Patents

Literature

50results about How to "Increase the surface contact angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

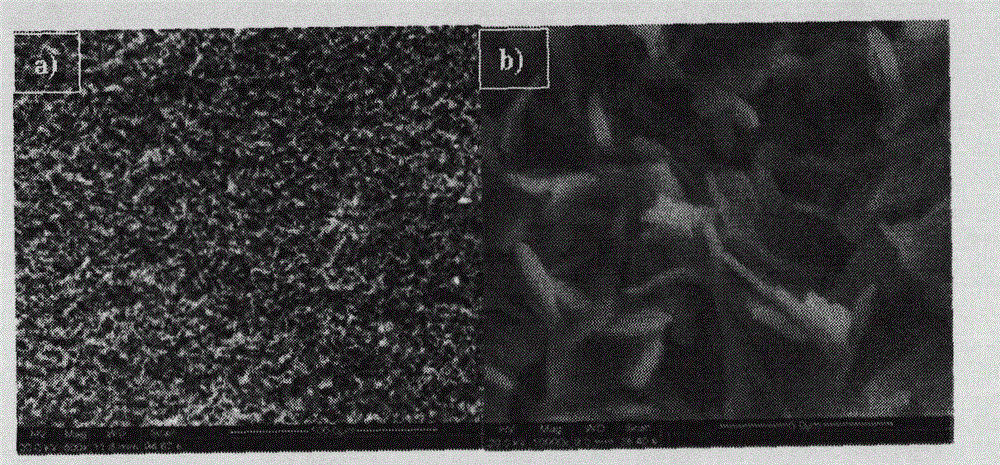

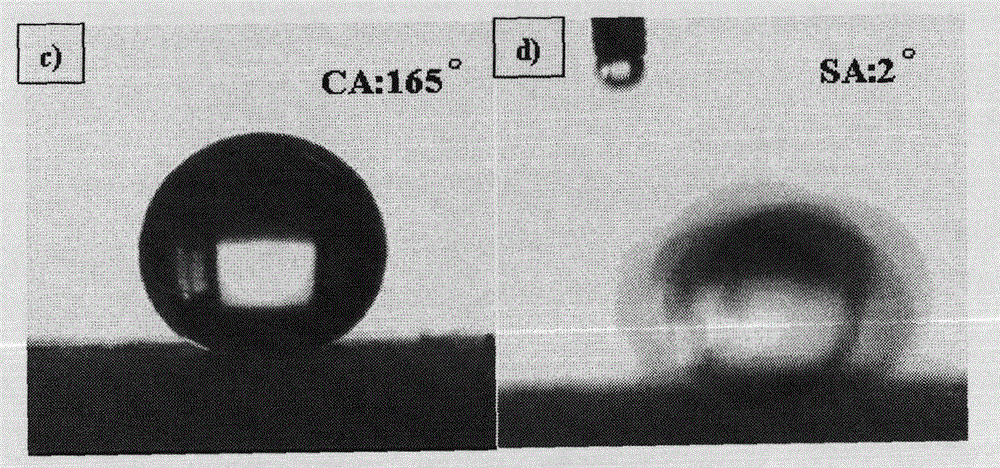

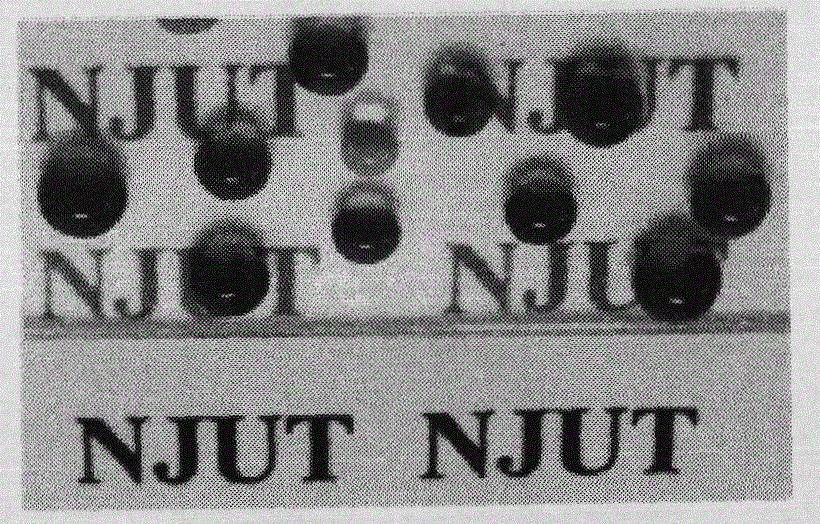

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

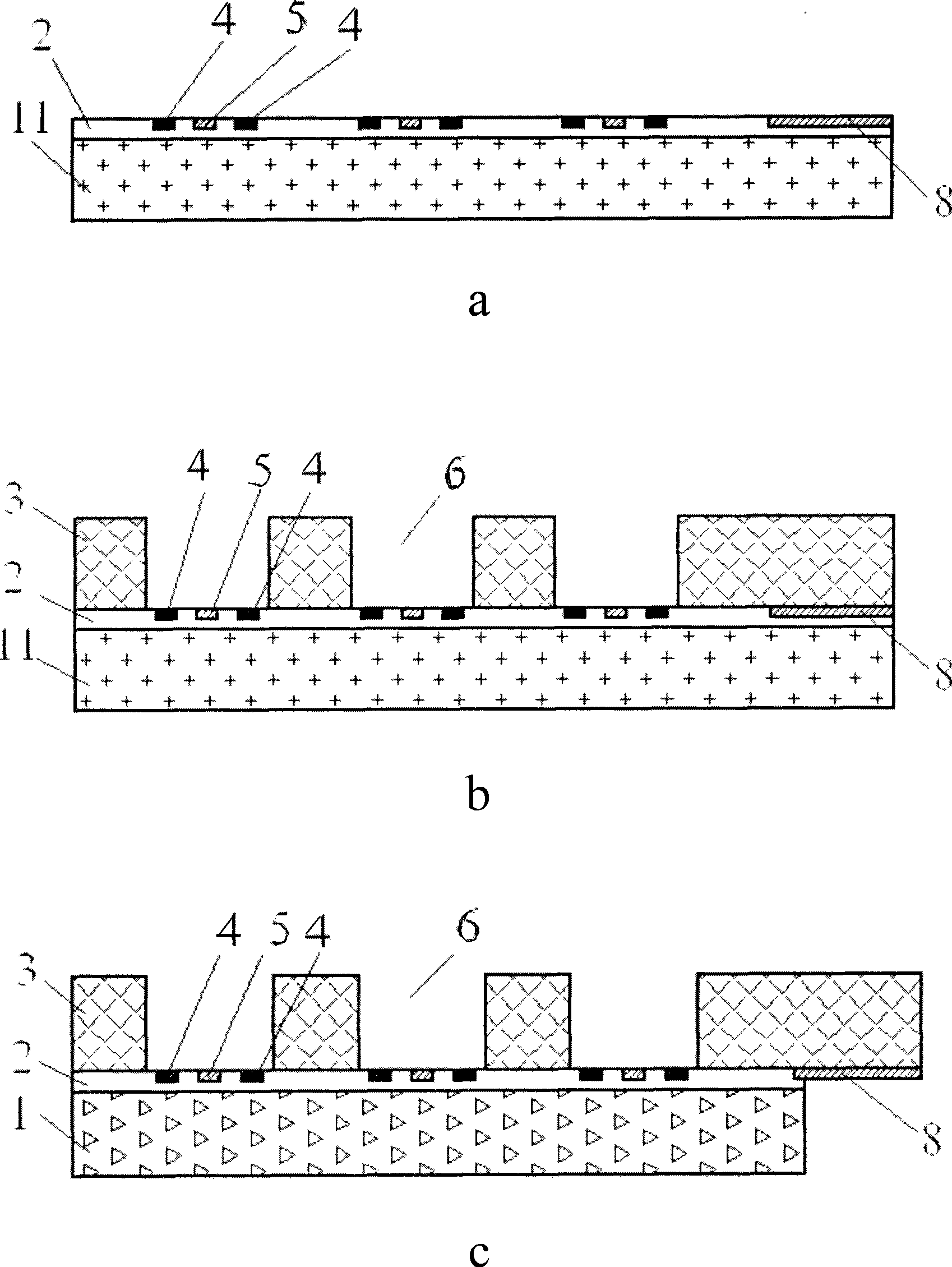

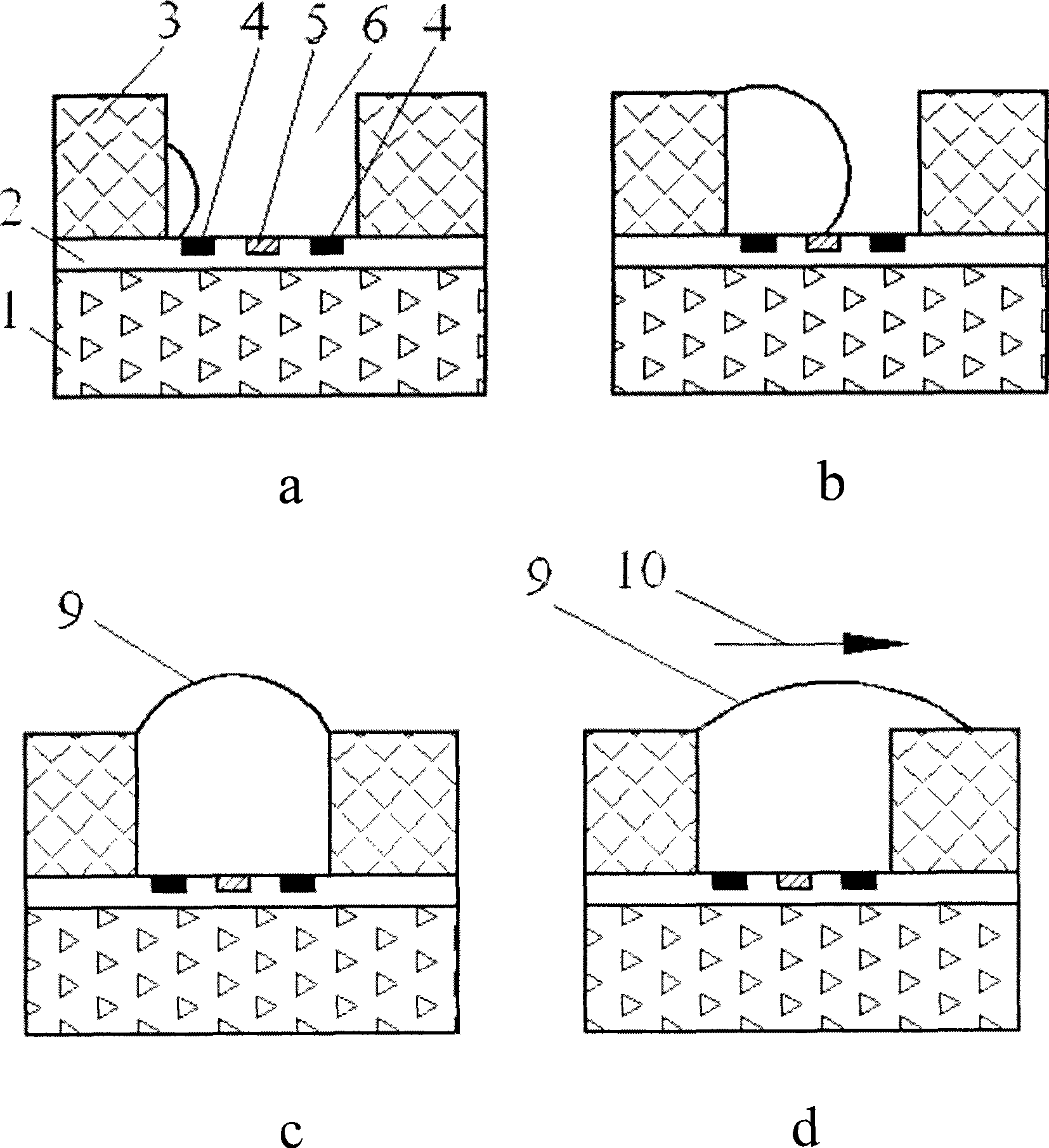

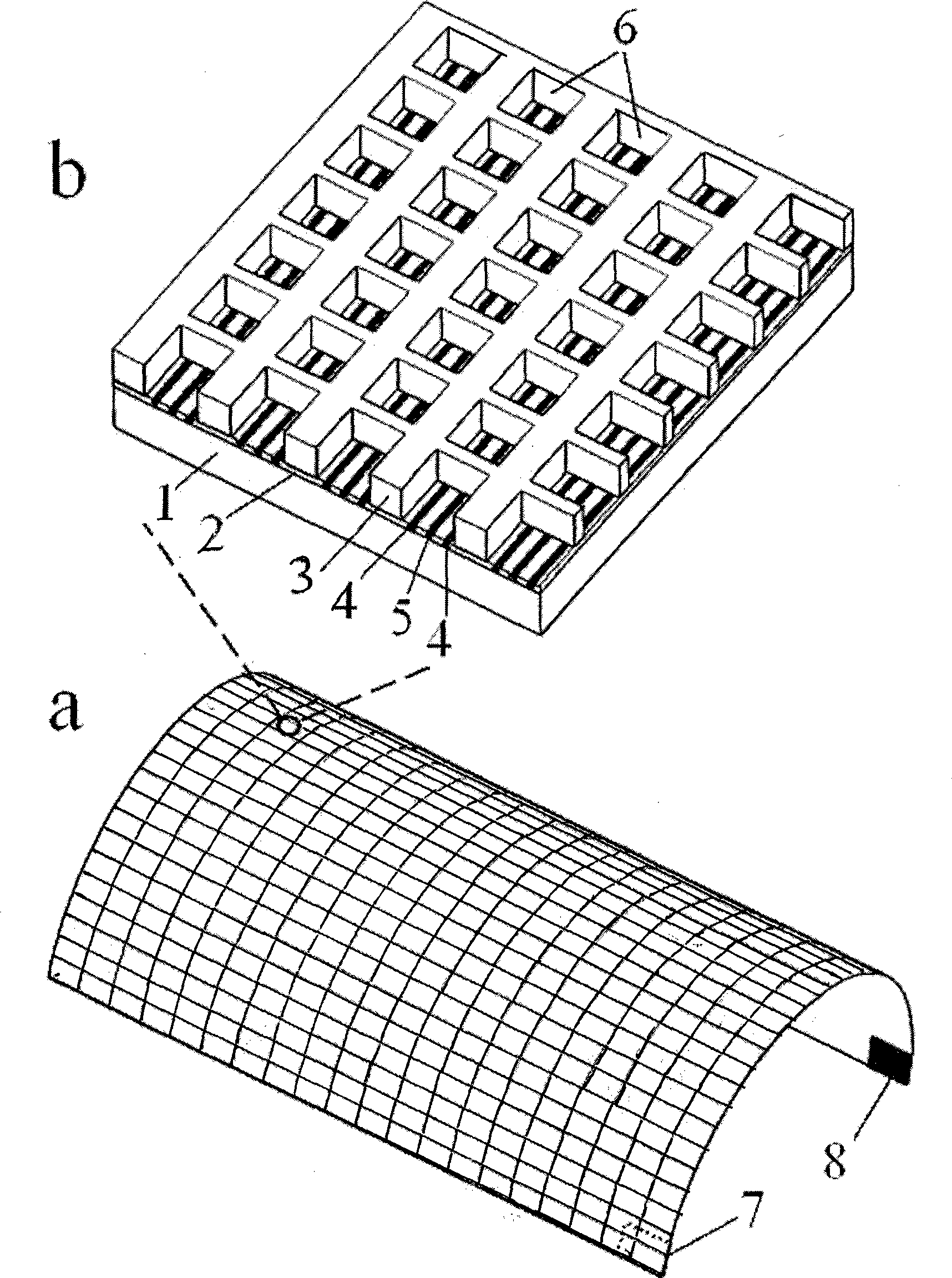

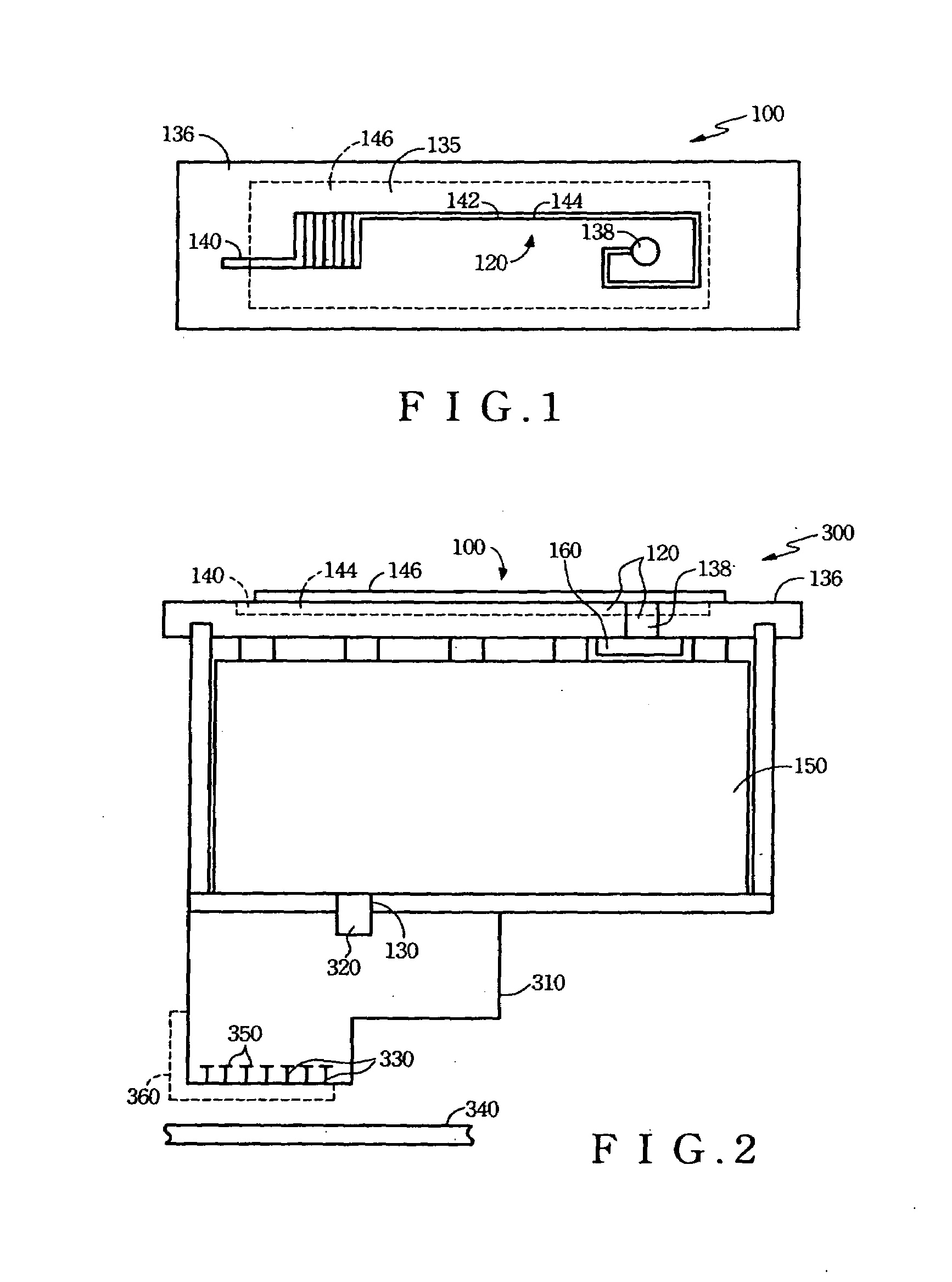

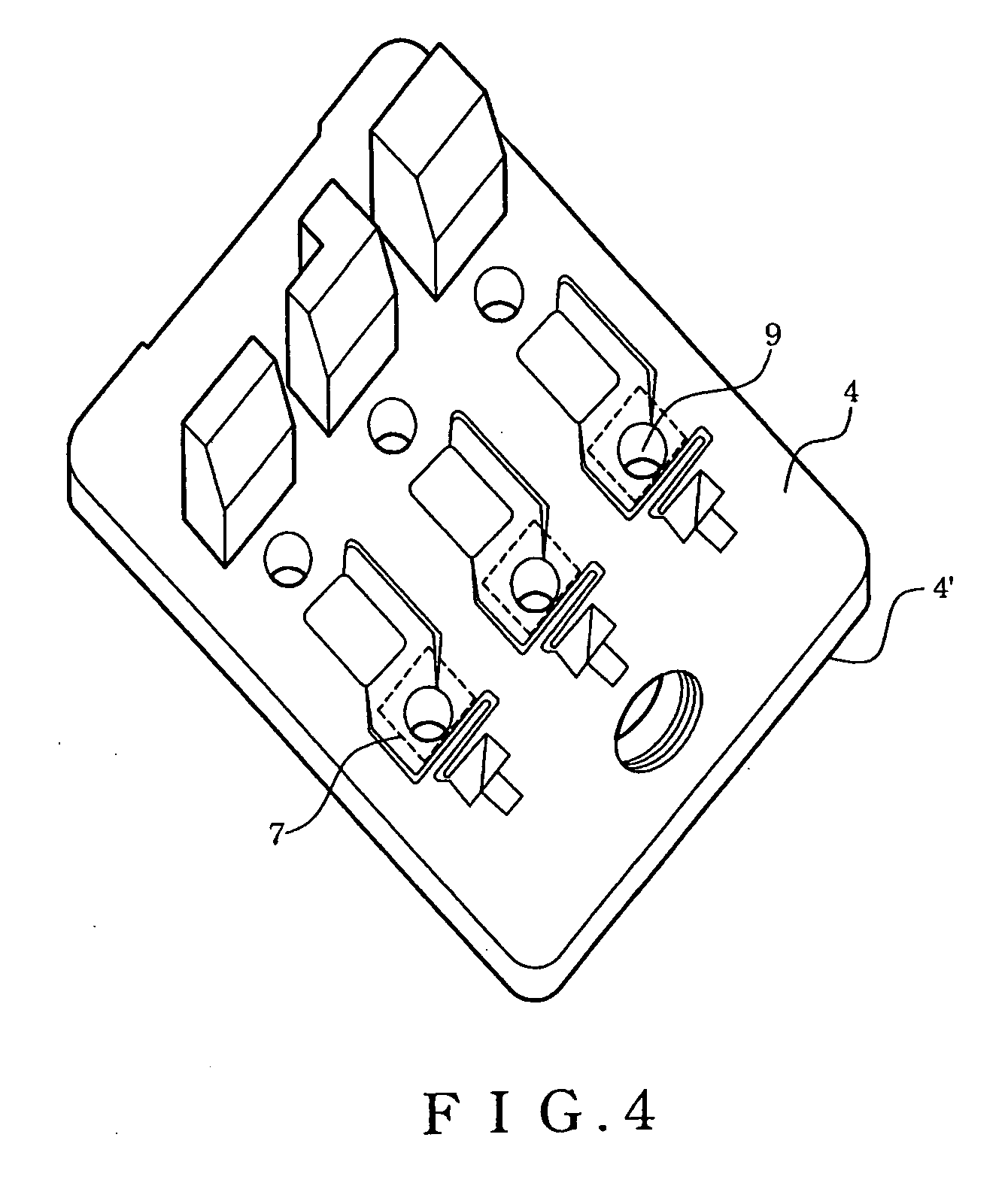

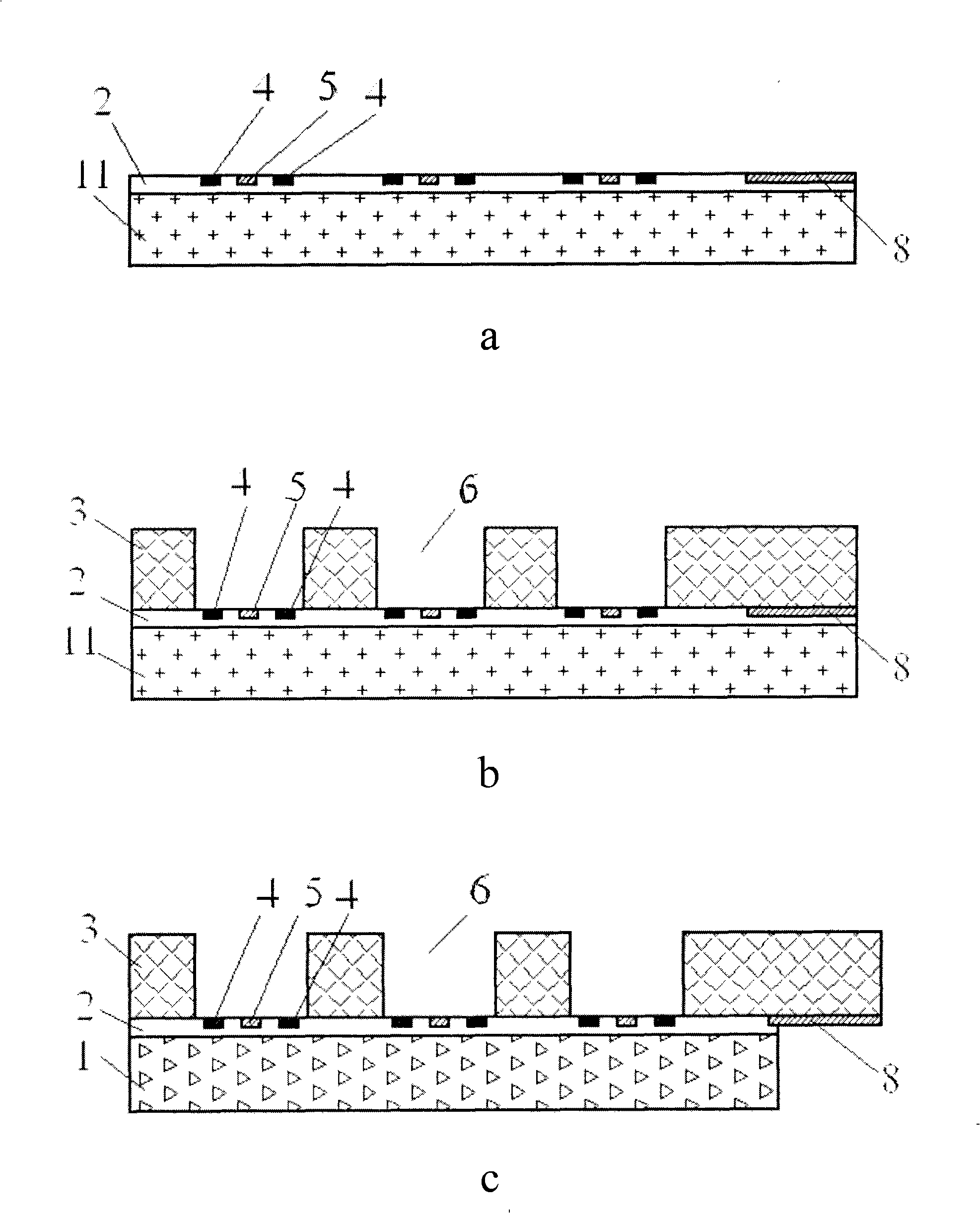

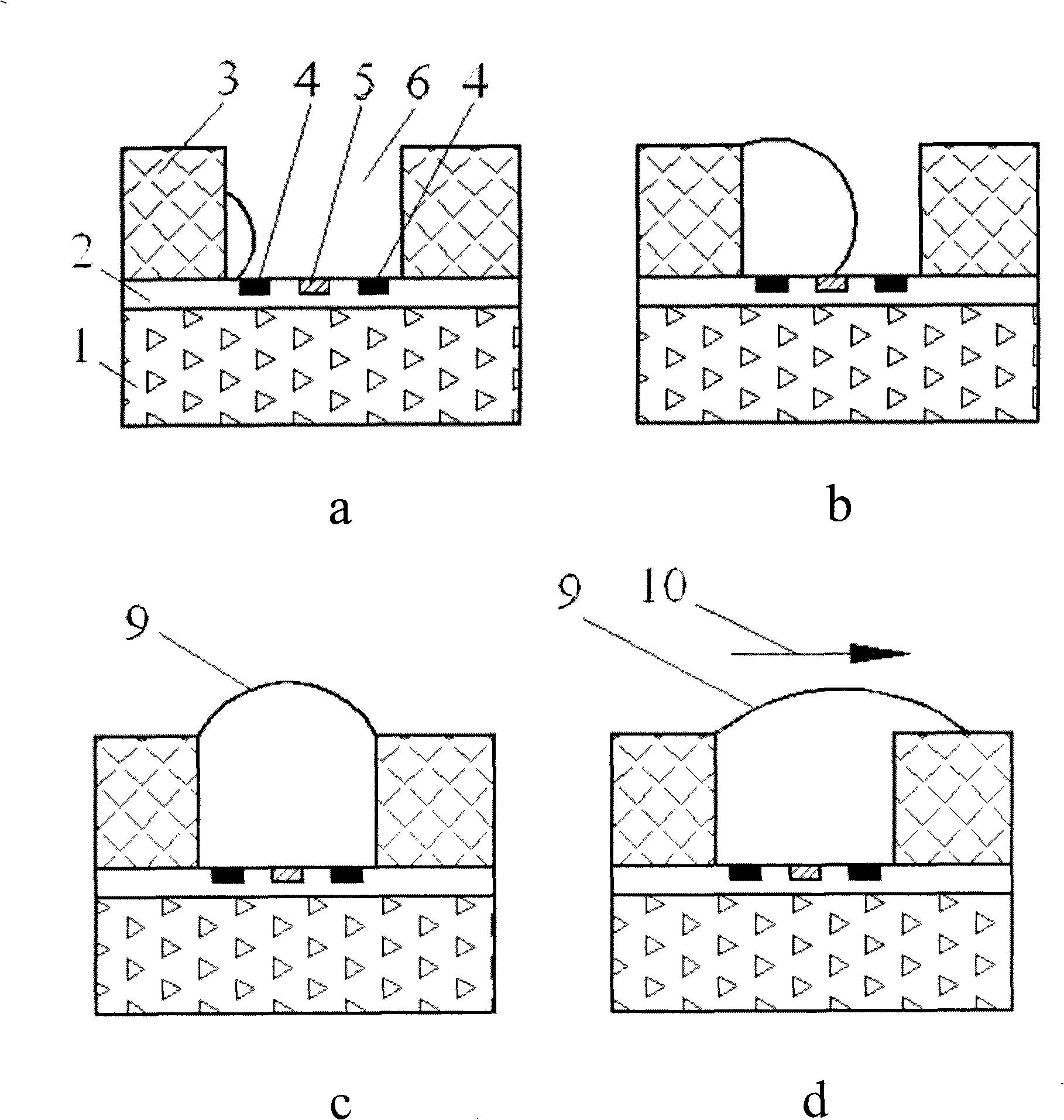

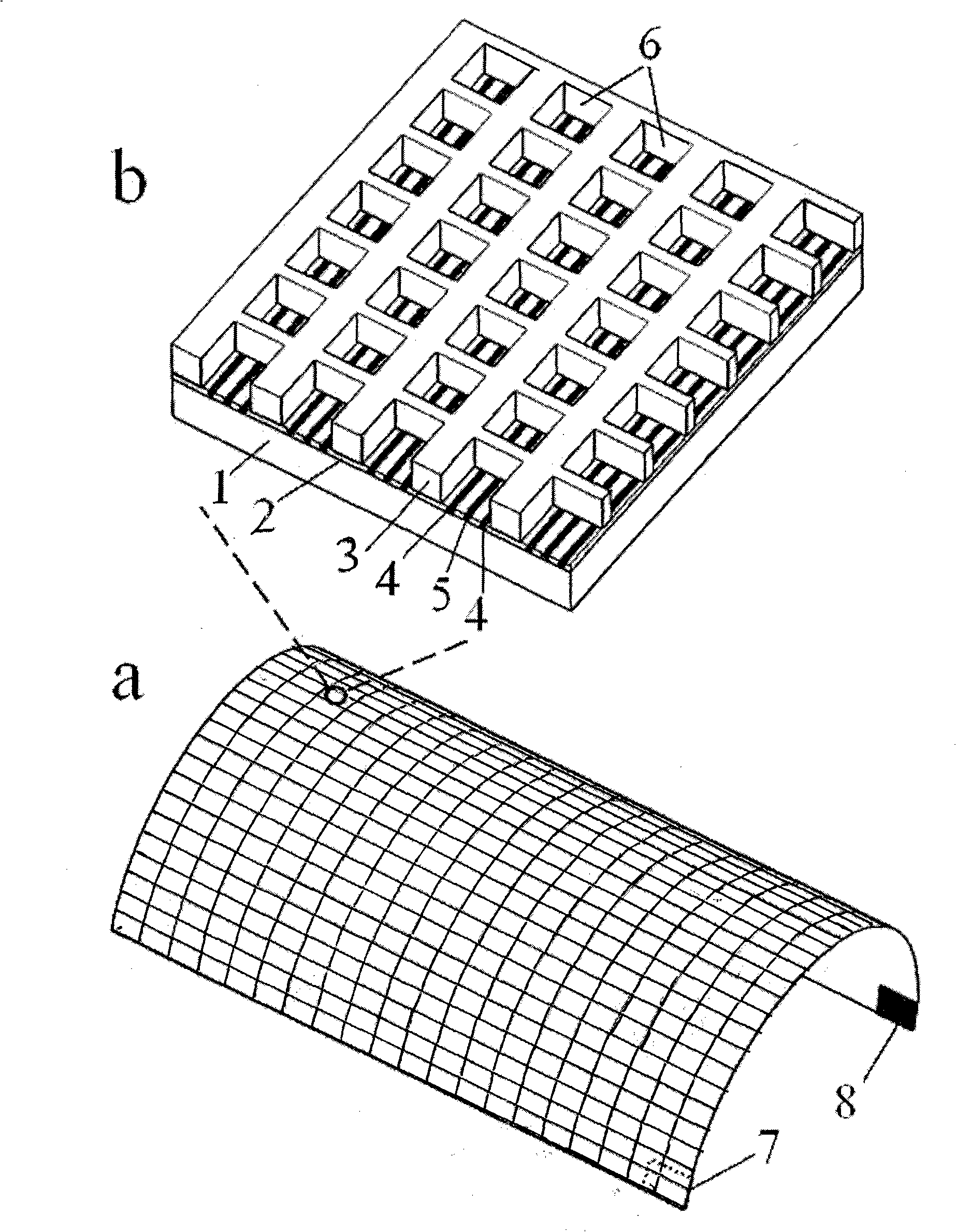

Flexible MEMS resistance reducing covering and method of manufacturing the same

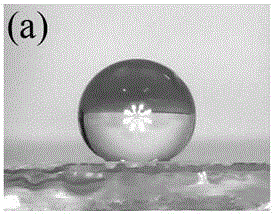

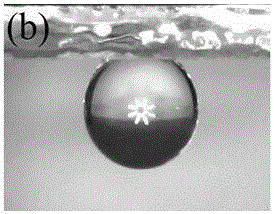

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

Method for separating quartz from low-grade potassium and sodium feldspar ore

ActiveCN105618271ALower surface oxidation potentialIncrease the surface contact angleFlotationPhysical chemistryPotassium

The invention provides a method for separating quartz from low-grade potassium and sodium feldspar ore. The method comprises the steps of providing low-grade potassium and sodium feldspar ore powder; mixing the low-grade potassium and sodium feldspar ore powder and water for obtaining low-grade potassium and sodium feldspar ore slurry; adjusting the pH value of the low-grade potassium and sodium feldspar ore slurry to 8-10 through conditioning agents, and then carrying out roughing, scavenging, concentrating and drying on the low-grade potassium and sodium feldspar ore slurry for obtaining fine potassium and sodium feldspar powder and floating the quartz; adding activating agents, inhibitors and amine collecting agents in the roughing process and the scavenging process each time. The method has the advantages that the production cost is low, the requirement for corrosion prevention of equipment is low, pollution to the environment is small, and the quality of the obtained fine potassium and sodium feldspar powder meets the use standard GB / T9195-1999 of the ceramic industry.

