Patents

Literature

815results about How to "Good environmental effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

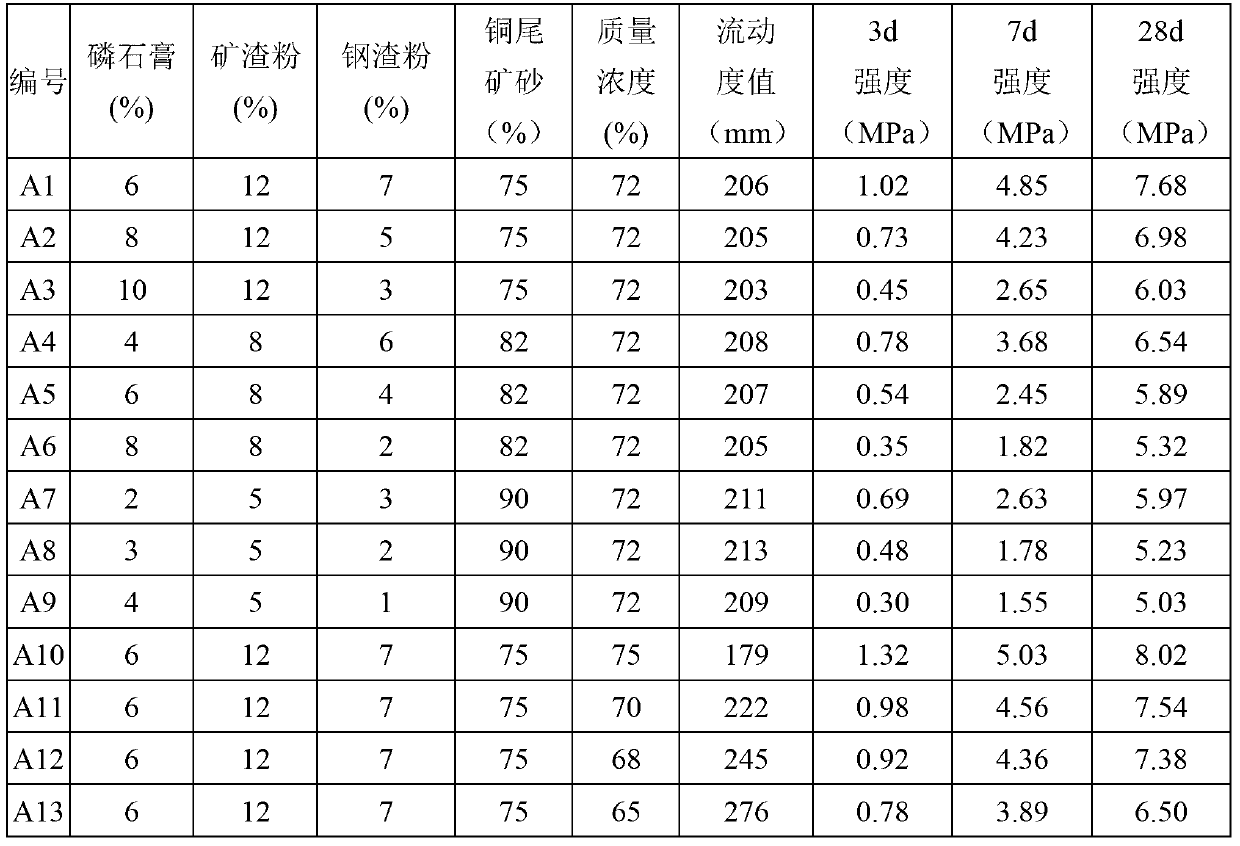

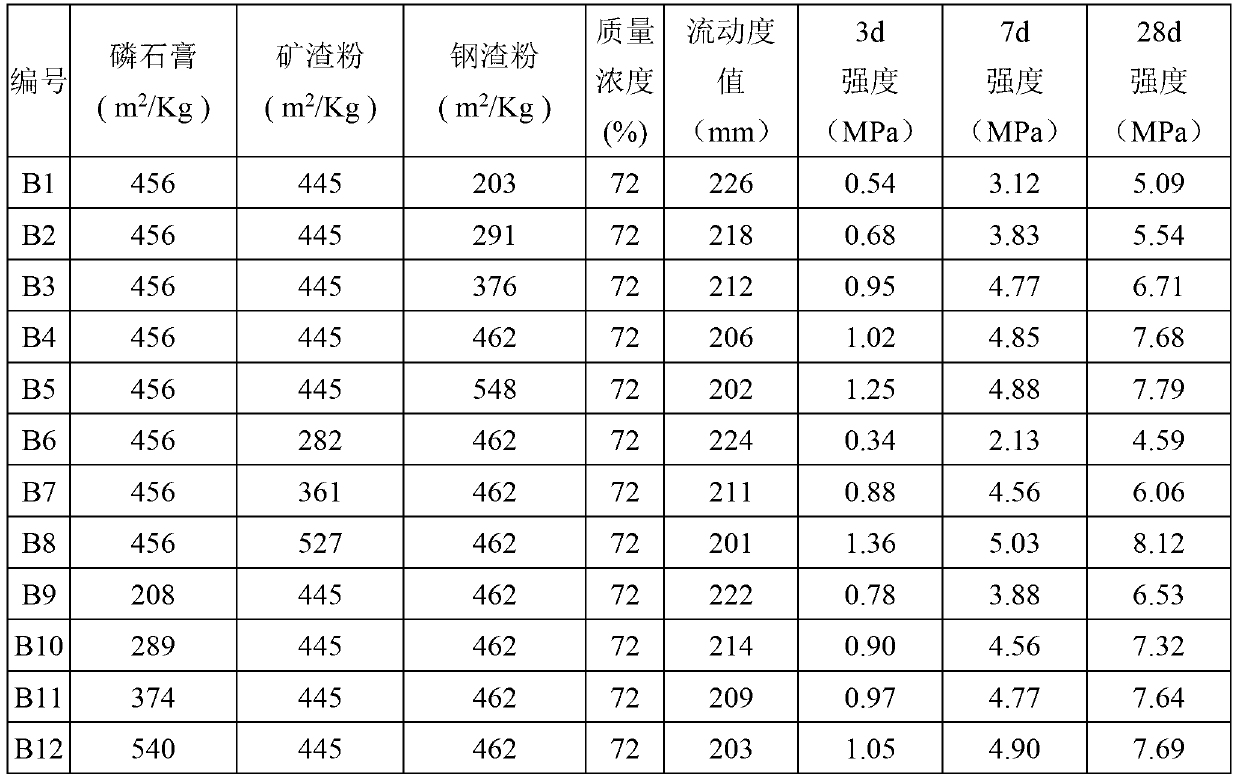

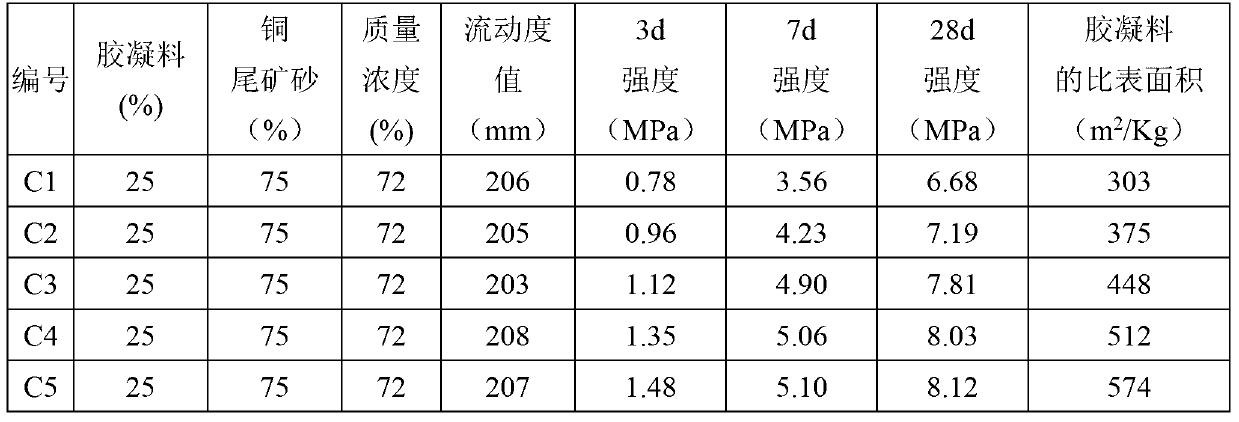

Mine filling cementing material slurry and preparation method thereof

The invention belongs to the technical field of mining engineering and building materials and particularly relates to a mine filling cementing material slurry and a preparation method thereof. The preparation method comprises the following steps of: with steel slag, mineral slag and industrial byproduct gypsum as cementing agents and tailing sand as a filling aggregate, adding water, mixing and stirring uniformly to prepare mine filling cementing material slurry, wherein a dry basis of raw materials comprises the following components in percentage by weight: 1-7% of steel slag, 5-12% of mineral slag, 2-10% of industrial byproduct gypsum and 75-90% of tailing sand, and the sum of the weight percentage of the dry basis of all the raw materials is 100%; adding water to regulate the mass concentration of the filling cementing material slurry to be between 65-75%. The mine filling cementing material slurry has the beneficial effects of higher strength, simple process, high flowability and suitablity for self-flowing filling; no cement or cement clinker or additives are added in the components of the filling cementing material slurry which is completely made of solid wastes, so that the utilization rate of the tailing sand is high, and the production cost is very low.

