Patents

Literature

516 results about "SUSPENDING VEHICLE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suspending vehicles and pharmaceutical suspensions for drug dosage forms

InactiveUS20060216242A1Process stabilityPeptide/protein ingredientsAerosol deliverySUSPENDING VEHICLESolvent

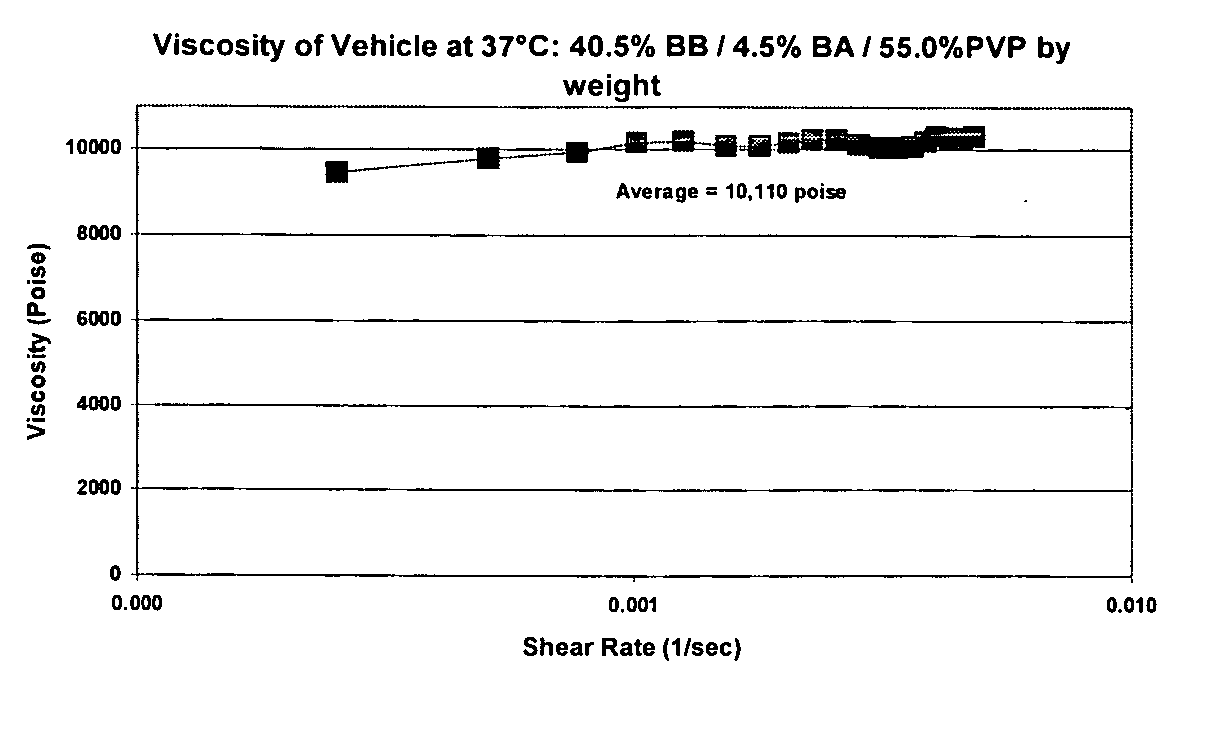

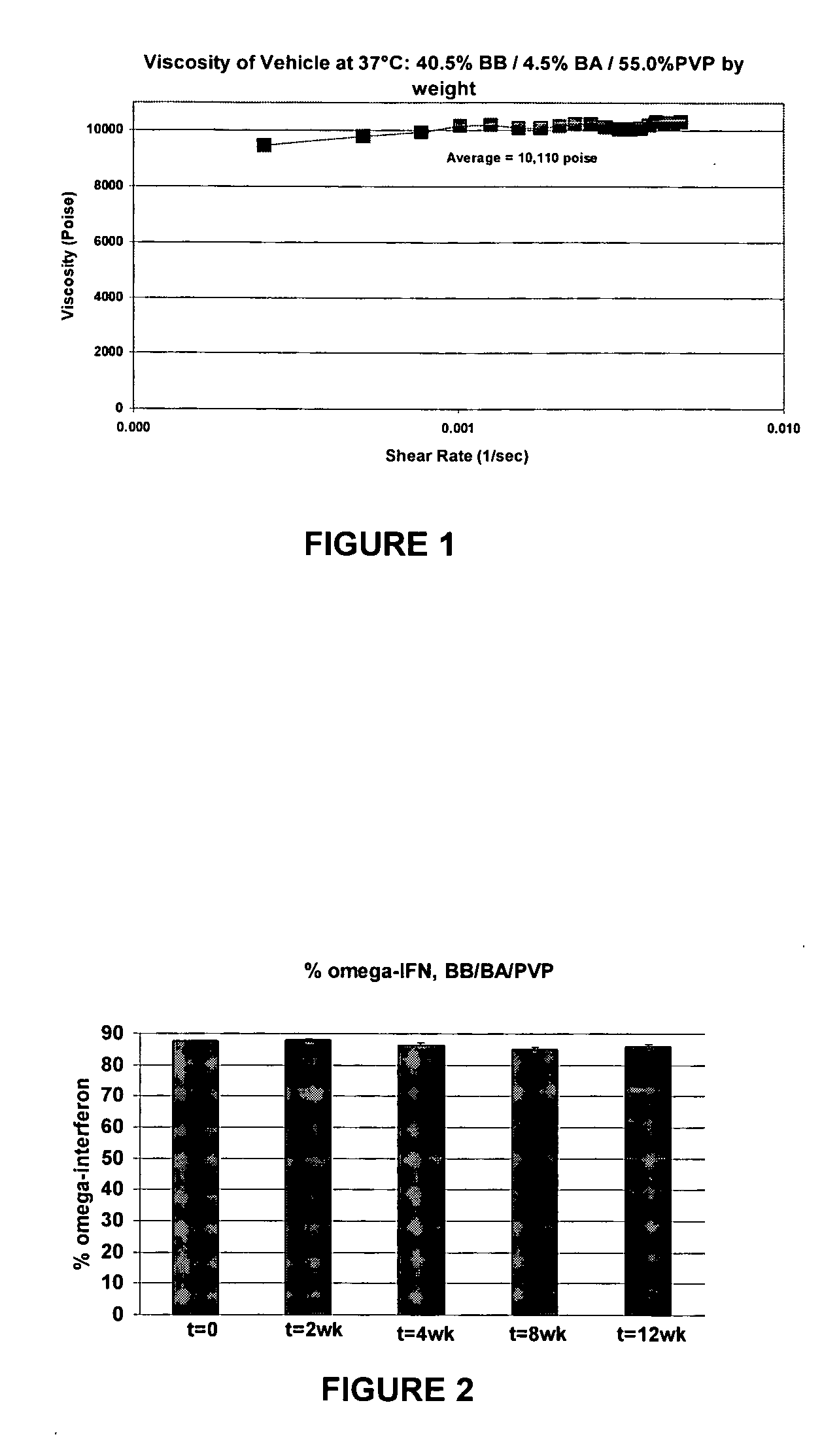

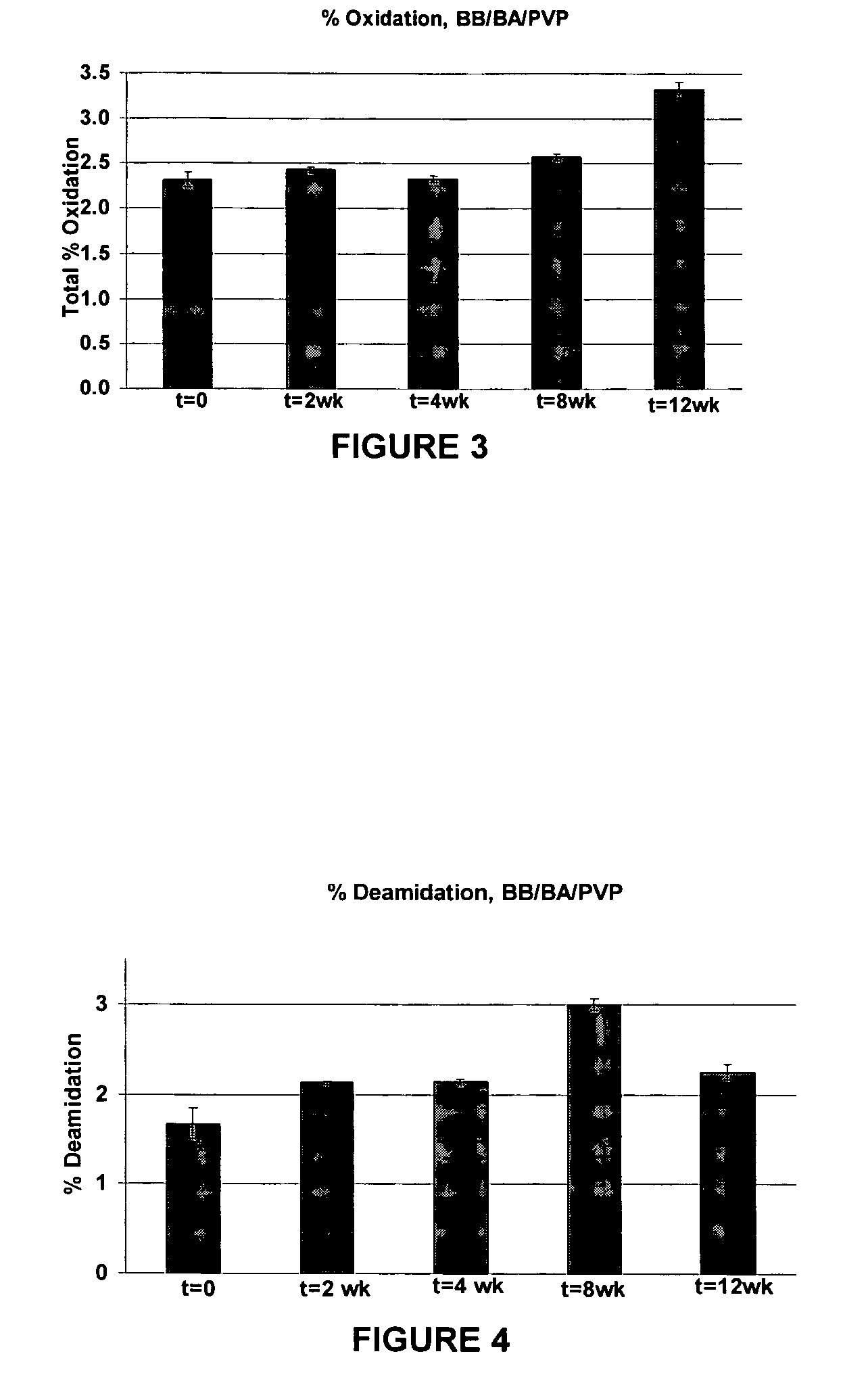

Suspending vehicles and pharmaceutical suspensions that include a biocompatible polymer that can be combined with a hydrophobic solvent and a hydrophilic solvent to provide vehicles and suspensions that are substantially free of stiff gels upon contact with an aqueous medium are provided. Vehicles and suspensions remain flowable out of a pump-driven dosage form over the life of the dosage form. Such vehicles and suspensions are also biocompatible, suitable for creating and maintaining drug suspensions, and capable of providing stable drug formulations.

Owner:DURECT CORP

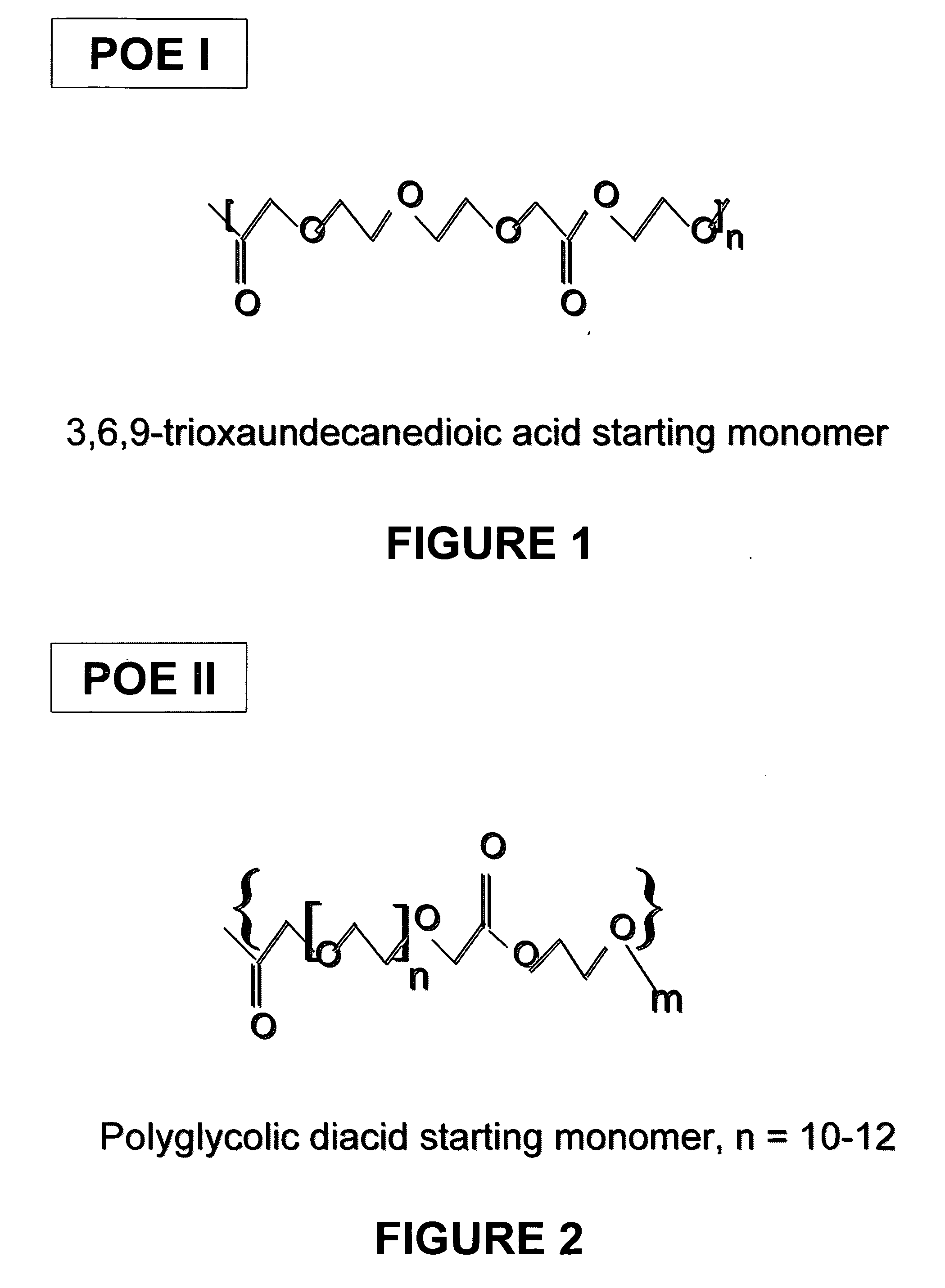

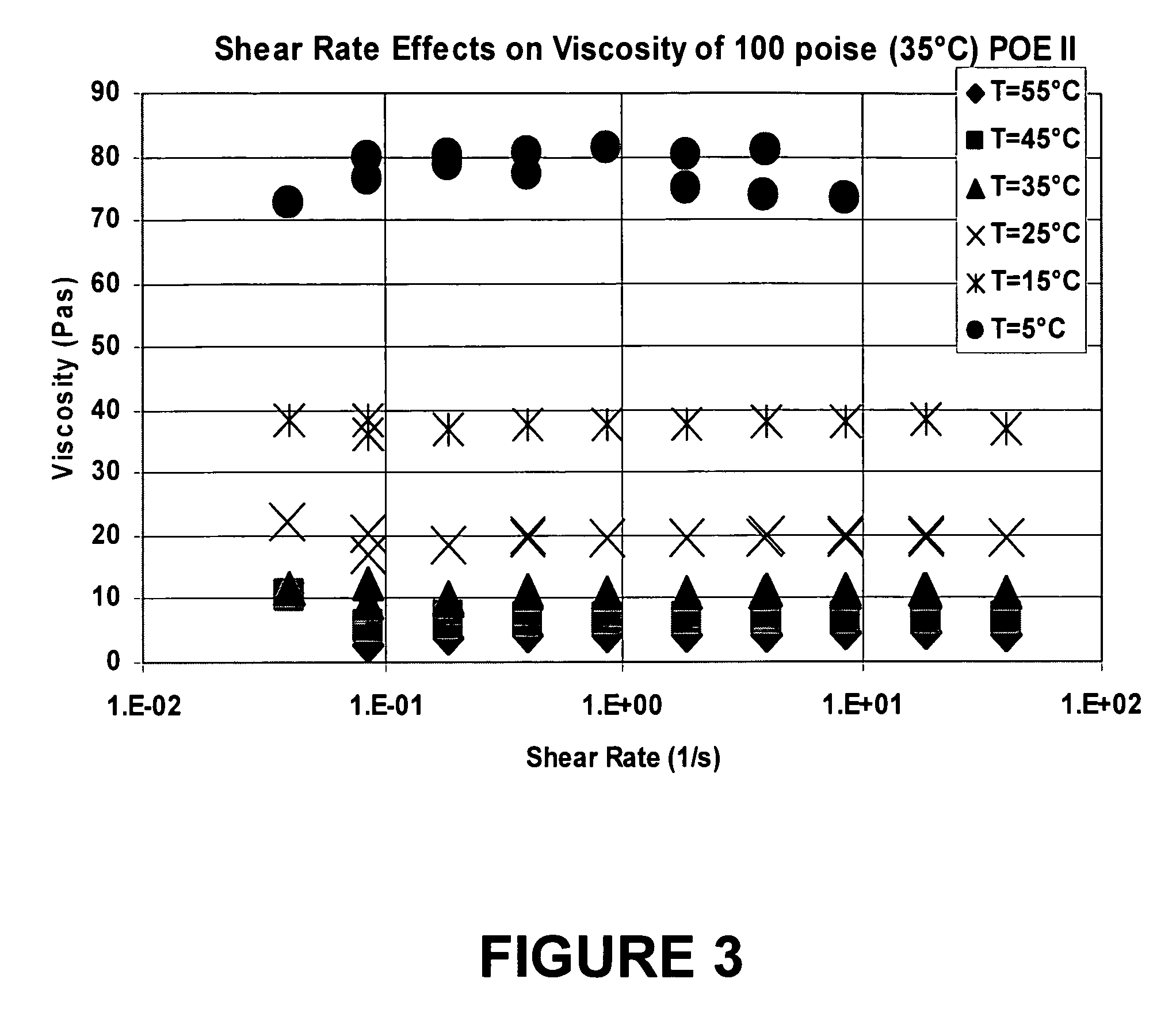

Polyoxaester suspending vehicles for use with implantable delivery systems

ActiveUS20060246138A1LimitMaintain stabilityPowder deliveryOrganic active ingredientsSUSPENDING VEHICLEActive agent

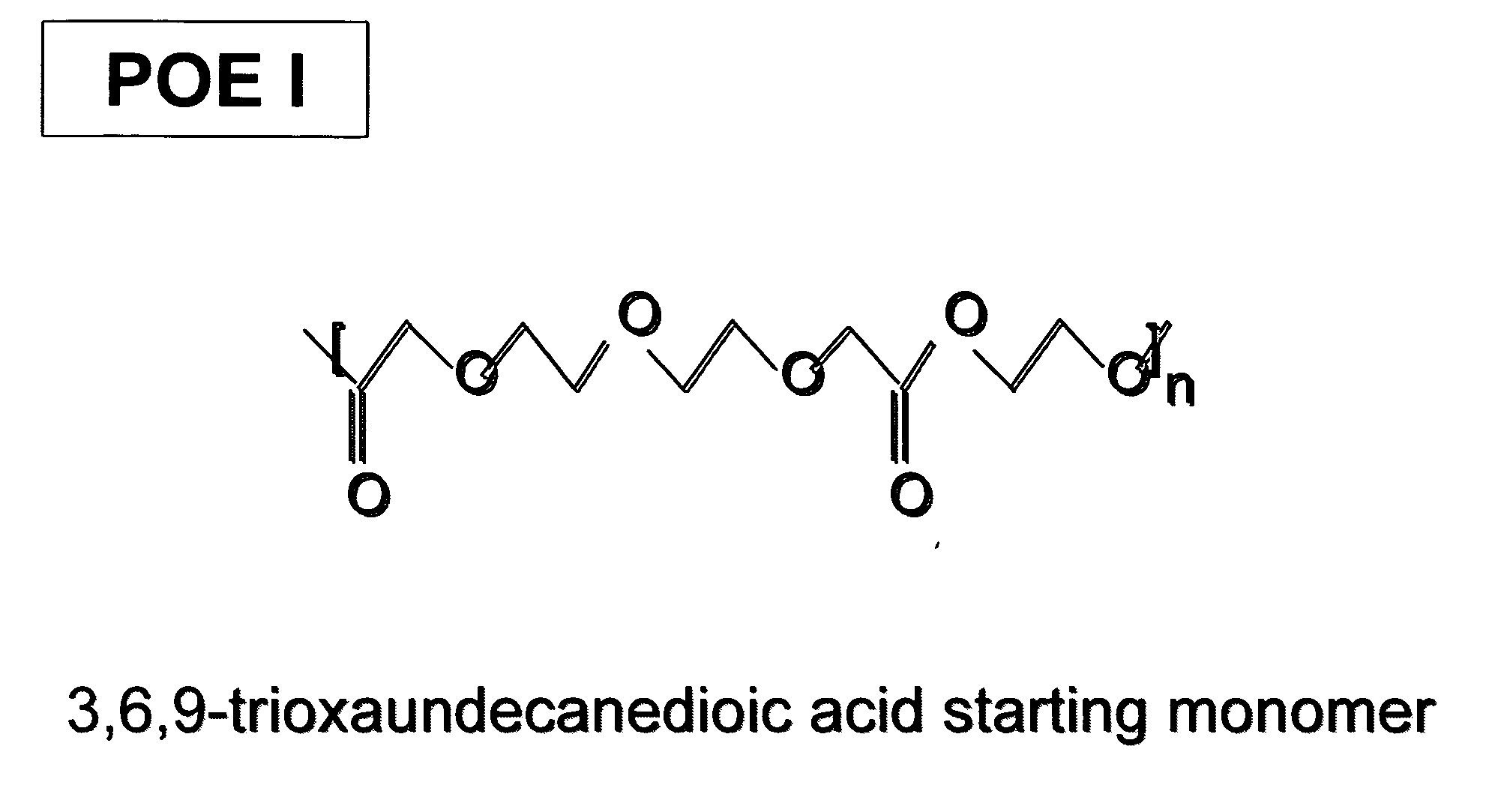

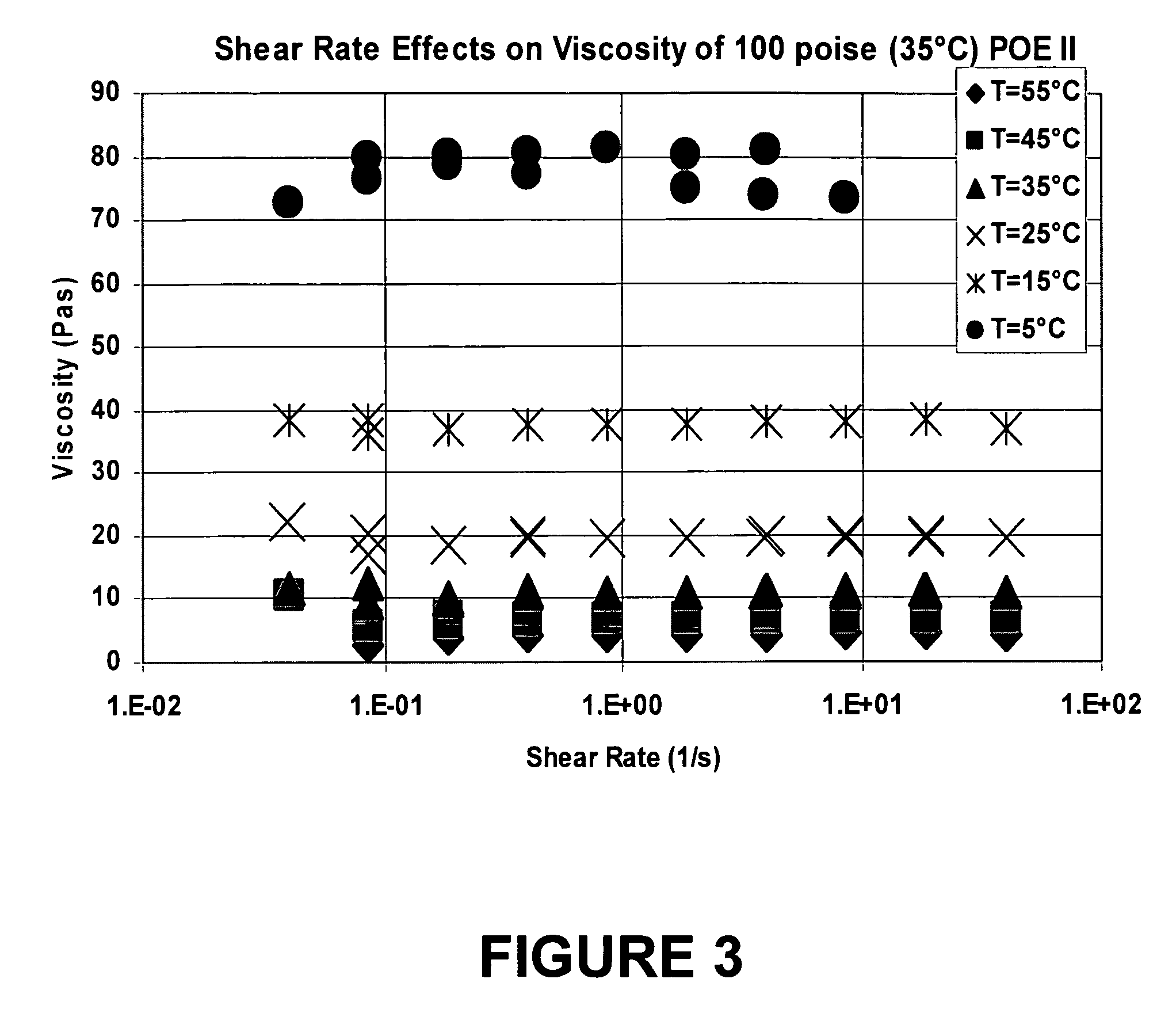

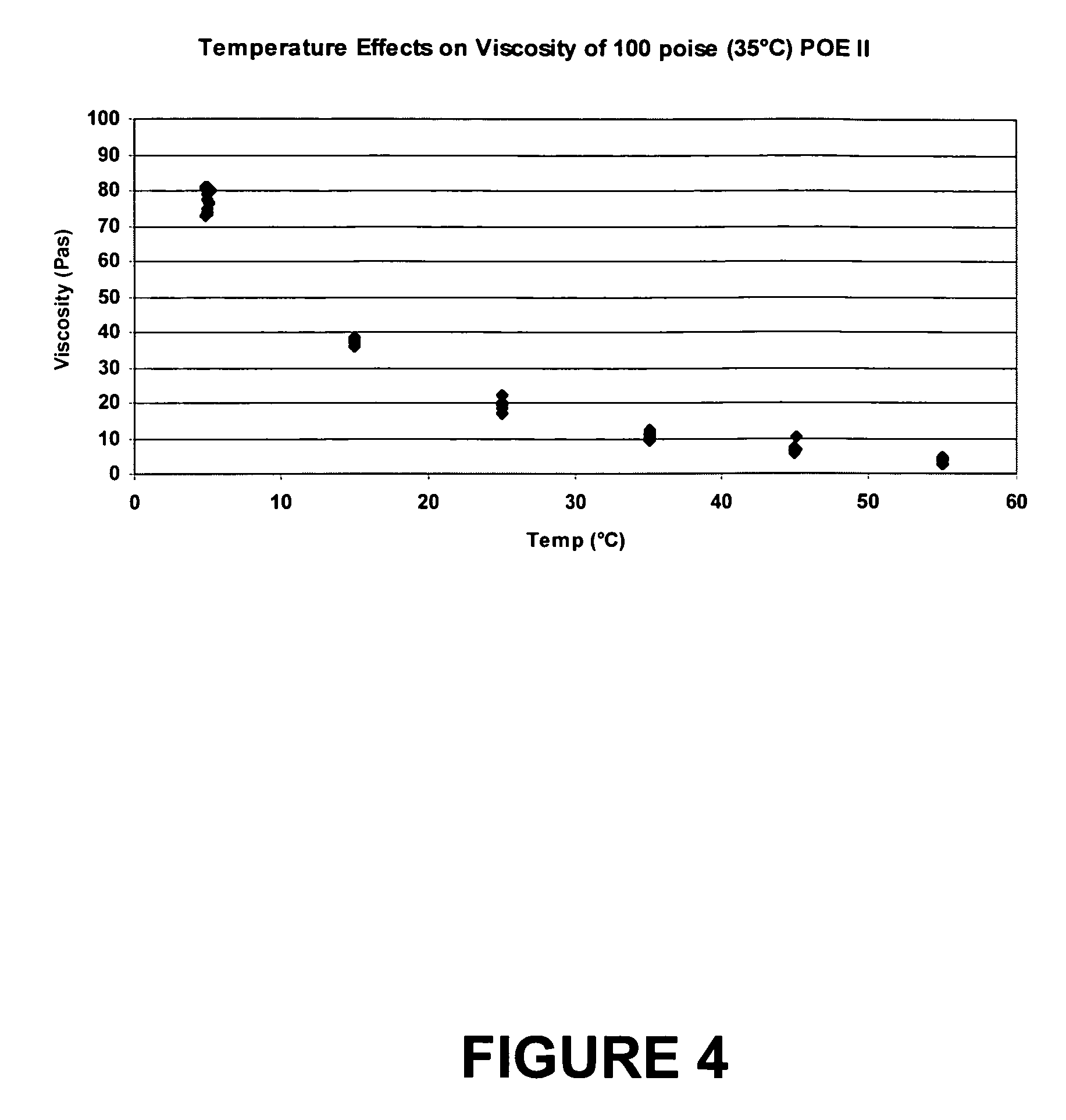

Liquid polyoxaester polymer materials are provided as suspending vehicles suitable for dispensing of pharmaceutically active agents, such as proteins, from delivery devices, for example, pump-driven dosage forms. Polyoxaesters are made from at least one diacid and at least one diol. Through the use of polyoxaesters virtually solvent-free pharmaceutical suspensions can be created.