Owner:ZHENGZHOU SHANCHUAN HEAVY IND CO LTD

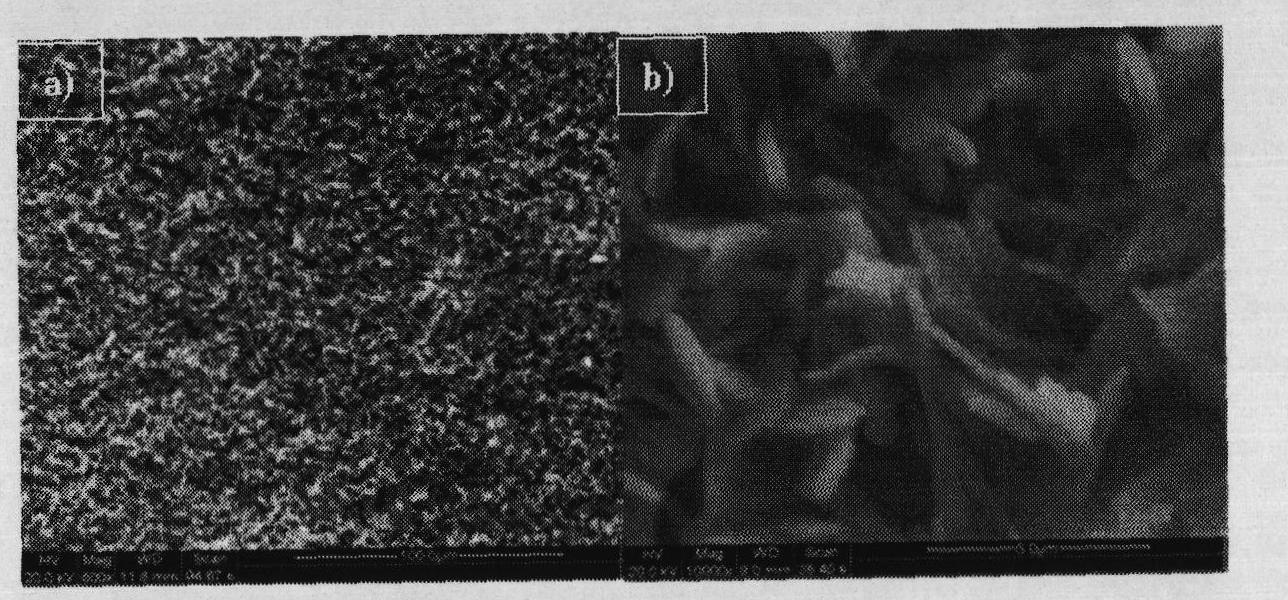

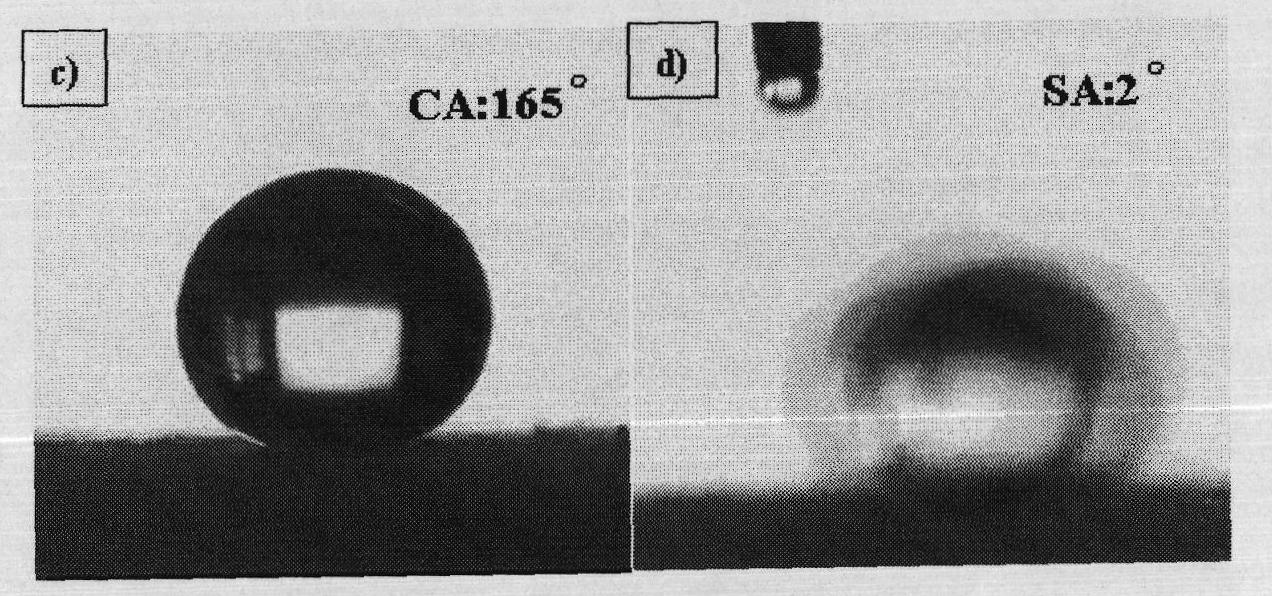

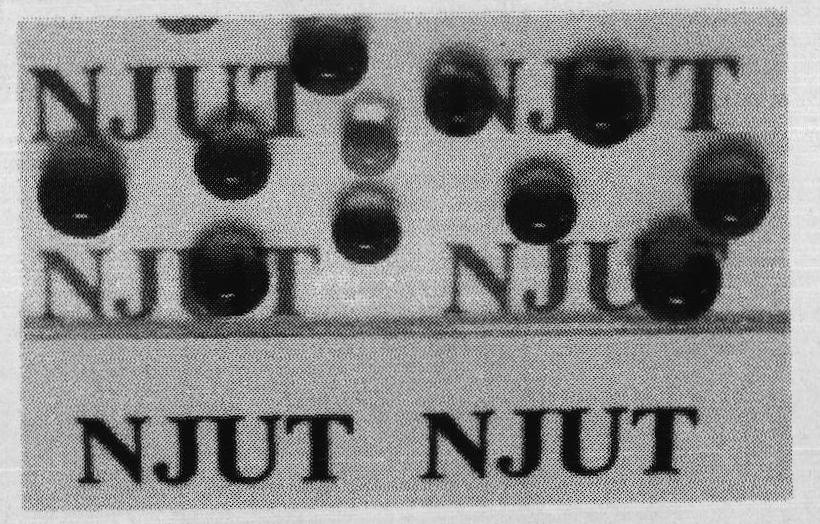

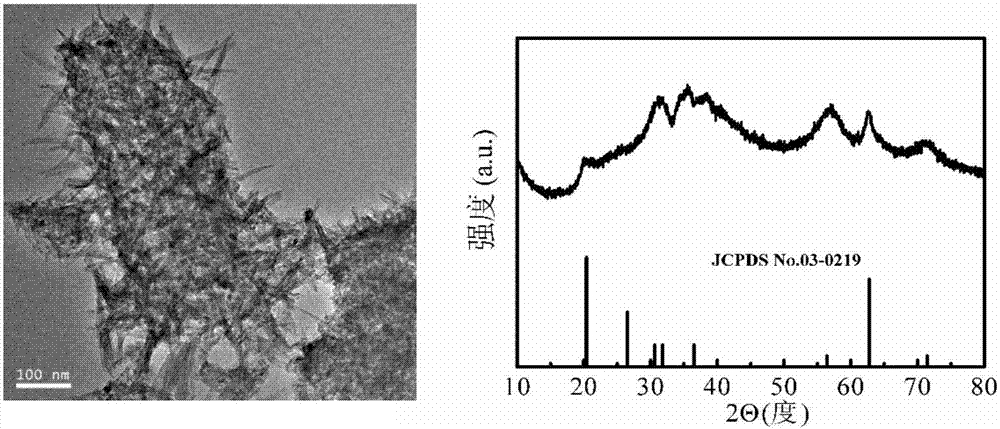

Graphene oxide/copper silicate composite powder, preparation method of composite powder and application thereof in super-hydrophobic coating

InactiveCN107128937ASimple processMild reaction conditionsMaterial nanotechnologyCarbon compoundsMicro nanoUltraviolet lights

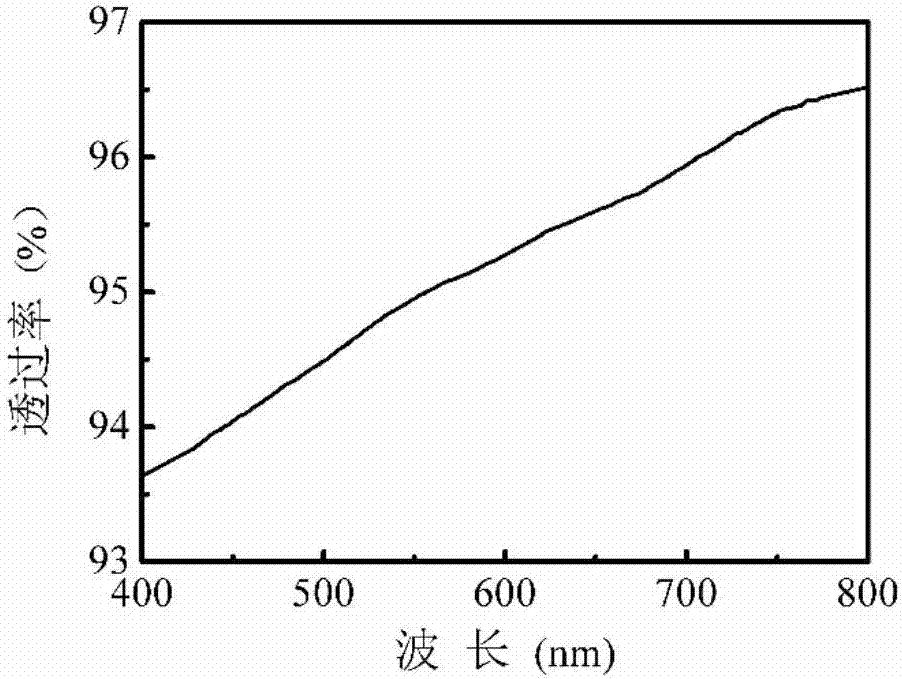

The invention discloses graphene oxide / copper silicate composite powder, a preparation method of the composite powder and application thereof in a super-hydrophobic coating. The graphene oxide / copper silicate composite powder with a micro-nano structure on the surface comprises a core formed by flake graphene oxide and a shell layer formed by needle-like nano copper silicate, wherein the needle-like nano copper silicate is arranged on the surface of the core in an array form. The super-hydrophobic coating is prepared by the following steps: coating the surface of a base material with the graphene oxide / copper silicate composite powder with the micro-nano structure on the surface, drying, and performing fluoroalkyl silane low-surface energy treatment, thereby obtaining the product. The preparation method disclosed by the invention is mild in reaction conditions, easy to realize and excellent in process repeatability; the prepared high-transparency, self-cleaning and anticorrosive super-hydrophobic coating has a static water drop contact angle of not less than 150 degrees; the slide angle does not exceed 1 degree; and the light transmissivity is not lower than 90% in a visible-ultraviolet light wave range. The product has excellent corrosion resistance and is expected to be widely applied to the fields of automobiles, spaceflight, solar cells, articles of daily use and the like.

Owner:ZHEJIANG UNIV OF TECH

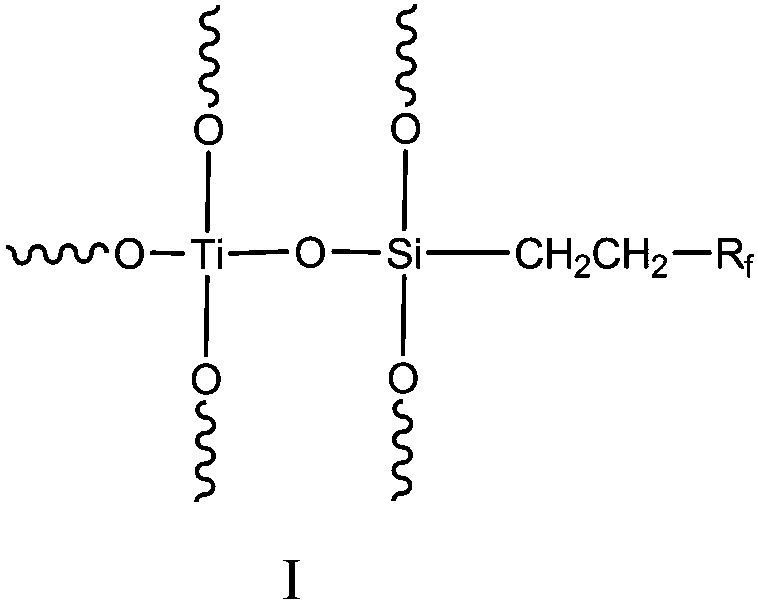

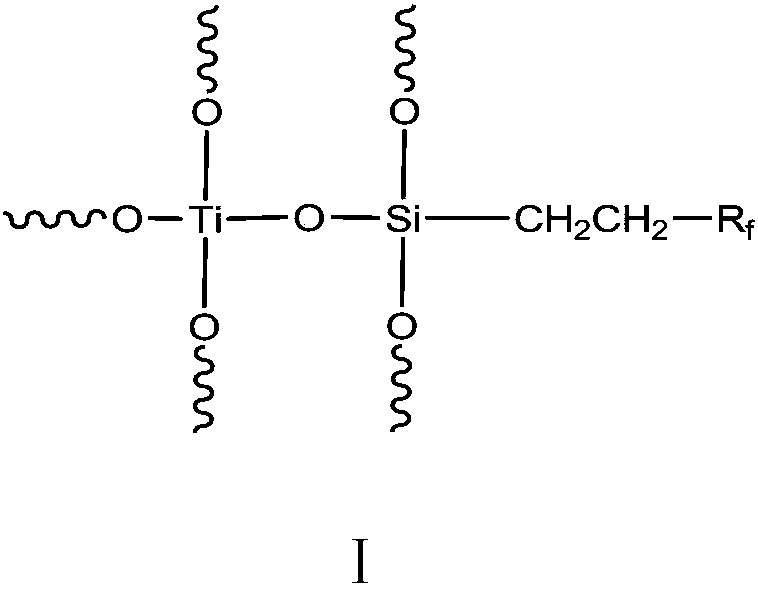

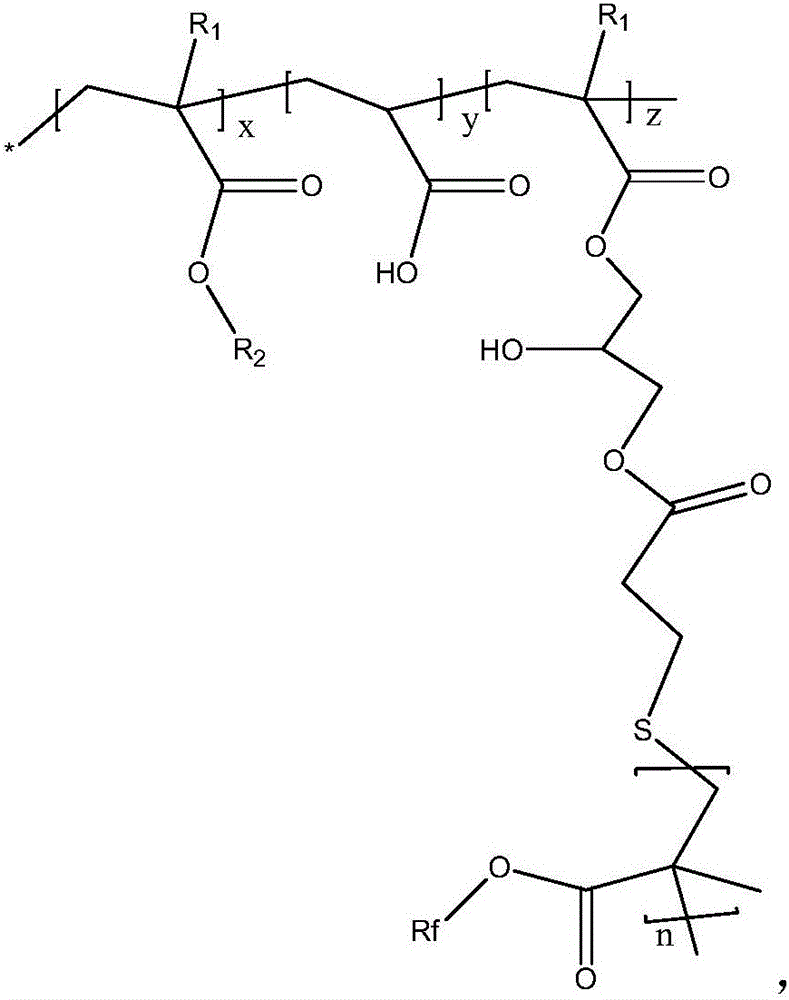

Fluorine-containing titanium sol, inorganic silicate coating and preparation method thereof

ActiveCN108084751AIncrease the surface contact anglePowerful photocatalysisAntifouling/underwater paintsAlkali metal silicate coatingsSpray coatingSurface coating

