Patents

Literature

580results about How to "Strong wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

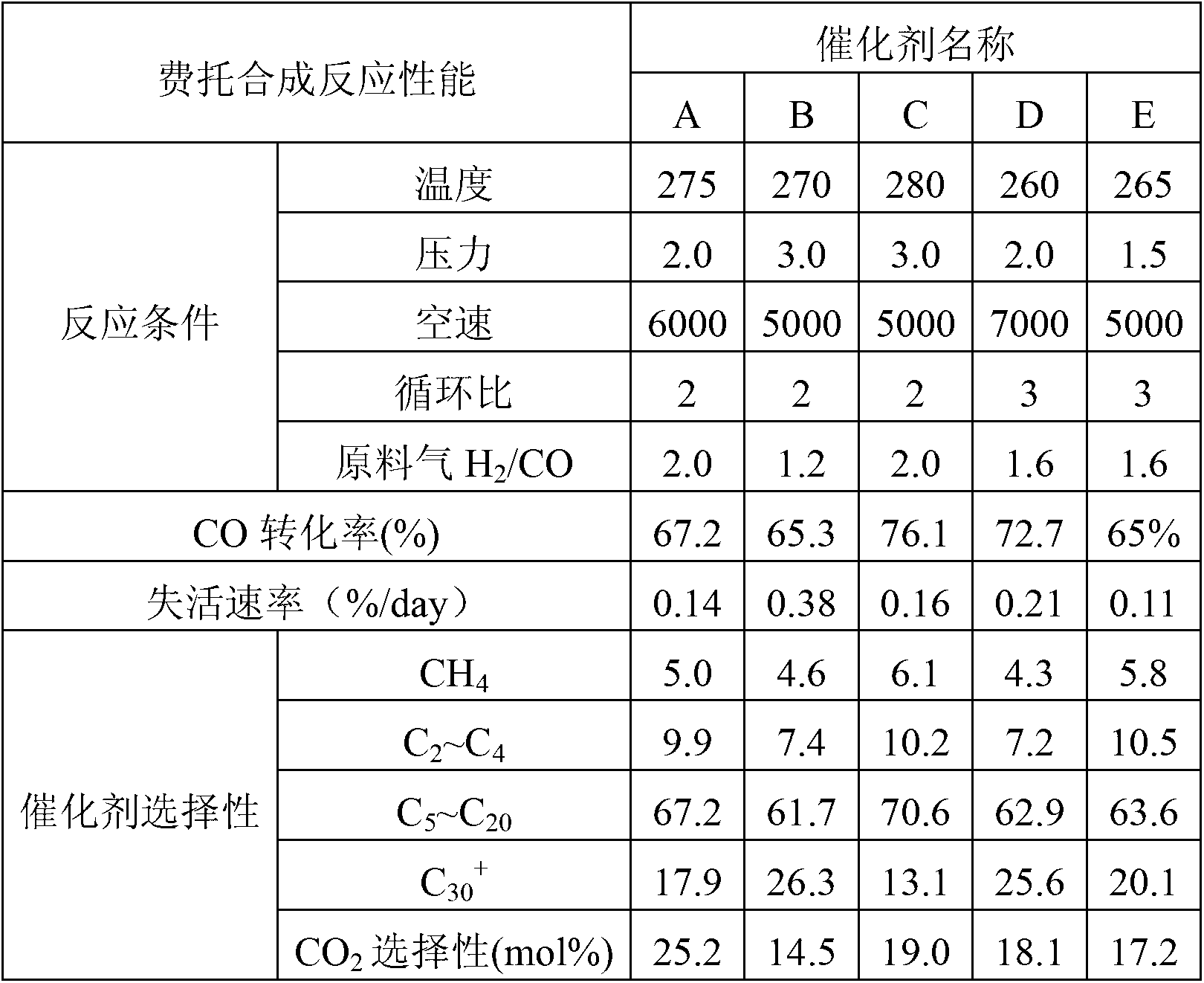

Reduction method for iron-based catalyst for Fischer-Tropsch synthesis in fixed bed

ActiveCN103071543AReduce carbon depositionHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionHydrogenFixed bed

The invention discloses a reduction method for an iron-based catalyst for Fischer-Tropsch synthesis in a fixed bed. The method comprises the following steps: adding the iron-based catalyst into a fixed bed reactor; and introducing gaseous hydrocarbon or mixed gas of hydrogen and gaseous hydrocarbon into the fixed bed reactor for reduction reaction to reduce the iron-based catalyst. The reduction method has the advantages that (1) the reduced catalyst has a little carbon deposit, so the catalyst has high activity and stability; (2) the product selectivity of the catalyst can be effectively modulated, and the selectivity for C5-30 in products is high; and (3) the reduced catalyst has a little carburization, so the catalyst has high wear resistance.

Owner:SYNFUELS CHINA TECH CO LTD

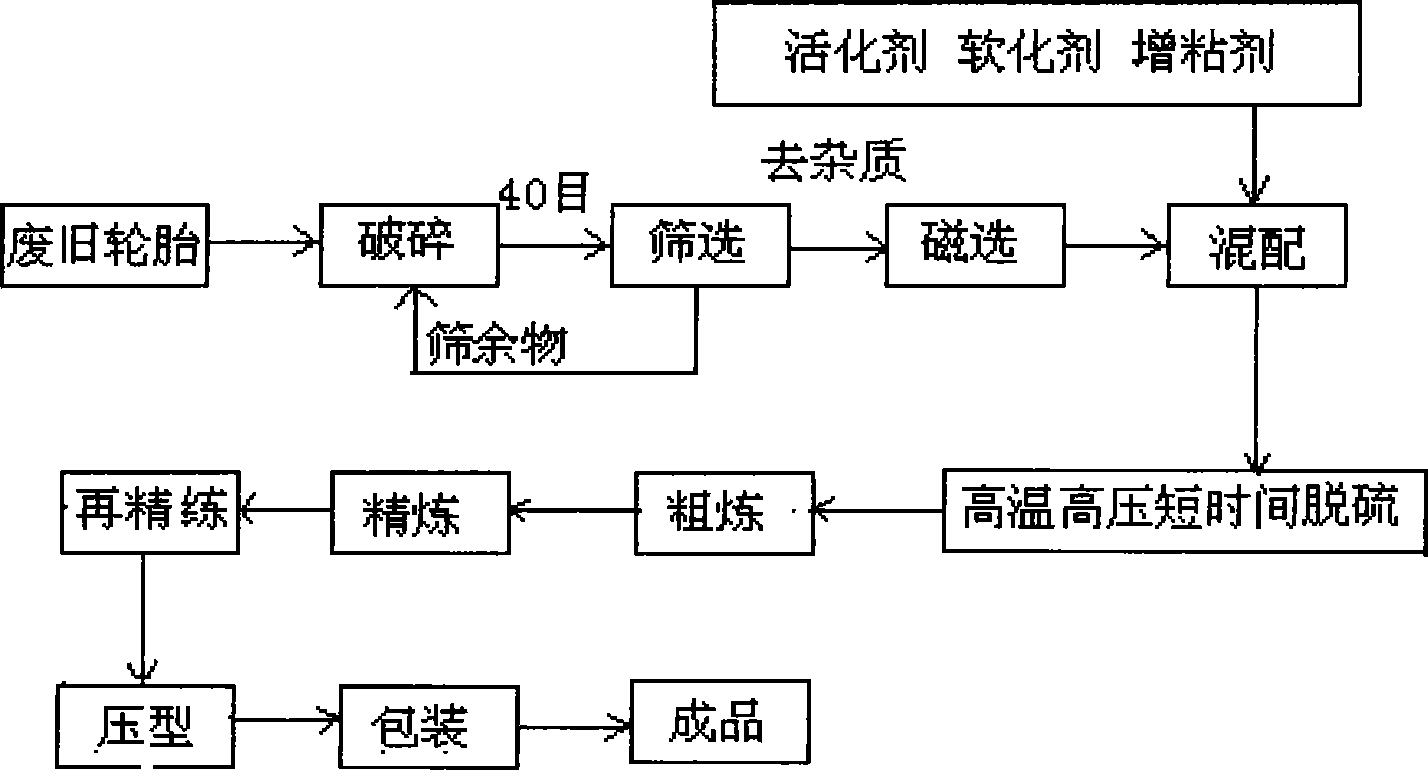

High-quality regenerated rubber and its production

InactiveCN101074302AStrong wear resistanceExtended service lifePlastic recyclingHigh pressureTemperature and pressure

A high-quality regenerated rubber and its production are disclosed. It improves composition and proportion, it adopts high-temperature and pressure desulfurizing method in short time and refining process is added. The tensile strength and breaking extensibility can be increased by 30-60%; it can substitute natural rubber or synthetic rubber and be used as various tyre and raw material of rubber products. It's simple, efficient and smokeless, has excellent abrasive performance, long life, less noise and no refused water discharge.

