Patents

Literature

45results about How to "Avoid secondary entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

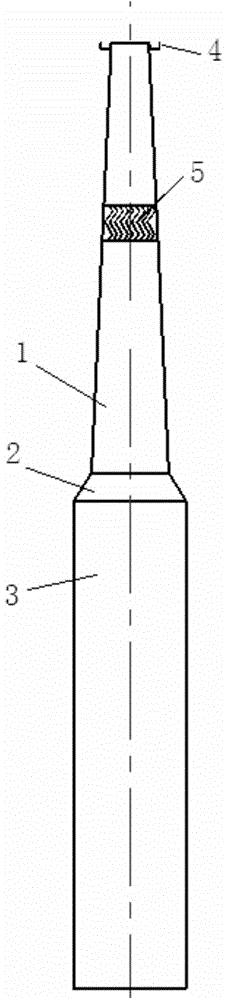

Dedusting and demisting device of spiral flow plate

ActiveCN104874235AGood effect of dust removal and fog removalReduce energy consumptionDispersed particle separationCycloneFlue gas

The invention discloses a dedusting and demisting device of a spiral flow plate. The dedusting and demisting device comprises a plurality of dedusting and demisting units, wherein each dedusting and demisting unit comprises a hollow overflowing barrel body, a spiral flow cyclone is arranged in the overflowing barrel body, a flue gas guiding device is connected to the lower part of the spiral flow cyclone, the flue gas guiding device is fixedly connected with the overflowing barrel body, a blowing hole is formed in the flue gas guiding device, and a discharge hole is formed in the inner wall of the overflowing barrel body; the flue gas guiding device is a variable cross-section truncated cone-shaped hollow barrel body of which the cross-sectional area changes continuously, and the upper end surface of the truncated cone-shaped hollow barrel body is connected with the spiral flow cyclone. By using the flue gas guiding device, continuous change of the airflow moving state is realized, the stability of a formed liquid film is good, and secondary entrainment of liquid drops is effectively prevented. Compared with a dedusting and demisting device without the guiding device, the gas distribution state is more uniform, and local disturbance of airflow which passes through the spiral flow cyclone is effectively reduced, so that the airflow moving state is more stable, and the stability of the formed liquid film is better.

Owner:SHANDONG SHANDA WIT ENVIRONMENTAL ENGINEERING CO LTD

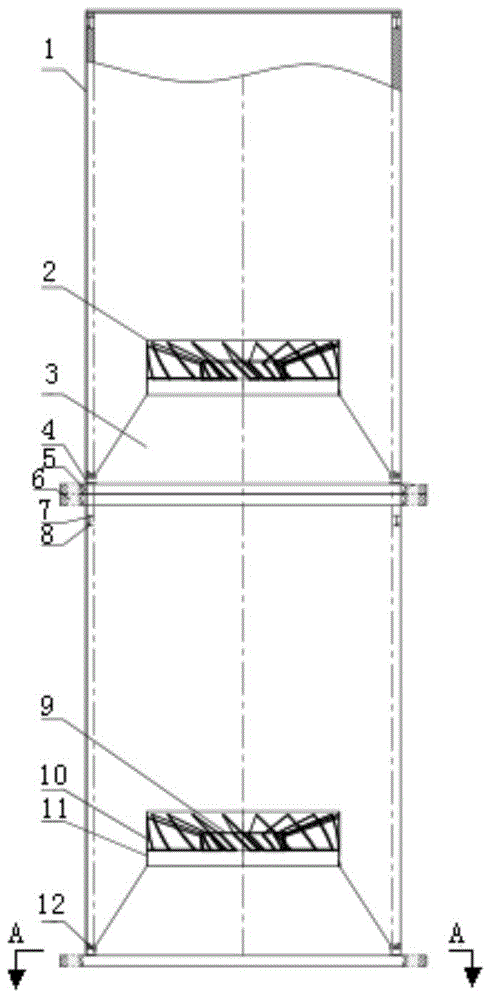

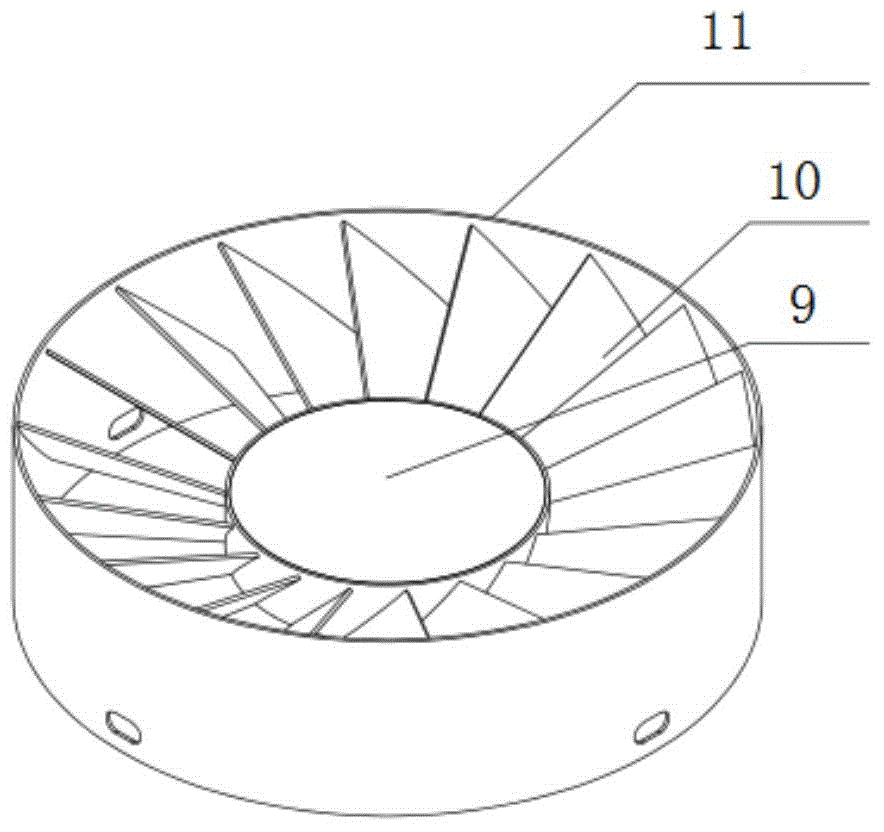

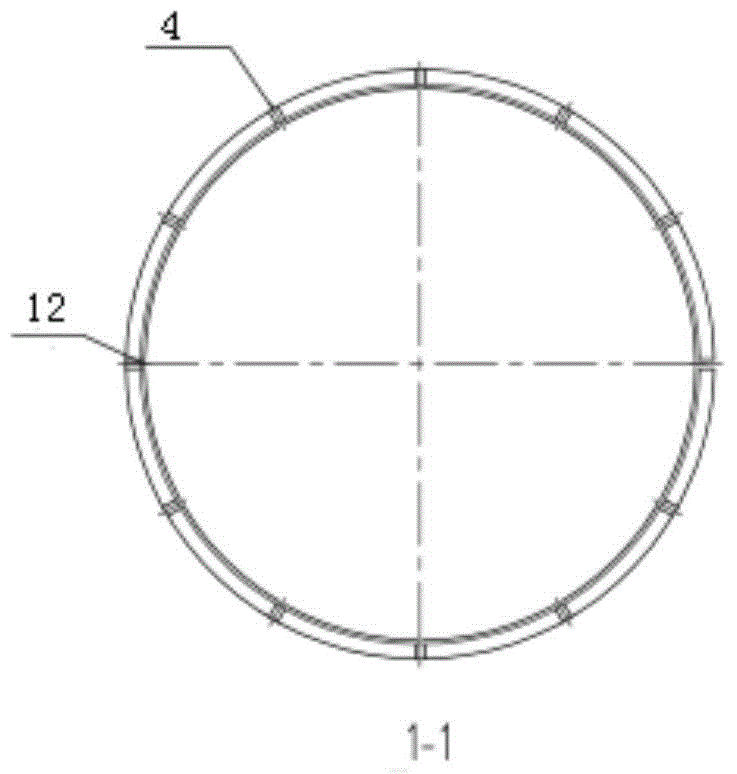

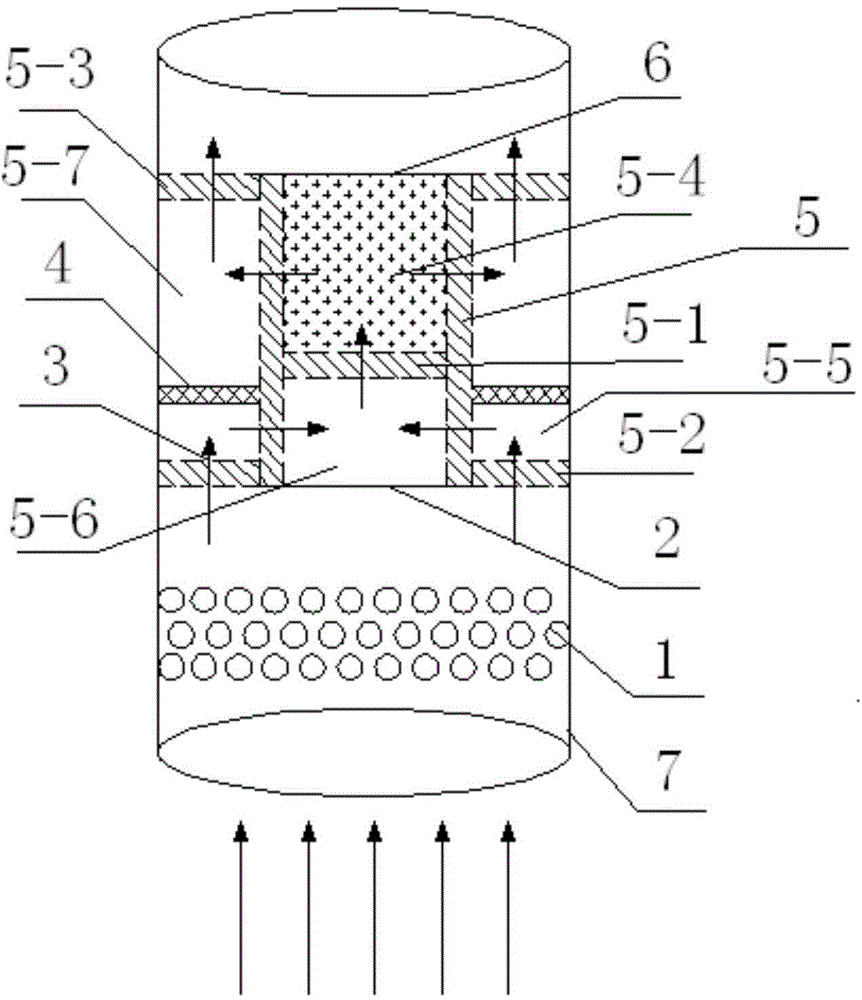

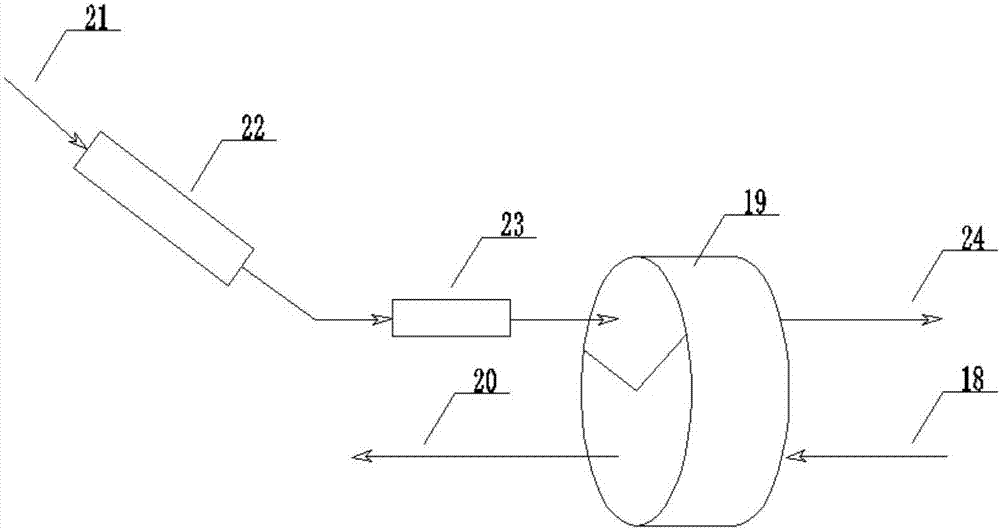

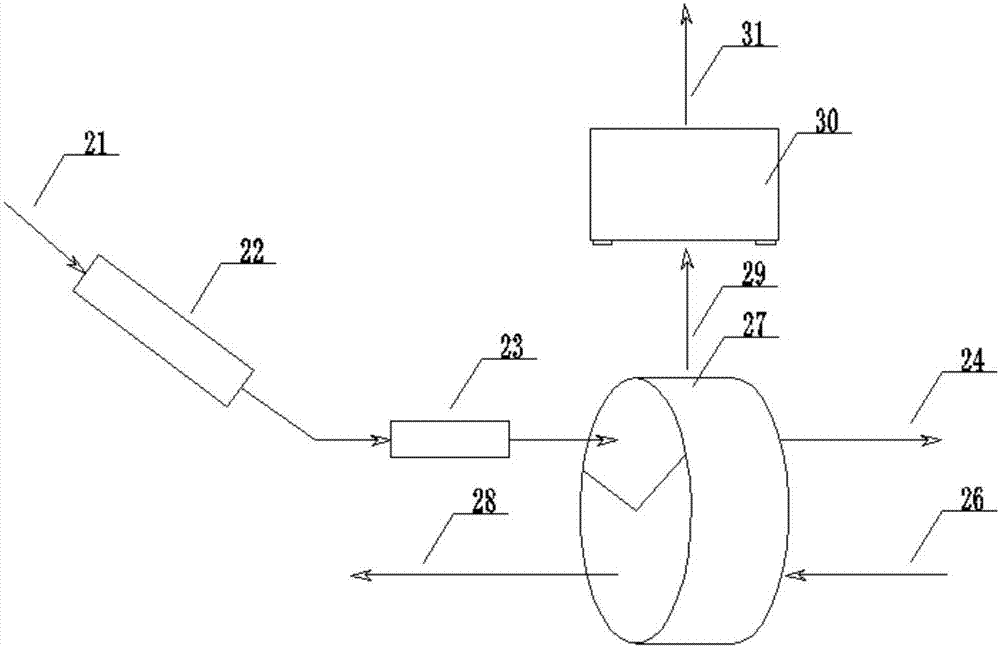

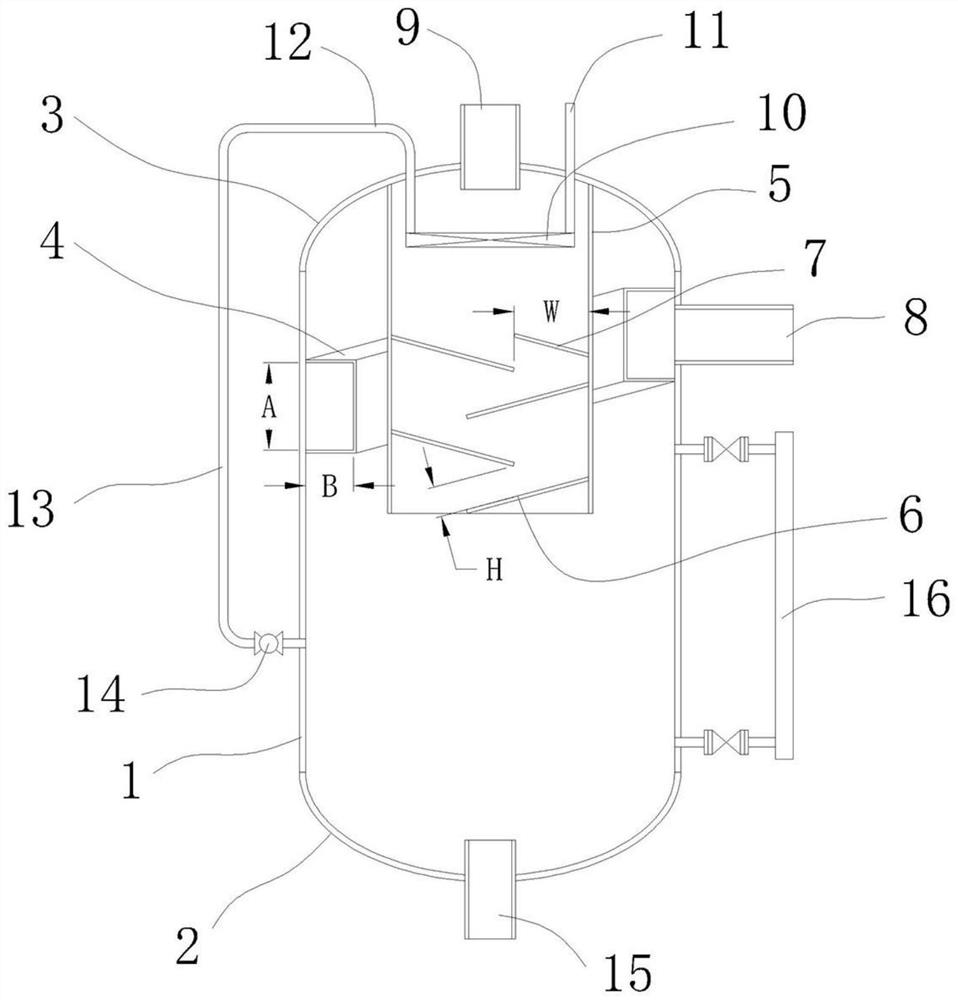

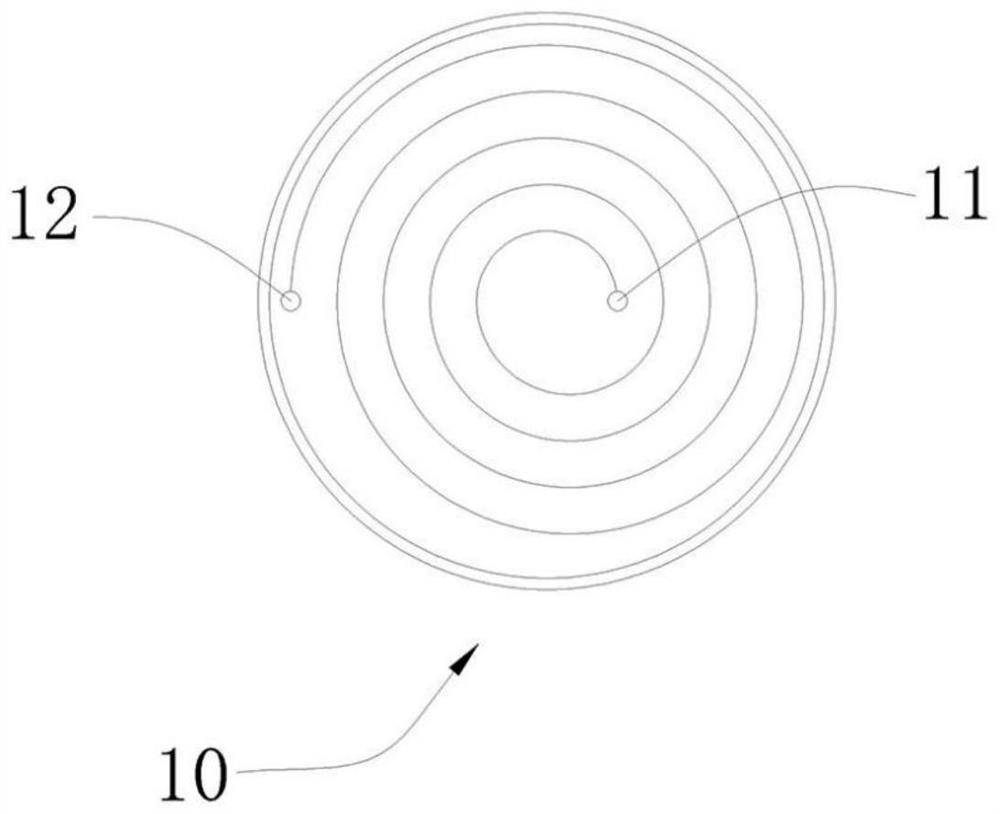

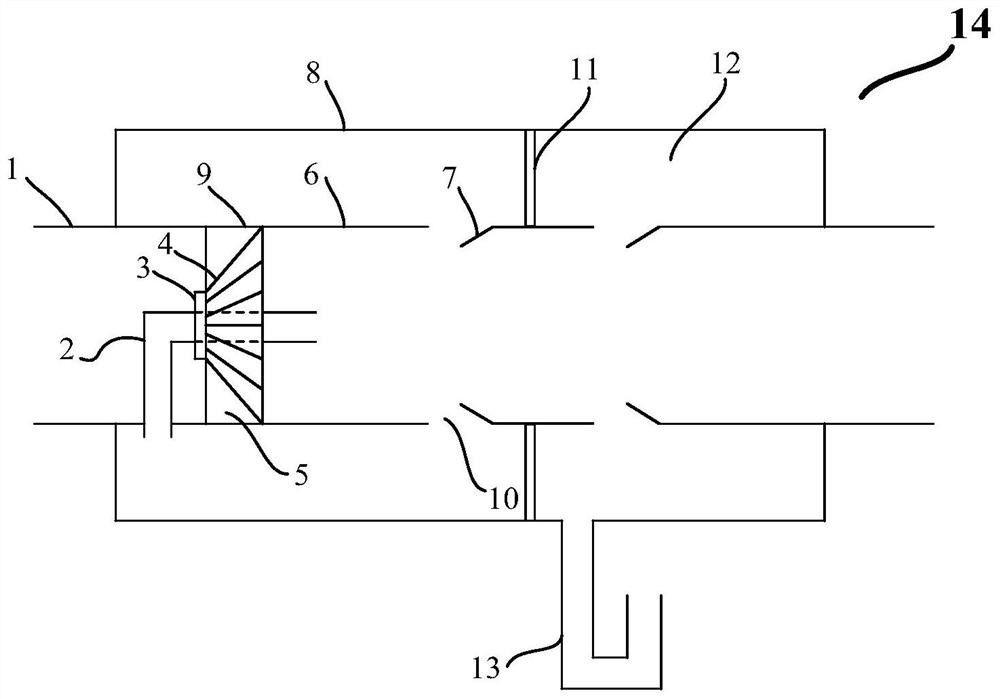

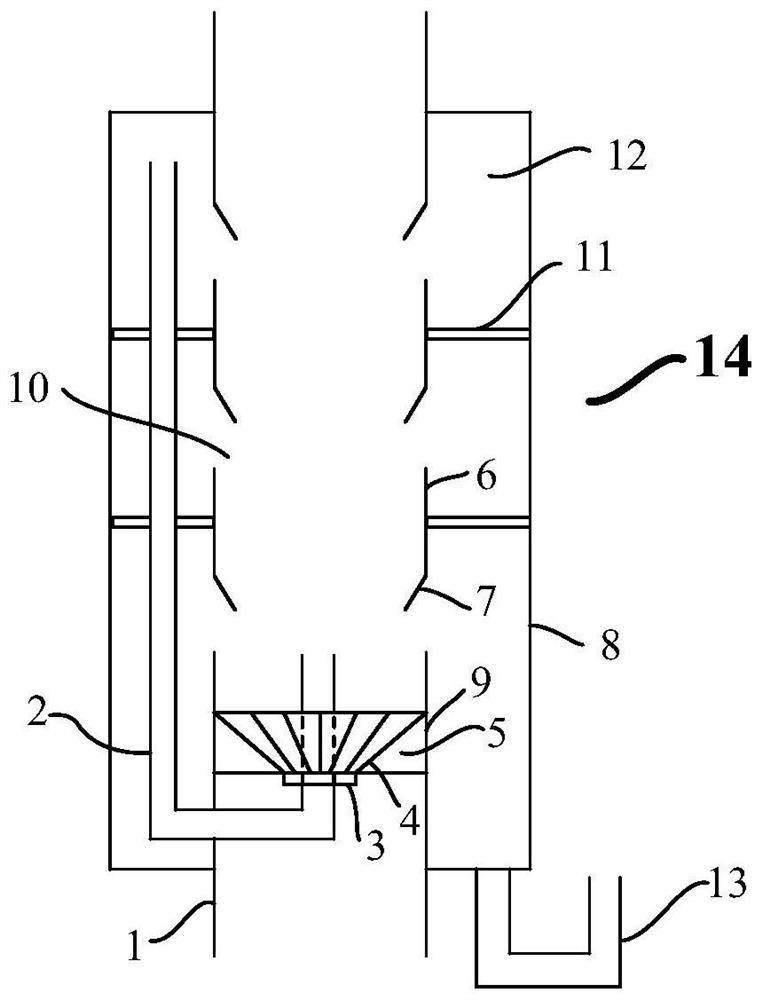

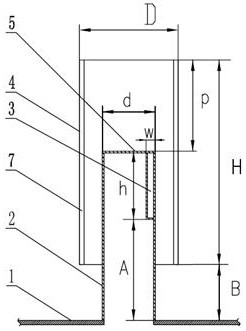

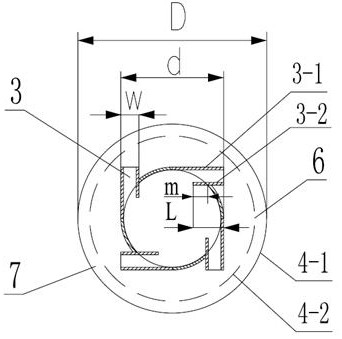

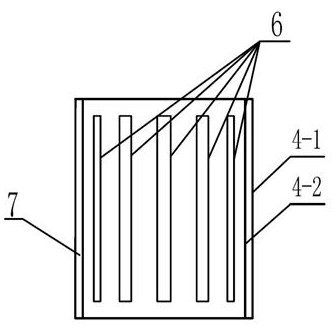

Gas-liquid separation device

ActiveCN108786285AReduce resistanceEasy to separateDispersed particle separationProduct gasEngineering

The invention relates to a gas-liquid separation device, and belongs to the field of chemical machinery. The gas-liquid separation device comprises an inner cylinder, an outer cylinder, and a rotational flow part; the inner cylinder is connected with a supply pipeline for conveying liquid-containing airflow and is composed of a plurality of pipe sections, liquid dividing troughs are formed betweenthe pipe sections, and the drainage resistance is reduced; the outer cylinder sleeves the exterior of the inner cylinder with a certain gap, a closed annular cavity is formed between the inner cylinder and the outer cylinder, and a U-shaped liquid-sealed drainage pipe is arranged on the outer cylinder; the rotational flow part is arranged between the upstream side of the inner cylinder and the supply pipeline; the outer cylinder is connected with a low-pressure zone of the center of the inner cylinder through a blind plate of the rotational flow part via an elbow pipe; gas of the outer cylinder is sucked by using the pressure difference between the inner cylinder and the outer cylinder, and the pressure of the outer cylinder is reduced. The gas-liquid separation device has the characteristics of high gas-liquid separation efficiency and low pressure drop, and has strong adaptability to different production devices.

