Patents

Literature

107results about How to "Uniform orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

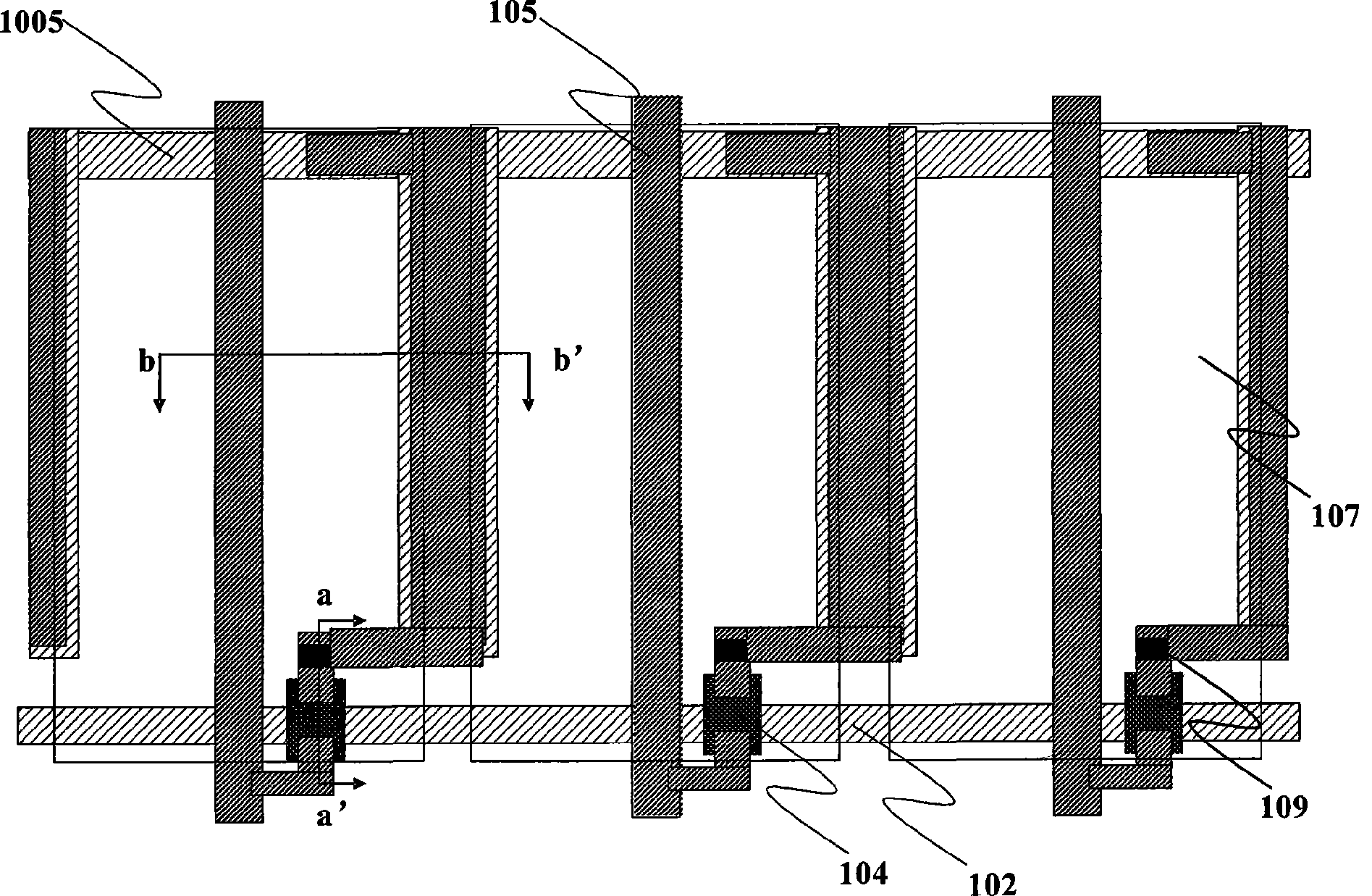

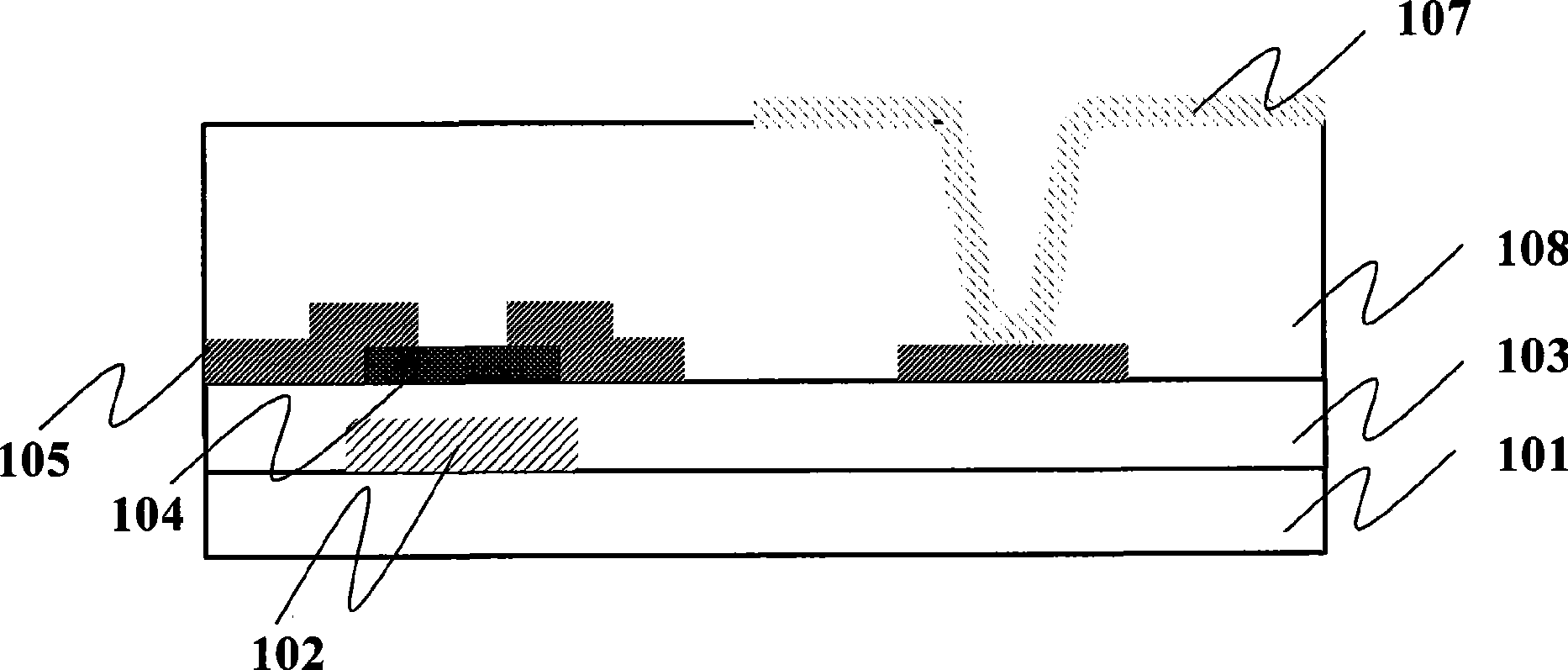

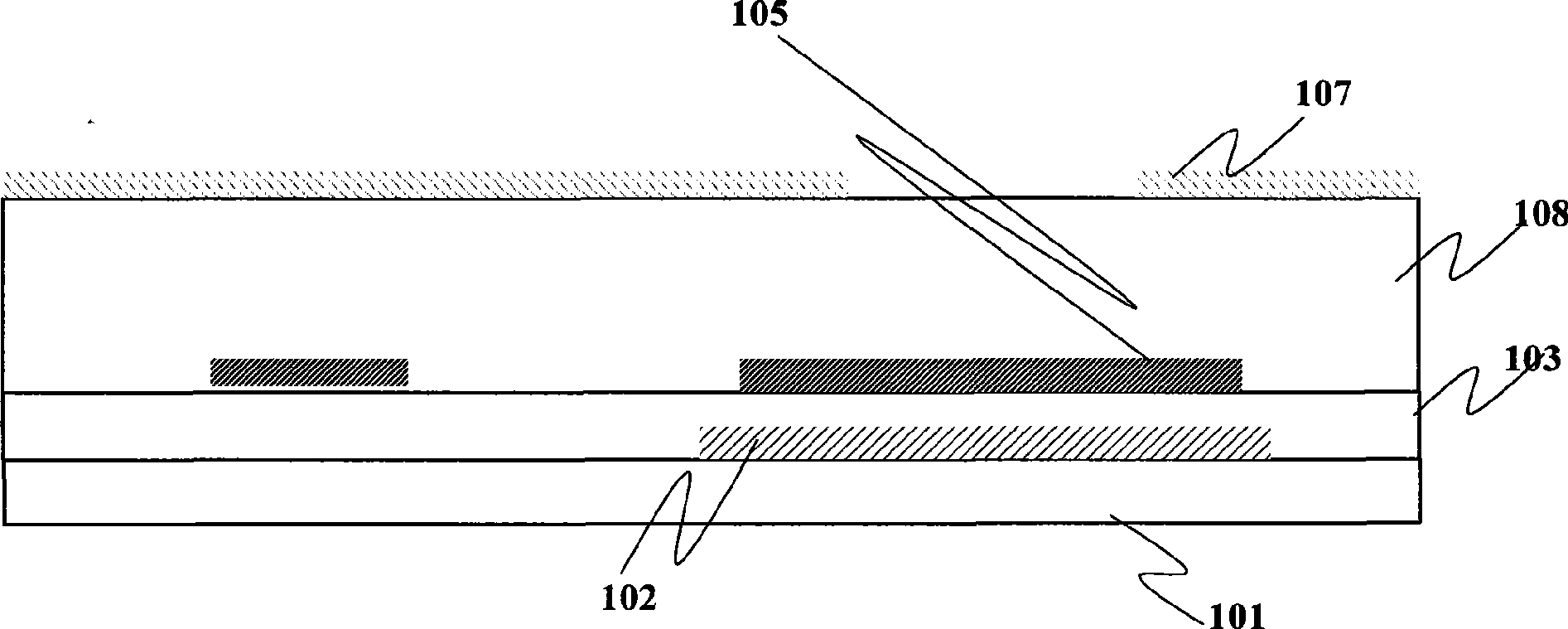

LCD device and method for producing the same

InactiveCN101430463AImprove efficiencyIncrease opening ratioStatic indicating devicesSemiconductor/solid-state device detailsCapacitanceOrganic film

The invention relates to a liquid crystal display device and a manufacture method thereof. The liquid crystal display device comprises a glass basic board as well as a grid scanning line layer, an insulating layer, a data line layer, a memory capacitance and a pixel electrode layer which are formed on the glass basic layer in sequence; wherein, the insulating layer is formed by overlapping an inorganic film and an organic film or an inorganic film with low specific inductive capacity or an organic film with low specific inductive capacity. The liquid crystal display device and a manufacture method thereof can improve the aperture opening ratio thereof, and reduce the signal delay of the data line or the grid scanning line.

Owner:SHANGHAI SVA LIQUID CRYSTAL DISPLAY

Modified graphene/polyimide heat-conducting composite material and preparation method thereof

ActiveCN106750296AEasy reunionHigh thermal conductivityFilament/thread formingHeating/cooling textile fabricsFiberBenzene

The invention provides a modified graphene / polyimide heat-conducting composite material and a preparation method thereof. The preparation method comprises the following steps: by taking 1,3-bis(4-aminophenoxy)benzene and 4,4'-oxydiphthalic dianhydride as raw materials and taking modified graphene prepared from monoamino-polyhedral oligomeric silsesquioxane surface functionalization modified graphene oxide as a heat-conducting filler, preparing a CMG (chemically modified graphene) / polyamic acid heat-conducting composite fiber felt through an in-situ polymerization and electrostatic spinning method, preparing a CMG / polyimide heat-conducting composite material through a hot imidization and die pressing forming process, and realizing high heat conductivity of a PI (polyimide) resin matrix at a low filling amount of the CMG heat-conducting filler.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

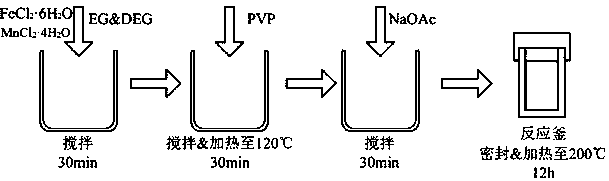

Preparation method of oriented carbon nanotube film

The invention discloses a preparation method of an oriented carbon nanotube film, and belongs to the field of film material preparation. The preparation method is characterized by comprising the following steps: step A, adopting a magnetic multi-walled carbon nanotube, which is prepared by steps of subjecting carboxylated multi-walled carbon nanotubes to polymeric modification and evenly loading magnetic particles on the modified multi-walled carbon nanotubes through a chemical co-precipitation method; step B, adding the obtained magnetic carbon nanotubes obtained in the step A into a solvent, mixing, and fully dispersing the carbon nanotubes to obtain a stable carbon nanotube solution; step C, adopting a vacuum suction filtration method: pouring the magnetic carbon nanotube solution obtained in the step B into a vacuum suction filtration device, applying a magnetic field on the device, and changing the direction of the magnetic field so as to obtain an in-plane vertical oriented film or an in-plane horizontal oriented film; step D, removing the substrate film by liquid nitrogen so as to obtain the oriented carbon nanotube film. The method is simple and efficient, the film structure is uniform and complete; the orientation degree can be controlled by changing the strength of magnetic field and the grafting rate of magnetic nano particles on the carbon nanotubes, and the integrity of oriented film structure is guaranteed by spraying liquid nitrogen.

Owner:BEIJING UNIV OF CHEM TECH

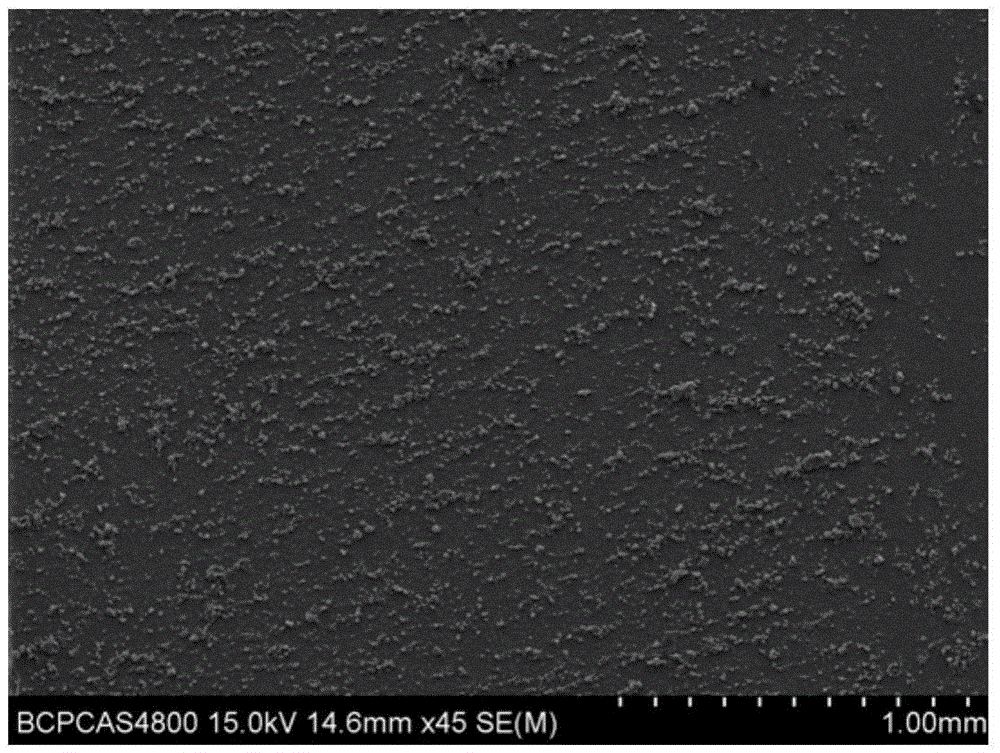

Processing method for high-purity titanium sheet for coating titanium anode base material

Provided is a processing method for a high-purity titanium sheet for a coating titanium anode base material. O-stage sponge titanium with the average particle size being 3-25.4 mm is placed in an electron beam cold hearth and melted in a vacuum state so that a high-purity titanium slab can be obtained through purification; a hot coil which is 2.5-5 mm thick is manufactured through rolling of a steckel mill, and annealing is performed; shot blasting and pickling treatment need to be performed after annealing; the hot coil is placed on a reversible cold rolling machine to be subjected to many times of rolling; finally, a cold coil which is 0.5-2 mm thick can be obtained; the deformation rate is controlled to be 40-60% during each time of rolling; then the cold coil is subjected to degreasing treatment; then complete recrystallization annealing is performed in the vacuum state or the argon protection state, wherein the annealing temperature is controlled to be 600-720 DEG C and a titanium coil is obtained. As is detected, the average grain size of the titanium is controlled to be 15-30 microns, and the high-purity titanium sheet for the coating titanium anode base material is obtained after the titanium coil is straightened. The unevenness of the high-purity titanium sheet is smaller than or equal to 3 mm / m, and no strip-shaped flow direction lines exist after the high-purity titanium sheet is used as a coating.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