Owner:QINGWEI RUBBER SUQIAN

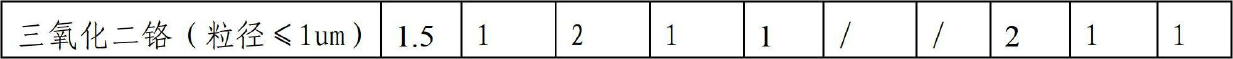

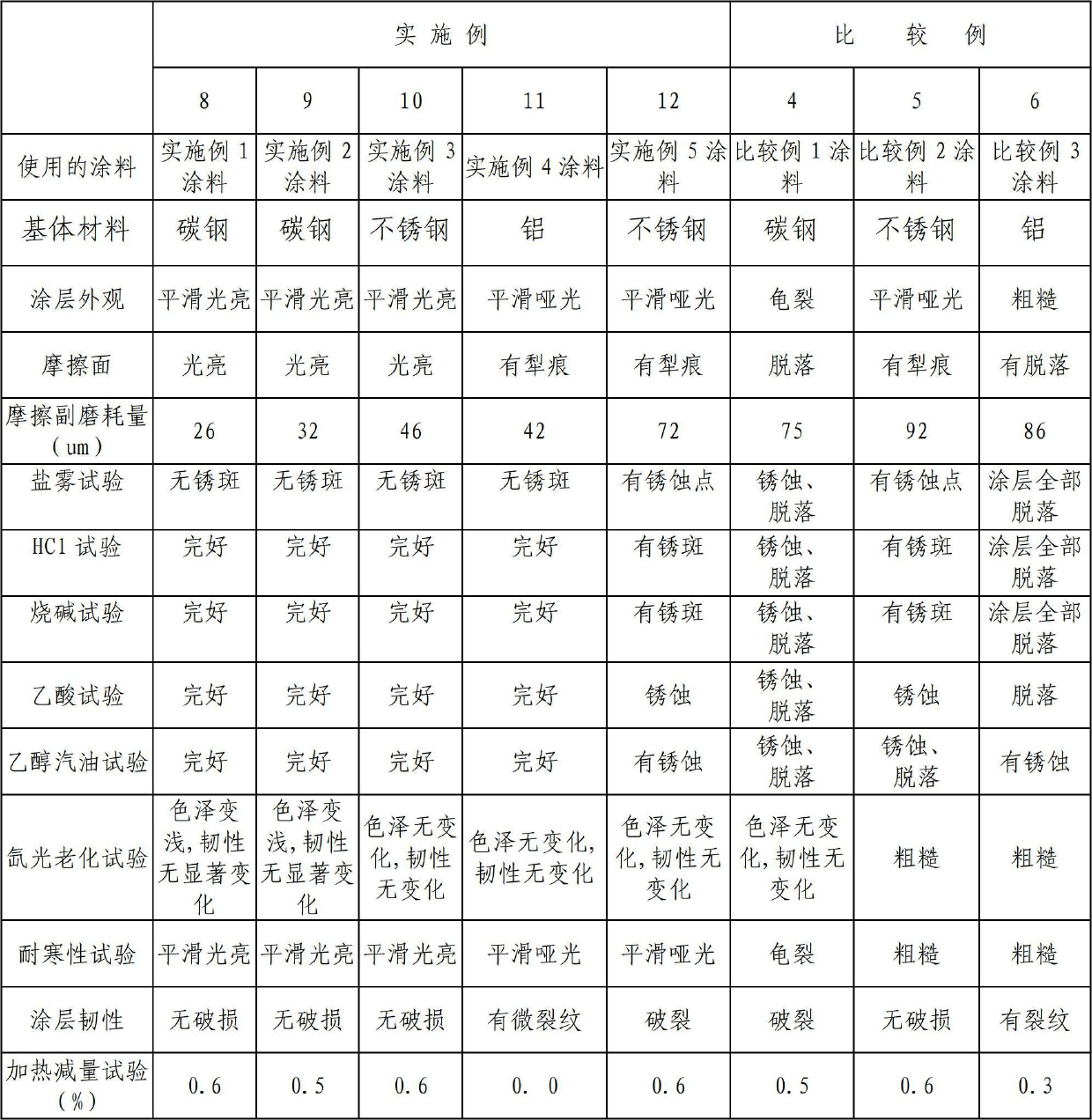

Modified polyphenylene sulfide coating and application thereof

ActiveCN102676048AImprove corrosion resistanceSelf-lubricatingAnti-corrosive paintsWear resistantCorrosion

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Owner:CHENGDU LETIAN PLASTICS

Catalyst used for direct preparation of light olefin from synthetic gas, preparation method and application thereof

InactiveCN103157489ALow priceLow costHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSyngasAlkane

The invention relates to a catalyst used for direct preparation of light olefin from synthetic gas, a preparation method and an application thereof. According to the invention, a parallel flow precipitation method is used to highly disperse Fe and auxiliary agents on surfaces of self-made alkaline carriers, and thus a catalyst load is low, a preparing technology is simple and a cost is lower than that of product with a same type. When the catalyst is used for direct preparation of the light olefin from the synthetic gas, a CO conversion rate can reach 75-85 % under a one-way catalytic condition of the synthetic gas, an alkene-alkane ratio can reach 4.5-6.0 in organic gas products, an alkene weight is 50-60 % and more than 98% of the liquid product is water. The catalyst is good in abrasion resistance and pressure resistance, and can be used for slurry beds and fixed beds. A reaction technology of the catalyst is that the temperature is 200-500 DEG C, a pressure is 0-5 MPa, and an air speed of the synthetic gas is 600-2400 <-1>.

Owner:SHANXI LUAN MINING GRP +1

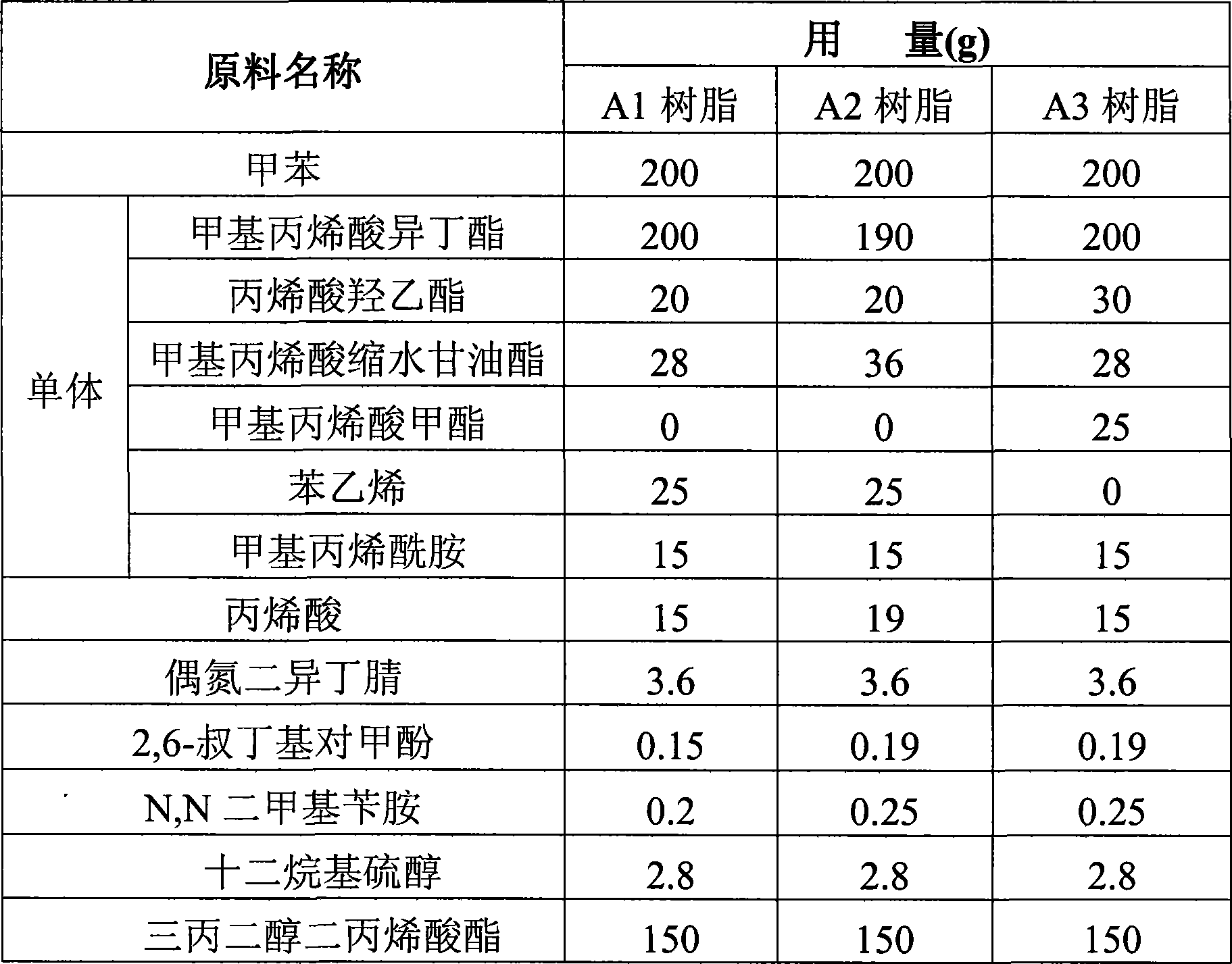

Ultraviolet light curing oil polish and preparation thereof

The invention provides ultraviolet solidifying gloss oil and a preparation method thereof. The ultraviolet solidifying gloss oil comprises 30 to 65 percent of reactive oligomer, 20 to 60 percent of reactive diluent, 4 to 15 percent of photoinitiator, and 0.1 to 2 percent of additive. The ultraviolet solidifying gloss oil is prepared by the following steps: adding the reactive oligomer, the reactive diluent and the additive in turn into a reaction kettle and agitating the mixture evenly; then adding the photoinitiator and agitating the mixture at a high speed to dissolve the photoinitiator; and finally adding the additive into the reaction kettle. The ultraviolet solidifying gloss oil has excellent adhesion, high brightness and abrasion resistance, and no easy leakage on paper printed work. When the ultraviolet solidifying gloss oil is applied to the printed work and no low oil is required. The ultraviolet solidifying gloss oil is particularly suitable for the direct online glazing on a printer, saves time and reduces the production cost, and has the same good adhesion to non-absorbent objects to be printed such as plastics.

Owner:恒昌涂料(惠阳)有限公司

Axle gear ring tray machining process

The invention discloses an axle gear ring tray machining process which includes blank preparation, rough machining, heat treatment, semi-finishing, finish machining and product inspection. The heat treatment adopts thermal refining treatment, so that machined axle gear ring trays can be high in surface hardness and abrasion resistance, and the service life of the machined axle gear ring trays can be prolonged.