The invention belongs to the field of coatings and discloses fluorine-containing titanium sol, an inorganic silicate coating and a preparation method thereof. The fluorine-containing titanium sol hasa structure shown in the formula I, wherein Rf represents a fluorine-containing alkyl group with a C1-8 carbon atom chain and -O represents a -Si-O or -Ti-O repeating structural unit. The inorganic silicate coating comprises, by weight, 100 parts of an inorganic silicate solution, 2 to 30 parts of fluorine-containing titanium sol, 5 to 50 parts of silica sol, 0.5 to 5 parts of small molecule organosiloxane, 10 to 100 parts of water, 15 to 65 parts of a filler, 5 to 40 parts of a pigment, 0.5 to 3 parts of a defoamer, 0.5 to 3 parts of a dispersant and 0.5 to 3 parts of a wetting agent. The coating can be used through roll-coating, spray-coating and brush-coating technologies, has the surface contact angle of 110-145 degrees, has good water resistance and alkali resistance, prevents alkaliresistance abnormity in 48h, has excellent washability (for preventing bottom exposure after washing by 1200 times) and can be widely used in the field of high anti-fouling and self-cleaning buildingmaterial surface coatings.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +4

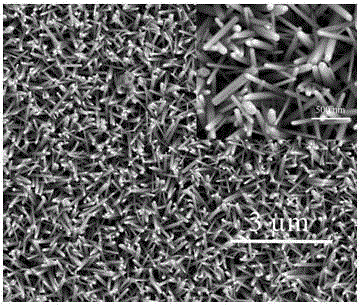

Preparation method of ZnO nano-structure with petal effect

InactiveCN105271362AIncrease the surface contact angleStrong adhesionMaterial nanotechnologyZinc oxides/hydroxidesEthylic acidEngineering

The invention discloses a preparation method of a ZnO nano-structure with a petal effect. The preparation method comprises the following steps of: respectively using zinc acetate, ethylene glycol monomethyl ether and ethanol amine as a precursor, a solvent and a stabilizer, carrying out coating by adopting a rotary coating technology and carrying out annealing processing to obtain zinc oxide seed crystals; then placing the prepared zinc oxide seed crystals into aqueous solution of zinc nitrate, regulating a pH value of solution by using ammonia water, and performing the hydrothermal reaction in an autoclave to obtain a great number of randomly growing zinc oxide nanorods, wherein the surfaces of the zinc oxide nanorods are of a netted structure. The zinc oxide nano-structure provided by the invention is a super-hydrophobic nano-structure with super-strong water drop adsorption capacity, and wettability of the petal-like surface of the zinc oxide nano-structure is superior to that of an existing zinc oxide nano material. The preparation method disclosed by the invention is simple, has no pollution, is low in cost, is easy to implement and is convenient to control.

Owner:HEFEI NORMAL UNIV

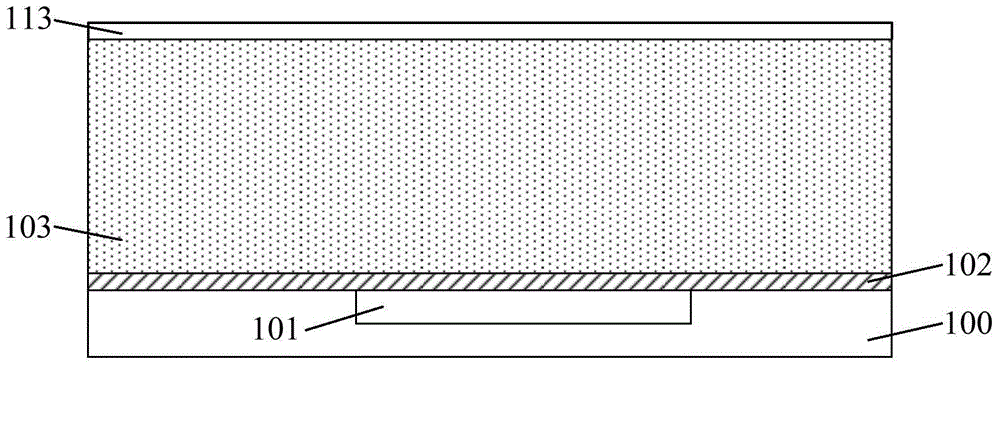

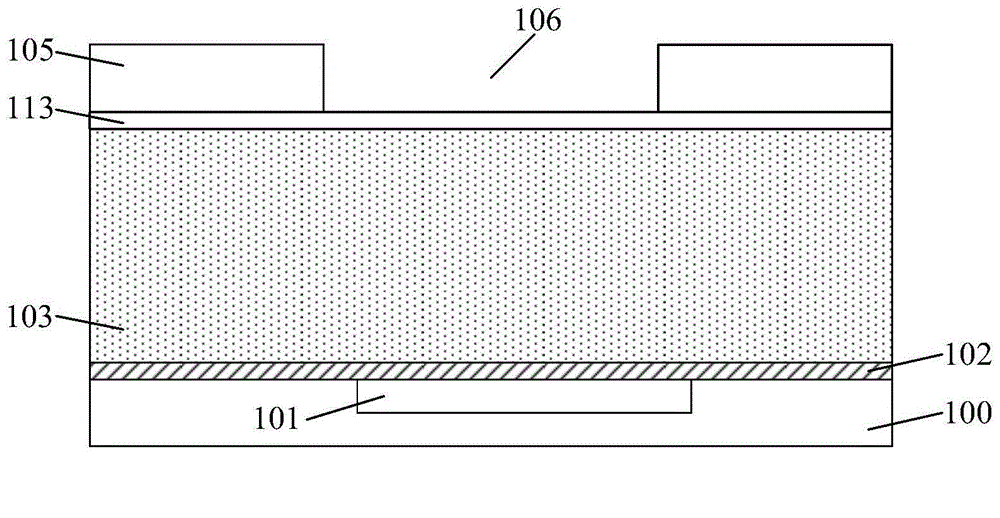

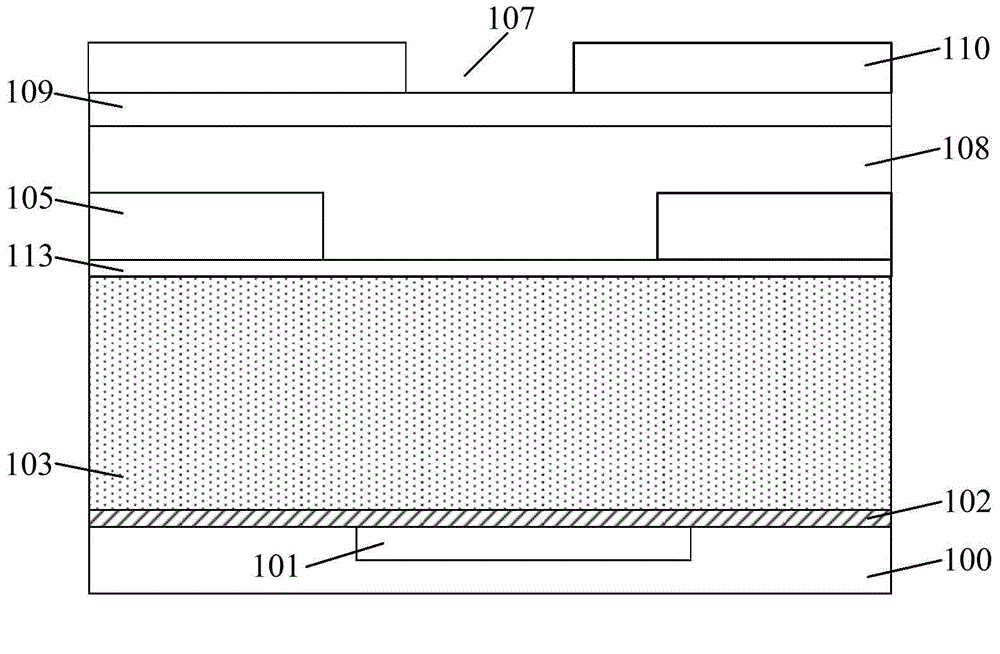

Formation method of semiconductor structure

InactiveCN105702619AImprove hydrophobicityImprove corrosion resistanceSemiconductor/solid-state device manufacturingCorrosionSemiconductor structure

Provided is a formation method of a semiconductor structure. The method includes: a substrate and a dielectric layer positioned on the surface of the substrate are provided, and a bottom metal layer is arranged in the substrate; the dielectric layer is etched to form an opening penetrating through the dielectric layer, and the surface of the bottom metal layer is exposed at the bottom of the opening; pre-restoration irradiation processing of the dielectric layer at sidewalls of the opening is performed, and contact angles on the surface of the dielectric layer at the sidewalls of the opening are increased; after the pre-restoration irradiation processing, wet-process cleaning processing of the opening is performed; and a conductive layer filling the opening is formed. According to the method, the contact angles on the surface of the dielectric layer at the sidewalls of the opening are increased, the hydrophobicity capability of the surface of the dielectric layer at the sidewalls of the opening is improved, the corrosion of the dielectric layer at the sidewalls of the opening due to the wet-process cleaning processing is avoided, the breakdown voltage is increased, the problem of time dependent dielectric breakdown is suppressed, and the reliability and the electrical performance of the semiconductor structure are enhanced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Fluoridized TPU car body film as well as preparation method and application thereof

InactiveCN107163872AEasy to installEasy maintenanceAntifouling/underwater paintsFilm/foil adhesivesSulfite saltNational level

The invention discloses a fluoridized TPU car body film. The fluoridized TPU car body film sequentially comprises a PET peeling layer, an adhesive layer, a TPU base material and a hydrophobic anti-fouling coating from bottom to top, wherein the hydrophobic anti-fouling coating comprises, in parts by mass, 25-35 parts of polyphenylene sulfide, 30-45 parts of a fluorinated ethylene propylene emulsion, 2-6 parts of aluminum oxide, 1-3 parts of sodium sulfite and 20-30 parts of deionized water. The fluoridized TPU car body film has atmosphere aging resistance, can resist harsh weather such as acid rain, wind, snow and the like and has high anti-radiation performance and lower permeability, and the surface and performance can keep unchanged even if the car body film is exposed in the atmosphere for a long time; the car body film is non-sticky and has a self-cleaning property and a smooth and transparent surface, so that dirt cannot stick to the car body film easily, the car washing frequency can be reduced, and the car body film is energy-saving and environment-friendly; the car body film has repairability and is scratch-resistant, small scratches on the surface can automatically disappear, and the appearance of a car is under no influence, the car body film is non-toxic and pollution-free and meets the specification standard for national-level environment-friendly additives and the like.

Owner:日氟荣高分子材料(上海)有限公司

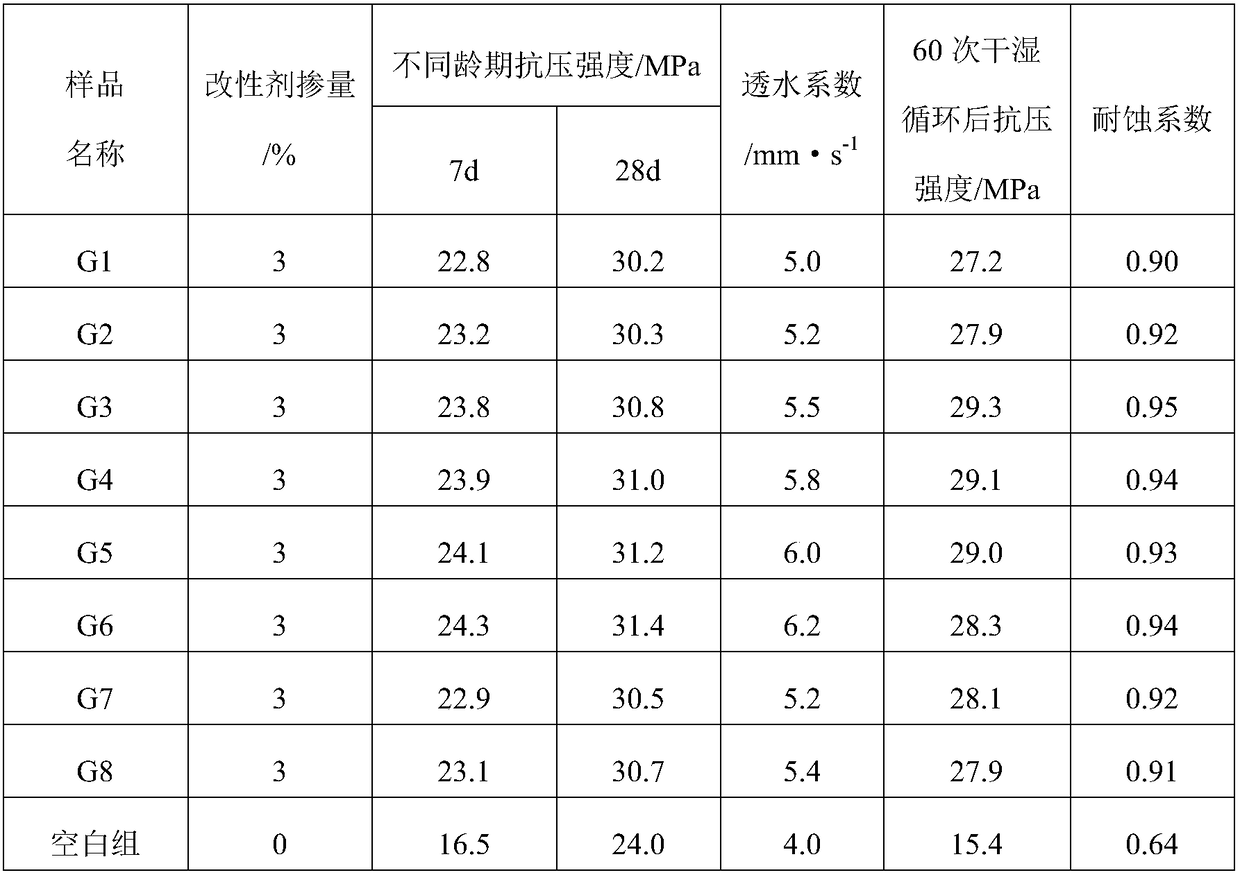

Special modifying agent for water-permeable concrete and preparation method thereof

The invention discloses a special modifying agent for water-permeable concrete. The special modifying agent is characterized by comprising the following components in percentage by mass: 10 percent to15 percent of long-carbon-chain silane, 45 percent to 60 percent of a dispersant, 5 percent to 10 percent of polysiloxane resin, 5 percent to 10 percent of fluorocarbon resin emulsion and 10 percentto 20 percent of de-ionized water, wherein the sum of the mass percent is 100 percent. The special modifying agent for the water-permeable concrete, disclosed by the invention, is doped into the water-permeable concrete and a hydrophobic effect enforces water molecules to be dispersed into the concrete, so that cement is more easily hydrated; after molding, dense hydrophobic films are formed on the surface of the concrete and an inner wall of a pore structure, and the water in the concrete can be effectively prevented from being evaporated, so that later-period sufficient hydration of the concrete is ensured and the strength of the concrete is easy to improve.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES

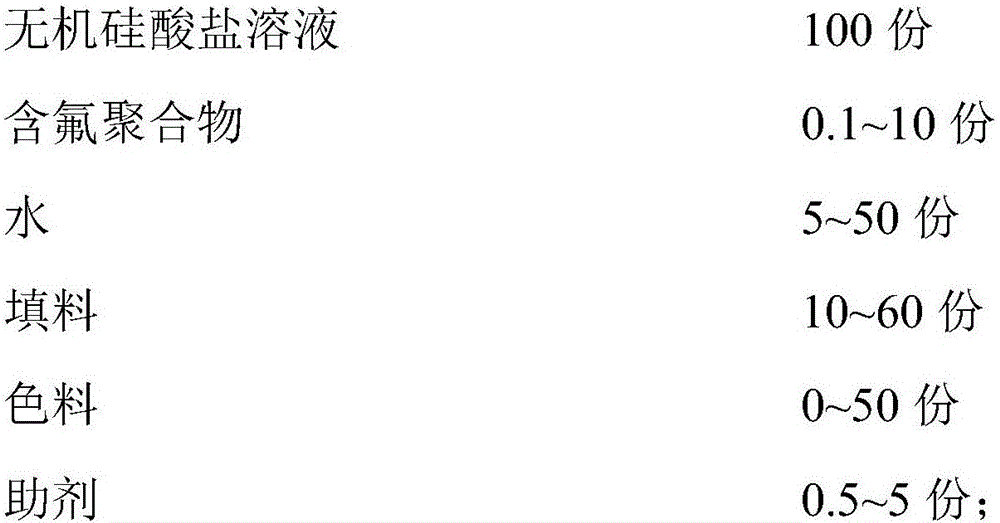

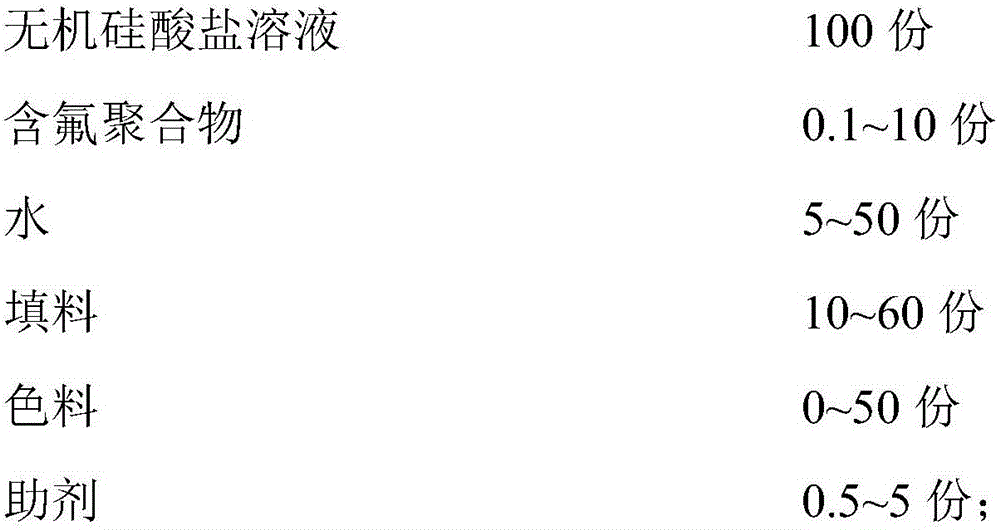

High-fouling-resistant inorganic silicate coating prepared from fluorine-containing polymer and preparation method and application of coating

ActiveCN106189391AGood flexibilityGood weather resistanceAntifouling/underwater paintsPaints with biocidesFluorine containingPigment

The invention belongs to the field of inorganic silicate coatings, and particularly relates to a high-fouling-resistant inorganic silicate coating prepared from a fluorine-containing polymer and a preparation method and application of the coating. The high-fouling-resistant inorganic silicate coating prepared from the fluorine-containing polymer is prepared from, by weight, 0.1-10 parts of fluorine-containing polymer, 5-50 parts of water, 100 parts of inorganic silicate solution, 0.5-5 parts of auxiliaries, 10-60 parts of filler and 0-50 parts of pigment. The high-fouling-resistant inorganic silicate coating prepared from the fluorine-containing polymer has good flexibility, water resistance, acid and alkali resistance and scrubbing resistance, wherein no abnormality of alkali resistance occurs within 48 h, and base exposure does not occur after scrubbing is conducted 1,200 times; the problems of cracking, disengaging, peeling-off and the like of the coating are effectively prevented, and the coating has wide application in the field of high-fouling-resistant building interior and exterior walls.

