Patents

Literature

99 results about "Pearl oyster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pinctada is a genus of saltwater oysters, marine bivalve mollusks in the family Pteriidae, the pearl oysters.These oysters have a strong inner shell layer composed of nacre, also known as "mother of pearl".. Pearl oysters are not closely related to either the edible oysters of family Ostreidae or the freshwater pearl mussels of the families Unionidae and Margaritiferidae.

Pearl sacs processing method for cultivating nucleated pearls

InactiveCN101036449AEnhanced nucleophilicityImprove formation qualityClimate change adaptationPisciculture and aquariaTropismBiological activation

The present invention discloses a pearl nucleus processing method for culturing nucleated pearl which comprise the following steps: (1)Choosing pearl nucleus of 12-17mm diameter, (2) purifying pearl nucleus, washing pearl nucleus with 5-10% dilute hydrochloric acid, then washing repeatedly with limewater until the pearl nucleus is neutral in pH, placing pearl nucleus in boiled water for disinfection; (3) activating the immersed pearl nuleus, placing pearl nucleus in activation liquor and processed pearl nucleus is obtained. The present invention purifies the pearl nucleus and activate the pearl nucleus before transplanting that effectively promote the tropism of pearl oyster to pearl nuclus reduce the cut infection probability of nucleus-transplanting tissue quick the healing rate of wound, promote the forming quality of pearl sac, reduce the surface blemish forming rate of nucleated pearl, promote the yield of nucleated pearl.

Owner:ZHEJIANG GRACE PEARL JEWELRY +1

Breeding method of night fluorescent pearl oyster

InactiveCN102246715ANo radioactivityLong glow timeClimate change adaptationPisciculture and aquariaEpoxyFresh water organism

The invention discloses a breeding method of a night fluorescent pearl oyster, comprising the following steps of: uniformly mixing night fluorescent powder with epoxide resin; coating an obtained mixture on the surface of a pearl nucleus; curing, and coating methyl methacrylate as a protecting layer; treating by using a pearl nucleus adjusting agent prepared from algal polysaccharides and aureomycin; treating cell shells by using an adjusting agent prepared from shellfish meat hydrolyzate same as that for a pearl oyster (mussel), and aureomycin, and carrying out an pearl-nucleus-inserting operation; and then fostering a freshwater mussel or pearl-breeding shellfish in a recuperation pool temporarily after the pearl-nucleus-inserting operation, then placing the freshwater mussel or pearl-breeding shellfish in a breeding water area for hoisted breeding, and harvesting after maturity to obtain a pearl, namely a night fluorescent pearl. According to the breeding method of the night fluorescent pearl oyster, the problems that the traditional pearls have single kind and low added value as well as the pearl-nucleus-inserting operation has low nucleus reserving rate and great repelling force are mainly solved; the ornament and the added value of the pearls are increased; and the nucleus splitting rate and the repelling force of the pearl oyster subjected to the operation are reduced.

Owner:GUANGDONG OCEAN UNIVERSITY

Pearl cultivation method

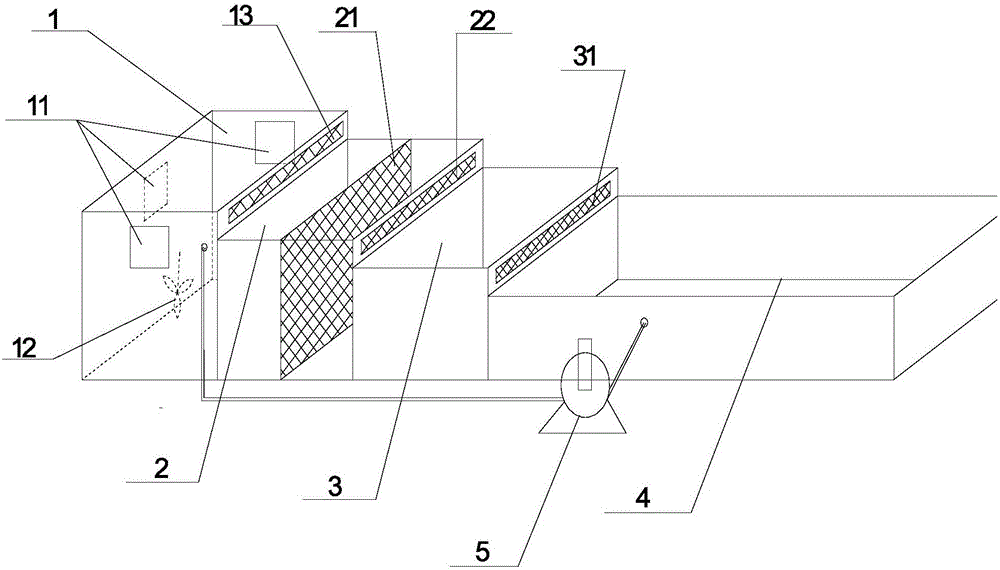

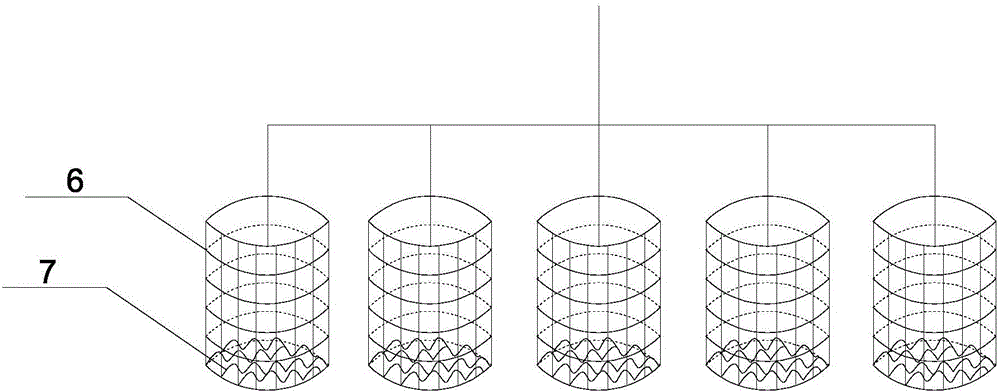

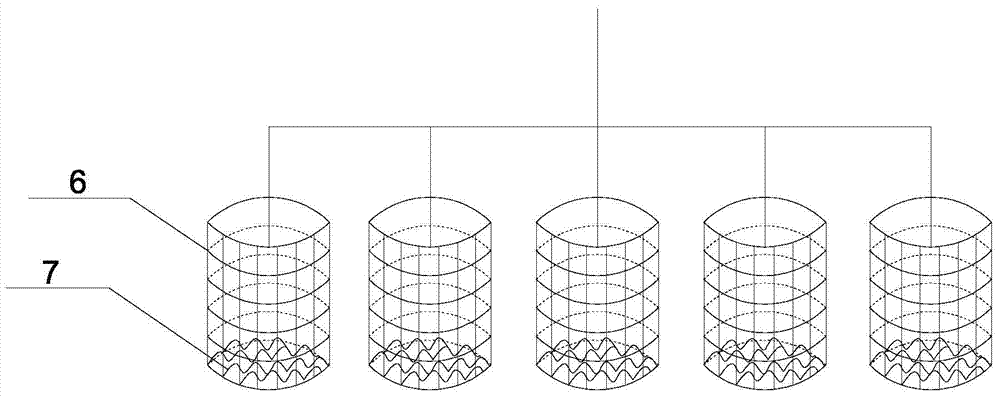

InactiveCN105145417AImprove the growing environmentPromote maturityClimate change adaptationPisciculture and aquariaNutrient solutionEnergy conservation

The invention discloses a pearl cultivation method, and belongs to the aquatic product cultivation technical field; the method comprises the following steps: selecting a cultivation room to cultivate pearl oysters, wherein the cultivation room comprises a culture pond, a first purifying pond, a second purifying pond, and a water storage pond connected in sequence, and top surfaces of the four parts gradually descends in a stepped manner; utilizing a tide difference principle to realize water self-discharge self-irrigation in the pond; arranging a filtering net and a mesh screen to purify water body, thus saving energy, and reducing cultivation cost; arranging the bottom of a net cage to be a waveform surface so as to prevent pathogen infection, thus providing better growth environment for the pearl oysters; preparing nutrient solutions of different components to process cell small particles and pearl cores, thus improving core planting rate, and reducing core repelling phenomenon; applying different fertilizers to accelerate pearl oyster maturation in different stages, and promoting pearl quality in the same time.

