Patents

Literature

76 results about "Freeze-casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

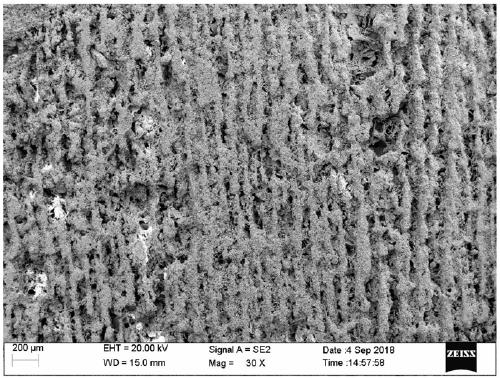

Freeze-casting, also frequently referred to as ice-templating, is a technique that exploits the highly anisotropic solidification behavior of a solvent (generally water) in a well-dispersed slurry to template controllably a directionally porous ceramic. By subjecting an aqueous slurry to a directional temperature gradient, ice crystals will nucleate on one side of the slurry and grow along the temperature gradient. The ice crystals will redistribute the suspended ceramic particles as they grow within the slurry, effectively templating the ceramic.

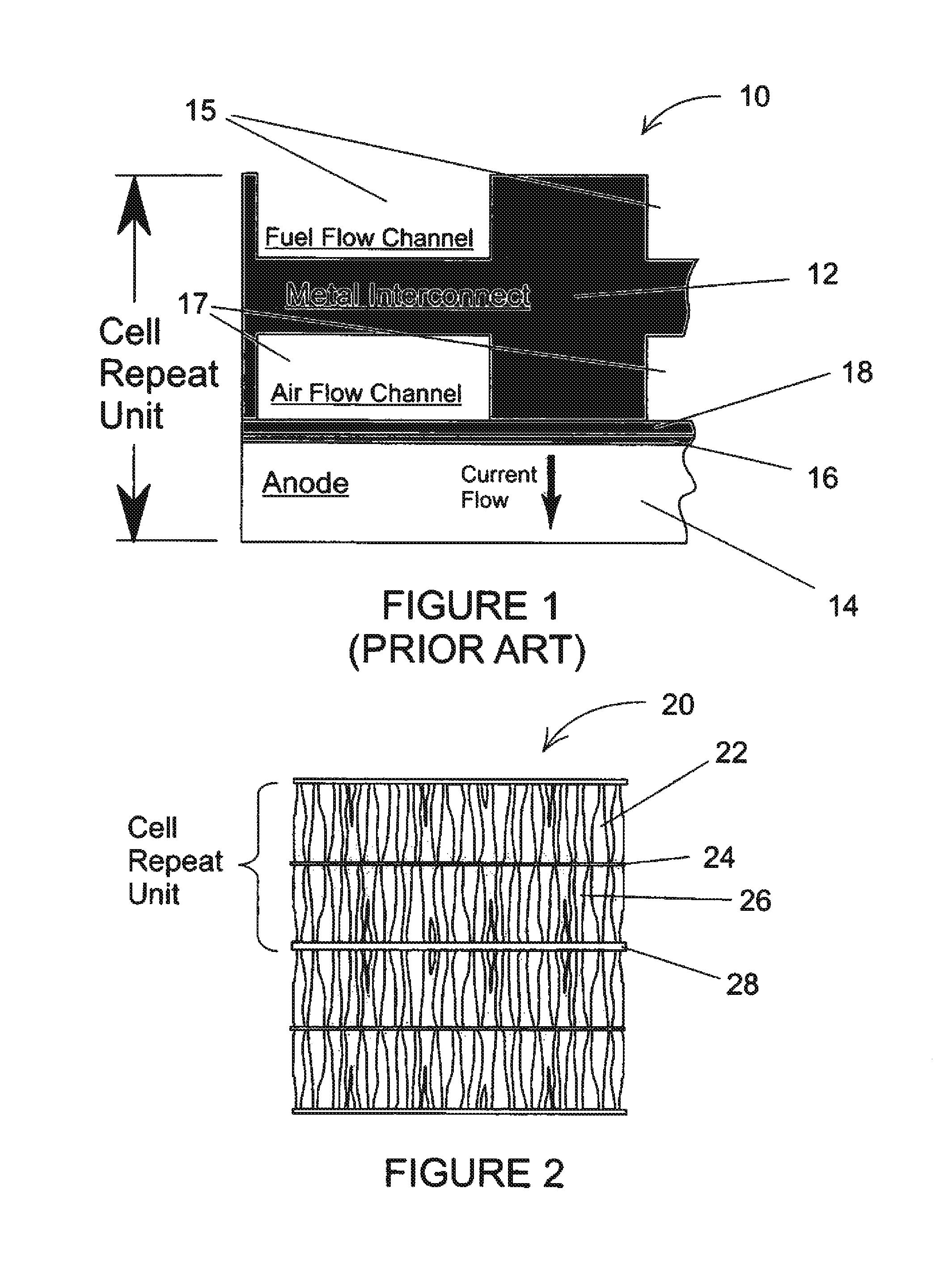

Symmetrical, bi-electrode supported solid oxide fuel cell

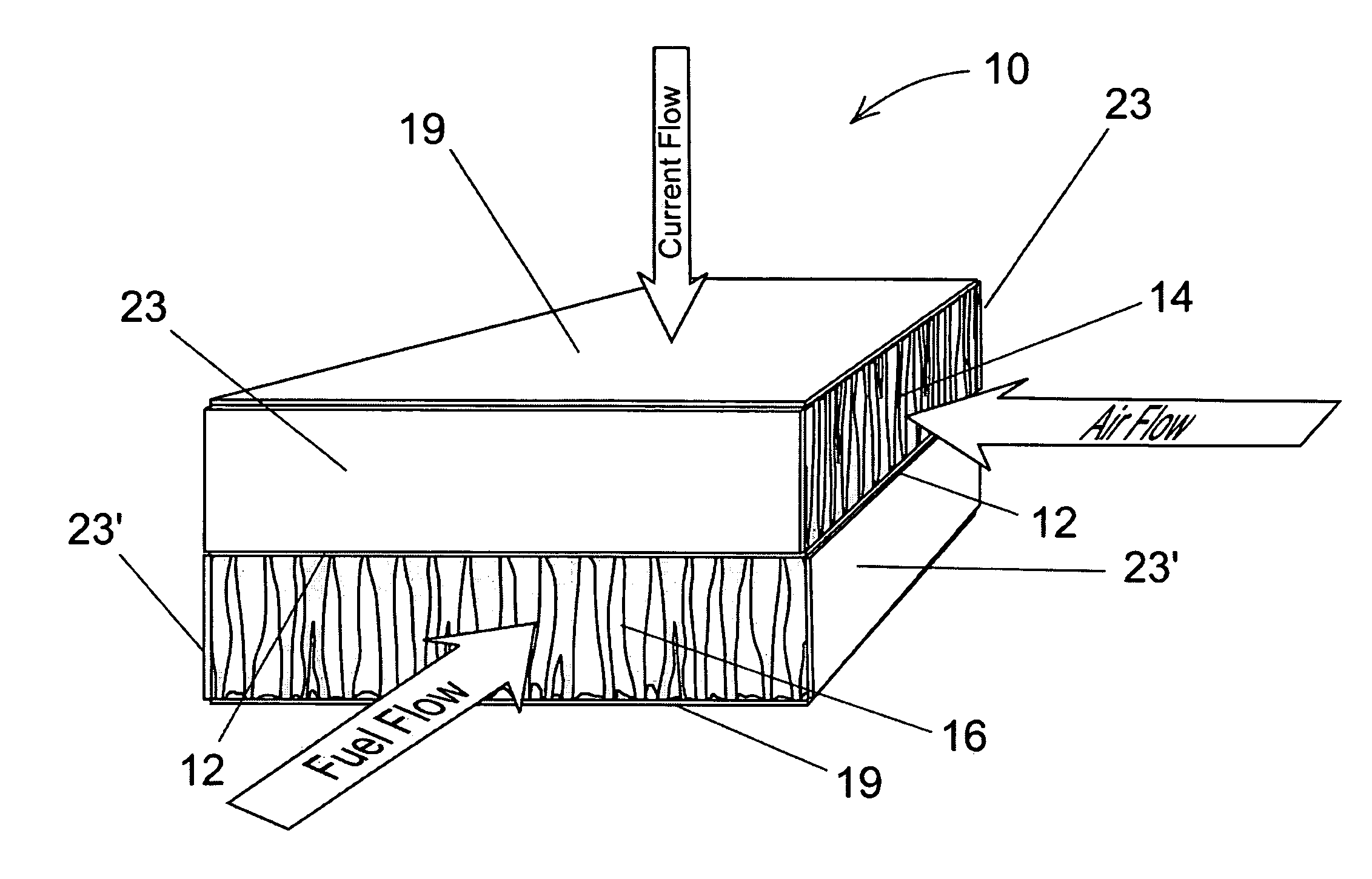

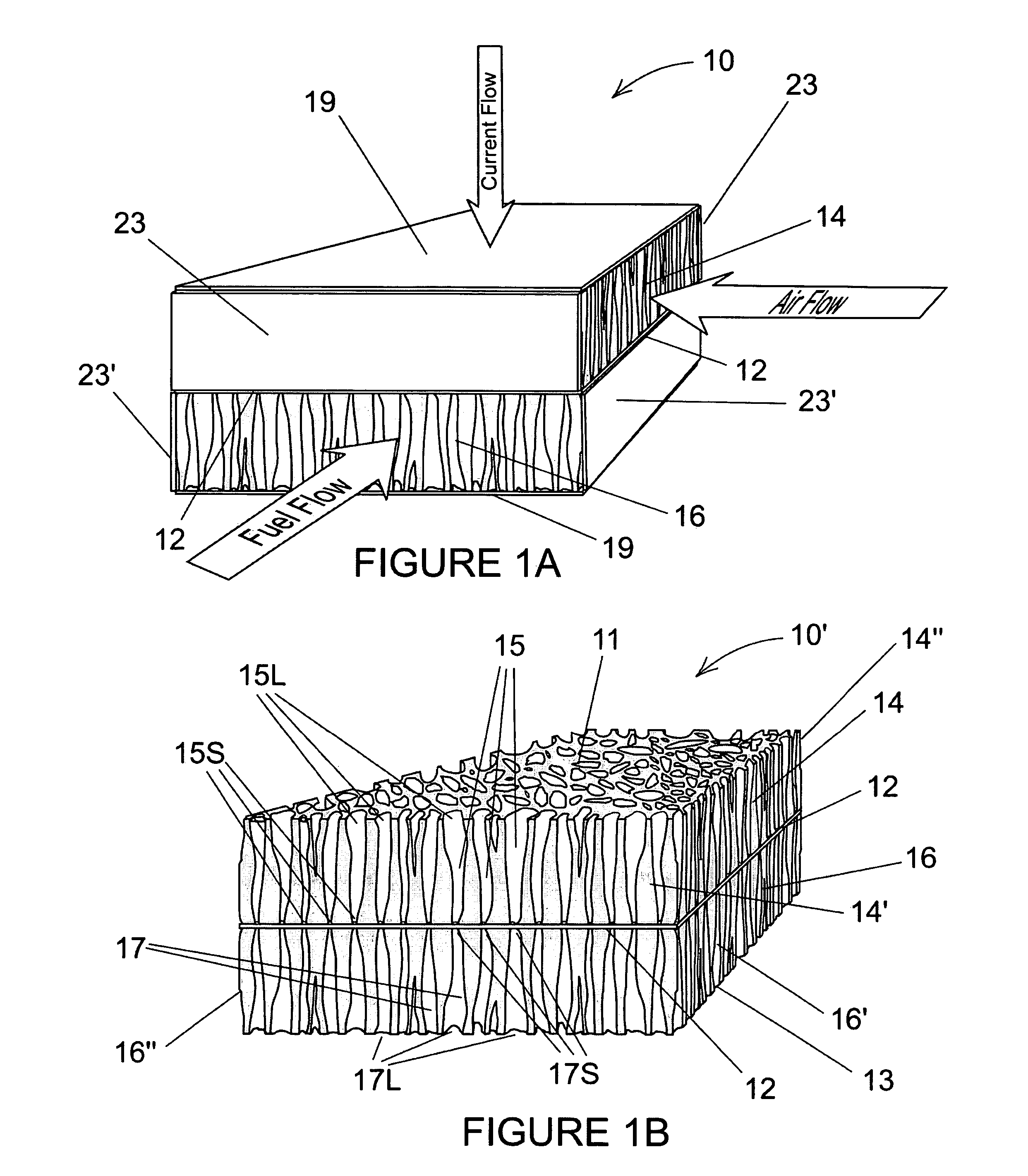

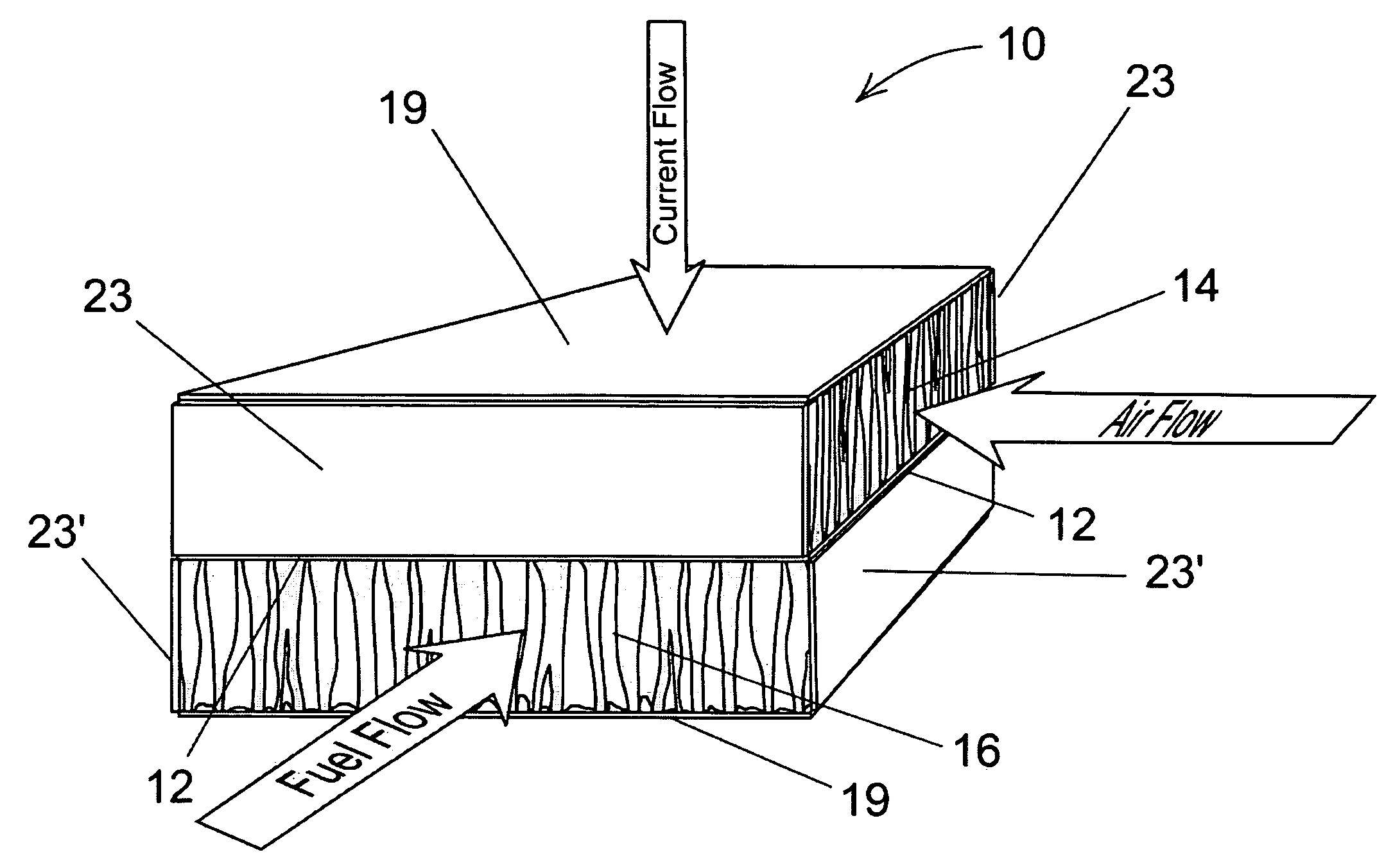

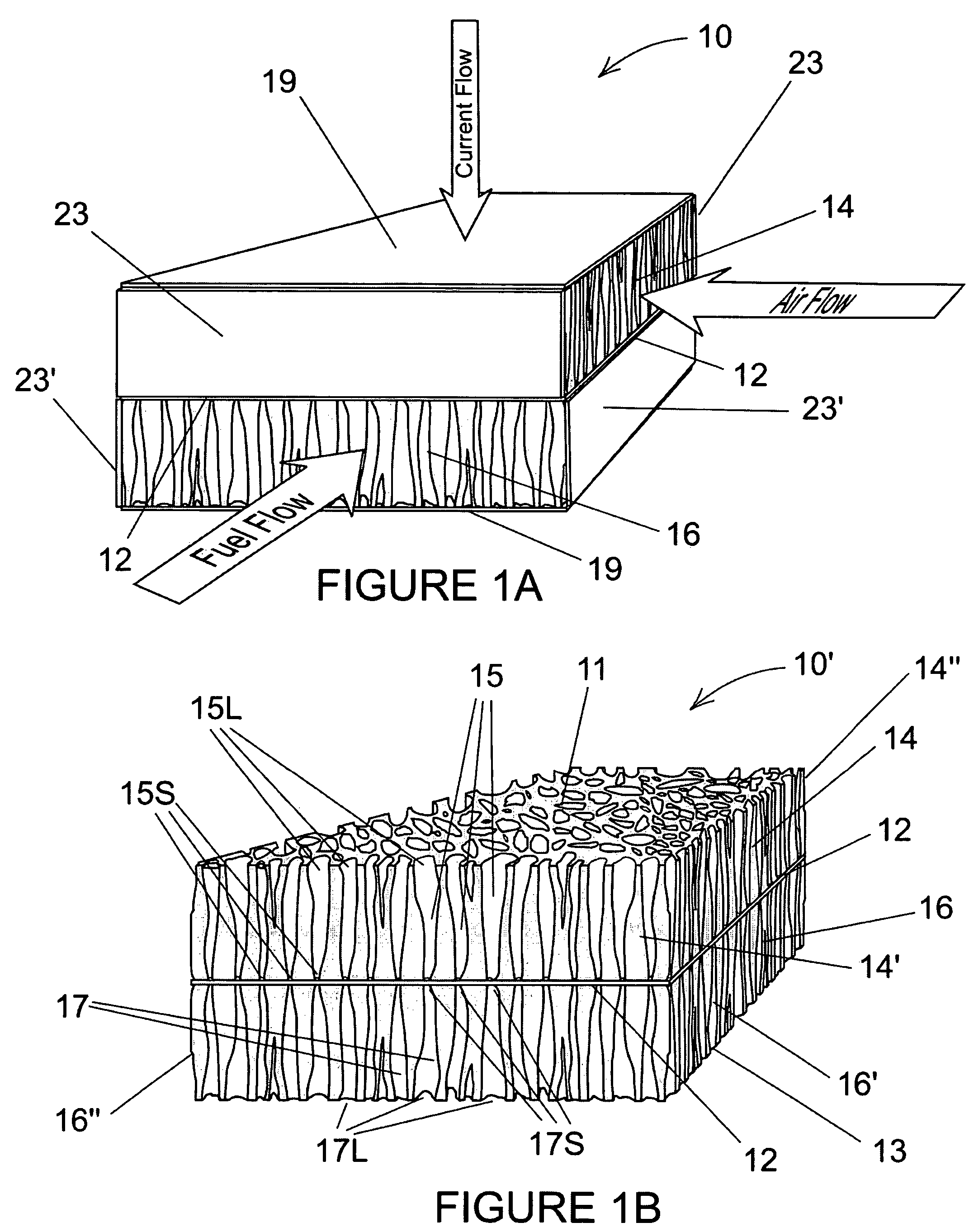

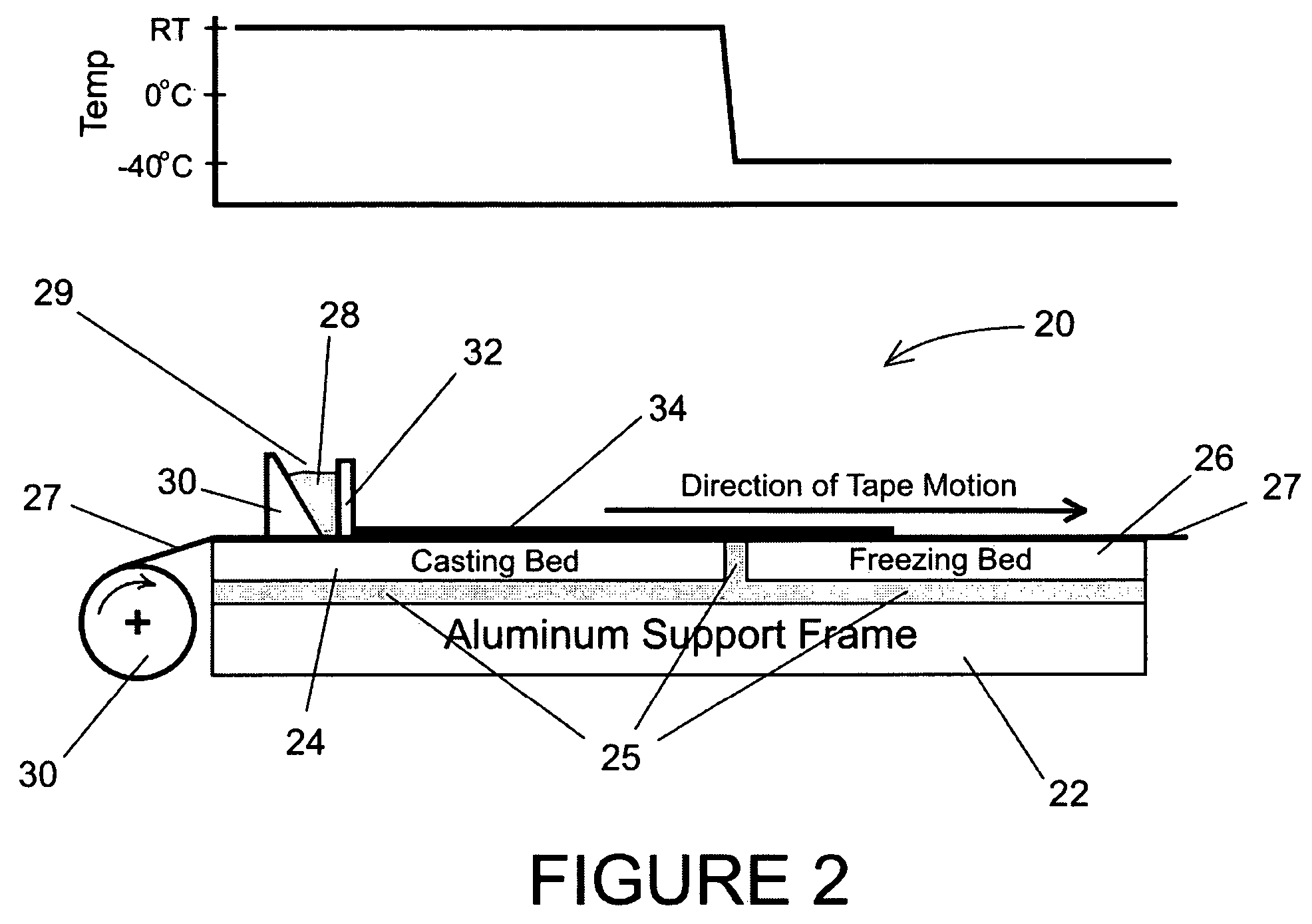

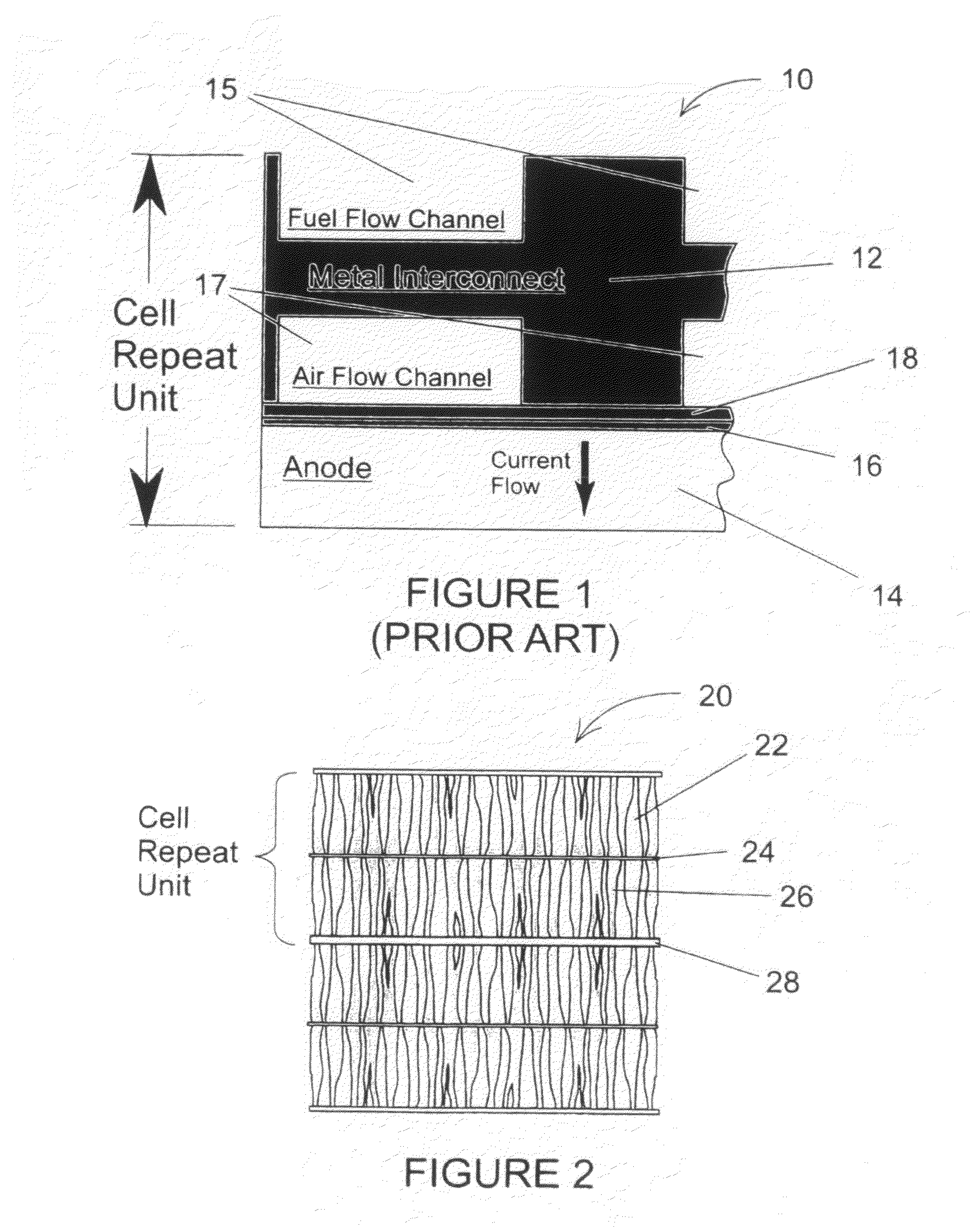

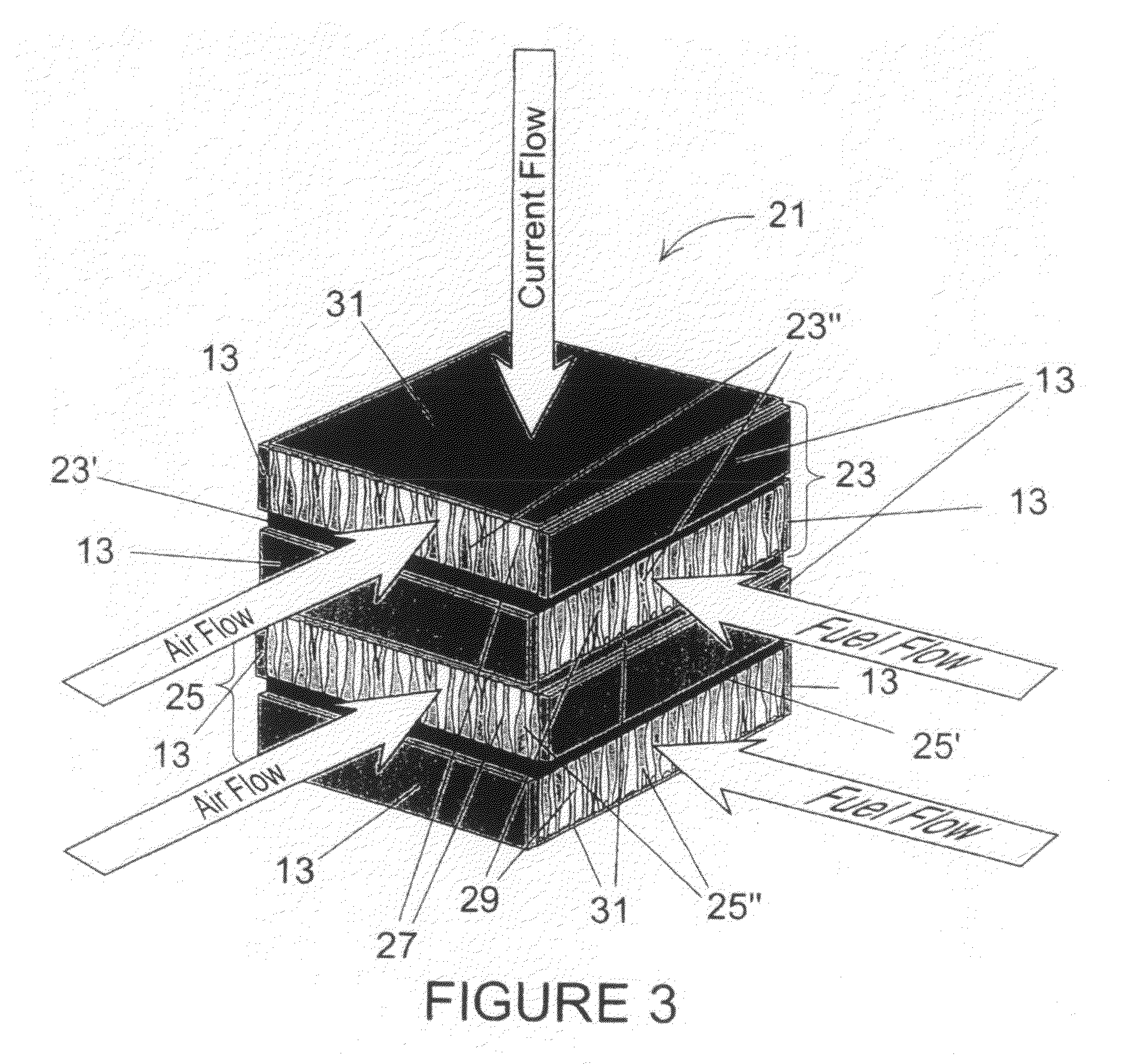

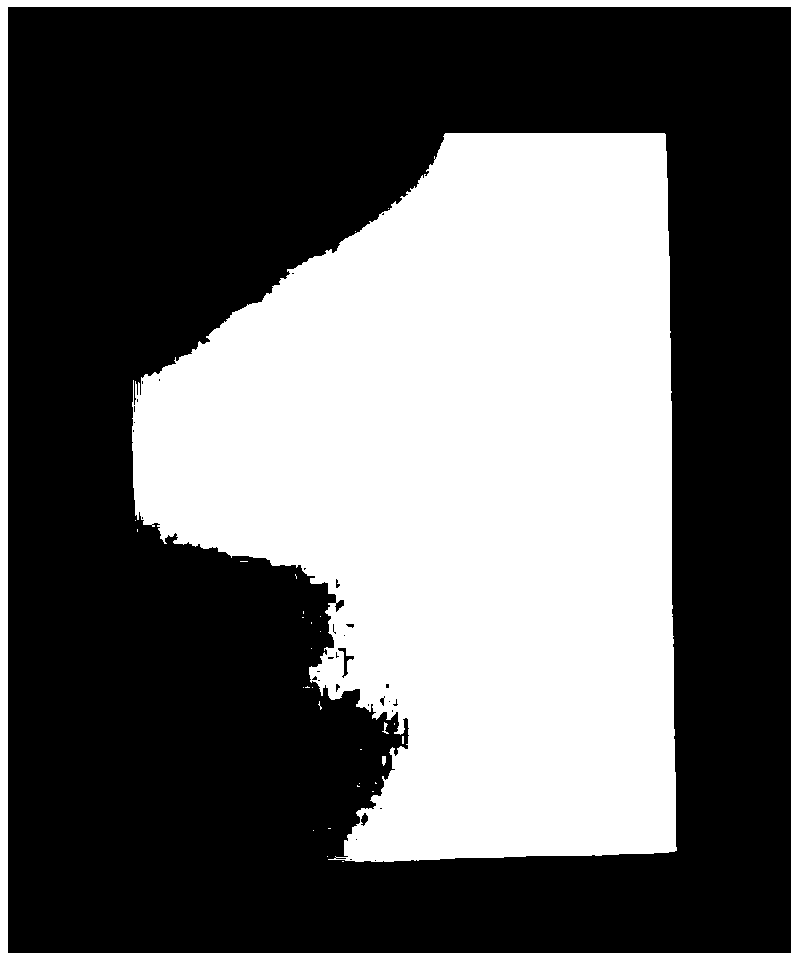

The present invention is a symmetrical bi-electrode supported solid oxide fuel cell comprising a sintered monolithic framework having graded pore electrode scaffolds that, upon treatment with metal solutions and heat subsequent to sintering, acquire respective anodic and cathodic catalytic activity. The invention is also a method for making such a solid oxide fuel cell. The graded pore structure of the graded pore electrode scaffolds in achieved by a novel freeze casting for YSZ tape.

Owner:U S GOVERNMENT AS REPRESENTED BY THE ADMINSTRATOR OF NAT AERONAUTICS & SPACE ADMINISTATION

Symmetrical, bi-electrode supported solid oxide fuel cell

