Patents

Literature

2386results about How to "Construction safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

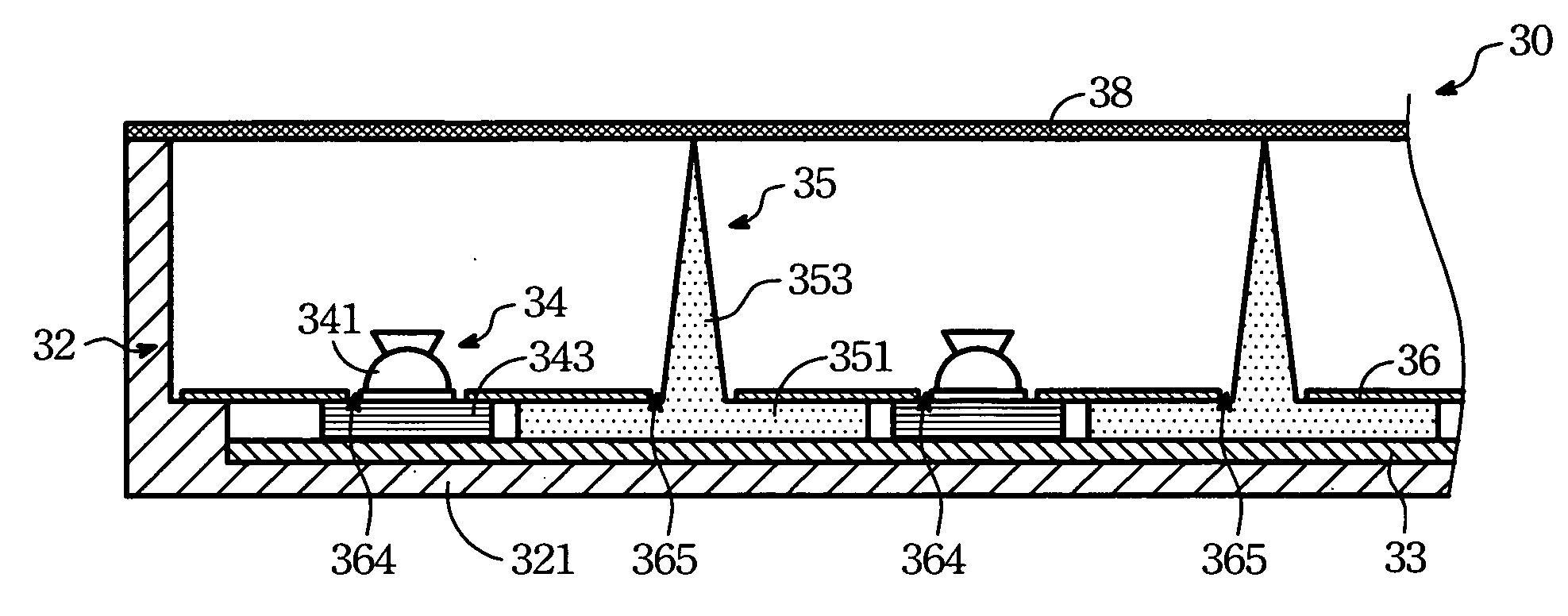

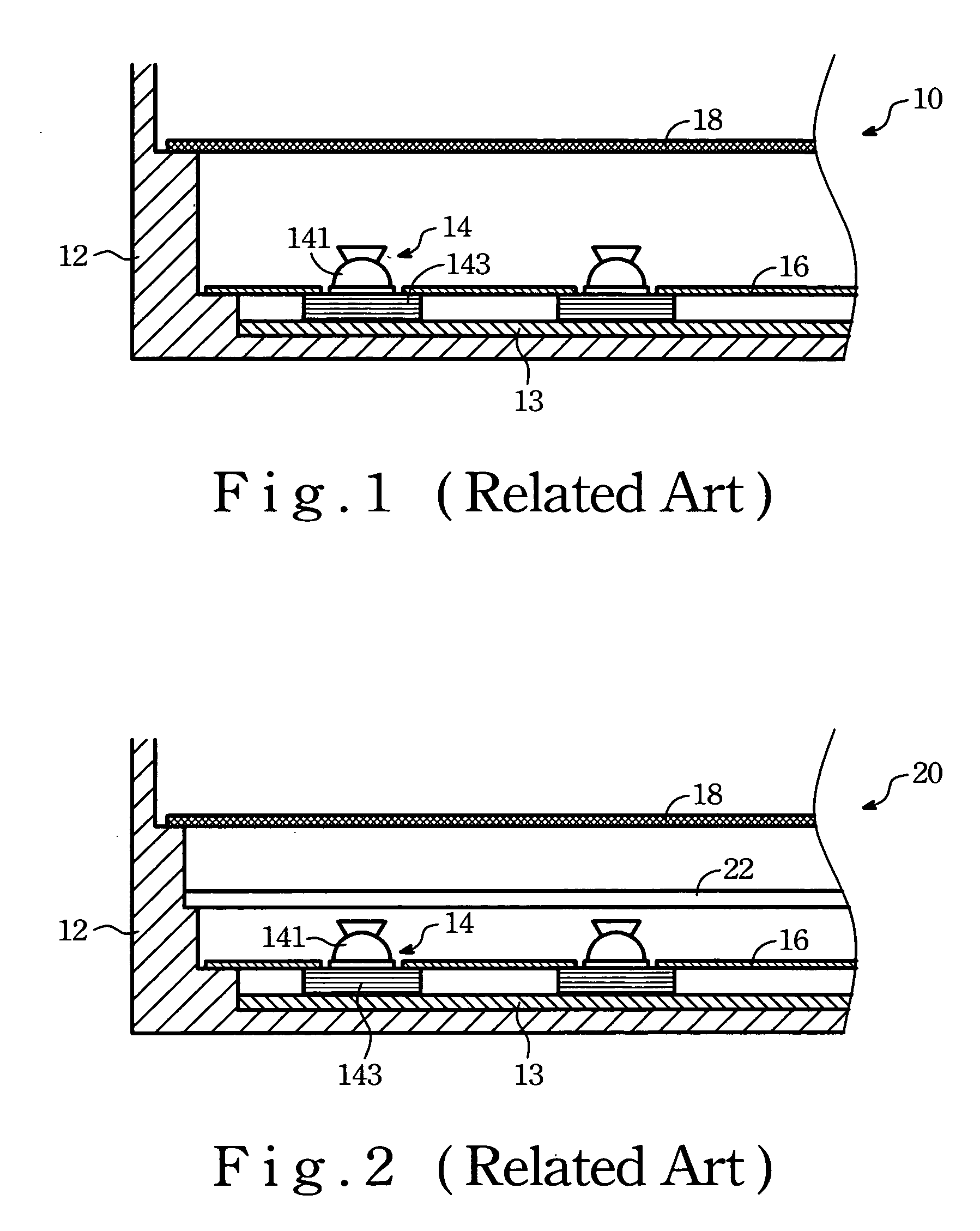

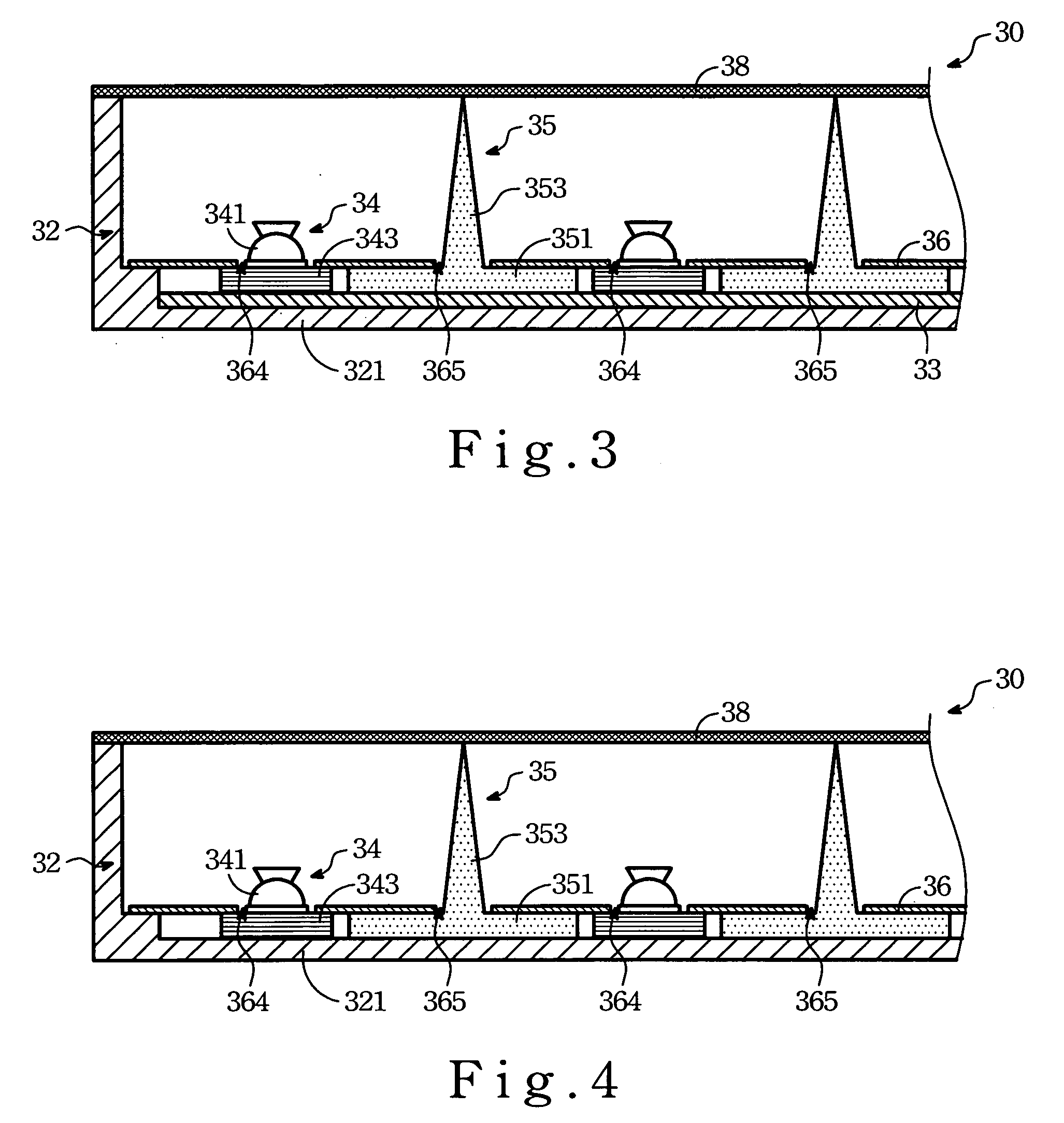

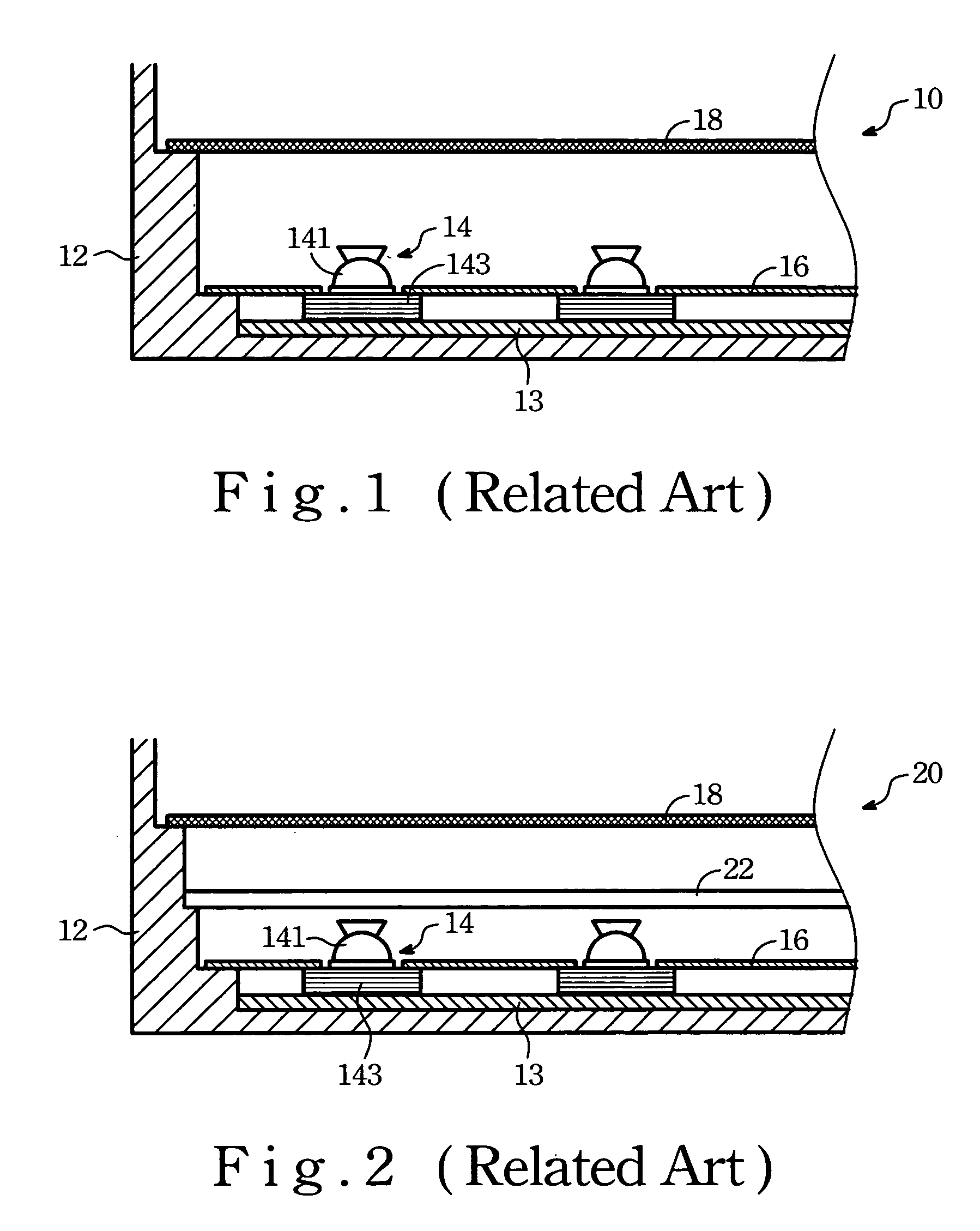

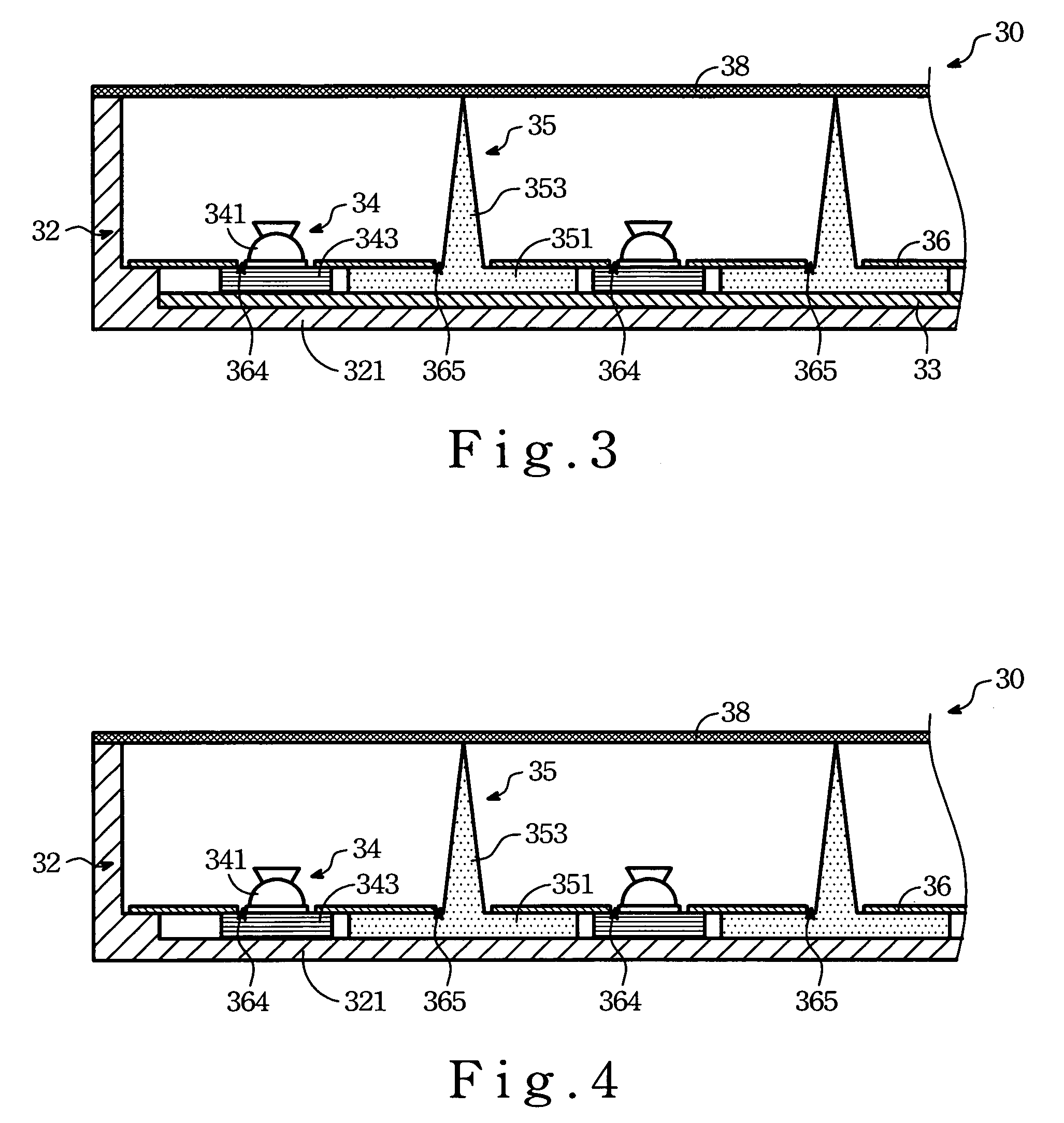

Support member and light emitting diode module using the same

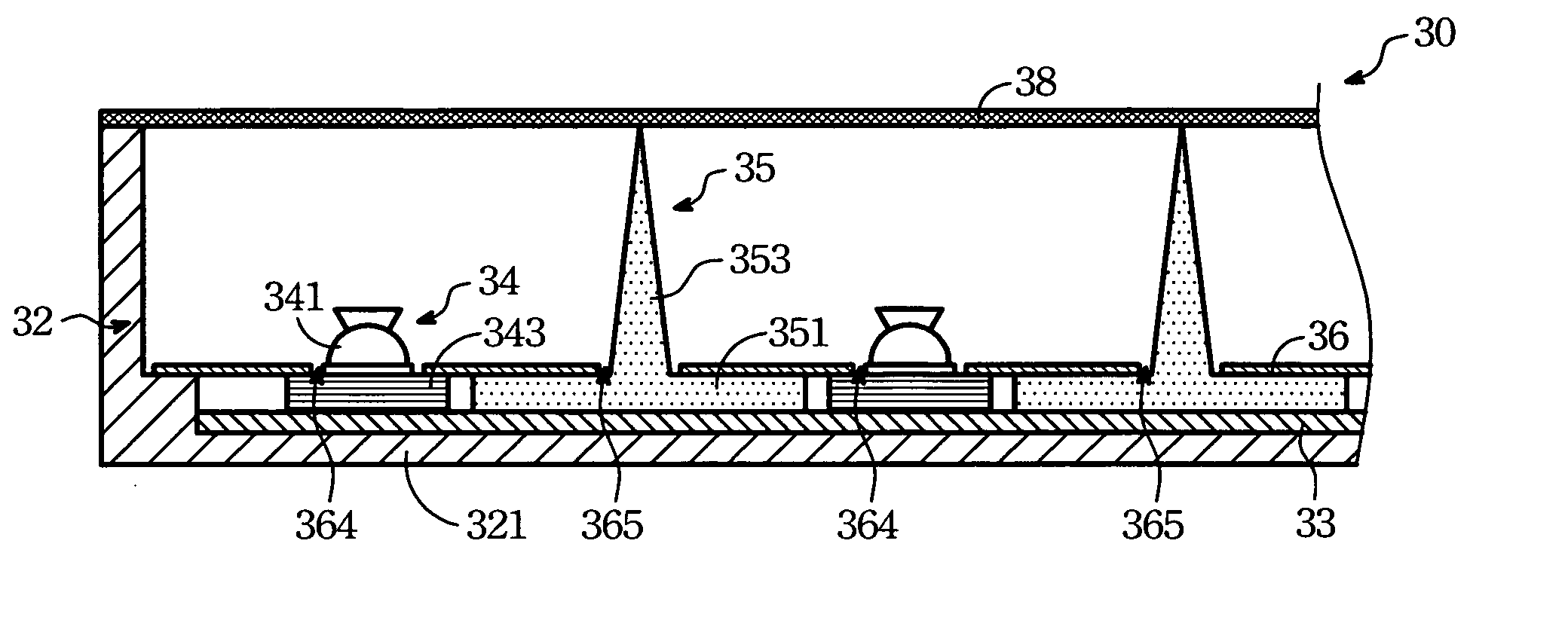

ActiveUS20050281050A1Avoid it happening againReduce distractionsPoint-like light sourceOptical signallingEngineeringLight-emitting diode

