Patents

Literature

127results about How to "Implement auto-replenishment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Circulating cooling water quality monitoring system and equipment

InactiveCN1514248AEmission reductionReduce processingMaterial analysisAutomatic controlMonitoring system

A system uses PLC programmable controller as a core with nine attachment units as pH on line detection unit, electric conductivity on line detection unit, flow rate on line detection unit, hardness on line detection unit, corrosion resistance on line detection unit, C1 concentration on line detection unit, automatic control unit for proportionally adding medicine, water supplementing automatic control unit and pollution discharging automatic control unit so that automatic control for adding medicine, automatic discharging of concentrated water and automatic supplementing of fresh water can be realized.

Owner:UNIV OF SCI & TECH BEIJING

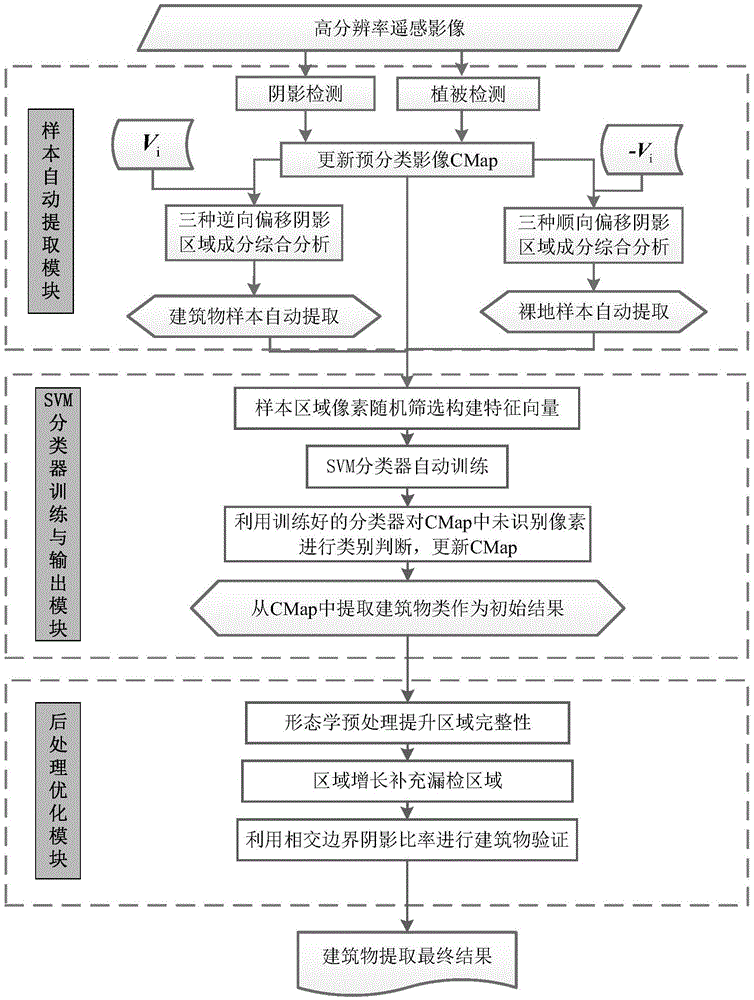

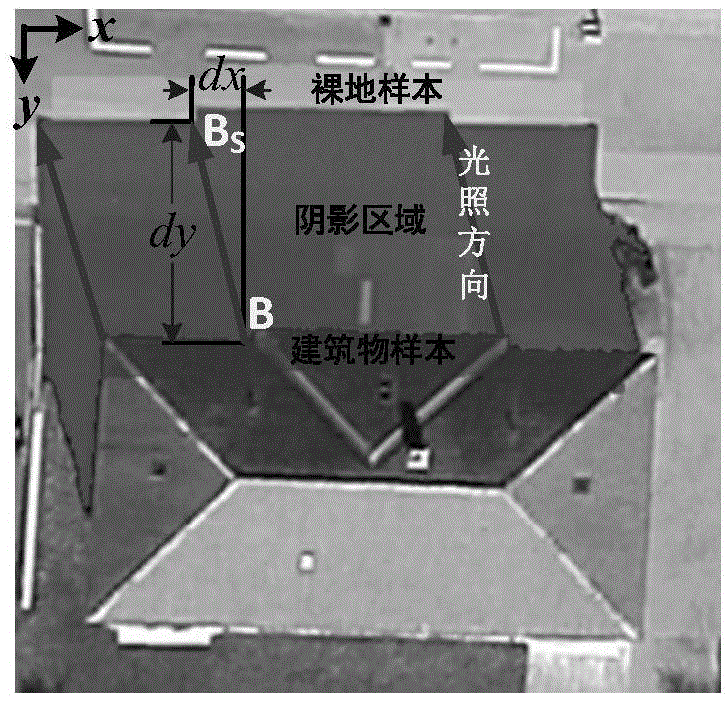

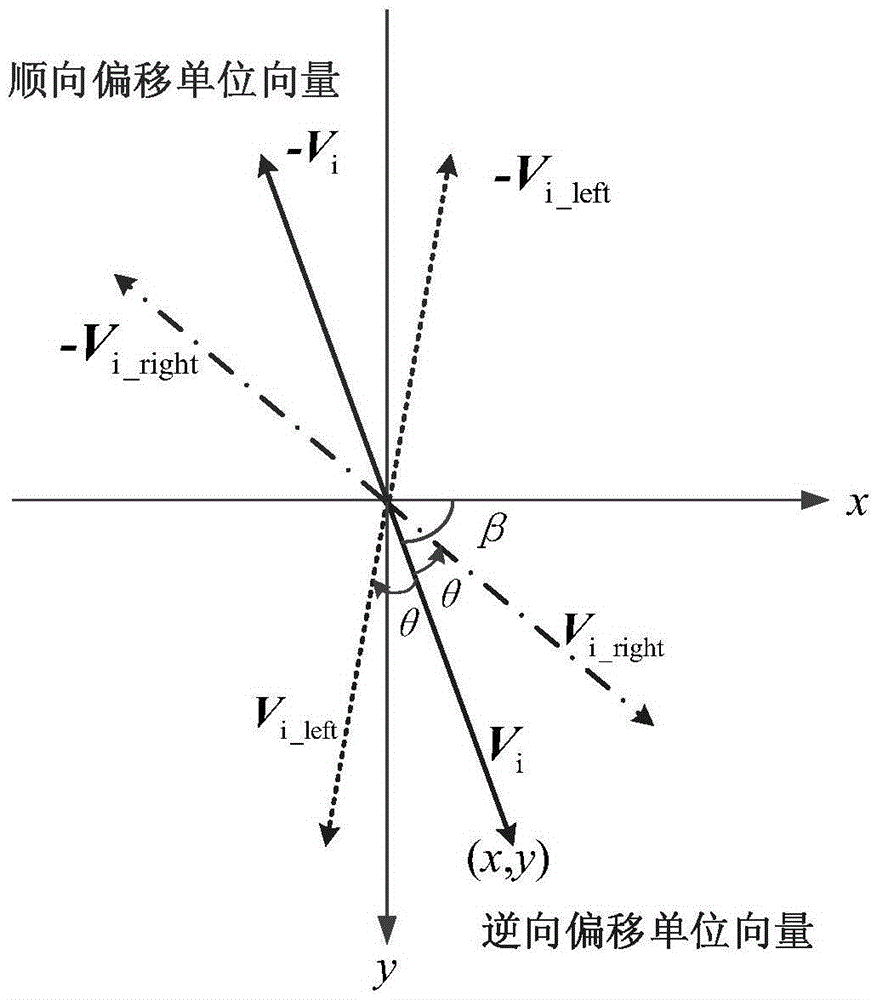

High-resolution remote sensing image building automatic extraction method and system by using shadow

ActiveCN105528596AUniversalWide coverageCharacter and pattern recognitionSvm classifierHigh resolution

The invention discloses a high-resolution remote sensing image building automatic extraction method and system by using shadow. The method comprises the steps of: firstly performing sample automatic extraction of shadow, vegetation, bare land, and building on an image, combining an SVM classification principle and realizing automatic classification, and extracting a building initial result; and then performing post-processing optimization on the initial result, the post-processing optimization including morphology pre-processing, missed detection supplement and building verification or the like, and outputting the building final result. The system includes a sample area automatic extraction module, an SVM classifier training and outputting module, and a post-processing optimization module. The building extraction automation degree is effectively improved and the precision can be ensured by designing the sample automatic extraction method and effective post-processing optimization measures.

Owner:YANGTZE UNIVERSITY

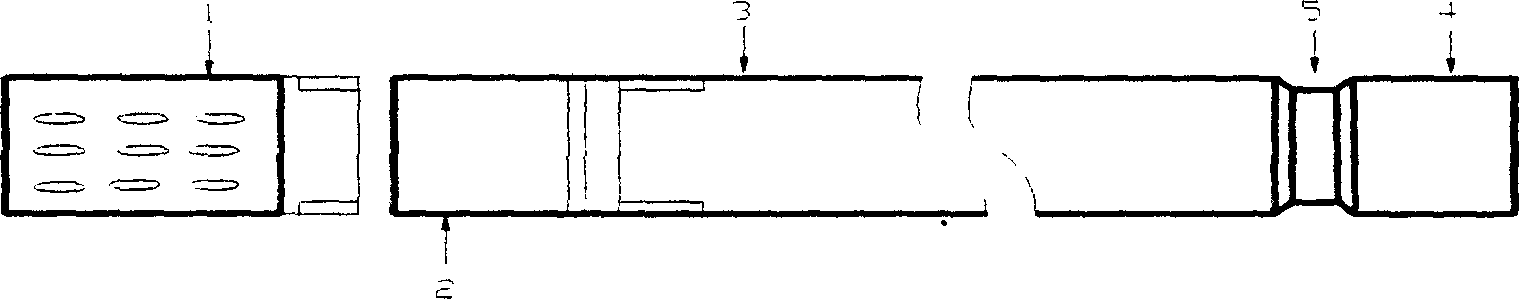

Cigarette automatic sorting process

InactiveCN1803559AFlexible configurationMeet the requirements of the orderArticle unpackingConveyor partsEngineeringTransmission equipment

The invention discloses a bar-cigarette self-picking craft, which is characterized by the following: opening the cigarette box automatically; fetching cigarette pile from box; feeding material automatically through over two picking equipments; picking different kinds of bar-cigarette on respective transmission equipment according to the need of order. The invention can improve material-supplement and picking efficiency and system disposal ability, which reduces the labor strength.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Medical material intelligent storage system

InactiveCN108182564AImprove management efficiencyImprove reliabilityCo-operative working arrangementsDigital data authenticationExecution controlTouchscreen

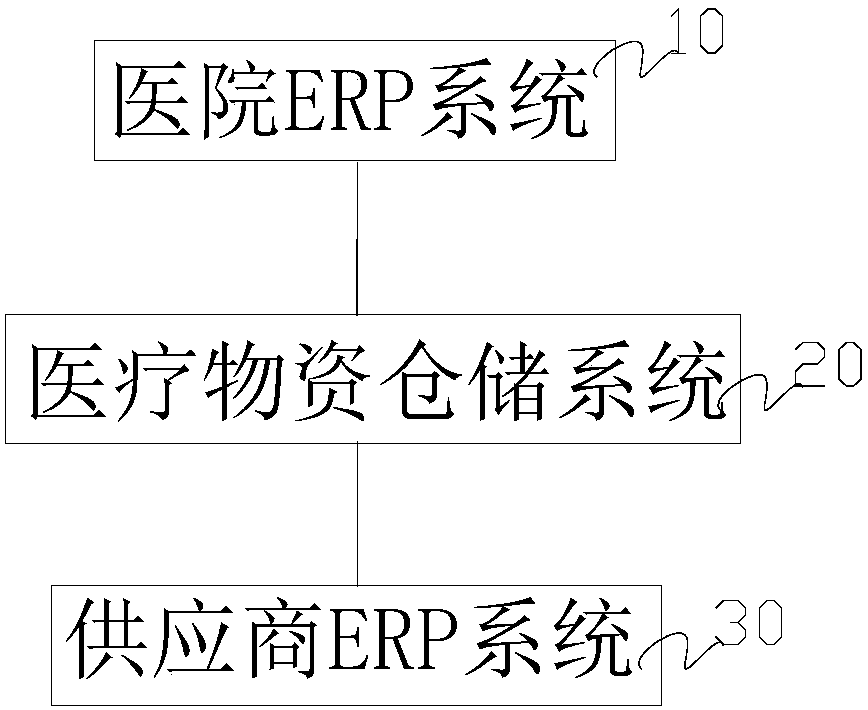

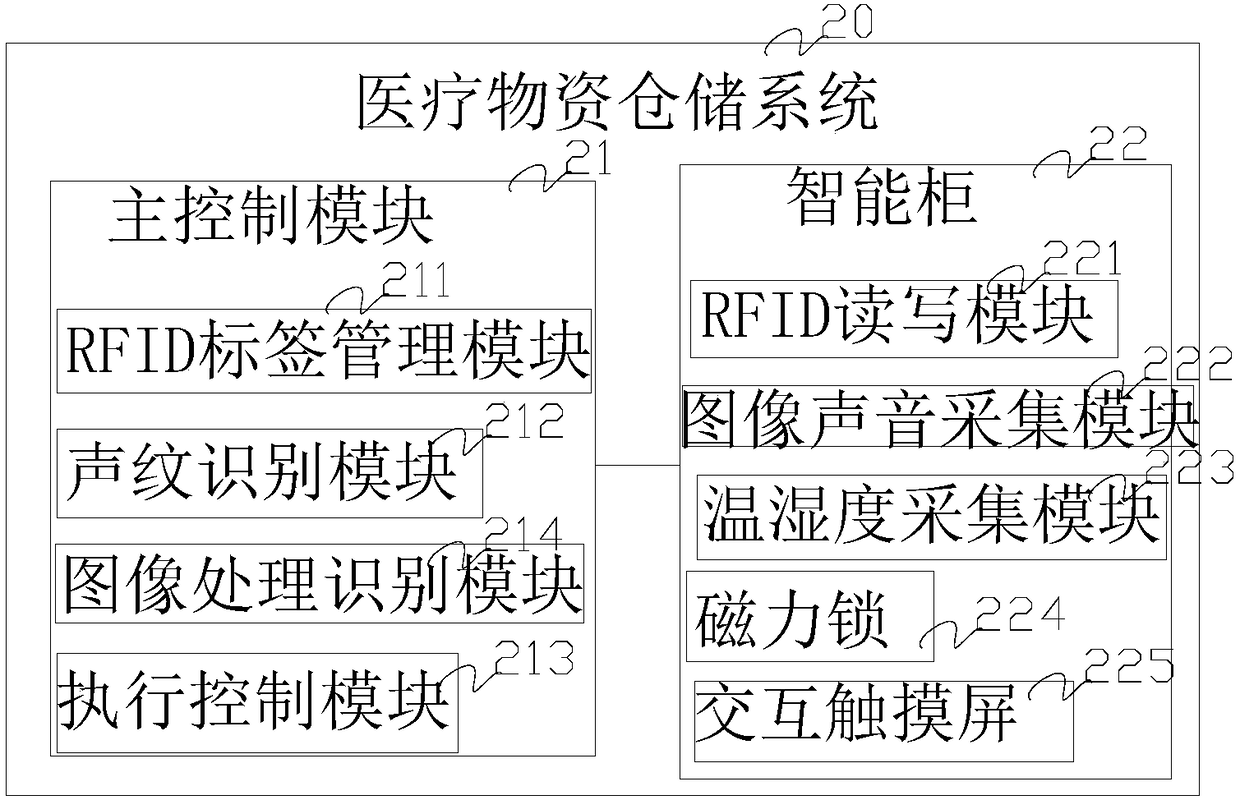

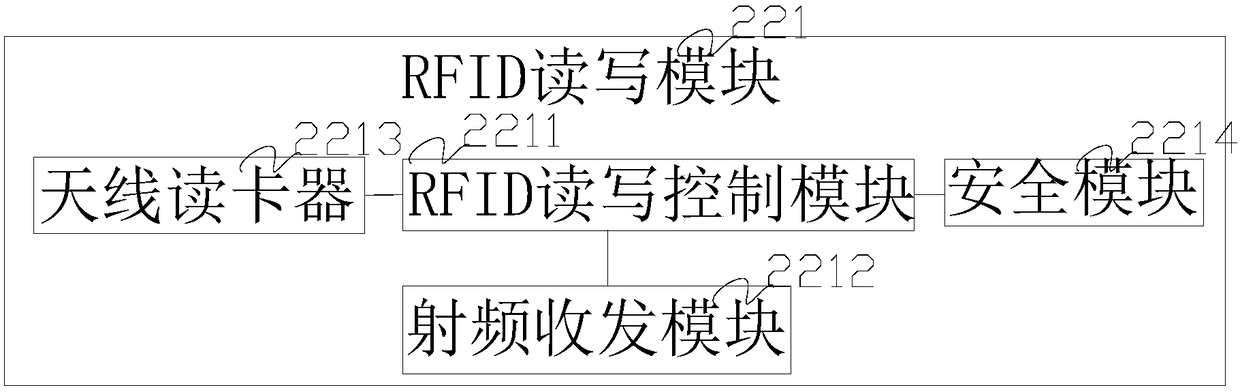

The invention discloses a medical material intelligent storage system which is connected to a hospital ERP system and a supplier ERP system. The medical material intelligent storage system comprises amain control module and an intelligent cabinet. The main control module is connected to at least one intelligent cabinet through a first wireless communication module. The intelligent cabinet includes an RFID reading and writing module, an image sound collecting module, a temperature and humidity collecting module, a magnetic lock and an interactive touch screen. The main control module includesan RFID tag management module, a voiceprint recognition module, an image processing recognition module and an execution control module. The main control module sends an unlocking instruction, a closing instruction, a cooling instruction, a ventilation instruction, a lighting instruction and / or an alarming instruction to the intelligent cabinet through the execution control module. Based on medicalinstitution material information management / hospital ERP, the functions of automatic replenishment, first-in-first-out and inventory monitoring of medical devices are achieved, the timeliness of thedevices are ensured, the error rate of physical access is reduced, and the hidden risks of medical quality and medical safety are reduced.

Owner:上海郢奇智能科技有限公司

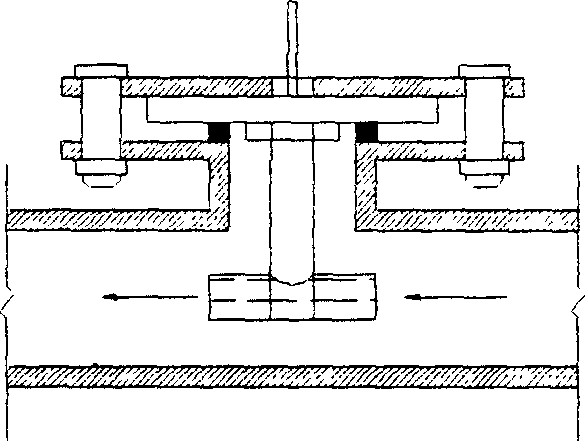

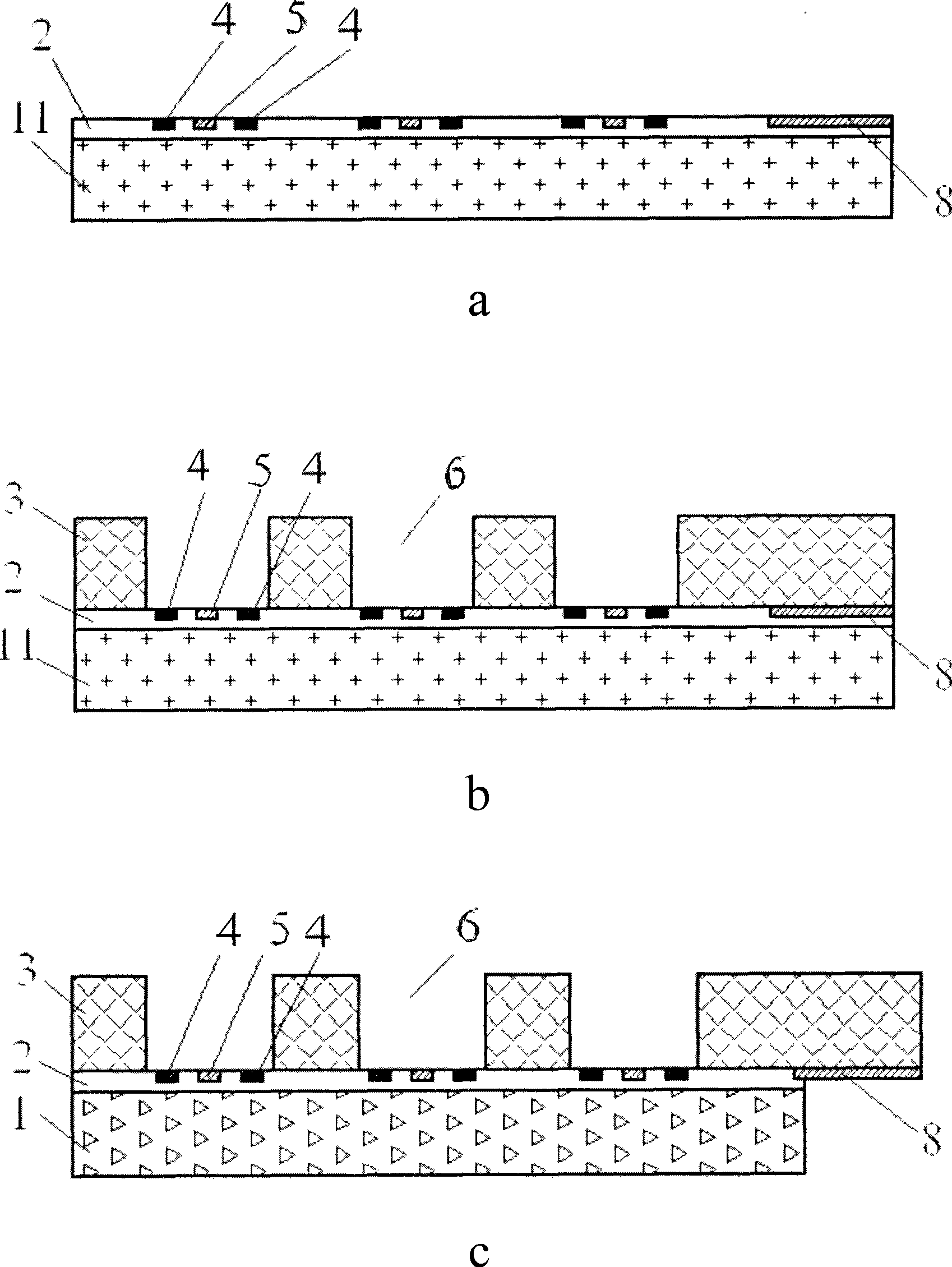

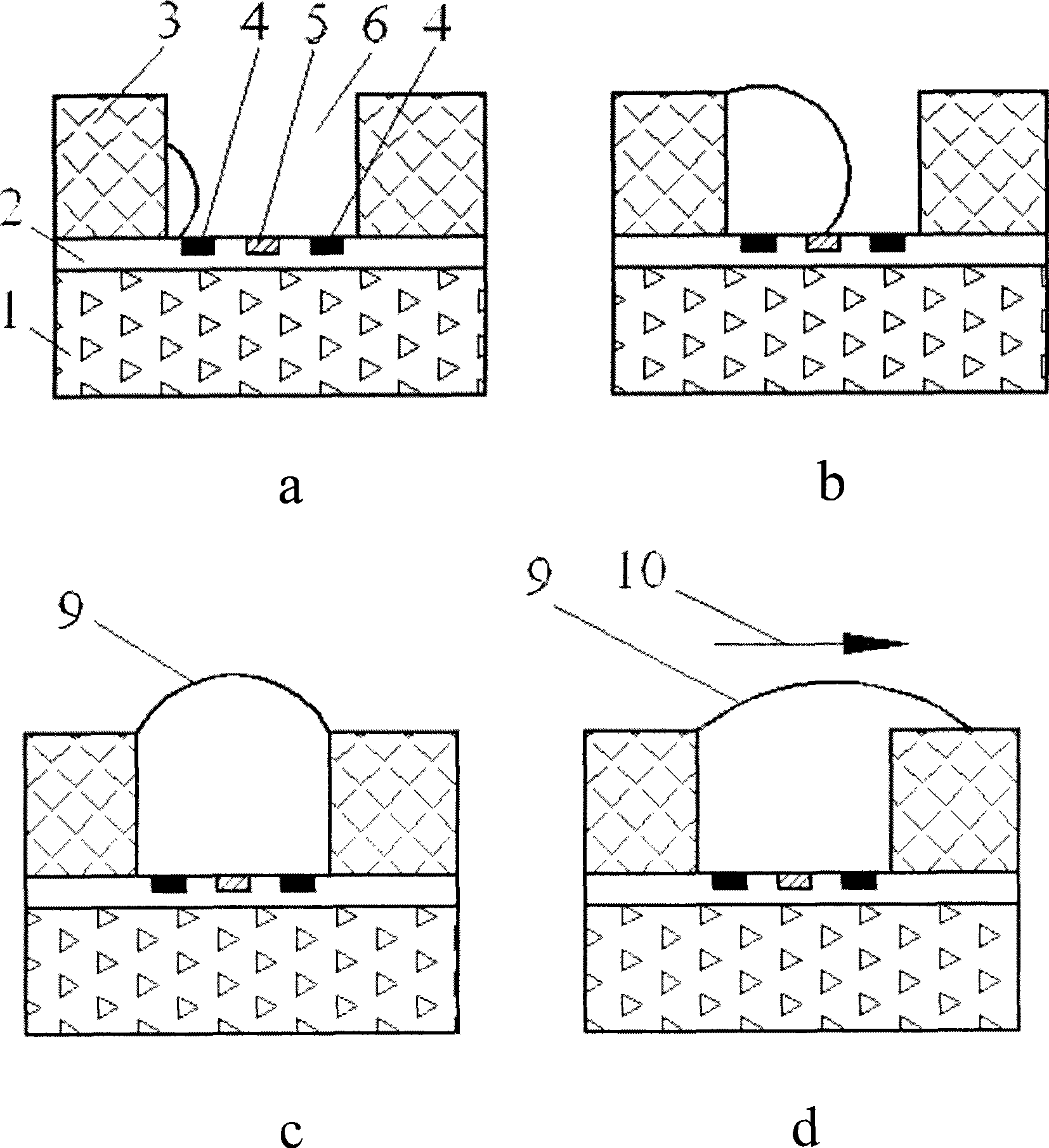

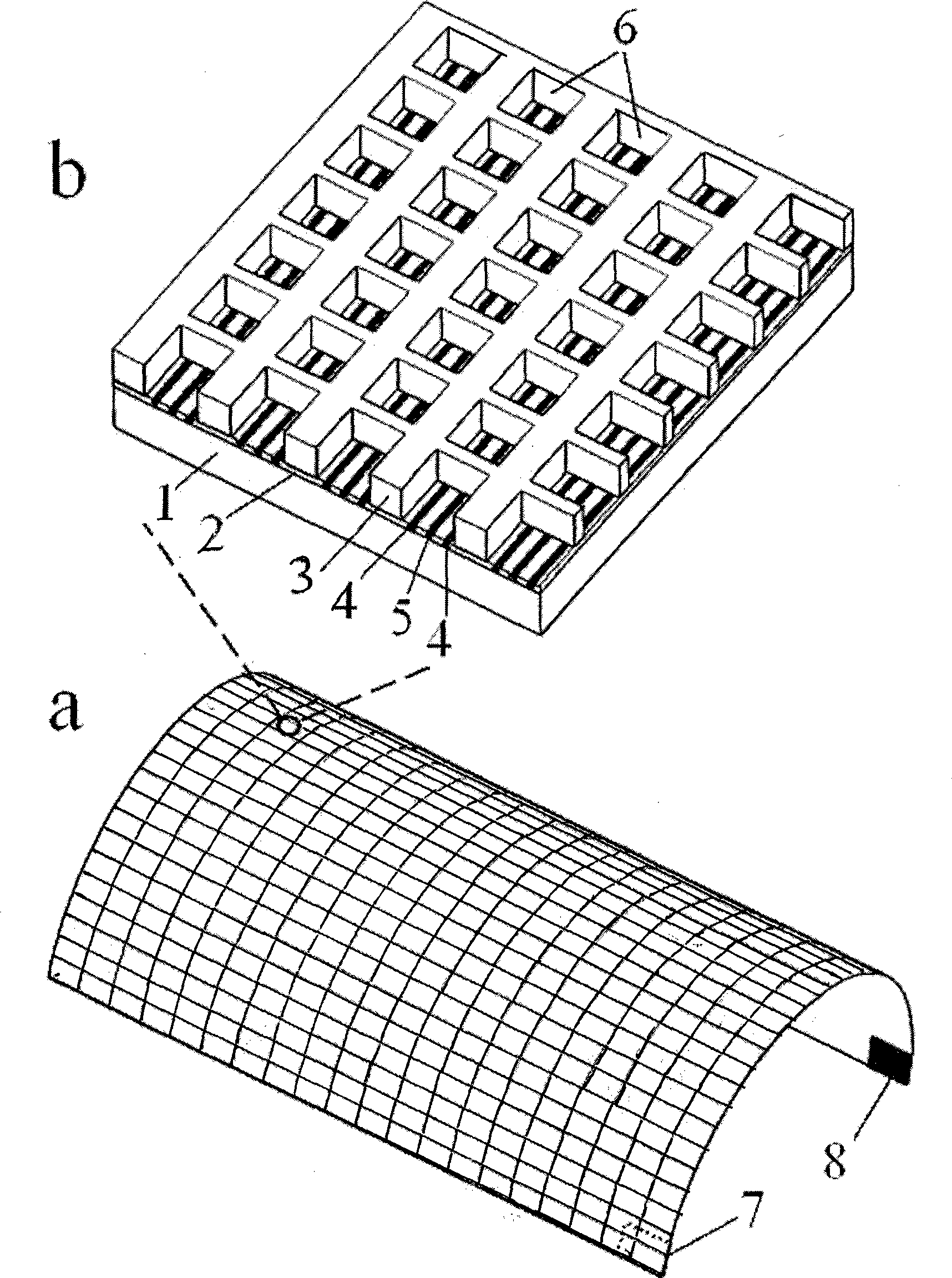

Flexible MEMS resistance reducing covering and method of manufacturing the same

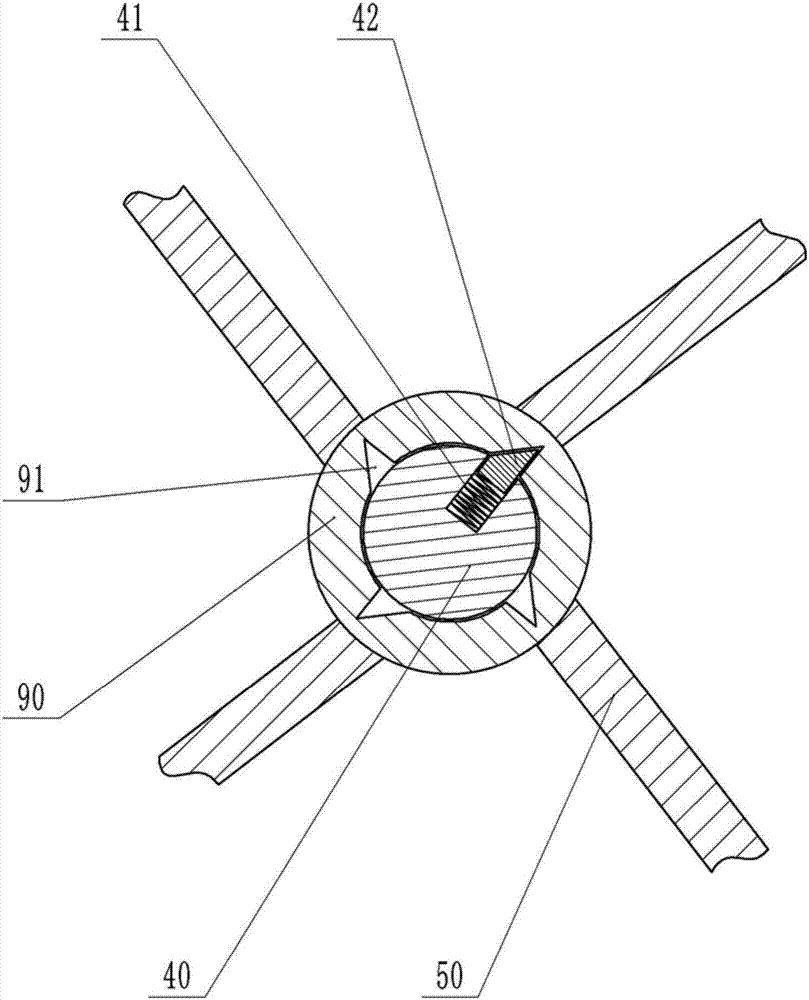

InactiveCN101486438AAchieve residencyImplement auto-replenishmentTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesElectrolysisMicrobubbles

The invention discloses a flexible MEMS resistance-reducing skin and a manufacturing method thereof used for reducing skin friction resistance during the advancing of on-water or underwater vehicles, which employs micro-fine resident bubbles to reduce resistance and belongs to the fields of micro-machinery and fluid dynamics. The upper surface of the skin is a surface layer coated with micro-pit arrays and processed by surface soakage; electrolytic anodes and cathodes of comb-shaped micro-fine planar metal, which are attached on an insulating layer, are arranged at the bottom of the micro-pits; a flexible substrate is positioned below the insulating layer; wire leading terminals for electrodes are arranged on the lower surface of the skin; and both the surface layer and the substrate are made by flexible materials. The overall thickness of the resistance reducing skin is at sub-millimeter level, and the skin is in the status of flexible film. The manufacturing method is an MEMS micro machining technique compatible with the flexible MEMS technology. The flexible MEMS resistance-reducing skin is coated on the outer surfaces of the on-water or underwater vehicles, with power thereof supplied by the on-water or under-water vehicles. Micro-bubbles stably residing in the micro-pits are formed by water electrolysis reaction to coat most parts of the surfaces of the on-water or under-water vehicles, thus realizing the function of reducing skin friction resistance.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

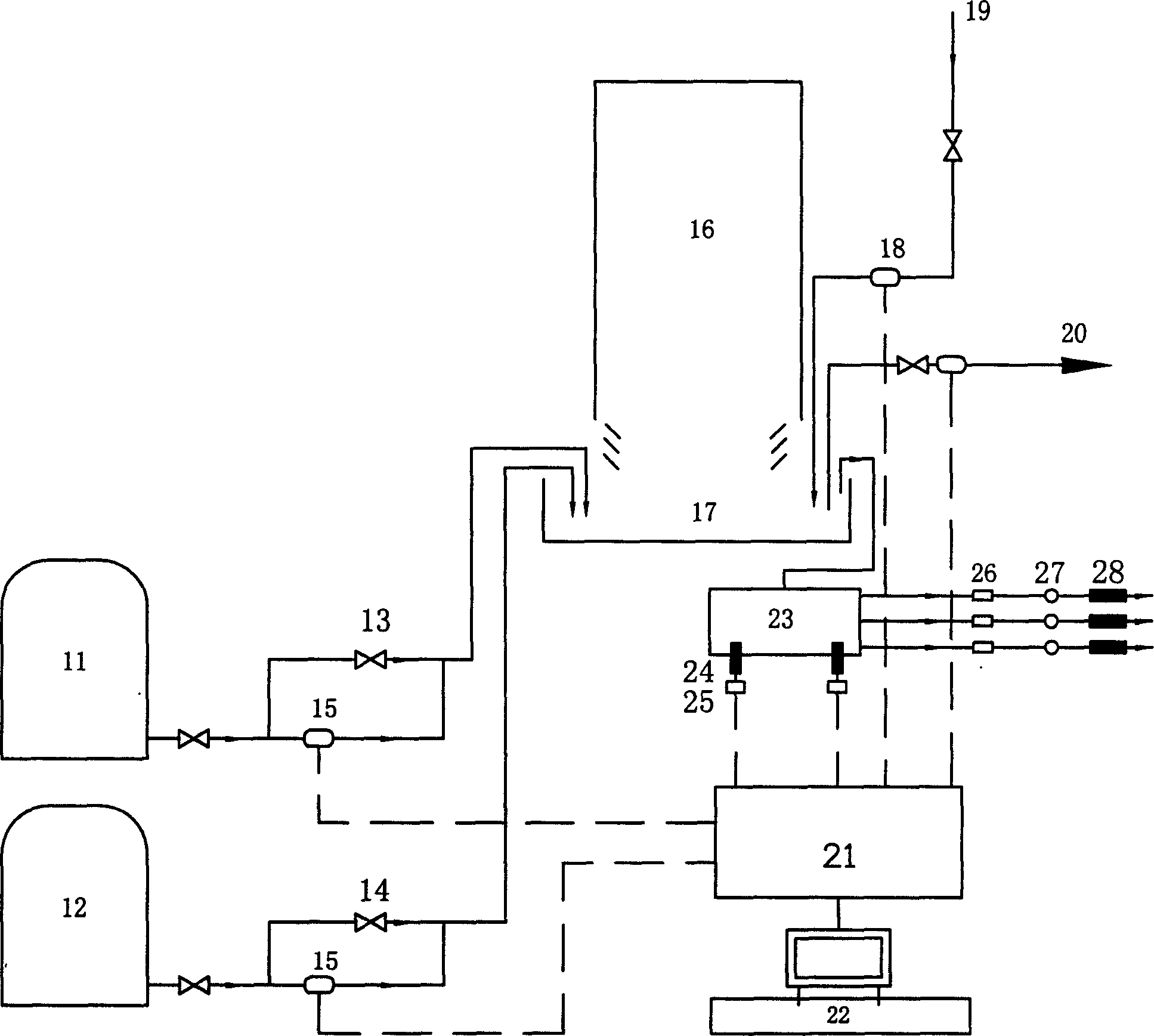

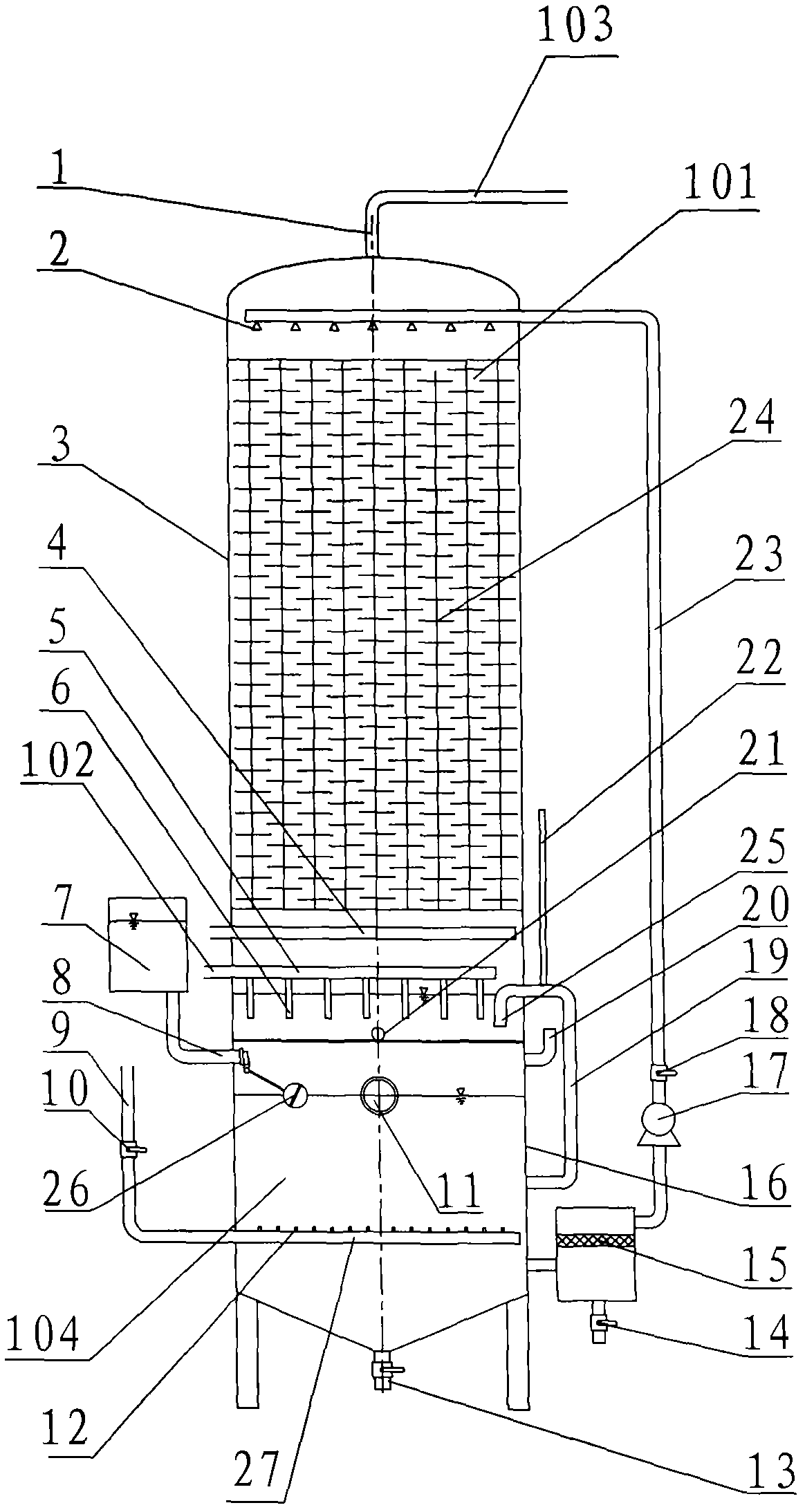

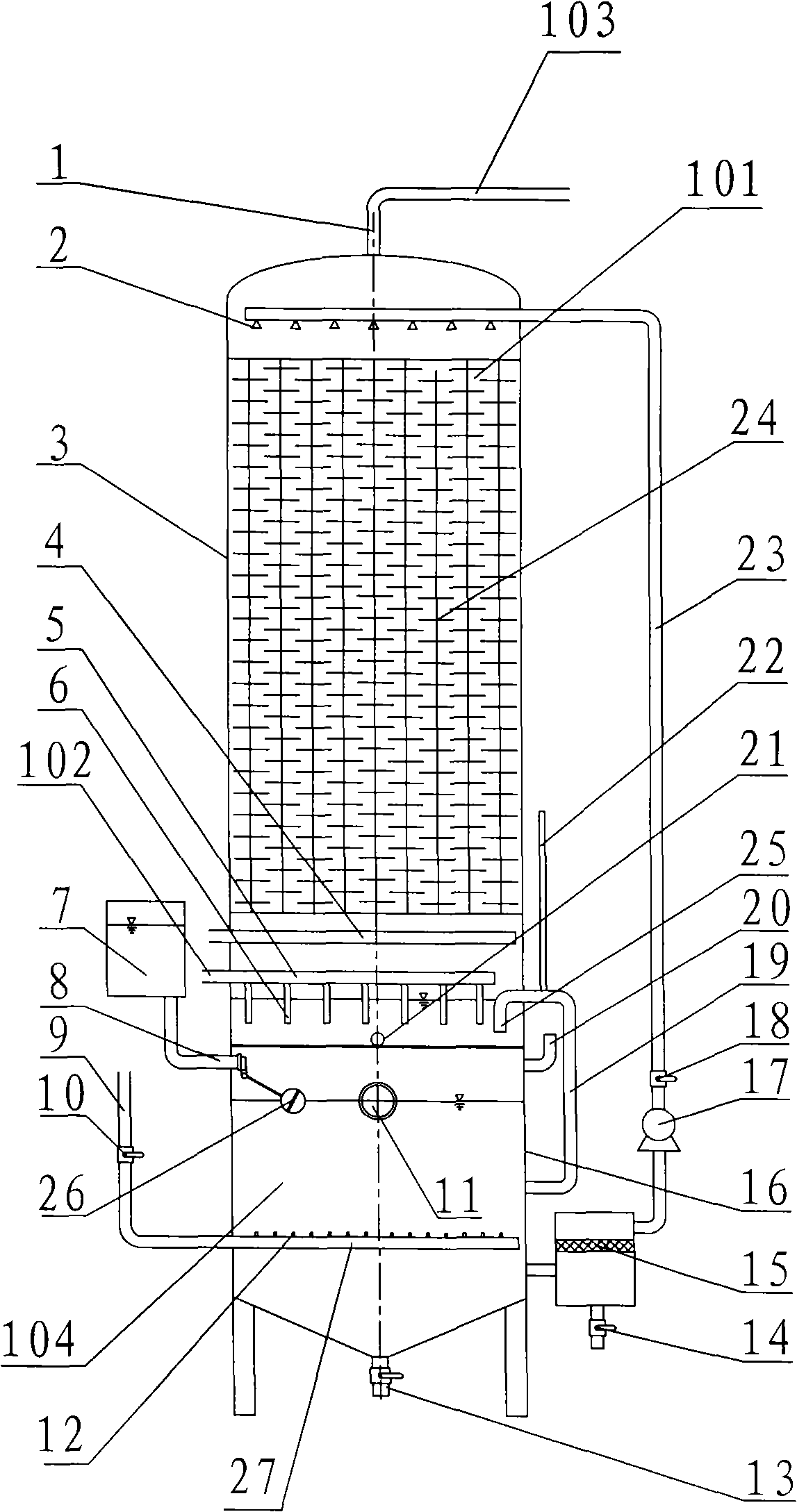

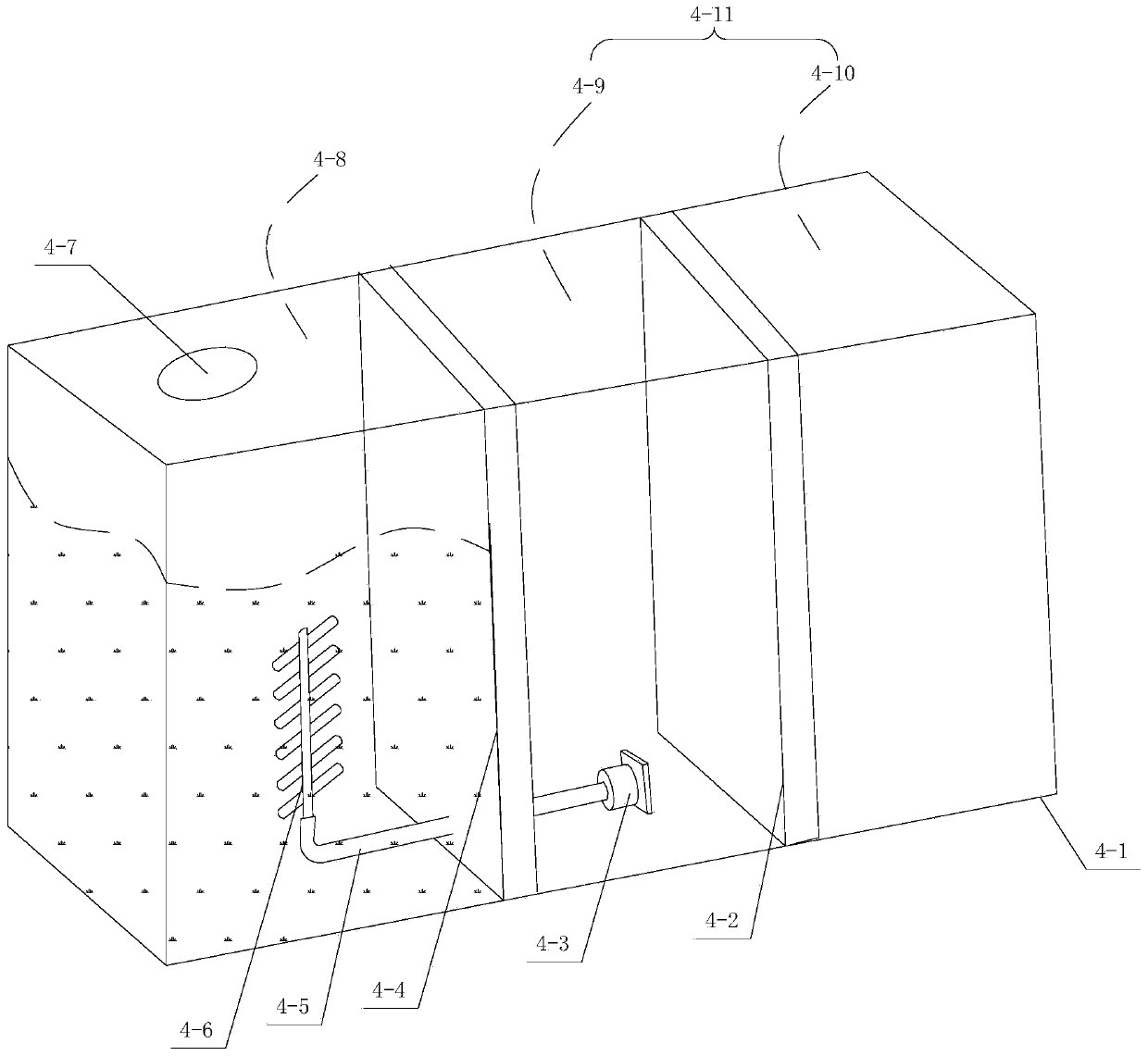

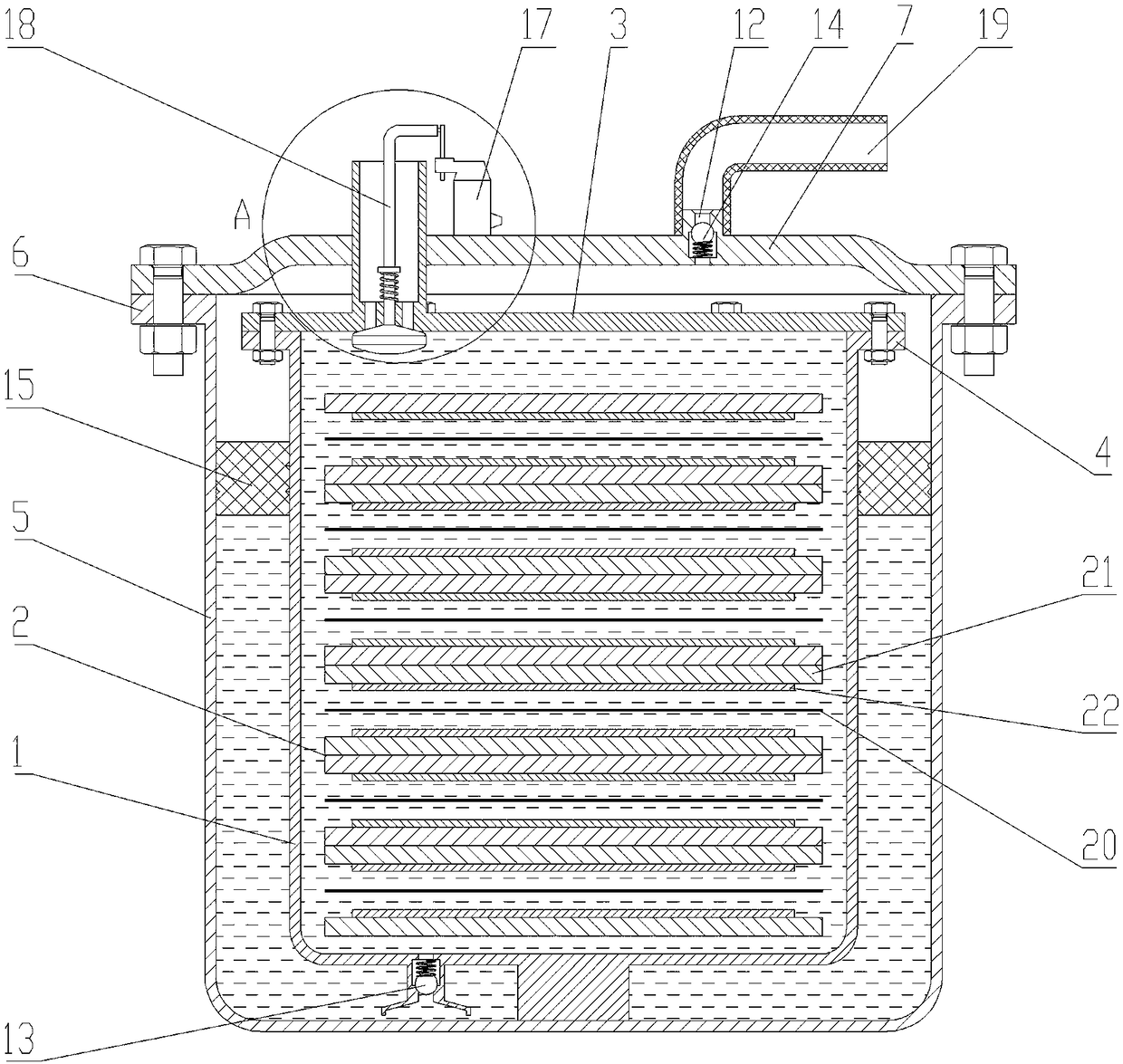

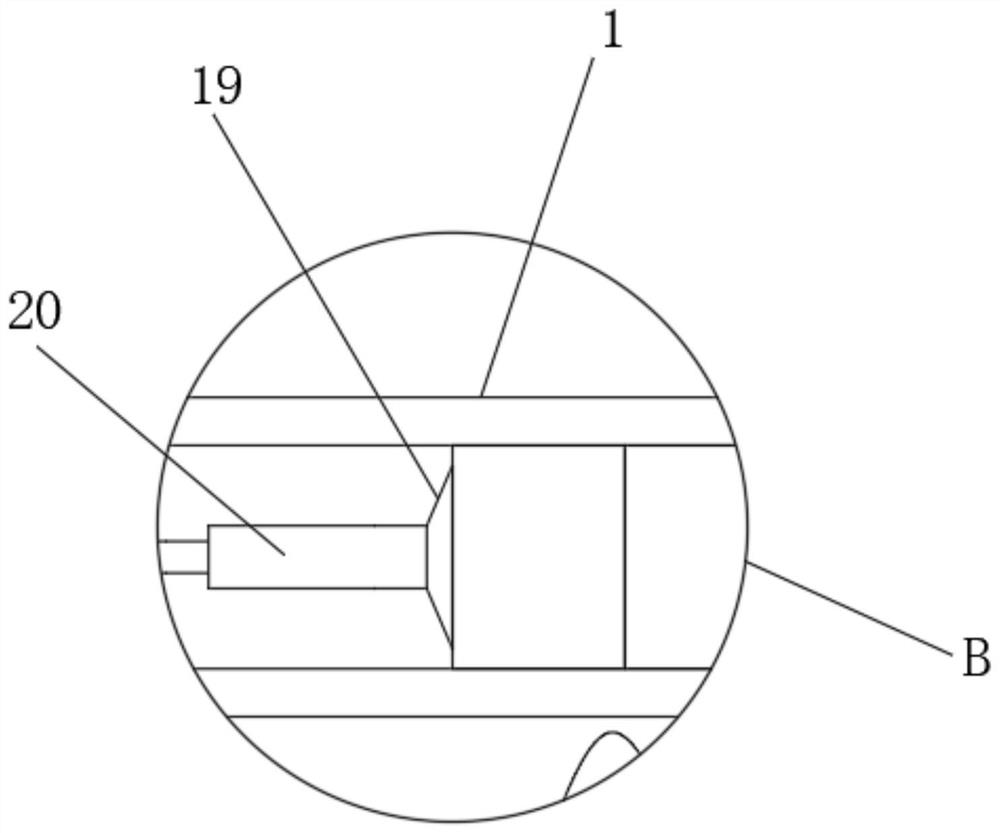

Integrated methane biological desulphurization device

The invention discloses an integrated methane biological desulphurization device which comprises a tower body composed of an upper desulphurization tower (3) and a lower desulphurization tower (16) which are isolated from each other, a spray system and a reflux system, wherein, the top of the upper desulphurization tower (3) is equipped with a methane outlet (1); the spray system comprises a spray header (2) arranged at the top half of an inner chamber of the upper desulphurization tower (3) and a delivery pipe (23) arranged outside the tower body; two ends of the delivery pipe (23) are respectively communicated with the spray header (2) in the upper desulphurization tower (3) and an inner chamber of the lower desulphurization tower (16); the delivery pipe (23) is equipped with a circulating pump (17); and the reflux system comprises a reflux pipe (19) arranged outside the tower body, and two ends of the reflux pipe (19) are respectively communicated with the bottom of the inner chamber of the upper desulphurization tower (3) and the inner chamber of the lower desulphurization tower (16). The integrated methane biological desulphurization device has the characteristics of being safe and efficient and being capable of monitoring technological parameters in real time and the like.

Owner:ZHEJIANG UNIV

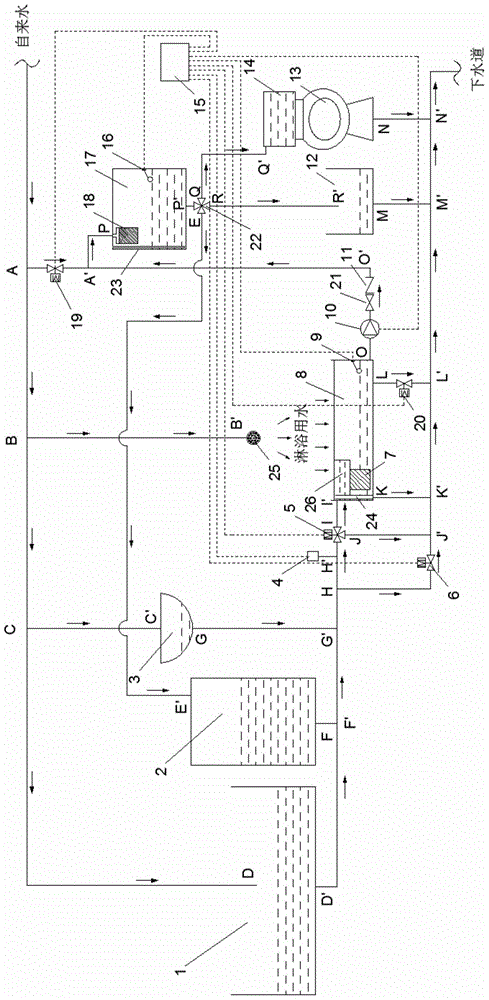

Bathroom sewage omni-directional recycling and automatic cyclic utilization system

InactiveCN104695513AMaximize recoveryNo wasteDomestic plumbingMultistage water/sewage treatmentAutomatic controlWater storage tank

A bathroom sewage omni-directional recycling and automatic cyclic utilization system comprises a sanitary ware sewage module, a primary recycling and processing module, a secondary recycling and processing module and a recycled water reuse module. The primary recycling and processing module comprises a primary lower water storage tank with a primary filter device. The secondary recycling and processing module comprises a secondary high water storage tank with a secondary filter device. Sewage generated by the sanitary ware sewage module enters a sewer or a sewage isolation chamber, the sewage in the sewage isolation chamber enters the primary lower water storage tank after being filtered through the primary filter device and then is conveyed to the secondary high water storage tank through a water pump to be secondarily filtered through the secondary high water storage tank, and secondarily filtered water is conveyed to the recycled water reuse module to achieve reuse. The bathroom sewage omni-directional recycling and automatic cyclic utilization system further comprises a pipe valve conveying module and an automatic control module, so that automatic cyclic utilization is achieved, and water resources are saved.

Owner:XI'AN PETROLEUM UNIVERSITY

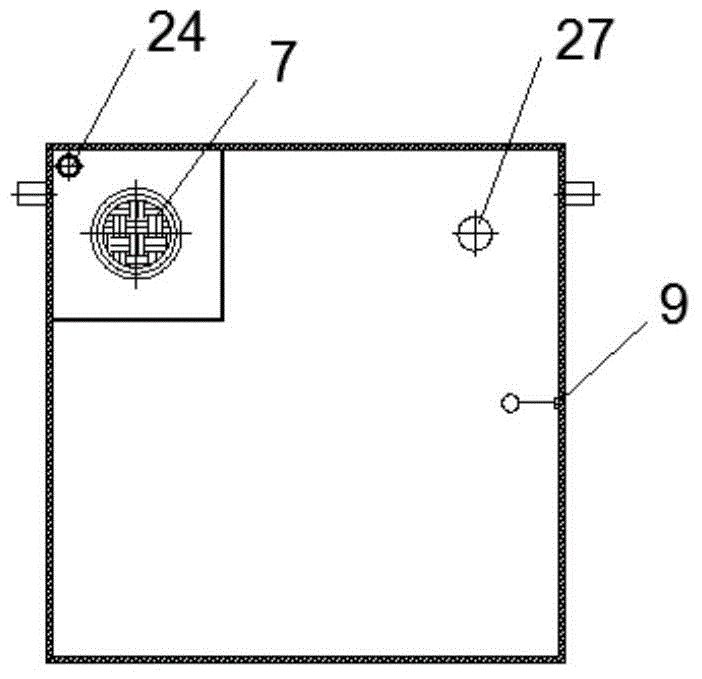

Monitoring low-resistance module grounding device

InactiveCN101728661AGuaranteed reliabilityKeep moist for a long timeEarth resistance measurementsConnection contact member materialComputer moduleEngineering

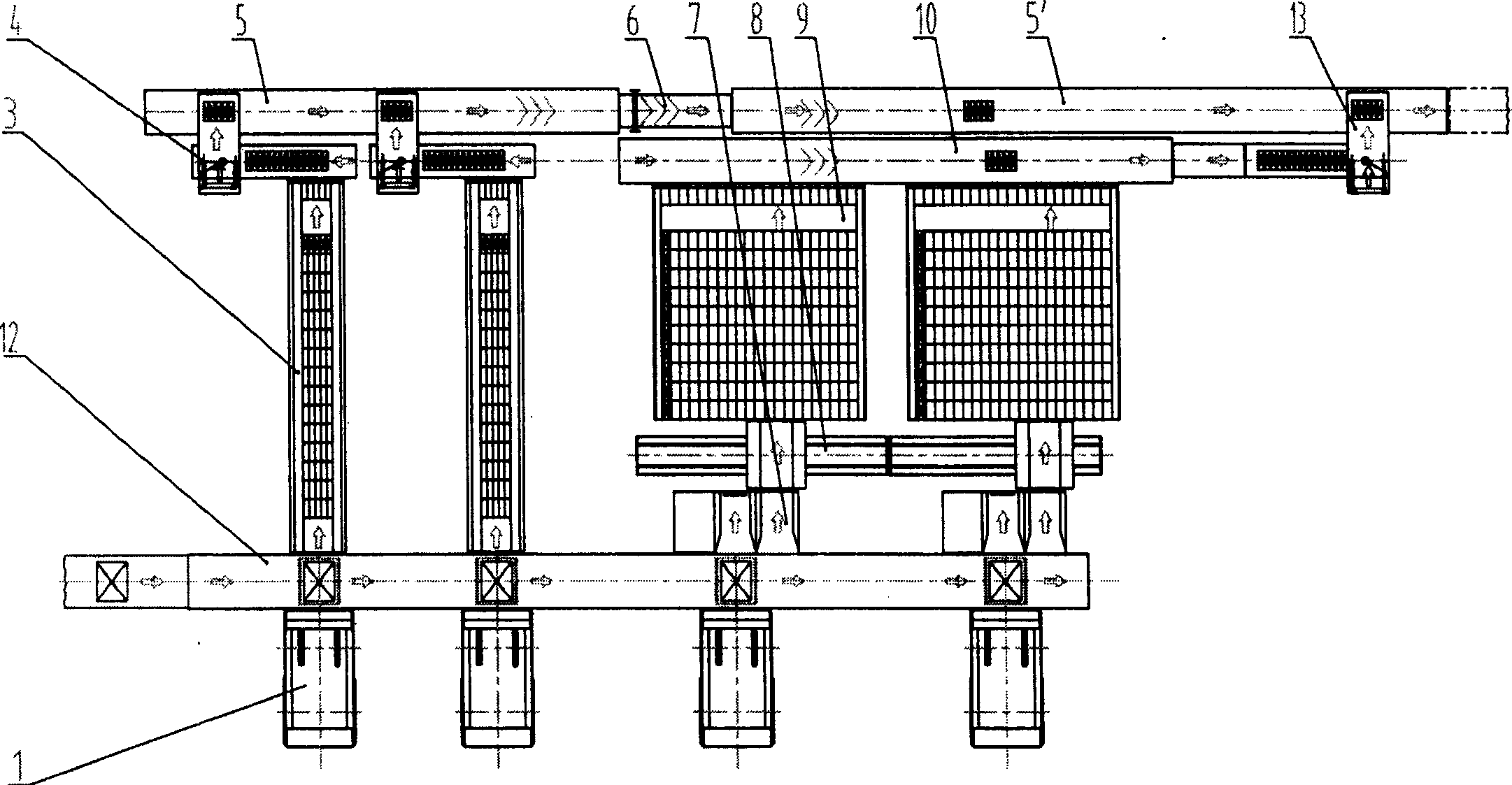

The invention discloses a monitoring low-resistance module grounding device, which comprises a grounding body connected with a grounding downlead (8) and a liquid tank (10) for containing liquid, wherein the grounding body comprises a plurality of sequentially communicated horizontal grounding tubes (4) and a plurality of vertical grounding tubes (5) communicated with the horizontal grounding tubes (4) respectively; both the horizontal grounding pipes (4) and the vertical grounding pipes (5) are provided with a plurality of seepage holes (6); and the liquid tank (10) is communicated with the grounding pipes through liquid injection pipes (9). Cathode protection electrolyte is filled in the grounding pipes and seeps into soil through the seepage holes (6) to keep the soil wet constantly and increase the free ions in the soil. The device has the advantages of obviously reducing grounding resistance and effectively ensuring the reliability of a grounding network. Particularly in areas and seasons of high soil resistance and he device has obvious effects.