The present invention is a symmetrical bi-electrode supported solid oxide fuel cell comprising a sintered monolithic framework having graded pore electrode scaffolds that, upon treatment with metal solutions and heat subsequent to sintering, acquire respective anodic and cathodic catalytic activity. The invention is also a method for making such a solid oxide fuel cell. The graded pore structure of the graded pore electrode scaffolds in achieved by a novel freeze casting for YSZ tape.

Owner:U S GOVERNMENT AS REPRESENTED BY THE ADMINSTRATOR OF NAT AERONAUTICS & SPACE ADMINISTATION

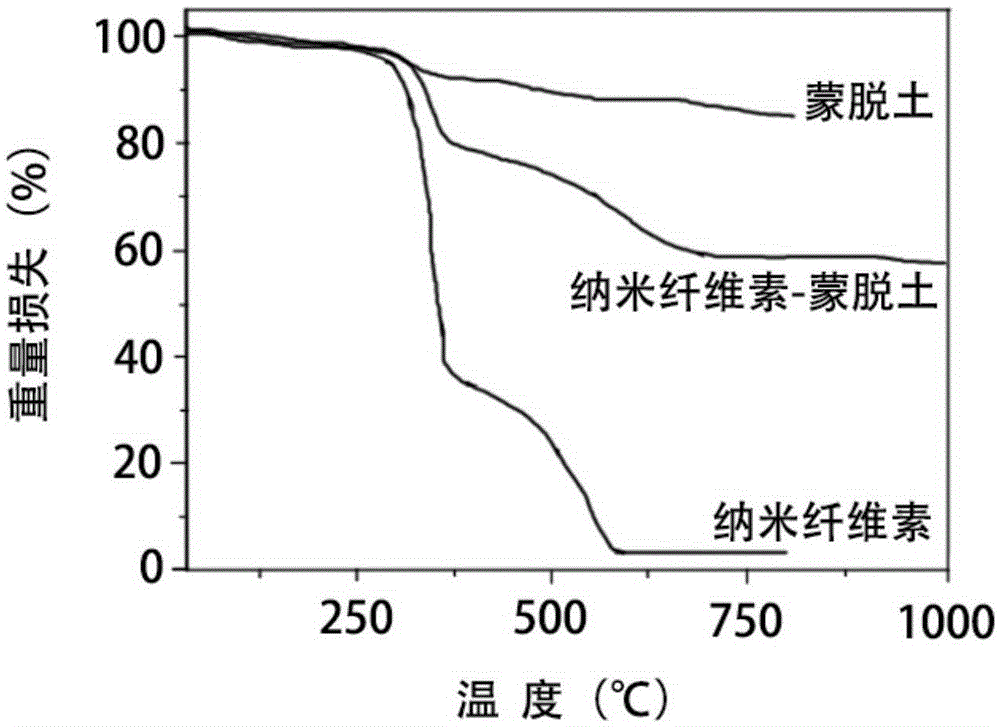

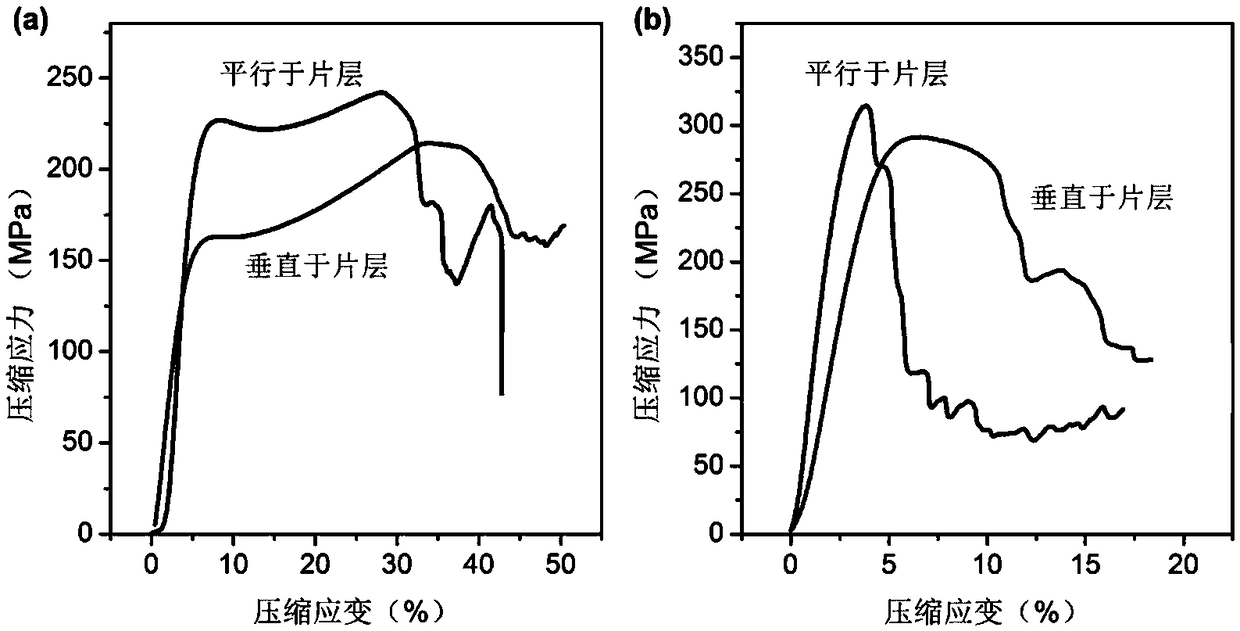

Anisotropic nano-cellulose/montmorillonite composite aerogel and preparation method thereof

The invention discloses anisotropic nano-cellulose / montmorillonite composite aerogel. The aerogel is prepared by mixing a nano-cellulose suspension with a montmorillonite suspension and performing freeze casting. The invention further discloses a preparation method of the aerogel. The method comprises the following steps: (1) respectively preparing nano-cellulose suspension and montmorillonite suspension; (2) mixing the montmorillonite suspension with the nano-cellulose suspension to form uniformly dispersed nano-cellulose / montmorillonite suspension; (3) performing freeze casting on the nano-cellulose / montmorillonite suspension to obtain the nano-cellulose / montmorillonite composite aerogel. The rigidity and heat tolerance of the nano-cellulose aerogel are improved by adding the montmorillonite, and the anisotropic honeycomb shaped aerogel is prepared by means of a directional freeze drying method; and the mechanical performance of the anisotropic nano-cellulose / montmorillonite composite aerogel is superior to that of anisotropic foam-shaped nano-cellulose / montmorillonite composite aerogel prepared by a conventional freeze drying method since the stress of the aerogel mainly depends on cell wall stretching of the material rather than bending deformation of the material.

