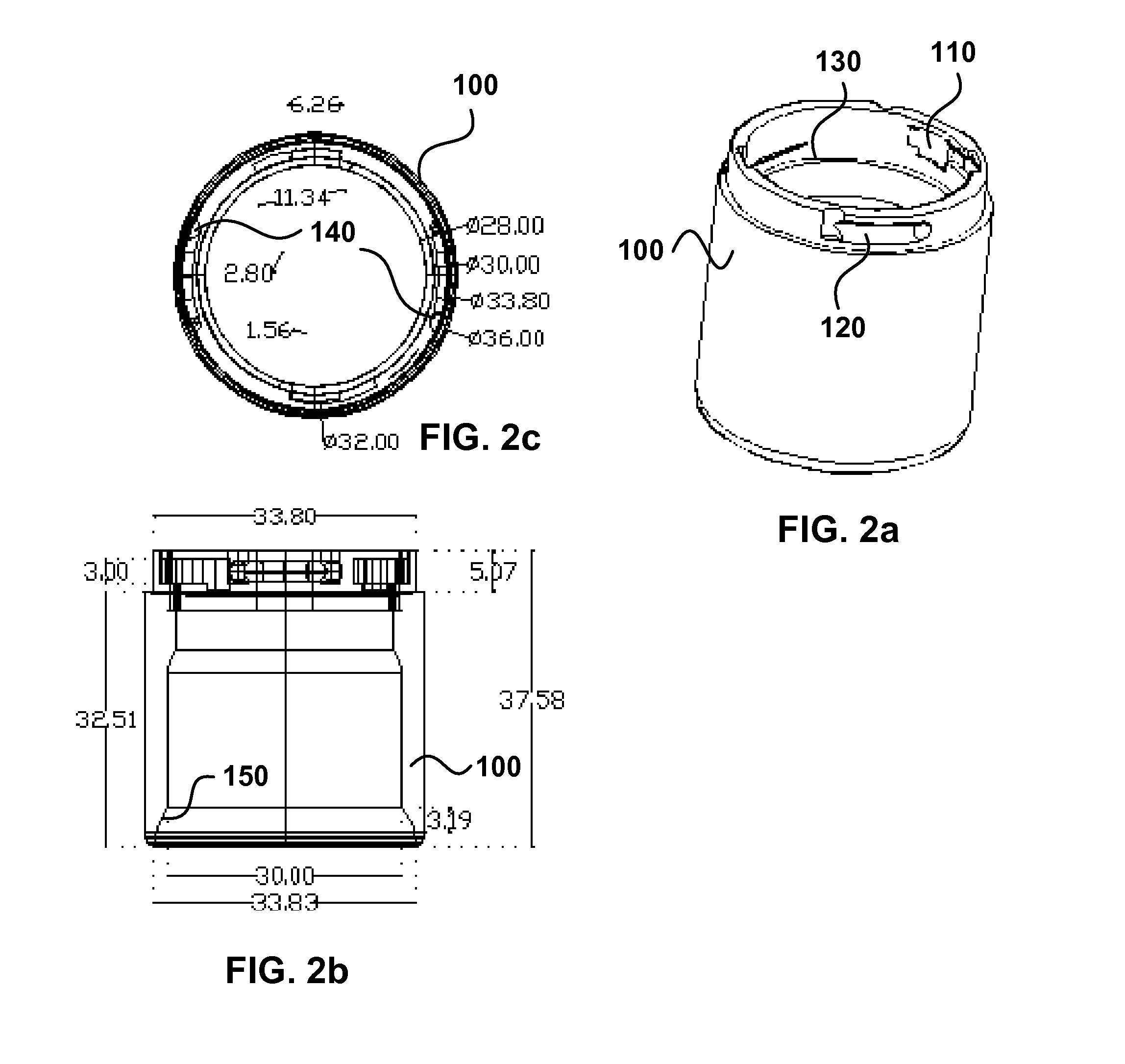

A packaged semiconductor device (100) has a first (110) and a second (111) side, the second side including a plurality of metal terminals (120) extending to the first side. Each terminal includes an oblong groove (122) extending to the first side and ending in an orifice (123) at the first side. The terminals are made of a base metal and may have a solder-wettable surface except for the terminal surface (121) exposed at the first device side.

Owner:TEXAS INSTR INC

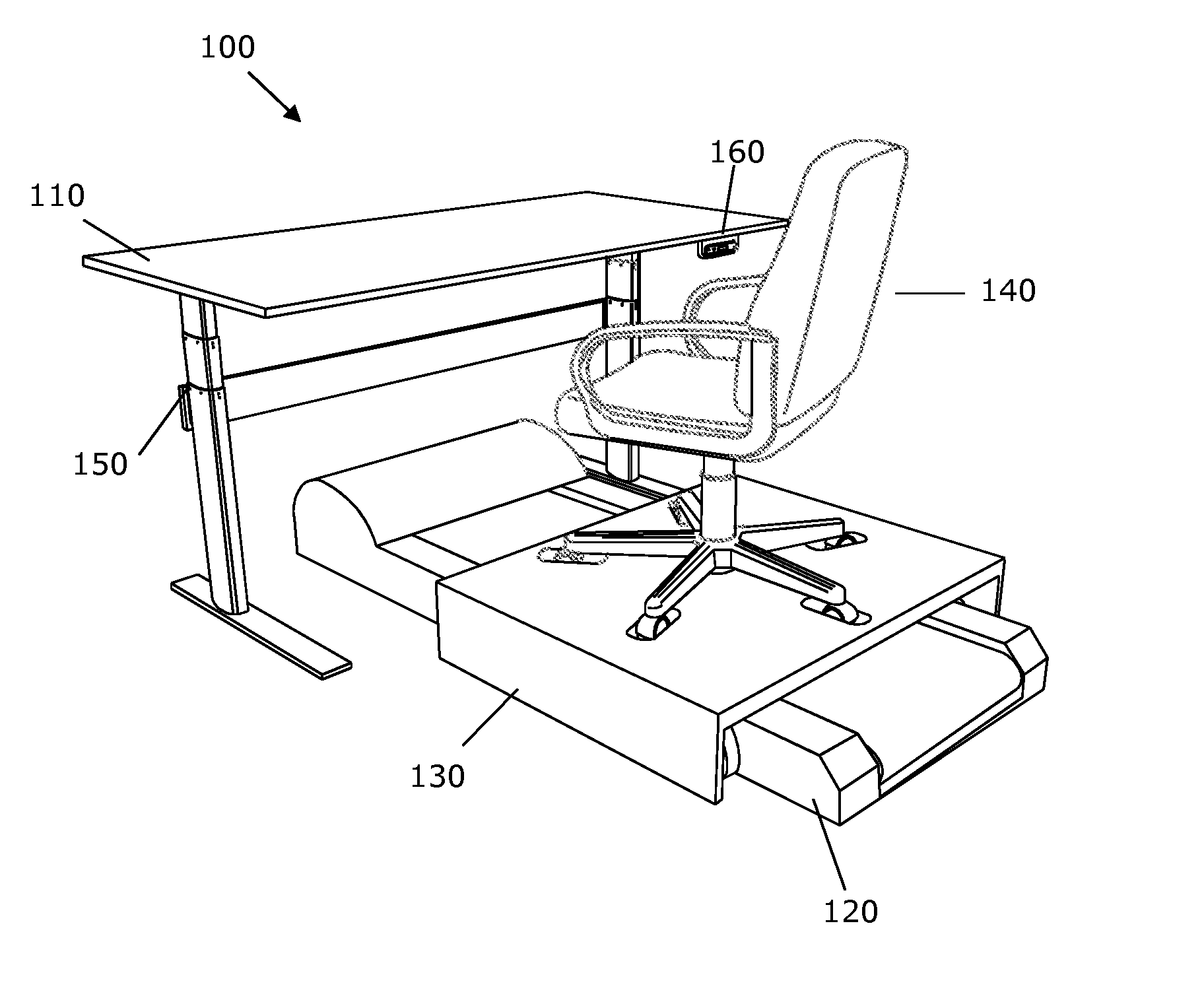

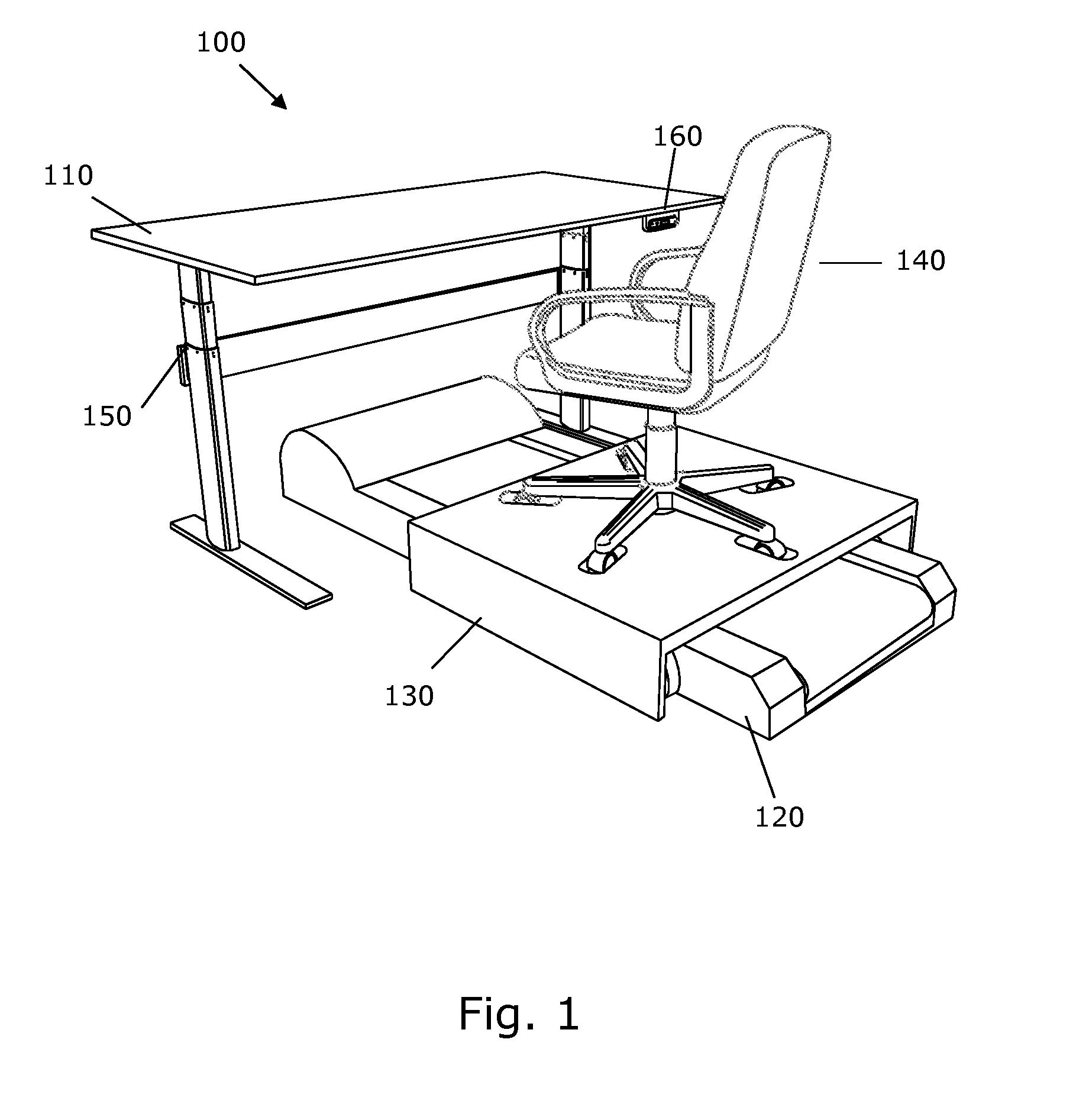

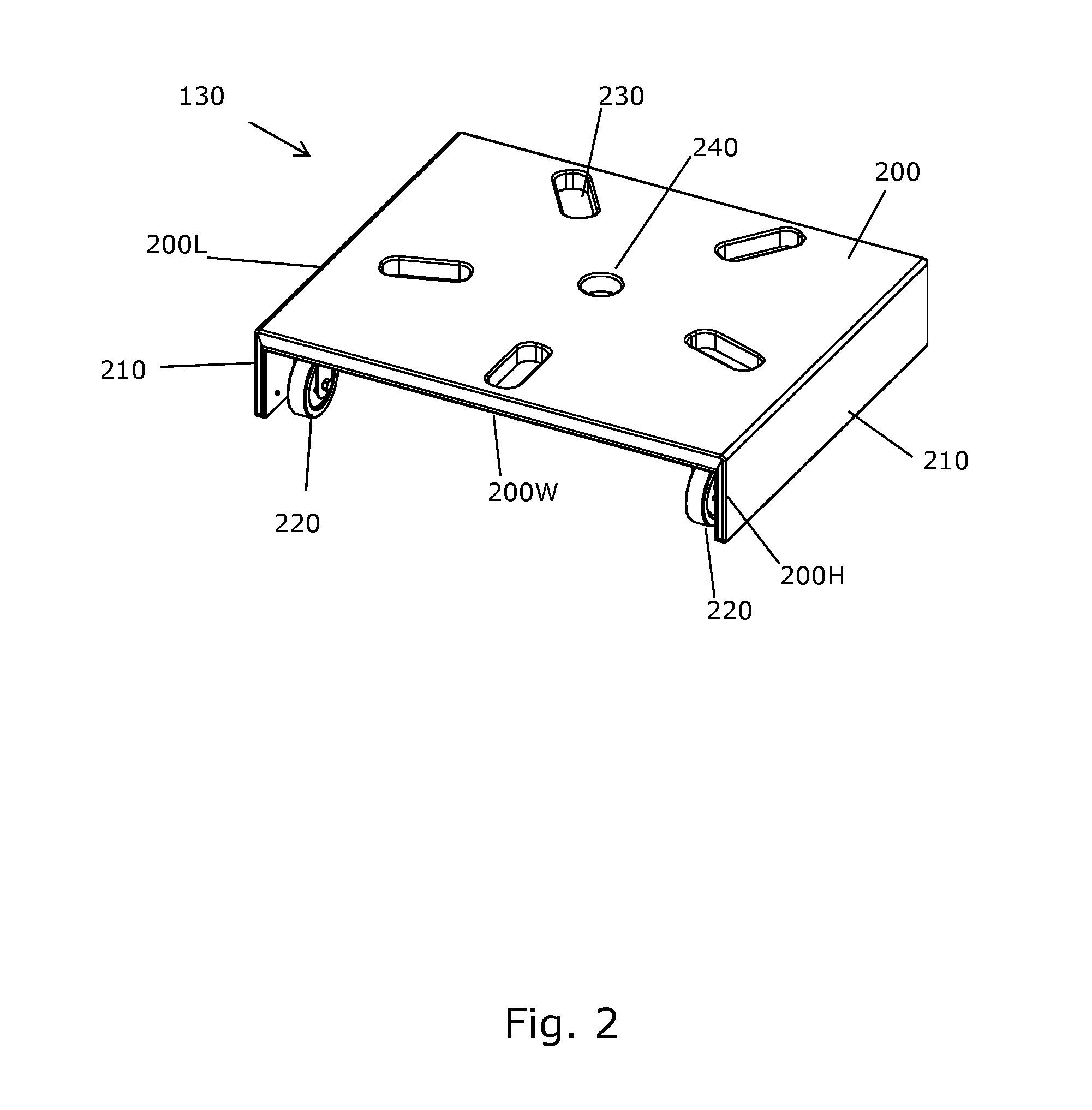

Desk treadmill assembly with chair platform

Exercise treadmill chair platform that resides horizontally over a treadmill when it is not in use to stabilize an office chair while it resides beneath the desk. The platform has a top and bottom flat plate, aligned, square or rectangular shaped, and of a low profile, that slides over the treadmill to cover the belt when the treadmill is not in use, thus enabling the user to safely sit at the desk without having to store away the treadmill. The platform may further comprise a right and left side wall; and, four corner wheels to assist the user in moving the platform, and two bumpers to protect the wheels from entanglements. The top flat plate further comprises oval shaped grooves arranged in a circle, designed to house the wheels of a variety of types of swivel chairs in order to keep the chair from rolling off of the platform.

Owner:NEXTG TECH CO LTD

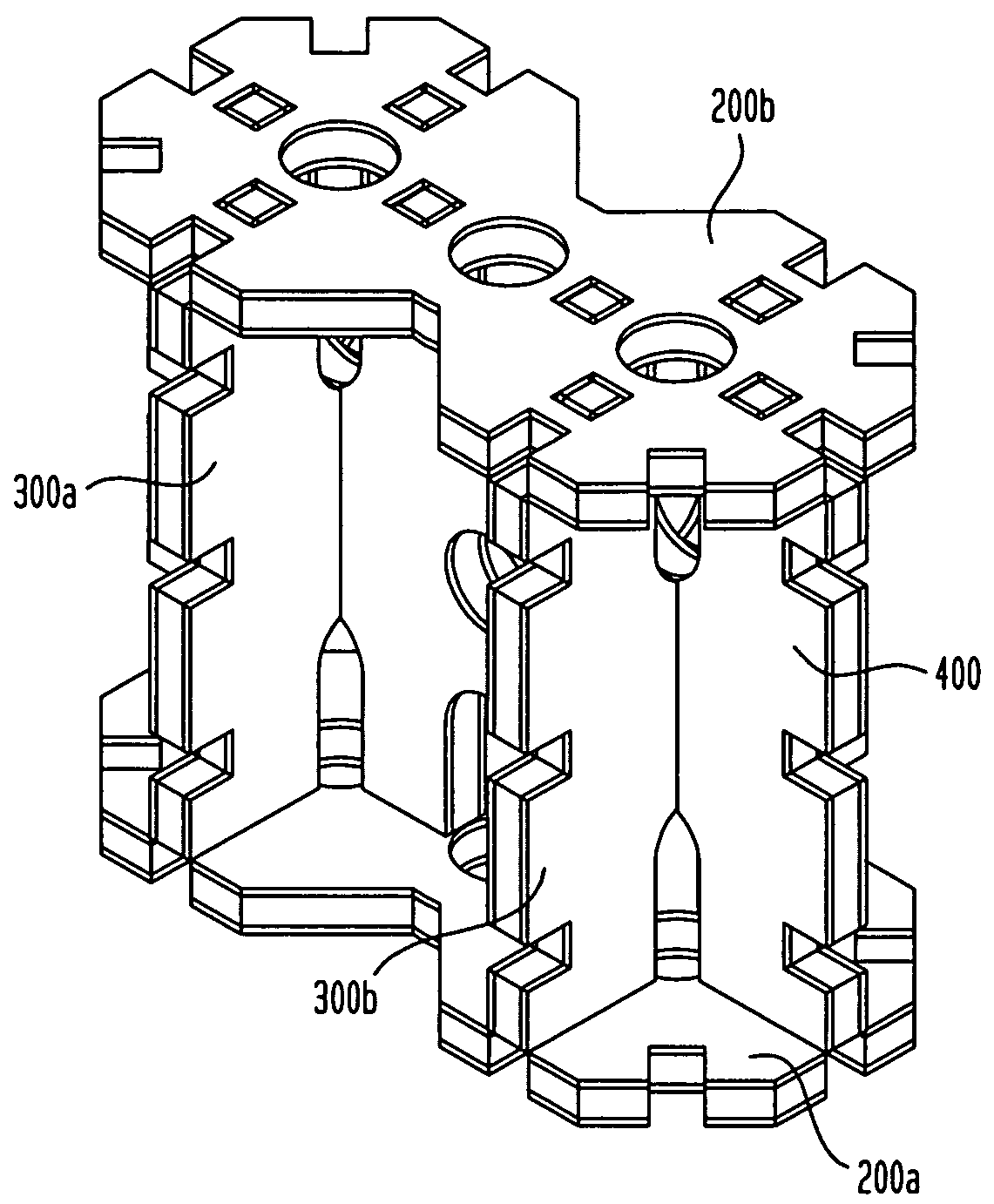

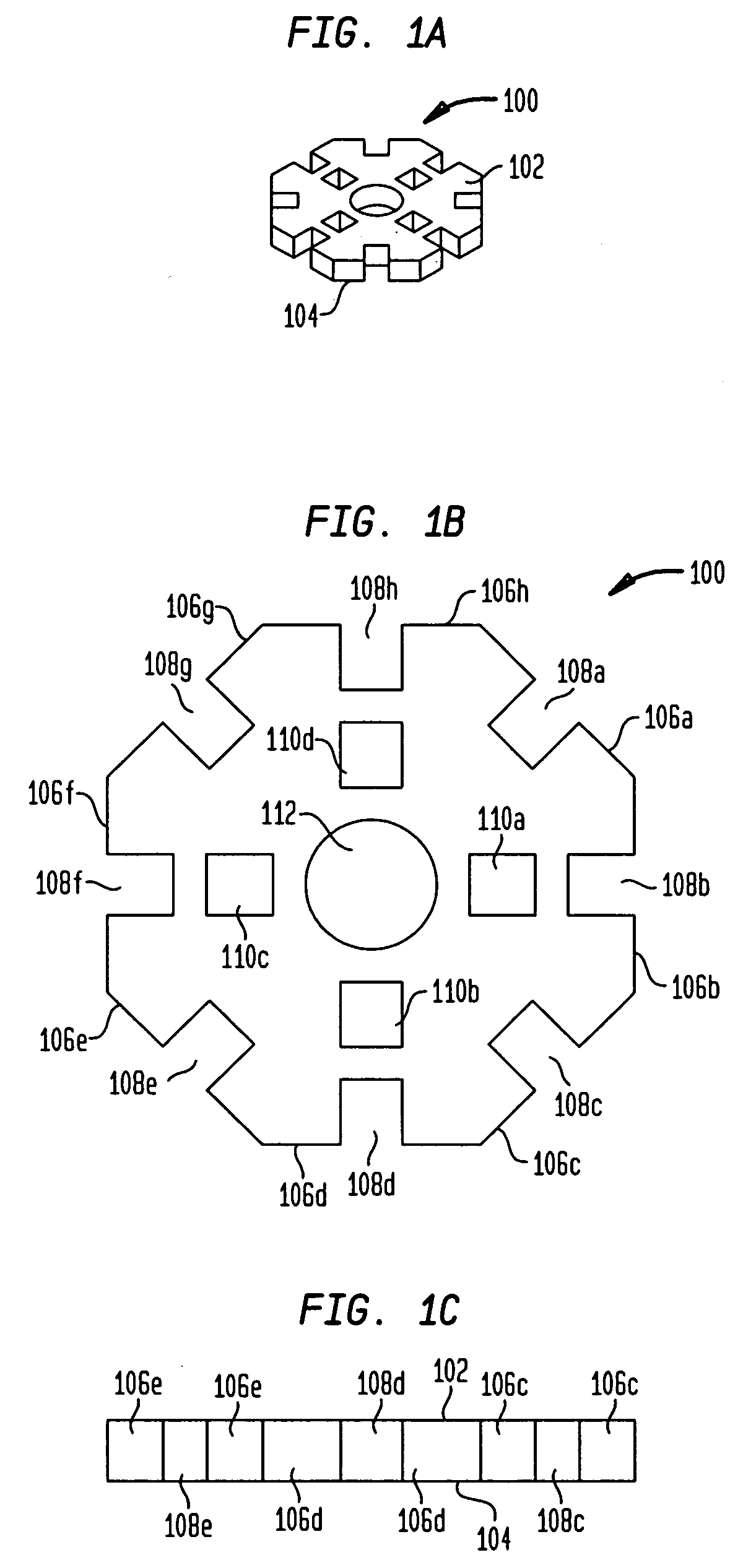

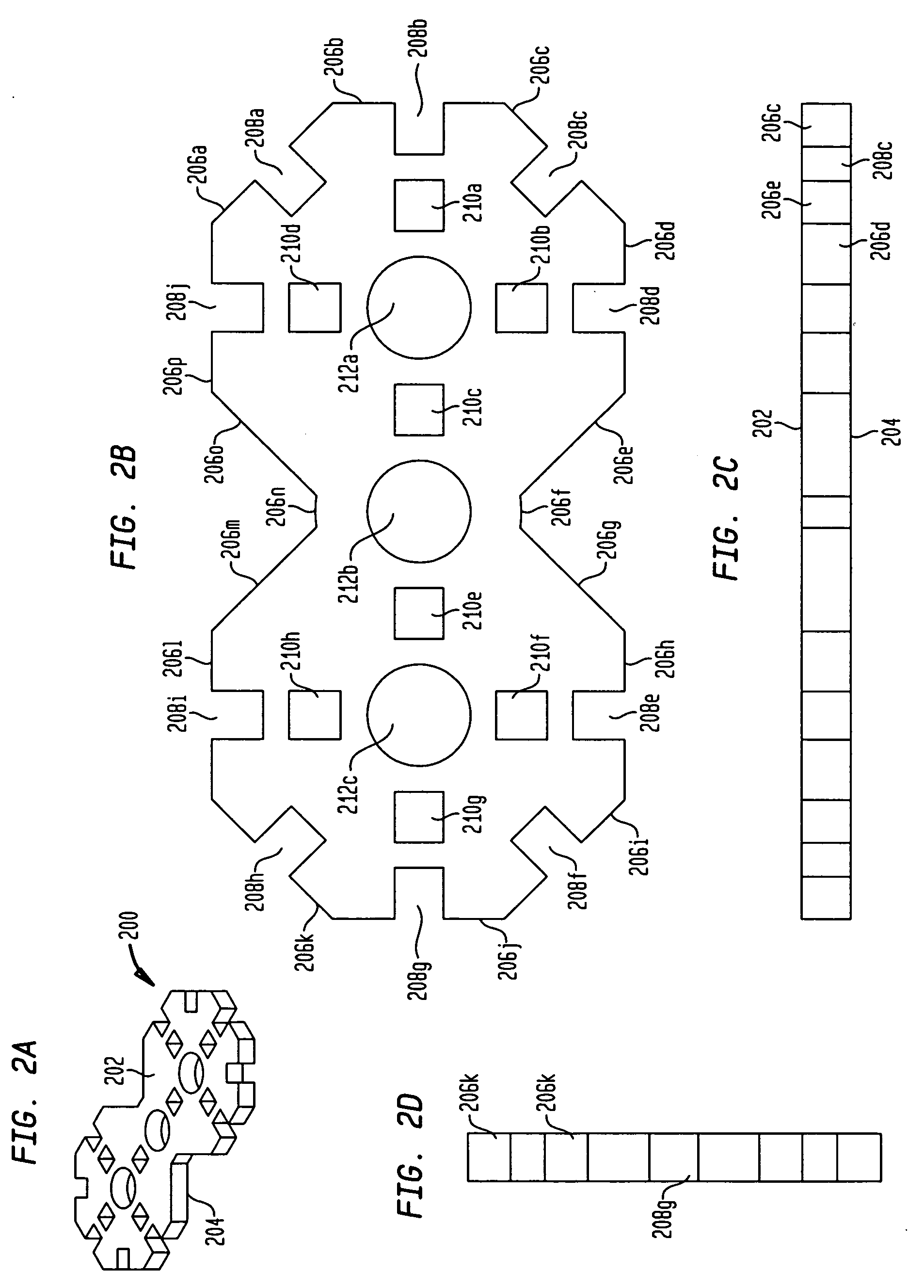

Interlocking toy

An interlocking toy formed from construction units, where certain of the construction units include assembly members, preferably in a matrix, that are capable of interlocking with assembly members, preferably in a matching matrix, from certain other construction units. The assembly members may be in the form of notches, slots, tabs, apertures (preferably square apertures or circular apertures), oblong recesses, and tapered oblong recesses, among other similar and other geometric and non-geometric constructs. Similarly, the construction units may be formed to any geometric or non-geometric configuration. An exemplary construction unit may include assembly members in the form of notches, square apertures, and circular apertures.

