Patents

Literature

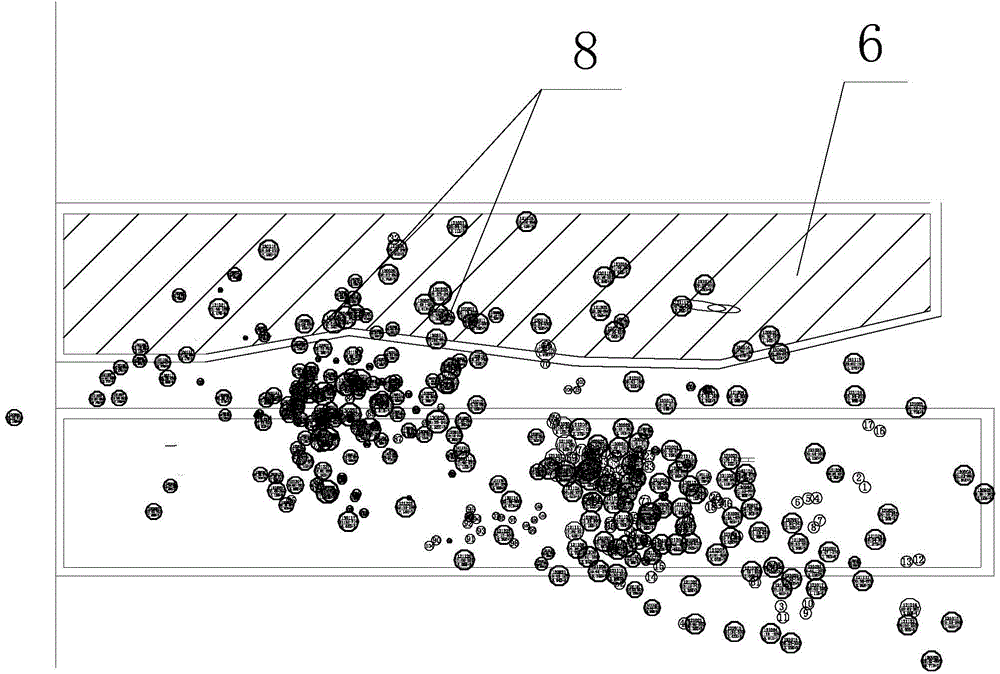

637 results about "Ground pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ground pressure is the pressure exerted on the ground by the tires or tracks of a motorized vehicle, and is one measure of its potential mobility, especially over soft ground. It also applies to the feet of a walking person or machine. Ground pressure is measured in pascals (Pa) which corresponds to the United States customary units unit of pounds per square inch (psi). Average ground pressure can be calculated using the standard formula for average pressure: P = F/A. In an idealized case, i.e. a static, uniform net force normal to level ground, this is simply the object's weight divided by contact area. The ground pressure of motorized vehicles is often compared to the ground pressure of a human foot, which can be 60 – 80 kPa while walking or as much as 13 MPa for a person in spike heels.

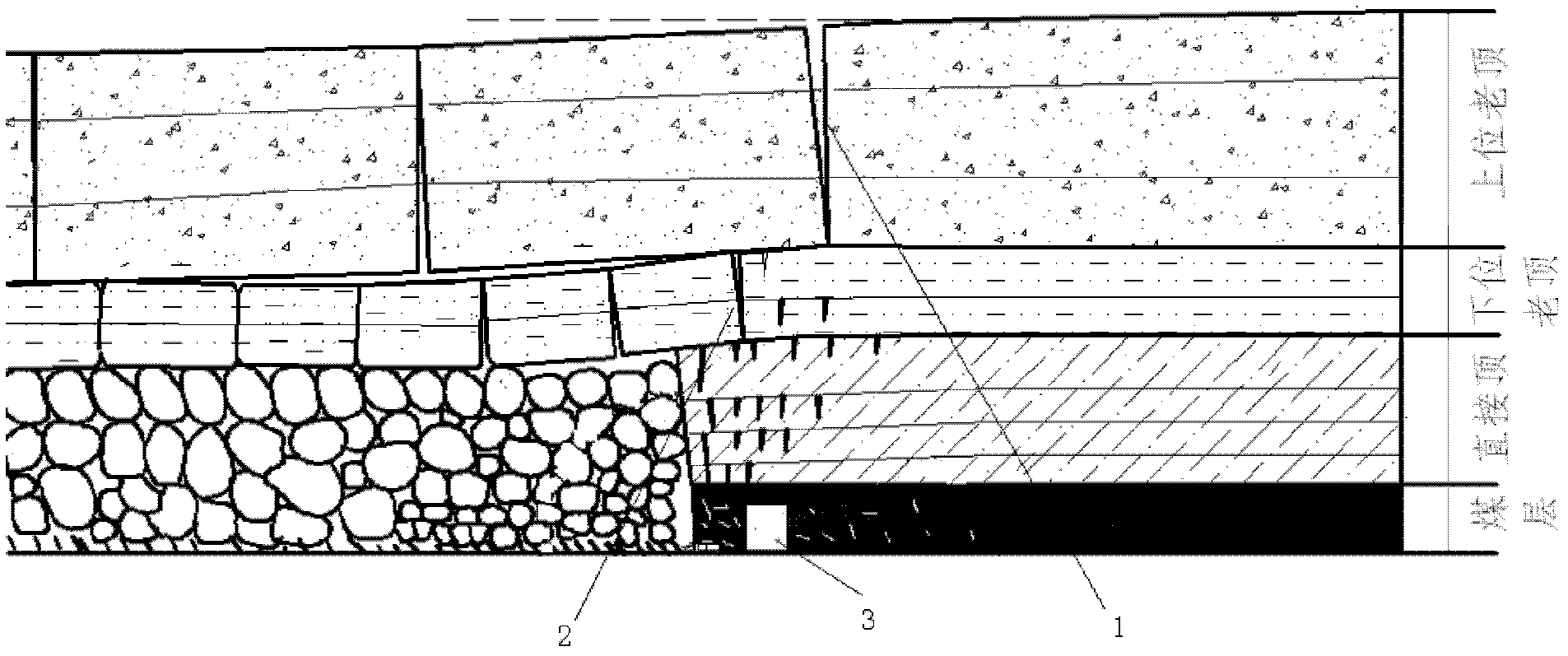

Sublevel shrinkage caving stage open stope afterwards filling mining method

InactiveCN101881169ALarge amount of filling at one timeIncrease production capacityUnderground miningSurface miningEarth surfaceComputer science

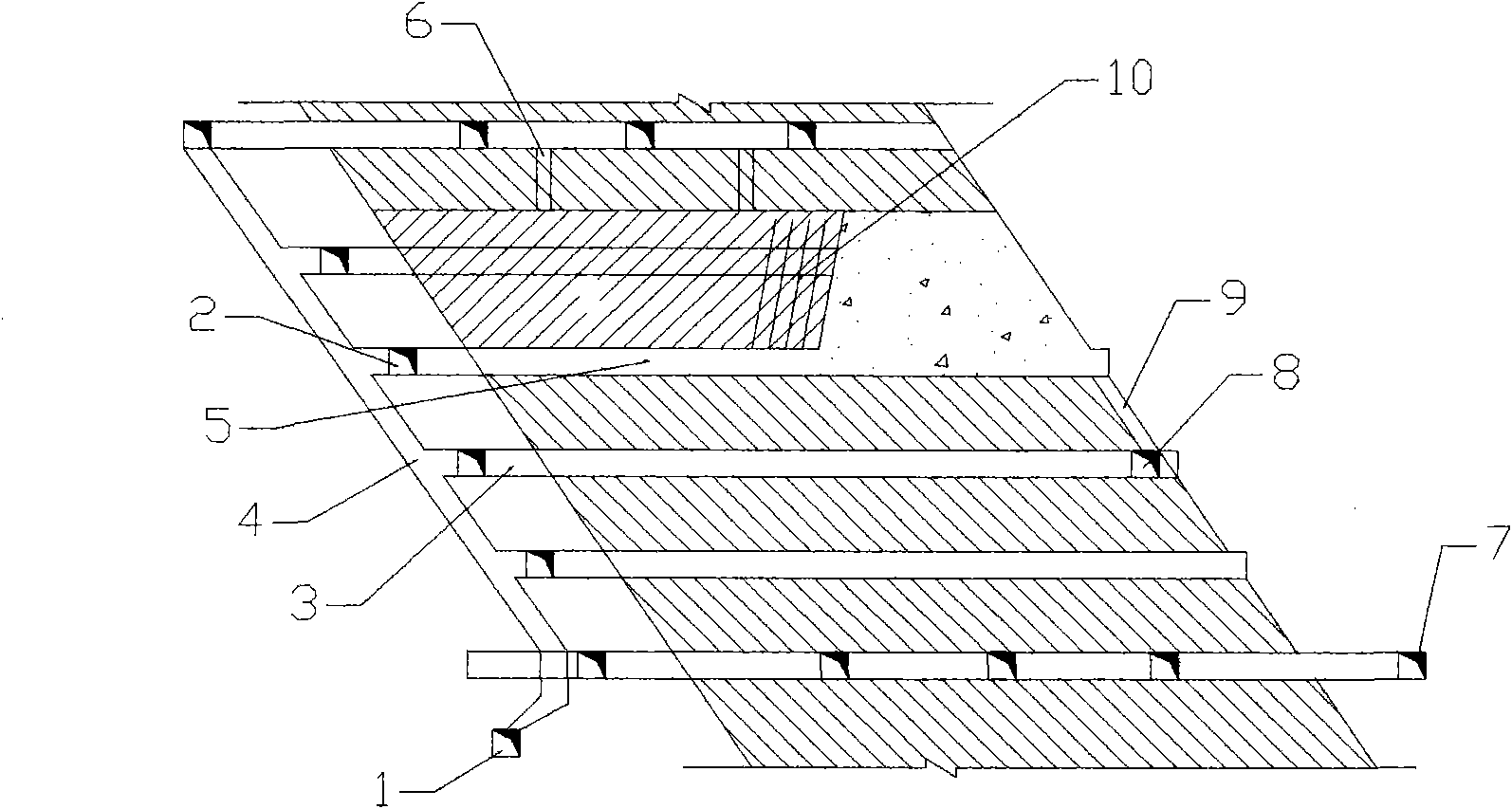

The invention discloses a sublevel shrinkage caving stage open afterwards filling mining method. In the earlier stage of stoping, caved ores are utilized to support surrounding rocks on a top tray, and in the later stage of stoping, a goaf area is filled with fillers to control ground pressure so as to achieve safe and efficient mining. Ore blocks are mined in two steps, mining blocks in step two are stoped after the mining blocks in step one are stoped and filled. After the ores are completely let out, the goaf area is filled with the fillers to control the ground pressure. Because the stoping modes of sublevel ore caving, sublevel shrinkage, final ore drawing and empty area afterwards filling are adopted, the mining method has large one-time filling amount and low cost; the method adopts middle-deep hole drilling and blasting and carry scraper ore removal, and the device has high level and large production capacity; the method has the advantages of large production capacity of the sublevel caving method and the stage open stope method, high recovery rate of the filling method, and earth surface protection; the safety is good, and drilling, ore removal and other operations are all carried out in a sublevel drilling and ore removal approach roadway; and the ores can be removed in advance, and the ores can be removed partially after the first sublevel is ready.

Owner:NORTHEASTERN UNIV +1

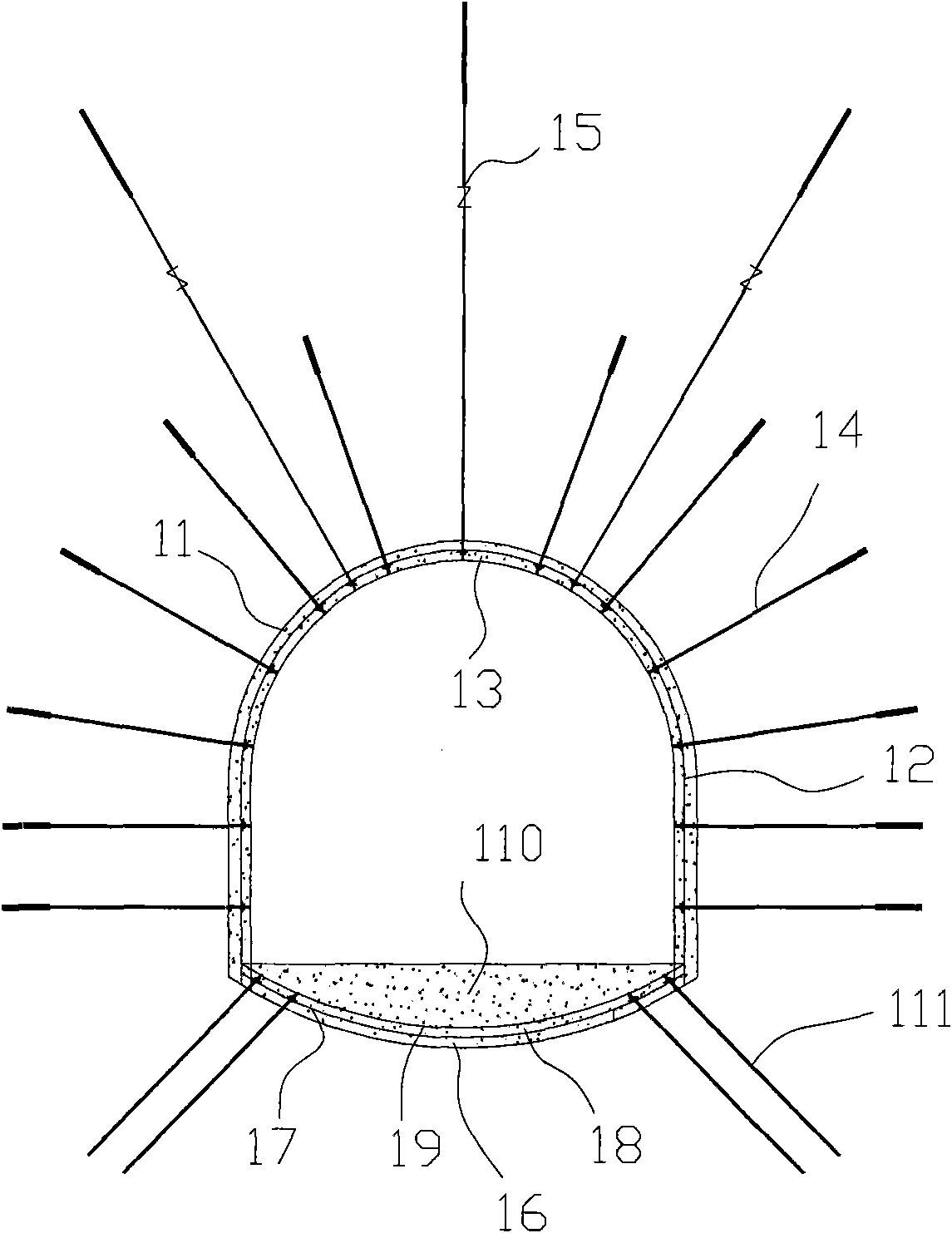

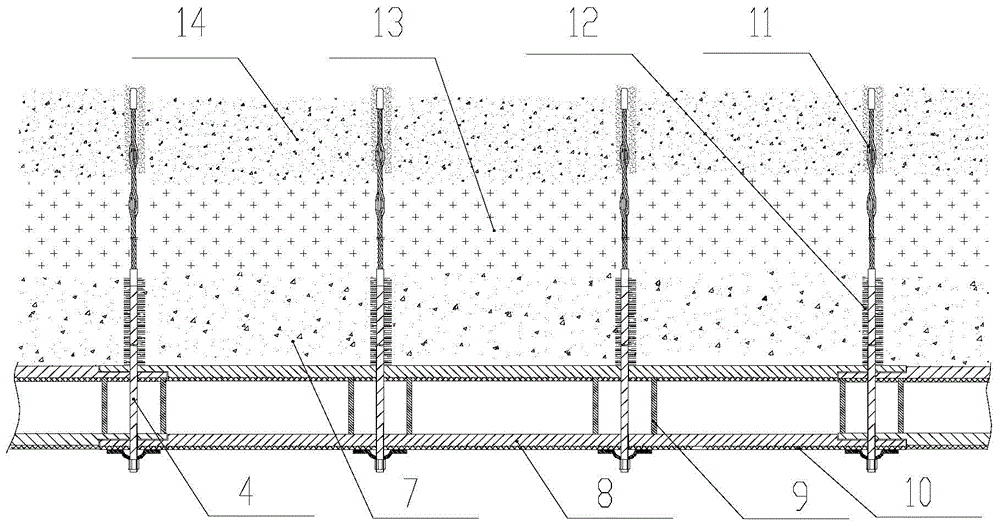

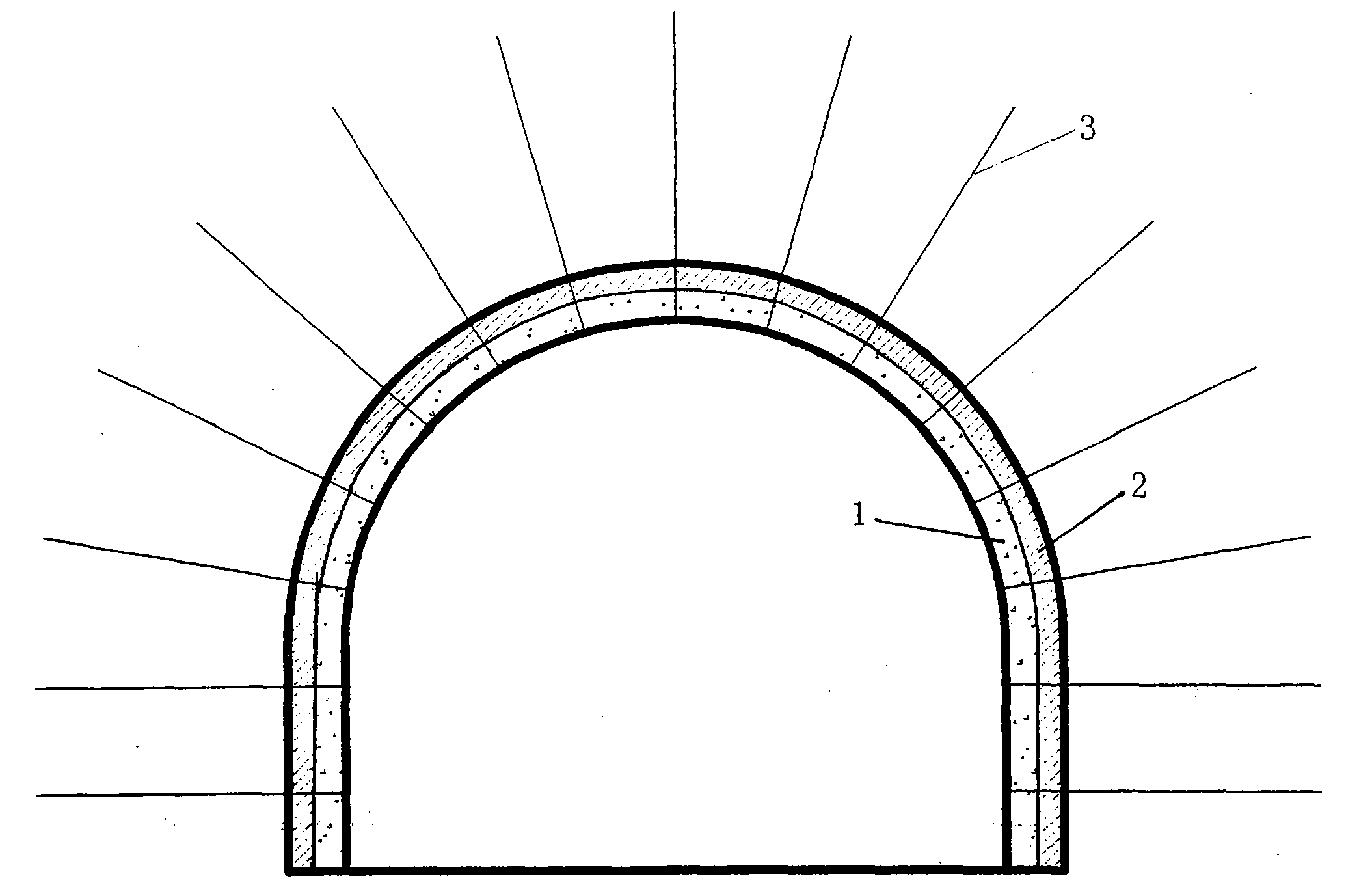

Method for preventing and treating large deformation and collapse of softrock tunnel

ActiveCN101906977AImprove pullout resistanceGuaranteed stabilityUnderground chambersTunnel liningLarge deformationRock bolt

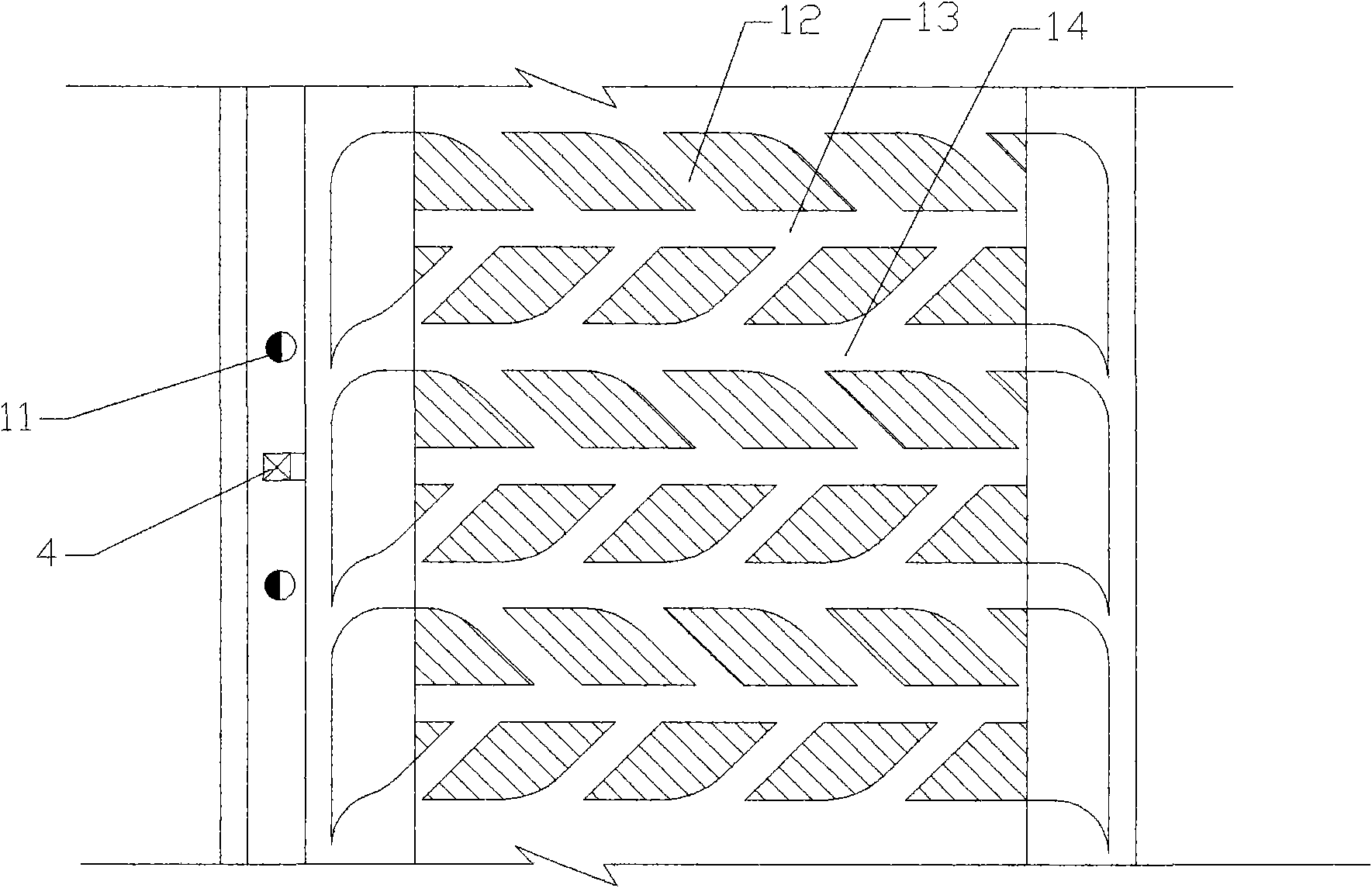

The invention relates to a method for preventing and treating large deformation and collapse of a softrock tunnel, which comprises the following steps: tunneling molding or enlarging a tunnel; primarily spraying the first layer of concrete, and hanging a side net and a top net at the first layer of concrete; arranging a constant-resistance large deformation rock bolt; multiply spraying the second layer of concrete; arranging a constant-resistance large deformation anchor cable on the top plate; digging and laying the first layer of base plate concrete; hanging a layer of backing screen on the first layer of base plate concrete, and arranging a base angle anchor rod at the base angle; laying the second layer of base plate concrete onto the grade level; setting a long-term ground pressure monitoring point, if the tunnel deforms to a certain preset valve, carrying out secondary support at the key position of the tunnel and carrying out pressurization and slip casting on surrounding rock. The invention can well ensure the stability of softrock tunnel under the condition of large deformation, in addition, the invention has the advantages of simple and practicable implement and lower cost.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

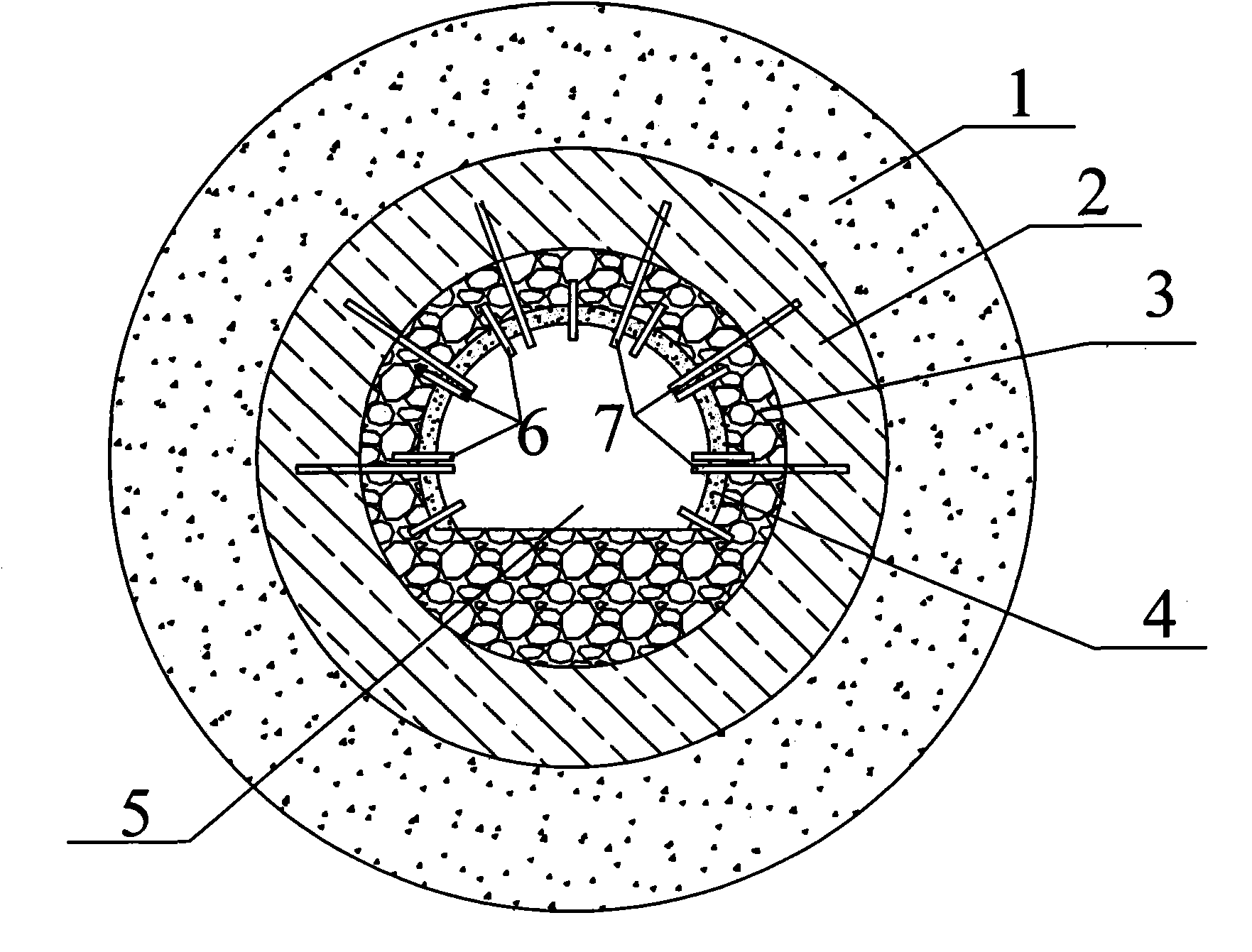

Strengthening and reinforcing method of high-ground-pressure soft rock laneway by hierarchical grouting

InactiveCN101864967AImprove the strengthening effectWill not blockUnderground chambersTunnel liningSlurryHigh pressure

The invention relates to a strengthening and reinforcing method of a high-ground-pressure soft rock laneway by hierarchical grouting. Aiming at the deformation damage and crack distribution rules of laneway wall rock of high-ground-pressure soft rock, a hierarchical grouting mode for a shallow layer and a deep layer is adopted to hierarchically and emphatically strengthen and reinforce the shallow layer and the deep layer by grouting. The method comprises the following steps of: firstly, carrying out shallow-hole low-pressure grouting to a laneway shallow-layer gap development zone and then carrying out deep-hole high-pressure grouting to deep rock bodies; constructing shallow-hole grouting with small grouting pressure so that grout is scarcely diffused into the deep part, and grouting passages, such as a deep gap of the deep part and the like, are well preserved without blockage; and adopting a double-component chemical grout malisan with easy dispersion and strong permeability in constructing deep-hole grouting to realize deep high-pressure grouting on the basis of a formed grout-stopping shielding shell formed by former-period shallow-hole grouting so that the distribution compactness and the dispersion evenness of the grout in the deep grouting are improved, and the strengthening effect of the deep grouting on the wall rock is effectively improved. The method is simple and easy to implement.