Owner:GUANGXI PEARL ROYAL INVESTMENT HLDG GRP CO LTD +1

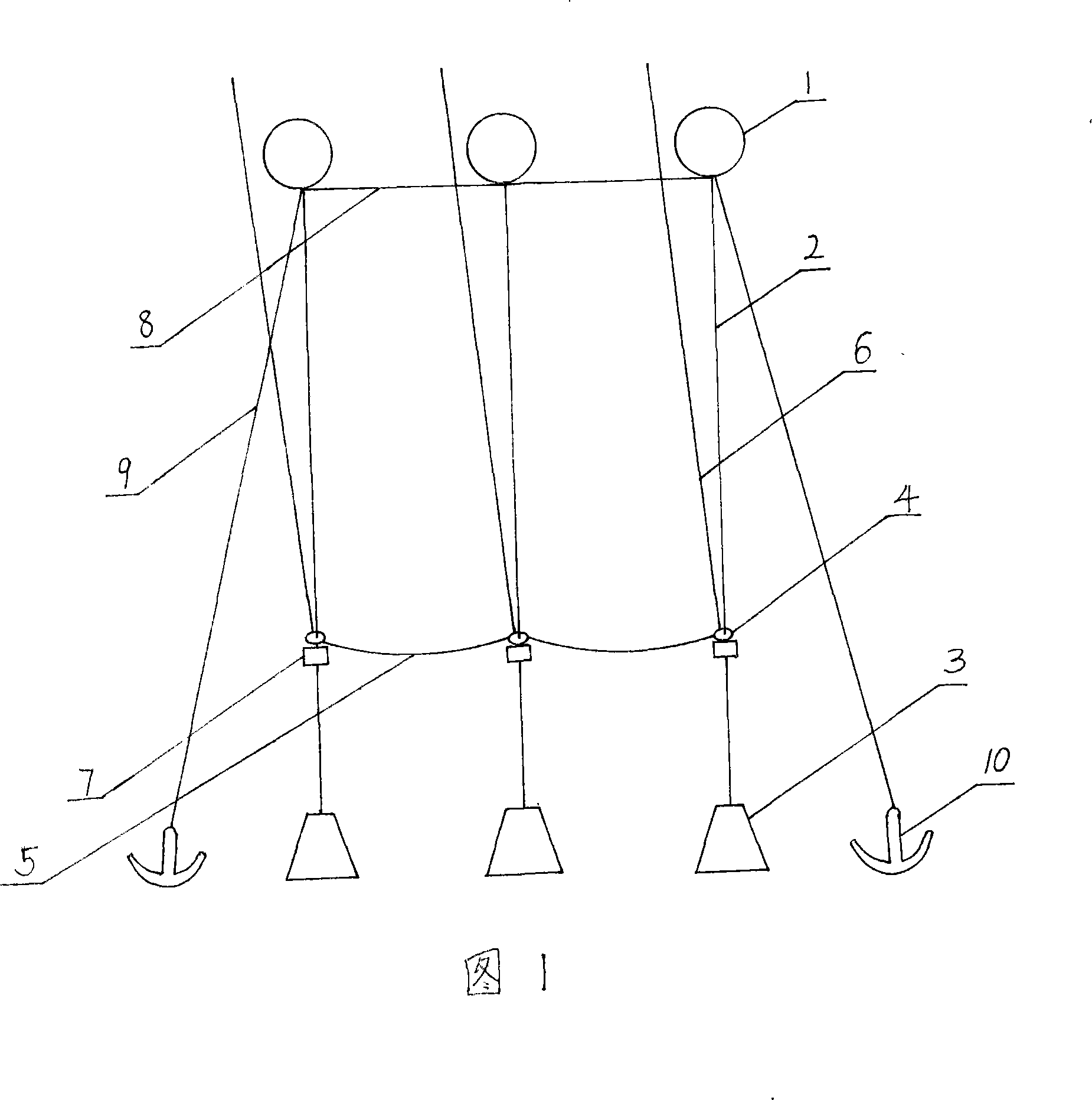

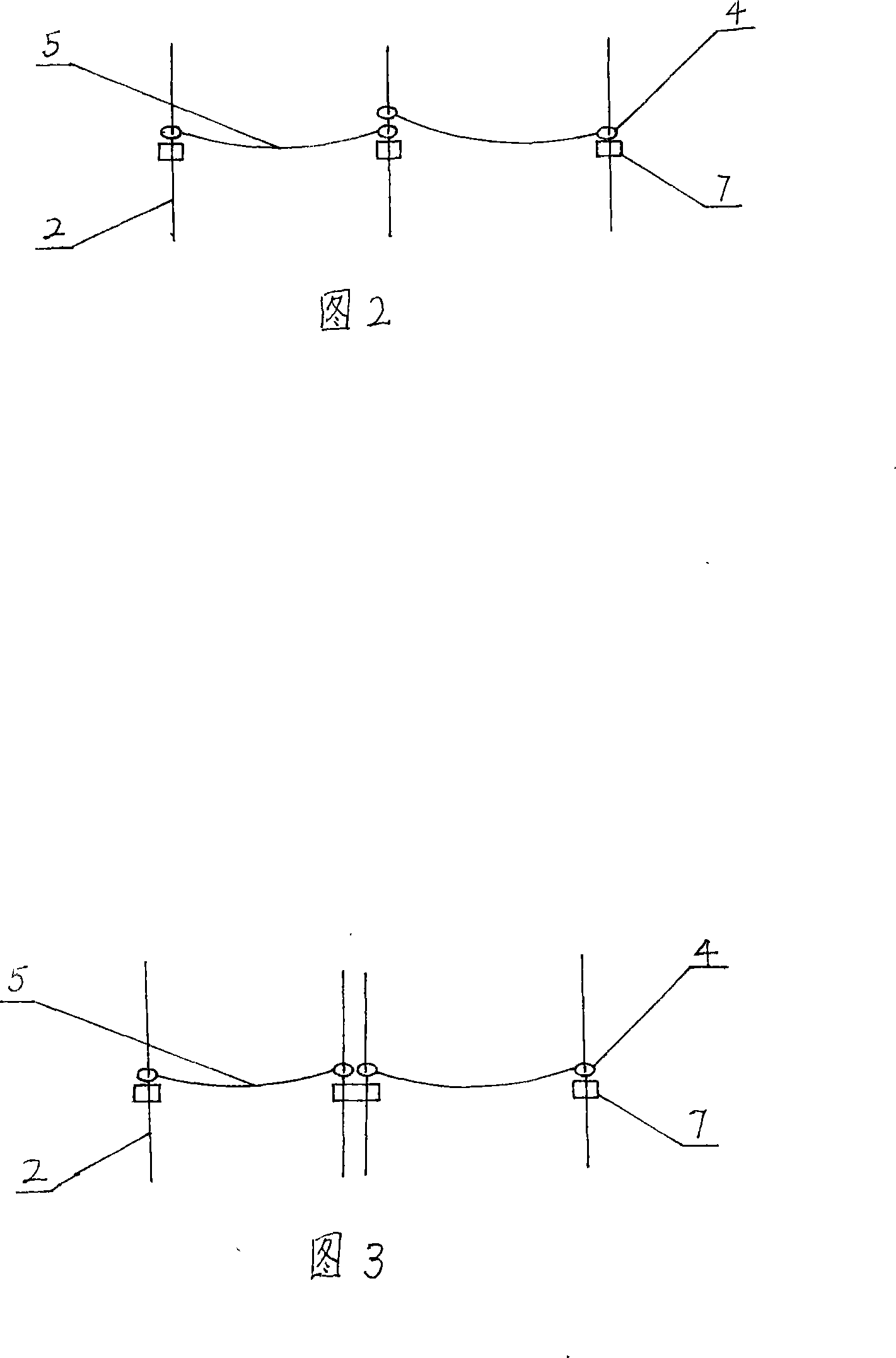

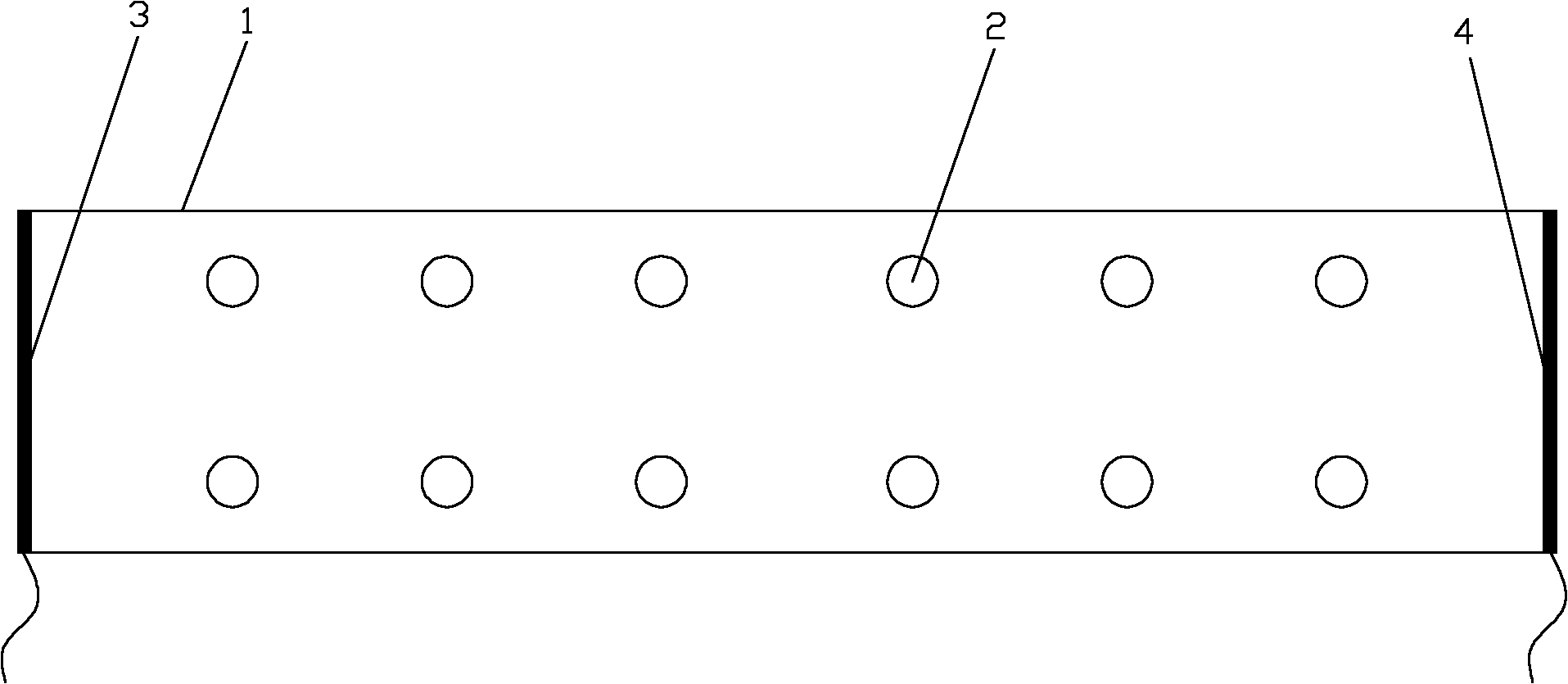

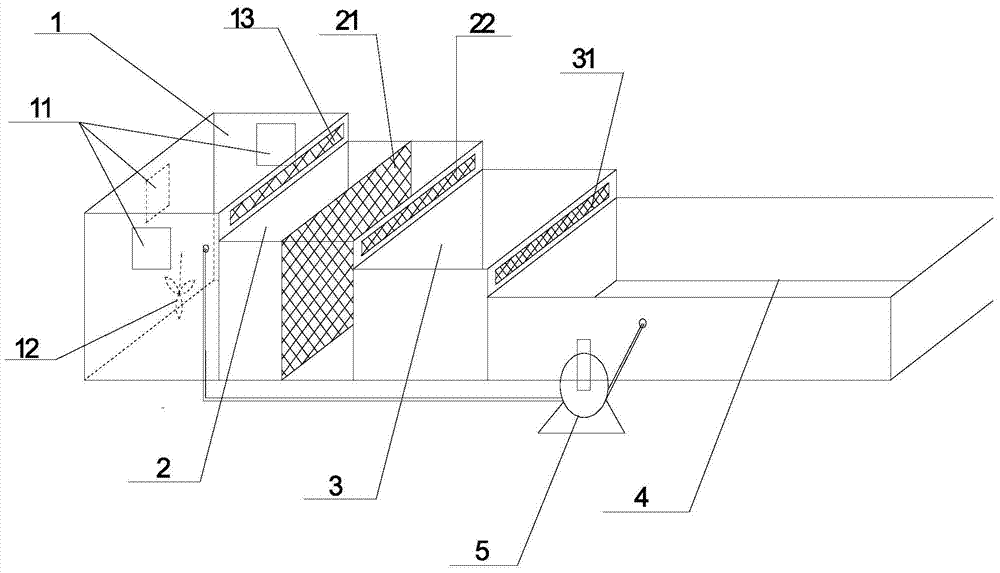

Liftable expansion rope wind wave resistant cultivation method for pearl oyster

InactiveCN101243780AReduce shakingReduce shockClimate change adaptationPisciculture and aquariaSurface layerWind wave

The invention relates to a lift long line windproof culturing method of pearl shell. A series of upright main lines are fixed by floats and weights in the culturing area and slip rings are arranged on the main lines. The slip rings are connected with each other by long lines and a pull rope is arranged on the slip ring. The whole pull rope and the pearl shells cultured on the pull rope can be risen or dropped under the action of pulling the pull rope upwards or the gravity actions of slip rings, pull rope and the pearl shells cultured on the pull rope. The windproof function can be achieved when the long lines drop down to the underlayer of the water body and the culturing management operations can be carried out when the long lines rise up to the surface layer of the water body.