Owner:ZINKOTEK

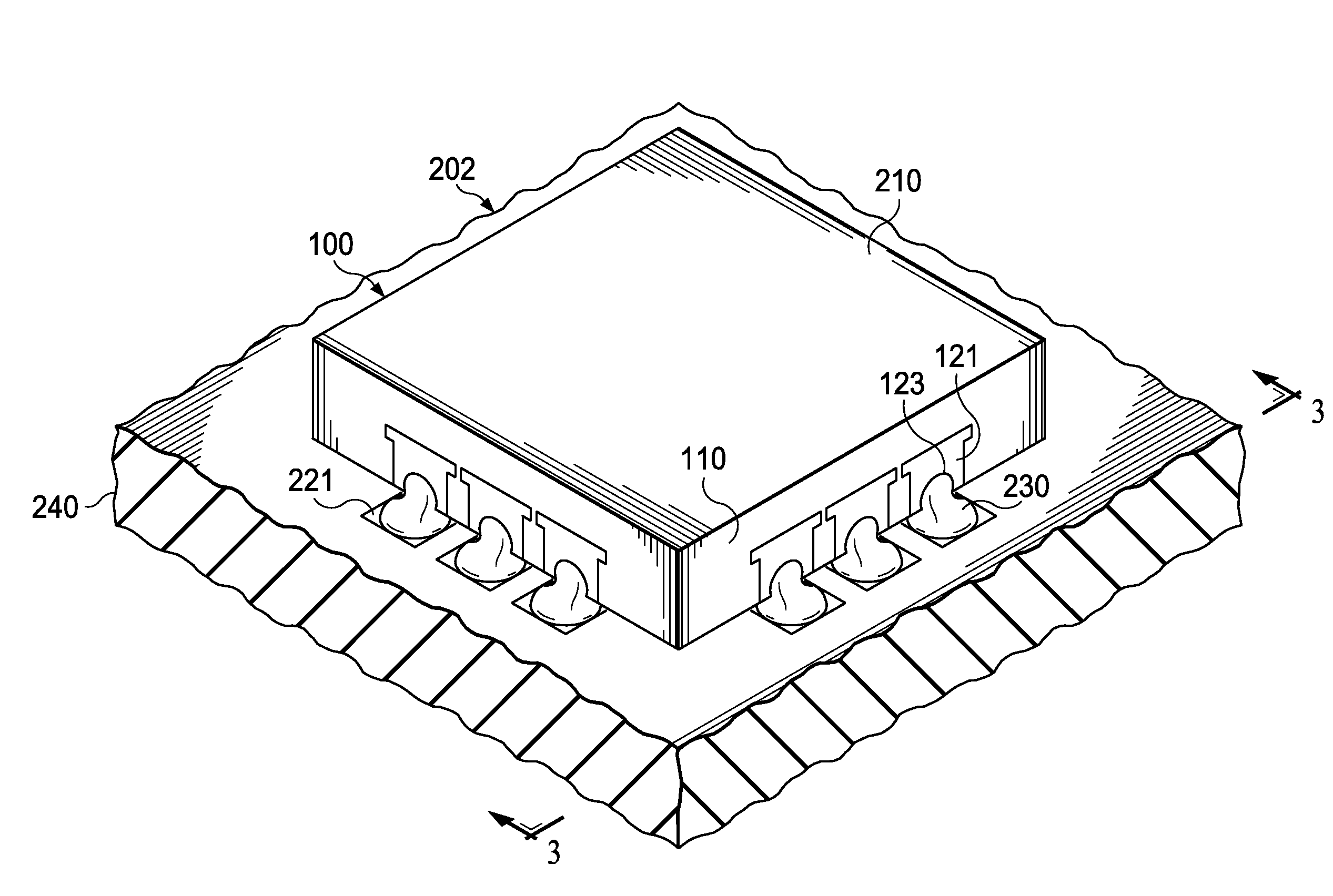

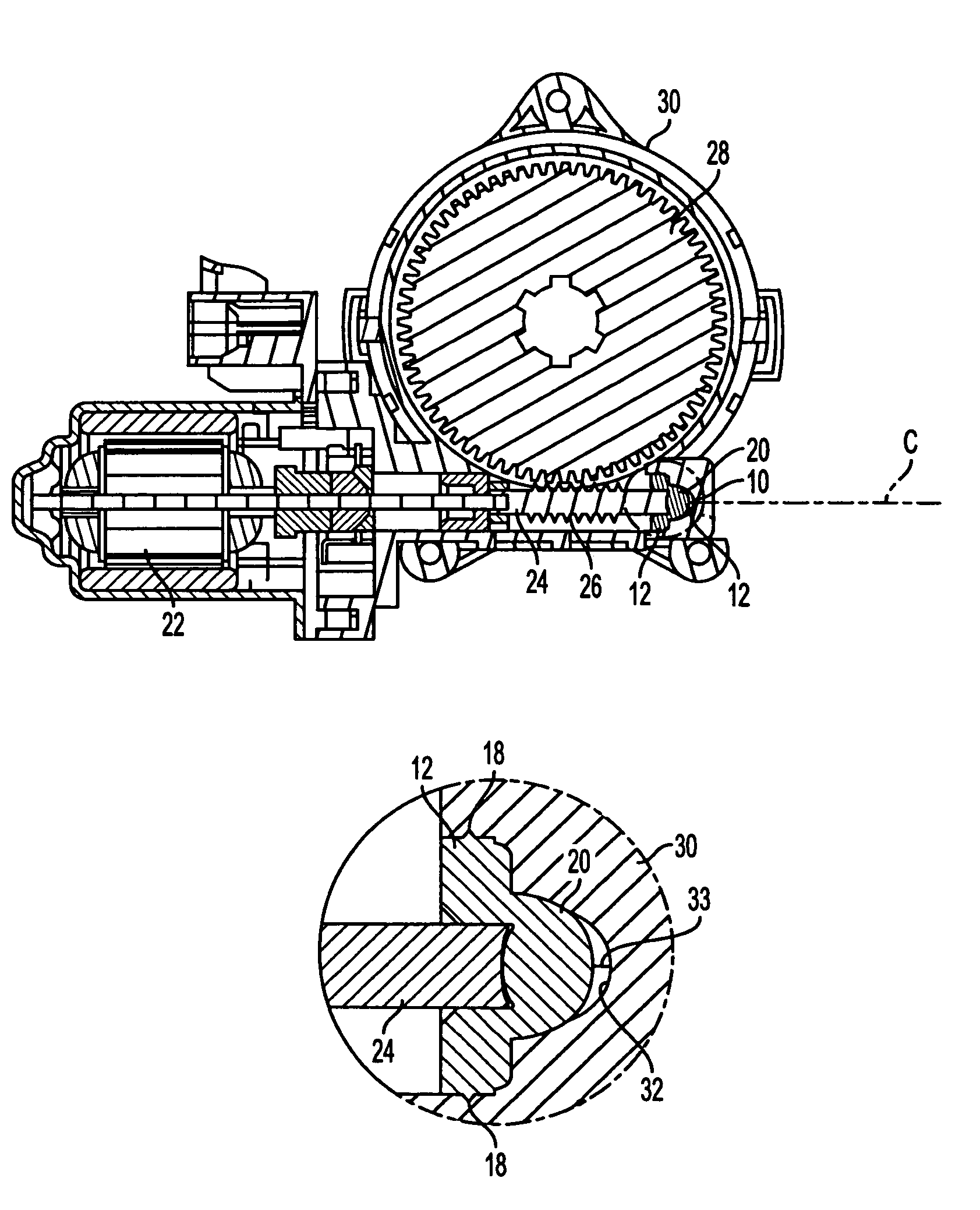

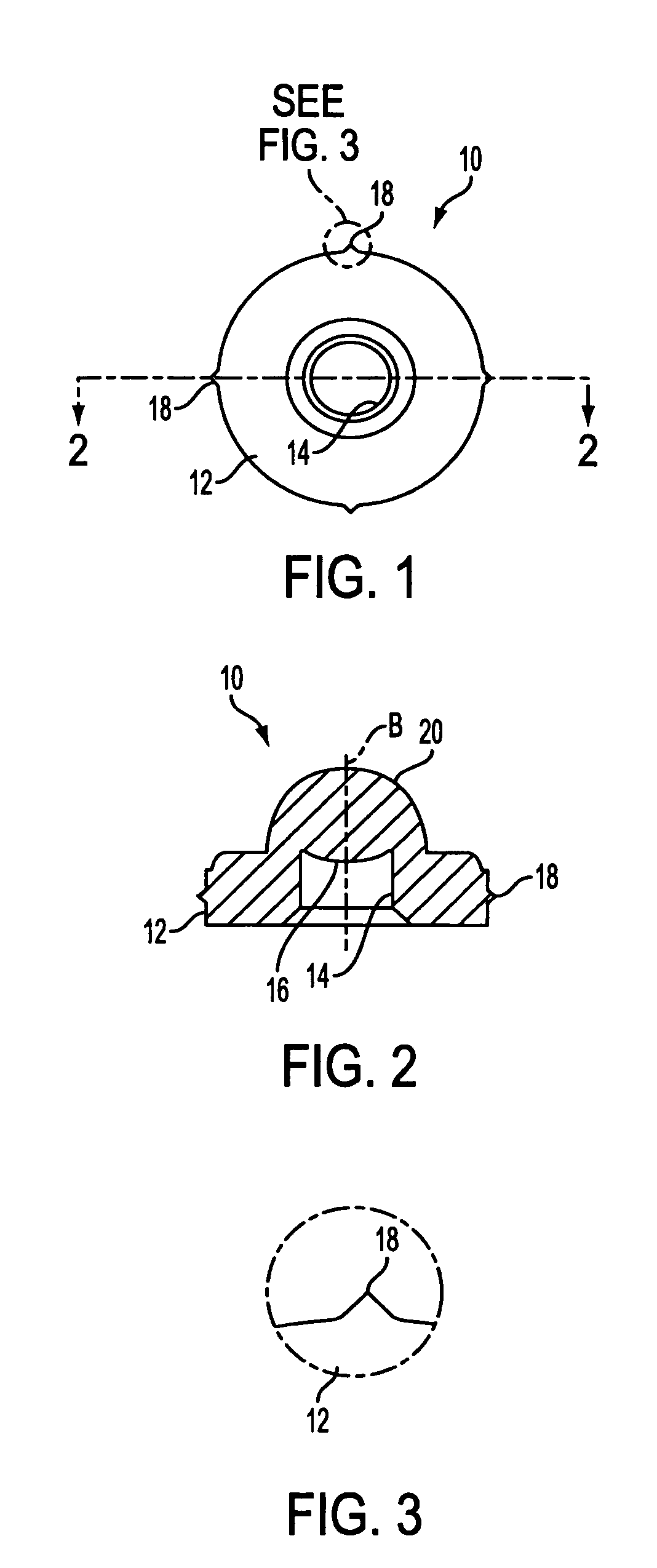

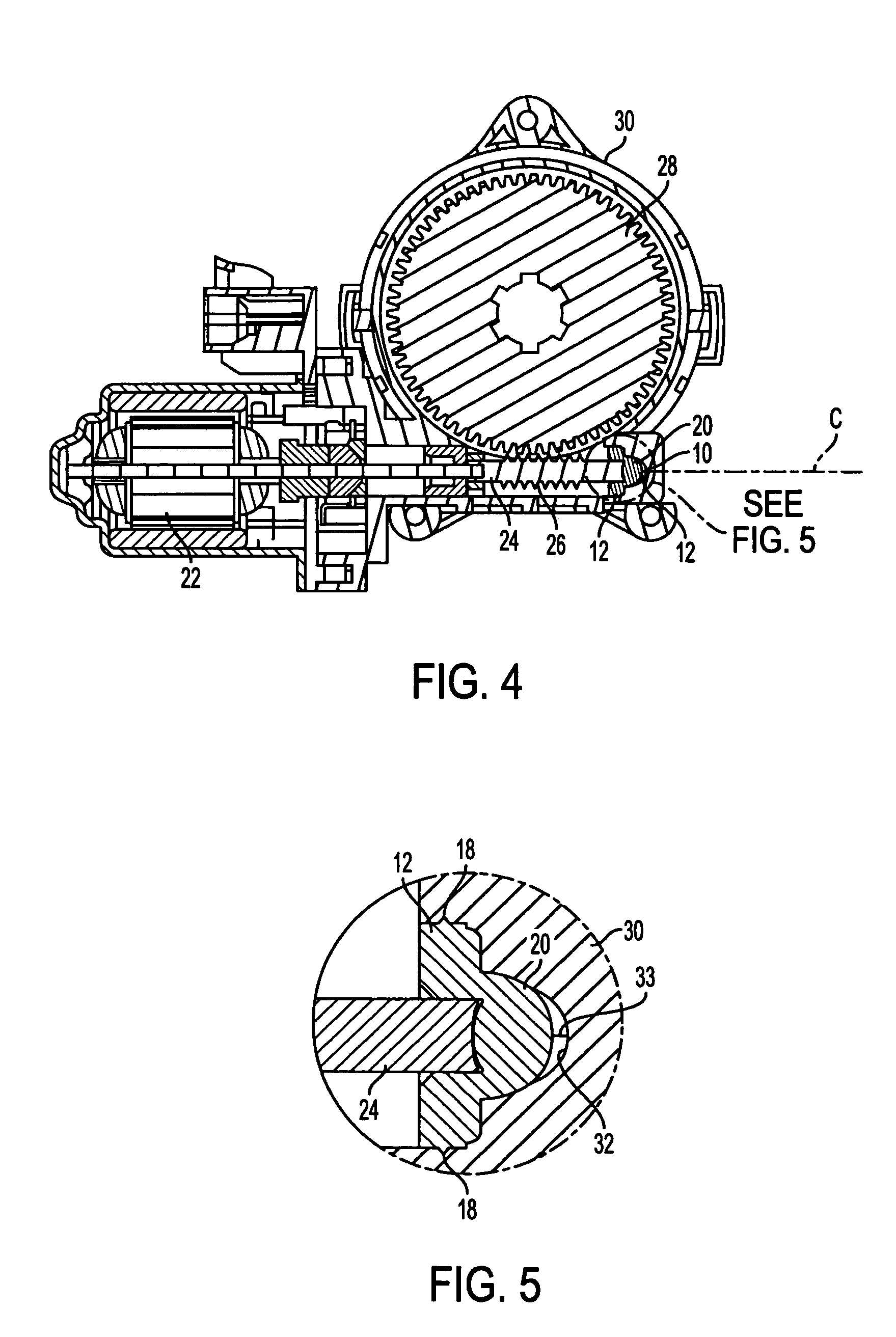

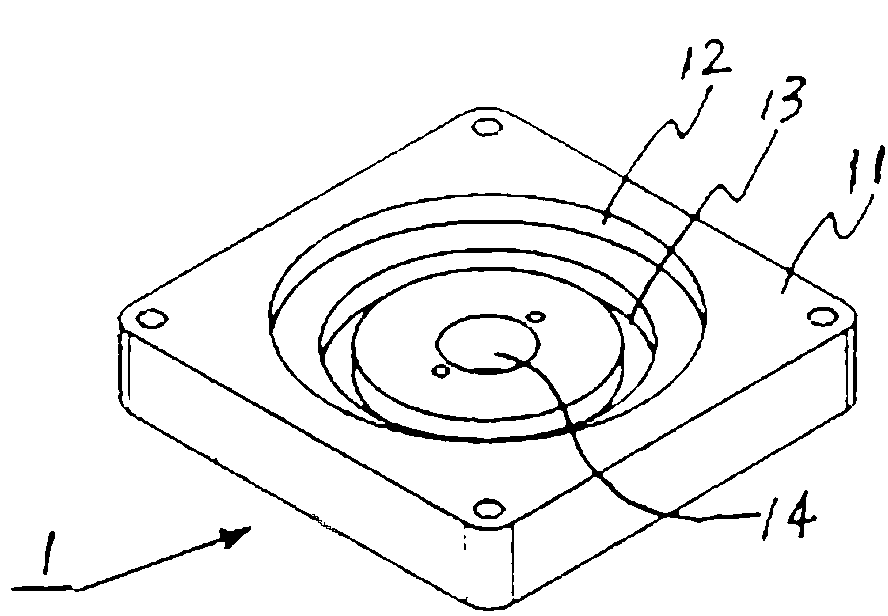

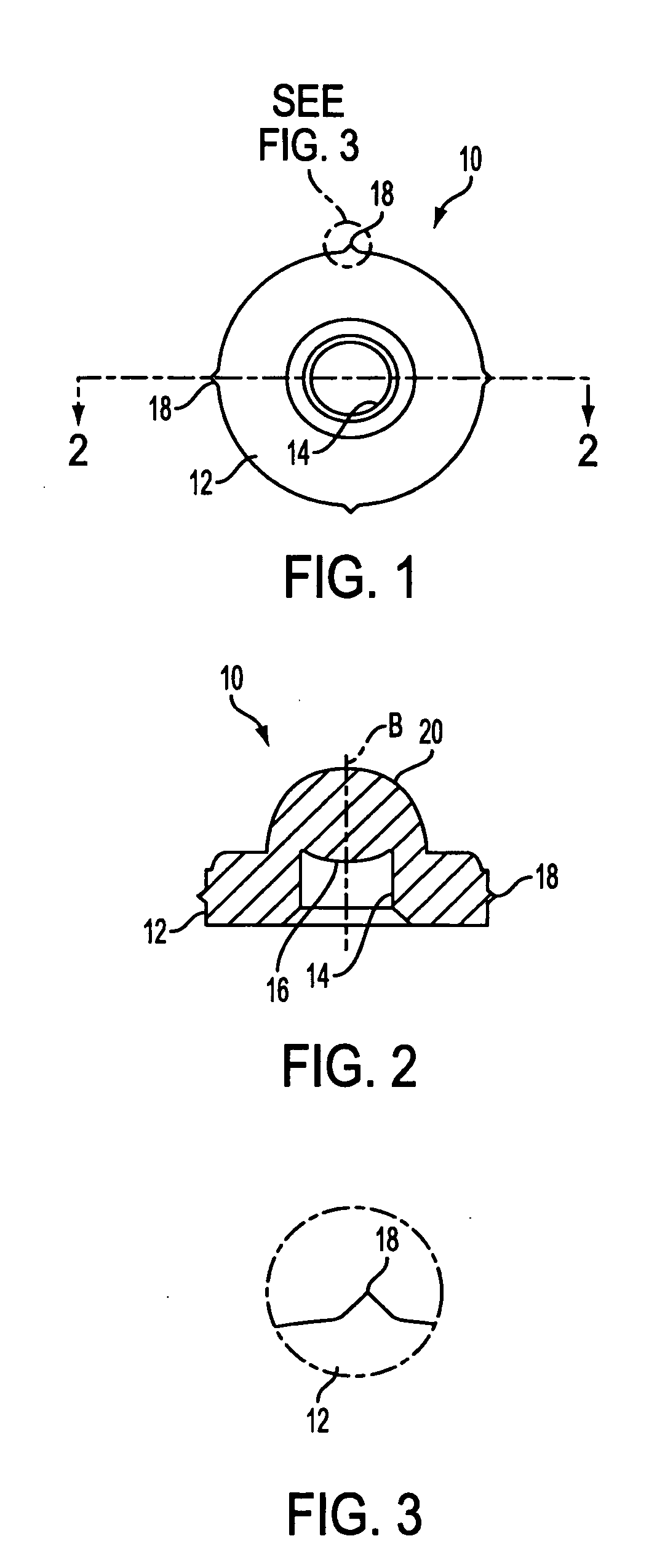

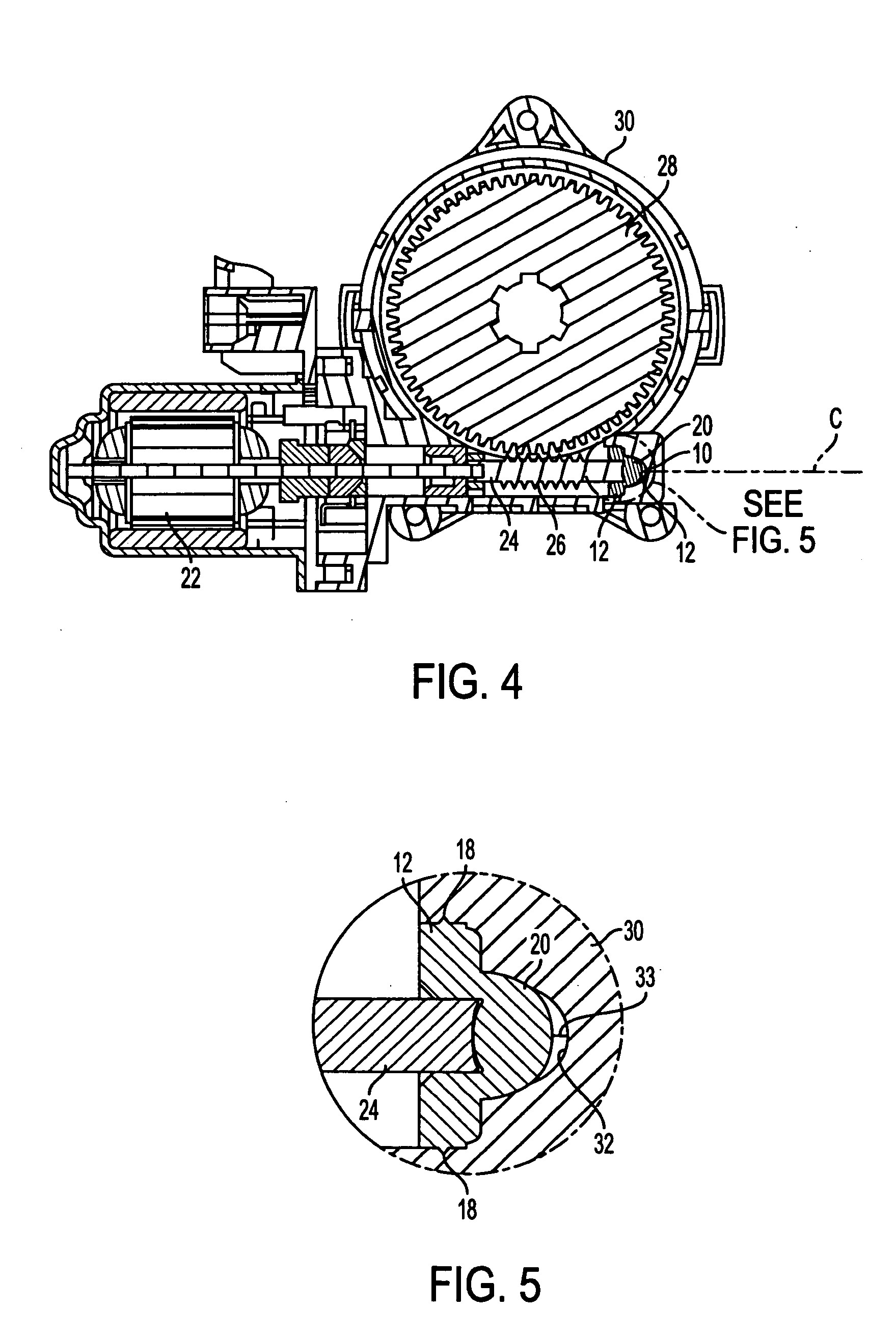

Electric motor with self-adjusting bushing structure

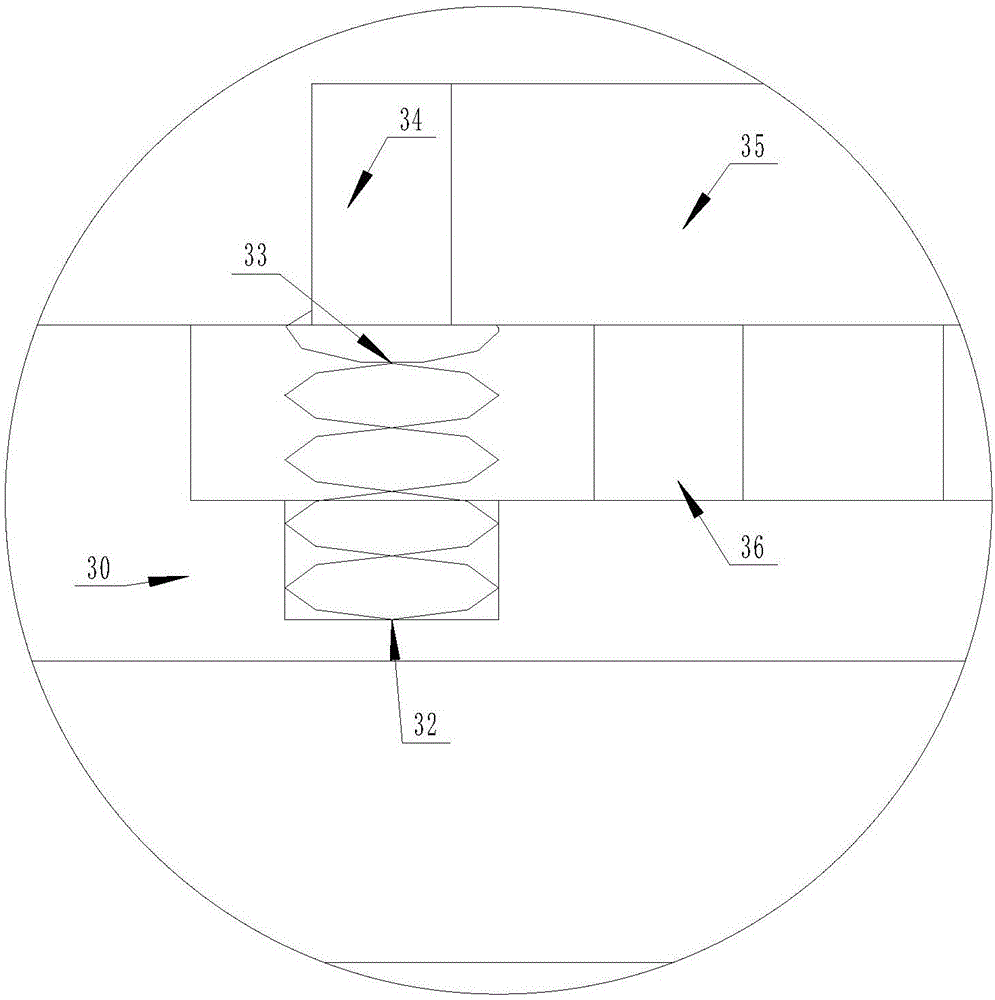

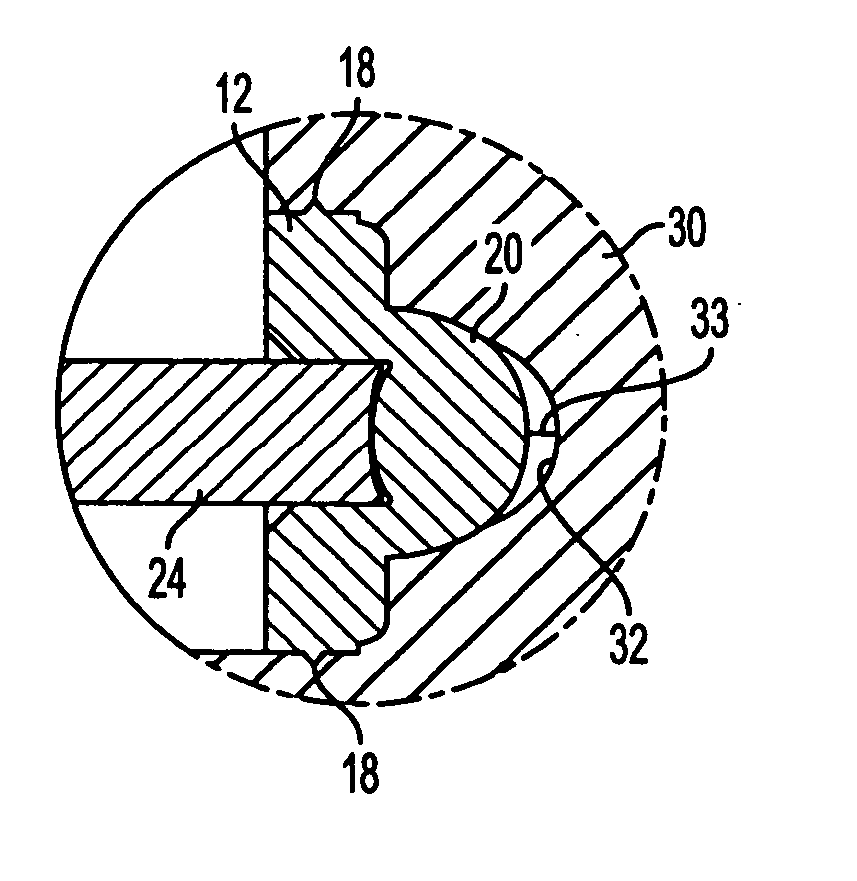

A bushing structure 10 is constructed and arranged to be operatively associated with a shaft 24 of an electric motor 22. The motor has a housing 30 including a generally elliptical recess 32 therein defined along an axis C of the shaft. The bushing structure includes a generally cylindrical bushing member 12 constructed and arranged to engage an end of the shaft so as to locate the shaft with respect to the housing and to prevent lockup of the motor. An endplay member 20 is associated with the bushing member and with the end of the shaft. The endplay member includes a spherical portion constructed and arranged to be received in the elliptical recess so as to control endplay of the shaft.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