Owner:WUHAN UNIV OF TECH

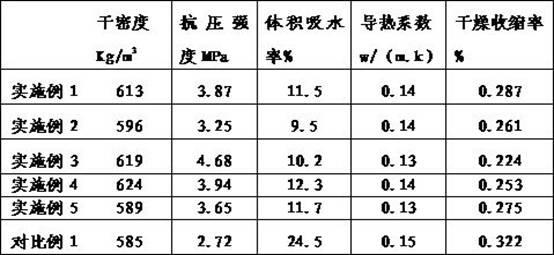

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

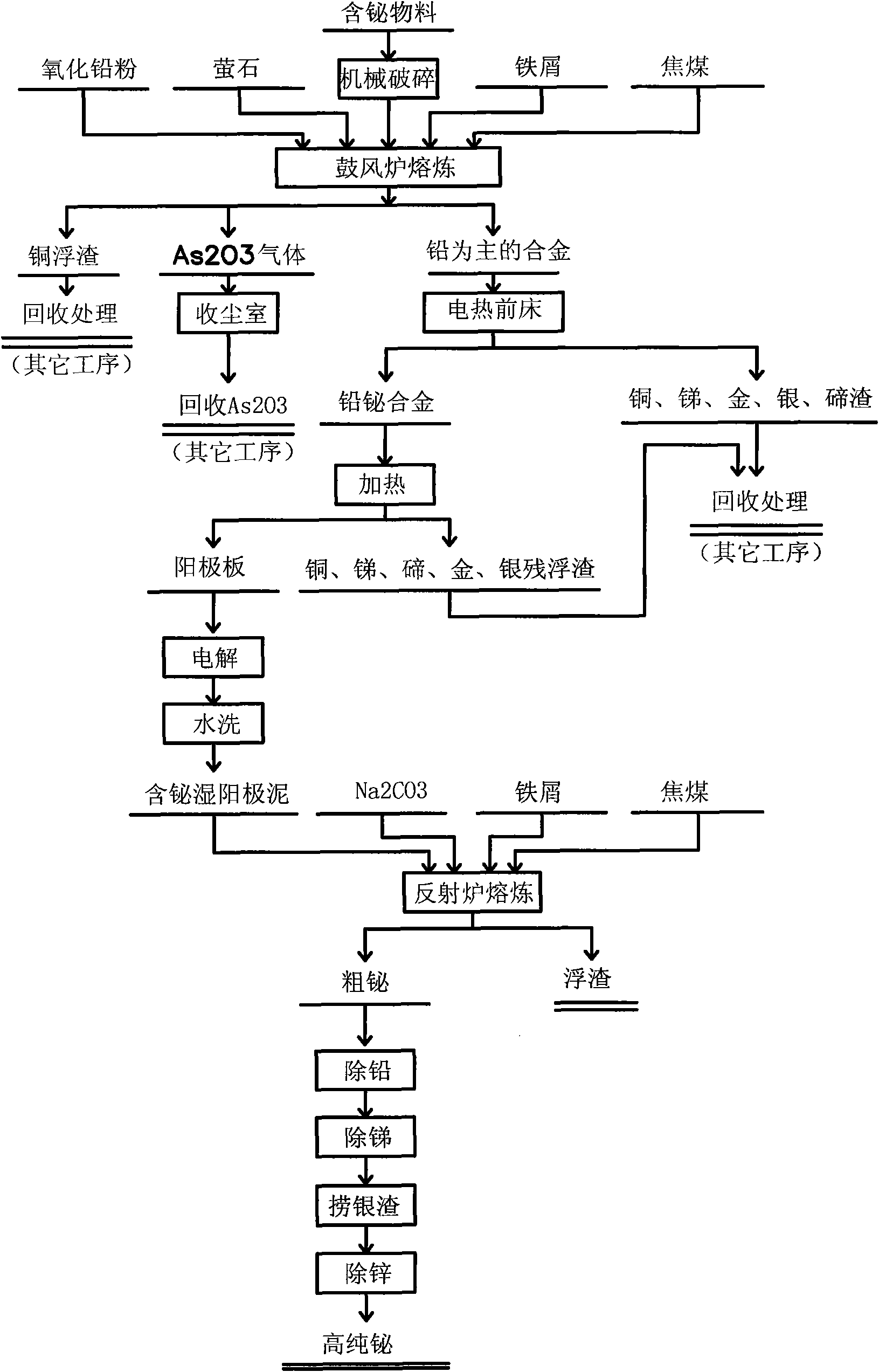

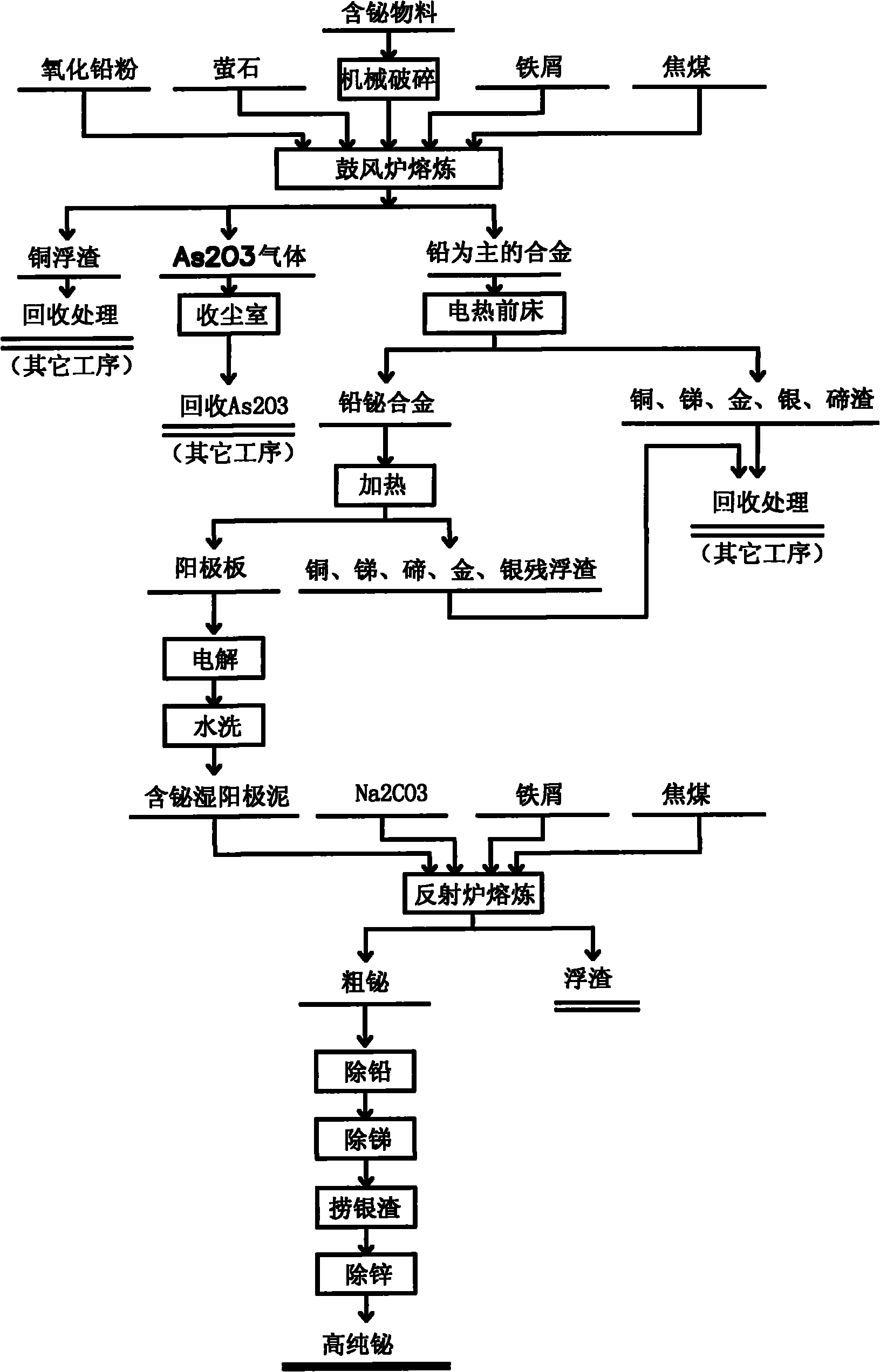

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

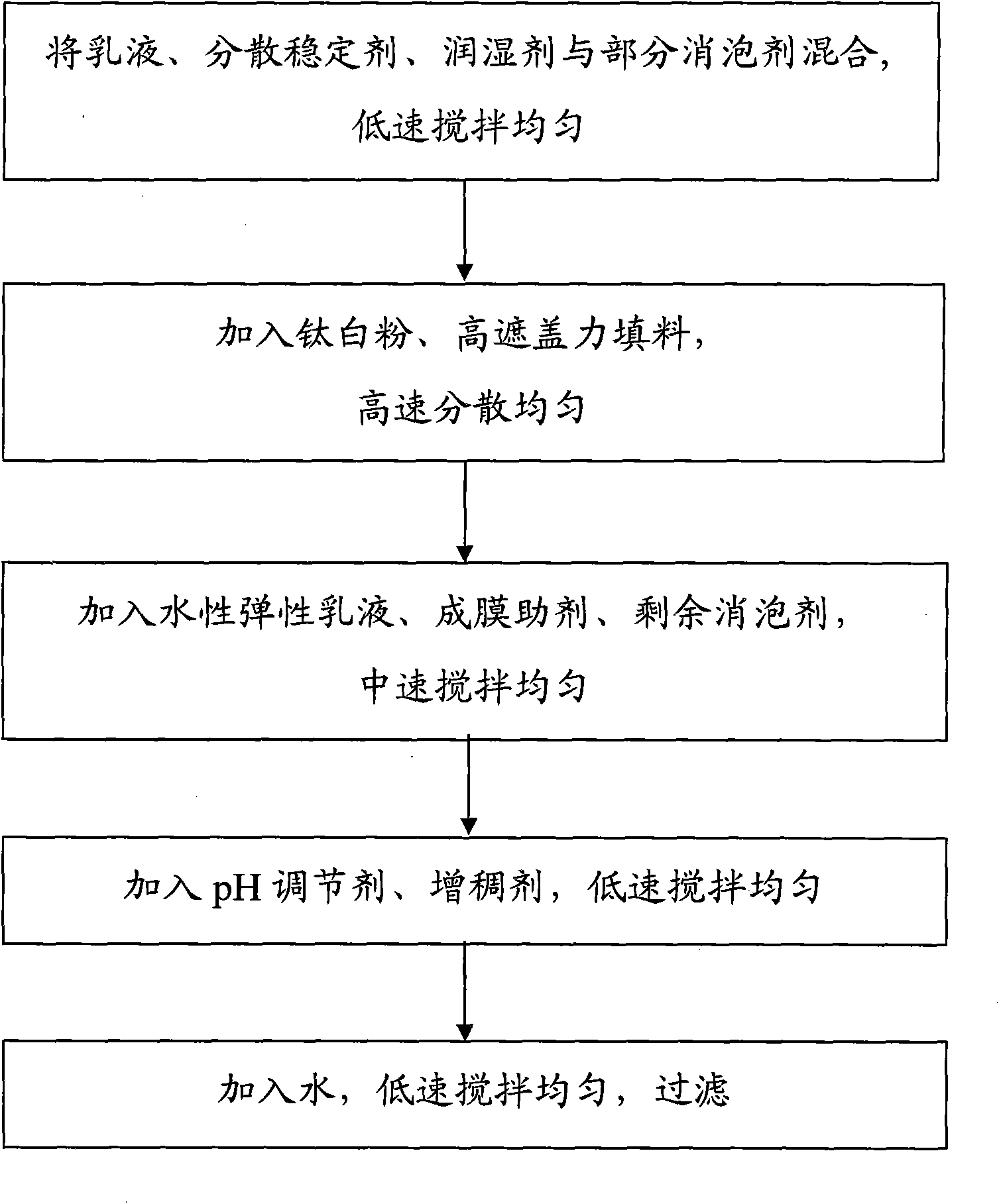

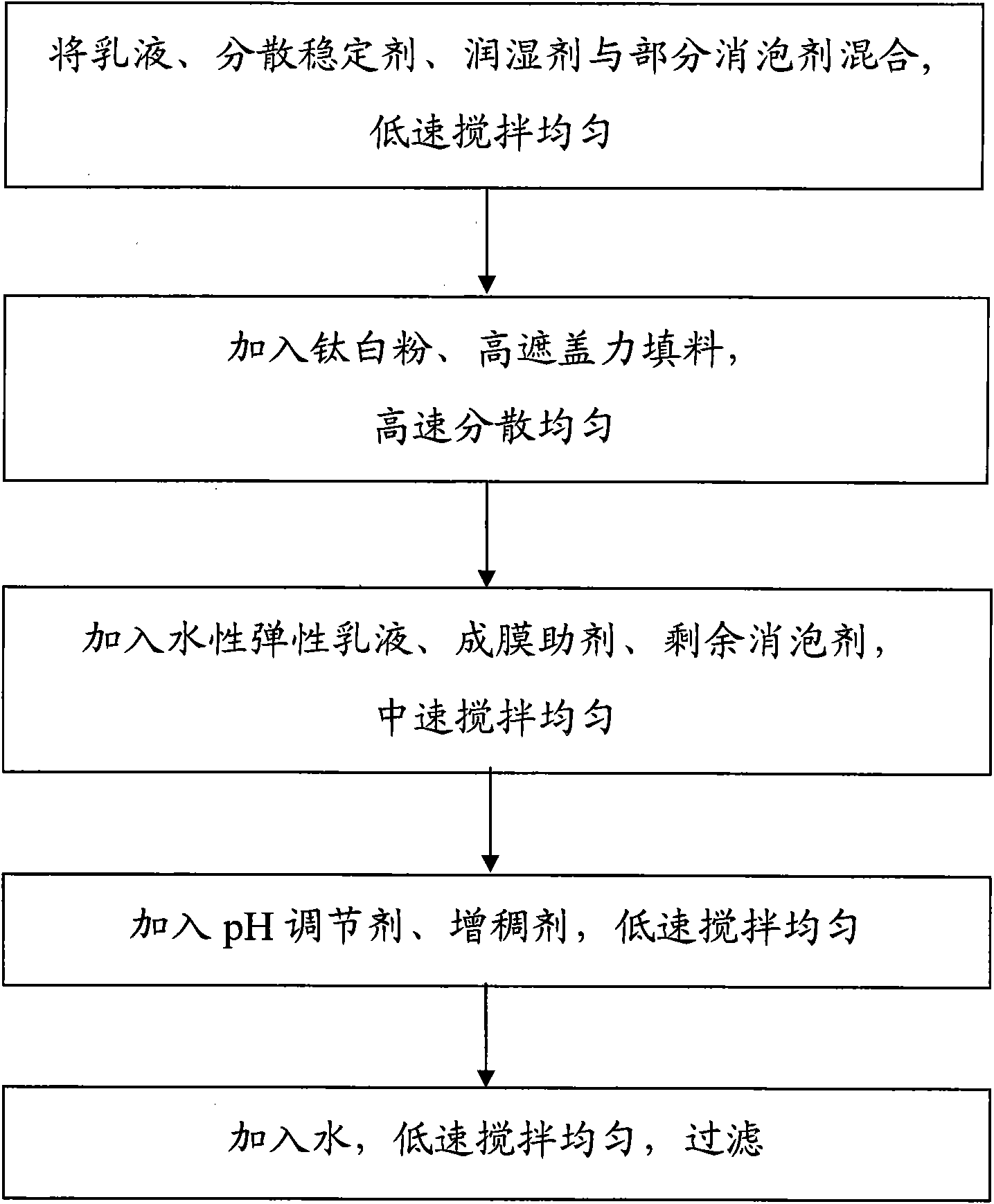

Aqueous exterior wall coating material with high solid content and low viscosity

The invention discloses an aqueous exterior wall coating material with high solid content and low viscosity. The coating material with low viscosity and easy construction can be prepared by the following steps of: fully mixing components such as water, a dispersion stabilizer, a filler with high covering power, a wetting agent, titanium white, aqueous styrene-acrylic emulsion with high solid content, elastic acrylic acid emulsion with high solid content, a pH regulator, an antifoaming agent, a thickening agent, a film-forming additive and the like according to a certain process flow; and reasonably matching and combing the filler with high covering power and other components by fully utilizing the high solid content and high stabilizing effect of the aqueous styrene-acrylic emulsion and the high-efficiency film-forming property and weather resistance of the elastic acrylic acid emulsion. The coating material can directly achieve the construction effect during the construction of an exterior wall and can achieve the effect of high covering power without being thinned by adding water.

Owner:CHINA PAINT MFG CO SHENZHEN

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

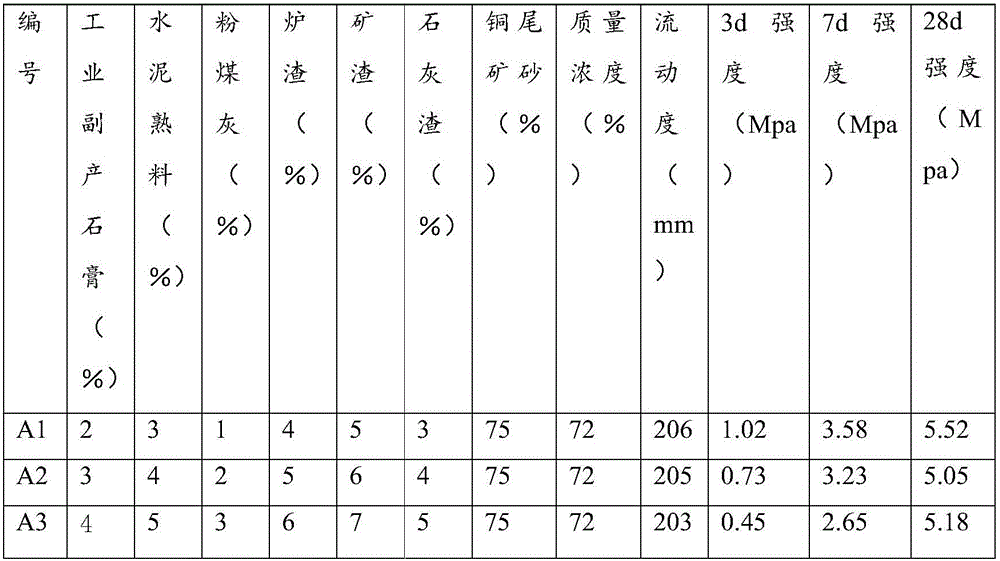

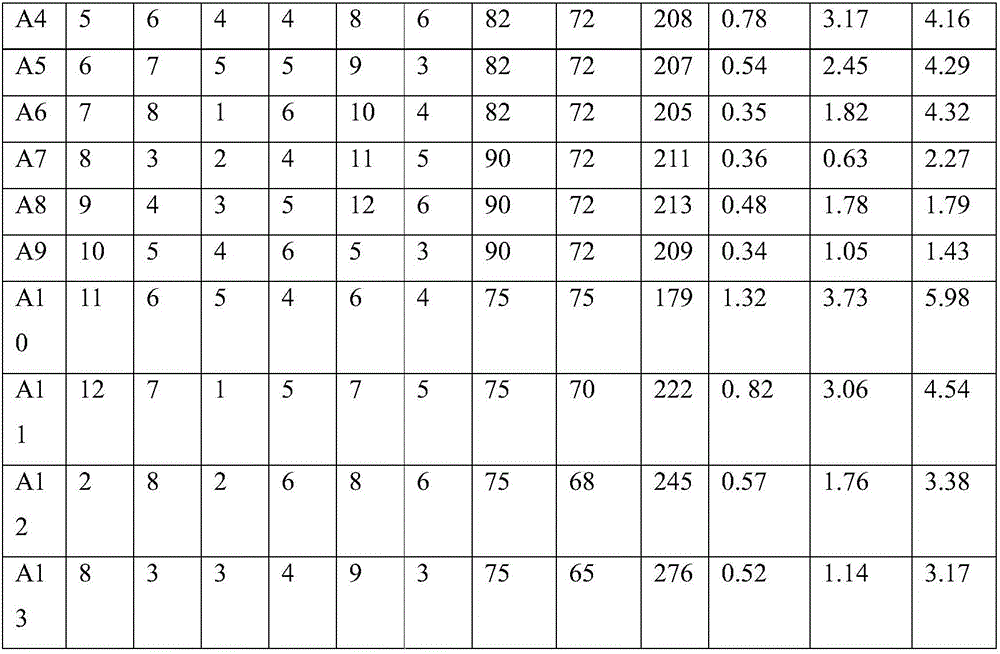

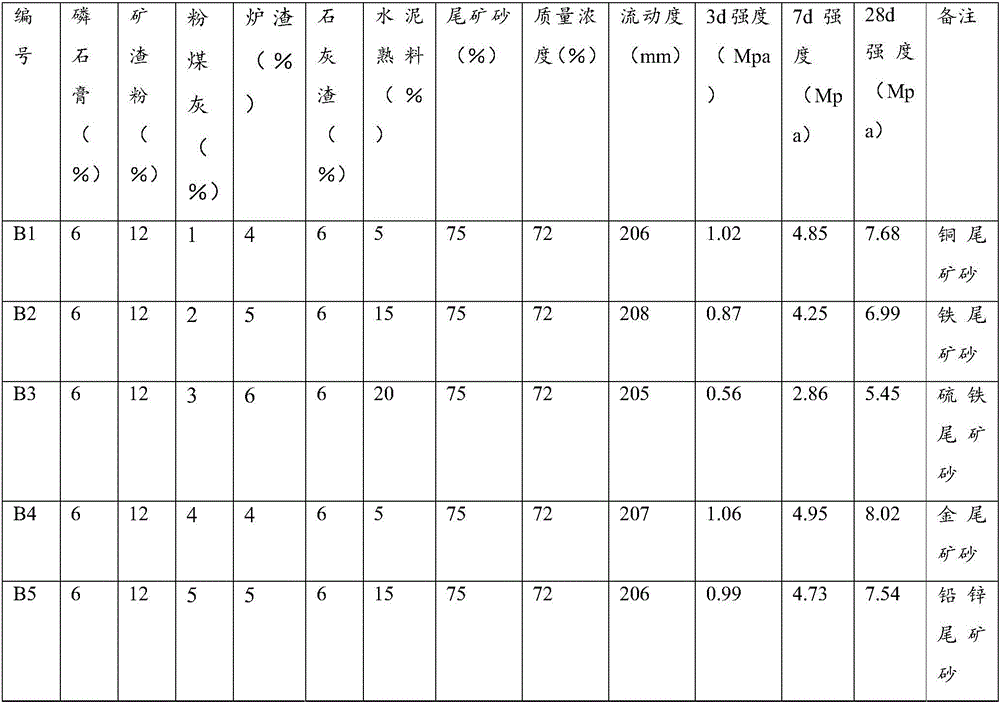

Tailing cementing agent

The invention provides a tailing cementing agent which is formed by mixing a raw material dry basis and water. The tailing cementing agent is characterized in that the dry basis is prepared from, by weight, 5%-12% of slag, 1%-5% of fly ash, 4%-6% of furnace slag, 3%-6% of lime sludge, 5%-20% of cement clinker, 2%-10% of industrial by-product gypsum and 75%-90% of tailing sand; the weight percentage of the raw material dry basis ranges from 65% to 75%, and the weight percentage of the water ranges from 25% to 35%. The tailing cementing agent is high in strength, simple in process, large in fluidity and suitable for gravity-flowed filling; less cement or cement clinker exists in the component of filling slurry, the utilization rate of the tailing sand is high, and the production cost is very low; the tailing sand is not subjected to stage treatment, the tailing cementing agent is not limited to single tailing, the application range is wide, stacking and pollution problems of the tailings are partially solved, resource utilization of other industrial waste residues such as steel slag, the slag and the industrial by-product gypsum is achieved, and the environmental protection effect is very significant.

Owner:贾志奎 +1

Process for preparing magnesium alloy chemical conversion coating

ActiveCN1880503AEliminate hazardsImprove corrosion resistanceMetallic material coating processesSodium iodideFluohydric acid

The invention discloses a chemical transmission film preparing technology of magnesium alloy, which comprises the following steps: a. proceeding degreasing disposal for magnesium or magnesium alloy through sodium hydroxide or one or multiple hybrid solutions of sodium phosphate with sodium hydroxide, sodium carbonate and sodium silicate solution; b. proceeding acid cleaning disposal for degreased magnesium or magnesium alloy through hybrid solution of phosphoric acid and sodium phosphate; c. proceeding activating disposal for acid cleaned magnesium or magnesium alloy through hybrid solution of fluohydric acid and sodium phosphate; d proceeding chemical synthesizing disposal for activated magnesium or magnesium alloy through composite solution of calcium nitrate hydrate, sodium nitrite, sodium iodide and hydrogen dioxide solution; e. packing hole of synthetic magnesium or magnesium alloy through deionized water. The invention doesn't utilize chromic composition, which eliminates danger for environment.

Owner:靖江市华信科技创业园有限公司

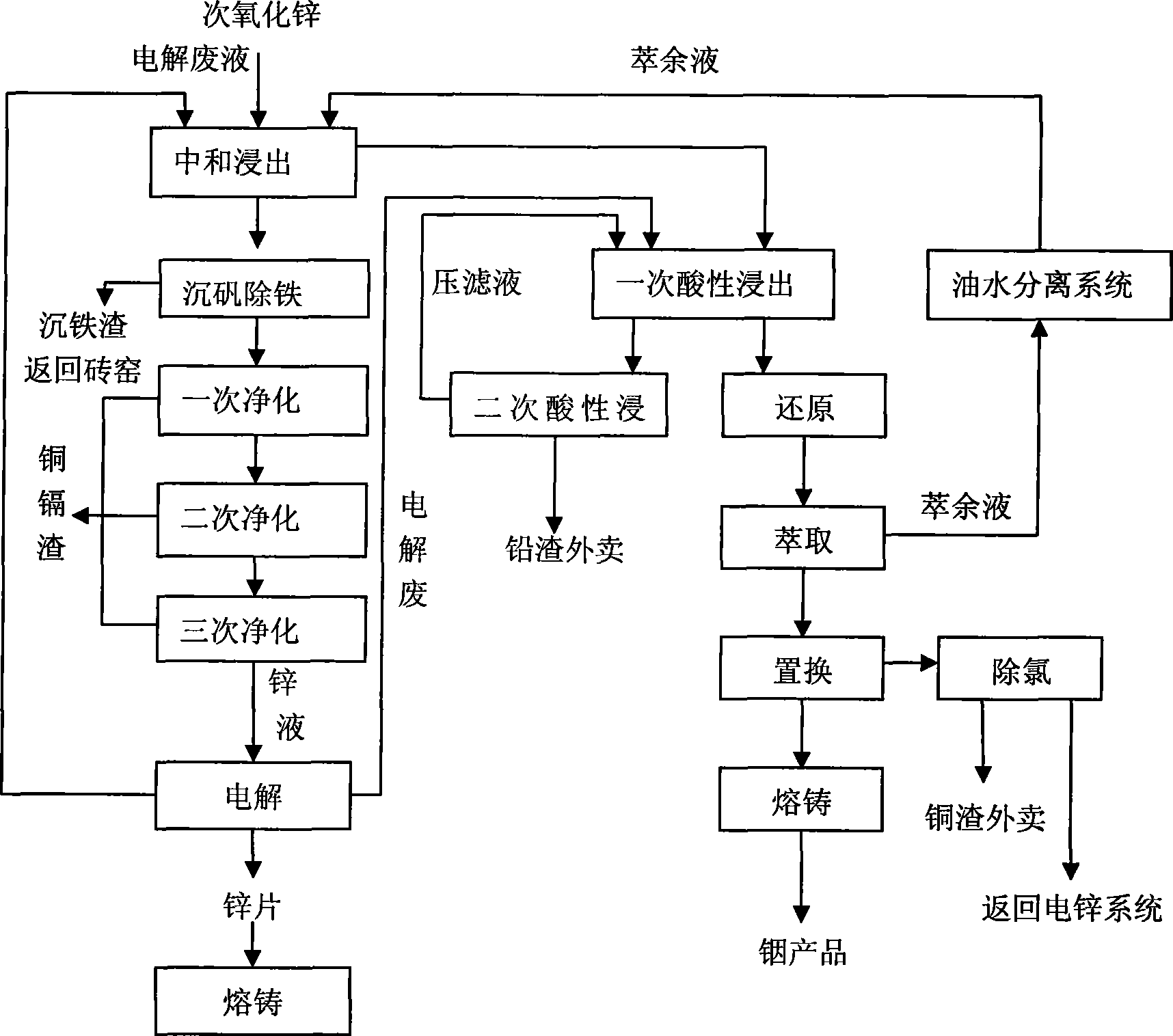

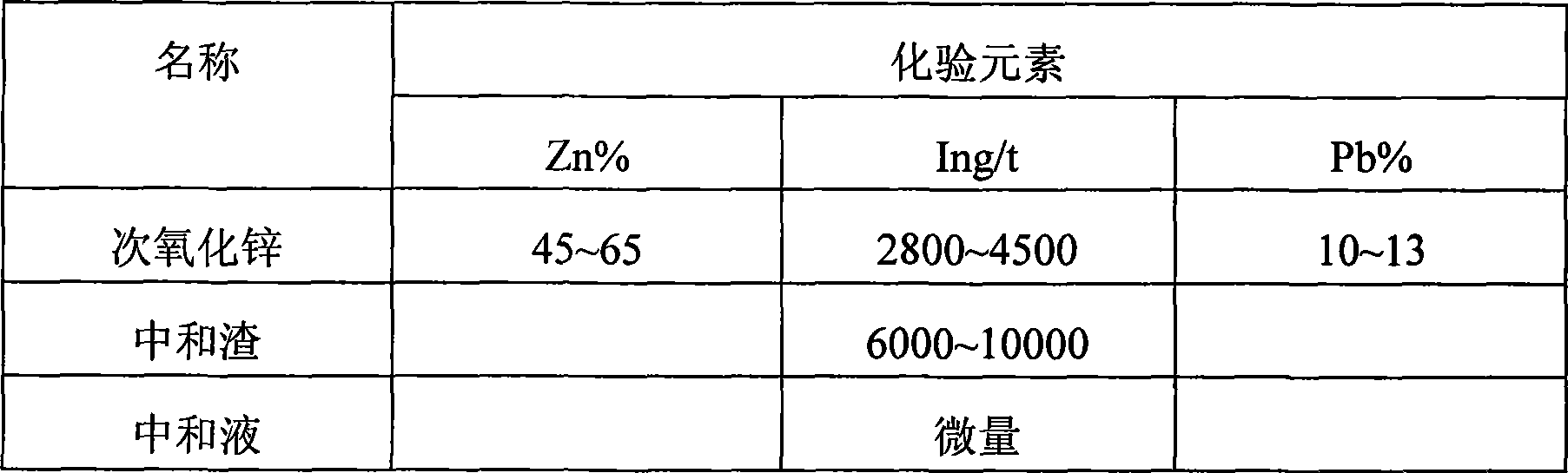

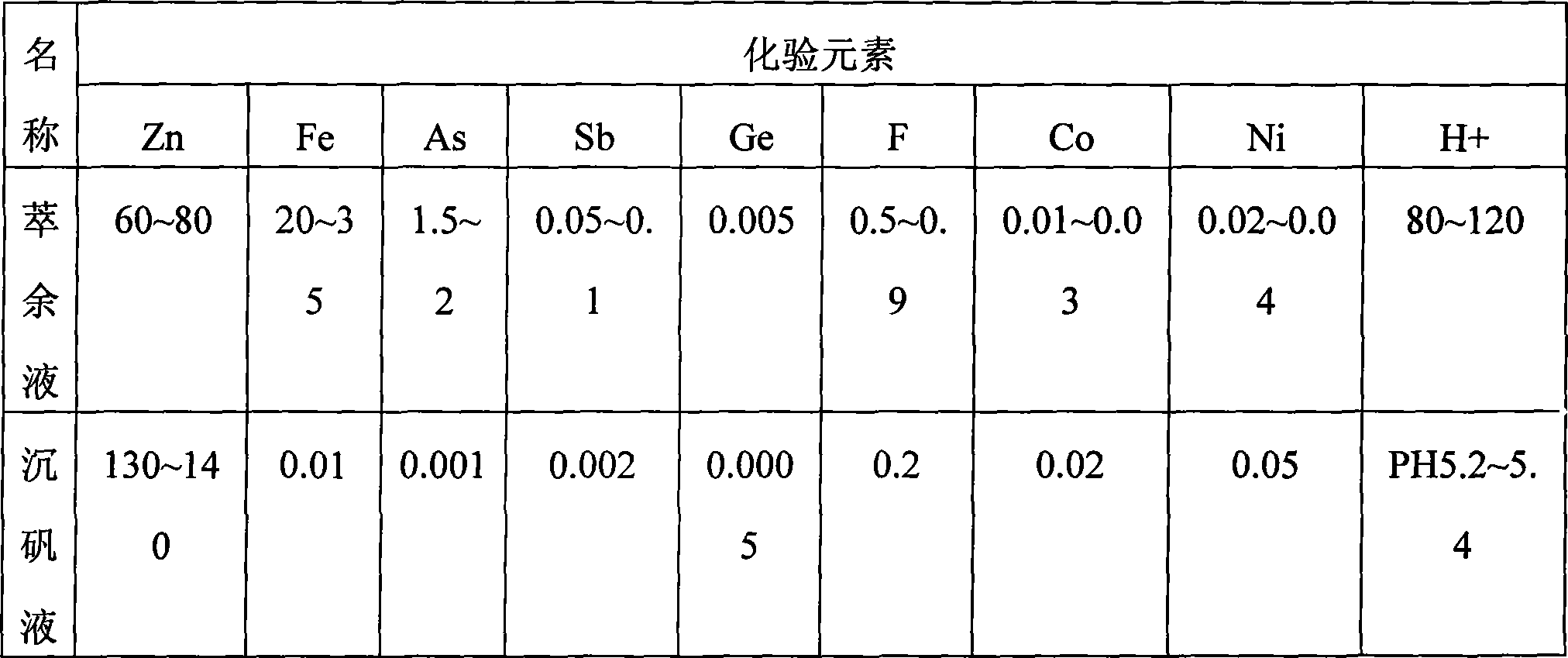

Process for comprehensively and efficiently recycling zinc and indium in indium raffinate

