Rubbing cloth and preparation method and preparation device thereof

A technology of rubbing cloth and carbon nanotubes, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as uneven cotton cloth warp and weft density friction strength, poor pre-tilt angle uniformity of orientation grooves, and static electricity accumulation damage to array substrates, etc. Achieve the effects of not easy to shed hair, uniform orientation direction and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

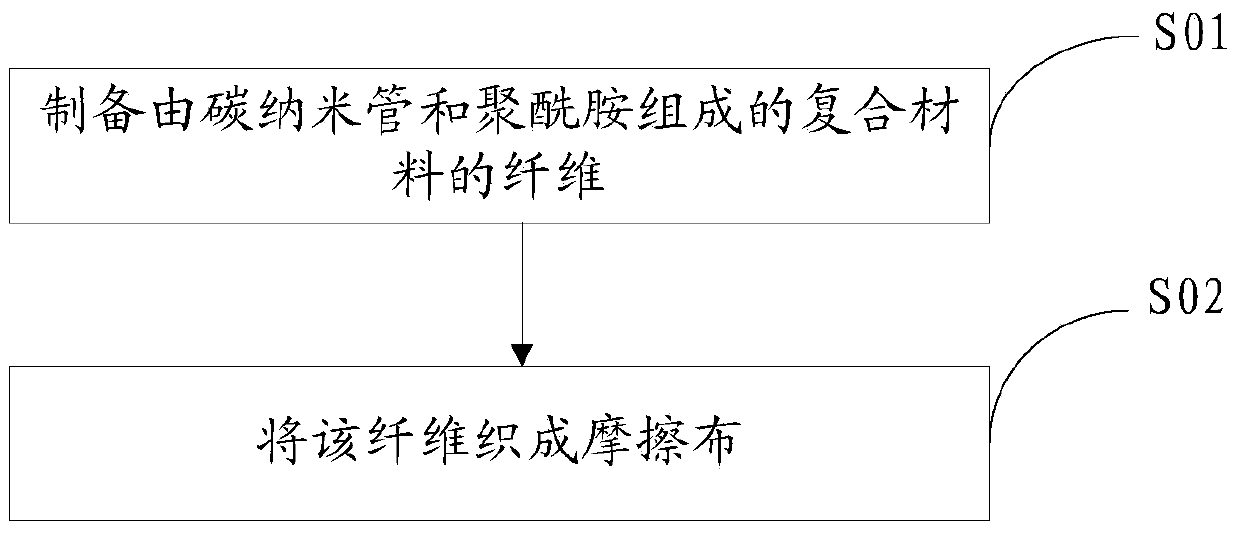

[0071] Based on the same inventive concept, the embodiment of the present invention also provides a preparation method of rubbing cloth, such as figure 1 As shown, the following steps may be included:

[0072] S01, prepare the fiber of the composite material that is made up of carbon nanotube and polyamide;

[0073] S02. Weaving the fiber into friction cloth.

[0074] In the preparation method of the above-mentioned rubbing cloth provided in the embodiment of the present invention, the rubbing cloth is prepared by using fibers of a composite material composed of carbon nanotubes and polyamides. Since carbon nanotubes have good antistatic properties, polyamide materials It has good friction ability, so the fiber of the composite material composed of carbon nanotubes and polyamide has good antistatic property and good friction ability; and, because the fiber is a man-made material, when weaving, the cloth The warp and weft density of the fiber is easy to control, so the unifor...