Owner:NANJING FORESTRY UNIV

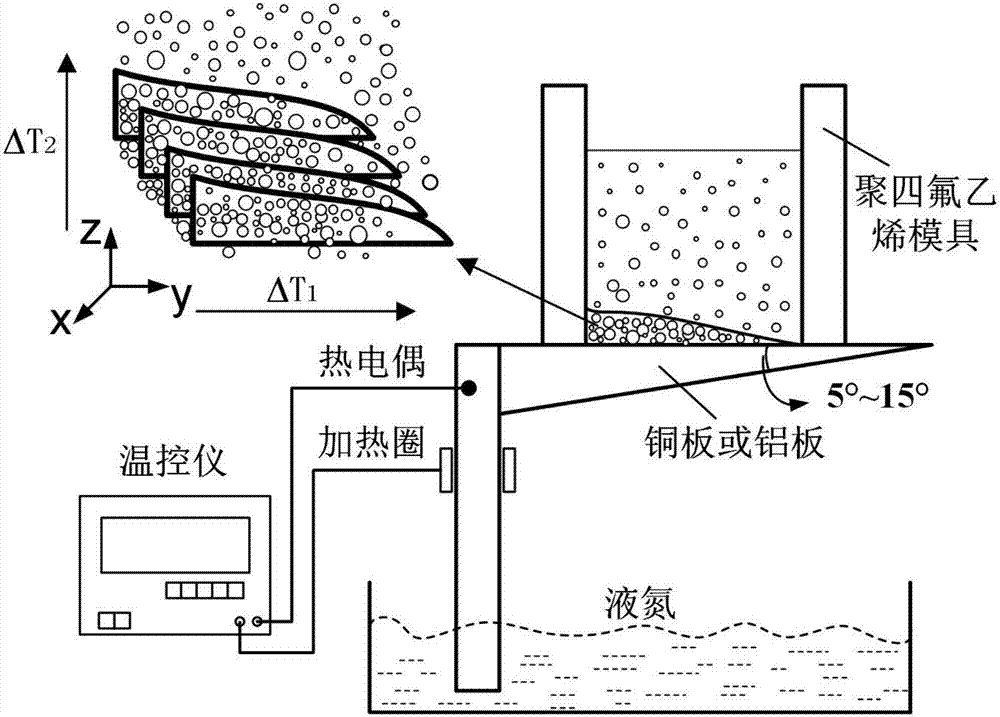

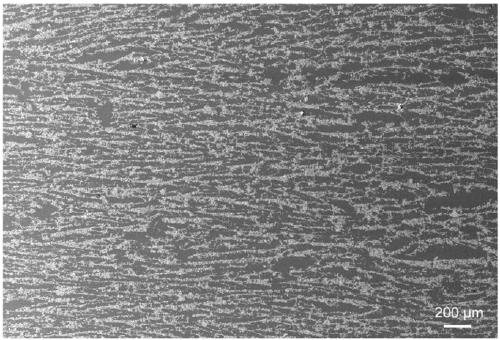

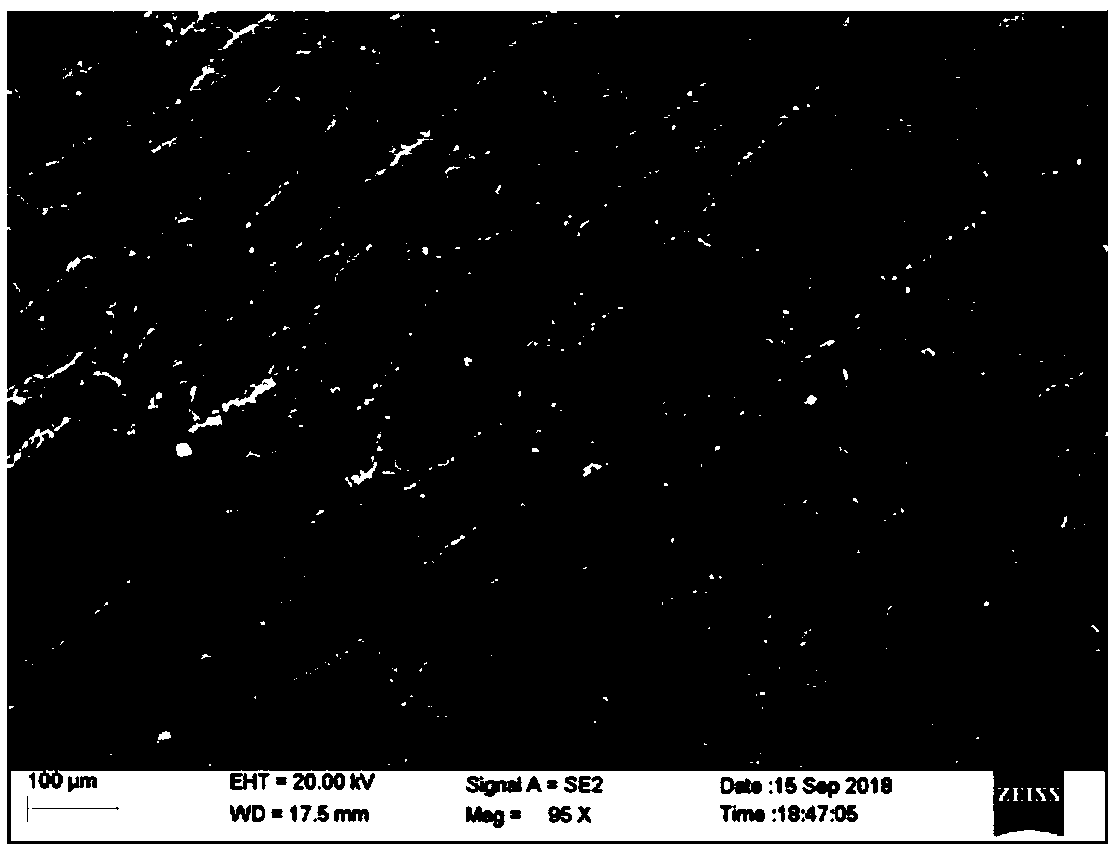

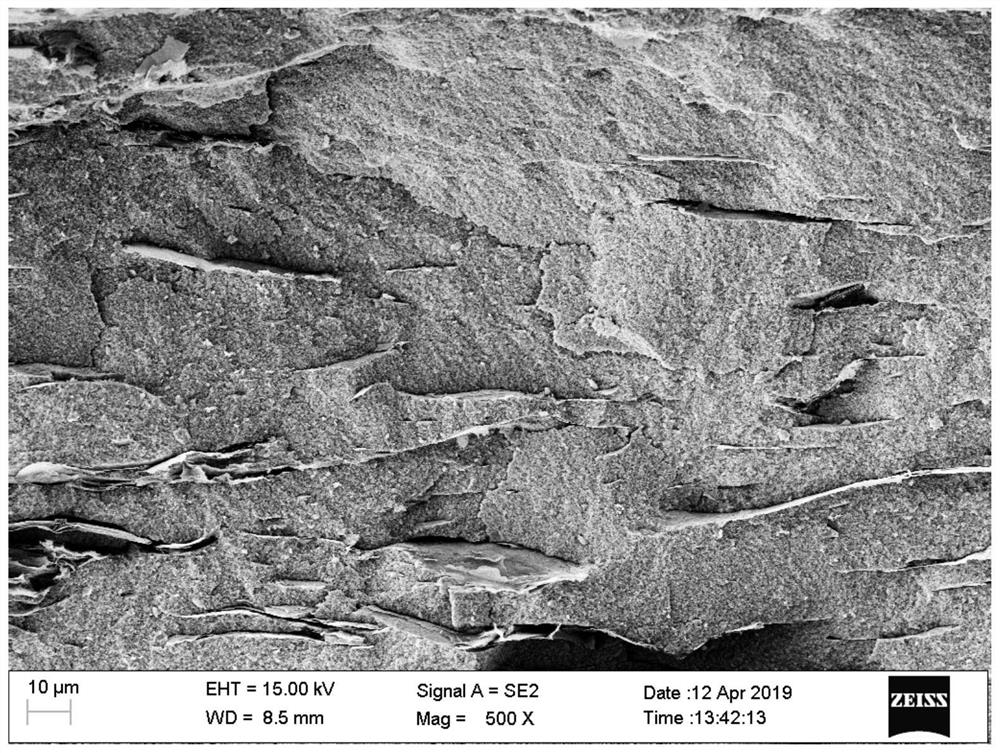

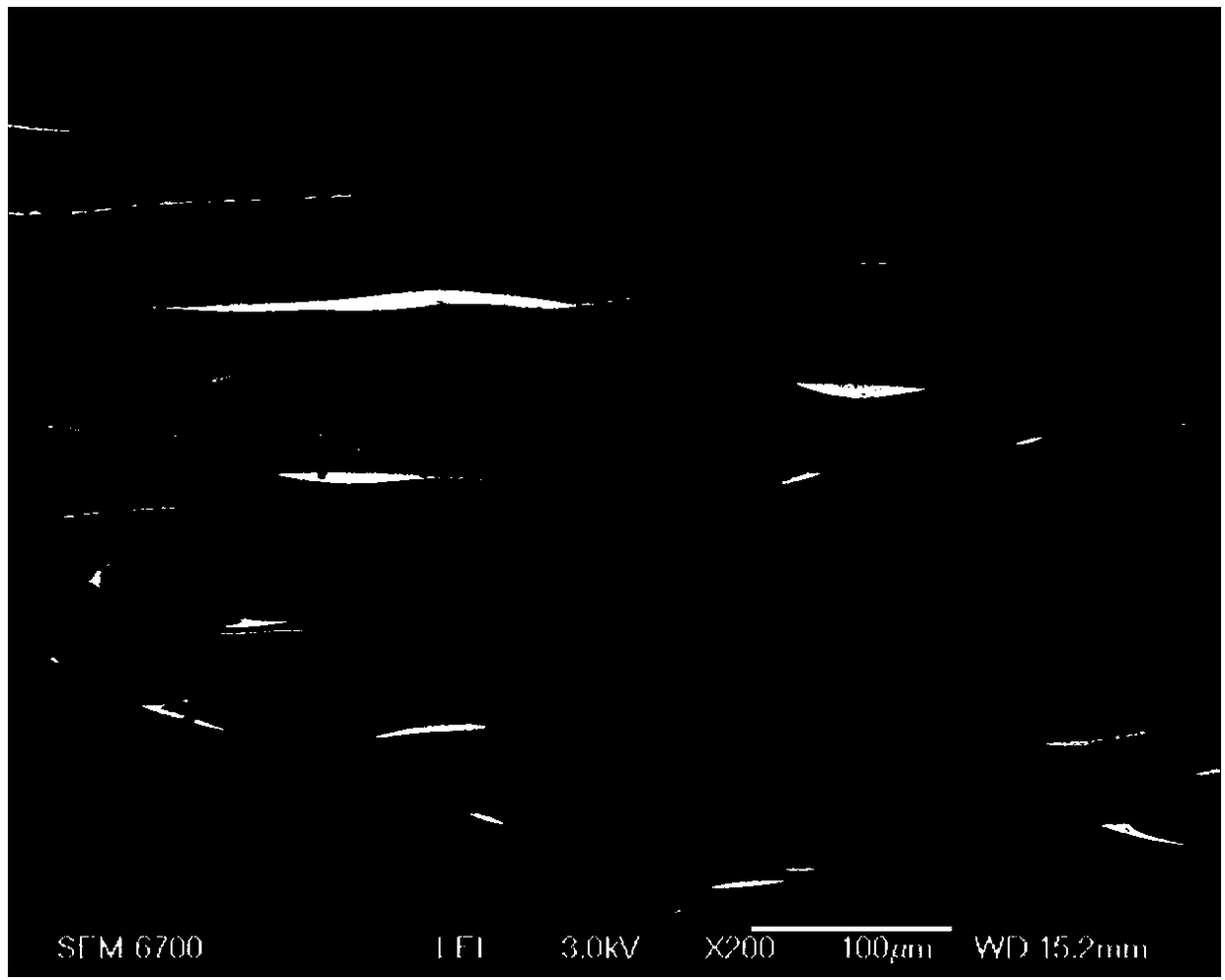

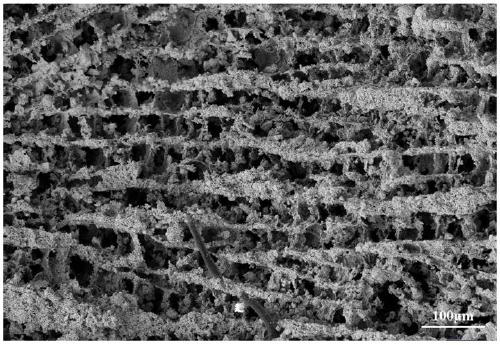

High-volume-fraction ceramic-metal layered composite material and preparation method thereof

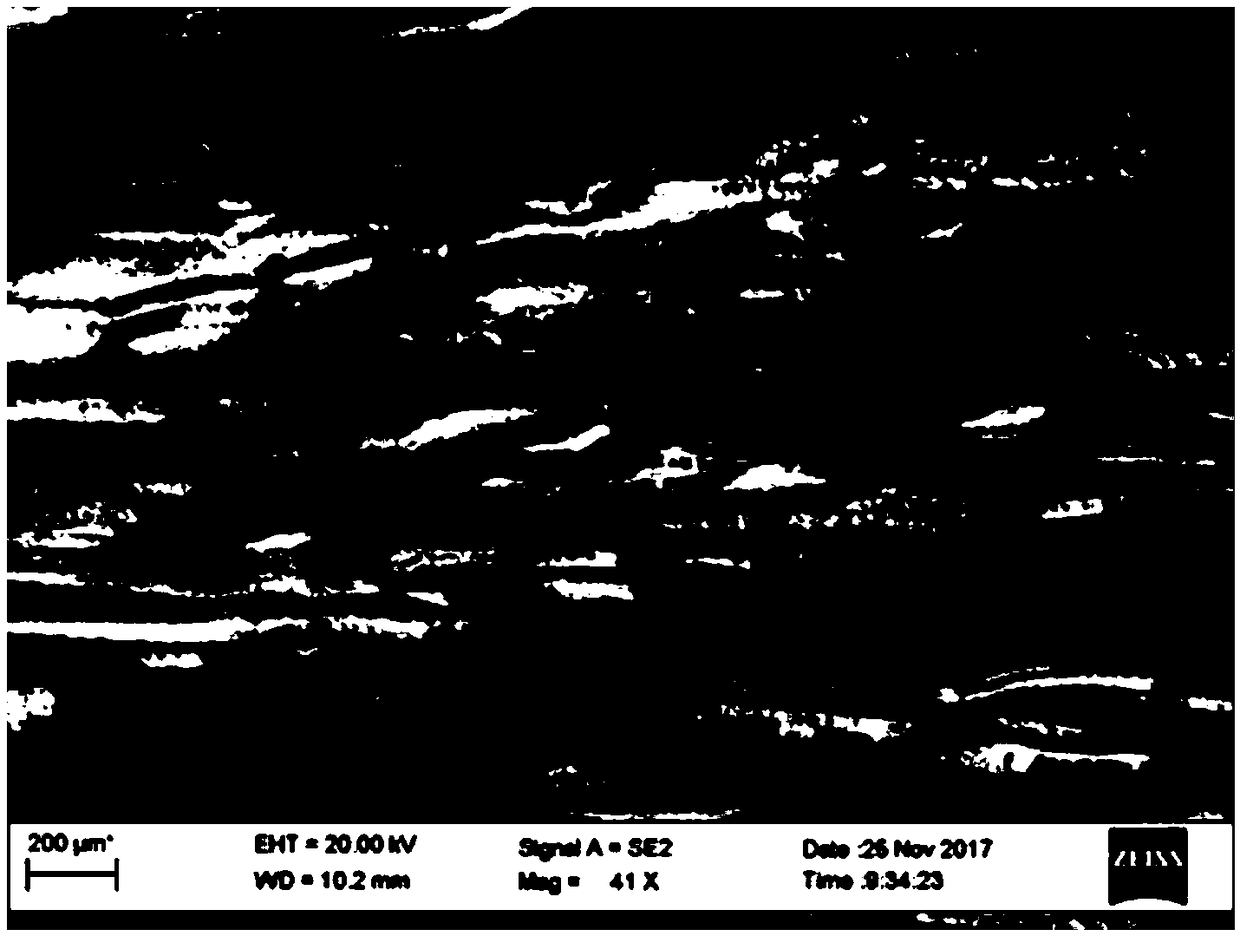

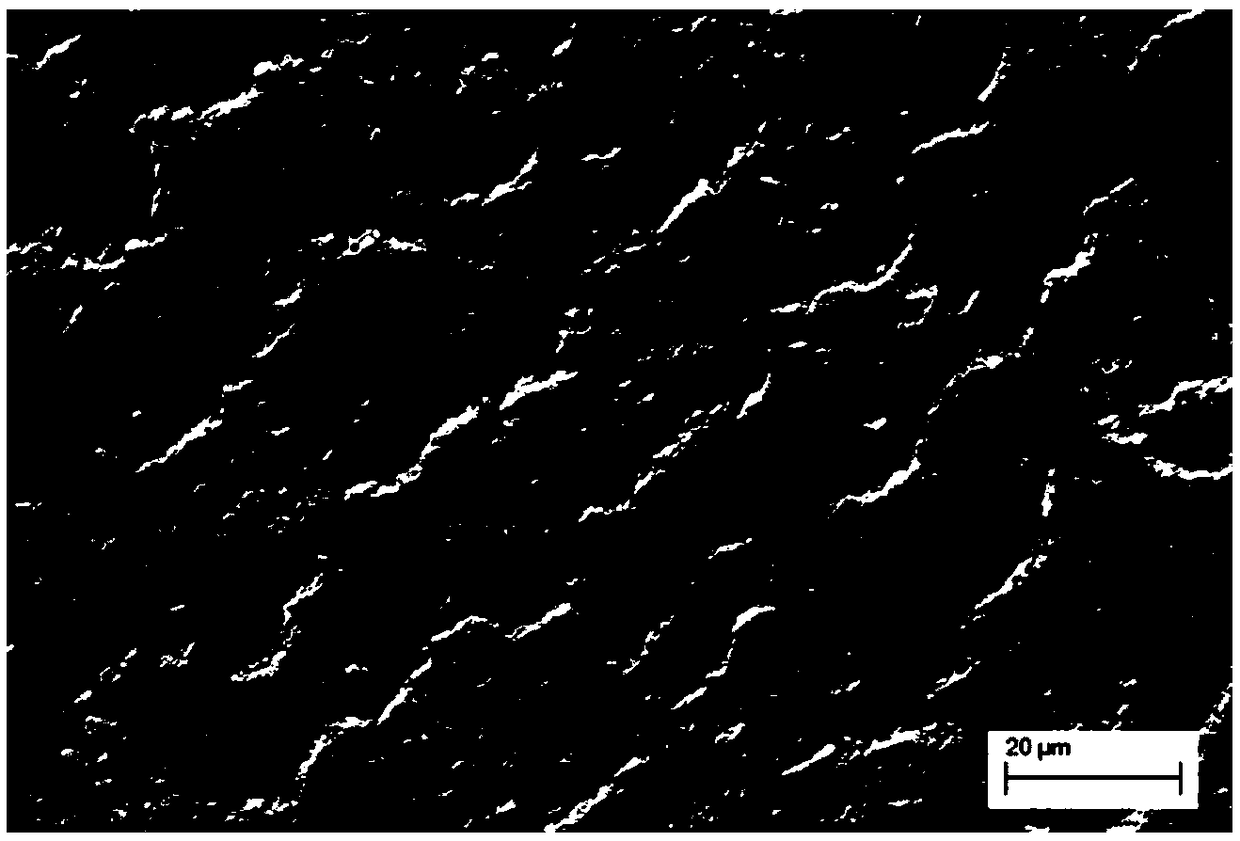

The invention relates to a high-volume-fraction ceramic-metal layered composite material. The volume fraction of ceramics reaches 70-90 vol.%, and the ceramics are of high directional layered parallel structures; ceramic layers are connected through a metal ligament bridge; the thickness of the ceramic layer is 20-80 [mu]m, and the thickness of the metal ligament bridge is 5-10 [mu]m. According to the high-volume-fraction ceramic-metal layered composite material and a preparation method thereof, a layered porous ceramic skeleton is made by the double-temperature gradient freezing casting process, the whole (three-dimensional) layered structures are regular and are arranged in parallel; excess metal phase in the layered composite material is pressed out by utilizing the hot pressing process, so that the layered ceramic-metal composite material with the ceramic volume fraction being up to 70-90 vol.% is successfully prepared and is closer to the composition ratio of a shell pearl layer; the ceramic layers which are stem grafting are broken into separated layer pieces by utilizing the hot pressing process, the excess metal phase is squeezed into the gap between these separated ceramic layers, a brick-mud structure which is very similar to the shell pearl layer is formed, and the strengthening and toughening effect is better.

Owner:JILIN UNIV

Porous Polymer Scaffolds for Neural Tissue Engineering and Methods of Producing the Same

