Silicon carbide/resin bionic composite material with directional microstructure, and preparation method thereof

A biomimetic composite material and composite material technology are applied in the field of silicon carbide/resin biomimetic composite materials and their preparation, which can solve the problems of coarse structure, weak interface bonding force and high equipment requirements of composite materials, and achieve enhanced fracture toughness and impact resistance. The effect of improved performance, fracture toughness and impact resistance, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

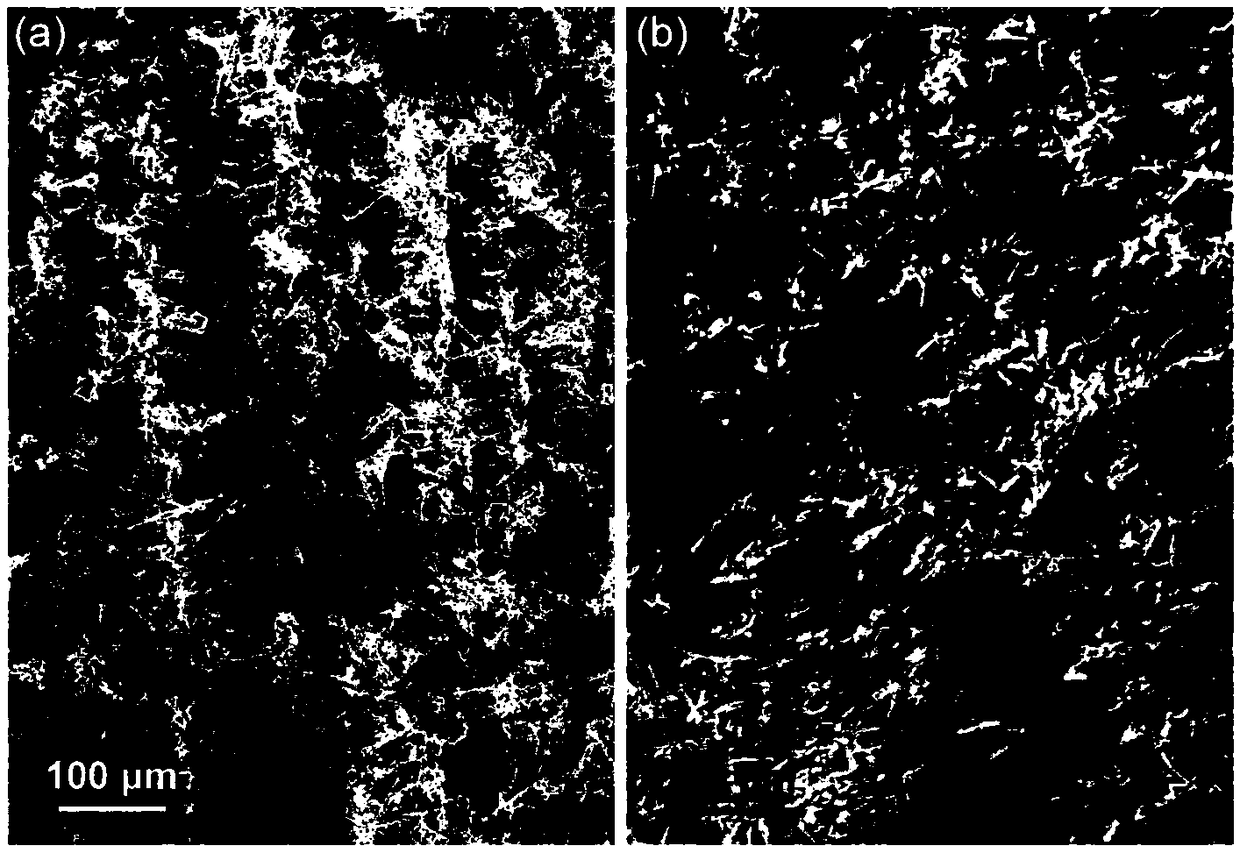

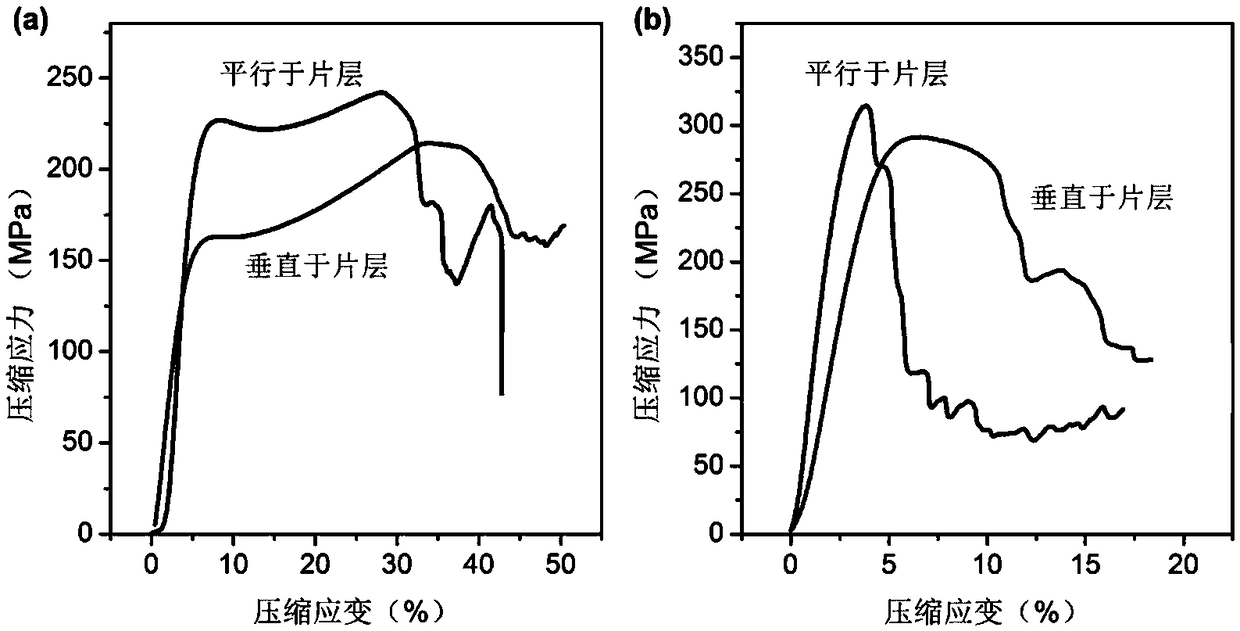

[0042] In this example, a silicon carbide whisker / polymethyl methacrylate composite material with a microscopic oriented structure was prepared. The raw materials used mainly include silicon carbide whiskers (average diameter 2.5μm, length 50-200μm), silicon oxide powder (average particle size 20nm), deionized water, polyvinyl alcohol, hydroxypropyl methylcellulose powder (average particle size 180 μm), polyacrylic acid and methyl methacrylate, the specific preparation process is as follows:

[0043] (A) Preparation of slurry

