Patents

Literature

272 results about "Dibutyl maleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl Maleate (DBM) DBM is a colorless liquid with a characteristic "ester" odor. It is used as a comonomer in vinyl and acrylic emulsion polymerization for paints and adhesives. DBM is also a suitable intermediate for use in organic synthesis, e.g. in the production of derivatives of succinic acid.

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

Chloroprene rubber gasket with high abrasion resistance and preparation method thereof

InactiveCN102993517AImprove flame retardant performanceAccelerated corrosionLow-density polyethylenePolymer science

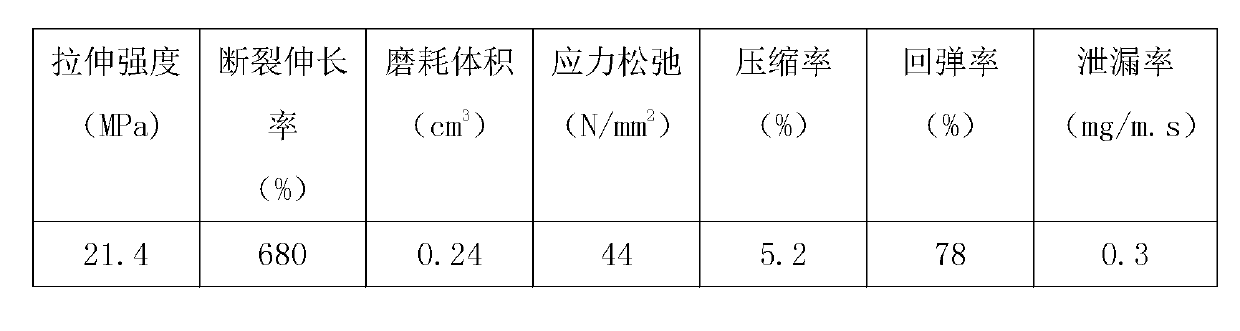

The invention discloses a chloroprene rubber gasket with high abrasion resistance. The chloroprene rubber gasket comprises the following raw materials in parts by weight: 135-145 parts of chloroprene rubber (CR)121, 10-15 parts of butyl rubber CBK139, 20-25 parts of low density polyethylene, 3-5 parts of acetyl triethyl citrate, 2-5 parts of dibutyl maleate, 1-2 parts of isooctyl dimercaptoacetate di-n-octyl tin and the like. The chloroprene rubber gasket has the beneficial effects that the gasket has good high temperature resistance, sealability, flame retardance and corrosion resistance and can work in such medias as acid, alkali and oil for a long time; the volume and hardness of the gasket are small in variation; the gasket does not adhere to metal surfaces; and the gasket has small friction coefficient and good abrasion resistance and has the advantages of softness of bonding with sealing surfaces, good weathering aging and ozone aging resistance, durability and the like.

Owner:ANHUI RONGDA VALVE

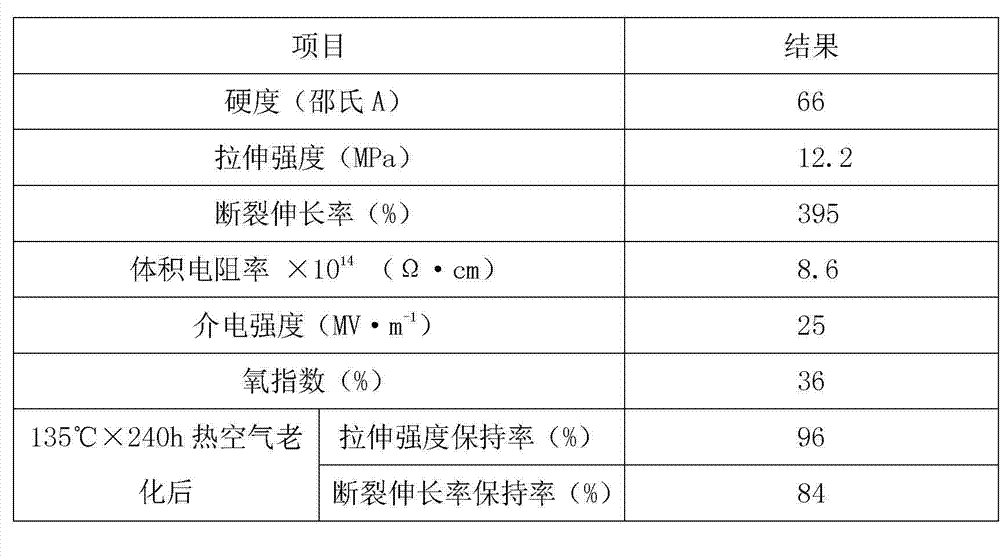

Pliable tough cold-resistant anti-aging modified acrylate rubber cable material

ActiveCN103589102AImprove performanceGood mechanical propertiesRubber insulatorsPlastic/resin/waxes insulatorsWear resistantPolyvinyl chloride

The invention relates to a cable material, and specifically relates to a pliable tough cold-resistant anti-aging modified acrylate rubber cable material. The cable material comprises the following raw materials in parts by weight: 25-30 parts of acrylate rubber, 15-20 parts of epichlorohydrin rubber, 12-15 parts of fluororubber, 23-26 parts of precipitation-process white carbon black, 18-20 parts of polystyrene, 15-18 parts of polyvinyl chloride, 12-15 parts of wollastonite powder, 2-3 parts of anti-aging agnet KY-405, 1-2 parts of anti-aging agent MB, 1-2 parts of anti-oxidant 1035, 3-4 parts of magnesium oxide, 4-5 parts of stearic acid, 1-2 parts of promoter PZ, 5-7 parts of acetyl triethyl citrate, 5-6 parts of dibutyl maleate, 30-34 parts of spraying carbon black, 4-5 parts of engine oil, 2-3 parts of sulphur, 2-3 parts of zinc oxide and 4-5 parts of an auxiliary agent. The cable material combines the advantages of acrylate rubber, epichlorohydrin rubber, fluororubber, polystyrene, polyvinyl chloride and the like, so that the properties of conventional acrylate rubber cable materials are improved; and the cable material provided by the invention has good mechanical properties, is pliable, tough, wear-resistant, low temperature resistant, anti-aging and long in service life, is capable of being adaptive to specific usage environment conditions, and has wide market application prospect.

Owner:东莞市胜牌电线电缆有限公司

Preparation method of package-purposed plastic-based film containing modified calcined fluorite powder

ActiveCN103044756AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethylenePolyvinyl chloride

The invention discloses a preparation method of a package-purposed plastic-based film containing modified calcined fluorite powder. The package-purposed plastic-based film is prepared from the following raw materials in parts by weight:10-15 parts of SG-1 type polyvinyl chloride, 3-5 parts of epoxidized linseed oil, 2-3 parts of oxidized polyethlene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of kieselguhr, 35-40 parts of mLLDPE (metallocene Linear Low-Density Polyethylene), 38-42 parts of ethylene / alpha olefin copolymer, 8-12 parts of LDPE, 1-2 parts of polyisobutene, 1.2-2.5 parts of poly-4-methyl-1-amylene, 0.8-1.6 parts of nano potassium feldspar powder, 4-6 parts of modified calcined fluorite powder, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 1.5-3 parts of dibutyl maleate, 0.5-1 part of dioctyl maleate, 0.8-1.6 parts of calcium stearate and 1-2 parts of modified sepiolite powder. The package-purposed plastic-based film has good barrier property, gas tightness, pressure resistance and impact resistance and has the characteristics of high heat seal strength and good heat seal property.