Owner:AU OPTRONICS CORP

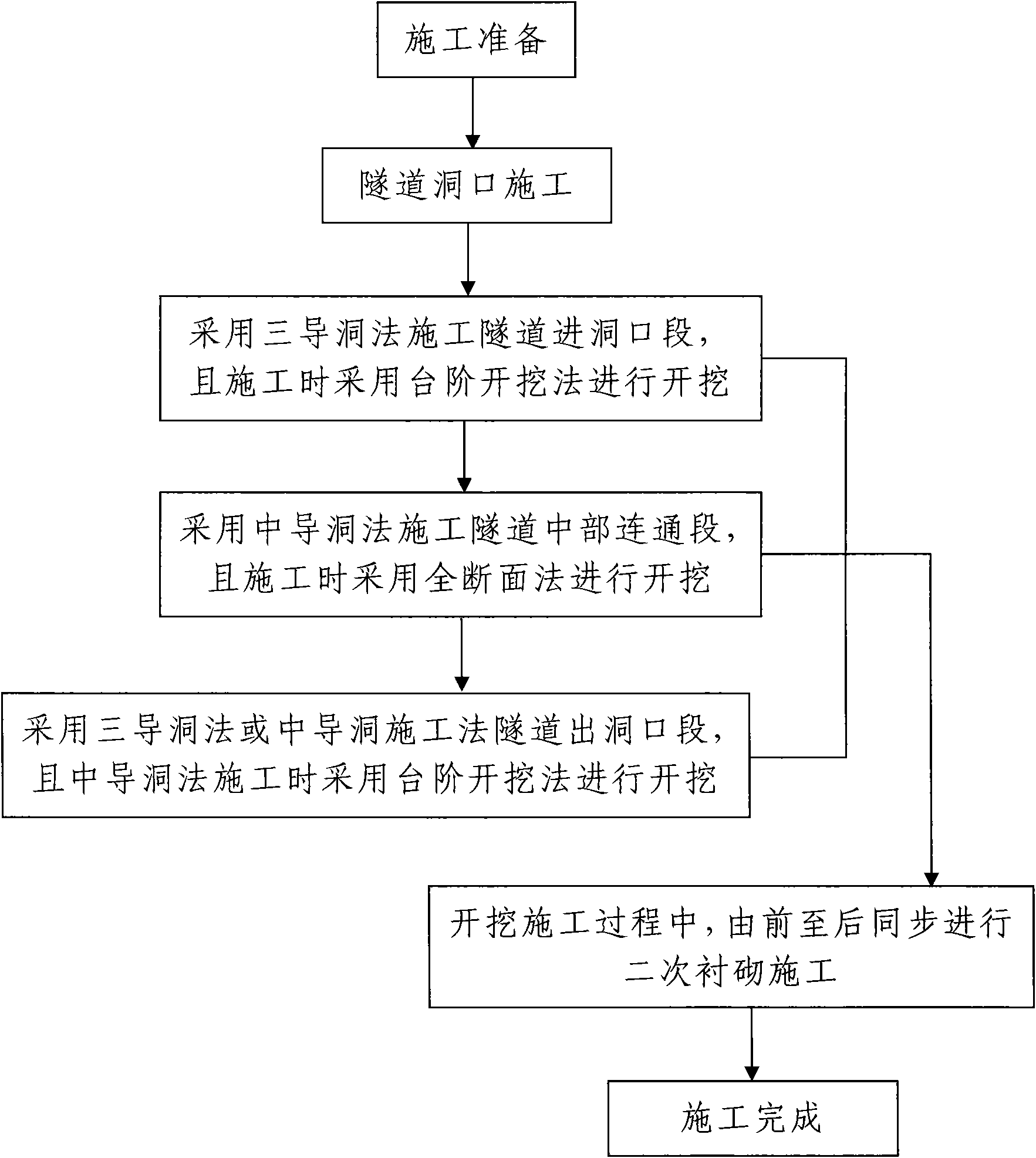

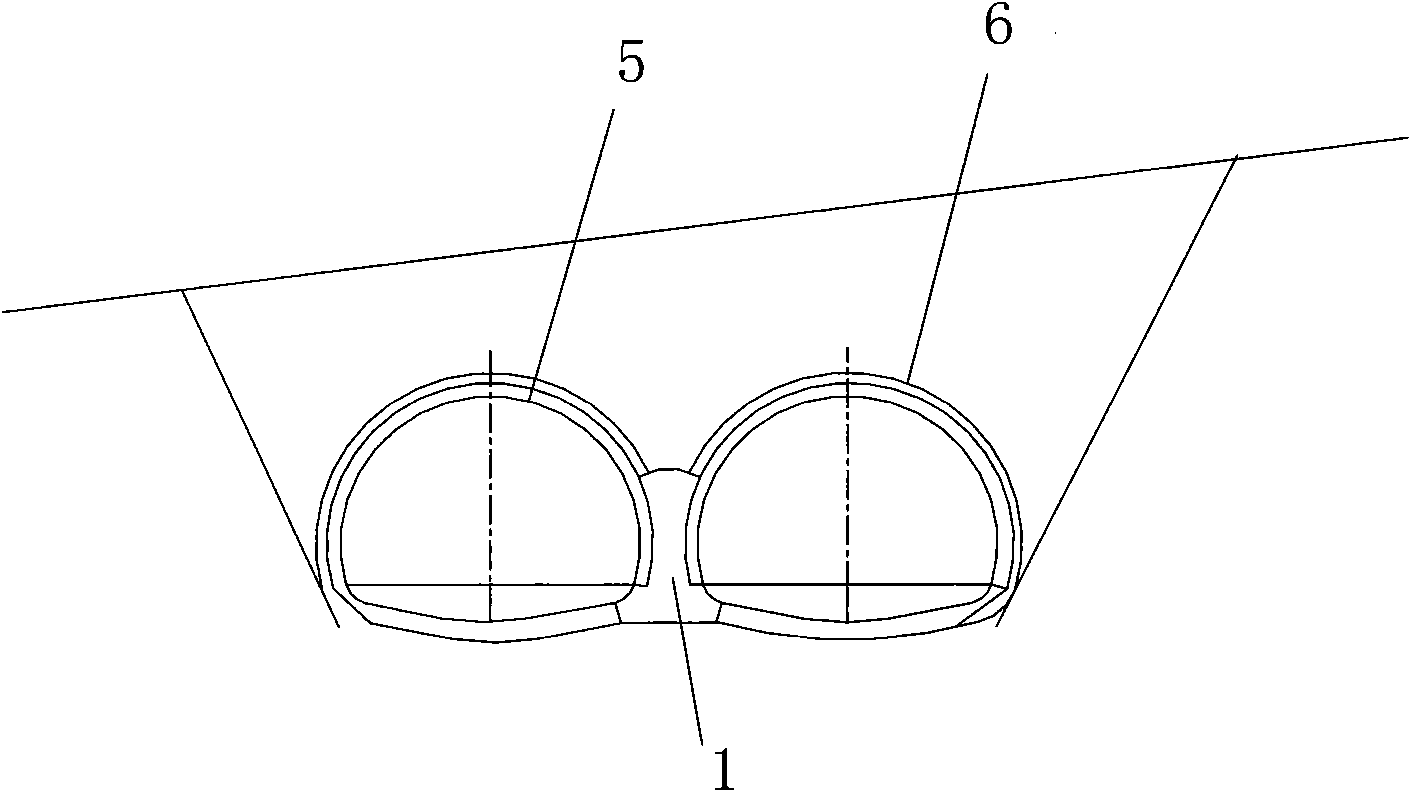

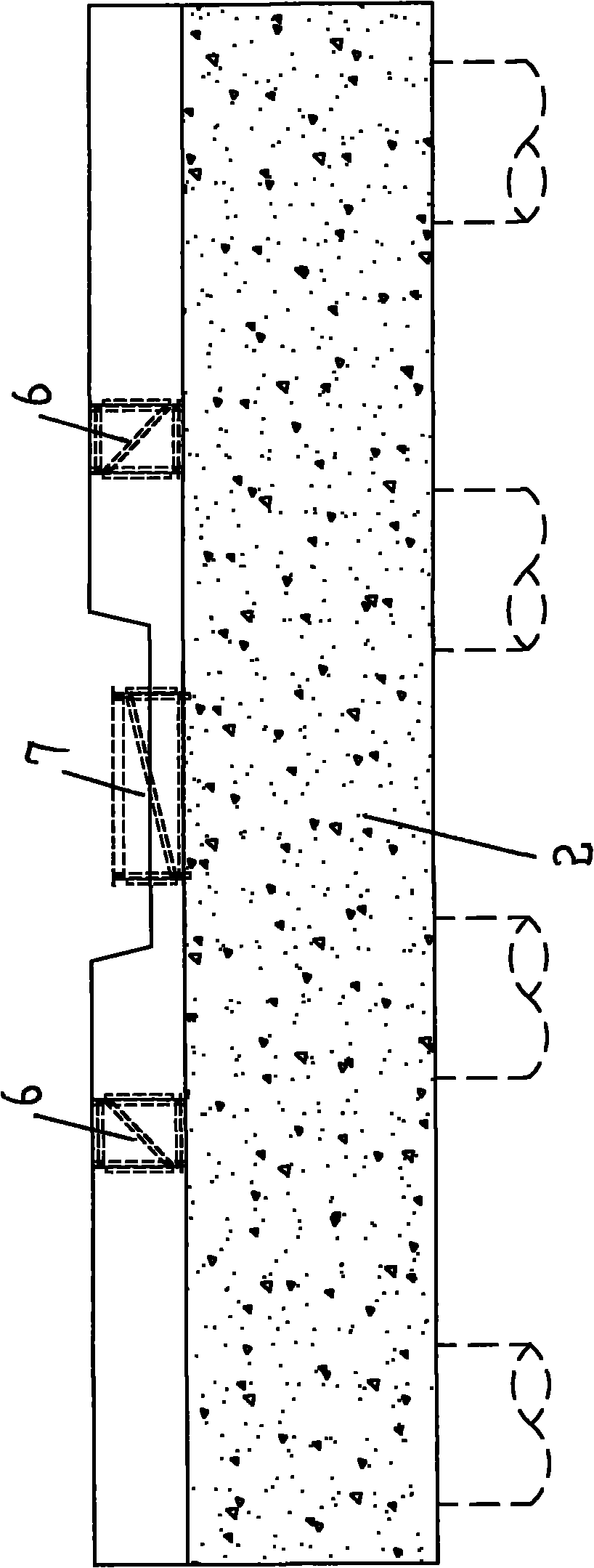

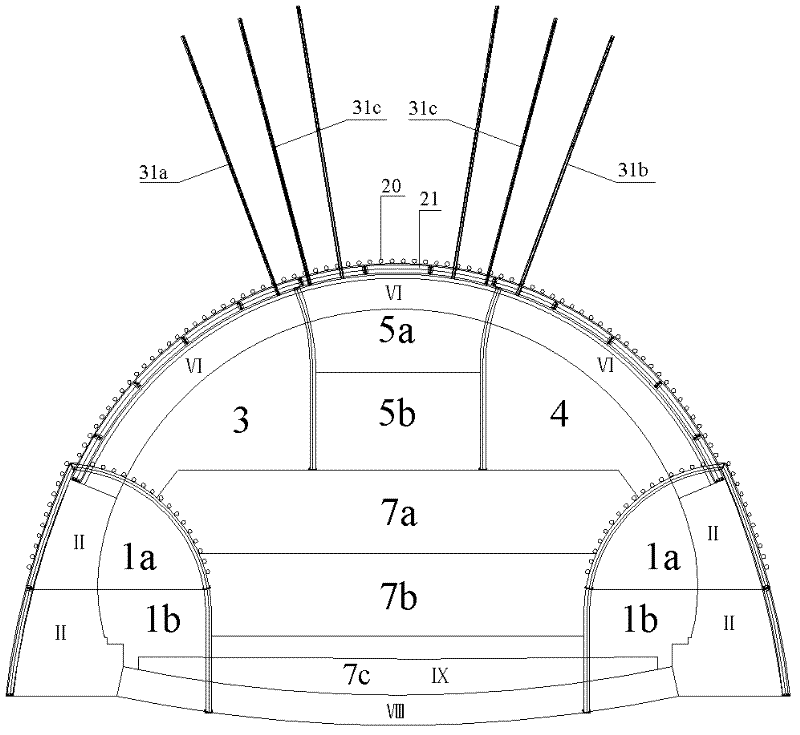

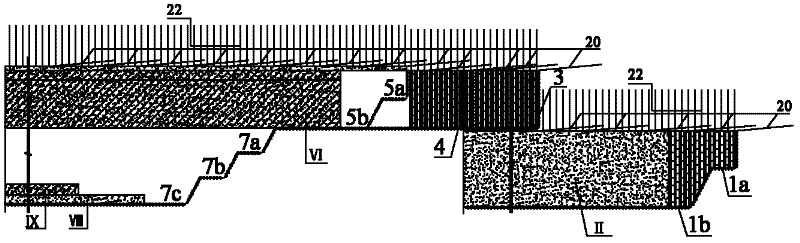

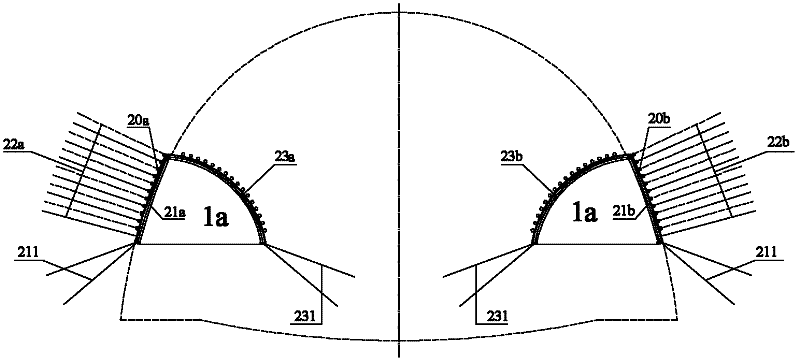

Carst region double-arch road tunnel construction method

ActiveCN101864960AReasonable designSimplify construction stepsUnderground chambersTunnel liningTunnel constructionChannel inlet

The invention discloses a carst region double-arch road tunnel construction method, which comprises the following steps; 1. carrying out construction preparation; 2. carrying out construction at channel openings; 3. adopting a three-pilot-tunnel method for constructing the channel inlet opening section, and adopting a step digging method for digging during the three-pilot-tunnel method construction; 4. adopting a middle-pilot-tunnel method for constructing the middle communication section of the channel, and adopting a full cross section method for digging during the middle-pilot-tunnel method construction; 5. adopting the three-pilot-tunnel method or the middle-pilot-tunnel method for constructing the channel outlet opening section, adopting the step digging method for digging when the middle-pilot-tunnel method is adopted for digging construction of the channel outlet opening section, and synchronously carrying out secondary lining construction from the front part to the back part in the digging construction process of the channel inlet opening section, the middle communication section of the channel and the channel outlet opening section. The invention has the advantages of reasonable design, simple and convenient construction, safe and reliable construction process, flexible construction mode, short construction period and greatly simplified construction steps, and effectively overcomes various defects during the traditional carst region double-arch road tunnel construction.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

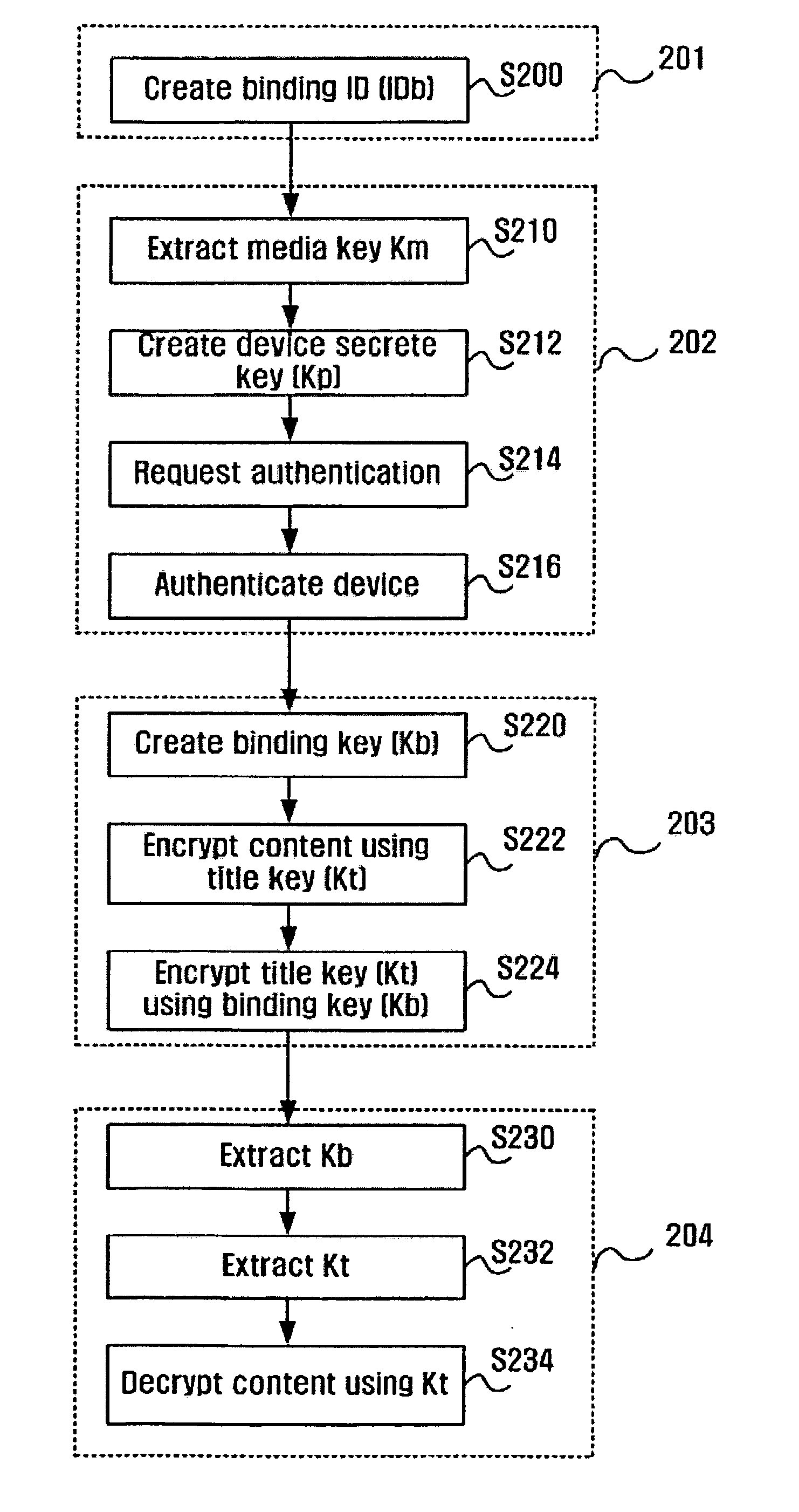

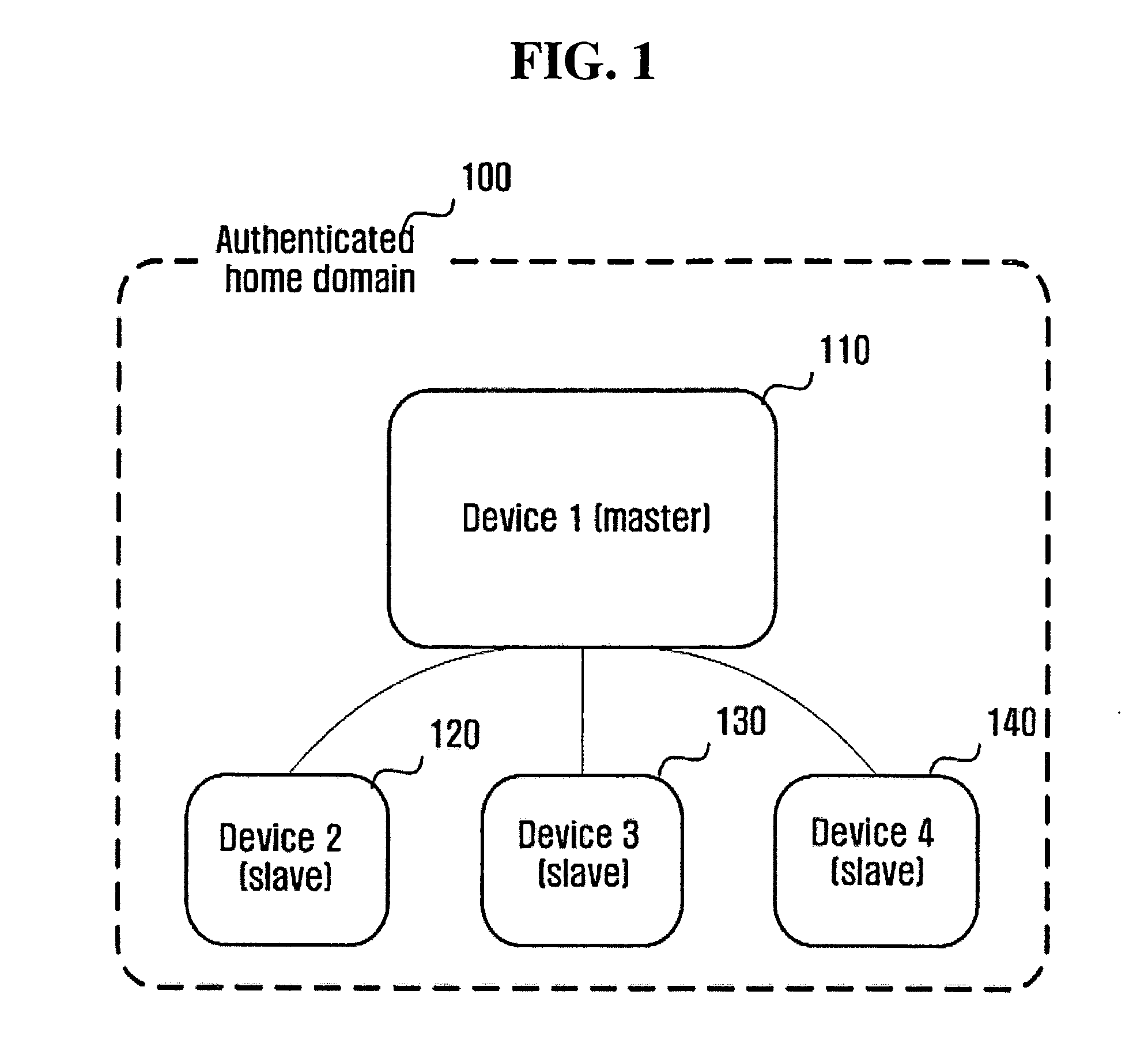

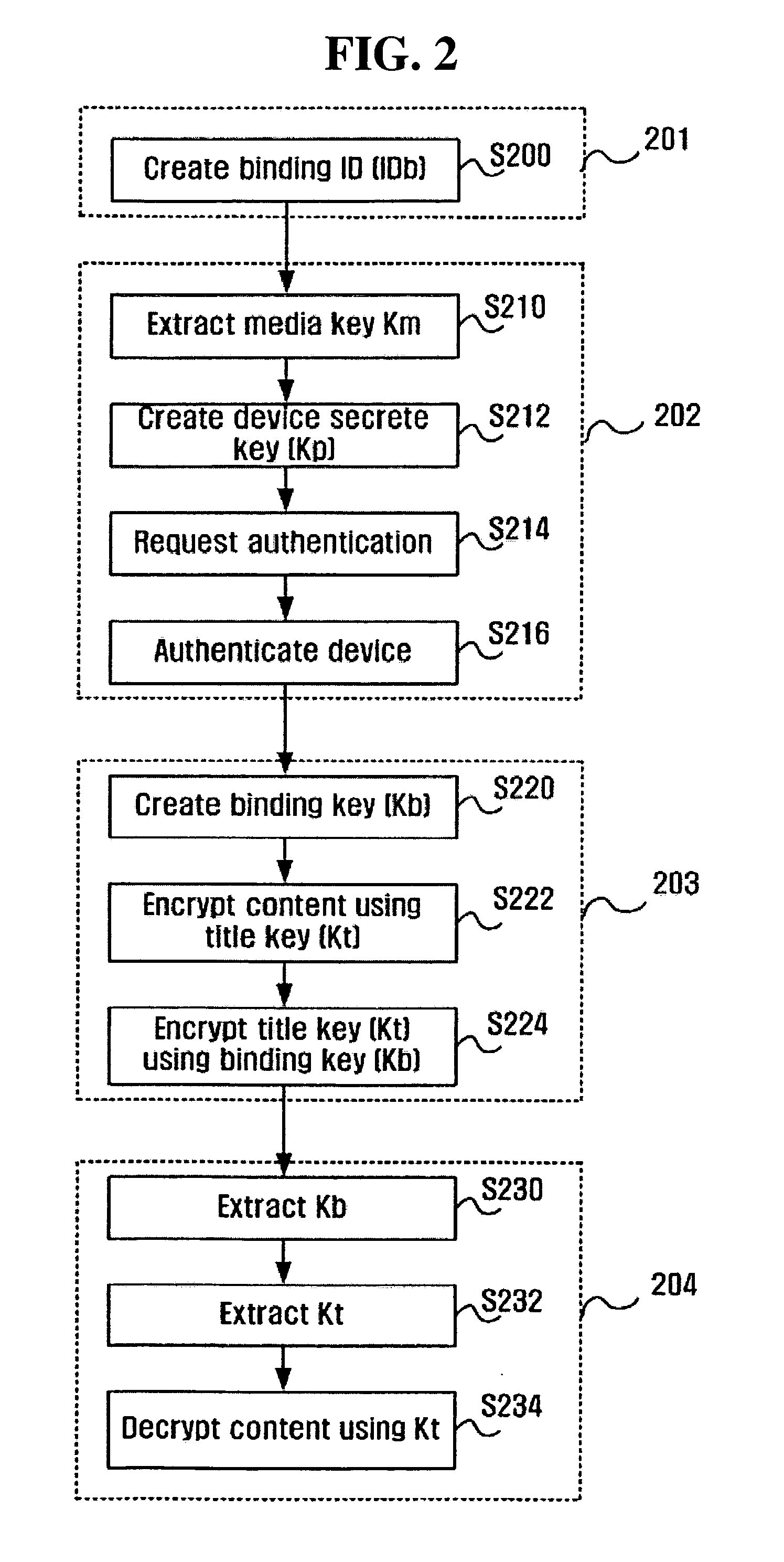

Method of constructing domain based on public key and implementing the domain through universal plug and play (UPnP)

InactiveUS20050086514A1Construction safetyPrevent illegal useDigital data processing detailsUser identity/authority verificationFamily networkNetsniff-ng

A method of constructing a unique domain for preventing content from being illegally used by an unauthorized third person in a public key-based architecture and applying the constructed domain to a home network using universal plug and play (UPnP). The method of the present invention includes selecting one of controlled devices that are operable as a master device and determining the selected device as the master device; performing device authentication in such a manner that other controlled devices receive a secret information block from the determined master device and create certificates; and determining slave devices by selecting one or more devices among the authenticated controlled devices.

