Hollow aluminum alloy tube grounding device capable of being assembled

A technology of aluminum alloy tube and grounding device, which is applied in the direction of connecting contact materials, etc., can solve the problems of poor corrosion resistance of steel, grounding corrosion and fracture, and high engineering cost, so as to improve the electrical characteristics of the soil, increase the contact area, The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

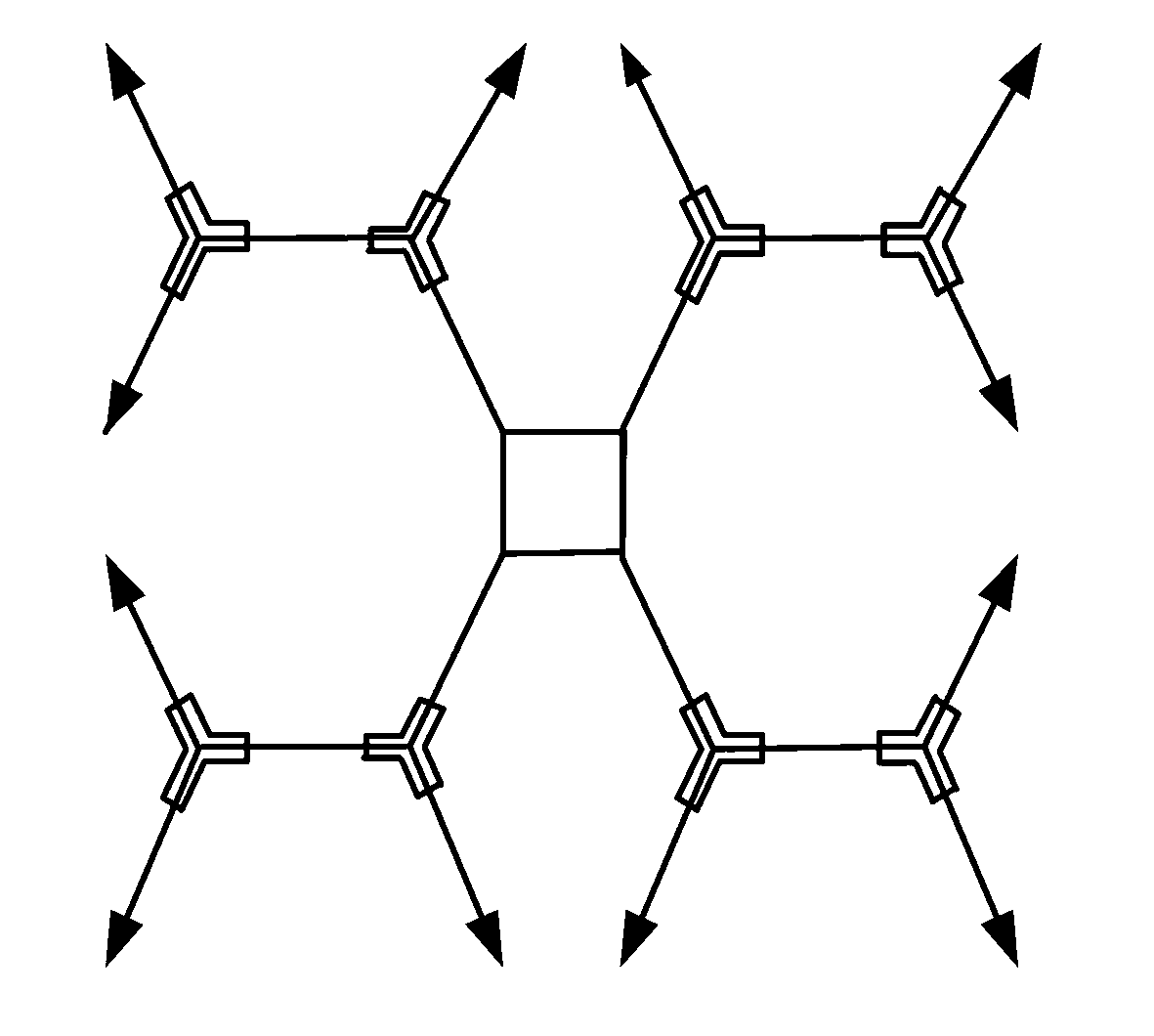

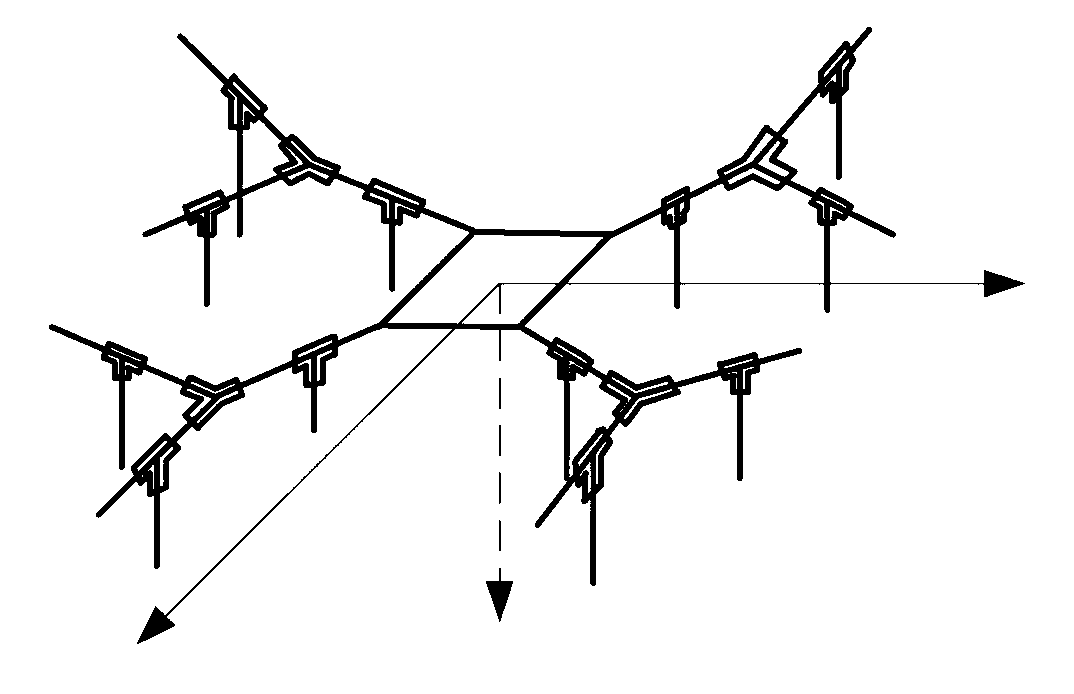

[0044]An assemblable hollow aluminum alloy tube grounding device, which includes a closed ring 1 made of aluminum alloy, 4 sets of grounding bodies 2 connected to the closed ring, the unit grounding body 3 in the grounding body 2 is a hollow tubular structure, and its outer The diameter is 39mm, and the inner diameter is 32mm. One end of the unit grounding body is welded to the closed ring, and the other end is connected to the outside by a sleeve.

[0045] According to the needs, the grounding body can be extended radially in the horizontal plane by using the axial bushing, the horizontal size of the grounding body can be expanded by using the "Y" type bushing, or the vertical extension of the grounding body can be made by using the "T" type bushing. Any combination of the three bushings can also be used in one grounding body at the same time.

[0046] During construction, when the device is located in an area with a soil resistivity of 1500Ω·m or more, the length of each gro...

Embodiment 2

[0049] China Three Gorges University and Sanmenxia Power Supply Company of Henan Provincial Electric Power Company conducted on-site measurement on April 25, 2013 for the reconstruction project of the 63# tower grounding device of the 110kV Zhuming Line around Lushi and Lingbao in the south of Sanmenxia. One of the legs of the tower was backfilled with large stones The ground grid is difficult to dig; the other 3 are extended with two ground connection plates, the ground grid at each leg is buried at a depth of about 1m, the soil quality is the surface layer of 100-450mm soil, and the bottom is rocky mountain or rock-concrete, so it is impossible to install a vertical ground electrode . Therefore, the "Y" structure assembled grounding device is adopted, and the measured soil resistivity is 1673Ω·m. The grounding body of the hollow aluminum alloy tube is 216m in total, and the total length of the grounding body is 216m. Assemble, share 8 "Y" type bushings, and the measured grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com