Owner:INTARCIA THERAPEUTICS INC

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

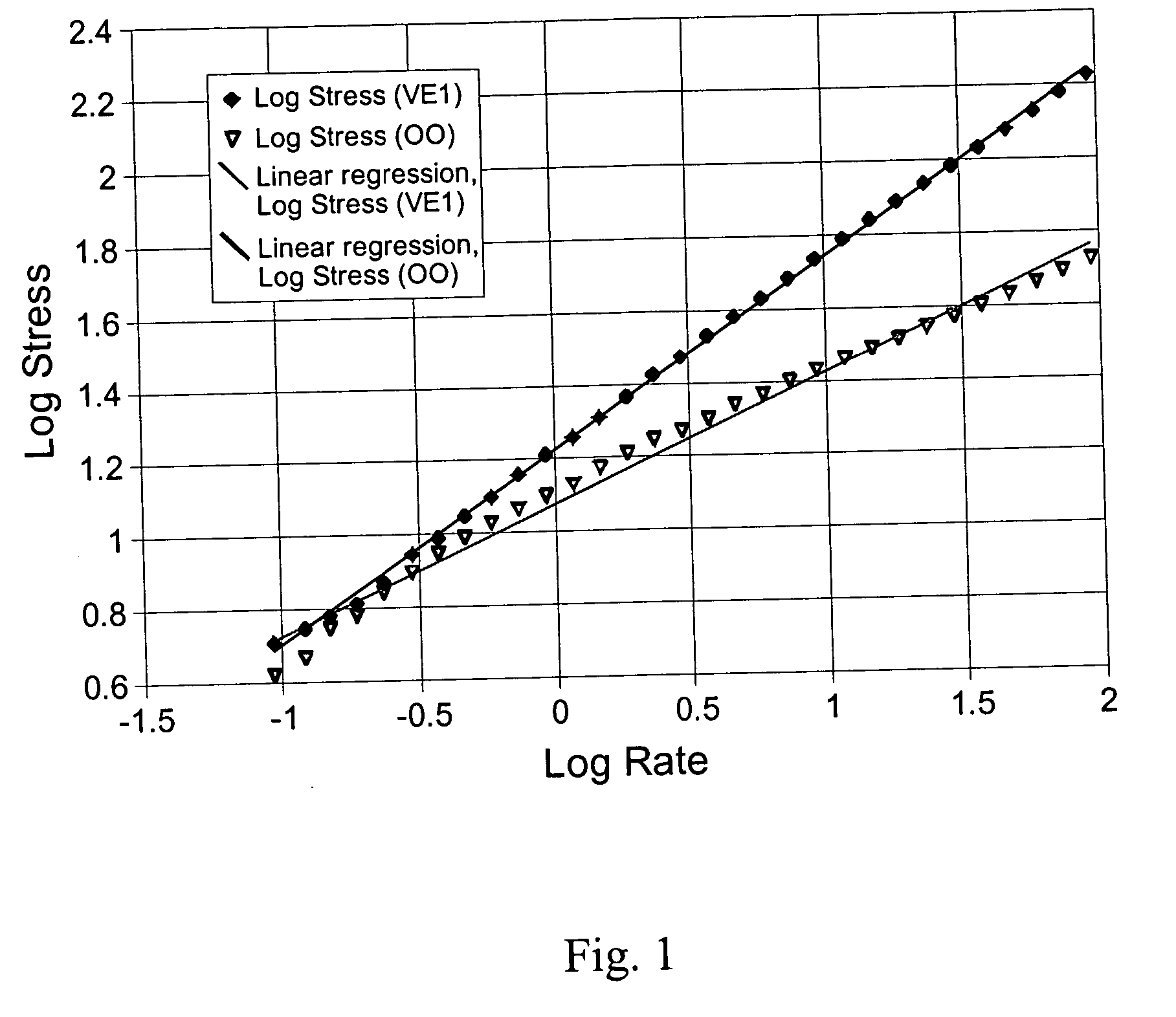

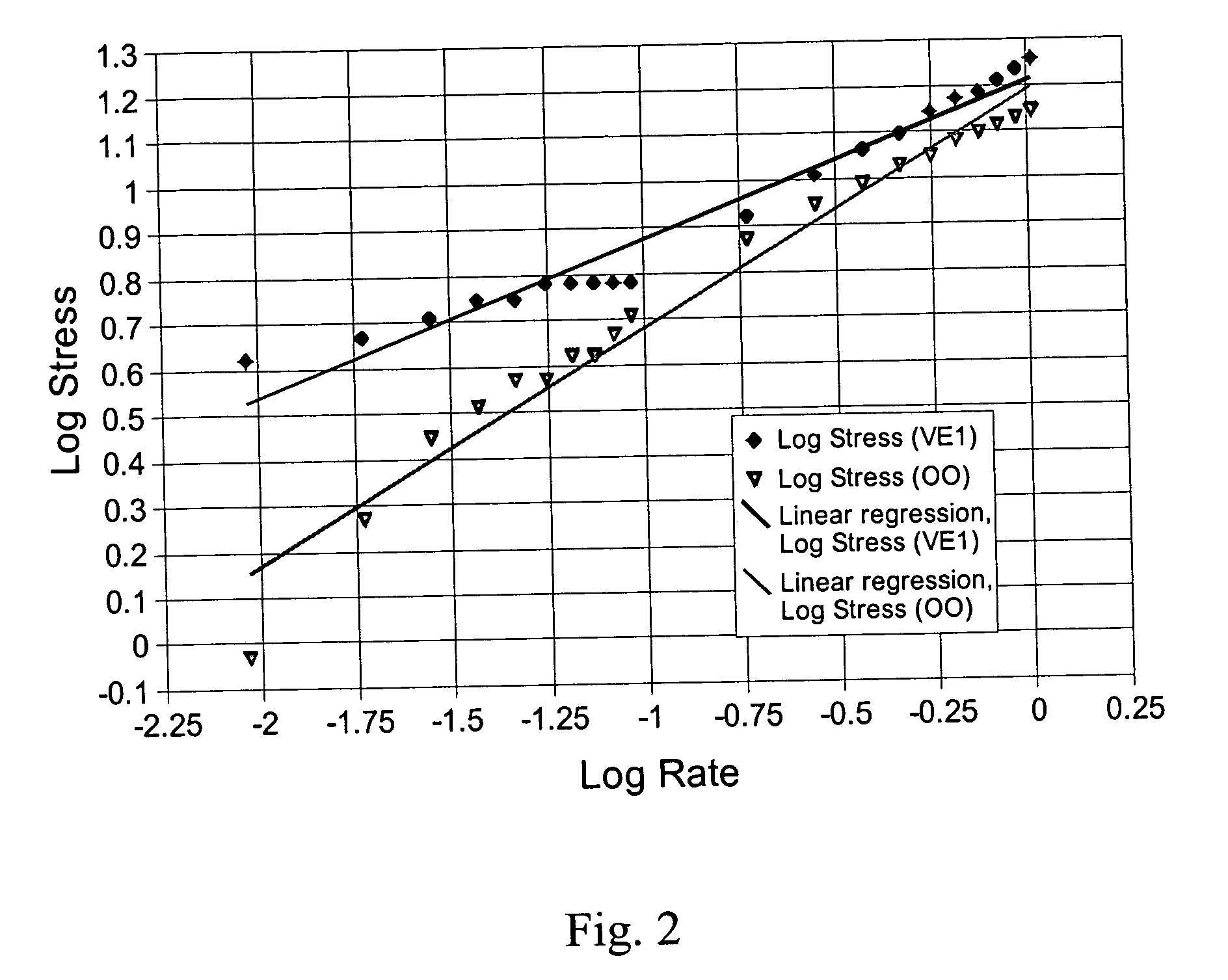

Palatable suspending vehicle for pharmaceutical ingredients

ActiveUS20060034873A1Improved Theological characteristic and stabilityEasy and quick resuspensionDispersion deliverySolution deliveryAdditive ingredientSuspending Agents

The invention relates to a liquid vehicle that can be used to create suspensions and / or solutions of liquid or powdered medications. The vehicle is thixotropic and has improved stability and rheologic characteristics. Vehicles of the invention include an aqueous medium and a suspending agent comprising a polysaccharide having at least 50% glucose repeating saccharide units and at least 90% beta linkages. The polysaccharide can be a starch, modified starch, or glycogen. The aqueous medium and individual components of the vehicle provide a palatable and easily ingested drug preparation. The invention also provides a vehicle containing an aqueous medium, suspending agent comprising a polysaccharide having at least 50% glucose repeating saccharide units and at least 90% beta linkages, buffer, and artificial sweetener, the combined suspending vehicle having a pH of about 3 to about 10 and an osmolality of 300 mOmsol or less.

Owner:GALLIPOT

Polyoxaester suspending vehicles for use with implantable delivery systems

ActiveUS7959938B2LimitMaintain stabilityOrganic active ingredientsPowder deliverySUSPENDING VEHICLEActive agent

Liquid polyoxaester polymer materials are provided as suspending vehicles suitable for dispensing of pharmaceutically active agents, such as proteins, from delivery devices, for example, pump-driven dosage forms. Polyoxaesters are made from at least one diacid and at least one diol. Through the use of polyoxaesters virtually solvent-free pharmaceutical suspensions can be created.

Owner:INTARCIA THERAPEUTICS INC

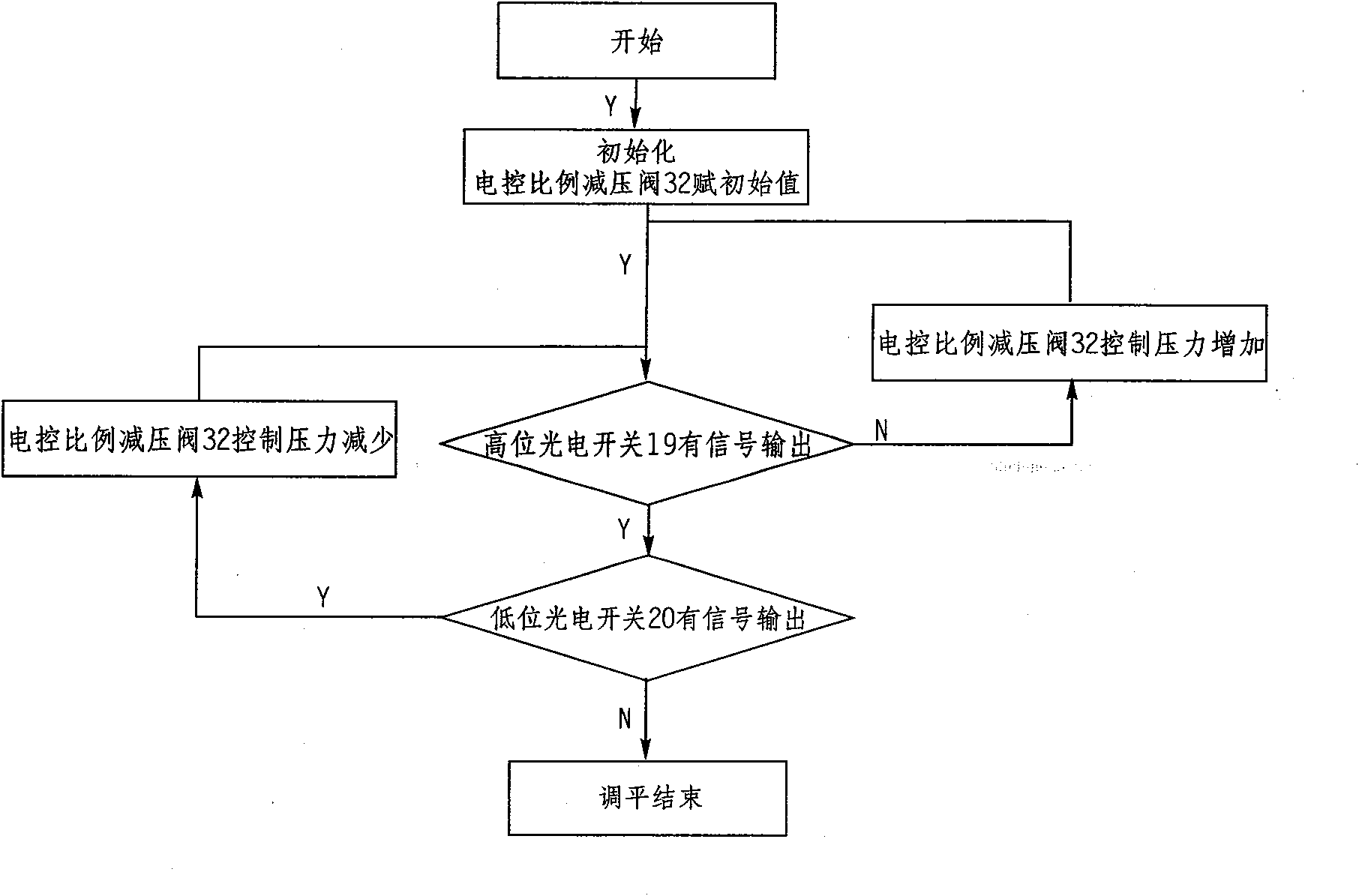

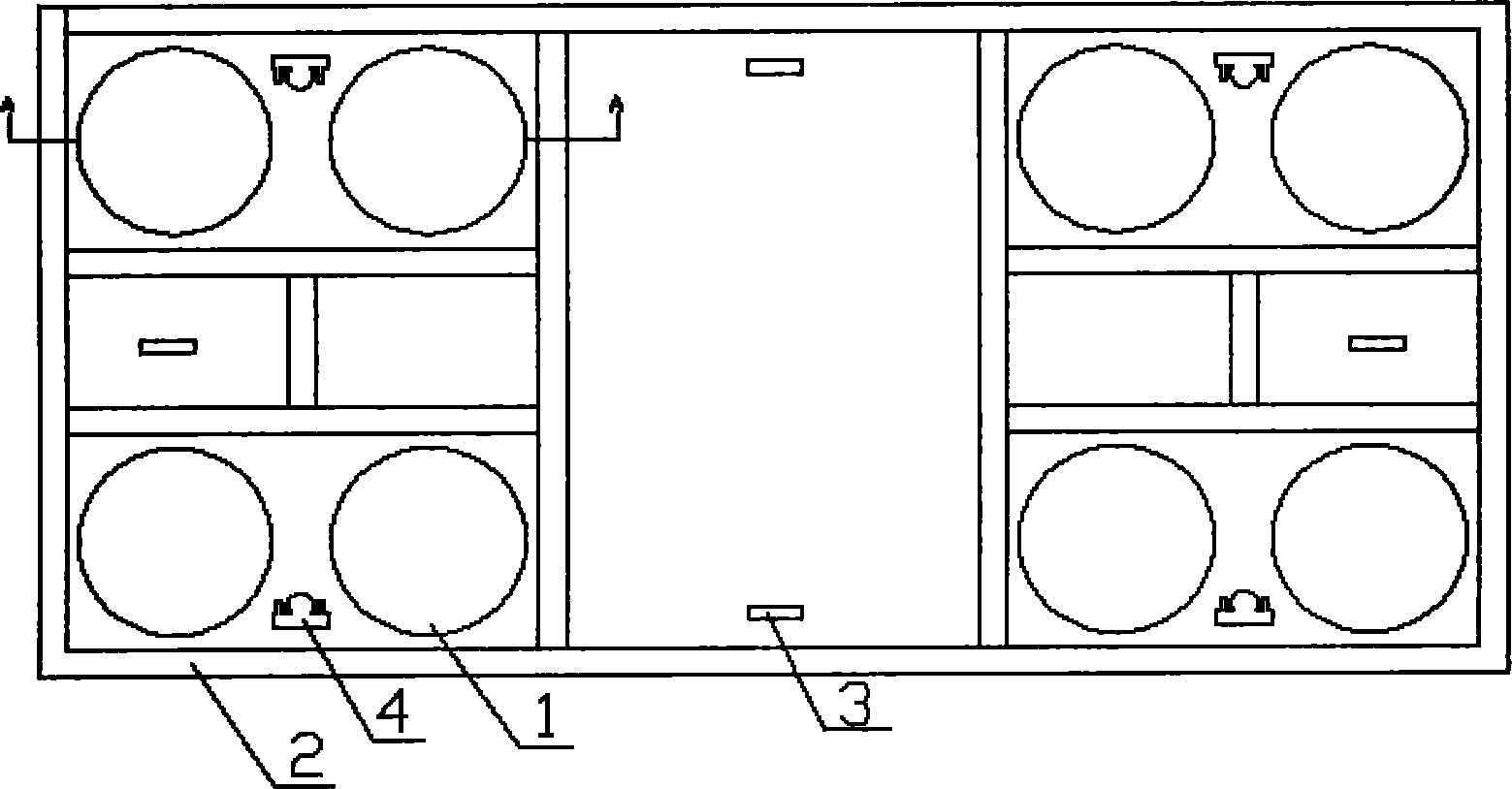

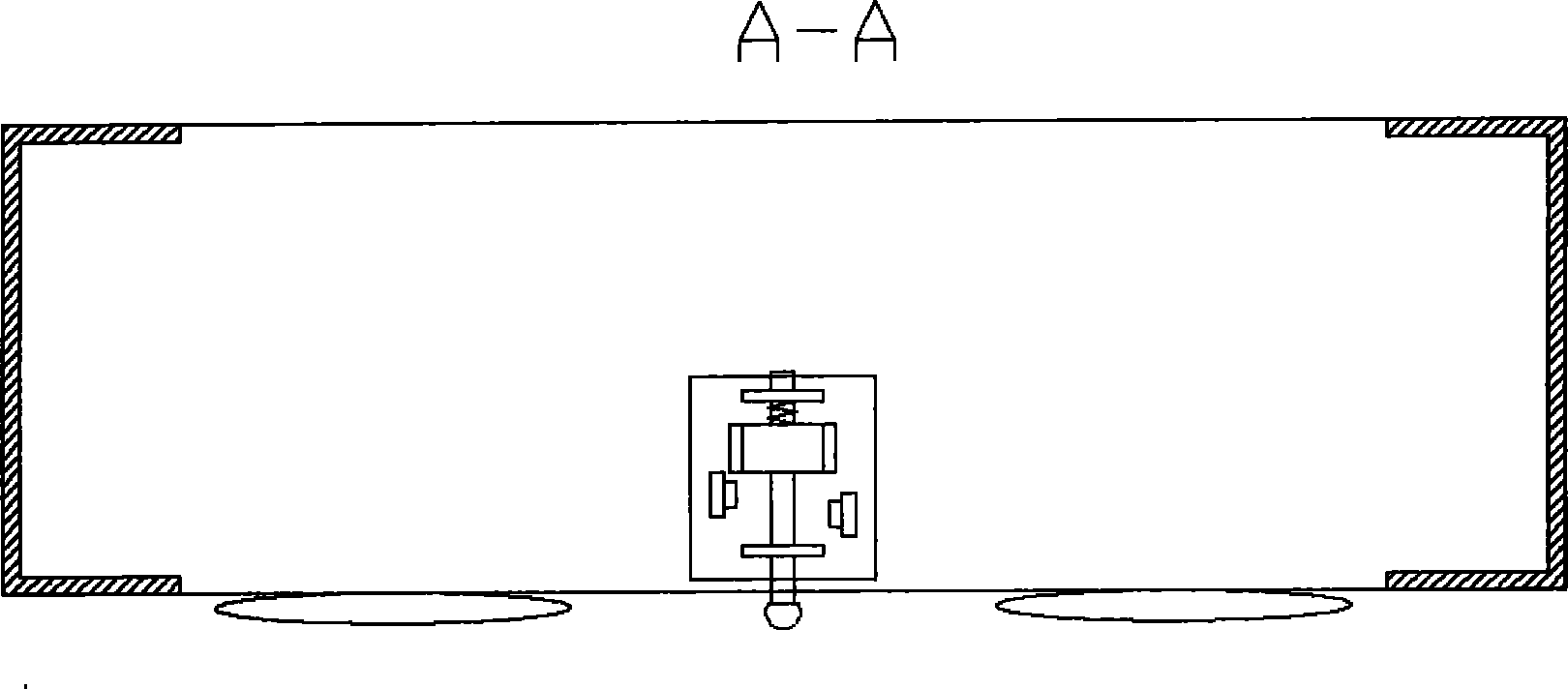

Automatic leveling control device for air cushion suspended transport vehicle

ActiveCN101962014ACapable of load adaptationAvoid bumpsAir-cushionSUSPENDING VEHICLEAttitude control

The invention relates to an automatic leveling control device for an air cushion suspended transport vehicle, which controls the posture of the air cushion suspended transport vehicle. The device comprises an electric-controlled proportional pressure reducing valve (32), a remote-controlled pressure-reducing valve (31) and a height detection device (4). The height detection device (4) comprises a guide rod (11), a high-position baffle plate (17), a low-position baffle plate (18), a high-position optoelectronic switch (19) and a low-position optoelectronic switch (20) and is fixed on the air cushion vehicle, wherein the guide rod (11) is contacted with the ground; the high-position baffle plate (17) and the low-position baffle plate (18) are positioned at the same horizontal position on the left and right sides of the guide rod (11); and the high-position optoelectronic switch (19) and the low-position optoelectronic switch (20) are fixed on a pedestal (21). When the guide rod (11) glides up and down, the high-position and low-position baffle plates can baffle the high-position and low-position optoelectronic switches (19, 20). The automatic leveling control device is applicable to the air cushion suspended vehicle.