Owner:CHINA UNIV OF MINING & TECH

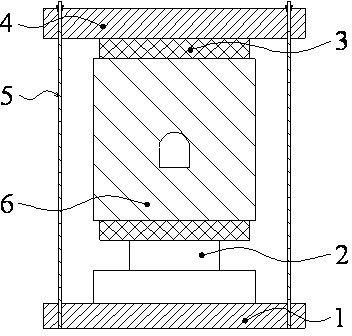

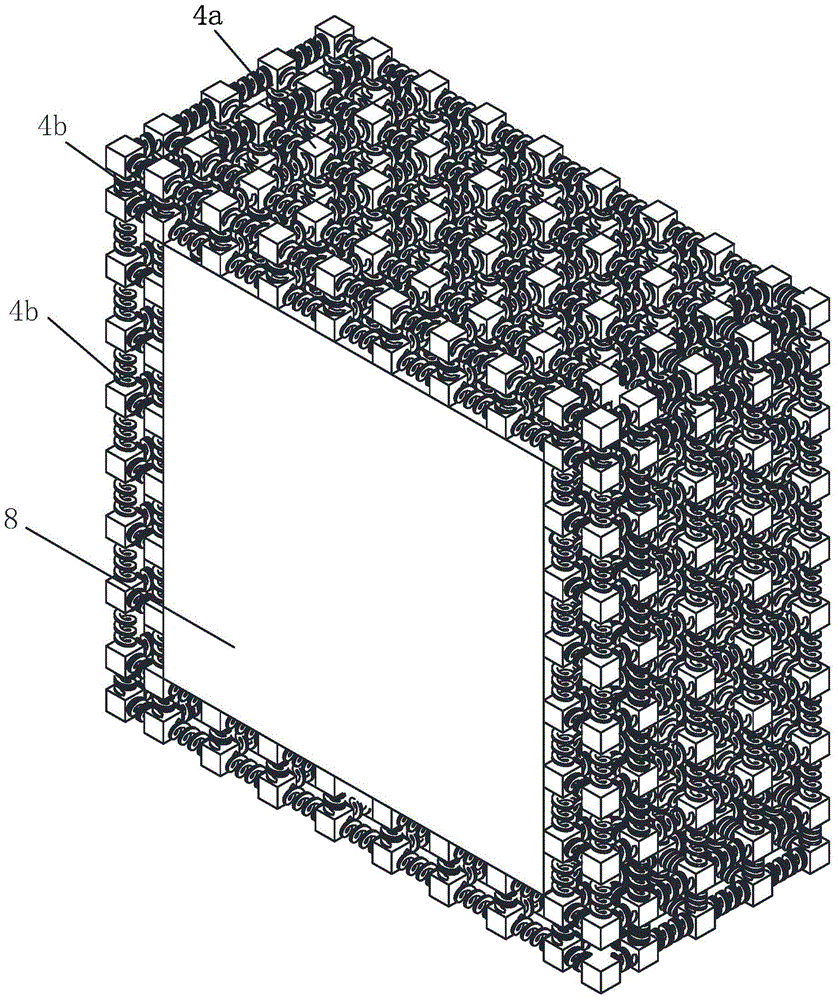

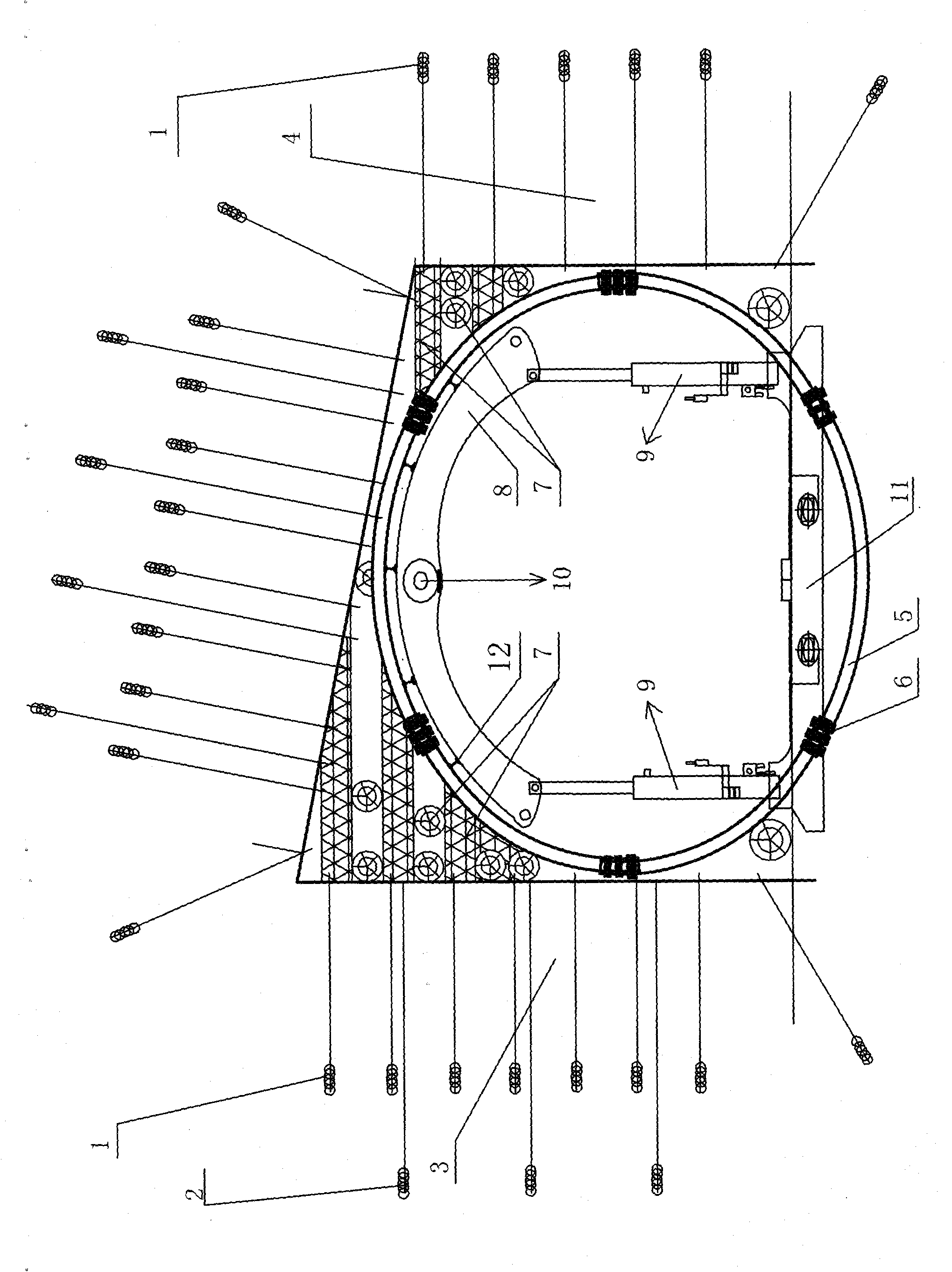

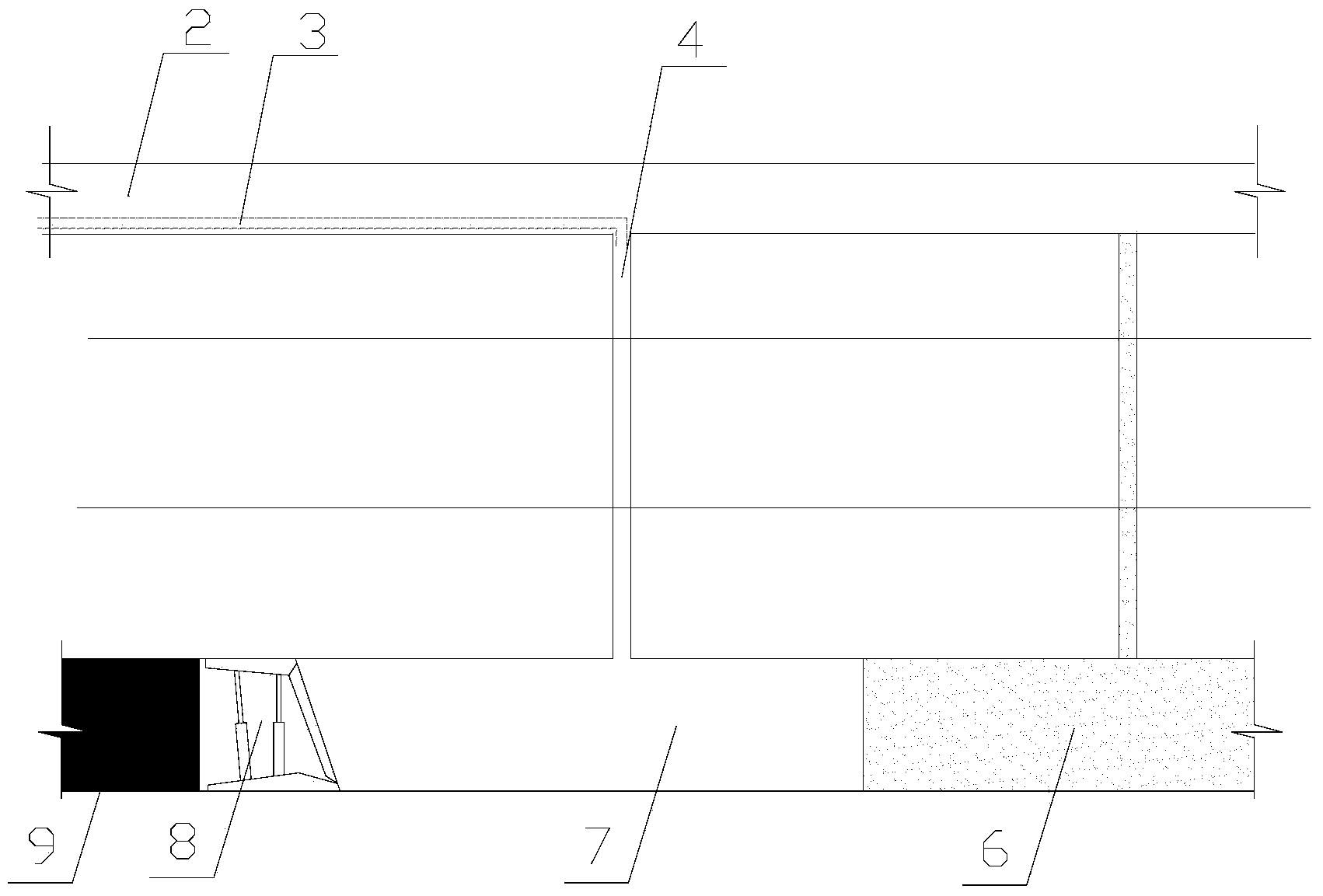

Triaxial impact ground pressure true simulation test system

InactiveCN103471914AReduce intensityMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceEngineeringHigh stress

The invention discloses a triaxial impact ground pressure true simulation test system. The triaxial impact ground pressure true simulation test system is characterized by comprising a flexible loading unit, a confining pressure loading unit and an impact loading unit, wherein the flexible loading unit is used for applying vertical pressure on a test piece through a loading oil cylinder and a counterforce steel strand, the confining pressure loading unit is used for enabling the test piece to be under the condition of triaxial stress, the impact loading system is used for applying impact load on the test piece, the test piece is destroyed under the conditions of high stress and impact disturbance, the strength of the test piece is reduced, the test piece generates a certain displacement, in the process, the counterforce steel strand in the flexible loading unit is used for quickly supplementing load to the test piece, and further the extrusion and the action of external surrounding rocks to coal and rock masses are simulated. The triaxial impact ground pressure true simulation test system can be used for well simulating the occurring conditions of impact ground pressure, and the triaxial loading conditions are especially applicable to the simulation of gravity type impact ground pressure in a mining roadway.

Owner:SHANDONG UNIV OF SCI & TECH

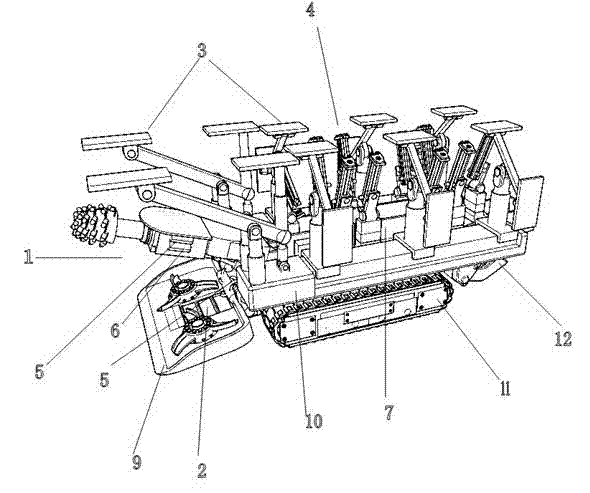

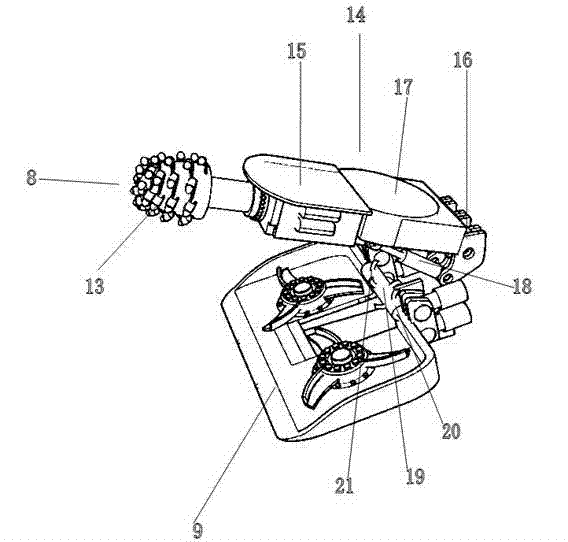

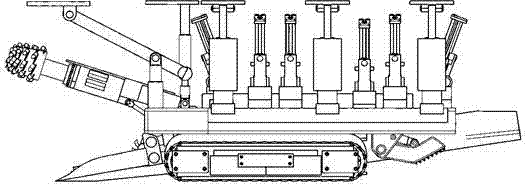

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

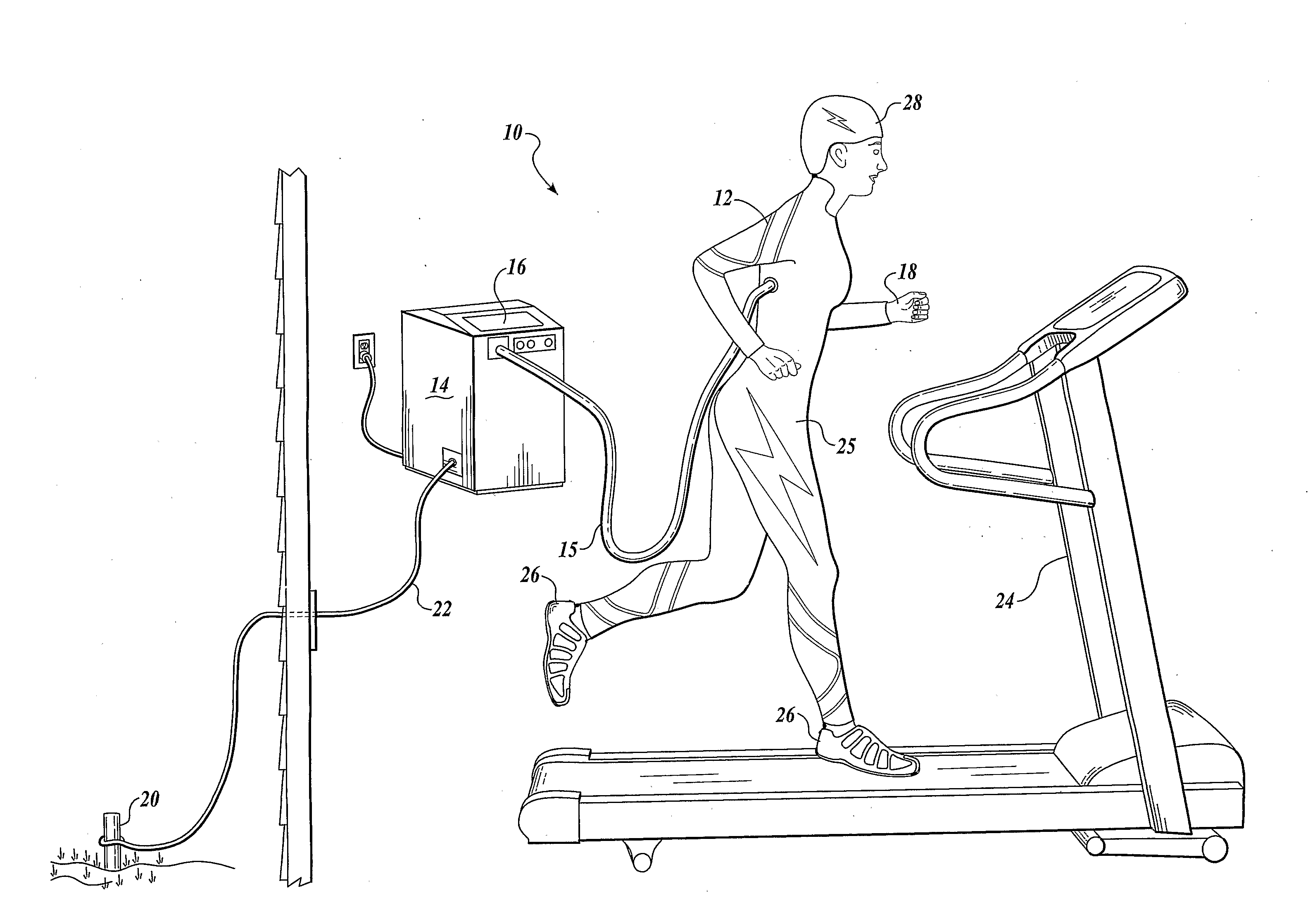

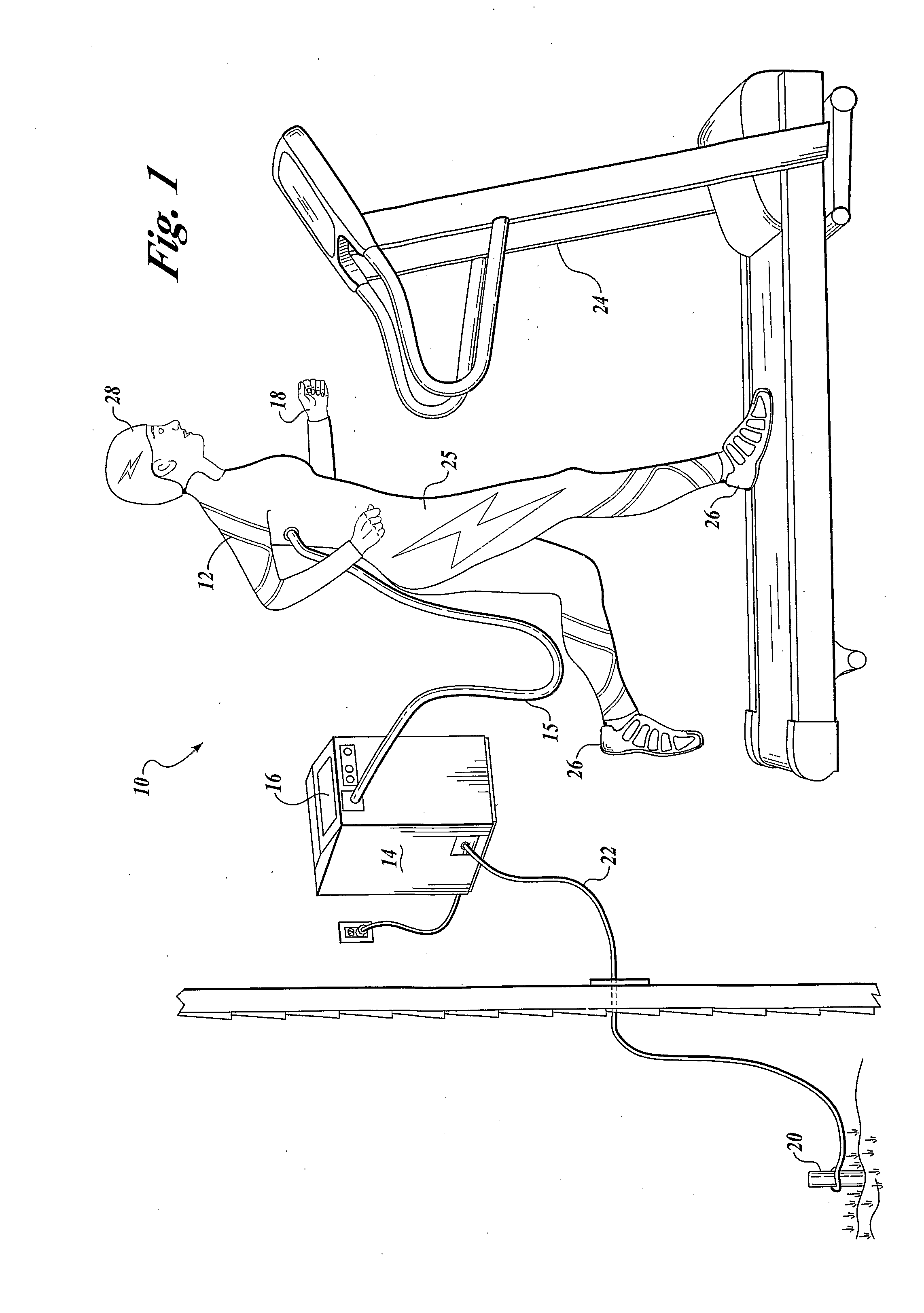

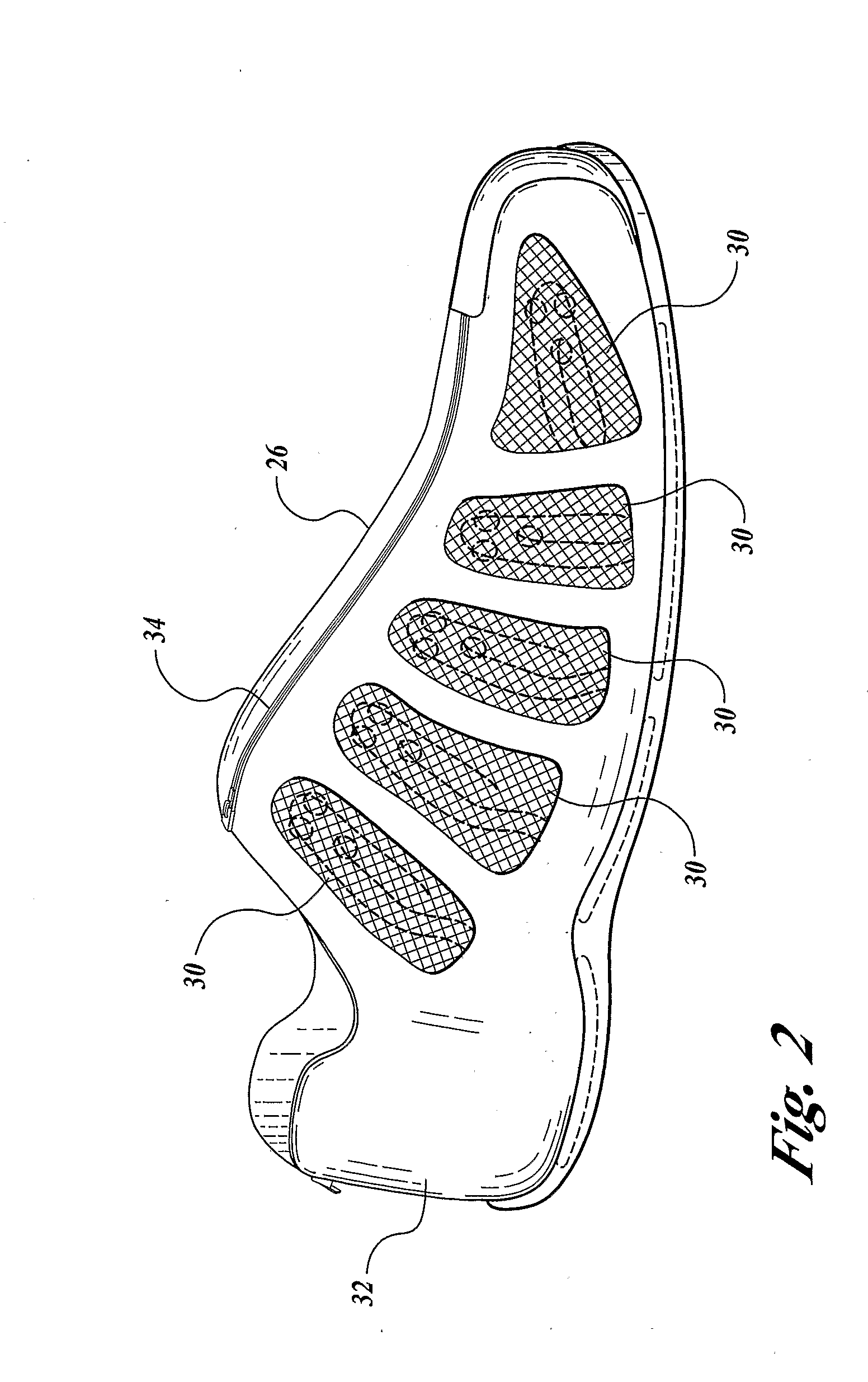

Grounded Pressure Cooling

ActiveUS20080234788A1Prevent perspirationRelieve stressSurgical instruments for heatingFootwearCore temperatureBlood vessel

Owner:VASPER SYST

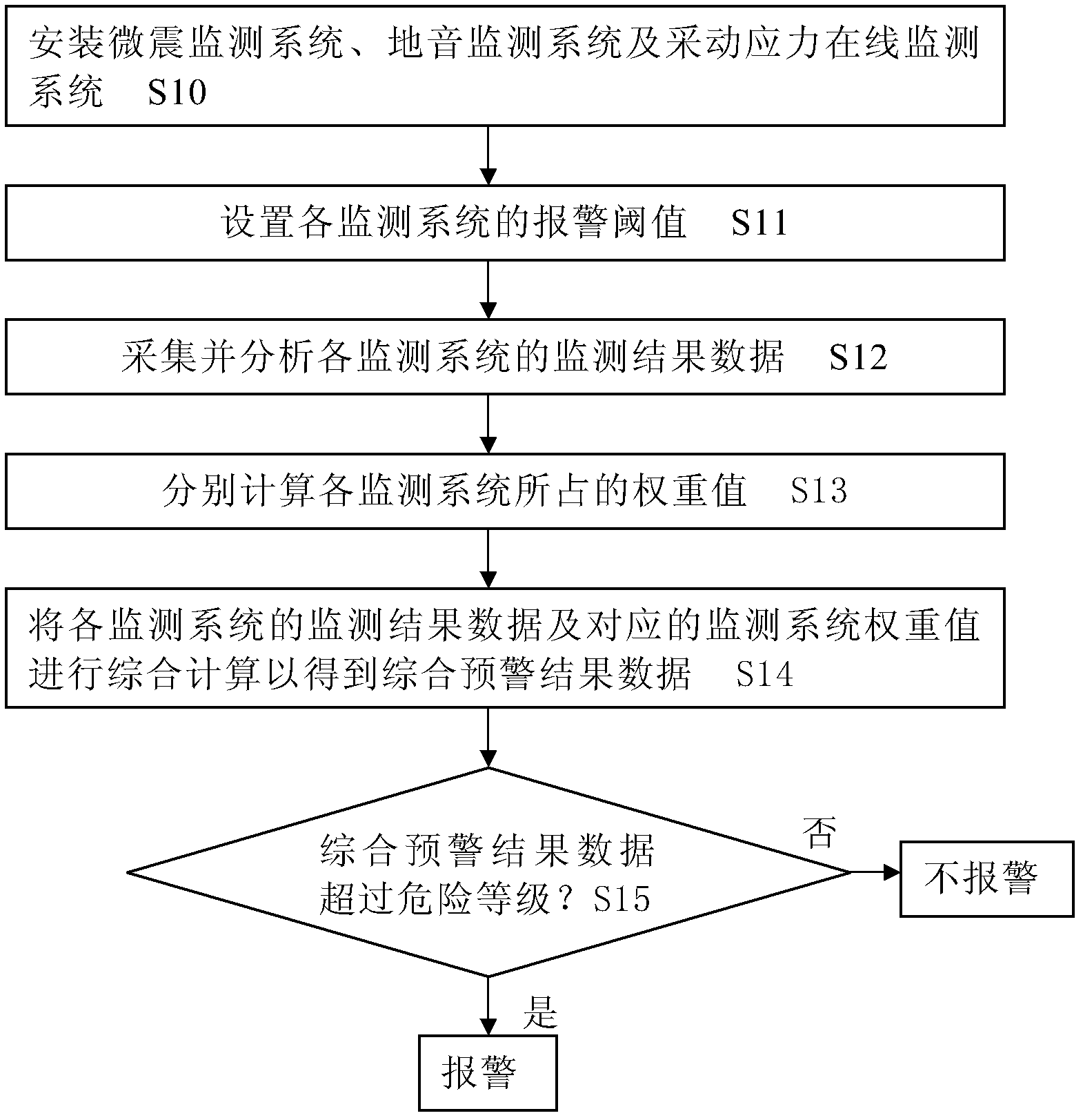

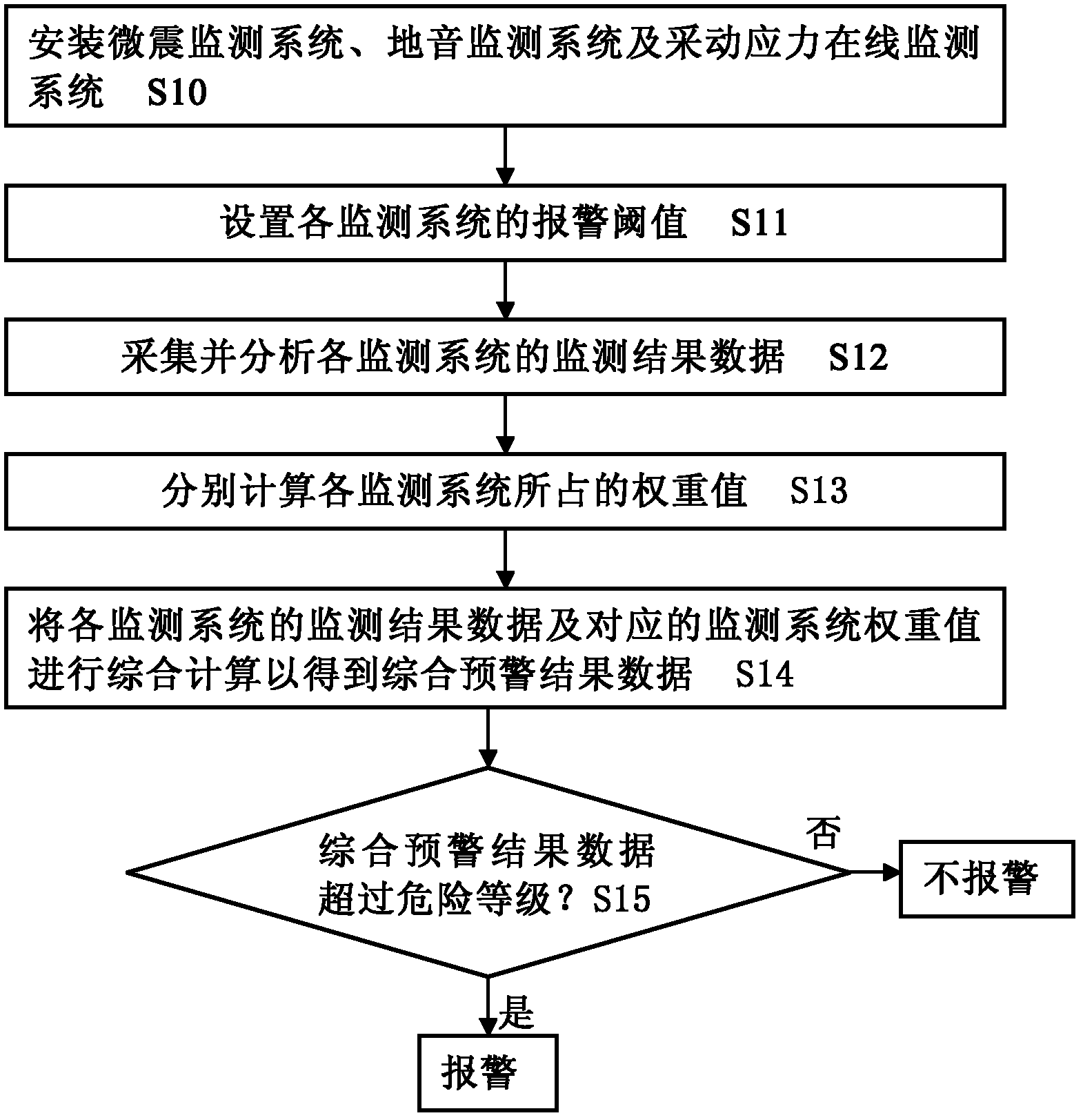

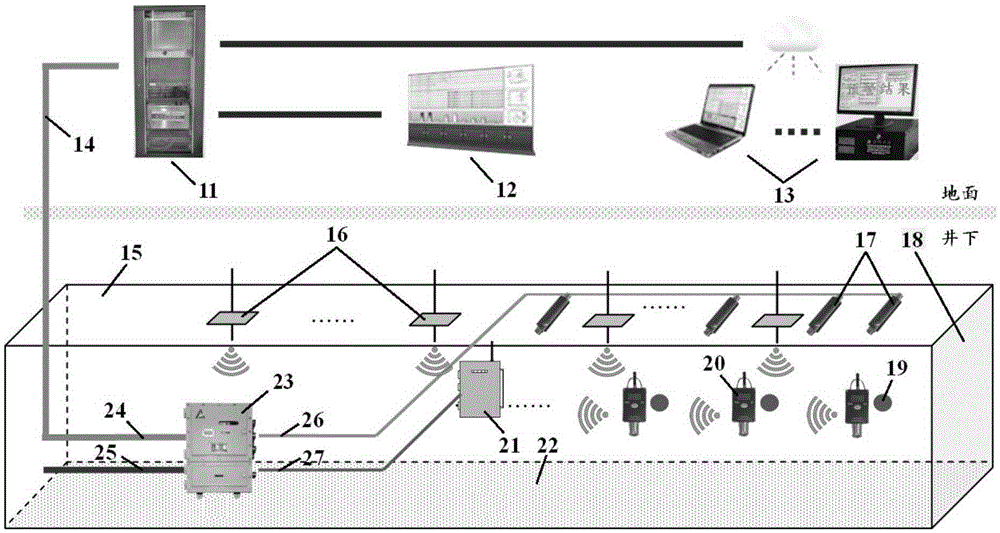

Impact ground pressure split source comprehensive early-warning method of coal mine