[0044] Add 720g of deionized water into a 1000mL plastic jar, add 100g of silicon carbide whiskers, 4g of silicon oxide powder, 35g of polyvinyl alcohol and 2g of polyacrylic acid into the bottle, and stir at a speed of 60rpm until the solid powder is evenly dispersed in the water. Place the jar in a constant temperature water bath at 70°C, keep it warm for 30 minutes, slowly add 14g of hydroxypropyl methylcellulose powder into the bottle, and stir un...

Embodiment 2

[0057] In this example, a silicon carbide / epoxy resin composite material with a microscopically oriented cross lamination structure was prepared. The raw materials used mainly include nano-silicon carbide powder (average particle size 100nm), nano-yttrium oxide powder (average particle size 30nm), nano-alumina powder (average particle size 20nm), deionized water, polyvinyl alcohol, hydroxypropyl Base methyl cellulose powder (average particle diameter 180 μ m), polyacrylic acid, epoxy resin and curing agent, concrete preparation process is as follows:

[0058] (A) Preparation of slurry

[0059] Add 185g of deionized water to a 500mL plastic jar, add 45g of nano-silicon carbide powder, 2.853g of nano-yttrium oxide powder, 2.147g of nano-alumina powder, 8g of polyvinyl alcohol and 1g of polyacrylic acid into the bottle , stirring at a speed of 100rpm until the solid powder is evenly dispersed in water. Place the jar in a constant temperature water bath at 70°C, keep it warm for...