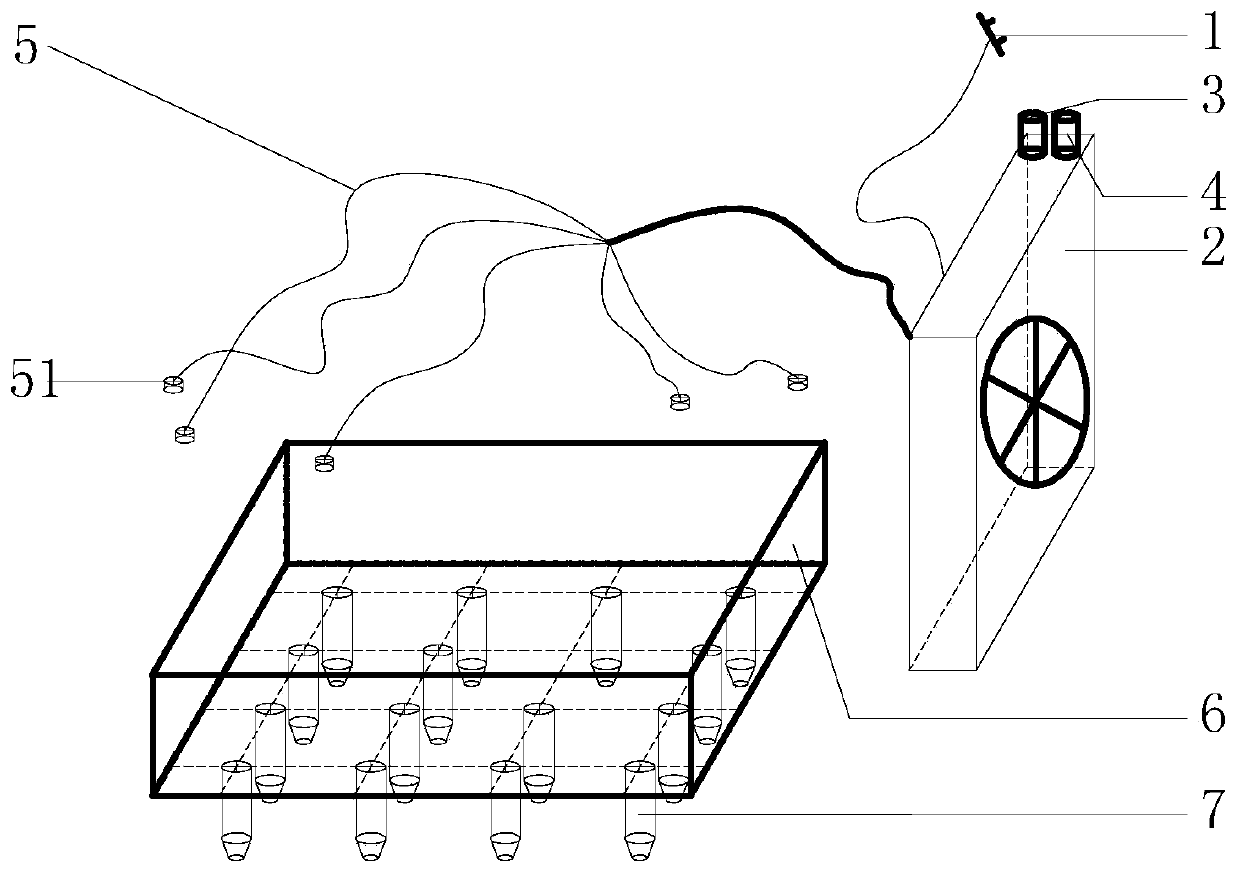

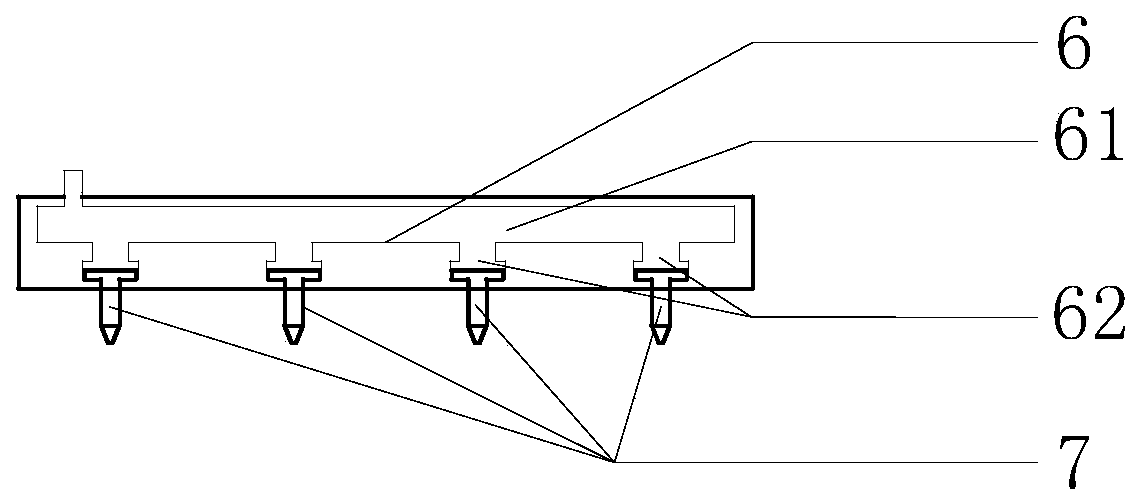

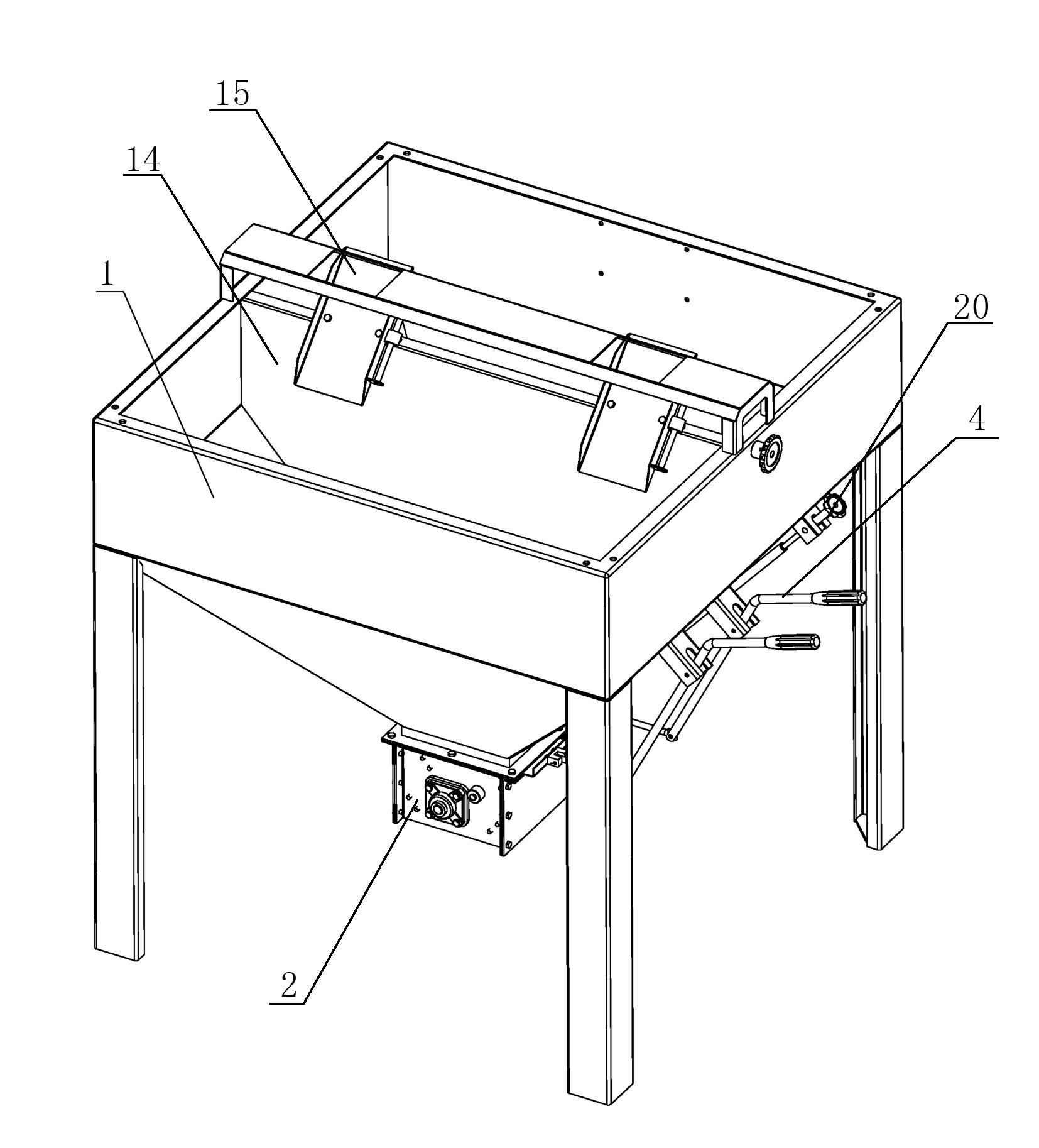

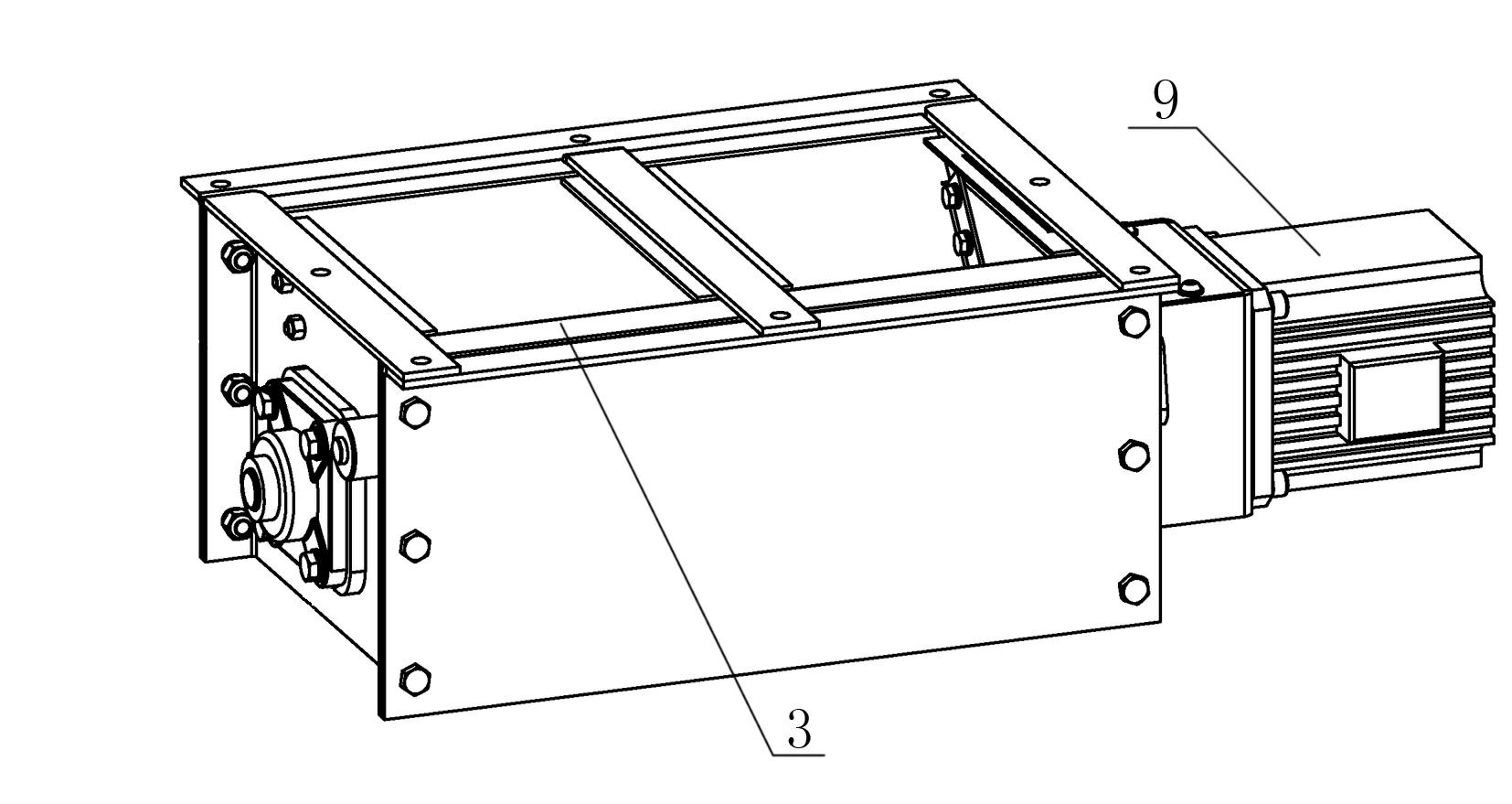

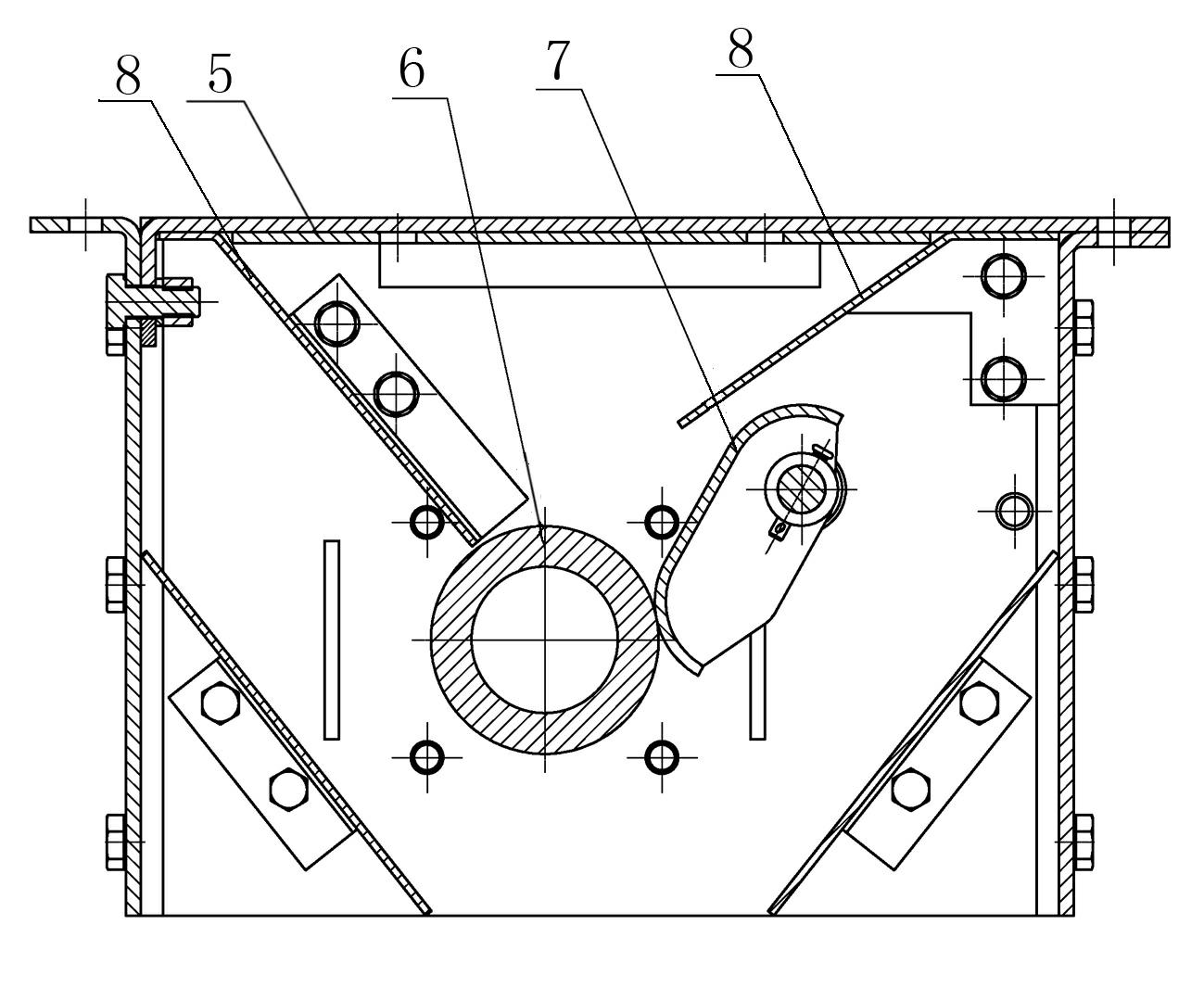

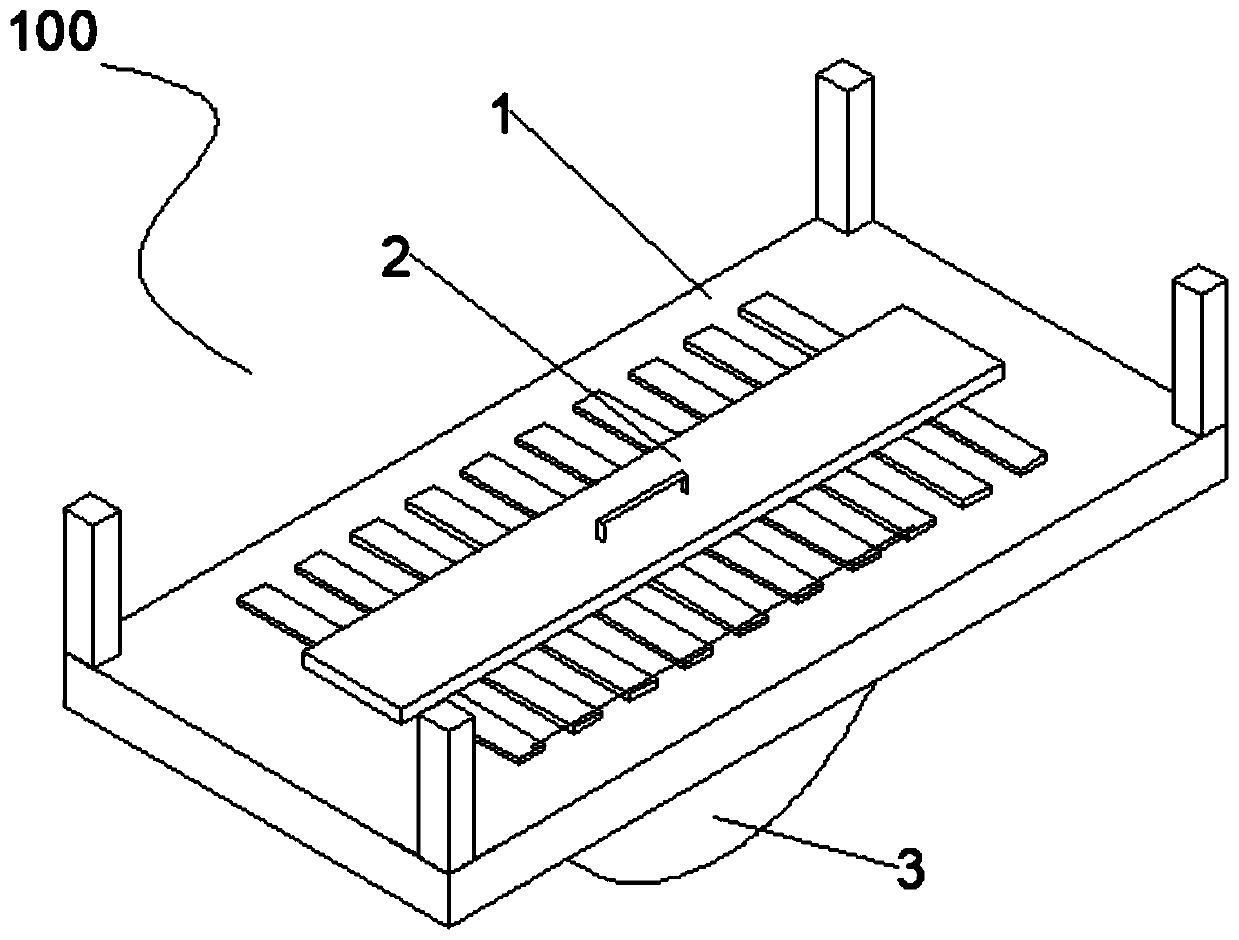

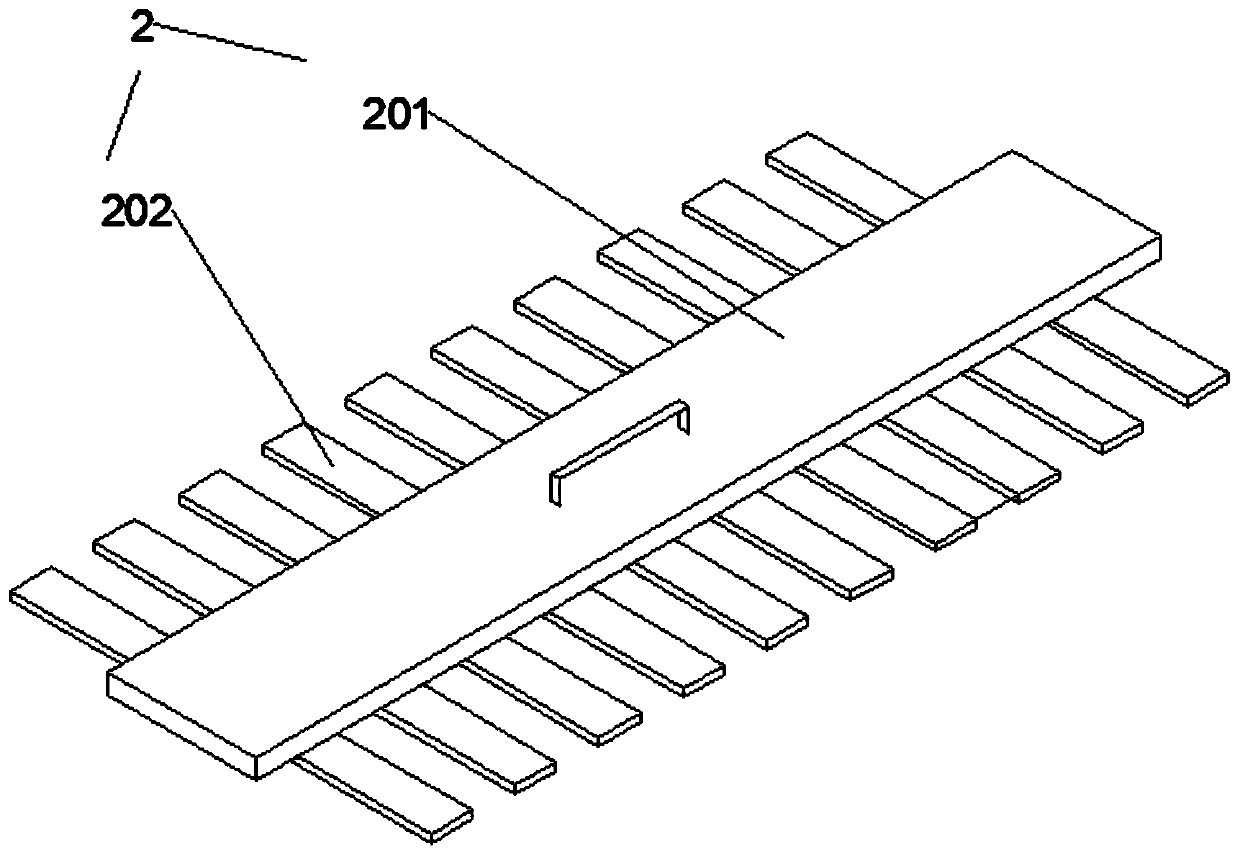

Oriented steel fiber arrangement device and steel fiber concrete manufacturing method

ActiveCN110216776AUniform orientationImprove tensile propertiesCeramic shaping apparatusSurface layerSuction stress

The invention discloses an oriented steel fiber arrangement device and a steel fiber concrete manufacturing method. An air blower, an adsorption switch, a tight adsorbing switch, an air pipe, a steelfiber adsorption disc, adsorption needles and an oriented magnetic field belt are included. The air blower is utilized for driving gas to generate attraction force, the gas pipe is used for transmitting the attraction force to the adsorption needles of the steel fiber adsorption disc, after the adsorption needles tightly absorb fiber, the fiber tends to be arranged in the same direction under theaction of magnetic force of the oriented magnetic field belt, the tight adsorbing switch is turned on, it is guaranteed that the steel fiber and the adsorption needles are fixed, then, the steel fiberarranged in the oriented manner is placed in a layer-by-layer poured concrete surface layer, and steel fiber concrete in which the steel fiber is arranged in the oriented manner is formed. The oriented steel fiber arrangement device and the steel fiber concrete manufacturing method have a series of preparing advantages that operation is simple, and steel fiber arrangement is uniform, and the oriented steel fiber arrangement device and the steel fiber concrete manufacturing method are suitable for manufacturing of the steel fiber concrete in which the steel fiber is arranged in the oriented manner.

