Patents

Literature

84results about How to "Repairable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room-temperature cured epoxy resin flexible sealant and preparation method thereof

InactiveCN102417805ASimple preparation processMedium viscosityNon-macromolecular adhesive additivesOther chemical processesEpoxyPlasticizer

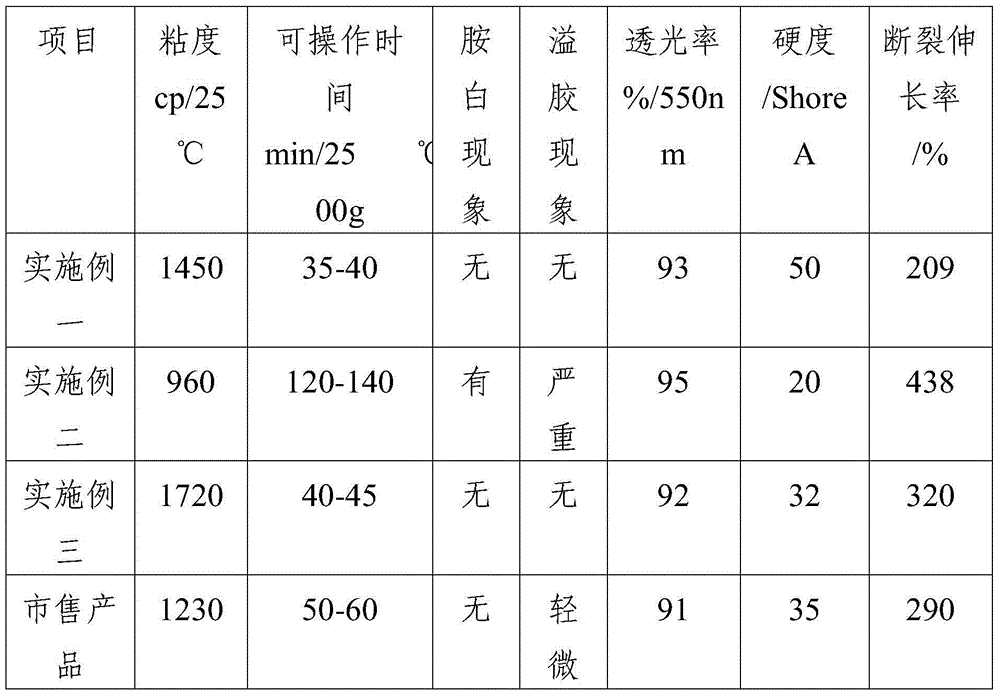

The invention discloses a room-temperature cured epoxy resin flexible sealant and a preparation method thereof. The room-temperature cured epoxy resin flexible sealant comprises a component A and a component B, wherein, the component A comprises 40-80 weight portions of epoxy resin, 10-40 weight portions of diluent, 10-30 weight portions of plasticizer, 0.5-5.0 weight portions of silane coupling agent, 0.05-2.0 weight portions of antifoaming agent, and 0.2-2.0 weight portions of anti-oxidant, the component B comprises 10-50 weight portions of aliphatic short-chain amine curing agent and 30-90 weight portions of aliphatic long-chain amine curing agent, and the weight ratio of the component A to the component B is (0.8-1.0):1.0. The invention further discloses a preparation method of the epoxy resin flexible sealant. The epoxy resin flexible sealant disclosed herein has moderate mixing viscosity and good levelability, and can be rapidly cured at room temperature. The cured substance has good light transmittance and flexibility, and can be applied for surface coating of LED strip light, LED path light, LED mold strip and other technology products.

Owner:CHANGSHA LANXING CHEM NEW MATERIAL

Normal-temperature-curing epoxy resin flexible pouring sealant

ActiveCN104388029AHigh light transmittanceWill not affect the light brightnessMacromolecular adhesive additivesEpoxy resin adhesivesFlexible circuitsPlasticizer

The invention discloses a normal-temperature-curing epoxy resin flexible pouring sealant and relates to the technical field of polymer materials. The normal-temperature-curing epoxy resin flexible pouring sealant is prepared by mixing a component A and a component B in equal parts by weight, wherein the component A comprises 60-90 parts of epoxy resin, 10-30 parts of reactive diluent, 5-10 parts of a plasticizer, 1-5 parts of a silane coupling agent, 0.5-2 parts of a defoaming agent, 0.5-2 parts of an antioxidant and 0.5-1 part of an ultraviolet absorber; and the component B comprises 1-3 parts of an accelerator, 30-60 parts of polyether amine and 0-50 parts of modified amine prepolymer I and 0-55 parts of modified amine prepolymer II. The ambient-curing epoxy resin flexible pouring sealant has the characteristics that the pouring sealant can be rapidly cured under the room temperature condition and is especially suitable for pouring LED flexible strips and the cured substance has better flexibility and higher elongation at break and transparency and the like and is suitable for pouring and sealing the surfaces of products having requirements on flexibility and transparency, for example, surface coating of LED flexible strips, LED module strips, flexible circuit boards and the like.

Owner:HUNAN HAOZHI TECH

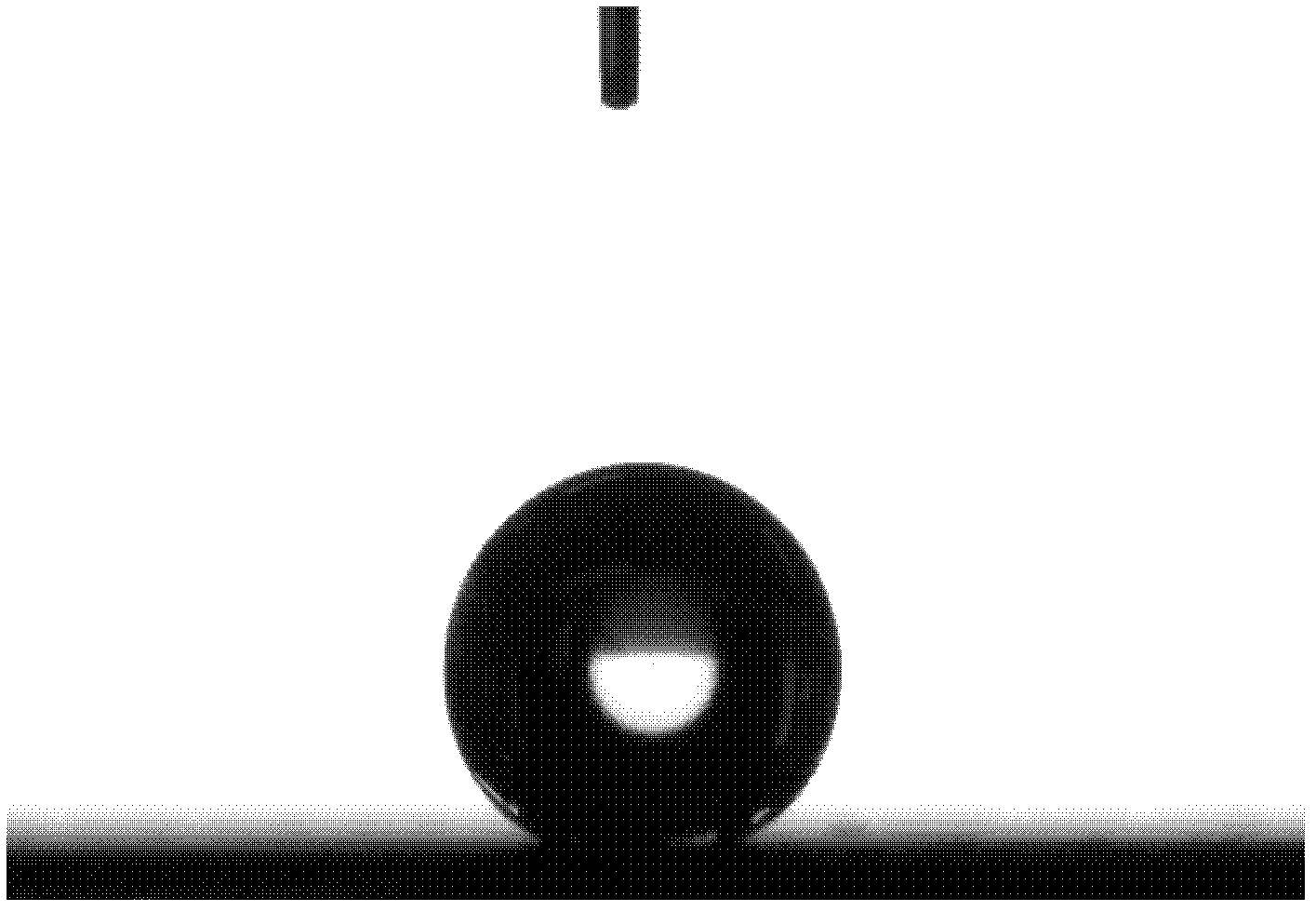

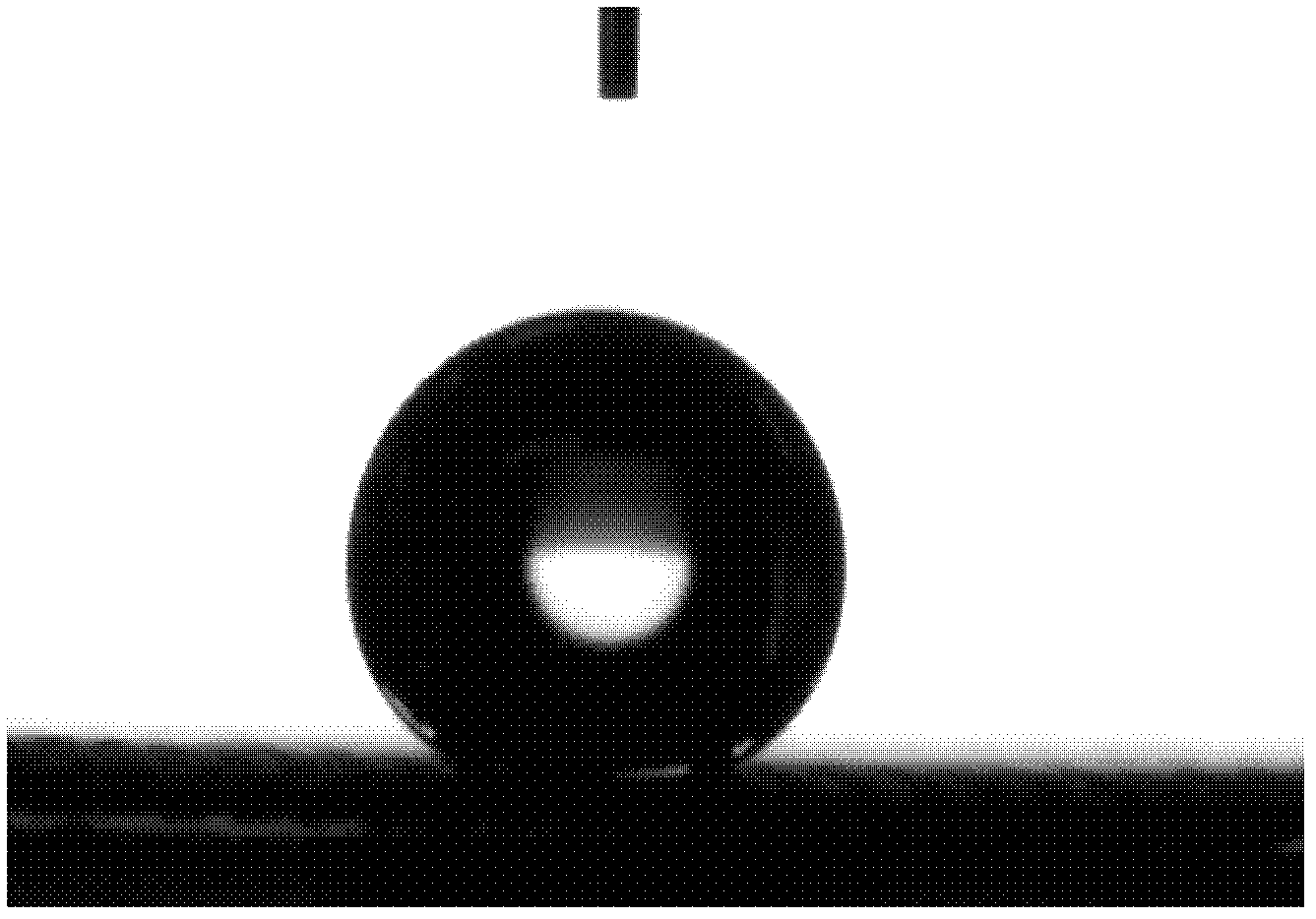

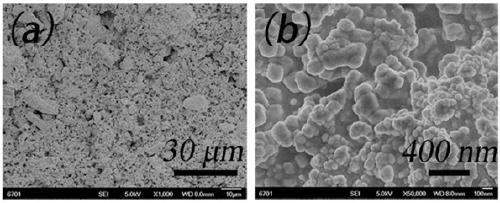

Drag reduction superhydrophobic coating and preparation method thereof

InactiveCN102492942AImprove hydrophobicityAntisepticVacuum evaporation coatingSputtering coatingReduction rateStrong acids

A drag reduction superhydrophobic coating and a preparation method thereof belong to the technical field of functional nanometer material application. A base of the drag reduction superhydrophobic coating adopts electroless metal deposition technique, a precious metal micro-nanometer binary grading composite structure is constructed on the base and decorated by a low surface energy material, a water static contact angle of the coating is larger than 150 degrees, and a rolling angle is smaller than 5 degrees. The drag reduction superhydrophobic coating is used for a model with motive power by itself, running speed of the model is obviously increased, and drag reduction rate is as high as 20%. The drag reduction superhydrophobic coating has good corrosivity resistance and can resist corrosion of strong acid and strong base solutions. The drag reduction superhydrophobic coating has repairability, and the preparation method can enable hydrophobicity of damaged areas to be rapidly recovered in a short period. The preparation method of the drag reduction superhydrophobic coating is simple, short in preparation period, and high in drag reduction rate.

Owner:BEIJING UNIV OF CHEM TECH

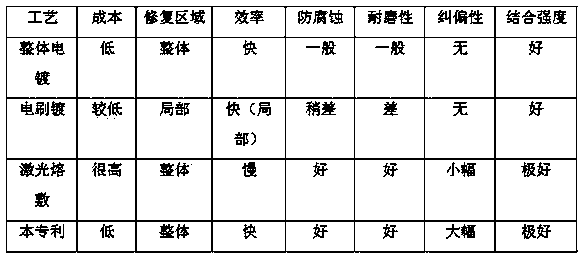

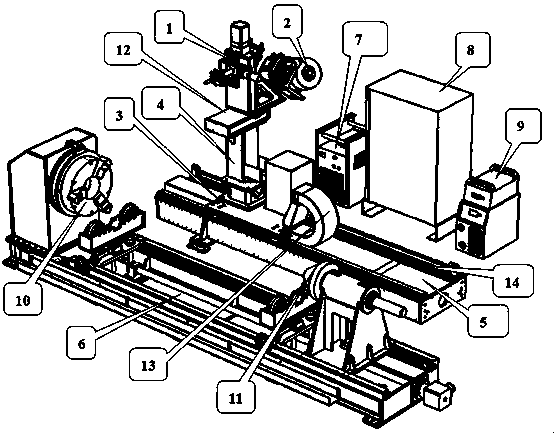

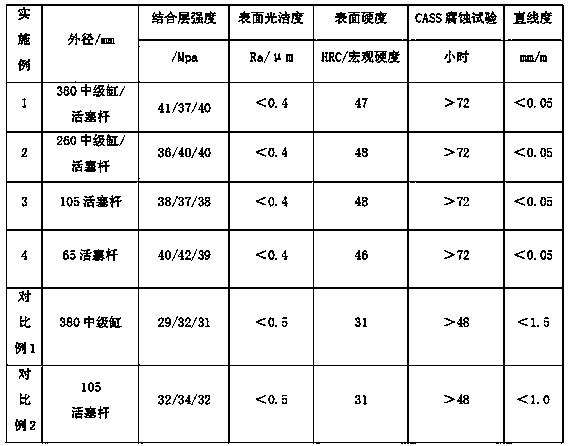

Method for repairing and remanufacturing outer surface of piston rod of hydraulic cylinder or outer surface of intermediate cylinder

ActiveCN104191152AHigh surface macrohardnessImprove wear resistanceArc welding apparatusHydraulic cylinderMetal filament

The invention provides a method for repairing and remanufacturing the surface of a piston rod of a hydraulic cylinder or the outer surface of an intermediate cylinder for coal mines. Aiming at remanufacturing after the surface of the piston rod of the hydraulic cylinder or the outer surface of the intermediate cylinder for the coal mines is damaged and fails, the long-term practice is combined, a metal wire adopting the specific metal powder proportion is creatively designed to serve as a powder core wire, and namely the metal wire is formed by wrapping the metal powder with Cr, Ni and Fe as the main ingredients through a stainless steel foil layer; based on the arc thermal spraying process method, the surface is repaired and remanufactured creatively, and on the premise that the corrosion resistance and the hardness of the repaired layer of the surface are equal to those of the surface treated through the surface laser cladding technology, consideration is given to the good economic applicability and the good practical production efficiency; an existing electroplating technology can be completely replaced, and the method has the wide application and popularization prospects in repairing of the piston rod of the hydraulic support oil cylinder and the intermediate cylinder for the coal mines.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