InactiveCN101413059AHigh recovery rateAvoid accumulationPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention provides a process for comprehensively and efficiently recovering zinc and indium in indium raffinate. The process adopts an iron-indium technique, adds the procedures of precipitating alum and removing iron, removes impurities, and determines a principle of returning raffinate to an electrolytic zinc system in a process of producing electrolytic zinc through wet smelting and comprehensively recovering indium. The process recycles a large amount of sulphuric acid and zinc metal in the raffinate without affecting the running of the electrolytic zinc system, and saves cost without polluting environment at the same time.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

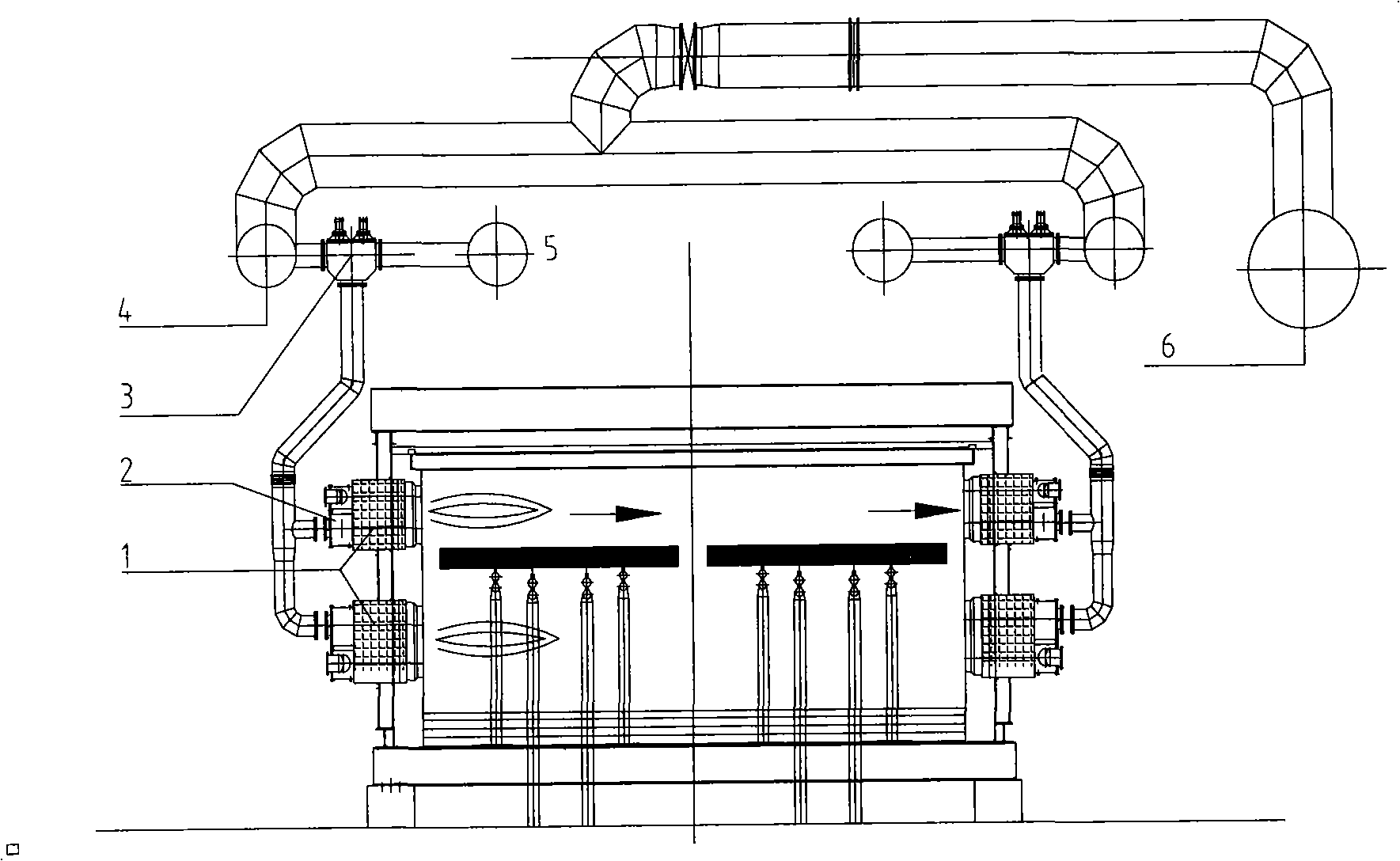

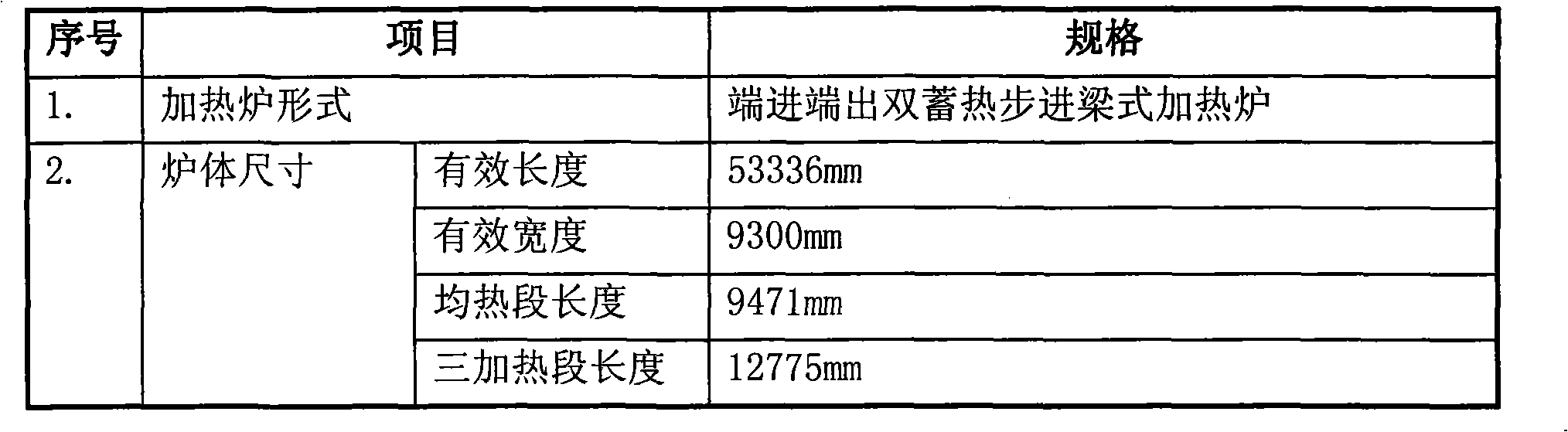

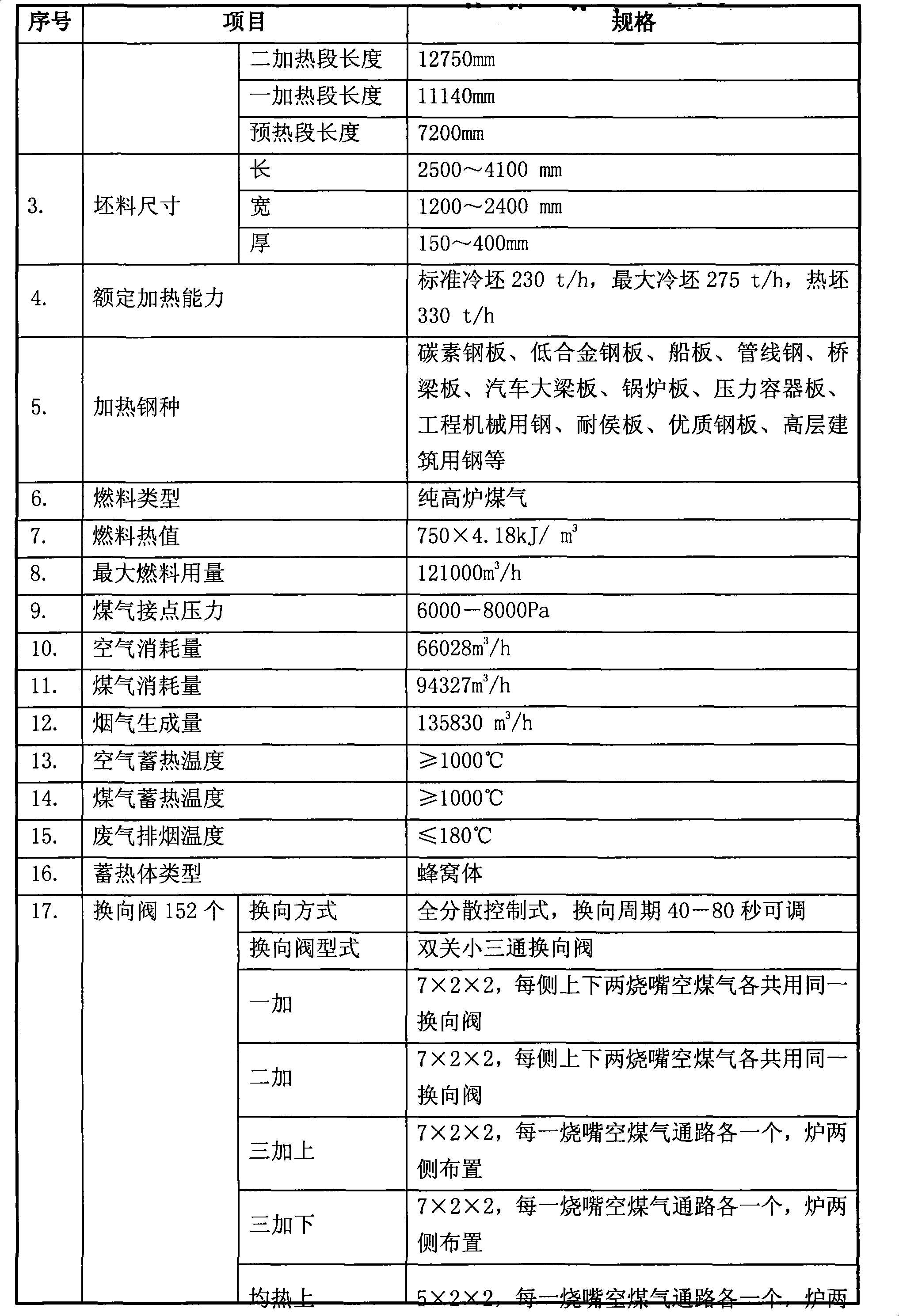

Method for using blast furnace gas to heat of large-scale walking beam type plate blank heating furnace

ActiveCN101314811AMeet process temperature requirementsSolve major issuesFurnace typesHeat treatment furnacesTemperature controlFlue gas

The invention relates to a large-scale walking-beam type slab heating furnace which adopts a blast furnace gas heating method, and belongs to the technology field of a heating furnace. A plate blank steps from a furnace feeding end to a furnace discharging end through a walking beam, and passes through a preheating section, a first heating section, a second heating section, a third heating section and a soaking section; the heating temperature of each heating section is controlled according to the heating technology requirements of various steel grades; the quantity of stored-heat burners which are arranged in the corresponding heating sections is controlled; after the stored-heat burners are arranged in the position of each heating section, blast furnace gas and air respectively pass through refrigerating chambers of the stored-heat burners and are processed through thermal storage until the temperature reaches 800 to 1000 DEG C, and then enter the furnace for fully burning, thereby realizing the heating of the plate blank; when flue gas passes through the refrigerating chambers of the stored-heat burners, the heat of the flue gas is absorbed fully; the whole heating process is completed through alternate burning and exhaustsmoke of the stored-heat burners which are arranged on two sides of the heating furnace. The large-scale walking-beam type slab heating furnace has the advantages that the stored-heat heating technology is utilized to reduce the exhaust of NOx compound dusty gas greatly, and the energy-saving and environment-protecting effects are obvious.

Owner:SHOUGANG CORPORATION

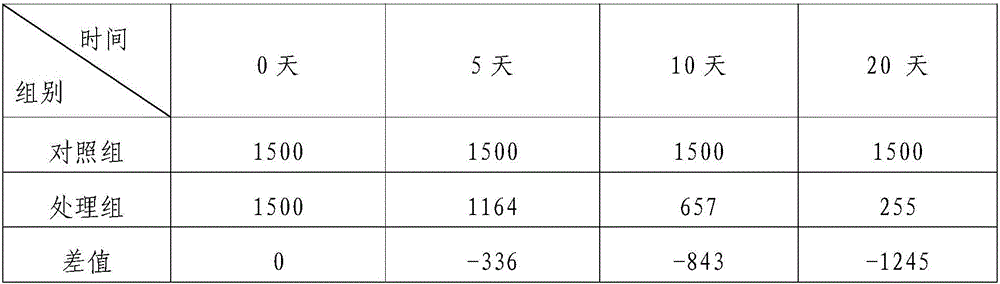

Mixed bacterial agent capable of degrading antibiotics in soil and preparation method thereof

InactiveCN106635933AStrong stress resistanceImprove degradation rateBacteriaContaminated soil reclamationMicroorganismPenicillin

The invention discloses a mixed bacterial agent capable of degrading antibiotics in soil, belonging to the field of microbial technology. The mixed bacterial agent is prepared by mixing Bacillus subtilis J5P2 and Pseudomonas J2 according to a volume ratio of (0.1-3): 1. A preparation method for the mixed bacterial agent comprises the following steps: I, preparation of a suspension; II, colony culture: (1) preparation of a medium and (2) culture; III, separation of strains; IV, subculture and domestication: (1) domestication, (2) preparation of a LB medium, and (3) preservation; V, preparation of inoculum liquid; and VI, preparation of the mixed bacterial agent. The mixed bacterial agent provided by the invention has the characteristics of capacity of effectively degrading a plurality of residual antibiotics in soil and reducing environmental pollution, etc., and can be used for the remediation of land contaminated by antibiotics such as tetracycline, penicillin, sulfadiazines and quinolones.