Owner:HOHAI UNIV

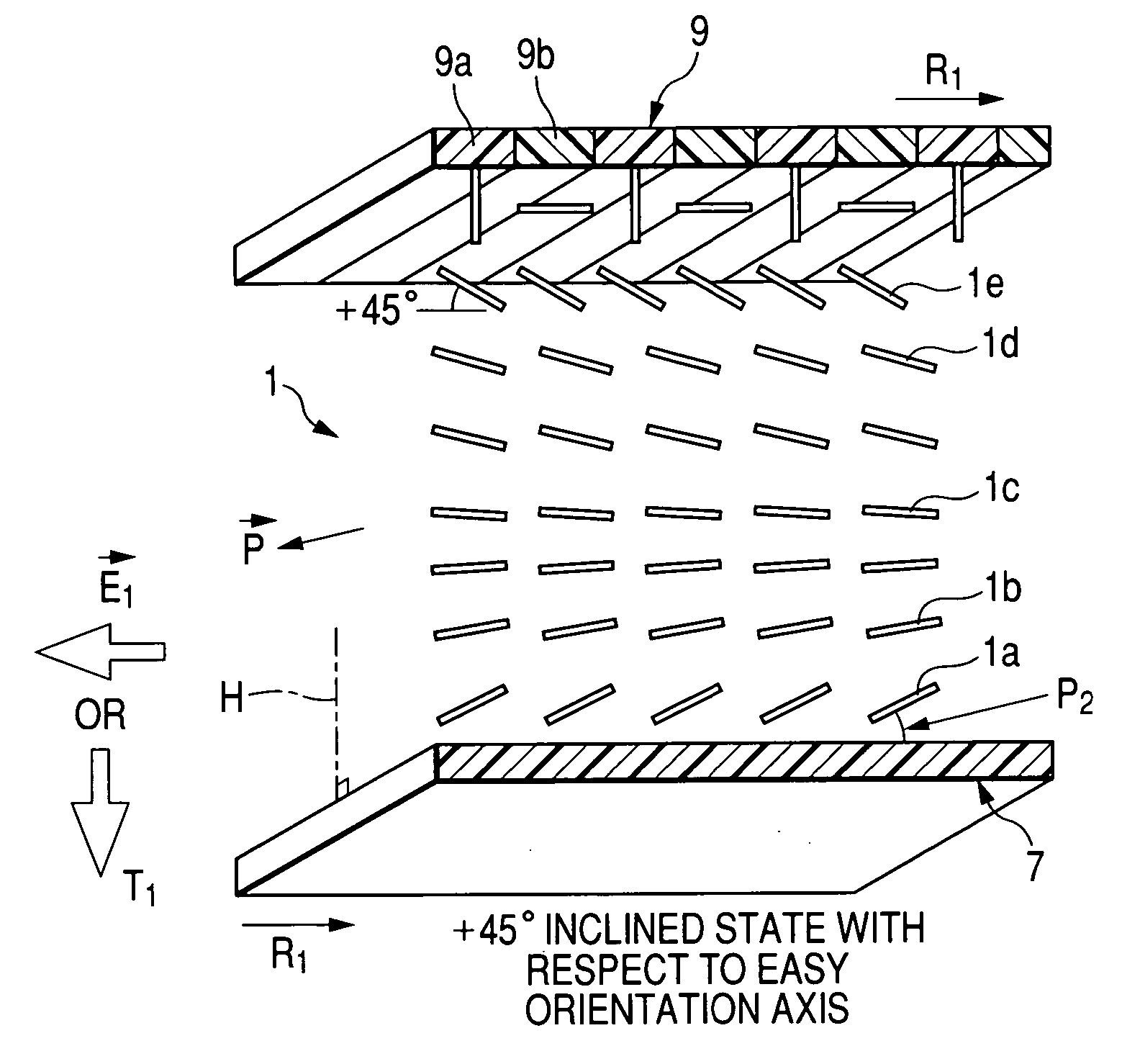

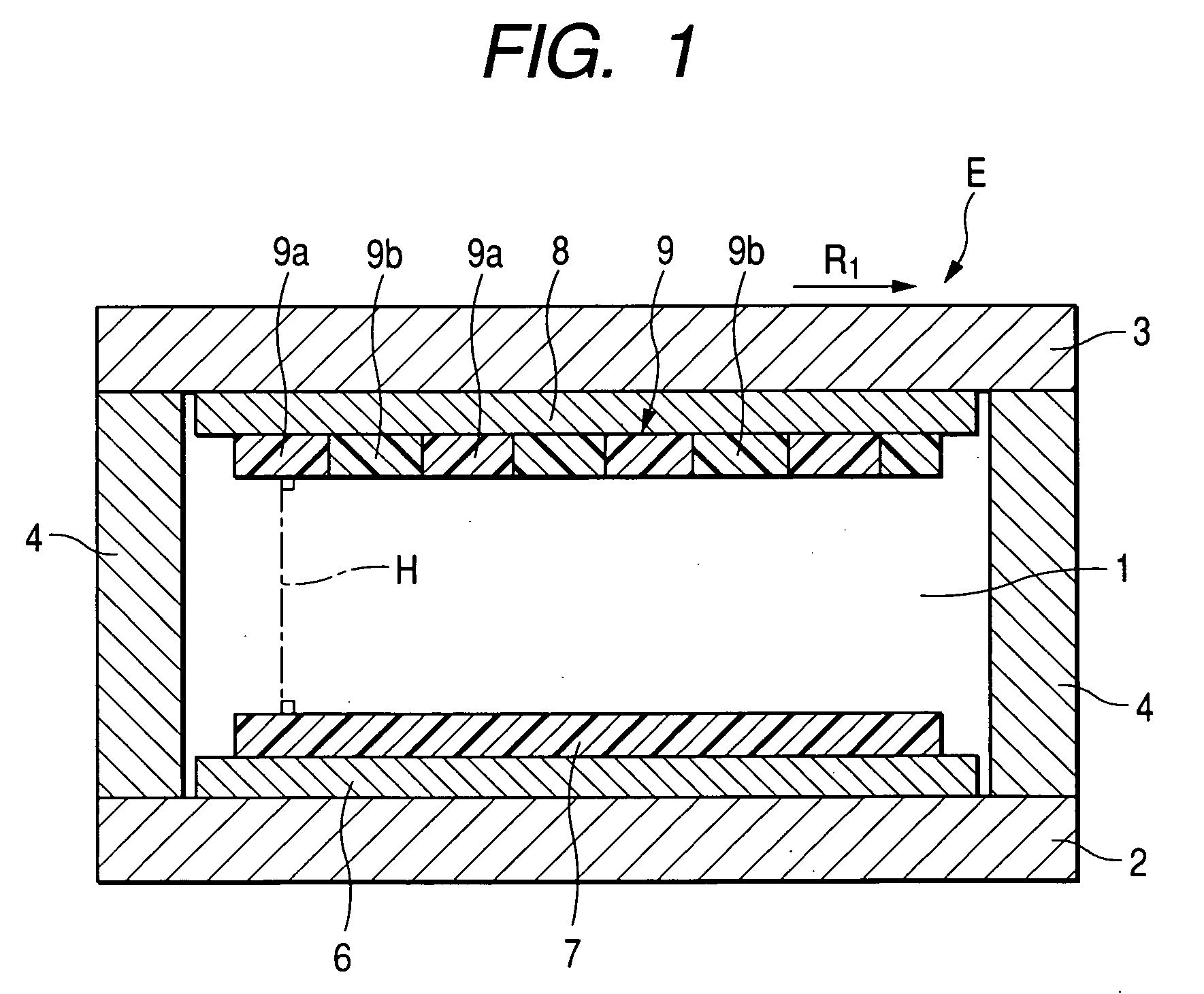

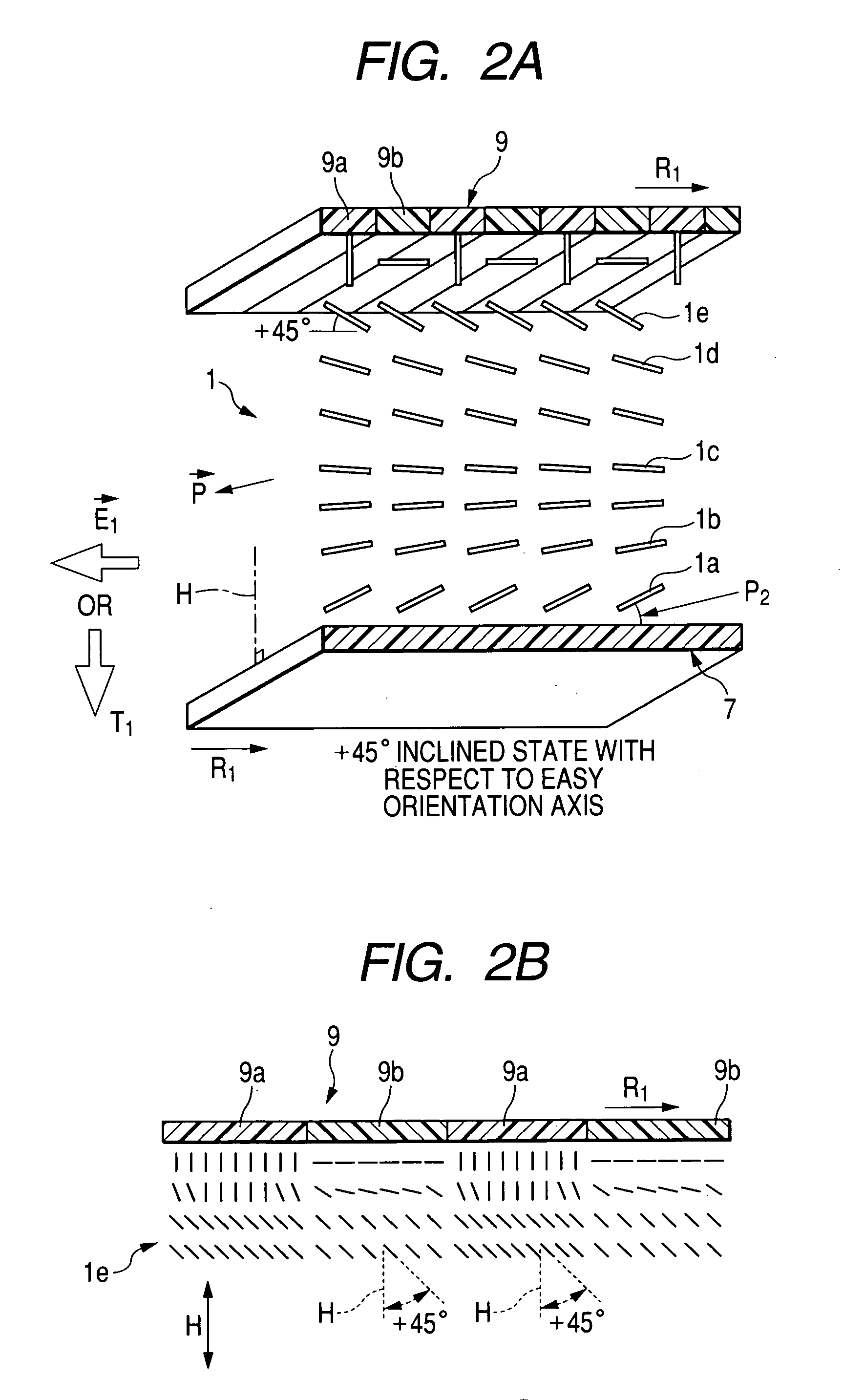

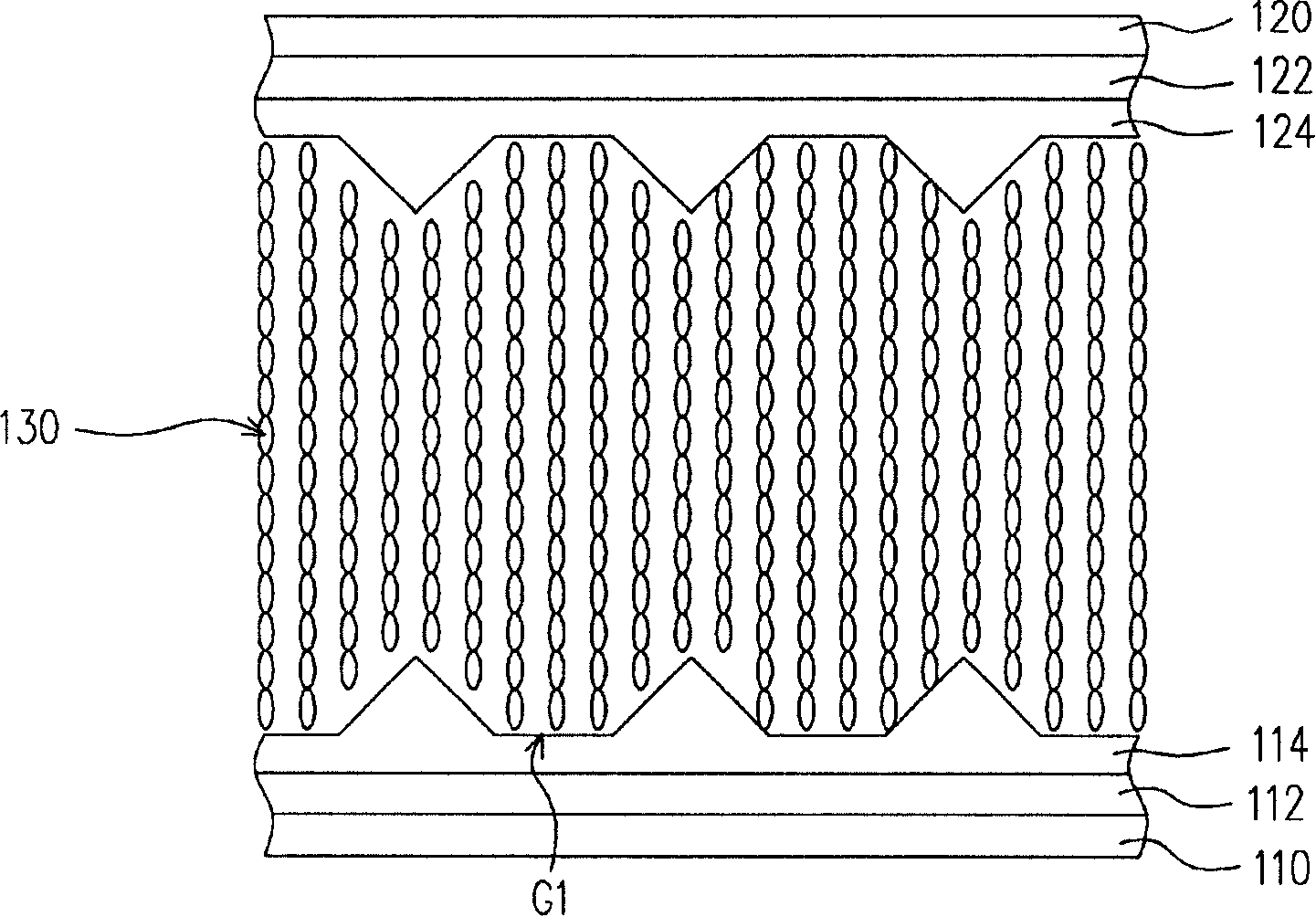

Bistable liquid crystal display device

InactiveUS20050270463A1Easy to manufactureBistability to be revealedStatic indicating devicesNon-linear opticsHorizontal orientationSteady state

A bistable liquid crystal display device includes nematic liquid crystal that is interposed between a pair of substrates, an orientation film that is subjected to a uniform inclined orientation treatment and an electrode, on one of the substrates, and an orientation film that has alternately formed vertical and horizontal orientation regions and an electrode, on the other substrate. An angle of an easy orientation axis of liquid crystal molecules close to the other substrate is changed between an orientation state in which one end of the easy orientation axis of the liquid crystal molecules is inclined toward the one substrate with respect to a normal of the pair of substrates and an orientation state in which the one end is inclined toward the other substrate.

Owner:ALPS ALPINE CO LTD

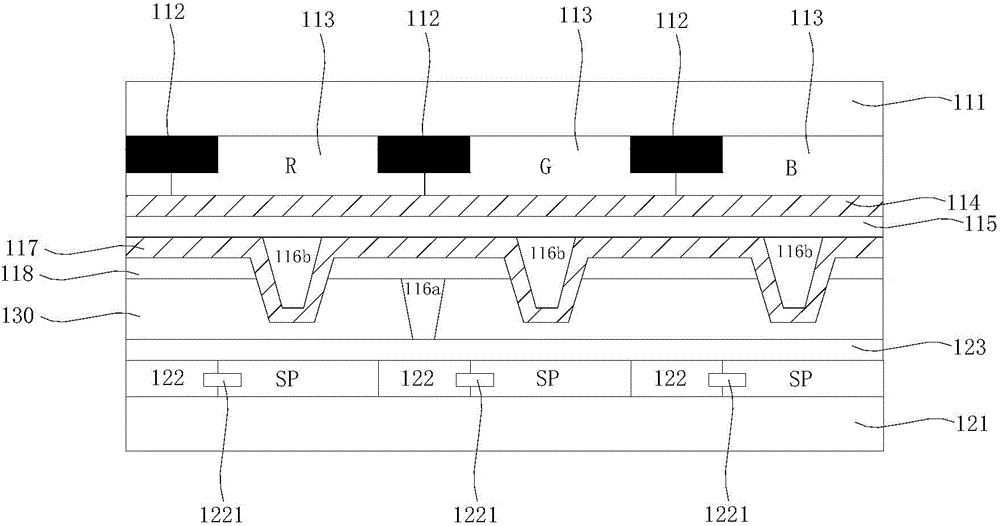

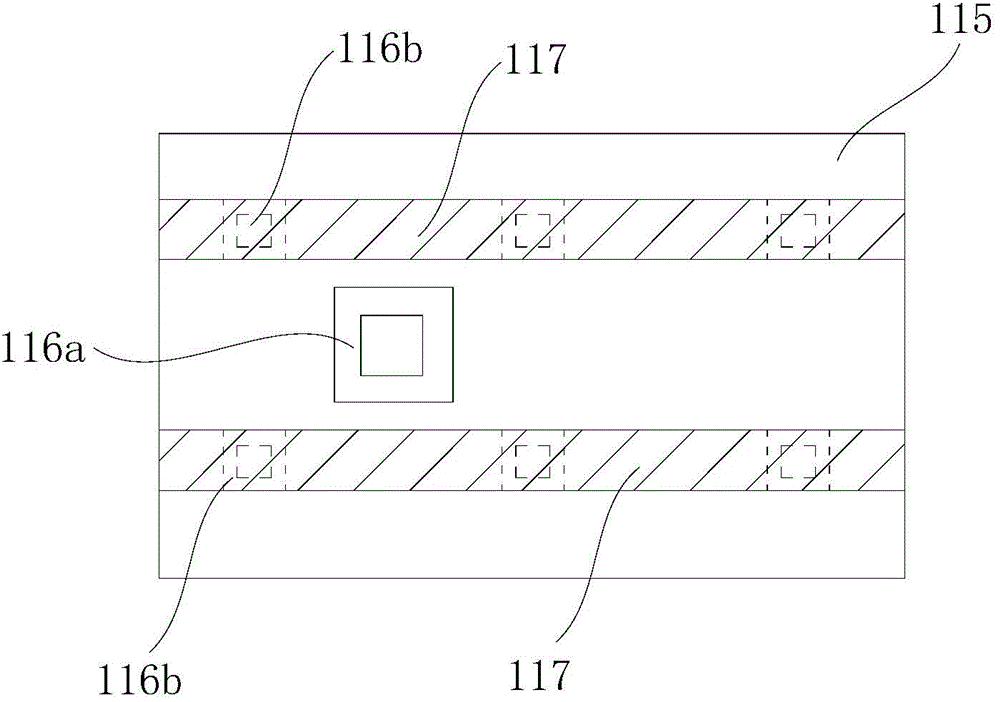

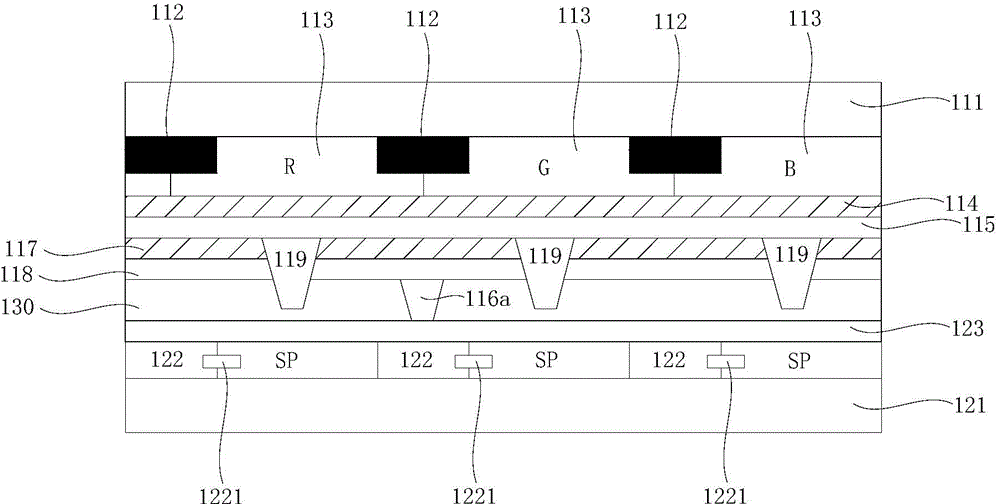

Liquid crystal display panel

ActiveCN104460142ASimplify the manufacturing processLow costNon-linear opticsEngineeringInsulation layer

The invention discloses a liquid crystal display panel. The liquid crystal display panel comprises a second substrate structure, and the second substrate structure at least comprises a plurality of subpixel areas. A first substrate structure at least comprises a first substrate (111), a public electrode layer (114), an insulation layer (115), a plurality of auxiliary isolators (116b), a first conductive film layer (117) and a first alignment film layer (118), wherein the public electrode layer (114), the insulation layer (115) and the auxiliary isolators (116b) are sequentially arranged on the first substrate (111), the auxiliary isolators (116b) are arranged above the corresponding subpixel areas and spaced from the second substrate structure, the first conductive film layer (117) is arranged on the insulation layer (115) and covers the auxiliary isolators (116b), the first alignment film layer (118) covers the insulation layer (115) outside the coverage of the first conductive film layer (117) and the first conductive film layer (117) except the auxiliary isolators (116b). By the aid of the isolators, liquid crystal molecules are uniformly aligned, manufacturing process is simplified and cost is saved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

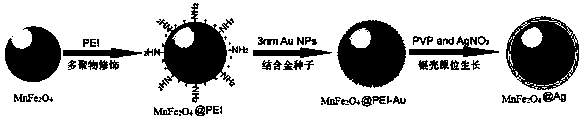

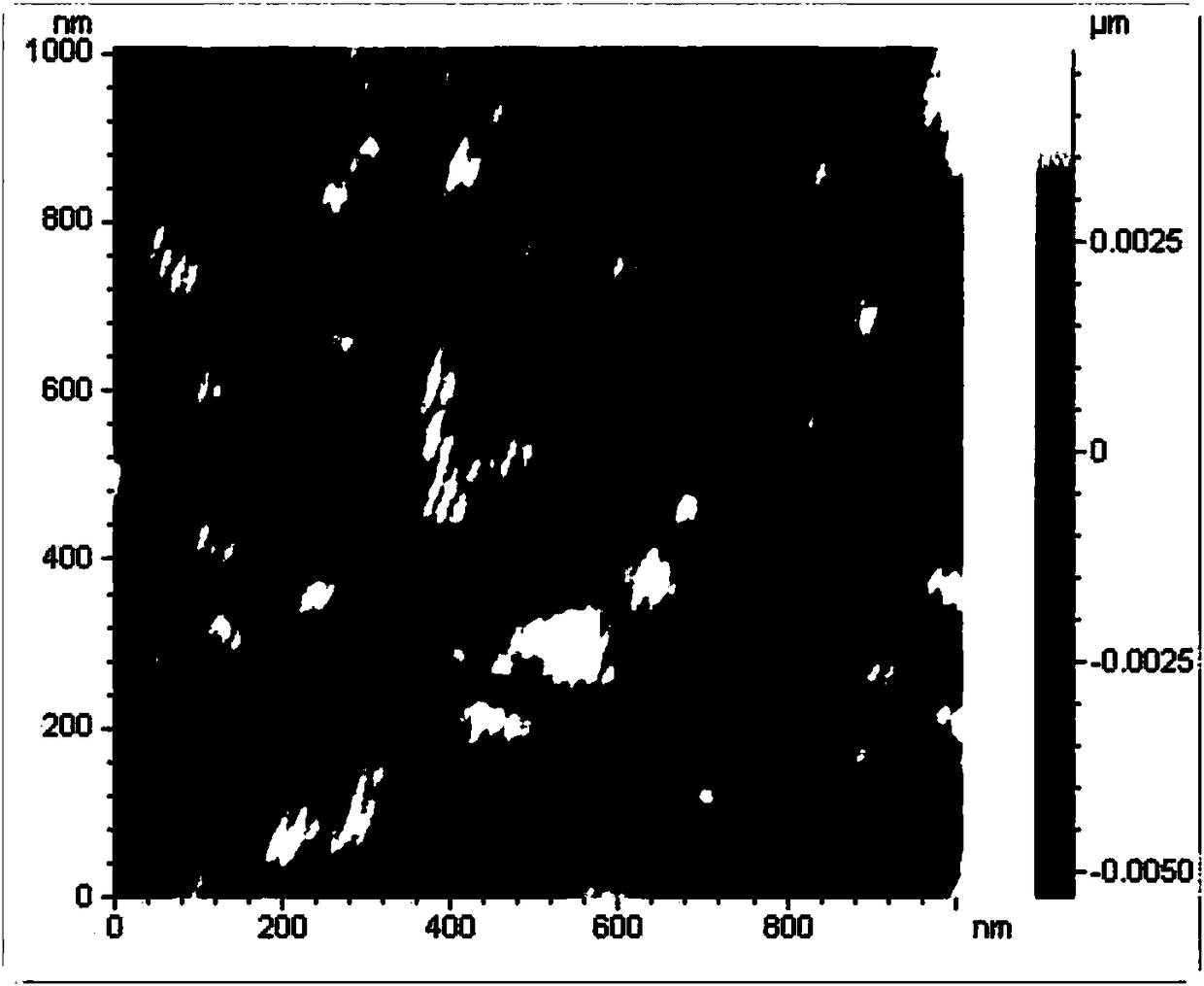

Surface enhanced raman scattering substrate and preparation method thereof

InactiveCN108956579AUniform OrientationStrong process controllabilityRaman scatteringDepth directionControllability

The invention discloses a surface enhanced raman scattering substrate and a preparation method thereof. The preparation method comprises the following steps: preparing metal magnetic balls, each of which comprises a magnetic ball core and a noble metal shell layer coated on the outer surface of the magnetic ball core; preparing a plurality of limited range pits distributed in array on a preparation zone of a substrate main body; adding a magnetic field to the exterior of the substrate main body, repeatedly vibrating the magnetic field, thereby driving the metal magnetic balls on the surface ofthe substrate main body with the limited range pits to enter into the limited range pits and forming at least one metal magnetic ball layer along the depth direction of the limited range pits, wherein each metal magnetic ball layer is composed of a plurality of metal magnetic balls uniformly and closely arrayed in the limited range pits, and the metal magnetic balls of each metal magnetic ball layer are arrayed in a crystal-oriented form and in a hexagonal structure. The scheme is capable of solving the problems of high cost, complex process or low controllability of the prior art, reducing the processing cost of the surface enhanced raman scattering substrate and increasing the controllability of substrate hotspot forming and the controllability of an assembling process.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of high-orientation conductive polymer film, prepared film and application thereof

ActiveCN103451698AUniform orientationGood orientationSolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePolymer thin films

The invention claims a preparation method of a high-orientation conductive polymer film. The method comprises the following steps: preparing a high-orientation polymer film by adopting a melt stretching method, then modifying the electrode for electrochemical polymerization by using the polymer film, and finally electrochemically polymerizing the conductive polymer monomer on the modified electrode to form the high-orientation conductive polymer film. The conductivity of the conductive polymer film is anisotropic, namely showing obviously different conductivity in the polymer orientation film direction vertical or parallel to the modified electrode. The conductive polymer film can be applied to the fields of light emitting diodes, solar batteries and filed effect transistors and the like.

Owner:BEIJING UNIV OF CHEM TECH

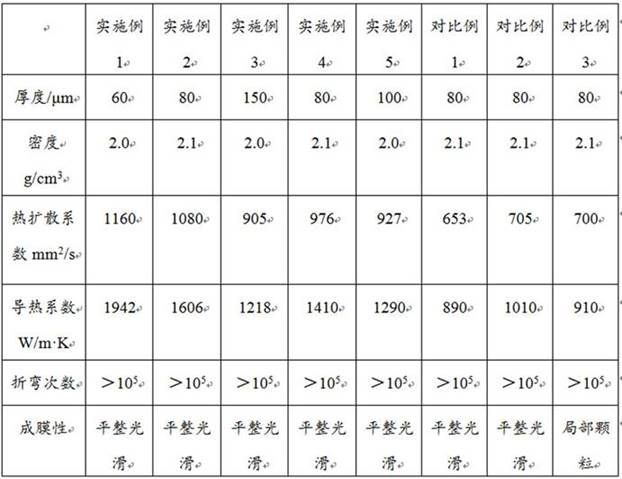

Preparation method of graphene heat-conducting film and product obtained by preparation method

ActiveCN111924830AEasy to filmGood film formingGrapheneModifications by conduction heat transferFoaming agentGraphite oxide

The invention discloses a preparation method of a graphene heat-conducting film and a product obtained by the preparation method, and belongs to the technical field of heat conduction devices. The preparation method comprises the following steps: 1) mixing an aqueous solution of graphene oxide with a foaming agent, and sequentially carrying out vacuum defoaming and filtering on the obtained mixedsolution to obtain a graphene oxide dispersion liquid, 2) coating and drying the graphene oxide dispersion liquid to obtain a dried graphene oxide film, 3) foaming the dried graphene oxide film to obtain a foamed graphene oxide film, and 4) putting the graphene oxide film into a graphite flake interlayer, and sequentially carrying out high-temperature treatment, vacuumizing treatment, air replacement treatment and hot-pressing treatment to obtain the graphene heat-conducting film. The heat-conducting film prepared by the preparation method of the graphene heat-conducting film provided by the invention has good film-forming property, strong heat conductivity, low production cost and high production efficiency, and is convenient for large-scale production.