Owner:ZHEJIANG UNIV

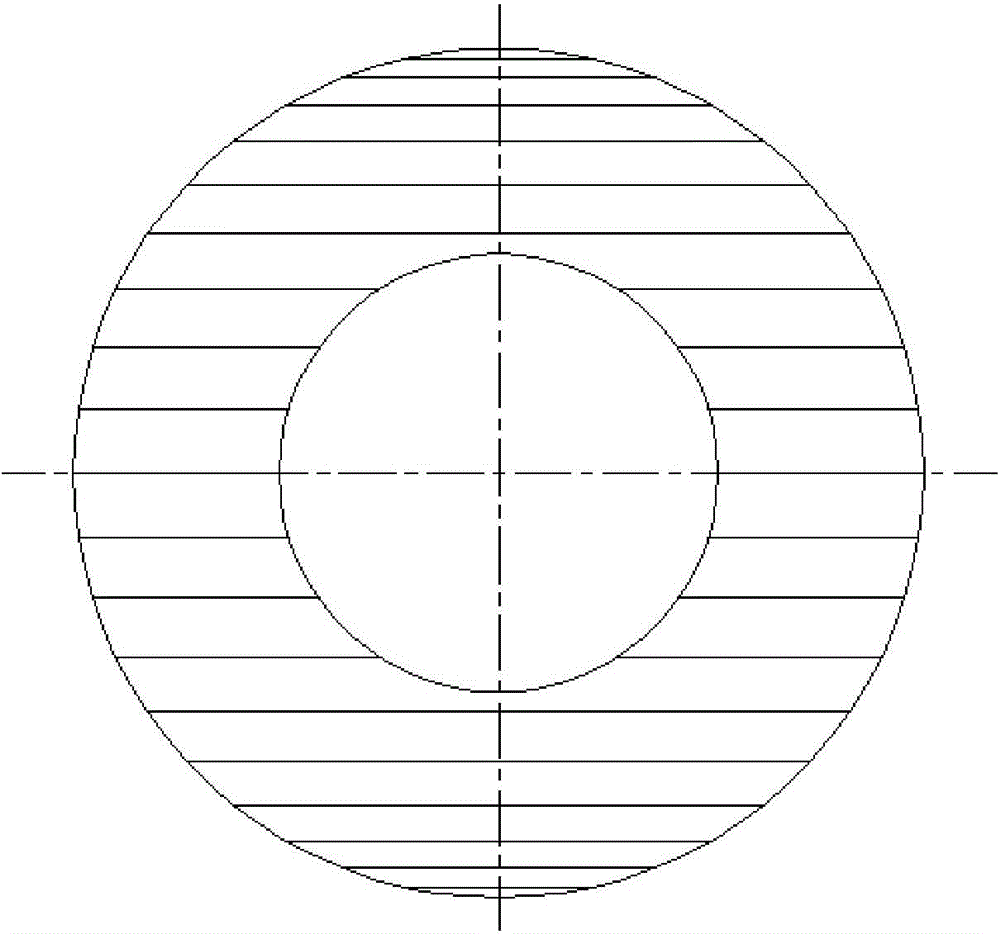

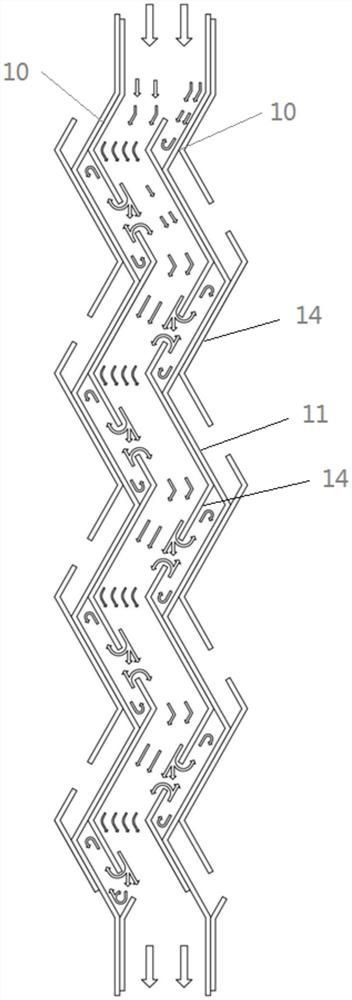

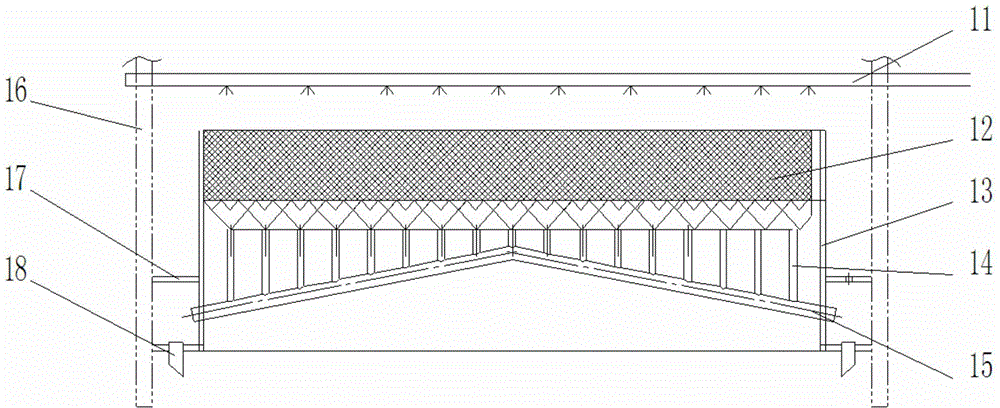

Multichannel-type composite demister and demisting method

ActiveCN104815501ADisadvantages of changing single-stage defoggingInsufficient changeCombination devicesFilling materialsMechanical engineering

The invention discloses a multichannel-type composite demister and a demisting method. The multichannel-type composite demister comprises a demister case and a cylindrical structure enclosed by a baffle plate and arranged in the demister case with axial direction, the inner part of the cylindrical structure is divided into a filling material chamber and an intermediate rectification chamber; a second baffle plate and a third baffle plate are arranged between an upper end of the cylindrical structure and the demister case as well as a lower end of the cylindrical structure demister case; a support plate is arranged between central section of the outer wall of the cylindrical structure and the demister case, a bottom circulation chamber is formed by a cavity defined by the second baffle plate and the support plate, a top circulation chamber is formed by a cavity defined by the support plate and the third baffle plate; air flow is introduced into the bottom circulation chamber, an intermediate rectification chamber, a filling material chamber and the top circulation chamber from the bottom of the demister case in order, and is discharged from the top of the demister case. By employing a composite demisting effect with combination of multichannel separating, baffle plate inertia separating and filling material separating, little liquid drop can be removed, so that the demister can better solve the raining or gypsum rain phenomenon of a chimney.

Owner:SOUTH CHINA UNIV OF TECH

Doublestage desulfurizing and dedusting apparatus

ActiveCN1544127AMake sure you don't bring waterAvoid secondary entrainmentUsing liquid separation agentLow speedEngineering

The invention is a two-stage desulfurizing and dust-cleaning device, including a shell and a lye circulating system, and its character lies in that it is composed of low-resistance spray head, low-speed venturi tube, impact baffle and annular-arranged baffling plate demister, which are installed in turn from top to bottom. Its beneficial effect: during two-stage desulfurization circulation, adopting a low-speed venturi tube plus impact baffle structure to make the gas resistance low and desulfurizing efficiency high and play a role in primary dehydrating, and the low-resistance demister on the top of the desulfurizing tower can thoroughly eliminate fine water drops in the fume, ensuring that the fume carries no water. It is of a unit structure, convenient for installing and overhauling, the baffling plate can thoroughly dehydrate all the more because of vertical installation, avoiding secondary carrying of the fume, and it has higher flow speed and compacter device, saving the space.

Owner:北京德厚朴化工技术股份有限公司

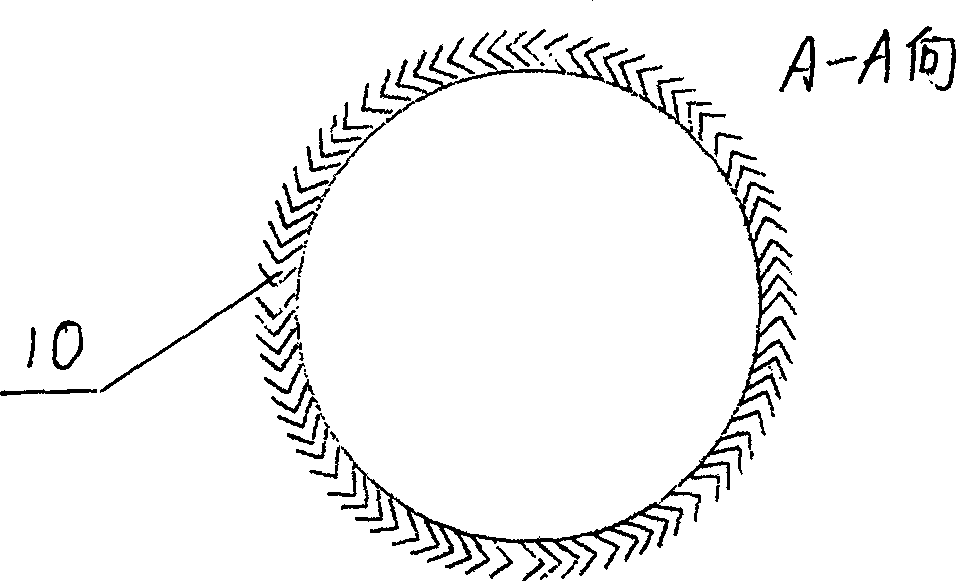

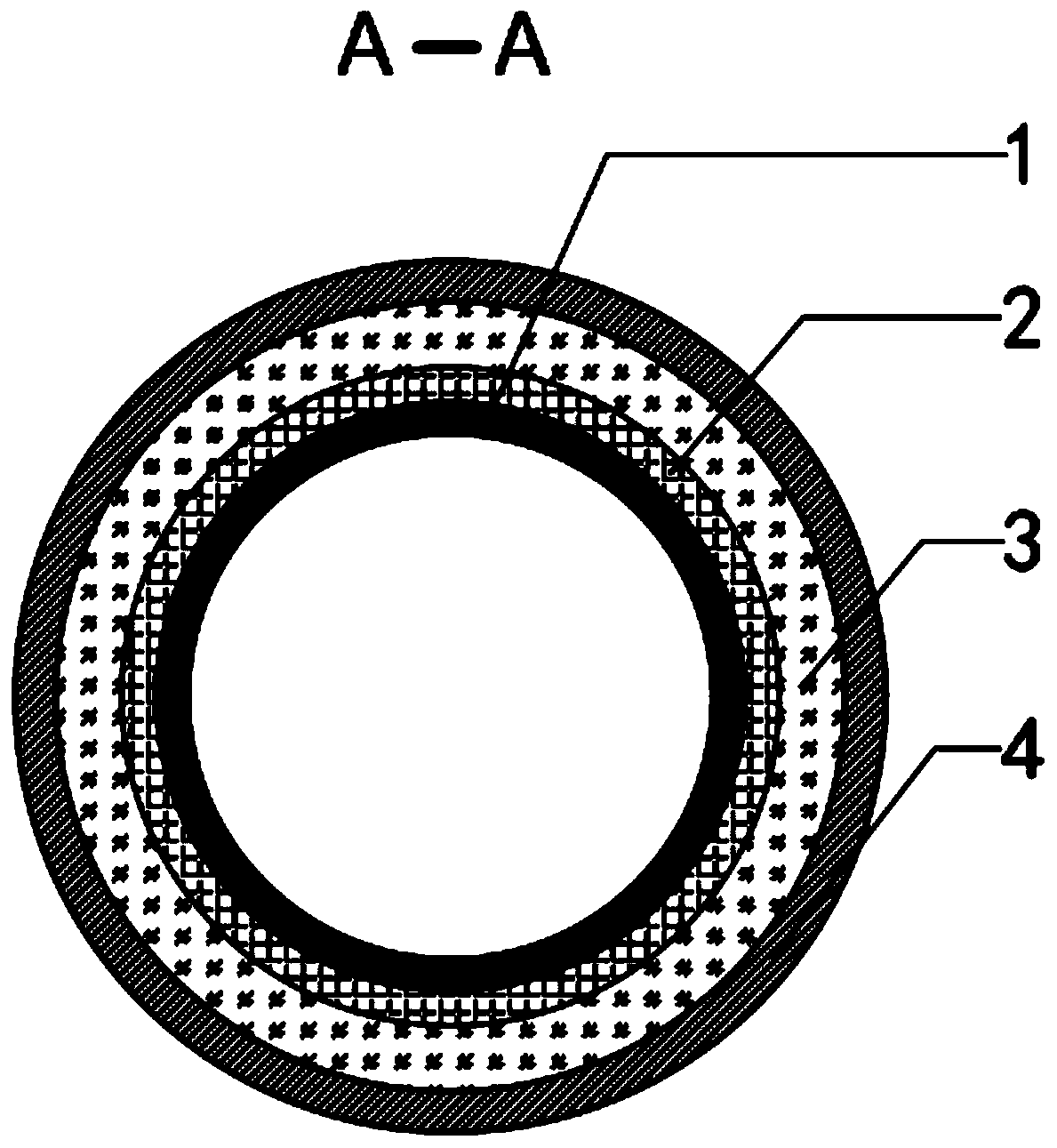

Gas-liquid coalescence filter element and application and filtering device containing gas-liquid coalescence filter element

PendingCN110917749AImprove interception effectSolve the problem of excessive pressure dropDispersed particle filtrationFiberEngineering

The invention provides a gas-liquid coalescence filter element and application and a filtering device containing the gas-liquid coalescence filter element. The filter element comprises a pre-separation layer, a coalescence layer and a liquid discharging layer which are sequentially arranged in the airflow direction. The pore diameter of the pre-separation layer is 8-12 [mu] m, the thickness of thepre-separation layer is 1-2 mm, the pre-separation layer is formed by profiled fibers and the whole pre-separation layer has hydrophobicity and lipophobicity. The pore diameter of the coalescence layer is 3-8 [mu] m, the thickness of the coalescence layer is 0.4-0.6 mm, the coalescence layer is formed by profiled fibers and the coalescence layer is divided into a hydrophobic and oleophobic area and a hydrophilic and oleophylic area which are arranged at intervals in the circumferential direction. The pore diameter of the liquid discharging layer is 10-20 [mu] m, the thickness of the liquid discharging layer is 2-3 mm, the liquid discharging layer is formed by profiled fibers, the air inlet side is a hydrophilic and oleophylic area, and the air outlet side is a hydrophobic and oleophobic area. The filter element can be used for filtering a gas-liquid mixture. The filtering device containing the filter element can remarkably reduce the filtering pressure drop while improving the filtering efficiency.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device

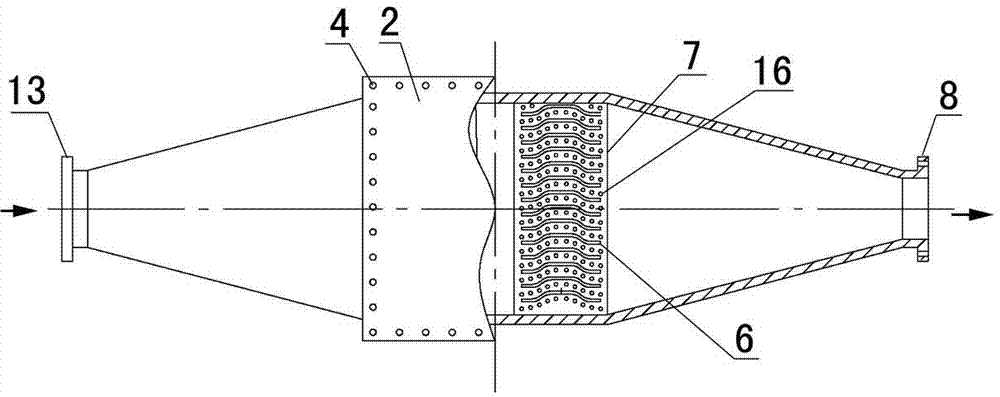

ActiveCN103055609AEasy to separateEfficient separationDispersed particle separationFlue gasEngineering

A flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device comprises a housing, one side of the housing is provided with an inlet, the inlet is provided with an inlet flange, the other side of the housing is provided with an outlet, and the outlet is provided with an outlet flange; the housing is sequentially divided into a diffusion section, a large internal diameter section and a conflux section from the inlet to the outlet, the internal diameter of the diffusion segment gradually increases from the inlet to the outlet, and the internal diameter of the conflux gradually decreases from the inlet to the outlet; and the bottom of the large internal diameter section is a funnel-shaped liquid collection room, the top liquid inlet of the liquid collection room is provided with a baffle plate bracket, and the baffle plate bracket supports a baffle plate. The device is a two-phase fluid separation device combining baffling separation with settling separation, can effectively separate and collect fine droplets in the two-phase fluid at the outlet of a vacuum pump, can prevent the secondary entrainment of the collected droplets by a gas, and effectively treats the environmental pollution.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

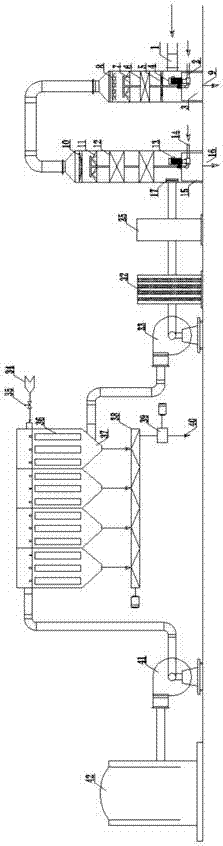

Deodorization and purification treatment system of biological sludge pyrolysis synthesis gas

InactiveCN107297112AReduce pressure drop resistanceIncreased number of spinsCombination devicesGas treatmentCycloneSludge

The invention relates to a deodorization and purification treatment system of biological sludge pyrolysis synthesis gas. The system comprises a cyclone plate water spraying tower module, a spraying reaction acid removal tower module, a solar energy-rotary wheel dehumidification module, a sludge base activated carbon absorption module and a pulse bag type dust remover module in sequential connection, wherein the cyclone plate water spraying tower module comprises a pyrolysis tail gas inlet, a cyclone plate, a filling material layer, a circulation water pump, a water supplementing opening, a first sedimentation pool, a clean water spray head, a first screen defogging device and a sludge outlet; the spraying reaction acid removal tower module comprises a cyclone device, an atomization device, a two-stage filling material layer, a metering circulation pump, a second sedimentation pool, a liquid supplementing pipe and a second screen defogging device; the sludge base activated carbon absorption module consists of a solar heat collector, an electric heater, a sludge base activated carbon rotary wheel, a photocatalysis waste gas treatment device and the like. The deodorization and purification treatment system has the advantages that the structure is reasonable; fetor gas in the pyrolysis tail gas can be controlled in a national standard range; in addition, the pyrolysis synthesis gas is purified; the synthesis gas fuel gas quality is improved.

Owner:ZHEJIANG UNIV OF TECH

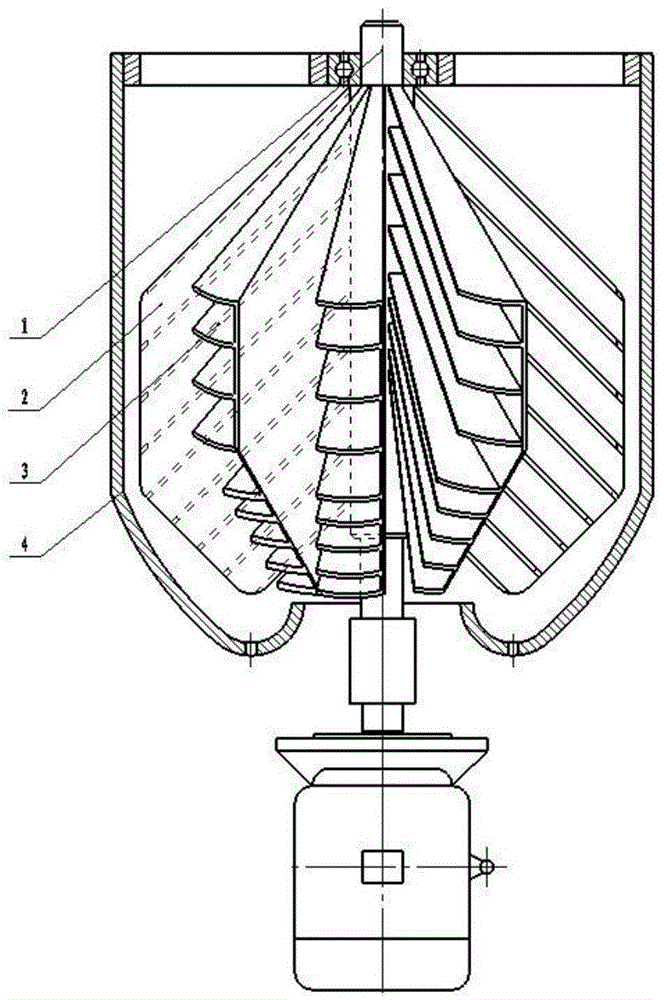

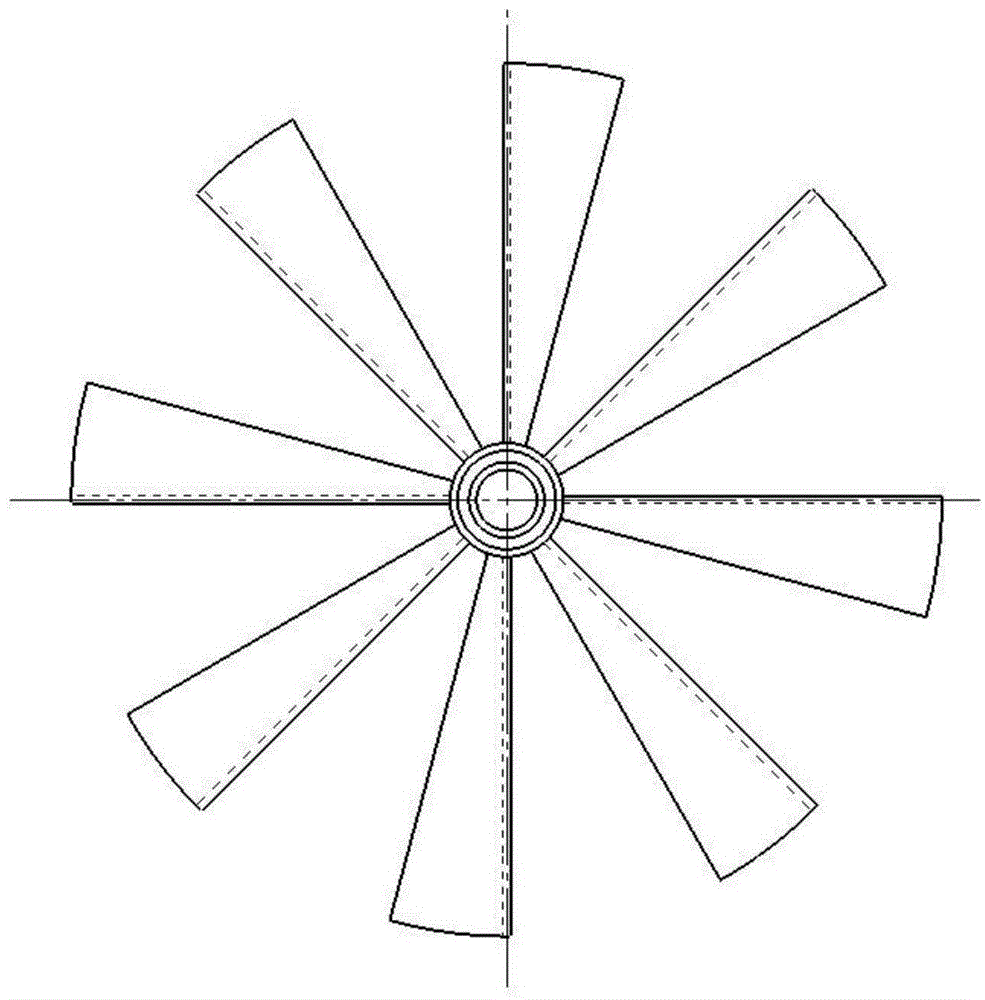

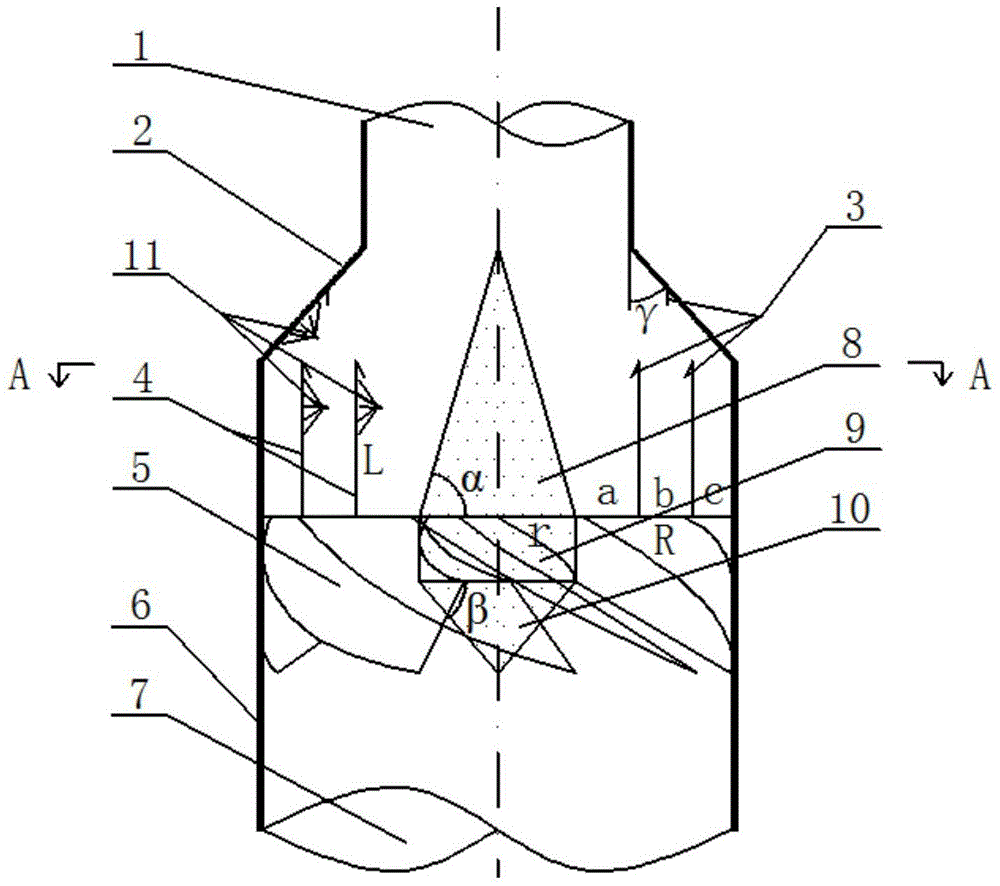

Rotary gas-liquid separator

InactiveCN105617767ARealize the centrifugal separation functionReduce volumePressurized chemical processDispersed particle separationVapor–liquid separatorChemical physics

