Mine filling cementing material slurry and preparation method thereof

A mine filling and cementing material technology, which is applied in cement production and other directions, can solve the problems of high production cost, complicated preparation method of filling materials, high dosage, etc., and achieve the effects of high fluidity, remarkable environmental protection effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The steel slag is taken from Wuhan Iron and Steel Co., Ltd., and after drying, it is ground into steel slag powder. According to GB8074-87 "Measurement Method of Cement Specific Surface Area", its Bo's specific surface area is 462m 2 / Kg; The slag is taken from Wuhan Iron and Steel Co., Ltd., and it is ground into slag powder after drying, and the specific surface area of Bo’s is 445m 2 / Kg; industrial by-product gypsum, selected phosphogypsum, from Anhui Tongling Chemical Group, dried and ground to a specific surface area of 456m 2 / Kg; The tailings sand is copper tailings sand, which is taken from Tongling, Anhui Province, and the particle size is less than 2mm, without classification or other treatment.

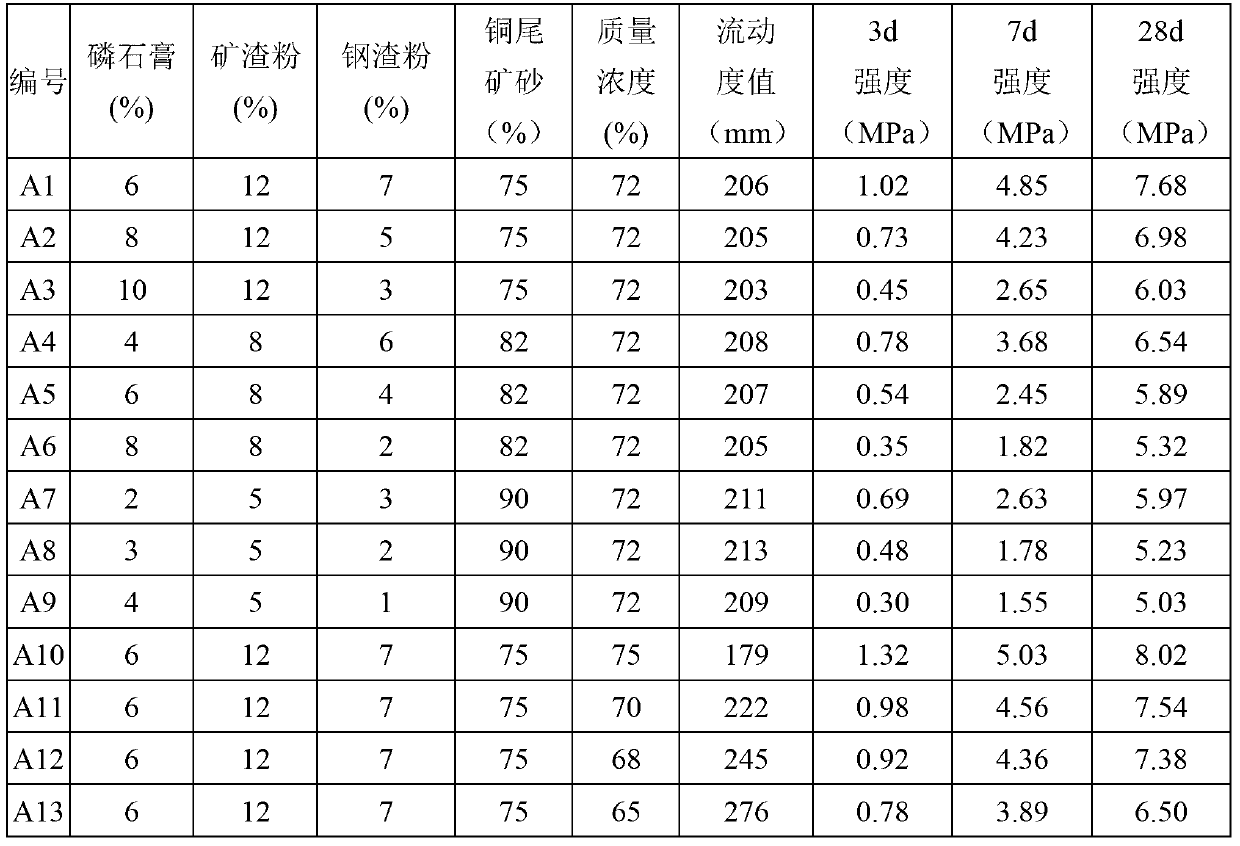

[0028] Mix the prepared raw materials according to the ratio in Table 1, add water and stir it evenly with a mixer to make a slurry (see "mass concentration" in Table 1), refer to GB / T8077-2000 "Concrete Admixture Uniformity" Qualitative Test Method", using the...

