Patents

Literature

81results about How to "Low construction environment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pavement quick-repair asphalt mixture, and preparation method and application method thereof

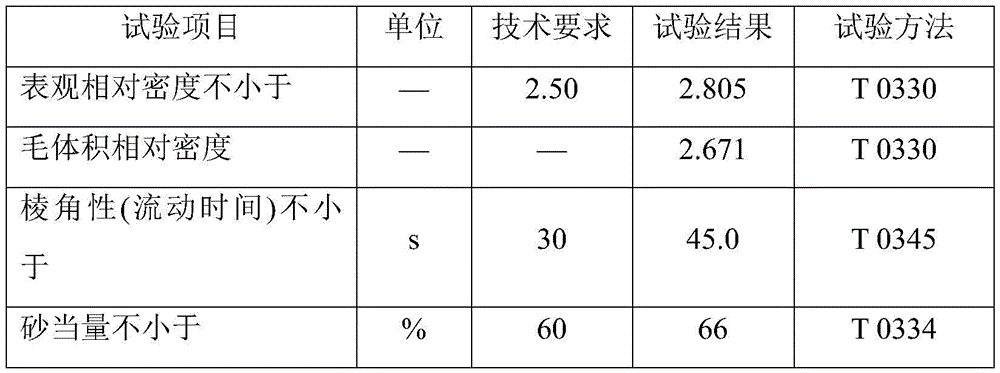

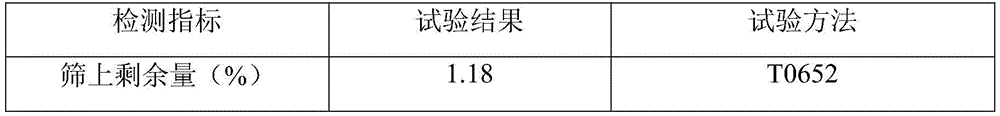

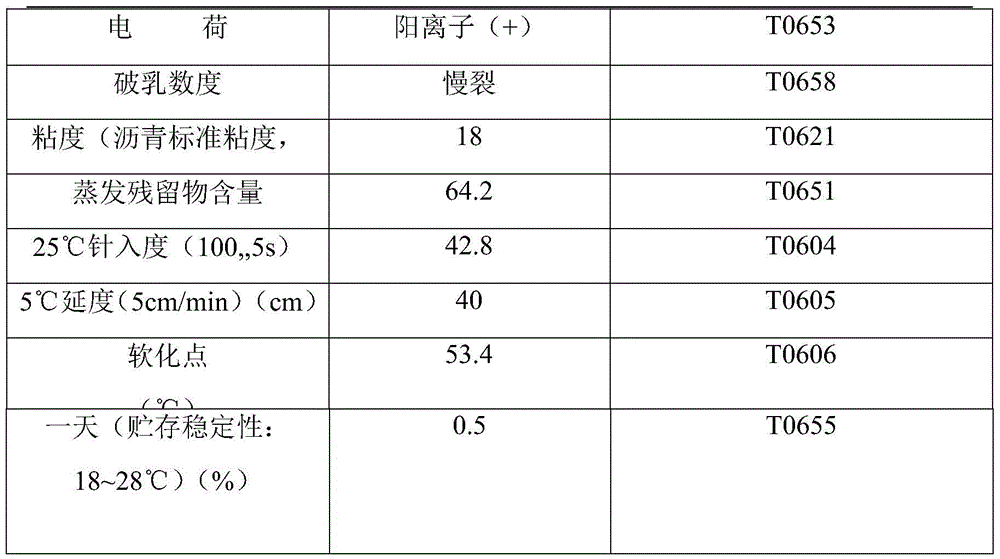

The invention relates to a pavement quick-repair asphalt mixture, and a preparation method and application method thereof. The pavement quick-repair asphalt mixture is prepared from water, aggregate, water-based epoxy resin modified emulsified asphalt, ore powder and cement according to the weight ratio of (0-5):100:(5-10):(1-10):(0-3). The pavement quick-repair asphalt mixture is simple and easy to operate, is convenient and quick for construction, does not have volatile contaminants, can implement in-time opening to traffic, and has low requirements for the construction environment.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

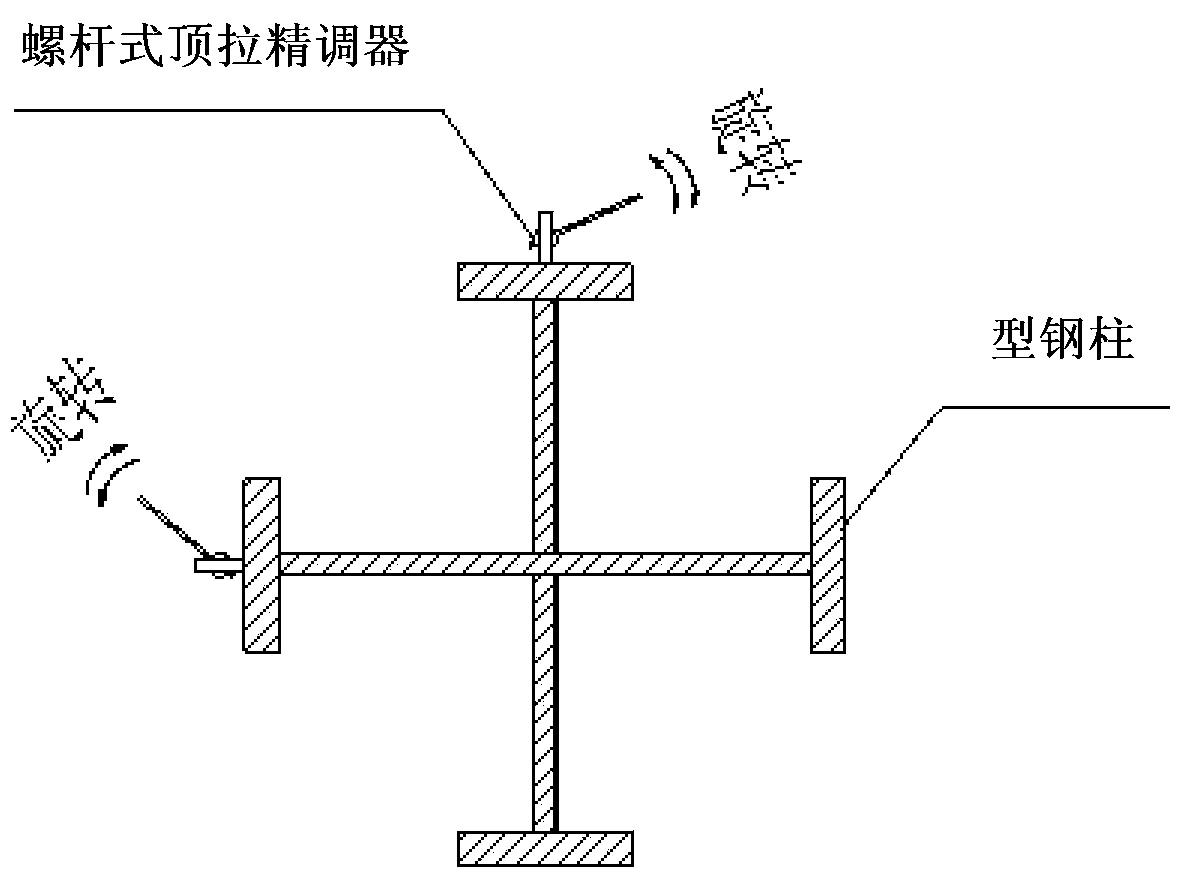

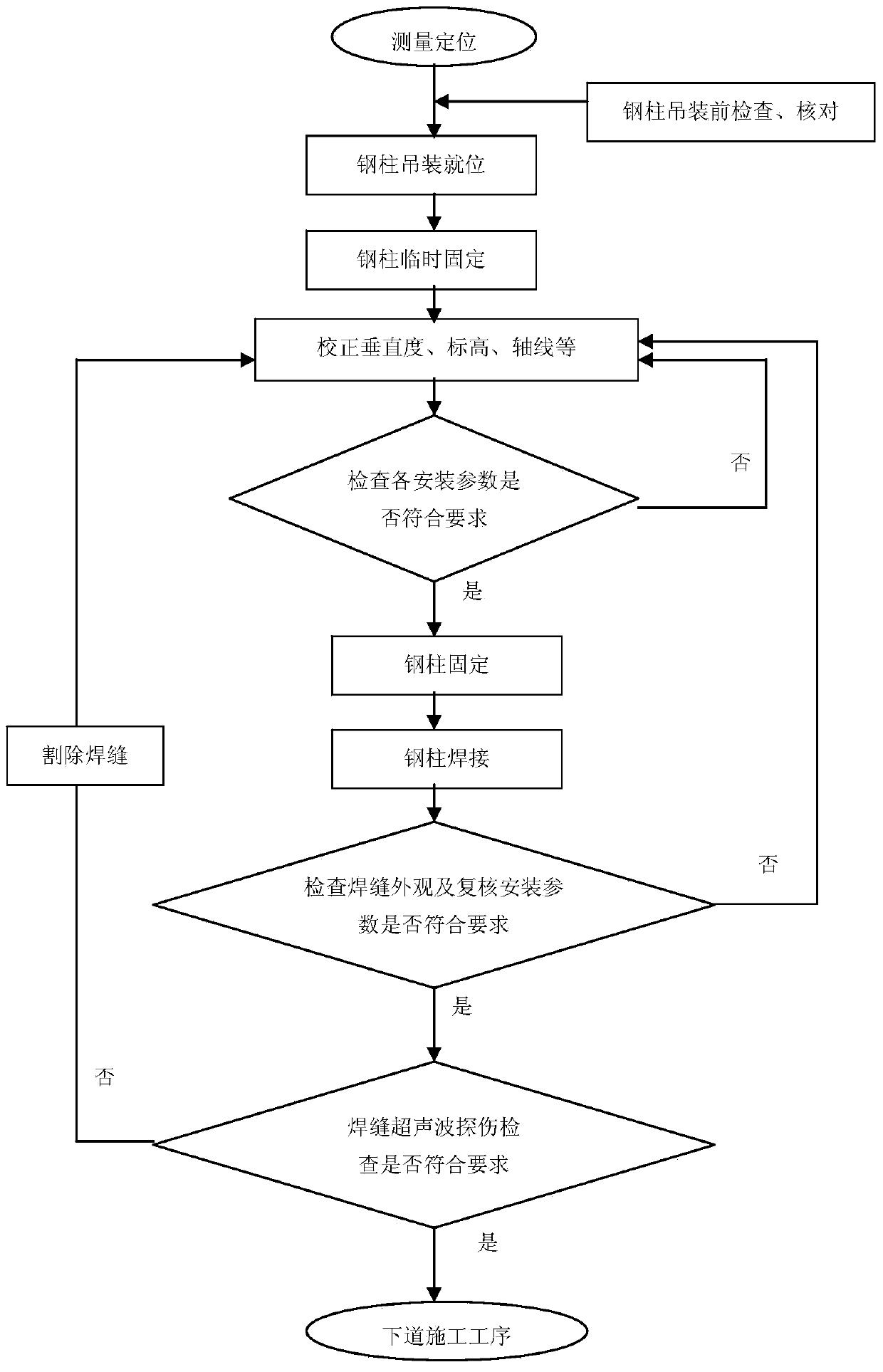

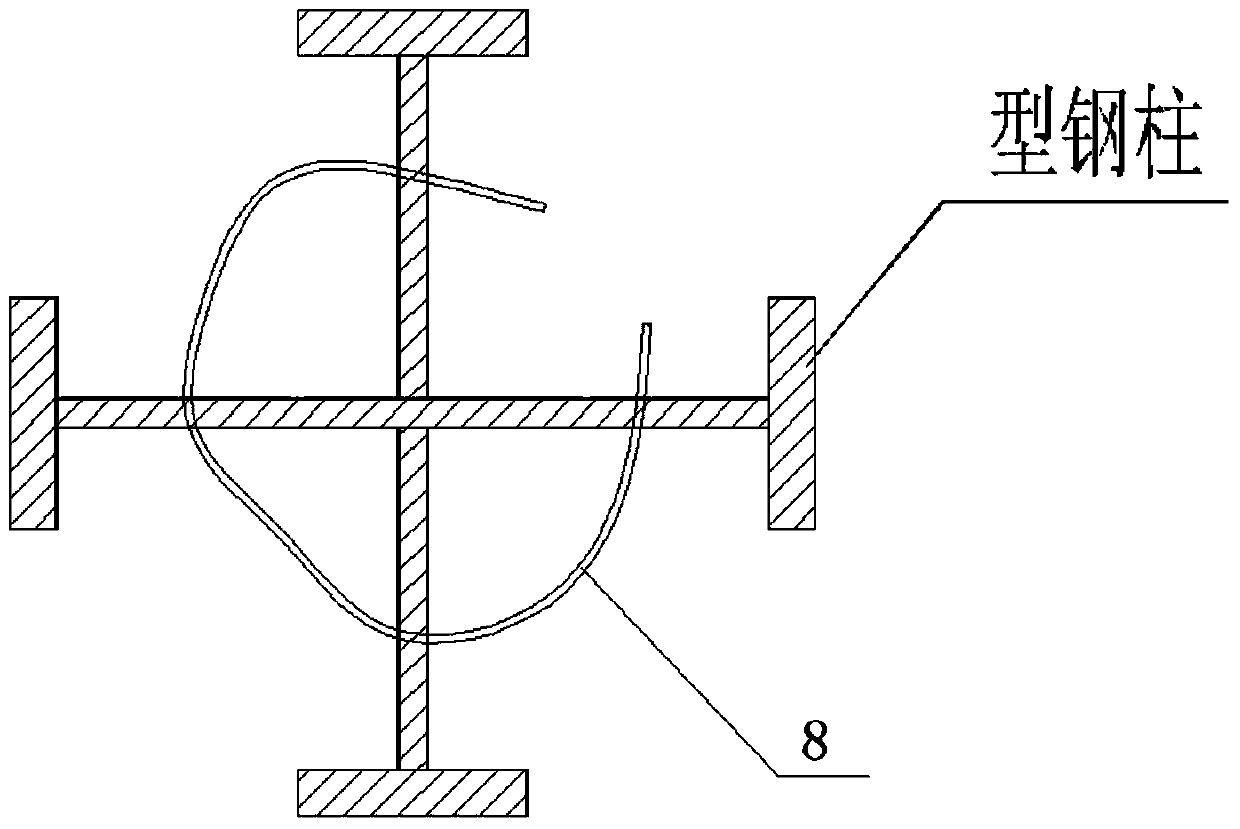

Construction method for H-type steel stiff column with cross fracture surface

InactiveCN103806669AAccurate axis controlAccurate control of verticalityBuilding material handlingSteel columnsHigh rise

The invention discloses a construction method for an H-type steel stiff column with a cross fracture surface. The construction method includes the steps of measuring and positioning, inspecting and checking before hoisting the H-type steel stiff column, hoisting the H-type steel stiff column in place, fixing the H-type steel stiff column temporarily, correcting the H-type steel stiff column, fixing the H-type steel stiff column, welding H-type steel stiff column and the like. The axis and perpendicularity of section steel column installation can be controlled accurately, structural construction is high in precision, construction quality is reliable, and the construction method is suitable for installation and construction of the H-type steel stiff columns with the cross fracture surfaces in a high-rise building, a super high-rise building, a long-span structure and a common structure.

