Patents

Literature

187results about How to "Reduce ground resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

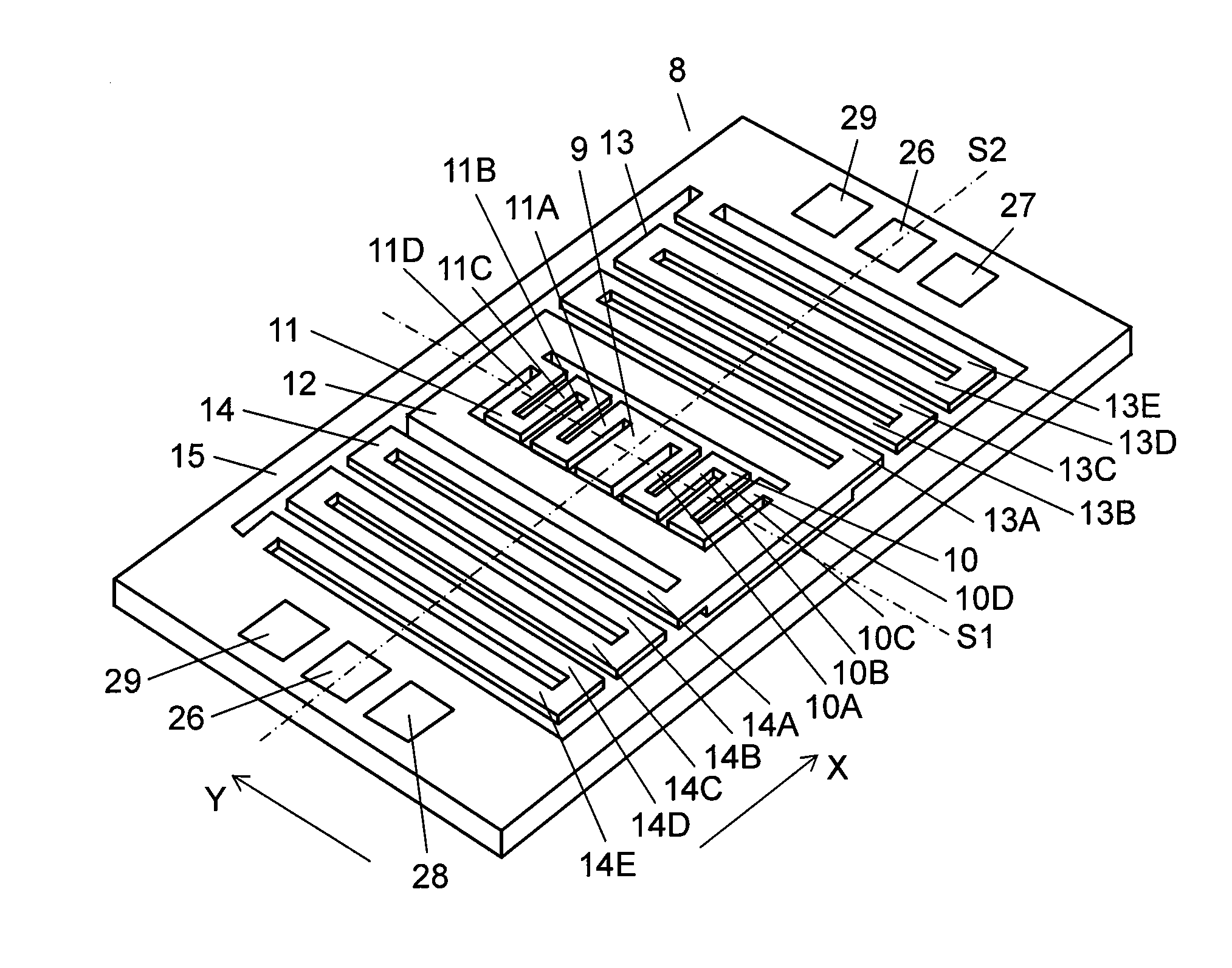

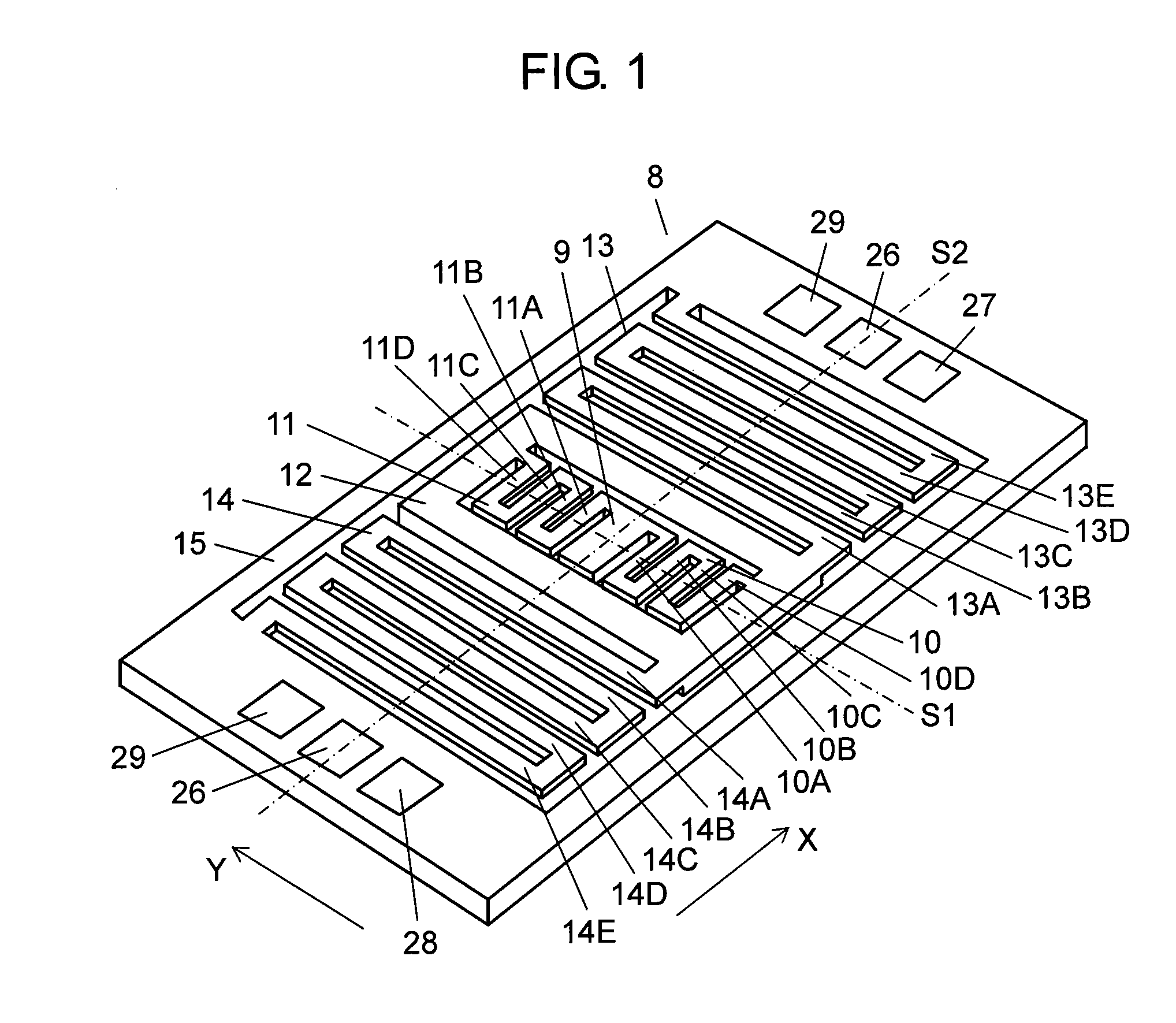

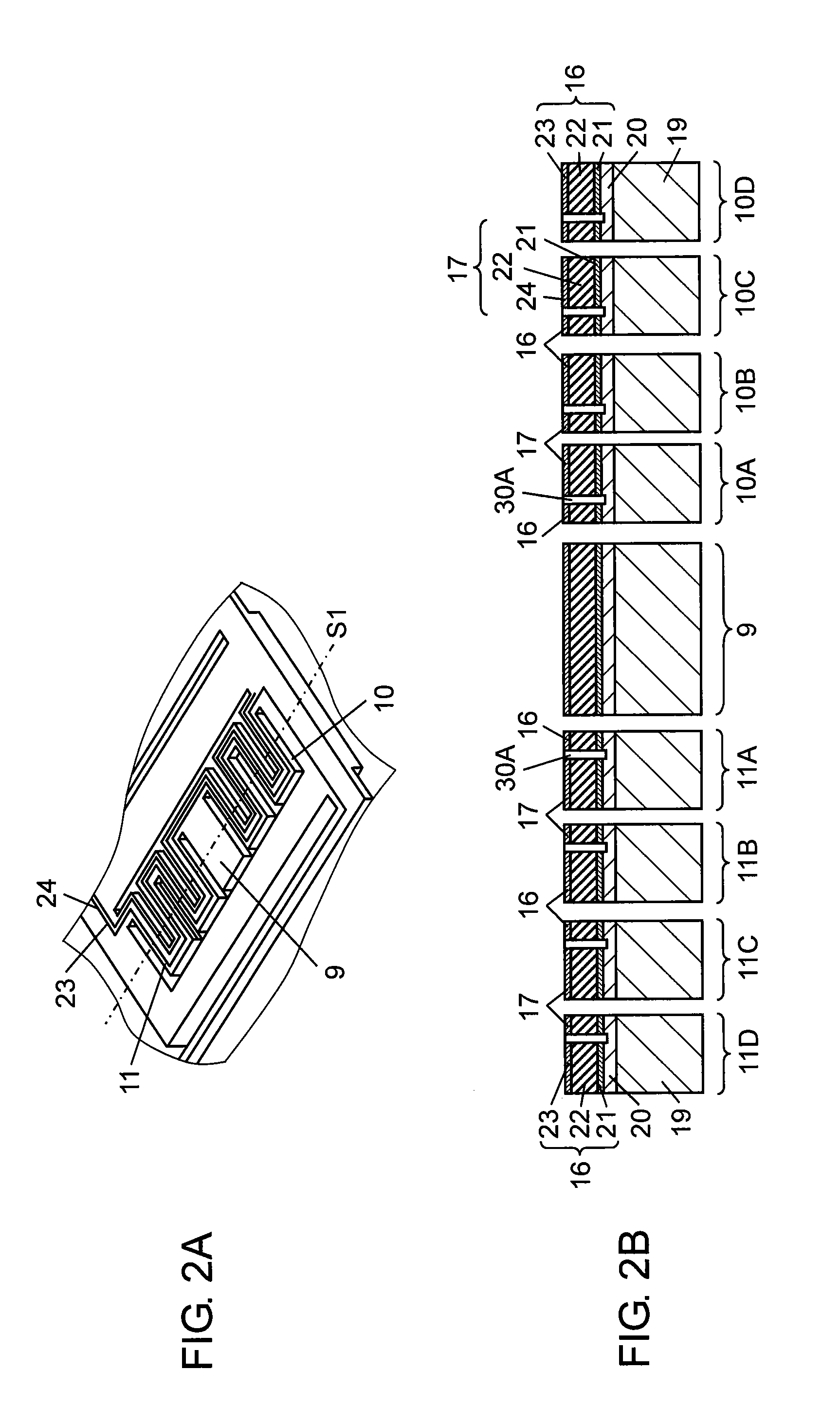

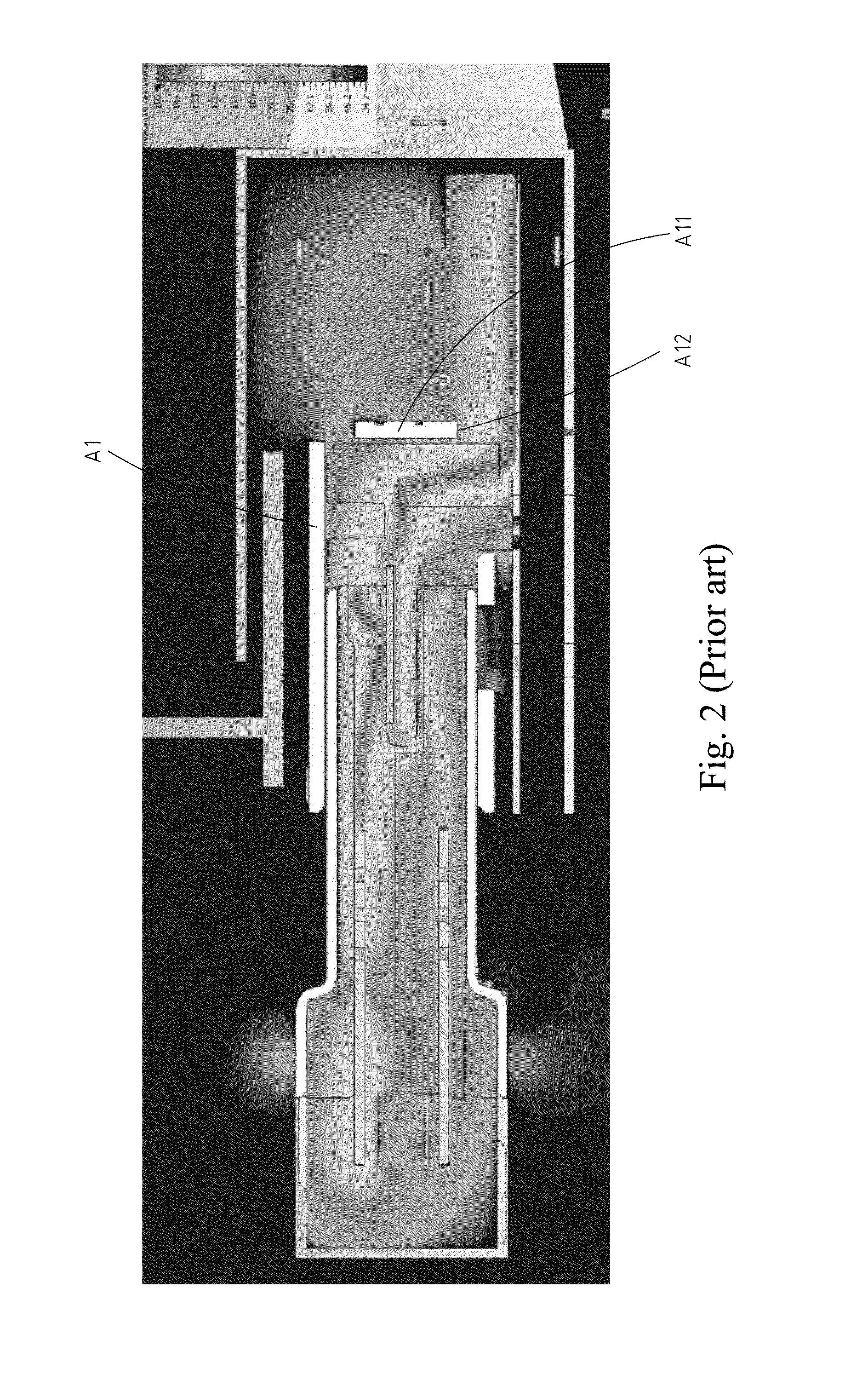

Optical reflection element

ActiveUS20110292479A1Improve detection accuracyImprove accuracyMirrorsPiezoelectric/electrostriction/magnetostriction machinesOptical reflectionSelf excited

An optical reflection element includes a mirror portion and an oscillator coupled to the mirror portion. The oscillator includes a base, an insulating layer, a drive element, and a monitor element. The insulating layer is formed on the base. The drive element and the monitor element are formed on the insulating layer, and are separated from each other by a separation groove. Each of the drive element and the monitor element includes a lower electrode layer, a piezoelectric layer, and an upper electrode layer formed in that order on the insulating layer. The monitor element has high detection accuracy, allowing the optical reflection element to perform self-excited driving with high accuracy.

Owner:PANASONIC CORP

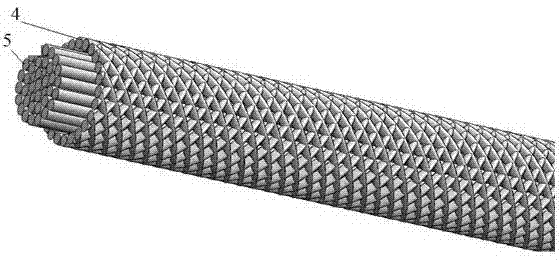

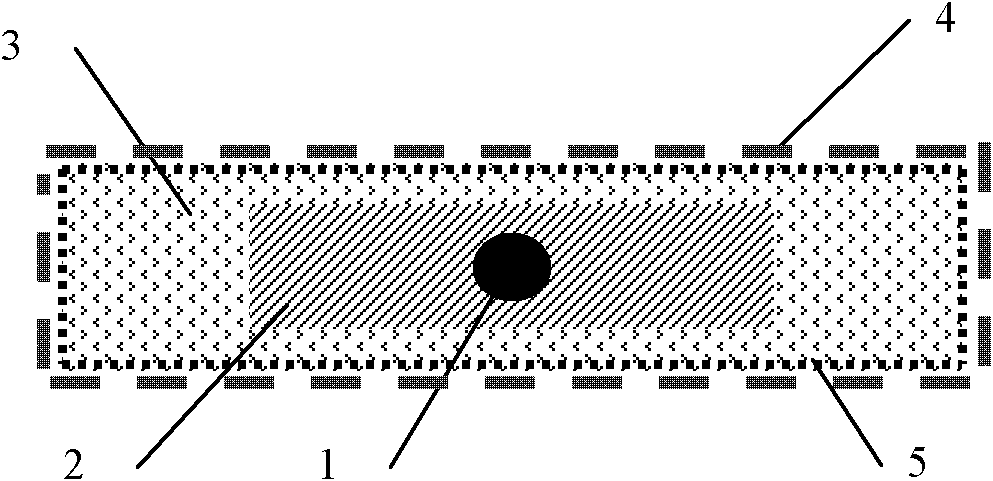

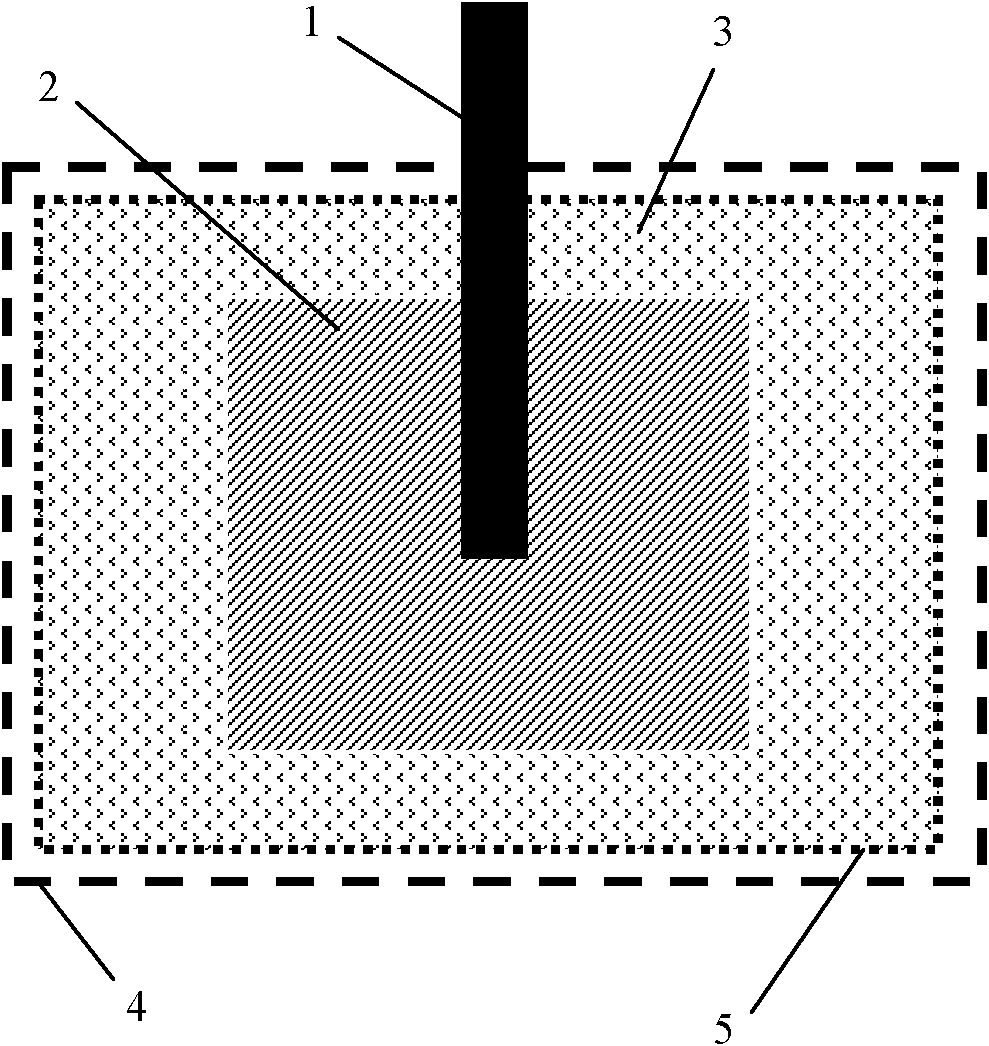

Novel graphite composite grounding material and preparation method thereof

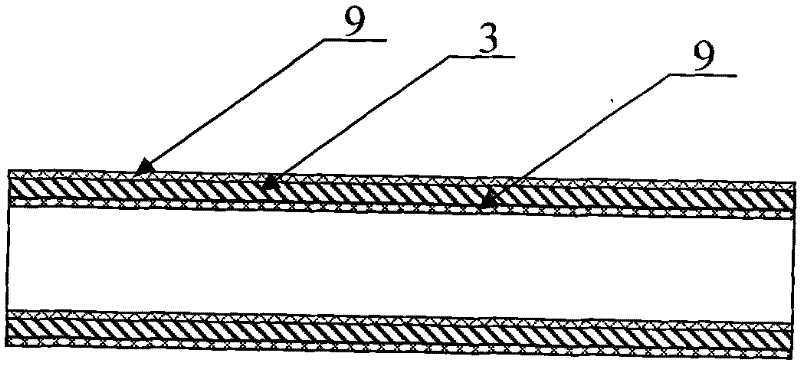

ActiveCN103490180ASolving Corrosion ProblemsIncrease contact areaContact member manufacturingConnection contact member materialYarnCorrosion resistant

The invention discloses a novel graphite composite grounding material and a preparation method thereof. The novel graphite composite grounding material is in the shape of a rope or stranded wire, and comprises a composite graphite yarn inner core and a composite graphite yarn knitted layer wrapped outside the composite graphite yarn inner core, wherein the composite graphite yarn inner core is a composite graphite yarn bundle composed of a plurality of first composite graphite yarns or a single first composite graphite yarn; each first composite graphite yarn is prepared by twisting a first composite graphite belt; the composite graphite yarn knitted layer is prepared by knitting a second composite graphite yarn; and the second composite graphite yarn is prepared by twisting a second composite graphite belt. The graphite composite grounding material disclosed by the invention has the advantages of corrosion resistance, favorable conductivity, high flexibility, low price, precise soil association and the like, and is easy for transportation; since the price is low, artificial theft destroy can be avoided; and the graphite composite grounding material is suitable for the fields of transformer stations, overhead transmission line towers, tall buildings and all other projects in need of electric grounding.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