Owner:SAMSUNG ELECTRONICS CO LTD

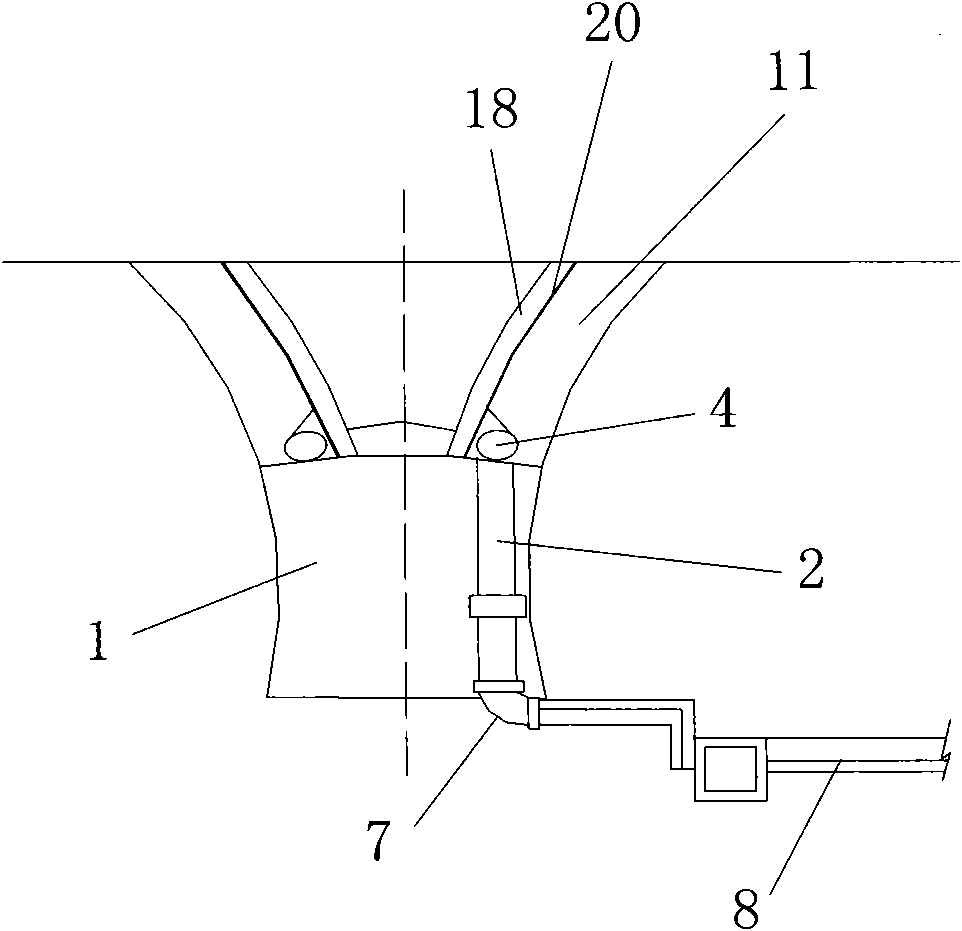

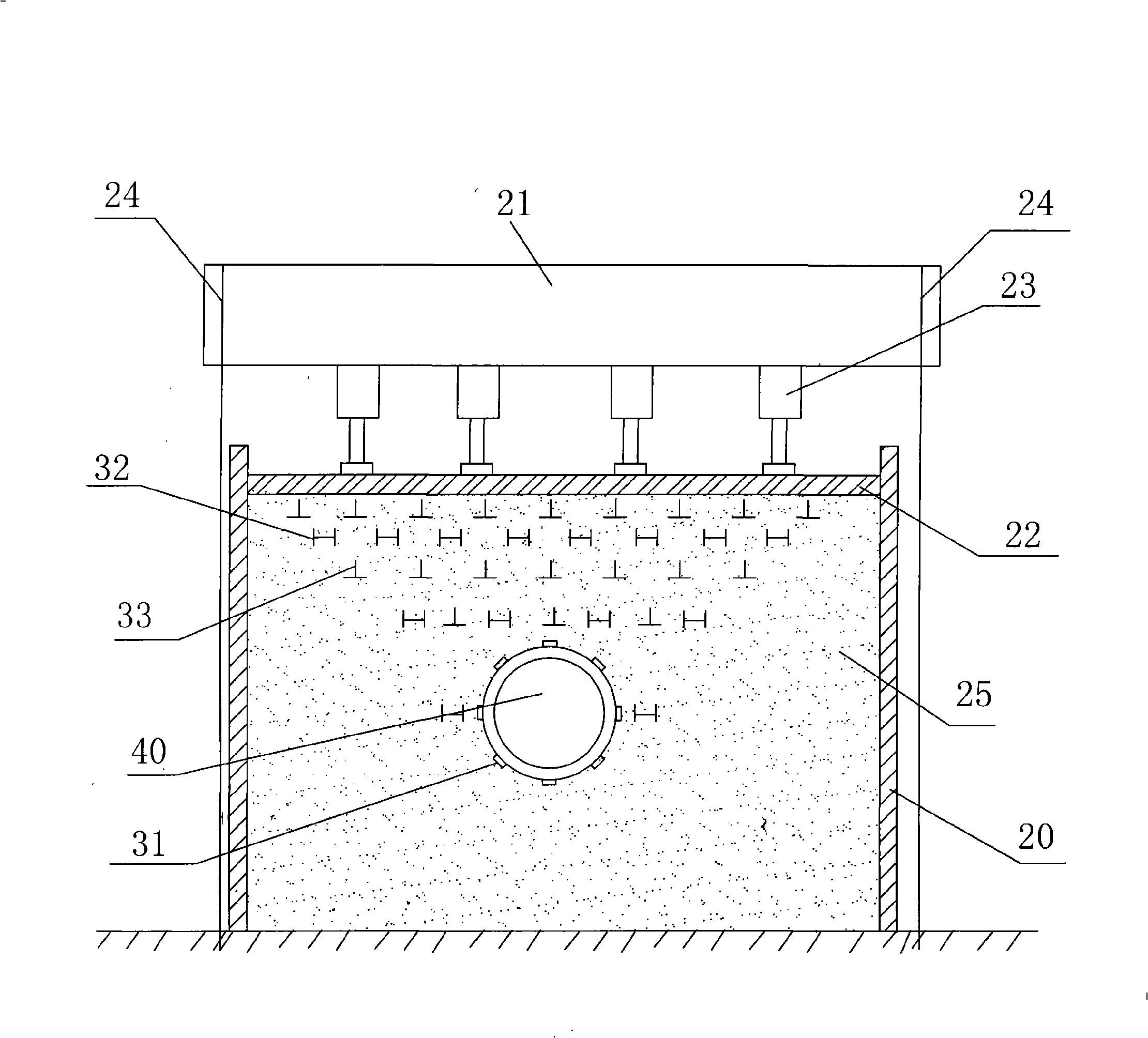

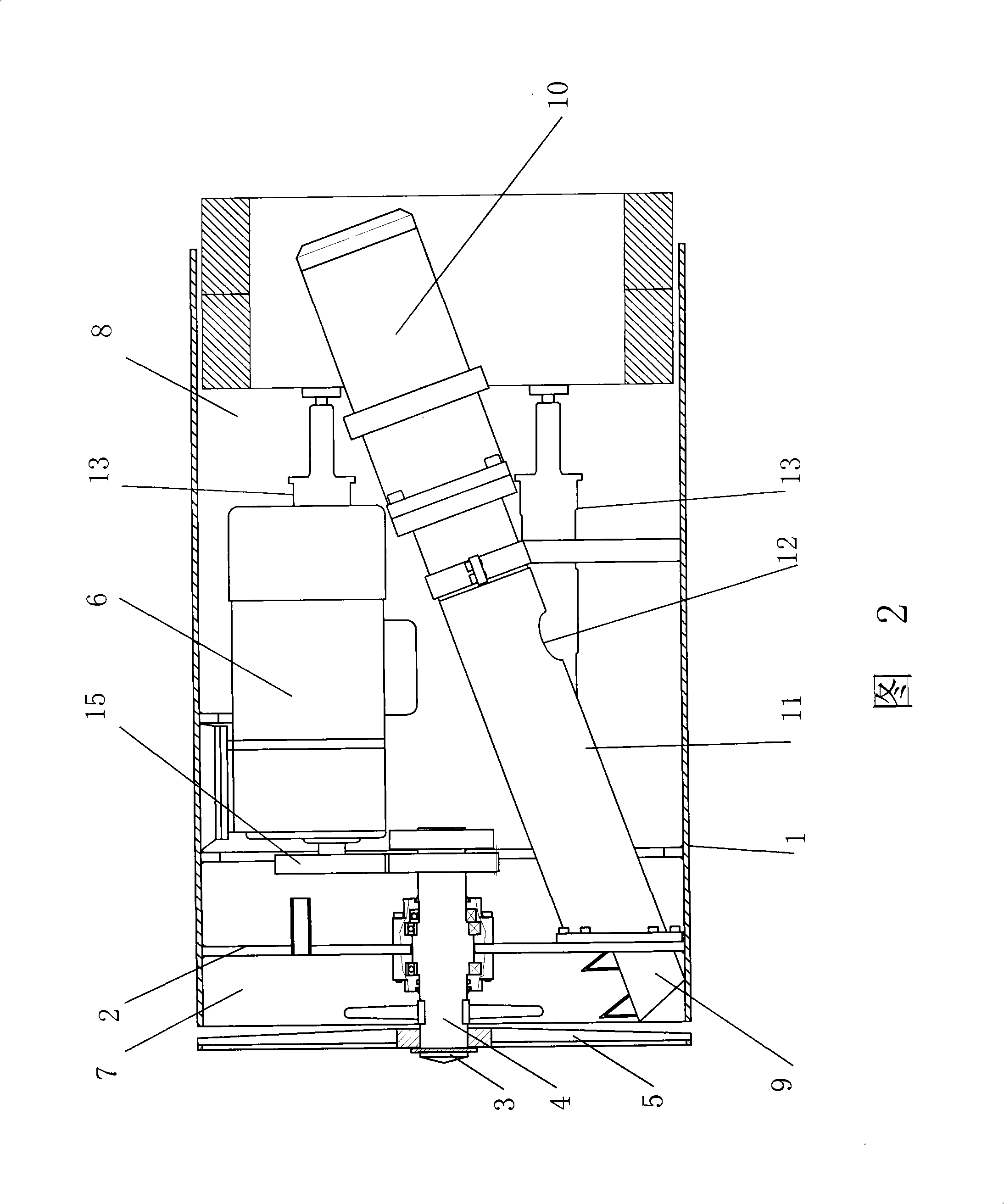

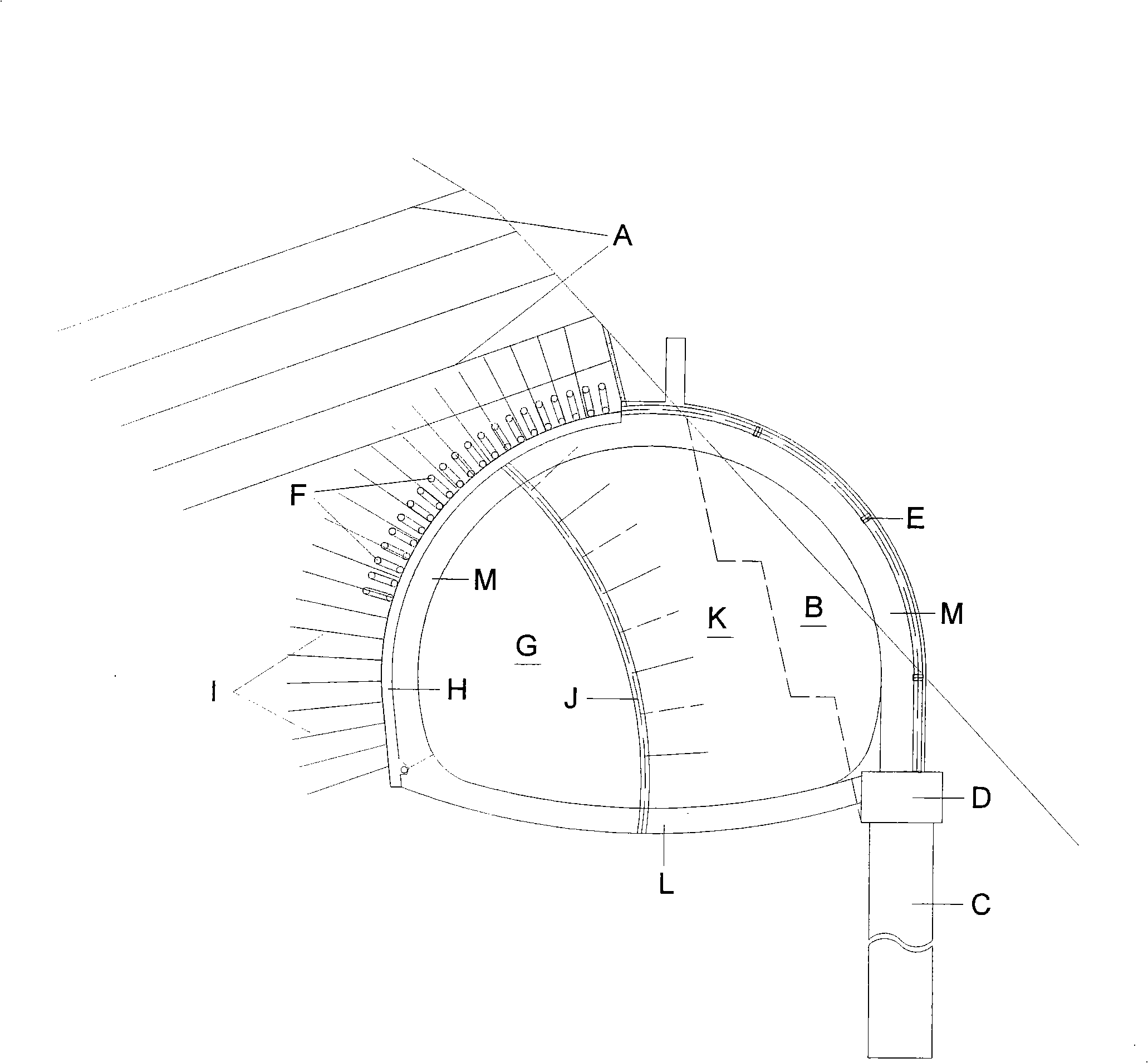

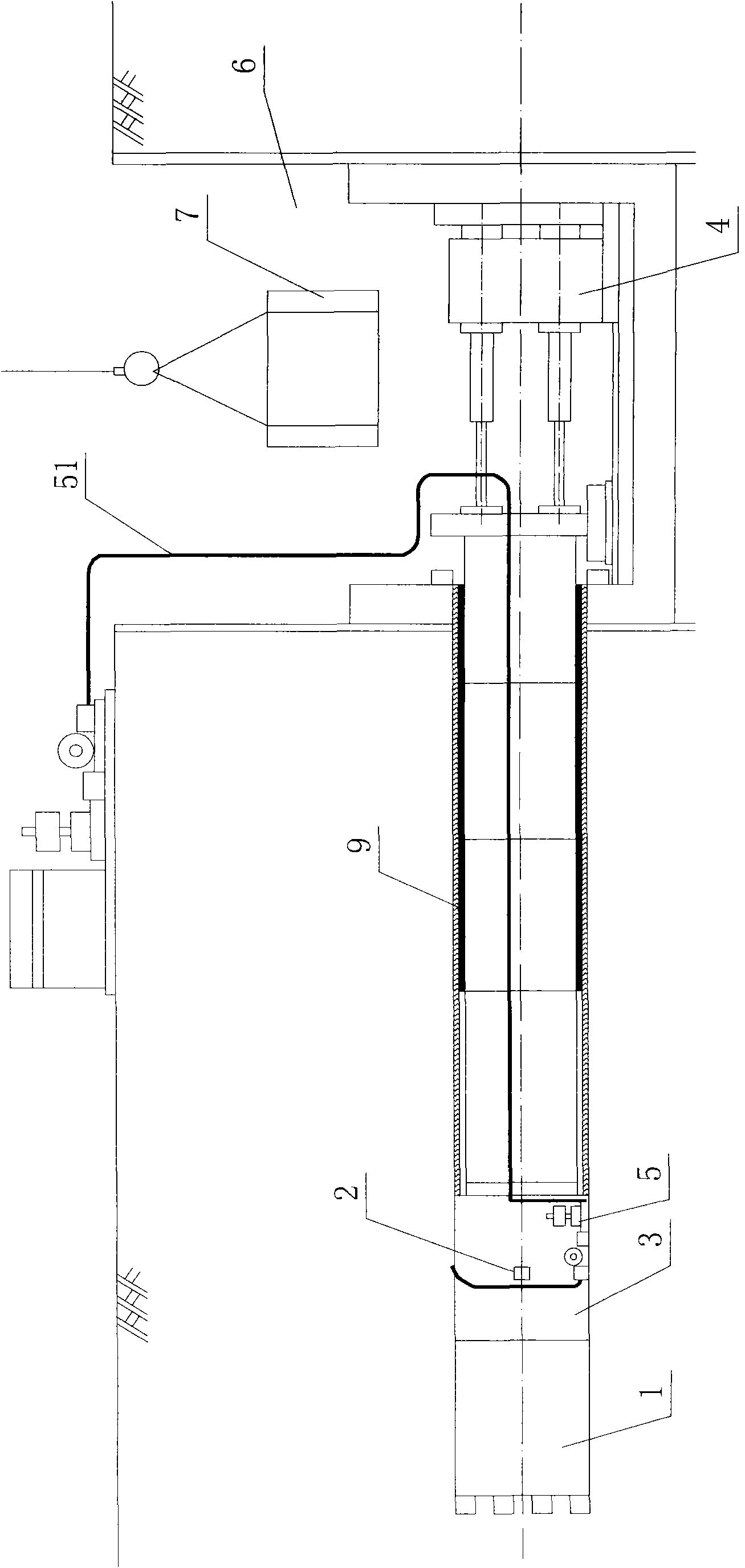

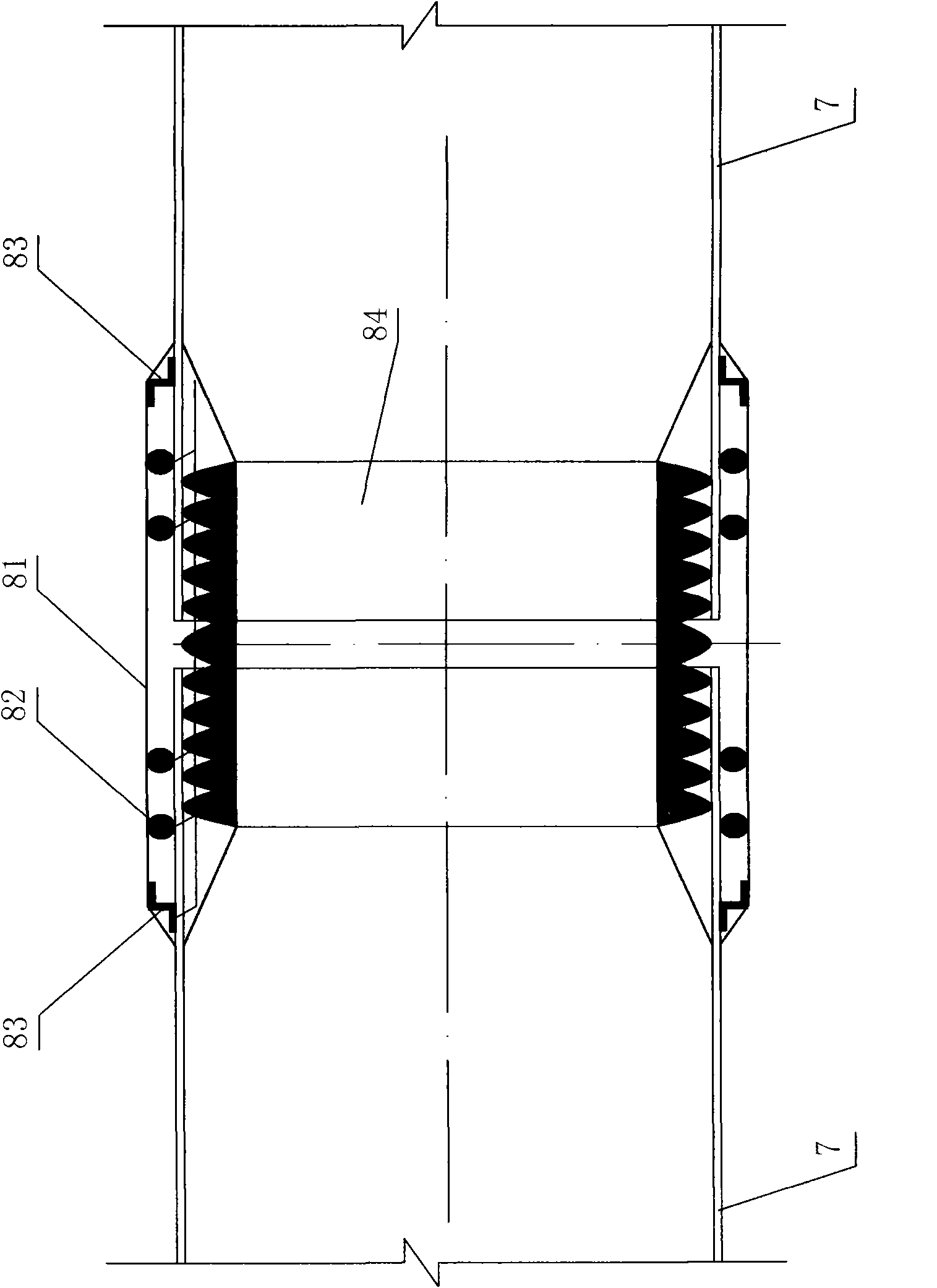

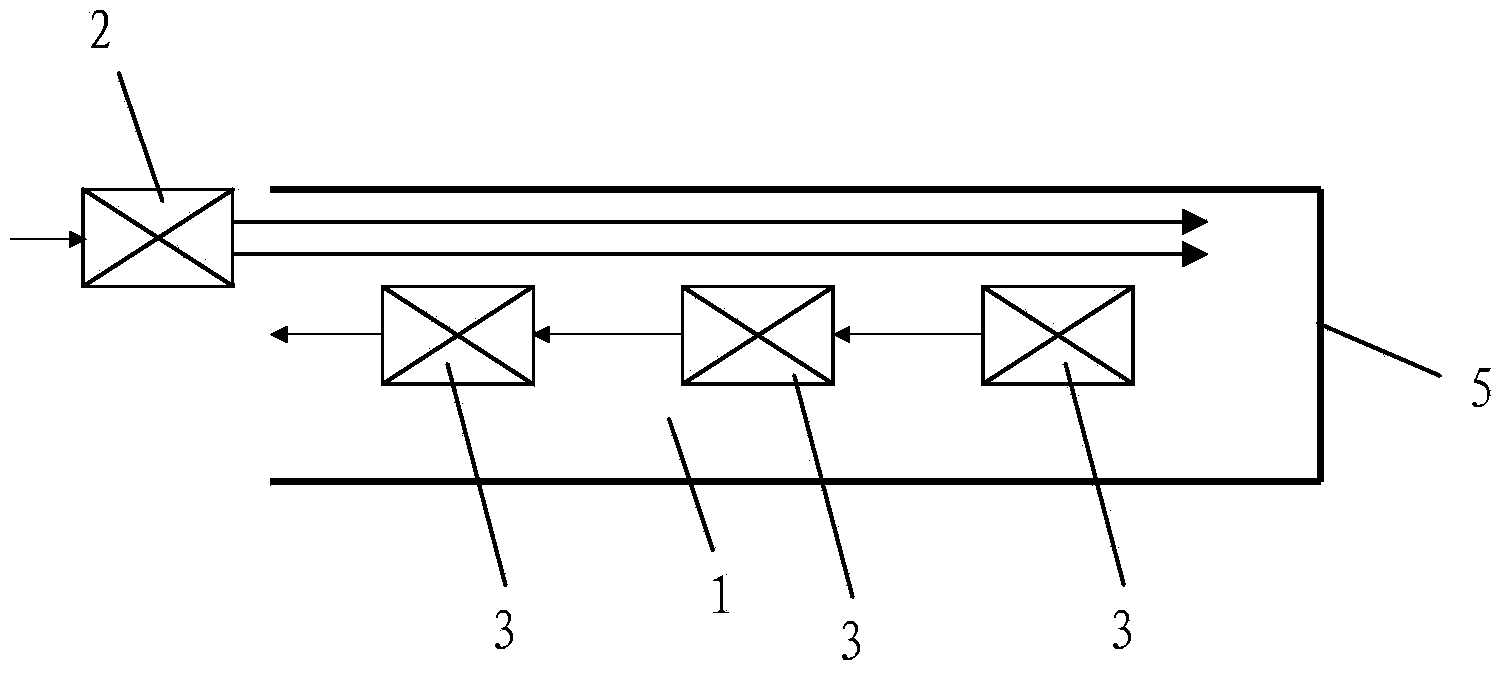

Soil pressure balancing type tunnel shielding simulation experiment system

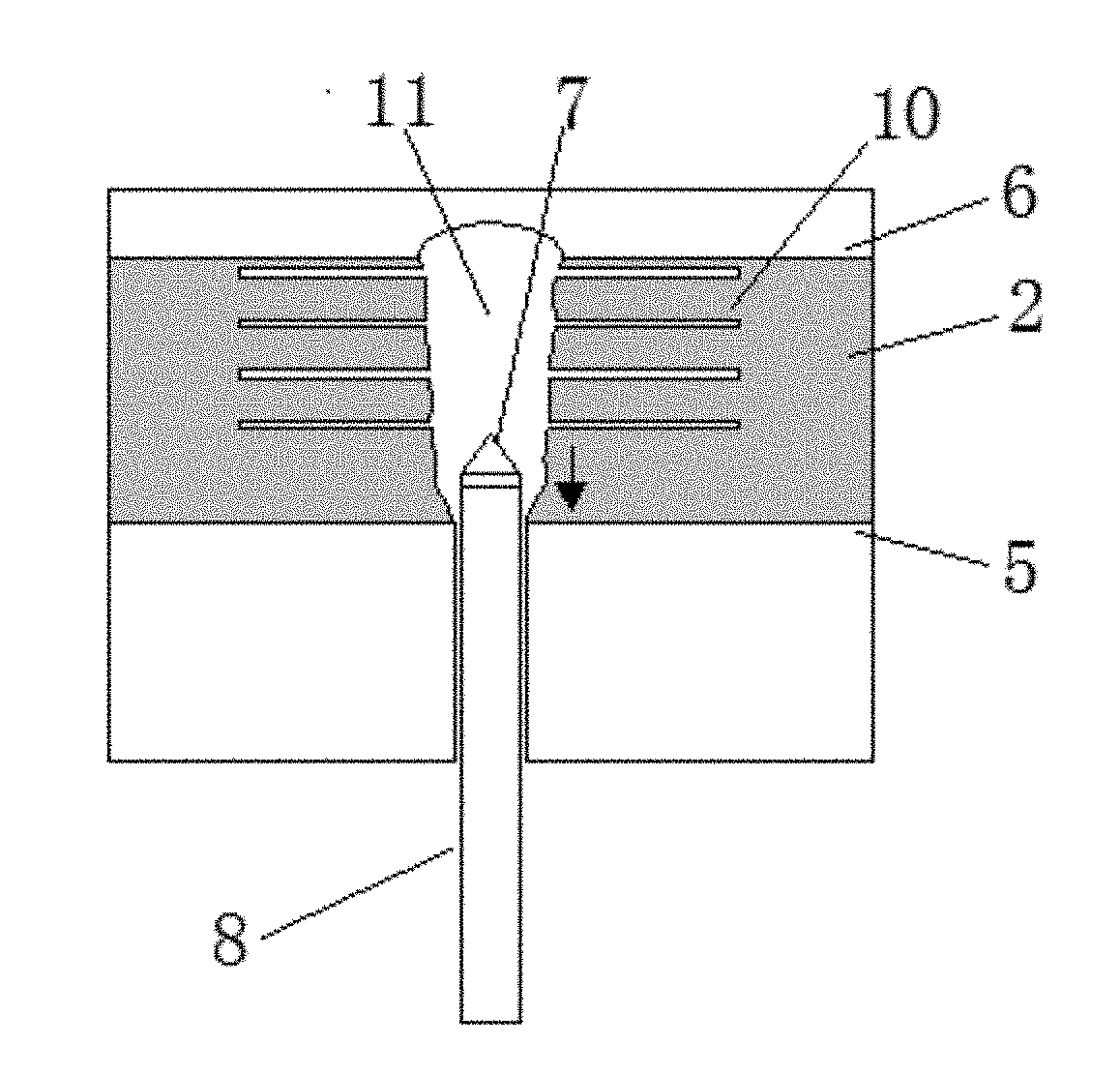

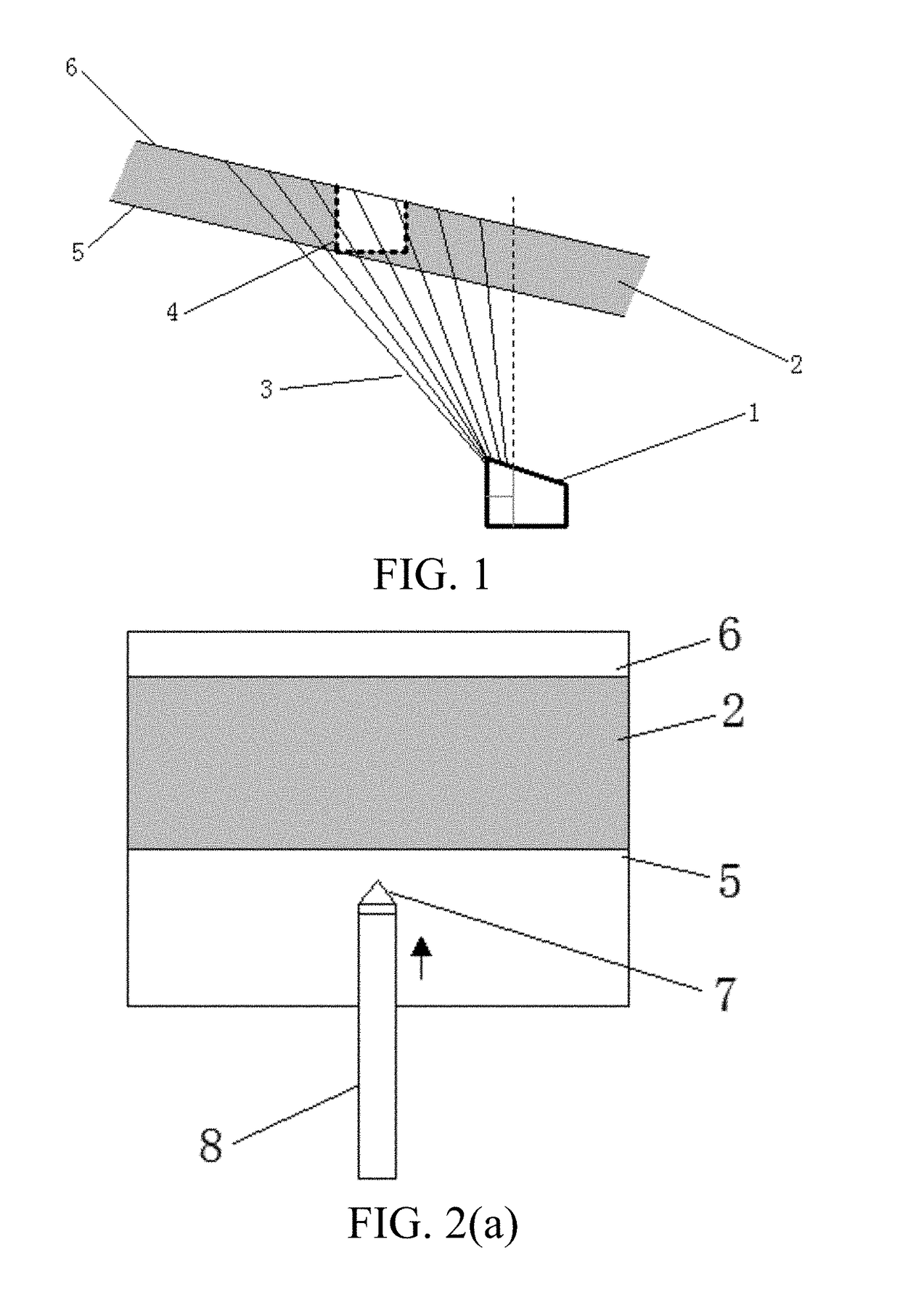

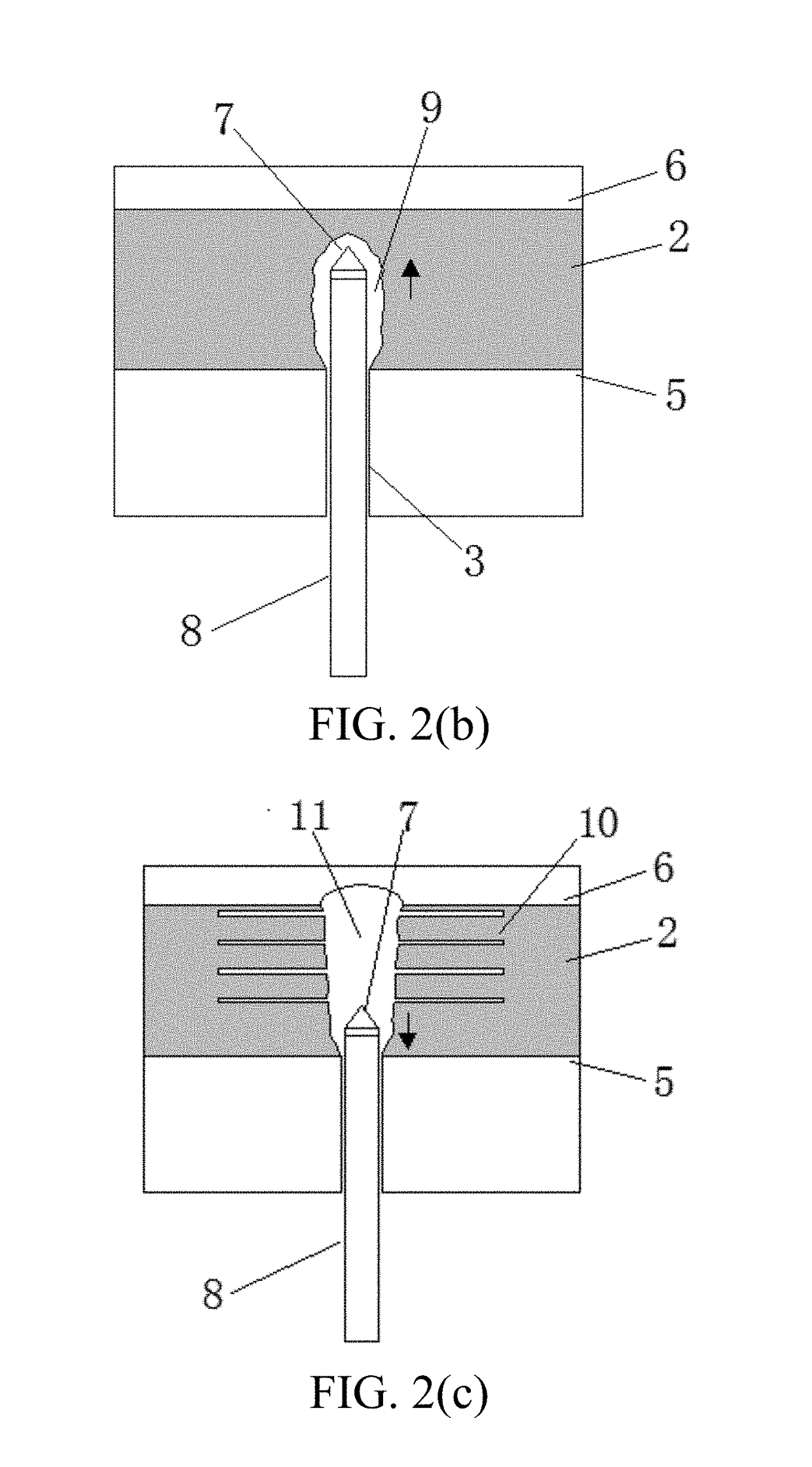

ActiveCN101403306AEfficient constructionConstruction safetyEducational modelsTunnelsElectricityGrating

The invention relates to a soil pressure balance type tunnel shield analog experiment system, a rectangular soil coelom with the upper part provided with an opening is internally provided with a shield machine model and filled with a simulated soil body, the axle wire of the shield machine model is overlapped with that of the soil coelom; the upper surface of the simulated soil body is covered with a layer of concrete cushion the upper surface of which is connected with a horizontal loading beam by more than two soil pressure jacks, the horizontal loading beam is connected with the bottom of the soil coelom by an anchor rope; and the simulated soil body is also internally embedded with a soil pressure box, a grating fiber optical sensor and a displacement meter, wherein, the soil pressure box, the grating fiber optical sensor and the displacement meter are all electrically connected with a data acquisition and processing device. The system can simulate the influence of shield tunnel construction between subways of cities on the stratum and surrounding environment more conveniently, actually and effectively, and provide more actual and accurate experimental data for tunnel construction and design so as to guarantee the high-efficiency and safety of the shield tunnel construction of cities.

Owner:SOUTHWEST JIAOTONG UNIV

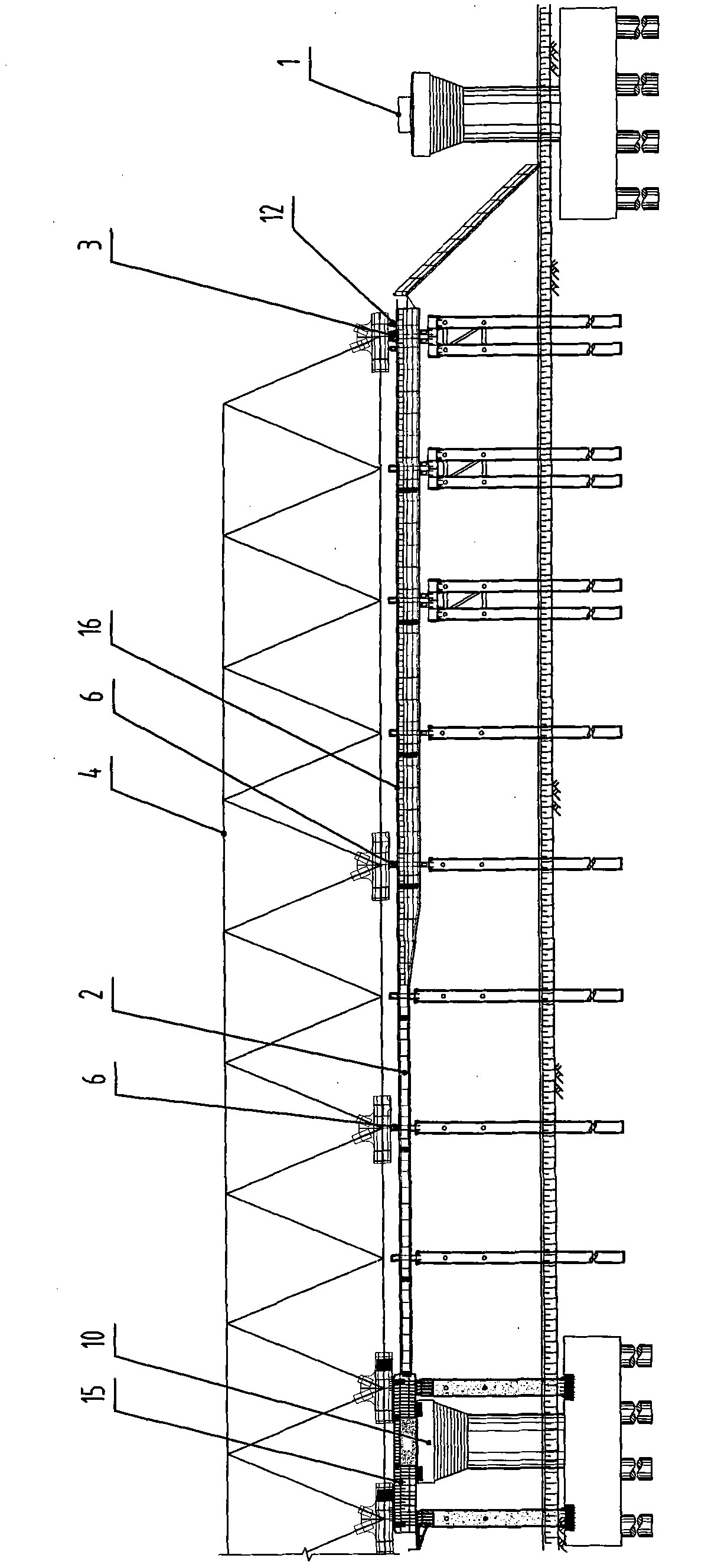

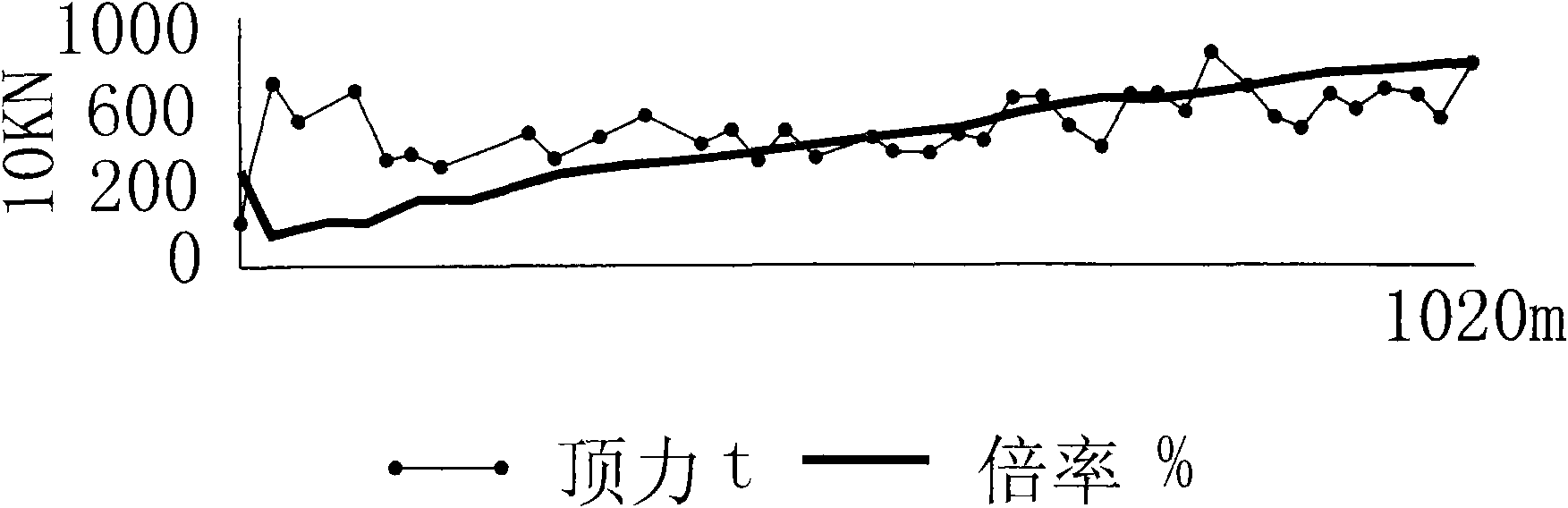

Multipoint synchronous push construction method for porous large-span continuous steel truss girder

ActiveCN101831874AEasy constructionReduce labor intensityBridge erection/assemblyControl systemEngineering

The invention discloses a multipoint synchronous push construction method for a porous large-span continuous steel truss girder, which comprises the following steps of: (1) assembling a steel truss girder assembling platform and a push slideway in a shoreside bridge pier position; (2) assembling a section of steel truss girder and a guide girder on the steel truss girder assembling platform; (3) installing a vertical jack for carrying out support conversion on the steel truss girder and then installing a continuous push jack, a steel strand and an electrohydraulic integrated control system; (4) operating the electrohydraulic integrated control system for carrying out push operation on the steel truss girder; and (5) after the push operation of the section of steel truss girder is finished, continuously assembling the steel truss girder on the steel truss girder assembling platform, carrying out next push operation, repeating the step for circulating operation and finishing the push construction of the porous large-span steel truss girder. The invention has the advantages of short construction period, safe construction, quality guarantee, low cost, and the like, realizes the push operation of the large-span steel truss girder, saves the construction cost, and reduces the pollution to a river channel.