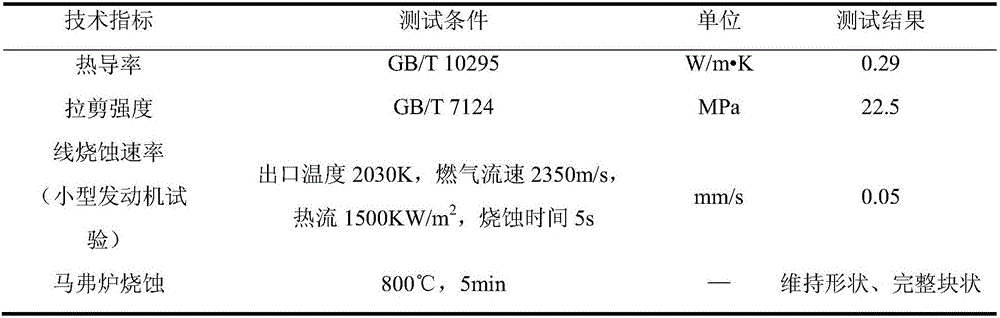

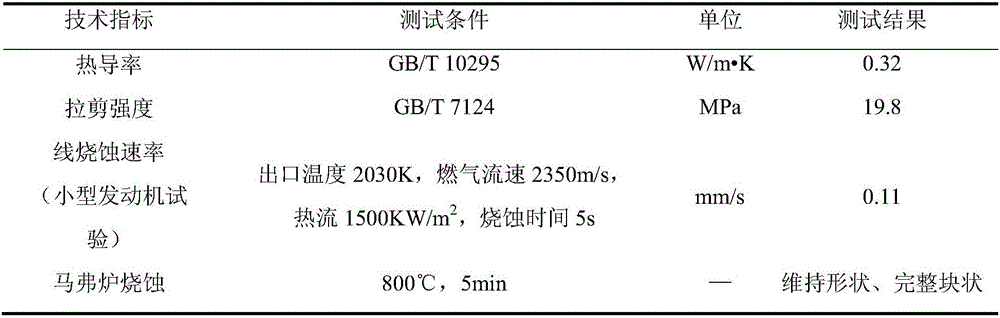

High-strength flame-retardant ablation-resistant coating and preparation method thereof

ActiveCN106467699AHigh heat resistanceImprove performanceFireproof paintsEpoxy resin coatingsFiberPolyamide

The invention relates to a high-strength flame-retardant ablation-resistant coating and a preparation method thereof. the coating comprises the following ingredients (by weight): 40-60 parts of high-temperature-resistant resin, 20-40 parts of an ablation-resistant filler, 5-15 parts of a flame-retardant filler, 15-35 parts of reinforced fiber, 0.5-2 parts of an auxiliary agent and 10-40 parts of a solvent. When the coating is used, 20-30 parts by weight of a polyamide curing agent and 0.3-2 parts by weight of a phenols curing agent promoter are added. Through a method of blade coating, roller painting and spraying for coating the surface of a device, a film is formed. In comparison with the prior art, the film formed by the coating can be resistant to instant high temperature of 1500 DEG C and above, has excellent flame-retardant effect and high bonding strength, and has been successfully applied to parts of guided missile launcher, etc. to effectively solve the thermal protection problem of the surface during missile launching, can be resistant to multiple times of ablation and scouring, and has repairability.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

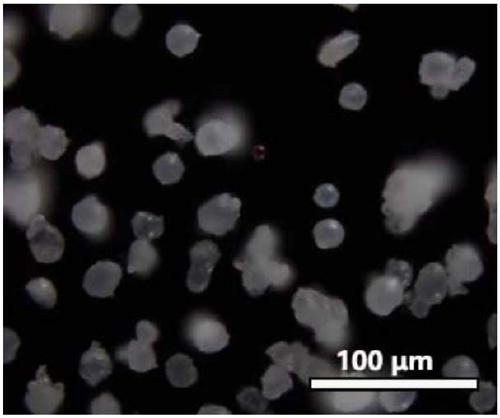

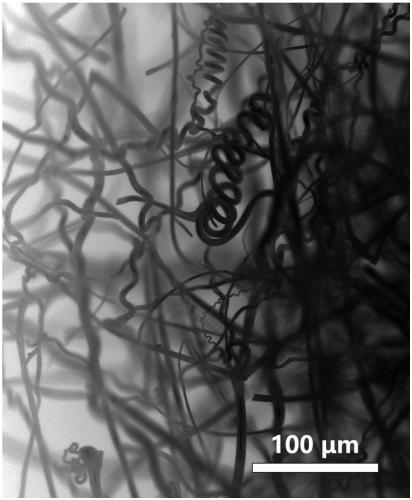

Ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application thereof

ActiveCN109161331AImprove the interface binding forceImprove erosion resistanceFireproof paintsPolymer scienceThermal insulation

The invention relates to a ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application of the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating, the ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating is a double-layer composite coating systemand is compounded from a TI thermal insulation coating on the inner layer and a TA ablation resistance coating on the outer layer, the thickness ratio of the TI thermal insulation coating to the TA ablation resistance coating is (4-7):(2-5), a component B is added in a component A of the TI coating prepared according to the formula in the application, the mixture is blended by using a solvent inthe component A to the specified spraying viscosity and is blade-coated, roller-coated or sprayed to the thickness of 4-7 mm on the surface of a device; a component D is added in a component C of theTA coating prepared according to the formula, the mixture is blended by using a solvent in the component C to the specified spraying viscosity, is sprayed on the surface of a dried TI coating film, and is blade-coated or roller-coated to the thickness of 2-5 mm. Compared with the prior art, the bonding strength of a formed coating is high, and the coating can resist the instantaneous high temperature of more than 1500 DEG C, has an excellent heatproof effect, effectively protects a launcher against ablation damages, and is higher in strength.

Owner:SHANGHAI JIAO TONG UNIV +1

A liquid metal-based frequency reconfigurable slot couple antenna

ActiveCN109244643AChange radiation areaChange radiation characteristicsSimultaneous aerial operationsRadiating elements structural formsIndiumElectronic switch

The invention belongs to the technical field of anteannae, and discloses a liquid metal-based frequency- reconfigurable slot couple antenna, which comprises a feed network and a radiating part, The feeding network is a lower layer dielectric substrate, and the radiation part is an upper layer dielectric substrate. A rectangular microstrip patch is printed on the upper surface of the upper dielectric substrate, and a microfluidic channel annular groove filled with liquid metal or Teflon solution is engraved inside the rectangular microstrip patch. The invention adopts liquid metal to realize the reconfigurable characteristic. Compared with the traditional reconfigurable antenna, a pair of antennas can be used to realize the reconfigurable characteristic, and the structure is simple. Liquidmetal reconfigurable is simpler than electronic switch in realizing reconfigurable and wider tuning range. The liquid metal is braked by microfluidic channel, which is easy to realize and control compared with other braking methods. Gallium-indium-tin alloy is used as liquid metal, which is low cost and non-toxic; A large bandwidth is realized by using slot coupling feed.

Owner:XIDIAN UNIV

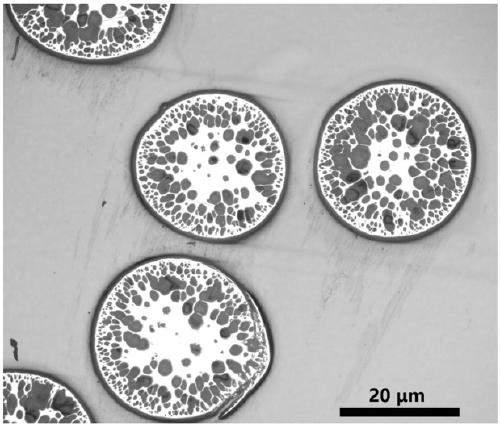

Sprayable silicone rubber-based lightweight ablation-resistant thermal insulation coating and application thereof

InactiveCN109852238AImprove toughnessImprove the interface binding forceFireproof paintsFilling pastesTetraethyl orthosilicateAstronautics

The invention relates to a sprayable silicone rubber-based lightweight ablation-resistant thermal insulation coating and an application thereof. The coating is prepared from a component A and a component B according to a mass ratio of 100:0.5 to 100:3, the component A is prepared from, by weight, 80-110 parts of room temperature-vulcanized silicone rubber, 40-50 parts of a flame-retardant filler,3-5 parts of a chopped carbon fiber filler, 10-12 parts of a silicon-based reinforcing filler, 0.5-1 part of a dispersing aid, 5-10 parts of a coupling agent and 100-150 parts of a solvent, and the component B is prepared from a cross-linking agent tetraethyl orthosilicate or hydrogen-containing silicone oil and a catalyst dibutyltin dilaurate or tetrabutyl titanate according to a mass part ratioof 7:3. Compared with coatings in the prior art, the coating in the invention has a higher bonding strength with the coating layer of a metal substrate; the chopped carbon fibers form a strong honeycomb structure in a residual carbon layer, so that the coating layer has excellent erosion resistance, and can effectively protect the surfaces of rockets and other aeronautics and astronautics devicesfrom being ablated and damaged; and the ablation products of the coating mainly comprise CO2 and SiO2, so the coating is green and non-polluting.

Owner:SHANGHAI JIAO TONG UNIV +1

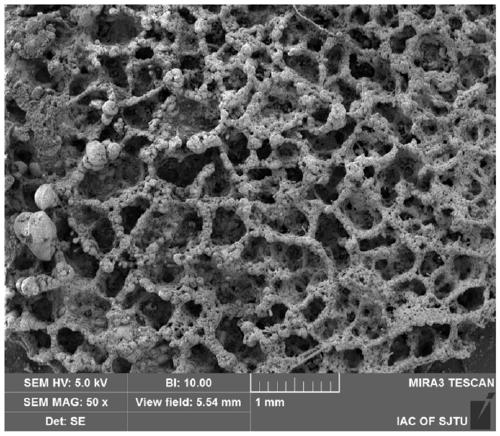

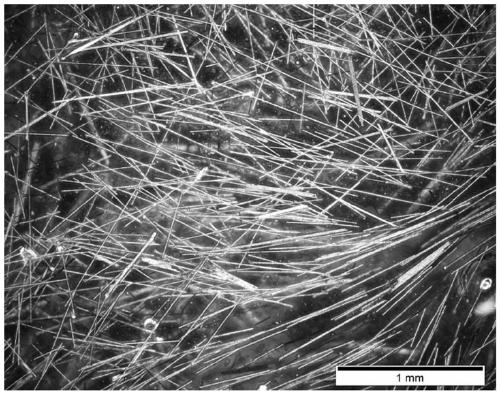

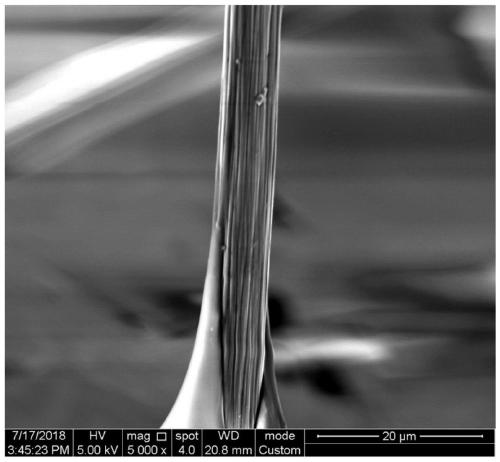

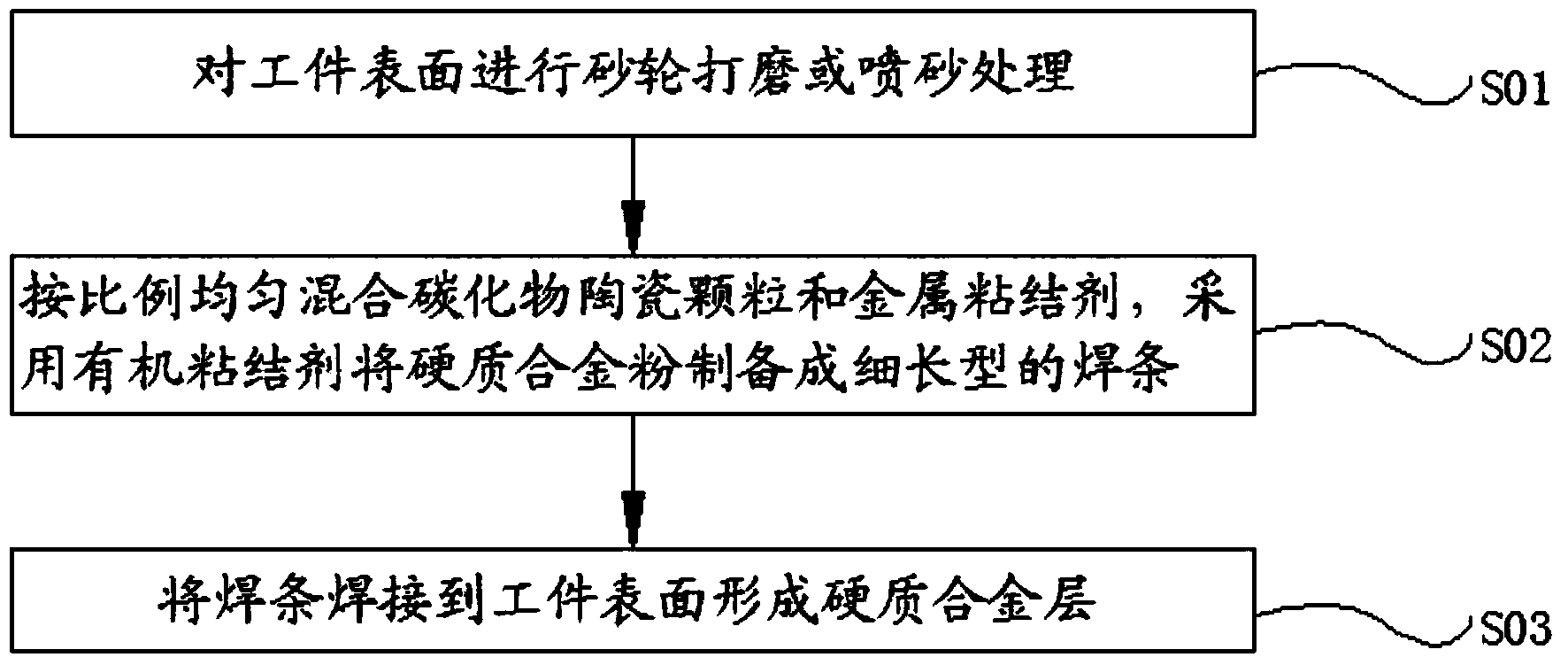

Hard alloy and method for producing hard alloy layer on surface of workpiece

InactiveCN103725944ARepairableGuaranteed bonding strengthPlasma welding apparatusGas flame welding apparatusAdhesiveSand blasting

The invention relates to a hard alloy and a method for producing a hard alloy layer on surface of a workpiece. The hard alloy is formed by taking carbide ceramic particles as a matrix and adding a metal adhesive for organically mixing, wherein the carbide ceramic particles refer to a mixture of one or several in WC, TiC, B4C and SiC; the metal adhesive is a mixture of one or several in Co, Ni, Mo, Fe-based alloy powder and Ti; the carbide ceramic particles account for 30-95 percent; the metal adhesive accounts for 5-70 percent. The method for producing the hard alloy layer on the surface of the workpiece comprises the following steps: 1, performing grinding wheel polishing or sand blasting treatment on the surface of the workpiece; 2, preparing the carbide ceramic particles and the metal adhesive which are uniformly mixed into a welding rod; and 3, welding the welding rod on the surface of the workpiece. According to an alloy layer welded on an outer surface of the workpiece, metallurgical bonding between a welding material and a workpiece matrix is ensured, the bonding strength is guaranteed, and the service life of the welded workpiece is increased by several times over.