Owner:BEIJING INST OF SPECIALIZED MACHINERY

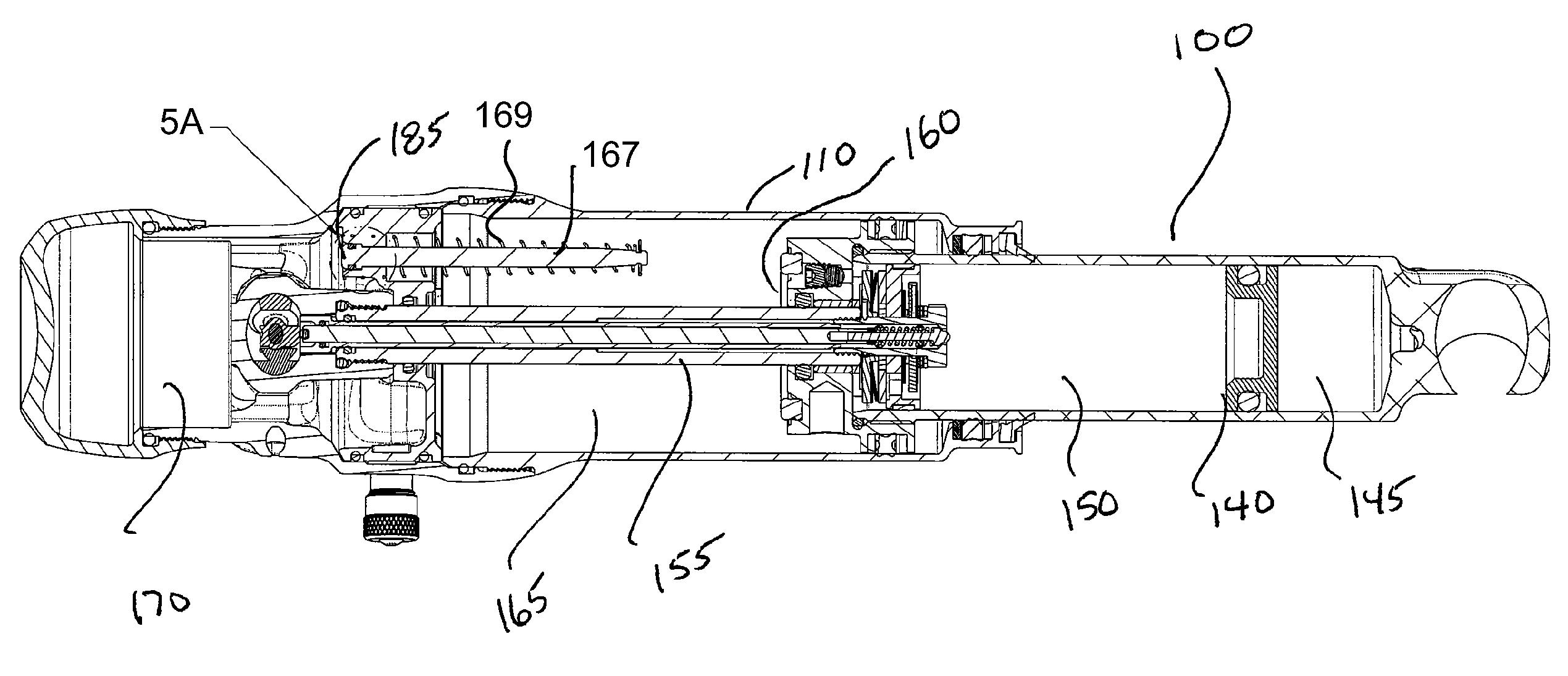

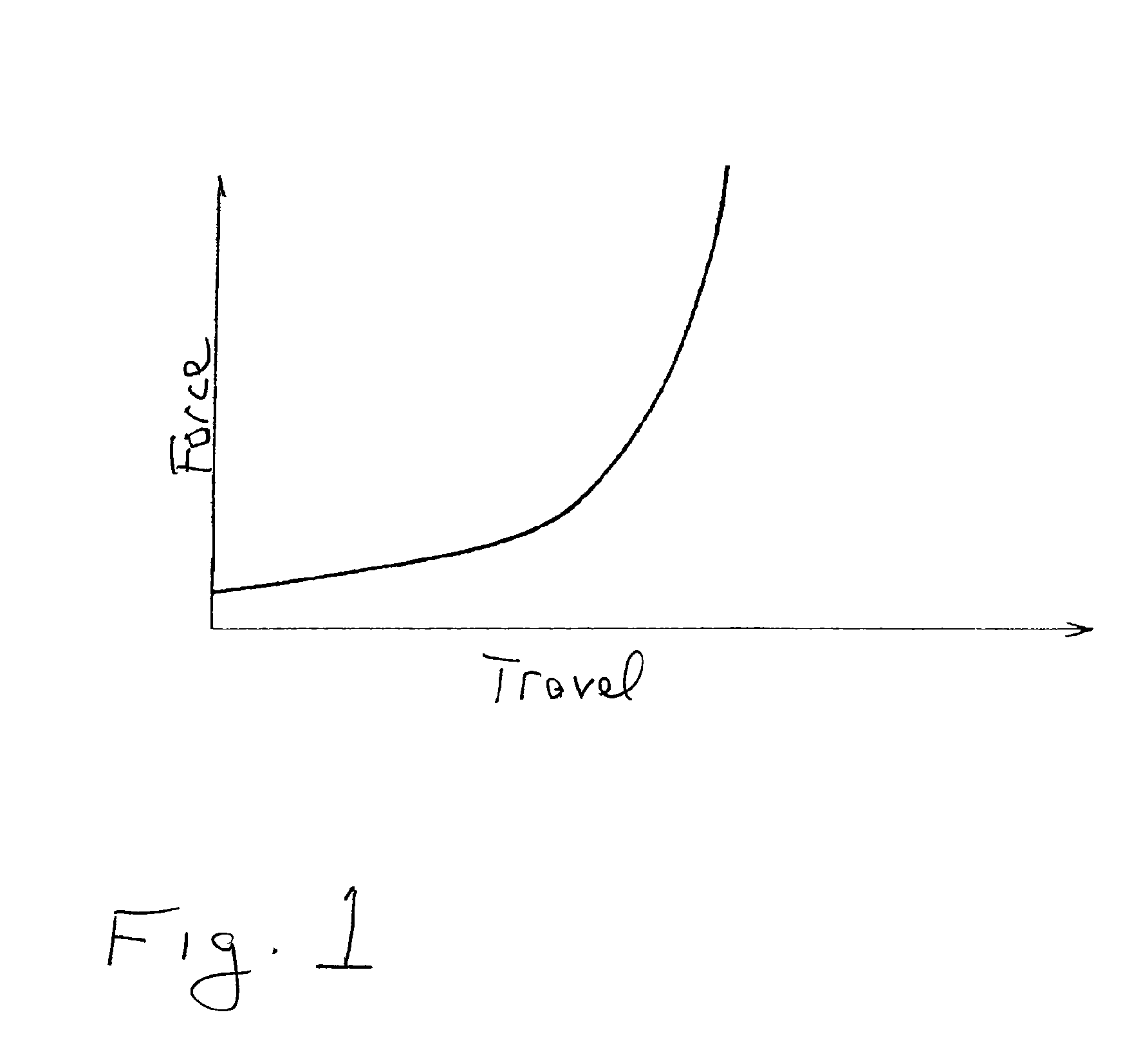

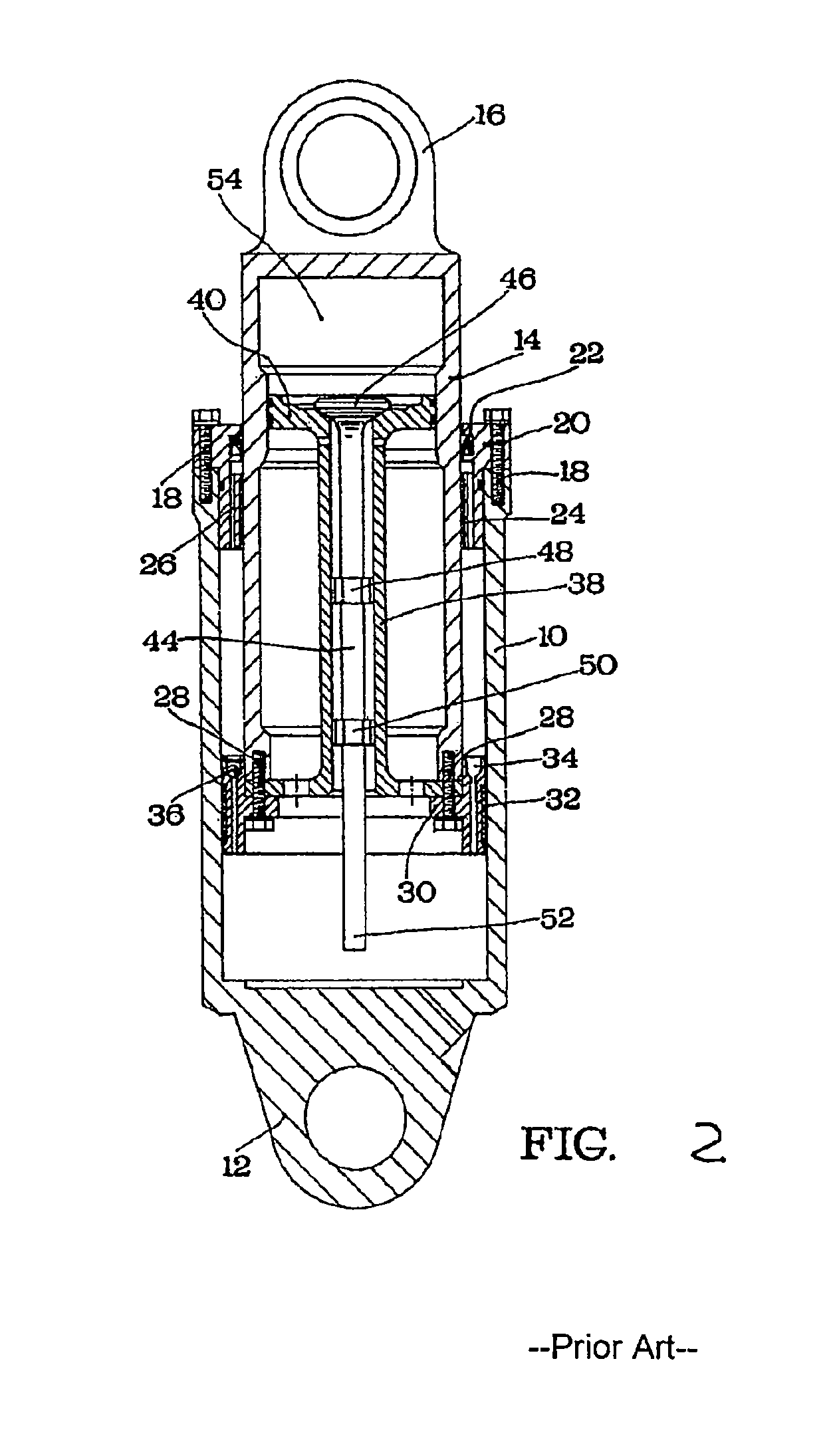

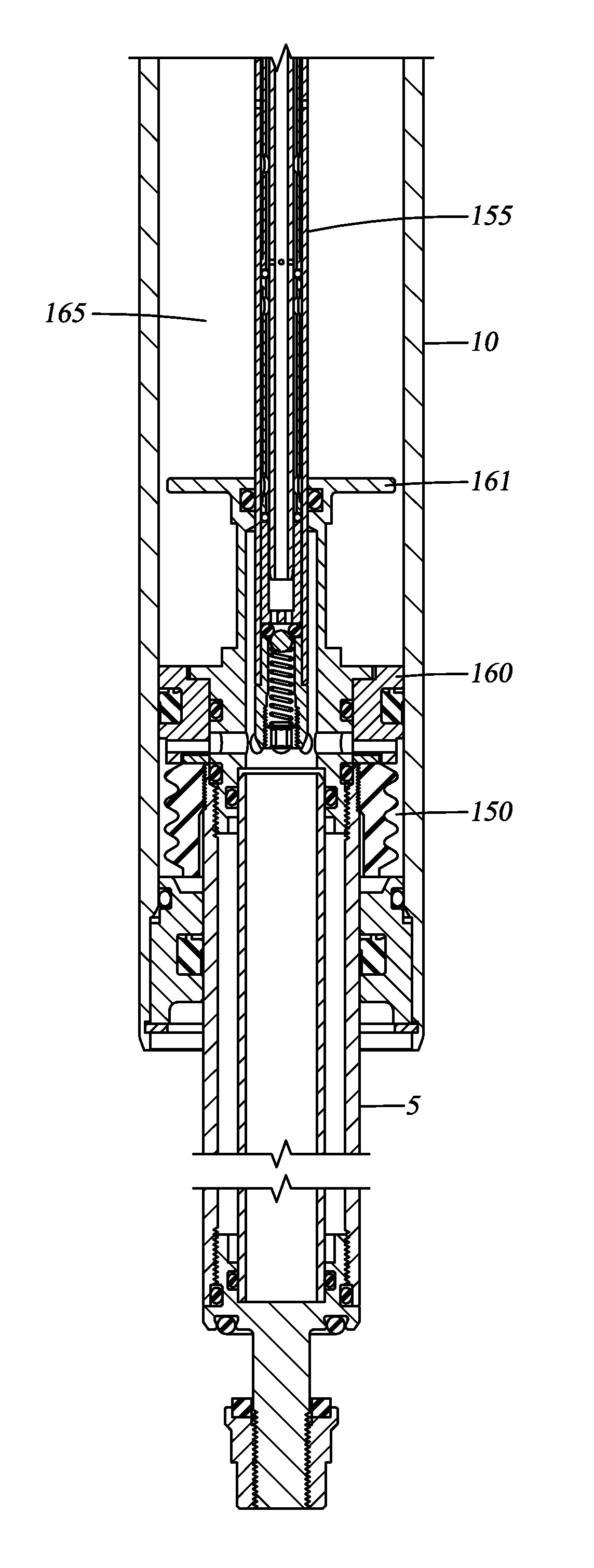

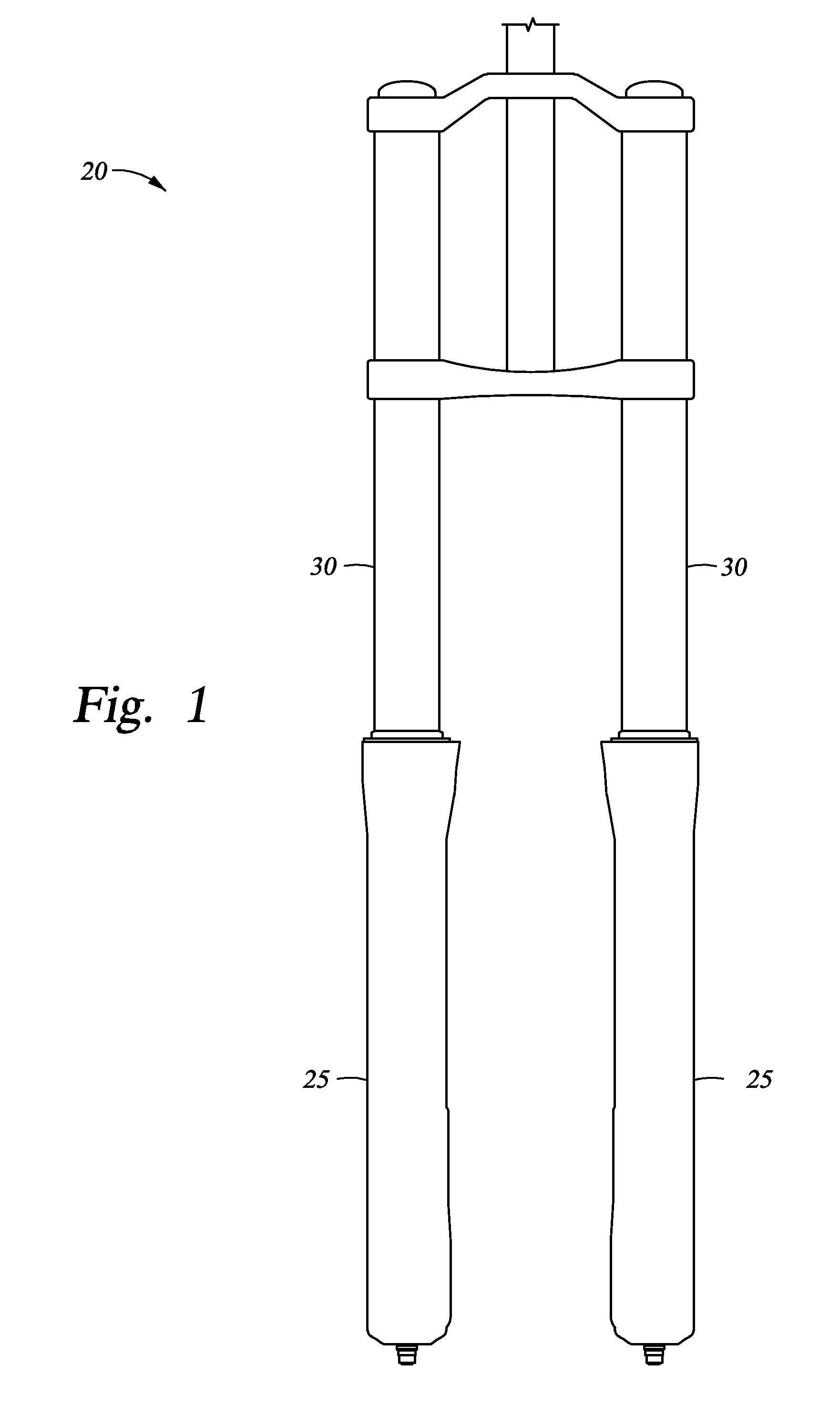

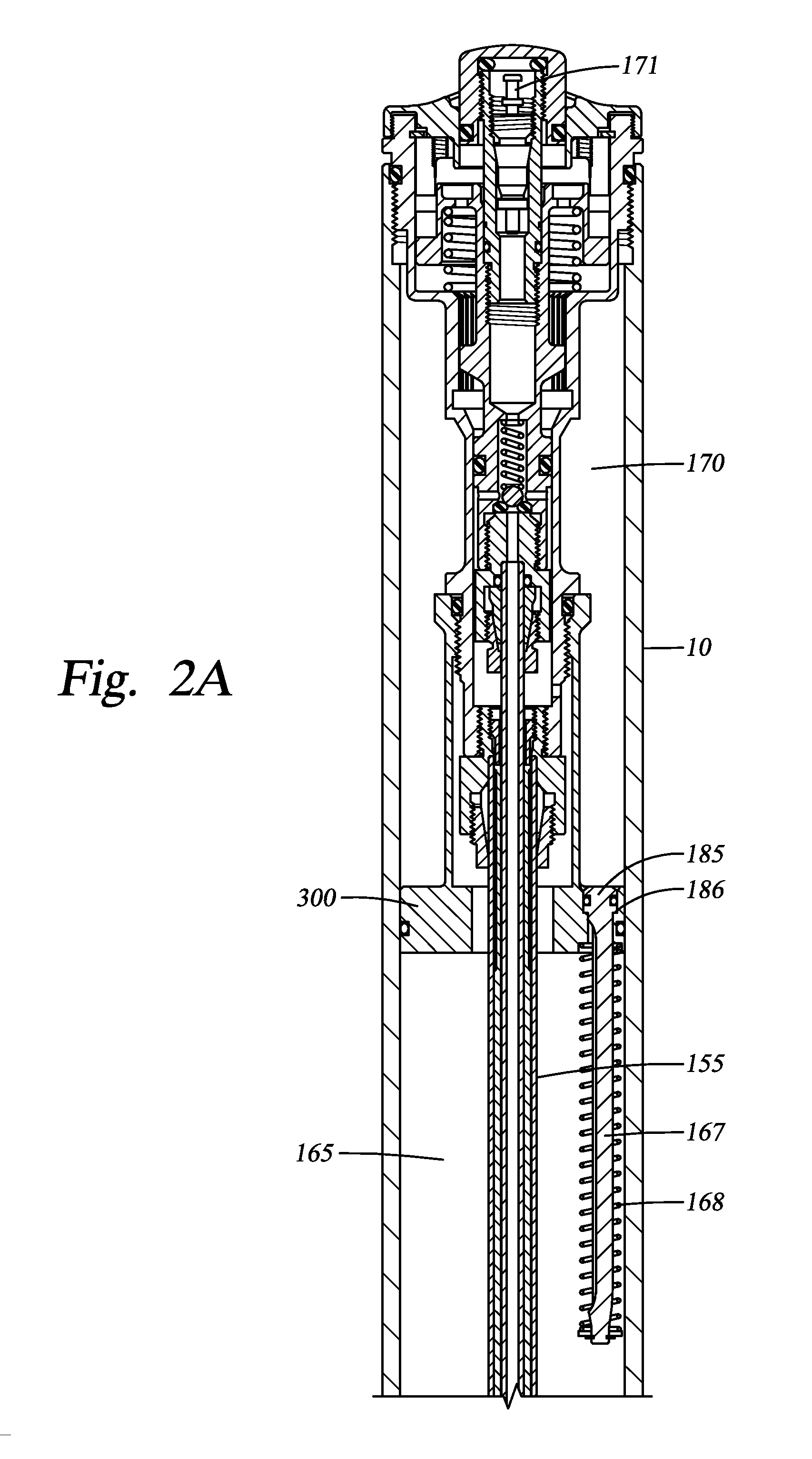

Methods and apparatus for suspending vehicles

Embodiments of the invention generally relate to methods and apparatus for use in vehicle suspension. Particular embodiments of the invention relate to methods and apparatus useful for variable spring rate and / or variable damping rate vehicle suspension. In one embodiment, a shock absorber for a vehicle includes a gas spring having first and second gas chambers. The first chamber is utilized during a first travel portion of the shock absorber and the first and second chambers are both utilized during a second portion of travel. The shock absorber further includes a fluid isolated damper for regulating the speed of travel throughout both portions of travel.

Owner:FOX FACTORY

Method for measuring safety distance between suspension arm of crane and running super high voltage transmission line

ActiveCN101825666AAdapt to power supplyLow power operationOptical rangefindersTransmission systemsElectrical field strengthMeasurement device

The invention relates to a method for measuring a safety distance between a suspension arm of a crane and a running super high voltage transmission line. The method comprises the following steps of: detecting a surrounding electric field intensity by using a detecting head arranged on the suspension arm, inputting a detection result into a comparison module and comparing the detection result witha pre-set value; using the strength of an electric field intensity signal as a start / stop signal of the operation of laser distance-measuring equipment; when the electric field intensity signal is higher than the pre-set value, scanning in a semispherical region to measure a distance by using the laser distance-measuring equipment; when the electric field intensity signal is lower than the pre-set value, stopping a distance detection module to reduce the power consumption of the entire detecting head; and arranging a data acquiring and displaying device in an operation room of the crane and transmitting the detection results of a high voltage electric field intensity detection module and the distance detection module to the data acquiring and displaying device in a radio signal transmitting mode so as to display, alarm or control externally. The invention also provides a corresponding safety distance measuring device which can adapt to electric transmission and transformation lines with different voltage levels and different working angles of the suspension arm and can realize low-consumption operation.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Methods and apparatus for suspending vehicles

ActiveUS20130134687A1Wheel based transmissionFrictional rollers based transmissionSUSPENDING VEHICLEGas spring

A method and apparatus for a shock absorber for a vehicle having a gas spring with first and second gas chambers, wherein the first chamber is utilized during a first travel portion of the shock absorber and the first and second chambers are both utilized during a second portion of travel. In one embodiment, a travel adjustment assembly is configured to selectively communicate a first gas chamber with a negative gas chamber.

Owner:FOX FACTORY

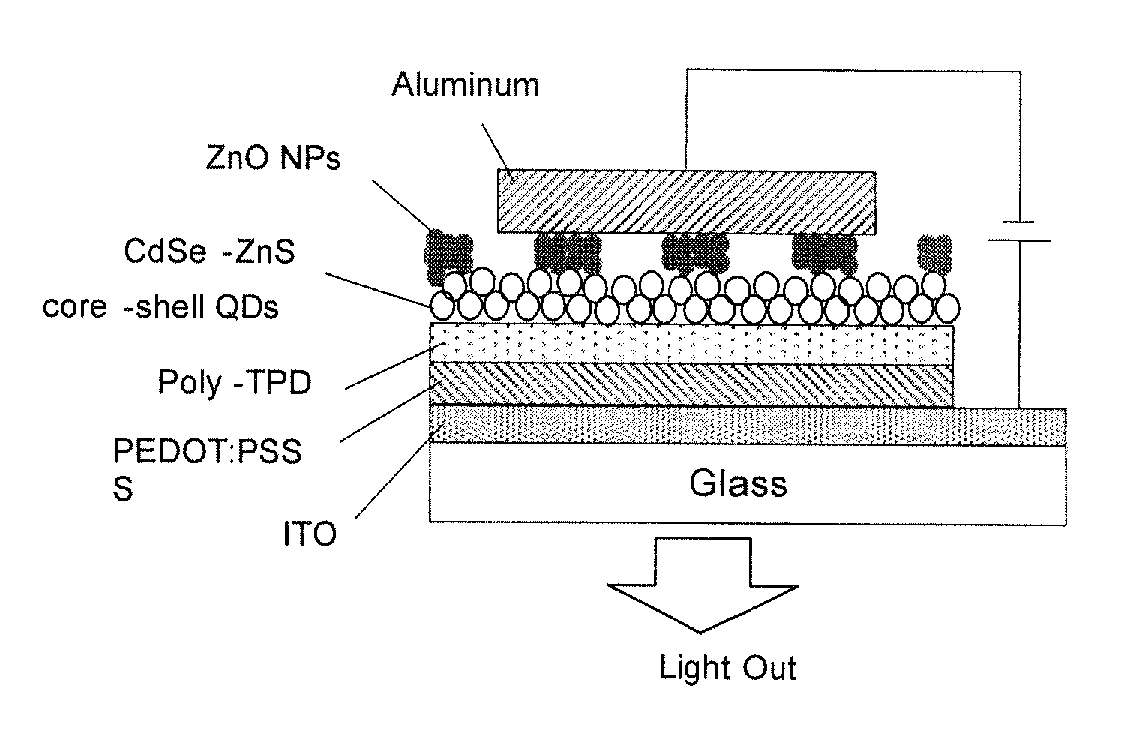

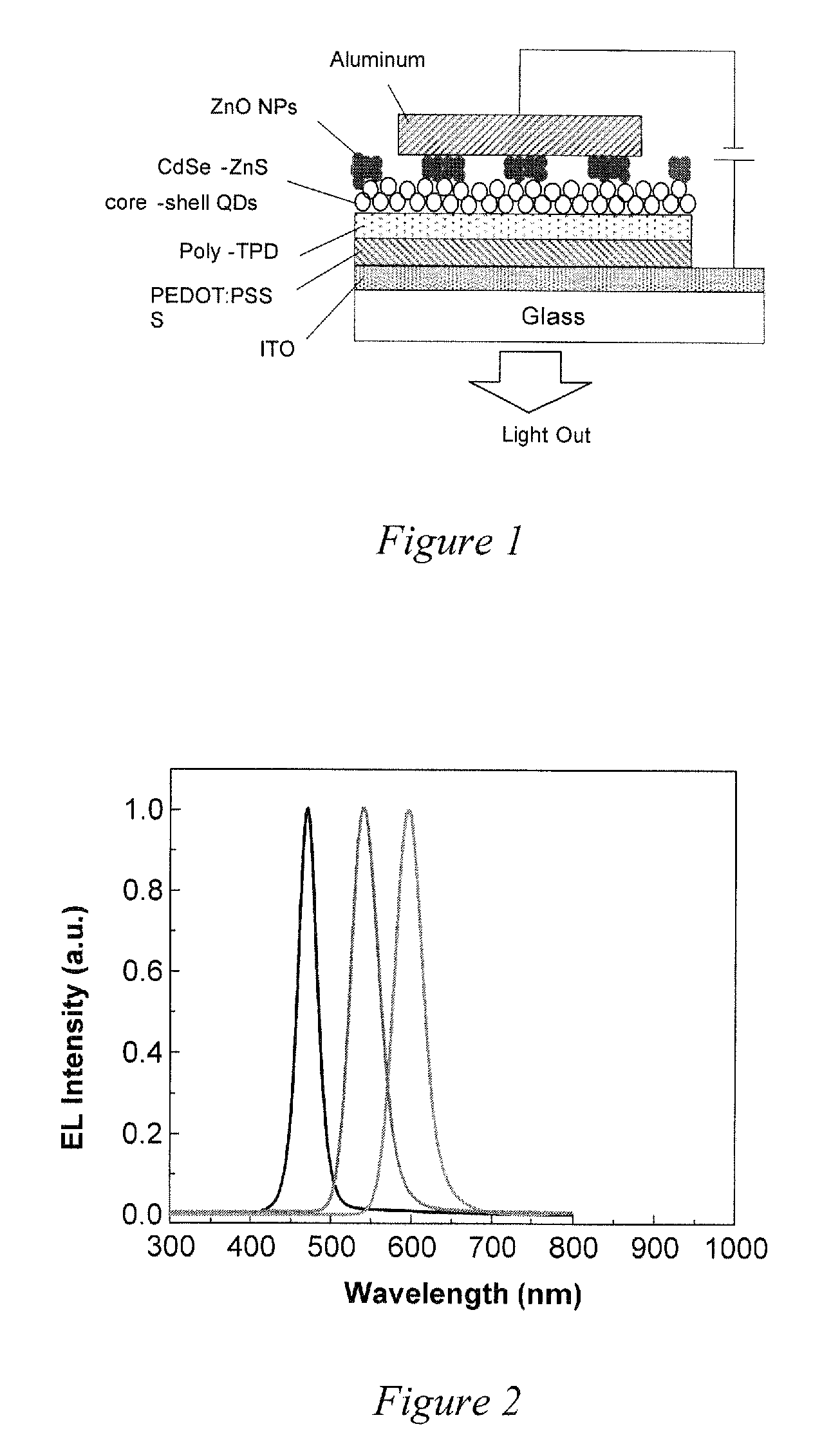

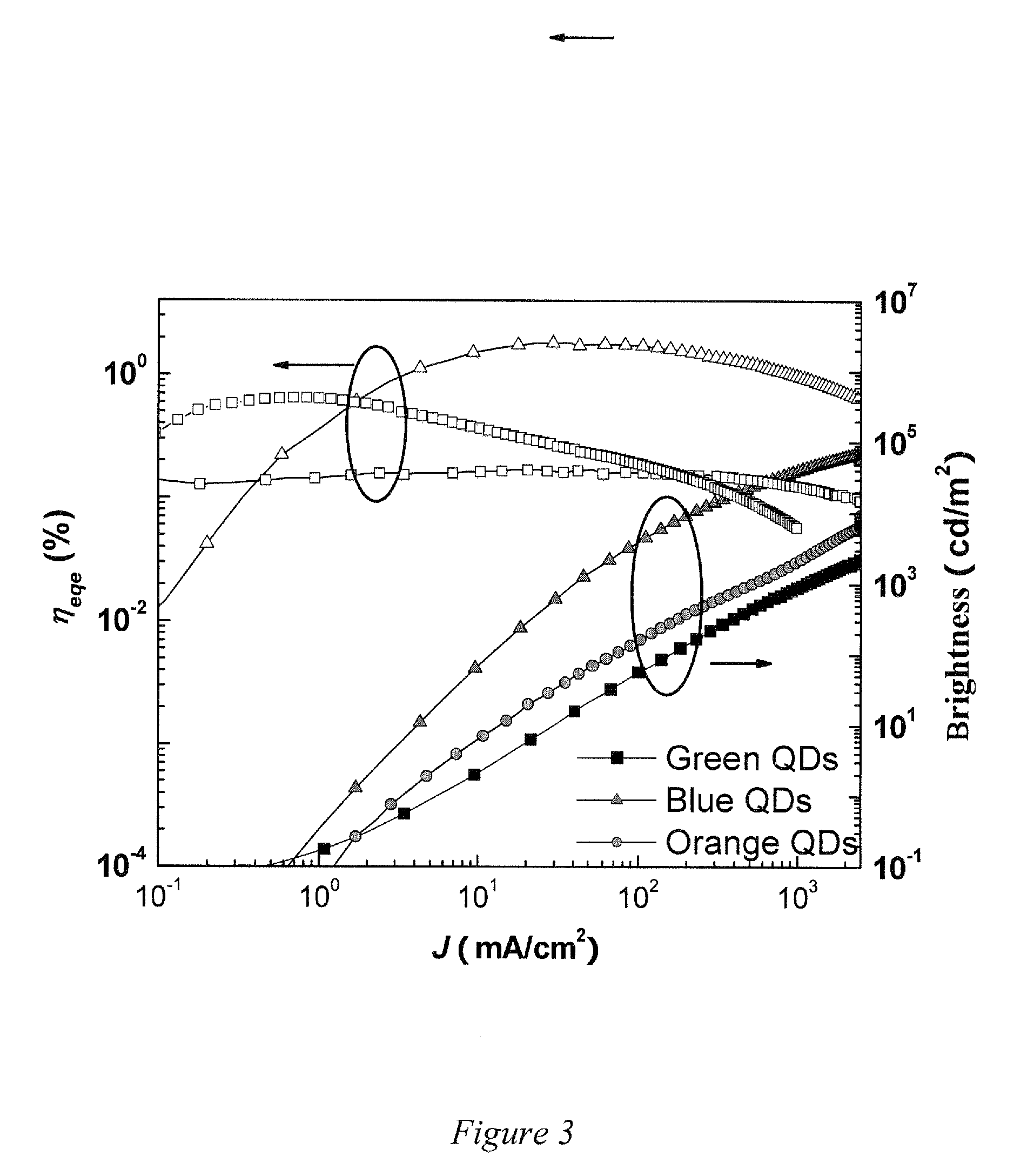

Stable and all solution processable quantum dot light-emitting diodes

InactiveUS9054330B2Electroluminescent light sourcesSolid-state devicesSUSPENDING VEHICLEChemical reaction

Owner:UNIV OF FLORIDA RES FOUNDATION INC

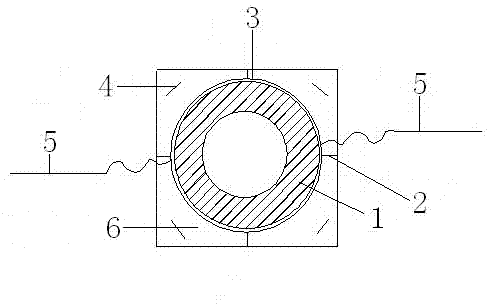

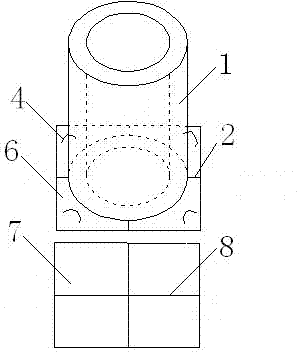

Reinforced concrete inspection well whole prefabricated hoisting construction method

ActiveCN103088844AGuaranteed spacingGuaranteed thicknessArtificial islandsUnderwater structuresSocial benefitsWork period

The invention relates to a construction method for an inspection well, in particular to a reinforced concrete inspection well whole prefabricated hoisting construction method. The method comprises that a formwork of a base plate is firstly erected, then reinforcing steel bars of the base plate are bound, finally concrete is poured on the base plate and burrs need to be removed thoroughly between the reinforcing steel bars in the inner circle and the outer circle; reinforcing steel bars of a well body are bound through the reserved bars of the base plate, after binding, a crane hoists inner steel formworks in the crane with cooperation of manual power, outer steel formworks are installed, finally the concrete is poured, after the formworks are disassembled, the formworks are wound by plastic thin films and water is sprayed on the formworks to cure the formworks; and a drawing method of double cross is adopted in hoisting process. Compared with the prior art, the reinforced concrete inspection well whole prefabricated hoisting construction method has the advantages of effectively solving the quality problem caused by insufficient construction space, greatly improving work efficiency, shortening work period, having good social benefit and economic benefit and being wide in application space in concrete inspection well engineering and high in popularization value.

