Preparation method of solvent-free elastic metallic paint producing high thermal radiation

An elastic metal and radiation technology, applied in the field of metallic paint, can solve the problems of poor color retention and gloss retention, easy cracking of metallic paint, poor high and low temperature deformation resistance, etc., and achieves good decoration, excellent weather resistance and stain resistance. , the effect of excellent elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The elastic weathering resin is prepared by adding dibutyl maleate dropwise to a four-necked flask equipped with a dispersion, thermometer, and reflux condenser at room temperature and under nitrogen protection, and then adding a metered linear amino-terminated polyether, heating Insulate for 3 hours at 60℃ and 20h when heated to 80℃. After the temperature drops to room temperature, the elastic weathering tree will be obtained. This elastic weathering resin is a kind of low viscosity and yellowing resistant steric elastic aliphatic secondary Metaamine resin, it is recommended that the above-mentioned dibutyl maleate be provided by Shanghai Feida Industry and Trade Co., Ltd., and the above-mentioned linear amino-terminated polyether is recommended to be Jeffamine D2000 provided by Huntsman.

[0038] The preparation of composite cellulose acetate butyrate slurry is to mix 1 part by weight of CAB-551-0.2 and 1 part by weight of CAB-381-2, and then add 8 parts by weight of elas...

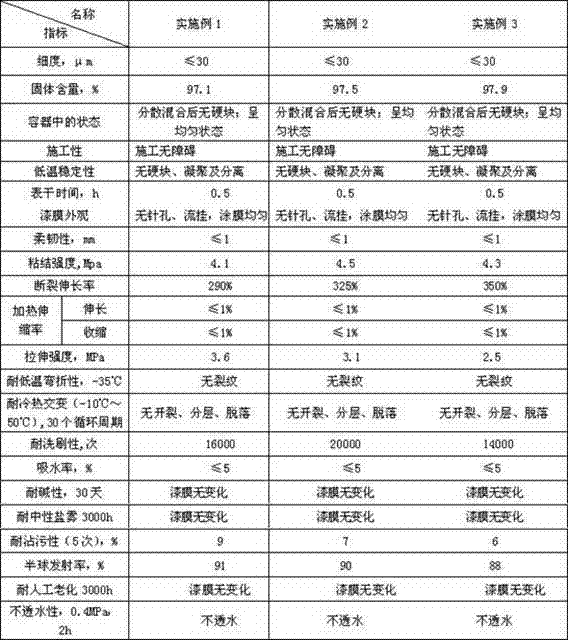

Embodiment 1

[0050] First, the elastic weather-resistant resin, the composite cellulose acetate butyrate slurry and the yellowing-resistant elastic curing agent are prepared according to the above method.

[0051] Then take 30 parts of elastic weathering resin, 5 parts of ETERFLON 4101, 22 parts of composite cellulose acetate butyrate slurry, 0.6 parts of BYK-162, 0.3 parts of Tinuvin384-2 in the upper abrasive group by weight. , 0.5 parts of Tinuvin292, 5 parts of YT-803 and 7 parts of BASF-EVA3 wax are put into a high-speed disperser and mixed and dispersed for 30-40 minutes. The speed of the high-speed disperser is controlled at 600-800 rpm, mixing and dispersing After finishing, transfer to sand mill to grind to fineness ≤30um, then transfer back to high-speed disperser, and then add 13 parts of CE-110 and 0.6 parts of EFKA3600N in the lower abrasive group according to parts by weight. Mix and disperse at 600-800 rpm for 30-40 minutes, and finally use 6 parts of Lexomer WA98 to adjust its...

Embodiment 2

[0055] First, the elastic weather-resistant resin, the composite cellulose acetate butyrate slurry and the yellowing-resistant elastic curing agent are prepared according to the above method.

[0056] Then take 35 parts of elastic weathering resin, 3 parts of ETERFLON 4101, 25 parts of composite cellulose acetate butyrate slurry, 0.4 parts of BYK-162, 0.3 parts of Tinuvin384-2 in the upper abrasive group according to parts by weight. , 0.7 parts of Tinuvin292, 7 parts of YT-803 and 5 parts of BASF-EVA3 wax are put into a high-speed disperser and mixed and dispersed for 30-40 minutes. The speed of the high-speed disperser is controlled at 600-800 rpm, mixing and dispersing After finishing, transfer to sand mill to grind to fineness ≤30um, then transfer back to high-speed disperser, transfer the upper abrasive group after grinding to the disperser, and then add to the lower abrasive group in parts by weight 10 parts of CE-160 and 0.6 parts of EFKA3288 are mixed and dispersed for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com