Owner:1ST ENG OF CHINA ZHONGTIE MAJORBRIDGE GROUP +1

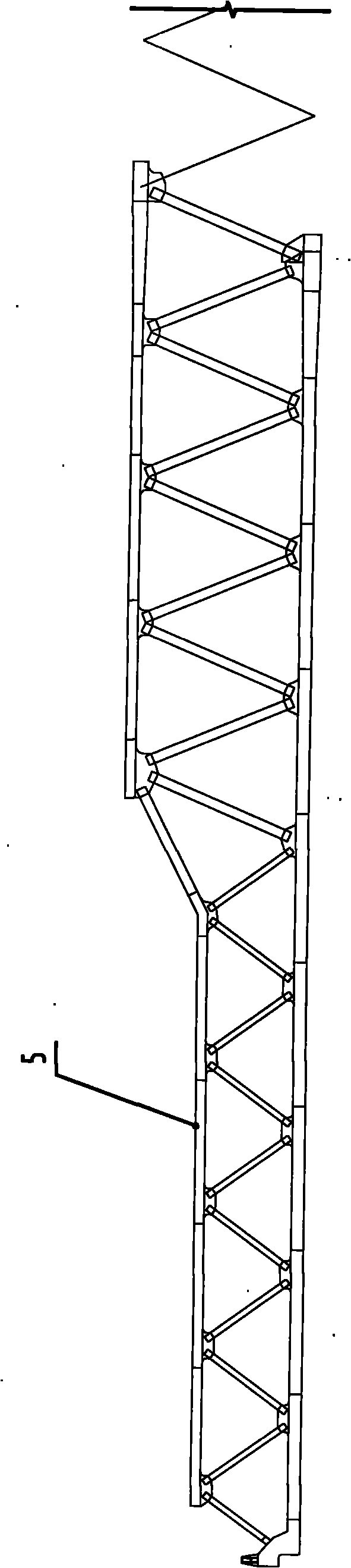

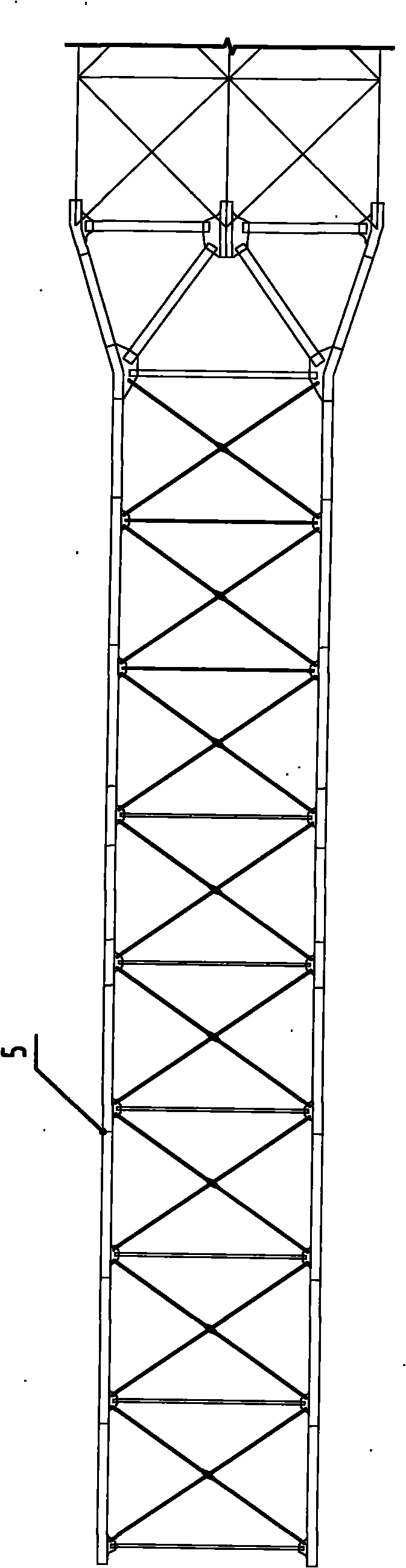

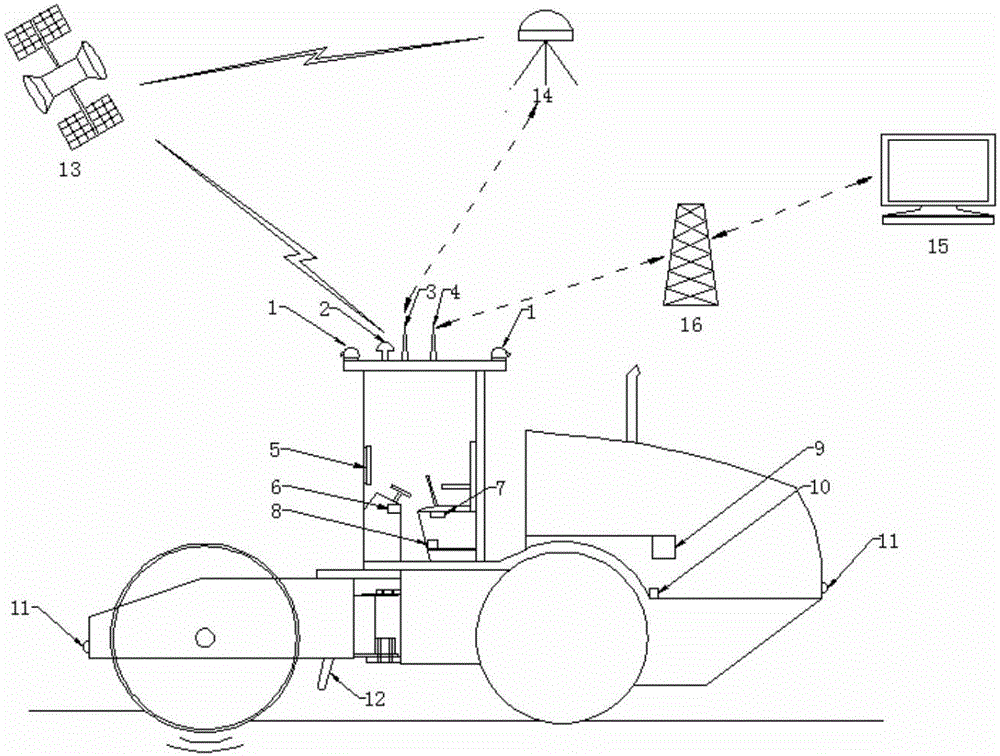

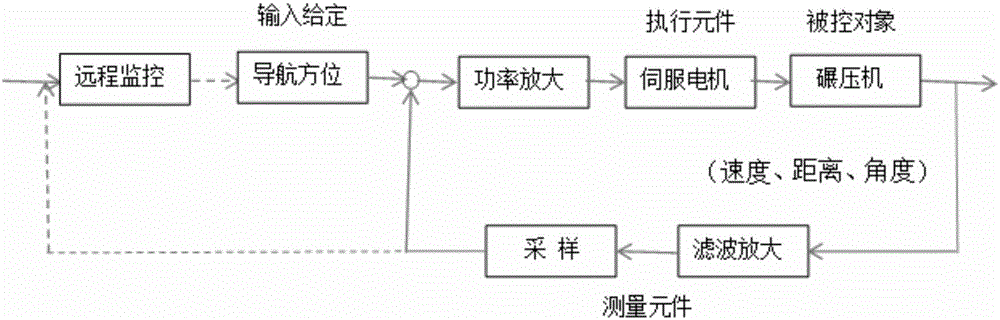

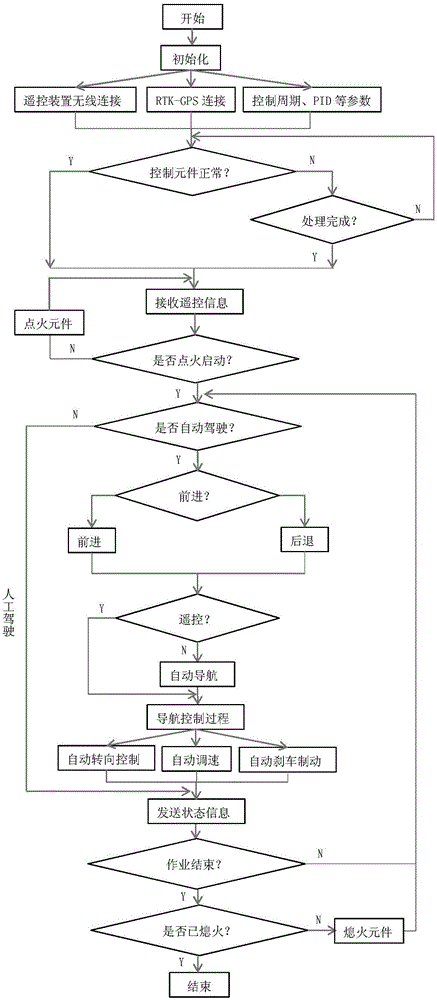

Automatic driving system and method of water conservancy construction vibration roller

ActiveCN105137997AImprove construction qualityPrecise AutopilotPosition/course control in two dimensionsSoil preservationSteering wheelAutomatic control

The invention provides an automatic driving system and method of a water conservancy construction vibration roller. The system comprises a remote monitoring device and an onboard automatic control device. The remote monitoring device plans working areas and navigation routes according to 3D digital model man-machine interaction of construction projects, receives data like position, speed and rotation direction of the roller and working environment video information in a wireless communication manner and sends automatic navigation data and instructions to the onboard automatic control device. The remote monitoring device can also remotely control the roller based on received emergent processing requests in a man-machine interaction manner. The onboard automatic control device receives the automatic navigation instruction and remote control driving information sent by the remote monitoring device in real time, and compares the information sent by the onboard automatic control device with the information like position, speed and rotation angle detected by an onboard RTK-GPS and a sensor. After being adjusted via the PID algorithm, deviation is sent to execution elements like an electric steering wheel, an electric throttle and an electric brake to control the vibration roller to finish respected rolling work. According to the invention, the automatic driving system is compatible with a manual driving system.

Owner:TSINGHUA UNIV

Plugging flexibilizer

ActiveCN103740346AImprove flexural strengthGood toughening effectDrilling compositionCellulosePetroleum

The invention discloses a plugging flexibilizer, comprising the components in parts by weight: 5-12 parts of polypropylene fiber, 20-30 parts of rubber particles, 1-5 parts of high molecular polyacrylamide, 2-8 parts of toughened nylon, 2-8 parts of asbestos section, 5-12 parts of plant fibers, 4-7 parts of calcium hydroxide, and 0.1-0.4 part of polyanionic cellulose PAC-HV. A preparation method of the plugging flexibilizer comprises the following steps: orderly adding the components in parts by weight to a kneading machine according to a conventional preparation method at constant temperature and constant pressure; evenly mixing and stirring; and crushing into a 0.05-1mm granular product. The plugging flexibilizer has the characteristics of being wide in material source, free of toxicity and pollution, simple and convenient in construction technology, good in rheological property, good in pillar-forming property, strong in tenacity, not easy to fragilely fall off, high in plugging success rate and the like, does not easily generate a rupture and a brittle fracture in the drilling process after plugging, and is widely applied to pressure-loaded plugging engineering of low-pressure fractured formation, large cracks, large caves, subterranean rivers and serious voidage formation in petroleum and geological drilling.

Owner:DONGYING TAIER GASOLINE TECH

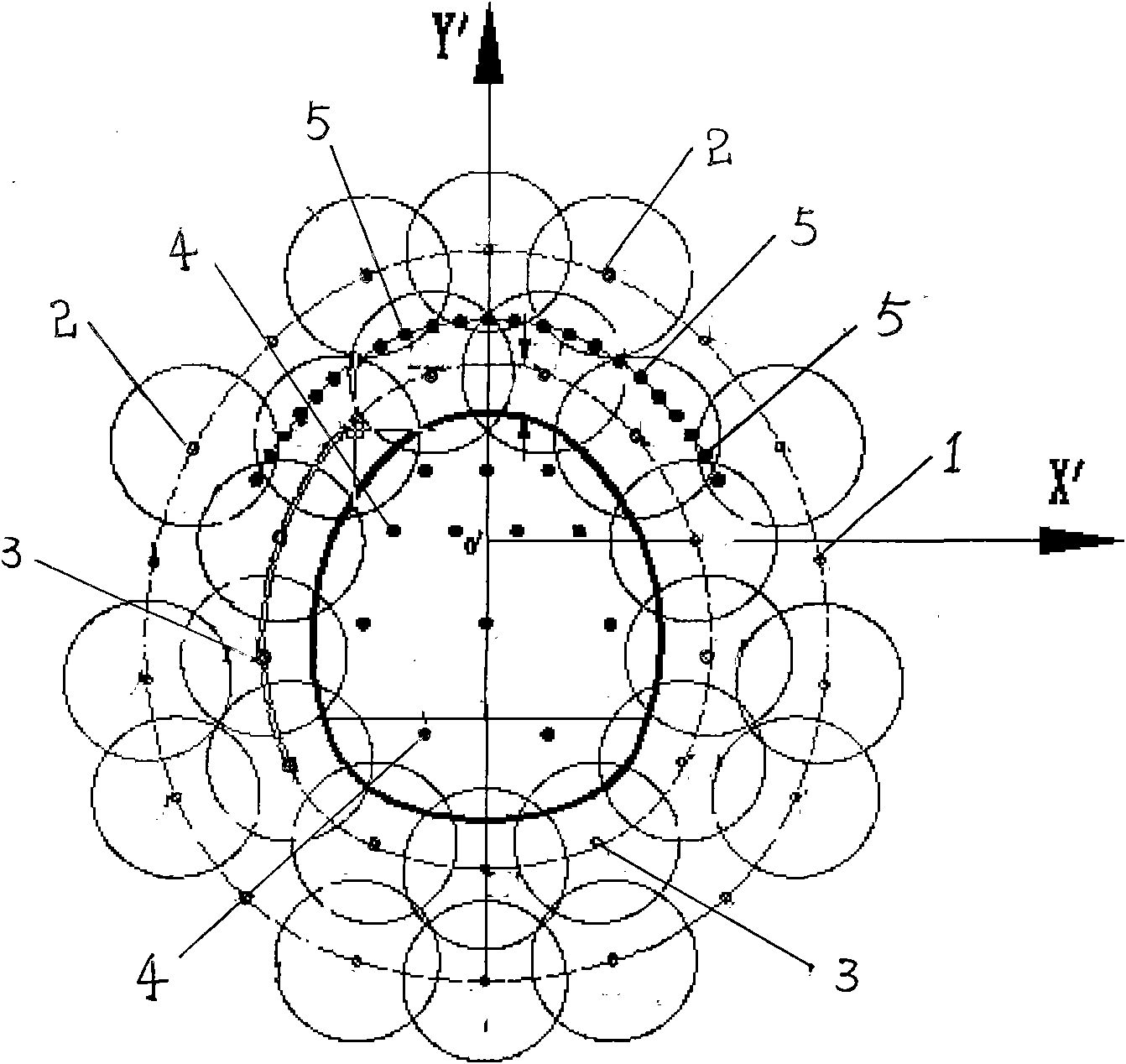

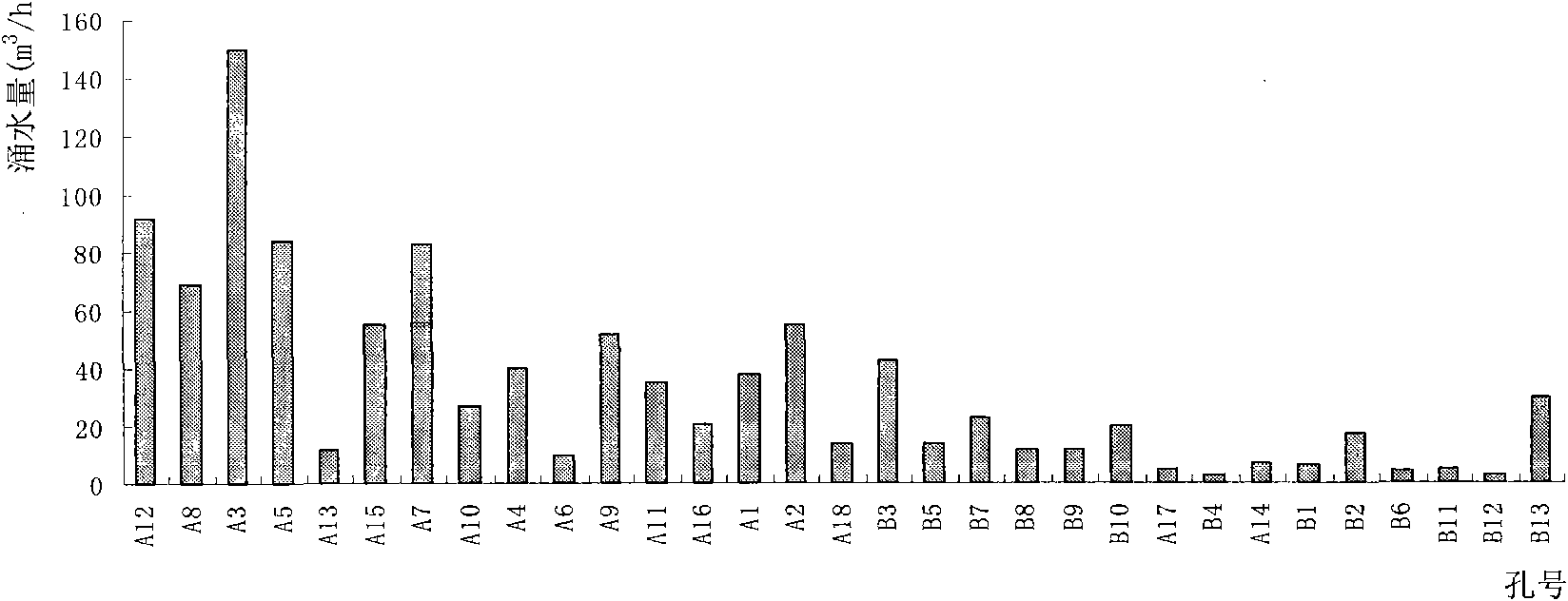

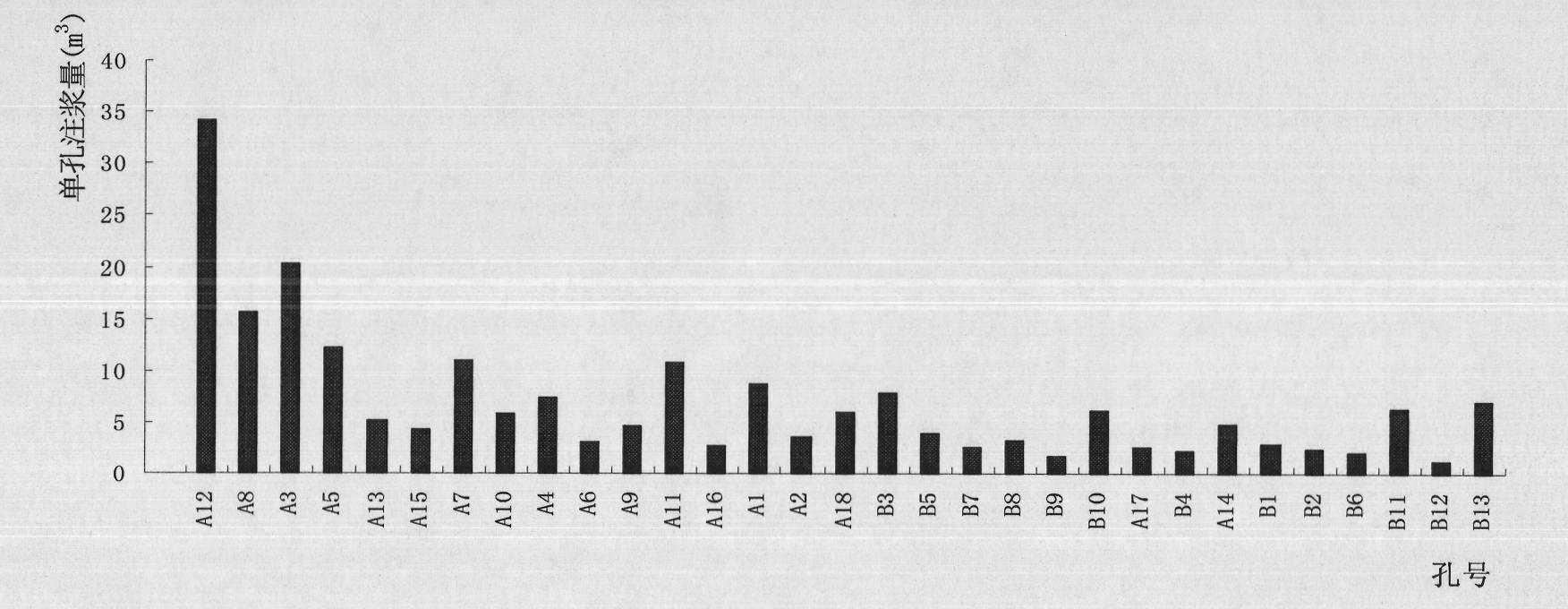

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

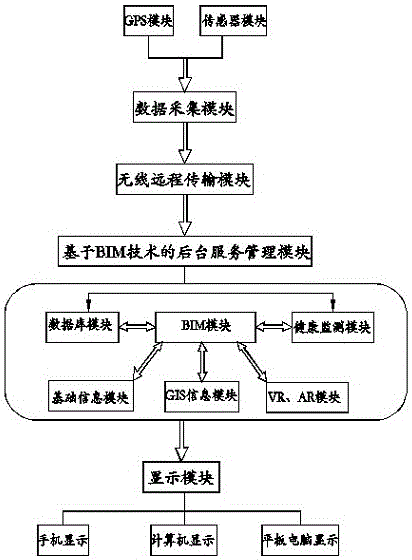

BIM-based intelligent monitoring system

ActiveCN106595565AAuxiliary construction managementOptimized designMeasurement devicesPotential riskData acquisition module

The invention discloses a BIM-based intelligent monitoring system which comprises a GPS, a sensor module, a data acquisition module, a wireless remote transmission module, and a backstage service management module based on BIM technology. The backstage service management module based on BIM technology comprises a database, a BIM module, a GIS information module, VR, an AR module, a health monitoring module, and a display module. According to the system, the real-time monitoring of a foundation pit can be realized, the foundation pit visual display is realized through the BIM and a GIS, the combination of virtuality and reality is realized through VR and AR technology, through a health monitoring module, the early alarm and alarm of the potential risk of the foundation pit are realized through the health monitoring module, and thus the construction of the foundation pit is safely and smoothly completed.

Owner:SUN YAT SEN UNIV

Nano-silica sol-modified outer wall paint and preparation method thereof

The invention discloses nano-silica sol-modified outer wall paint and a preparation method thereof. The nano-silica sol-modified outer wall paint comprises, by weight, 10-25% of nano-silica sol, 0.1-0.2% of a coupling agent, 0.2-2.0% of a neutralizer, 10-30% of an acrylic emulsion or a styrene-acrylic emulsion, 10-15% of a pigment, 10-20% of a filler, 0.2-0.4% of a dispersant, 0.2-0.4% of a wetting agent, 0.3-2.0% of a thickening agent, 0.2-0.4% of an antifoaming agent, 0.4-0.6% of a mildew-resistant antiseptic, 0.6-1.4% of an antifreezing agent, 0.4-1.2% of a film forming assistant and 20-30% of deionized water. The invention also provides the preparation method of the nano-silica sol-modified outer wall paint. The nano-silica sol-modified outer wall paint has good storage stability and can form a paint film which does not effloresce and fall off easily, has good permeability, does not mildew easily, and has excellent water resistance and alkali resistance.

Owner:CHANGSHA UNIVERSITY

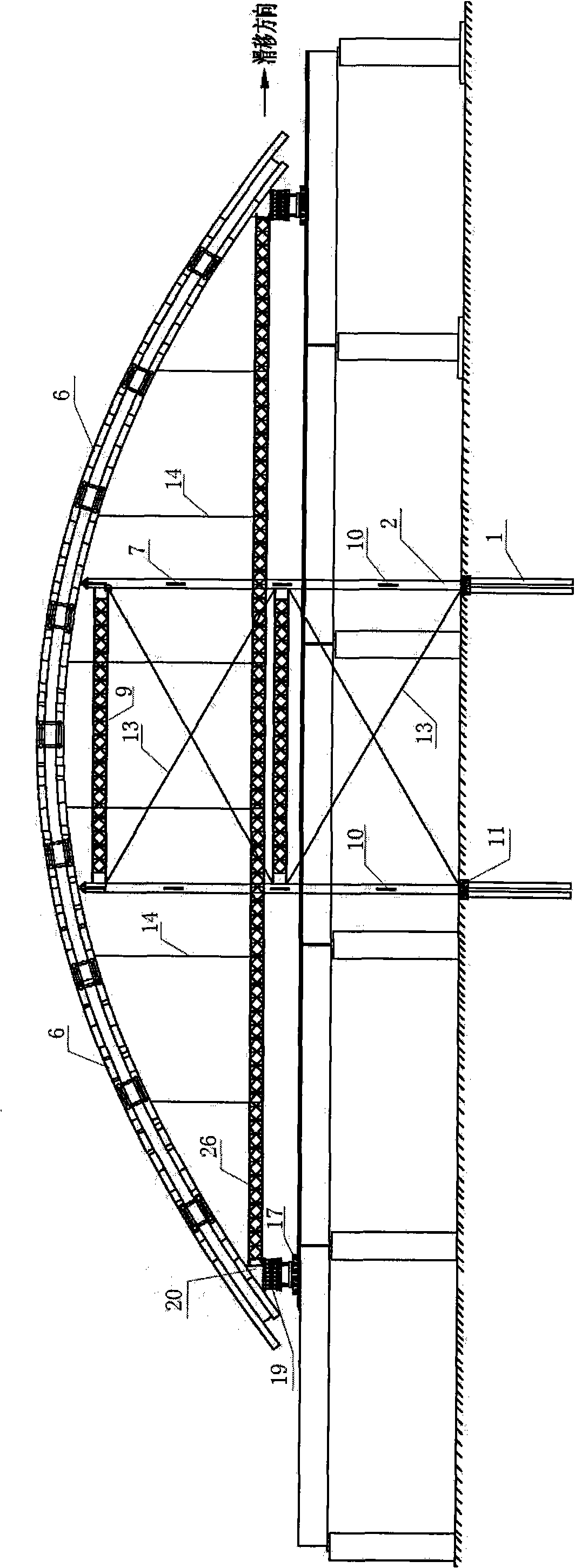

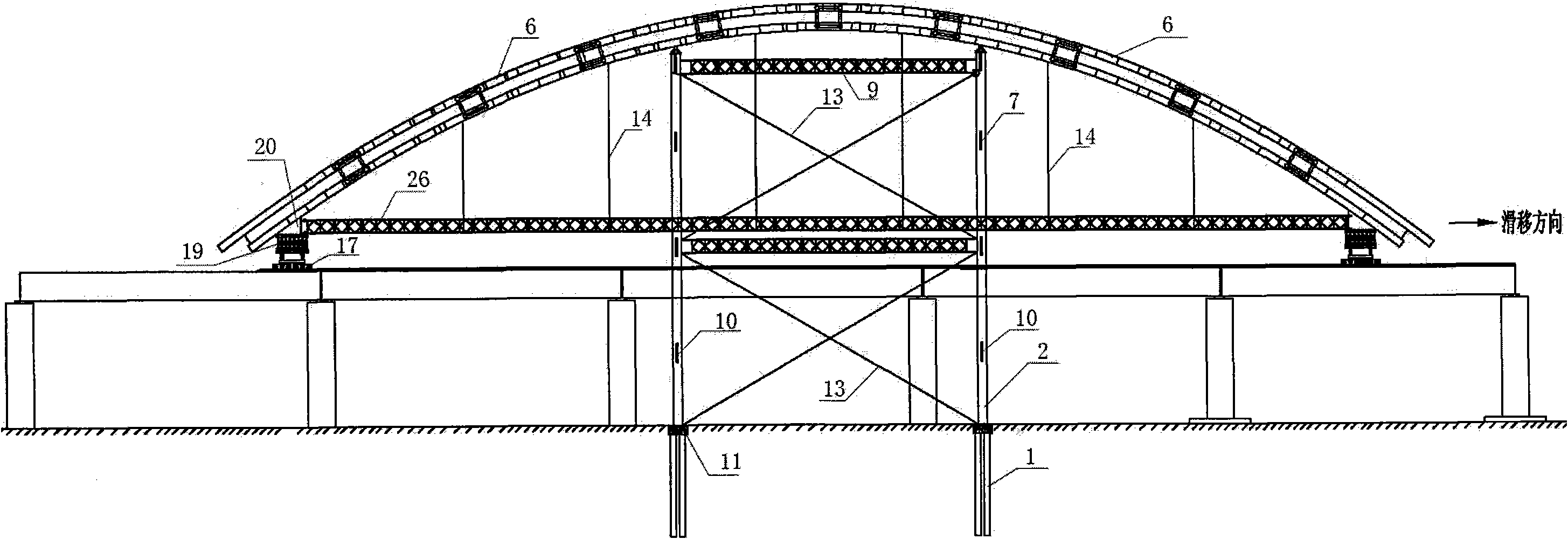

Construction method for integrally sliding large-span steel pipe arch of curved bridge

ActiveCN101935987AReduce occupancyReduce in quantityBridge erection/assemblyBridge engineeringConcrete beams

The invention relates to a construction method for integrally sliding a large-span steel pipe arch of a curved bridge, belonging to the field of bridge engineering construction. The method comprises the following steps: firstly, carrying out on-site splicing and welding on the manufacturing and installing sections of a steel pipe arch to form a large hoisting section; then installing a temporary arch-splicing support on a bridge-site longitudinal splicing site position, arranging arch ribs on the temporary arch-splicing support, and adopting an arch springing restraint device to preload arch springings after finishing splicing the steel pipe arch, thus enabling the steel pipe arch to form a stressed entirety; and finally, dismantling the temporary arch-splicing support, and adopting a pushing power system to realize integrally sliding the whole steel pipe arch into a proper position. The construction method of the invention has the advantages of small site occupation, integral hoisting of large sections, less hoisting subsection and less arch-splicing support amount, thus the construction cost is economical, the high-altitude welding quantity is less, the welding quality is ensured, the arch axis linetype control is easy, the steel pipe arch splicing and a concrete beam can be simultaneously constructed, arch splicing is carried out on an ectopic bridge site, the underbridge navigation is not influenced, the construction is safe and the construction progress can be quickened.