Owner:吕良

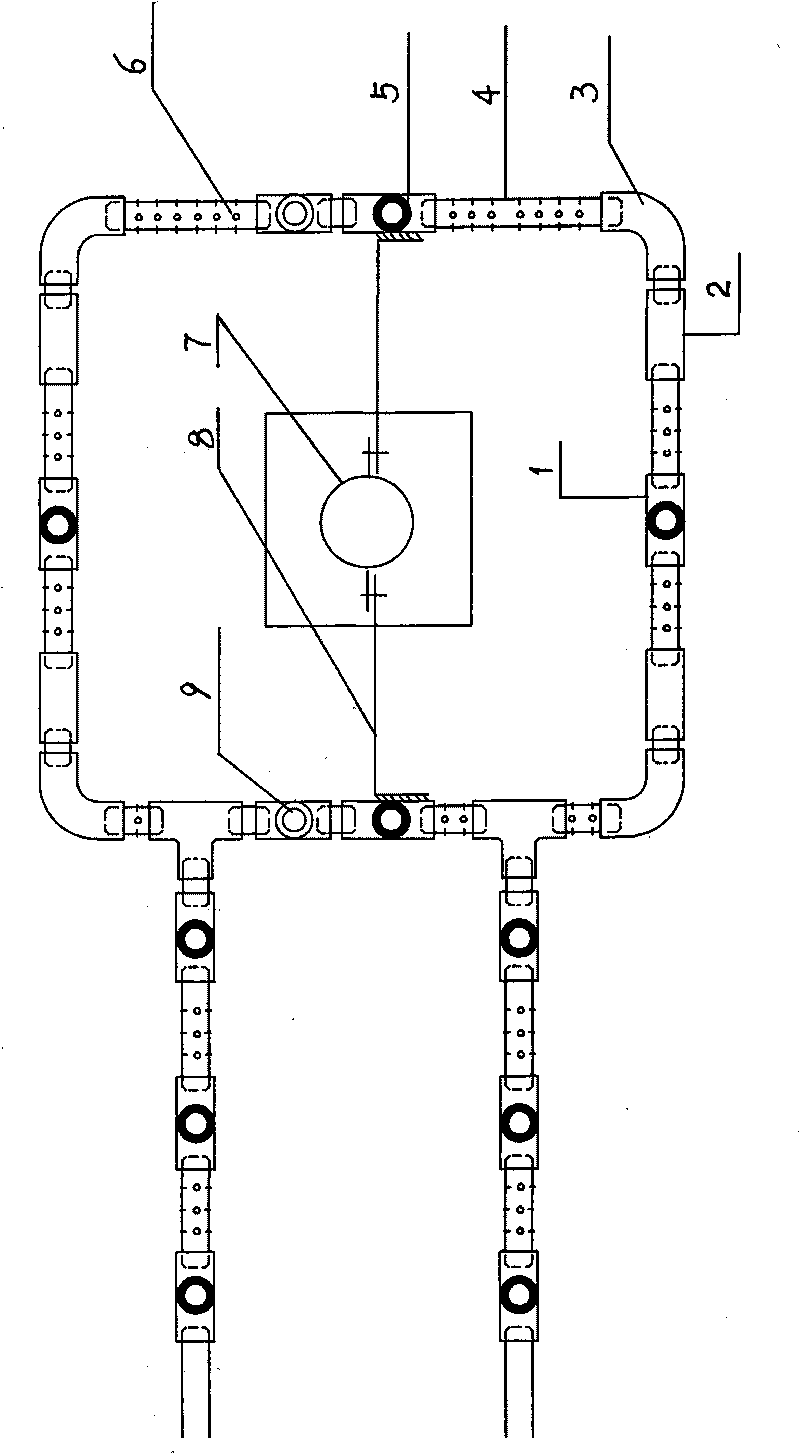

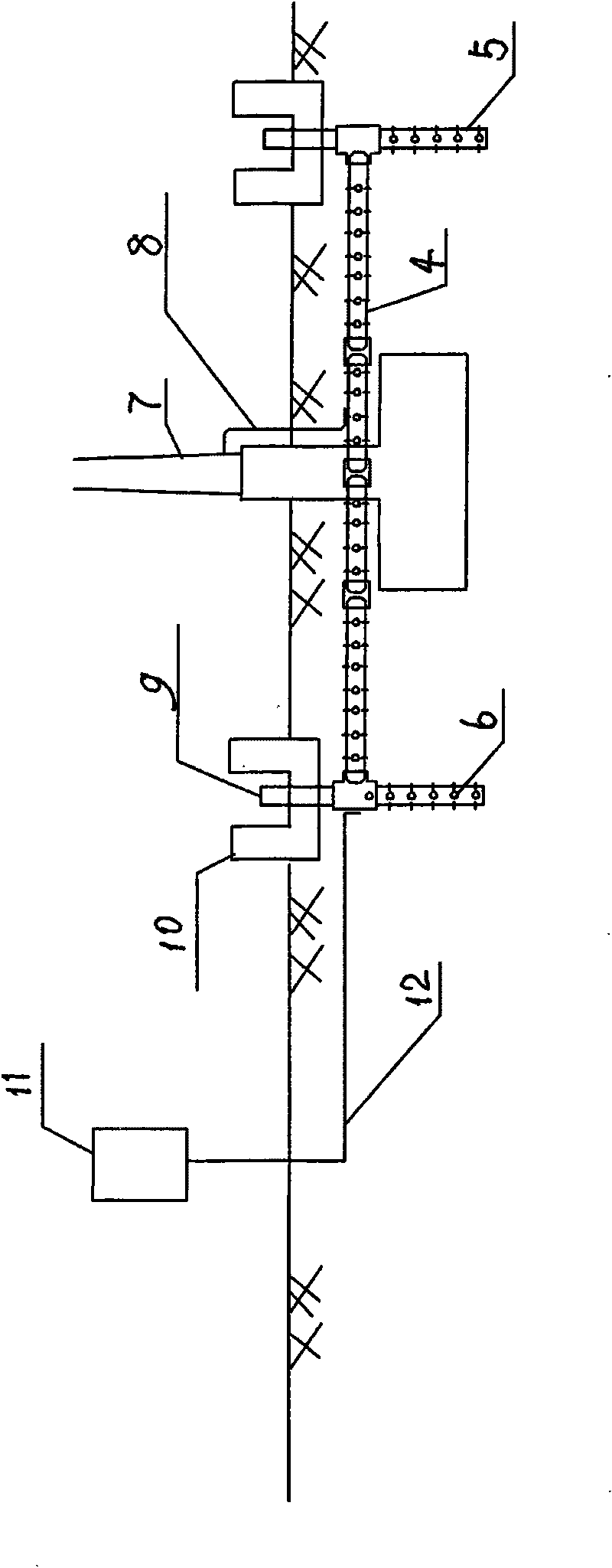

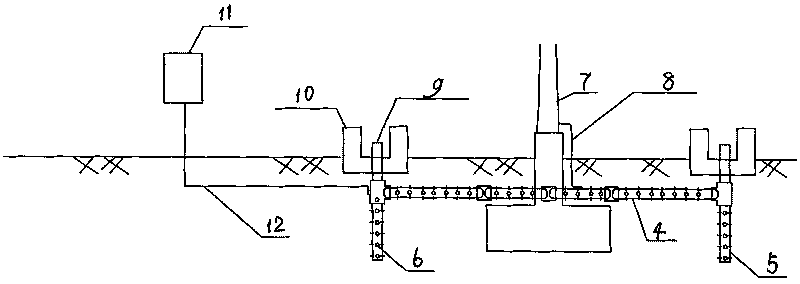

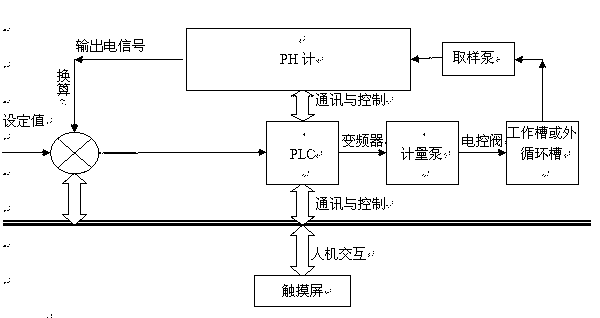

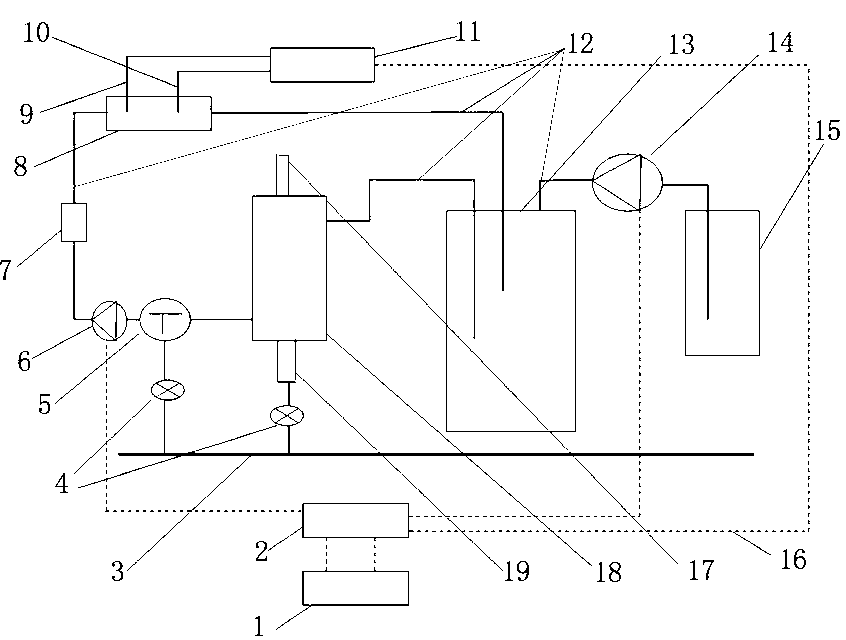

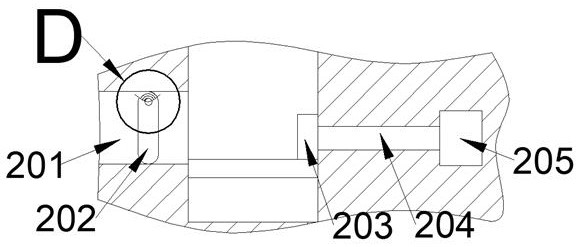

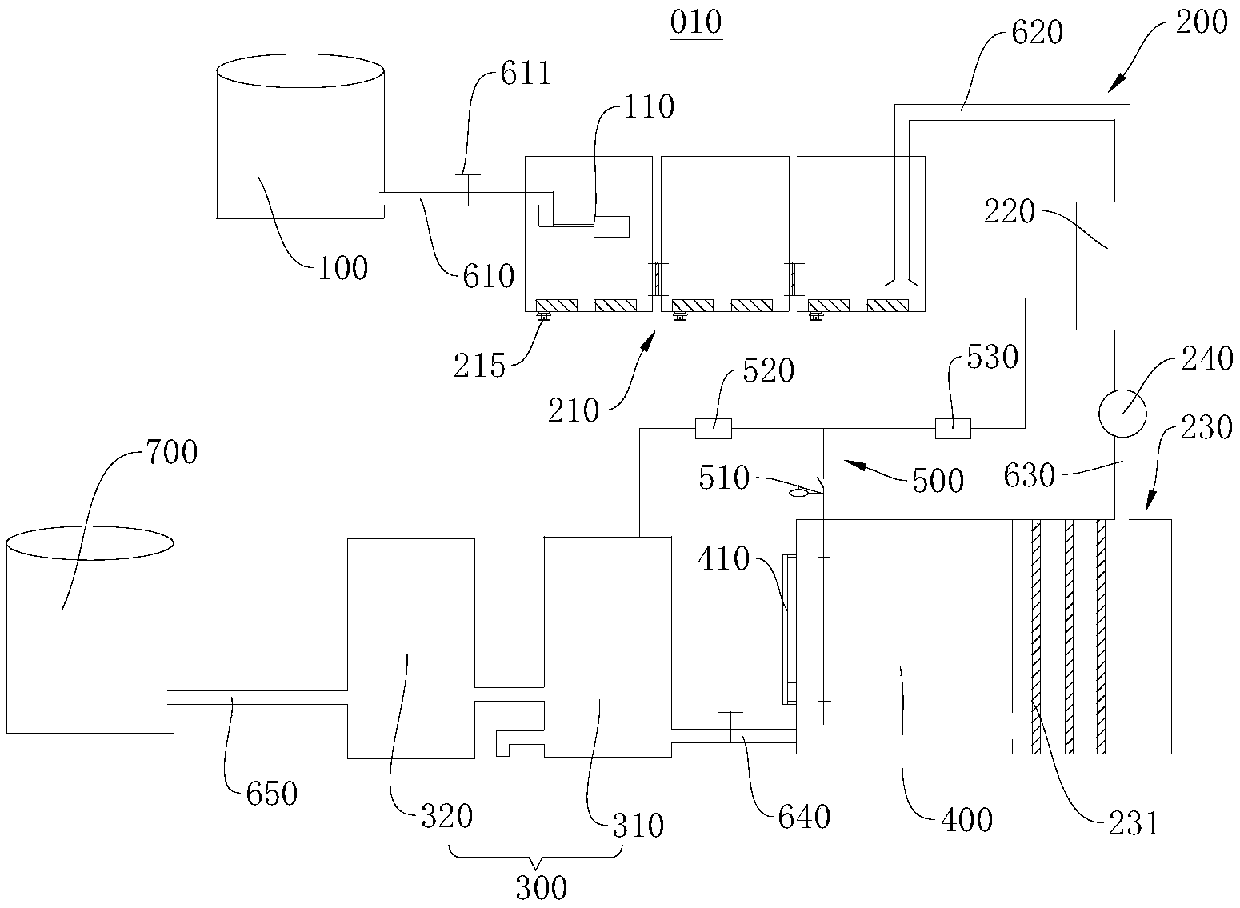

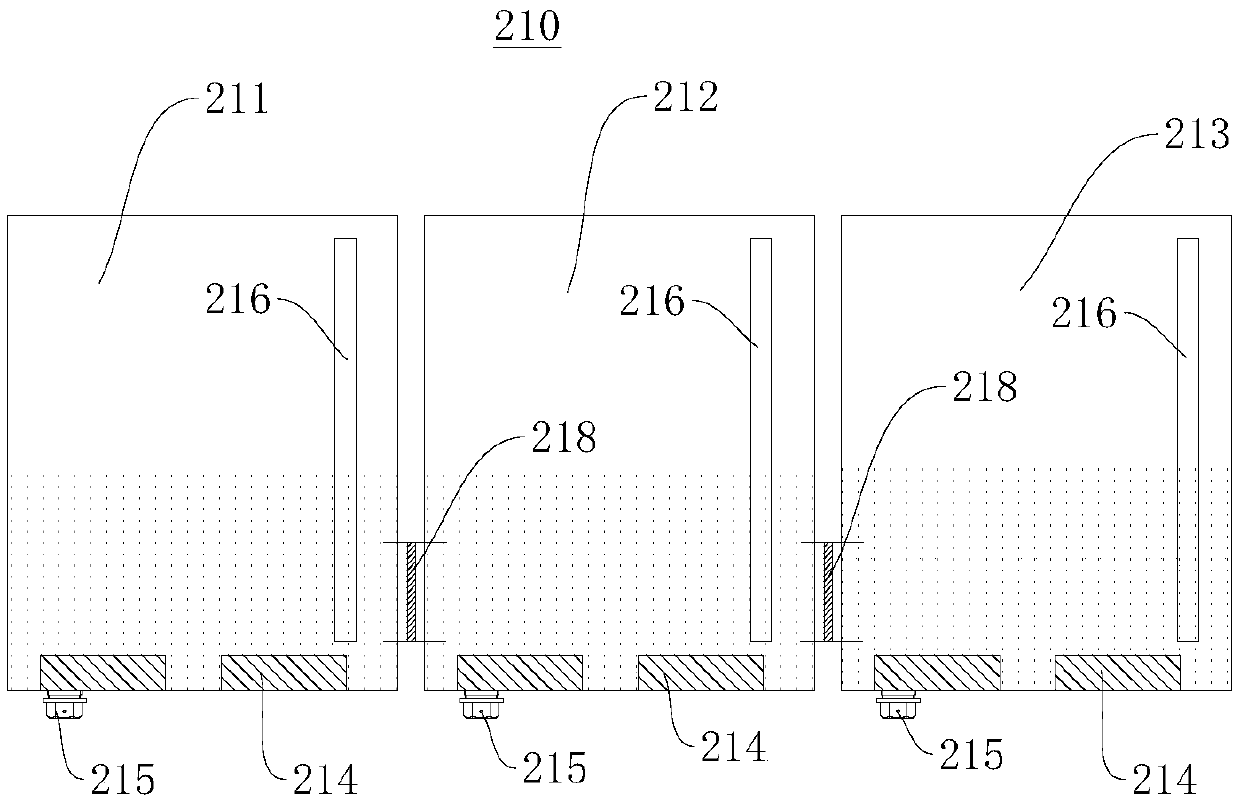

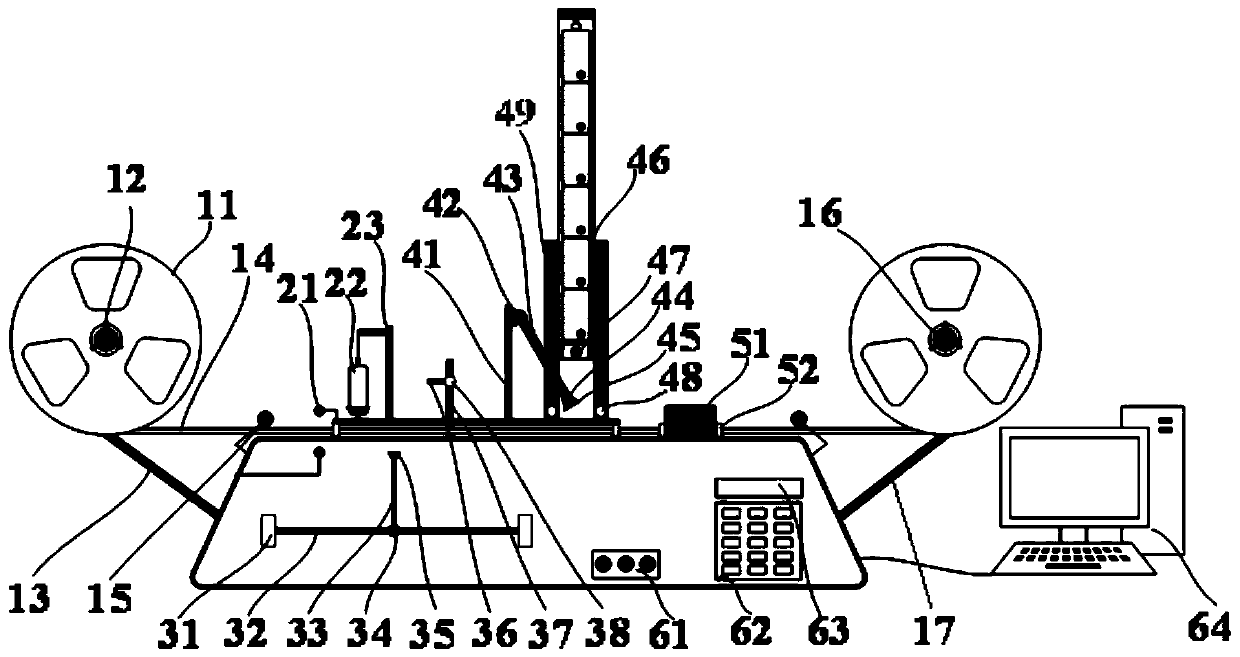

Phosphating solution online-monitoring and automatic-supplementing apparatus

InactiveCN103266316AImplement auto-replenishmentNot easy to slaggingCellsPhosphatisationEngineeringPh probe

The invention provides a phosphating solution online-monitoring and automatic-supplementing apparatus. The apparatus comprises a work tank or a circulation tank, a measuring pool, a concentrate pool and pipelines, and the work tank or the circulation tank is connected with a metering pump to the concentrate pool through a pipeline; the work tank or the circulation tank is connected to the measuring pool through a pipeline; the work tank or the circulation tank is connected with a condenser through a pipeline, the condenser is connected with a sampling pump, and the sampling pump is connected to the measuring pool through a float flow meter; and a temperature sensor and a pH probe are arranged in the measuring pool, and the measuring pool is connected to a control portion through a pH meter and a communication line. The online monitoring and automatic supplementing of a phosphating solution are realized through adopting a real-time control technology. The apparatus which allows the fluctuation of technological indexes of the phosphating work tank solution to be controlled in a small range guarantees the product quality stability, increases the labor efficiency and improves the labor environment of workers.

Owner:DONGFENG MOTOR FASTENER CO LTD

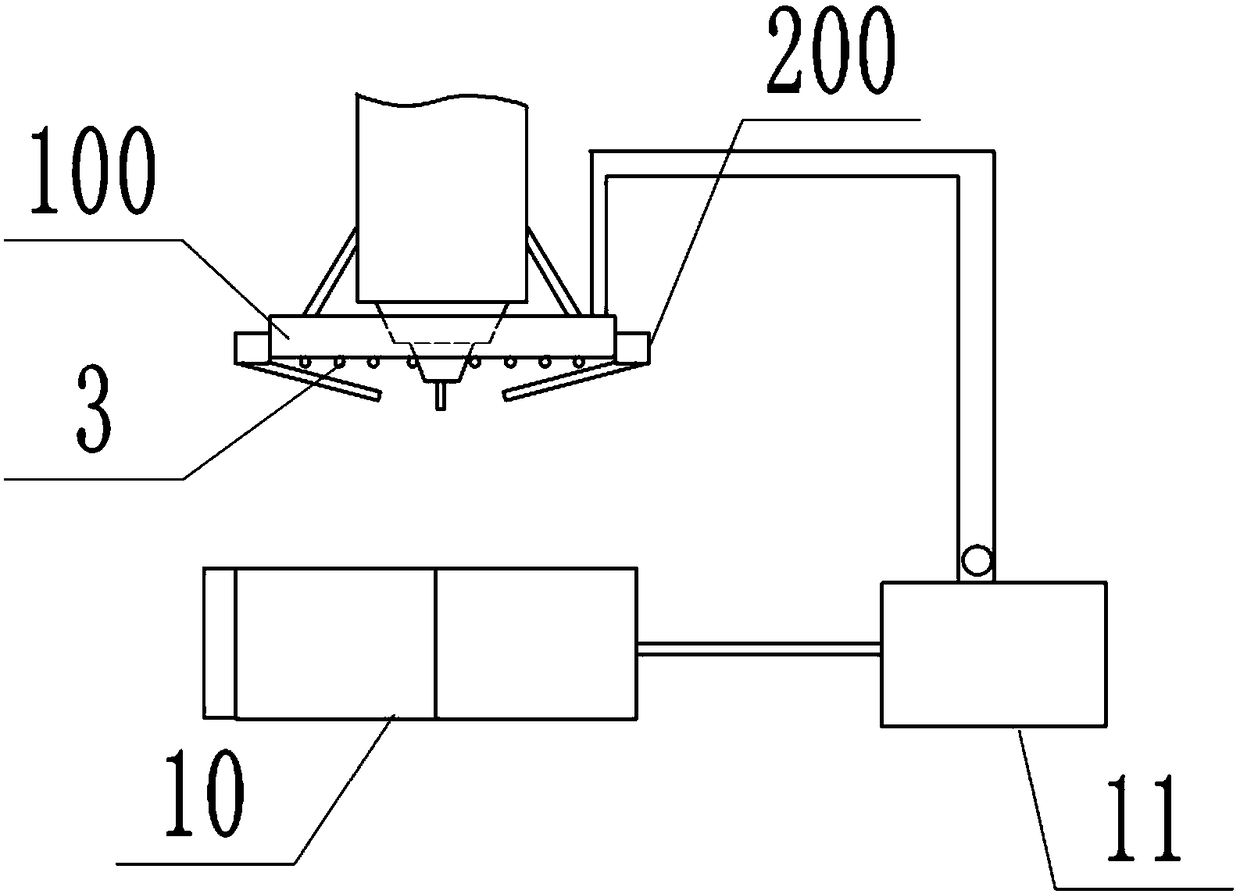

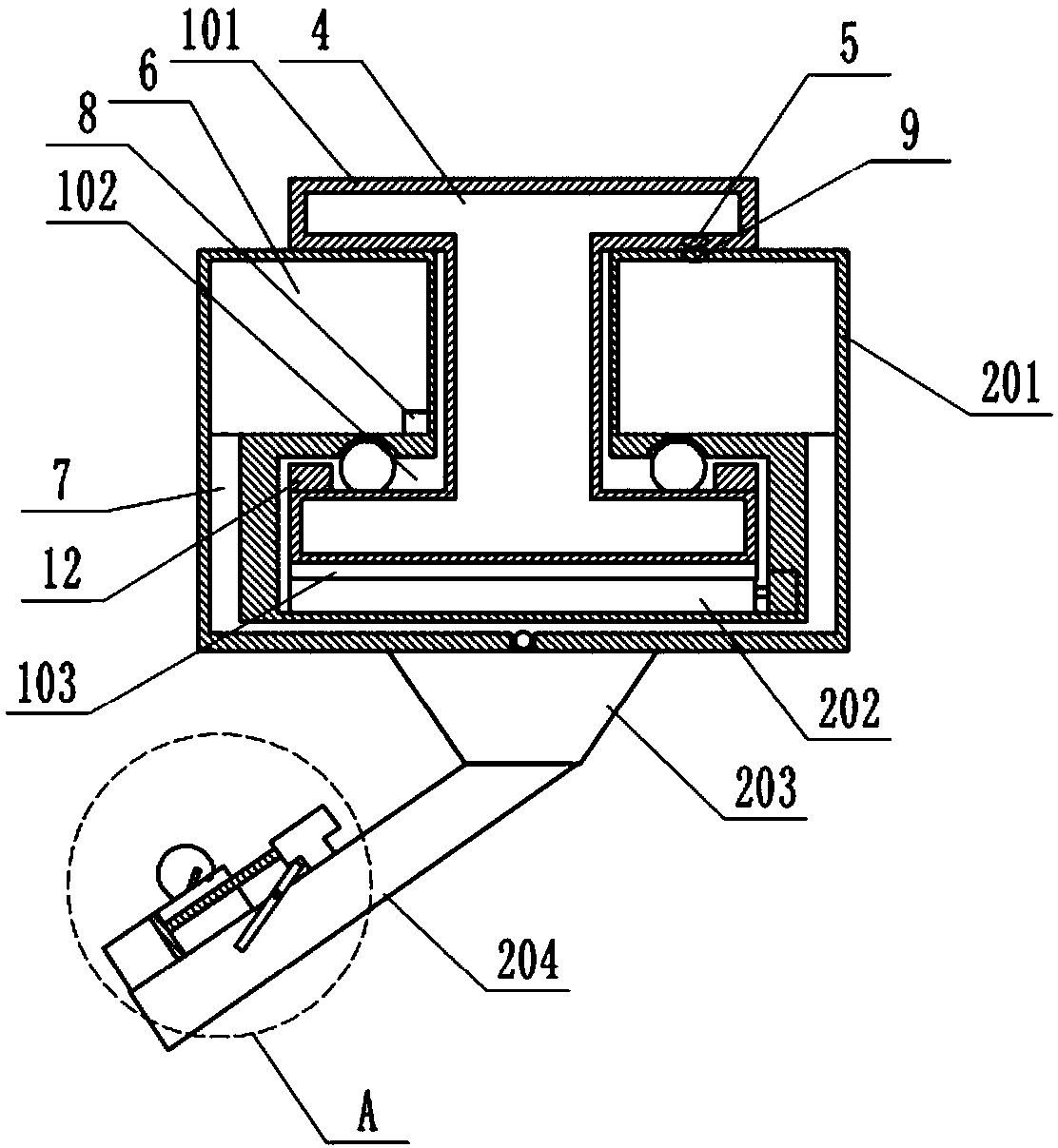

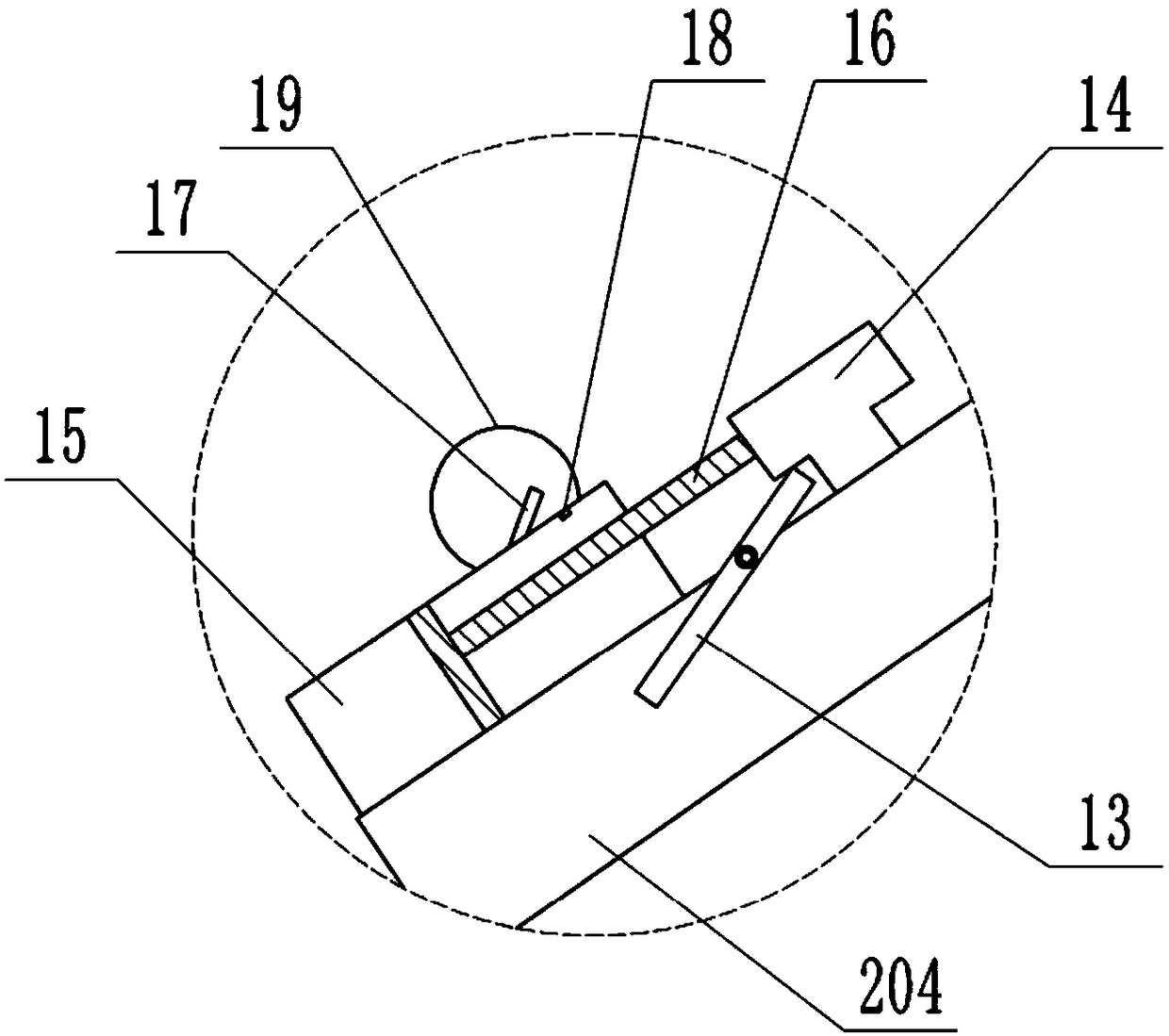

Cooling system for numerically-controlled machine tool

ActiveCN108857568AGuaranteed effective coolingGuarantee the quality of the workpieceMeasurement/indication equipmentsMaintainance and safety accessoriesEngineeringMachining process

The invention discloses a cooling system for a numerically-controlled machine tool and relates to the field of numerically-controlled machine tool equipment. The cooling system comprises an annular guide rail and a moving mechanism. Multiple temperature sensors are arranged on the lower portion of the annular guide rail. The annular guide rail is internally provided with a cavity. A liquid inlet pipe is arranged on the annular guide rail, wherein the liquid inlet pipe communicates with the cavity. The wall of the cavity is provided with a first solenoid valve. An infrared sensor is arranged atone side of the first solenoid valve. A buckling ring is internally provided with an inner cavity. A conveying channel is formed in the buckling ring and a connecting plate. The conveying channel enables a spray head to communicate with the inner cavity. A water pump is arranged at the connection position of the conveying channel and the inner cavity. The inner cavity is internally provided witha liquid level sensor. The wall of the inner cavity of the buckling ring is provided with a second solenoid valve. The second solenoid valve can be opposite to the first solenoid valve in position. Bymeans of the cooling system, the problem that in the workpiece machining process of a traditional numerically-controlled machine tool, the spray flow of cooling liquid cannot be adjusted automatically according to the machining heat quantity is solved; and the cooling system is mainly used for guaranteeing the cooling effect and workpiece quality.