Owner:平湖市泓博科技有限公司

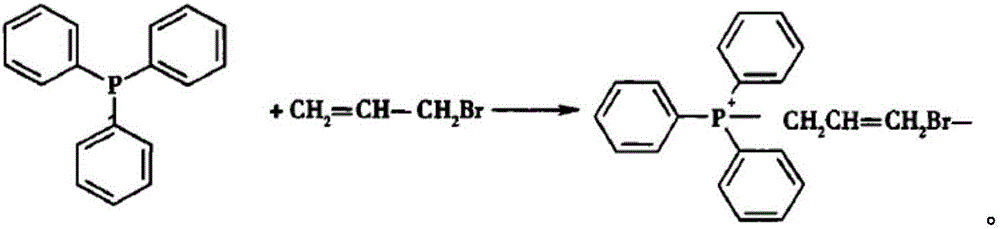

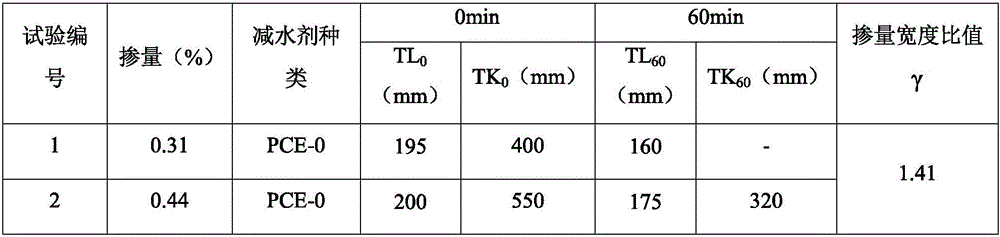

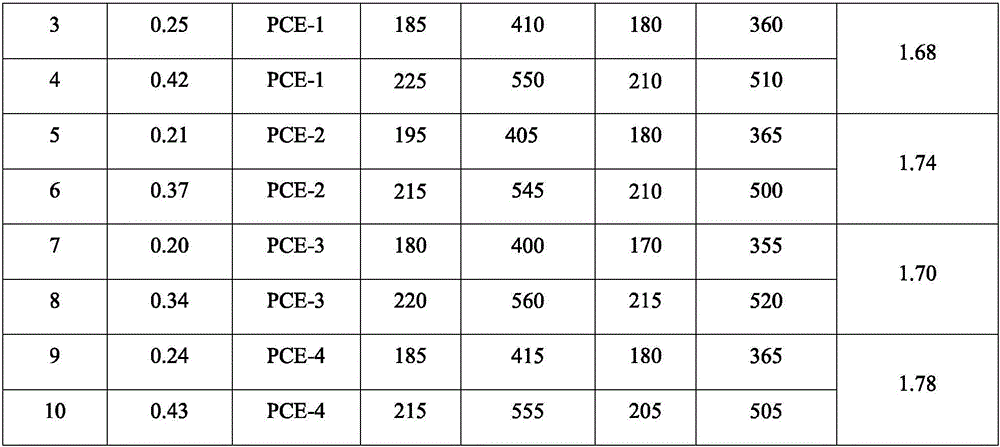

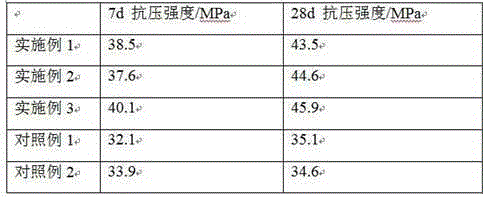

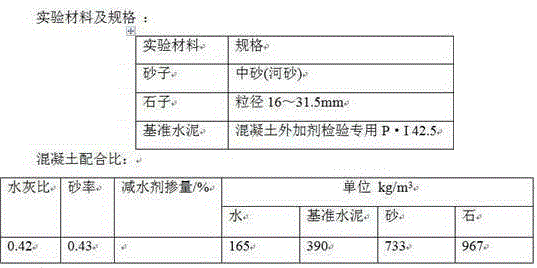

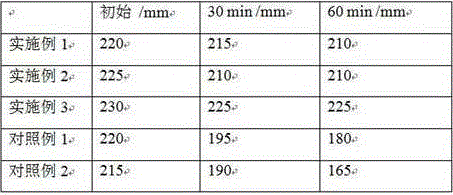

Low-sensitivity anti-mud crossed branched chain type polycarboxylate superplasticizer and preparation method thereof

The invention discloses a low-sensitivity anti-mud crossed branched chain type polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer comprises, by weight, the raw materials of 10-60 parts of 4-hydroxyl vinyl polyoxyethylene ether, 0-40 parts of allyl polyoxyethylene polyether, 0-40 parts of methyl allyl ether polyoxyethylene polyether, 0-40 parts of isopentenyl polyoxyethylene polyether, 6-10 parts of unsaturated monocarboxylic acid, 3-6 parts of unsaturated carboxylic ester monomers, 2-6 parts of 2-(dimethylamino)ethyl methacrylate, 2-6 parts of dibutyl maleate, 1-5 parts of unsaturated amphoteric quaternary phosphonium, 0.2-0.8 part of oxidant, 0.2-1.0 part of first reducing agent, 0.02-0.06 part of second reducing agent, 0.2-0.6 part of chain transfer agent and an appropriate quantity of a potassium hydroxide water solution and a sodium hydroxide water solution and an appropriate amount of deionized water. Lateral chains of the polycarboxylate superplasticizer are distributed more uniformly, are good in slump loss resistance, and the polycarboxylate superplasticizer has excellent low-sensitivity performance for the amount change of the doped polycarboxylate superplasticizer.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Carbon nanotube reinforced anti-oxidation geogrid and preparation method thereof

InactiveCN105968522APromote oxidation chain reactionReduce free radical contentPolymer scienceALUMINUM HYDRIDE

The invention discloses a carbon nanotube reinforced anti-oxidation geogrid, which is composed of the following raw materials in parts by weight: 1.6-2 calcium acetylacetonate, 0.7-1 alkenyl succinic anhydride, and 1-2 barium stearate , lithium aluminum hydride 0.1‑0.3, 4‑dimethylaminopyridine 0.3‑1, antioxidant 10100.4‑1, multi-walled carbon nanotubes 10‑15, antioxidant 1680.6‑1, polypropylene imine 10‑17, acrylic acid Tert-butyl ester 6-8, high-density polyethylene 140-160, bisphenol a diglycidyl ether 0.3-1, 2-mercaptobenzimidazole 0.6-1, dibutyl maleate 4-6, cycloalkane Lithium Oxide 0.4‑1. The invention greatly reduces the content of free radicals participating in the automatic oxidation chain reaction of polymers, delays the oxidation degradation process of polymers, and improves the oxidation resistance of finished materials.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Isolation coating of outer vamp of roller skate

InactiveCN107760081AAnti-corrosionWaterproof and impact resistantAnti-corrosive paintsAdjuvantWear resistant

The invention discloses an isolation coating of an outer vamp of a roller skate, and relates to the technical field of processing and manufacturing of sports equipment. The isolation coating is characterized by being prepared from the following materials in parts by weight: 13-20 parts of resin, 1-4 parts of polydimethylsiloxane, 2-6 parts of dibutyl maleate, 1-3 parts of 2,6-di-tert-butyl-p-cresol, 7-11 parts of a silane coupling agent KH-550, 8-13 parts of modified diatomite, 1-5 parts of diethanolamide laurate, 1-4 parts of hydrogenated castor oil, 1-4 parts of N-methylolacrylamide, 8-13 parts of ethanol, 8-13 parts of an anti-aging agent, 9-13 parts of a biological adjuvant and 27-33 parts of deionized water. The method provided by the invention is reasonable, and convenient to operate, and the product is wear-resistant and good in toughness.

Owner:阜南县邰氏宇崴运动器材有限公司

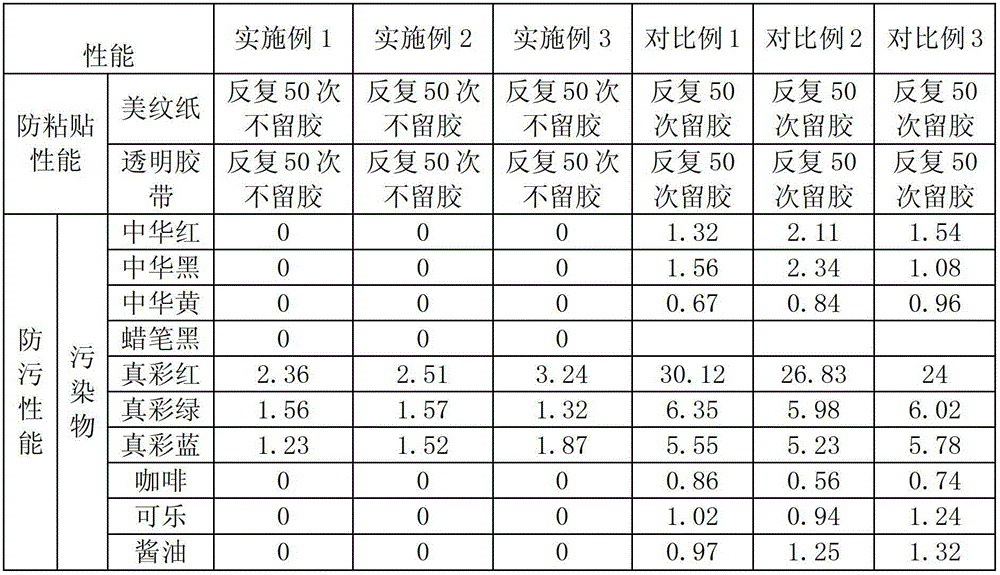

Anti-sticking water-based coating

InactiveCN102719125ALow water resistanceImprove water resistanceAnti-corrosive paintsSodium acetateWater based

The invention relates to anti-sticking water-based coating which comprises, by weight, 50-80 parts of polymer latex, 10-15 parts of methyl methacrylate, 6-9 parts of butyl acrylate, 2-5 parts of 2-ethylhexyl acrylate, 3-6 parts of dibutyl maleate, 0.6-1 part of hydroxyethyl acrylate, 0.3-1.0 part of sodium dodecyl sulfate, 0.1-0.4 part of potassium peroxydisulfate, 0.05-0.2 part of sodium acetate, 1-10 parts of water repellent agents and 0.5-5 parts of fluorine-modified surface additives with hydrophobic and oleophobic structures. The anti-sticking water-based coating is non-toxic and harmless, thereby being less in environmental pollution; a coating layer formed after coating is not only high in brightness and excellent in toughness and explosive spalling resistance but also good in ageing resistance and weather resistance, and is extraordinary in subsequent processing performance so that rapid and efficient gold stamping processing can be carried out, and gold stamping effects are fine; and the water-based coating is anti-sticking and is environment-friendly water-based coating beneficial to surface clearness maintaining after coating.

