Patents

Literature

31 results about "World class" patented technology

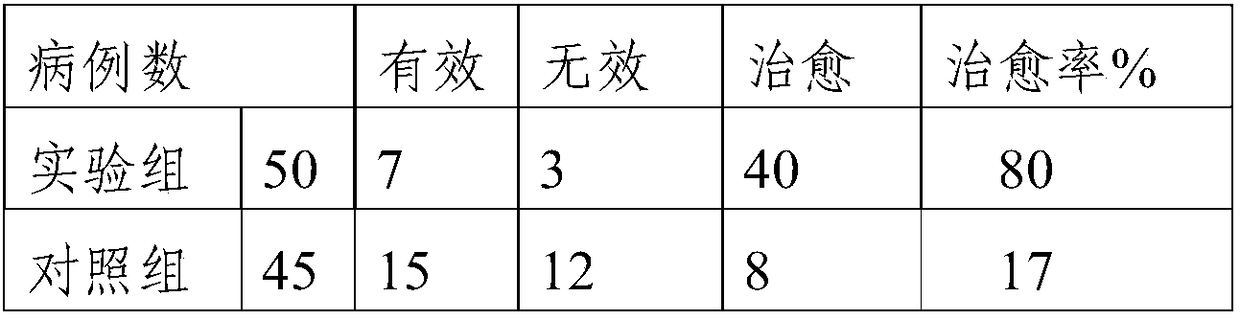

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

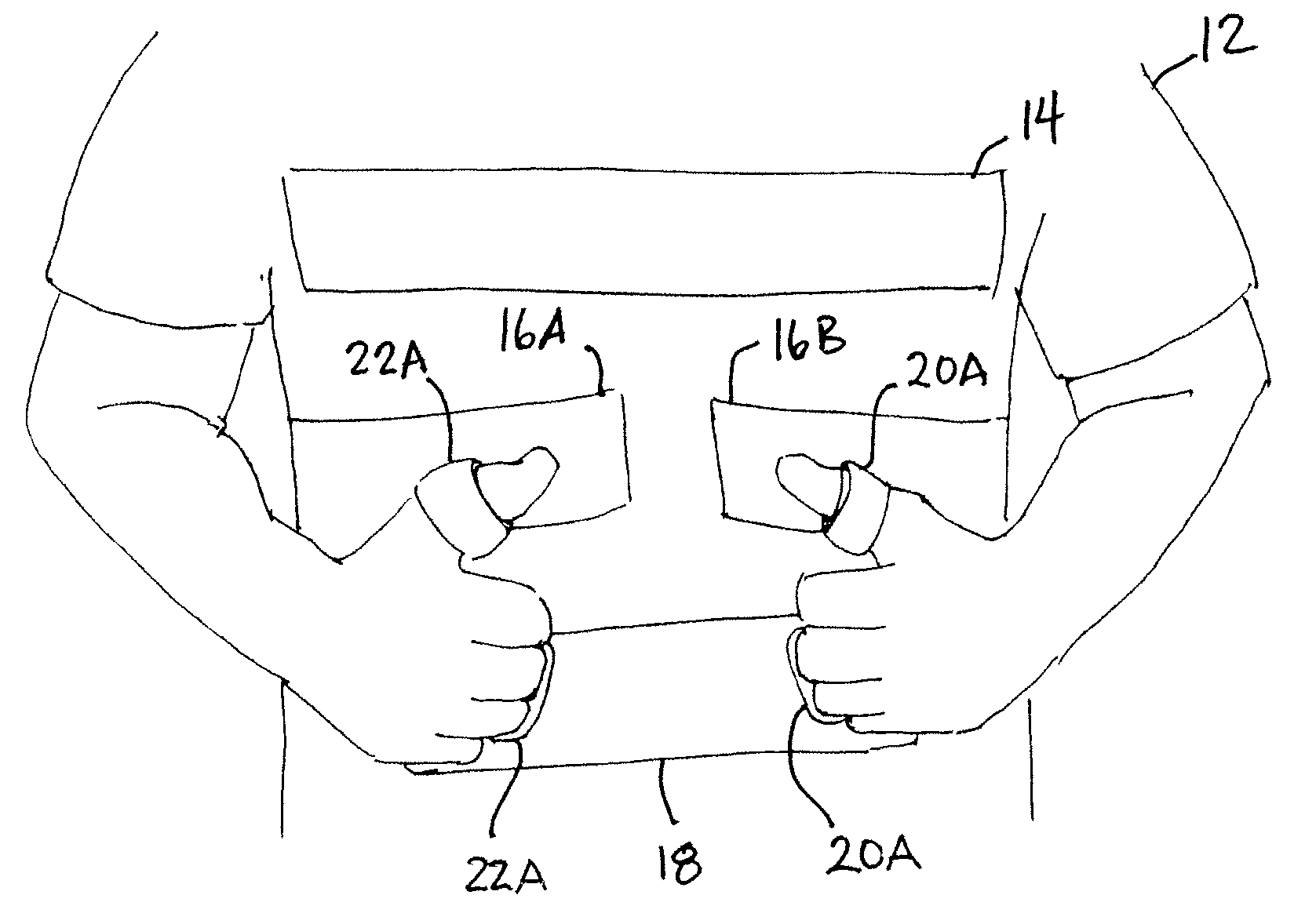

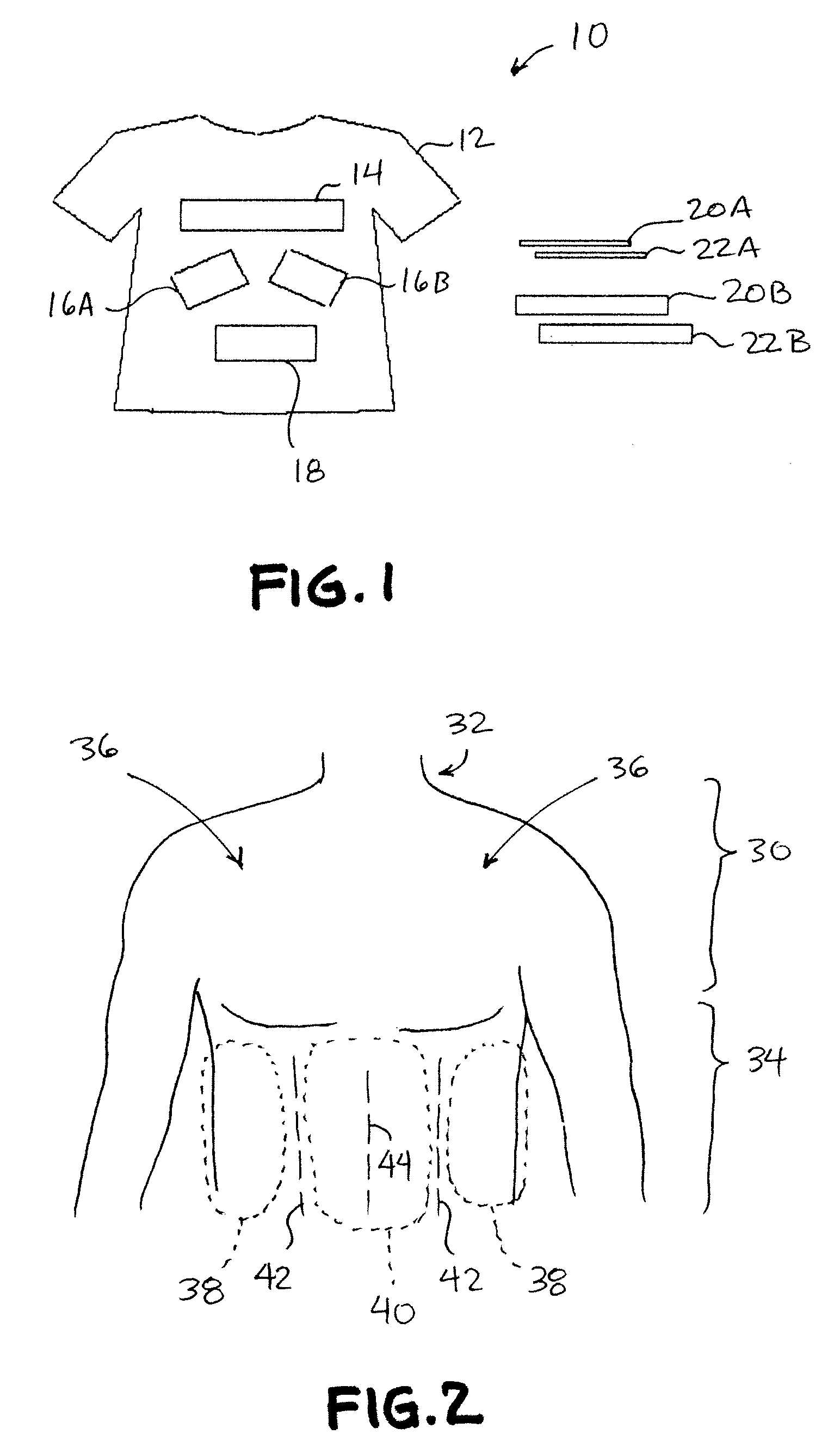

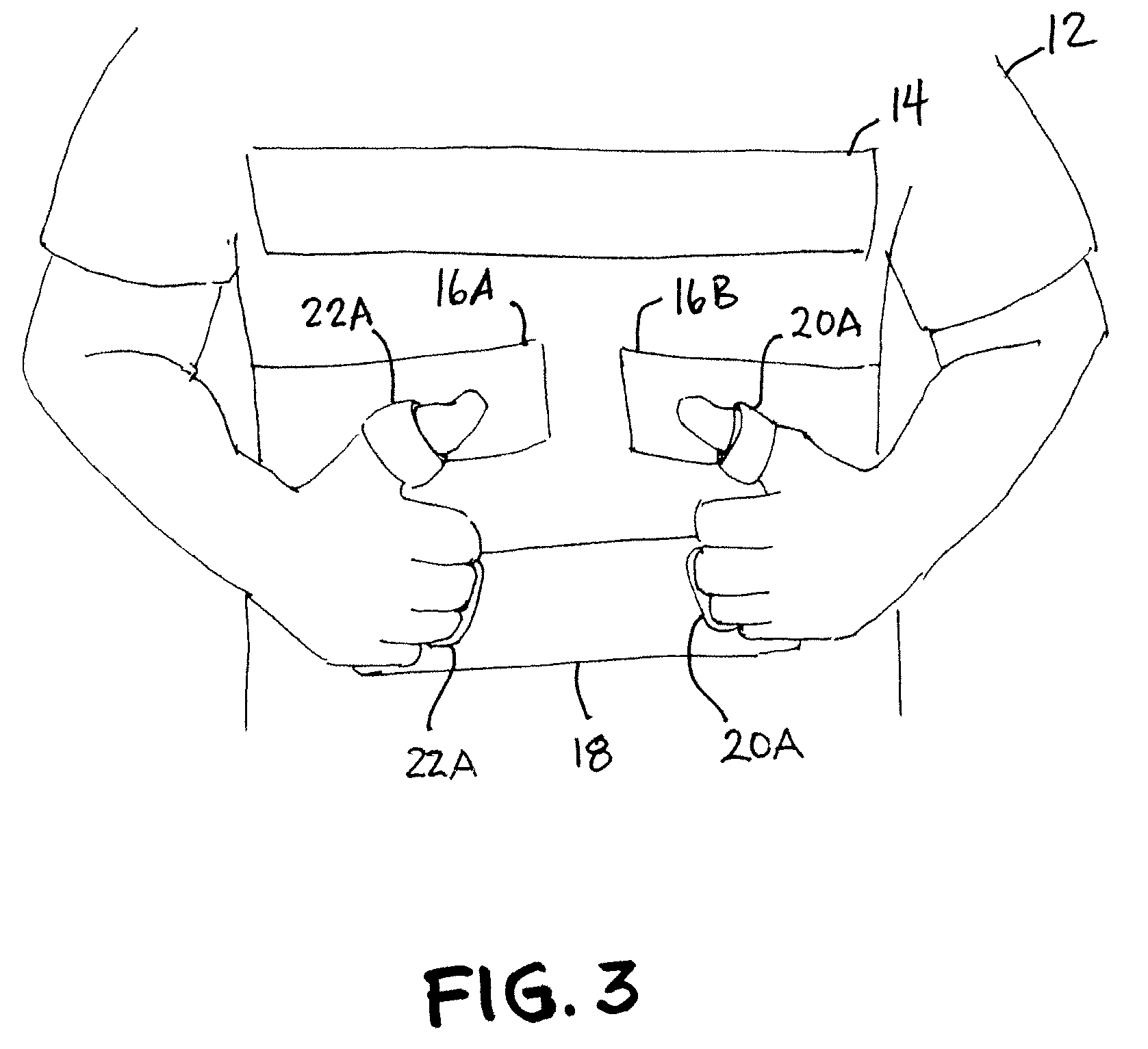

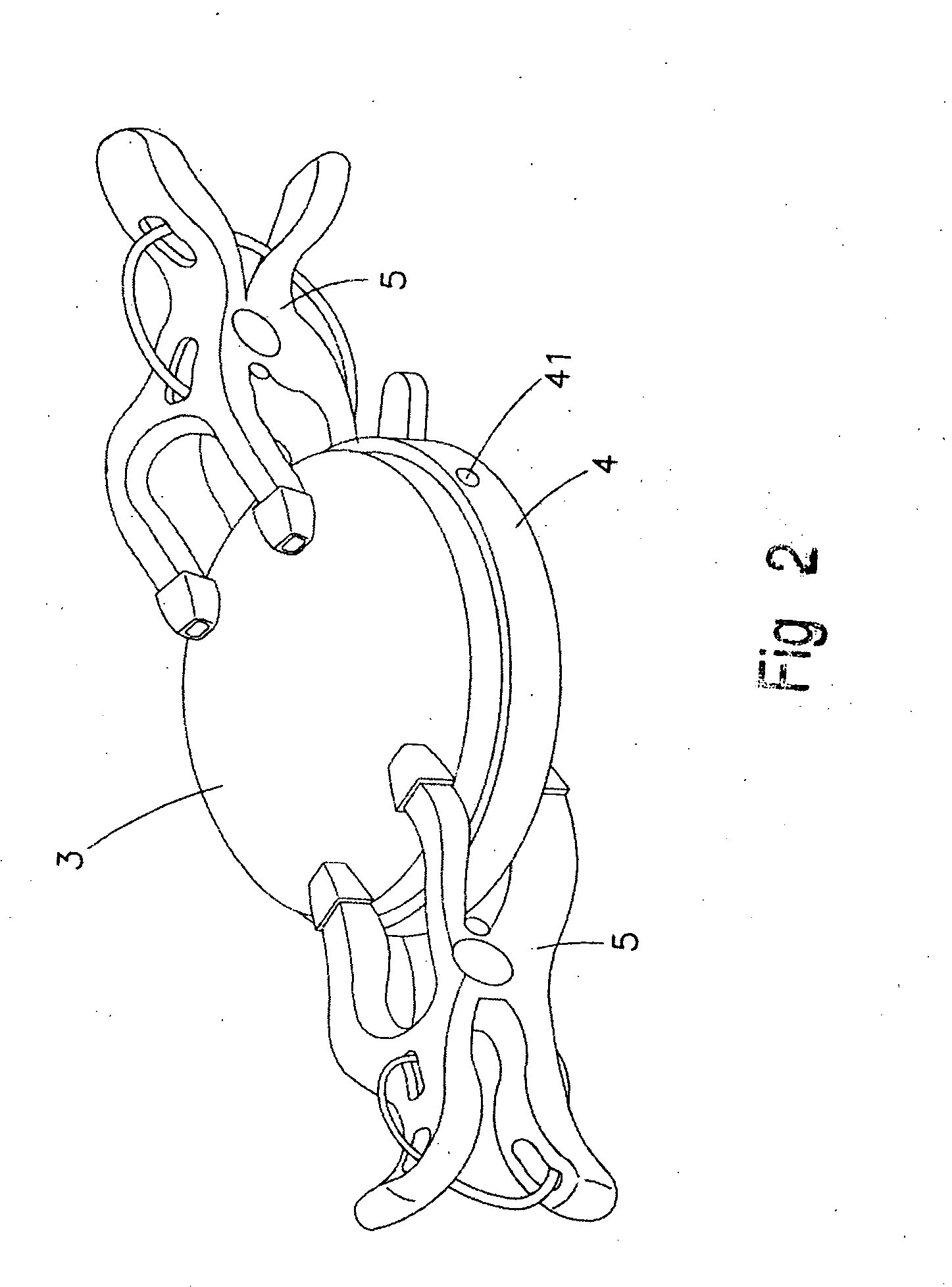

Athletic Training Aid and Method

A training aid includes a garment including multiple securements. The securements are located at areas corresponding to predetermined anatomical areas of the torso including but not limited to the chest and abdomen. The training aid also includes at least one pair of securements worn on opposite upper extremities, such as the left and right forearms, wrists, hands, fingers, and / or thumbs and are configured to releasably attach the upper extremities in close proximity to any of the anatomical areas of the torso as desired by the wearer. When attached, the wearer is trained to emulate efficient running styles of world class runners. The various securements can include fibers that interlock when they are brought into pressing contact with each other.

Owner:TANNER MARK

Learning System for Digitalisation of An Educational Institution

InactiveUS20110250580A1Revolutionizes content and community resourceElectrical appliancesWorld classComputer science

A system that catalyses world-class quality in education in any institutionalized setting, howsoever small and formal or informal by integrating all processes, transactions, resources and controls (such as security of children, emergency response) for an educational organization, gated educational communities such as schools, dispersed private learning communities of kinships / professional organizations / neighborhood / any other source of association, or virtual self-learning communities. The system includes tools and devices which enhance the process, content and context of learning. Intelligence-embedded, self-help tools and appropriate macro- and micro-inputs to the community members, as well as the individual learners within, enable comprehensively unaided instruction and learning context at the community level. All academic subjects in a curricular framework up to a higher secondary level, across a plurality of nations, are covered.