Owner:温州市职业中等专业学校

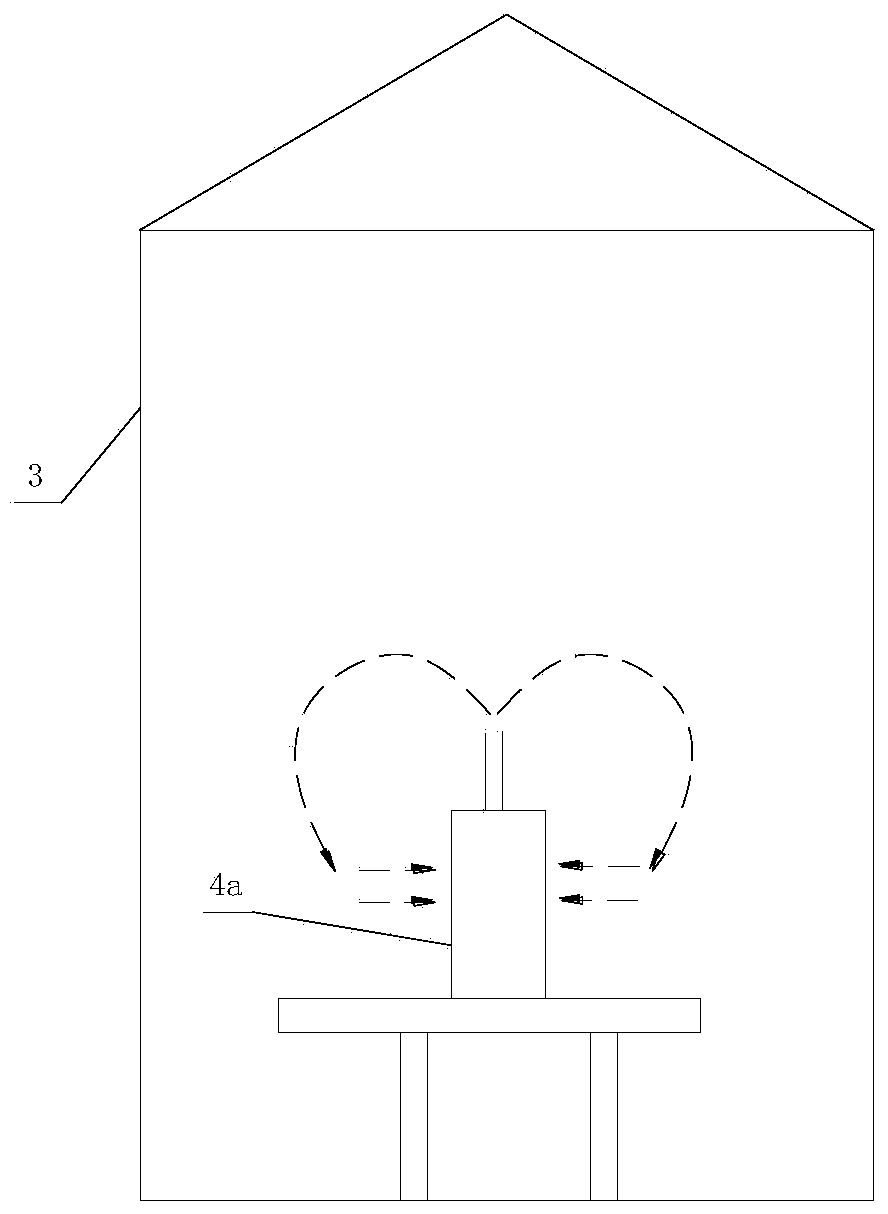

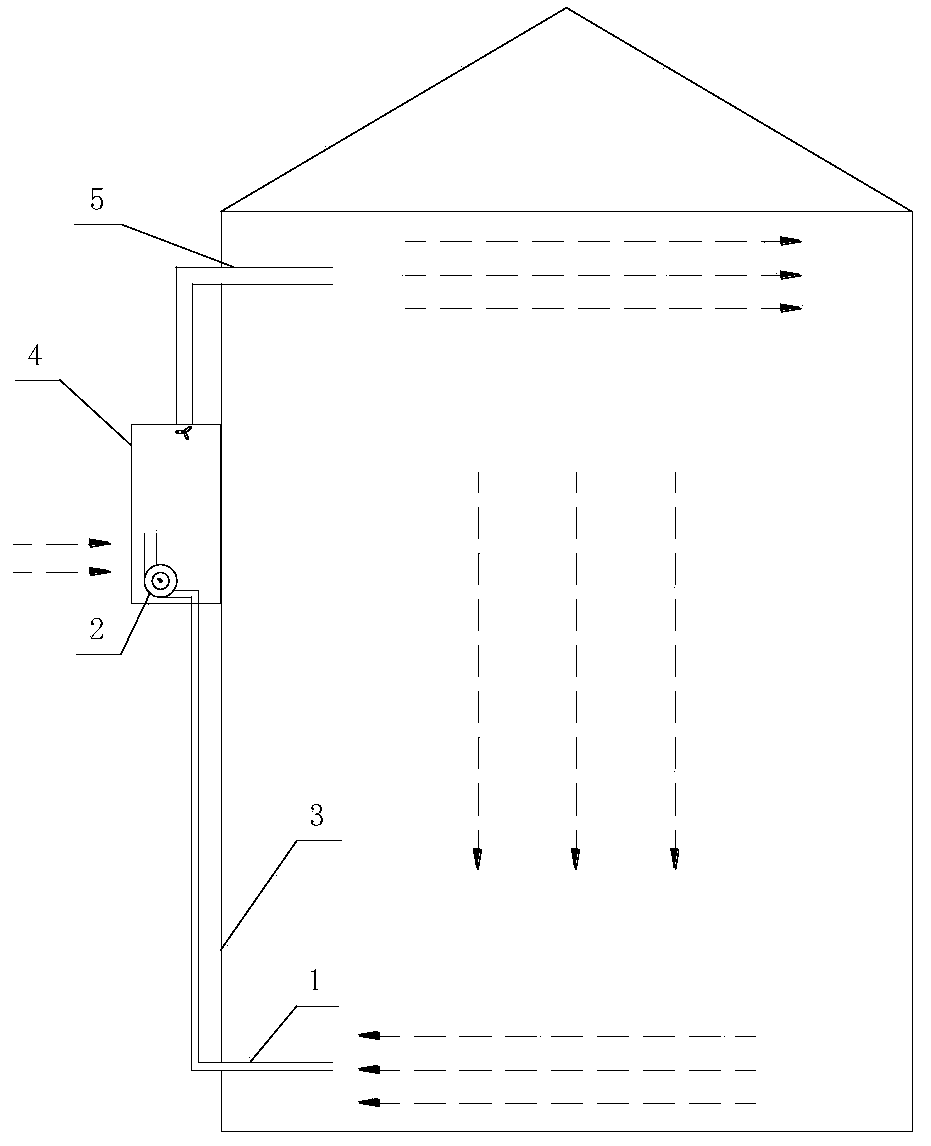

Air purifying system

InactiveCN104197412AAchieve replacementAvoid Hazardous SituationsDucting arrangementsSpace heating and ventilation safety systemsSide effectAir pump

The invention relates to the technical field of air purifying and provides an air purifying system. The air purifying system overcomes the defects that an air purifying system in the prior art has the general defects of being poor in air purifying effect, high in side effect, low in intelligent degree, poor in use comfort of a user and the like. The air purifying system comprises an air purifier (4) fixedly arranged on the outer side of the wall of a room (3), an air supplying pipeline (5) communicated with an air outlet of the air purifier (4), an air pump (2) and an exhaust pipeline (1) communicated with an air sucking opening of the air pump (2). The air supplying pipeline (5) penetrates through and is fixed to the upper middle of the wall of the room (3), and the exhaust pipeline (1) penetrates through and is fixed to the lower portion of the wall of the room (3). Due to the structural layout arrangement of the air purifying system, all air in the room can be replaced within a short time when the air purifier and the air pump are started, and residual unpurified air cannot remain.

Owner:CHENGDU HANGHAO TECH

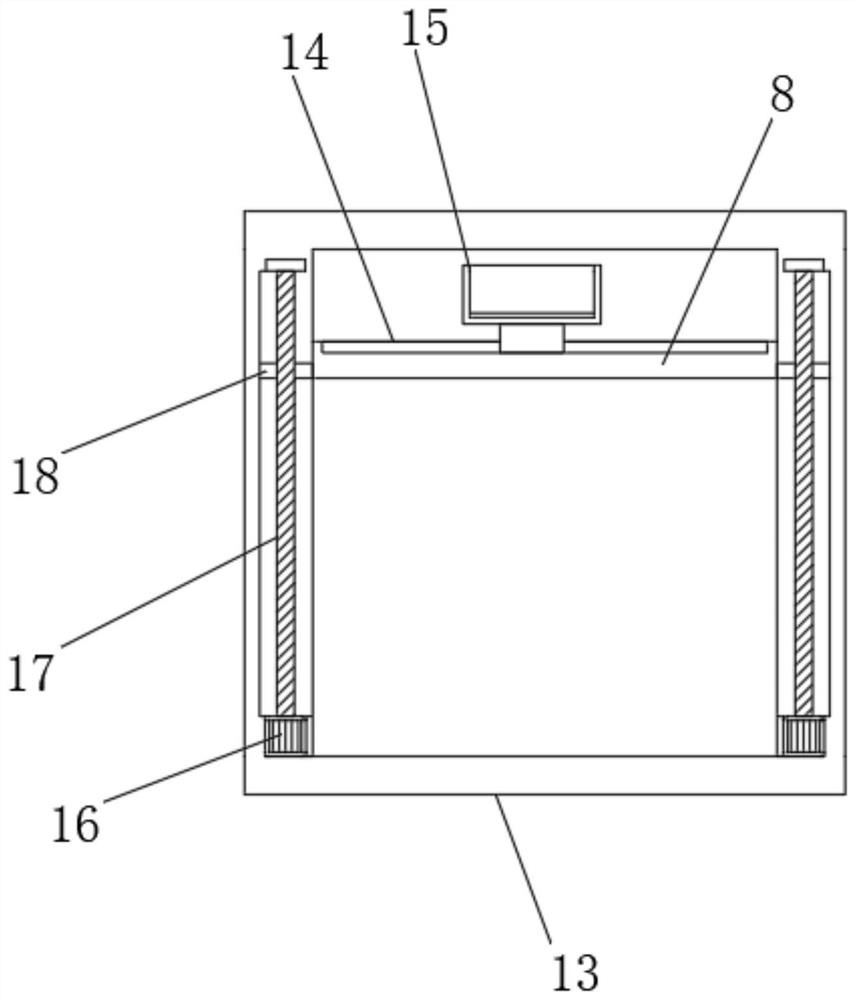

Automatic cleaning device of measuring instrument

ActiveCN108814612AFast dryingAutomate the disinfection processDiagnostic recording/measuringSensorsMeasuring instrumentLiquid storage tank

The invention relates to an automatic cleaning device of a measuring instrument. The device comprises a base and a measuring plate, a first support column and a second support column are fixedly connected to the bottom of the measuring plate, a first air bag is arranged between the first support column and the second support column which are sleeved with support springs, and the support springs are located between the base and the measuring plate; a stand column is fixedly connected to the side of the measuring plate, a first support platform and a second support platform are fixedly connectedto the two sides of the stand column respectively, a second air bag is fixedly connected to the first support platform, a gas-guide tube is communicated between the second air bag and the first air bag, the second support platform is provided with a disinfection tank and a liquid storage tank, a piston is slidably connected into the disinfection box, the piston divides the interior of the liquidstorage tank into a liquid chamber and a gas chamber, a piston rod is fixedly connected to the piston, the free end of the piston rod is movably connected to the second air bag, a sprinkler pipe is arranged at the bottom of the liquid chamber, a gas ejector pipe is communicated with the bottom of the gas chamber, and a U-shaped pipe is communicated between the liquid chamber and the liquid storagetank. By means of the device, the measuring instrument can be cleaned.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

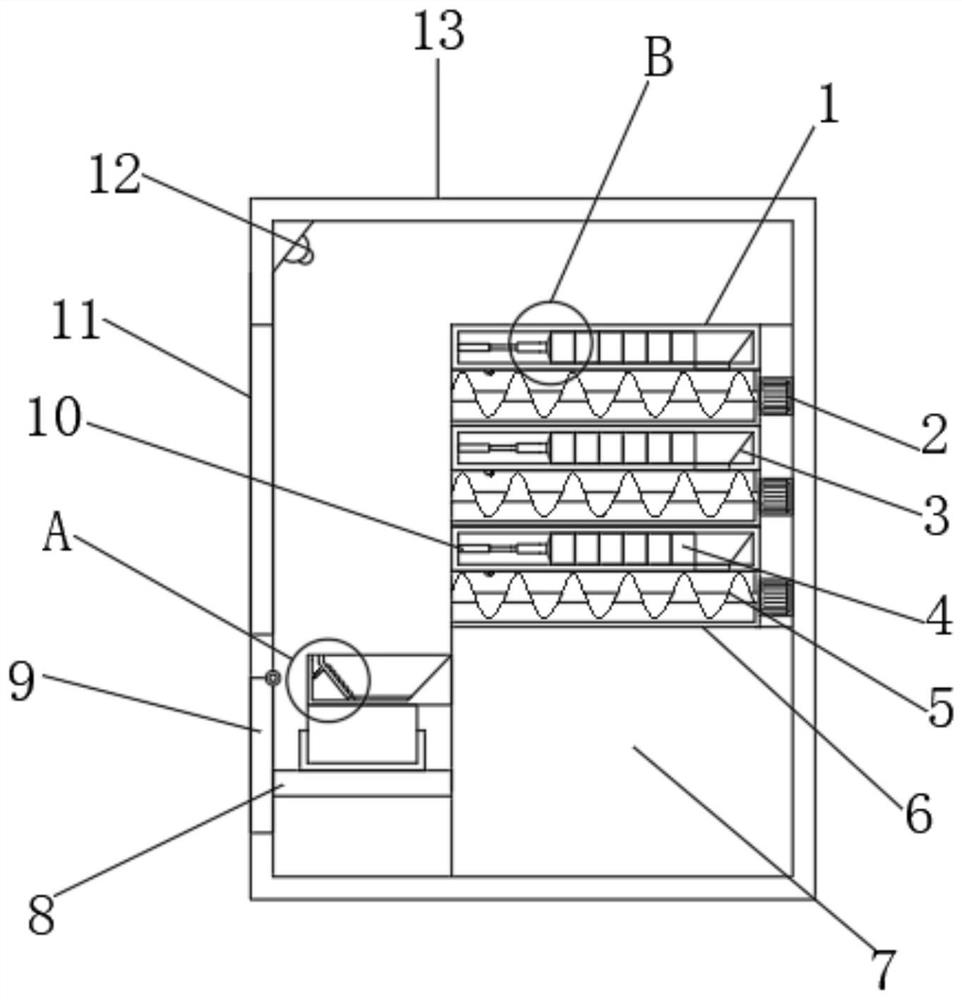

Vending machine and management method thereof

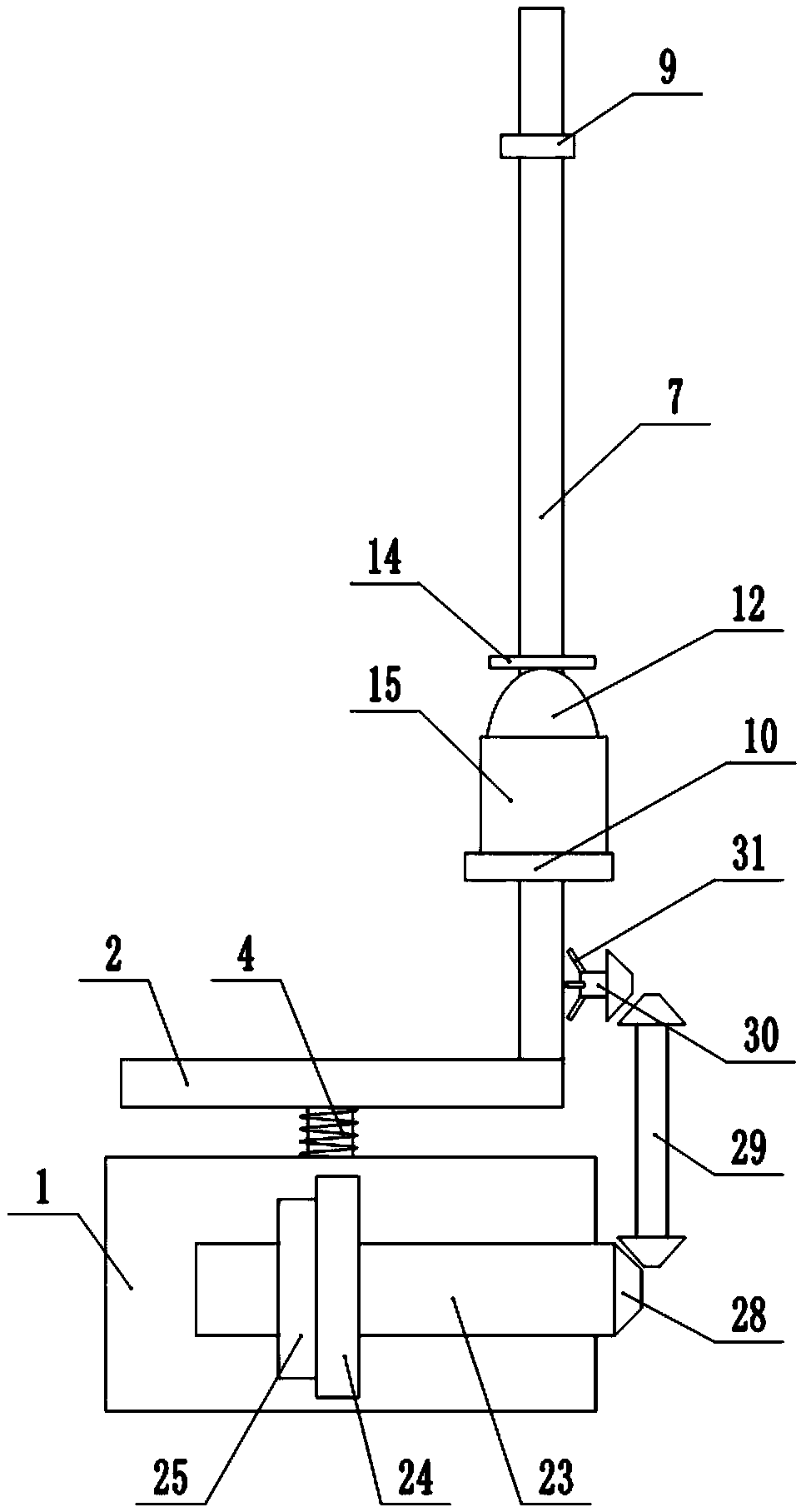

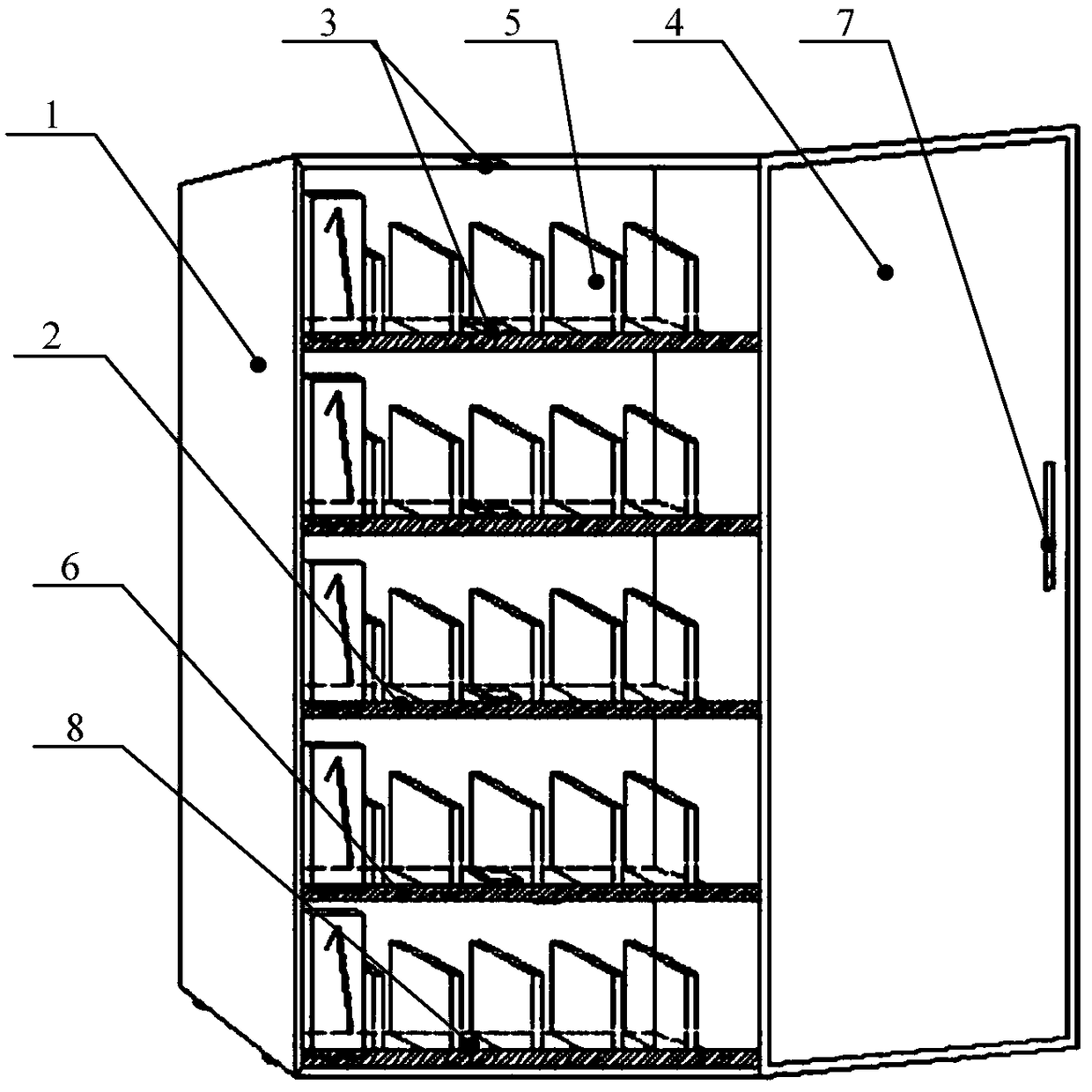

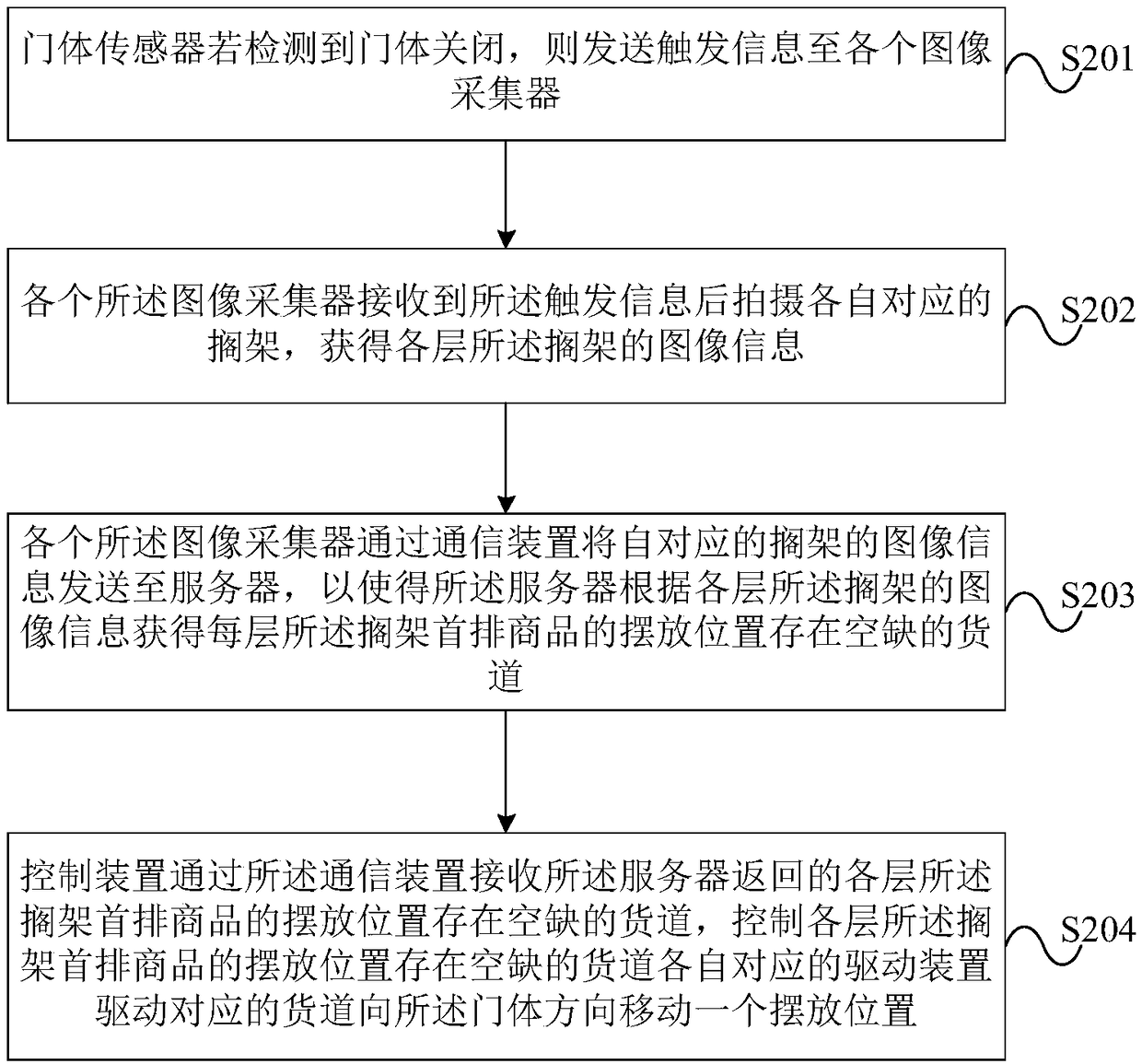

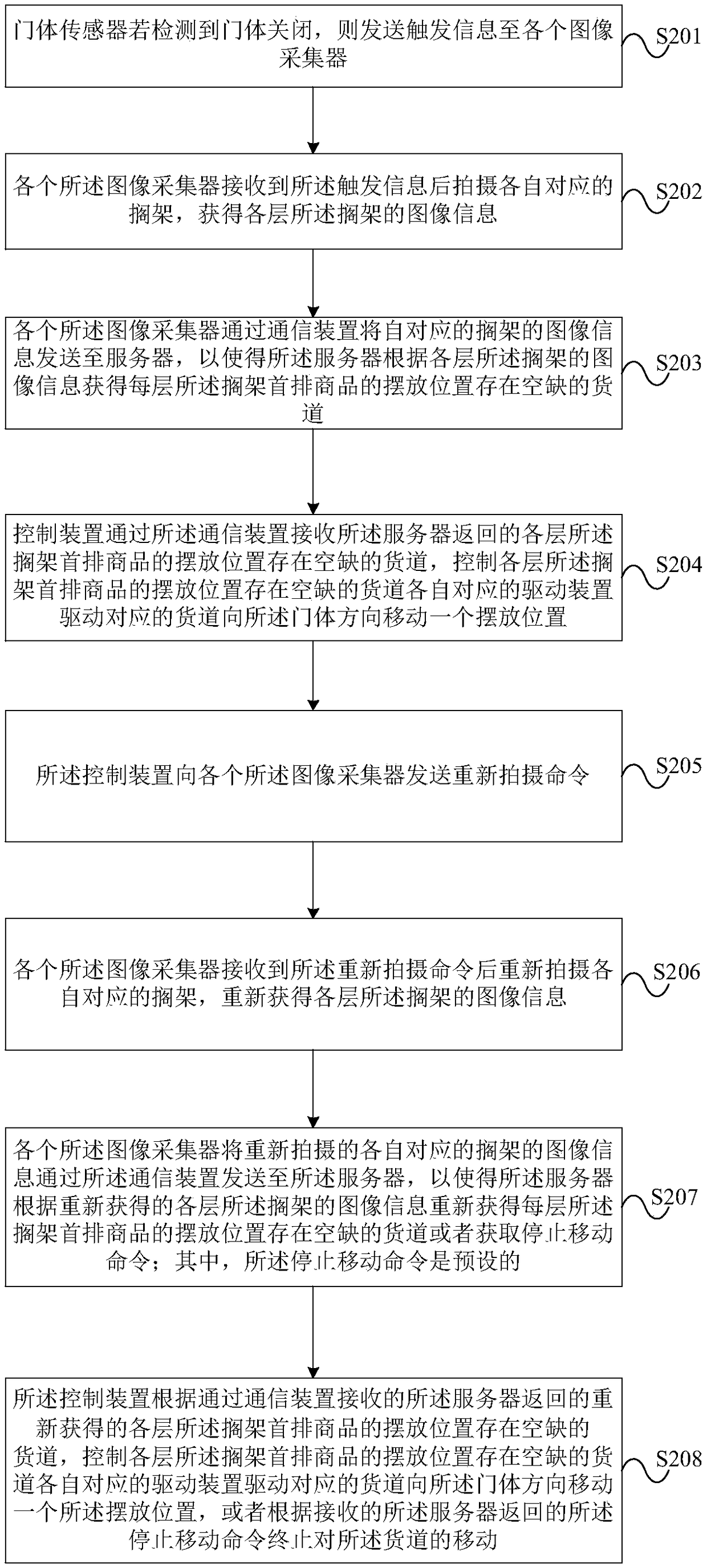

InactiveCN108986310AImprove replenishment efficiencyImplement auto-replenishmentCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringCommunication device

The invention provides a vending machine and a management method thereof. The vending machine comprises a cabinet, shelves, image acquirers, a control device, a door, a door sensor and a communicationdevice. At least one shelf is arranged in the cabinet, each shelf comprises a plurality of rows of movable goods passages, and each row of the goods passage is provided with a plurality of goods placement positions and a driving device for driving the corresponding goods passage to move goods towards the door. The door sensor is connected with the control device and used for detecting opening andclosing of the door. The control device is connected with the driving device, the communication device and the image acquirers, the image acquirers are arranged corresponding to the shelves and connected with the communication device, and the image acquirers are used for acquiring image information of the corresponding shelves and uploading the image information to a server through the communication device. The management method is applied to the vending machine. By the vending machine and the management method thereof, replenishing efficiency of goods in the first row of the shelves is improved.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

