Patents

Literature

133results about How to "Increase girth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

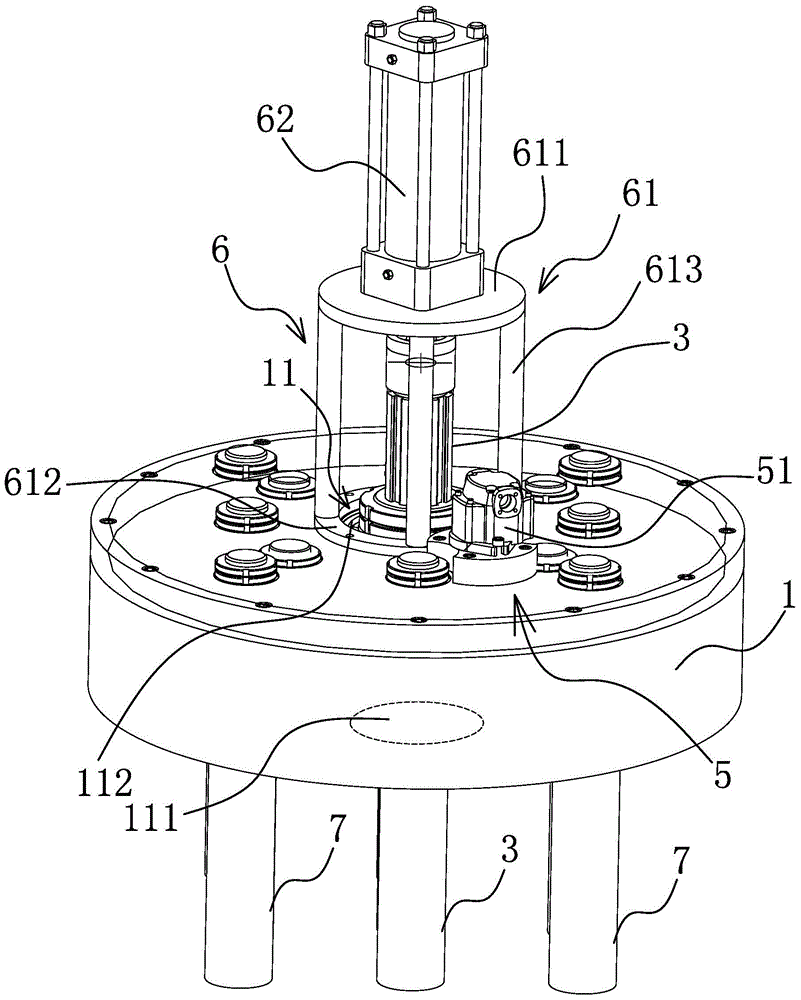

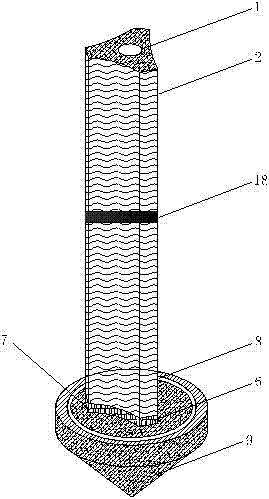

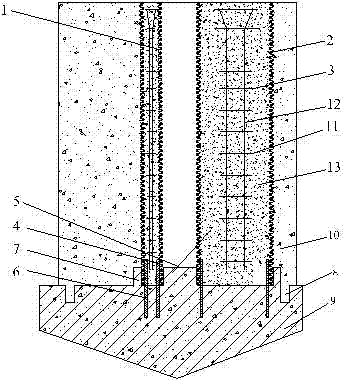

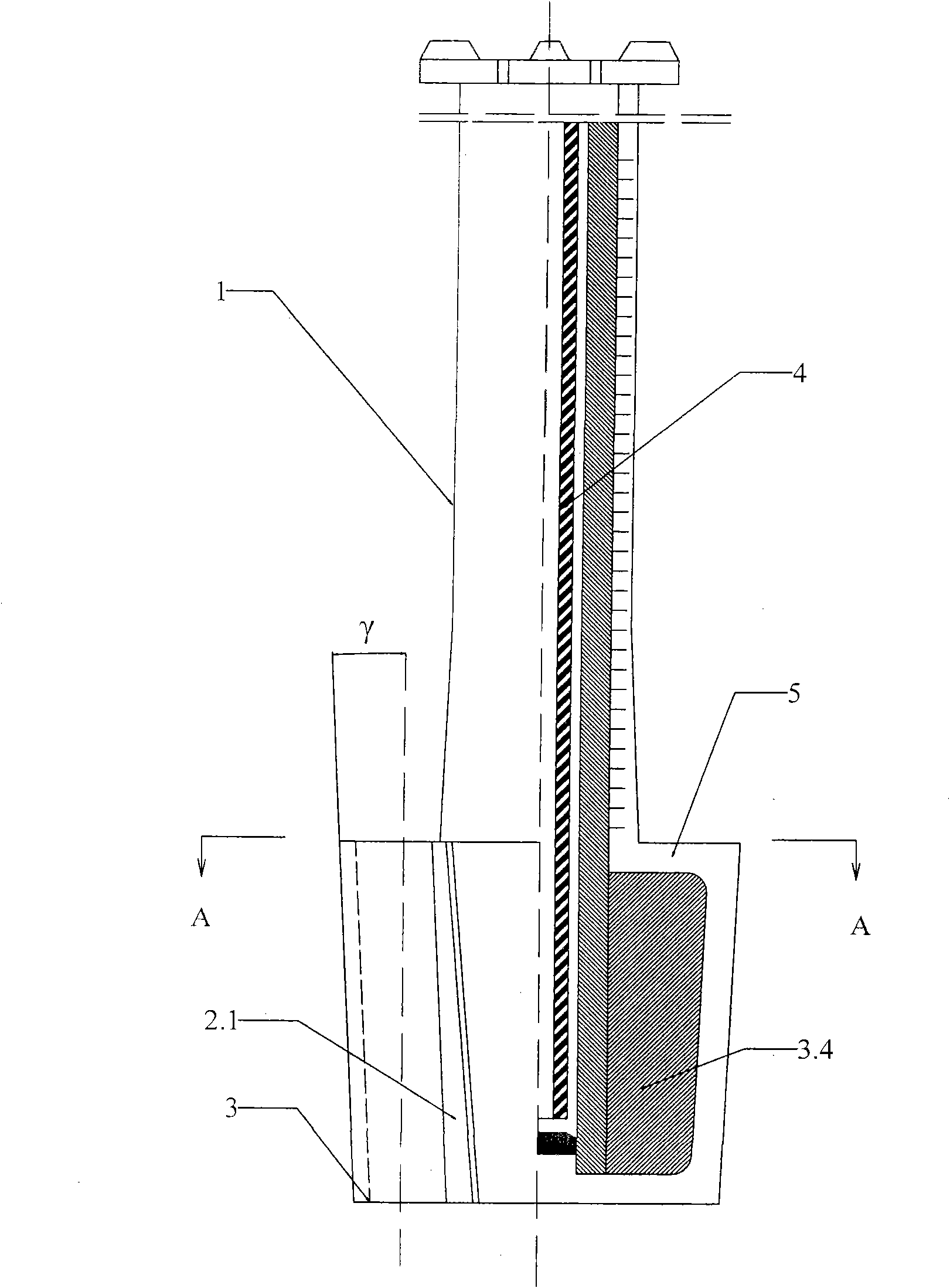

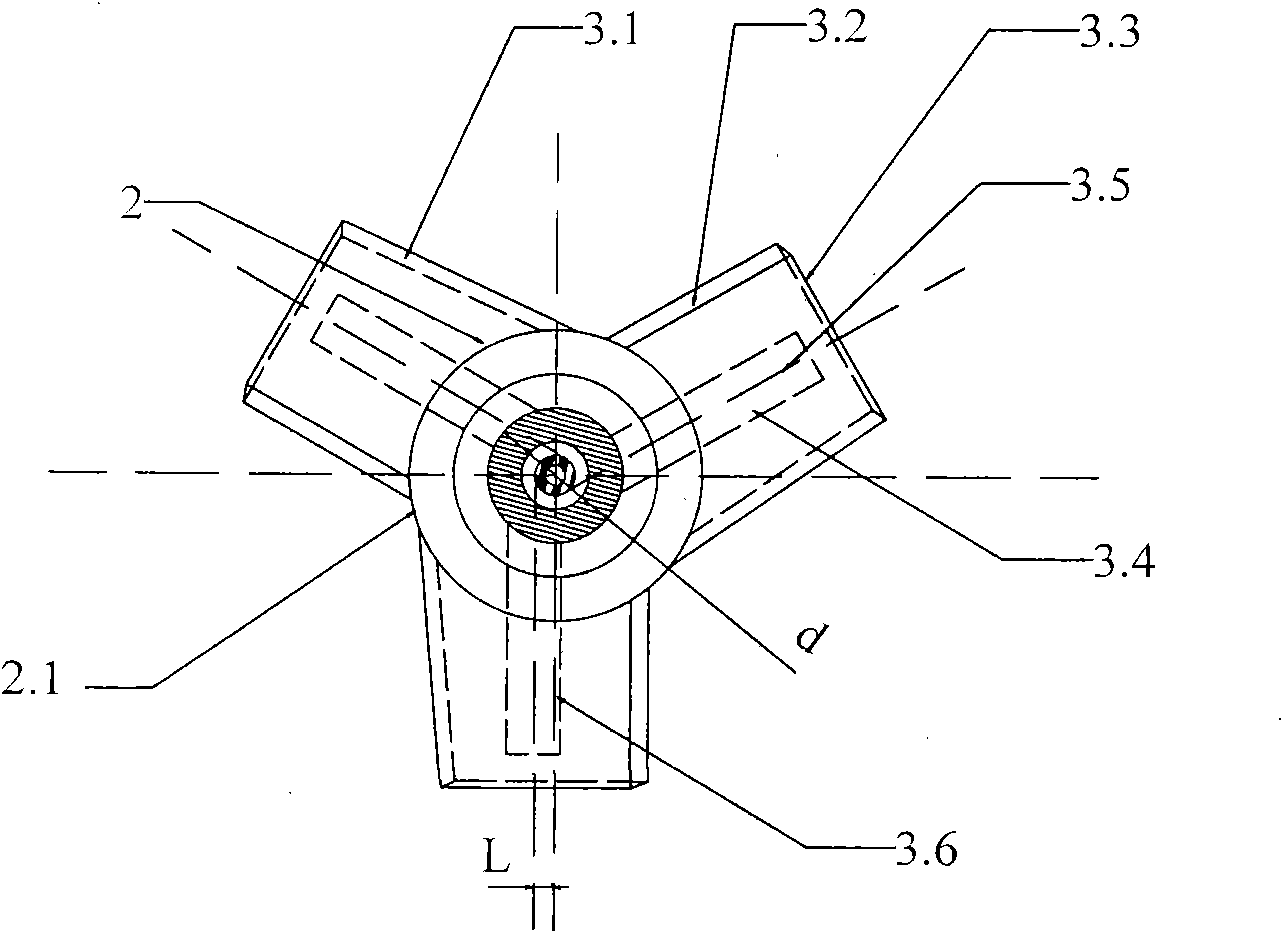

Moving drill rod of cement-soil mixing pile driver

ActiveCN105064911AImprove pullout resistanceIncrease girthRotary drillingRotary-drilling machinesDrill pipeSoil mixing

The invention belongs to the technical field of building equipment, and particularly relates to a moving drill rod of a cement-soil mixing pile driver. The moving drill rod solves the problem that existing cement-soil mixing pile drivers are prone to drill failures when drilling and the like, and comprises a driving box with an inner cavity, wherein the driving box is provided with at least one through hole which runs through the whole driving box in the axial direction; a guiding sleeve which can rotate in the circumferential direction and is cylindrical is arranged in the through hole; a drill rod which runs through the whole driving box is arranged in the guiding sleeve in a penetrating manner; an axial guiding structure is arranged between the drill rod and the guiding sleeve; the guiding sleeve is connected with a circumferential rotating mechanism which can drive the guiding sleeve to rotate in the circumferential direction; and the drill rod is connected with an axial driving mechanism which can drive the drill rod to slide back and forth in the axial direction. The moving drill rod of the cement-soil mixing pile driver has the advantages that a drill rod body can stretch in the axial direction, can rotate in the circumferential direction and slide in the axial direction at the same time, and thus is not prone to rotation failures; the perimeter of the cross section of a cement-soil mixing pile after constructing is increased; and the pull-out capacity of the cement-soil mixing pile is improved.

Owner:周兆弟

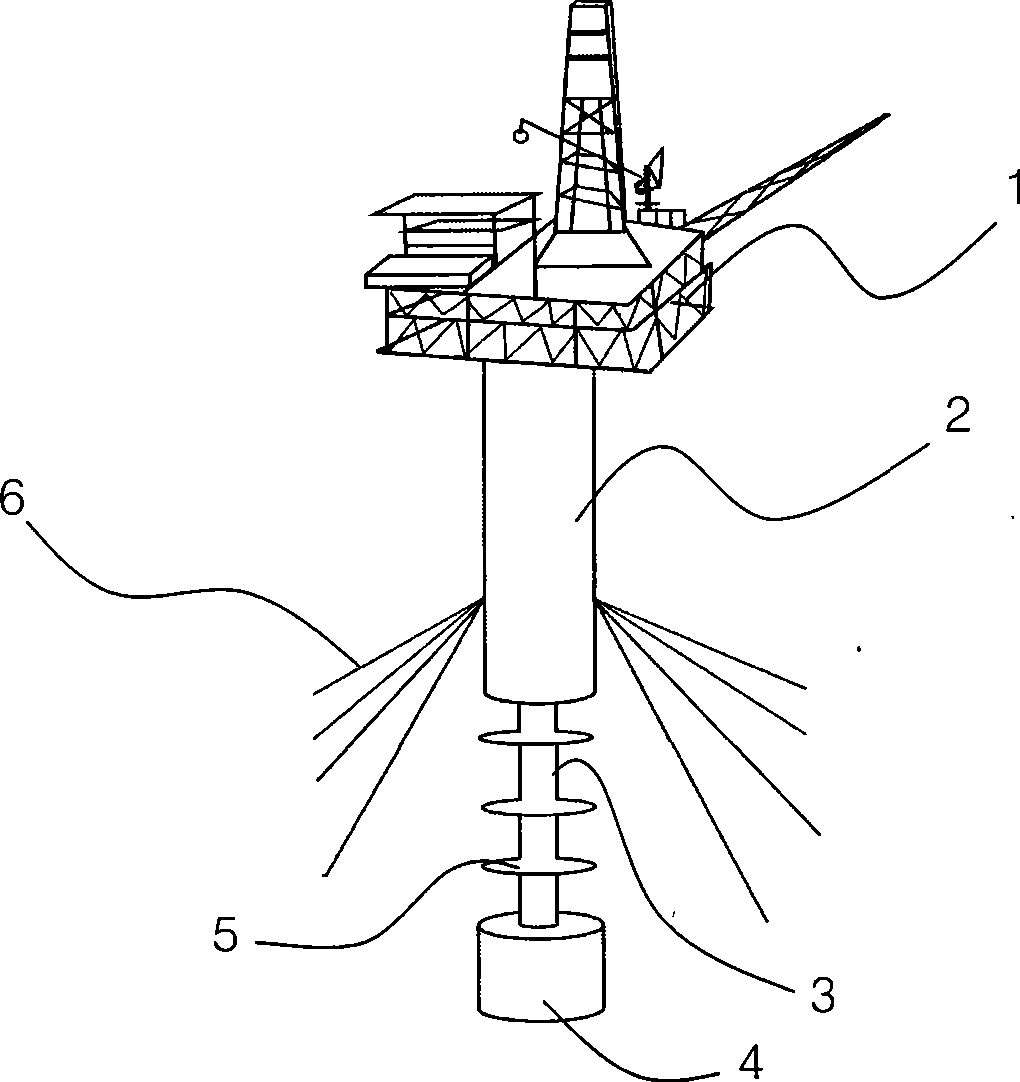

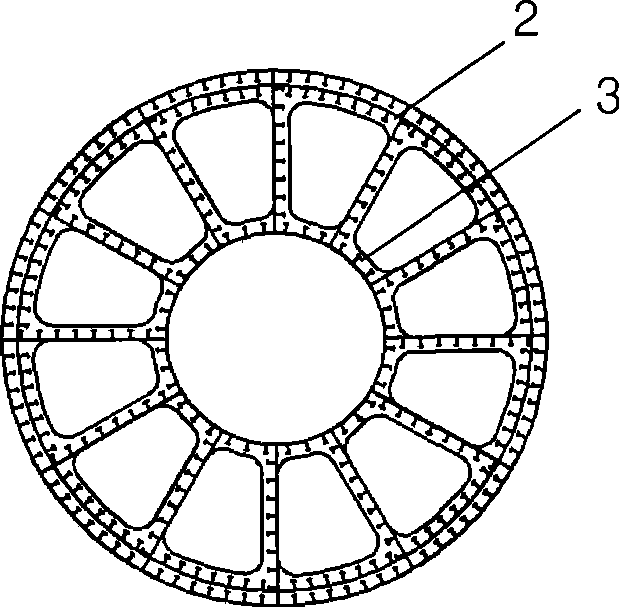

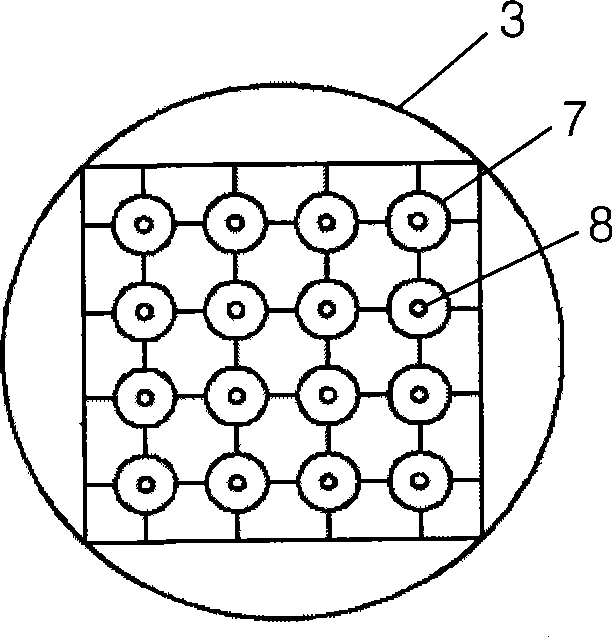

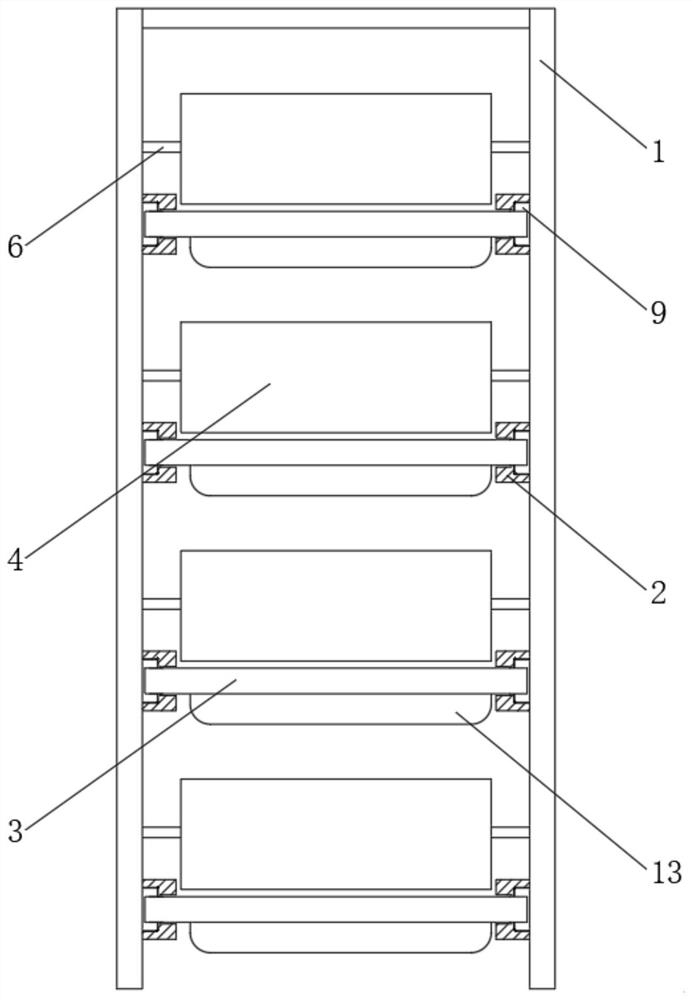

Novel sea deep water buoy platform

InactiveCN101475048AReduce surgeReduced heave responseMovement controllersFloating buildingsOcean bottomOcean sea

The invention relates to an ocean working platform, in particular to a novel ocean deepwater floating pontoon platform. The structure of the platform comprises a platform deck for operating, wherein a hard cabin is connected under the platform deck; a plurality of mooring ropes are connected on the outer wall of the hard cabin, while the other ends of the mooring ropes are connected with a submarine anchorage ; a soft cabin is arranged under the hard cabin; the hard cabin and the soft cabin are connected through a cylindrical center well; a plurality of layers of heave plates are vertically arranged outside the center well; the heave plates along circumferential direction is symmetrically provided with a plurality of square holes; and a plurality of oil extraction vertical pipes pass through the center well to a submarine well mouth. Compared with the prior Spar platform, the novel ocean deepwater floating pontoon platform has strong supporting capability and low structure cost, and is applicable to abyssalpelagic operation with internal waves.