Owner:DALI CONSTR GRP +2

UV intimating super-antiwear floor paint

InactiveCN101298537AOvercome the problems of high cost and complicated constructionWide range of usePolyurea/polyurethane coatingsPolyester coatingsCyclohexanoneButyl acetate

The invention discloses a UV imitated super abrasion resistant floor paint which consists of component A and component B, when in use, the weight ratio of the component A and the component B is equal to 10:1 to 10:3, and the proportion is uniformly mixed. The formula of the floor paint consists of following components by weight portion, wherein, component A: 45-70 portions of polyisocyanate resin, 20-30 portions of butyl acetate, 10-30 portions of cyclohexanone; component B: 20-40 portions of alkyd resin, 0.1-30 portions of aldehyde ketone resin liquid, 0.1-10 portions of the cyclohexanone, 1-2 portions of defoamer, 5-10 portions of anti-settling agent, 5-65 portions of abrasion resistant addition agent A, 5-65 portions of abrasion resistant addition agent B, and 0.5-2 portions of levelling agent. Compared with the prior art, the invention has following advantages: 1. excellent abrasion resistance; 2. good slip resistance and contamination resistance properties of a painted surface, as well as good chemical resistance property; 3. free from the use of a specialized UV coating light curing tool during usage and construction, forming the pitted surface paint film of the UV imitated floor paint, with convenient construction and low requirements on construction environment; 4. good painted surface decoration effect, being similar to the UV floor paint, with greater cost competitive advantage on market.

Owner:GUANGDONG SANVO CHEM IND TECH

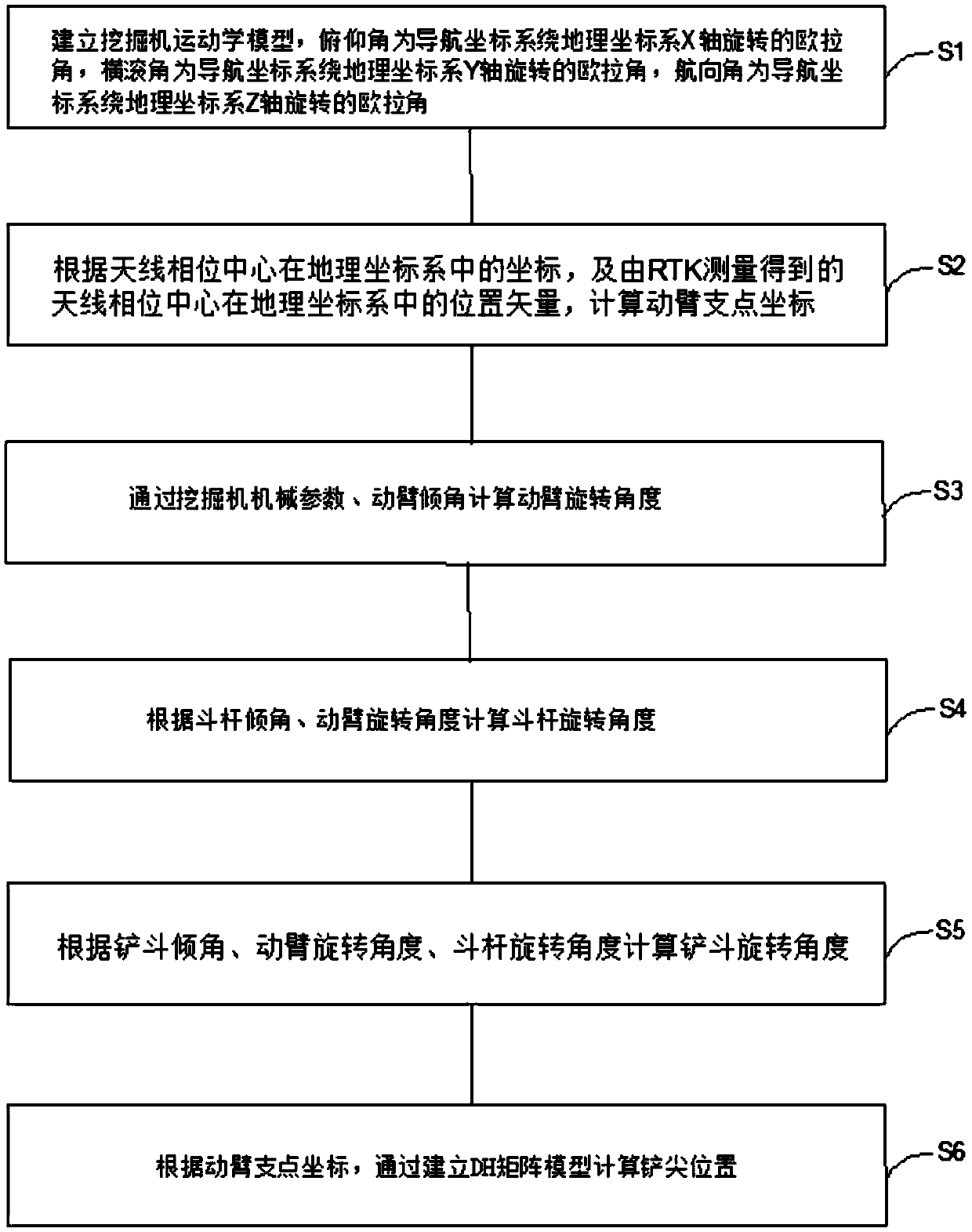

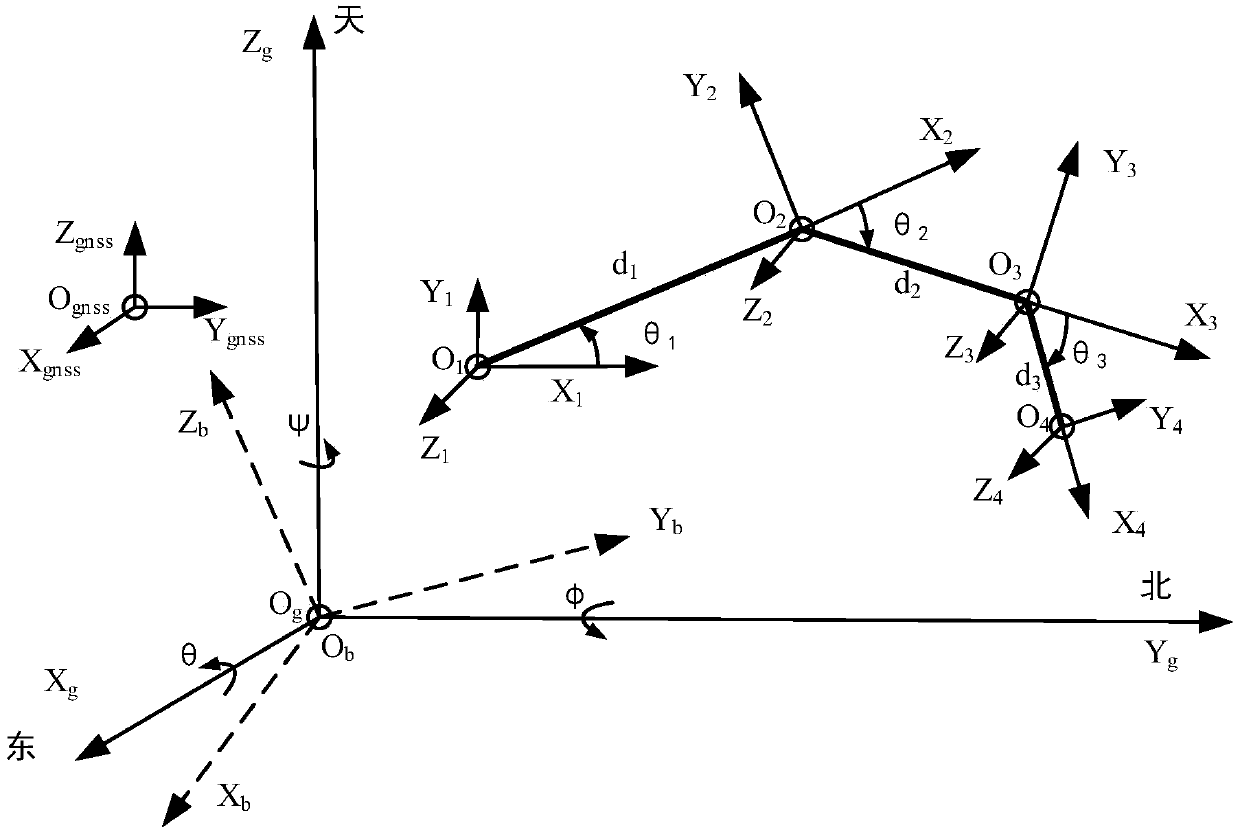

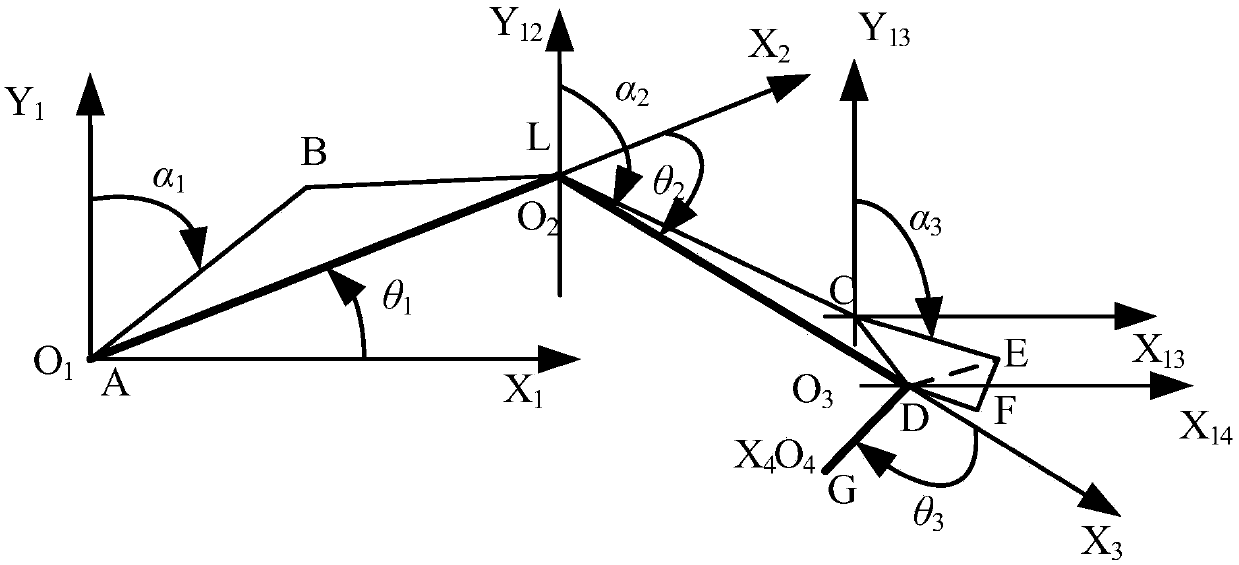

Excavator, bucket positioning method thereof, electronic equipment and storage medium

PendingCN109614743AHigh sensitivityLow construction environment requirementsMechanical machines/dredgersDesign optimisation/simulationRight-hand ruleKinematics

The invention discloses a bucket positioning method, which is applied to an excavator and comprises the following steps of: specifying a positive direction by adopting a right hand rule and establishing an excavator kinematics model; C; calculating a movable arm fulcrum coordinate according to the coordinate of the antenna phase center in the geographic coordinate system and the position vector ofthe antenna phase center measured by the RTK in the geographic coordinate system; C; calculating the rotating angle of the movable arm according to the excavator mechanical parameters and the movablearm inclination angle; C; calculating a bucket rod rotation angle according to the bucket rod inclination angle and the movable arm rotation angle; C; calculating the bucket rotation angle accordingto the bucket inclination angle, t, the movable arm rotation angle and the bucket rod rotation angle; A; and calculating the position of the shovel tip by establishing a DH matrix model according to the coordinates of the movable arm fulcrum. The method can solve the problem that the excavator is difficult to accurately calculate and position the bucket.

Owner:GUANGZHOU HI TARGET SURVEYING INSTRUMENT CO LTD

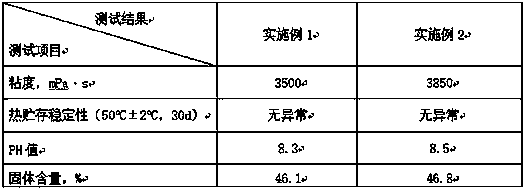

Rapid macromolecule machine-sprayable demulsification solidification filming waterproof coating and preparation method thereof

InactiveCN104312328AHigh solid contentLow viscosityConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer chemistryRubber material

The invention belongs to the technical field of waterproof coatings, and in particular relates to a rapid macromolecule machine-sprayable demulsification solidification filming waterproof coating and a preparation method thereof. The rapid macromolecule machine-sprayable demulsification solidification filming waterproof coating consists of a component A and a component B, wherein the component A consists of the following components in percentage by weight: 25-35% of macromolecule, 20-40% of water, 1-5% of an emulsifying agent, 20-50% of rubber latex and 0-5% of packing; the component B consists of the following components in percentage by weight: 30-40% of a demulsification agent and 60-70% of water. The waterproof coating can be rapidly demulsified and dehydrated to form a coating waterproof protecting layer which is excellent in waterproof property, after the coating is sprayed, the coated layer is dried into a film, the high elasticity, the low temperature flexibility and the aging resistance of a rubber material are maintained, and the coating has the advantages of high puncture force resistance, water permeation prevention, temperature resistance, freezing resistance, chemical corrosion resistance, cracking resistance and the like.