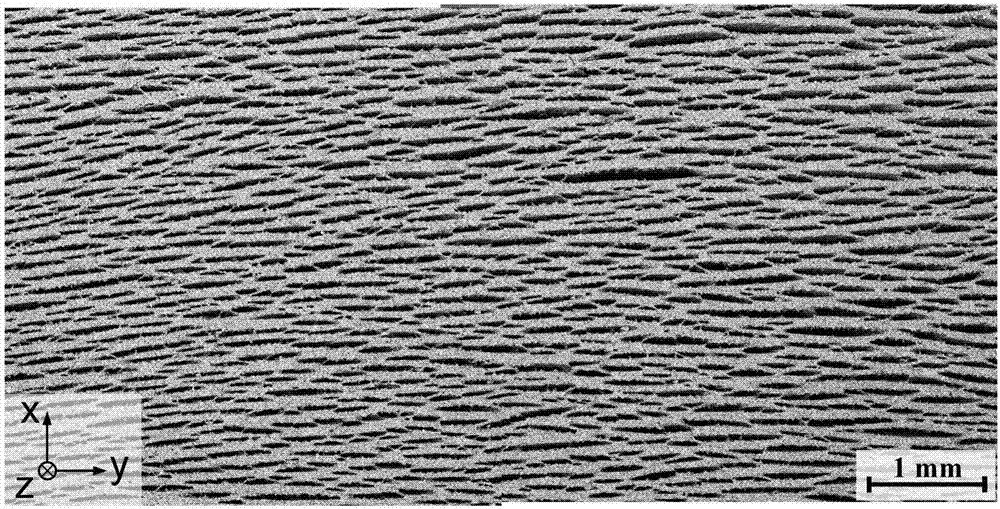

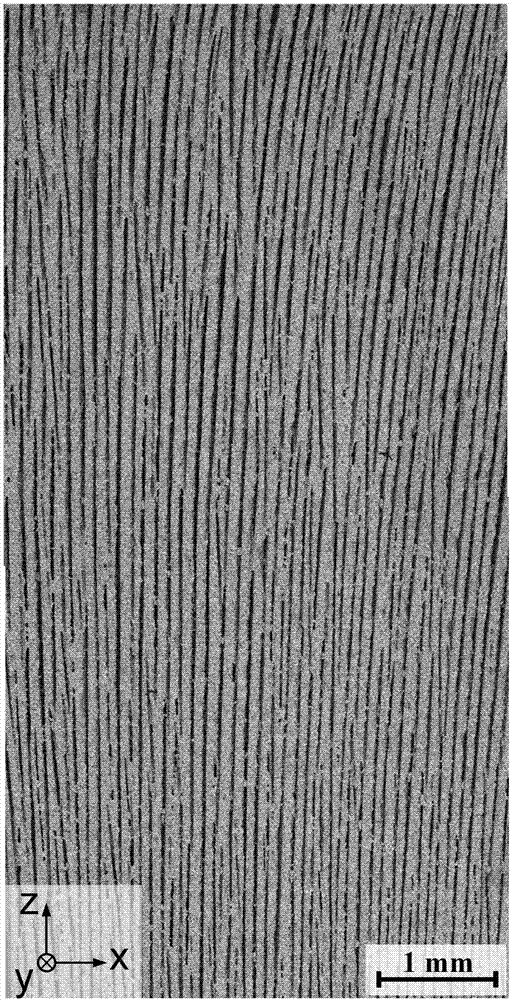

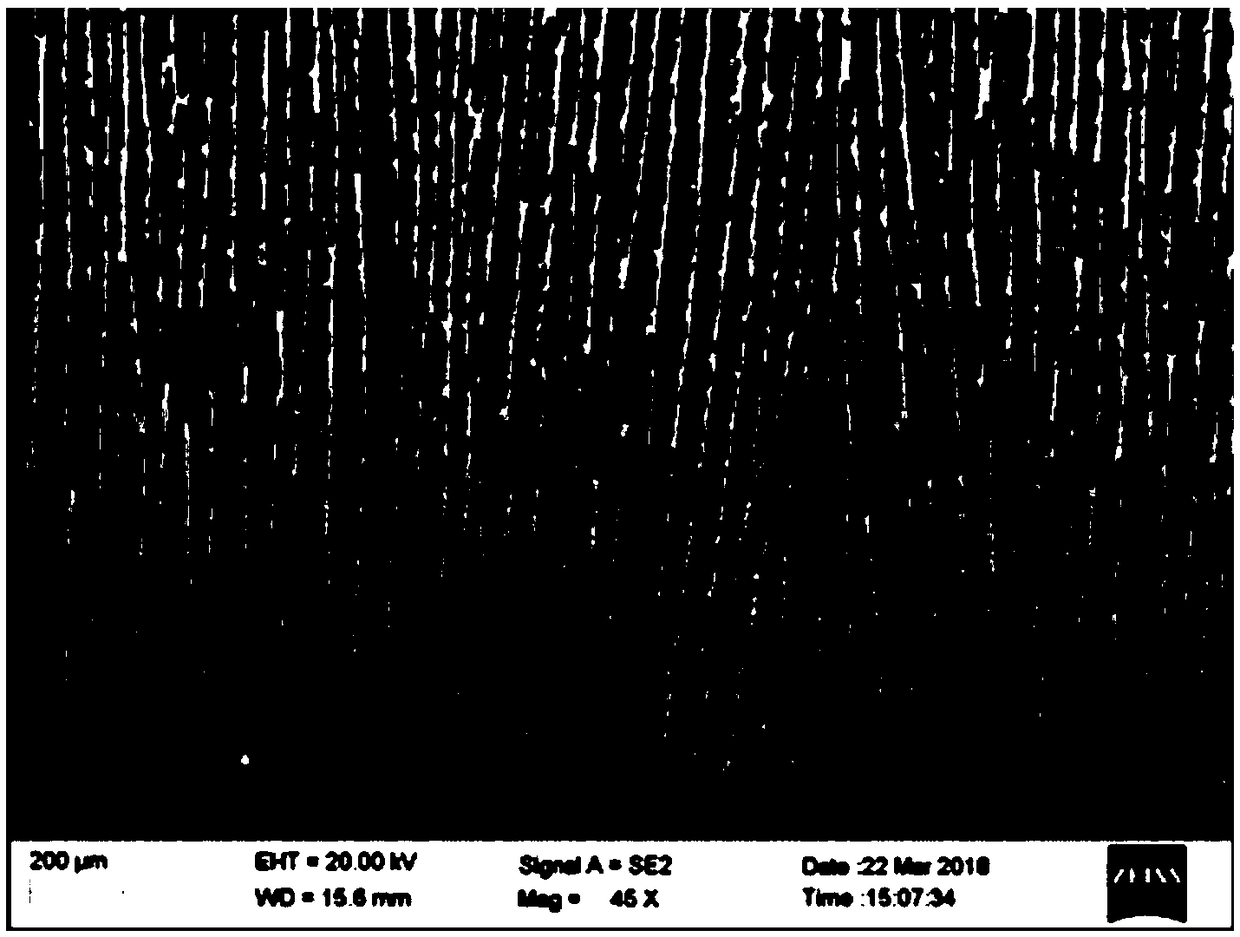

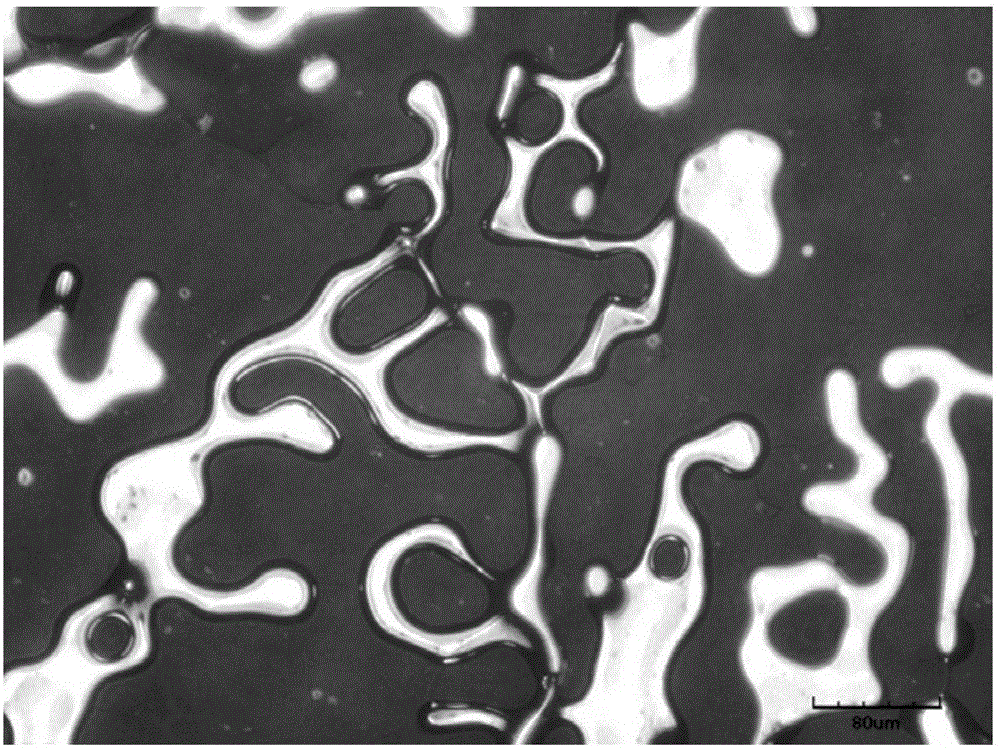

The present invention relates to scaffolds that can physically guide cells, e.g. neurons, while best matching the material properties of native tissue. The present invention also relates to methods of generating such scaffolds, and for the use of such scaffolds, e.g. in spinal cord and peripheral nerve injury repair. The methods of the present invention include a uniquely controlled freeze casting process to generate highly porous, linearly oriented scaffolds. The scaffolds of the present invention not only comprise a highly aligned porosity, but also contain secondary guidance structures in the form of ridges running parallel to the pores to create a series of microstructured and highly aligned channels. This hierarchy of structural guidance aligns and guides neurite outgrowth down the channels created by the ridges, and keep neurites from branching perpendicular to the inter-ridge grooves.

Owner:DREXEL UNIV

Heat-insulated baffle for oriented freezing cast

A heat isolating plate for the directionally solidified casting is composed of two or more plates for splicing them together to become a single one, an external ring matched with the internal surface of temp holding furnace tightly, and an internal ring matched with the mould casing but retaining a gap (0.5-10 mm) between them for moving the mould casing easily. Said plate is just combined hard graphite felt.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

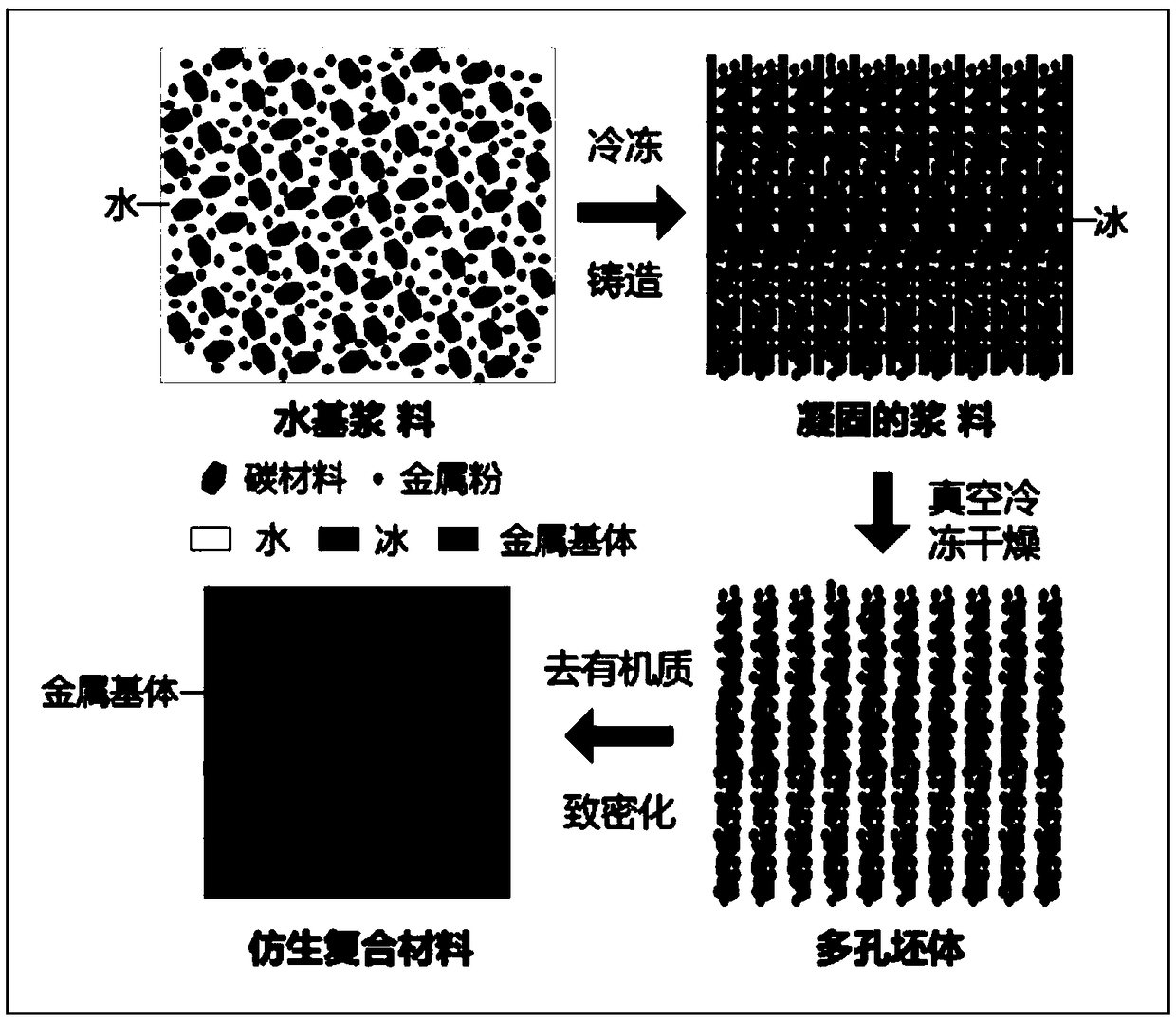

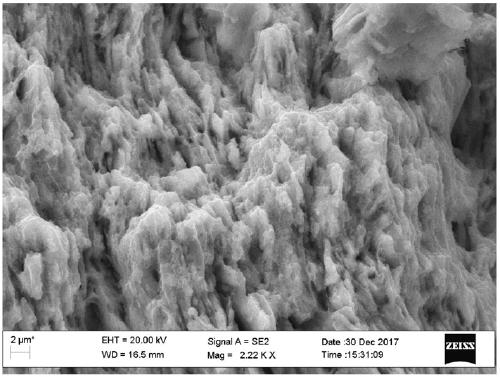

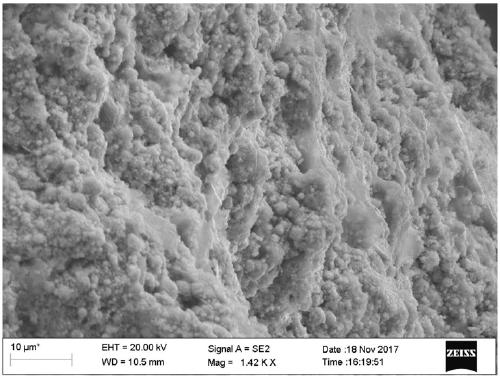

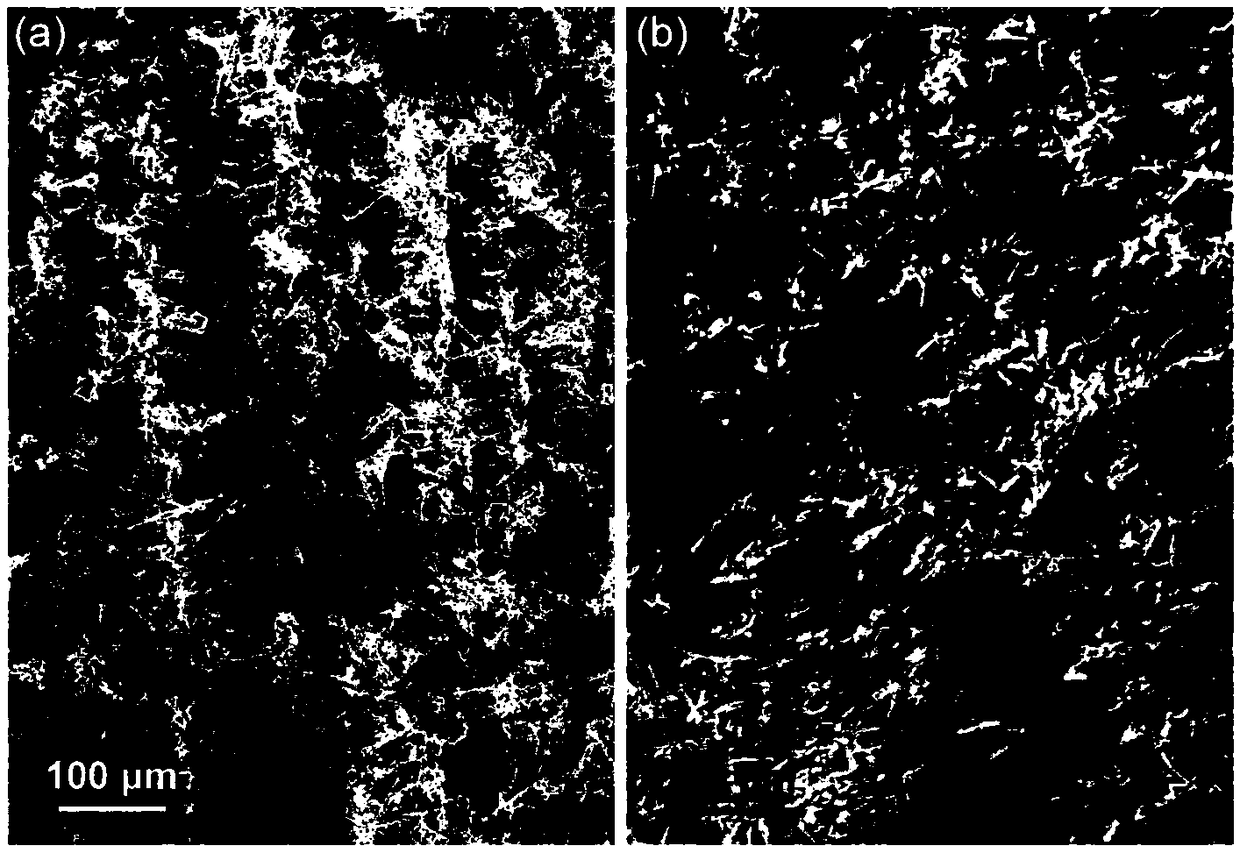

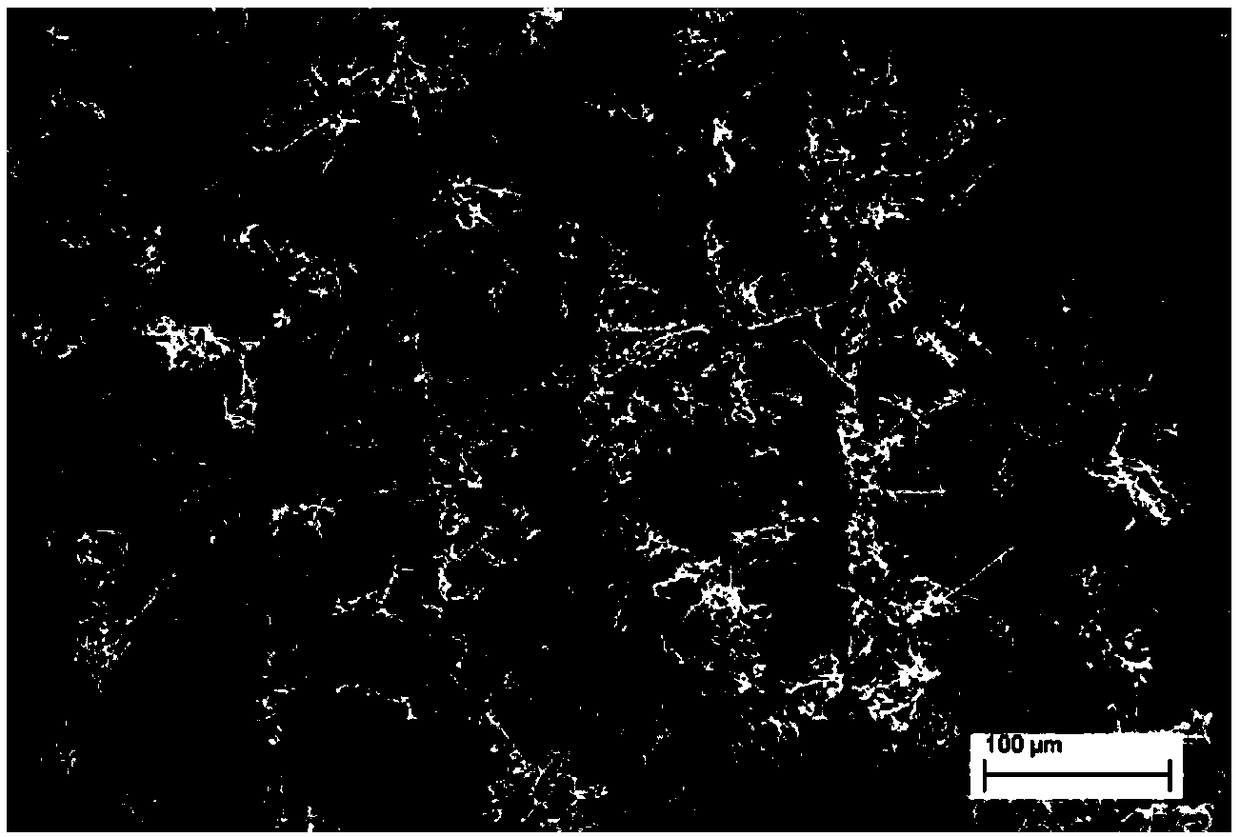

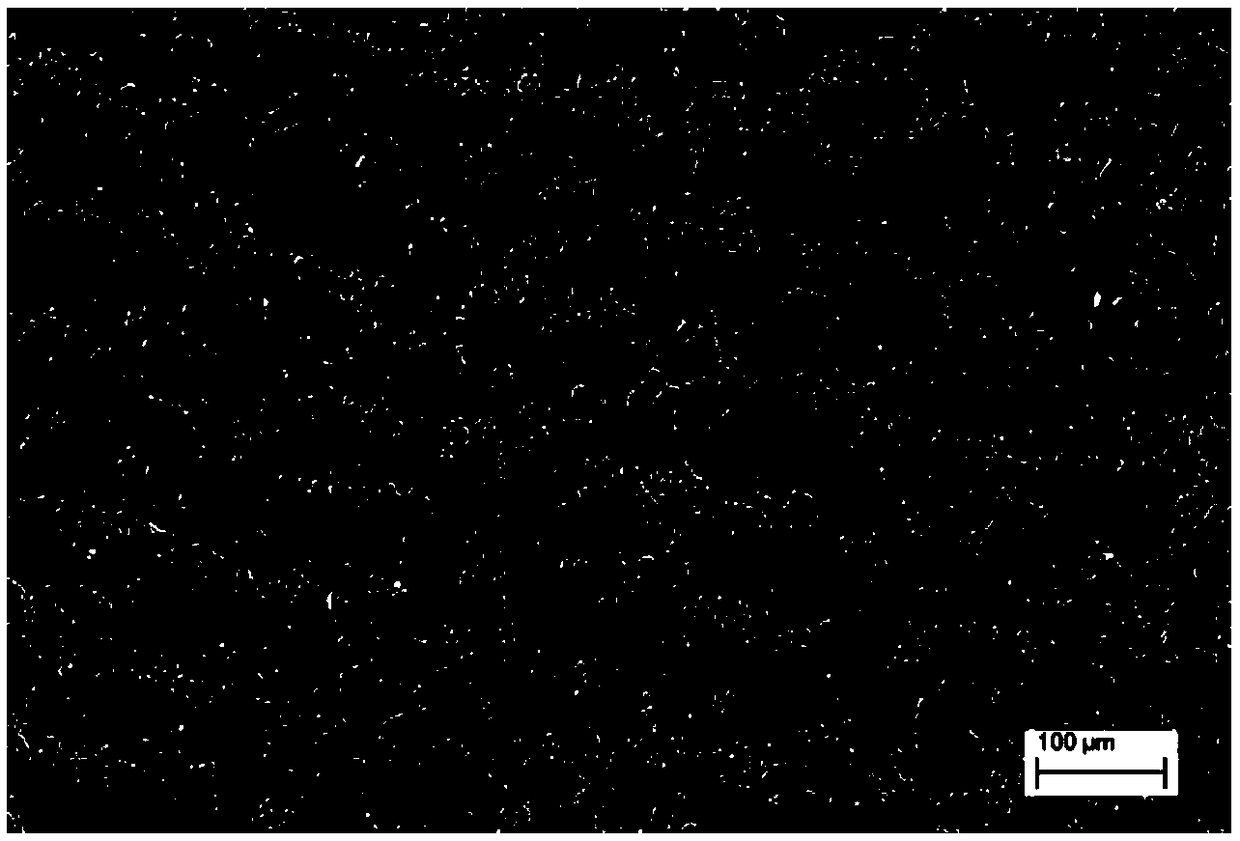

Metal-matrix bionic composite material reinforced by carbon nanomaterials, and preparation method thereof