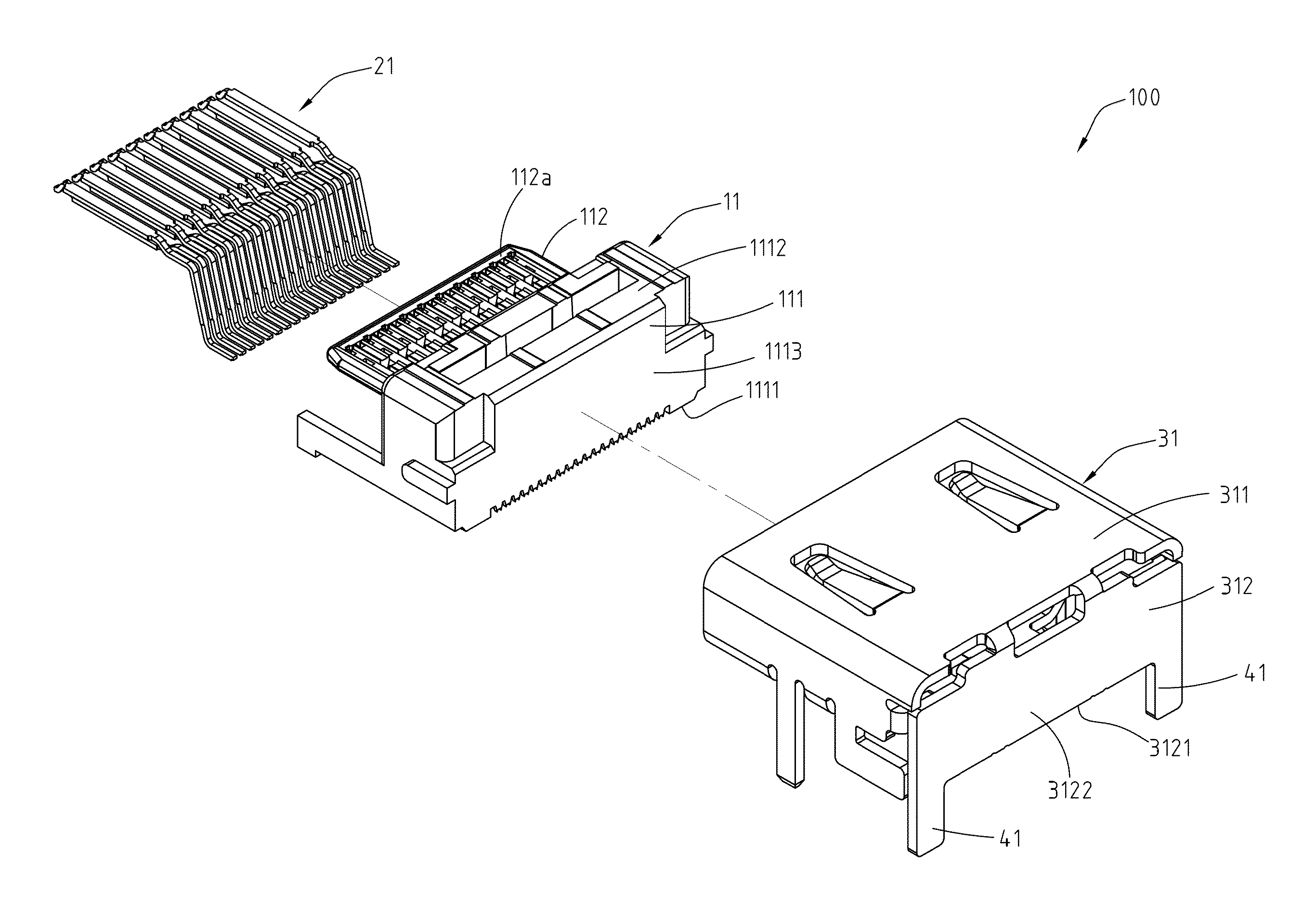

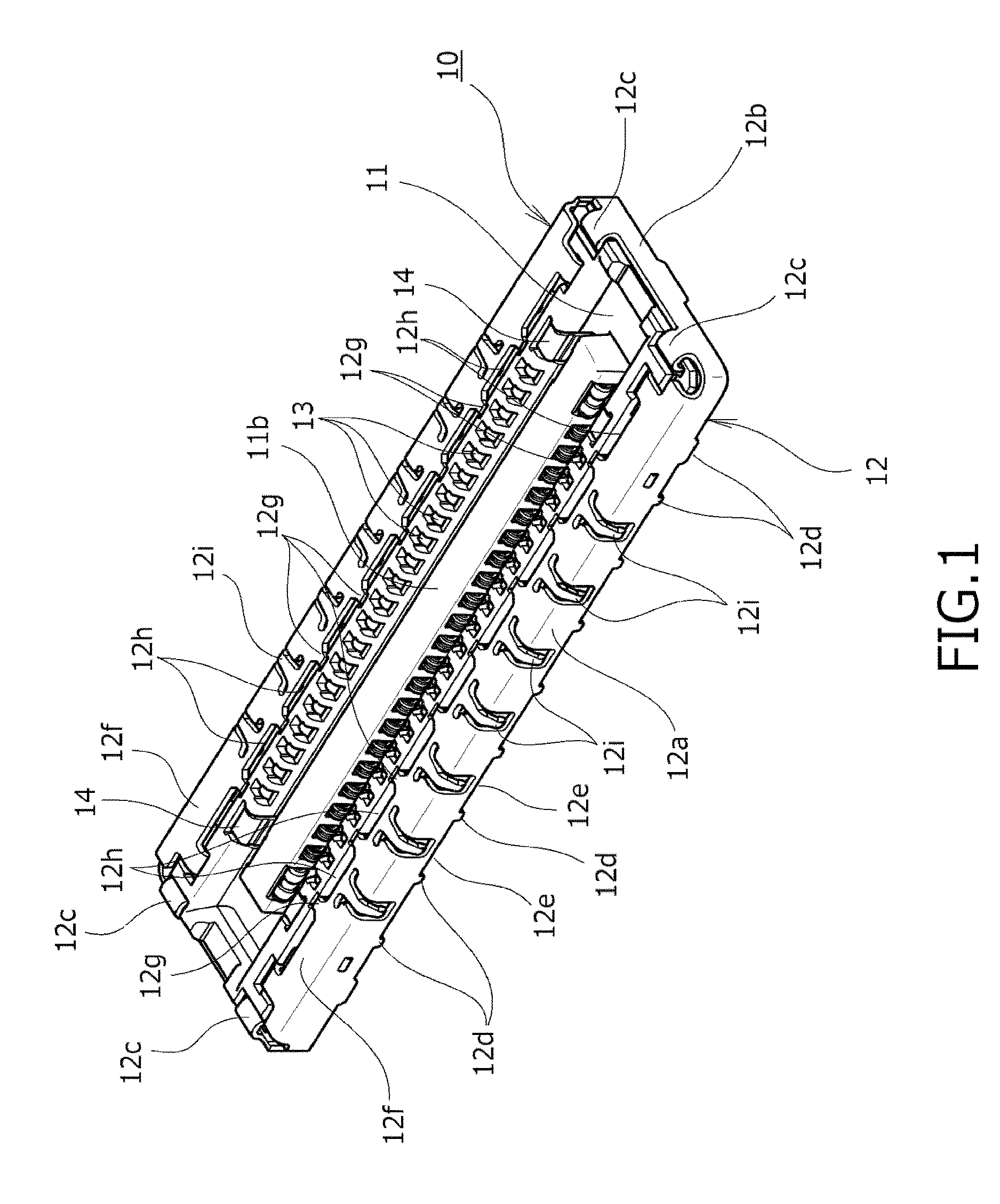

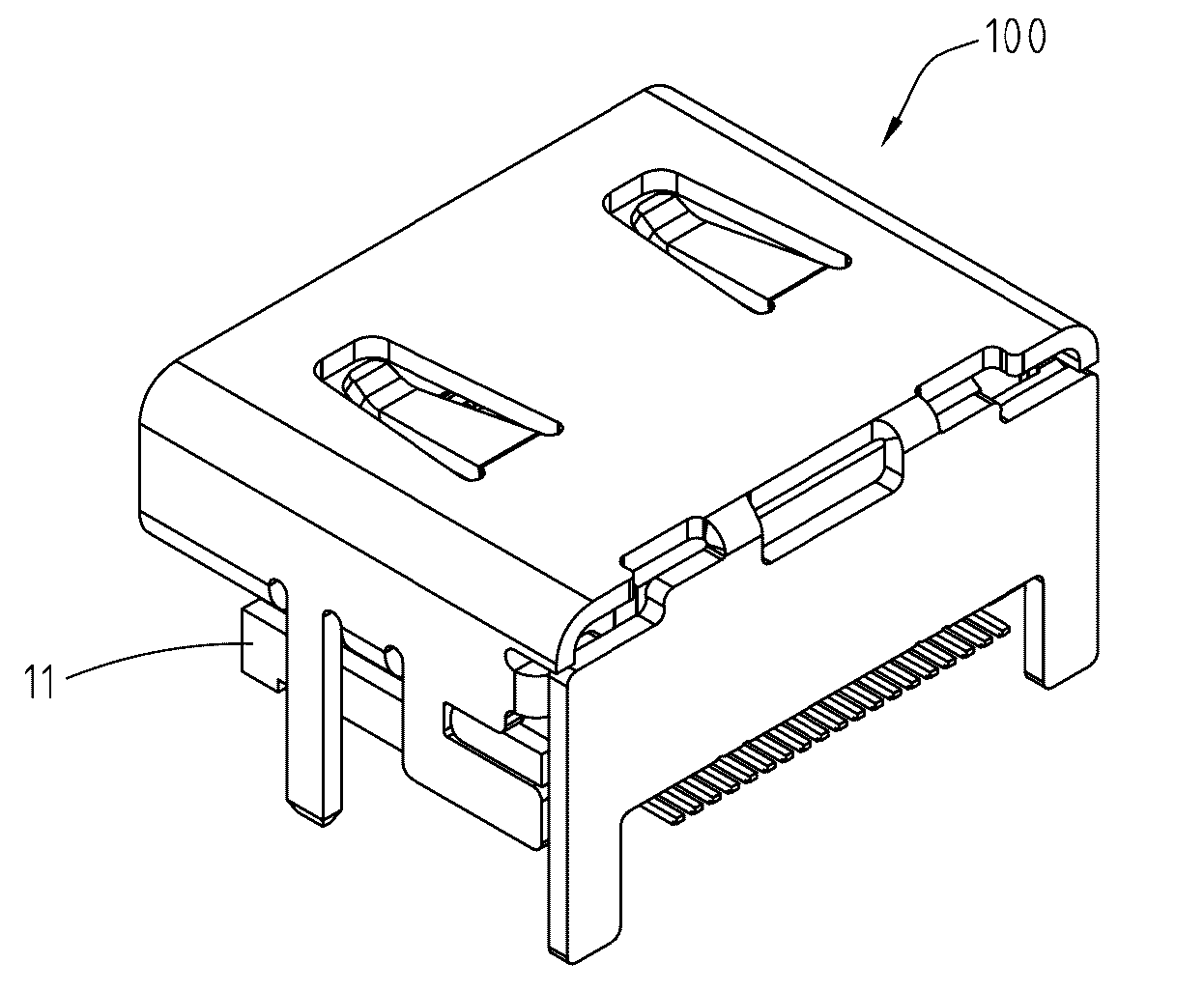

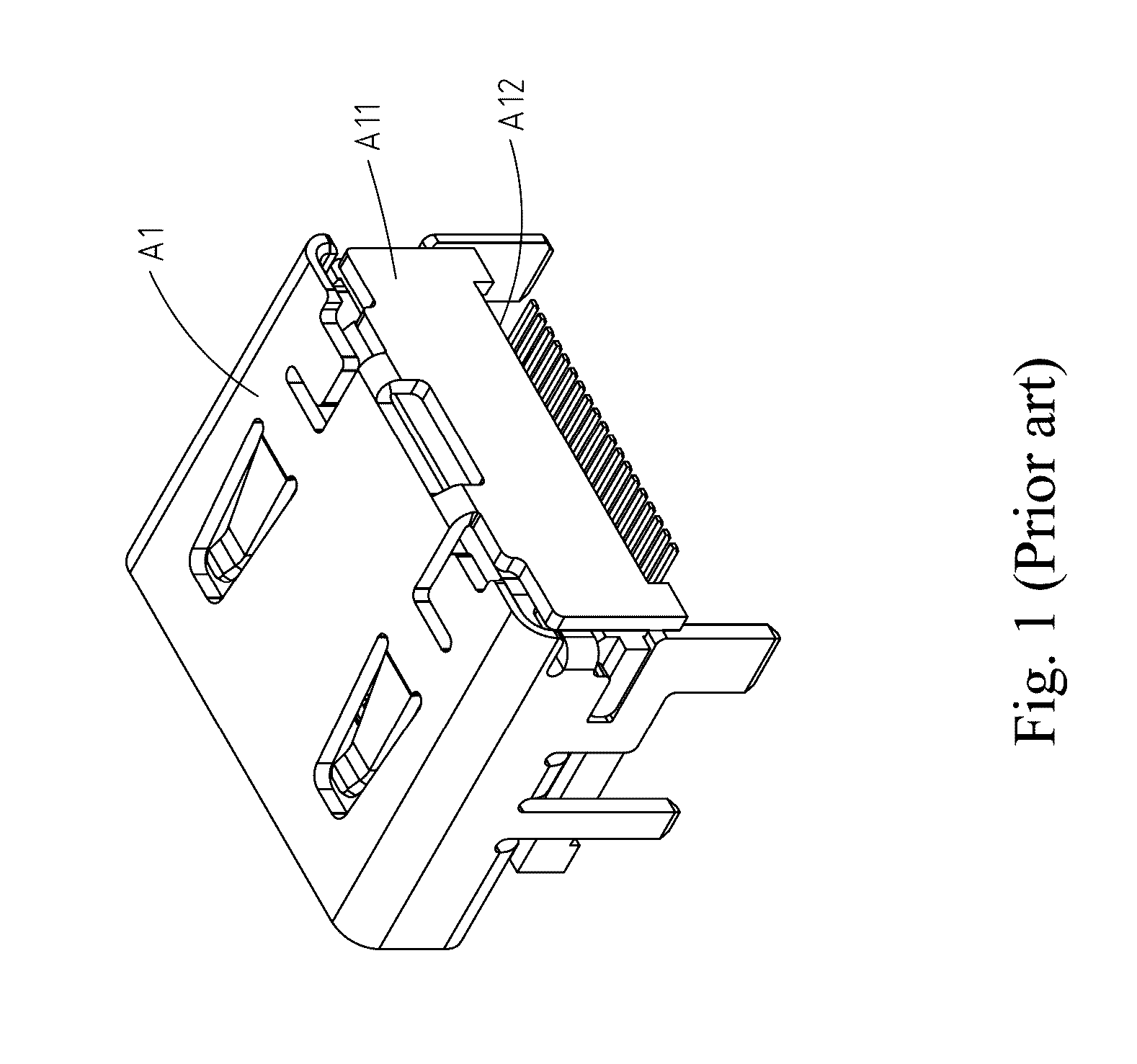

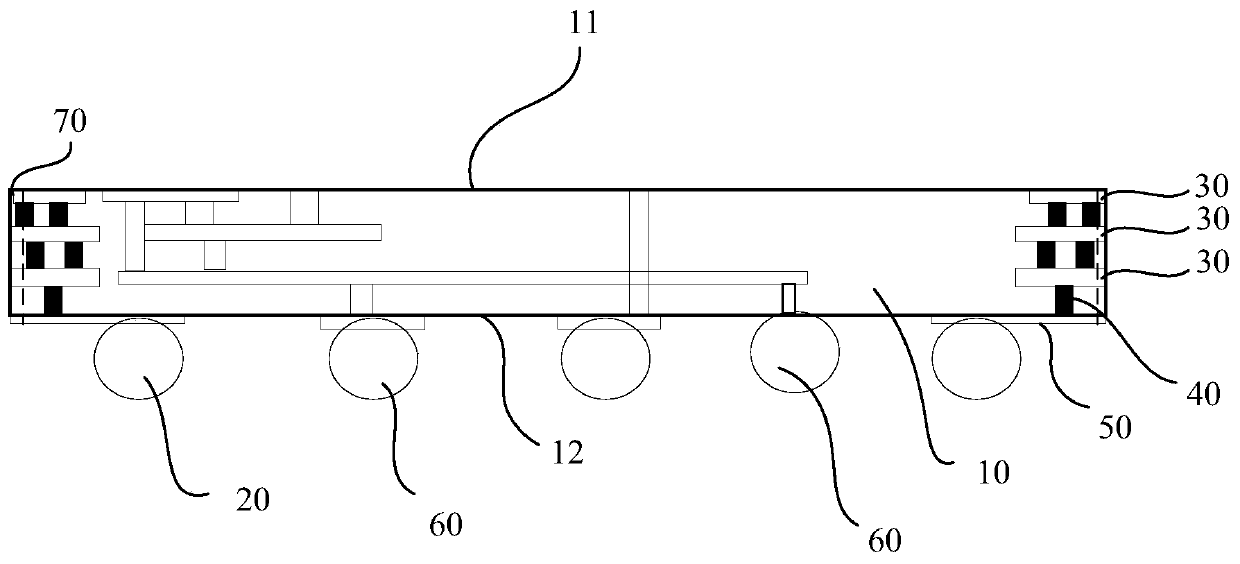

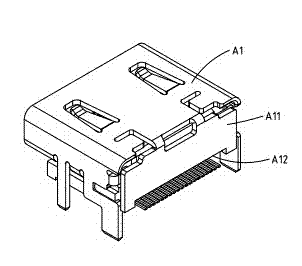

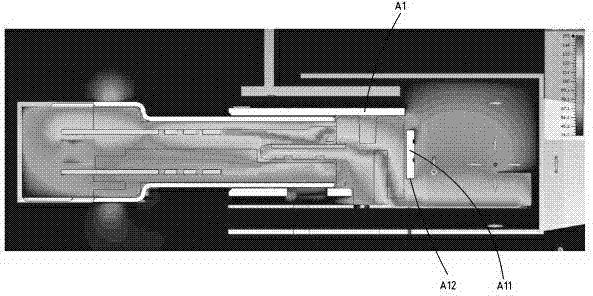

Electrical receptacle connector

ActiveUS20150340798A1Reduce ground resistanceReduce spacingElectric discharge tubesCoupling device detailsEngineeringSoldering

An electrical receptacle connector includes an insulated housing, plate terminals, and a metallic shell. The insulated housing includes a base portion. The plate terminals are at the insulated housing. The plate terminals include soldering segments exposed out of the bottom of the base portion. The metallic shell encloses four sides of the insulated housing and includes a top cover plate, a rear cover plate, and pins. The top cover plate is located atop the base portion. The rear cover plate is extending downwardly to the rear side of the base portion from the rear side of the top cover plate. The rear cover plate includes a bottom surface and a bent sheet substantially perpendicular to an outer wall of the rear cover plate and extended outward from the outer wall of the rear cover plate, and the pins are extending downwardly from the bottom surface.

Owner:ADVANCED CONNECTEK INC

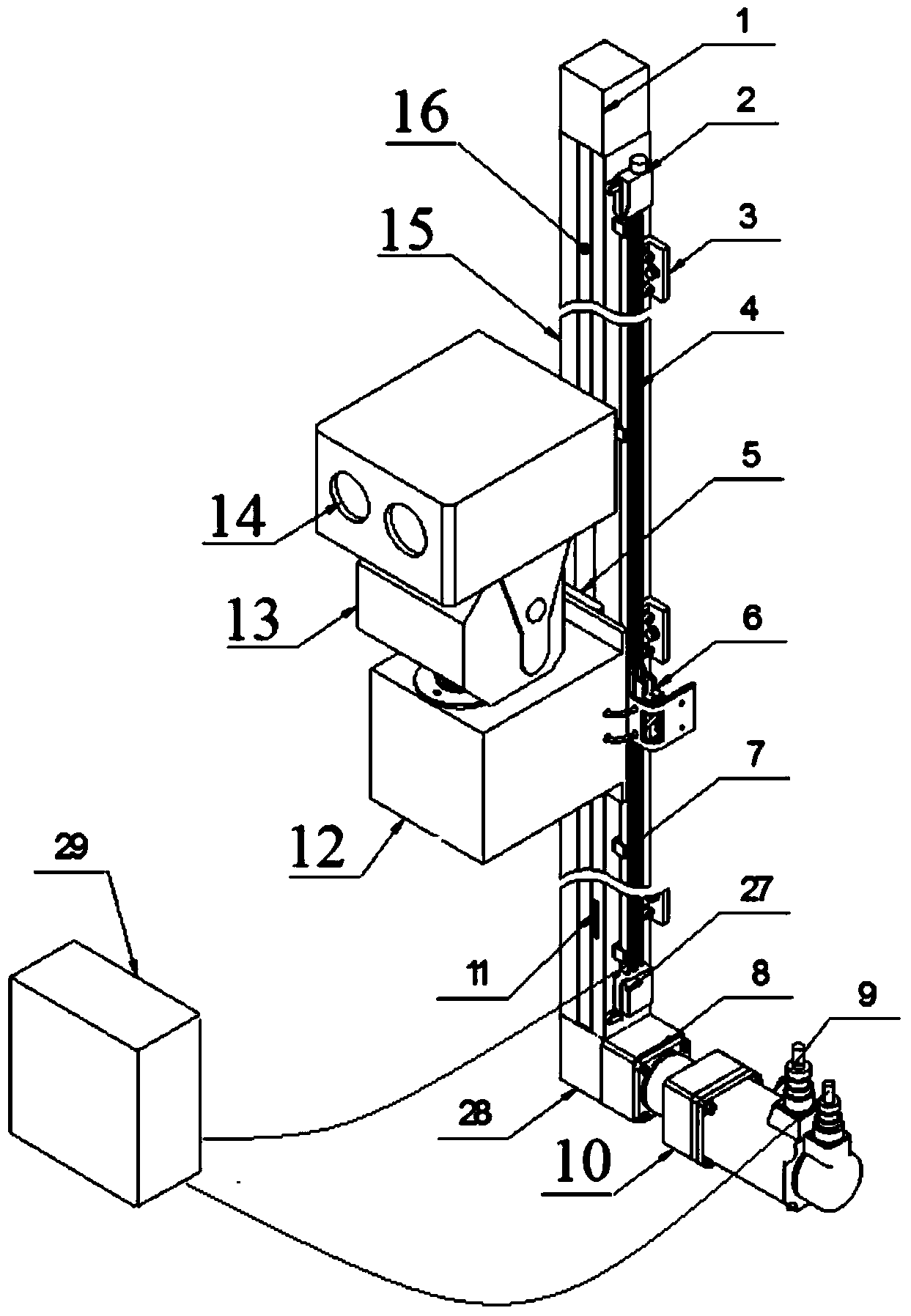

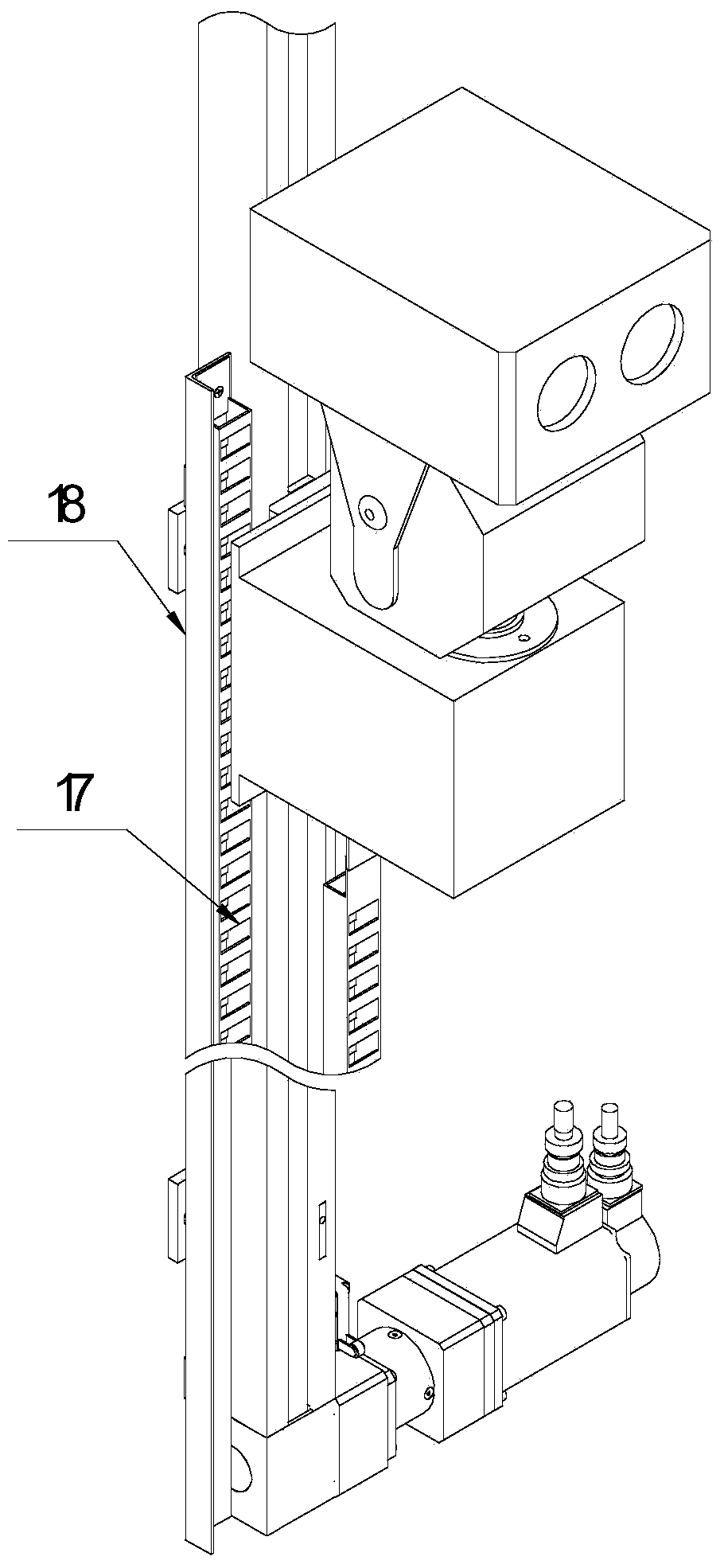

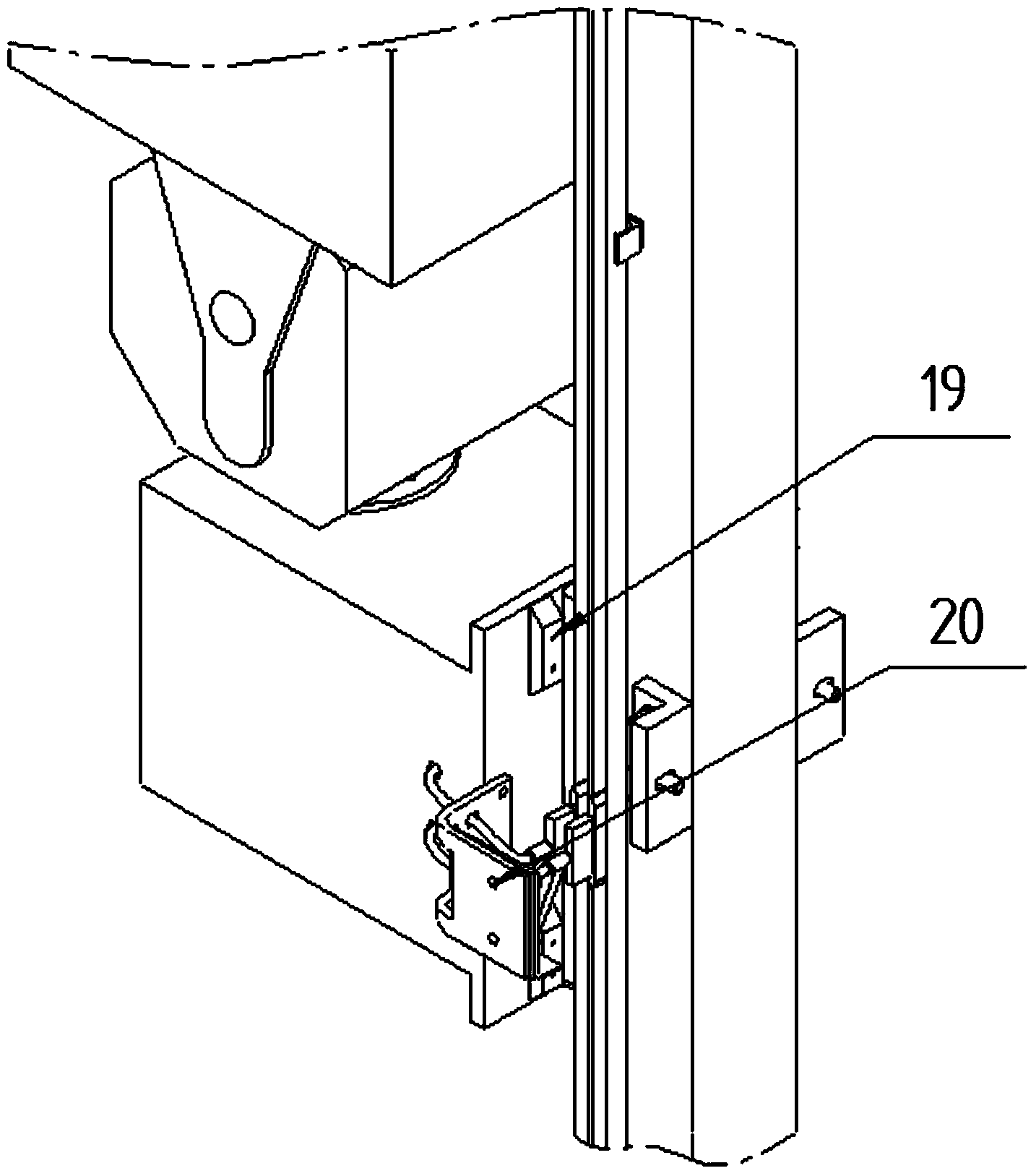

Indoor rail-type intelligent patrolling robot

ActiveCN104267729AImprove structural strengthIncrease stiffnessPosition/course control in two dimensionsEngineeringTerminal system

The invention discloses an indoor rail-type intelligent patrolling robot. The indoor rail-type intelligent patrolling robot comprises a robot terminal system. The robot terminal system comprises a sectional material rail. The sectional material rail is installed on the indoor wall, and a movement mechanism, a movement driving mechanism and a detecting mechanism are installed on the sectional material rail. The detecting mechanism comprises a holder and a detecting assembly and is installed on the movement mechanism. The movement mechanism is driven by the movement driving mechanism and drives the detecting mechanism to vertically move along the sectional material rail, wide-range detection on an indoor to-be-detected device is achieved in cooperation with running of the holder, and the robot terminal system carries out power supply and communication in a cable pulling mode or carries out power supply in a wire sliding contact mode and carries out communication in a power line carrier mode. The indoor rail-type intelligent patrolling robot is compact and attractive in structure, rapid and convenient to install, stable and reliable in running, high in positioning accuracy, wide in detection range and high in automation degree.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