Owner:浙江鲁班建筑防水有限公司

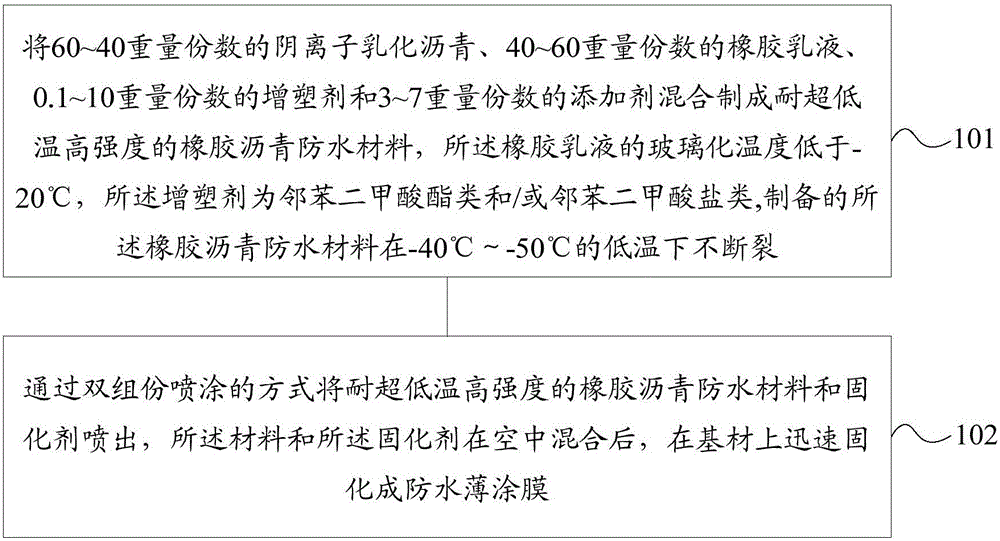

Ultralow-temperature-resistant high-strength rubber asphalt waterproof material, and preparation and construction methods thereof

InactiveCN105860555AFast constructionLow construction environment requirementsBuilding insulationsPolymer sciencePlasticizer

The invention provides an ultra-low temperature resistant and high-strength rubber asphalt waterproof material and a preparation and construction method thereof. The ultra-low temperature resistant and high-strength rubber asphalt waterproof material is composed of anionic emulsified asphalt, rubber emulsion, plasticizer and additives, the weight parts of the anionic emulsified asphalt is 60-40, and the weight parts of the rubber emulsion is 40 ~60, the parts by weight of the plasticizer are 0.1~10, the parts by weight of the additives are 3~7; the glass transition temperature of the rubber emulsion is lower than -20°C; the plasticizer is o Phthalate esters and / or phthalates; the material does not break at a low temperature of -40°C to -50°C after being cured into a film.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

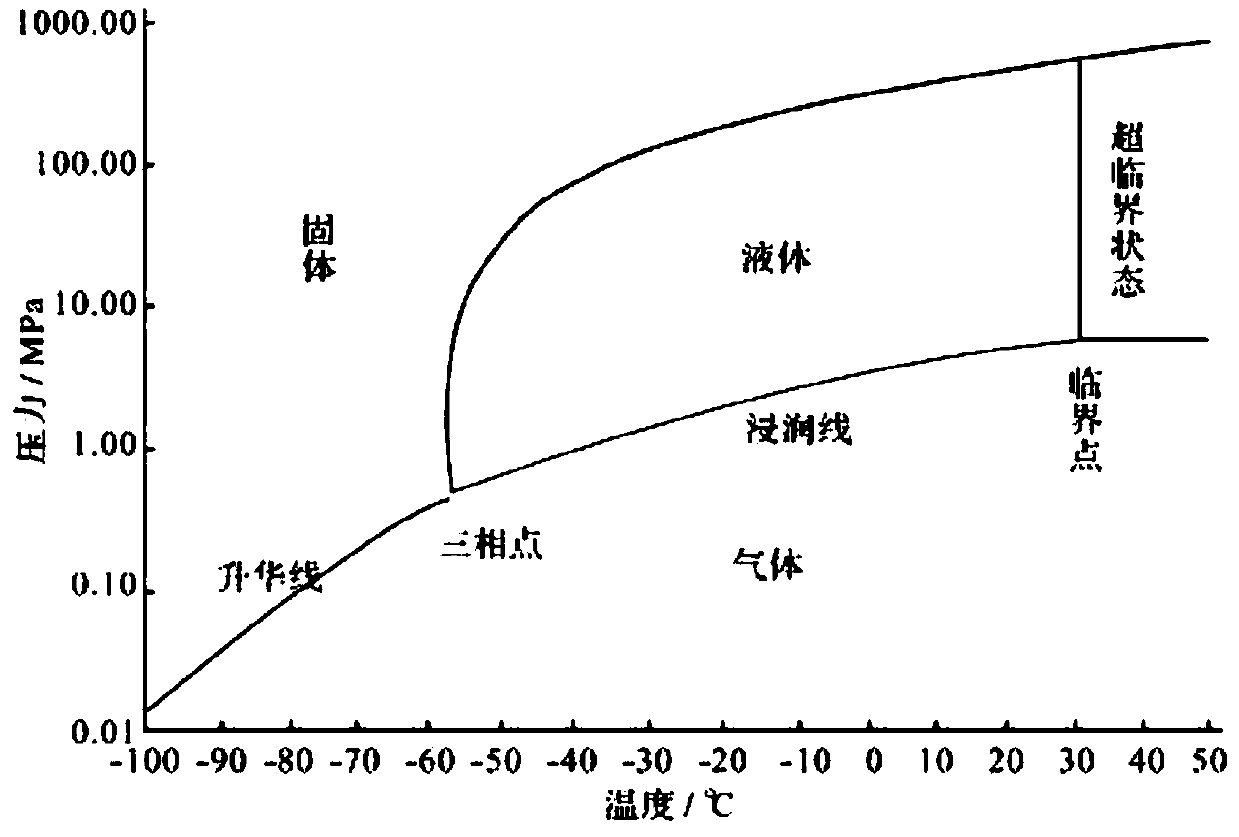

Novel supercritical CO2 fracturing process

PendingCN109538177AIncrease productionHigh yieldSurveyFluid removalFracturing fluidMaterial Perforation

The invention relates to a novel supercritical CO2 fracturing process and belongs to the technical field of petroleum exploitation. The provided novel supercritical CO2 fracturing process mainly overcomes the defects in the prior art and comprises the following steps of (1) well cleaning, (2) perforation, (3) fracturing treatment, (4) proppant injection, (5) sectional fracturing, (6) isolation treatment, (7) well closing treatment and (8) blowout and flowback after pressing. According to an adopted method, a supercritical CO2 fracturing fluid and a conventional fracturing fluid sand-carrying fluid are simultaneously pumped, the effect of supplementing formation energy of the supercritical CO2 fracturing fluid is fully exerted, and complex cracks are more likely to be generated at the sametime; a method for conventional fracturing combined with mixed injection is utilized; under the condition that a closed system is not needed, the advantages of supercritical CO2 fracturing are fully exerted, and the defects of conventional fracturing are avoided.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +2

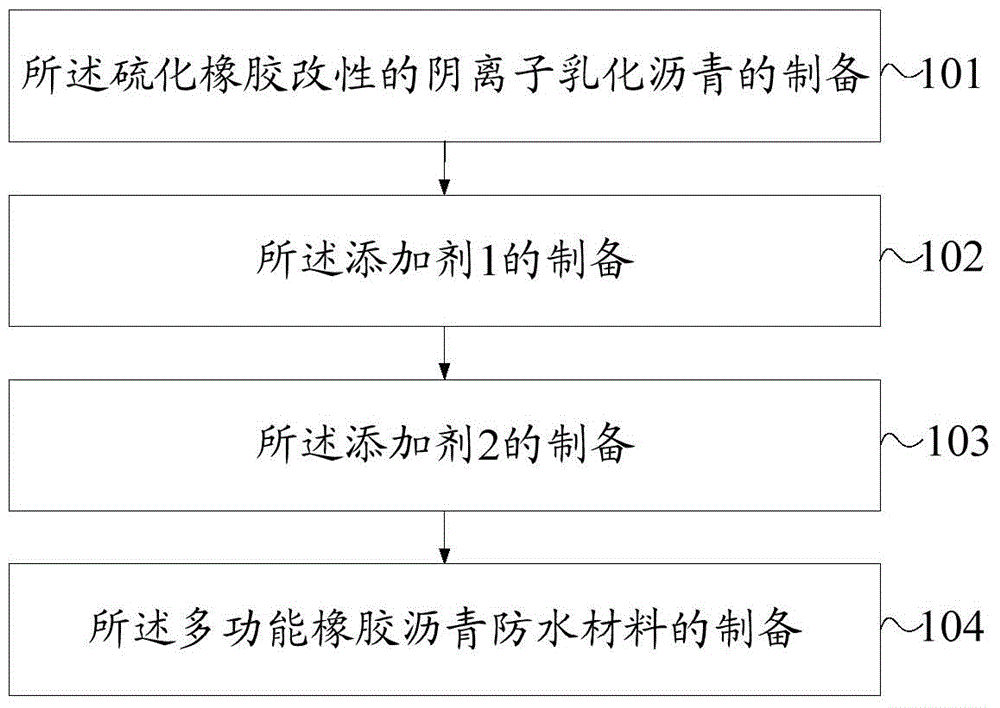

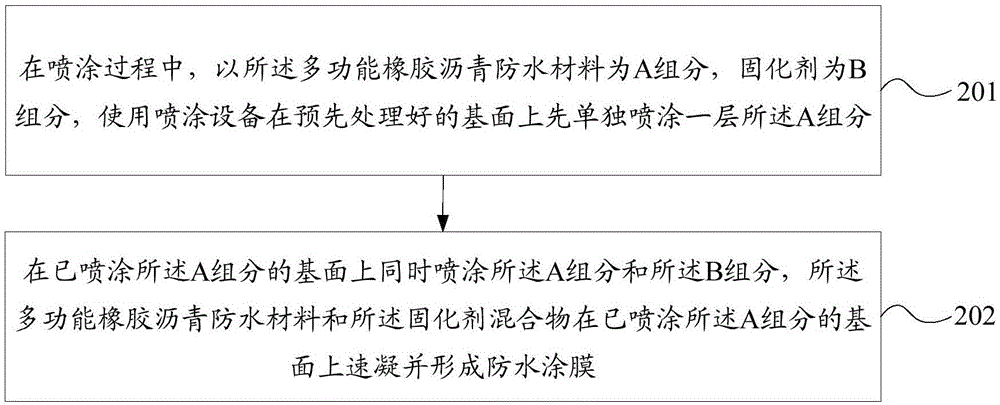

Multifunctional rubber asphalt waterproof material as well as preparation method and construction method thereof

ActiveCN104893579AImprove adhesionGood weather resistanceConjugated diene hydrocarbon coatingsCarboxyl rubber coatingsPolymer scienceNoise reduction

The invention provides a multifunctional rubber asphalt waterproof material. The multifunctional rubber asphalt waterproof material is prepared by mixing vulcanized rubber modified negative ion emulsified asphalt, rubber latex, an additive 1 and an additive 2, wherein the additive 1 comprises the following components in parts by weight: 0.1-2 parts of silicon dioxide, 0.1-2 parts of diatomite, 0.1-2 parts of a silane coupling agent, 0.1-2 parts of a surfactant, 0.1-1 part of a wetting agent, 0.1-1 part of a dispersing agent and 0.1-2 parts of deionized water. According to the embodiment of the invention, rubber components in the waterproof material are creatively modified by virtue of silicon dioxide, diatomite and the silane coupling agent, so that the physical and mechanical performance of vulcanized rubber for modifying can be improved by virtue of silicon dioxide, diatomite and the silane coupling agent in the additive 1, and the sound insulation performance, noise reduction performance and wear resistance of the vulcanized rubber can be obviously improved.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

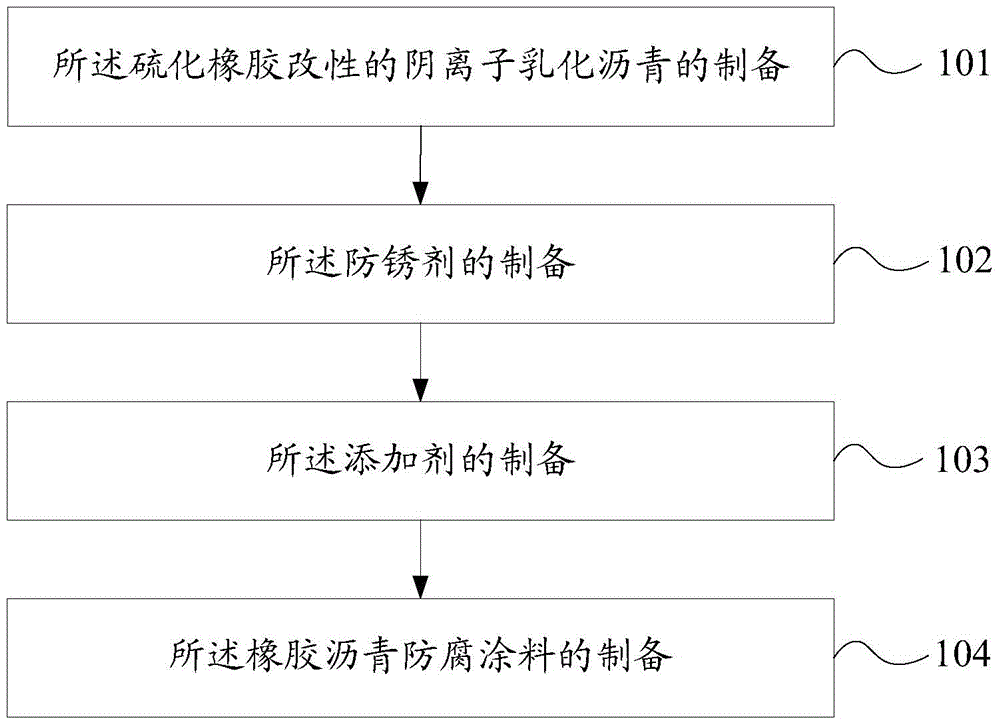

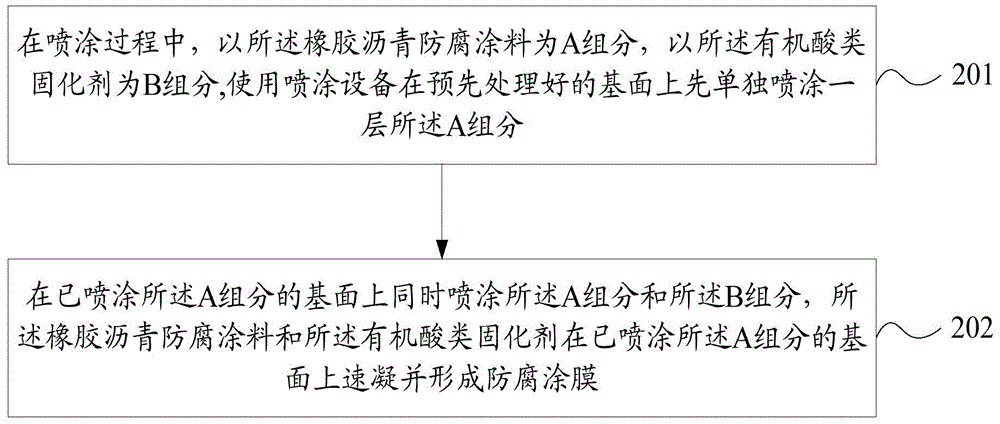

Anticorrosive material for metallic equipment and preparation and construction methods thereof