Owner:TIANCHANG JULONG TRAVEL PAINT

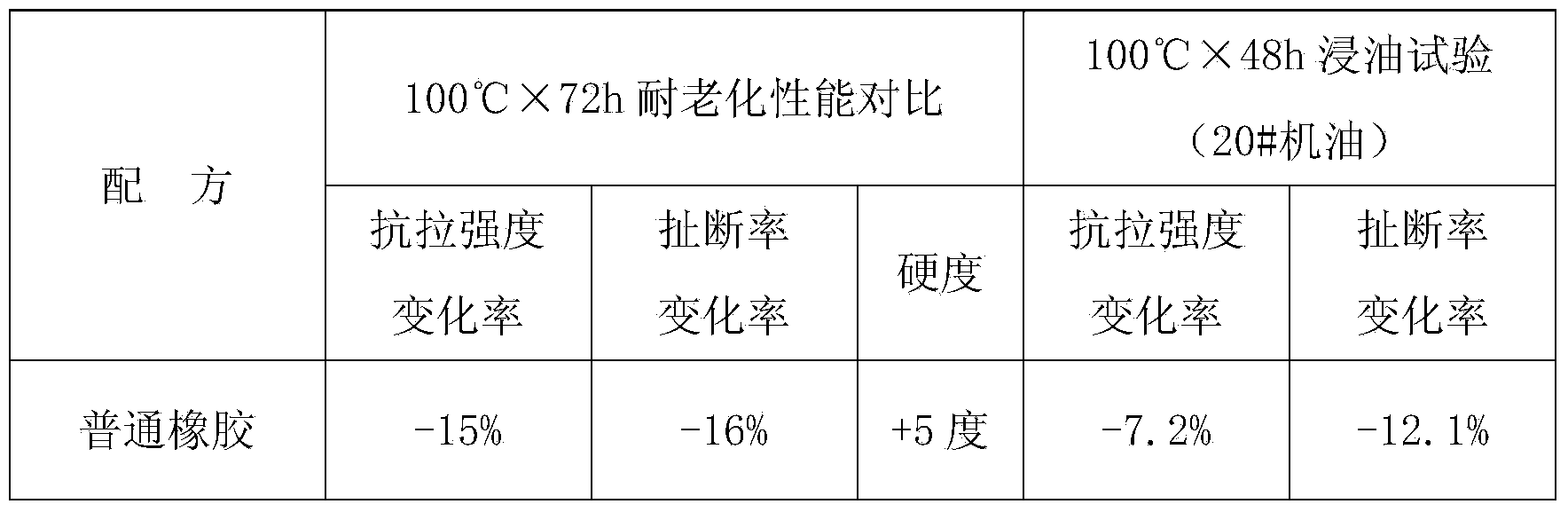

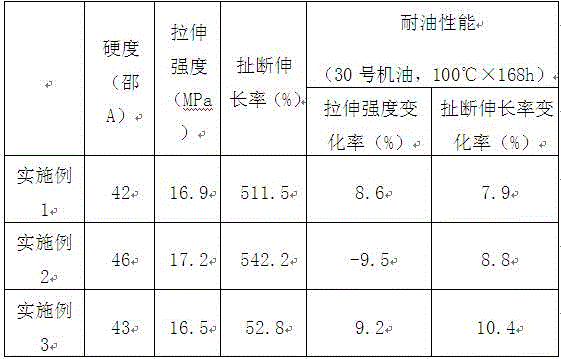

Combined rubber gasket material and preparation method thereof

The invention discloses a combined rubber gasket material which is characterized in that the material is prepared from the following raw materials by weight: 70-75 parts of butyl rubber (CBK139), 10-15 parts of butadiene-acrylonitrile rubber, 6-8 parts of natural rubber, 1-2 parts of sulphur, 3-5 parts of polydimethylsiloxane, 1-2 parts of phenol, 8-10 parts of zinc acetate, 6-8 parts of dibutyl maleate, 1-2 parts of bis(isooctyl thioglycolate) di(n-octyl tin), 3-5 parts of zinc oxide, 10-12 parts of cork powder, 24-28 parts of N550 carbon black, and 10-12 parts of modified attapulgite. According to the invention, modified attapulgite is added, which improves rubber processing property; environment-friendly type compounding agents are used, which reduces toxic and side effects and environment pollution; the material of the invention has elasticity, good thermal stability, good oil resistance, and aging resistance.