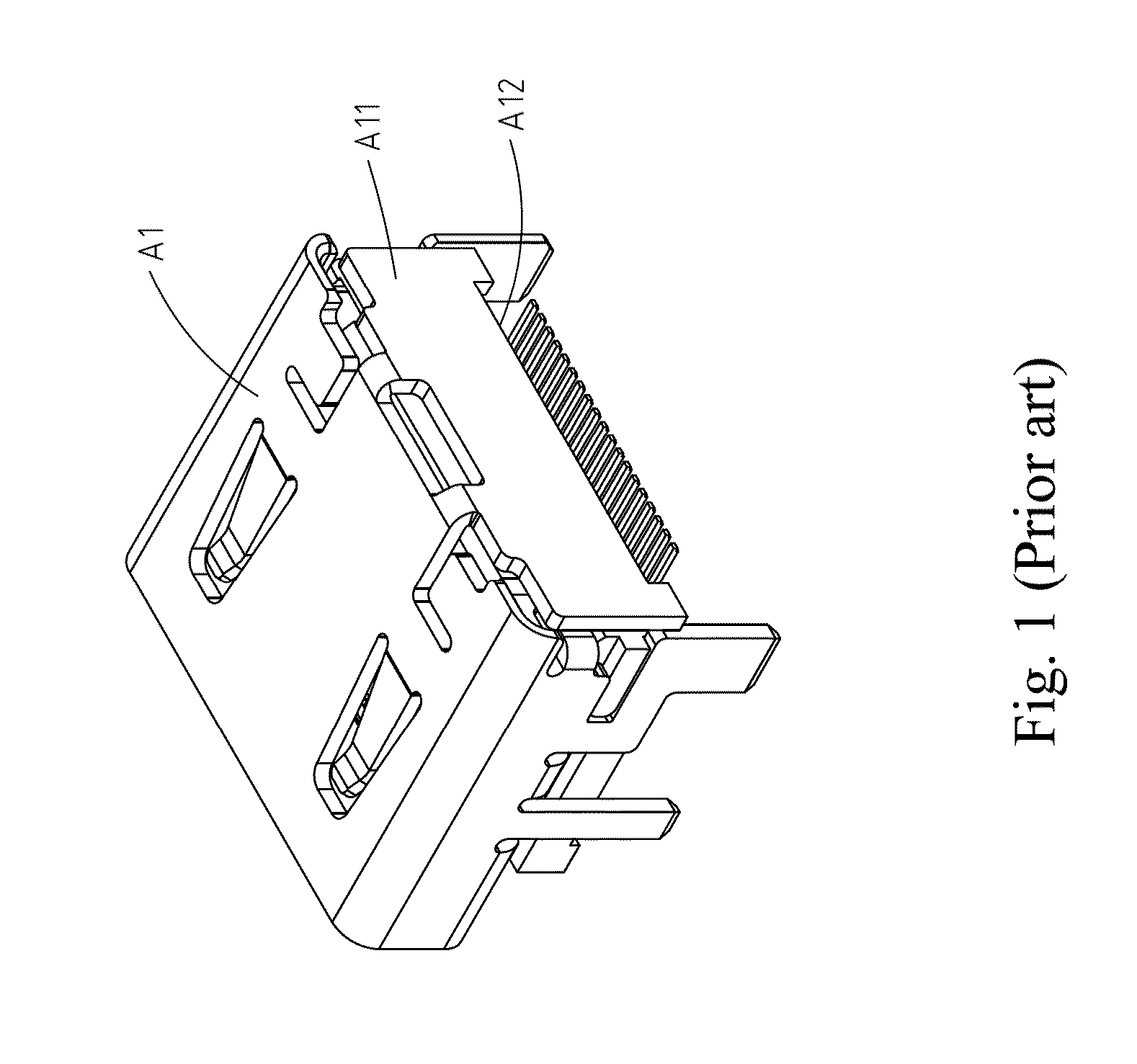

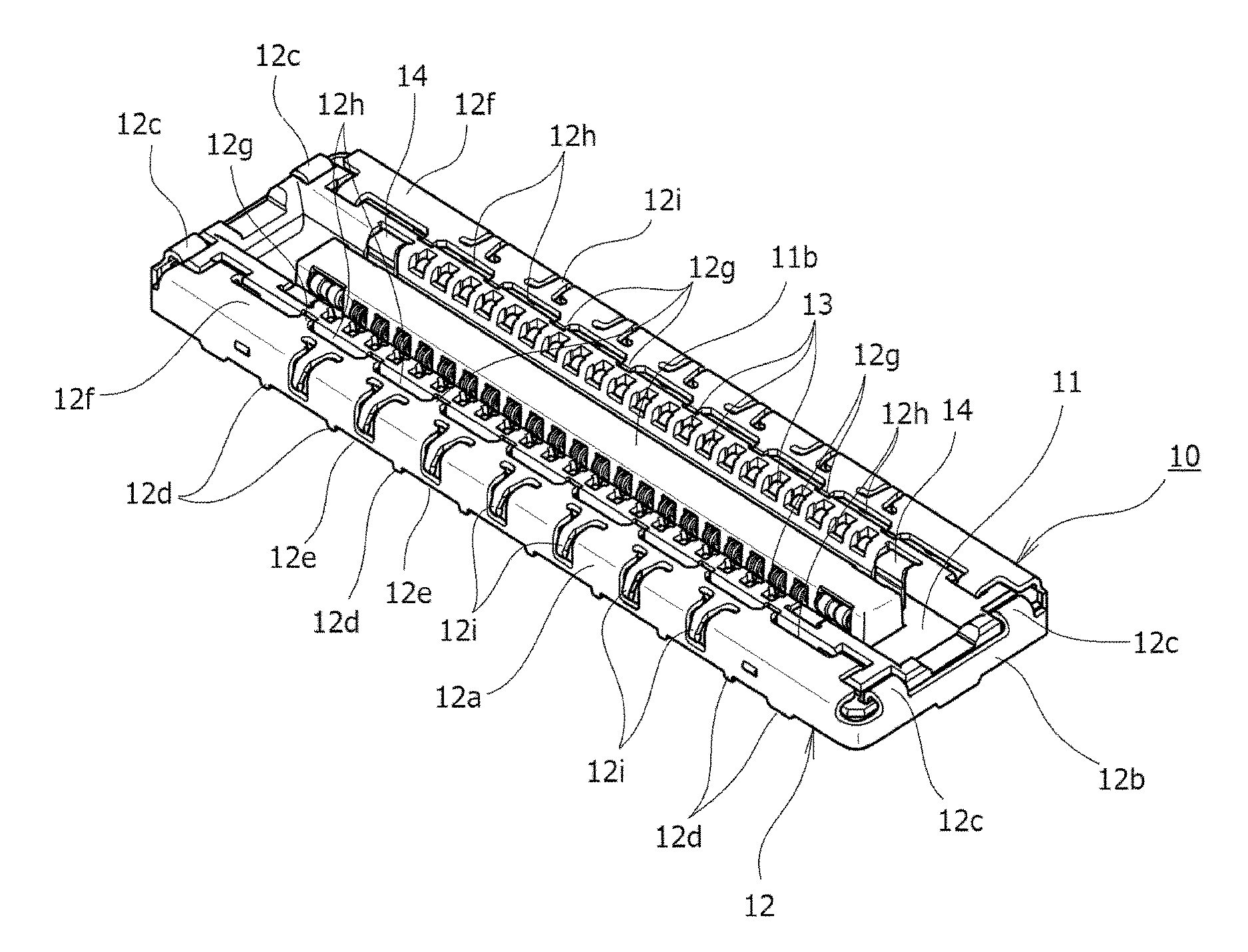

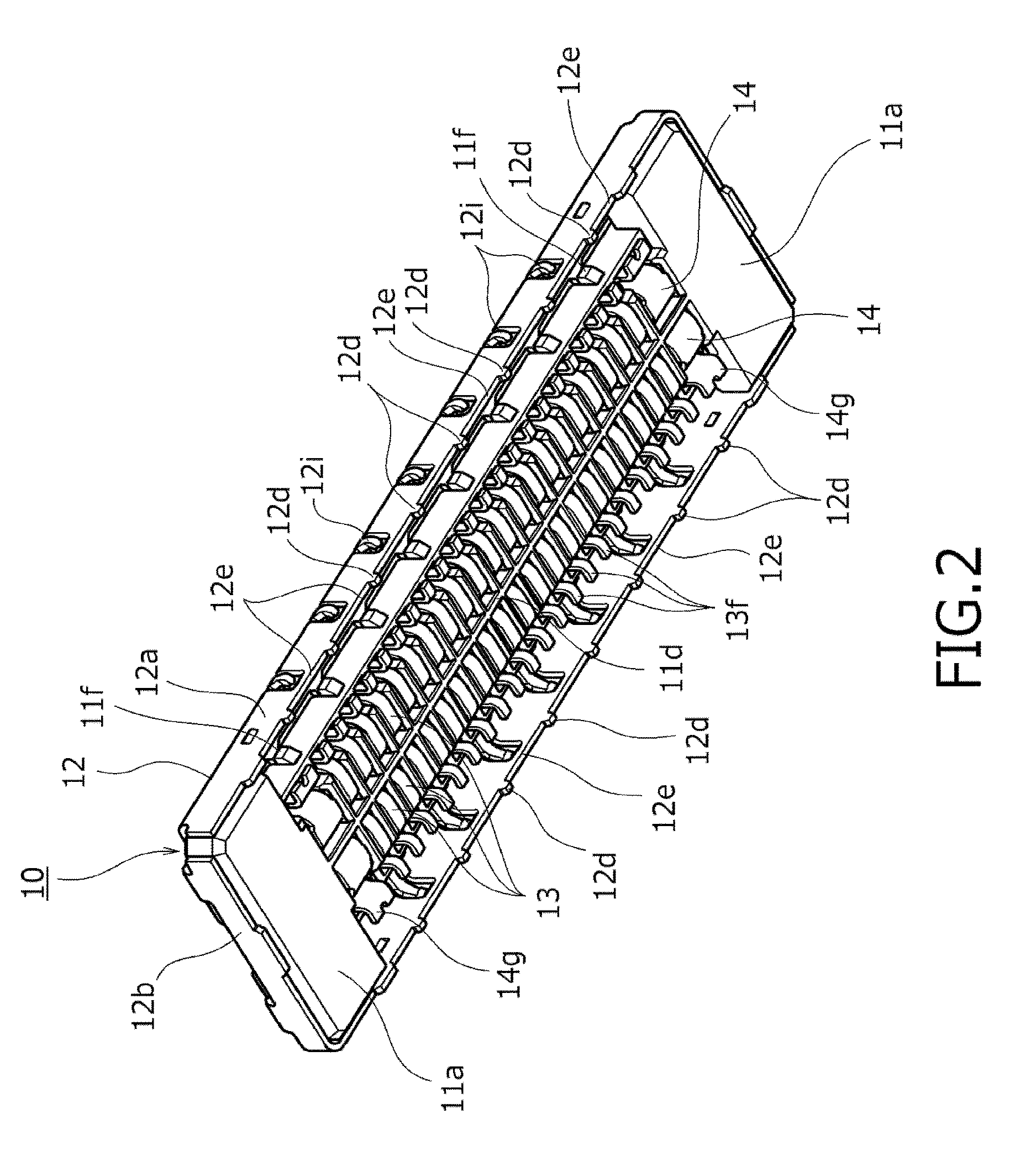

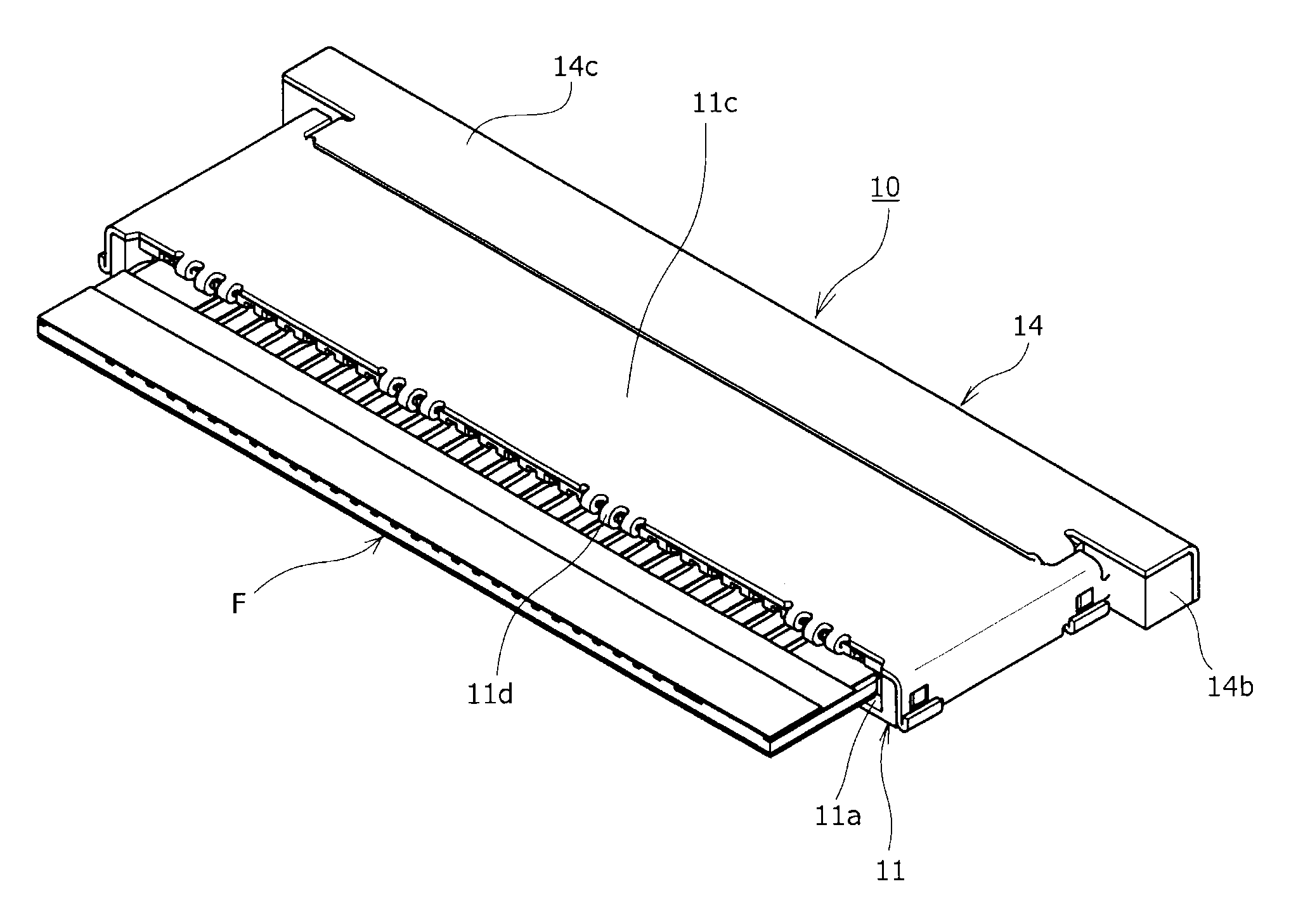

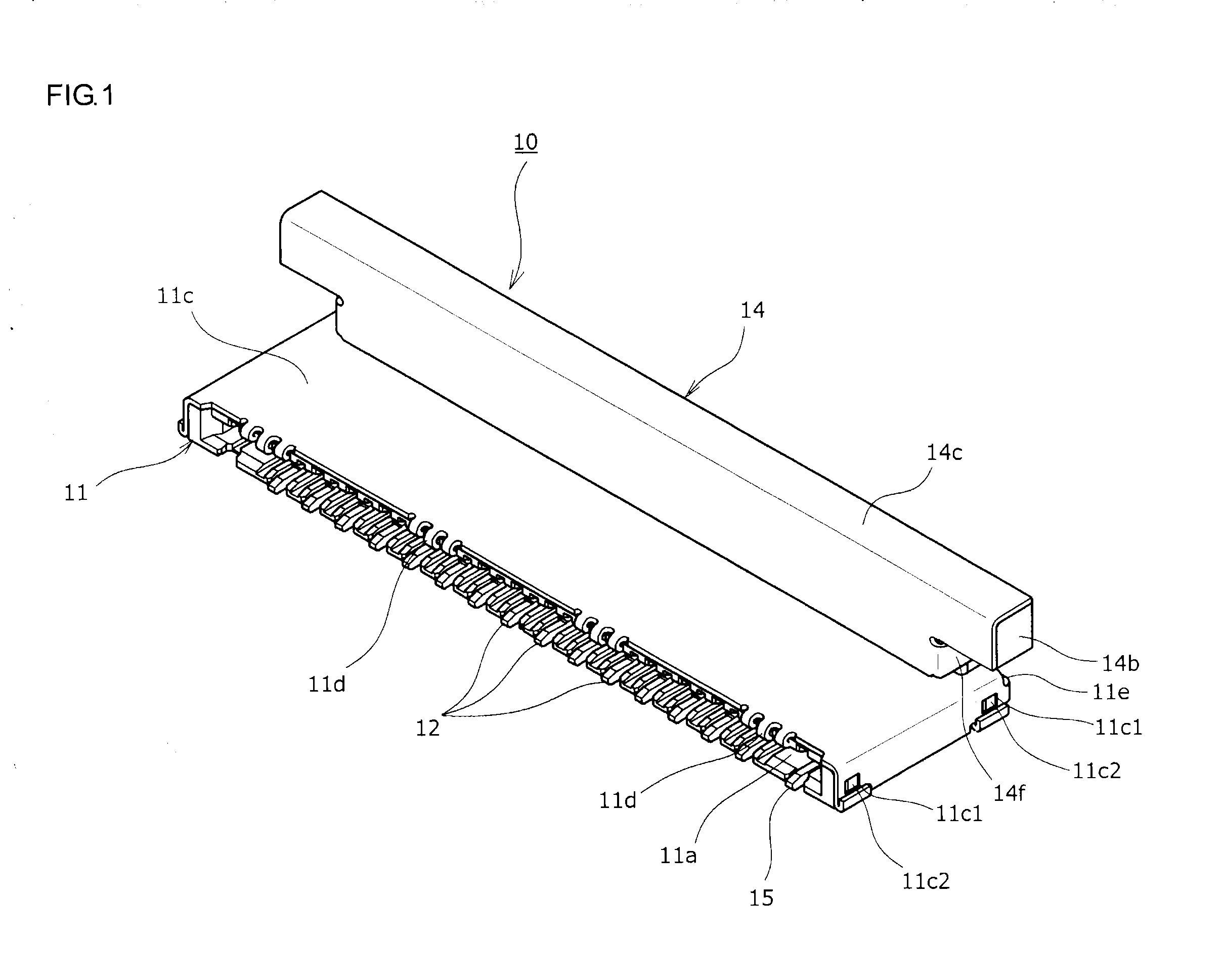

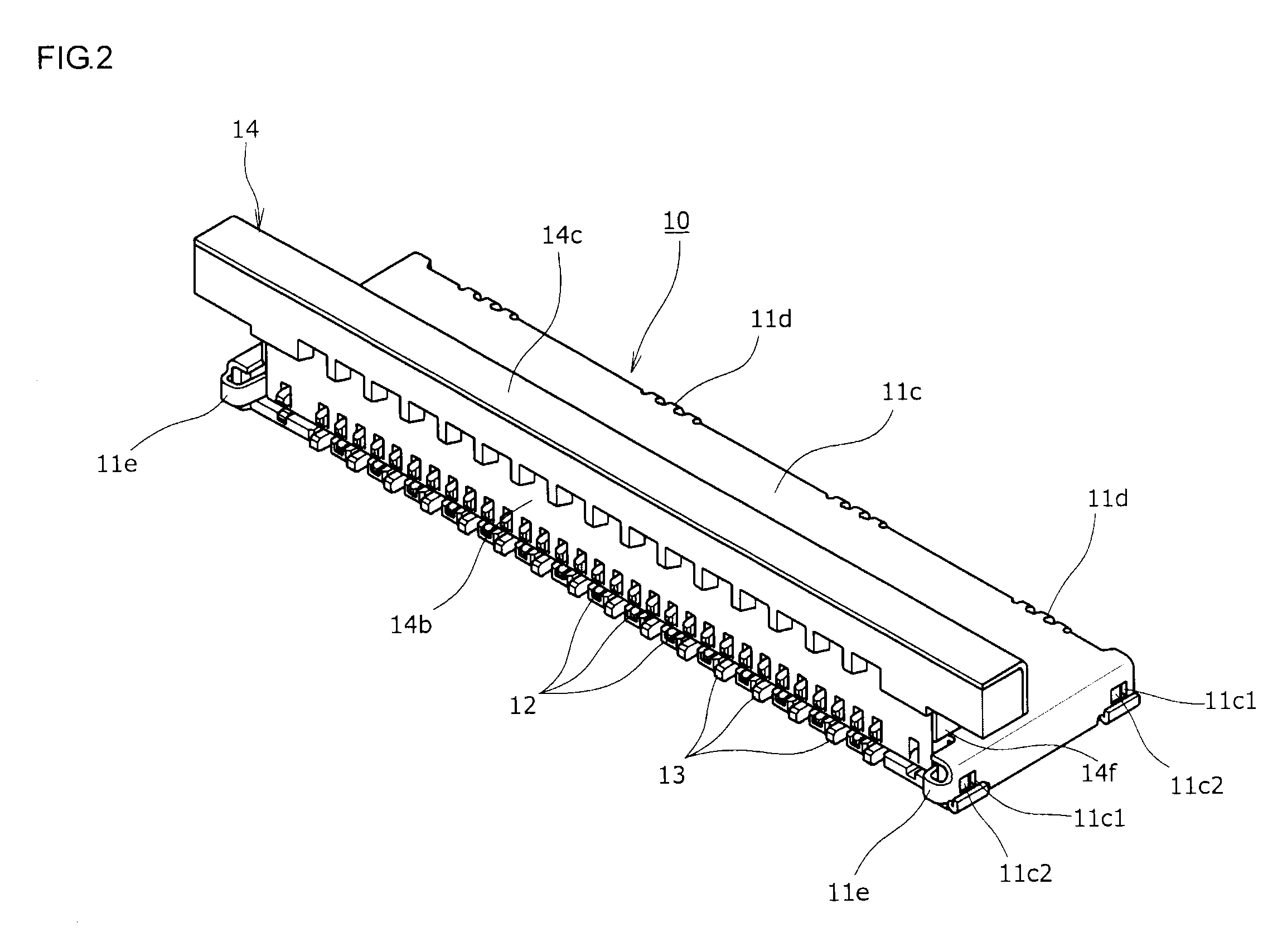

Board-connecting electric connector

ActiveUS20170033510A1Easy to checkSimple configurationLine/current collector detailsFixed connectionsElectromagnetic shieldingElectrically conductive

The connection state of contact members with respect to a wiring board can be easily visually checked by a simple configuration. A shield wall portion composed of an electrically-conductive member opposed to contact connecting portions (board connecting portions) of a plurality of contact members arranged in a multipolar shape is provided; each of ground connecting portions provided in the shield wall portion is disposed at the part between the contact connecting portions, which are adjacent to each other; a lateral check window composed of the space which enables visual check of the contact connecting portions is formed in the interval region in which the ground connecting portions are adjacent to each other; an electromagnetic shielding function with respect to the contact connecting portions is obtained by the shield wall portion; and, at the same time, the connection state of the contact connecting portions with respect to the wiring board can be visually checked through the lateral check window provided in the shield wall portion.

Owner:DAIICHI SEIKO CO LTD

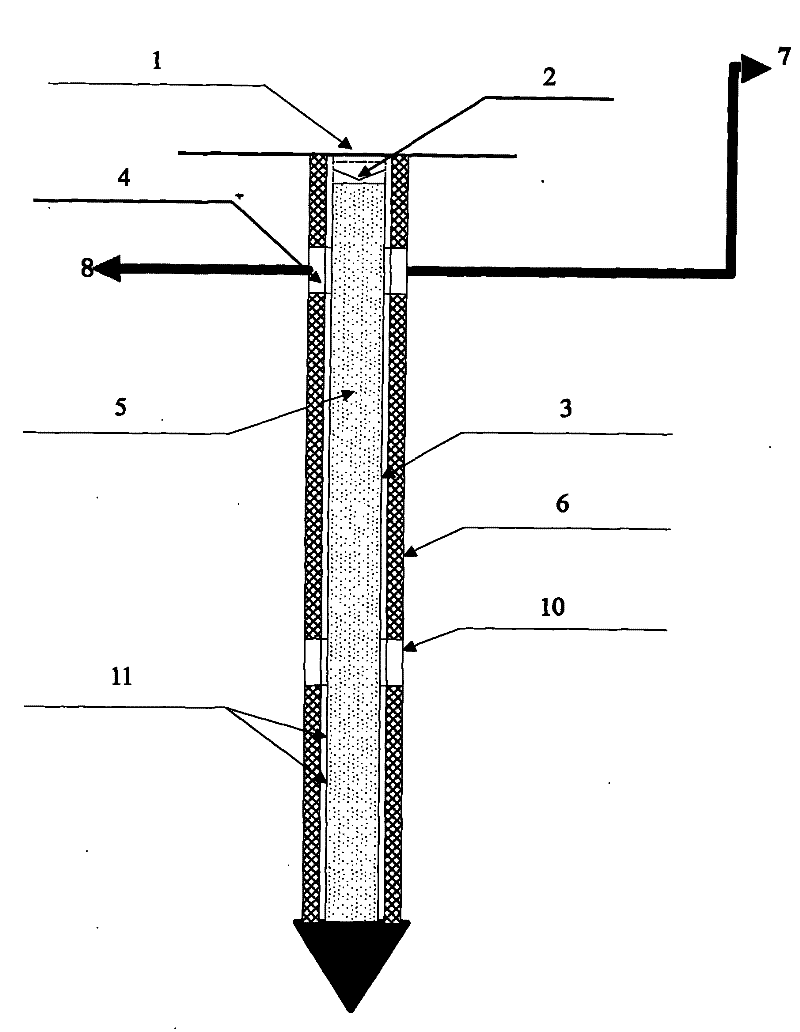

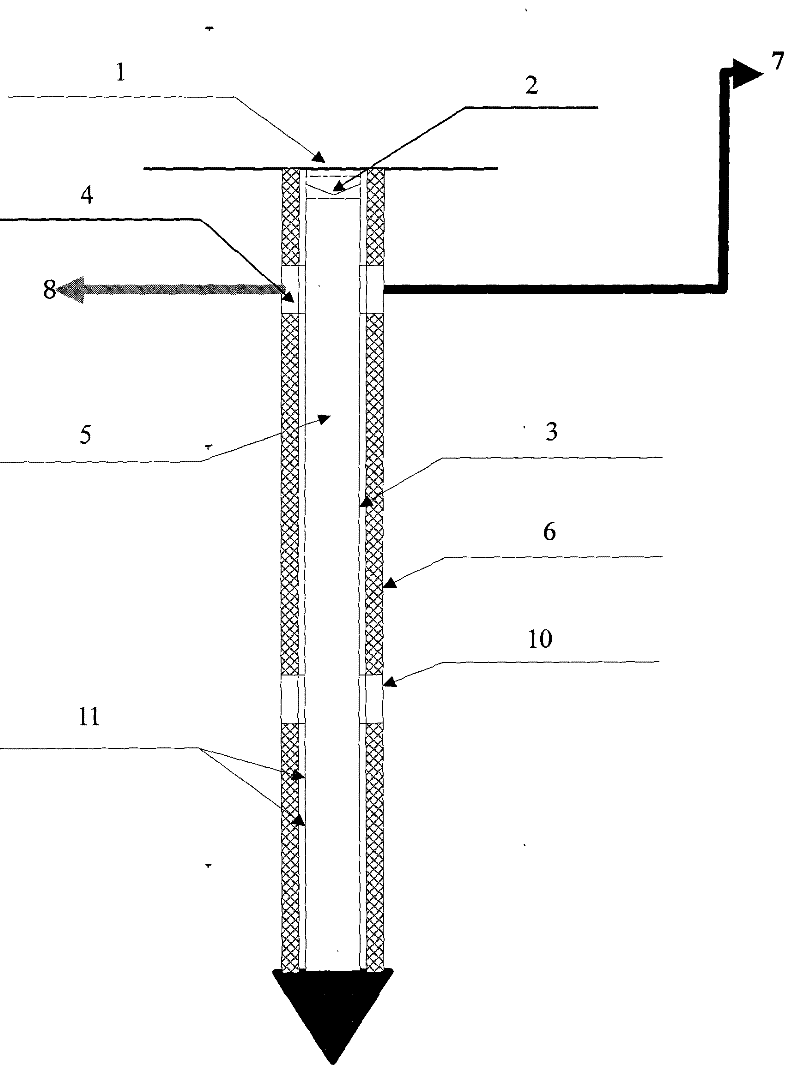

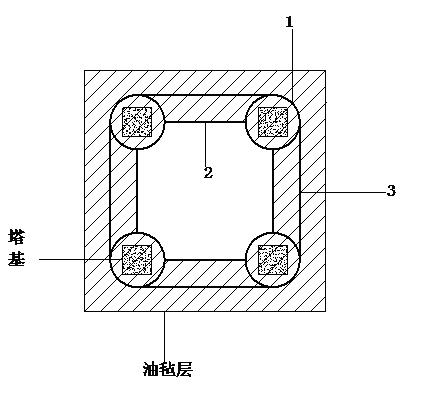

Grounding electrode of anti-corrosion and adjustable grounding resistor

InactiveCN101752684ALong corrosion lifeWith anti-corrosion functionConnection contact member materialTransformerGrounding resistance

The invention relates to a grounding electrode in a lightning protection grounding system of a power station, a transformer grounding network, a high-voltage power transmission line iron tower, an electrified railway grounding system, a wireless communication transmitting tower, a transformer neutral point, a high-rise building, a large computer and a microelectronic equipment system equipment center. The grounding electrode comprises a grounding electrode main body which is a thick-walled and seamless steel tube; the thickness of the wall of the steel tube is more than 8-10mm, the inner wall and the outer wall thereof are provided with an anti-corrosion conducting film, the lower end thereof is provided with a sealing head, the top end thereof is provided with an openable packing port, and the wall thereof is provided with a releasing hole; and the steel tube is externally provided with an external packing with good electric conduction, corrosion prevention and water permeability, and an interface connected with the grounding network and an equipment grounding lead. The grounding electrode has convenient and fast installation and construction, good resistance-reducing effect and convenient maintenance with the service life thereof of being not lower than that of the grounding equipment, and is a grounding electrode which not only meets the anti-corrosion function of the grounding electrode in the grounding network, but also reduces the grounding resistance performance of the grounding electrode.