Owner:HAIKE GRP RES INST OF INNOVATION & TECH

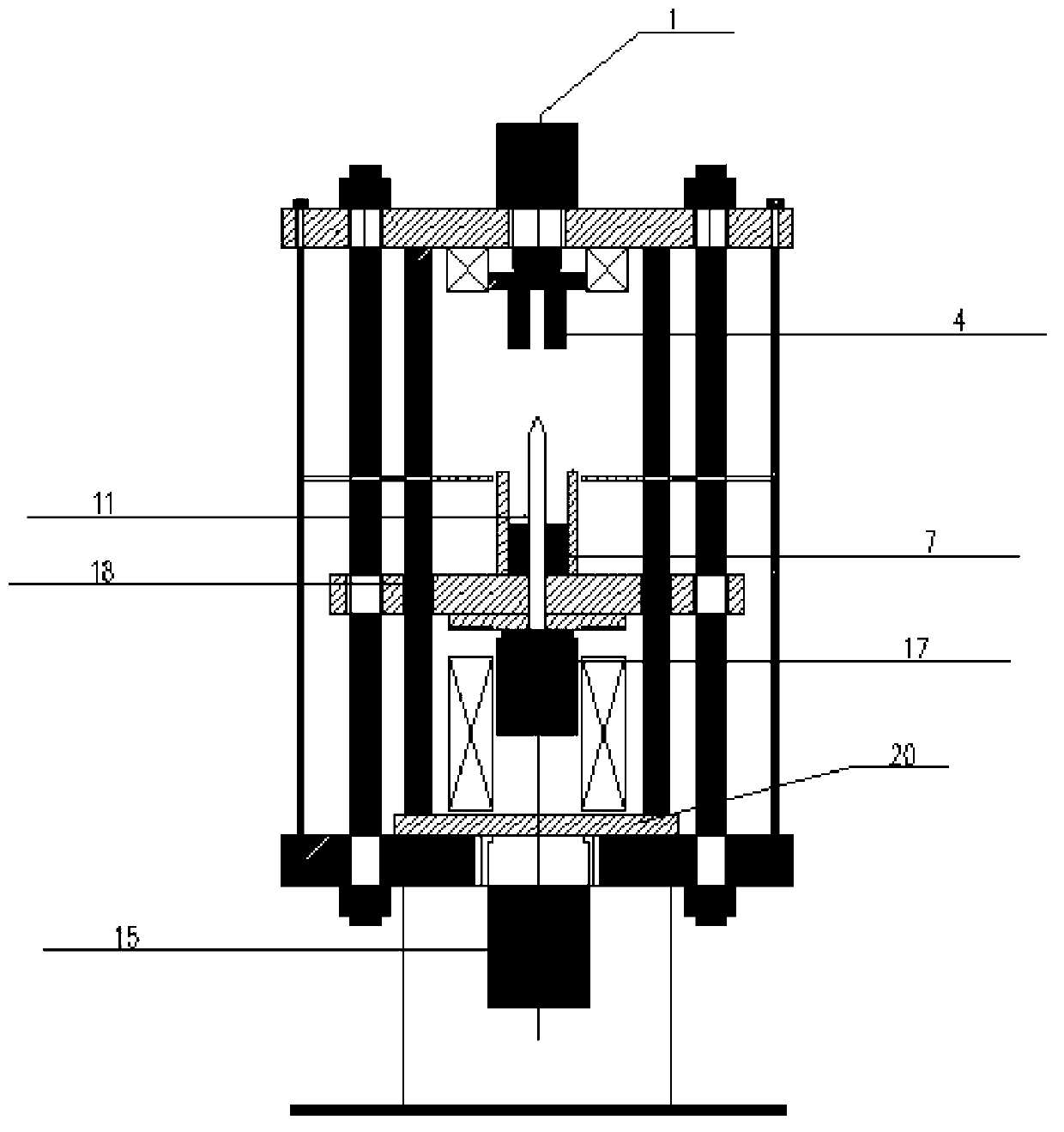

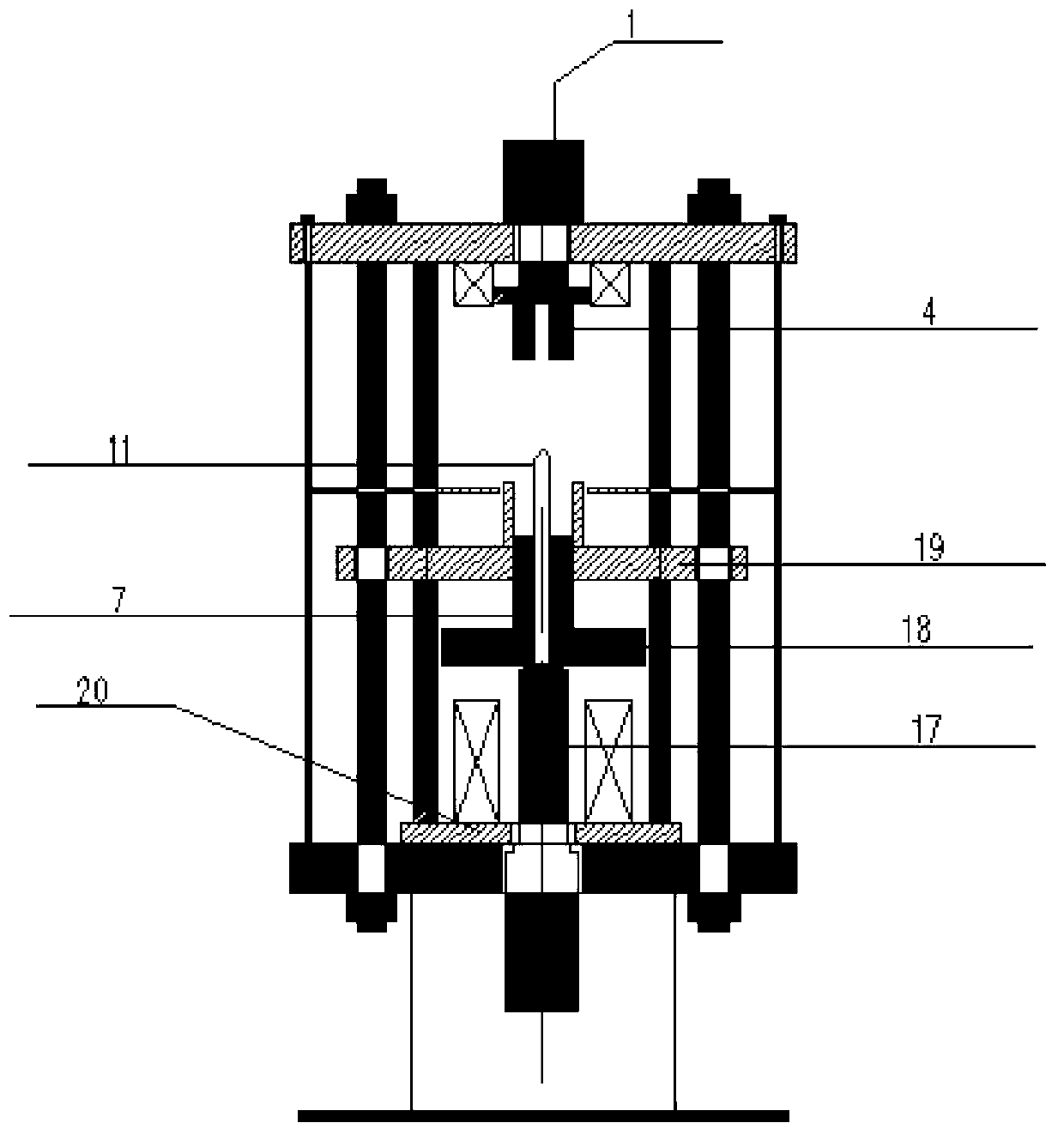

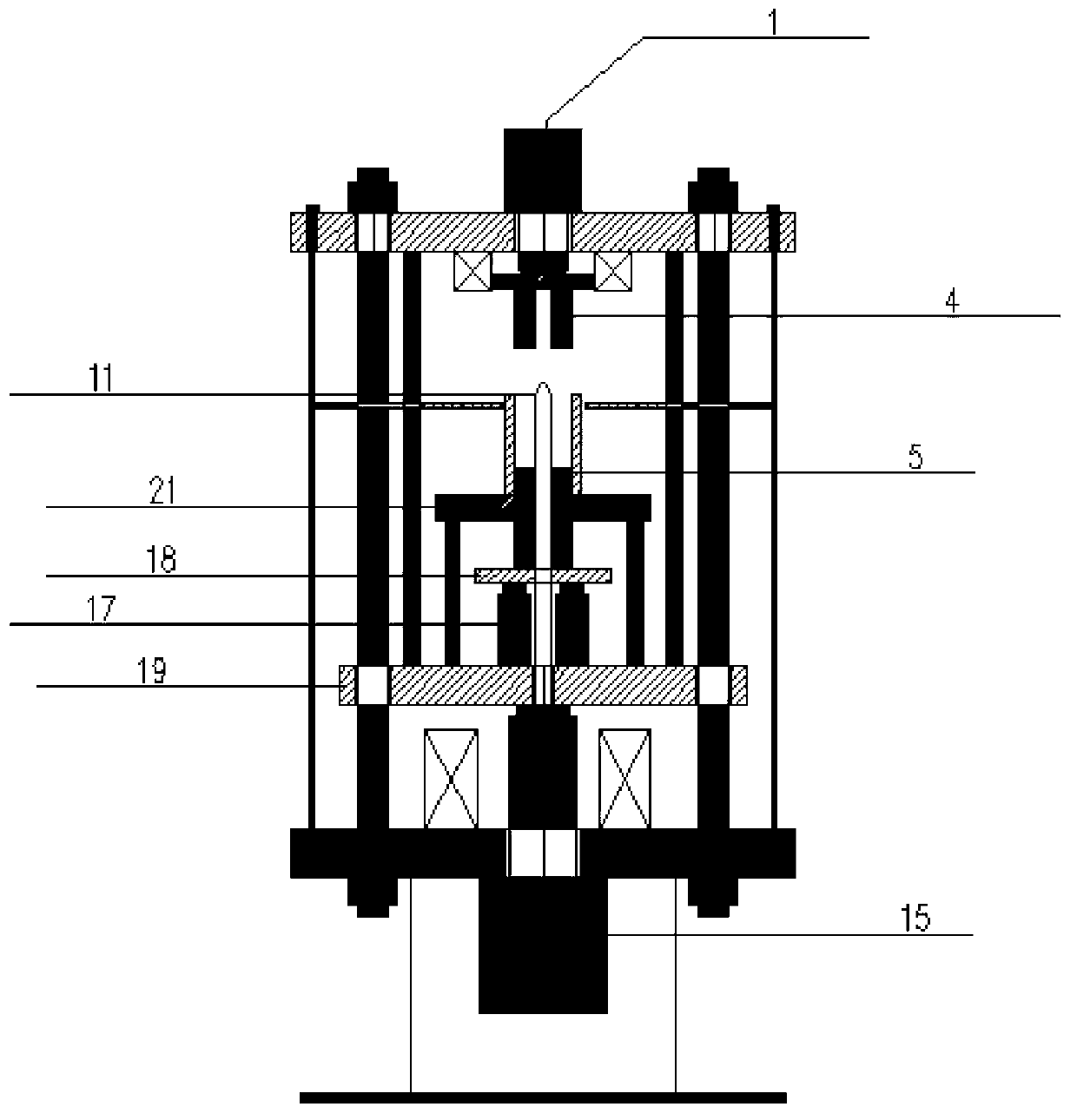

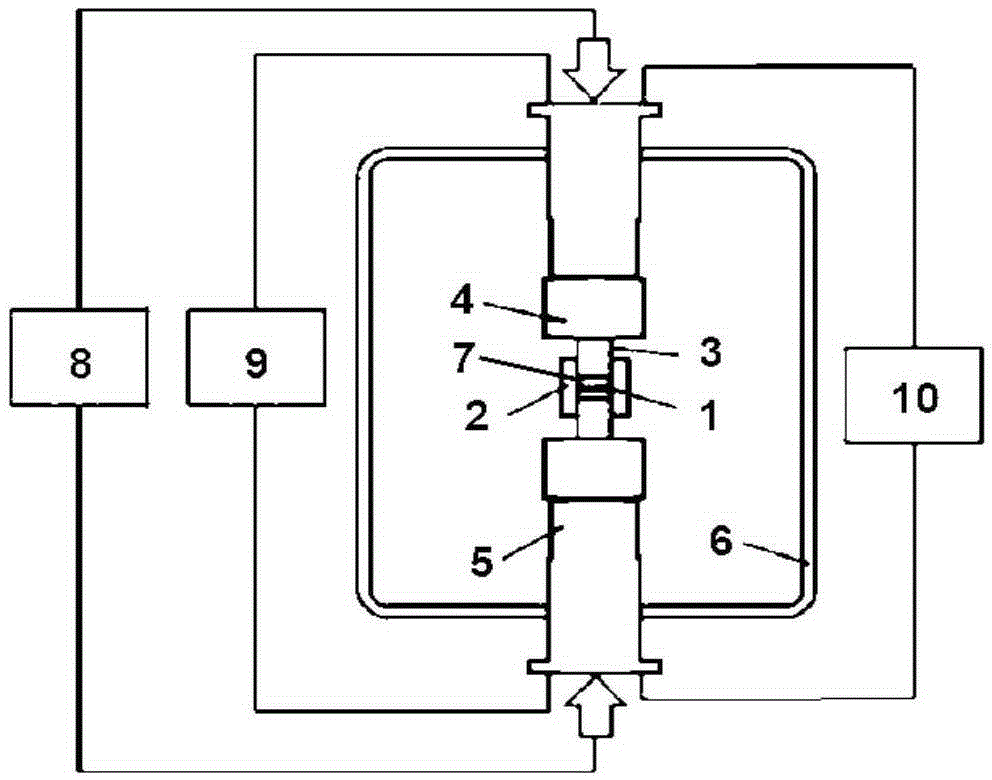

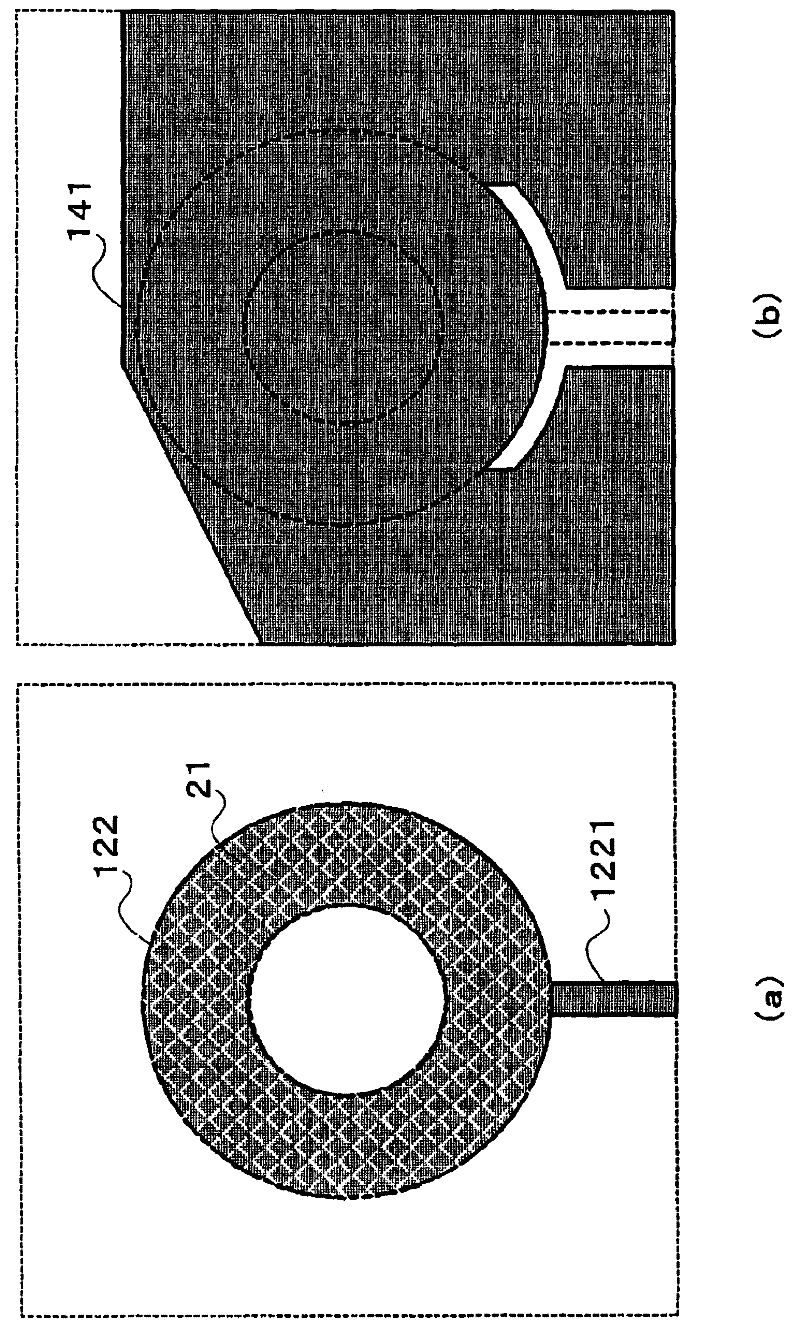

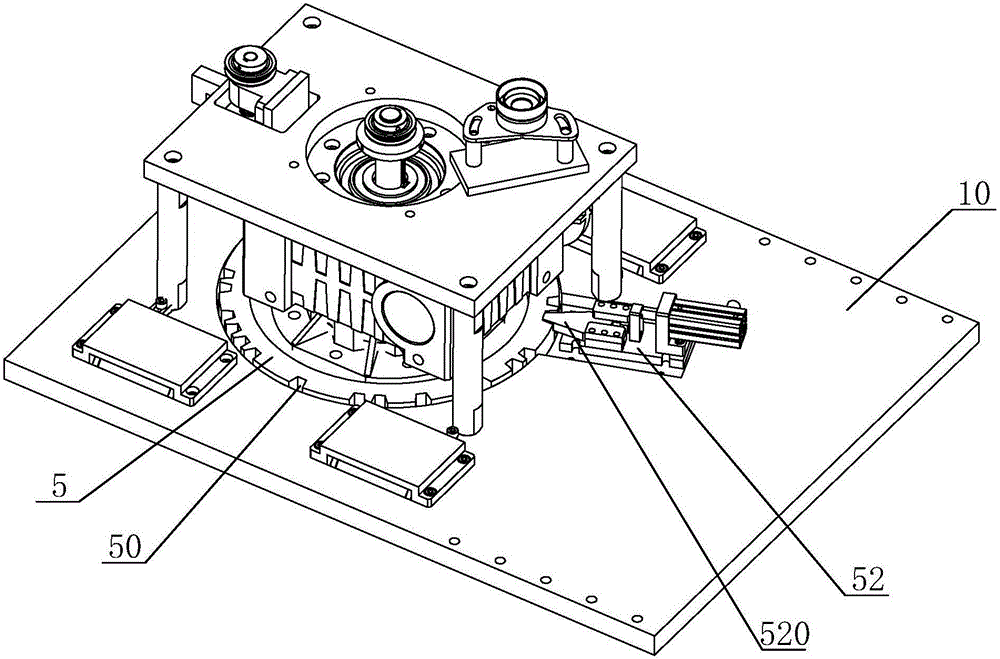

Preparation device for radial orientation permanent magnet ring

ActiveCN103123863AGood orientationFully orientedPermanent magnetsInductances/transformers/magnets manufactureExcitation currentMagnetic poles

The invention relates to a preparation device for a radial orientation permanent magnet ring. An outer magnetic pole is fixed on an outer magnetic pole connection support, and the thickness of the outer magnetic pole is far smaller than the height of a mold cavity. When exciting current passes through a coil, a radial magnetic field is generated in a ranged space of the mold cavity between a core rod and the outer magnetic pole, powder materials in the mold cavity are pushed by an oil cylinder to move vertically in a reciprocating mode, and therefore the power materials sequentially and circularly pass through the plane where the outer magnetic pole is located when the powder materials are pressed. When all the power materials sequentially and repeatedly pass through the plane where the outer magnetic pole is located and are pressed, the powder materials in a whole mold can be fully and uniformly oriented, radial orientation uniformity of the radial permanent magnet ring is greatly improved, meanwhile, axial uniformity of orientation degrees can also be improved, and the advantage is obvious especially for high radial rings. Besides, according to the preparation device for the radial orientation permanent magnet ring, the methods of manual mold release and automatic mold release can be adopted, operation is flexile, and the qualification rate of the pressed radial rings is greatly improved.

Owner:ORIENT MAGNET TECH OMT

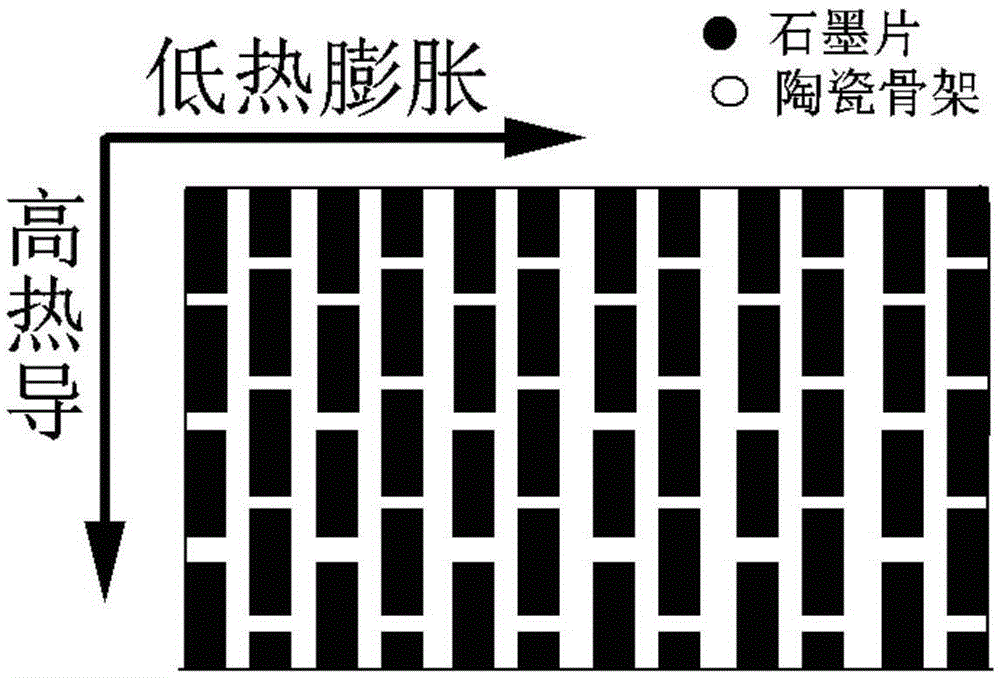

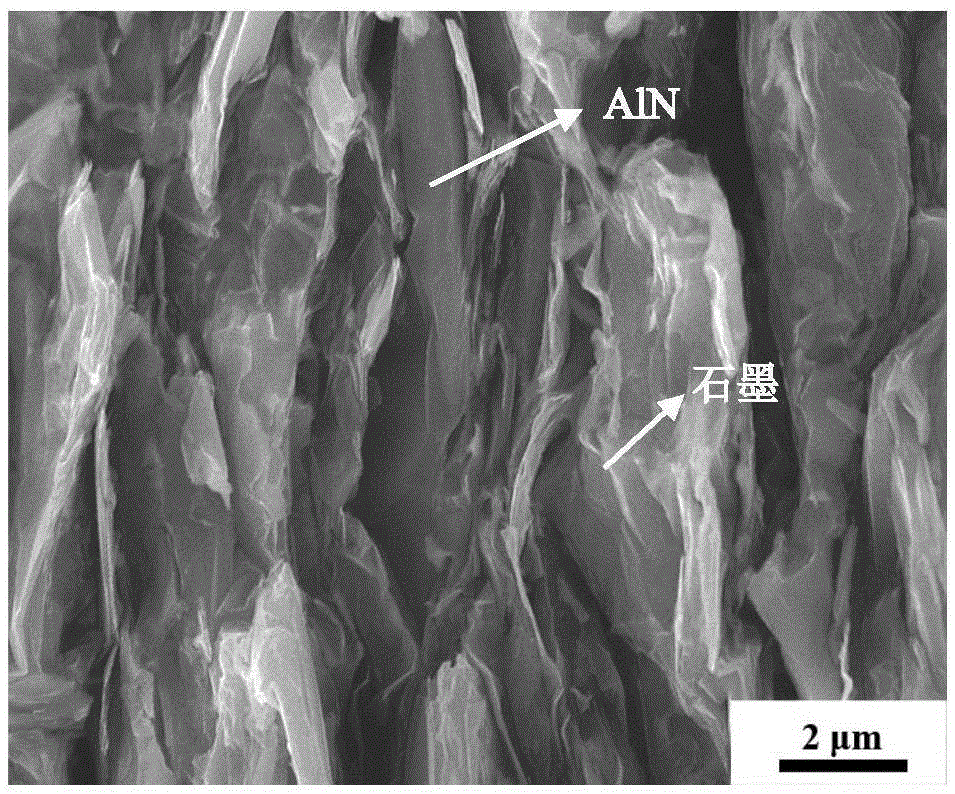

Aluminum nitride reinforced graphite-based composite material and preparation process thereof

ActiveCN105236982AHigh thermal conductivitySmall coefficient of thermal expansionAxial pressureNitrogen

The present invention discloses an aluminum nitride reinforced graphite-based composite material and a preparation process thereof. The aluminum nitride reinforced graphite-based composite material is characterized in that flake graphite is adopted as a substrate, and aluminum nitride is adopted as a reinforcing phase and is uniformly distributed between the graphite laminas so as to form a three-dimensional network nitrogen aluminum skeleton and directionally-arranged graphite lamina combined anisotropic structure. According to the process, flake graphite particles, aluminum nitride powder and an appropriate amount of a sintering aid are used, material mixing is performed through a ball mill, drying screening is performed, pre-pressing molding is performed, discharge plasma sintering is performed at a temperature of 1500-1700 DEG C, axial pressure is applied during the sintering process to make the graphite laminas be directionally arranged, and the three-dimensional network ceramic skeleton is formed after sintering the aluminum nitride powder, such that the strength of the graphite substrate can be significantly increased, and the thermal expansion of the graphite can be restrained so as to form the compact and uniform anisotropic composite material with characteristics of high thermal conductivity along the lamina direction and low thermal expansion along the vertical lamina direction, wherein the excellent comprehensive performance of the composite material has wide application prospects in the field of heat transfer, heat dissipating and the like of electronic devices.

Owner:咸阳瞪羚谷新材料科技有限公司

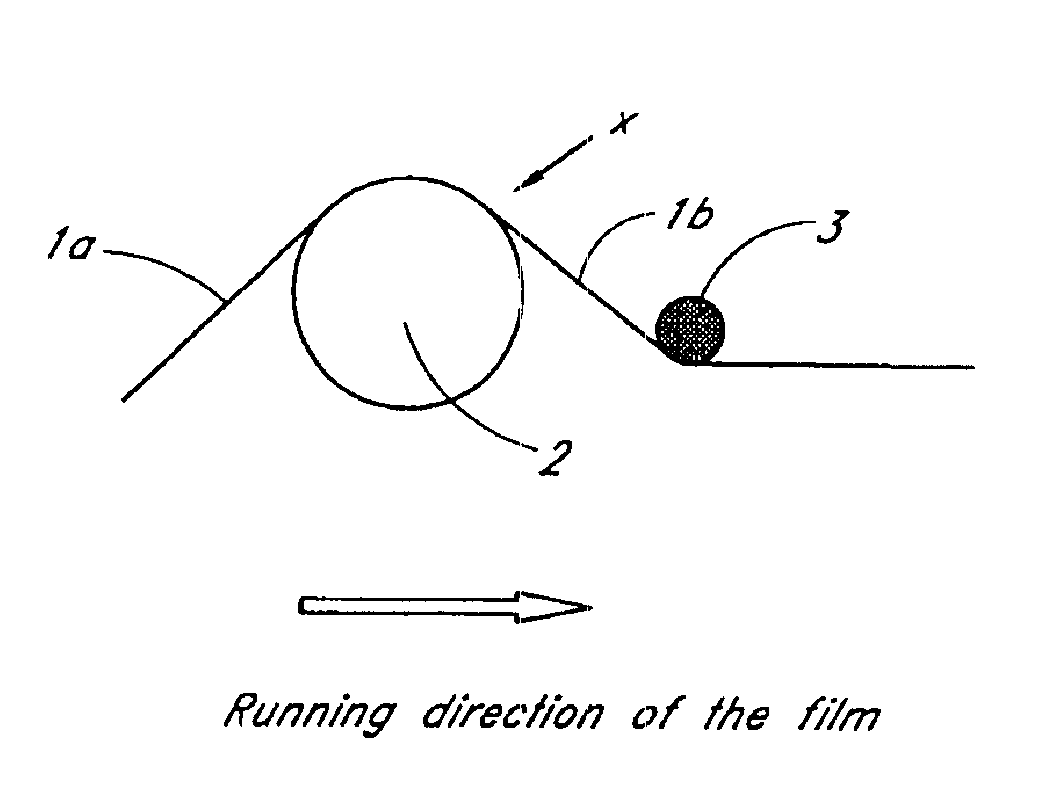

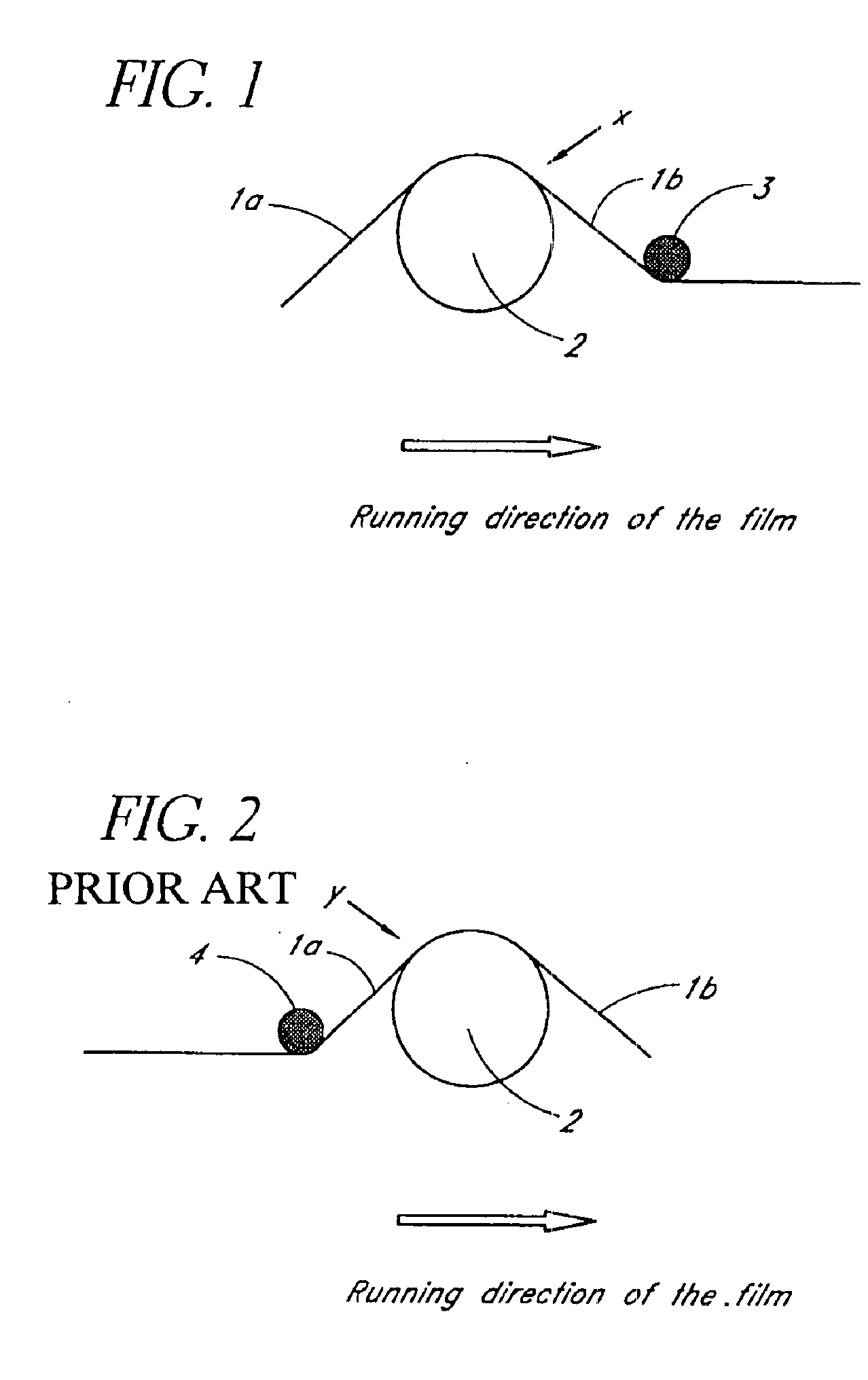

Manufacturing method for oriented film, polarizing film, polarizing plate, and visual display

InactiveUS6855276B2Reduce stretch irregularityUniform orientationMirrorsDiffusing elementsPolyvinyl alcoholMoisture

An oriented film of polyvinyl alcohol derived film with reduced stretch irregularity and uniform orientation in a wide range of a stretching ratio is obtained by a manufacturing method for an oriented film, comprising the steps of: contacting a non-stretched film, comprising polyvinyl alcohols or derivatives thereof, with moisture percentage adjusted to no more than 10%, to at least one heating roll currently driven and heating the film at no less than 70° C.; subsequently giving a tension and stretching using a peripheral velocity difference between the heating roll concerned and a stretch roll in a position ahead of said heating roll in a running direction of the film.