Owner:QIJIANG HEAVY DUTY TRUCK GEAR

Alkyne selective hydrogenation catalyst carrier and preparation method and catalyst thereof

InactiveCN102688783ASimple manufacturing processStrong impact resistanceCatalyst carriersHydrocarbon purification/separationRare-earth elementAlkaline earth metal

The invention discloses an alkyne selective hydrogenation catalyst carrier and a preparation method thereof; the hydrogenation catalyst carrier is obtained by well mixing and compounding alumina with one or two of SiC and talcum, and a catalyst containing an active ingredient of palladium is prepared. The catalyst can also contain co-catalytic ingredients of Ag, Mn, Bi, Mo, W, Cu, Zn, alkali metal, alkaline earth metal, and rare earth elements. The catalyst carrier has low raw material cost, and the obtained catalyst has high selective hydrogenation activity and good selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

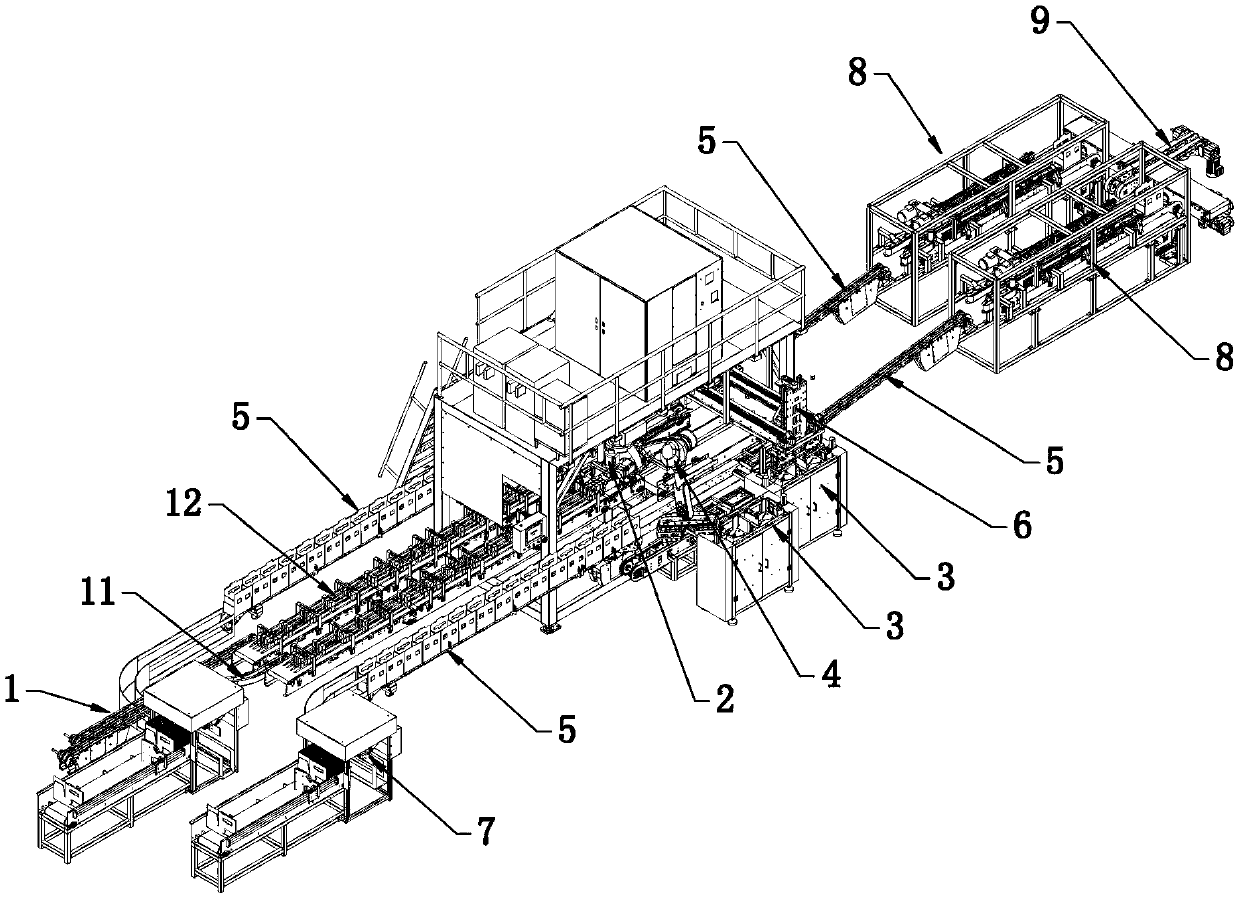

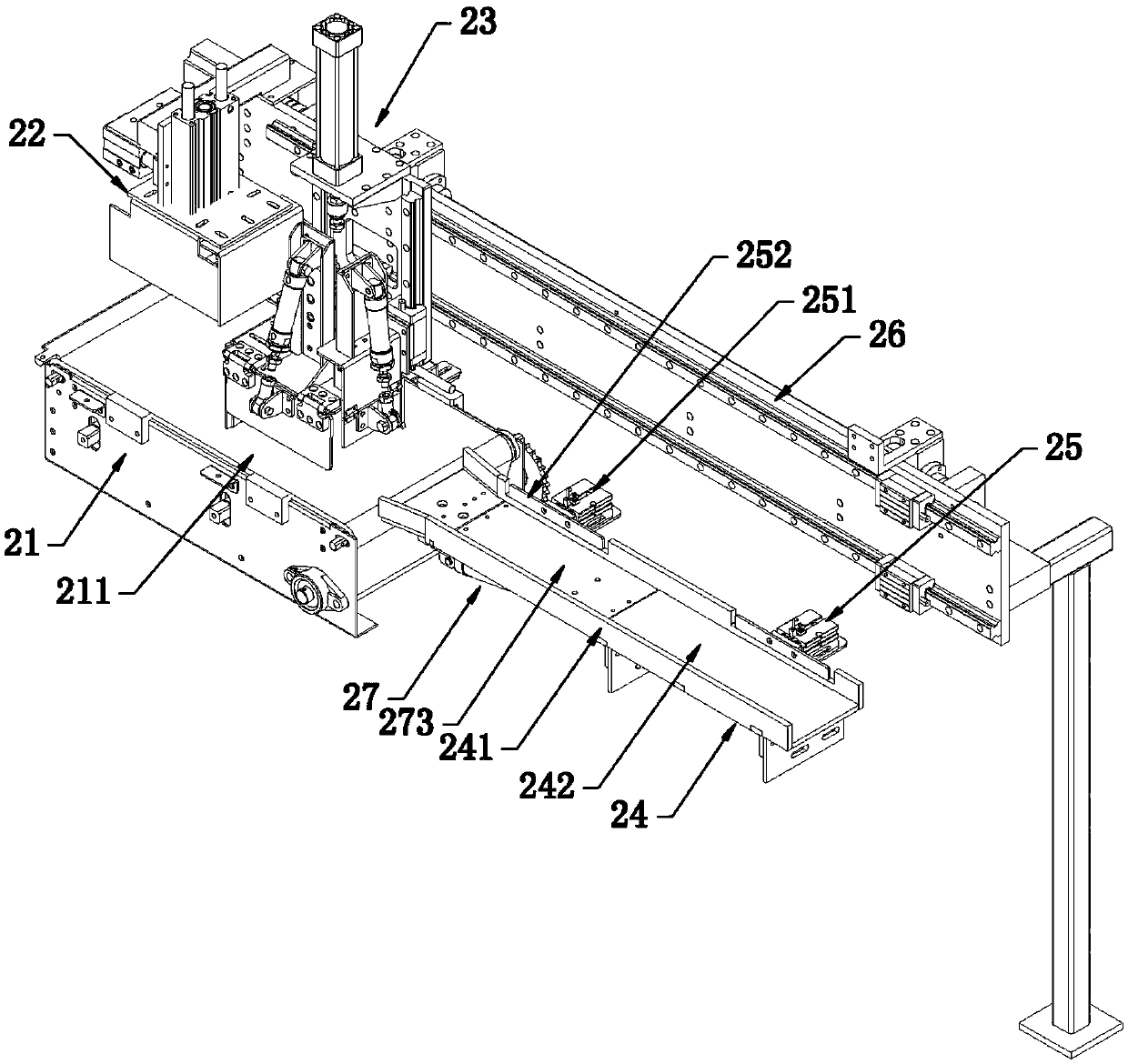

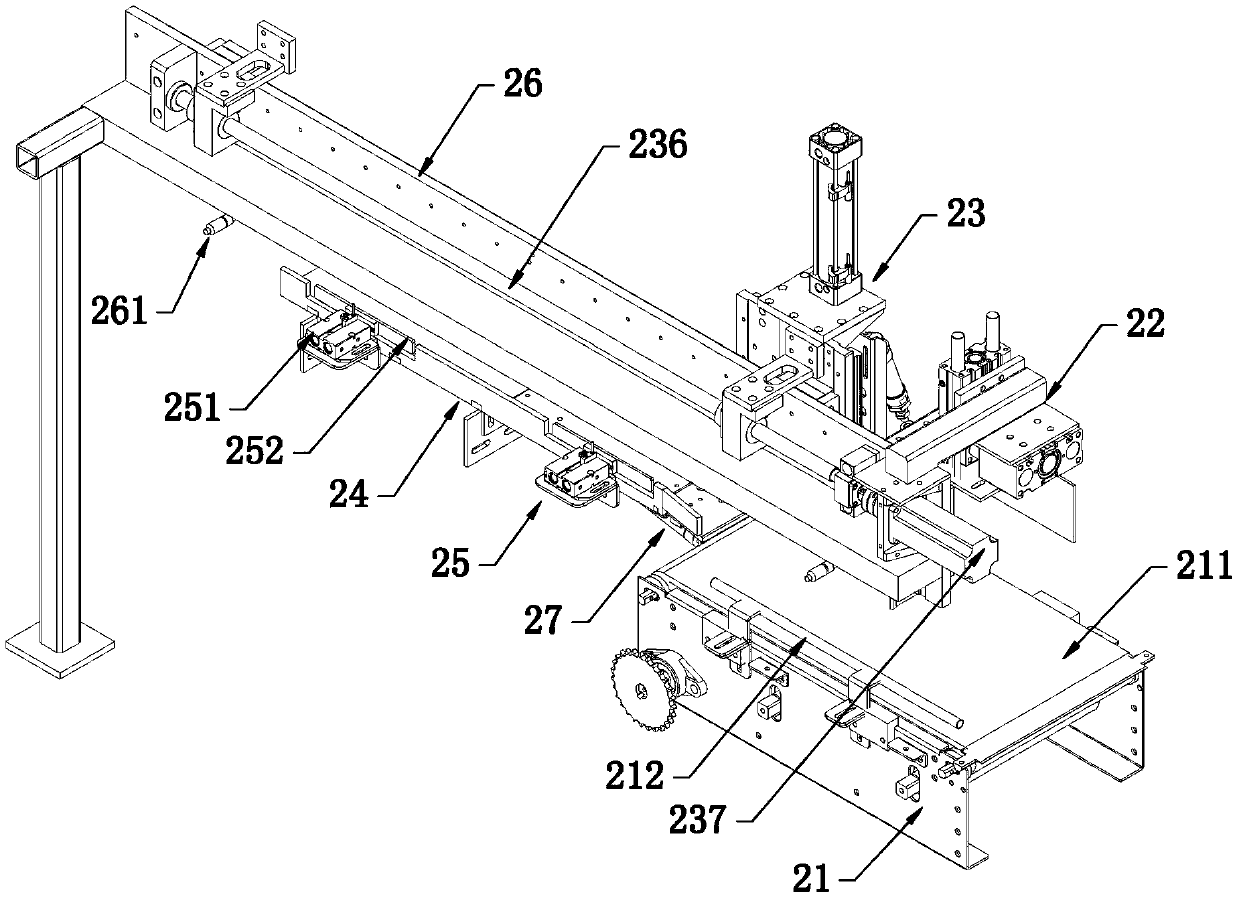

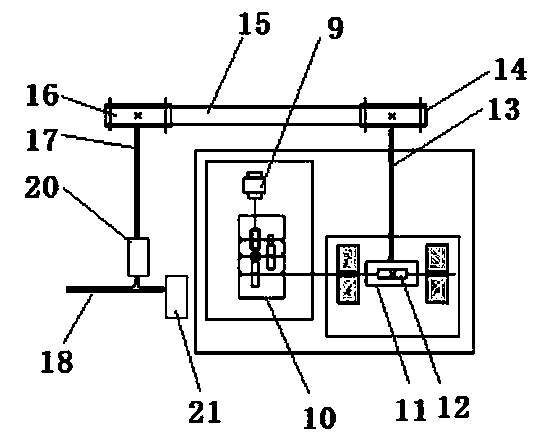

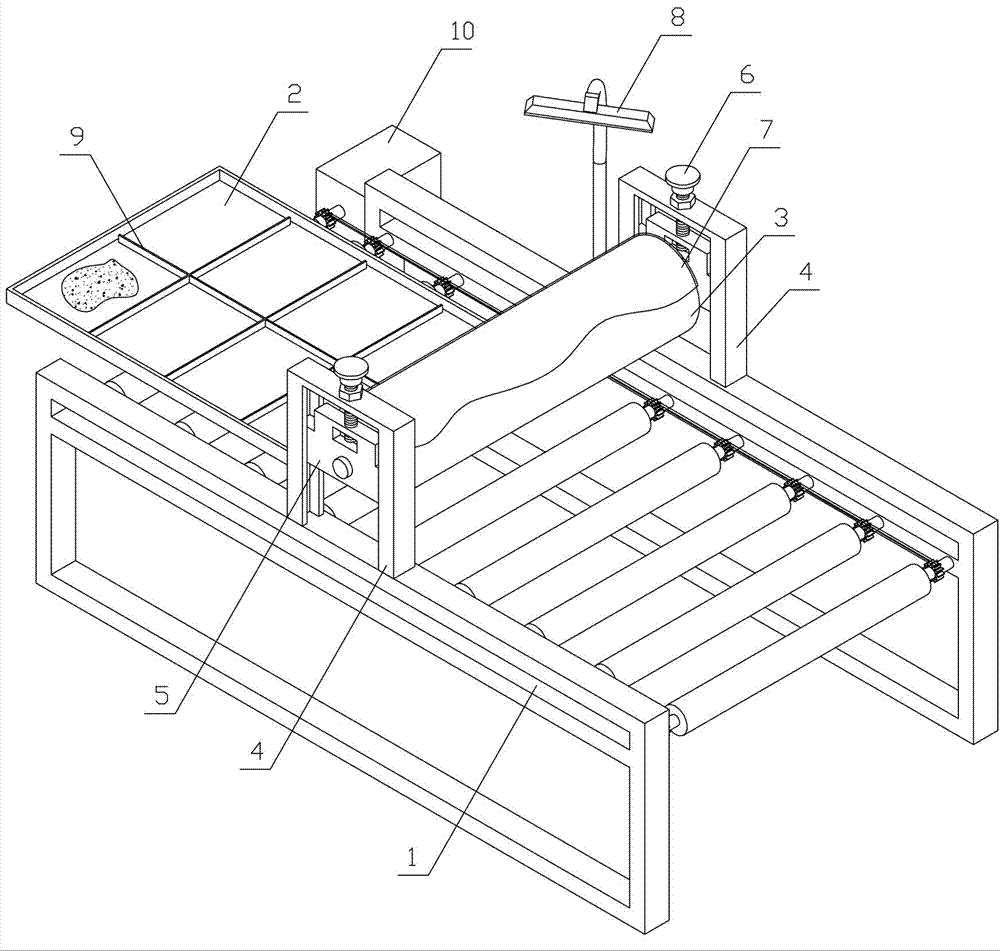

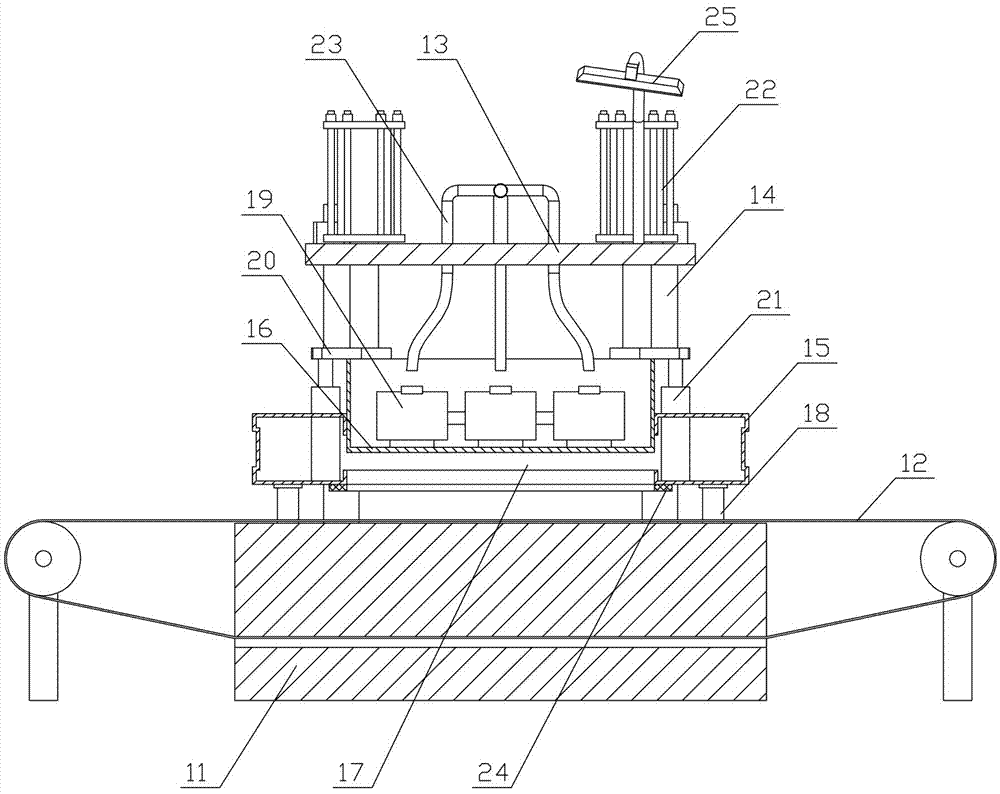

Automatic boxing system for second generation of tetra brik milk bag gift box

ActiveCN105501526AImprove the operating environmentImprove stabilityConveyorsPackagingEngineeringMechanical engineering

The invention discloses an automatic boxing system for a second generation of tetra brik milk bag gift box. The automatic boxing system comprises a separation mechanism (1), wherein the separation mechanism (1) comprises a primary separation mechanism (11) and two secondary separation mechanisms (12); an integration device (2) is correspondingly arranged at the tail end of each secondary separation mechanism (12), and two groups of partition board feeding mechanisms (3) and a milk box conveying line (5) which are corresponding are arranged beside each integration device (2) successively, the two groups of partition board feeding mechanisms (3) are respectively sleeved with lower partition boards, and a milk bag unit inbox mechanism (4) corresponds to an upper partition board straight-line module (6). A milk box sleeved with the partition board is conveyed to a corresponding lid buckling and box sealing machine (8) for lid buckling and box sealing through the milk box conveying line (5), and a two-in-one conveying mechanism (9) on the rear side of the lid buckling and box sealing machine (8) continues to convey the milk box. The automatic boxing system carries out automatic boxing in a two-in-one way, therefore reducing the speed, reducing links and increasing the output.

Owner:苏州澳昆智能机器人技术有限公司

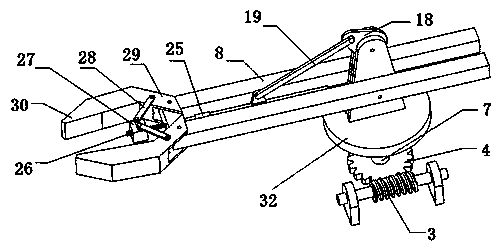

Three-freedom degree manipulator

InactiveCN103878763AStrong wear resistanceFlexible liftingProgramme-controlled manipulatorGripping headsDegrees of freedomEngineering