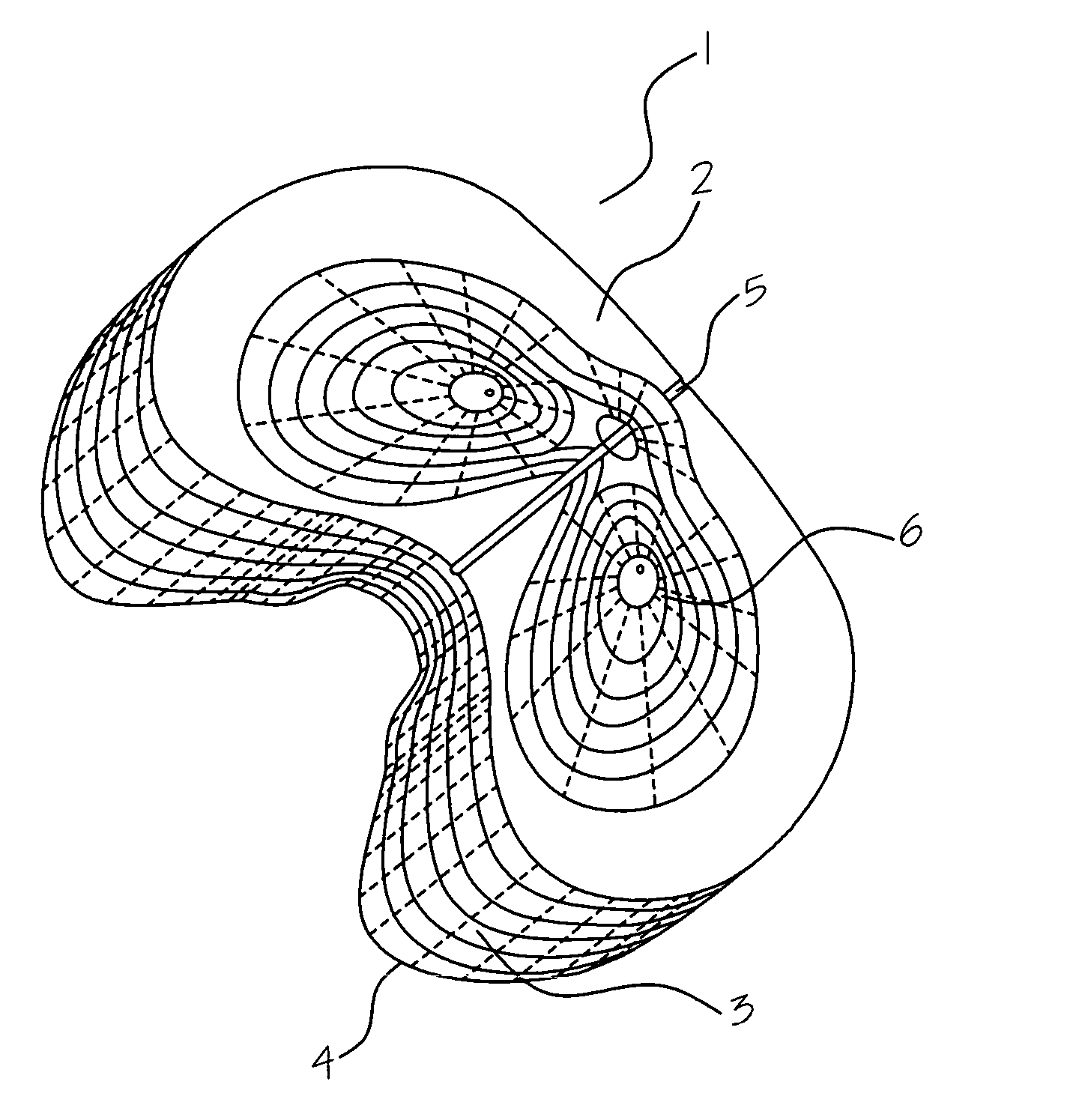

Ergonomically designed portable seat cushion

InactiveUS20060103225A1Reduce pressureMaximize contact areaStuffed mattressesSpring mattressesIschial tuberosityEngineering

A portable cushion that minimizes the blocking of blood circulation, stress, and pain in the femoral region caused by sitting on a chair for long hours or an extended time is provided. The overall shape of the cushion resembles human lungs connected to each other at the upper part with an upper surface that is flat, except for two wing portions. The wings are in a convex shape. The cushion is made of EP (Ethylene-Propylene Copolymer) rubber foam. A straight shallow center groove is concavely developed on the upper surface of the cushion along the direction of the wings. Two concave grooves, resembling hemi-oval shapes being cut along the long center axis thereof are developed on the flat upper surface of the seat cushion to receive ischial tuberosities of a user. A shell-shaped concave groove for receiving the coccyx of the user is developed on the rear part of the flat upper surface of the cushion between the two hemi-oval shape grooves. The front side of the cushion, between the two wings, is caved in for receiving and positioning of genitals of the user. The unique geometry of the cushion reduces the pressure to the ischial tuberosities and the coccyx of a user by maximizing the contact area and distribute the user's weight throughout the surface, while minimizing the blocking of blood circulation by minimizing the contact area of the wings of the cushion and the rear part of the thighs of the user.