Owner:HUNAN ZHONGKE AGRI

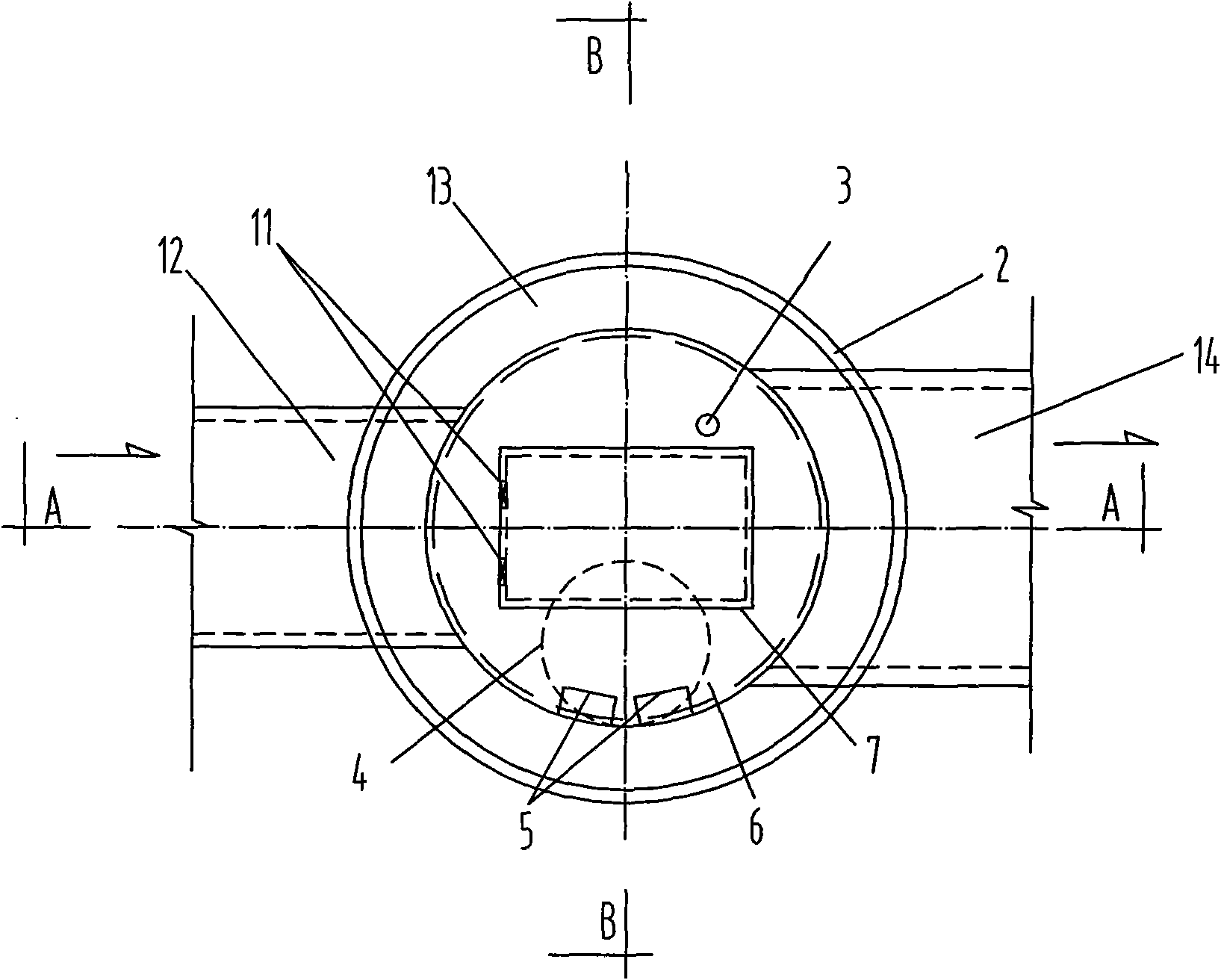

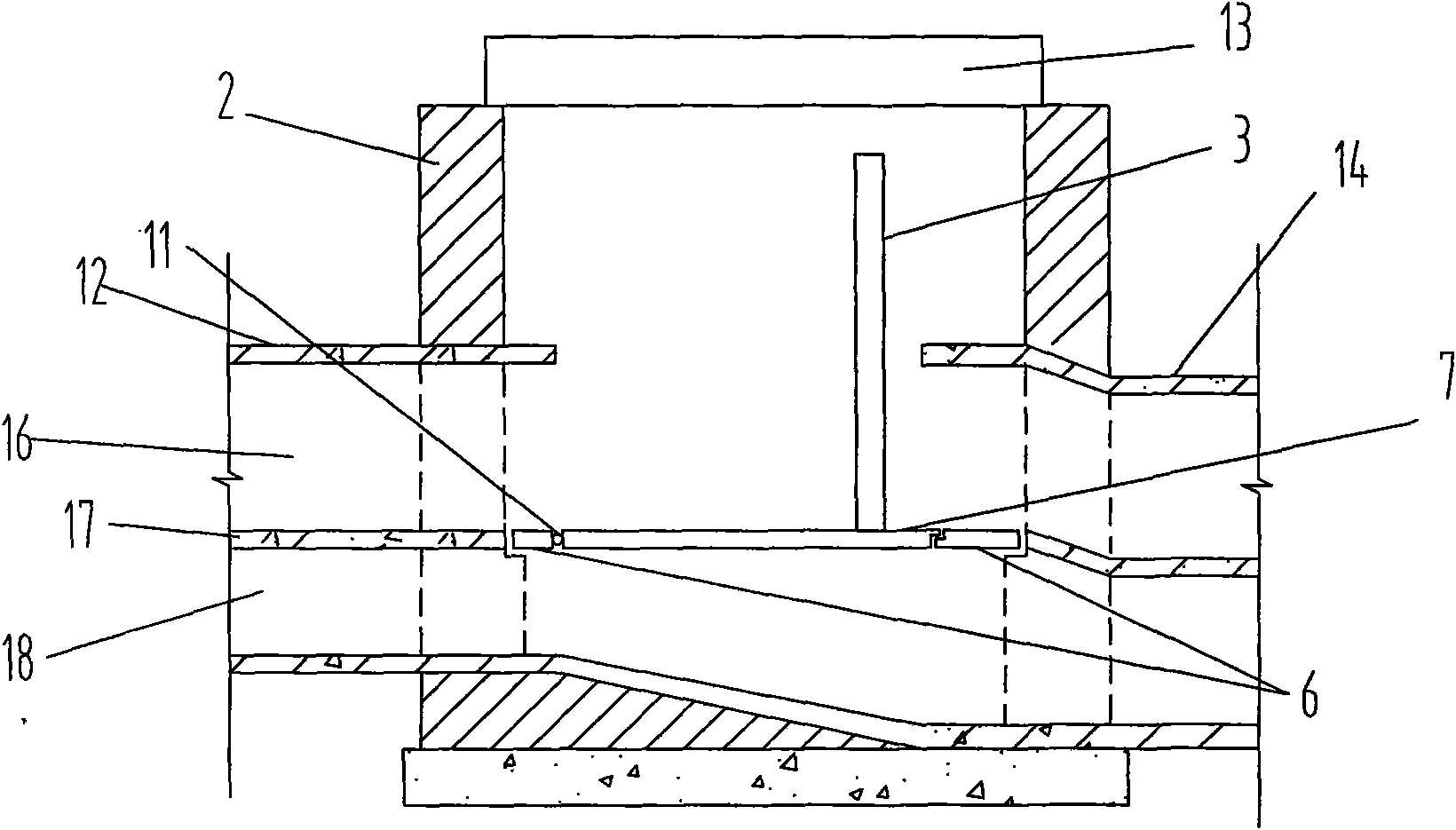

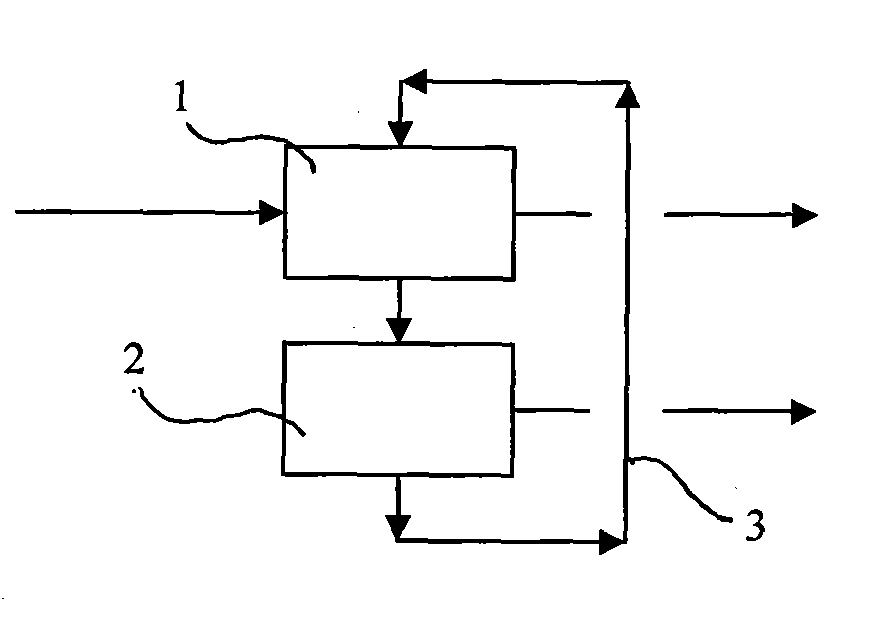

Drainage system used in cities, towns and communities

ActiveCN101666116AReduce the number of crossoversDelay in construction investmentSewerage structuresSewage drainingLine tubingSurface runoff

The invention requests to protect a drainage system used in cities, towns and communities, which is formed by connecting at least a co-line divided-flow dual-layer drainage pipe and channel or a common drainage pipe and channel with a rainwater-sewage compound dual-layer manhole. An intercepting rainwater-sewage compound dual-layer drainage manhole can be arranged on the drainage system accordingto the requirement so as to realize that the initial surface runoff is intercepted into a sewage pipe and channel and is delivered to a sewage treatment plant to be treated, and a non-intercepting rainwater-sewage compound dual-layer drainage manhole can be arranged according to the requirements of direction change, gradient change, connector change, pipe and channel intersection, examination andrepair of linear pipes and channels every certain distance and other special purposes. The drainage system can realize individual delivery and drainage of the rainwater and sewage by layers on the same pipeline and has the characteristics of simple pipelines, few manholes, low investment, operation and maintenance cost, capability of reducing the pollution effects of first rain runoff in an economic and effective manner, and no rainwater-sewage interflow and overflow water pollution, etc.

Owner:CHONGQING UNIV

Compound feed for improving red drum flavor and preparation method thereof

The invention relates to a compound feed for improving red drum flavor and a preparation method thereof. The compound feed comprises fishmeal, high-gluten flour, soy protein concentrate, fermented peanut meal, beer yeast, corn meal, fish oil, vegetable oil, squid paste, soy lecithin, blood protein powder, binder carboxymethyl cellulose, composite vitamins, composite minerals, choline chloride, betaine, carnitine, sodium dehydroacetate, and butyl hydroxy anisole. The compound feed of the invention has advantages of good attractant effect, good palatability, high feed utilization rate, good-quality red drum. The compound feed can better prevent a feed from oxidative deterioration, improves the feed utilization rate, improves red drum growth, reduces environmental pollution and has a significant environment-protection effect.

Owner:ZHEJIANG MARINE DEV RES INST

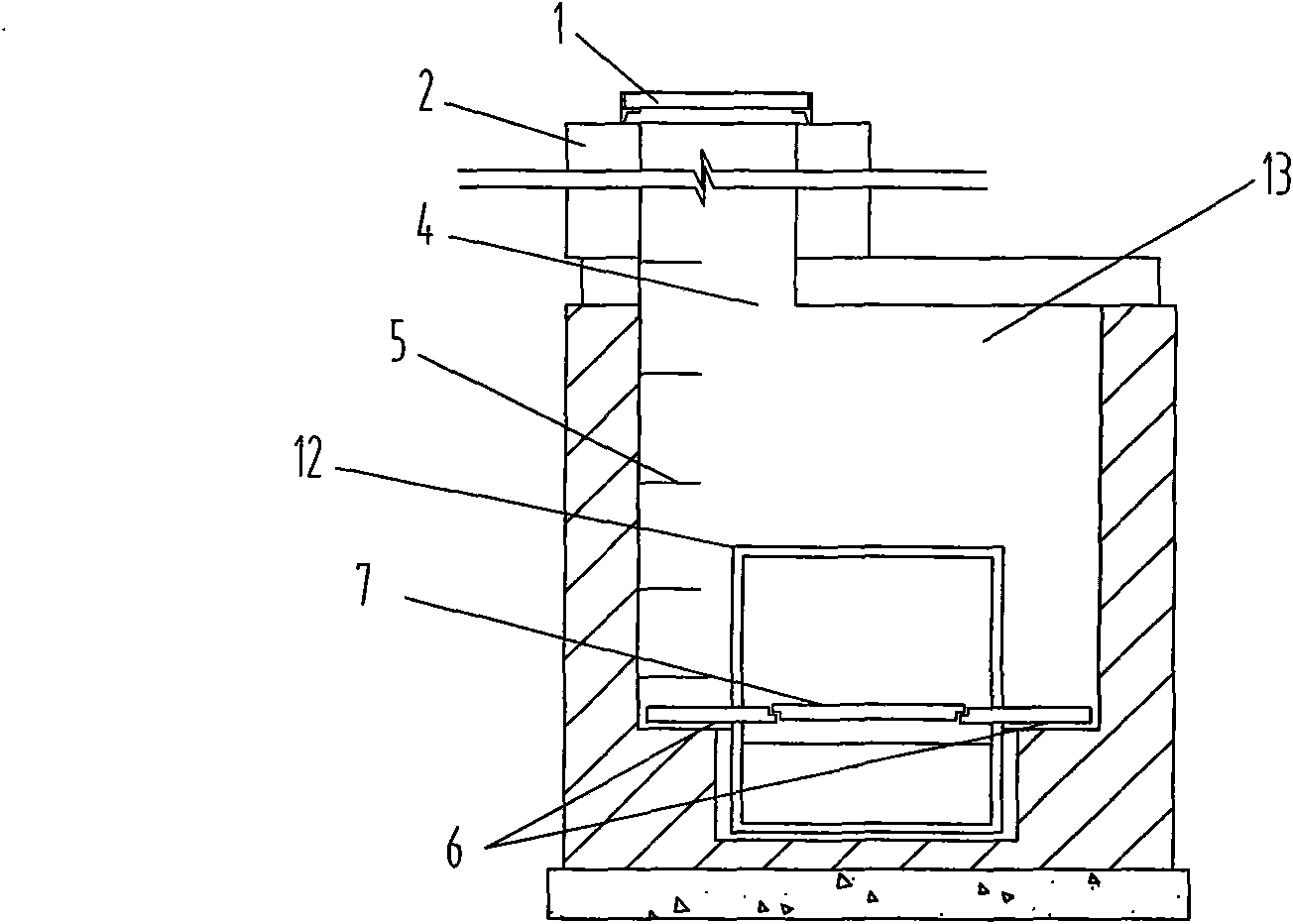

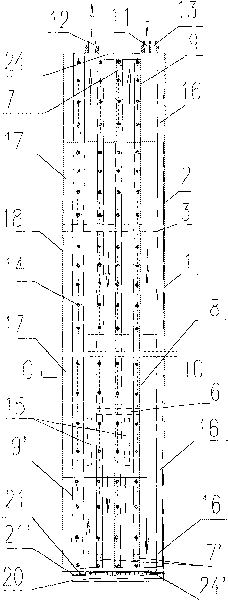

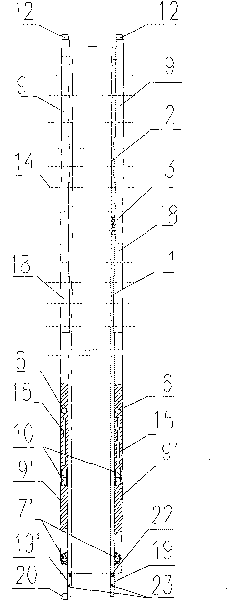

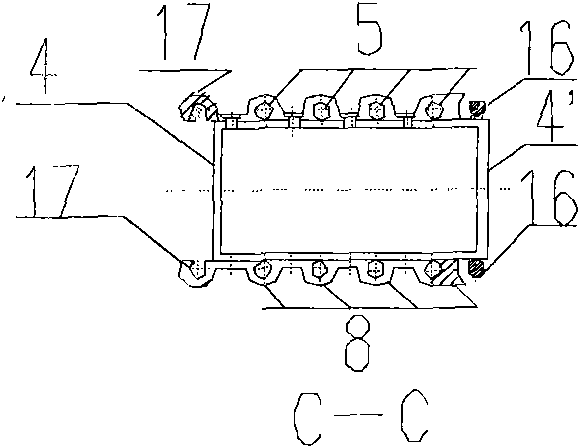

Automatic wall-forming device and method of static pressure continuous concrete wall

ActiveCN101718099AEasy constructionPrevent leakageArtificial islandsUnderwater structuresSlurry wallReinforced concrete

The invention belongs to the technical field of buildings, relating to an automatic wall-forming device and method of static pressure continuous concrete wall used for anti-seepage, water interception and retaining occasions such as deep foundation pit, tunnel and riverbank; the existing full hydraulic static pile machine is used as a host machine; two automatic wall-forming device combinations mutually associated and respectively independently moved having wave-shaped sections can be clamped simultaneously; the surface shape of the wave-shaped plate and the rectangle inside casing are used as references, and the two short outer edges thereof are respectively provided with connectors having specific guiding limit function; the automatic wall-forming device provided with a double-open type valve at the end part thereof is internally pre-hung with a steel reinforcement cage; concrete is filled sequentially, and the wall-forming device is pressed into a preset thickness of soil layer one by one; one of the wall-forming device combination is lifted, and simultaneously a high frequency vibrator installed in a wave-shaped body is started; a reinforced concrete unit wall sections are formed by vibrating and lifting the wall-forming device; and the device and method has novel technology, good environmental protection effect, reliable quality, high bearing capacity, board applicability and short construction period.

Owner:QINGDAO JINGLI ENG

Flame retardant and heat-insulation foamed concrete and preparation method thereof

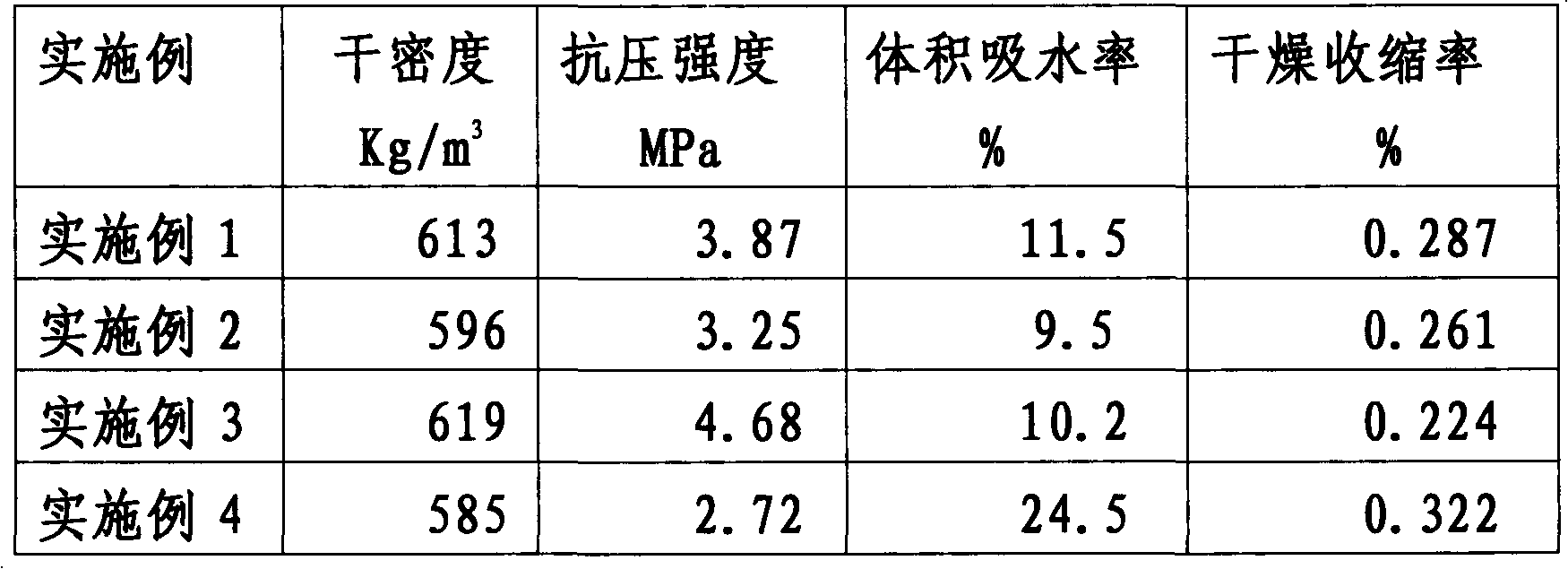

InactiveCN102320858AHigh strengthImprove flame retardant insulation performanceCeramicwareFoam concreteCellulose

The invention belongs to a flame retardant and heat-insulation building material, relates to flame retardant and heat-insulation foamed concrete and a preparation method thereof. In the prior art, the foamed concrete has disadvantages of low strength, large shrinkage, easy cracking due to water absorption. The flame retardant and heat-insulation foamed concrete provided by the present invention comprises the following materials, wherein the materials comprise, by mass, 30-60 parts of cement, 30-70 parts of fly ash, 10-40 parts of mineral powder, 0.05-1.0 parts of a siloxane water reducing agent, 0.02-0.2 parts of a cellulose ether, 0.05-1.0 parts of a silane water-repelling agent, 1-10 parts of anhydrite, 0.06-0.2 parts of polypropylene fibers, 0.1-0.4 parts of a foaming agent and 0.30-0.60 parts of water. The flame retardant and heat-insulation foamed concrete and the preparation method provided by the present invention have the following advantages that: the foamed concrete has characteristics of high strength, low shrinkage and good water repellency; the foamed concrete has excellent heat insulation property, such that different heat insulation requirements of the building can be met; the preparation process is simple; the industrial waste materials such as fly ash, mineral powder and the like are adopted so as to protect the environment.

Owner:杨淑贤

Geothermal greenhouse

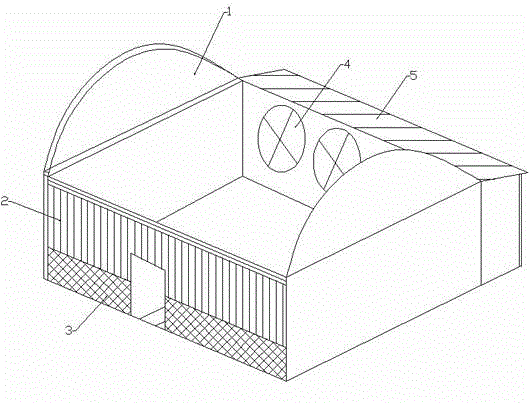

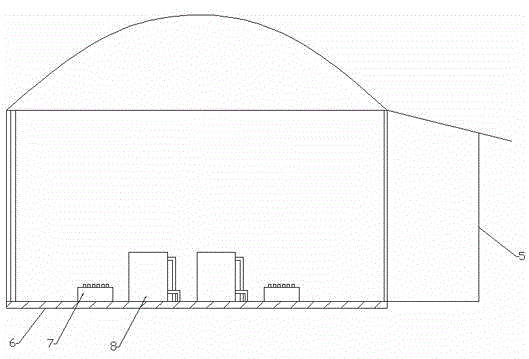

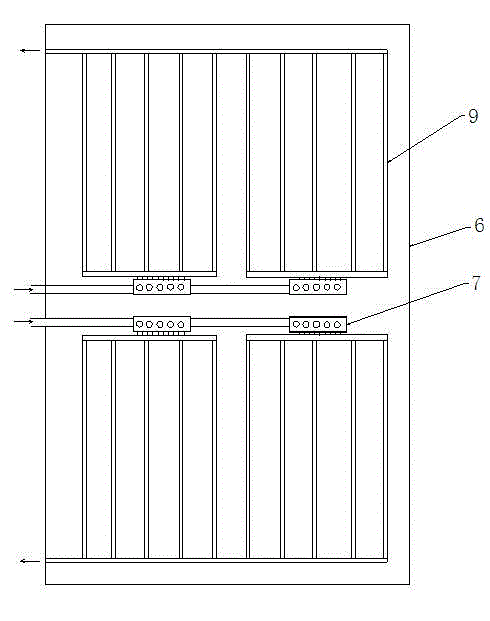

InactiveCN102939870AImprove ventilation effectWarming up fastClimate change adaptationGreenhouse cultivationGreenhouseUnderwater

The invention belongs to the technical field of greenhouses and relates to a greenhouse utilizing heat of underwater to achieve heat preservation, in particular to a geothermal greenhouse. The geothermal greenhouse comprises a closed heat-preservation greenhouse body which adopts a combined frame structure. A wall body on one side of the greenhouse is a water curtain radiation wall which comprises a wall foundation and geothermal water curtain radiators, a wall body opposite to the water curtain radiation wall is a fan wall where a plurality of fans are arranged side by side, and the ground of the greenhouse adopts a floor heating system with built-in radiation pipes. The geothermal greenhouse fully utilizes heat of the underwater, is high in heat exchange efficiency, achieves environment-friendly and pollution-free heating, and has excellent environment-friendly effect.