Owner:IYC WORD SOFT INFRASTRUCTURE PVT

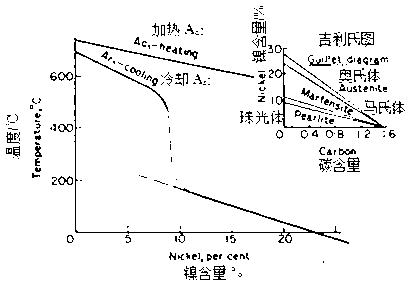

Anti-seismic, weather-proof and high-strength YS700MPa hot-rolled reinforced bar

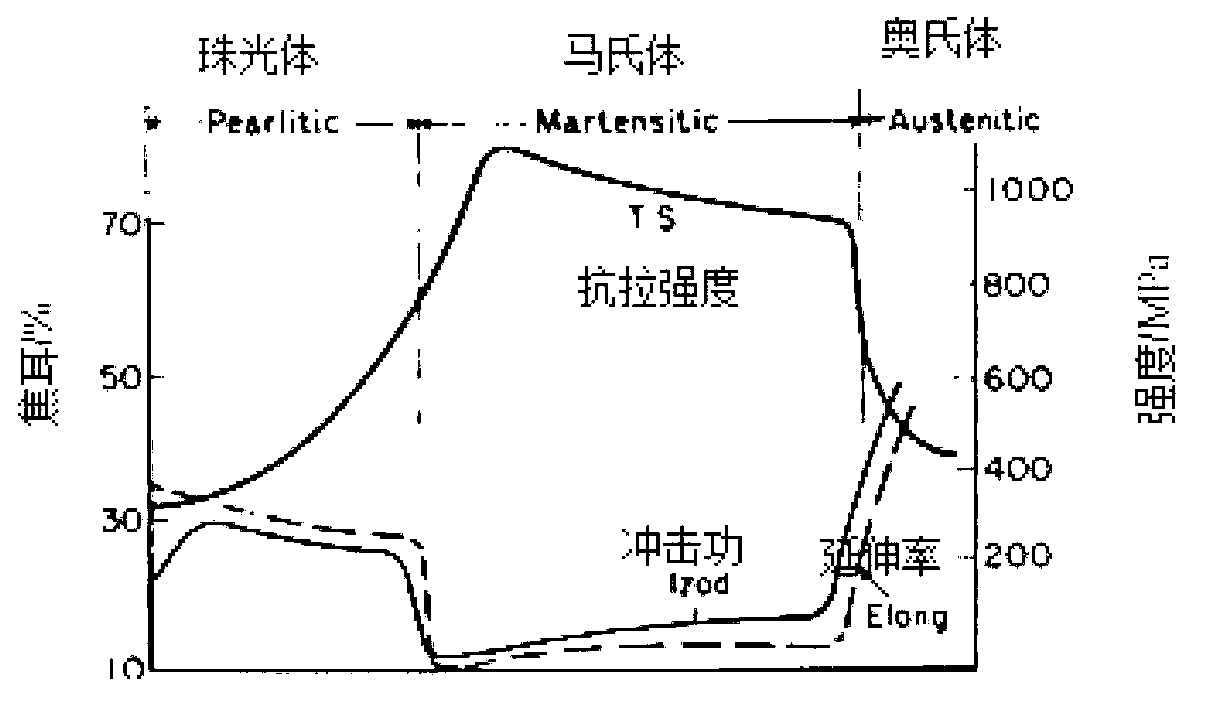

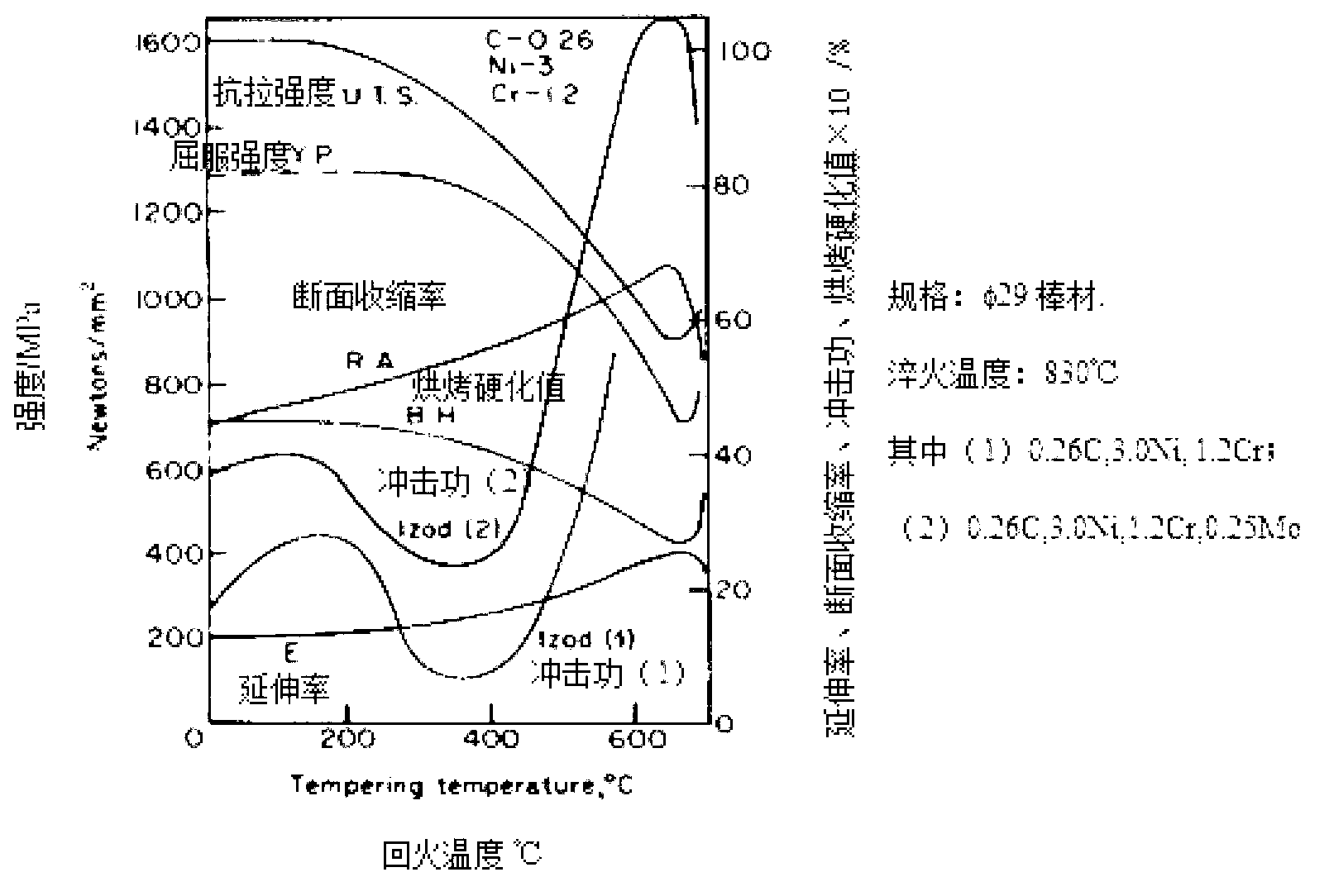

The invention provides an anti-seismic, weather-proof and high-strength YS700MPa hot-rolled reinforced bar, which belongs to the technical field of steel and iron raw materials. A low nickel-chromium content (Ni (Nickel) (2.0%), Cr (Chromium) (2.0%)) and vanadium-nitrogen micro-alloying combined component design is adopted; and the hot-rolled reinforced bar comprises the following components in percentage by mass: 0.20-0.25% of C (Carbon), 0.40-0.80% of Si (Silicon), 1.20-1.60% of Mn (Manganese), no more than 0.035% of P (Phosphorus), no more than 0.035% of S (Sulfur), 0.06-0.20% of V (Vanadium), 0.010-0.030% of N (Nitrogen), 0.20-2.0% of Ni (Nickel), 0.20-2.0% of Cr (Chromium), 0.01-0.03% of Ti (Titanium) and the balance of Fe (Ferrum). The anti-seismic, weather-proof and high-strength YS700MPa hot-rolled reinforced bar provided by the invention has the advantages as follows: under a condition that yield strength of the reinforced bar reaches YS700 MPa in a hot rolled state, the total elongation rate of the reinforced bar after being broken reaches 12.5-18.0%, the uniform elongation rate of the reinforced bar after being broken reaches 5.5-9.5%, the tensile-to-yielding ratio of the reinforced bar after being broken reaches 1.27-1.45, and technical index requirements on anti-seismic performance are satisfied; moreover, the weather resistance of the reinforced bar is superior to that of world-class brand weathering resistant steel Corten A.

Owner:CENT IRON & STEEL RES INST +1

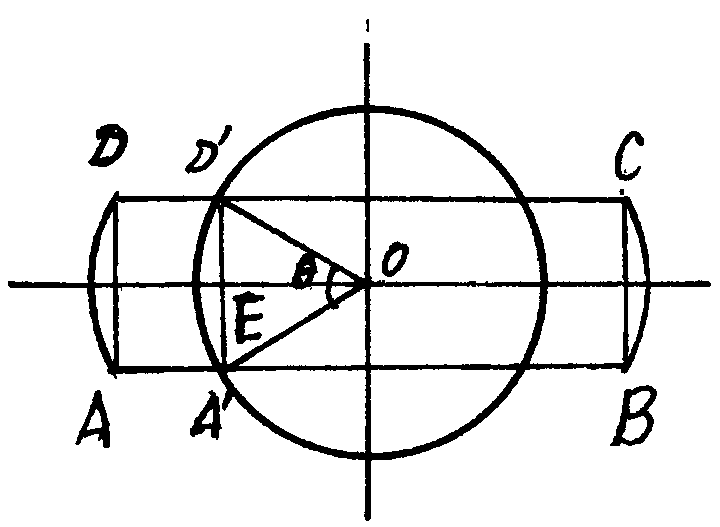

Polarized optical lens

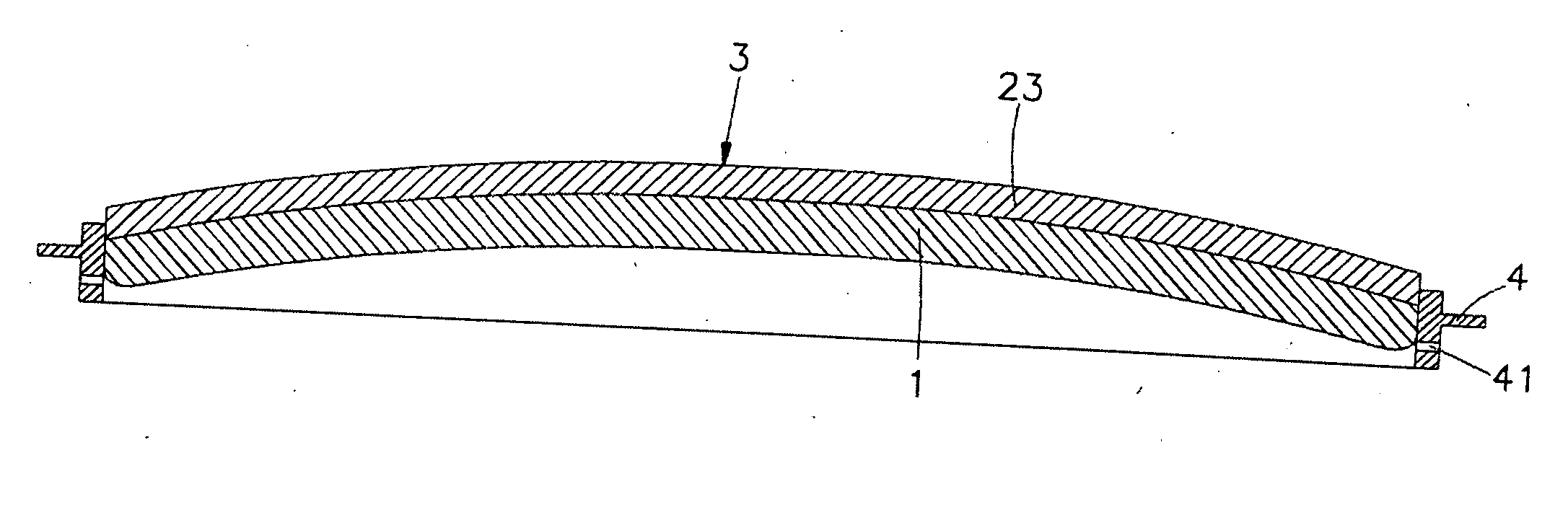

InactiveUS20070115428A1Rich in colorMany choicesSpectales/gogglesOptical articlesTectorial membraneAdhesive

This invention relates to a structure improvement for a polarized optical lens, it comprising of an optical lens of certain curvature and a polarized piece, wherein the polarized piece is made up of cellulose protective film, adhesive and polarized thin film, it is pressed to matched curvature as injected and plasticized optical lens, then the cellulose protective film of the polarized piece is peeled off, through the use of injection and plasticization principle, polarized thin film is combined and pasted to the inner surface or outer surface of the optical lens, then this synthesized lens is placed in the ring of an optical mold, light adjustment and color change liquid colophony is then injected into through a through-hole in the ring, and through the clamping of synthesized lens and light adjustment and color change liquid colophony, the whole set then solidifies and forms a shape so that the diversified functions and light adjustment and color change function of the product is achieved, meanwhile, the optical lens possesses polarization effect and reaches the world class grade lens level, therefore, when it is worn outdoors, dark and light change will be created due to the absorption of UV light, the user can feel more comfortable, and the optical lens thus possesses more diversified color.

Owner:TONY OPTICAL ENTERPRISES

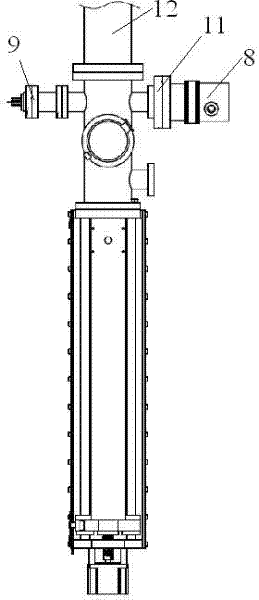

Sinusoidal optical pressure sensitive coating dynamic pressure calibration chamber

ActiveCN109269720AImprove frequency response characteristicsSimple structureFluid pressure measurementUltraviolet lightsEngineering

Owner:NORTHWESTERN POLYTECHNICAL UNIV

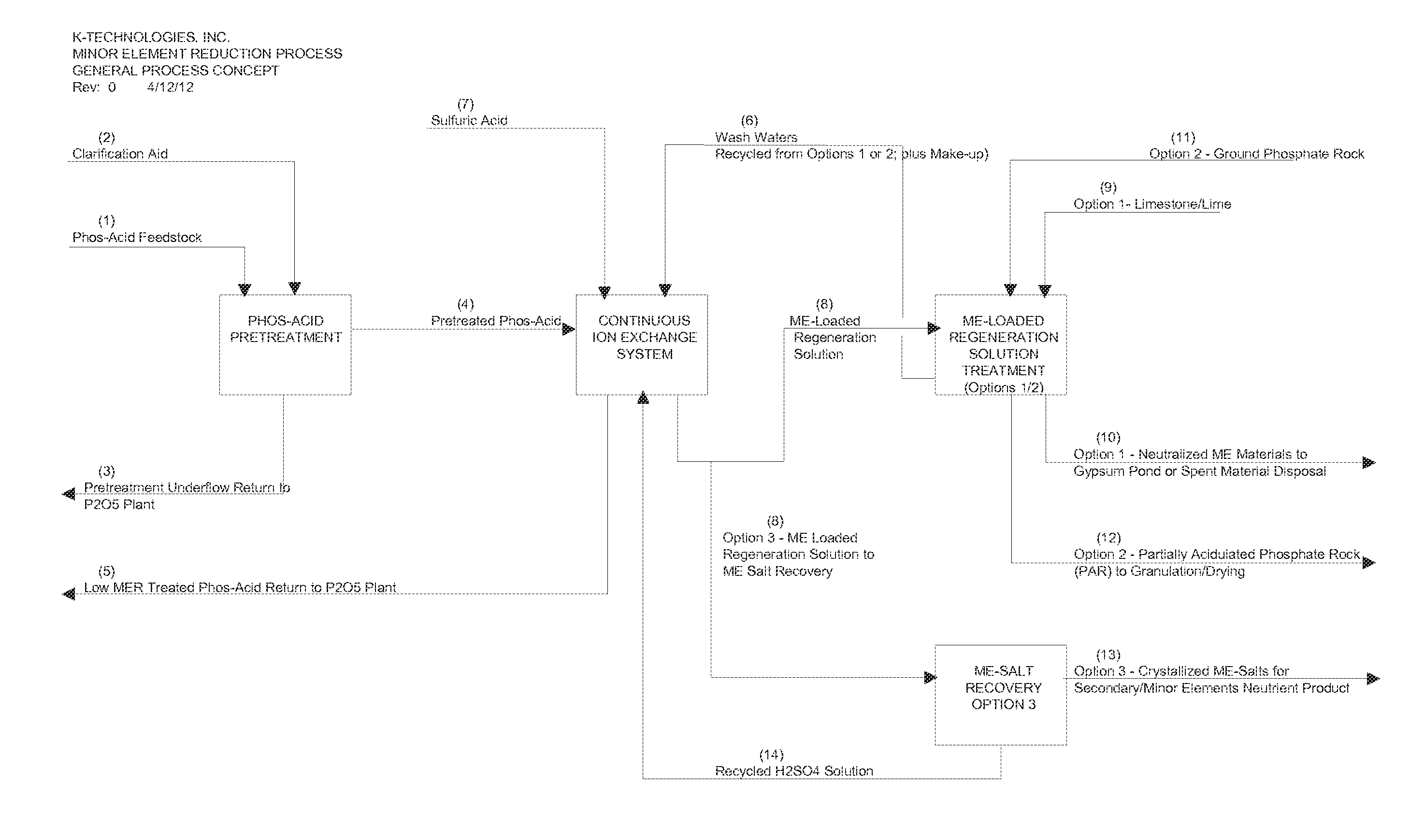

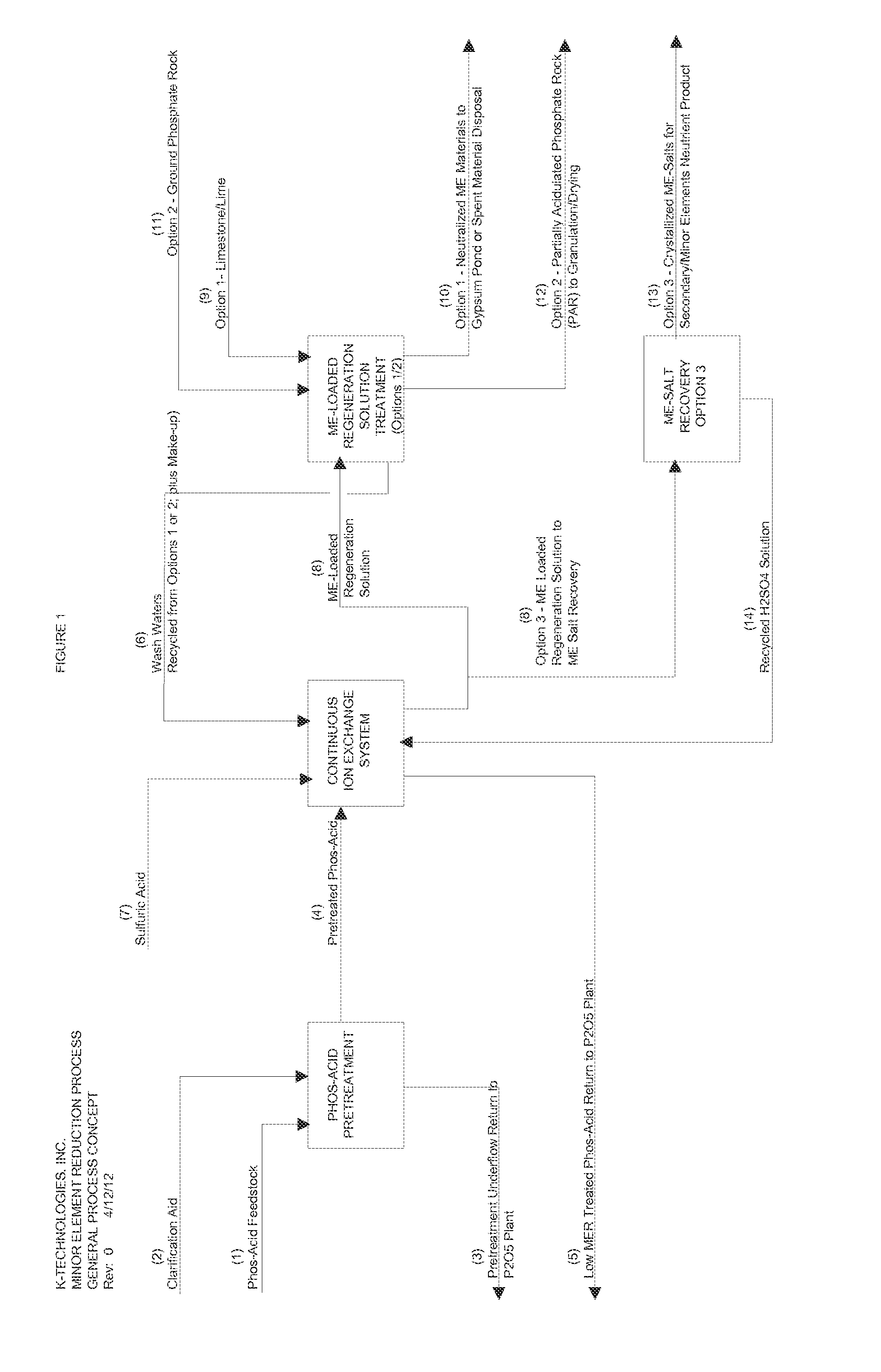

Processes for the removal and recovery of minor elements in wet-process phosphoric acid

ActiveUS20150166343A1Minimal phosphate lossSuitable for productionCation exchanger materialsIon-exchanger regenerationMinor elementPhosphoric acid

In alternative embodiments, the invention provides processes and methods for the recovery or the removal of the so-called “Minor Elements” consisting of iron, aluminum and magnesium (expressed as oxides), from wet-process phosphoric acid using a continuous ion exchange approach. In alternative embodiments, use of processes and methods of the invention allows for the reduction of these Minor Elements with minimal phosphate losses and dilution in order to produce a phosphoric acid that is suitable for the production of fertilizer products such as world-class diammonium phosphate (DAP), merchant-grade phosphoric acid, superphosphoric acid, and other phosphoric acid products. Further, use of the invention would allow the use of lower grade phosphate rock or ore, which would greatly expand the potential phosphate rock reserve base for phosphate mining activities, and allow for better overall utilization of resources from a given developed mine site.