Owner:TONGLING SIDE TECH

Environment-friendly dacron dyeing repairing agent

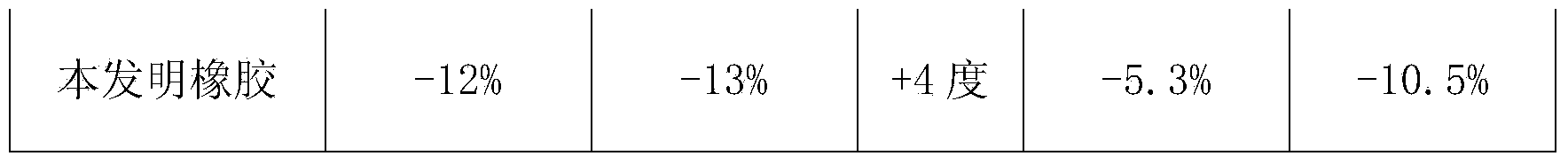

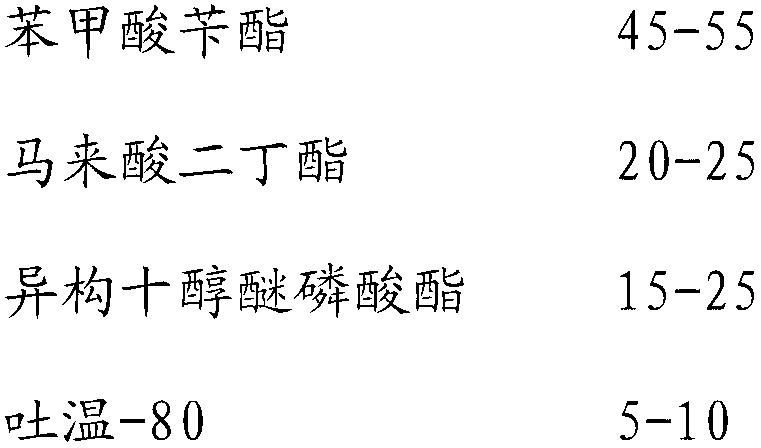

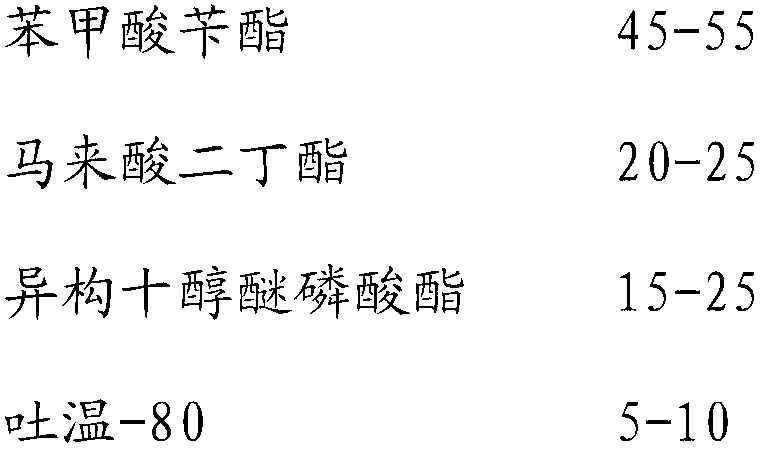

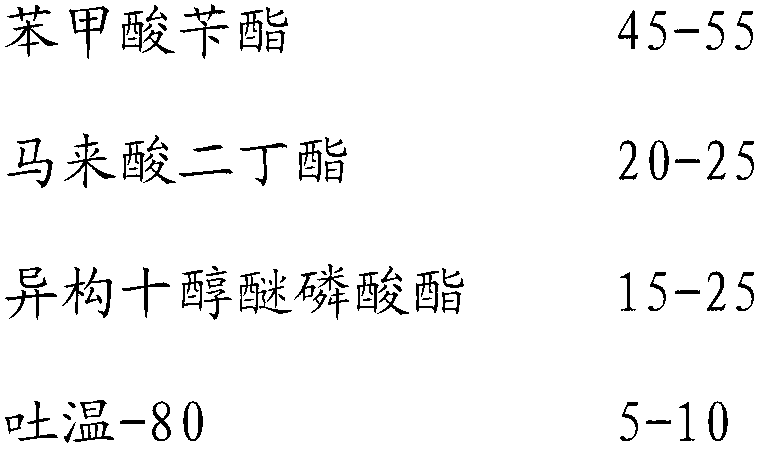

The invention discloses an environment-friendly dacron dyeing repairing agent which is prepared from the following raw materials in parts by weight: 45-55 parts of benzyl benzoate, 20-25 parts of dibutyl maleate, 15-25 parts of isomeric deca-alcohol phosphate and 5-10 parts of tween-80, wherein benzyl benzoate is a plasticizer and a solvent, dibutyl maleate is a main detergent, isomeric deca-alcohol phosphate is a main penetrant and an emulgator, and tween-80 is an emulgator. When dacron fiber is dyed at a high temperature (at 130 DEG C or even higher), disperse dye is easier to migrate from inside of fiber to outside of fiber under the synergistic effect of benzyl benzoate and dibutyl maleate, so that disperse dye is re-arranged in dacron fiber so as to realize true uniform color. Raw materials adopted by the scheme do not contain substances of very high concern (SHVC) forbidden in Europe such as APEO (Alkylphenol Ethoxylates) and the like, and the repairing agent is in accordance with demand of European Union Okeo-TexStandard 100 and REACH (Registration, Evaluation and Authorization of CHemicals), and is the environment-friendly dacron dyeing repairing agent.

Owner:JINJIANG NANXING PRINTING & DYEING MATERIAL

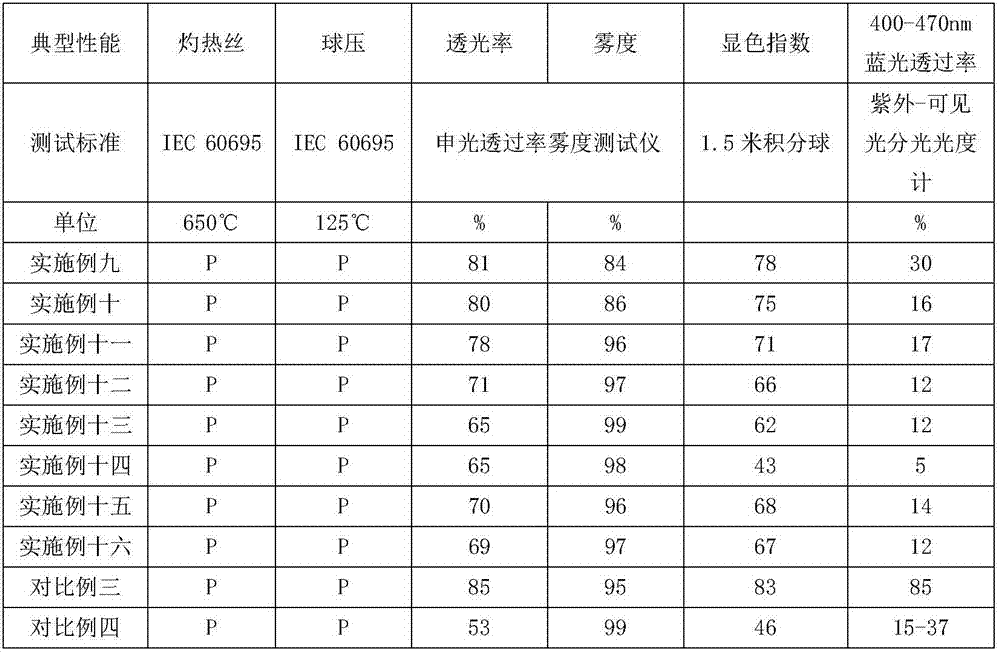

PC material with low blue light transmittance

ActiveCN107474508AReduce the problem of light transmittance reductionAntioxidantOptical transmittance

The invention discloses a PC material with low blue light transmittance. The PC material is mainly prepared from the following raw materials in parts by weight: 100 parts of PC, 1-2 parts of a light diffusing agent and 0.05-0.2 parts of a blue light absorbing agent, and also comprises the following raw materials in parts by weight: 0.2-0.5 parts of a lubricant and 0.2-0.3 parts of an antioxidant, wherein the lubricant is one or a mixture of EBS and dibutyl maleate. The PC material with low blue light transmittance provided by the invention can effectively reduce a problem of decrease of the light transmittance caused by adding the blue light absorbing agent, has long-term absorption for the blue light, and has low probability of deformation.

Owner:宁波公牛光电科技有限公司

Ozone-resistant cable sheath material

ActiveCN103265740AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesBenzoyl peroxideCis-Butenedioic Acid

The invention discloses an ozone-resistant cable sheath material. The ozone-resistant cable sheath material comprises the following raw materials by weight: 93 to 100 parts of chloroprene rubber M-40, 14 to 19 parts of an SG-4 type PVC resin, 20 to 30 parts of mica powder, 15 to 25 parts of a modification filling material, 4 to 7 parts of glass powder, 4 to 6 parts of dibutyl maleate, 3 to 5 parts of oxidized polyethlene wax, 1 to 2 parts of hydroquinones, 1 to 2 parts of the antioxidant 1010, 2 to 4 parts of borax, 1 to 2 parts of isopropyl tri(dioctylpyrophosphate) titanate, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of benzoyl peroxide, 0.8 to 1 part of sulphur and 0.6 to 1 part of ziram. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

Special toughened reinforced nylon 66 composite material for automobiles and preparation method thereof

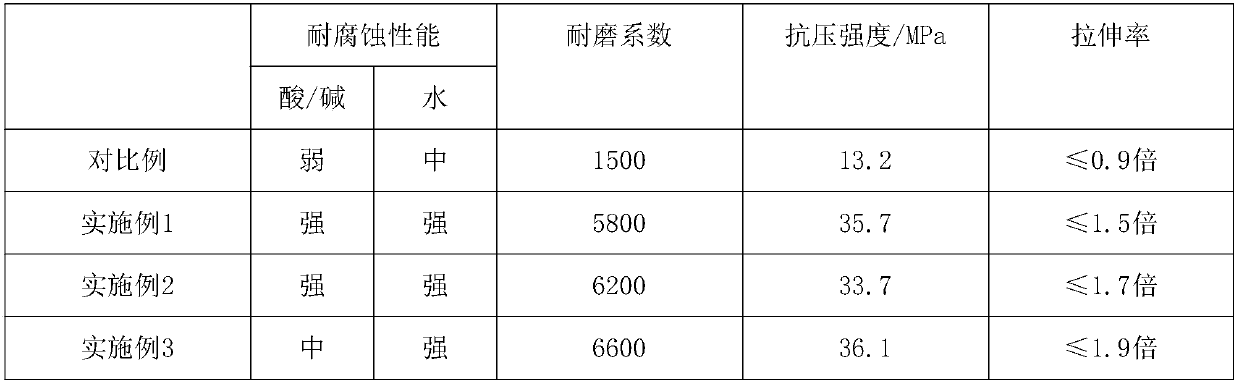

The invention discloses a special toughened reinforced nylon 66 composite material for automobiles, which comprises the following components in parts by weight: 40-50 parts of nylon 66, 10-20 parts of nylon 6, 2-8 parts of glass fiber, 0.5-2 parts of hollow glass microsphere, 5-10 parts of bamboo powder, 2-5 parts of polycrystalline mullite whisker, 3-10 parts of polylactic acid, 8-12 parts of POE (polyolefin elastomer), 1-4 parts of dibutyl maleate, 10-15 parts of polypropylene, 0.1-0.5 part of initiator, 0.5-1.5 parts of antioxidant and 1-2 parts of other assistants. The invention also discloses a preparation method of the special toughened reinforced nylon 66 composite material for automobiles. The special nylon composite material for automobiles has the advantages of superhigh impact resistance, high toughness, excellent heat resistance, excellent wear resistance, excellent corrosion resistance, stable size and favorable sound insulation property, and can be widely used for various automobile parts.