Owner:GUANGDONG OCEAN UNIVERSITY

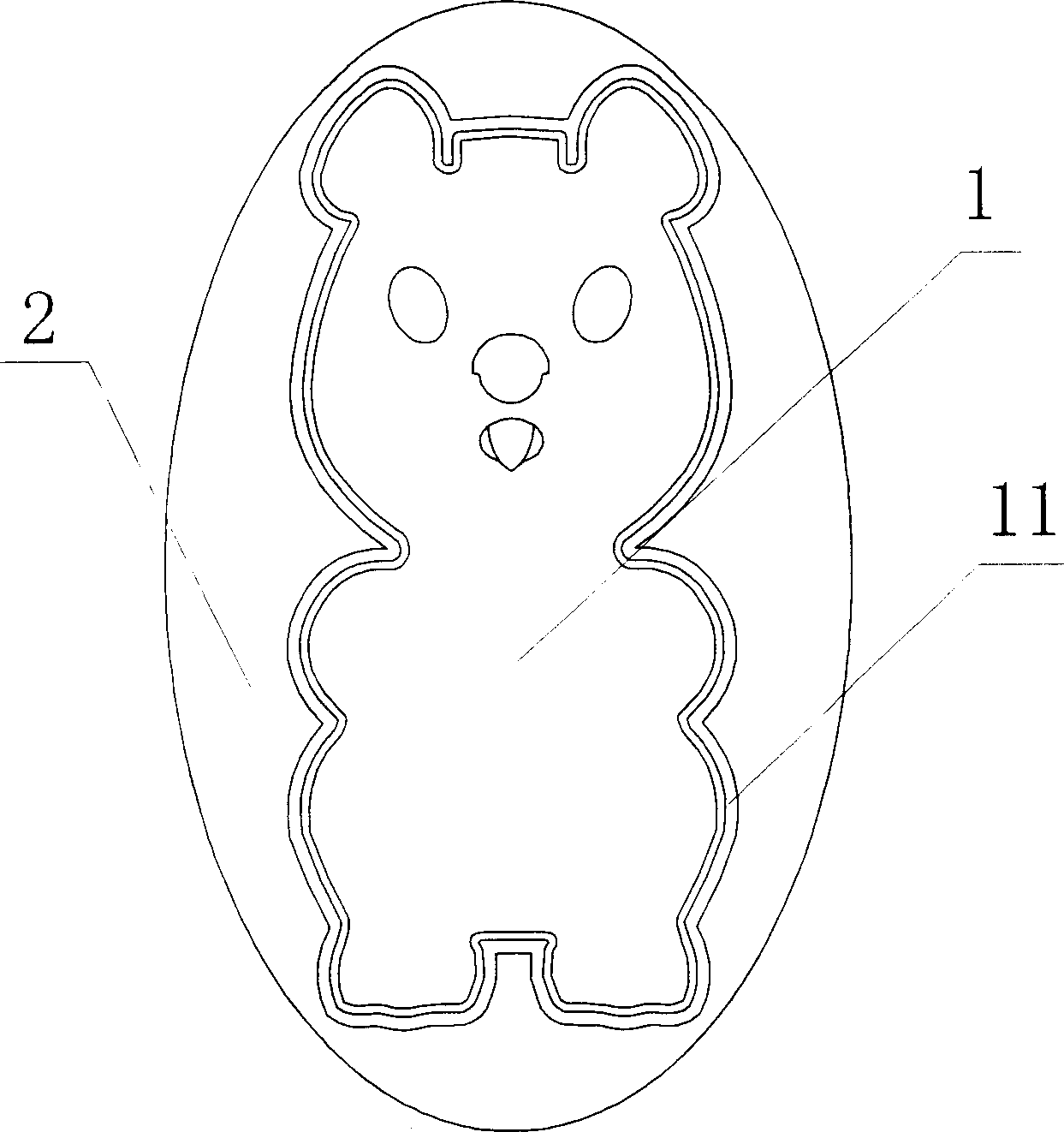

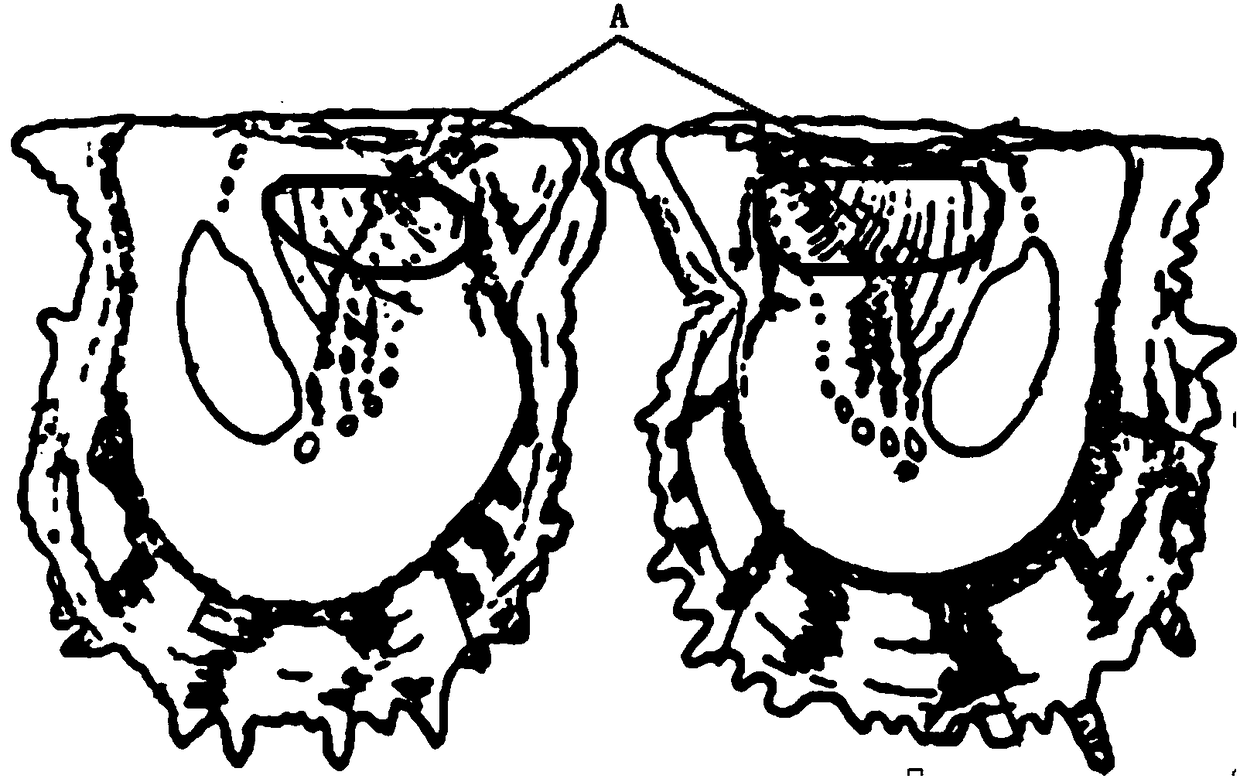

Method for culturing pearl oyster with model pearls contacting shell, and kernels for model thereof

InactiveCN1513303AImprove qualityStrong production costClimate change adaptationPisciculture and aquariaFresh water organismPearl oyster

A method for culturing the shaped pearl includes preparing the shaped core from non-toxic hard plastics, inserting it in freshwater mussel or pearl oyster, culturing by hanging them in water, and picking up the shaped pearls from them. Its advantages are beautiful appearance, high quality, and high output of shaped pearls.

Owner:GUANGDONG SHAOHE PEARL

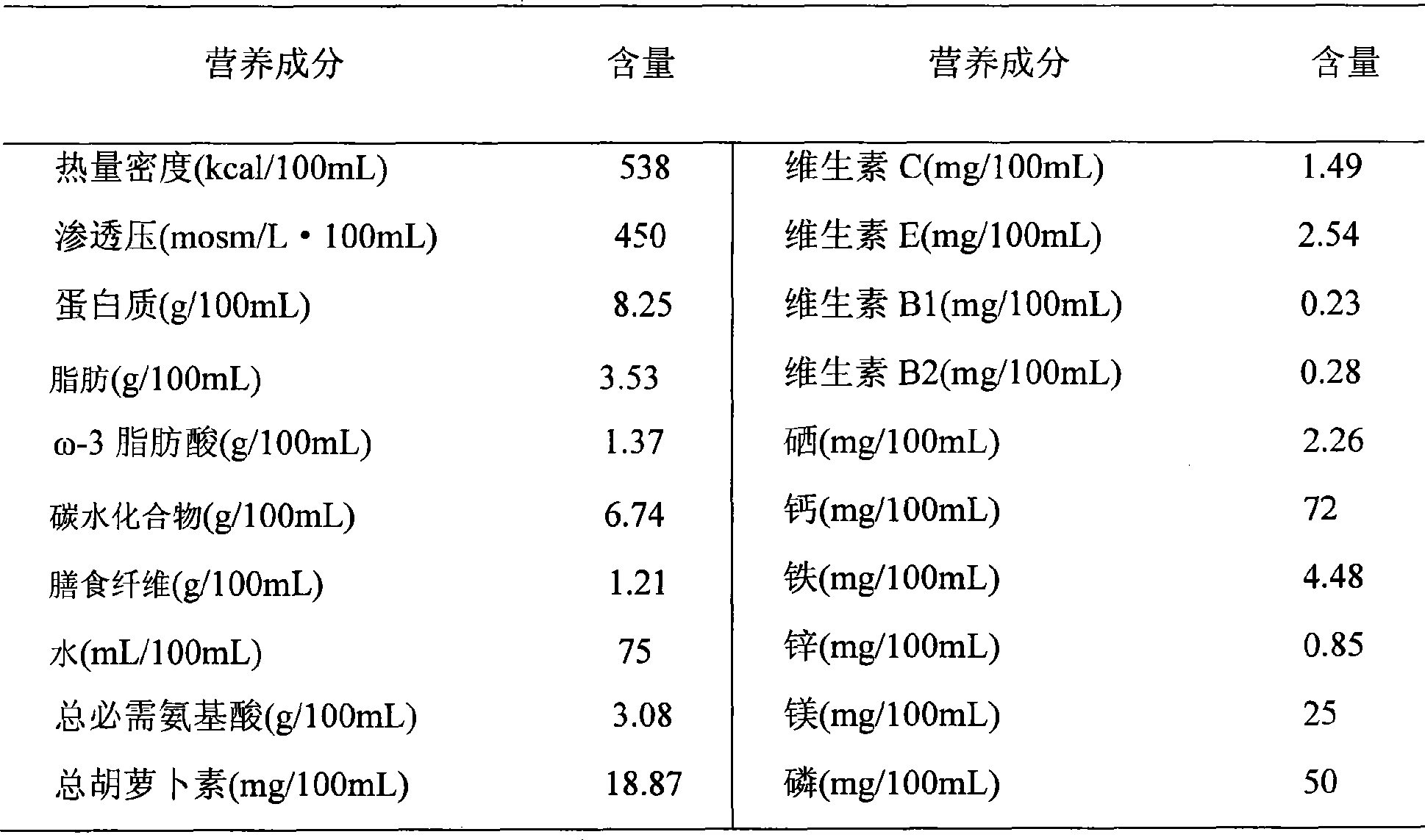

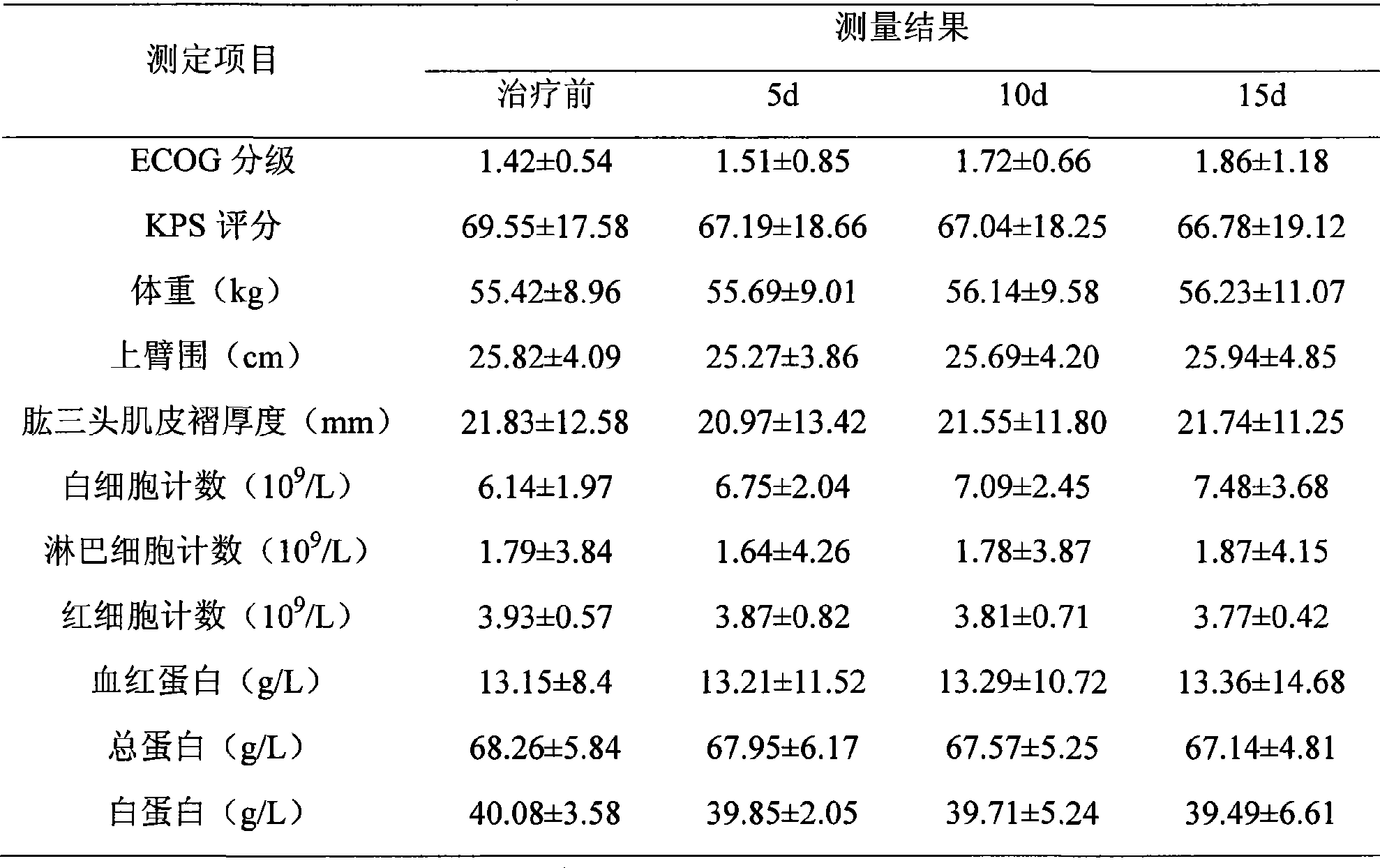

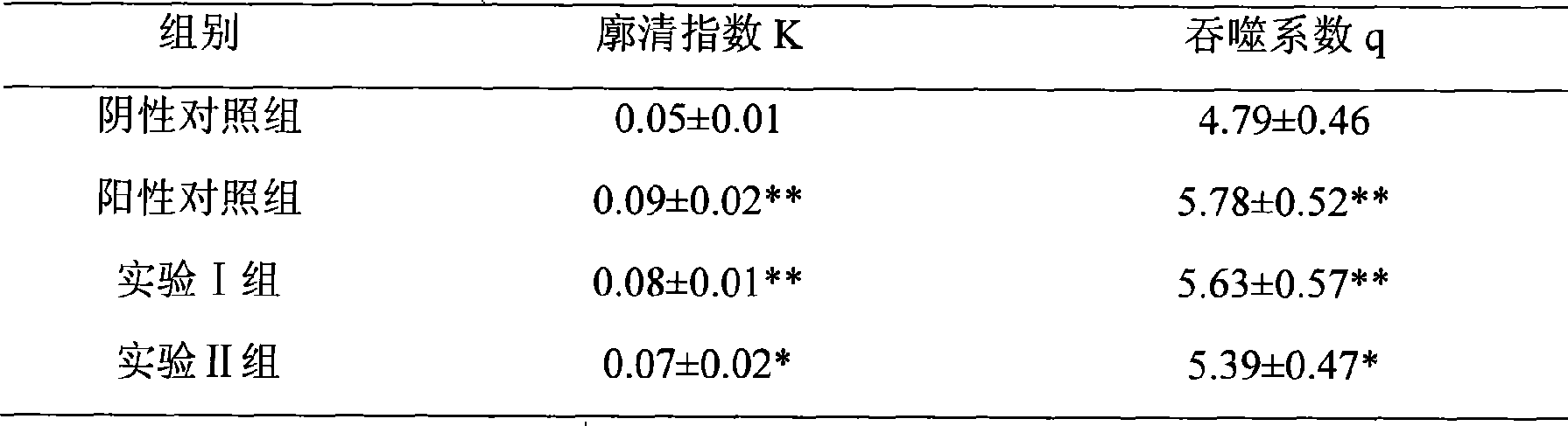

Enteral nutrition emulsion for tumor patient

ActiveCN101361804AHigh activityImprove antioxidant capacityOrganic active ingredientsPeptide/protein ingredientsOysterThird generation