Owner:高政

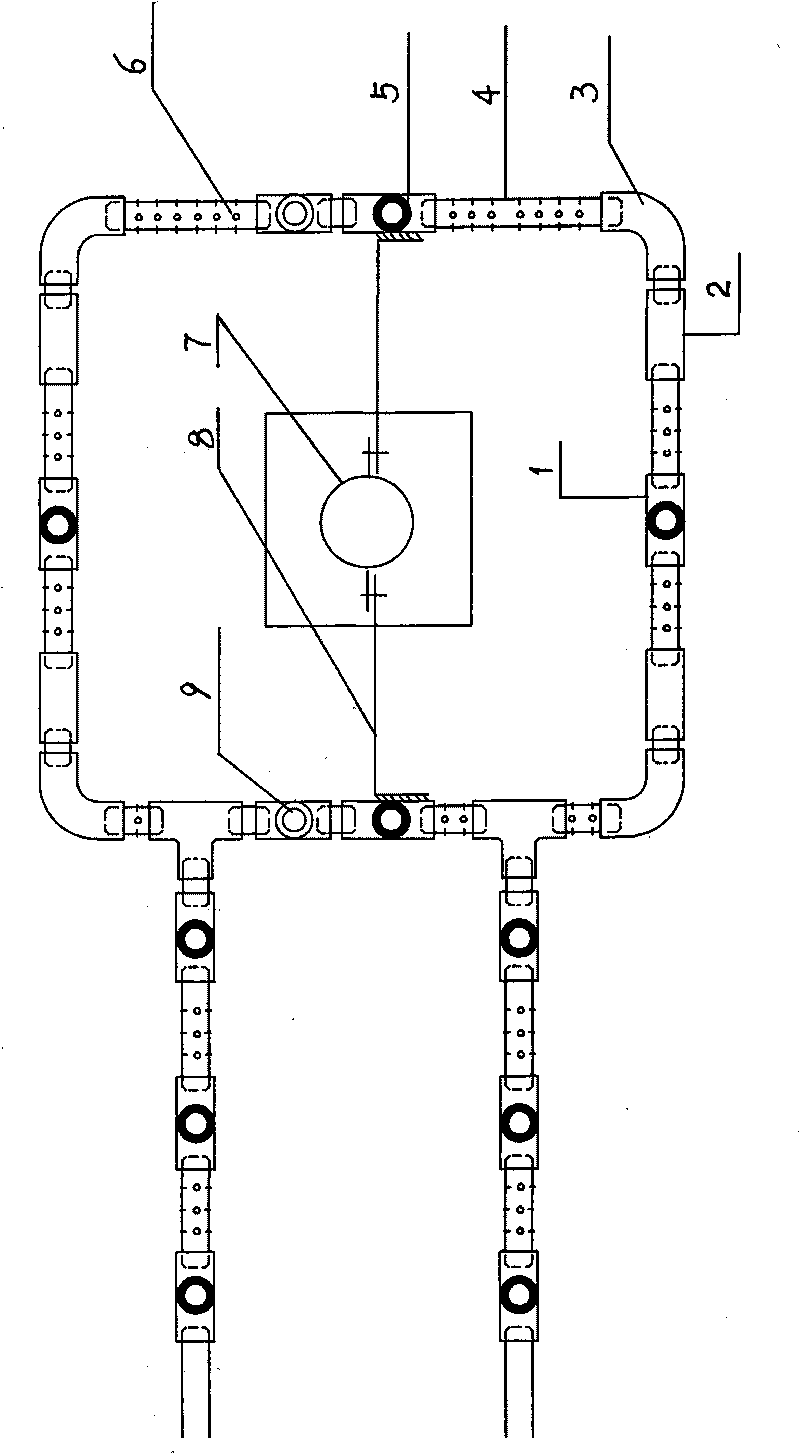

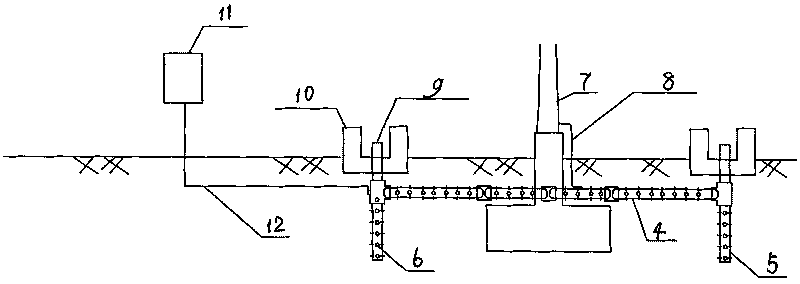

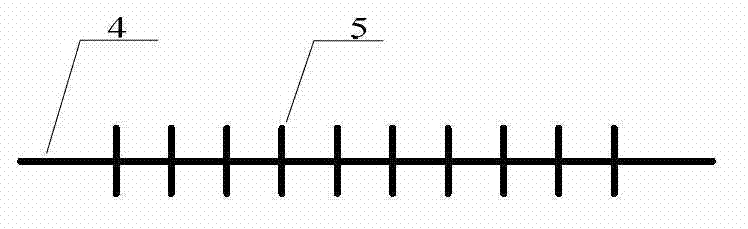

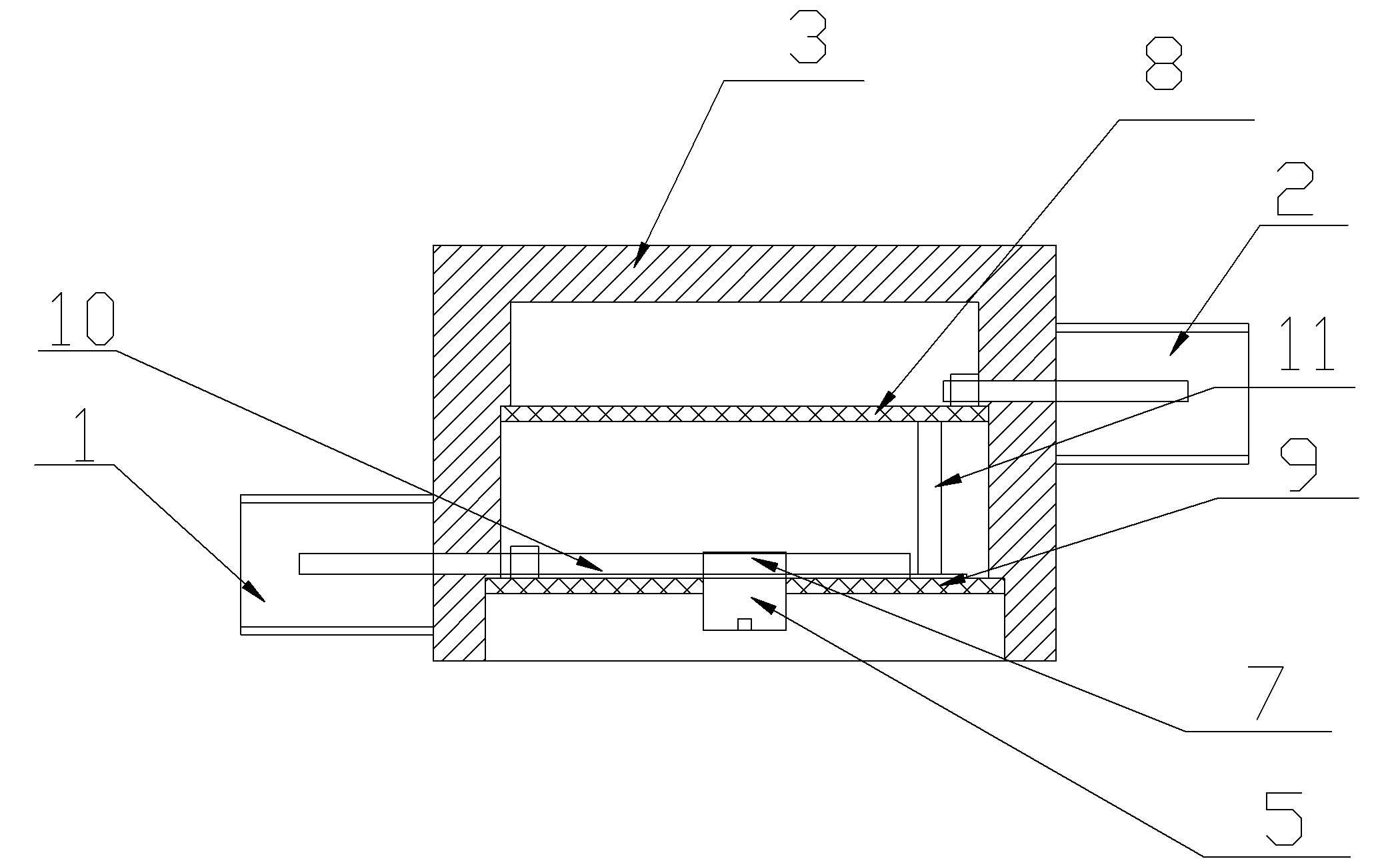

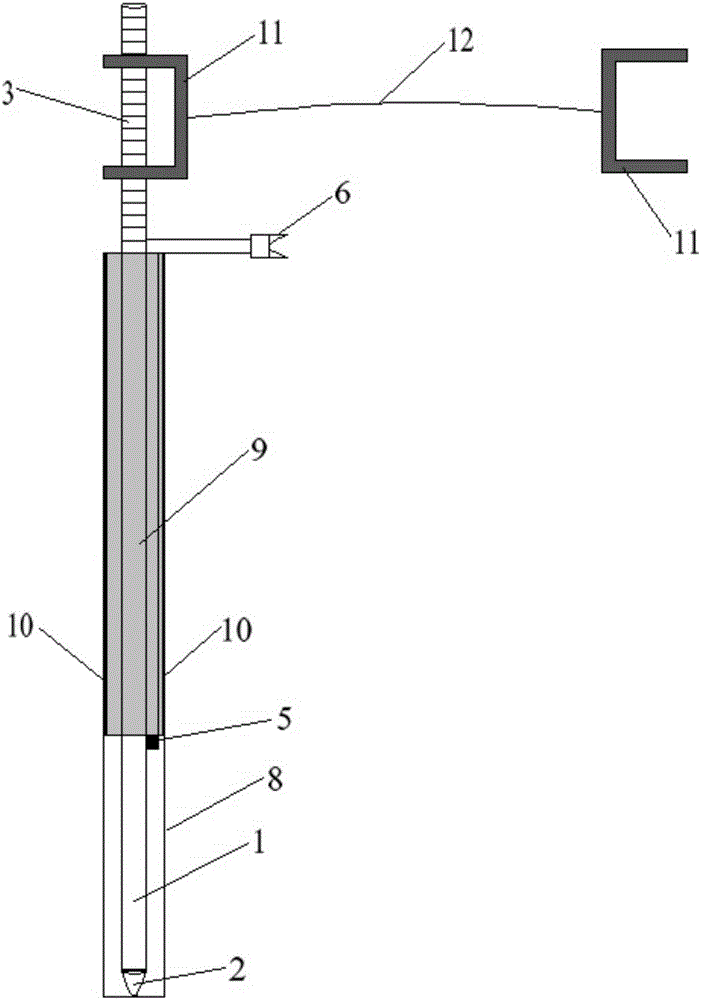

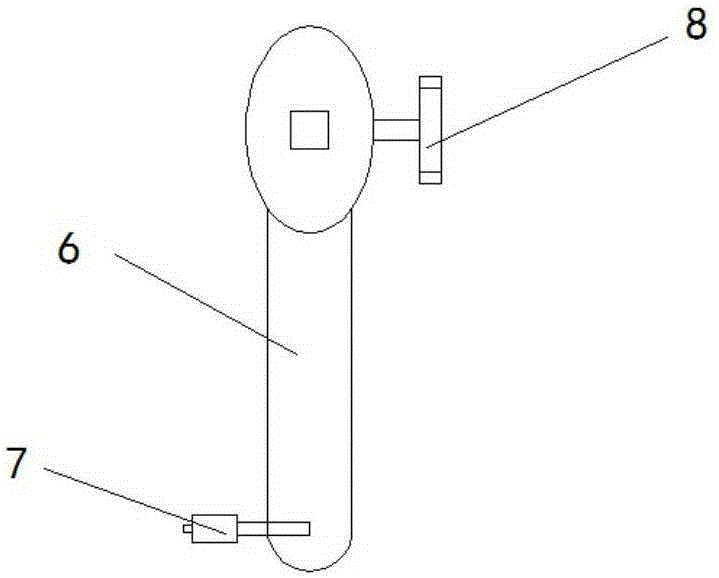

Monitoring low-resistance module grounding device

InactiveCN101728661AGuaranteed reliabilityKeep moist for a long timeEarth resistance measurementsConnection contact member materialComputer moduleEngineering

The invention discloses a monitoring low-resistance module grounding device, which comprises a grounding body connected with a grounding downlead (8) and a liquid tank (10) for containing liquid, wherein the grounding body comprises a plurality of sequentially communicated horizontal grounding tubes (4) and a plurality of vertical grounding tubes (5) communicated with the horizontal grounding tubes (4) respectively; both the horizontal grounding pipes (4) and the vertical grounding pipes (5) are provided with a plurality of seepage holes (6); and the liquid tank (10) is communicated with the grounding pipes through liquid injection pipes (9). Cathode protection electrolyte is filled in the grounding pipes and seeps into soil through the seepage holes (6) to keep the soil wet constantly and increase the free ions in the soil. The device has the advantages of obviously reducing grounding resistance and effectively ensuring the reliability of a grounding network. Particularly in areas and seasons of high soil resistance and he device has obvious effects.

Owner:吕良

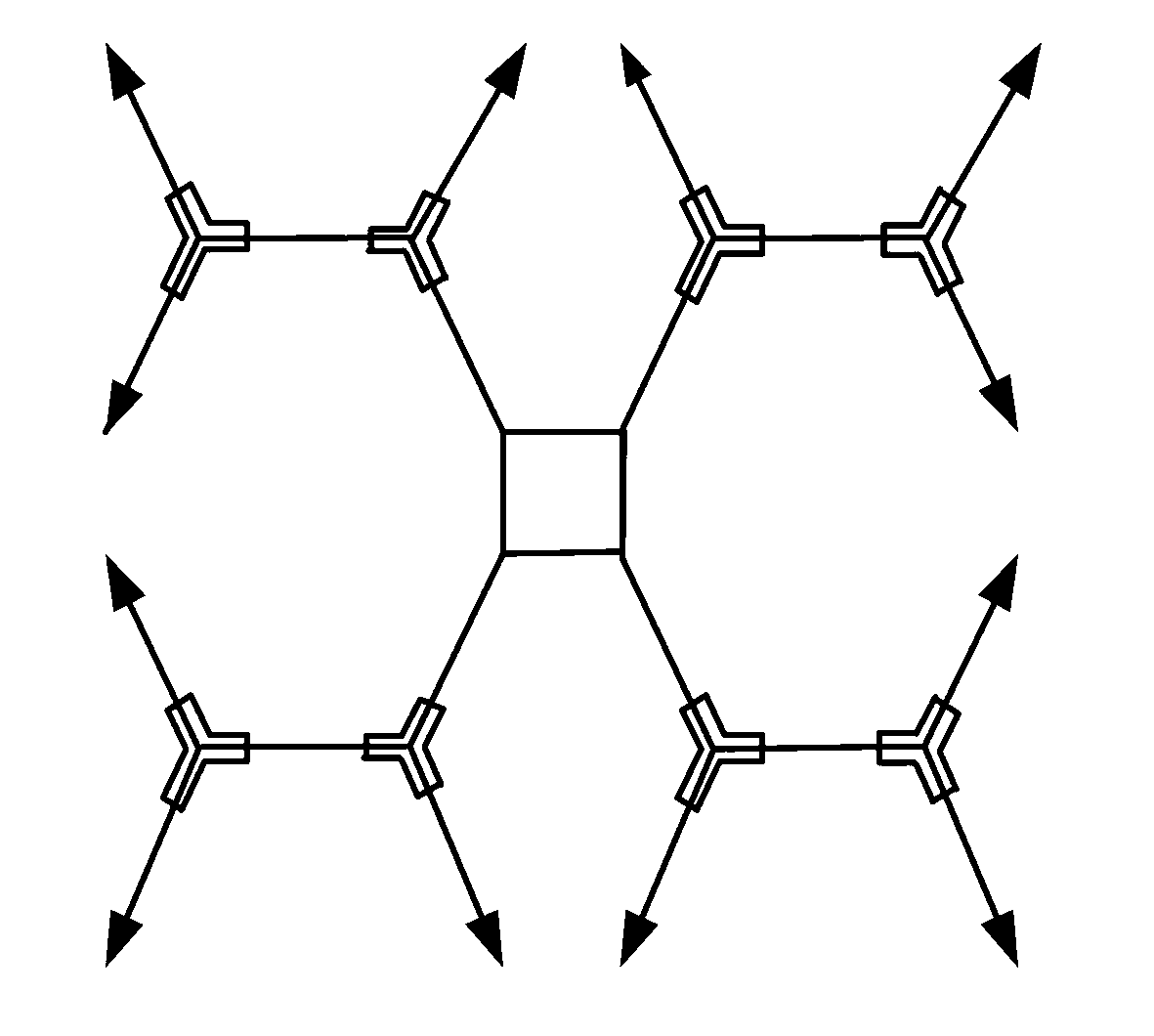

Hollow aluminum alloy tube grounding device capable of being assembled

InactiveCN103326139AGuaranteed uptimeExtended service lifeConnection contact member materialClosed loopMaterials science

A hollow aluminum alloy tube grounding device capable of being assembled comprises a closed loop. Multiple groups of grounding bodies are welded on the closed loop. Each grounding body comprises at least one unit grounding body, and the unit grounding bodies are connected through matched sleeves and are hollow aluminum alloy tubes. The sleeves are one kind or several kinds of axial sleeves, Y-type sleeve and T-type sleeves. Four groups of grounding bodies are welded on the closed loop, one end of each grounding body is welded on the closed loop, and the other end of each grounding body can be extended according to needs through the sleeves. Each unit grounding body is 1m long, threads are machined at the two ends of each unit grounding body, and threads matched with the two ends of the unit grounding bodies are arranged in the sleeves. Each grounding body is of a hollow aluminum alloy tubular structure, so the hollow aluminum alloy tube grounding device is light in weight, good in electrical conductivity and thermal conductivity, and strong in corrosion resistance; an assembled structure is adopted, so the hollow aluminum alloy tube grounding device is convenient to transport, easy to construct, and suitable for various environments due to the fact that multiple sleeves are adopted.

Owner:CHINA THREE GORGES UNIV +1

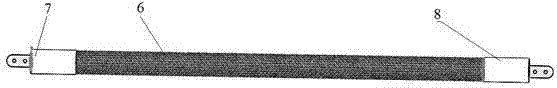

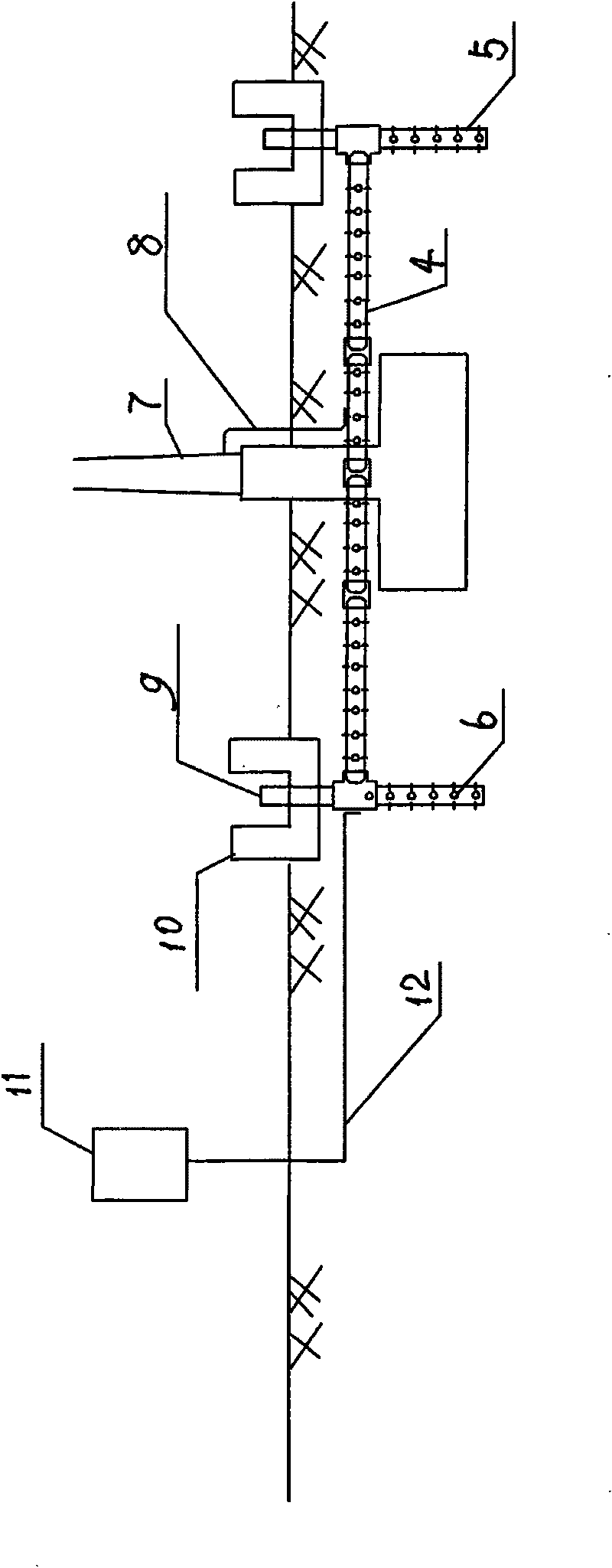

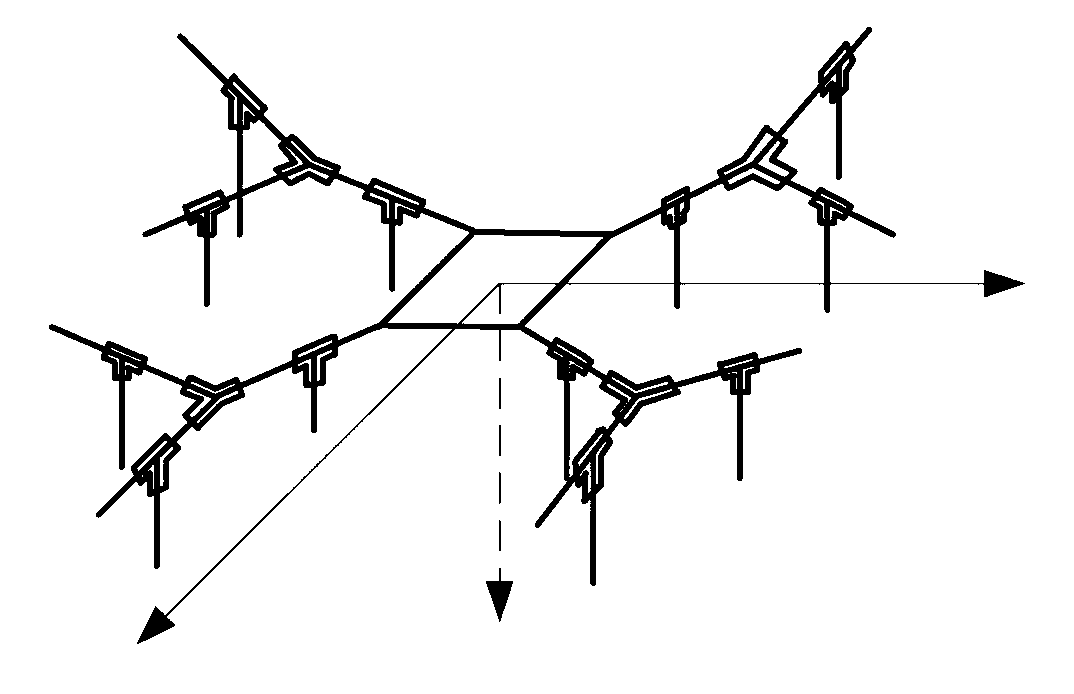

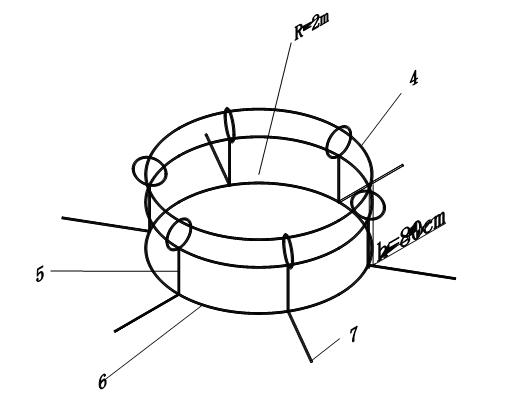

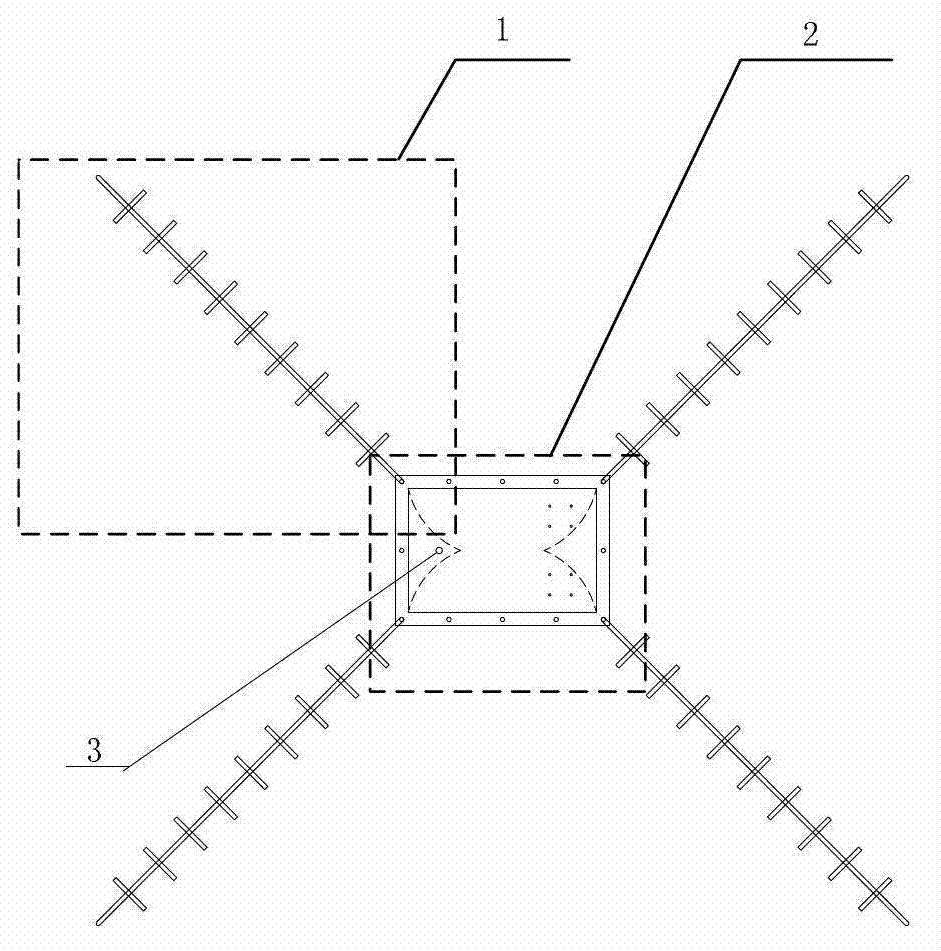

Grounding method for decreasing step voltage of transmission line tower

InactiveCN102593618AImprove soil parametersReduce ground resistanceLine/current collector detailsConnection contact member materialElectrical resistance and conductanceEngineering

The invention discloses a novel safe grounding method of a transmission line tower. The method includes that a linoleum insulating layer is laid on the upper layer, and a three-dimensional ring-shaped grounding body is laid on the lower layer, so that hazard caused by step voltage and touch voltage of the transmission line tower is reduced. The three-dimensional ring-shaped grounding body comprises an upper layer cylindrical grounding body (4), a middle layer vertical connection body (5), a bottom circular ring (6) and a peripheral welding level radiation pole (7) with a circular ring structure. According to the method, dispersion resistance is effectively reduced, a GPF-94 resistance reducing agent is filled to the inside of the ring shape to improve soil parameters, reduce ground resistance and enlarge an effective cross section of the grounding body, and a good voltage balancing function is achieved. By means of the level radiation pole, current dispersing is greatly performed. The linoleum insulating layer is laid at a position of a peripheral ground voltage balancing body, which is 0.8m above the ground surface, so that permissible value of the step voltage is increased, and value of current which flows through a human body is decreased. The grounding method for decreasing step voltage of the transmission line tower has the advantages of being good in current dispersing and voltage balancing effects of the bottom layer, wide in application range, convenient to construct, corrosion resistant, safe and reliable.