Owner:NITTO DENKO CORP

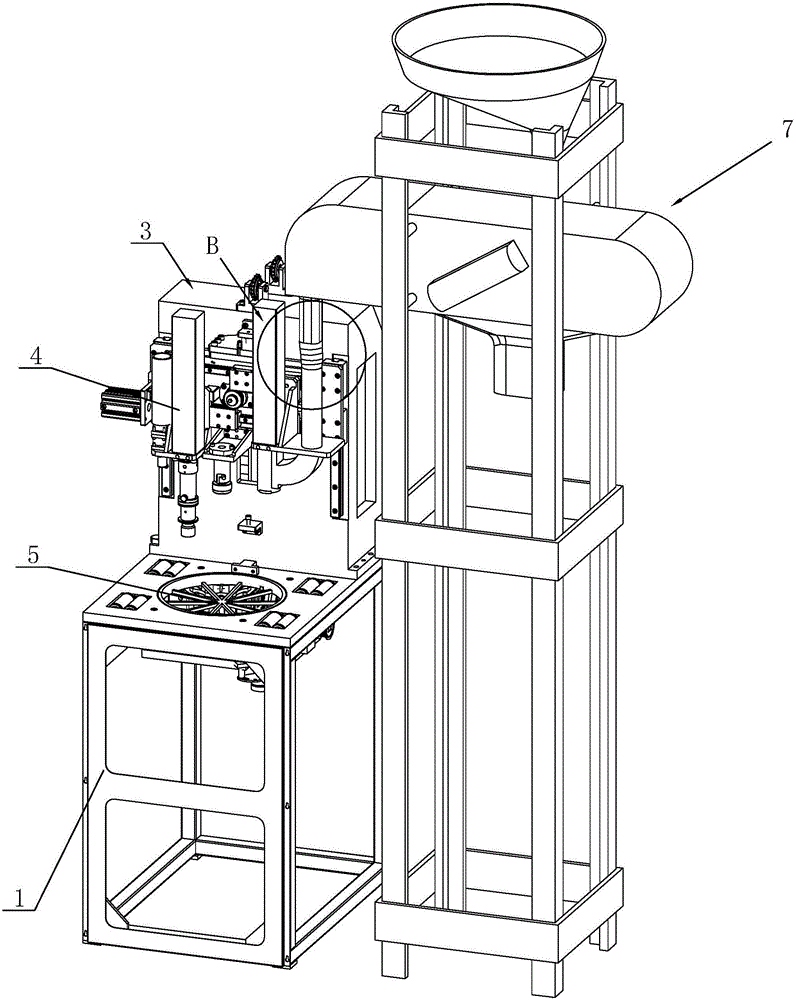

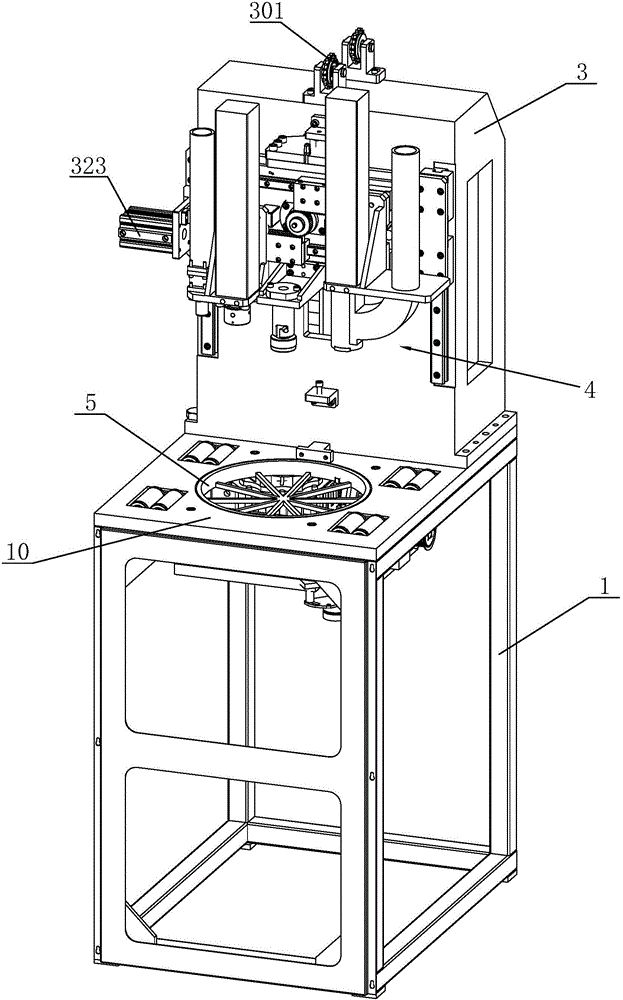

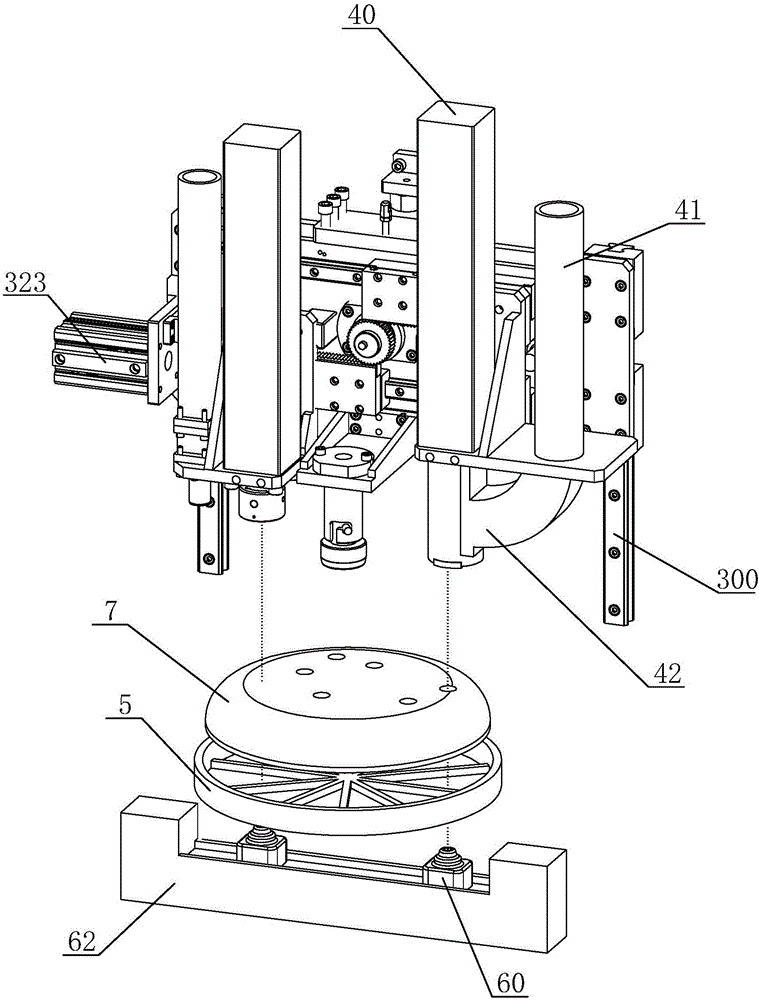

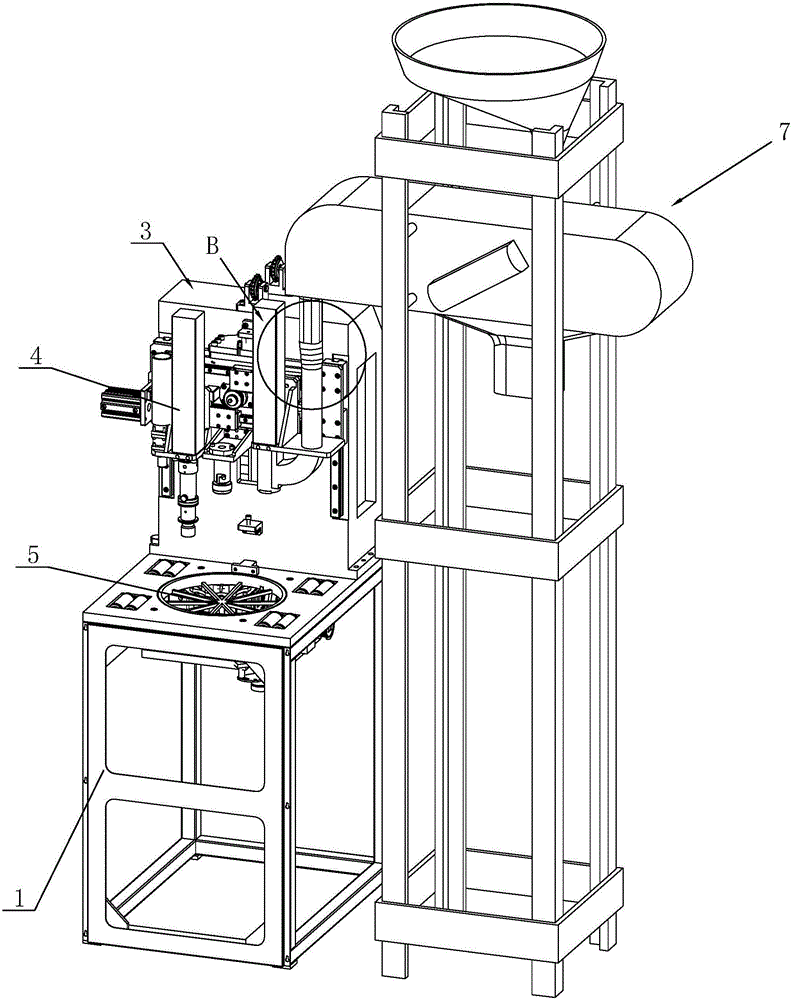

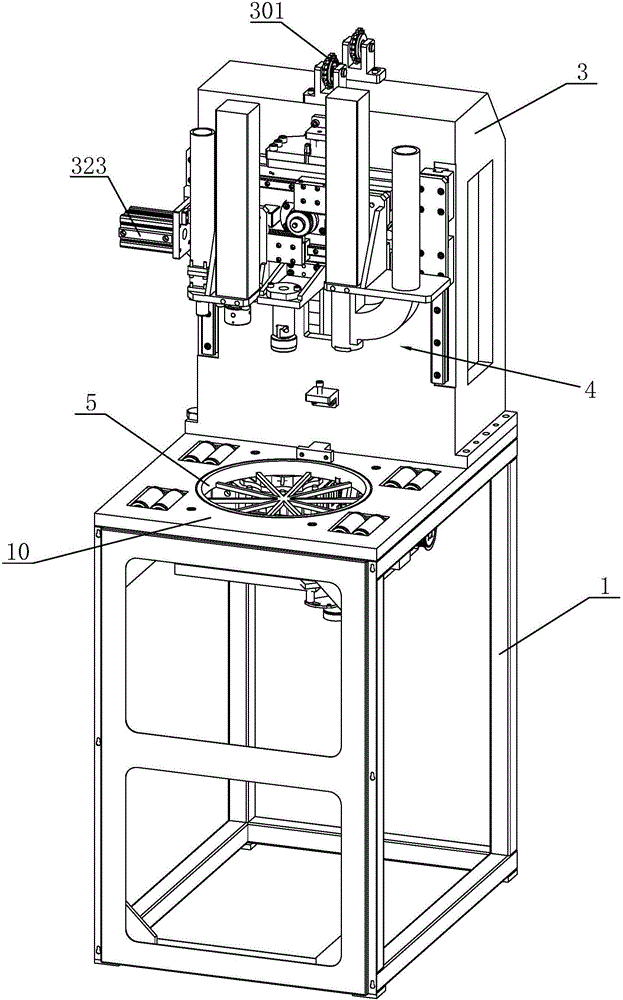

Bolt tightening machine capable of highly automatically searching, straightening and filling

ActiveCN105666114AHigh degree of automationImprove efficiencyMetal working apparatusEngineeringButt joint

The invention discloses a bolt tightening machine capable of highly automatically searching, straightening and filling. The bolt tightening machine comprises a bolt assembling device and a straightening device, wherein the straightening device can be used for straightening bolts and enabling arrangement directions to be uniform; the bolts are conveyed to a bolt assembling device for later use; a laser butt joint device of the bolt assembling device can be used for carrying out sweeping of vortexes on thread through holes in the surface of a carrier; and when the butt joint is succeeded, a tightening device is aligned to the thread holes in the carrier, and the screwing device is pressed down under the action of a longitudinal displacement mechanism to screw the bolts into the through holes. The straightening device disclosed by the invention can be used for unifying the arrangement directions of the bolts, and then the bolts are conveyed to the bolt assembling device for later use; and a screwing connector of the bolt assembling device can be used for automatically searching the thread through holes in the carrier and screwing the bolts into the through holes.

Owner:南通东环环境科技有限公司

Material dividing and feeding large hopper

InactiveCN102320434APrevent archingGuaranteed continuityLarge containersLoading/unloadingEngineeringMaterial storage

The invention relates to a material dividing and feeding large hopper, which consists of a hopper casing and a feeding material dividing device arranged in the hopper casing, wherein the feeding material dividing device consists of a feeding box and a pull plate type material door, the feeding box is provided with more than two cabin storage passages, the pull plate type material door is used for controlling the opening and closing of the cabin storage passages, and the upper end of the feeding box is provided with a referral plate for separating the cabin storage passages. The feeding box part of the material dividing and feeding large hopper adopts a feeding roller for feeding, and a circular arc groove is milled on the feeding roller, so the flow speed of the materials is stable and uniform, and in addition, the material blockage and the material arching can be prevented. The closing and the opening of different material storage spaces are controlled through the pull plate type material door, and the material flow speed is precisely controlled through combining a material pressing cutter and a fine adjusting device of the material pressing cutter. Therefore, the material discharge flow rate can be precisely controlled, and the material dividing and feeding large hopper can preferably adapt to the requirements of subsequent equipment.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

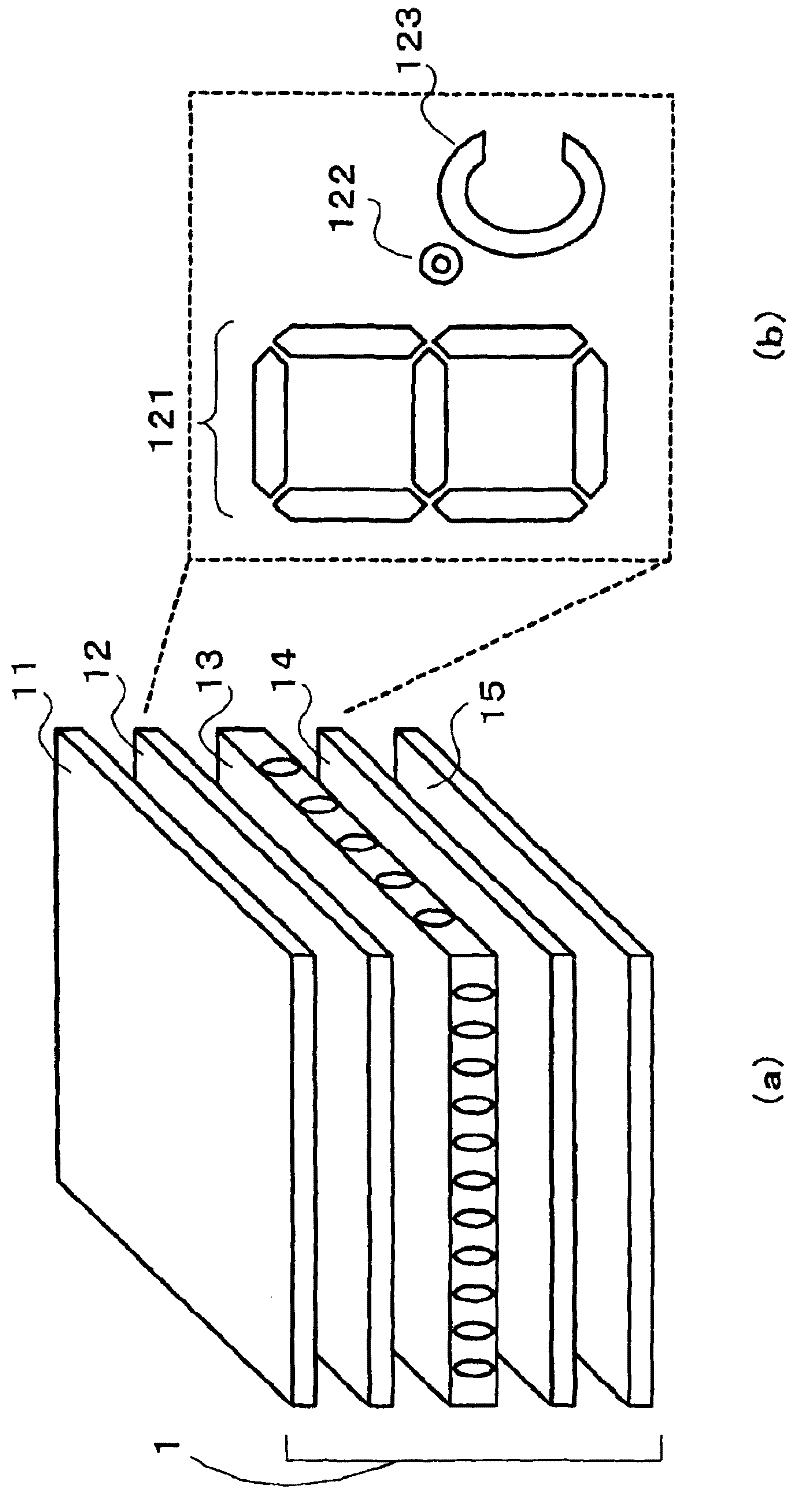

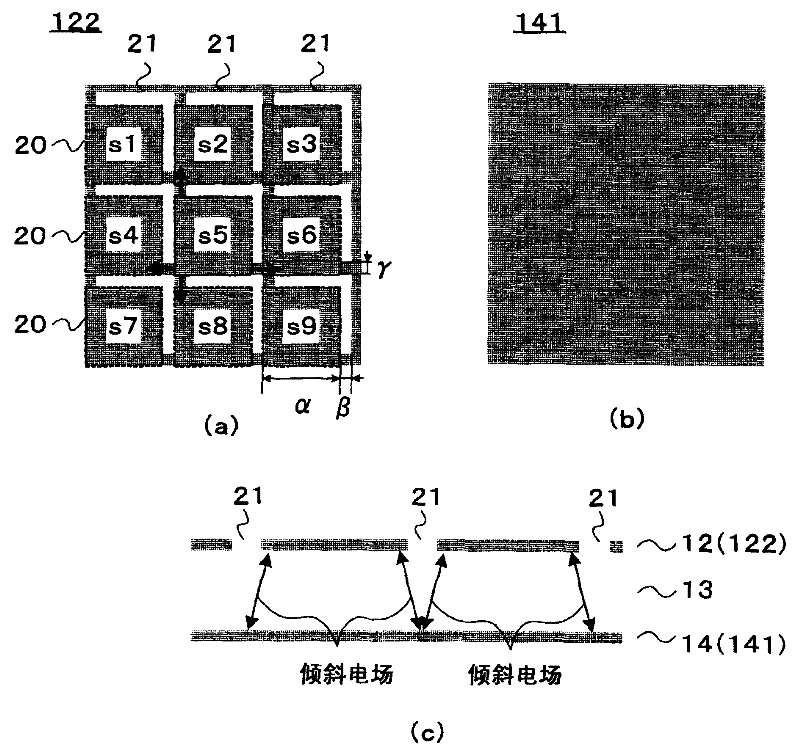

Liquid crystal display element

ActiveCN102411235AReduce orientation confusionUniform orientationNon-linear opticsVertical alignmentEngineering

The object is to make alignment of passive, vertically aligned liquid crystal displays more uniform by reducing alignment disorder when a voltage is applied and to improve the display quality. A liquid crystal display element comprises a first electrode (122) disposed to display a prescribed display pattern in a display area, a second electrode (141) opposed to the first electrode, and a liquid crystal layer provided between the first electrode and the second electrode and exhibiting vertical alignment of liquid crystal molecules in the voltage-off state, wherein either one of the first electrode and the second electrode is provided with a plurality of regularly disposed L-shaped slits (21), and the L-shaped slits (21) are formed so that at least within an area where the first electrode and the second electrode overlap each other, the electrode provided with the slits is divided into a plurality of rectangular electrode regions each having connection portions at three corners for connection to adjacent electrode regions.

Owner:KYOCERA CORP

Quick-melting and slow crystal growth high-efficiency polycrystalline silicon ingot casting process

InactiveCN103436956AImprove photoelectric conversion efficiencyQuality improvementPolycrystalline material growthSingle crystal growth detailsIngot castingShielding gas

The invention belongs to the field of polycrystalline silicon cast ingots and particularly relates to a quick-melting and slow crystal growth high-efficiency polycrystalline silicon ingot casting process. The quick-melting and slow crystal growth high-efficiency polycrystalline silicon ingot casting process comprises the steps of loading, vacuumizing and preheating, melting and preserving heat, growing the crystal, annealing, cooling and blocking, wherein the melting and heat preserving phase and the crystal growing phase are carried out according to the following steps: introducing argon gas into an ingot casting furnace to be used as shielding gas; then heating and raising temperature to enable the temperature of a quartz crucible to reach 1545-1560 DEG C within 4-5 hours, and preserving heat for 7-8 hours; reducing the temperature to 1440 DEG C after 0.5 hour; reducing the temperature of the quartz crucible from 1440 DEG C to 1420 DEG C through 29 hours and finishing the central crystal growing phase of the polycrystalline silicon cast ingot; reducing the temperature to 1410 DEG C after 3 hours to finish the corner crystal growing phase of the polycrystalline silicon cast ingot. The quick-melting and slow crystal growth high-efficiency polycrystalline silicon ingot casting process disclosed by the invention has the advantages that firstly, the photoelectric conversion efficiency of a solar cell can be improved from 17.1 percent to 17.4 percent; secondly, the time of the whole process is shortened while the quality of the polycrystalline silicon cast ingot is improved.