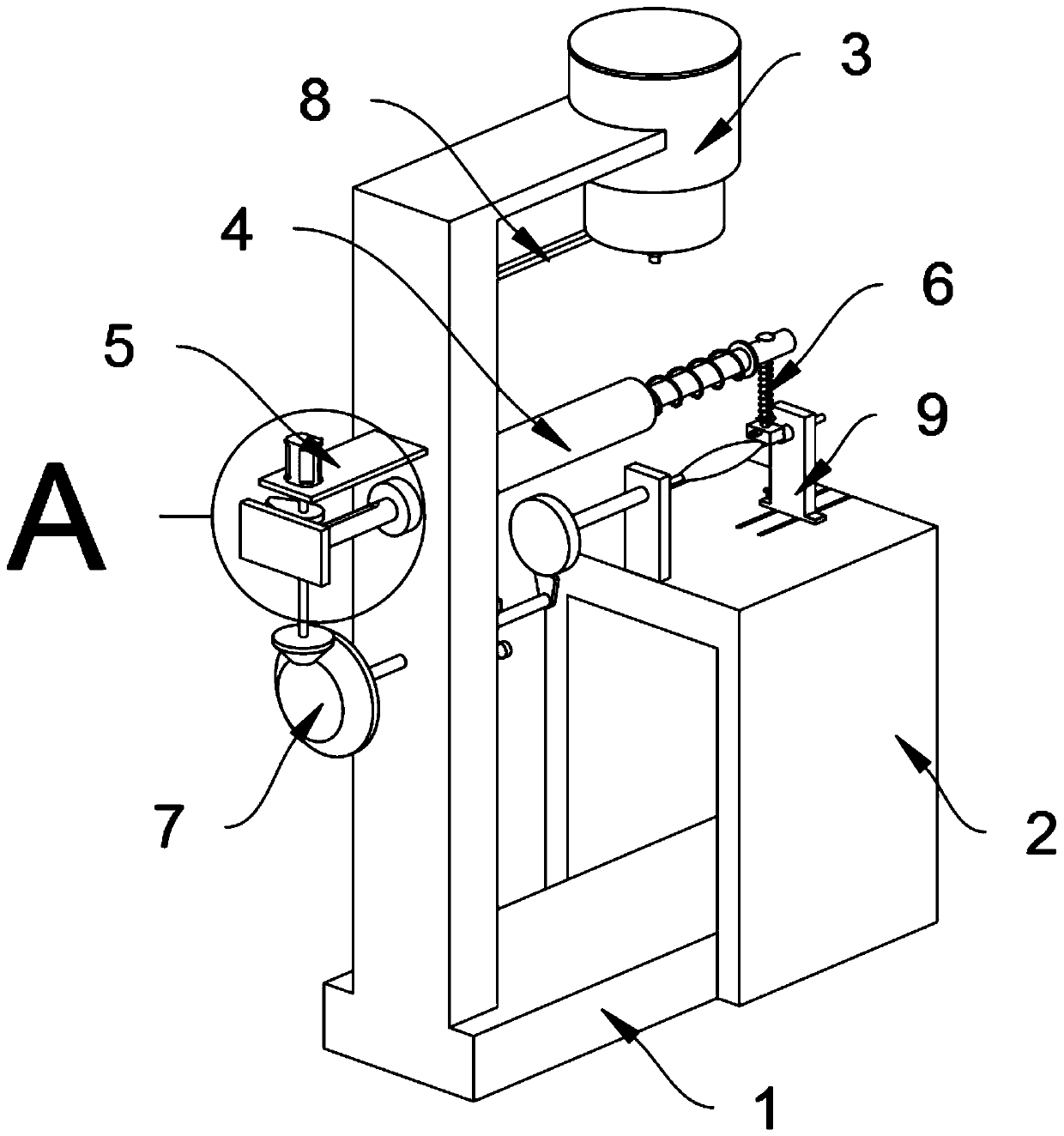

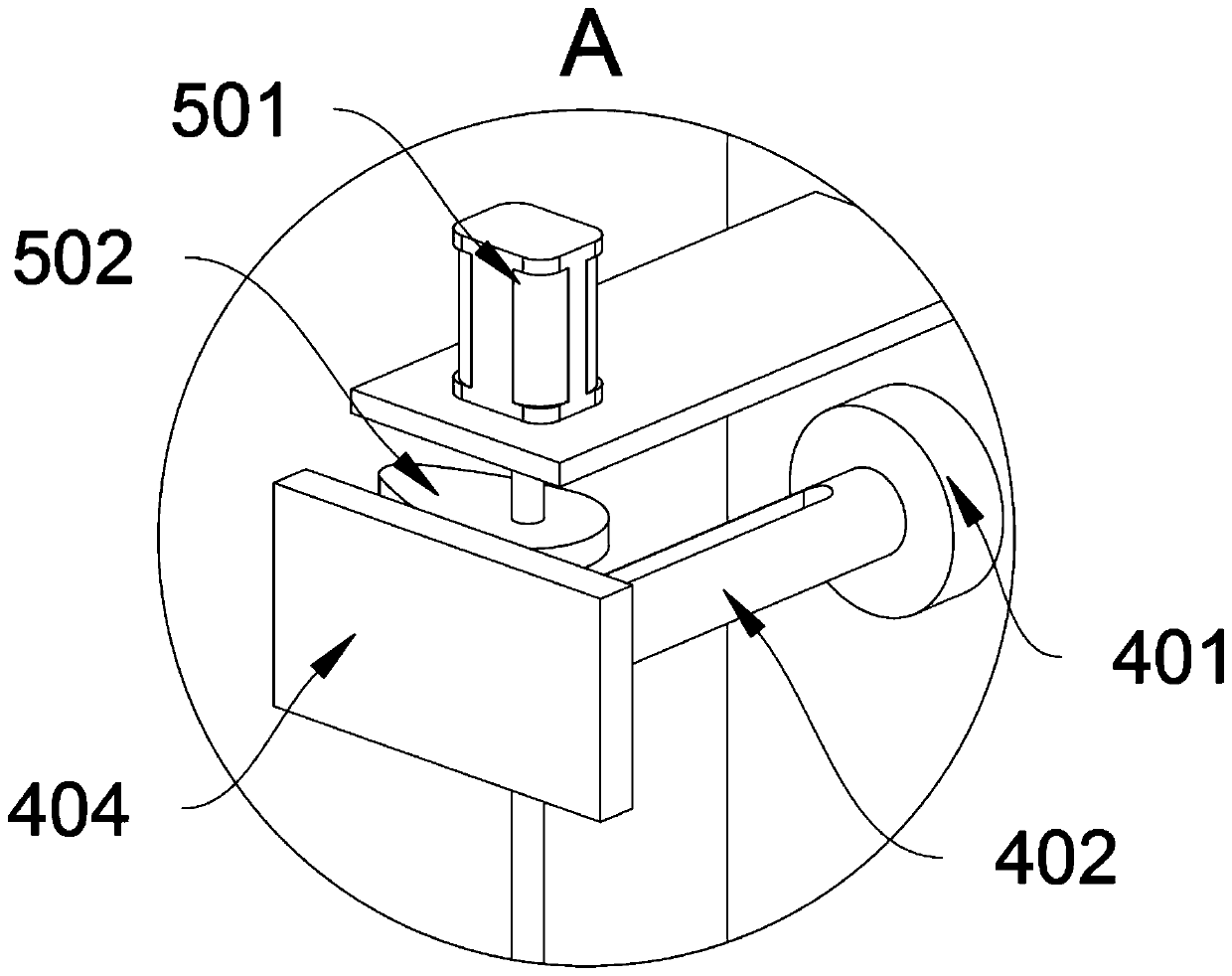

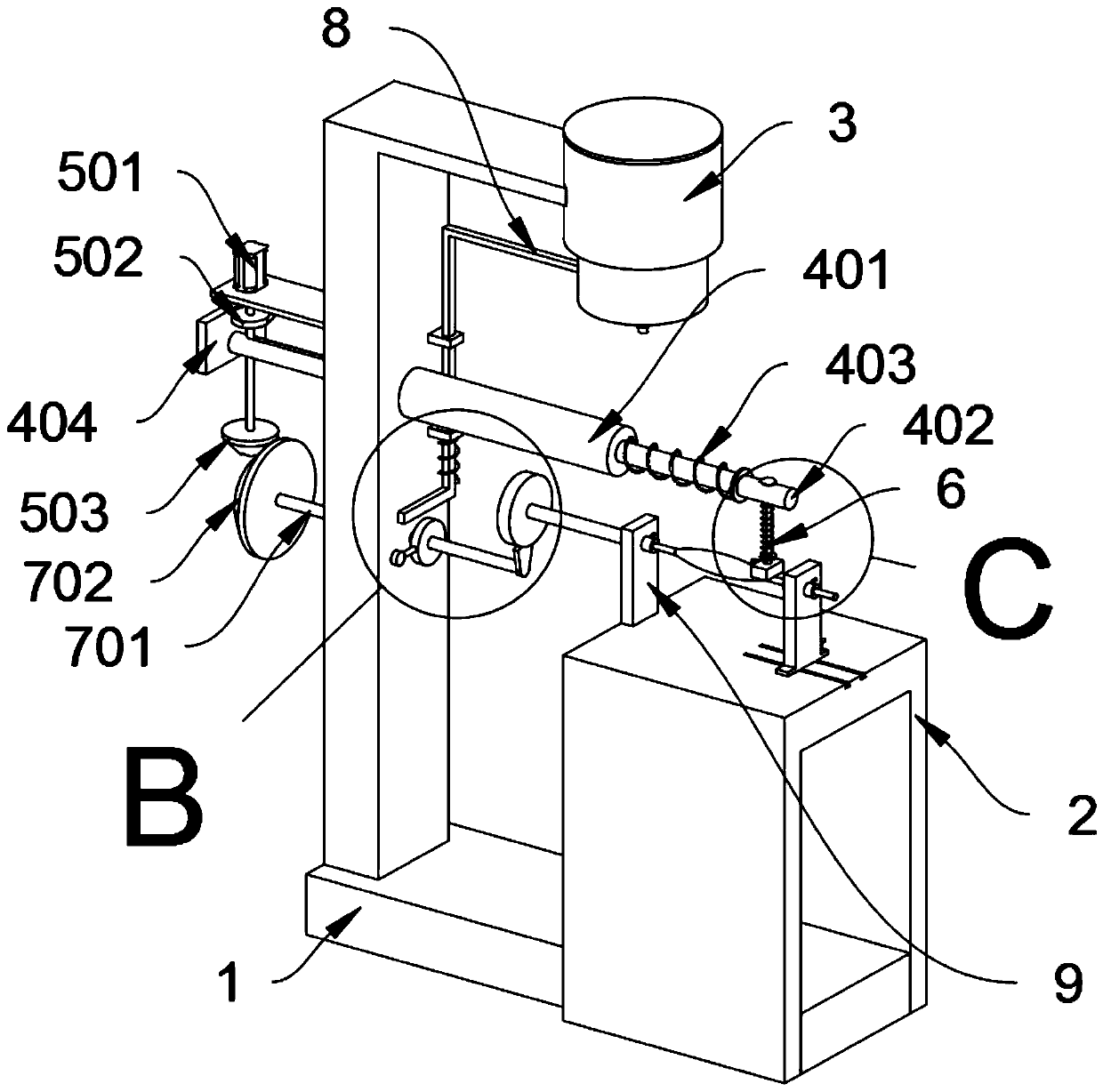

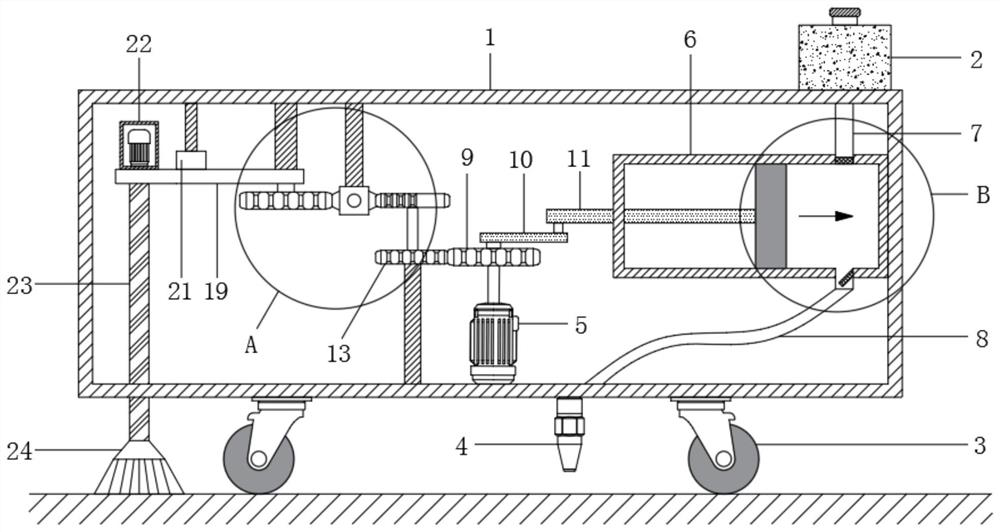

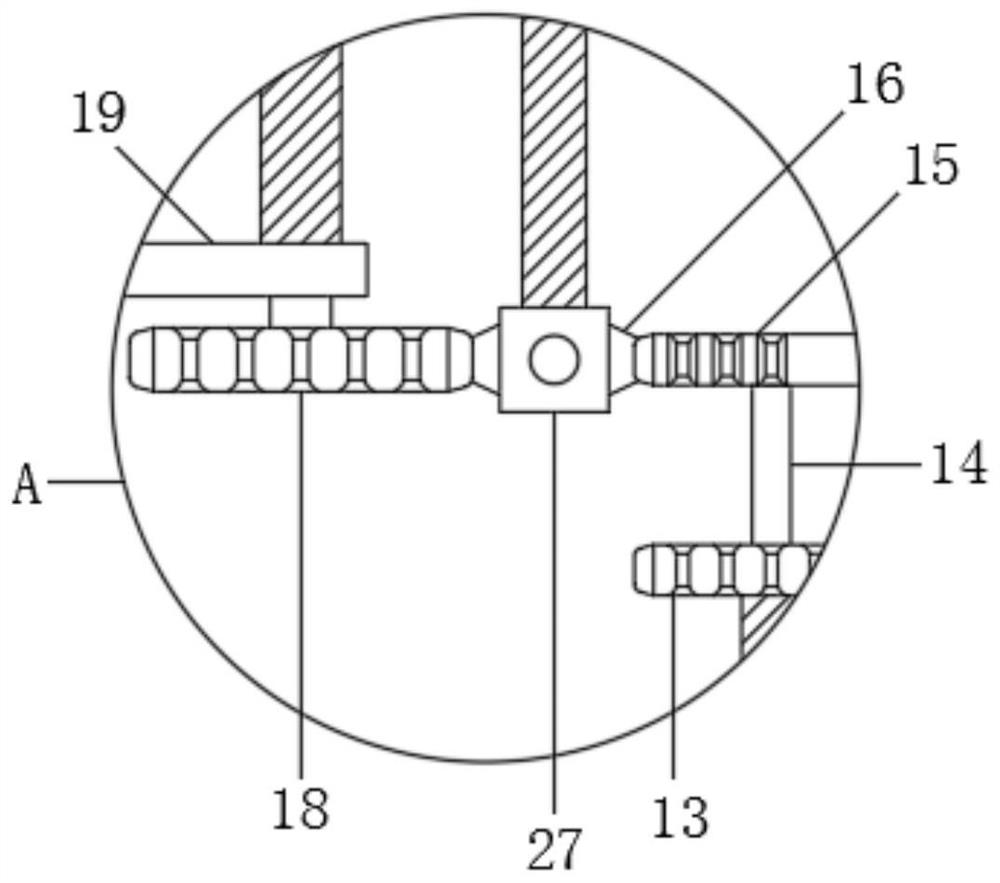

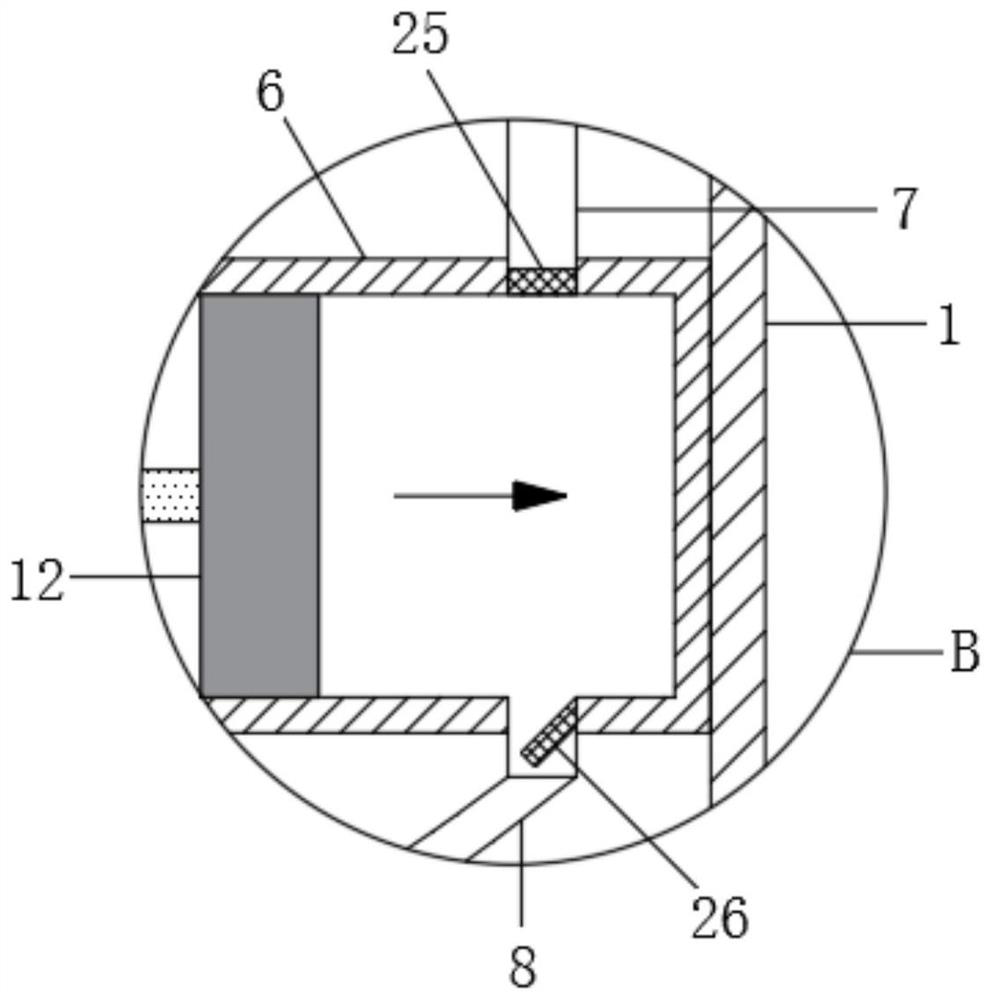

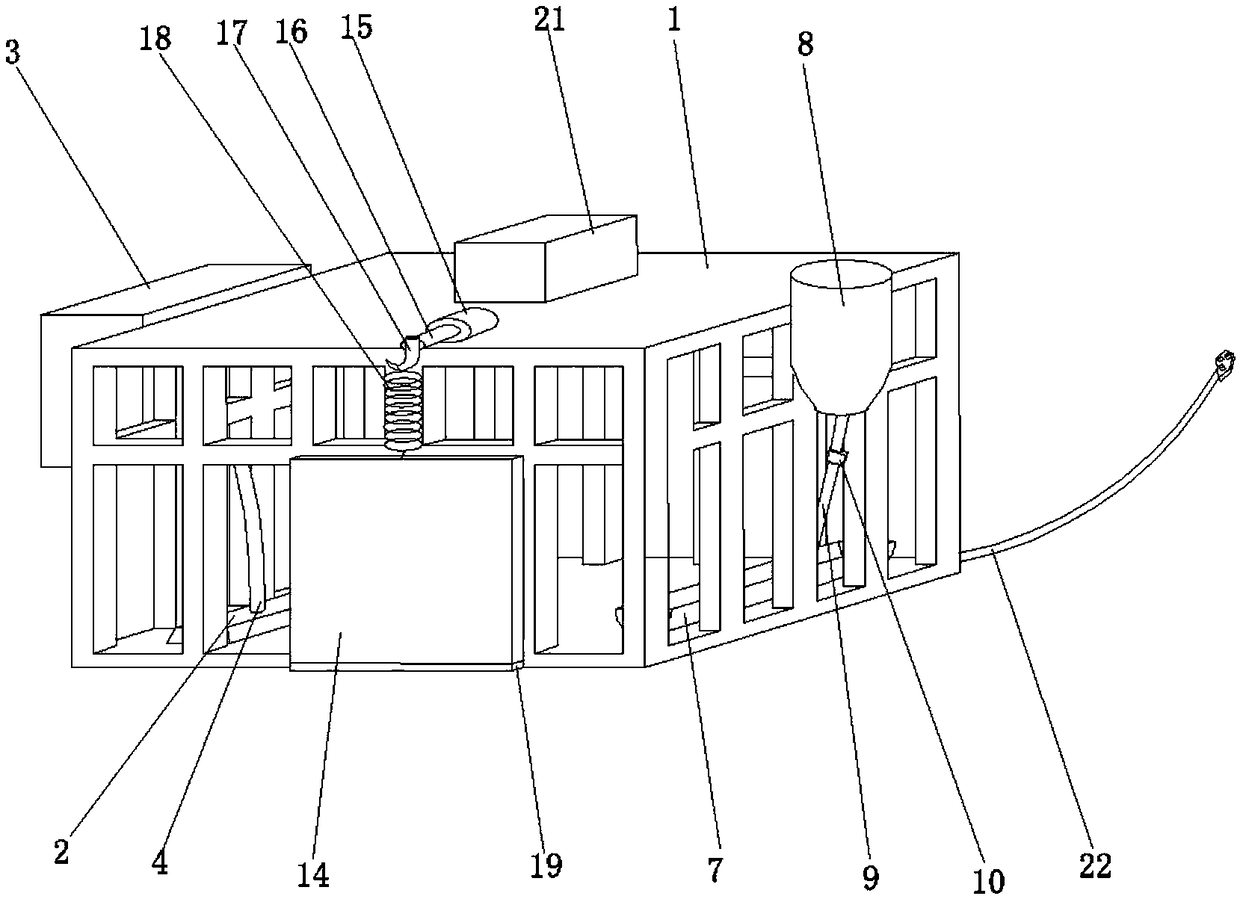

Buoy linkage paint brushing device

ActiveCN111318408AImplement auto-replenishmentSimple structureLiquid surface applicatorsCoatingsGear wheelElectric machinery

The invention provides a buoy linkage paint brushing device and relates to the field of brushing devices. The problems that during brushing, repeated dipping of pigment is needed mostly due to manualbrushing, a buoy needs to be constantly rotated, and the whole efficiency is low are solved. The buoy linkage paint brushing device comprises an installation frame, and a clamp seat is fixedly connected to the installation frame through bolts. According to the device, by means of a driving structure, a buoy rotation driving structure and a squeezing structure, as a bevel gear A and a bevel gear Bare engaged with each other, when a motor rotates, a rotating rod on the buoy rotation driving structure can be driven to rotate, at the moment, firstly, the rotating rod drives a poking head to rotate, the squeezing structure can be poked by rotation of the poking head to squeeze an elastic paint barrel, and supplement of the pigment of a brushing head is achieved; and secondly, the rotating roddrives an incomplete gear to rotate, the incomplete gear is engaged with the gears so that intermittent rotation of the buoy can be achieved through rotation of the motor.

Owner:陈依琳

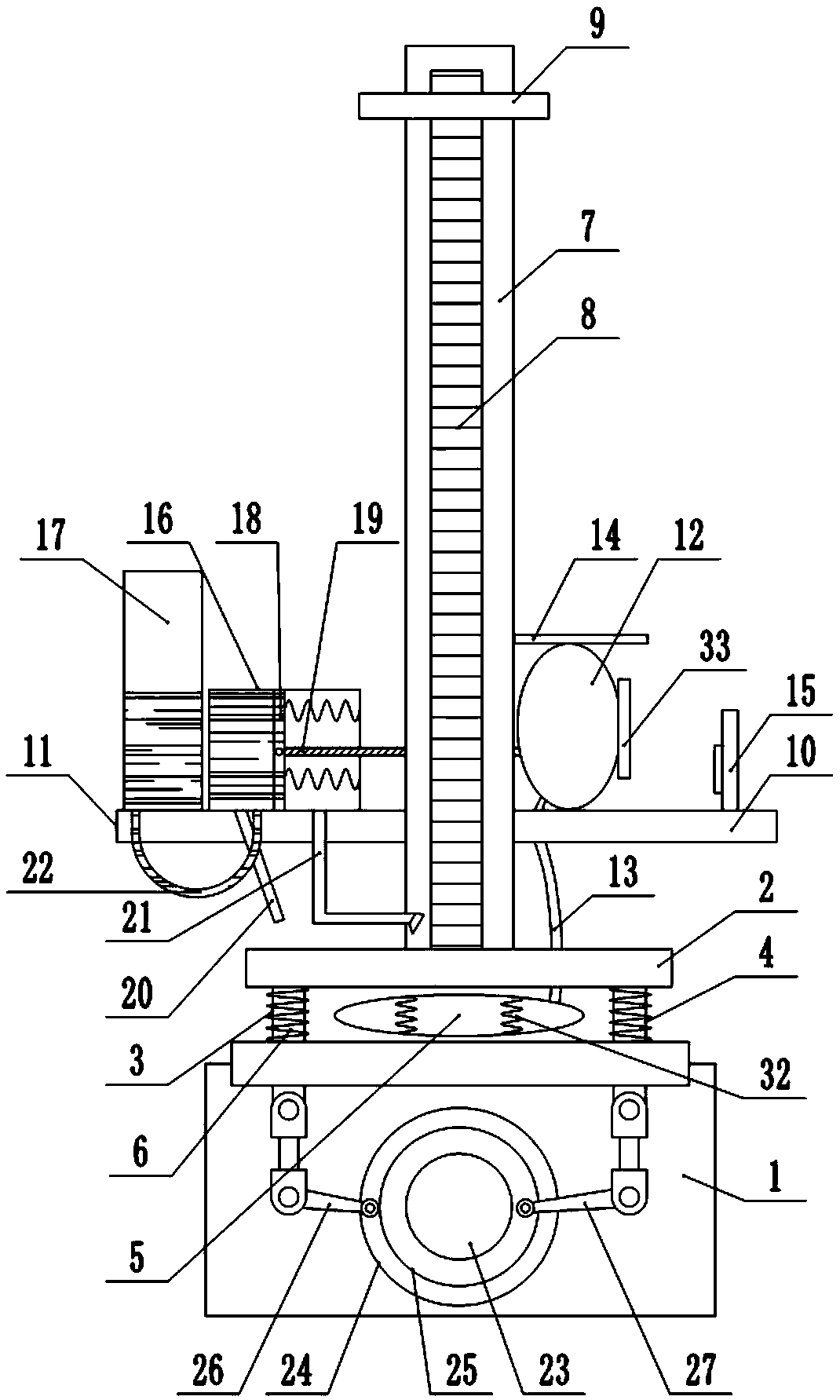

Use method of quenching device

ActiveCN108004379AReduce labor intensityImplement auto-replenishmentFurnace typesHeat treatment furnacesHeating furnaceVacuum pump

The invention belongs to the technical field of heat treatment and particularly discloses a use method of the quenching device. The use method comprises the following steps that (1) the quenching device is inspected; (2) a metal workpiece is placed in a preheating furnace for preheating; (3) the preheated metal workpiece is placed on a roll-over stand, and an electric heating wire and a vacuum pump are started to suck out gas in a vacuum heating furnace; (4) the heated metal workpiece is manually transferred to an oil quenching bath after the metal workpiece is heated to the fixed temperature,and the preheated metal workpiece is supplemented to the roll-over stand; (5) after a new metal workpiece is supplemented into the vacuum heating furnace automatically, the vacuum pump is started tosuck gas out; and (6) after a period of time, a pressure valve is opened again, the metal workpiece on the roll-over stand is transferred to the oil quenching bath and the metal workpiece in the preheating furnace is transferred onto the roll-over stand, and circulating operation is carried out in this way. By using the used method, the metal workpiece can be supplemented automatically, and the metal workpiece is automatically sent into the oil quenching bath after the metal workpiece is heated, so that the machining efficiency is improved.

Owner:宁波隆锐机械制造有限公司

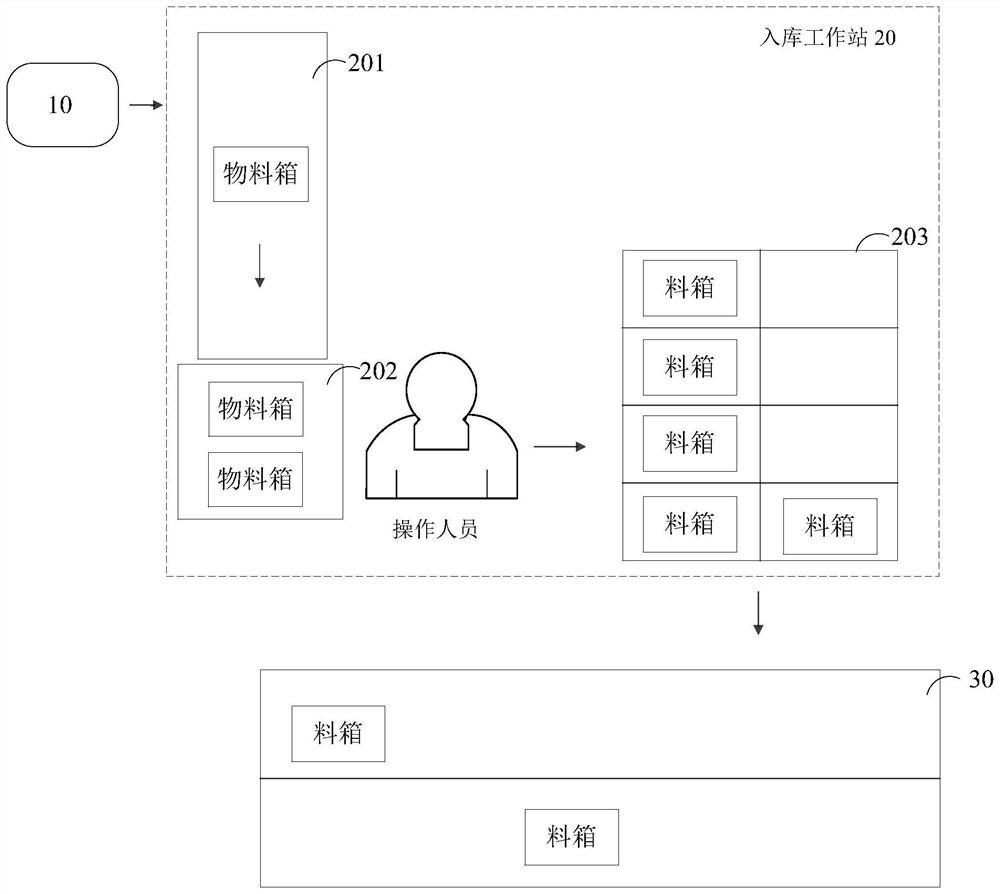

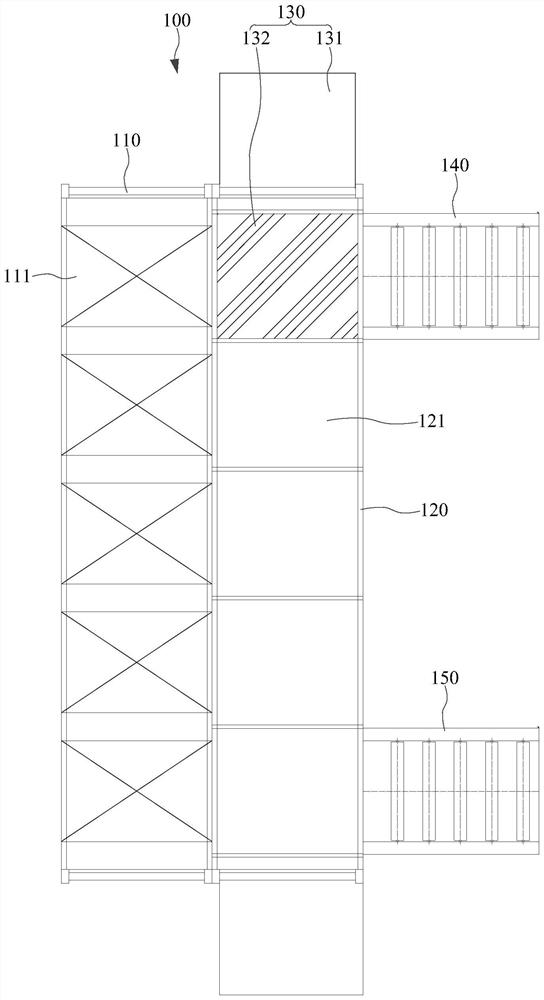

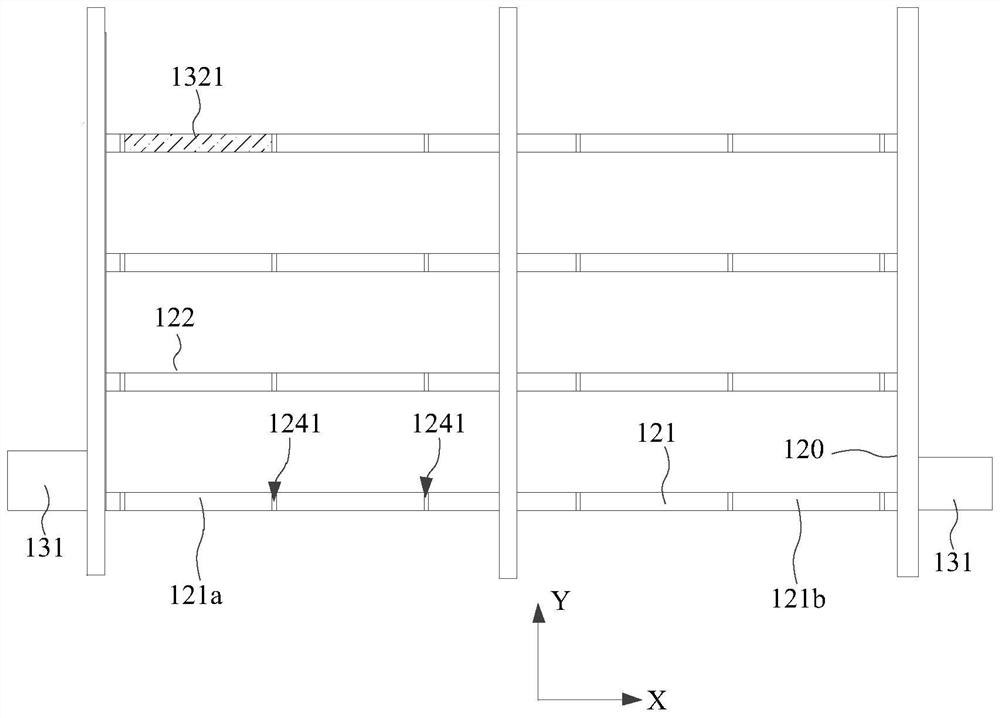

Material box scheduling method and device, scheduling equipment, warehousing system and storage medium

ActiveCN113978993AImprove replenishment efficiencyImplement auto-replenishmentControl devices for conveyorsResourcesParallel computingEngineering

The embodiment of the invention provides a material box scheduling method and device, scheduling equipment, a warehousing system and a storage medium, and the material box scheduling method comprises the steps: obtaining the number of cache positions above a cache goods shelf of a warehousing work station when a to-be-warehoused material box exists on the cache goods shelf of the warehousing work station; according to the number of the empty cache positions and the storage positions corresponding to the to-be-stored material boxes, carrying instructions of one or more target robots are generated so as to control the one or more target robots to carry the to-be-stored material boxes to the corresponding storage positions from the cache positions where the to-be-stored material boxes are located, and carry at least one empty material box to the empty cache position or the cache position corresponding to the to-be-stored material box, wherein the storage position is an empty storage position located on a storage goods shelf of the warehouse, parallel scheduling of the to-be-stored material box and the empty material box is achieved, and the supplementing efficiency of the empty material box and the warehousing order processing efficiency are improved.