Owner:SUZHOU HONGHENG CHEM

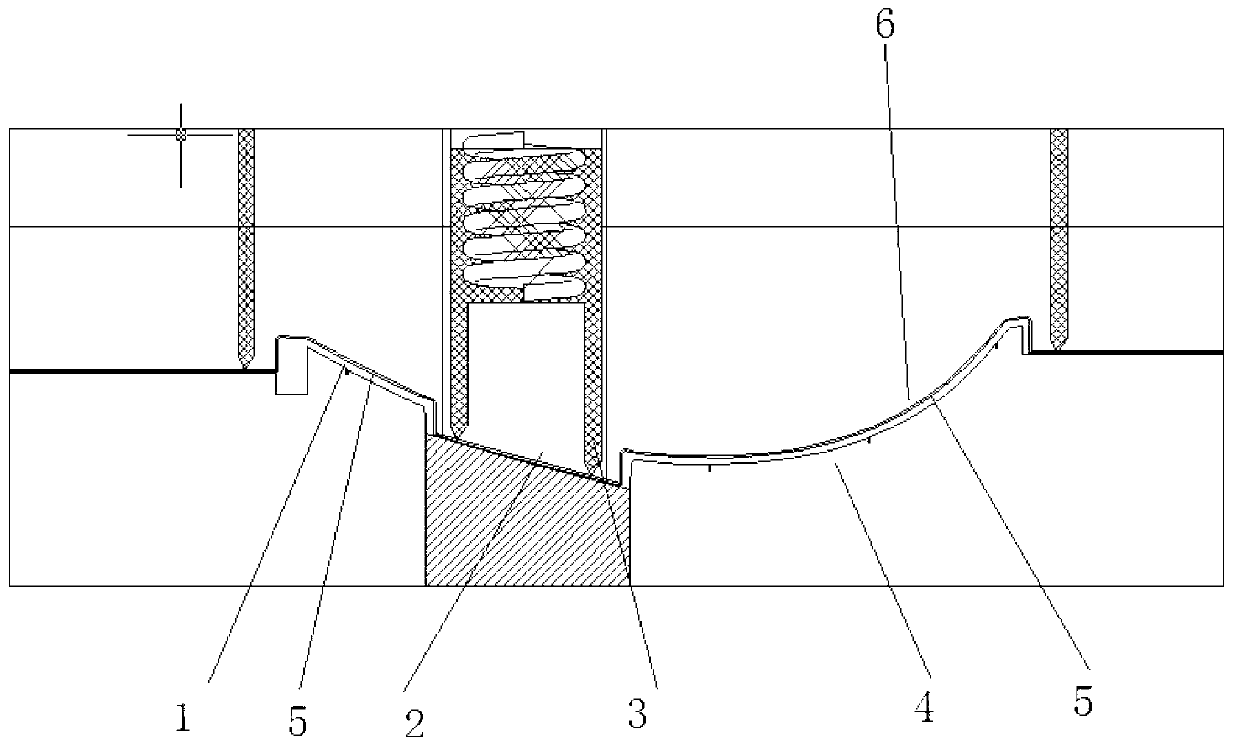

Nanometer potash feldspar powder modified chloroprene rubber sealing gasket and its preparation method

ActiveCN102977434AImprove flame retardant performanceAccelerated corrosionCis-Butenedioic AcidTemperature resistance

The invention discloses a nanometer potash feldspar powder modified chloroprene rubber sealing gasket. The sealing gasket comprises the following raw materials, by weight, 135-145 parts of chloroprene rubber CR121, 10-15 parts of butyl rubber CBK139, 15-20 parts of chlorosulfonated polyethylene rubber CSM2305, 10-15 parts of an SG-7 type PVC resin, 3-5 parts of acetyltriethyl citrate, 2-4 parts of dibutyl maleate, 1-2 parts of sulfur and 2-3 parts of magnesium oxide. The sealing gasket has the advantages of good high-temperature resistance, good sealing performance, good flame retardation, good corrosion resistance, realization of long-term working in mediums comprising acids, alkalis, oils and the like, small volume and hardness changes, no adhesion on the metal surface, small friction coefficient, good abrasion resistance, combination flexibility with the sealing surface, good weather ageing and ozone ageing resistances, durability and the like.

Owner:凭祥市新秀新材料科技有限公司

Thermal insulation waterproof paint

The invention discloses thermal insulation waterproof paint which consists of the following raw materials in parts by weight: 70-76 parts of silicone acrylic emulsion, 0.7-1 part of triterpenoid saponin, 2-3 parts of hexafluorobutyl acrylate, 1-2 parts of ammonium polyphosphate, 0.7-1 part of N-hydroxymethyl acrylamide, 0.1-0.3 part of polybenzimidazole, 1.3-2 parts of hydrogenated castor oil, 3-4 parts of ceramic powder, 1-2 parts of diacetone alcohol, 0.1-0.2 part of molybdenum boride, 1-2 parts of saturated stearamide, 0.8-1 part of dibutyl maleate, 6-8 parts of quartz sand, 0.5-1 part of ammonium trimolybdate, 6-8 parts of coalescing agents and 10-30 parts of deionized water. The waterproof paint has high fluidity and adhesiveness; and due to the addition of the ammonium trimolybdate and ceramic powder, the gas tightness, elasticity and wear resistance of the film can be effectively improved, and the water resistance of the film is further enhanced.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

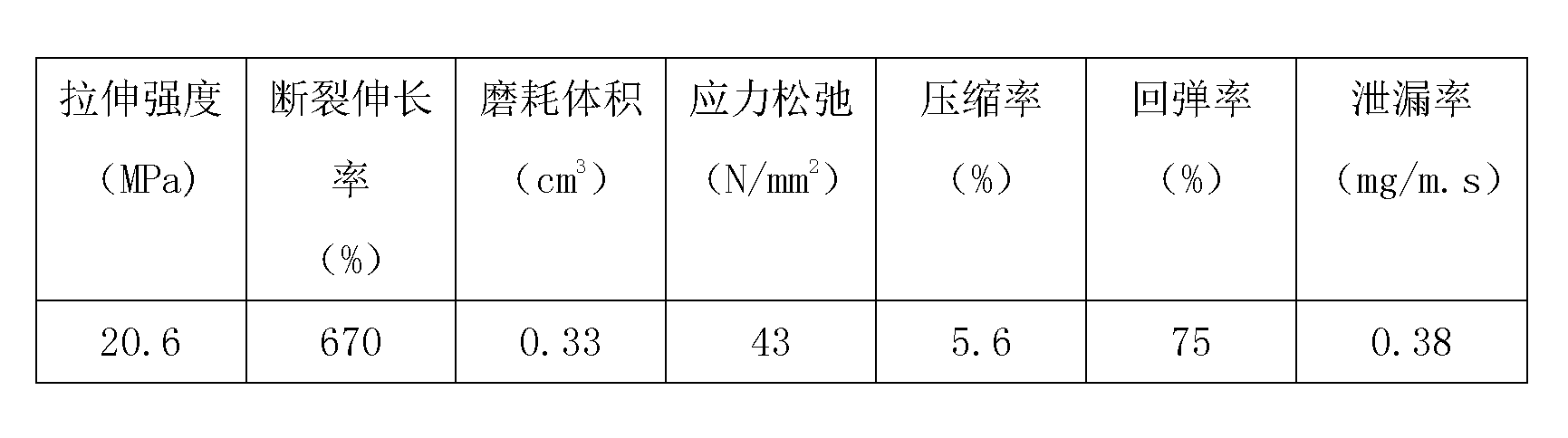

High-oil-resistance high-wear-resistance sealing gasket and preparation method thereof

The invention discloses a high-oil-resistance high-wear-resistance sealing gasket and a preparation method thereof, relating to the technical field of sealing gaskets. The high-oil-resistance high-wear-resistance sealing gasket is mainly prepared from nitrile-butadiene rubber, natural rubber, silicon rubber, halloysite, spherical silicon micropowder, carbon black N660, zinc stearate, dibutyl maleate, zinc oxide, aluminum oxide, polyethyleneglycol, sodium tripolyphosphate, a silane coupling agent KH550, nano chromium boride, a nano carbon sol, an anti-aging agent RD, rosin and castor oil. By using the nitrile-butadiene rubber as the main raw material, the sealing gasket has high oil resistance and wear resistance. By matching the natural rubber and silicon rubber, the sealing gasket overcomes the defects of the nitrile-butadiene rubber in aspects of elasticity and cold resistance. The added chromium boride, halloysite, nano carbon sol and the like can enhance the stretching resistance and mechanical properties of the sealing gasket and also enhance the wear resistance and aging resistance of the sealing gasket. The produced sealing gasket has the advantages of favorable overall performance, high applicability and long service life.