Owner:CHINA FIRST HIGHWAY ENG +1

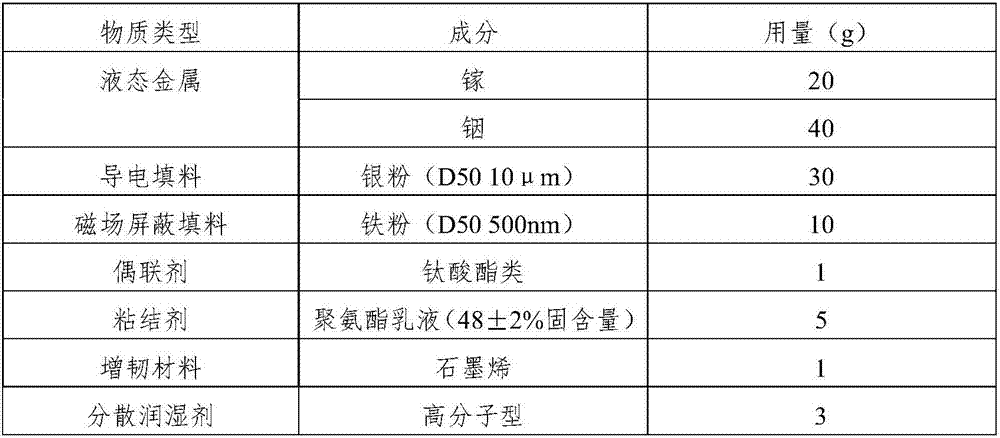

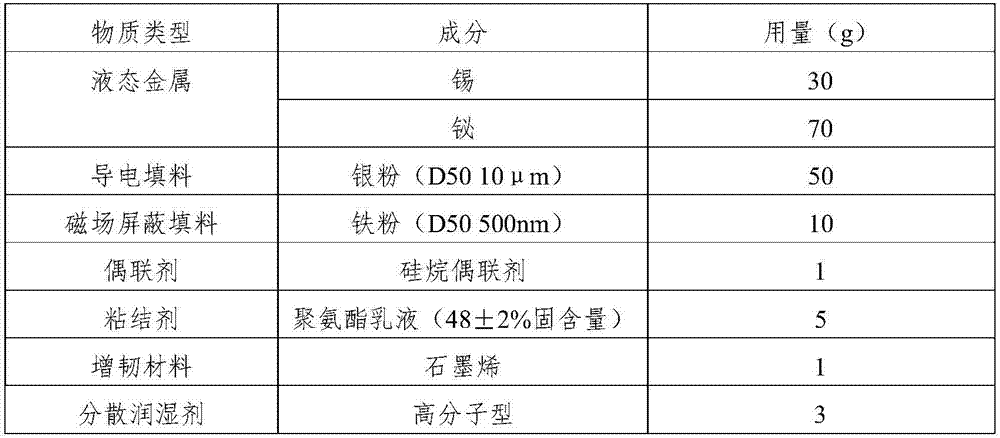

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

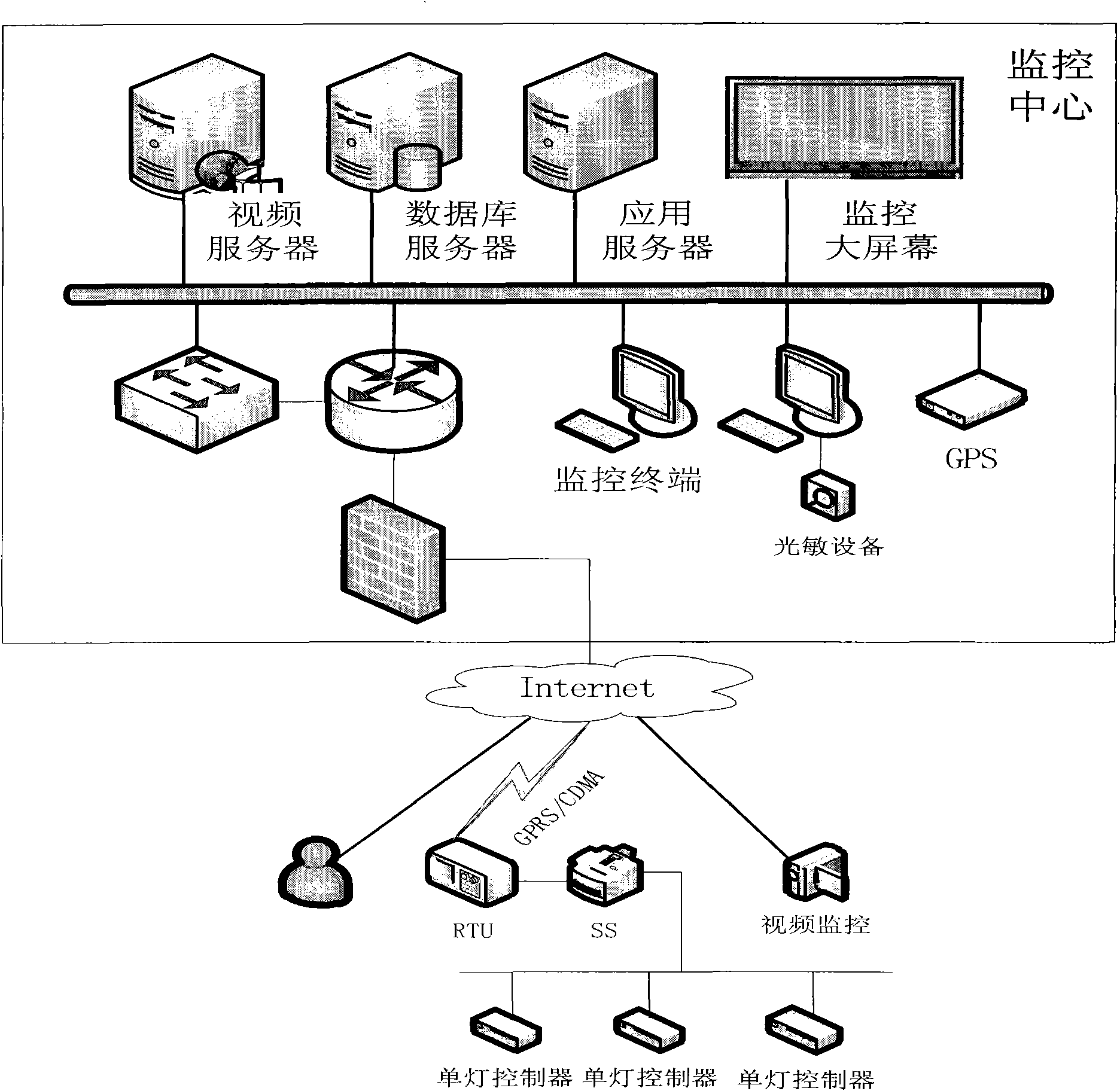

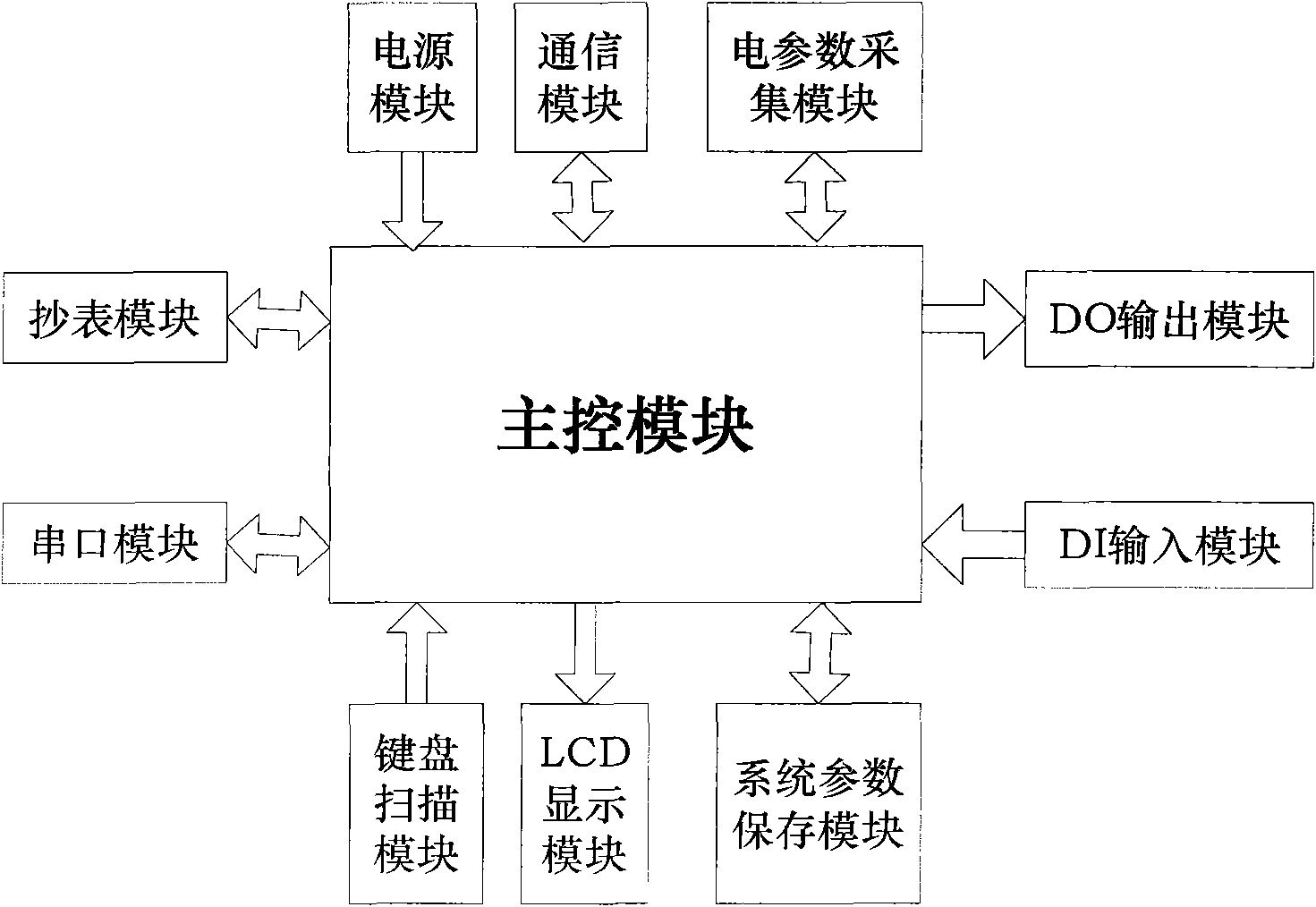

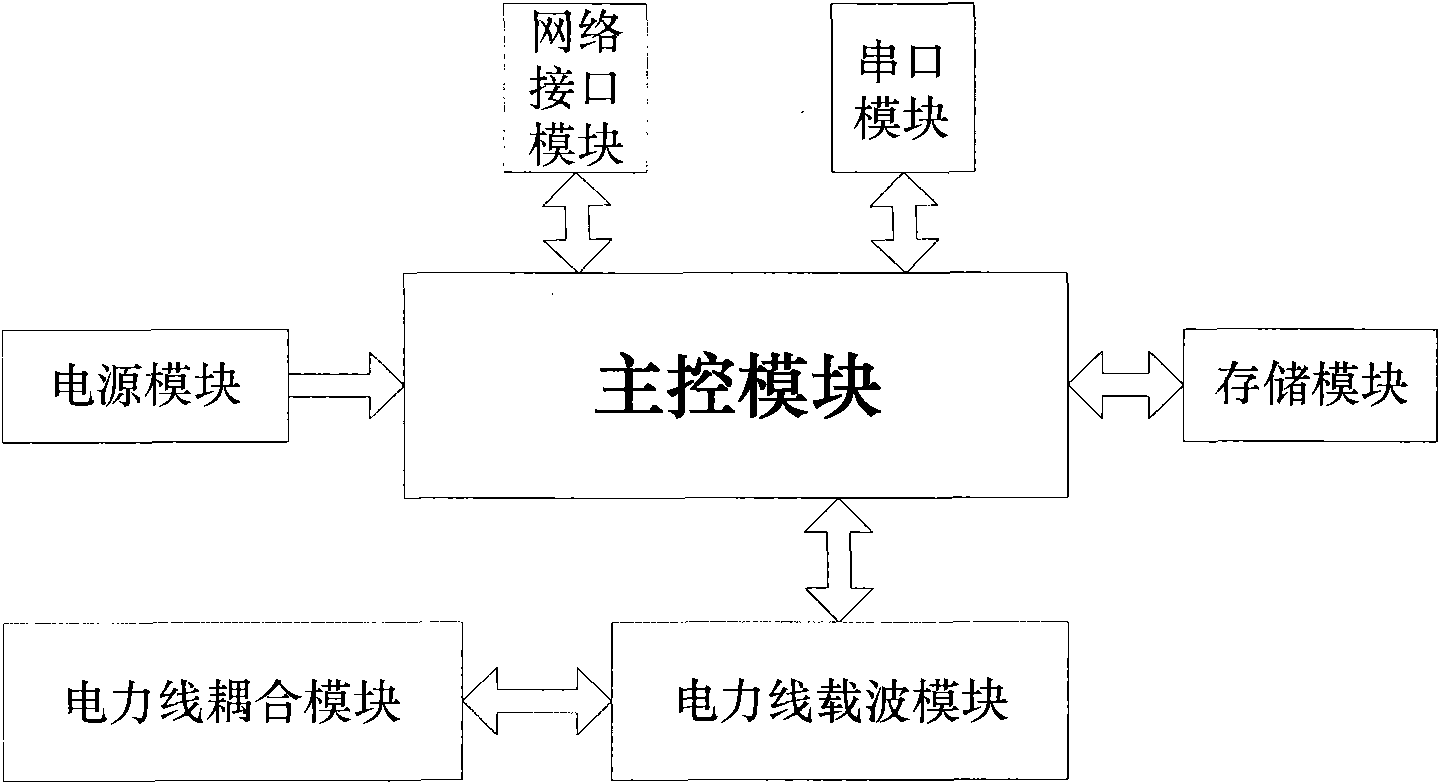

Environment-protective illumination intelligent management system

ActiveCN102076143AImprove modern management levelEnhance the imageEnergy efficient ICTElectric signal transmission systemsElectricityComputer terminal

The invention discloses an environment-protective illumination intelligent management system which comprises an upper computer, an intelligent monitoring terminal, an intelligent server and a single-lamp energy-saving controller, wherein the upper computer is arranged in a monitoring center and is provided with an intelligent management software, and the functions that the remote monitoring management (remote metering, remote controlling, remote signaling, remote viewing, and remote regulating) of urban public lighting facilities, electronic map operation and management of street lamp monitoring, map direct-viewing presentation and convenient positioning of relevant facility resources of the street lamp, as well as production management, warehouse management, artificial intelligence, and the like are realized by the upper computer; the intelligent monitoring terminal actualizes the measurement and gathering of electrical parameters of the street lamp, and the control of an illumination return circuit and a branch circuit, is connected with the intelligent server, and performs communication with the upper computer through an operator public network (GPRS, CDMA); the intelligent server is connected with the intelligent monitoring terminal, performs communication with a single lamp controller through a power-line carrier mode with automatic relay, delivers the control command, and receives single lamp status data and warning data; and the single lamp energy-saving controller receives the instructions of the intelligent server, and the control of the switching, power decreasing, light adjusting and the like for the single lamp is realized, and gathers the data such as electrical parameters, state, alarming of the single lamp.

Owner:TAIHUA WISDOM IND GRP CO LTD

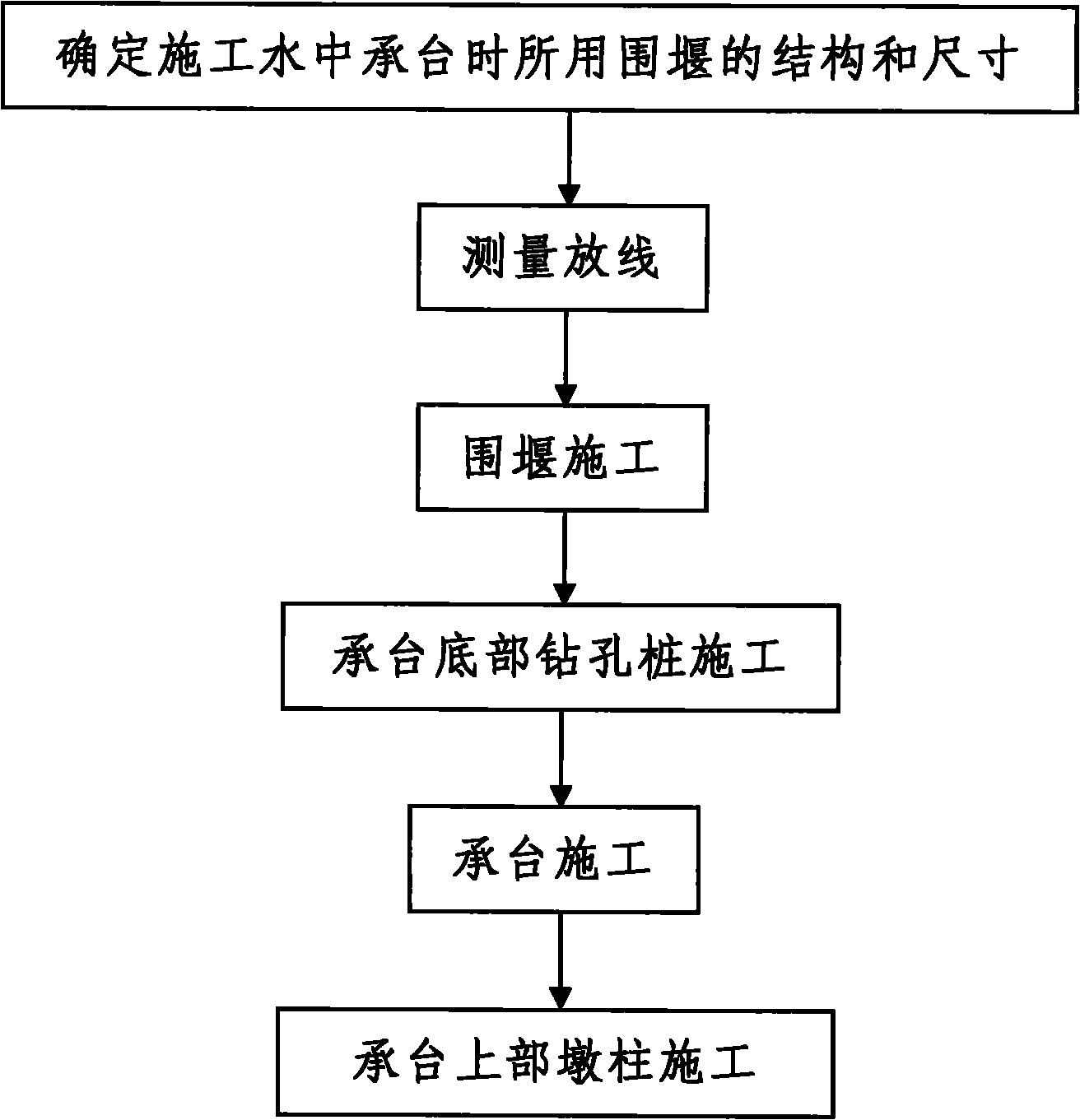

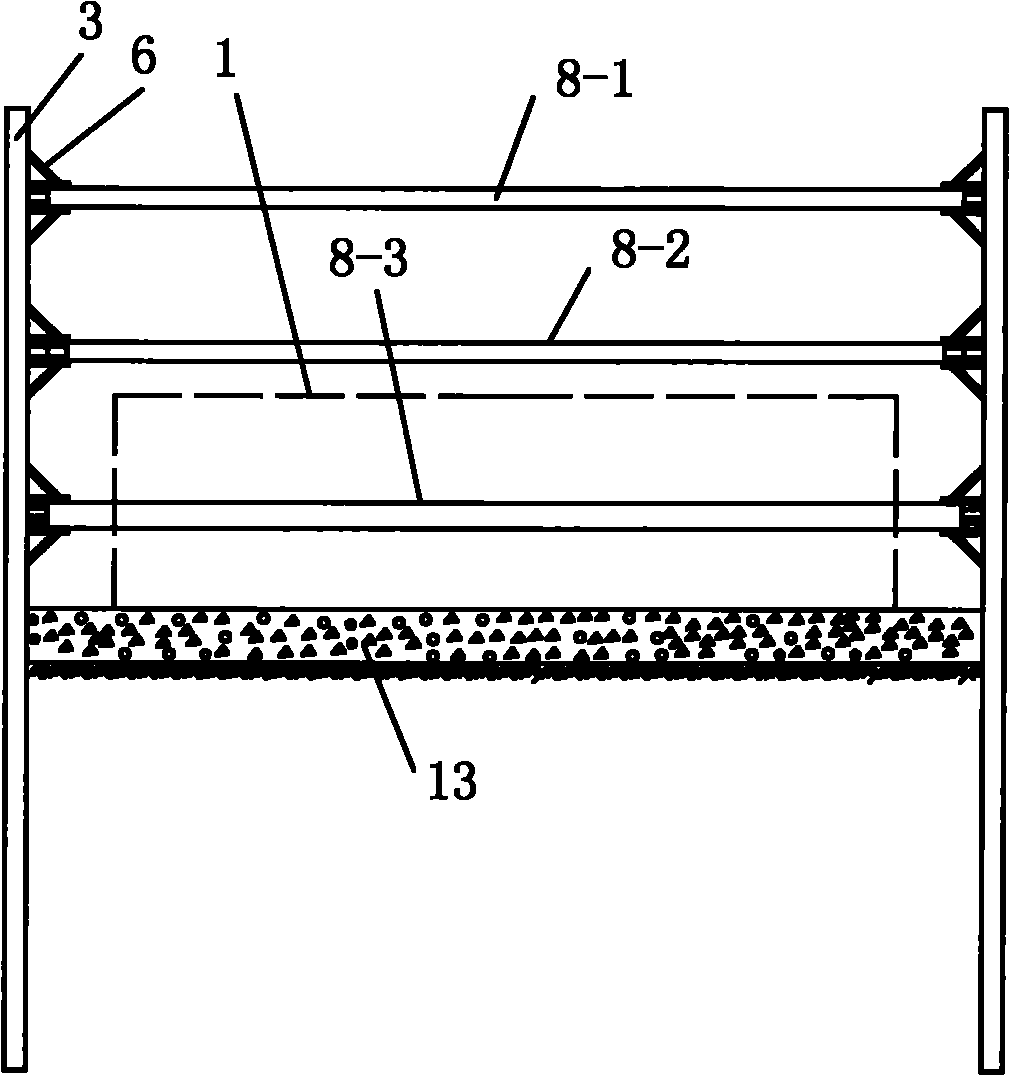

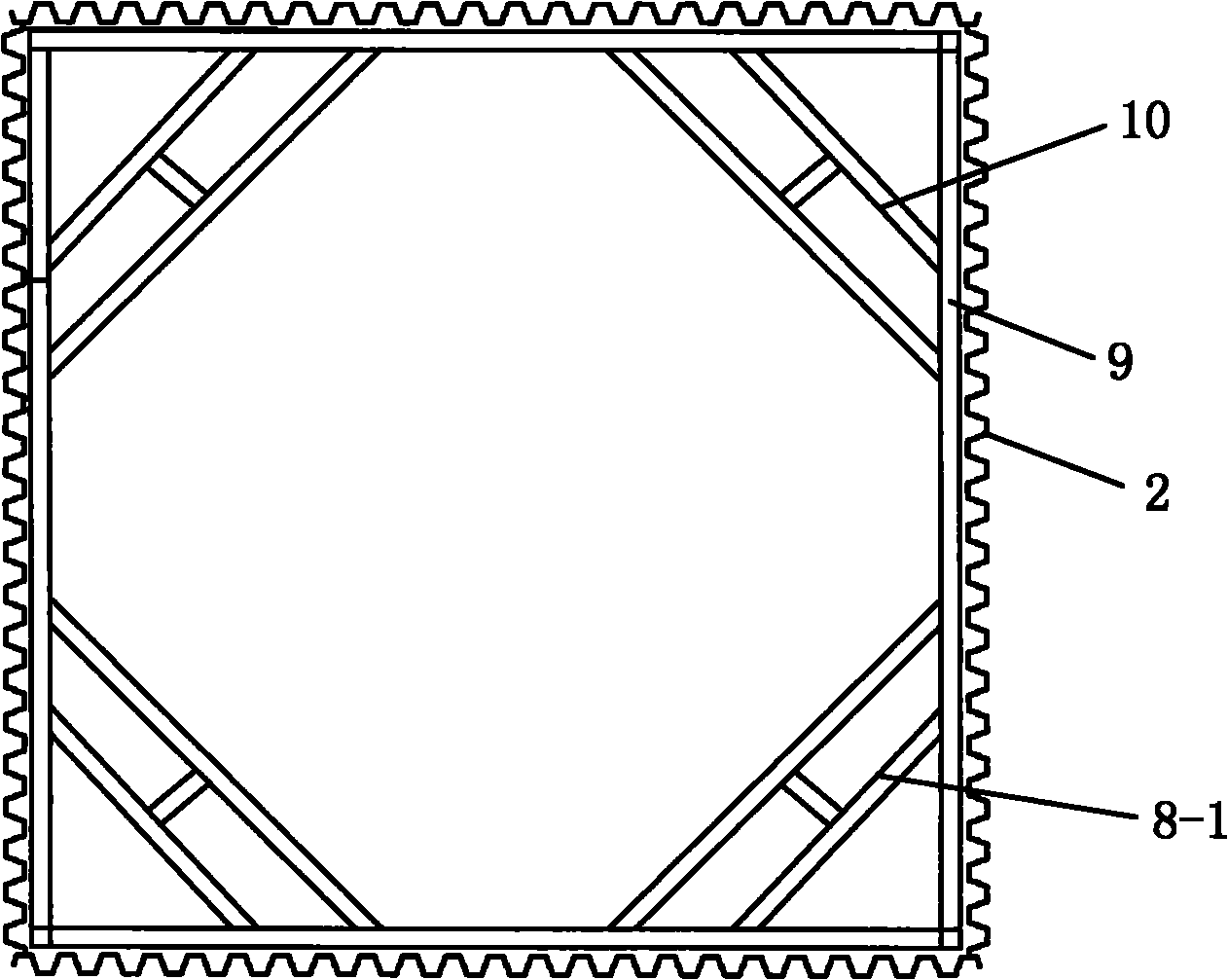

Construction technology of steel sheet pile cofferdam for Yellow River Channel internal support table construction

The invention discloses a construction technology of a steel sheet pile cofferdam for Yellow River Channel internal support table construction. A construction support table is an underwater support table arranged in a Yellow River Channel. The technology comprises the following steps of firstly, determining a structure and the size of a used cofferdam in the process of underwater support table construction; secondly, surveying and setting out; thirdly, constructing the cofferdam; fourthly, constructing a bored pile at the bottom of the support table; fifthly, constructing the support table: carrying out forming construction of the underwater support table on the top of the bored pile after construction when the bored pile construction is finished, and finishing integrative construction of the bored pile and the underwater support table; and sixthly, constructing a pier column at the upper part of the support table. The invention has the advantages of reasonable design, convenient construction and low construction cost, carrys out construction by adopting an integrative construction method of the support table and the bored pile and can efficiently solve the defects of long construction period, large investment, needs of setting up a plurality of construction platforms, large construction difficulty and the like in the successive construction process of the bored pile and the support table in the traditional construction process of the steel sheet pile cofferdam.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

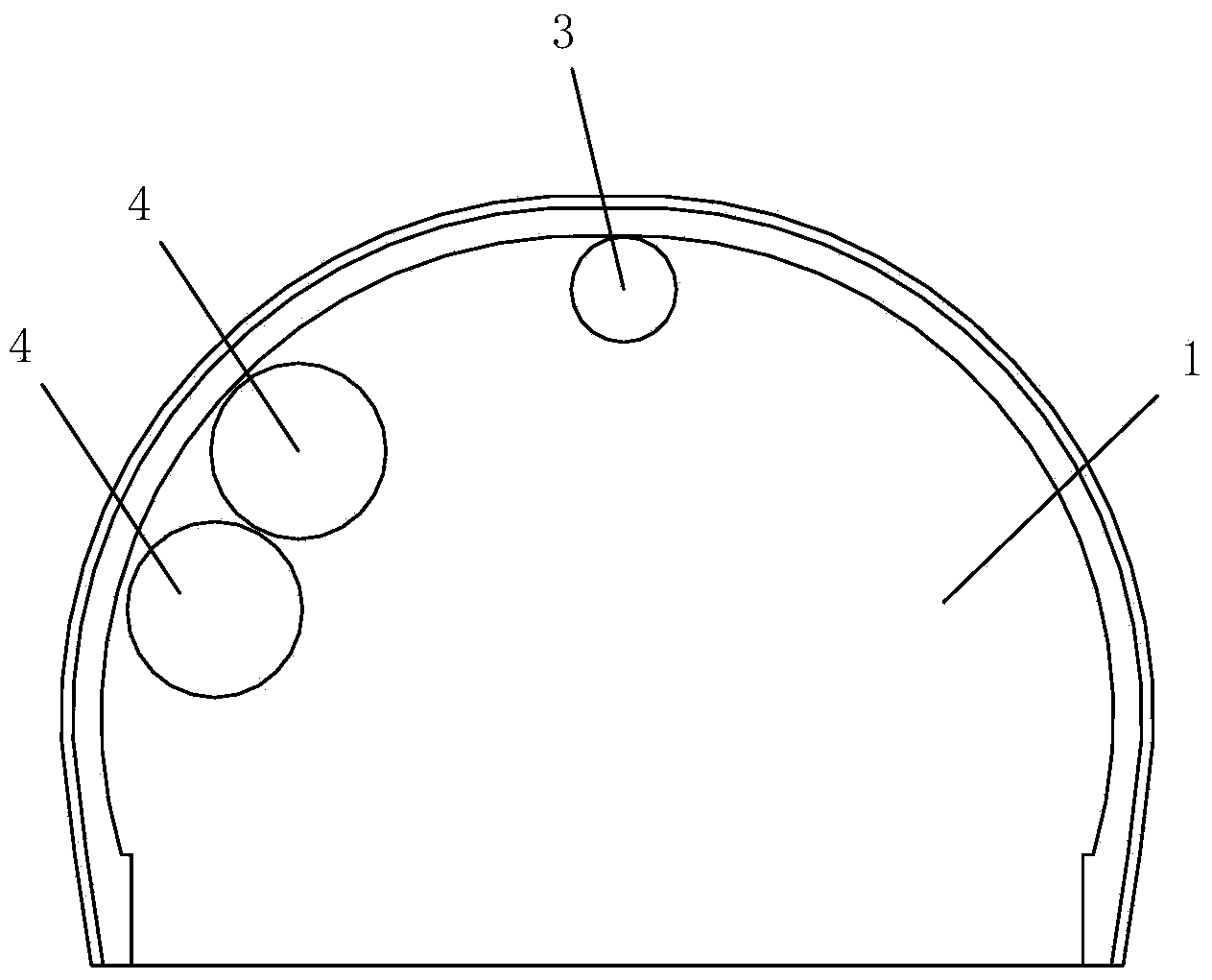

Construction method of pervious rib type arch beam tunnel

ActiveCN101324072AEasy constructionConstruction safetyArtificial islandsClimate change adaptationSupporting systemProcess safety