Owner:OCP

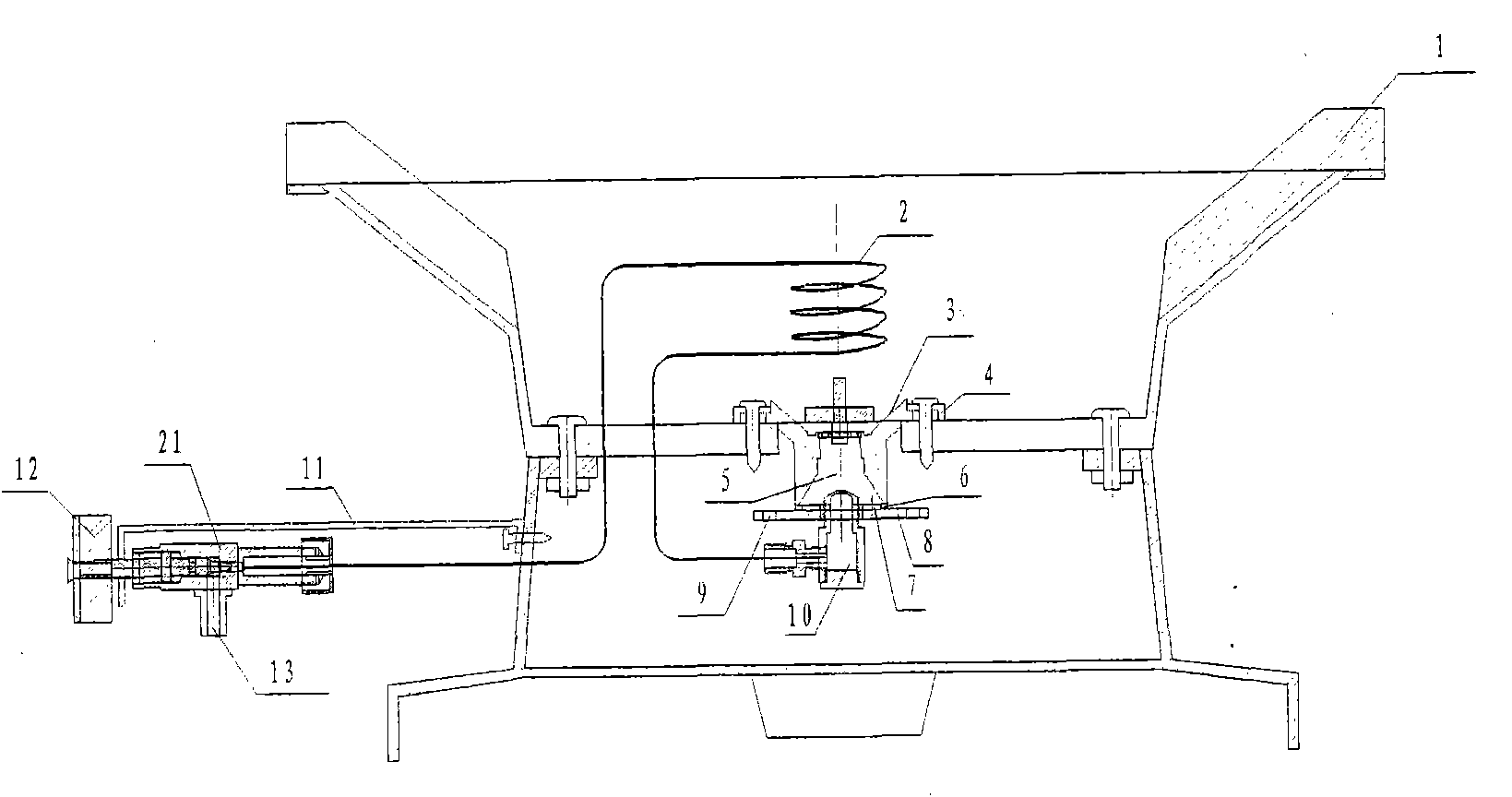

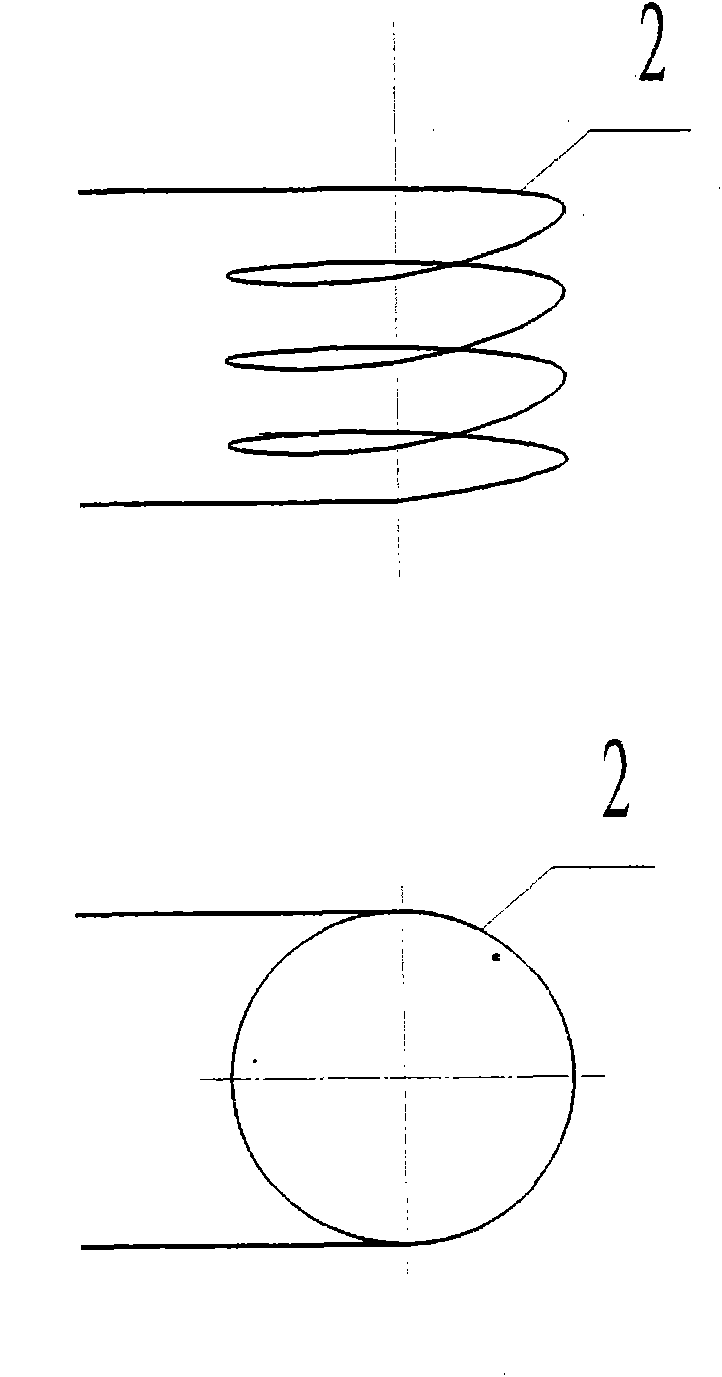

Liquid fuel burner

The invention provides a liquid fuel burner. The liquid fuel burner consists of a burning device, a gasification device and a preheating device, wherein the gasification device is arranged on the burning device; the gas outlet end of the gasification device is connected with the furnace end gas inlet hole of the burning device; and the preheating device is arranged outside the gasification device. The liquid fuel burner solves the following world-class problems: firstly, liquid burning of the liquid fuel is changed into gas burning, so that the problem of high energy consumption is solved, and the tests show that energy can be saved by over 65 percent; secondly, the temperature of the liquid fuel in the gasification device is effectively controlled to be about 250 DEG C, so that the problem of carbon accumulation is solved; thirdly, the flame temperature is improved to be over 1,100 DEG C, the fire is fierce and the heating speed is high, so that the problem of low heat value is solved; fourthly, the gasification speed is high and the burning is stable; and the fifthly, the burning is complete and the exhaust emission load after burning is less than one tenth that of the national relative standard, so that the effect of environmental friendliness is achieved. The liquid fuel burner breaks through the technical barriers of the liquid fuel burning and makes the popularization of the liquid fuel, particularly the alcohol-based fuel, come true. Meanwhile, the liquid fuel burner is an ideal choice for the industrial furnace burners and the popularization of the burner greatly contributes to the country.

Owner:李永安

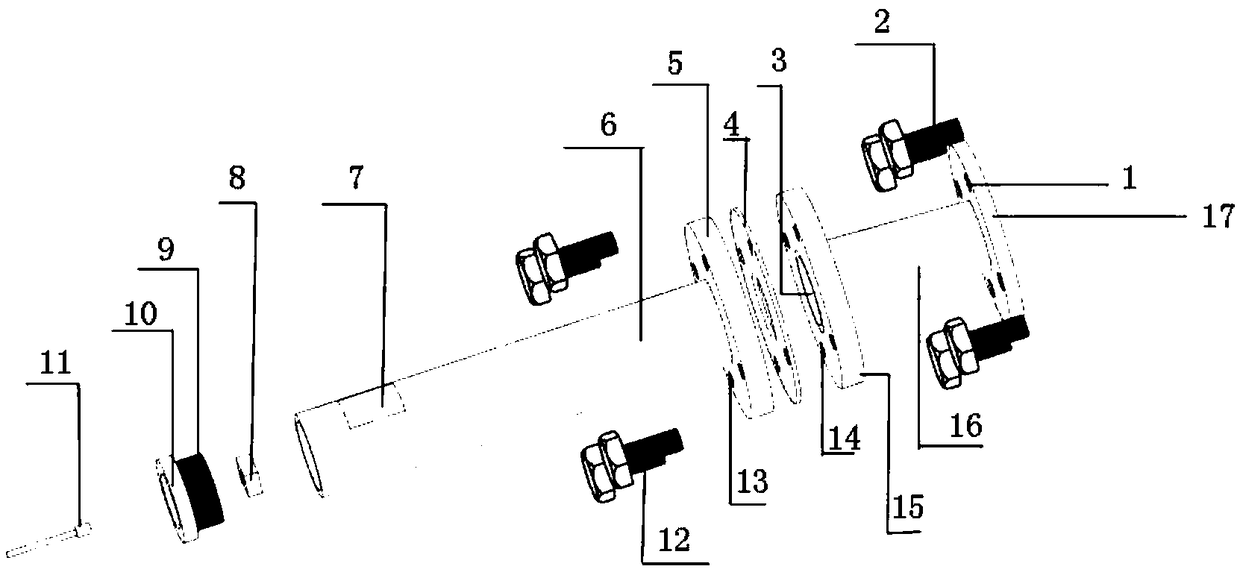

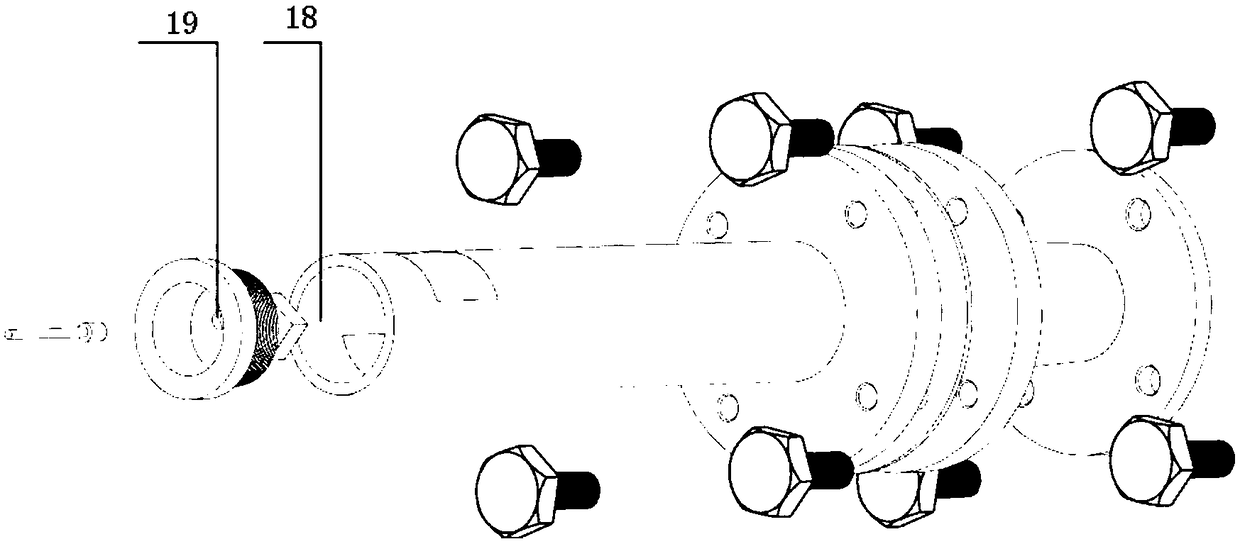

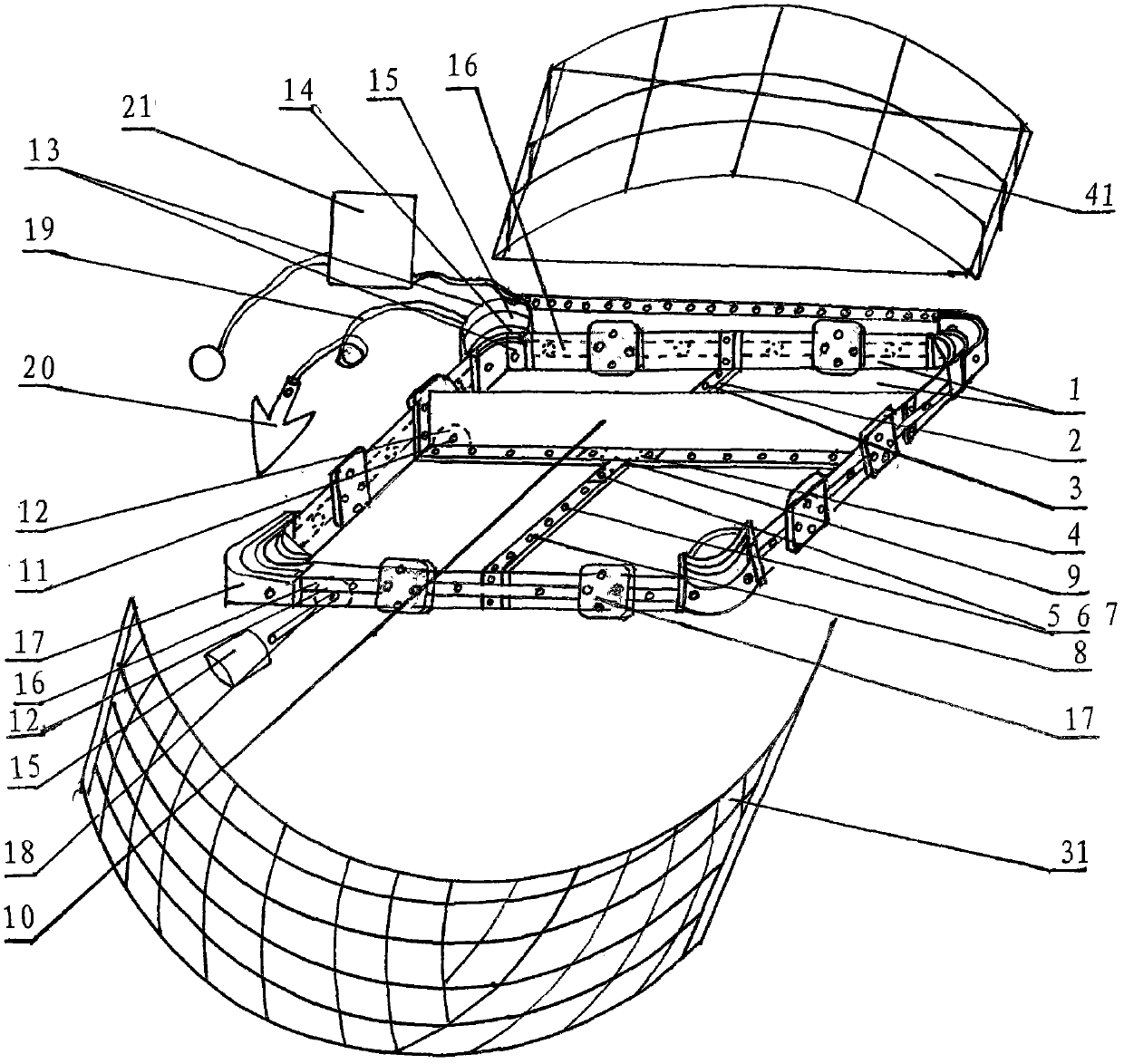

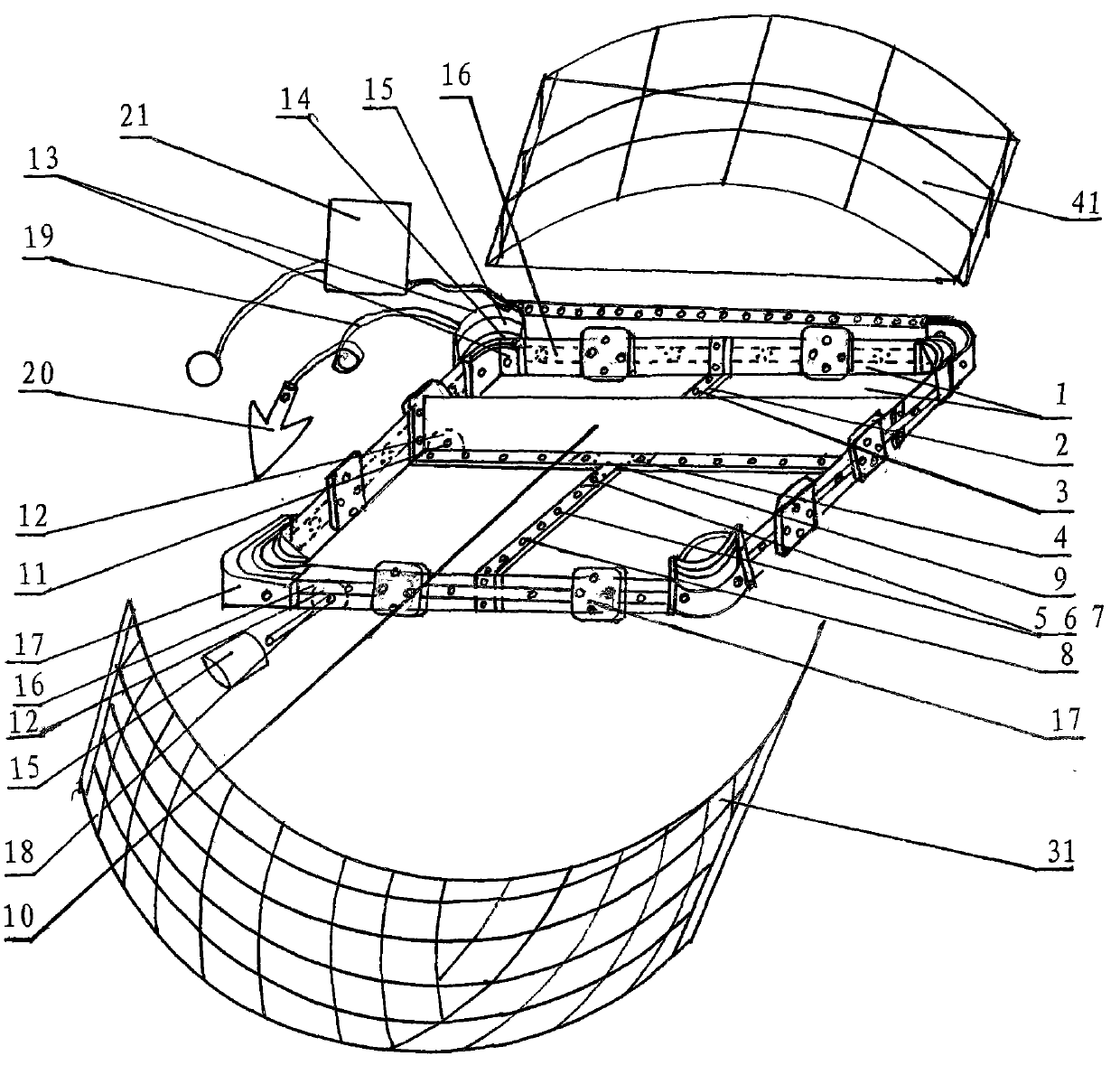

Moving tank and manufacturing method of moving tank

InactiveCN102605744AOvercoming Governance DifficultiesStop scourClimate change adaptationCoastlines protectionWorld classEngineering

