Method for testing strata of horizontal well

A technology for formation testing and horizontal wells, which is used in earth-moving drilling, wellbore/well components, and valve devices for wells/wells, etc. It can solve the problems of excessively long assembly length and unsuitable horizontal well formation testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Taking a horizontal well formation testing process string as an example, the present invention will be further described in detail.

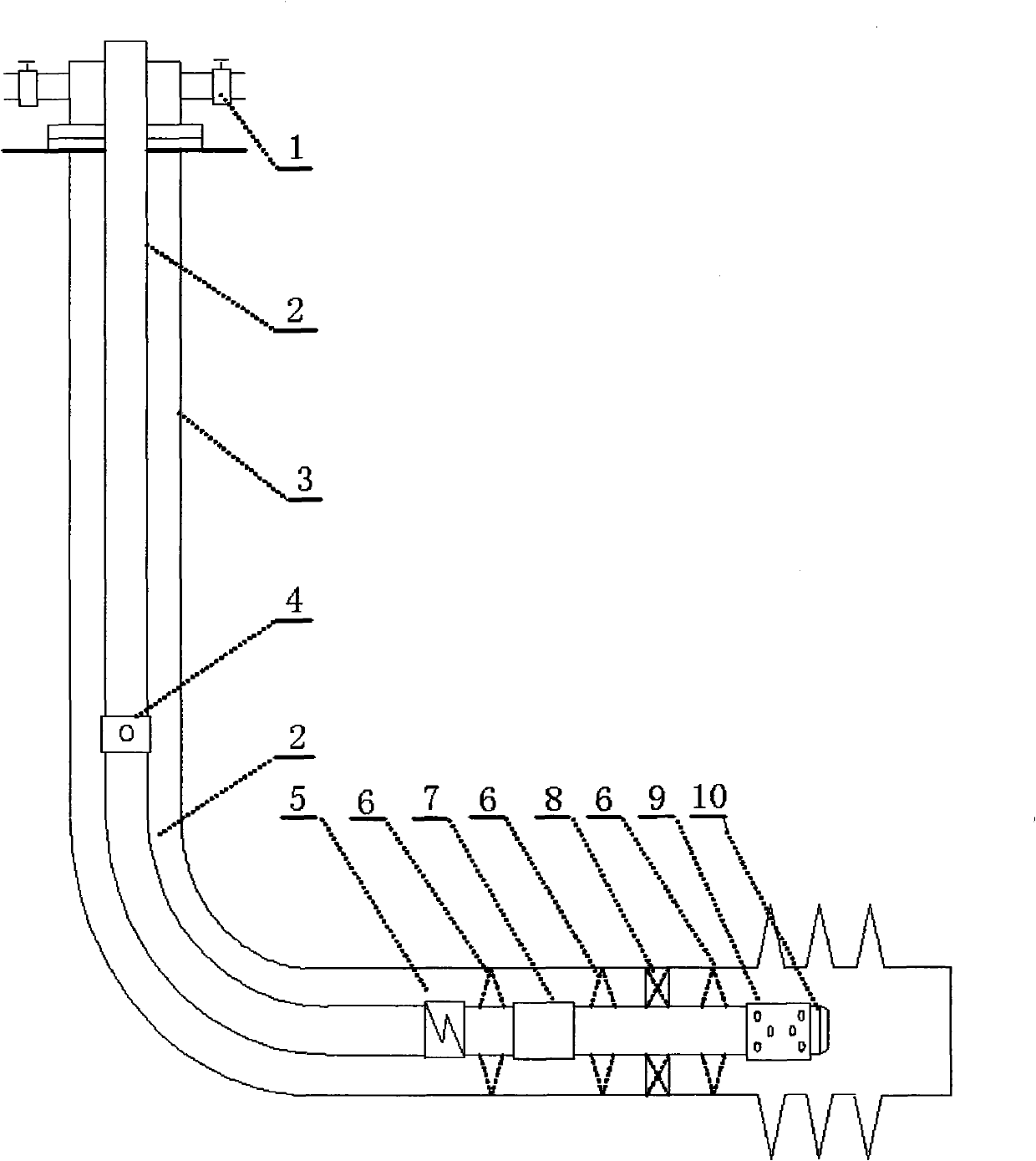

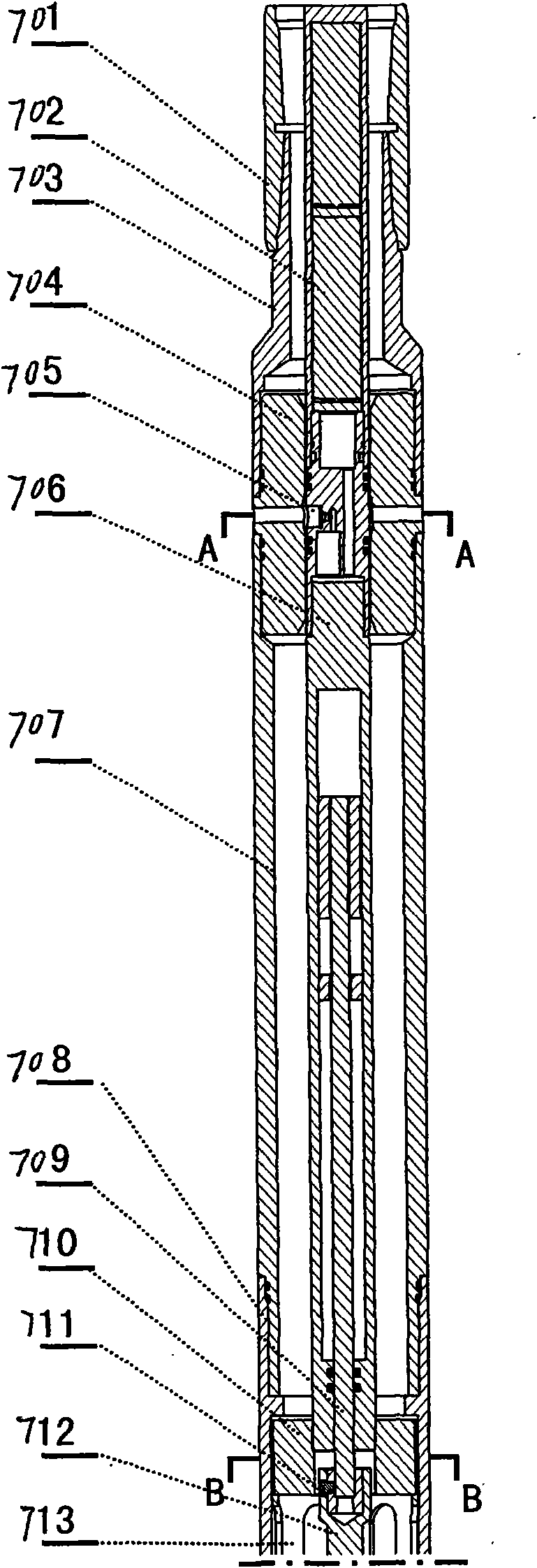

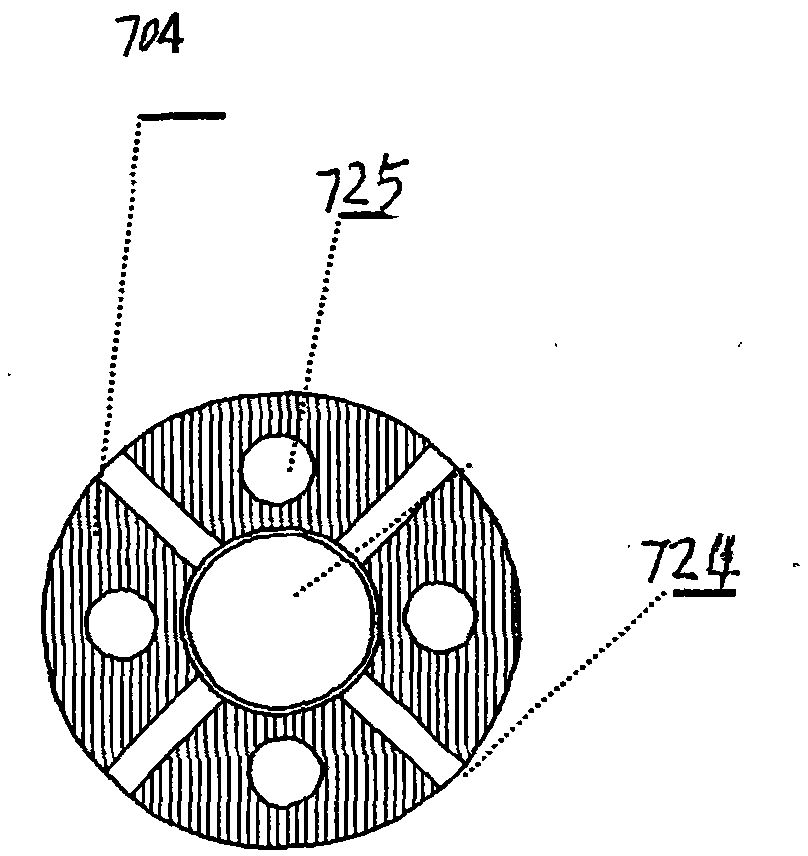

[0048] refer to figure 1 The horizontal well formation testing process string of the present invention is mainly composed of oil pipe 2, reverse circulation valve 4, oil pipe hydraulic control 5, oil pipe centralizer 6, pressure-controlled electric multi-flow test valve 7, annular hydrostatic packer 8, The screen pipe 9 and the guide cone 10 are composed.

[0049] The oil pipe 2 is 2 with an inner diameter of 62 mm 7 / 8 inE-U. The lower part of the tubing 2 is connected to the reverse circulation valve 4, which is cylindrical and located at the end of the vertical well section. Its function is to open the reverse circulation valve with the help of external force after the test, and perform positive and reverse circulation well washing and well killing. The lower end of the reverse circulation valve 4 continues to be co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com