ActiveCN108994301AWear-resistantPreserve electromagnetic shieldingTransportation and packagingMetal-working apparatusFreeze-dryingFreeze-casting

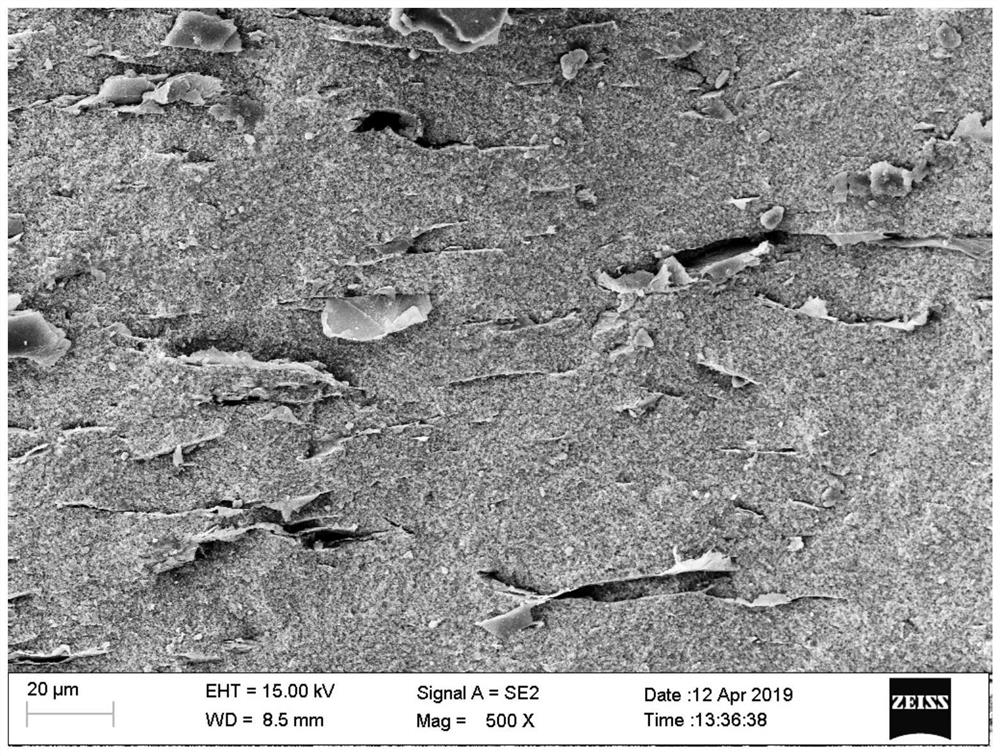

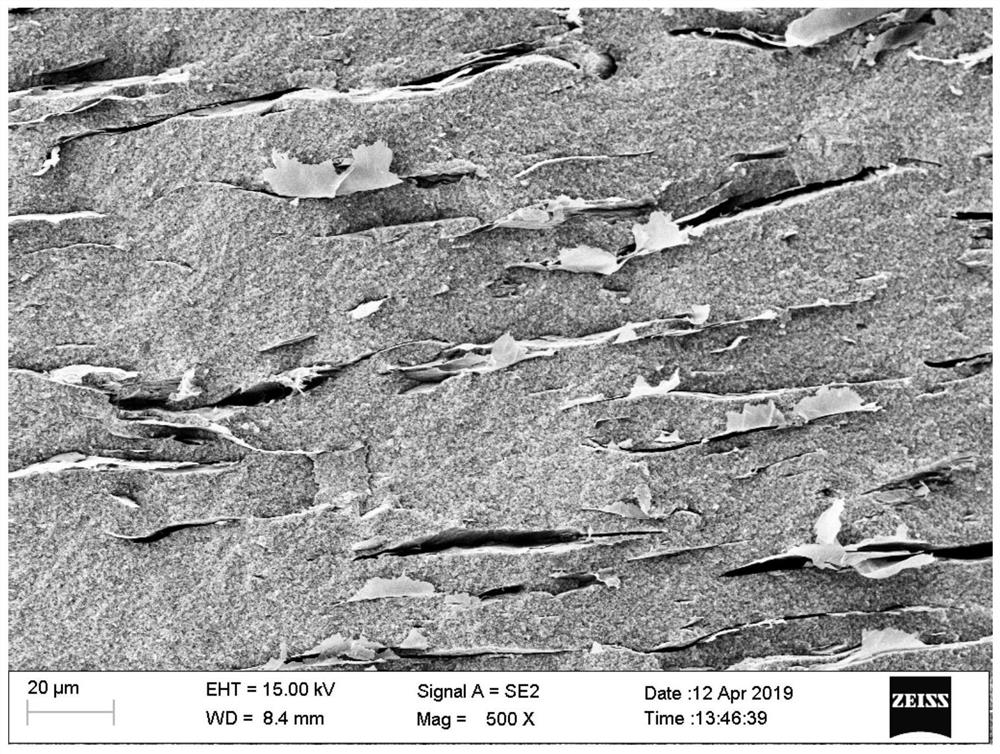

The invention relates to the field of bionic composite materials, and specifically relates to a metal-matrix bionic composite material reinforced by carbon nanomaterials, and a preparation method thereof. The composite material is composed of the carbon nanomaterials and metal, wherein in percentage by volume, the content of the carbon nanomaterials is 0.5%-40%, and the balance is metal; and the composite material microscopically has a bionic oriented structure, and is presented as that the carbon nanomaterials are arranged in a metal matrix in an oriented manner and in the form of sheet layers. According to the metal-matrix bionic composite material reinforced by the carbon nanomaterials, and the preparation method thereof, the metal-matrix bionic composite material reinforced by the carbon nanomaterials is prepared through the process flow of slurry preparation, freeze-casting, vacuum freeze-drying, organic matter removal and compaction treatment. The composite material has the excellent performance of light weight, high strength, wear resistance and the like, and reserves the function characteristics of electromagnetic shielding, electricity conduction, heat conduction and the like of matrix metal; and moreover, the structure and performance of the composite material can be effectively controlled by adjusting a preparation process, and therefore, the composite material has aconsiderable application prospect in the case of being used as a wave absorption material, a structure material and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

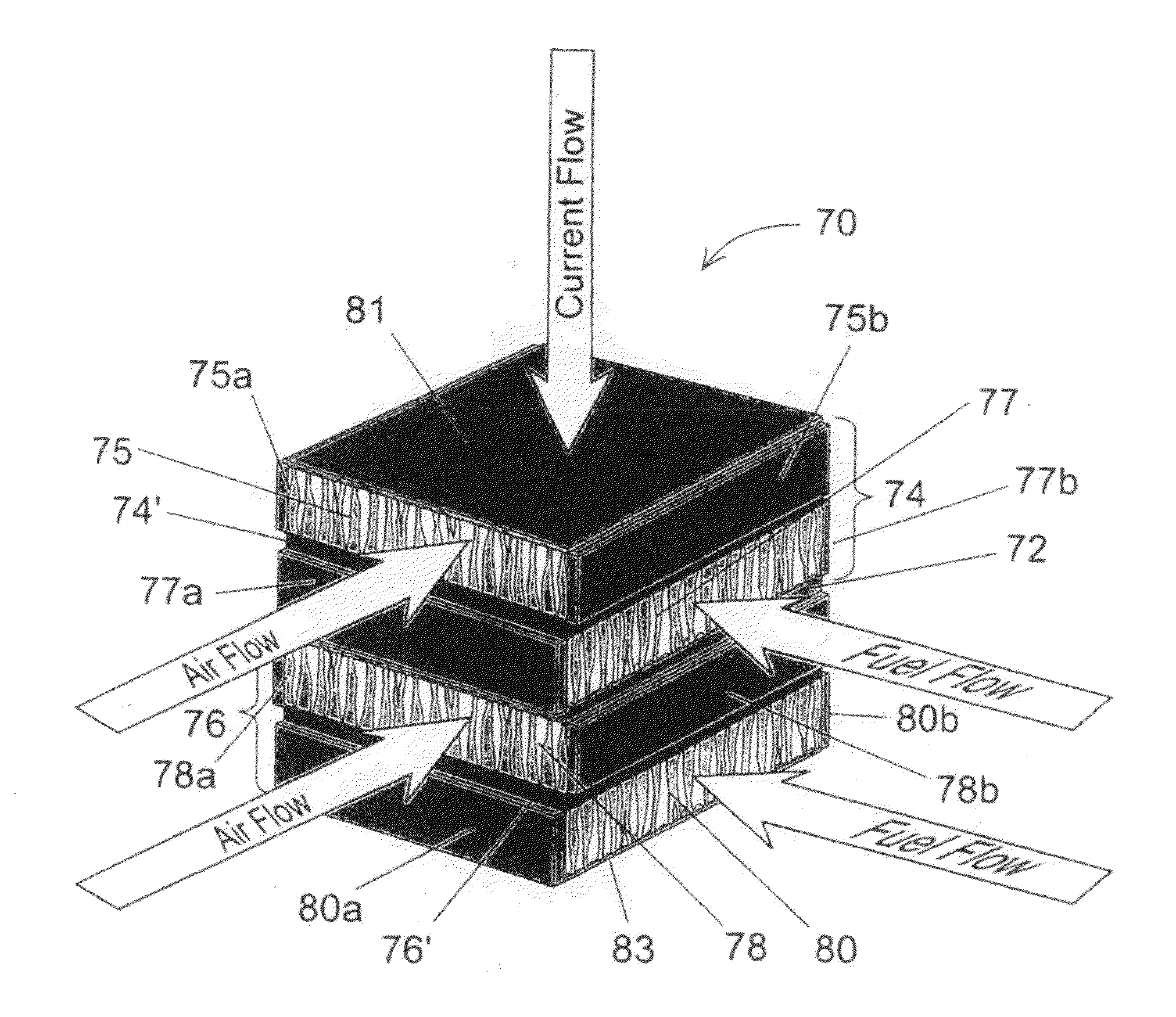

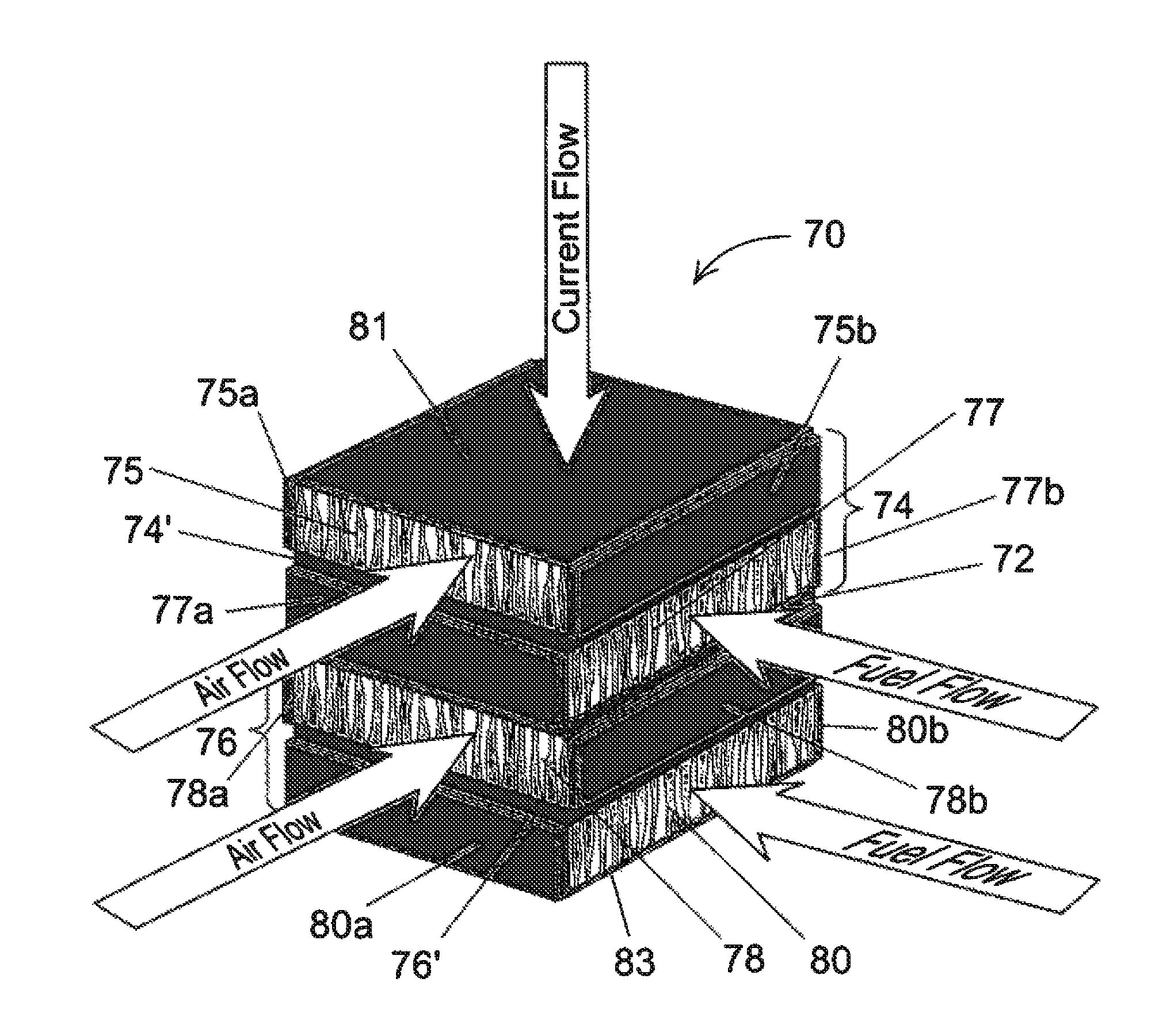

Method For Making A Fuel Cell

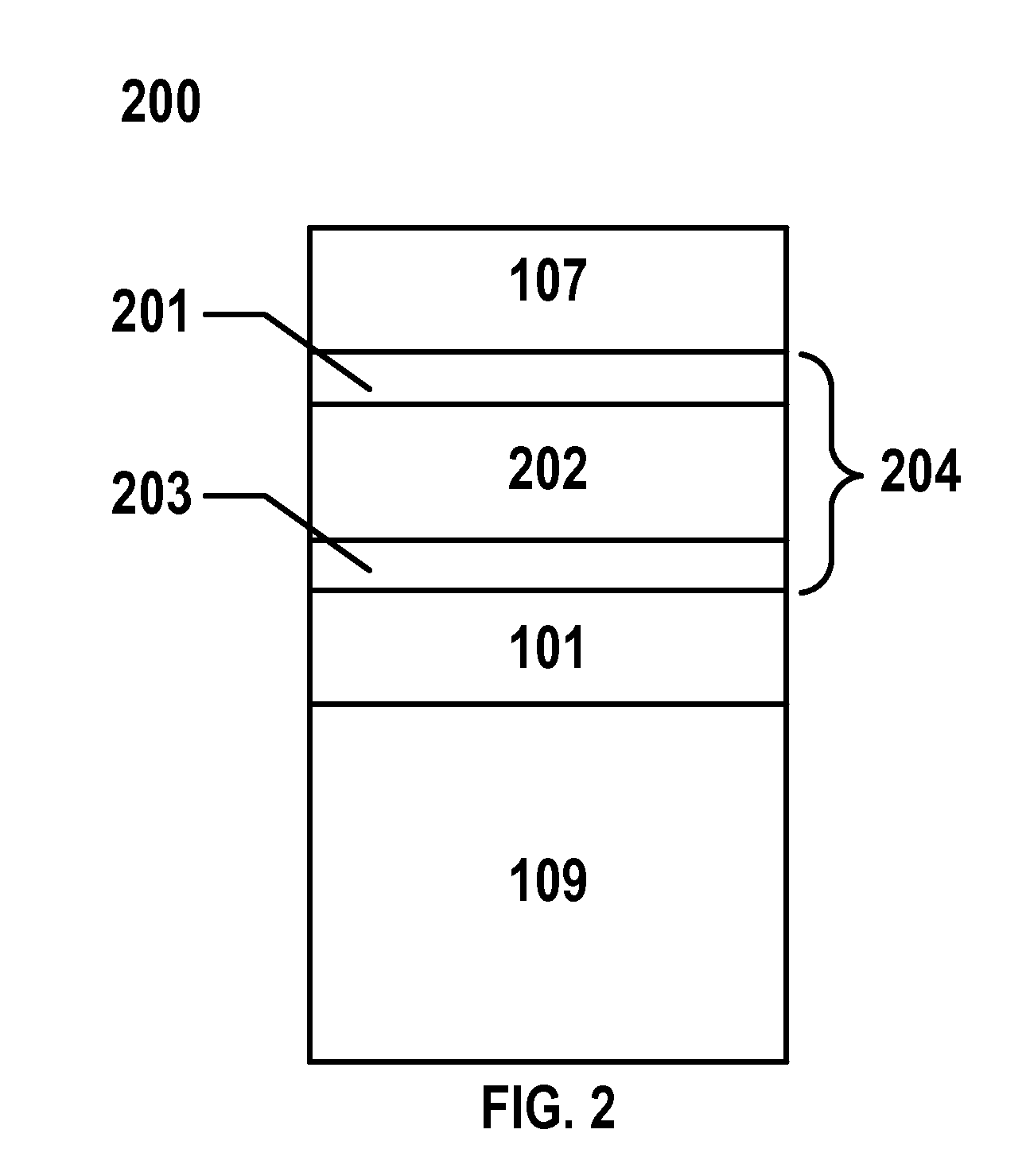

ActiveUS20110045386A1Facilitate electrolysisCell electrodesFinal product manufactureCell layerMetallurgy

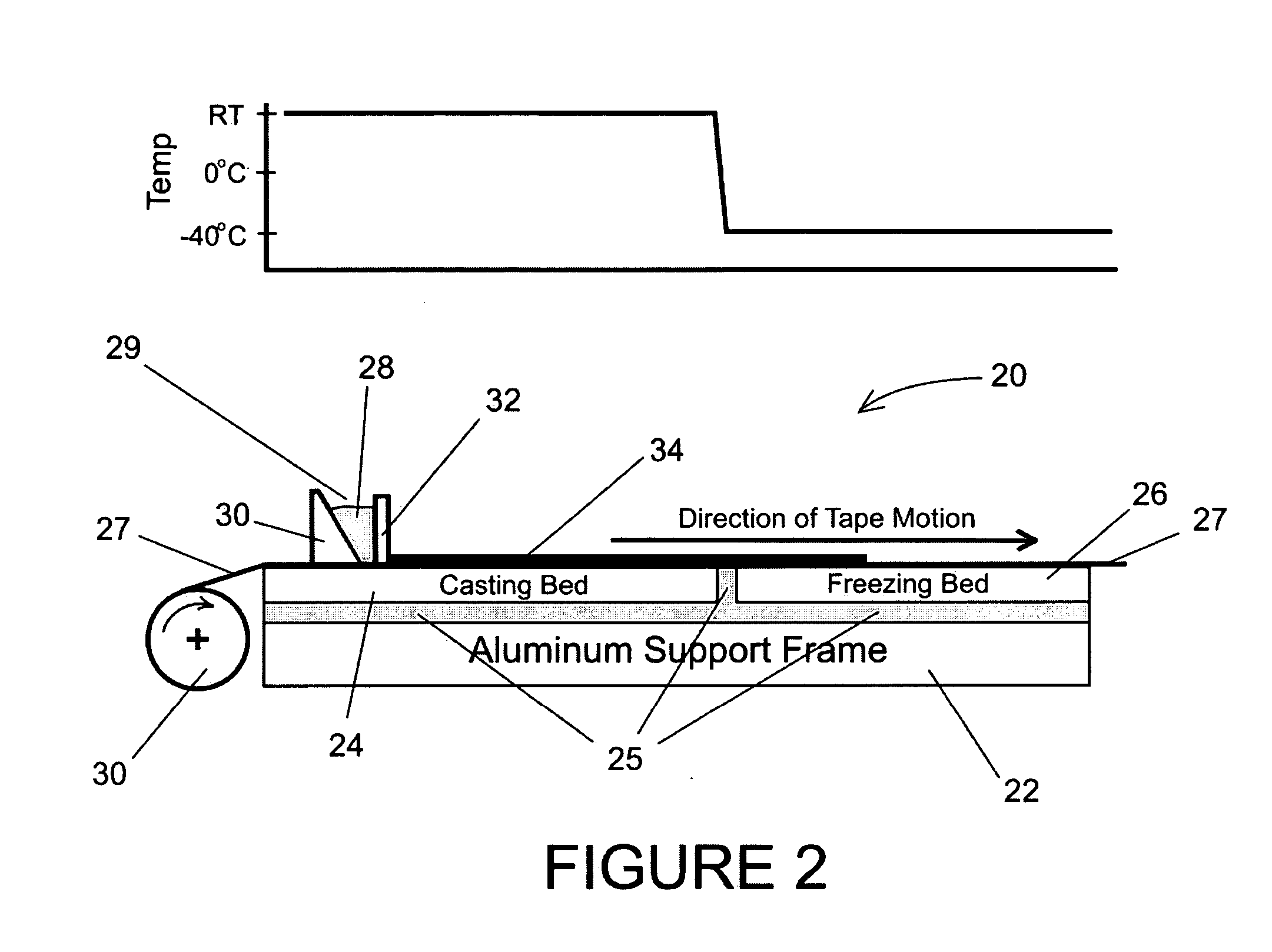

The invention is a novel solid oxide fuel cell (SOFC) stack comprising individual bi-electrode supported fuel cells in which a thin electrolyte is supported between electrodes of essentially equal thickness. Individual cell units are made from graded pore ceramic tape that has been created by the freeze cast method followed by freeze drying. Each piece of graded pore tape later becomes a graded pore electrode scaffold that subsequent to sintering, is made into either an anode or a cathode by means of appropriate solution and thermal treatment means. Each cell unit is assembled by depositing of a thin coating of ion conducting ceramic material upon the side of each of two pieces of tape surface having the smallest pore openings, and then mating the coated surfaces to create an unsintered electrode scaffold pair sandwiching an electrolyte layer. The opposing major outer exposed surfaces of each cell unit is given a thin coating of electrically conductive ceramic, and multiple cell units are stacked, or built up by stacking of individual cell layers, to create an unsintered fuel cell stack. Ceramic or glass edge seals are installed to create flow channels for fuel and air. The cell stack with edge sealants is then sintered into a ceramic monolithic framework. Said solution and thermal treatments means convert the electrode scaffolds into anodes and cathodes. The thin layers of electrically conductive ceramic become the interconnects in the assembled stack.