Owner:KIM JUNGIN

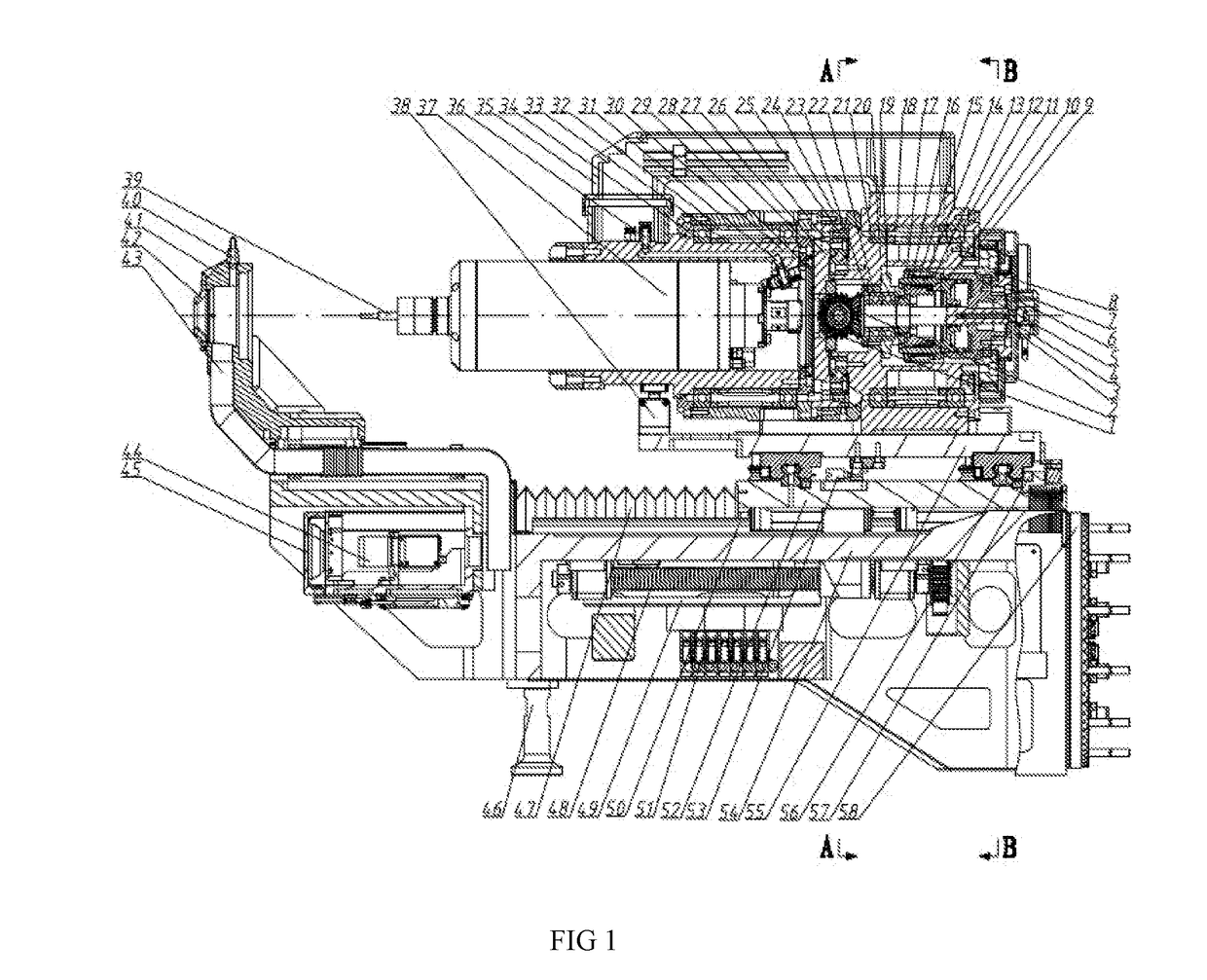

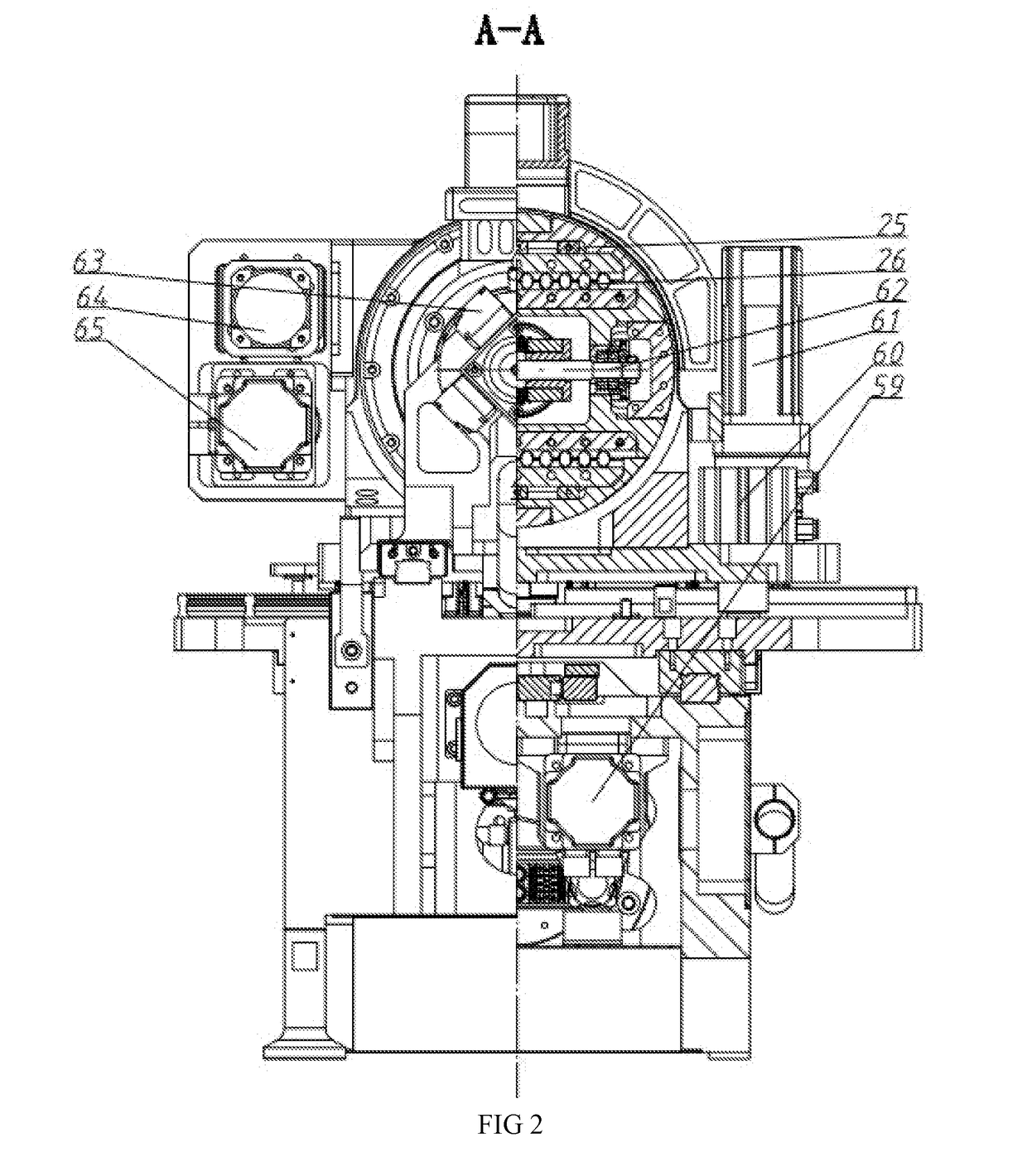

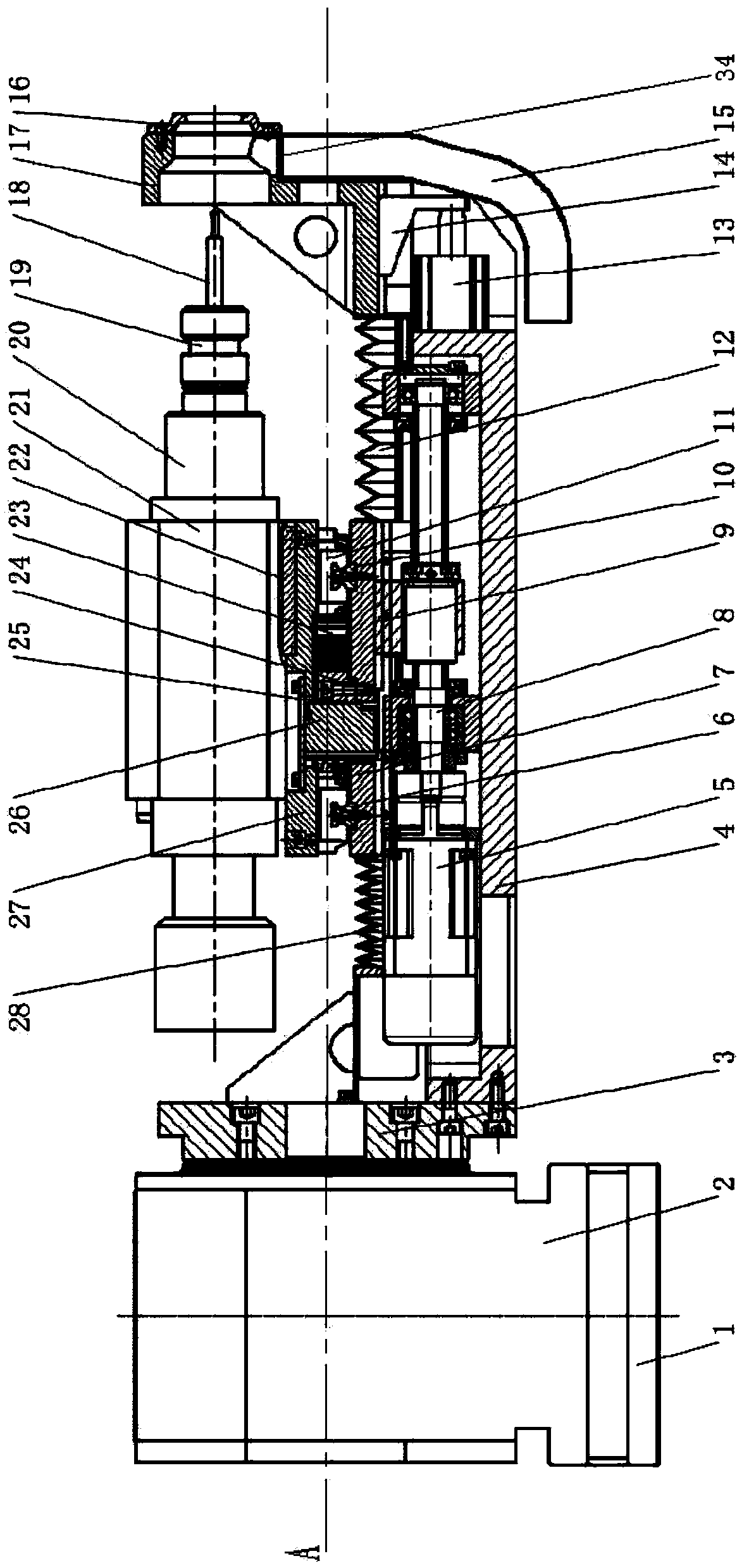

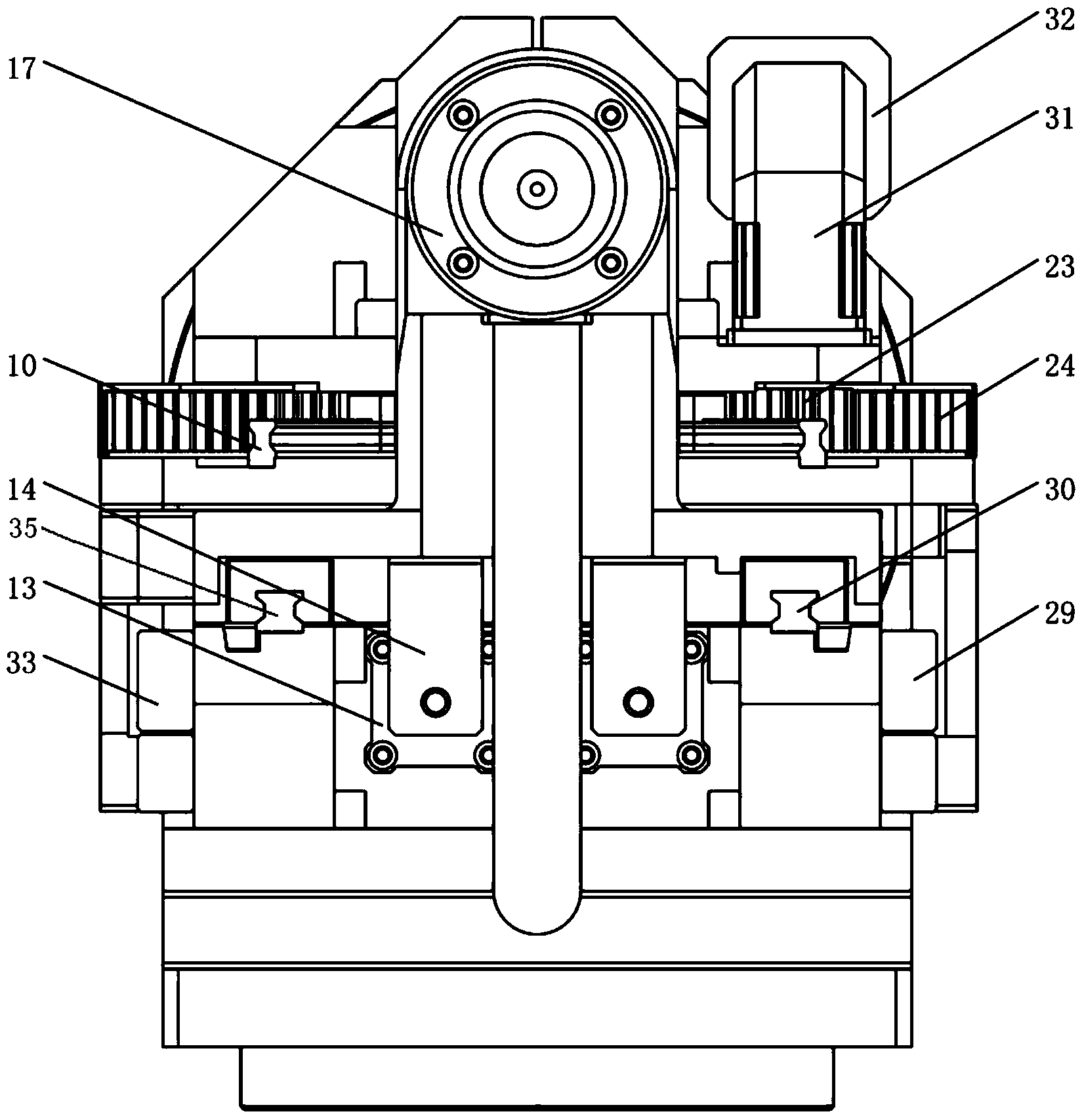

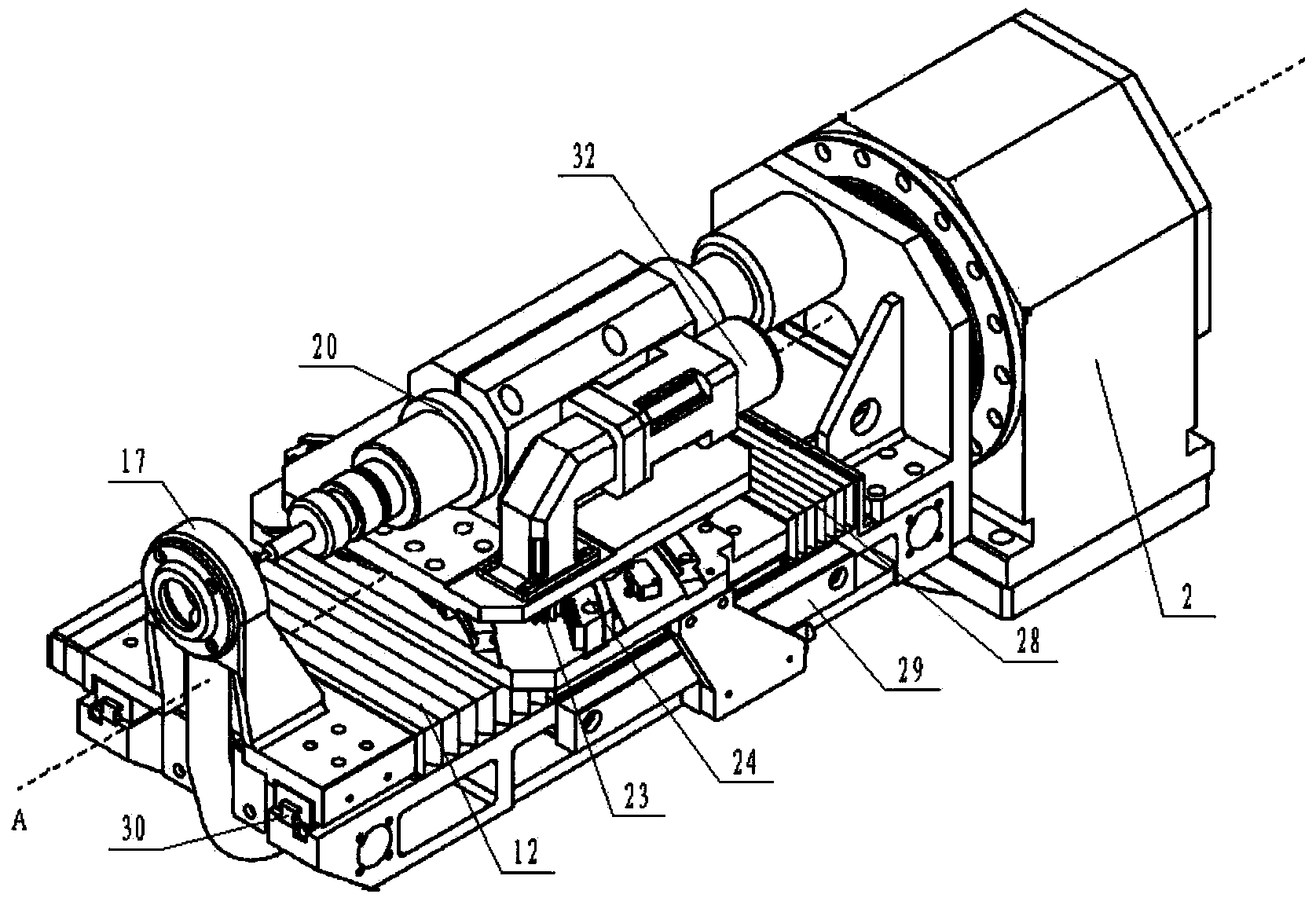

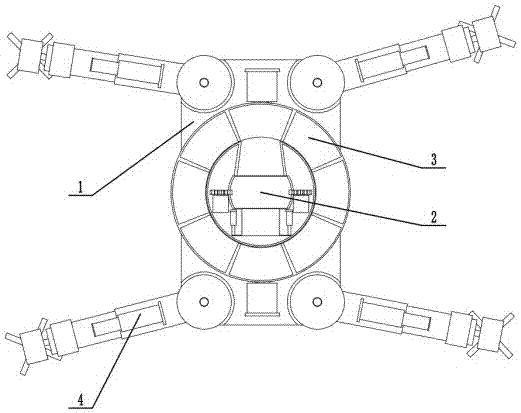

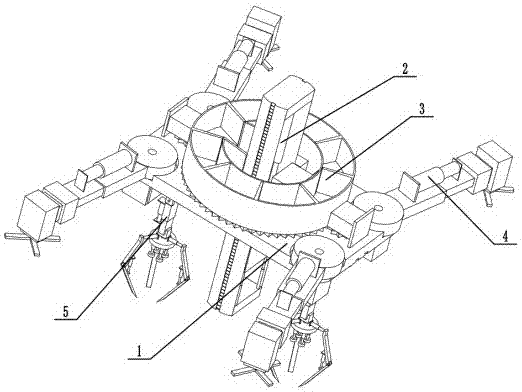

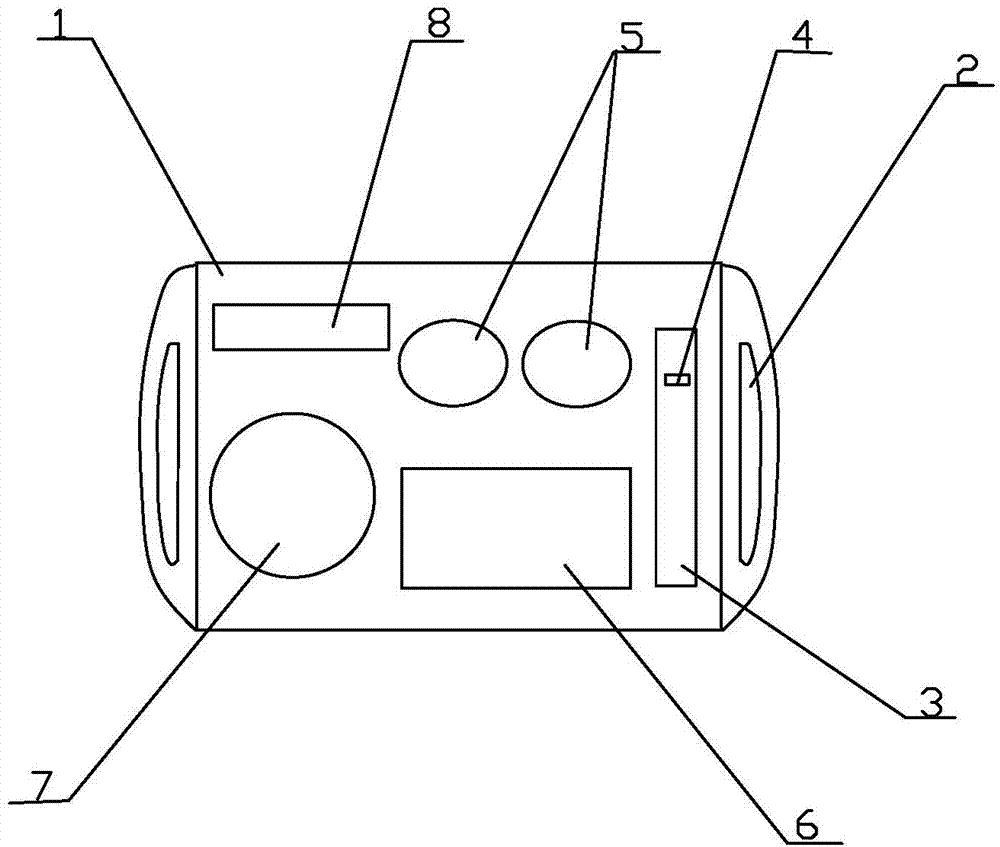

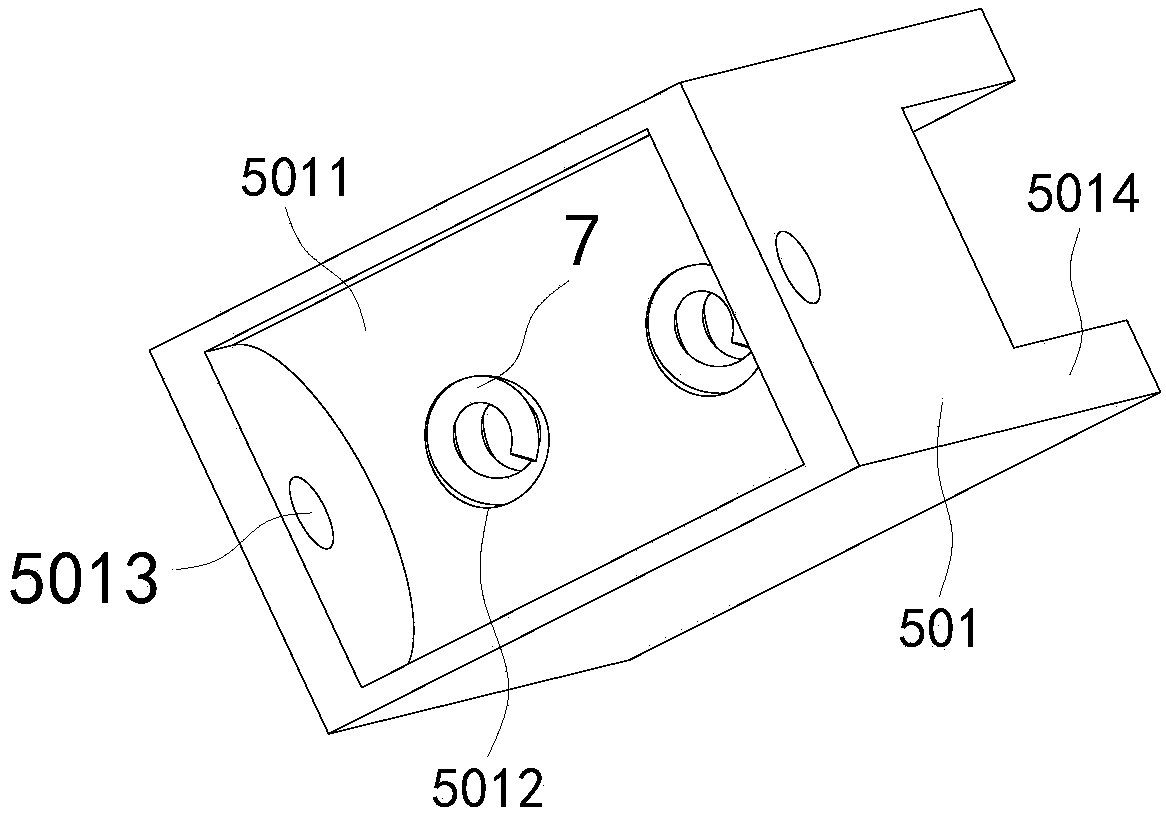

Multi-functional end effector

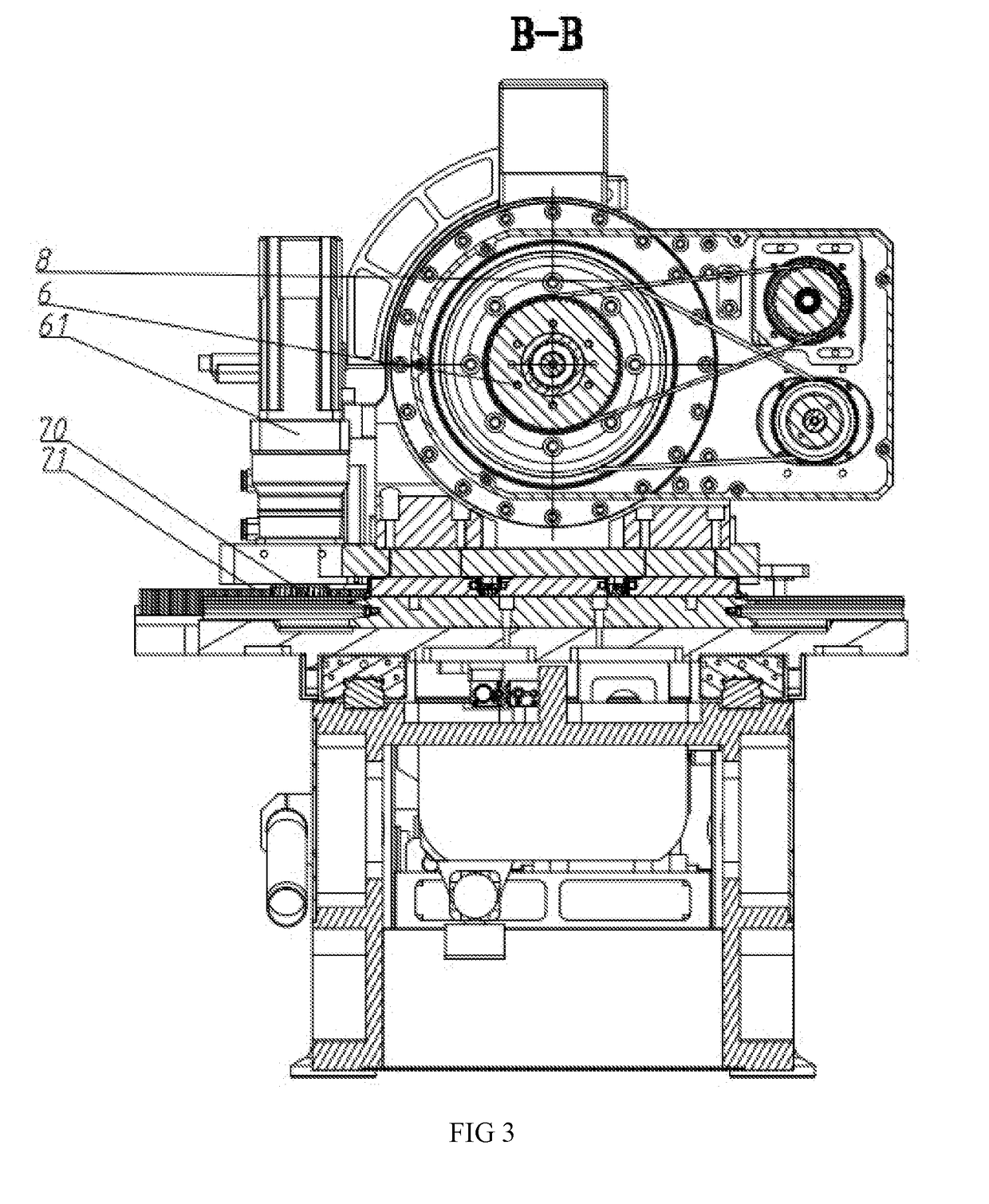

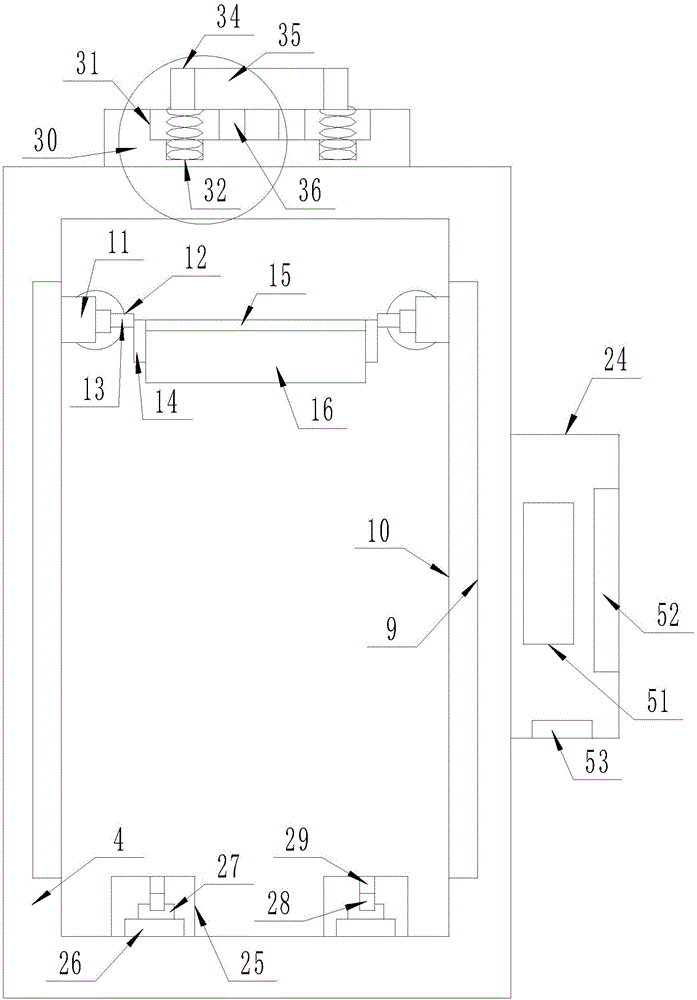

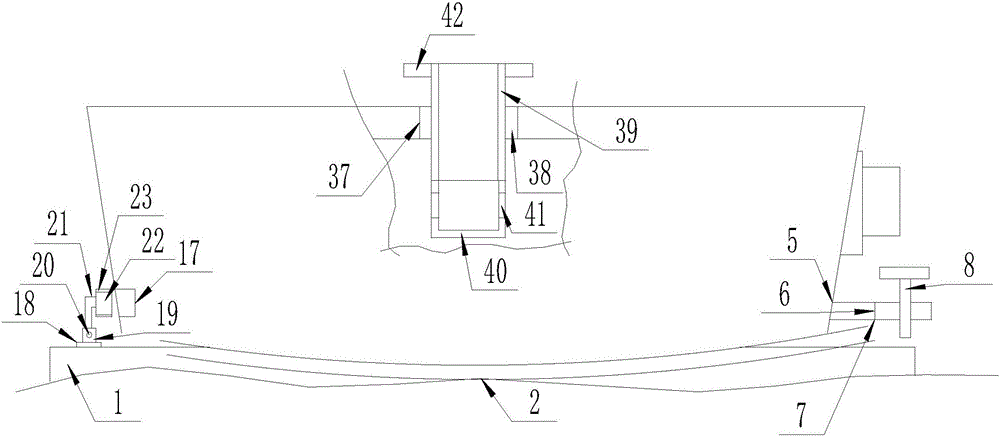

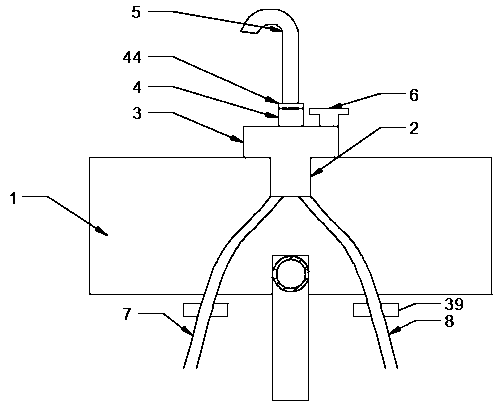

ActiveUS20190061019A1High precisionImprove efficiencyMilling machinesAircraft assemblyFeed driveEngineering

The present invention discloses a multifunctional end effector, comprising a base (54) and a cutting tool (39); a feed slide (52) on the base (54) and a feed driving mechanism used to drive feed slide (52) to feed cutting tool (39); a swing slide (55) on the feed slide (52) and a swing driving mechanism used to drive swing slide (55) to realize circular arc swing of cutting tool (39); a mounting base (12) on the swing slider (55); a revolving rotation shaft (20) and a rotation shaft driving mechanism used to drive revolving rotation shaft (20) to make the cutting tool rotate in the mounting base (12); an eccentric slide (27) fixed to the end of revolving rotation shaft (20); cutting tool (39) is connected to the end of eccentric slide (27) via the electric spindle (37) and an eccentric regulating mechanism used to regulate eccentric slide (27) and control radial bias of cutting tool (39). Use feed driving mechanism to realize feed of cutting tool or feed of cutting tool along the swing trail through combination with swing driving mechanism; use eccentric regulating mechanism to realize radial bias of cutting tool; make use of rotation shaft driving mechanism to realize feed of cutting tool along the helical trail; it can realize such functions as drilling, boring, reaming, helical milling and reaming of elliptical recess.

Owner:ZHEJIANG UNIV

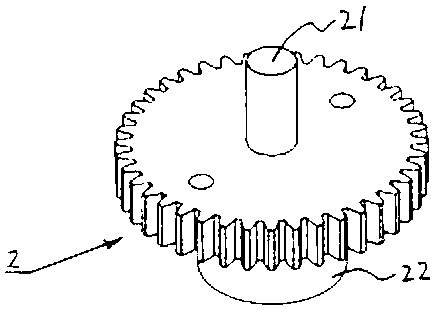

Elliptical gear profile generator

InactiveCN102991216ASimple structureReduce manufacturing costNon-circular curve drawing instrumentsGear wheelEngineering

Owner:LIAONING INST OF SCI & TECH

Fluid dynamic bearings

A fluid dynamic bearing. A shaft is fit in the sleeve and rotates with respect thereto. A lubricant is filled between the shaft and the sleeve. At least one elliptical groove is formed on either the shaft or the sleeve and between the shaft and the sleeve. When the shaft rotates with respect to the sleeve, the lubricant is filled in the elliptical groove.

Owner:NAT TAIWAN UNIV

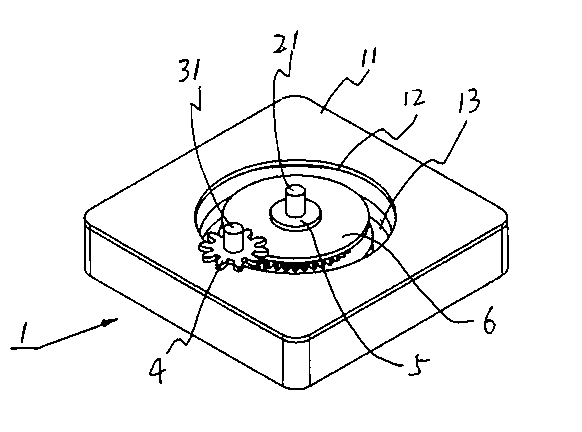

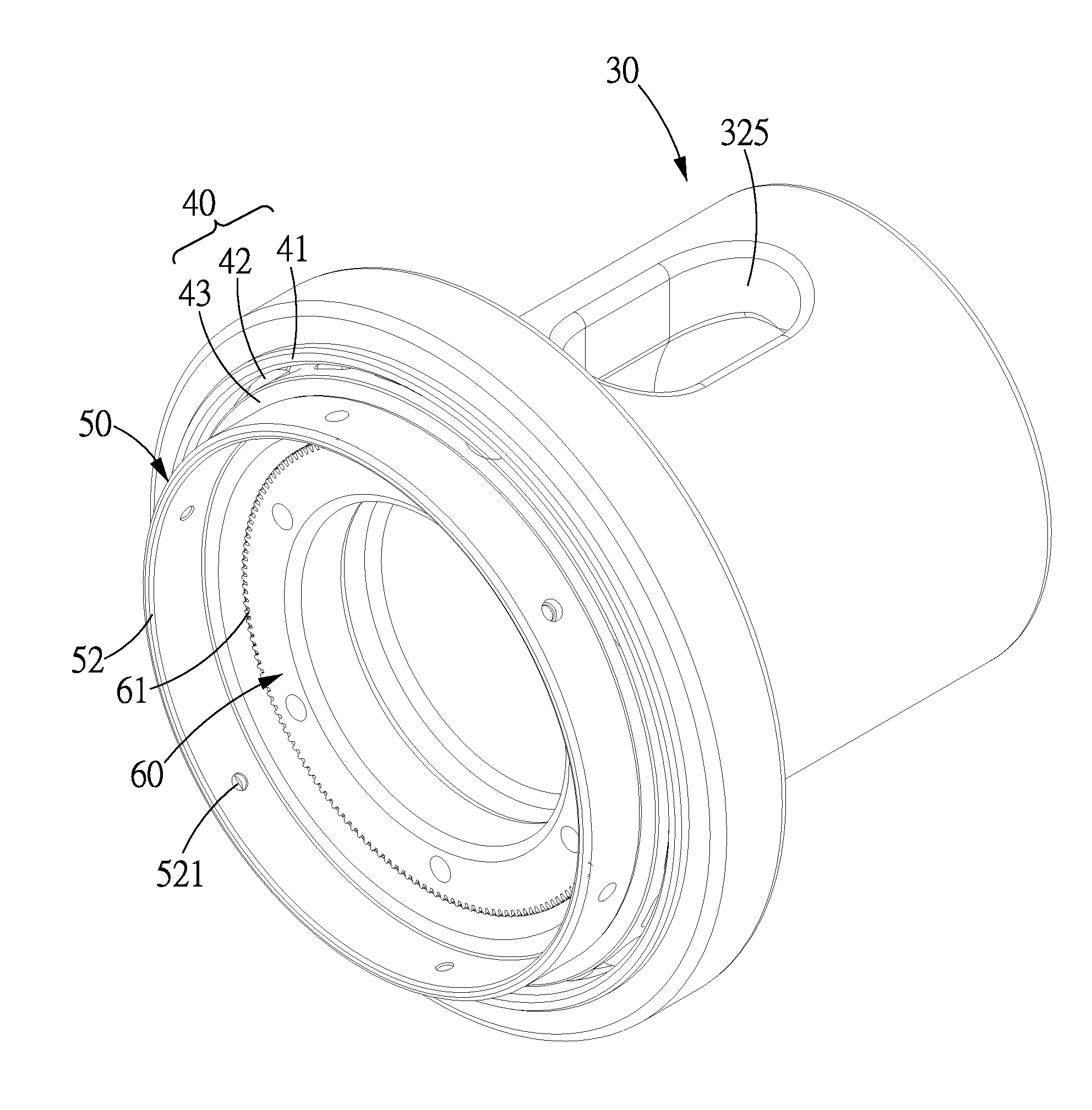

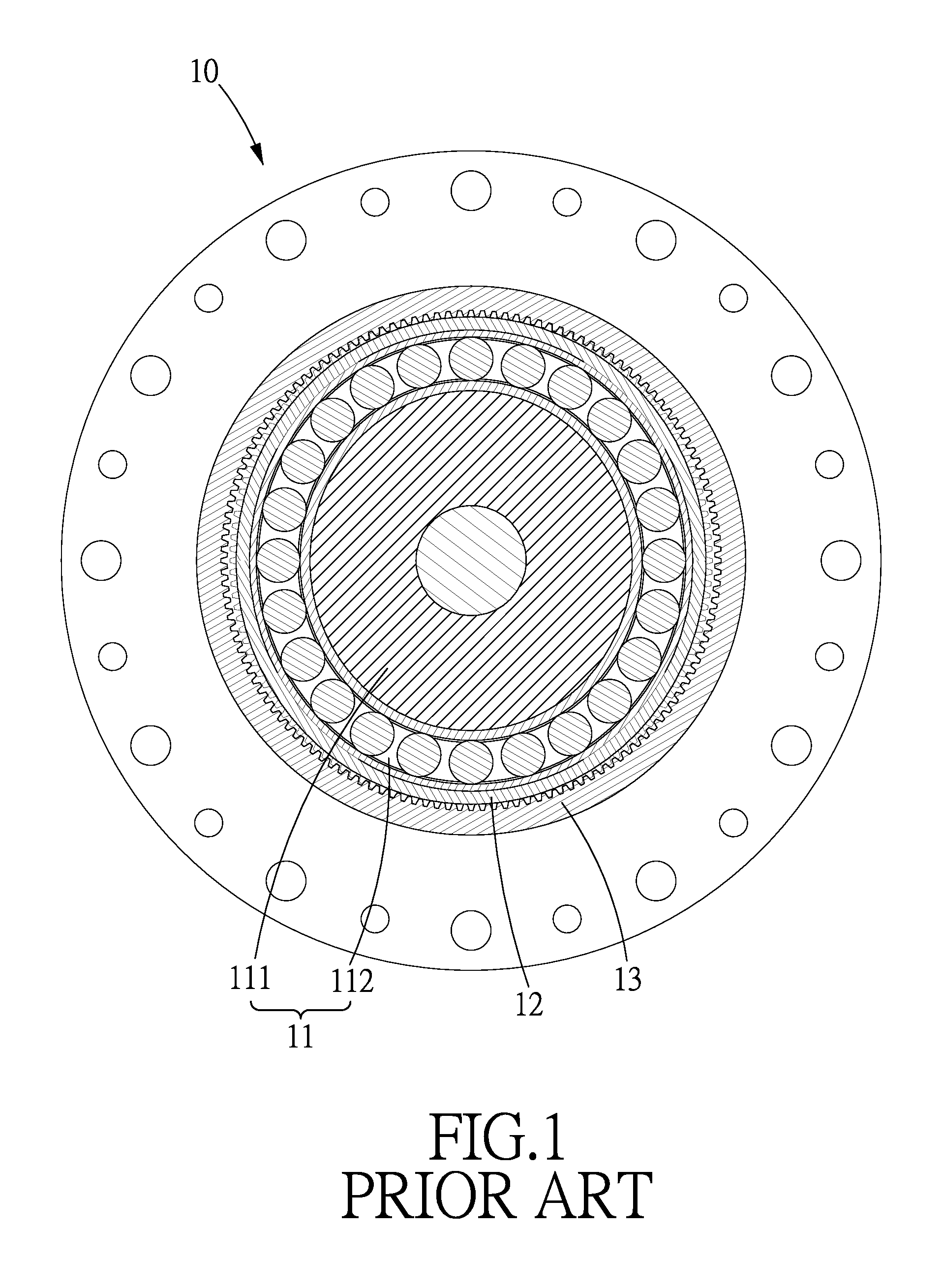

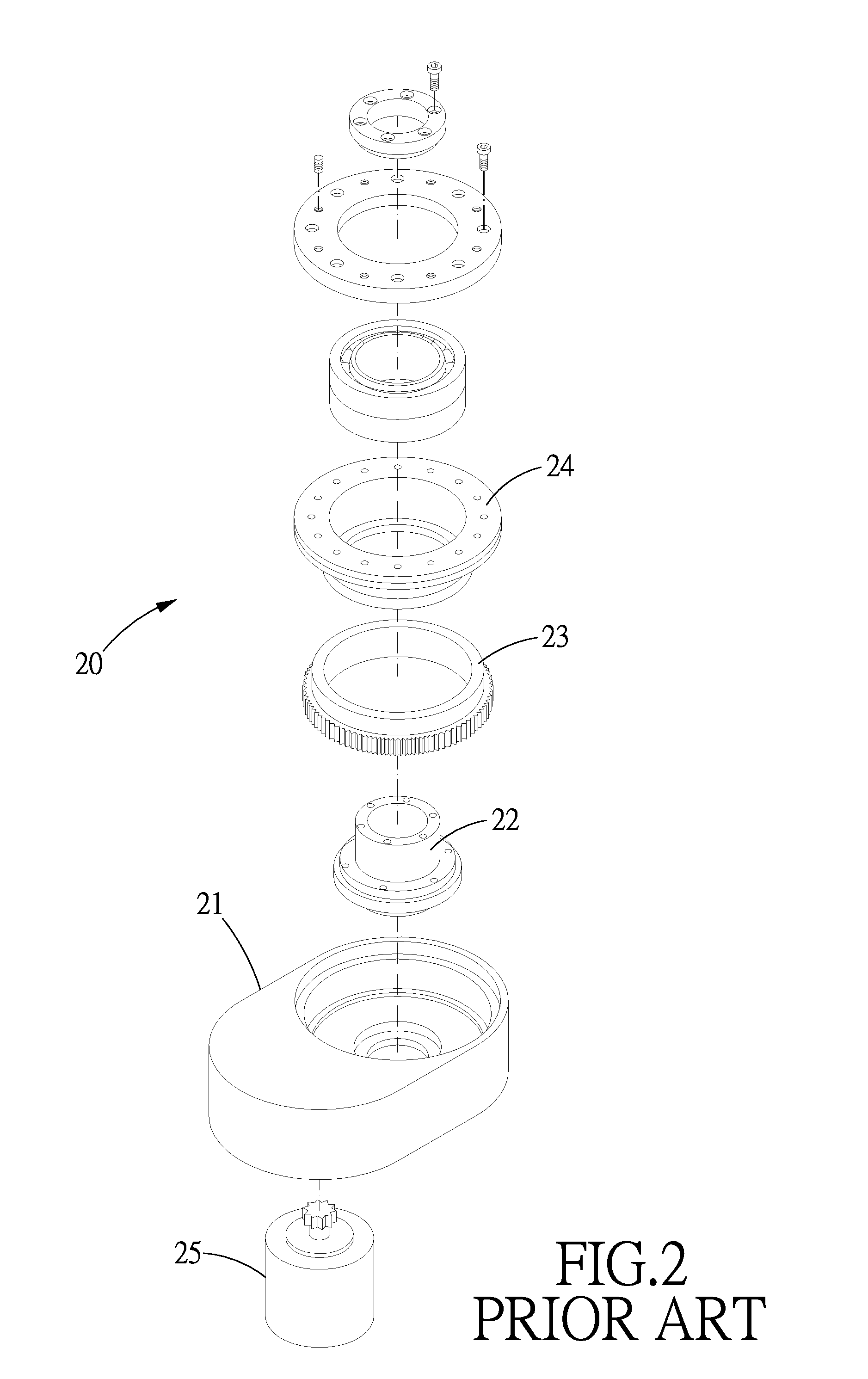

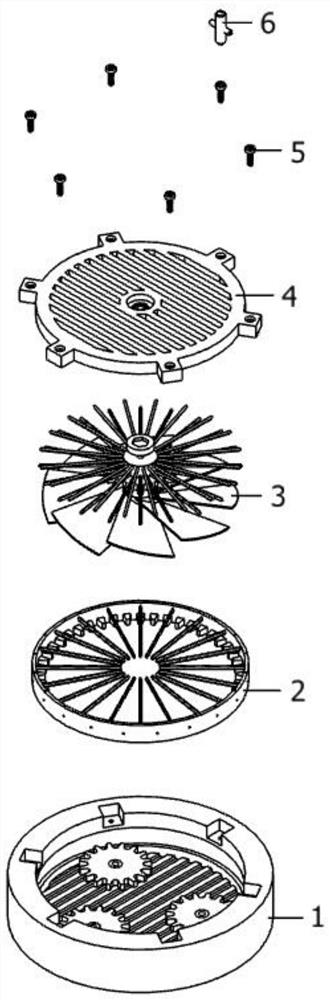

Hollow Drive Gear Reduction Mechanism

ActiveUS20150285355A1Simple structureEasy to assembleGearingGearing detailsEngineeringElliptical recess

A hollow drive gear reduction mechanism includes a hollow wave generator, an annular flexible bearing, a flexible wheel, and a rigid wheel. The annular flexible bearing is disposed in and driven to rotate by an elliptical recess of the wave generator. The flexible wheel includes an inner toothed section and is inserted in the annular flexible bearing and has an outer surface abutted against an inner surface of the inner ring, and the flexible wheel is driven to rotate by the annular flexible bearing. The rigid wheel includes a plurality of outer teeth which are different in number from the inner teeth of the flexible wheel, the rigid wheel is inserted in the flexible wheel, and a part of the outer teeth are meshed with the inner teeth. The respective components are hollow structures, and a lateral aperture is formed on the hollow wave generator.