Owner:JINAN URBAN CONSTR GRP

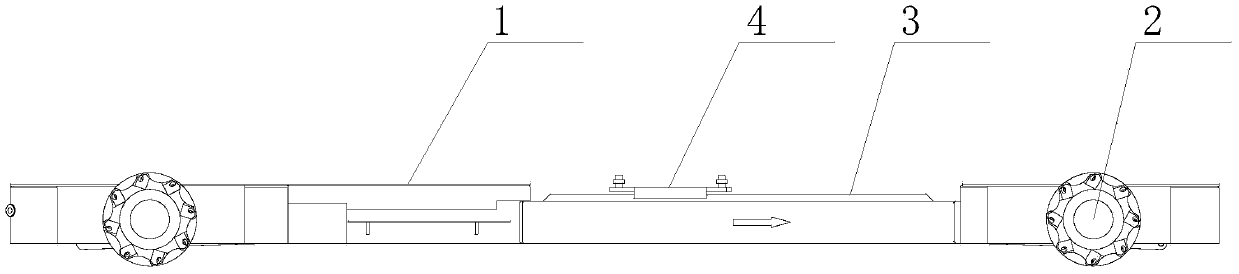

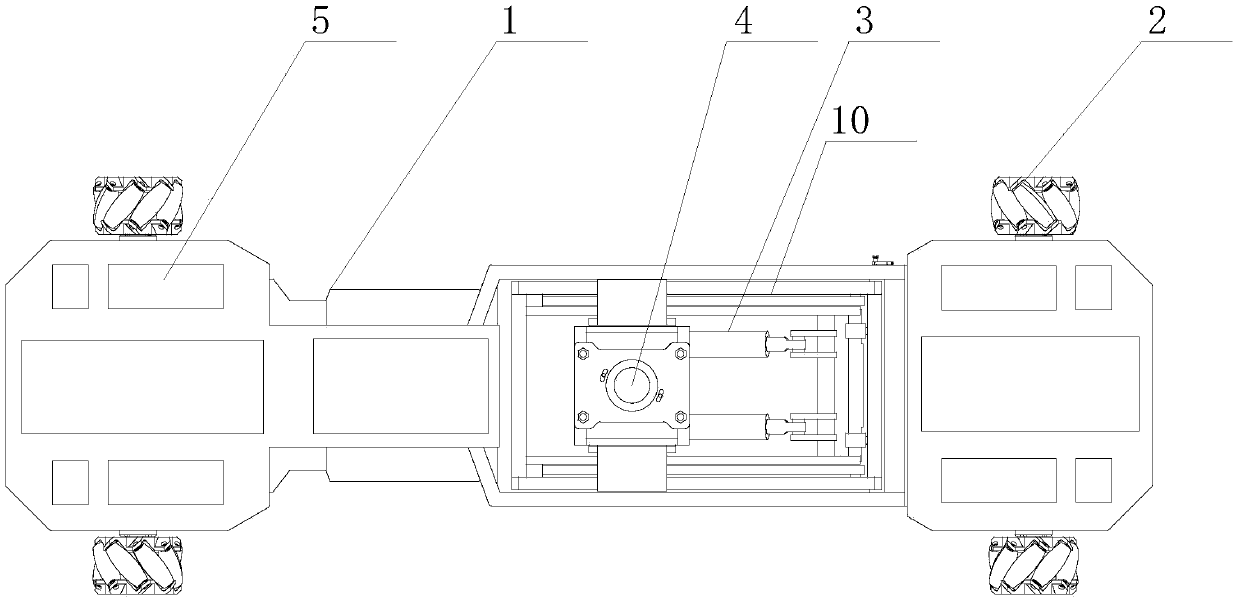

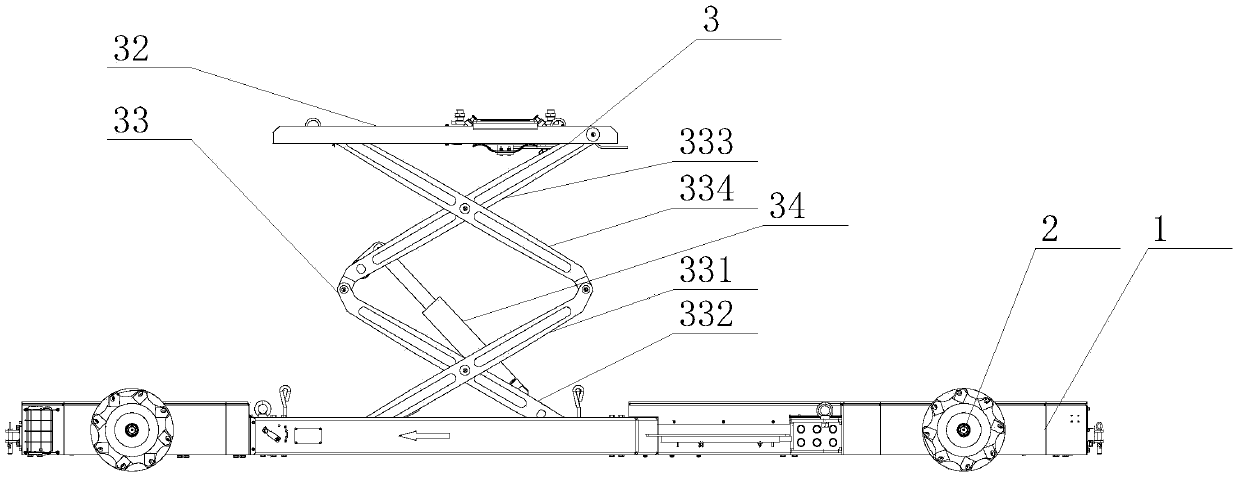

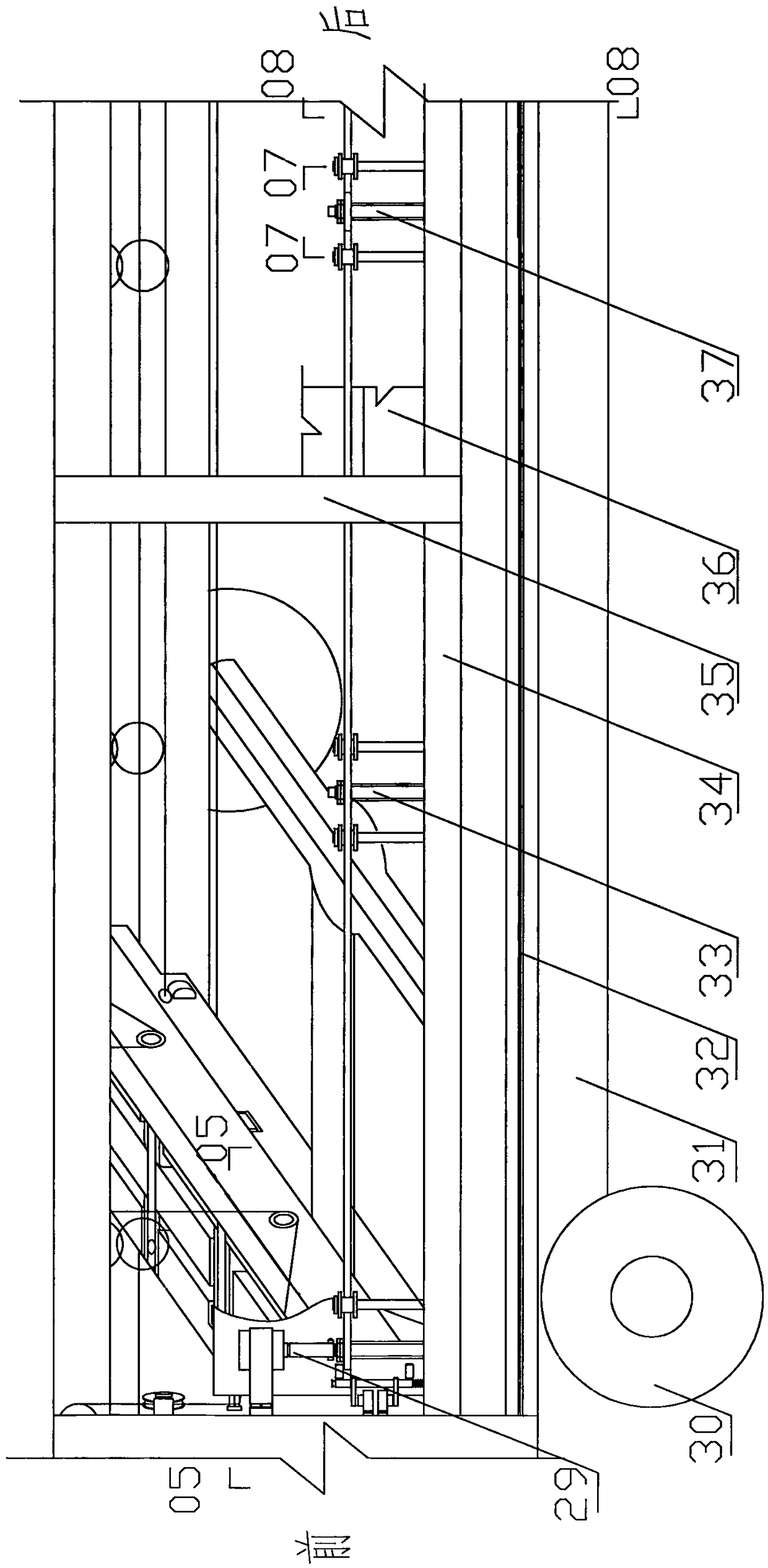

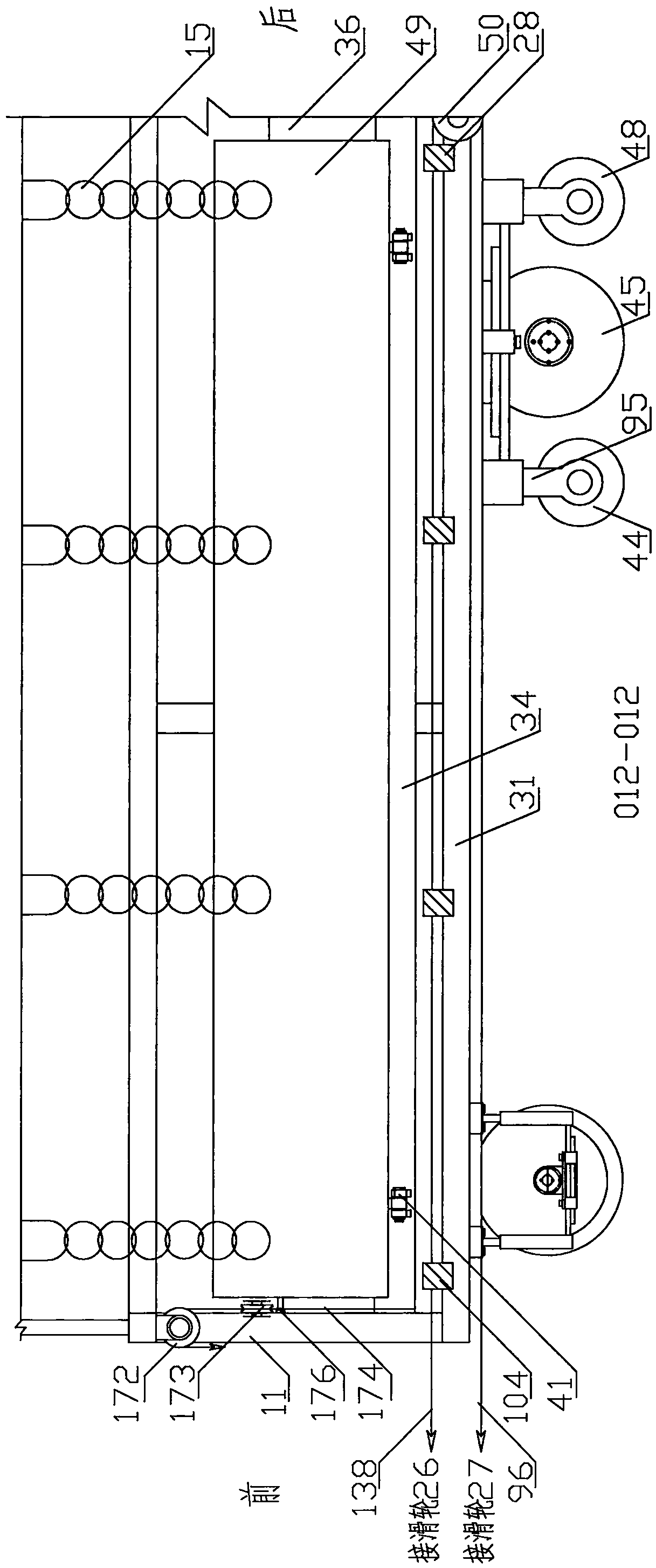

Novel ammunition suspending vehicle

ActiveCN104192320AEasy to adjustImprove stabilityFreight handling installationsSUSPENDING VEHICLEMecanum wheel

The invention relates to a novel ammunition suspending vehicle and relates to the field of military equipment. The vehicle comprises a vehicle body and two pairs of Mecanum wheels which are arranged at two ends of the vehicle body; the vehicle further comprises a lifting mechanism, a holding mechanism and four walking drive mechanisms; the four walking drive mechanisms are arranged in the vehicle body, are connected to the Mecanum wheels respectively and are used for driving the Mecanum wheels; the middle of the vehicle body is provided with a square hole used for accommodating a lifting mechanism, and the side walls of the square hole are provided with a pair of first sliding grooves along the length of the vehicle body; the lifting mechanism comprises a sliding rod, an ejecting seat, two parallel crossing rod groups and a lifting drive mechanism; the holding mechanism comprises a base plate, a pitching platform, a horizontal moving platform, a hanger tray, an adjusting handle, two tensioning hand wheels, two pairs of pitching and adjusting bolts and a plurality of stretching springs. The vehicle has the advantages of fine using effect and high operation reliability.

Owner:YANGZHOU WANFANG ELECTRONICS TECH

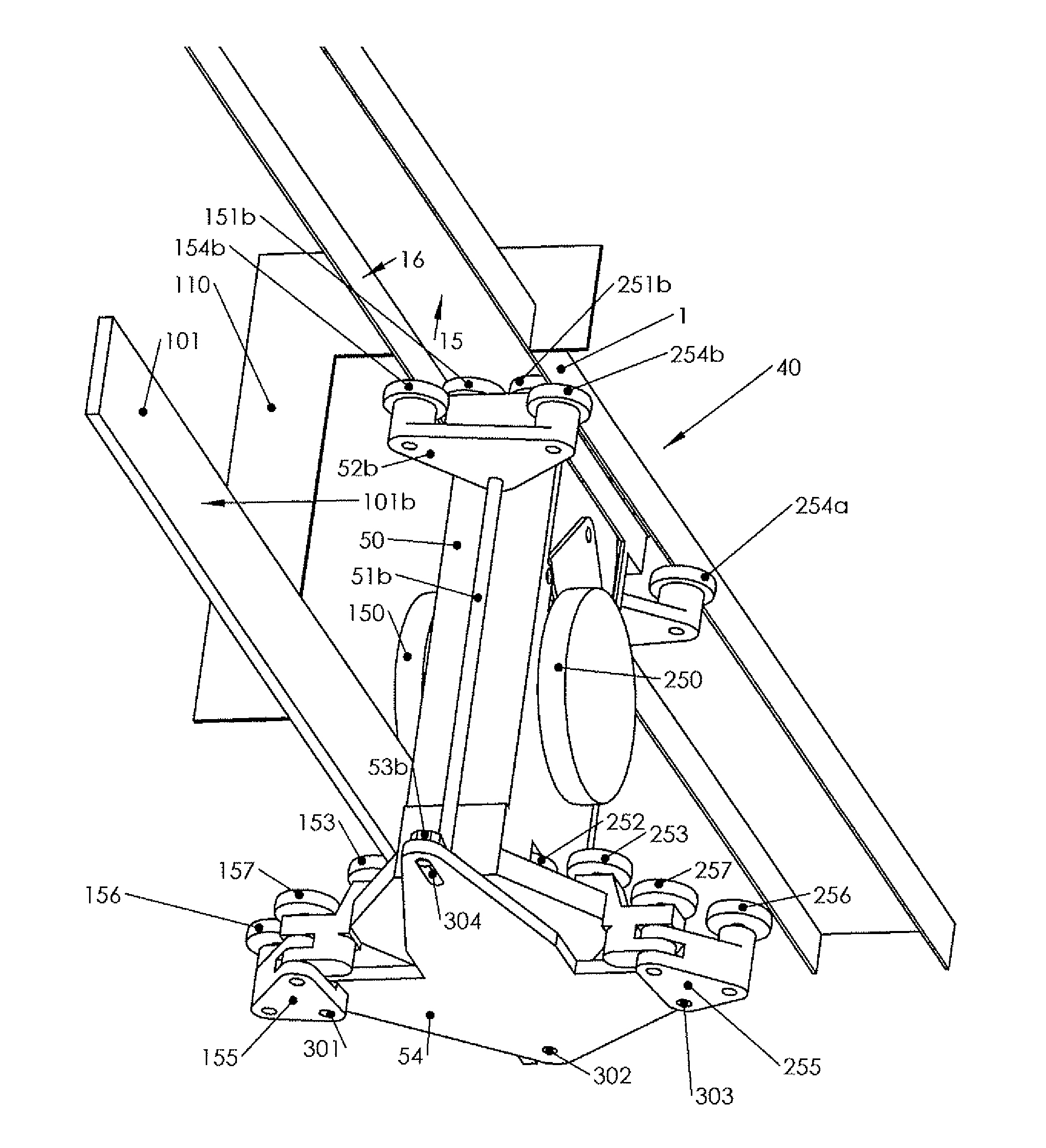

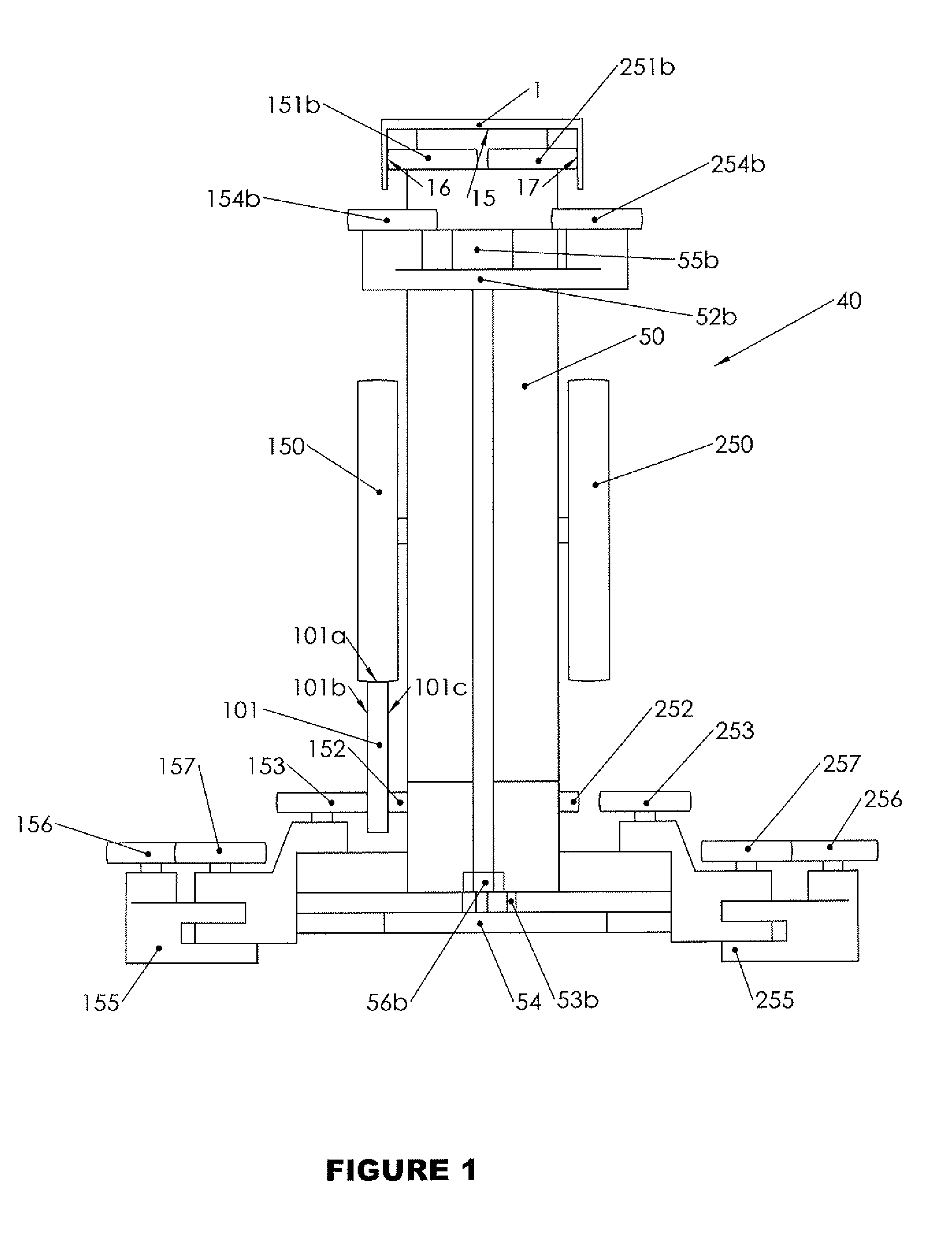

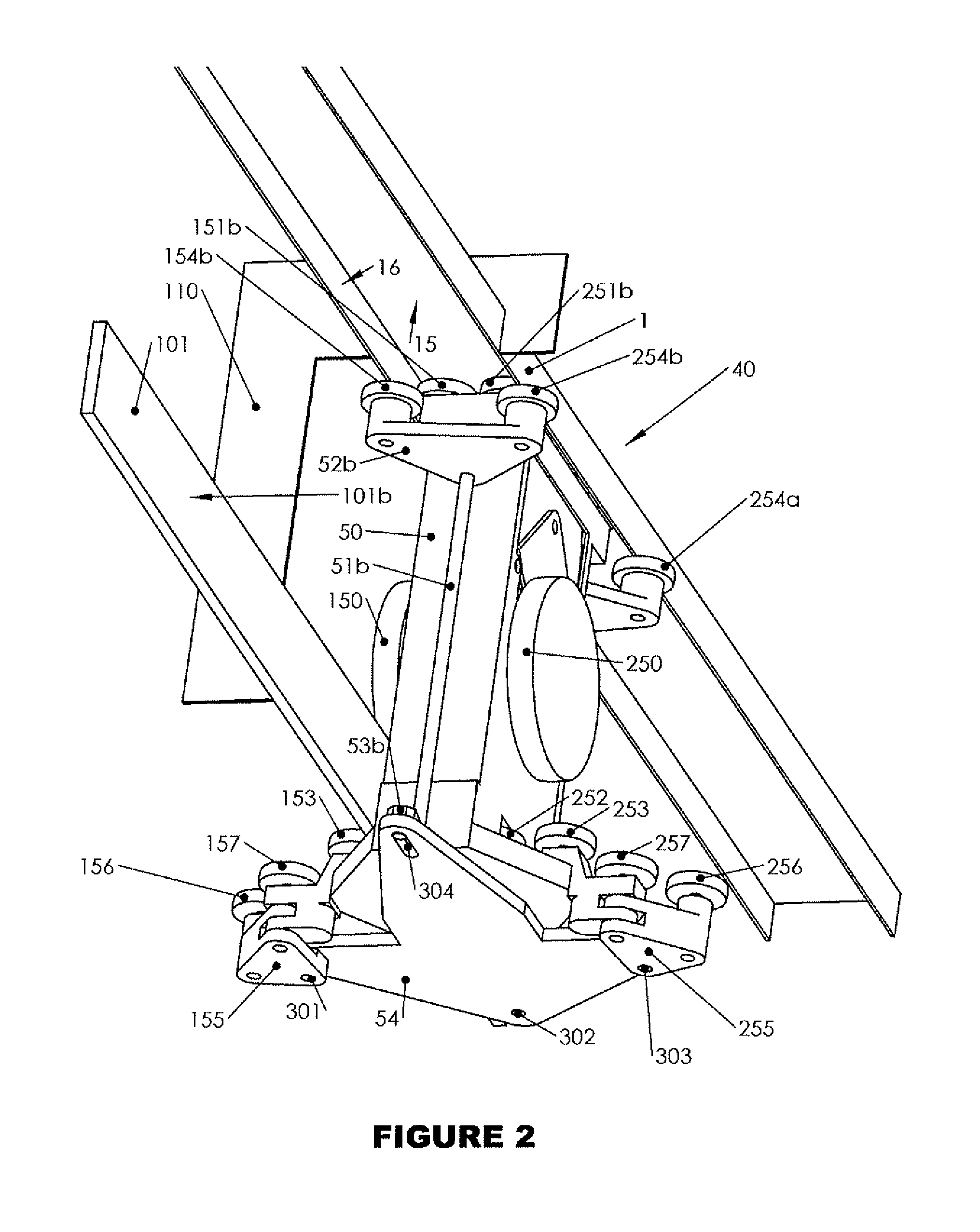

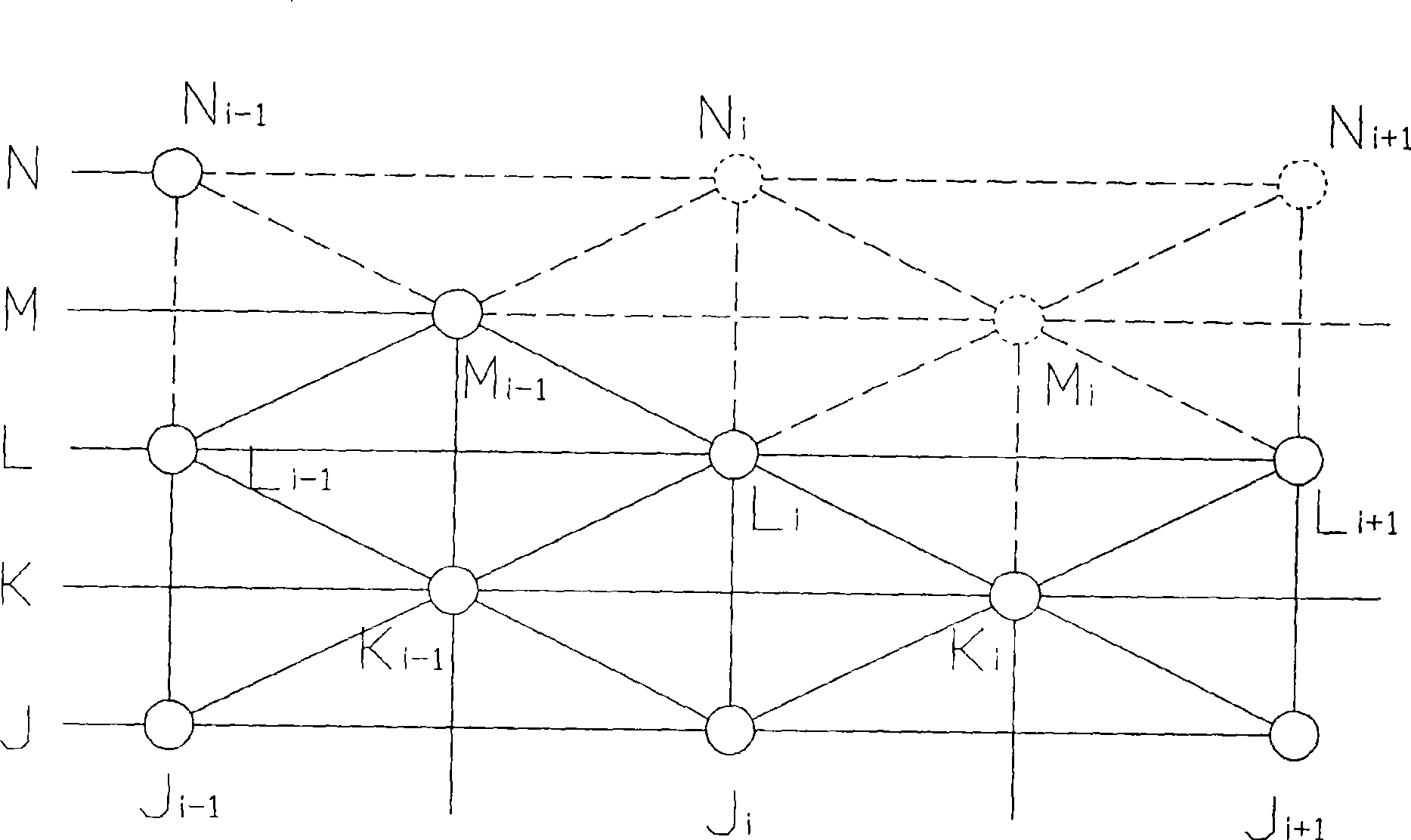

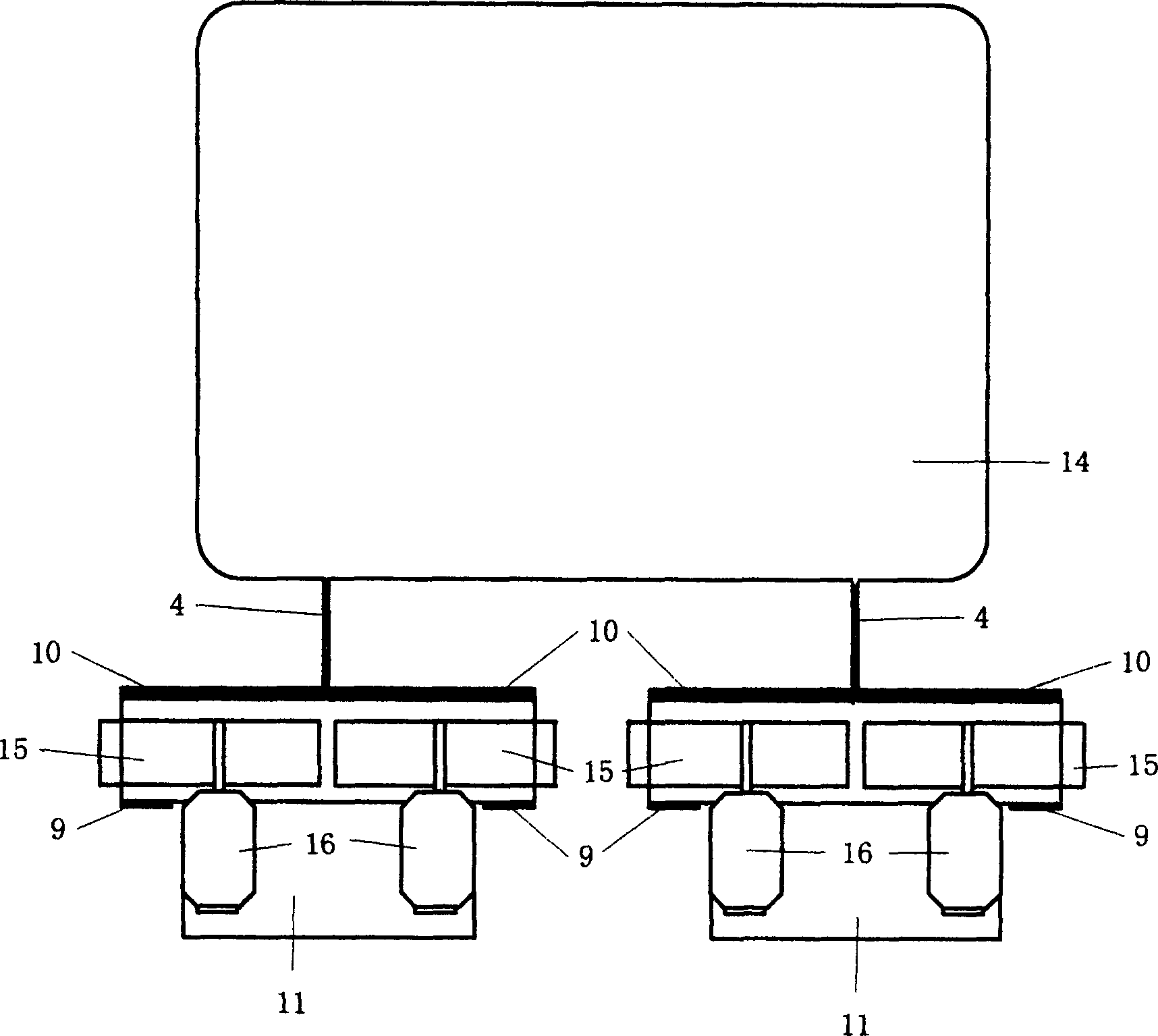

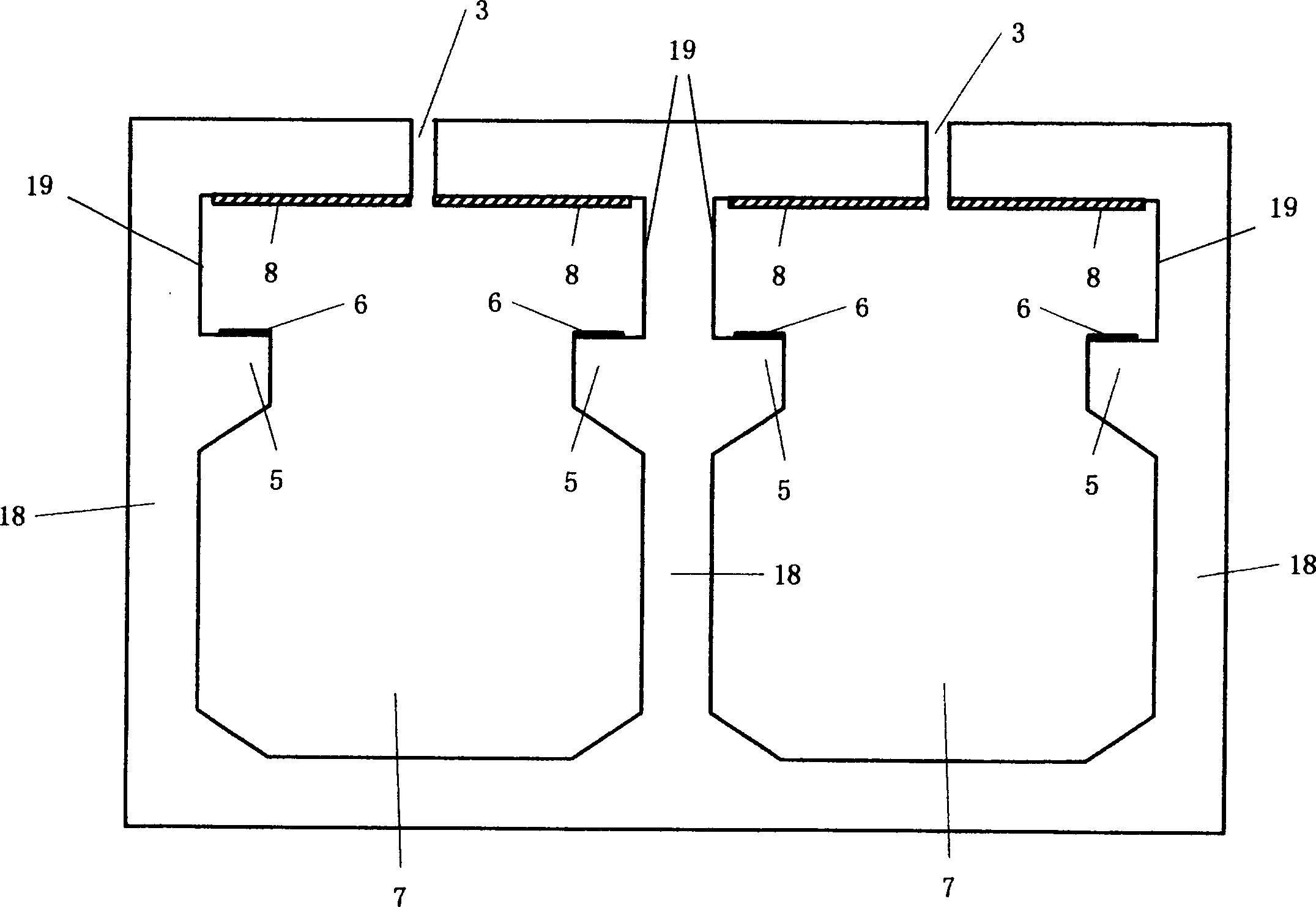

Track and bogie for suspended vehicles

ActiveUS20120125221A1Minimize rolling resistanceReliable frictionMonorailsRailway tracksBogieSUSPENDING VEHICLE

The present invention includes a track (1, 101) of a track system with straight, transition, curved, and switch track sections. The invention further comprises bogies (40) for vehicle cabins suspended under the track. Track sections of the track have an upper rail (1) and one or two lower rails (101, 201). Further, a bogie (40) has fore and aft sets of upper guide and switch wheels (151, 251, 154, 254), and one set of lower guide and switch wheels (152, 153, 252, 253, 156, 157, 256, 257). The bogies (40) also have one left and / or one right load bearing wheel (150, 250) and one drive wheel facing upwards and engaging a downwards directed drive wheel running surface (15) of the upper rail. Each set of lower guide wheels consist of left and right wheel pairs (152, 153, 252, 253) so that transition sections can be passed without moving any parts of the bogie (40). Switch wheels (154, 254, 156, 157, 256, 257) are separated from guide wheels so that they can be positioned according to the preferred direction of travel well before reaching a switch.