The invention relates to the technical field of mechanical automation, in particular to a three-freedom degree manipulator which is formed by a base assembly, an arm assembly and a gripper assembly. The arm assembly is arranged on the base assembly, and the gripper assembly is arranged at the end of the arm assembly. The three-freedom degree manipulator has the advantages that a three-freedom degree manipulator work station can be applied to automatic meal delivery of the catering industry and mechanical principle and designed experiment practical teaching of colleges and universities, and the automation degree reaches the international advanced level; the base assembly, the arm assembly and the gripper assembly are installed as a set, a mechanical structure is high in abrasion resistance, and the manipulator is safer and more reliable in operation.

Owner:JIANGSU UNIV

Rubber seal material formula

InactiveCN104262724AReduce coefficient of frictionStrong wear resistanceVulcanizationMechanical equipment

The invention relates to a rubber seal material formula which comprises 25 parts of hydrogenated nitrile-butadiene rubber, 70 parts of chloroprene rubber, 50 parts of acrylate rubber, 20 parts of silicon rubber, 30 parts of polyurethane rubber, 3 parts of plasticizer, 2 parts of softening agent dioctyl ester, 2 parts of activator zinc oxide, 1 part of oleyl alcohol, 9 parts of sulfur, 1 part of diacetyl peroxide, 2 parts of hydroxy silicon oil, 2 parts of alumina, 8 parts of flame retardant and 2 parts of anti-aging agent sulfydryl benzimidazole. Compared with the prior art, the rubber seal material provided by the invention can bear higher pressure, has the advantages of low friction factor and high abrasion resistance; and more scientific and reliable proportioning is performed in the vulcanization system and filler system to better display the synergistic action and prolong the normal working time of mechanical equipment.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Preparation method of chinlon 6 cool jade fiber

ActiveCN103757738AStrong wear resistanceStrong coolnessArtifical filament manufactureMonocomponent polyamides artificial filamentWoven fabricAluminium

The invention discloses a preparation method of a chinlon 6 cool jade fiber. The fiber is prepared by the steps of adopting an extraction technology and a nanotechnology, allowing jade and other beneficial mineral materials such as aluminum, silicon, titanium, zirconium and other elements to reach the sub-nanometer particle size, then fusing into a chinlon 6 melt, and carrying out spinning processing to obtain the fiber. The chinlon 6 cool jade fiber has the strength equivalent to a conventional chinlon 6 fiber, has strong wear resistance, has strong cool feel compared with an ordinary silk woven fabric, and is simple in spinning process and high in practicability.