Owner:南通鼎佳橡胶科技有限公司

Flame-retardant polypropylene cable material

The invention discloses a flame-retardant polypropylene cable material. The flame-retardant polypropylene cable material is prepared from 100-110 weight parts of chlorinated polyethylene, 10-20 weight parts of isotactic polypropylene, 1-2 weight parts of magnesium stearate, 10-15 weight parts of aluminum hydroxide, 2-4 weight parts of magnesium hydroxide, 1-2 weight parts of dibutyl maleate, 1.5-3 weight parts of calcium oxide, 0.8-1 weight part of zinc oxide, 0.4-0.6 weight parts of zinc stearate, 0.3-0.5 weight parts of phthalic polyester, 1-2 weight parts of epoxidized soybean oil, 1-2 weight parts of barium sulfate, 60-70 weight parts of modified dolomite powder, 1-2 weight parts of methyltrimethoxysilane and 1.4-3 weight parts of an anti-oxidant DLTP.

Owner:安徽华鸿电气股份有限公司

Special epoxy-cotton-oil-containing binding agent for automobile interior ornament surface composite leather

InactiveCN103087655AImprove temperature resistanceComposite effect levelingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer science(Hydroxyethyl)methacrylate

The invention discloses a special epoxy-cotton-oil-containing binding agent for automobile interior ornament surface composite leather, which is prepared from the following raw materials in parts by weight: 58-62 parts of EVA (ethylene-vinyl acetate), 14-18 parts of octyl phenolic resin 203, 10-12 parts of C5 petroleum resin, 0.5-1 part of WPP polypropylene wax, 5-7 parts of oxidized polyethylene wax, 6-8 parts of modified bamboo charcoal powder, 2-3 parts of rice hull ash, 1-2 parts of nano carbon, 0.8-1.3 parts of silane coupling agent KH550, 0.1-0.2 part of antioxidant 264, 0.8-1.2 parts of antioxidant 3010, 1-2 parts of n-butyl methylacrylate, 0.5-1 part of hydroxyethyl methacrylate, 0.3-0.5 part of dibutyl maleate, 0.3-0.6 part of epoxy cotton oil and 0.1-0.2 part of triethyl citrate. The raw materials for preparing the binding agent contain the modified bamboo charcoal powder, rice hull ash and nano carbon, and thus, the binding agent has the advantages of favorable temperature tolerance and flat composite effect, can not bubble after long-term usage, and is very suitable for automobile interior ornament surface composite leather.

Owner:WUHU ZHONGLI PARTS

Polyethylene/nylon composite material and preparing method thereof

The invention discloses a polyethylene / nylon composite material. The polyethylene / nylon composite material comprises, by weight, 10-20 parts of polyethylene, 30-60 parts of nylon 6, 2-8 parts of nano silicon dioxide, 1-5 parts of dibutyl maleate, 2-6 parts of zinc maleate, 5-8 parts of glass fibers, 1-3 parts of silane coupling agent, 6-10 parts of white oil, 1-5 parts of octadecyl trimethyl ammonium chloride, 0.1-0.3 part of dicumyl peroxide, 0.8-2.5 parts of antioxygen and 1-3 parts of other auxiliaries. The invention further discloses a preparing method of the polyethylene / nylon composite material. The polyethylene / nylon composite material is good in heat resistance and high temperature resistance, excellent in low temperature impact resistance, good in waterproof performance, and high in dimensional stability; in addition, the raw materials are nontoxic, and environmental protection is facilitated.

Owner:SUZHOU HONGHENG CHEM

Calcium sulfate crystal whisker modified chlorosulfonated polyethylene rubber cable material

InactiveCN102964706AImprove flame retardant performanceImprove heat resistancePlastic/resin/waxes insulatorsPolymer scienceDi-tert-butyl peroxide

The invention discloses a calcium sulfate crystal whisker modified chlorosulfonated polyethylene rubber cable material. The cable material is prepared from the following raw materials in parts by weight: 100-120 parts of chlorosulfonated polyethylene rubber CSM2305, 20-30 parts of Lanxess Deutschland 9650 ethylene propylene diene copolymer, 10-20 parts of brominated butyl rubber 2244, 5-10 parts of n-octyl-n-decyl adipate, 5-10 parts of tri(2-chloroethyl) phosphate, 10-15 parts of dibutyl maleate, 1-2 parts of sulphur, 4-6 parts of di-tert-butyl peroxide, and the like. The cable material not only has excellent flame retardance and incombustibility, but also has the advantages of good high and low temperature resistance, corrosion resistance, water resistance, wear resistance, ozone resistance, ageing resistance and the like at the same time, and is durable in use.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

Preparation method of modified carboxylic acid water reducer

The invention relates to a preparation method of a modified carboxylic acid water reducer. The preparation method comprises adding acrylamide, sodium lignosulphonate, maleic anhydride, methacrylic acid, dibutyl itaconate, dibutyl maleate, a silane coupling agent and a catalyst into a reactor with a water bath, adding deionized water into the reactor, feeding inert gas into the reactor to remove oxygen, carrying out a stirring reaction process, adding polyoxyethylene isopentenyl ether, maleic anhydride, cyclohexyl methacrylate, acyclic acid, maleic anhydride, sodium methallyl sulfonate, dimethylaminoethyl methacrylate and an azo-initiator into the mixture, continuously feeding inert gas into the mixture, carrying out a stirring reaction process, stopping stirring and inert gas feeding after the reaction is finished, adjusting pH by an alkaline solution and carrying out discharging to obtain the desired product. Through a polymerization monomer, a polycarboxylic acid host molecule is modified and cement particles can be coated so that dispersibility is improved.

Owner:宋介珍

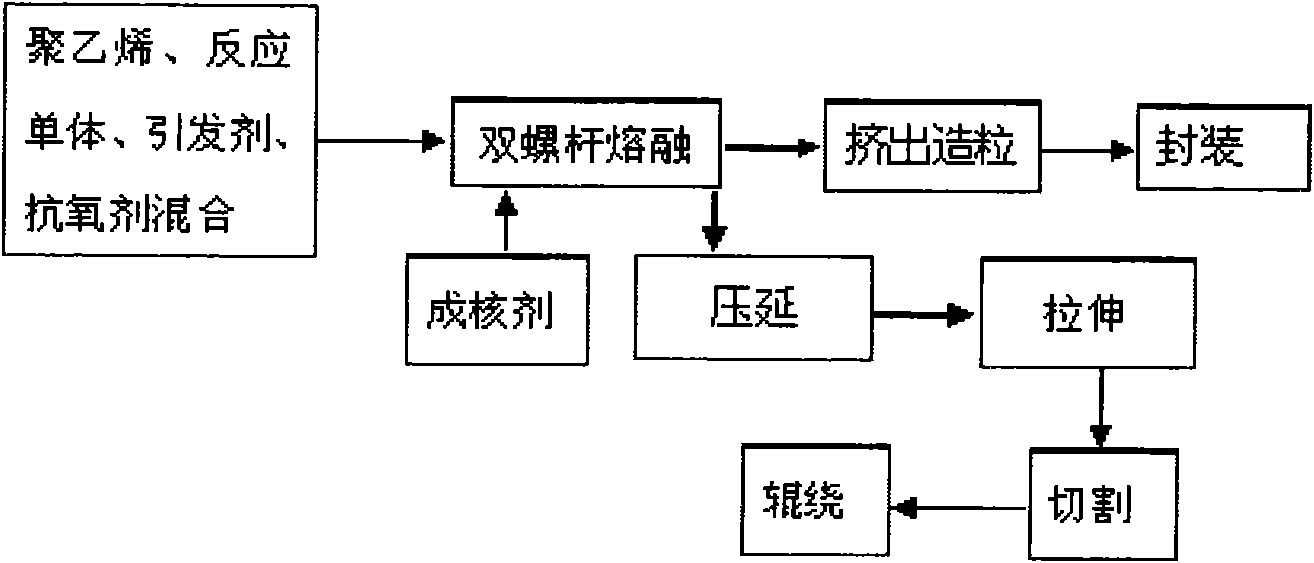

Polyethylene glue nucleation melting-boosting adhesive special for oil and gas pipelines

InactiveCN101643634AUniform and stable structureHigh mechanical strengthGraft polymer adhesivesAdhesivePhosphate

The invention discloses a polyethylene glue nucleation melting-boosting adhesive special for oil and gas pipelines. The adhesive comprises the following raw materials in percentage by mass: 60 to 80 percent of polyethylene, 5 to 20 percent of reaction monomer, 0.1 to 1 percent of initiator, 0.5 to 5 percent of nucleating agent, 0.1 to 2 percent of anti-oxidant, and 5 to 25 percent of carbon black,wherein the reaction monomer may be one or more of maleic anhydride, dibutyl maleate or derivatives of acrylamide; the initiator may be one of dibenzoyl peroxide, dicumyl peroxide, ditert-butyl peroxide, tert-butyl hydroperoxide or cumene hydroperoxide; the nucleating agent is selected from benzyl sorbitol derivative series nucleating agent or phosphate salt derivative series nucleating agent; and the anti-oxidant is the main anti-oxidant 1010 and the auxiliary anti-oxidant 618. The adhesive has the advantages of excellent mechanical property, wear-resisting property and thermal property andwide application.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL +3