Owner:HIWIN TECH

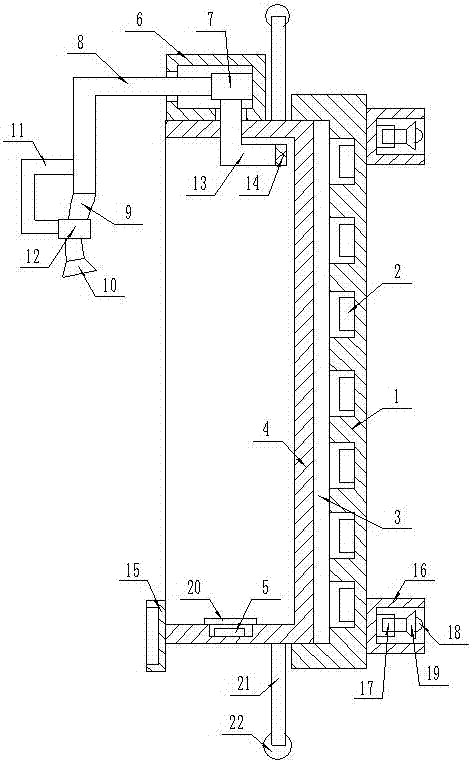

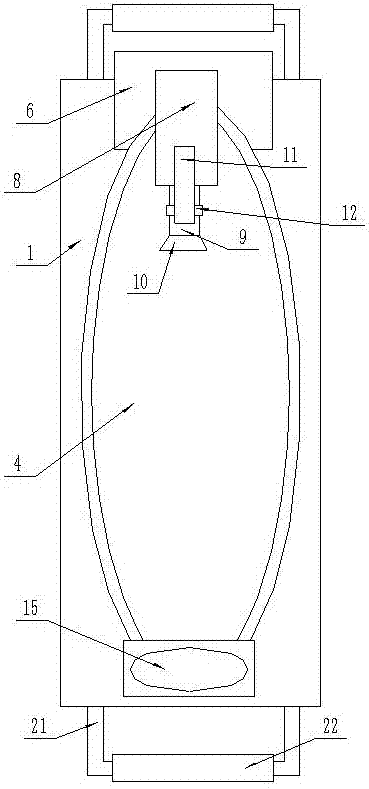

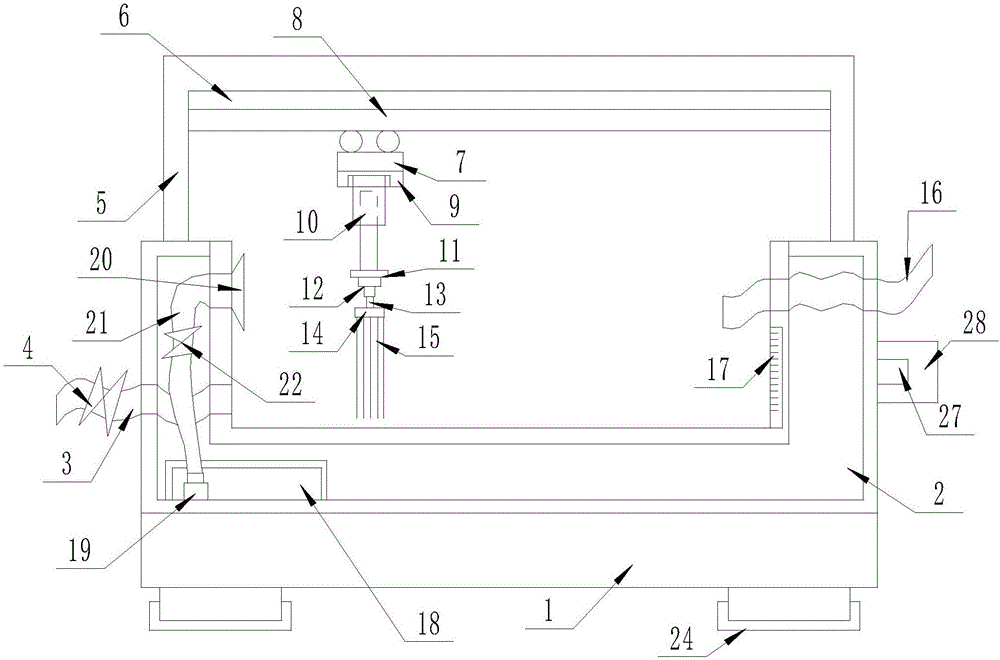

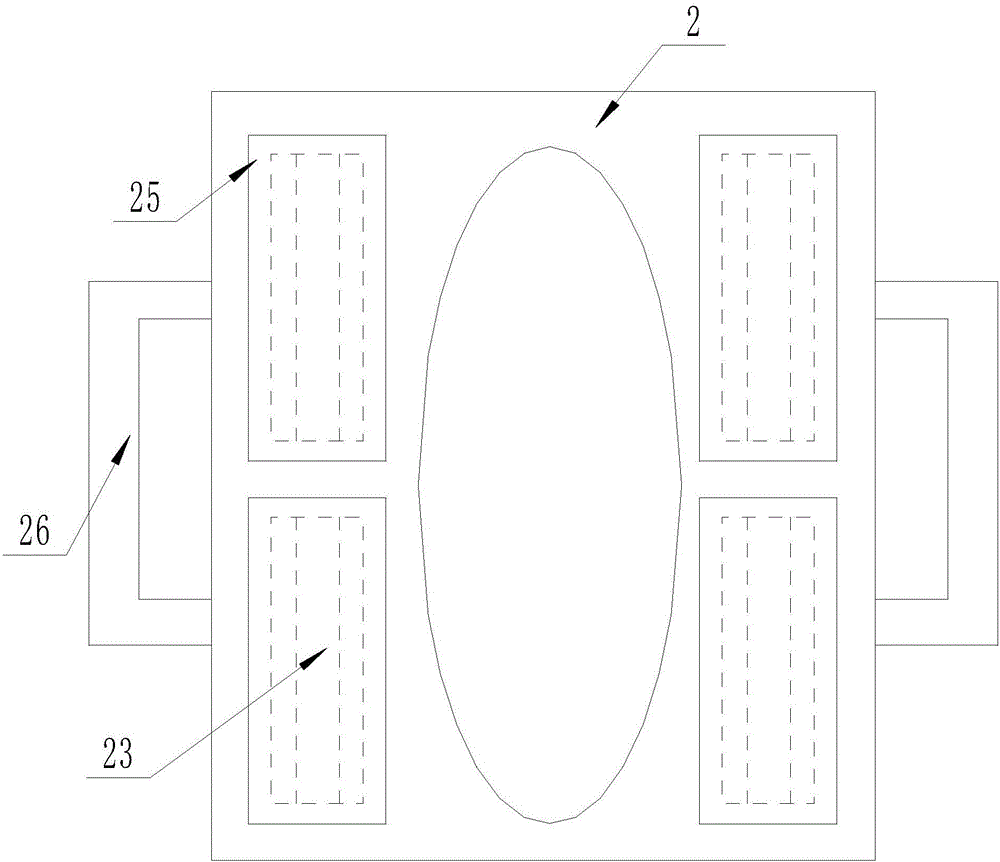

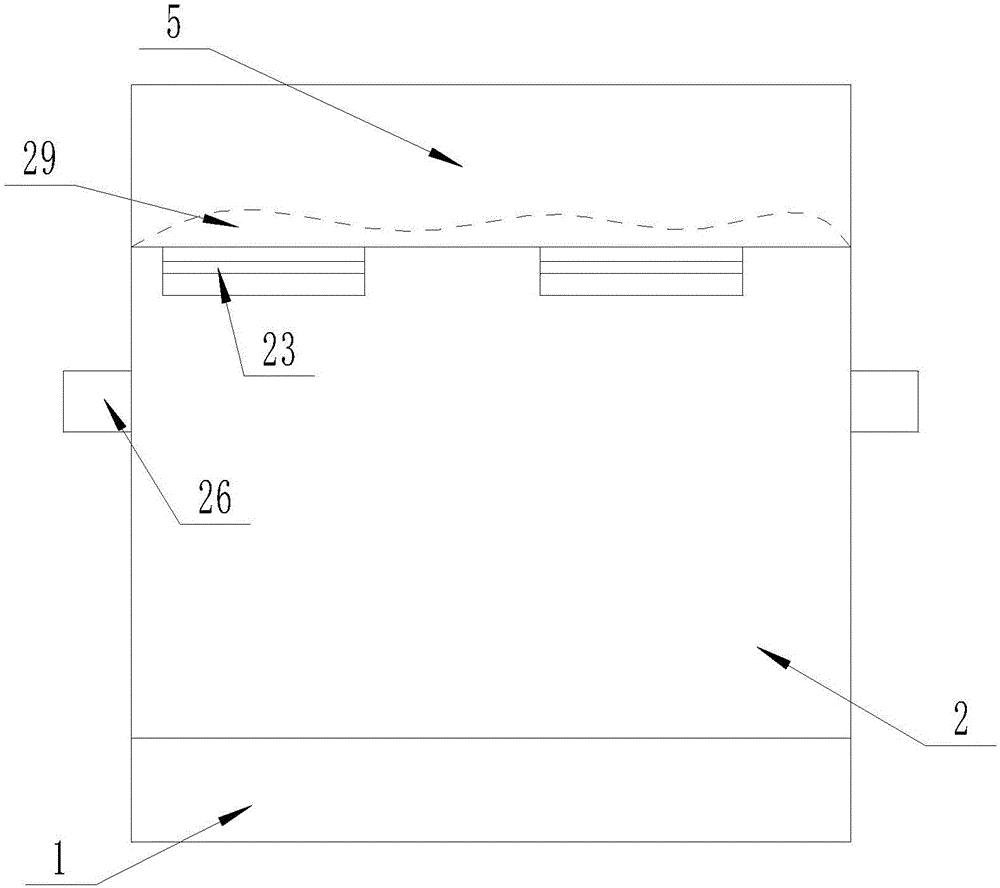

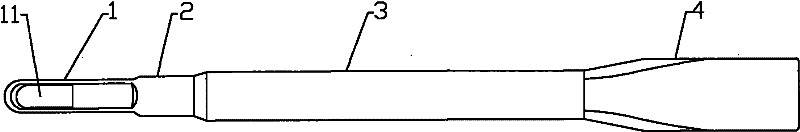

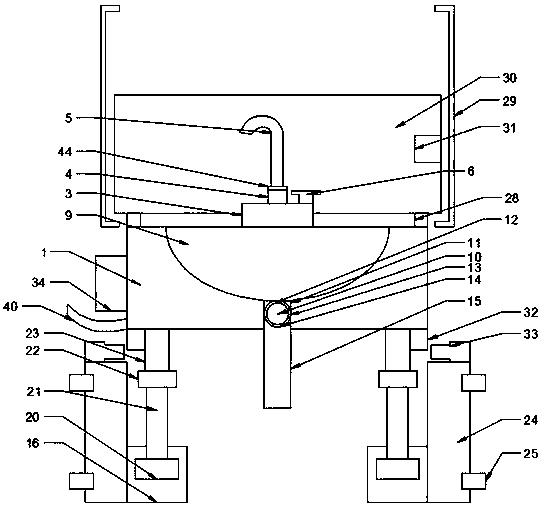

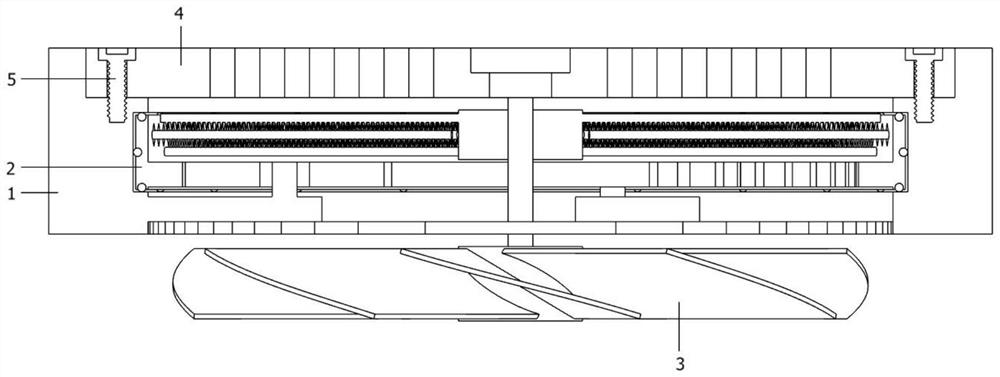

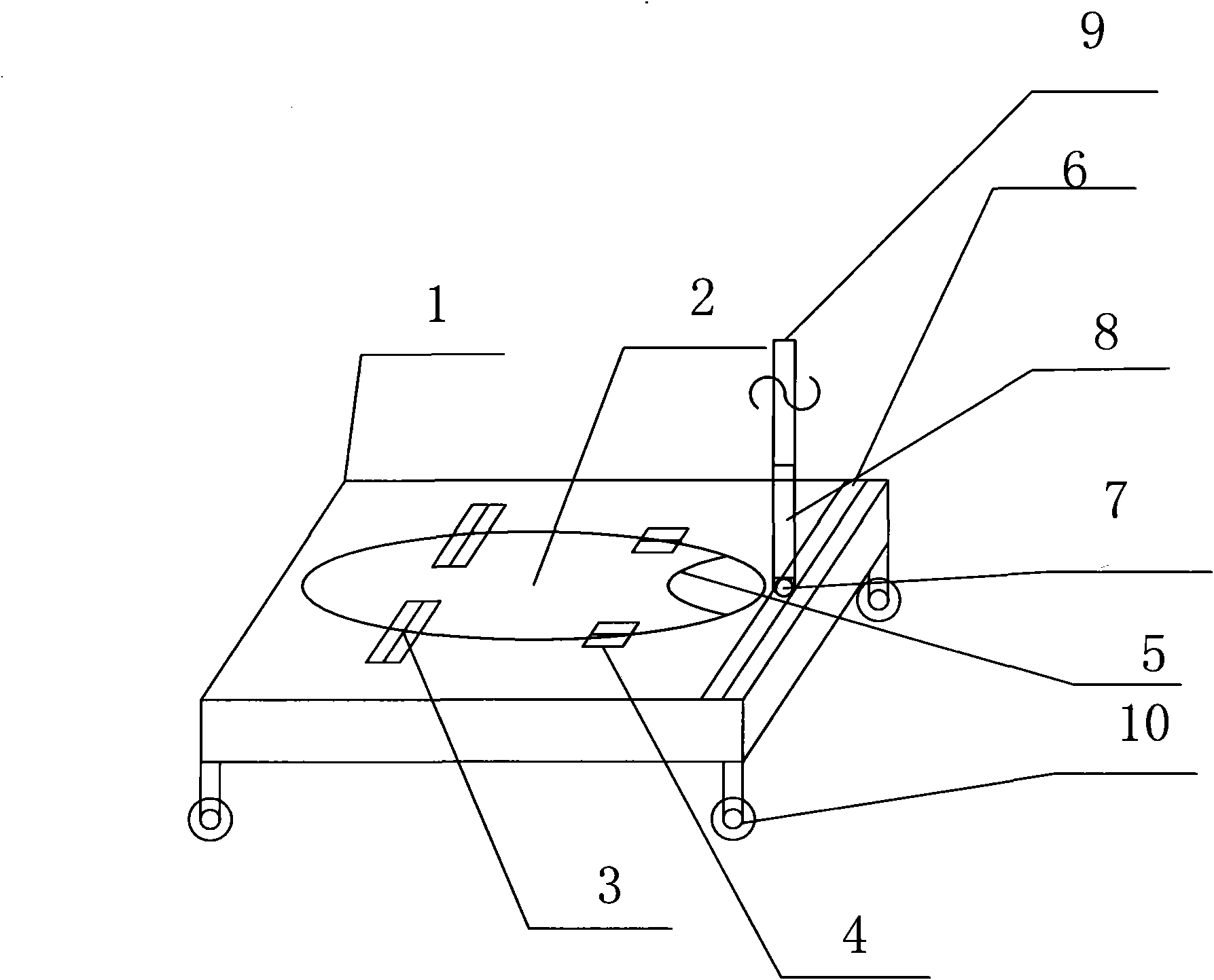

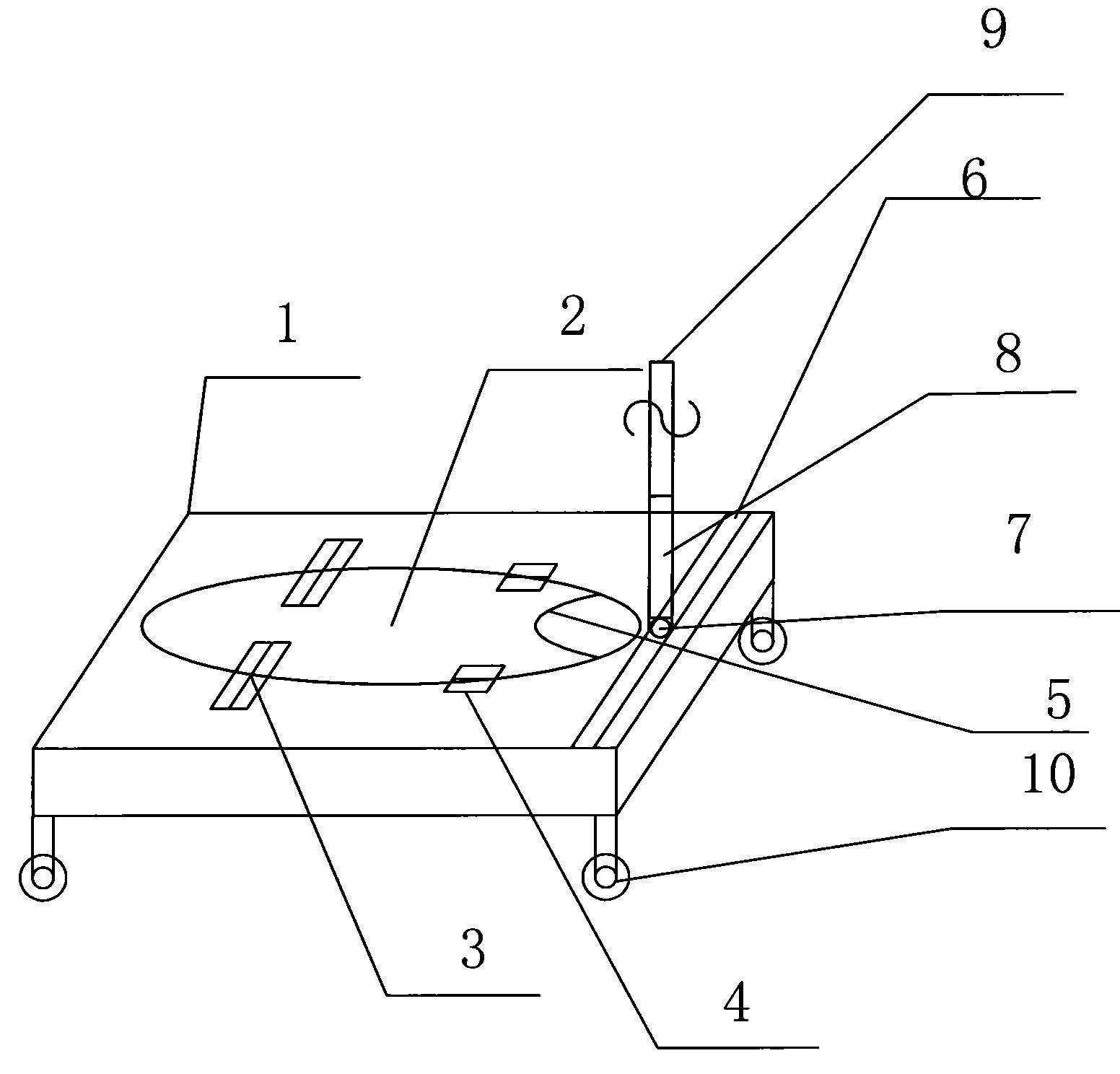

Elliptical recess reaming device

The invention discloses an elliptical recess reaming device which comprises a numerical-control turntable, a rotary base, linear guide rails, a feeding ram, a swinging ram, arc guide rails, an electric spindle, a cutter and the like. The rotary base is mounted on the numerical-control turntable and can rotate around a first axis, the linear guide rails are arranged on the rotary base, the feeding ram is slidably mounted on the linear guide rails, the swinging ram is slidably mounted on the feeding ram, the arc guide rails are fixed onto the feeding ram and are used for guiding the swinging ram, the electric spindle is arranged on the swinging ram and is parallel to the first axis, and the cutter is mounted on the electric spindle. The elliptical recess reaming device has the advantages that the feeding ram, the swinging ram and the rotary base are matched with one another according to shape and dimension features of elliptical recesses, so that the cutter can be fed and can swing, angles of swinging planes of the cutter can be changed, and the elliptical recesses can be precisely machined.

Owner:ZHEJIANG UNIV

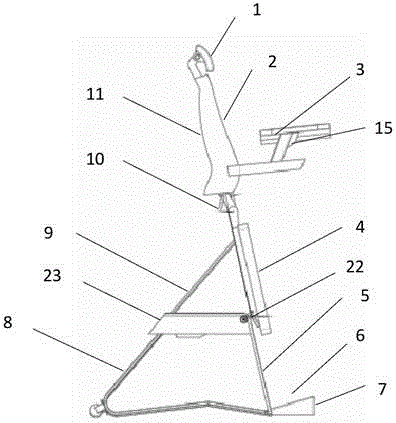

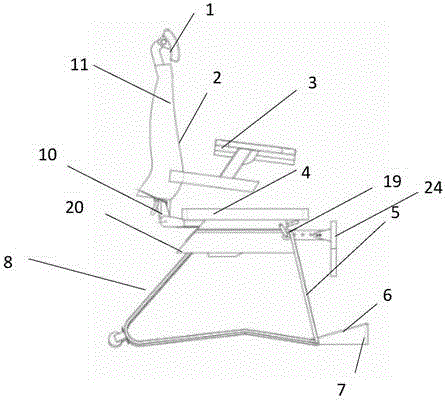

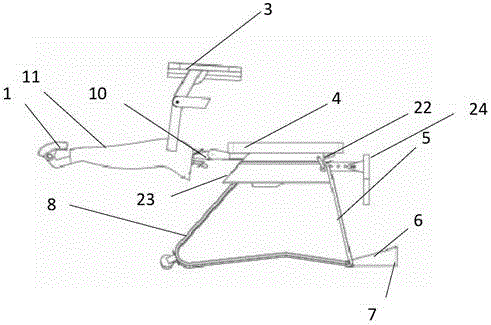

Standing type office chair

PendingCN106175232AAchieve upright officeRelieve fatigueBenchesConvertible chairsGluteal regionOffice chair

The present invention discloses a standing type office chair. According to the standing type office chair, with a support leg frame comprising two length adjustable rear brackets, and a connection member capable of adjusting the angles of a supporting plate and a waist supporting member, the office chair can stand so as to achieve the standing office; with the arrangement of height adjustable arm supporting members on a backrest, the two arms of a user can be held up and supported, such that periarthritis caused by the arm suspending of the user using the computer for a long time and other diseases can be reduced; with the arced projection positioned on the middle-lower portion of the waist supporting member, the protection can be provided for the waist of the user; the supporting plate presents the elliptical concave groove shape, such that the gluteal region of the user can comfortably lean on the chair in the use state; and a pedal is arranged between two front supporting legs, and the front end of the pedal is provided with two rotatable vertical columns, such that the feet and the body of the user can maintain the comfortable and coordinated state during the use.