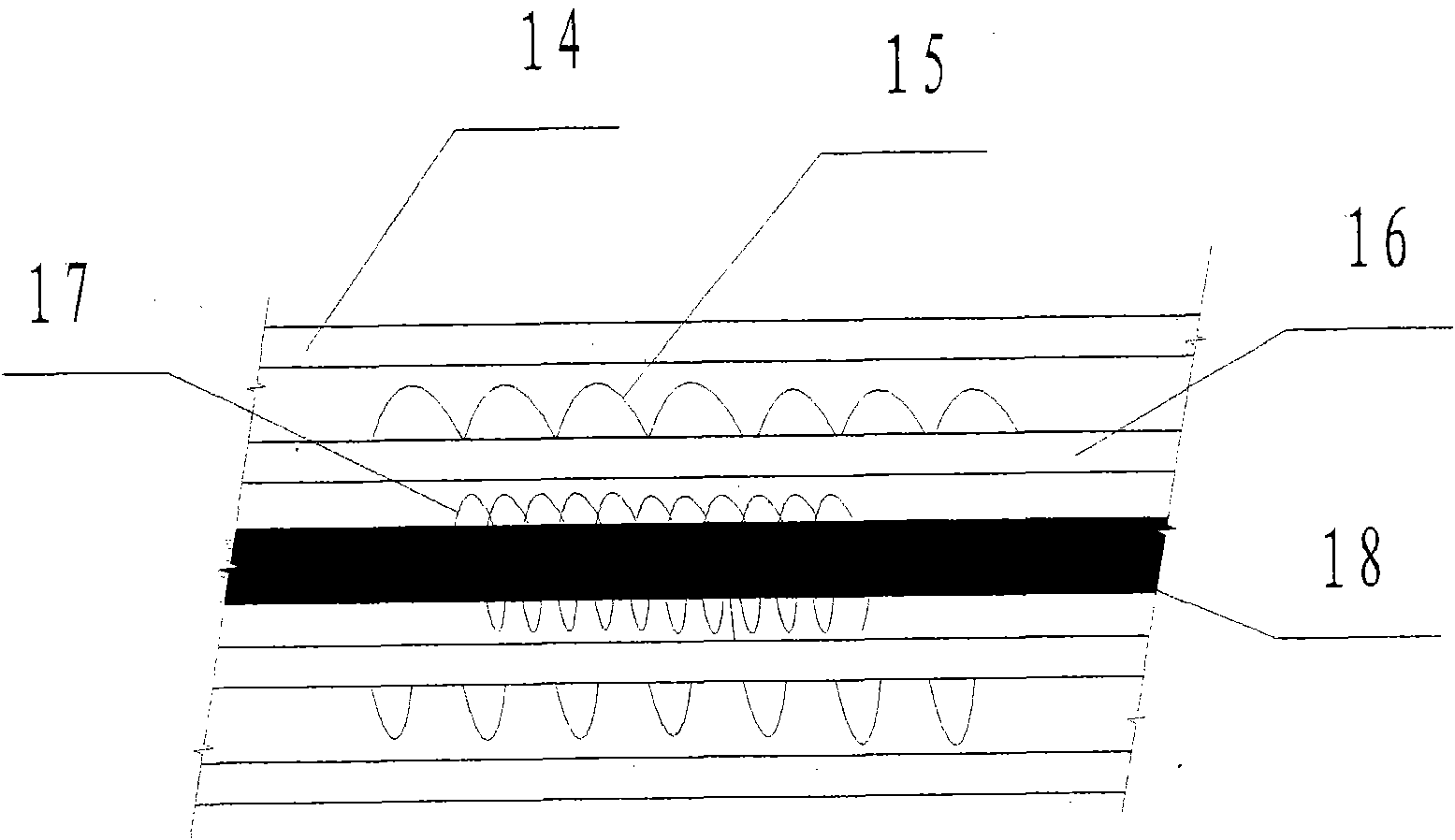

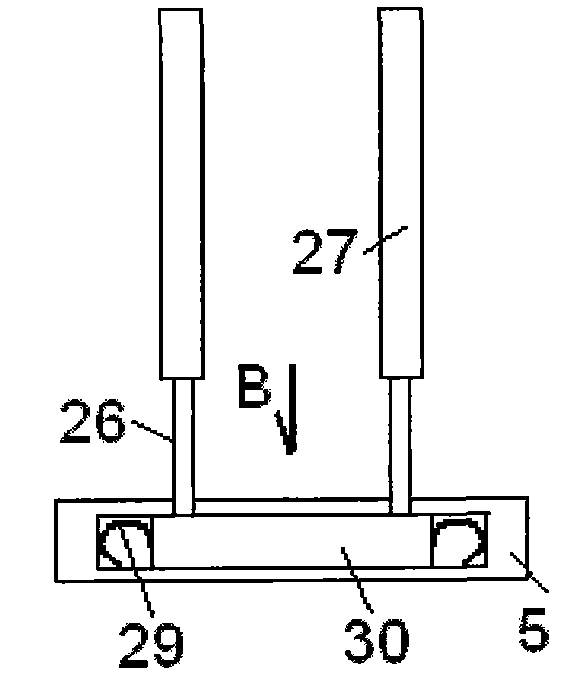

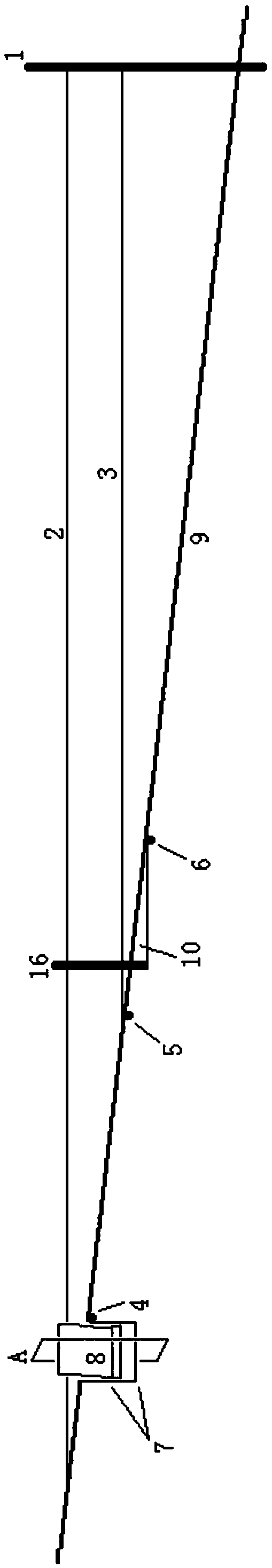

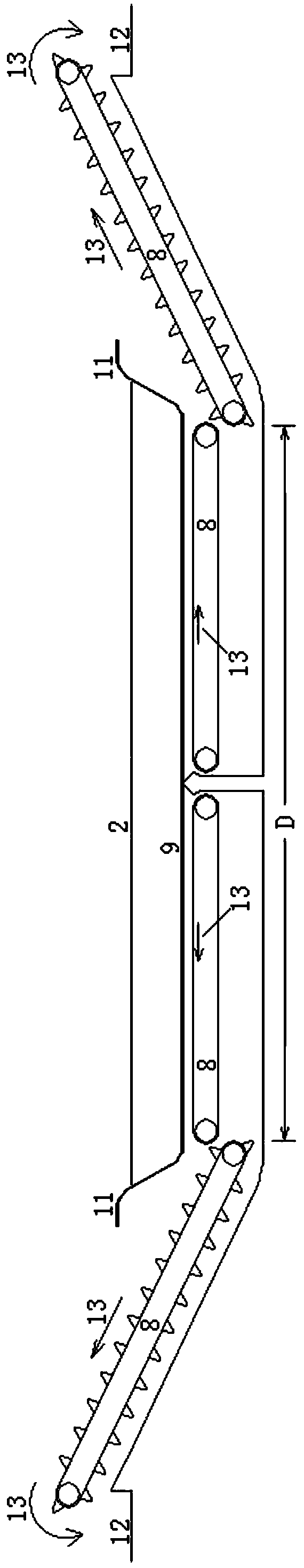

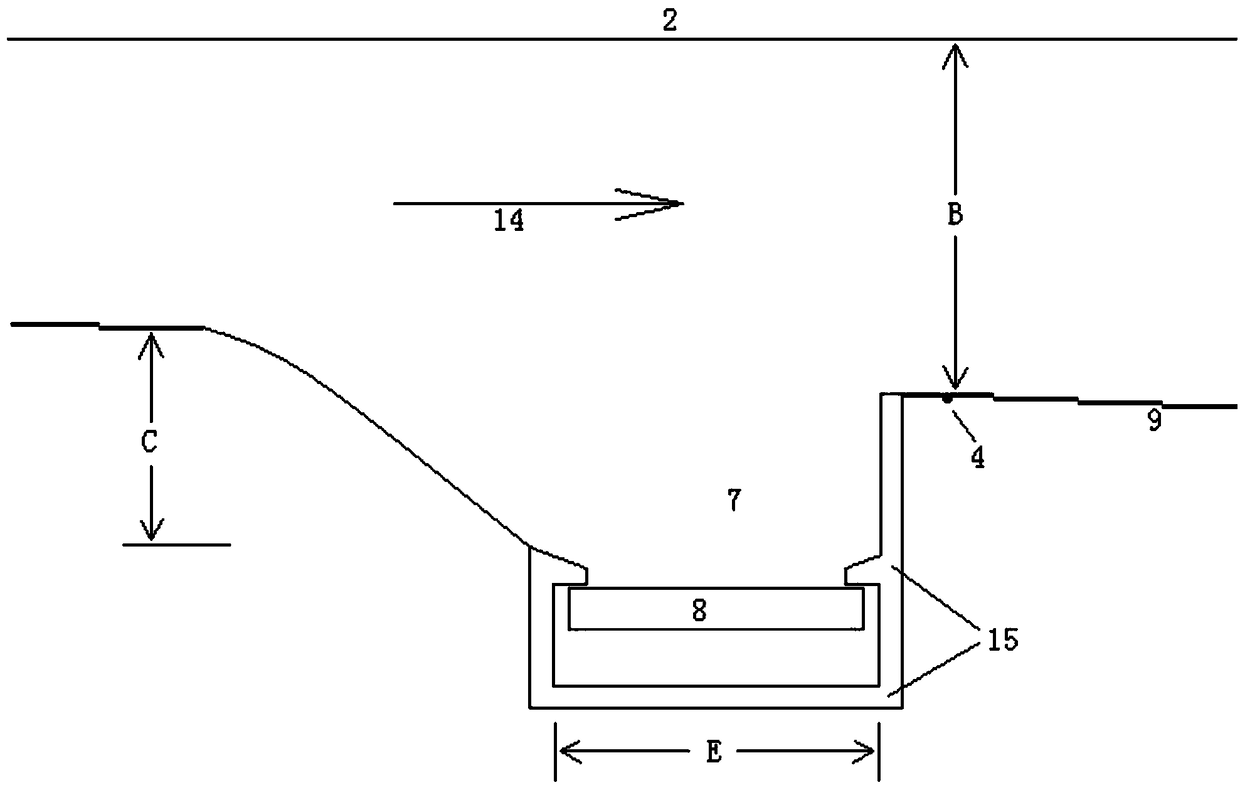

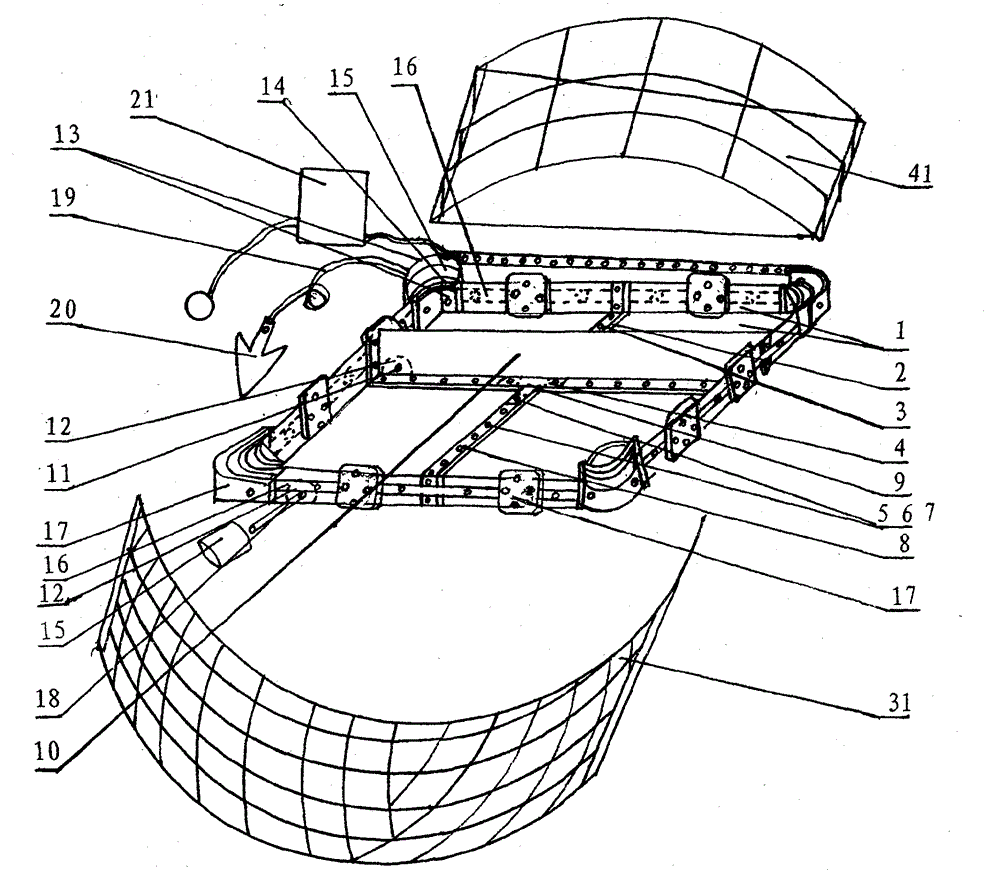

The invention relates to a moving tank and a manufacturing method of the moving tank, in particular to the moving tank which is used on water-level-fluctuating zones of rivers, lakes and water reservoirs and is used for treating the water loss and soil erosion, protecting the environment, protecting the bank, blocking the leakage, fighting a flood, planting and culturing, wherein the technical scheme of the moving tank protected belongs to the technical field of the water conservancy project. The invention also discloses the manufacturing method and applications of the moving tank. Aiming at the world-class difficulty for the treatment of the water-level-fluctuating zones, the moving tank is technically characterized by comprising water cloth (1), a cloth receiving clamp (8), a tank bank seat (17) and a connecting block (16), so that the difficulty of the treatment of the water-level-fluctuating zones is overcome, meanwhile, the fertile and valuable resources of the good field are obtained, therefore, the moving tank is widely applied to the water-level-fluctuating zones and the water surfaces in the country, thereby obtaining achieve effect due to the prominent characteristics and obvious progress.

Owner:重庆市南川区华顺大树茶专业合作社

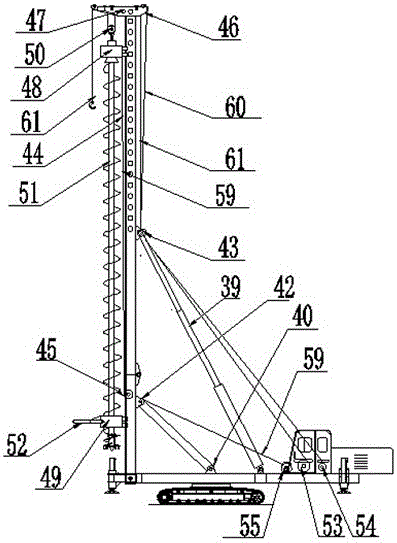

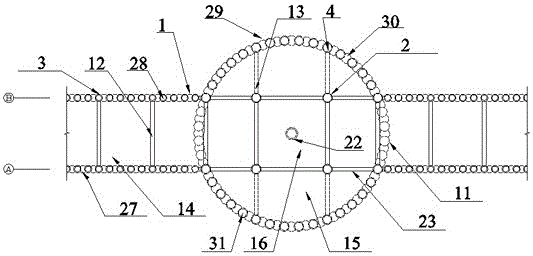

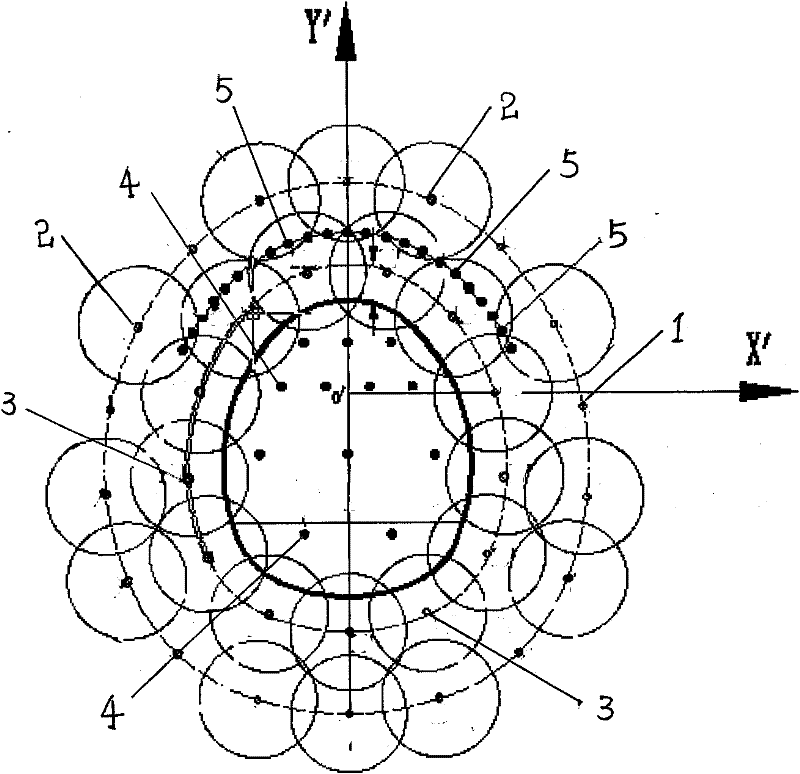

Construction method for subsurface excavated underground pipe rack and storage well

ActiveCN106545343ASolve world-class engineering problemsHigh speedArtificial islandsUnderwater structuresRoad surfaceEngineering

The invention relates to a construction method for a subsurface excavated underground pipe rack and storage well. Construction of the pipe rack and storage well is conducted through a reverse construction method in a subsurface excavation manner, reinforced concrete bearing piles, plain concrete water stop piles and reinforced concrete support piles are engaged with one another to be used as the wall of the pipe rack and storage well, a water storage well is arranged at the bottom of a pipe rack to be used for flood prevention, water storage and water resource secondary utilization of seaside cities, and seasonal water in a soil layer can effectively seep and be discharged through water seepage holes formed in the wall. By means of the technical scheme, the world-class engineering problem of successfully implanting the pipe rack in the underground portion of an old city on the premise of less influencing the city road surface traffic is solved, the comprehensive structure of the underground pipe rack and storage well which is high in speed, low in manufacturing cost and short in period and is obtained through subsurface excavation is provided for the seaside city construction in China, and therefore the construction method has wide market prospects and social value.

Owner:江西中恒地下空间科技有限公司

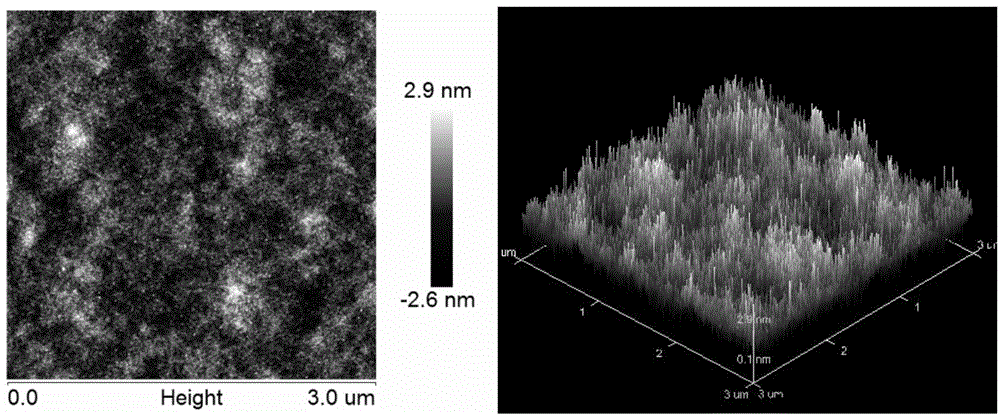

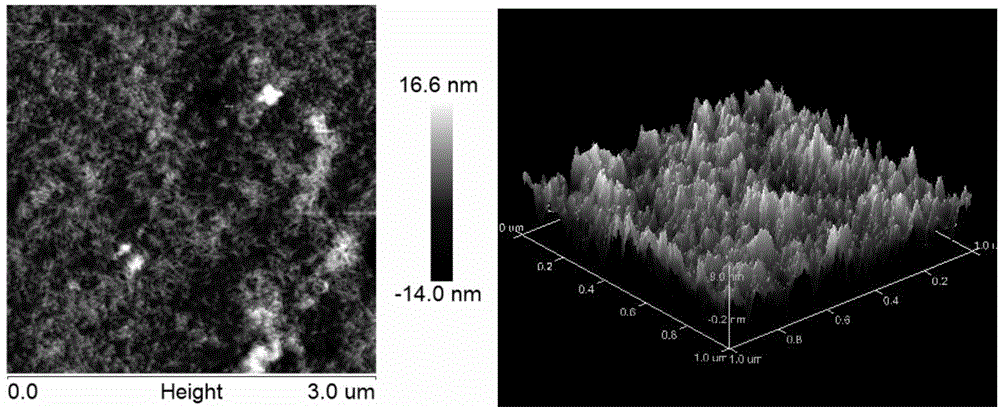

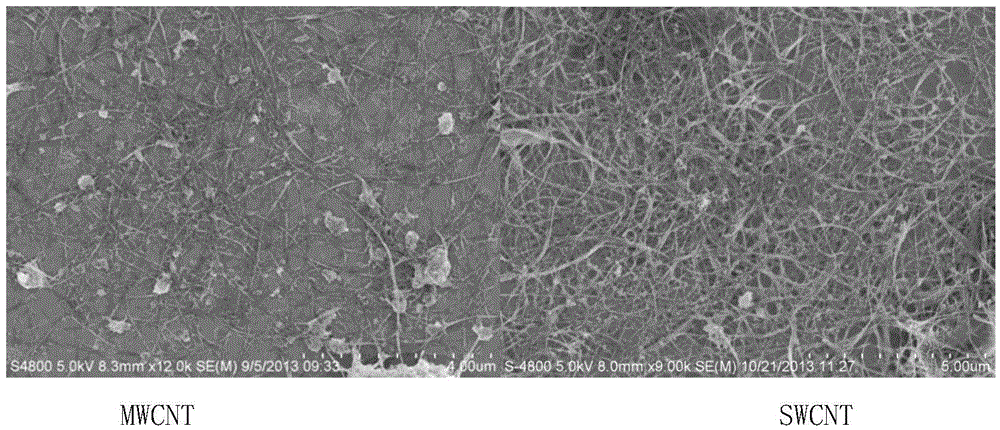

High-dispersion carbon nanotube composite conductive ink

InactiveUS20170029646A1Improve stabilityGood dispersionConductive materialInksModified carbonConductive polymer

A high-dispersion carbon nanotube composite conductive ink, consisting of modified carbon nanotubes, conductive polymeric material, and solvent; said modified carbon nanotubes being obtained from conventional carbon nanotubes that have been irradiated on a UV bench and then oxidized by a strong acid. Carbon nanotubes obtained via this process do not require, when preparing conductive composite ink, the addition of a surfactant to increase the dispersibility of the ink, such that the conductive layer obtained therefrom has good conductive properties, optical transmittance within the visible light range, and flexibility. The conductive properties of this flexible carbon nanotube polymeric transparent conductive film are world class, and the invention has good prospects for application.

Owner:BEIJING AGLAIA TECH DEV +1

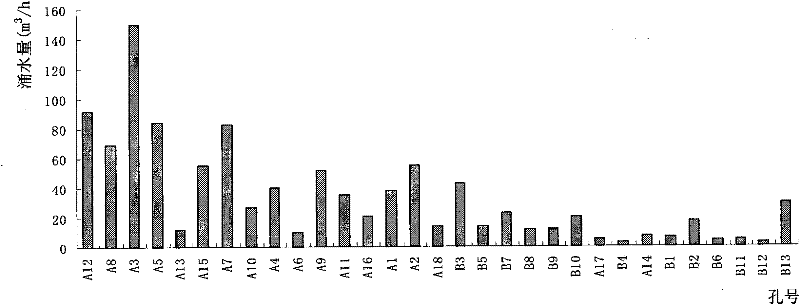

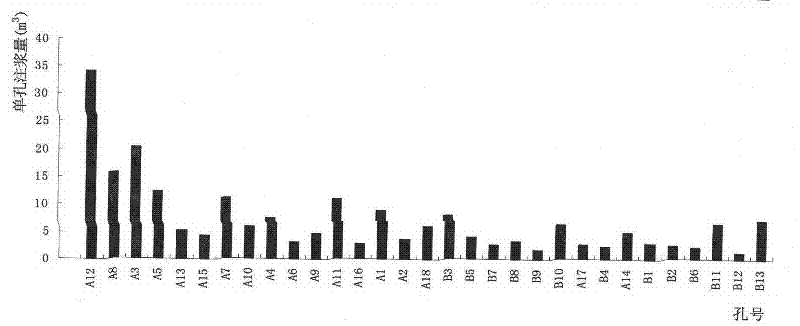

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930BSolve world-class problemsGood effect of water separation and pressure reductionUnderground chambersTunnel liningWater flowEngineering

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Alcohol-based fuel oven

InactiveCN101900361AFast gasificationEmission reductionDomestic stoves or rangesLiquid heating fuelTemperature controlAlcohol

The invention provides an alcohol-based fuel oven, which consists of a shell, a burning device, a gasification device and a valve assembly, wherein the gasification device is arranged on the burning device; the burning device is fixed on the shell; and one end of the gasification device is connected with the valve assembly, while the other end is connected with a burner of the burning device. The alcohol-based fuel oven solves the world-class problems that: 1, the alcohol-based fuel is changes from liquid to gas for burning to solve the problem of high energy consumption, and tests prove that energy conservation reaches over 60 percent; 2, the temperature of the alcohol-based fuel in a gasification pipe can be effectively controlled to be at 250 DEG C to solve the problem of carbonization; 3, the flame temperature is improved to be over 1,100 DEG C along with strong fire power and fast heating speed; 4, the gasification has high speed, and the liquid alcohol-based fuel can be completely changed into the gas for burning; and 5, the fuel is sufficiently burnt, and emission of waste gas after burning is over ten times lower than that of related standards in the country, so the fuel stove is every environmental protection. The alcohol-based fuel oven breaks through the technical barrier of alcohol-based fuel burning, and popularization of the alcohol-based fuel is changed from idea into reality. Popularization of the alcohol-based oven contributes to the country.

