Highly oil-resistant chloroprene rubber sealing gasket and preparation method thereof

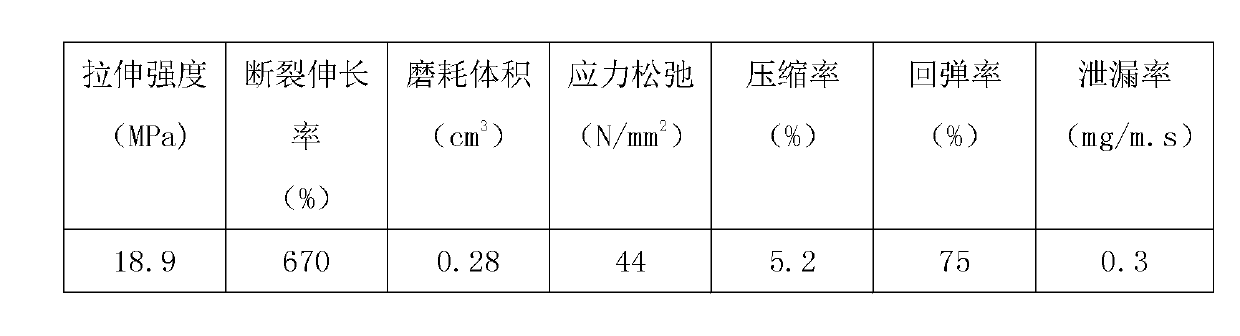

A neoprene rubber and gasket technology, applied in the field of gaskets, can solve the problems that the gasket can not meet the requirements, the material is not easy to remove, the adhesion is small, etc., and achieves excellent effects, good weathering and ozone aging resistance, and compression. Good effect of sex and resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A kind of high oil-resistant neoprene sealing gasket, the parts by weight of its raw materials are: 138 parts of neoprene rubber CR121, 22 parts of chlorohydrin rubber H45, 15 parts of SG-2 type PVC resin, acetyl citrate tris(2-ethyl 3 parts of hexyl) ester, 4 parts of dioctyl epoxy tetrahydrophthalate, 4 parts of dibutyl maleate, 2 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 36 parts of nano clay, carbon black 32 parts of N220, 35 parts of nano calcium carbonate powder, 1.5 parts of isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate, 2.5 parts of antioxidant 1035, 1.6 parts of antioxidant RD, 2- 1.8 parts of mercaptobenzimidazole, 2 parts of accelerator Na-22, 3 parts of accelerator DM, 4 parts of sulfur, 4 parts of zinc oxide, 5 parts of rhine wax, 2 parts of lubricant TR121, and 2 parts of modified tree ash.

[0016] Wherein, the modified tree ashes are prepared by the following method: first soak the tree ashes with 12% hydrogen per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com