Owner:国科广化(南雄)新材料研究院有限公司 +1

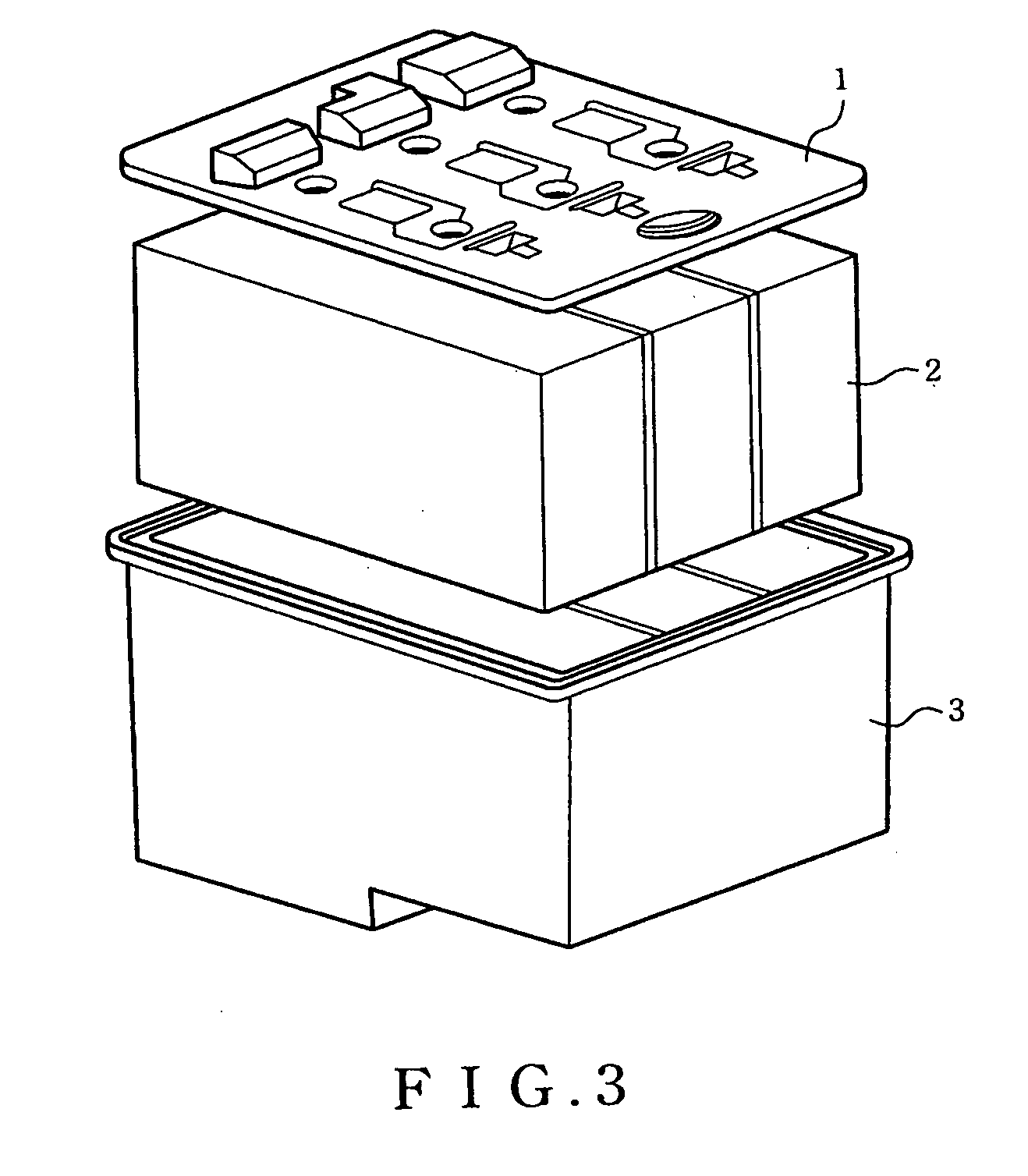

Anti-leaking cartridge and anti-leaking ink

The present invention is generally related to an anti-leaking cartridge and anti-leaking ink. The anti-leaking ink comprises: an organic solvent, which is selected from the group consisting of diethylene glycol, triethylene glycol, triethanolamine amine extra pure, polyethylene glycol 200, and ethylene glycol and functions with at least one seal member for avoiding leakage; at least one dye dissolved in the organic solvent; a buffer solution maintaining the pH value of the anti-leaking ink in between 6.0 to 8.0; an antibacterial avoiding that the properties of the ink is changed; surfactant, which homogenizes the aquas of ink and the organic solvent; and de-ionized water.

Owner:BENQ CORP +1

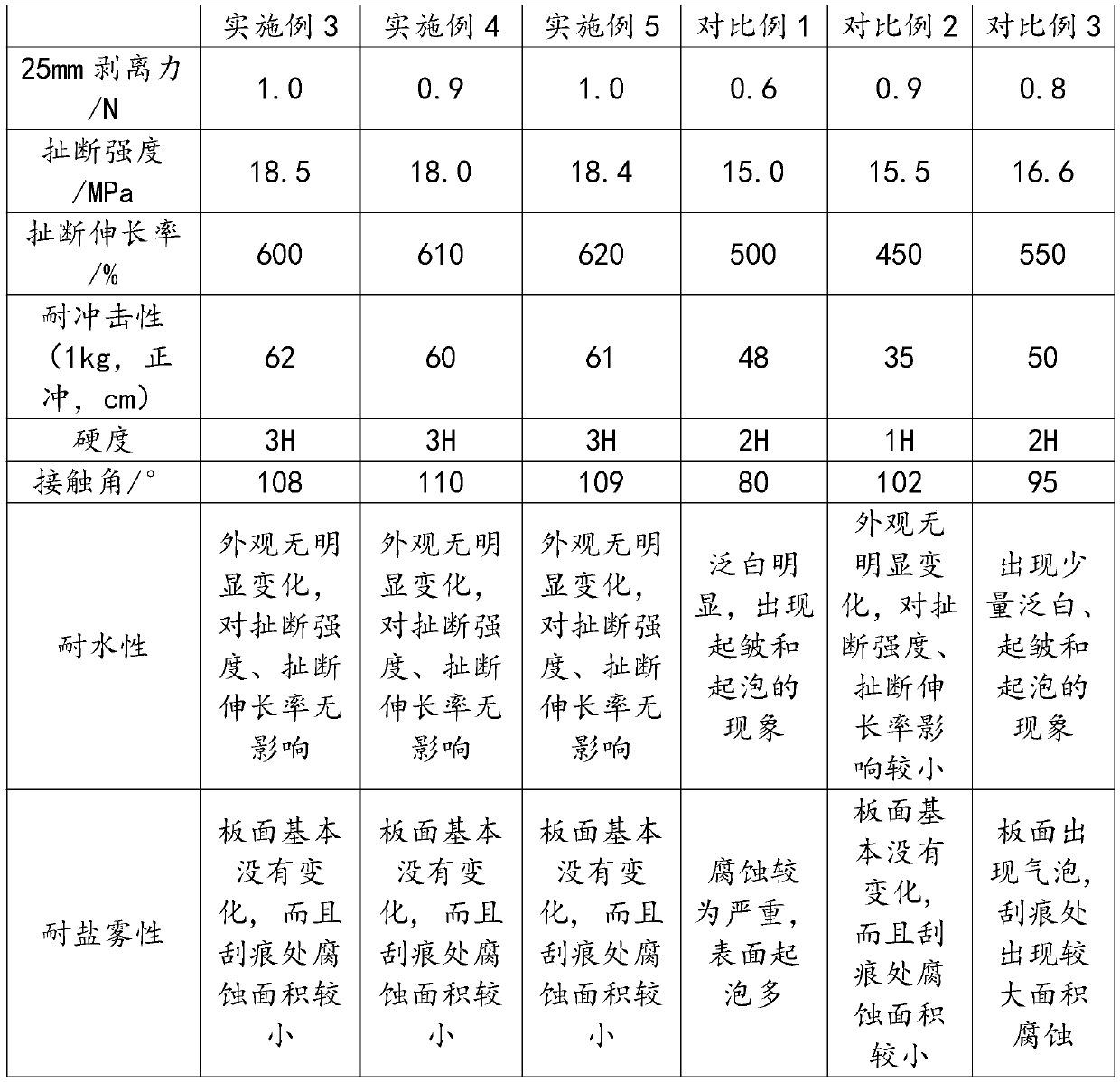

Vehicle paint film based on nanometer composite material, and preparation method thereof

The invention discloses a vehicle paint film based on a nanometer composite material. The vehicle paint film is prepared from, by weight, 55 to 65 parts of modified acrylic emulsion, 7 to 10 parts ofthe nanometer composite material, 3 to 4 parts of carnauba wax, 2 to 3 parts of a wetting and dispersing agent, 0.8 to 1 part of a defoaming agent, 0.6 to 0.9 part of a thickening agent, and 30 to 40parts of deionized water. The invention also discloses a preparation method of the vehicle paint film. According to the preparation method, water-soluble modified acrylic emulsion is taken as a paintfilm base body, deionized water is taken as a solvent, VOC content is low, and environment protection requirements are satisfied; and in addition, the modified acrylic emulsion is capable of providingthe paint film with excellent water resistance, and salt spray resistance; the nanometer composite material is capable of increasing the hardness and the adhesion force of the paint film greatly; theobtained vehicle paint film possesses water resistance, salt spray resistance, wear resistance, is capable of protecting vehicle paint effectively, is low in VOC content, is capable of reducing environment pollution degree, no organic solvent residue is left, and vehicle paint environment protection requirements are satisfied.

Owner:山东亿隆薄膜材料有限责任公司

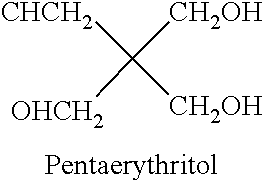

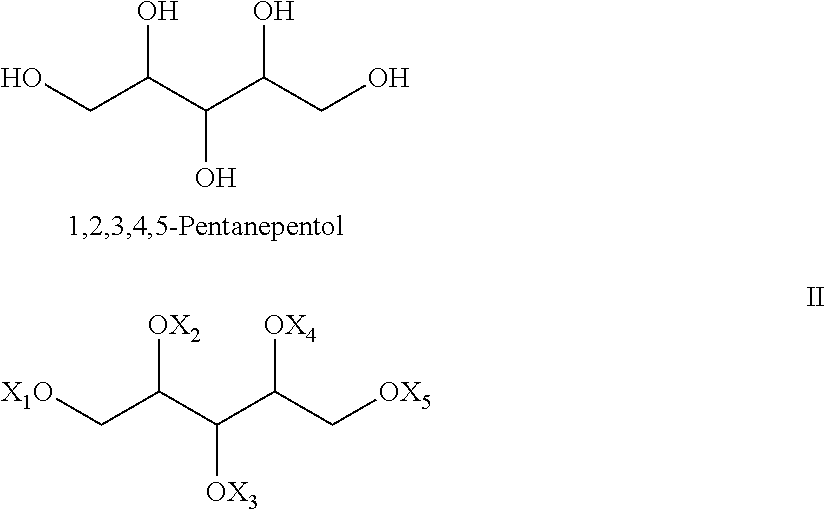

Polymer for contact lenses

ActiveUS20130274370A1Good storage stabilityPromotes rapid oxidationOptical elementsPolymer sciencePolyol

The present invention relates to a polyurethane polymer composition prepared by reacting a mixture comprising: a} at least one polyethylene glycol, and either b) at least one poly-isocyanate, having a functionality greater than 2 or c) at least one di-isocyanate and at least one polyol or at least one macropolyol having a functionality greater than 2, wherein the polyol or macropolyol is present at an amount of 0.1 to 9 wt % of the mixture. The invention also relates to a process for preparing a polyurethane xero-gel in the form of a moulded article, said process comprising the steps of: i.) preparing said mixture; ii. ) dispensing the reaction mixture formed in step i) into a mould; iii. ) allowing the reaction mixture to react and cure; iv. ) removing the moulded article from the mould; and v. ) hydrating the moulded article.