The invention discloses a gas-liquid separator for a singlet oxygen generator. The separator is arranged between the singlet oxygen generator and an outlet of the generator. The rotary gas-liquid separator comprises a rotating shaft, separating blades, flow deflectors and a gas-liquid separation main part. As a gas-phase product singlet oxygen has extremely short survival time, the singlet oxygen generator requires a miniature and efficient gas-liquid separator to realize gas-liquid separation function. Separation efficiency of a common plate-type separator, a centrifugal separator and the like doesn't meet operating requirements of the singlet oxygen generator. By adjusting function of rotating speed of the rotating shaft, sector angle of the flow deflectors, included angle between the flow deflector and the rotating shaft, gas-liquid separation with different gas flows and different liquid contents can be realized. The separator of the invention can be used under vacuum condition and is suitable for device testing application of a singlet oxygen generator.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

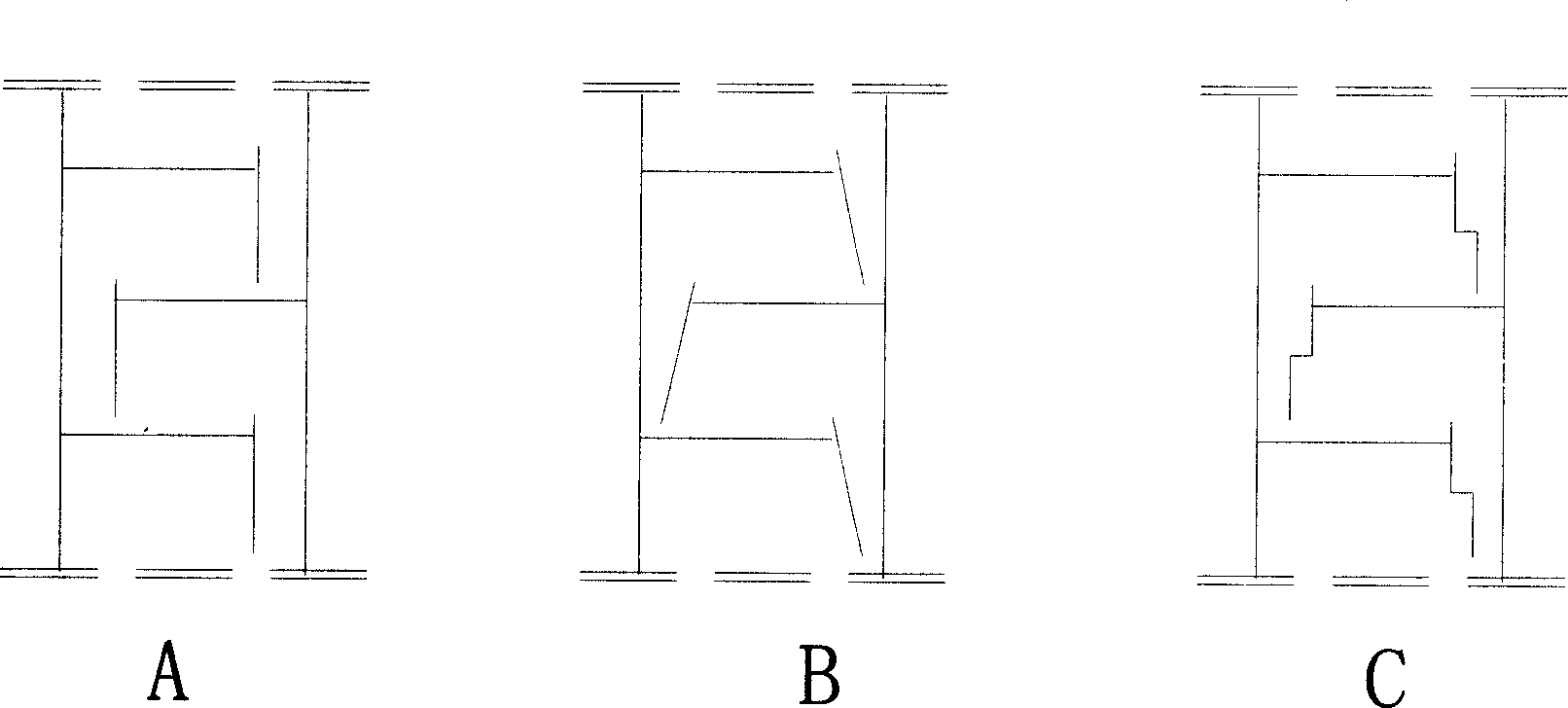

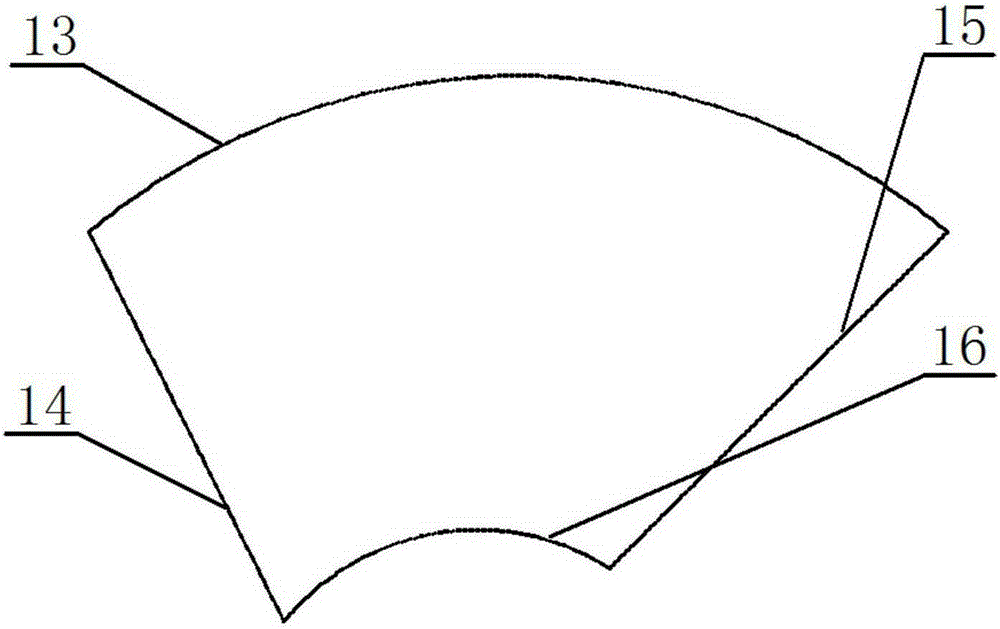

Gas liquid eddy flow type highly efficient downcomer

InactiveCN1698923AAvoid secondary entrainmentImprove throughputDistillation separationHorizonEngineering

This invention discloses an air current cyclonic type downcomer, which is used in the knockout tower in the chemical and petrifaction fields. Said downcomer comprises two inside and outside pipes with different diameters, wherein between the two pipes is arranged cyclonic guide blade. The guide blade is strip shape, fan shape or triangle, and has a certain angle of dip with the horizon. The invention is characterized in that, the fluid rotates in the guide of the cyclonic guide blade, and the centrifugal effort makes the gas to separate with the fluid, after separating the gas enter into the inner pipe through the hole in the pipe wall, while the fluid inlet into the fluid pan in the lower column plate through the gap of the inside and outside pipes. Such structure can increase the deairing ability of the downcomer and the efficiency of the column plate.

Owner:TIANJIN UNIV +1

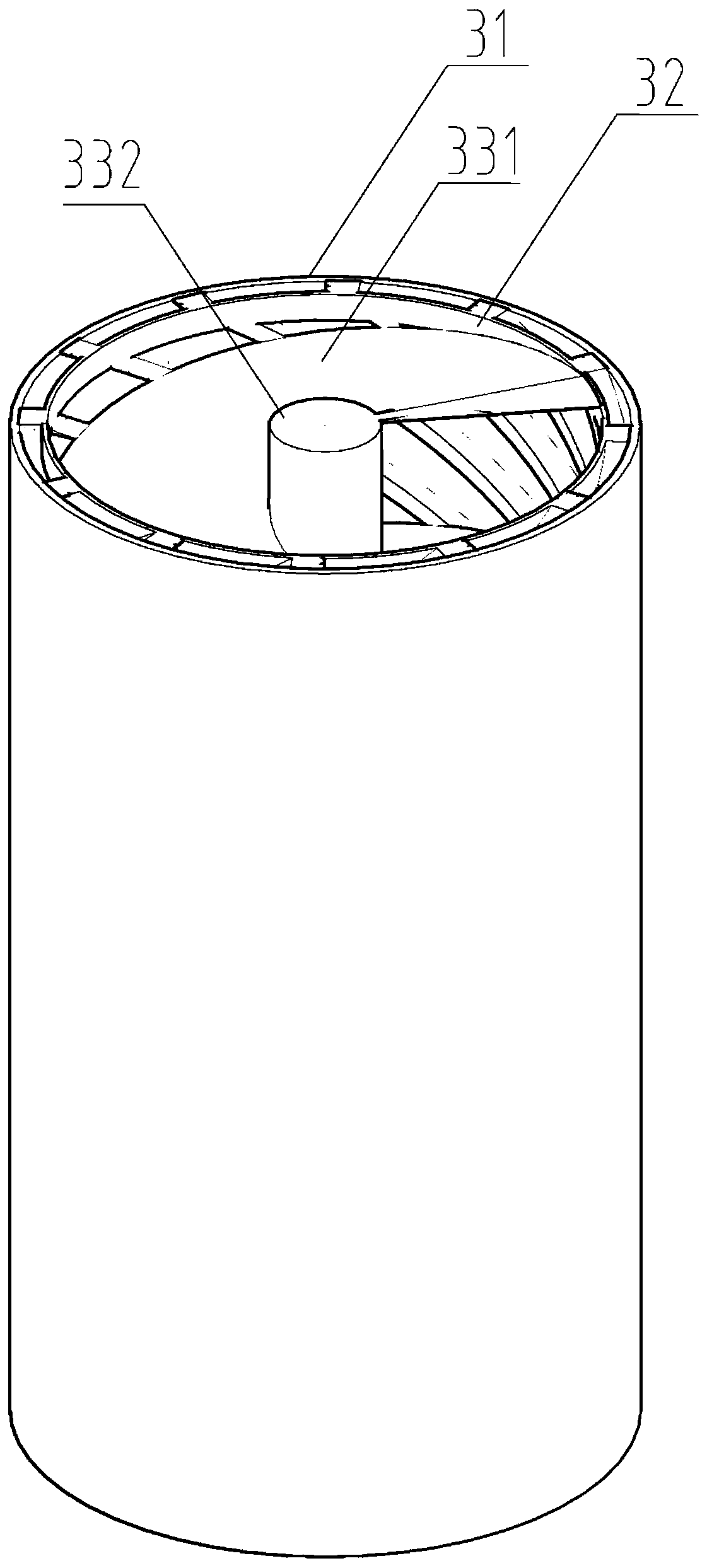

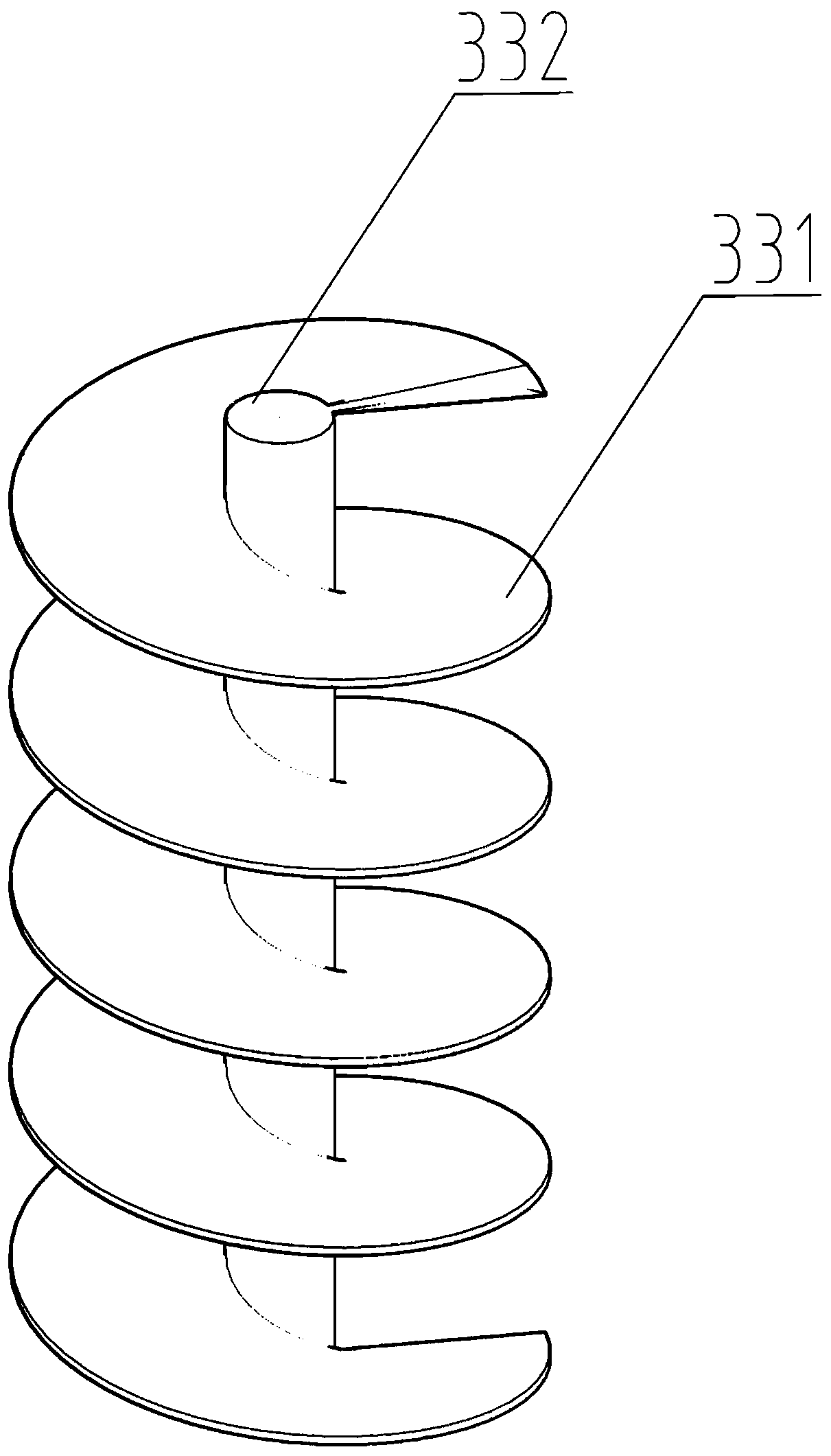

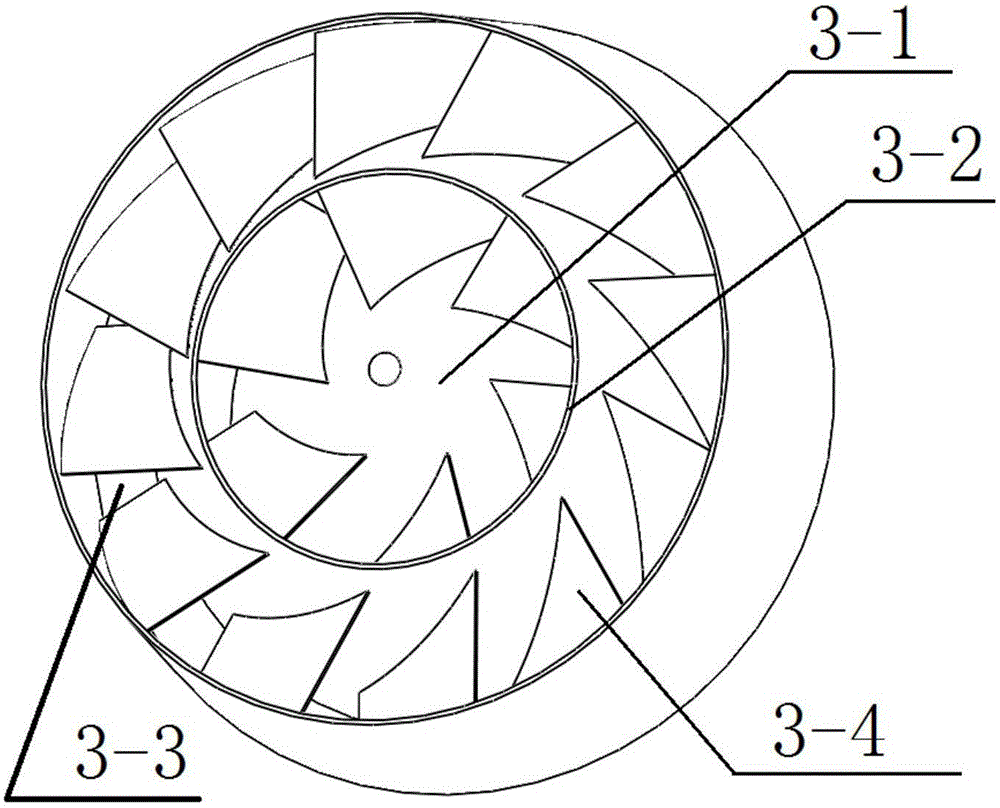

Spiral dedusting demister, demisting device and absorption tower

PendingCN111111328AAvoid secondary entrainmentImprove the ability of dust removal and fog removalDispersed particle separationDust controlEngineering

The invention discloses a spiral dedusting demister, a demisting device and an absorption tower. The spiral dedusting demister comprises a barrel, and a hollow cavity which is used for allowing flue gas to pass through and has two communicated ends is formed in the barrel. An inner spiral part is detachably connected into the hollow cavity. An outer spiral part is detachably connected into the inner spiral part. Meanwhile, the spiral path of the inner spiral part is different from that of the outer spiral part. The spiral dedusting demister is arranged to be a barrel with the two ends communicated, the inner wall face of the barrel is detachably connected with an internal thread part, and an external thread part is arranged in the internal thread part. Smoke enters the hollow cavity of thebarrel; the smoke enters the external thread part and forms high-speed centrifugal force, so that fog drops and dust contained in the smoke expand outwards, are separated from the smoke, enter threads of the internal thread part, are blocked by the threads of the internal thread part and flow down along the threads, the dust and the fog drops are prevented from being carried for the second time,and the effect of improving the dedusting and demisting performance is achieved.