Owner:FUJIAN JINJIANG TECH

Biodegradable quasi dry cutting oil and preparation method thereof

InactiveCN102002419AGood lubricityGood extreme pressure and anti-wear propertiesLubricant compositionChemistryPolyester

The invention relates to the technical field of chemistry, in particular to biodegradable quasi dry cutting oil and a preparation method thereof. The biodegradable quasi dry cutting oil is characterized in that the cutting oil is prepared from the following raw materials in percentage by weight: 30 to 40 percent of diester, 30 to 40 percent of polyol ester, 20 to 30 percent of poly alpha-olefin PAO20, 5 to 6 percent of zinc dialkyl dithiophosphate (ZDDP), 2 to 3 percent of polyester and 1 to 2 percent of N-laurel acyl alanine. Compared with the prior art, the cutting oil has good lubricating property and extreme pressure abrasion resistance, is biodegradable, and reduces the environmental pollution to minimum.

Owner:上海通快实业有限公司

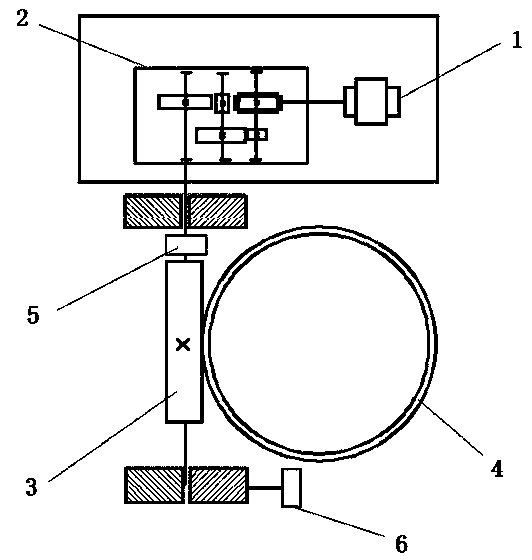

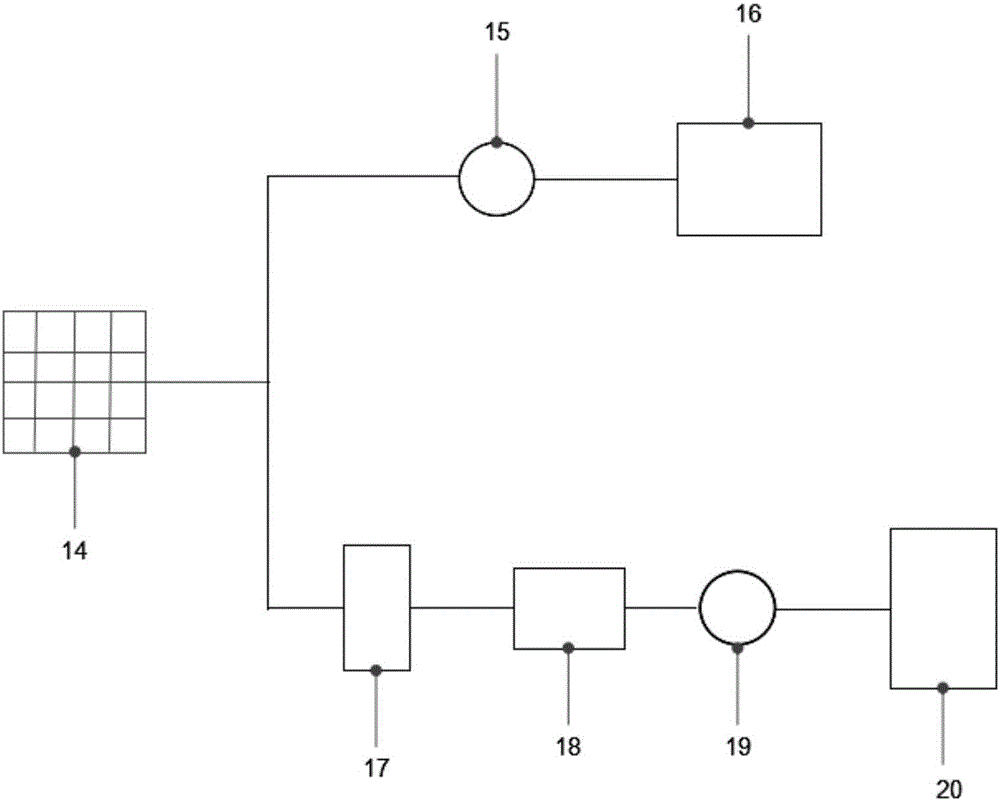

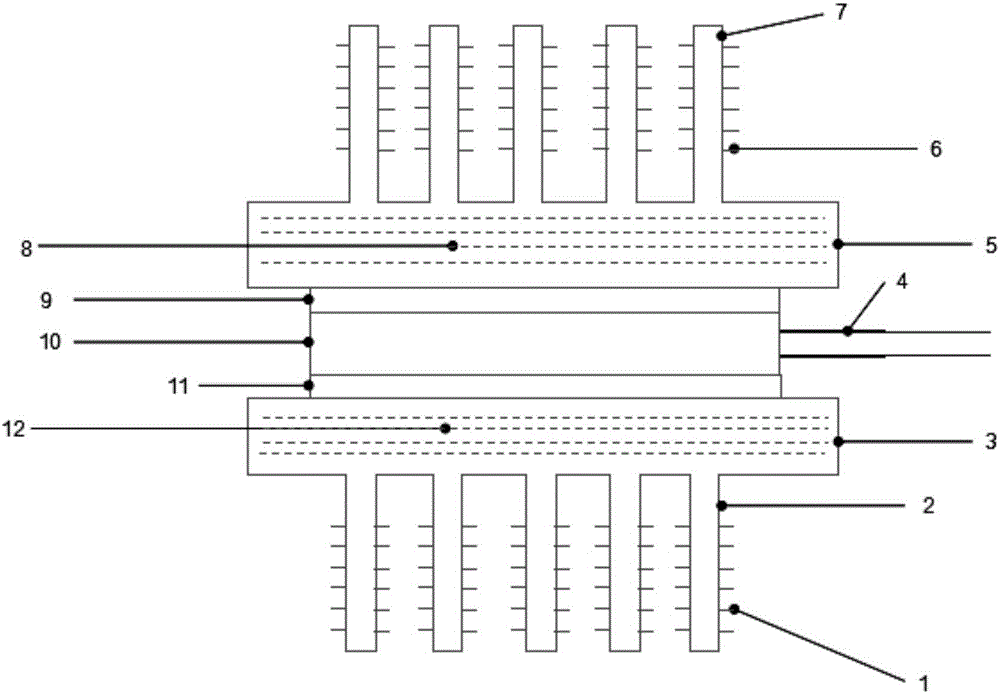

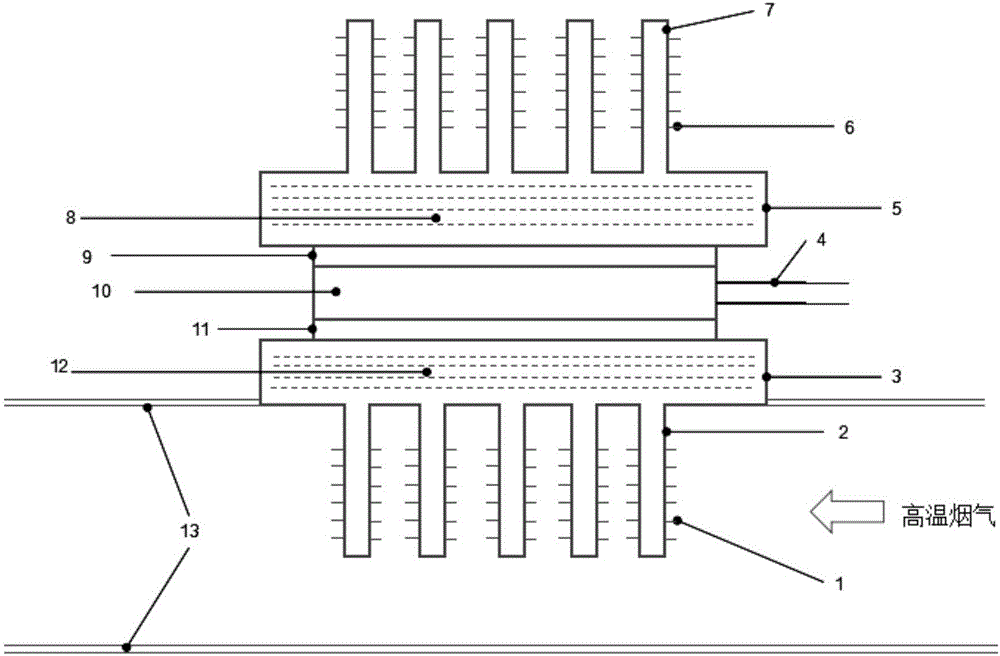

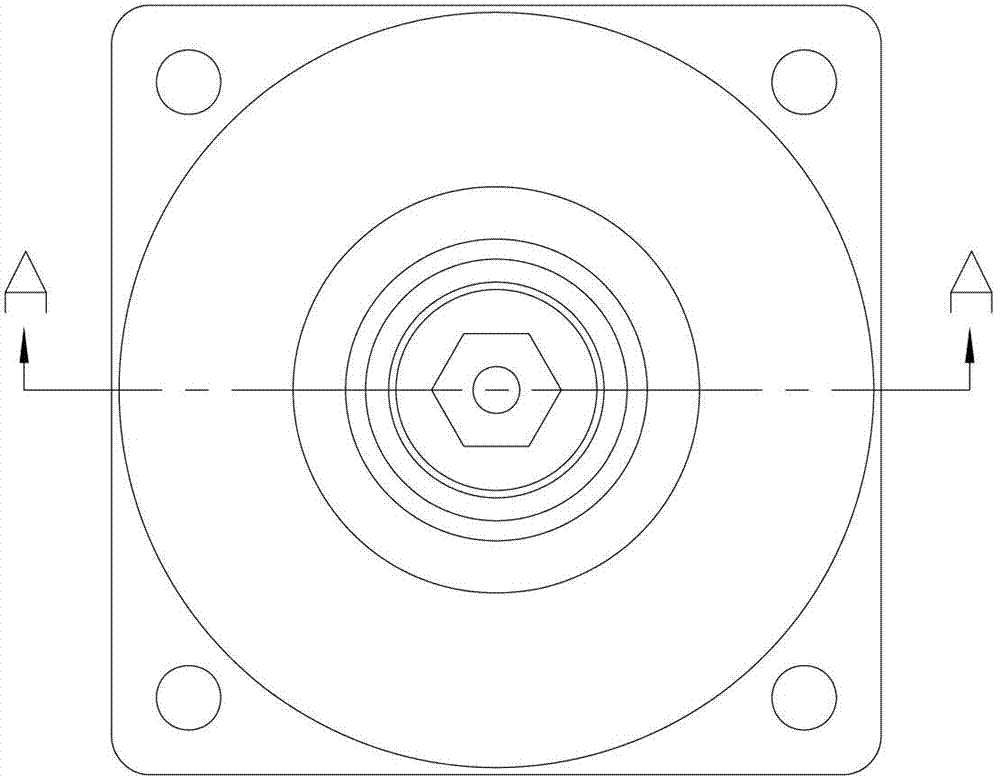

Heat-pipe thermoelectric power generation energy storage and power transmission system for rear smoke channel of boiler