Owner:烟台开发区蓝鲸金属修复有限公司

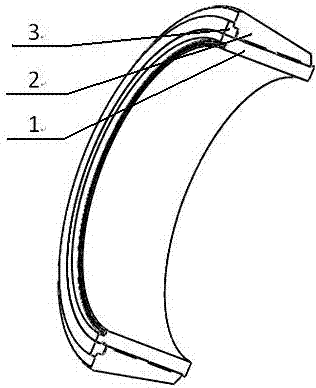

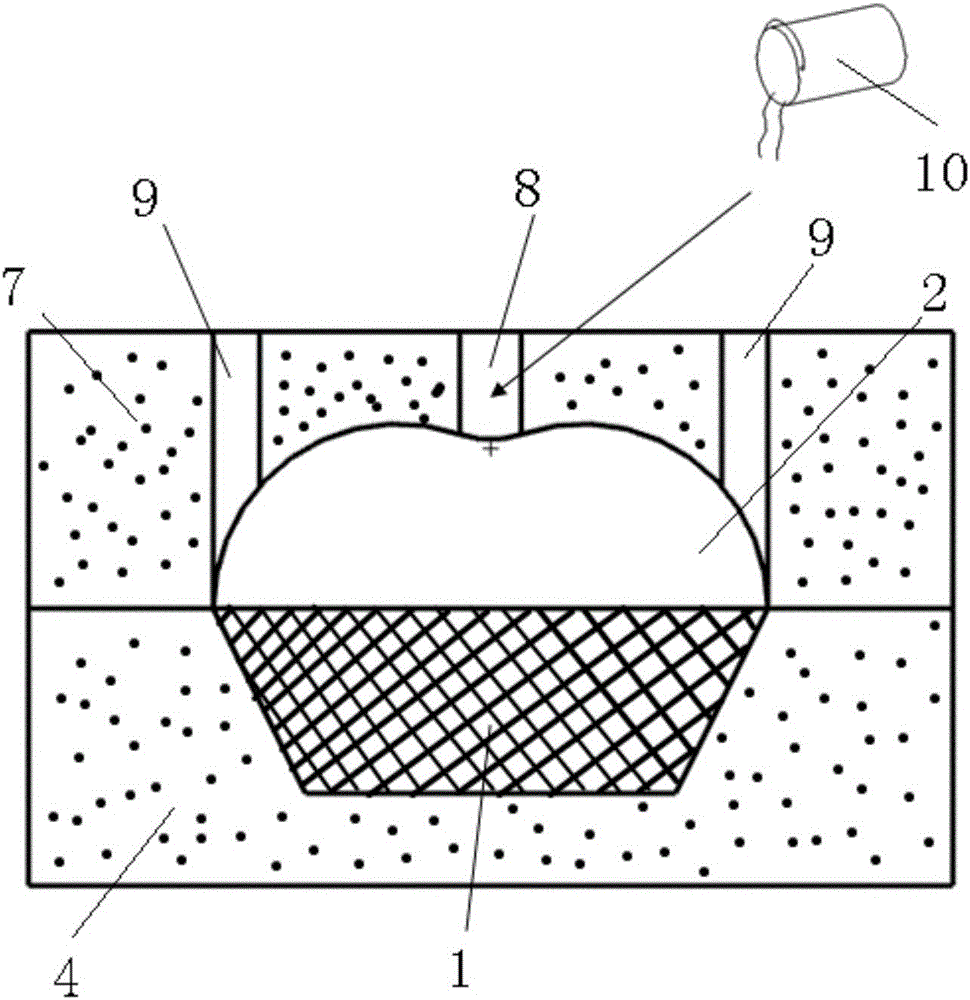

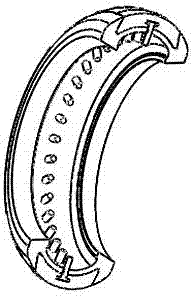

Low-cost repairable HP type ceramic composite grinding roller and manufacturing method

PendingCN107008535ARepairableWith self-locking abilityGrain treatmentsCeramic compositeMaterials science

The invention discloses a low-cost repairable HP type ceramic composite grinding roller and a manufacturing method. The grinding roller comprises a base body, a work layer and a positioning part; the work layer is assembled on the base body, one end of the work layer is limited through a limiting ring on the base body, the other end of the work layer is connected with the positioning part through a positioning groove, the joint position of the positioning part and the base body is welded and fixed, bosses which are arranged at intervals are arranged on the inner side face of the work layer, and a taper is arranged on the outer surface of the matching position of the base body and the work layer. According to the low-cost repairable HP type ceramic composite grinding roller and the manufacturing method, the high-wear-resisting composite grinding roller is prepared, the longer service life is achieved, meanwhile, the reparability is achieved, after wear, the base body is basically kept, the work layer is directly replaced, the grinding roller manufacturing method is simple, the machining period is short, and the cost is effectively reduced.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