Owner:SUPRAWAYS

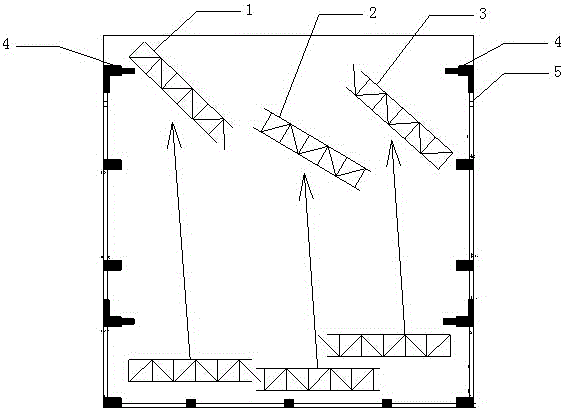

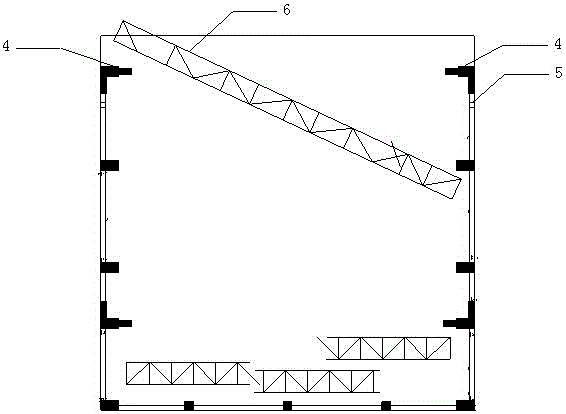

High altitude suspension selecting bulk construction method of barrel shell type bolt ball node network frame

InactiveCN101435224AImprove construction flexibilityImprove installation efficiencyBuilding constructionsSUSPENDING VEHICLESupport condition

The invention relates to a small assembling unit high suspending construction method for cylinder casing type bolt ball node grid. The cylinder casing type bolt ball node grid is divided into a plurality annuluses in longitudinal direction according to the support condition, a steel pipe scaffold is arranged in any one annulus, an upper net casing of the annulus is assemble on the annulus by a bulk method, and the scaffold is dismounted after the assembly is qualified; a second annulus is constructed by the small assembling unit high suspending method from the assembled first annulus, and the annulus is assembled one by one along the longitudinal direction, after the bolt balls on the lower boom loop wire in the annuluses are mounted in order, the bolt balls on adjacent upper boom loop wire are mounted in order, each bolt ball and a longitudinal boom, an annular boom and two web members are put together to form a one-ball-four-rod member on the ground before assembly, and then the formed members are suspended by crane to proper positions in the air to be connected to the bolt balls mounted on the periphery. The method of the invention is safe, flexible, convenient, fast, and has low cost.

Owner:河南中美铝业有限公司

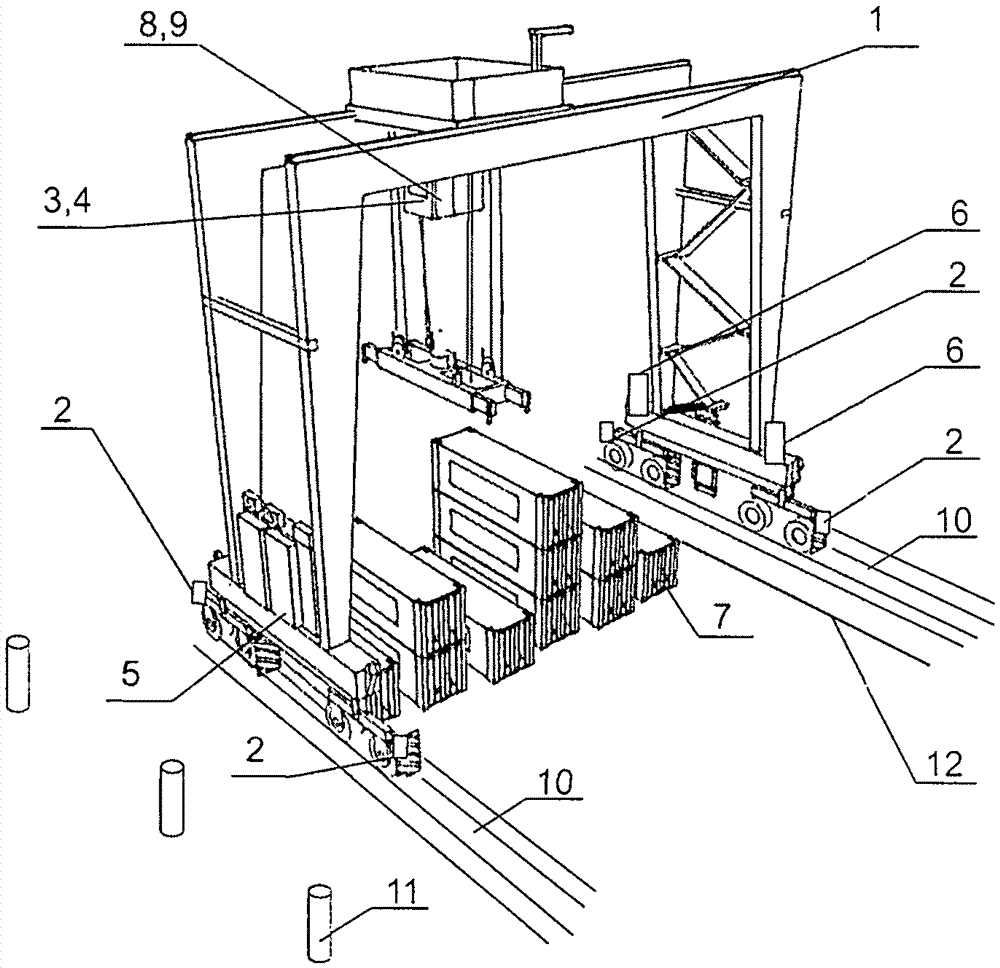

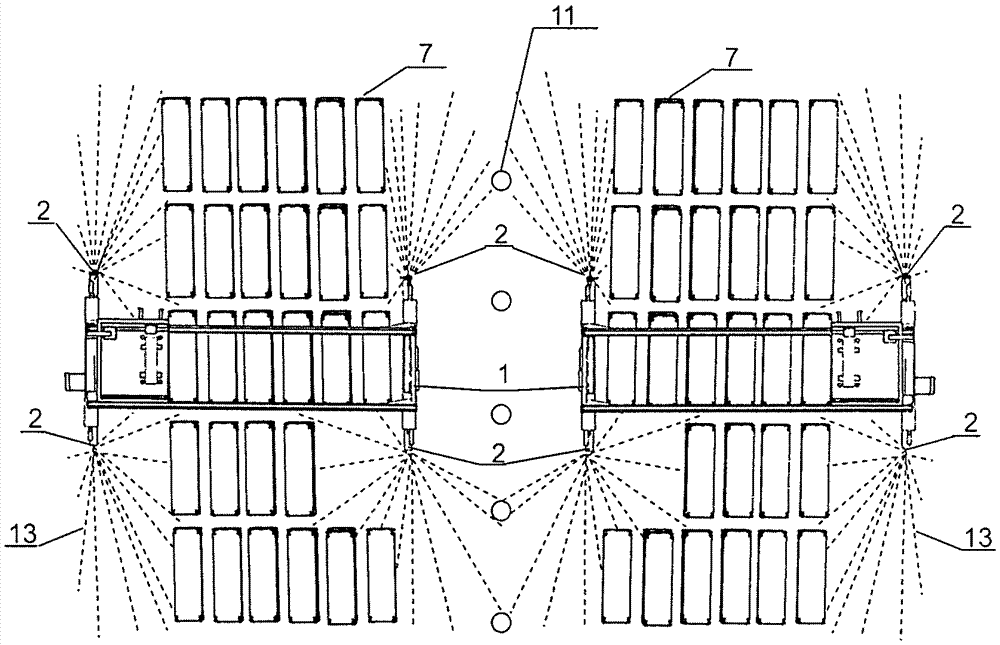

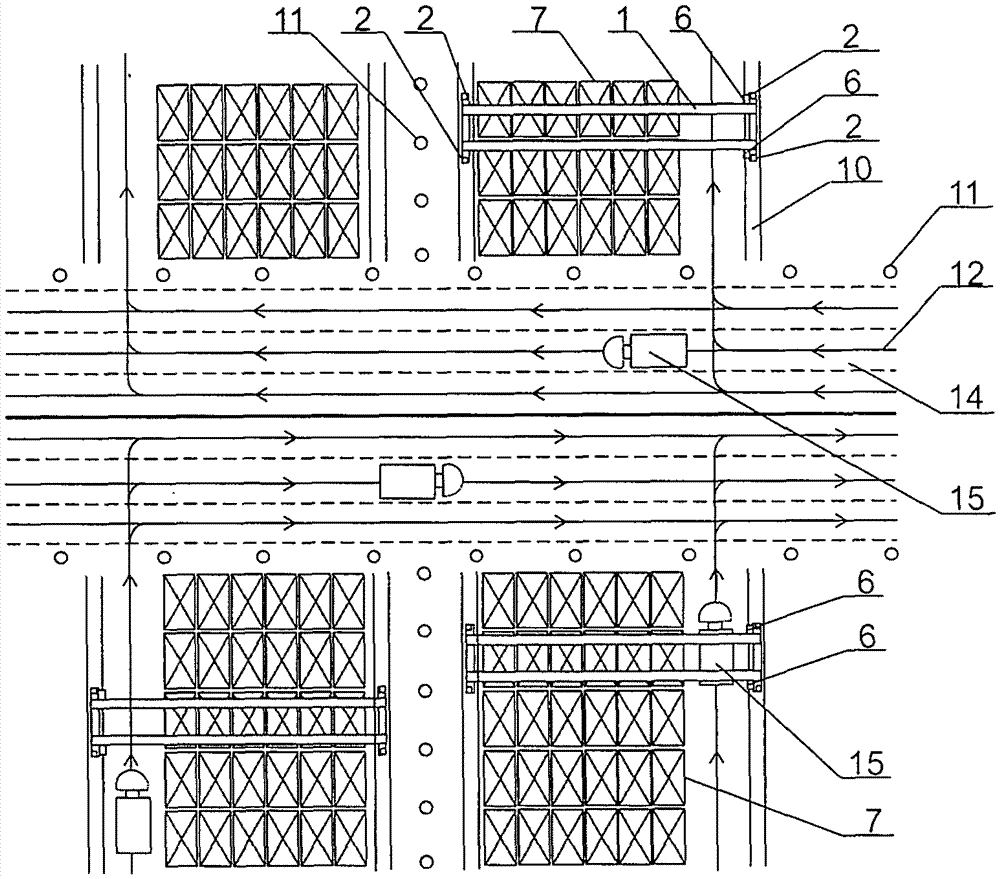

Container wharf flow equipment automatic walking method

InactiveCN106946049ARealize automatic walking correctionRealize automatic walkingStorage devicesImaging processingSimulation

The invention provides a container wharf flow equipment automatic walking method. Laser scanners are installed on four door leg tire front wheel brackets of a tire crane correspondingly, vertical columns are installed between the back surfaces of two tire crane lanes by a certain distance or the length of a container at intervals and are located in a straight line, the positions of the vertical columns are detected through the tire crane laser scanners, and automatic walking of the tire crane is achieved. Meanwhile, vertical columns are installed on the two sides of a road lane by a certain distance and are located in a straight line; vertical columns are installed on the inner sides of two door legs, close to the lane, of the tire crane correspondingly; and vertical columns are installed on the inner side and the outer side of each door leg of a bridge crane correspondingly. An ordinary container lorry is improved into an automatic navigation vehicle, the vertical columns higher than the top surface of the container, a camera and the laser scanners are installed on the navigation vehicle, walking datum line paint is at the center of the ground lane, the navigation vehicle shoots the walking datum line through the camera so as to conduct image processing and alignment, the positions of the vertical columns are detected through the scanners, and automatic walking of the navigation vehicle is achieved.

Owner:SHANGHAI HAILEI LASER TECH

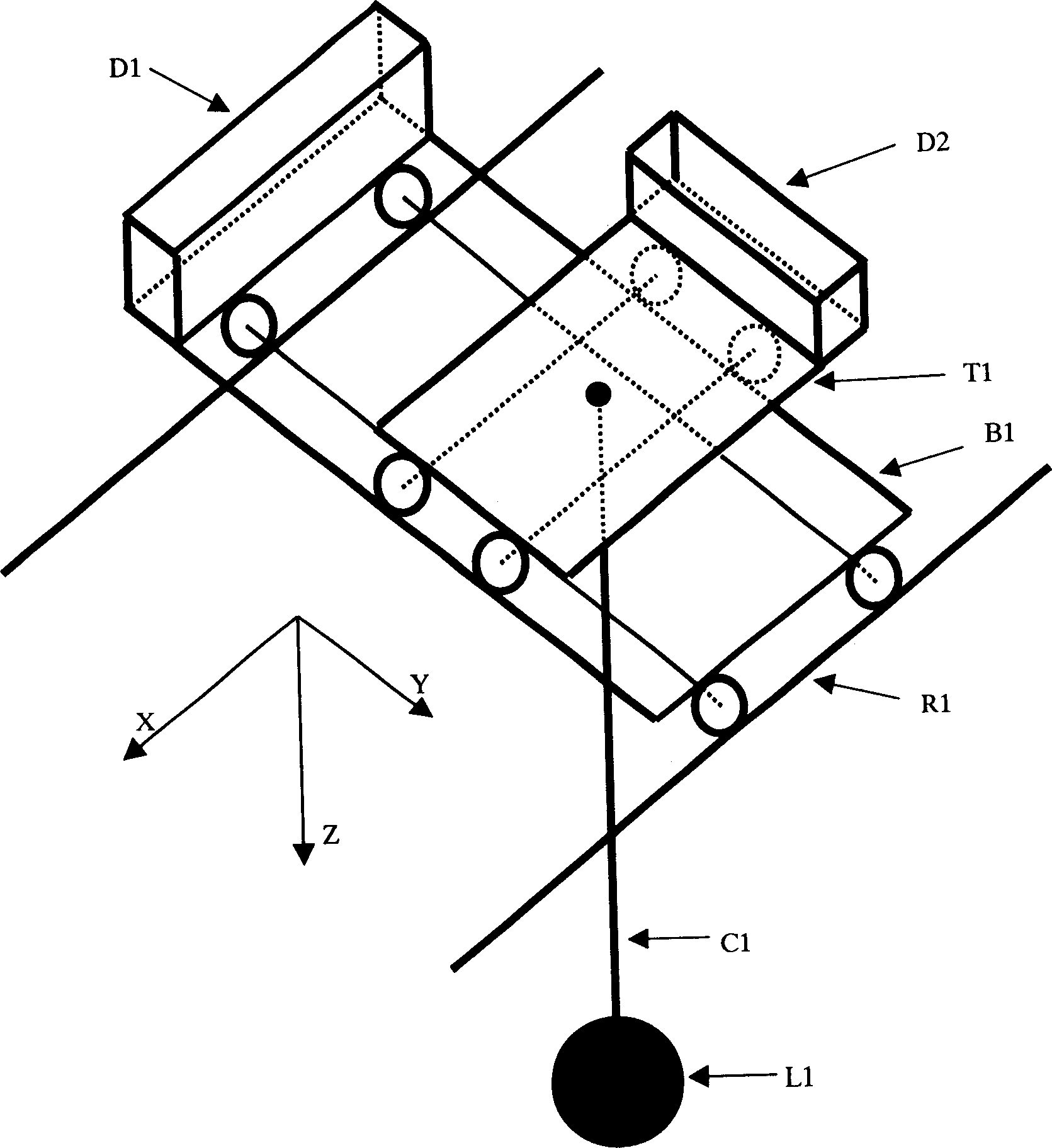

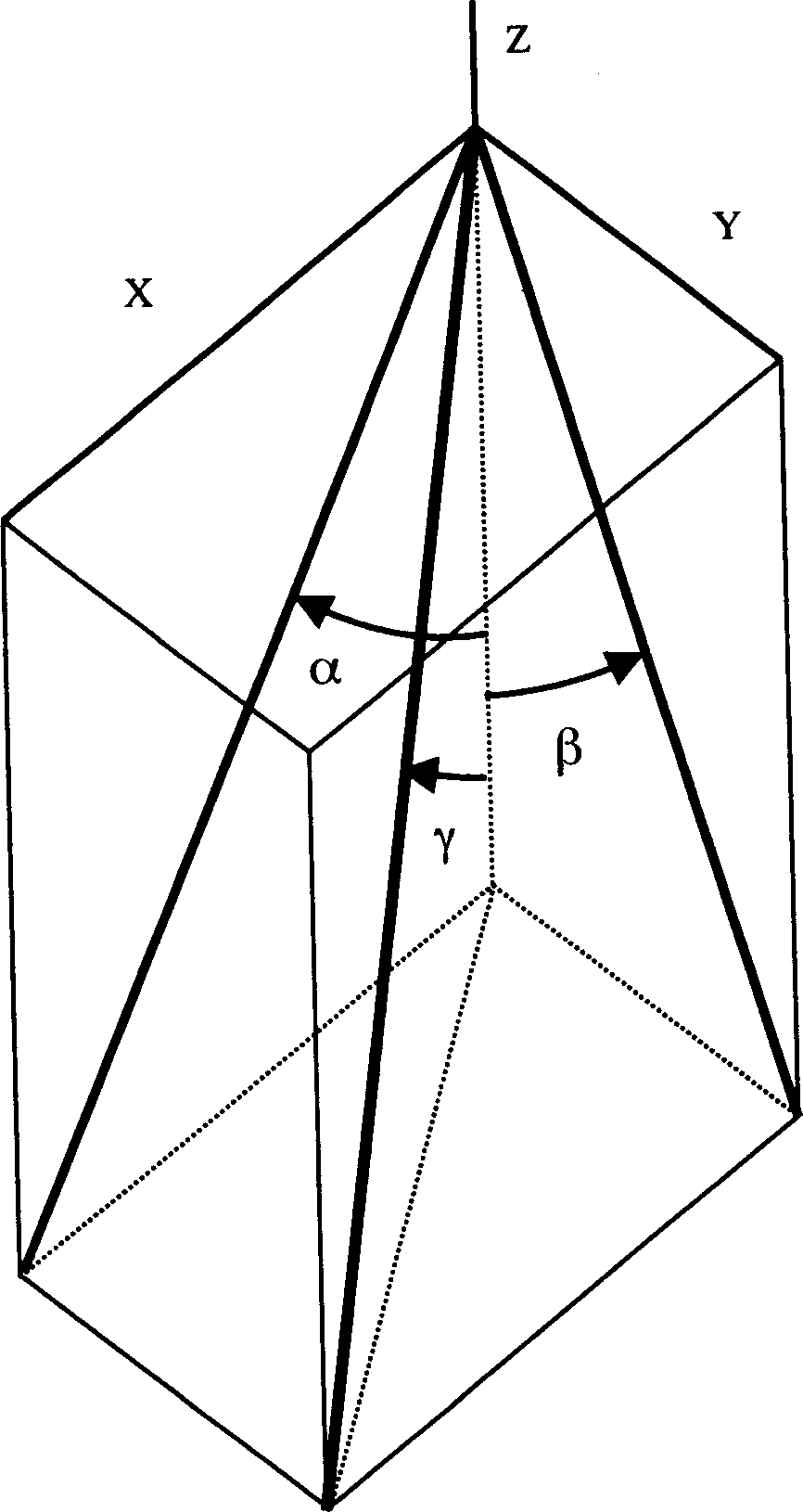

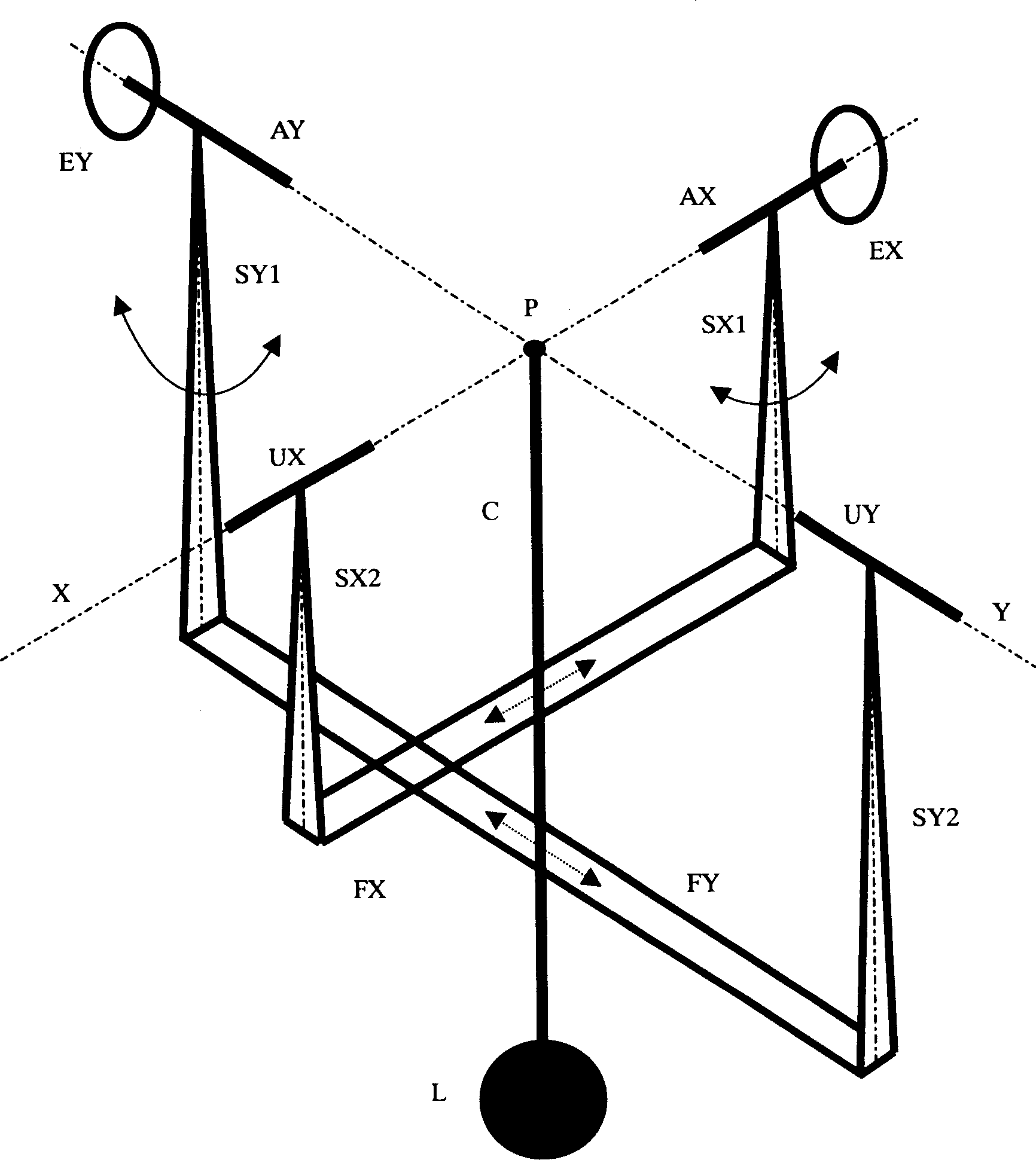

Lifting rope angle measurer for crane

InactiveCN1436715ASuitable for operation automationAutomate operationUsing electrical meansCranesSUSPENDING VEHICLEEngineering

The lifting rope angle measurer for crane includes an angle sensor EX installed on the rotation shaft AX; a support shaft UX; a frame rotating around X axis and with slender rectangular bottom, one cantilever SX1 fixed on the rotation shaft AX and other cantilever SX2 around the support shaft UX; an other angle sensor EY installed on the other rotation shaft AY; an other support shaft UY; and an other frame rotating around Y axis and with slender rectangular bottom, one cantilever SY1 fixed on the rotation shaft AY and one other cantilever SY2 around the support shaft UY; with the lifting rope C being passed through the bottoms of the two said frames. The present invention has simple structure, low cost, good real-time processing preformance, high reliability and high precision; is suitable for both indoor use and outdoor use.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

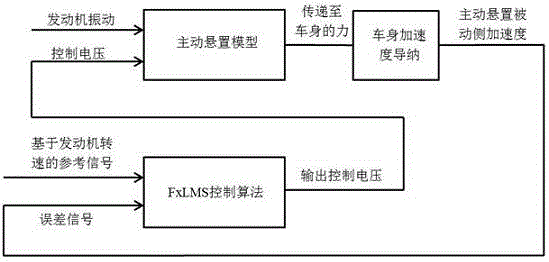

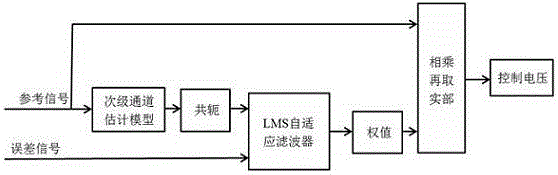

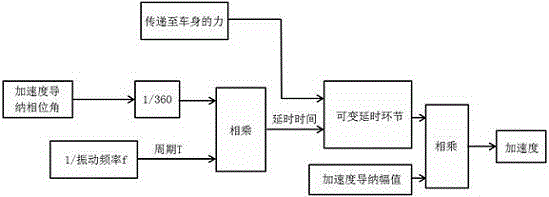

Active suspension FxLMS self-adaption control method based on acceleration signal feedback

The invention relates to an active suspension FxLMS self-adaption control method based on acceleration signal feedback.Active suspension control methods comprises the FxLMS self-adaption control method based on force feedback, a reference signal estimation method based on engine speed and a force feedback to acceleration feedback expansion method, wherein the FxLMS self-adaption control method based on force feedback comprises active suspension voltage to force secondary channel estimation and an LMS self-adapting filter.According to the force feedback to acceleration feedback expansion method, suspending vehicle body acceleration admittance phase angle frequency changing characteristics are adopted as reference, a secondary channel estimation model is expanded from force to acceleration, and acceleration of the passive side of an active suspension substitutes force transmitted to a vehicle body to serve as an error signal of a controller, so that acceleration feedback of the control method is achieved.According to the active suspension control method, engine speed and acceleration of the passive side of the active suspension are taken as input, processing is conducted through a control system, a proper voltage control signal is output, and the voltage signal is subjected to power amplification and then drives an actuator in the active suspension to actuate, so that vibration from an engine is counteracted.

Owner:TONGJI UNIV

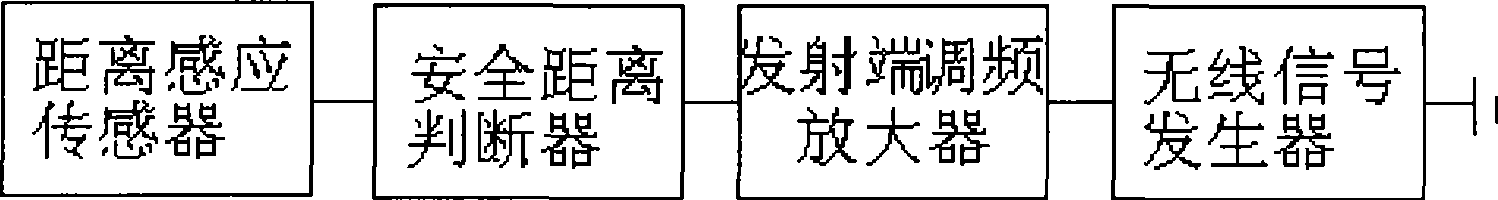

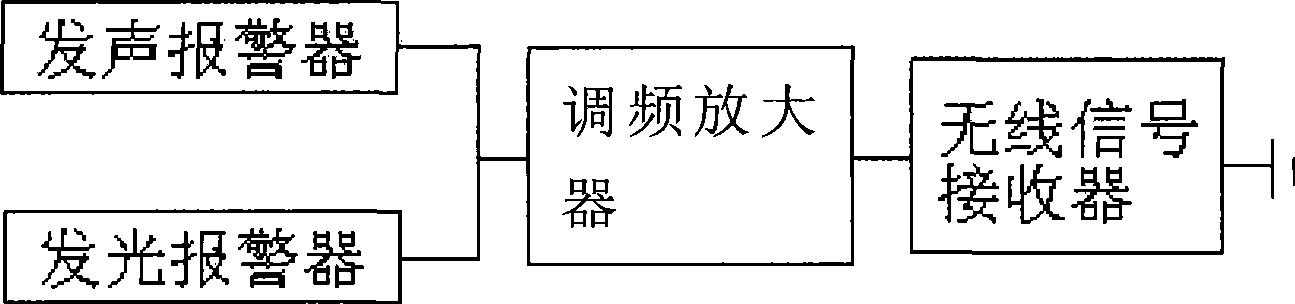

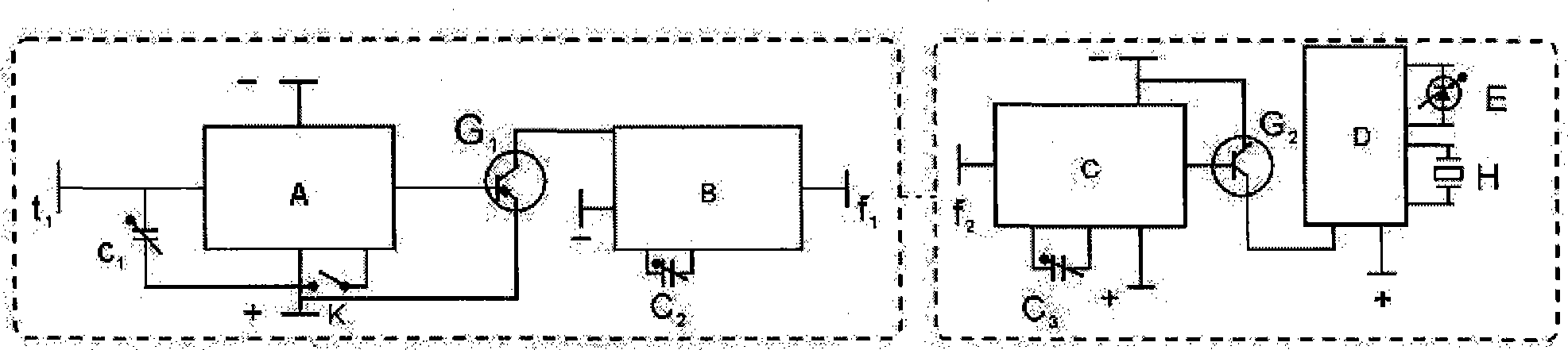

Alarm for construction machinery while approaching high tension power line

InactiveCN101425217AReduce tripsImprove power supply reliabilityUsing electrical meansAlarmsHigh pressureFrequency modulation

The invention relates to an alarm for the approach of construction equipment to a high-voltage power transmission circuit, in particular to an alarm preventing large-size construction equipment such as cranes, and the like from approaching high-voltage power transmission circuits in a distance which is smaller than a safety distance. The alarm mainly comprises a detection device and an alarm device, wherein a circuit structure of the detection device comprises a transmission line distance sensing transducer, a safety distance judger, a transmission terminal frequency-modulation amplifier, a wireless signal generator and a transmission antenna which are all sequentially connected. A circuit structure of an alarm device comprises a receiving antenna, a wireless signal receiver, a second amplification dynatron, a frequency-modulation amplifier, a light emitting diode connected with the frequency-modulation amplifier, and a buzzer which are all sequentially connected. The invention can meet different requirements of the safety distance of transmission lines in different voltage levels, has convenient maintenance, can reduce the transmission line trip, casualties and equipment damage caused by the external damage of transmission lines by large-size construction equipment such as cranes, and the like, and can improve the power supply reliability of transmission lines.