Owner:JINAN XIANGCUN LYUZHOU AGRI SCI & TECH DEV

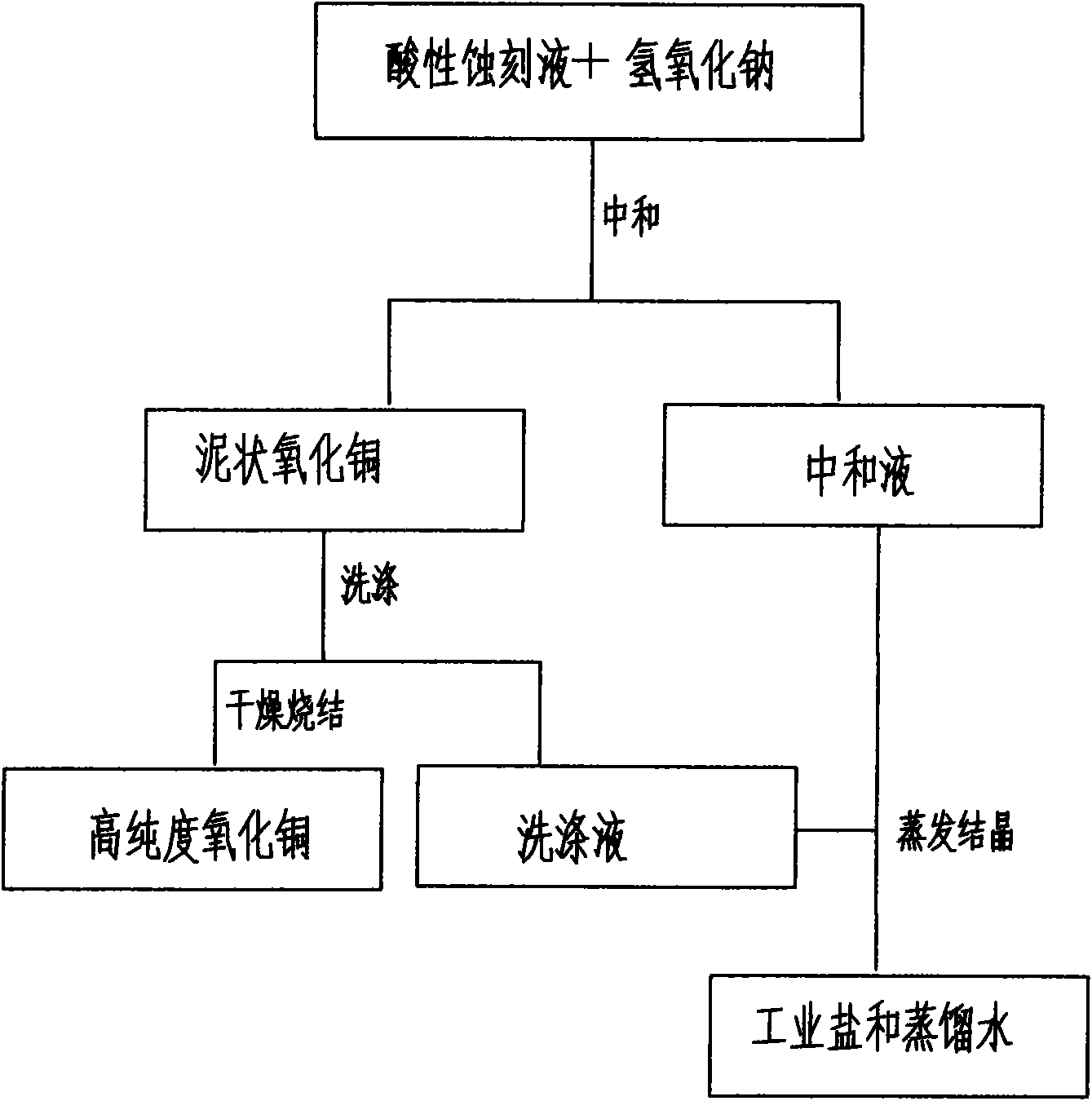

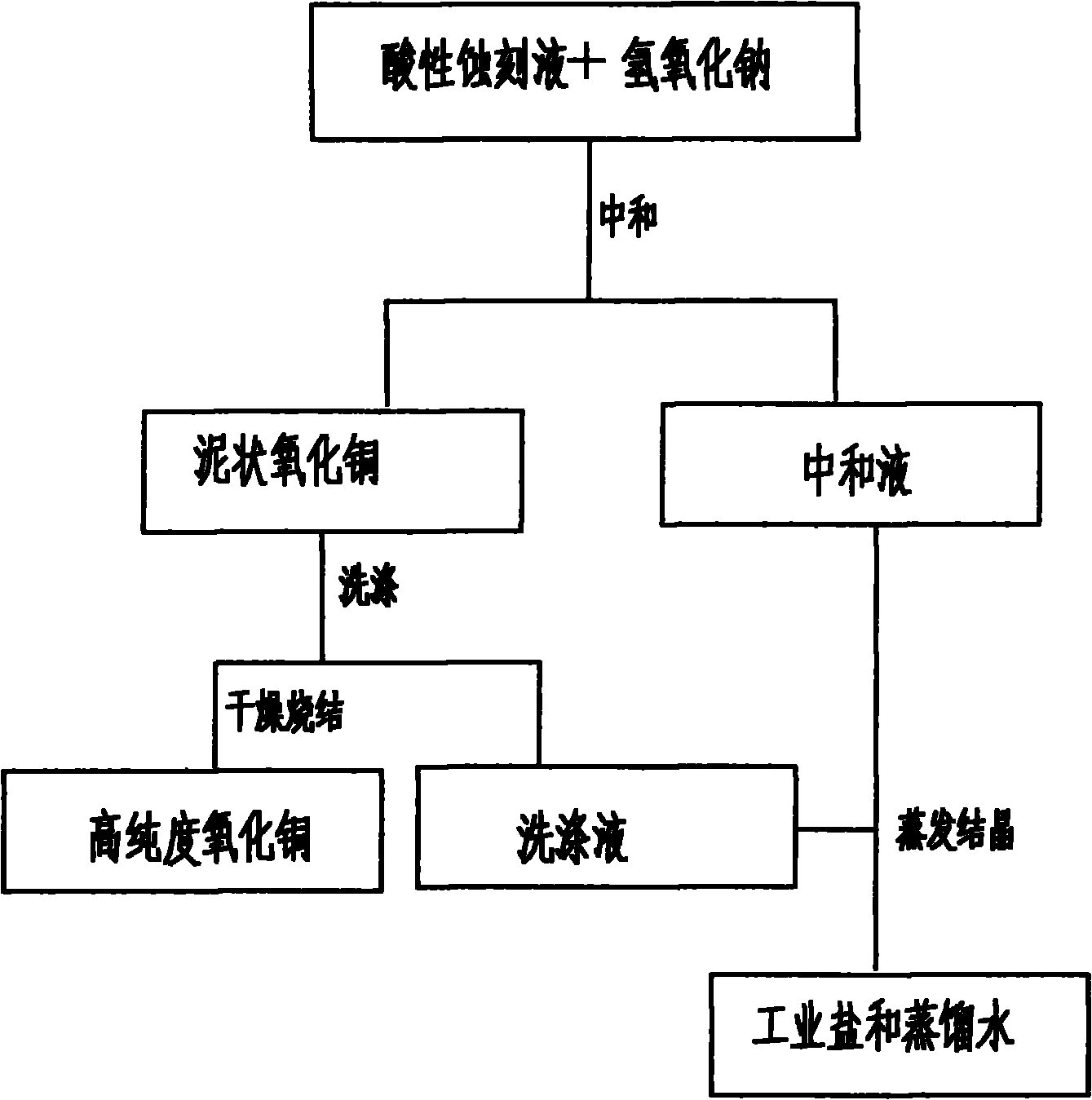

Method for preparing high-purity copper oxide by adopting acidic etching waste liquor

InactiveCN101935062AAchieving zero emissionsGood environmental effectMultistage water/sewage treatmentCopper oxides/halidesCopper chlorideCopper oxide

The invention discloses a method for preparing high-purity copper oxide by adopting acidic etching waste liquor, comprising the following steps of: (1) injecting acidic copper chloride etching waste liquor into 30-35% (by weight) sodium hydroxide solution at the temperature of 40-60 DEG C to generate copper oxide; (2) cleaning the copper oxide; (3) drying and sintering the copper oxide at 100-300 DEG C to obtain acicular crystal copper oxide with purity higher than 99.0%; and (4) mixing and heating a neutralization solution generated from the step (1) and a cleaning solution generated from the step (3), and evaporating and crystallizing to obtain industrial salt and distilled water. The method can be used for effectively recovering the copper contained in the acidic copper chloride etching waste liquor to generate the high-precision copper oxide, and the neutralization solution and the cleaning solution can be heated, evaporated and crystallized to form the industrial salt and the distilled water, therefore, the method realizes the zero draining of waste water and has very good environmental-friendly effect.

Owner:昆山联鼎环保科技有限公司

Method for drying materials by utilizing superheated steam

ActiveCN101968299AAvoid lostAvoid pollutionDrying solid materials with heatHearth type furnacesEvaporationEngineering

The invention discloses a method for drying materials by utilizing superheated steam, which is characterized in that the superheated steam is added into a sealed container in which materials to be dried are arranged, the superheated steam is used for evaporating the moisture in the materials to be dried to generate steam, and the superheated steam is cooled into low-temperature steam; the low-temperature steam enters a low-temperature steam system from the sealed container under the condition that the flow rate of the low-temperature steam is controlled; a mechanical pressurizing device is used by the low-temperature steam system for pressurizing the low-temperature steam to obtain the boosted steam; and the boosted steam is used for indirectly heating the steam in the sealed container, the boosted steam discharges the latent heat of vaporization to generate condensed water, and the steam in the sealed container receives the heat to become the superheated steam for continuously drying the materials to be dried. In the invention, the moisture of the materials to be dried is similar to the moisture of a multiple-effect evaporation system and is discharged in a form of the condensed water. The invention has the advantages of high drying efficiency, low energy consumption and simple processes, and has an industrial base of large-scale implementation.

Owner:武善东 +1

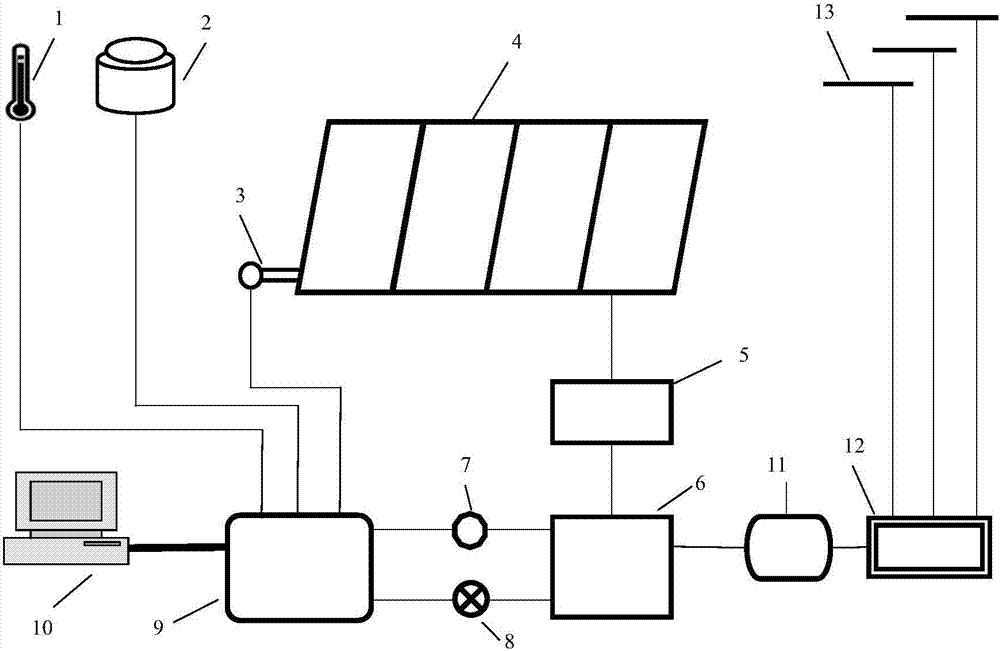

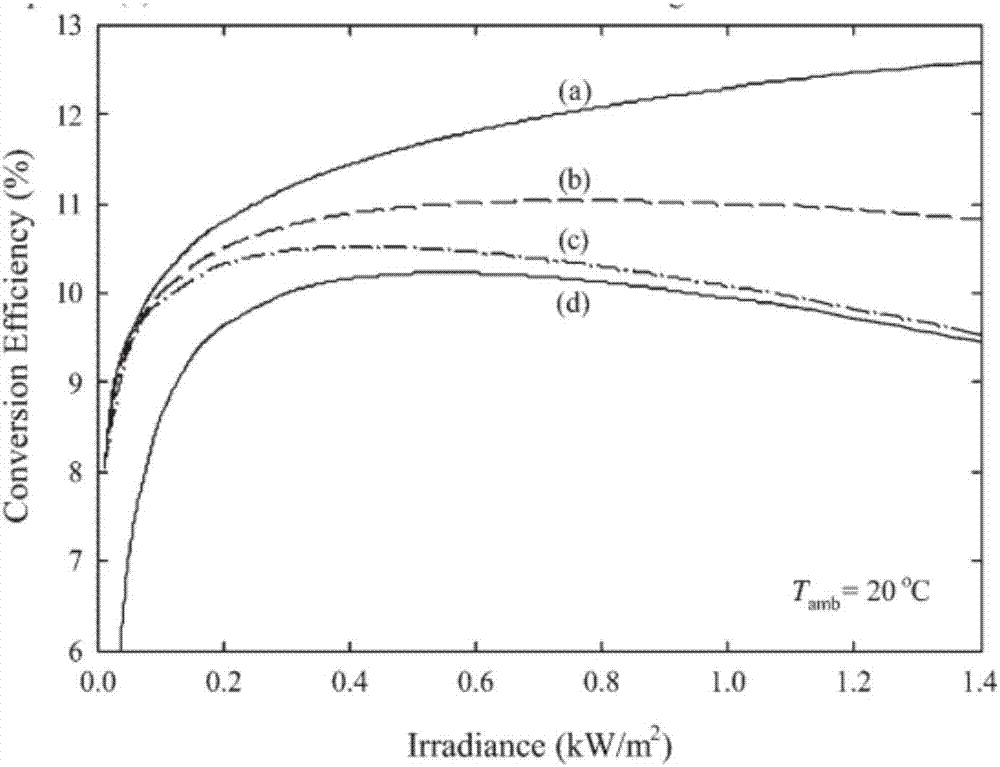

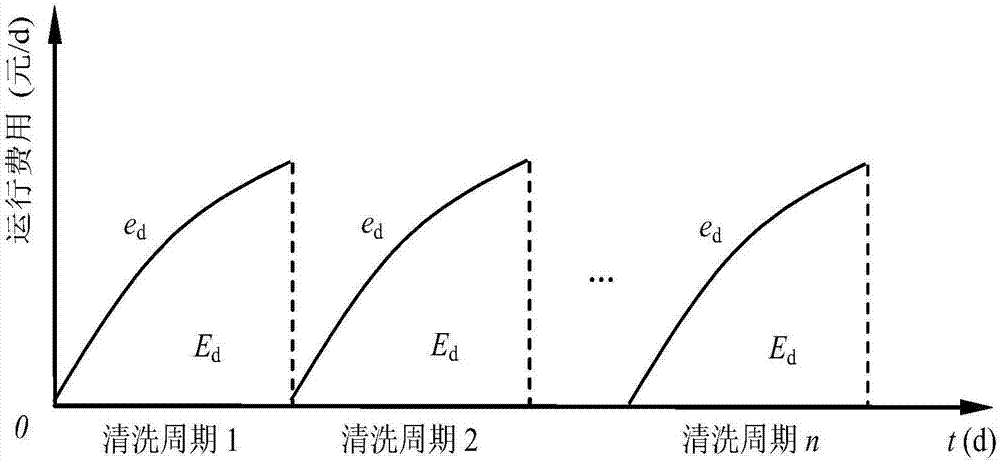

Photovoltaic cell panel ash deposition state monitoring system and cleaning period optimization method

ActiveCN107040206AAsh accumulation real-time monitoringLoss real-time monitoringPhotovoltaic monitoringPhotovoltaic energy generationTransformerData acquisition

A Photovoltaic cell panel ash deposition state monitoring system is characterized in that: the output end of an environmental temperature and humidity sensor is connected with the first input end of a data collector, the output end of a solar energy total radiation sensor is connected with the second input end of the data collector, and the output end of a battery pack backboard temperature sensor is connected with the third input end of the data collector; the battery pack backboard temperature sensor is embedded on the battery pack backboard of a photovoltaic cell panel array, the output end of the photovoltaic cell panel array is connected with the input end of a combiner box, and the output end of the combiner box is connected with the output end of a direct-current cabinet; the first output end of the direct-current cabinet is connected with the fourth input end of the data collector through a current sensor, the second output end of the direct-current cabinet is connected with the fifth input end of the data collector through a voltage sensor, and the output end of the data collector is connected with an industrial personal computer; and the third output end of the direct-current cabinet is connected with the input end of an inverter, the output end of the inverter is connected with the input end of a transformer, and the output end of the transformer is connected with a transmission-distribution network. The present invention provides a cleaning period optimization method.

Owner:NORTHEAST DIANLI UNIVERSITY

Compound feed for Scylla serrata, preparation and application method thereof

The invention relates to a compound feed for Scylla serrata, a preparation method, and an application method thereof. The compound feed comprises a solid part and a liquid part, wherein the solid part is composed of fish meal, strong flour, soybean meal, peanut meal, beer yeast, fish oil, shrimp shell powder, cuttlefish paste, phospholipids, plasma protein powder, choline chloride, compound vitamins, compound mineral substances, a decladding element, sodium diacetate, betaine, butylated hydroxyanisole, phytase and beta-carotene. The preparation method of the invention comprises the steps of raw material smashing and sifting, mixing, conditioning, granulating, drying and packaging, ant the like. The feed prepared by the method of the invention has the advantages of good food calling effect, good palatability, high feed utilization, rich and overall nutrient, a raised feed utilizing rate of the Scylla serrata, reduced pool pollution, and significant environmental protection effect.

Owner:ZHEJIANG MARINE DEV RES INST

Indoor air disinfectant

InactiveCN1634602AImprove disinfection effectRaw materials are easy to getDeodrantsDisinfectantMedicine

An indoor air disinfectant is disclosed. It is prepared by soaking the traditional Chinese medicinal materials of Chinese mugwort leaf, atractylodes rhizome, garlic and honeysuckle. The invention can be used for disinfecting indoor air, the effect can reach country standard. It also has certain preventing function for SARS.

Owner:尹琼剑

Method for reducing SO2 content in exhaust gas in production of sulfuric acid

InactiveCN101862575AIncrease productionReduce pollutionDispersed particle separationHigh concentrationChemical reaction

The invention relates to a method for reducing SO2 content in exhaust gas in production of sulfuric acid, which comprises the following steps that: an exhaust gas desulfurization device formed by an adsorption tower and a desorption tower is additionally arranged between a second acid absorber of the existing sulfuric acid device and an exhaust gas emission chimney; the sulfuric acid exhaust gas is guided into the adsorption tower, part of SO2 in the exhaust gas is adsorbed by an active coke desulfurization agent, and the exhaust gas from which part of SO2 is removed is adsorbed to be exhausted by the chimney; the adsorbed SO2 is chemically reacted with oxygen and water to produce sulfuric acid; the active coke desulfurization agent filled and flowed out of the adsorption tower enters the desorption tower and is heated, sulfuric acid or sulfate accumulated in active coke is decomposed and desorbed, and the desorbed high-concentration SO2 is sent back to the conversion section of the sulfuric acid device; and the desorbed active coke desulfurization agent enters the adsorption tower again to be circulated for reabsorbing. The method of the invention has high desulfurization efficiency, and the concentration of SO2 in exhaust gas in the production of the sulfuric acid is less than 120mg / m3, thereby greatly reducing the pollution of the SO2 on the atmosphere, and having obvious environmental effects; and the removed SO2 is directly sent back to the conversion section to be recovered, thereby increasing the yield of sulfuric acid.