Owner:NASA

A composite solid electrolyte with high ionic conductivity and a preparation method thereof

InactiveCN109148944AFast transferReduce contact interfaceSolid electrolytesSecondary cellsSolid state electrolyteMass ratio

The invention relates to a composite solid electrolyte with high ionic conductivity and a preparation method thereof, belonging to the technical field of solid electrolyte for lithium ion batteries. The composite solid electrolyte is composed of inorganic solid electrolyte, polymer electrolyte and lithium salt. The mass ratio of inorganic solid electrolyte, polymer electrolyte and lithium salt is0.2-0.8: 0.2-0.8: 0.05-0.5. The invention prepares inorganic solid electrolyte nanofibers by electrostatic spinning, prepares vertically oriented inorganic solid electrolyte skeleton by freeze castingmethod, and pours polymer and lithium salt to form composite solid electrolyte. Nanofibers instead of nanoparticles have obvious advantages in the preparation of intact and uniform inorganic solid electrolyte skeleton and the formation of fast Li + transport pathway, which can significantly improve the room temperature ionic conductivity of the electrolyte, up to 10<-4>S.cm<-1>. By adjusting thesize of nanofibers and freeze-casting conditions to control the skeleton structure, so as to regulate the comprehensive properties of the electrolyte.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Zirconium oxide/resin bionic composite material for denture and preparation method thereof

ActiveCN108743405AGood biocompatibilityAccelerated corrosionImpression capsDentistry preparationsBrickFreeze-drying

The invention relates to the field of composite materials for denture, in particular to a zirconium oxide / resin bionic composite material for the denture and a preparation method thereof. The zirconium oxide / resin bionic composite material is prepared from the following components of 20vol% to 97vol% of zirconium oxide and biocompatible resin, and is of a bionic lamellar structure, a brick-wall structure or a crossed laminating structure in a microscopic way. The zirconium oxide / resin bionic composite material has the advantages that the oriented porous blank with the lamellar structure is obtained by slurry preparation, freezing-casting and vacuum freeze-drying, and is compressed along the lamellar structure direction to form the crossed laminating structure; the zirconium oxide skeletonwith the lamellar structure or crossing laminating structure can be prepared by removing organic matters and sintering, and the zirconium oxide skeleton of the brick-wall structure can be obtained through the vertical compression of the lamellar structure skeleton and the secondary sintering; the surface is subjected to surface modifying and liquid resin monomer permeating, and the resin is polymerized, so as to obtain the zirconium oxide / resin bionic composite material for the denture with the bionic structure; the prepared zirconium oxide / resin bionic composite material is mainly used as thedenture, so as to reduce the abrasion to the normal teeth of a human body by the denture.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

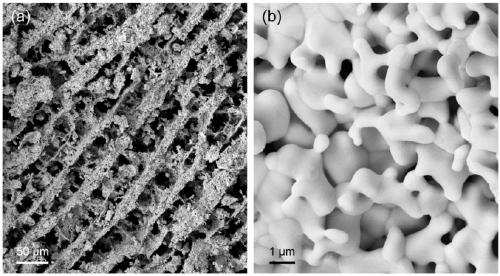

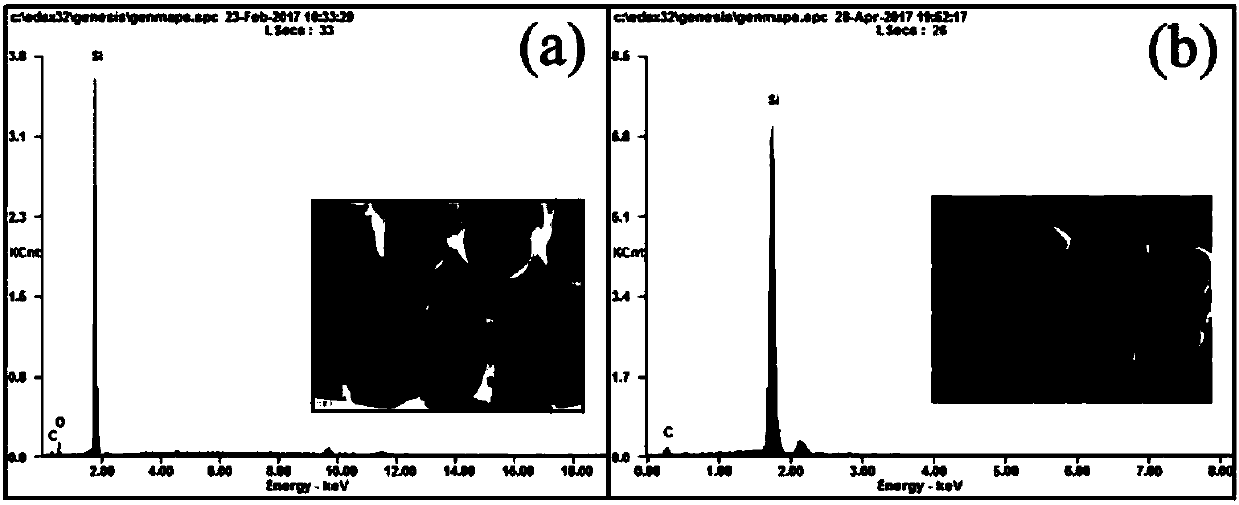

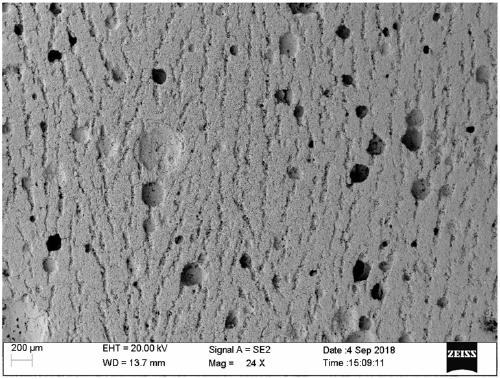

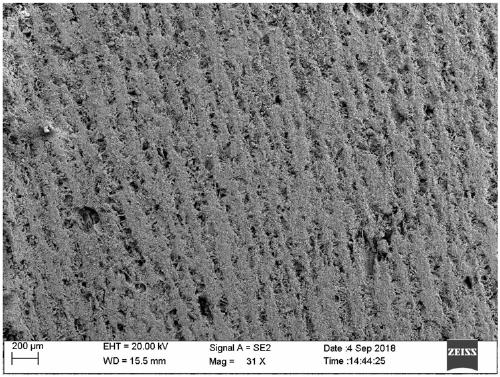

Silicon carbide/resin bionic composite material with directional microstructure, and preparation method thereof

The invention relates to a silicon carbide / resin bionic composite material with a directional microstructure, and a preparation method thereof. The composite material is prepared from silicon carbideof which the volume fraction is 10-95%, and resin, and microscopically has the directional microstructure so as to be shown in a way that silicon carbide is directionally arranged in a resin matrix. The preparation method comprises the following steps: firstly, preparing water base slurry which contains silicon carbide powder; then, through freezing casting and vacuum freezing drying, obtaining ablank with a directional porous structure; carrying out compressing on the blank, removing organic matters, and sintering to obtain the directional porous skeleton of silicon carbide; carrying out surface modification and liquid resin monomer impregnation on the skeleton, and obtaining the silicon carbide / resin bionic composite material with the directional microstructure after resin aggregationis carried out. The composite material has excellent performances of light weight, high strength, abrasion resistance and the like, the plasticity, the toughness and the impact resistance of the composite material are obviously improved than that of silicon carbide, and therefore, the silicon carbide / resin bionic composite material is expected to serve as a structural material to be used in fields including armor protection, transportation, electronic products and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Silicon carbide reinforced metal matrix composite with micro orientated structure and preparation method thereof

The invention relates to a silicon carbide reinforced metal matrix composite with a micro orientated structure and a preparation method thereof. The composite consists of silicon carbide with a volumefraction of 5-90% and metal, and has the micro orientated structure which is expressed as oriented arrangement of the silicon car bide in a metal matrix. The preparation method of the composite comprises the following steps of: firstly preparing water-based slurry containing silicon carbide powder; processing the slurry by utilizing freeze casting and vacuum freeze drying to obtain a green body with an orientated porous structure; compressing the green body and removing organic matters in the green body; carrying out sintering to obtain an oriented porous skeleton of silicon carbide; and finally infiltrating the skeleton by utilizing liquid metal bath, and carrying out solidification and cooling to obtain the silicon carbide reinforced metal matrix composite with the micro orientated structure. The composite has excellent properties such as light mass, high intensity, wear resistance and high-temperature creep resistance, the micro structures and properties of the composite can be effectively controlled through adjusting the preparation process, and the composite has considerable application prospect when serving as a structural material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

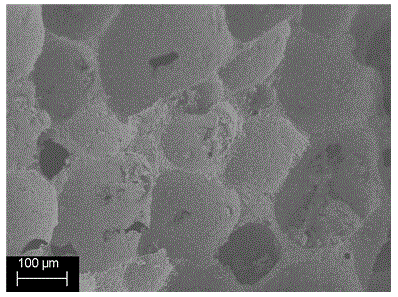

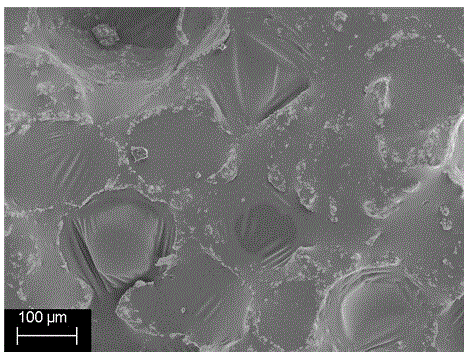

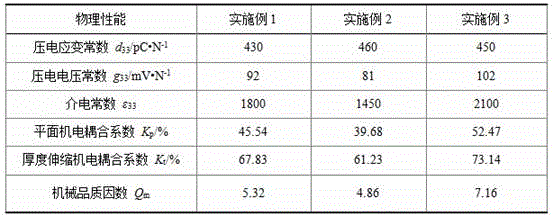

3-3 type piezoelectric ceramic/cement piezoelectric composite material and preparation method thereof

ActiveCN105552212AReduce inhibitionReduce porosityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionAmphiphileFoaming agent

The invention discloses a 3-3 type piezoelectric ceramic / cement piezoelectric composite material and a preparation method thereof, belonging to the technical field of a ceramic-based piezoelectric intelligent composite material and preparation thereof. The composite material comprises porous piezoelectric ceramic, cement, an upper electrode and a lower electrode, wherein the porous piezoelectric ceramic is a substrate and also a functional body, the interior and the periphery of the porous piezoelectric ceramic are filled with the cement, and the mass percentage of the piezoelectric ceramic accounts for 50-85%. The preparation method of the 3-3 type piezoelectric ceramic / cement piezoelectric composite material comprises the following steps of taking a short-chain amphiphilic molecule solvent as a foaming agent; combining freeze casting and organic monomer polymerization forming to prepare the porous piezoelectric ceramic with high porosity; and pouring a cement paste by taking the porous piezoelectric ceramic as the substrate to obtain the 3-3 type piezoelectric ceramic / cement piezoelectric composite material. The 3-3 type piezoelectric ceramic / cement piezoelectric composite material prepared according to the invention has the advantages of excellent piezoelectric performance, high compatibility with concrete, high durability and the like.

Owner:ZHONGBEI UNIV

Preparation method of sodium alginate/cattail/graphene oxide composite aerogel

ActiveCN108654579ALow costNo pollution in the processOther chemical processesWater contaminantsFiberSynthesis methods

The invention relates to a preparation method of a sodium alginate / cattail / graphene oxide composite aerogel, and belongs to the technical field of preparation of biomass-based functional materials. The preparation method comprises the following specific steps: mixing sodium alginate powder and cattail fiber, adding the mixture into graphene oxide dispersion, and carrying out stirring to obtain a uniform mixed solution; carrying out freeze-drying by a two-way freeze casting method to obtain an un-crosslinked composite aerogel, immersing the composite aerogel in an ethanol / water mixed solution containing CaCl2, and then carrying out freeze-drying for a second time to obtain a calcium ion crosslinked sodium alginate / cattail / graphene oxide composite aerogel. According to the preparation methodprovided by the invention, a simple, efficient, economical and environment-friendly synthesis method is adopted to obtain a three-dimensional parallel laminated structure, parallel sheets are connected with one another by honeycomb holes, and the three-dimensional parallel laminated structure has an excellent underwater super-oleophobic property; and after the composite aerogel and a filter instrument are assembled, insoluble oil and water-soluble dyes can be synchronously removed, and the composite aerogel has a good application value and a wide market prospect.

Owner:JIANGSU UNIV

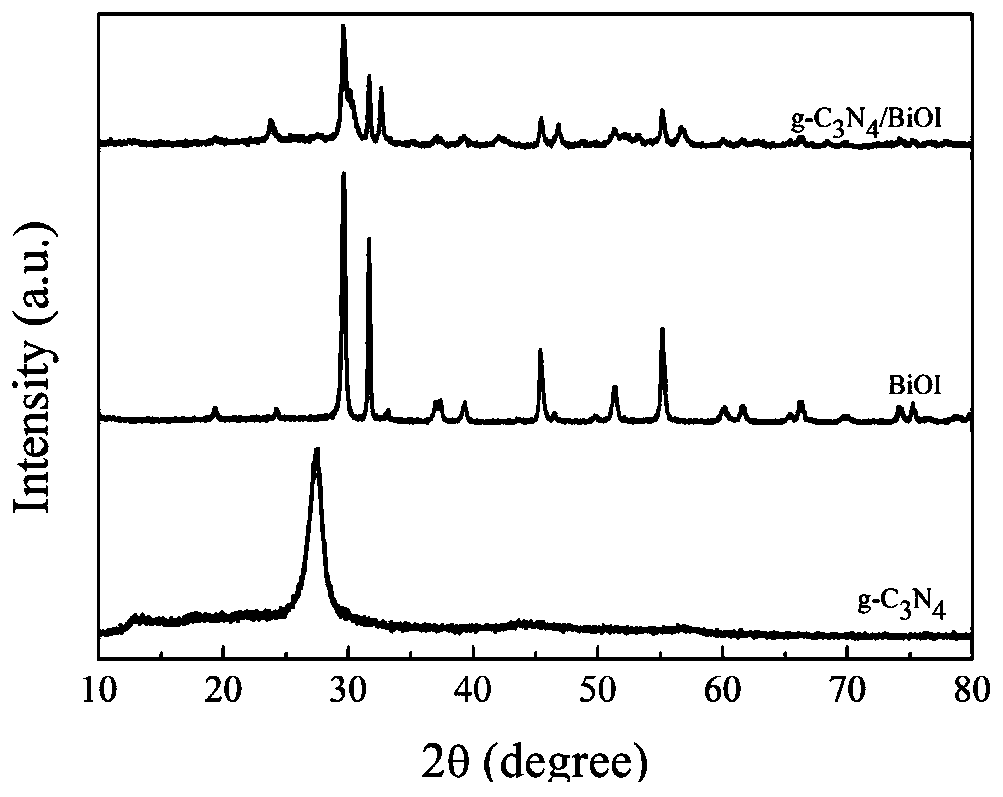

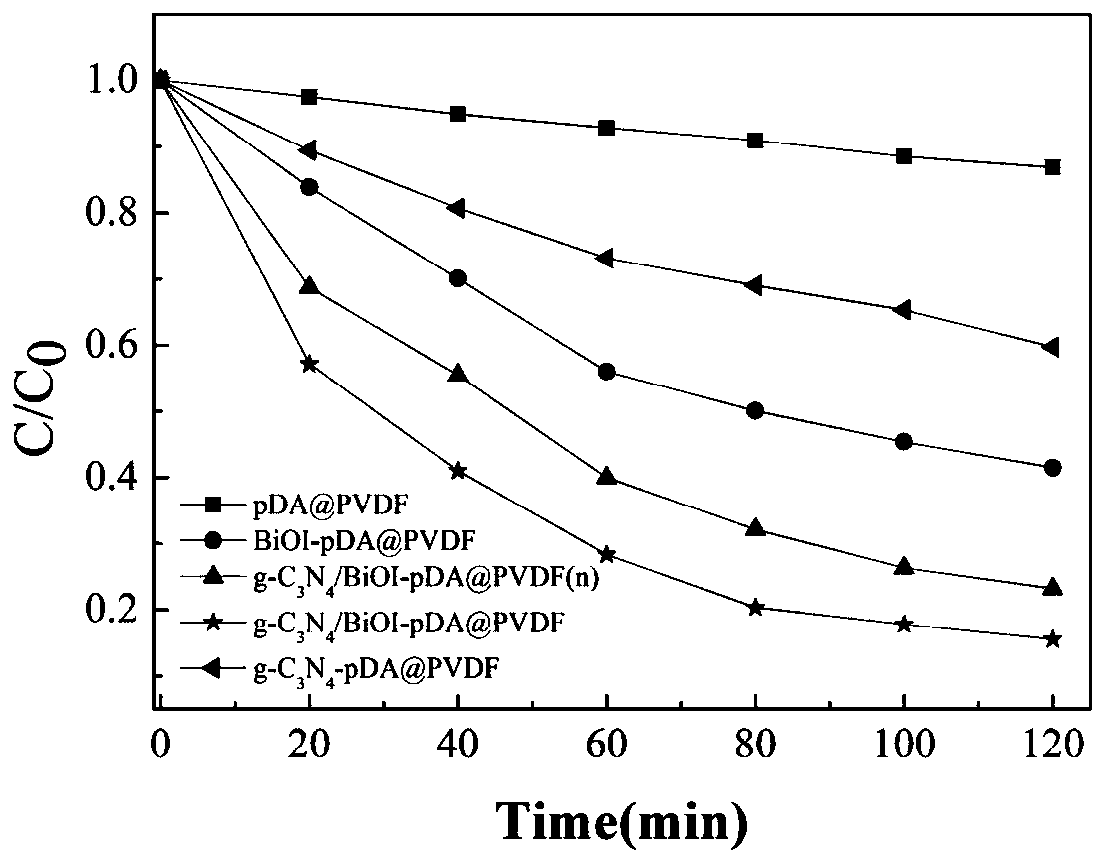

Biomimetic construction method of g-C3N4/BiOI-pDA@PVDF photocatalytic membrane and application thereof

InactiveCN110075923AShorten the transmission distanceReduce transfer timeWater/sewage treatment by irradiationWater treatment compoundsSeparation technologyFreeze-casting

The invention belongs to the technical field of preparation of environmental functional materials, and discloses a biomimetic construction method of a g-C3N4 / BiOI-pDA@PVDF photocatalytic membrane andapplication thereof. According to the biomimetic construction method, the photocatalytic membrane is prepared by using a freeze casting method after modifying PVDF powder with polydopamine (pDA), andthe photocatalytic membrane is used for removing tetracycline (TC) from a solution. Researches show that the modified PVDF powder can effectively solve the problem of compatibility between a photocatalyst and a membrane, the catalytic performance of the g-C3N4 / BiOI-pDA@PVDF photocatalytic membrane is further improved; according to the freeze casting method, an ordered lattice macroporous structureis formed inside the membrane, so that the flux of the membrane is increased, more catalytic active sites are provided and the catalytic activity is effectively improved; in addition, a composite membrane with a photocatalytic function is prepared through combination of a photocatalytic technology and a membrane separation technology, membrane fouling is effectively reduced, recycling of the composite membrane is facilitated, and the composite membrane is superior to a powder catalyst and has practical application.