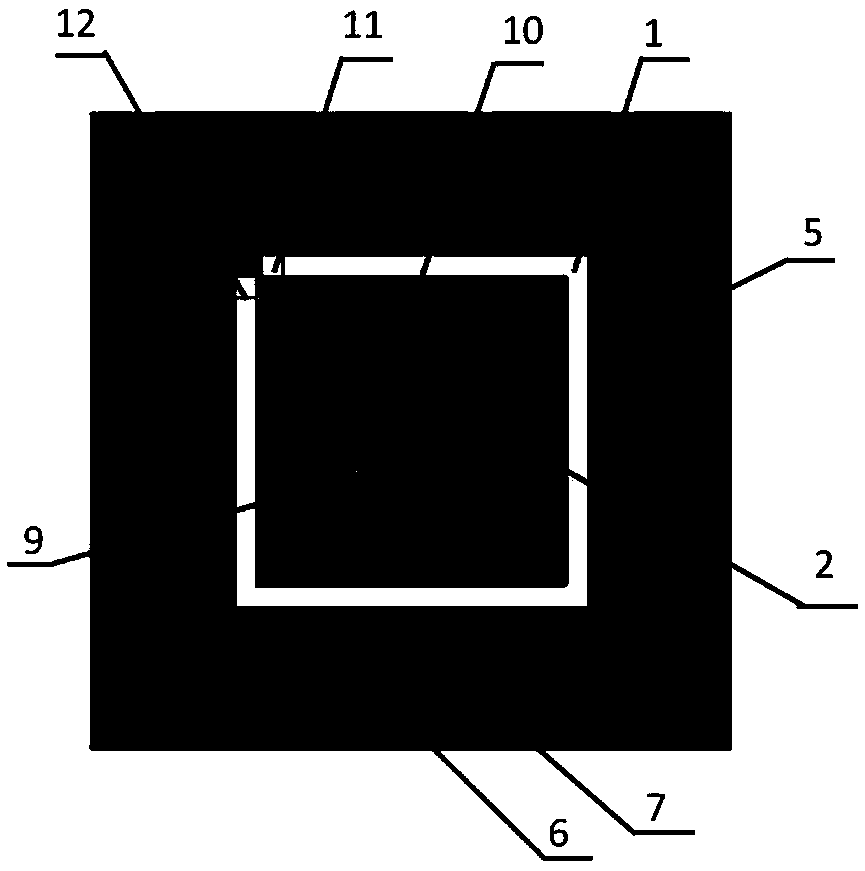

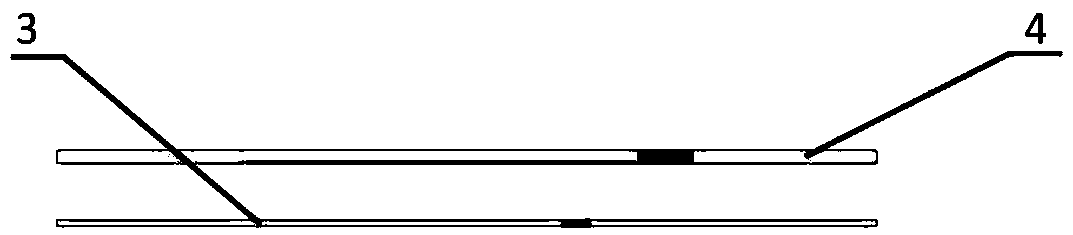

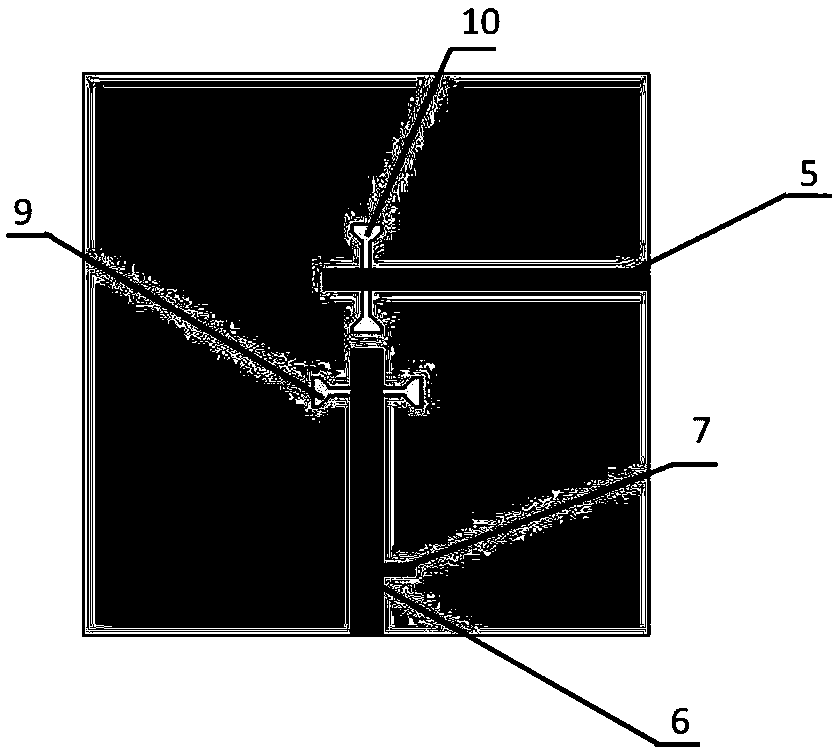

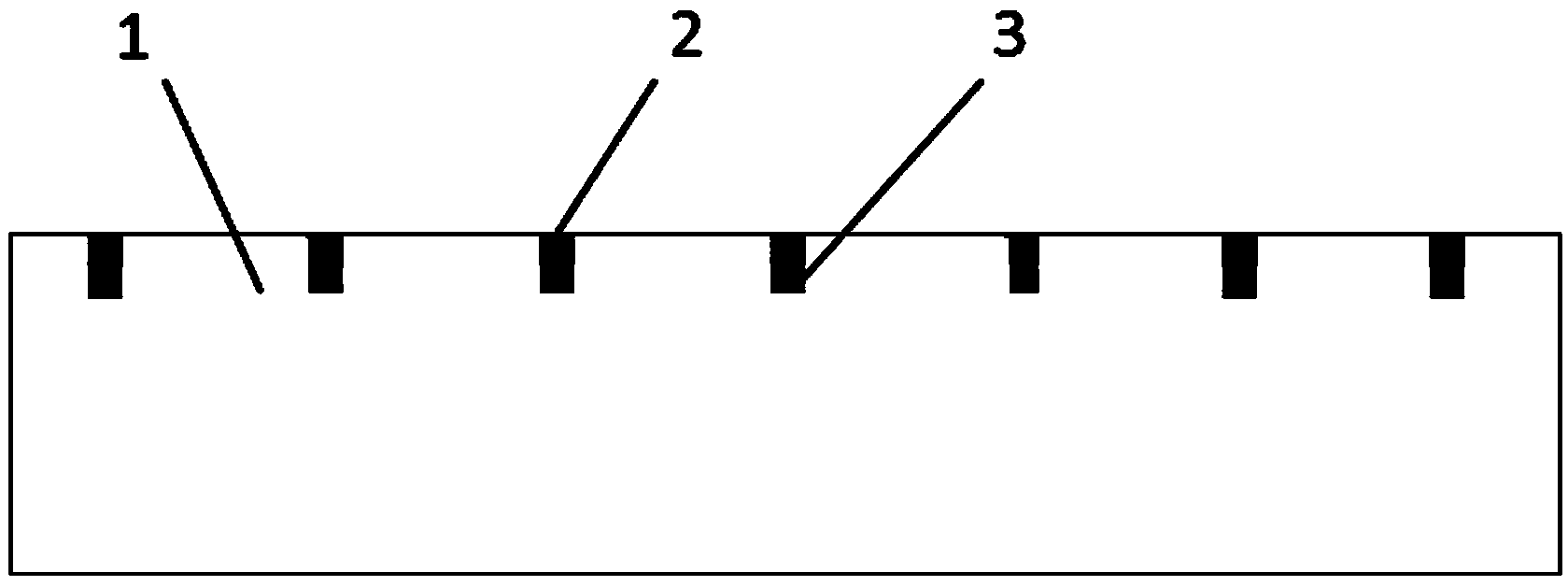

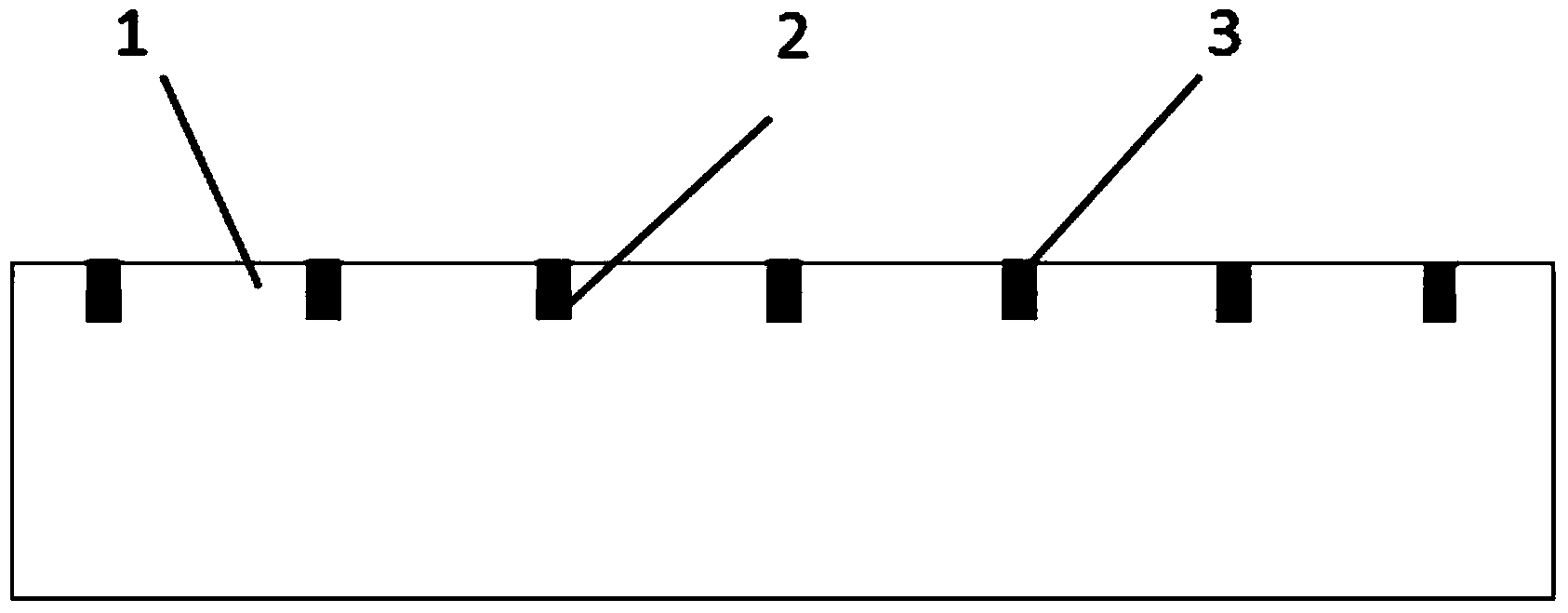

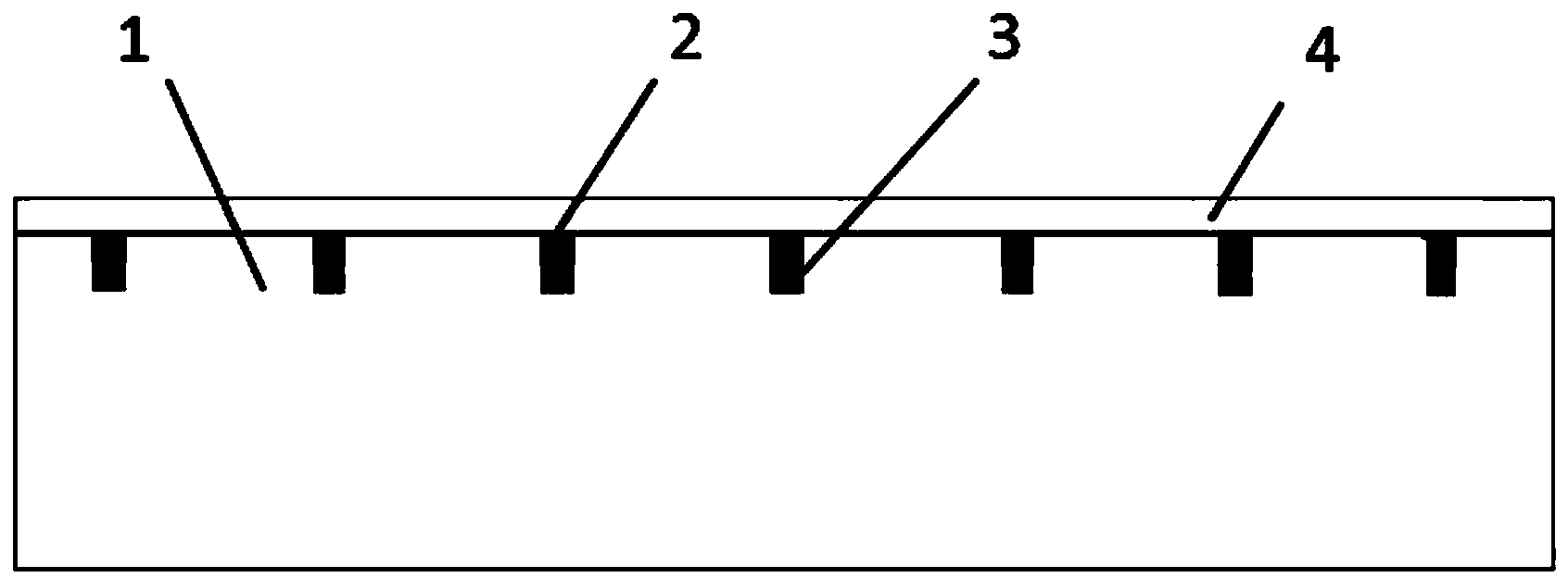

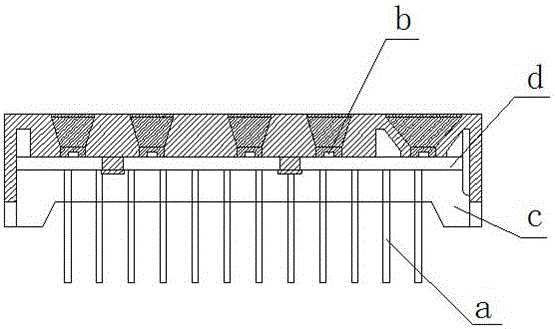

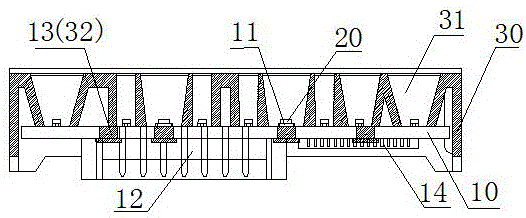

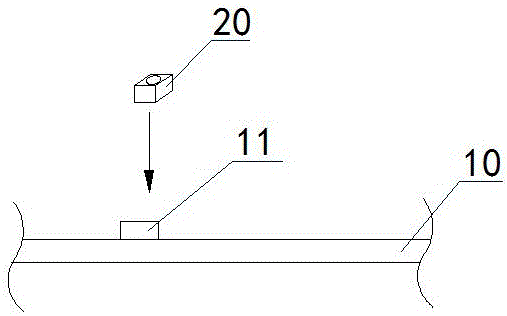

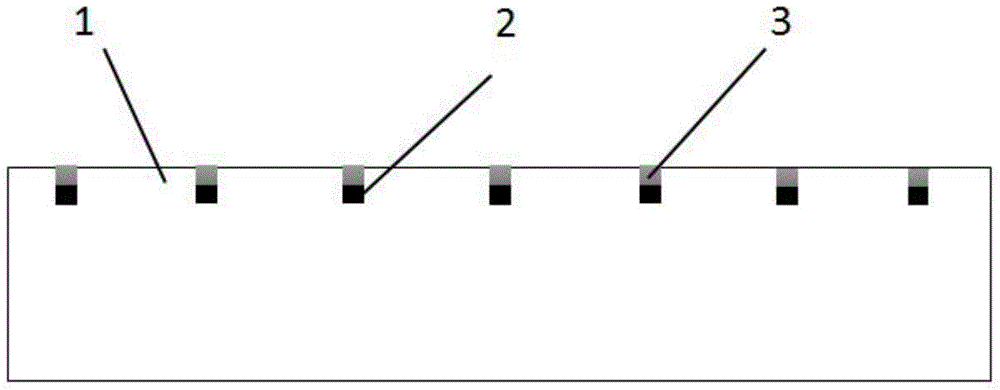

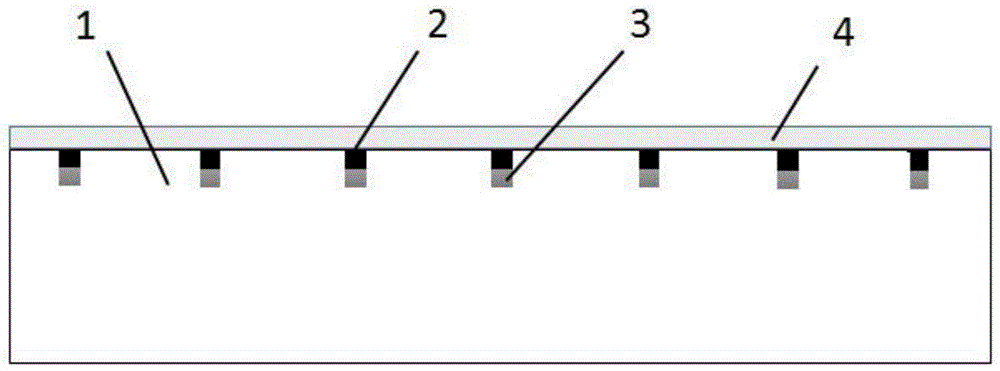

Wide-spectrum electromagnetic shielding light window

ActiveCN103687462ASmall impact on infrared transmission performanceImprove smoothnessMagnetic/electric field screeningAviationFrequency spectrum

A wide-spectrum electromagnetic shielding light window comprises a host material, a first metal mesh and a second metal mesh, and is characterized in that the first metal mesh and the second metal mesh are metal meshes with periodic structures, and are inlaid in the host material of the light window. The wide-spectrum electromagnetic shielding light window has the advantages that high-frequency electromagnetic waves and low-frequency electromagnetic waves are simultaneously shielded, wide-spectrum electromagnetic shielding is realized, the electromagnetic shielding efficiency is high, and the light window is wear-resistant and heat-resistant. Moreover, the wide-spectrum electromagnetic shielding light window is applicable to wide-spectrum electromagnetic shielding in the fields of remote sensing and telemetry, medical diagnosis, secure communication and space flight and aviation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

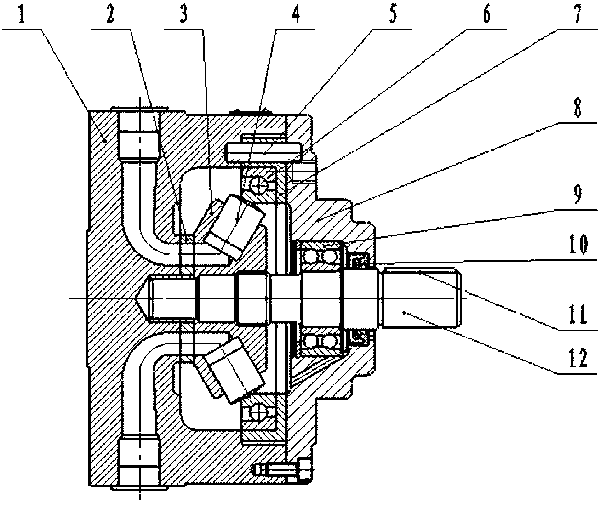

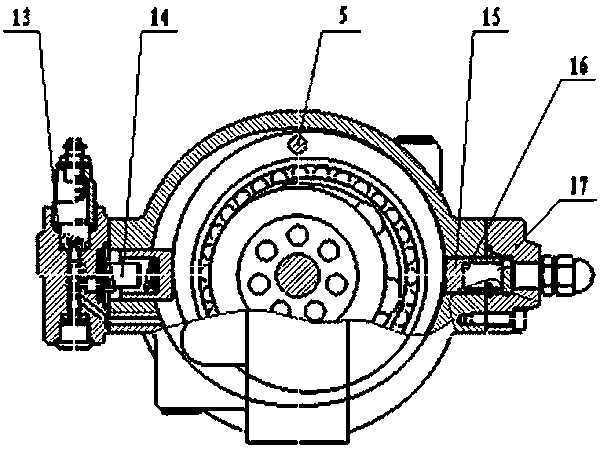

Disc flow allocation radial variable high pressure plunger pump

InactiveCN102966502ASignificant advantagesSignificant beneficial effectPositive displacement pump componentsPositive-displacement liquid enginesDrive shaftEngineering

The invention relates to a disc flow allocation radial variable high pressure plunger pump. An oil allocation disc refers to a circular oil allocation disc; an oil-through window, a static pressure support seal belt and a noise reduction groove are arranged in the oil allocation disc; an oil-through channel is formed by combining the oil allocation disc with a pump body and a rotor; plunger holes in the rotor are arranged in the radial direction; the flow allocation plane of the rotor is tightly adhered to the flow allocation disc; the plunger holes are designed into that an inclined angle is formed between the plunger holes and the axis of a transmission shaft; plungers are installed inside the plunger holes of the rotor; a hinge pin is tightly assembled on the pump body and is in clearance fit with an assembling hole in a stator; a rotating bearing is installed on a pump cover; a shaft seal is installed on the transmission shaft; a variable mechanism comprises a variable plunger which is matched with a limiting plunger, a limiting spring and a limiting body. As a disc flow allocation structure is adopted, the disc flow allocation radial variable high pressure plunger pump has simplified design and repairability, is low in manufacturing cost and convenient to use; as steel pieces can be used, the selection range of materials is expanded, and the standardization and generality of working are facilitated; and the performance of an original reusing pump and the system optimization are improved with relatively less transforming cost.

Owner:天津市泽华源泵业科技发展有限公司

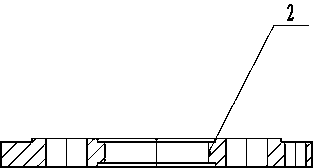

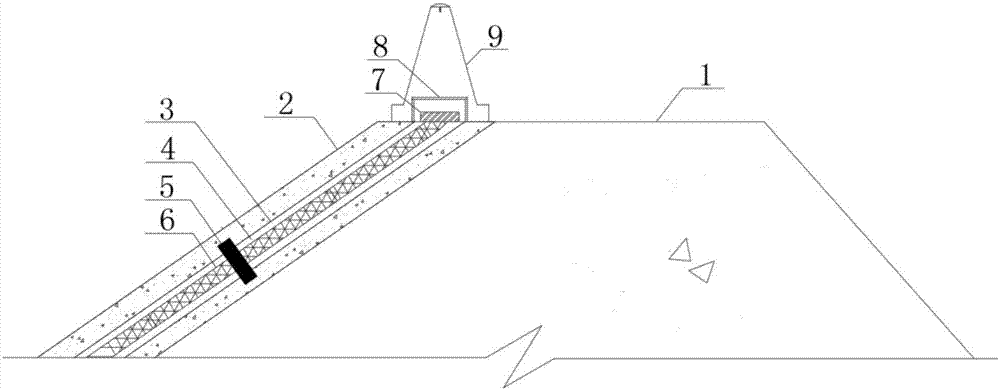

Rock-fill dam panel deformation monitoring device and construction method

ActiveCN107131862ARealize continuous observationRealize automated monitoringMeasurement devicesData acquisitionThree dimensional measurement

The invention discloses a rock-fill dam panel deformation monitoring device and method. The device comprises a concrete panel (2) located on the upstream side of a rock-fill dam (1); a pipeline (3) is arranged in the concrete panel (2); an array type three-dimensional measuring system (6) is installed in the pipeline (3); the array type three-dimensional measuring system (6) is connected with a data acquisition module (7), and the data acquisition module (7) is arranged in a protection pier (8); a surface deformation observation pier (9) is arranged at the same position of the protection pier (8). By means of the device, deformation of the panel can be monitored by arranging the array type three-dimensional measuring system in the panel, so that the purpose of continuous and automatic monitoring of deformation of the panel is achieved in the whole process.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

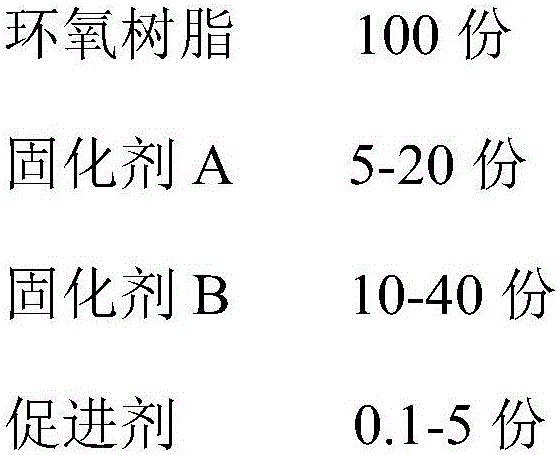

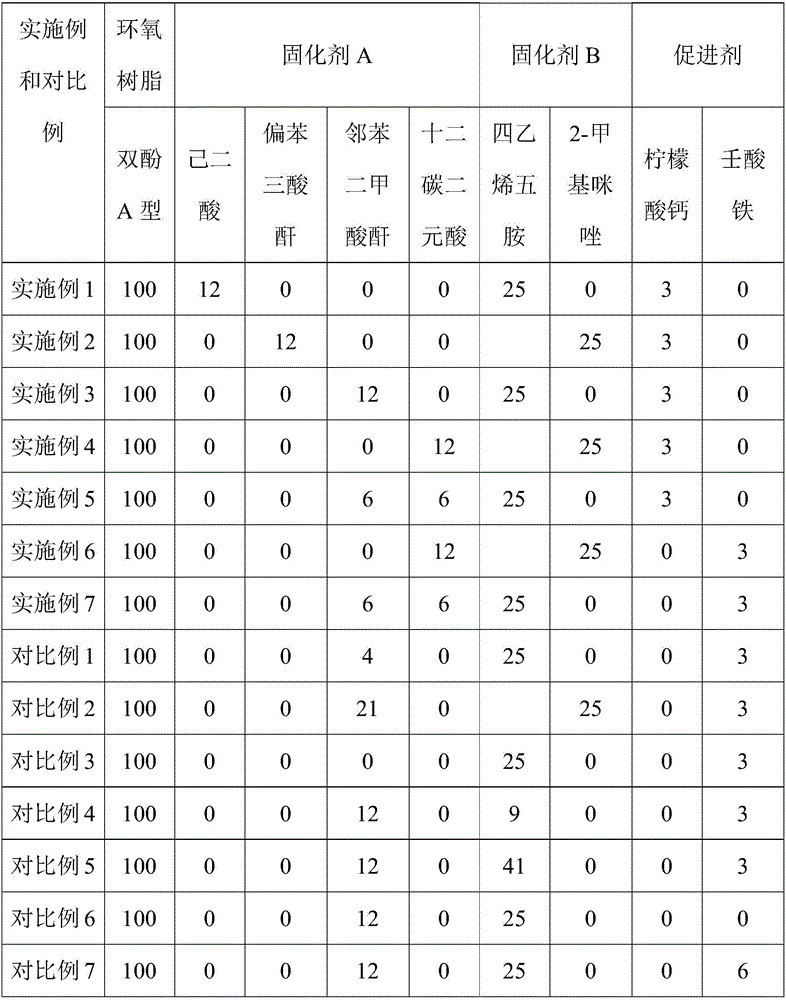

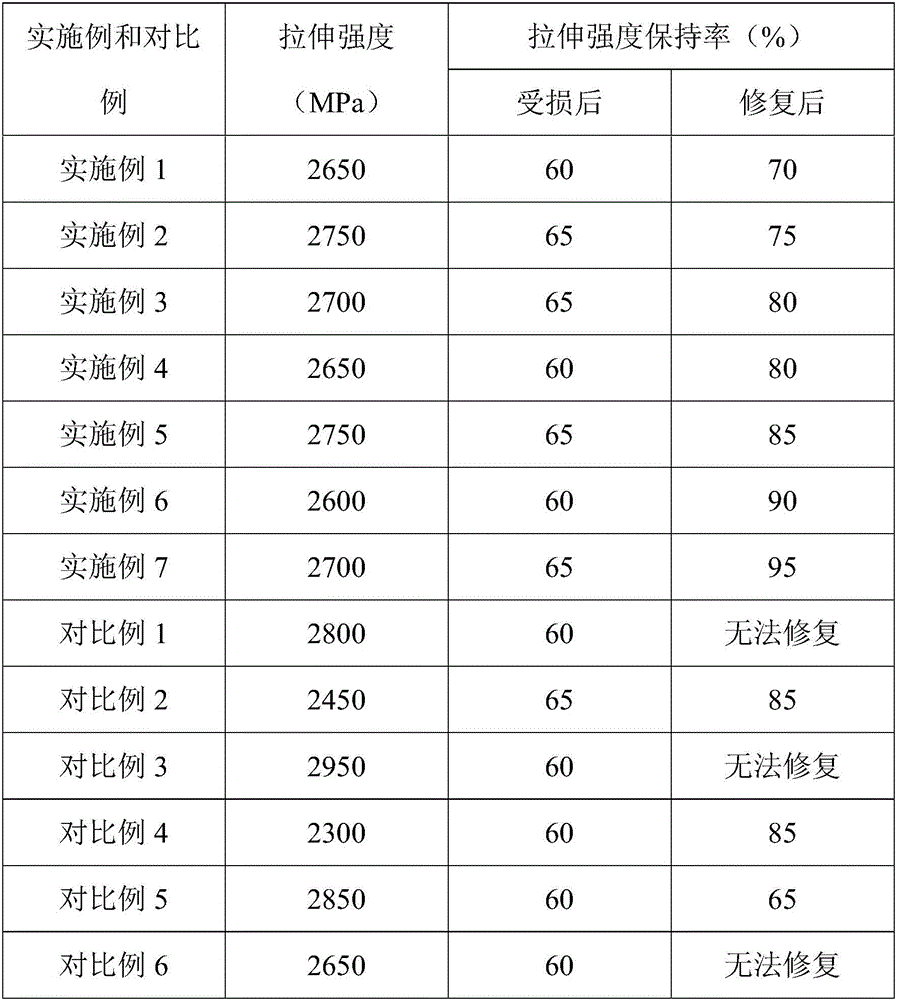

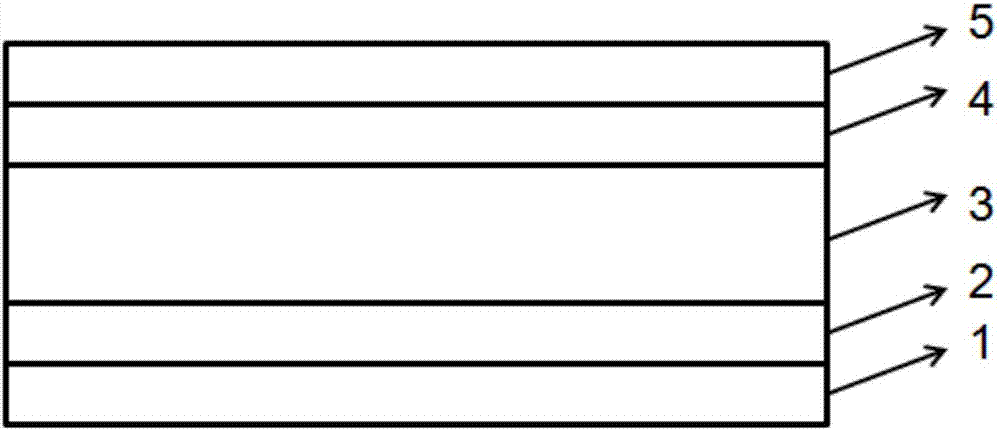

Repairable carbon fiber cloth reinforced epoxy resin plate and preparation and repairing methods thereof