Owner:WENGFU (GRP) CO LTD

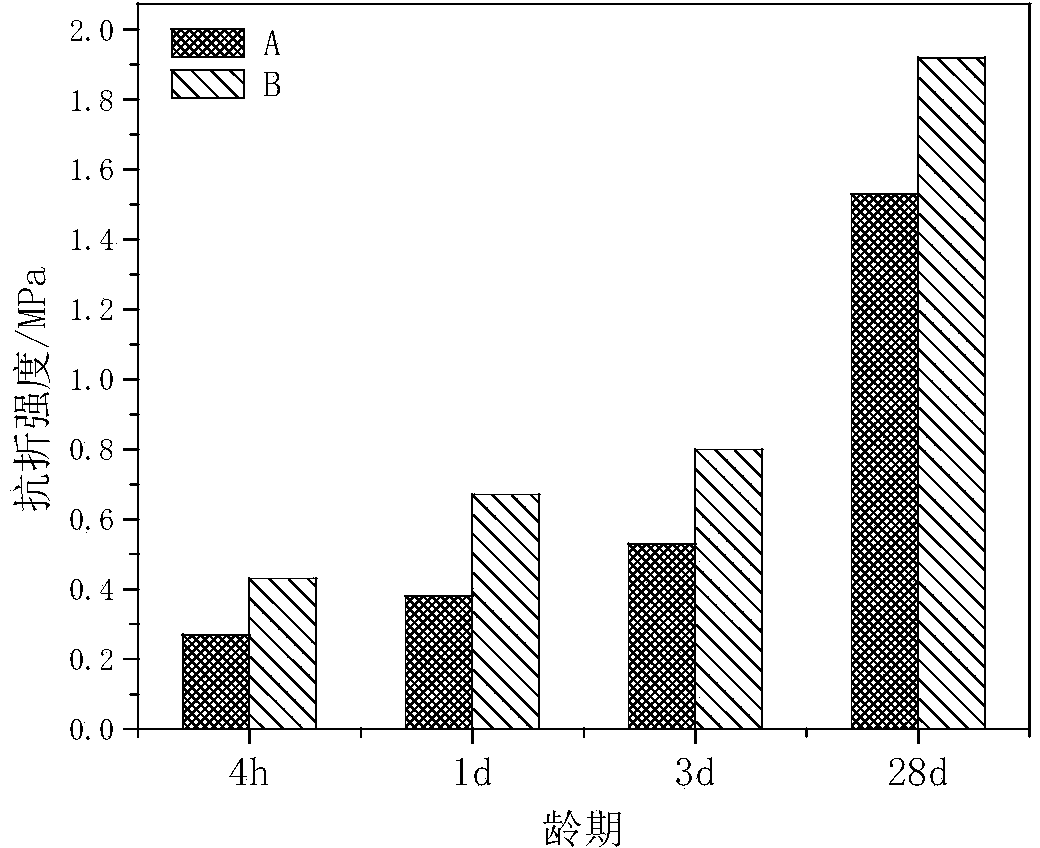

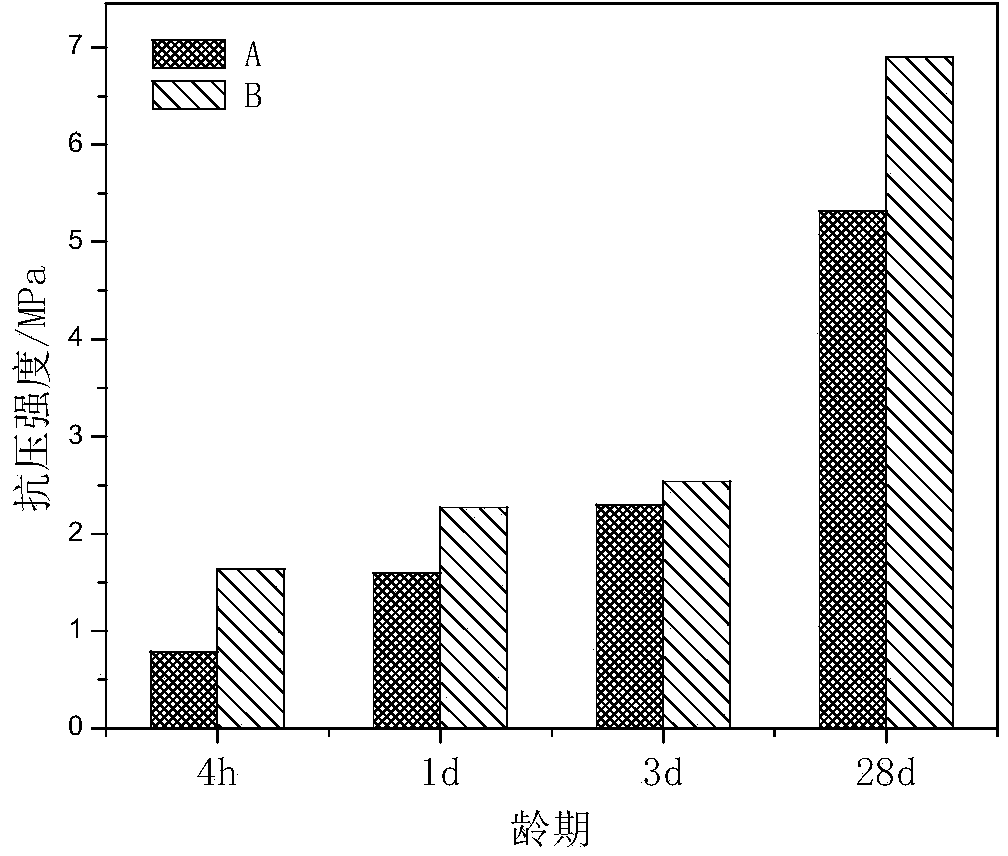

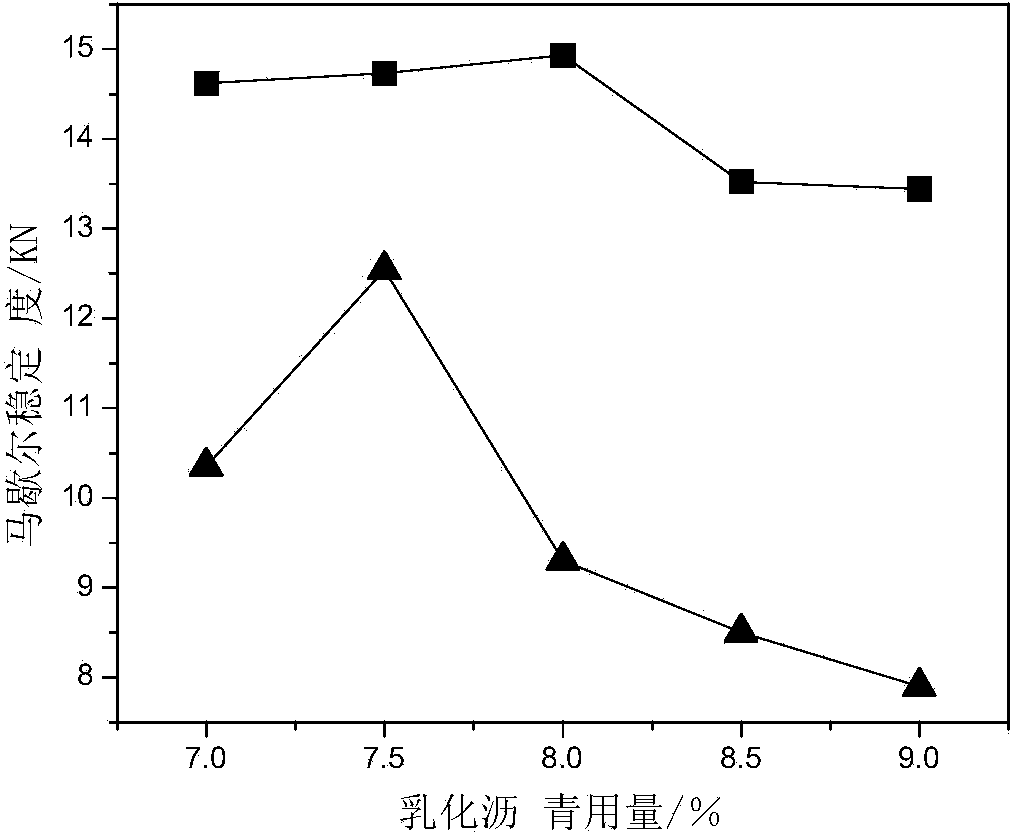

Asphalt modifier, modified emulsified asphalt, modified asphalt mixture and respective preparation methods thereof

ActiveCN104312175AExtended construction seasonEmission reductionBuilding insulationsEmulsionRoad surface

The invention provides an asphalt modifier which consists of a composition I and styrene-butadiene-styrene block copolymer emulsion, wherein the composition I consists of ethylvinylacetate emulsion, styrene-butadiene emulsion, waterborne bisphenol A epoxy resin emulsion and organic silicon modified acrylate emulsion. The invention also provides modified emulsified asphalt and a rapid-curing modified asphalt mixture which comprise the asphalt modifier, and respective preparation methods. The modified asphalt mixture provided by the invention is a brand new rapid-curing high-performance pavement material. The modified asphalt mixture not only has rigidity and intensity of mineral aggregates, but also has flexibility of asphalt and has Marshall stability of over 12KN and a flow value of between 2 to 4mm; and after an asphalt pavement repair layer with a thickness of 1 to 3cm is constructed for about 4 hours, the traffic can be opened.

Owner:XINJIANG MEIHUITE PETROCHEM PROD CO LTD

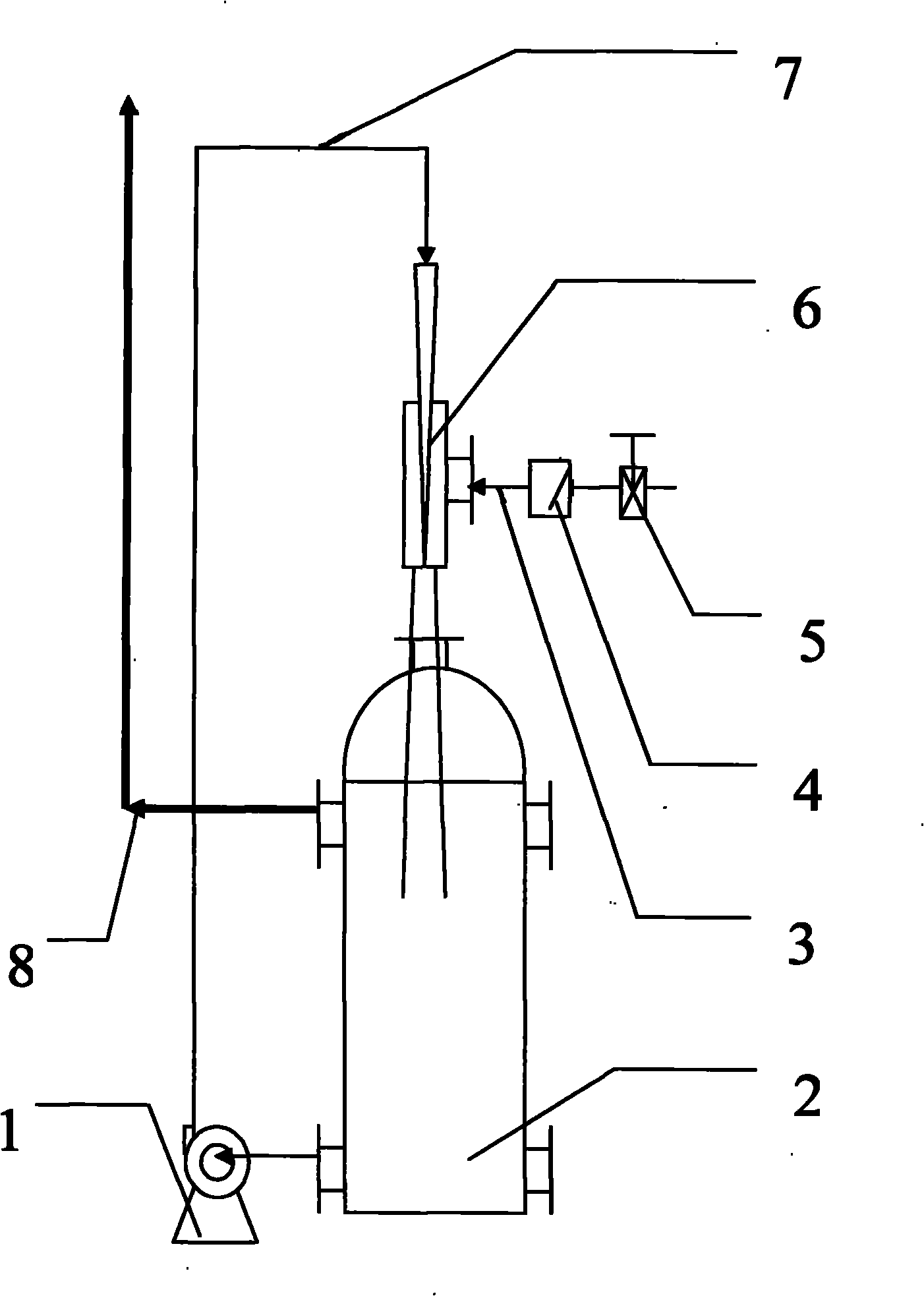

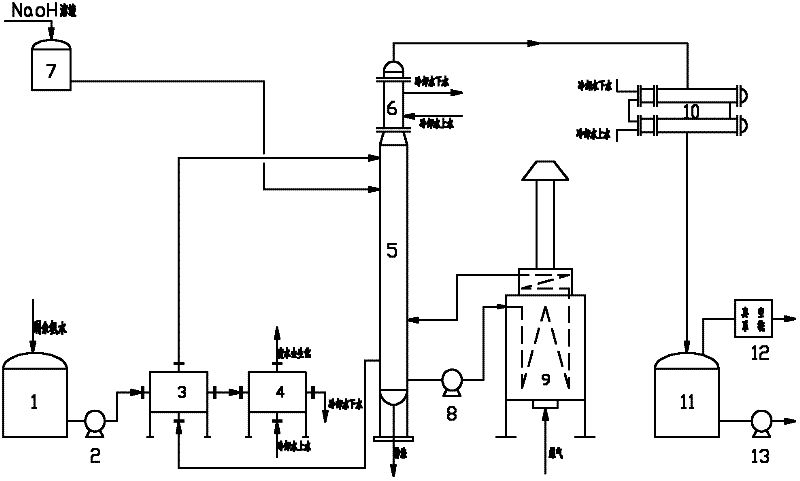

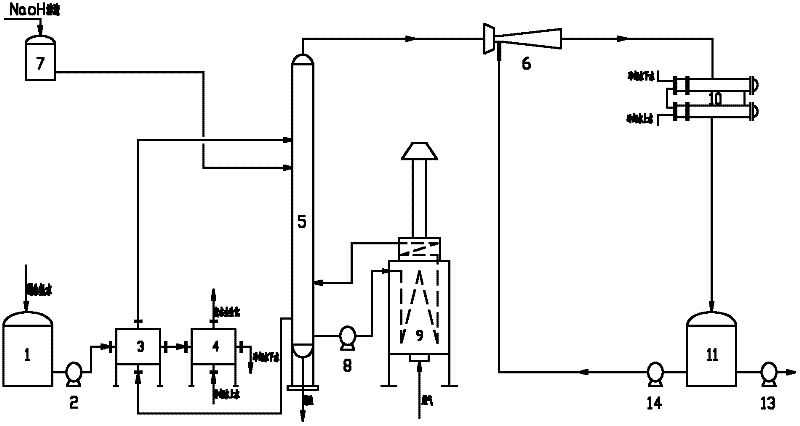

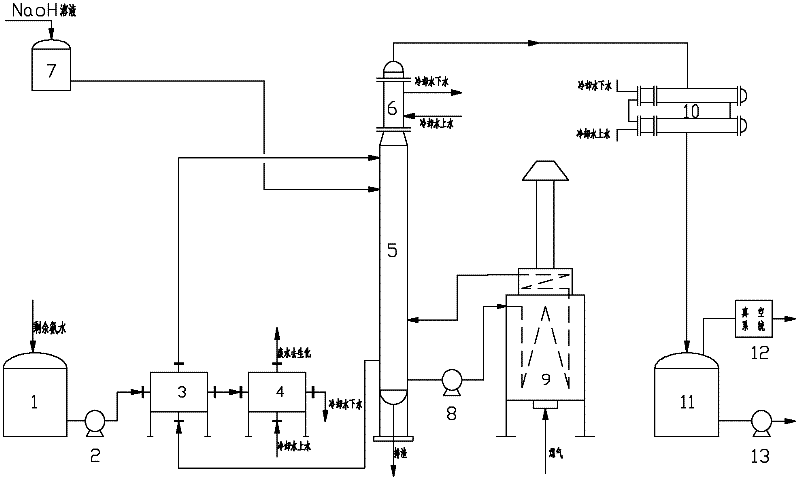

Tubular furnace negative pressure ammonia distillation process

ActiveCN102336415ALower operating temperatureReduce vibrationWater/sewage treatment by degassingAmmonia preparation/separationDaily operationDistillation

The invention discloses a tubular furnace negative pressure ammonia distillation process used for treating coking residual ammonia water. The residual ammonia water enters into an ammonia distillation tower which is used for drawing the negative pressure in the top of the tower by using a vacuum pump of a vacuum system or cooling ammonia in the top of the tower by using a venturi injector, the ammonia of the residual ammonia water is volatilized under the negative pressure state, heat source required by ammonia distillation is provided by the ammonia distillation waste water from the bottom of a circular heating ammonia distillation tower of the tubular furnace. The process of the invention has the advantages of energy conservation, emission reduction and daily operation cost reduction; simultaneously the operation state under the negative pressure and low temperature determines that the requirement of the material quality of the main equipment is not high so that the equipment investment cost at early stage is reduced.

Owner:上海同特化工科技有限公司 +2

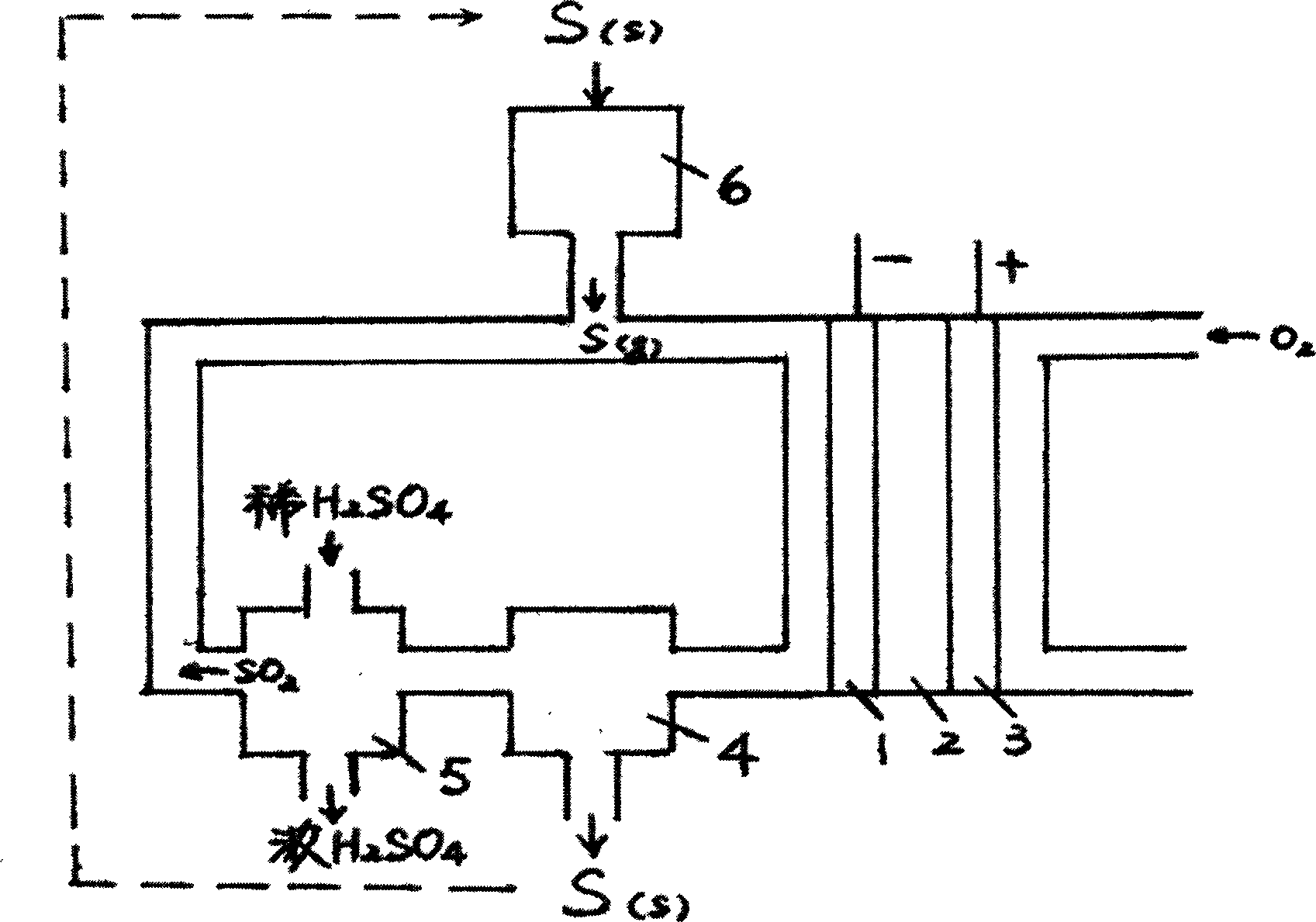

Sulfur-air fuel cell and its application in sulfuric acid production

InactiveCN1805195AGood environmental effectSave energyFinal product manufactureSulfur compoundsHydrogenFuel cells

The invention relates to a sulfur-air fuel battery and the application in the vitriol production, belonging to the chemical energy-saving producing technique. The structure of said invention is the same with solid oxide hydrogen-oxygen fuel battery. The cathode of said battery can use the electric chemical method to oxygenate the gas S into SO3 and transform the chemical energy into electric energy. The oxygenation of sulfur is processed in the battery sealed system without discharging waste gas. The invention can be used as the synthesizer to use sulfur to produce vitriol in the vitriol industry production, to combine the vitriol production, chemical discharge and environment protection.