Owner:OCEAN UNIV OF CHINA

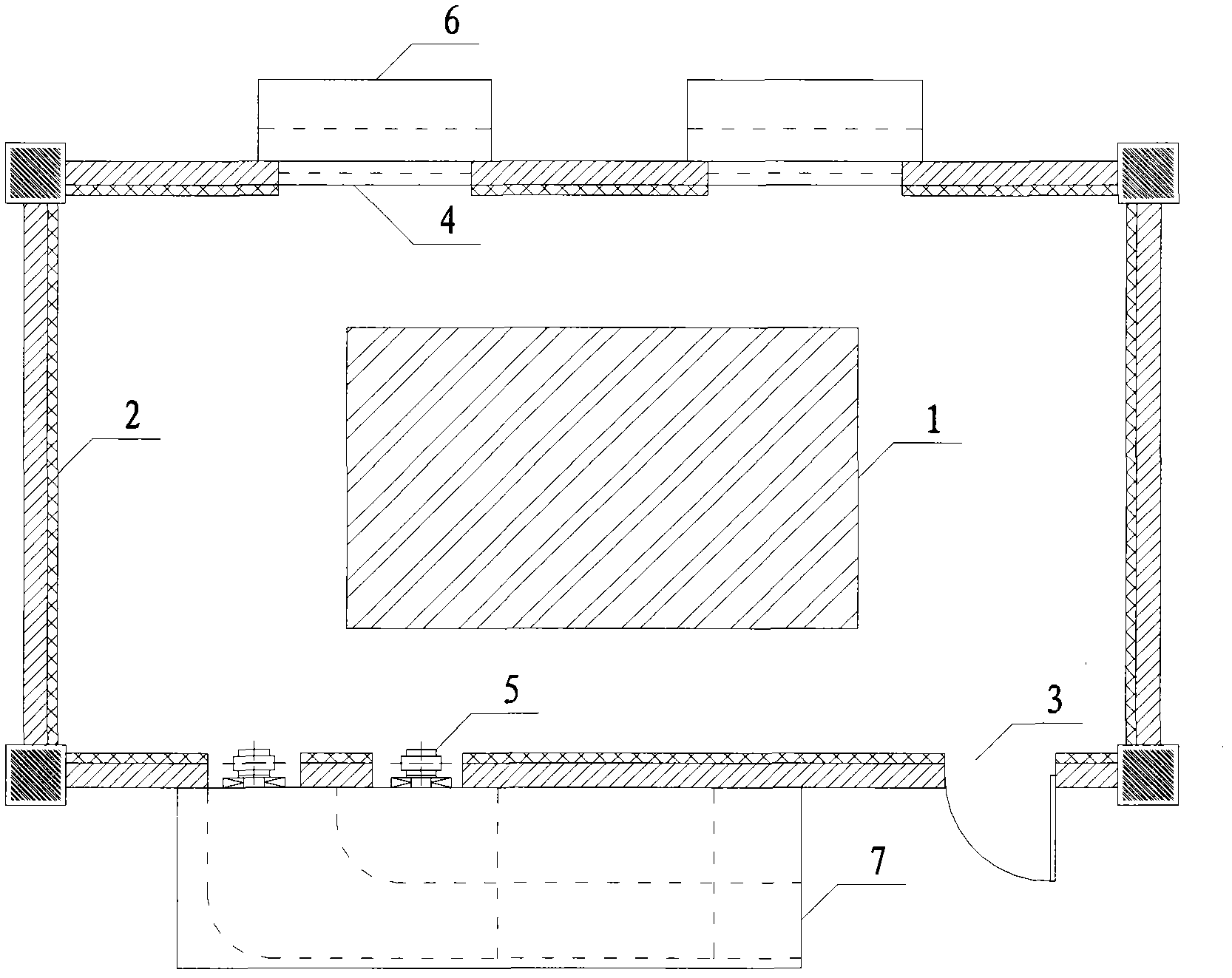

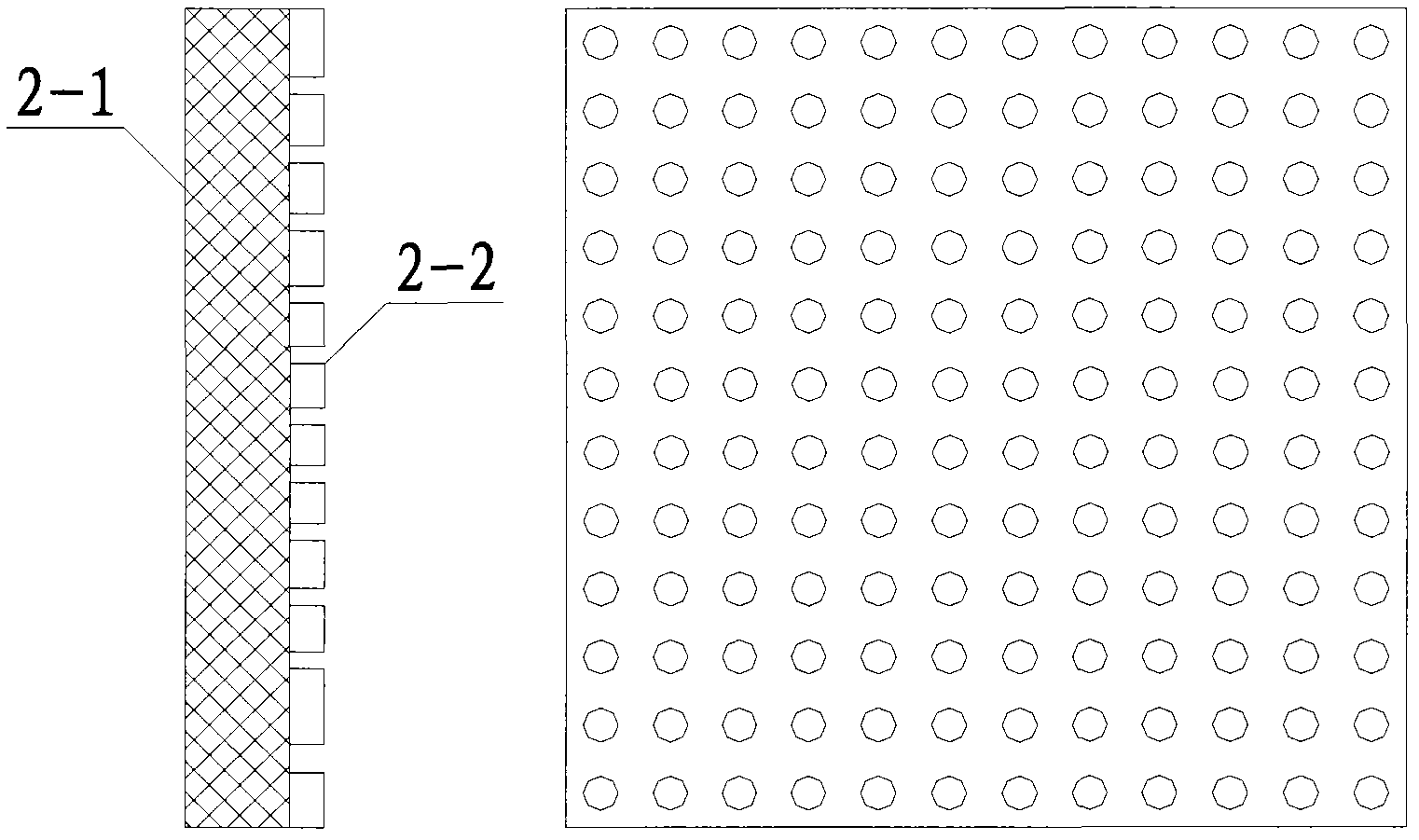

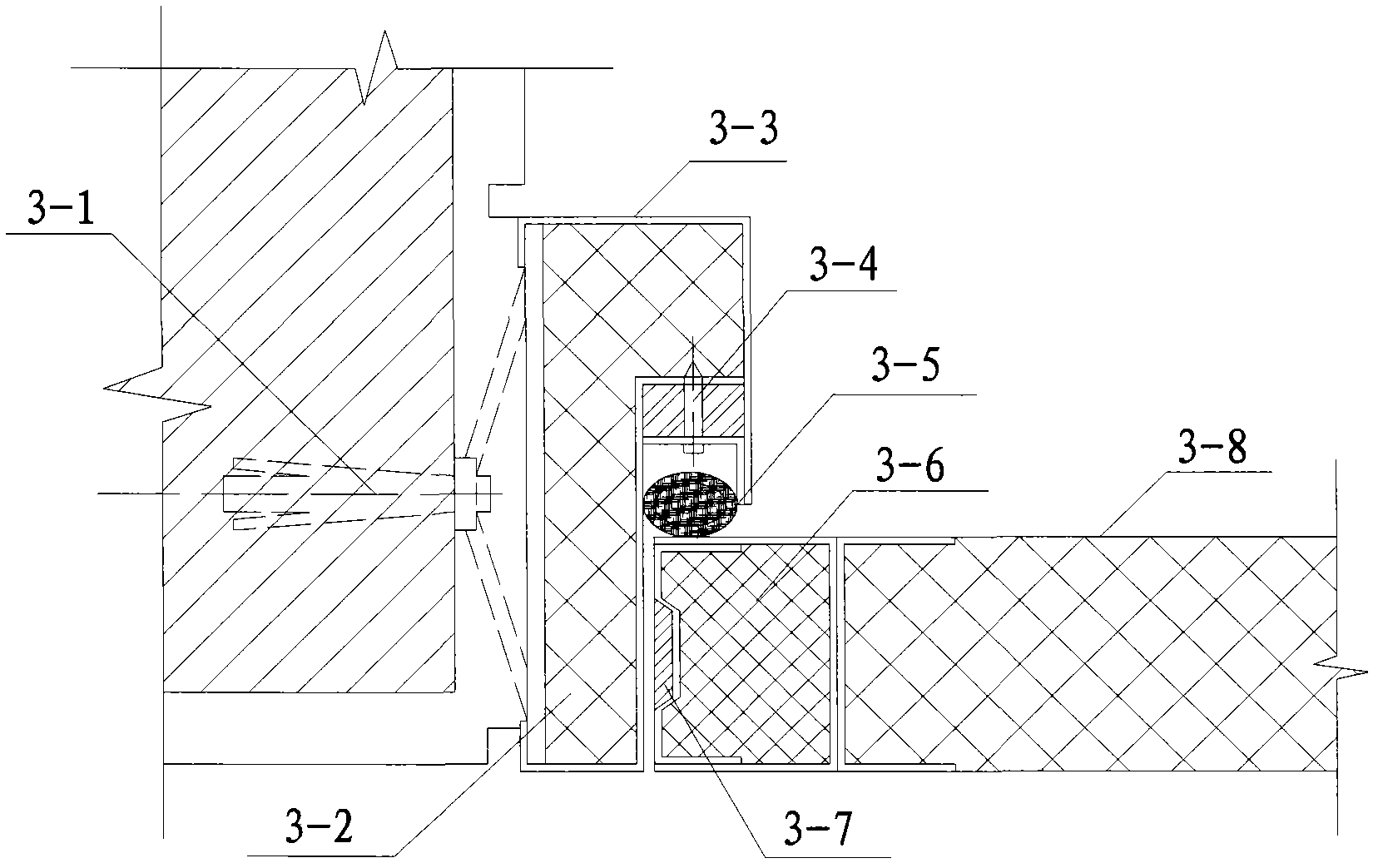

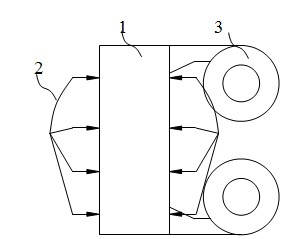

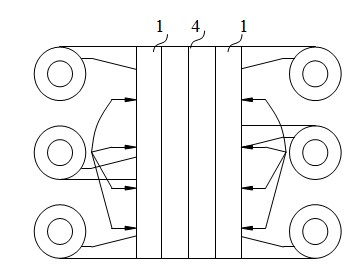

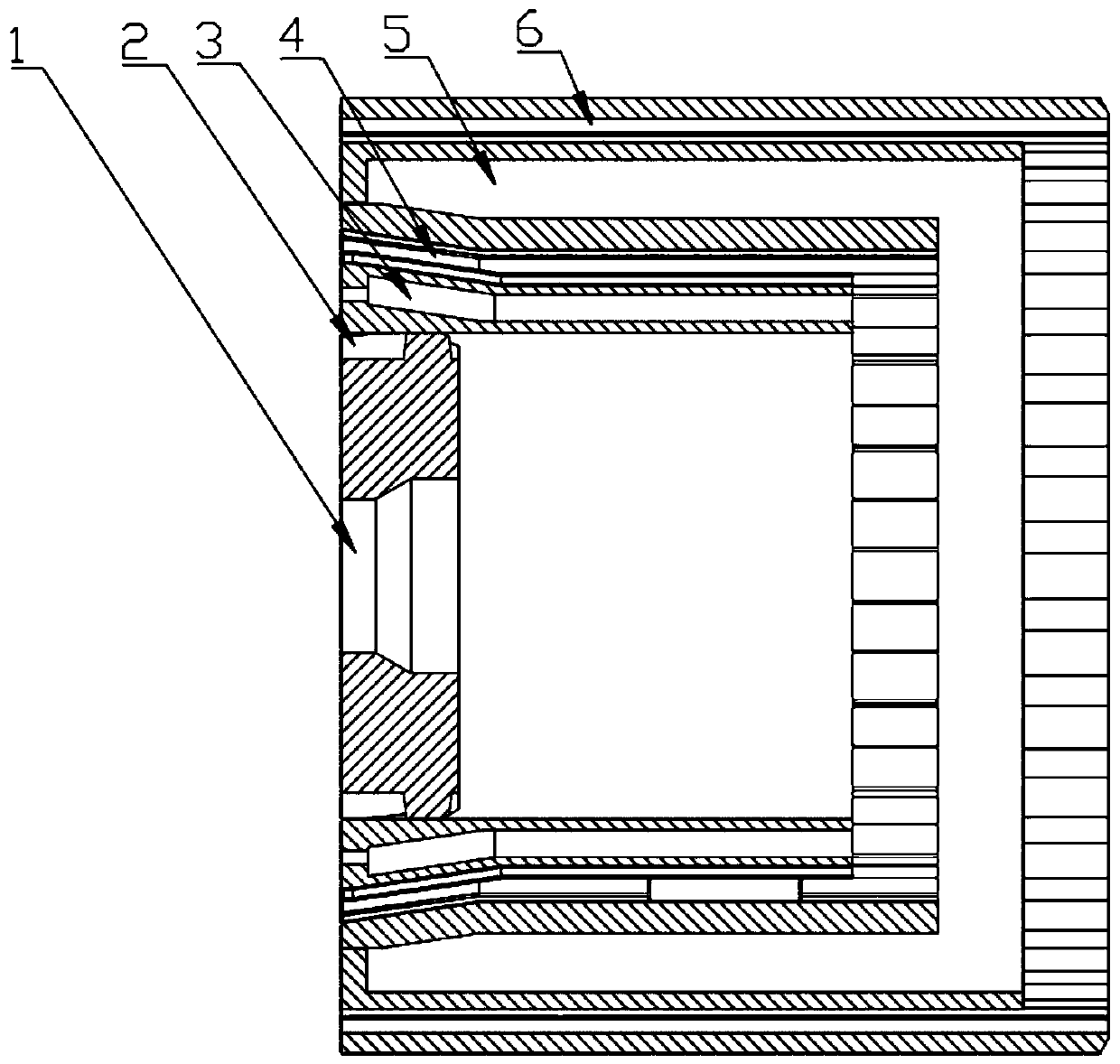

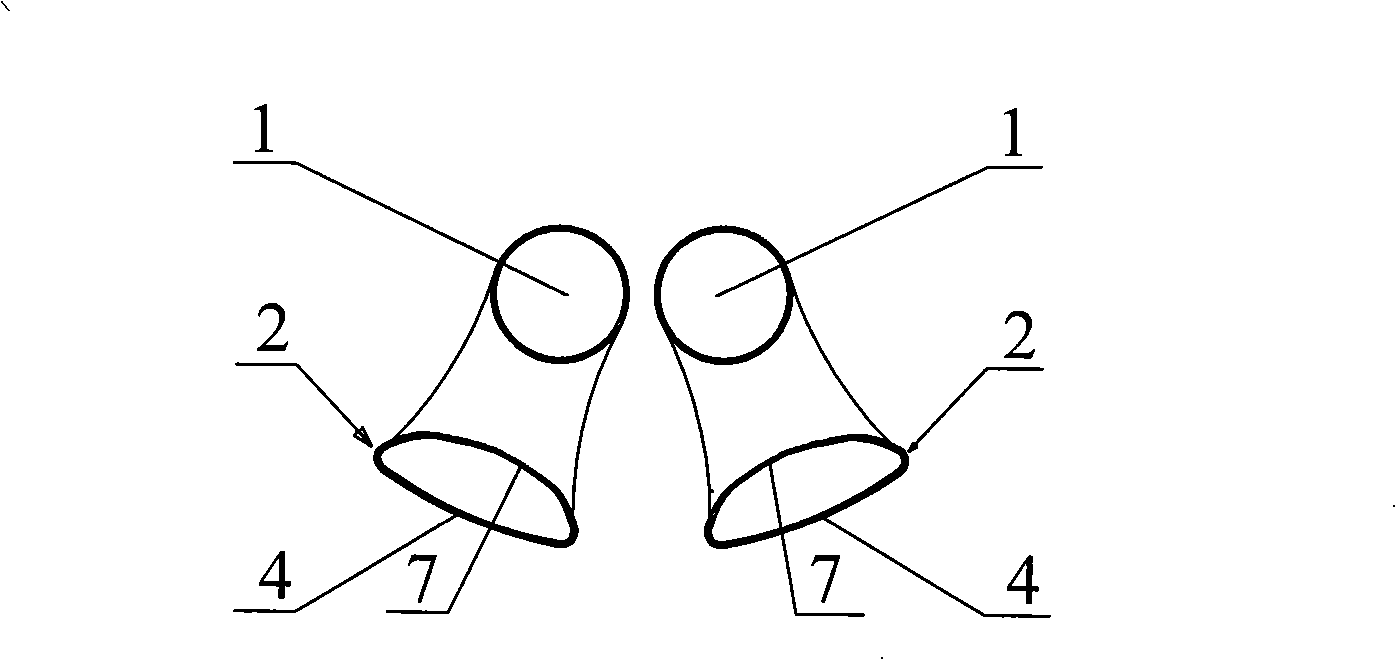

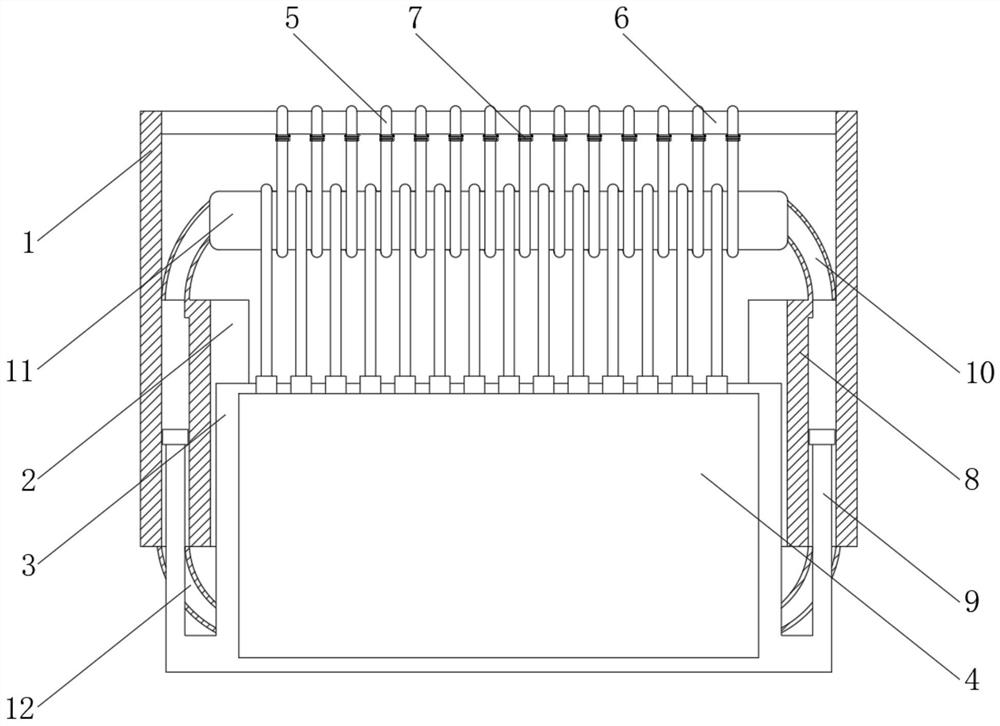

Noise reduction structure of main noise resources of urban indoor substation

The invention relates to a noise reduction structure of main noise resources of an urban indoor substation, belonging to the technical field of noise pollution control in environmental engineering. The noise reduction structure is mainly used for reducing the noise resources of the urban indoor substation, including noise radiated by a main transformer and a reactor 1. The noise reduction structure comprises a wall perforated plate resonance sound absorption structure 2, a sound isolation door 3, a ventilating shutter 4, a low-noise axial flow fan 5, an air intake silencer 6 and an air exhaust silencer 7, wherein the wall perforated plate resonance absorption structure 2 is located inside the wall and comprises a perforated gypsum plate and acrylic cotton; the sound isolation door 3 is filled with glass coated intermediate glass cotton fiber, and the gap of a door frame is filled with sealing strips; the ventilating shutter 4 and the low-noise axial flow fan 5 are used for ventilating and dissipating heat to ensure the safe and stable operation of the main transformer and the reactor; the air intake silencer 6 is installed on the outer part of the ventilating shutter 4, the upper part is a lighting sound-isolating window cover, and the lower part is an air flow channel covering the sound absorption material; and the air exhaust silencer 7 is installed outside a ventilating fan hole, and the interior is an air flow channel covering the sound absorption material.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

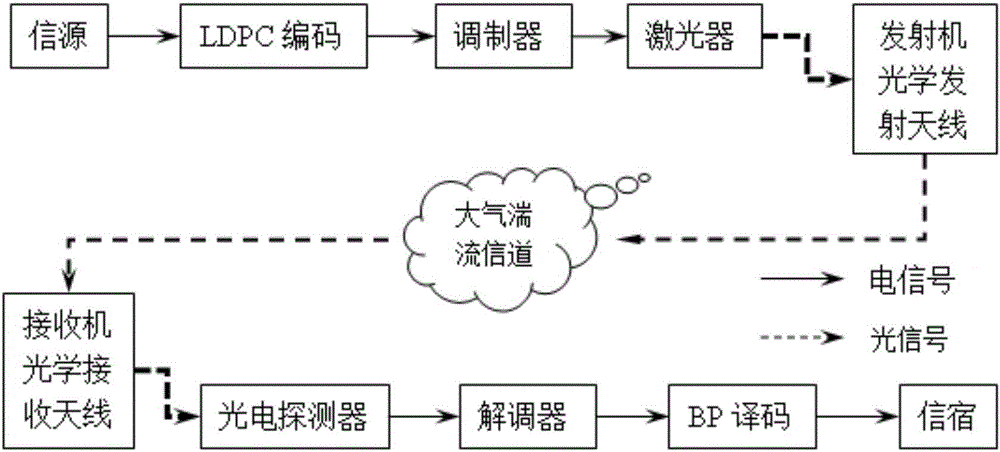

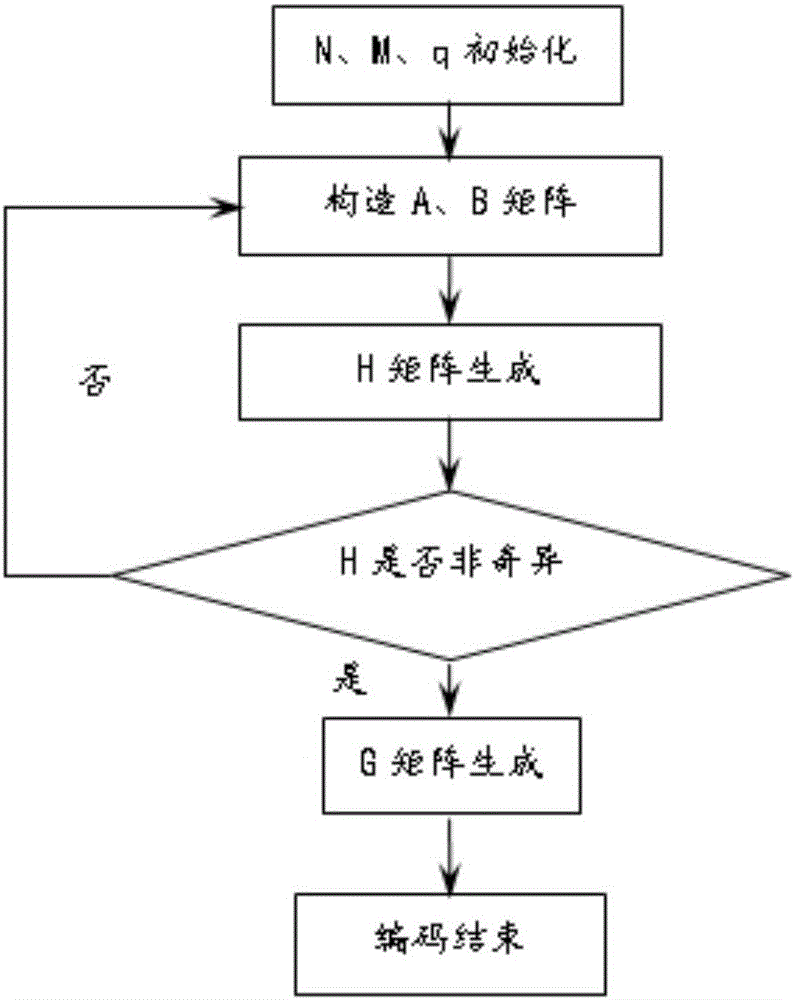

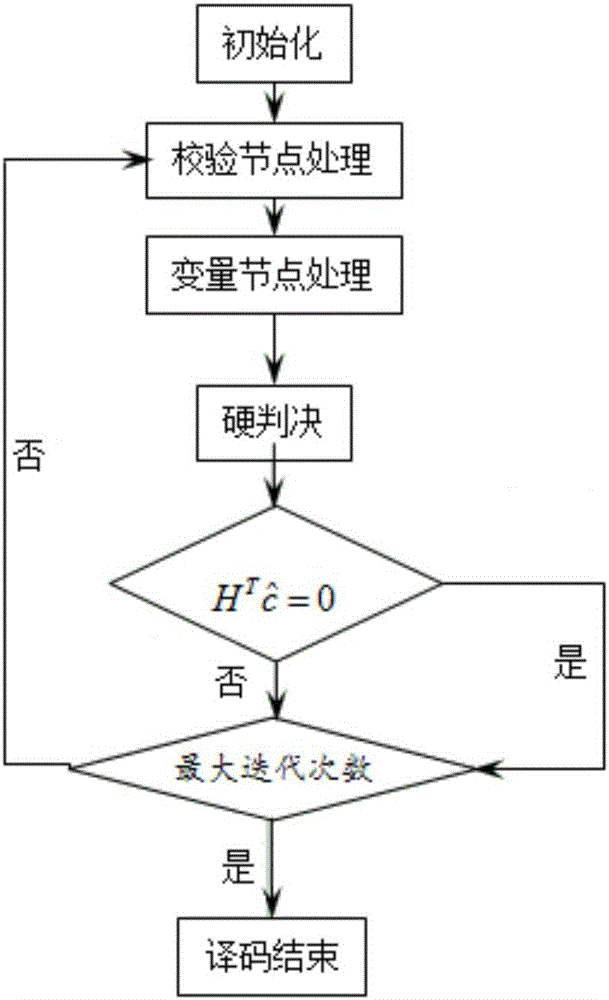

Free space optical communication method and system based on LDPC code

ActiveCN106685527AImprove performanceMeet the requirements of multiple scattering mechanismsError preventionClose-range type systemsSignal-to-noise ratio (imaging)Communications system

The invention provides a free space optical communication method and system based on an LDPC code. The method and system aim at a problem that the error rate, communication distance and communication bandwidth of a system are affected by the flicker and light beam drift and extension caused by atmosphere turbulence and the reduction of signal to noise ratio of a receiving end in laser communication. The method comprises the steps: firstly proposing a logarithmic normal distribution channel model under weak turbulence and a K-distribution channel model under strong turbulence according to the characteristics of atmosphere turbulence channels; secondly constructing an irregular QC-LDPC code on the basis of the proposed channel models; finally deducing an LLR probability density function, and carrying out the decoding through an LLR-BP algorithm. A confidence decoding BP result indicates the error rate of the system remarkably decreases along with the increase of signal to noise ratio. An experiment indicates that the method and system can effectively reduce the performance of an FSO system.

Owner:武汉全信通通信工程有限公司

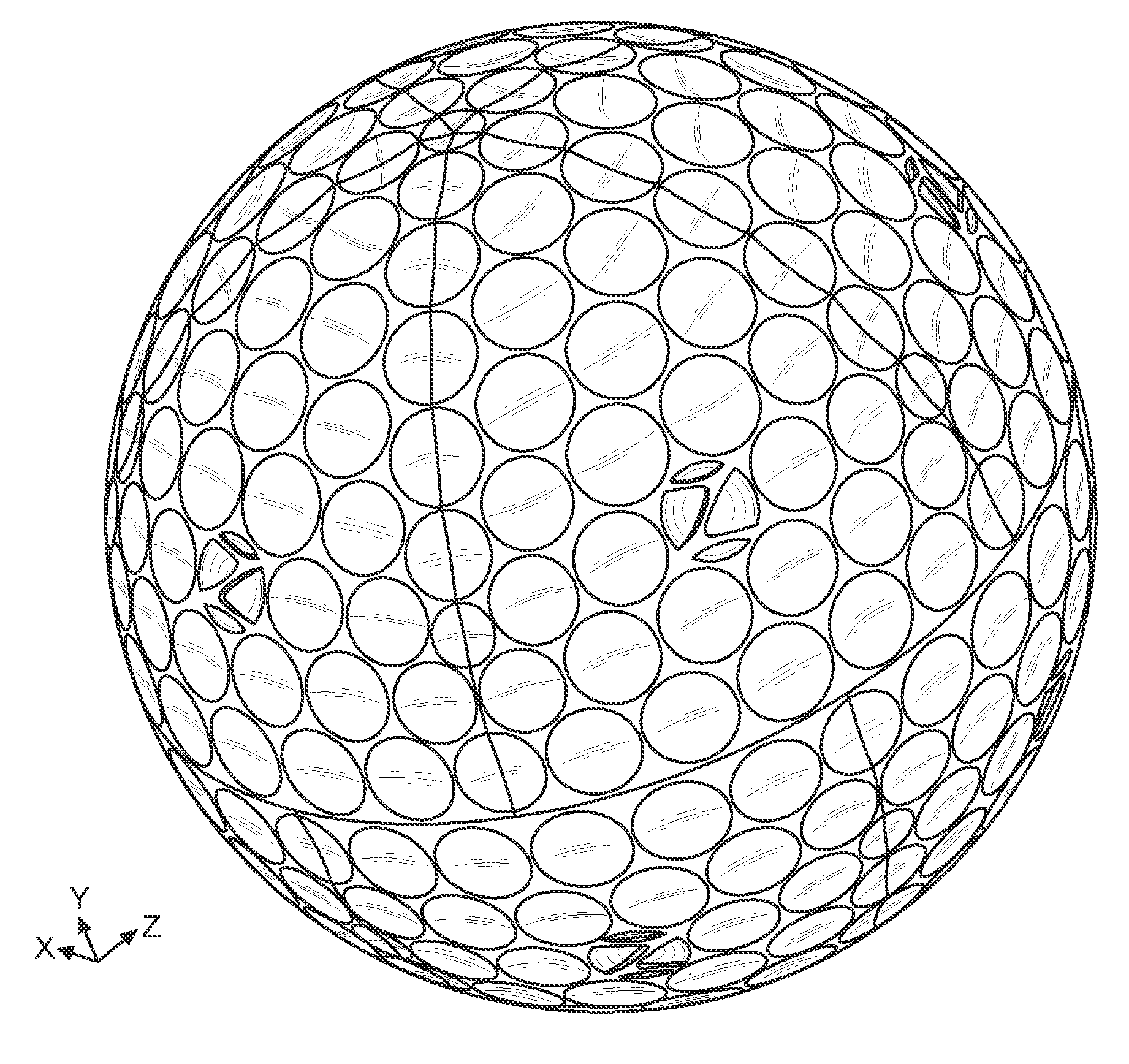

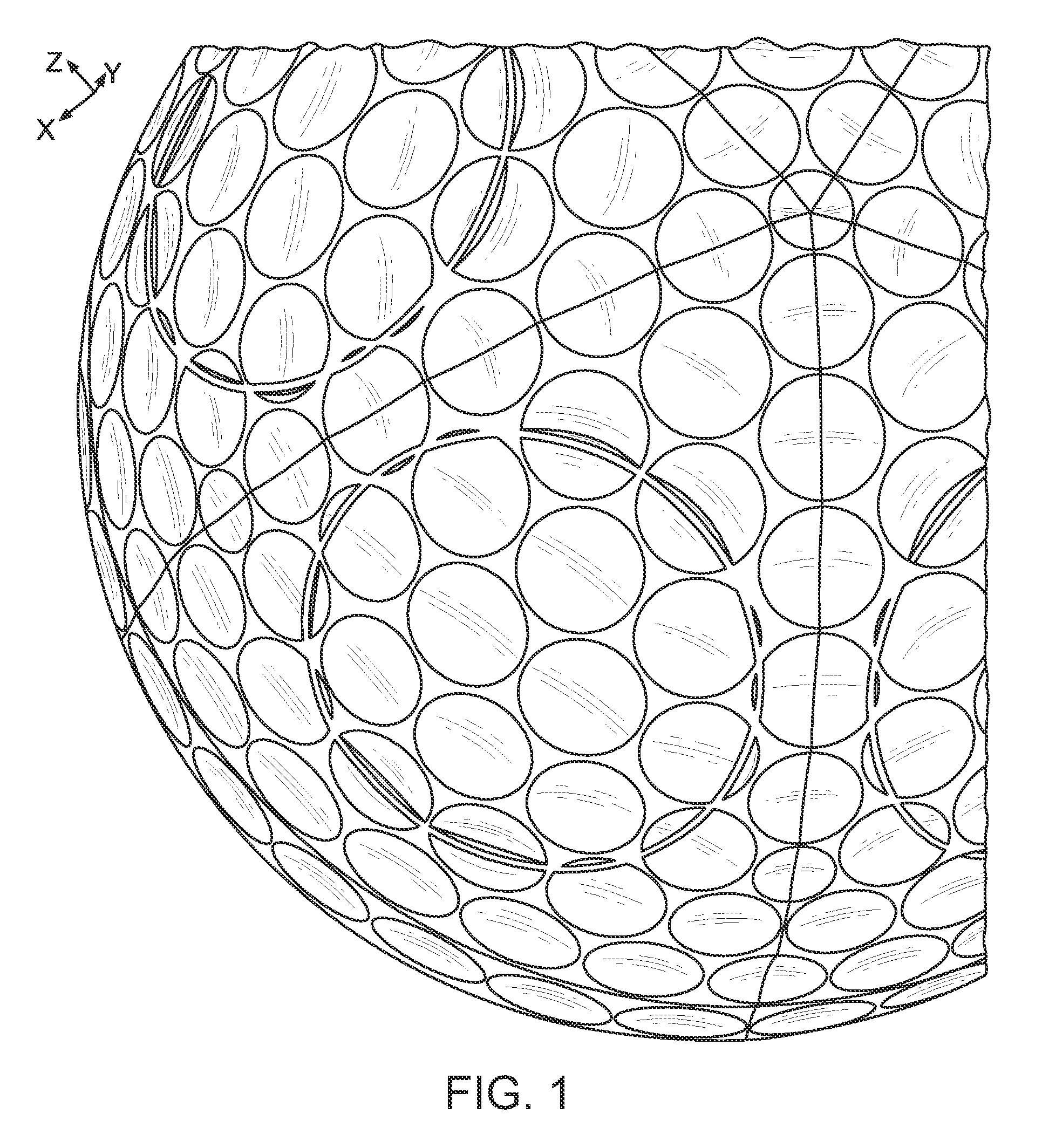

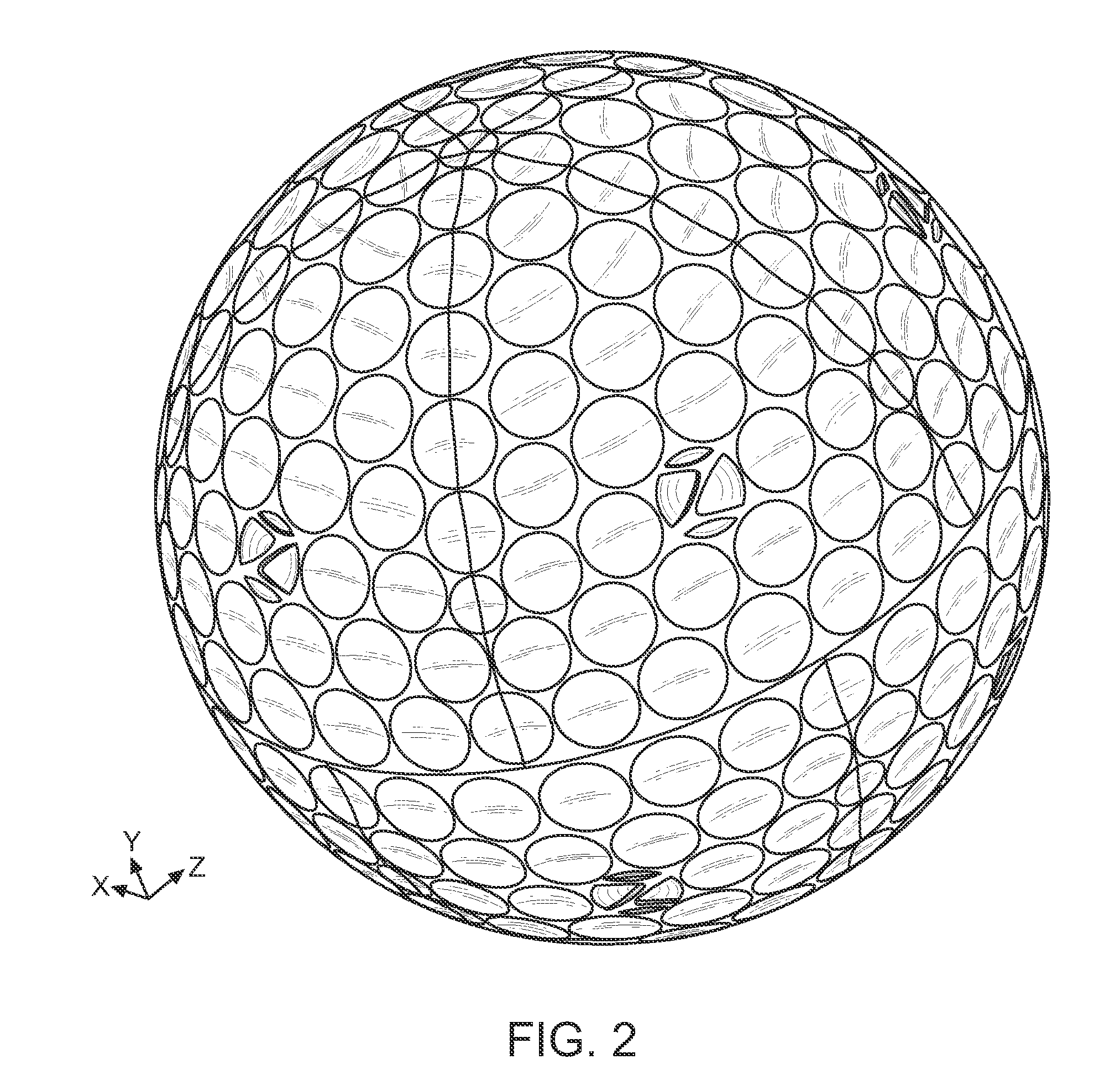

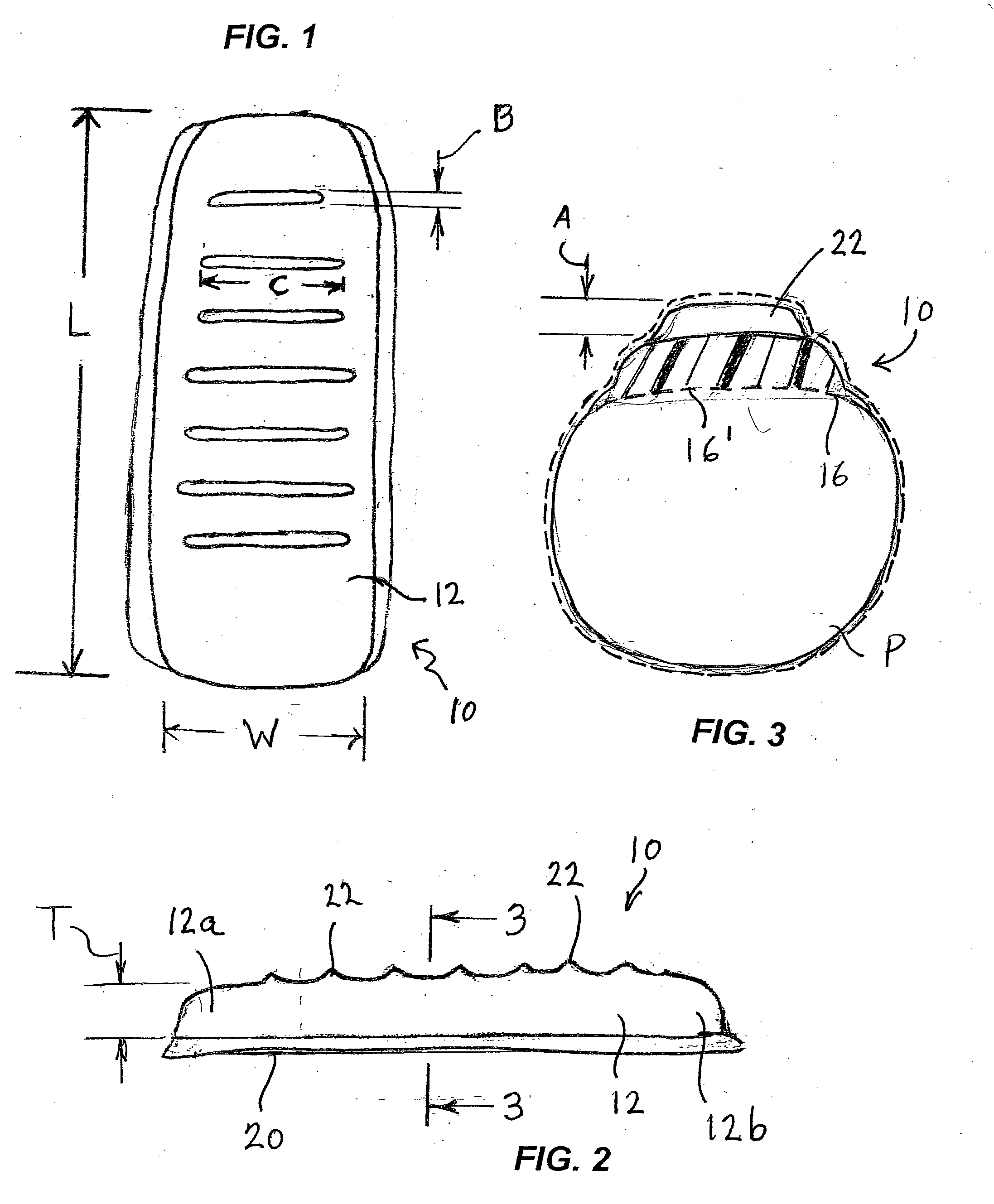

Golf ball dimples forming indicia

InactiveUS20100240472A1Increase girthImprove aerodynamic performanceGolf ballsSolid ballsCHEEK DIMPLESGeometric element

The present invention comprises a golf ball with dimples. Some of the dimples have markings that are raised geometric elements having substantially the same elevation as the undimpled land area. Innovatively, the markings interact with and become components of dimples themselves rather than being additions or replacements for dimples. Innovatively, the markings increase the total perimeter value of one or more dimples, and the aggregate dimple perimeter value of a golf ball. Such increased perimeter quantities provide a means to control and improve aerodynamic performance.