InactiveCN104893578AAccelerateSmall construction environmentUnspecified rubber coatingsAnti-corrosive paintsIonOrganic acid

The invention provides an anticorrosive material for metallic equipment. The material comprises a rubber-asphalt anticorrosive coating material and an organic acid type curing agent, wherein the organic acid type curing agent consists of one or more of citric acid type curing agent, sorbic acid, amino naphthalene disulfonic acid and tartaric acid, and an anti-rusting agent is added in the rubber-asphalt anticorrosive coating material and is prepared from one or more of zinc phosphate, modified zinc phosphate and zinc molybdate, a surfactant, a wetting agent, a dispersing agent and deionized water. According to the anticorrosive material for the metallic equipment and the preparation and construction methods thereof, the anti-rusting agent is innovatively added in the anticorrosive material for the metallic equipment, so that the anticorrosive material for the metallic equipment, prepared by using the anti-rusting agent, has more excellent corrosion resistance while guaranteeing environmental friendliness; meanwhile, the weather resistance is very excellent, and the service life of the metallic equipment is greatly prolonged; the organic acid type curing agent, of which the corrosiveness to metal can be neglected, is used innovatively, and the required curing performance can be effectively guaranteed by the organic acid type curing agent.

Owner:YUGREAT (BEIJING) INTERNATIONAL TECHNOLOGY CO LTD

Reactive polymer cement waterproof coating

InactiveCN102181224AImprove mechanical propertiesGood chemical propertiesPolyurea/polyurethane coatingsPolyolMechanical property

The invention discloses a reactive polymer cement waterproof coating that contains an organic component, an inorganic component and water of which the weight ratio is 1:1-2:0.6-0.9, wherein the organic component is an end NCO base prepolymer obtained from the reaction of vacuum dehydrated polyether polyol with polyisocyanates; and the inorganic component is cement and inorganic filler and the mixture of the two. The product is non-toxic, free of pollution and environment-friendly. The coating has excellent mechanical property and chemical property, as well as excellent waterproof property. The coating solidifies in reaction, has low requirement on construction environment, allows construction on a damp base surface without visible water, and is good in resistance to low temperature and water, free of swelling and applicable to underground waterproof engineering.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

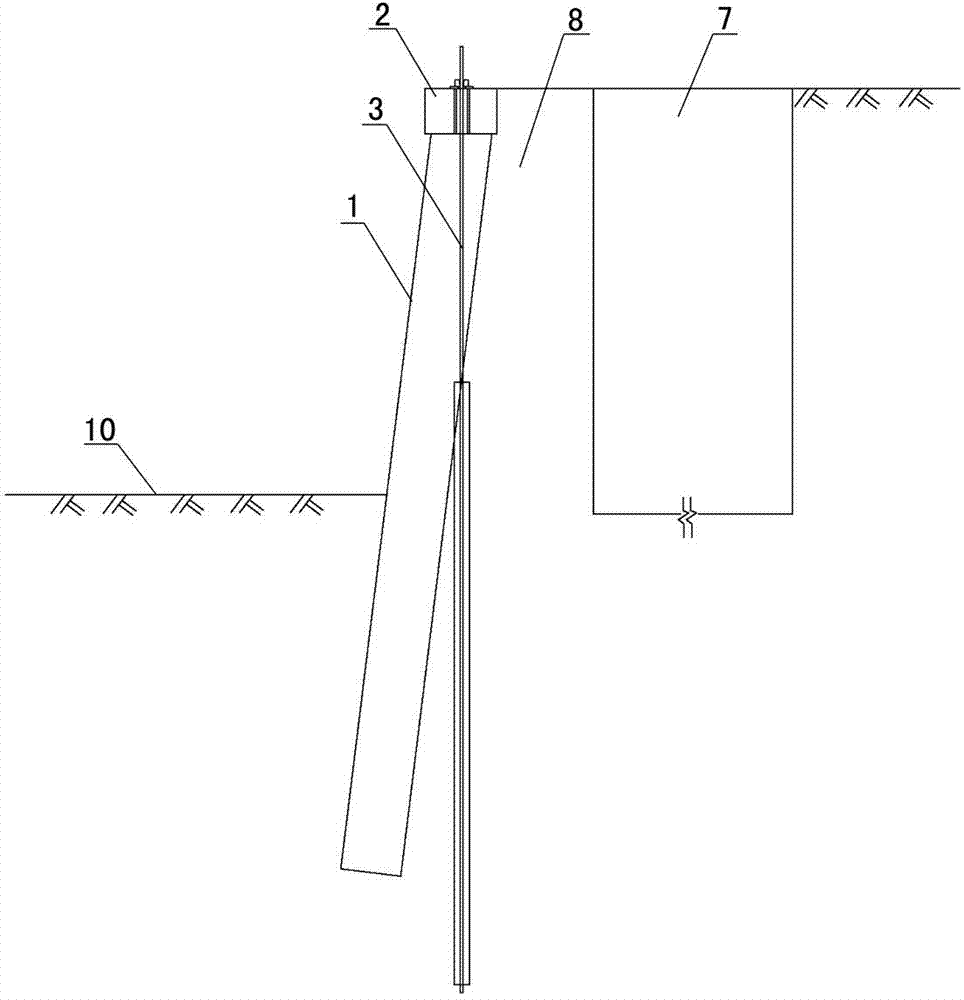

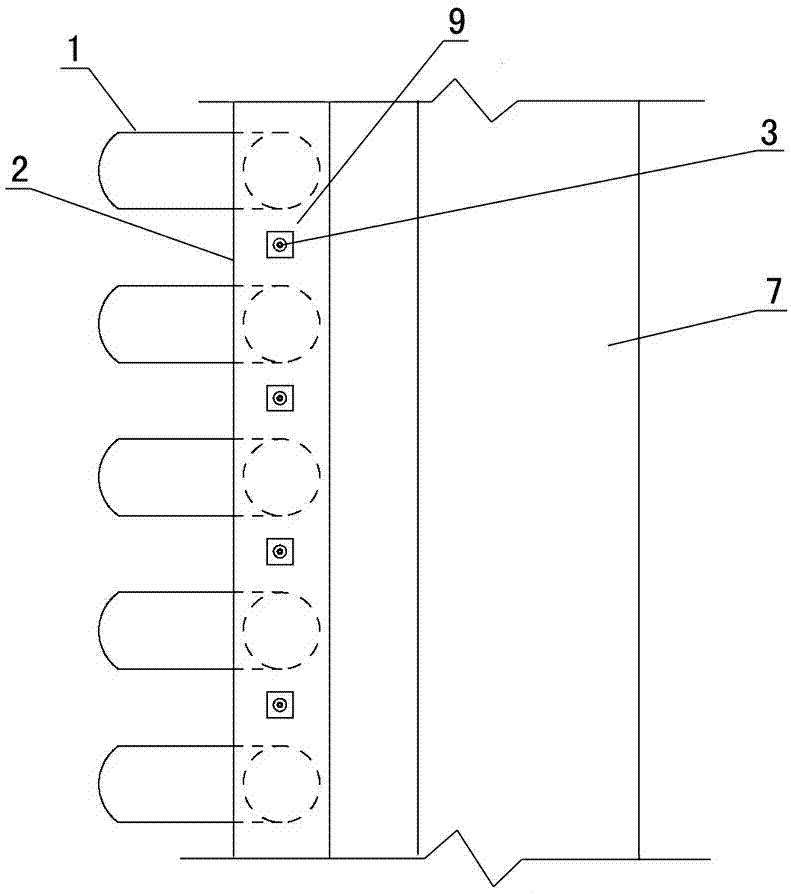

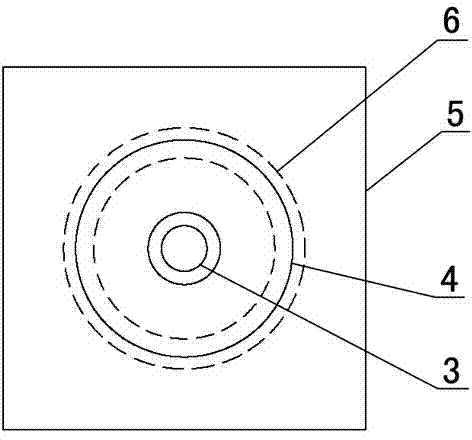

Inclined pile vertical anchor rod supporting structure for foundation pit supporting and construction method thereof

InactiveCN103485351ALow construction environment requirementsMake full use of anchoring forceExcavationsBulkheads/pilesPre stressPre stressing

The invention provides an inclined pile vertical anchor rod supporting structure for foundation pit supporting and a construction method thereof. The supporting structure comprises inclined slope protection piles, pile top beams and anchor rods. A row of the inclined slope protection piles are arranged on the edges of a foundation pit, and the bottoms of the inclined slope protection piles extend into the lower soil layer of the bottom of the foundation pit. The supporting structure is characterized in that the anchor rods comprise vertical pre-stress anchor rod bodies arranged in the stable soil layer between every two adjacent inclined slope protection piles and inserted and anchored in the stable soil layer from the ground between every two adjacent inclined slope protection piles, and the pile top beams are in rigid connection with the tops of the inclined slope protection piles and in flexible connection with the upper portions of the vertical pre-stress anchor rod bodies. The supporting structure and the construction method are particularly applied to the adjacent existing building foundation pits with limited underground space, and have the outstanding advantages of supporting the adjacent existing building deep foundation pits, and being good in supporting effect, convenient to construct, simple in working procedure and low in cost.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

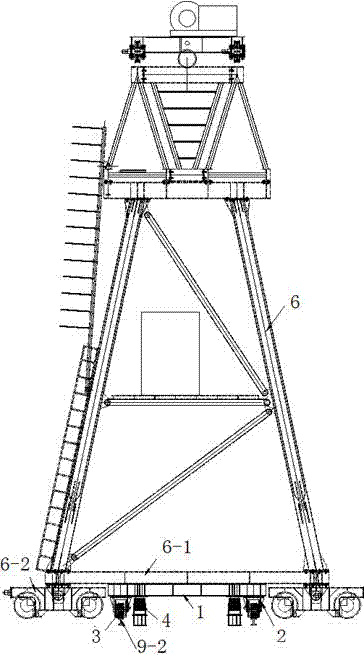

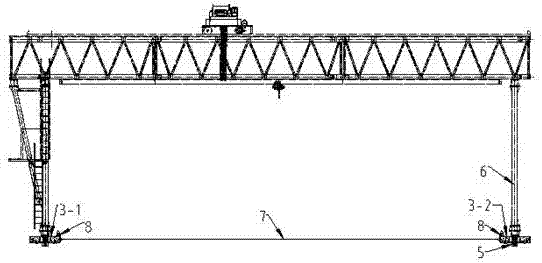

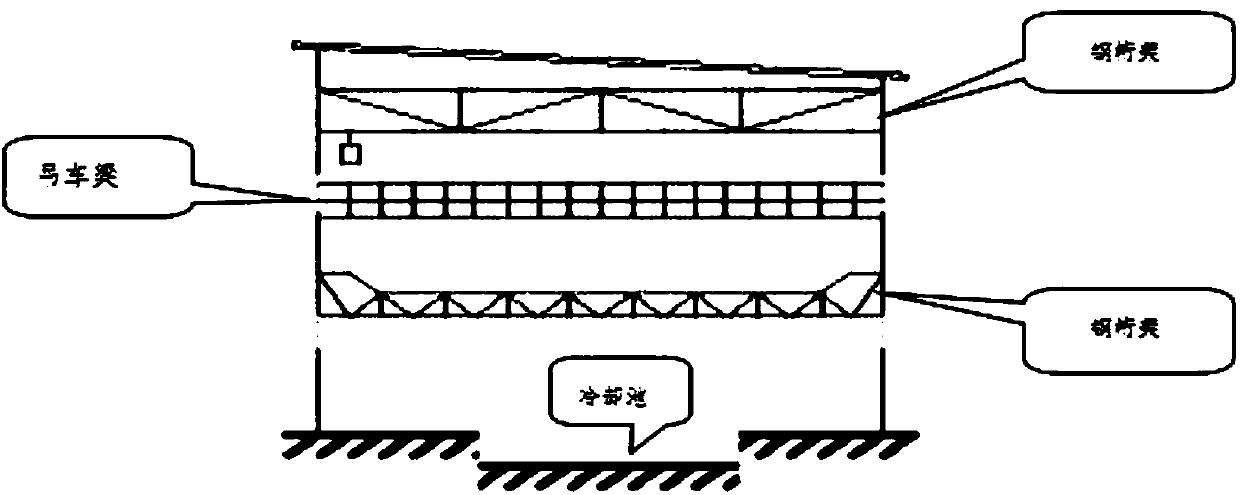

Transverse moving flat car of portal crane and transverse moving method

InactiveCN107285190AReduce processing timeImprove economyBase supporting structuresBraking devices for hoisting equipmentsGantry cranePetroleum engineering

Owner:SHANDONG LUQIAO GROUP

Paint for packing anti-counterfeit paper and preparation method thereof

InactiveCN101570946AGood reproducibilityClear detailsSpecial visual effect coatingsGeneral purposeSolvent

The invention discloses a paint for packing anti-counterfeit paper and a preparation technique thereof. The paint comprises the following components with mass proportion: 8 to 12 portions of cellulose acetate butyrate resin, 6 to 8 portions of additive resin and 82 to 90 portions of solvent. The invention has good reappearance effect of holographic patterns, clear holographic pattern details and strong radial visual effect, thus reappearing that the anti-counterfeit patterns on a holographic plate transfer onto the paper and achieving the anti-counterfeit purpose; the printing application range is wide, so various printing modes and techniques can be used; and the paint is easy to construct and has low requirements to the construction machinery and construction environment and belongs to the general-purpose product.