The invention provides a repairable carbon fiber cloth reinforced epoxy resin plate and preparation and repairing methods thereof; the repairable carbon fiber cloth reinforced epoxy resin plate is prepared from, by weight, 100 parts of epoxy resin, 5-20 parts of curing agent A, 10-40 parts of curing agent B, 0.1-5 parts of an accelerant, and at least one layer of carbon fiber cloth; the curing agent A is selected from one or more of acid anhydride and carboxylic acid curing agents, the curing agent B is selected from one or more of curing agents other than acid anhydride and carboxylic acid ones, and the accelerant is selected from one or more of calcium salts, zinc salts and iron salts. The repairable carbon fiber cloth reinforced epoxy resin plate of the invention has the advantages of common carbon fiber cloth reinforced epoxy resin plates, such as high rigidity, high hardness, high tolerance to temperatures, low flammability and good article size stability, is repairable, allows damage in use to be repaired easily, and has post-repairing mechanical properties basically identical with initial mechanical properties of the resin plate, and the repairing process is simple and low in cost.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

Fluoridized TPU car body film as well as preparation method and application thereof

InactiveCN107163872AEasy to installEasy maintenanceAntifouling/underwater paintsFilm/foil adhesivesSulfite saltNational level

The invention discloses a fluoridized TPU car body film. The fluoridized TPU car body film sequentially comprises a PET peeling layer, an adhesive layer, a TPU base material and a hydrophobic anti-fouling coating from bottom to top, wherein the hydrophobic anti-fouling coating comprises, in parts by mass, 25-35 parts of polyphenylene sulfide, 30-45 parts of a fluorinated ethylene propylene emulsion, 2-6 parts of aluminum oxide, 1-3 parts of sodium sulfite and 20-30 parts of deionized water. The fluoridized TPU car body film has atmosphere aging resistance, can resist harsh weather such as acid rain, wind, snow and the like and has high anti-radiation performance and lower permeability, and the surface and performance can keep unchanged even if the car body film is exposed in the atmosphere for a long time; the car body film is non-sticky and has a self-cleaning property and a smooth and transparent surface, so that dirt cannot stick to the car body film easily, the car washing frequency can be reduced, and the car body film is energy-saving and environment-friendly; the car body film has repairability and is scratch-resistant, small scratches on the surface can automatically disappear, and the appearance of a car is under no influence, the car body film is non-toxic and pollution-free and meets the specification standard for national-level environment-friendly additives and the like.

Owner:日氟荣高分子材料(上海)有限公司

Fog sealing layer material, preparation method and application

ActiveCN109627792AImprove wear resistanceImprove thermal conductivityBuilding insulationsThermal conductivityCarbon nanotube

The invention relates to a fog sealing layer material, a preparation method and application. The material is prepared from, by mass, 80-120 parts of emulsified asphalt, 2-5 parts of carbon nanotube dispersion liquid, 5-10 parts of a penetrating agent, 150-250 parts of silicon carbide and 30-60 parts of ferroferric oxide. The fog sealing layer material has the repairability, when microcracks existon a fog sealing layer, a second fog sealing layer and other maintenance overlay layers are not needed, and the fog sealing layer material can be repaired through microwaving treatment; the fog sealing layer material is compounded by carbon nanotubes, the silicon carbide, the ferroferric oxide and other materials, the thermal conductivity and microwave conversion efficiency of the material can besignificantly improved, so that under the microwave effect, the efficiency of the material is higher, and it is achieved that in the same melting state, microwave energy consumption can be reduced by10-15%; the adopted material makes the fog sealing layer achieve good thermal conductivity, good microwave conversion efficiency and good pavement performance, and the carbon nanotubes can improve theperformance of an asphalt material; the silicon carbide has good abrasive resistance performance, and the abrasive resistance performance of the fog sealing layer is further improved.

Owner:湖南鑫长胜材料科技有限公司

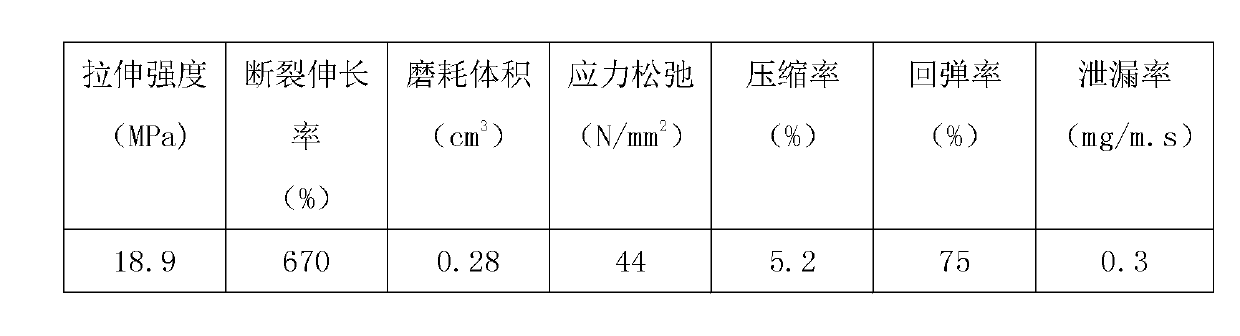

Highly oil-resistant chloroprene rubber sealing gasket and preparation method thereof

The invention discloses a highly oil-resistant chloroprene rubber sealing gasket comprising the following raw materials in parts by weight: 35-145 parts of chloroprene rubber CR1211, 20-25 parts of epichlorohydrin rubber, 10-20 parts of SG-2 type PVC (Polyvinyl Chloride) resin, 2-5 parts of tri(2-ethylhexyl)acetocitrate, 3-5 parts of dioctyl epoxy tetrahydrophthalate, 3-5 parts of dibutyl maleate, 1-2 parts of sodium alcohol ether sulphate, 30-40 parts of nano argil, 30-35 parts of carbon black N220, 30-35 parts of nano calcium carbonate powder and the like. The chloroprene rubber sealing gasket has excellent oil resistance and solvent resistance, is capable of satisfying the sealing requirement on an engine sump, and is easy to peel after being solidified, and cleanable and repairable without affecting dismounting and repairing.

Owner:ANHUI RONGDA VALVE

Drive-control LED digital display screen

PendingCN106128321AAchieve modularityRealize integrationStatic indicating devicesIdentification meansLead bondingEngineering

The invention relates to a drive-control LED digital display screen, and belongs to the technical field of display. The LED digital display screen comprises a PCB, LED patch lamps and a plastic shell; the PCB comprises a preset number of LED bonding pads which are arranged on the PCB, the LED bonding pads are correspondingly connected with a universal communication port connection socket through circuits, and the PCB further comprises an LED driving chip and positioning holes; each LED patch lamp is installed on the corresponding LED bonding pad of the PCB in an attached mode; the surface side of the plastic shell is provided with reflection cavities, the position of the center of the bottom cavity opening of each reflection cavity corresponds to one LED patch lamp, the back side of the plastic shell is provided with positioning columns, and the positioning columns and the positioning holes in the PCB are riveted in an aligned mode respectively. According to the LED digital display screen, the LED driving chip is integrated into the LED digital display screen, modularization and integration of the LED digital display screen and the drive control function are achieved, connection with an electric appliance control panel adopts the universal communication port connection socket instead of a guide needle pin connection mode of a traditional LED digital display screen, and installation is more standardized and simplified.

Owner:ZHONGSHAN YOUYANG OPTOELECTRONICS TECH

Manufacturing method for airplane part stretch-forming mold made of resin matrix composite

ActiveCN105945159AWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

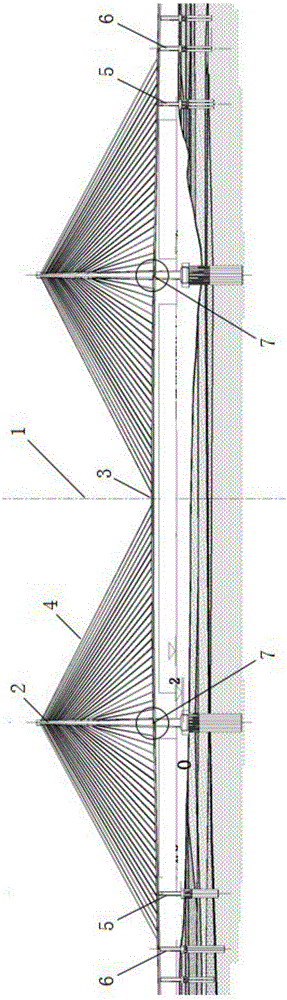

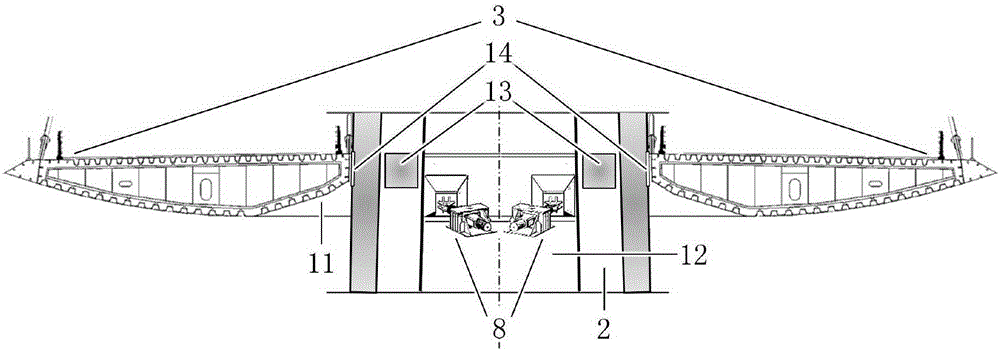

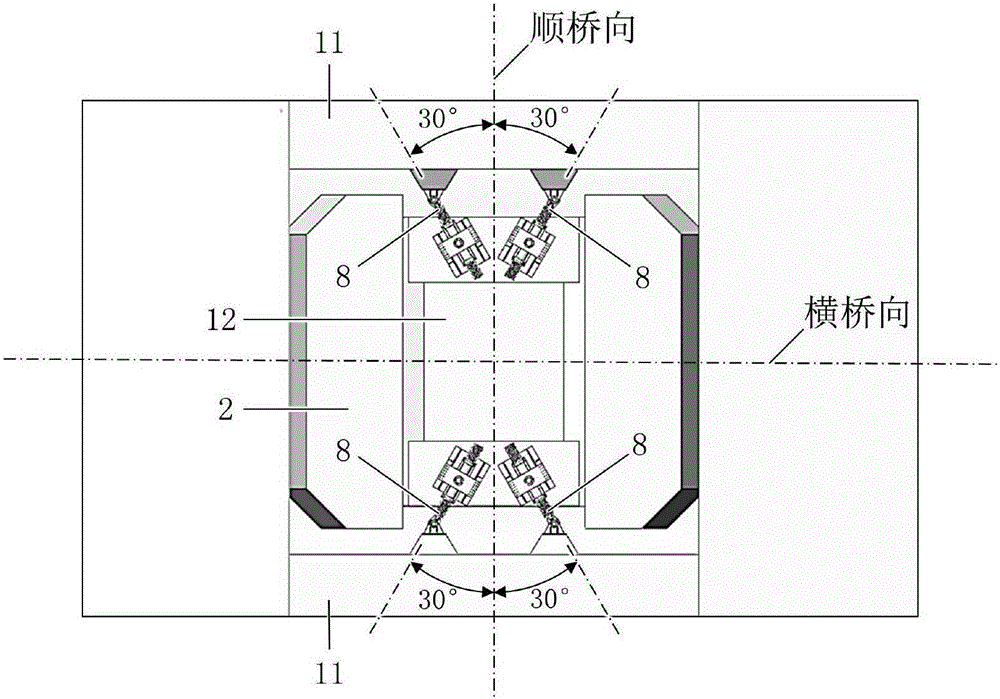

Oblique-damping restraint system for main girders of cable-stayed bridge

The invention provides an oblique-damping restraint system for main girders of a cable-stayed bridge. The oblique-damping restraint system consists of a group of obliquely arranged dampers, wherein one ends of the dampers are connected to the main girders of the cable-stayed bridge, and the other ends of the dampers are connected to the cable tower of the cable-stayed bridge; the dampers are symmetrically arranged on two sides of the cable tower along the longitudinal axis of the cable-stayed bridge; according to the obliquely arranged dampers, a horizontal plane is adopted as a datum plane, an included angle is formed between the arrangement axis of each damper and the longitudinal axis of each of the main girders, and damping restraint in the longitudinal bridge direction and damping restraint in the transverse bridge direction are simultaneously provided for the main girders. The fully new damping restraint system for main girders of the cable-stayed bridge, disclosed by the invention, is created through the integration of a technique of vibration damping and seismic resistance, a technique of vibration damping and wind resistance, a technique of two-way control, and a technique of limited limiting; the damping restraint system fills up the blank of the bridge vibration damping technique, and a new standard for the bridge vibration damping technique is provided; the bridge vibration is comprehensively controlled, and the safety, the durability and the economy of the bridge are guaranteed; the structure is simplified; an accessible condition, a detectable condition, a maintainable condition and a replaceable condition are good.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