The invention relates to an enteral nutrition emulsion used for tumor patients, which is characterized in that the emulsion of every 1000mL contains 30g to 50g of holothurian amylase, abalone amylase, oyster amylase or meretrix amylase, 50g to 70g of pearl oyster meat powder, soybean protein powder or fish protein powder, 15g to 25g of spirulina powder, 6ml to 8 ml of olive oil, 3g to 8g of an emulsifier and water of rest amount. The enteral nutrition emulsion can improve the activity of free radical scavenger enzymes of the organism, enhance the oxidation resistance of tissues and adjust the immune function so as to ensure the increasing trends of the weight, the upper-arm circumference and the skin fold thickness of the brachial triceps muscle of a sufferer, and gradually normalize various blood biochemical indicators, thereby reducing damages caused by operation or radiotherapy and chemotherapy to the immune system, being capable of providing nutritional supports for the tumor patients of head and neck cancer, esophageal cancer, pancreatic cancer, liver cancer, and the like as well as the tumor patients who accept radiotherapy and chemotherapy, and promoting the recovery of the patients.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Method for breeding natural pearls through pearl oysters and obtained pearls

ActiveCN108935249AImprove qualityLess investmentClimate change adaptationPisciculture and aquariaOysterPearl oyster

The invention relates to a method for breeding natural pearls through pearl oysters and obtained pearls, and belongs to the technical field of pearl breeding. The method includes the following steps that shells are taken and processed into nanometer shell powder, the nanometer shell powder is sterilized, sterilized and filtered seawater is added into the nanometer shell powder, and shell powder paste is prepared for usage; the pearl oysters are taken, oyster openings of the pearl oysters are formed downwards so that water and impurities in pearl oyster bodies can flow out of the pearl oysters,and through medicine anesthesia, all the oyster openings of the pearl oysters can be open for usage; an appropriate amount of shell powder paste is injected into vela of the pearl oyster bodies and the shells; the oyster openings of the pearl oysters into which the shell powder paste is injected are upward, standing is performed, then the pearl oysters are placed into seawater for breeding, and the pearls can be collected after the pearls grow up. According to the method for breeding the natural pearls through the pearl oysters, cell tab transplanting is not needed, substances containing calcium carbonate are directly injected into the vela, and nacre are formed by the utilization of the vela of the oyster bodies. According to the method for breeding the pearls, investment is small, benefits are high, the dead rate during breeding of the oysters is small, and return is large.

Owner:广东荣辉珍珠养殖有限公司

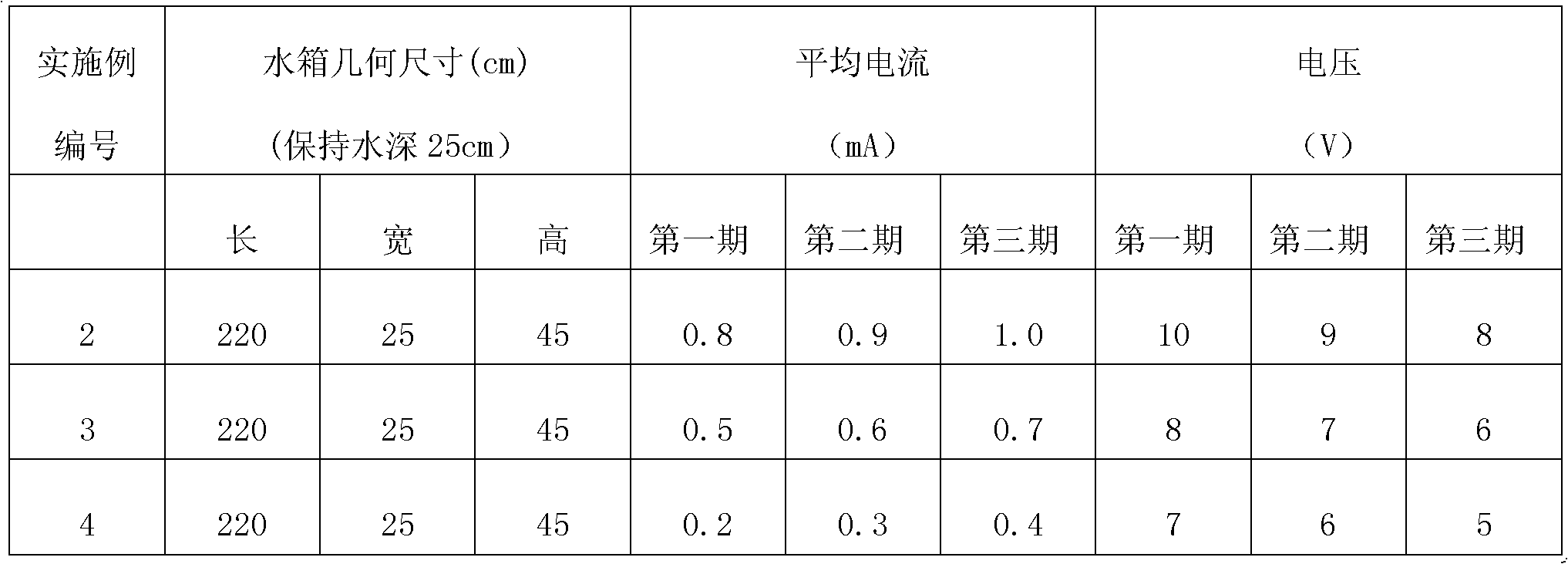

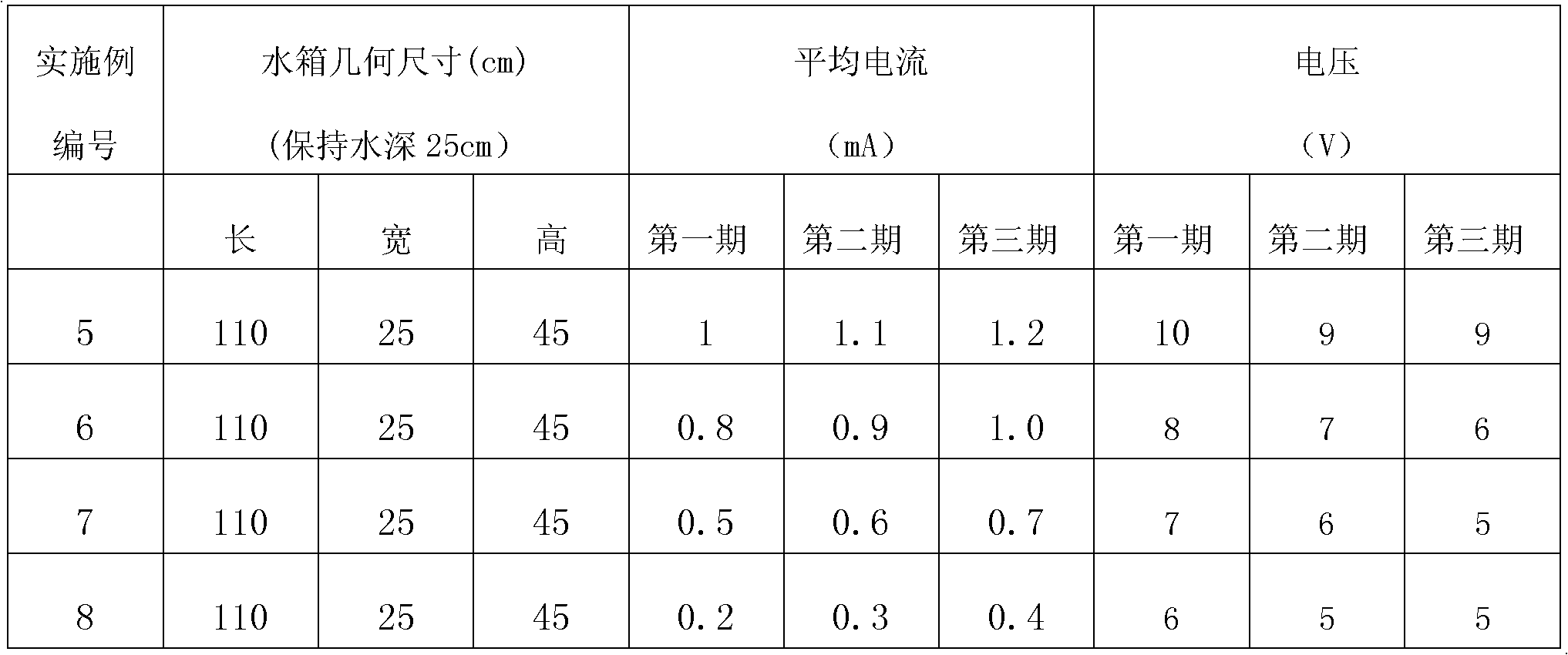

External physical stimulation method for promoting secretion of pearl oysters

ActiveCN102057885AImprove bead qualityEvenly secretedClimate change adaptationPisciculture and aquariaAverage currentPulsed DC

The invention discloses an external physical stimulation method for promoting secretion of pearl oysters. The method comprises the following steps: selecting a water tank and storing water in the water tank, wherein the water is pollution-free water, the pH value is 7.5-8.5, the water temperature is 25-28 DEG C, and the dissolved oxygen in the water is sufficient; keeping the depth of the water in the water tank at 20-30 cm, breeding the pearl oysters in the water, and keeping a space between adjacent pearl oysters; putting a pair of electrodes in the water tank, and immersing the electrodes in the water; and implanting pearl nuclei into the pearl oysters, and 40-50 days later, performing recurrent pulse galvanic stimulation, wherein during the galvanic stimulation, the galvanic stimulation is performed through the electrodes at fixed time every day, the time intervals of the galvanic stimulation every day are uniformly distributed within 24 hours, the average current of the electrodes is 0.1-1.5 mA, and the voltage between the two electrodes is 3-12 V. According to the external physical stimulation method for promoting the secretion of the pearl oysters disclosed by the invention, the intensity, frequency and distribution of the stimulation current are reasonably controlled, thus the uniform secretion of the pearl sacs can be promoted, and the effects of shortening the growth period and improving the pearl quality can be improved.

Owner:杭州元水生态农业发展有限公司

Method for extracting antibacterial peptide from pearl oyster meat

InactiveCN102220402APromote hydrolysisGood antibacterial effectPeptide preparation methodsFermentationWater bathsIce water

The invention discloses a method for extracting an antibacterial peptide from pearl oyster meat, which comprises the following steps: taking the pearl oyster meat after pretreatment, adding ice water for cold homogenation so as to get homogenate; adding flavourzyme into the homogenate, uniformly mixing, then regulating the working frequency of ultrasonic waves to 35kHz, regulating the strength of the ultrasonic waves to 280-360W and regulating the temperature to 50-65 DEG C for performing ultrasonic treatment for 90-100 minutes; continuing to performing enzymolysis on the homogenate for 1-2 hours after the ultrasonic treatment still in a constant-temperature water bath at the temperature of 50-65 DEG C and then performing enzyme inactivation and cooling treatment for getting enzymatic hydrolysate; and performing centrifugal treatment on the enzymatic hydrolysate, taking supernatant liquid, regulating the operation pressure of membrane separation to 2-3bar, regulating the temperature to 3-10 DEG C, utilizing the membrane separation technology for performing ultrafiltration treatment, collecting separation liquid with the intercepting molecular weight of 5000-10000Da, freeze-drying and then getting an antibacterial peptide product of the pearl oyster meat. The method uses the ultrasonic wave technology to assist the hydrolysis of the flavourzyme for carrying out the extraction of the antibacterial peptide in the pearl oyster meat, so that the operation is simple, the hydrolysis rate and the antibacterial activity can be improved, the hydrolysis time is shortened, the production cost is low, the product is safe, waste pearl oyster meat after opening pearls can be utilized with high value and further the economic benefits of a manufacturer are improved.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