Owner:斯蒙赫尔(上海)环保科技有限公司

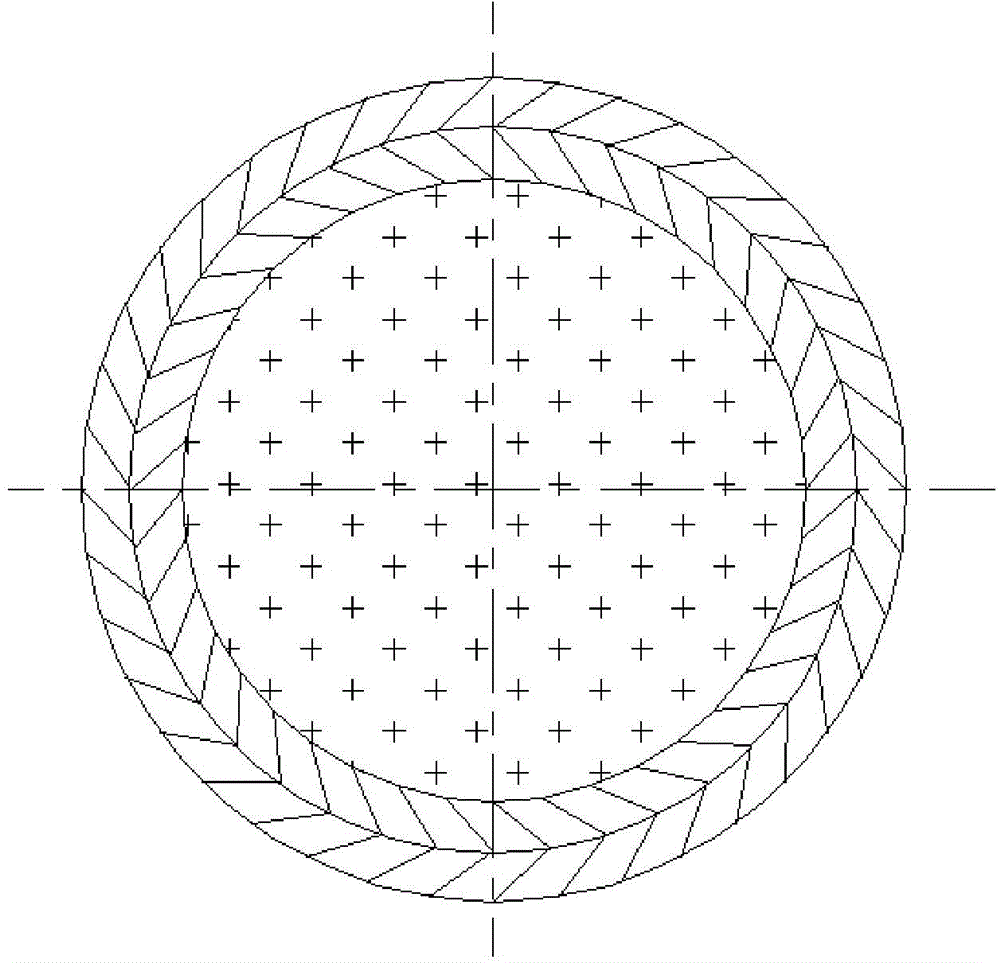

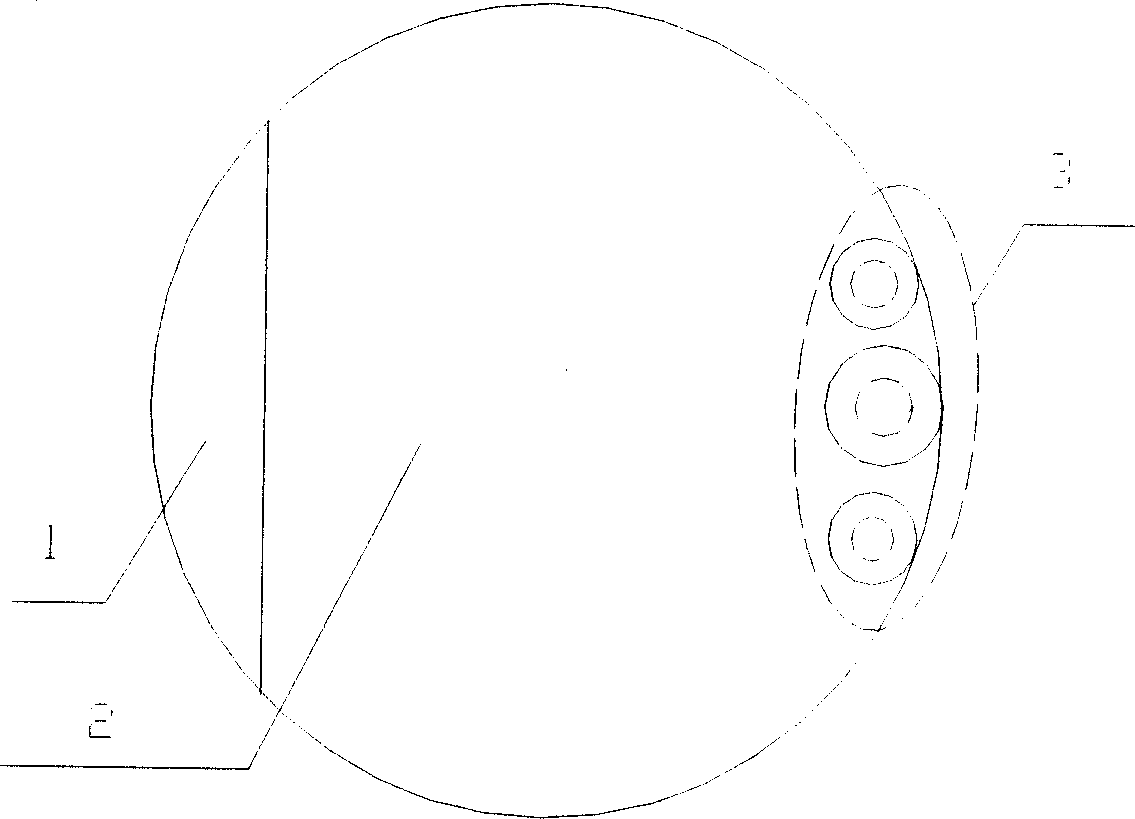

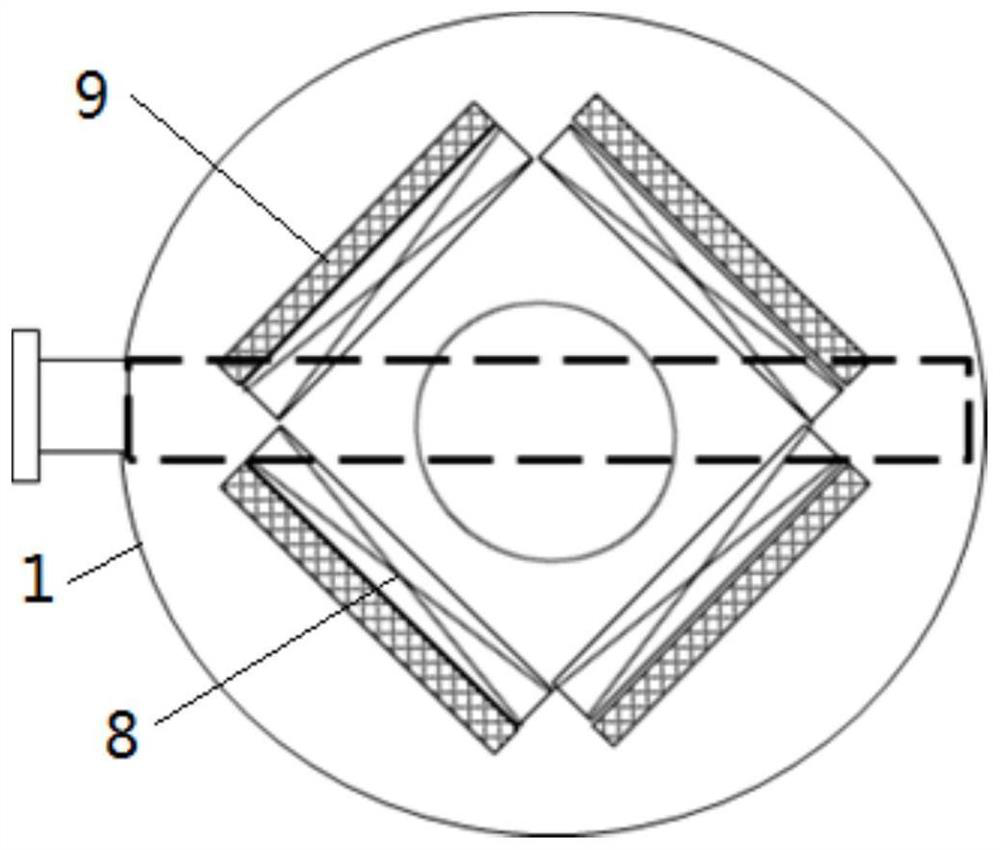

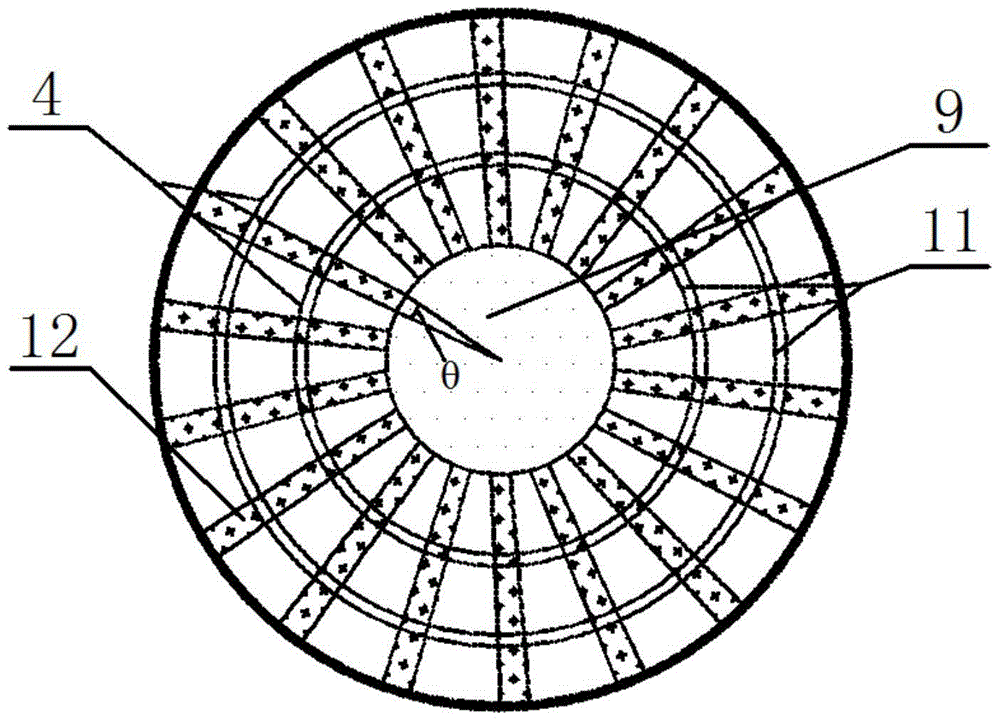

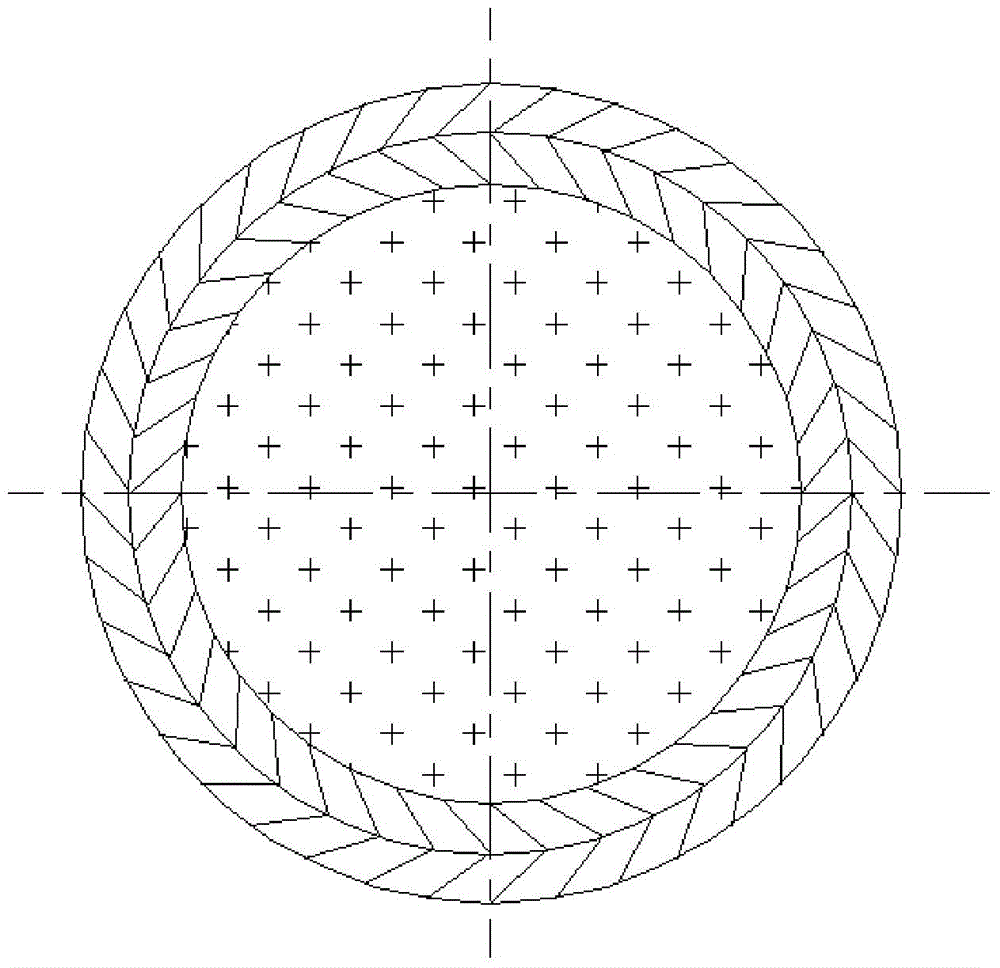

Ring whirlwind plate separator

ActiveCN105289116ASolve efficiency problemsResolve separabilityDispersed particle separationCentrifugationEngineering

The invention discloses a ring whirlwind plate separator. The ring whirlwind plate separator comprises a cylindrical outer wall of which the top end is provided with an outlet, an inner solid body vertically arranged in the outer wall, a whirlwind plate fixedly connected between the outer wall and the inner solid body, and a separation ring. The inner solid body is used for promoting air to flow close to the outer wall surface and accelerating a fluid flowing rate. The whirlwind plate is used for blocking particles and promoting air flow rotation. The separation ring is used for shortening a particle centrifugation motion distance. The separation ring is circularly fixed to the whirlwind plate. The ring whirlwind plate separator reduces critical separation particle sizes and can be designed in a low pressure drop scope.

Owner:HUNAN UNIV

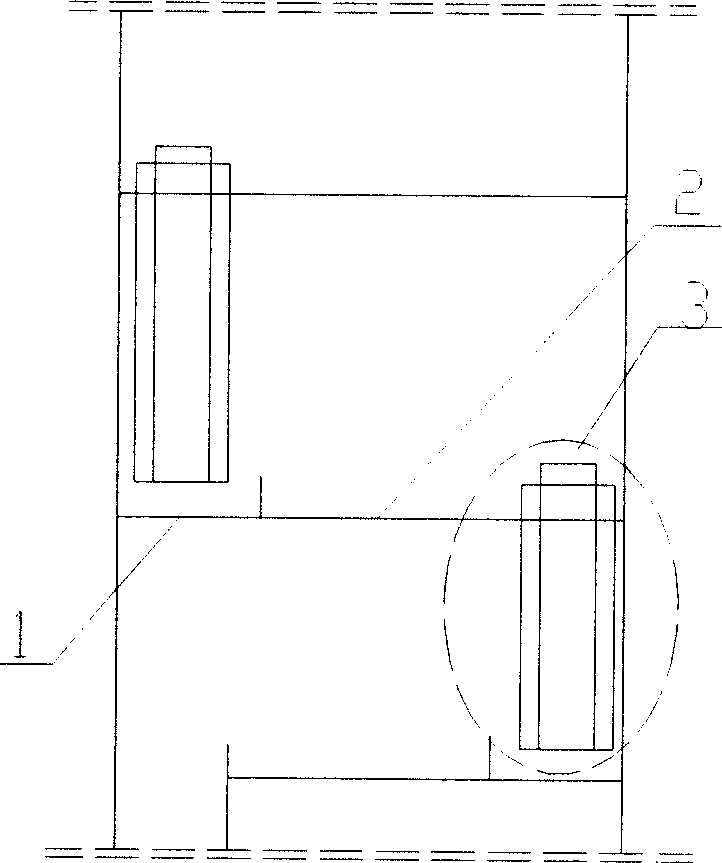

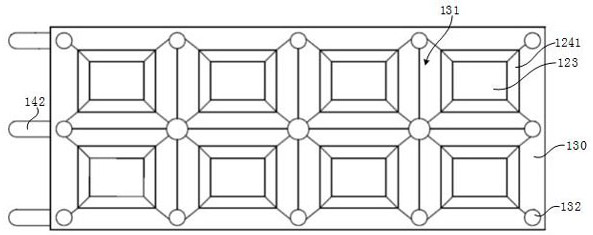

Polar plate for wet type electrostatic precipitator

InactiveCN105363558AEvenly distributedImprove cleanlinessElectrode constructionsElectrodes cleaningEffective heightWater flow

The invention relates to a polar plate for a wet type electrostatic precipitator. The polar plate comprises a current sharing tube (1) and a collecting plate (2) and has double characteristics of balanced distribution of washing water flows and uniform coverage of a polar plate water film. The polar plate is characterized in that the current sharing tube (1) is arranged at the top part of the collecting plate (2); the collecting plate (2) has a structure of double-layer symmetric concave-convex ripple surface and is shaped through a laser welding and bulging technology; concave surface welding spots on the collecting plate (2) are uniformly distributed in rows and lines in a stagger manner; with the combination of a non-spraying type polar plate washing mode such as dripping spraying or overflow spraying and the like and the adoption of the structure of the polar plate, flushing water can be uniformly distributed onto the two surfaces of the collecting plate (2) through the current sharing tube (1), and influence of the gravity to the water flows is overcome by utilizing the surface tension of water, so that a uniform washing water film is acquired. The polar plate for the wet type electrostatic precipitator has the remarkable advantages of balanced distribution of the water flows, uniform water film, good washing effect, stable electric field running and purification efficiency, great increase of rigidity and effective height of the polar plate, saved occupied places and investment and the like.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

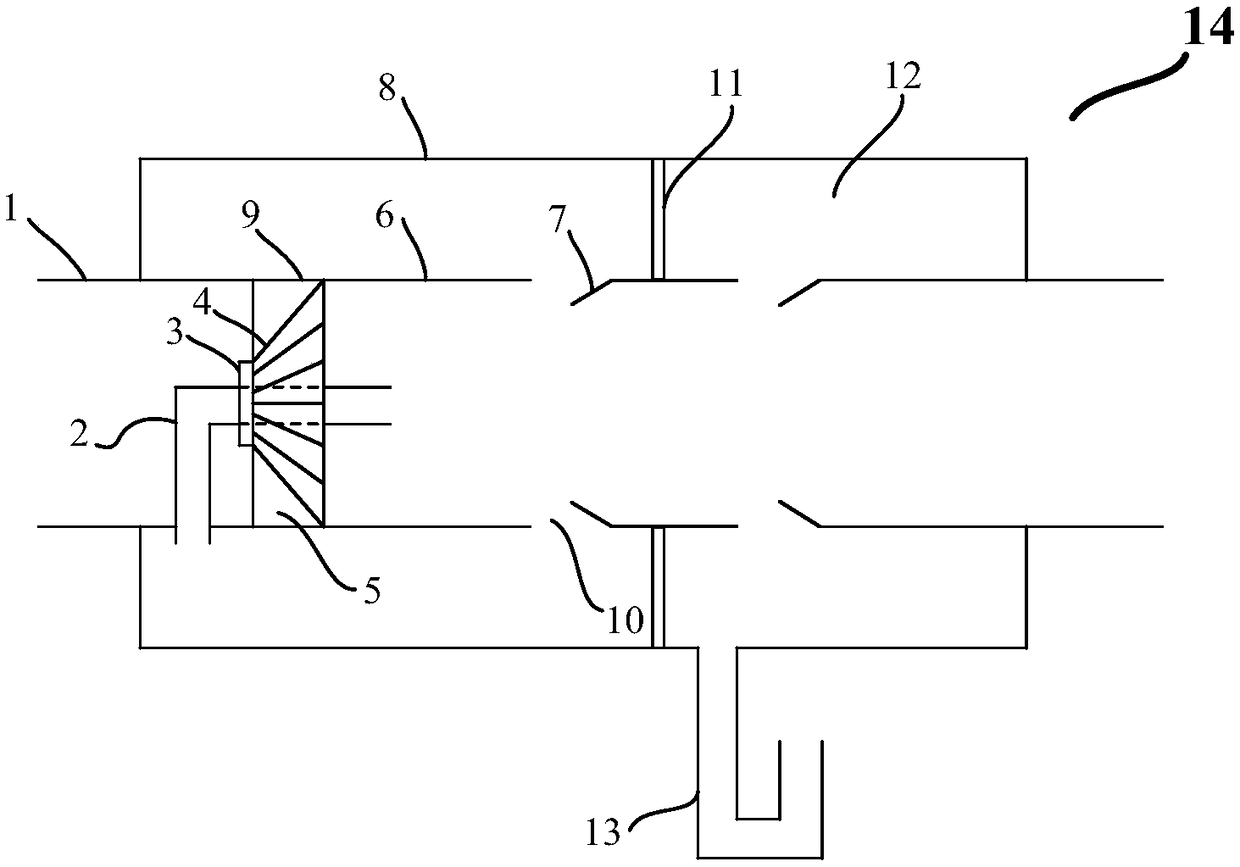

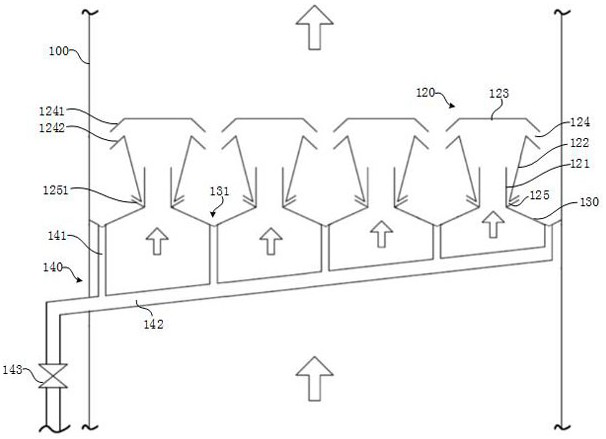

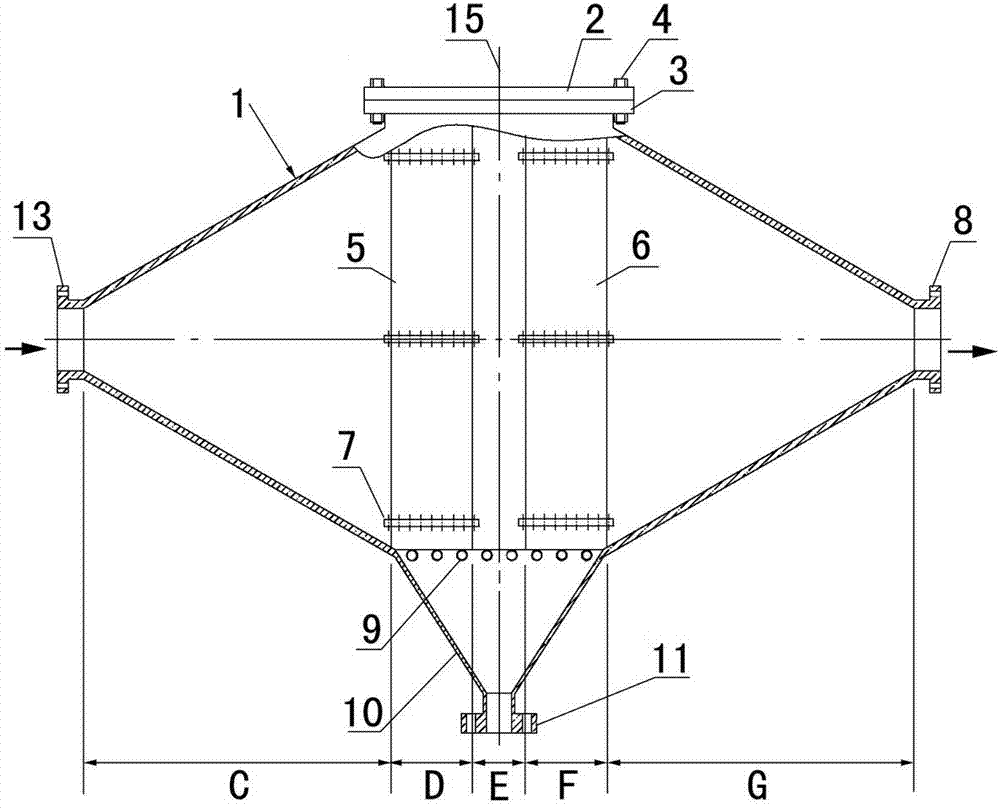

Flue gas denitration ammonia spraying mixing system and static mixer and ammonia spraying control method thereof

ActiveCN113522012AEfficient removalAchieve the first separationNitrous oxide captureGas treatmentFlue gasDust control

The invention discloses a static mixer which is arranged in a flue, the static mixer comprises a plurality of flow guide assemblies distributed in the flue, and each flow guide assembly comprises a gas inlet pipe extending in the axial direction of the flue, a gas outlet pipe extending in the axial direction of the flue, and a gas outlet pipe extending in the axial direction of the flue; the outer pipe is of a tubular structure with a thin lower part and a thick upper part, the lower end of the outer pipe is connected with the outer wall of the air inlet pipe, and the upper end is higher than the air inlet pipe; the top plate is arranged above the outer pipe; the air outlet channel obliquely extends downwards from the periphery of the top end of the outer pipe; the dust discharging hole is formed in the lower end of the outer pipe; and the ash collecting layer is in sealed connection with the inner wall of the flue, and an ash collecting groove is formed between the flow guide assemblies. The invention further discloses a flue gas denitration ammonia spraying mixing system and an ammonia spraying control method thereof. By arranging the flow guide assembly, two-time flue gas dust removal is achieved, and dust particles with large particle sizes in flue gas can be effectively removed; the static mixer disclosed by the invention can also effectively block large dust falling from the flue above, so that an ammonia gas nozzle below is prevented from being blocked.