Owner:ANHUI NENGHUA FUEL CELL

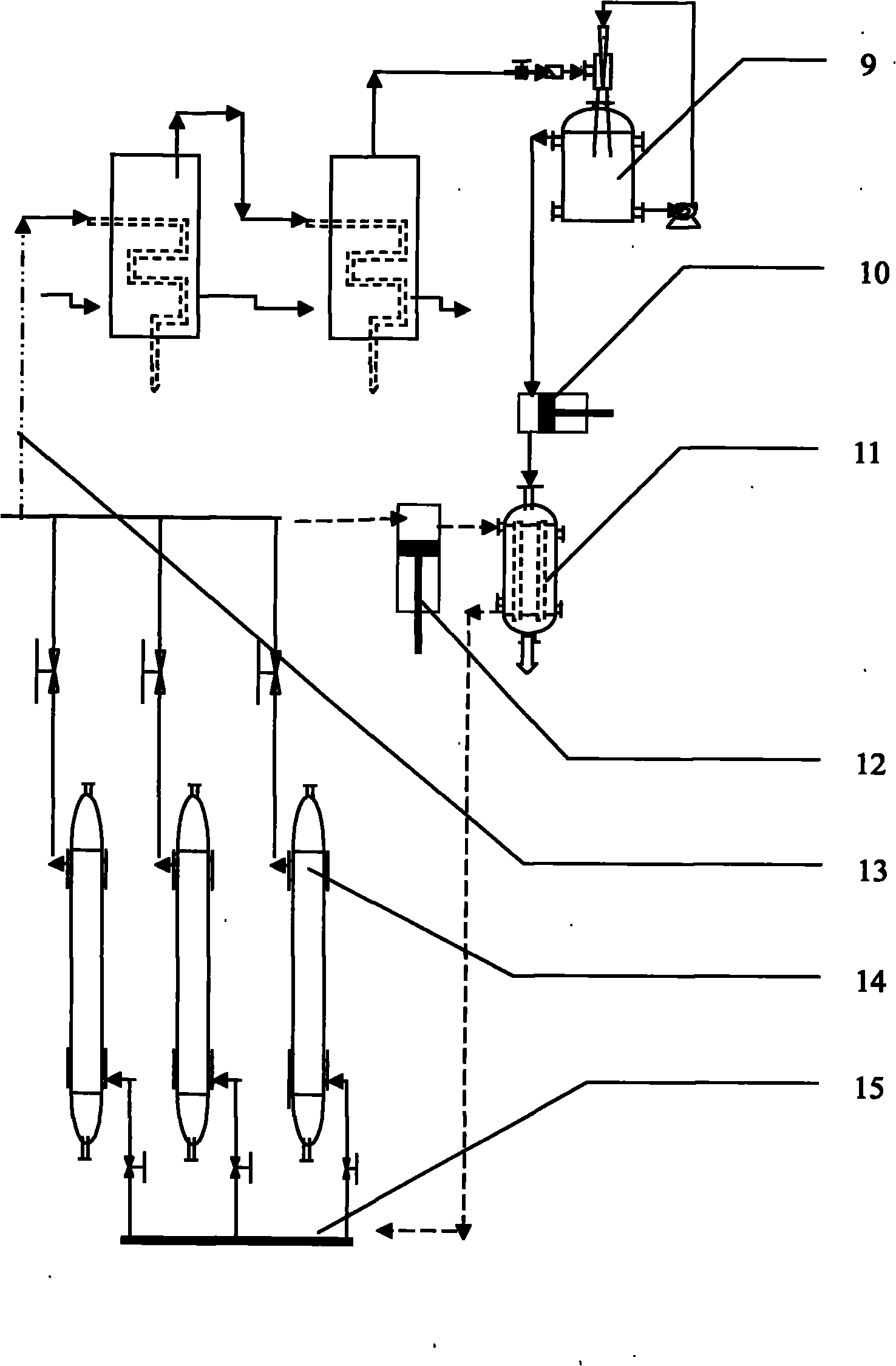

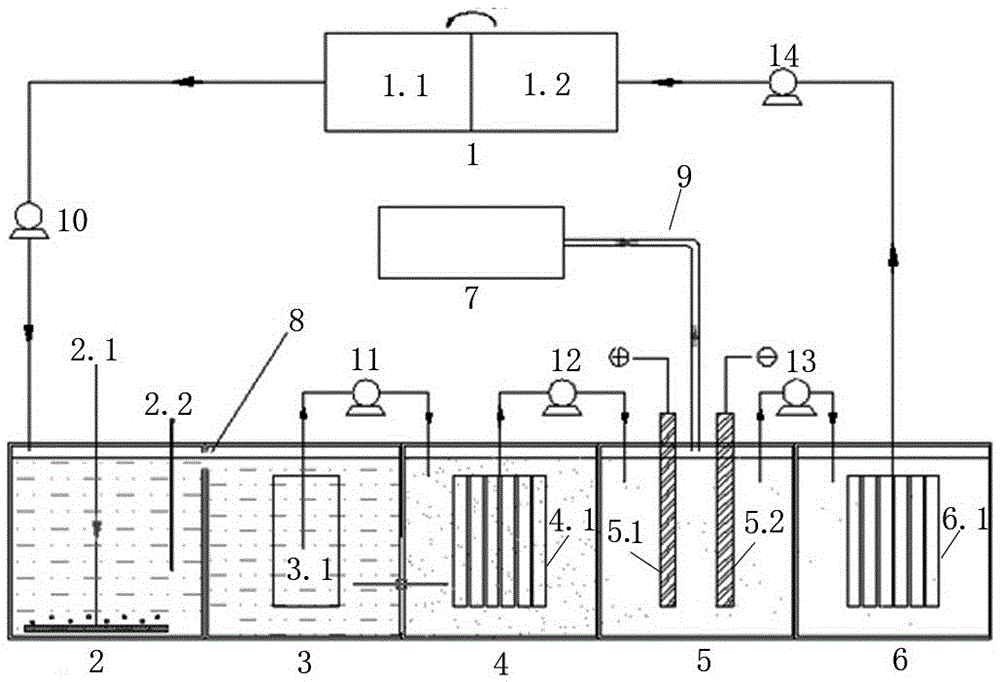

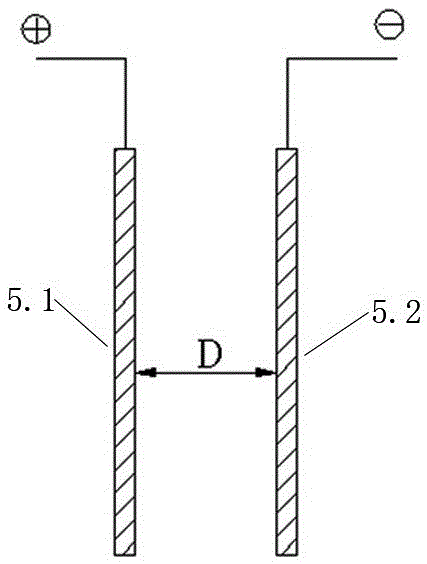

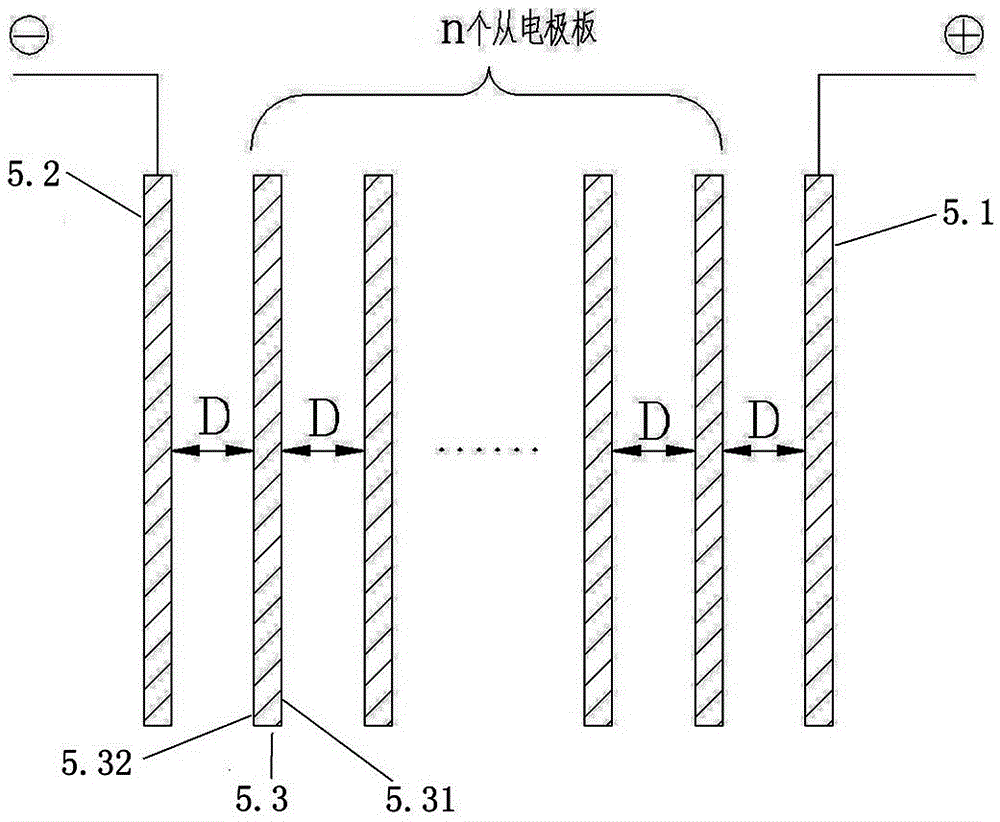

PCB ammonia-nitrogen wastewater zero discharge treatment method and device thereof

ActiveCN105523668AEfficient removalMeet industrial reuse water requirementsDispersed particle separationTreatment involving filtrationElectrolysisUltrafiltration

The invention discloses a PCB ammonia-nitrogen wastewater zero discharge treatment method and a device thereof. The invention is characterized in that the method comprises the following steps: adjusting pH value of etching washing wastewater to 8-11, carrying out rough filtration and ultrafiltration successively, electrolyzing a filtrate I by the use of electrodes with plate electrode distance D being less than or equal to 3 CM and an electrolysis system with electric current density being 1-3 ADS, and adsorbing the generated gas by the use of an alkaline etching liquid; treating the electrolyzed filtrate through a ultrafiltration system so as to obtain a filtrate II, and reusing the filtrate II. Local concentration of the electrolysis product between the plate electrodes is changed by adjusting the distance of the plate electrodes, and chlorine gas generated from the positive electrode escapes in a gaseous state due to too high local concentration so as to synchronously remove ammonia nitrogen and Cl<->. Thus, an effluent obtained after the treatment accords with technical requirements of the etching washing water and satisfies industrial reuse water so as to realize zero discharge.

Owner:珠海市华泰环保科技股份有限公司

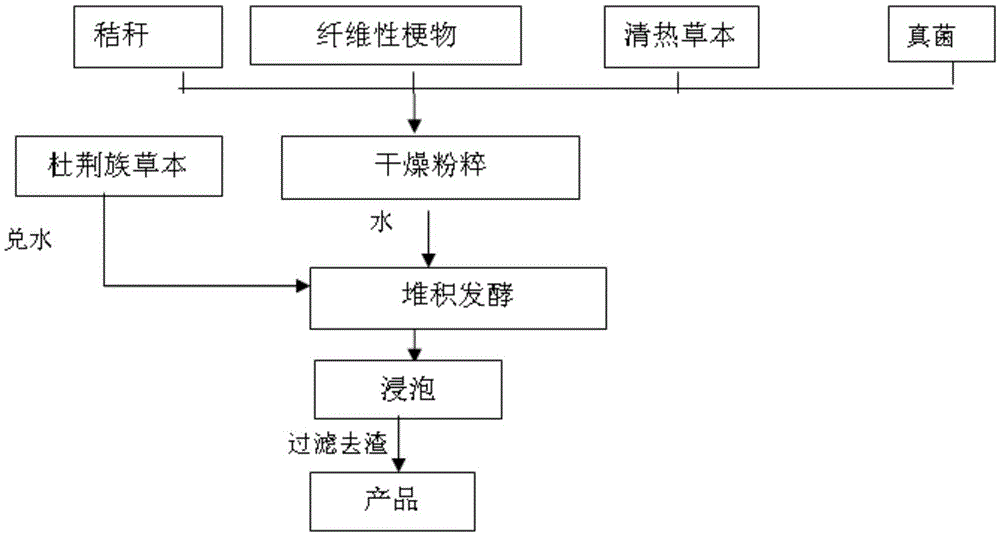

Herbaceous plant rare-earth precipitating agent and preparation method thereof

InactiveCN105603222AGood environmental effectRemarkable convenience for recyclingProcess efficiency improvementNitrogenVitex

The invention relates to the field of preparation of rare earth, in particular to a herbaceous plant rare-earth precipitating agent and a preparation method thereof. The herbaceous plant rare-earth precipitating agent is prepared from, by weight, 30-50 parts of straw, 25-65 parts of fibrous stalks, 0.5-5 parts of herb for clearing away heat, 0.5-5 parts of Vitex.negundo L.var. cannabifolia (sieb. et Zucc.) Hand.-Mazz. herb and 0.08-5 parts of fungi, and the raw materials are weighed, smashed, fermented and soaked so that the herbaceous plant rare-earth precipitating agent can be prepared. By means of the herbaceous plant precipitating agent, the mother liquid precipitating effect can reach 99.6% or above after mineral leaching is performed on rare earth minerals in different types, the concentration of ammonia and nitrogen in supernatant after precipitation is 0.94 mg / L, secondary pollution of ammonia and nitrogen is avoided, herb precipitate contained in the supernatant can be directly used circularly, and the herbaceous plant rare-earth precipitating agent is a natural and environment-friendly precipitating agent.

Owner:GUANGXI HAOZHAO ENVIRONMENT PROTECTION TECH CO LTD

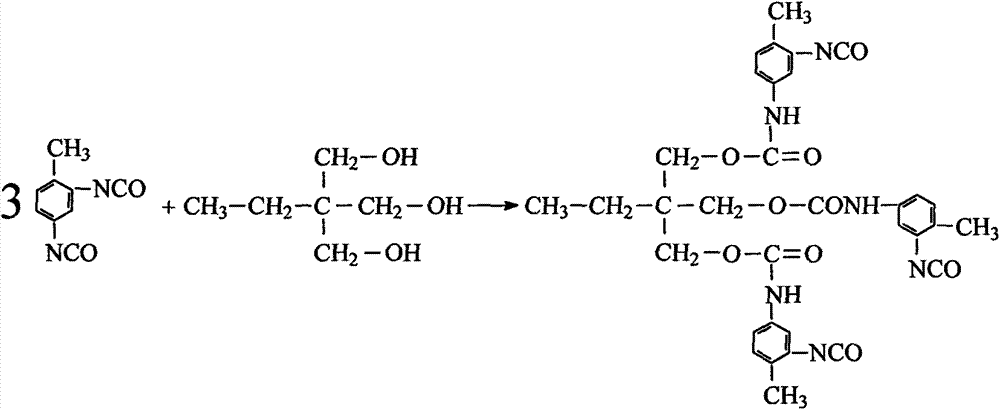

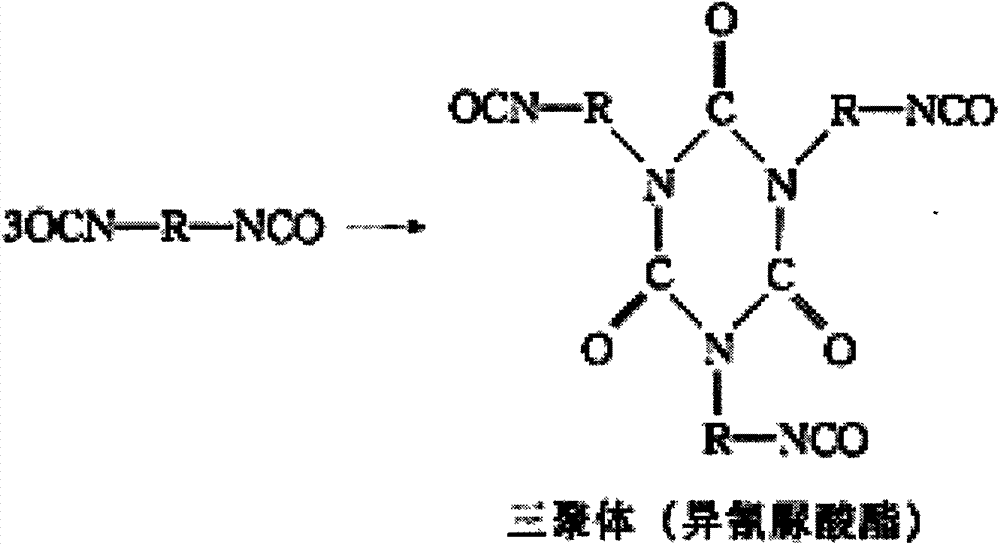

Preparation method of low-dissociation high-intermiscibility polyurethane curing agent

ActiveCN103483548ASmall molecular weightIncrease polarityPolyurea/polyurethane coatingsToluene diisocyanateSolvent

The invention discloses a preparation method of a low-dissociation high-intermiscibility polyurethane curing agent. The method is as below: preparing the following raw materials by weight: (A) 40-70 parts of toluene diisocyanate or a mixture of two toluene diisocyanates, (B) 23-27 parts of a ester solvent with boiling point no higher than 200 DEG C, (C) 5-20 parts of trimethylol propane, (D) 1-20 parts of composite polyol ethers, (E) 0.1-0.2 part of an isocyanate trimerization catalyst and (F) 0.1-0.3 part of an isocyanate trimerization inhibitor; carrying out reactions at different temperature conditions to remove most dissociated toluene diisocyanate monomers; and then carrying out trimerization on the dissociated monomers under the effect of the catalyst to remove remaining dissociated toluene diisocyanate monomers. The prepared curing agent products has content of dissociated toluene diisocyanate reaching requirements of the latest national standard, and has the advantages of high solid content, low viscosity, good compatibility, good stability and unchanged paint film performance after paint preparation.