Owner:青岛隆盛晶硅科技有限公司

High automatic filling bolt screwing machine

ActiveCN105666112AQuick tightenHigh degree of automationMetal working apparatusEngineeringScrew thread

The invention discloses a high automatic filling bolt screwing machine. The high automatic filling bolt screwing machine comprises a bolt assembling device and a straightening device; the straightening device can be used for straightening the bolts so that the placing directions of the bolts are unified, the bolts are conveyed to the bolt assembling device for later use through a conveyor belt, the bolt assembling device is used for driving the rotation of an objective table and the movement of a horizontal displacement mechanism so as to position a plurality of threaded holes on a carrier, and enable the screwing device to align with the threaded holes on the carrier, the screwing device is pressed under the effect of a longitudinal displacement mechanism so as to screw the bolt in a through hole; the straightening device can unify the placing directions of the bolts, and then the bolts are conveyed to the bolt assembling device for later use, a screwing joint of the bolt screwing device can orderly search out the threaded through hole on the carrier according to the program, and then screw the bolt into the hole.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

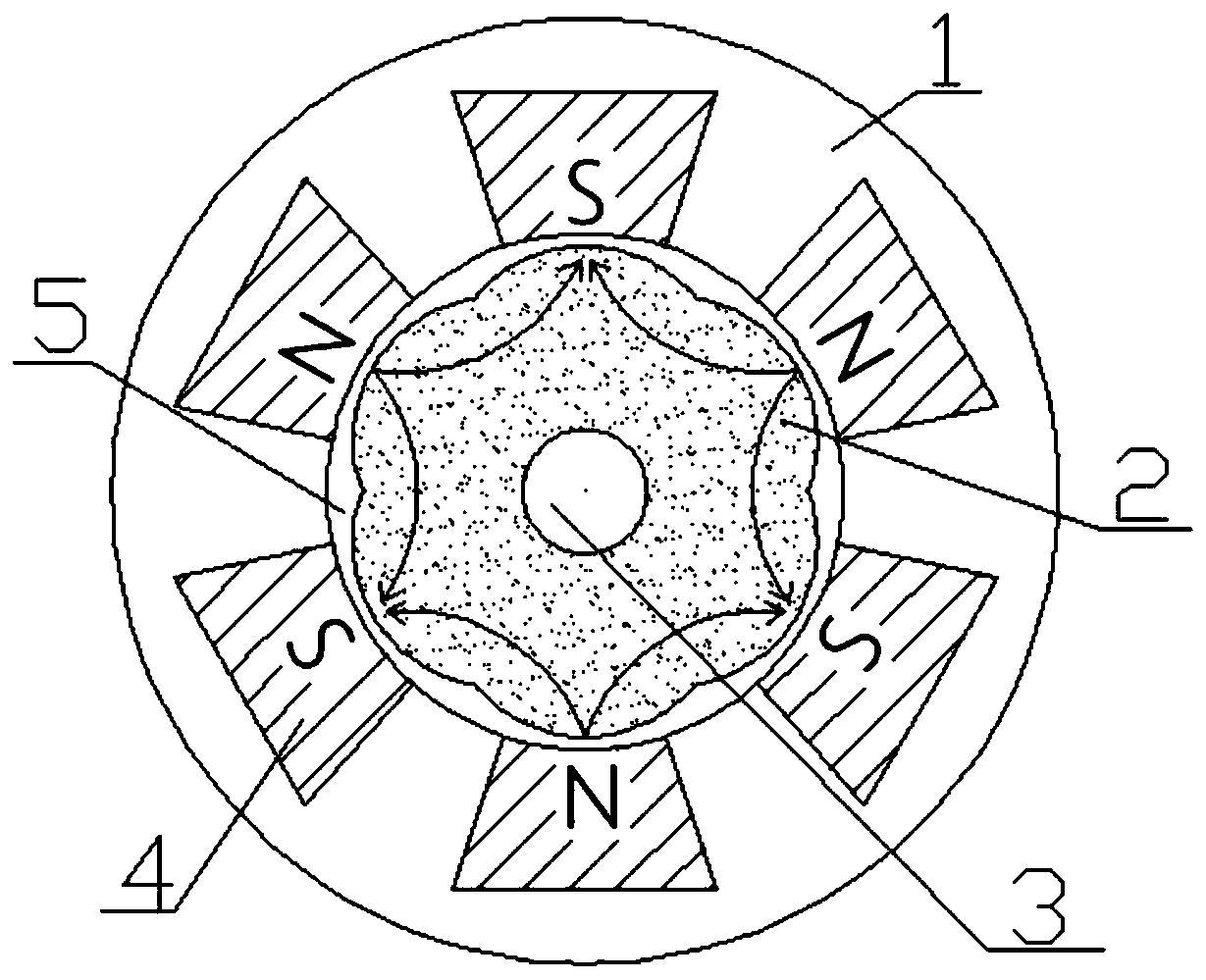

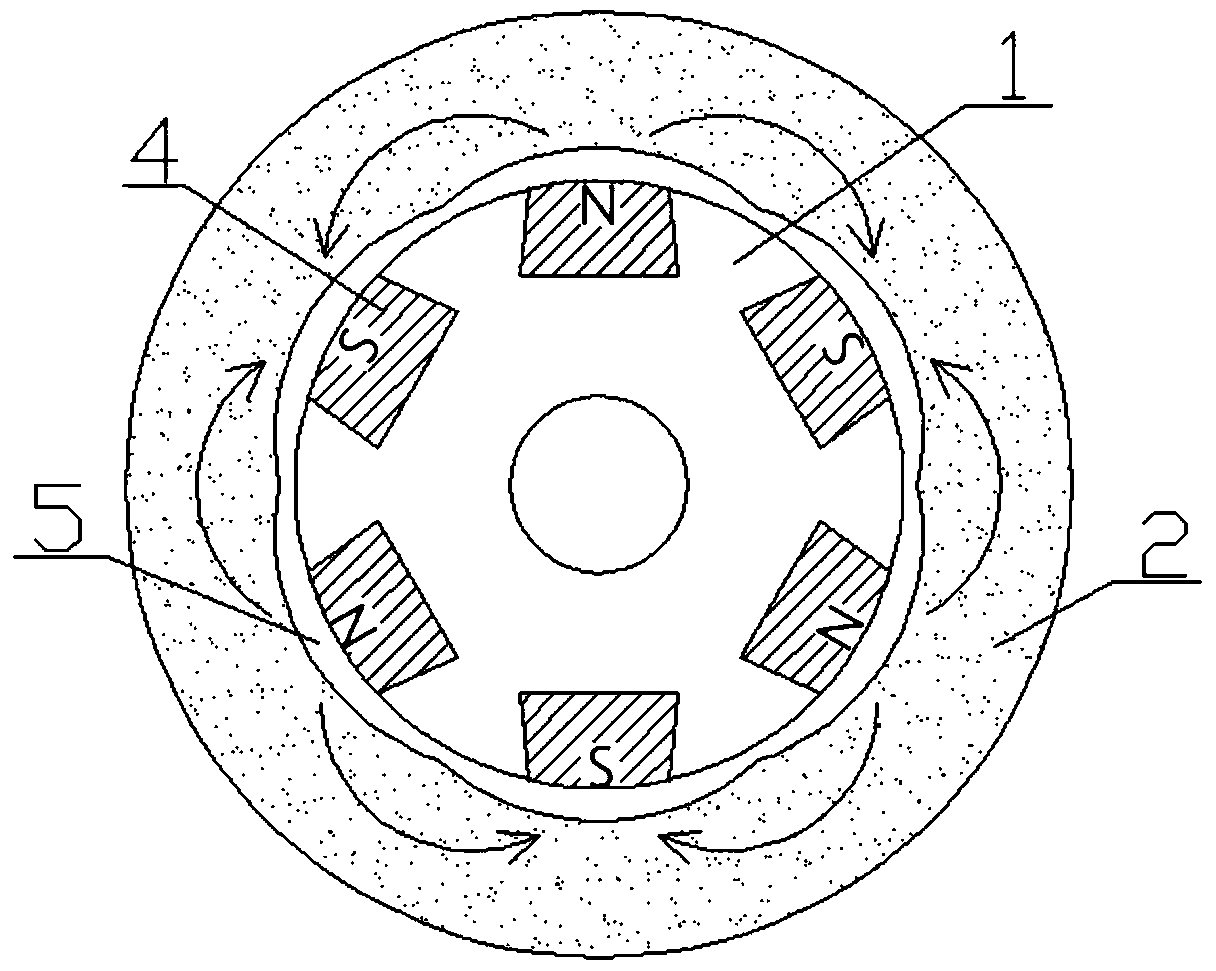

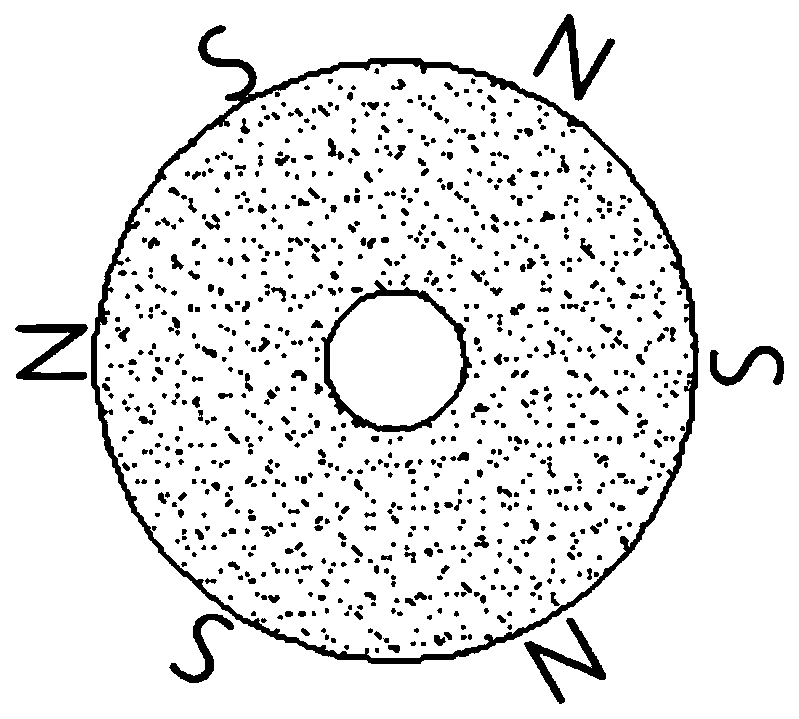

Low-cost anisotropic sintered permanent magnetic ferrite radial multi-pole magnetic ring forming mould and method

InactiveCN110265215AImprove cylindricityReduce wasteAuxillary shaping apparatusPermanent magnet manufactureShrinkage rateMaterials science

The invention discloses a low-cost anisotropic sintered permanent magnetic ferrite radial multi-pole magnetic ring near-net forming mould and a method. The forming mould mainly comprises magnetic yokes, ferrite magnetic powder, a core rod, neodymium-iron-boron magnetic blocks, and a mould wall; the inner side of the mould wall is filled with the ferrite magnetic powder; the core rod is arranged in the center of the inner side of the mould wall; the neodymium-iron-boron magnetic blocks are uniformly distributed on the circumference of the outer side of the mould wall; and the magnetic yokes are arranged on the outer sides of the neodymium-iron-boron magnetic blocks. The forming mould considering the difference of the shrinkage rates of one circle of a magnetic ring is adopted, so that the working surface side of the sintered blank magnetic ring has good cylindricity; the high-performance neodymium-iron-boron permanent magnetic blocks are adopted as orientation clamp magnetic field generation sources, so that the magnetic field is stable, and the orientation of the poles of the ferrite magnetic ring is ensured to be uniform; the advantages are more obvious in preparation of a series of products such as radial two-pole, four-pole, six-pole, eight-pole and ten-pole products and the like; and the forming mould is suitable for outer circular anisotropic radial multi-pole magnetic rings and inner circular anisotropic radial multi-pole magnetic rings, and has high universality.

Owner:HANGZHOUSNNER MACHINERY EQUIP

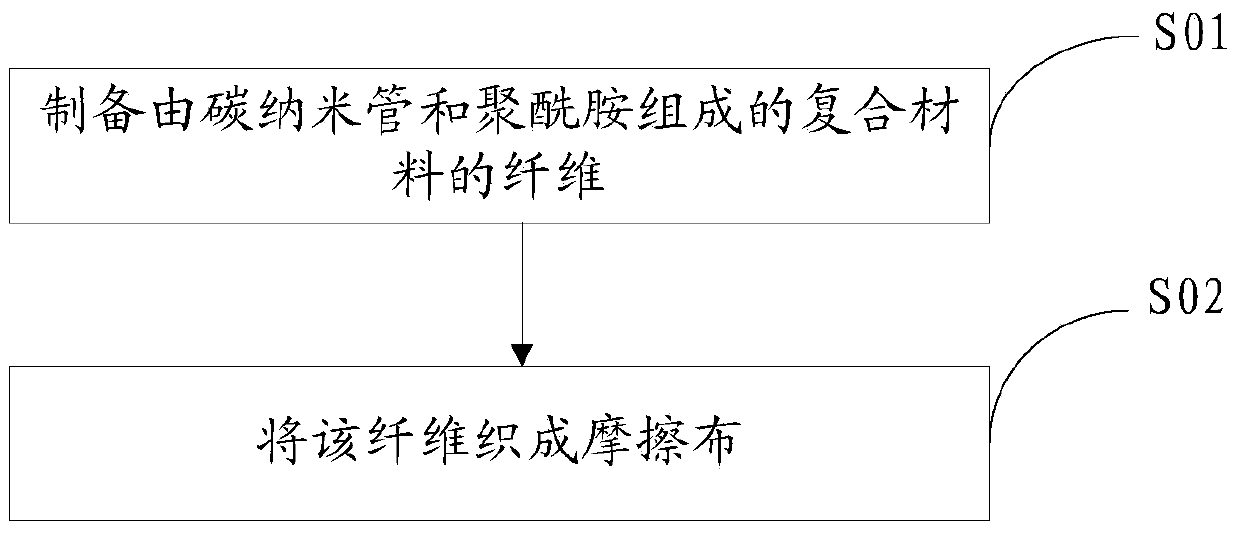

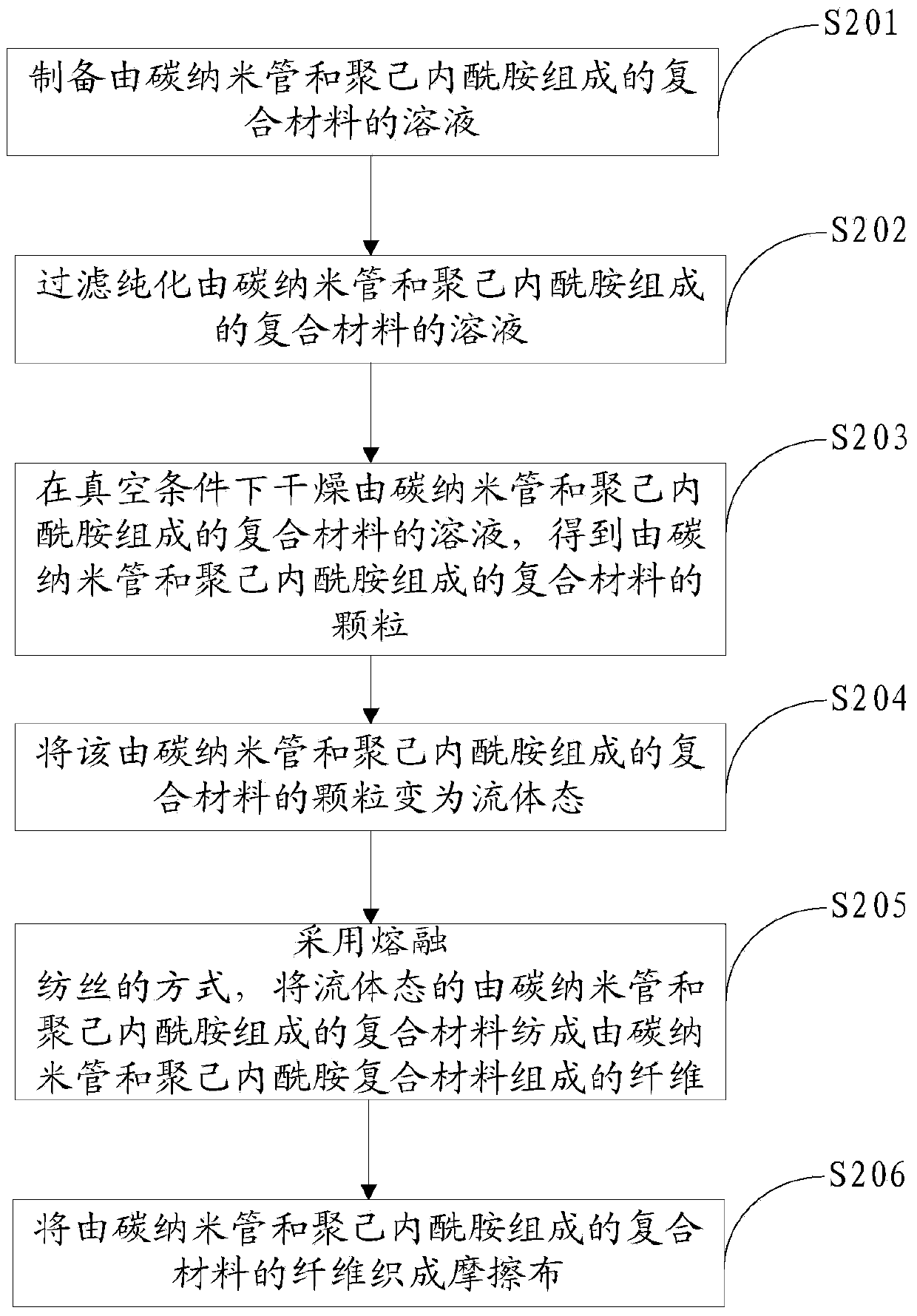

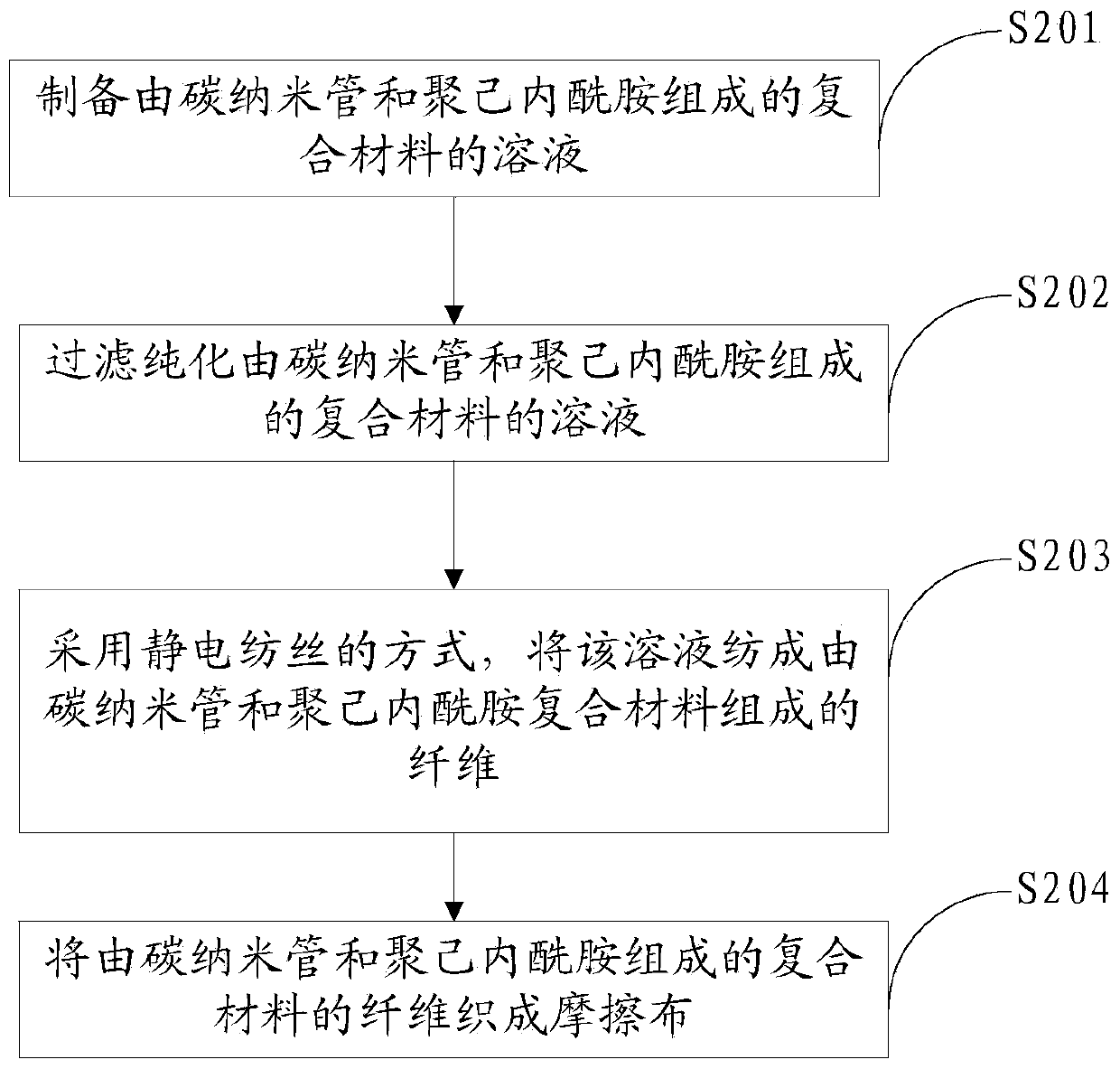

Rubbing cloth and preparation method and preparation device thereof

InactiveCN103472625AWarp and weft density is easy to controlNot easy to shed hairNon-linear opticsLiquid-crystal displayImaging quality

The invention discloses rubbing cloth and a preparation method and a preparation device thereof. The rubbing cloth is made of a composite material composed of carbon nano tubes and polyamide; since the carbon nano tubes have excellent antistatic property and the polyamide has excellent rubbing capability, the composite material composed of the carbon nano tubes and the polyamide has excellent antistatic property as well as excellent rubbing capability; moreover, as the composite material is an artificial material, wrap and weft density of the cloth are easily controlled during weaving, and further the rubbing cloth made of the composite material is high in uniformity; besides, the rubbing cloth made of the composite material is less prone to fur shedding. Therefore, the rubbing cloth is not only high in antistatic property and less prone to fur shedding, but also capable of realizing uniformity of orientation directions of orientation grooves under the condition of high rubbing strength, and further contrast and image quality of a liquid crystal display device are improved.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

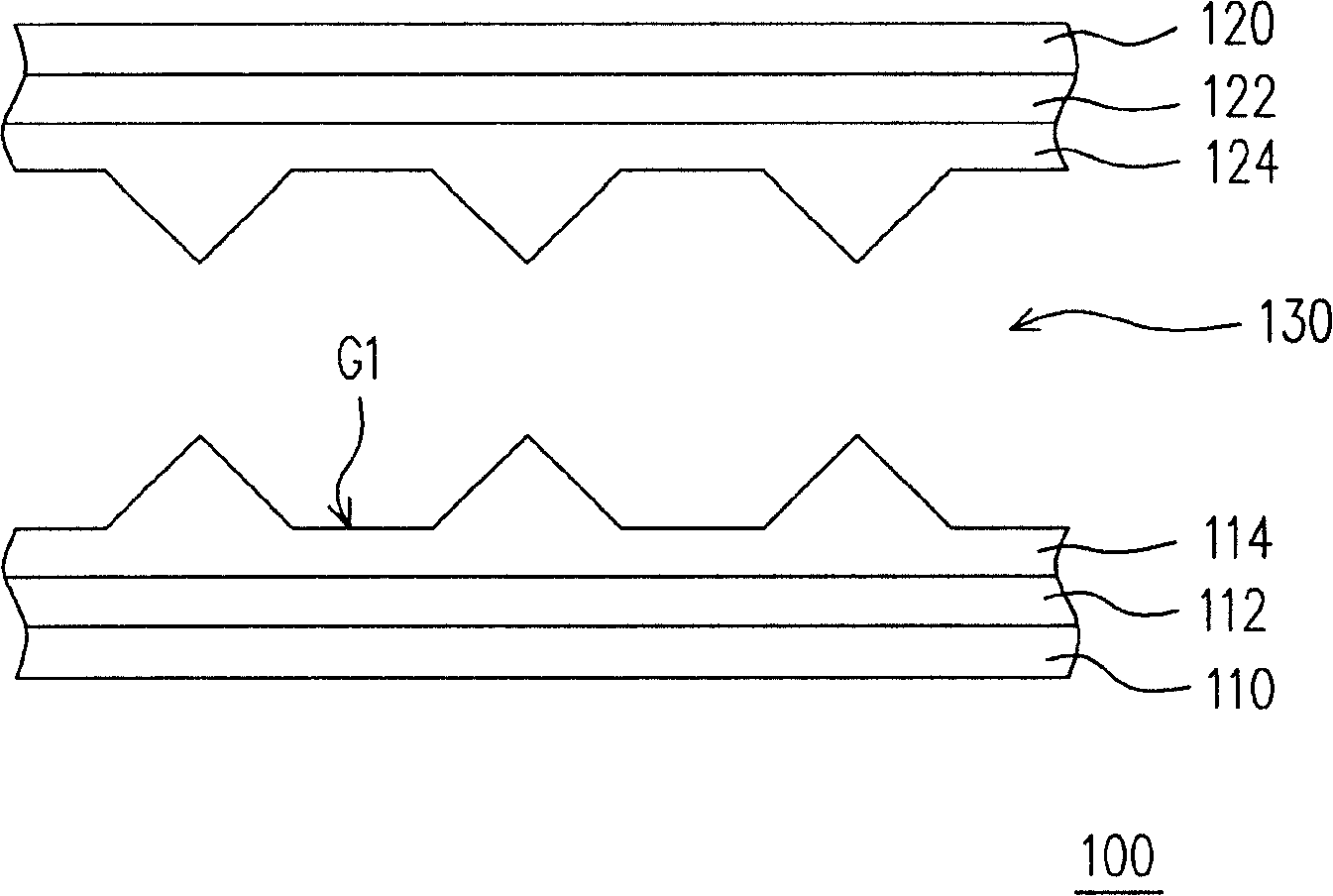

Liquid crystal display panel

InactiveCN101165555AImprove display qualityUniform orientationNon-linear opticsLiquid-crystal displayEngineering

The LCD panel comprises: a first baseboard, a first electrode layer, a first oriented film, a second baseboard, a second electrode layer, a second oriented film and liquid crystal layer. The first electrode layer is located on the first baseboard, and the first oriented film is located on the first baseboard and overlaps the first electrode layer. Said first oriented film has multi first oriented bulge structures, and each bulge structure has a first tangent plane shape at its vertical extending direction; the first axial line passes through the highest point of the first tangent plane shape and is normal to the first baseboard, and the first tangent plane shape is not asymmetry in relation to first tangent plane shape. In addition, the second electrode layer is located on the second baseboard, and the second oriented film is located on the second baseboard and overlaps the second electrode layer; the liquid crystal layer is located between the first oriented film and the second oriented film.