Owner:WUXI POWER SUPPLY JIANGSU PROVINCE ELECTRIC POWER

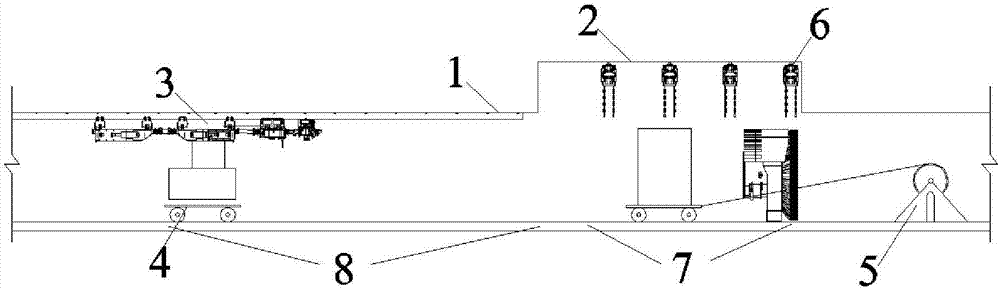

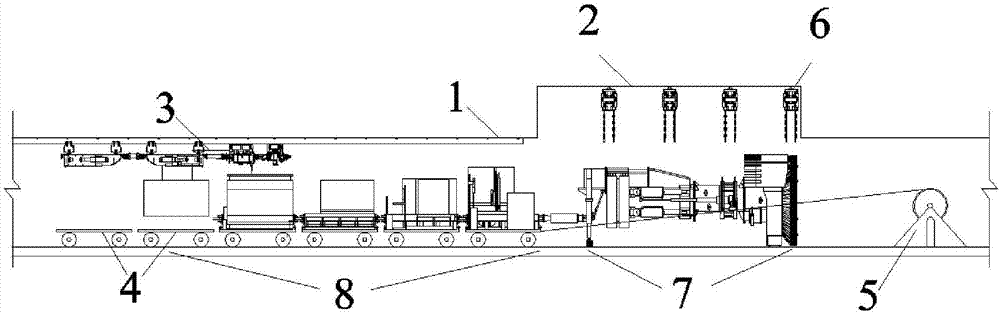

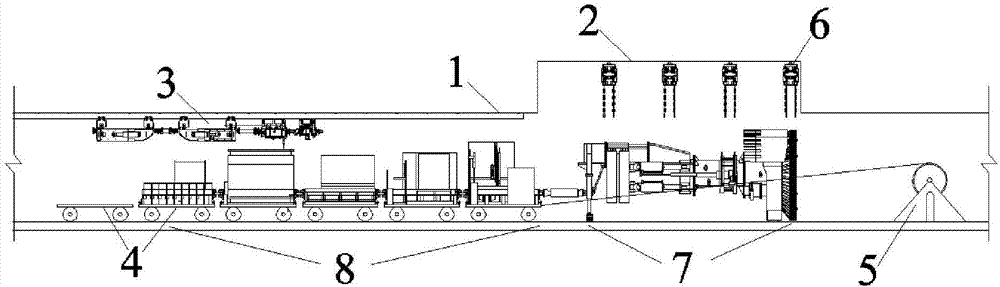

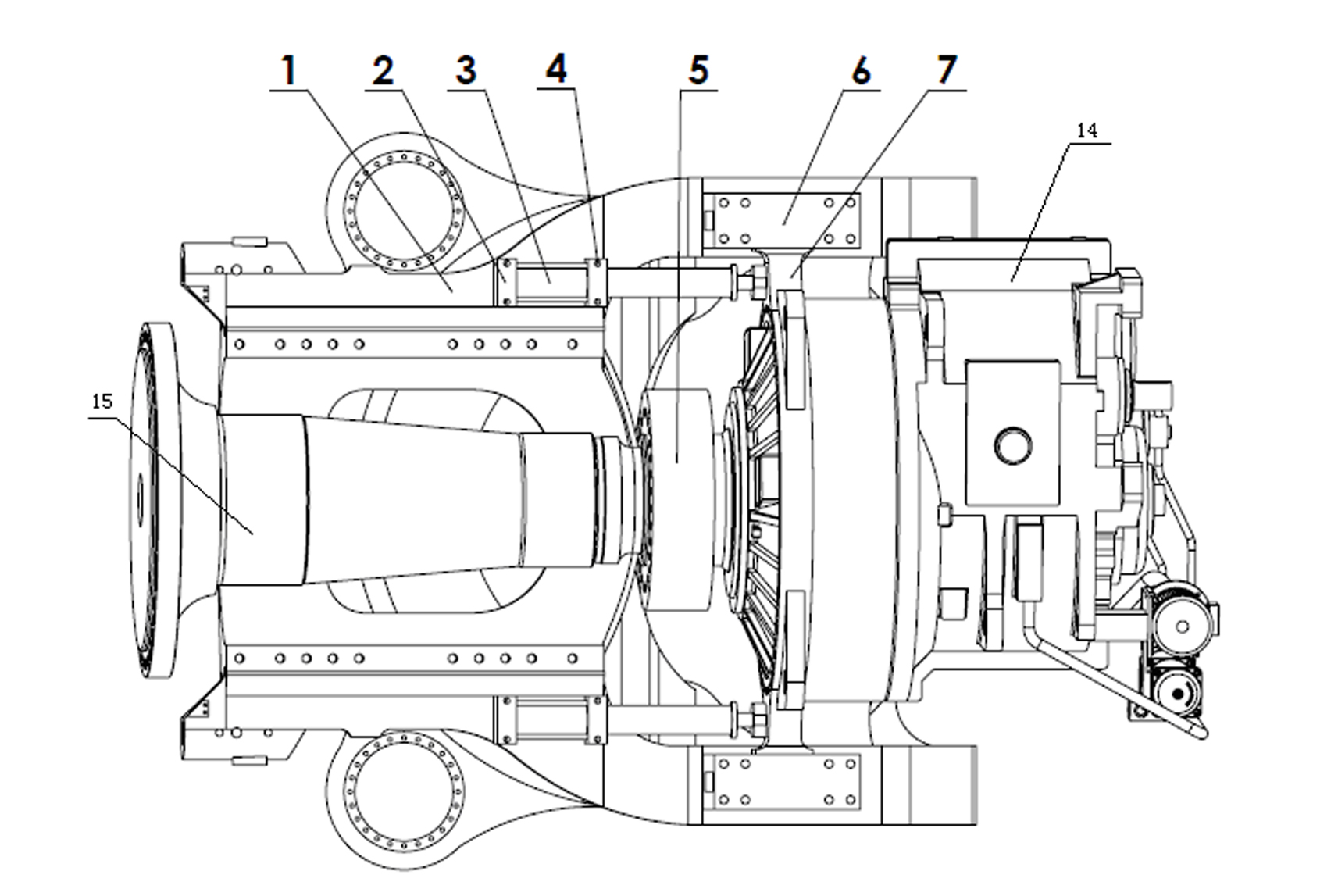

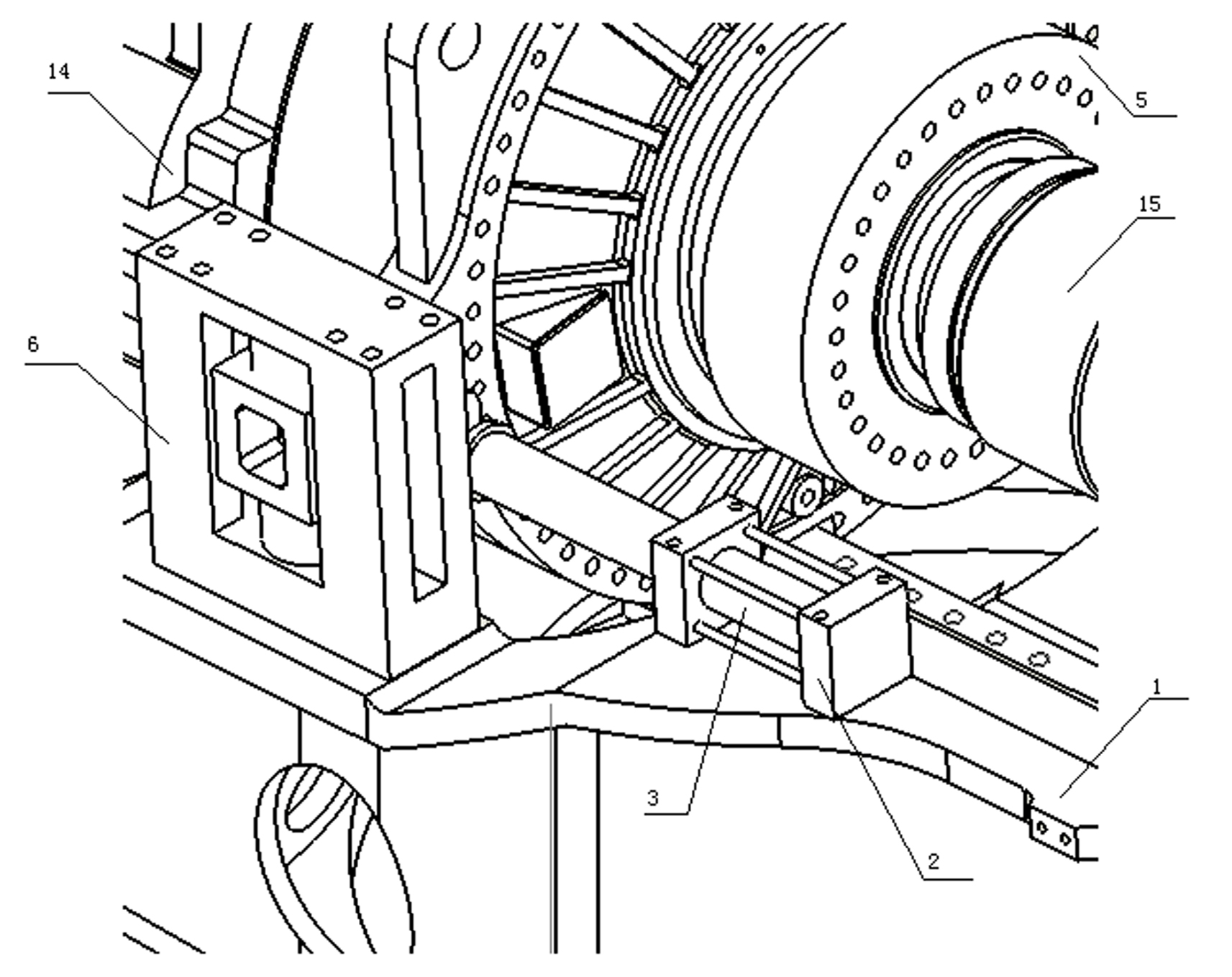

Underground mine TBM assembly construction method

The invention provides an underground mine TBM assembly construction method. The underground mine TBM assembly construction method comprises the following steps that (1) chamber assembly is constructed, and an existing roadway of an underground mine and a chamber assembly expanding excavation section serve as a TBM assembly chamber; and the chamber assembly expanding excavation section is formed through expanding excavation of one end of the existing roadway. (2) TBM parts transportation is constructed, TBM parts are placed on a platform truck through a monorail hoist, and a winch connected with the platform truck is pulled to a preinstalled position. (3) TBM parts assembly is constructed, the TBM parts are installed through a lifting pulley or the monorail hoist, and the TBM installation is finally completed. According to the underground mine TBM assembly construction method, the existing roadway is used as the assembly chamber, a vertical shaft is not needed to be re-excavated on an assembly site, and the feasibility of construction is improved; and large scale equipment of a gantry crane and the like are not needed to be installed under the shaft by using small scale installation equipment of the monorail hoist, the lifting pulley, the winch and the like, the work amount of the expanding excavation and transformation is small, the assembly construction period is shortened, and meanwhile the engineering cost is saved.

Owner:ANHUI UNIV OF SCI & TECH +1

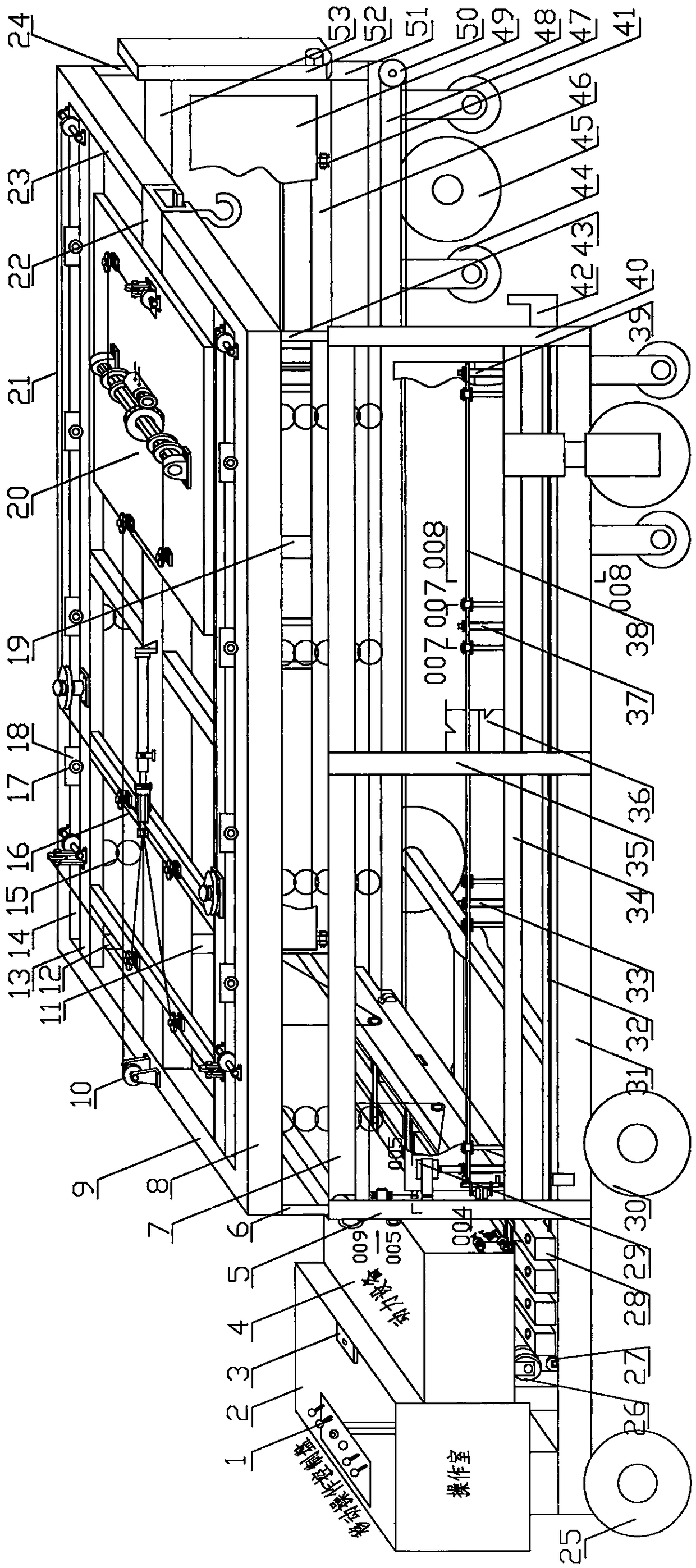

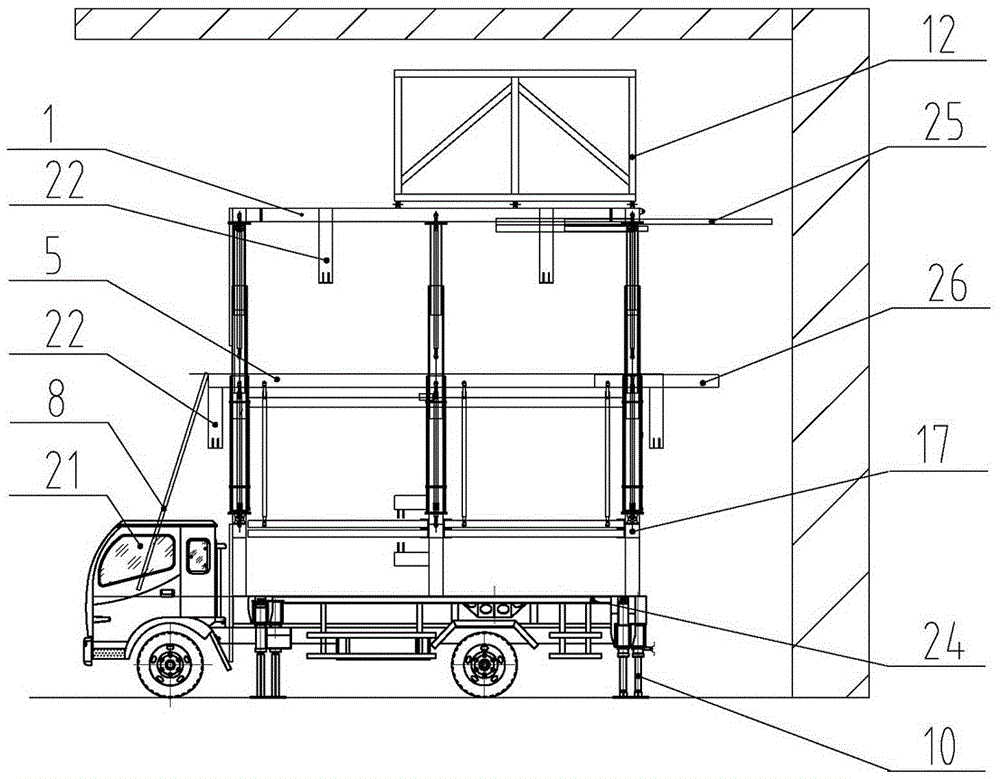

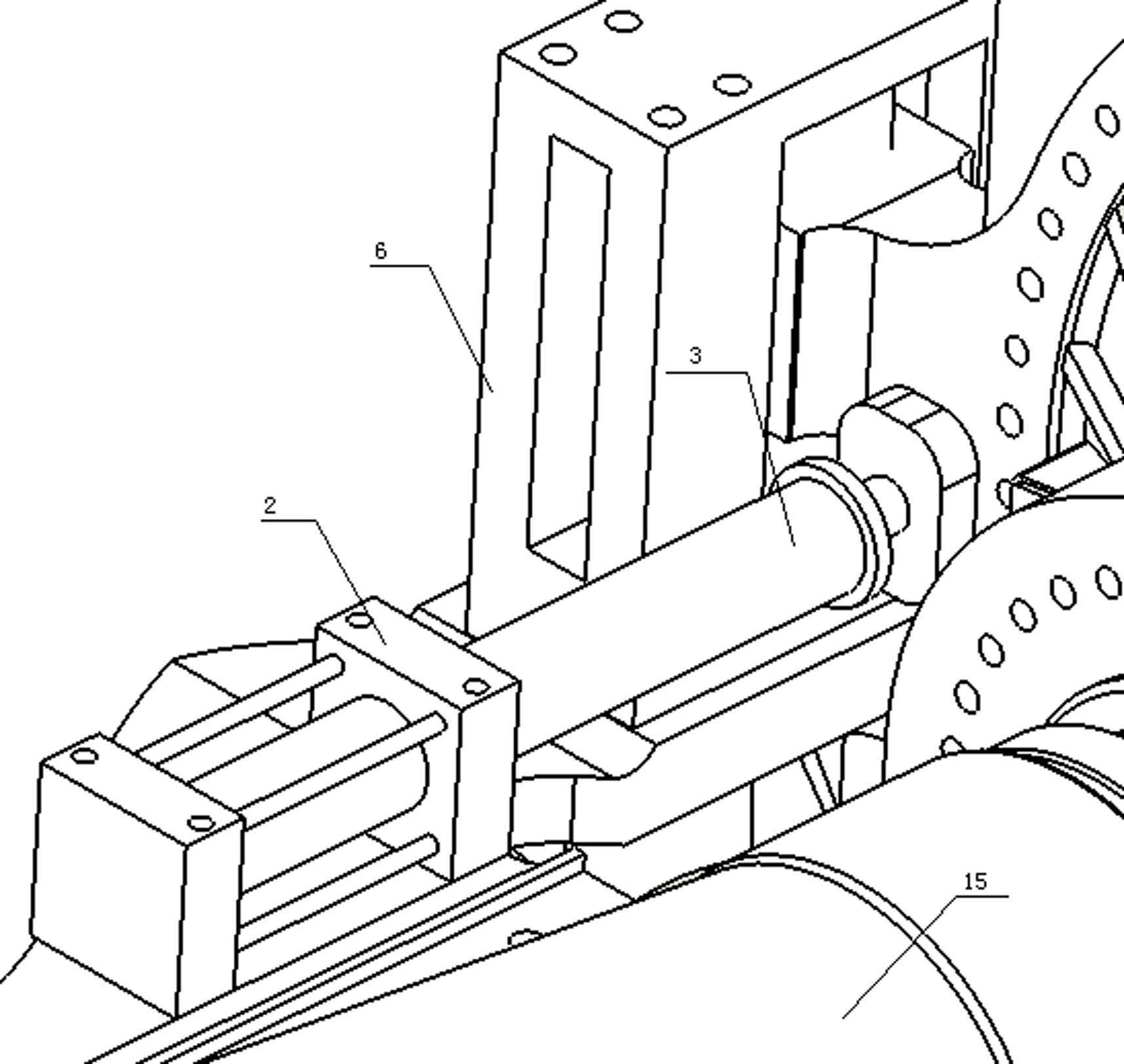

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

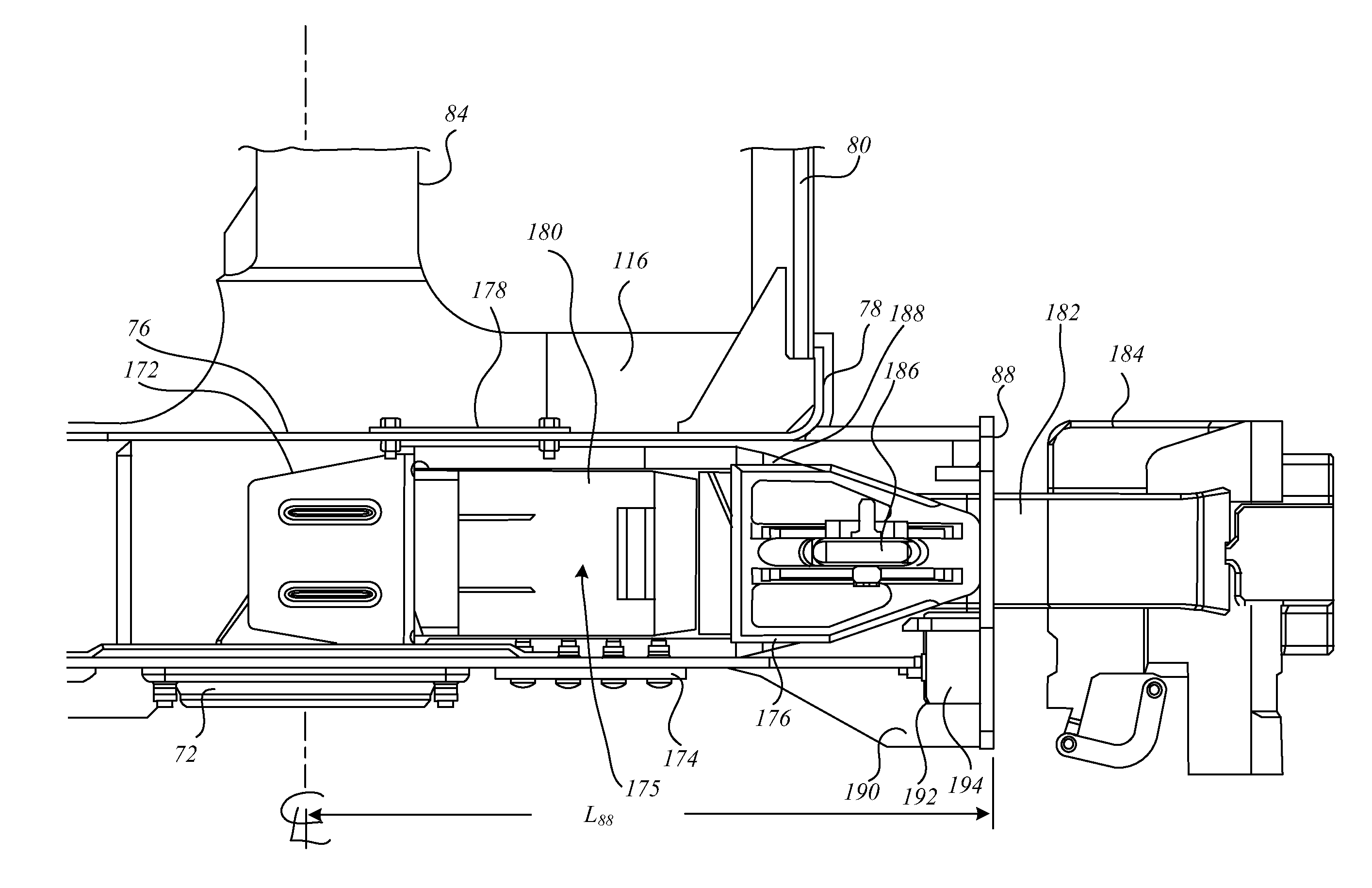

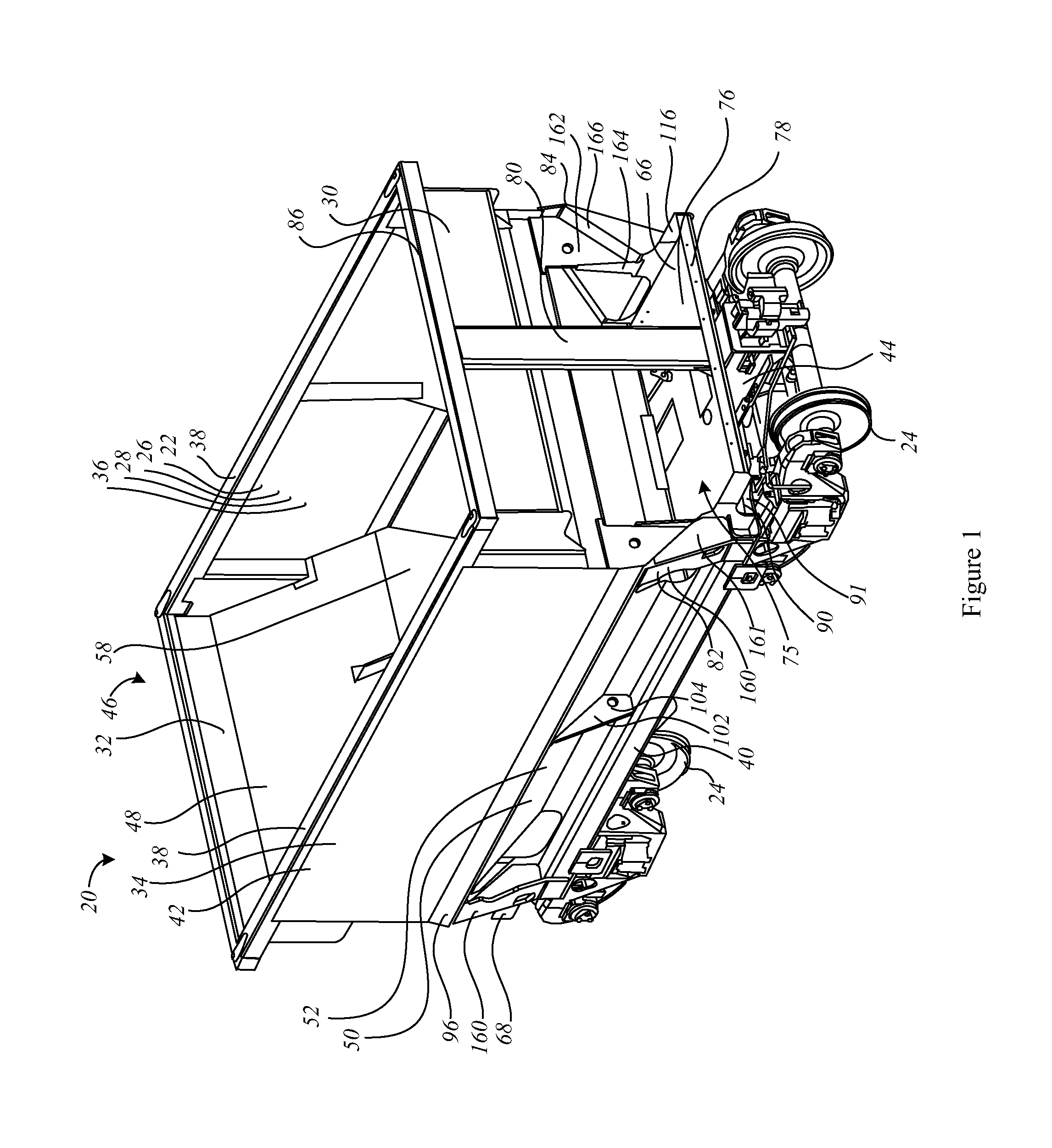

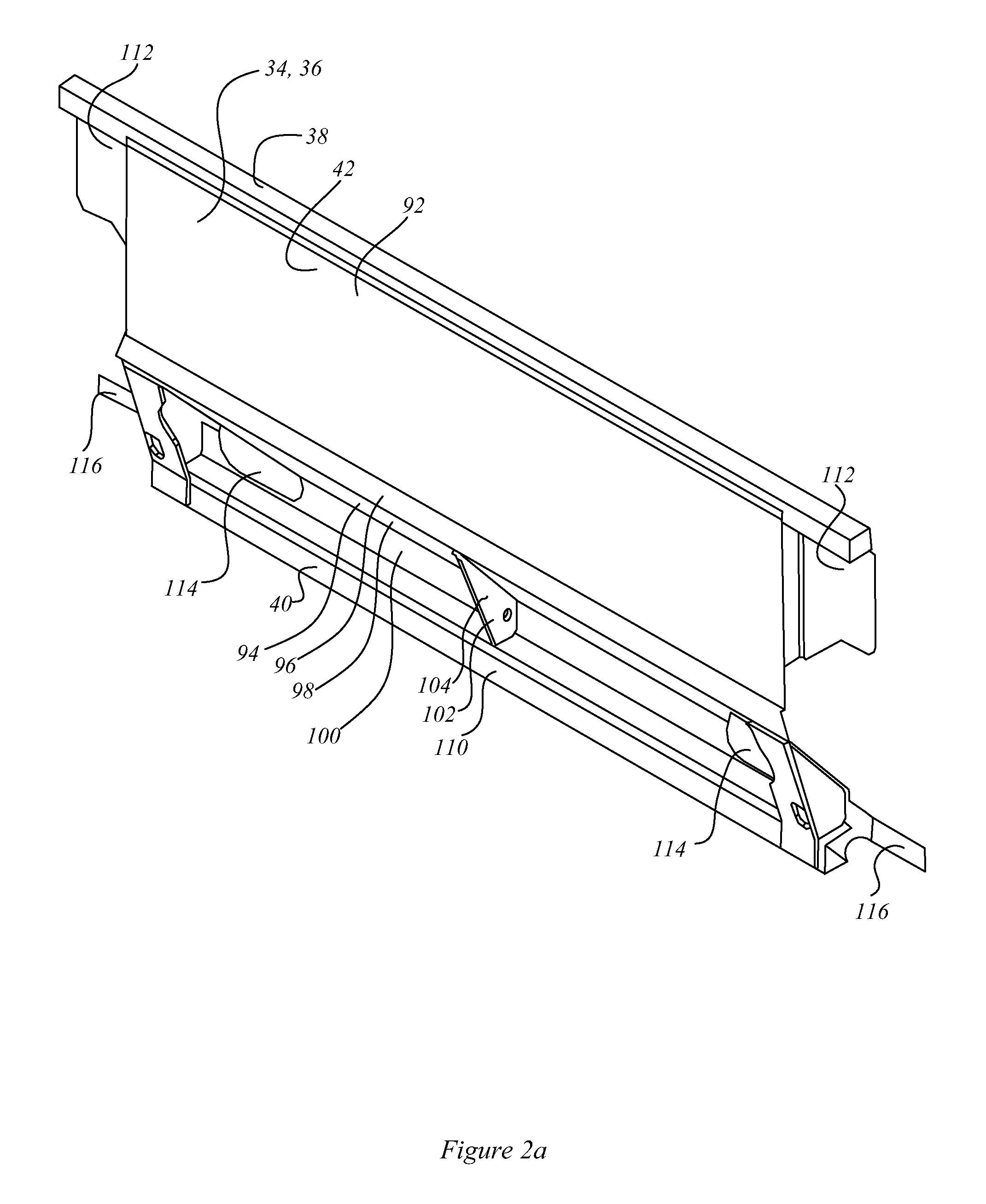

Railroad gondola car structure and mechanism therefor

A railroad gondola car has a hopper carried between two trucks. The hopper has convergent end and side slope sheets that feed a bottom discharge. The bottom discharge has a pair of longitudinal doors. The car has a very short draft installation that includes a removable coupler carrier bar, and the main shear plate has a removable draft gear installation cover. The rear draft stop extends longitudinally inboard past the truck center. The couple arrangement includes an AAR Type E shank with an AAR Type F coupler There is a machinery space above the end section shear plate. It is overhung by the slope sheet that is substantially unobstructed by any other primary structure. The pneumatic cylinder is mounted on an angle in this unobstructed machinery space, oriented longitudinally over the draft sill beneath the main drag link of the mechanical transmission, and above the main pivot of the driving input lever of the transmission. The main lever is bifurcated, and straddles the pneumatic cylinder. The lower portion of the side sheets lies laterally inboard of the stiffener web, while the upper portion lies laterally outboard of the stiffener web. The side slope sheet of the hopper meets the sidewall at the transition of the sidewall sheet from the inside-the-post to the outside-the-post condition.

