Cigarette automatic sorting process

An automatic sorting and carton technology, which is applied in packaging, conveyor objects, transportation and packaging, etc., can solve the problems of low degree of automation in carton sorting, low sorting efficiency, and unfavorable improvement of system capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

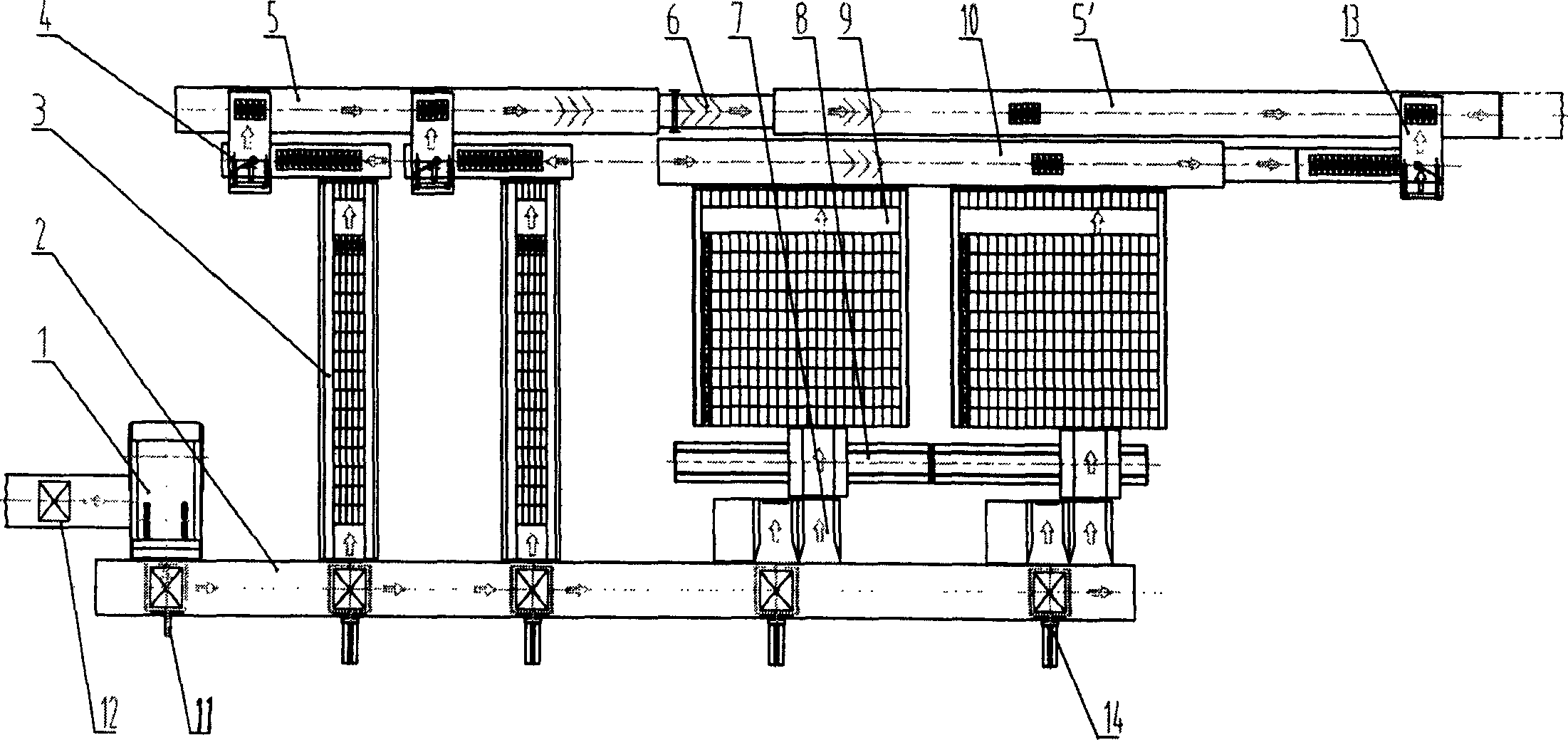

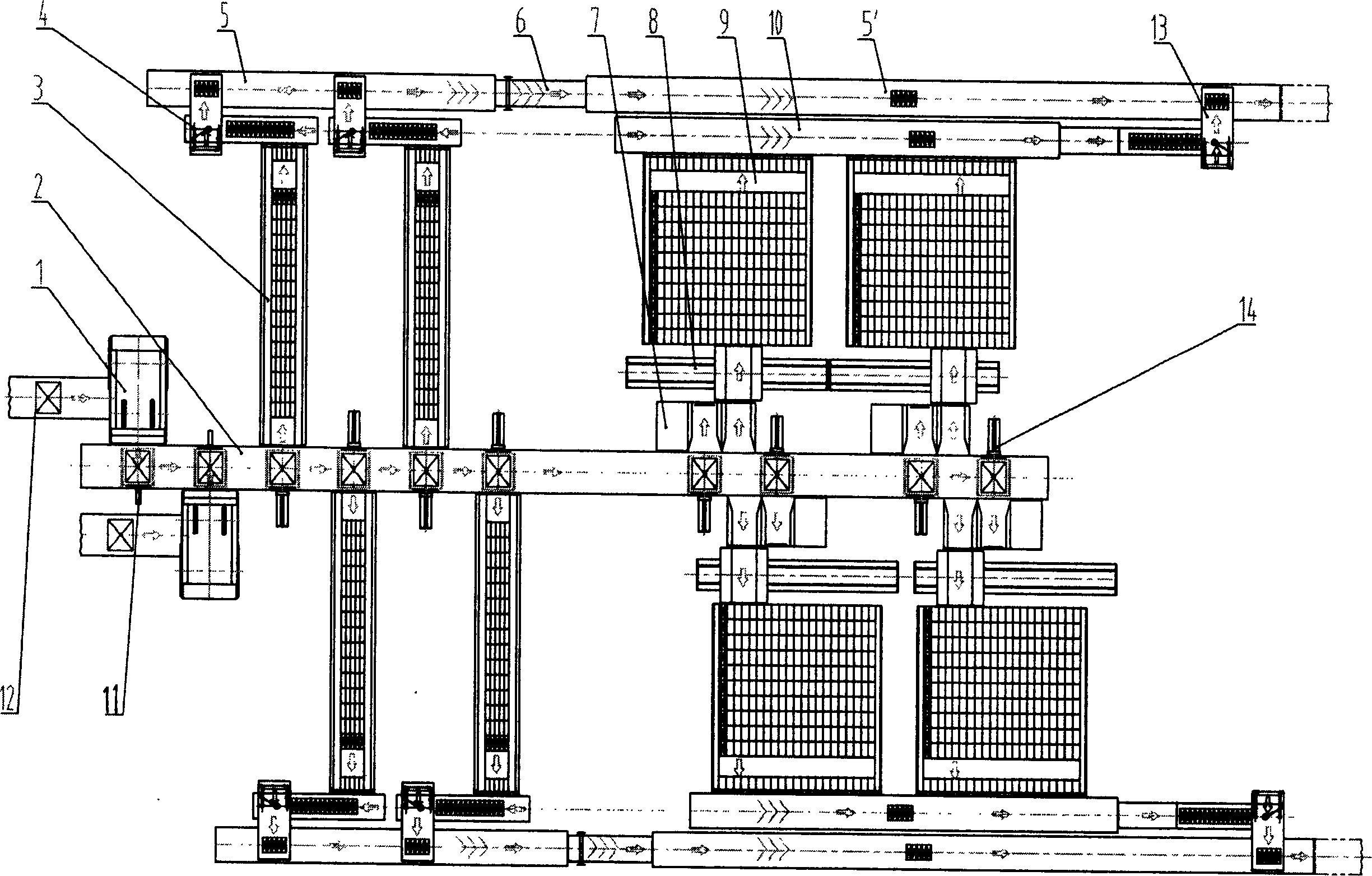

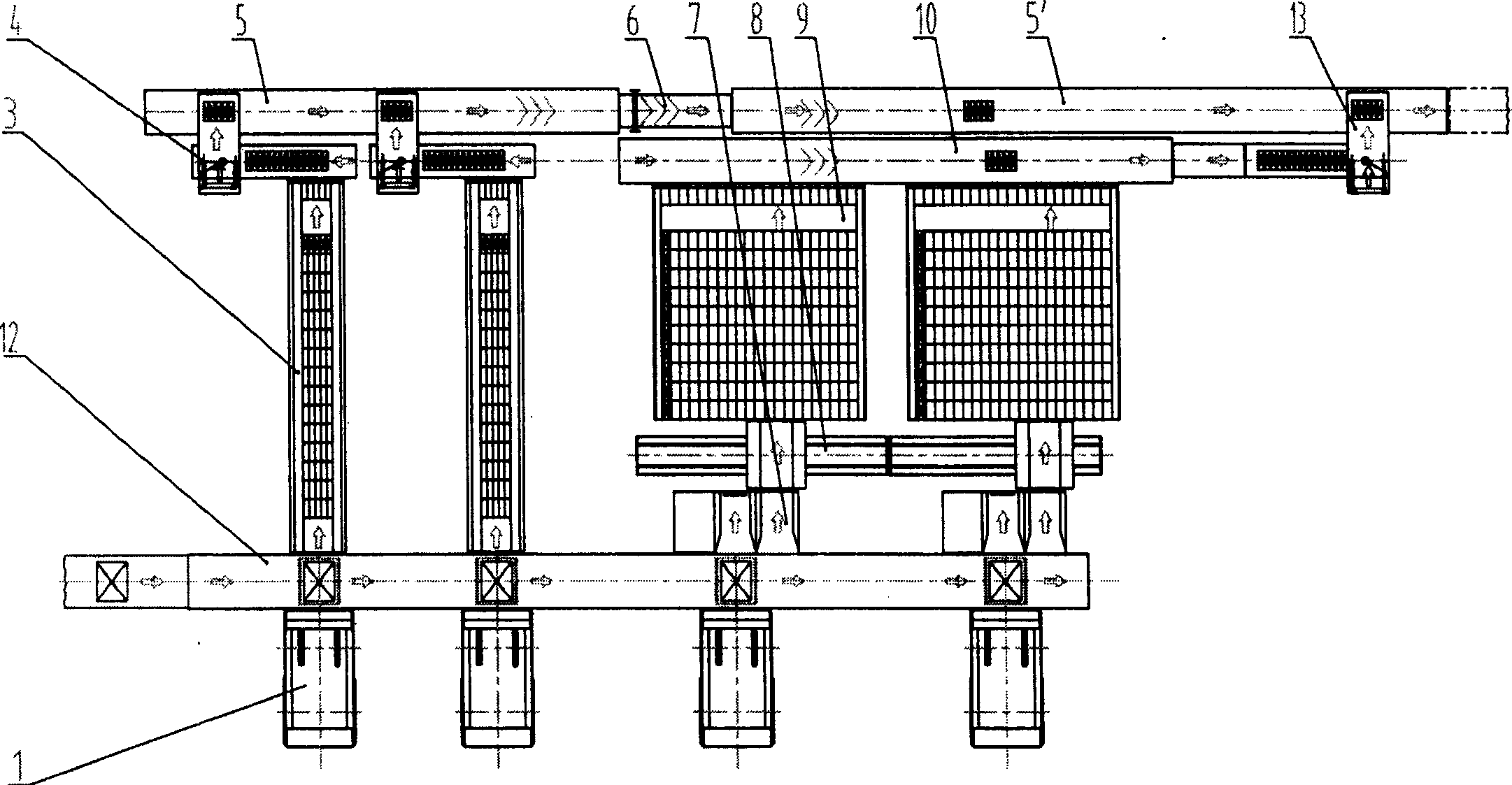

[0021] Realize technique of the present invention, can equipment such as figure 1 , figure 2 , image 3 , Figure 4 Set up as shown. Such as figure 1 As shown, the automatic unpacking machine 1, the sorter 3, and the replenishment shuttle car 8 are arranged in parallel on one side of the side chain conveyor 2, and the pushing device 14, the sorter 3, and the replenishment shuttle car are arranged on the other side. 8 opposite, used to push stacks of cigarettes into the sorting machine and the replenishment shuttle car for automatic replenishment, and set the pneumatic flexible baffle 11 opposite to the automatic case unpacking machine 1, so as to cooperate with the automatic case unpacking machine to open the imported pieces of cigarettes After the box, the stack of cigarettes is pushed onto the side chain conveyor 2. A secondary sorting mechanism 4 can also be set between the sorter 3 and its downstream conveyor 5, to carry out secondary sorting to the single-layer ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com