Owner:ACUSHNET CO

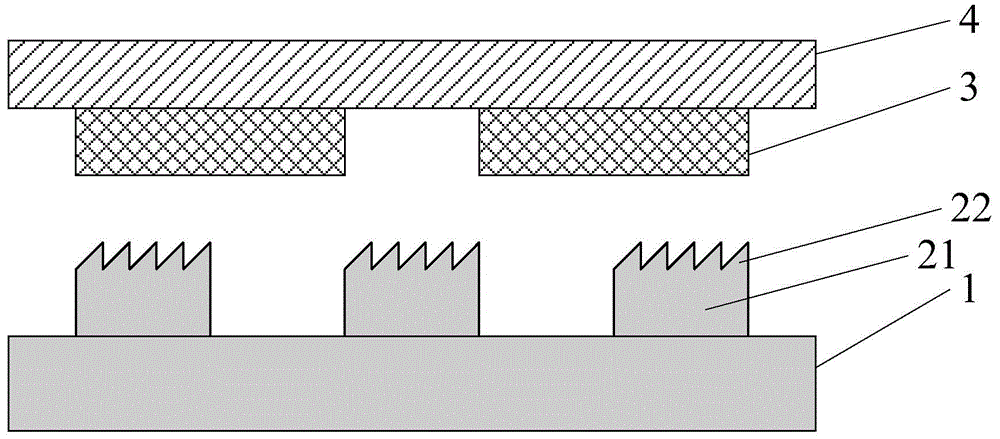

Bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and construction method

ActiveCN103485334BIncrease girthImprove mechanical performanceBulkheads/pilesReinforced concreteEngineering

The invention relates to a bi-layer plastic-bushing inverted-arch cambered hollow special-shaped pile and a construction method. The pile is characterized by structurally comprising the inverted-arch cambered hollow special-shaped pile, a pile toe arranged at the bottom end of the special-shaped pile and fixed through fixing parts, and a precast reinforced concrete pile tip; a cemented soil layer is arranged on the outer side of a pile body; a cross section of the special-shaped pile is Y-shaped or X-shaped, and bushings with threads are arranged in a round hole in the center of the pile body and on the outer side of the pile body; a reinforcement cage, which is in the same shape as the pile body but slightly smaller than the pile body, is arranged in the pile body; horizontal and longitudinal tensile reinforcements are arranged in the reinforcement cage; and the fixing parts corresponding to the bushings and an immersed tube are arranged on the top face of the precast reinforced concrete pile tip. During construction, the pile toe and the inner bushing are fixed firstly, then the reinforcement cage and the outer bushing are sleeved, and concrete is poured between the inner bushing and the outer bushing as well as between the outer bushing and the immersed tube to respectively form a concrete pile core and a pile-side cemented soil layer. Area of the cross section of the pile body is small, consumption of building materials is reduced, bearing capacity is high, and the pile body is high in capability of resisting to environmental erosion.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

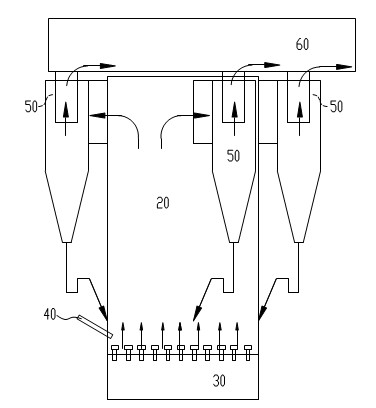

Recirculating fluidized bed boiler

ActiveCN102147106AIncrease the areaResolve central hypoxiaFluidized bed combustionApparatus for fluidised bed combustionSize increaseCirculating fluidized bed boiler

The invention discloses a recirculating fluidized bed boiler which comprises a hearth, wherein the hearth comprises an inner wall and an outer wall, wherein the outer wall surrounds outside the inner wall, and an annular space between the inner wall and the outer wall forms a hearth inside. When the area of the hearth is enlarged, sizes of all directions of the recirculating fluidized bed boiler can be simultaneously increased, thus, the problem caused by imbalance of width to depth ratio due to the size increase of the single direction of the traditional hearth is effectively overcome. Meanwhile, the annular hearth is completely through the integral hearth space without risks of pressure imbalance and pressure drastic fluctuation bed tilting during the operation of the boiler.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