InactiveCN107528499AReduce wearIncrease heat transfer areaIndirect heat exchangersGenerators/motorsElectric power transmissionSolid particle

The invention relates to a heat-pipe thermoelectric power generation energy storage and power transmission system for a rear smoke channel of a boiler, and the system comprises a thermoelectric power generation system, an energy supply system, and an energy storage system. A thermoelectric power generation unit in the thermoelectric power generation system comprises a cold-end heat pipe device, a hot-end heat pipe device and a thermoelectric power generation piece disposed between the cold-end heat pipe device and the hot-end heat pipe device, wherein the cold-end heat pipe device and the hot-end heat pipe device are vertically arranged in a structure. The thermoelectric power generation piece is disposed on the rear smoke channel, and the hot-end heat pipe device of the thermoelectric power generation unit makes contact with the high-temperature flue gas to absorb heat, and maintains the high temperature of the hot surface of the thermoelectric power generation piece. The cold-end heat pipe device makes contact with the ambient atmosphere, and maintains the low temperature of a cold surface of the thermoelectric power generation piece. A direct current generated by the thermoelectric power generation system is converted and then is outputted to an electric appliance. Meanwhile, the redundant electric energy is directly stored in the energy storage device. Two ends of the thermoelectric power generation piece form a big temperature difference through the high-efficiency thermal conduction characteristics of a hot pipe, thereby improving the power generation efficiency of the thermoelectric power generation piece. The hot pipe is changed to be elliptical, thereby effectively reducing the wear, caused by solid particles, of the hot pipe.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

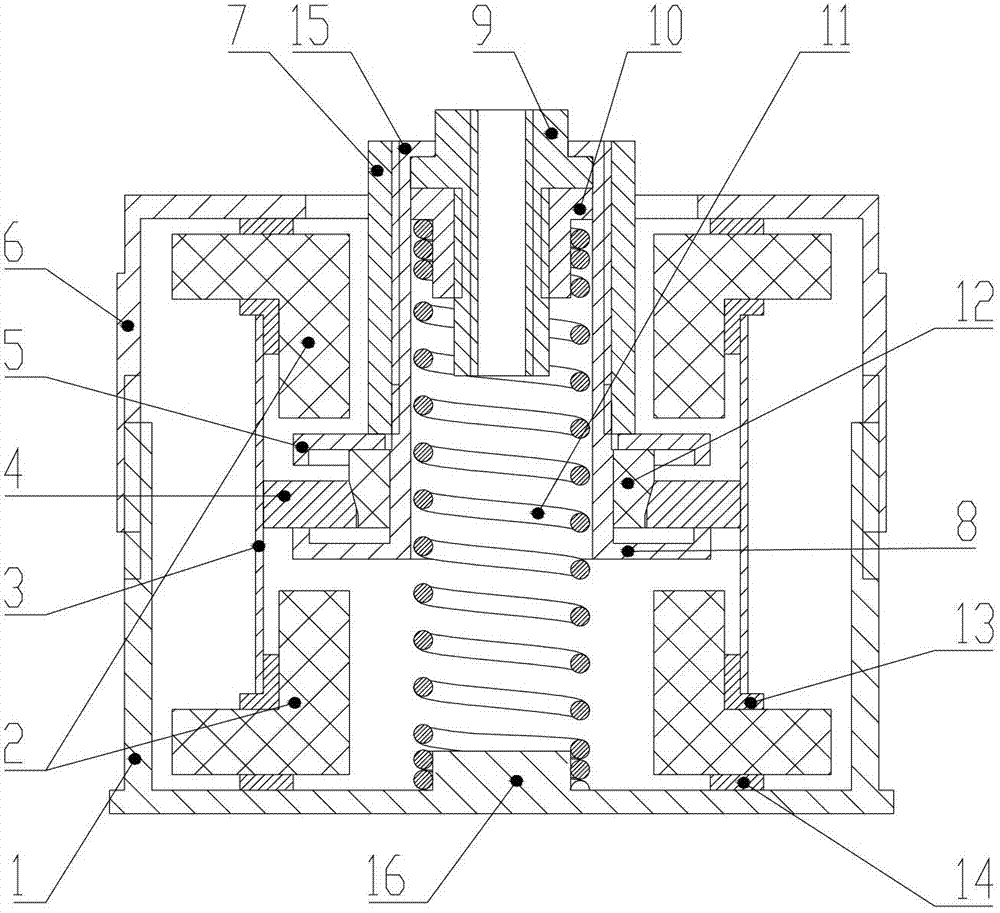

Three-directional friction adjustable strong-impact-resisting vibration isolator

InactiveCN103161864AAvoid damageExcellent variable stiffness and variable damping characteristicsElastic dampersShock absorbersEngineeringVibration isolation

The invention provides a three-directional friction adjustable strong-impact-resisting vibration isolator comprising a base, an upper cover, a vibration isolation spring component, a damping buffering component and a shock insulation component, wherein the damping buffering component comprises a friction sheet and a friction ring and the inner surface of the friction ring contacts with the outer surface of the friction sheet. The shock insulation component comprises a rubber block, a metal ring and a gasket, wherein the friction ring is arranged on the metal ring in a sleeved mode. The rubber block is clamped between the metal ring and the gasket, wherein the gasket contacts with the base or the upper cover. The three-directional friction adjustable strong-impact-resisting vibration isolator is strong in shock insulation performance and particularly suitable for a vibration isolation system in military electronic equipment. Besides, the three-directional friction adjustable strong-impact-resisting vibration isolator further has the advantages of bringing convenience to the spacial three-directional friction damping regulation, being anti-abrasive, being corrosion resisting and the like.

Owner:CHONGQING UNIV

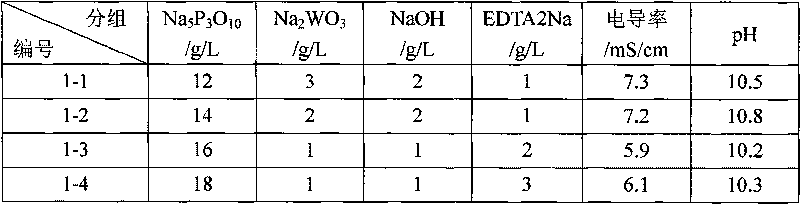

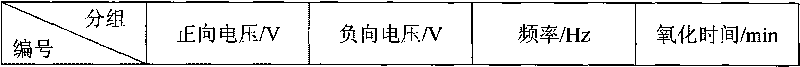

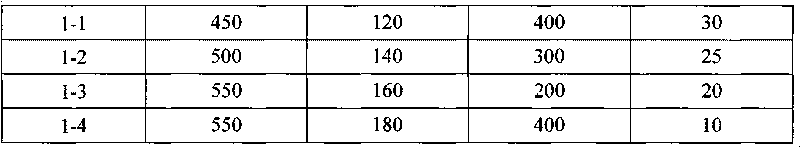

Electrolyte and technology for preparing ceramic coating formed by plasma micro-arc oxidation on zirconium alloy surface

InactiveCN101713091AExtended service lifeImprove wear resistanceSurface reaction electrolytic coatingAlkalinityMicro arc oxidation

The invention discloses an electrolyte and technology for preparing a ceramic coating formed by plasma micro-arc oxidation on a zirconium alloy surface. The technology comprises the following steps: (1) preparing the electrolyte; (2) treating the zirconium alloy surface; and (3) carrying out the micro-arc oxidation technology. The invention has the advantages that the electrolyte is water solution of various compounds, can provide a micro-arc discharge center, and has proper acidity and alkalinity, good ionic conductivity and chemical stability; the solutes of the electrolyte have wide source and low price; the treatment of the zirconium alloy surface has low requirement, and the micro-arc oxidation technology is simple and convenient in control; the ceramic coating formed by micro-arc oxidization has larger thickness, and by adjusting the formula of the electrolyte and the conditions of the micro-arc oxidation technology, the thickness of the ceramic coating can be controlled in a range of 30-80 micrometers; and the ceramic coating has good wear resistance and corrosion resistance.

Owner:INNER MONGOLIA UNIV OF TECH +1

Atomizing molding method of TS-1 titanium silicalite molecular sieve catalyst

InactiveCN102989503AHigh mechanical strengthStrong wear resistanceMolecular sieve catalystsMolecular sievePtru catalyst

The invention provides an atomizing molding method of a TS-1 titanium silicalite molecular sieve catalyst. The atomizing molding method is characterized by comprising the steps of preparing TS-1 raw powder, silica sol and boric acid into uniform slurry according to a ratio; adopting the atomizing molding method to mold the catalyst; and drying and roasting to obtain the TS-1 catalyst. In a molding process, the boric acid is introduced and the mechanical strength and the wear-resisting degree of the molded catalyst are improved after the catalyst is roasted; abrasion caused by impact and fluid flowing, which are generated in transportation, filling and utilization processes, can be effectively resisted; and according to the atomizing molding method, the service life of the catalyst is prolonged.