The invention discloses a through rib-typed arched girder tunnel construction method, comprising the steps as follows: before the excavation of the tunnel, the arch slope is reinforced by transverse pipe roof; the shaft excavation is carried out by a type of stepped excavation and reserving rock arch; after the wall rock deformation is basically stable, the internal side arch secondary lining, arch ground beam, the rock fall-proof retaining block, the rib-typed arched girder and the anti-collision wall are wholly constructed; the metering of each construction circulation excavation is 10-12m and the whole construction length is 6-8m. The invention is a set of whole construction method for the through rib-typed arched girder tunnel; the construction sequence and the supporting system are adaptable for the characteristics of the through rib-typed arched girder tunnel such as shallow burying, eccentric pressing and space forcing, effectively ensures the construction process safety and the stability of the tunnel structure, and provides a practically operatable construction technique for the generalization and application of the novel environmental-protective tunnel, namely, through rib-typed arched girder tunnel.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

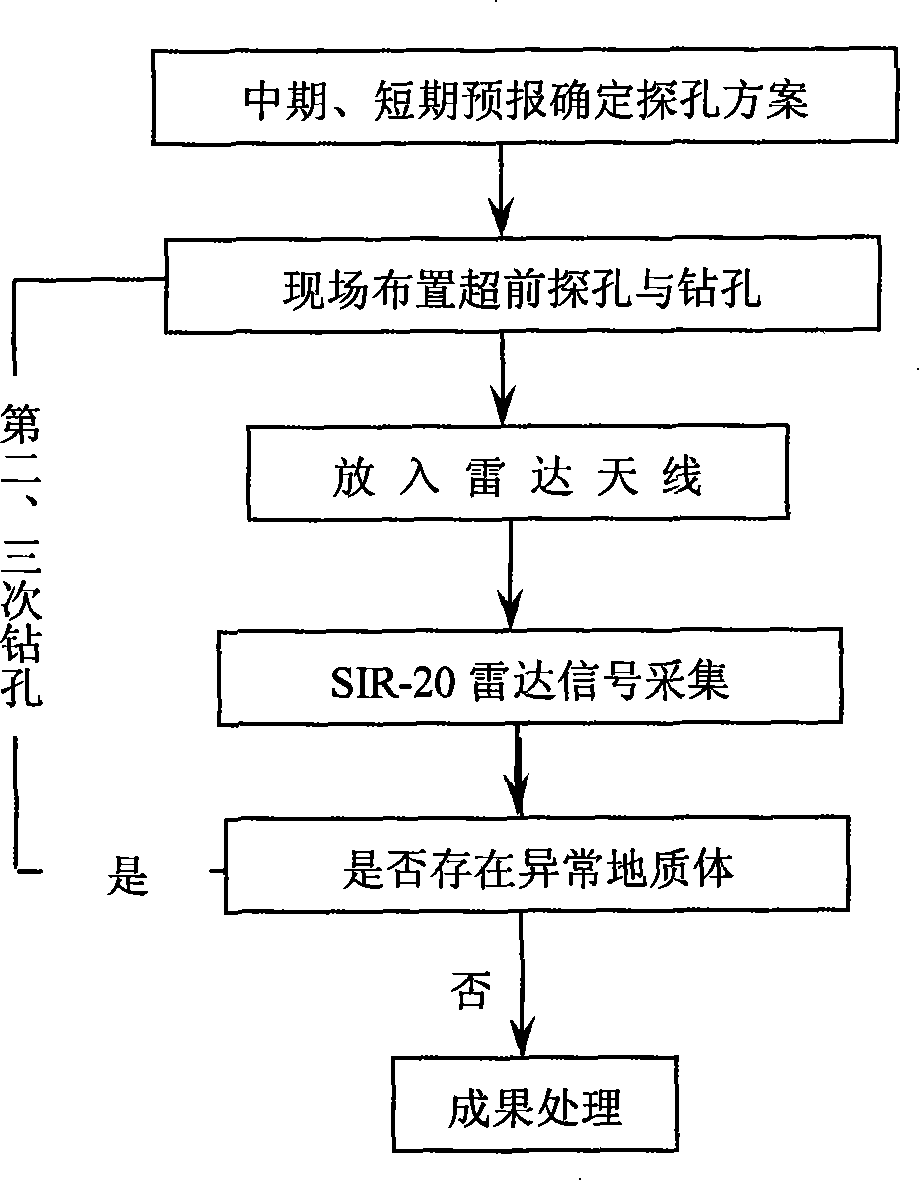

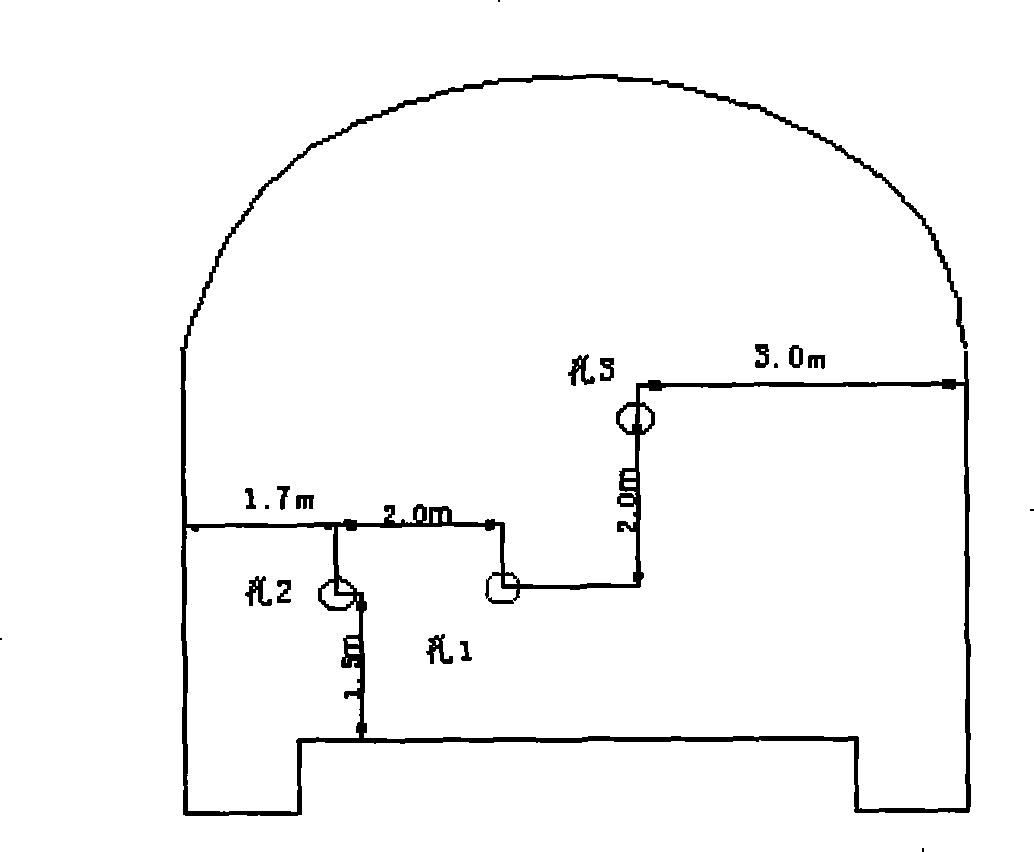

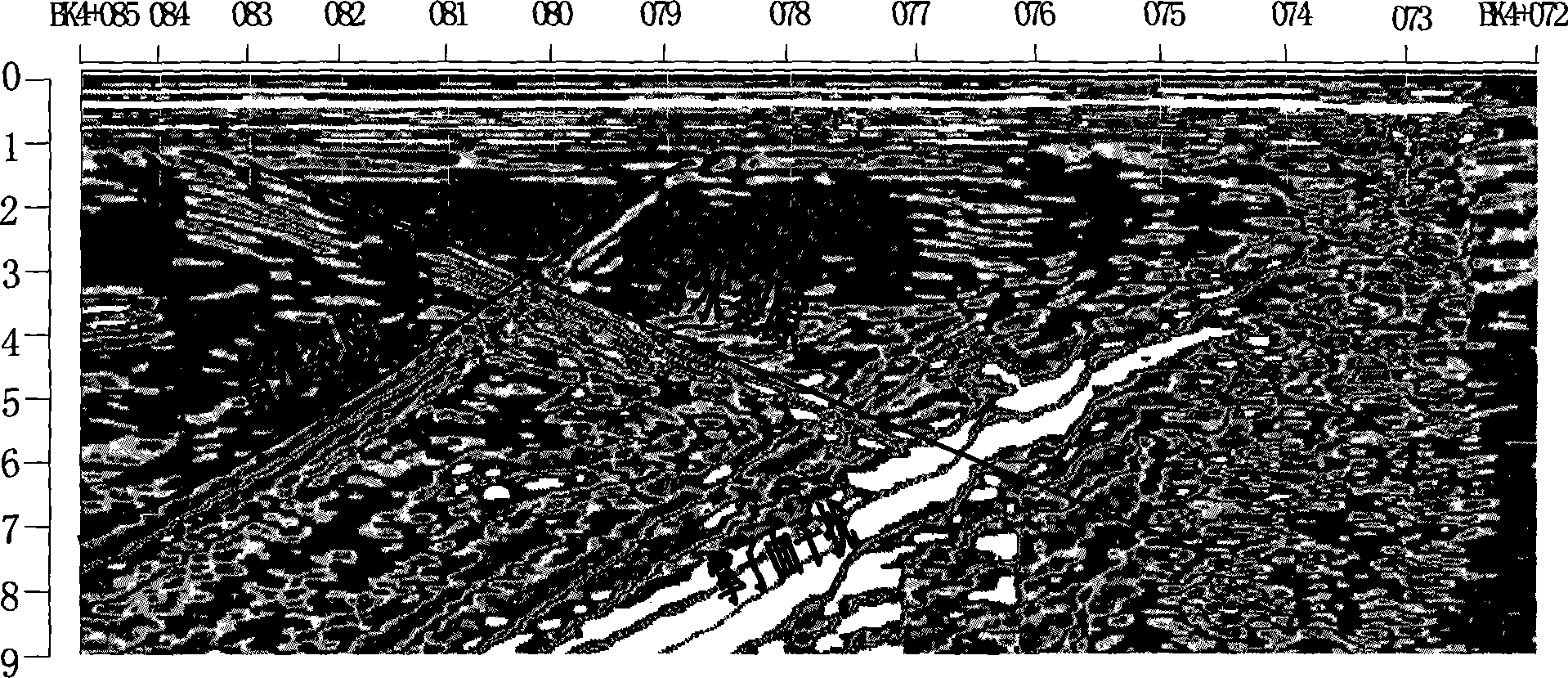

Method for forecasting advanced geology for tunnel construction

ActiveCN101251605AEasy to testAvoid blindnessDetection using electromagnetic wavesAcoustic wave reradiationTunnel constructionGeomorphology

The invention relates to an advanced geological forecast method in the tunnel construction filed, comprising the following steps of: determining a hole prospecting proposal according to a middle or short term forecast and placing a radar antenna in after a hole is drilled to collect radar signals and determine whether any abnormal geologic body exists; if no geologic body exist, continuing construction; if geologic body exists, drilling again, placing a radar antenna in so as to collect signal and determine whether any abnormal geologic body exists; if no geologic body exist, continuing construction; if geologic body exists, drilling again and placing a radar antenna in so as to collect signals. Describing the spatial positions of the abnormal geologic bodies according to the signals obtained during the three times so as to provide operational geologic information for further processing. The advanced geological forecast method can be used in a wide exploration scope, can accurately forecast the abnormal spatial geologic phenomenon in front of an excavating face, provides reliable assurance for reducing collapse and rapid construction, is applicable to exploration of high resolution at deep underground and deep tunnel excavating face and is an uniquely feasible and effective exploration means to deep engineering in many cases.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

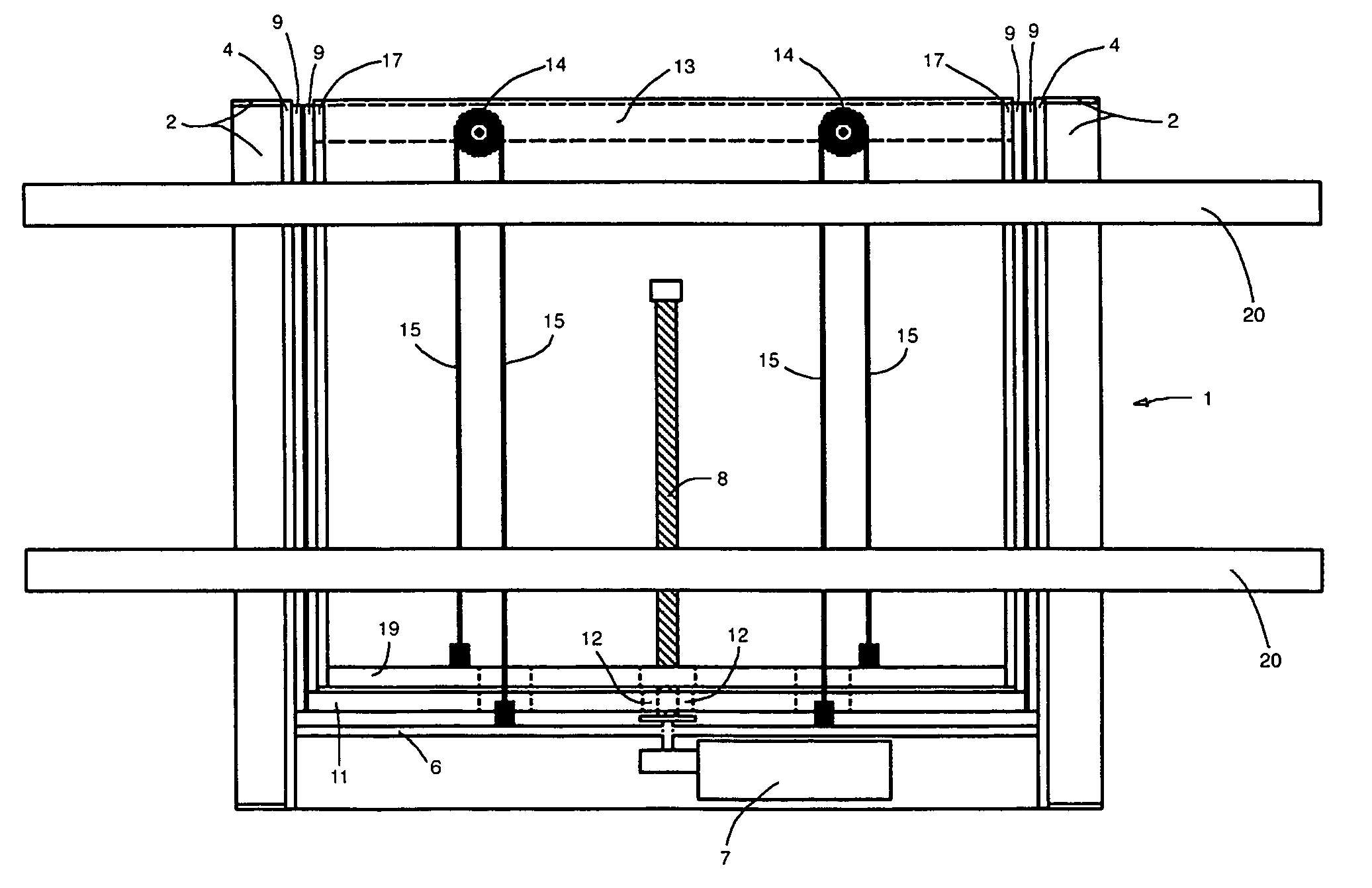

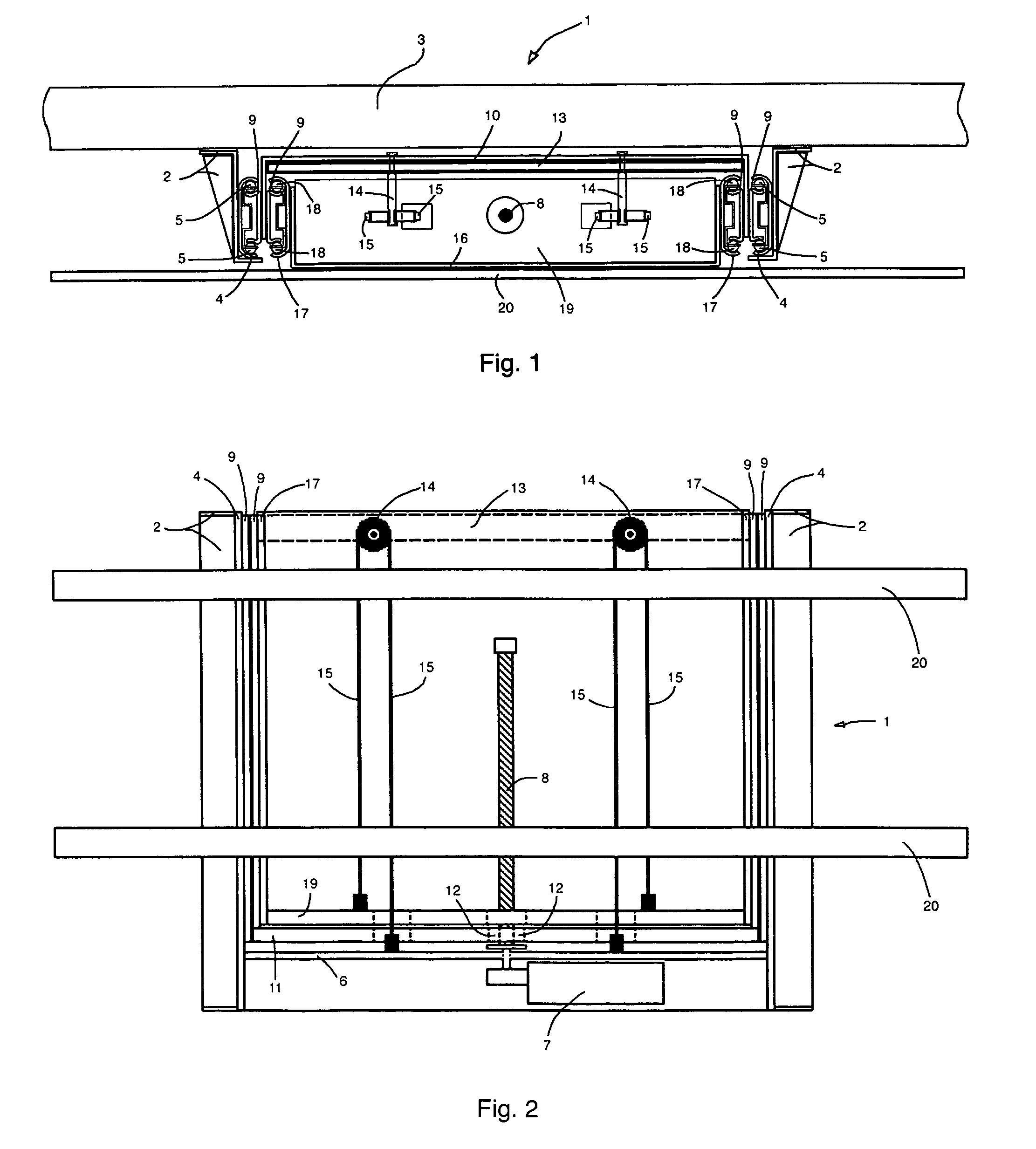

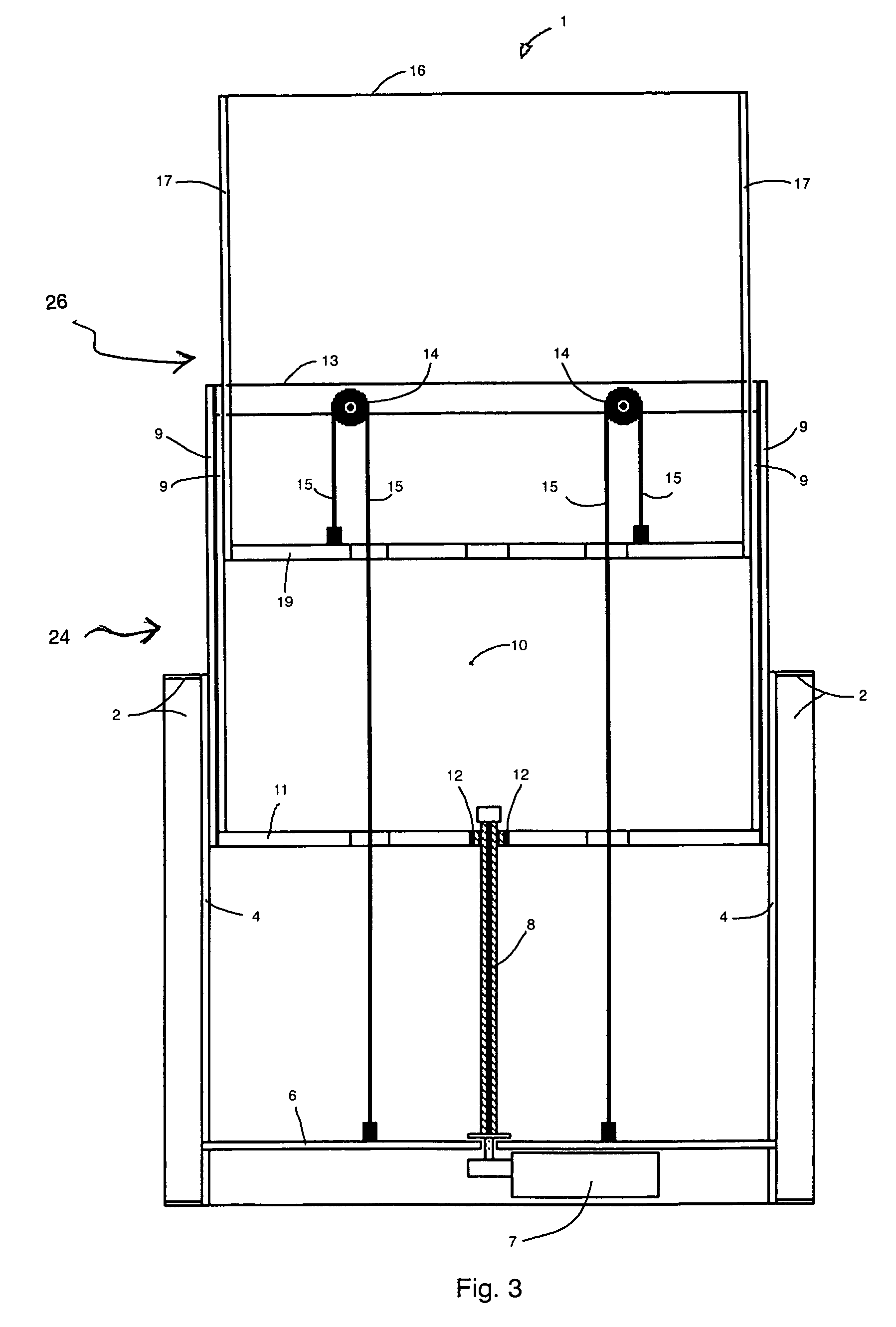

Lifting device for visual screens

InactiveUS7128003B2Reduce the chance of injuryConstruction safetyOffice tablesCabinetsDisplay deviceEngineering

A device for lifting and lowering visual displays, such as television sets, video monitors, plasma displays, pieces of art, or the like. The elevating device includes an elevating mechanism that elevates a first sliding frame and a second sliding frame. The first and second sliding frames move independently inside of a mounting frame. A motor rotates a pair of vertical threaded rods to drive the first sliding frame and cause the first sliding frame to rise and fall. A belt and pulley configuration transfers an elevating force from the first sliding frame to the second sliding frame. The second sliding frame includes supporting bars and is elevated to place the display at a desired height and is retracted to conceal the display in a cabinet, or the like.

Owner:OKNINSKI MAREK

Small-bore long distance curved pipe jacking method

The present invention discloses a small-bore long distance curved pipe jacking method, belonging to the technical field of architectural construction, and comprising the following steps: constructing a working well; mounting construction equipment; leading in a measuring axis and a benchmark; taking the jacking tubes in position; jacking; grouting; constructing pipelines in the working well; and finishing the cleaning; the construction equipment comprises a development machine, a curved guide machine with an automatic measurement system, a jack and a pump cylinder, wherein the curved guide machine is connected to a back end of the development machine; the jack is mounted in the working well; the pump cylinder is mounted in a duct of the curved guide machine; the pump cylinder is used for conveying thixotropic mud to between an outer wall of the jacking tube and a soil body via a slip casting tube; during the jacking procedure, the adjacent jacking tubes are connected by a pipe joint sleeve. The method of the present invention enables the prior impossible small-bore long distance quick turn construction to be possible; the economic benefit is good, and construction precision is high; the environment problems like traffic obstruction and the like are solved successfully.