Owner:INNOLUX CORP

Thermal interface material and its production method

InactiveCN1632040AUniform OrientationImprove thermal conductivityHeat-exchange elementsBoron nitrideSilver particles

The invention relates to a conducting hot interface material based on array of carbon nm pipes, comprising a silver glue matrix which includes a first surface and a second surface corresponding to the first one, several carbon nm pipes distributing in the silver glue matrix which is comprised of pure silver particle, boron nitride particle and synthesized oil, the carbon nm pipes are parallel to each other and extend from the first surface to the second one of the silver glue matrix. Besides, the preparing method of the heat interface material is also disclosed, including the following steps: supply an array of carbon nm pipe which are placed on a base, use silver glue to coat it, solidify the silver glue to form the hot interface material, than put it solidified away from the base.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

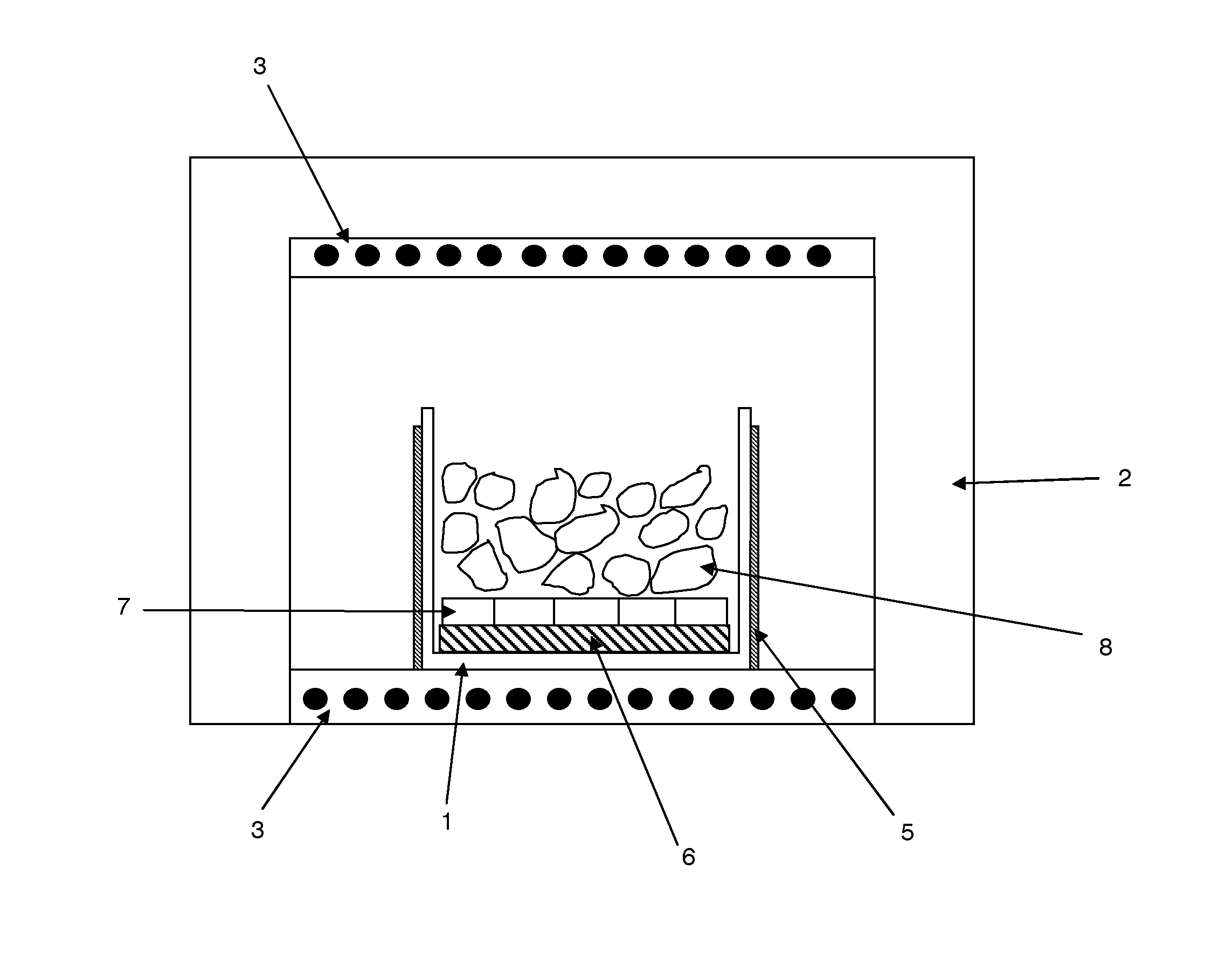

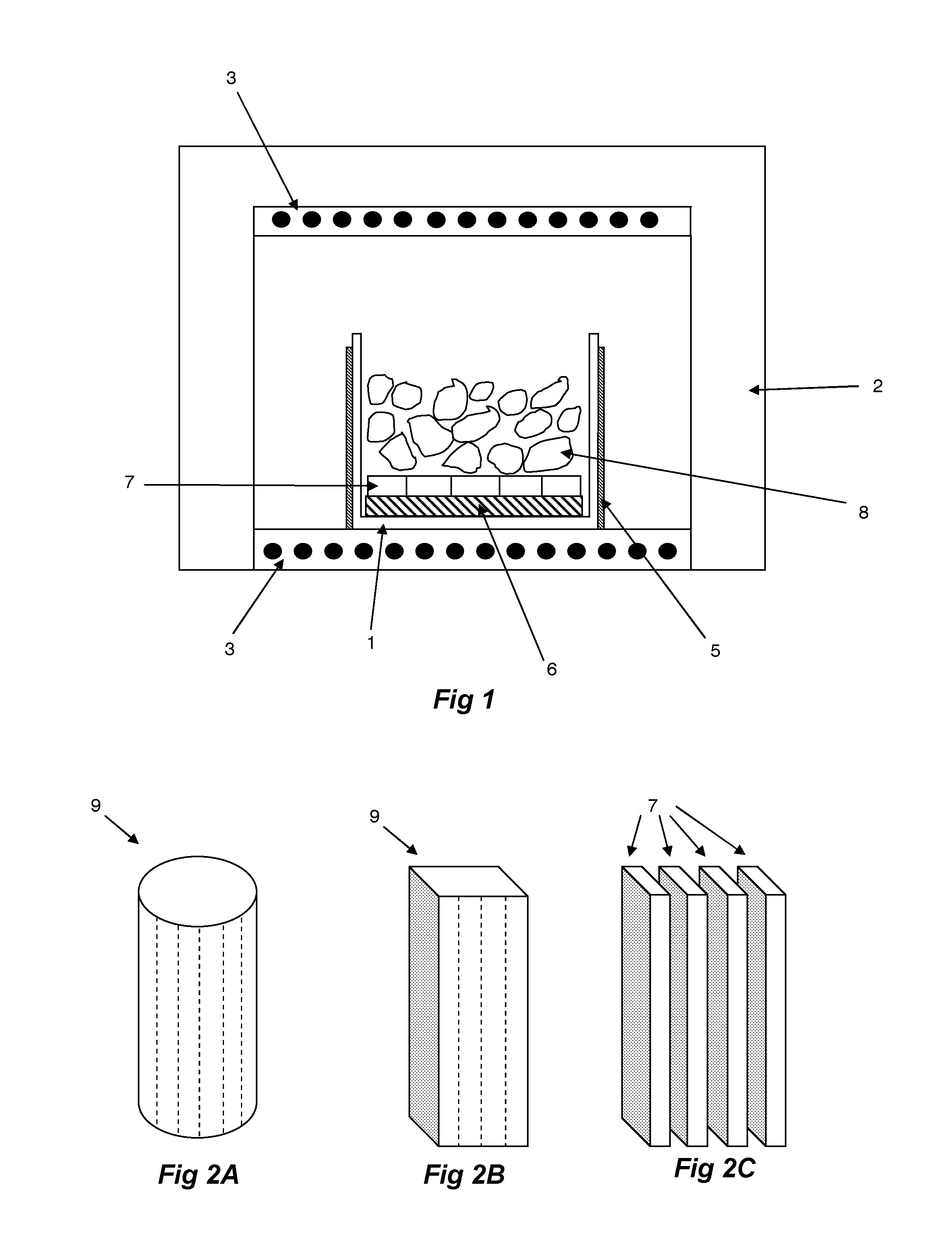

Production of mono-crystalline silicon

InactiveUS20150203986A1Easy alignmentAvoid misalignmentBy pulling from meltFrom melt solutionsCrucibleCrystal structure

A crystalline silicon ingot is produced using a directional solidification process. In particular, a crucible is loaded with silicon feedstock above a seed layer of uniform crystalline orientation. The silicon feedstock and an upper part of the seed layer are melted forming molten material in the crucible. This molten material is then solidified, during which process a crystalline structure based on that of the seed layer is formed in a silicon ingot. The seed layer is arranged such that a {110} crystallographic plane is normal to the direction of solidification. It is found that offers a substantial improvement in the proportion of mono-crystalline silicon formed in the ingot as compared to alternative crystallographic orientations and leads to highly uniform solar cells after an isotropic texture.

Owner:REC SOLAR

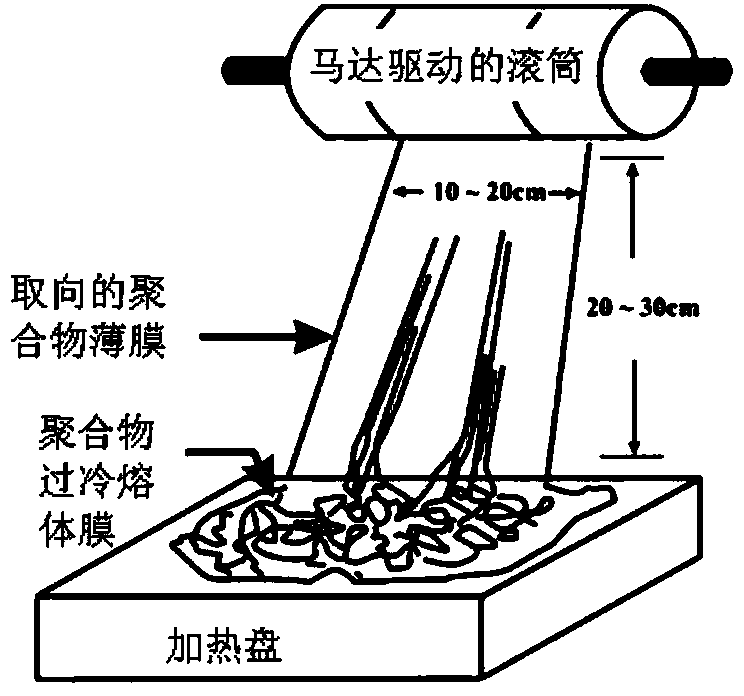

Macromolecular oriented film and preparation method and application thereof

ActiveCN108084477AUniform orientationEasy to operatePolyether coatingsPolyester coatingsPolymer sciencePolymer thin films

The invention discloses a macromolecular oriented film and a preparation method and application thereof. The preparation method comprises the following steps of (1) using a melting tension method to prepare a first polymer oriented film, and attaching the first polymer oriented film onto a substrate; (2) using a rotary coating method to attach a second polymer blending solution onto the first polymer oriented film, so as to form a second polymer film; then, performing heat treatment, so as to obtain the macromolecular oriented film with parallel lamella. The invention also provides a regulating and control method for separation of other nanometer-level phases of the macromolecular oriented film. The preparation method has the advantages that the operation is simple, and the macromolecularoriented film with high orienting degree and uniform orienting can be prepared in a large-area way.

Owner:BEIJING UNIV OF CHEM TECH

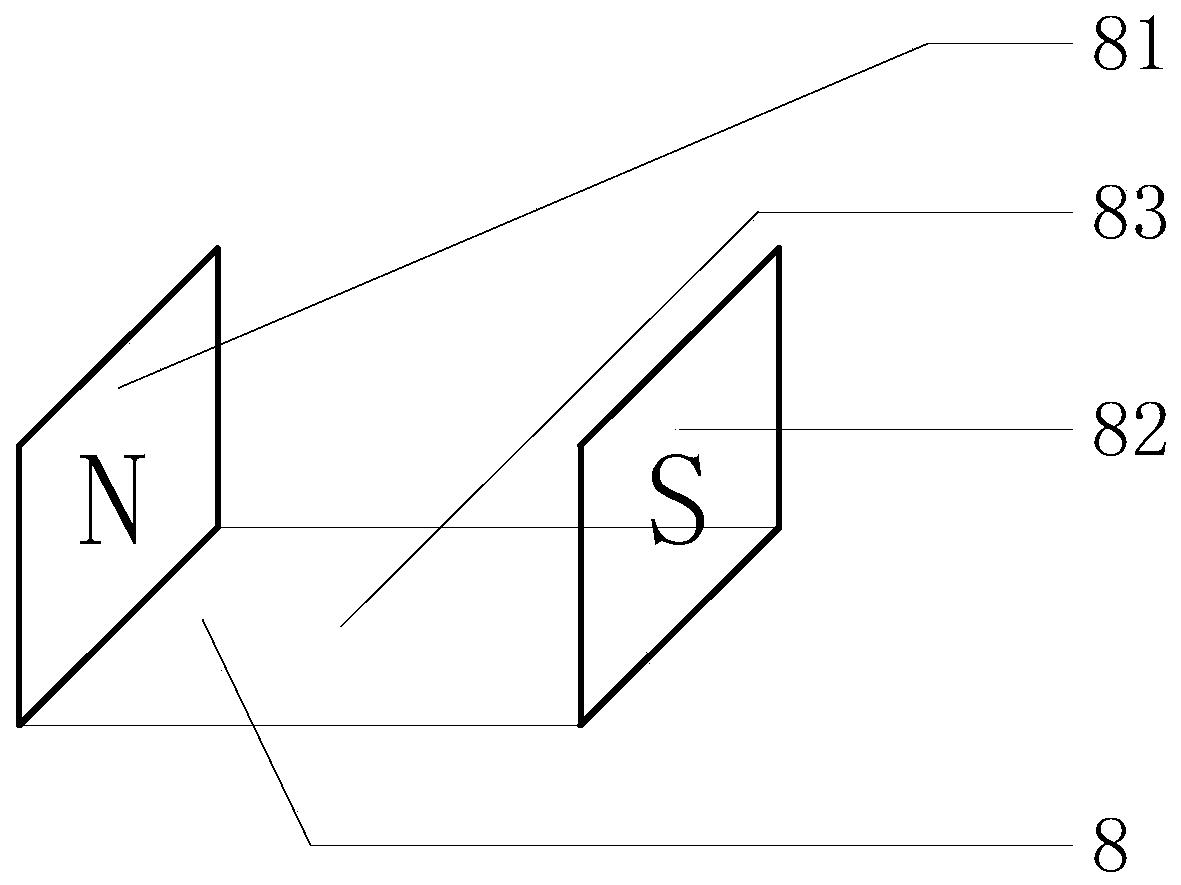

Device for directionally distributing steel fibers and application thereof

InactiveCN111424980AUniform orientationEasy to installBuilding material handlingEngineeringCement paste

The invention relates to the field of buildings, and discloses a device for directionally distributing steel fibers. The device is used for directionally distributing the steel fibers in cement paste.The device comprises a glass plate, a magnet block and a clamping piece, wherein the top surface of the glass plate is used for placing the steel fibers; the magnet block is positioned below the glass plate and used for uniformly and directionally distributing the steel fibers; and the clamping piece is used for moving the directionally distributed steel fibers into the cement paste. When the steel fibers are placed near a magnet, the steel fibers can be directionally arranged in the direction of a magnetic induction line under the action of a magnetic field force, meanwhile, the steel fiberscan also be magnetized in a magnetic field, the steel fibers with magnetism are formed, the steel fibers on the same column attract each other due to the action of magnetic poles, and the directionalcontinuity of steel fiber arrangement is guaranteed. The steel fibers on different columns repel each other due to the action of the magnetic poles, due to the fact that the fiber specifications areconsistent, the repulsive force is basically the same, the distances between the steel fibers on different columns are roughly the same, and therefore the tensile property and the toughening effect ofa steel fiber reinforced cement-based material are improved.

Owner:TONGJI UNIV

Large-specification high-carbon chromium bearing steel hot-rolled wire rod and high-speed wire rod production method thereof

ActiveCN112355054ADowngradeReduce the cost of spheroidizing annealingTemperature control deviceProcess efficiency improvementWire rodProduction line

The invention provides a large-specification high-carbon chromium bearing steel hot-rolled wire rod and a high-speed wire rod production method thereof. The method comprises the following steps that (1) a continuous casting square billet is heated in a heating furnace, the temperature of a preheating section ranges from 830 DEG C to 880 DEG C, the temperature of a heating section ranges from 1150DEG C to 1210 DEG C, and the temperature of a soaking section ranges from 1190 DEG C to 1220 DEG C; (2) the continuous casting square billet is subjected to heat preservation in a high-temperature section, and the heat preservation time is larger than or equal to 120 min; (3) the continuous casting square billet is rolled through a high-speed rolling mill, the initial rolling temperature is controlled to be 1090-1120 DEG C, the spinning temperature is controlled to be 860-900 DEG C, the swing amplitude of a spinning machine is controlled, and the continuous casting square billet is rolled intoa hot-rolled wire rod; (4) the rolled hot-rolled wire rod is cooled to be larger than or equal to 550 DEG C at the cooling speed of 0.7-0.9 DEG C / s, the speed of a Stelmor line roller way is controlled, coil collection is carried out, and then air cooling is carried out to reach the room temperature; (5) surface quality inspection, finishing and sampling are carried out on the collected hot-rolled wire rod; and (6) the finished hot-rolled wire rod is quickly packaged online. According to the high-speed wire rod production method, the bearing steel hot-rolled wire rod with phi 21-25 mm is produced.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

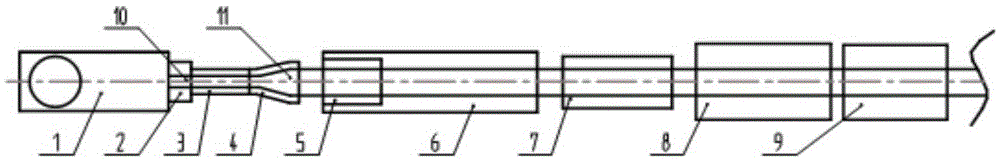

Technological method and device for preparing biaxial orientation plastic pipe through one-step method

InactiveCN105235228AAchieve Radial OrientationAchieve Axial OrientationProduction lineUltimate tensile strength

The invention relates to a technological method and device for preparing a biaxial orientation plastic pipe through a one-step method. The device comprises a plastic extruder, an extruding pipe die head, a pipe blank cooling heat-preserving section, a two-way drawing die, a vacuum cooling sizing device, a cooling box, a traction machine, a cutting machine and an automatic pipe discharge machine which are sequentially and linearly positioned to form a production line. The outer wall of a pipe blank is closely attached to the inner wall of the two-way drawing die to move, so that the two-way drawing die draws the pipe blank both in the radial direction and the axial direction. Radial drawing and axial drawing are completed through the two-way drawing die and the traction machine together. According to the method and device, the pipe is drawn through adsorption force of a vacuum machine and traction force of the traction machine, and radial orientation and axial orientation of the pipe are achieved. Besides, orientation is uniform, two-way performance of the oriented pipe can be greatly improved. Compared with common pipes, the tensile strength and the elasticity modulus of pipes in the same specification after biaxial orientation are improved by over 20%, the circular performance of the pipes is better than axial performance, and the actual use requirements of the oriented pipes are met.

