Use method of quenching device

A technology of quenching device and quenching oil pool, applied in the field of heat treatment, can solve problems such as troublesome operation, and achieve the effect of saving energy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific implementations:

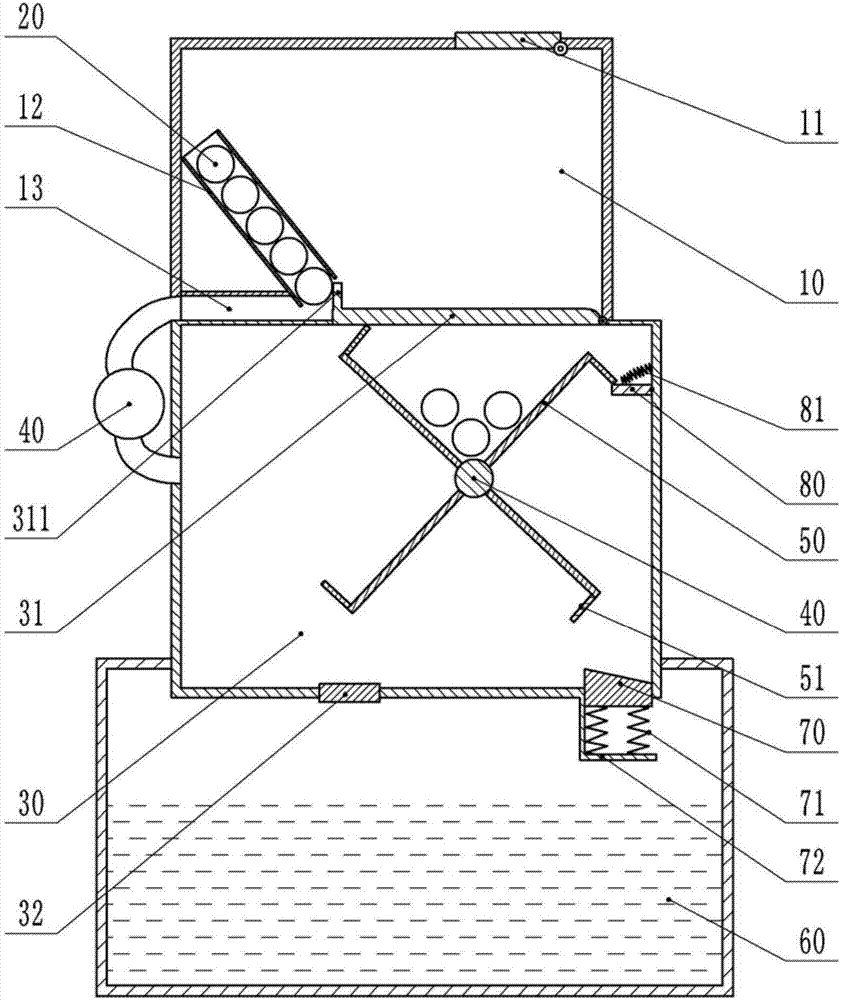

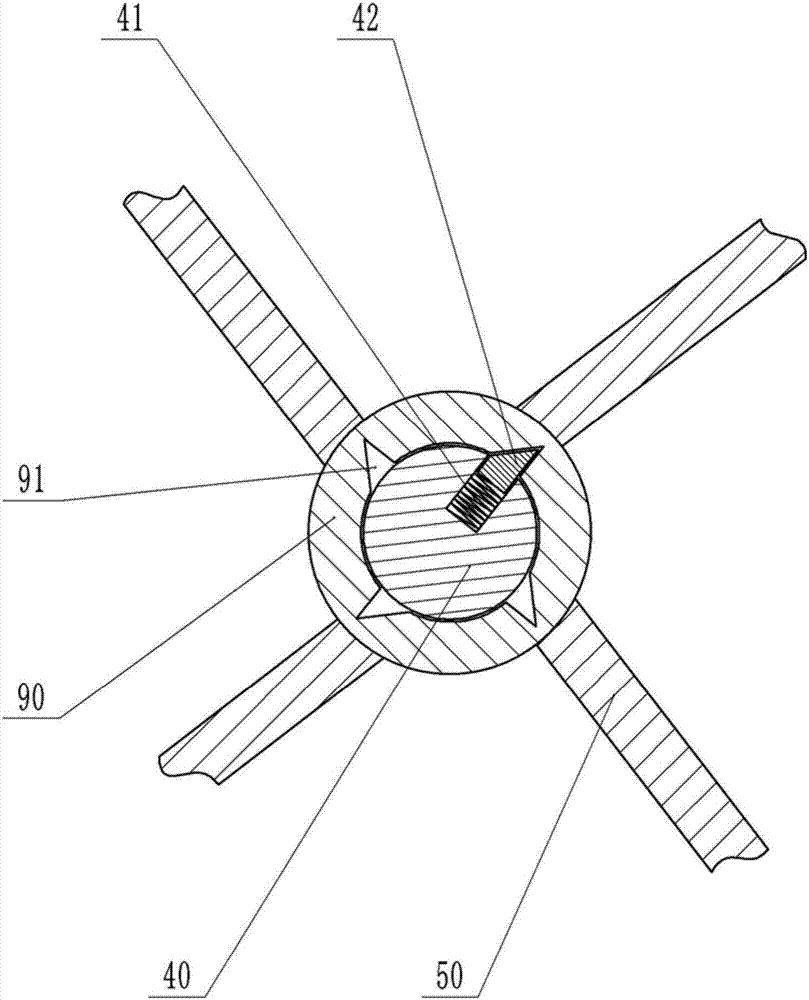

[0025] Instruction attached Figure 1 to 2 The reference signs in include: preheating furnace 10, flue gas valve 11, feed oblique section 12, flue gas channel 13, metal workpiece 20, vacuum heating furnace 30, one-way door 31, baffle plate 311, fixed column 40, Compression spring 41, wedge-shaped telescopic block 42, turning plate 50, receiving plate 51, quenching oil pool 60, wedge block 70, spring 71, support plate 72, brake plate 80, tension spring 81, drum 90, and card slot 91.

[0026] How to use the quenching device, such as figure 1 , figure 2 As shown, the quenching device includes a preheating furnace 10, a vacuum heating furnace 30, and a closed quenching oil pool 60 from top to bottom. The upper wall of the preheating furnace 10 is provided with a flue gas valve 11 that can only be opened upwards. An elastic member is connected between the air valve 11 and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com