Owner:JIANGSU UNIV

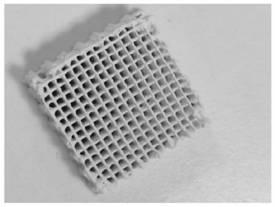

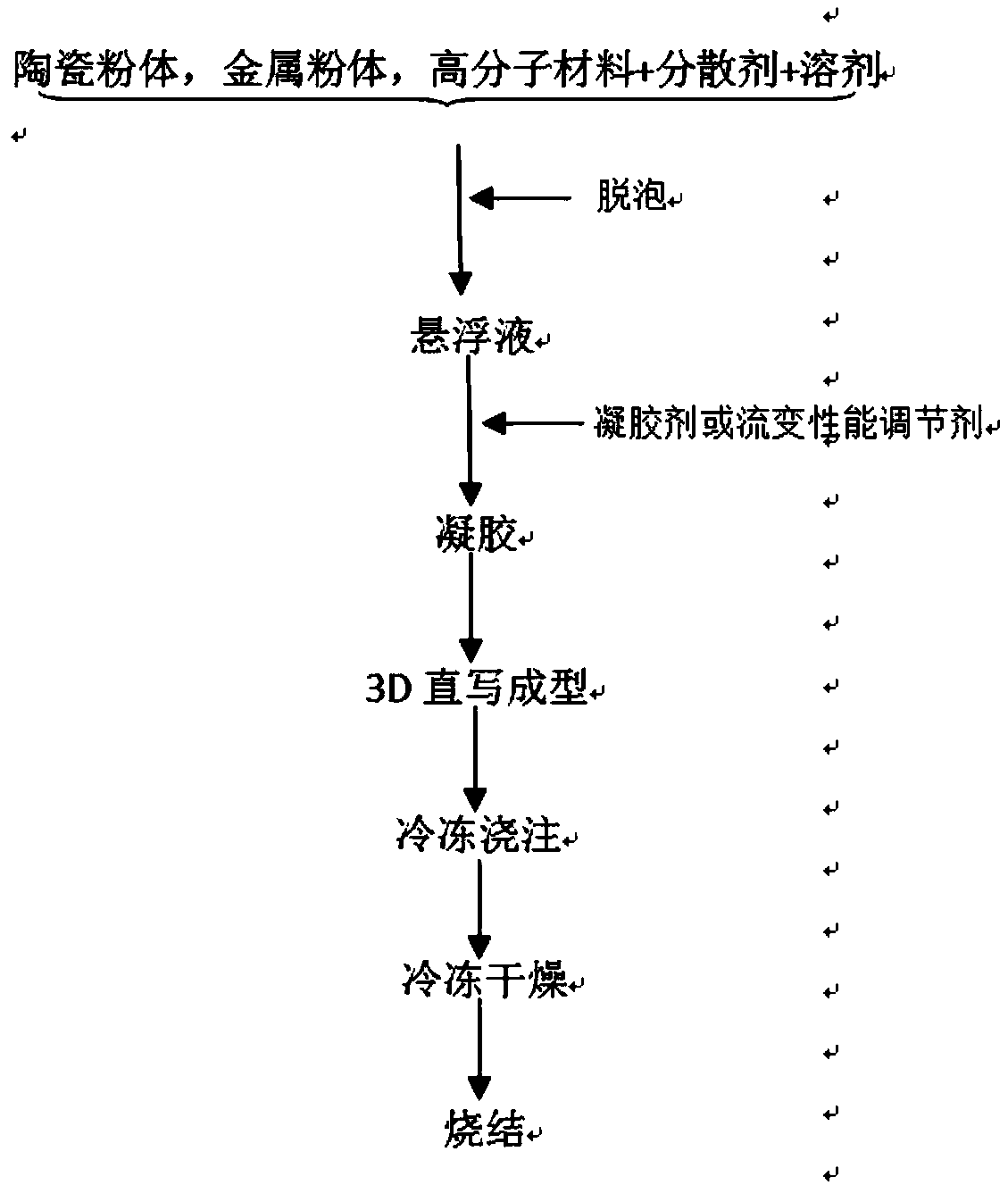

Method for preparing material with controllable macro and micro structures

ActiveCN109400179AImprove applicabilitySimple processAdditive manufacturing apparatusCeramicwareFreeze-dryingFreeze-casting

The invention discloses a method for preparing a material with controllable macro and micro structures. The method is realized by combining a 3D direct writing molding technology and a freezing casting method, and specifically includes adding a raw material A into a solvent containing a dispersant and mixing for the first time to obtain a suspension, and then adding a gel into the suspension and mixing for the second time to obtain a slurry material; and passing, by the slurry material, through 3D direct writing equipment, controlling the slurry material to be in a gel state when passing through the direct writing equipment, printing and freezing the material to obtain a blank body with a three-dimensional structure, freeze drying and sintering the blank body to obtain the material with controllable macro and micro structures. The method firstly realizes the high-efficiency combination of direct writing molding and the freezing casting technology, and overcomes the limitation of the traditional preparation technology in simultaneously realizing the microscopic pore structure and the complex three-dimensional structure.

Owner:CENT SOUTH UNIV

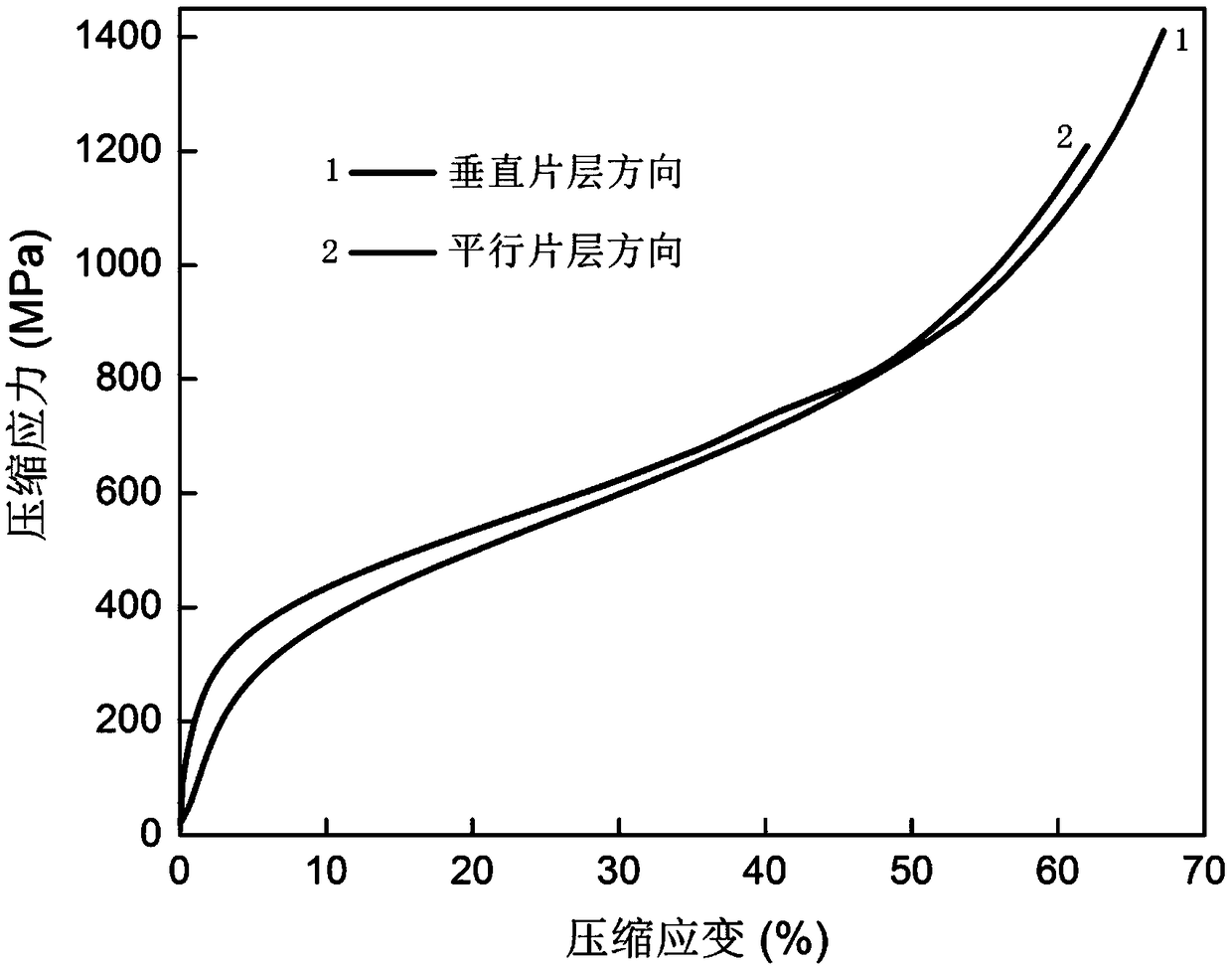

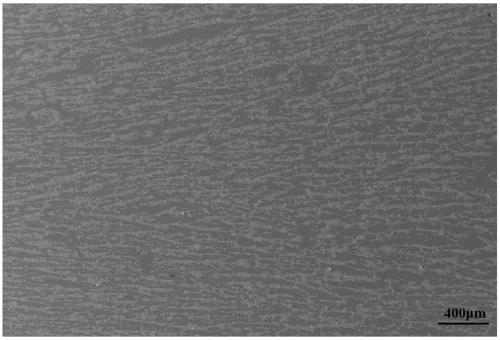

Copper-tungsten composite material with microscopic oriented structure and preparation method thereof

The invention discloses a copper-tungsten composite material with a microscopic oriented structure and a preparation method thereof. The composite material is prepared from tungsten and copper of massfraction being 30-97%. The microscopic oriented structure shows that tungsten and copper are arranged in a lamellar pattern along a specific direction at intervals. The copper-tungsten composite material with the microscopic oriented structure is prepared by the technical process of slurry preparing, freeze casting, vacuum freeze drying, organic matter removing, sintering and skeleton infiltrining, and the tungsten content of the material can be controlled by compressing a billet body or a skeleton along the direction vertical to a lamella. The composite material has the mechanical and functional properties of anisotropy and particularly has the characteristics of high strength, high hardness, good electrical and thermal conductivity and good resistance to arc ablation and resistance to electrical shock along the lamella direction. The composite material is expected to be used as an electrical contact material so as to significantly improve the using effect, prolong the service life,reduce component quality and reduce energy consumption.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

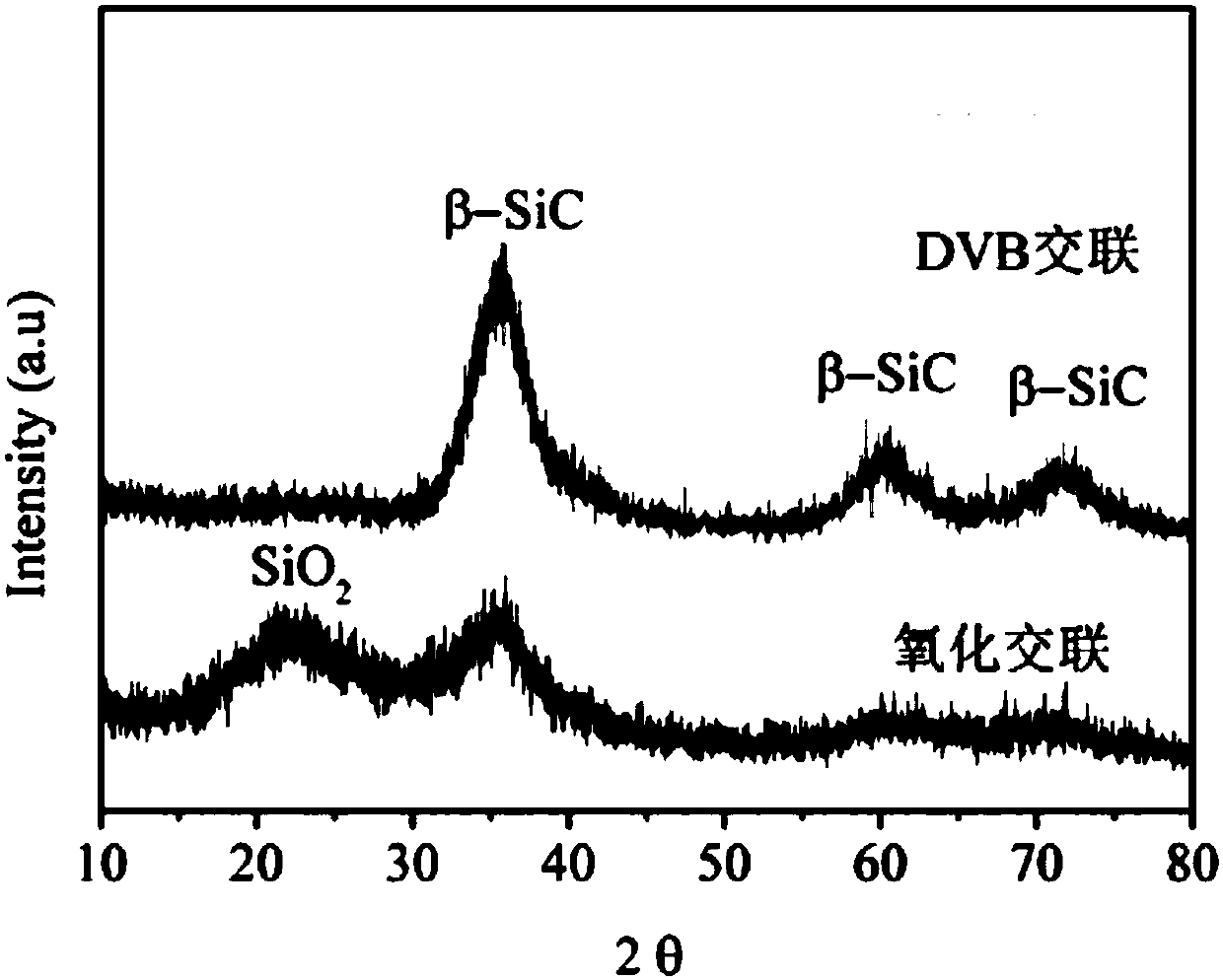

Method for preparing oriented porous structure of precursor conversion type ceramic

ActiveCN109534817AHigh strengthOvercoming disadvantages in pore size regulationCeramic shaping apparatusCeramicwareMaterials preparationMicrowave

The invention relates to a novel method for preparing porous ceramic by freeze casting, and belongs to the field of porous structure material preparation. The method includes the following steps: freeze-casting organic slurry containing ceramic precursors to obtain a body in a set temperature field, and freeze-drying the body to remove organic solvents to obtain a spare body; according to whetheror not the used organic slurry contains a crosslinking agent, using different crosslinking processed to obtain a to-be-cracked body; and finally, under the protective atmosphere, the to-be-cracked body obtained in the step two is cracked at 900 DEG C-160 DEG C until the ceramic precursors are completely converted into ceramic to obtain a finished product. The method adopts the ceramic precursor conversion mode to prepare the ceramic material, which greatly reduces the sintering temperature, reduces the energy consumption and significantly improves the performance of the obtained product, and has wide application biological materials, filter materials and microwave absorbing materials.

Owner:CENT SOUTH UNIV

Bionic cement with oriented porous structure and preparation method thereof

The invention relates to the field of porous cement, specifically to a bionic cement with an oriented porous structure and mainly used as a building material, and a preparation method thereof. The bionic cement has a porous structure with a porosity of 10% to 90%, a pore diameter of 0.5 [mu]m to 500 [mu]m and pore channels preferentially aligned in a specific direction. The preparation method forthe cement comprises three steps, i.e., slurry preparation, freeze-casting and green body maintenance, wherein the mass ratio of water to cement powder in a slurry is 0.25 to 3. The bionic cement provided by the invention has excellent performances like light weight, high specific strength and specific rigidity, heat preservation and insulation, noise insulation and reduction, fire prevention andinsusceptibility to cracking, specifically has good water permeability, air permeability and mechanical properties along a pore channel direction, and can be effectively controlled in performances through adjustment of a slurry proportion and a preparation process. The preparation method for the bionic cement provided by the invention has the advantages of simple process, short flow, low cost, energy conservation, environmental protection, and applicability to large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

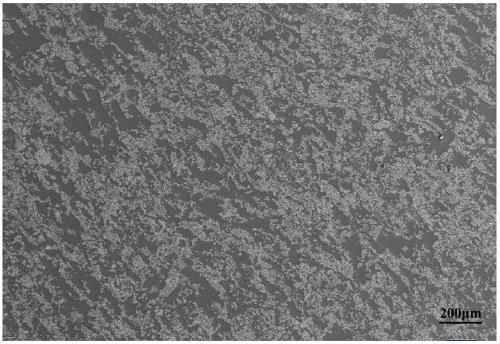

Foam metal with microscopic oriented hole structure and preparation method of foam metal

The invention relates to the field of foam metal materials, in particular to foam metal with a microscopic oriented hole structure and a preparation method of the foam metal. The foam metal has an oriented hole structure microscopically, it is shown that a metal skeleton and air holes are subjected to orientation arrangement in a slice layer mode in the freezing direction of a preparation process,the porosity is 10%-90%, the hole diameter is 0.3[mu]m-600[mu]m, and the skeleton of the foam metal can be reinforced by adding a nano carbon material, wherein the content of the nano carbon materialis 0%-10% in percentage by mass, the balance is metal, and the added nano carbon material is preferentially oriented in a metal skeleton matrix in the arrangement direction of the skeleton. Accordingto the foam metal with the microscopic oriented hole structure and the preparation method of the foam metal, the metal foam is prepared by the processes of water-based slurry preparation, freeze casting, vacuum freeze drying, organic matter removal and sintering. The foam metal has the outstanding performance of light weight, high specific strength, high energy absorption rate, sound absorption,heat insulation and the like, and the preparation method is simple in process, low in cost, energy-saving and environmentally friendly and suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Silicon carbide/graphene bionic composite material for bulletproof armor and preparation method thereof

The invention relates to the field of composite materials for bulletproof armor, particularly to a silicon carbide / graphene bionic composite material for bulletproof armor, and a preparation method thereof, wherein the composite material is composed of graphene with a volume percentage of 0.3-6% and silicon carbide, and graphene lamellas are preferentially and directionally distributed in a silicon carbide matrix microscopically. The preparation method of the composite material comprises the following steps: preparing mixed slurry of graphene and silicon carbide, then carrying out freeze casting and vacuum freeze drying treatment on the slurry to obtain a porous blank with an oriented lamellar structure, then compressing the blank along the direction vertical to the lamellar structure, andfinally carrying out organic matter removal treatment and sintering densification to obtain the silicon carbide / graphene composite material. According to the invention, the composite material is highin strength, high in hardness and simple in production process, has good fracture toughness, impact toughness and repeated impact resistance, can effectively improve the protection effect and durability of the bulletproof armor, and has a considerable application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

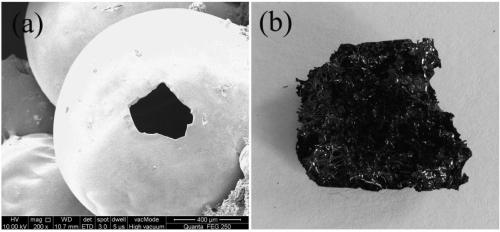

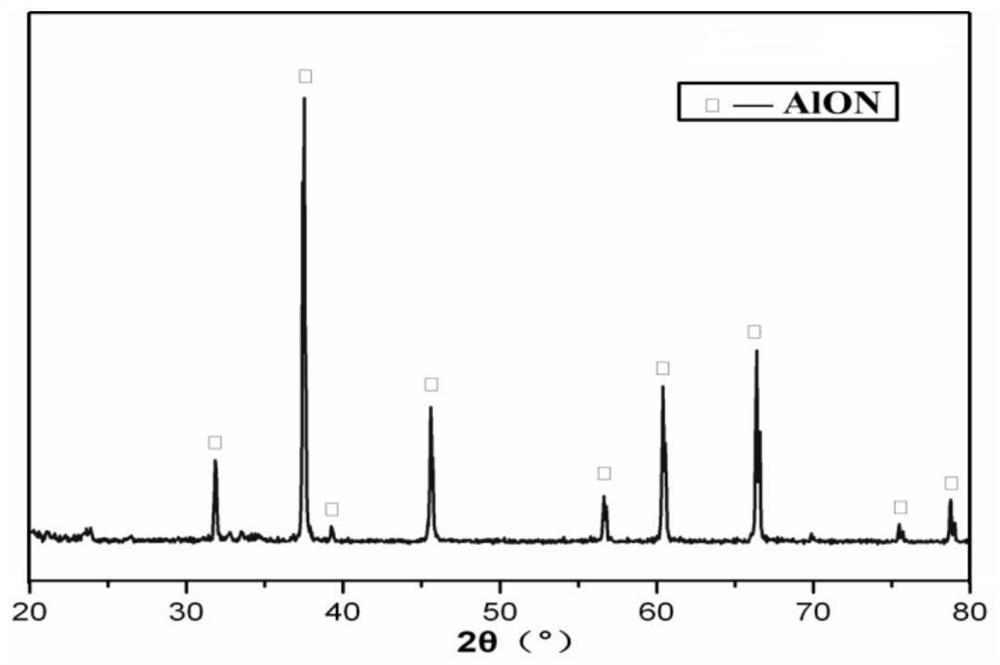

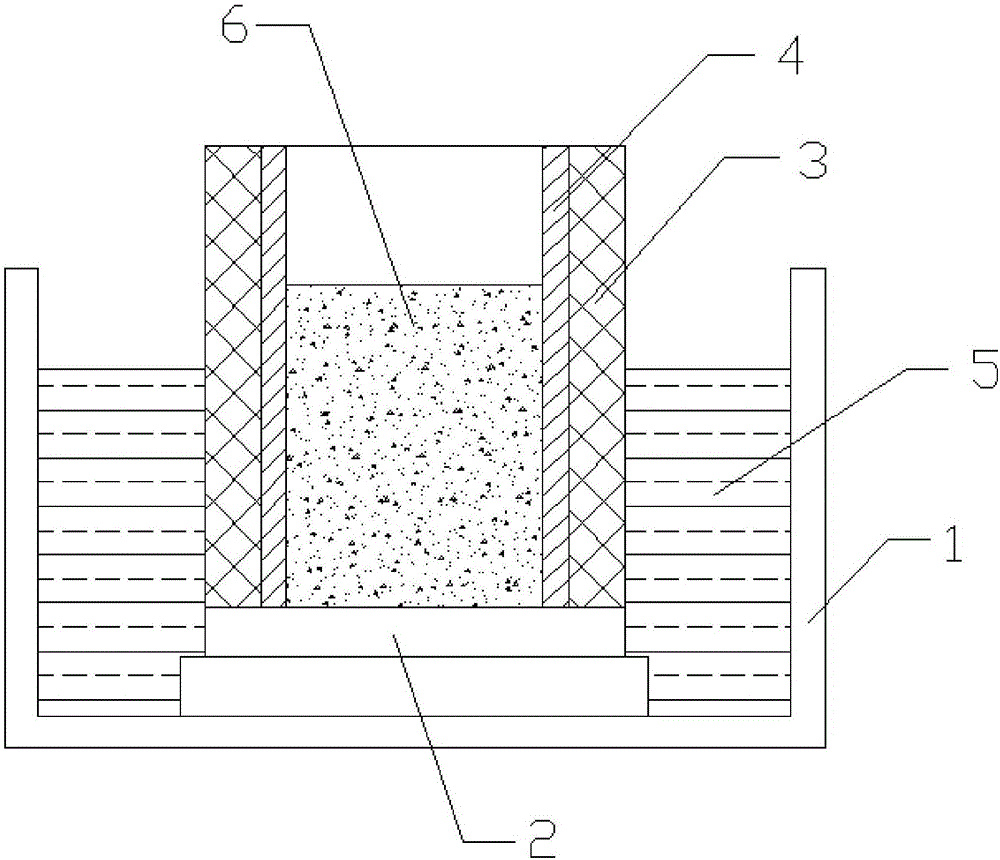

Ceramic powder preparation method based on freeze casting molding

ActiveCN112390653AFacilitated DiffusionRealize gas-solid reactionCeramic shaping apparatusNitrogen oxidesFreeze-drying