example 1

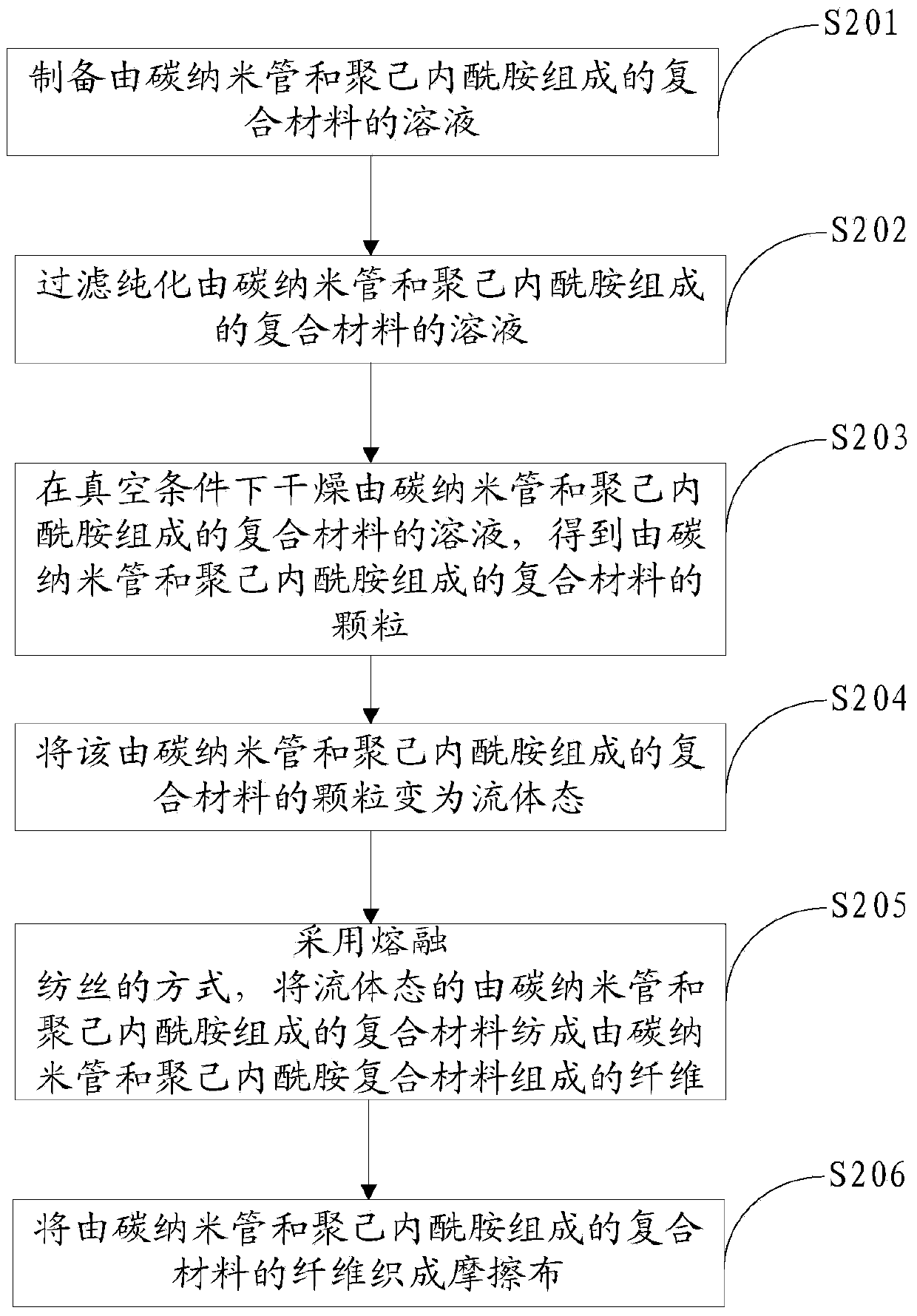

[0092] The fiber of the composite material composed of carbon nanotubes and polyamide is prepared by melt spinning, and then the fiber is woven into friction cloth by using an intelligent controller to control the warp tension of the air-jet loom, such as Figure 2a As shown, it specifically includes the following steps:

[0093] S201, preparing a solution of a composite material composed of carbon nanotubes and polycaprolactam;

[0094] In specific implementation, carbon nanotubes, polyamide and propylene solvent can be mixed according to the mass fraction of carbon nanotubes being 0.01%-0.8%, the mass fraction of polycaprolactam being 50%-60%, and the rest being propylene solvent. , and then ultrasonically treat the mixed solution to obtain a solution of a composite material composed of carbon nanotubes and polycaprolactam. Specifically, the ultrasonic frequency is generally controlled between 15KHZ-50KHZ.