Owner:WAO TRADING SHANGHAI CO LTD

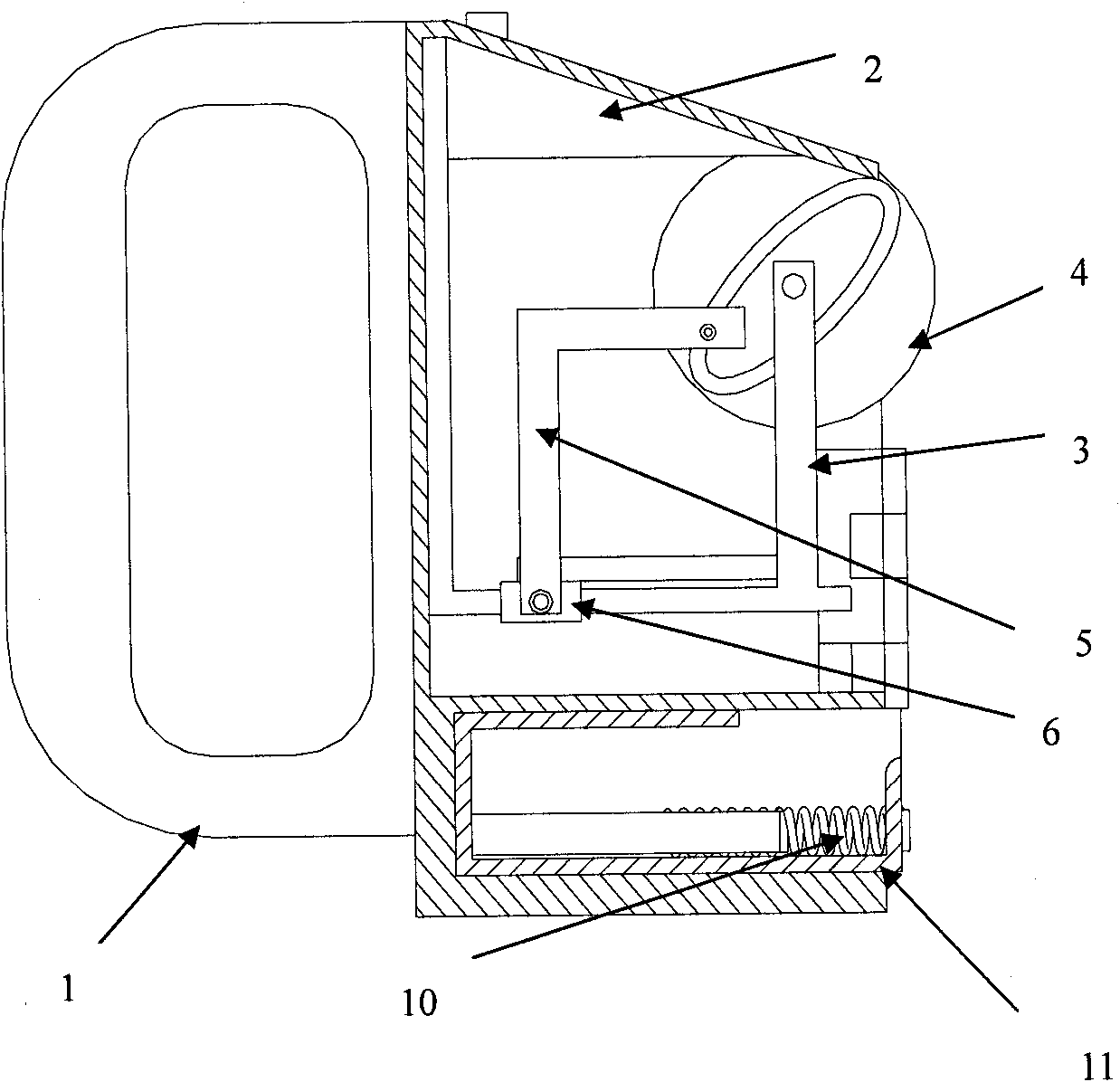

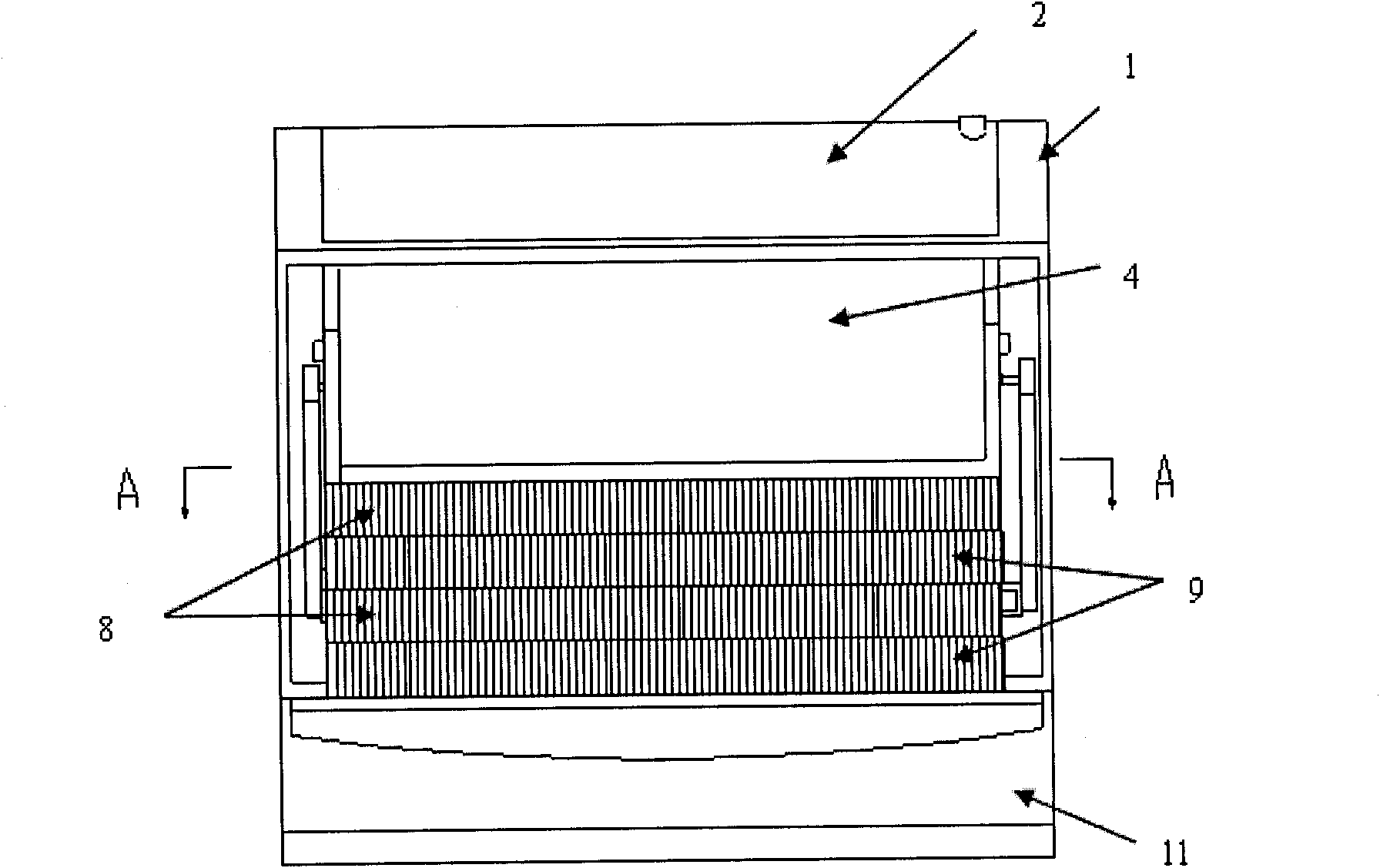

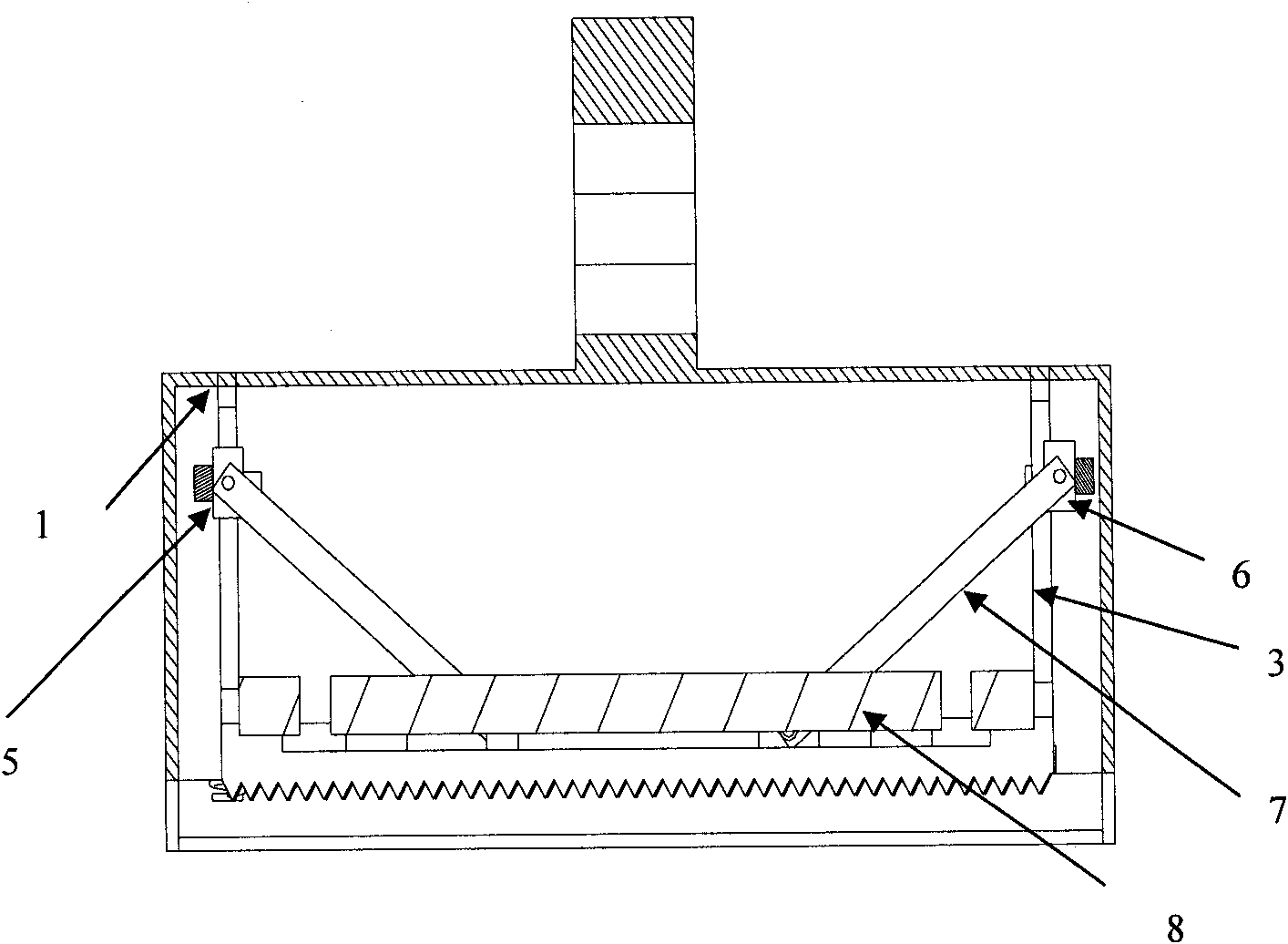

Portable mechanical type junk advertisement paper cleaner

InactiveCN101869898AEasy to cleanStable collectionCleaning using toolsCleaning using liquidsChinese charactersEngineering

The invention relates to a portable mechanical type junk advertisement paper cleaner. A cleansing liquid applying mechanism, a chipping mechanism and a chippings recycling mechanism are fixed in a box shell; a water tank of the cleansing liquid applying mechanism is fixed to the topside in the box shell; a water absorbing roller is fixed under the water tank by a roller support bracket, and both ends of the water absorbing roller are respectively provided with an elliptic groove; sawteeth which are distributed in a row are arranged on a sliding rack of the chipping mechanism; the front end of a connecting rod is provided with a roller follower, and the roller follower is installed in the elliptic groove; the other end of the connecting rod is in clearance fit with a sliding rod of the roller support bracket by a sliding sleeve in a shape like the Chinese character hui and meanwhile is connected with one end of an oscillating bar trough a rotating pair; the other end of the oscillating bar is connected with the sliding rack by a rotating pair; the back of the sliding rack is provided with a groove and forms a moving pair with the front end of the roller support bracket; a shovel-shaped tray of the chippings recycling mechanism is connected with the guide column moving pair of the box shell; and a reset spring is positioned between a guide column and the shovel-shaped tray. The invention has mechanical type, environmental-protection, sanitary and simple structure, small size, light weight and convenient carrying and use.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Water tank with automatic clearing and display functions

The invention discloses a water tank with automatic clearing and display functions. The water tank comprises a strip-shaped base, a fixed mechanism is arranged on the side surface of the strip-shaped base, an elliptical groove is formed in the upper surface of the strip-shaped base, an arc-shaped water accumulation bearing tank is embedded in the elliptical groove, a rotating clearing mechanism is arranged on the side surface of the lower end of the arc-shaped water accumulation bearing tank, a feeding mechanism is arranged on the upper surface of the arc-shaped water accumulation bearing tank, a detection mechanism is arranged on the inner side surface of the arc-shaped water accumulation bearing tank, a display mechanism is arranged on the side surface of the arc-shaped water accumulation bearing tank, a water outlet is formed in the side surface of the lower end of the arc-shaped water accumulation bearing tank, a dustproof screen is embedded in the water outlet, a drain pipe is embedded in the water outlet, a hand valve is arranged on the drain pipe, and a controller is arranged on the side surface of the arc-shaped water accumulation bearing tank. The water tank has the beneficial effects of having a simple structure and being strong in practicability.

Owner:中山佳立机电科技有限公司

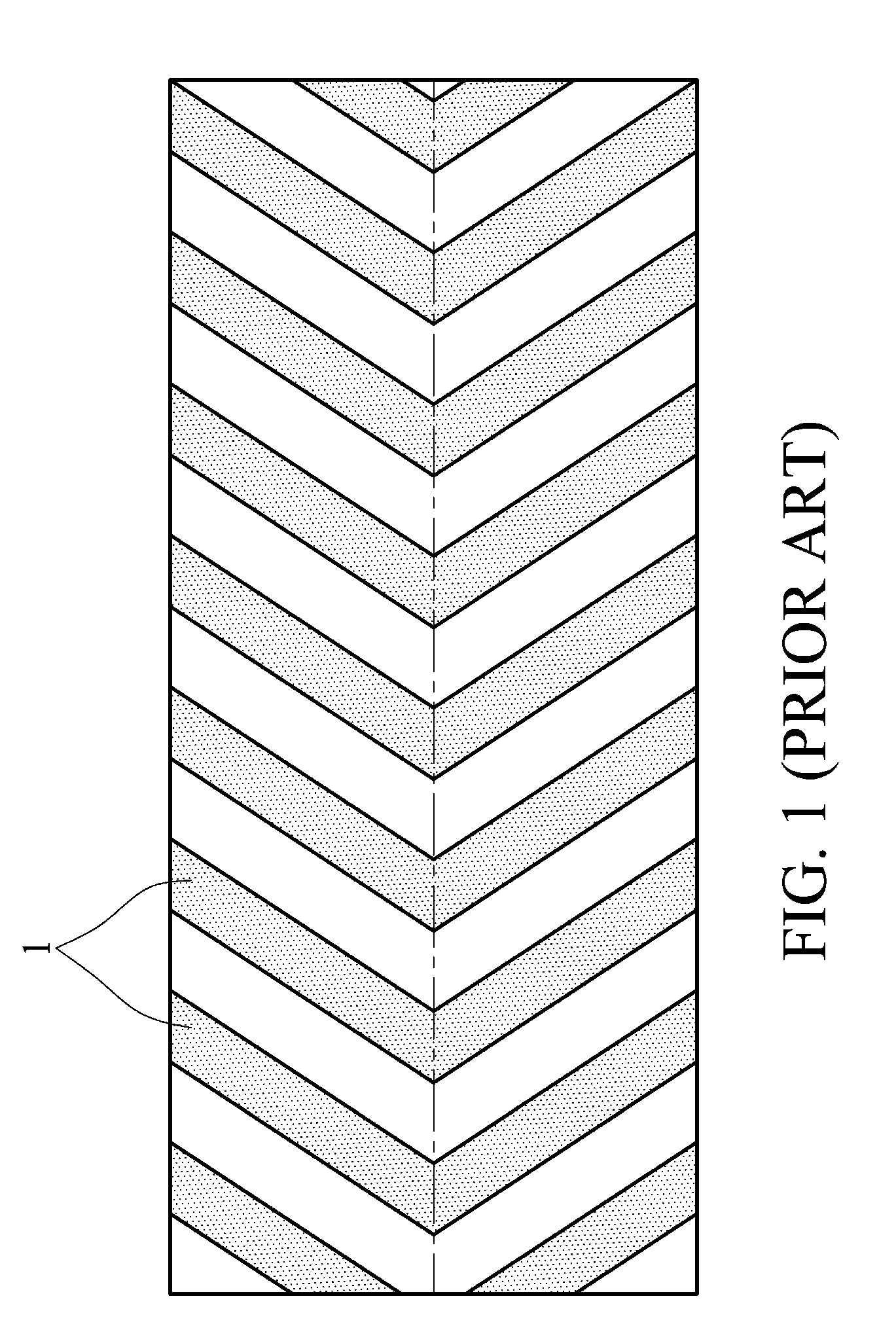

Polarizer and liquid crystal display employing same

A polarizer includes an optical anisotropic transparent substrate. The substrate includes a light incident surface, a light emitting surface and a plurality of substantially elliptical grooves defined in the light emitting surface. The light emitting surface is opposite to the light incident surface. The elliptical grooves are oriented in an essentially identical direction. Each elliptical groove has a major axis and a minor axis. A length of the major axis is essentially equal to or greater than a wavelength of incident light, and a length of the minor axis is less than the wavelength of the incident light.

Owner:HON HAI PRECISION IND CO LTD

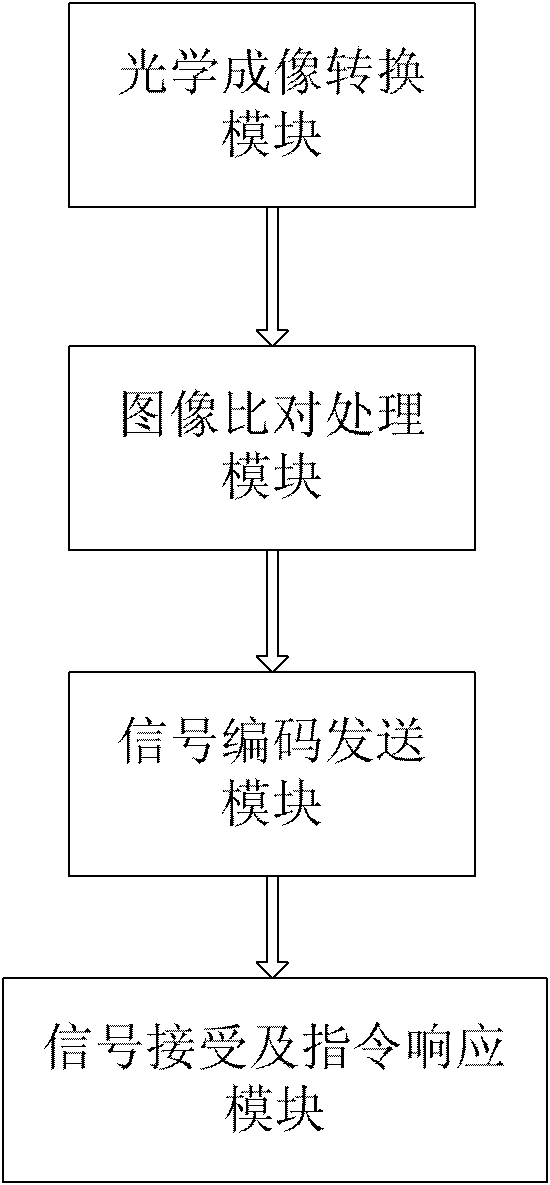

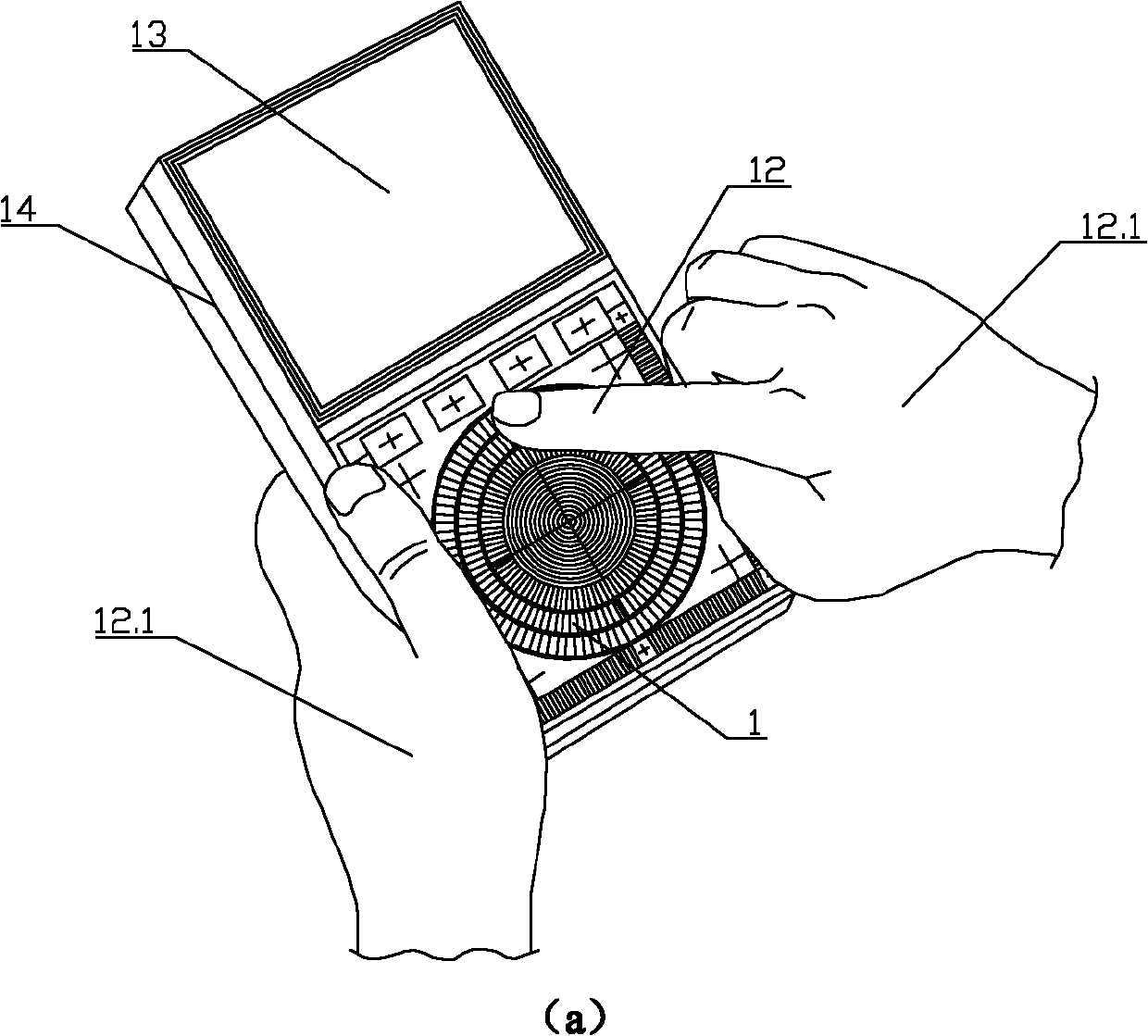

Optical imaging conversion module, object control system and control method

InactiveCN101950220AAchieve indirect controlInput/output for user-computer interactionGraph readingHuman–machine interfaceControl system

The invention discloses an optical imaging conversion module, an object control system and a control method. A human-computer interface board in the optical imaging conversion module uses a linear groove to represent the X, Y and Z axes in a three-dimensional space coordinate system, and uses a round or elliptical groove to represent rotations which take the X, Y and Z axes as centres in the three-dimensional space coordinate system; and user fingers or an operating pen moves in a human-computer interface groove to realize moving or rotating a controlled object in two-dimensional or three-dimensional space, and the central region of the human-computer interface board serves as a word hand input region. The whole control system identifies and codes the meaning of a mobile track of a user on the groove and a human-computer interface bulge by the optical imaging and electronic technologies, and controls an object by transmitting to an order identification and respond end in a wired or wireless mode. The invention unifies the control modes of two-dimensional and three-dimensional space objects.

Owner:王东

Children bath basin with thermal insulation function

InactiveCN107280543AImprove the heating effectEasy to take a bathBathsDouchesThermal insulationEngineering

The invention discloses a children's bath tub with heat preservation function, which comprises a mounting base, an elliptical groove is processed on the upper surface of the mounting base, and a plurality of bar-shaped grooves are processed on the lower surface of the elliptical groove , each of the plurality of strip-shaped grooves is provided with a heating sheet, the lower surface of the oval groove is fixedly connected with an oval heat-conducting waterproof plate, and the upper surface of the oval-shaped heat-conducting waterproof plate An elliptical bath tub body is provided, a circular groove is processed at the center of the inner surface of the oval bath tub body, a temperature sensor is arranged in the circular groove, and a load bearing is provided on the outer surface of the oval bath tub body The box body, the carrying box is equipped with a micro-pump, the upper surface of the carrying box is processed with a circular water outlet, and a folded water outlet is embedded in the circular water outlet, and the folded water outlet One end is fixedly connected with a stretching water pipe. The invention has the advantages of simple structure and strong practicability.