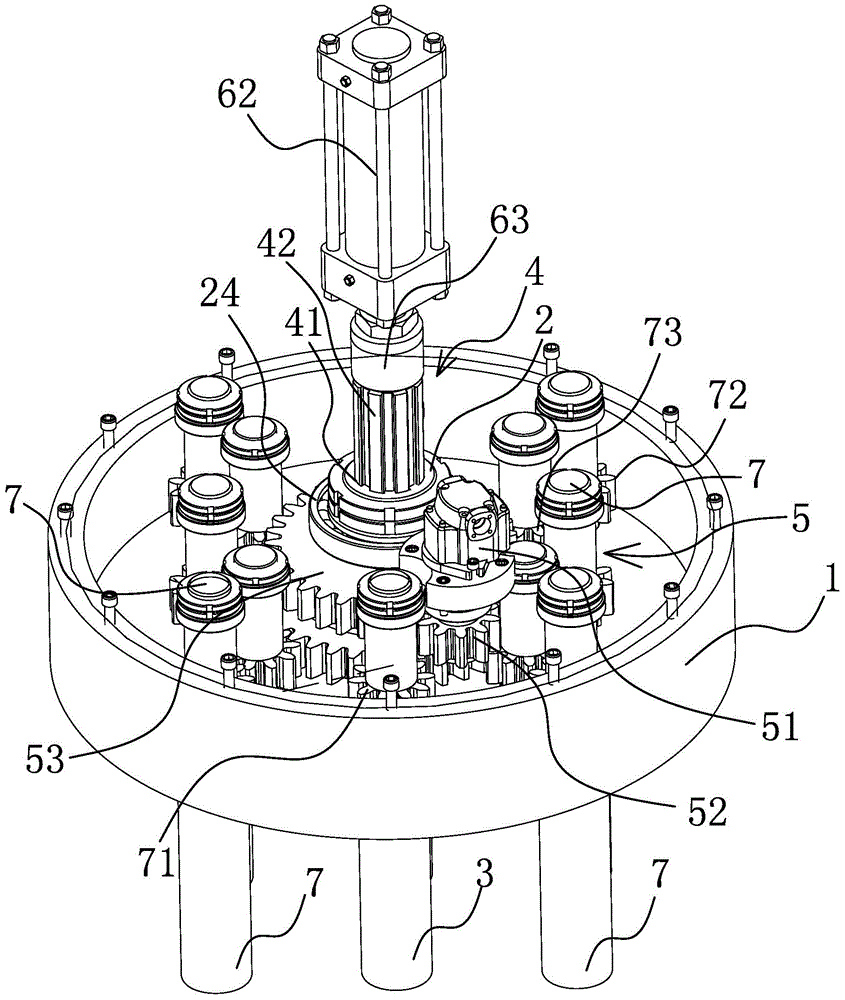

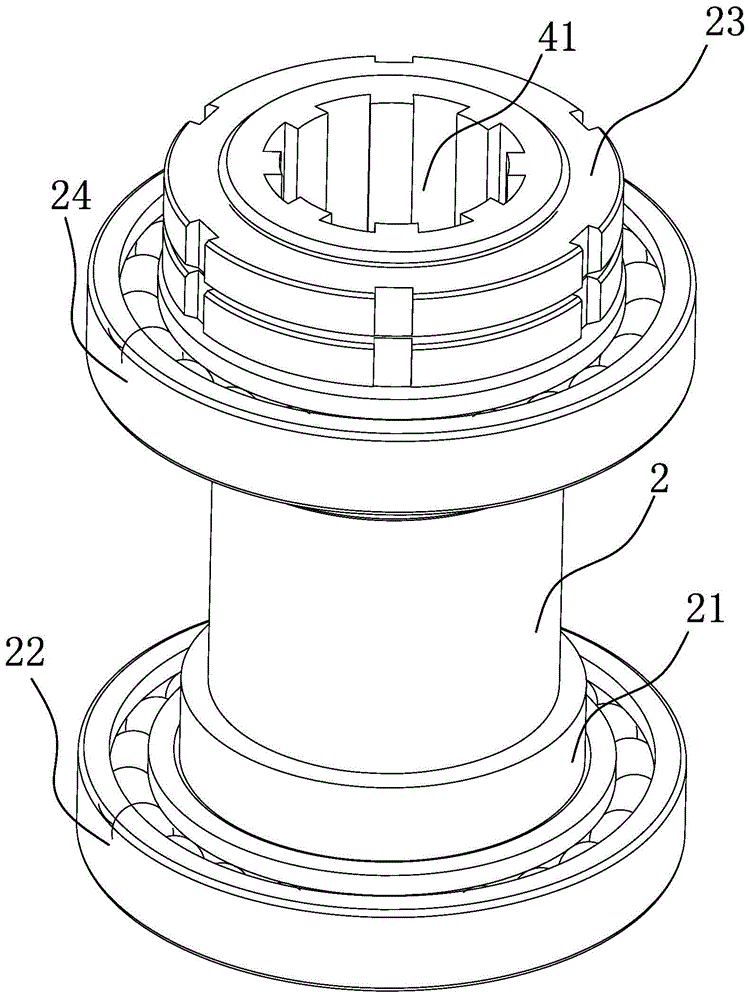

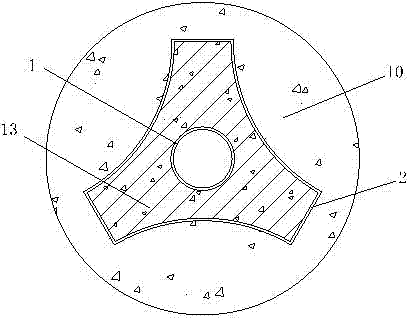

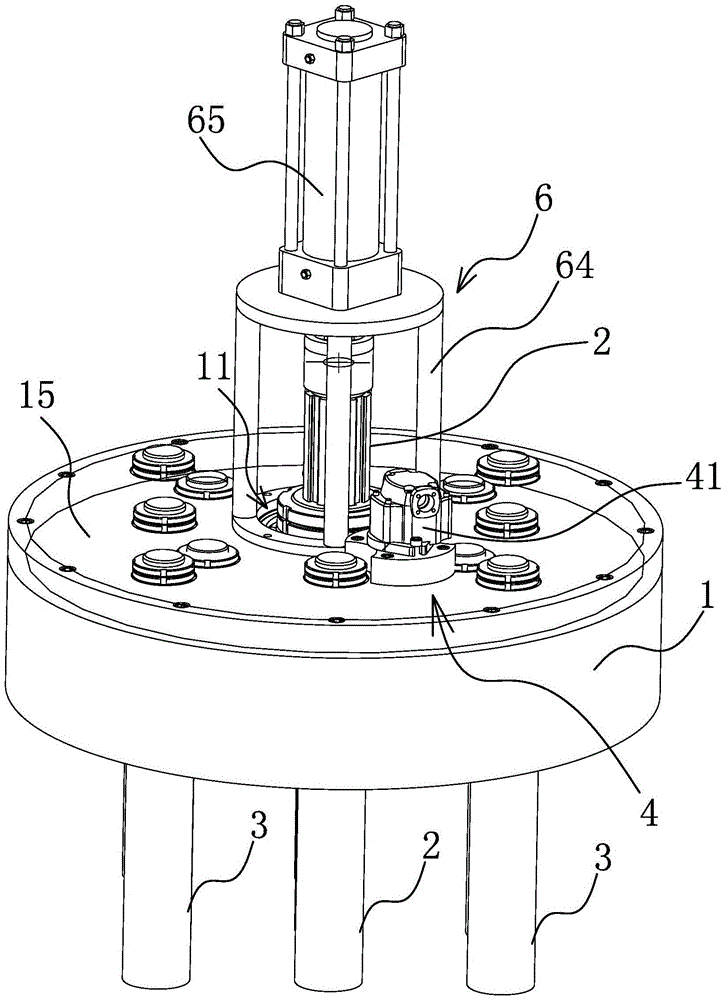

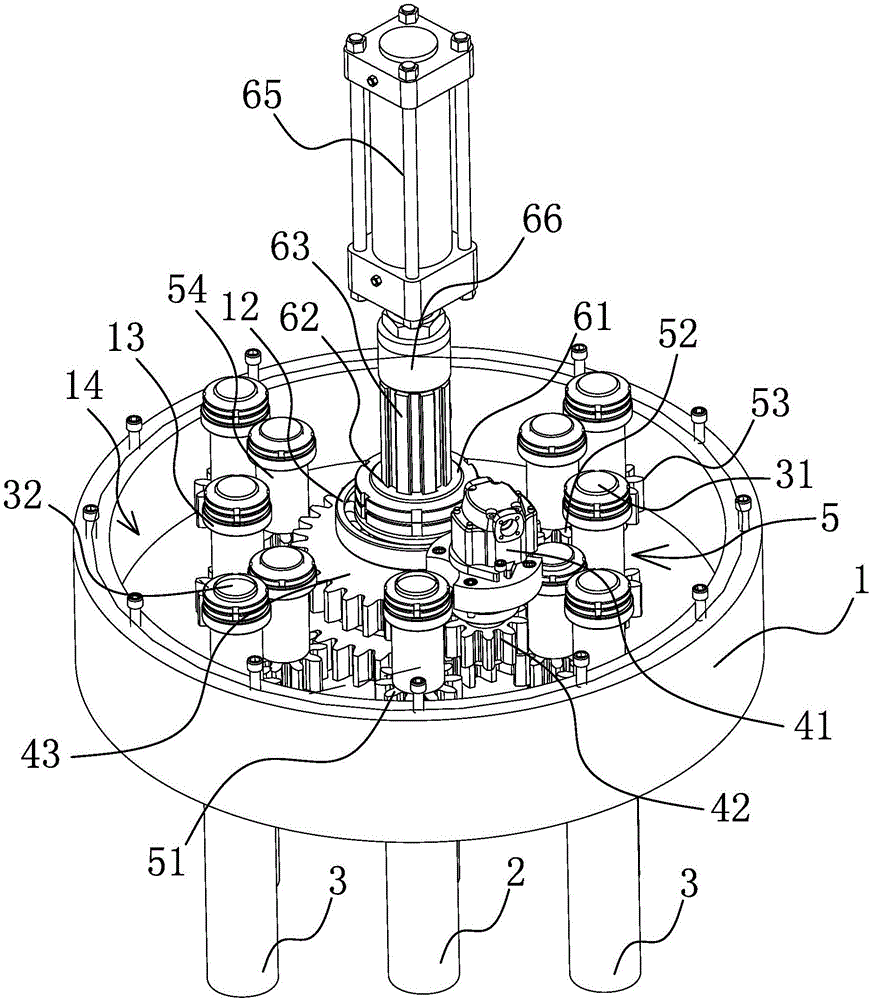

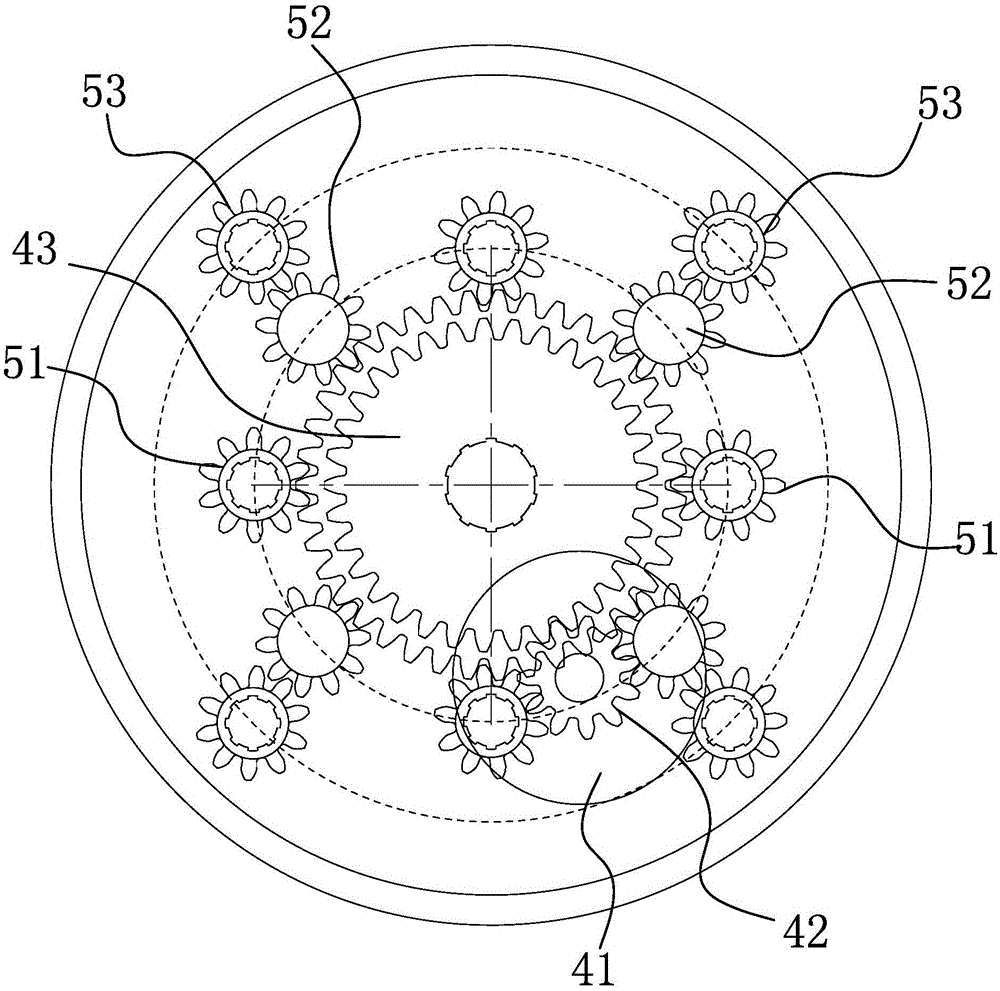

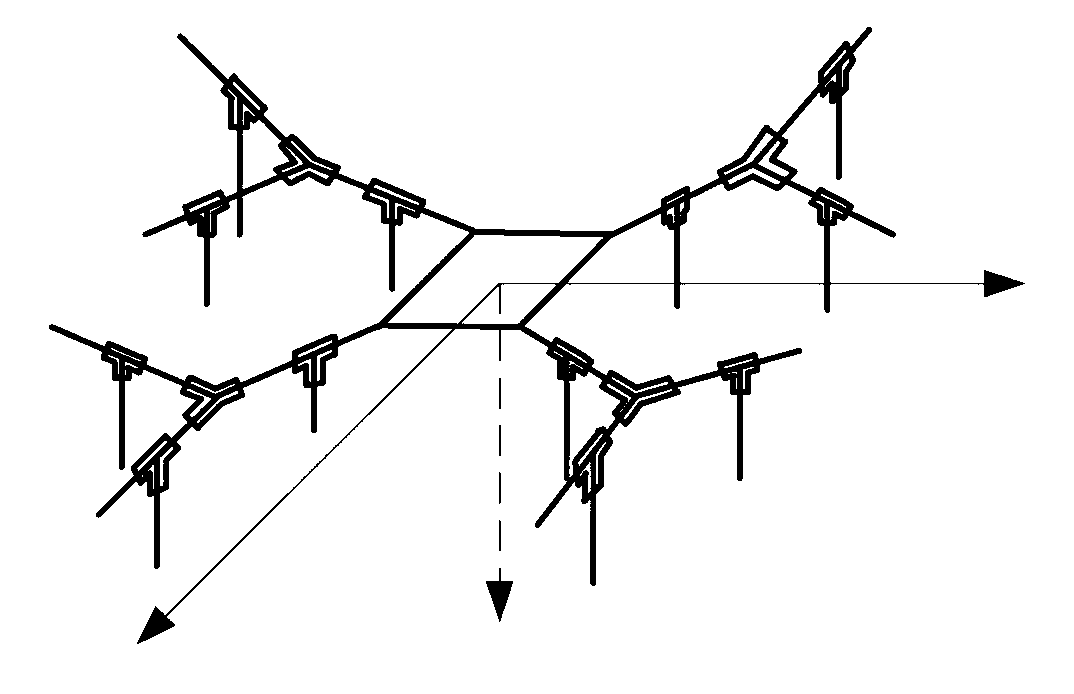

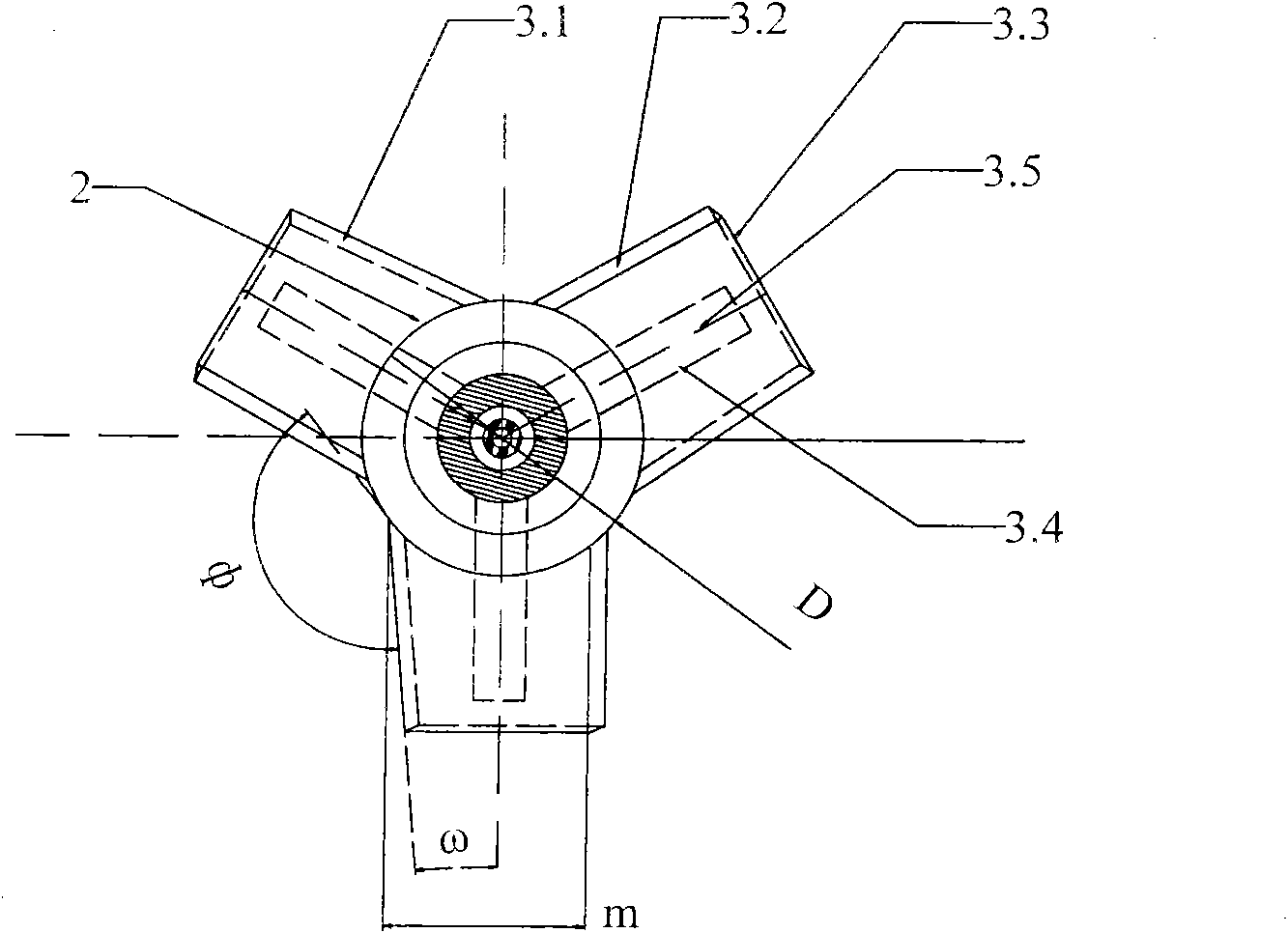

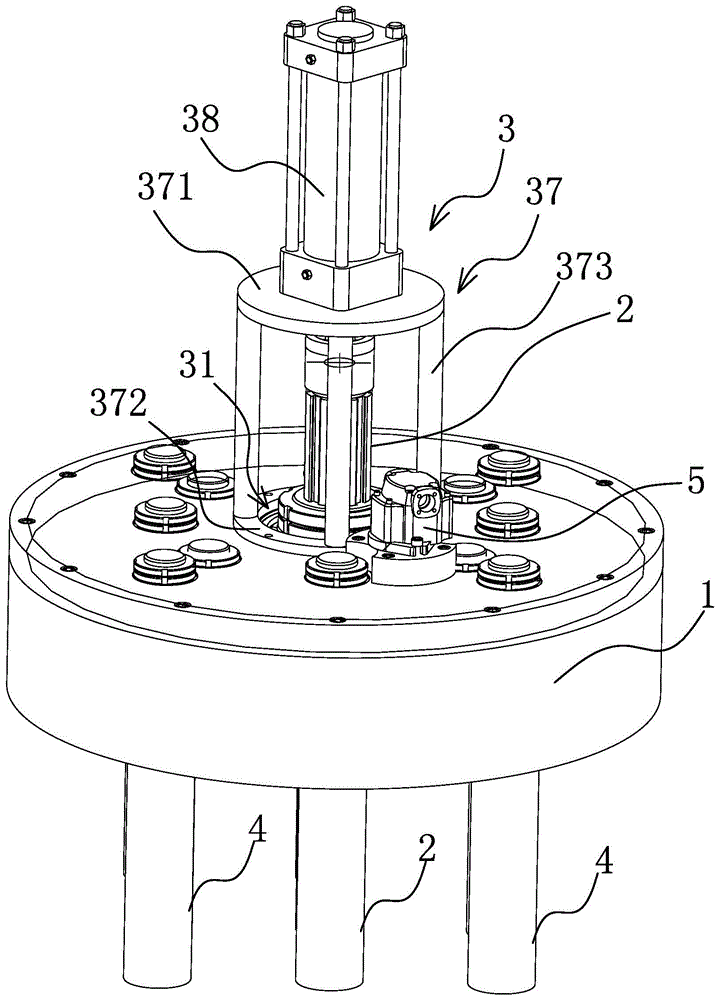

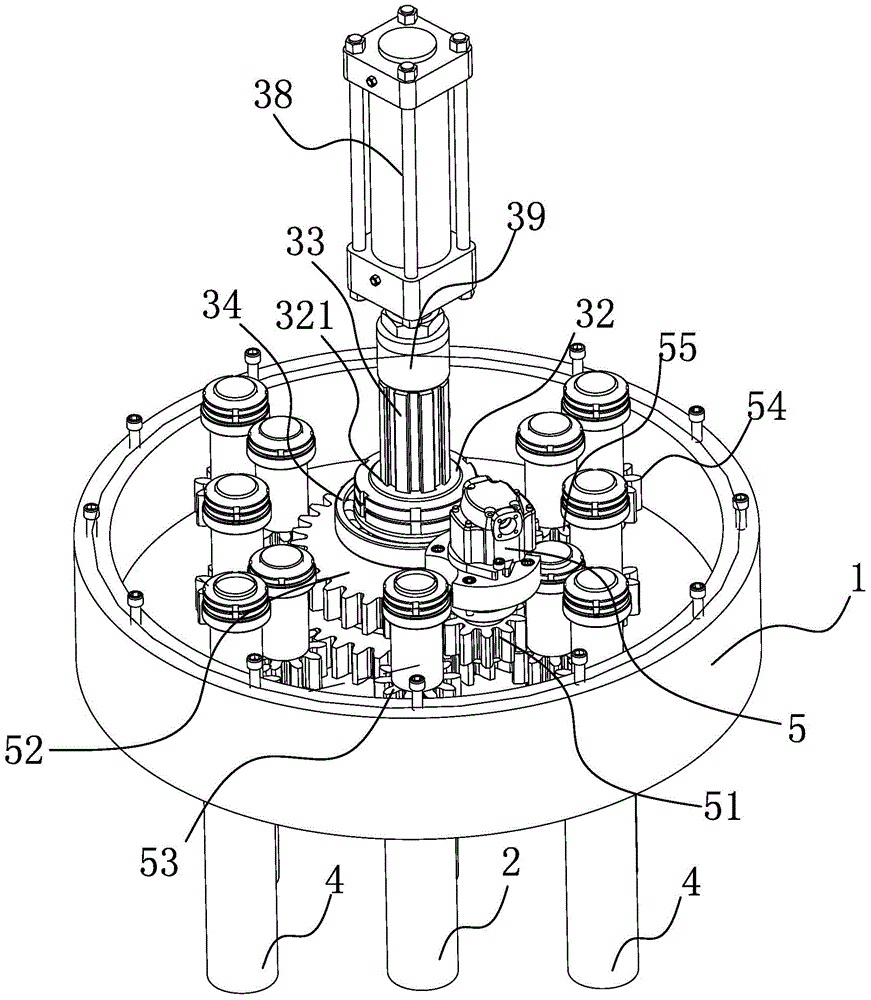

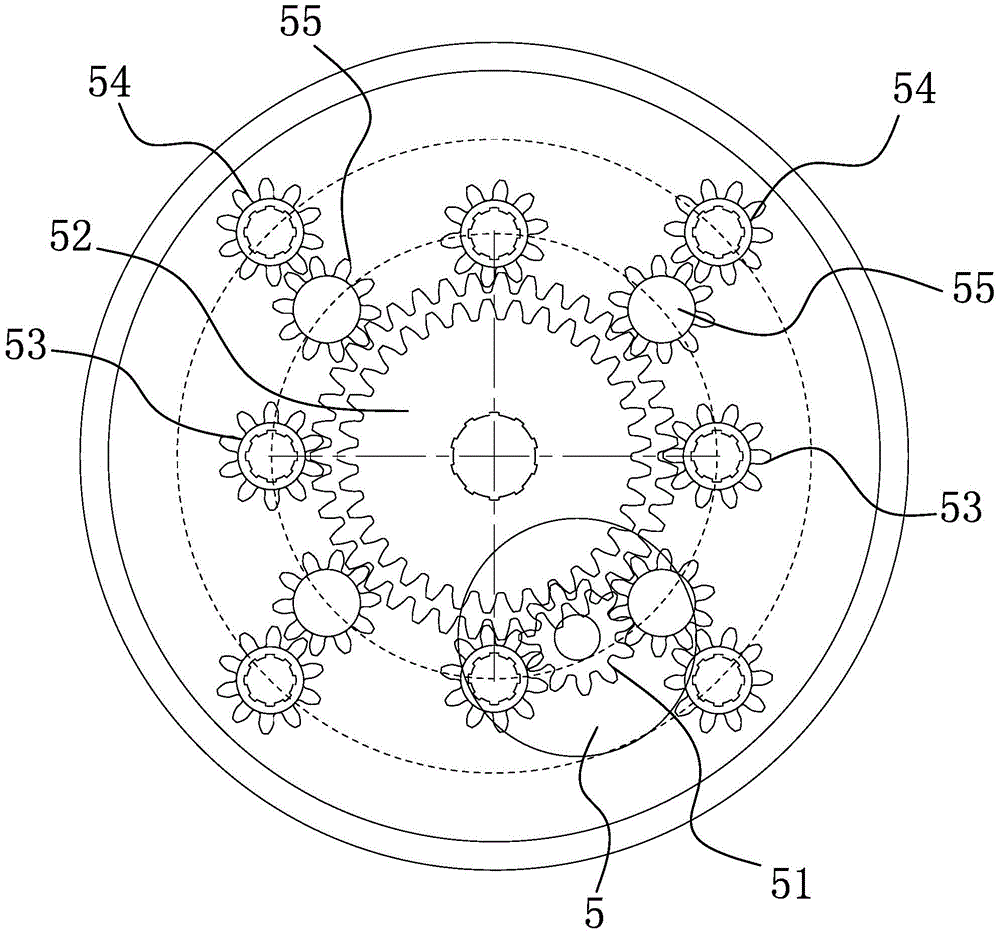

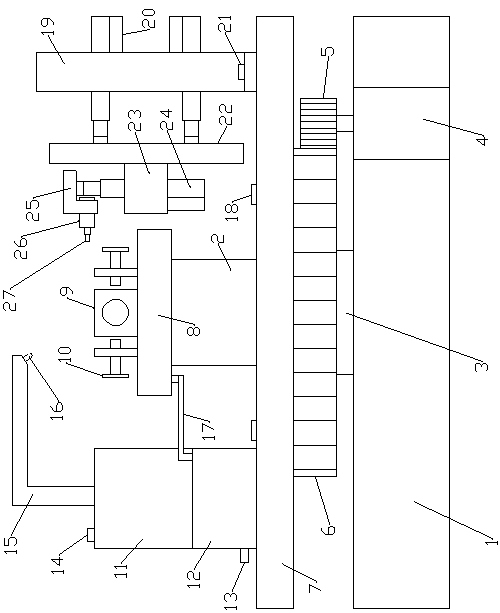

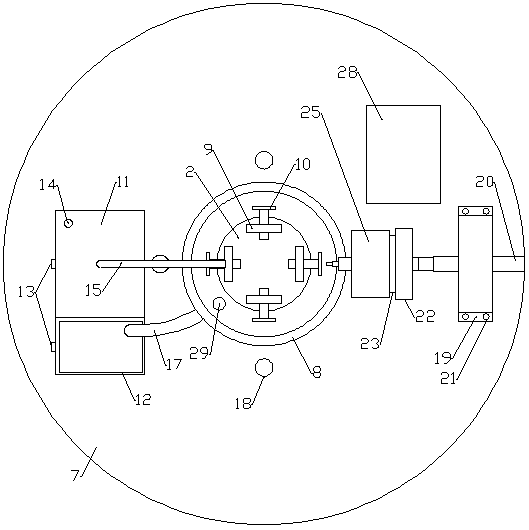

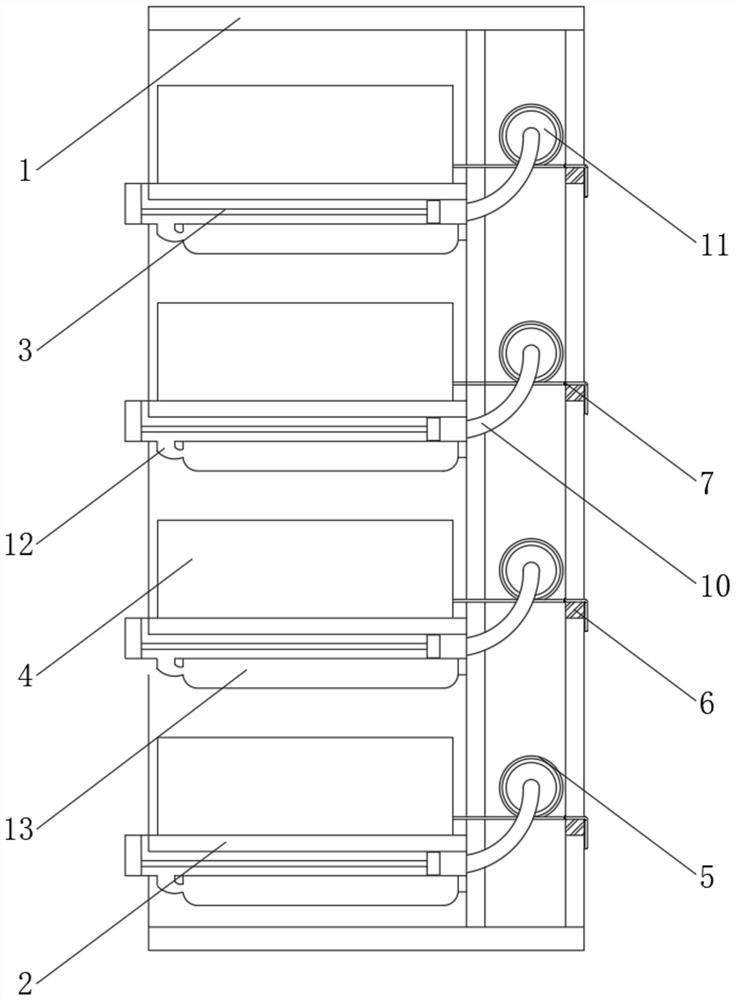

Drill rod rotation driving mechanism of cement soil mixing pile driver

ActiveCN105002898AImprove pullout resistanceIncrease girthBorehole drivesBulkheads/pilesSoil mixingPile driver

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod rotation driving mechanism of a cement soil mixing pile driver. The drill rod rotation driving mechanism of the cement soil mixing pile driver solves the problem that stirring is uneven when an existing cement soil mixing pile driver is used for drilling. The drill rod rotation driving mechanism of the cement soil mixing pile mixer comprises a drive box with an inner cavity; the drive box is provided with at least one main drill rod arranged in the vertical direction; at least two auxiliary drill rods are arranged on the outer side of the circumference of the main drill rod; the main drill rod is connected with a main drill rod driving structure capable of driving the main drill rod to rotate in the circumferential direction; an auxiliary drill rod transmission structure is arranged between the main drill rod and the auxiliary drill rods. The drill rod rotation driving mechanism of the cement soil mixing pile driver has the advantages that a single driver can achieve homodromous and reverse-direction movement of the main drill rod and the auxiliary drill rods, so that stirring uniformity is improved; drill rod bodies can axially stretch out and draw back and can axially slide while rotating circumferentially, the phenomenon of being unable to drill is not prone to happening, the perimeter of the cross section of a cement soil mixing pile after construction is increased, and the anti-pulling capacity of the cement soil mixing pile is improved.