Owner:李永安

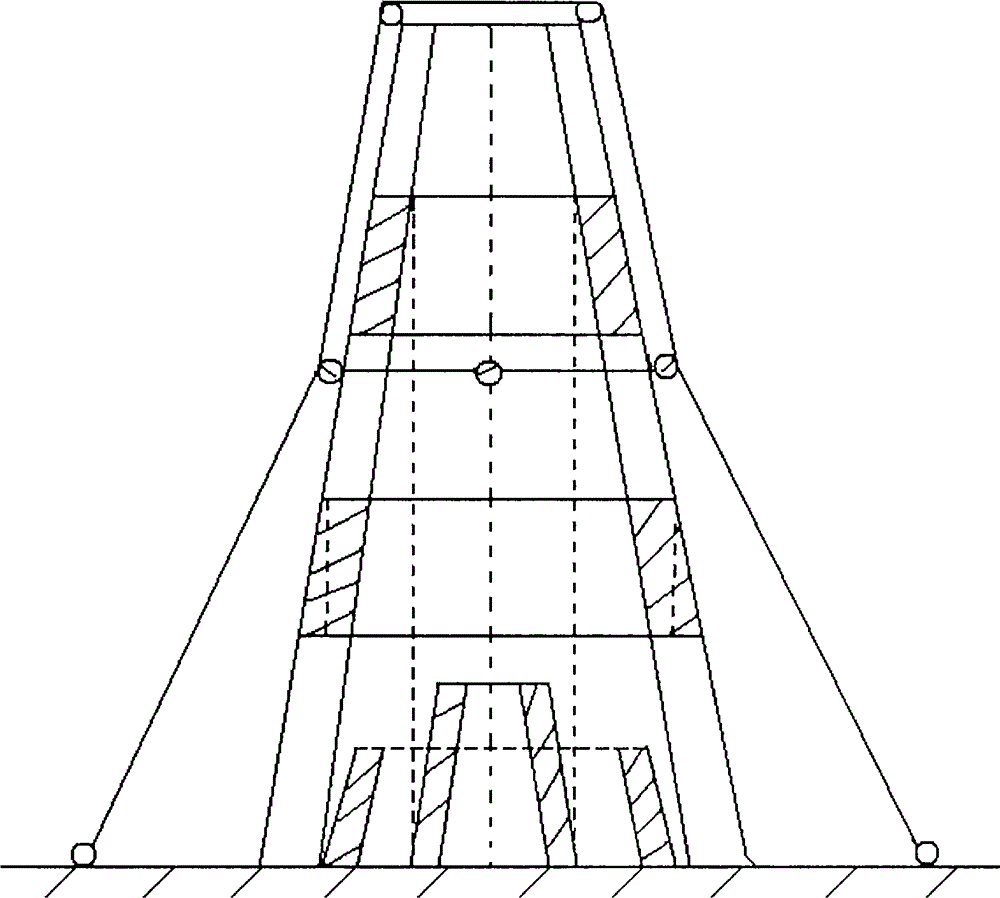

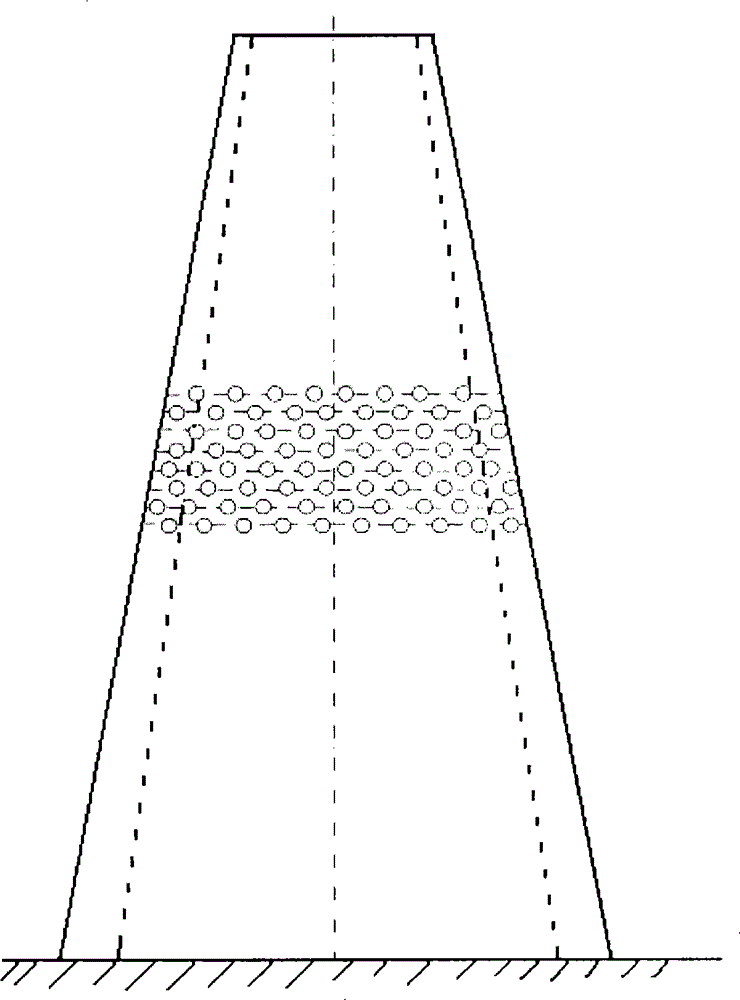

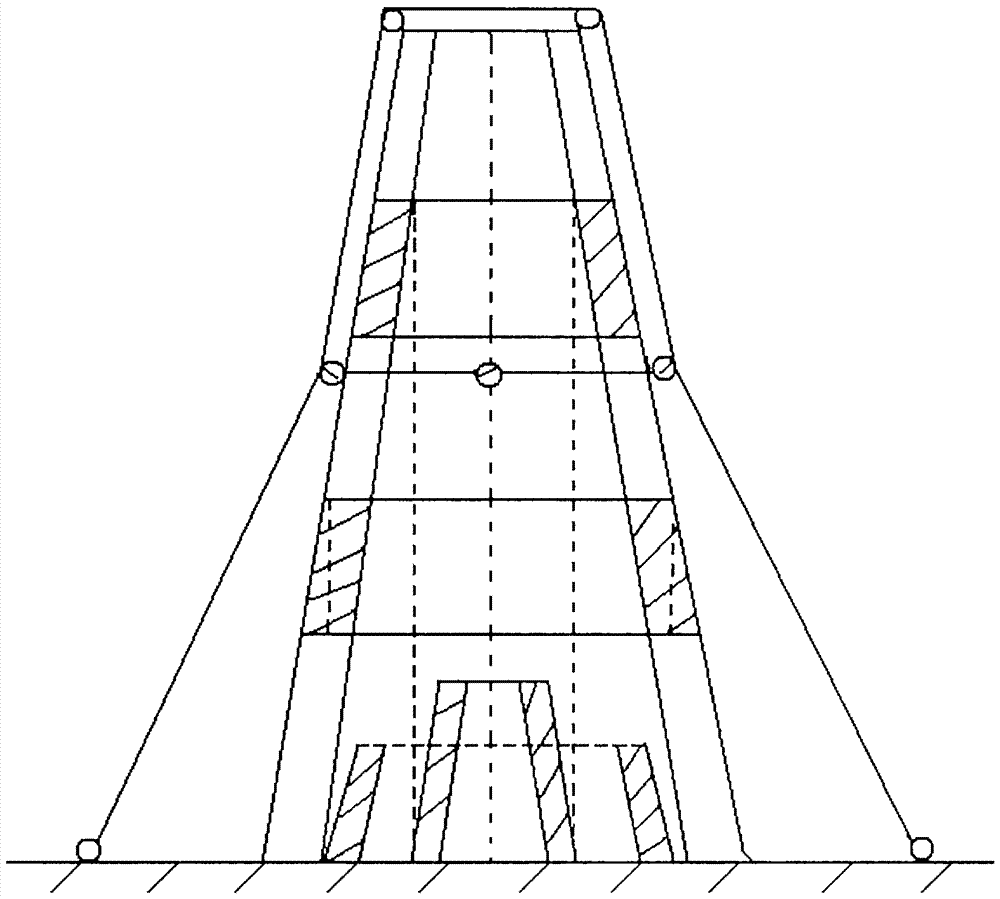

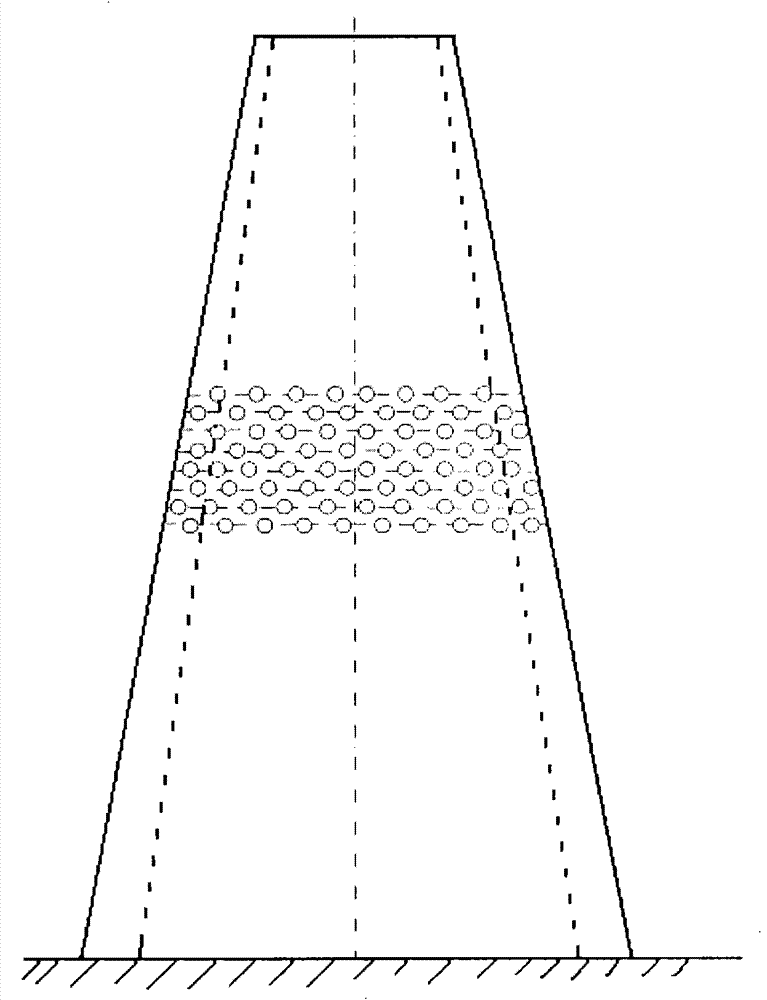

Conical building superposition type in-situ control and detonating dismounting method

InactiveCN105423831ASolve the technical problems of demolitionPromote productivityBlastingDetonatorReinforced concrete

Provided is a conical building superposition type in-situ control and detonating dismounting method. Reasonable segmentation is conducted on a conical building by fully utilizing the geometrical features and the symmetrical structure of the conical building, an annular notch is formed in the bottom of each segment according to the superposition conditions, detonation is conducted row by row from bottom to top through burst height computation, setting of blast holes, design of an orienting device and adoption of digital electronic detonators, reinforced concrete is destroyed symmetrically within the range of the annular notches, the segments of the conical building are accurately sleeved with the lowermost segment of a chimney, and the dismounted body diffusion range is only limited in the chimney. The method is novel in design and simple in process, the dismounted conical building falls into a conical structure accurately in segmented, oriented, detonating and superposition modes, the diffusion range is controlled in the conical structure, normal production of surrounding factories and daily life of surrounding residents are not affected, the national clean environmental protection and energy conservation policy is met, the innovation and energy conservation runs through the whole dismounting process, and the world-class technical problem that towering reinforced concrete conical buildings (structures) cannot be dismounted in complex site environments without collapsing is effectively solved.

Owner:张建平

Highly-dispersed carbon nano-tube composite electric conduction ink

A high-dispersion carbon nanotube composite conductive ink, consisting of modified carbon nanotubes, conductive polymeric material, and solvent; said modified carbon nanotubes being obtained from conventional carbon nanotubes that have been irradiated on a UV bench and then oxidized by a strong acid. Carbon nanotubes obtained via this process do not require, when preparing conductive composite ink, the addition of a surfactant to increase the dispersibility of the ink, such that the conductive layer obtained therefrom has good conductive properties, optical transmittance within the visible light range, and flexibility. The conductive properties of this flexible carbon nanotube polymeric transparent conductive film are world class, and the invention has good prospects for application.

Owner:BEIJING AGLAIA TECH DEV +1

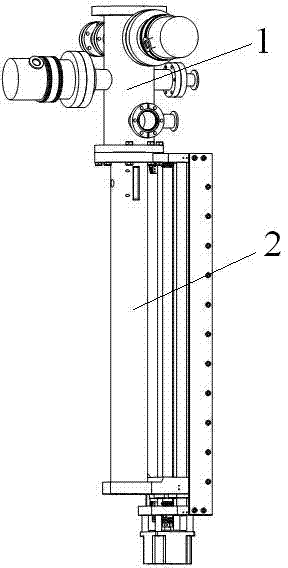

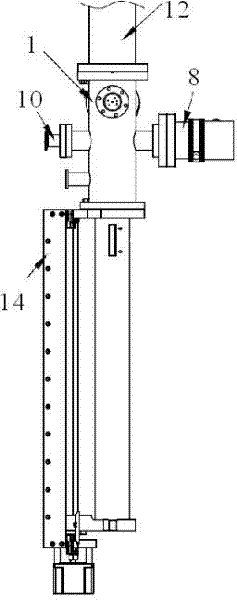

Multistage differential pumped ultrahigh vacuum sample transmission mechanism

InactiveCN102393468ASolve high-speed automatic transmissionImprove experimental efficiencyMaterial analysisUltra-high vacuumWorld class

The invention relates to the field of ultrahigh vacuum equipment development, in particular to a multistage differential pumped ultrahigh vacuum sample transmission mechanism, which consists of a differential pumping mechanism and a sample transmission rod driver, wherein the differential pumping mechanism is that a cavity is separated into 2 to 3 spaces by seal rings; each space has independent vacuum acquisition mechanism and detection mechanism; a first-stage differential pumping space is fixedly connected with the sample transmission rod driver; the vacuum acquisition capacities of the differential pumping spaces are improved in turn from the sample transmission rod driver end to the ultrahigh vacuum cavity end; the highest stage of differential pumping space is fixedly connected with the ultrahigh vacuum cavity; and a sample transmission rod of the sample transmission rod driver is inserted in a differential pumping chamber and drives the mechanism to rotate. The multistage differential pumped ultrahigh vacuum sample transmission mechanism realizes high-speed sample transmission between the atmosphere and the ultrahigh vacuum cavity, and greatly improves experiment efficiency and reliability. The invention solves a core technological problem that apparatus in a spacecraft are radiated by spatial cosmic rays, fills up a domestic blank and reaches a world-class level.

Owner:大连齐维科技发展有限公司

Epoxy urea bond underwater decorative coating

InactiveCN109096873AImprove adhesionLow construction environment requirementsPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolyol

The invention discloses an epoxy urea bond underwater decorative coating which comprises a component A and a component B. By mass percentage, the component A includes 50-70 parts of modified epoxy bond group, 20-40 parts of polyether polyol, 5-15 parts of plasticizer, 0.05-2 parts of antifoaming agent and 10-15 parts of leveling agent. By mass percentage, the component B comprises 30-45 parts of modified polyurea bond groups, 5-15 parts of plasticizer, 15-30 parts of chain extender, 30-50 parts of filler, 10-15 parts of leveling agent, 1-5 parts of anti-slip agent and 10-15 parts of fusion agent. The epoxy urea bond underwater decorative coating has the advantages that the adhesion of the coating is high and is three times that of an existing underwater paint product, the requirements forthe construction environment are relatively low, a construction process is simple, all the products are constructed outdoors, so that the risk of a blistering coating is greatly reduced, and the epoxyurea bond underwater decorative coating is always used for a long time by world-class parks.

Owner:广州尚卓新材料科技有限公司

Oral sublingual tablet formula and method for preparing oral sublingual tablet by using insulin lipidosome, insulin microsphere (capsule), and insulin nanoparticle (capsule) as raw materials

PendingCN105193751ASmall particle sizeUniform particle sizePowder deliveryPeptide/protein ingredientsMicrosphereHepatic first pass effect

The invention relates to a sublingual tablet formula and a method for preparing the sublingual tablet by using an insulin lipidosome, an insulin microsphere (capsule), and an insulin nanoparticle (capsule) as raw materials. The method is ingenious in conception; various oral sticking agents, oral mucus membrane absorption promoters, oral enzyme inhibitors and the like are scientifically selected and mixed, so that the insulin lipidosome, the insulin microsphere (capsule) and the insulin nanoparticle (capsule) can fast penetrate the oral mucus membrane to enter blood. Through the adoption of the method, a difficult problem that effects of an oral insulin can be reduced by enzymolysis of intestines and stomach enzymes and an first-pass effect of the liver is broken over; the sublingual tablet is safe, effective, controlled in slow release, stable in stability, and excellent in blood sugar reducing effect, and can completely replace an injection; a world-class difficult problem which troubles the medical field for many years can be fundamentally solved, and great convenience is brought to a patient with diabetes.

Owner:孙民富

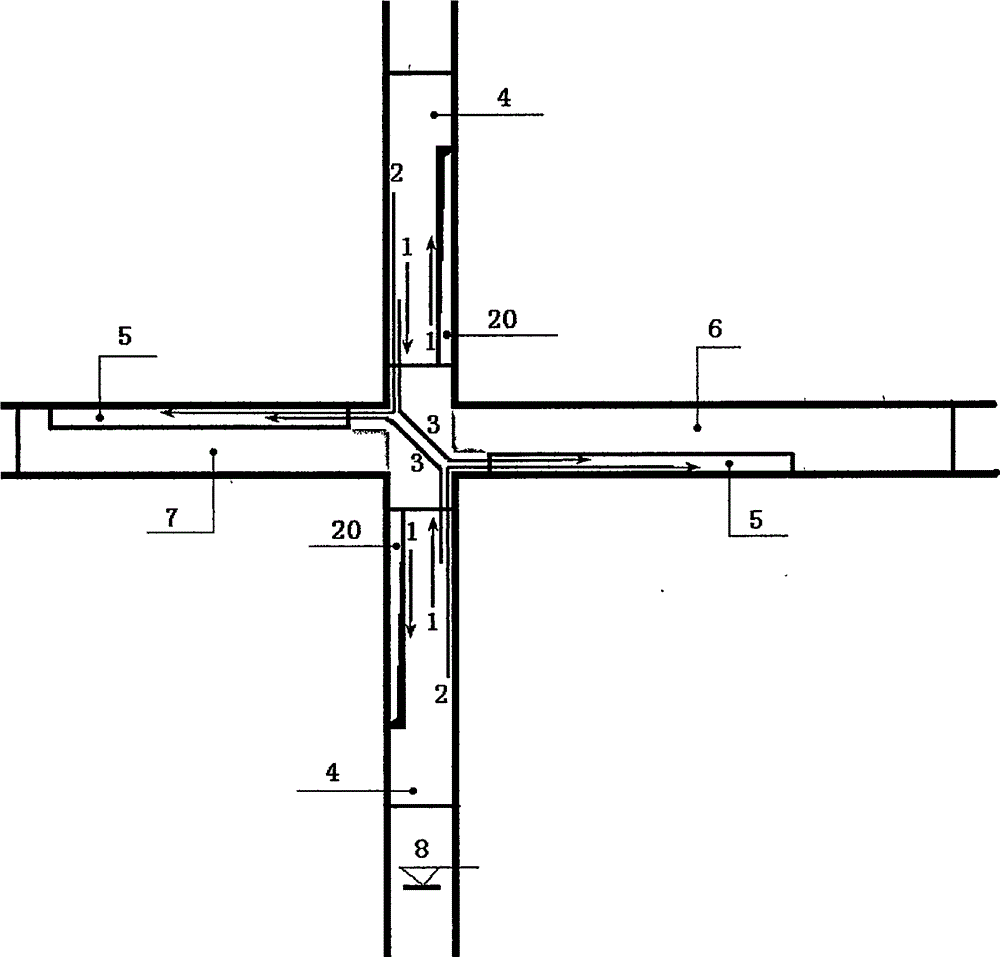

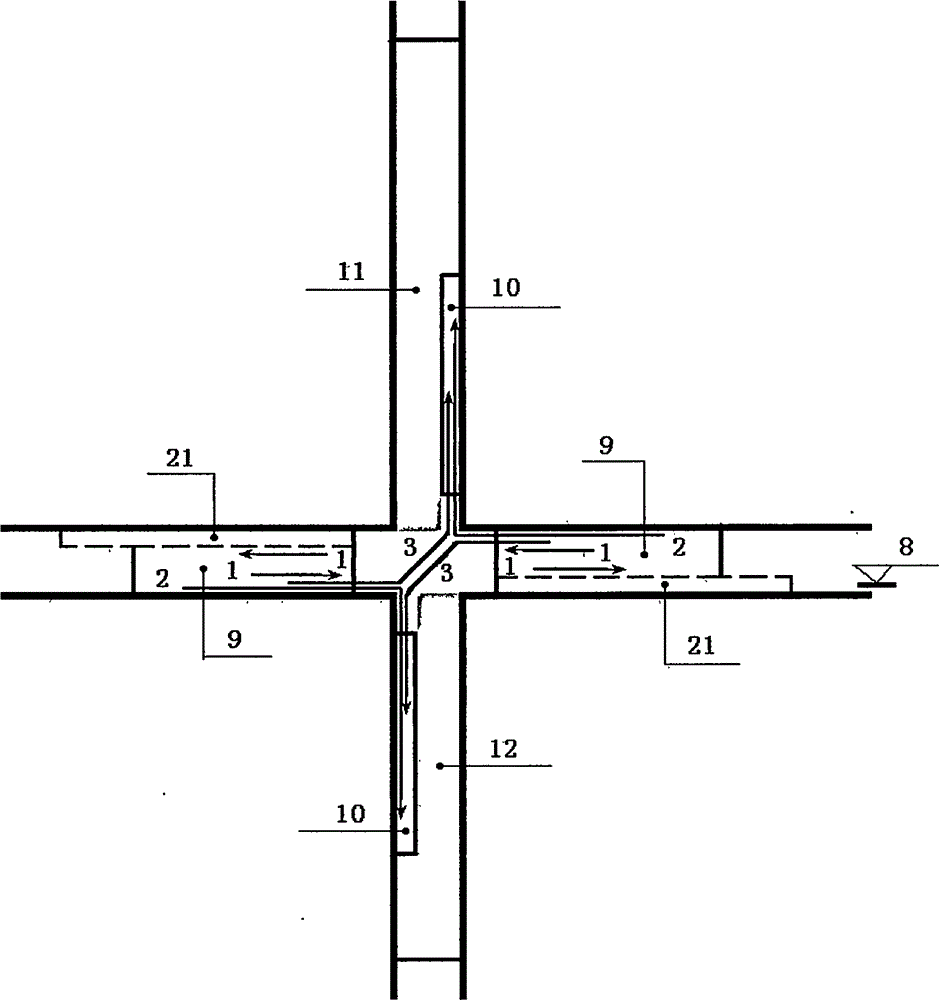

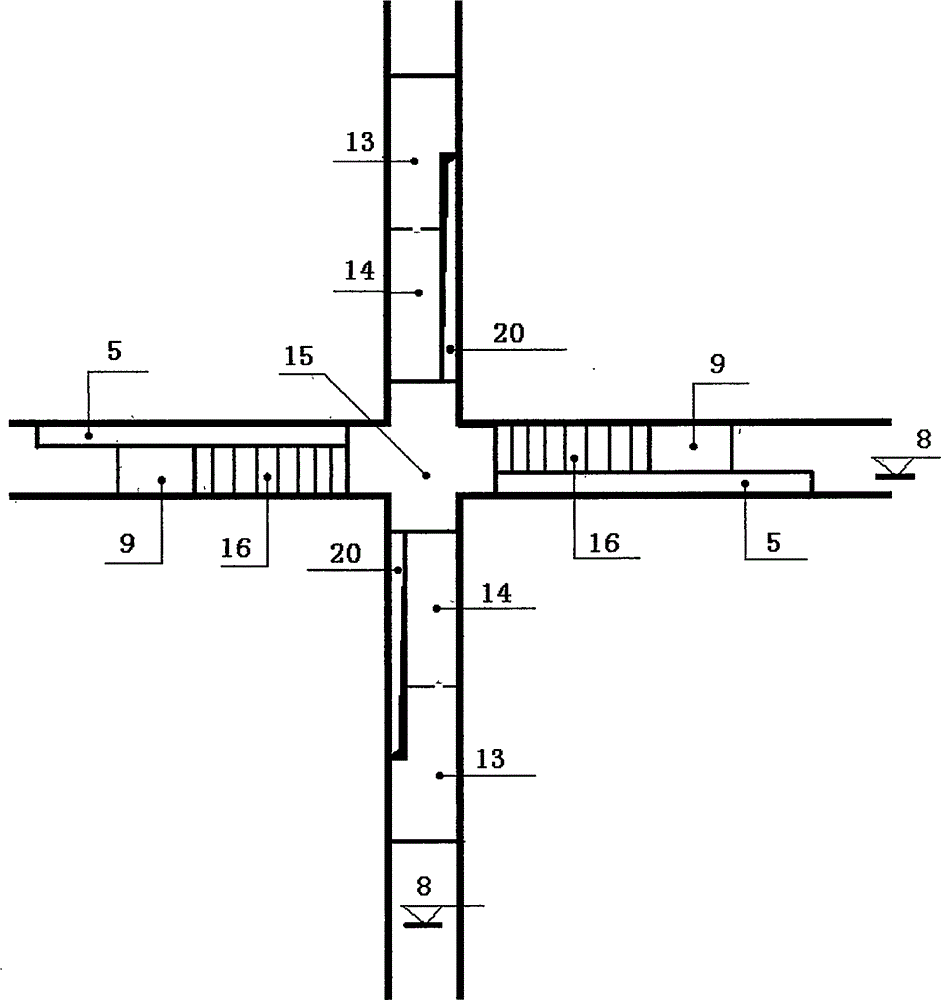

Interchange crossing designed for pedestrians walking on ground, cars running above or under ground level, and mutual accommodation only among cars on same road