Owner:ZHEJIANG YAXIN PAPER IND

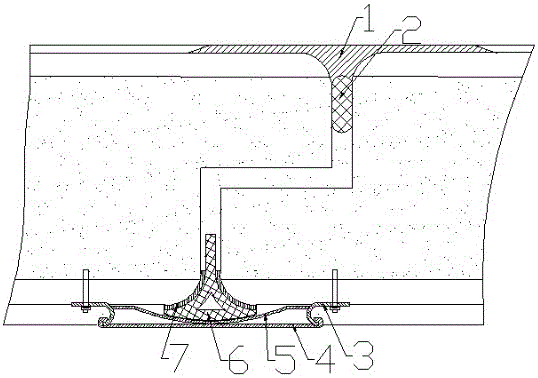

Waterproof structure used for abutted seam position of 3D printed building

InactiveCN106639001ASolve the waterproof problemLower technical barriersBuilding insulationsEngineering3d printed

The invention belongs to the technical field of buildings and particularly relates to a waterproof structure used for an abutted seam position of a 3D printed building. The waterproof structure used for the abutted seam position of the 3D printed building comprises a T-shaped waterproof buckle embedded into an abutted seam of an outer wall. The T-shaped waterproof buckle comprises a top cover plate and a clamping strip. The top cover plate covers a wall seam, and the clamping strip is clamped inside the seam. Elastic seal paste is filled between the T-shaped waterproof buckle and a wall body for caulking. The outer side of the T-shaped waterproof buckle is further covered with a waterproof coiled material. According to the provided waterproof structure used for the abutted seam position of the 3D printed building, in the construction process of the 3D printed building, the waterproof problem in the abutted seam position between a roofing board and an outer wall plate. All the members can be subjected to industrialized batch production. The requirement of a construction environment is low. The technical threshold of constructors can be reduced through an assembly-type construction mode. The waterproof structure used for the abutted seam position of the 3D printed building has positive significance to the construction, use and popularization of the 3D printed building.

Owner:NANJING XINGHUA ARCHITECTURE DESIGN & RES INST CO LTD

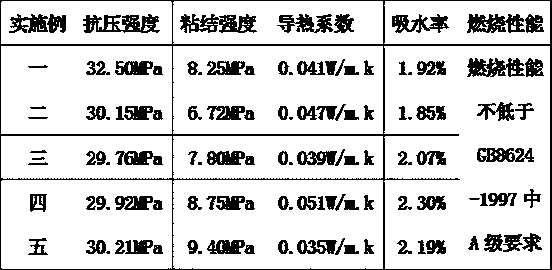

Special decorative mortar for lightweight thermal insulation walls

The invention discloses a special decorative mortar for lightweight thermal insulation walls, wherein the special decorative mortar comprises raw materials and water according to a mass ratio of 4.2-6.8:1-1.2, and the raw materials comprise, by weight, 30-50 parts of cement, 8-15 parts of calcined gypsum, 15-25 parts of slag micropowder, 20-30 parts of a polyphenyl particle and vitrified microbeadcomposition, 1-2 parts of polyurethane fiber, 3-8 parts of a polyacrylate emulsion, 0.3-0.8 part of a mortar water retention agent, and 2-5 parts of an additive. According to the present invention, the special decorative mortar has advantages of excellent adhesion, excellent water retention property, low thermal conductivity and excellent thermal insulation performance, can be used as the lightweight thermal insulation wall decorative mortar, and can well solve the problems of difficult lightweight thermal insulation wall plastering, easy cracking, bubbling, powder falling and shedding.

Owner:天津宇屹新材料科技发展有限公司

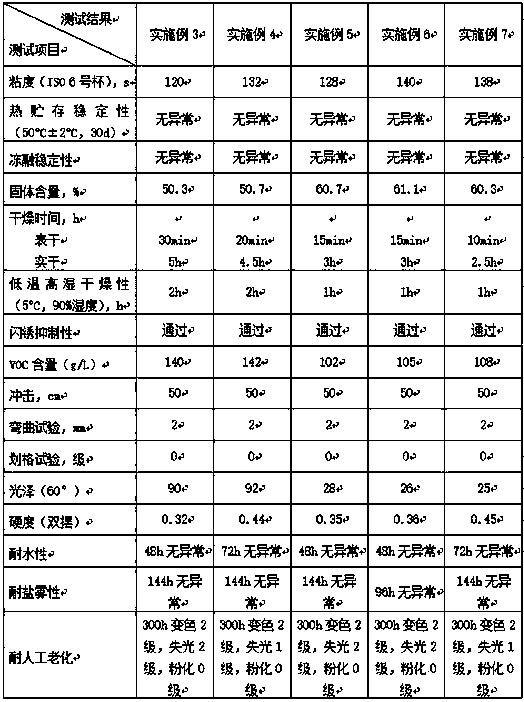

Special water-based acrylic acid modified alkyd anticorrosive paint for steel structures and preparation method thereof

InactiveCN111073438AHigh solid contentSolid content fastAnti-corrosive paintsHigh humidityWeather resistance

The invention relates to the technical field of coating preparation, in particular to a special anticorrosive coating for a steel structure and a preparation method thereof. The invention relates to aspecial water-based acrylic acid modified alkyd anticorrosive coating for a steel structure. The special water-based acrylic acid modified alkyd anticorrosive coating is prepared from water-based acrylic acid modified alkyd resin, a dispersing agent, deionized water, an anti-settling aid, pigment, filler, an antirust base material, a leveling aid, a defoaming agent, an anti-flash-rust agent and athickening agent. The anticorrosive paint combines the advantages of alkyd resin paint and acrylic resin paint, has excellent drying speed, water resistance, weather resistance and corrosion resistance, can be used for construction under severe conditions of low temperature and high humidity, and has favorable adhesive force and corrosion resistance for substrates with a small amount of oil stains and rust on the surfaces.

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

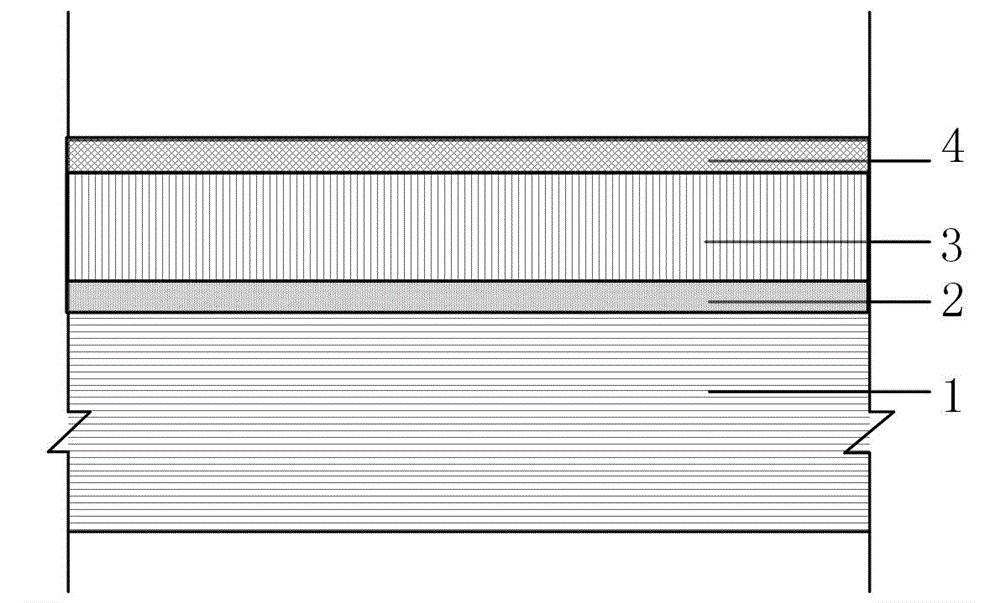

Steel bridge deck laying structure

InactiveCN104452584ALose weightReduce engineering costsBridge structural detailsBridge materialsBridge deckEngineering

A steel bridge deck laying structure comprises a bonding layer, an elastic anti-cracking layer and an abrasion layer. The elastic anti-cracking layer is laid on the upper surface of the bonding layer, and the abrasion layer is tightly attached to the upper surface of the elastic anti-cracking layer. The bonding layer is made from bi-component polyurethane modified special resin glue, the elastic anti-cracking layer is made from bi-component high-thixotropic purely elastic polyurethane modified polymer gravels, and the abrasion layer is made from bi-component polyurethane modified polymer gravels.

Owner:ANHUI TRANSPORTATION INVESTMENT GRP

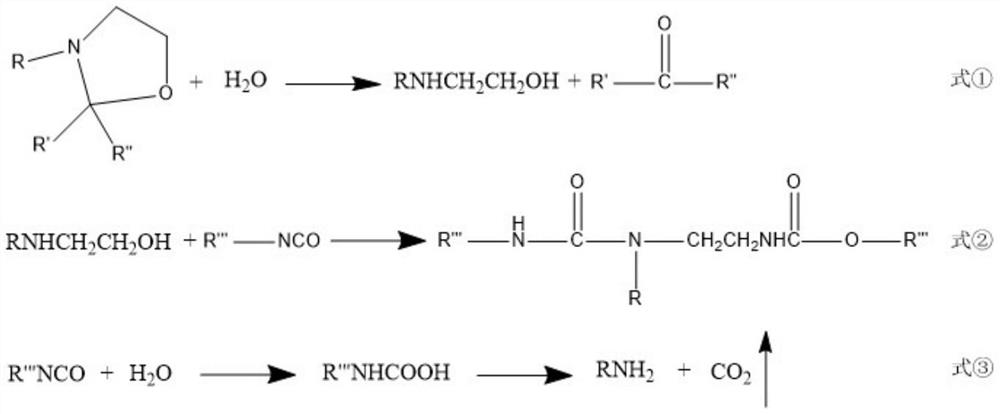

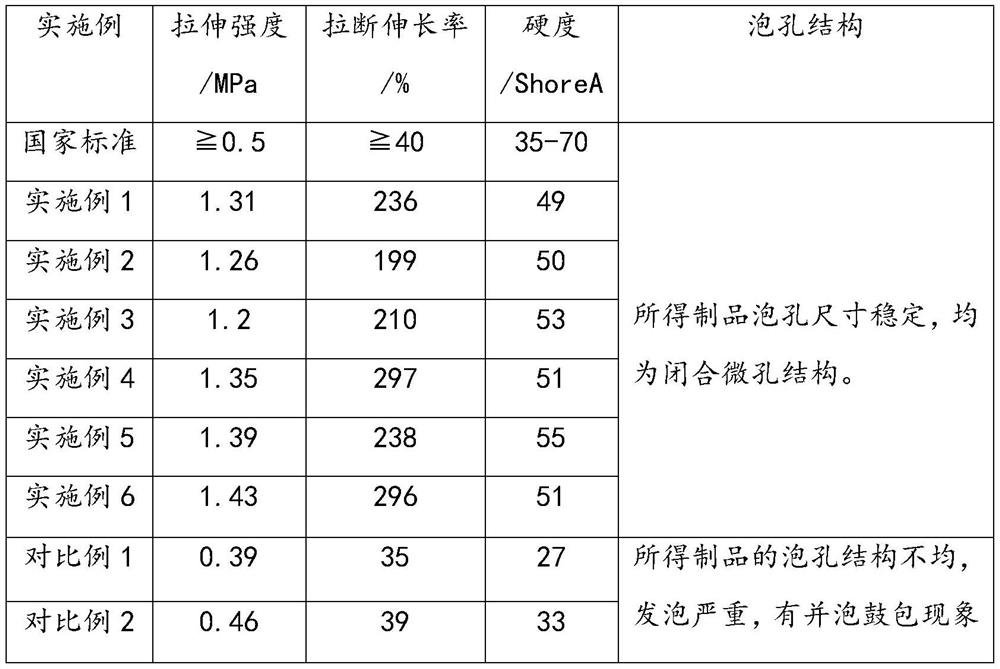

Polyurethane plastic material and preparation method thereof

The invention relates to a polyurethane plastic material, which is prepared from the following raw materials by mass: 35-55wt% of polyether polyol; 7-15wt% of isocyanate; 10-20wt% of a plasticizer; 15-25wt% of an inorganic filler; 1-3.0wt% of a colorant; 0.5-2.0wt% of a wetting dispersant; 0.1-3.0wt% of an antioxidant; 1-5wt% of oxazolidine; and 0.1-2wt% phosphoric acid. The invention also discloses a preparation method of the polyurethane plastic material, and the method comprises the following steps of: (1) adding polyether polyol and additives into a reaction kettle, performing dehydratinguntil the water content of the system is lower than 0.05%, and conducting cooling; (2) adding isocyanate, carrying out reaction for 2-3h, and carrying out dehydration and cooling; (3) adding oxazolidine and phosphoric acid; and (4) uniformly mixing the product with water and a catalyst, and conducting flattening and curing to obtain the polyurethane plastic material. The polyurethane plastic material prepared according to the invention has a stable micropore structure and unshrinkable foam pores, is convenient to construct and has low requirements on construction conditions.

