Lifting method of steel structure roof truss pulling bar in narrow space

A technology of narrow space and hoisting method, which is applied in the direction of building structure, building material processing, construction, etc. It can solve the problems that the crane cannot directly complete the hoisting task and the hoisting method is inconvenient, so as to achieve the small demand for hoisting space and reduce the construction cost , The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

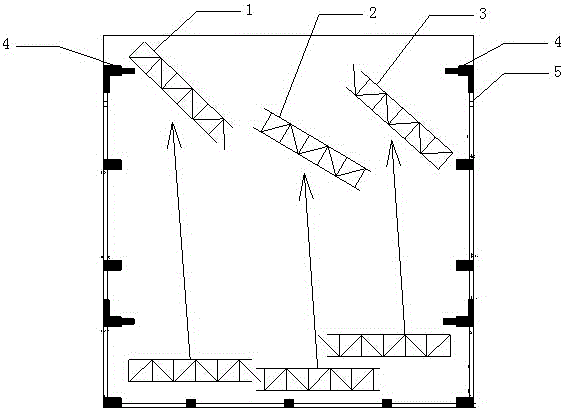

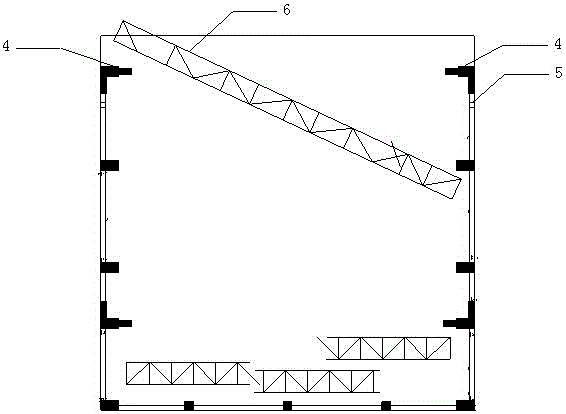

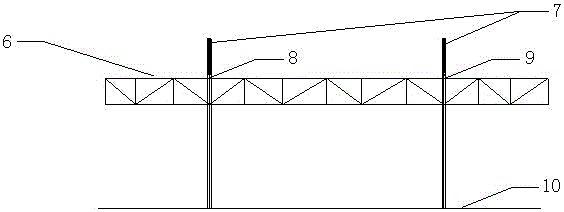

[0032] Fuzhou Rail Transit Command Center Project is located in the northeast corner of the intersection of Guangda Road and Da Road, Taijiang District, Fuzhou City. In this project, the roof of the 5th floor of the tower podium adopts the form of steel structure roof truss. The design service life of the steel structure is 100 years, and the structural safety level is the first grade. The length and width of the steel roof truss are 34m*30.3m, the elevation is 20.5m, and the total weight is about 400t . The upper and lower chords of the roof truss adopt welded box-shaped pipes, the maximum specification is 300*350*50*50, the minimum specification is 200*300*14*14, and the intermediate connecting rods include welded I-beams, H-beams, and welded box-shaped pipes.

[0033] The steel structure roof truss of this project is composed of 5 GHJ1 welded box tubes, 25 GHJ2 welded box tubes and GL1, GL2, GC1 steel structure connectors. The steel structure roof truss of the middle tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com