The invention discloses an interchange crossing designed for pedestrians walking on the ground, cars running above or under ground level, and mutual accommodation only among cars on the same road, and belongs to the technical field of urban construction road engineering. The interchange crossing adopts a layered separation structure that the ground is exclusive for citizens; an interlayer is exclusive for bicycles; the cars run above or under ground level, that is, one road for the cars is an overpass, and the other road for the cars is an underpass; an extra-large area urban vacant lot is formed in the ground, and used as a public living room for surrounding buildings; only the cars on the same overpass road or the same underpass road need to be mutually accommodated, so that the traffic light waiting time is unified and relatively short; a large-area parking area can be developed; big steps are designed on the underpass; an urban expressway featured by the technology of the interchange crossing designed for the pedestrians walking on the ground, the cars running above or under ground level, and mutual accommodation only among the cars on the same road needs to execute. Through the adoption of the interchange crossing provided by the invention, the world-class problems of a traffic jam, parking, an urban vacant lot, the communication among walking streets near the surrounding buildings, and the like can be solved without extra land outside the roads, the design effects for all urban construction road engineering occasions, especially the most crowded downtown, can be achieved similarly and completely.

Owner:刘长寿

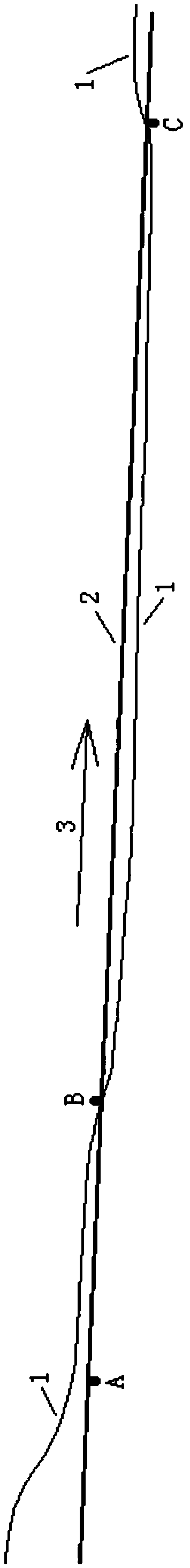

Method for treating plain river course

InactiveCN109267535ASolve the elevated problemImprove navigabilityStream regulationDiversion damCanyon

The invention is a method for treating a plain river course. The technical problem to be solved by the method is to completely solve a world-class problem of plain river course regulation. According to the technical scheme, a diversion dam is constructed at a position between the boundary point of a canyon river and a lowland river and the boundary point of the lowland river and an aboveground river, two river channels are separated from the diversion dam, one is a flood water flow river, the other is a low water flow river, the navigation capacity is expanded, and the expanded navigation capacity is maintained throughout the year.

Owner:彭国洪

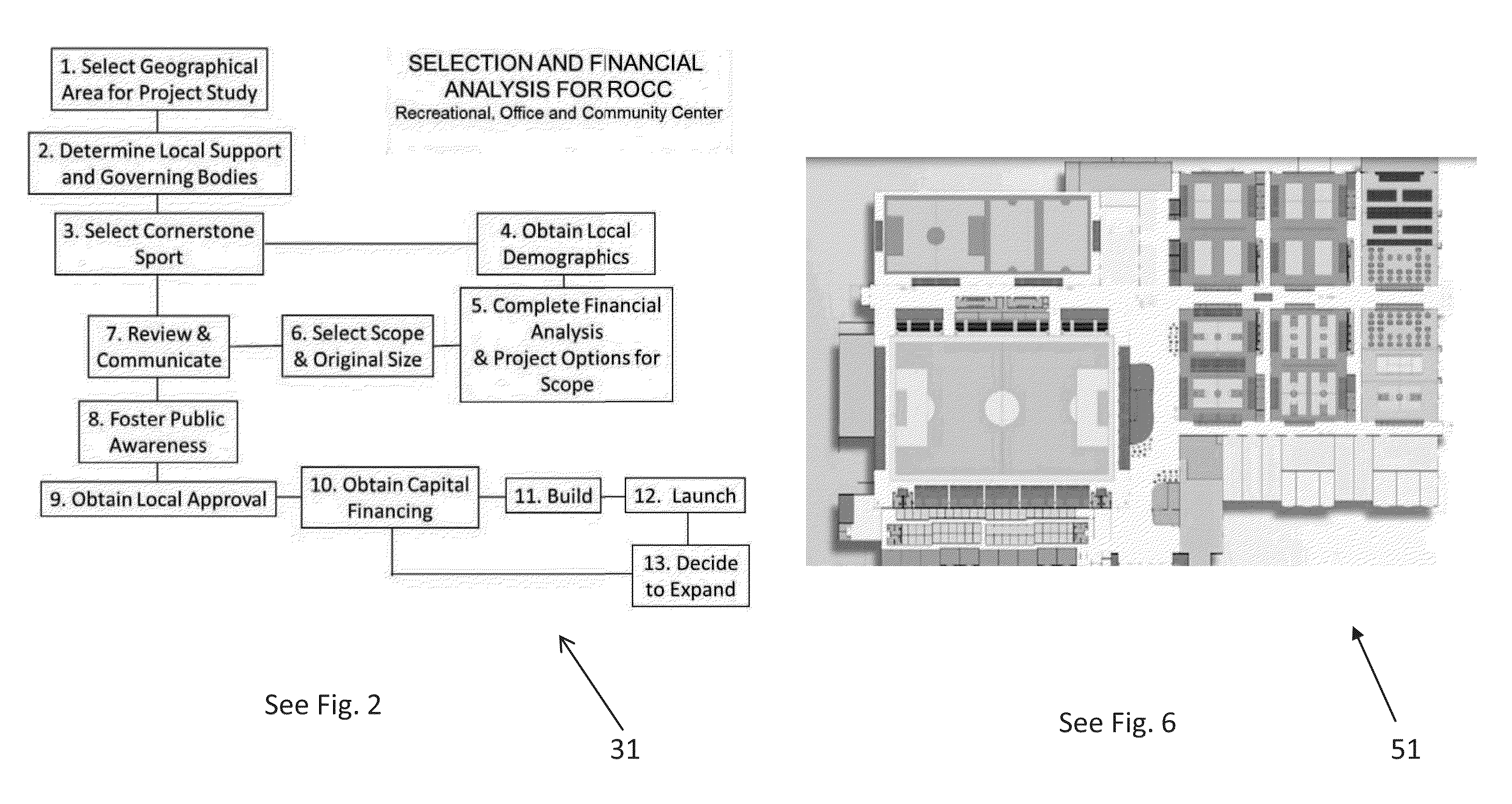

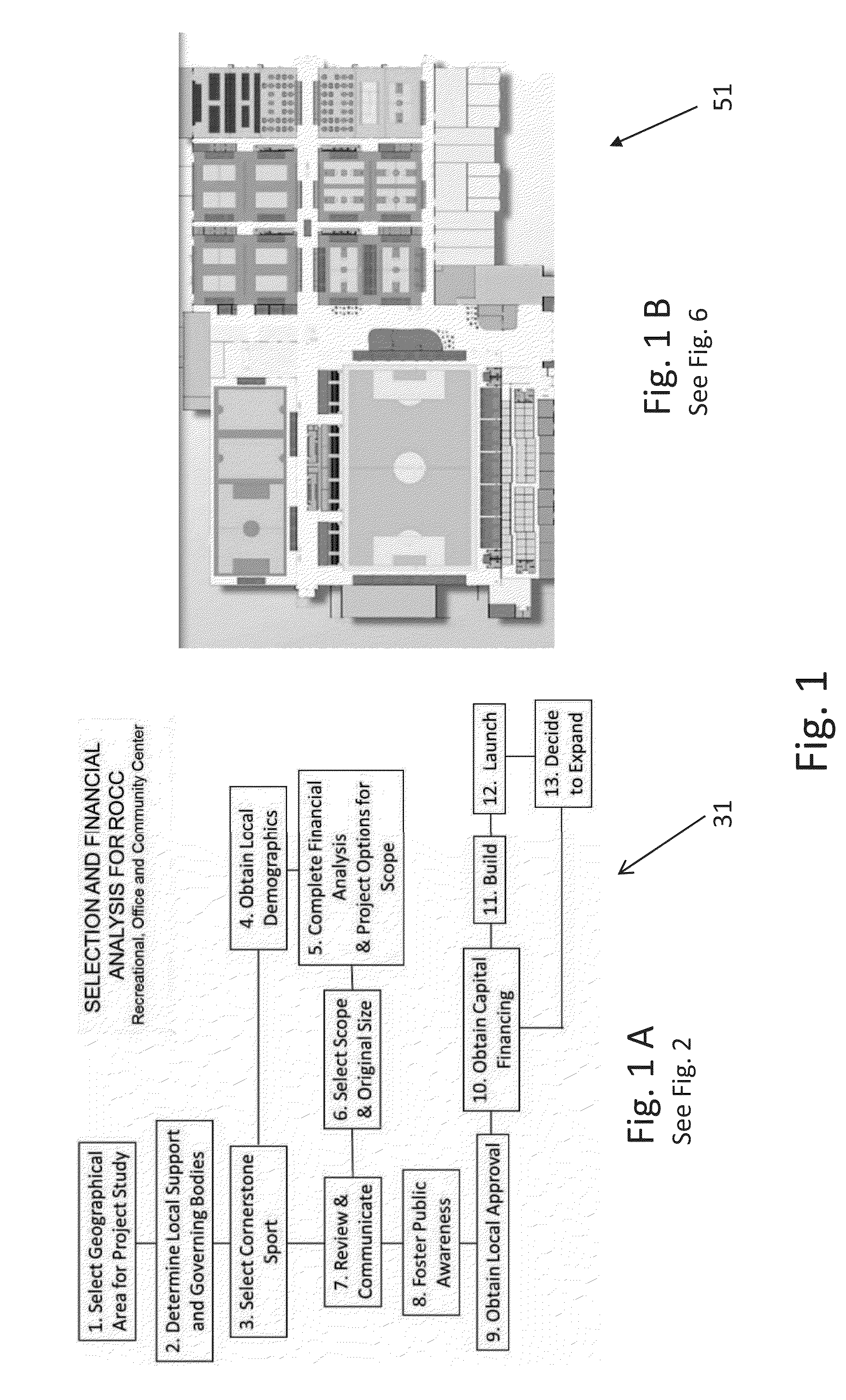

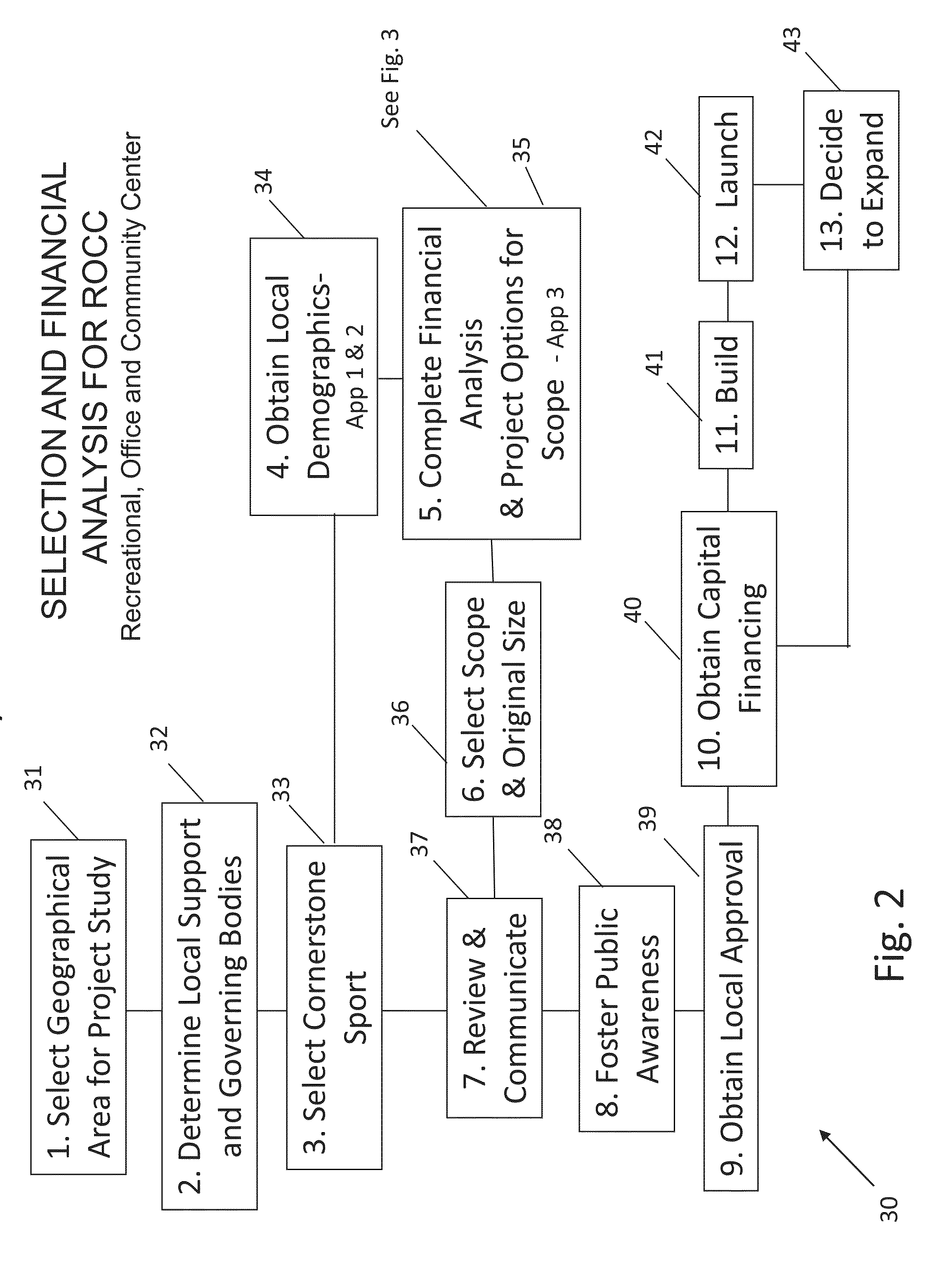

Business Method Patent for determining the Financial Viability of Constructing a Recreation Center and a Flexible Commercial Center known as the ROCC

InactiveUS20130006895A1Easy to adaptData processing applicationsSpecial data processing applicationsRecreationWorld class

A Business Method Patent for determining the Financial Viability of Constructing a Recreation Center and a Flexible Commercial Center known as the ROCC. The complex device is a one of a kind world class facility that will have a positive impact on wellness, fitness, and the economy of the entire community. Included with this complex is a COMMUNITY CENTER that is a private business. The primary goal of the-ROCC is to create a positive impact on the community. The-ROCC will help promote youth, adult, and family wellness; provide one centralized location for community events and will help spur additional, residential and commercial growth.

Owner:BURTON J BRENT

A nested in-situ controlled blasting demolition method for conical buildings

InactiveCN105423831BSolve the technical problems of demolitionPromote productivityBlastingEffective solutionDetonator

A nested in-situ control blasting demolition method for conical buildings, which makes full use of the geometric characteristics and symmetrical structure of conical buildings to reasonably divide them into sections, and sets an annular gap at the bottom of each section according to the nesting conditions. High calculation, blast hole setting, directional device design and digital electronic detonators are used to detonate row by row from bottom to top, symmetrically destroying the reinforced concrete within the range of the annular gap, so that the segment-by-section conical buildings can be accurately inserted into the bottom section of the chimney , the diffusion range of the demolition body is limited to the chimney. The patent is novel in design and simple in process. The demolished conical building falls into the conical structure accurately by means of segmentation, orientation, blasting, and nesting. The diffusion range is controlled within the conical structure without affecting the normal production and operation of surrounding factories. The daily life of residents complies with the national clean, environmental protection and energy-saving policy. Innovation and energy conservation run through the whole process of demolition, effectively solving the world-class technical problem of demolition of towering reinforced concrete conical buildings (structures) in a complex environment without collapse sites.