Owner:应剑波

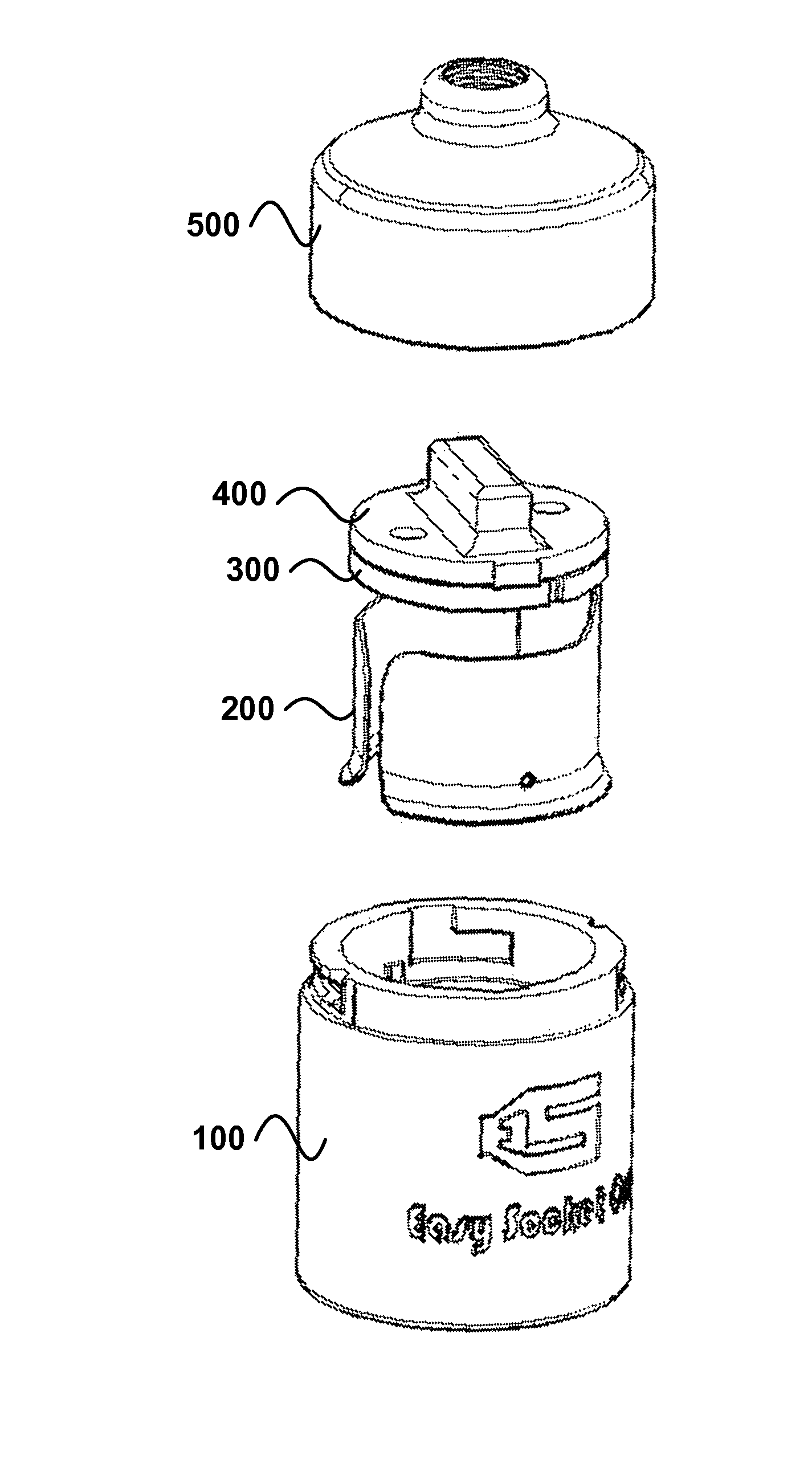

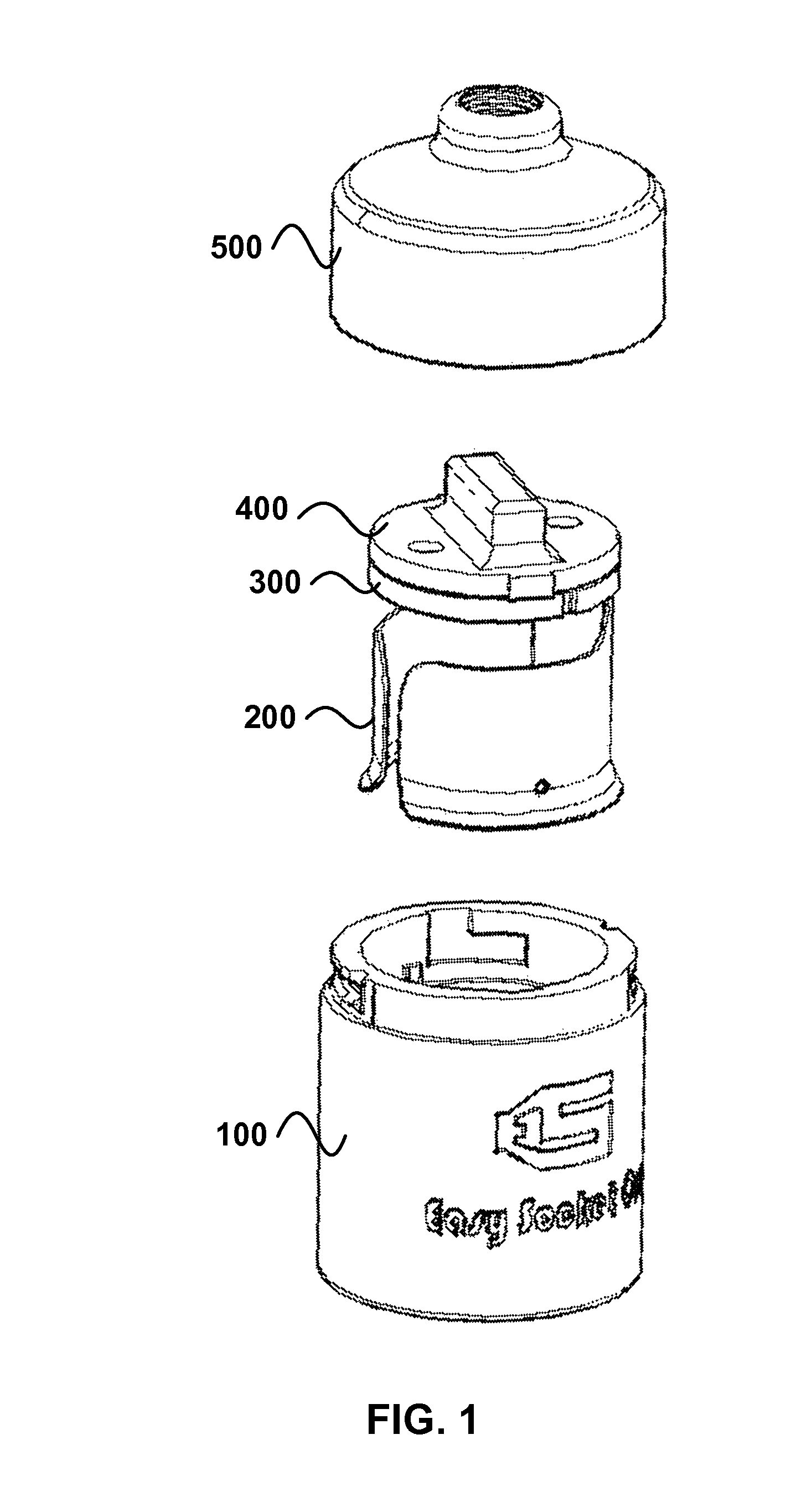

Easy assembling one click bulb socket

An easily assembling light bulb socket as disclosed secures a light bulb in a single clicking action. The disclosed socket comprises an electrically conductive sleeve configured to clasp a threaded end of the light bulb. The sleeve comprises a bump configured to slide into a thread recess and click-secure the bulb in the sleeve. A first disk received into the socket is riveted to the sleeve and to a metallic ribbon. The sleeve rivet makes a connection with a first wire and the ribbon rivet makes a connection with a second wire. The socket additionally comprises a second disk defining two holes aligned with the rivet holes in the first disk to receive a respective wire there through. The second disk holes include elliptical recesses configured to channel and secure the first and second wires between the disks when the second disk is axially rotated adjacent the first disk.

Owner:SANCHEZ ISAAC

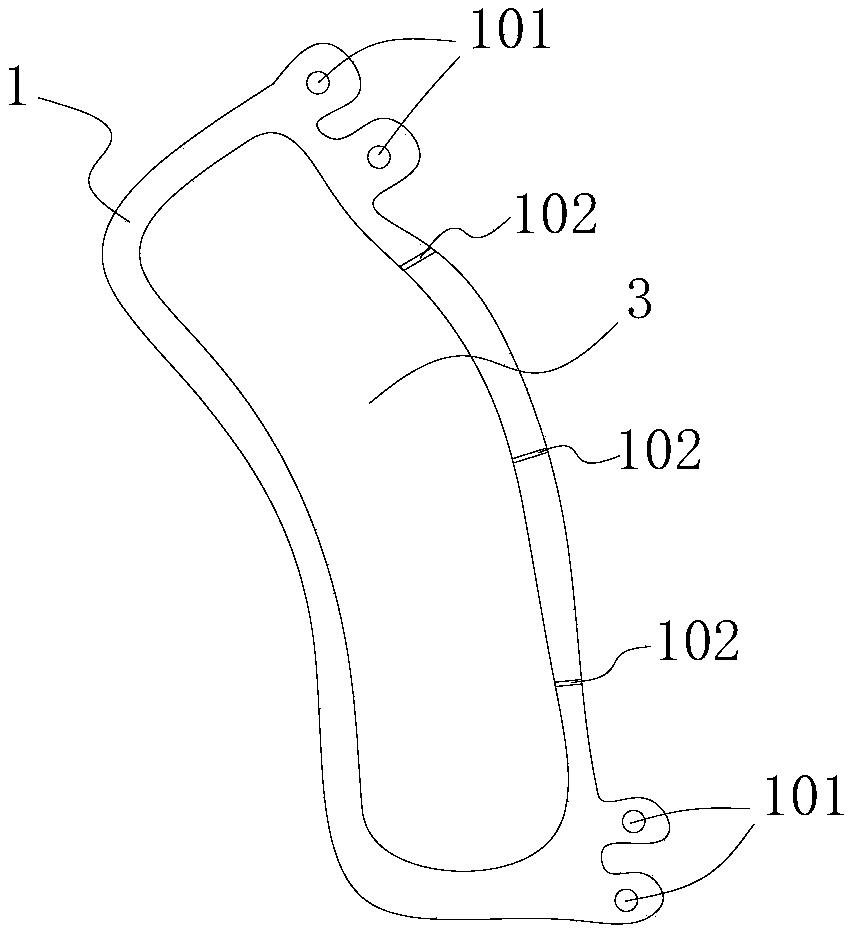

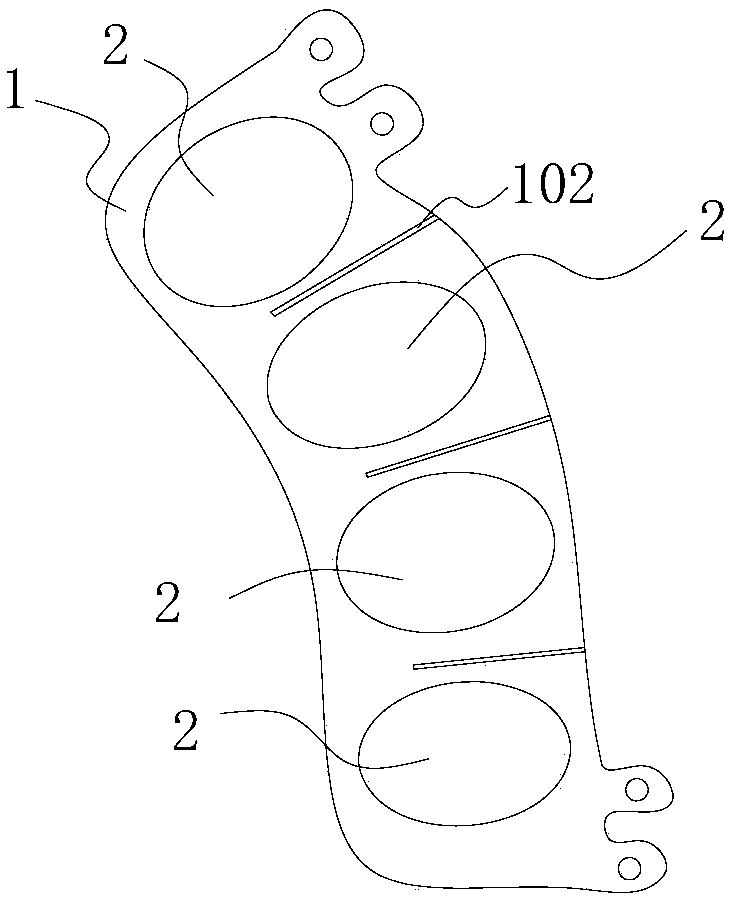

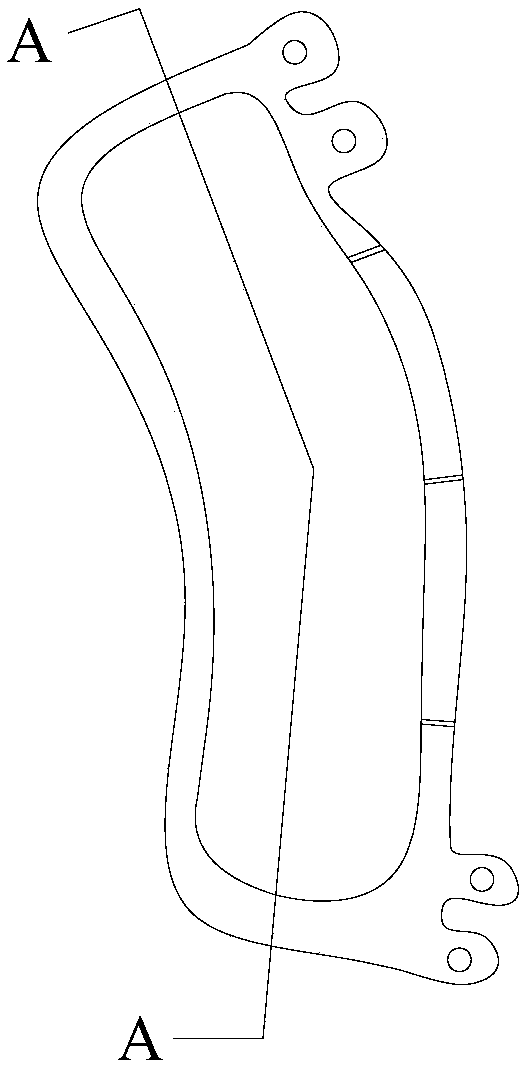

Brake pad

InactiveCN108331860AImprove performanceTimely replacementBraking membersFriction liningEpoxyFilling materials

The invention discloses a brake pad which comprises a brake pad framework, filling materials and a friction block. The brake pad framework is provided with at least four oval-shaped grooves, the filling materials are arranged in the grooves, the grooves are filled with the filling materials, and therefore the surface of the brake pad framework is flat. The friction block is attached to the flat surface of the filling materials and the framework. The friction block is made from carborundum, iron oxide powder, bitumen mastic and furan epoxy resin. According to the brake pad, the overall structure is optimally designed, the framework structure with the oval-shaped grooves is adopted, on one hand, the weight of the brake pad framework is reduced, the overall weight is optimized, on the other hand, the filling materials can be added into the groove structure of the brake pad framework, the overall performance of the brake pad is optimized, and binding force is improved by means of the cooperation of the filling materials and the friction block.

Owner:河北金雕新材料科技有限公司

Forming die and method for preparing pressed billet of non-oriented neodymium iron boron cylindrical magnet

ActiveCN103128283ASolve the problem of being unable to press compacts of cylindrical magnets with a diameter below 10mmReasonable designInductances/transformers/magnets manufactureMetallurgyElliptical recess

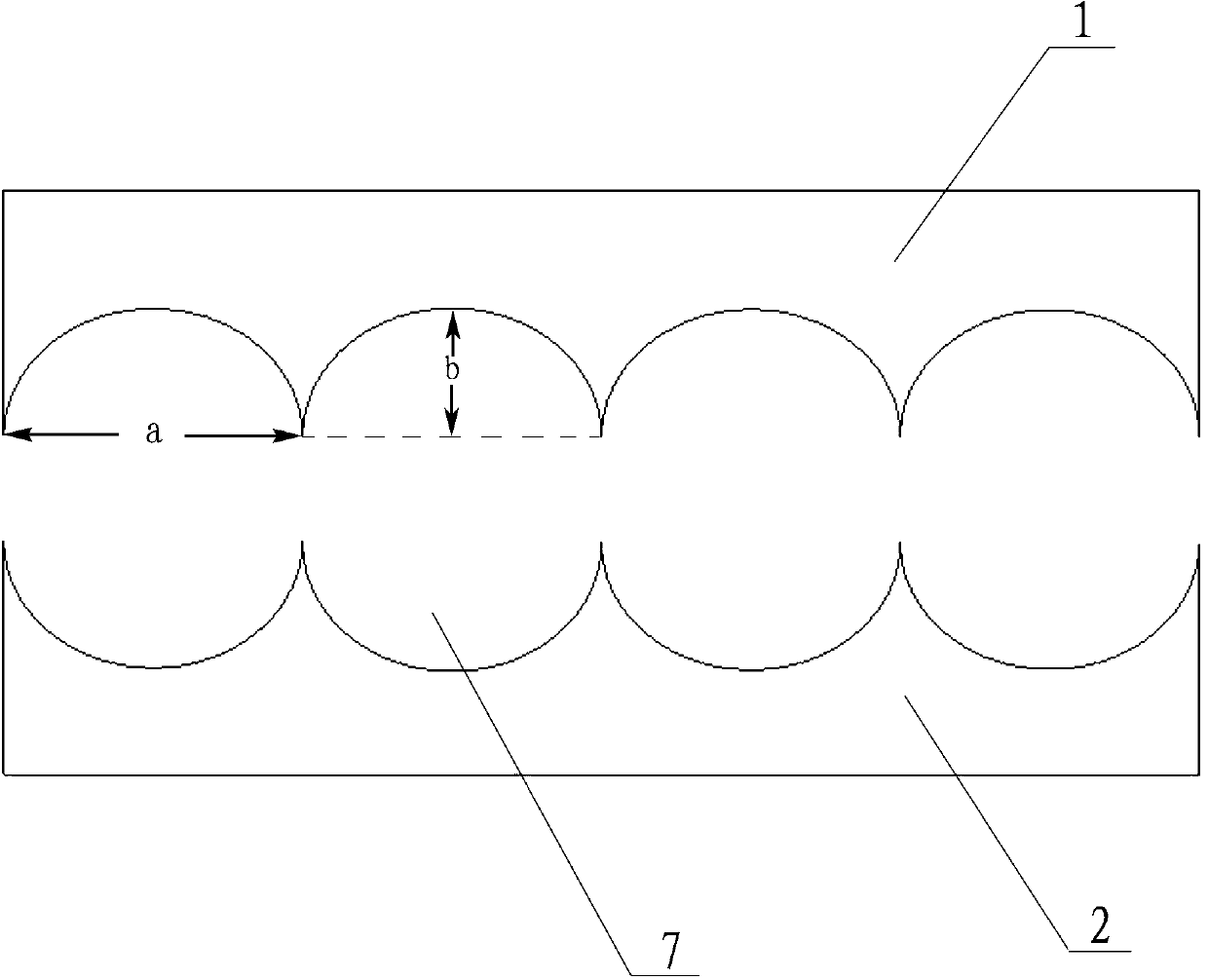

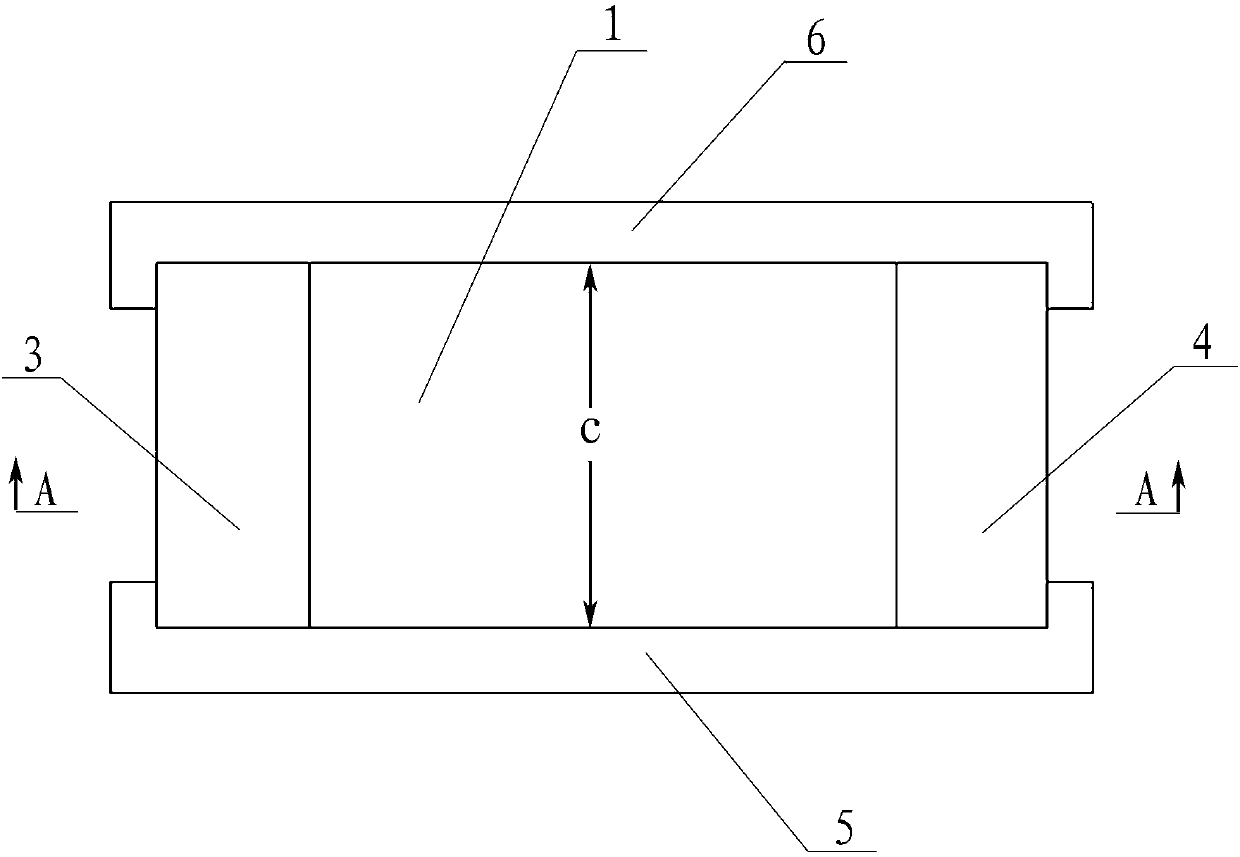

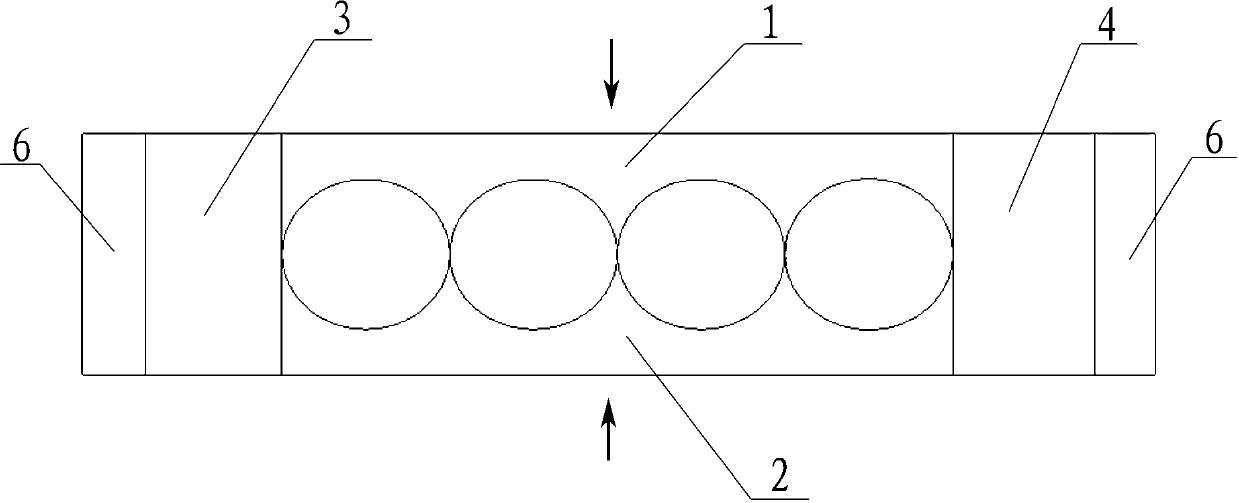

The invention relates to preparation of neodymium iron boron cylindrical magnets, in particular to a forming die and a method for preparing a pressed billet of a non-oriented neodymium iron boron cylindrical magnet, and solves the problem that an existing forming die cannot press a pressed billet of a cylindrical magnet with the diameter smaller than 10mm. The forming die for preparing the pressed billet of the non-oriented neodymium iron boron cylindrical magnet comprises a cavity, the cavity includes an upper cavity and a lower cavity, a plurality of parallel half-elliptic grooves can be combined into an elliptic cavity and are correspondingly formed on the contact surfaces of the upper cavity and the lower cavity respectively, and the cross sectional dimension of the elliptic cavity includes: an elliptic long axis=the magnet diameter / (0.75-0.77), an elliptic short axis=the magnet diameter / (0.825-0.835), and the length of each half-elliptic groove=the magnet length / (0.75-0.76), wherein the magnet refers to the non-oriented neodymium iron boron cylindrical magnet finally manufactured. The forming die is reasonable in design and simple in structure.

Owner:SHANXI HUIQIANG MAGNETIC MATERIAL MFG

Electric motor with self-adjusting bushing structure

A bushing structure 10 is constructed and arranged to be operatively associated with a shaft 24 of an electric motor 22. The motor has a housing 30 including a generally elliptical recess 32 therein defined along an axis C of the shaft. The bushing structure includes a generally cylindrical bushing member 12 constructed and arranged to engage an end of the shaft so as to locate the shaft with respect to the housing and to prevent lockup of the motor. An endplay member 20 is associated with the bushing member and with the end of the shaft. The endplay member includes a spherical portion constructed and arranged to be received in the elliptical recess so as to control endplay of the shaft.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

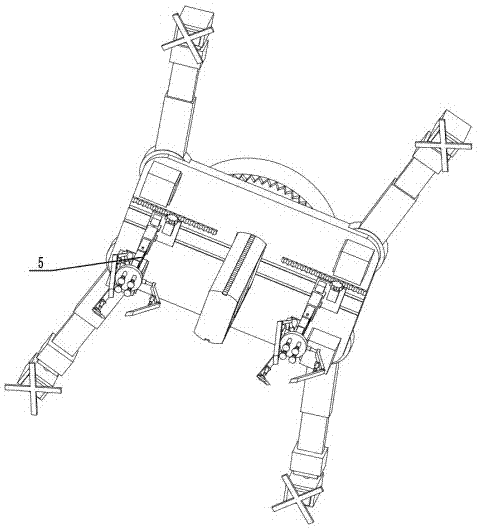

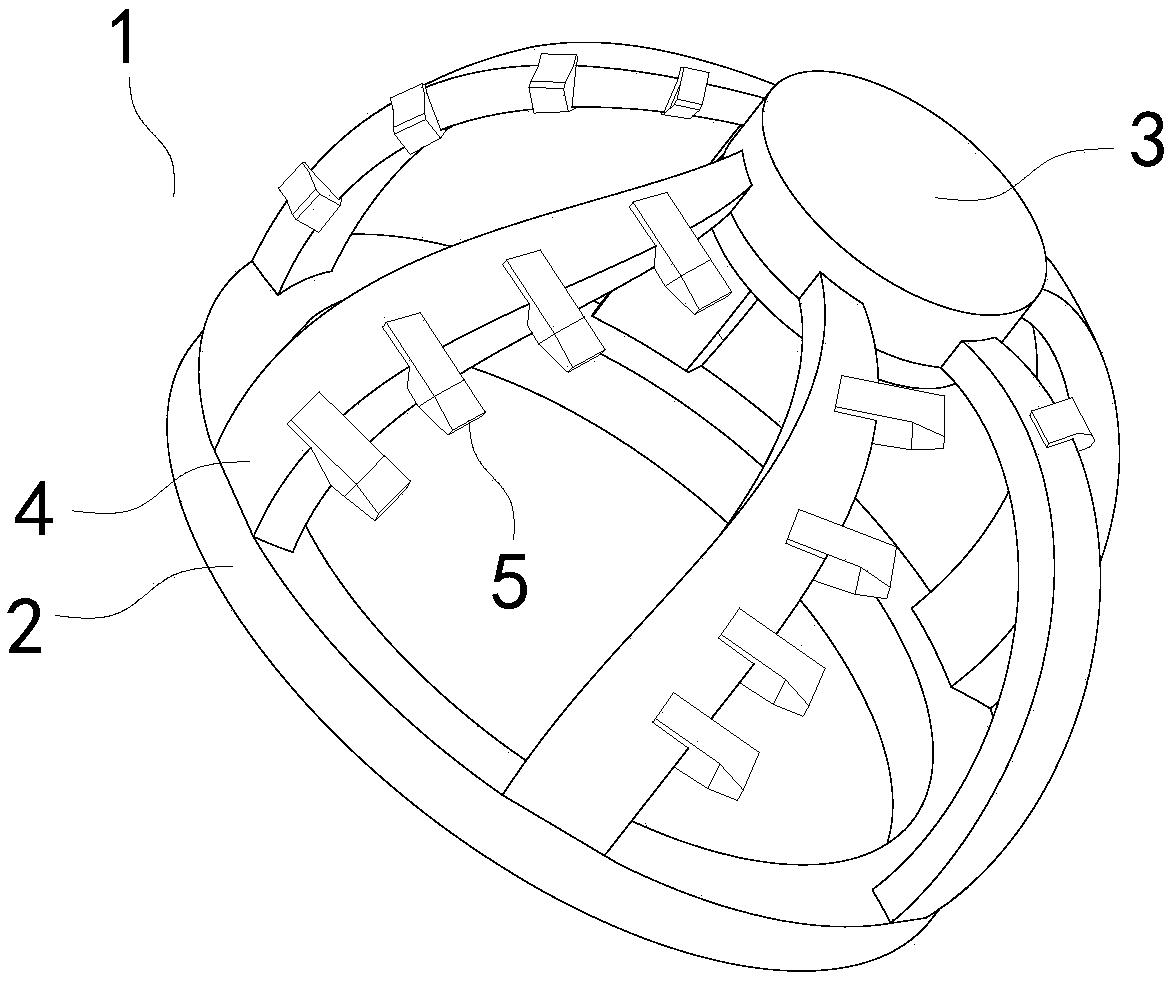

Large-scale bulb fritillaria catching robot

InactiveCN107877525AAutomated crawlingImprove crawling efficiencyPisciculture and aquariaMechanical energy handlingHydraulic cylinderEngineering

The invention discloses a large-scale pearl oyster catching robot. The catching robot comprises a base, a pearl oyster loading part, a pearl oyster storing part, four turbine parts and two pearl oyster grabbing parts, and is characterized in that the pearl oyster loading part is sliadably installed in an oval groove of the base, and two second racks are meshed with two second gears respectively. According to the large-scale pearl oyster catching robot, third gears are driven by fourth stepping motors of the two pearl oyster grabbing parts to drive the pearl oyster grabbing parts to move, foursuction discs are driven by four ninth hydraulic cylinders to suck pearl oysters, and next, three seventh hydraulic cylinders and three eighth hydraulic cylinders are coordinated to enable three second connecting rods to clamp the pearl oysters, and next, the pearl oysters are put into a pearl oyster storage box through the pearl oyster grabbing parts; and therefore automatic pearl oyster grabbingis realized, grabbing efficiency is improved, and grabbing operation is facilitated.