Owner:NATIONAL STEEL CAR

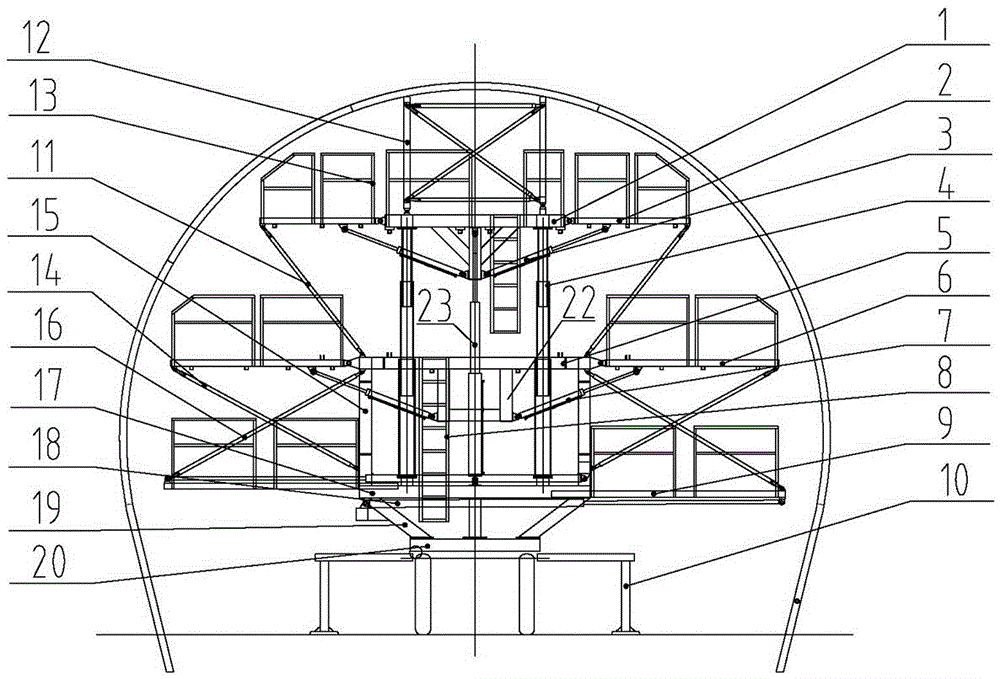

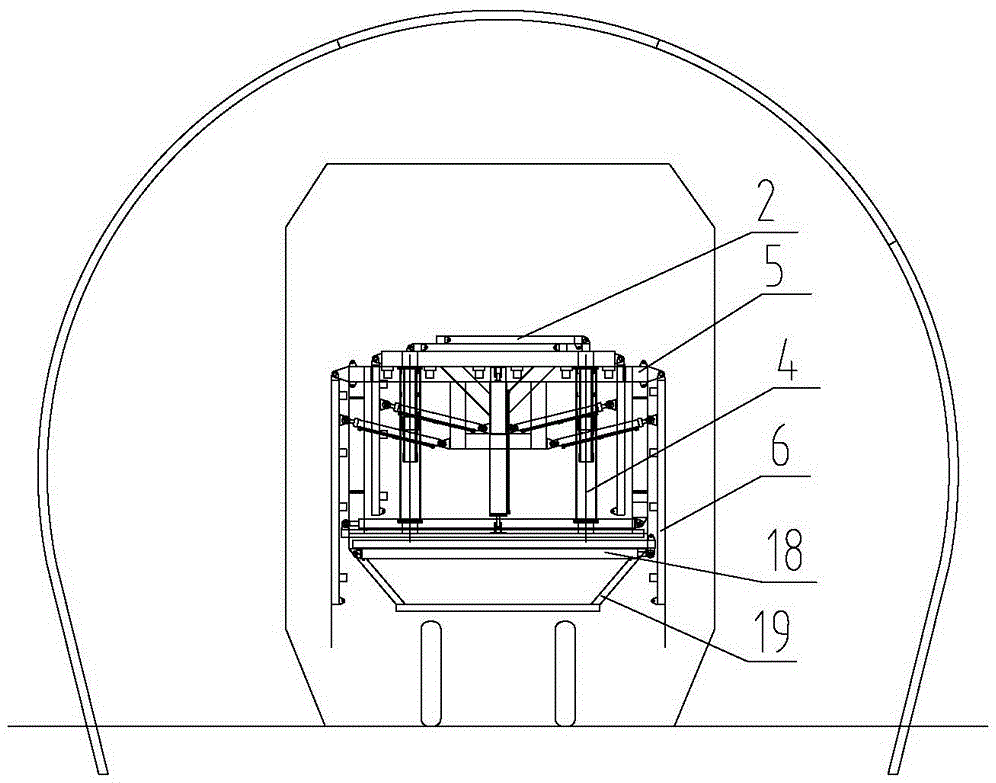

Tunnel vehicle-mounted folding type multifunctional work rack

ActiveCN106437795AMeet the installation requirements of any height spaceSatisfy initial support workUnderground chambersTunnel liningSUSPENDING VEHICLESteel bar

Provided is a tunnel vehicle-mounted folding type multifunctional work rack. According to the tunnel vehicle-mounted folding type multifunctional work rack, a crane chassis is used as a mobile power, and a vehicle-mounted hydraulic system is used as a hydraulic power. A fixed main supporting structure is arranged on the crane chassis. A bottom layer stretching work platform is arranged below the fixed main supporting structure, a middle layer replicating work platform is arranged above the fixed main supporting structure, and a top layer replicating work platform connected through a top layer work platform ring beam is arranged in the middle of the fixed main supporting structure. A hydraulic oil cylinder manipulates the three layers of work platforms to stretch or retract, thus the work rack is convenient and efficient. Stretching height of the top layer platform can be adjusted at random, thus installation requirements of random height space of a loopfull lagging jack can be met; landing legs are used to support the work rack, thus the work rack is safe and reliable and has good stability. The volume of the tunnel vehicle-mounted folding type multifunctional work rack is more than half smaller than a traditional rack, and the tunnel vehicle-mounted folding type multifunctional work rack can drive fast in preset grooving equipment travel space so that the speed of entry and retreat of constructions is quickened. After stretch, the work rack can meet elementary shoring construction and advanced reinforcement work of tunnel face under a whole fracture surface excavation method, and is also applicable to work of secondary lining waterproof construction and reinforcing steel bar construction.

Owner:CHINA RAILWAY TUNNEL GRP ROAD & BRIDGE ENG CO LTD

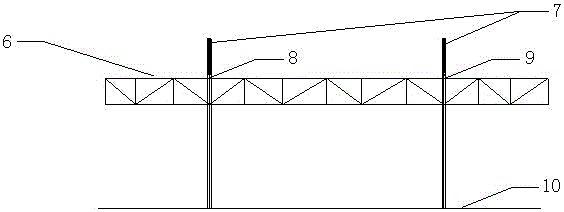

Lifting method of steel structure roof truss pulling bar in narrow space

ActiveCN106703416AAdvantages of the rod lifting methodLittle need for hoisting spaceBuilding material handlingSUSPENDING VEHICLEEconomic benefits

The invention provides a lifting method of a steel structure roof truss pulling bar in a narrow space. The steel structure roof trusses have a total weight of 400 tons, and 5 steel trusses are provided. Each steel truss is 34 meters in length, and 2 meters in height. Towers located at both sides obstruct, and do not allow a crane to enter into a site for a lifting operation. The method is characterized by comprising the steps of step a, each steel truss of the steel structure roof truss section is lifted to the assembling position of all the steel trusses, step b, assembling and welding the steel truss sections into the whole truss, step C, enabling a whole truss to be located on a concrete column by the lifting of a pulling bar to complete the installation of the steel structure roof truss. The lifting method of the steel structure roof truss pulling bar in the narrow space has the advantages of being low in space demand, simple in method, convenient in construction, capable of securing the construction of a wide-span steel truss in an effective mode, greatly reducing the safety risks in the lifting operation in the narrow space and the construction cost in the steel truss lifting operation, and satisfying the economic benefits of the lifting operation.

Owner:MCC5 GROUP CORP SHANGHAI

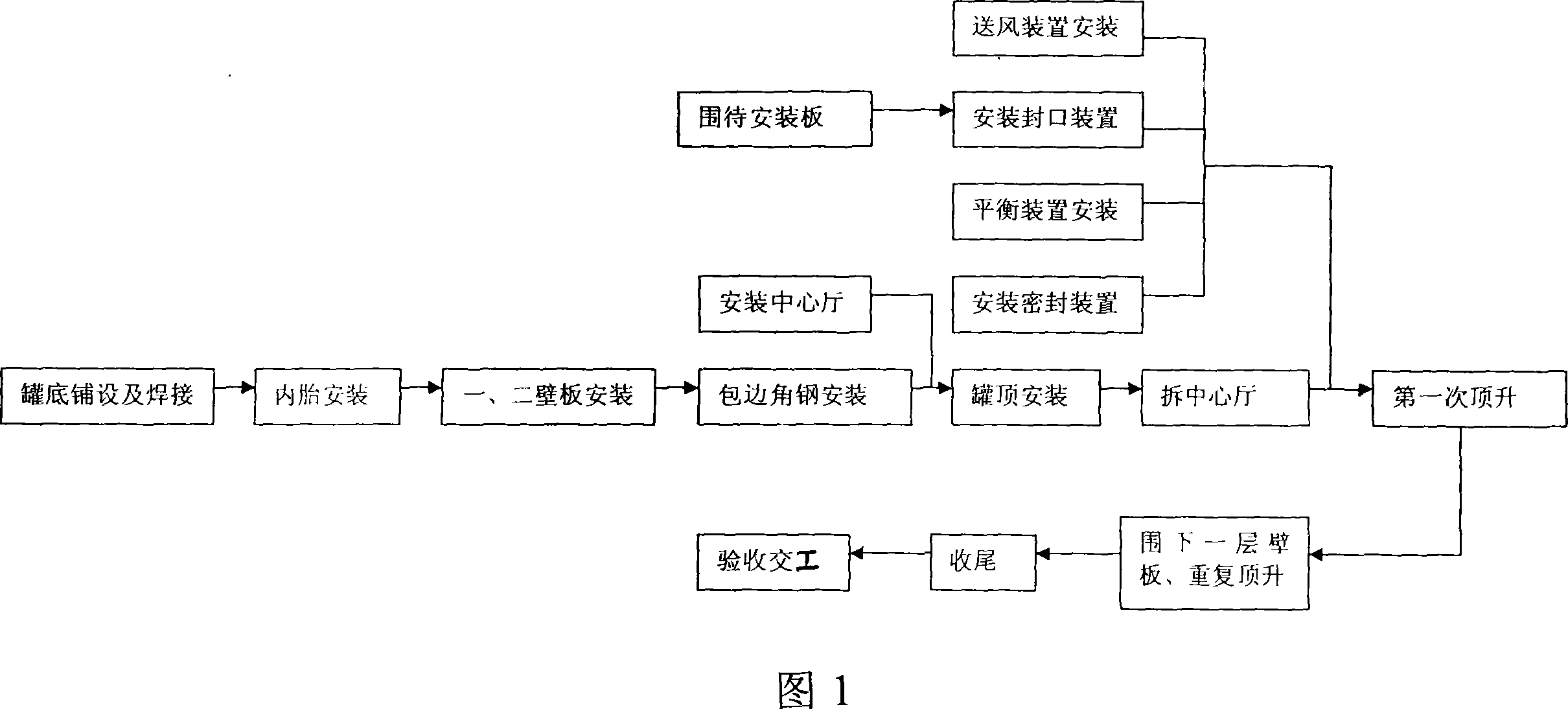

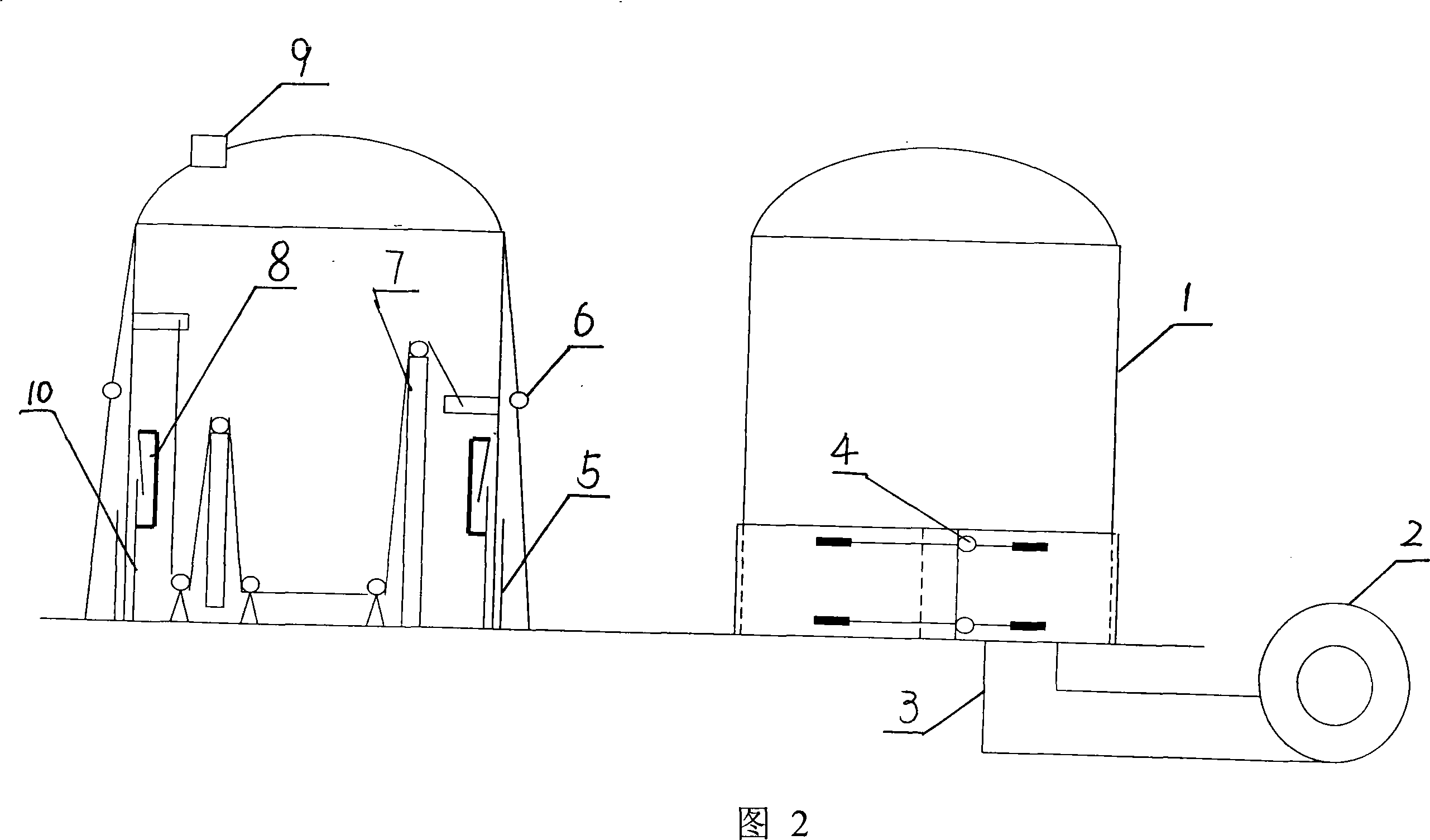

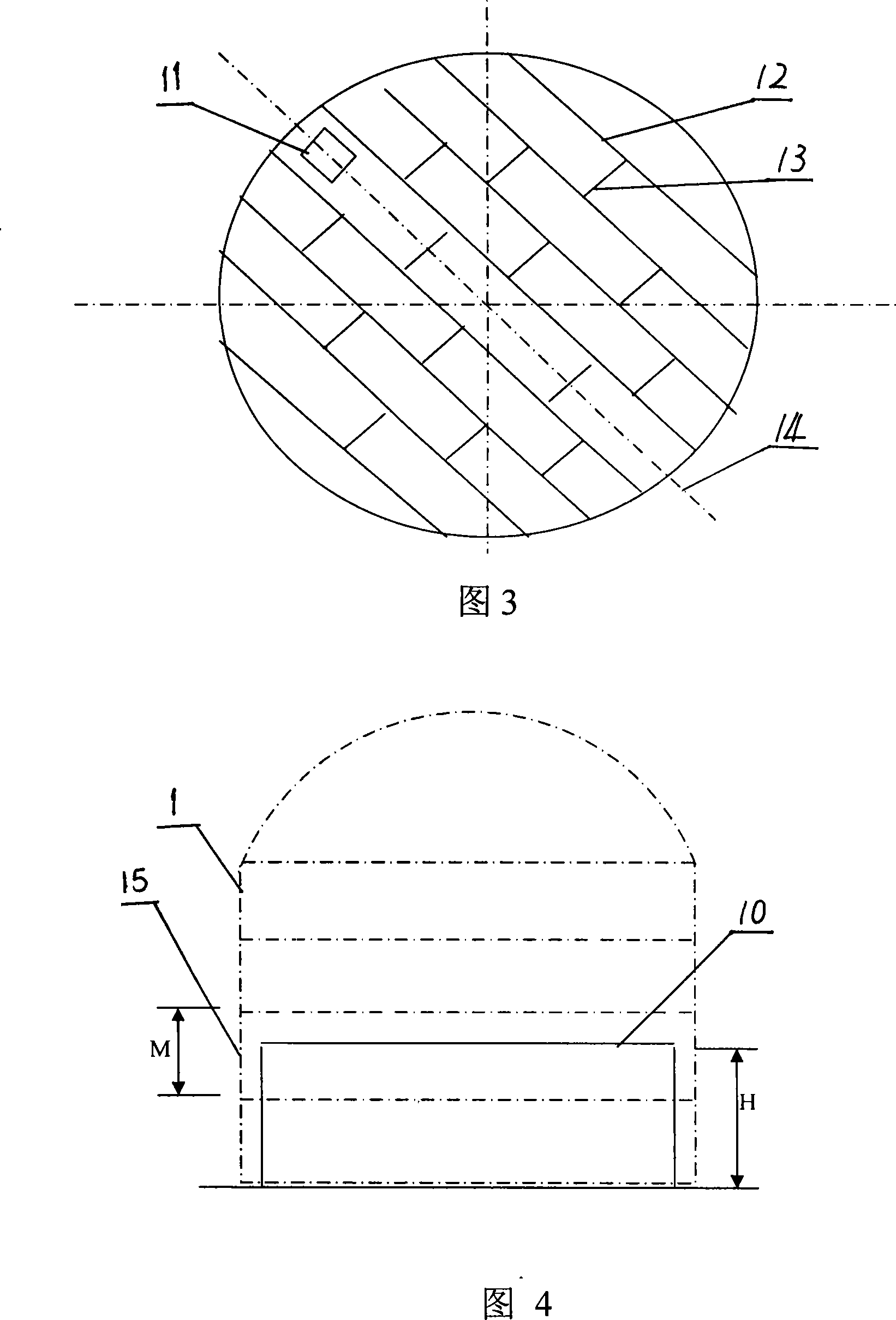

Silo high-altitude pressure-swing gas-cap mounting process

ActiveCN101200982AEasy to masterLarge working surfaceBulk storage containerSUSPENDING VEHICLEEngineering

The invention provides a high altitude mounting method of pressure transformative gas cap of silo, belonging to the high altitude machine mounting method technical field, and comprising a storage tank body. The mounting method includes the following steps: the mounting and welding of the bottom plate of the tank; the mounting of the inner tube; the mounting of first and the second wainscot and the angle steel for wrapping the edge; the mounting of a central space; the mounting of the tank roof; the removing of the central space; wrapping of the plates to be mounted; mounting of the mouth closing device; mounting of the balancing device; mounting of the sealing device. The invention is a mounting method of storage tank, which adopts the gas cap technology. The method is simple and easily grasped, the working space is wide, the construction period is short, few types of equipment are used, the structure is simple and nonbreakable, and the maintenance is convenient. As the invention is an inverted mounting method of gas cap, large-scale crane and high altitude operations are unnecessary, thereby large amount of falsework is saved, and the operations are safe.

Owner:CHINA 22MCC GROUP CORP

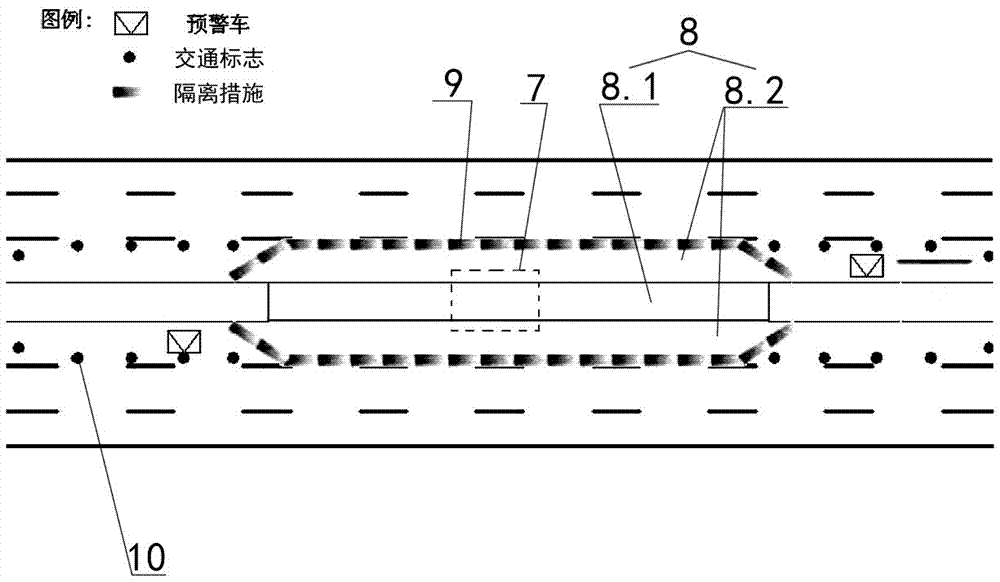

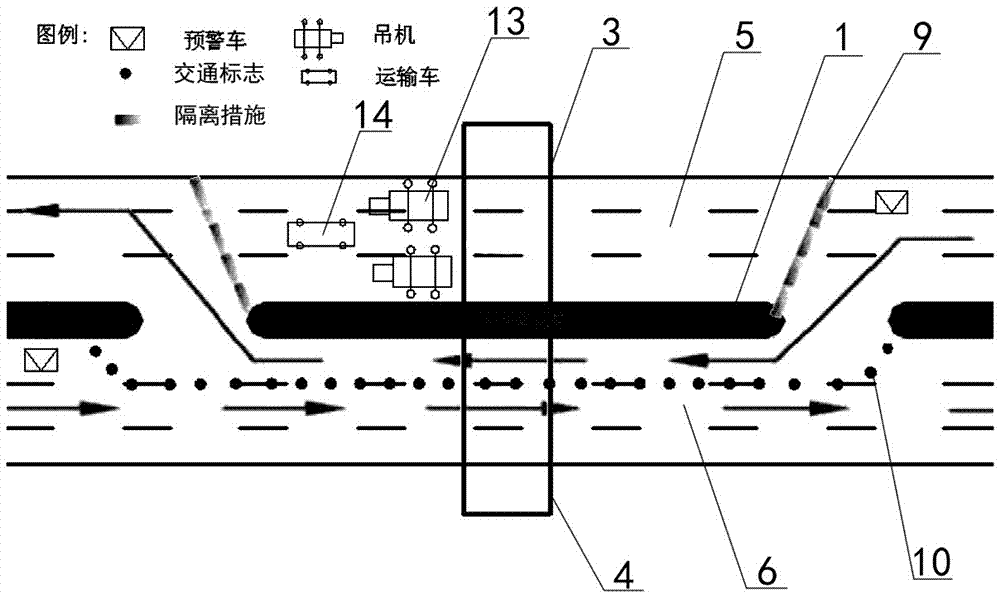

Construction method and special guard screen for static demolition and home position reconstruction of overpass bridge

PendingCN107268462AImprove the level of civilized constructionEnsure safetyRoadwaysBuilding repairsSocial benefitsEconomic benefits

The invention relates to a construction method and a special guard screen for static demolition and home position reconstruction of an overpass bridge. A static demolition method comprises the following steps of performing mid-span bridge surface separation; performing hoisting hole arrangement, blocking, symmetric cutting and hoisting away on anti-collision walls on two sides; performing hoisting hole arrangement and hinging crack cutting and separation on same-span simply supported beams; and performing sequential hanging away one by one from left to right or from right to left and the like. A home position reconstruction method comprises the following steps of constructing stand columns and bent caps, constructing beam plates, constructing auxiliary engineering, and the like. According to the construction method disclosed by the invention, the structure of the overpass bridge is demolished according to the requirement that the traffic is not interrupted, a method comprising the following steps of determining the sequence of demolishing the bridge and separating spans, blocking and cutting anti-collision guardrails, and cutting and lifting a main beam is adopted, so that beam members are cut into blocks, are hoisted by a crane, and can be directly transported away by a transporting vehicle; the method is high in civil construction degree, simple and easy to operate, wide in application range, and easy to popularize; the situation that passing under the overpass bridge and the construction are safe is guaranteed; during construction, the situation that passing of the highway is smooth and safe is guaranteed; the civil construction degree is high; and the construction method has good social benefits and economic benefits.

Owner:ZHEJIANG COMM CONSTR GRP CO LTD

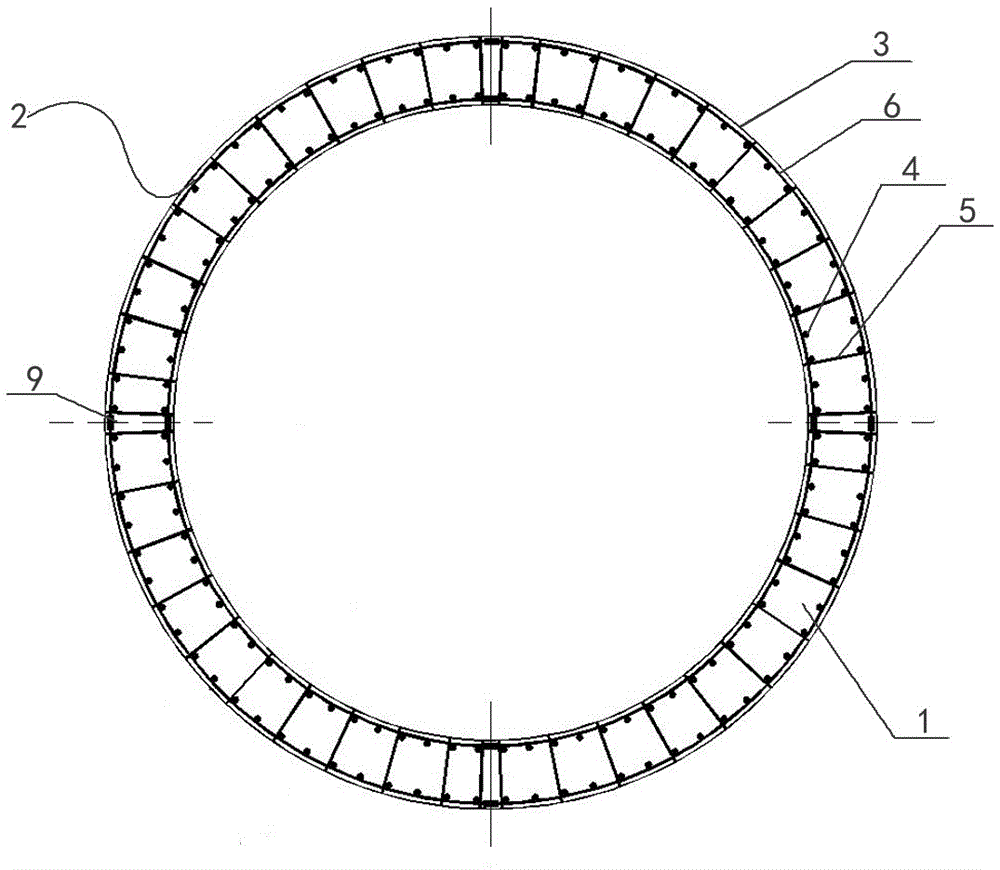

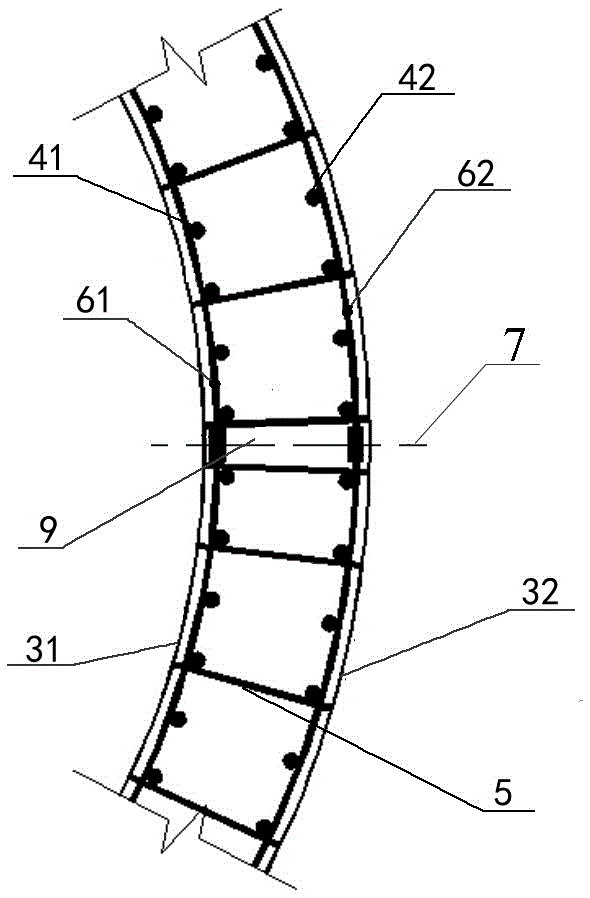

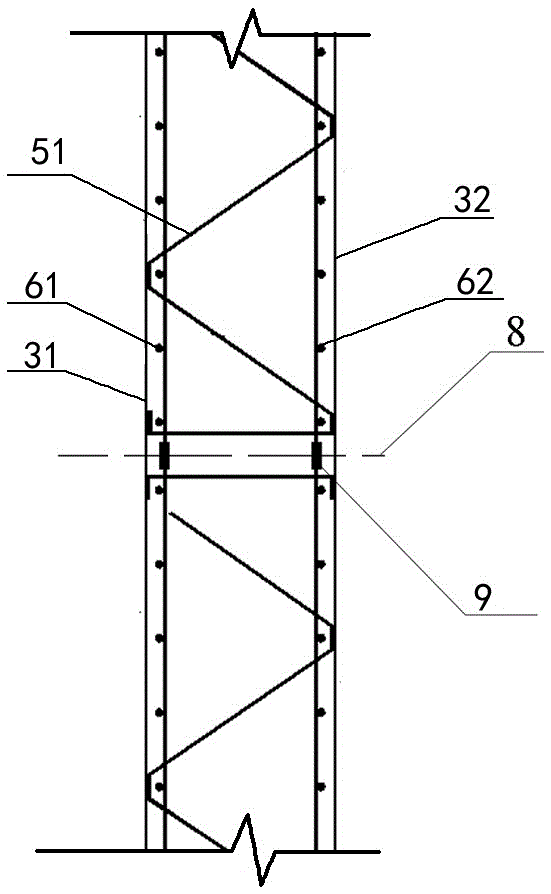

Cast-in-place concrete tower with prefabricated spatial steel bar truss formwork and construction method of cast-in-place concrete tower