Owner:张建平

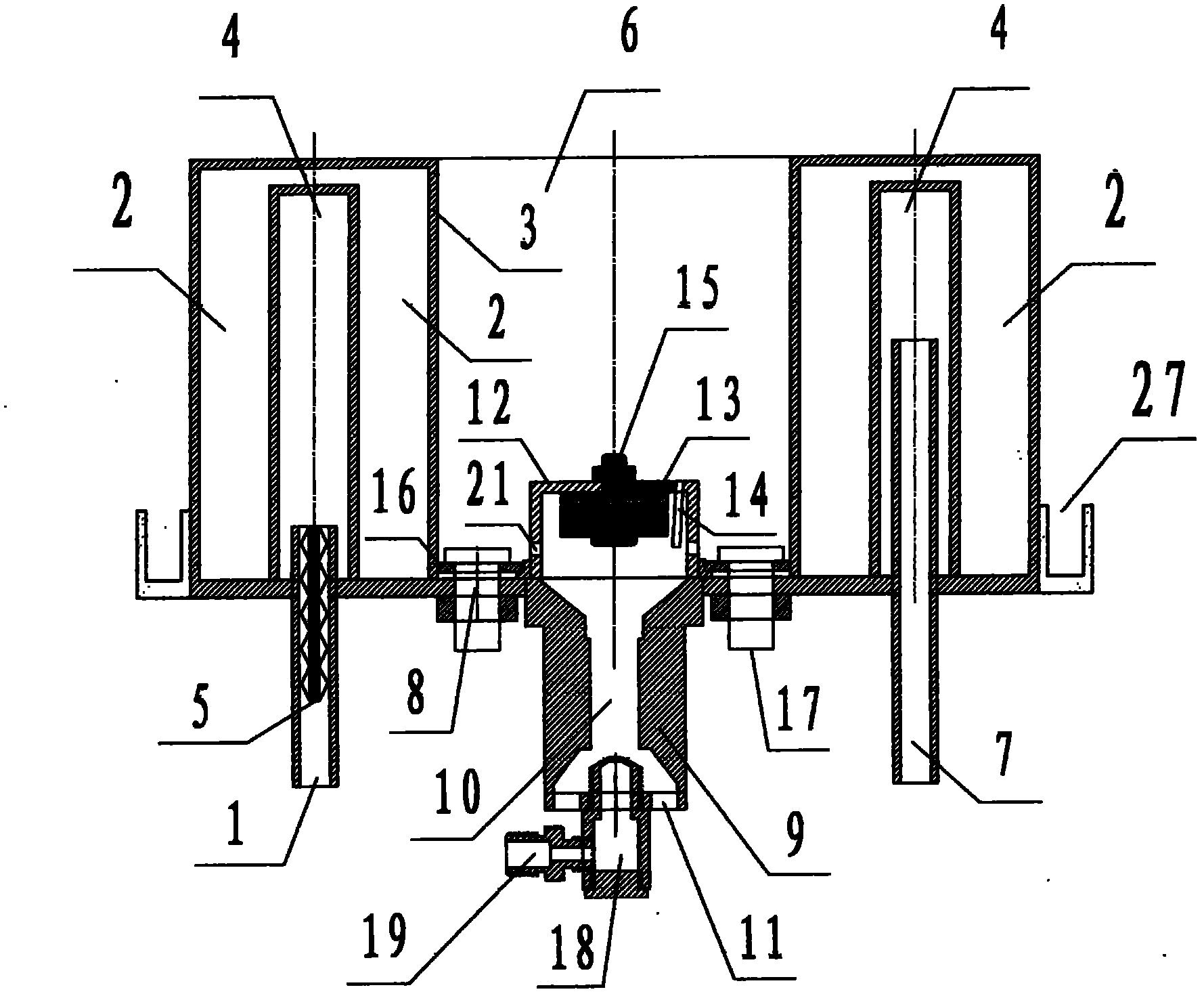

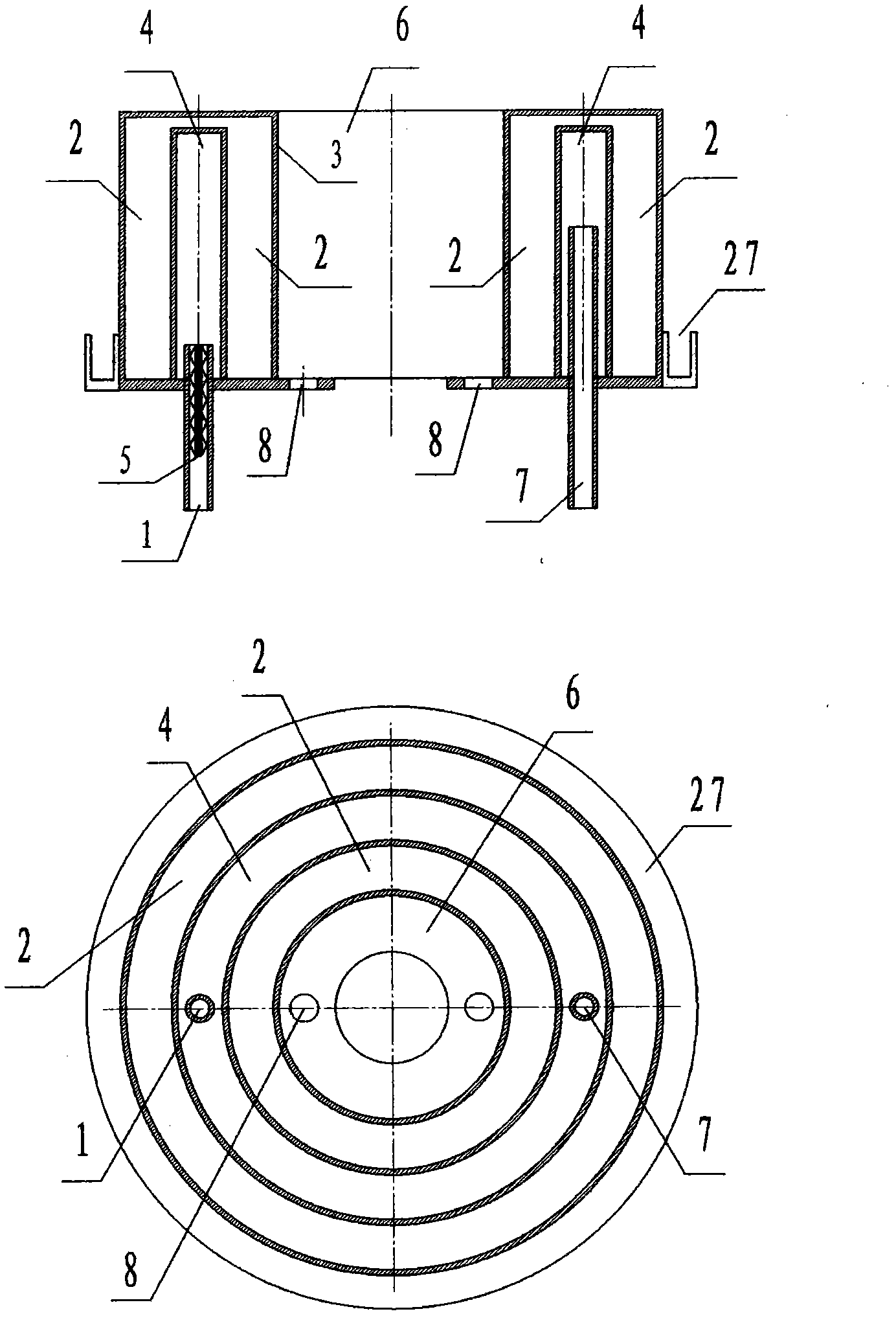

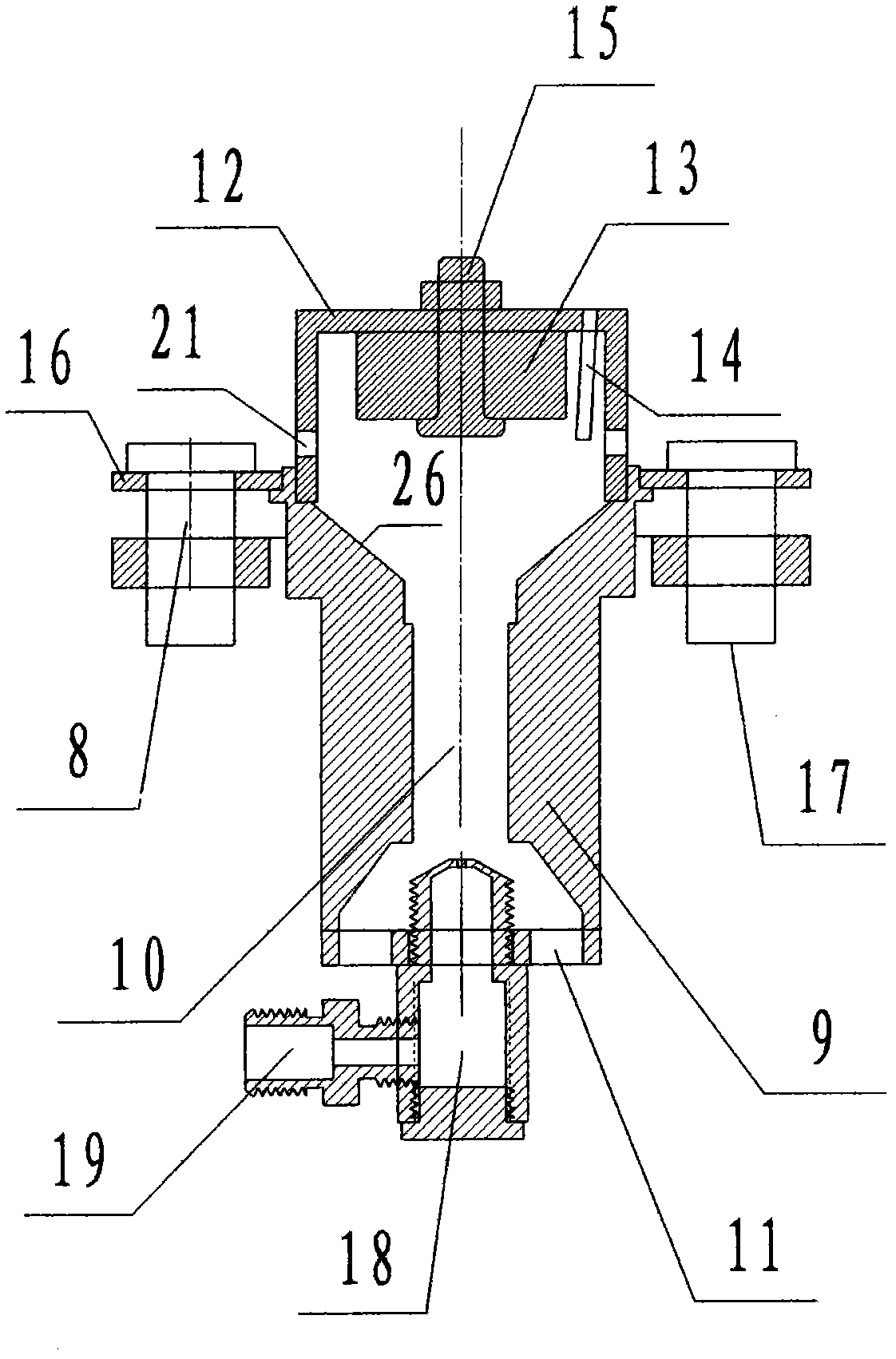

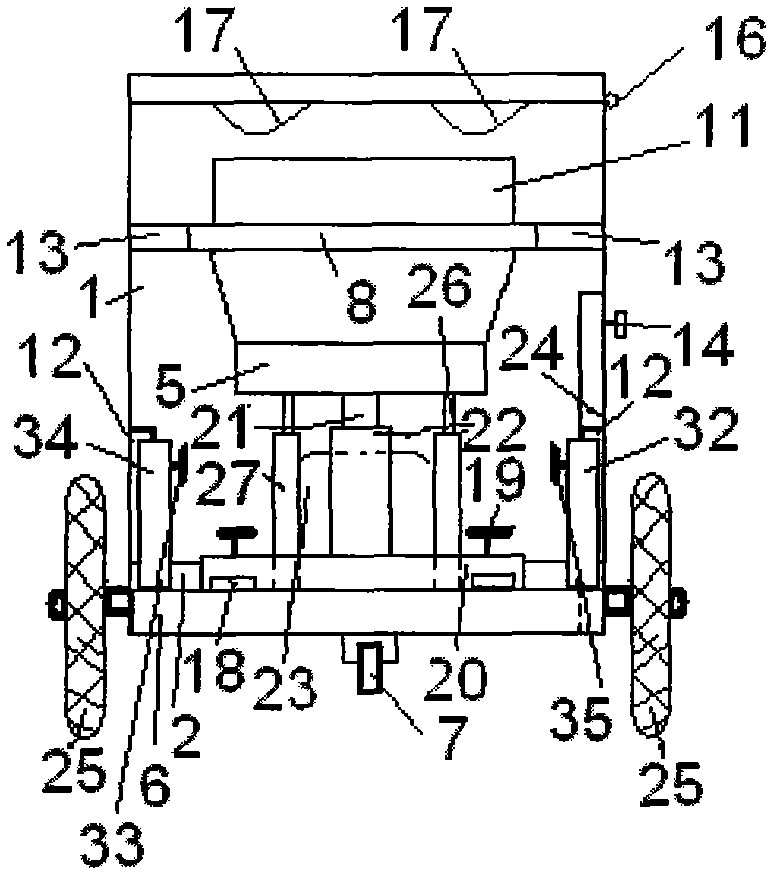

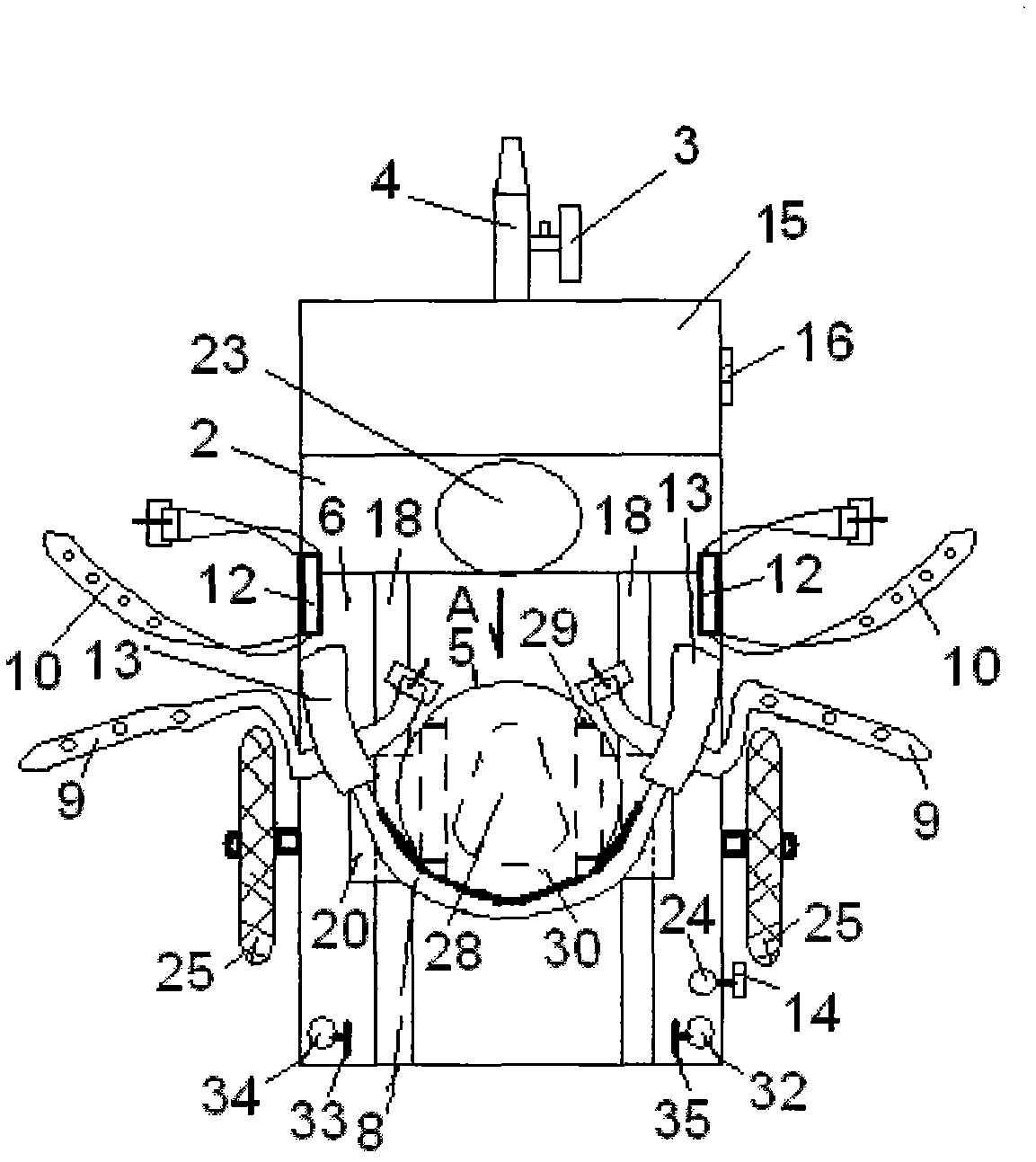

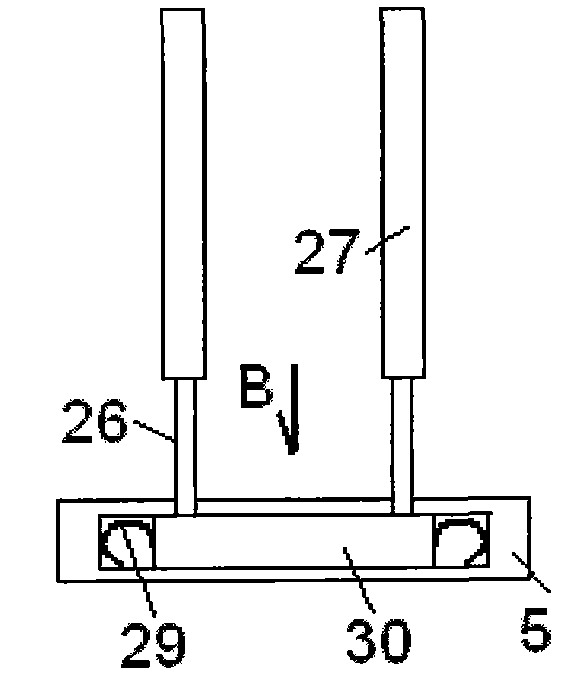

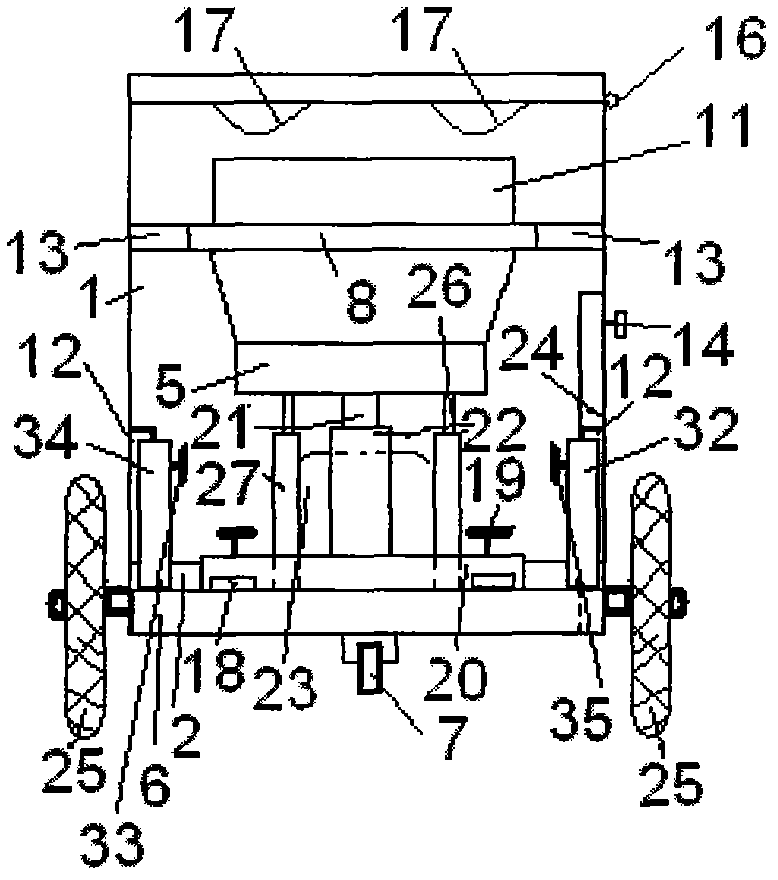

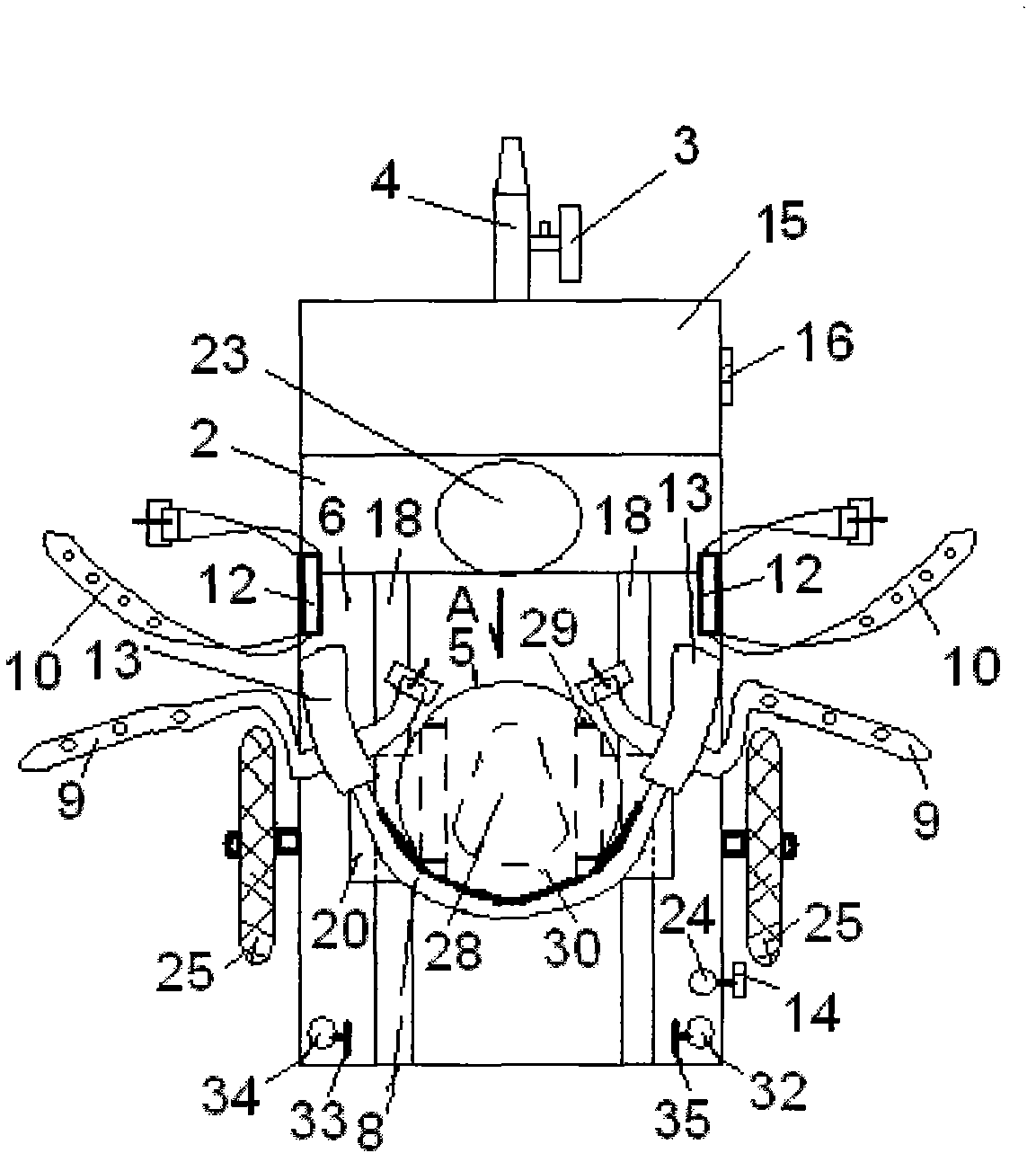

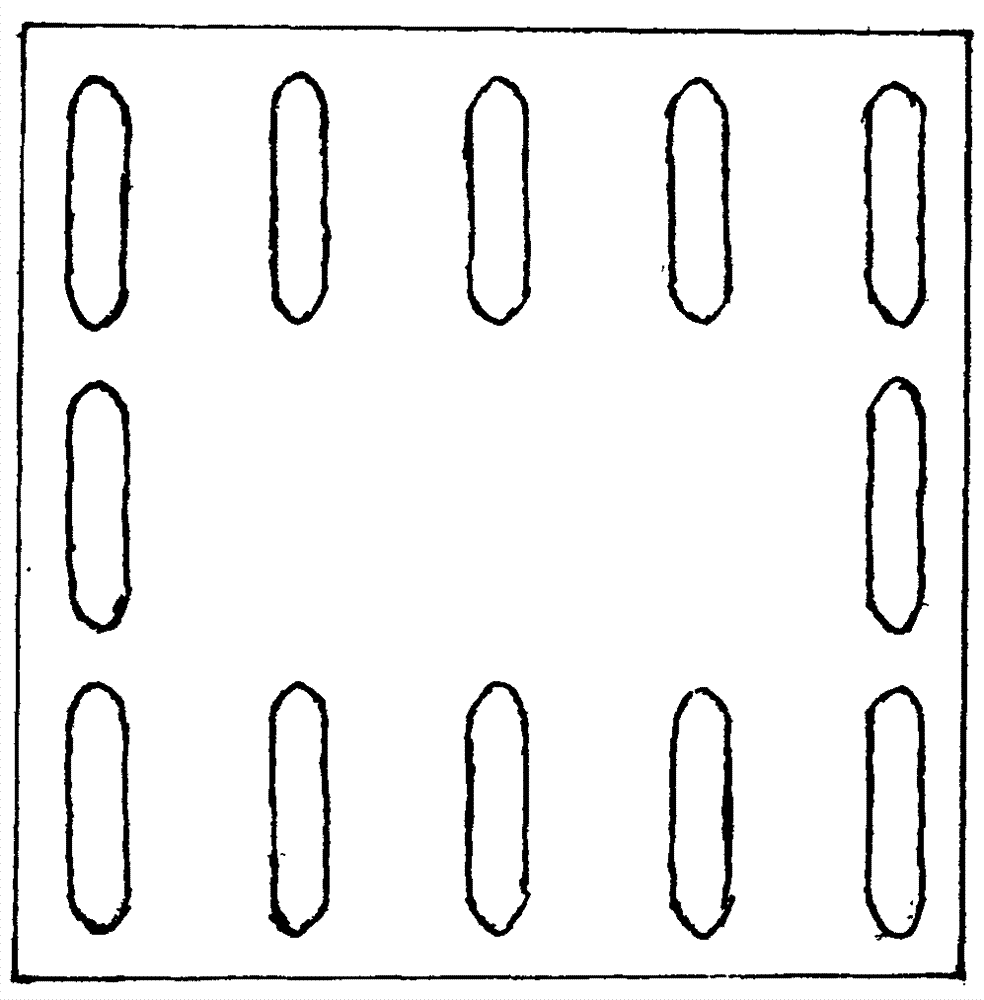

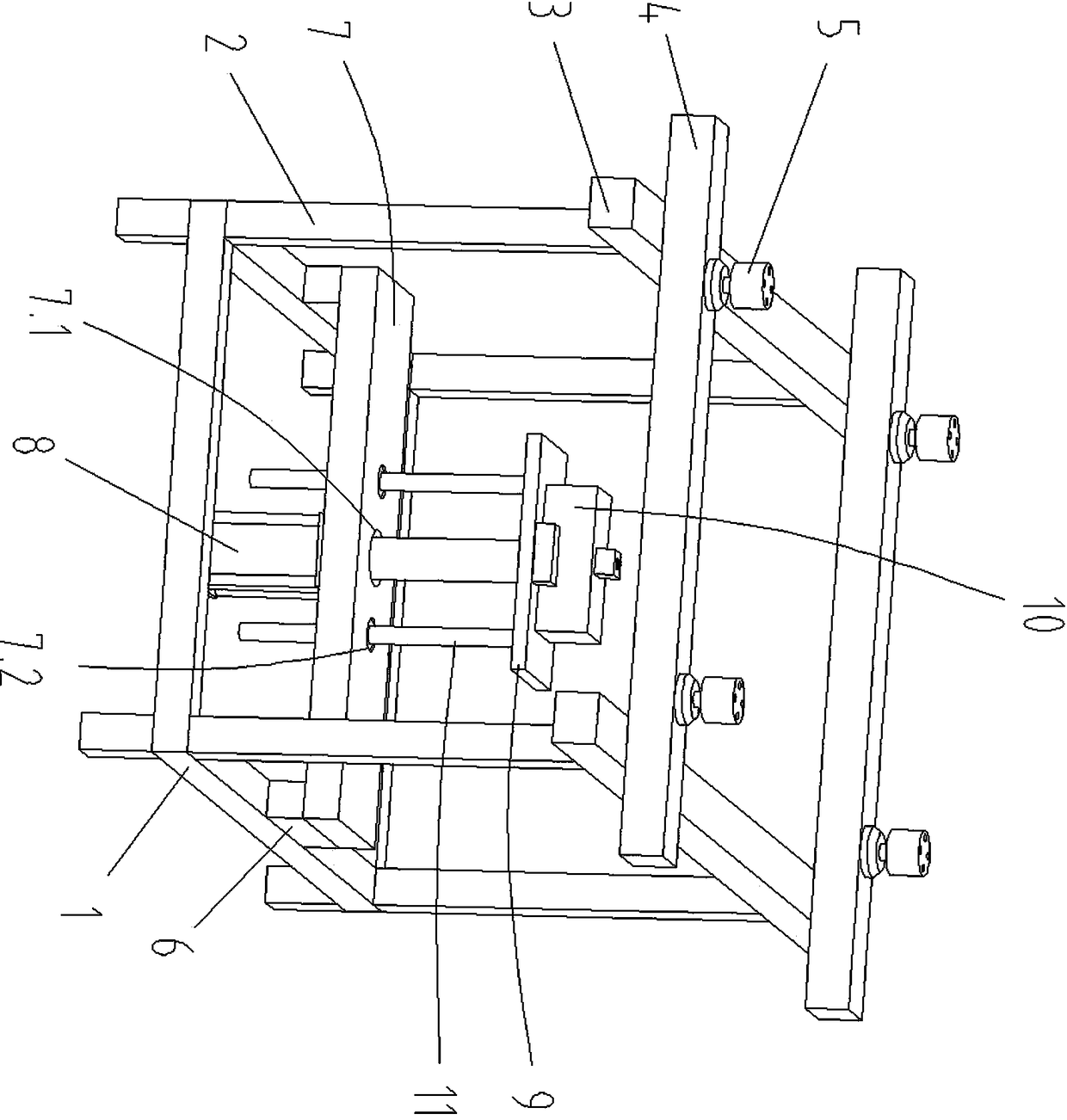

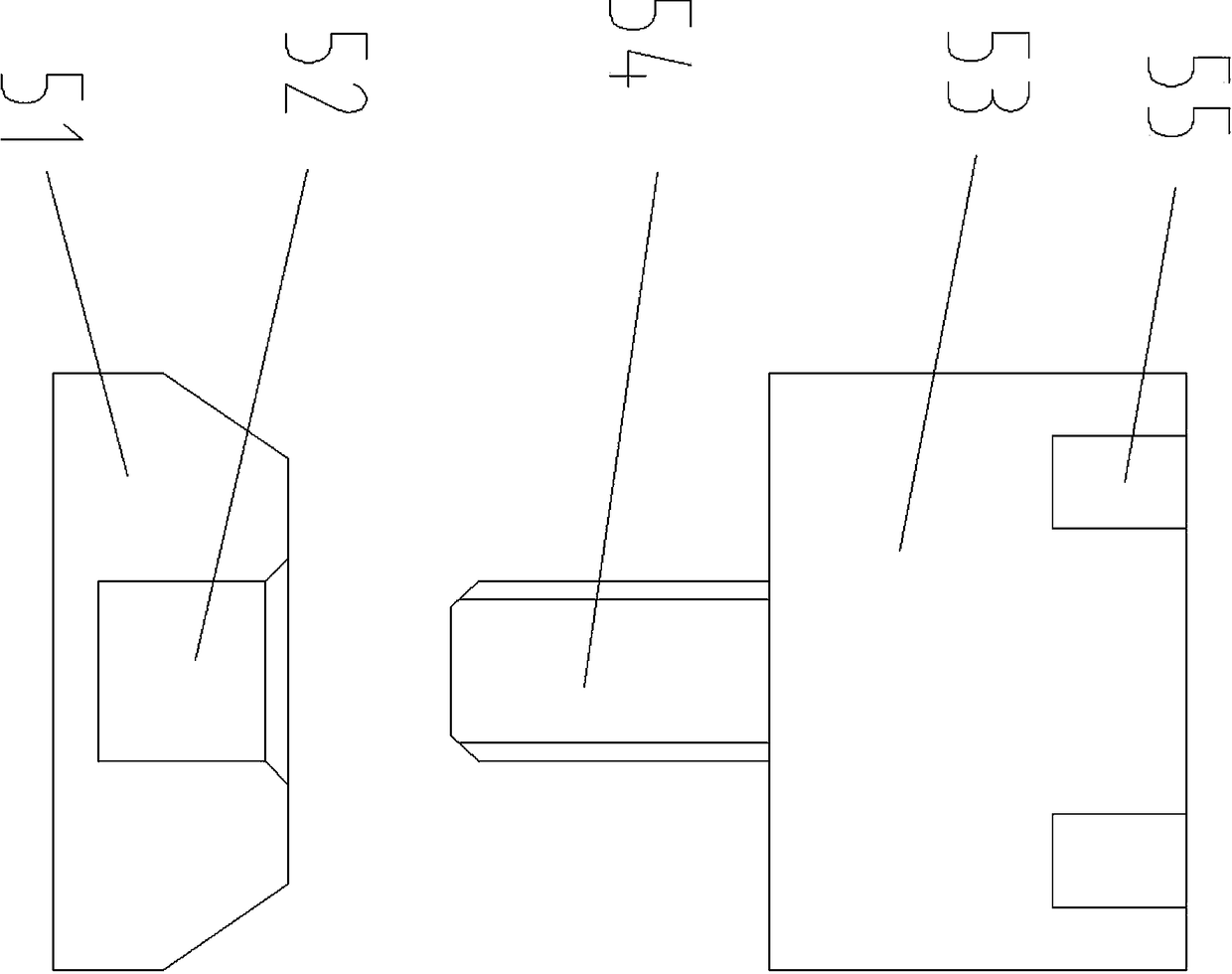

Multifunctional cart with enclosing barrier for facilitating excretion of mental patients

InactiveCN102100603BEasy to checkConvenient treatmentWheelchairs/patient conveyanceMedical equipmentEngineering

The invention relates to a multifunctional cart with an enclosing barrier for facilitating excretion of mental patients, belonging to the technical field of medical equipment. The traditional conveying tools in hospitals have many problems and cannot meet requirements on various aspects of mental patients. In the technical scheme provided by the invention, an inflating supporting stand column (1)is articulated with a table board (15) through a hinge (16), the upper surface of the inflating supporting stand column (1) is provided with two grooves (17) for placement of legs, the bottom of a small-size oxygen-cylinder insertion drum (23) is fixed on a foot pedal (2), two dovetail chutes (18) are respectively fixed on a base plate (6), a dovetail slide (20) screwed with a positioning screw (19) is embedded on each dovetail chute (18), and one end of a lead screw (21) is fixedly connected with the bottom surface of a seat (5). The multifunctional cart has the advantage of multiple functions and wide application range, can meet overall needs of mental patients and bring great convenience to the living and the medical treatment of the mental patients, and is a world-class initiation forfilling a gap on equipment serving the mental patients.

Owner:王秀菊

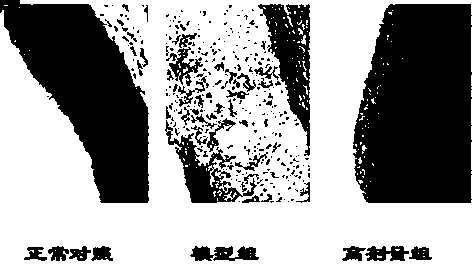

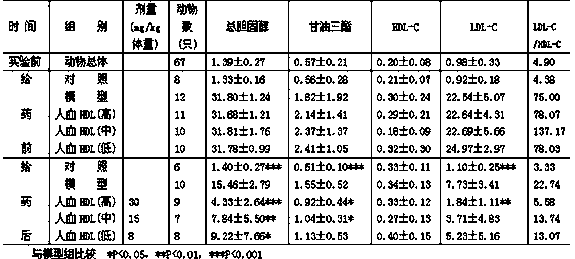

Preparation method and applications of human blood apolipoprotein A1 product

PendingCN110590937ALower plasma total cholesterolApolipeptidesPeptide/protein ingredientsHuman bodyFiltration

The present invention discloses a preparation method and applications of a human blood apolipoprotein A1 product, and belongs to the field of biopharmaceuticals. The product not only can reduce bloodlipids, more importantly also can remove atherosclerotic plaques, can be used for prevention and treatment of arteriosclerotic cardio-cerebral vascular diseases, is a world-class major innovative drug, can open a new era of the cardio-cerebral vascular diseases in human body treatment based on atherosclerosis as pathological basis. The preparation method of the human blood apolipoprotein A1 product is as follows: using an ammonium sulfate solution at an appropriate concentration to separate apolipoprotein A1 from human plasma, removing dextran sulfate from the obtained apolipoprotein A1 component by using potassium oxalate, conducting ultrafiltration to remove impurities, and then conducting sterilization and filtration, virus inactivating, sub-packaging, freeze-drying, etc. to obtain thehuman blood apolipoprotein A1 product. The preparation method comprehensively utilizes various protein components in plasma, is simple in operation and relatively low in investment. The obtained product is good in stability, safety, etc.

Owner:杨宝田

Multifunctional cart with enclosing barrier for facilitating excretion of mental patients

InactiveCN102100603AEasy to checkConvenient treatmentWheelchairs/patient conveyanceMedical equipmentEngineering

The invention relates to a multifunctional cart with an enclosing barrier for facilitating excretion of mental patients, belonging to the technical field of medical equipment. The traditional conveying tools in hospitals have many problems and cannot meet requirements on various aspects of mental patients. In the technical scheme provided by the invention, an inflating supporting stand column (1) is articulated with a table board (15) through a hinge (16), the upper surface of the inflating supporting stand column (1) is provided with two grooves (17) for placement of legs, the bottom of a small-size oxygen-cylinder insertion drum (23) is fixed on a foot pedal (2), two dovetail chutes (18) are respectively fixed on a base plate (6), a dovetail slide (20) screwed with a positioning screw (19) is embedded on each dovetail chute (18), and one end of a lead screw (21) is fixedly connected with the bottom surface of a seat (5). The multifunctional cart has the advantage of multiple functions and wide application range, can meet overall needs of mental patients and bring great convenience to the living and the medical treatment of the mental patients, and is a world-class initiation for filling a gap on equipment serving the mental patients.

Owner:王秀菊

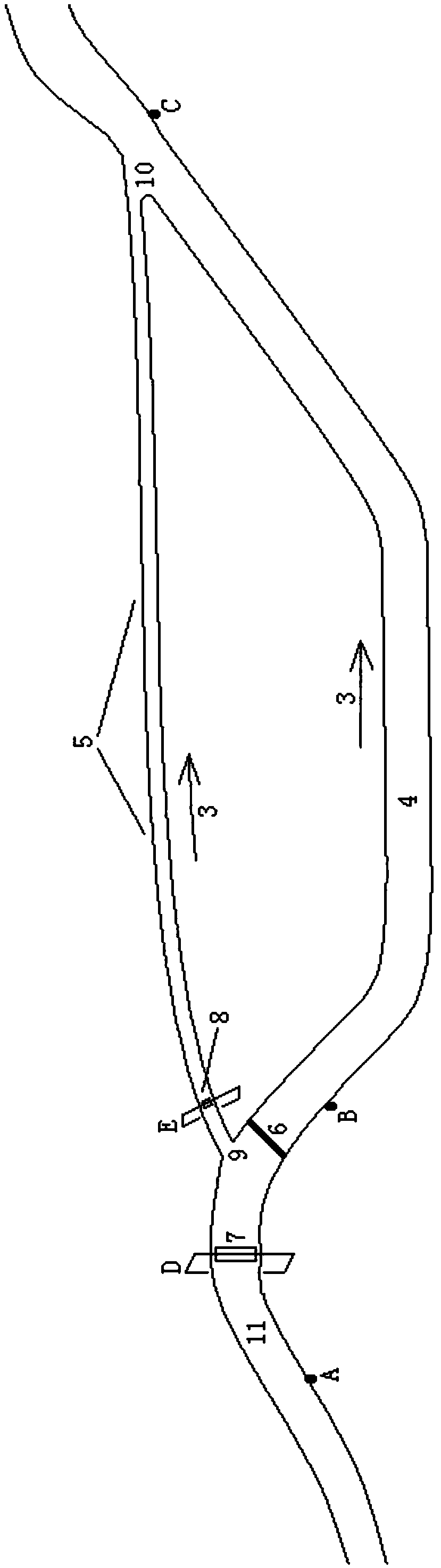

Channel regulation of reservoir tail drawdown area

The invention relates to channel regulation of a reservoir tail drawdown area. The to-be-solved technical problem is to completely solve the world-class problem of the reservoir tail river channel regulation. According to the technical scheme, a concrete deep pit is constructed at the upper end of a reservoir tail channel, and a gravel conveyor belt is arranged at the bottom of the deep pit; a water level retaining dam is constructed between the lower end of the drawdown area and the lower end of the reservoir tail channel.

Owner:彭国洪

Traditional Chinese medicine composition for treating uremia

InactiveCN108379338AEasy to prepareGood for treating uremiaUrinary disorderPlant ingredientsWorld classUremia