Owner:大有环境有限公司

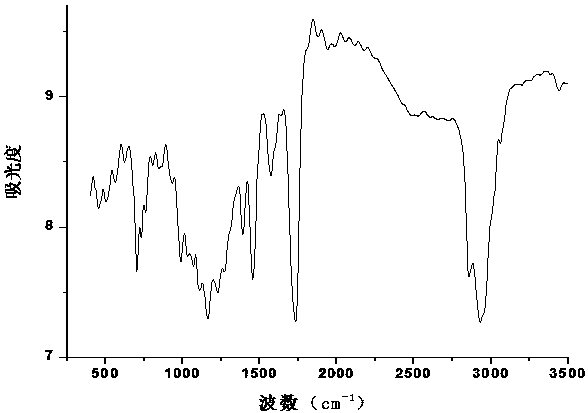

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

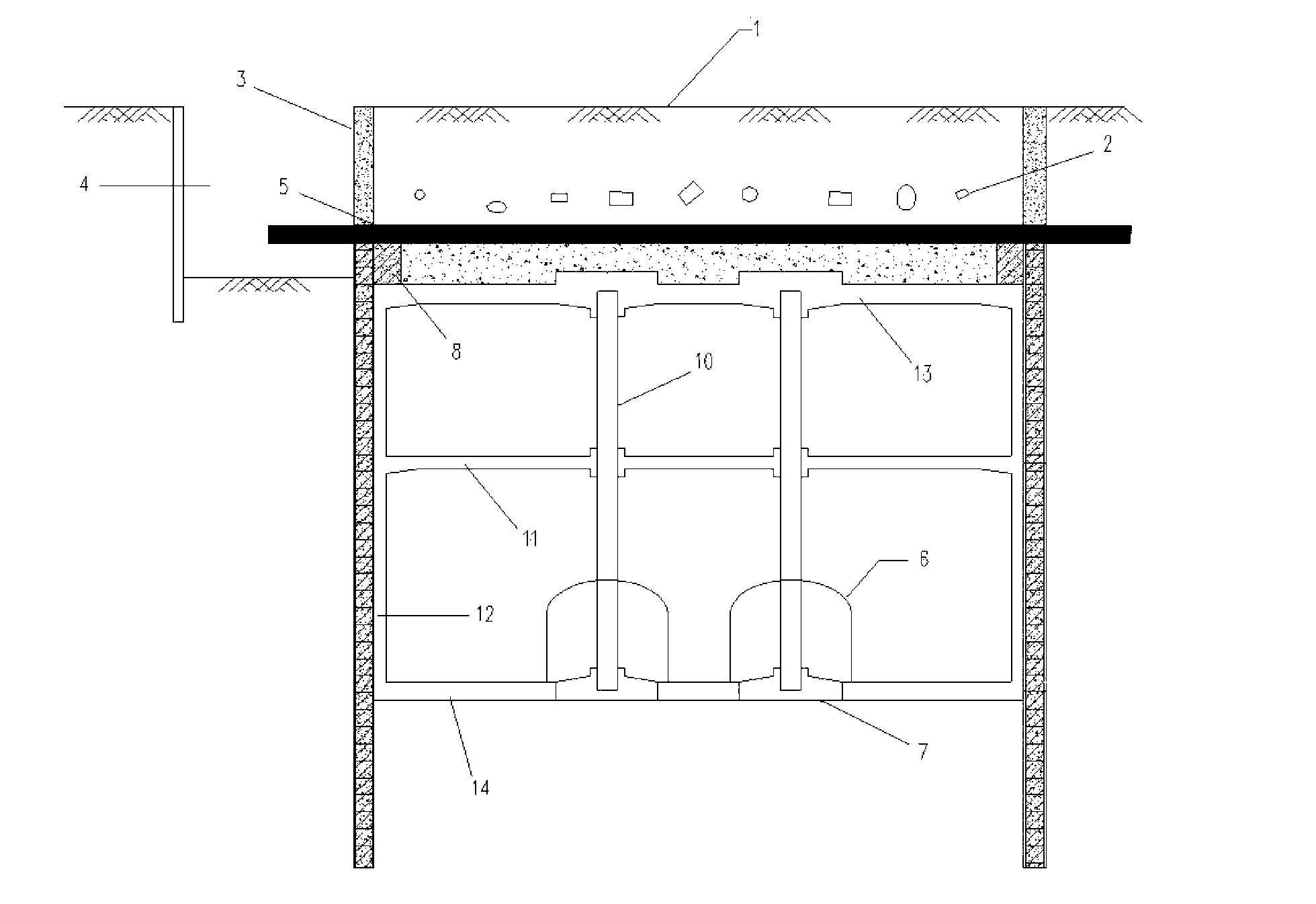

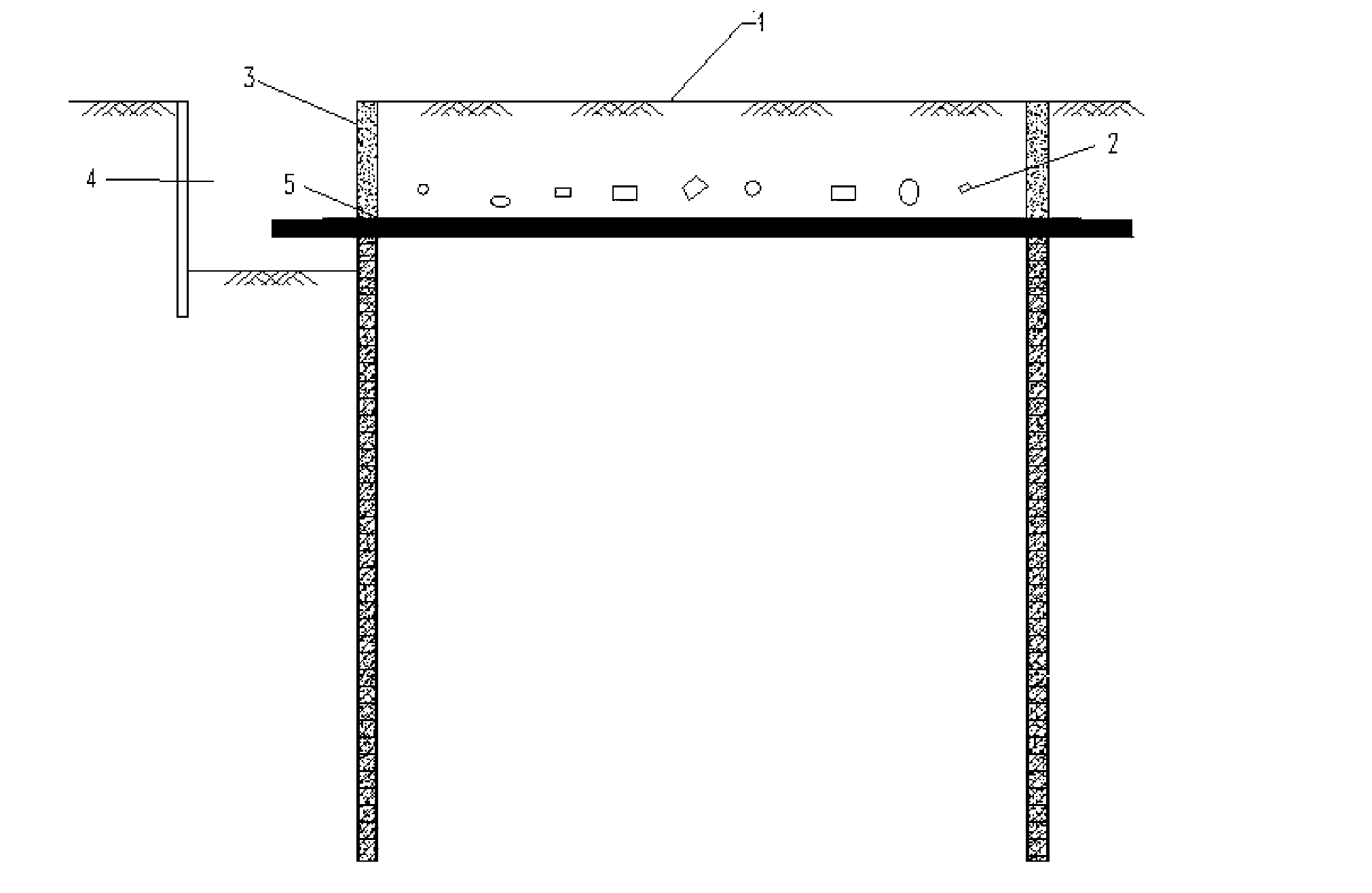

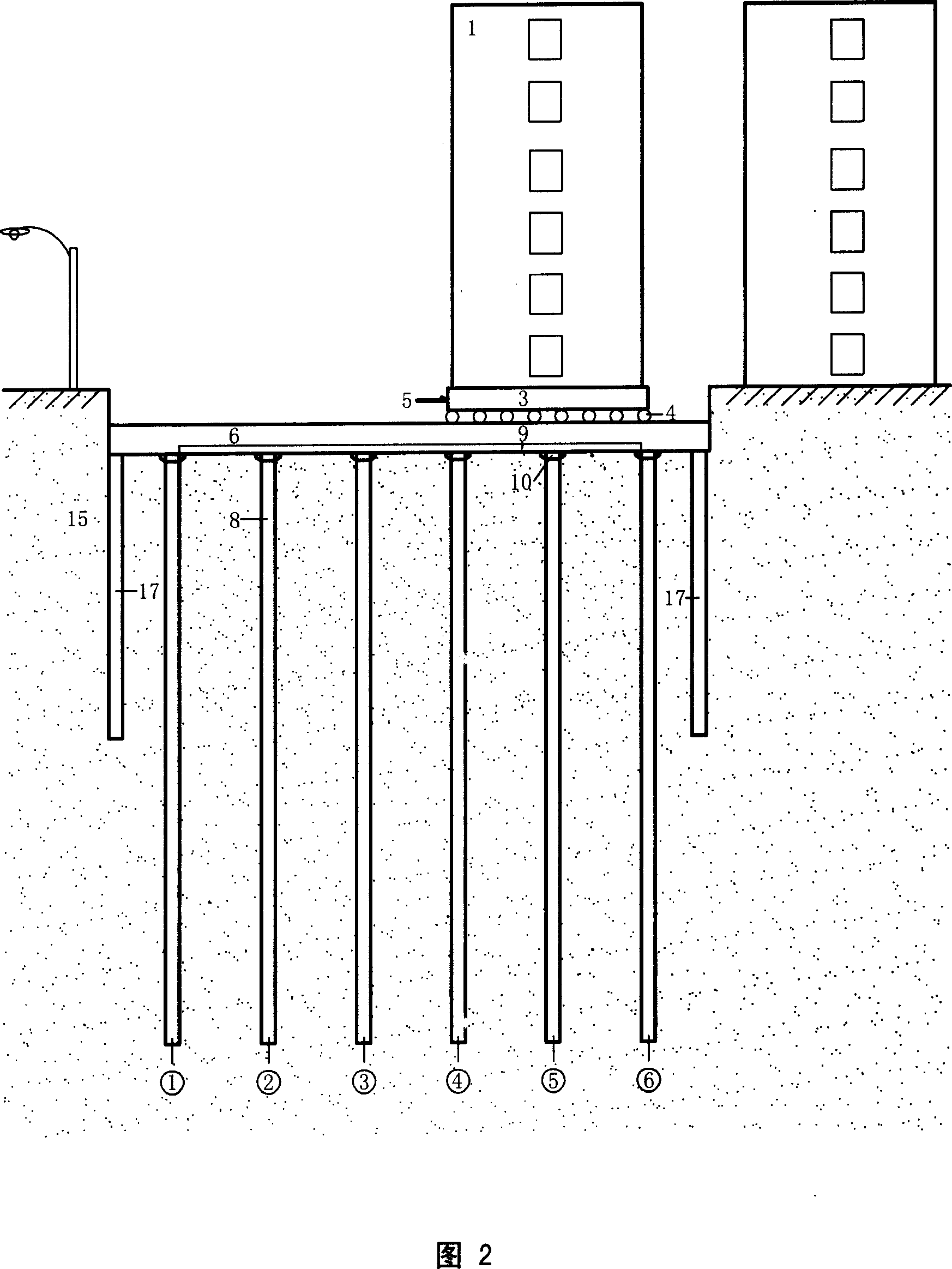

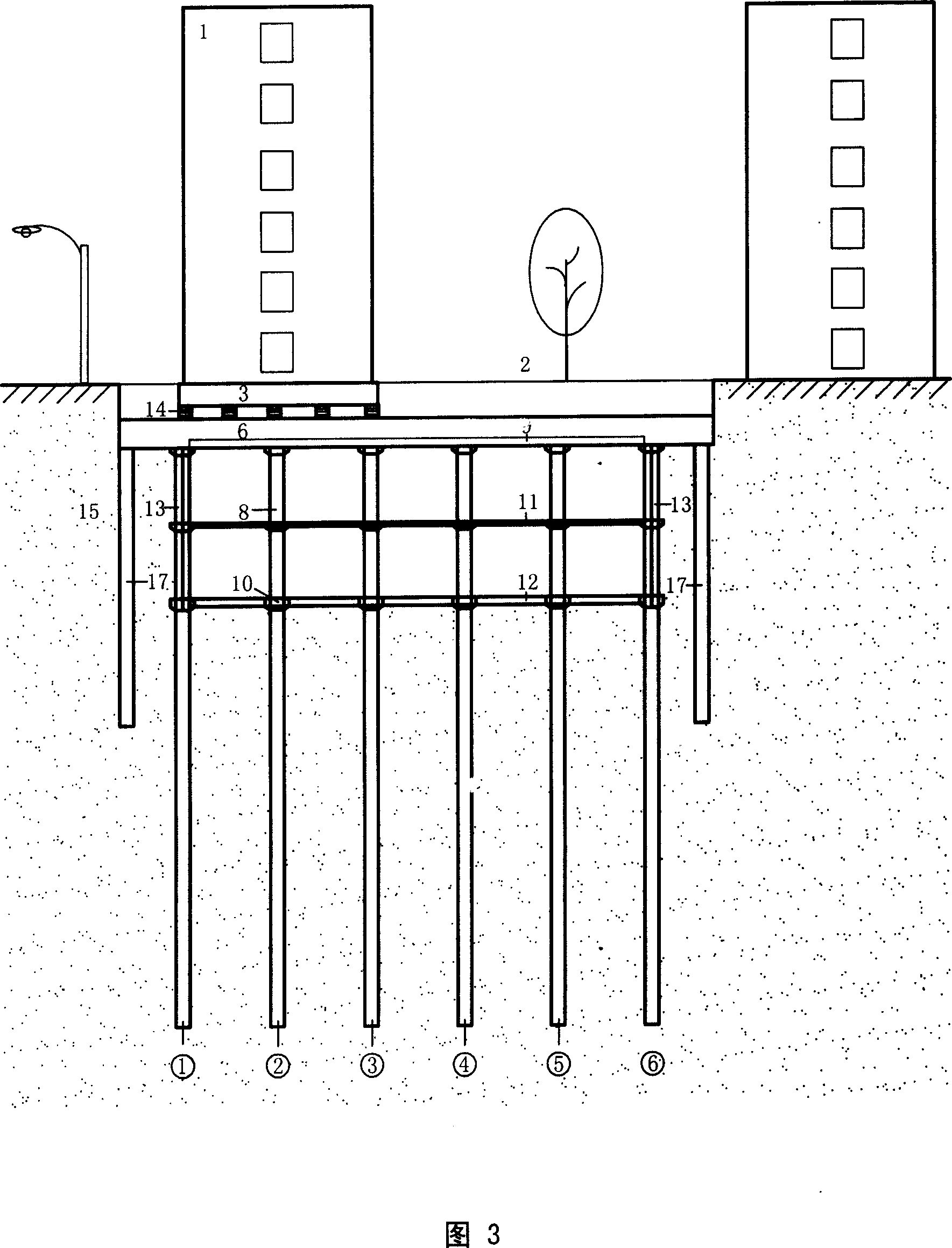

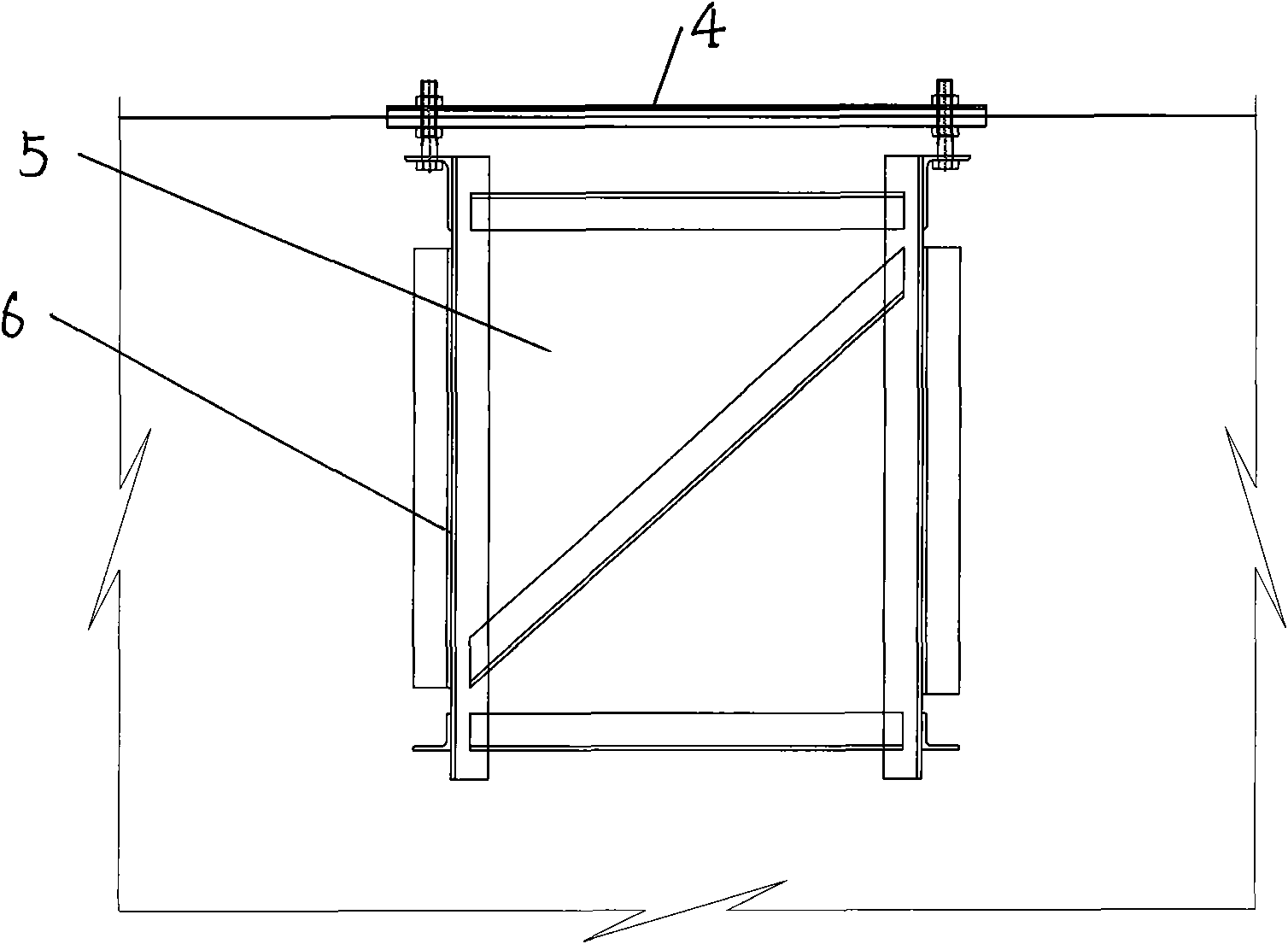

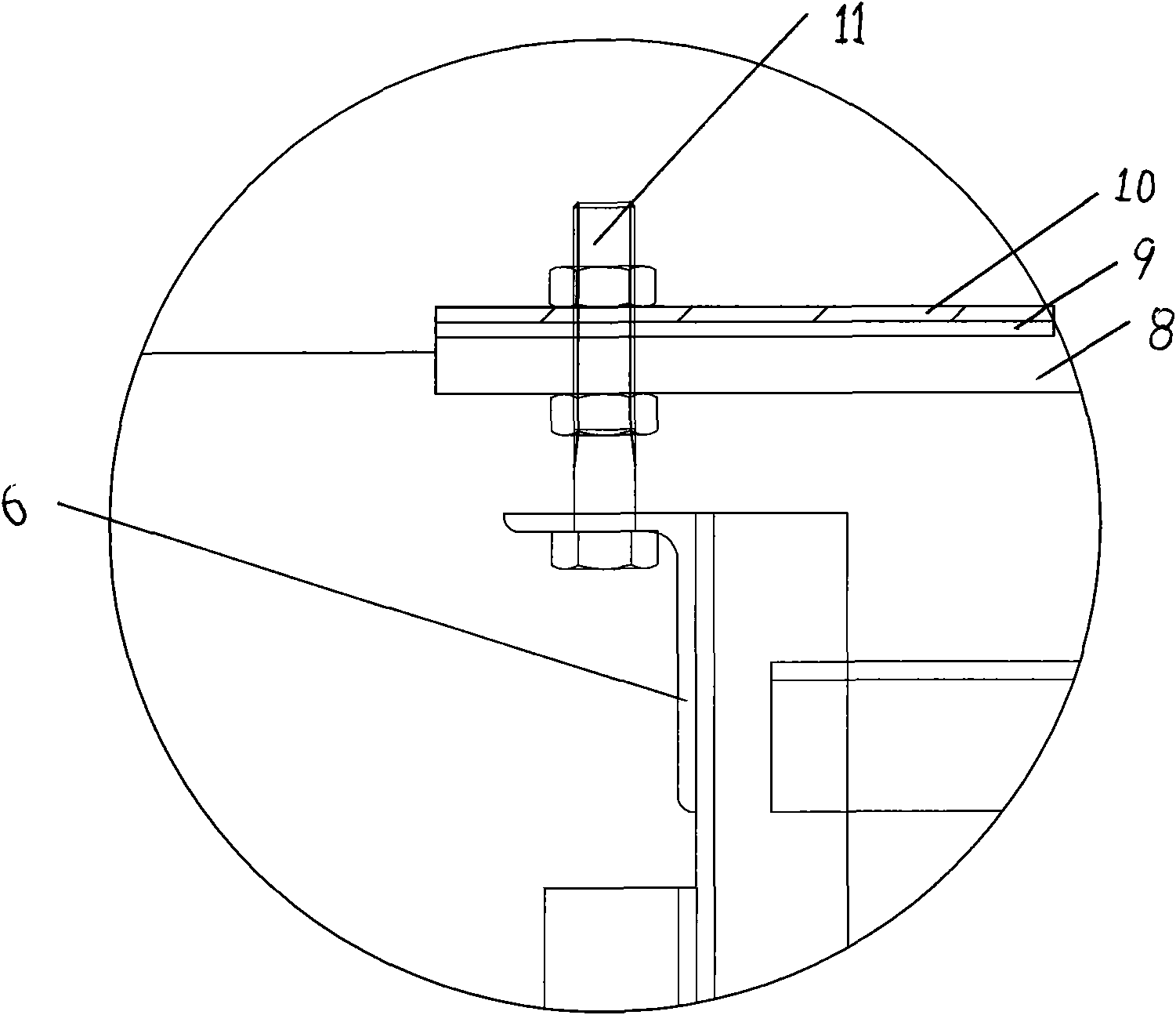

Shed-frame method for shallowly burying large-sized underground structure construction

InactiveCN102704957AGuaranteed lateral stabilityIncrease stiffnessUnderground chambersSupporting systemRoad surface

The invention relates to a shed-frame method for shallowly burying a large-sized underground structure construction. A construction principle is as follows: an envelope enclosure is adopted for retaining soil and water and resisting lateral deformation; a large-diameter pipe shed is arranged to bear the load of road surfaces and stratums and protecting underground pipelines; strip foundation construction of a center pillar in a main structure is carried out in a small pilot tunnel which is excavated with a subsurface excavation method; and under the protection of a top pipe shed frame, main structure construction is carried out with a cover-and-excavation half-top-town half-bottom-up method, and the center pillar, side walls, a center plate and a top plate which are pre-constructed well are utilized for providing vertical and horizontal support systems in an excavation space. The invention aims at providing a new method for shallowly burying the large-sized underground structure construction under an urban road; and the method is reasonable and feasible in technique and strong in operability, the quality of the main structure is guaranteed easily, construction is safe and rapid, the influences on ground transportation and the dismantlement and change to underground pipelines are reduced, and the comprehensive benefits are remarkable, therefore the shed-frame method has an important engineering application value and development prospect.

Owner:BEIJING UNIV OF TECH

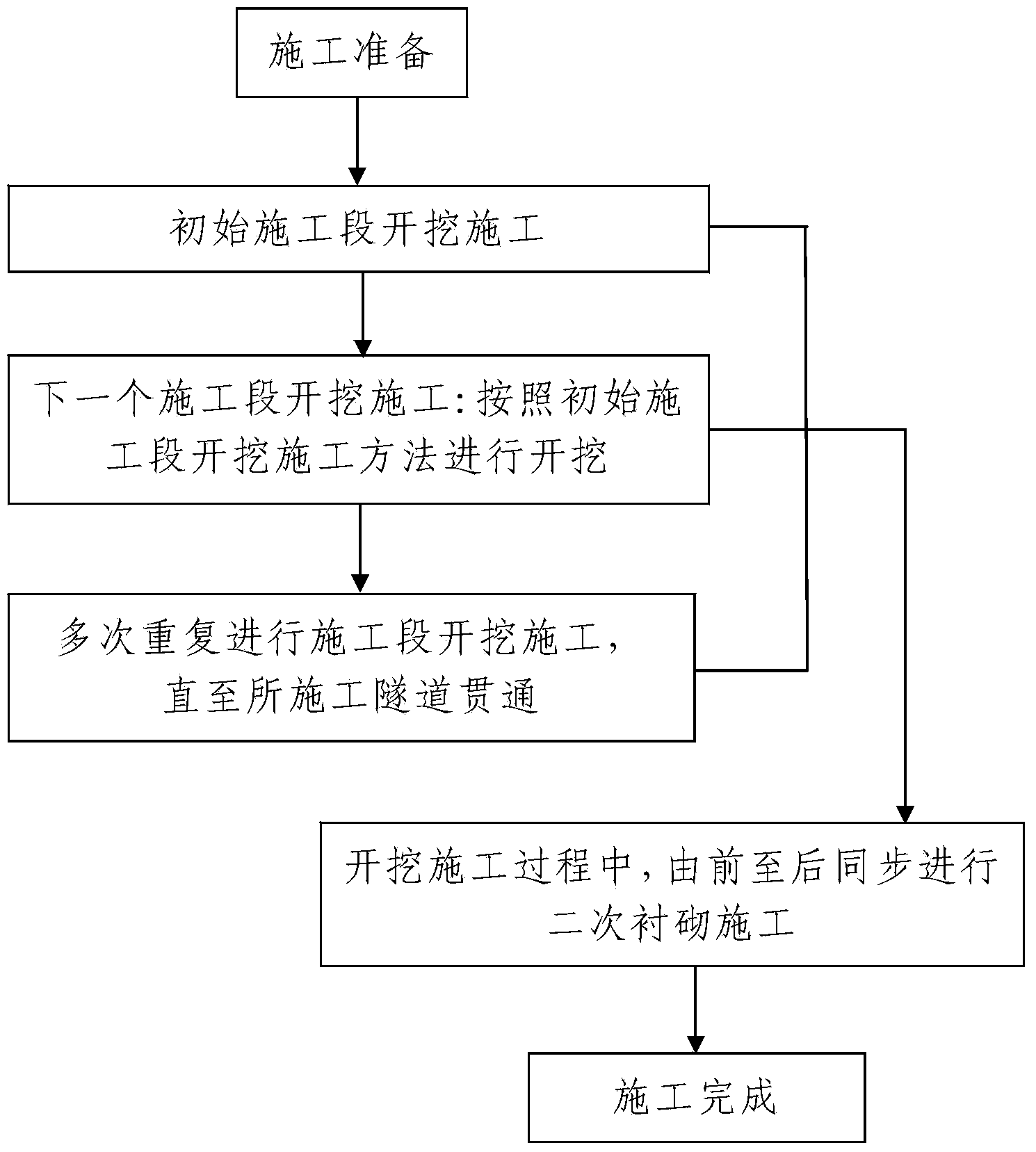

Long tunnel fast construction process

ActiveCN103470267AReasonable designSimplify construction stepsUnderground chambersTunnel/mines ventillationTunnel constructionWater seepage

The invention discloses a long tunnel fast construction process. The tunnel construction method in the direction from the entrance to the exit and the tunnel construction method in the direction from the exit to the entrance are the same and each construction section is respectively constructed from back to front. The construction process is as follows: 1, excavating construction at an initial construction section, the process is as follows: performing advance geology forecast, determining the excavating construction method for the current construction section, excavating and primary supporting; 2, excavating construction at the next construction section; 3, repeating the step 2 for multiple times until the construction tunnel is through, wherein in the tunnel construction process, found water seepage areas are timely subjected to draining treatment, and the secondary lining construction is synchronously performed on the tunnel holes formed by excavating from front to back. The long tunnel fast construction method is reasonable in design, simple and convenient in construction, safe in the construction process, short in construction process and fast in construction progress, thus effectively solving the defects and shortcomings such as large equipment investment, long construction period and slow construction progress of the existing long tunnel construction.