Owner:周兆弟

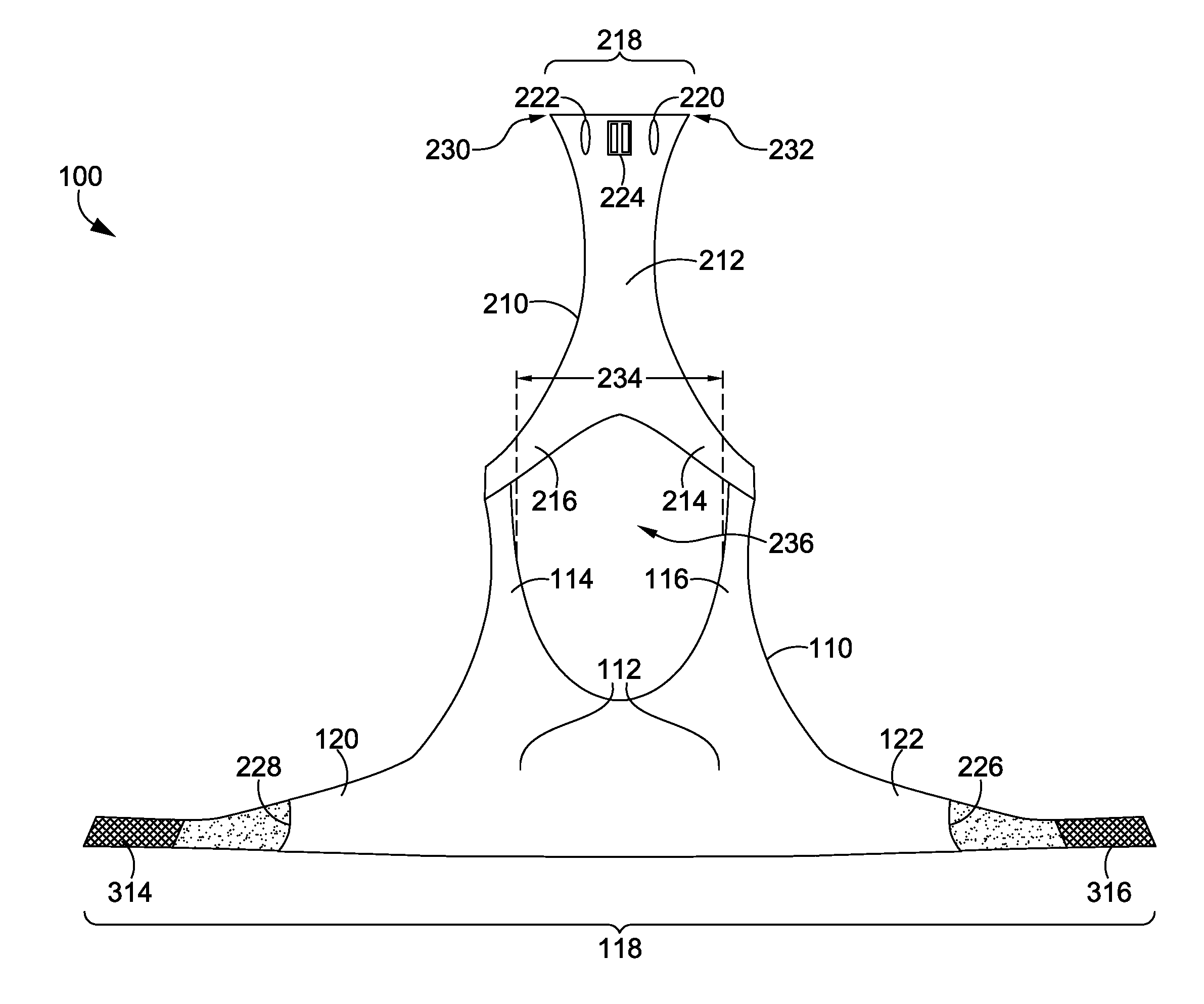

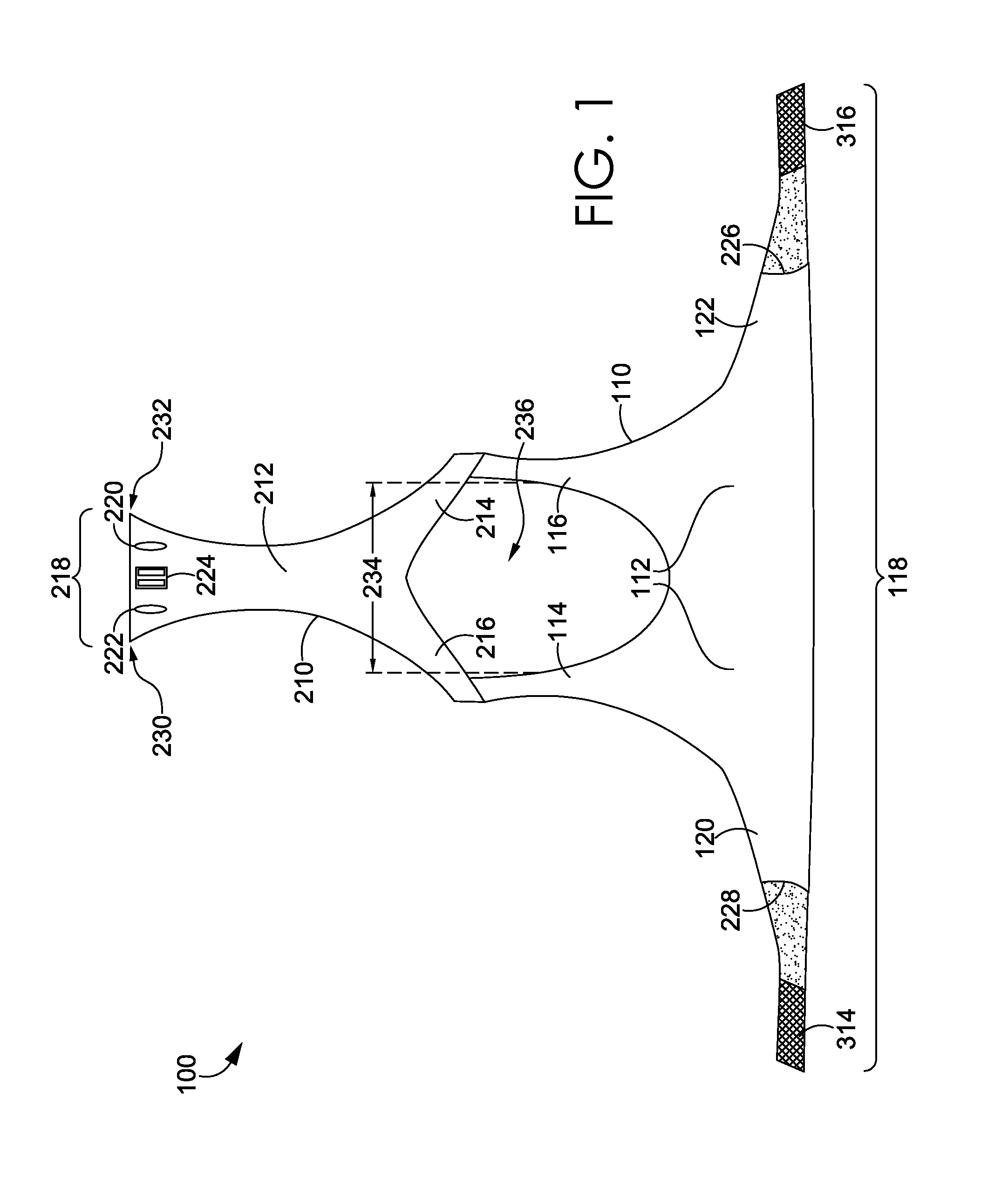

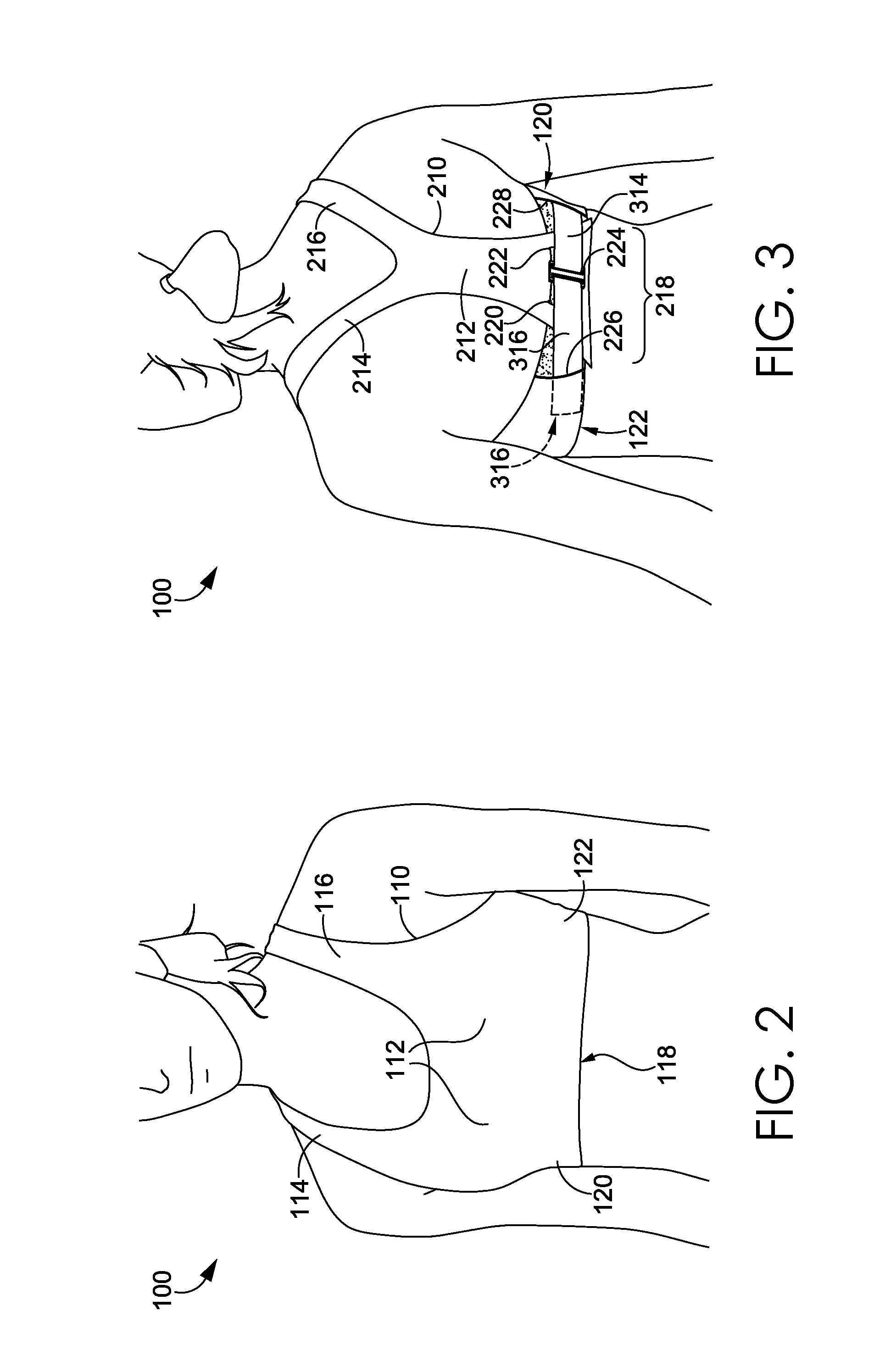

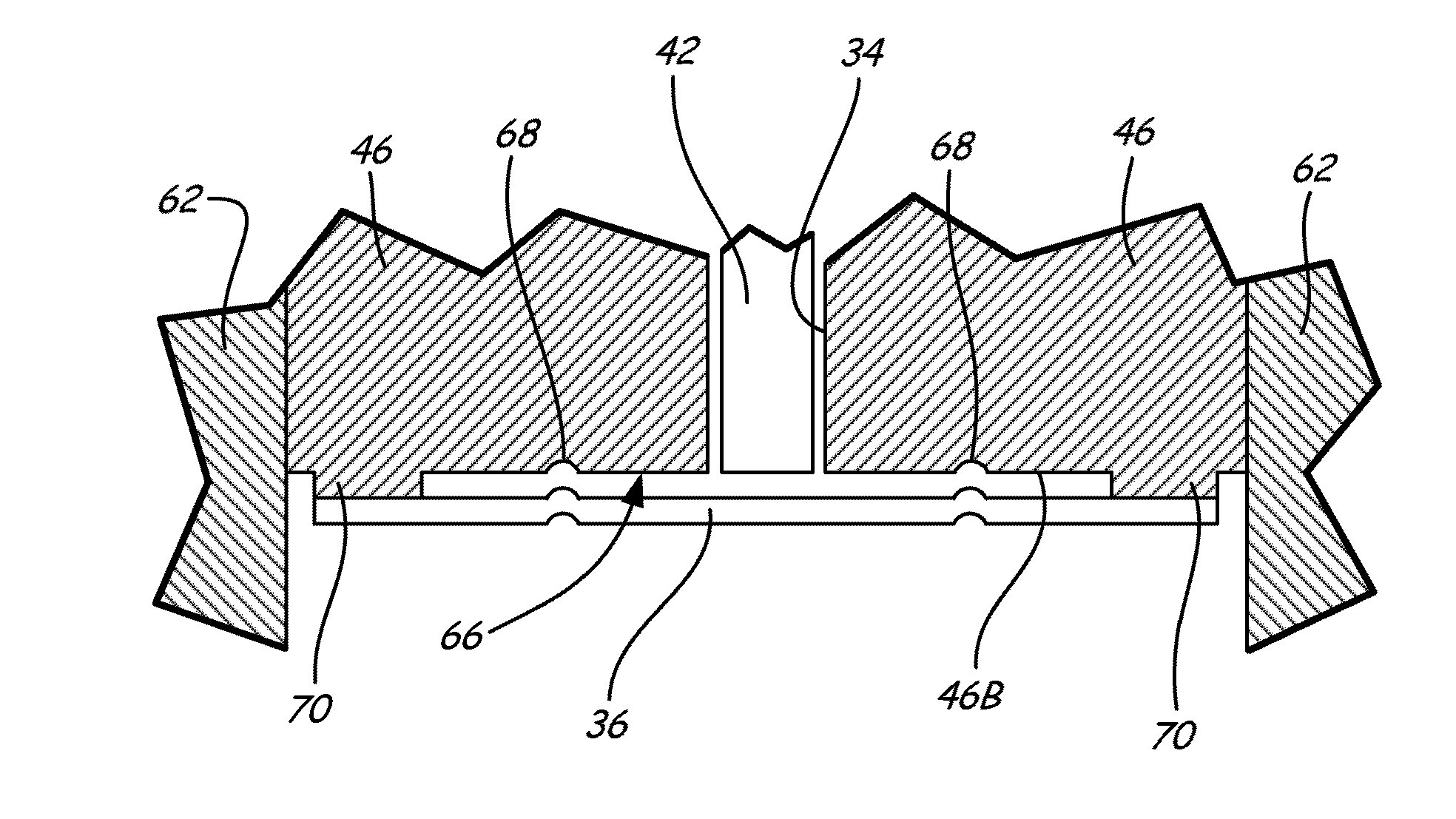

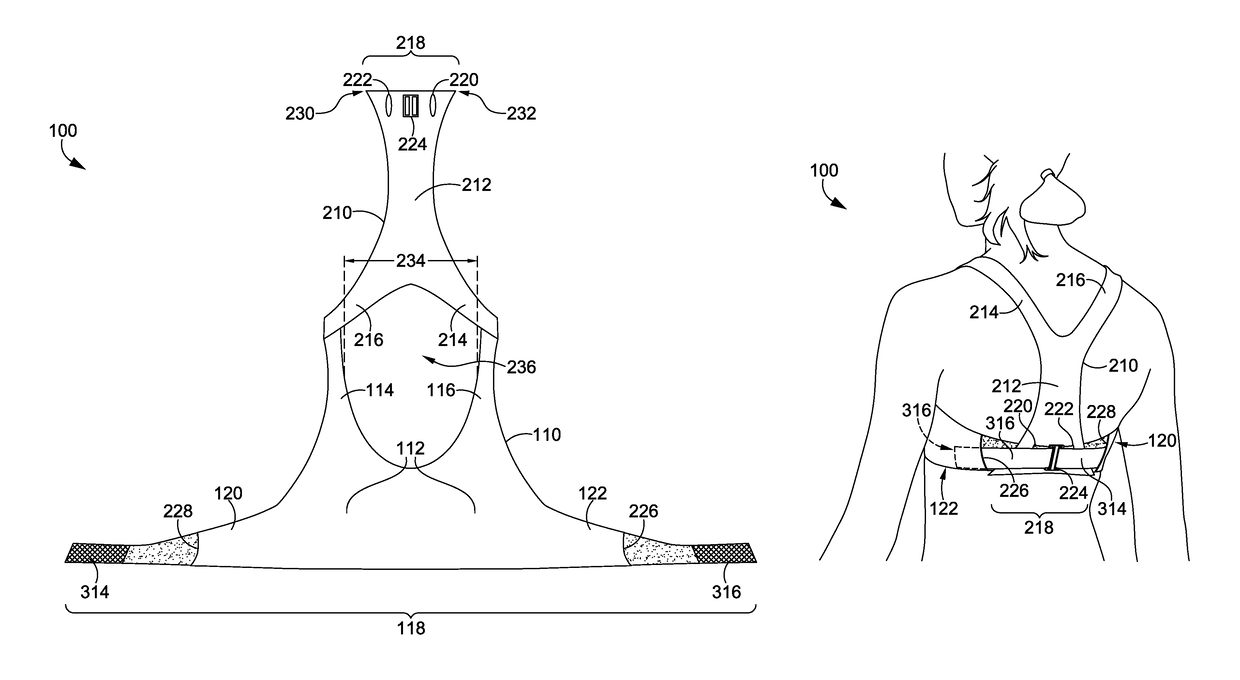

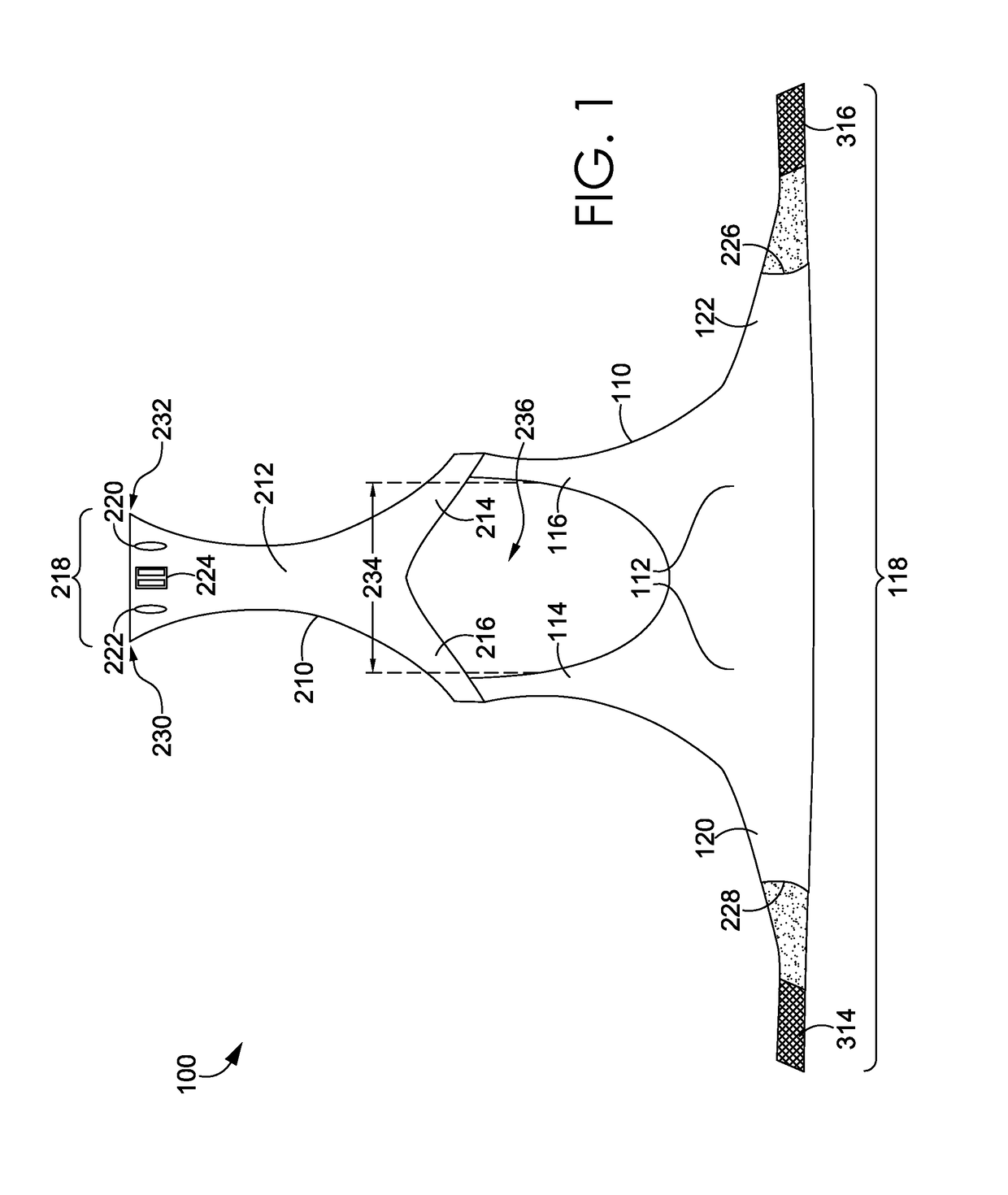

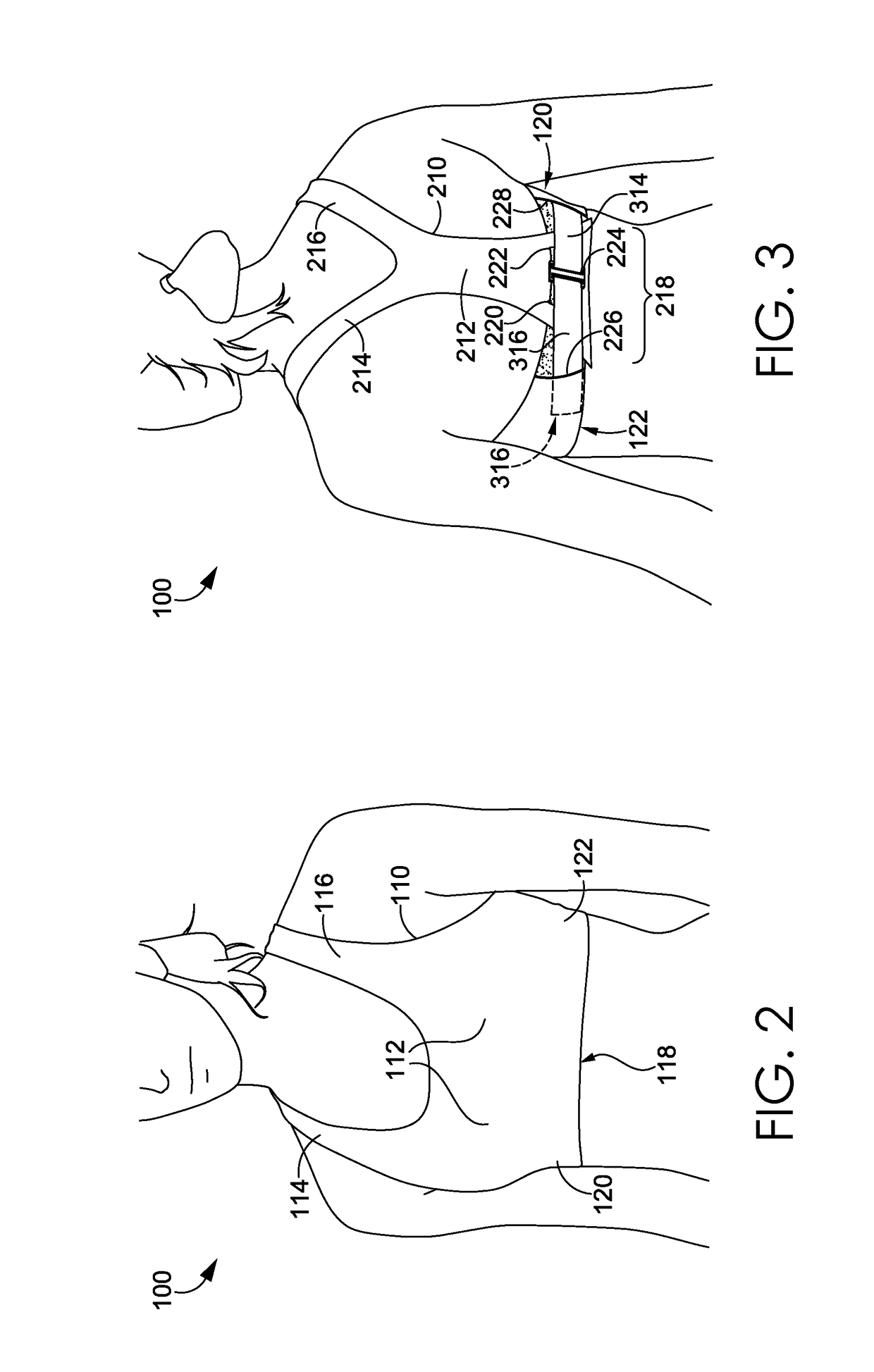

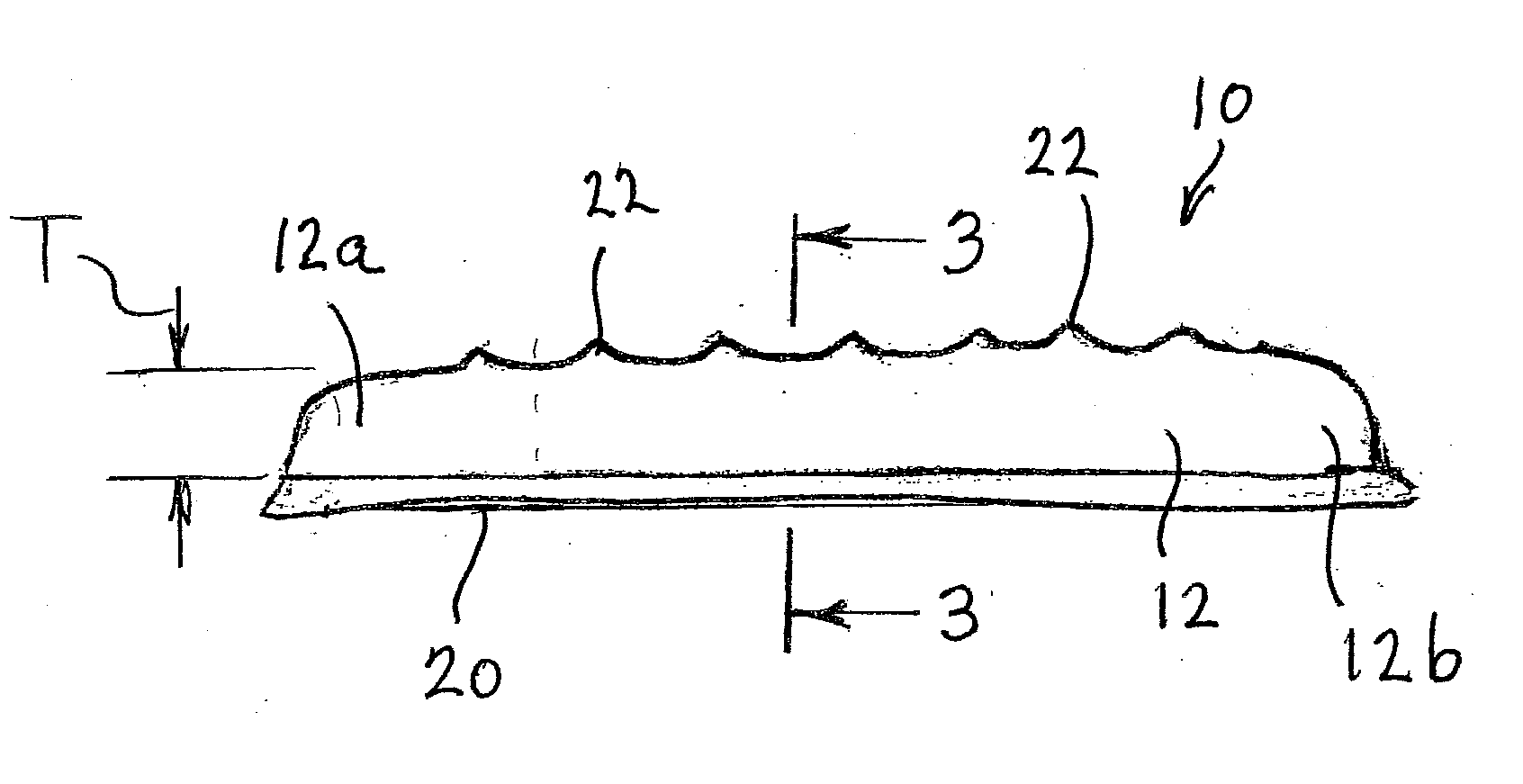

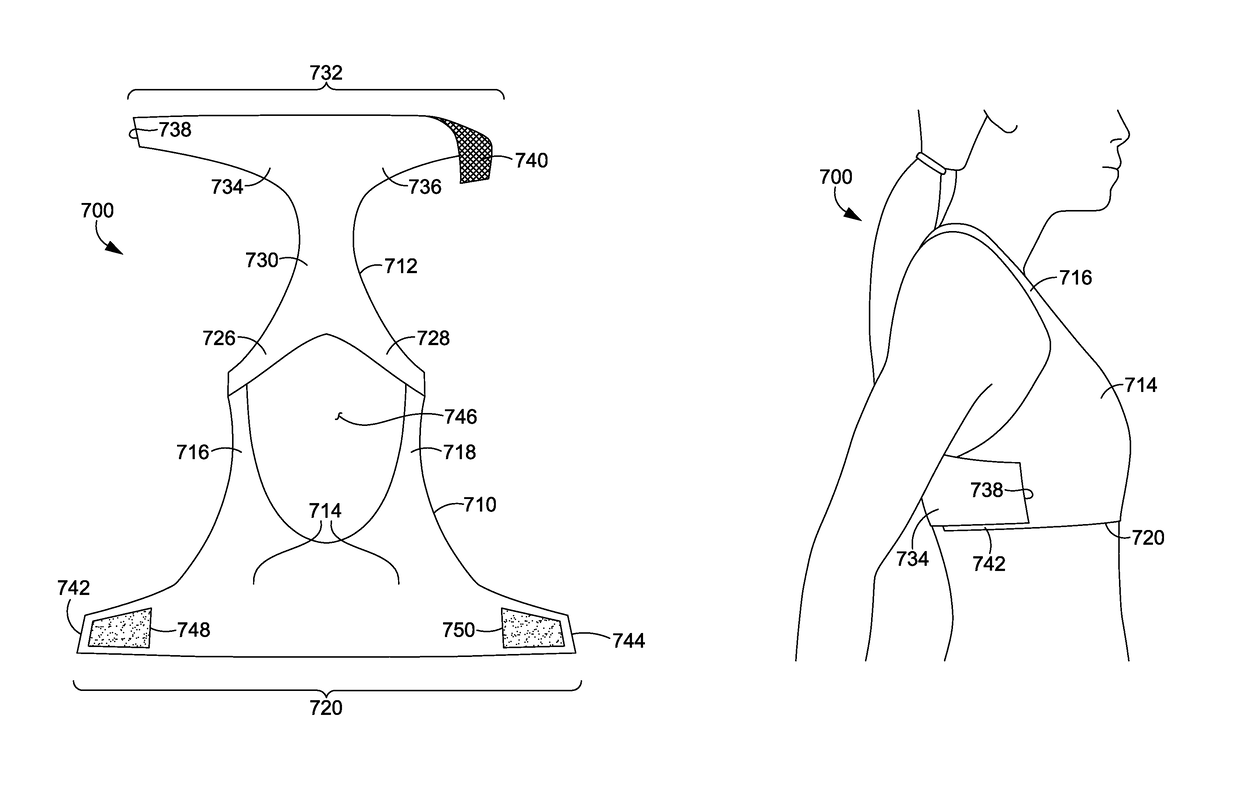

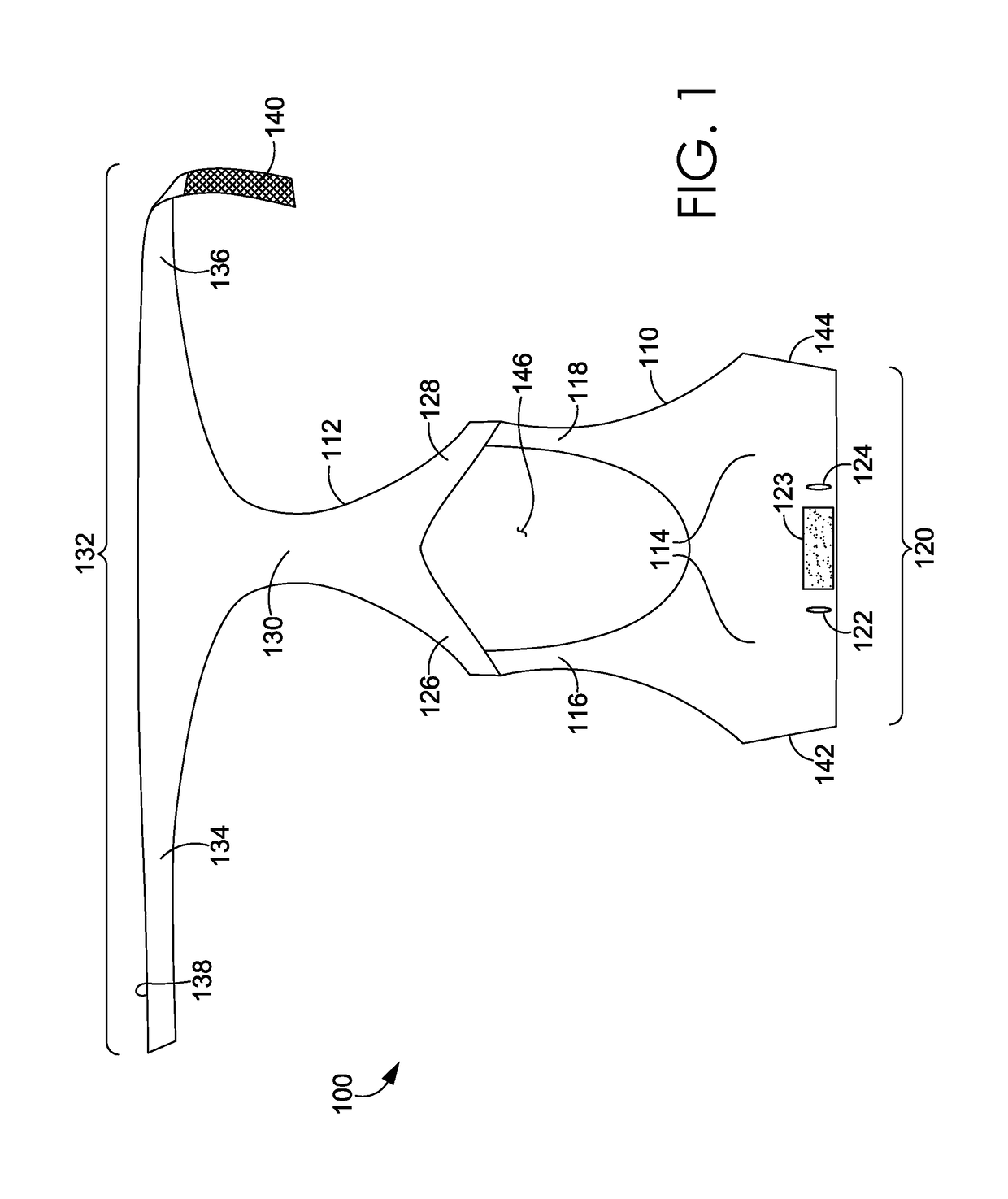

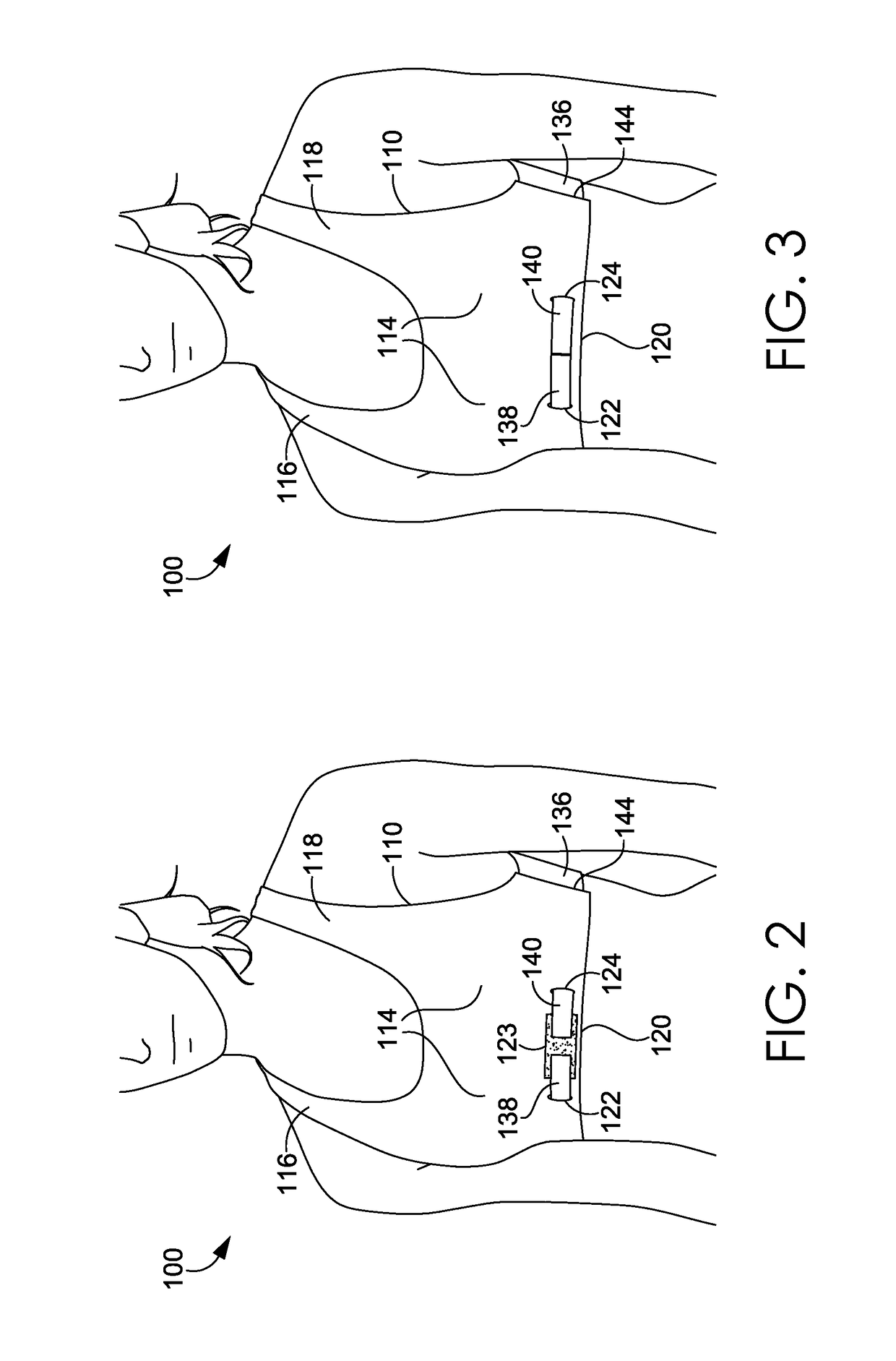

Wrap back bra

ActiveUS20160081398A1Easy to donIncrease girthBrassieresGarment fastenersPhysical medicine and rehabilitationEngineering

A sport bra having an adjustable underband tightening assembly is provided herein. The sport bra comprises a front portion having a pair of breast cups, a pair of shoulder straps, and a front underband segment comprising a first wing extending away from a first side of the front underband segment and terminating in a first free end and a second wing extending away from a second side of the front underband segment and terminating in a second free end. The sport bra further comprises a back portion having a central body portion, a pair of shoulder straps secured to the shoulder straps of the front portion, and a back underband segment unaffixed to the front underband segment in an un-worn configuration.

Owner:NIKE INC

Hollow aluminum alloy tube grounding device capable of being assembled

InactiveCN103326139AGuaranteed uptimeExtended service lifeConnection contact member materialClosed loopMaterials science

A hollow aluminum alloy tube grounding device capable of being assembled comprises a closed loop. Multiple groups of grounding bodies are welded on the closed loop. Each grounding body comprises at least one unit grounding body, and the unit grounding bodies are connected through matched sleeves and are hollow aluminum alloy tubes. The sleeves are one kind or several kinds of axial sleeves, Y-type sleeve and T-type sleeves. Four groups of grounding bodies are welded on the closed loop, one end of each grounding body is welded on the closed loop, and the other end of each grounding body can be extended according to needs through the sleeves. Each unit grounding body is 1m long, threads are machined at the two ends of each unit grounding body, and threads matched with the two ends of the unit grounding bodies are arranged in the sleeves. Each grounding body is of a hollow aluminum alloy tubular structure, so the hollow aluminum alloy tube grounding device is light in weight, good in electrical conductivity and thermal conductivity, and strong in corrosion resistance; an assembled structure is adopted, so the hollow aluminum alloy tube grounding device is convenient to transport, easy to construct, and suitable for various environments due to the fact that multiple sleeves are adopted.

Owner:CHINA THREE GORGES UNIV +1

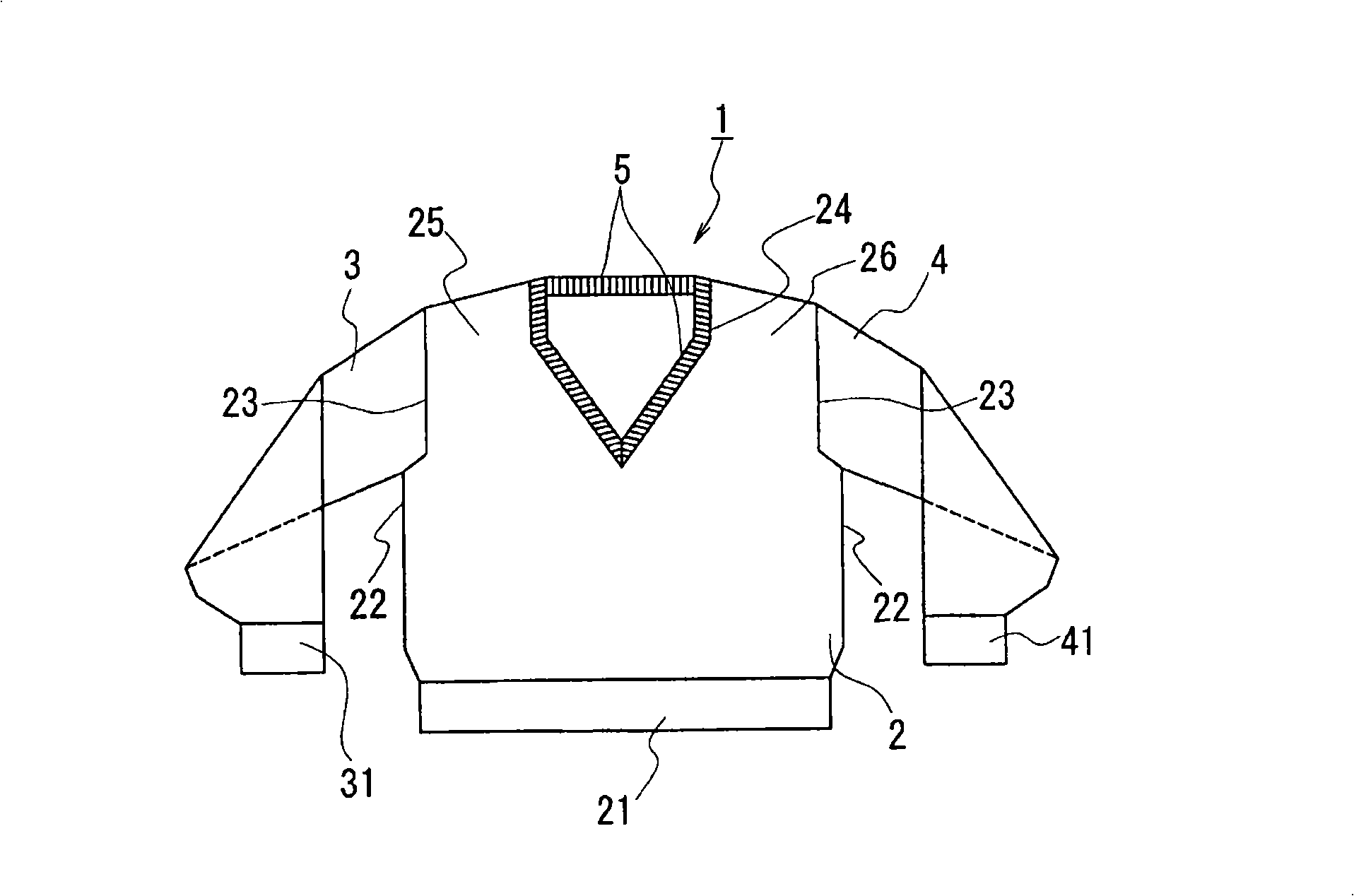

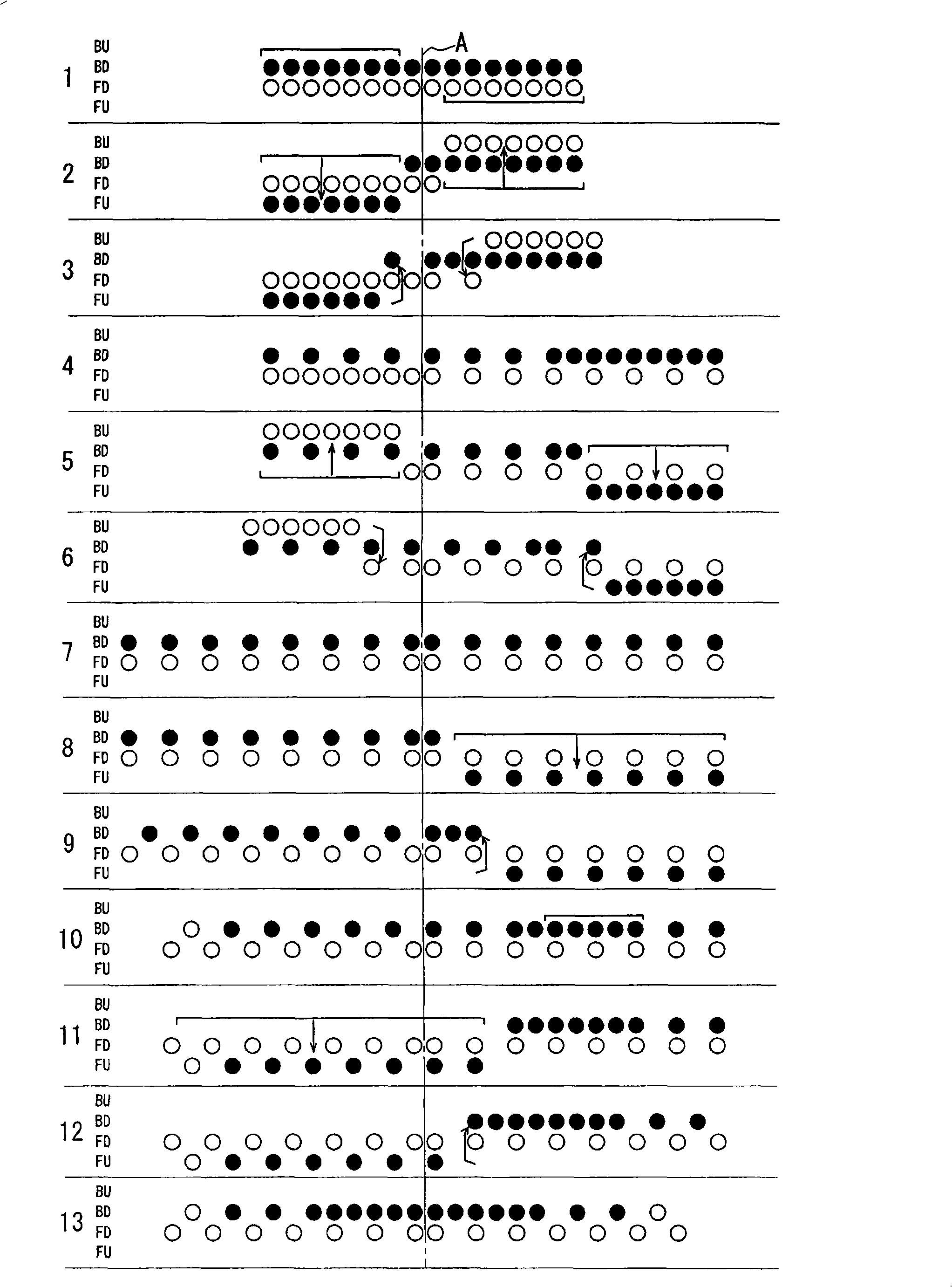

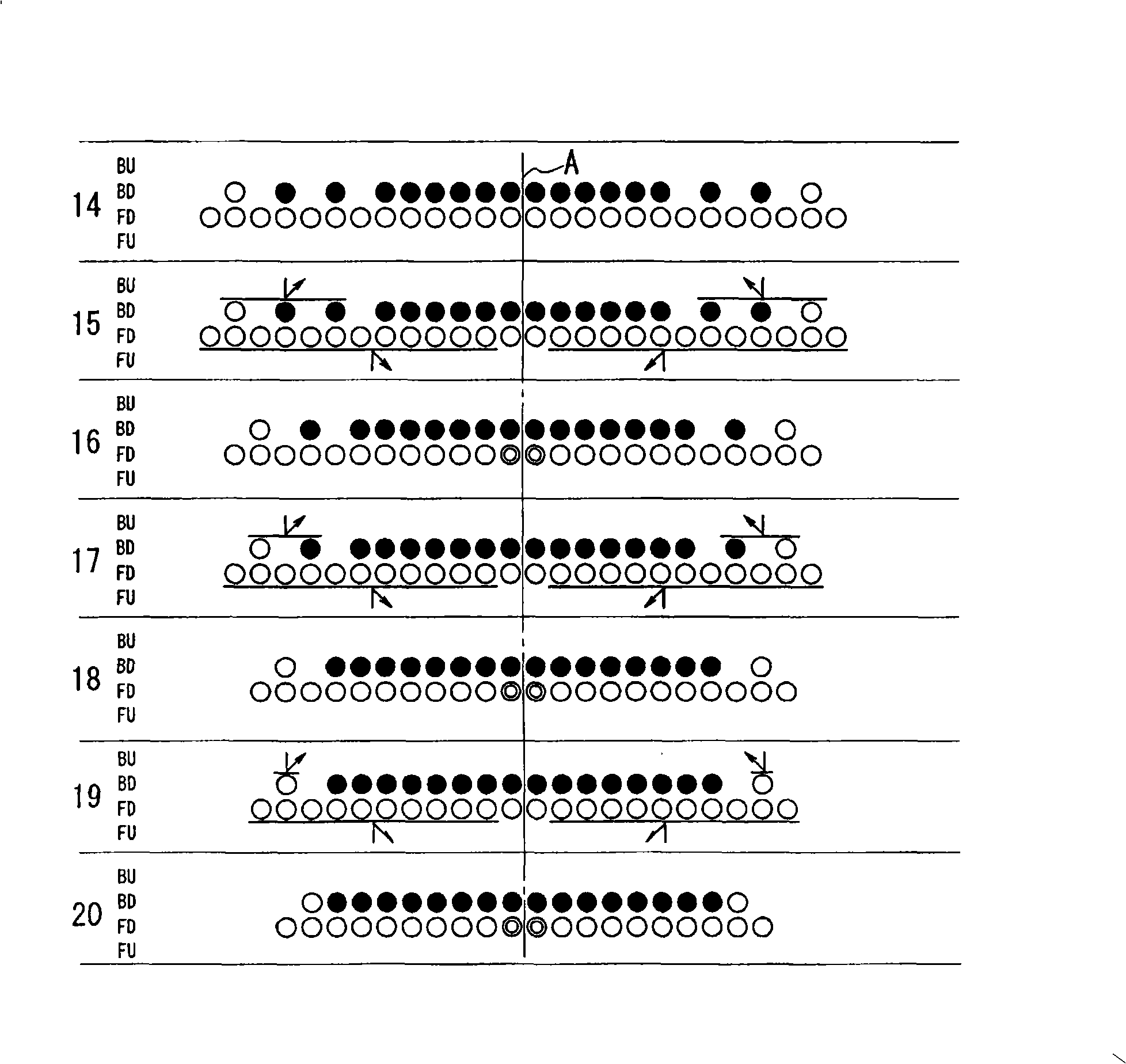

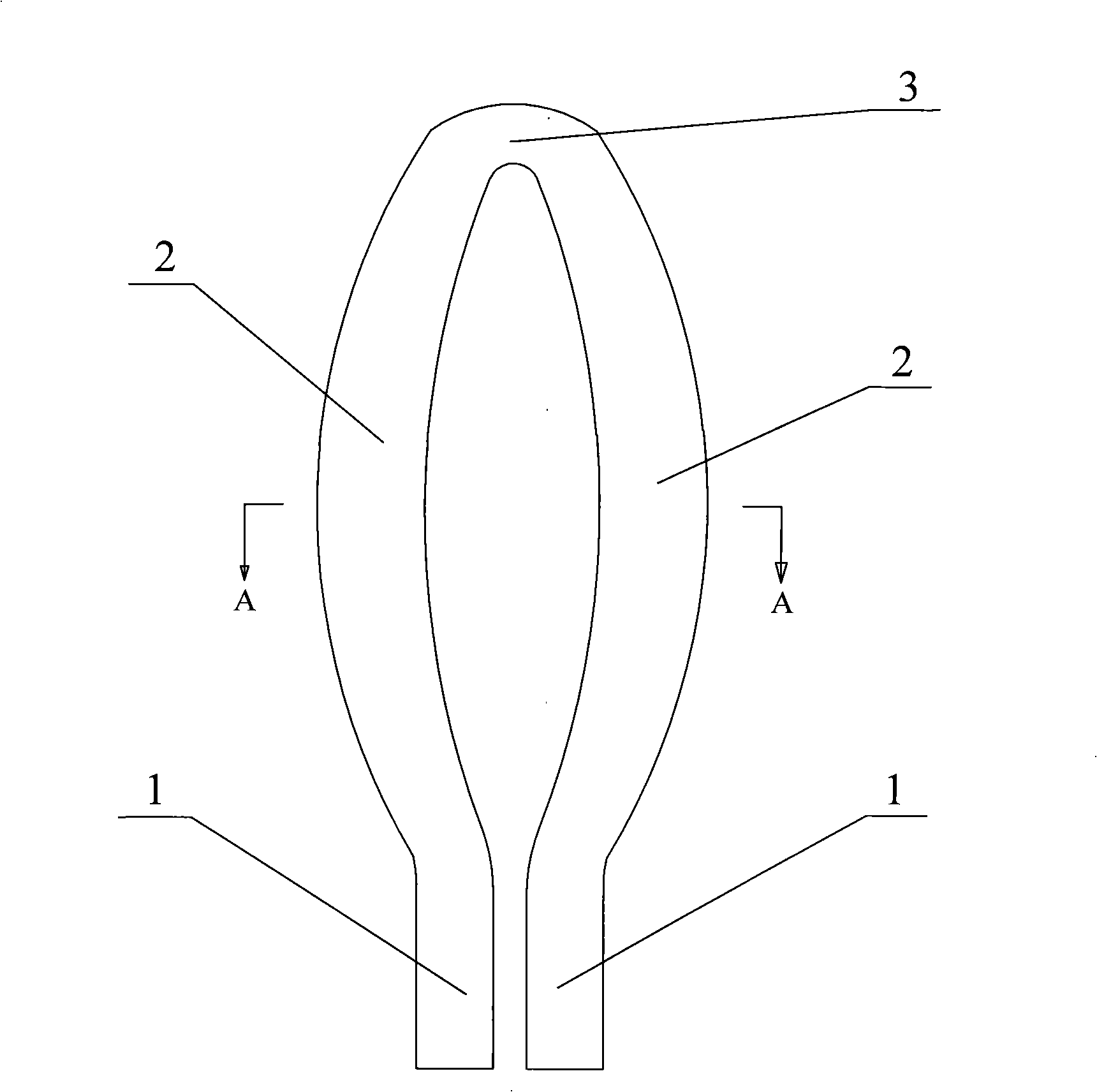

Method of knitting knit wear with collar

InactiveCN101263251ADoes not produce twisted coilsIncrease girthGarmentsFlat-bed knitting machinesBiomedical engineeringNeck collar

A method of knitting a knitwear capable of widening the opening angle of a V-neck collar without forming twisted stitches is provided. A knitwear with a collar is knitted using a flat knitting machine wherein a body is knitted and shoulder parts are joined while holding stitches for forming a neckline part on a needle bed in a resting state, the stitches for the front neckline part are transferred so that the stitches are held in the needle extracted status with empty needles of at least a number of widening stitches, and the stitches for the back neckline part are transferred so that the stitches are held in the needle extracted status with empty needles in at least one part so that a length in the knitting width direction of a knitted fabrics held on the needles of the front and back needle beds becomes substantially the same, widening stitches are formed on some or all of the empty needles on the needle bed holding the stitches for the front neckline part to increase a peripheral length of the front neckline part, and stitches are formed on the stitches including the widening stitches at the front and back needle beds to knit the collar.