Owner:CHINA PETROLEUM & CHEM CORP +1

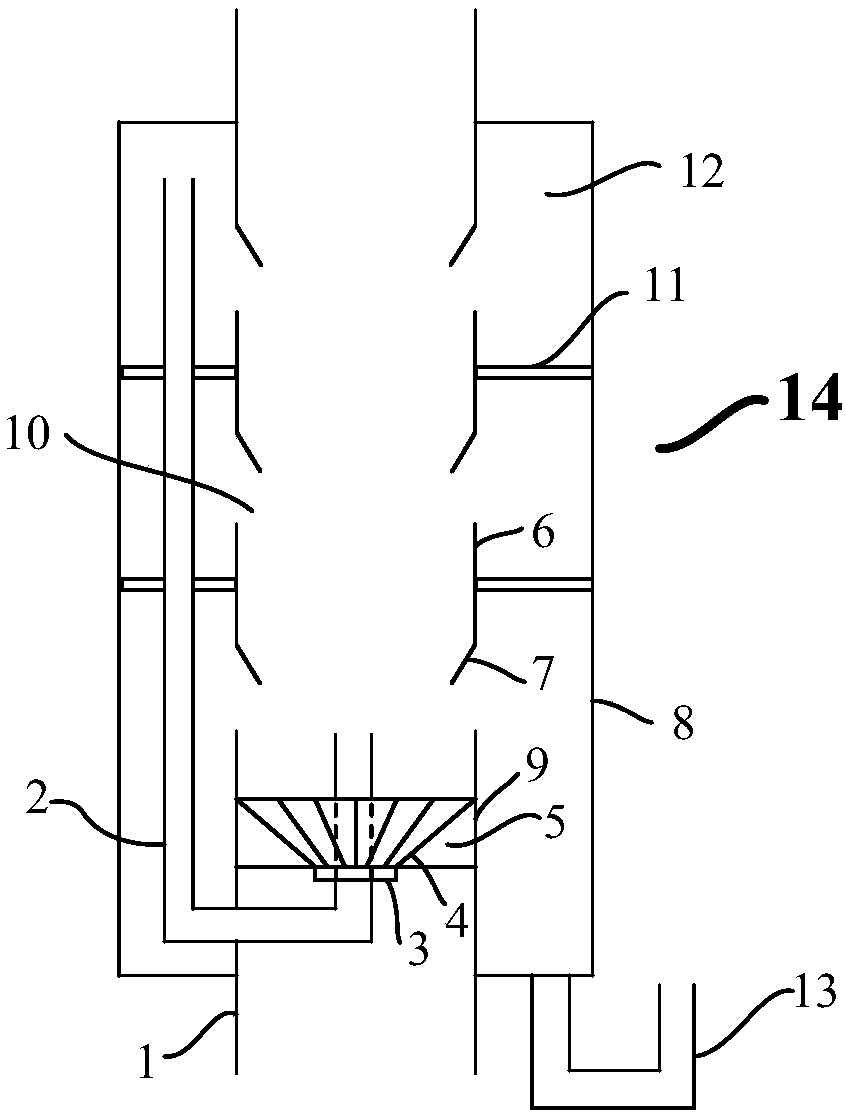

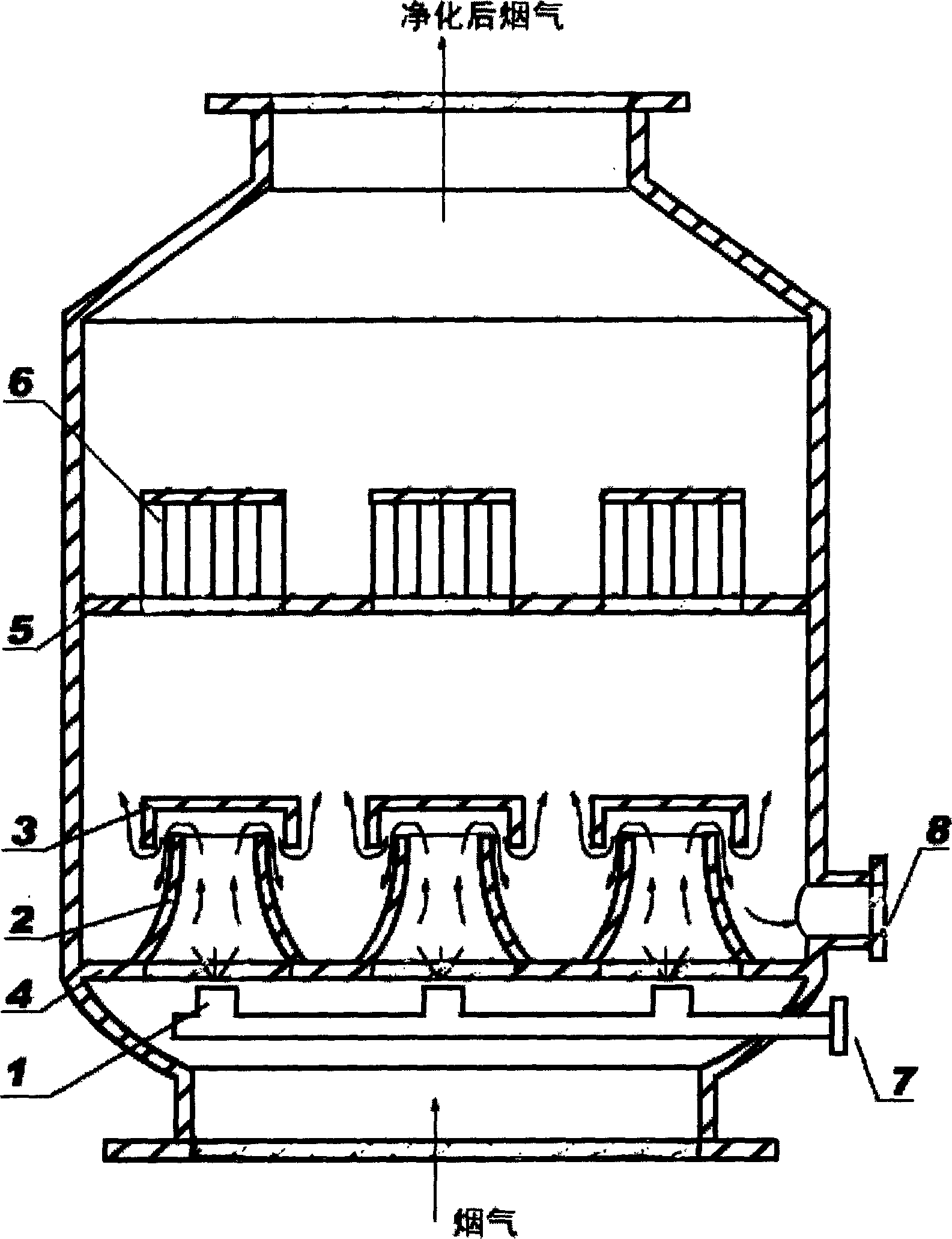

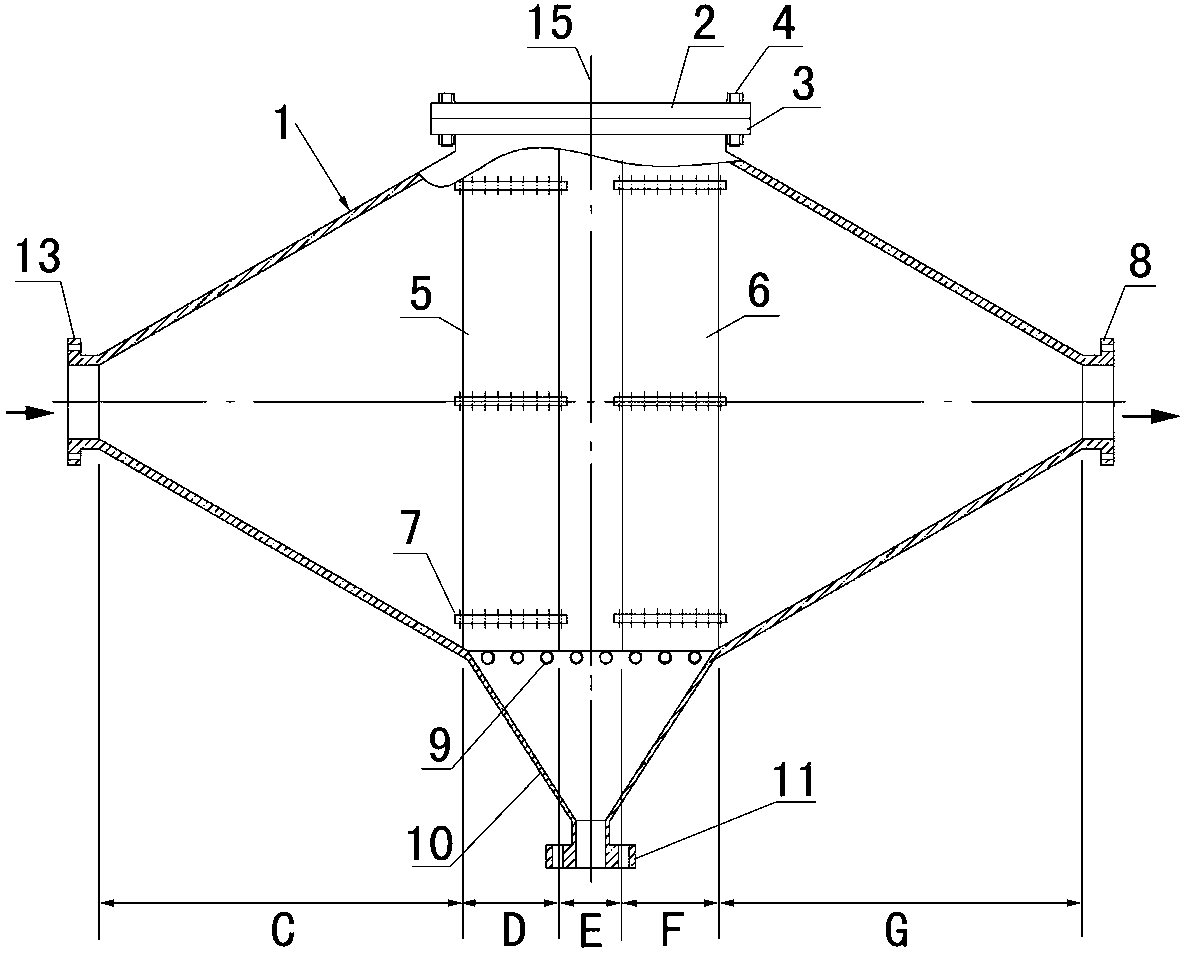

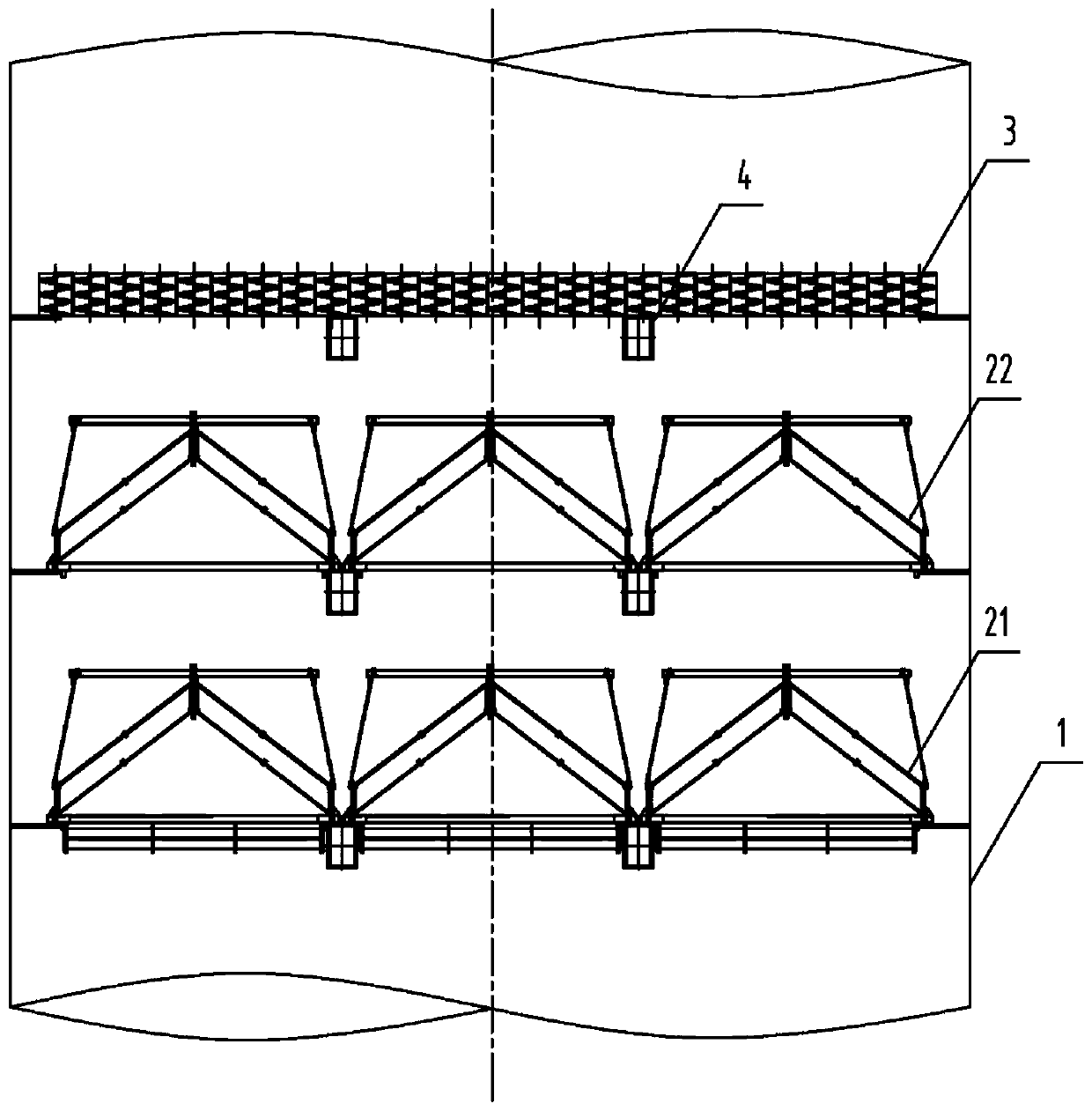

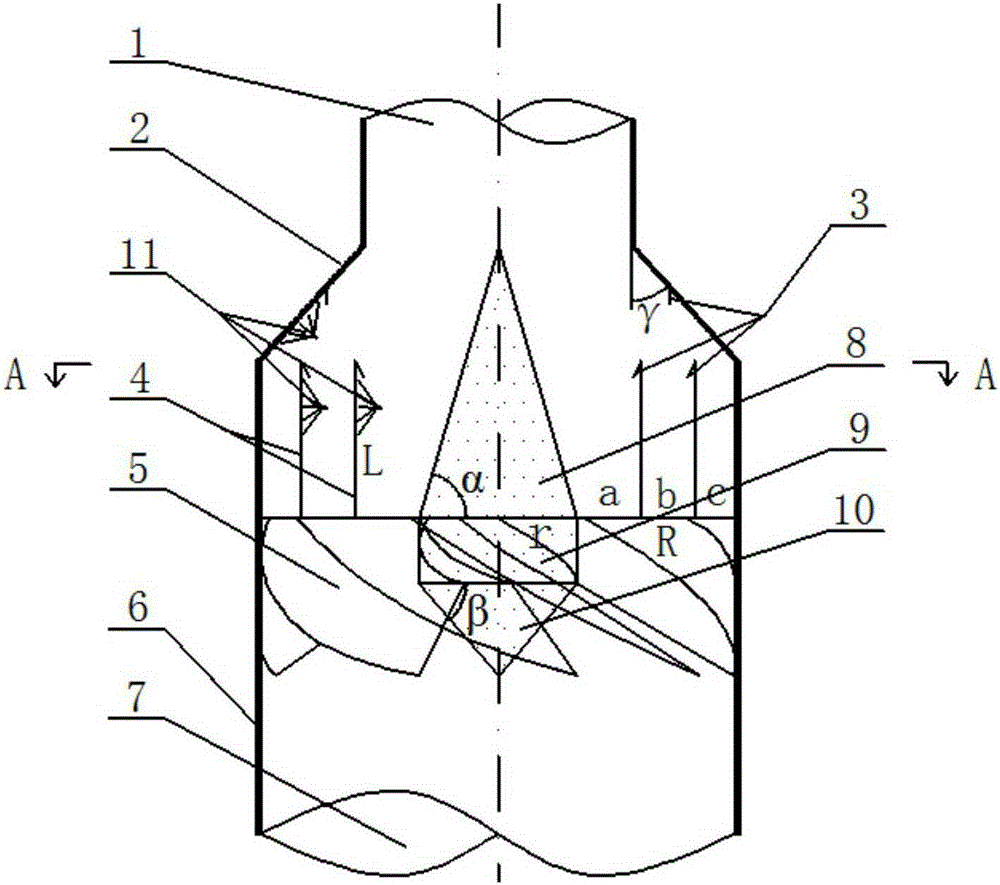

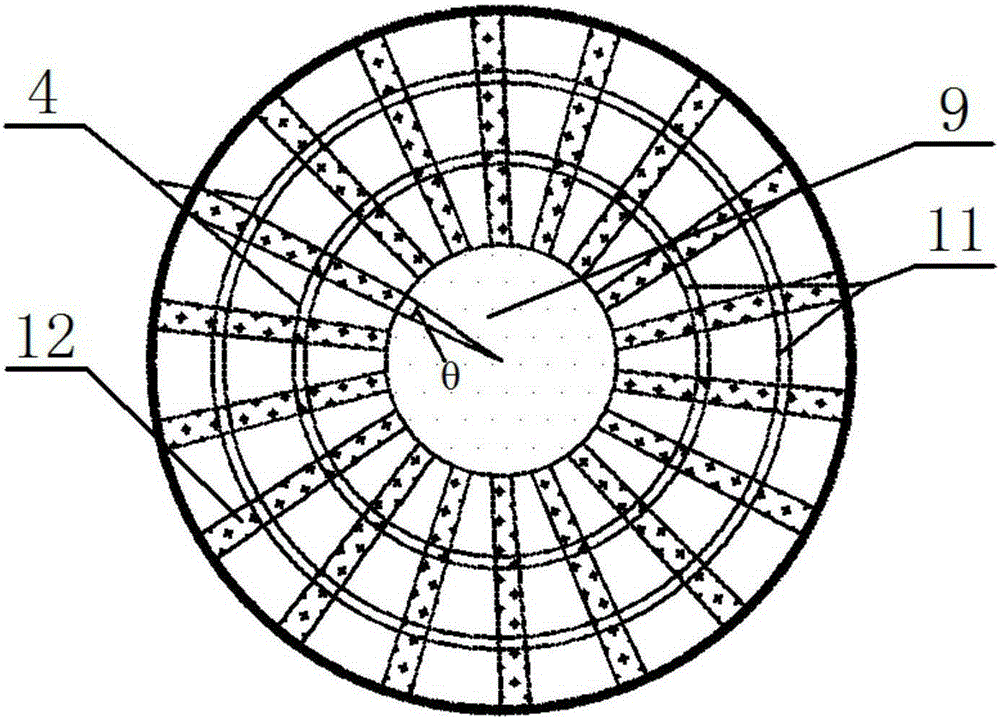

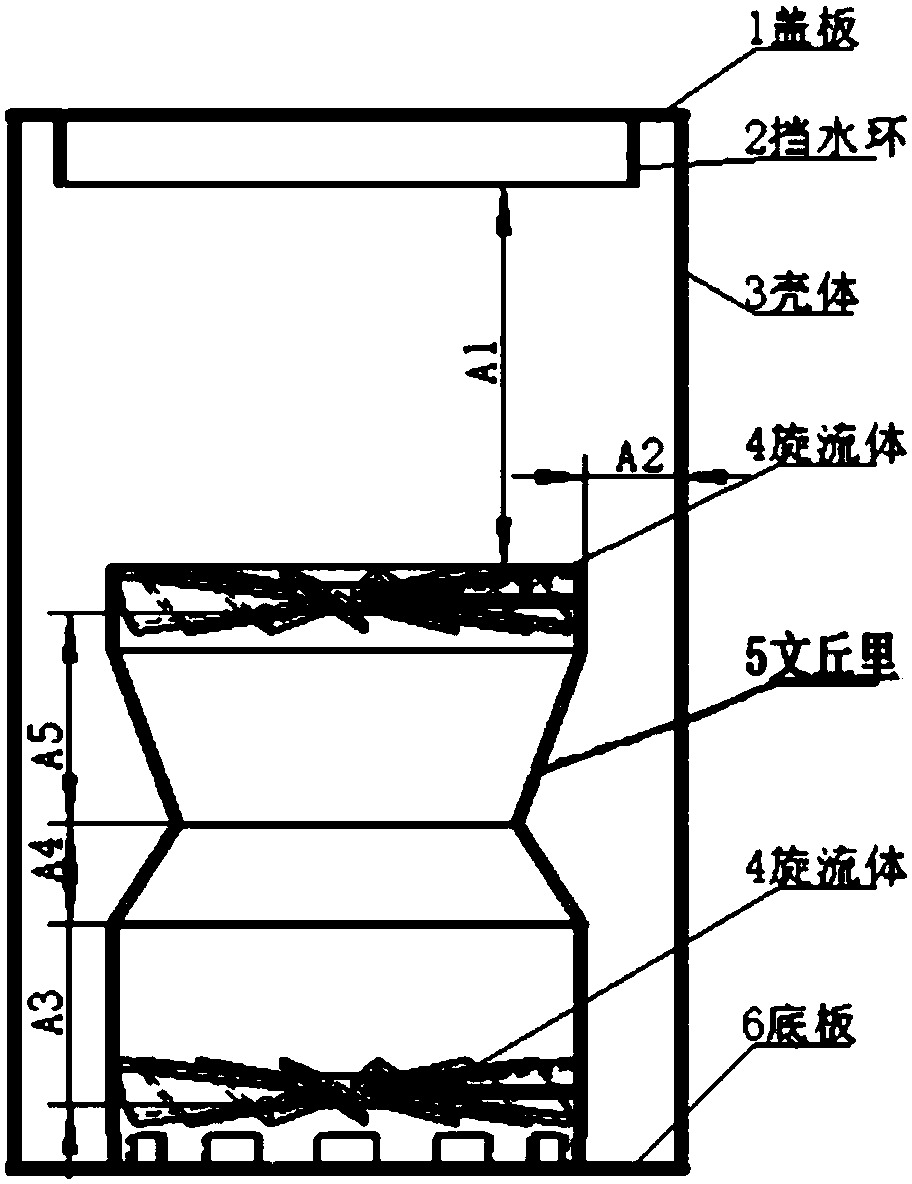

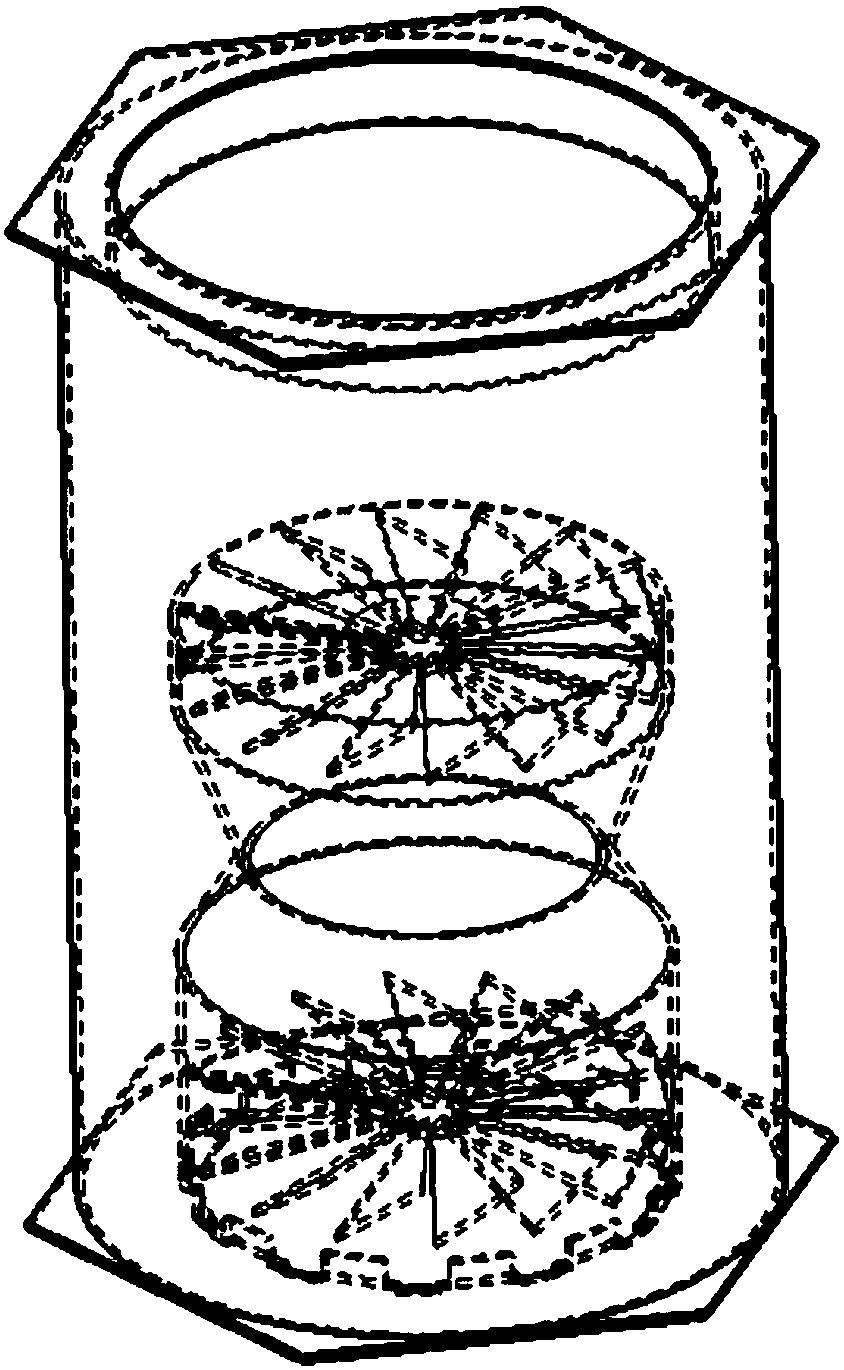

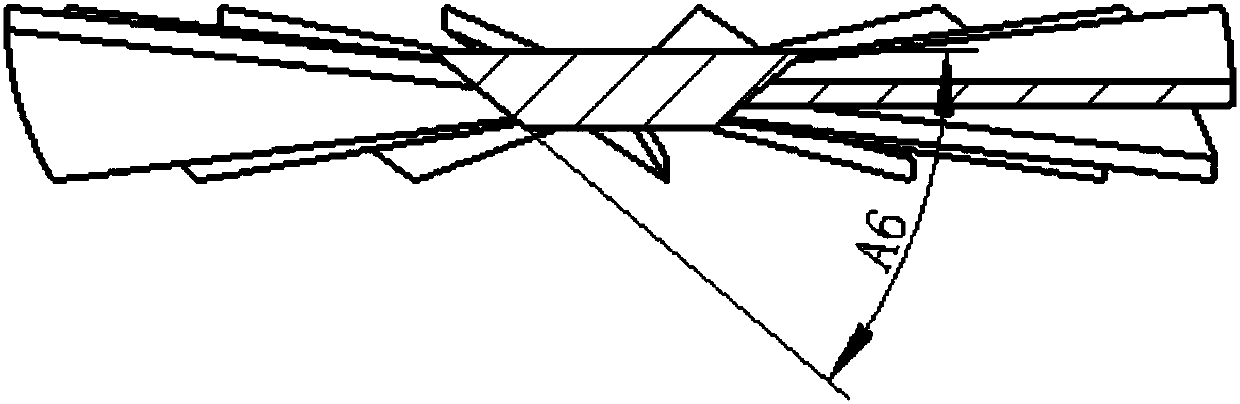

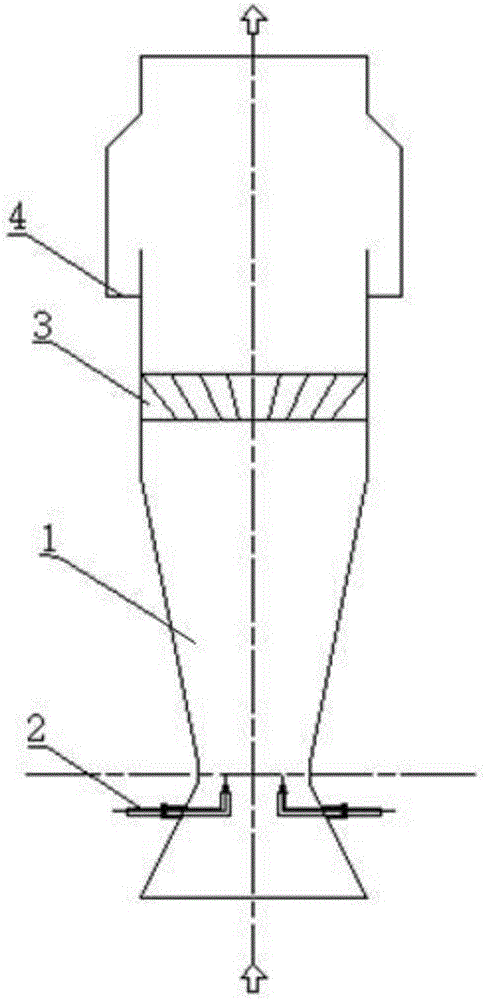

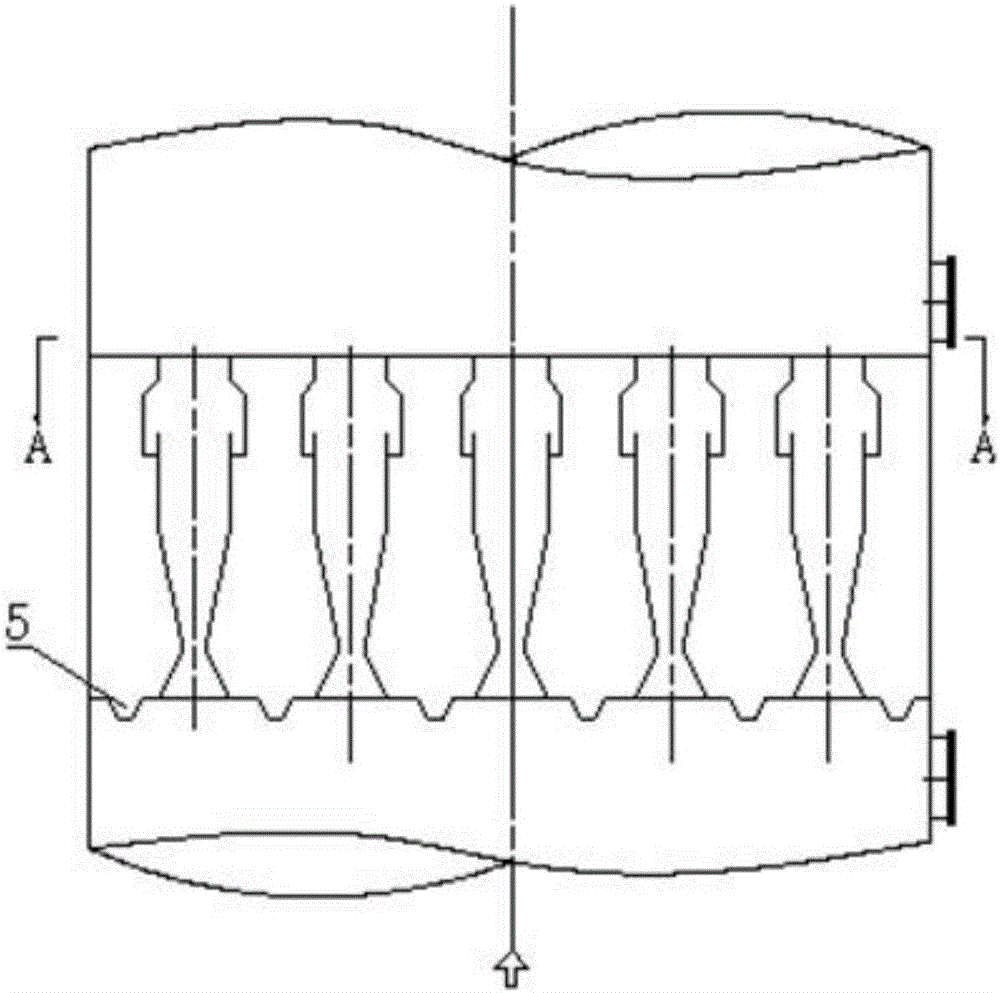

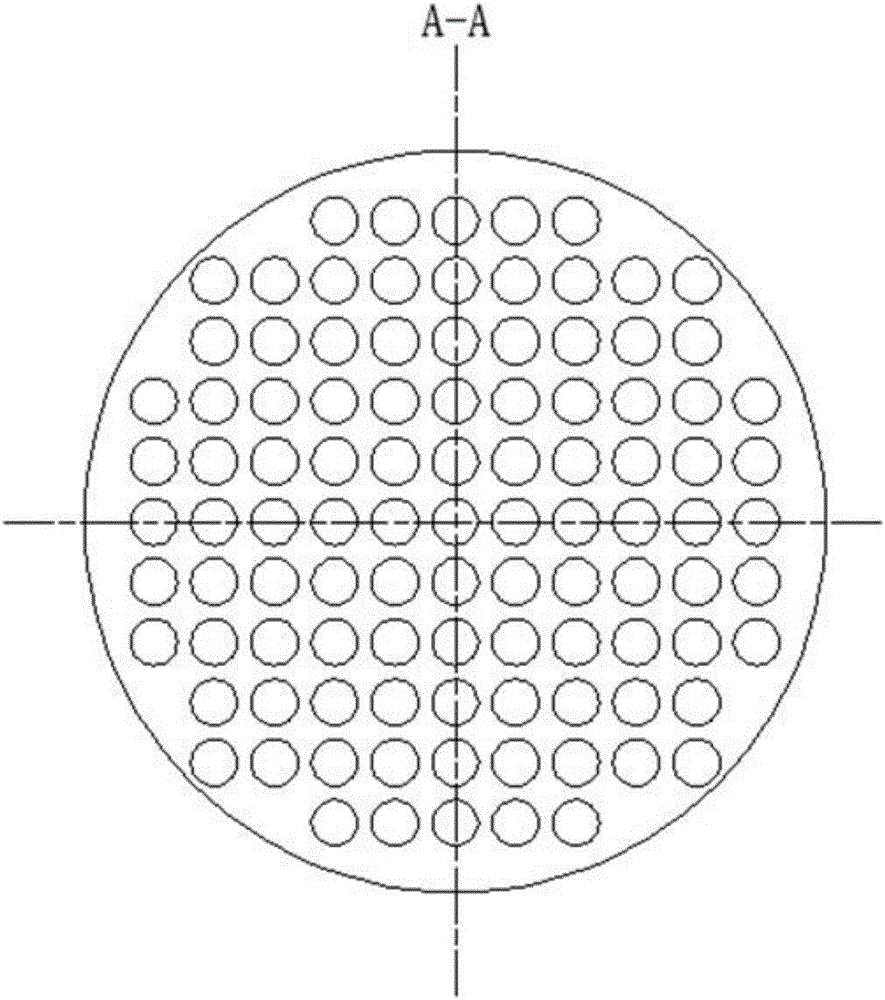

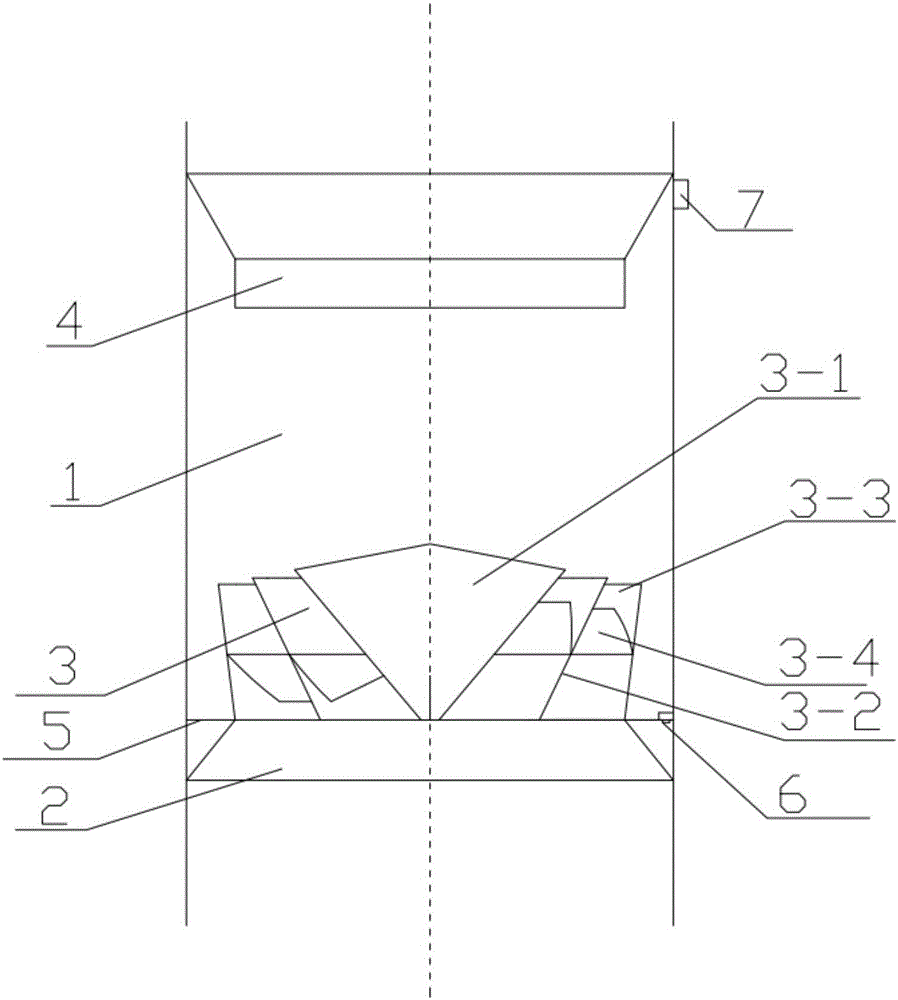

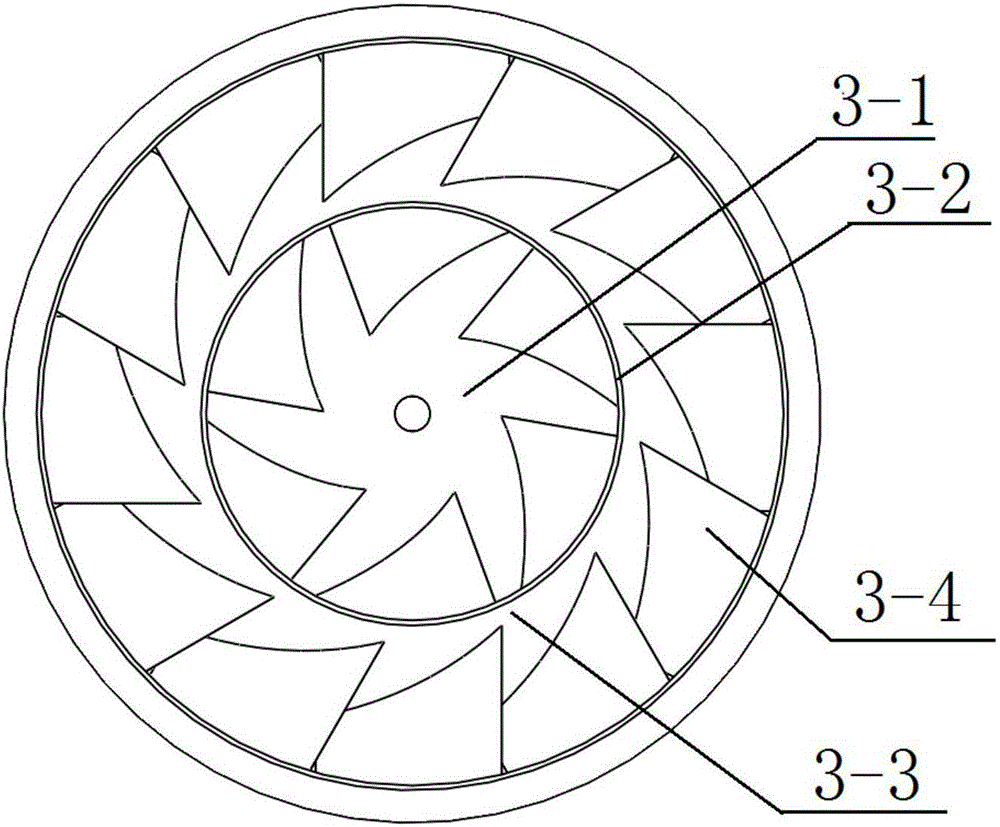

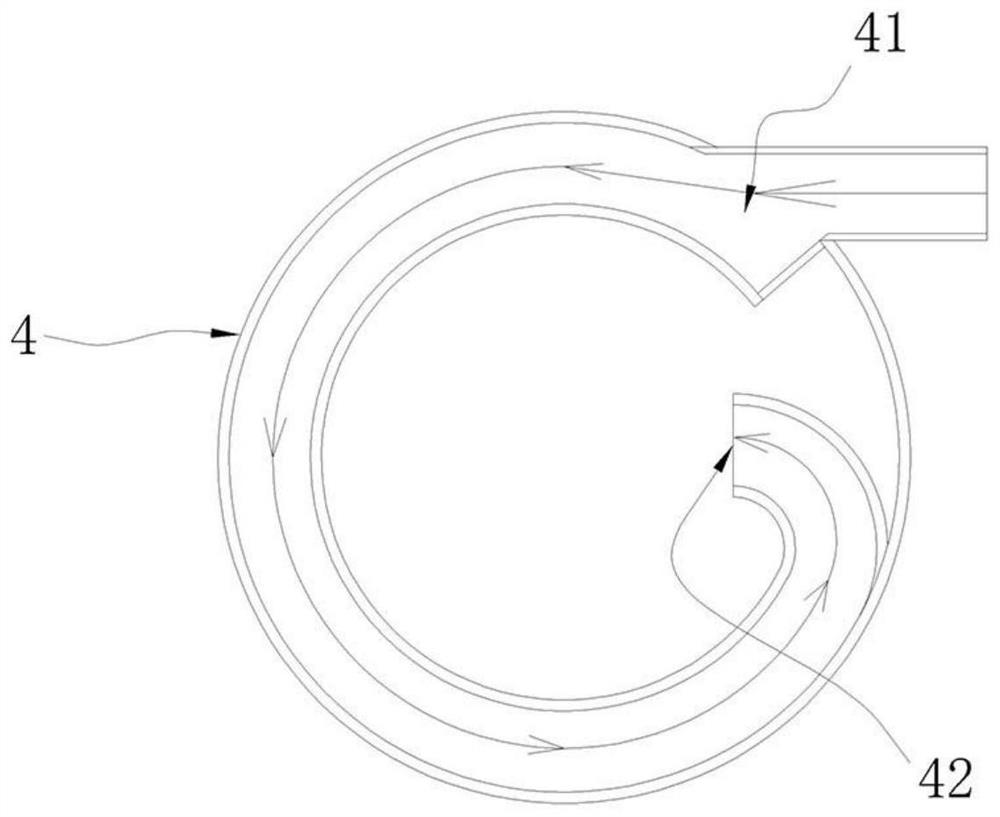

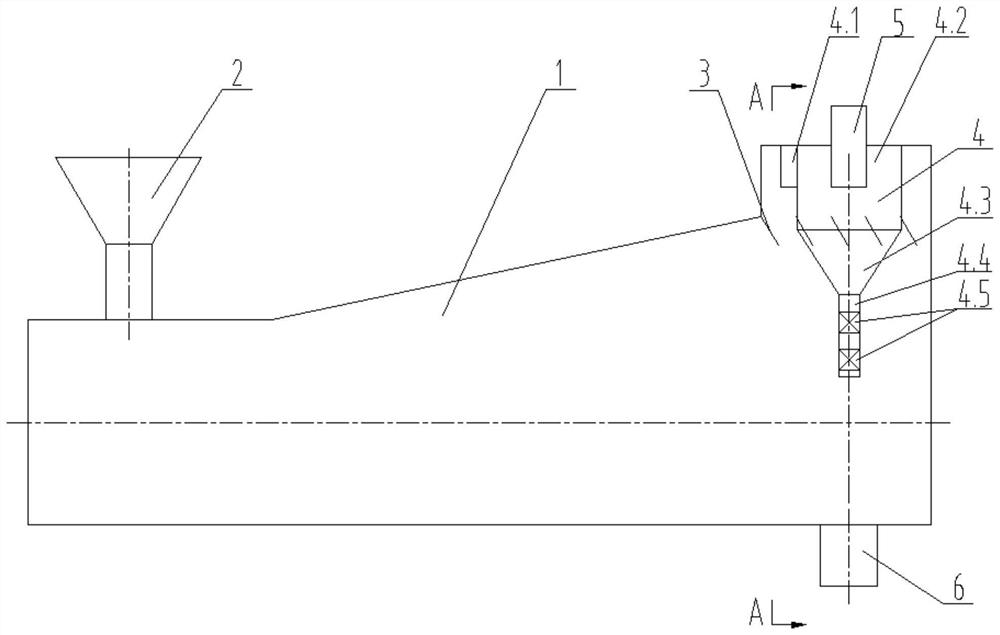

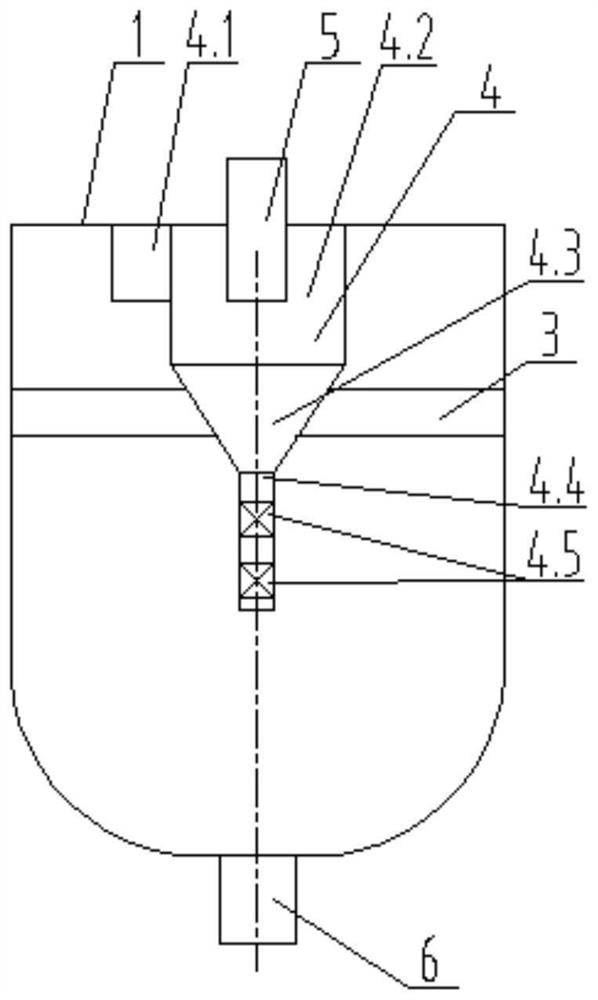

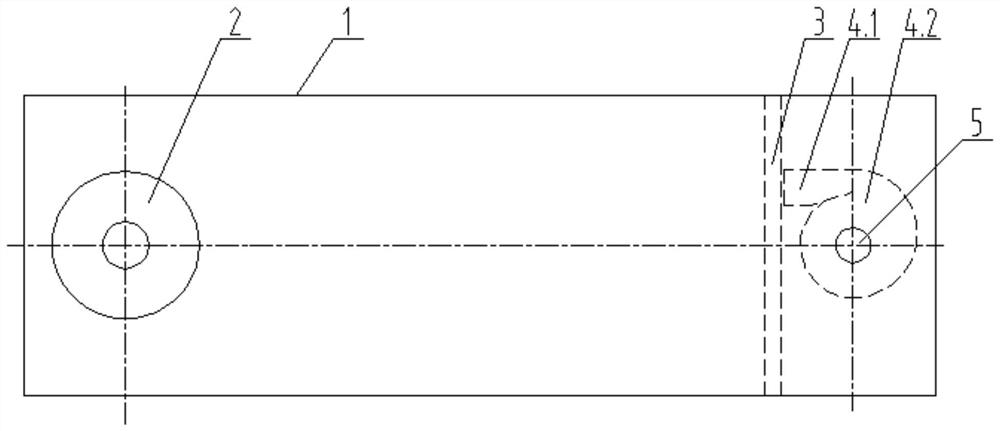

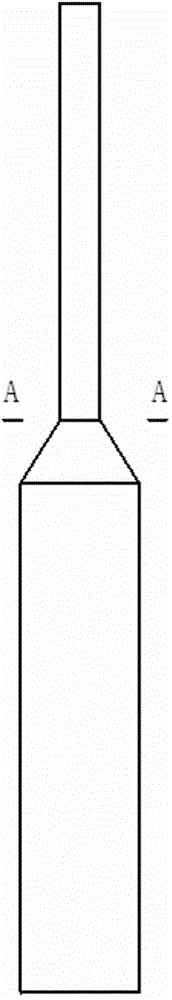

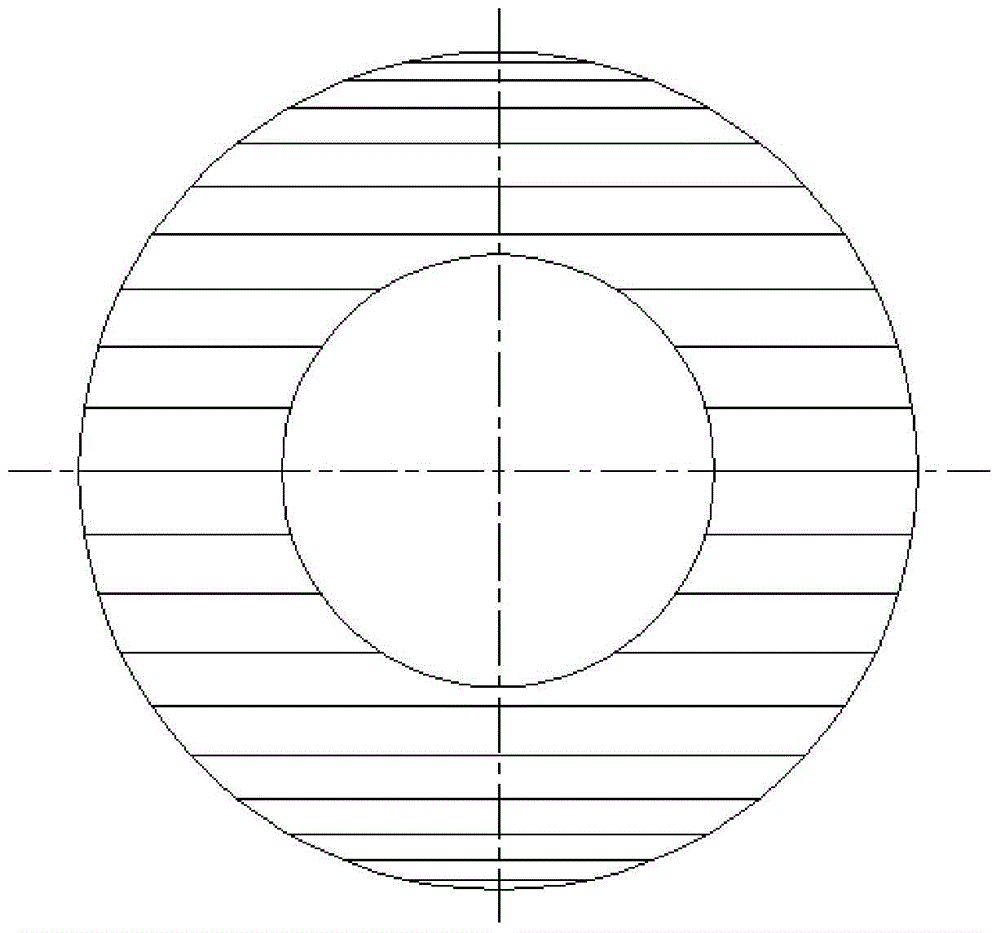

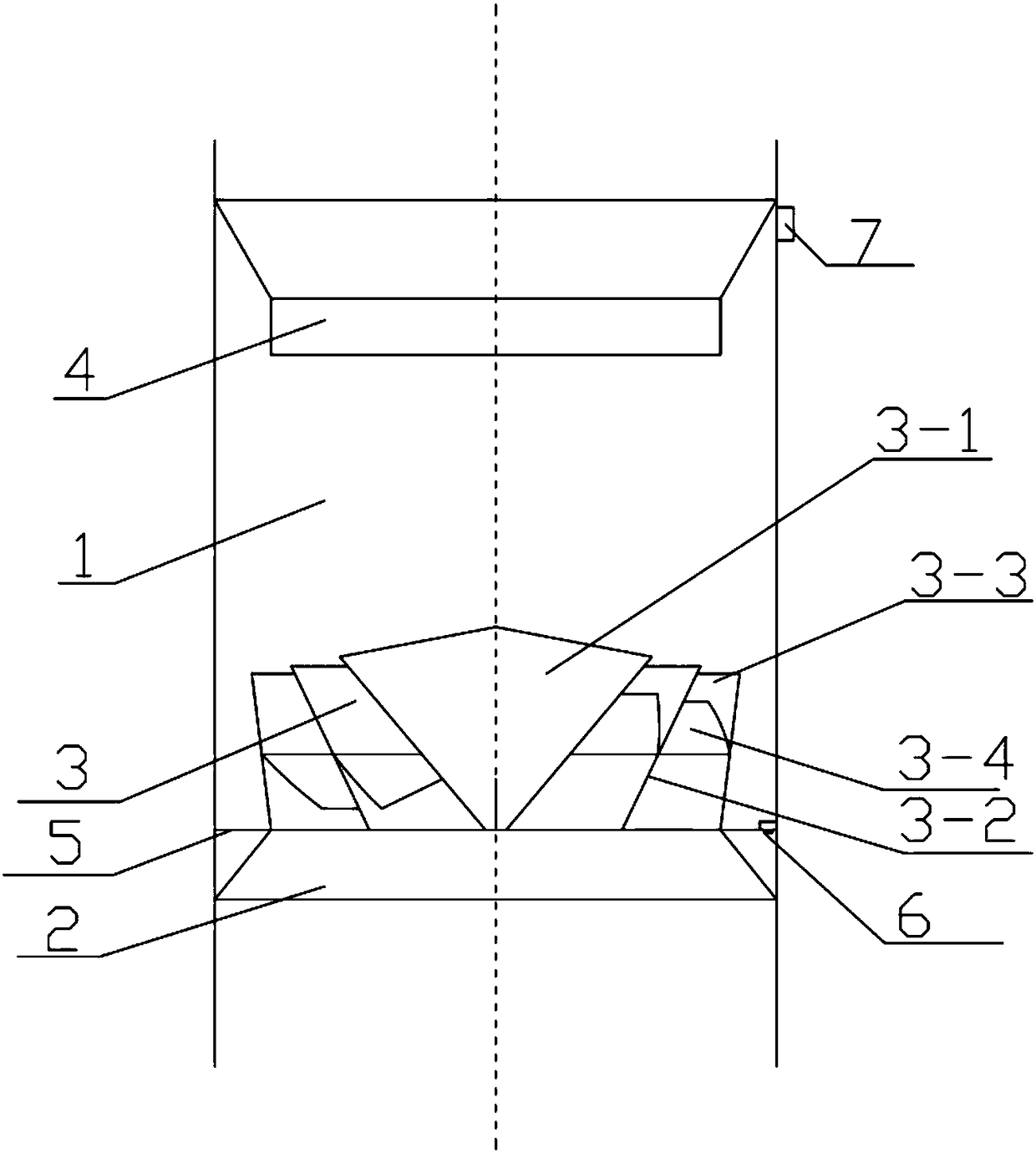

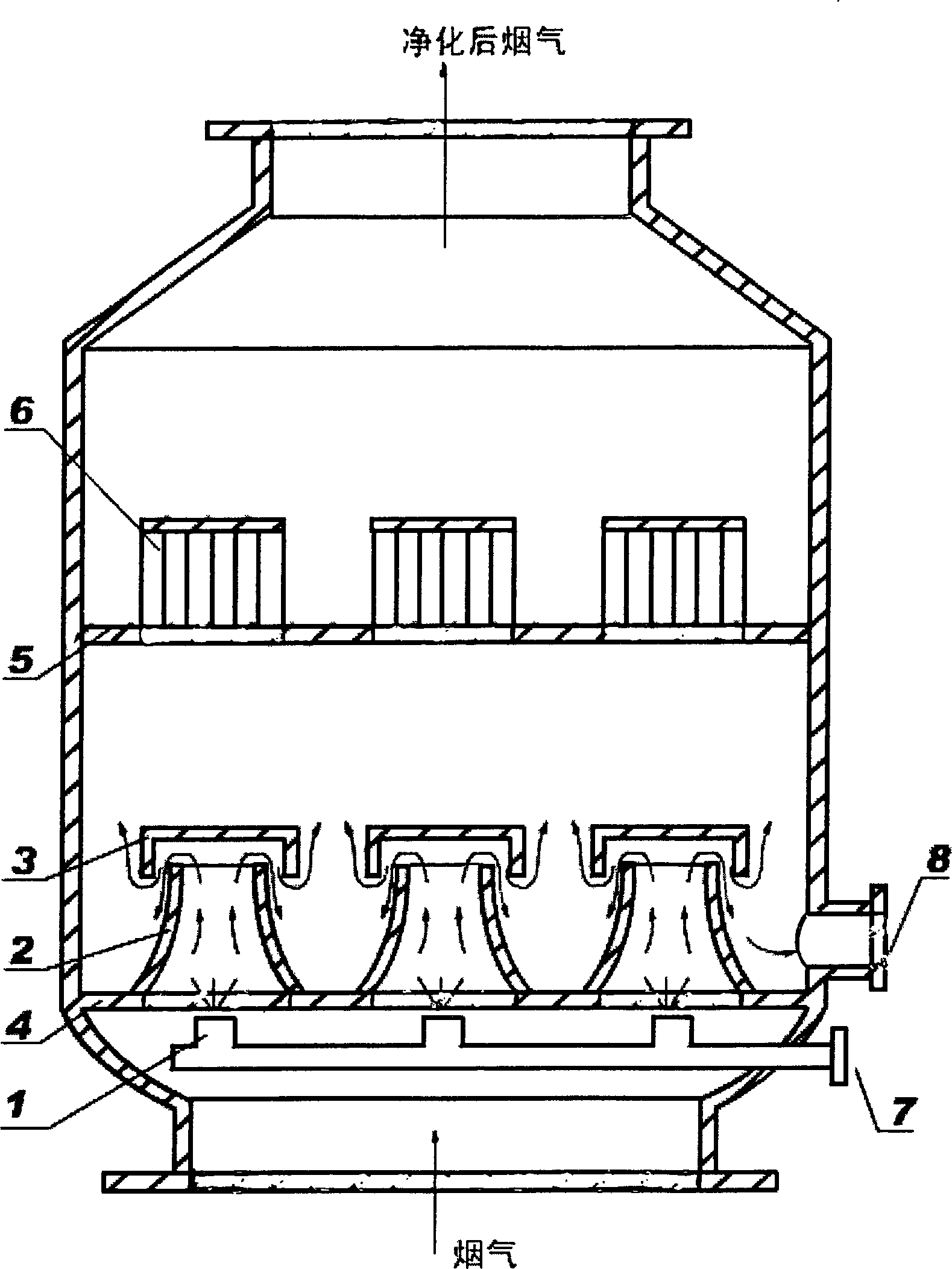

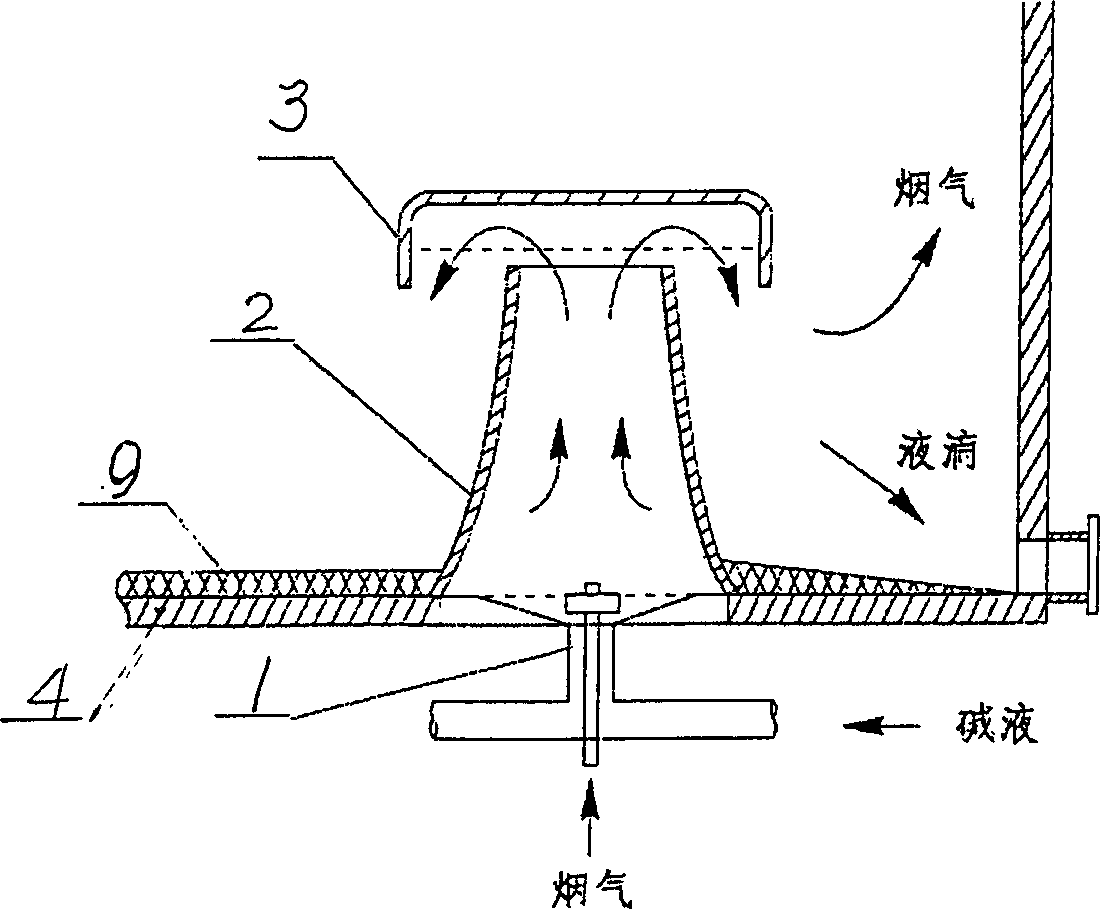

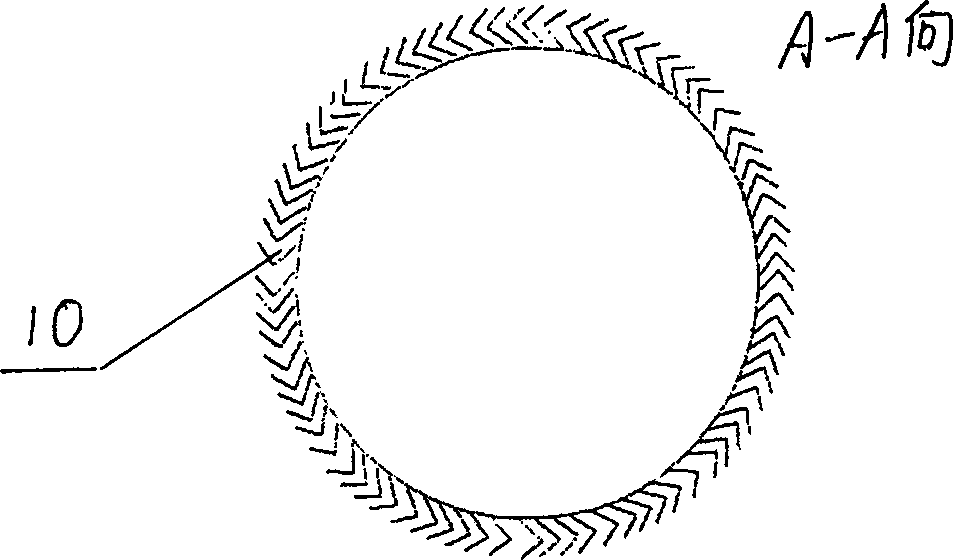

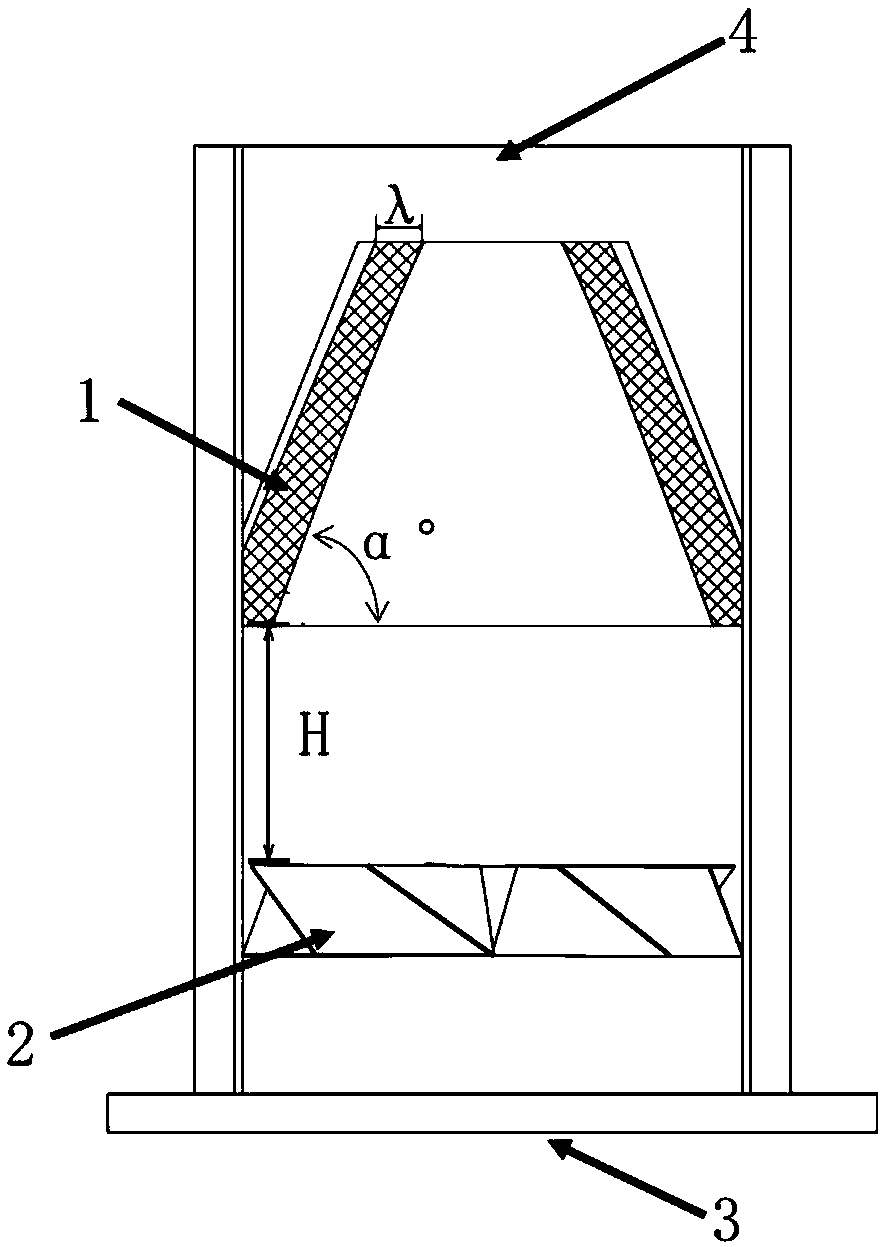

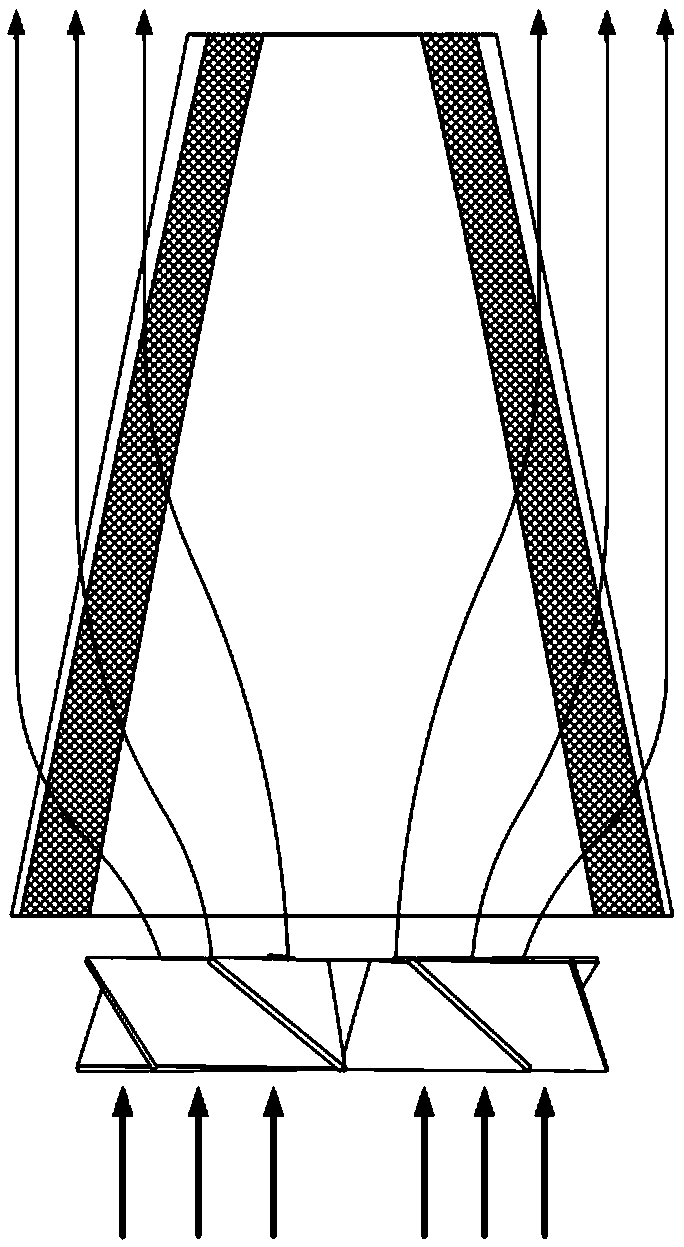

High-performance ultralow emission equipment

PendingCN110339943AAvoid secondary entrainmentImprove separation efficiencyElectrostatic separationWhole bodyFlue gas

The invention provides high-performance ultralow emission equipment. The technological position of the equipment is positioned between a desulfurization device and a wet-type electrical dust remover,the equipment is mounted at a front end position in an electric field area of the wet-type electrical dust remover, desulfurization flue gas enters into high-performance