Monitoring low-resistance module grounding device

A grounding device and low-resistance technology, applied in the field of low-resistance module grounding devices that can be monitored, can solve the problems of reduced grounding grid performance, heavy workload, and high cost, and can reduce grounding resistance, ensure reliability, and be easy to install. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the present invention below in conjunction with accompanying drawing.

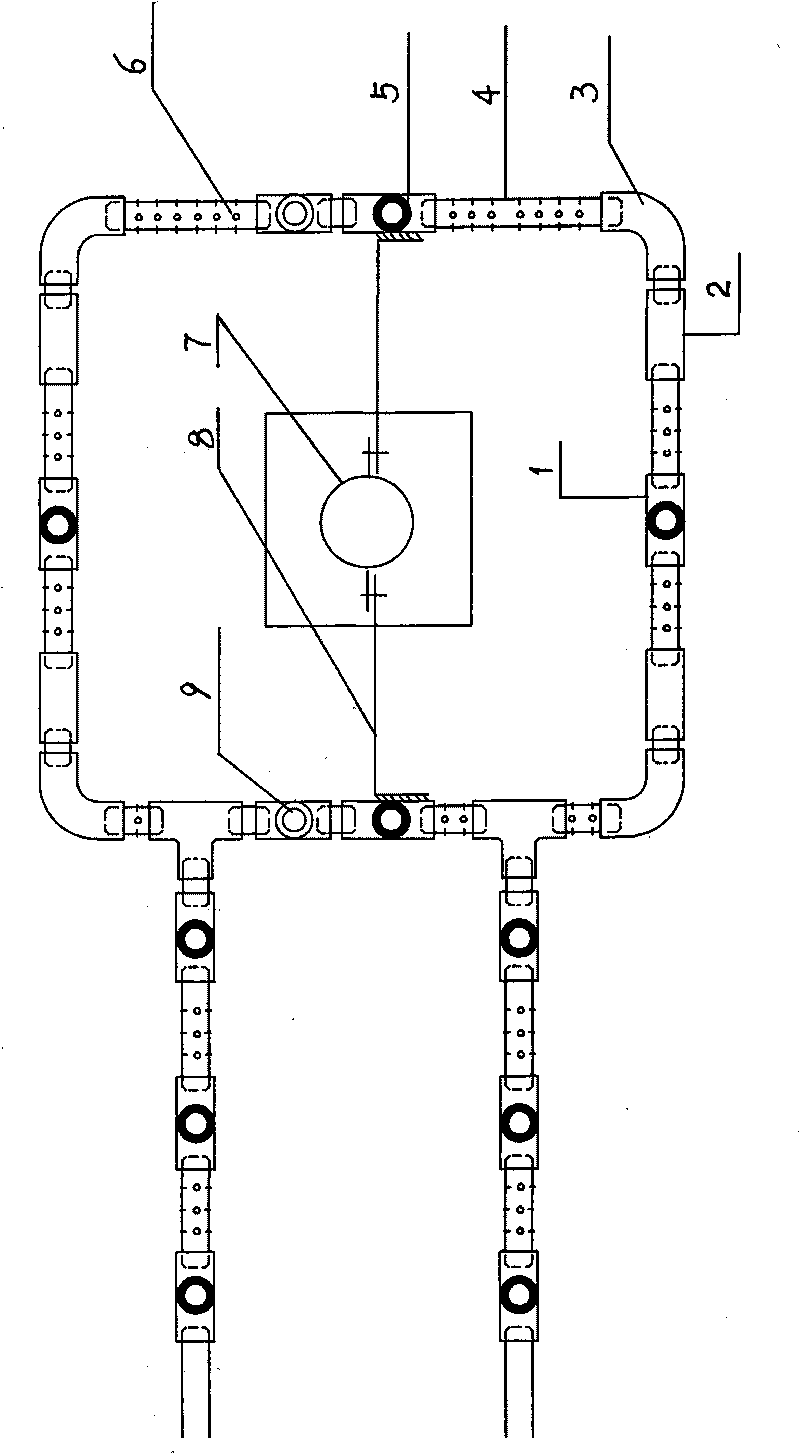

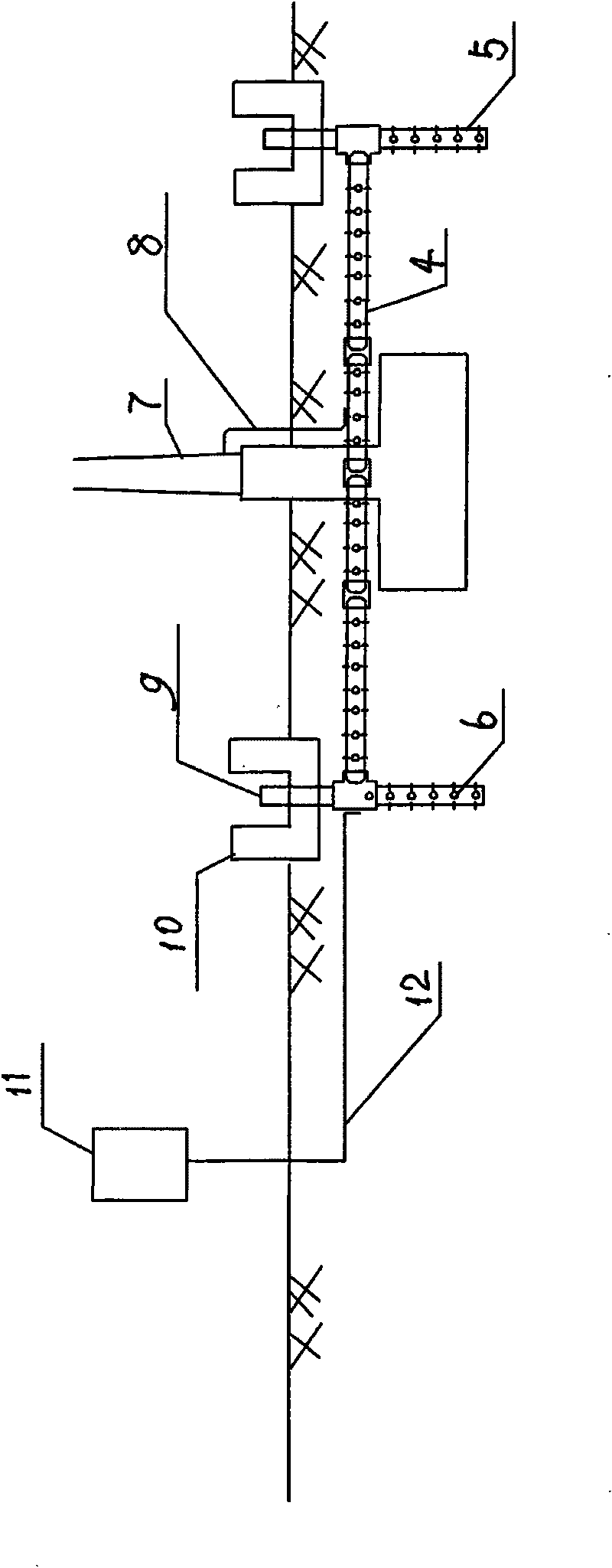

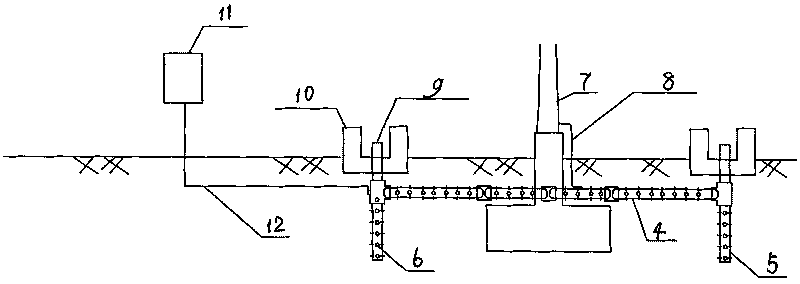

[0016] figure 1 , 2 As shown, the equipment support 7 is connected to the grounding body through the grounding down conductor 8, and the grounding body includes several horizontal grounding pipes 4 connected in sequence and several vertical grounding pipes 5 connected with the horizontal grounding pipes 4 respectively. The above-mentioned grounding pipes all use metal pipes or composite pipes with high conductivity as conductors, and a number of seepage holes 6 are provided on the horizontal grounding pipe 4 and the vertical grounding pipe 5 . Use tee 1, cross, elbow 3, straight 2 and other pipe fittings of the same material to arbitrarily combine into various forms of hollow pipe grounding grids according to different requirements, and implant them underground at a depth of 0.8-3.0m.

[0017] The liquid storage tank 10 for holding the liquid communicates with the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com