Owner:SHIMA SEIKI MFG LTD

Turbine type stirrer used for molten iron mechanical stirring desulfuration

The invention discloses a turbine type stirrer used for molten iron mechanical stirring desulfuration, comprising a rotating shaft, a wheel hub and three stirring vanes, wherein, each stirring vane comprises a stirring vane metal core and is evenly distributed at the periphery of the wheel hub; the surface facing melt iron, the surface deviating melt iron and the side face of the stirring vane are all inclined planes inclining forwards from bottom to top, and the angles of inclination alpha, beta and gamma respectively satisfy the following conditions: alpha is more than or equal to 1 degree and less than or equal to 10 degrees, beta is more than or equal to alpha and less than or equal to 15 degrees, and gamma is more than or equal to 0 degree and less than or equal to 3 degrees; the stirring vane metal core is in eccentric arrangement; the flat surface on which the thickness symmetry plane of the stirring vane metal core is located is a first vertical plane; the flat surface parallel to the first vertical plane and passing the centre line of the rotating shaft is a second vertical plane; the first vertical plane is overlapped with the second vertical plane horizontally moving a distance of L towards the direction of the surface facing melt iron, wherein, L satisfies the condition that L is more than 0 and less than or equal to (d-a) / 2; d is the diameter of the metal core of the rotating shaft; and a is the thickness of the stirring vane metal core; by applying the invention, the stirring power consumption of the invention is low, the sticky dregs between the stirring vanes are less; and the dynamical condition of stirring desulfuration is good.

Owner:武钢集团有限公司

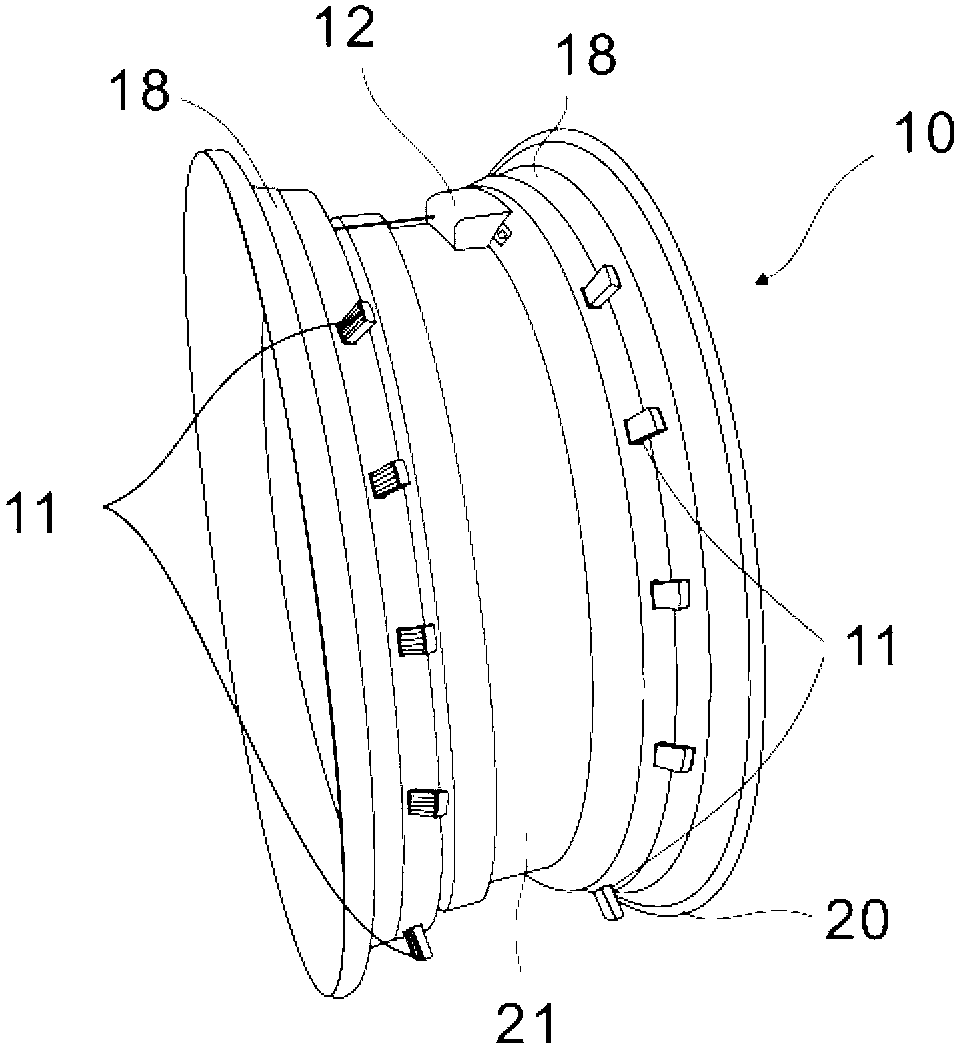

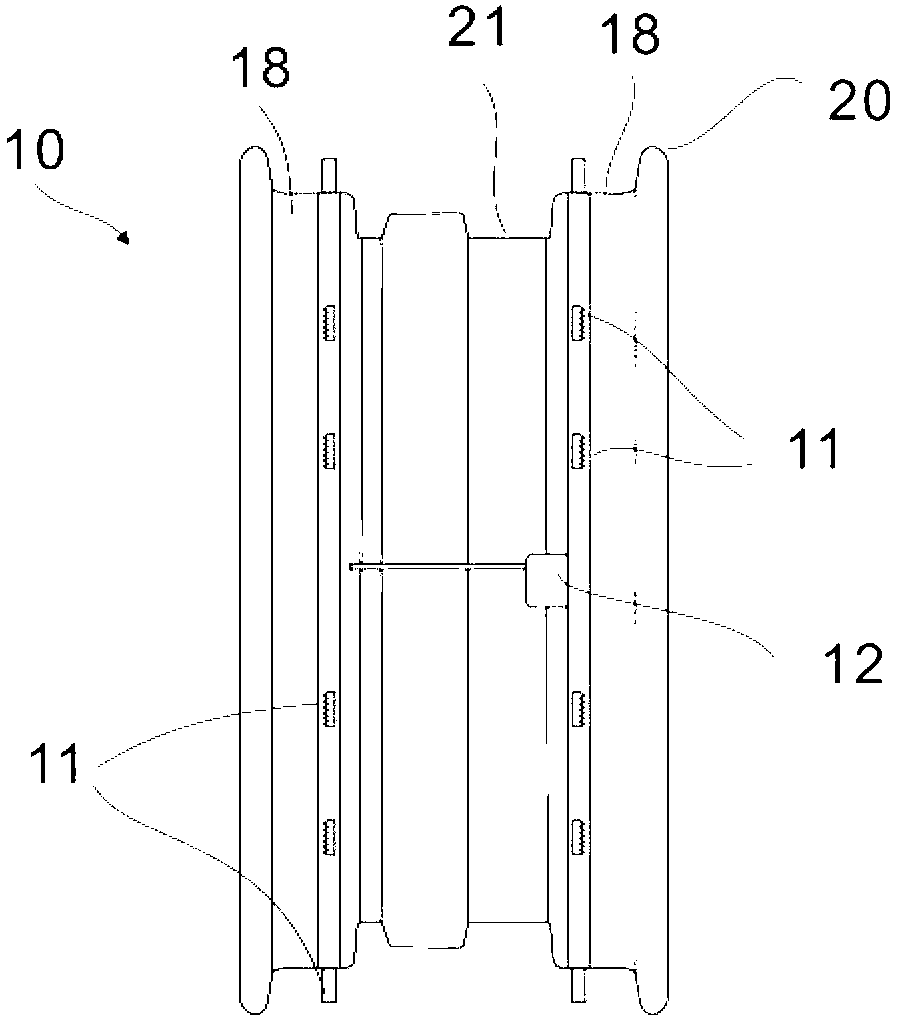

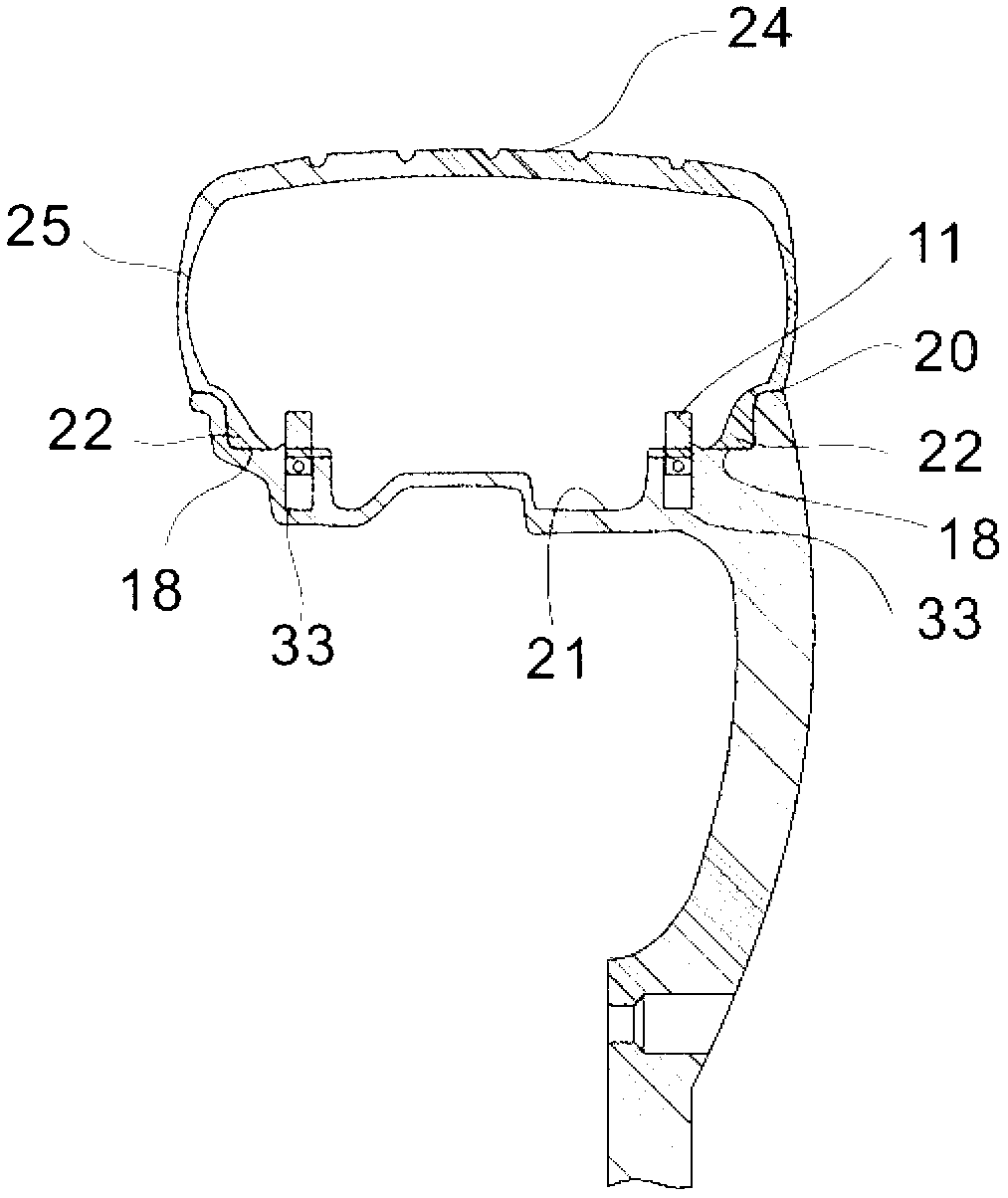

Safety hub for lock tire assembly of tubeless tire wheel

InactiveCN102991268APerformance is not affectedDoes not affect normal disassemblyRimsTyre beadsTire beadTubeless tire

A safety hub (10) of a lock tire assembly mainly comprises a plurality of tire edge lock blocks (11), and a lock transmission device (12) corresponding to an air valve hole, wherein the tire edge lock blocks are annularly distributed on the inner edge of a bead seat (18) and are used for preventing a tire bead from slipping to a groove bottom (21) and separating from the hub and for preventing a wheel flange (20) from touching the ground; and the lock transmission device (12) is used for locking and unlocking the tire edge lock blocks (11). The safety hub (10) provided by the invention is mainly used for preventing a vehicle from losing control when the tubeless tire is punctured or loses pressure severely, and can enable the flat tire to keep synchronous with the hub, thereby giving the same road holding force and brake force to the wheel, and ensuring the normal operation of the vehicle.

Owner:毕博

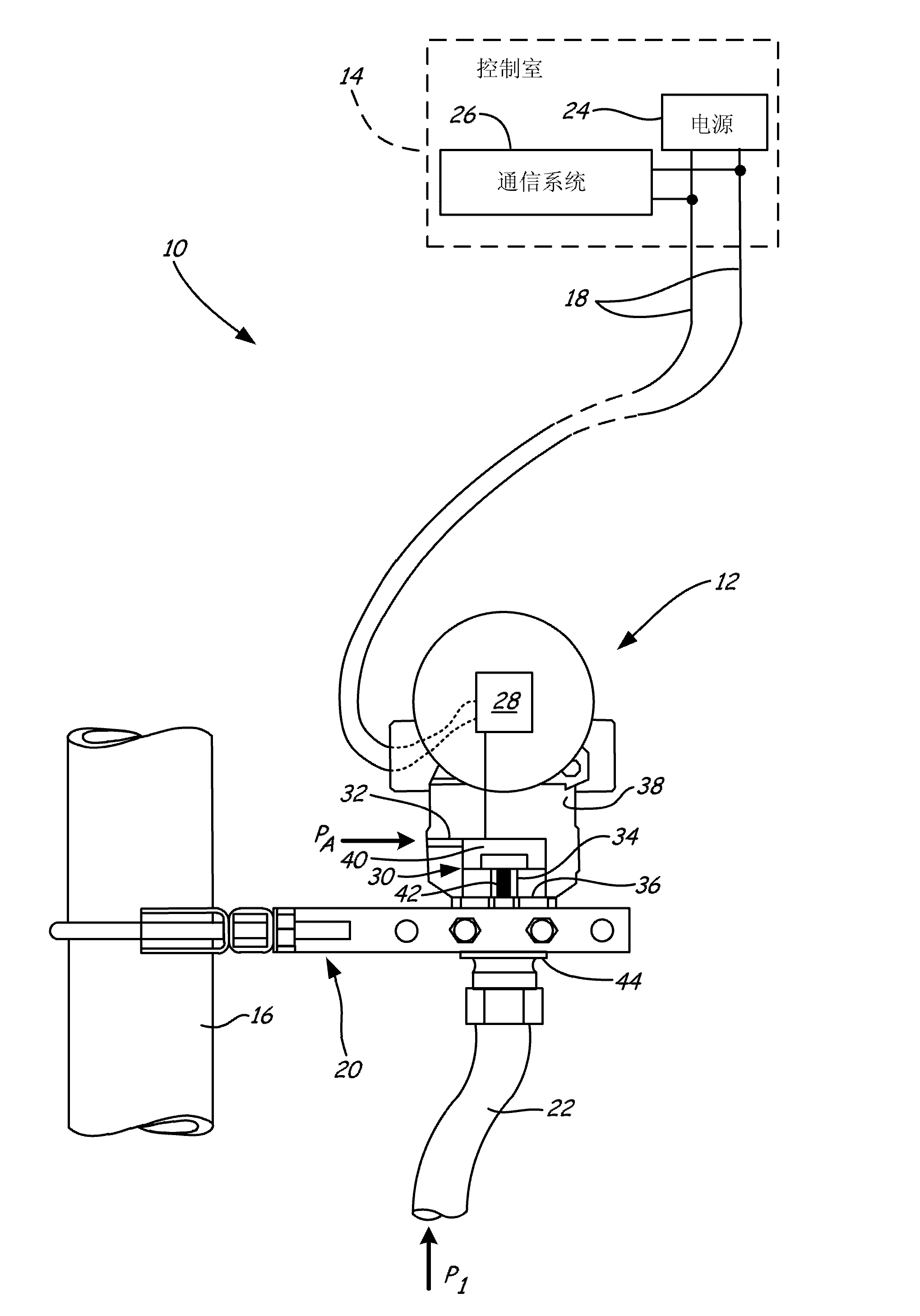

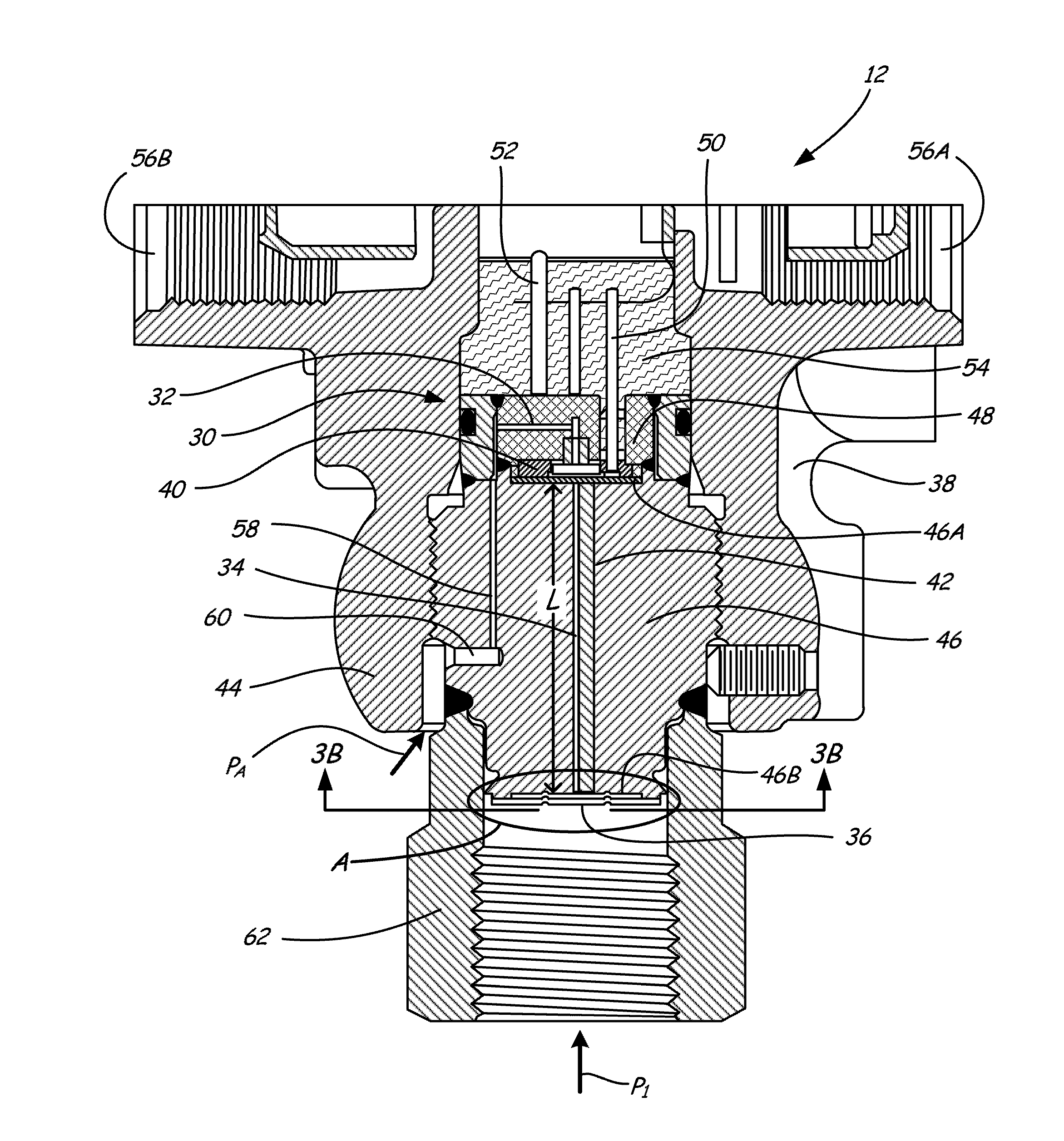

Flame arrestor for process transmitter

ActiveCN102680163AShorten the lengthReduce performanceFire rescuePressure difference measurement between multiple valvesInterior spaceTransmitter

A process transmitter for sensing a process variable includes a transmitter housing, a sensor, transmitter circuitry, a passageway and a flame arrestor. The transmitter housing has an interior. The sensor is disposed within the interior, senses a process variable of an industrial process and generates a sensor signal. The transmitter circuitry is disposed within the interior and connects to the sensor. The passageway is in communication with the sensor and extends through the interior of the transmitter housing. The passageway has a first cross-sectional profile. The flame arrestor is positioned in the passageway. The flame arrestor has a second cross-sectional profile different from the first cross-sectional profile. The flame arrestor produces a path in an interior of the passageway having a smaller cross-sectional area than that of the first cross-sectional profile of the passageway.

Owner:ROSEMOUNT INC

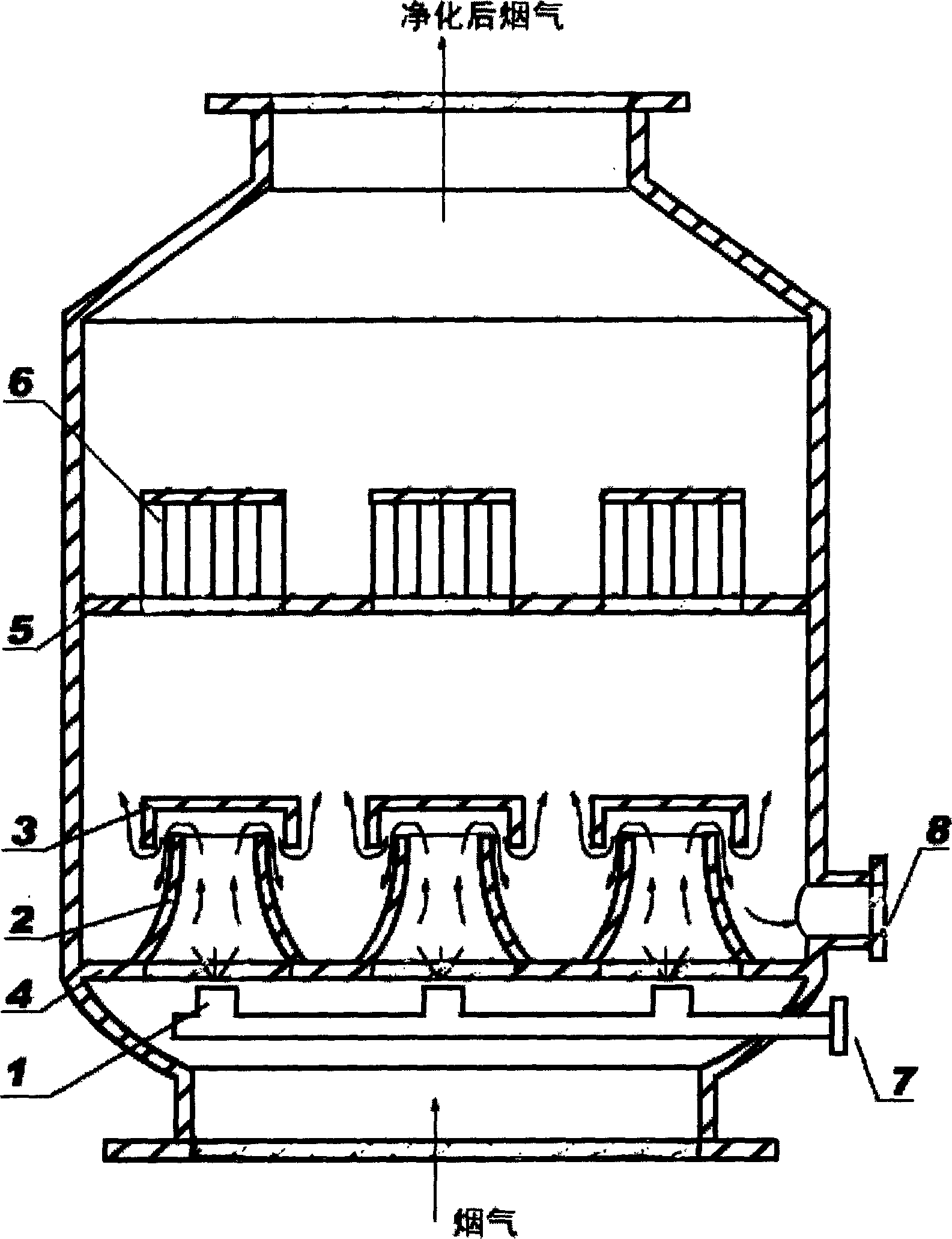

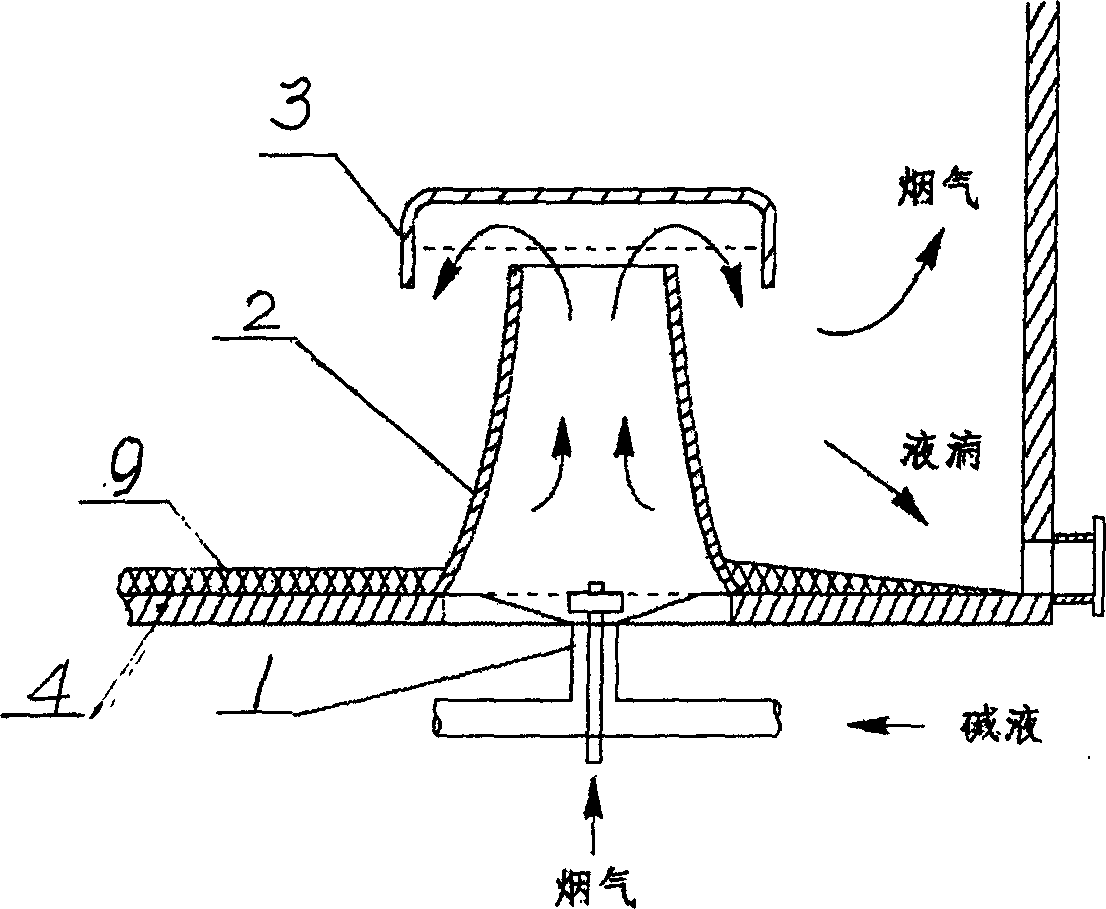

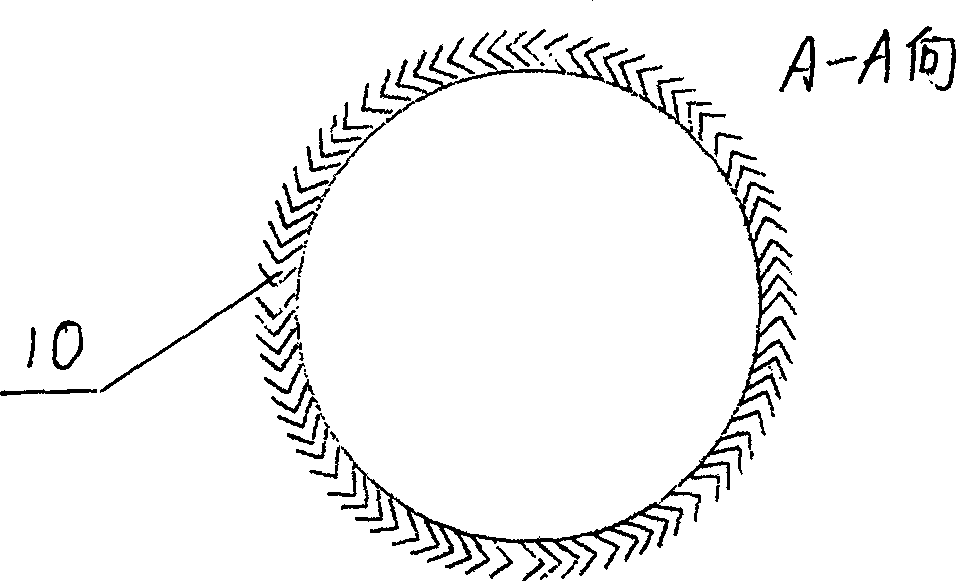

Doublestage desulfurizing and dedusting apparatus

ActiveCN1544127AMake sure you don't bring waterAvoid secondary entrainmentUsing liquid separation agentLow speedEngineering

The invention is a two-stage desulfurizing and dust-cleaning device, including a shell and a lye circulating system, and its character lies in that it is composed of low-resistance spray head, low-speed venturi tube, impact baffle and annular-arranged baffling plate demister, which are installed in turn from top to bottom. Its beneficial effect: during two-stage desulfurization circulation, adopting a low-speed venturi tube plus impact baffle structure to make the gas resistance low and desulfurizing efficiency high and play a role in primary dehydrating, and the low-resistance demister on the top of the desulfurizing tower can thoroughly eliminate fine water drops in the fume, ensuring that the fume carries no water. It is of a unit structure, convenient for installing and overhauling, the baffling plate can thoroughly dehydrate all the more because of vertical installation, avoiding secondary carrying of the fume, and it has higher flow speed and compacter device, saving the space.