Owner:SHENZHEN KUBO SOFTWARE CO LTD +1

Road dotted line marking device capable of automatically cleaning to-be-marked road surface

InactiveCN111996968AAvoid affecting the aesthetic effect of the lineIncrease the cleaning areaRoad cleaningRoads maintainenceGear wheelElectric machinery

The invention relates to the technical field of municipal administration and discloses a road dotted line marking device capable of automatically cleaning a to-be-marked road surface. A carriage is included, and moving wheels and a spraying type mark scriber are arranged at the bottom of the carriage. A first motor and a cylinder body are arranged in the carriage, an output end of the first motoris fixedly connected with a first gear, the upper end of the first gear is fixedly connected with a rotating rod, the end, away from the first gear, of the rotating rod is movably connected with a piston rod, and the end, away from the rotating rod, of the piston rod is hinged to a piston. According to the road dotted line marking device capable of automatically cleaning the to-be-marked road surface, a sweeper is driven by a rocker arm and a second motor to swing back and forth on the road surface while rotating; and the piston is matched to reciprocate left and right in the cylinder body sothat a coating is repeatedly sucked into or output from the cylinder body, the spraying type mark scriber intermittently sprays the coating by controlling the amount of the coating, namely intermittent drawing and scribing are achieved, and therefore the effects of automatically sweeping a to-be-marked road surface and automatically drawing dotted lines are achieved.

Owner:嘉兴市茂景园林有限公司

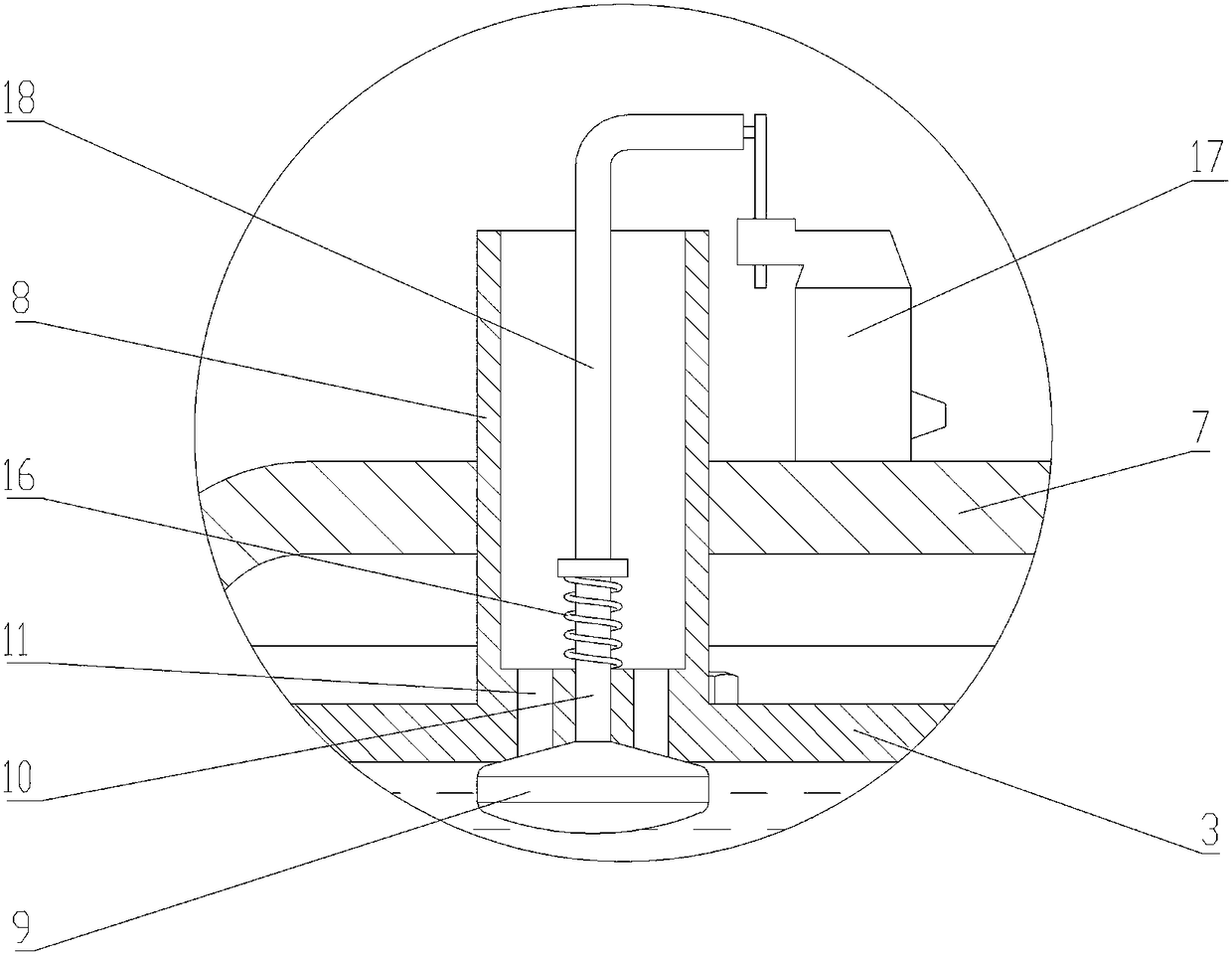

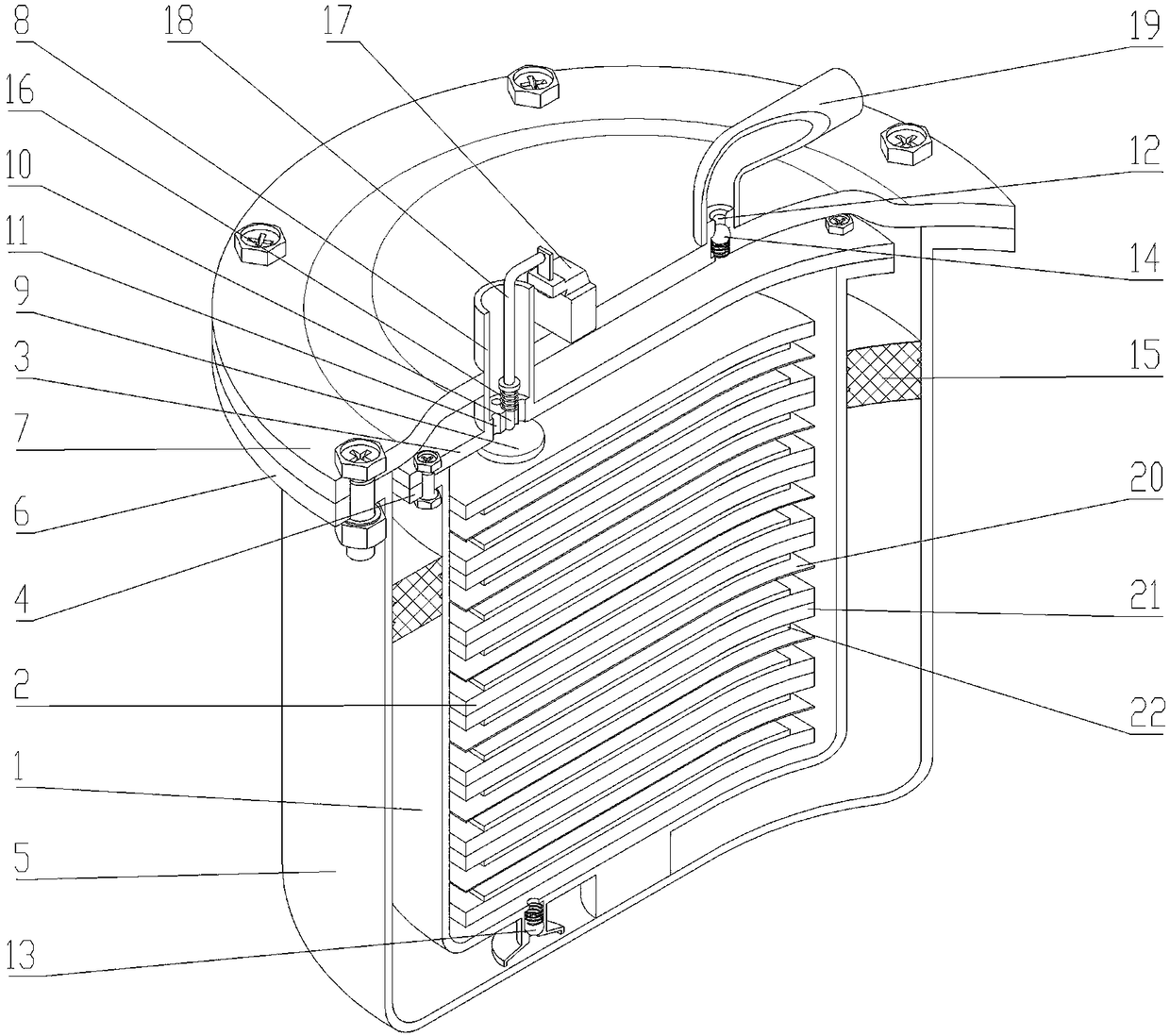

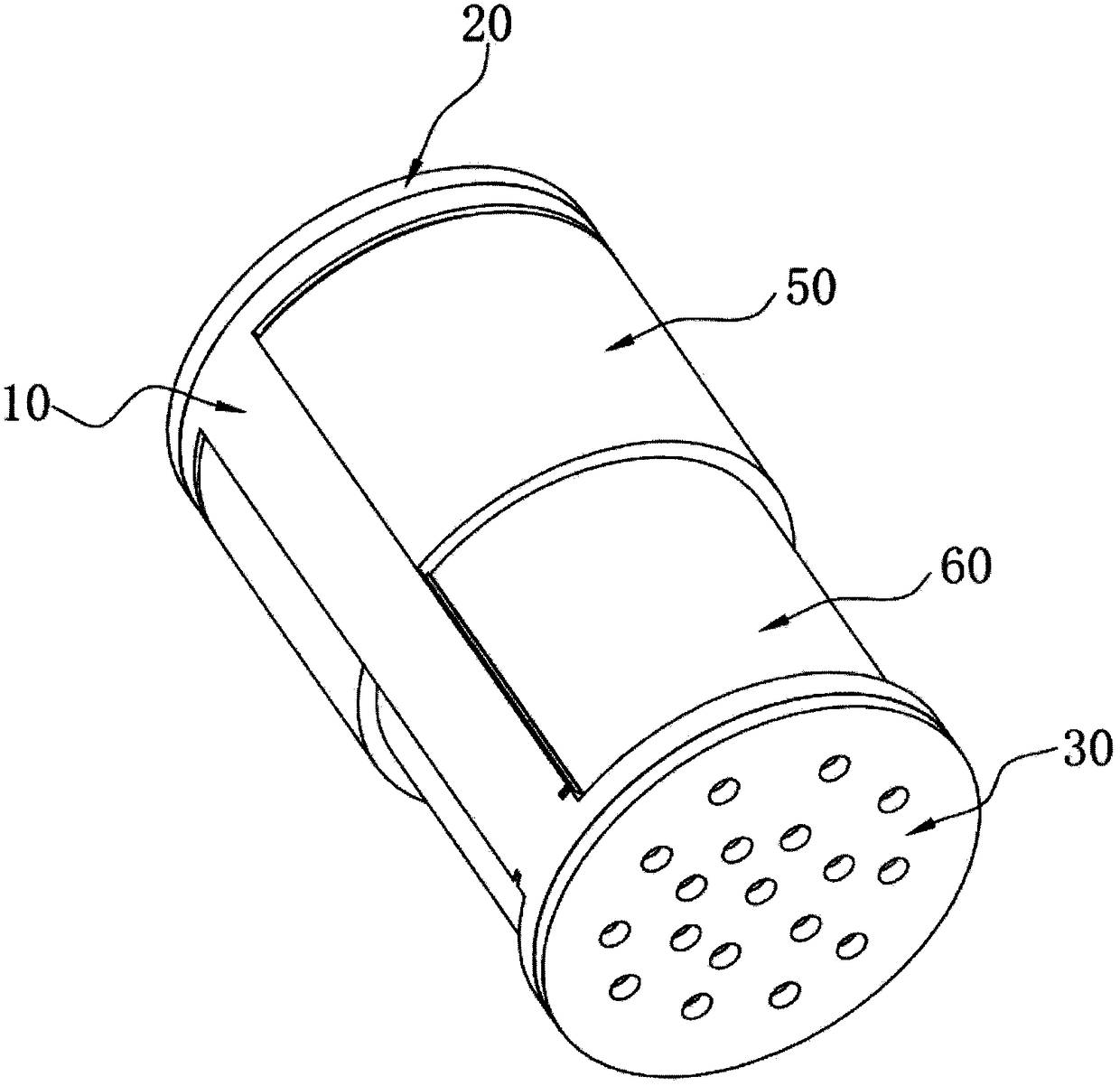

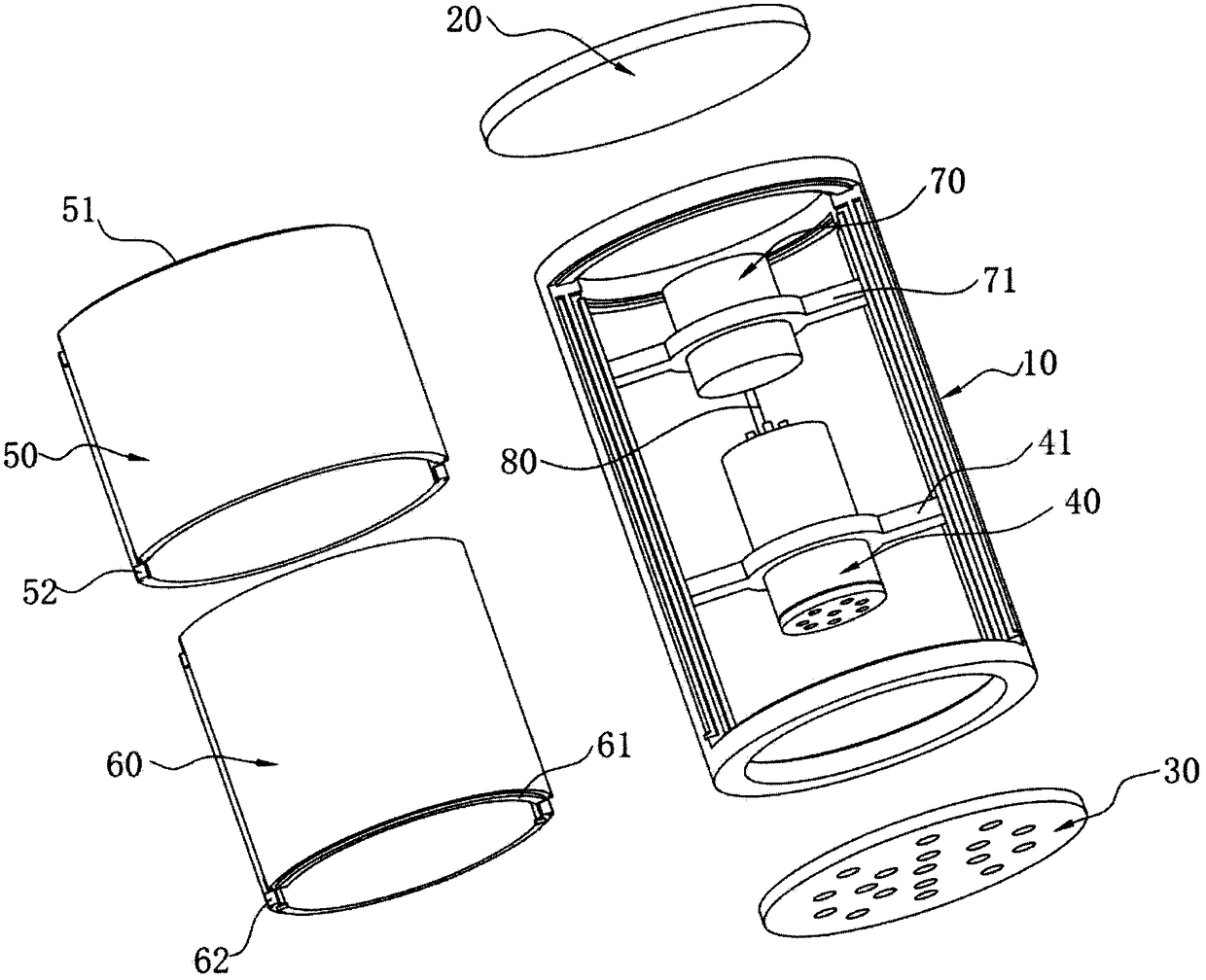

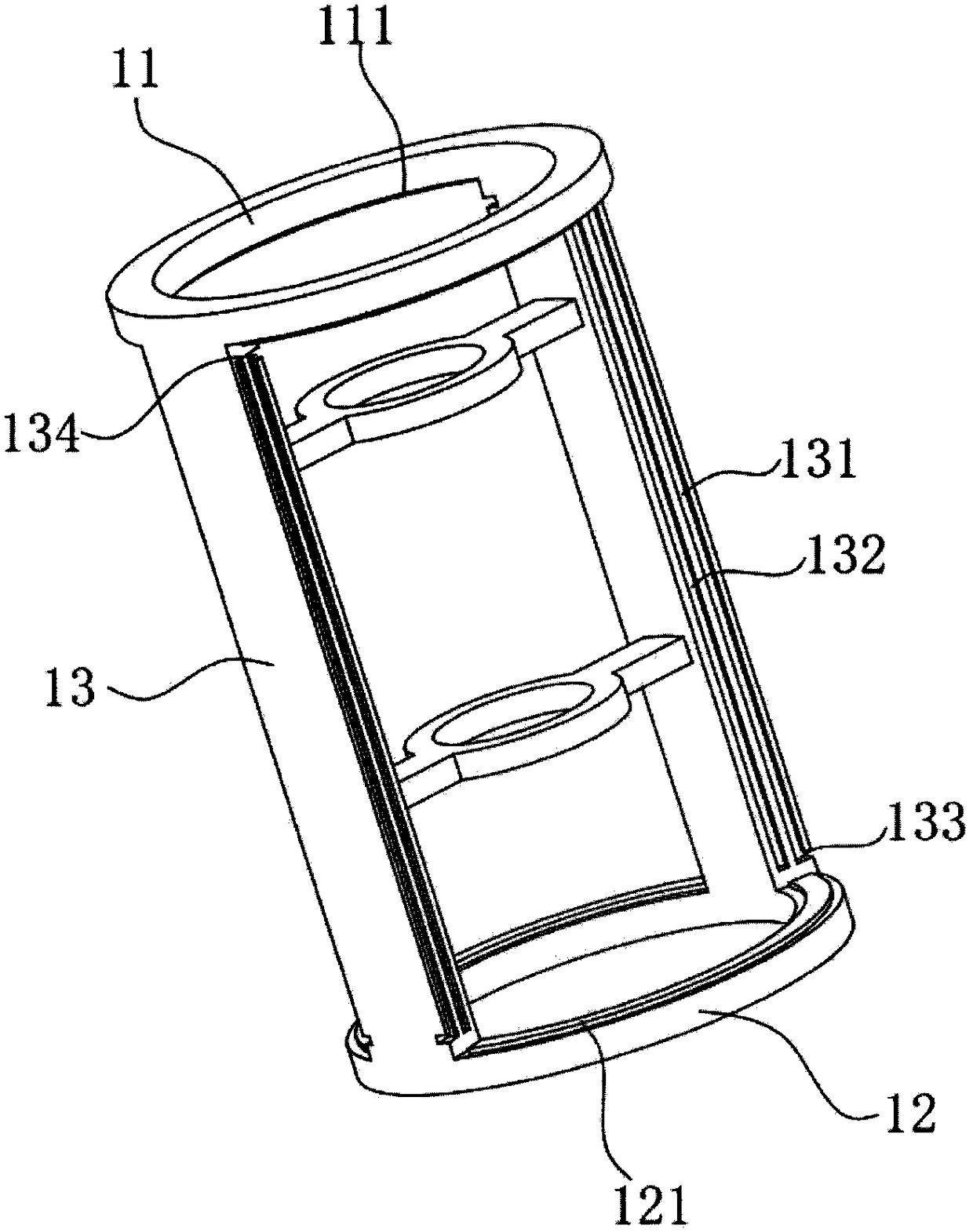

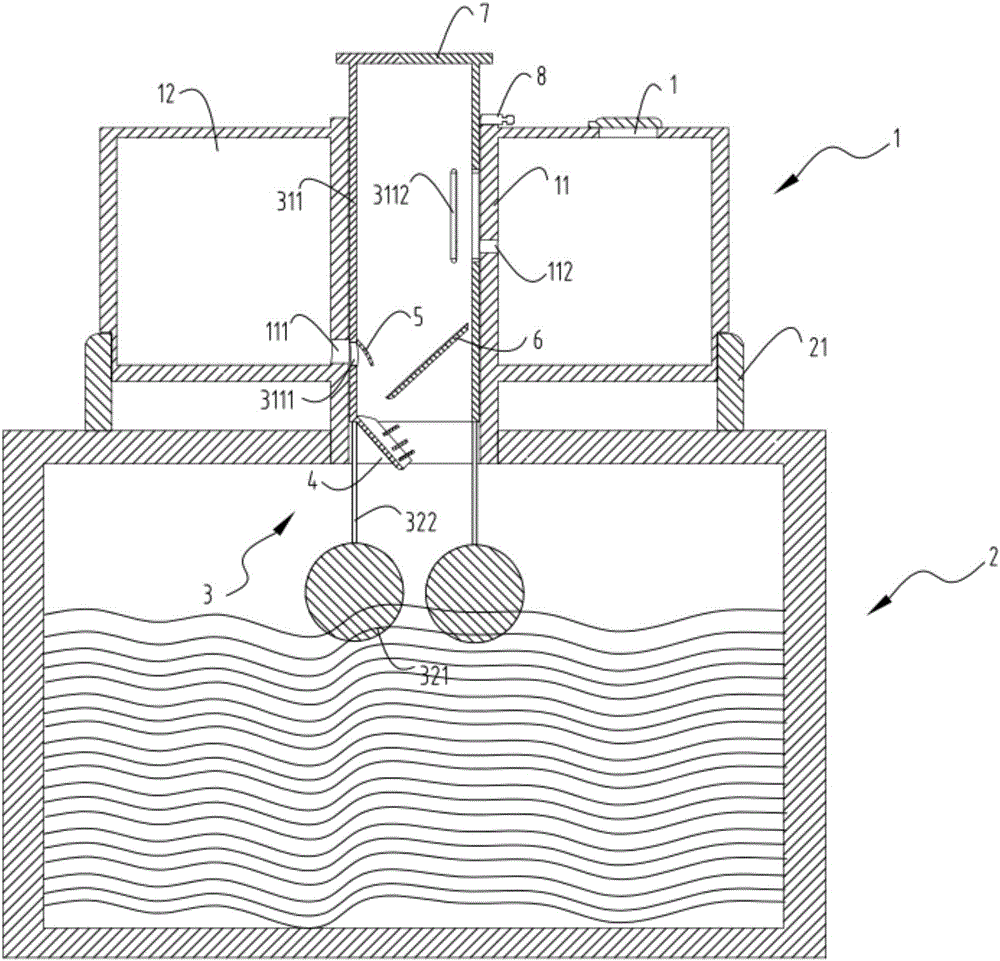

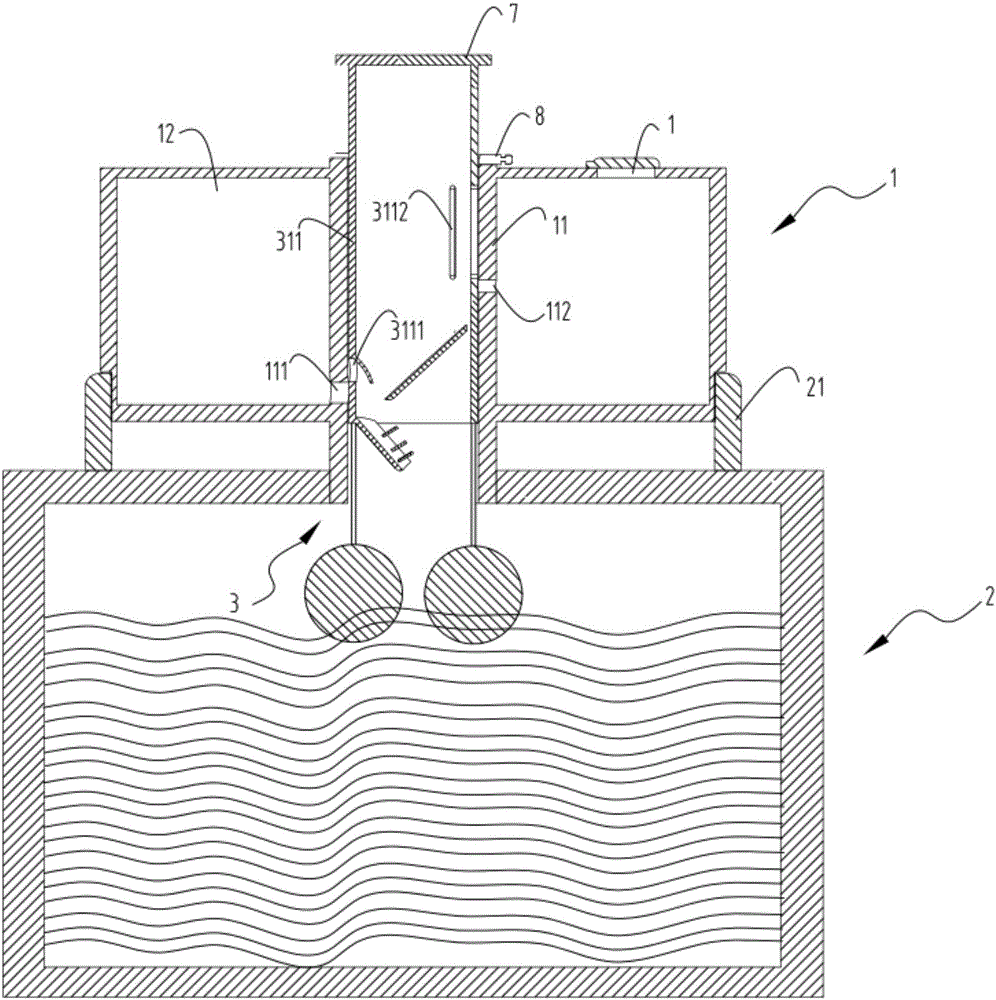

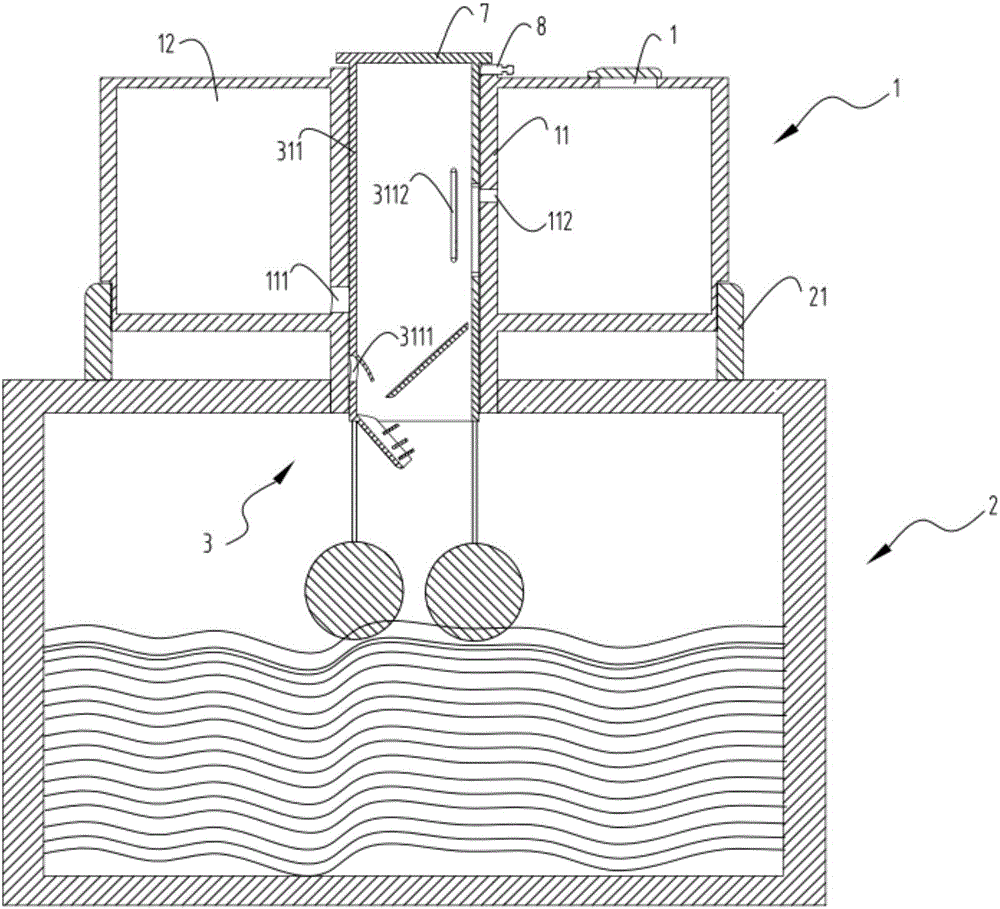

Super capacitor

ActiveCN108538636AIngenious structureEasy to implementHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorEngineeringFlange

The invention relates to a super capacitor. The technical scheme of the super capacitor is characterized in that the super capacitor comprises a housing, a core body at the inner side of the housing and an end cover; the end cover is screwed with a first flange at the opening end of the housing; the super capacitor also includes a shell accommodating the housing, the core body and the end cover; the housing and the shell are arranged coaxially; an outer cover is screwed with a second flange of the opening end of the housing; the end cover is provided with a protruding tube which is arranged above the end cover; the upper end of the protruding tube penetrates the outer cover; the end cover is provided with a floater composed of a floating ball and a vertically arranged slide rod; the floating ball is arranged at the inner side of the housing; the slide rod is vertically slidably connected to the end cover and is arranged coaxially with the protruding tube; vertical through holes communicated with inner holes of the protruding tube are formed in the end cover; air inlet holes vertically penetrating the outer cover are formed in the outer cover; and a first one-way valve is arranged at the lower portion of the housing.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Automatic bag discharging device of vending machine

InactiveCN111915795AImprove buffering effectImplement auto-replenishmentCoin-freed apparatus detailsApparatus for dispensing discrete articlesSlide plateMachine

The invention belongs to the technical field of vending machines, particularly relates to an automatic bag discharging device of a vending machine, and provides the following scheme aiming at the problems that goods cannot be received by a bag discharging device in the patent, the goods damaged when falling down in the bag discharging process, and meanwhile, the goods cannot be supplemented in time after being sold. The automatic bag discharging device comprises a vending machine body, servo motors are fixed to the inner walls of the two sides of the vending machine body through screws, the output shafts of the servo motors are connected with lead screws through couplers, the outer walls of the lead screws are sleeved with sliding plates, and lifting plates are arranged on the outer wallsof the sliding plates. According to the present invention, a buffer spring and a foam pad can achieve a good buffer effect, goods can be prevented from being broken, the sales quality of the goods isimproved; a piston rod of an electric telescopic rod is controlled to extend, and a push plate can push the goods into a goods discharging barrel from a goods discharging barrel, so that the automaticgoods supplementation is achieved, operation is convenient, maintenance is convenient, and the use requirements of people are met.

