Fluoridized TPU car body film as well as preparation method and application thereof

A car body film and fluorine coating technology, which is applied in coatings, antifouling/underwater coatings, film/sheet adhesives, etc., can solve the general use effect, higher and higher requirements, and can not meet the requirements of the car body Protection and other issues, to achieve the effect of low permeability, good shielding protection, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings. These embodiments are only used to illustrate the present invention, and are not intended to limit the protection scope of the present invention.

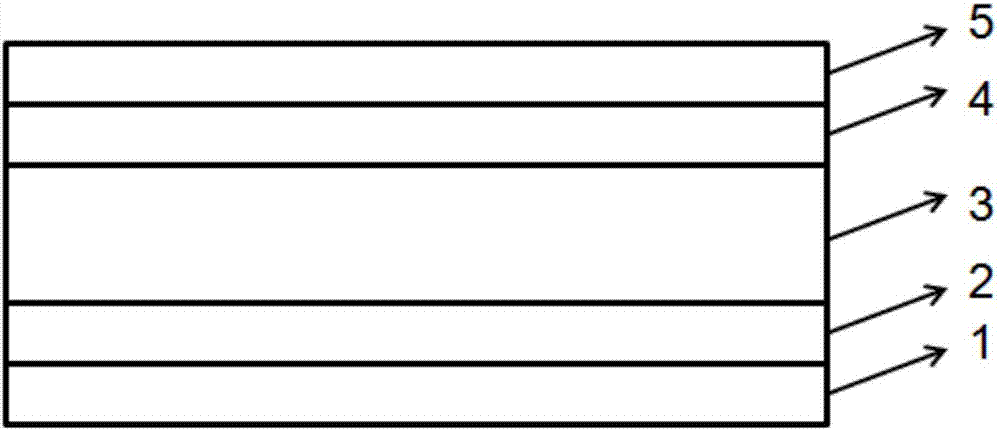

[0020] Such as figure 1 As shown, the present invention provides a kind of TPU coating fluorine body film, is provided with PET release layer 1, adhesive layer 2, TPU base material 3 and hydrophobic antifouling coating 4 successively from bottom to top; Said hydrophobic antifouling coating 4 includes: the following parts by mass, 25-35 parts of polyphenylene sulfide, 30-45 parts of polyfluoroethylene propylene emulsion, 2-6 parts of aluminum oxide, 1-3 parts of sodium sulfite and 20- 30 parts of deionized water.

[0021] The above-mentioned TPU fluorine-coated body film, wherein, the TPU fluorine-coated body film further includes a PET protective film 5 arranged on the hydrophobic antifouling coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com