Owner:李景禄 +2

Electrical receptacle connector

ActiveUS9537250B2Reduce spacingEasy to fixCoupling device detailsTwo-part coupling devicesSolderingMechanical engineering

An electrical receptacle connector includes an insulated housing, plate terminals, and a metallic shell. The insulated housing includes a base portion. The plate terminals are at the insulated housing. The plate terminals include soldering segments exposed out of the bottom of the base portion. The metallic shell encloses four sides of the insulated housing and includes a top cover plate, a rear cover plate, and pins. The top cover plate is located atop the base portion. The rear cover plate is extending downwardly to the rear side of the base portion from the rear side of the top cover plate. The rear cover plate includes a bottom surface and a bent sheet substantially perpendicular to an outer wall of the rear cover plate and extended outward from the outer wall of the rear cover plate, and the pins are extending downwardly from the bottom surface.

Owner:ADVANCED CONNECTEK INC

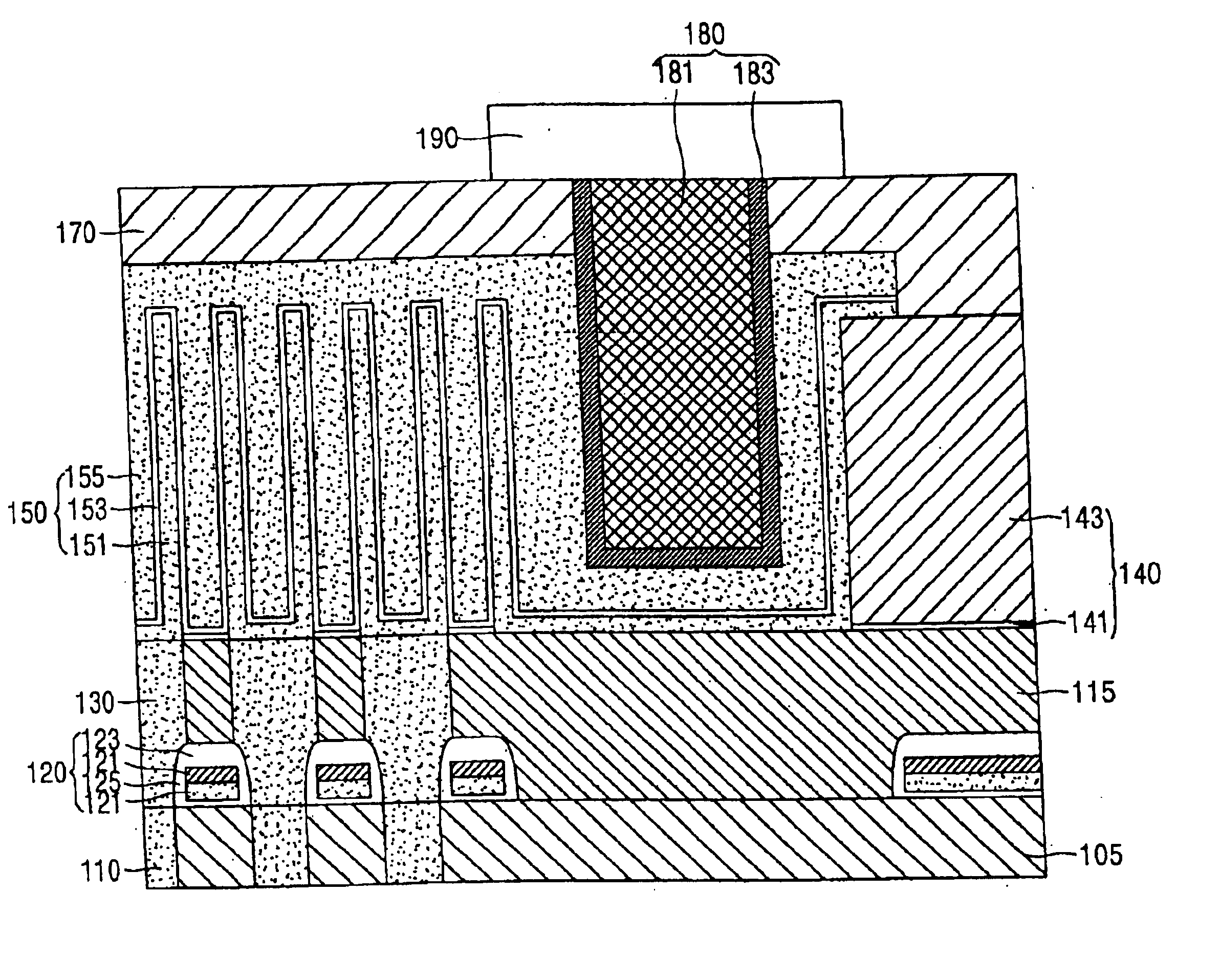

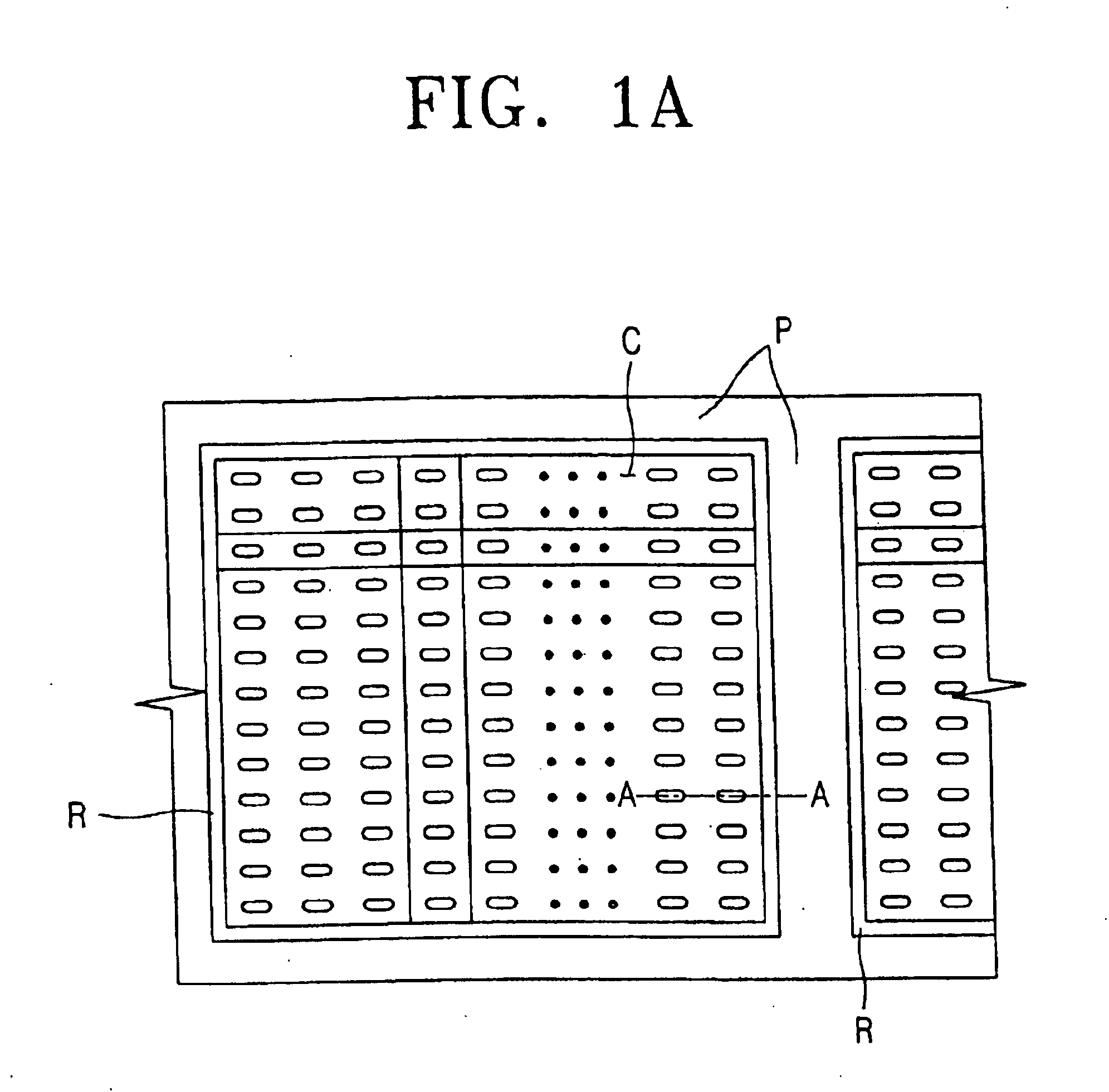

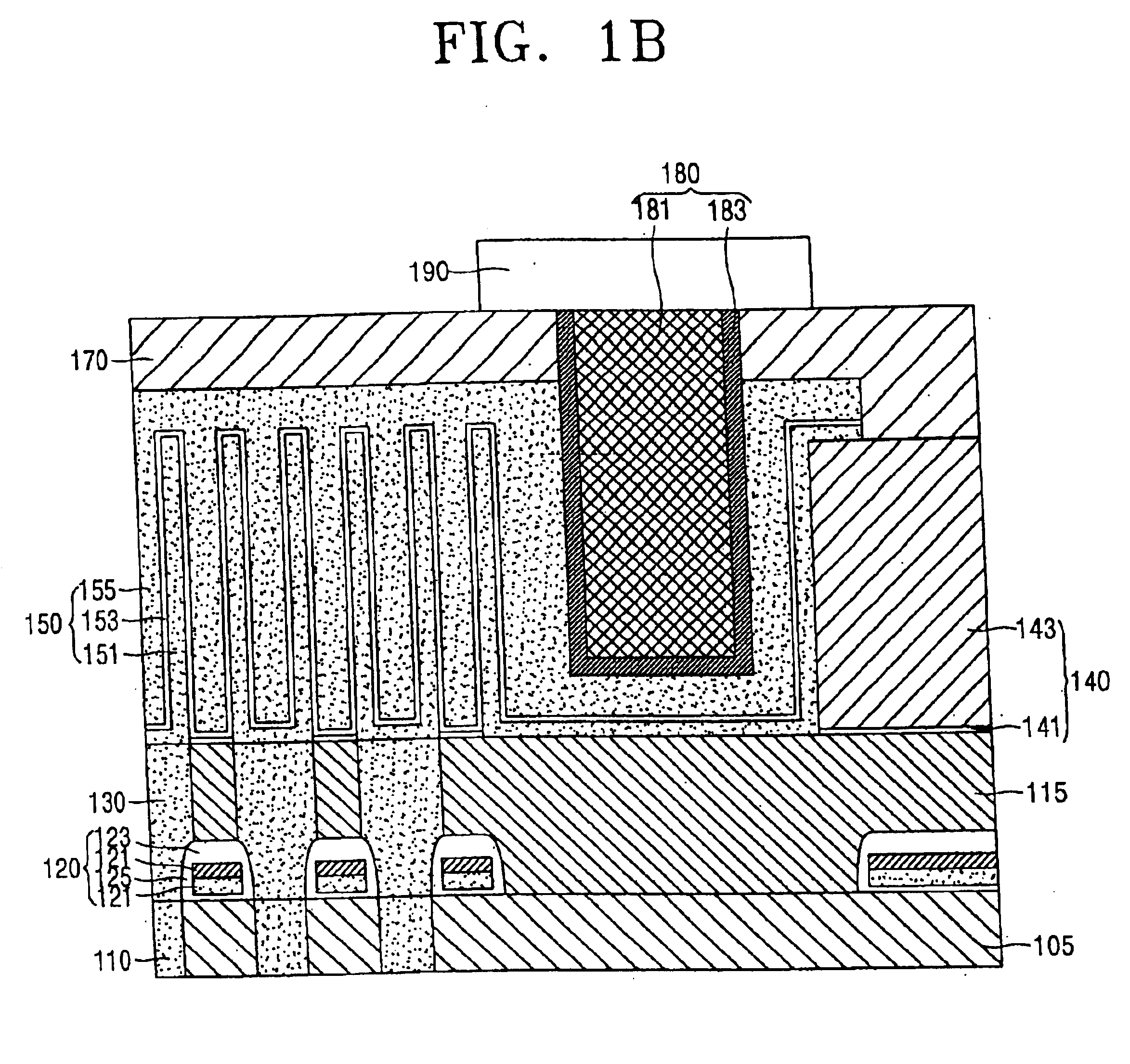

Semiconductor memory device and method for manufacturing the same

InactiveUS6949429B2Increase contact areaReduce contact resistanceTransistorSolid-state devicesSource areaGuard ring

A semiconductor memory device and a method for manufacturing the same are provided. The semiconductor memory device includes an oxide layer for isolating individual devices which define device areas so that a cell area and a peripheral circuit area are separated from each other on a semiconductor substrate, a plurality of MOS transistors, which are comprised of source areas, drain areas, and gates that are formed in the cell area and the peripheral circuit area, a bit line, which is formed on the plurality of MOS transistors and is electrically connected to the MOS transistor, a stack-shaped capacitor, which is comprised of a first electrode, a dielectric layer, and a second electrode between which the MOS transistors and the bit line in the cell area is interposed, a guard-ring pattern, which are interposed between the cell area and the peripheral circuit area, surrounds the cell area and is apart from the peripheral circuit area, and a contact fill for plate electrode, which is formed in the guard-ring pattern and is in contact with the second electrode that is formed on the internal sidewall and the bottom of the guard-ring pattern. The guard-ring pattern is formed in a boundary between the cell area and the peripheral circuit area while surrounding the cell area, and thereby step caused by manufacture of the stack-shaped capacitor are removed during a manufacturing process, and the contact fill for plate electrode is formed in the guard-ring pattern, and thereby the ground resistance of the capacitor is reduced, and the electrical characteristics of the memory device are improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Grounding module

ActiveCN103199349AStrong moisture absorption and moisturizing abilityImprove conductivityLine/current collector detailsConnection contact member materialHigh concentrationMetallic materials

A grounding module comprises a module body and is characterized in that the formula of the grounding module basically comprises the following components in parts by weight: 13-17 parts of coke powder, 1.5-8 parts of cement, and 0.3-5 parts of graphite powder. The formula of the grounding module further comprises 0.3-5 parts of ion releasing agent. The grounding module has the advantages that the grounding module adopts natural nonmetallic mineral materials which have excellent conductivity and soil compatibility as conducting medium of the grounding module, conductivity of the grounding module is not affected by seasons, so that stable ground resistance is provided, besides, due to the nonmetallic mineral materials, a low resistance zone which is gentle in variation is formed between metal and soil which have huge difference in resistivity, step voltage and contact voltage are lowered, probability of occurrence of ground potential counterattack is reduced, moreover, by matching an ion releaser, electrolyte can durably permeate into the soil in a high concentration mode, the goal that ground resistance can be rapidly lowered is achieved, and characteristics of the grounding module such as density, corrosion resistance, conductivity, compressive strength are enhanced.

Owner:SUZHOU BIJIA INTERNET TECH CO LTD

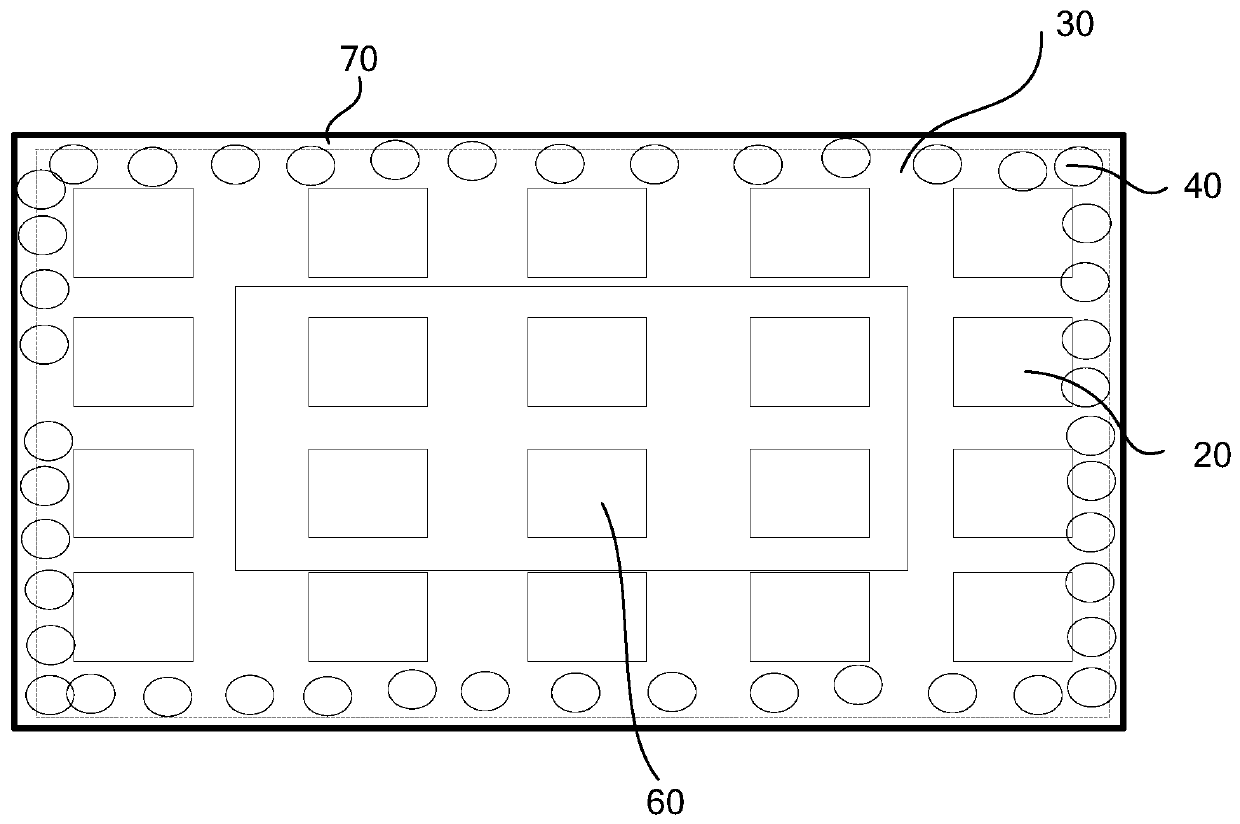

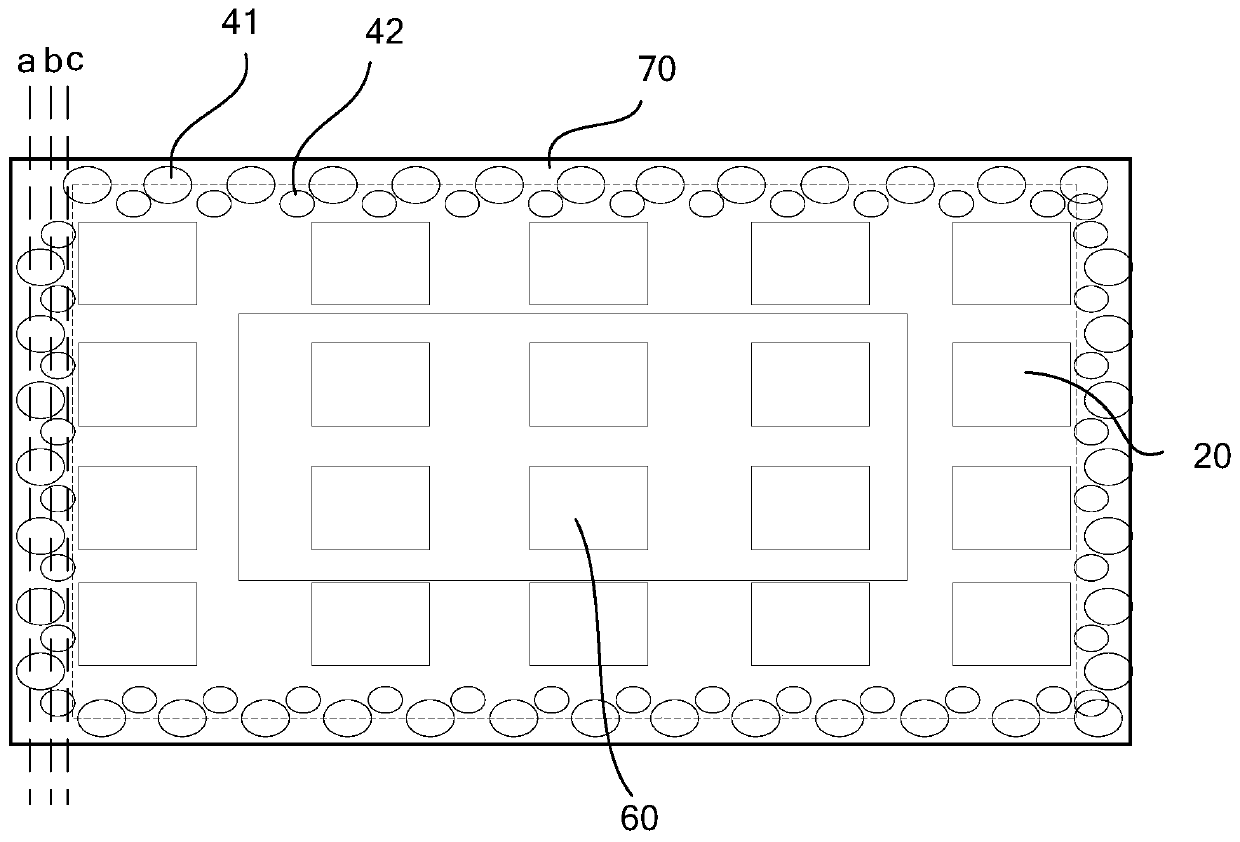

Packaging shielding structure and electronic equipment

ActiveCN109803523AImprove electromagnetic shielding performanceAvoid electromagnetic interferenceMagnetic/electric field screeningSemiconductor/solid-state device detailsSet distanceGround plane

The invention provides a shielding packaging structure and electronic equipment, and the shielding packaging structure comprises a substrate. At least two stacked first grounding layers are arranged in the substrate, and one surface of the substrate is provided with a second grounding layer. The second grounding layer is provided with grounding bonding pads arranged along the edge of the substrate. Moreover, grounding holes for electrically connecting the adjacent grounding layers are formed in the substrate, and the grounding holes are arranged in a circle around a plate body, and the distance between the adjacent grounding holes is smaller than a set distance, so that the grounding holes can form a good Faraday electric cage. A device is arranged on the other surface of the substrate, and a packaging layer for packaging the device is also arranged on the device. In addition, the structure also comprises a shielding layer wrapped by the packaging layer, and the shielding layer extendsto the substrate and is electrically connected with the first grounding layers. According to the scheme, the grounding resistance is reduced through the arranged grounding holes, and the electromagnetic shielding effect of the shielding layer is improved. Electromagnetic interference at the bottom of the substrate is avoided through the second grounding layer and the grounding bonding pad, and the shielding effect is improved.

Owner:HUAWEI TECH CO LTD

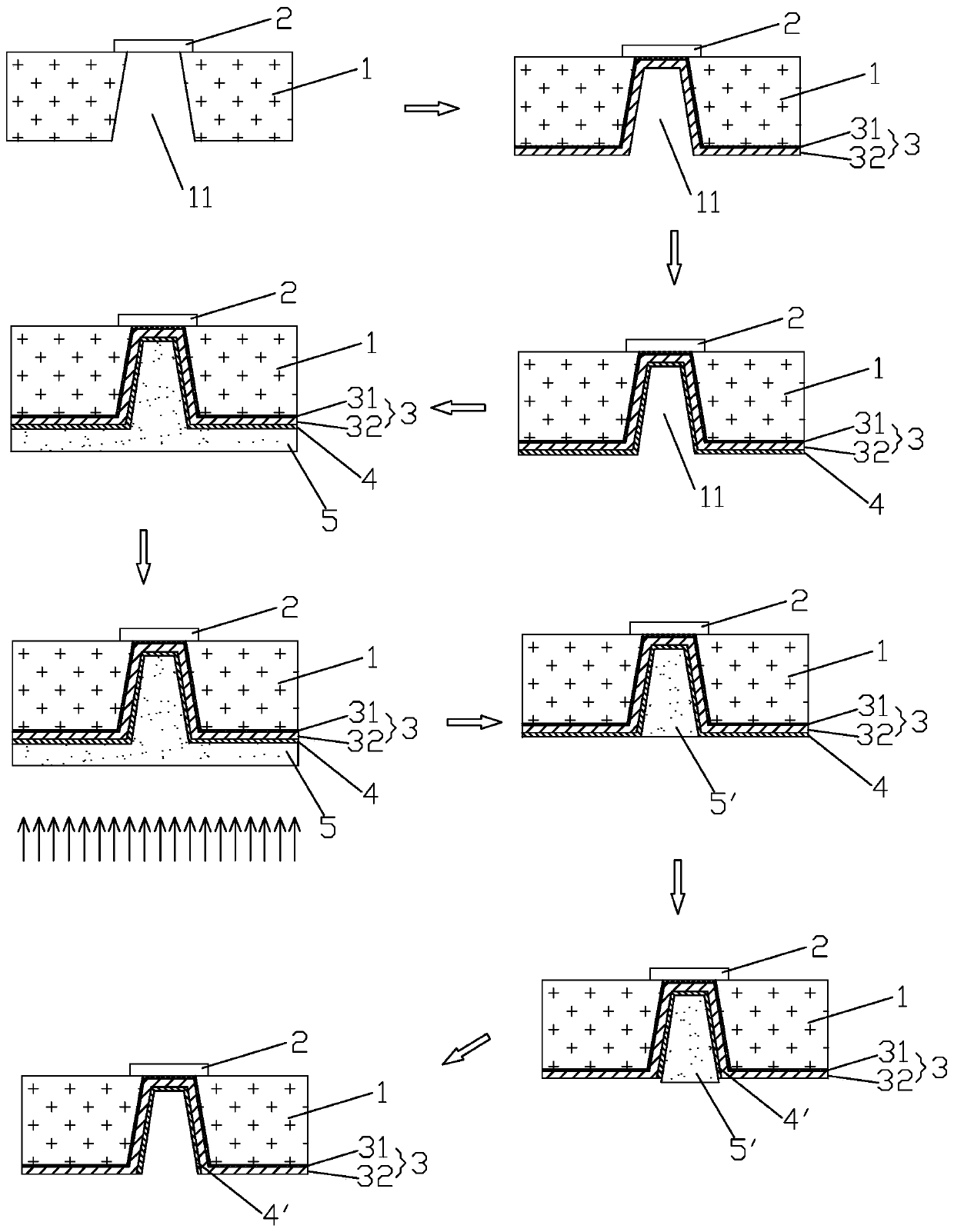

Back segment technology for improving reliability performance of compound semiconductor device

ActiveCN109920757APrevent from being etchedReduce ground resistanceSemiconductor/solid-state device manufacturingPorosityGround resistance

The invention discloses a back segment technology for improving the reliability performance of a compound semiconductor device. After a wafer finishes a front side manufacture procedure and steps including back hole, back metal layer and barrier layer manufacture and the like, the surface of the barrier layer is infiltrated by isopropyl alcohol, then, photoresist is coated and is subjected to general exposure, exposure time is controlled until photoresist out of the back hole is completely exposed and at least parts of photoresist in the back hole are not completely exposed, and development iscarried out to remove the completely exposed photoresist. After the exposed barrier layer is removed by etching, residual photoresist in the back hole is removed, and therefore, the barrier layer inthe back hole is left. By use of a method for infiltrating the barrier layer by IPA (isopropyl alcohol), the photoresist can be evenly coated in the hole, a photomask plate is not required, exposure adhesive thickness is controlled by the general exposure time, and the barrier layer guarantees to be only positioned in the back hole after etching. Compared with a traditional technological structure, the technology disclosed by the invention reduces device ground resistance, meanwhile, sintering porosity is reduced, and the reliable performance of the device is improved.

