Coal mine gob filling mining system and gob-side entry retaining filling process

A technology for filling mining and gobs, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of occupying good land, damage to building facilities, and increase in strength, so as to eliminate the occupation of good land, reduce surface subsidence, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

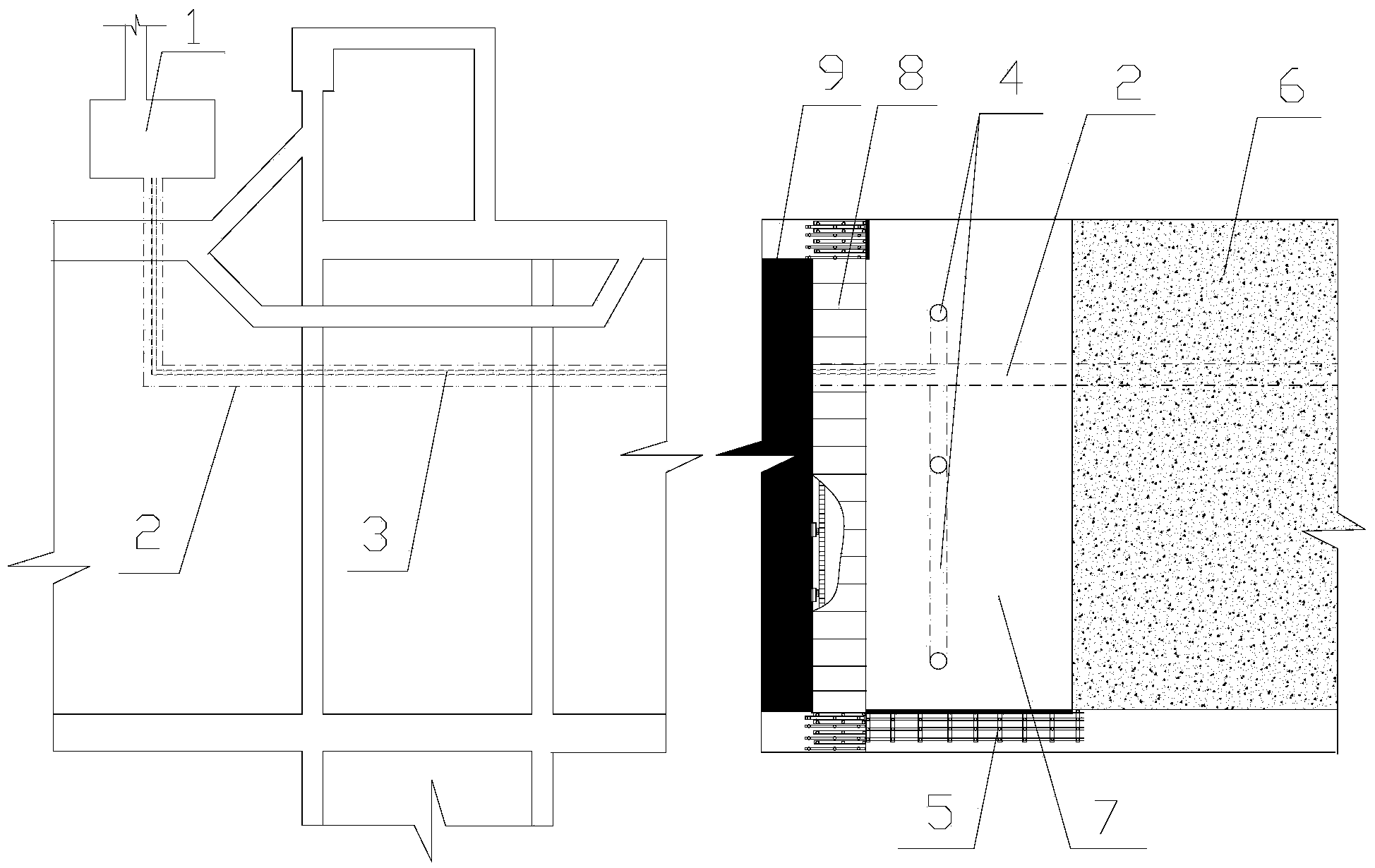

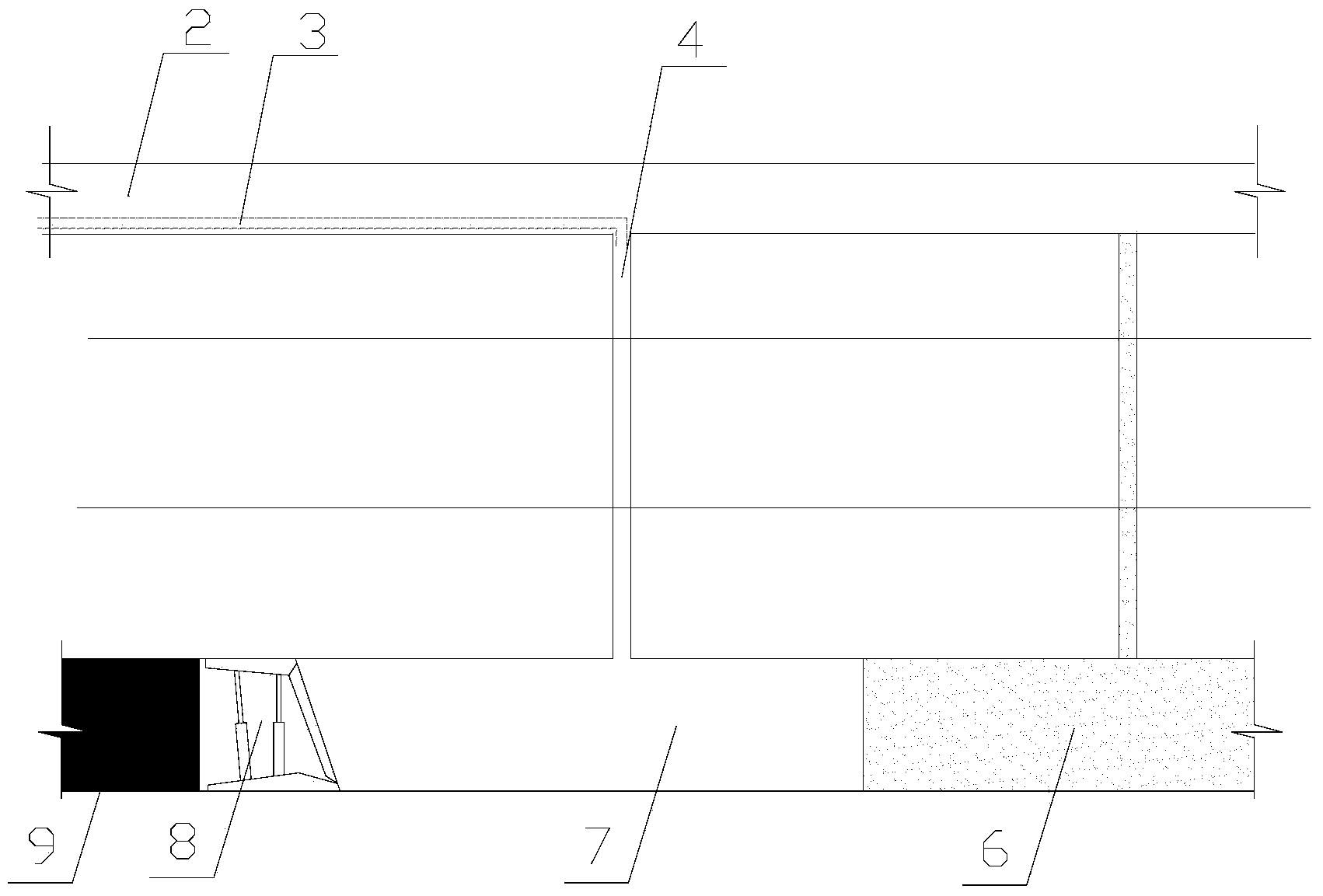

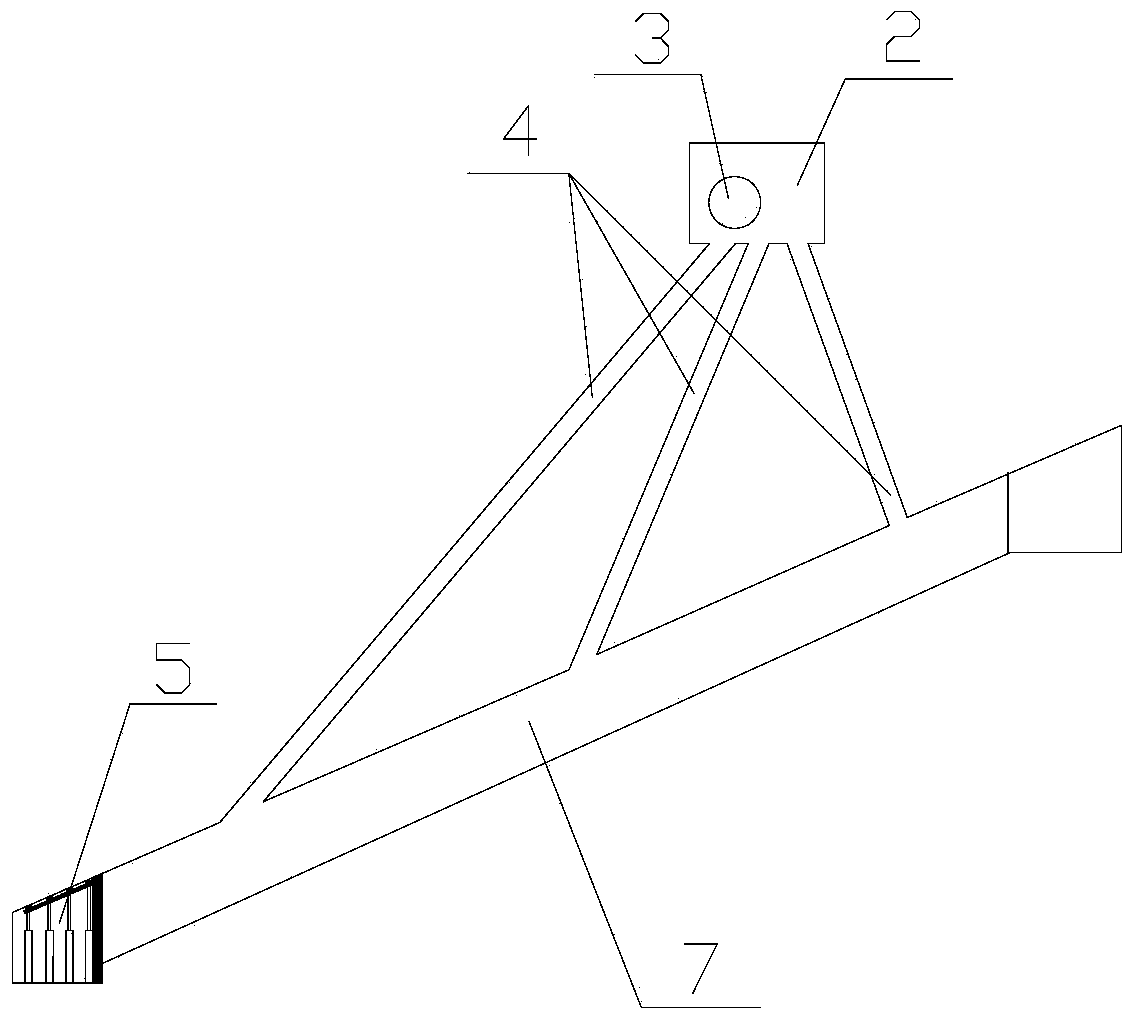

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] The coal mine filling and mining system is carried out according to the following steps: (1) During the mining process of the coal mining face 8, the filling materials are prepared at the same time, and the gangue on the gangue pile that already exists on the ground is crushed on the ground and then transported to the underground mining area for filling materials to be crushed and the chamber 1 of the mixing station. The waste rocks excavated from the rock roadway under the mine are directly transported to the mining area for filling material crushing and the chamber 1 of the mixing station; Mining area filling material crushing and mixing station chamber 1, underground filling roadway 2, wherein the filling roadway is located at the upper part of the inclined coal mining face; (3) after the coal mining face 8 advances beyond the width of the cut hole, it starts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com