The invention discloses a traditional Chinese medicine composition for treating uremia. The traditional Chinese medicine composition is prepared from, by mass, 30-80 parts of milkvetch roots, 20-50 parts of ginseng, 60-90 parts of loofah seedlings and 5-10 parts of cordyceps sinensis. According to the traditional Chinese medicine composition for treating the uremia, the preparation method is simple, the effect of treating the uremia is good, the treating cost is low, and the composition takes effect quickly. The traditional Chinese medicine brings honor for China and builds a world-class brand; the traditional Chinese medicine is dedicated to the country and people and is world magic medicine.

Owner:刘俊廷

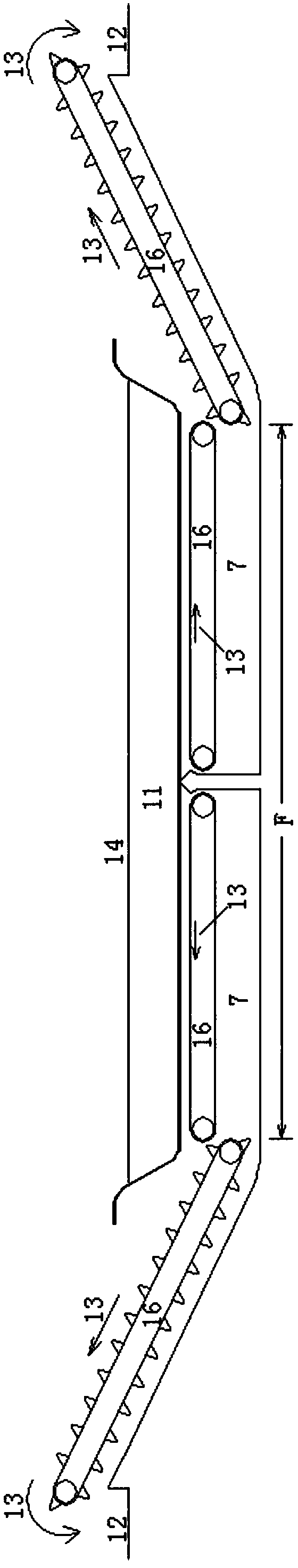

Moving tank and manufacturing method of moving tank

The invention relates to a moving tank and a manufacturing method of the moving tank, in particular to the moving tank which is used on water-level-fluctuating zones of rivers, lakes and water reservoirs and is used for treating the water loss and soil erosion, protecting the environment, protecting the bank, blocking the leakage, fighting a flood, planting and culturing, wherein the technical scheme of the moving tank protected belongs to the technical field of the water conservancy project. The invention also discloses the manufacturing method and applications of the moving tank. Aiming at the world-class difficulty for the treatment of the water-level-fluctuating zones, the moving tank is technically characterized by comprising water cloth (1), a cloth receiving clamp (8), a tank bank seat (17) and a connecting block (16), so that the difficulty of the treatment of the water-level-fluctuating zones is overcome, meanwhile, the fertile and valuable resources of the good field are obtained, therefore, the moving tank is widely applied to the water-level-fluctuating zones and the water surfaces in the country, thereby obtaining achieve effect due to the prominent characteristics and obvious progress.

Owner:重庆市南川区华顺大树茶专业合作社

Flat-circular (flat-elliptical) efficient high-strength threaded reinforcing steel bar and use method thereof

InactiveCN103758287AIncrease contact bonding areaCombine Stronger StrongerBuilding reinforcementsReinforced concreteHigh intensity

The invention relates to a flat-circular (flat-elliptical) efficient high-strength threaded reinforcing steel bar and a use method thereof, belonging to threaded reinforcing steel bar series products, of which reinforcing steel bars have flat-circular (flat-elliptical) cross sections. The flat-circular (flat-elliptical) efficient high-strength threaded reinforcing steel bar is a threaded reinforcing steel bar with high efficiency, high strength and high mechanical properties; the flat-circular (flat-elliptical) efficient high-strength threaded reinforcing steel bar has the technical characteristics that compared with circular threaded reinforcing steel bars with the same sectional area, the surface area can be increased by or to over 12.5% and the tolerance strength in a certain direction can also be increased by or to over 1.5 times; the flat-circular (flat-elliptical) threaded reinforcing steel bar simultaneously has a large surface area and high-strength directional tolerance; the flat-circular (flat-elliptical) threaded reinforcing steel bar particularly meets the technical purposes that high strength, large surface area and firmer solidification on reinforcing steel bars are required by reinforced concrete, thereby being very suitable for the reinforced concrete pouring of modern buildings. Therefore, a basis for constructing residential houses capable of resisting great earthquakes is laid. If the flat-circular (flat-elliptical) threaded reinforcing steel bar is used in a manner of abiding by the mechanical and directional principles of the flat-circular (flat-elliptical) threaded reinforcing steel bar, world-class high and large buildings can be constructed.

Owner:陈胜民 +1

Testing method for glass deflection

InactiveCN109297659AAchieving a historic breakthroughEasy to operateElasticity measurementFlat glassPhotovoltaic industry

The invention discloses a testing method for glass deflection, which comprises the following steps of: step 1, cutting a pattern; step 2, marking the pattern; step 3, leveling a deflection measuring device; step 4, performing deflection testing on the pattern; and step 5, calculating the deflection value of the pattern. The invention further discloses a testing method for a flat glass. The invention has the following advantages: the method is simple to operate and high in practicability, and can measure the glass deflection of 2mm or below, thereby making up for the blank of measuring the glass deflection by the float lines in China, and guiding the tin bath and annealing production of the float glass industry in China, laying a solid foundation for producing a high-quality float glass, and playing a good role in promoting the float glass into the solar photovoltaic industry; so that the historical breakthrough in the base materials of the thin film solar cell modules in China is realized, and a solid step is taken for the photovoltaic cell module technology in China to enter the world-class.

Owner:ANHUI HUAGUANG PHOTOELECTRIC MATERIAL TECH GRP CO LTD

Corrosion-resistant rare earth aluminum alloy and application thereof

InactiveCN105586512AImprove performanceExtend project lifeMolten spray coatingWorld classCorrosion resistant

The invention creatively relates to a corrosion-resistant rare earth aluminum alloy and application thereof. Due to the application to the iron and steel industry, corrosion is world-class problem, national demands for engineering priority and quality first are needed to be met, and particularly, rare earth is applied a little in the world. According to the corrosion-resistant rare earth aluminum alloy, the application range of rare earth in the corrosion resistance field is widened, the service life of steel is prolonged and is 50 times as long as that of any other corrosion-resistant material, wealth is created for the society, and positive contribution is made for the nation.

Owner:CHONGZHOU DILONG HAILONG BIOLOGICAL PRODS DEV INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com