ActiveCN102628373AEffective monitoring and early warningAddress abuseMining devicesNoise monitoringMonitoring system

The invention discloses an impact ground pressure split source comprehensive early-warning method of a coal mine which is capable of carrying out split source monitoring early warning by aiming at different load sources of induced impact ground pressure from different space ranges. The method comprises the steps of: installing a microquake monitoring system, a rock noise monitoring system and a mining-induced stress on-line monitoring system; respectively setting the warning threshold value of each monitoring system; collecting and analyzing the monitoring result data of each monitoring system; respectively calculating the weight value occupied by each monitoring system according to the relative importance degree of each monitoring system in the impact ground pressure early warning and the danger level corresponding to the monitoring result data of each monitoring system; comprehensively calculating the monitoring result data of each monitoring system and the weight value of the corresponding monitoring system to obtain the comprehensive early-warning result data; and judging whether the comprehensive early-warning result data exceeds the preset impact ground pressure damager level or not, if so, carrying out the warning, and if not, avoiding the warning. The method has the advantages that missing warning and error warning can be avoided, the operability is high, and in addition, labor and material sources can be saved.

Owner:TIANDI SCI & TECH CO LTD

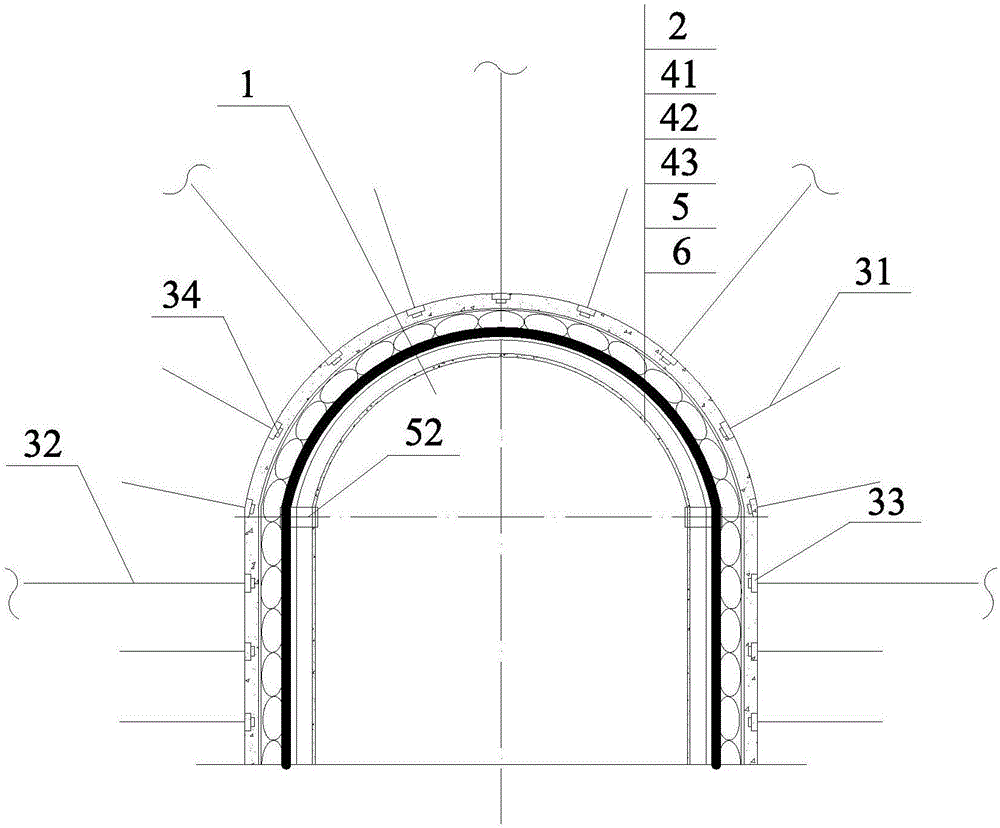

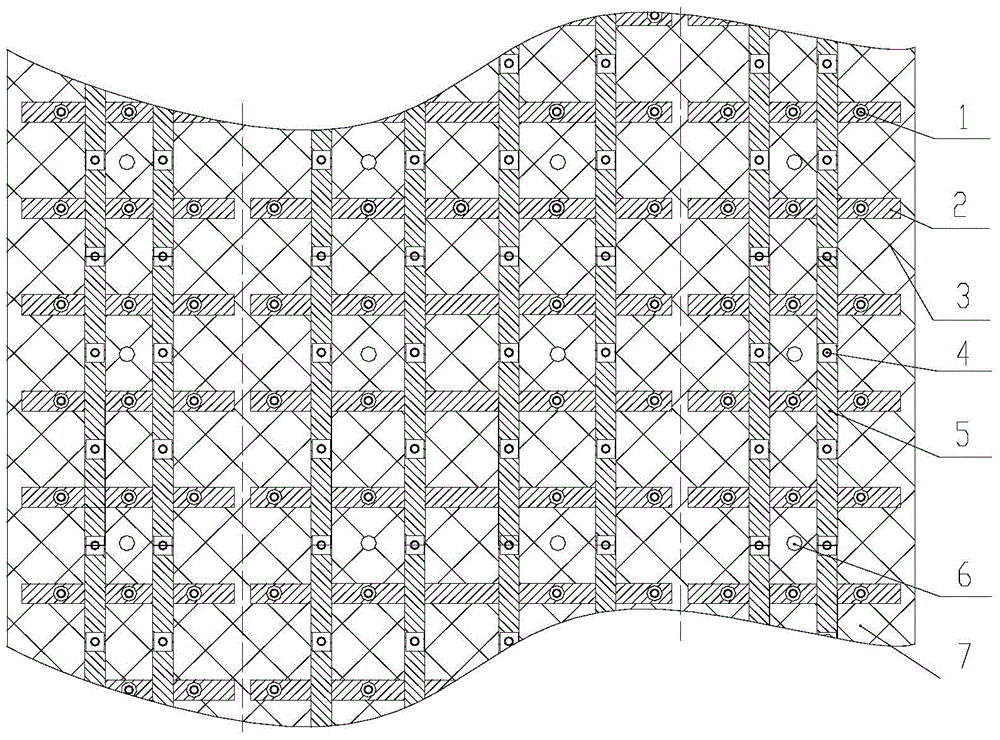

U-shaped steel composite support structure for deep dynamic pressure soft rock roadway and construction method of U-shaped steel composite support structure

InactiveCN106677797AConform to the law of deformationAvoid local damageUnderground chambersTunnel liningFiberPolyester

Owner:ANHUI UNIV OF SCI & TECH

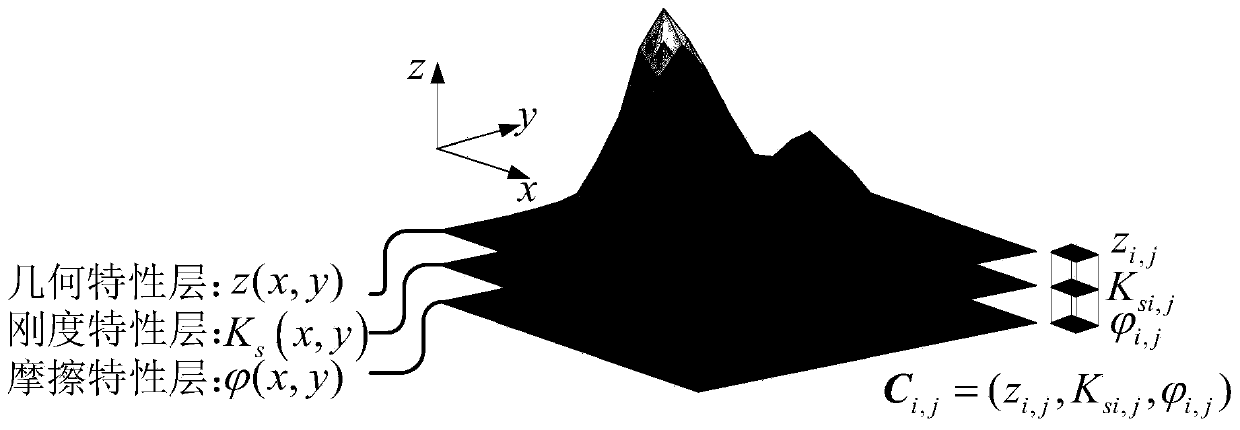

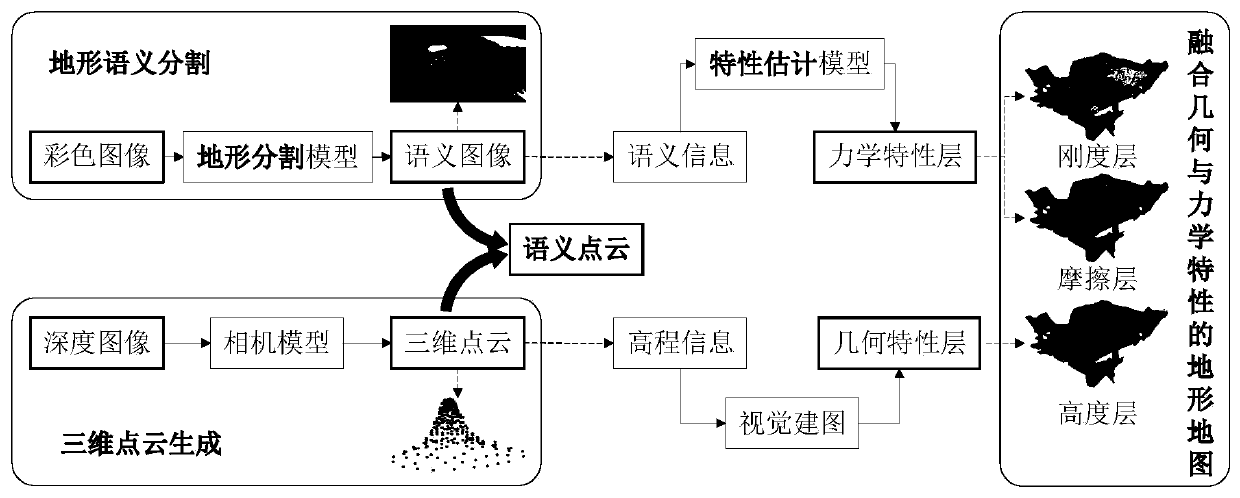

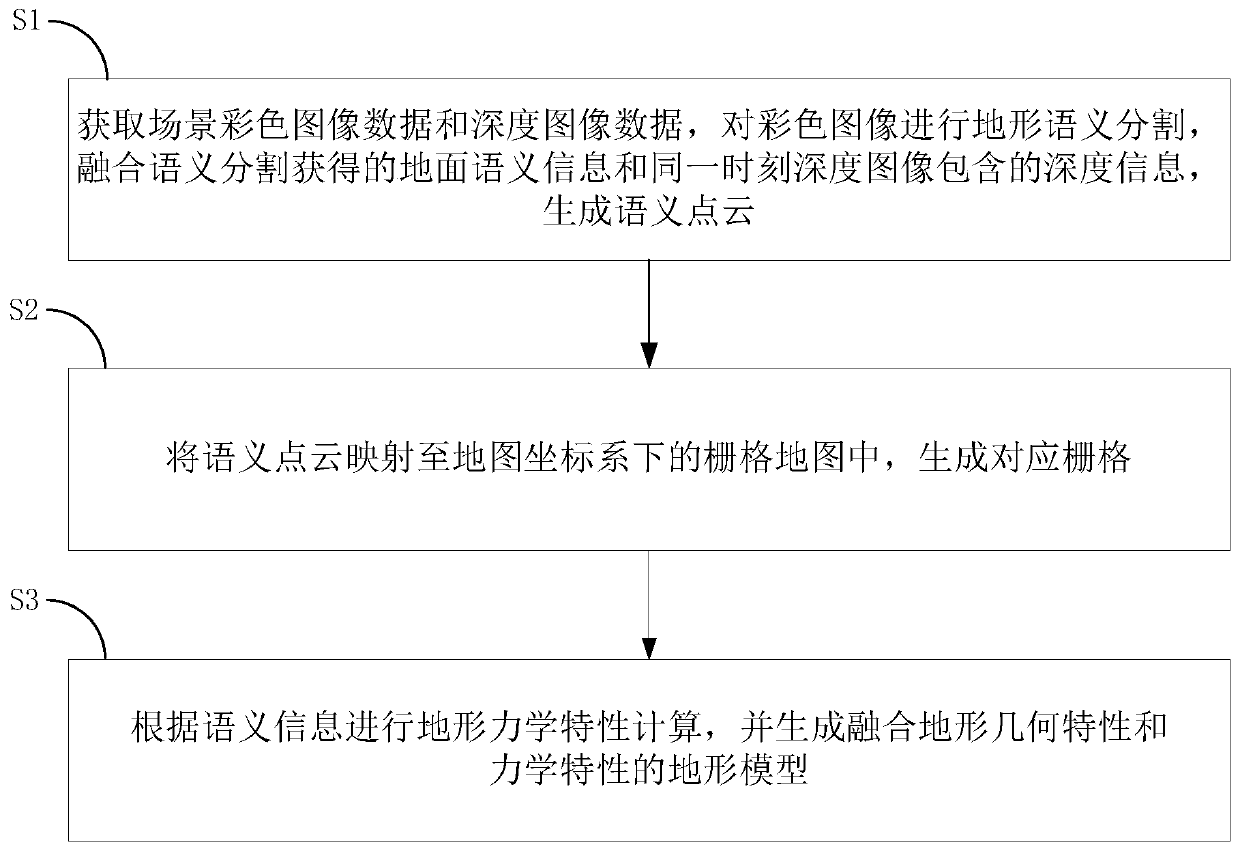

Terrain modeling method and system fusing geometric characteristics and mechanical characteristics

The invention provides a terrain modeling method and system integrating the geometric characteristics and the mechanical characteristics, and relates to the technical field of environment modeling. The method comprises the following steps of obtaining a color image and a depth image of a detection area, carrying out terrain semantic segmentation on the color image, and fusing a semantic segmentation result and the depth information contained in the depth image at the same moment to generate a semantic point cloud; mapping the semantic point cloud into a grid map under a map coordinate system to generate the corresponding grids, and updating the elevation values and the semantic information in the semantic point cloud to the corresponding grids; and performing ground mechanical property calculation according to the semantic information, updating a calculation result to the corresponding grid, and generating a terrain model. According to the method, the mechanical property parameters are added into topographic factors, and the topographic characterization is innovatively carried out from two dimensions of geometric properties and mechanical properties. The ground pressure-bearing characteristic and the shear characteristic of a non-contact area are deduced in advance in a visual perception mode, and the perception range is expanded.

Owner:HARBIN INST OF TECH

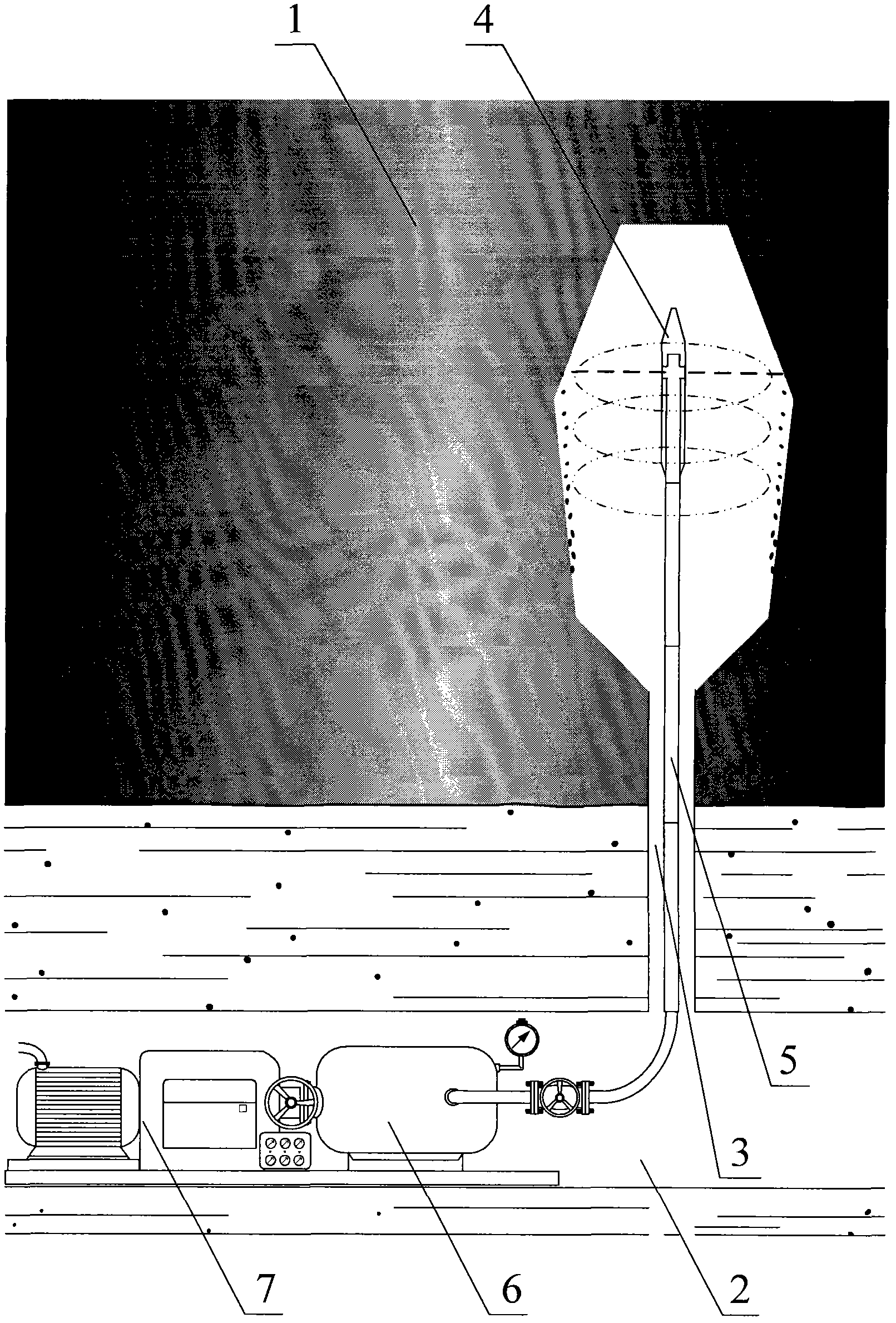

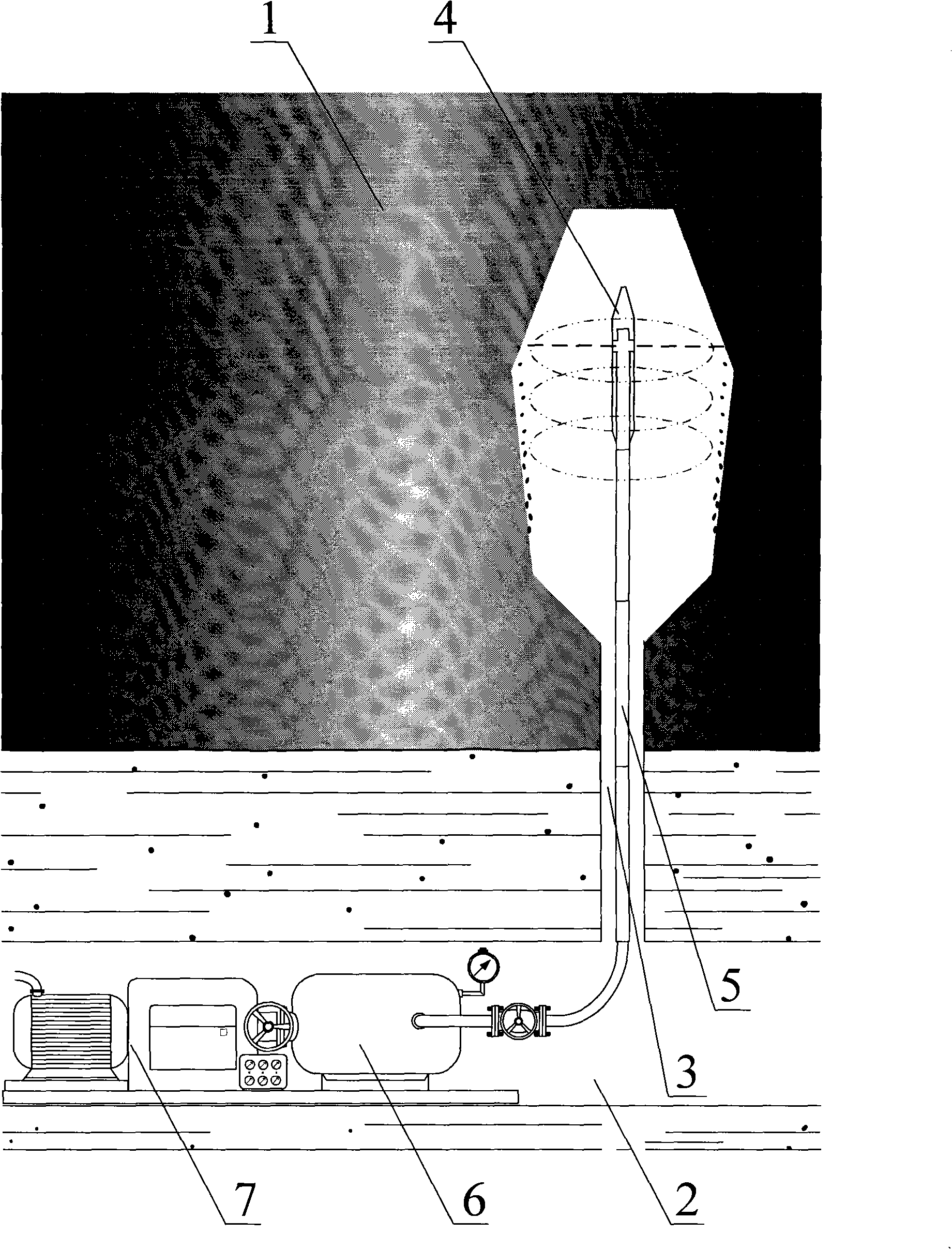

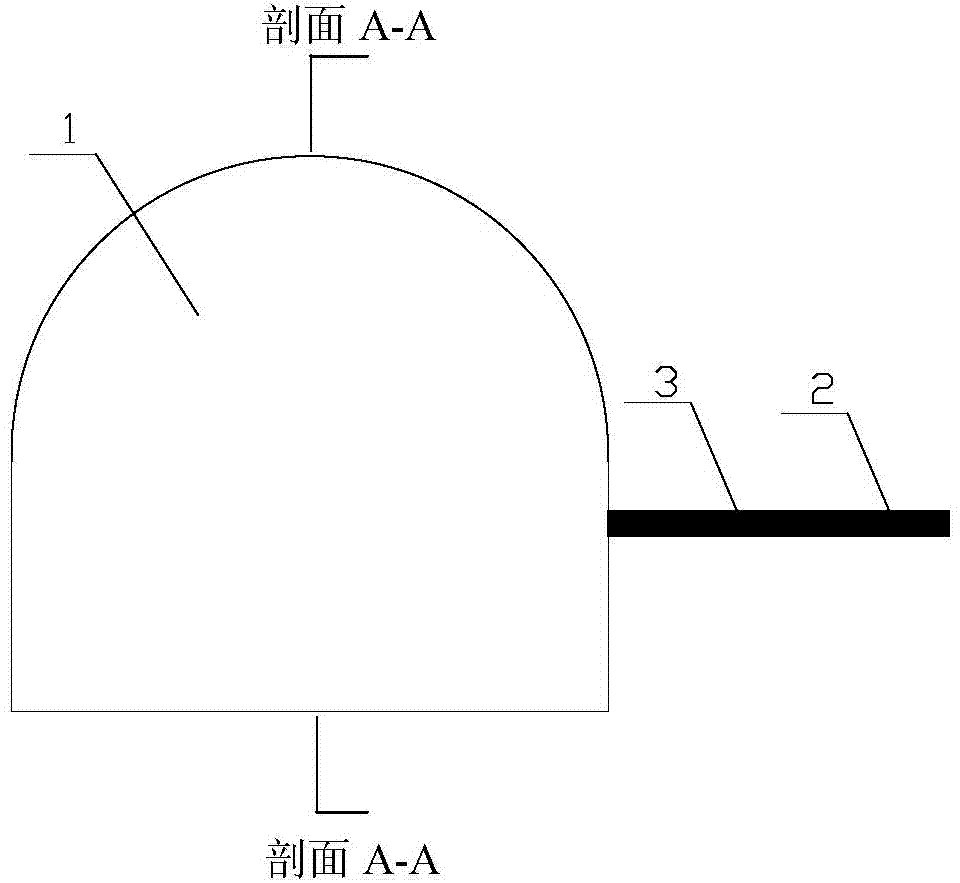

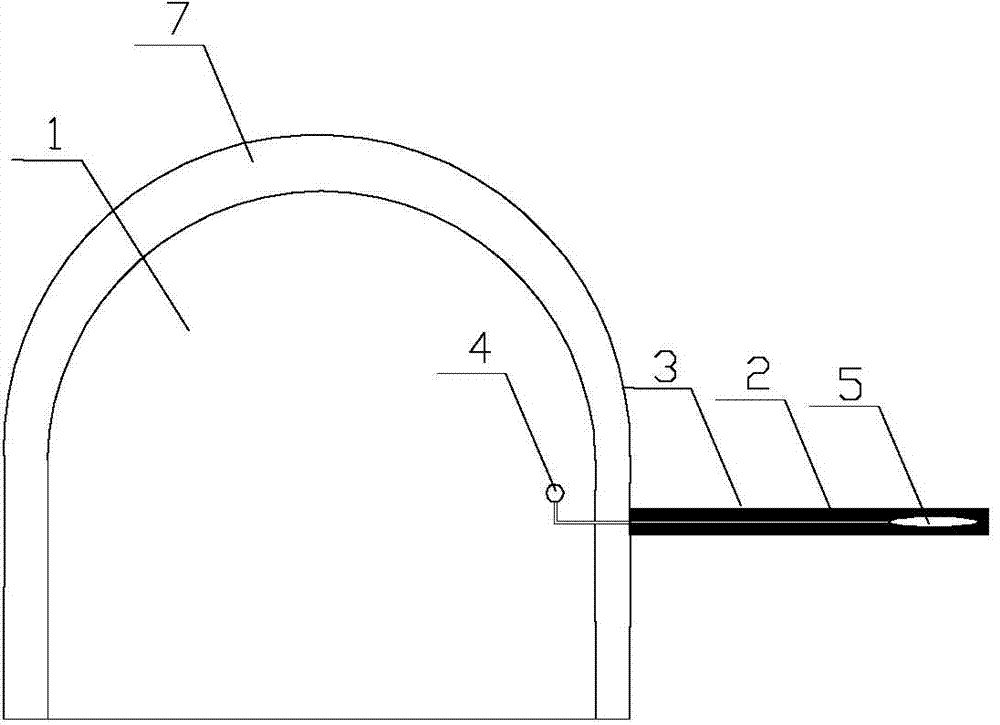

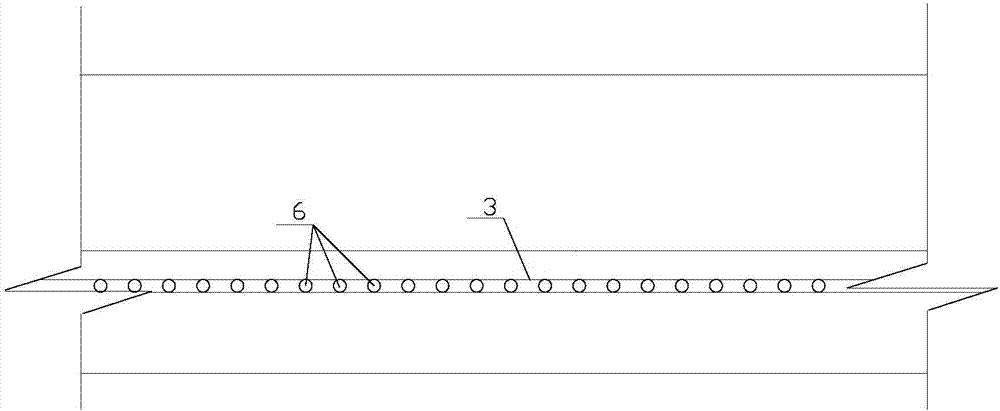

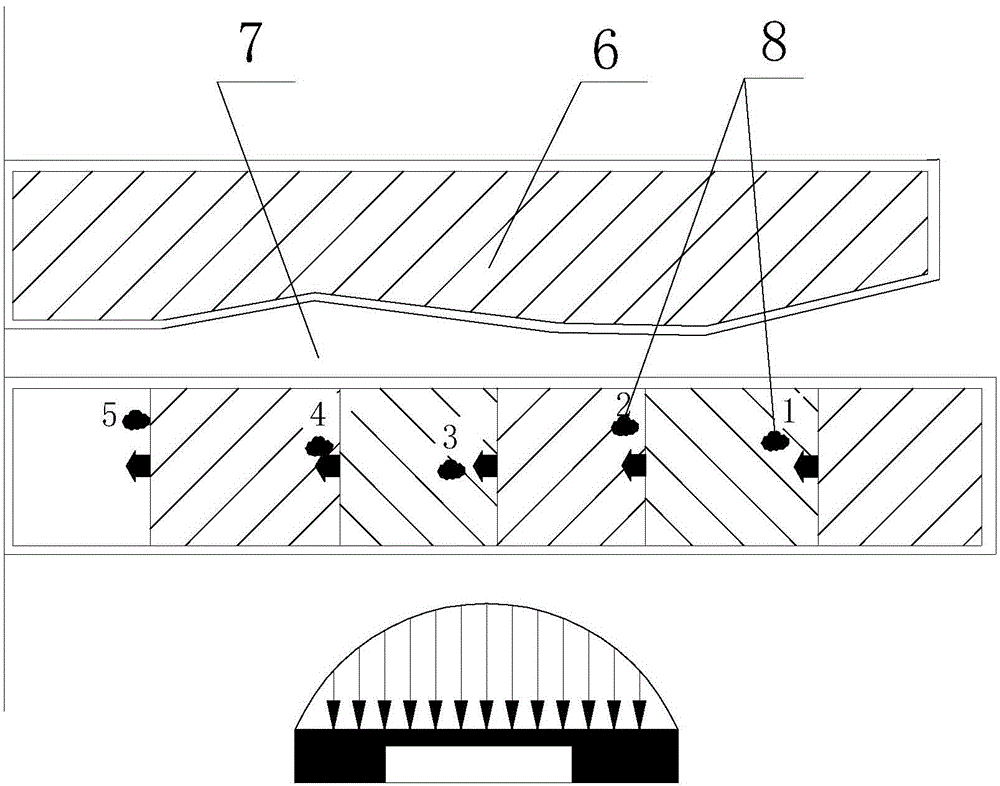

High-pressure gas injection hole-drilling pressure-releasing outburst prevention method