Owner:山东蓝岳新材料科技有限公司

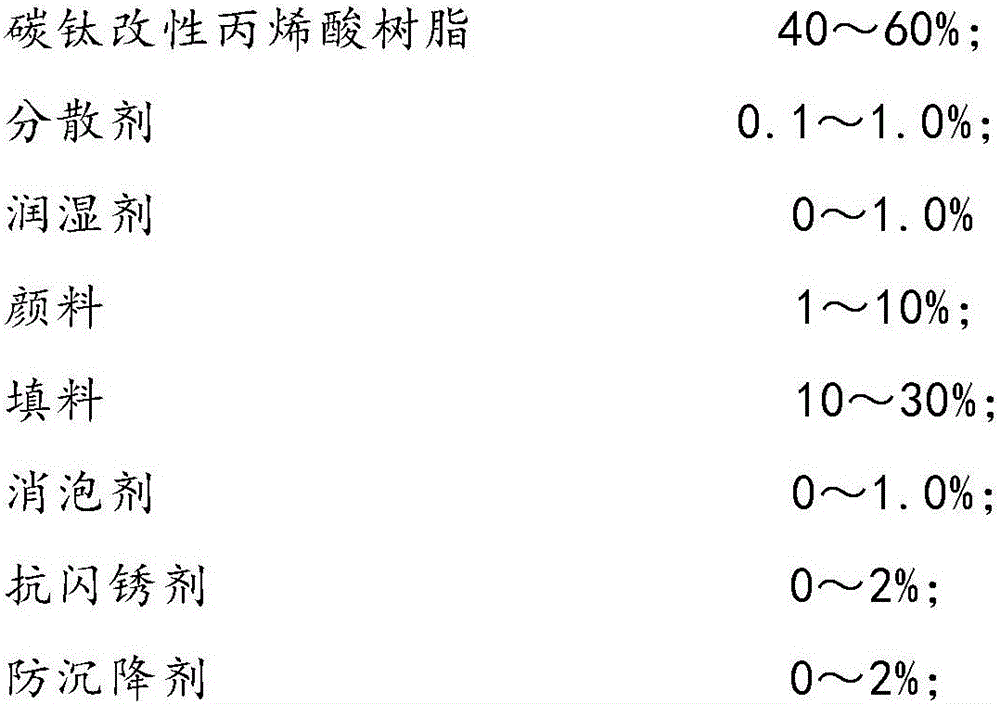

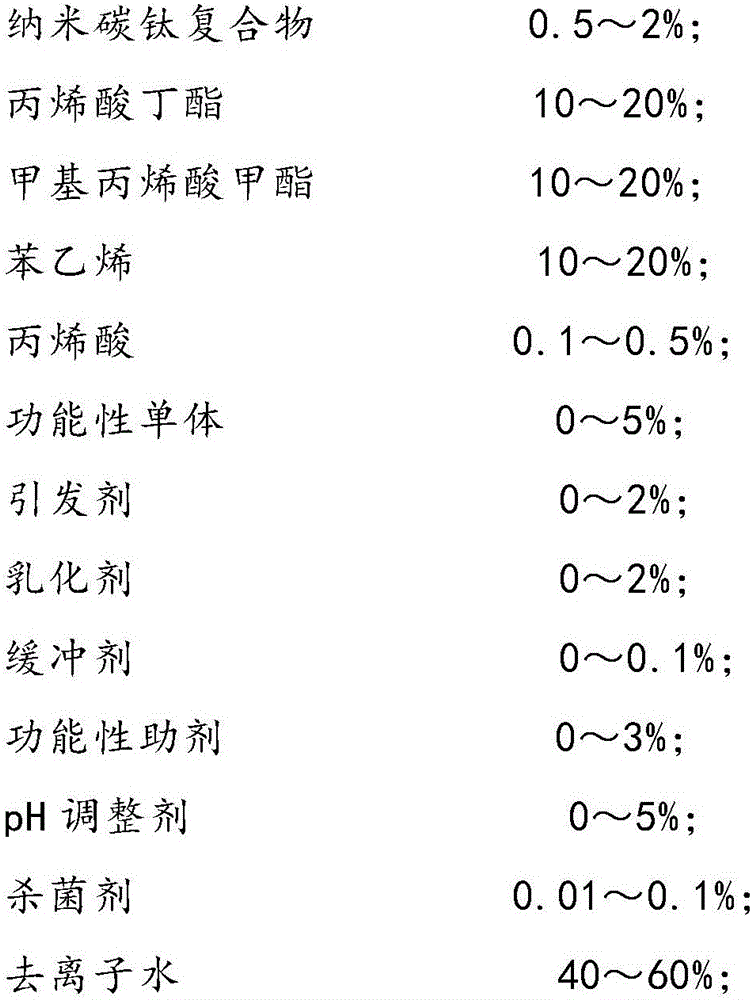

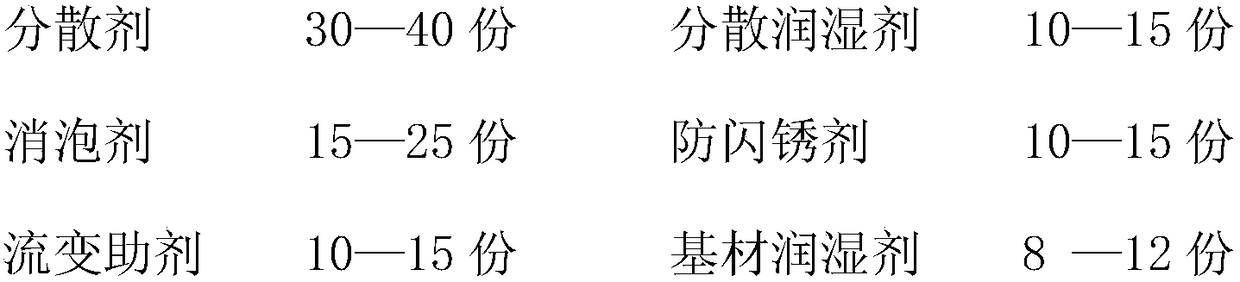

Water-based steel structural anti-corrosive coating and preparation method thereof

PendingCN106634364AReduce labor intensityLow construction environment requirementsAnti-corrosive paintsWater basedAcrylic resin

The invention discloses a water-based steel structural anti-corrosive coating. The water-based steel structural anti-corrosive coating is prepared from, carbon titanium modified acrylic resin, dispersing agent, wetting agent, pigment, filler, anti-foaming agent, anti-flash-rust agent, anti-sinking agent, coalescing agent, thickening agent, pH adjusting agent, fungicide, and de-ionized water. The water-based steel structural anti-corrosive coating can carry out construction along with rust, and has low requirement on construction environment, thus the coating labor intensity is largely reduced; especially, the coating has super-strong scratching self-repair ability, and the heavy anti-corrosive field needs not use the zinc-enriched primer, thus the environmental protection property and reliability of the heavy corrosion prevention are greatly increased. The water-based coating is applied to the heavy corrosion prevention, and the construction simplicity and corrosion prevention are better than the existed oily coating. The coating has very strong weather resistance, and can realize the long-term protection under the condition of thin coating thickness.

Owner:上海奇想青晨新材料科技股份有限公司

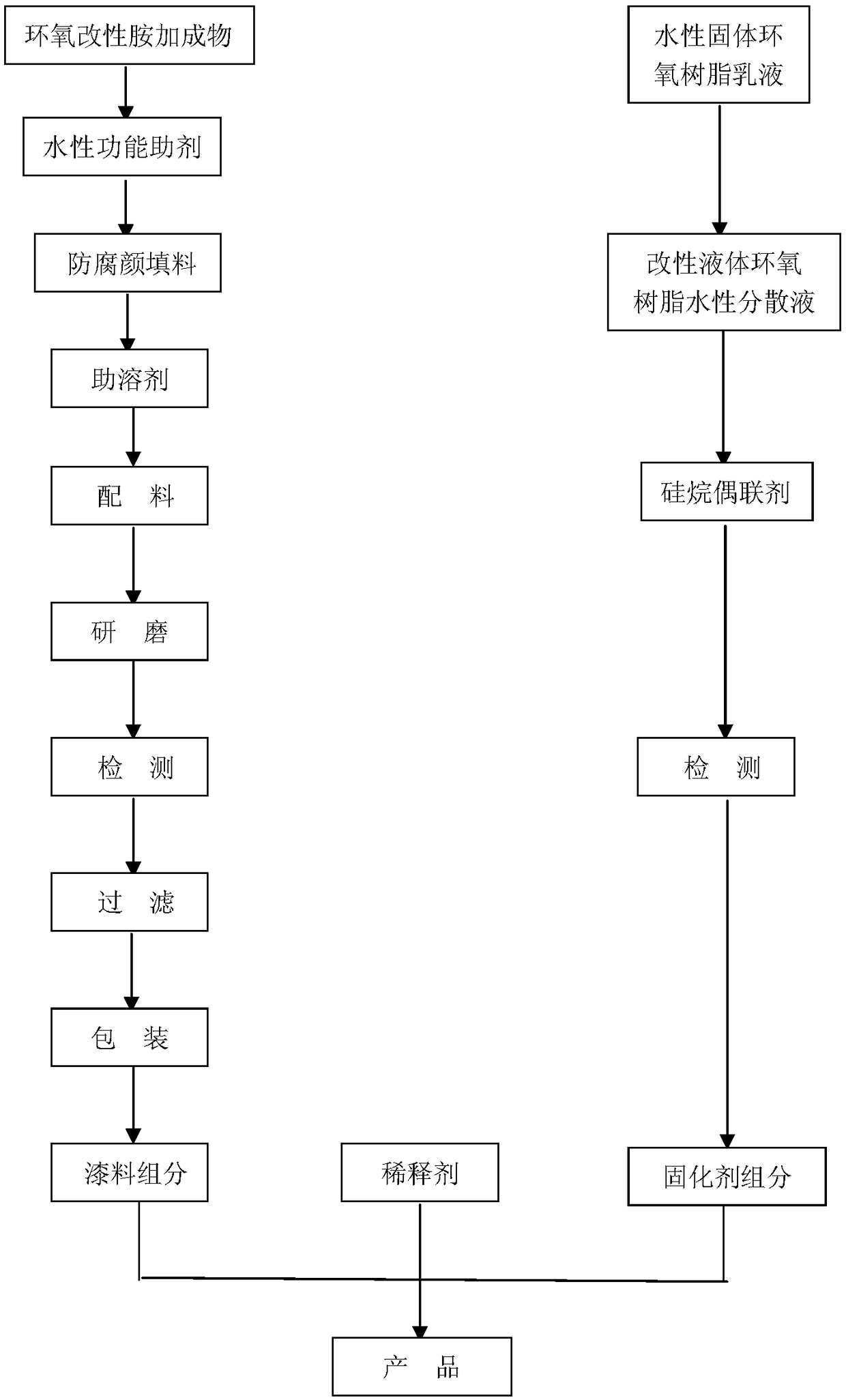

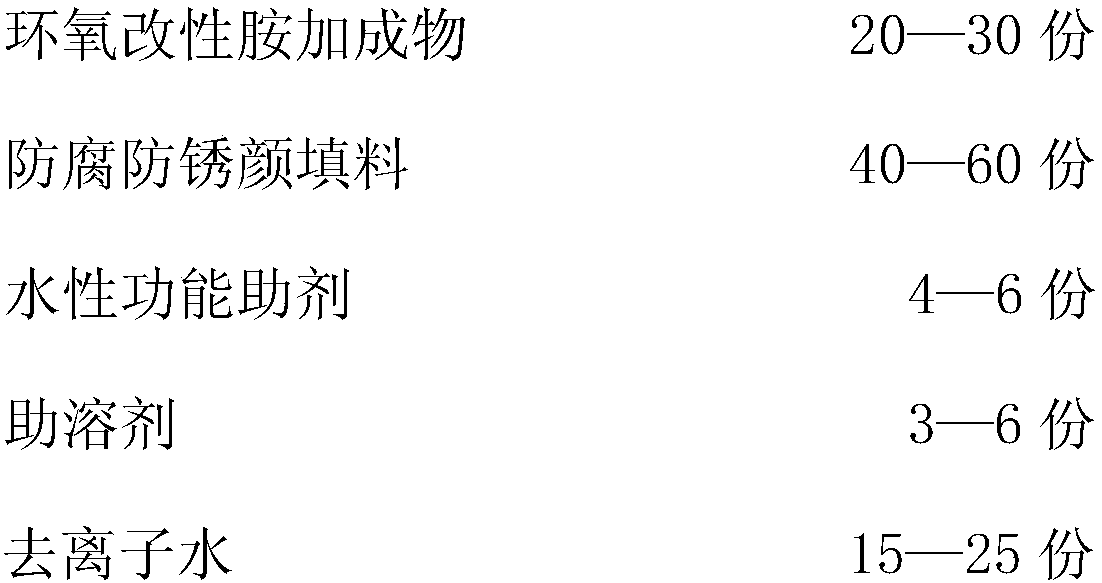

Waterborne electrostatic epoxy anticorrosive primer for wheel shafts and preparation method thereof

ActiveCN108165131AGood physical and mechanical propertiesStrong adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEmulsion

The invention relates to a waterborne electrostatic epoxy anticorrosive primer for wheel shafts and a preparation method thereof. The waterborne electrostatic epoxy anticorrosive primer for wheel shafts adopts an epoxy modified amine adduct, anticorrosive and antirust pigment and filler, a water-based functional assistant, a cosolvent and deionized water as the paint ingredients, and takes a water-based solid epoxy resin emulsion, a modified liquid epoxy resin aqueous dispersion liquid and a silane coupling agent as the curing agent ingredients, and is blended with a proper amount of deionizedwater during construction. The invention mainly aims to acquire the environment-friendly and excellent overall performance waterborne paint product for rail traffic locomotive / vehicle wheel shafts with the advantages of efficient corrosion resistance, excellent salt spray resistance, rapid drying, good physical and mechanical properties, strong chemical resistance, good embracing effect, convenience for electrostatic spraying construction and the like.