PM2.5 ultralow emission equipment through a desulfurization outlet flue, and a cover plate (1), a water baffle ring (2), a shell (3), a rotational flow body (4), a Venturi tube (5) and a base plate (6) included in the equipment are used for connecting the components into a whole body. The equipment is applicable for the requirement of ultralow emission in the industry, the stability and reliability of ultralow emission are guaranteed, and the equipment is widely applied to capturing of fine particles such as dust and fog drips in boiler and kiln gas.

Owner:XIANGYANG JIUDING HAOTIAN ENVIRONMENTAL PROTECTION EQUIP

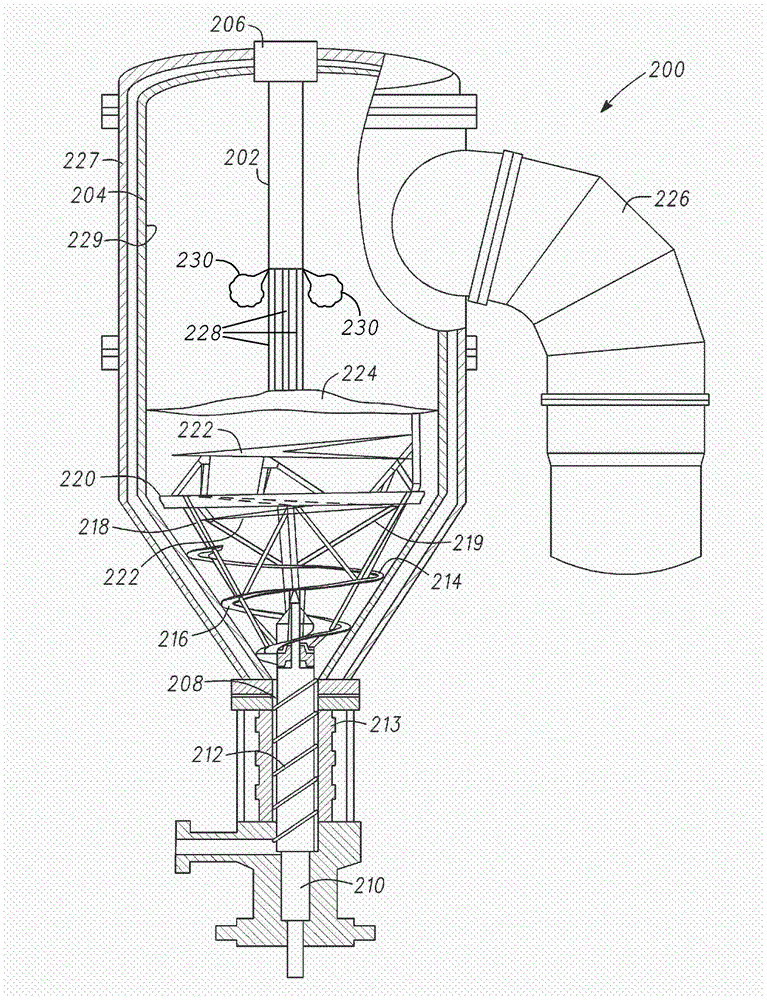

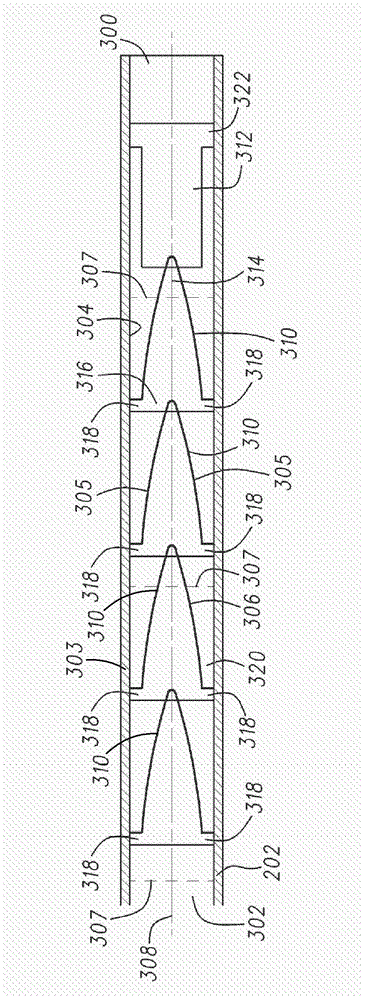

Finisher nozzle and finisher assembly including the same

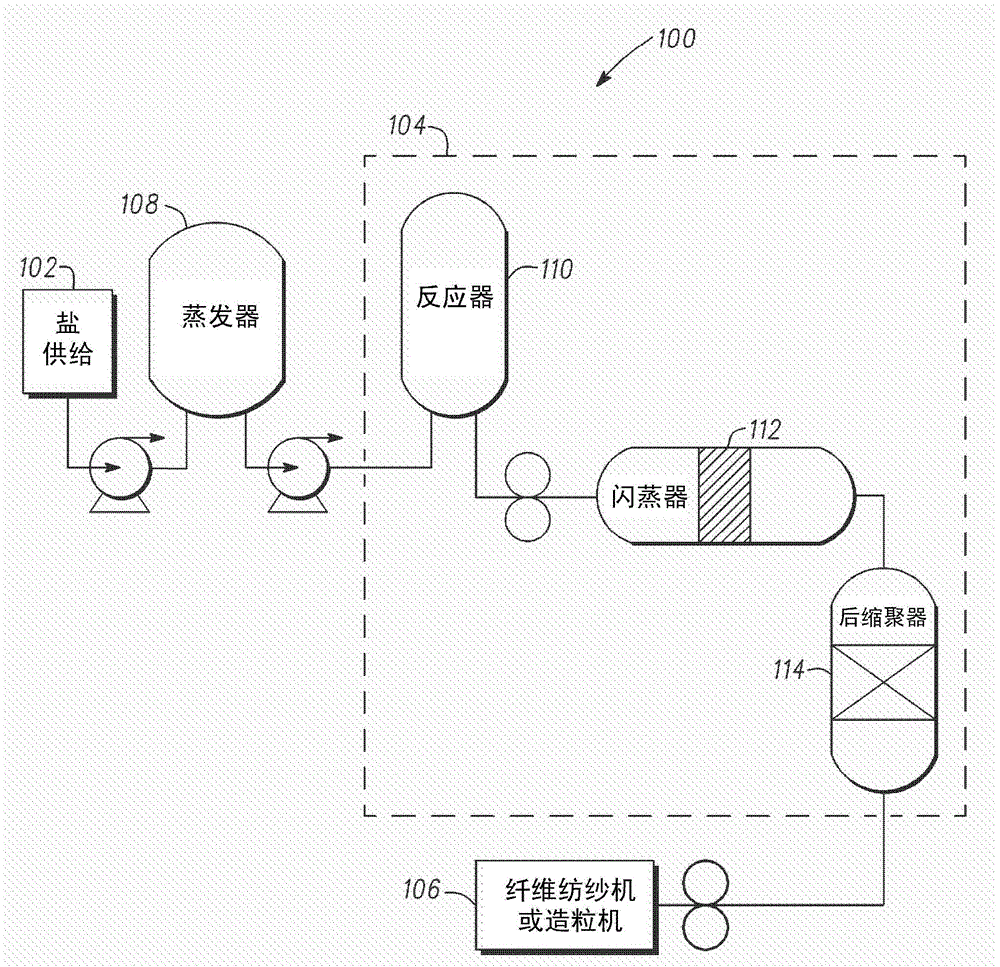

ActiveCN104128157AReduce generationShorten speedTransportation and packagingSpray nozzlesMixed flowWater vapor

A polymer finisher assembly having a finisher nozzle includes a vessel including an outlet orifice and an inlet orifice. The finisher nozzle extends through the inlet orifice of the vessel. The finisher nozzle includes an isometric barrel extending between a nozzle inlet port and a nozzle outlet port. A separator helix is within the isometric barrel. The separator helix separates a mixed flow of steam and polymer fluid and directs steam toward a barrel inner perimeter and directs the polymer fluid separated from the steam toward a helix axis and the nozzle outlet port. The isometric barrel and the separator helix cooperate to confine spattering of polymer fluid separated from steam to the melt pool and isolate an inner vessel wall of the vessel from spattering.