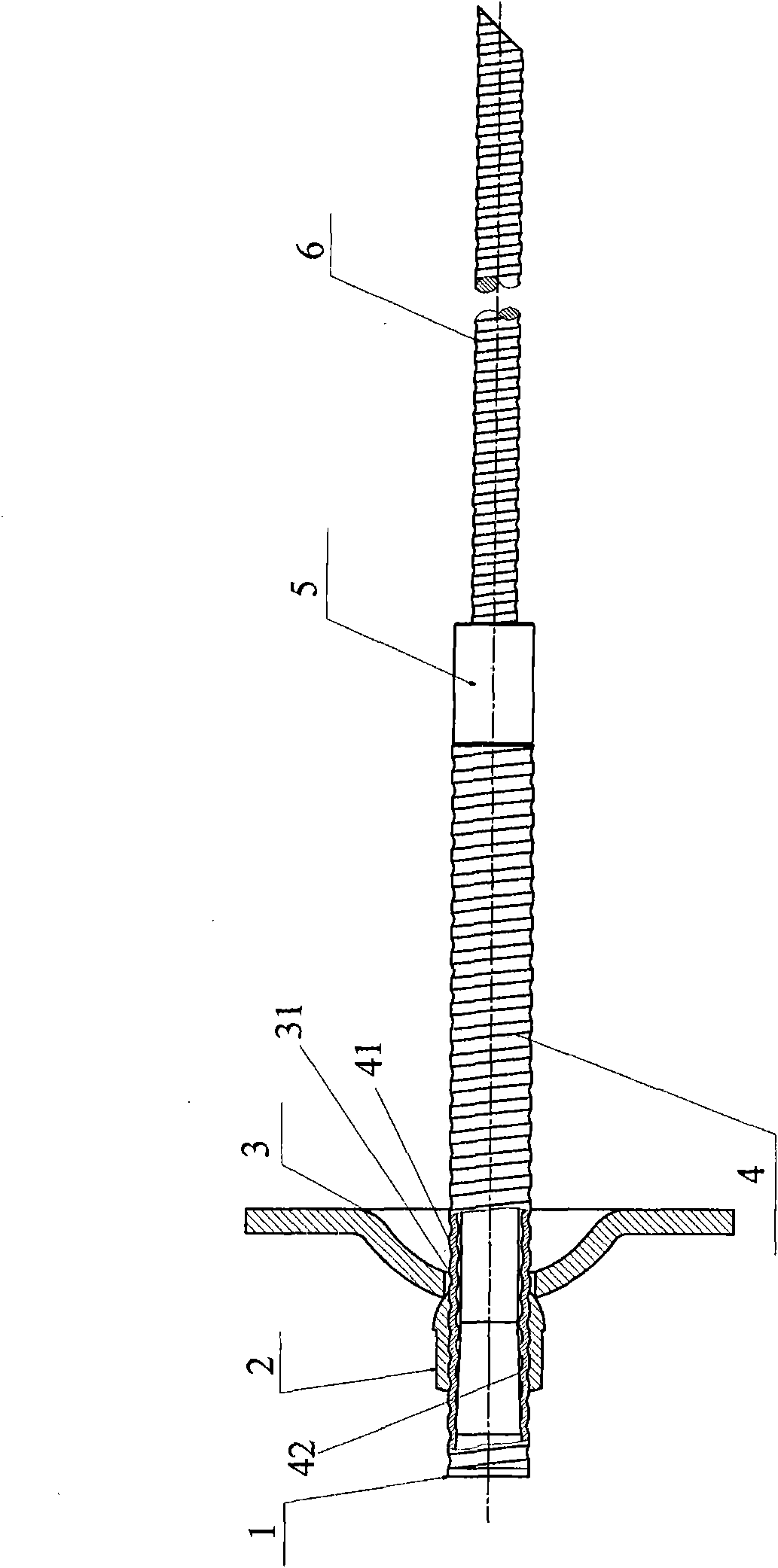

ActiveCN102080525AIncrease the exposed areaImprove breathabilityLiquid/gas jet drillingFluid removalEngineeringHigh pressure

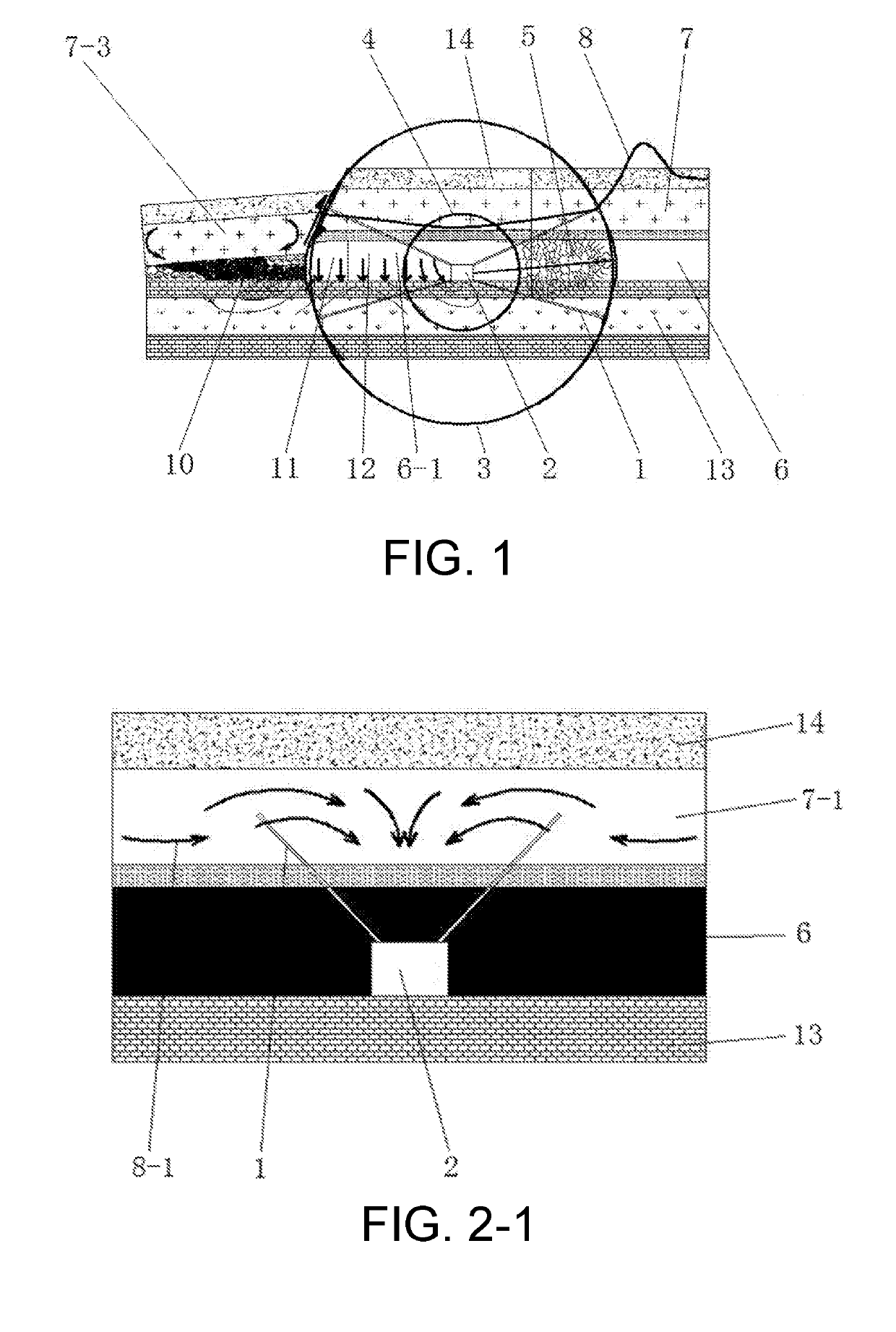

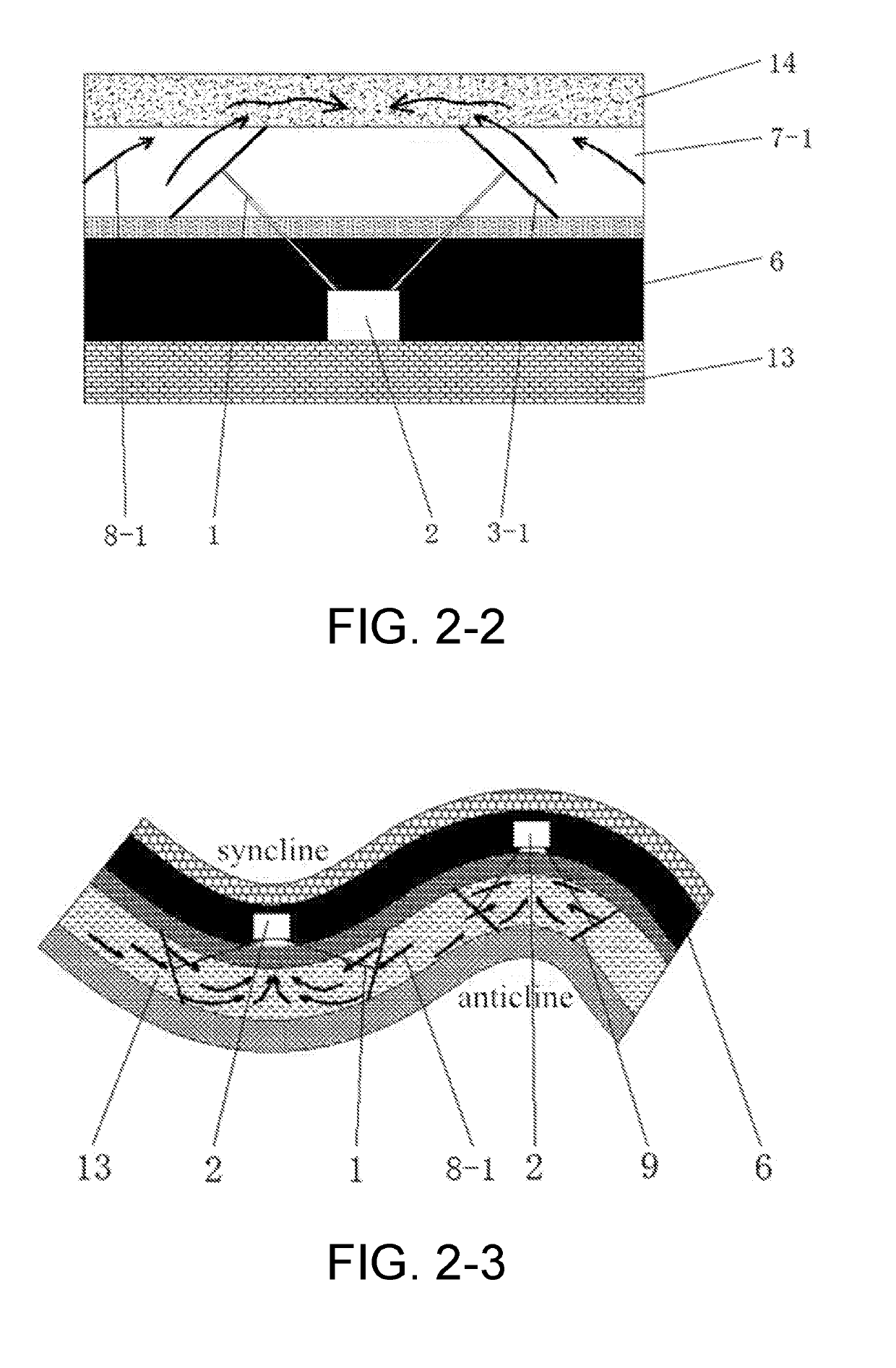

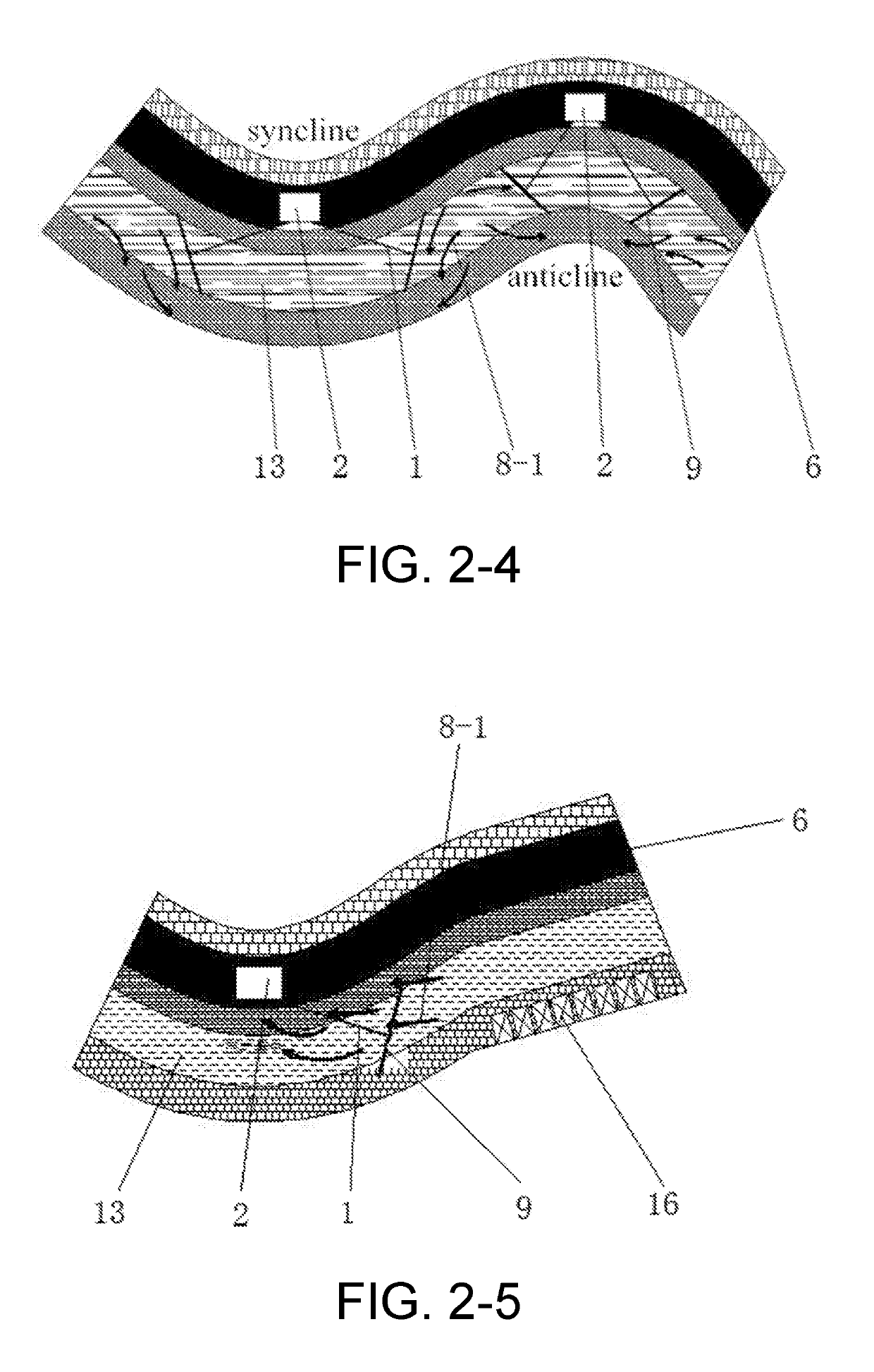

The invention discloses a high-pressure gas injection hole-drilling pressure-releasing outburst prevention method which comprises the steps of: firstly, carrying out common drilling operation in a bottom plate stone drift (2) of a coal bed (1) in front of a coal mining or driving face; after a drill hole (3) enters a design depth of the coal bed, drawing back a drill, sending a jet nozzle (4) anda high-pressure drill rod (5) connected with the jet nozzle into the drill hole, and connecting a high-pressure gas-storing device (6) connected with the tail of the high-pressure drill rod (5) with a high-pressure gas compressing device (7) through a high-pressure tube; starting the high-pressure gas compressing device (7), carrying out near cylinder rotary impacting, cutting and holing on the hole wall of the drill hole in the coal bed (1) by using high-pressure impact wave as a power source through the jet nozzle (4) capable of jetting high-pressure airflow and automatically rotating to ensure that the coal body around the drill hole (3) is gradually crushed and separated from the hole wall to form pressure releasing space and subjected to the pressure balanced permeability increase through ground pressure and gas pressure action. According to the invention, the drainage efficiency of the gas in the coal bed is greatly improved and the outburst damage of the coal bed is reduced.

Owner:河南省迪卡尔机电设备制造有限公司

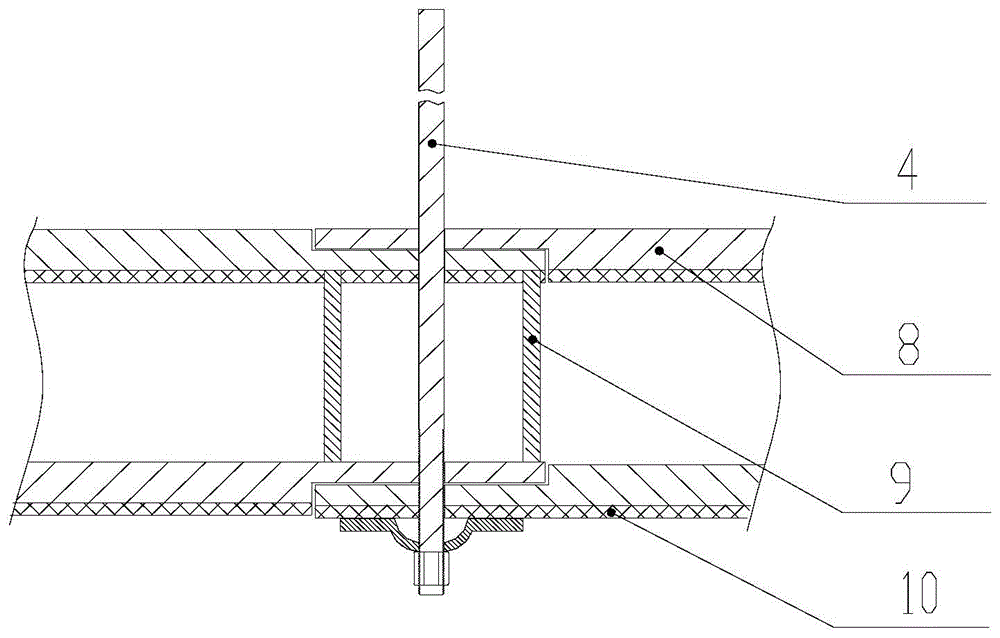

Method for controlling large deformation by releasing pressure of high-stress roadway surrounding rocks

ActiveCN104763432AEffective control of deformationControl deformationMining devicesTunnelsDeformation monitoringHigh stress

Owner:徐州天骋智能科技有限公司

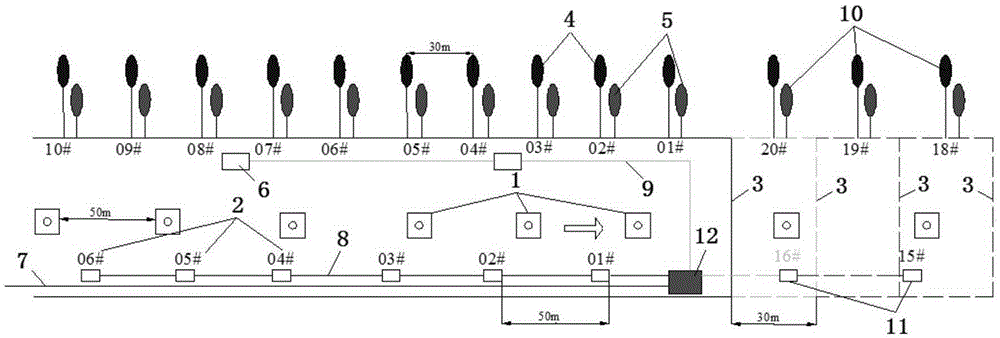

Multi-parameter integrated monitoring and early-warning method for excavation working face

ActiveCN105257339ARealize comprehensive early warningSolve the problem that it is impossible to predict and warn the risk of rock burst in the excavation faceMining devicesIntegrated monitoringCoupling

The invention discloses a multi-parameter integrated monitoring and early-warning method for an excavation working face, and belongs to the field of coal mine dynamic disaster monitoring and early-warning. The method comprises the steps that 1, partitioned monitoring is performed on the excavation working face; 2, at least two of a coal bed stress monitoring system, a ground sound and microquake monitoring system and an anchor rod and anchor cable stress monitoring system are arranged in an excavation roadway; 4, certain weight is assigned to all monitoring and early-warning indexes, and accumulation is performed to obtain an integrated early-warning index. According to the multi-parameter integrated monitoring and early-warning method for the excavation working face, the thought of partitioned monitoring of the excavation working face is presented according to the excavation working face impact ground pressure occurrence mechanism, coupling is performed on the change conditions of all the monitoring indexes in the different partitions, and the multi-parameter integrated monitoring indexes serve as early-warning parameters to achieve integrated early-warning of the impact dangerousness of the excavation working face; the problem that in the prior art, the purpose of predicting the impact ground pressure dangerousness of the excavation working face only depending on a single-index monitoring method for the impact ground pressure of the excavation working face cannot be achieved is solved.

Owner:北京安科兴业科技股份有限公司

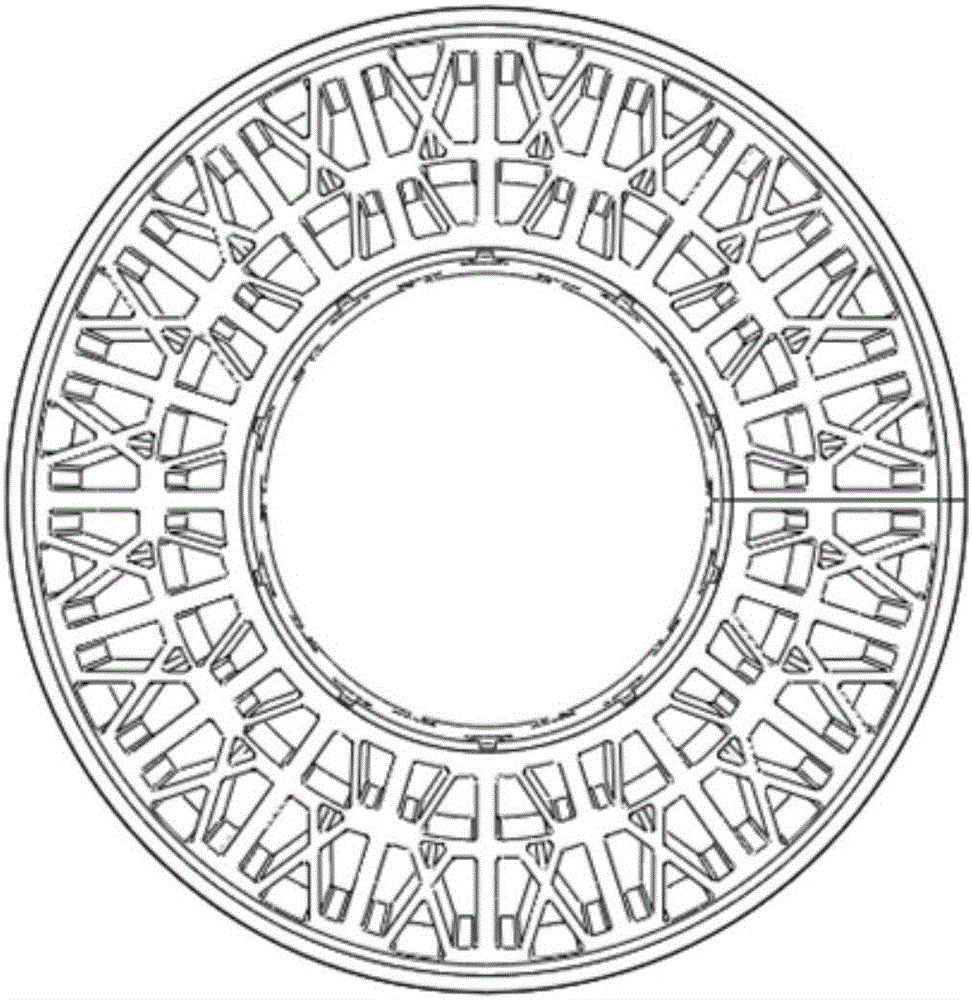

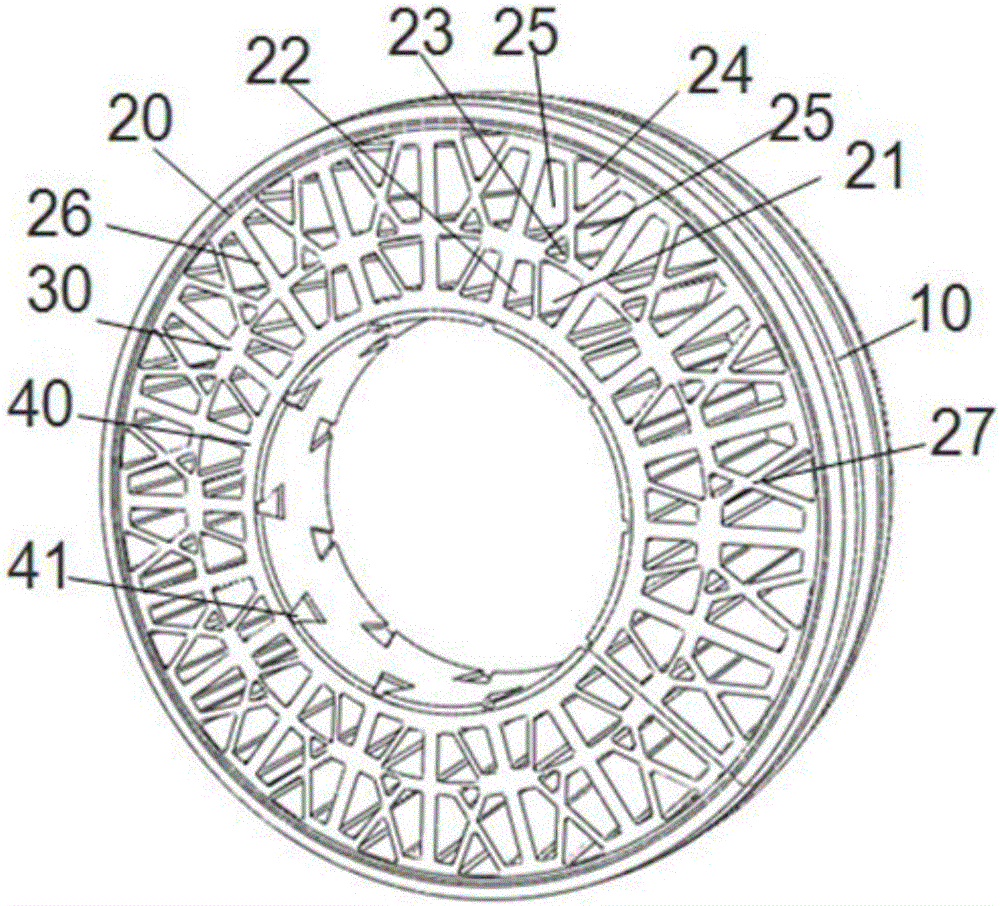

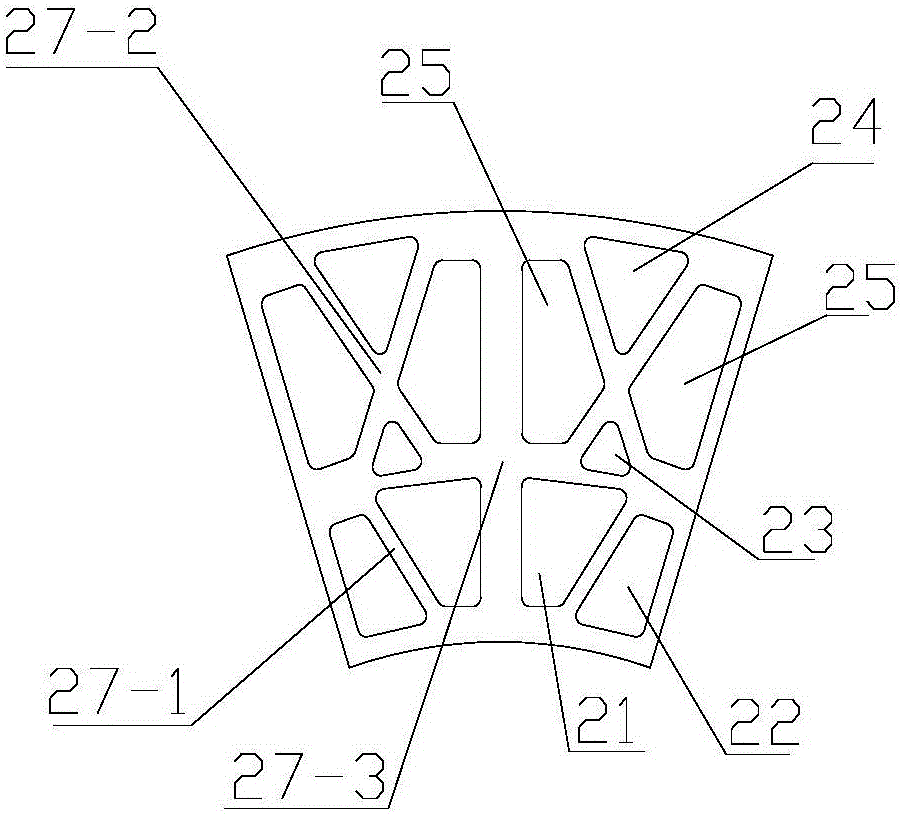

Non-pneumatic safety tire

The invention provides a non-pneumatic safety tire, which comprises a tread, an outer ring, a support body and an inner ring from the outside to the inside in order. The tread is bonded or vulcanized on the outer ring, the support body is arranged between the inner ring and the outer ring along the radial direction and circumferential direction from the outer ring, multiple groups of damping units and support ribs, each group of damping unit consists of two sets of damping structures, and two sets of damping structures are circumferentially disposed with the radial direction as the symmetric axis. The non-pneumatic tire provided by the invention has good bearing capacity, and by means of wheel disk thickening and multiple damping hole diameter change, the bearing capacity of the tire can be enhanced. The non-pneumatic safety tire not only has the carrying capacity and static rigidity characteristics of pneumatic tyres, but also has rationally distributed ground pressure, the abrasion resistance and trip distance of the tire are increased, especially the reasonable distribution of multiple damping holes and support ribs in the radial and circumferential direction can enhance the carrying capacity of the tire and also can improve the static rigidity of the tire.