Owner:南京迈科拓信息科技有限公司

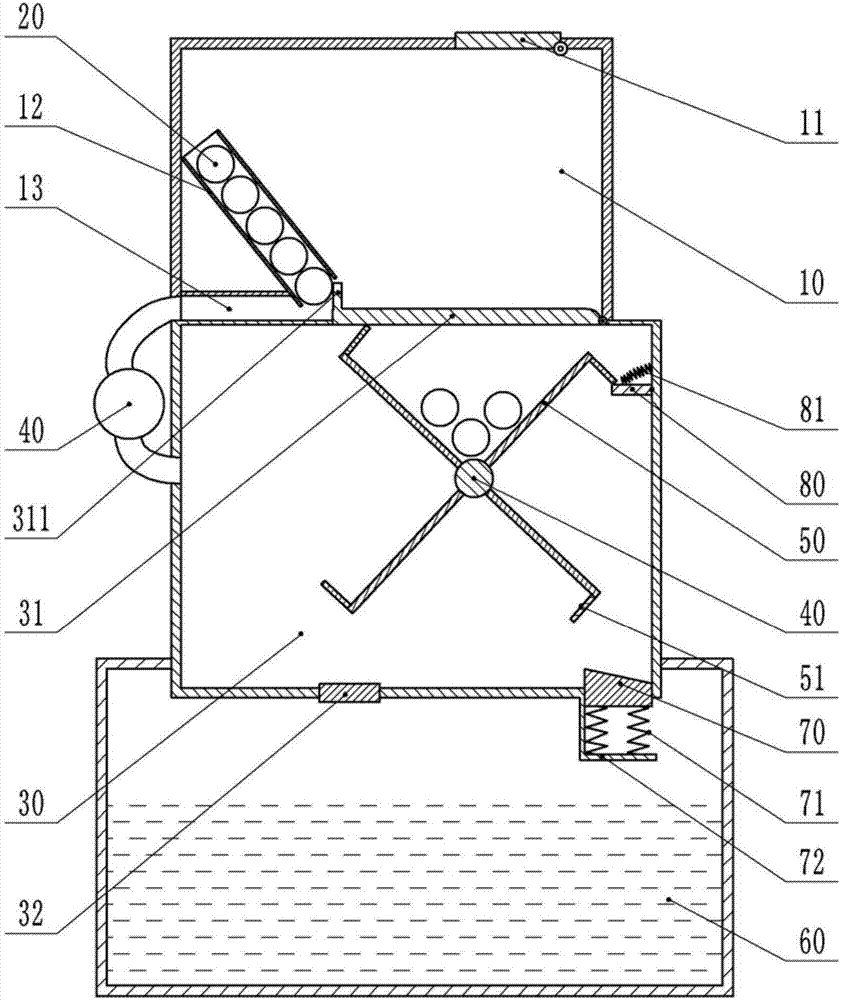

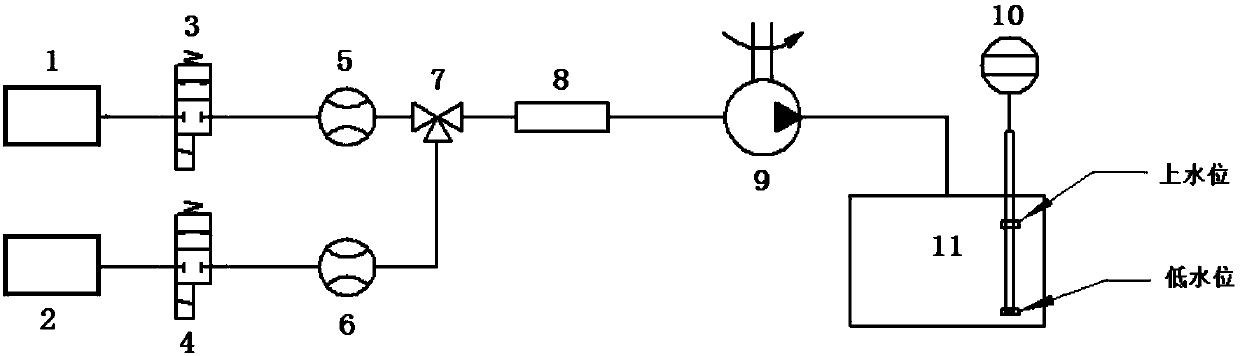

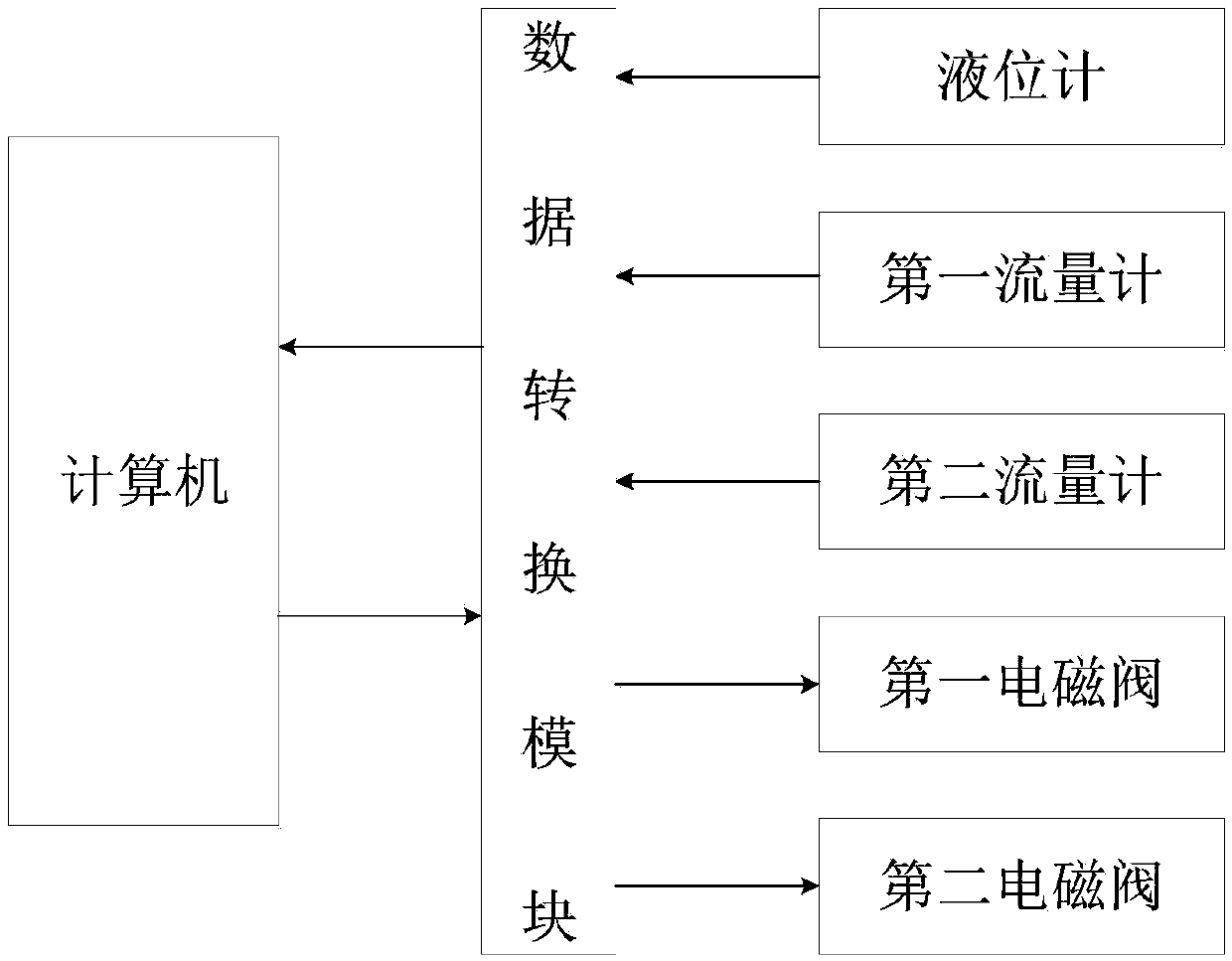

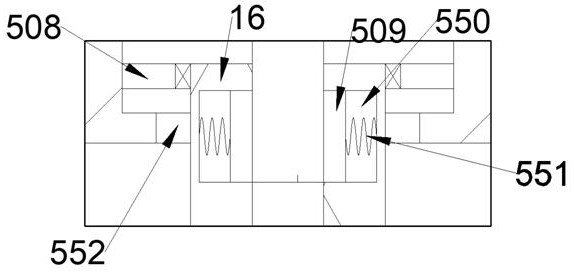

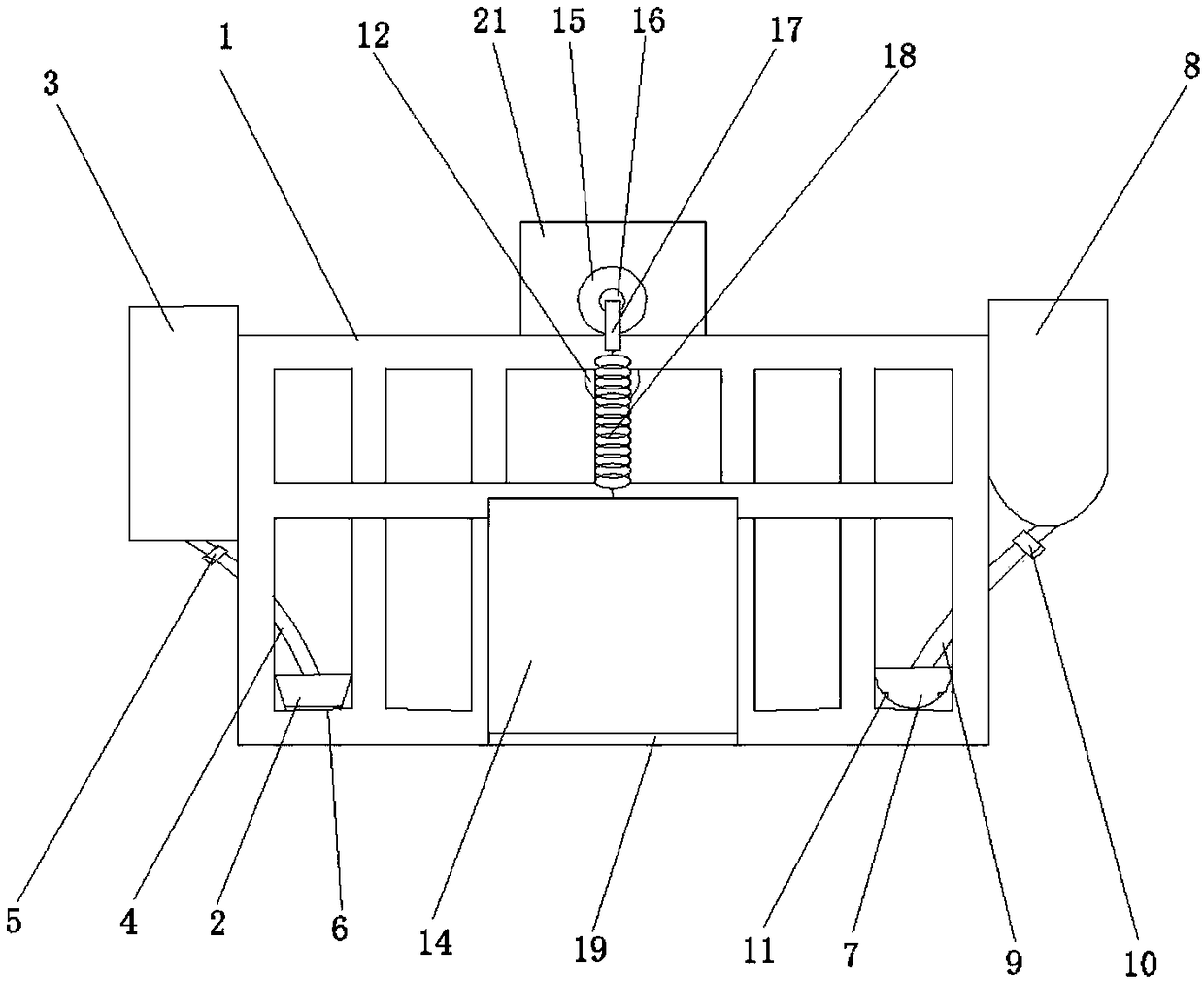

Apparatus for automatically replenishing and maintaining specific concentration of coolant

PendingCN107562080AImplement auto-replenishmentResponse to Operational ControlControlling ratio of multiple fluid flowsMaintainance and safety accessoriesNumerical controlSolenoid valve

The invention provides an apparatus for automatically replenishing and maintaining a specific concentration of a coolant. The apparatus comprises a water inlet, a raw liquid coolant filling port, a first solenoid valve, a second solenoid valve, a first flow meter, a second flow meter, a jet device, a pipeline mixer and a water pump. The apparatus can realize the automatic replenishment of the coolant in a cooling box of a machine tool, the function of controlling the flow of the water inlet and the raw liquid coolant filling port by respectively controlling the opening and closing of the firstsolenoid valve and the second solenoid valve, and the automatic replenishment of the coolant according to the liquid level in the cooling box of the machine tool. The apparatus of the invention is also equipped with an electronic control system which can respond to the operation control of a user. The apparatus of the invention can be widely applied in the CNC machine tool processing industry.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Electroplating equipment capable of automatically supplementing anode material

The invention relates to the technical field of electroplating equipment, in particular to electroplating equipment capable of automatically supplementing an anode material. The electroplating equipment comprises a box body, an electrolytic bath is arranged in the box body, a uniform mixing mechanism for uniformly mixing electrolyte in the electrolytic bath is arranged on the bottom wall of the electrolytic bath, electroplating protection can be carried out on objects with different shapes, and moreover, an electroplated object can be pushed out by utilizing the pushing of a pushing mechanism; the concentration of the electrolyte can be detected, and the concentration of the electrolyte can be improved; the homogeneity degree of the electrolyte can be detected, the homogeneity of the electrolyte can be realized, and precipitation is prevented; the electrolyte can be recycled, and the utilization efficiency of the electrolyte is improved; and the powder of the anode material can be automatically supplemented, the difficulty of directly replacing the anode in the prior art is improved, the waste of the anode material is avoided, and the utilization rate of the anode material is improved.

Owner:深圳市瑞佳锦贸易有限公司

Carbon monoxide sensor for agricultural machinery,

PendingCN109030586ASimple structureEasy to useMaterial electrochemical variablesChemistrySupporting wall

The invention discloses a carbon monoxide sensor for agricultural machinery. The carbon monoxide sensor comprises: a supporting frame comprising a top ring, a bottom ring and a pair of supporting walls; the carbon monoxide sensor located in the supporting frame; an electrolyte replenishing chamber located in the supporting frame and located directly above the carbon monoxide sensor; a connecting pipe for communicating the electrolyte replenishing chamber with the carbon monoxide sensor; a pair of sliding plate units symmetrically arranged on the supporting wall and located on both sides of thesupporting wall; a closed end fastened to the top ring; and a filter screen detachably arranged on the bottom ring, wherein the carbon monoxide sensor is formed with a first chamber, the electrolytereplenishing chamber is formed with a second chamber, and a vent hole is formed in a top end face of the electrolyte replenishing chamber. The carbon monoxide sensor for agricultural machinery can automatically replenish the electrolyte, and has the advantages of simple structure and convenient use.

Owner:YANCHENG INST OF IND TECH

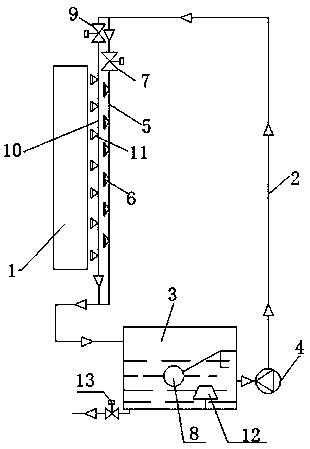

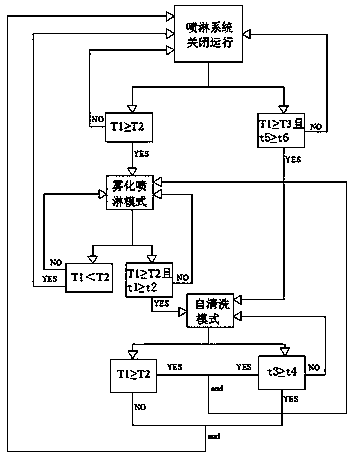

Evaporative condenser system having self-cleaning function and control method

ActiveCN110500816AAchieve cleanupSpray realizationEvaporators/condensersFlush cleaningSolenoid valveEngineering

The invention discloses an evaporative condenser system having a self-cleaning function and a control method. The system comprises a heat exchanger as well as a water storage box, a spraying water pump and an atomizing spraying branch which are connected in series through pipelines; the atomizing spraying branch directly faces the heat exchanger and can spray water mist; the atomizing spraying branch is connected with a cleaning spraying branch in parallel; the cleaning spraying branch comprises a connecting pipe I, multiple cleaning nozzles and a solenoid valve I; the cleaning nozzles and thesolenoid valve I are mounted on the connecting pipe I; and two ends of the connecting pipe I are connected with the pipelines. The method includes control on the atomizing spraying mode and the self-cleaning mode. By the aid of the system and the method, scale condensation and dust attachment can be avoided effectively, normal working of a condenser can be guaranteed, and meanwhile, the purposesof avoiding scaling and dust adhesion are achieved with the control method.

Owner:YIMIKANG TECH GRP CO LTD

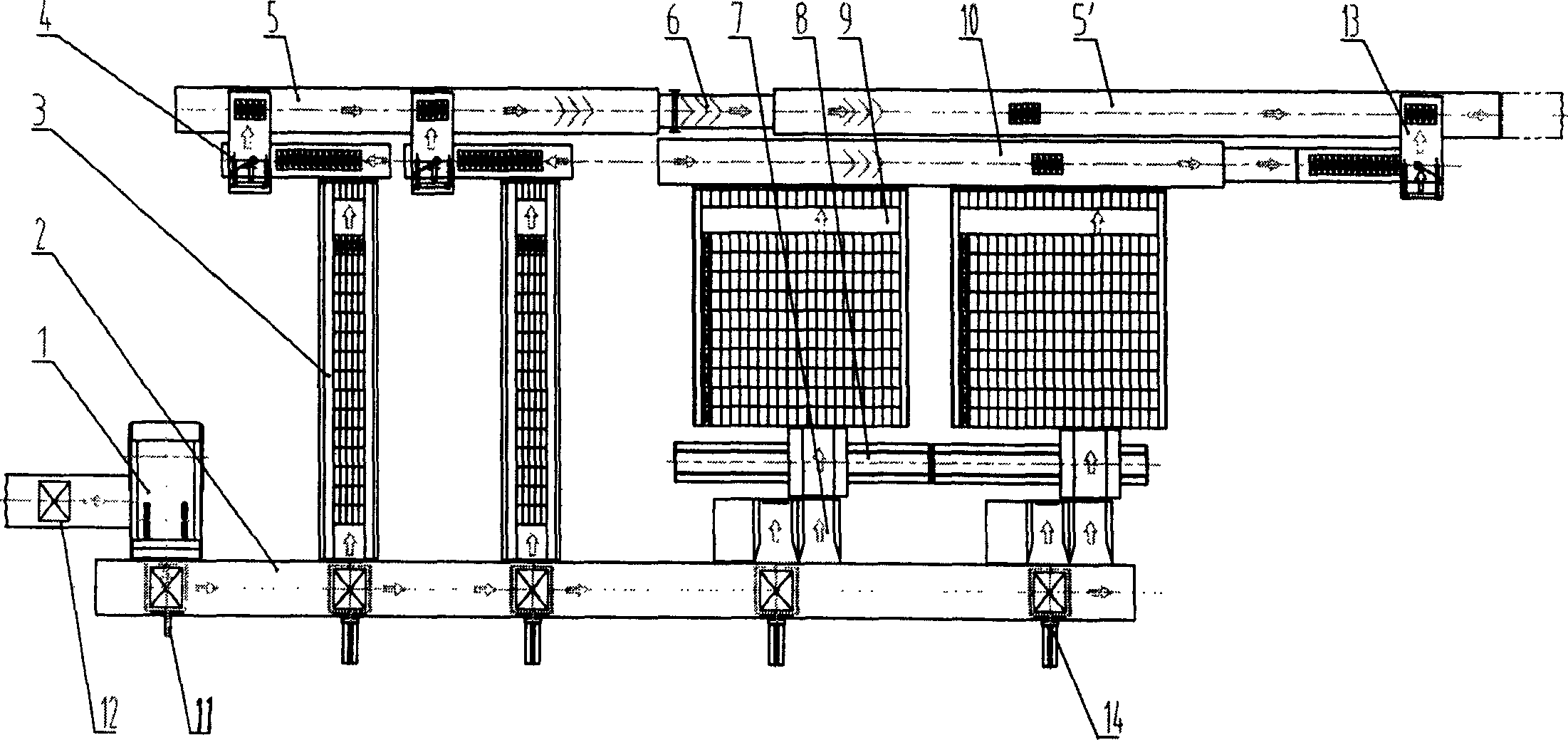

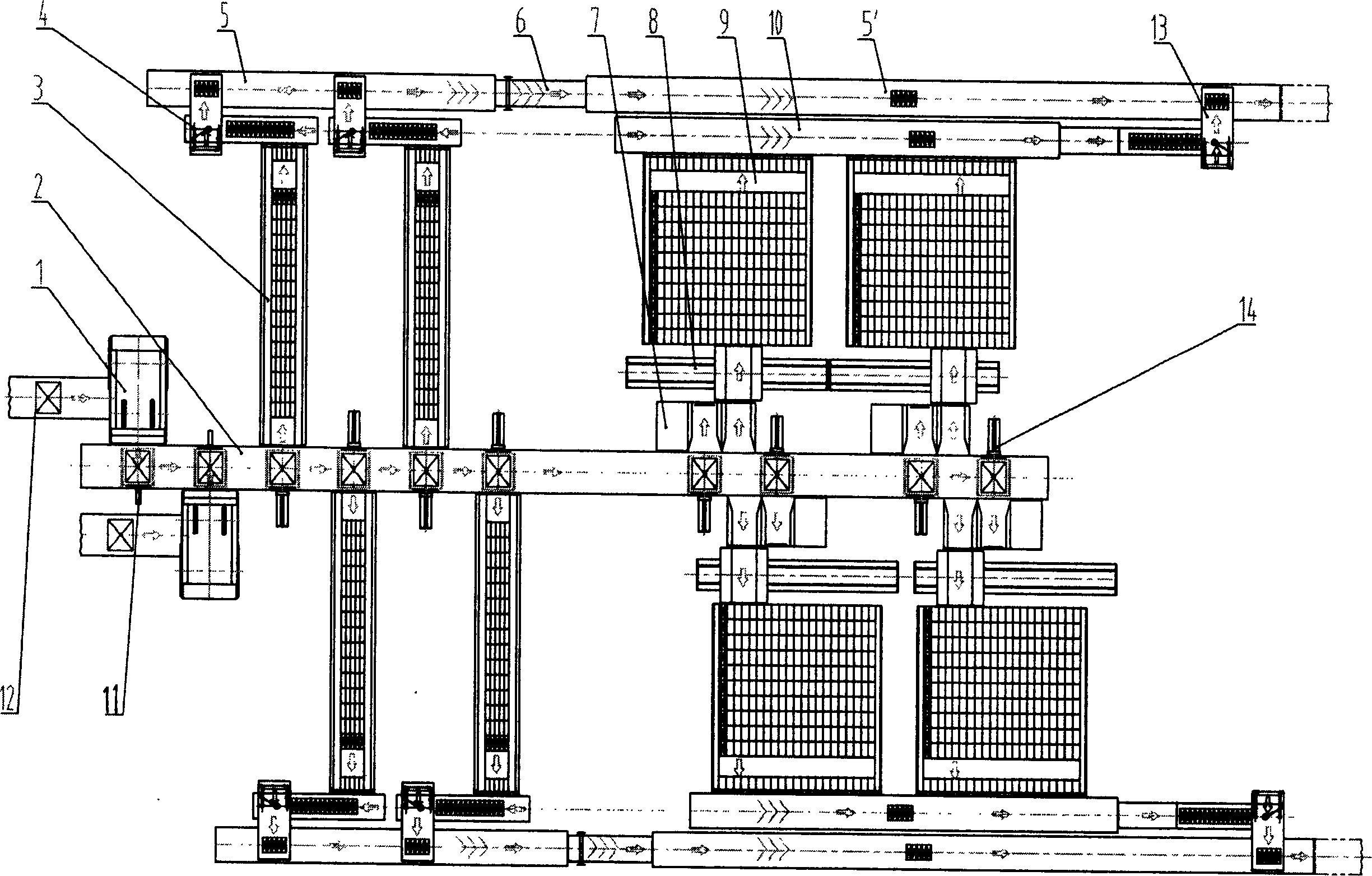

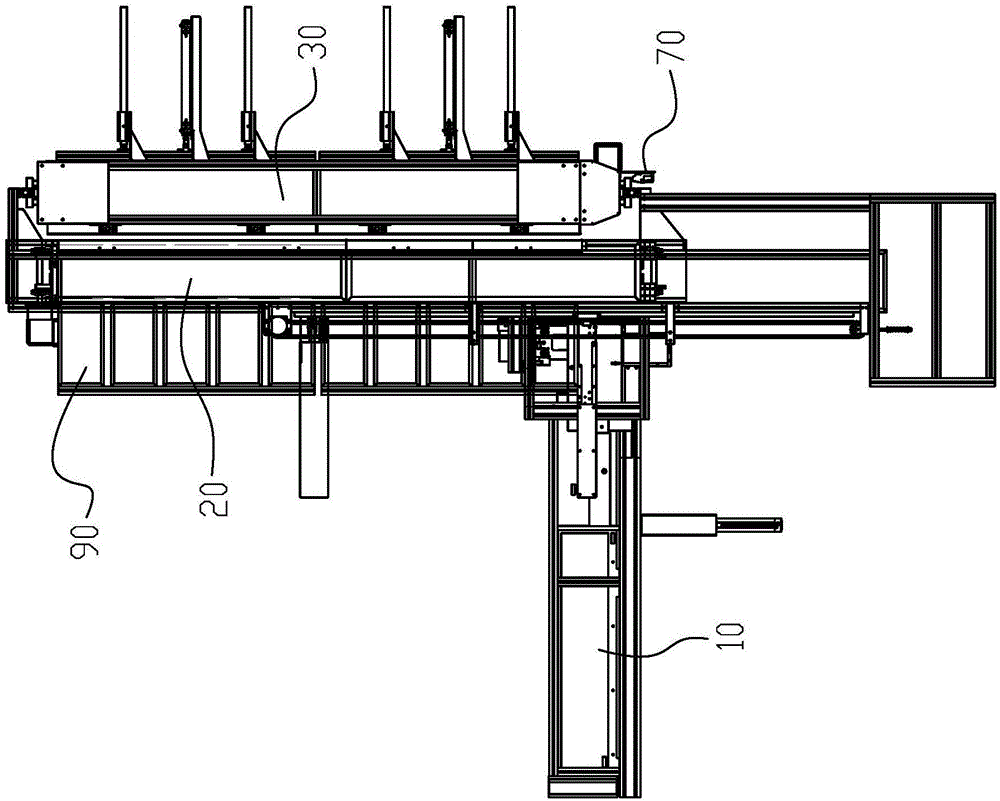

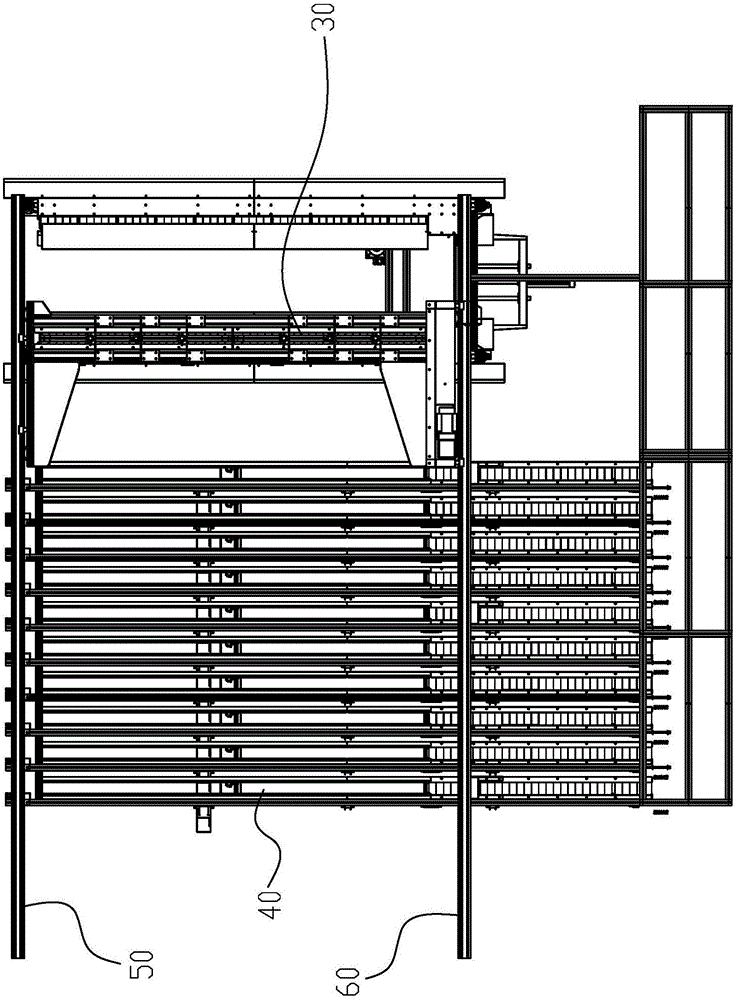

Cigarette supplementing and sorting method

The invention discloses a cigarette supplementing and sorting method. The cigarette supplementing and sorting method comprises the steps that five lines and five columns of cigarette stacks are pushed into a lifter in the longitudinal direction column by column by a channel storage machine; the lifter lifts the cigarettes vertically upwards column by column, so that the cigarettes are arranged into one column in the vertical direction; a pusher pushes the cigarettes out of the lifter horizontally in the longitudinal direction, and feeds the cigarettes into a supplementing trolley, and the cigarettes are stored in a vertical cigarette storage channel of the supplementing trolley; the supplementing trolley transversely moves to a vertical sorting cigarette bin; a longitudinally pushing mechanism of the supplementing trolley pushes the cigarettes in the vertical cigarette storage channel into the vertical sorting cigarette bin, and the cigarettes are stacked on a cigarette collection board of the vertical sorting cigarette bin; and a lifting machine drives the cigarette collection board to descend to the bottom of the vertical sorting cigarette bin, the cigarette collection boards moves out of the vertical sorting cigarette bin, and the cigarettes fall down and are stacked in the vertical sorting cigarette bin. When the supplementing trolley is used for moving a whole column of cigarettes, the vertical cigarette storage channel can limit the cigarettes from moving, the effect that the whole column of cigarettes can be conveyed into the vertical sorting cigarette bin in order is ensured, and the whole column of cigarettes are released only when the cigarette collection board descends to the bottom of the vertical sorting cigarette bin, so that scattering is avoided.

Owner:TIANHAI OUKANG TECH INFORMATION XIAMEN

Lubricating oil filtering and purifying system

PendingCN109647006AImprove filtering effectImplement auto-replenishmentMagnetic separationLiquid separation by thermal diffusionEngineeringCleansing Agents

The invention relates to the technical field of filtering equipment and aims to solve the problem of single function of a lubricating oil treatment device in the prior art, and provides a lubricatingoil filtering and purifying system. The lubricating oil filtering and purifying system comprises a filtering device and a separating device which are communicated with each other; solid impurities inlubricating oil are filtered and removed after lubricating oil to be filtered and purified passes through the filtering device; and filtered lubricating oil enters the separating device. The separating device comprises a centrifugal separation mechanism and a heating separation mechanism which are communicated with each other; water in lubricating oil is separated and removed under the action of centrifugal force after filtered lubricating oil enters the centrifugal separation mechanism; the cleaning agent in lubricating oil is separated and removed under the heating action after filtered lubricating oil enters the heating separation mechanism. By arranging the centrifugal separation mechanism and the heating separation mechanism to remove liquid impurity water and the cleaning agent in lubricating oil, the purity of treated lubricating oil can be effectively improved.