Owner:OCUTEC

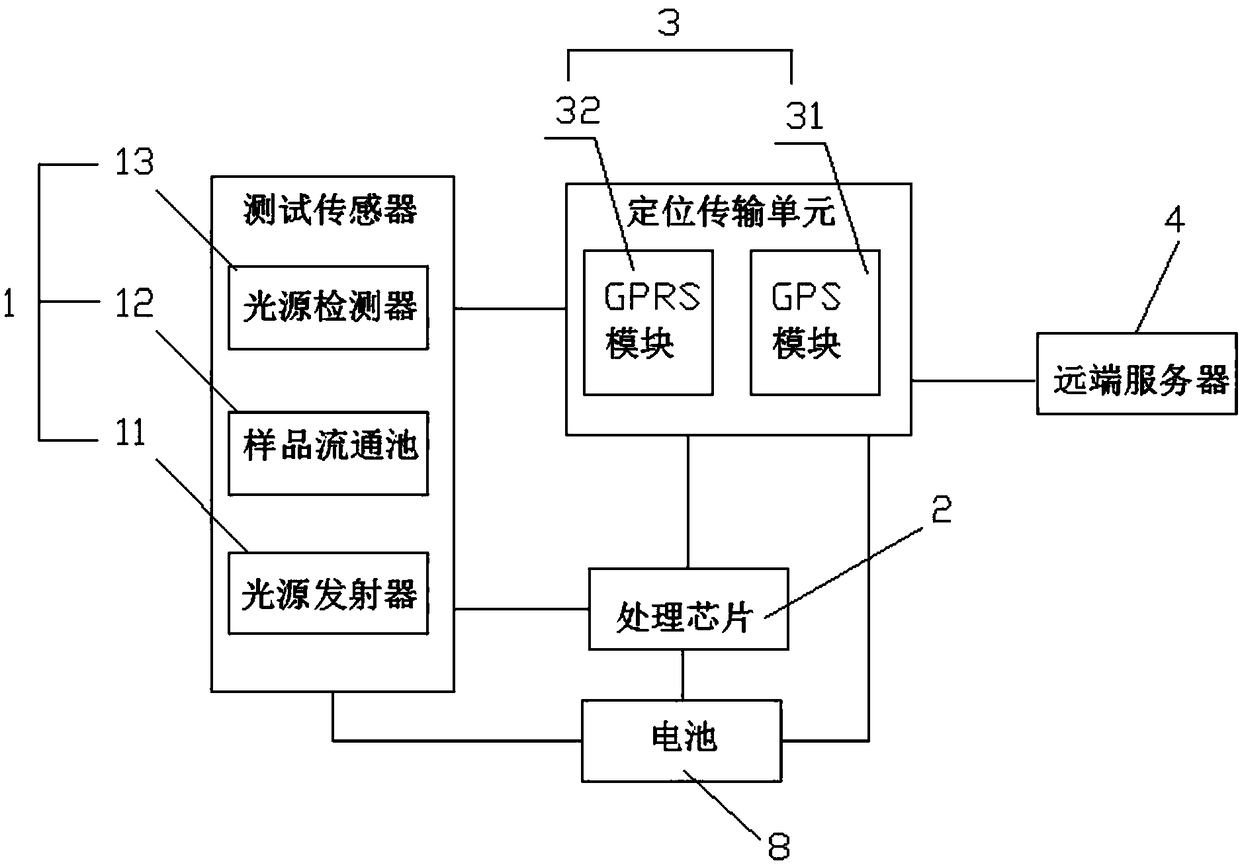

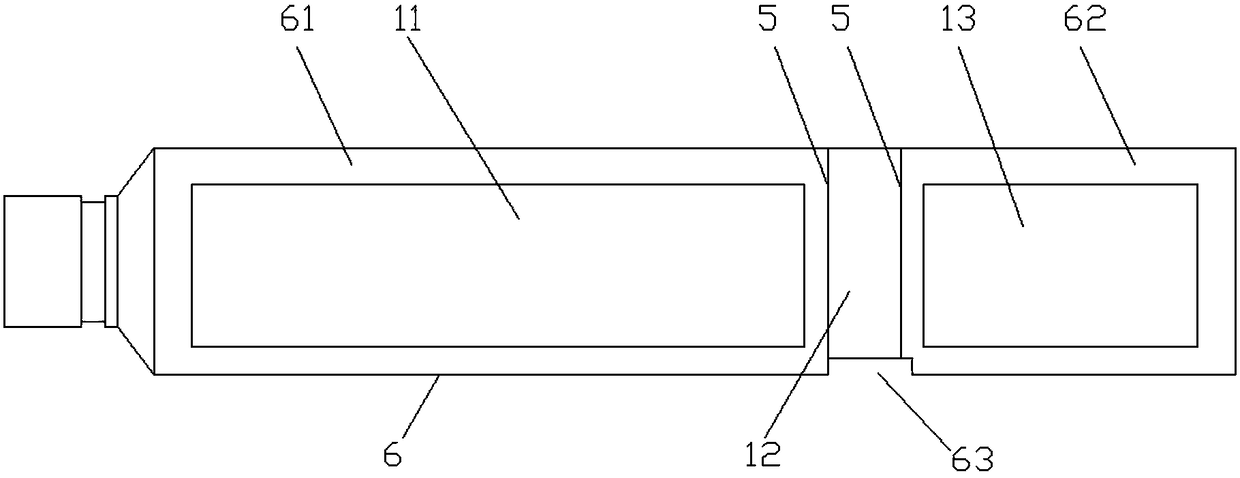

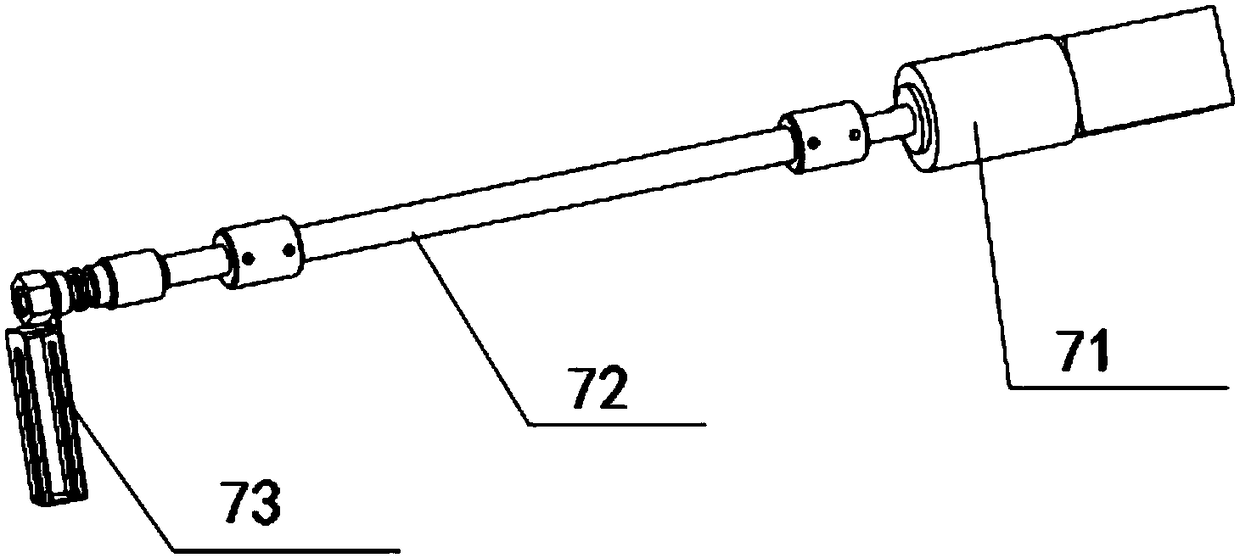

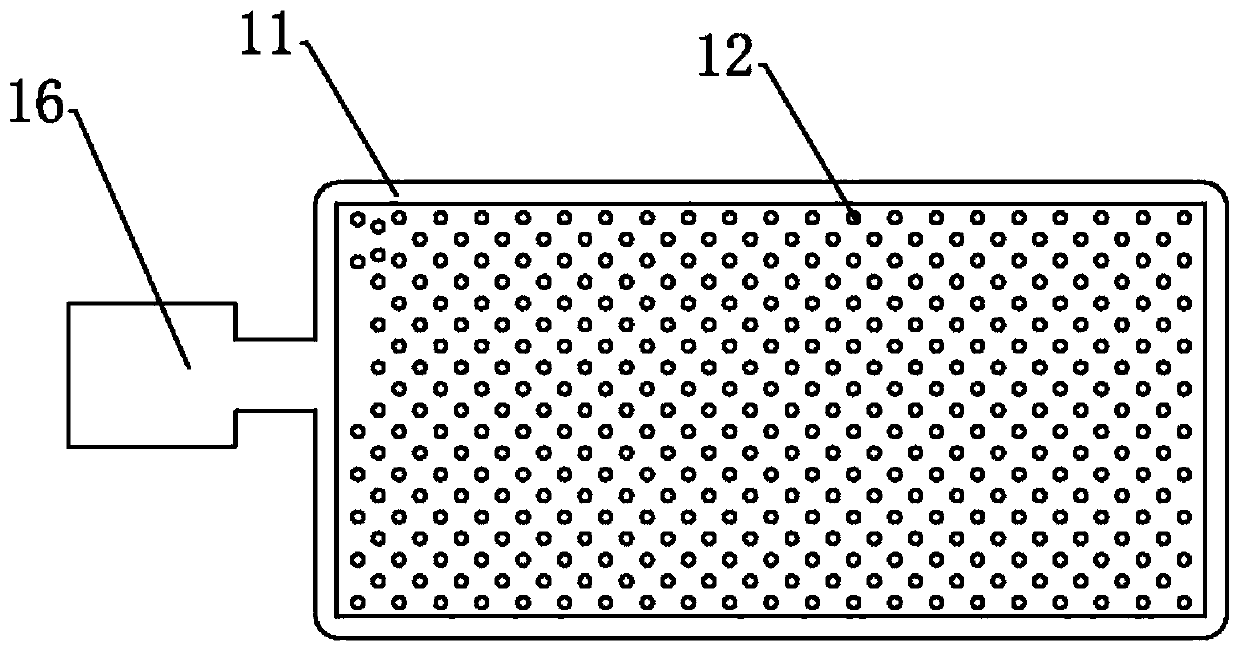

Water quality monitoring device

ActiveCN108426836AHydrophobicMinimize air bubblesTransmissivity measurementsTransmittanceWater quality

The invention relates to a water quality monitoring device. The device comprises a test sensor, a processing chip and a positioning and transmission unit, wherein the test sensor comprises a light source emitter, a sample flow cell and a light source detector; light transmitting pieces are arranged at a light path inlet end and a light path outlet end of the sample flow cell respectively; the surfaces of the light transmitting pieces are polished and plated with light transmitting hydrophobic films. The surfaces of the light transmitting pieces are polished and plated with light transmitting hydrophobic films, so that the light transmitting pieces can have the hydrophobic property, tiny bubbles attached to the surfaces of the light transmitting pieces can be reduced, light ray refraction,diffuse reflection and other phenomena can be reduced, and the transmittance at an ultraviolet-visible light waveband can be improved. Meanwhile, the surface contact angle between water and the lighttransmitting hydrophobic films is enlarged, thus, the surfaces of the light transmitting pieces cannot be soaked by water, the possibility of absorption of dust in water is reduced, and the light transmittance and the like are improved.

Owner:力德(中山)环境科技发展有限公司

Lotus leaf effect self cleaning fluorocarbon paint

The present invention belongs to the field of self-cleaning coating technology. In the concrete, it relates to a self-cleaning fluorocarbon coating with lotus leaf effect. It is made up by using organic silicon modified fluorocarbon resin, solidifying agent, hydrophobic particles, pigment, filling material, adjuvant and solvent according to the mixing ratio of 1:0.1-0.3:0.03-0.1:0-0.36:0-0.1:0.01-0.05:0.1-0.3 through a certain preparation process.

Owner:鳄鱼制漆(上海)有限公司

Temperature equalization plate and preparation method thereof

The invention relates to the technical field of temperature equalization plates, and particularly discloses a temperature equalization plate and a preparation method thereof. The temperature equalization plate comprises an upper cover plate and a lower cover plate connected with the upper cover plate, a hollow cavity is defined by the upper cover plate and the lower cover plate and used for containing a working fluid, and a capillary structure is arranged in the cavity. The preparation method of the temperature equalization plate is convenient to operate and control, high in production efficiency, low in production cost and suitable for large-scale industrial production, thus the prepared product is stable in quality, simple in structure, small in thickness, not prone to deforming, good inheat dissipation performance, good in corrosion resistance and long in service life, and compared with an in-situ welded copper mesh capillary structure adopted by a temperature equalization plate inthe prior art, the prepared temperature equalization plate is simpler in structure, smaller in thickness, better in heat dissipation performance and longer in service life.

Owner:东莞赛诺高德蚀刻科技有限公司

Method for modifying acrylic ester by using organic silicon

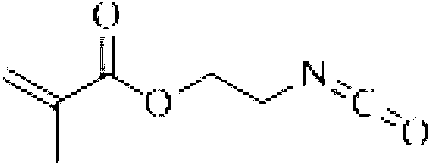

The invention discloses a method for modifying acrylic ester by using organic silicon. The method comprises the following steps of: reacting amino silane or amino silicone oil with the molecular weight of 100-10 000 with the acrylic ester containing an isocyanate group for 2-24 hours, wherein the molar ratio of the isocyanate group to amino is 1:(0.9-6). The synthesis method for modifying the acrylic ester by using the organic silicon provided by the invention is free from side reaction occurrence, simple in synthesis method, and high in product purity, and the obtained modified acrylic ester not only can be independently photo-cured to form a membrane, but also can be used as a reactive diluent in an ultraviolet photo-curing system.

Owner:HUAINAN UNITED UNIVERSITY

Warm-keeping and moisture-absorbing composite polyester fiber with synergistic effect of skin-core components and preparation method thereof

ActiveCN113846392AHigh strengthThere will be no interface separationClimate change adaptationConjugated synthetic polymer artificial filamentsFiberPolymer science

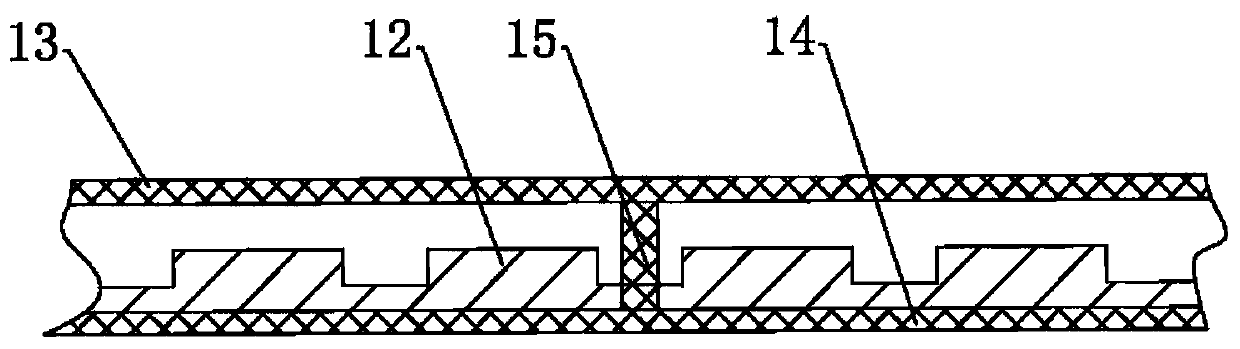

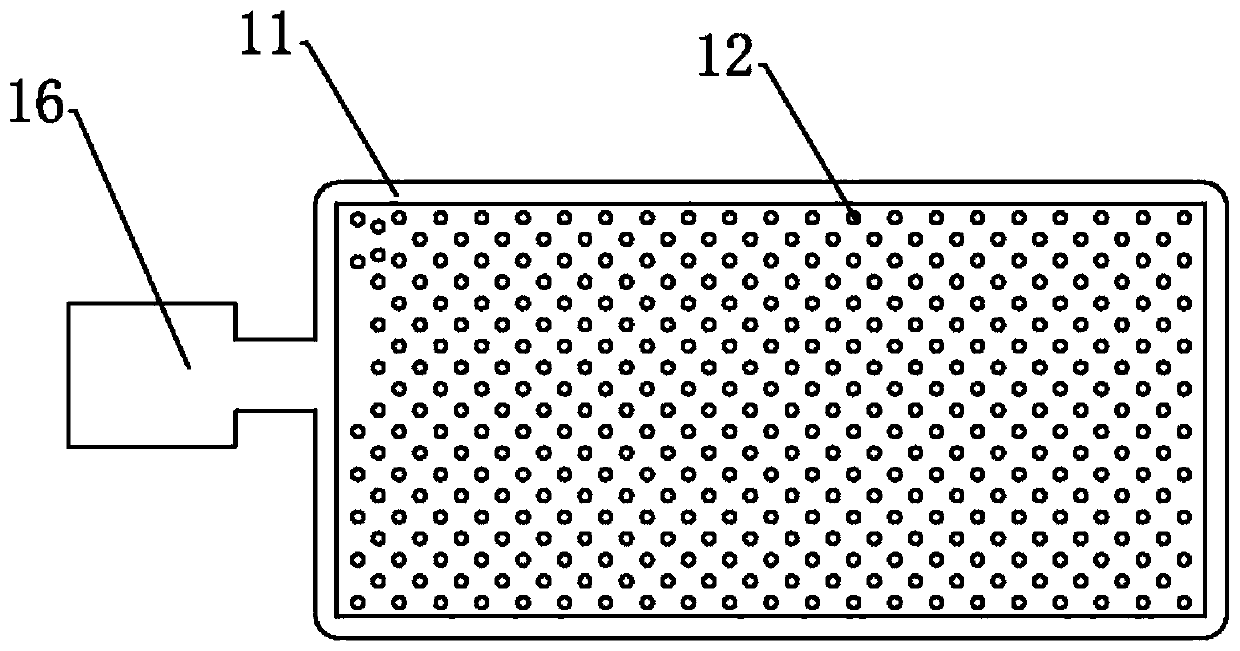

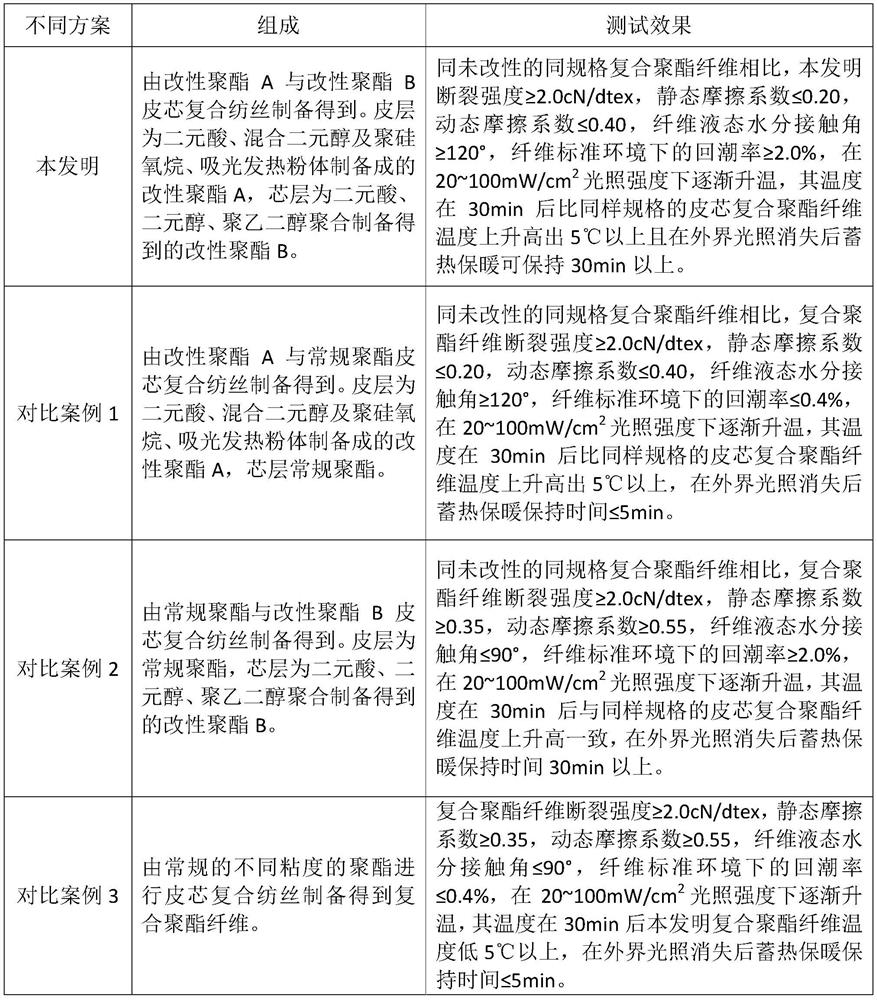

The invention relates to a warm-keeping and moisture-absorbing composite polyester fiber with a synergistic effect of skin-core components and a preparation method thereof. A skin layer is modified polyester A prepared from dibasic acid, mixed dihydric alcohol, polysiloxane and light-absorbing heating powder; a core layer is modified polyester B prepared from dibasic acid, dihydric alcohol and polyethylene glycol through polymerization; the dried modified polyester A is used as the skin layer; the dried modified polyester B is used as the core layer; and the mass ratio of the skin layer to the core layer is 2: 8 to 8: 2. The skin layer component and the core layer component are respectively extruded and melted into melts in respective screw extruders, and then the melts are subjected to spinning, circular blowing cooling, winding and forming to prepare the bi-component skin-core structure fiber. The skin-core composite structure endows the fiber with good elasticity, and meanwhile, the skin-core components have a synergistic effect in the use process and play a role in keeping warm. The composite polyester fiber disclosed by the invention is comfortable to wear, is particularly a textile used outdoors in autumn and winter, and has a wide application market.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

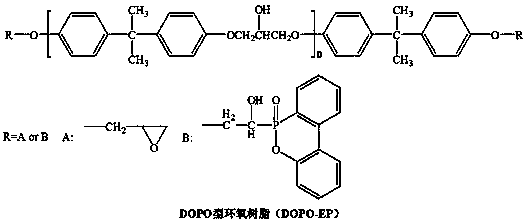

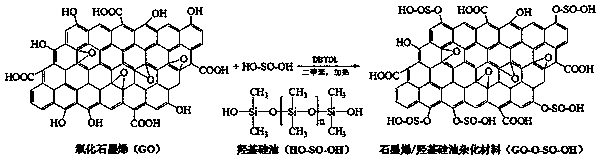

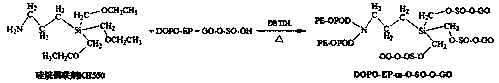

Hydrophobic flame-retardant epoxy resin and preparation method thereof

The invention discloses hydrophobic flame-retardant epoxy resin and a preparation method thereof, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: carrying out chemical bonding to connect hydroxyl silicone oil, graphene and DOPO type epoxy resin by taking the hydroxyl silicone oil as a water repellent agent andtaking the graphene and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) as a fire retardant; and then carrying out curing and preparation to obtain the final product. The obtained epoxy resin has excellent hydrophobicity, fire resistance and mechanical property, the vertical combustion grade reaches V-0 grade, a surface contact angle is increased to be 107.6-117.5 degrees, the stretching strength is 49.5-53.9 MPa, the impacting strength is 6.8-12.6 kJ / m<2>, meanwhile, the hydrophobic flame-retardant epoxy resin has the characteristics of zero poisonousness and environmental protection, can be used in an outdoor or humid severe environment, and is wide in application prospect.