Owner:中铁二十局集团第二工程有限公司

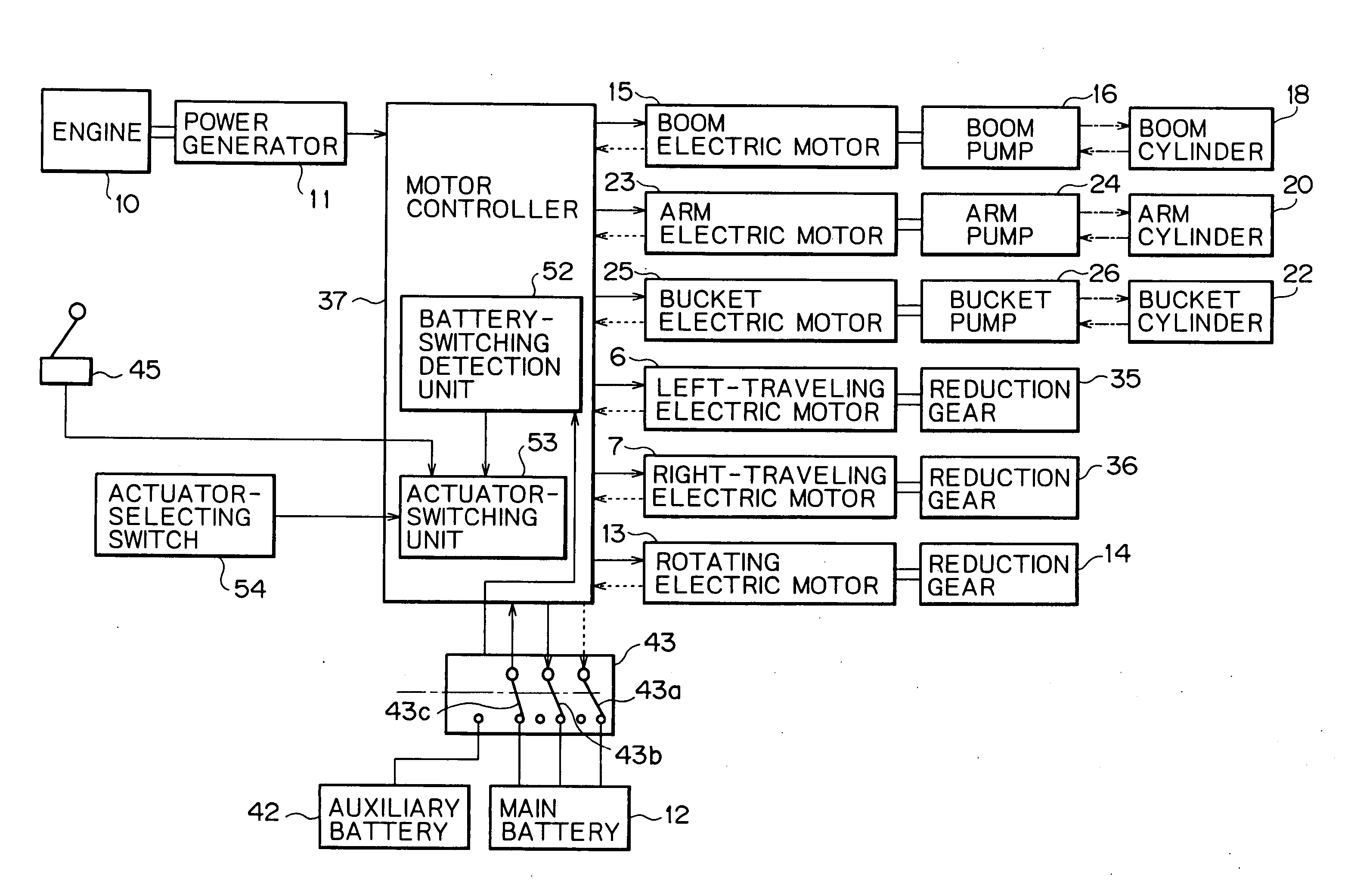

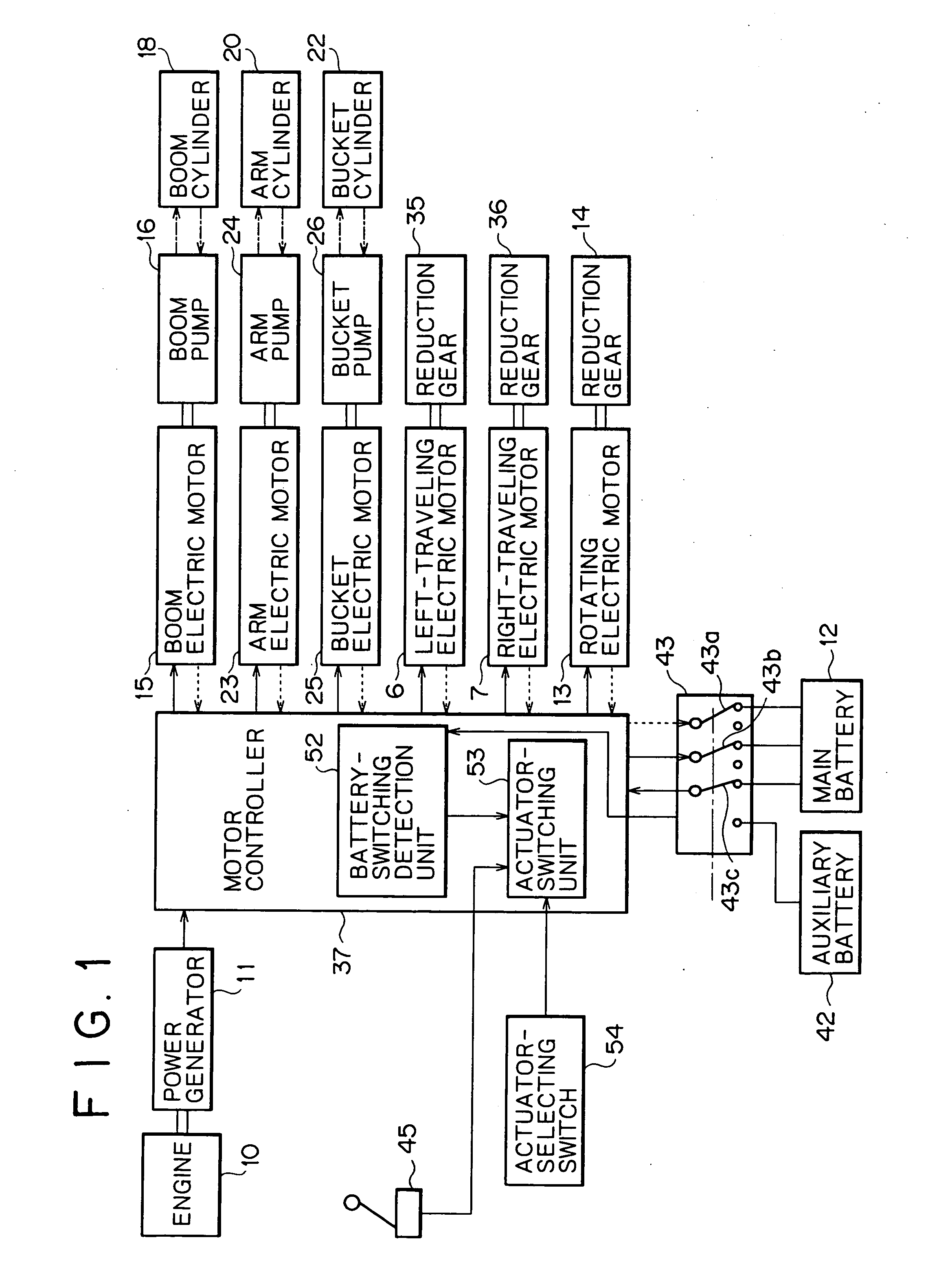

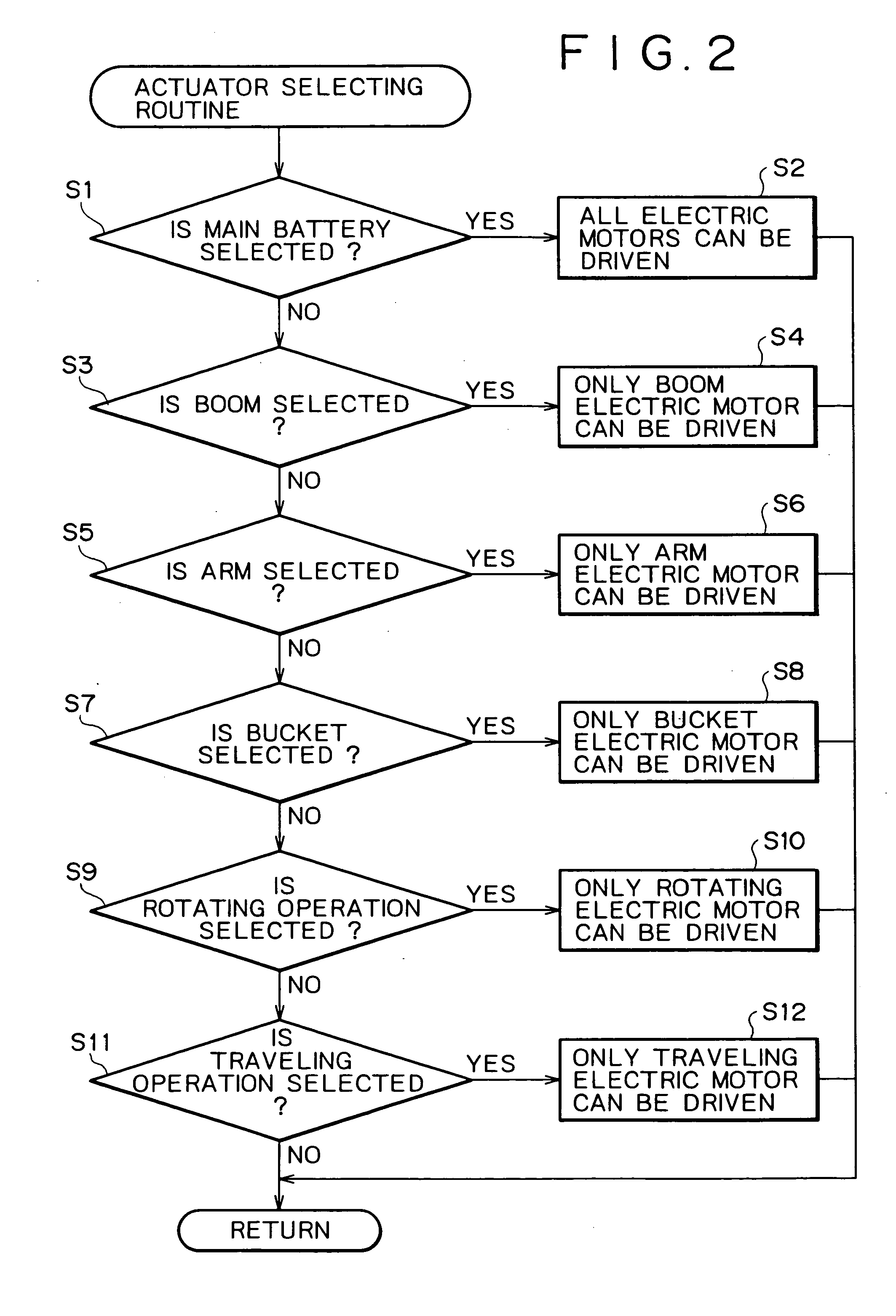

Hybride construction machine having auxiliary battery and control apparatus thereof

InactiveUS20050001606A1Improve reliabilityExcessive chargingAuxillary drivesServomotorsElectrical batteryEngineering

A hybrid construction machine according to the present invention is constructed to drive electric motors (6, 7, 13, 15, 23, 25) by means of power of a power generator (11) to be driven by an engine (10), power of an auxiliary battery (42) and power of a main battery (12) charged with power of the power generator (11). The hybrid construction machine has a switch (43) for switching to drive the electric motors (6, 7, 13, 15, 23, 25) by means of power of at least one of the power generator (11) and the main battery (12) when operating normally and to drive the electric motors (6, 7, 13, 15, 23, 25) by means of power of the auxiliary battery (42) when operating emergency such that the electric motors (6, 7, 13, 15, 23, 25) can not be driven by means of the normal power.

Owner:KOBELCO CONSTR MASCH CO LTD

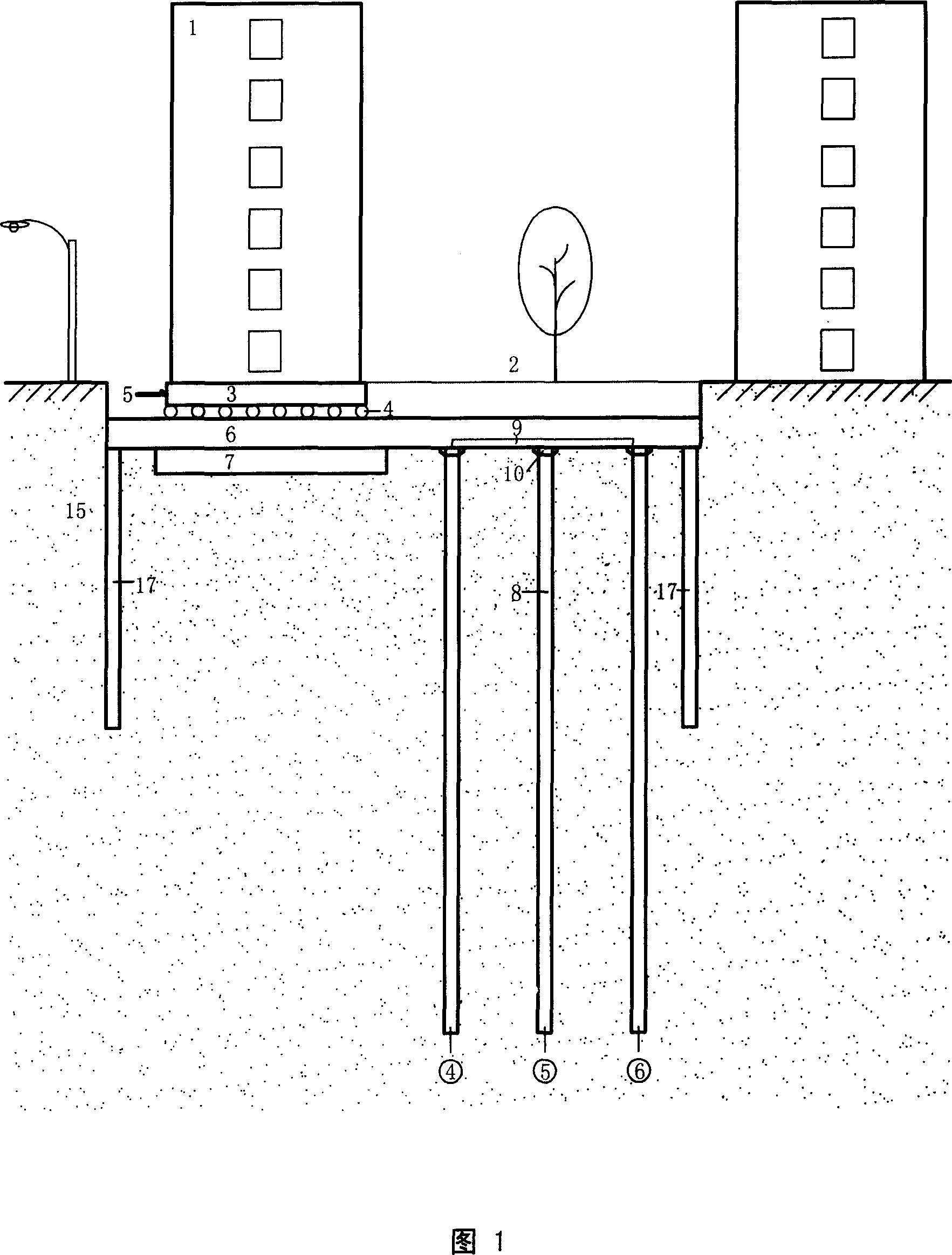

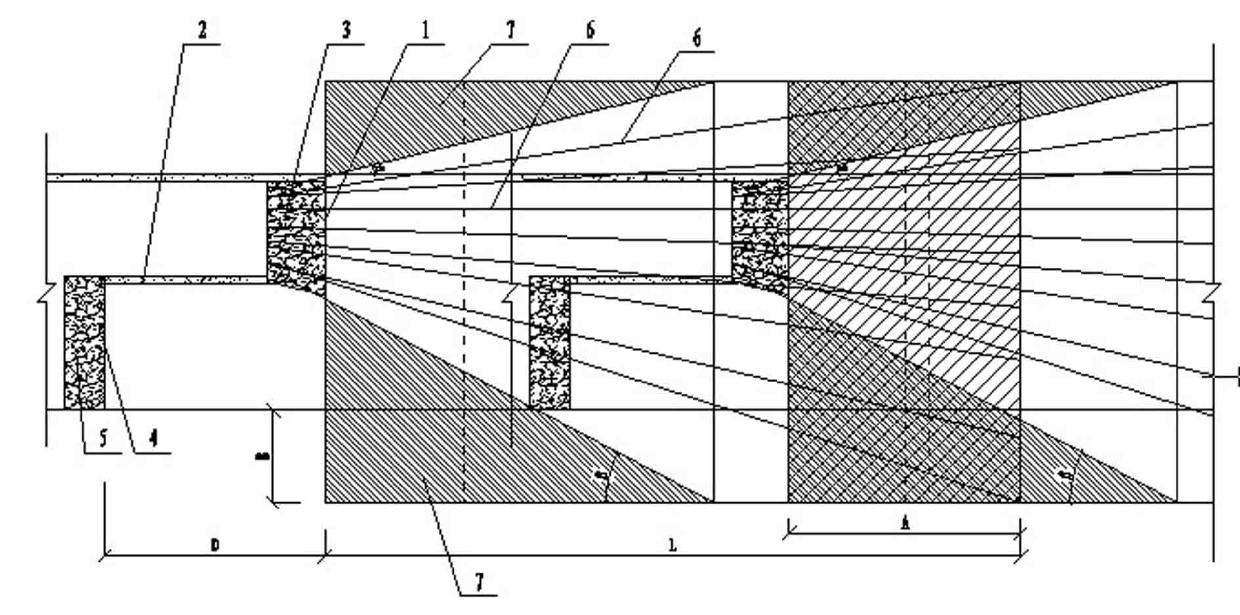

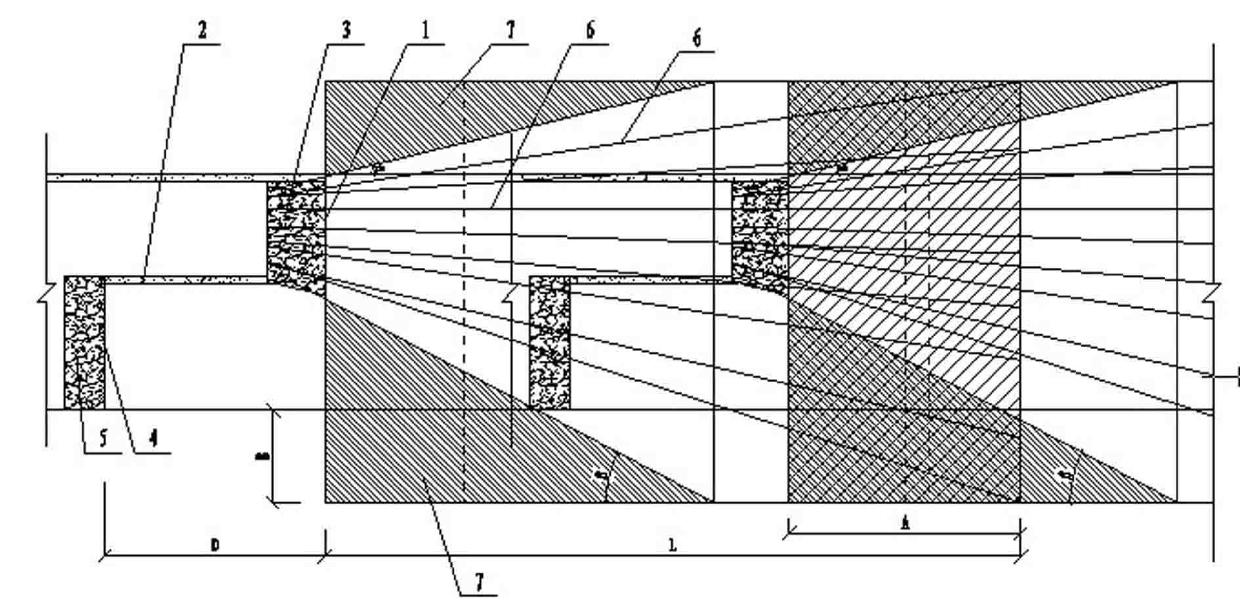

Method and device for building underground space structure for established building by using public land

InactiveCN1970897AReduce distractionsSave landArtificial islandsBuilding repairsEngineeringStructural engineering

Owner:张准胜

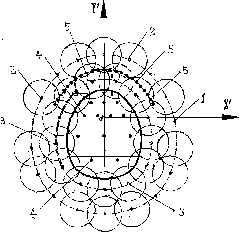

Method for constructing tunnel by finishing full section curtain grouting from upper-half section

ActiveCN101994513AReduce construction difficultyShorten the construction periodUnderground chambersTunnel liningArchitectural engineeringGeological section

The invention relates to the field of tunnel construction, in particular to a method for constructing a tunnel by finishing full section curtain grouting from an upper-half section, which solves the problems of long construction period, difficult construction, high construction safety risk and the like during full section curtain grouting construction of a complex geological section. The method comprises the following steps of: firstly, excavating the upper-half section, and strengthening the support of a tunnel face; secondly, constructing a temporary inverted arch and a grout-stopping wall of the upper-half section; thirdly, excavating the lower-half section in place, and strengthening the support of the tunnel face; fourthly, constructing a grout-stopping wall of the lower-half section; fifthly, forming grouting holes on the upper-half section, wherein the maximum elevation angle alpha is between 25 and 45 degrees, the maximum depression angle beta is between 30 and 70 degrees, andthe longitudinal strengthening length is between 15 and 30 m; sixth, performing grouting operation; seventh, constructing a large-scale lead pipe roof; eighth, excavating a grout-stopping wall; ninth, excavating a tunnel trunk; and finally, continuously cycling by taking an area of 15 to 30 m as a grouting strengthening cycling section to realize the construction of the tunnel by curtain groutingfrom the upper-half section. The method can greatly reduce the construction difficulty, shorten the construction period, and ensure the construction quality, and the construction is safe, quick and economic, so the method can be widely used in the field of tunnel construction.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP

Method for constructing road swivel bridge and railway swivel bridge by using turnplate spherical hinge

ActiveCN101818482AConstruction safetySimple and fast operationBridge erection/assemblyPile capThree stage

The invention relates to a method for constructing a bridge, in particular to the method for constructing a road swivel bridge and a railway swivel bridge by using a turnplate spherical hinge, which aims to solve the problems of the complex process, inconvenient construction, high requirements on construction sites, and the like of the conventional swivel bridge construction. The method specifically comprises the following steps of: machining the turnplate spherical hinge; constructing a lower pile cap and mounting a lower spherical hinge and an endless track, wherein the concrete of the lower pile cap is poured in three stages; constructing an upper pile cap and mounting an upper spherical hinge and a support steel cylinder; and after the upper pile cap and the lower pile cap are swiveled in place under the action of the turnplate spherical hinge, pouring rear sealed concrete between the upper pile cap and the lower pile cap. The method has the advantages of the capacity of changing overhead barrier operation into operation on the coast or near the ground, safe and reliable construction, simple and convenient operation, fast implementation and construction cost reduction, is suitable for both straight bridges and curved bridges, and compared with the conventional construction methods, also has the advantages of shortening construction period, saving a part of big construction machinery and labor force and greatly saving construction cost.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

Support member and light emitting diode module using the same

ActiveUS7204604B2Avoid it happening againReduce distractionsPoint-like light sourceOptical signallingEngineeringLight-emitting diode

Owner:AU OPTRONICS CORP

Soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method

InactiveCN102226398AExpand the working areaInternal force redistribution is not obviousUnderground chambersTunnel liningEngineeringBuilding construction

The invention relates to a soft rock four-line large-span tunnel compound double-side wall bracing cable conversion excavation construction method which has the characteristics of safety in construction, speediness and simpleness in operation, and is further applicable to large-scale machines for construction. The method comprises the following steps: (1) excavating pilot holes on side walls on two sides, firstly implementing corresponding forepoling before excavation, and immediately implementing corresponding preliminary bracing and temporary bracing after the excavation; (2) pouring pedestal foundations on the two sides; (3) excavating side pilot holes of arch parts on the two sides respectively, firstly implementing the corresponding forepoling before the excavation, immediately implementing the corresponding preliminary bracing and the temporary bracing after the excavation, and implementing a pre-stressed anchor cable connected with a surrounding rock anchor at the top of the corresponding preliminary bracing; (4) excavating core soil of the arch parts bench by bench, firstly implementing the corresponding forepoling before excavating an upper bench, immediately implementing the corresponding preliminary bracing after the excavation, and implementing the pre-stressed anchor cables connected with the surrounding rock anchor at two end parts of the preliminary bracing; (5) pouring secondary lining of the arch parts; (6) excavating the lower core coil bench by bench; and (7) pouring an inverted arch, and pouring the inverted arch to the design height.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

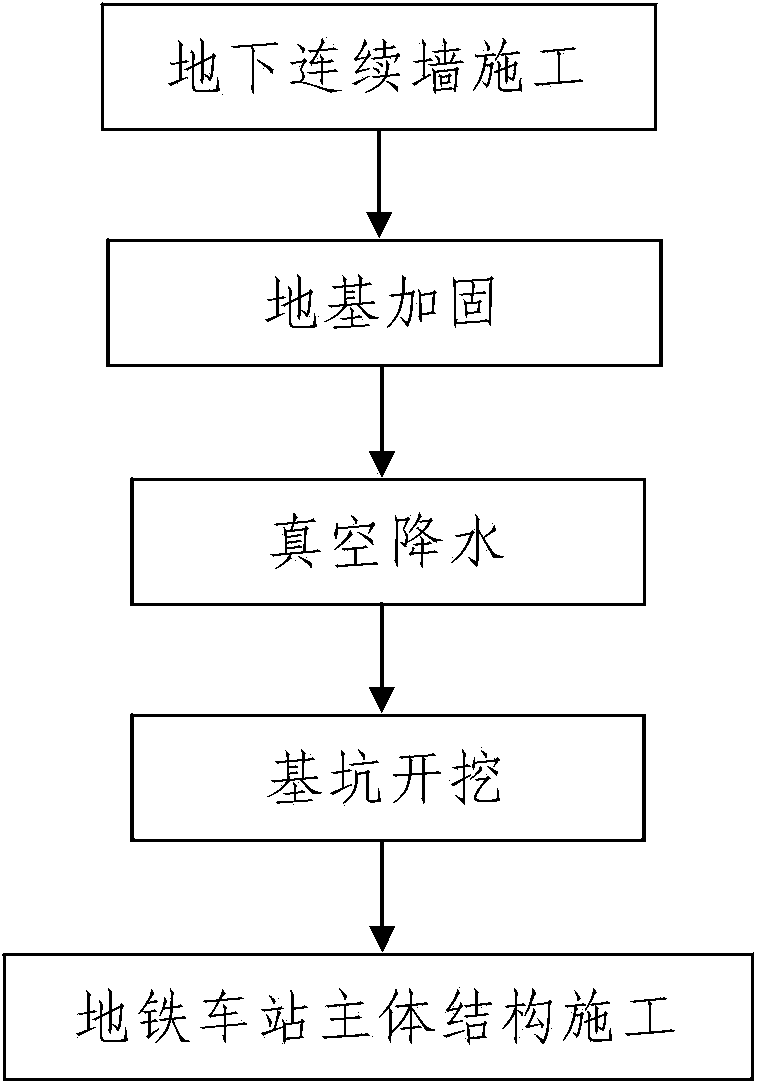

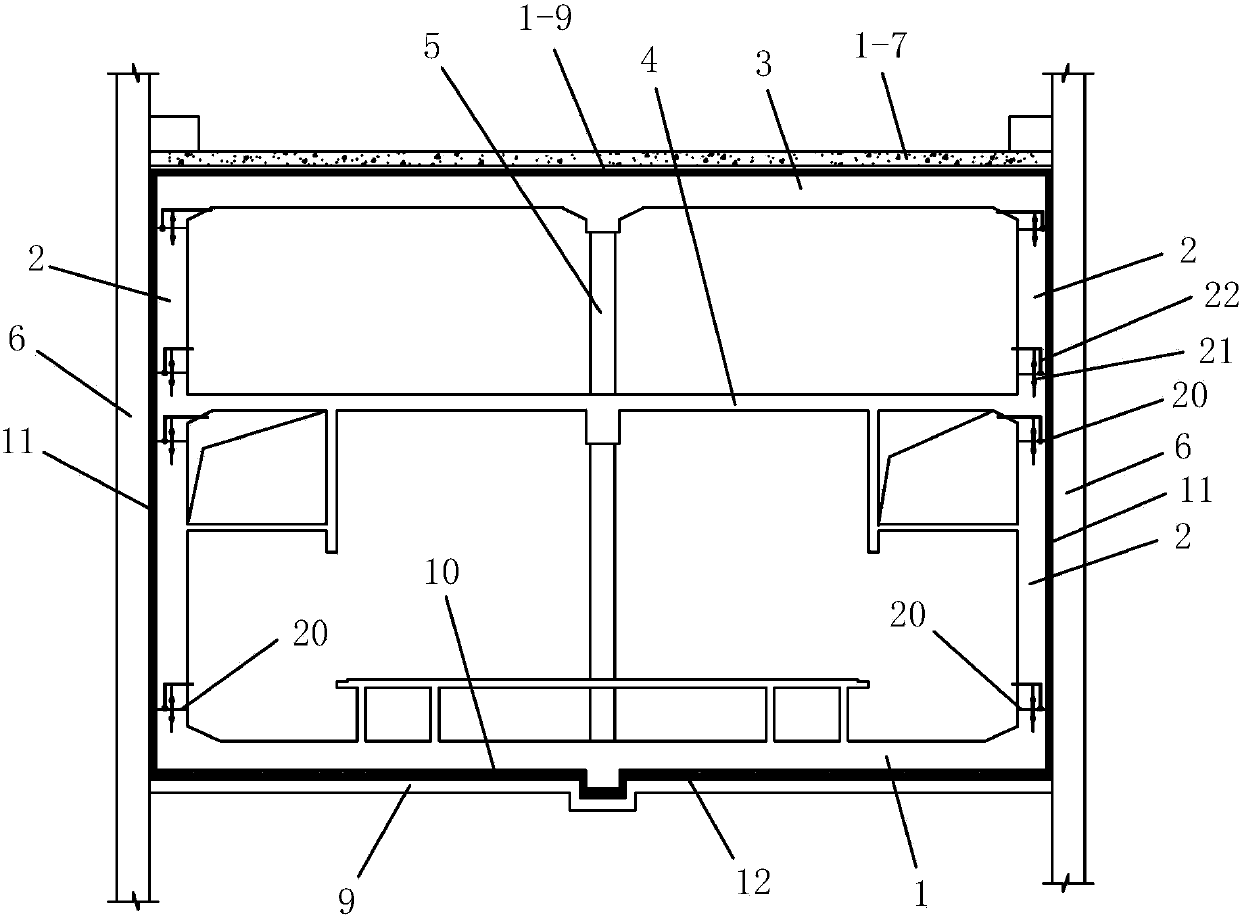

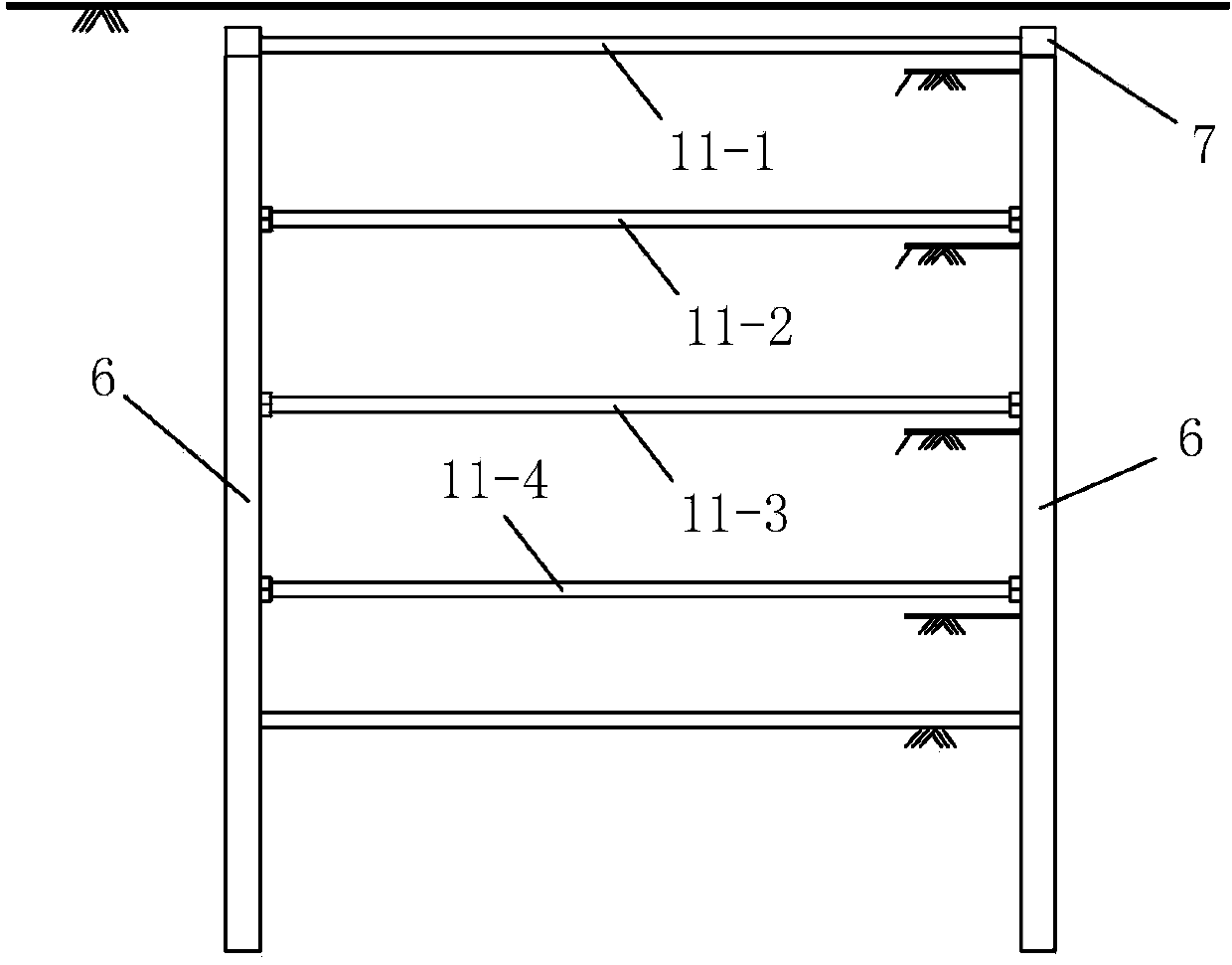

Peaty soft soil stratum subway station construction technology

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

Method of performing combined drilling, flushing, and cutting operations on coal seam having high gas content and prone to bursts to relieve pressure and increase permeability

ActiveUS20170370156A1Simple processEfficient amplificationConstructionsLiquid/gas jet drillingWell drillingDesorption

The present invention relates to a “drilling-flushing-slotting” coupled pressure relief and permeability increasing method for a high gas outburst coal seam, which is more particularly suitable for the pressure relief and permeability increasing when gas of a roadway band of the high gas outburst coal seam is pre-extracted through crossing boreholes. On the basis of the crossing borehole pre-extraction measures for the coal seam gas, the hydraulic flushing and the hydraulic slotting are reasonably combined, and a “drilling-flushing-slotting” dedicated device is utilized to implement the coupled operation of “low pressure drilling-medium pressure flushing-high pressure slotting” in a borehole, so that the coal in the pre-extraction area is deformed and moved to form network cracks, passages are provided to the desorption flow of the gas, and the gas is easier to extract. The method can enlarge the single-hole pressure relief influence range, increase the gas permeability of the coal seam, improve the gas extraction efficiency, reduce the number of pre-extraction boreholes, shorten the pre-extraction time and have good applicability to the coal seams in different occurrence states. The present invention can reduce the number of the crossing boreholes by 32.5% and can reduce the length of each crossing borehole by 42.9%, is remarkable in coal roadway regional outburst eliminating effect, and obviously increases the tunneling speed.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com