Elliptical recess reaming device

An ellipse and arc guide rail technology, applied in the field of automatic hole making in aircraft digital assembly, can solve the problems of large cutting reaction force, machining error, inability to realize elliptical socket machining, etc., and achieve the effect of improving machining accuracy and control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

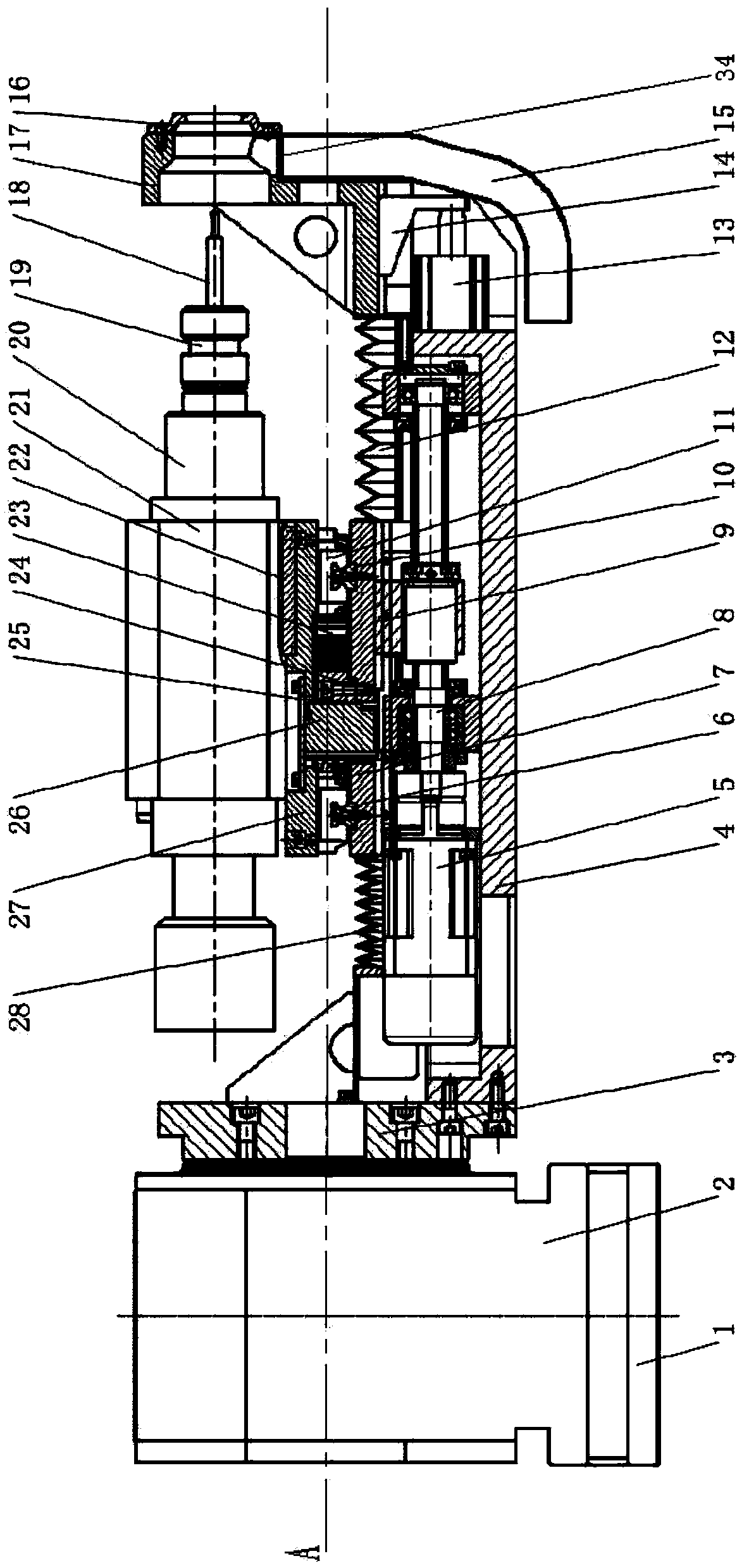

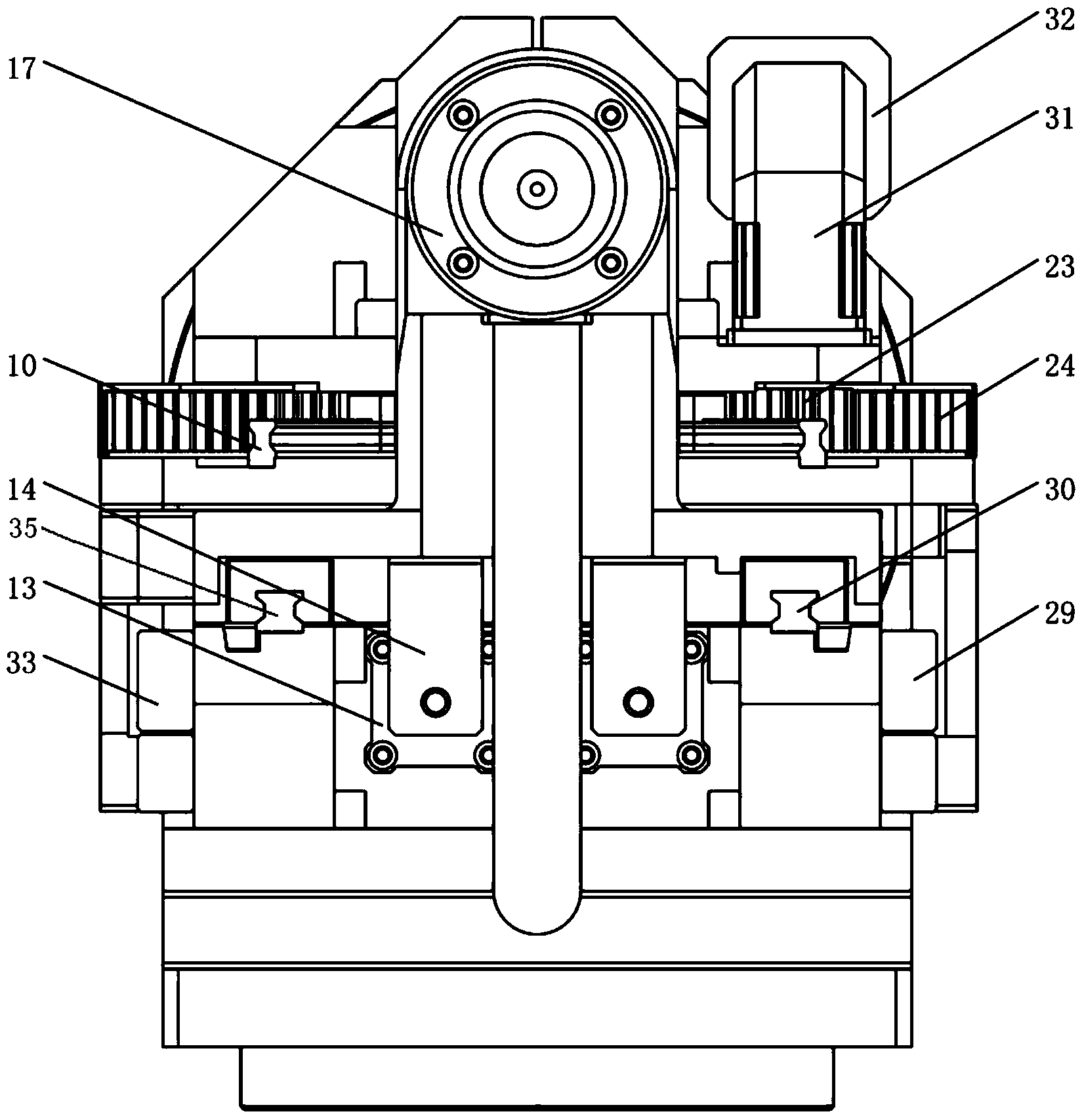

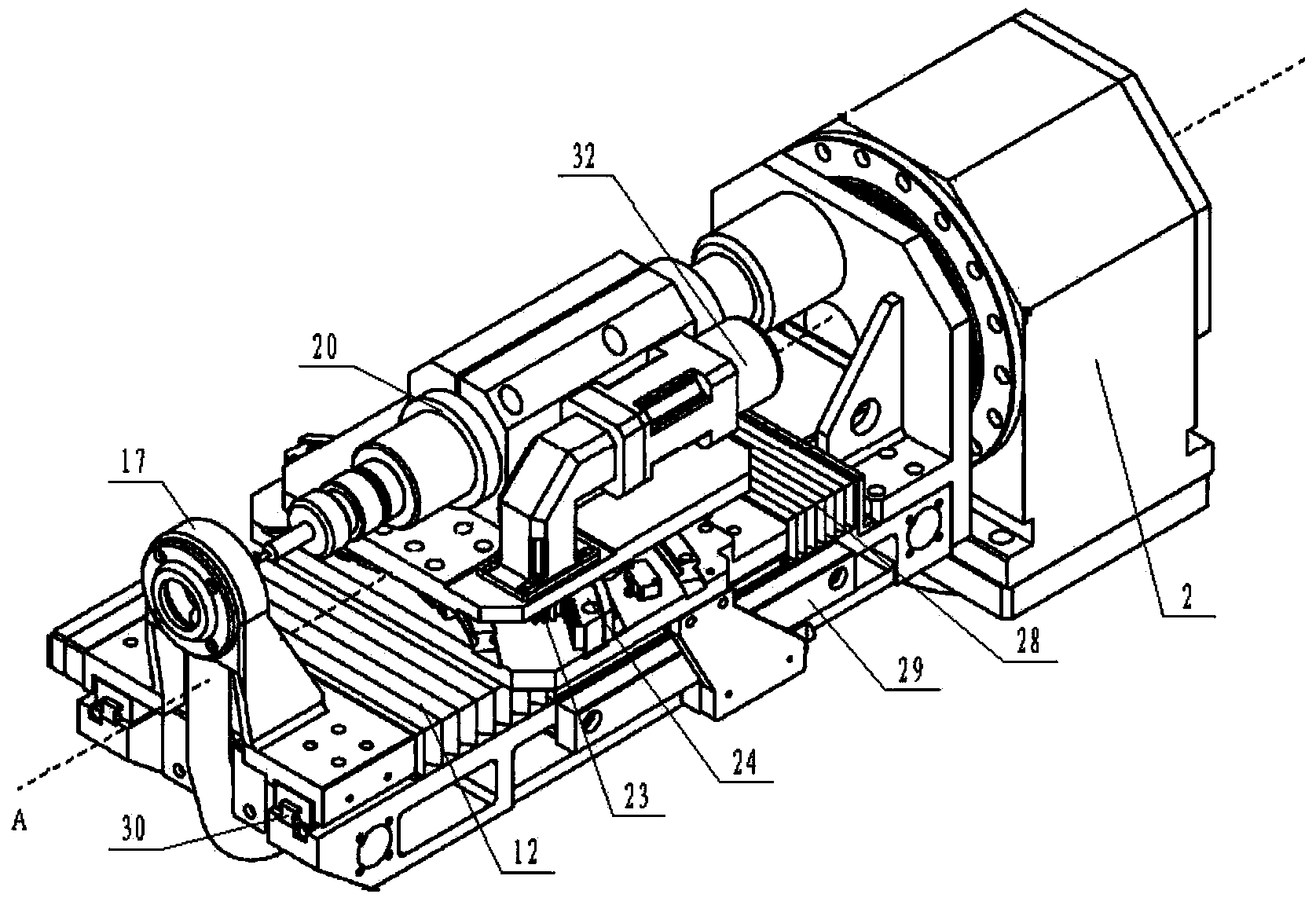

[0030] see Figure 1~4 , a countersinking elliptical dimple device, including a numerically controlled turntable 2 and a rotating base 4, in order to enable the countersinking elliptical dimple device to accurately move to the workpiece, this countersinking elliptical dimple device can be installed on an industrial robot or a numerically controlled machine tool through a mounting flange 1 and other automated numerical control equipment (not shown in the figure).

[0031] The numerically controlled turntable 2 is linked with the rotating base 4 through the flange 3, the rotating base 4 rotates around the first axis A, and the numerically controlled turntable 2 can control the deflection angle of the rotating base 4.

[0032] The rotating base 4 is fixed with a linear guide rail 30 and a linear guide rail 35 parallel to each other, and the linear guide rail 30 and the linear guide rail 35 are parallel to the first axis A, and a feed ram 7 is slidably installed on the linear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com