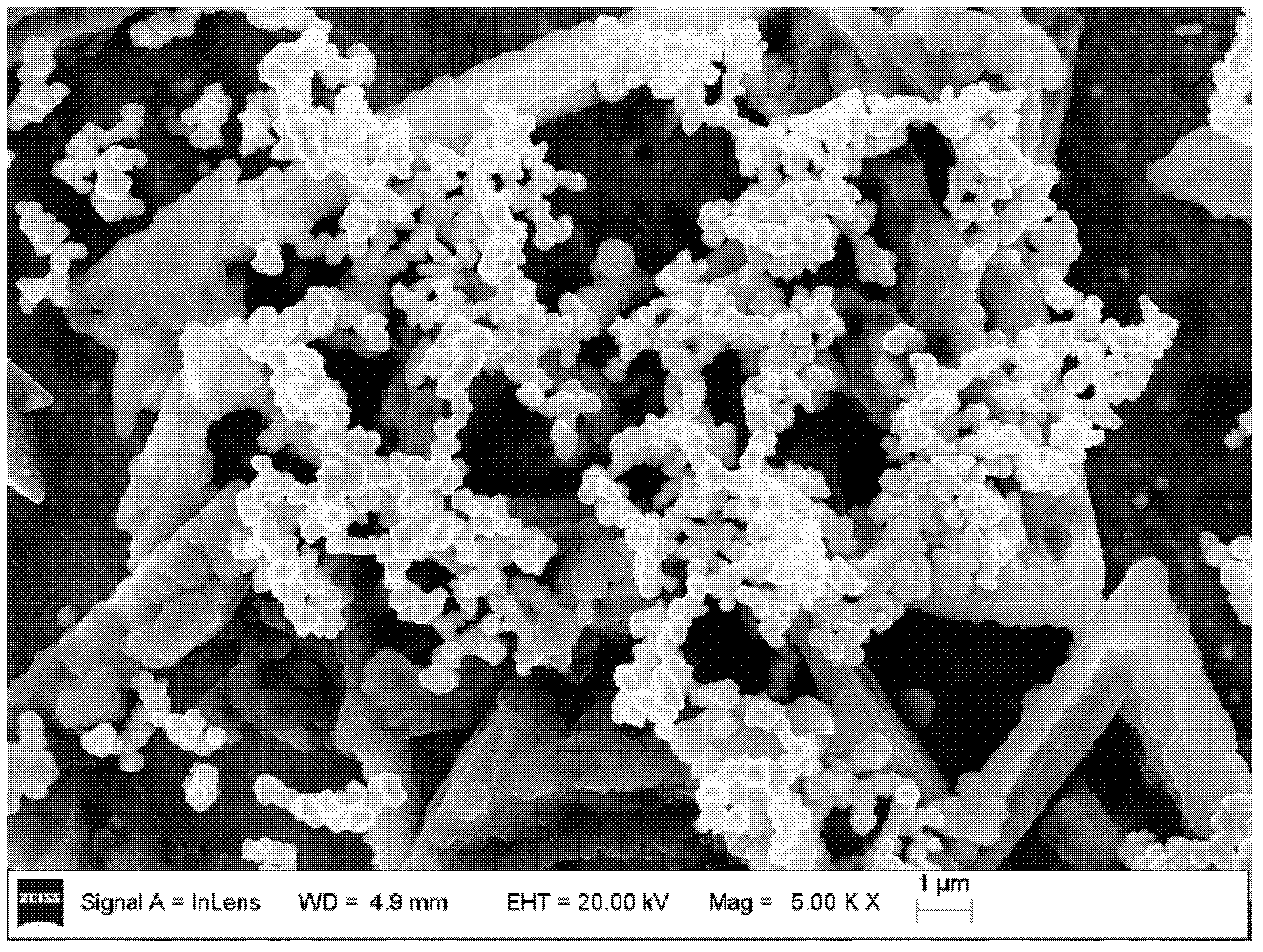

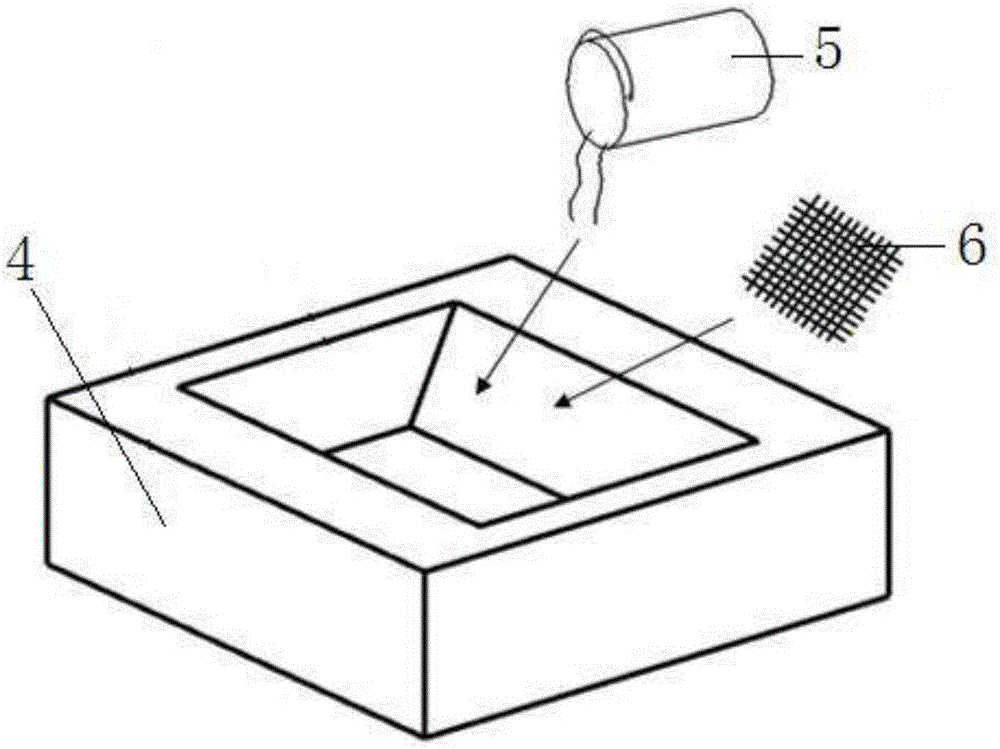

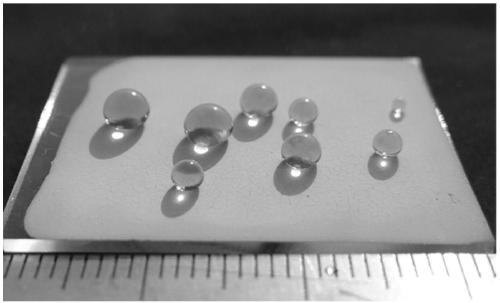

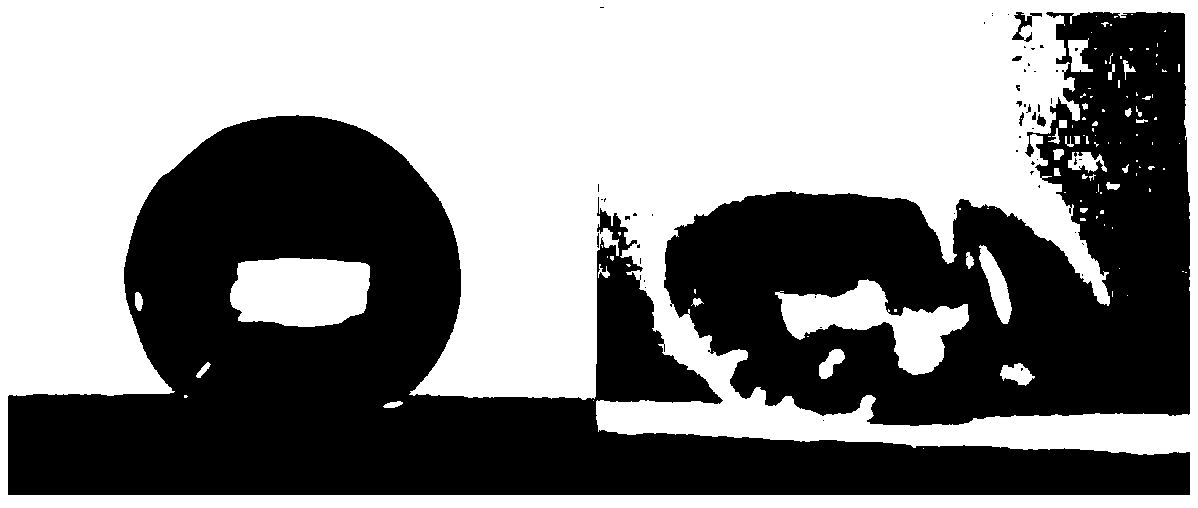

A facile preparation method for low-cost high-strength repairable superhydrophobic coatings

The invention belongs to the technical field of the preparation of super-hydrophobic coating materials, and in particular relates to a simple preparation method of a low-cost high-strength repairable super-hydrophobic coating. The preparation method comprises the following steps: preparing an epoxy resin super-hydrophobic suspension coating, preparing an epoxy resin super-hydrophobic coating, and the like. The epoxy resin super-hydrophobic coating material can be applied to different solid substrates of different dimensions; and moreover, in the existence of the high-strength epoxy resin, the epoxy resin super-hydrophobic coating has extremely high mechanical stability, and has rapid friction-induced repairing performance so as to deal with different extreme application environments. The preparation method of the epoxy resin super-hydrophobic coating is very simple and can be formed by mixing and stirring all raw materials in a short time by virtue of a one-pot method. The preparation process is simple, raw materials are easy to get and non-toxic and environment-friendly, the cost is low, the stability is high, and mass preparation can be realized.

Owner:HUBEI UNIV

Composite material of mixed and knitted chemical fibers and natural veneers and preparation method of composite material

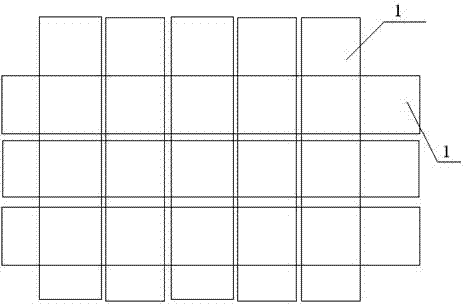

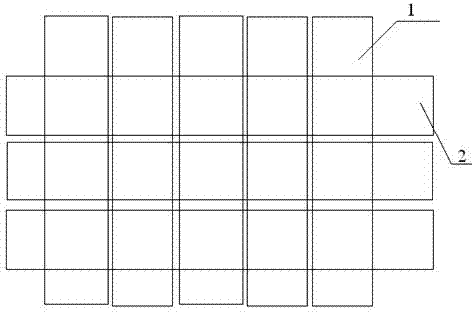

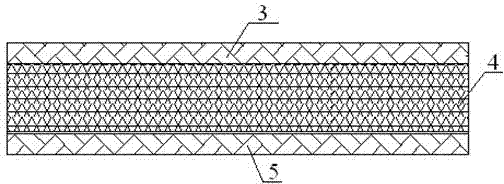

ActiveCN103696123AHigh tensile strengthHigh hardnessSynthetic resin layered productsLaminationGlass fiberFiber

The invention discloses a composite material of mixed and knitted chemical fibers and natural veneers and a preparation method of the composite material. The composite material is formed by knitting composite materials (1) comprising chemical fibers and wood fibers or knitting the composite materials (1) comprising the chemical fibers and the wood fibers with chemical fibers (2), and the composite materials (1) are formed by compounding and knitting the surface layers of the wood fibers with the bottom layers of the chemical fibers of presoaked resin, or the surface layers of the glass fibers of the presoaked resin with the bottom layers of the wood fibers. According to the composite material provided by the invention, the surface layer has the appearance and texture of natural wood fibers, high requirement standards can be met, and carbon fibers are compounded and knitted to form the composite material; the whole composite material is superior in properties such as tensile strength, elastic modulus, hardness, impact resistance and natural wood texture, and can be widely used for preparing electric appliance shells, furniture and building materials and the like. The preparation method provided by the invention is reasonable in process and high in product qualification rate, and can achieve large-scale industrialization production.

Owner:宜兴市中碳科技有限公司

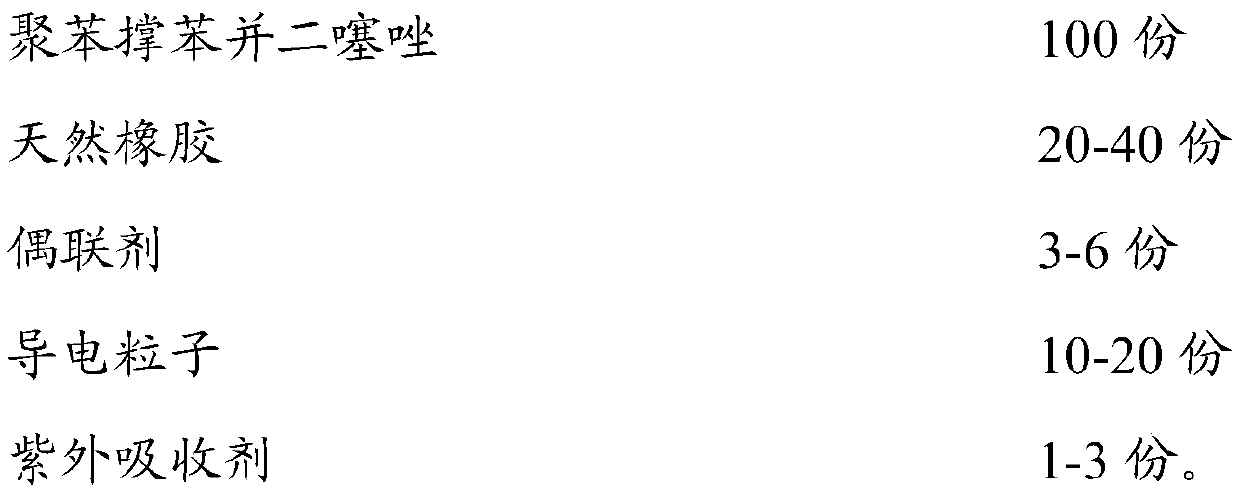

Flexible copper clad laminate and preparation method thereof

ActiveCN110505767AThermoplasticRepairableInsulating substrate metal adhesion improvementNon-macromolecular adhesive additivesUltraviolet lightsMoisture absorption

The invention belongs to the technical field of flexible printed circuit boards, and in particular relates to a flexible copper clad laminate and a preparation method thereof. The flexible copper cladlaminate comprises at least one layer of flexible insulation base film, at least one layer of metal copper clad and an adhesive film, which is used for adhering the adjacent insulation base film andmetal copper clad; the adhesive film comprises the following components: polyphenylene benzothiazole, a coupling agent, natural rubber, conducting particles and an ultraviolet light absorber; and thecoupling agent is gamma-(2,3-poxyl propyl oxygen) propyl trimethoxysilane. In the technical scheme provided by the invention, the adhesive film is composed of a thermoplastic liquid crystal polymer material, and has the good performances of being low in moisture absorption, low in dielectric constant and dielectric loss, high-temperature resistant and the like; furthermore, no organic solvent is added in the process; and, compared with the thermosetting performance of the current adhesive film, the thermoplasticity has the characteristics of being repairable and reducible.