Nanometer meerschaum-modified chlorhydrin rubber gasket and preparation method thereof

ActiveCN102977581AImprove flame retardant performanceAccelerated corrosionPolymer scienceLead phosphate

The invention discloses a nanometer meerschaum-modified chlorhydrin rubber gasket. Raw materials for the nanometer meerschaum-modified chlorhydrin rubber gasket comprise, by weight, 135 to 145 parts of chlorhydrin rubber H45, 10 to 15 parts of butyl rubber CBK139, 5 to 10 parts of chloroprene rubber A-90, 3 to 5 parts of triethyl acetyl citrate, 3 to 5 parts of dibutyl maleate, 1 to 2 parts of dibasic lead phosphate, 1 to 2 parts of sulphur, 3 to 5 parts of zinc oxide, 1 to 2 parts of sodium polyoxyethylene fatty alcohol ether sulfate, 40 to 50 parts of nanometer meerschaum powder, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Highly oil-resistant chloroprene rubber sealing gasket and preparation method thereof

The invention discloses a highly oil-resistant chloroprene rubber sealing gasket comprising the following raw materials in parts by weight: 35-145 parts of chloroprene rubber CR1211, 20-25 parts of epichlorohydrin rubber, 10-20 parts of SG-2 type PVC (Polyvinyl Chloride) resin, 2-5 parts of tri(2-ethylhexyl)acetocitrate, 3-5 parts of dioctyl epoxy tetrahydrophthalate, 3-5 parts of dibutyl maleate, 1-2 parts of sodium alcohol ether sulphate, 30-40 parts of nano argil, 30-35 parts of carbon black N220, 30-35 parts of nano calcium carbonate powder and the like. The chloroprene rubber sealing gasket has excellent oil resistance and solvent resistance, is capable of satisfying the sealing requirement on an engine sump, and is easy to peel after being solidified, and cleanable and repairable without affecting dismounting and repairing.

Owner:ANHUI RONGDA VALVE

Method for synthesizing dibutyl maleate

InactiveCN101239912AReduce dosageNo pollution in the processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsN-ButanolMalic acid