Owner:DALIAN LIGONG QIWANGDA CHEM TECH +1

Method for preparing activated kaolin by washing kaolin with water

ActiveCN104045092AOptimizing the firing temperatureOptimize dwell timeSilicon compoundsRebarChemistry

The invention belongs to the technical field of the production process of activated kaolin and in particular relates to a method for preparing activated kaolin by washing kaolin with water. The method comprises the steps of preparing a kaolin filter cake, preparing kaolin dry powder, thermally activating kaolin, and preparing activated kaolin by performing depolymerization and modification on the thermally activated kaolin. Deep treatment is performed on kaolin resources by use of processes such as appropriate-temperature calcination, efficient depolymerization and dispersion and modification on the basis of the traditional treatment process of washing the kaolin with water, therefore, the activated kaolin having the characteristics of volcanic ash can be prepared; the activated kaolin can be applied to the fields such as a high-grade concrete additive, a cable filler, a water-based coating and the like, and has the characteristics of short setting time, high early strength, shrinkage compensation, no corrosion to reinforcements, high resistivity and the like; as a result, the valued added of the kaolin resources can be increased, and the activated kaolin has enormous market space potential.

Owner:北海高岭科技有限公司

Reduction method of syrup state bed Fischer Tropsch synthesis iron base catalyst

ActiveCN1651136AReduce capacityEasy to operateHydrocarbon from carbon oxidesCatalyst activation/preparationSlurryHigh pressure

A reduction process for Fischer-Tropsch synthesis of iron-base catalyst in slurry bed includes adding liquid-phase hydrocarbon medium and catalyst to slury-bed reactor, displacing air, programmed heating, reducing catalyst by H2 and then by CO, and Fischer-Tropsch synthesis.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

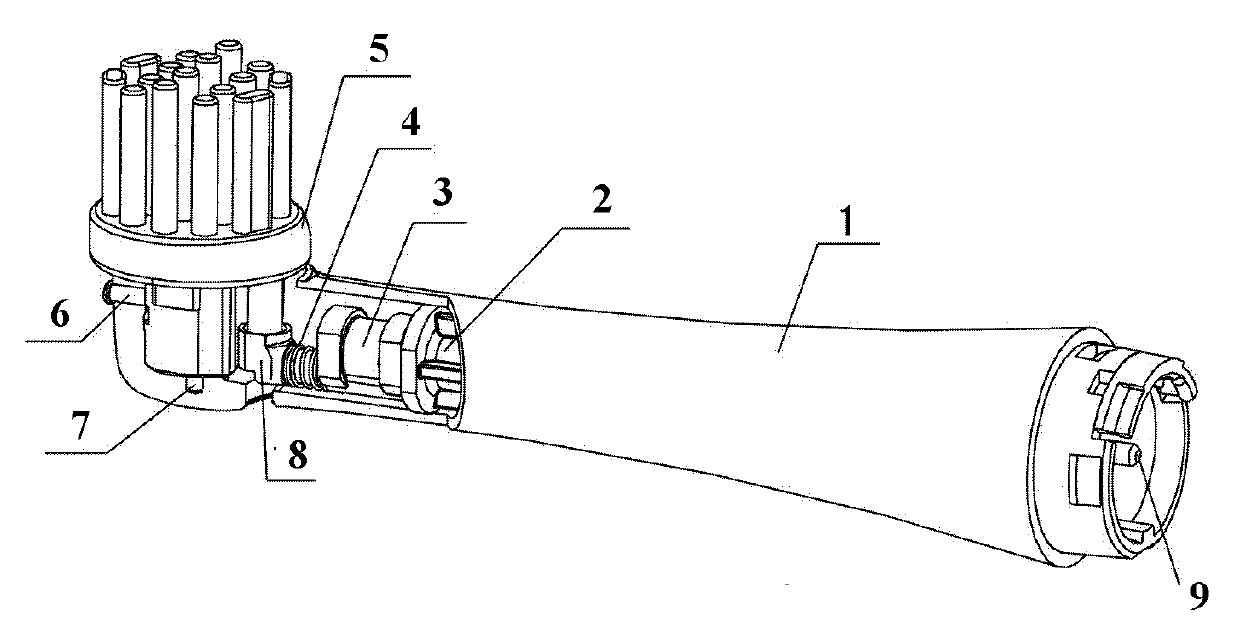

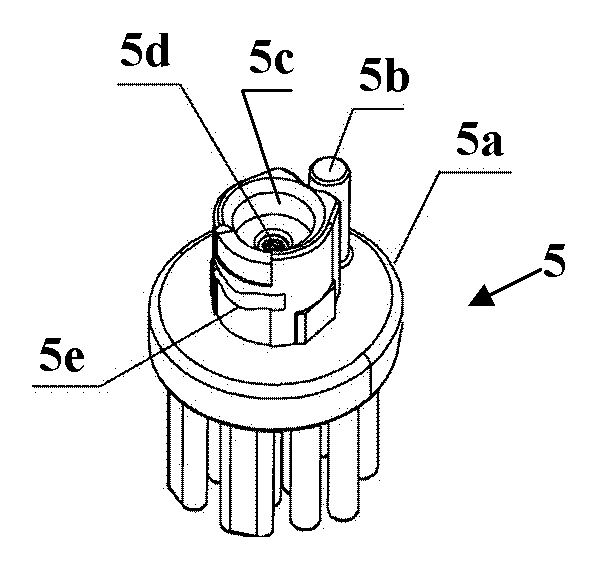

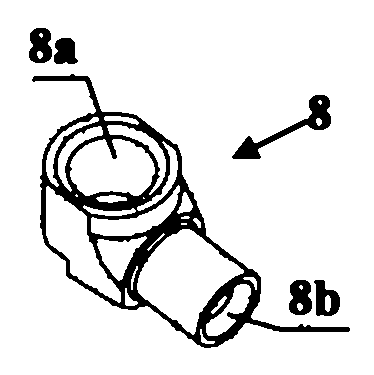

Electric toothbrush head and electric toothbrush

The invention provides an electric toothbrush head which comprises a brush rod (1) and a brush disc (5), wherein a transmission shaft (9) is mounted in the brush rod; an eccentric wheel (3) is mounted at the front end of the transmission shaft; the brush disc is mounted at the front end of the brush rod through a shaft hole connection device; a motion conversion device is arranged between the brush disc and the eccentric wheel and used for converting the linear motion of the eccentric wheel into reciprocating swing motion of the brush disc around a rotary shaft (7) of the motion conversion device; the motion conversion device comprises an L-shaped sliding sleeve (8), a protruding shaft (5b) arranged on the back of the brush disc and a smooth eccentric shaft (3a) arranged at the front end of the eccentric wheel; a first movable hole (8a) and a second movable hole (8b) vertical to each other are formed in the L-shaped sliding sleeve; the first movable hole is in movable fit with the protruding shaft; the second movable hole is in movable fit with the smooth eccentric shaft. The invention also provides an electric toothbrush with the electric toothbrush head. The electric toothbrush head has the characteristics of long service life, good safety, stable operation, low noise and the like.

Owner:OASIS GLOBAL

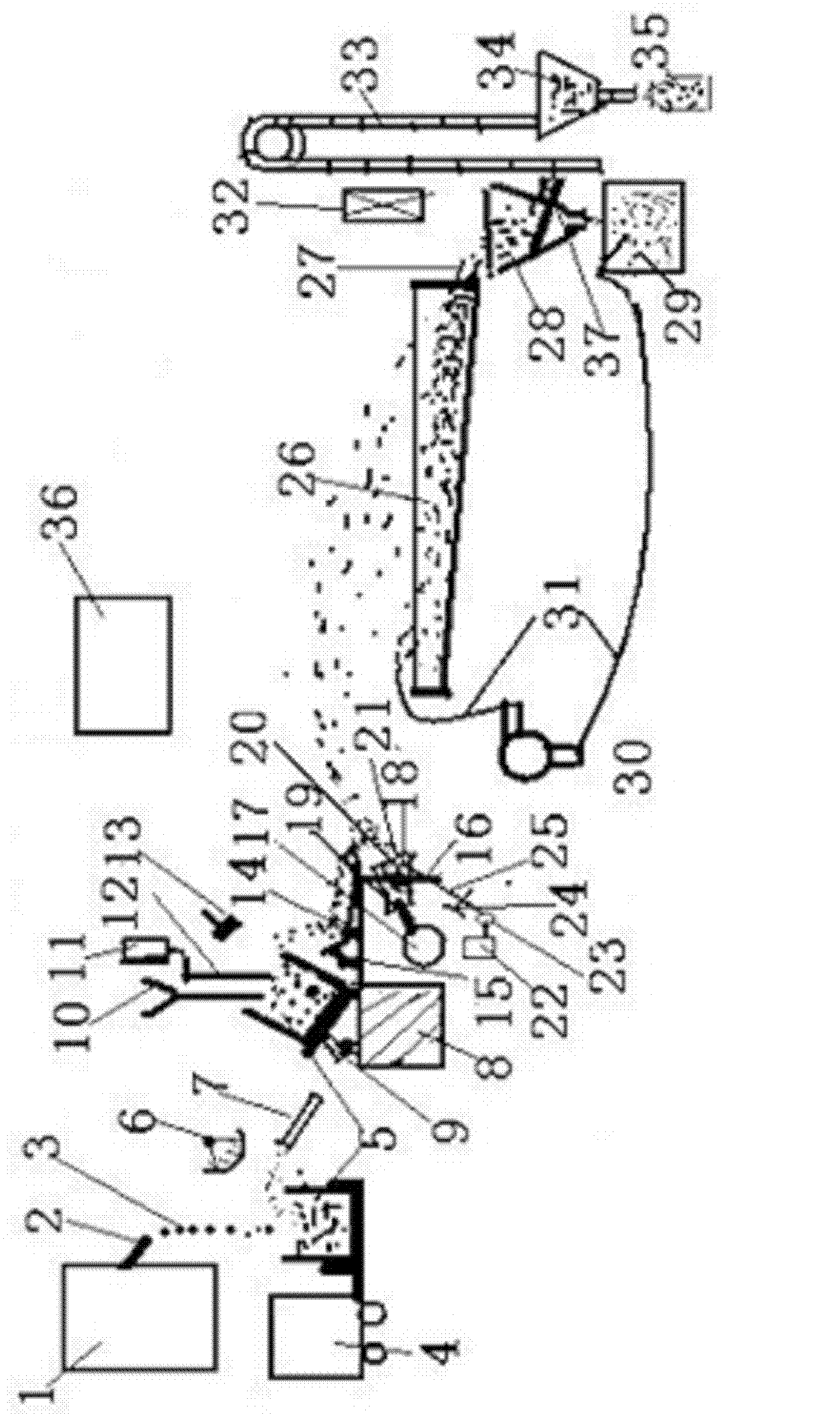

Steel slag ball production equipment and granulating system thereof

InactiveCN102690907AProlong the action timeFully oxidizedRecycling and recovery technologiesSlagAir compressor

The invention discloses steel slag ball production equipment and a granulating system thereof. The steel slag ball production equipment comprises the granulating system for spraying and cooling steel slag flowing out from a flowing groove by using high-pressure air water flow, wherein the granulating system comprises an air spraying mechanism and a cooling liquid spraying mechanism which are distributed up and down; the air spraying mechanism comprises an air compressor or a fan for supplying a high-pressure air source, and an air box for guiding air flow to be sprayed along a certain direction; the air box is provided with an air inlet and an air outlet; an air outlet of the air compressor or the fan is communicated with the air inlet of the air box through a pipeline; spraying panels are arranged at the front end of the air box; the spraying panels are provided with nozzles which are communicated with the air outlet of the air box; and more than two layers of spraying panels are arranged from top to bottom and each layer of spraying panel is horizontally provided with a plurality of nozzles in parallel. The granulating system of the steel slag ball production equipment adopts air and cooling liquid to commonly act on steel slag and the acting time in the air is long; the oxidization reaction is sufficient; the configuration of an organization is stable; and the granulating system can be used for grinding materials, building materials, water treatment, desulfurization agents and the like.