[0095] S202, filtering and purifying the solution of the composit...

example 2

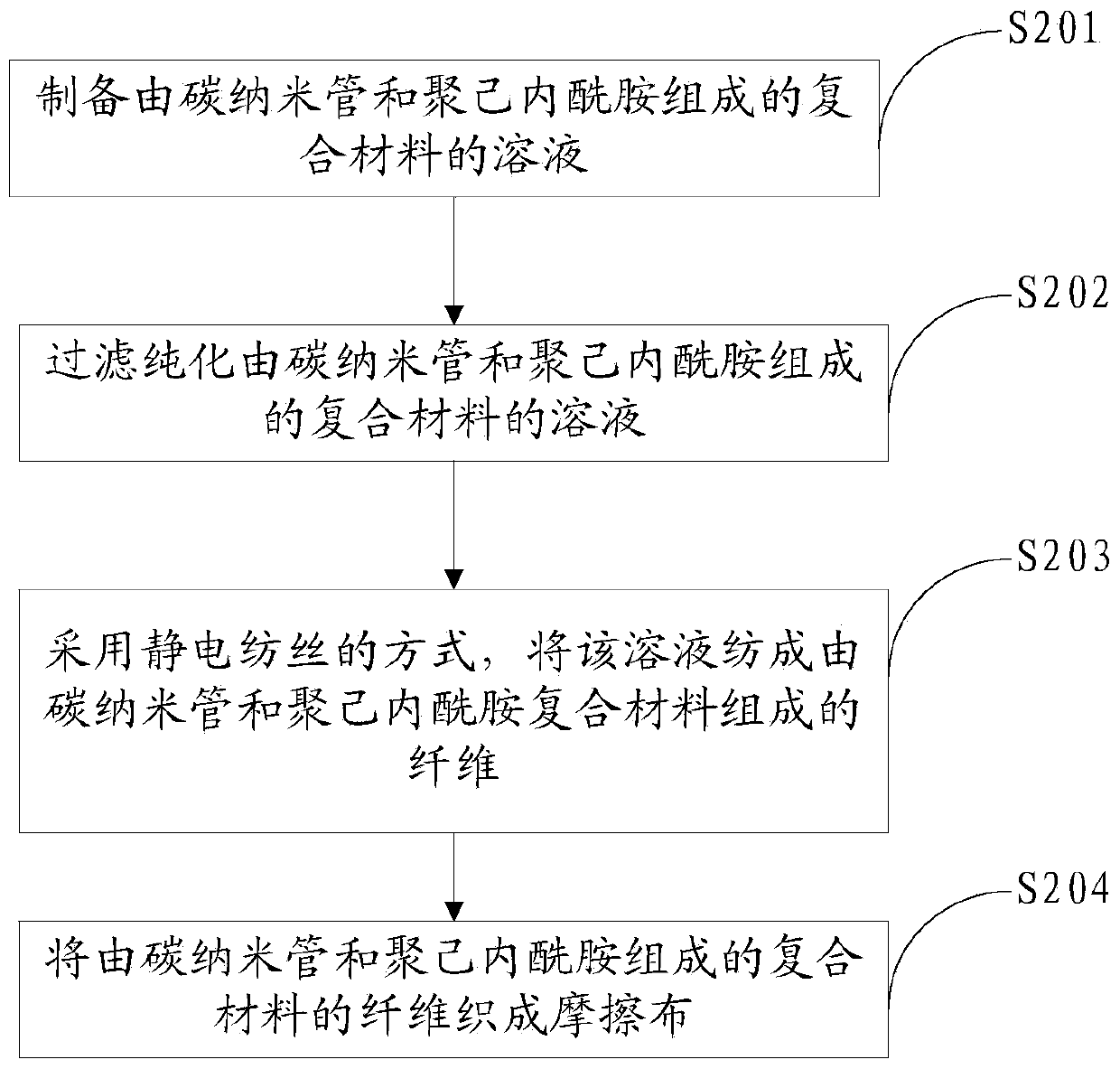

[0106] The fiber of the composite material composed of carbon nanotubes and polyamide is prepared by electrospinning, and then the fiber is woven into a friction cloth by using an intelligent controller to control the warp tension of the air-jet loom, such as Figure 2b As shown, it specifically includes the following steps:

[0107] S201, preparing a solution of a composite material composed of carbon nanotubes and polycaprolactam;

[0108] In specific implementation, carbon nanotubes, polyamide and propylene solvent can be mixed according to the mass fraction of carbon nanotubes being 0.01%-0.8%, the mass fraction of polycaprolactam being 50%-60%, and the rest being propylene solvent. , and then ultrasonically treat the mixed solution to obtain a solution of a composite material composed of carbon nanotubes and polycaprolactam. Specifically, the ultrasonic frequency is generally controlled between 15KHZ-50KHZ.

[0109] S202, filtering and purifying the solution of the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com