Owner:QINGDAO UNIV OF SCI & TECH

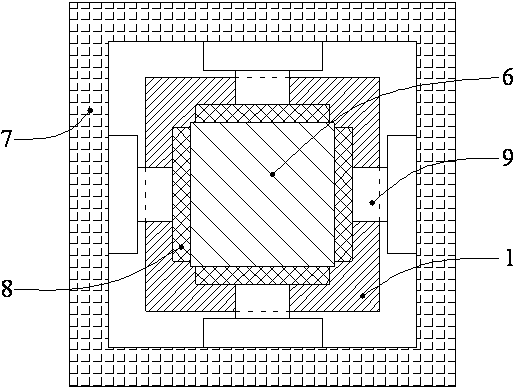

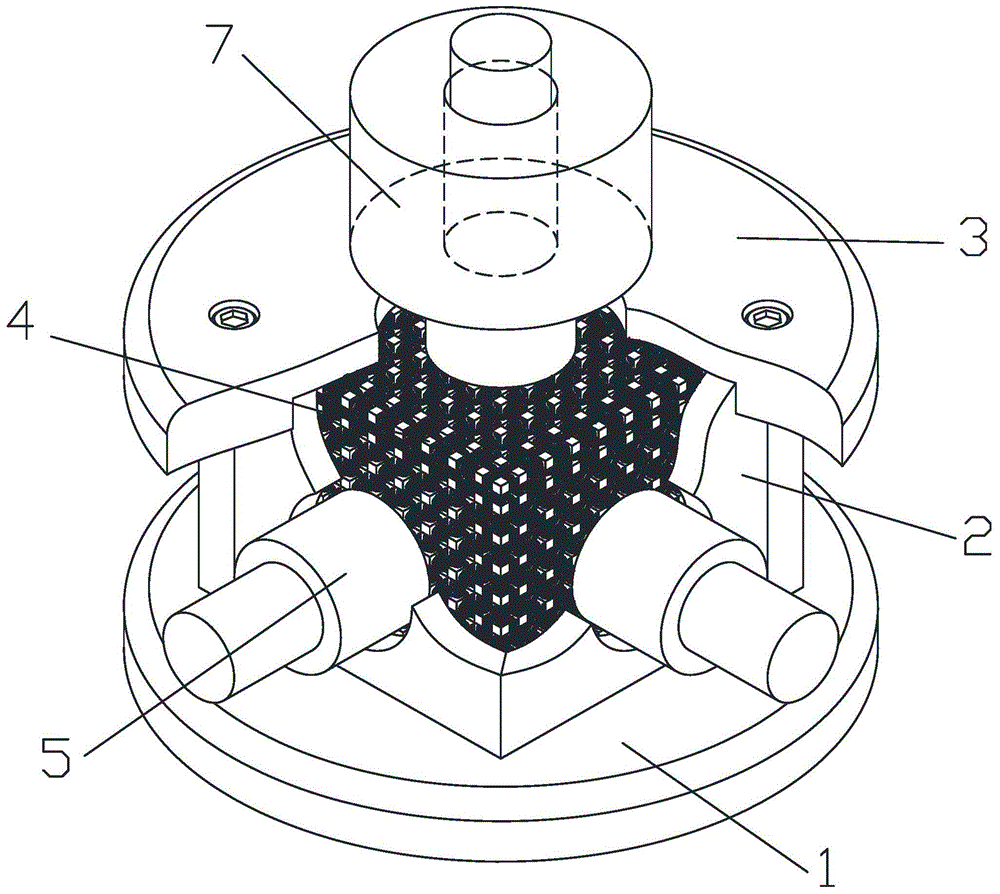

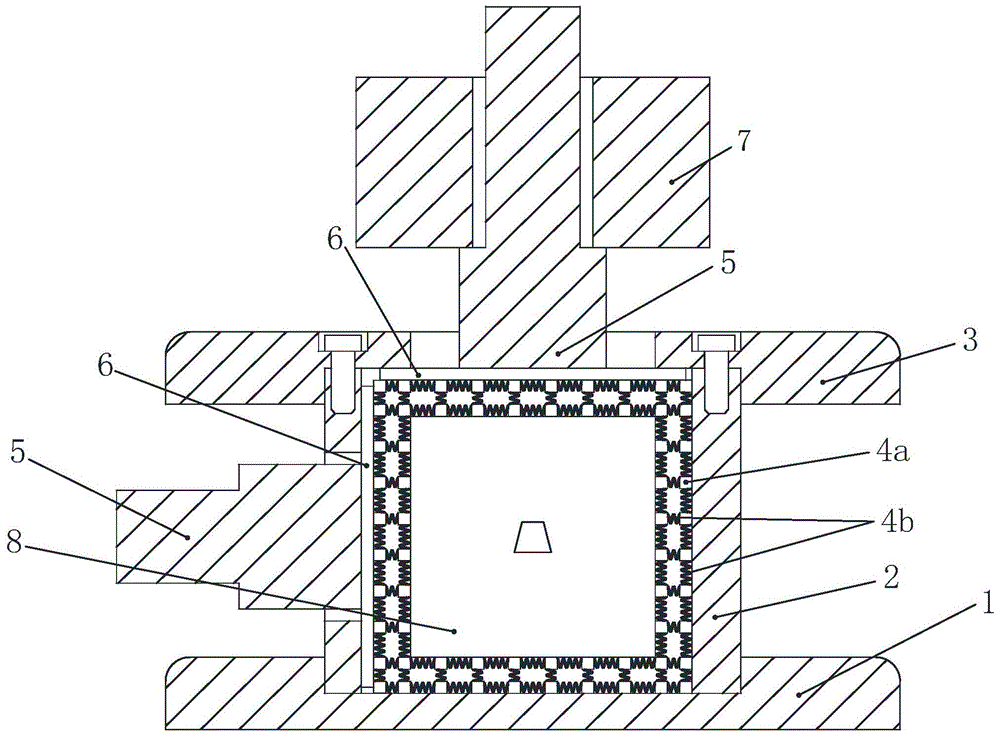

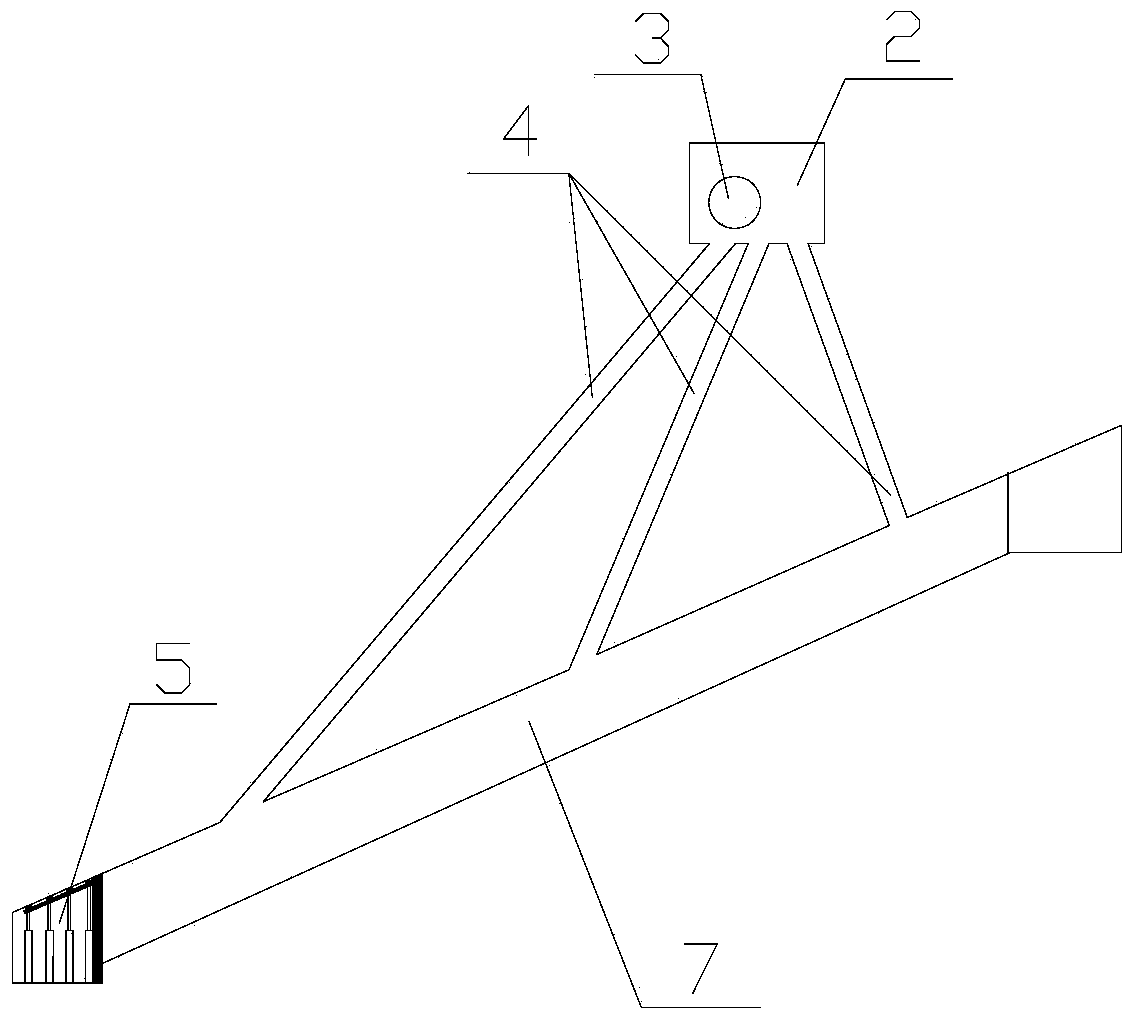

True triaxial simulation test device for three-directional rigid loading impact ground pressure

ActiveCN104390859AAvoid mutual influenceAvoid the impact of support effectMaterial strength using tensile/compressive forcesEngineeringImpact loading

The invention provides a true triaxial simulation test device for three-directional rigid loading impact ground pressure. The problem that the simulation is not vivid in an existing impact ground pressure test device is solved. The true triaxial simulation test device comprises a pressure box, wherein the pressure box is internally provided with a pressure cavity, and further comprises a rigid loading unit and an impact loading unit; the inner periphery of the pressure cavity is provided with a flexible confining pressure loading jacket; the flexible confining pressure loading jacket has elastic deformation amounts in X, Y and Z directions; the rigid loading unit comprises loading oil cylinders of the pressure box in the X, Y and Z directions; telescopic shafts of the loading oil cylinders penetrate through the outer wall of the pressure box and the inner ends of the telescopic shafts are fixedly connected with loading base plates; the inner surfaces of the loading base plates abut against the outer surface of the flexible confining pressure loading jacket; and the impact loading unit comprises a lifting device in the Z direction and an impact weight is hung under the lifting device. According to the true triaxial simulation test device, the influences of deformation with one another in the three directions are solved, and the influences of a supporting effect are also avoided, so that the impact ground pressure is simulated relatively vividly.

Owner:SHANDONG UNIV OF SCI & TECH

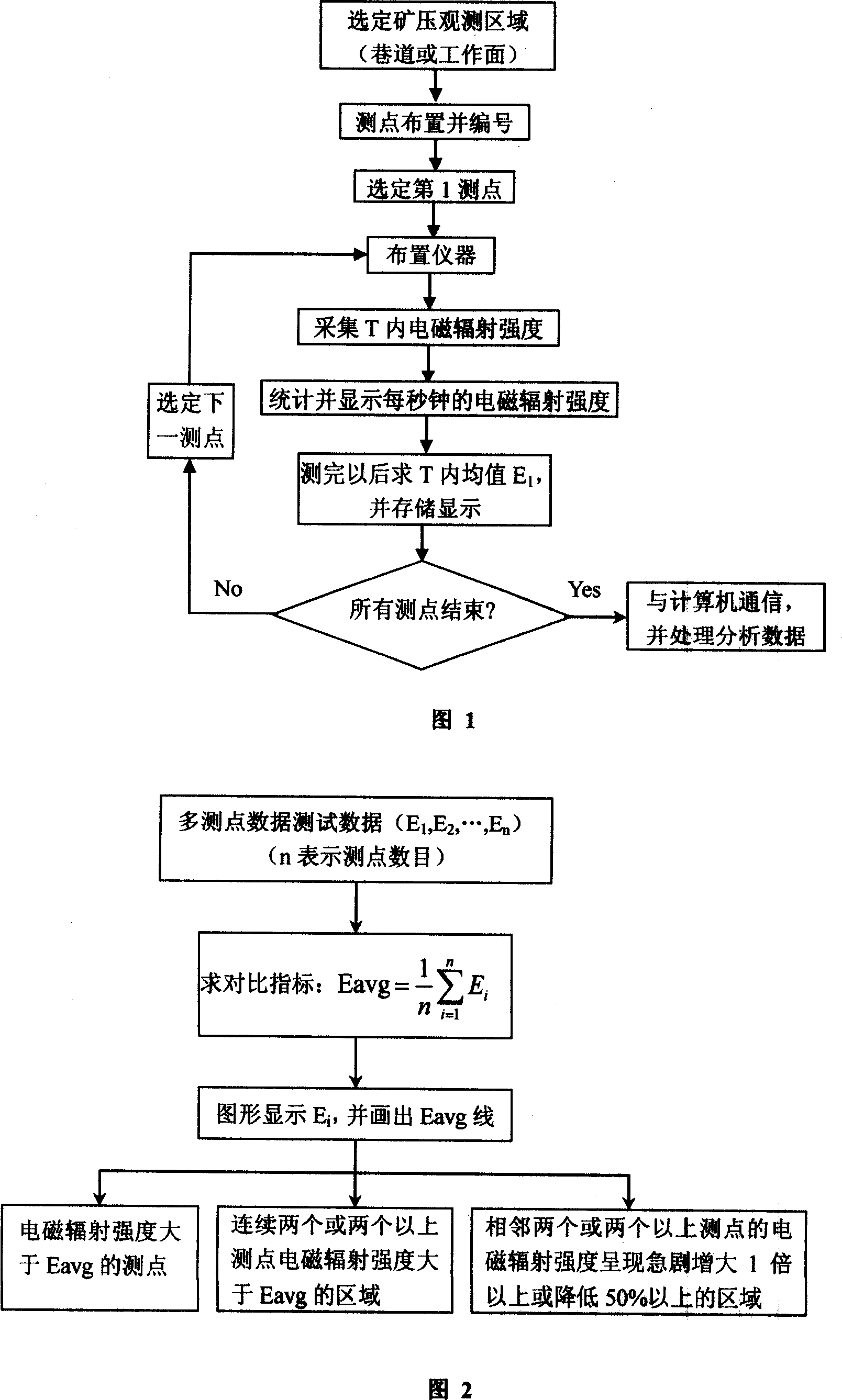

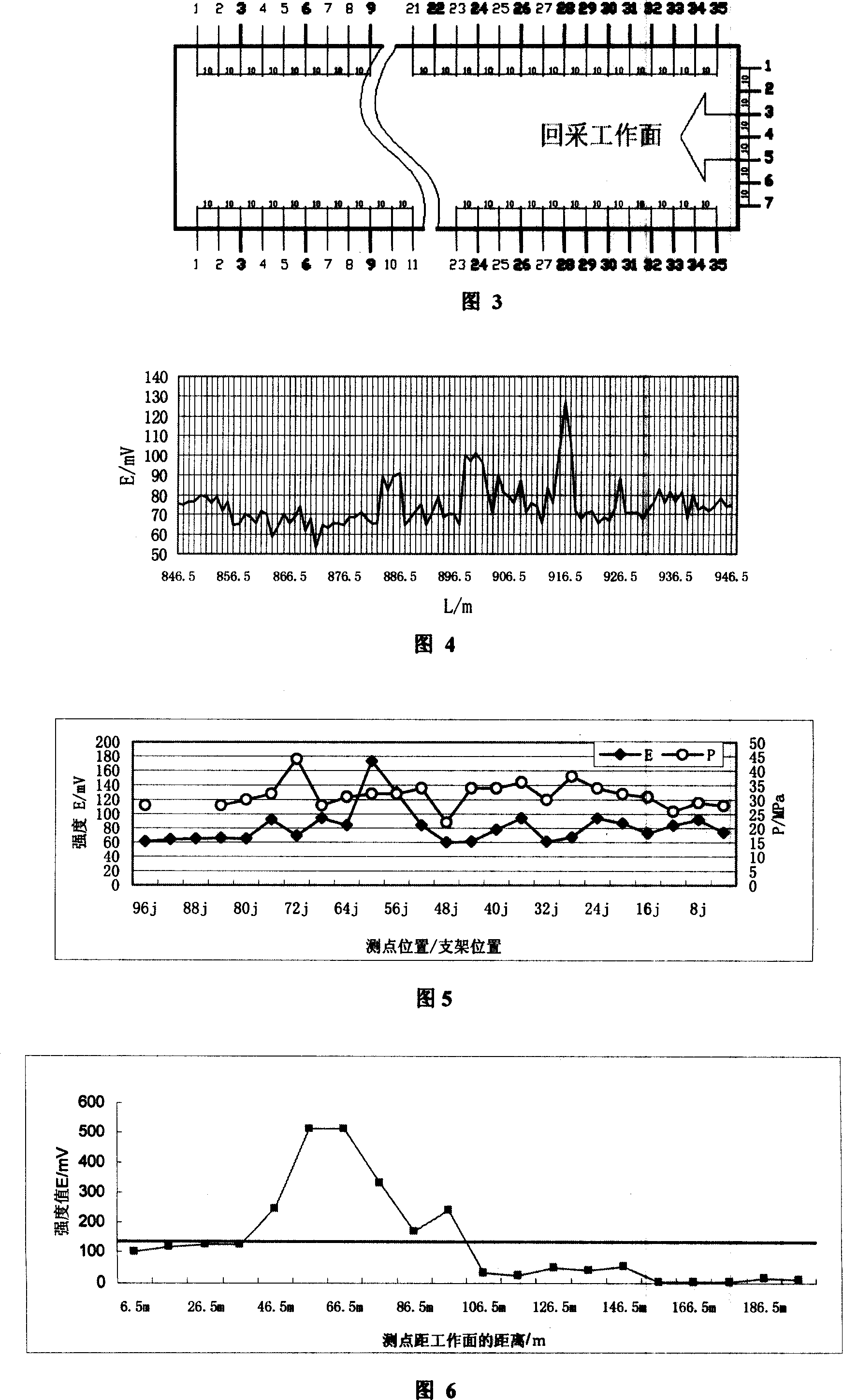

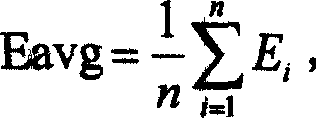

Non-contact mine ground pressure observing and estimating method

ActiveCN101021570AEffective orientationEffective evaluationMaterial analysis by electric/magnetic meansApparatus for force/torque/work measurementTunnel wallHigh stress

The invention is a non-contact mine pressure observing and evaluating method, relating to a technique of monitoring and evaluating relative stress state of mine digging space or tunnel wall rock by non-contact monitoring the electromagnetic radiation information generated by loaded coal and rock, and the observing method: firstly selecting a region to be monitored, aligning the valid receiving direction of an oriented receiving electromagnetic antenna to an test point and obtaining Ei after test and testing until all test points are tested. And the evaluating method: index of mine pressure evaluation adopts average values Ei of electromagnetic radiation strengths of coal and rock, and calculating average value Eavg of all Ei; displaying the test results Ei in figure, and when the obtained electromagnetic radiation strength of a test point is higher than Eavg, the test point is evaluated as a high stress point; a region with two or more continuous test points whose electromagnetic radiation strengths are all higher than Eavg is evaluated as a high stress region; a region with two or more adjacent test points whose electromagnetic radiation strengths sharply increase by twice above or sharply decrease by above 50%, is evaluated as a high stress gradient region.

Owner:CHINA UNIV OF MINING & TECH

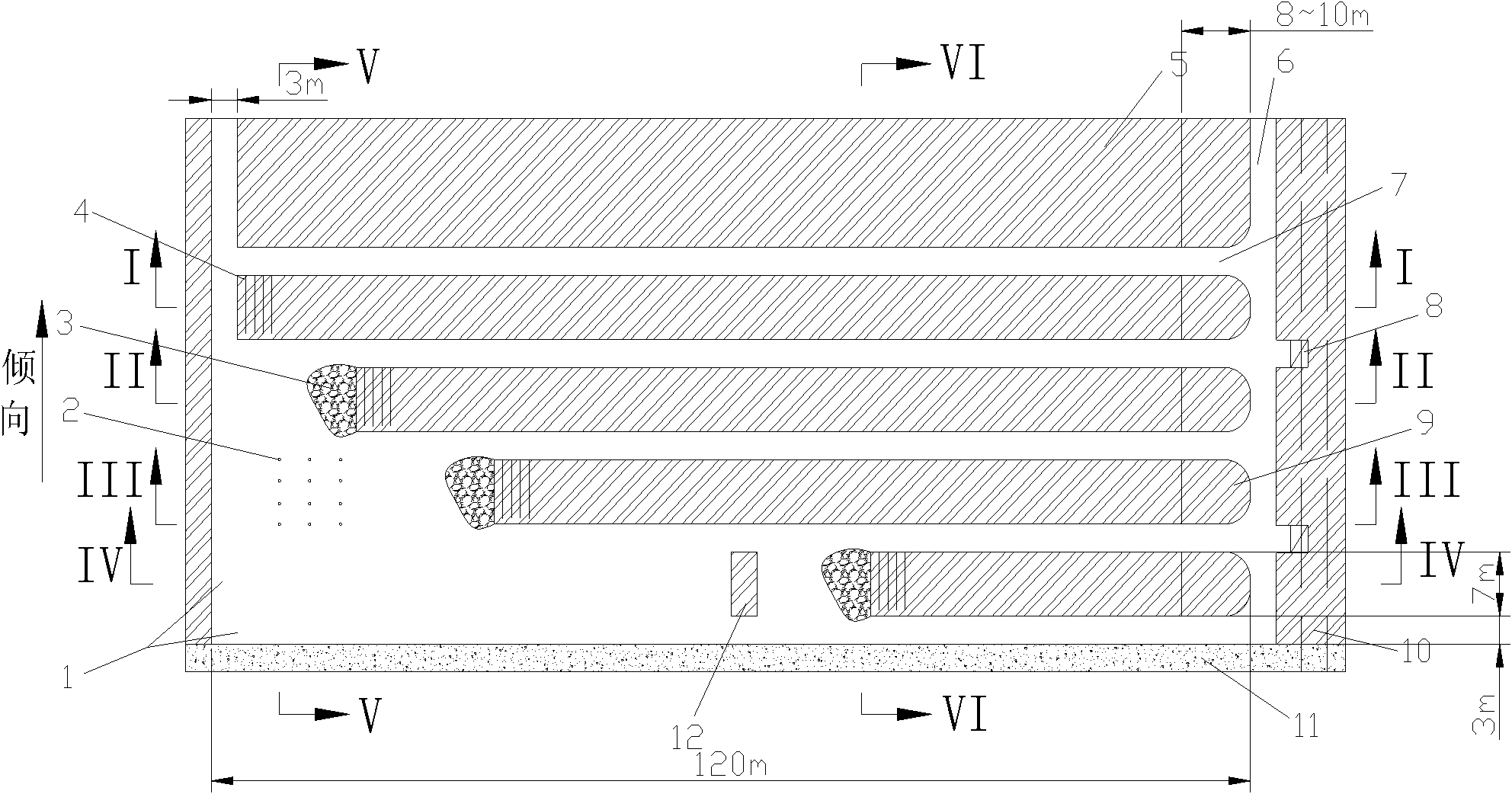

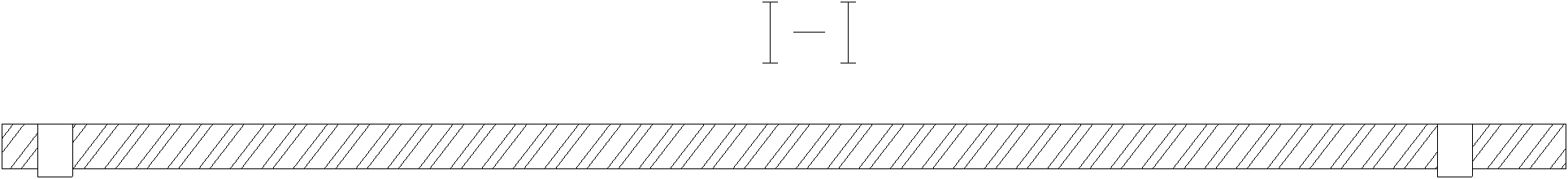

Mechanized continuous mining method for wall-type gentle-inclined thin ore body

ActiveCN102493806ASolve the root cause of blastingSolve the blasting stepsUnderground miningBlastingDrillMineralogy

The invention discloses a mechanized continuous mining method for a wall-type gentle-inclined thin ore body. A stope parameter with large structure size is designed in the thin ore body to realize the mining mode of the mechanized operation. A drill jumbo is used for drilling rocks, a scooptram is used for ore removal, the mechanized level and the production efficiency of the stope are improved, and through-thickness continuous mining is realized; bottom presplitting and hole blasting is carried out in the stope; in order to prevent from forming blasted steps on drilled rock which carries outexploding and hole blasting on an ore body side and carries out induced exploding and hole blasting on a top plate, a rock drilling roadway sinks for 0.5m; the dilution and the loss of the ore can becontrolled by presplitting blasting; and induced exploding and hole blasting on a top plate is carried out for induced spallation caving treatment of the top plate to process a goaf. The pressing, stacking and blasting technology is adopted for production blasting to control the position of slungshots and ores generated in blasting, and the ores in the step are conveyed by the scooptram. In the production process, the stope ground pressure is managed by hydraulic props. After certain production layout is carried out, the hydraulic props of the previous mining section are recovered, and induced spallation treatment is implemented to process the goaf.