Owner:INVISTA TEXTILES (U K) LTD

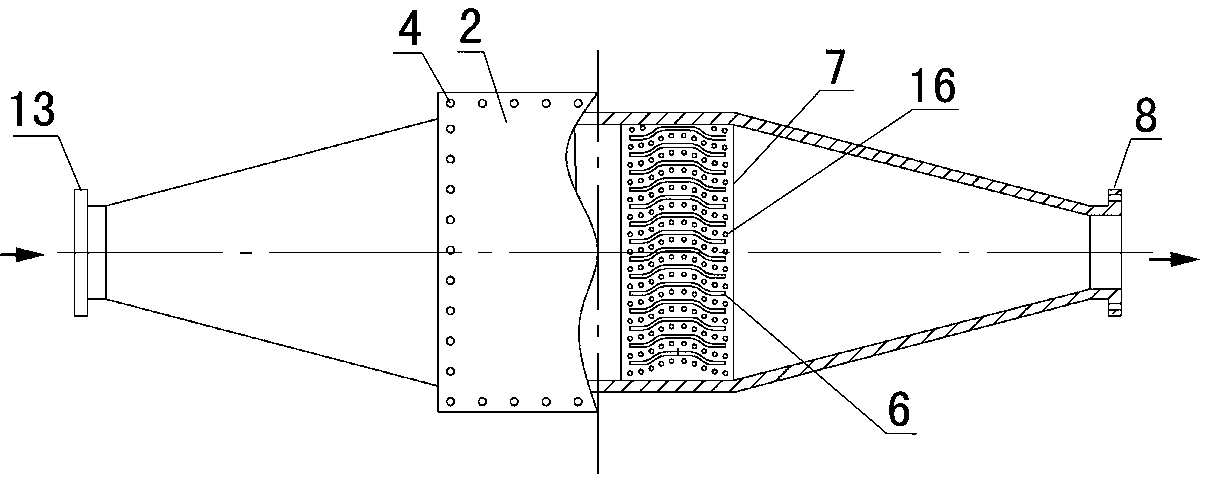

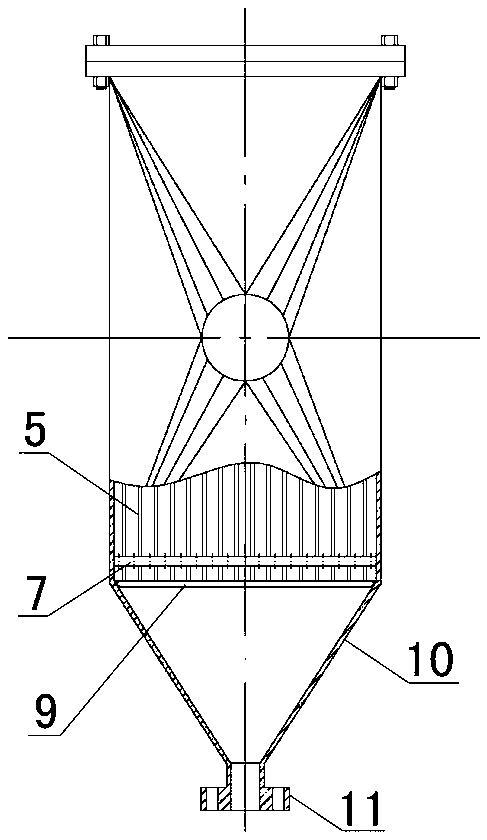

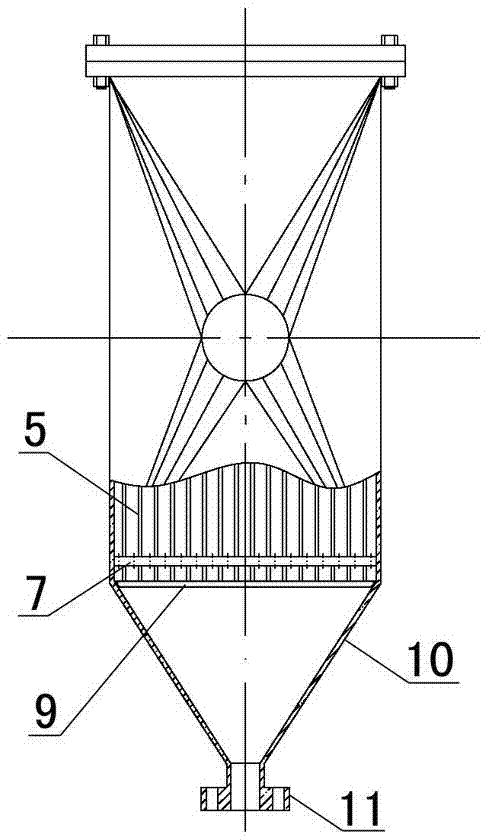

Venturi tube bundle type dust and mist eliminator

InactiveCN106731430AImprove the ability of dust removal and fog removalAvoid secondary entrainmentCombination devicesFlue gasEngineering

The invention relates to the technical field of flue gas dust and mist elimination, and in particular relates to a venturi tube bundle type dust and mist eliminator comprising a venturi tube, single fluid spray lances, a centrifuge, an expansion chamber and a drain board, wherein the bottom of the venturi tube is mounted on a circular hole of the drain board; a number of single fluid spray lances are arranged on the outer wall of a contraction section of the lower end of the venturi tube, and the centrifuge is arranged at the upper end of the venturi tube; and the expansion chamber is arranged at the upper part of the centrifuge. According to the invention, the single fluid spray lances are arranged at the reduced section of the venturi tube, so that water mist ejected by the single fluid spray lances is changed into fine droplets through the venturi effect, and then fine dust and gypsum droplets having a grain size below 20mu m (in particular PM2.5) can be eliminated, so that the effect of dust and mist elimination is improved. A dust-containing liquid is separated by the centrifuge and then enters the expansion chamber without contact with ascending gas, thereby avoiding secondary gas-liquid entrainment and further improving the effect of dust and mist elimination.