ActiveCN106088780ASmall tonnageReduce lifting weightForms/shuttering/falseworksTowersHorizontal stressSUSPENDING VEHICLE

The invention discloses a cast-in-place concrete tower with a prefabricated spatial steel bar truss formwork and a construction method of the cast-in-place concrete tower. The cast-in-place concrete tower comprises the spatial steel bar truss formwork and concrete cast into the spatial steel bar truss formwork in place, and is characterized in that the spatial steel bar truss formwork is a disposable prefabricated formwork, is formed by splicing a plurality of spatial steel bar truss formwork units and is in a cylinder shape; each spatial steel bar truss formwork unit is of an arc-shaped sheet structure and comprises reinforcing bars in the middle and disposable steel formworks attached to the inner and outer sides of the reinforcing bars respectively, wherein the reinforcing bars comprise an inner layer of evenly-arranged vertical stressed steel bars, an outer layer of evenly-arranged vertical stressed steel bars, horizontal stressed steel bars used for tying the vertical stressed steel bars on the same layer, and tie stirrups arranged in a radial mode and used for tying the inner layer of vertical stressed steel bars, the outer layer of vertical stressed steel bars and the horizontal stressed steel bars at the same time. By adopting the technology, it is only needed to install the spatial steel bar truss formwork in a hoisting mode in site construction, the hoisting weight is greatly reduced, the needed crane tonnage is greatly reduced, and the construction cost is greatly reduced.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

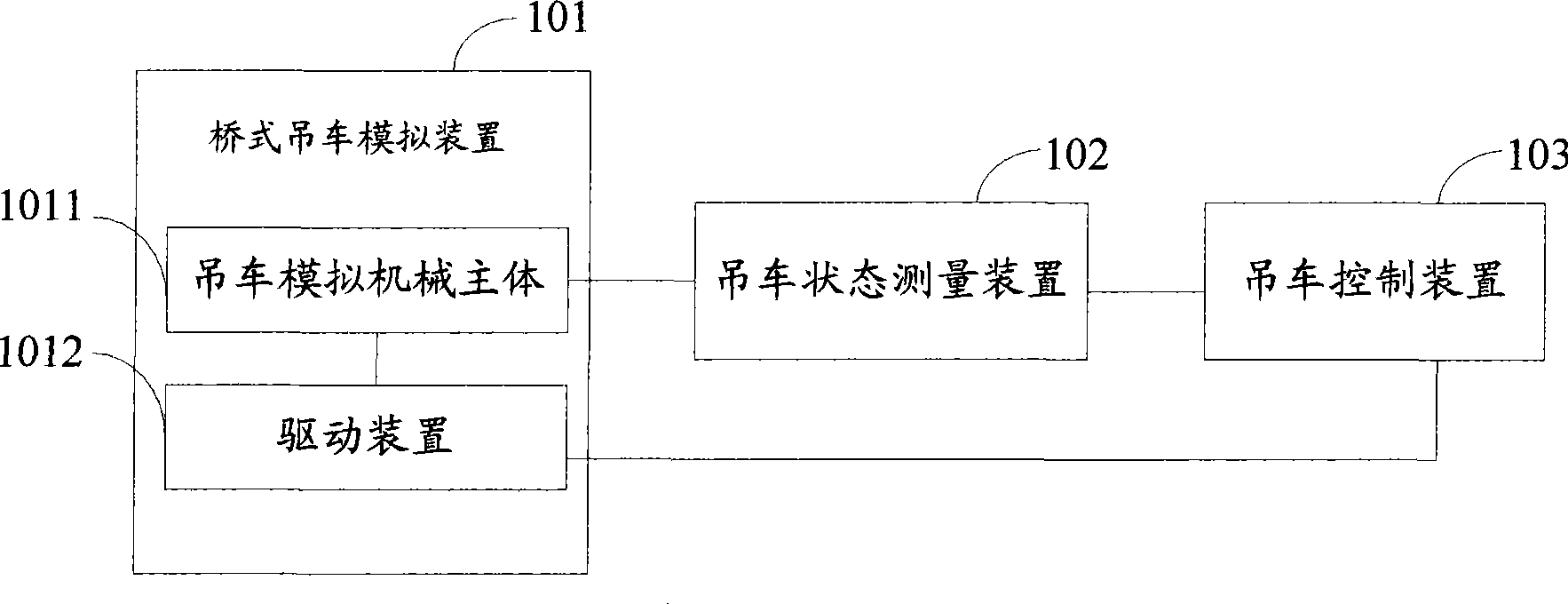

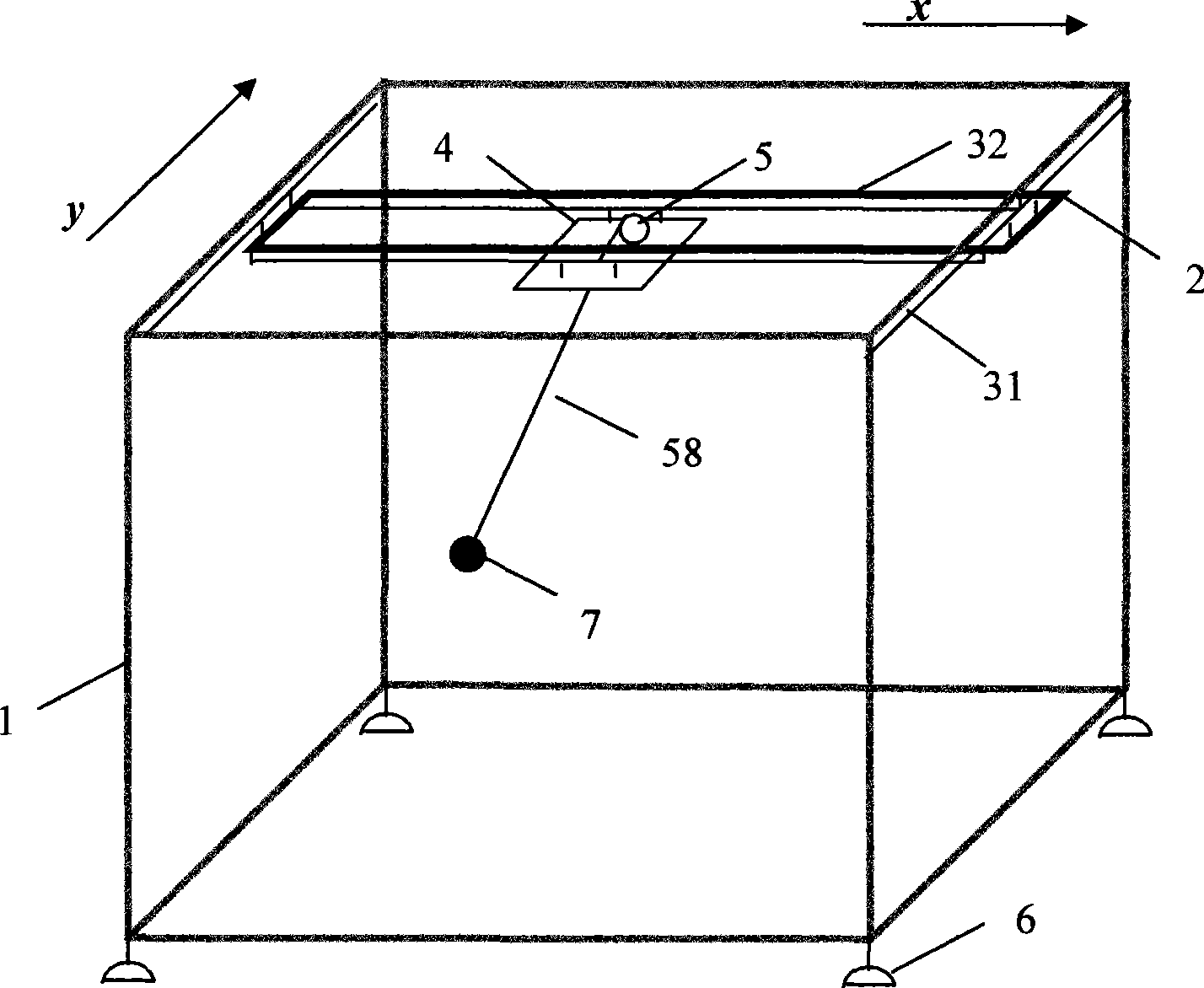

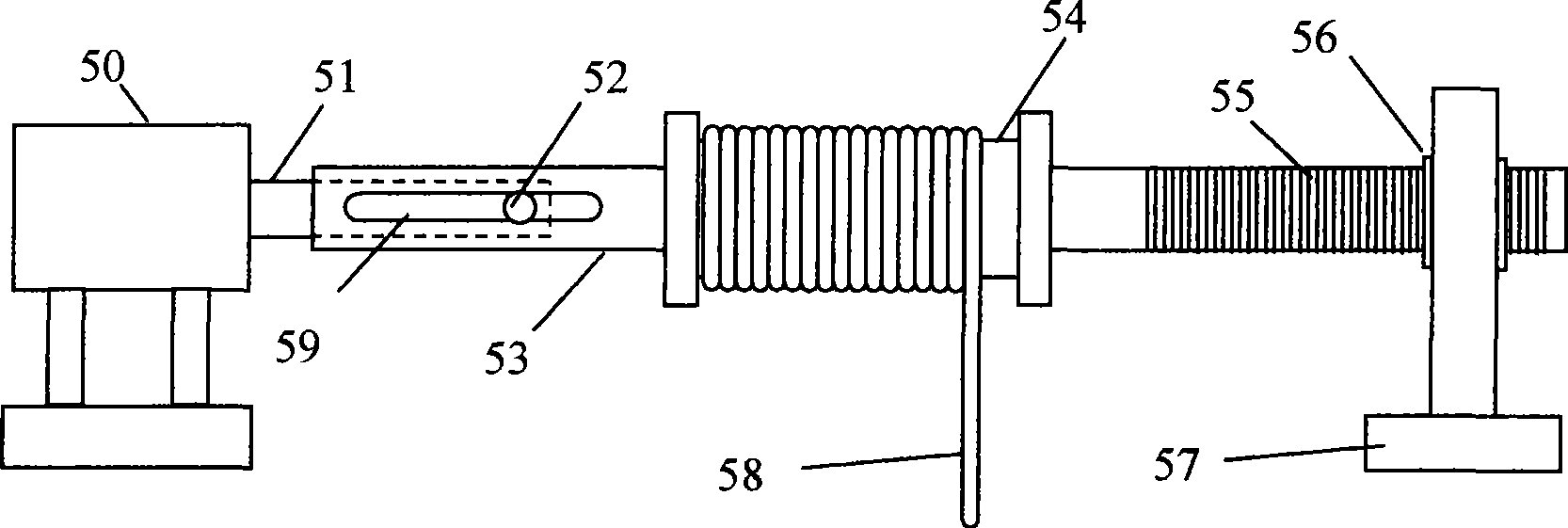

Automatic experiment system for bridge type crane

InactiveCN101419764AEasy to replaceOptimize data processingEducational modelsSUSPENDING VEHICLEAutomatic control

The invention discloses a bridge crane automatic control experimental system which comprises a real bridge crane simulating device, a crane state measuring device and a crane control apparatus, wherein, the bridge crane simulating device is used for simulating a structure of a real bridge crane system which is a control object of the whole experimental system; the crane state measuring device is used for measuring the state quantity information of the bridge crane simulating device in real time and sends the information to the crane control apparatus; and the crane control apparatus is used for receiving the state quantity information of the bridge crane simulating device, which is measured by the crane state measuring device, calculates a corresponding control signal at real time by a preset control method according to the state quantity information and then sends the control signal to the bridge crane simulating device, so as to control the bridge crane simulating device to operate according to preset requirement. The bridge crane automatic control experimental system reflects the kinematic and dynamic characteristics of the bridge crane actually and can validate the practical effect of existing different crane control methods.

Owner:NANKAI UNIV

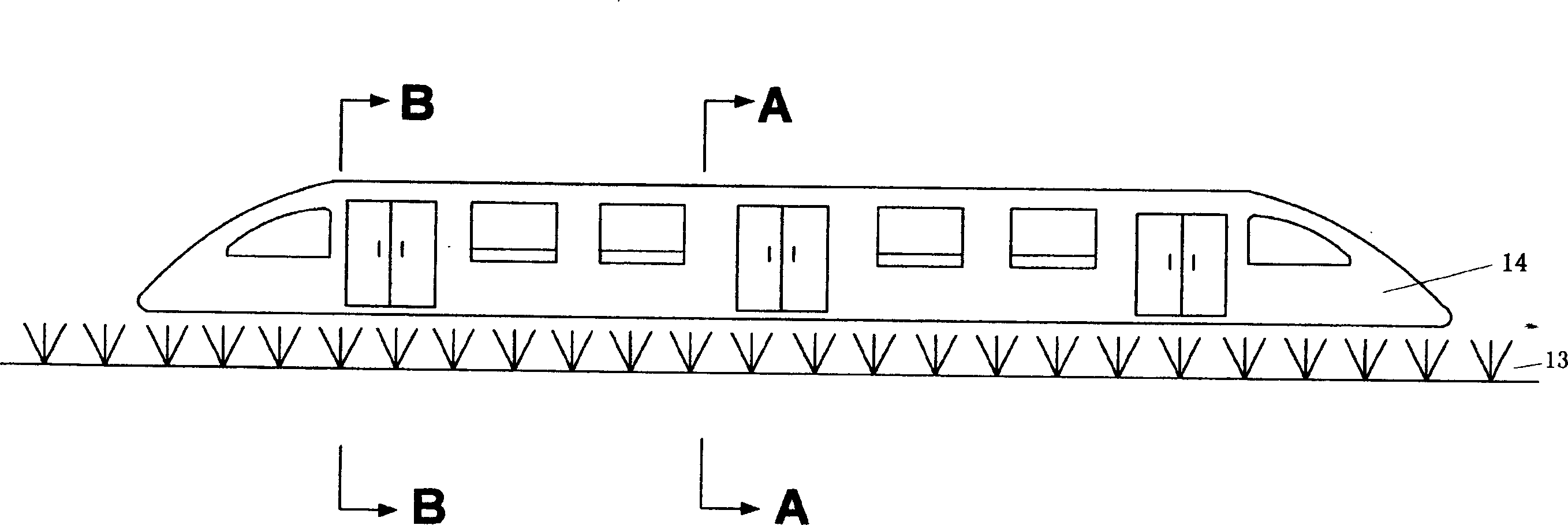

Concealed rail permanent magnet compensation type suspension railway-train system

InactiveCN1557650ALow costImprove transportation capacityRailway componentsElectric propulsionSUSPENDING VEHICLECulvert

The hidden-rail permanently magnetic compensating suspension road-vehicle system includes hidden rails in two culverts with opening to ground and including permanently magnetic rails, suspension guide rails and side guide rails; and magnetically suspended vehicle including two underground suspended driving compartments and ground load compartment connected via plate web girder. There are winged permanent magnet below the driving compartment corresponding to the permanently magnetic rail, suspension permanent magnet over the driving compartment corresponding to the suspension guide rail, and web girder over the driving compartment connected to the ground load compartment. Inside the suspended driving compartment, there are one driving mechanism and two guiding fixed pulley to contact with the guide rail.

Owner:李岭群

Method and device for disassembling gear box of wind driven generator

The invention relates to a method for disassembling a gear box of a wind driven generator, which comprises the following steps of: a, suspending the gear box on a crane arm through a rope; b, loosening an expansion sleeve and a nut on an elastic supporting seat to ensure that the gear box is detachably connected with an underframe of a forward engine room; and c, respectively arranging a hydraulic jack on two sides of an output shaft of a wind wheel, wherein the bottom end of each hydraulic jack is fixed with the underframe of the forward engine room, and the top end is in contact with the gear box. A device for disassembling the gear box of the wind driven generator comprises two hydraulic jacks connected with a hydraulic pump station and is characterized in that the hydraulic jacks are fixedly arranged on a supporting device, top ends of piston rods of the hydraulic jacks are fixedly provided with fixed blocks, and the supporting device comprises a first supporting block, a second supporting block and a connecting shaft. The method and the device can realize the independent disassembly of the gear box during the user period without disassembling the engine room, thereby shortening the maintenance time and lowering the maintenance cost.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

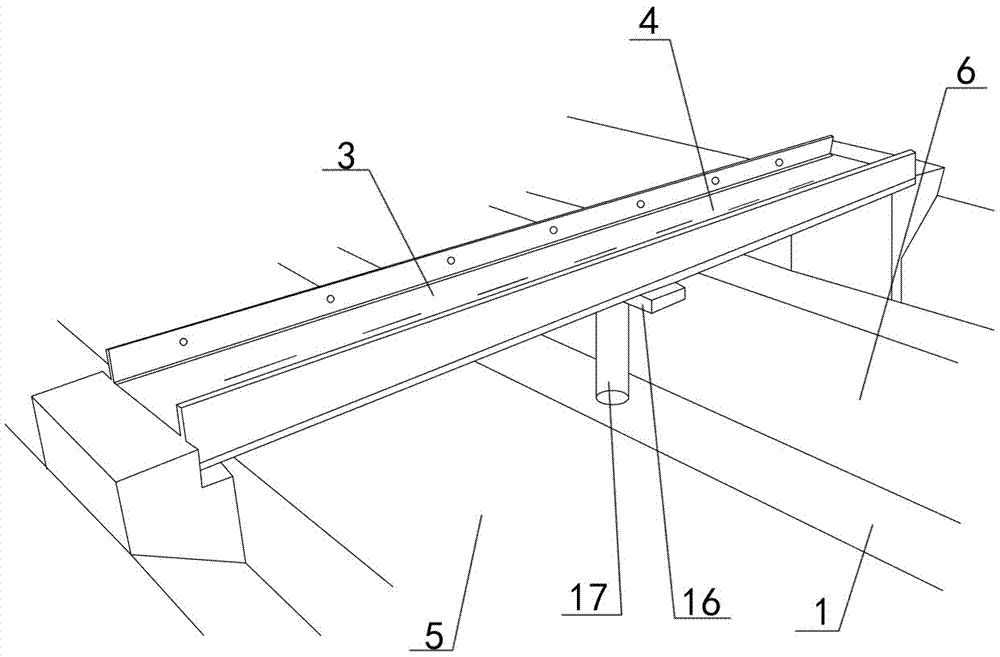

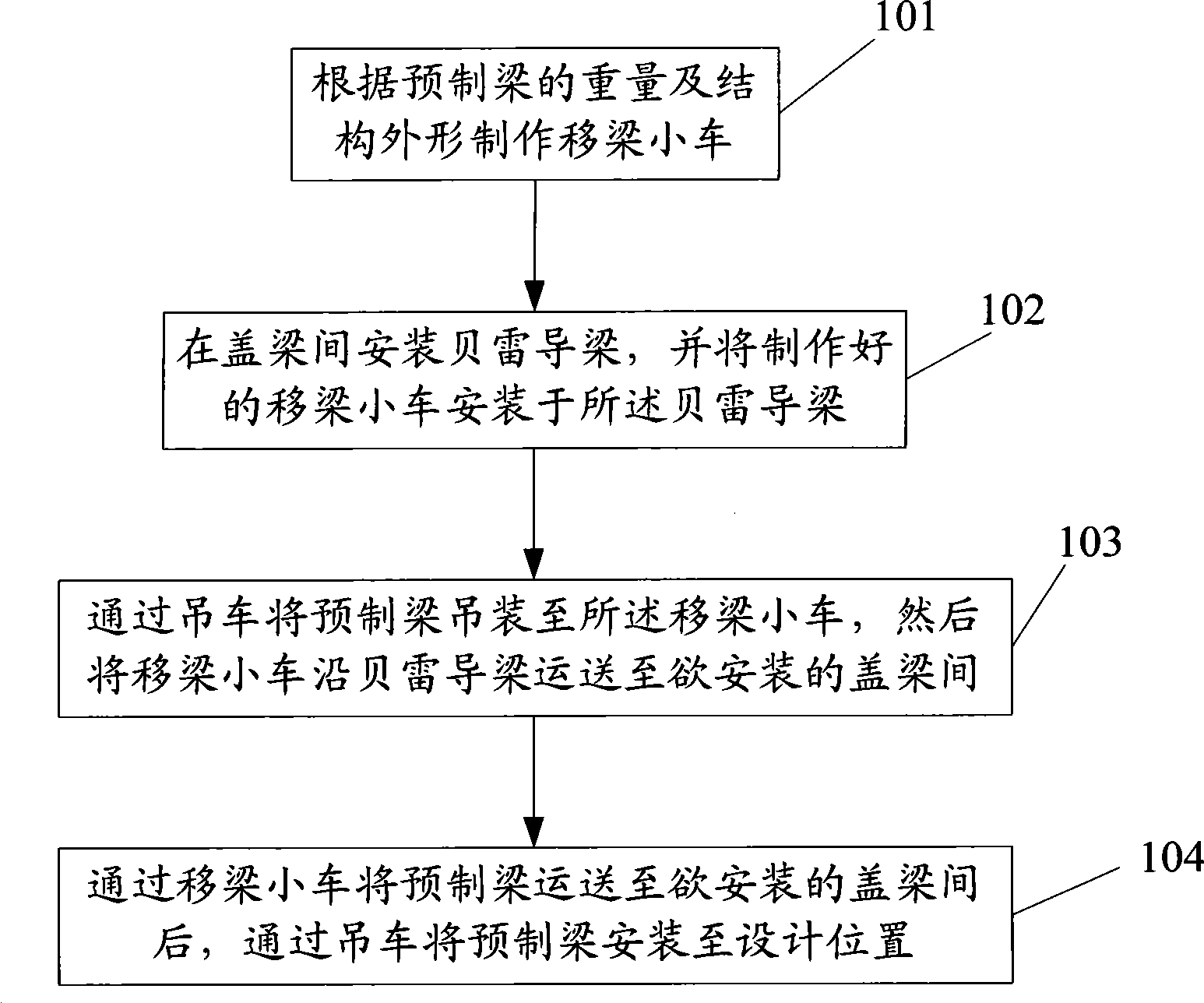

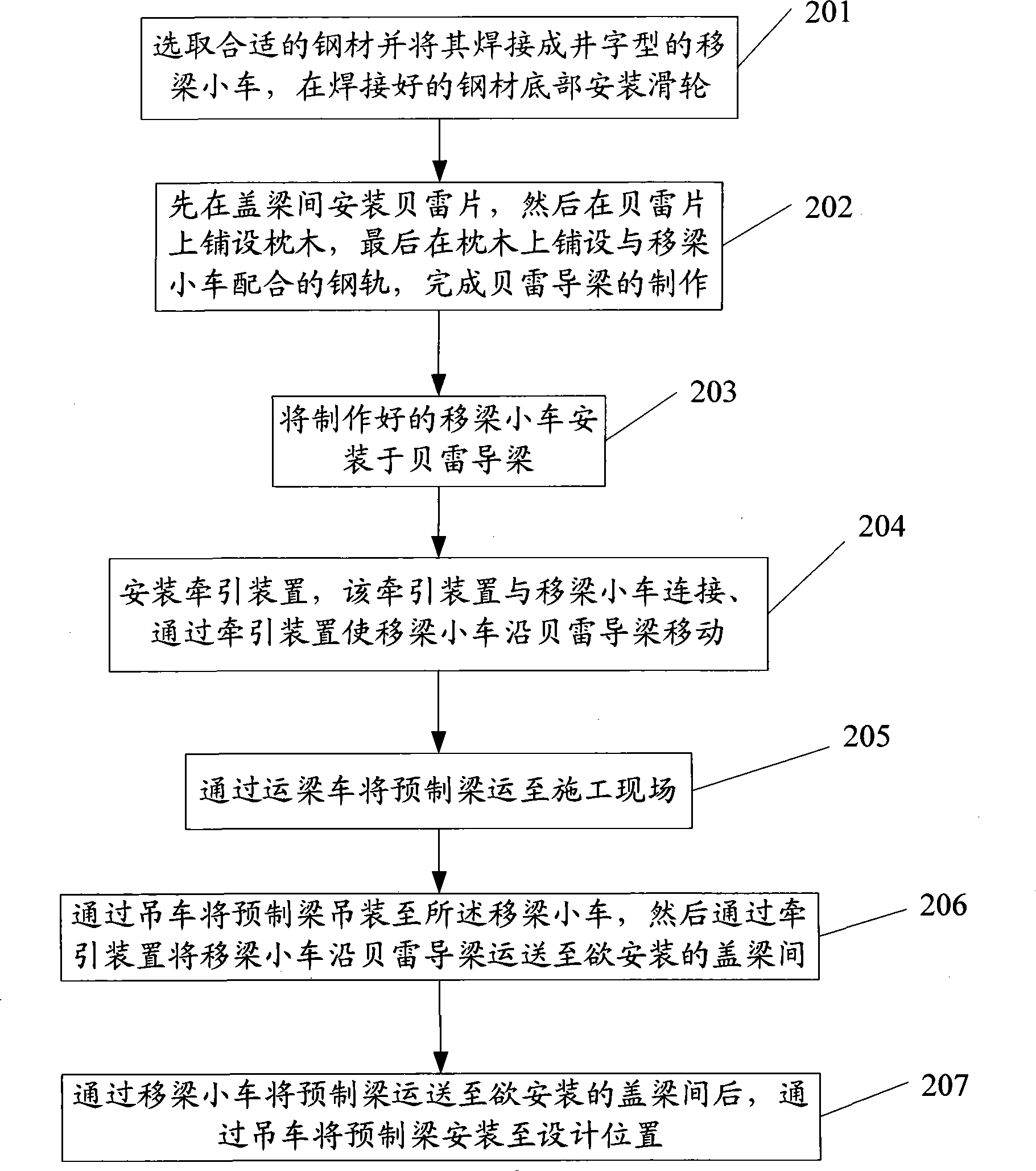

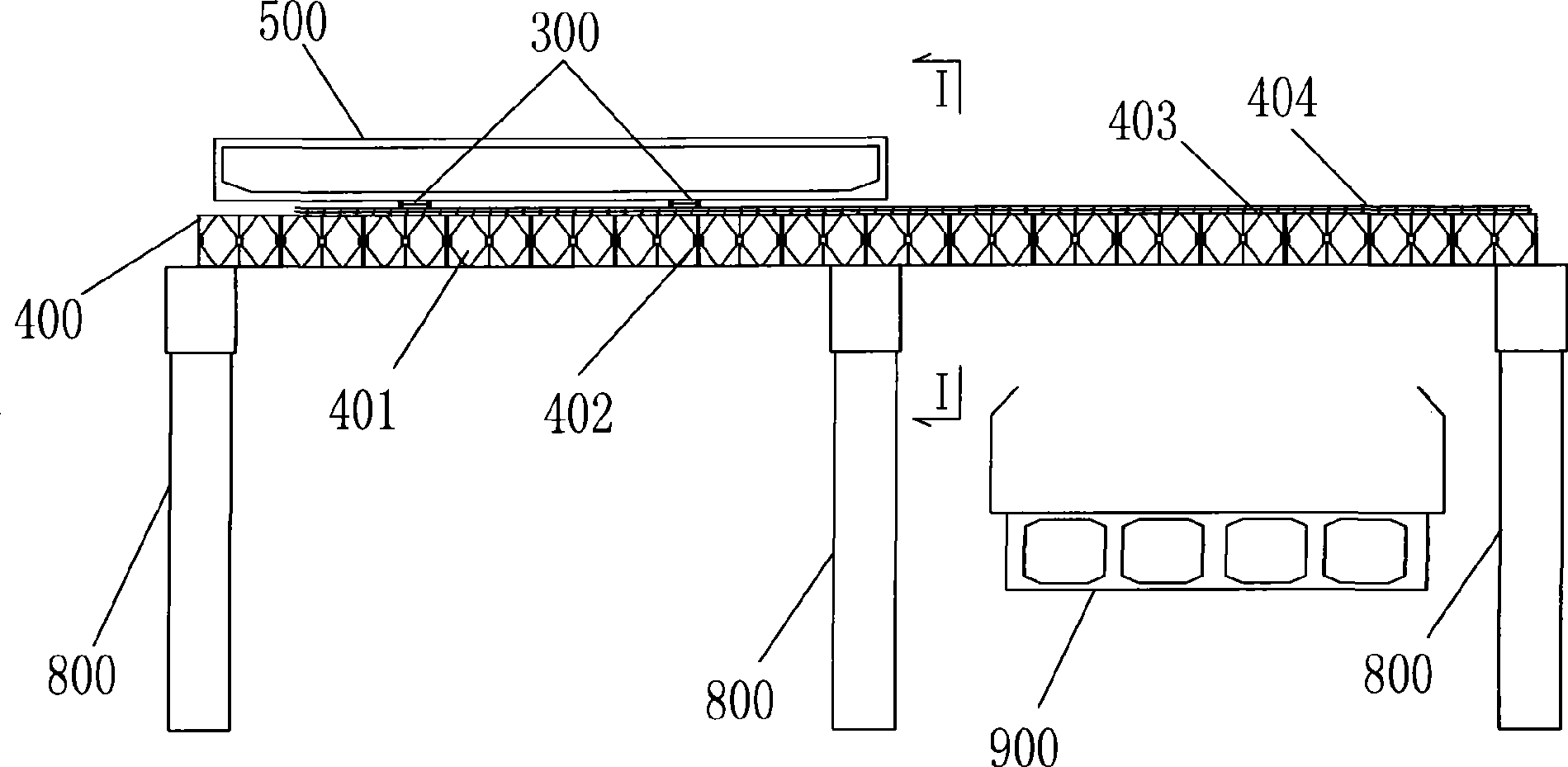

Method and equipment for mounting precast beam

ActiveCN101476292AEasy to installQuick installationBridge erection/assemblySUSPENDING VEHICLEBuilding construction

The invention relates to a prefabricated beam mounting method used for mounting prefabricated beam on the coping of bridge spanning old bridge or other barrier, which comprises the following steps: a, manufacturing a beam moving dolly according to the weight, structure and shape of the prefabricated beam; b, mounting the bailey launching nose between the copings and mounting the beam moving dolly on the bailey launching nose; c, hanging the prefabricated beam to the beam moving dolly by a crane and conveying the beam moving dolly along the bailey launching nose to the target position between the copings; d, mounting the prefabricated beam to the designed position by the crane. The prefabricated beam mounting method achieves the advantages of low cost, high construction efficiency and simple operation. The invention further discloses an equipment for mounting prefabricated beam.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com