Owner:CENT SOUTH UNIV

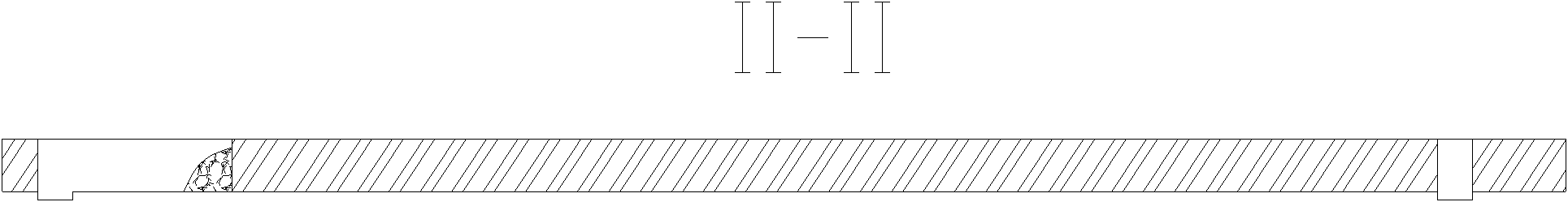

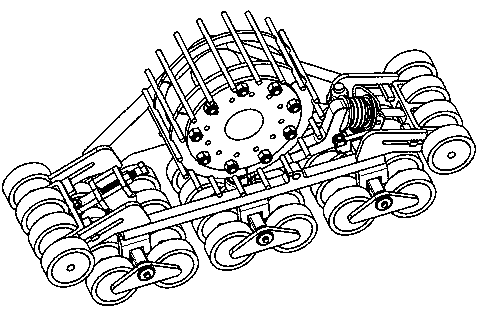

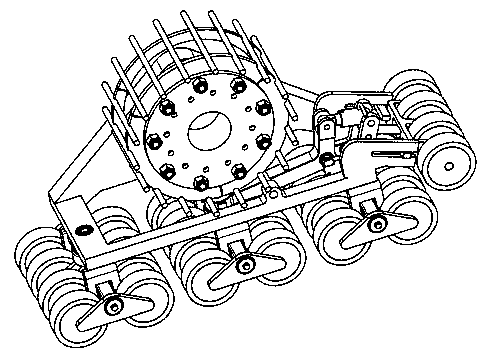

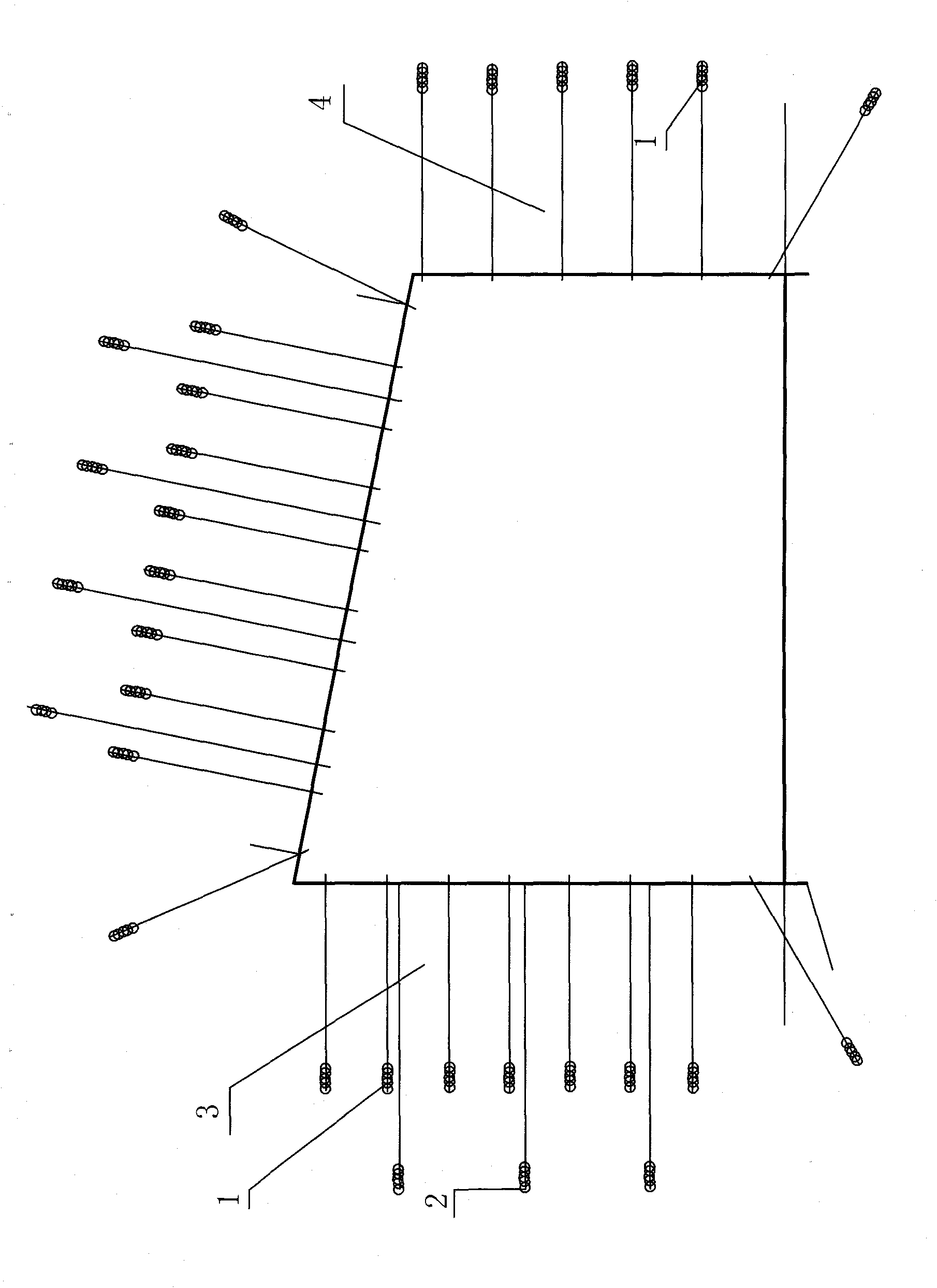

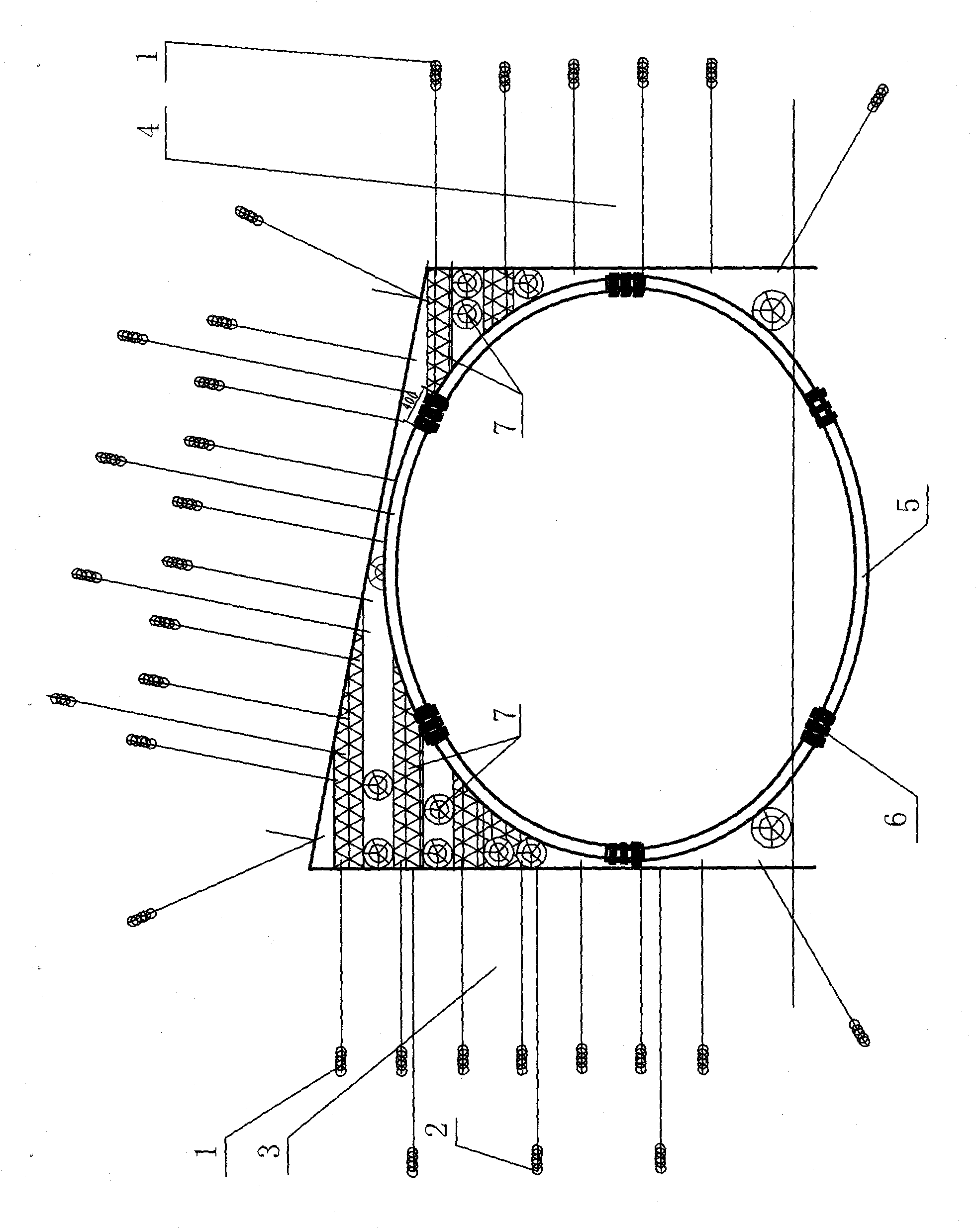

Modularized rubber crawler wheel

ActiveCN103935412AReduce sliding frictionReduce wearEndless track vehiclesDrive wheelAgricultural engineering

The invention discloses a modularized rubber crawler wheel, and relates to a crawler walking device. The modularized rubber crawler wheel comprises a frame, a modularized drive wheel, a guide wheel train, a modularized load bearing wheel train, an independent swing arm suspension and a rubber crawler. A plurality of load bearing wheel sets, a multi-dimensional balance suspension and a linear-moving type following tension structure or a fixed type tension structure are adopted, a bend steering function and a power-assisted steering function are achieved, all components and the integrated wheel are modularized, quick wheel and crawler exchanging of high-speed and heavy-duty cross-country engineering vehicles can be achieved, ground pressure of the vehicles is substantially reduced, adhesive force is improved, smoothness, stability and passing ability of the vehicles on rough topography are improved, stable traction is maintained, working reliability is improved, and using and maintaining are convenient. Meanwhile, different structures of the modularized rubber crawler wheel can be selected according to vehicle loads.

Owner:NO 63908 TROOPS PLA

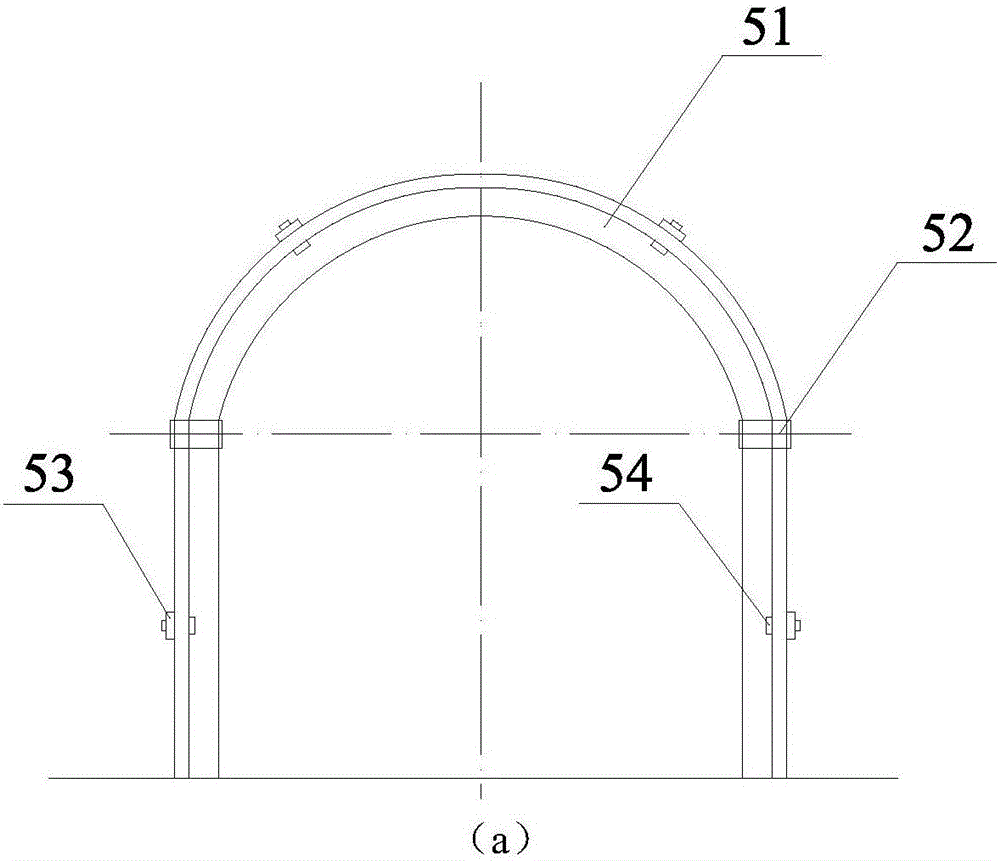

Impact-resistant combined anti-pressure supporting system

InactiveCN102182482AImprove efficiencyReduce maintenanceProps/chocksAnchoring boltsSupporting systemSocial benefits

The invention discloses an impact-resistant combined anti-pressure supporting system which is characterized by comprises a three-grade supporting system; and the impact-resistant combined anti-pressure supporting system has the advantages that: (1) by an optimized three-grade supporting manner, the maintenance amount of engineering roadways is reduced, the coal mining rate and the recovery ratio of a working face are increased, the safety coefficient is enlarged, and the comprehensive benefits of a mine are increased; (2) by applying a combined supporting system technology, the deformation of the roadway is effectively controlled when the working face is influenced by the ground pressure; and when the rock burst generates during production, the system plays a role of impact-resisting, realizes shrinkage and buffering changes and protects the safety of equipments and operators; and (3) according to the supporting system during recovery, dynamic alternatively circulative operation is realized, thus the purposes of resisting impaction, removing pressure and solving danger are realized, the construction process is simplified, various costs are saved, the quality is easy to control, the economic benefit is remarkable, the social benefit is also gained at the same time, and the competition among enterprises is improved.

Owner:义马煤业集团股份有限公司跃进煤矿

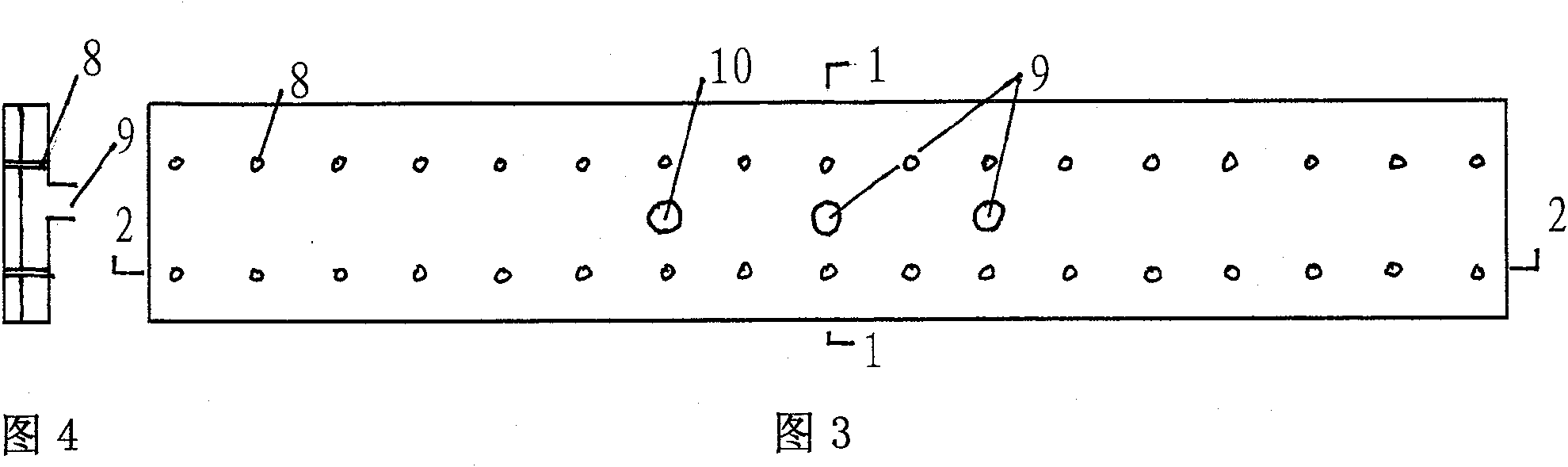

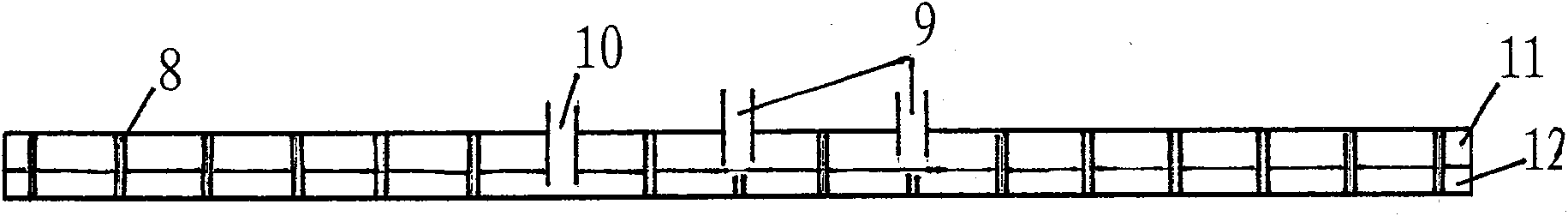

Application of thermoplastic resin composite materials in preparing road reinforcing plate

ActiveCN102312404AImprove the level of rapid operationImprove same-sex performanceTemporary pavingsMarshPolyresin

The invention relates to an application of thermoplastic resin composite materials in preparing a road reinforcing plate, which comprises the following steps: continuous fibres are placed in a soaking composite device to be soaked with the thermoplastic resin, so a unilateral continuous fibre reinforcement presoaking belt is obtained, wherein the weight percentage of the continuous fibre is 15%-85%; and a plurality of layers of unilateral continuous fibre reinforcement presoaking belts are laid on a hot-pressing machine of a plate, and under the melting temperature of the resin, a laminated road reinforcing plate is formed through hot-pressing for a certain time. Compared with the prior art, the invention is used as the road reinforcing plate for tanks and other engineering vehicles to run on deserts, marshes, mud basins and other soft grounds, the grounding pressure of the tanks is reduce, and the pass performance of the tanks and other engineering vehicles are favorably improved.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Impact ground pressure preventing method of full seam gateway

ActiveCN104806265AImproved anti-shock performanceEven by forceUnderground chambersBlastingSupporting systemEngineering

The invention provides an impact ground pressure preventing method of a full seam gateway. The method is that an impact preventing support consisting of energy absorbing steel beams and energy absorbing anchor rod ropes is added on the basis of the general support composed of an iron wire net, a steel belt and an anchor rod, wherein the energy absorbing steel beams are lengthways distributed at intervals along the gateway, comprising two layers of steel plates, and energy absorbing boxes which are fixed at intervals between the two layers of steel plates; gateway surrounded rock in a propping plate and two sides is drilled and grouted, so that the gateway surrounded rock can damp the impact; two bottom corners of the gateway within the advance influence range of a workface are blasted to release pressure. According to the method, the general support, the impact preventing support, the surrounded rock modification and the blasting and pressure release of the bottom corners of the gateway are synchronously carried out to form a point-line-face-body 3D distribution type energy absorbing and impact preventing system; the incident stress wave can be reduced through the support system, and the reflecting stress wave of the gateway surface can be reduced; the modified loose surrounded rock mass can greatly reduce the influence of the impact energy on the support structure; the four measures supplement each other and synergistically interacted, so that the impact ground pressure preventing capacity of the gateway can be greatly improved.

Owner:LIAONING TECHNICAL UNIVERSITY

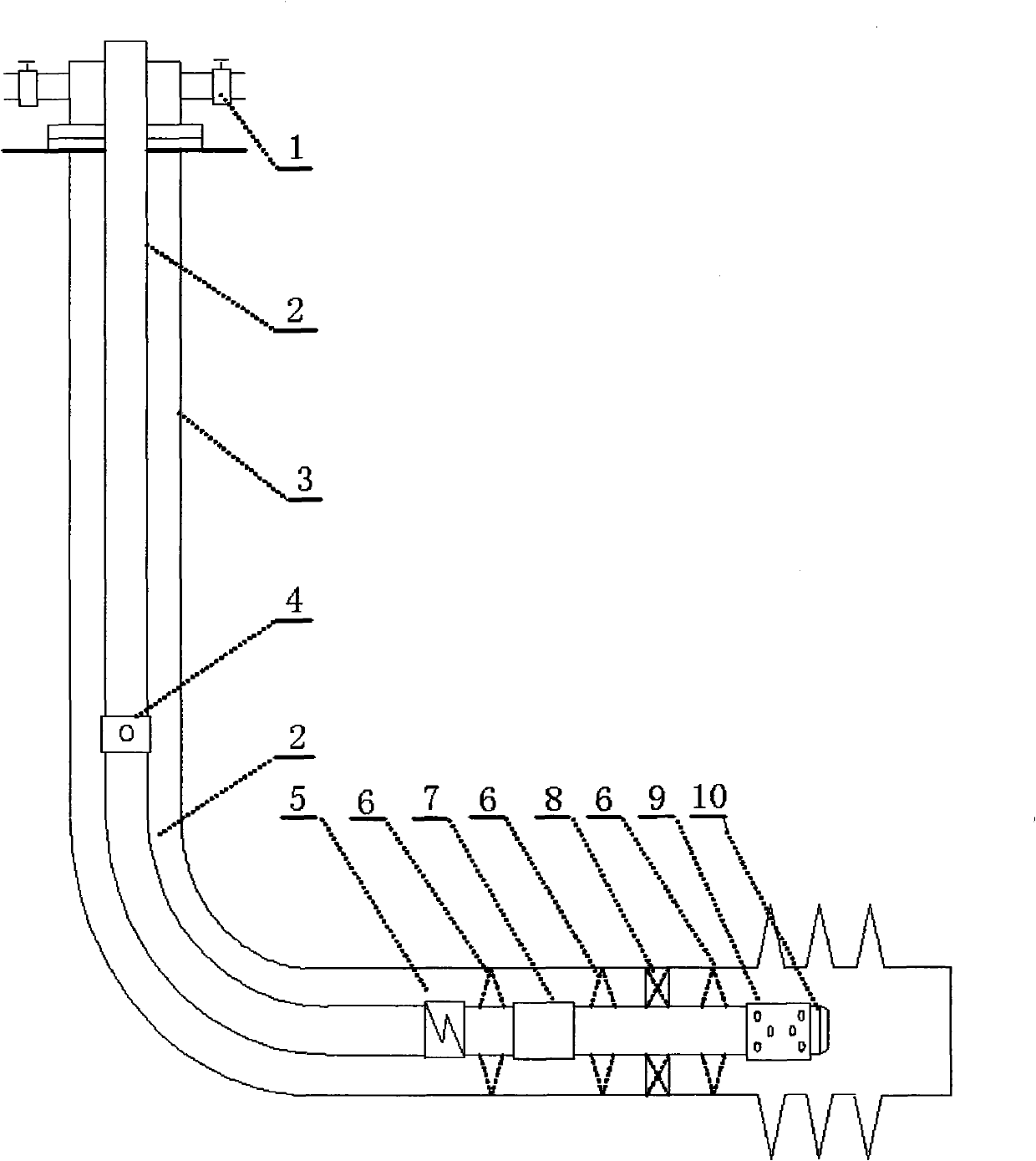

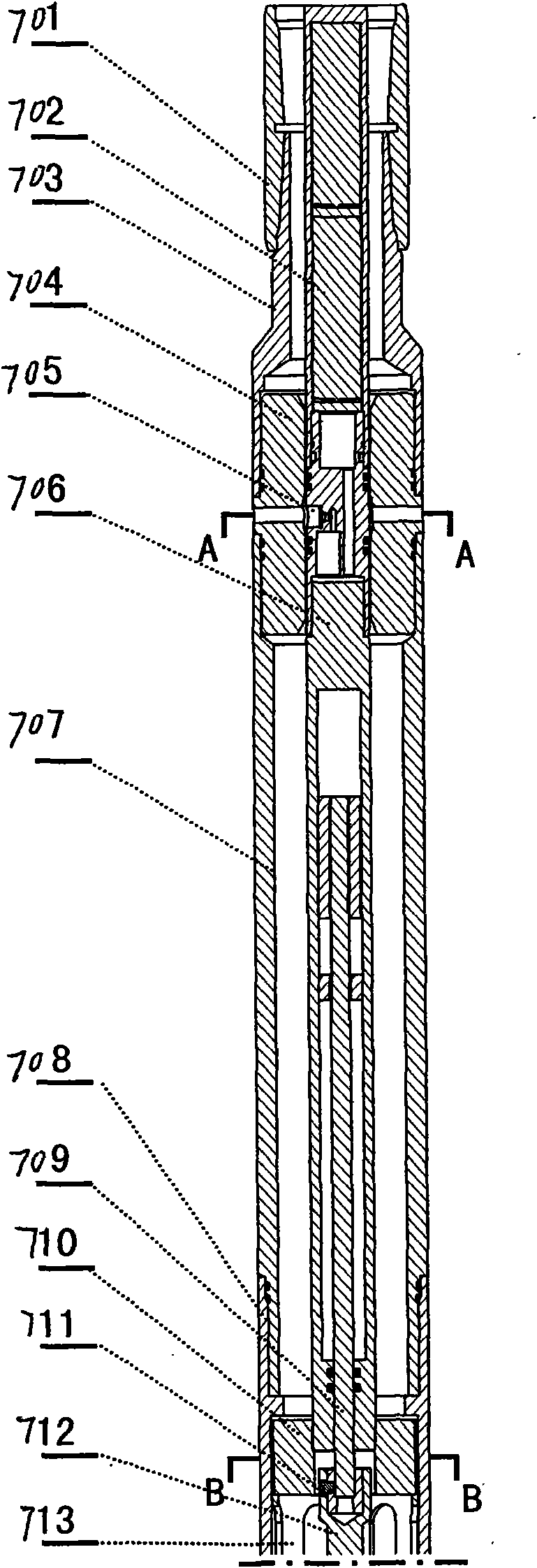

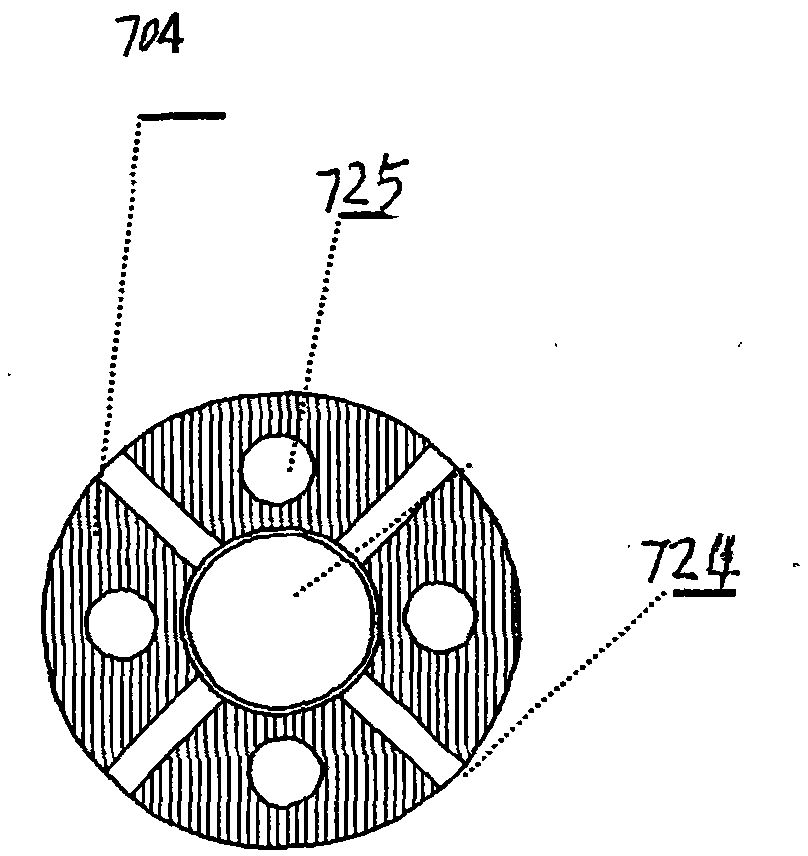

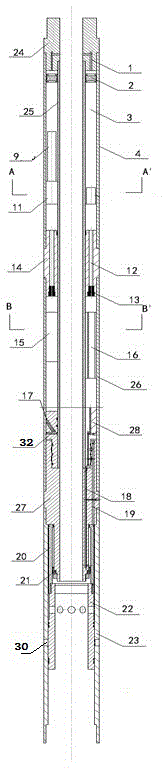

Method for testing strata of horizontal well

ActiveCN101793146ASolving testing challengesSimple structureWell/borehole valve arrangementsSealing/packingMulti streamVoltage control

The invention relates to a method for testing strata of a horizontal well, which is applied to the test of the strata of a horizontal well during casing well completion. The method comprises the steps of: setting parameters for a voltage-controlled electric multi-stream test valve, and putting the test valve into a casing of an oil well; performing the settlement of an annulus hydrostatic packer;performing annulus pressurization on an oil jacket by utilizing a pumper on the ground to realize well opening and well closing; completing sampling operation during the last closing operation, and simultaneously, recording the variation conditions of pressure and temperature in the overall process of construction by a pressure gauge in a pressure gauge support cylinder of the voltage-controlled electric multi-stream test valve; opening a reverse circulation valve by utilizing an external-force punch, deblocking the annulus hydrostatic packer by lifting a pipe column upwards to lift a stratumtesting pipe column and a mating tool safely. The method has the advantages that in a process pipe column for testing the strata of the horizontal well, the settlement of the packer is performed by utilizing the pressure of a casing annulus hydrostatic column, so that other stratum sections and well completion liquid are isolated from a test layer; and ground pressure pulse signals control the voltage-controlled electric multi-stream test valve to realize the well opening and well closing operation.