Owner:HENAN UNIV OF SCI & TECH

Wear-resistant alloy steel and preparation method thereof

The invention discloses wear-resistant alloy steel and a preparation method thereof. The alloy steel, prepared by the steps of smelting waste iron, waste steel and alloy containing silicon, manganese, chromium and molybdenum by using an intermediate frequency furnace, sampling and adjusting, moulding by casting and performing heat treatment, comprises the following components in percentage by weight: 0.33 to 0.55 percent of carbon, 0.60 to 1.20 percent of silicon, 1.50 to 3.20 percent of manganese, less than 0.04 percent of phosphorus, less than 0.04 percent of sulfur, 5.60 to 8.30 percent of chromium, 0.20 to 0.30 percent of molybdenum, 0.05 to 0.80 percent of vanadium and the balance of iron. According to the alloy steel, the wear resistance is greatly improved and is 2 to 5 times of that of high-chromium cast iron and high-manganese steel, the brittleness is low and the relative production cost is low.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

Preparation method of artificial quartz stone composite color plate

The invention provides a preparation method of an artificial quartz stone composite color plate. The quartz stone composite color plate is prepared from quartz sand with different meshes, quartz powder, unsaturated polyester resin, a coupling agent, a curing agent, and an accelerant through the steps of batching, mixing, dyeing, distributing materials, performing vacuum vibration forming, curing by a drying oven as well as grinding and molding. During preparation of the quartz stone composite color plate, the treatment method of the raw materials is unique and the used equipment is improved by an inventor, so that the prepared quartz stone composite color plate has higher quality, the problems that flowing and blooming phenomena are liable to occur in the preparation process of the quartz stone composite color plate are solved, and outstanding contribution is made for the artificial quartz stone industry.

Owner:湖北赛典新材料科技有限公司

Lightweight environment-friendly type pumice for ceramic ware and its production method and usage

InactiveCN1762910AStrong wear resistanceReduce cleanup workloadDry-cleaning apparatus for textilesCeramicwareSewage treatmentMetallurgy

The present invention relates to light environment friendly ceramic pumice and its manufacture and usage. The ceramic pumice is used widely in fading, fluffing, softening, ageing and other processing of clothing, fabric, cloth, etc. The ceramic pumice of the present invention contains no harmful matter, and results in simplified fabric cleaning post-treatment and no environmental pollution. Treating fabric with the ceramic pumice makes fabric soft, good look, personalized, permeable and comfortable.

Owner:何晓洪

Method for preparing lubricating grease with excellent anti-wear and wear-resistant performance

The invention discloses a method for preparing polyurea lubricating grease with high PB value. By changing an addition process of an additive, the additive is used as a part of base oil to undergo a thickening reaction so as to double the wear-resistant extreme pressure effect of the additive, reduce the proportion of the anti-wear and wear-resistant additive and improve economic efficiency, and the preparation method is favorable for environmental protection. An ureido lubricating grease composite consists of the base oil, a thickening agent and the additive; and the base oil is a mixture ofvarious kinds of mineral base oil, synthetic oil, tackifier and anti-wear and wear-resistant additives. The polyurea lubricating grease prepared by the method has the excellent anti-wear and wear-resistant performance, has the maximum nonseizure load PB of over 135 kilograms, has the characteristics of high drop point, low noise and strong adhesivity, can be used for machinery lubrication under the severe operating conditions, such as high temperature, overloading, moist, harmful media and the like and can be used as bearing lubricating grease for bearings operating at a high speed and a superspeed.

Owner:河北九熙新材料科技有限公司

Anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and preparation method thereof

ActiveCN105523761AGood for anodizingUnique electrochemical performanceWater/sewage treatment by electrochemical methodsElectrochemical sludge treatmentFiberEpoxy

The invention discloses an anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and a preparation method of the anti-corrosion conductive ceramic electrode material. The anti-corrosion conductive ceramic electrode material is characterized in that carbon is used as aggregate; the anti-corrosion conductive ceramic electrode material is prepared from artificial graphite, graphitized mesocarbon microbeads, a reinforcement binder, graphitized carbon fiber and E-44 epoxy resin. The preparation method comprises the following steps of adding a Ti4O7 functional additive having strong electrode performance, simultaneously adding one or several of ceramic anti-wear-corrosion components of TiB2, TiO2, TiC, B2O3, SiO2 and SiC, carrying out solidification, compression molding and high-temperature sintering after adding a mixing solvent and completely mixing the mixture, and finally preparing the anti-corrosion conductive ceramic electrode material. According to the anti-corrosion conductive ceramic electrode material and the preparation method, disclosed by the invention, aiming at an actual working situation of a sewage and sludge treatment environment, unique anti-corrosion components are added while low specific resistance of the anti-corrosion conductive ceramic electrode material is ensured, not only are wearing resistance and corrosion resistance of traditional ceramics obtained, but also excellent conductivity and excellent electrochemical performance are obtained, and the service life is up to more than 3500 hours.

Owner:JIANGSU UNITED CERALLOY MATERIALS TECH

Rubber sealing material

The invention provides a rubber sealing material which has a long service life under high pressure. The rubber sealing material consists of the following components in parts by mass: 70-80 parts of hydrogenated butadiene-acrylonitrile rubber, 30-40 parts of acrylate rubber, 3-5 parts of allyl alcohol, 10-12 parts of diacetyl peroxide, 8-10 parts of aluminum oxide, 5-8 parts of zinc oxide, 6-8 parts of white carbon black, 0.3-2 parts of an anti-aging agent, and 2-3 parts of sulfur. The rubber sealing material provided by the invention has the advantages of high mechanical strength, low friction coefficient (0.19-0.21), strong wear resistance and long service life (130-160 days) under the working conditions of high temperature (190 DEG C) and high pressure (410 MPa).

Owner:佛山市美捷远电器实业股份有限公司

Revetment structure composed of plastic steel plate piles and concrete

ActiveCN104695380AReduce the impactCombination structure is stableBreakwatersQuaysStructural engineeringRevetment

The invention relates to a revetment structure composed of plastic steel plate piles and concrete. The revetment structure comprises plastic steel plate piles and a concrete coping, wherein the plastic steel plate piles are connected through a connector having two mutually matched ends; the concrete coping is preformed and can be stably buckled with the upper ends of the plate piles. The revetment structure can be used for revetments of rivers or lakes, is safe and stable, high in construction speed, low in construction cost, environment-friendly and pollution-free, less in influence on the surrounding environment, and long in durability, can be further used for resisting the seepage of embankments and dike bodies of rivers and protecting dams.

Owner:海盐汇祥新型建材科技有限公司

ZSM-5 zeolite molecular sieve and preparation method thereof

ActiveCN104211086AGood catalytic effectPlay a catalytic effectPentasil aluminosilicate zeoliteMolecular sieveKaolin clay

The invention relates to a composite material containing ZSM-5 zeolite and a preparation method thereof. By taking kaolin, diatomite and modified kaolin as main raw materials, the preparation method comprises the following steps: A) roasting the kaolin at the temperature of 500-1000 DEG C for 0.5-10h to obtain a roasted material, adding water into the roasted material, uniformly stirring to prepare slurry, adding an alkali or acid, then reacting at the temperature of 60-90 DEG C for 30-120min and filtering to obtain the modified kaolin; B) adding water and one or more of a dispersant and a pore expanding agent into the material obtained in the step A), the kaolin and the diatomite, uniformly stirring to prepare slurry, forming by spray drying, and roasting the formed material at the temperature of 700-1000 DEG C for 0.5-6h to obtain the roasted material; C) adding sodium silicate, lye and zeolite into the material obtained in the step B), then putting into a crystallization reaction kettle, adjusting the final pH value of the slurry to 9.5-11.5 with an acid, performing hydrothermal crystallization at the temperature of 120-180 DEG C for 30-120h, filtering to remove mother liquor, washing the filtered material with deionized water, filtering and drying the filtered material to prepare a target product. The method has low preparation cost, the content of the ZSM-5 zeolite in the material is high, and the material has good wear resistance and has rich microporous and macroporous structures.

Owner:YUEYANG YITIAN CHEM

Alloy nodular cast iron for railway vehicle brake disks

The invention relates to an alloy nodular cast iron which comprises the following components in percentage by weight: 2.0-5.0% of carbon, 1.0-4.0% of silicon, 0.2-1.0% of manganese, 0.1-0.6% of nickel, 0.1-0.80% of molybdenum, 0.01-0.08% of copper, 0.01-0.08% of magnesium, 0.01-0.06% of rare-earth Re, and the balance of iron and inevitable impurities.

Owner:BEIJING ZONGHENG ELECTROMECHANICAL TECH DEV +1

High temperature fireproof brick and preparation method thereof

The invention discloses a high-temperature refractory brick, which comprises the following components in weight portion: 10 to 12 portions of corundum powder, 6 to 8 portions of kaolin, 50 to 56 portions of Zircon sand, 13 to 16 portions of chromium dioxide, 8 to 10 portions of zirconium dioxide and 3 to 5 portions of water. The invention also discloses a technology for preparing the high-temperature refractory brick. The high-temperature refractory brick can tolerate the high temperature up to 2,100 DEG C and fully meet the working conditions of a high-temperature furnace, and has the advantages of stronger scouring and wearing resistance, good corrosion resistance and thermal shock resistance, and long service life. The preparation method adopts a unique twice baking technology to allow the ultra-temperature condition of the high-temperature refractory brick to fulfill super-high temperature conditions, and is simple and easy to realize.

Owner:宜兴市张泽工业炉材料厂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com