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

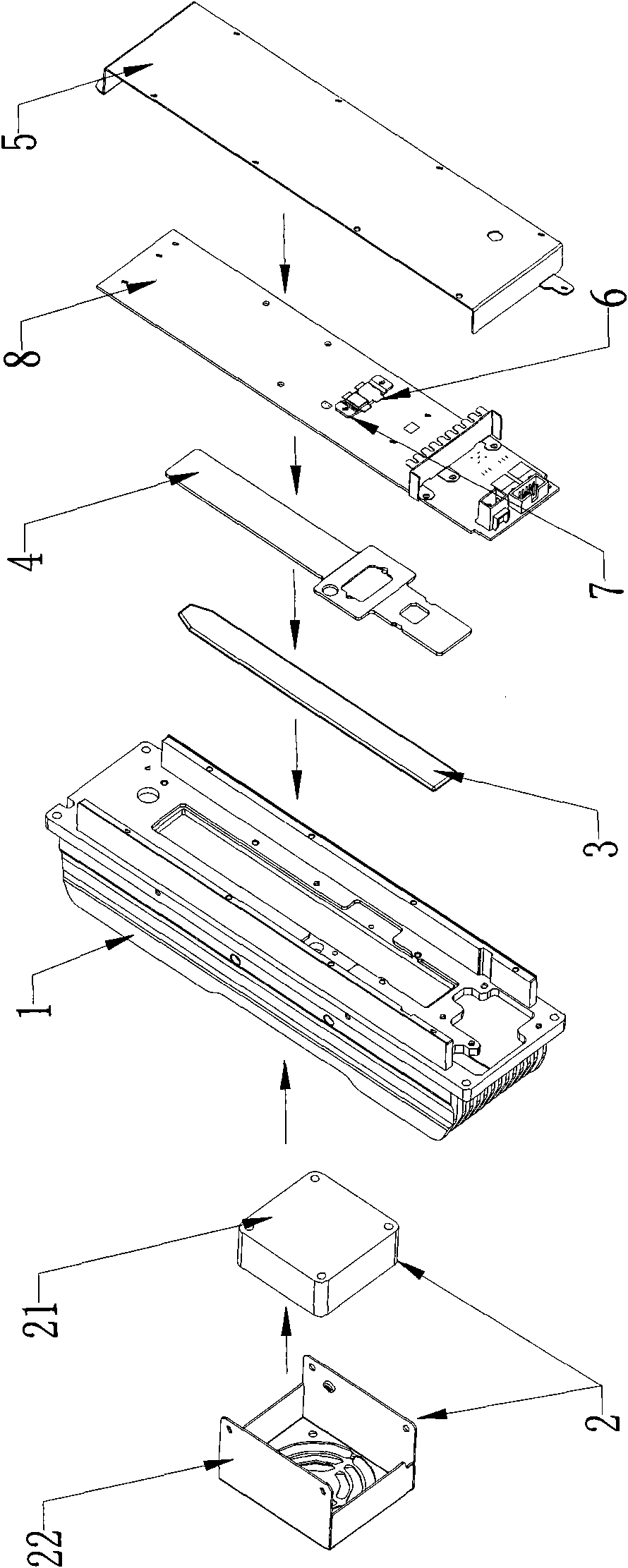

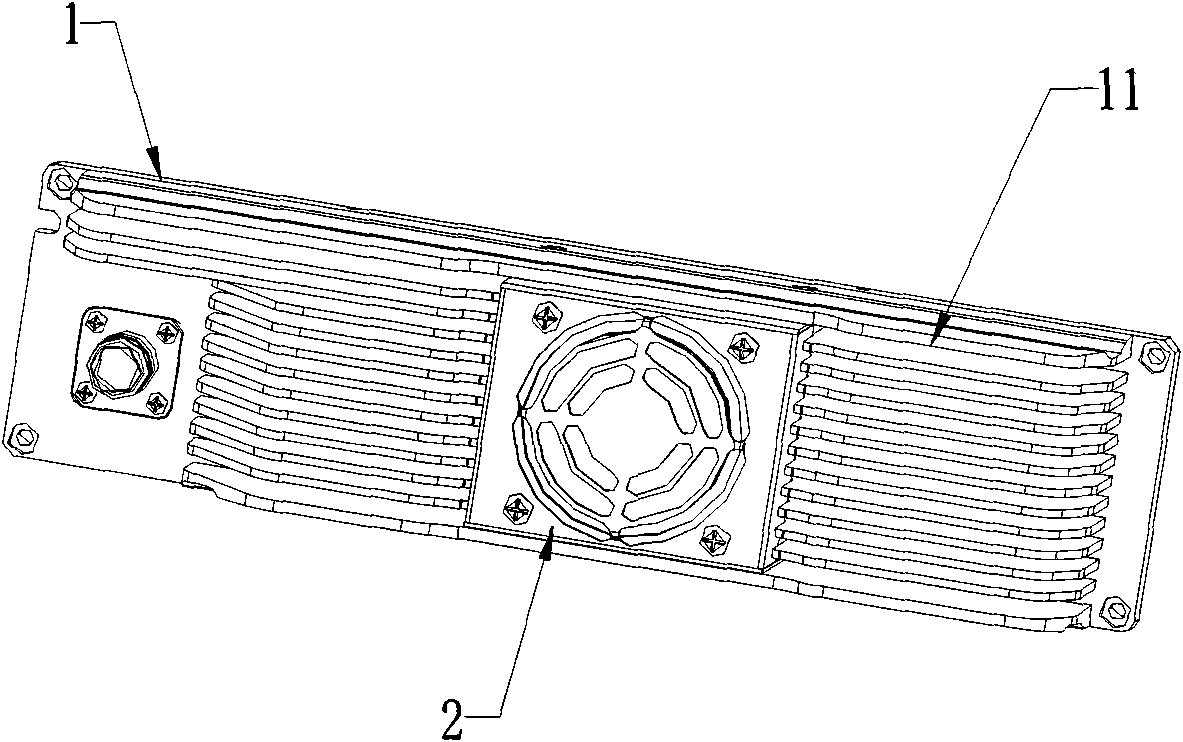

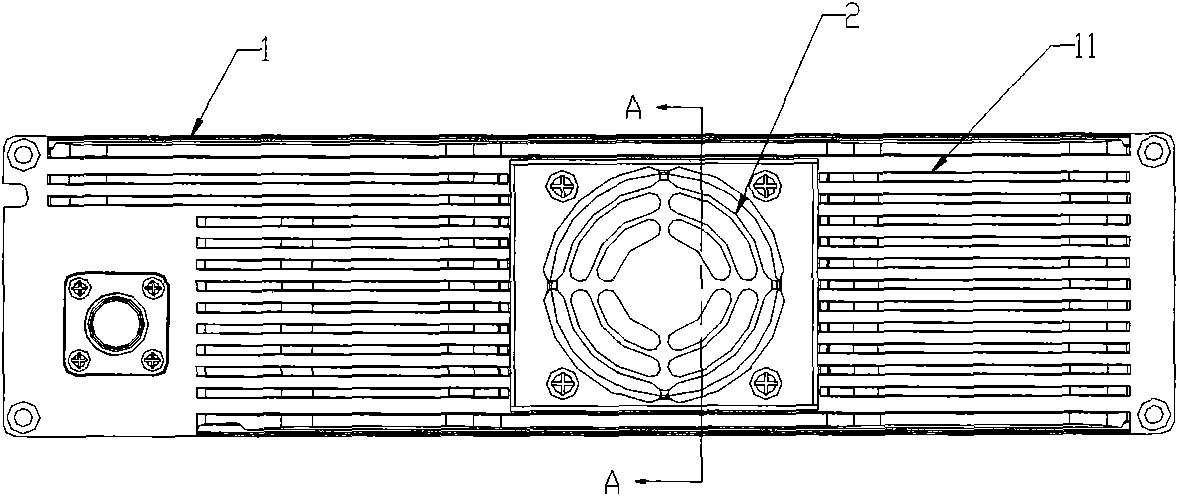

Radio frequency high-power heat pipe radiator

ActiveCN101808494AImprove cooling effectReduce thermal resistanceCooling/ventilation/heating modificationsAudio power amplifierGround resistance

The invention relates to a radio frequency high-power heat pipe radiator. The radiator comprises a radiating base (1), a radiating fan (2), a heat pipe and a mask (4), wherein the lower surface of the radiating base (1) is provided with a fin (11); the radiating fan (2) is fixed on the lower surface of the radiating base (1); the heat pipe (3) is embedded in the upper surface of the radiating base (1); and the mask (4) is covered on the heat pipe (3). The heat pipe is arranged in the radiating base, and the mask in close contact with a PCB board which is provided with a radio frequency high-power amplifier chip is arranged on the heat pipe, so thermal resistance and grounding resistance between the radio frequency high-power amplifier chip and the radiating base is reduced, radiating area is saved, and radiating efficiency is enhanced.

Owner:HEBI TIANHAI ELECTRONICS INFORMATION SYST

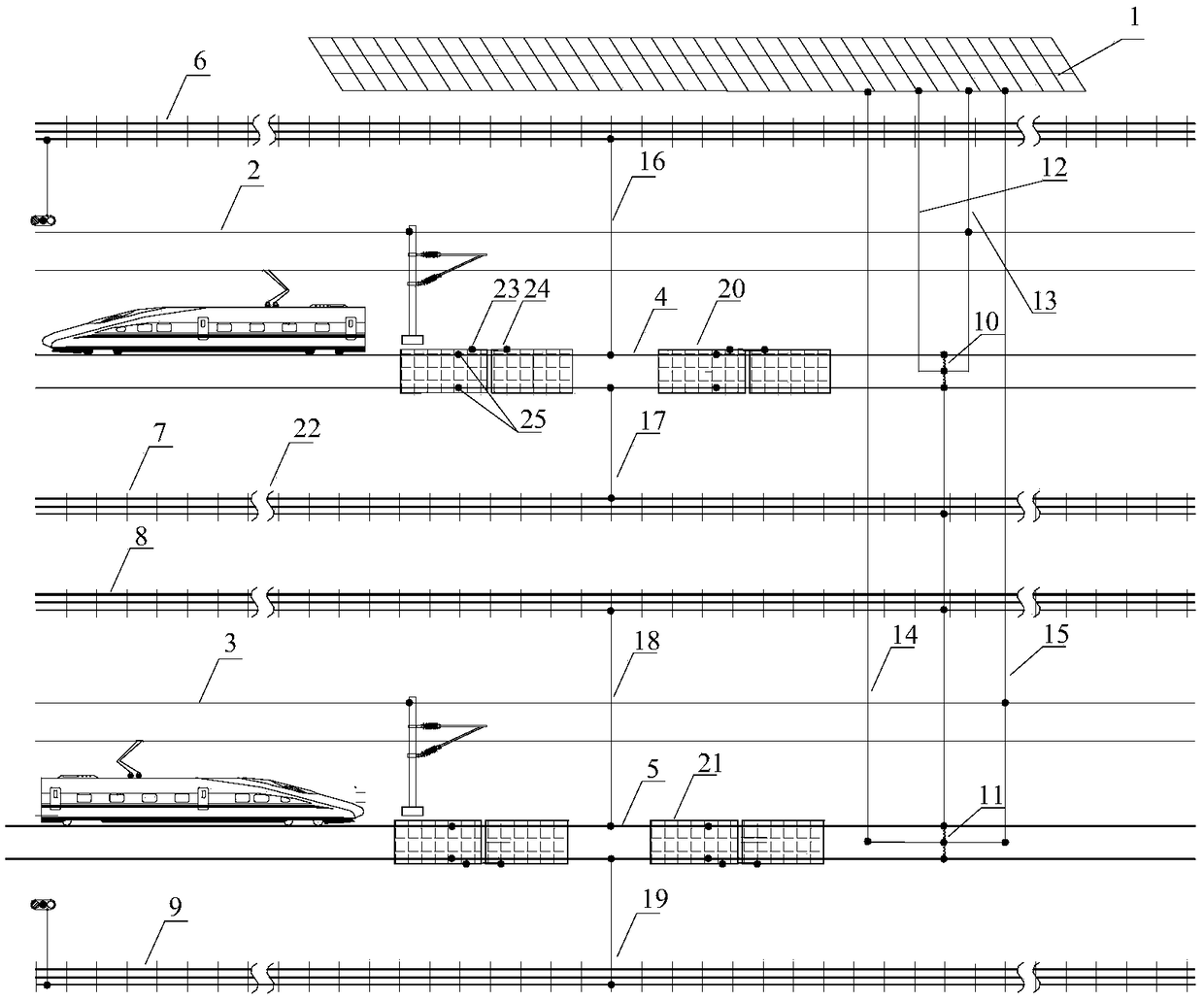

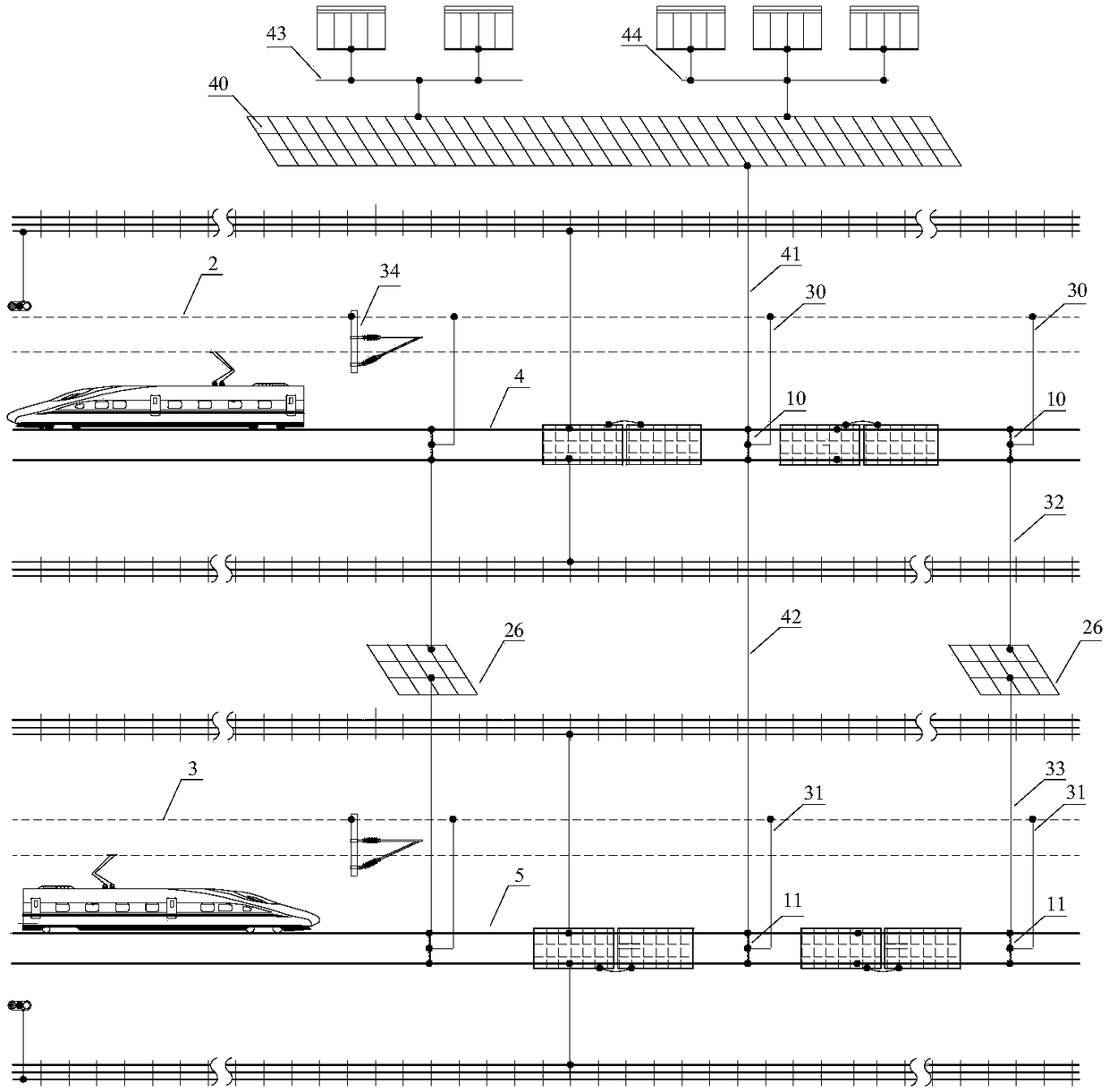

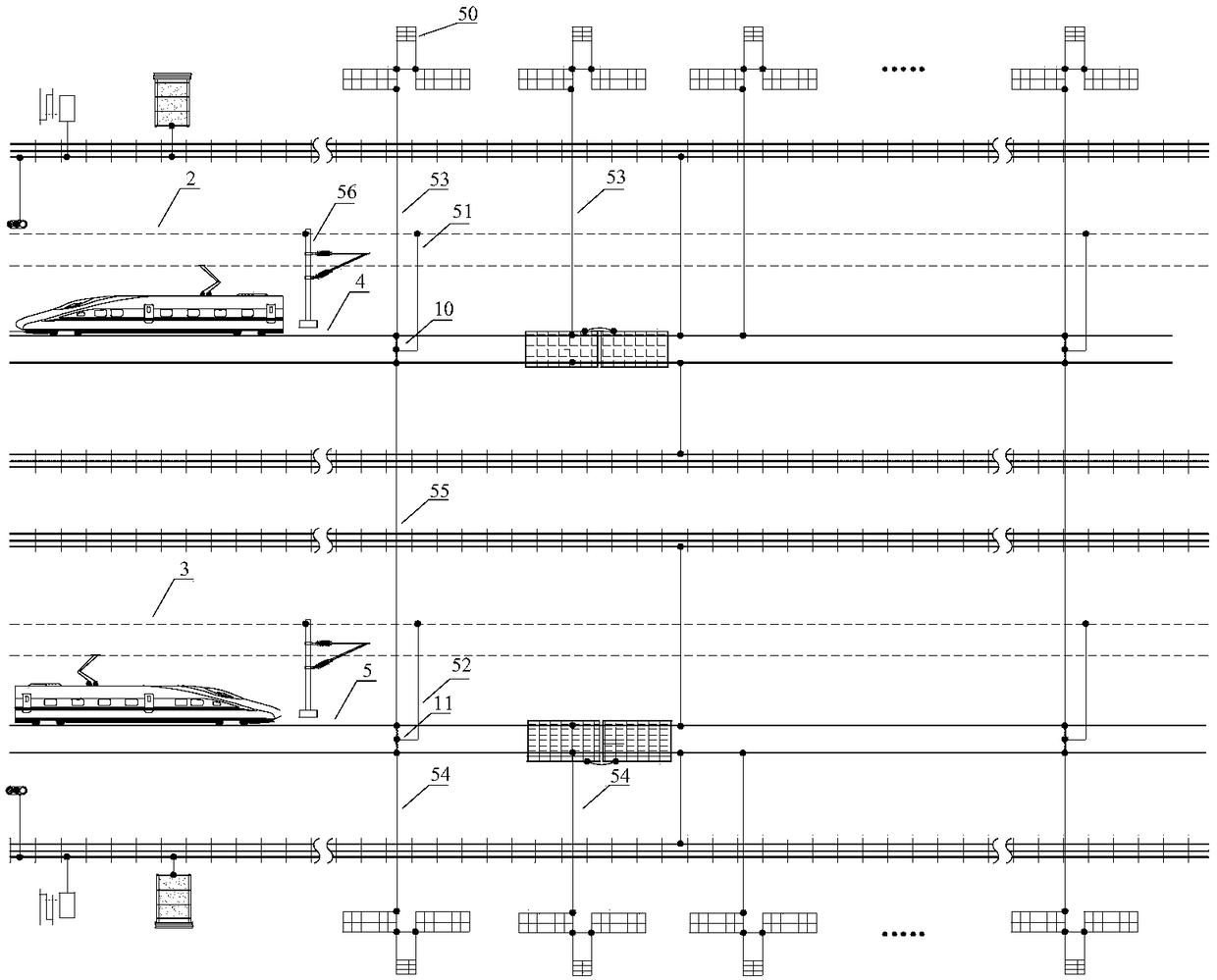

Integrated grounding system applied to urban rail transit adopting alternate current traction power supply system

ActiveCN108790957ASolve traffic grounding issuesEnsure safetyRail devicesHarmonic reduction arrangementElectrical resistance and conductanceElectrical conductor

The invention provides an integrated grounding system applied to urban rail transit adopting an alternate current traction power supply system. The grounding problem of the urban rail transit adoptingthe alternate current traction power supply system is solved, and the safety of equipment and personnel is ensured. The traction power supply system working ground (current returning access) is constituted by an upward steel rail, a downward steel rail, a catenary current returning line and the ground, and an upward steel rail conductor and a downward steel rail conductor are completely and transversely connected at the 500-600 m interval. The working ground (current returning access) is in single-point reliable connection with grounding devices of an integrated ground network of stations along a line, an interval air shaft ground network, a contact transverse channel ground network, a traction substation ground network, a tunnel, a bridge and the like, an equipotential platform is constructed while the grounding resistance of the system is reduced, and meanwhile, the situation that all systems are connected with the strong electricity working ground to become the strong electricity system current returning access is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