Owner:FUZHOU UNIV

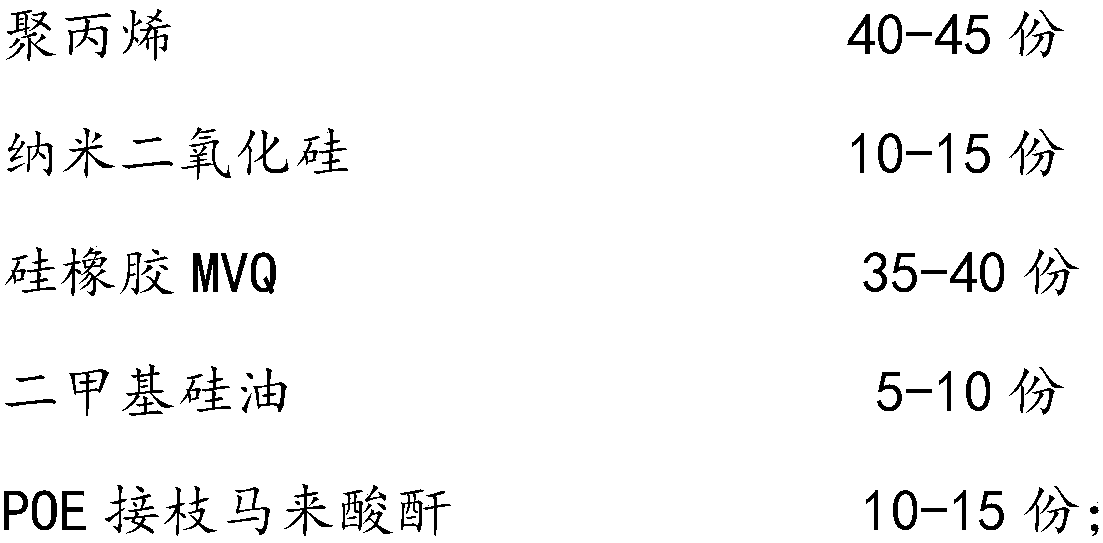

High-toughness wear-resisting cable material

PendingCN110041661ALarge poresImprove mechanical propertiesPlastic/resin/waxes insulatorsCastor oilActive ingredient

The invention discloses a high-toughness wear-resisting cable material and belongs to the technical field of wires and cables. According to the invention, biogas slurry is firstly treated and then shrimp shells are treated in the manner of mixed fermentation, so that chitin is differentiated and degraded, active ingredients can be generated, cross-linking action can be enhanced and overall wear-resisting property can be promoted; aramid fiber pulp has a fluff structure, has an ultra-large contact area with a resin component and is capable of promoting interaction of inner components of the system, improving shock resistance, promoting toughness, increasing degree of orientation, increasing surface roughness, promoting compatibility thereof with a modified resin component and jointly promoting toughness and wearing resistance; due to the addition of castor oil, vibration strength of covalent bonds in the resin component can be reduced, tensile strength can be effectively promoted, and the castor oil and the compound modified resin component can be combined into an interwound firm three-dimensional network so as to promote the inner mechanical properties. The high-toughness wear-resisting cable material is capable of solving the problems of inferior wear-resisting property, low tensile strength, low toughness and inconvenience in processing of the present common cable material.

Owner:北京中科惠景储能材料科技有限公司

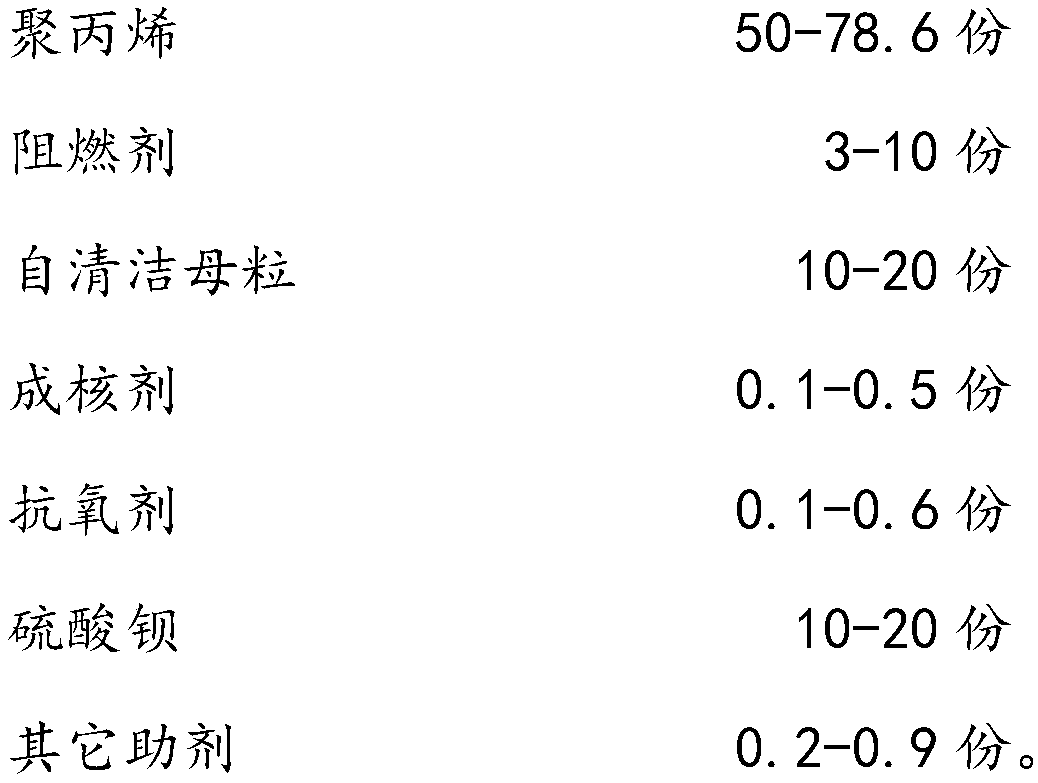

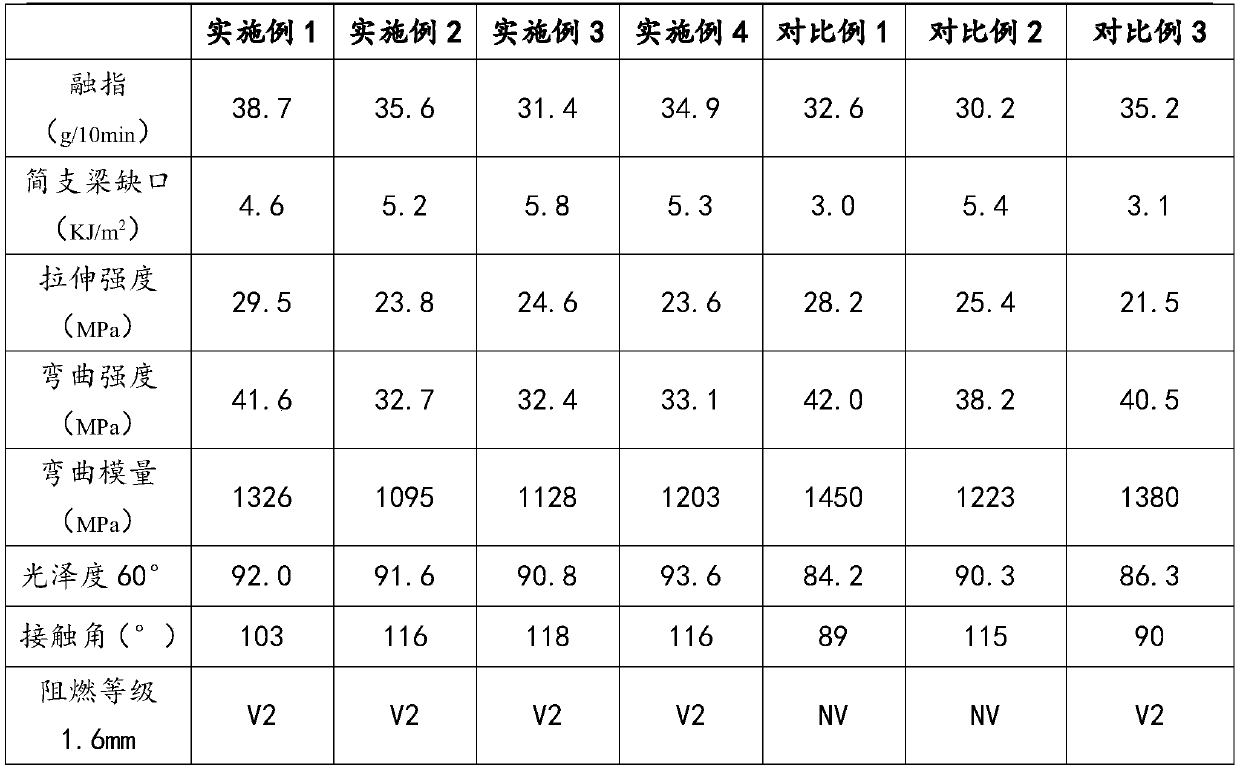

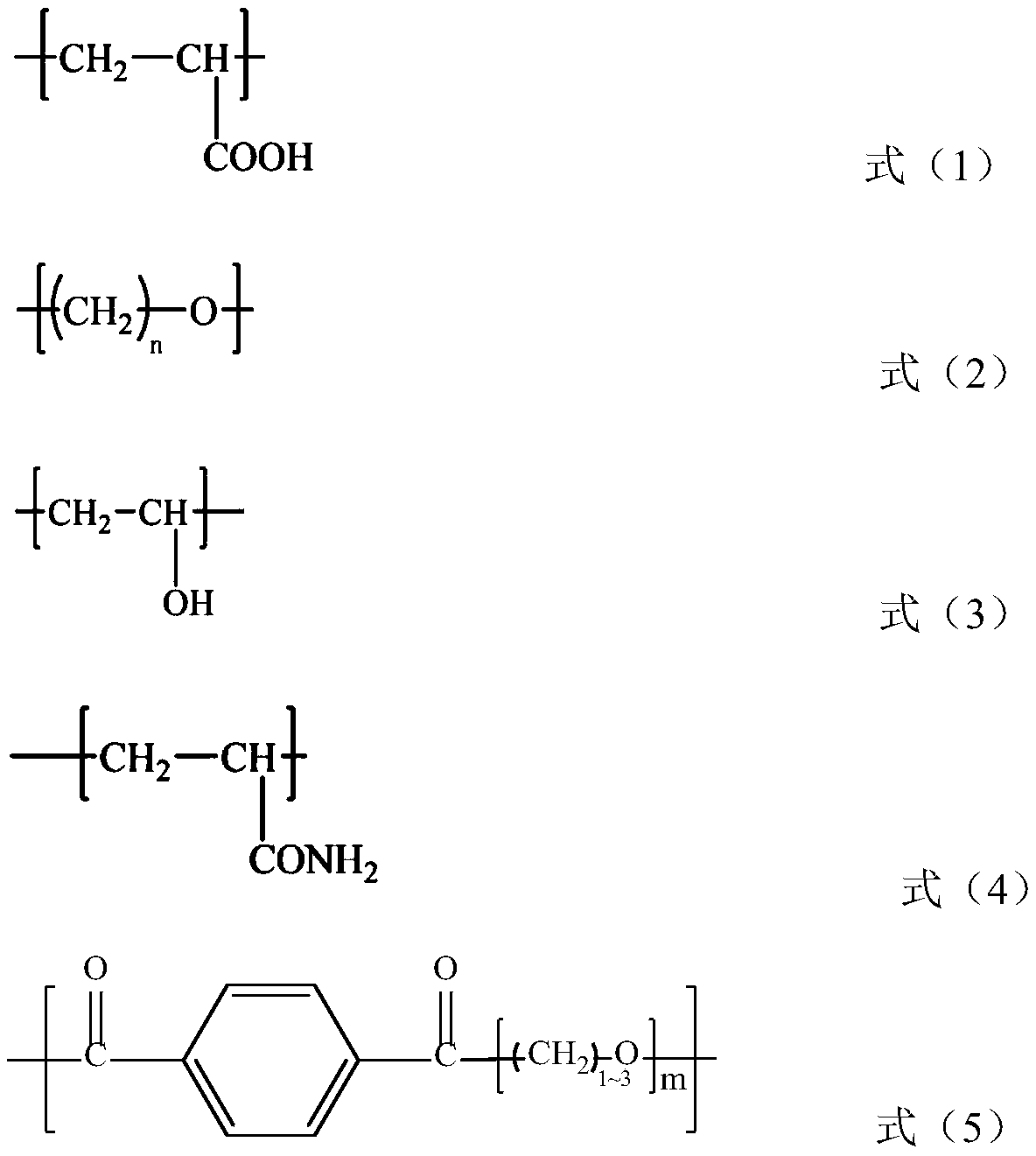

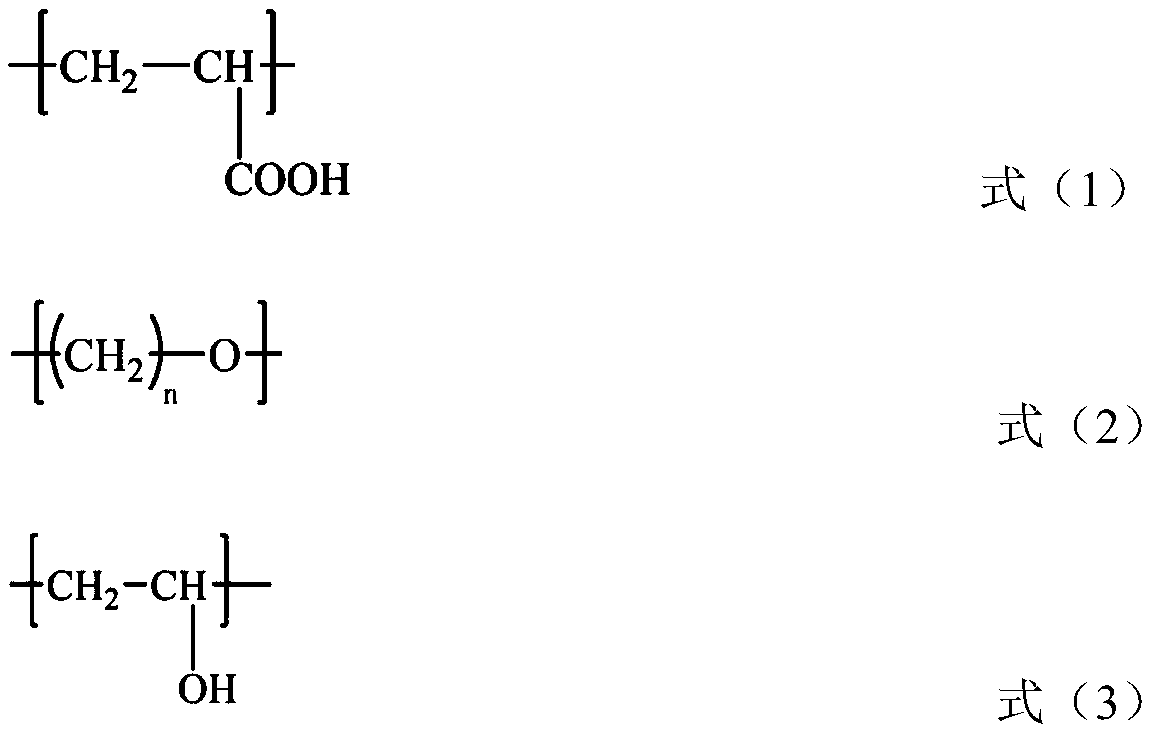

Self-cleaning masterbatch and flame retardant high gloss polypropylene composite material special for intelligent closestools and preparation method

The invention relates to the technical field of polypropylene material modification, in particular to a self-cleaning masterbatch and a flame retardant high gloss polypropylene composite material special for intelligent closestools and a preparation method. The composite material comprises the following raw materials by weight: 50-78.6 parts of polypropylene; 3-10 parts of a flame retardant; 10-20parts of self-cleaning masterbatch; 0.1-0.5 part of a nucleating agent; 0.1-0.6 part of an antioxidant; 10-20 parts of barium sulfate; and 0.2-0.9 part of other additives. By cooperating with the self-cleaning masterbatch, the flame retardant high gloss polypropylene composite material special for intelligent closestools prepared according to the invention can overcome the shortcomings of flammability, difficult self-cleaning and high price in closestool seat materials in the prior art, is suitable for use in intelligent closestool seat and other product materials, and has important practicalapplication value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Method for preparing aluminum oxide nanostructure on surface of titanium alloy and improving antifouling property of titanium alloy

ActiveCN112663010AIncrease the surface contact angleDoes not change original surface propertiesVacuum evaporation coatingSputtering coatingNano al2o3Alloy deposition

The invention relates to the field of metal surface modification, in particular to a method for preparing an aluminum oxide nanostructure on the surface of a titanium alloy and improving the antifouling property of the titanium alloy. The method comprises the steps that firstly, after the surface of the titanium alloy is cleaned, a nanometer aluminum coating is arranged on the surface of the titanium alloy in a magnetron sputtering manner, through heat treatment in air, an unoxidized Al and Ti substrate forms an alloy layer through atom diffusion, a magnesium powder solid phase method is used for dealloying, and the titanium alloy with nanometer aluminum oxide particles dispersed on the surface is obtained through cleaning and drying; and then, the titanium alloy surface with the nanometer aluminum oxide particles deposited on the surface is subjected to chemical modification through an ethanol solution of (3, 3, 3-trifluoropropyl) methyldimethoxysilane, and the hydrophobic performance of the titanium alloy surface is further improved. The method is simple and feasible, an atomic diffusion alloy deposition layer and a stable aluminum oxide coating are obtained through heat treatment in air, and a dispersed aluminum oxide structure can be prepared on the titanium alloy surface.