Embodiment 3

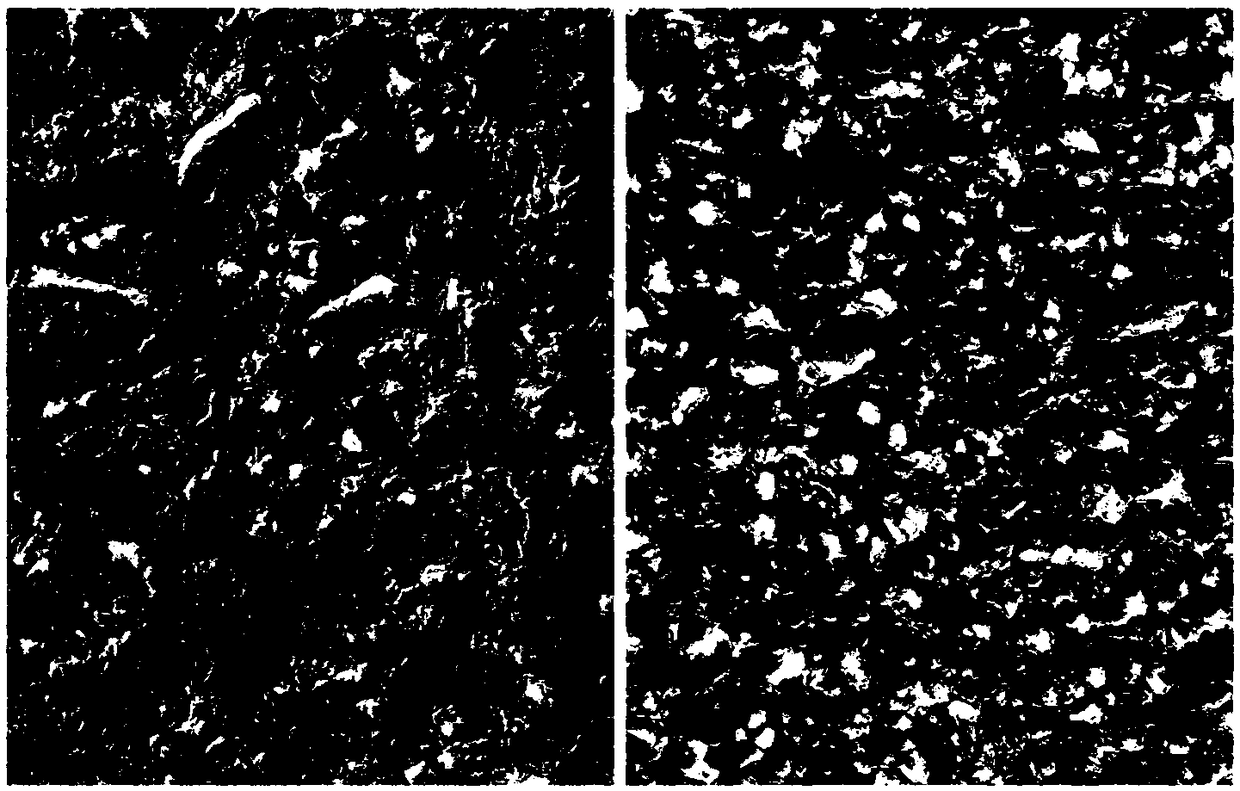

[0070] In this example, a silicon carbide / epoxy resin composite material with a microscopically oriented lamellar structure was prepared. Used raw material is identical with embodiment 2, and concrete preparation process is as follows:

[0071] (A) Preparation of slurry and preparation of porous body

[0072] According to the same operation as the steps (A) and (B) of Example 2, a green body with an oriented porous structure composed of silicon carbide powder and additives was prepared.

[0073] (B) Body compression treatment

[0074] Place the freeze-dried green body in a steel mold, and use a hot press to compress the green body in a direction perpendicular to the silicon carbide layer at 100°C. The compression deformation is 50%, and the pressure is kept for 10 minutes. After cooling, unload and The green body is taken out from the mould.

[0075] (C) Organic matter removal and sintering

[0076] The green body was deorganized and sintered according to the same operatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com