Cigarette supplementing and sorting method

A technology for replenishing cigarettes and storing cigarettes, which is applied to conveyors, storage devices, transportation and packaging, etc. It can solve the problems of easy sliding and turning of cigarettes and cigarette stacks, and achieves small footprint, high efficiency, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

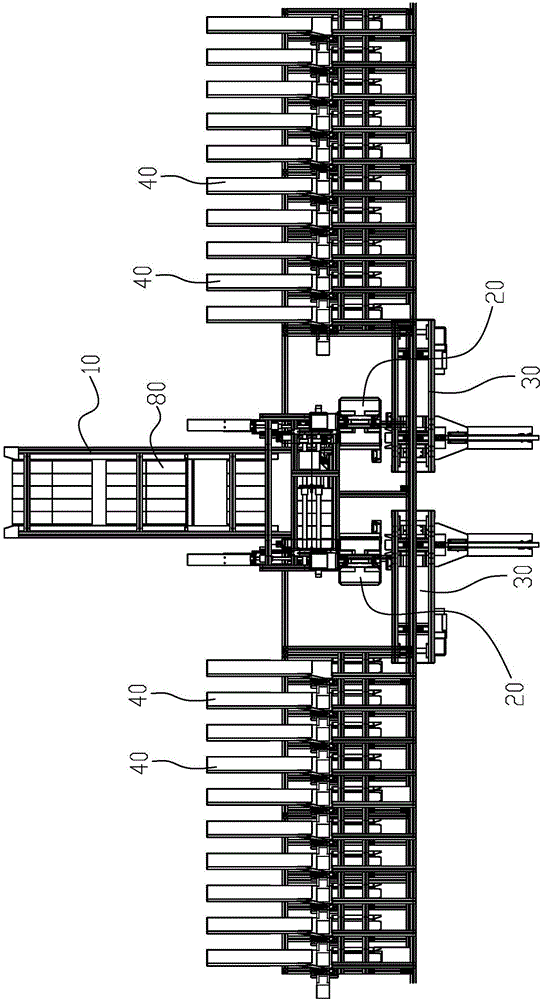

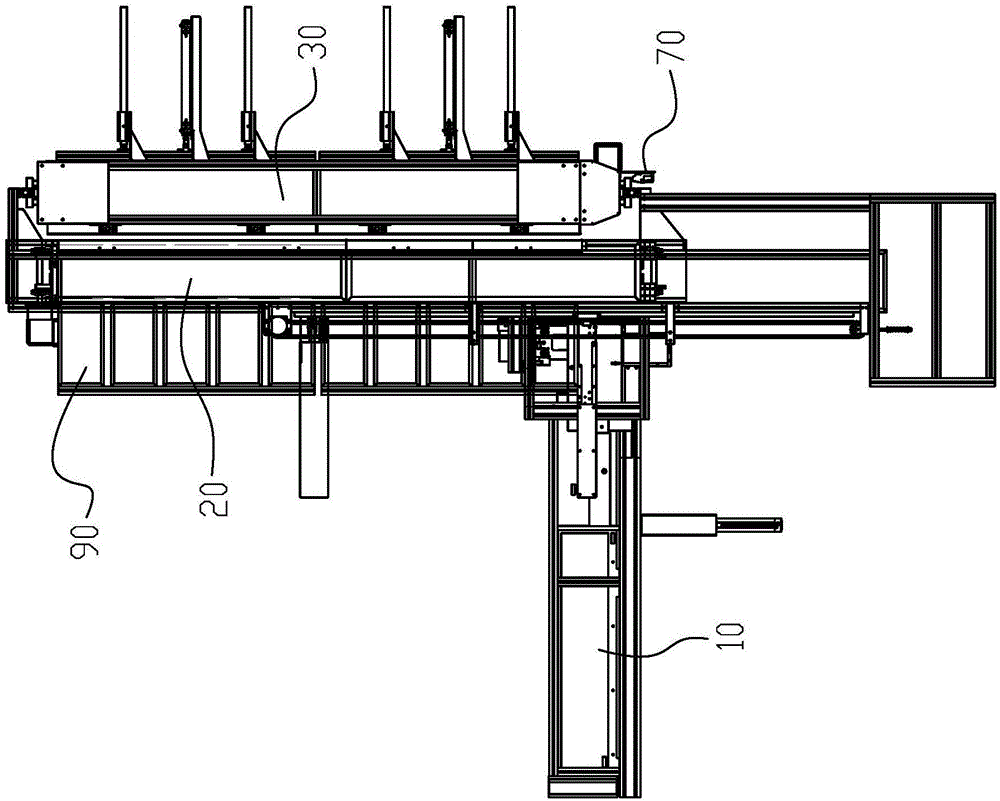

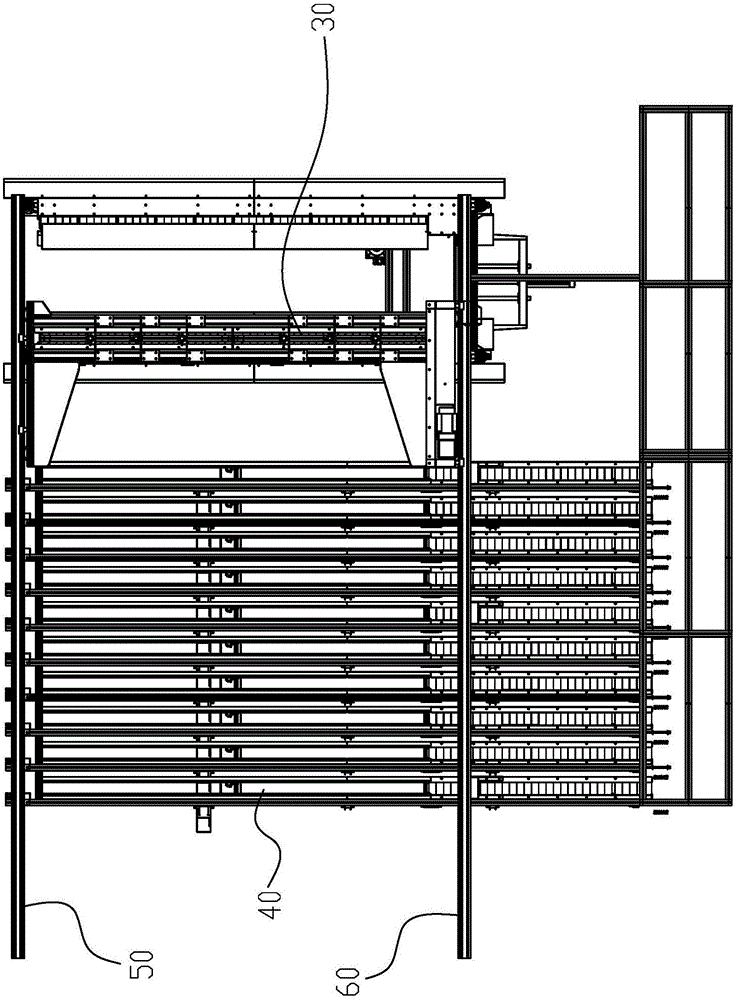

[0033] Please refer to Figure 1 to Figure 3 , the smoke replenishment sorting equipment applying the cigarette replenishment sorting method of the present invention includes a channel buffer machine 10 , a hoist 20 , a replenishment trolley 30 , and a vertical sorting cigarette bin 40 . There are two elevators 20, and one elevator 20 is provided on the left and right sides of the channel buffer machine 10 in the transverse direction. There are multiple vertical sorting bins 40, which are divided into two rows arranged horizontally. The number of replenishment trolleys 30 is two, and the two replenishment trolleys 30 are connected to the elevators 20 on the left and right sides respectively, and replenish cigarettes to the two rows of vertical sorting cigarette bins 40 respectively. The pulley at the top of the replenishment trolley 30 is in rolling contact with the upper rail 50, and the pulley at the bottom of the replenishment trolley 30 is in rolling contact with the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com