Preparation method of low-dissociation high-intermiscibility polyurethane curing agent

A polyurethane curing agent and compatibility technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of environmental protection, low free, low viscosity, high solid content, high compatibility, etc., and achieve good environmental protection effect, high compatibility, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

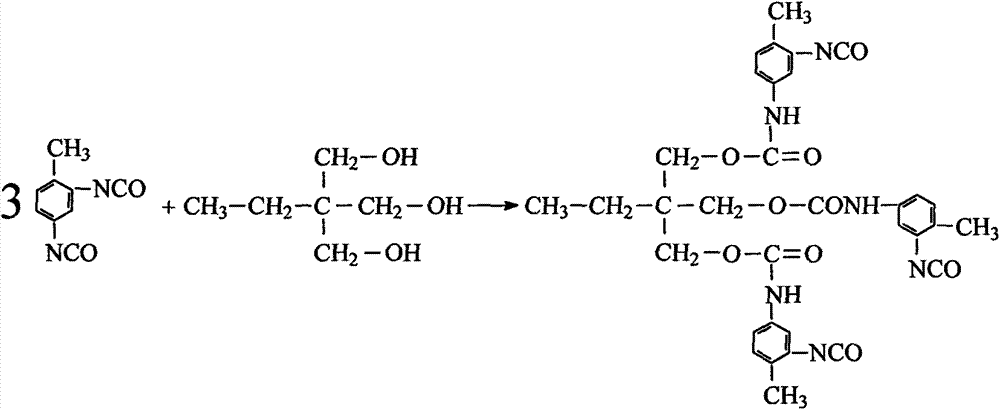

[0020] As a specific example one of the present invention, 60% of toluene diisocyanate, 12% of trimethylolpropane, 25% of ethyl acetate, 2.5% of compound polyol ethers, 0.2% of catalyst and 0.3% polymerization inhibitor, and then prepared according to the above method, the polyurethane curing agent produced has the advantages of low free, low viscosity, high solid content and high compatibility.

Embodiment 2

[0021] Embodiment two, can weigh 55% toluene diisocyanate, 10% trimethylolpropane, 25% ethyl acetate, 9.8% compound polyol ethers, 0.1% catalyst and 0.1% Inhibitors were then prepared as described above.

Embodiment 3

[0022] Embodiment three, can weigh 50% toluene diisocyanate, 8% trimethylolpropane, 25% ethyl acetate, 16.7% complex polyol ethers, 0.1% catalyst and 0.2% Inhibitors were then prepared as described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com