Turbine type stirrer used for molten iron mechanical stirring desulfuration

A mechanical stirring and turbine-type technology, which is applied in the field of turbine-type agitators for mechanical stirring and desulfurization of molten iron, can solve the problems of difficulty in reducing the consumption of stirring power, increasing the forward tilt angle, strengthening the agitator, etc., and achieving enhanced axial entrainment circulation volume, reducing stagnant area, increasing area and stirring the effect of radial thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

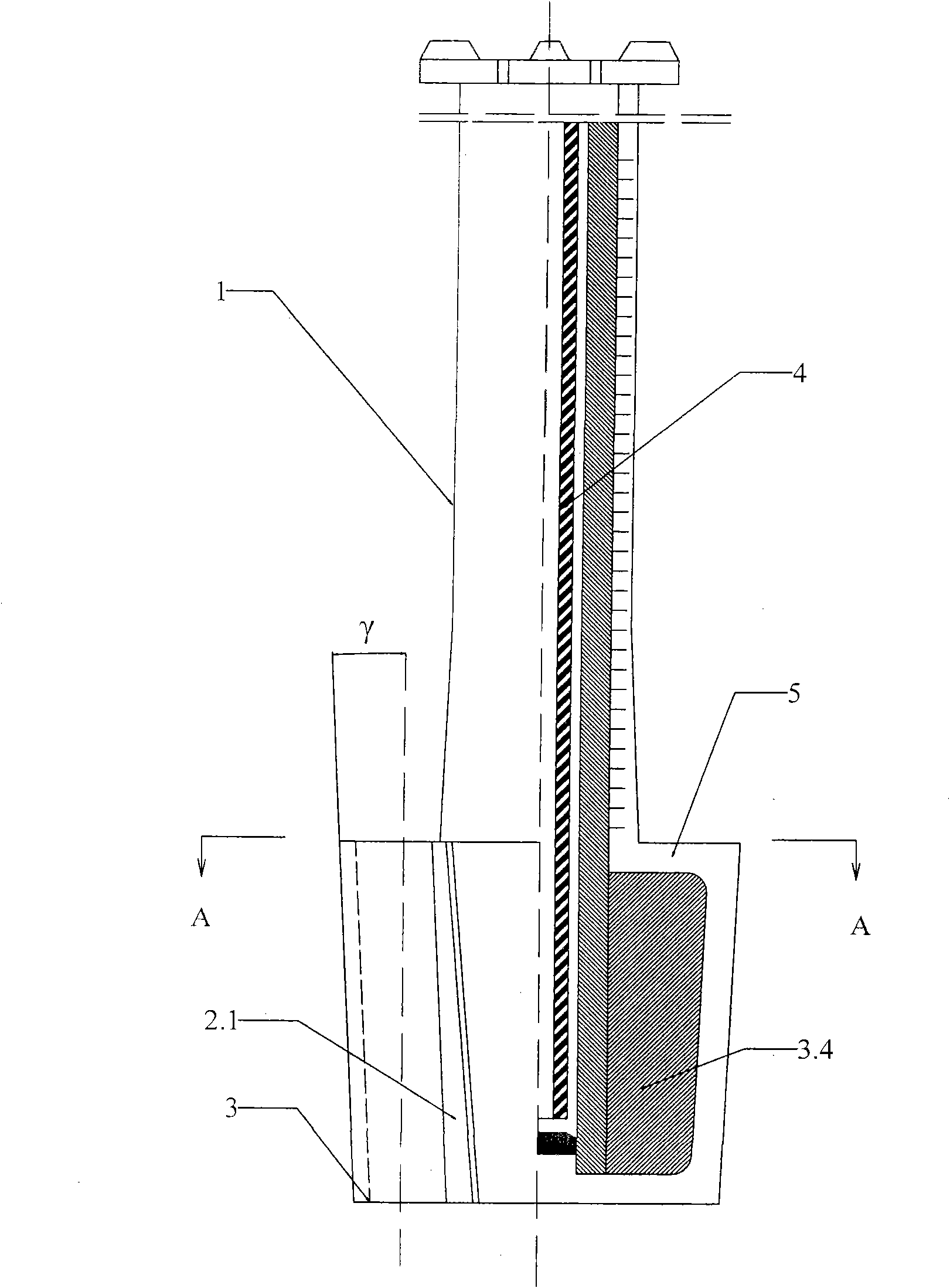

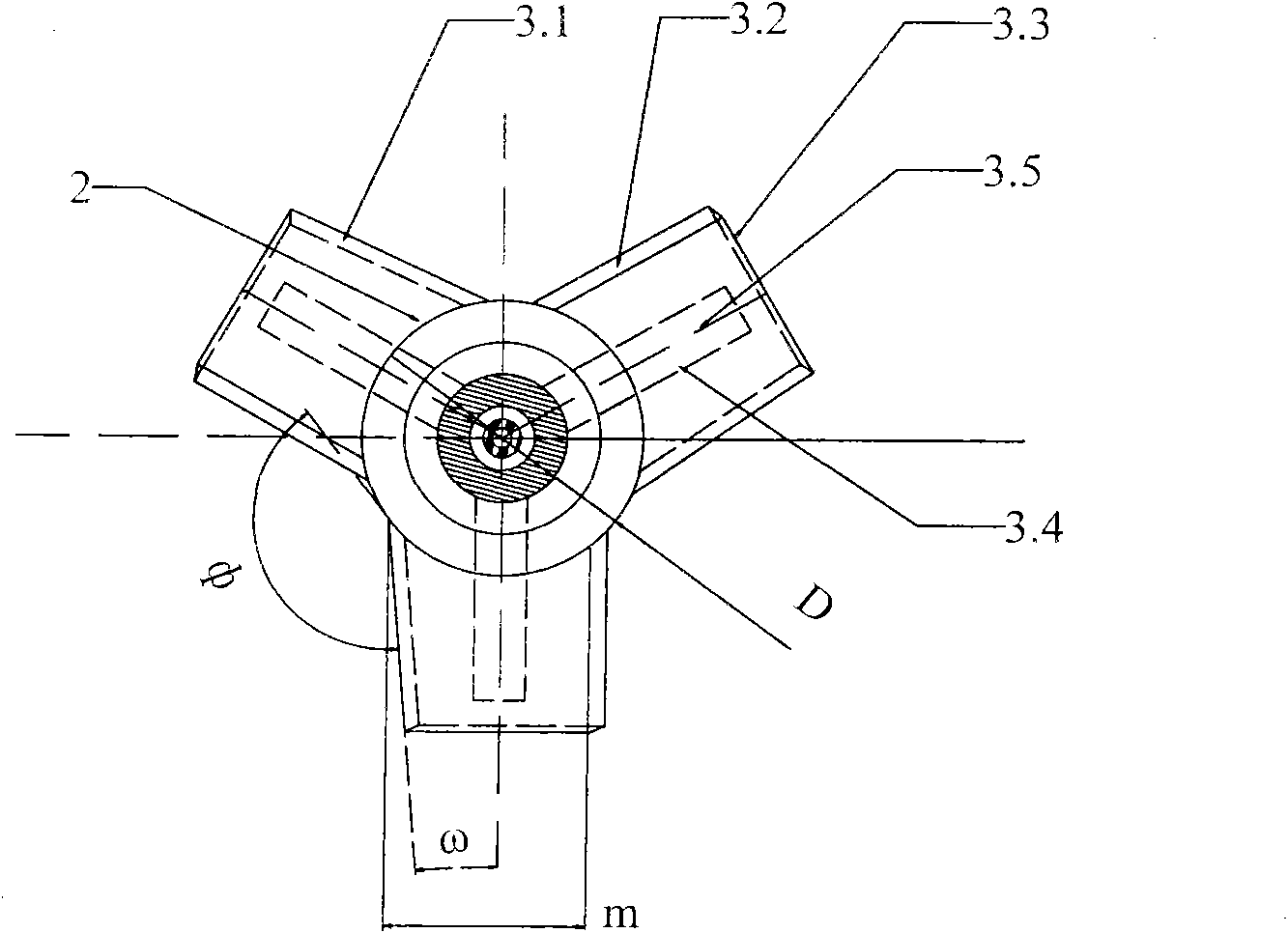

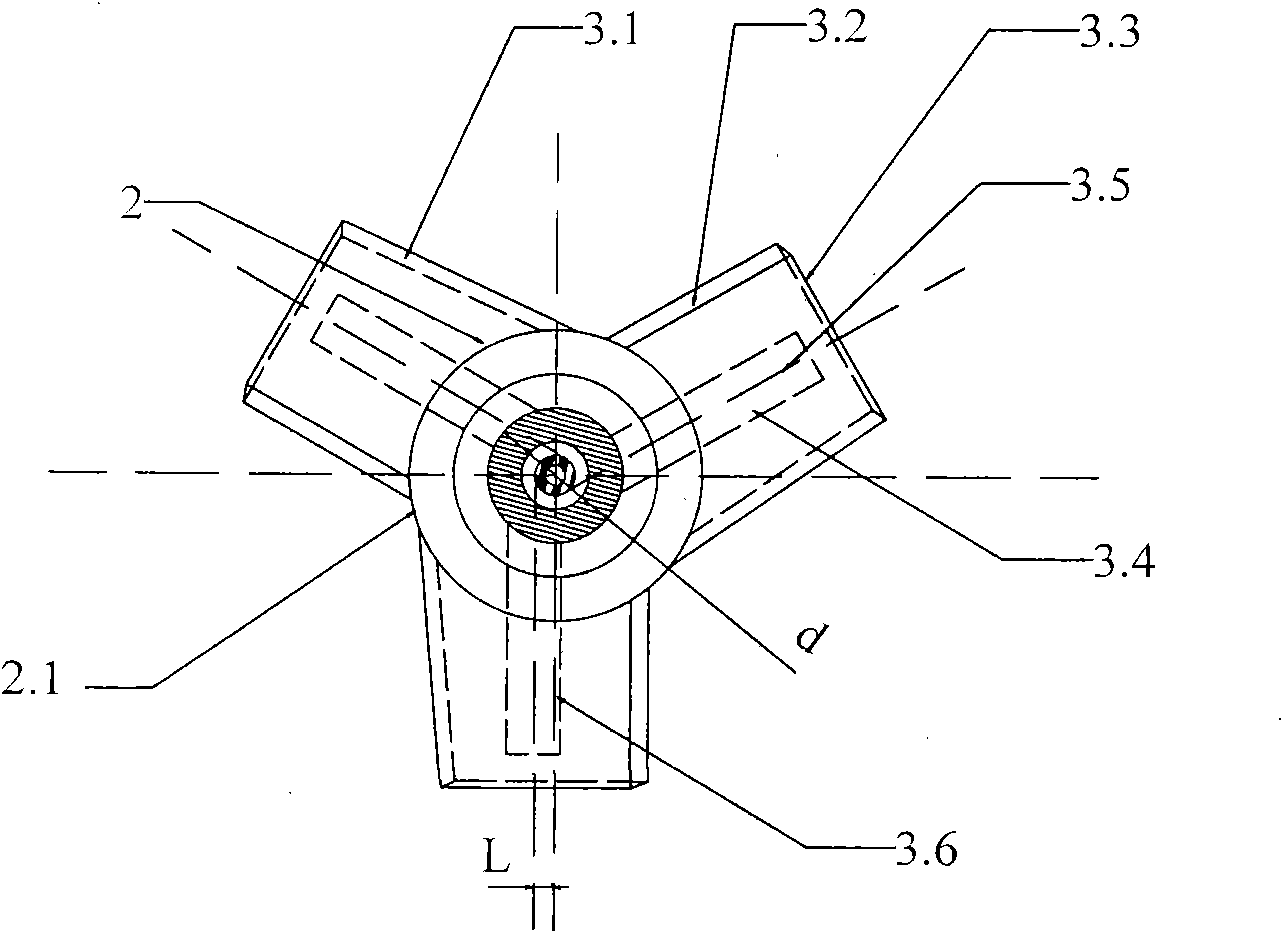

[0022] Below in conjunction with accompanying drawing and specific embodiment, the turbine agitator of the present invention is described in further detail with mechanical agitation desulfurization of molten iron:

[0023] like Figure 1 to Figure 3 As shown, the turbine agitator for mechanical stirring desulfurization of molten iron of the present invention includes a rotating shaft 1, an air-cooled tube 4 placed in the rotating shaft 1, a hub 2 and three stirring blades 3 uniformly arranged around the circumference of the hub 2. The hub 2 is a frustum-shaped structure whose diameter gradually decreases from top to bottom in the axial direction, and is made of refractory material, and is cast together with the stirring blade 3 . The stirring blade 3 includes a stirring blade metal core 3.4 and a refractory working lining 5 . The iron-facing water surface 3.1, the back-iron water surface 3.2 and the side surfaces 3.3 of the stirring blade 3 are slopes inclined from bottom to to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com