Owner:株洲市九华新材料涂装实业有限公司

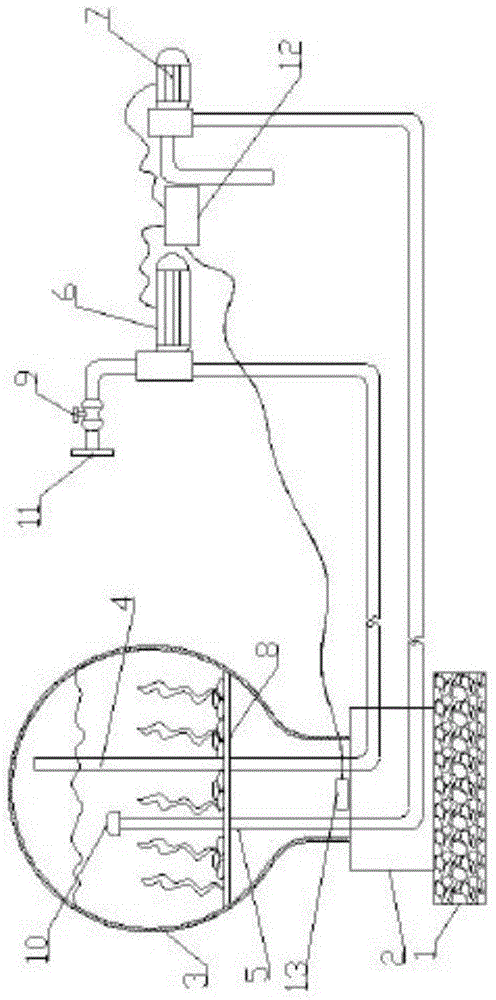

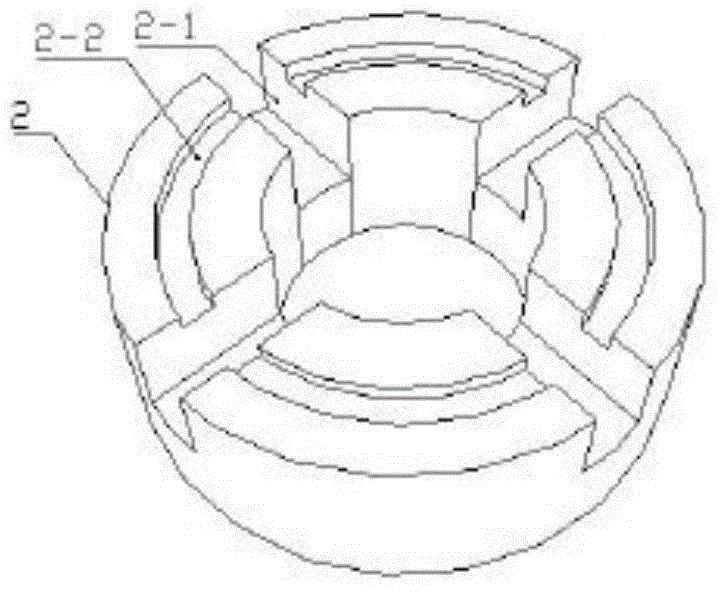

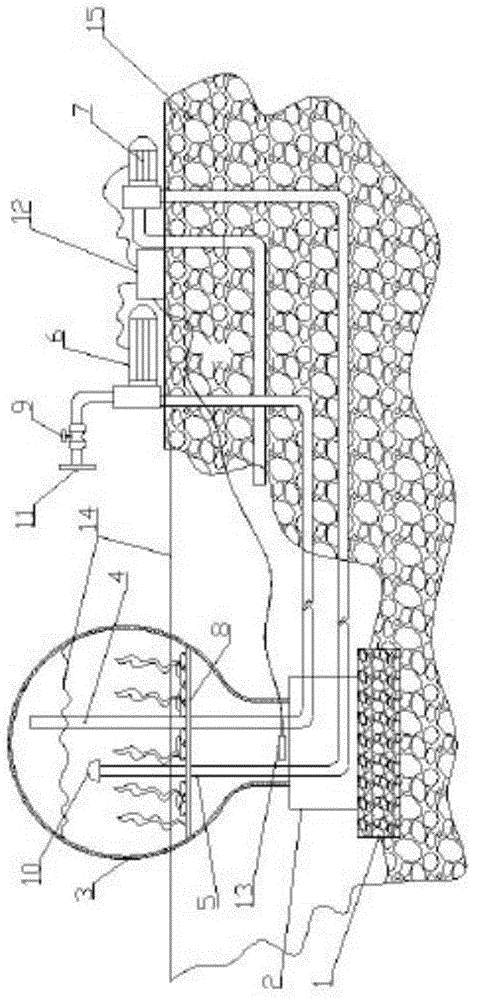

Water-surface landscape device with filter

InactiveCN104996350AAchieve cycleSimple structureSpecial ornamental structuresPisciculture and aquariaUnderwaterCommunicating vessels

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Composite foundation composed of rubble/ sand inverted filter layer and porous concrete piles and treatment method

InactiveCN103938609AContinuous and effective drainageReduce congestionSoil preservationPorosityCrushed stone

The invention discloses a composite foundation composed of a rubble / sand inverted filter layer and porous concrete piles and a treatment method. The exterior structure of the foundation is the rubber / sand inverted filter layer, and the interior of the foundation is porous concrete. The pile diameter is 0.3 m-0.8 m, and the thickness of the rubble / sand inverted filter layer outside the piles is 0.2 m-0.4 m. After underwater maintenance for 28 days, the compressive strength of the porous concrete is not lower than 5 MPa, the permeability coefficient is not lower than 5 mm / s, the pile spacing is 3-5 times of the pile diameter, and the porosity rate of the porous concrete is greater than 20 percent. The treatment method of the foundation comprises the steps that according to the requirements for foundation settlement and bearing capacity, the pile diameter, the pile spacing, the foundation reinforcement range, the reinforcement depth, the pile arrangement mode, the amount of packing in pile holes and the thickness of pile top granular materials or wet clay are determined, and piles are constructed. According to the composite foundation, the problem that the porous concretes are blocked by slurry is effectively weakened; the rubble / sand inverted filter layer plays a role in water permeability and inverted filtering, and therefore the piles can be drained continuously and effectively in the composite foundation.

Owner:SHANDONG UNIV

Steel bridge floor pavement structure containing polyurethane modified polymers

InactiveCN104404851ALose weightReduce engineering costsIn situ pavingsBridge structural detailsEngineeringPolymer

The invention discloses a steel bridge floor pavement structure containing polyurethane modified polymers. The steel bridge floor pavement structure comprises a steel bridge floor, wherein an interlayer is laid on the steel bridge floor through a bonding layer; a wearing layer is laid on the interlayer; the bonding layer is made of special glue for bi-component polyurethane modified resin, and is 1-2 mm thick; the interlayer is made of bi-component high-thixotropic polyurethane modified polymer gravel, and is 6-7 mm thick; the wearing layer is made of bi-component polyurethane modified polymer gravel, and is 2-3 mm thick; the materials of the bonding layer, the interlayer and the wearing layer are all solidified at normal temperature.

Owner:ANHUI TRANSPORTATION INVESTMENT GRP

Method for connecting rubber waterstops

ActiveCN102493559AEasy to masterImprove firm performanceUnderground chambersBuilding constructionsVulcanizationEngineering

The invention provides a method for connecting rubber waterstops. The method comprises the following steps of: 1, firstly, polishing bonding faces at connecting ends of two rubber waterstops to be connected to evenness; 2, uniformly coating mix glue on the bonding faces of the two rubber waterstops respectively, and waiting until the mix glue on the bonding faces is dried to reach a specified requirement; and 3, finally, sticking the bonding face of one rubber waterstop to the bonding face of the other rubber waterstop so as to press-fit and bond the two bonding faces in an aligned manner. A cold vulcanization connection manner is adopted in the invention, during construction, no special heating equipment is needed; the method is simple in a construction process, can be easily mastered by constructors, has a lower requirement on construction environment and is simple and convenient to operate; and the connected rubber waterstops are greatly improved in firmness and low in cost.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

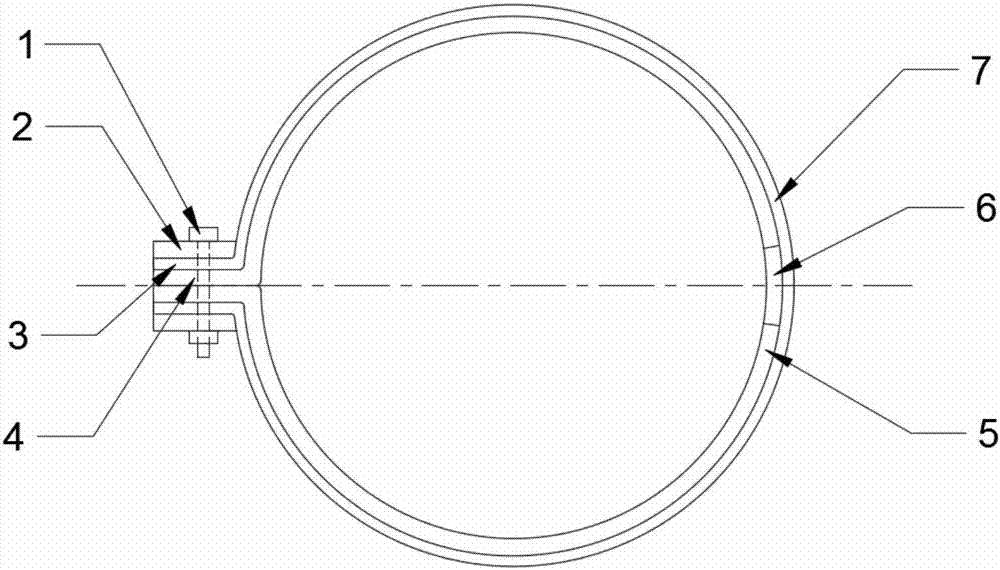

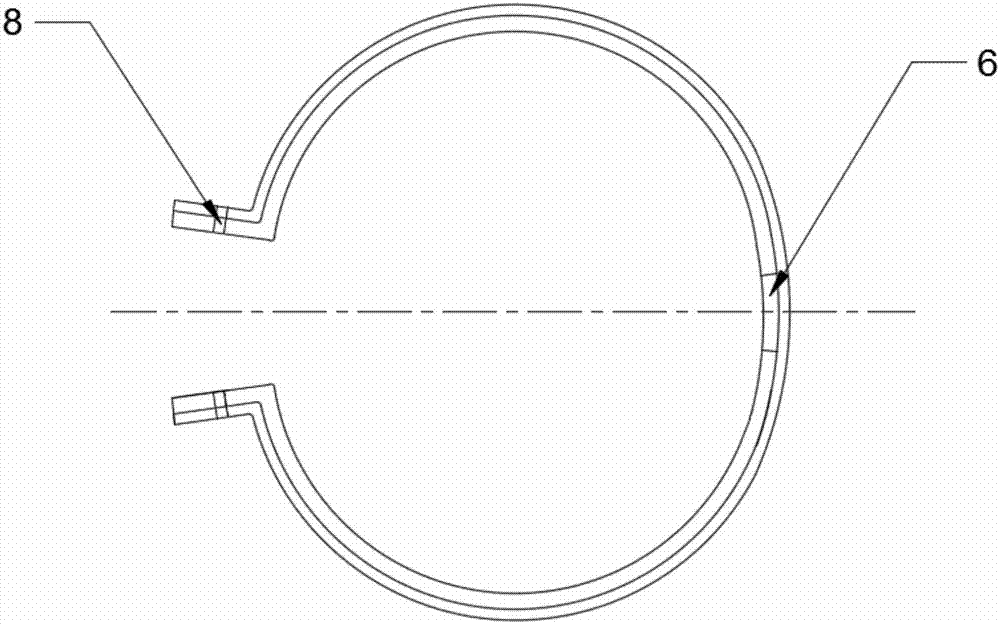

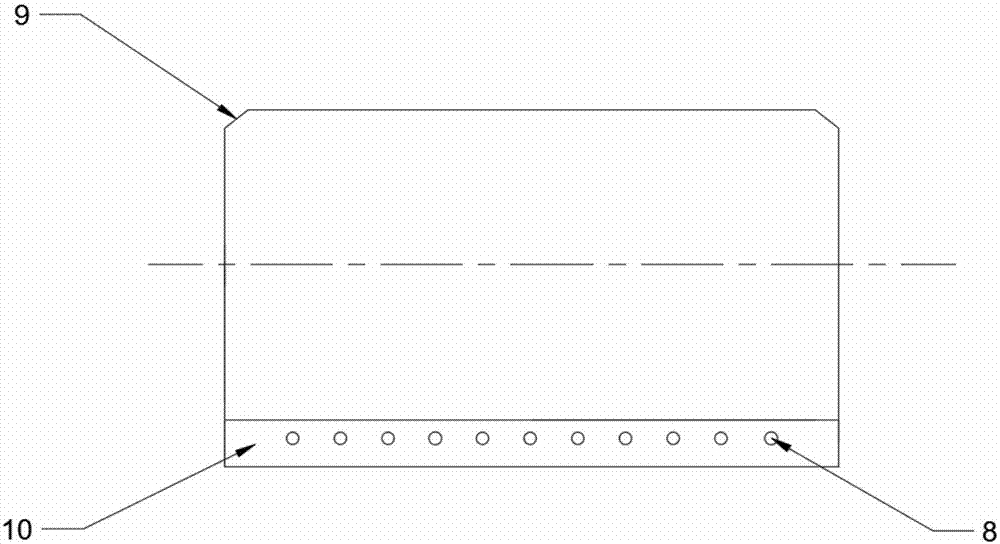

Construction method for reinforced carbon fiber cloth composite layer and pipeline crack arrester applying same

ActiveCN107310167AResolves defects limited to axial cracks onlyStrong flexible crack arrestPipe protection against damage/wearCarbon fibersFiber orientation

The invention provides a construction method for a movable reinforced carbon fiber cloth composite layer and a pipeline crack arrester applying the same. The invention mainly aims at providing the pipeline crack arrester which has a relatively strong flexible crack arresting effect on cracks in each direction of a pipeline. The construction method is characterized by comprising the following steps: laying and stacking at least four layers of reinforced carbon fiber cloth with the same shape; after impregnating the reinforced carbon fiber cloth with a binding agent, carrying out curing to form the reinforced carbon fiber cloth composite layer. An included angle is alternately formed between tensile directions of each two layers of the reinforced carbon fiber cloth according to a sequence from top to bottom and the range of the included angle is 15 degrees to 60 degrees; the reinforced carbon fiber cloth at each angle is formed by stacking at least two pieces of the reinforced carbon fiber cloth with the same main fiber direction; and a non-curing belt, which is not impregnated with the binding agent, is remained on the middle section of the reinforced carbon fiber cloth composite layer. The crack arrester constructed by the method provided by the invention can be used for effectively preventing various cracks of the pipeline from being expanded and flexible crack arresting of ductile fracture of the pipeline is realized.

Owner:NORTHEAST GASOLINEEUM UNIV

Magnesium phosphate cement with good water resistance and application thereof

ActiveCN111253142AImprove water resistanceGood controllability of coagulation timeSolid waste managementMagnesium phosphateMagnesium orthophosphate

The invention relates to the technical field of building materials, in particular to magnesium phosphate cement with good water resistance. The cement disclosed by the invention is prepared from the following raw materials in parts by weight: 50 to 100 parts of pre-modified caustic calcined magnesite, 15 to 30 parts of composite acidic phosphate, 6 to 12 parts of a water-reducing retarder, 6 to 12parts of a pH value regulating agent, 20 to 40 parts of ultrafine filling aggregate, 0.5 to 1.5 parts of a composite expansion component, 0.5 to 2 parts of a slow-release hydrophobic component and 0.5 to 2 parts of a thixotropic lubricant. The invention also provides a preparation method of the cement. The magnesium phosphate cement with good water resistance has the characteristics of good waterresistance, high setting time controllability, good construction performance, early strength, high strength, high bonding strength, strong rib protection performance and good aging resistance.