Embodiment 2

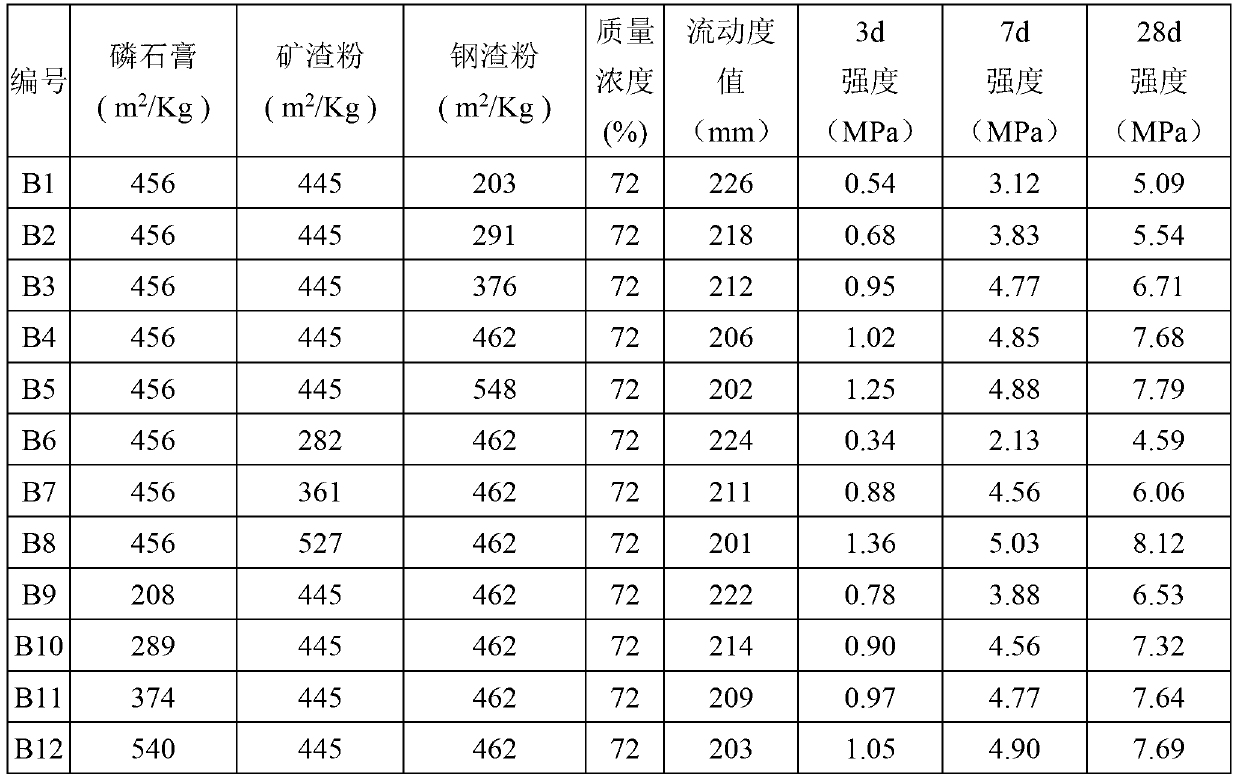

[0032] The type and source of raw materials used in this example are the same as in Example 1.

[0033] The difference is that the specific surface area of the slag powder, steel slag powder and phosphogypsum used varies. As shown in Table 2, the specific surface area of one of the steel slag powder, slag powder and phosphogypsum is changed in turn.

[0034] Each raw material is mixed according to the ratio of Group A1 in Example 1, and after adding water, stir it with a mixer to make a slurry (see "mass concentration" in Table 2). Qualitative Test Method", using the "miniature slump meter method" to measure the fluidity value of the slurry, and then inject the prepared slurry into a triple test mold of 40mm×40mm×160mm, and put it into the curing box (temperature is 20°C and 90% humidity) for 3 days to remove the mold, put the demoulded test block into 20°C water to continue curing, and then measure the strength of each age.

[0035] Table 2 Strength results of different ag...

Embodiment 3

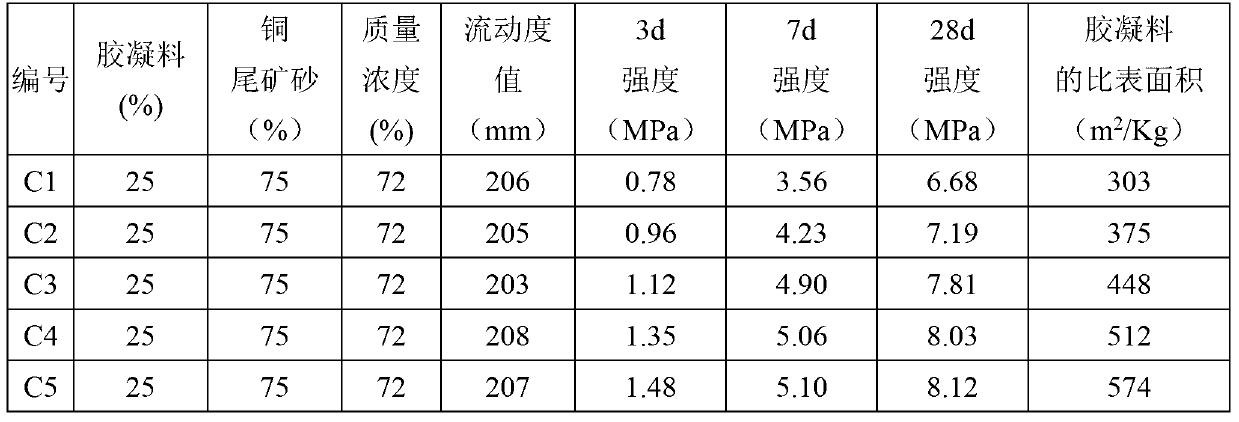

[0038] The type and source of raw materials used in this example are the same as in Example 1.

[0039] The difference is that in this example, the slag, steel slag and industrial by-product gypsum were dried separately and mixed and ground according to the proportion of Group A1 in Example 1 to prepare cementitious materials with different specific surface areas. Mix it with water, and then use a mixer to stir it evenly to make a slurry (see "mass concentration" in Table 3). Refer to GB / T8077-2000 "Test Method for Homogeneity of Concrete Admixtures" and use "micro slump Measure the fluidity value of the slurry by using the instrument method, and then inject the prepared slurry into a triple test mold of 40mm×40mm×160mm, put it in a curing box (at a temperature of 20°C and a humidity of 90%) for 3 days to remove After demoulding, the test pieces were put into water at 20°C for further curing, and then the strength of each age was measured respectively. The results are shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com