Owner:SUZHOU GOLDEN TECH MATERIAL

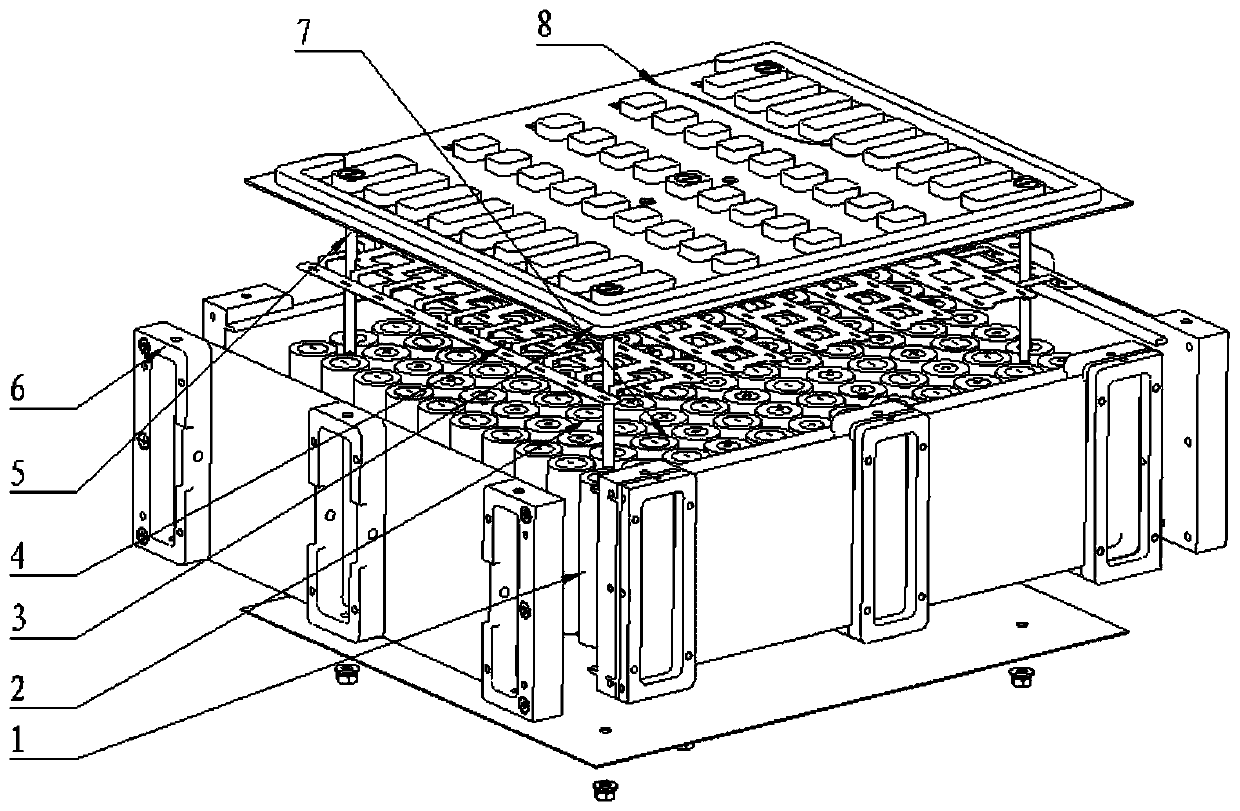

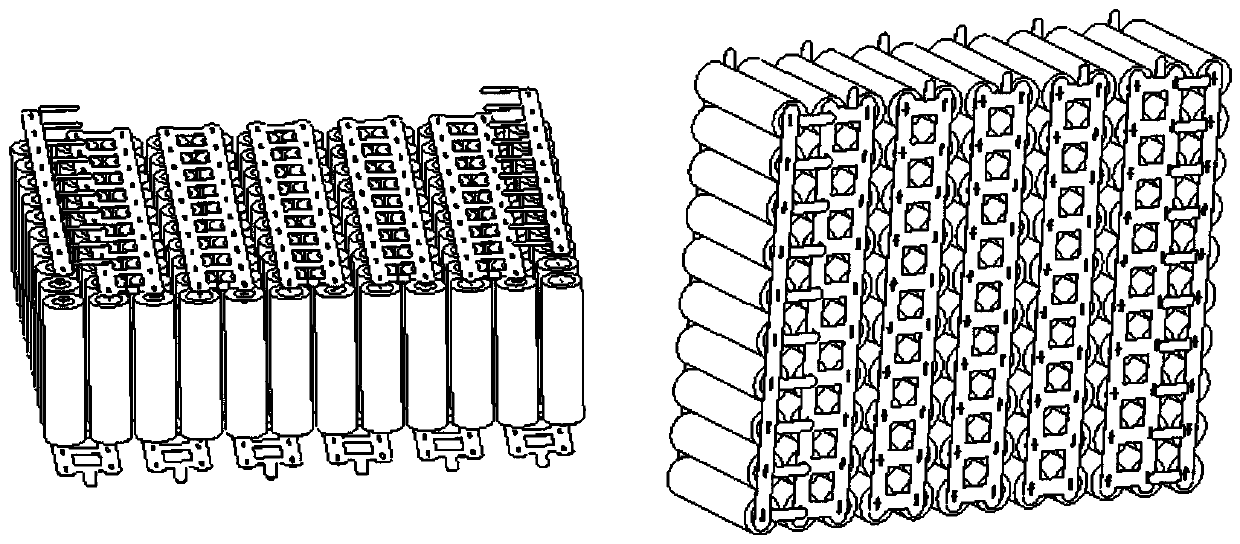

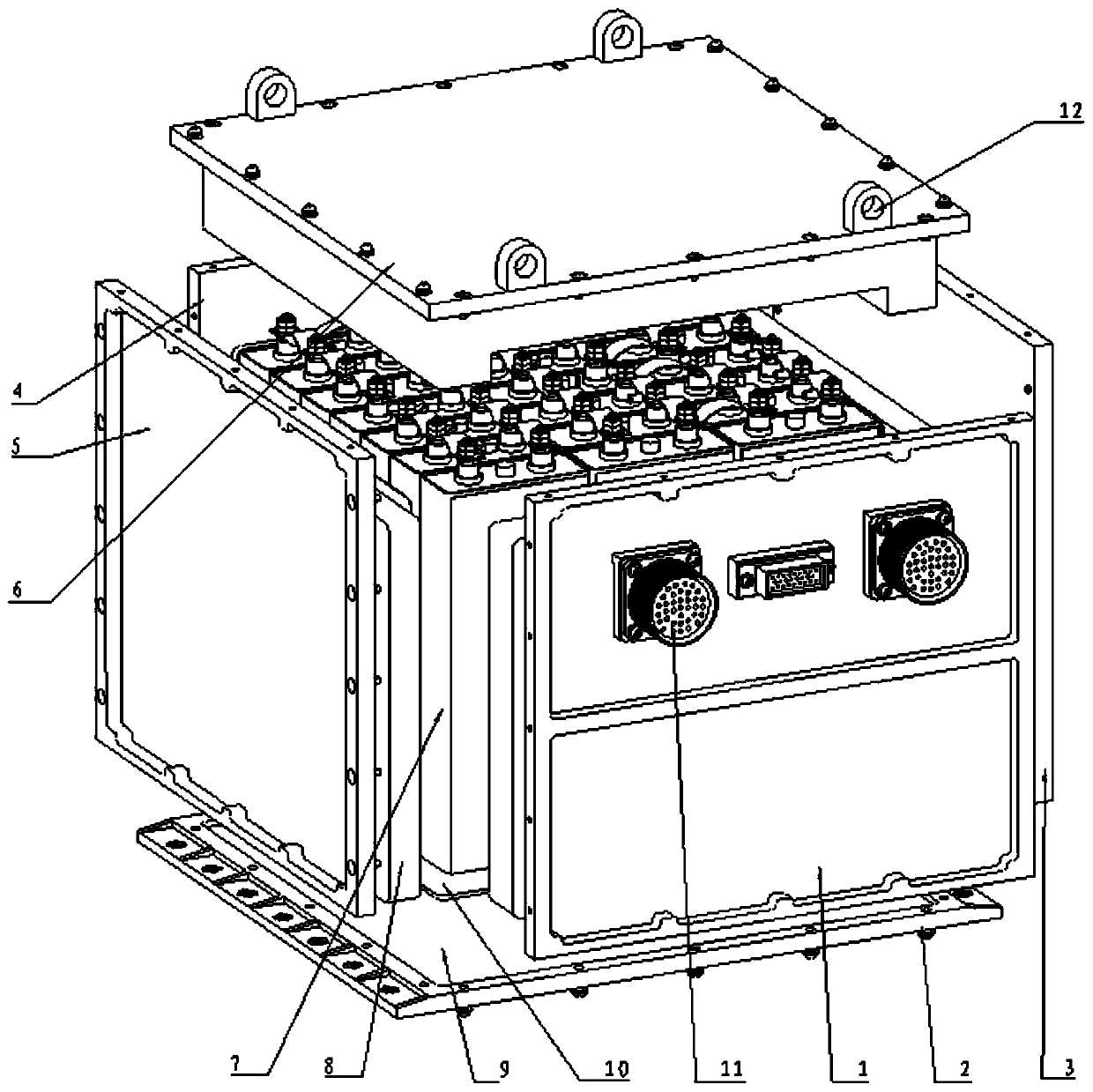

Modular lithium ion storage battery pack for carrier rocket

InactiveCN110581241ATo achieve cooling needsAchieve security and standardize designSecondary cellsCell component detailsElectrical batteryHigh pressure

The invention discloses a modular lithium ion storage battery pack for a carrier rocket. The battery pack is formed by connecting a plurality of storage battery modules, wherein each storage battery module comprises a cylindrical lithium ion single battery, a battery bracket, a wiring board, a bridging sheet, a fastening pull rod and a clamping plate, the single battery, the battery support, the wiring board and the bridging sheet form a battery stack, the battery stack is fixed through the fastening pull rod and the clamping plate to form a storage battery module, a power output and signal detection mode of the bridging sheet welding the wires is adopted, the structure is beneficial to battery heat dissipation, and flight reliability is improved. The storage battery module is provided with an extensible through hole structure, so a plurality of modules can be extended to finally form a high-voltage and high-power lithium ion storage battery pack.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

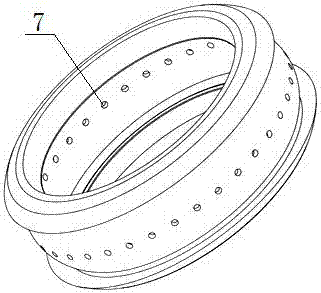

ZGM type repairable metal ceramic composite grinding roller and manufacturing method

The invention discloses a ZGM type repairable metal ceramic composite grinding roller and a manufacturing method. The composite grinding roller comprises a substrate, a plurality of ceramic composite grinding roller skins, a clamping block and a plurality of reinforcing parts. The multiple mutually spliced ceramic composite grinding roller skins are assembled to the outer substrate face of the substrate. Clamping grooves are formed in the inner sides of the ceramic composite grinding roller skins. A plurality of through holes distributed in the circumferential direction are formed in the inner side face of the substrate. One ends of the reinforcing parts are connected with the ceramic composite grinding roller skins through the clamping grooves in a clamped mode. The other ends of the reinforcing parts penetrate through the through holes and are fixedly connected through nuts. The clamping block is arranged on the side portion of one of the ceramic composite grinding roller skins. Through the ZGM type repairable metal ceramic composite grinding roller and the manufacturing method, the prepared high-abrasion-resistance composite grinding roller has long service life and reparability, the grinding roller manufacturing method is simple, the machining period is short, and the cost is effectively lowered.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

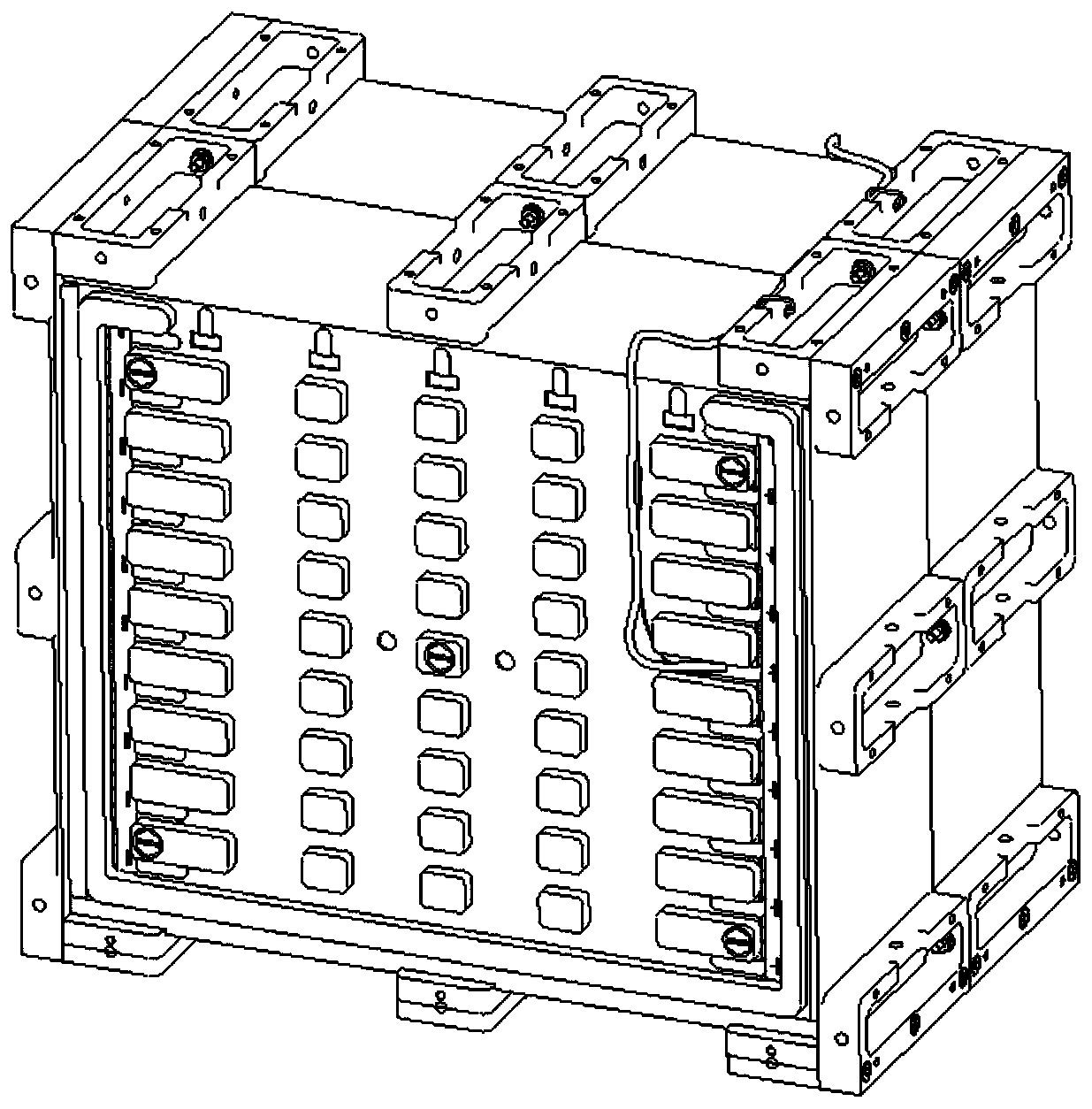

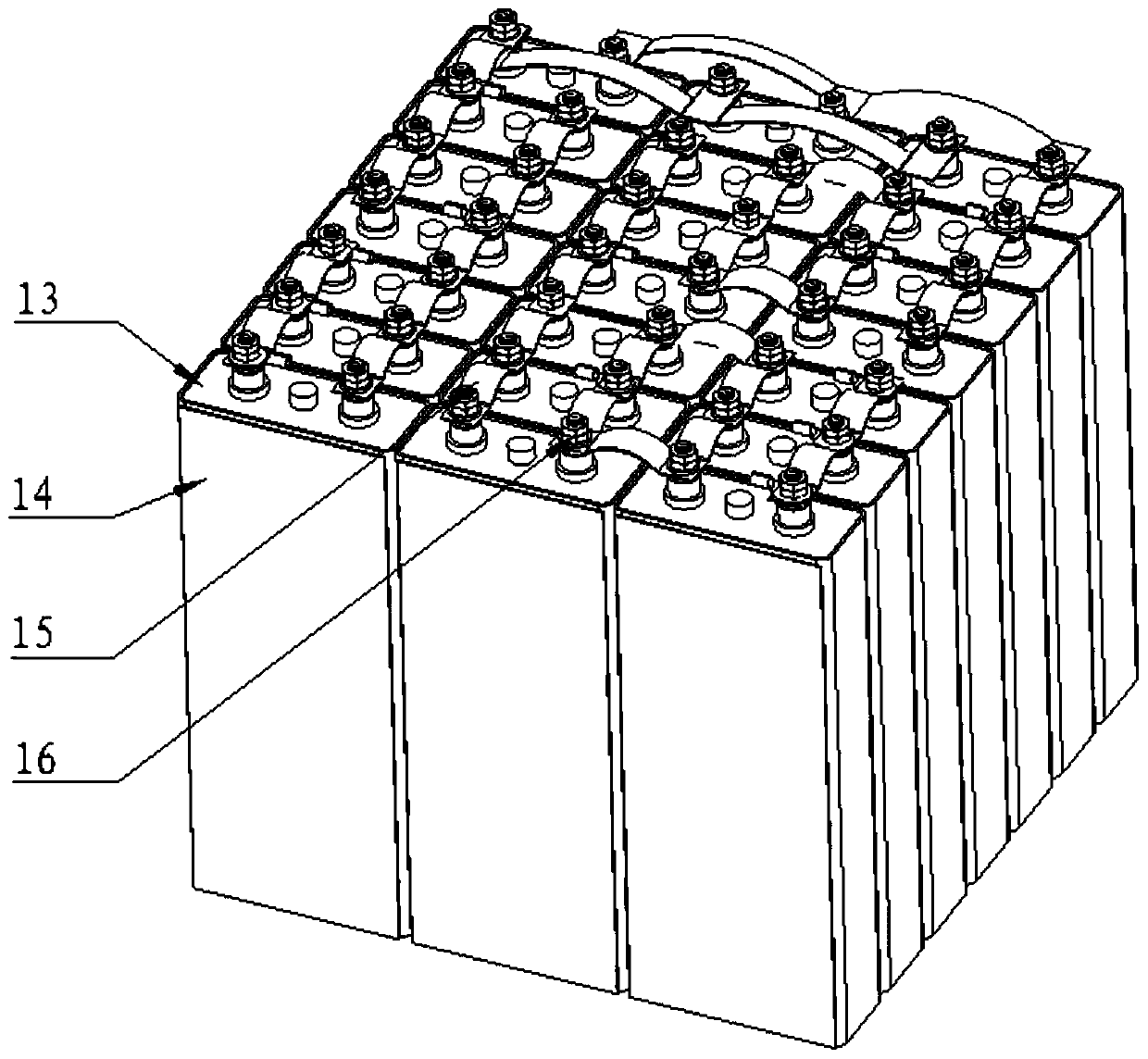

Lithium ion battery pack for upper stage

InactiveCN110474130AFulfill cooling needsRepairableCell temperature controlCell component detailsElectricityElectrical battery

The present invention provides a lithium ion battery pack for an upper stage. The lithium ion battery pack comprises a shell, a battery cell stack, an insulation board, rubber pads, heat conduction silica gel and an electric connector, wherein the battery cell stack is arranged in the shell and comprises single batteries, adjusting sheets and bridging sheets; the single batteries are sequentiallyarranged in the transverse direction and the longitudinal direction, the adjusting sheets are arranged between the single batteries, and the single batteries are connected in series and in parallel through the bridging sheets; the rubber pads are arranged at the bottom of each single battery; heat conduction silica gel is coated between the single batteries and the rubber pads and between the single batteries and the adjusting sheets; the insulation board is arranged between the side wall plate of the shell and the battery cell stack, and the electric connector is arranged on the shell. According to the lithium ion storage battery disclosed by the invention, all electric energy required by load of the whole device can be provided for 48 hours in orbit from the time when the whole device atthe upper stage is converted into internal electricity to the time when the task at the upper stage is completed.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