Owner:PETROCHINA CO LTD

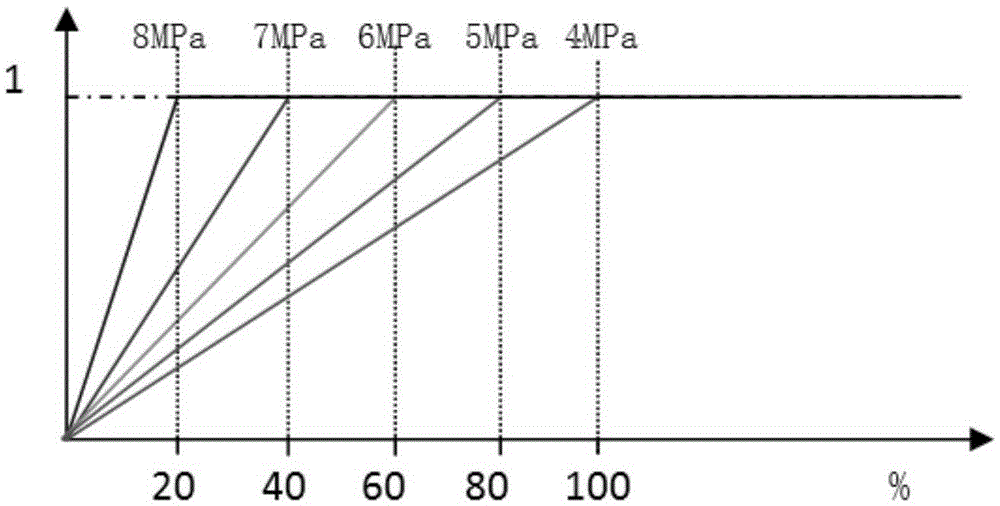

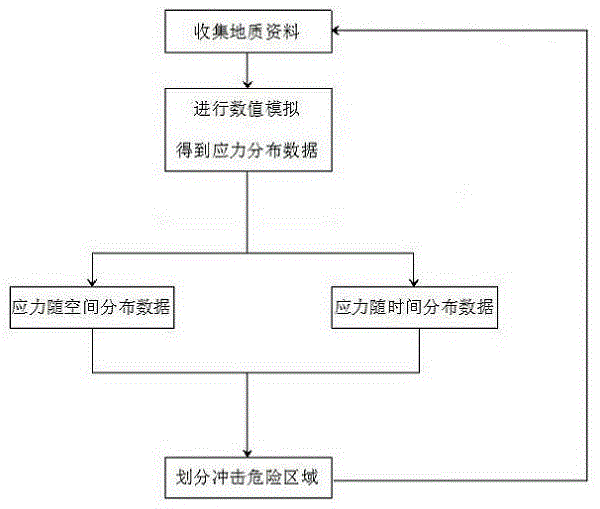

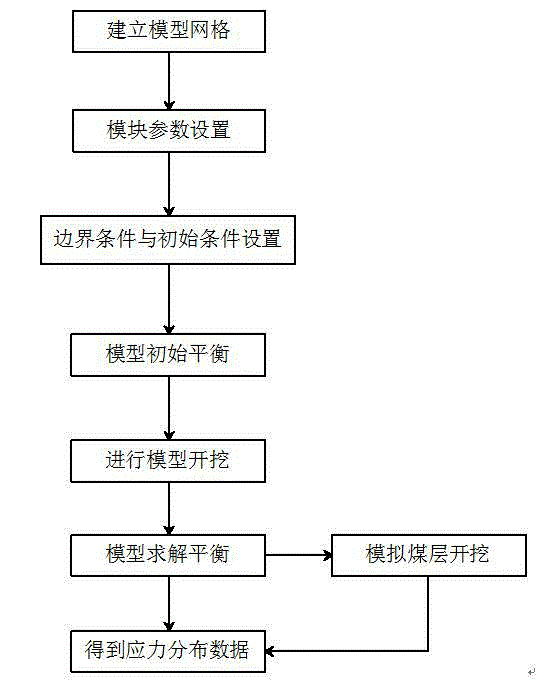

Stress-gradient-based method for dividing coal impact ground pressure danger area

InactiveCN104653226AGuarantee property securityGuarantee the safety of lifeMining devicesEnvironmental resource managementBusiness forecasting

The invention discloses a stress-gradient-based method for dividing a coal impact ground pressure danger area. The method comprises the following steps: collecting geological data; simulating a mining value; calculating stress space distribution data and stress time distribution data; dividing an impact danger area; simulating the divided impact danger area according to the above values after a working surface is mined, monitoring stress of the area on line in real time to obtain a stress filed of the monitoring area, repeating the above steps, collecting geological data, dividing, forecasting and early warning the impact ground pressure danger area according to stress data. According to the stress-gradient-based method for dividing the coal impact ground pressure danger area, an impact ground pressure is forecasted and early warned due to a coupling relation existing between the stress gradient of the area and the coal rock impact damage condition; the impact danger area is divided according to the abnormal stress gradient; the method is strong in applicability and high in accuracy, is capable of accurately forecasting and early warning the impact ground pressure danger area and ensuring the property safety of mine and the life safety of workers, and has great significance to the coal mine safety.

Owner:CHINA UNIV OF MINING & TECH

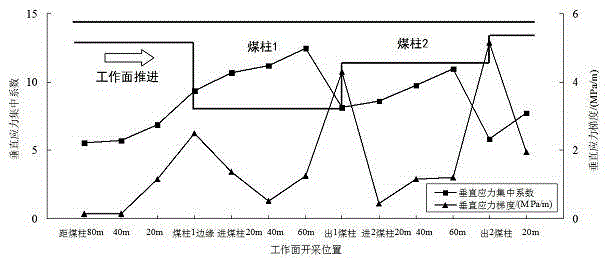

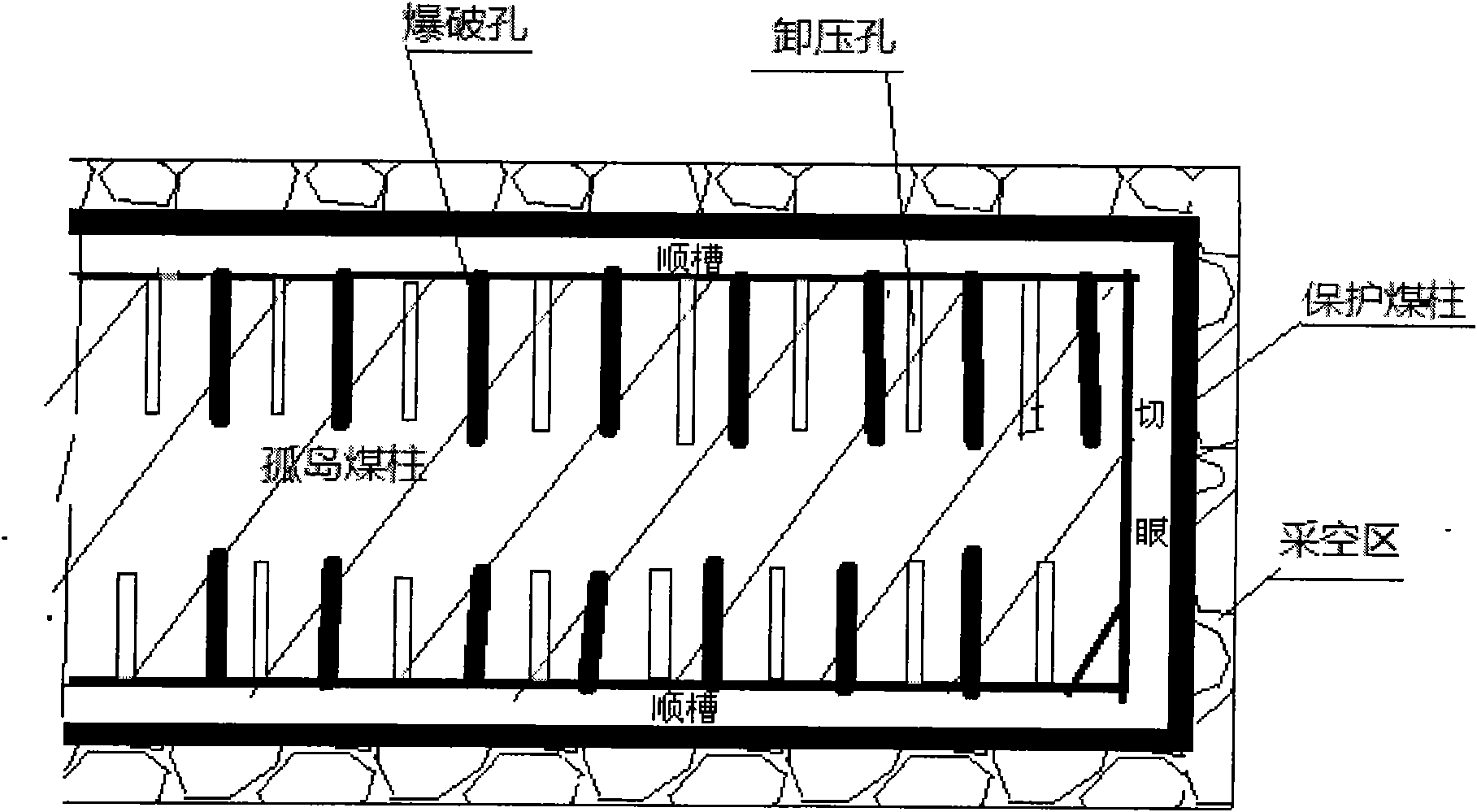

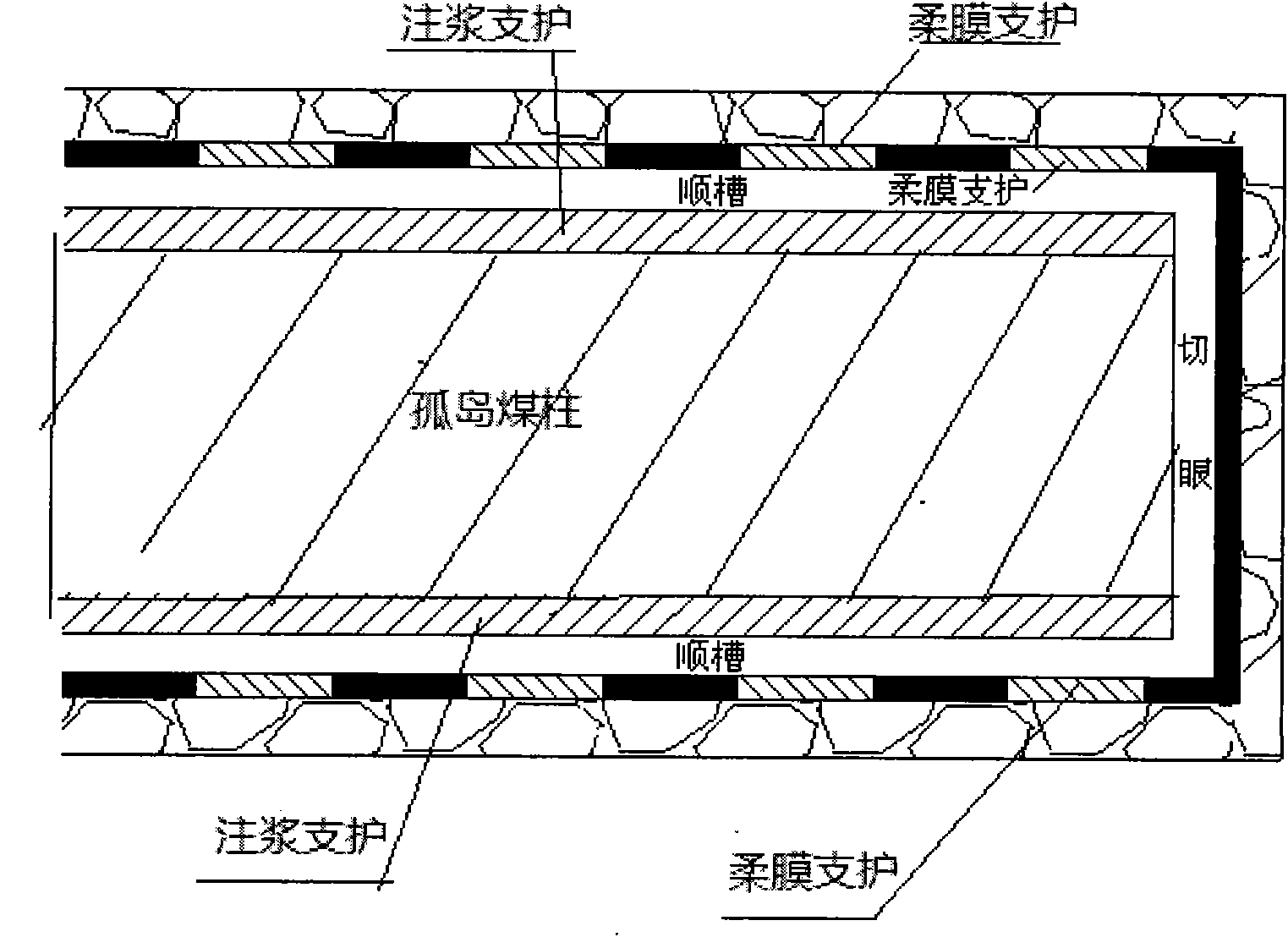

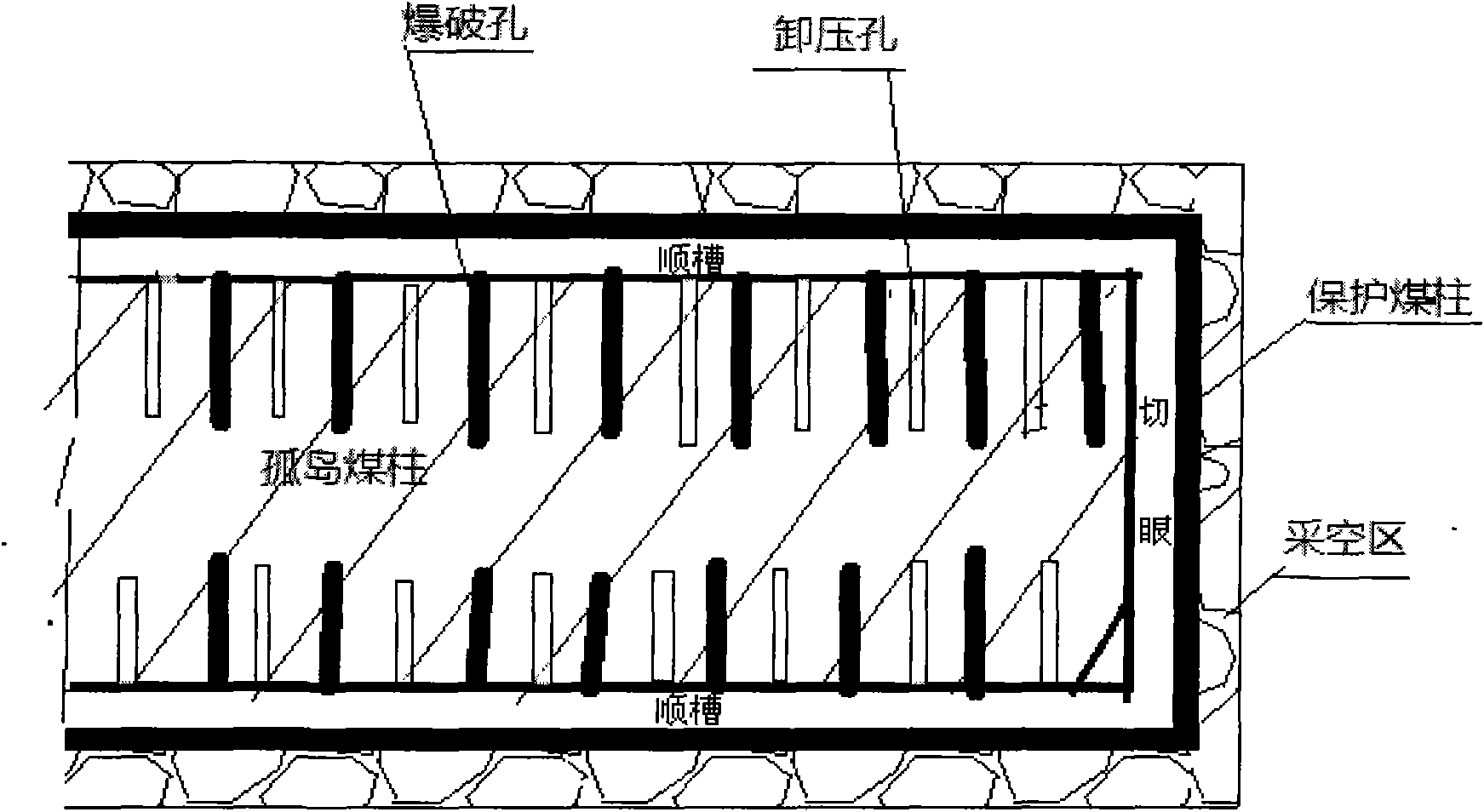

Control method for coal mine insular coal pillar crossheading rock burst

InactiveCN102322262AHigh strengthAct as a protective wallUnderground chambersUnderground miningDistressingCoal pillar

The present invention discloses a control method for coal mine insular coal pillar crossheading rock burst. According to the method, firstly, roadways of a coal mine insular coal pillar are dug and arranged on an upper crossheading, a lower crossheading and a coal face cut; treatments of drilling and blasting distressing are performed on inner side walls of the upper crossheading and the lower crossheading; then, a treatment of interval strong supporting is performed on outer side walls of goaf sides of the upper crossheading and the lower crossheading; finally, a treatment of grouting is applied on the inner side walls of the upper crossheading and the lower crossheading to reinforce the support, wherein the upper crossheading and the lower crossheading are subjected to the blasting distressing. With the present invention, the drilling and the blasting distressing are adopted, the ground pressure of the coal pillar is released, such that the coal body with the impact trend is transformed in the coal body with the weak impact trend; the strong supporting is performed for both side walls, such that the strength of the coal body from the coal wall of the roadway to the deep roadway is improved, the protection wall effect is provided for the roadway, and the safeties of the workers are protected.

Owner:SHANDONG UNIV OF SCI & TECH

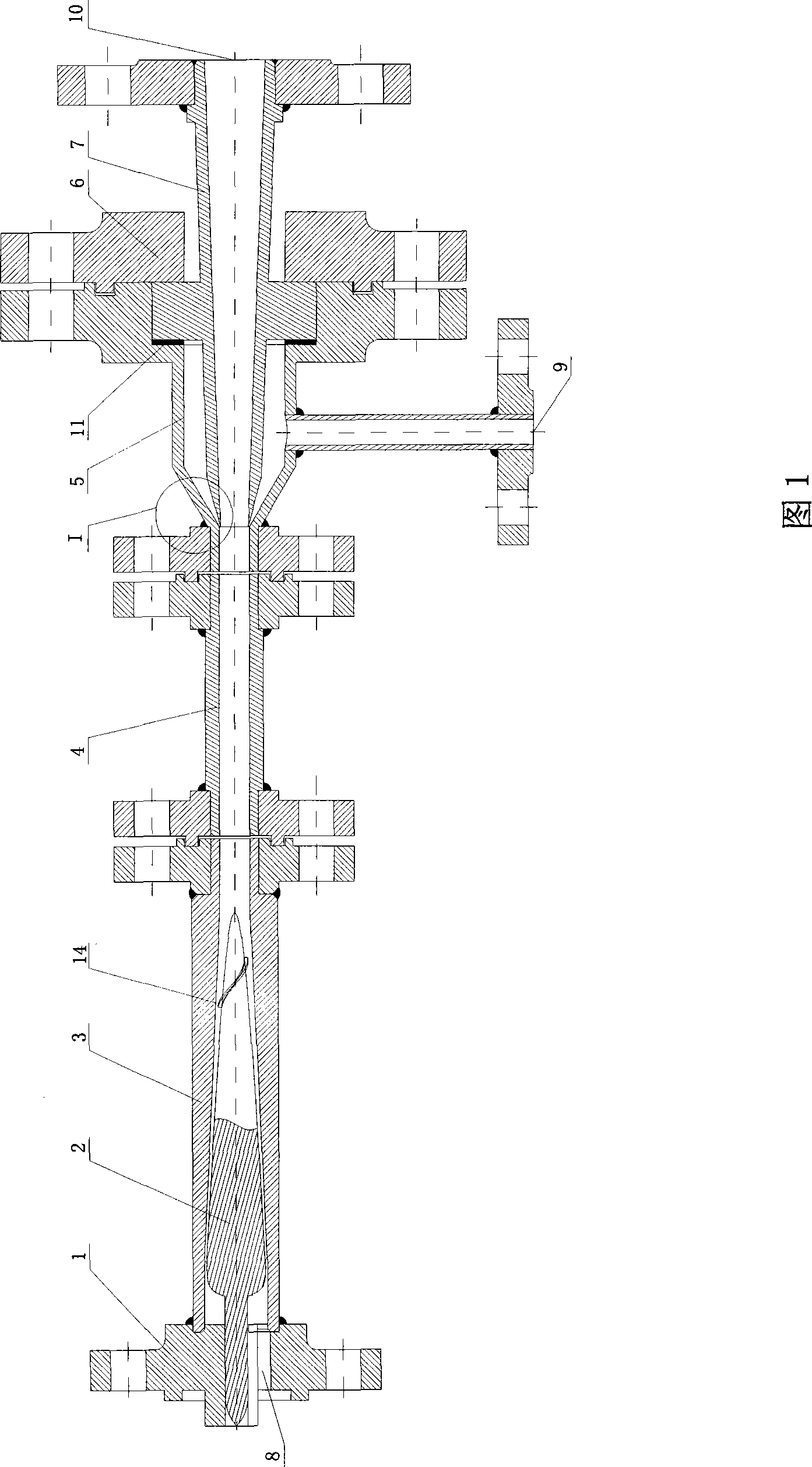

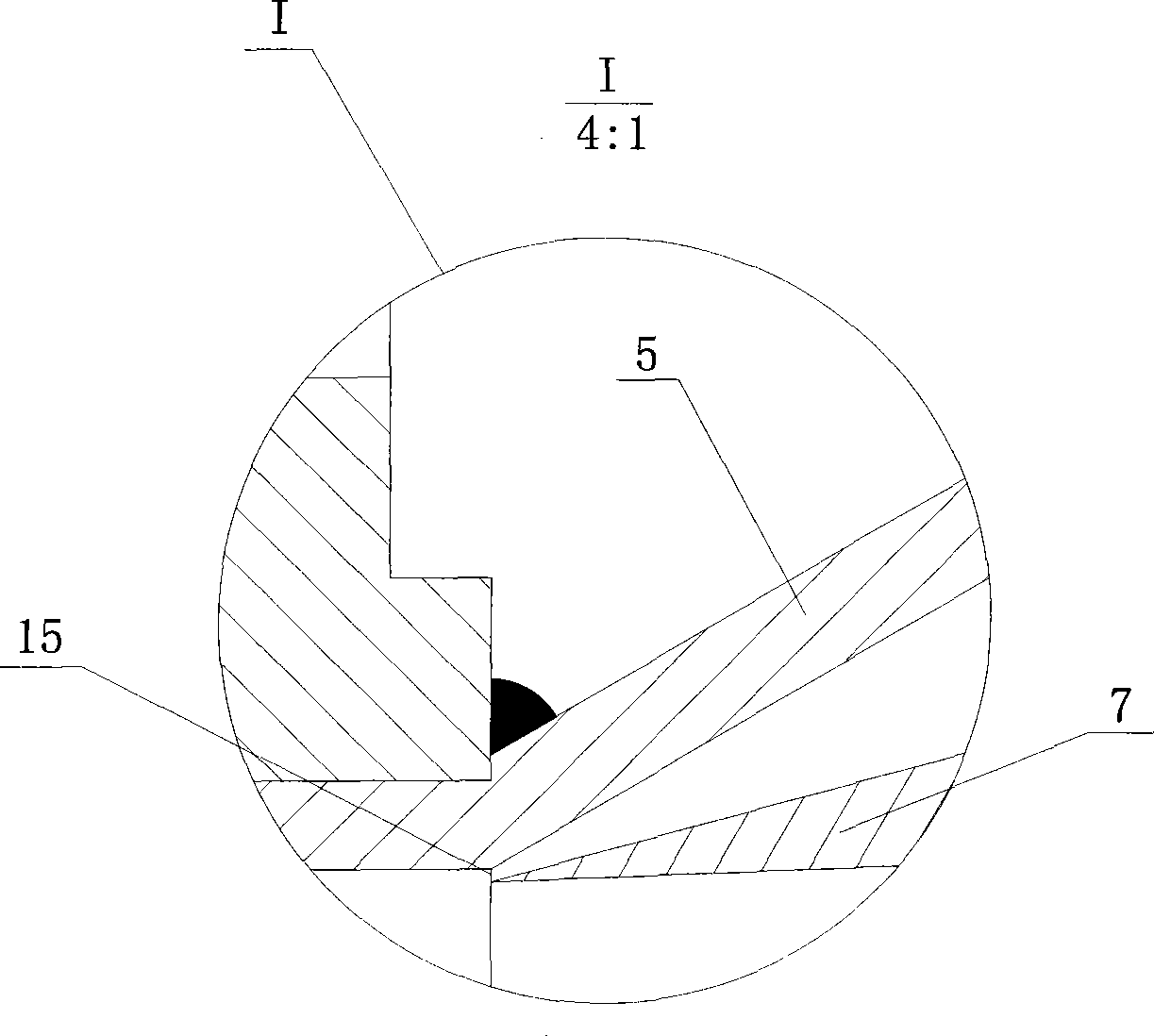

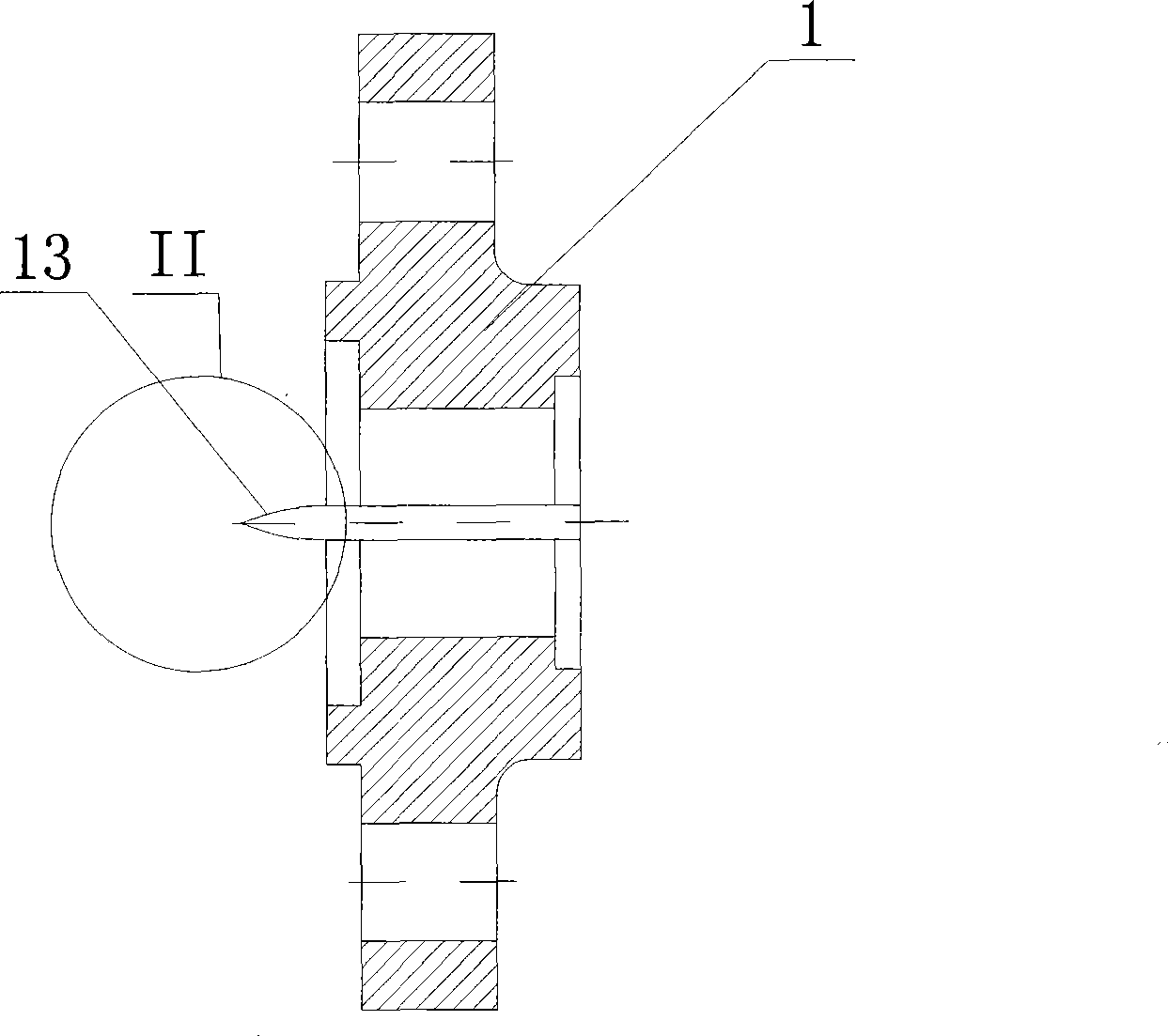

Low flow resistance supersonic speed gas purification and separation device

InactiveCN101380537ASimple structureUnmanned operationGaseous fuelsDispersed particle separationEngineeringSupersonic speed

The invention relates to a low flow resistance supersonic device for purifying and separating gas and is applied to the field of gas separation and purification such as natural gas dehydration, etc. Natural gas enters a laval nozzle by a gas inlet, the temperature and pressure thereof lowers, the speed is increased, then the gas mixture floating at high speed flows through a whirl vane, the swirl with high speed is produced, the swirl with high speed enters a separation pipe, for the temperature becomes low, when the gas is below ground pressure and saturation temperature, the water or partial dew points in the gas are condensed into liquid, for the centrifugal forces born are different, the liquid from the gas by condensation is 'flung' to the wall of the pipe and forms a very thin layer of liquor film, the liquid flows out of the separation pipe through the ring-shaped groove between the separation pipe and a diffuser pipe and flows out from the liquor outlet. Then the dry gas in which water is removed enters the diffuser pipe, and the gas flows out of the separation device by the gas outlet. The device does not comprise motion components and structure is simple; and the circulation transversal area of the laval nozzle in the device is ring-shaped and can be processed easily.