Owner:RIFENG ENTERPRISE GRP CO LTD +1

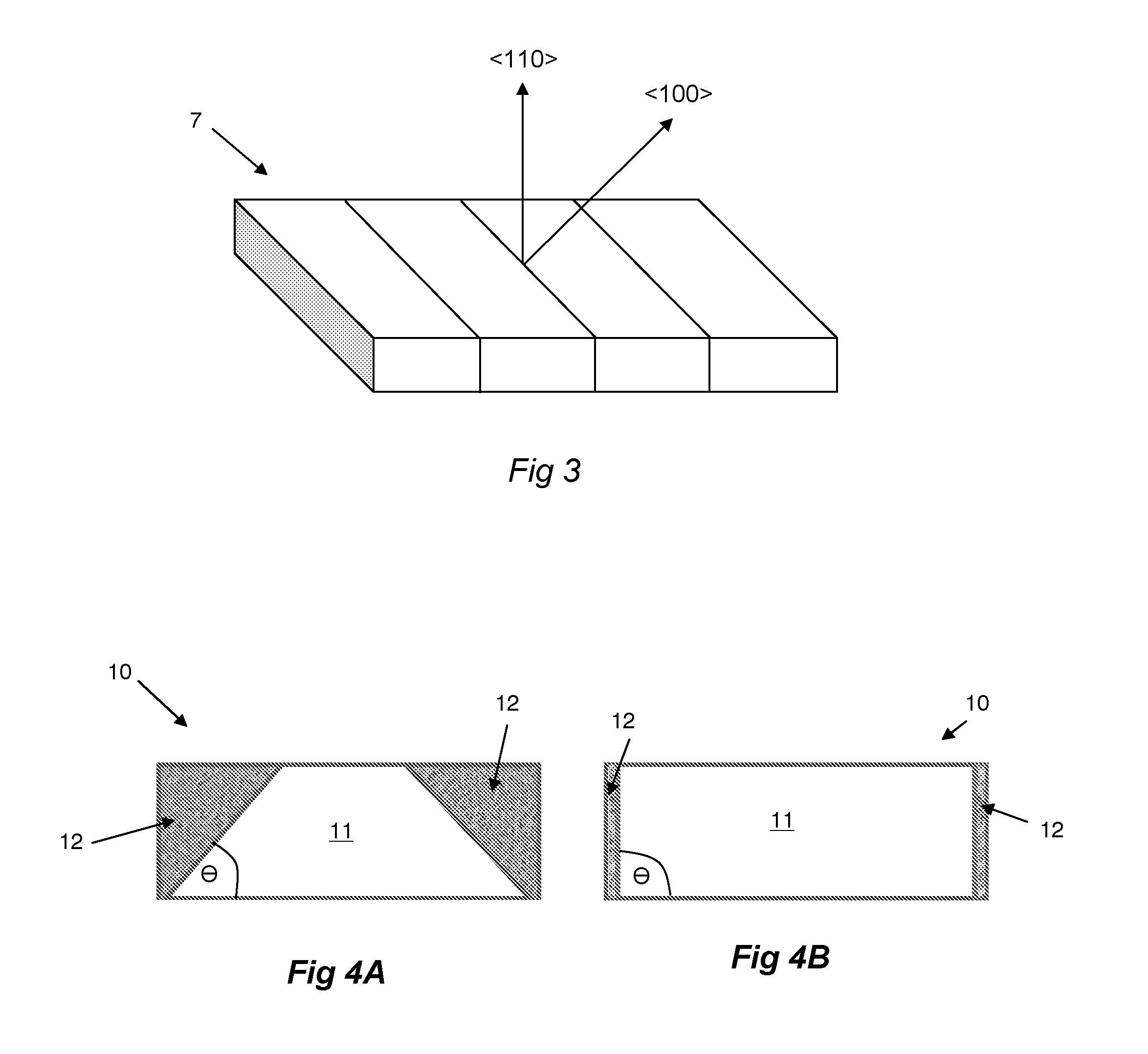

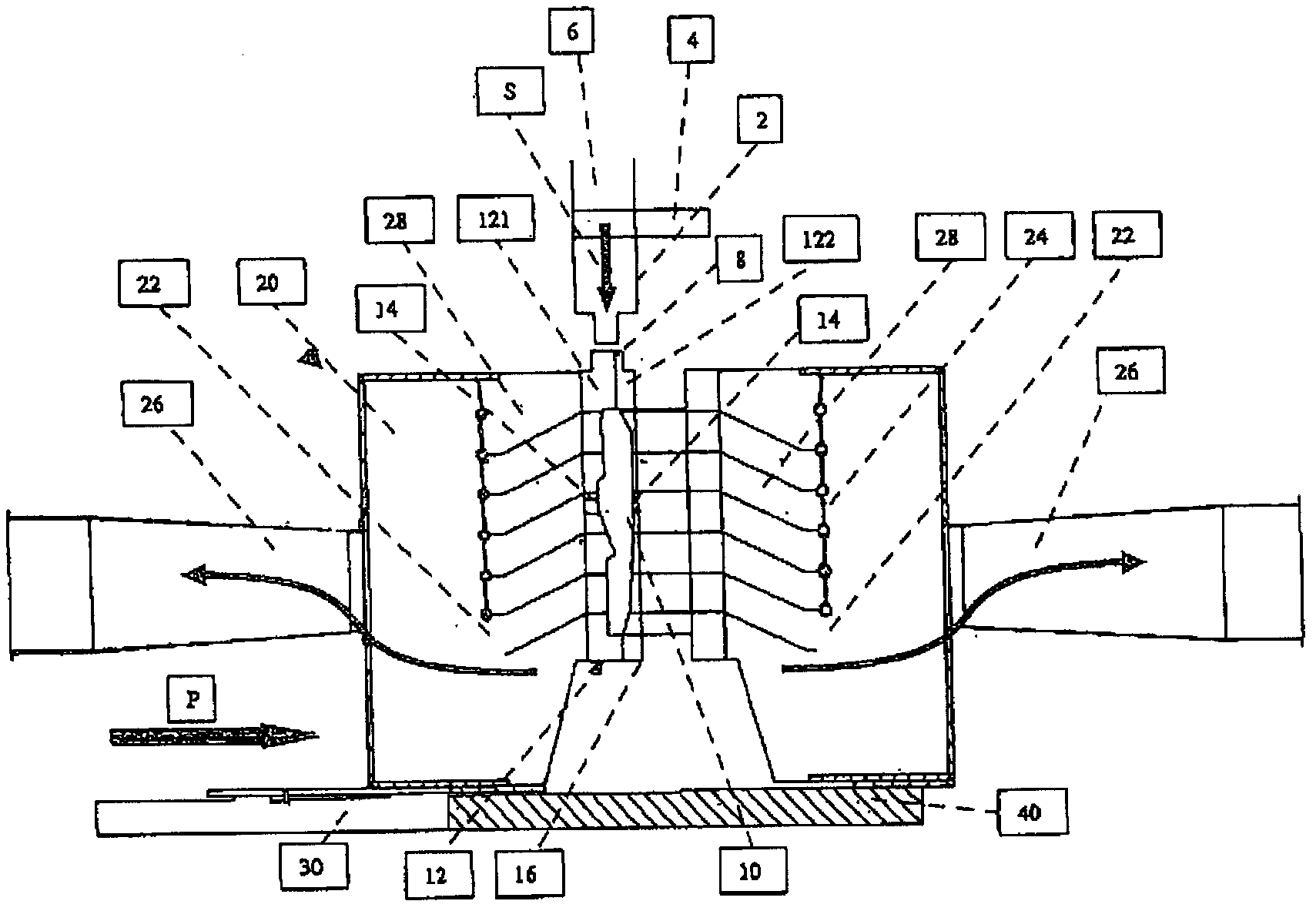

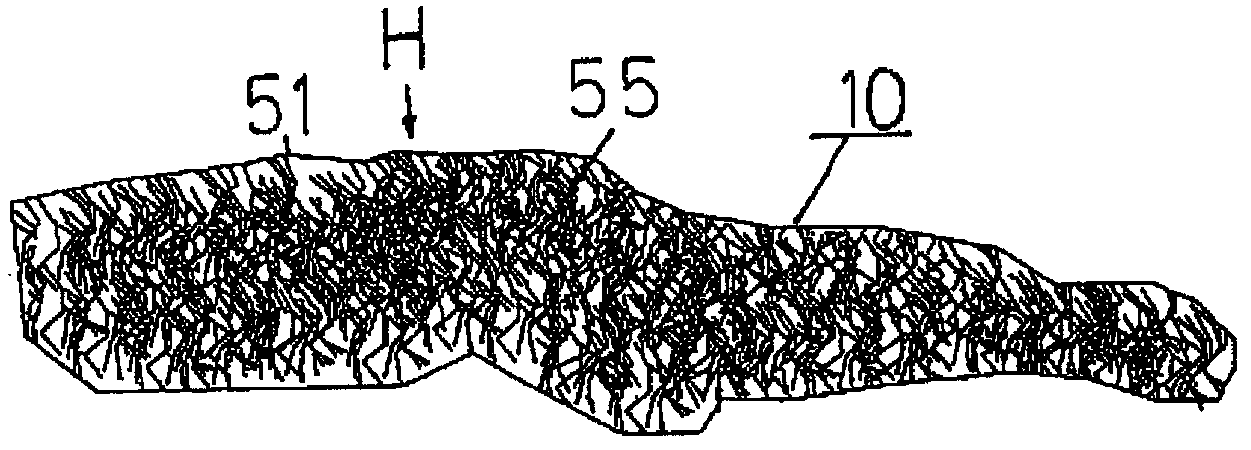

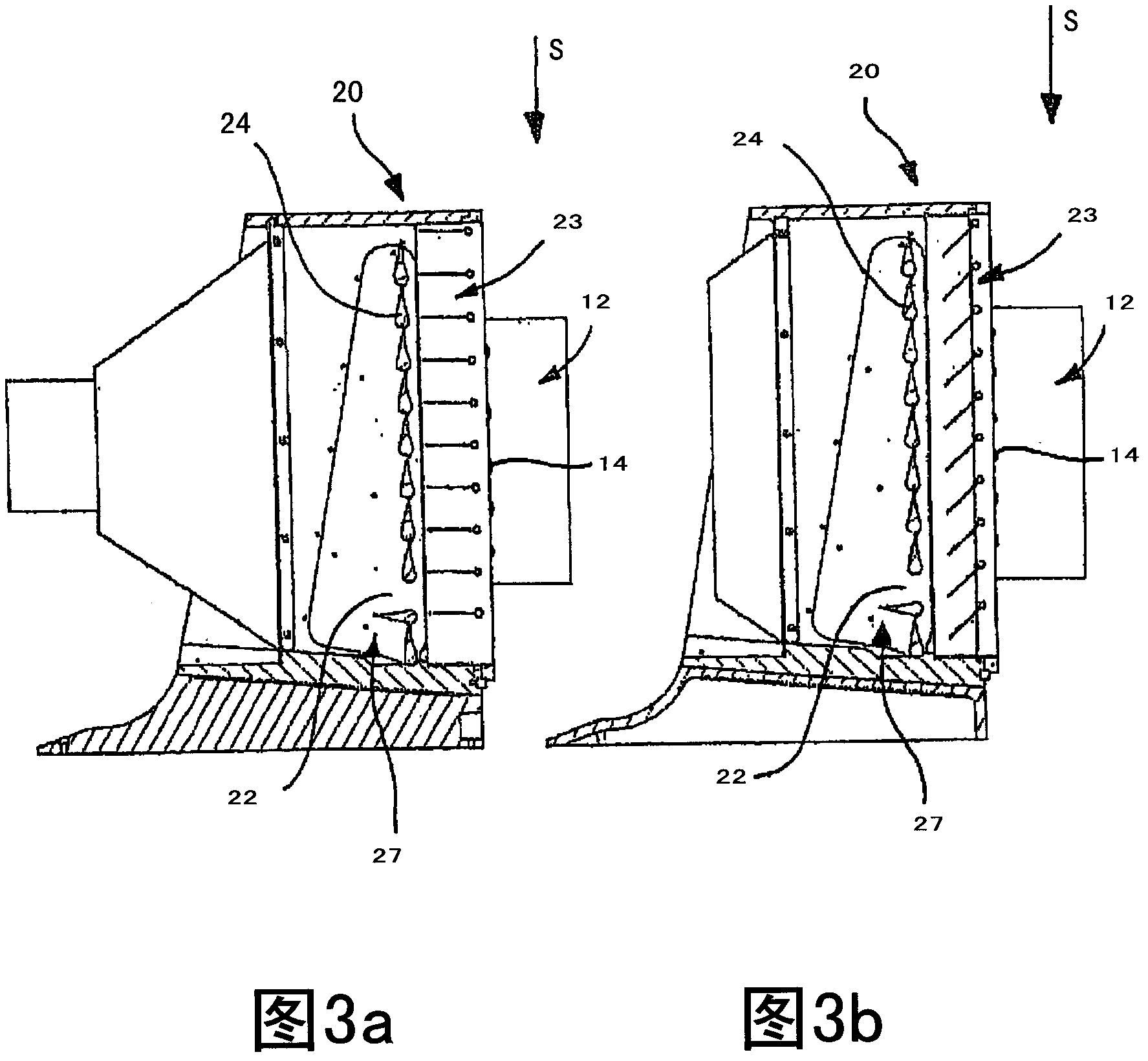

Device and method for producing a molded pulp part and molded pulp part

InactiveCN103384735AFast and even heatingSmall flow sectionWoven fabricsDomestic articlesMolded pulpFiber

The invention relates to a device for producing a molded pulp part (10), comprising a pneumatic fiber feeding apparatus (2) having an associated heating apparatus (4) having at least one heat exchanger (6) for heating up heating air and a mold (12), which has through-flow holes (14) for the transport air on at least one side, wherein the mold (12) has an outlet controller (20) arranged on the side of the through-flow holes (14), said outlet controller having a plurality of outlet openings (22), which can be closed and which are arranged one behind the other in the feeding direction of the fibers.

Owner:GRIMM SCHIRP GS TECH

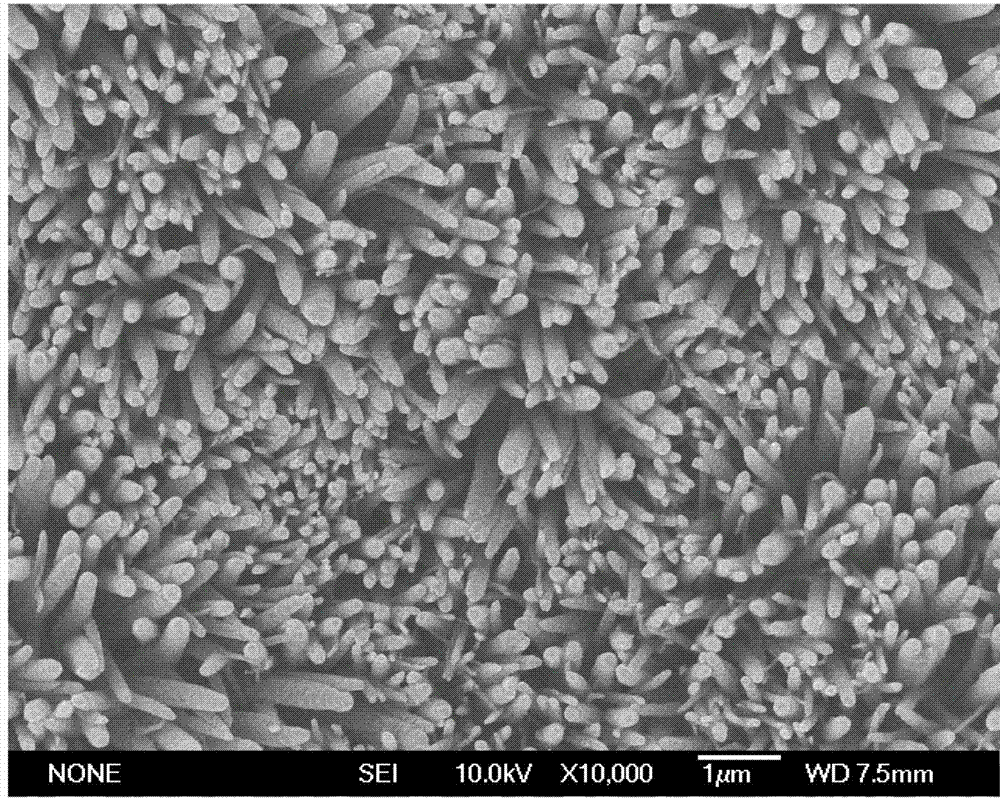

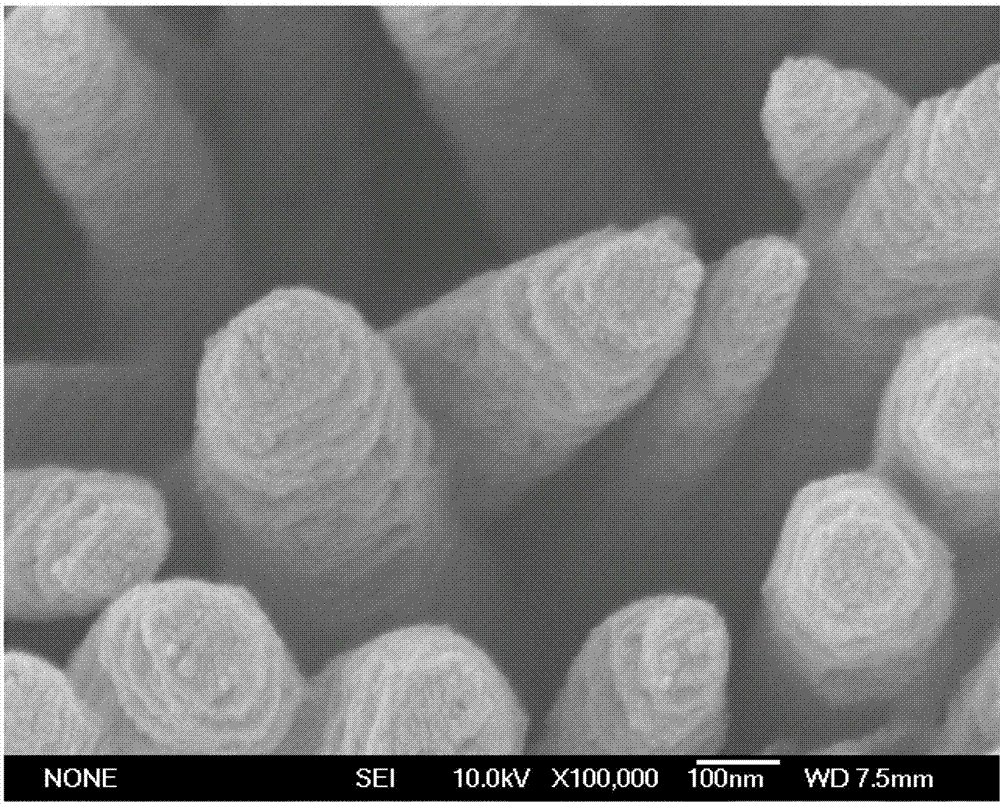

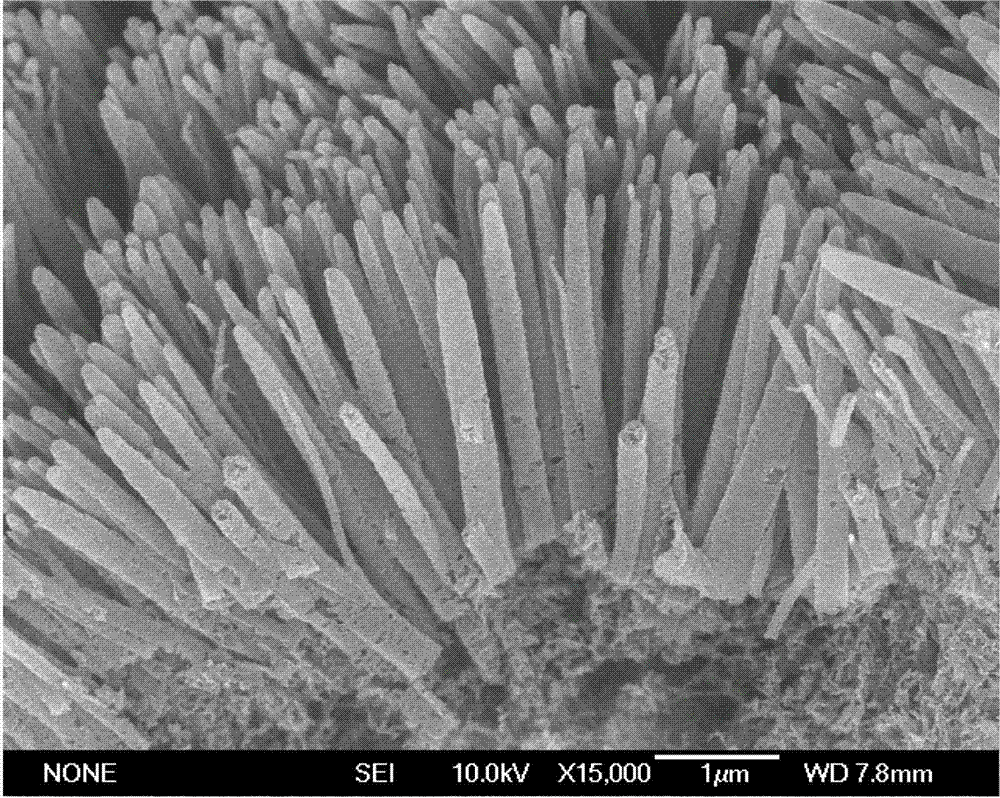

Porous carbon nanorod array electrode and preparation method thereof

ActiveCN104715933AEasy transferLarge specific surface areaMaterial nanotechnologyHybrid capacitor electrodesPorous carbonSupercapacitor

The invention discloses a porous carbon nanorod array electrode and a preparation method thereof. A zinc oxide nanowire array is used as a template, hydrocarbon gas is used as a carbon source, and an in-situ CVD method is used for manufacturing a carbon nanorod array. The surface of the carbon nanorod array is of a porous structure, the array length is 2.5-4 microns, and the diameter of the array is 50-200 nm. The carbon nanorod array is of a one-dimensional array structure so as to be beneficial to transmitting charges, the surface of the carbon nanorod array is of the porous structure, the large specific surface area is achieved, and the carbon nanorod array electrode can be used as a supercapacitor electrode.

Owner:CHINA THREE GORGES UNIV

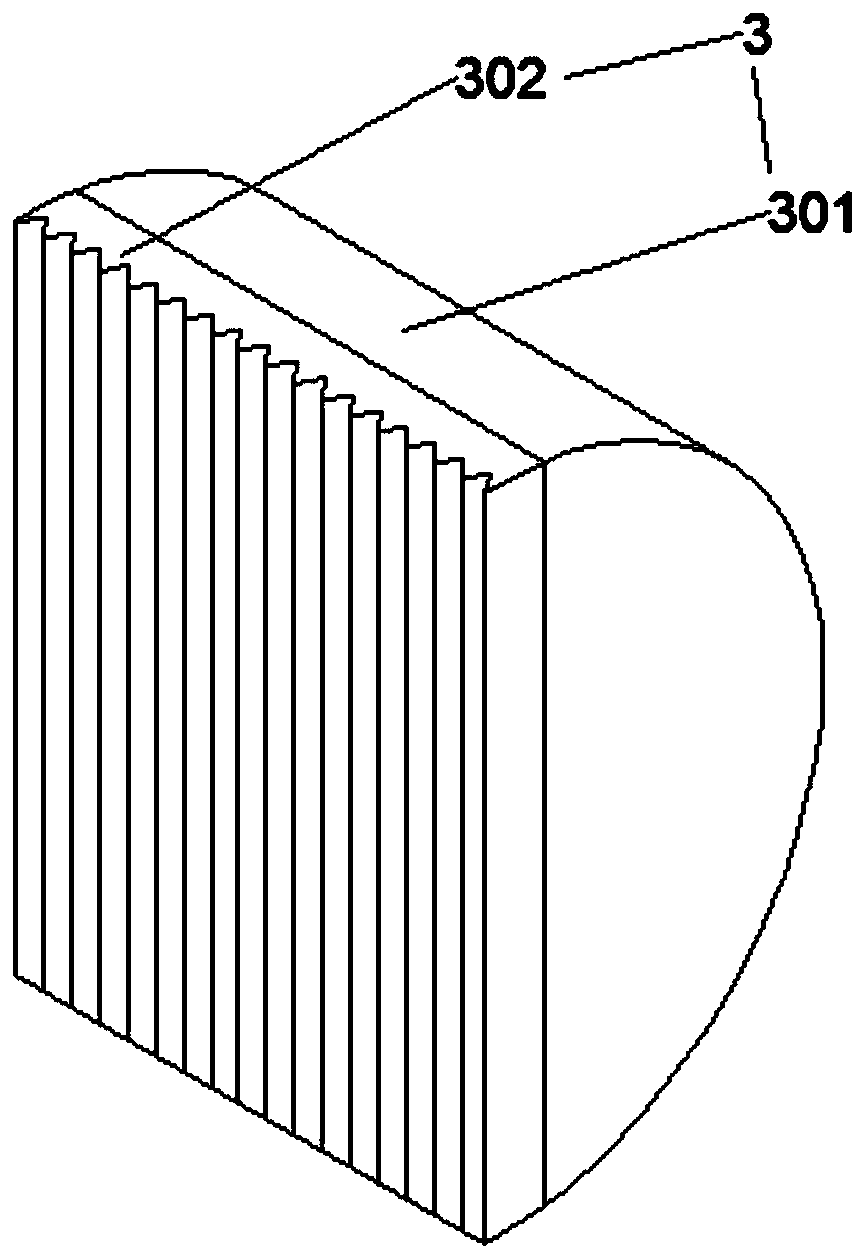

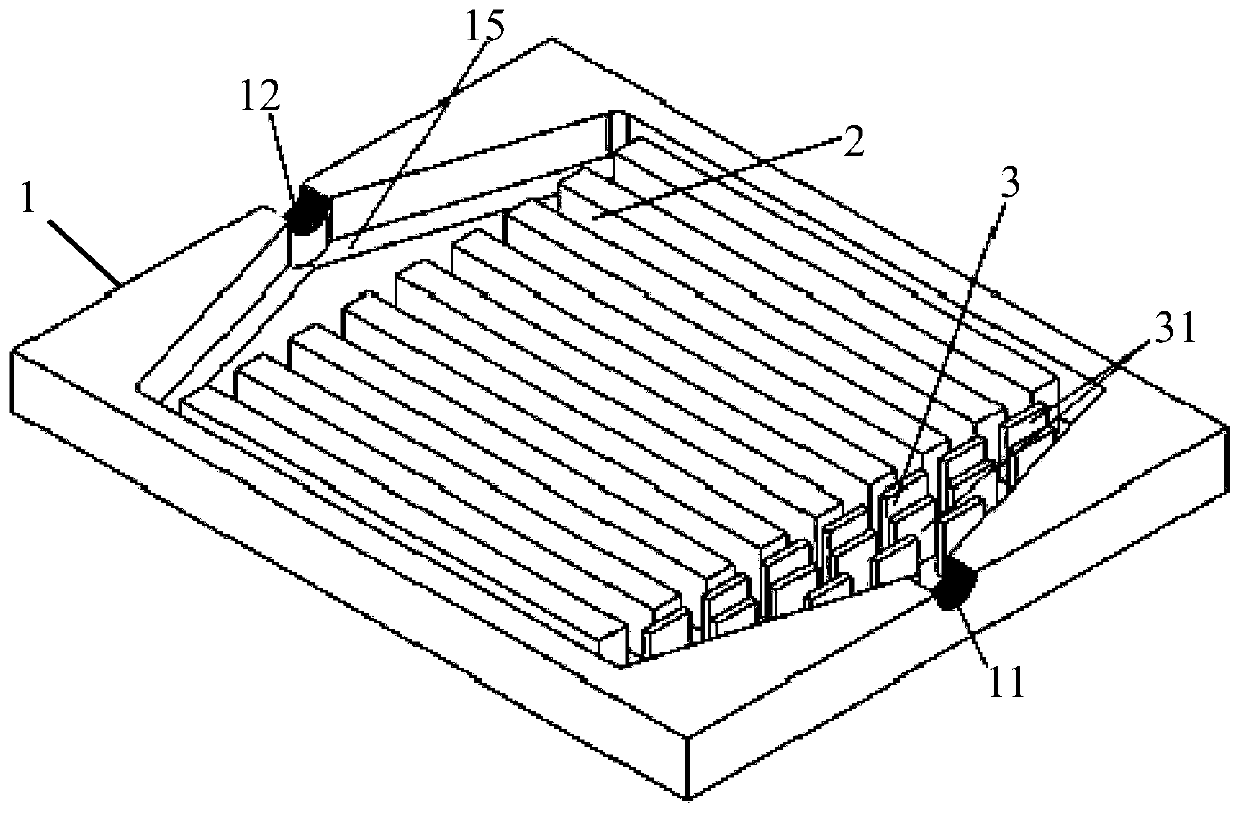

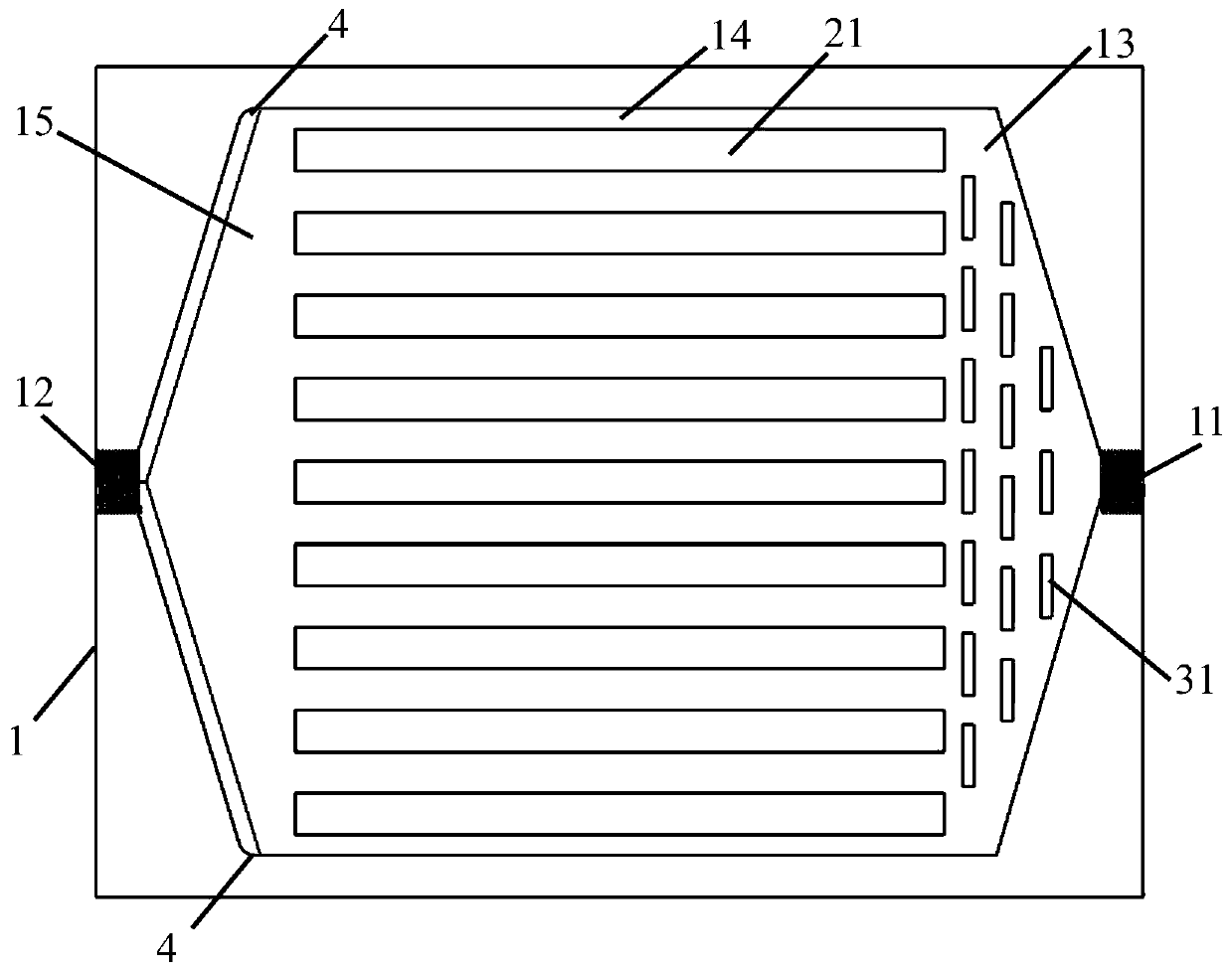

Radiator

PendingCN110996630AUniform orientationEven heat dissipationCooling/ventilation/heating modificationsSpoilerEngineering

The invention relates to the technical field of heat dissipation, and discloses a radiator. The radiator comprises a shell, a flow equalizing structure and a flow channel structure, wherein an inlet and an outlet are formed in the shell; a first containing cavity and a second containing cavity are formed in the shell, the first containing cavity communicates with the second containing cavity, theflow equalizing structure is arranged in the first containing cavity, the flow channel structure is arranged in the second containing cavity, the inlet communicates with the flow equalizing structure,and the flow equalizing structure communicates with the outlet through the flow channel structure. The flow channel structure comprises a plurality of heat dissipation flow channels. The flow equalizing structure comprises at least three spoilers which are sequentially arranged at intervals; a channel opening for a cooling medium to pass through is formed between every two adjacent spoilers, andafter entering the shell from the inlet, the cooling medium is shunted through the channel openings, so that the cooling medium can be uniformly shunted to the heat dissipation flow channels, and uniform heat dissipation is facilitated.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com