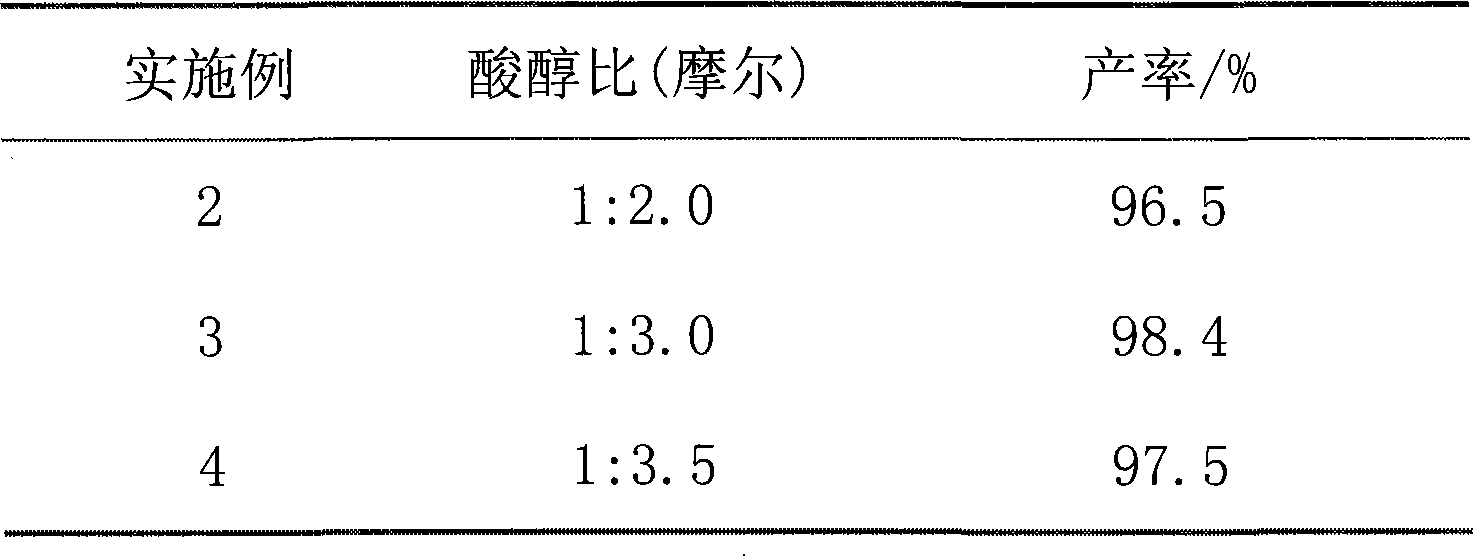

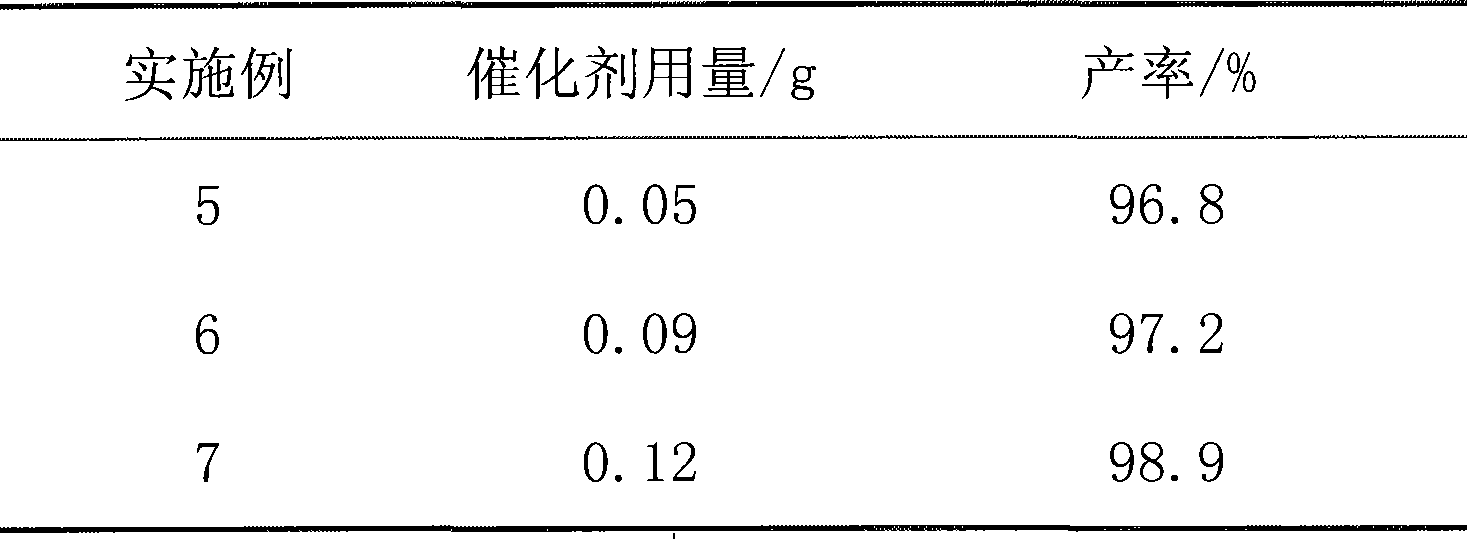

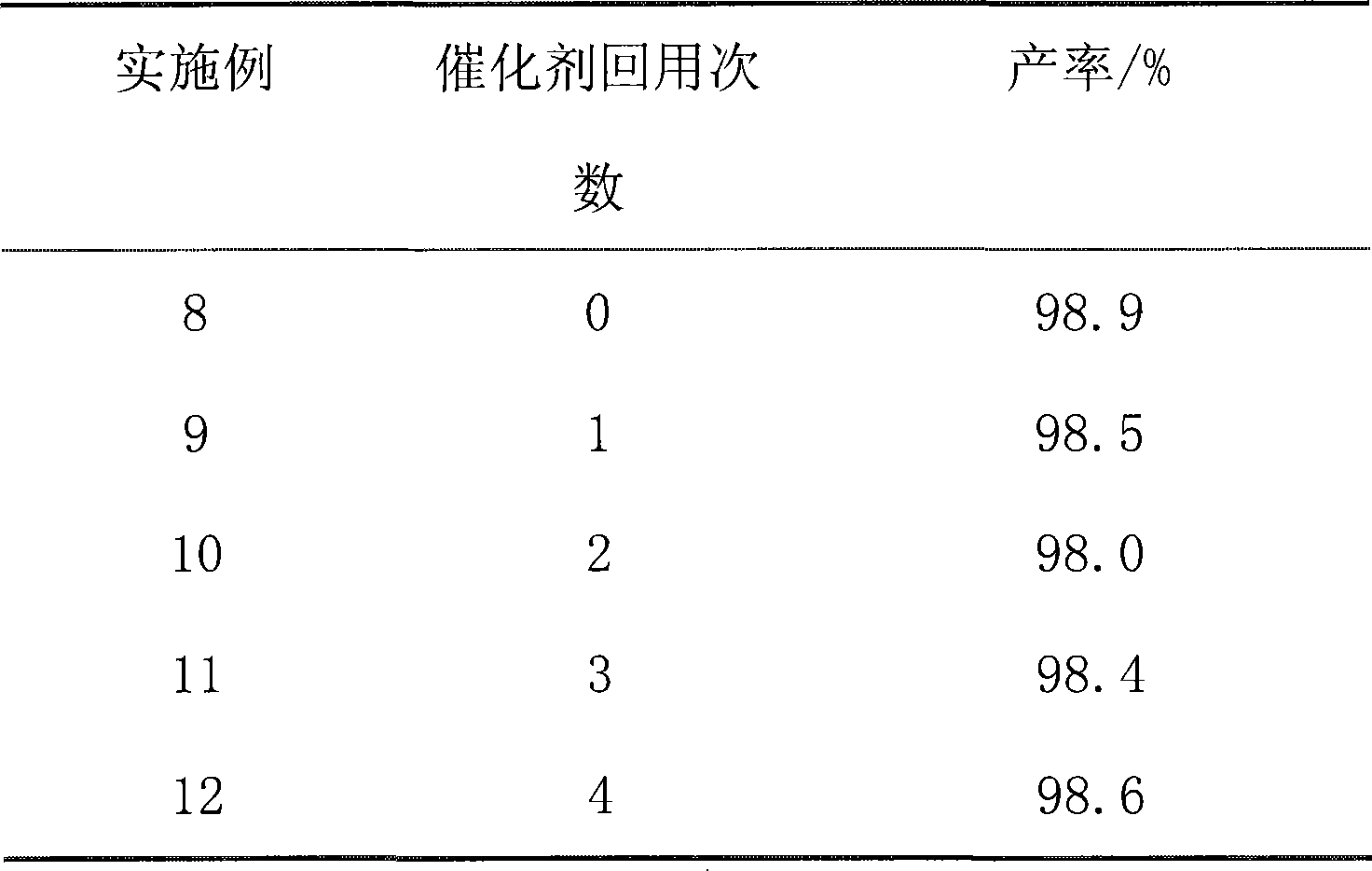

The invention discloses a method for synthesizing dibutyl malate, which uses malic acid and n-butanol as reaction articles, uses naphthalenesulfonic acid methylal as the catalyst during the ester synthesis process, filtering the catalyst from reacted articles after reaction, water-washing, alkaline-washing, distilling the filtrate to obatin dibutyl malate. The invention has the advantages of: (1) high yield of 95.5-99.6%, (2) cheap catalyst and small usage which is 0.1-2.0% of the total weight of the reaction materials; (3) gentle reaction condition, short reaction time; (4) repeatedly-usable catalyst; (5) no environmental contamination.

Owner:EAST CHINA NORMAL UNIV

Antibacterial polyvinyl chloride plastic tube and preparation method thereof

InactiveCN105778351AHigh mechanical strengthImprove antibacterial and antiseptic effectPolyvinyl chlorideCarbon nanotube

The invention discloses an antibacterial polyvinyl chloride plastic tube and a preparation method thereof. The antibacterial polyvinyl chloride plastic tube consists of the following raw materials in parts by weight: 0.1-0.2 part of isothiazolinone, 0.7-1 part of polybenzimidazole, 2-3 parts of calcium propionate, 0.1-0.3 part of alkanolamide, 1-3 parts of palm wax, 3-5 parts of dibutyl maleate, 0.2-0.4 part of polypropylene oxide glyceryl ether, 1-2 parts of sodium diacetate, 3-4 parts of carbon nanotubes, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of a liquid ethylene propylene diene monomer, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride and 10-15 parts of attapulgite. By adopting the antibacterial polyvinyl chloride plastic tube, the antibacterial and anti-corrosion properties of a finished tube product are effectively improved, the adaptability of the tube to the environment is improved, and the service life of the tube is prolonged.

Owner:安徽玉发塑业有限公司

Bio-adhesive timber glue

InactiveCN105001809AImprove adhesionResilientNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberAdhesive

The invention discloses bio-adhesive timber glue. The bio-adhesive timber glue comprises, by weight, 0.2-0.4 parts of sarcosyl, 0.1-0.3 parts of polydimethylsiloxane, 0.1-0.2 parts of tri-n-butyltin chloride, 2-3 parts of bone black, 2-4 parts of distearyl thiodipropionate, 3-5 parts of trumpet shell powder, 0.4-1 part of linoleic acid, 3-4 parts of dibutyl maleate, 5-7 parts of perchloroethylene resin, 80-86 parts of chlorosulfonated polyethylene, 0.6-1 part of tert-butyl peroxyformate, 0.3-1 part of turpentine and 5-6 parts of a bio-adhesive. The bio-adhesive utilizes elm bark powder as a structure reinforcing agent and also utilizes high viscosity polyacrylamide so that the gel has fiber characteristics and a certain toughness and thus finished product viscosity is improved and finished product toughness is improved.

Owner:BENGBU HONGAN PRECISION MACHINERY

High-heat-resistant oil-resistant ethylene-acrylate rubber cable material

InactiveCN103554638AImprove performanceExcellent high temperature and oil resistanceInsulatorsPolystyreneEngineering

The invention relates to a cable material, particularly a high-heat-resistant oil-resistant ethylene-acrylate rubber cable material which comprises the following raw materials in parts by weight: 40-45 parts of ethylene-acrylate rubber (AEM), 20-24 parts of N339 carbon black, 12-15 parts of fluororubber, 20-24 parts of polystyrene, 1.5-2.5 parts of triallyl isocyanurate, 1.1-1.3 parts of accelerator CZ, 0.19-0.21 part of accelerator TT, 5-6 parts of zinc stearate, 18-22 parts of N220 carbon black, 20-22 parts of silica white, 2-4 parts of dibutyl maleate, 1-2 parts of imarcaptoacetate dioctyltin, 1-2 parts of dibasic lead phosphite, 1-2 parts of silane coupling agent KH550, 2-3 parts of crosslinking agent TAC, 5-8 parts of diglycol benzoate and 4-5 parts of assistant. The cable material combines the advantages of the AEM, fluororubber, polystyrene and other raw materials, and enhances the properties of the traditional ethylene-acrylate rubber cable material; and thus, the ethylene-acrylate rubber cable material has excellent high temperature resistance and oil resistance, can adapt to specific operating ambient conditions, is especially suitable for a high-temperature high-oil environment, and has wide market application prospects.

Owner:安徽文峰电子科技集团有限公司

Thixotropic anhydrous shear thinning peroxide dispersions

ActiveUS20110291045A1Easily pumped/pouredResistant to separationOther chemical processesTransportation and packagingSilicon dioxideFumed silica

Provided are dispersions which comprise more than about up to 55 percent by weight or more of an organic peroxide which is normally solid in an anhydrous liquid phase such as dibutyl maleate or dioctyl adipate, with about 5% by weight or more fumed silica to provide a thixotropic, storage stable organic peroxide paste. Addition of about 5 weight % or more of fumed silica was found to result in the formation of a shear thinning anhydrous dispersion of organic peroxide which was storage stable.

Owner:ARKEMA INC

Acrylic resin thermal transfer glue and preparation method thereof

The invention discloses acrylic resin thermal transfer glue and a preparation method thereof. The acrylic resin thermal transfer glue is prepared from the following raw materials in parts by weight: 25-28 parts of acrylic resin (AR-1520), 12-15 parts of polyisobutene, 4-6 parts of aminopropyltriethoxysilane, 3-5 parts of methyl triethoxysilane, 2-3 parts of dicumyl peroxide, 12-15 parts of dibutyl maleate, 4-6 parts of dodecyl mercaptan, 5-8 parts of rosin, 1-2 parts of cross-linking agent TAC, 3-5 parts of dioctyl phthalate, 1-2 parts of 1-hydroxyethyl-2-oleic imidazoline, 2-3 parts of p-phenylenediamine, 55-60 parts of acetone and 40-45 parts of xylene. Compared with the prior art, the acrylic resin thermal transfer glue disclosed by the invention has the advantages of firm bonding and rare breakage, drop and yellowing, and improves the product quality. According to the invention, the rosin and polyisobutene are added into the formula, thus the bonding capacity is greatly improved through polymerization cross-linking, and the weather resistance is improved. The corrosion resistance is greatly improved by the 1-hydroxyethyl-2-oleic imidazoline.

Owner:ANHUI YICAI GLASSWARE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com