Owner:BEIJING UNIV OF TECH

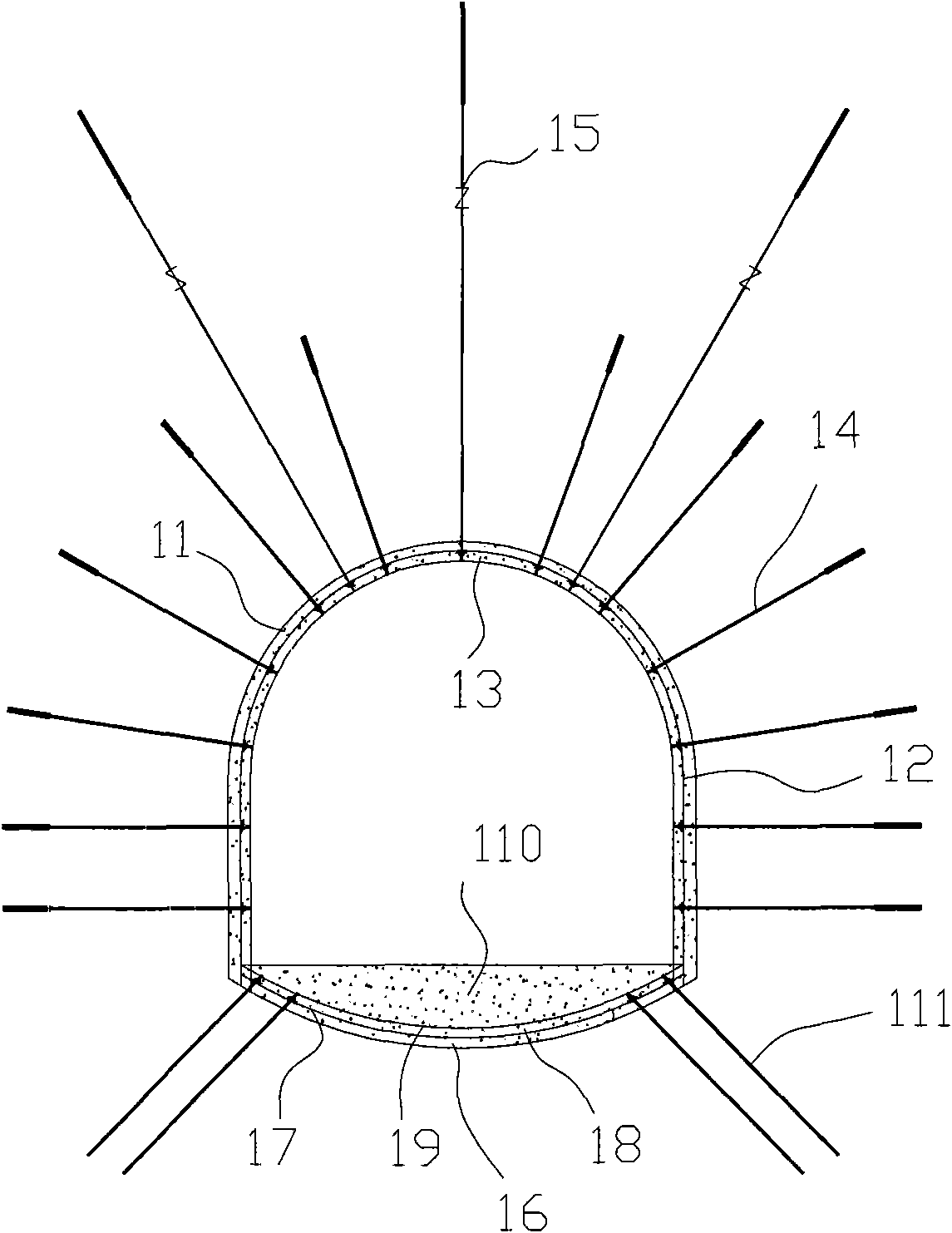

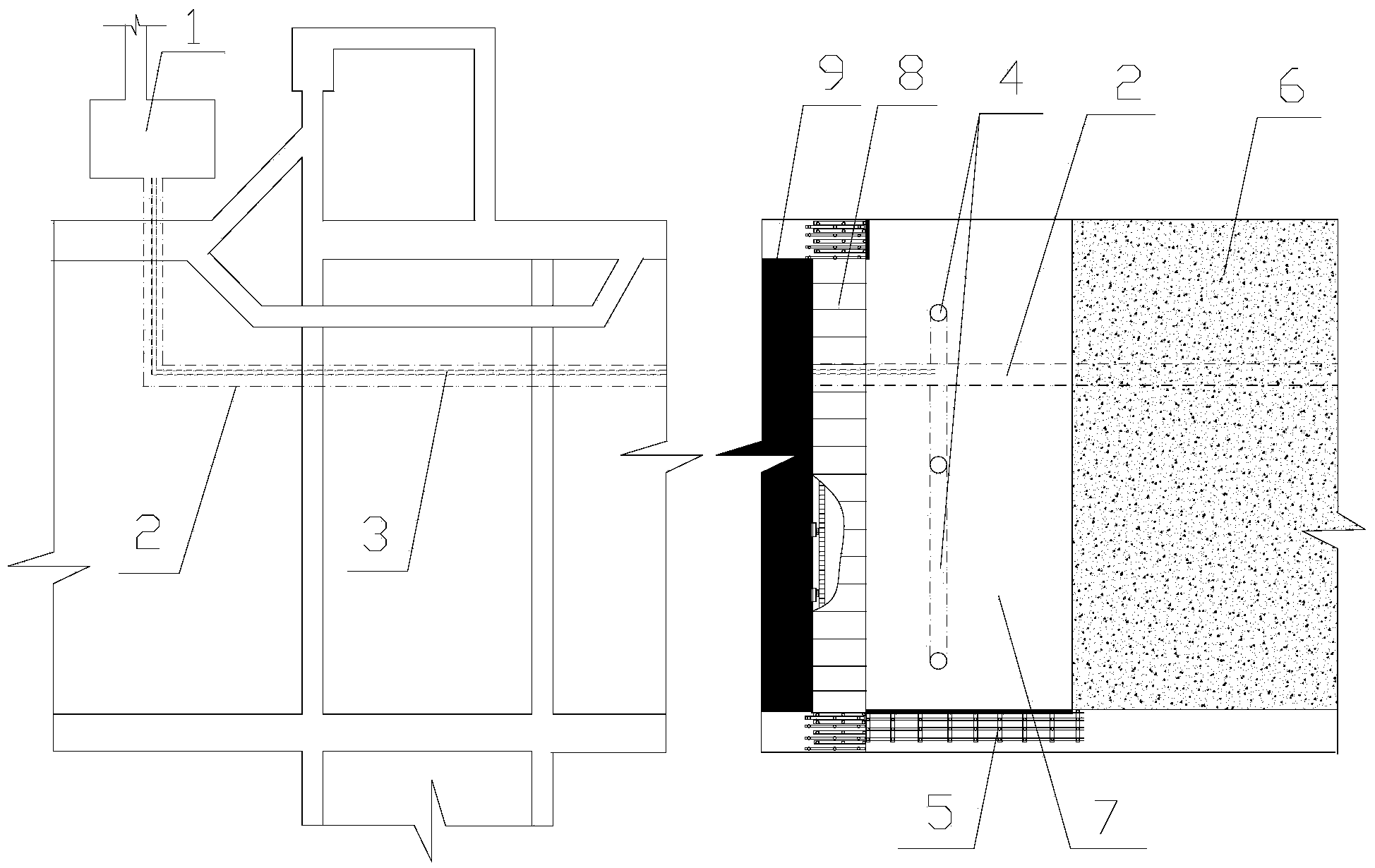

Stress-transfer method in tunnel with high ground pressure based on fracturing ring

ActiveUS20190316454A1Relieve pressureLow rangeMining devicesUnderground miningGeomorphologyStress conditions

A stress-transfer method in tunnel with high ground pressure based on fracturing ring. According to the stress source of the tunnel, fracturing by drilling holes to form artificial weaken zones in surrounding rocks, that's named fracturing ring. The fracturing ring is the weaken zone with some width, whose inner boundary is the protective circle. The fracturing ring with small width is called the cutting and interruption circle and the cutting or interruption arc. The radius of the protective circle is determined by setting a certain width of safety coal pillar barriers at the edge of a support body. The radius of the fracturing ring is determined by the surrounding rock structure and the stress conditions as well as the construction technology. Usually, the higher the stress, the wider the radius of the fracturing ring. The cutting and interruption circle or arc could cut off all of the targeted rock which transmits the stress.

Owner:CHINA UNIV OF MINING & TECH +1

Coal mine gob filling mining system and gob-side entry retaining filling process

ActiveCN103821558AReduce mine pressureReduce settlementUnderground miningSurface miningMining engineeringFilling materials

A filling system applicable to coal mining is characterized in that a gob filling material crushing and mixing station chamber is arranged on a ginney top, a stowboard is arranged within a certain distance of a rock coverage stratum on a coal mining face, fan drilling construction is performed from the stowboard above a gob to the gob, filling pipelines are laid in the stowboard, a measure for blocking between the coal mining face and the gob includes that the coal mining face and the gob are separated by a shielding plate at the rear of a hydraulic support, the gob-side entry retaining filling process includes that a gob-side entry retaining and the filling gob are separated by an individual hydraulic prop and a steel mould plate. Filling materials are conveyed to the gob through the filling pipeline; after the filling materials are solidified in certain strength, the coal mining face is pushed ahead, and mining and filling are performed circularly. The coal mine gob filling mining system and the gob-side entry retaining filling process have the advantages that stope ground pressure is effectively controlled to reduce subsidence; occupation of fertile farmland by coal gangue is avoided to eliminate environment pollution caused by the coal gangue, and green mining of coal mines can be realized.

Owner:鄂托克前旗长城煤矿有限责任公司

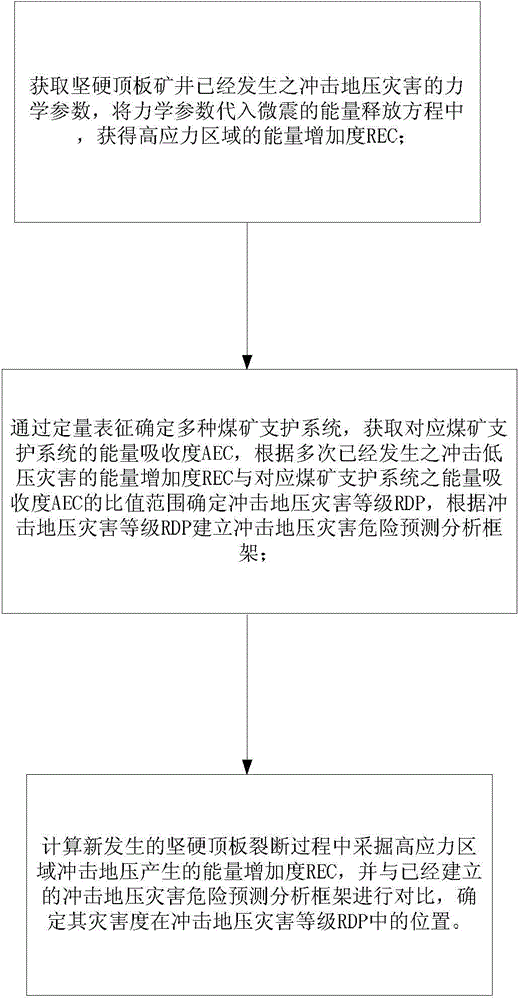

Hard roof mine impact ground pressure hazard risk prediction analysis method

ActiveCN104533443ASituations to Avoid DisastersCalculation method is simpleMining devicesUnderground chambersEnergy absorptionEngineering

The invention discloses a hard roof mine impact ground pressure hazard risk prediction analysis method. The hard roof mine impact ground pressure hazard risk prediction analysis method comprises substituting obtained mechanical parameters into an energy release equation based on an occurred impact ground pressure hazard to obtain the energy increase degree REC; performing the quantitative characterization on the energy absorption degree AEC according to six divided supporting schemes; dividing specific mine impact ground pressure hazard risk prediction analysis frameworks according to the degree of the influence on mining, wherein the formula of the impact ground pressure hazard potential RDP is as follow; calculating the impact ground pressure hazard potential produced in the mining process of the high press area in the process of the newly occurred hard roof breaking and performing comparison on the impact ground pressure hazard potential and the established impact ground pressure hazard risk prediction analysis frameworks to determine the hazard degree of the impact ground pressure. According to the hard roof mine impact ground pressure hazard risk prediction analysis method, the scientific quantification is performed on the impact ground pressure hazard potential induced by the hard roof breaking in a mine, the calculation method is simple, the required mechanical parameters are easy to obtain, and the impact ground pressure hazard risk of the hard roof mine is simply and conveniently determined.

Owner:SHANDONG UNIV OF SCI & TECH

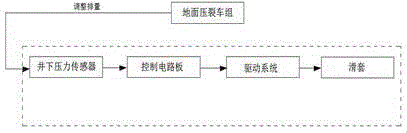

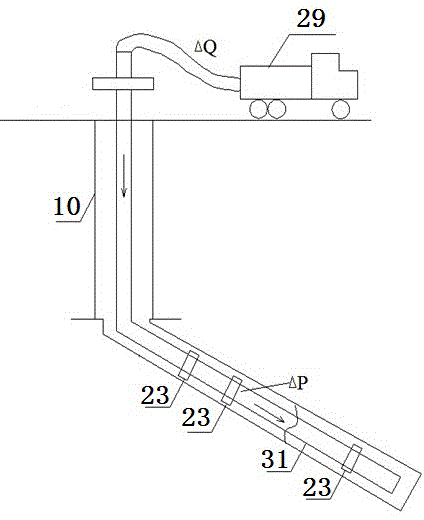

Method for controlling underground sliding sleeves by ground pressure waves

ActiveCN104088603AReal-time control switch actionShorten the timeFluid removalWell/borehole valve arrangementsControl theoryGround pressure

The invention discloses a method for controlling underground sliding sleeves by ground pressure waves. The method comprises the steps as follows: the ground pumping displacement is adjusted regularly to enable underground pressure to change according to the same rule, that is, a pressure fluctuation signal comprising a control command is transmitted to the underground; a receiving device arranged on each sliding sleeve receives the ground control command, and the ground control command is compared with command information assigned by the sliding sleeve; if the ground control command is different from the command information assigned in each sliding sleeve, the sliding sleeve does not act and waits for a next ground control command; and if the ground control command is the same as the command information assigned in each sliding sleeve, the sliding sleeve acts and finishes the opening or closing operation required by the control command. According to the method for controlling the underground sliding sleeves by the ground pressure waves, the underground pressure changes regularly according to regular adjustment of the ground pumping displacement, opening and closing actions of the underground sliding sleeves are remotely controlled by recognizing the signals transmitted through regular pressure change, and opening and closing of the sliding sleeves can be controlled in real time.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

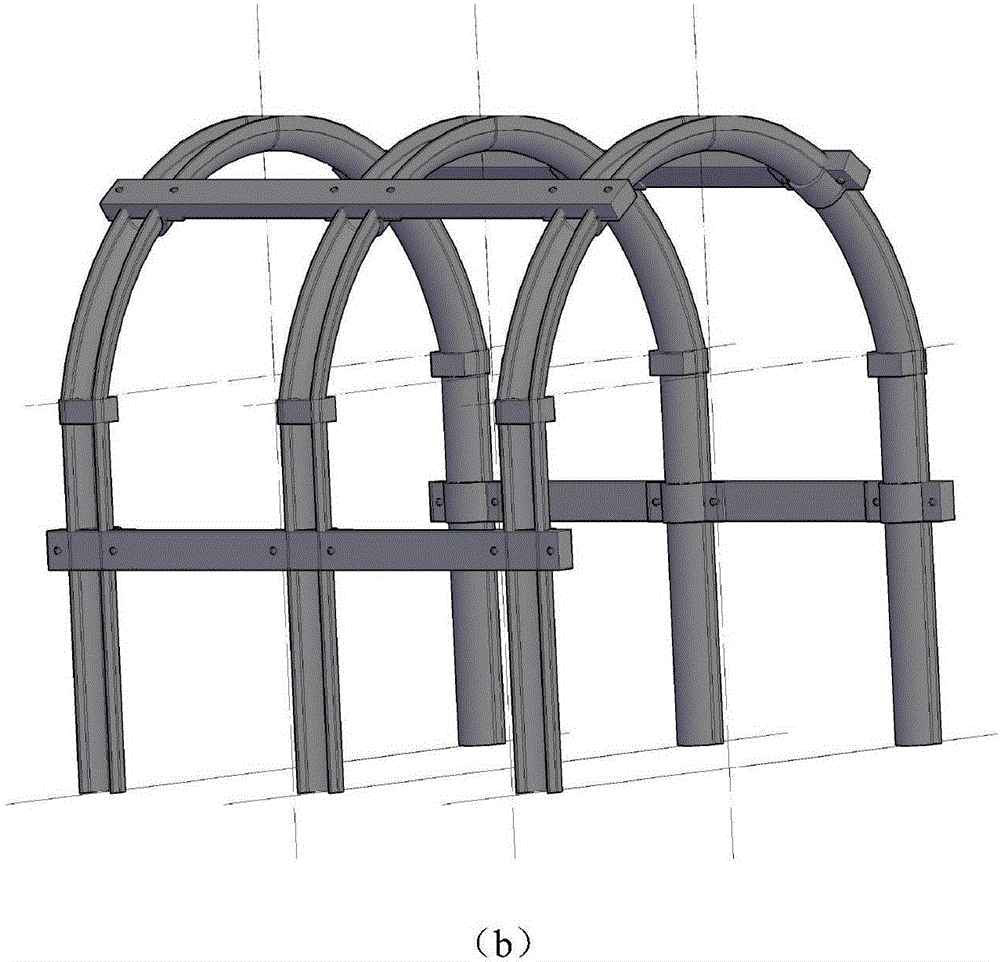

Retractable concrete arch and anchor rod combined support system and construction method

ActiveCN101975073AReduce labor intensityThe supporting structure is simple and reliableUnderground chambersTunnel liningFoam concreteFiber

The invention discloses a retractable concrete arch and anchor rod combined support system and a construction method. A retractable concrete arch is compounded by a double-layer material, one layer is a concrete layer, and the other layer is a high-pressure retractable material layer; an anchor rod passes through the concrete layer and the high-pressure retractable material layer and is connectedwith surrounding rock to form the retractable concrete arch and anchor rod combined support system. The method comprises the following steps of: pumping normal concrete or fast hardening concrete into an inter-layer space of a double-layer fiber flexible template through a delivery pipe and an inner-layer perfusion opening by a concrete pump; and after the concrete is solidified, pumping foam concrete or yellow mud into an outer-layer space of the double-layer fiber flexible template. The retractable concrete arch and anchor rod combined support system has a simple and reliable support structure, is convenient to construct, has high mechanization degree, is suitable for supporting soft rock and large-ground pressure and large-deformation underground engineering, and is widely used for supporting mine roadways, traffic tunnels and underground engineering such as water conservation, national defense and the like, and the labor intensity of workers is low.

Owner:XIAN UNIV OF SCI & TECH +1

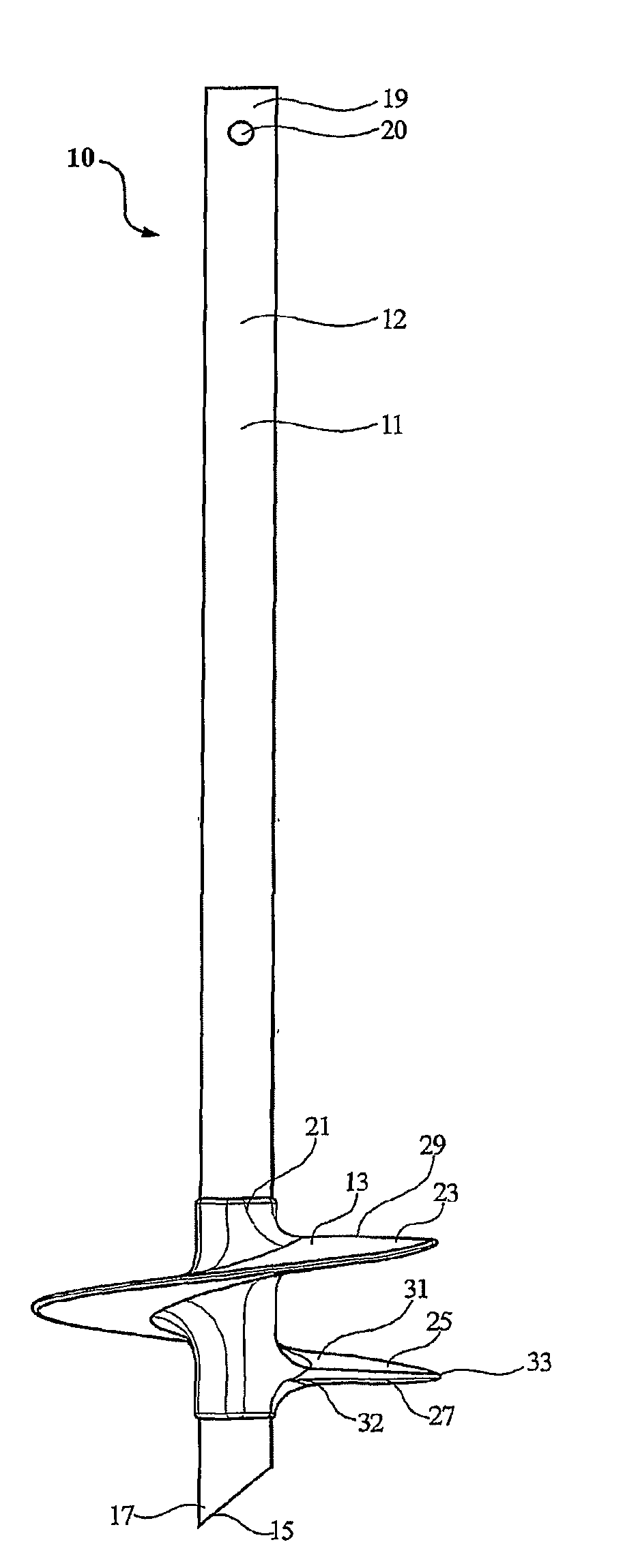

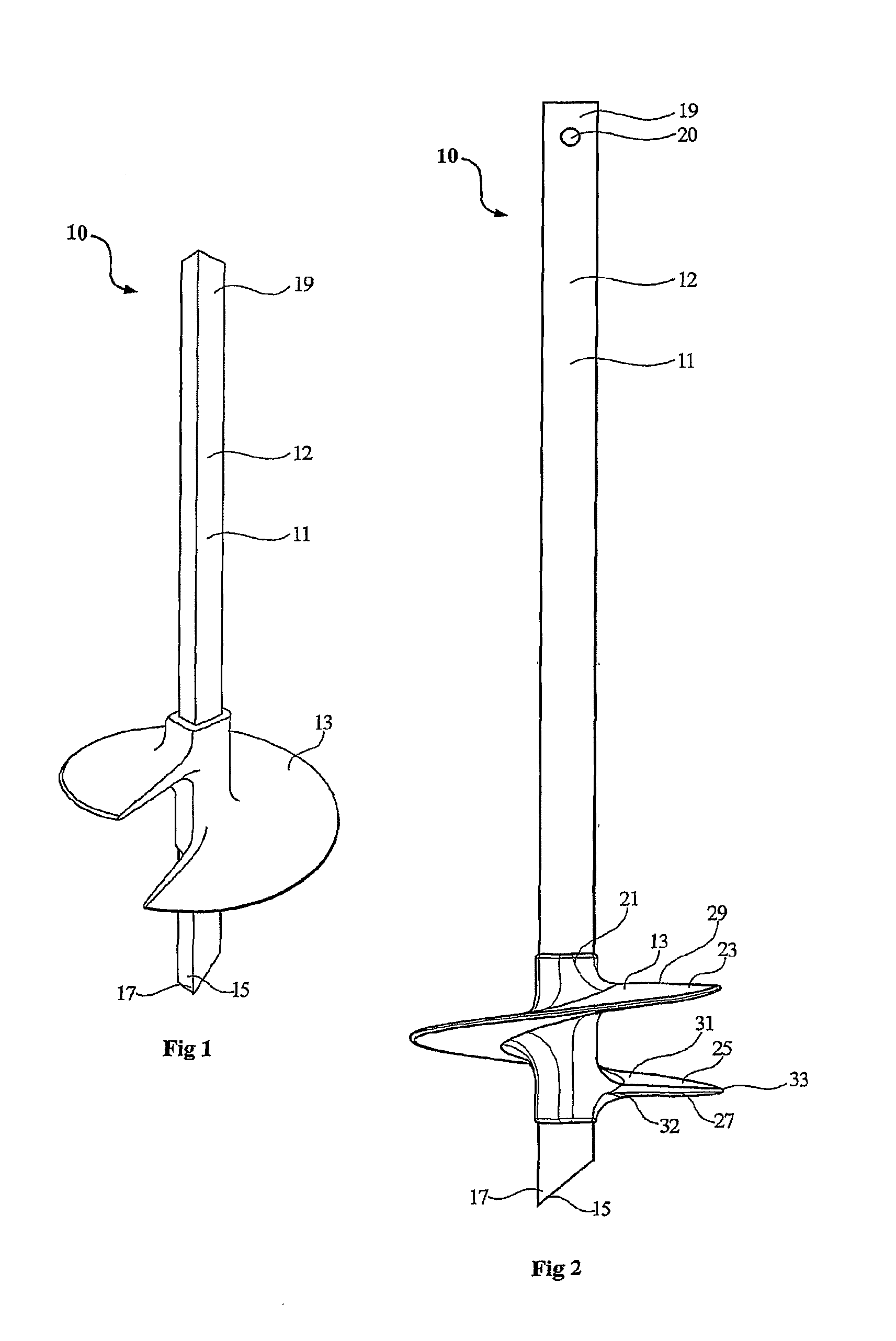

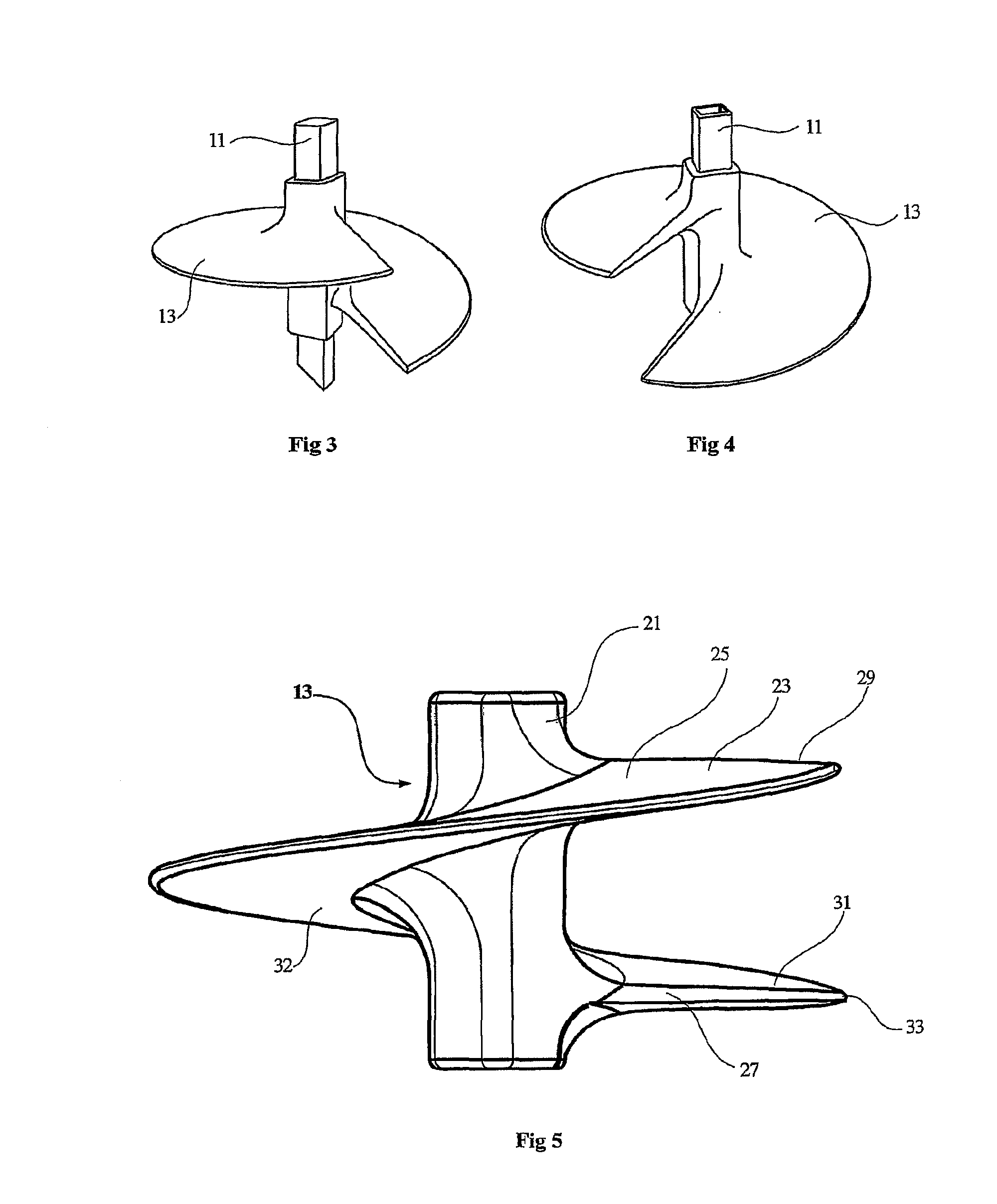

Ground Anchor

InactiveUS20080302028A1Improved holding abilityIncrease the effective diameterTowersBuilding constructionsNormal loadPropeller

A ground anchor (10) comprising an anchor shaft (11) and an anchoring screw (13) moulded onto the anchoring shaft adjacent the lower end thereof. The anchoring shaft (11) is of a rectangular cross-section with four side walls (12). The anchoring shaft (11) is configured at its bottom end (15) for ground penetration. The upper end (19) of the anchor shaft (11) is configured to receive torque applied thereto. The anchoring screw (13) comprises a hub (21) and a screw flight (23) on the hub. The anchoring screw (13) is moulded onto the anchor shaft (11), and the hub (21) is keyed to the anchor shaft. The anchoring screw (13) is so constructed that the spiral flight (23) is rigid yet has some resilient flexibility which allows the flight to deflect laterally in the direction of the screw axis. Specifically, the screw flight (23) has sufficient rigidity to allow it to penetrate the ground in which it is intended to be used when torque is applied to the anchor shaft (11). Further, the screw flight (23) has sufficient rigidity in order to retain the ground anchor (10) embedded in the ground when subjected to the normal load conditions for which it is intended, as is the case with conventional ground anchors. The resilient flexibility provides the screw flight (23) with a degree of ‘springiness’, so allowing the screw flight (23) to deflect laterally in the direction of the screw axis when subjected to the loadings to which it is exposed when winding into the ground. With this arrangement, the pitch of the helical screw (25) is permitted to alter during ground embedment as ground pressure increases.

Owner:LEWENHOFF STEPHEN MARK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com