Owner:北京德厚朴化工技术股份有限公司

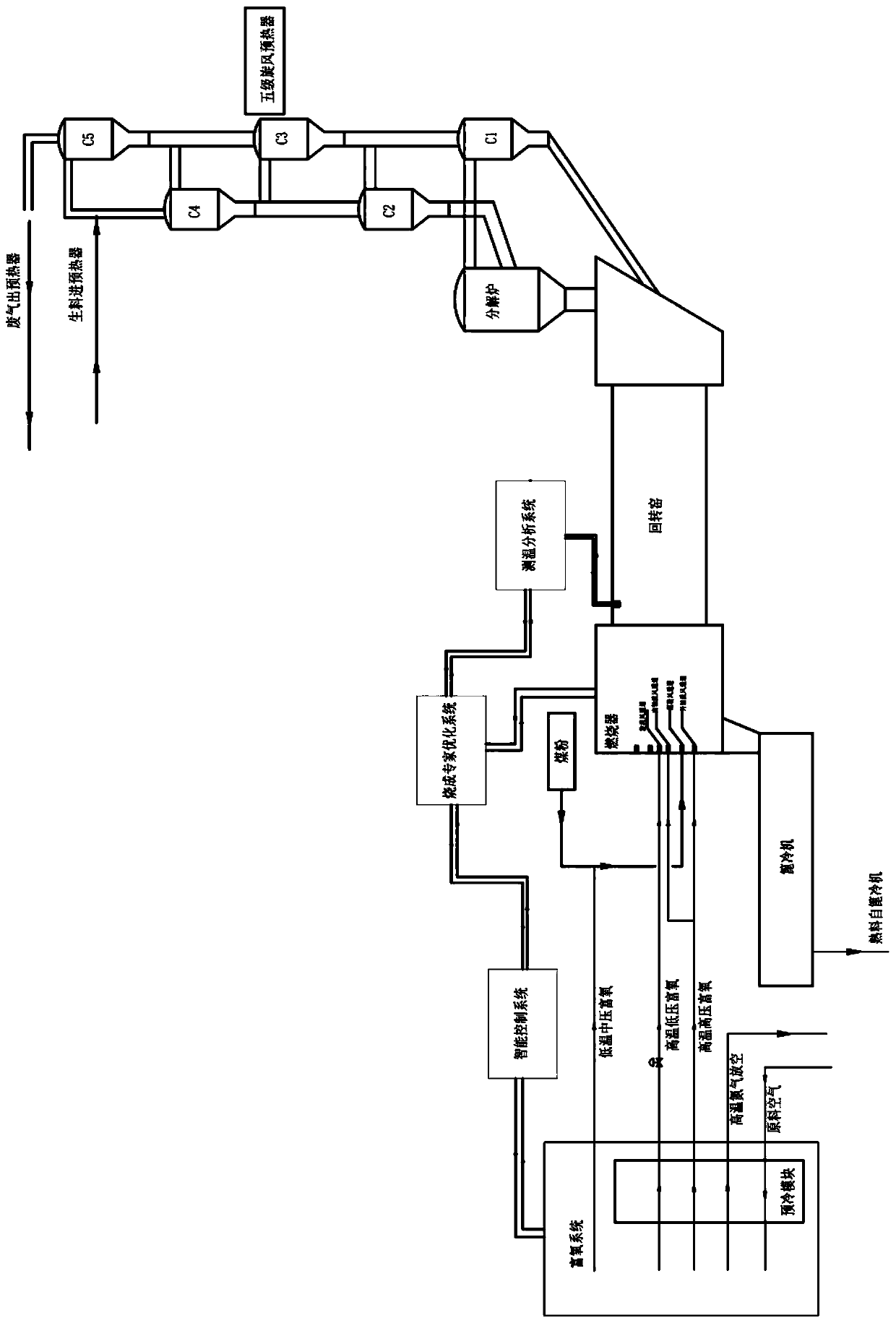

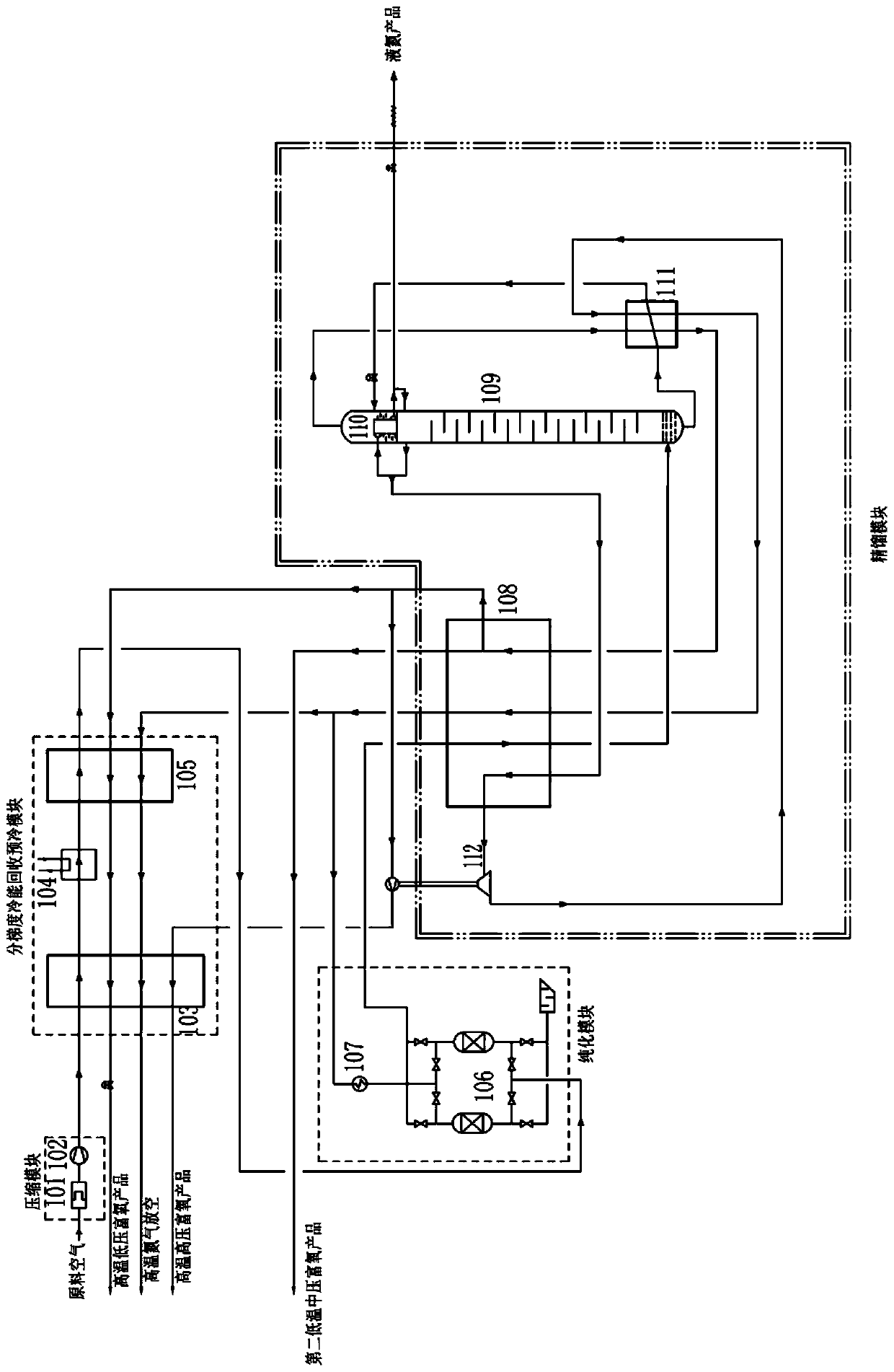

Intelligent control oxygen-enriched firing system and method for kiln

ActiveCN111521003ASmall fluctuationReduce dosageSolidificationLiquefactionThermodynamicsProcess engineering

The invention discloses an intelligent control oxygen-enriched firing system for a kiln. The intelligent control oxygen-enriched firing system for the kiln comprises an oxygen-enriched system, an oxygen-enriched burner, a temperature measurement and analysis system, a firing expert optimization system and an intelligent control system. According to the intelligent control oxygen-enriched firing system for the kiln, the oxygen enrichment is produced and provided by a special oxygen-enriched system; the novel oxygen-enriched burner is adopted; according to different coal powder types, coal powder amount and grinding granularity of a kiln system, the shapes and temperature distribution of flames are obtained by the accurate temperature measurement and analysis system, all on-site actual thermal parameters and on-site states of the kiln are combined, the system analysis and the prediction and judgment are carried out by the firing expert optimization system, and the intelligent regulationand dynamic matching of the special oxygen-enriched system are controlled by the intelligent control system, so that the optimal operation state of the firing system of the kiln is kept, the efficientand stable burning of coal powder in the oxygen-enriched burner is realized, the consumption of the coal powder is reduced, the quality of burned materials is improved, the generation and emission ofNOx are effectively reduced, meanwhile, the fluctuation of the kiln system caused by the debugging experience and level difference of operators is reduced, and the normal and stable operation of thekiln system is guaranteed.

Owner:HANGZHOU TURNING ENERGY TECH DEV CO LTD

Wrap back bra

ActiveUS9700081B2Girth of the sport bra to be increasedIncrease girthBrassieresGarment fastenersPhysical medicine and rehabilitationEngineering

Owner:NIKE INC

Flat circuit lamp tube and spherical lotus lamp made of this tube

InactiveCN101266911AIncrease girthCircumference smallGas discharge lamp detailsEngineeringLight tube

The invention discloses an oblate lamp and a spherical lotus lamp formed by the same. The oblate lamp comprises two or more than two root parts of lamp body in parallel arrangement, each of the root part of lamp body is set with a middle part of lamp body matching with the root part of lamp body, the outer surfaces of the middle part of the lamp body are luminous faces, the two ends of the middle part of the lamp body are connected in a whole a connecting part of the lamp body, the cross-section of the middle part of the lamp body is in oblate shape, the spherical lotus lamp is composed by connecting several of the oblate lamps. Compared with the existing round lamp, the oblate lamp according to the invention effectively enlarges luminous surface under condition of same perimeter of the luminous lamp, in order to enhance the luminous efficiency; meanwhile, compared to the existing round lamp, the oblate lamp in the middle part of the lamp body enables massively reduced perimeter of middle part of the lamp body under condition that the two has same luminous surface areas, in order to save disposable material for manufacturing the lamp body with low costs.

Owner:王赛君

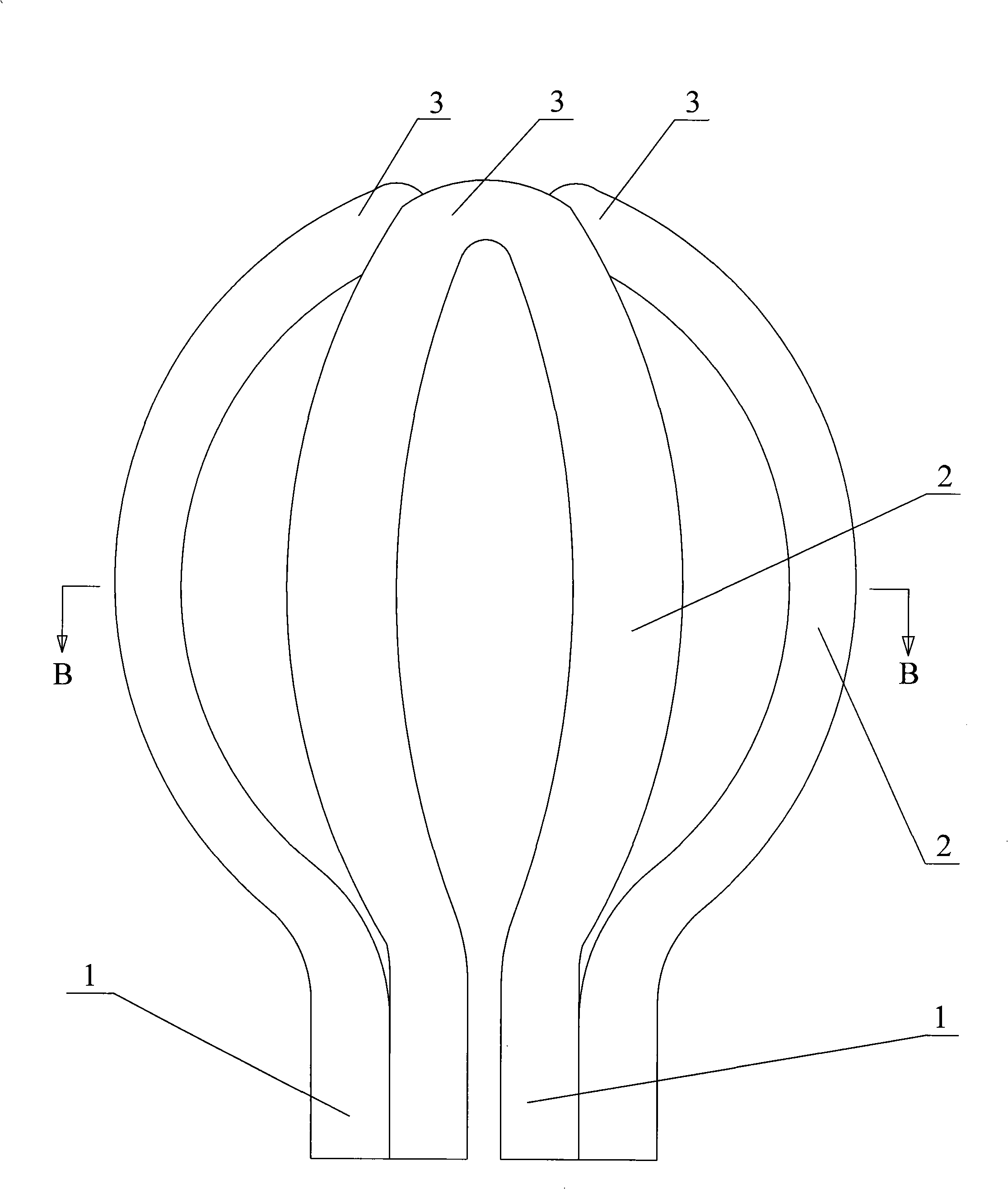

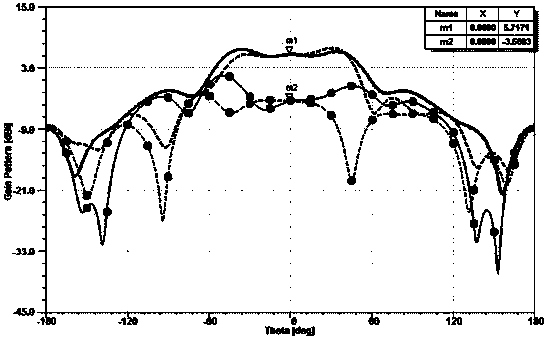

Fractal miniaturization method for axial mode cylinder helical antenna

ActiveCN103943949AIncrease girthReduce operating frequencyRadiating elements structural formsAntenna earthingsHelical lineImpedance transformer

The invention discloses a fractal miniaturization method for an axial mode cylinder helical antenna. The method includes the first step of constructing a fractal curve, the second step of constructing a longer periodic fractal curve, the third step of drawing a cylinder, the fourth step of counterclockwise rotating the periodic fractal curve constructed in the second step along the starting point of the periodic fractal curve by the angle alpha or the angle of pi-alpha, the fifth step of forming a circle of dextrorotation or levorotation cylinder helix, the sixth step of combining M circles of fractal helixes to form a fractal helix strip, the seventh step of turning the M circles of the fractal helixes in the sixth step into a metal conduction band with the thickness of T, the eighth step of placing concentric round copper plates, and the ninth step of adding a lambda / 4 impedance transformer at the initial end of a fractal helical line. According to the method, operating frequency of an axial mode of the helical antenna is lowered, so that size miniaturization is achieved.

Owner:SHANGHAI JIAO TONG UNIV

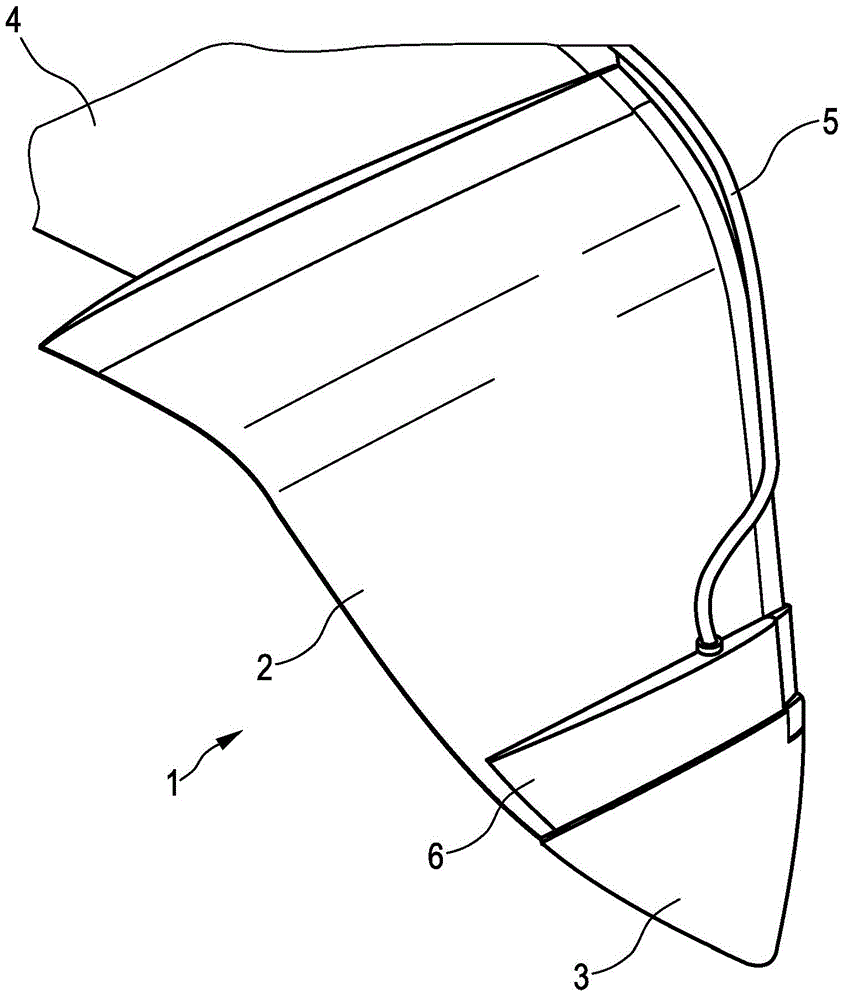

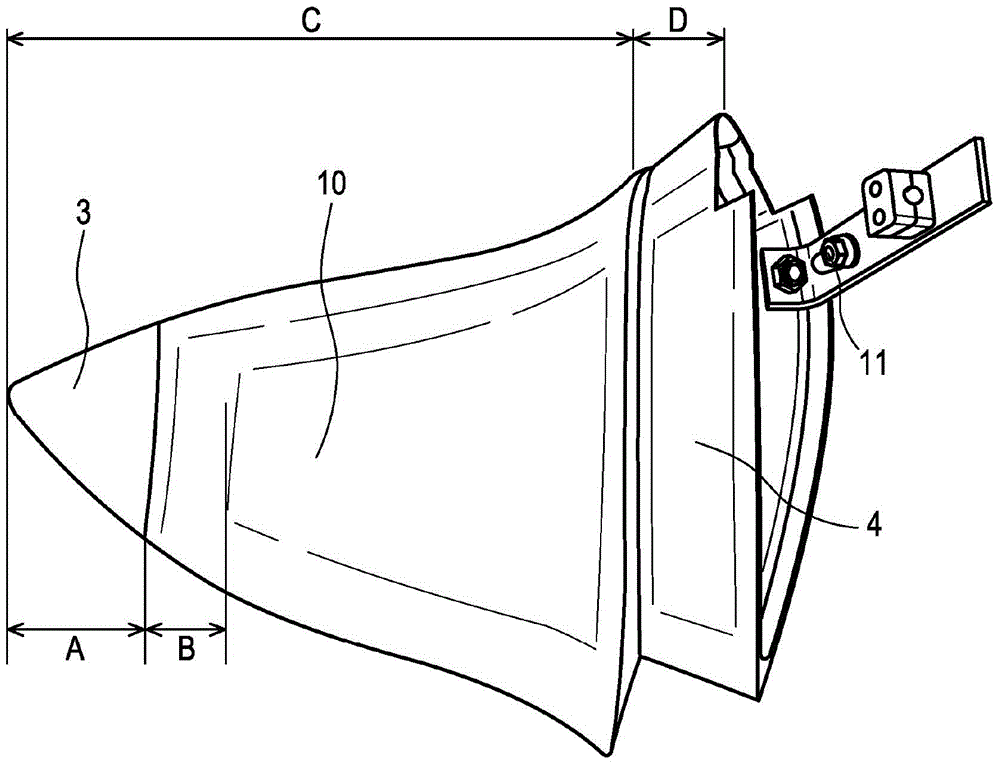

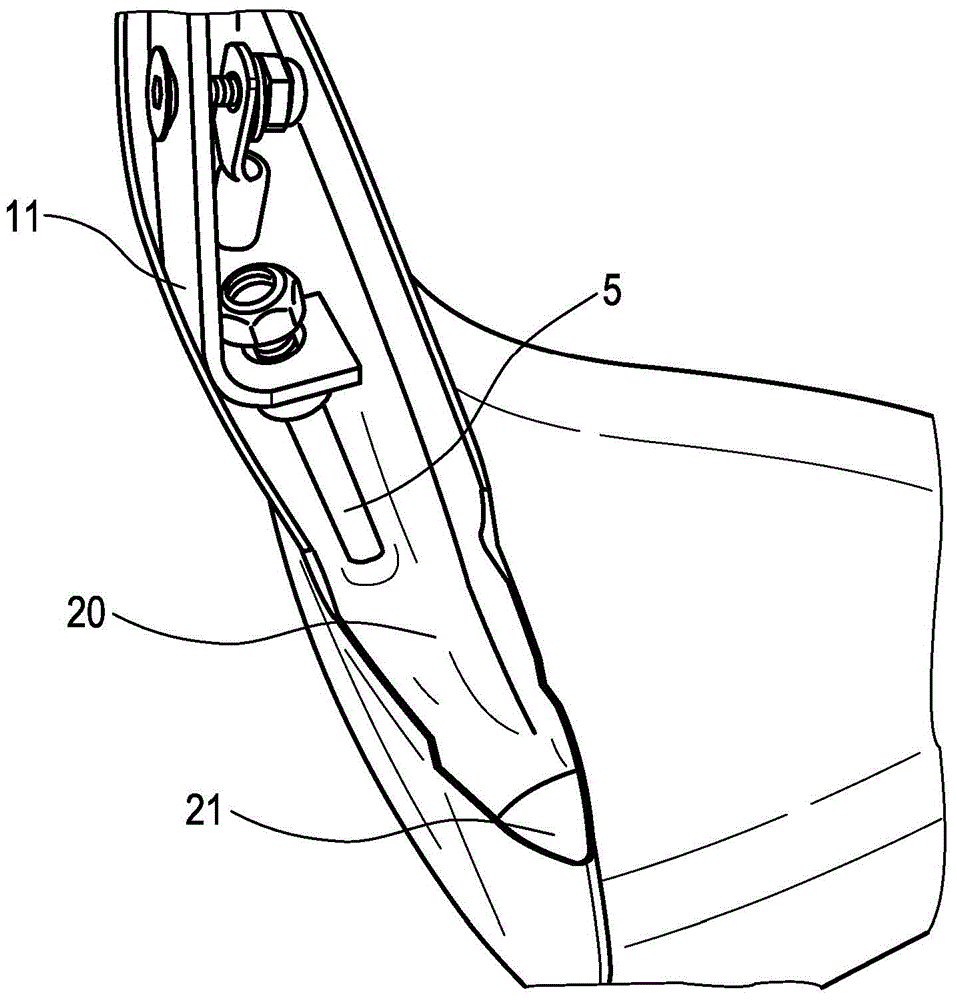

Rotor blade tip

InactiveCN104797815AAvoid damageEasy to manufactureEngine manufactureFinal product manufactureEngineeringTurbine

The invention relates to a rotor blade (30) of a wind turbine (100), comprising a main blade part and a blade tip (260), the blade tip (260) being detachably fastened to the main part by means of a connecting device (202). The connecting device (202) comprises a tip section (206) fastened to the blade tip (260) and a base section (204) for receiving the tip section (206), said base section being fastened to the main blade part. The tip section (206) comprises at least one securing means (242) for securing the tip section (206) to the base section (204), said securing means extending at least to the base section (204). The securing means (242) can be actuated through an opening (286) in the surface (282) of the blade tip (260) to secure the tip section.

Owner:WOBBEN PROPERTIES GMBH

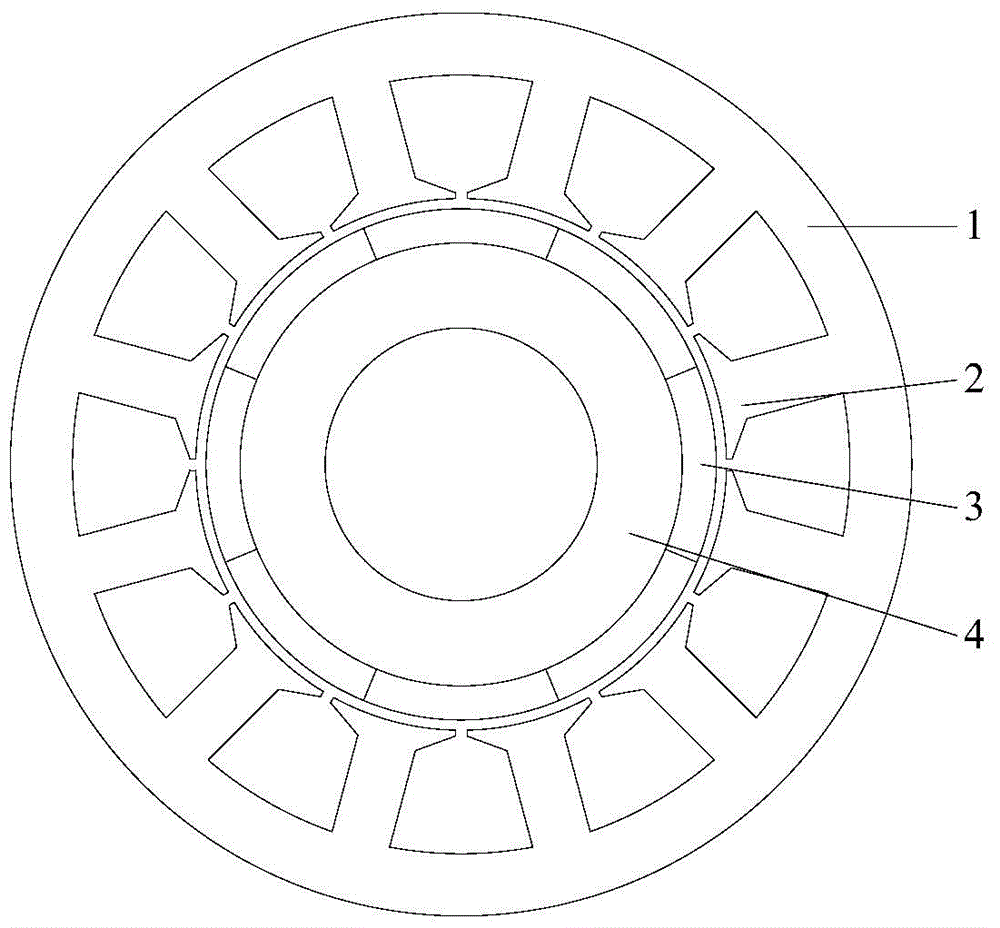

Motor with irregular tooth crests for reducing radial electromagnetic exciting force

ActiveCN104158311AIncrease girthReduce radial electromagnetic excitation forceMagnetic circuit rotating partsMagnetic circuit stationary partsSynchronous motorWave shape

The invention relates to a motor with irregular tooth crests for reducing radial electromagnetic exciting force. The structure of the motor is the same as that of the motor in the prior art. The motor is characterized in that a plurality of teeth with irregular tooth crests are arranged on a stator core or a rotor core, or are simultaneously arranged on the stator core and the rotor core, the tooth crests of the teeth consist of a plurality of small teeth, each small tooth adopts a zigzag-shaped, ladder-shaped, semicircle-shaped, semi-elliptic-shaped, or wave-shaped structure. As long as the perimeters of the tooth crests are increased, the radial force is changed into the component force of the normal force, and the action for reducing the radial electromagnetic exciting force can be exerted. When the tooth crests of the teeth adopt the zigzag-shaped structures, the structures with one-way zigzags can be adopted, the structures with two-way zigzags can also be adopted, and included angles between the bevel edges and the radial edges of the zigzag-shaped structures can be selected according to requirements. The motor disclosed by the invention can be widely applied to various motors, such as permanent magnet motors, asynchronous motors, electro-magnetic synchronous motors, switch reluctance motors and the like.

Owner:TSINGHUA UNIV

Stimulation enhancement device

InactiveUS20080306331A1Increase girthPrevent movementNon-surgical orthopedic devicesGenitals massageEngineering

A stimulation enhancement device includes a generally elongate main body portion having predetermined length, width and thickness, and defines an upwardly-facing surface and an opposing downwardly-facing surface. The downwardly facing surface is generally flat and said upwardly-facing surface is provided with a plurality of generally transverse protuberances spaced from each other along the length direction of the main body portion and that rise above the upwardly-facing surface. The downwardly-facing surface of the device may be positioned on the upper surface of an erect penis and, when maintained thereon, effectively increases the girth of the penis while the protuberances are effective to provide enhanced vaginal and clitoral stimulation.