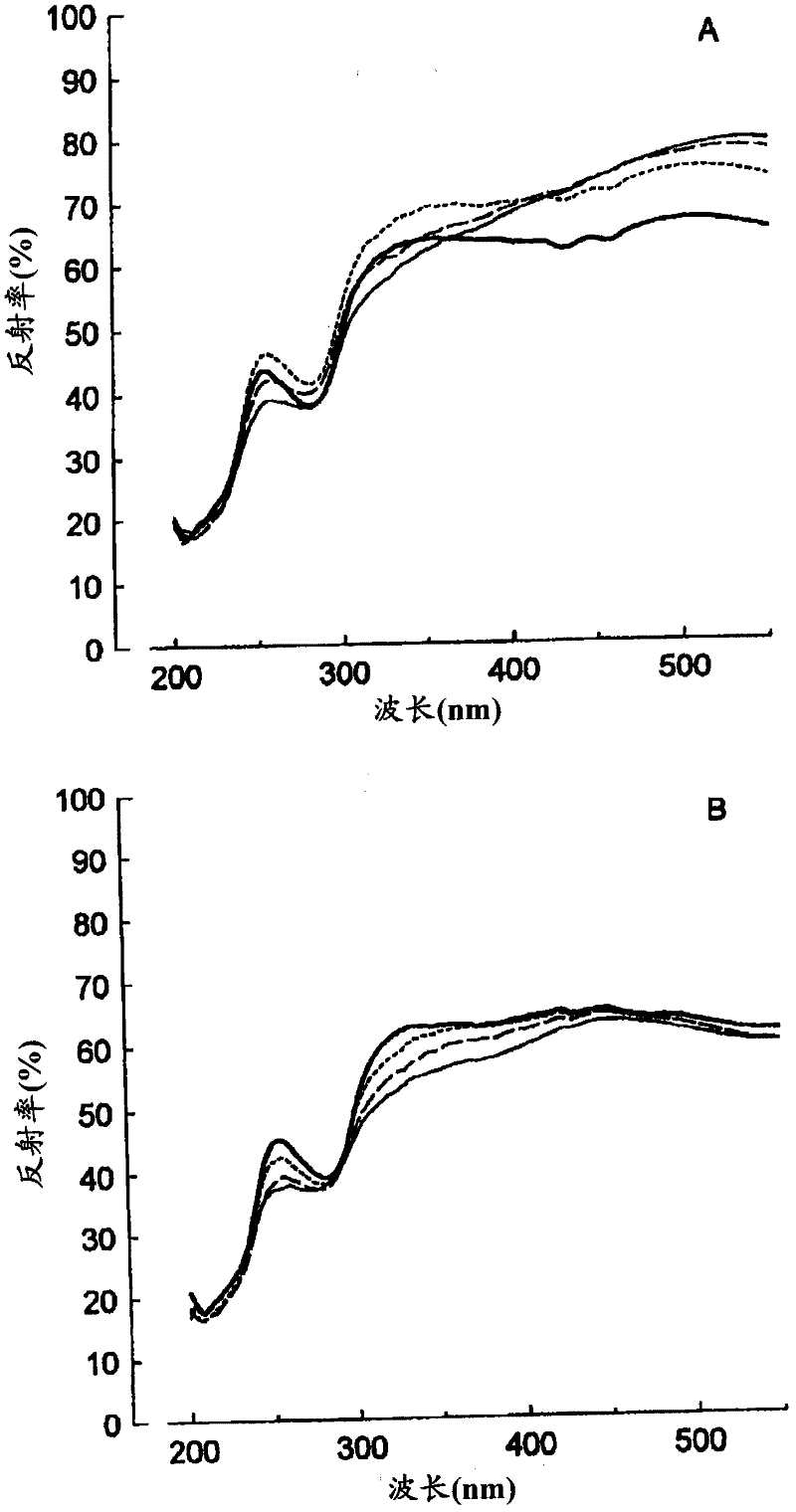

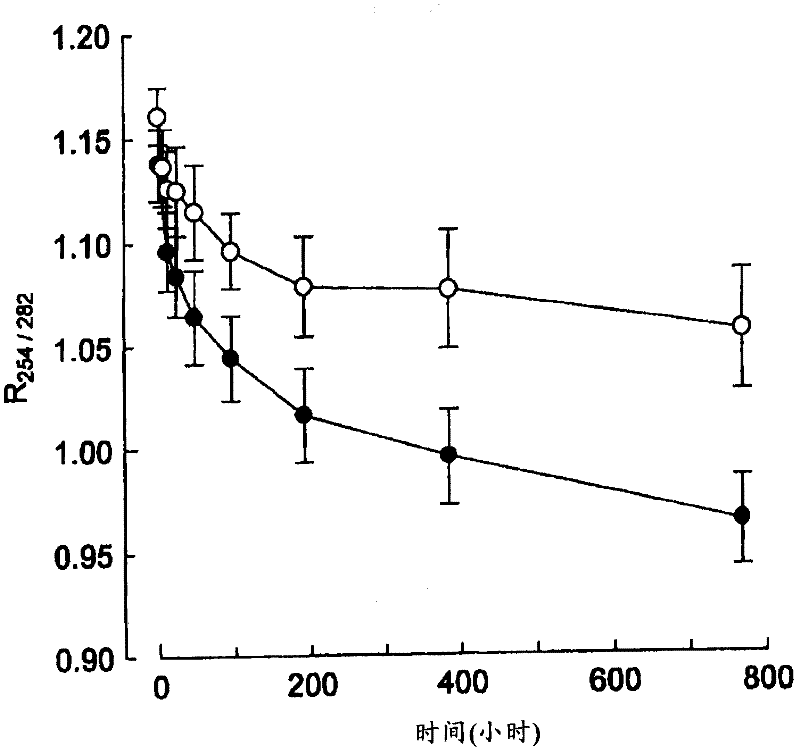

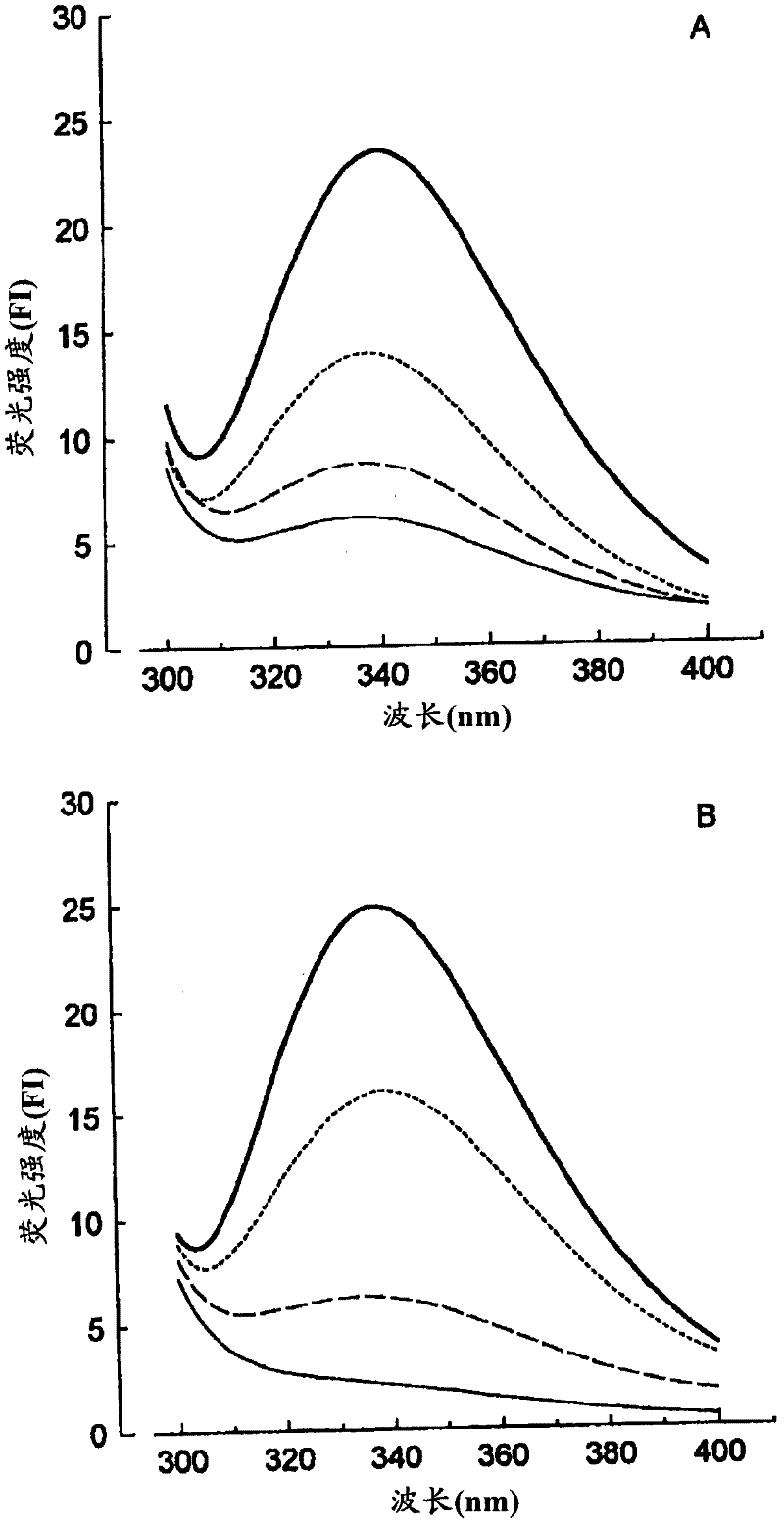

Method for nondestructively inspecting pearl qualities

ActiveCN102549411AEasy to judgeEasy to operateScattering properties measurementsInvestigating jewelsFluorescence spectrometryPearl oyster

Provided is a method for nondestructively inspecting pearl qualities, said method comprising measuring the reflection spectrum of a pearl or pearl oyster shell, that is to be inspected, from the ultraviolet region to the visible region and / or measuring the fluorescent spectrum thereof from the ultraviolet region to the visible region, and then comparing the thus obtained value with a pre-measured value of a normal pearl or pearl oyster shell. Also provided is a device for nondestructively inspecting pearl qualities. According to the present invention, the qualities of a target pearl or pearl oyster shell can be nondestructively, easily and quickly inspected.

Owner:K MIKIMOTO

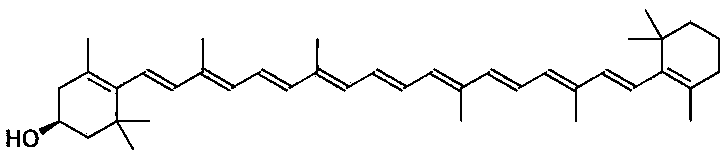

Preparation method of pearl oyster peptide calcium

The invention discloses a preparation method of pearl oyster peptide calcium. The method comprises the following steps: hydrolyzing pearl oyster meat with protease, ultrasonically modifying the enzymatic hydrolysate, and chelating with calcium chloride to obtain the final product of peptide calcium. The product has the characteristics of high calcium content, good absorbability and strong solubility. The preparation method has the positive effects as follows: (1), the polypeptides are treated with ultrasonic wave, so as to enhance the calcium-binding capacity of polypeptides and thus to increase calcium content of the product; (2), the solubility of the product is improved, which overcomes the problems of first-generation and second-generation calcium supplement products; (3), the product is made from pearl oyster after pearl extraction, which recycles a large amount of waste and can not only achieve high-value added utilization of pearl oyster meat but also make a positive contribution to environmental protection; and (4), the preparation method has a simple process, is easy to implement in industrial production and has positive significance for calcium supplement product industry.