Owner:SOUTHERN MARINE SCI & ENG GUANGDONG LAB (ZHUHAI) +1

Hydrophobic multifunctional snow-melting agent and preparation method thereof

ActiveCN109135674AExtension of timeLowering the freezing pointOther chemical processesSnow meltingRoad surface

The invention discloses a hydrophobic multifunctional snow-melting agent and a preparation method thereof. The hydrophobic multifunctional snow-melting agent comprises a hydrophobic salts composite snow-melting agent, a hydrophobic composite freezing relieving agent and a hydrophobic composite ice layer softening agent according to the mass ratio of 6-7: 1-2: 1-2; the hydrophobic salts composite snow-melting agent is formed by carrying out slow release treatment and hydrophobic treatment on a salts snow-melting agent successively; the hydrophobic composite freezing relieving agent is formed bycarrying out slow release treatment and hydrophobic treatment on a freezing relieving agent successively; and the hydrophobic composite ice layer softening agent is formed by carrying out slow release treatment and hydrophobic treatment on an ice layer softening agent successively. An ice suppressing coating formed on a road surface by coating has various effects of greatly reducing a freezing point, relieving freezing and softening an ice layer.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Surface coating agent for treating drilling solidified waste and process

ActiveCN110240840AGuaranteed StrengthHigh strengthPretreated surfacesAnti-corrosive paintsCarboxylic acidPollution

The invention discloses a surface coating agent for treating drilling solidified waste. The surface coating agent is prepared from the following components by weight: 20-40% of polyether ester resin, 5-20% of inorganic filler, 0.5-5% of organic carboxylic acid, 10-35% of silane coupling agent and the balance of water; the sum of the mass percentages of the components is 100%. The invention also discloses a coating process, comprising solidified waste conserving, surface pretreatment, surface coating, and conserving of a coated solidified material. The surface coating agent and the coating process disclosed by the invention have the advantages of low cost, simple method, short processing time and little influence on the environment, and can alleviate compressive strength loss caused by water invasion and acid-base corrosion, and the immersion strength loss rate is reduced from the lowest 59% to 14%; the acid and alkali resistance of the solidified waste is enhanced, secondary pollution caused by leaching of internal organic pollutants and heavy metal ions can be prevented, and the environmental adaptability and environmental protection of the drilling solidified waste are improved, thus helping to achieve reuse and resource utilization of the drilling waste in various environments.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +2

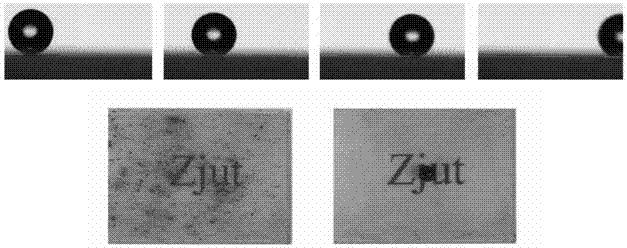

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496BRaw materials are easy to getLow costPolyurea/polyurethane coatingsSilanesNanometre

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and the prepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Flexible MEMS resistance reducing covering and method of manufacturing the same

InactiveCN101486438BImplement auto-replenishmentReduce frictional resistanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisSurface layer

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

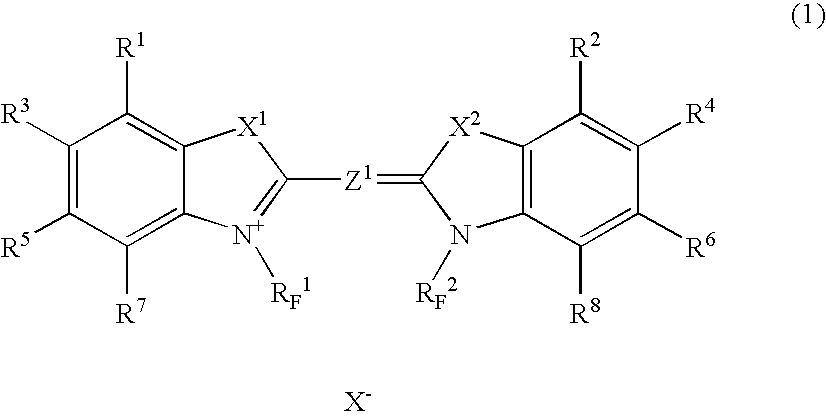

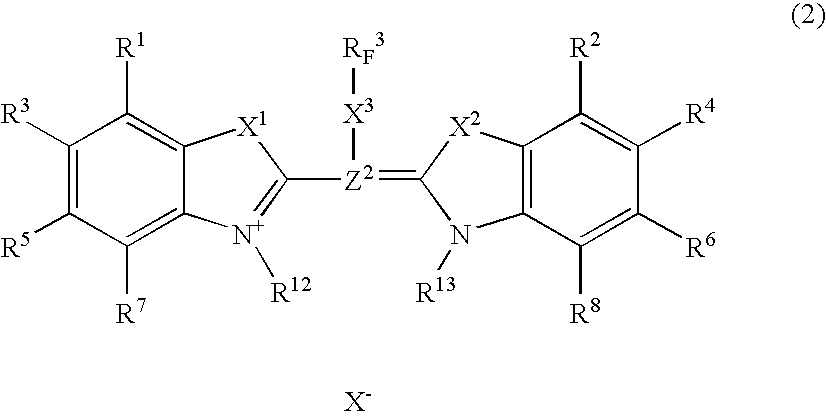

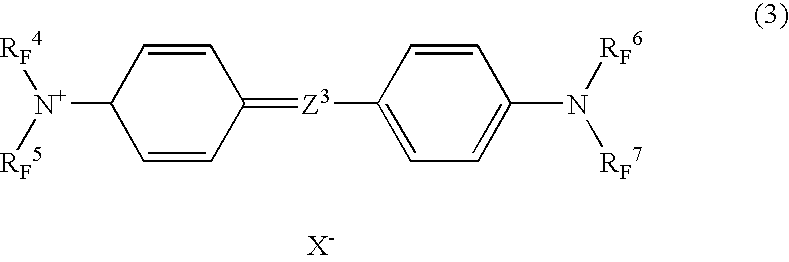

Image-formation material and infrared absorber

InactiveUS7087358B2High sensitivityImprove imaging effectMethine/polymethine dyesOrganic chemistrySolubilitySulfur

A heat mode-applicable image-formation material having high sensitivity and excellent image-forming property, and a novel infrared absorber which can be suitably used in this material. The present invention relates to a substrate carrying thereon an image-formation layer which contains an infrared absorption agent. The agent has at least one surface orientation group in the molecule, and solubility of the image-formation layer in an alkaline aqueous solution is changed by action of radiation in the near-infrared range. Preferable as the infrared absorbing agent is an infrared absorber comprising, in a molecule thereof, a fluorine-containing substituent which have at least 5 fluorine atoms, or a polymethine chain of at least 5 carbon atoms and an alkyl group of at least 8 carbon atoms, said alkyl group being connected to the polymethine chain via any of nitrogen, oxygen and sulfur.

Owner:FUJIFILM CORP

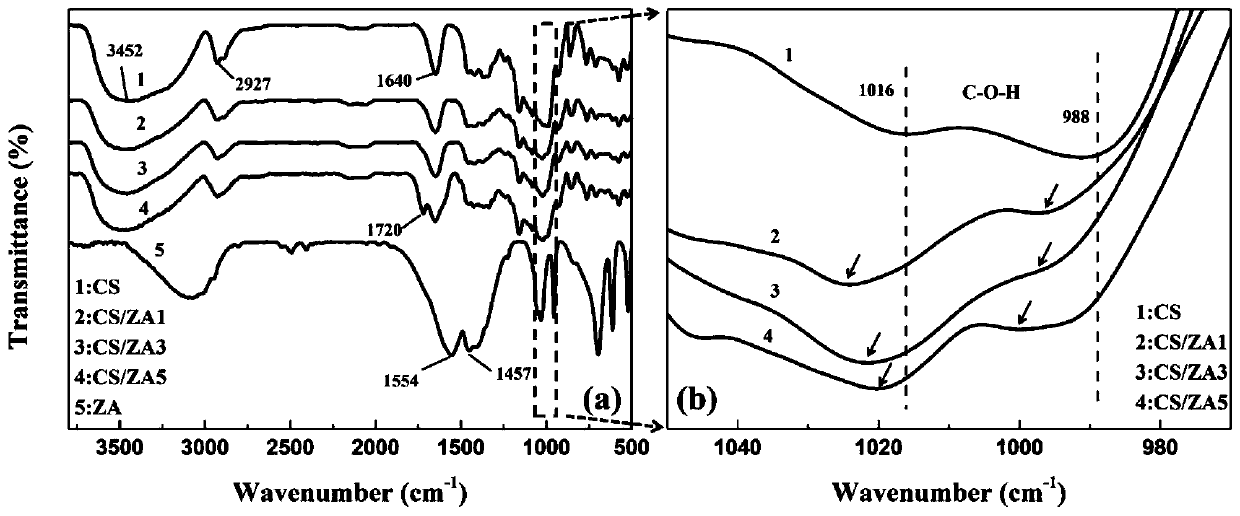

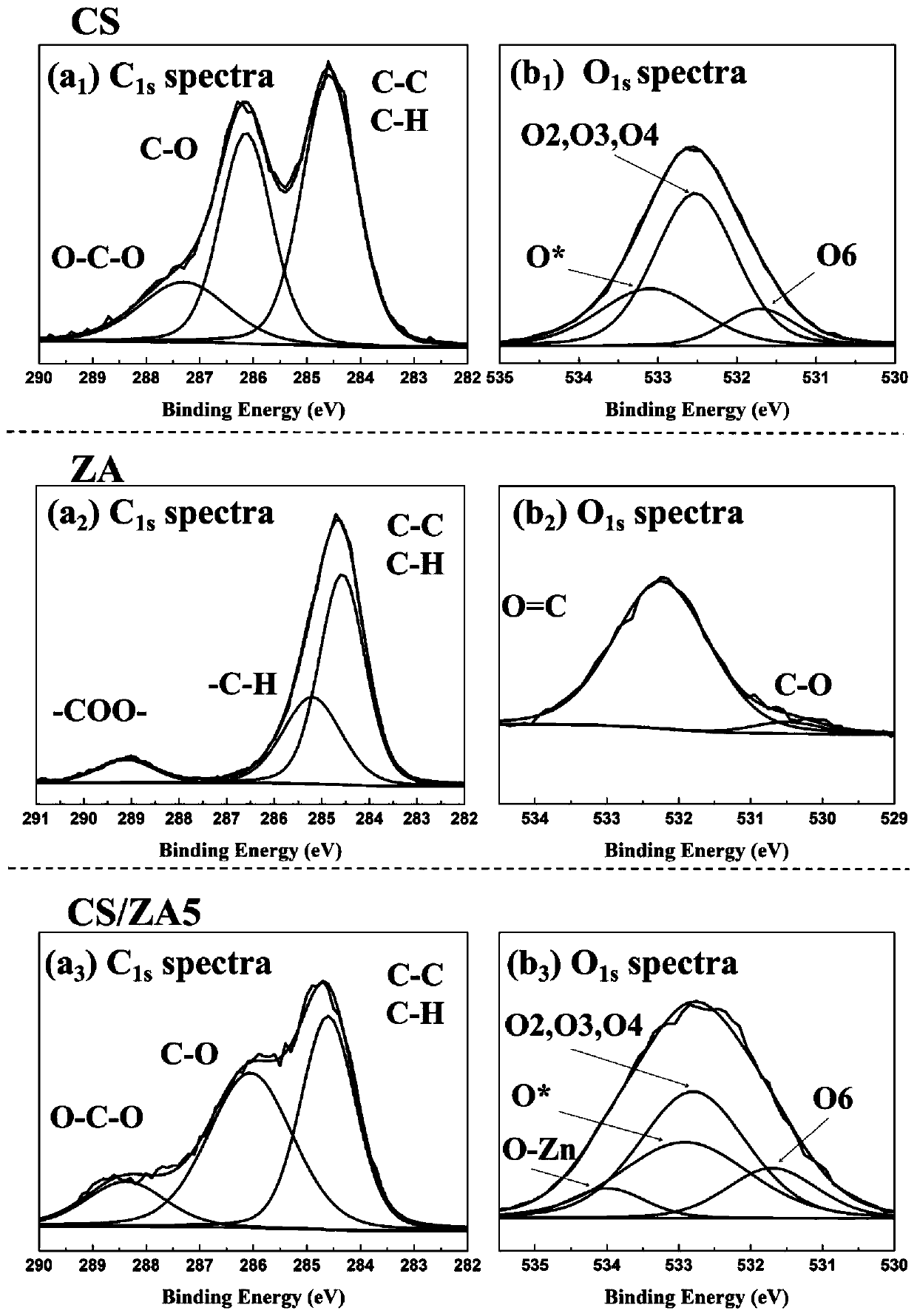

Thermoplastic starch based on coordination effect as well as preparation method and application of thermoplastic starch

The invention discloses thermoplastic starch based on a coordination effect as well as a preparation method and application of the thermoplastic starch. The preparation method comprises the followingsteps: premixing starch and a plasticizer to obtain a premixed material, adding anhydrous zinc acetate, carrying out further mixing, and carrying out extrusion granulation to obtain the thermoplasticstarch based on the coordination effect. According to the method, through reactive extrusion, efficient coordination of starch hydroxyl and Zn<2+> is realized, and the modified thermoplastic starch with outstanding advantages of high heat resistance, high hydrophobicity, high strength and the like can be obtained only by adding a small amount of anhydrous zinc acetate, the glass transition temperature is improved to 89.1 DEG C, the surface contact angle is improved to 118.2 degrees, and the tensile strength is improved to 9.2 MPa; and the modified thermoplastic starch is biodegradable, green,environment-friendly, excellent in comprehensive performance and easy to process, and is expected to be applied to the fields of packaging, disposable tableware, agricultural mulching films and the like.

Owner:SOUTH CHINA UNIV OF TECH

High-heat-conductivity and high-temperature stability electronic packaging composite material and preparation method thereof

The invention provides a high-heat-conductivity and high-temperature stability electronic packaging composite material and a preparation method thereof. The composite material is prepared from, 3-aminopropyl triethoxysilane modified waterborne polyurethane, polyimide siloxane, ethylene-vinyl acetate copolymers, carbon nano tubes, graphene oxide, ceramic micro-beads, molybdenum disulfide, boron nitride, silane coupling agents, tetra hydro phthalic anhydride, methylene diphenyl diisocyanate, diaminodiphenylmethane, 2-ethyl-4-methylimidazole, ethylene glycol dimethacrylate, polypropylene glycol diglycidyl ether, dispersing agents, defoaming agents, leveling agents and solvents. The prepared electronic packaging material has good heat conductivity, low moisture absorption performance, good mechanical strength and excellent high-temperature stability. The prepared packaging material is a material with high heat conductivity and high-temperature stability and good in mechanical property andhas wide application prospects.

Owner:莫爱军

Chromium-free passivation treatment process for aluminum alloy surface

InactiveCN111893472AReduce tensionImprove solubilityMetallic material coating processesSolution treatmentLaser processing

The invention discloses a chromium-free passivation treatment process for an aluminum alloy surface and relates to the technical field of aluminum alloys. The chromium-free passivation treatment process for the aluminum alloy surface comprises the following steps: (1) grinding; (2) tannic acid solution treatment; (3) femtosecond laser processing; (4) passivation. According to the method, a uniformand compact passivation film is formed on the surface of the aluminum alloy through passivation, and after neutral salt fog treatment, the passivation film has excellent salt fog corrosion resistanceand can better protect the aluminum alloy; and the contact angle of the surface of the passivation film formed by the method is greatly increased, so that the hydrophobic property of the surface of the aluminum alloy after passivation treatment by the process is obviously improved.

Owner:合肥卓汇新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com