Owner:MORREALE STEVEN C +1

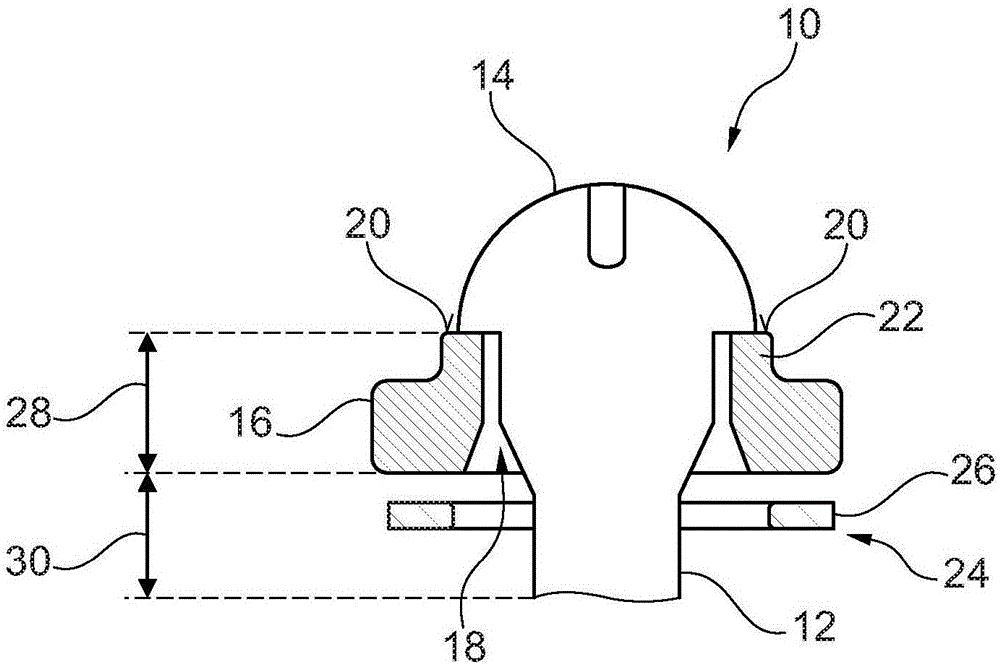

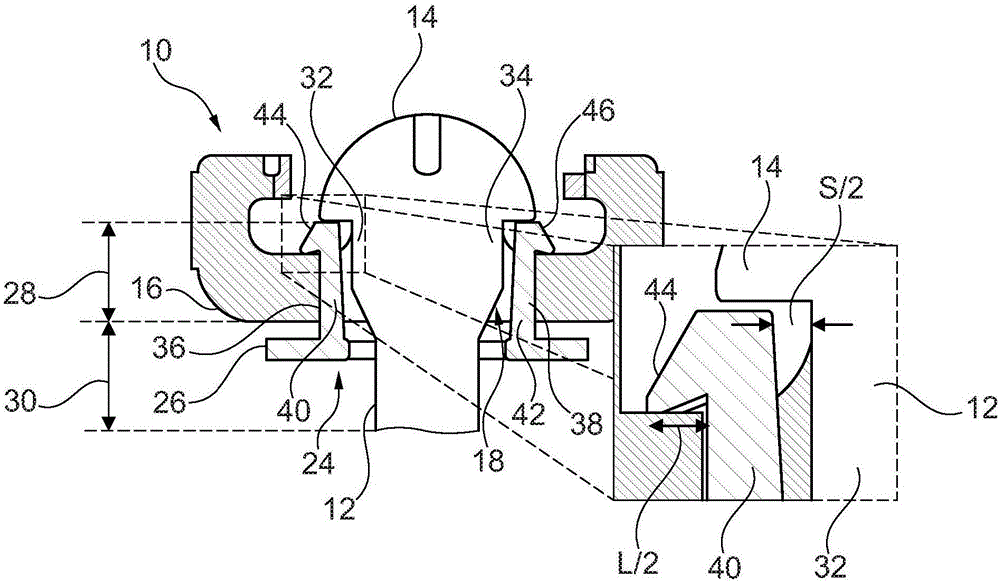

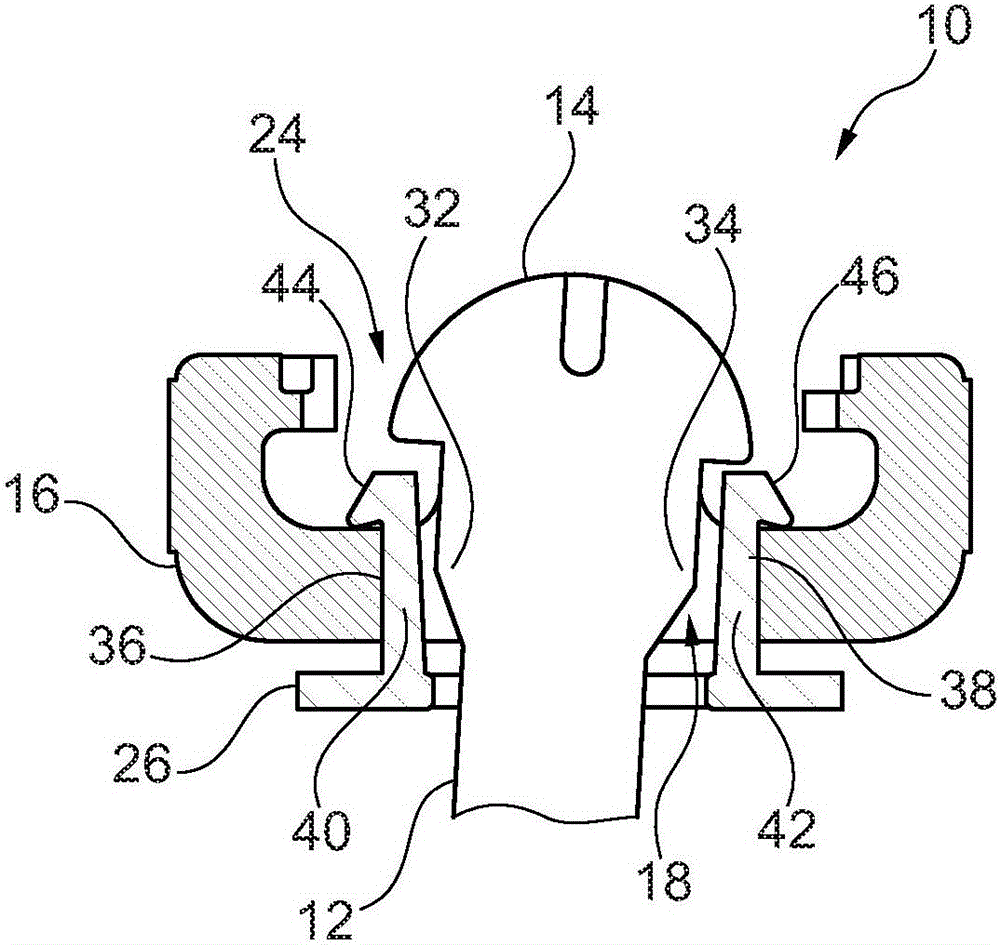

Connection arrangement of a piston rod

The invention relates to an actuating device for mechanical connection to a piston of a working cylinder, comprising a piston rod (12), which has a piston-rod base (14) at one end, a stop ring (16) for the piston-rod base (14), which stop ring accommodates the piston rod (12) in the interior of the stop ring with play, wherein the piston-rod base can pass through the stop ring (16) in at least one angular position of the piston rod (12) in relation to the stop ring, and a retaining device (24) to prevent such passing through, which retaining device has a main body (28) and a clip device. The clip device has at least one clip element (36, 38) comprising a spring arm (40, 42), which is fastened to the main body (26) and reaches through the interior of the stop ring (16) parallel to the piston rod, and comprising a latching projection (44, 46), which is arranged on the spring arm, wherein the remaining play S of the assembly of the piston rod and the at least one spring arm in the interior of the stop ring, with the piston-rod base lying against the stop ring or the clip element and being in the angular position permitting the passing through, is less than the rearward-engagement length L of the at least one latching projection.

Owner:SCHAEFFLER TECH AG & CO KG

Wrap front bra

ActiveUS9700082B2Girth of the sport bra to be increasedIncrease girthBrassieresGarment fastenersMechanical engineering

Owner:NIKE INC

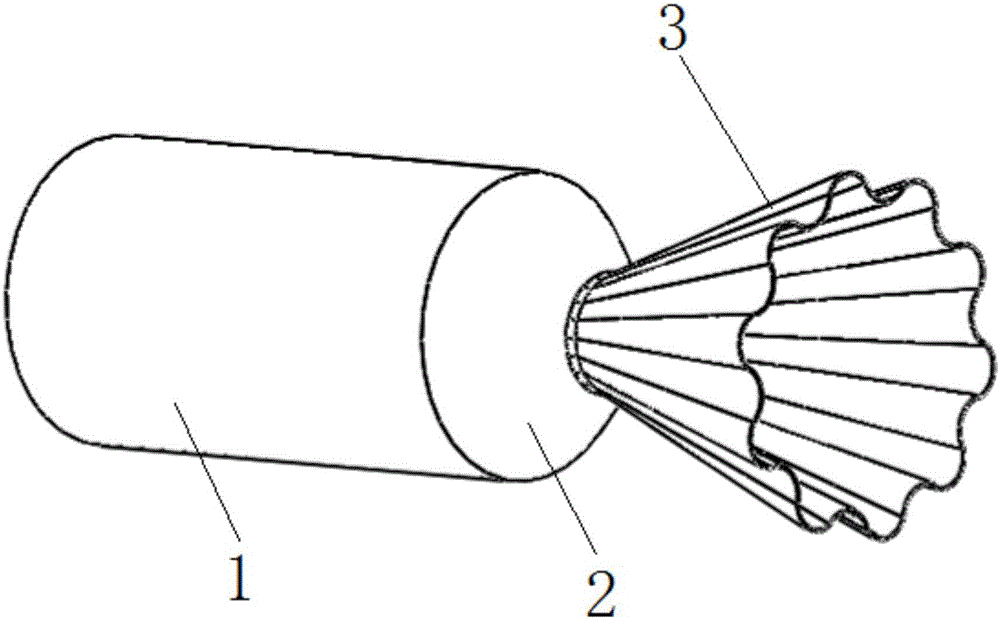

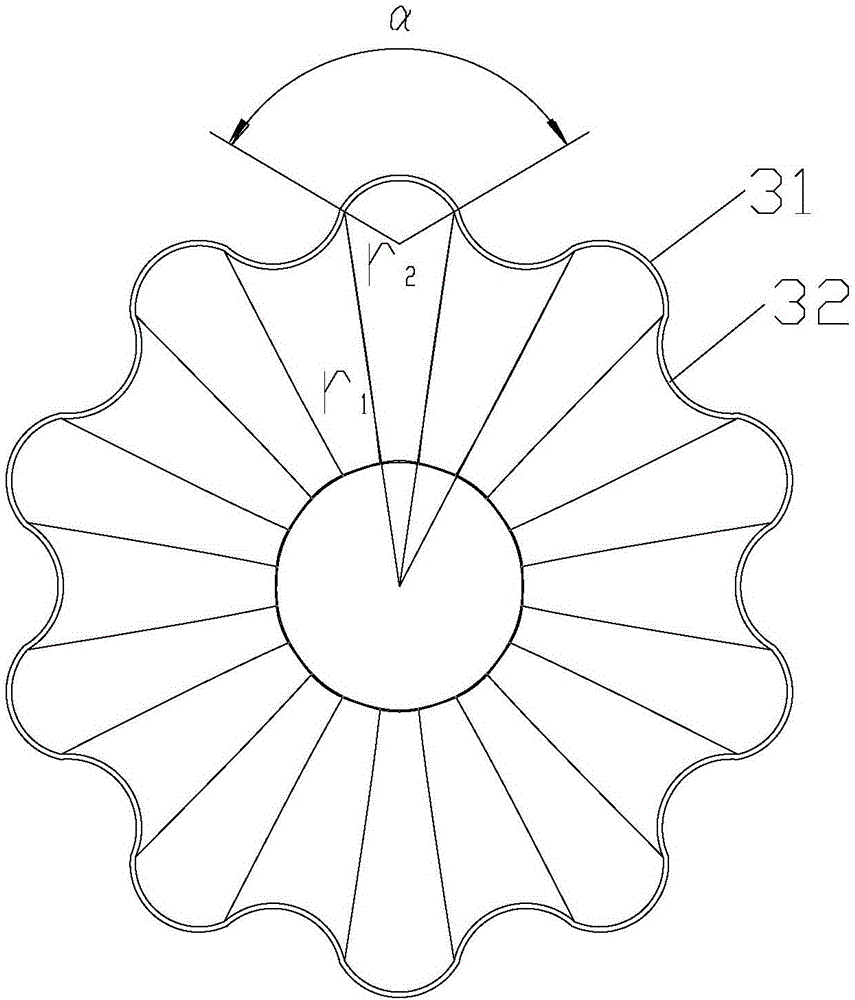

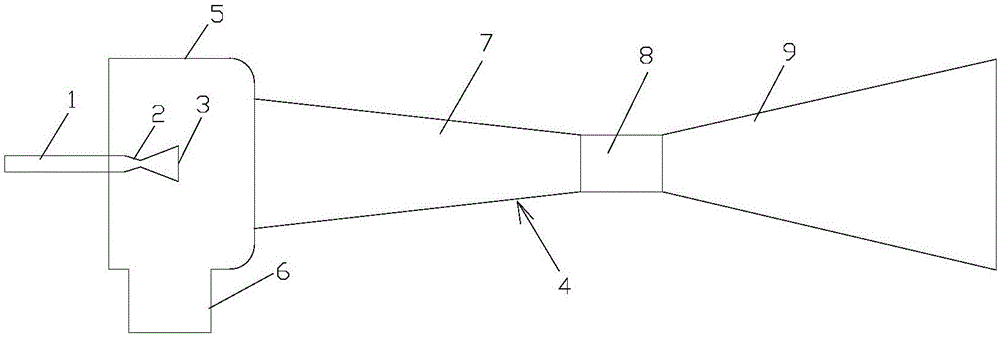

Nozzle and steam ejector

InactiveCN106391341AIncrease contact areaImprove uniformitySpray nozzlesLiquid spraying apparatusEngineeringCircular section

The invention discloses a nozzle and a steam ejector. The nozzle comprises an inlet pipe section (1), a transition pipe section (2) and an outlet pipe section (3) that are connected sequentially; a tapered expansion pipe with the inner diameter increasing along the direction from an inlet to an outlet forms at the outlet pipe section (3); a peripheral part of the outlet pipe section (3) comprises convex edge parts (31) and concave edge parts (32) that are formed in a staggered manner along the circumferential direction of the peripheral part sequentially, thus at any cross section of the outlet pipe section (3), a concave-convex petal shape is formed at an outline of an inner wall surface of the outlet pipe section (3) along the circumferential direction. With the adoption of the technical scheme, compared with a nozzle having a circular cross section, the nozzle with the cross section being petal-shaped has a greater perimeter on the condition that flow areas are equal, a contact area between the inner wall of the nozzle and a fluid is increased, the rolling suction and compounding effects of the fluid and other fluids at an outlet can be improved, an injection system can be improved, and a mixed fluid having better uniformity can be formed.

Owner:CHINA SHENHUA ENERGY CO LTD +3

Axial lifting driving structure for drill rods of pile driver for cement mixing piles

ActiveCN105019441AImprove pullout resistanceIncrease girthRotary drillingRotary-drilling machinesStationary statePile driver

The invention belongs to the technical field of building equipment, and particularly relates to an axial lifting driving structure for drill rods of a pile driver for cement mixing piles. The problem that an existing pile driver for cement mixing piles cannot achieve drilling properly is solved. The axial lifting driving structure comprises a driving box body with an inner cavity. The driving box body is provided with at least one drill rod body which is arranged in the vertical direction and can rotate circumferentially. One end of the drill rod body penetrates in the driving box body. An axial driving mechanism is arranged between the drill rod body and the driving box body, wherein the axial driving mechanism can drive the drill rod body to vertically slide in a reciprocating mode when the drill rod body is in a circumferentially-rotary state or in a circumferentially-stationary state. The axial lifting driving structure for the drill rods of the pile driver for the cement mixing piles has the advantages that the drill rod body can be stretched in the axial direction and also can slide in the axial direction during circumferential rotation, and the phenomenon that drilling cannot be achieved tends not to happen; drilling efficiency is improved, the perimeter of the cross section of each cement mixing pile is increased after construction, the pull-out capacity of the cement mixing piles is improved, and the mixing homogeneity is improved as well.

Owner:周兆弟

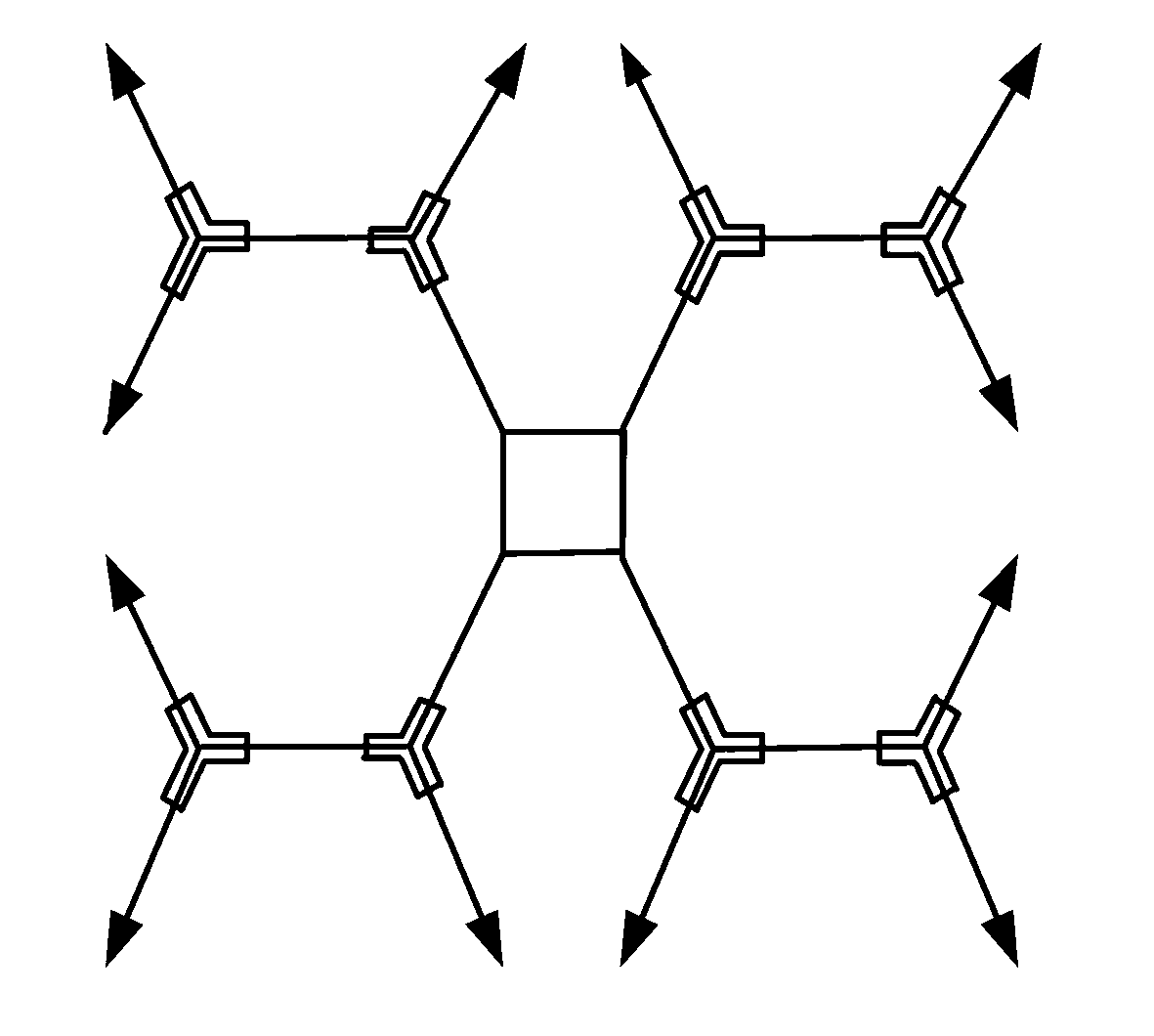

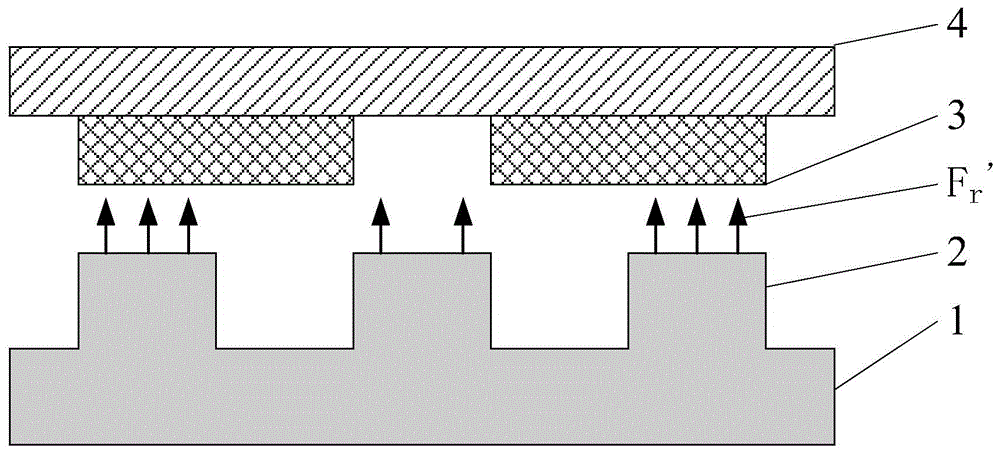

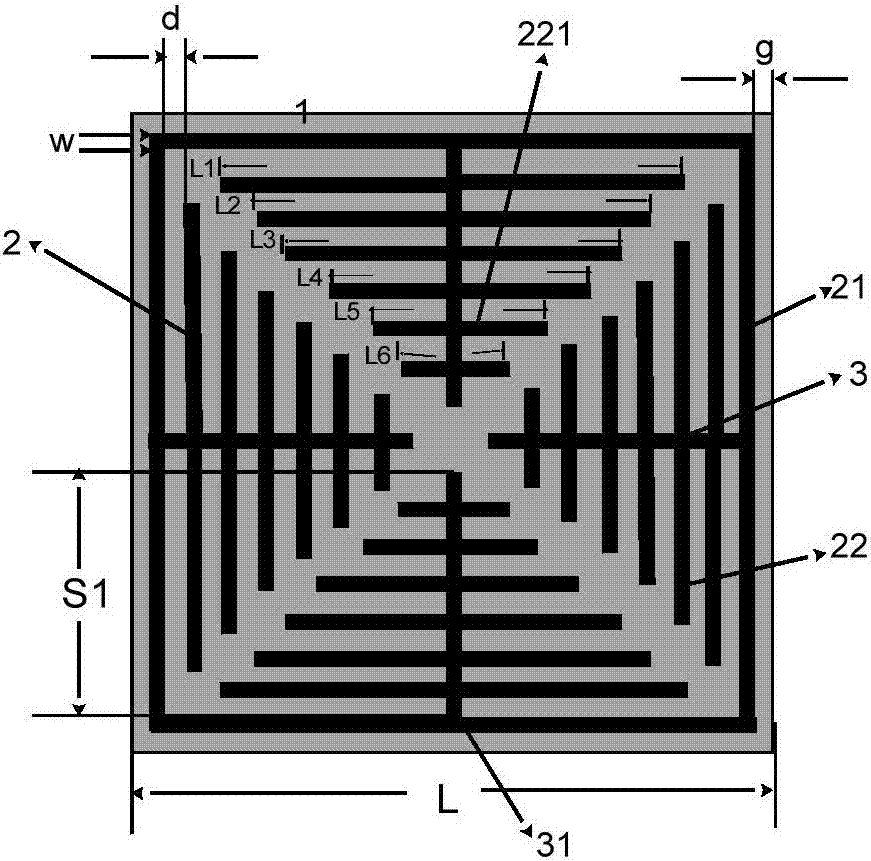

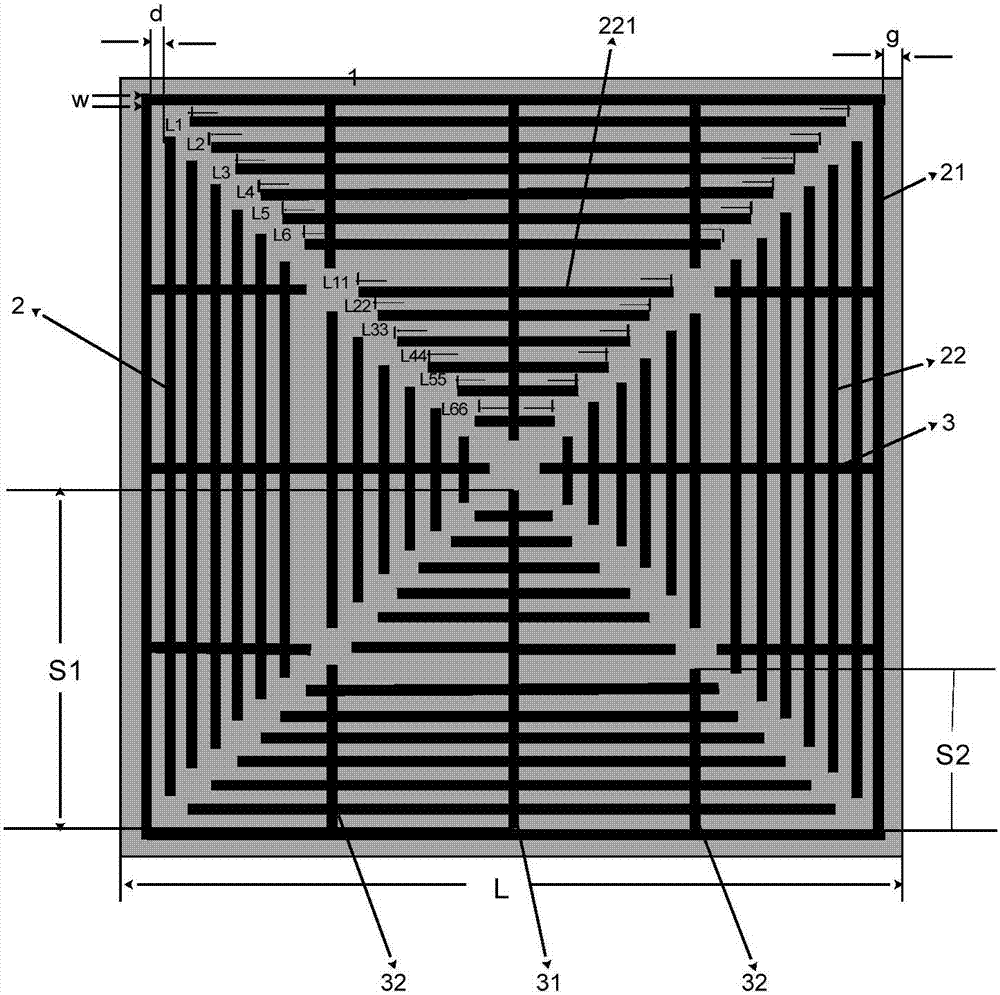

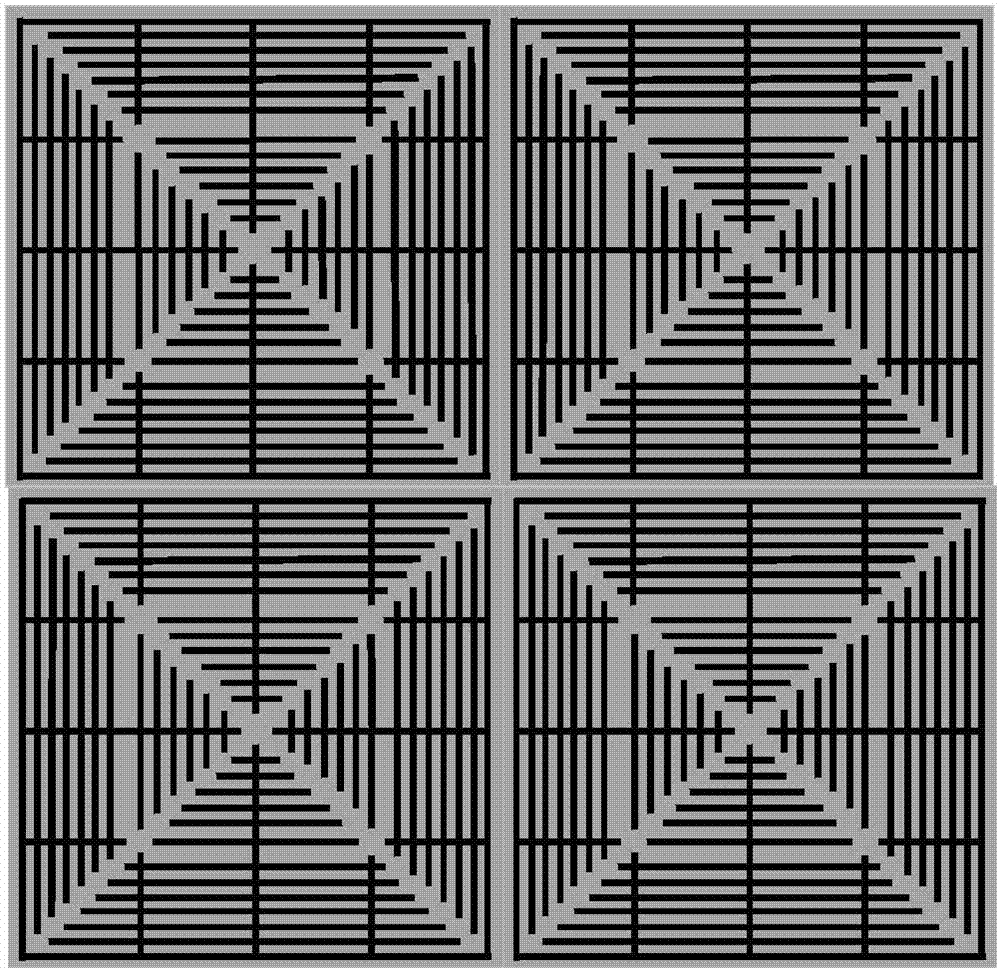

Frequency selective surface structure

ActiveCN107171042AIncrease girthIncrease the resonance wavelengthWaveguide type devicesDielectric substrateMolecular physics

The invention discloses a frequency selective surface structure. The frequency selective surface structure unit comprises a dielectric substrate (1), a square ring array (2) and metal strips (3), wherein the square ring array (2) is arranged on a dielectric plane of the dielectric substrate (1) and comprises sealed square ring metal lines (21) and gap square ring arrays (22), the sealed square ring metal lines (21) are arranged at four strip edges of the dielectric substrate (1), the gap square ring arrays (22) are arranged in the sealed square ring metal lines (21), share same center with the sealed square ring metal lines (21) and are sequentially arranged, the gap square ring arrays (22) are provided with two diagonal line gaps which are crossed, each gap square ring of the gap square ring arrays (22) is divided into four metal lines (221) in different directions by the diagonal line gaps, the metal strips comprise first metal strips (31), the first metal strips (31) perpendicularly intersect with the sealed square ring metal lines (21) and each metal line (221) of the gap square ring arrays (22) in a corresponding direction.

Owner:XIAN ZHONGXING NEW SOFTWARE

Enamel-covered multipath parallel combined high-efficiency energy-saving enamelled wire and manufacturing and application method thereof

InactiveCN105244090AImprove functional efficiencyIncrease the number of rootsInsulated cablesCable/conductor manufactureElectrical conductorEngineering

The invention relates to an enamel-covered multipath parallel combined high-efficiency energy-saving enamelled wire and a manufacturing and application method thereof. On the basis of the theory of the alternating-current skin effect phenomenon, especially the theory of the conductor current law demonstrating a direct ratio of a maximum current allowed by a conductor to a perimeter of a section of the conductor, an enameled isolation perimeter increasing method, an ellipse perimeter increasing method, a reducing root-extending perimeter increasing principle, and a method of reducing inductance by using a linear arrangement structure with parallel layered tight extruding and bonding from inside to outside of enameled combined wire cores are used comprehensively. The technical method of transmitting the electric energy and converting the energy by the multi-path parallel movement way of electron currents is realized. The provided enamelled wire is a combined enamelled wire having the high efficiency of electric energy transmission and energy conversion. Realization of production and application of the provided enamelled wire as well as direct usage of the method by replacing multiple thin enamelled wires with small diameters in the prior art with a single thick enamelled wire is based on calculation and design; and the total perimeter of the section of the multipath and multi-core combined enamelled wire needs to be equal to or larger than the perimeter of the single-core enamelled wire slightly in the prior art.

Owner:陈胜民

Fine art work full-automatic carving system and method thereof

InactiveCN110281678AEnsure continuityStrong process controllabilityModel makingWater savingWater discharge

The invention relates to a fine art work full-automatic carving system and a method thereof. At least two longitudinal clamping blocks corresponding to each other are fixedly installed above a central supporting shaft. A spiral regulation clamping rod is movably installed at the center position of each longitudinal clamping block. A containing tank is installed outside the upper position of the central supporting shaft in a sleeving manner. A water tank and a water saving tank are fixedly installed on the portion, on one side of the central supporting shaft, of a rotation platform. The bottom of the containing tank communicates with the top of the water saving tank through a connection hose. A water discharge pipe is installed on the water tank, wherein a water discharge pump is arranged at the bottom of the water discharge pipe. A water discharge spray nozzle is fixedly installed on the end portion of the water discharge pipe. The water discharge direction of the water discharge spray nozzle faces the top center position of the central supporting shaft. A full-automatic carving device is fixedly installed on the portion, on the other side of the central supporting shaft, of the rotation platform. Carving of special parts of to-be-carved objects is better controlled, the final continuity of carving works is ensured, carving is conducted at a time, the work and operation efficiency is high, and the carving precision control is precise.

Owner:ZHENGZHOU INST OF TECH

Cloud computing storage rack-mounted server

InactiveCN112105215AOrganize effectivelySection perimeter increasesServersCooling/ventilation/heating modificationsSlide plateCloud computing

The invention relates to the technical field of computers, and discloses a cloud computing storage rack type server which comprises a server rack, sliding rails are fixedly connected to the two sidesof the server rack, a sliding plate is movably connected to the top ends of the sliding rails, a server is placed at the top end of the sliding plate, and an electronic cable is movably connected to the back face of the server. A fixing rod is fixedly connected to the back face of the server rack, a fixing binding belt is fixedly connected to the middle of the electronic cable, the electronic cable is fixed to the fixing rod through the fixing binding belt, and a piston cylinder is fixedly connected to the outer side of the sliding rail. According to the invention, an air bag is additionally arranged to arrange electronic cables with excessive lengths, a piston is connected to the sliding plate, and the movement of the piston is realized by pushing and pulling the sliding plate, so that the perimeter of the section of the air bag filled with gas is increased when the sliding plate is pushed into the rack, and messy electronic cables on the back surface of the server are effectively arranged and stored.

Owner:肇庆悦能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com