Owner:JIANGXI NORMAL UNIV

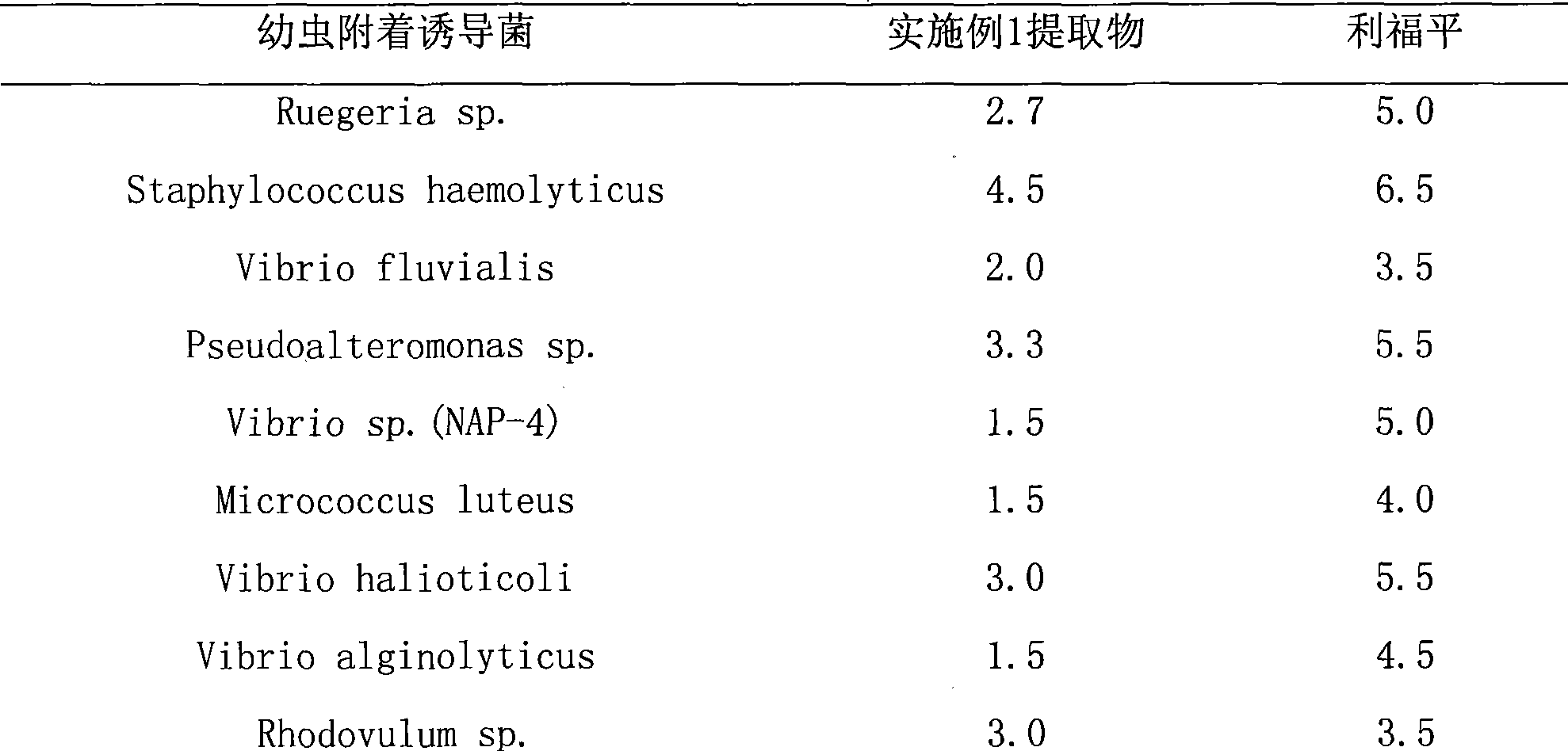

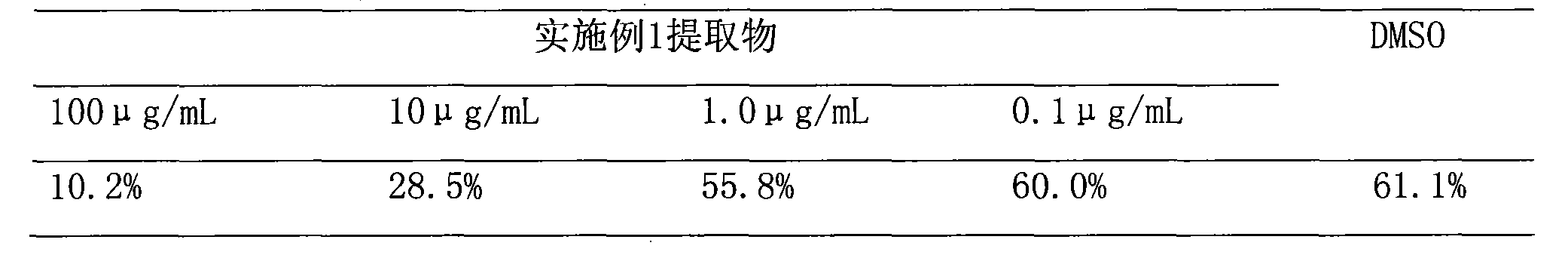

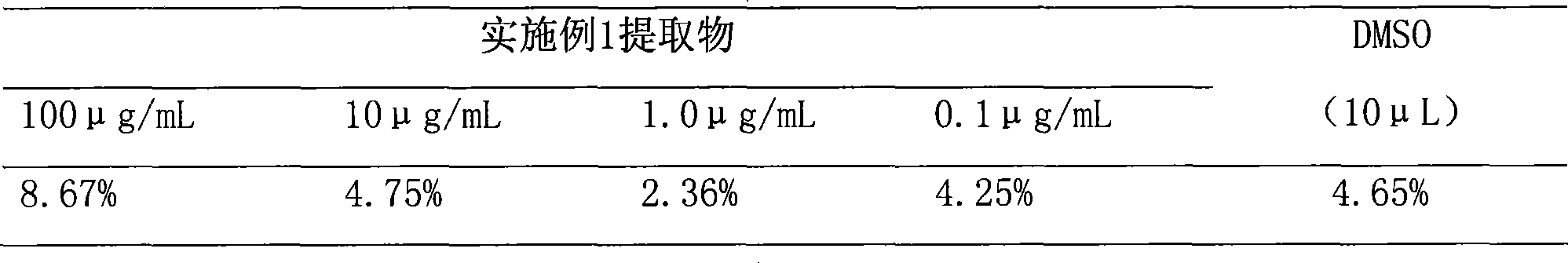

Ocean actinomycete fermentation extract, composite thereof, and application in biofouling resistance

The invention relates to an application of ocean actinomycete (Salinispora pacifica) SCSIO 00013 fermentation extract in biofouling resistnace and is characterized in that the ocean actinomycete SCSIO 00013 stain is inoculated to a Gause 1 cultural medium so as to be fermented; the gained mycelium is separated from fermentation solution and is then extracted by organic solvent; coarse extract is gained by concentrating and combining the extract; the coarse extract is suspended on water and extracted by chloroform or ethyl acetate; chromatography of the extract is carried out by a normal-pressure silica gel column; a solution system such as chloroform-acetone and the like is used as eluent so as to carry out gradient elution; thin layer chromatography analysis of fraction is carried out; chloroform-acetone with the volume ratio of 4:1 is used as solvent to extend the system; the fraction with the Rf value Rf ranging from 0.20 to 0.75 is collected and is then combined; subsequently, the pigment is removed, thus gaining target extract. The fermentation extract can be used for halobios fouling resistance; the coating consisting of the fermentation extract and film-forming material contains no heavy metal, has no harm on the environment and can be suitable for the cultivation of marine pearl oyster.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Cultivation method of non-nucleus one-shell multi-pearl seawater pearls

InactiveCN107517899ANo surgical traumaImprove survival rateClimate change adaptationPisciculture and aquariaOysterTissue fluid

The invention discloses a cultivation method of non-nucleus one-shell multi-pearl seawater pearls. The cultivation method mainly comprises the steps that adult pearl oysters are taken as donors and washed clean, and external permeable membrane tissue in pearl oyster meat is taken in a clean environment and washed clean with adenosine disodium triphosphate diluent; the external permeable membrane tissue is cut into particles, and the particles and external permeable membrane slime form external permeable tissue fluid; adult healthy seawater pearl oysters are taken as receptors, a slot is formed in the portion between the upper shell and the lower shell of each receptor oyster in a clean environment, and the external permeable tissue fluid is implanted into the receptor oysters through receptor oyster external permeable membranes; the overall steps are completed within three minutes. The receptor oysters implanted with the external permeable tissue particles are rapidly placed into clean seawater to be bred temporarily, and then are placed into a seawater breeding environment in three hours to be naturally bred. The adenosine disodium triphosphate diluent is prepared with 10 milliliters and 10 milligrams of commodity adenosine disodium triphosphate and 50 milliliters of sterile water. The pearl oysters cultivated by using the method have no surgical wound and are high in survival rate and yield and good in quality.

Owner:北海市旺海海洋科技有限公司

Polyculture mode for marine products

InactiveCN104719202AEnough room to growLow costClimate change adaptationPisciculture and aquariaCarrageenanPolyculture

The invention discloses a polyculture mode for marine products. Traditional marine product culturing modes are culturing modes of single varieties, fodder needs to be cast in the culturing process, the utilization rate of net cages is low, and the culturing cost is high. According to the polyculture mode for the marine products, pearl oysters and seaweeds are cast in a net cage in which fishes are cultured, the fishes, the pearl oysters and the seaweeds are cultured in the net cage together, the cast quantity of the pearl oysters meets the standard that a pearl oyster layer with the thickness of 10-12 cm is formed at the bottom of the net cage, and the quantity ratio of the cast quantity of the seaweeds to the cast quantity of the fish is 10 kilograms : 100-300 pieces, and the seaweeds meet the standard that the carrageenan content reaches 25-60%, the seaweeds are suitable for growing in the environment with the seawater temperature of 25-33 DEG C and the seawater salinity of 1.018-1.025 baume degrees. The three different cultured varieties can form a food chain in benign circulation, so that fodder does not need to be cast in the whole culturing process; by means of the food chain in benign circulation, a culturing sea area is made to be clean and environmentally friendly, the water body is clean, pest and disease damage is not prone to occurring, the culturing cost is low, and benefits are obvious.

Owner:北海市珍源海洋生物有限公司

Molecular and genetic engineering technology for cultivating colorful fluorescent pearls

The invention discloses a molecular and genetic engineering technology for cultivating colorful fluorescent pearls, and relates to a technology for cultivating bright-colored pearls and fluorescent pearls. The preparing technology includes the steps that a chemical self-assembled technology is used, natural dye molecules (algas rich in natural dye molecules are selected to be used as feed) are led in during the process of pearl forming, self-assembling is achieved on organic matrixes of pearl layers, and therefore the purpose of dying the pearls which are finally formed is achieved. Natural dye is used for conducting dyeing on the pearl layers, so that various colorful pearls can be achieved in a controllable mode. Through the modern genetic technology, fluorescent protein which is used widely in the biological chemistry scientific researches is applied to pearl oyster mantle tissue, and therefore the pearls with various fluorescent effects can be produced.

Owner:段升华

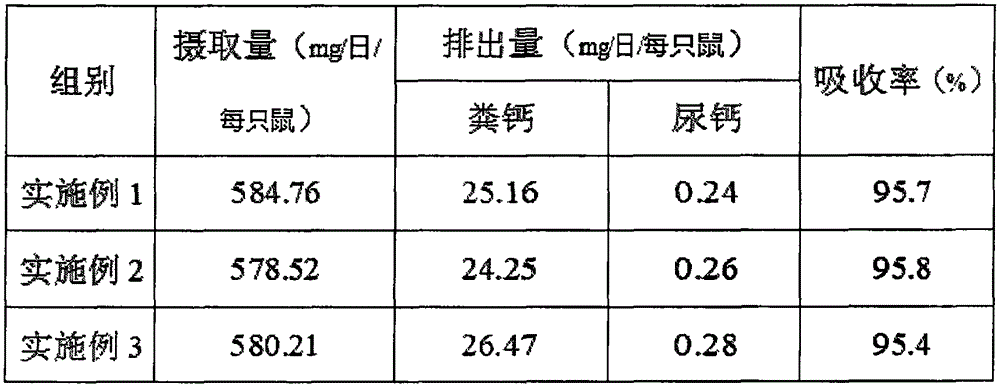

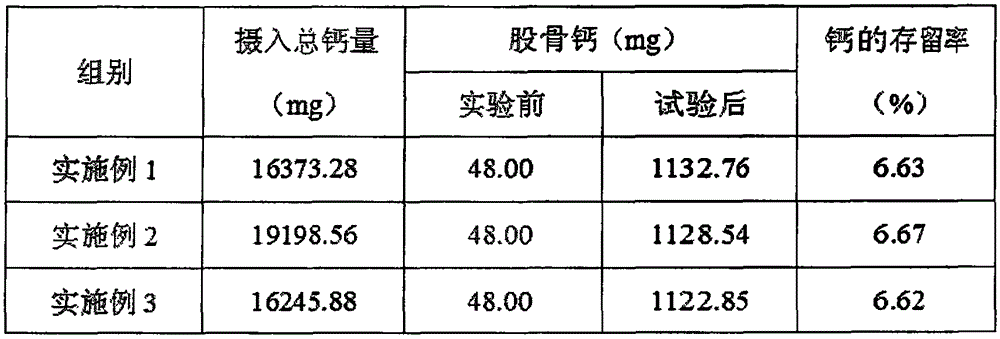

Processing method of ionized calcium water-soluble preparation and product

InactiveCN106491779AHigh in calciumGood degree of ionizationDispersion deliveryPeptide/protein ingredientsStalactiteOyster shells

The invention relates to a processing method of an ionized calcium water-soluble preparation and a product. The ionized calcium water-soluble preparation is prepared from the following raw materials in parts by weight: 100 to 120 parts of oyster shells, 20 to 28 parts of stalactite, 60 to 72 parts of pearl oysters, 55 to 65 parts of seven horn shells, 70 to 85 parts of fossil fragments, 28 to 35 parts of ricinus communis, 25 to 34 parts of salviae miltiorrhizae, 17 to 22 parts of selfheal, 12 to 18 parts of hawthorns, 10 to 15 parts of semen ziziphi spinosae, 25 to 32 parts of lemons, 40 to 62 parts of donkey bones and 20 to 26 parts of egg albumen. The ionized calcium water-soluble preparation is high in calcium content and high in ionization degree, and is ionized calcium active water which is easily absorbed by a human body; the pH value is 14 after the ionized calcium active water is flushed, so that the acid-base balance of the human body can be adjusted, and various trace elements and mineral substances which are required by the human body are supplemented; the human body absorption rate can reach 95 percent or above.

Owner:时传彬

Culture method of amorphous pearls

InactiveCN102461471AImprove survival rateImprove secretion capacityClimate change adaptationPisciculture and aquariaCuticleMicrobiology

The invention provides a culture method of amorphous pearls. The method comprises the following steps of: (1) cutting off edge membranes of freshwater mussels or pearl oysters, cutting off color lines, taking pallium exocuticles and putting the pallium exocuticles in a culture dish containing a Hanks liquid; (2) taking the pallium exocuticles out of the culture dish and mashing the pallium exocuticles for 3-5 minutes to obtain pulp; (3) sucking the pulp into a centrifuge tube, and naturally settling for 3-5 minutes to obtain a suspending liquid; (4) transferring the suspending liquid into another centrifuge tube and removing larger tissue blocks to obtain the final suspending liquid for layer use; and (5) pumping the suspending liquid by using an injector and injecting the suspending liquid into palliums or visceral masses of the freshwater mussels or pearl oysters by using the injector. In the production process of non-nucleated pearls, the culture method has the advantages that the wound is small; the wound can be healed easily and the survival rate of the freshwater mussels or pearl oysters is high; in the production process of nucleated pearls, the problems of uneven flakelet wrapping, uneven nacre secretion or flakelet falling off can be overcome; and the secretion capability of nacre of the freshwater mussels or pearl oysters can be improved greatly and the production cycle can be reduced by more than 20%, therefore, the culture method has the advantage of high beneficial and practical value.

Owner:HUNAN UNIV OF ARTS & SCI +1

Pearl sacs assistant formation method after nucleus-insertion

InactiveCN101036450AShorten the formation timeReduce formation rateAnimal cellsClimate change adaptationCell engineeringBiology

The present invention discloses a pearl sac assistant forming method after transplanting nuleus, which comprise the following steps: (1) cutting front segment mantle tissue of pearl oyster (2) using protease for enzymolysis of mantle tissue under temperature 20-25 degree, pH value 6.9-8.3, dispersing the tissue and obtaining cell (3) separating the obtained cell in step (2) by high speed centrifugal apparatus, cell fluid is obtained; (4) neutralizing the cell liquor, (5) immersing neutralized cell fluid in protection liquid; (4) taking optimum volume of cell liquor, dropping it at the wound of transplant operation. The cell liquid integrated with mantle and pearl nucleus to form pearl sac. The present invention successfully operate the cell engineering method in pearl cultivation that cell sac forming time is shortened 10 days, pearl quality is obviously promoted as compared to normal pearl breeding method which largely reduce the formation rate of abnormal pearl and nude pearl without pearl layer.

