Foam metal with microscopic oriented hole structure and preparation method of foam metal

A metal foam and directional hole technology, which is applied in the field of metal foam materials, can solve the problems of poor energy absorption efficiency and low strength, and achieve the effects of simple preparation process, high energy absorption rate, and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

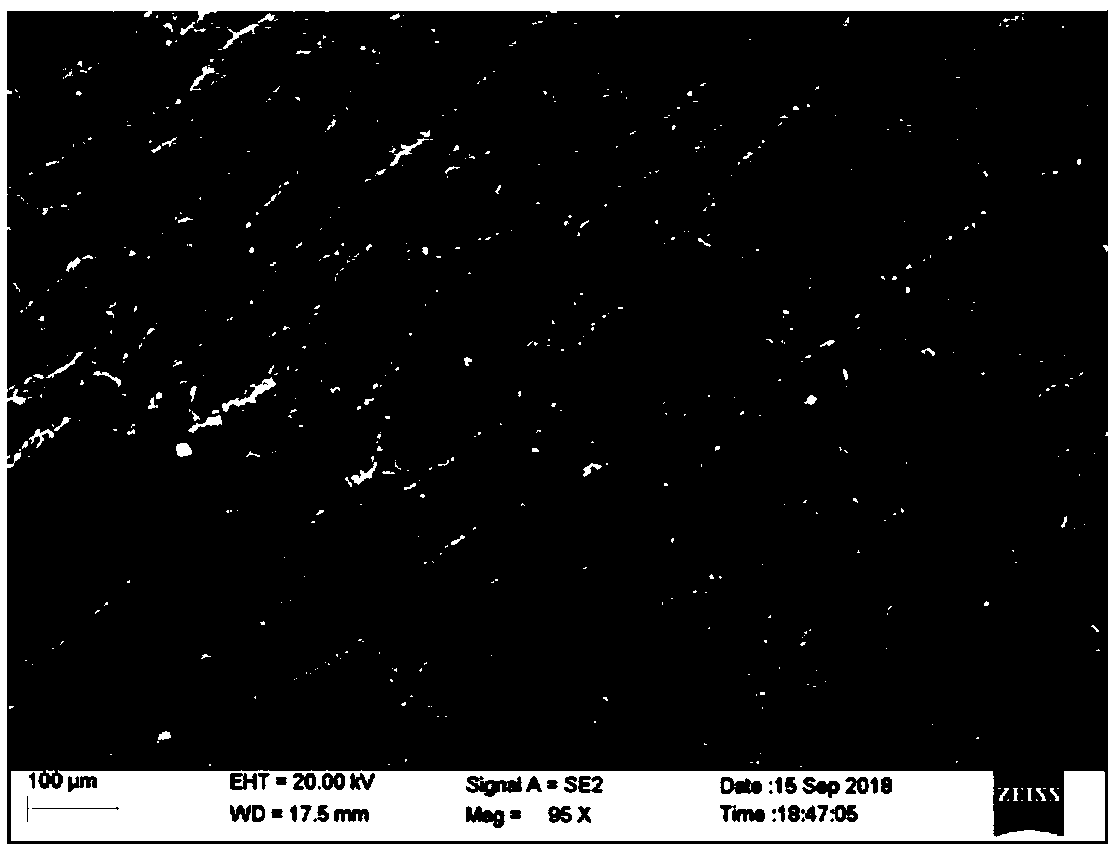

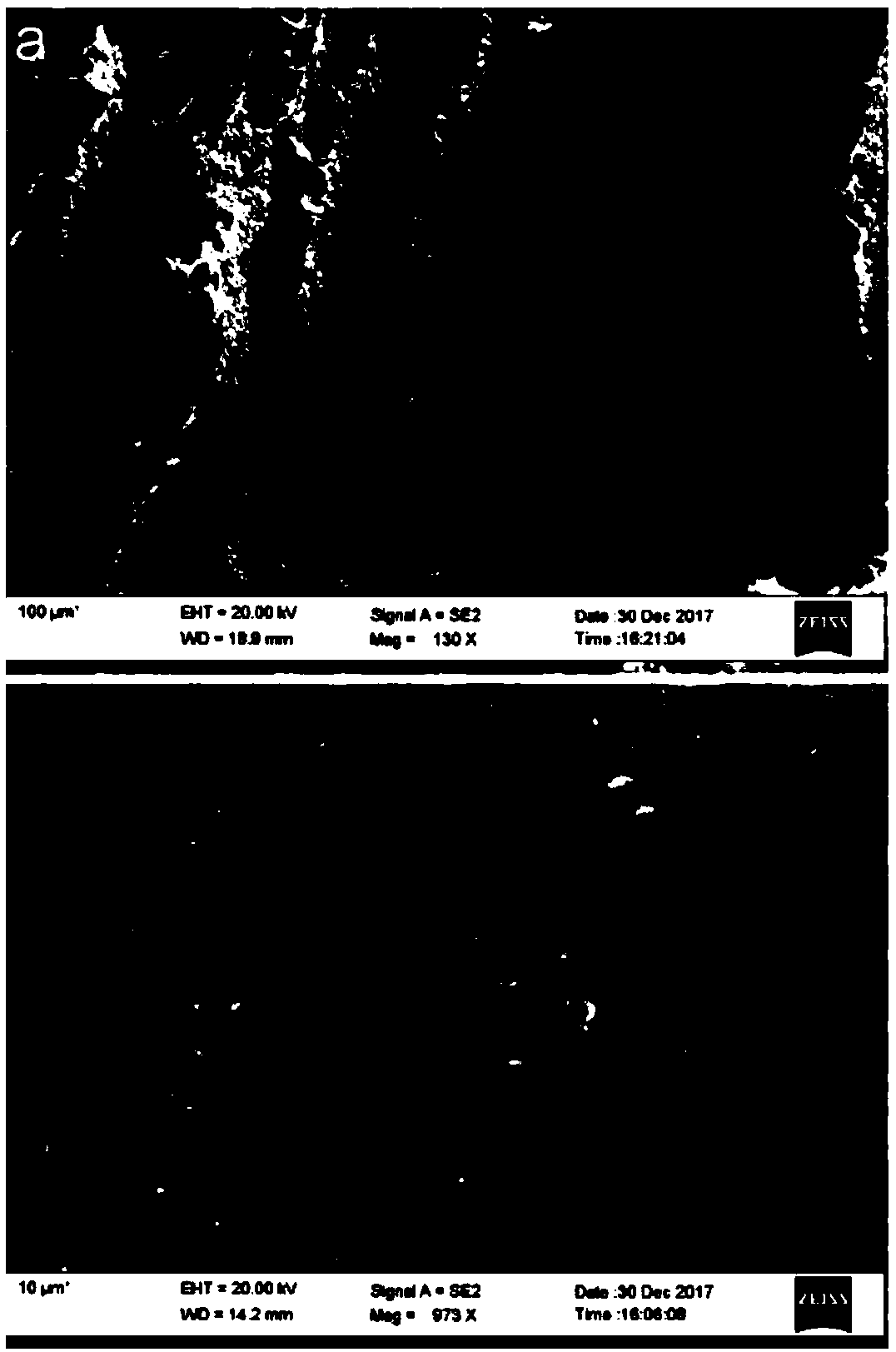

Image

Examples

Embodiment 1

[0030]In this embodiment, the nickel foam with microscopic directional pore structure is prepared, and the raw materials used include metal nickel powder (average particle diameter 50nm), water, hydroxypropyl methylcellulose powder (average particle diameter 180 μm), polyvinyl alcohol, Sucrose and polyacrylic acid. Concrete preparation process is as follows:

[0031] (A) Preparation of water-based slurry

[0032] Weigh 440g of water and add it to a 2L plastic jar, then add 2.2g of hydroxypropyl methylcellulose powder, 80g of metal nickel powder, 4g of sucrose, 4g of polyvinyl alcohol and 2g of polyacrylic acid to the jar, stirring continuously Until the slurry is evenly dispersed, add 6 zirconia balls each with a diameter of 3mm, 6mm and 10mm to the slurry, and drop 5 drops of defoamer (about 0.35mL). The defoamer is Nanjing Huaxing defoamer The XPM-120 defoamer produced by Agent Co., Ltd., after sealing the cap of the jar, placed it on a roller ball mill for ball milling. T...

Embodiment 2

[0041] In this example, the nickel foam reinforced with graphene with a microscopic oriented pore structure is prepared, and the raw materials used include graphene (diameter 5-10 μm, thickness 3-10 nm), metal nickel powder (average particle size 50 nm), water , sodium lauryl sulfate, hydroxypropyl methylcellulose (average particle size of 180 μm), polyvinyl alcohol, sucrose and polyacrylic acid. Concrete preparation process is as follows:

[0042] (A) Preparation of water-based slurry

[0043] The difference between this step and step (A) in Example 1 lies in the type and amount of raw materials, specifically: 48g of metal nickel powder, 120g of water, 0.24g of sodium lauryl sulfate, 0.12g of graphene, hydroxypropyl Methylcellulose 1.8g, sucrose 1.44g, polyvinyl alcohol 1.44g, polyacrylic acid 0.72g. All the other operations are the same as step (A) in Example 1.

[0044] (B) Frozen casting

[0045] The operation of this step is the same as step (B) in Example 1.

[0046...

Embodiment 3

[0052] In this example, aluminum foam with a microscopic directional pore structure is prepared, and the raw materials used include graphene (diameter 5-10 μm, thickness 3-10 nm), flake metal aluminum powder (average sheet diameter 10 μm), water, dodecane Sodium Hydroxyl Sulfate, Polyvinyl Alcohol, Sucrose, and Polyacrylic Acid. Concrete preparation process is as follows:

[0053] (A) Preparation of water-based slurry

[0054] The difference between this step and step (A) in Example 1 lies in the type and amount of raw materials, specifically: 40 g of flake metal aluminum powder, 200 g of water, 0.4 g of sodium lauryl sulfate, 0.336 g of graphene, sucrose 2g, polyvinyl alcohol 2g, polyacrylic acid 0.8g. All the other operations are the same as step (A) in Example 1.

[0055] (B) Frozen casting

[0056] The operation of this step is the same as step (B) in Example 1.

[0057] (C) vacuum freeze drying

[0058] The operation of this step is the same as step (C) in Example 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com