Owner:韶关东森合成材料有限公司

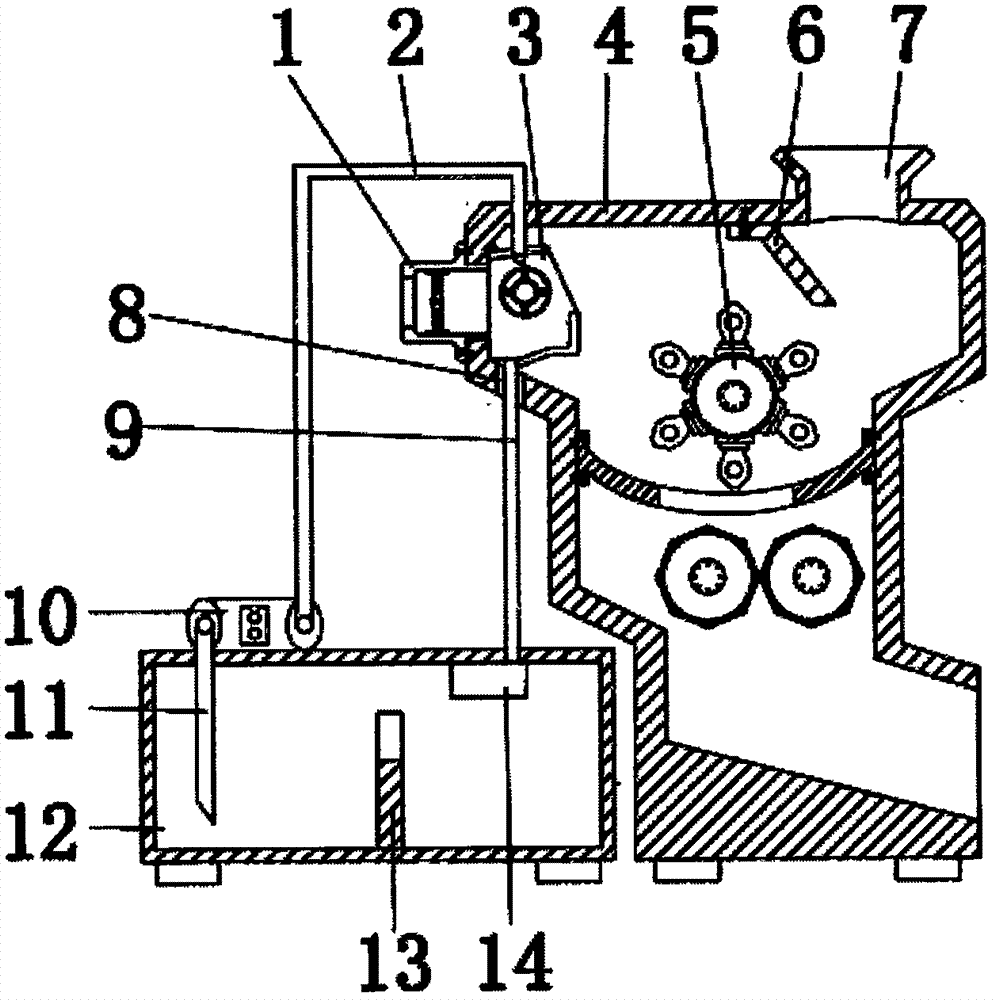

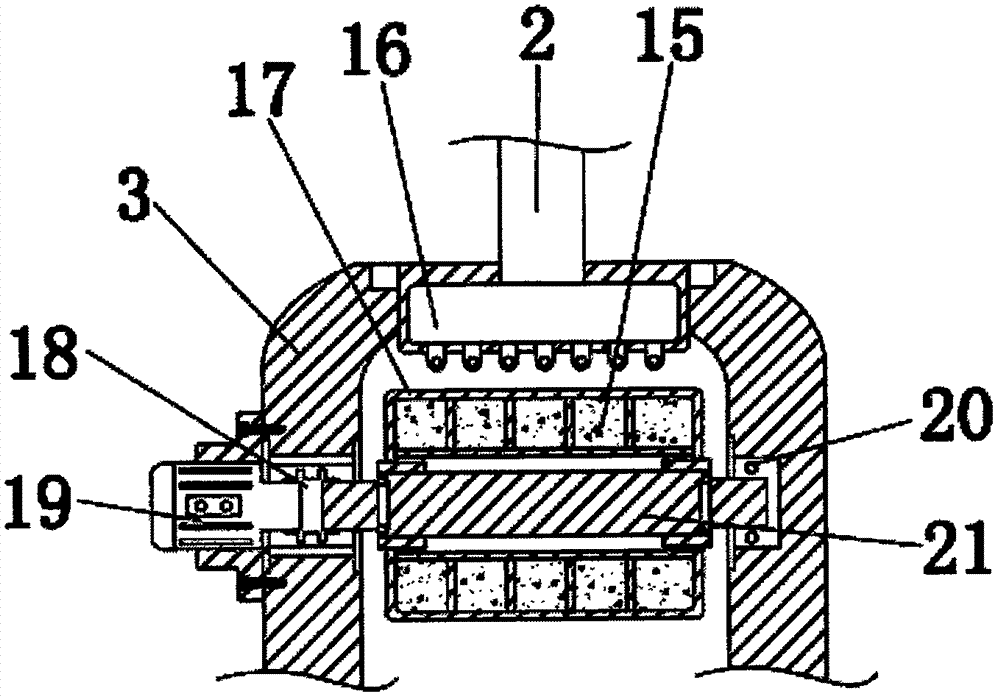

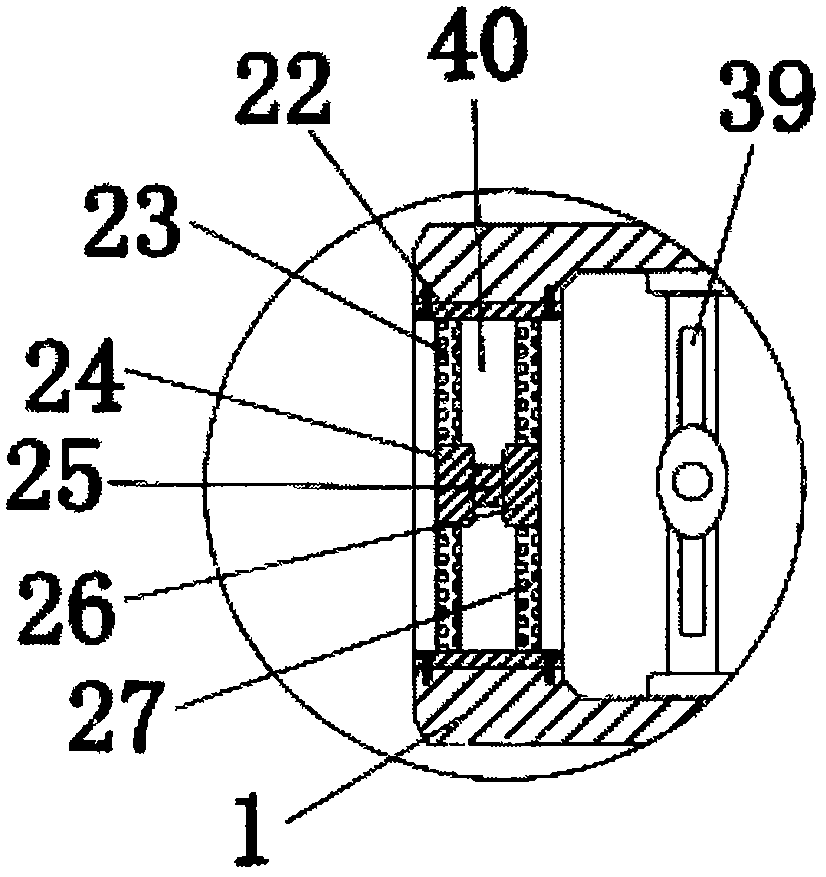

Environment-friendly dust removal type ore crusher

InactiveCN107413472AEasy to handleAvoid harmUsing liquid separation agentSeparation devicesWater dischargeSuction force

The invention discloses an environment-friendly and dust-removing ore crusher, which comprises a crushing shell, a dust-absorbing cover is installed on the left top of the inside of the crushing shell, a water spray nozzle is installed on the top of the dust-absorbing cover, and the rotor A network frame is installed outside the roller, and a humidifying filter is installed inside the network frame. The bottom end of the dust collection cover is connected with the water tank through a drain pipe, and an axial flow fan is installed inside the outer cover. The environment-friendly dust removal type ore crusher, through the cooperation of the dust collection hood, humidification filter and water nozzle, the axial flow fan works to make the suction force generated drive the dust in the crushing shell to enter the dust collection hood, and the water nozzle sprays out The mist-like water droplets are sprayed onto the humidification filter, and at the same time, they can be in contact with the dust in the inhaled air during spraying, which strengthens the treatment effect on dust, and absorbs a large amount of dust generated, which has a better environmental protection effect and avoids cause physical harm to workers.

Owner:张志通

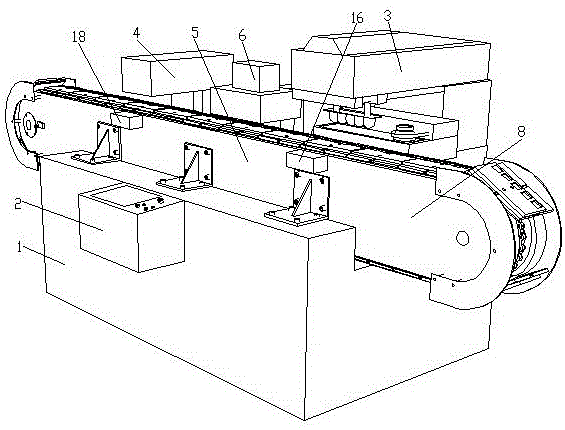

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

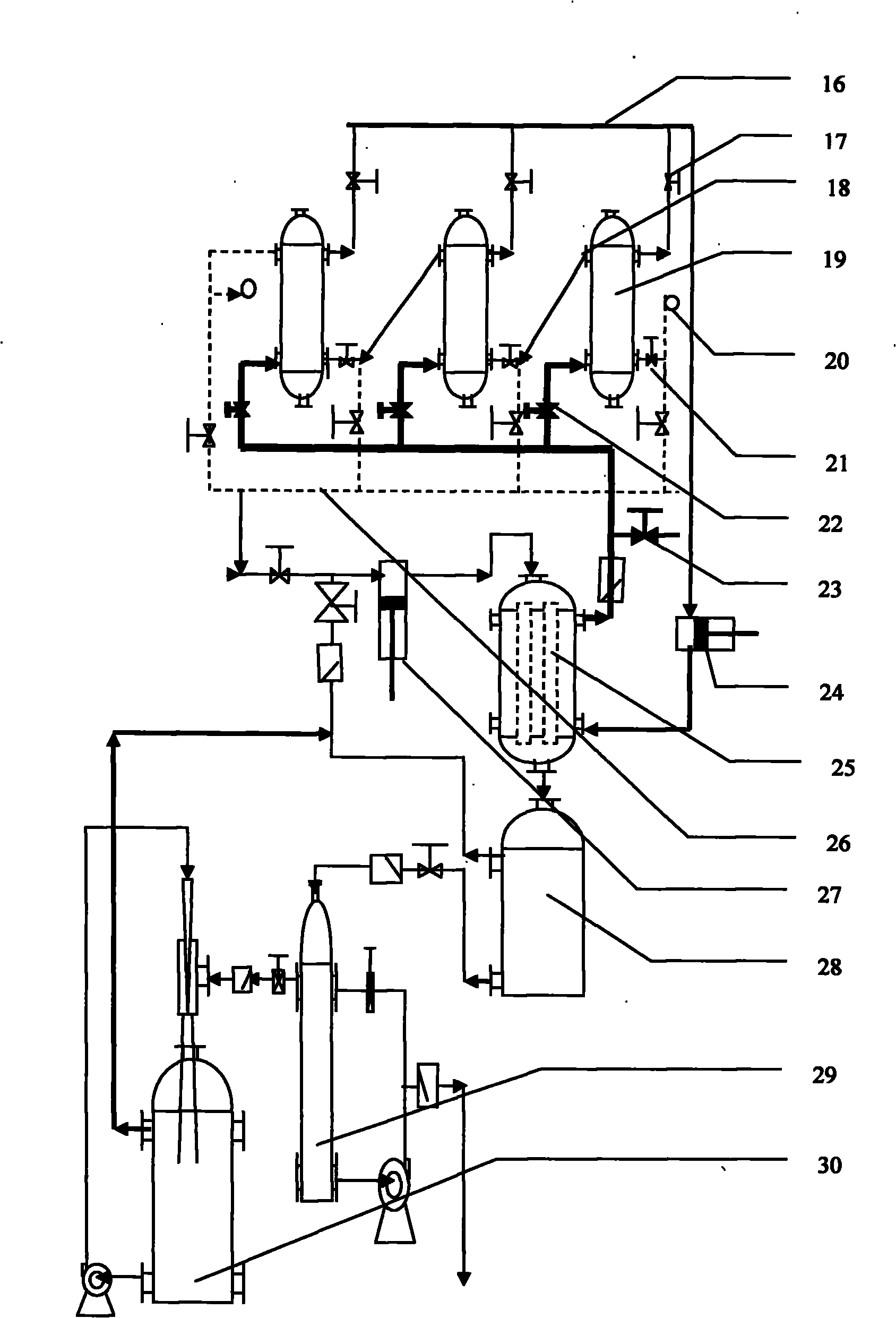

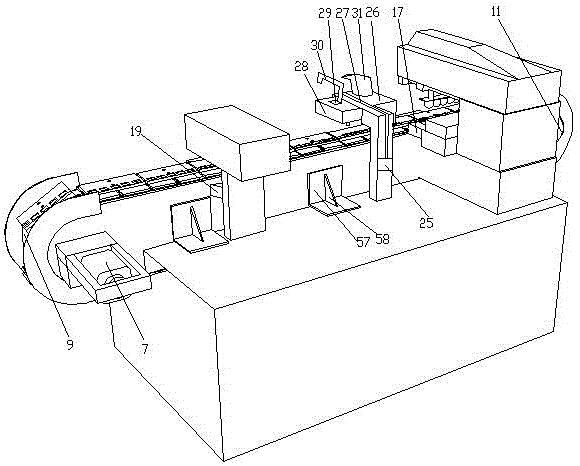

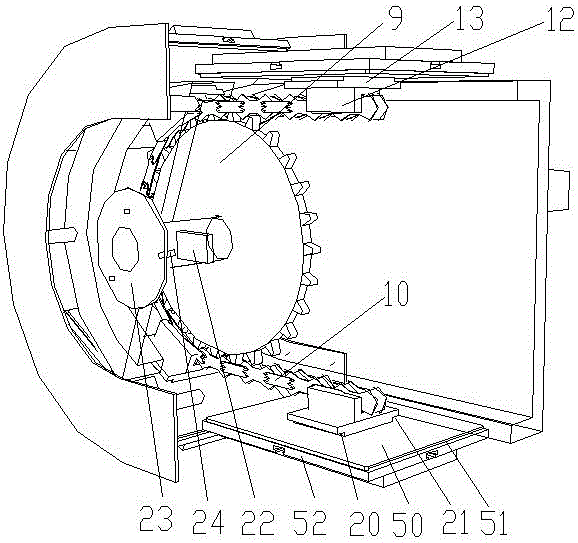

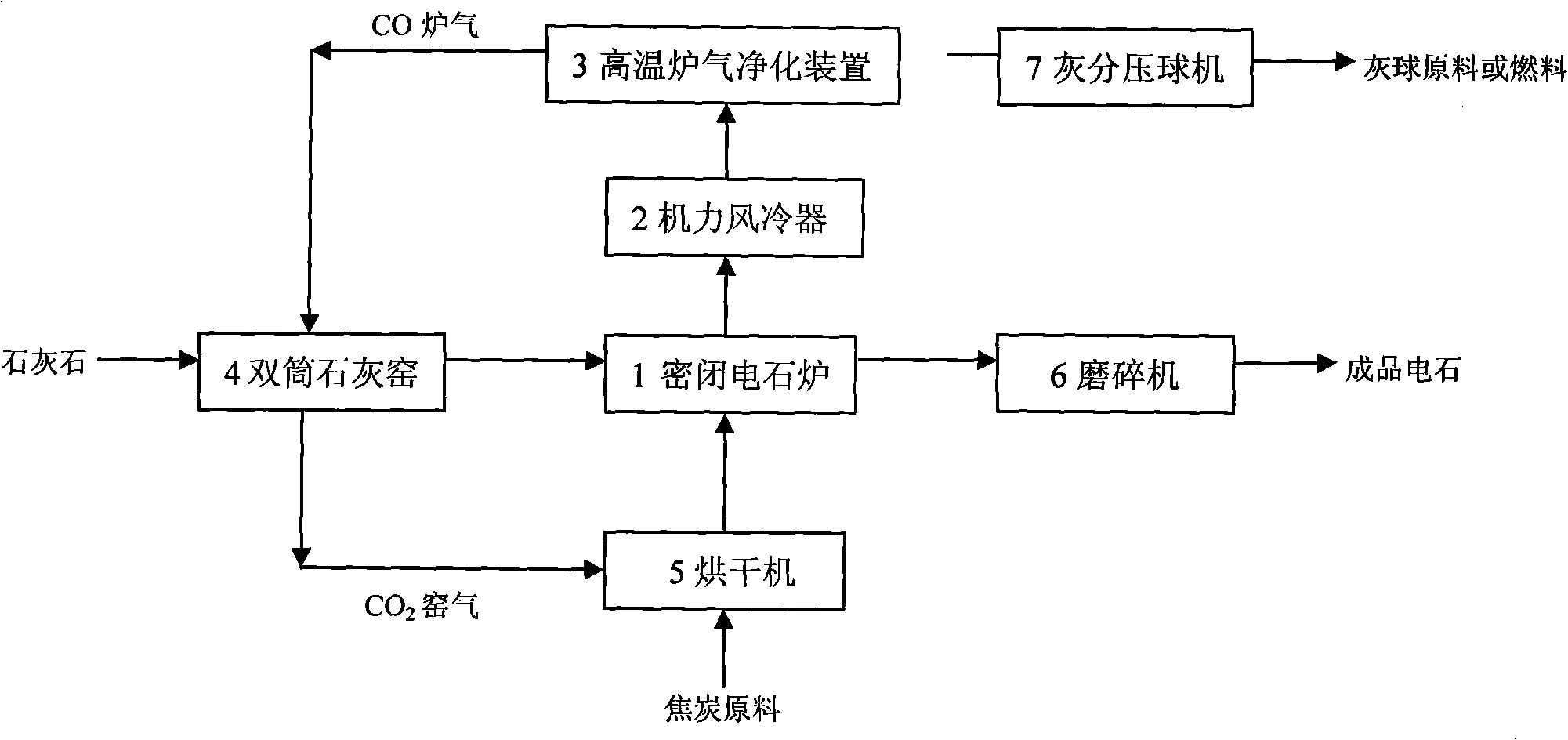

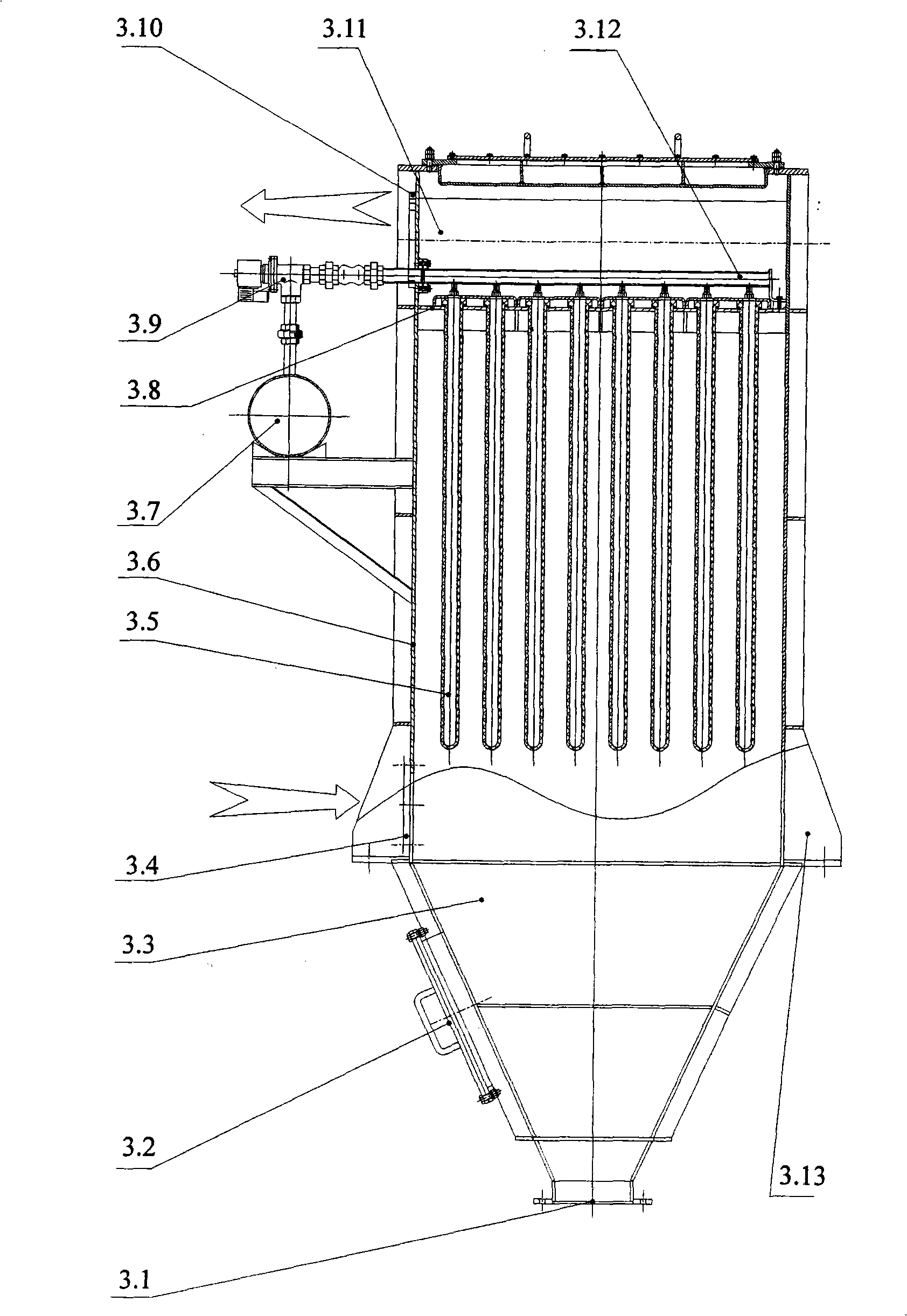

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com