Owner:ZHEJIANG GRACE PEARL JEWELRY +1

A method of cultivating pearls

InactiveCN105145417BIncrease oxygen contentSave energyClimate change adaptationPisciculture and aquariaNutrient solutionEnergy conservation

The invention discloses a pearl cultivation method, and belongs to the aquatic product cultivation technical field; the method comprises the following steps: selecting a cultivation room to cultivate pearl oysters, wherein the cultivation room comprises a culture pond, a first purifying pond, a second purifying pond, and a water storage pond connected in sequence, and top surfaces of the four parts gradually descends in a stepped manner; utilizing a tide difference principle to realize water self-discharge self-irrigation in the pond; arranging a filtering net and a mesh screen to purify water body, thus saving energy, and reducing cultivation cost; arranging the bottom of a net cage to be a waveform surface so as to prevent pathogen infection, thus providing better growth environment for the pearl oysters; preparing nutrient solutions of different components to process cell small particles and pearl cores, thus improving core planting rate, and reducing core repelling phenomenon; applying different fertilizers to accelerate pearl oyster maturation in different stages, and promoting pearl quality in the same time.

Owner:GUANGXI PEARL ROYAL INVESTMENT HLDG GRP CO LTD +1

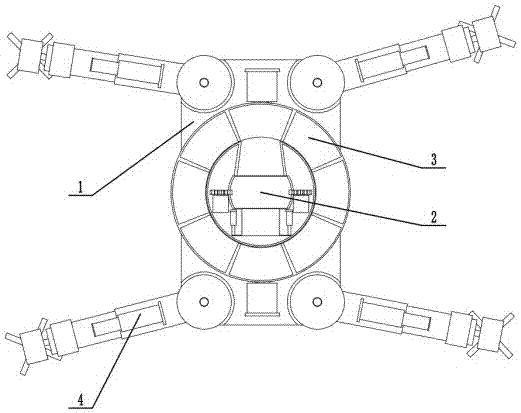

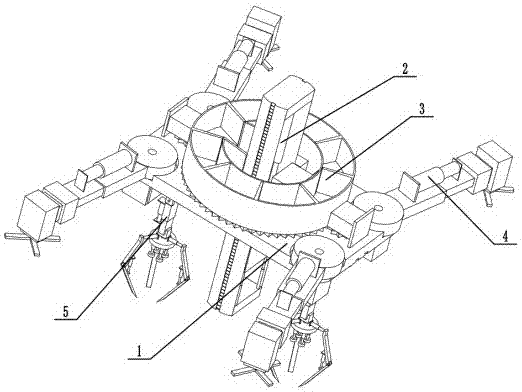

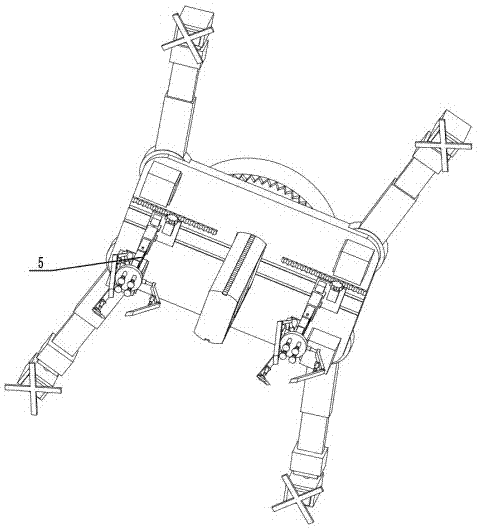

Large-scale bulb fritillaria catching robot

InactiveCN107877525AAutomated crawlingImprove crawling efficiencyPisciculture and aquariaMechanical energy handlingHydraulic cylinderEngineering

The invention discloses a large-scale pearl oyster catching robot. The catching robot comprises a base, a pearl oyster loading part, a pearl oyster storing part, four turbine parts and two pearl oyster grabbing parts, and is characterized in that the pearl oyster loading part is sliadably installed in an oval groove of the base, and two second racks are meshed with two second gears respectively. According to the large-scale pearl oyster catching robot, third gears are driven by fourth stepping motors of the two pearl oyster grabbing parts to drive the pearl oyster grabbing parts to move, foursuction discs are driven by four ninth hydraulic cylinders to suck pearl oysters, and next, three seventh hydraulic cylinders and three eighth hydraulic cylinders are coordinated to enable three second connecting rods to clamp the pearl oysters, and next, the pearl oysters are put into a pearl oyster storage box through the pearl oyster grabbing parts; and therefore automatic pearl oyster grabbingis realized, grabbing efficiency is improved, and grabbing operation is facilitated.

Owner:韩朝锋

Pearl mussel breeding method

InactiveCN103918583ABright colorIncrease productionClimate change adaptationPisciculture and aquariaHydrogenPregnancy examination

The invention discloses a pearl mussel breeding method. The pearl mussel breeding method includes steps of 1) breeding in a pond which is 2-2.5 meters in depth, 6.5-8 in pH (potential of hydrogen) value and 4-8mg / l in dissolved oxygen; 2) fertilizing the pond in 3-5 days before pearl mussels are placed into the pond; 3) breeding non-carnivorous fishes such as grass carps, breams, bighead carps and crucians in the pond; 4) drilling small holes on the shells of the pearl mussels so as to string the pearl mussels by ropes; 5) feeding proper food organisms, applying rare-earth nutrient sources once in the peak period of growth of the pearl mussels so that the concentration of the pond is 0.1mg / l; 6) subjecting all pregnant mussels to pregnancy examination in three to four months before collecting the pearl mussels, and classifying according to fetal development. The pearl mussel breeding method adopts mixed breeding technology, and the bred pearl mussels are bright in pearl luster, high in yield and low in cost.

Owner:SUZHOU YANGCHENGHU MODERN AGRI INDPARK SPECIAL AQUACULTURE

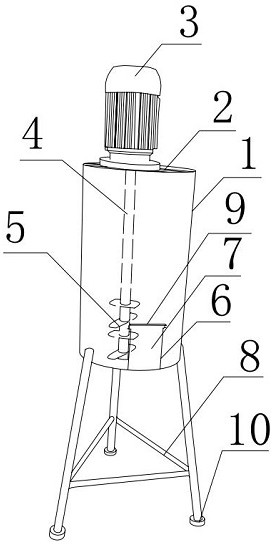

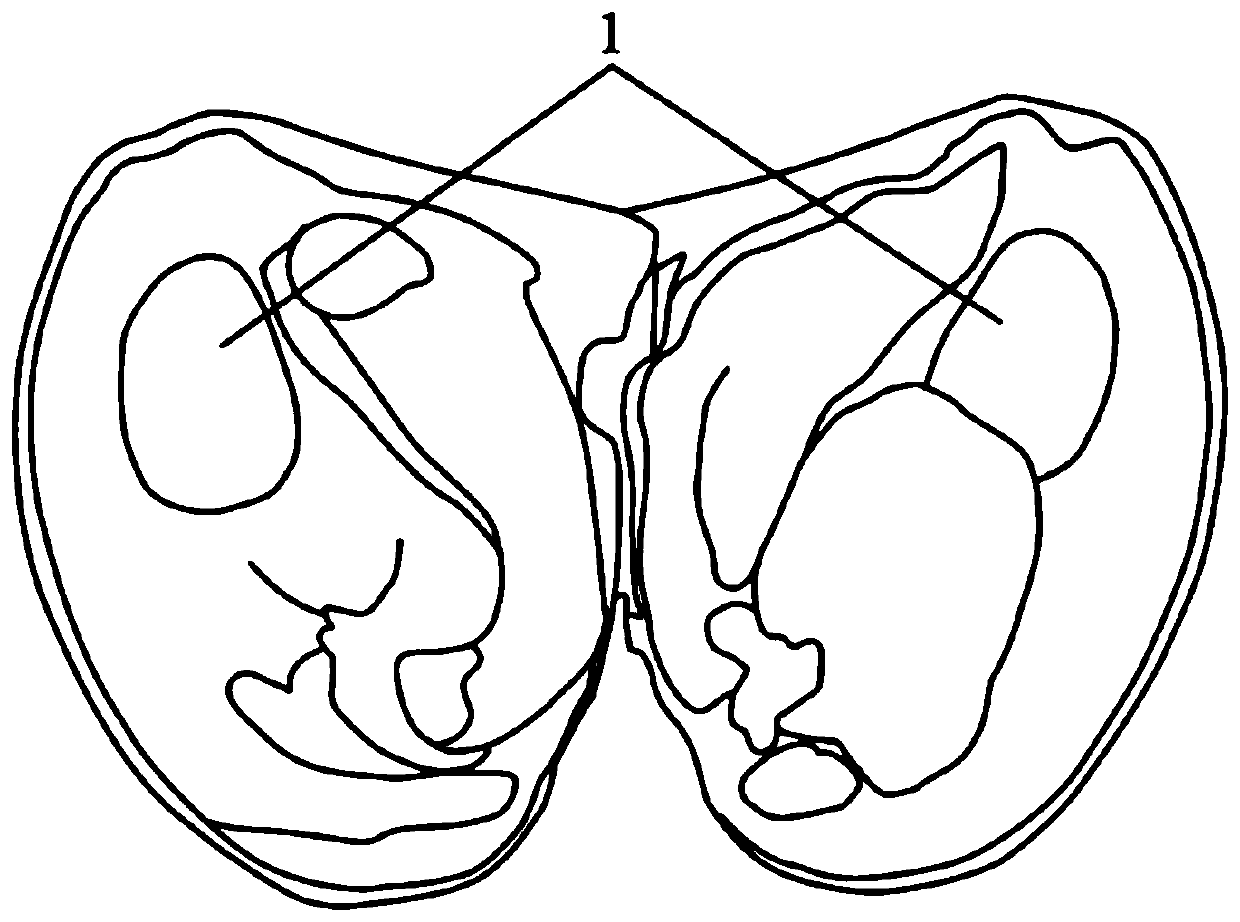

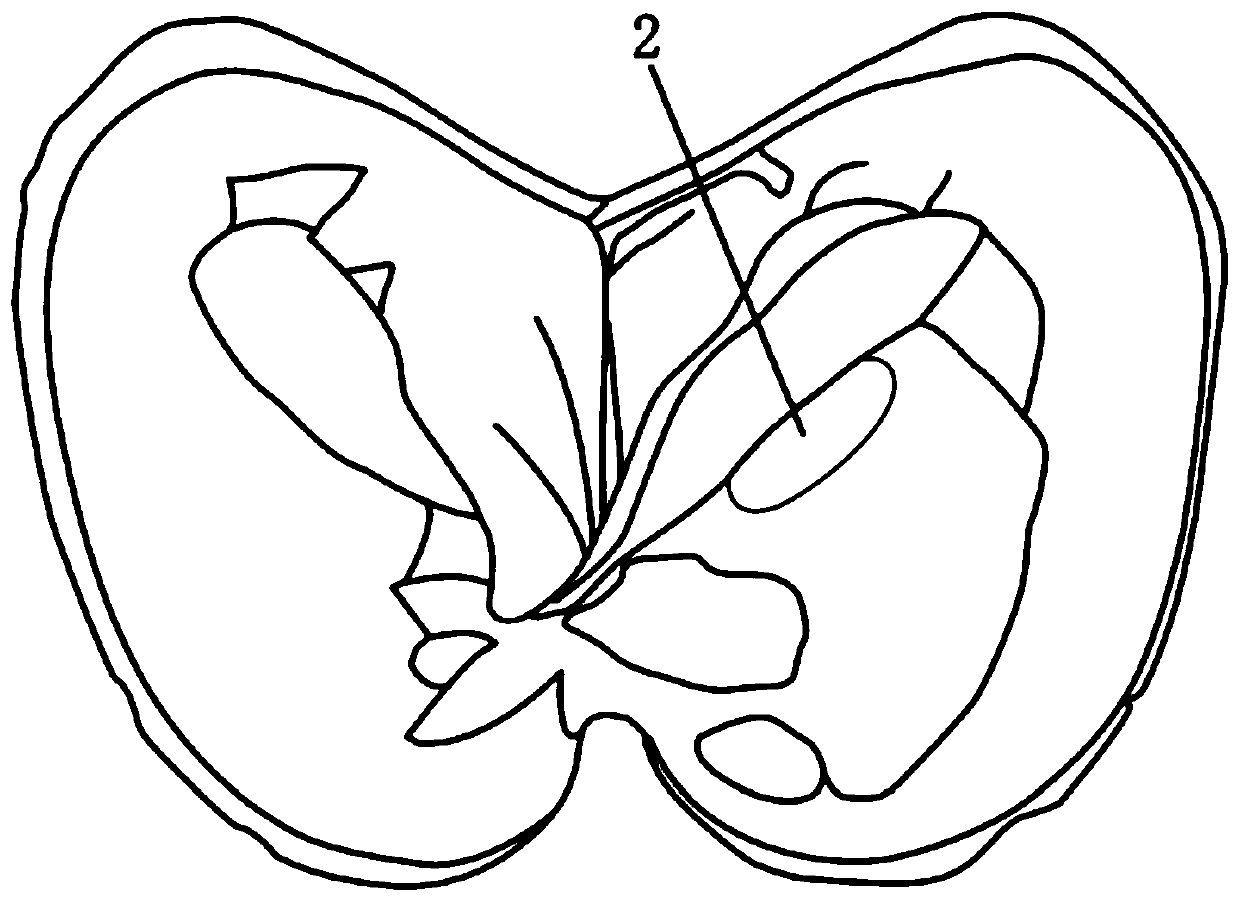

Meat and pearl separation equipment

PendingCN112535130AEasy to put inEfficient separationClimate change adaptationPisciculture and aquariaAnimal scienceElectric machine

The invention discloses meat and pearl separation equipment which comprises a barrel body used for loading pearl oyster meat. A fixing rod is transversely arranged in the middle of a barrel opening ofthe barrel body, a motor is arranged on the fixing rod, the motor is arranged at the left side of the fixing rod, and a space at the right side is reserved, so that a large amount of pearl oyster meat is conveniently put in; the motor is connected with a power supply through a power line, a rotating shaft of the motor aligns to the bottom of the barrel body and is connected with a transmission rod, a stirrer is arranged outside the bottom of the transmission rod, the motor is started to drive the transmission rod to rotate, and the pearl shell meat is smashed through the stirrer; the side surface of the barrel body is provided with a discharge port for discharging pearl mother liquor and pearls, and the discharge port is provided with a gate for controlling opening and closing; and a support frame is arranged at the bottom of the barrel body. The meat and pearl separation equipment has the characteristics of efficient separation of a large amount of pearl oyster meat and the pearls, small occupied area and convenience in daily use, and reduces the labor investment.