The invention discloses a ceramic powder preparation method based on freezing casting molding. The method comprises the following steps: (1) mixing a powder raw material, a solvent and an additive toobtain slurry with the solid phase content of 30-70wt%; (2) converting the slurry into a raw material blank with an internal through hole structure by adopting freezing casting molding and vacuum freeze drying processes and utilizing a temperature gradient formed by a mold; (3) putting the raw material blank into a reaction device with airflow control and anti-pollution functions in a high-temperature graphite sintering furnace, and carrying out high-temperature synthesis in a controlled reaction environment; and (4) carrying out ball milling and carbon removal process treatment on the raw material blank synthesized at high temperature to obtain the high-purity ceramic powder. The method can be used for macroscopic preparation of ceramic powder such as nitride and nitric oxide based on high-temperature gas-solid synthesis reaction, and has good application prospect and popularization value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

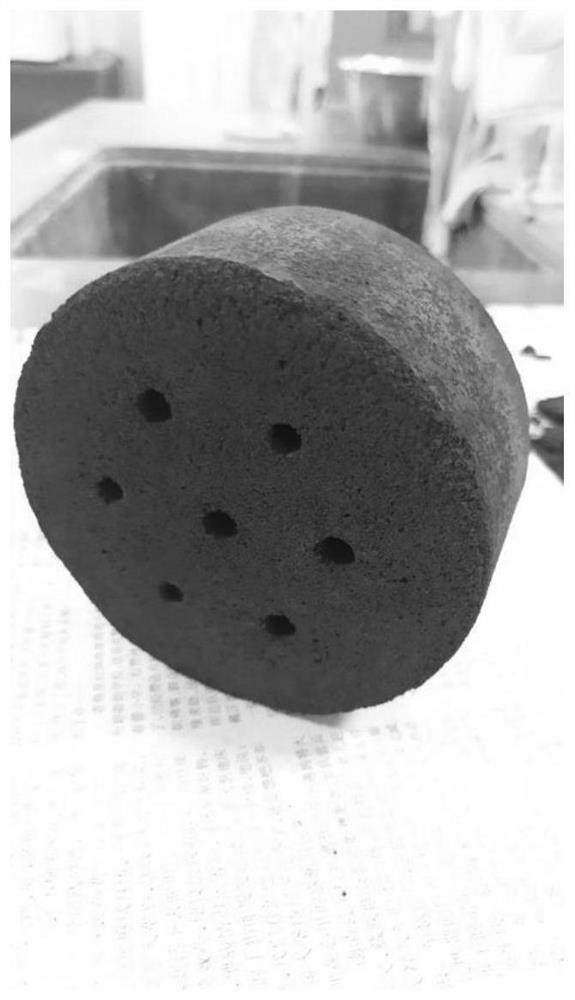

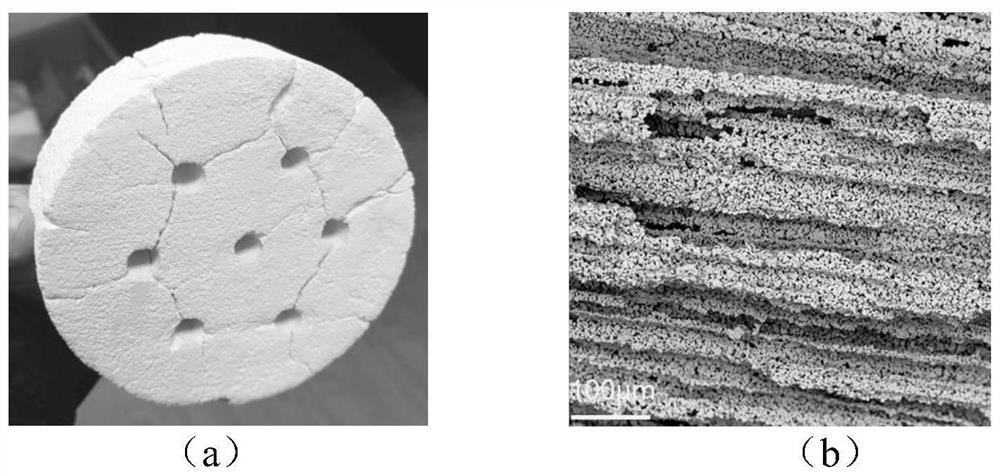

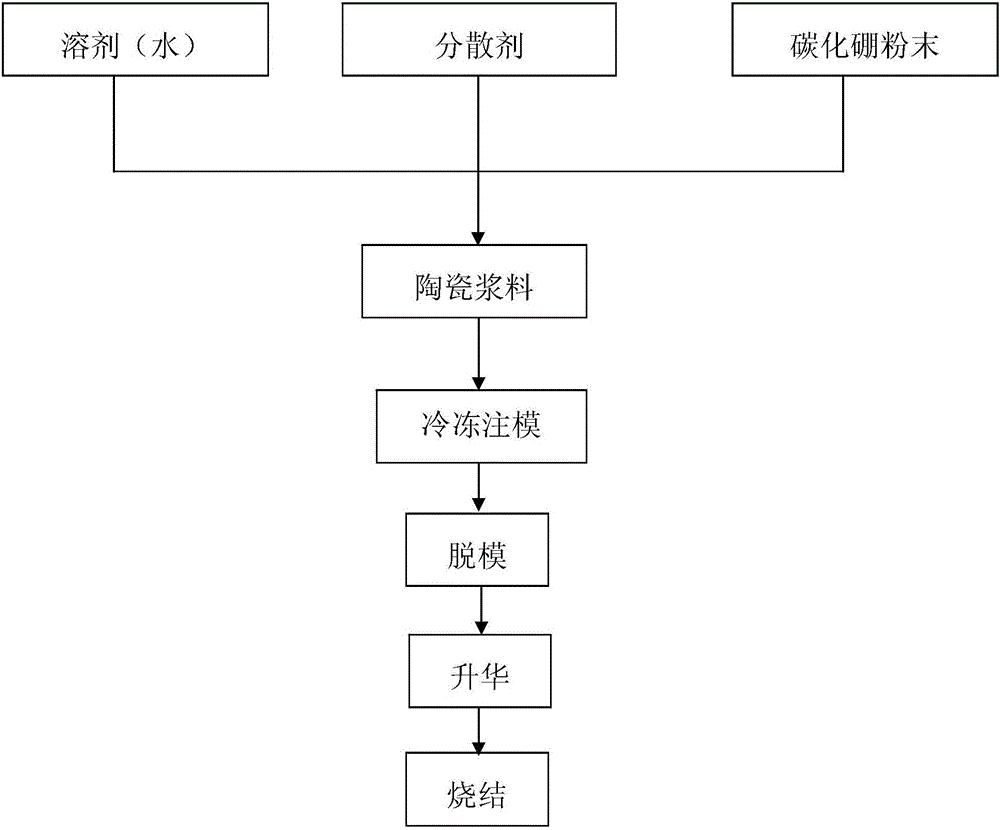

Porous B4C ceramic skeleton and freeze-casting process thereof

ActiveCN106830942AEvenly dispersedWith mechanical strengthAuxillary shaping apparatusCeramicwareAdhesiveFreeze-casting

The invention relates to a porous B4C ceramic skeleton and a freeze-casting process thereof. Porous B4C is a ceramic skeleton of B4C / Al serving as a neutron absorption material, and Al is impregnated in the B4C skeleton through an impregnation method, thereby increasing the B4C ceramic content in the B4C / Al structure and improving the neutron absorption capability. The B4C ceramic skeleton for Al impregnation is prepared through the following steps: taking different B4C particles respectively having particle diameters of 5 mu m, 10 mu m, 20 mu m and 40 mu m, selecting water as freeze-casting solvent, mixing according to mass percents, adding a proper amount of dispersing agent and adhesive, freezing, sublimating to obtain a B4C ceramic body, and sintering at 2000 DEG C. The B4C ceramic skeleton provided by the invention is moderate in strength and high in B4C ceramic content, has a favorable through hole structure, and can tolerate pressure produced in the Al impregnation process; the preparation process is simple; and the increase of the B4C content can greatly improve the neutron absorption efficiency of the B4C / Al.

Owner:镇江纽科利核能新材料科技有限公司 +1

Porous polymer scaffolds for neural tissue engineering and methods of producing the same

The present invention relates to scaffolds that can physically guide cells, e.g. neurons, while best matching the material properties of native tissue. The present invention also relates to methods of generating such scaffolds, and for the use of such scaffolds, e.g. in spinal cord and peripheral nerve injury repair. The methods of the present invention include a uniquely controlled freeze casting process to generate highly porous, linearly oriented scaffolds. The scaffolds of the present invention not only comprise a highly aligned porosity, but also contain secondary guidance structures in the form of ridges running parallel to the pores to create a series of microstructured and highly aligned channels. This hierarchy of structural guidance aligns and guides neurite outgrowth down the channels created by the ridges, and keep neurites from branching perpendicular to the inter-ridge grooves.

Owner:DREXEL UNIV

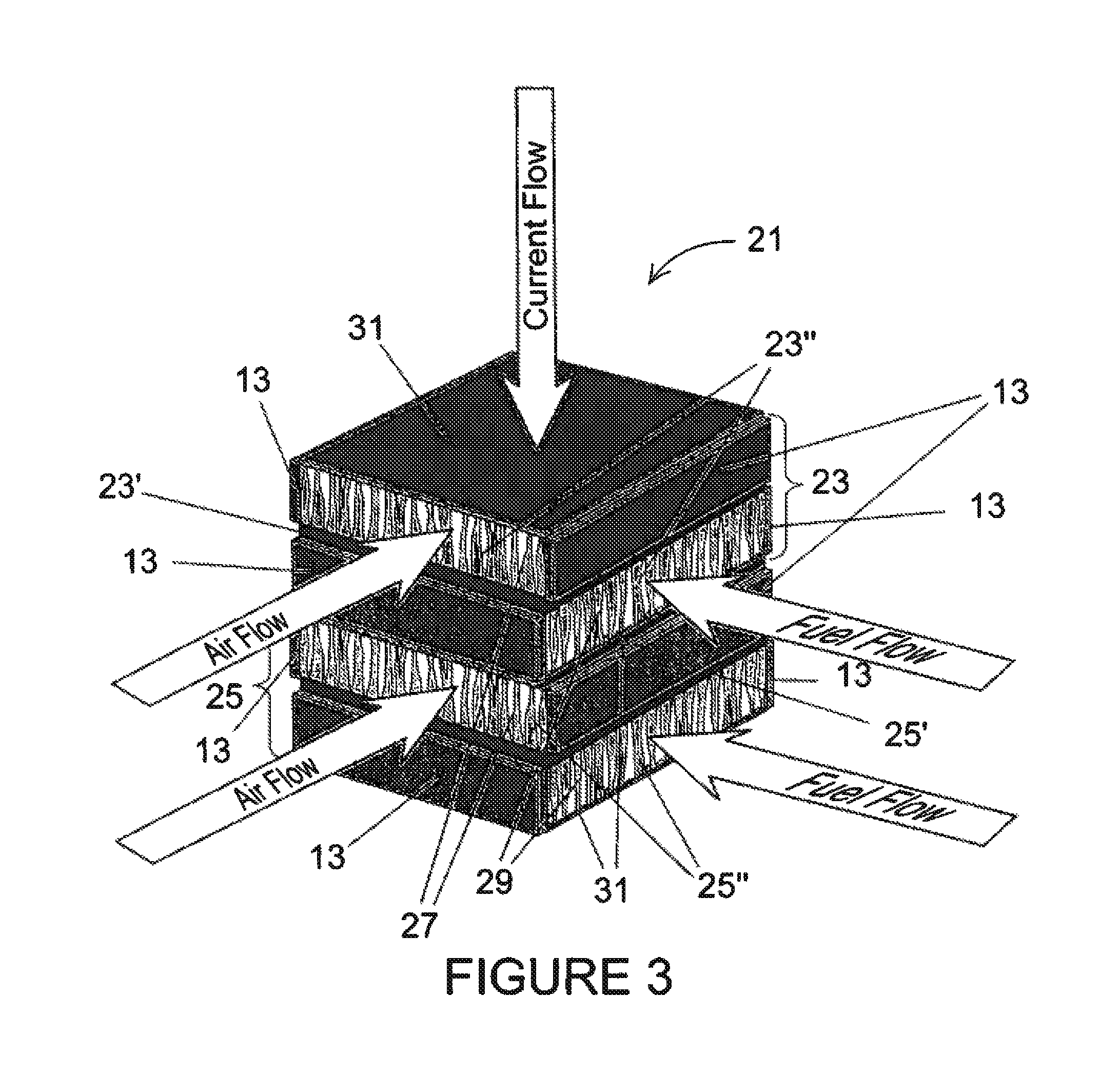

Solid oxide fuel cell and method of forming

A method of forming a solid oxide fuel cell (SOFC) article includes providing a green electrode layer formed by a freeze-casting process and forming a green SOFC unit cell. The green SOFC unit cell includes a green electrolyte layer, a green cathode layer overlying the electrolyte layer, a green interconnect layer, and a green anode layer disposed between the green electrolyte layer and the interconnect layer. The method includes sintering the green SOFC unit cell in a single sintering process to form a sintered SOFC unit cell.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Small-diameter artificial blood vessel based on freeze casting technology and preparation method thereof

ActiveCN108404219AHigh tensile strengthGood anticoagulant effectCoatingsProsthesisFreeze-dryingFreeze-casting

The invention belongs to the field of biomedical materials, and particularly relates to a small-diameter artificial blood vessel based on freeze casting technology and a preparation method thereof. The preparation method comprises the following steps: dissolving a natural polymer material in water to prepare a natural polymer solution, pouring the natural polymer solution into a mold, and inserting the mold into liquid nitrogen for freezing forming; and taking a frozen formed artificial blood vessel out of the mold for freezing drying, immersing the artificial blood vessel in a glutaraldehydesolution for cross-linking treatment, and finally evenly coating the surface of the artificial blood vessel with a synthetic polymer solution to obtain the small-diameter artificial blood vessel. Theinner layer of the small-diameter artificial blood vessel is the natural polymer material which has the characteristics of short degradation period and rapid promotion of autologous blood vessel regeneration, and the outer layer of the small-diameter artificial blood vessel is a synthetic polymer material which has certain mechanical properties, and prevents blood leakage; the inner surface of thesmall-diameter artificial blood vessel has a radial structure, and can promote the adhesion of endothelial cells on the surface of the material so as to promote the endothelialization of the artificial blood vessel, and the anticoagulant ability of the artificial blood vessel can be greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for making a fuel cell

The invention is a novel solid oxide fuel cell (SOFC) stack comprising individual bi-electrode supported fuel cells in which an electrolyte layer is supported between porous electrodes. The porous electrodes may be made from graded pore ceramic tape that has been created by the freeze cast method followed by freeze-drying. Each piece of graded pore tape later becomes a graded pore electrode scaffold that, subsequent to sintering, is made into either an anode or a cathode. The electrode scaffold comprising the anode includes a layer of liquid metal. The pores of the electrode scaffolds gradually increase in diameter as the layer extends away from the electrolyte layer. As a result of this diameter increase, any forces that would tend to pull the liquid metal away from the electrolyte are reduced while maintaining a diffusion path for the fuel. Advantageously, the fuel cell of the invention may utilize a hydrocarbon fuel without pre-processing to remove sulfur.

Owner:NASA

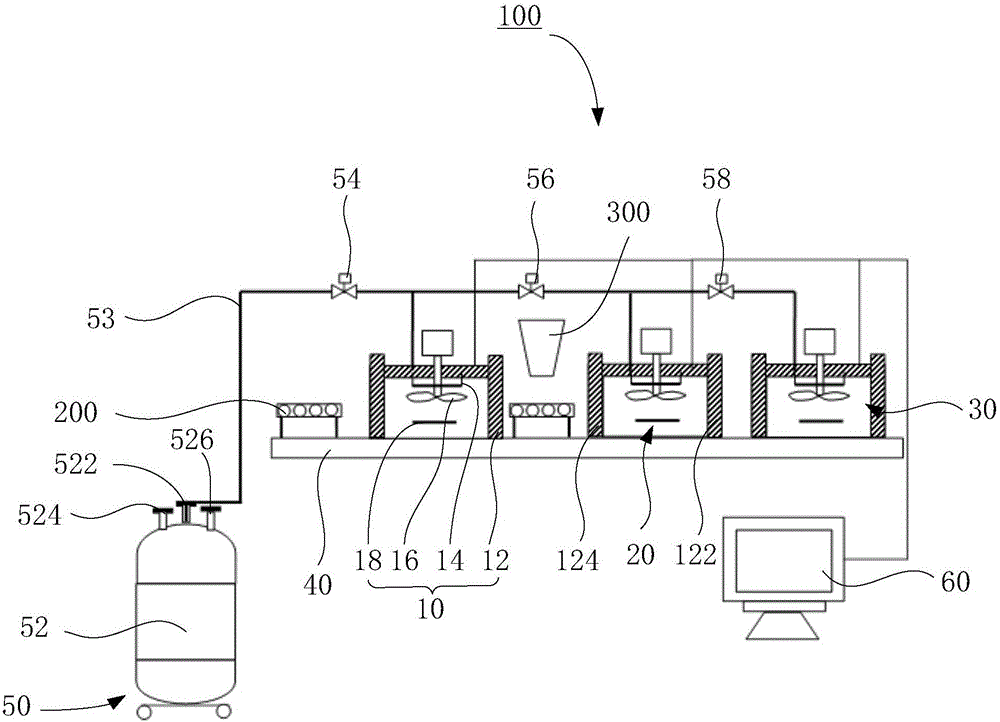

Freeze casting device and method

ActiveCN105728699ASimple processAccurate and controllable heating and cooling rateTemperature controlControl system

The invention provides a freeze casting device. The freeze casting device comprises a casting mold cooling chamber, a casting process cooling chamber, a deep-cooling treatment chamber, a transmission mechanism, cold quantity supply equipment and a control system. The casting mold cooling chamber, the casting process cooling chamber and the deep-cooling treatment chamber are sequentially arranged on one side of the transmission mechanism. The cold quantity supply equipment is connected with the casting mold cooling chamber, the casting process cooling chamber and the deep-cooling treatment chamber and used for supplying cold quantity to the casting mold cooling chamber, the casting process cooling chamber and the deep-cooling treatment chamber. The control system is connected with the casting mold cooling chamber, the casting process cooling chamber, the deep-cooling treatment chamber and the cold quantity supply equipment and used for controlling the temperature of the casting mold cooling chamber, the casting process cooling chamber and the deep-cooling treatment chamber. According to the freeze casting device and a method adopting the freeze casting device, the technological process is simple, temperature control over the casting mold cooling chamber, the casting process cooling chamber and the deep-cooling treatment chamber is conducted through the control system, and the heating rate, the cooling rate and the cryogenic temperature can be precisely controlled.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of freeze-cast Y-TZP slurry

A preparation method of freeze-cast Y-TZP slurry is disclosed. The slurry is composed of micron-size Y-TZP (tetragonal polycrystal zirconia with Y2O3 as a stabilizing agent) powder and a mixed liquid. The mass ratio of the Y-TZP powder to the mixed liquid is (320-600): 100. The mixed liquid is obtained by the following steps: using deionized water as a solvent, adding a freezing auxiliary agent which accounts for 1.0-2.5% of mass of deionized water, a dispersant which accounts for 0.5-2.0% of mass of deionized water and an organic binder which accounts for 0.4-1.0% of mass of deionized water, and mixing. By adding the Y-TZP powder into the mixed liquid in batches and ball-milling for 12-24 h, the slurry is then prepared. According to requirements of the forming process, viscosity of the slurry also can be further adjusted through pH value. The Y-TZP slurry is freeze-cast in a low-temperature environment, and can be used for extrusion freezing 3D printing technology and a slip-casting freezing forming technology.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Copper-based contact material with microscopic orientation structure and preparation method of copper-based contact material

The invention belongs to the field of metal-based composite materials, and particularly discloses a copper-based contact material with a microscopic orientation structure and a preparation method of the copper-based contact material. The material is prepared by compounding a matrix phase (copper or copper alloy) with a mass fraction of 5%-85% and a second phase (chromium, chromium alloy, tungstencarbide or silicon carbide), and the two phases are microscopically arranged alternately in the freezing direction of a preparation process. The material is prepared by the technological processes ofslurry preparation, freeze casting and vacuum freeze drying, organic matter removal and skeleton sintering and skeleton infiltration, and the content of the two phases in the material is controlled byadjusting the slurry ratio. The copper-based contact material has good plasticity and toughness and high-temperature mechanical properties, and particularly exhibits excellent electrical and thermalconductivity in the microstructure direction, and thus the use effect of a contact is expected to be significantly improved, and energy consumption is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com