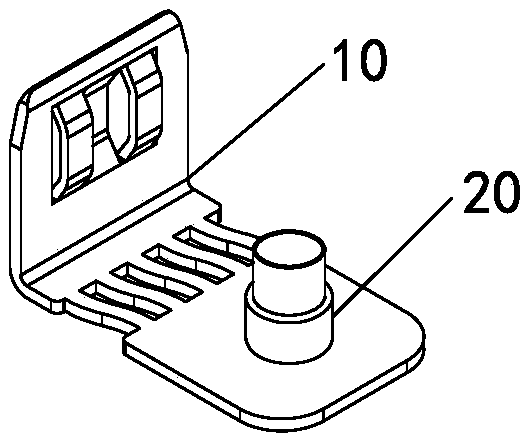

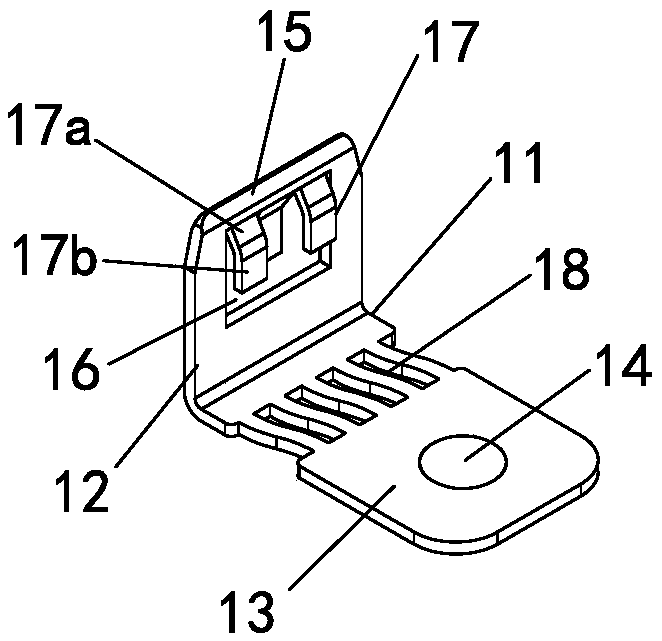

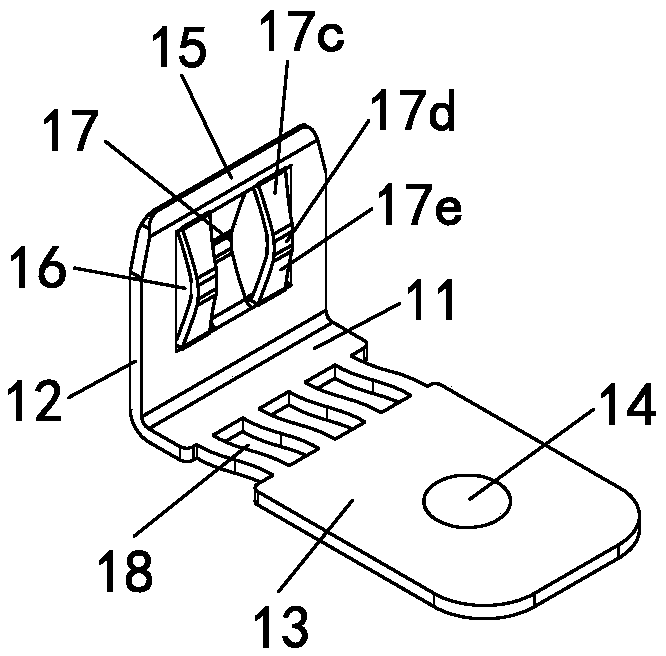

Plug-in PCBA connection terminals and electrical connection assemblies

InactiveCN109066110ARepairableEasy to replaceCoupling contact membersCouplings bases/casesAutomotive batteryMaintainability

The invention solves the technical problem that the PCBA board of the automobile battery module is soldered and fixedly connected with the connection terminal in the prior art, and the PCBA board cannot be replaced separately. The invention provides a plug-in type PCBA connection terminal. The connecting terminal comprises a first metal terminal and a second metal terminal, wherein one end of thefirst metal terminal is an elastic part and the other end is a first connecting part; The elastic portion has a plurality of elastic pieces arranged in a front-rear arrangement, the elastic pieces areinserted into a PCBA board jack hole, and the elastic pieces are elastic pressed on an inner wall of the jack hole. In addition, the invention also provides an electrical connection assembly, which comprises a plastic member, a bus bar, a PCBA board and the connection terminal. The elastic part of the first metal terminal is inserted into the nickel-plated jack hole of the PCBA board, and the elastic piece is elastically pressed on the inner wall of the jack hole of the PCBA board and electrically connected with the PCBA board. The connecting terminal and the PCBA board are plugged and pulledout by the elastic piece for many times, and the PCBA board is provided with maintainability and convenient replacement by the bolt fixation. The elastic part of the first metal terminal is insertedinto the nickel plated jack hole of the PCBA board.

Owner:毛黎莉

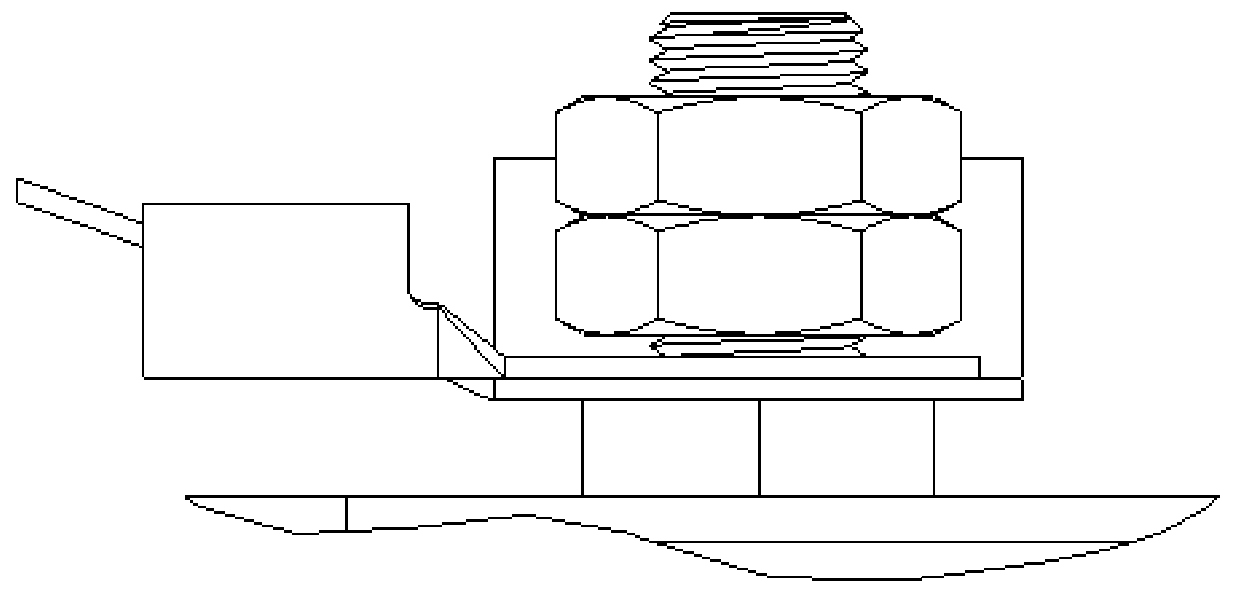

Detachable fixing structure for high-current terminals of automotive electric box

ActiveCN103635055AImplement error-proofing in assemblyImplement anti-following designCasings/cabinets/drawers detailsEngineeringCable harness

The invention relates to a detachable fixing structure for high-current terminals of an automotive electric box. The structure comprises an electric box body, fixing nuts, convergence sheets and the high-current terminals, wherein the electric box body is provided with two fixing nut positions; the convergence sheet is arranged above each fixing nut position; the high-current terminals are fixed on the electric box body through bolts after being matched with the convergence sheets. According to the structure, the fixing nuts for the high-current terminals in the electric box are replaceable, so that the scrapping of the electric box and wire harnesses due to the problems of the nuts in processes of assembly and the like is avoided, and the electric box is repairable.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

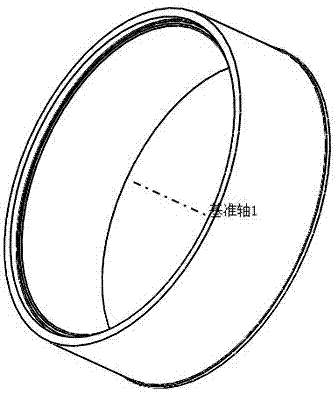

Wide Spectrum Electromagnetic Shielding Light Window

ActiveCN103687462BSmall impact on infrared transmission performanceImprove smoothnessMagnetic/electric field screeningAviationFrequency spectrum

A wide-spectrum electromagnetic shielding light window comprises a host material, a first metal mesh and a second metal mesh, and is characterized in that the first metal mesh and the second metal mesh are metal meshes with periodic structures, and are inlaid in the host material of the light window. The wide-spectrum electromagnetic shielding light window has the advantages that high-frequency electromagnetic waves and low-frequency electromagnetic waves are simultaneously shielded, wide-spectrum electromagnetic shielding is realized, the electromagnetic shielding efficiency is high, and the light window is wear-resistant and heat-resistant. Moreover, the wide-spectrum electromagnetic shielding light window is applicable to wide-spectrum electromagnetic shielding in the fields of remote sensing and telemetry, medical diagnosis, secure communication and space flight and aviation.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

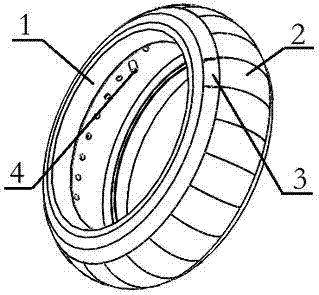

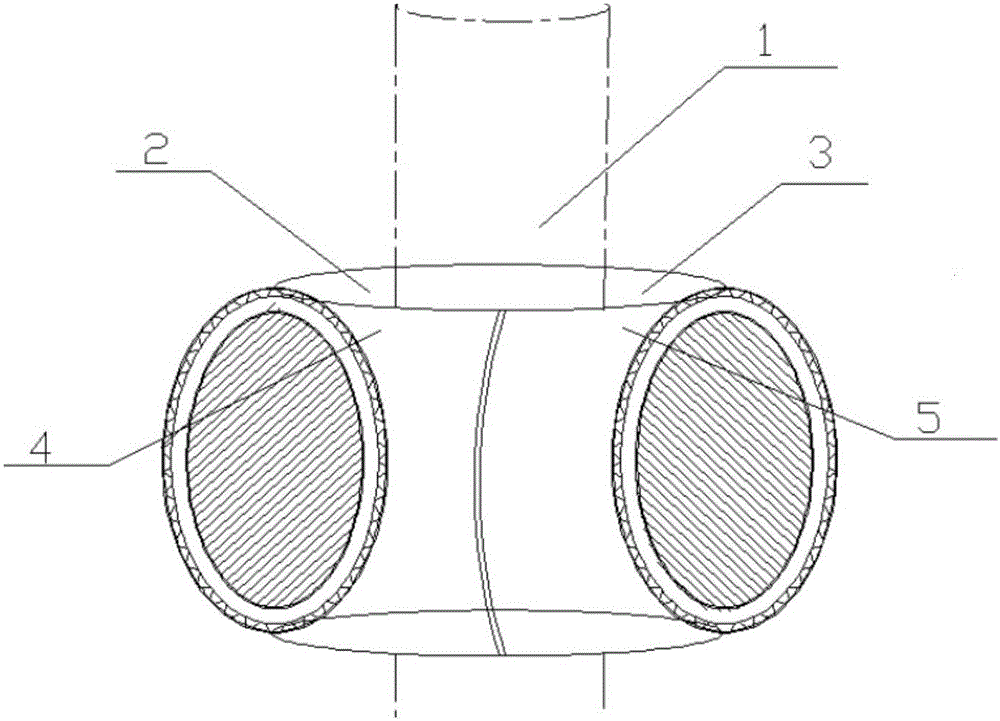

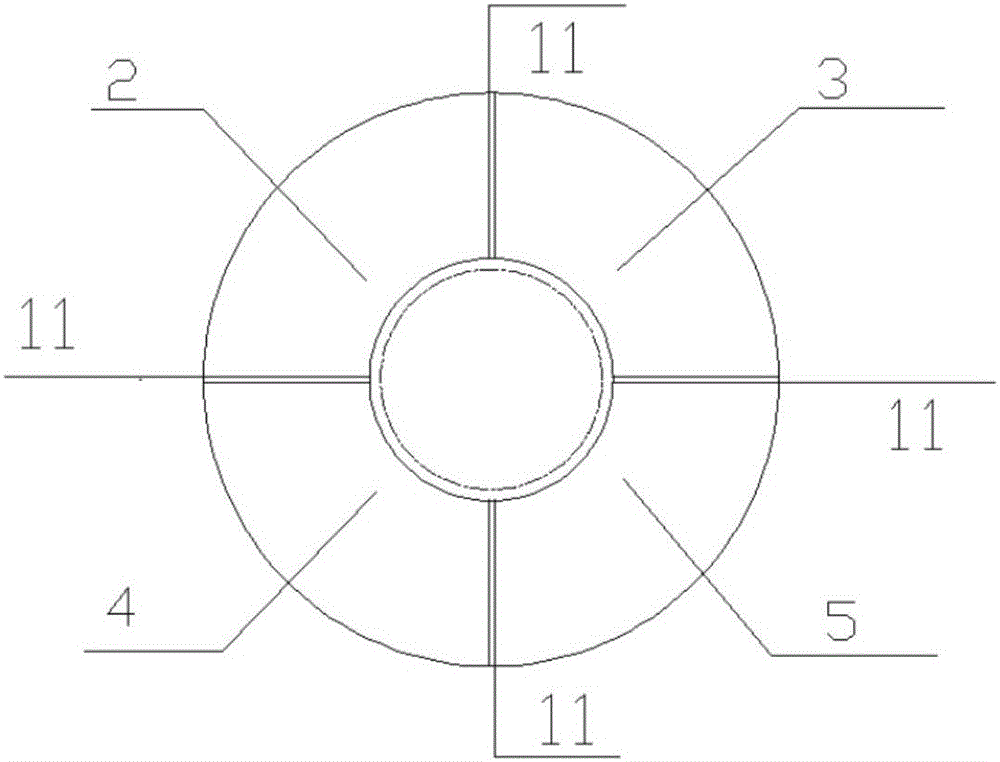

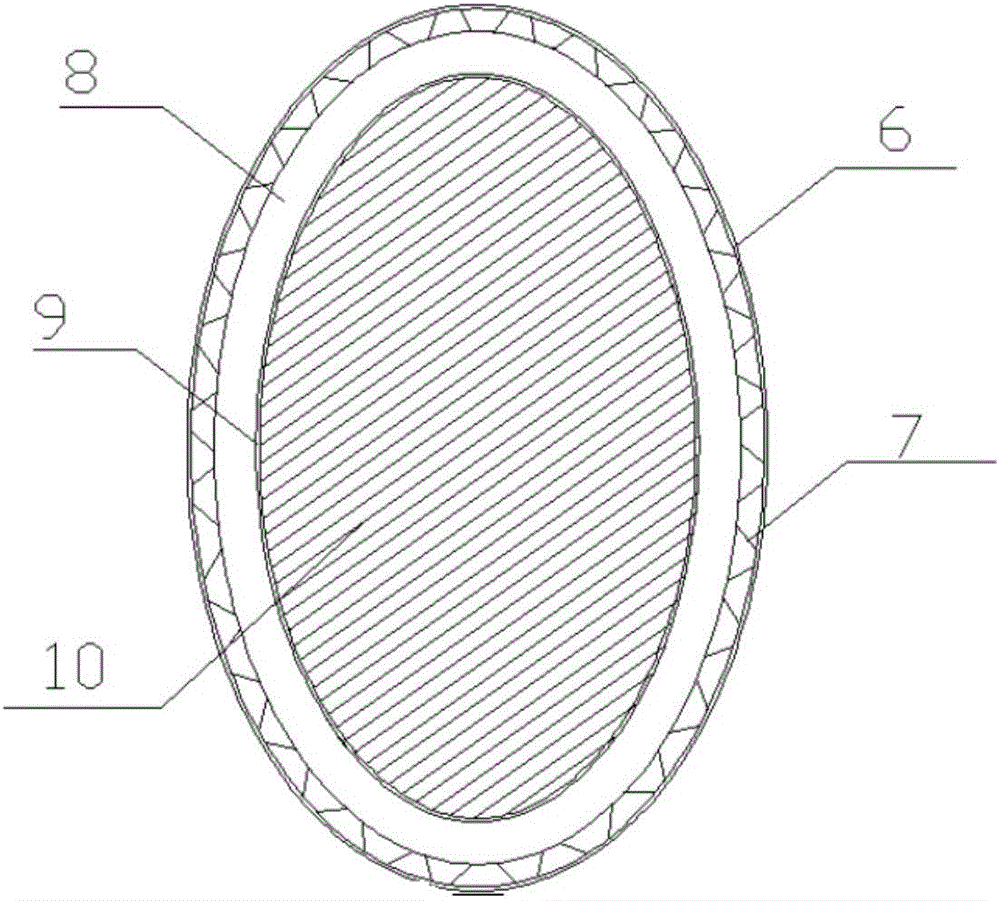

Self-floating collision prevention device based on composite materials

InactiveCN105908678AGood mechanical propertiesStable in natureClimate change adaptationShipping equipmentPolyurethane elastomerInterior space

The invention discloses a self-floating collision prevention device based on composite materials; and the device coasts a stand column of a marine structure, and floats up and down along with a water level. The device is characterized by forming a ring body by multiple connected collision prevention units; the cross sections of the collision prevention units are fan rings, and the longitudinal sections are ellipses; and the collision prevention units are formed by glass fiber resins, corrugated sandwich steel plates, polyurethane elastomers, inner-layer steel plates and polyurethane foam multilayer composite materials from edge to internal in sequence, wherein an internal space formed by the inner-layer steel plates is filled with polyurethane foams. The self-floating collision prevention device is stable in water property, resistant in corrosion, excellent in impact resistance, and green and environment-friendly.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com