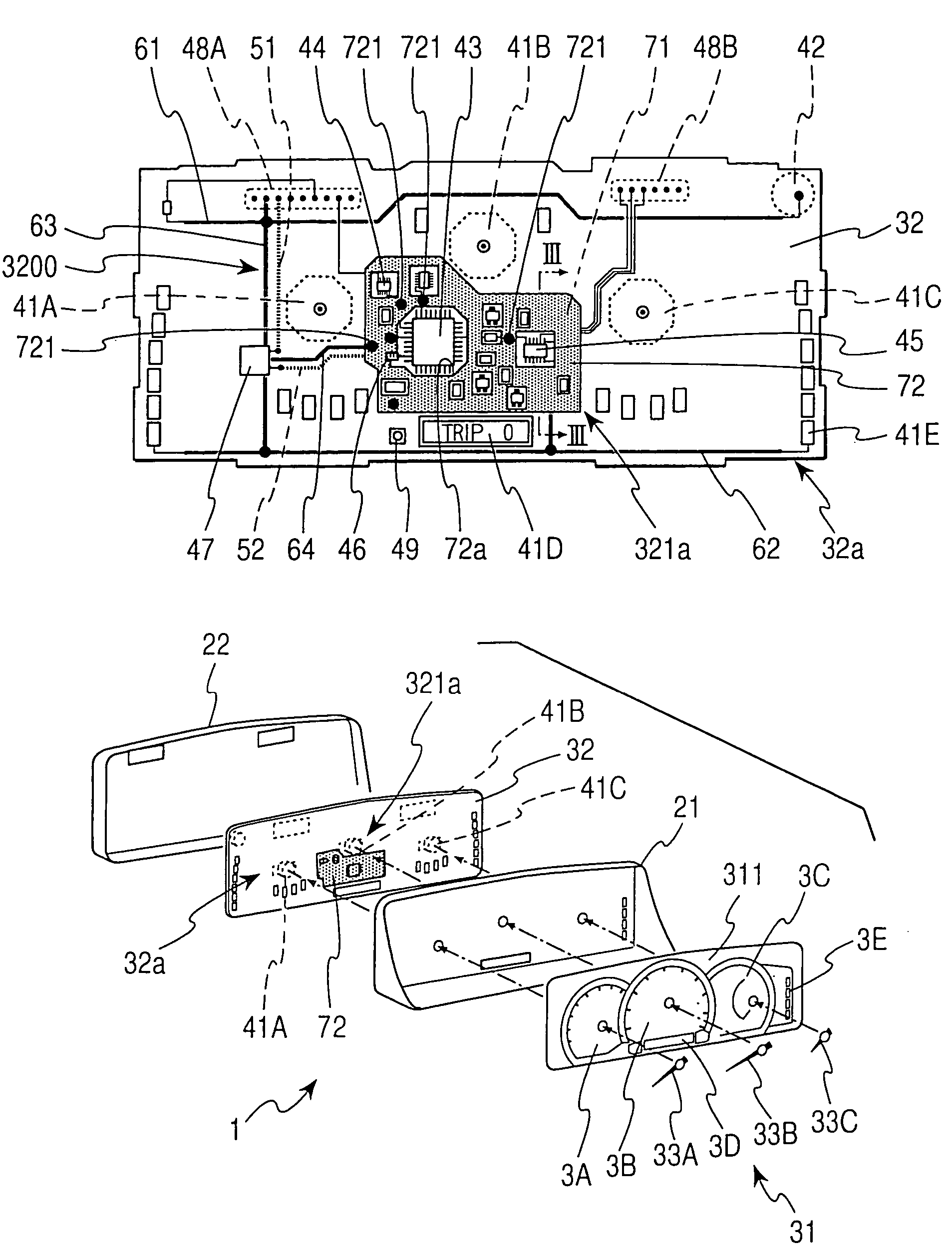

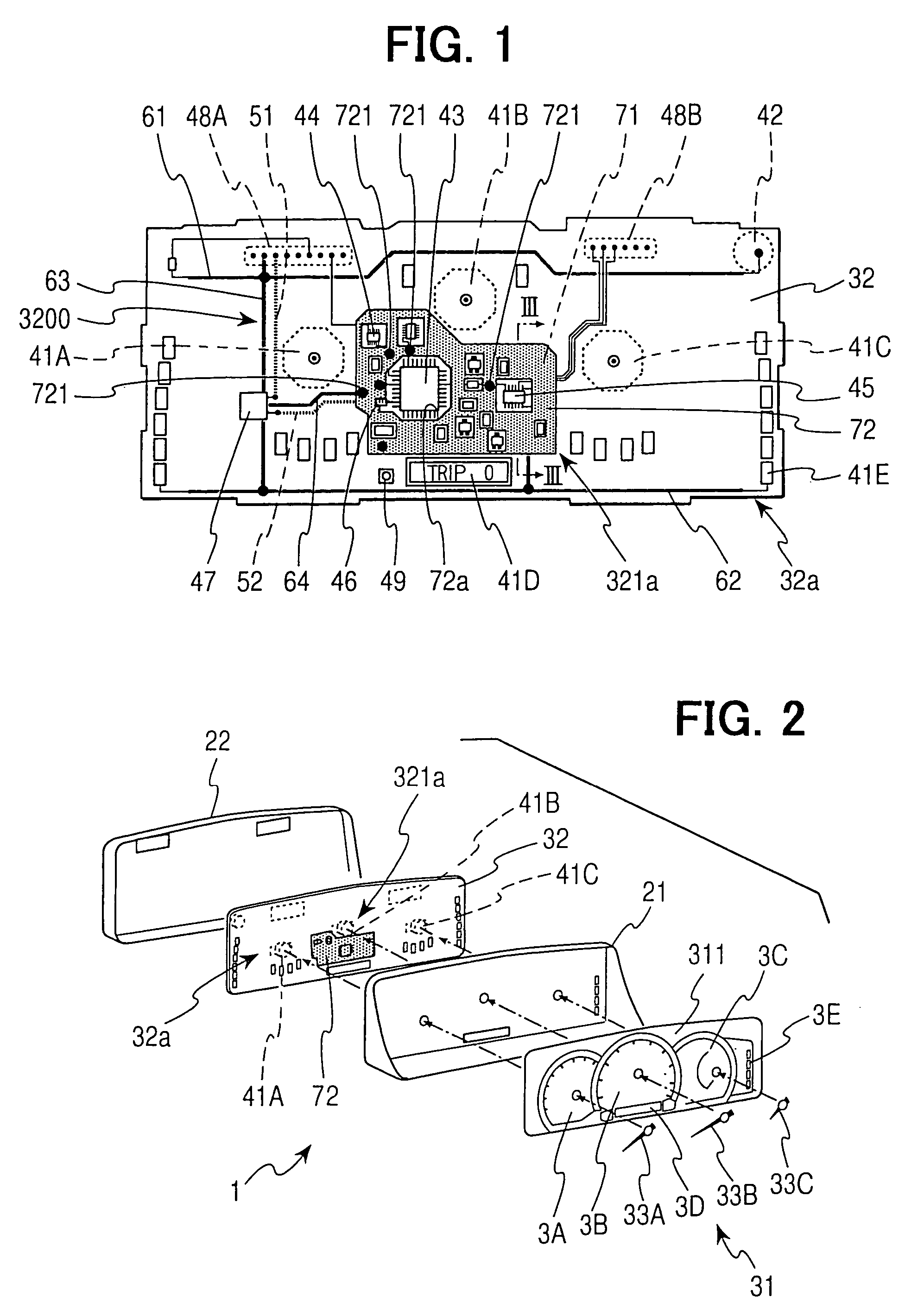

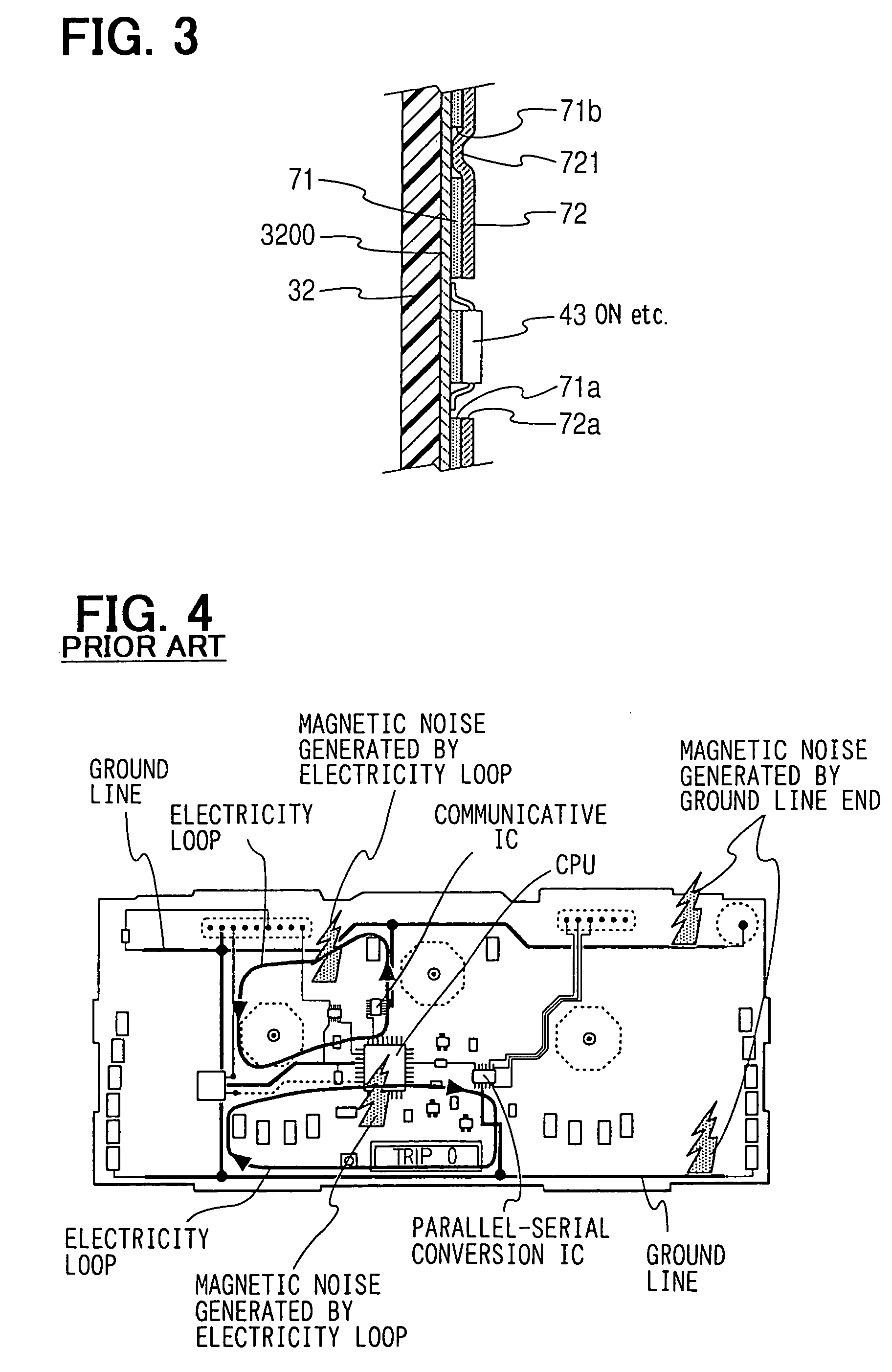

Printed board and meter unit provided therewith

InactiveUS7173827B2Reduce noiseAvoid noiseMagnetic/electric field screeningDigital data processing detailsElectricityEngineering

A printed board has a board, an electrically insulative membrane, formed on the board, and an electrically conductive membrane, formed on the electrically insulative membrane, in its area where a control circuit, including a CPU and etc., is installed. The electrically conductive membrane is electrically connected with ground patterns of a wiring pattern. Accordingly, ground connections at the control circuit are sufficiently performed. Therefore, even though ground connections in an area other than the control circuit are not sufficiently performed, a magnetic noise is prevented from being generated in a loop-shaped electricity supply line passing through a CPU and etc. Consequently, noises in printed board can be effectively reduced.

Owner:NIPPON SOKEN +1

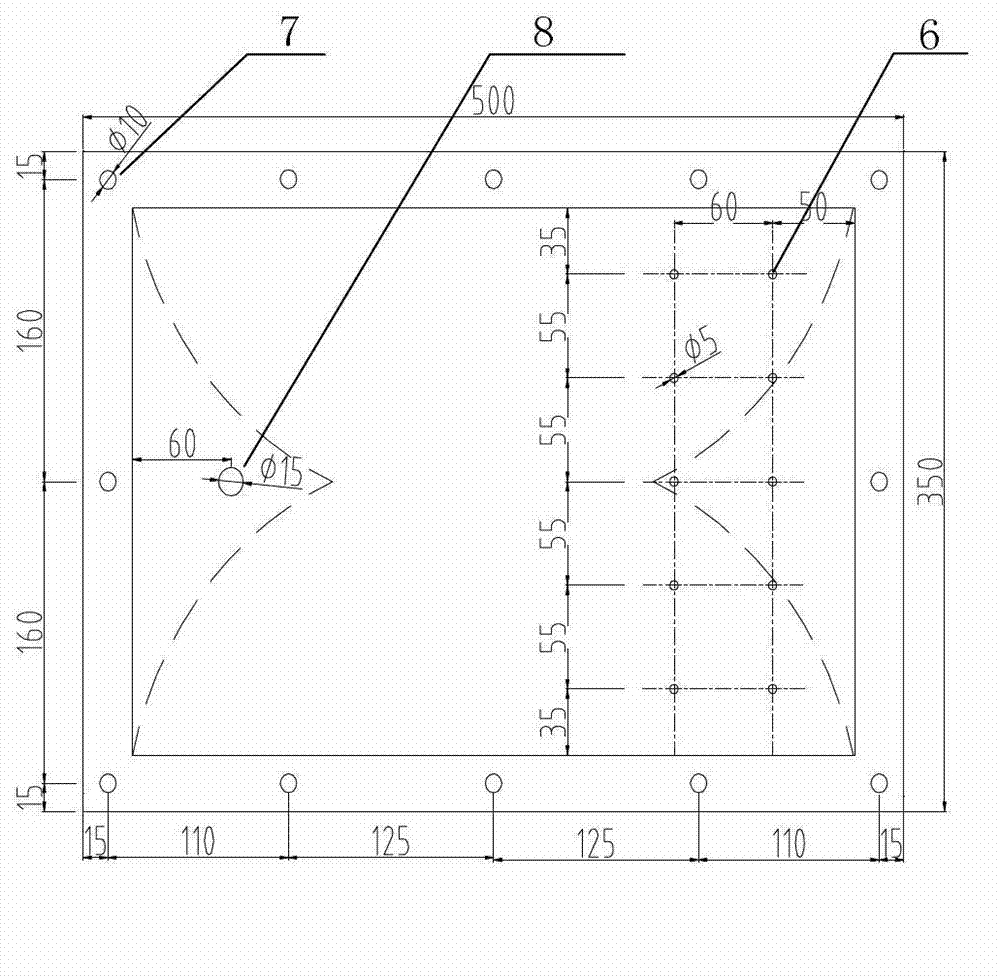

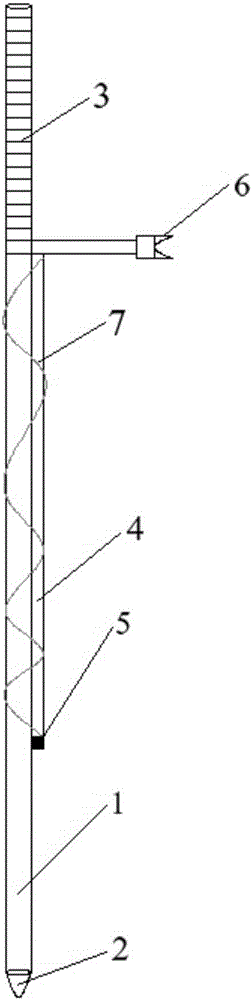

Reinforced grounding current diffusion device of power transmission line tower

ActiveCN103117459AReduce areaReduce workloadMetal/alloy conductorsConnection contact member materialElectrical resistance and conductanceThunderstorm

The invention discloses a reinforced grounding current diffusion device of a power transmission line tower. The reinforced grounding current diffusion device mainly comprises needle grounding electrodes, a hollow column and a water injection pipe. The reinforced grounding current diffusion device has the advantages of simple structure, convenience in construction, low engineering cost, good current diffusion characteristic, low grounding resistance, corrosion resistance, zero environmental pollution and the like, can be widely applied to reducing grounding resistance, and is particularly applicable to arid regions, rocky regions, regions with high soil resistivity and regions with violent thunderstorm activities.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

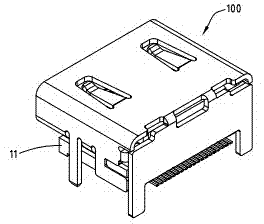

Housing structure of socket electric connector

InactiveCN104505648AReduce spacingGood bending test resultsCoupling parts mountingCoupling protective earth/shielding arrangementsEngineeringMechanical engineering

A housing structure of a socket electric connector includes an insulation body, a plurality of terminals and a shielding shell. The insulation body includes a base. The terminals are disposed on the insulation body. The terminals include a plurality of welding pins exposed outside the bottom of the base. The shielding housing covers the insulation body and includes a top cover board, a rear cover board and a plurality of connecting pins. The top cover board is disposed on the top face of the base. The rear cover board is connected to the rear side of the top cover board. The rear cover board extends downward to the rear side of the base. The rear cover body includes a bottom face. The connecting pins are connected to the bottom face. The shielding shell is disposed on the circuit board. The distance between vertical sections of the bottom face and the circuit board is smaller than or equal to 1.0 mm.

Owner:连展科技电子(昆山)有限公司

Method for preventing rust and reducing grounding resistivity for lightning protection grounding body

InactiveCN102403577AReduce ground resistanceContact member manufacturingConnection contact member materialCopper platingHigh carbon

The invention relates to a method for preventing rust and reducing grounding resistivity for a lightning protection grounding body, which mainly solves the problems of singleness in rust-resistant plating metal protection materials, poor rust-resistant performance, short service life, instability in grounding resistivity, high potential safety hazards, high weight, breakability, difficulty in carrying and mounting and occupation of the ground. The surface of the steel grounding body is plated with nickel after being plated with copper, the rust resistance of the grounding body is superior to that of an existing grounding body singly subjected to copper or nickel plating anti-corrosion process, the service life of the grounding body can be up to 30 years, and the grounding resistivity is stable, safe and reliable. High-carbon flexible conductive graphite wire jackets are high in ductility, free of being pulverized or smashed and low in electric resistivity, the conductive direction can be changed into longitudinal conductive direction by means of extrusion, reactance is overcome, electric resistivity is low, current can be dispersed fast, and simultaneously, the grounding body is combined firmly with resistivity-reducing plaster film attached on the surface thereof during reduction of electric resistivity. The resistivity-reducing plaster film composited by coating level polyving alcohol glue and high-carbon graphite phosphorus powder has the advantages that the resistivity-reducing plaster film is solid before being mounted, stick-proof and easy to transport, carry and mount and after being mounted, can expand by 20 times when absorbing moisture, and thereby, water and soil can be combined excellently and lightning flowing to the ground can be released quickly.

Owner:刘建华 +2

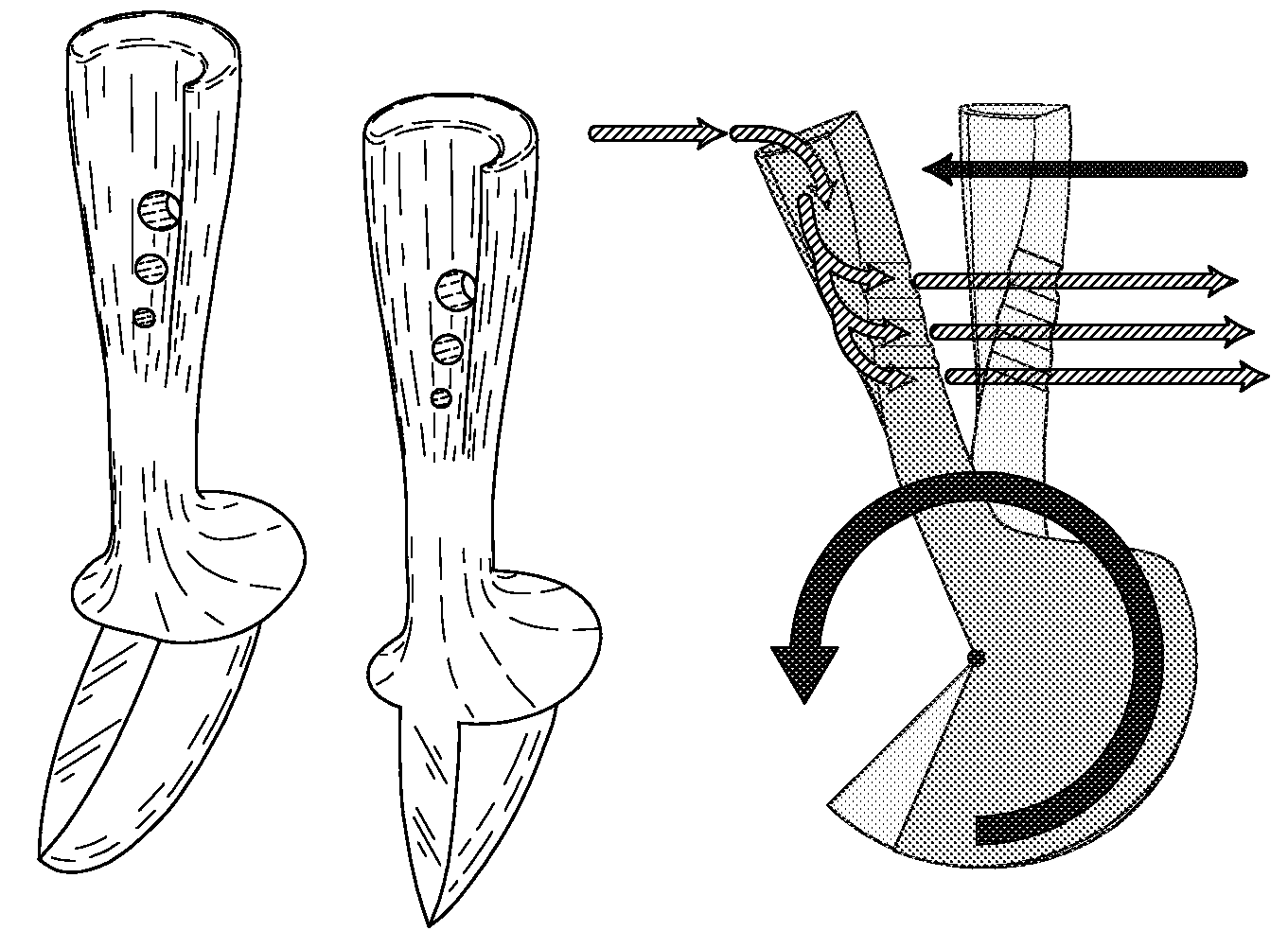

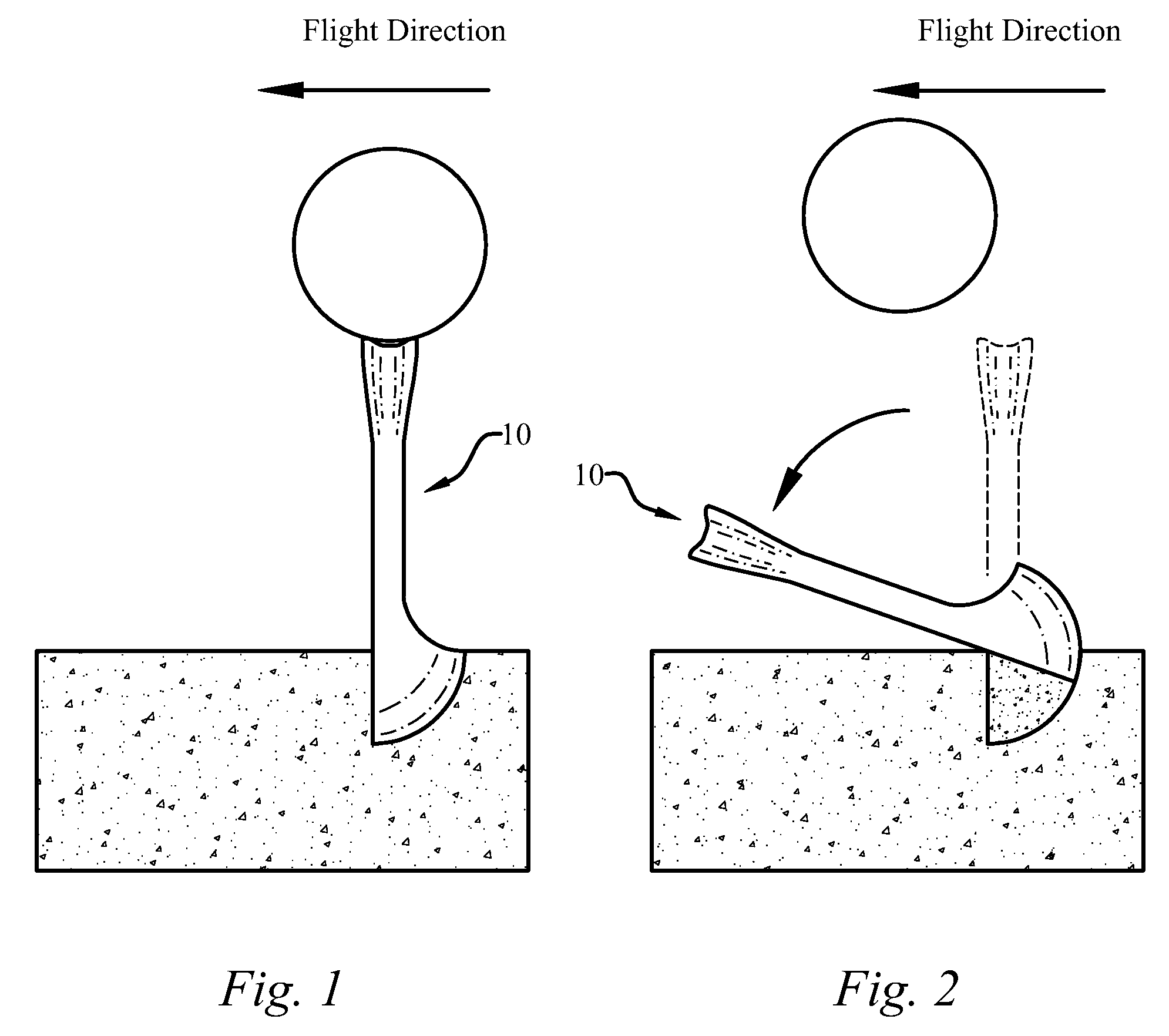

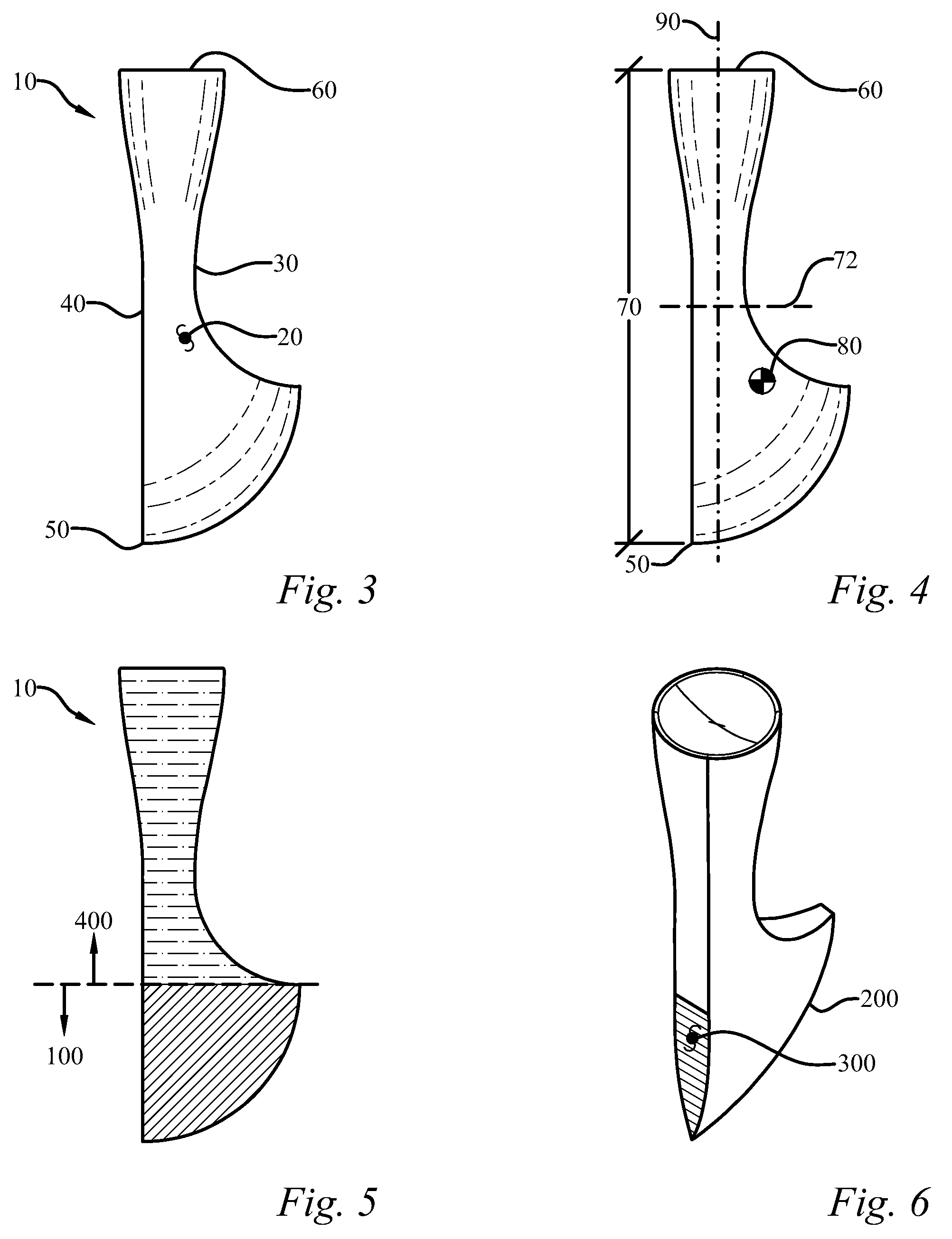

Low ground resistance golf tee

InactiveUS20100173731A1Reduce ground resistanceMinimize final distanceGolf teesFlight directionGrounding resistance

A low ground resistance golf tee for insertion into a playing surface to support a golf ball above the playing surface to be struck by a golf club launching the golf ball in a flight direction is provided. The golf tee includes a body having an impact side, a release side, an insertion end, and a ball support end. The golf tee has a low exit resistance region that includes a low exit resistance region insertion edge for penetrating and separating the playing surface to create a preferred exit path for the low exit resistance region upon impact by the golf club. The golf tee further includes a stem region located between the low exit resistance region and the ball support end, which is designed to be displayed above the playing surface. Upon impact, the golf tee pivots forward in the flight direction with minimal resistance from the playing surface.

Owner:SCHNEIDER MARK ALLEN

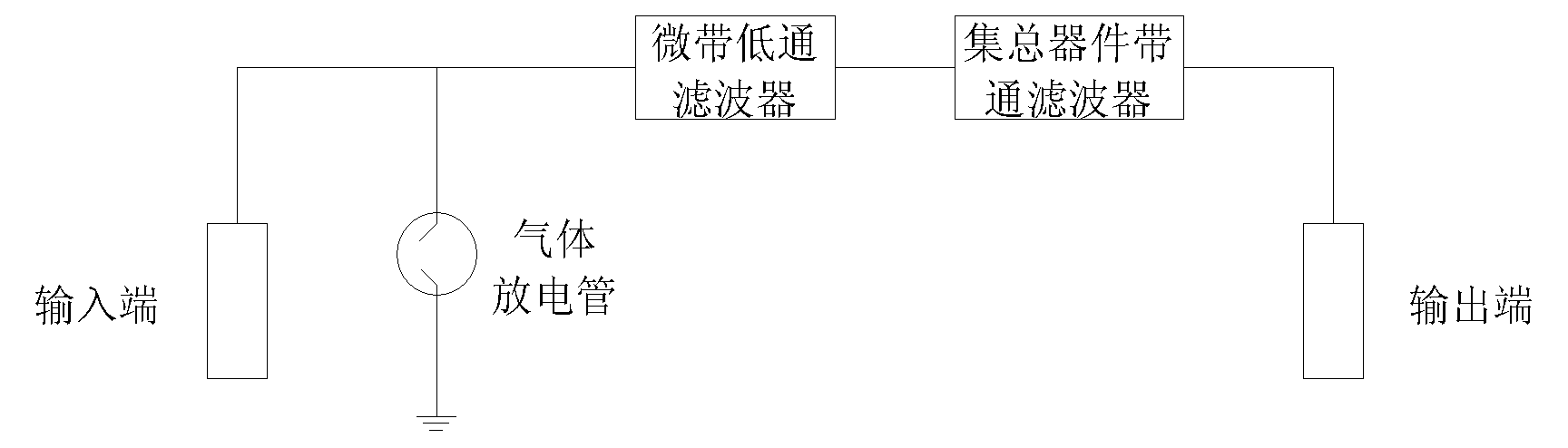

Strong-electromagnetic pulse protection device of ultra-short wave communication frequency range

ActiveCN102142679AReliable filteringLarge in-band differential lossEmergency protective arrangements for limiting excess voltage/currentLow-pass filterBand-pass filter

The invention provides a strong-electromagnetic pulse protection device of an ultra-short wave communication frequency range. The device is characterized by comprising a gas discharge pipe, a micro-strip low-pass filter and a lumped parameter band-pass filter which are encapsulated in a metal box, wherein an input end and an output end are arranged at two ends of the metal box; the input end is connected with one end of the gas discharge pipe and the input end of the micro-strip low-pass filter respectively; the other end of the gas discharge pipe is grounded; the output end of the micro-strip low-pass filter is connected with the input end of the lumped parameter band-pass filter; the output end of the lumped parameter band-pass filter is connected with the output end of the metal box; and the input end and the output end at the two ends of the metal box are coaxial ports. By adoption of two-stage protection circuits of the gas discharge pipe and the micro-strip low-pass filter, the strong-electromagnetic pulse protection device of the ultra-short wave communication frequency range can more reliably filter a strong-electromagnetic pulse having a shorter rising front edge.