Owner:韩朝锋

Medical chamber pot having automatic cleaning function

InactiveCN106618911AImprove practicalityAvoid it happening againCleaning devicesBedpansElliptical recessEngineering

The invention discloses a medical chamber pot having an automatic cleaning function. The medical chamber pot comprises a rectangular base, wherein a rectangular box body is fixedly connected to the upper surface of the rectangular base; the interior of the rectangular box body is of a hollow structure; an elliptic groove is processed in the upper surface of the rectangular box body; a No. 1 round through hole is processed in the inner side surface of the elliptic groove; a No.2 round through hole, which is matched with the No.1 round through hole, is processed in the side surface of the rectangular box body; a drainage pipe is fixedly connected between the No.1 round through hole and the No.2 round through hole; a No.1 electromagnetic control valve sleeves the drainage pipe; and an electromagnetic retaining door, which is matched with the elliptic groove, is arranged on the upper surface of the rectangular box body. The medical chamber pot provided by the invention has the beneficial effects that the medical chamber pot is high in practicability and capable of conducting automatic cleaning thoroughly, and meanwhile, the medical chamber pot is capable of implementing disinfecting and sterilizing, so as to facilitate people's use in the next time; meanwhile, people's life safety is prevented from being threatened by the generation of bacteria; and meanwhile, a good warning effect is guaranteed.

Owner:上海正邻机电自动化设备有限公司

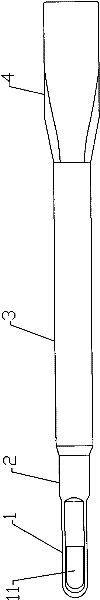

Pipeline slotter for wall

InactiveCN102191850AReduce labor intensityImprove slotting efficiencyBuilding constructionsElliptical recessBiomedical engineering

The invention provides a pipe slotter for a wall. The pipeline slotter comprises a fixed section, a transition section, an extension section and an end which are fixedly connected into a whole in sequence, wherein the fixed section is in the shape of a square column; an oval groove is arranged on each surface of the square column so as to fix the square column on an electric hammer; the diameter of the transition section is larger than that of the fixed section and the transition section is cylindrical; the diameter of the extension section is larger than that of the transition section and the extension section is also cylindrical; and the end is provided with double blades and the width of the end is larger than the diameter of the extension section. The pipeline slotter has the beneficial effects of improving the slotting efficiency by more than 5 times and reducing the labor intensity of workers.

Owner:山东金柱集团有限公司

Dinner plate for canteen

The invention discloses a dinner plate for a canteen. The dinner plate for the canteen comprises a dinner plate body. The dinner plate is cuboid, the two sides of the dinner plate body are respectively provided with a hollow handle, the right side of the dinner plate body is provided with a longitudinal groove, an arc-shaped protrusion is arranged inside the longitudinal groove, the lower portion of the left side of the dinner plate body is provided with a round groove for containing soup, and the upper portion of the left side of the dinner plate body is provided with a transverse groove. The upper end of the middle portion of the dinner plate body is provided with two oval grooves, the lower end of the middle portion of the dinner plate body is provided with a boss higher than the oval grooves, and a square groove is formed in the boss. The dinner plate can contain various dishes and tableware, and is more sanitary than an ordinary dinner plate. The dinner plate has good popularization and application value.

Owner:李明聪

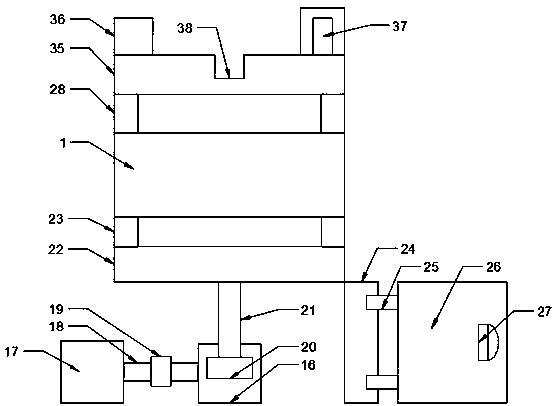

Automatic-height-adjustment washstand

The invention discloses an automatic-height-adjustment washstand, which comprises a washstand body. A water outlet mechanism is arranged on the washstand body and provided with first through holes, awater outlet pipe base, a rotating head, a water outlet pipe, a first waterproof sleeve, a water flow control valve, a first telescopic water pipe and a second telescopic water pipe. A drainage mechanism is arranged on the washstand body and provided with an oval groove, a second through hole, a round ring, a water retaining ring, a rotating rod, a second waterproof sleeve and a telescopic drainage pipe. A lifting mechanism is arranged on the washstand body and comprises hydraulic cylinders, oil cylinders, oil inlet and outlet pipes, bidirectional electromagnetic valves, pistons, lifting vertical columns, connection plates, short vertical columns, retaining plates, hinges, open-close doors, handles, vertical connection rods, slide grooves, a mirror, a first infrared sensor, second infraredsensors and infrared probes. A controller is arranged on the washstand body. The automatic-height-adjustment washstand has advantages of simple structure and high practicality.

Owner:常熟梁方智能技术有限公司

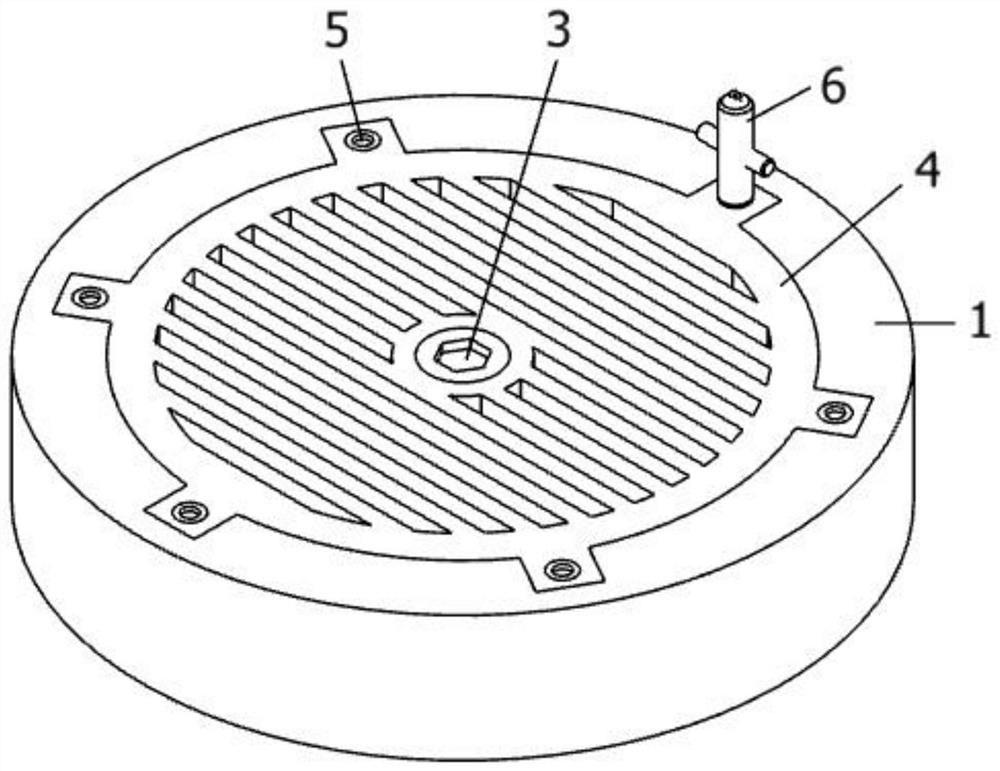

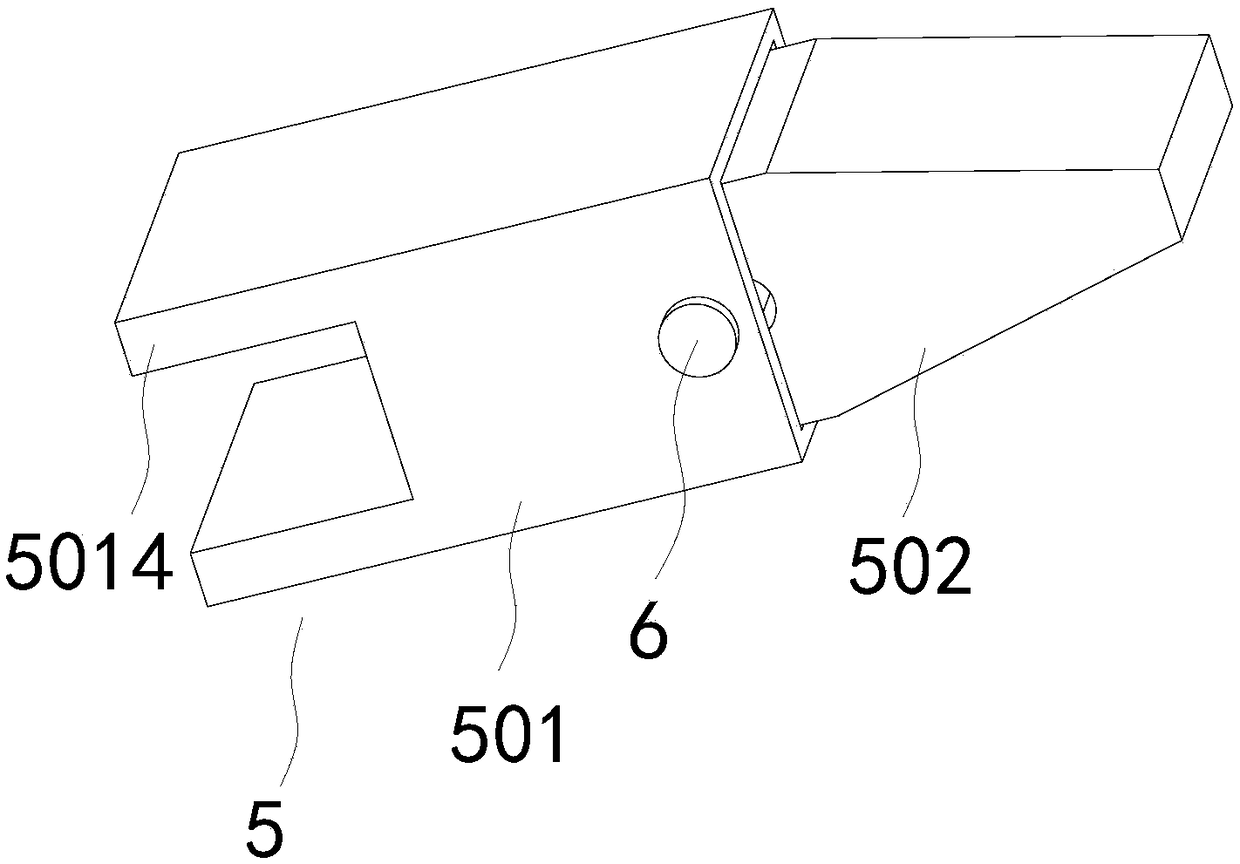

Municipal road well lid based on gear driving and used for efficient drainage

InactiveCN111691464AAnti-theft effectEfficient emissionsArtificial islandsSewerage structuresGear wheelArchitectural engineering

Owner:马晓

Cutter suction device used for sewage removal boat on river surface

ActiveCN108894264AReduce cost pressureReduce labor pressureMechanical machines/dredgersSewageEngineering

The invention discloses a cutter suction device used for a sewage removal boat on a river surface and relates to the field of silt removal equipment. The cutter suction device includes a reamer head connected to the end of a cutter suction pipe and comprises a fixing ring, a connecting sleeve and multiple reamer arms, the curved reamer arms are fixed between the fixing ring and the connecting sleeve, and multiple reamer teeth are uniformly and fixedly distributed on one side face of each curved reamer arm; each reamer tooth includes a toothed base and a reaming tooth, and the toothed bases areconnected with the reaming teeth through bolts. Each toothed base is of a cubic structure, one side face of each toothed base is fixedly connected with the side face of the corresponding curved reamer arm, and an oval groove is formed in the other side face of each toothed base; a blind hole communicated with the corresponding oval groove is formed in each toothed base, and a first spring is clamped into each blind hole. Through holes are symmetrically formed in the opposite side walls of each oval groove. By fixedly installing the reaming teeth in the toothed bases, under the cooperation ofthe first springs, straight groove openings and bolts, damping performance is provided for the reamer teeth, the efficiency of maintaining the reamer teeth is improved, and labor pressure of people isreduced.

Owner:ANHUI JIAMING ENVIRONMENTAL PROTECTION TECHCO

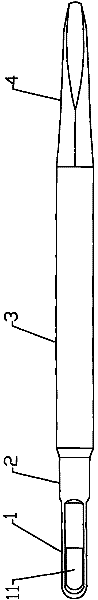

Infant transfusion bed

InactiveCN101816812AEasy to prick the needleSimple structureIntravenous devicesAcupunctureElliptical recess

The invention relates to a bed, in particular to an infant transfusion bed for infant transfusion. The infant transfusion bed comprises a transfusion bed board and is characterized in that: the central position of the transfusion bed board is provided with an oval groove; leg binding belts are fixed on both sides at the back edge of the groove; hand bonding belts are fixed on the both sides at the front edge of the groove; and a soft pillow is arranged in the middle of the front of the groove. Therefore, the infant transfusion bed has the advantages of simple structure, convenient use and convenient infant acupuncture.

Owner:潘馨

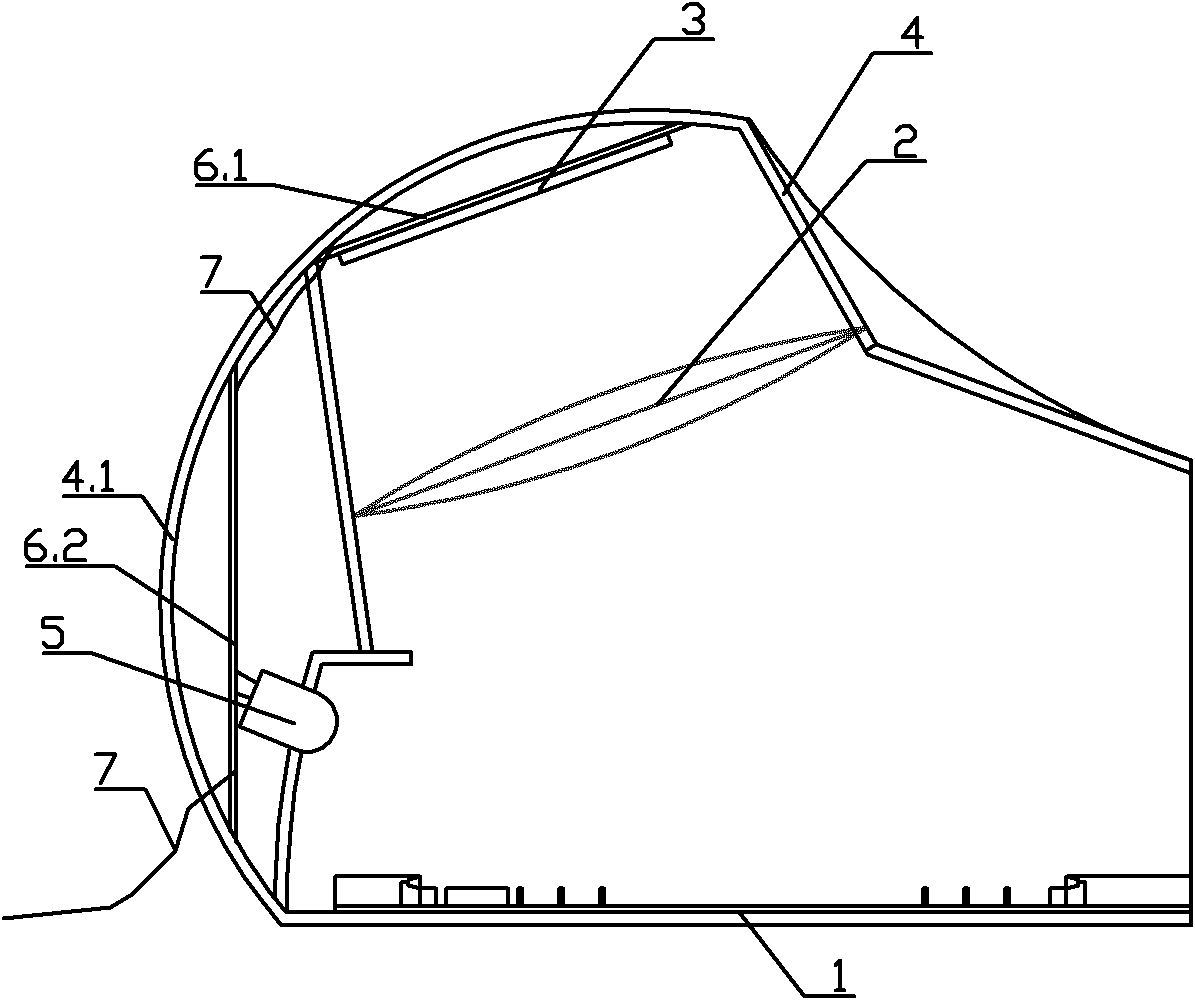

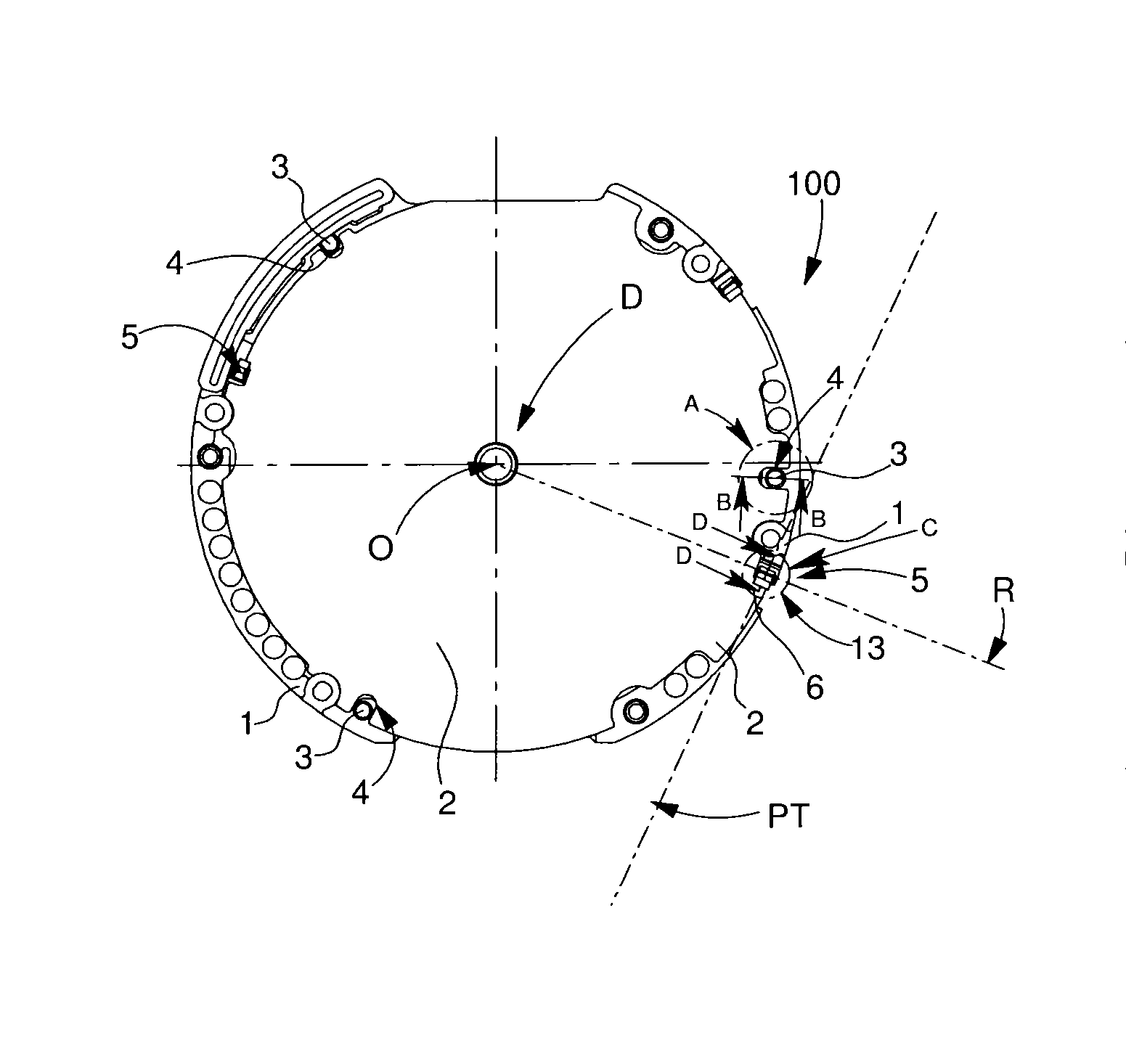

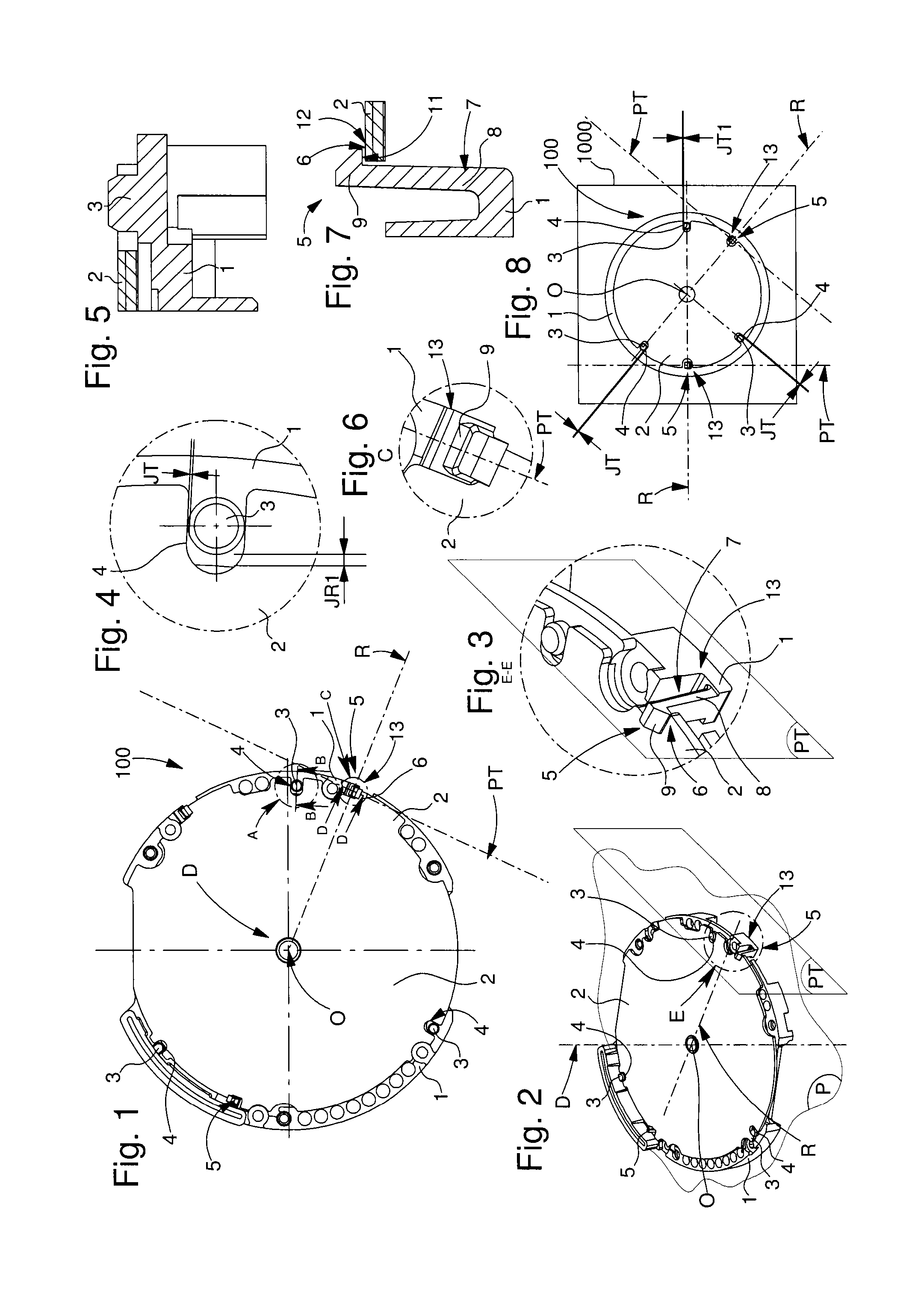

Fastening of a dial to a timepiece bottom plate

Timepiece assembly (100) comprising centring pins (3) integral with a bottom plate (1), each arranged to cooperate with radial and tangential play with an oblong groove (4) in a dial (2), for the relative positioning of said dial with respect to said bottom plate (1), and a holding means (5) integral with said bottom plate (1), arranged to cooperate with a complementary holding means (6) integral with said dial (2), said holding means (5) and / or complementary holding means (6) comprising an elastic return means (7) for pressing said dial (82) resting onto said bottom plate (1).Said elastic return means (7) has tangential mobility in a plane (PT) perpendicular to the plane (P) of said bottom plate (2) and to a radial line (R) connecting the centre (O) of said bottom plate (2) to said elastic return means (7).

Owner:ETA SA MFG HORLOGERE SUISSE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com