Owner:广东尊鼎珍珠有限公司

A kind of mixed culture method of pearl mussel and soft-shelled turtle

InactiveCN102265794APromote growthMeet food needsClimate change adaptationPisciculture and aquariaMixed cultureZoology

A mixed breeding method of pearl mussels and soft-shelled turtles, including the selection and transformation of the breeding pond, the control of the breeding quantity, the control of the number of beneficial bacteria and oxygen in the breeding water, and the control of the matching breeding quantity of other fish, so that the whole breeding The ecology is at its best. Advantages of the present invention: the present invention effectively utilizes the leftover bait of soft-shelled turtles and the excrement of soft-shelled turtles, and pearl oysters play the role of removing pollution from soft-shelled turtle culture in the breeding process, which is not only beneficial to the growth of soft-shelled turtles, but also satisfies the food demand of soft-shelled turtles, reducing The waste of bait organisms is reduced, the water environment is protected, and the total benefit of breeding is increased by more than 30%.

Owner:DATONG LAKE TIANHONG FISHERY +1

Oyster semi-artificial seeding method

ActiveCN103609500AHigh precisionHigh seedling accuracyClimate change adaptationPisciculture and aquariaHigh densityPearl oyster

The invention relates to an oyster semi-artificial seeding method. Oviposition and spermiation of parent oysters are monitored with high precision and high density and planktonic larvae are monitored. The quality of oyster seeding is strictly controlled, the seeding precision is high, the quality is good, the method is simple and easy to carry out, sea water will not be polluted and the oyster semi-artificial seeding method can meet the requirement for large-scale oyster cultivation.

Owner:GUANGXI ZHENGWU MARINE IND

Method for culturing 3D baroque pearls

ActiveCN111264429AGood shapeGood aestheticsClimate change adaptationPisciculture and aquariaBiotechnologyMicrobiology

The invention relates to a method for culturing 3D baroque pearls. The method is characterized by comprising the following steps: carrying out tissue culture with mantle tissue cell slices cut from afreshwater mussel or pearl oyster to provide implanted cell slices used for pearl culture; selecting pearl culture mussels or pearl culture oysters as pearl culture female parents; implanting the cellslices into pearl culture positions of the pearl culture female parents by an operation method after combining a plurality of implanted cell slices into a shape or combining a plurality of implantedcell slices with a pearl nucleus into a shape, and then putting the postoperative pearl culture female parents into water for pearl culture, thereby producing nucleated or enucleated 3D baroque pearls. The 3D baroque pearls are individualized products that are rough and uneven in surface, three-dimensional (3D) inside and outside and irregular in outer shape, and can be widely applied to design and creation, for example, formed into various high-end accessories by inlay such as pendants, earrings, brooches, necklaces and model bras.

Owner:谢郁 +1

Sobering-up agent of pearl oyster meat and preparation thereof

ActiveCN101244084AWide variety of sourcesLow priceNervous disorderMolluscs material medical ingredientsAlcoholSleeping time

The invention provides a pearl oyster meat alcohol relieving agent and the preparation method. The invention is characterized in that the preparation technology is: the pearl oyster meat is added to 4 to 8 time amount of water and is homogenized and ground; then the pH value is adjusted to 5 to 8. One or a plurality of proteinase of 0.2 to 2% pearl oyster meat quality is added; the enzymolysis is made under the temperature of 40 to 65 DEG C in 5 to 8 hours and the stirring is continued in the process; the enzyme is killed in the boiling water for 10 minutes; the extraction is made in hot water of 60 to 100 DEG C for 20 to 40 minutes; the residue is filtered out; the filtered liquid is concentrated and spray dried to powder; the original powder of pearl oyster meat alcohol relieving agent is obtained. The powder can be produced into tablet, capsule and oral liquid. The pearl oyster meat alcohol relieving agent has the advantage that the alcohol relieving and liver protecting effect is excellent; the product can reduce the intoxication rate of a mouse from 90% to 20%, shorten nearly 200 minutes of the intoxication sleep time of the mouse, and obviously reduce the alcohol concentration in blood of the mouse.

Owner:GUANGDONG OCEAN UNIVERSITY

Biomass pearl oyster-simulated material and preparation method thereof

ActiveCN110724390ANanoparticle distributionNanoparticles can be evenly distributedFiberFreeze-casting

The invention discloses a preparation method of a biomass pearl oyster-simulated material. The preparation method is characterized by comprising the following steps: S1, attaching a nano material to biomass fiber uniformly by using a thermal grinding method so as to prepare a nano-material / bio-fiber composite material mixed suspension; S2, using a freeze casting method to prepare a layered pearl oyster structure-simulated matrix mixed suspension from the mixed suspension obtained in the step S1; and S3, immersing an organic polymer material in the matrix mixed suspension obtained in the step S2, and then performing hot pressing so as to obtain the wood-like pearl oyster material. The preparation method is more environmentally friendly, the prepared pearl oyster-simulated biomass-simulatedlayered material has higher mechanical strength and higher specific strength, and novel performance is given to the material through functional groups, so that the material has a wide range of application.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Health oyster-turtle powder

InactiveCN1973687AGrowth inhibitionImprove absorption and utilizationMetabolism disorderImmunological disordersOysterExcipient

The present invention relates to health oyster-turtle powder, which is prepared with turtle, oyster, cassia seed, plantain herb and cistanche, and through treatment, drying, crushing, sieving and mixing. The health oyster-turtle powder consists of oyster powder 33-40 wt%, turtle powder 28-38 wt%, cassia seed powder 8-12 wt%, plantain herb powder 7.5-10 wt% and cistanche powder 1-5 wt%, except excipient. The health oyster-turtle powder may be well absorbed and utilized by human body, and possesses the functions of promoting metabolism, enhancing memory, resisting fatigue, delaying senility, raising immunity, etc. It may be taken by all the people all the year round.

Owner:SHANGHAI FISHERIES UNIV

Pearl oyster monomer polysaccharide ZBP-I and extraction method and uses in preparation of drugs for tumor

InactiveCN1544478AGrowth inhibitionSuppress generationOrganic active ingredientsAntineoplastic agentsCelluloseWhite blood cell

The invention discloses a process for separating and purifying pearl oyster monomer polysaccharide ZBP-I from the crude polysaccharides extracted from pearl oyster, which comprises, dissolving the crude polysaccharide powder into water, charging into cellulose columns, eluting with dissolvent, subjecting the eluent to hyperfiltration by ultrafilter membrane and vacuum drying or lyophilization to prepare pearl oyster polysaccharide I powder, dissolving the polysaccharide I in water, separating through Sephadex G-200 column, the pearl oyster monomer polysaccharide ZBP-I is finally obtained from the eluent through alcohol deposition of polysaccharide, filtering, vacuum drying or freeze drying. The monomer polysaccharide ZBP-I exhibites appreciable enhancing action for the anti-tumor activity of the natural killer NK cells.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

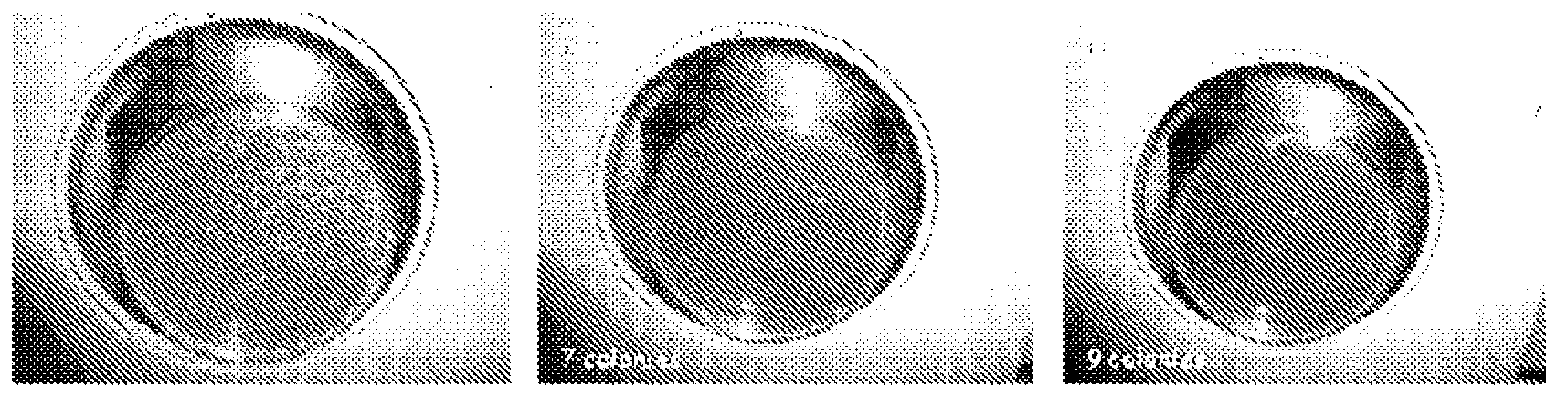

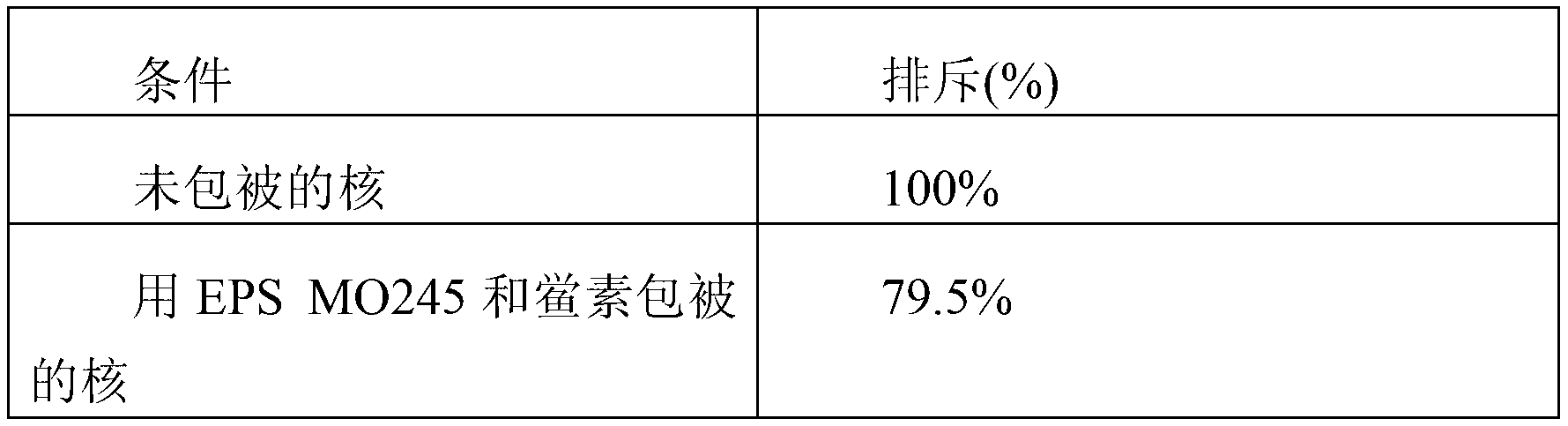

Nucleus coated with a film-orming coating having antibacterial and cicatrizing properties, and method for obtaining same

ActiveCN103260395AImprove uniformityQuality improvementOrganic active ingredientsClimate change adaptationPearl oysterBioactive molecules

The invention relates to a nucleus coated with a film comprising one or more exopolysaccharides (EPS) and optionally one or more bioactive molecules such as bactericidal or bacteriostatic agents, cicatrizing agents and / or anti-inflammatory agents, as well as to a method for obtaining said nucleus, in order to inhibit graft rejection in pearl oysters.

Owner:法国海洋勘探研究所 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com