Owner:CHINA SHIP DEV & DESIGN CENT

Device for improving hardened dam contact and electrical imaging directional detecting method of potential hazard body

ActiveCN106154335AExpand the scope of useFacilitate repair workElectric/magnetic detectionAcoustic wave reradiationRisk detectionElectricity

The invention relates to the field of potential dame risk detection, and particularly relates to a hardened dam potential risk detection method and device applying the parallel electrical survey. The device comprises an electrode for an electrical prospecting apparatus, wherein the frame inside the electrode comprises a copper bar and a transfusion duct; conductive sponge and conductive lint sequentially coat the outer part of the middle part of the electrode. The method and the device have the advantages of convenience in field operation, flexibility in operation, low labor intensity and wide application environment since a charging mode electric hammer is adopted to drill the surface of hardened dam; the drilling hole has a small diameter, so that the work for repairing the hardened surface layer of the dam in later phase can be facilitated.

Owner:浙江广川工程咨询有限公司

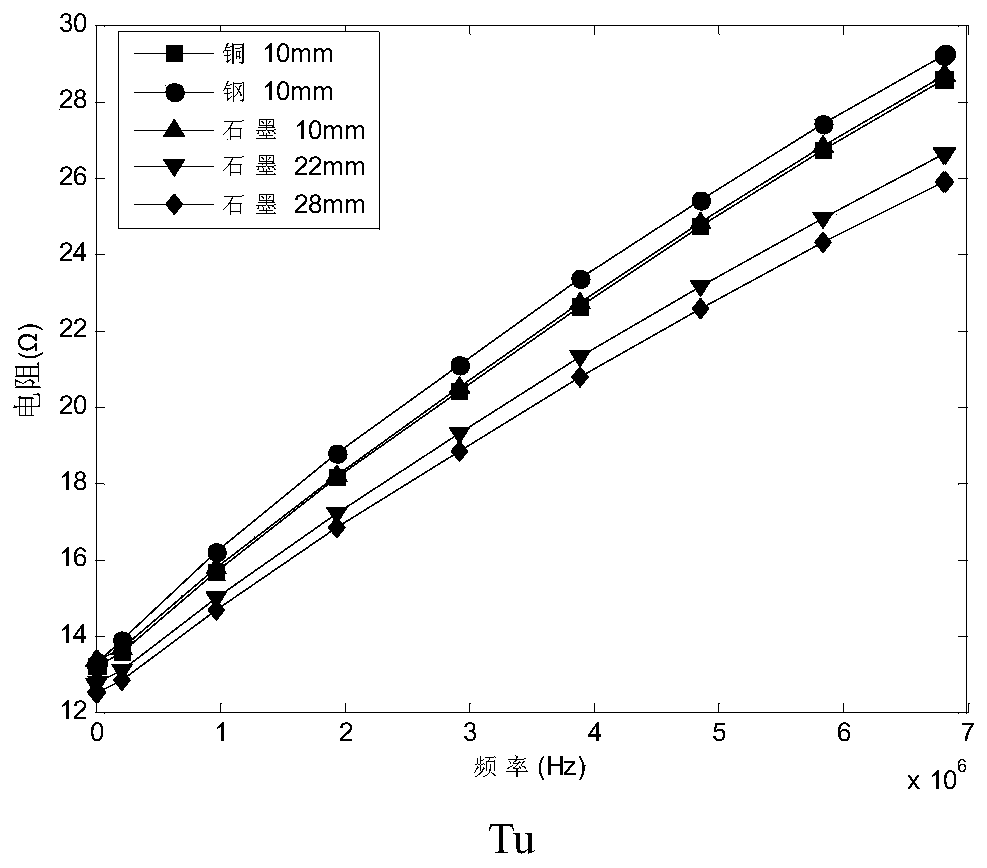

Lightning protection performance analysis method for graphite grounding device of power transmission line tower

InactiveCN110895300AReduce ground resistanceImprove lightning resistance levelTesting dielectric strengthComputer aided designSoil modelGrounding resistance

The invention relates to a lightning protection performance analysis method for a graphite grounding device of a power transmission line tower, and the method comprises the following steps: (1), analyzing the structure of the tower grounding device according to the grounding data of the power transmission line, changing a round steel grounding material into a graphene material, and building a grounding grid model through an SESCAD module of CDEGS simulation software; (2) introducing the soil model, calculating the power frequency grounding resistance by using an MALZ module, comparing the power frequency grounding resistance with the grounding resistance of the original round steel grounding model, and judging whether the grounding resistance of the graphite grounding device meets the standard or not; (3) aiming at the tower top lightning stroke mode, adopting ATP-EMTP software simulation to establish a line and tower model, and analyzing the influence on the lightning resistance levelunder the graphite grounding condition; and (4) modifying the lightning current amplitude for multiple times as required, and performing simulation calculation for multiple times until the lightningresistance level is obtained. According to the method, the grounding resistance can be effectively reduced, the lightning resistance level is improved, and a basis is provided for design, popularization and application of the graphene grounding device.

Owner:ECONOMIC TECH RES INST OF STATE GRID ANHUI ELECTRIC POWER +1

Corrosion-preventing and resistance-reducing grounding module

The invention discloses a corrosion-preventing and resistance-reducing grounding module. The straw pulp paper or the wood pulp paper is laid on the inner surface of a shell, the middle in the shell is provided with a sacrificial anode, and a sacrificial anode inner core is embedded into the sacrificial anode; and an inner cavity between the sacrificial anode and the shell is provided with a filling medium. The invention adopts the sacrificial anode using iron or copper as the inner core as a framework, adopts a high-water-retention material, a forming material, a metal corrosion inhibiting agent and a conducting electrolyte as the filling medium, adopts a porous plate made of a thin-wall sacrificial anode material as the shell and can prevent the corrosion of a grounding net and effectively reduce the resistance of the grounding net.

Owner:SHAANXI ELECTRIC POWER RES INST

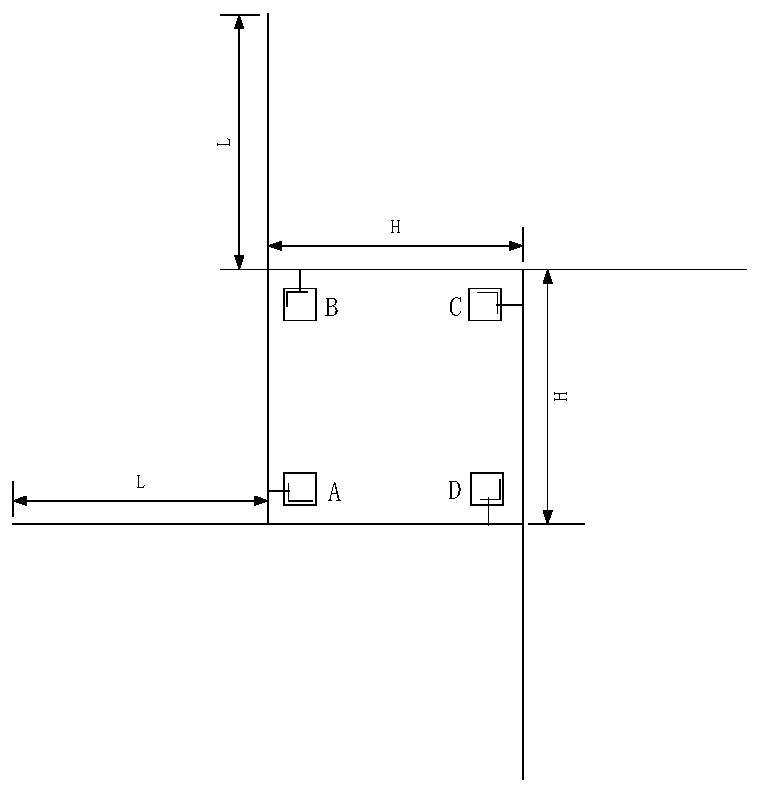

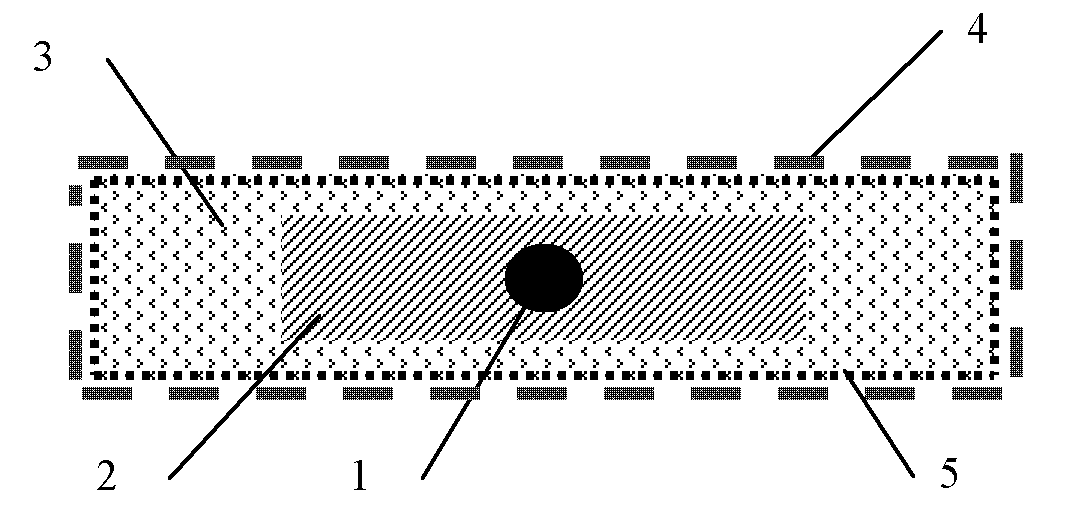

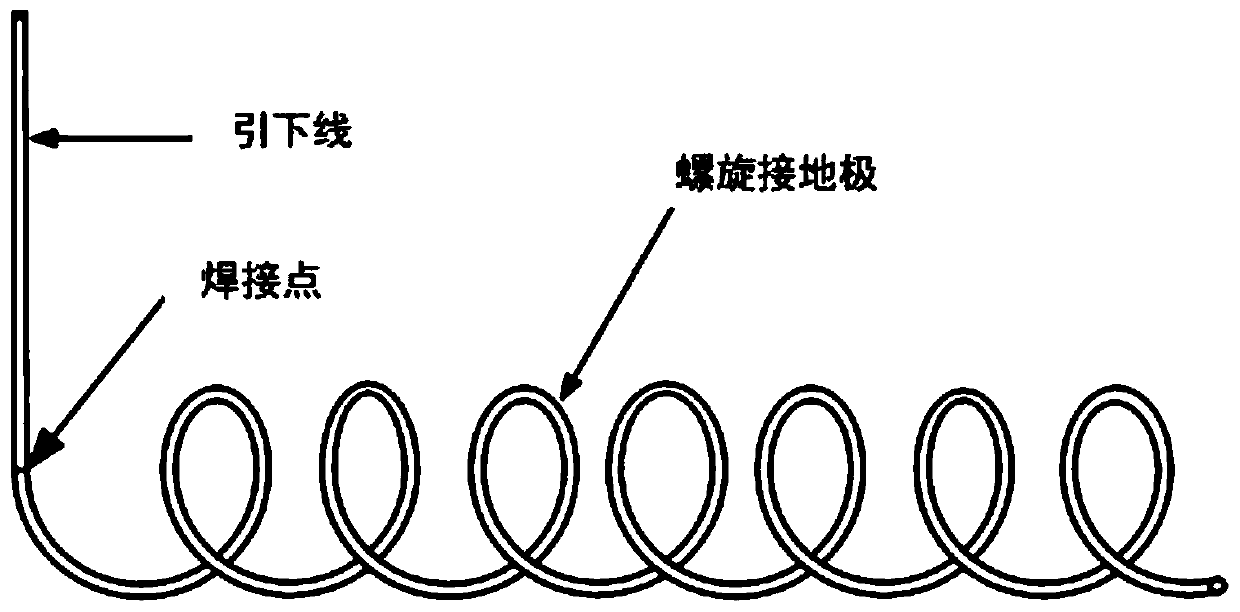

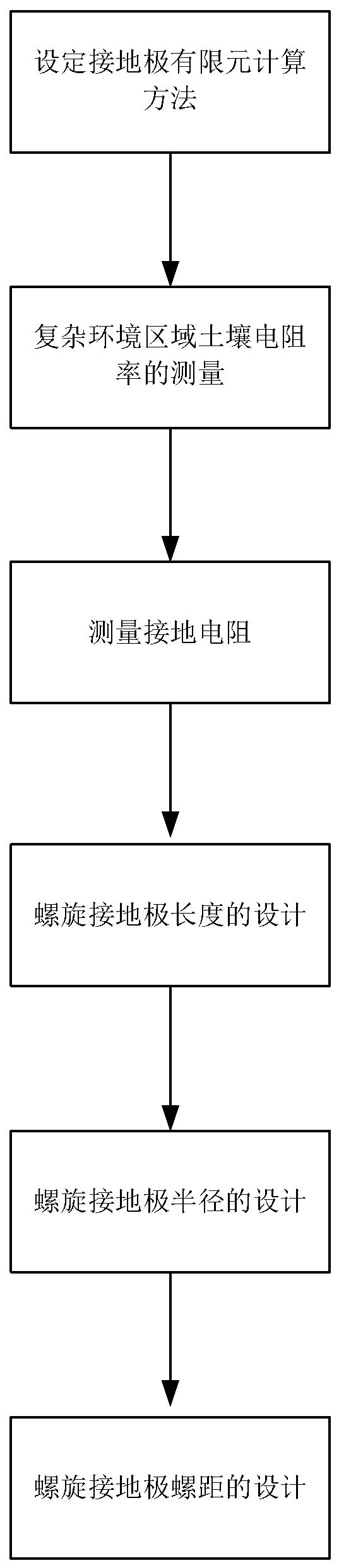

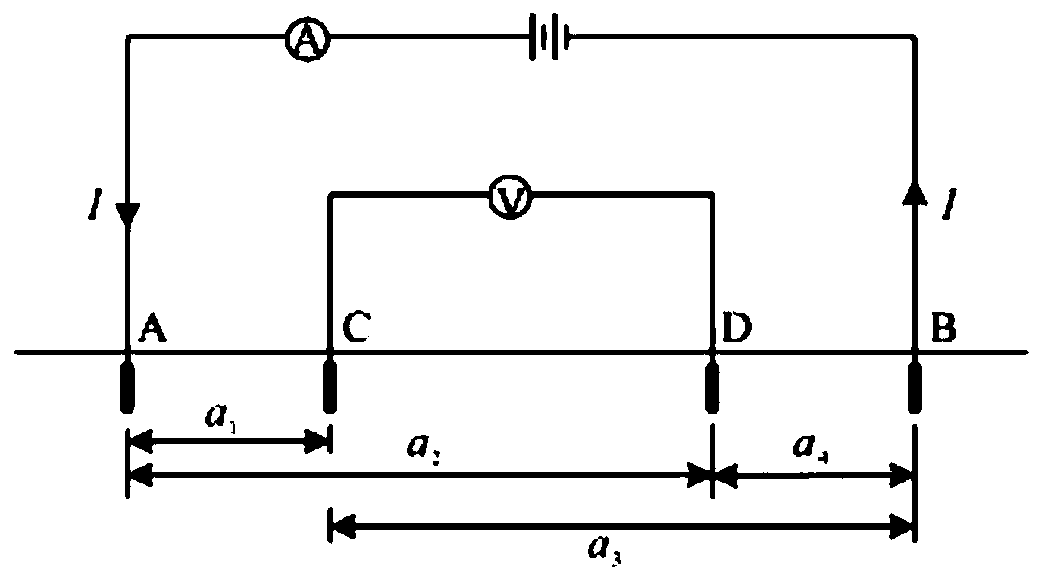

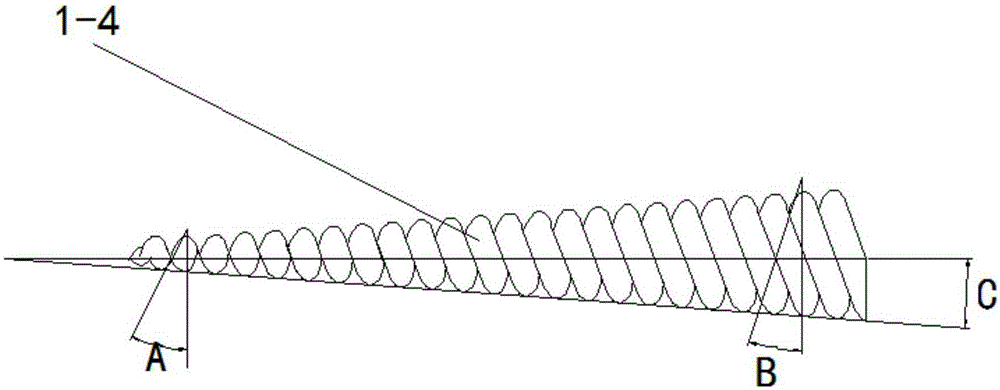

Spiral grounding electrode size parameter design method suitable for complex environment area

ActiveCN110119544AGood groundingSpill MaximizationDesign optimisation/simulationSpecial data processing applicationsElectrical resistance and conductanceAgricultural engineering

The invention relates to a spiral grounding electrode size parameter design method suitable for a complex environment area. Compared with the prior art, the spiral grounding electrode size parameter design method overcomes the defect that a spiral grounding electrode size design method does not exist. The method comprises the following steps: setting a grounding electrode finite element calculation method; measuring the soil resistivity in a complex environment area; measuring ground resistance; designing the length of the spiral grounding electrode; designing the radius of the spiral grounding electrode; and designing the screw pitch of the spiral grounding electrode. According to the method for designing the specific size parameters of the spiral grounding electrode, through reasonable parameter design, it can be guaranteed that the spiral grounding electrode has good grounding performance in complex soil environments with limited axial electrode arrangement space, high resistivity and the like.

Owner:MAANSHAN POWER SUPPLY COMPANY STATE GRID ANHUI ELECTRIC POWER +1

Lightning arrester grounding rod

The invention provides a lightning arrester grounding rod comprising a core rod formed by high-melting-point metal. The upper end of the core rod is provided with a wiring terminal, and the lower end is conical. The side wall of the core rod is wrapped by a metal wall formed by low-melting-point metal. According to the lightning arrester grounding rod, a surface oxide layer can be automatically eliminated, and maintenance is not required in a long period of time so that maintenance cost can be greatly reduced.

Owner:吉林市能兴电力设备有限公司

Electrical connector

InactiveUS20150311640A1Reduce ground resistanceImprove shielding effectCoupling protective earth/shielding arrangementsElectricityOperability

While efficient assembly performance of an electrical connector is obtained, good operability can be also obtained by a simple configuration. Good shielding performance with respect to transmission paths are configured to be obtained by a simple configuration in which movement of an actuator causes both shield shells to contact each other by covering at least part of outer surfaces of an insulating housing and the actuator by the shield shells consisting of electrically-conductive metal members, causing the actuator-side shield shell moved to an action position to contact the insulating-housing-side shield shell, and continuously covering the transmission paths, which are from a signal transmission medium to a printed wiring board through electrically-conductive contact members.

Owner:DAIICHI SEIKO CO LTD

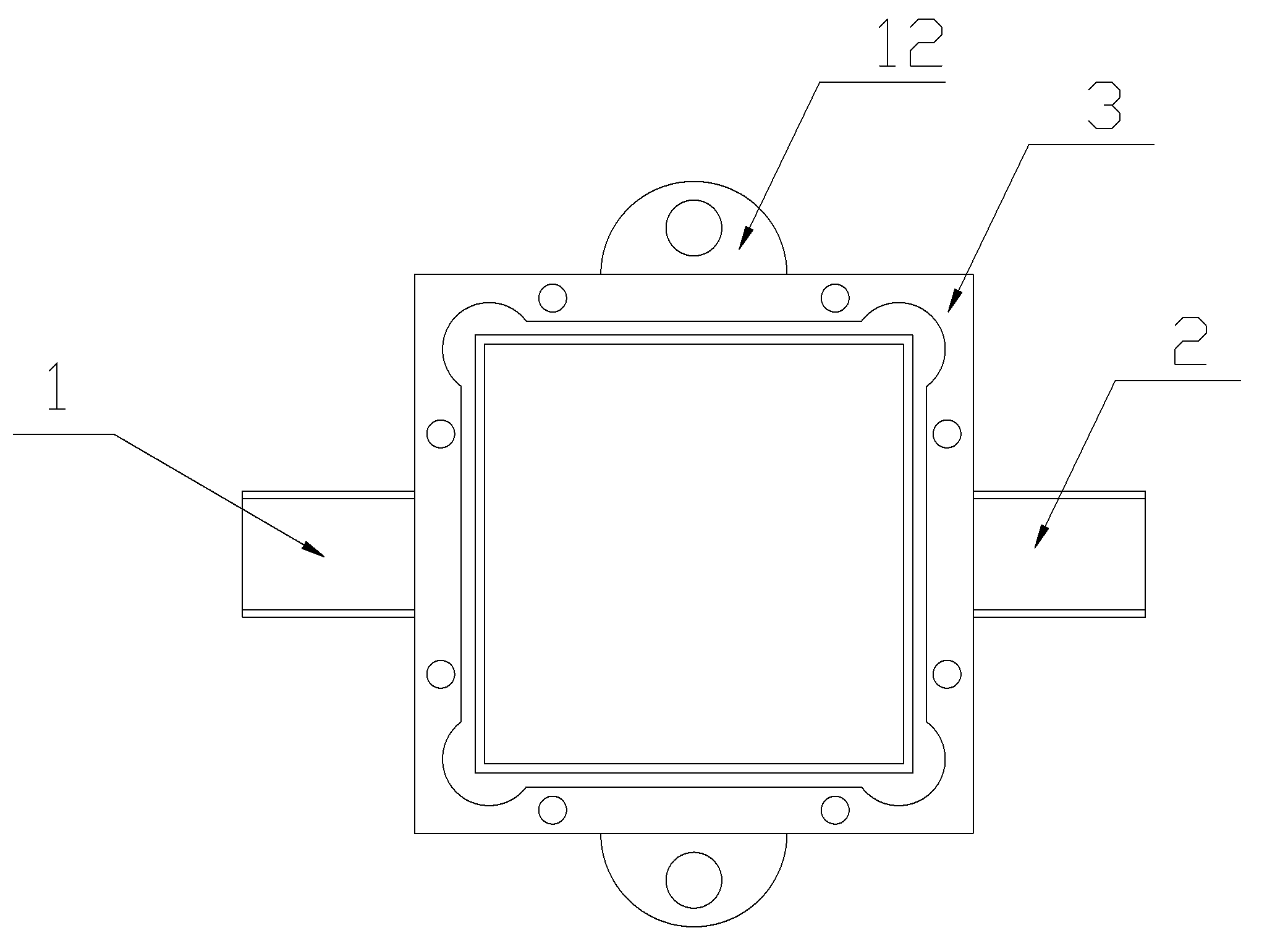

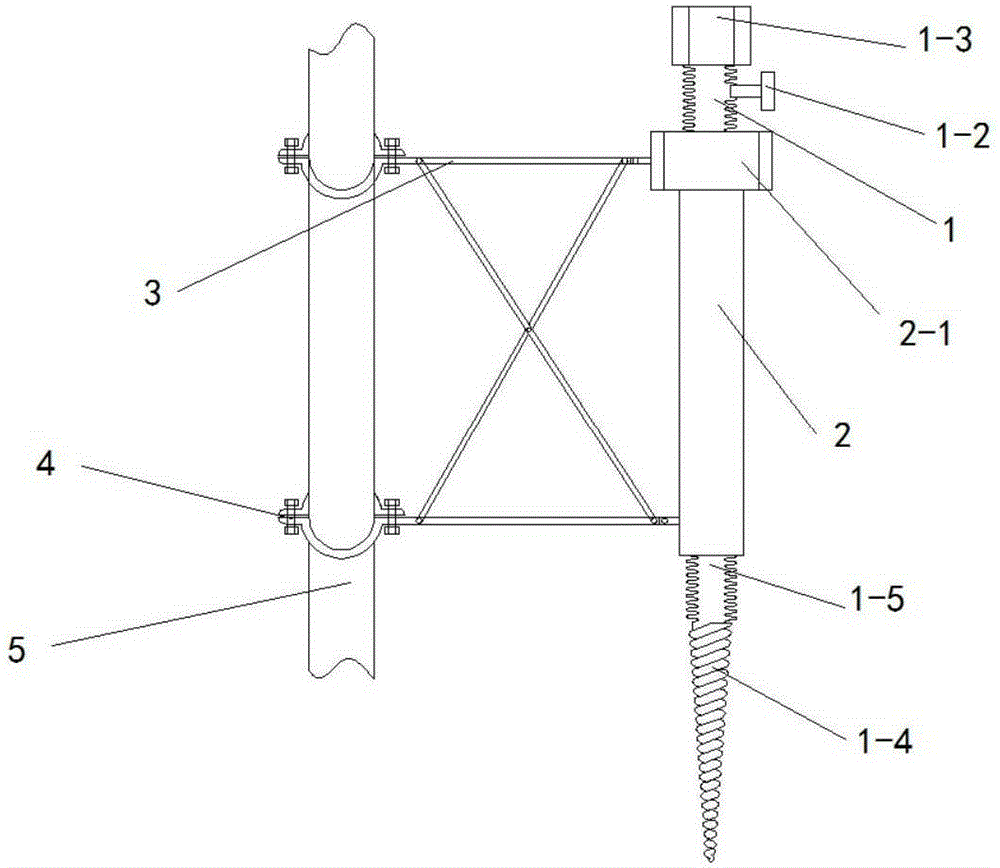

Screw-type earth electrode and mounting device

PendingCN106558772AOptimize the installation methodReduce ground resistanceConnection contact member materialElectrical resistance and conductanceEngineering

The invention discloses a screw-type earth electrode and a mounting device. The screw-type earth electrode is composed of two parts of an external thread auxiliary earth electrode and a thread variant earth body, wherein the external thread has the same thread pitch; the radius of the thread variant earth body is increased gradually from the bottom end to the top end smoothly; and the thread lower edge angle of the thread variant earth body is decreased gradually from the bottom end to the top end smoothly. The mounting device comprises an electric pole hoop, a mounting sleeve, a four-connection rod assembly, a rotating handle and an electrical power part. By adopting the above device, the fact that the maintenance operation field earth electrode mounting mode is improved, and the earth resistance is reduced becomes possible.

Owner:STATE GRID CORP OF CHINA +2

Novel polymer skeleton resistance-reducing agent

InactiveCN106205769AImprove space densityImprove the diffusion effectNon-conductive material with dispersed conductive materialCable/conductor manufactureWater basedHigh resistivity

The invention relates to the technical field of grounding resistance-reducing materials in the fields of electric power, transportation, petroleum, petrochemicals and the like, in particular to a novel polymer skeleton resistance-reducing agent, which is a novel physical resistance-reducing agent, namely a graphite-based physical resistance-reducing material, with a novel water-based polymer material skeleton structure and is suitable for the resistance reduction requirements of a grounding material, a grounding grid and a lightning protection grounding system in the fields of petroleum, petrochemicals, electric power, buildings and the like. The novel polymer skeleton resistance-reducing agent is prepared from the following raw materials in part ratios by weight: 10%-30% of a water-soluble polymer skeleton, 10%-30% of a water-retaining agent, 40%-80% of a diffusing conductive agent and 0.5%-2% of an assistant. The novel polymer skeleton resistance-reducing agent has a solid space structure; the overall spatial density of the resistance-reducing agent is improved; combination of the inside of the resistance-reducing agent, the resistance-reducing agent and soil is tighter; the diffusing effect of the resistance-reducing agent is improved; the bulk conductivity and the grounding resistance of the resistance-reducing agent can also be improved; and the effect of reducing the grounding resistance of the grounding material in a high-resistivity soil region is achieved.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com