Owner:山东坊能新动能科学研究院有限公司

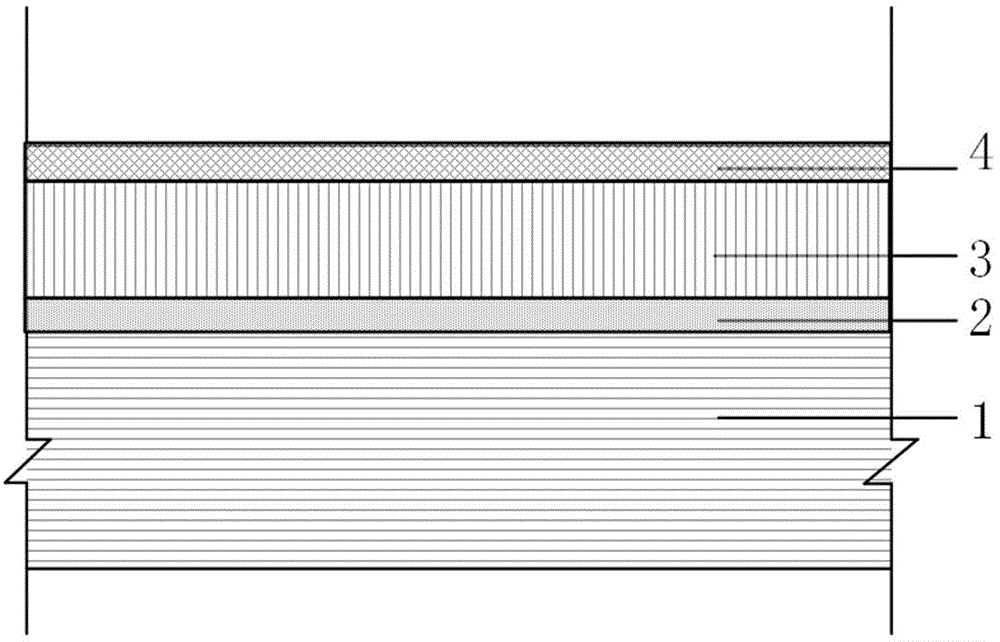

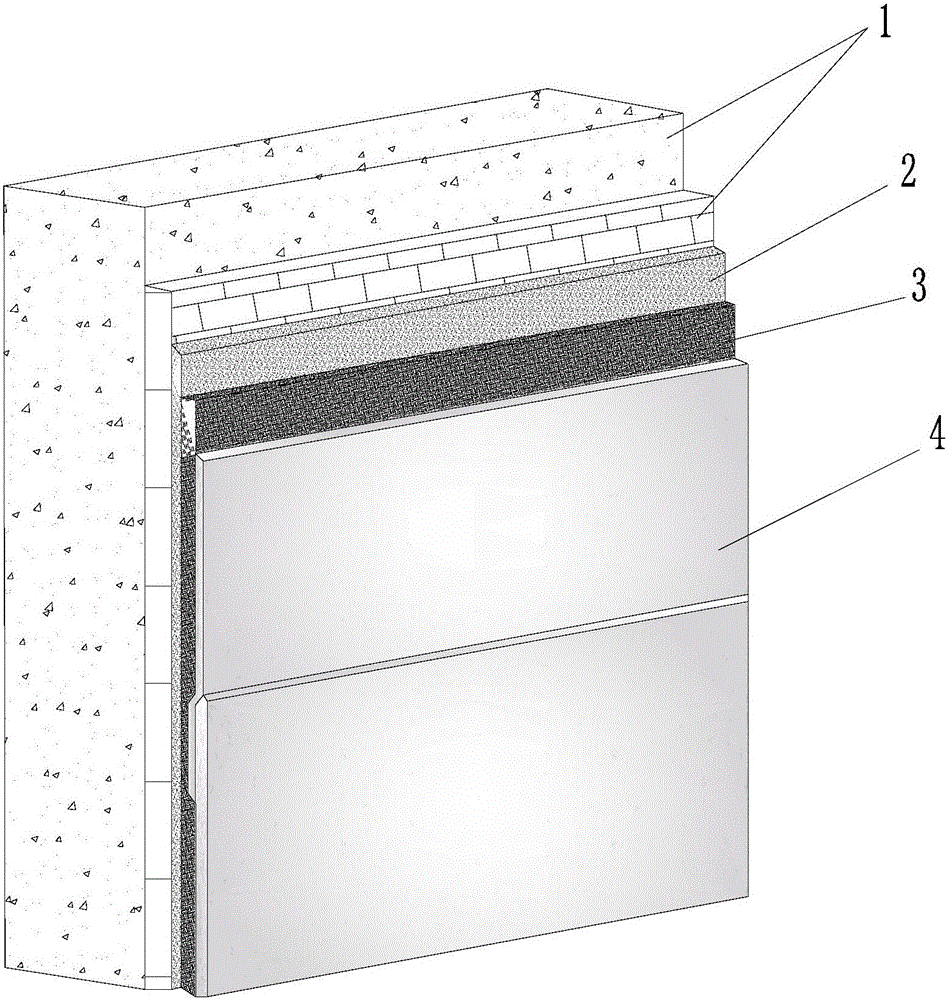

Anti-corrosion structure for chimney and construction method thereof

ActiveCN104989167AAvoid spot weldingAvoid Weld Quality IssuesTowersBuilding insulationsAdhesiveTitanium plate

The invention discloses an anti-corrosion structure for a chimney. The anti-corrosion structure comprises a first coat (2), an adhesive layer (3) and a titanium plate layer (4) which are arranged in sequence, wherein a chimney base (1) is coated with the first coat (2), and the titanium plate layer (4) adheres to the first coat (2) through the adhesive layer (3). The invention further discloses a construction method of the anti-corrosion structure for the chimney. The method comprises the steps of cleaning the chimney base, coating the cleaned chimney base with the first coat material, applying adhesive and sticking a titanium plate after the first coat material on the chimney base is solidified, and conducting inspection and repair. According to the method, the lapped titanium plate is directly stuck onto the structural layer of a chimney by means of the titanium plate adhesive. The method has the advantages that construction period is short, the requirement for the site construction environment is low, and the problem that titanium plate welding quality is poor due to poor construction site welding environment is solved.

Owner:BEIJING CPCEP ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

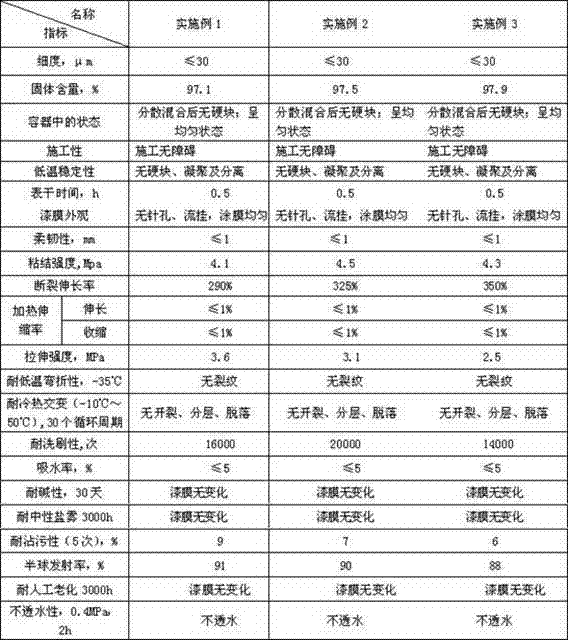

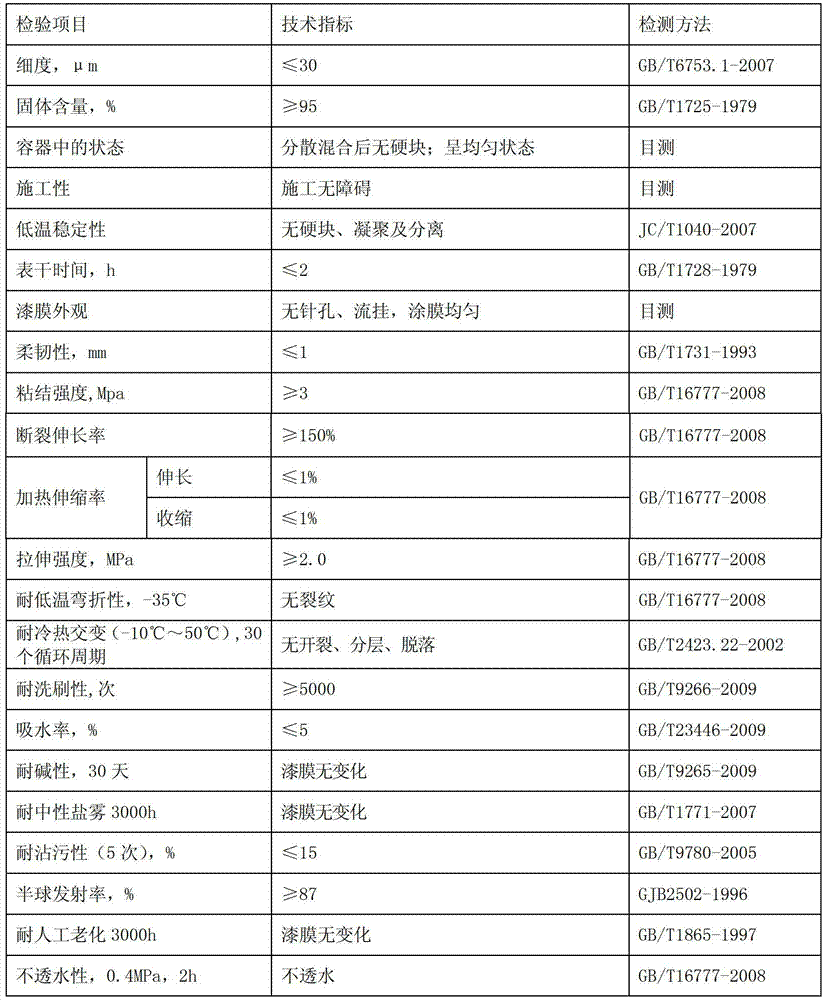

Anticorrosive coating for steel structure in alkaline steam environment and preparation method thereof

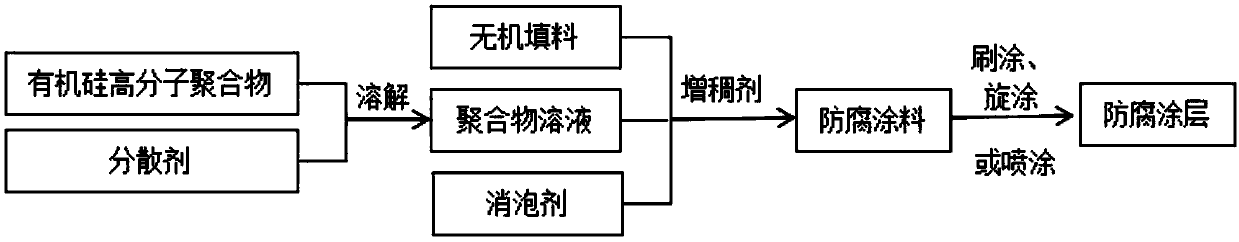

ActiveCN107663419AReduce labor intensityPromote environmental protectionAnti-corrosive paintsSilicon dioxideUltimate tensile strength

The invention discloses an anticorrosive coating for a steel structure in alkaline steam environment. The anticorrosive coating is prepared from the following components in percentage by mass: 25% to30% of organosilicone macromolecular polymer, 10% to 30% of dispersant, 0.8% of defoaming agent, 1.1% to 1.3% of thickener, 25% to 30% of SiO2 (silicon dioxide) powder, 20% to 25% of Al2O3 (aluminum oxide) powder, and 3% to 5% of TiO2 (titanium dioxide) powder. The anticorrosive coating has the advantages that the anticorrosive coating can be constructed with rust, the requirement for constructionenvironment is low, and the labor intensity of coating is greatly decreased; the certain self-cleaning ability is realized, the zinc-rich primer is not needed in the heavy anticorrosive field, and the environment-friendly property and reliability of heavy anticorrosive treatment are greatly improved.

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH +1

Preparation method of solvent-free elastic metallic paint producing high thermal radiation

ActiveCN103073980AIncrease elasticityCover up small cracksPolyurea/polyurethane coatingsCelluloseCrazing

The invention discloses a preparation method of solvent-free elastic metallic paint producing high thermal radiation. The preparation method comprises the following steps of 1, preparing an elastic weather-resistant resin, composite cellulose acetate butyrate slurry, and a yellowing-resistant elastic curing agent, 2, respectively preparing a component A comprising the elastic weather-resistant resin, a fluorocarbon resin, the composite cellulose acetate butyrate slurry, a wetting dispersant, an ultraviolet light absorber, a light stabilizer, a nano-titanium aldehyde powder, a directional alignment assistant, aluminum powder, a leveling agent and an active toughening agent, and a component B comprising the yellowing-resistant elastic curing agent and an HDI tripolymer, and 3, mixing the component A and the component B according to the ratio of 1: 1, and carrying out uniform dispersion to obtain the solvent-free elastic metallic paint. The solvent-free elastic metallic paint has characteristics of excellent elasticity, excellent stain resistance, high / low temperature deformation resistance, good color retention, good gloss retention, low-temperature film formation and environmental protection, has good heat-insulating properties and water resistance, can cover external wall tiny-cracks produced by deformation, and solves the problem that the existing metallic paint for an external wall crazes easily, has poor color retention and gloss retention, and poor high / low temperature deformation resistance.

Owner:洛阳双瑞防腐工程技术有限公司

Phosphorus and magnesium anchoring glue and preparation method thereof

The invention relates to the technical field of building materials, and especially relates to a phosphorus and magnesium anchoring glue and a preparation method thereof. The glue comprises, by weight,80-120 parts of dead-burned magnesia, 80-120 parts of ammonium dihydrogen phosphate and 10-20 parts of water. The preparation method includes the following steps: S1, taking 80-120 parts of the dead-burned magnesia and 40-60 parts of ammonium dihydrogen phosphate, and performing dry mixing until uniformity in order to obtain a dry material mixture; S2, adding 10-20 parts of the water to the dry material mixture, and performing stirring and mixing until uniformity in order to obtain a wet material mixture; and S3, adding 40-60 parts of the ammonium dihydrogen phosphate to the wet material mixture, and performing stirring and mixing until uniformity in order to obtain the phosphorus and magnesium anchoring glue. The phosphorus and magnesium anchoring glue has can firmly bond to steel and other metals, has an excellent reinforcement performance, no special requirements for anchoring or fixing parts, very low creep and shrinkage and good resistance to acid and groundwater corrosion, is suitable for rapidly anchoring post-anchor bolts (reinforcements) and anchor poles of concrete structures, and has excellent application prospects in the fields of rapid repairing, first-aid repairing and reinforcement.

Owner:广州市泰宇科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com