Owner:CHANGZHOU RUIYANG TRANSMISSION TECH +1

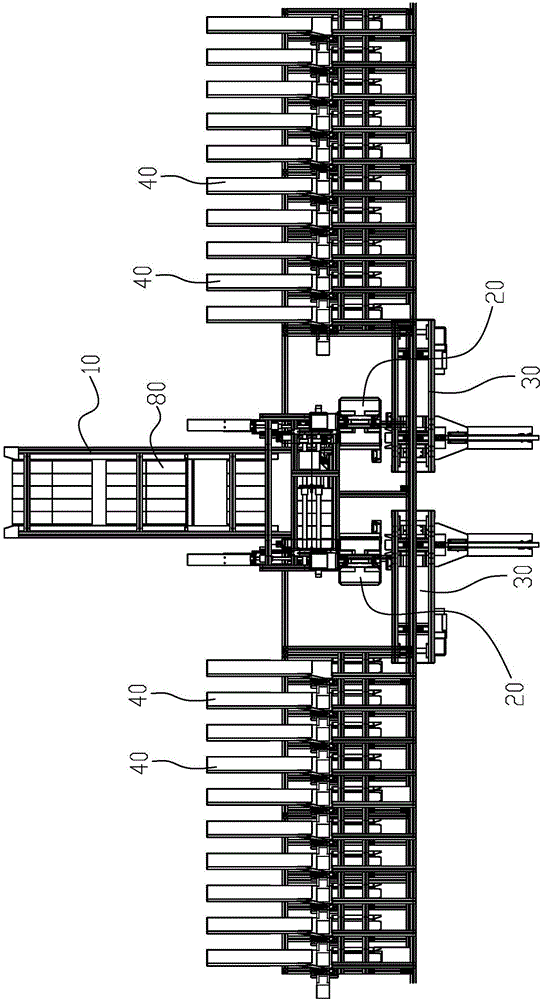

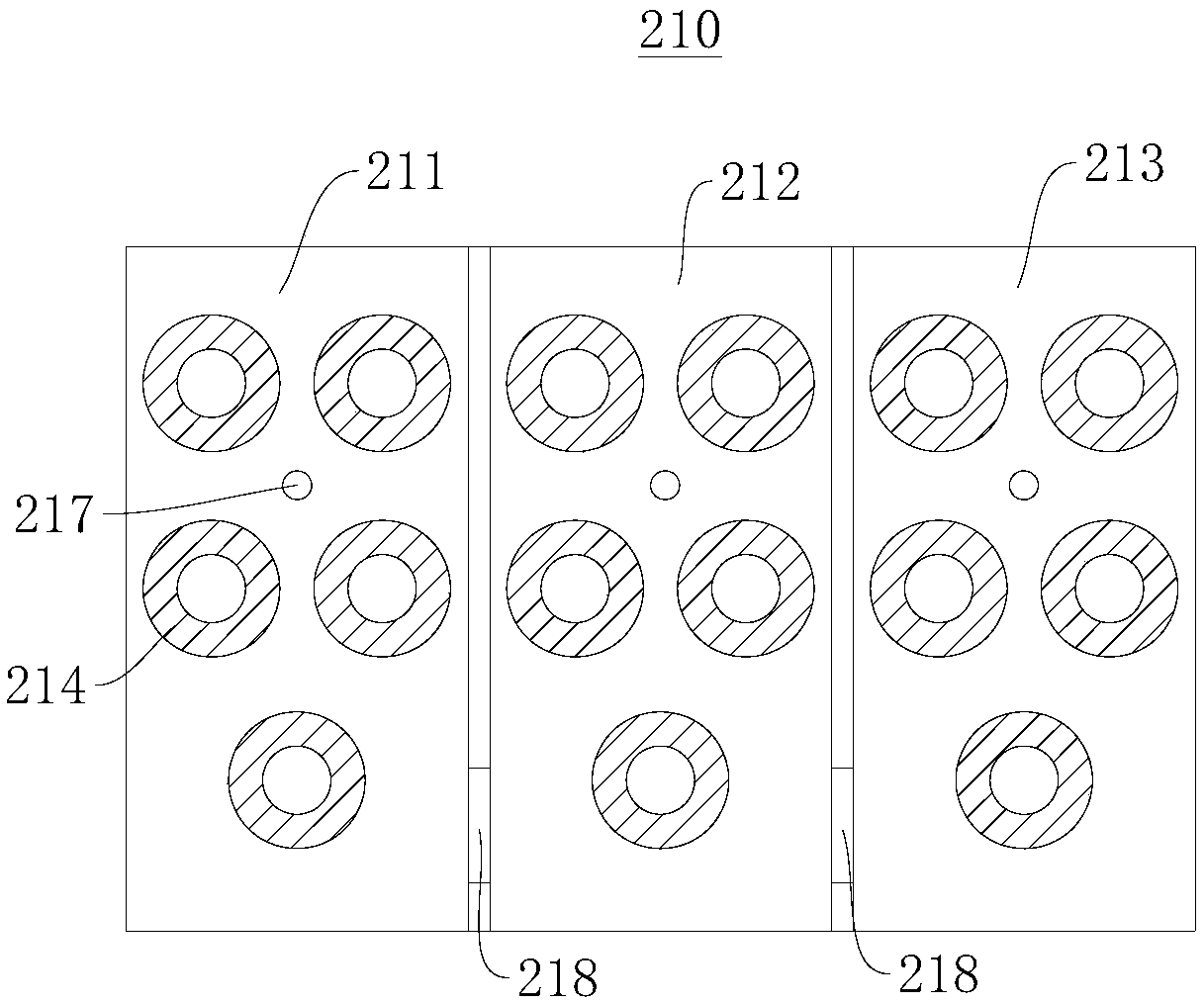

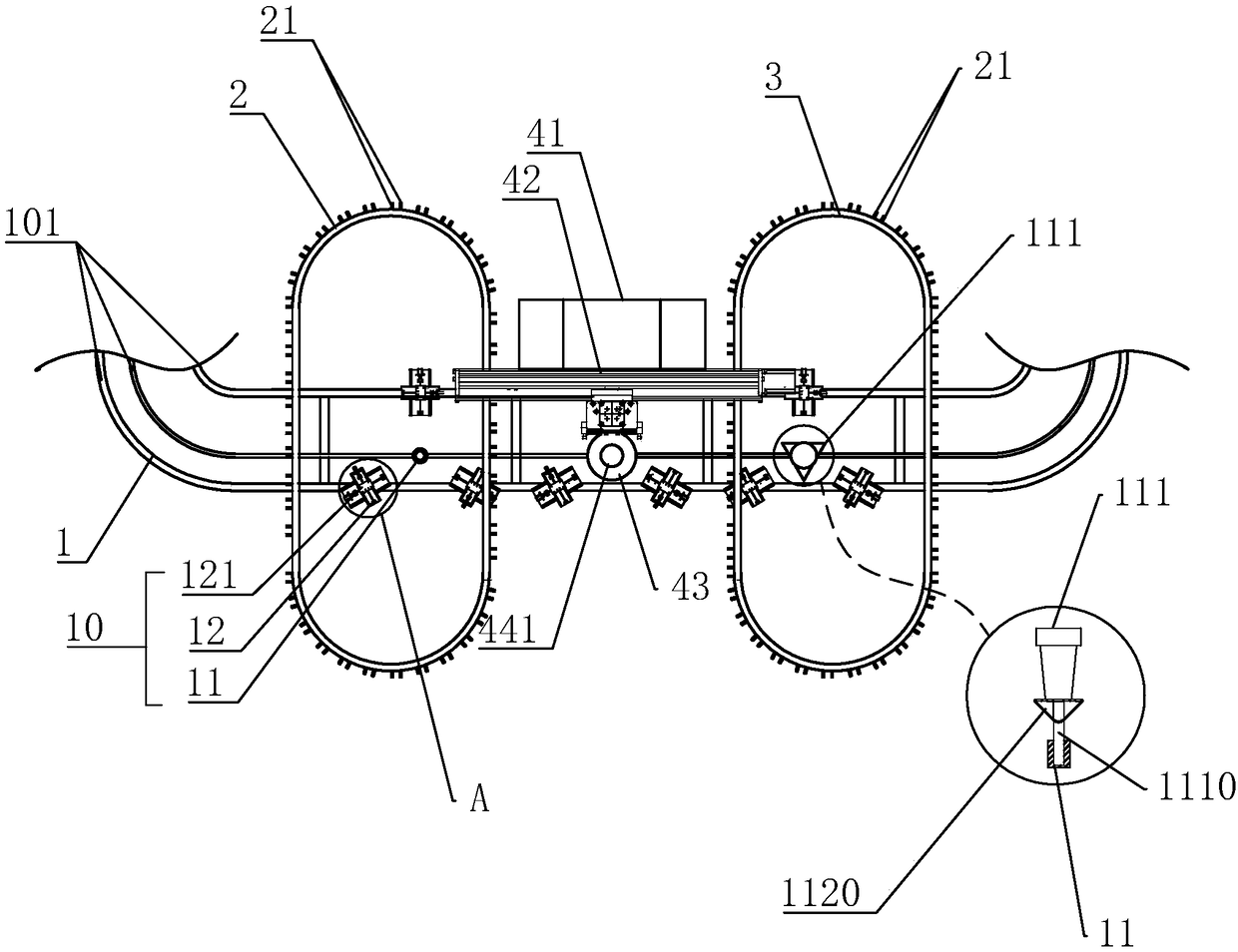

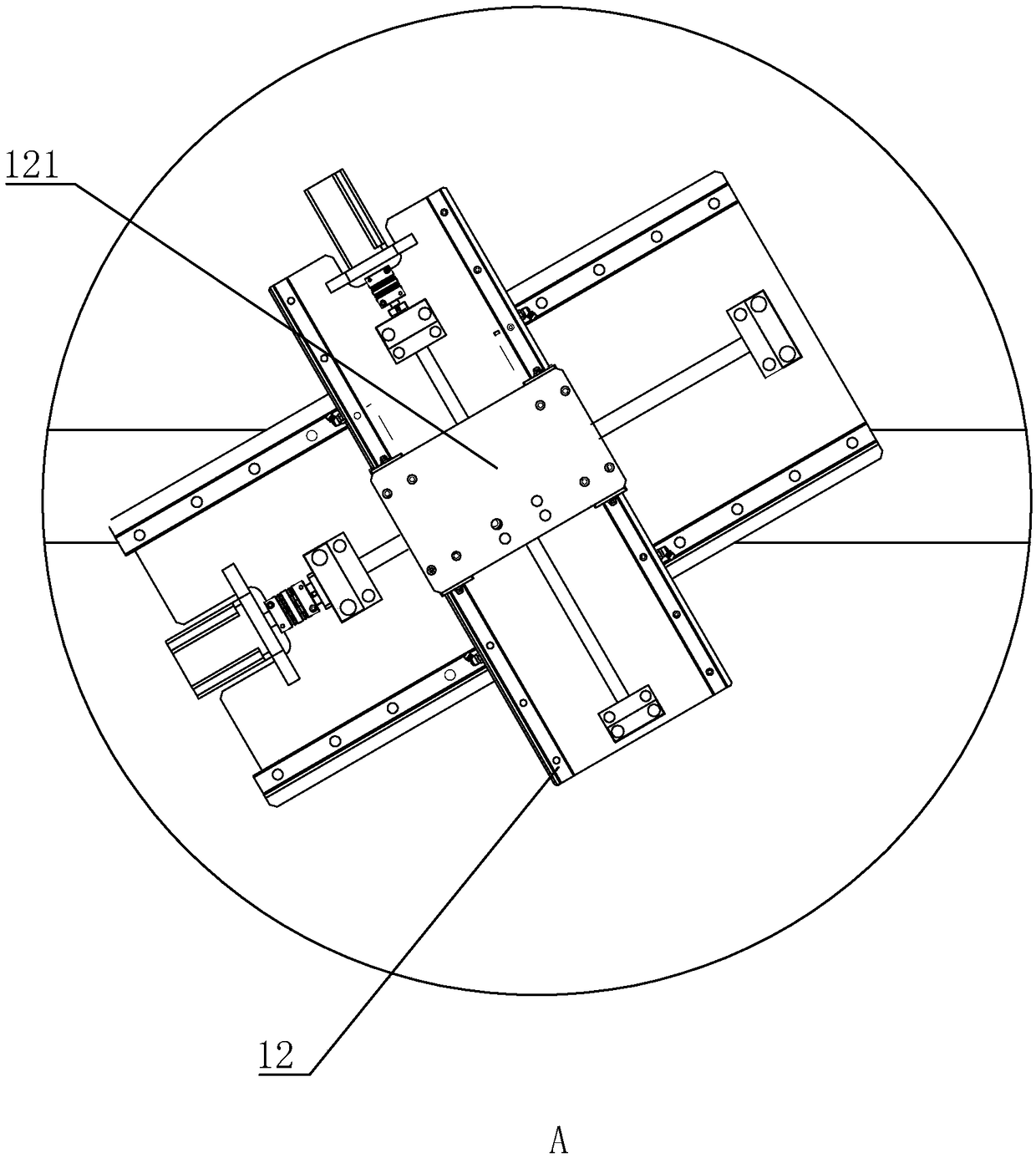

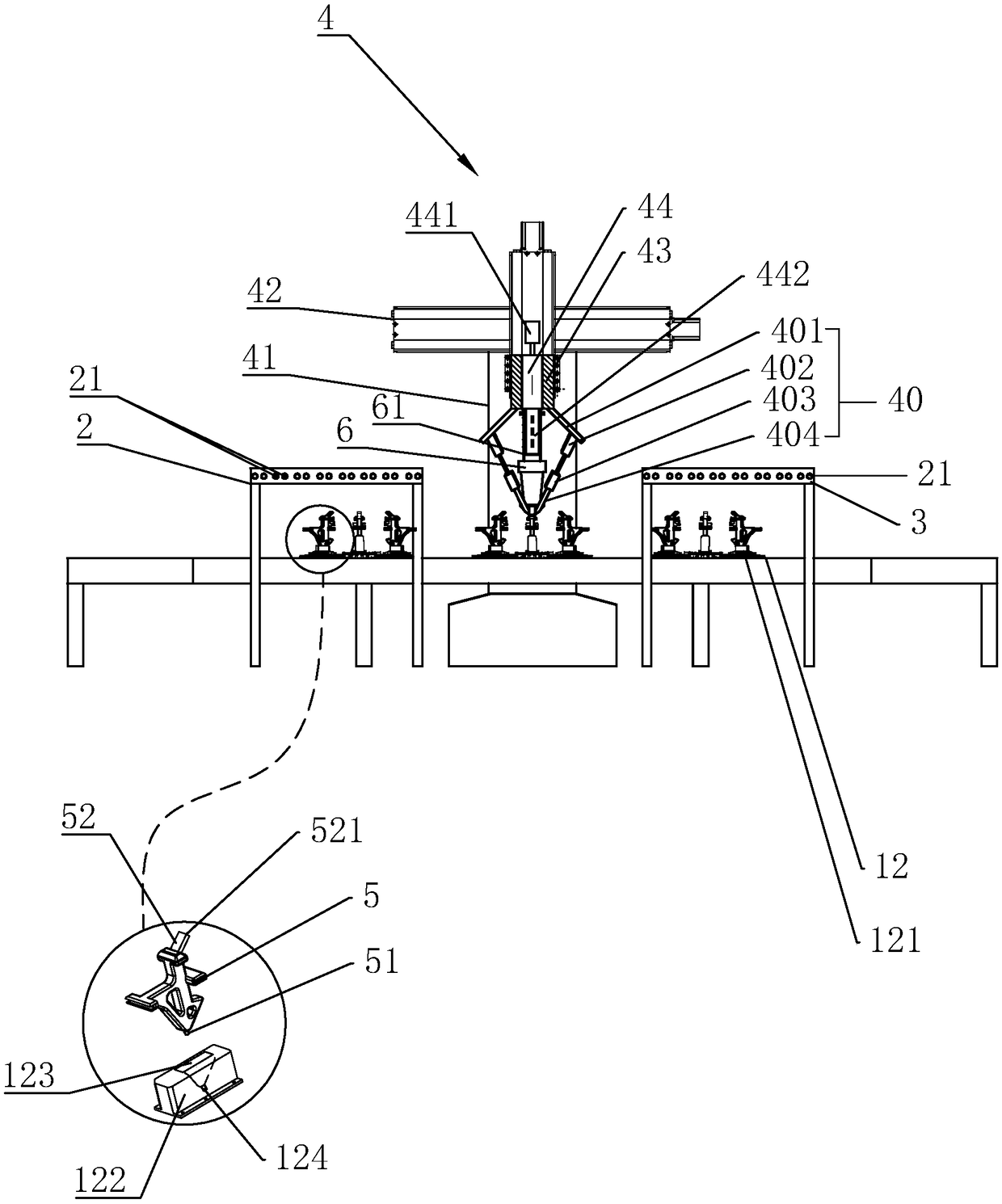

Precision metal part wax mold assembly automatic adhesion machine and precision metal part wax mold assembly automatic adhesion method

ActiveCN108746487ARapid positioningRealize automated productionFoundry moulding apparatusNumerical controlProduction line

The invention relates to a precision metal part wax mold assembly automatic adhesion machine and a precision metal part wax mold assembly automatic adhesion method. The precision metal part wax mold assembly automatic adhesion machine comprises a first assembly line, a second assembly line, a third assembly line, an adhesion mechanism and a control unit, wherein the second assembly line, the adhesion mechanism and the third assembly line are arranged above the first assembly line and are sequentially arranged along the conveying direction of the first assembly line, a plurality of hanging members are uniformly distributed on the second assembly line and the third assembly line, and a plurality of clamping mechanisms are uniformly distributed on the first assembly line. According to the present invention, the positioning of the to-be-adhered wax mold is achieved by the three-dimensional numerical control sliding table, and the heating melting and adhesion is automatically performed by automatically using the heating device and the screw stepping motor; the connecting member is grasped and fixed by the gas expansion shaft, and the transfer is performed by using the two-dimensional sliding table, such that the automated production process from the grasping of the connecting member, the adhesion of the wax mold to the transfer of the wax mold set is achieved; and through the threeassembly lines, the automatic replenishment of the to-be-adhered mold and the connecting member is achieved, the automatic transfer of the wax mold set is achieved, and the automated production line production is achieved.

Owner:UNITED LASHING PRECISION CASTING

Intelligent pet cage

InactiveCN108419692ASolving Feed ProblemsVersatileProgramme controlComputer controlFood guideWater storage tank

The invention provides an intelligent pet cage which comprises a pet cage body. A feeding trough is arranged on one side of the bottom in the pet cage body. A food storage tank is arranged on one sideoutside the pet cage body. The feeding trough and the food storage tank are located on the same side. A food guide pipe is arranged at the bottom of the food storage tank. One end of the food guide pipe is communicated with the food storage tank. The other end of the food guide pipe extends into the feeding trough. A first electromagnetic valve is arranged on the food guide pipe. A weighing sensor is arranged at the bottom of the feeding trough. A water drinking trough is arranged on the other side of the bottom in the pet cage body. A water storage tank is arranged on the outer side outsidethe pet cage body. The water drinking trough and the water storage tank are located on the same side. A water guide pipe is arranged at the bottom of the water storage tank. One end of the water guidepipe is communicated with the water storage tank. The problem of feeding a pet when no people at home is effectively solved; the dynamic conditions of the pet can be observed through a camera, and people can interact with the pet through a loudspeaker.

Owner:湖州南浔美瑞鑫家具有限公司

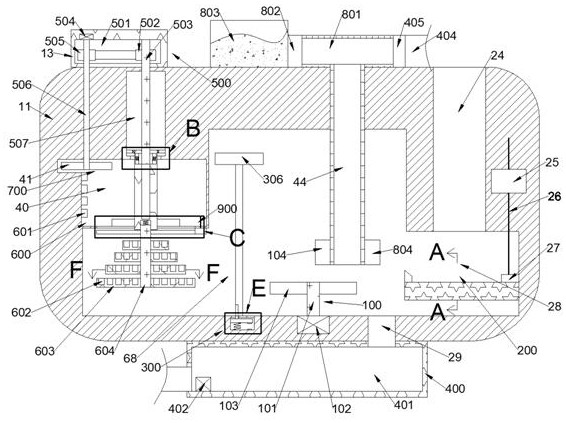

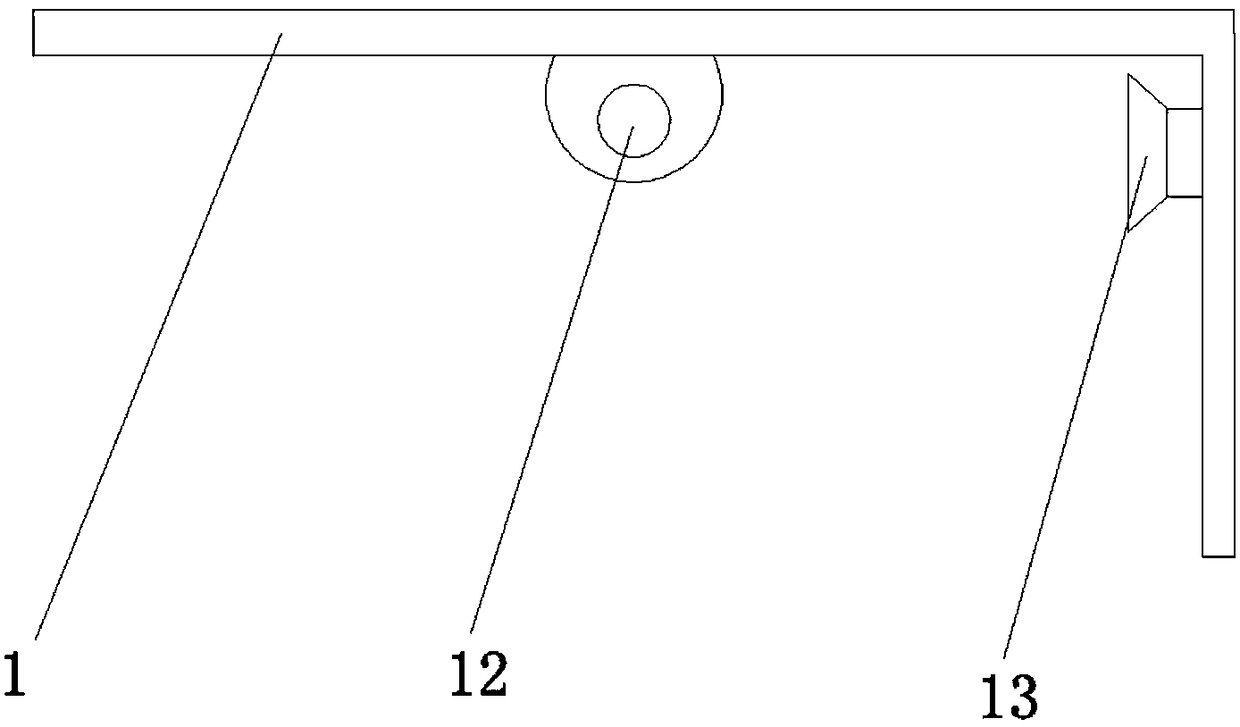

Chip checking and supplementing equipment for material strips

ActiveCN109775331AEasy to detectImplement auto-replenishmentOptical detectionControl devices for conveyorsEngineeringMechanical engineering

The invention discloses chip checking and supplementing equipment for material strips. The chip checking and supplementing equipment comprises a base, a control device, a conveying device, a detectiondevice, a stripping device, a material supplementing device and a sealing device, wherein the conveying device, the detection device, the stripping device, the material supplementing device and the sealing device are arranged on the base in sequence. The conveying device is used for driving material discs to rotate so as to convey the material strips in the material discs from a first material disc to a second material disc. The detection device is located on a material strip conveying path and is used for detecting whether chips in the material strips are absent or not. The stripping deviceis used for stripping carrier strips and cover strips at missing positions of the chips in the material strips. The material supplementing device is used for supplementing chips to the carrier stripsseparated from the cover strips. The sealing device is used for sealing the carrier strips and cover strips with supplemented chips. The conveying device, the detection device, the stripping device, the material supplementing device and the sealing device are in signal connection to the control device. The automatic detection and automatic supplement of the absence of chips can be realized. Problems like low efficiency and material waste during manual operation are effectively prevented. The delivery efficiency and quality of the chips are greatly improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Printer ink feeding device with refining function

ActiveCN106827819AImplement auto-replenishmentAvoid depositionPrintingEngineeringMechanical engineering

The invention relates to a printer ink feeding device with a refining function. The device comprises a feed box and a feeding mechanism. The feed box is arranged above a work box and provided with a keep-off barrel, a storing cavity is formed between the keep-off barrel and the feed box. The feeding mechanism is arranged between the feed box and the work box and comprises a feeding device and a floating device, the floating device rises and falls along with the rising and falling of the ink surface in the work box and is used for driving the feeding device to match slidingly to the keep-off barrel and controlling the communication between the feed box and the feeding device, so when the ink in the work box is reduced, the ink in the feed box added to the work box is achieved, the amount of the ink in the working box is restored and the ink supply in the feed box to the working box is interrupted. The problems that the printer does not have the function of automatic feeding and refining, the amount of ink in the printer within a reasonable range is always ensured and the feeding ink is uneven in shade are overcome.

Owner:嘉兴百川打印科技有限公司

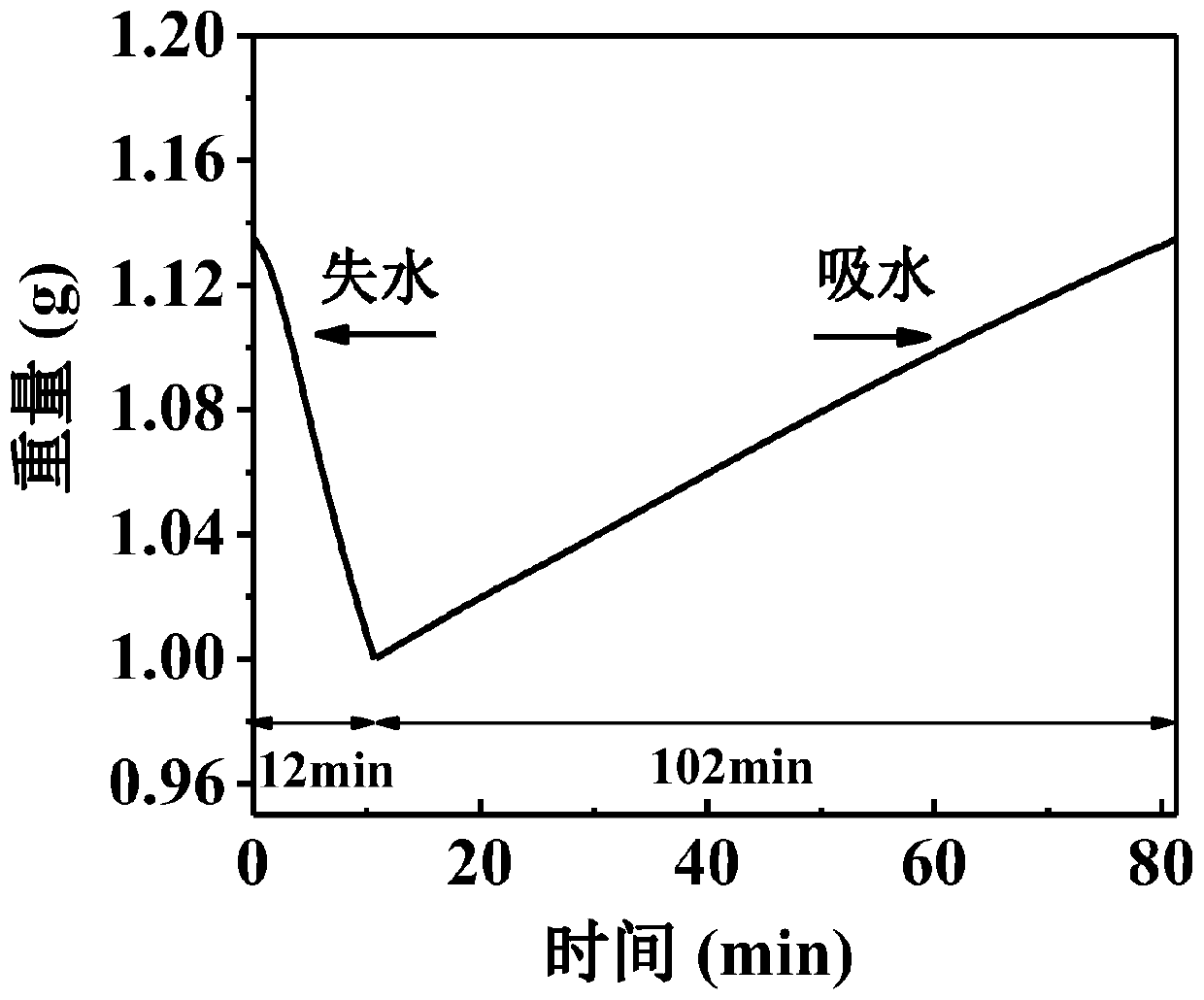

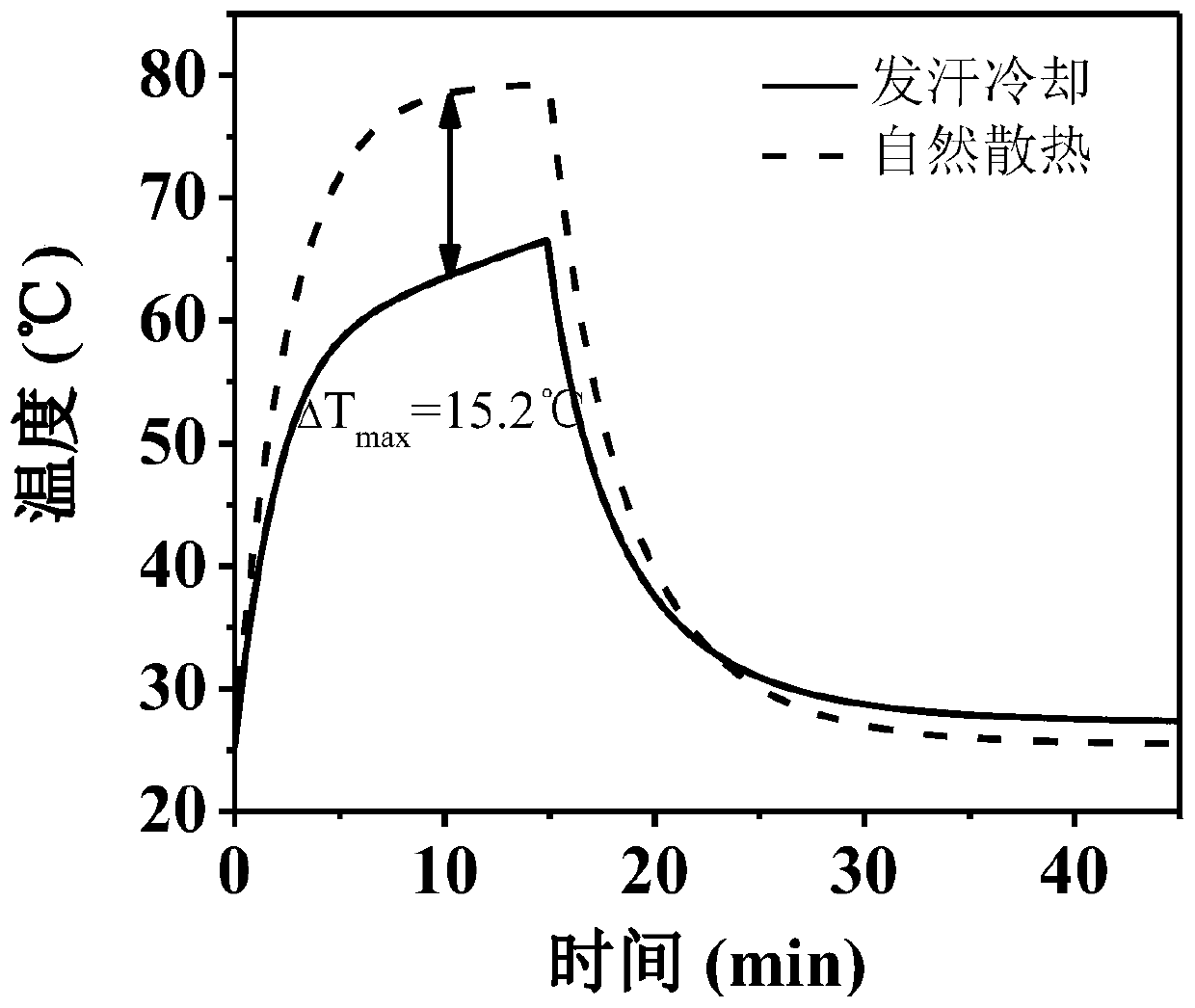

A self-absorbing hydrogel, preparation method and thermal management method based thereon

ActiveCN109943002BSimple structureImprove cooling effectHeat-exchange elementsEngineeringMoisture absorption

The invention discloses a self-absorbing hydrogel, a preparation method and a heat management method based on the self-absorbing hydrogel. The self-absorbing hydrogel is a hygroscopic hydrogel composed of a salt water-resistant gel and a certain concentration of hygroscopic salt solution. In the preparation process, the hydrogel is first prepared; then the hydrogel is heated and dried, and then the dried hydrogel is soaked in high-concentration hygroscopic salt until the hydrogel is completely swollen, and it is self-hygroscopic when taken out Hydrogels. The self-hygroscopic hydrogel can absorb moisture in the air for automatic water replenishment at low temperature, and can take away a large amount of heat when water evaporates at high temperature, and can realize the automatic cycle of moisture absorption and heat dissipation. The invention has the characteristics of simple structure and excellent heat dissipation ability, and can intelligently manage heat for various objects that need heat dissipation by imitating biological sweating and heat dissipation. It can automatically dissipate heat for the heating element without external power, and has the characteristics of no noise, small size, low cost, convenience and intelligence.

Owner:纾酷科技(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com