Owner:哈尔滨电气环保有限公司

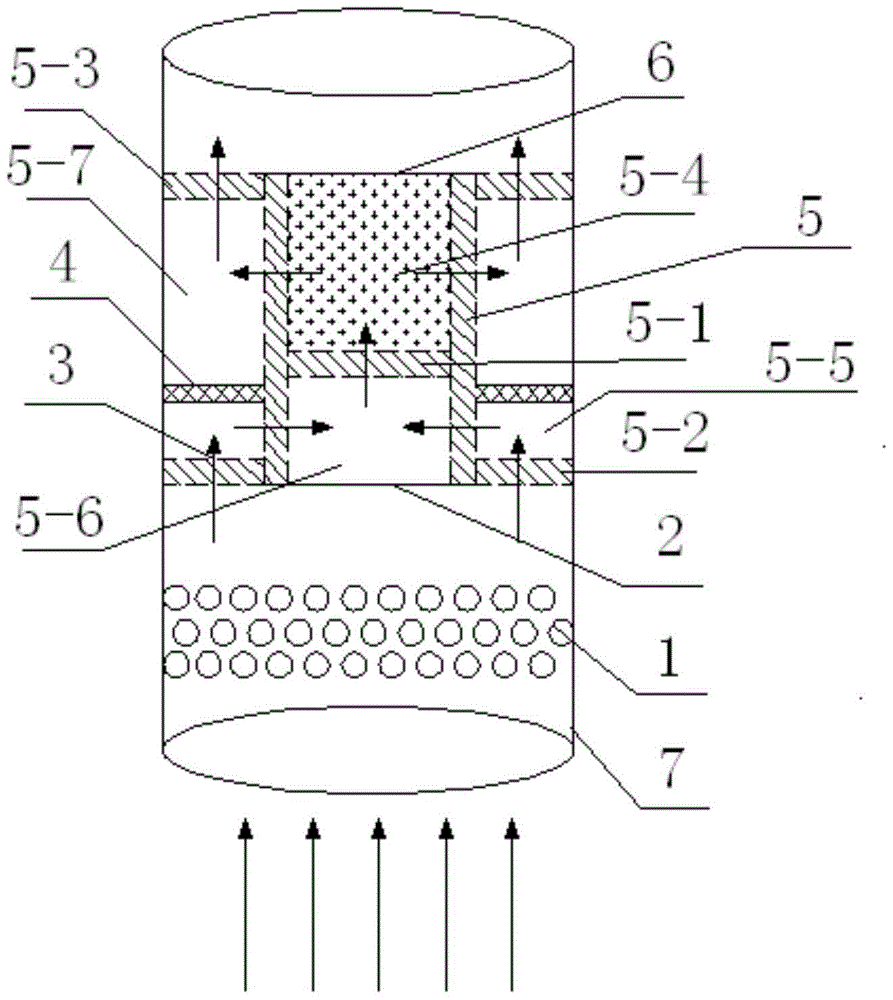

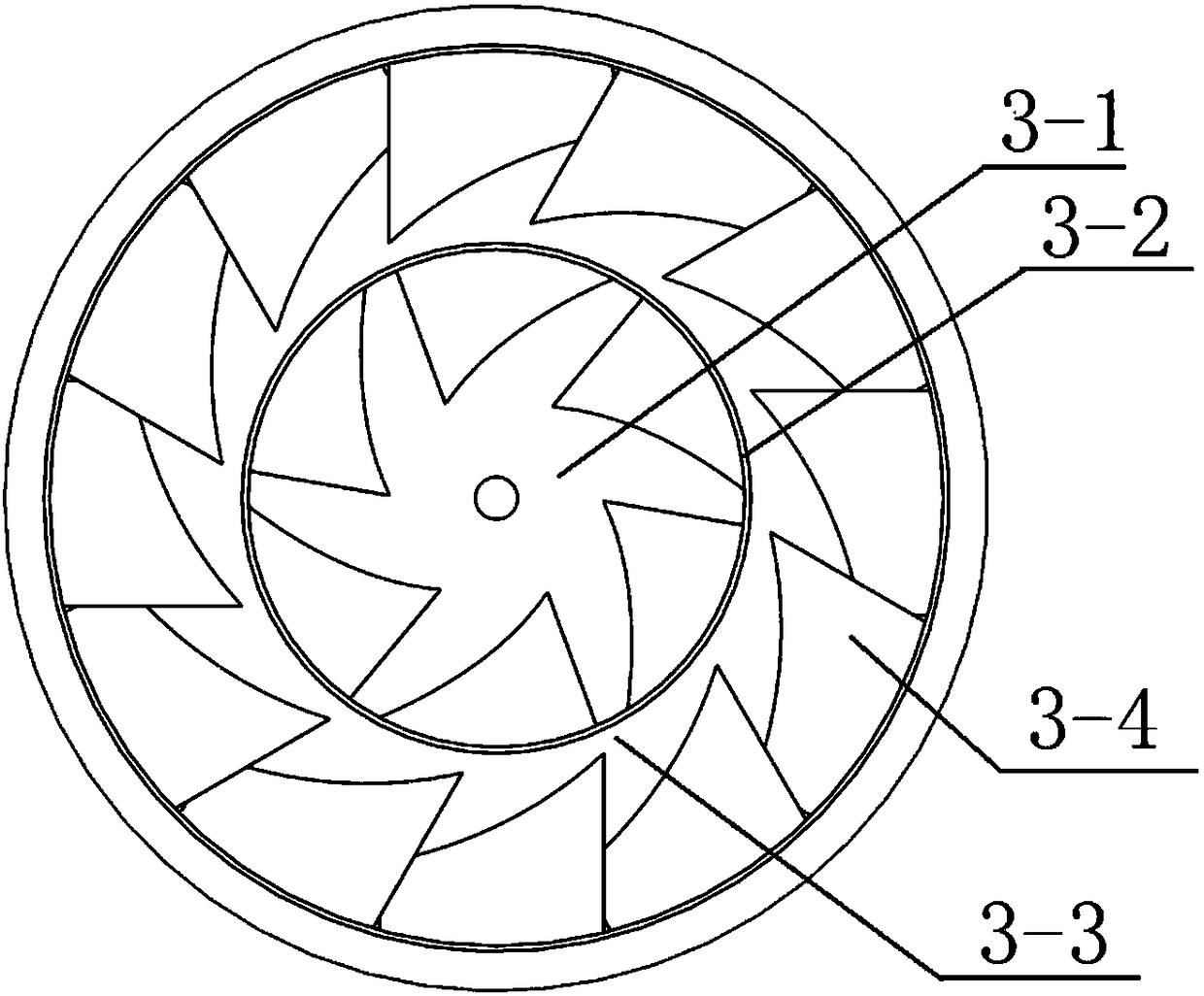

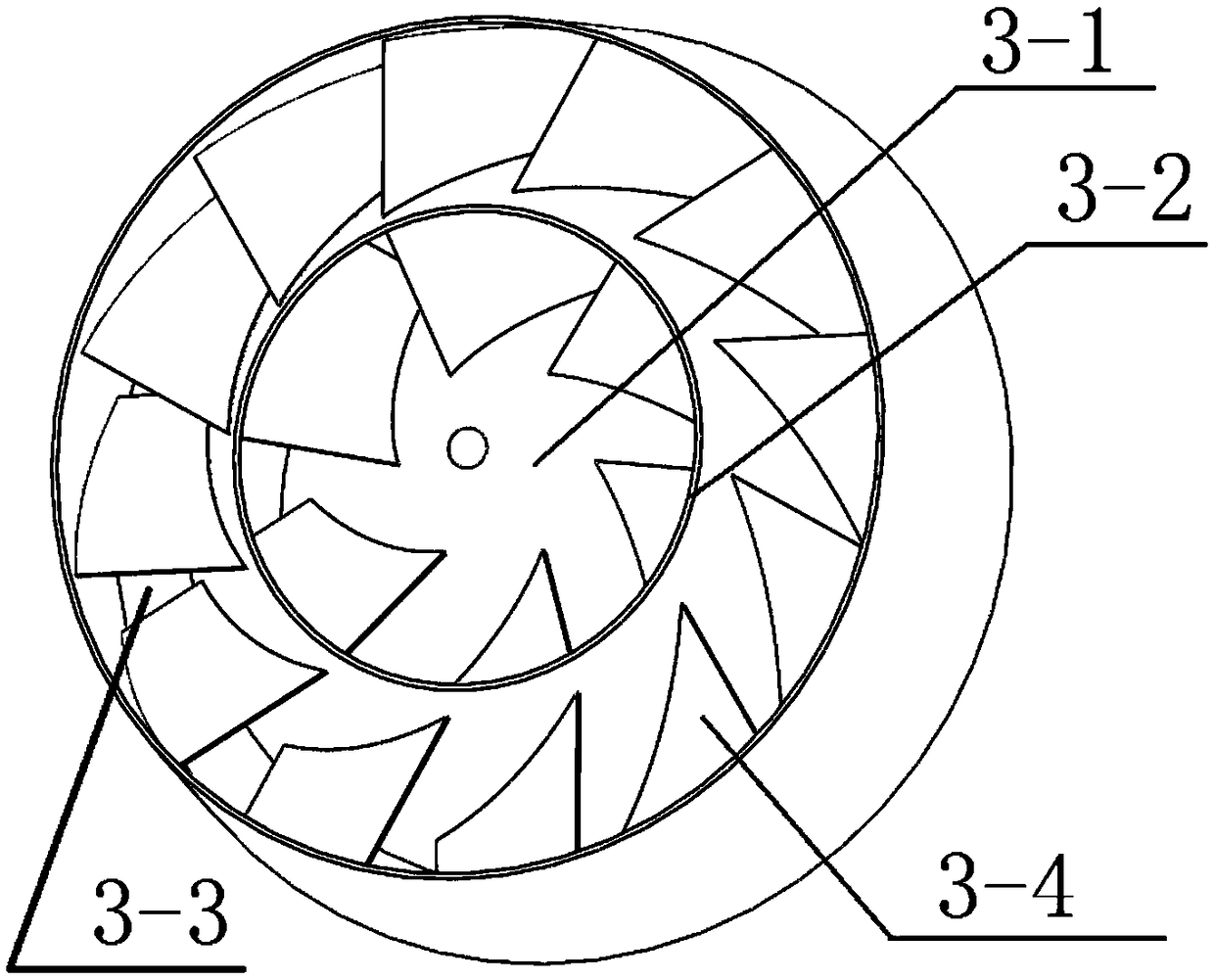

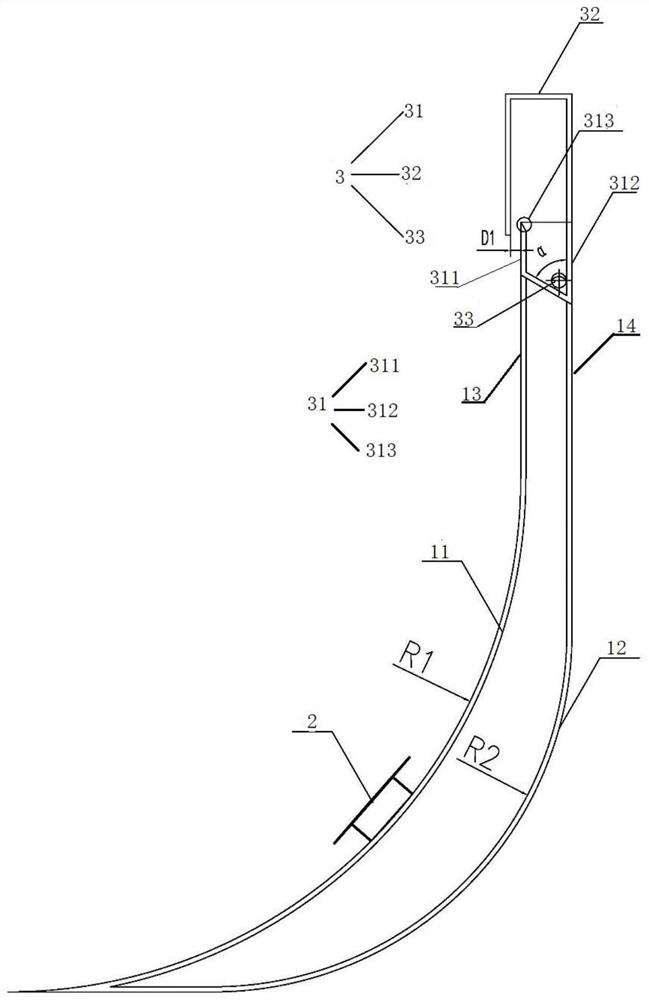

Vortex-radial-acceleration dedusting and defogging device

ActiveCN106422636APrevents premature low pressureAvoid secondary entrainmentCombination devicesEngineeringAcceleration Unit

The invention discloses a vortex-radial-acceleration dedusting and defogging device. The vortex-radial-acceleration dedusting and defogging device comprises a cylinder, an air inlet, a vortex acceleration body and an air outlet, wherein the air inlet is formed in the lower end in the cylinder, the vortex acceleration body is mounted at the air inlet through a support plate, and the air outlet is formed in the upper end in the cylinder; the vortex acceleration body comprises a central body, a diverging pipe, an annular air duct and vortex blades, and the central body and the diverging pipe are coaxial, are arranged on the support plate and are fixedly connected with the support plate; the central body is a sealed cavity and is a curved-surface body with a large upper end and a small lower end, the section diameter, from bottom to top, of the diverging pipe continuously increases, and the diverging pipe is a hollow curved-surface body with a large upper end and a small lower end. The dedusting and defogging device is compact in structure, convenient to maintain, good in separation effect, small in flue gas resistance, low in operation cost and promising in application prospect.

Owner:广州创能电力技术工程有限公司

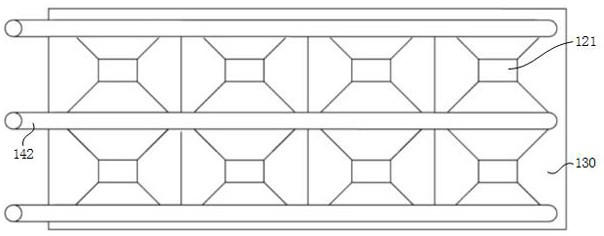

Centrifugal separation pipe, gas-liquid separation device and refrigerating system with device

PendingCN113713508AImprove gas-liquid separation efficiencyImprove drynessDispersed particle separationRefrigeration componentsEngineeringMechanical engineering

The invention discloses a centrifugal separation pipe, a gas-liquid separation device and a refrigerating system with the device. The centrifugal separation pipe comprises a spiral pipe body, the inlet end of the pipe body is higher than the outlet end, the centrifugal separation pipe is characterized in that the section of the pipe body is rectangular, the extending direction of the inlet end is located in the tangential direction of the pipe body; the outlet end is bent in the direction of the spiral axis and right faces the axis. The centrifugal separation pipe can conduct effective gas-liquid separation on fluid through the rectangular pipe body. According to the gas-liquid separation device, a centrifugal separation pipe, a flow guide component and a heat exchange component are used for carrying out gas-liquid separation on fluid for multiple times, and the gas-liquid separation effect is improved; after the gas-liquid separation device is adopted by the refrigerating system, the refrigerating efficiency can be greatly improved.

Owner:TAIZHOU LONGJIANG CHEM MACHINERY TECH

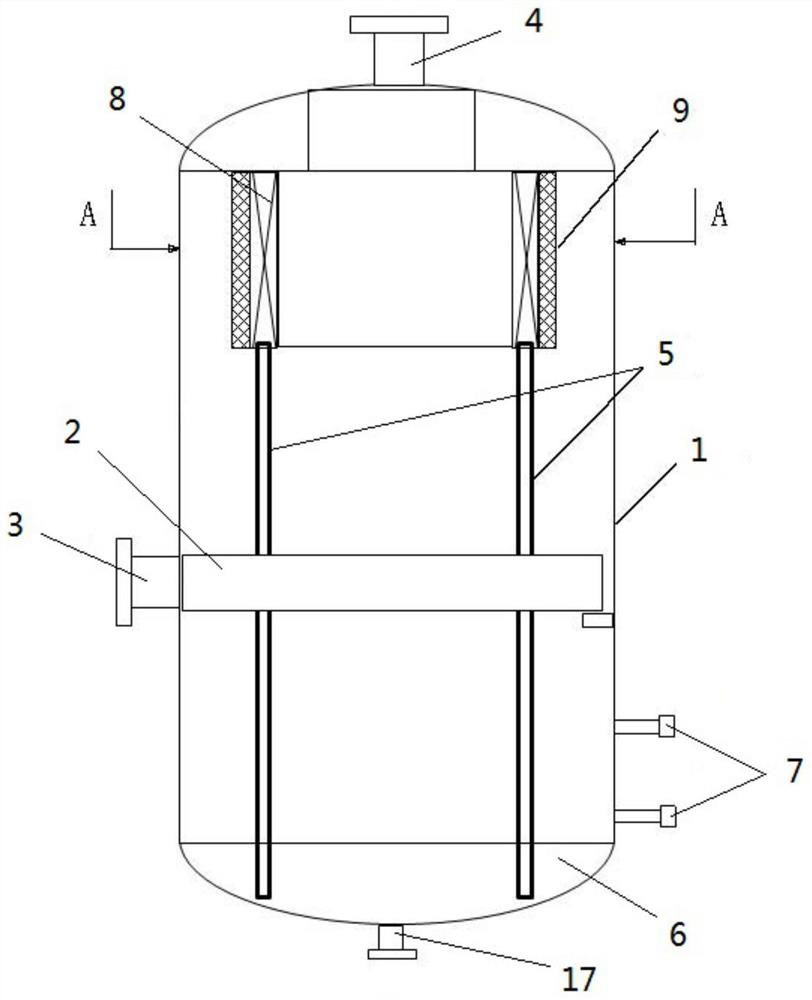

High-temperature pyrolysis reactor for reducing dust content of oil gas

PendingCN113136229ASimplified post-processing difficultyAvoid gasSpecial form destructive distillationGas dust removalProcess engineeringEnvironmental geology

The invention belongs to the technical field of garbage pyrolysis, and particularly relates to a high-temperature pyrolysis reactor for reducing the dust content of oil gas. The pyrolysis reactor shell adopts a stepped structure with a small front part and a large rear part, the front end is provided with a reactor material inlet, and the tail part is provided with a pyrolysis solid product outlet; and the rear middle portion of the reactor shell is a shell amplification section, a protruding cavity in the upper portion of the amplification section serves as a pyrolysis gas outlet area, a shutter baffle is arranged at a gas phase inlet of the area, a rotational flow device is arranged in the area, a pyrolysis gas outlet is formed in a gas phase outlet, and the pyrolysis gas outlet is a rotational flow device outlet. And the rotational flow device and the pyrolysis gas outlet are arranged above the pyrolysis solid product outlet. By utilizing the structure of the pyrolysis reactor, the pyrolysis gas is subjected to gas-phase dry-type dust removal in the pyrolysis reactor, so that the dust content of a pyrolysis gas outlet is reduced, the subsequent dust removal process configuration of the pyrolysis gas is simplified, and the pyrolysis oil treatment difficulty is reduced.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Novel blade type demister

PendingCN112999759AAvoid secondary entrainmentImprove separation efficiencyDispersed particle separationProcess engineeringMechanical engineering

The invention discloses a novel blade type demister, and relates to the technical field of demisters, the novel blade type demister comprises a shell, a pre-separator and a separator, one side surface of the shell is provided with an air inlet, the top of the shell is provided with an air outlet, the air inlet is communicated with the pre-separator, the shell is internally provided with the separator, and an air flow outlet of the pre-separator corresponds to an air flow inlet of the separator. An air flow outlet in the top of the separator corresponds to the air outlet, a liquid outlet end at the bottom of the separator is communicated with a condensate discharge pipe, the separator comprises a silk screen collector and a blade separator, the silk screen collector is arranged on the outer side of the blade separator, the blade separator comprises a plurality of blades vertically arranged in the shell, and the blades are of a double-pocket type structure. The condition of secondary entrainment is avoided, and the separation efficiency is effectively improved; the utility model solves the defects of a silk screen filter separator, and has the effects of high efficiency, reasonable design, simple structure, convenience in cleaning, small volume, lower manufacturing cost, no energy consumption, small airflow pressure drop, reliability, stability and effective reduction of investment cost.

Owner:EUROSLOT KDSS SHANGHAI

Power plant flue gas desulfurization absorption tower in-line chimney

InactiveCN104383791ALower center of gravityPrevent backflowDispersed particle separationFlue gasAtmospheric air

The invention discloses a power plant flue gas desulfurization absorption tower in-line chimney. The power plant flue gas desulfurization absorption tower in-line chimney comprises a chimney, wherein the chimney adopts a conical cylinder structure, the lower part of the conical cylinder is in transitional connection with an absorption tower through an intermediate conical cylinder, the upper part of an inner cavity of the conical cylinder is provided with a demisting device, and a condensate backflow device is arranged on the outer side of an opening in the top of the conical cylinder. The conical cylinder of the power plant flue gas desulfurization absorption tower in-line chimney disclosed by the invention enables the center of gravity of a chimney section to be lowered obviously, so that the stability and reliability of the whole machine are improved, meanwhile, the outlet flow velocity of flue gas is increased, and greater lifting height and diffusion capability are achieved; by additionally arranging the demisting device and the condensate backflow device, the pollution of chimney rain to the atmosphere and environment is eliminated, the carrying amount of condensate is decreased, the occurrence of 'chimney rain' is alleviated and avoided, and meanwhile, the power plant flue gas desulfurization absorption tower in-line chimney has the effects of lowering investment and saving energy.

Owner:山东碧空环保科技股份有限公司

A Ring Swirl Plate Separator

ActiveCN105289116BReach critical separation particle size requirementsImprove separation efficiencyDispersed particle separationCentrifugationEngineering

The invention discloses a ring whirlwind plate separator. The ring whirlwind plate separator comprises a cylindrical outer wall of which the top end is provided with an outlet, an inner solid body vertically arranged in the outer wall, a whirlwind plate fixedly connected between the outer wall and the inner solid body, and a separation ring. The inner solid body is used for promoting air to flow close to the outer wall surface and accelerating a fluid flowing rate. The whirlwind plate is used for blocking particles and promoting air flow rotation. The separation ring is used for shortening a particle centrifugation motion distance. The separation ring is circularly fixed to the whirlwind plate. The ring whirlwind plate separator reduces critical separation particle sizes and can be designed in a low pressure drop scope.

Owner:HUNAN UNIV

A gas-liquid separation device

ActiveCN108786285BReduce resistanceEasy to separateDispersed particle separationEngineeringMechanical engineering

The invention relates to a gas-liquid separation device, and belongs to the field of chemical machinery. The gas-liquid separation device comprises an inner cylinder, an outer cylinder, and a rotational flow part; the inner cylinder is connected with a supply pipeline for conveying liquid-containing airflow and is composed of a plurality of pipe sections, liquid dividing troughs are formed betweenthe pipe sections, and the drainage resistance is reduced; the outer cylinder sleeves the exterior of the inner cylinder with a certain gap, a closed annular cavity is formed between the inner cylinder and the outer cylinder, and a U-shaped liquid-sealed drainage pipe is arranged on the outer cylinder; the rotational flow part is arranged between the upstream side of the inner cylinder and the supply pipeline; the outer cylinder is connected with a low-pressure zone of the center of the inner cylinder through a blind plate of the rotational flow part via an elbow pipe; gas of the outer cylinder is sucked by using the pressure difference between the inner cylinder and the outer cylinder, and the pressure of the outer cylinder is reduced. The gas-liquid separation device has the characteristics of high gas-liquid separation efficiency and low pressure drop, and has strong adaptability to different production devices.

Owner:ZHEJIANG UNIV

A kind of multi-channel composite mist eliminator and its mist removal method

ActiveCN104815501BReduced carrying capacitySmall liquid holding capacityCombination devicesFilling materialsEngineering

The invention discloses a multichannel-type composite demister and a demisting method. The multichannel-type composite demister comprises a demister case and a cylindrical structure enclosed by a baffle plate and arranged in the demister case with axial direction, the inner part of the cylindrical structure is divided into a filling material chamber and an intermediate rectification chamber; a second baffle plate and a third baffle plate are arranged between an upper end of the cylindrical structure and the demister case as well as a lower end of the cylindrical structure demister case; a support plate is arranged between central section of the outer wall of the cylindrical structure and the demister case, a bottom circulation chamber is formed by a cavity defined by the second baffle plate and the support plate, a top circulation chamber is formed by a cavity defined by the support plate and the third baffle plate; air flow is introduced into the bottom circulation chamber, an intermediate rectification chamber, a filling material chamber and the top circulation chamber from the bottom of the demister case in order, and is discharged from the top of the demister case. By employing a composite demisting effect with combination of multichannel separating, baffle plate inertia separating and filling material separating, little liquid drop can be removed, so that the demister can better solve the raining or gypsum rain phenomenon of a chimney.

Owner:SOUTH CHINA UNIV OF TECH

A vortex radial acceleration dust removal and mist removal device

The invention discloses a vortex radial acceleration dedusting and mist removal device, which comprises a cylinder body, an air inlet, a vortex acceleration body, and an air outlet. The support plate is installed on the air inlet, and the air outlet is arranged at the upper end of the cylinder; the vortex acceleration body includes a central body, an expander tube, an annular air channel and a vortex blade, and the center body and the expander tube are the same The shafts are arranged on the support plate and fixedly connected with the support plate; the central body is a sealed cavity, and the shape is a curved body with a large upper part and a smaller lower part. The diameter of the expanding tube expands continuously from bottom to top It is a hollow surface with a large top and a small bottom; the dust and mist removal device of the present invention has the advantages of compact structure, convenient maintenance, good separation effect, small smoke resistance, low operating cost, and has good application prospects.

Owner:广州创能电力技术工程有限公司

A cyclone demister

ActiveCN111298523BAvoid secondary entrainmentImprove removal efficiencyGas treatmentDispersed particle separationEngineeringMechanical engineering

The invention discloses a cyclone demister. The cyclone demister includes several defogging assemblies, each defogging assembly includes a riser pipe and an outer cylinder, the outer cylinder is arranged on the outside of the riser pipe, and is on the same axis as the riser pipe; the riser pipe is fixed on On the tray, a cover plate is set on the top of the gas riser, and a rectification channel is set on the circumference of the gas riser; the wall of the outer cylinder includes an inner wall and an outer wall, and the inner wall and the outer wall are hollow structures, and the hollow structure is closed at the top and open at the bottom . The demister of the present invention realizes the separation of liquid droplets and gases through the rectification, acceleration and scraping effect of the fluid in the flow process. The mist eliminator of the present invention has simple structure, high mist removal efficiency, single-layer arrangement can effectively realize gas-liquid separation, and satisfies the requirement of carrying amount of mist in gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device

ActiveCN103055609BEasy to separateEfficient separationDispersed particle separationFlue gasProduct gas

A flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device comprises a housing, one side of the housing is provided with an inlet, the inlet is provided with an inlet flange, the other side of the housing is provided with an outlet, and the outlet is provided with an outlet flange; the housing is sequentially divided into a diffusion section, a large internal diameter section and a conflux section from the inlet to the outlet, the internal diameter of the diffusion segment gradually increases from the inlet to the outlet, and the internal diameter of the conflux gradually decreases from the inlet to the outlet; and the bottom of the large internal diameter section is a funnel-shaped liquid collection room, the top liquid inlet of the liquid collection room is provided with a baffle plate bracket, and the baffle plate bracket supports a baffle plate. The device is a two-phase fluid separation device combining baffling separation with settling separation, can effectively separate and collect fine droplets in the two-phase fluid at the outlet of a vacuum pump, can prevent the secondary entrainment of the collected droplets by a gas, and effectively treats the environmental pollution.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

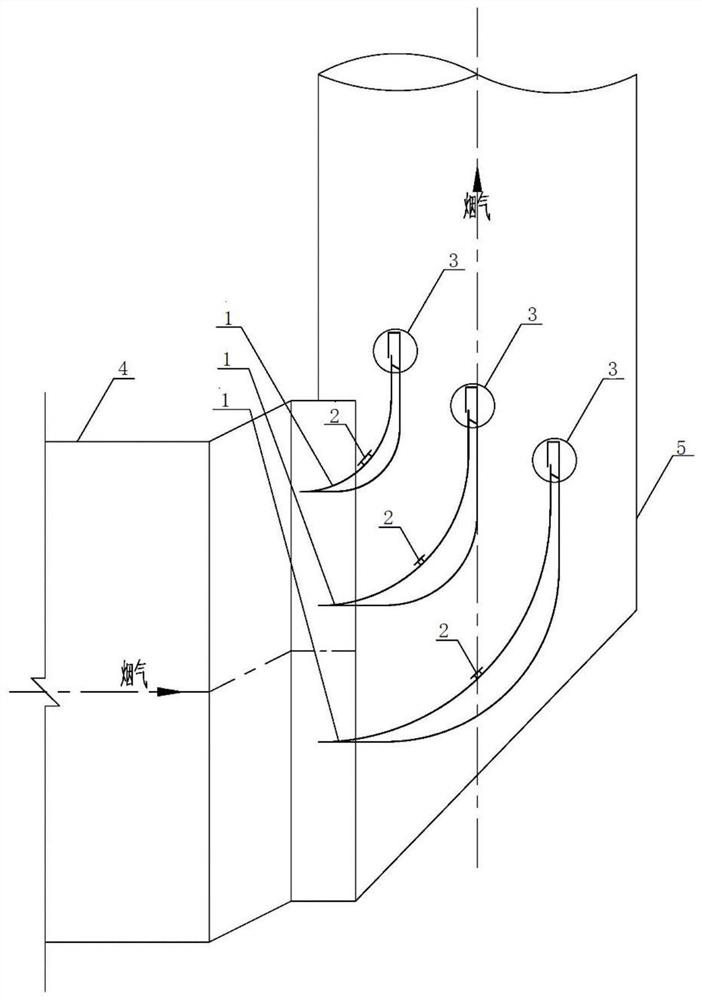

Liquid-collecting flow-guiding assembly and device

ActiveCN112856465ASlow flow transitionUniform flow fieldDispersed particle separationChimneysCavity wallMechanical engineering

The invention discloses a liquid-collecting flow-guiding assembly. The liquid-collecting flow-guiding assembly comprises at least one flow-guiding part which is used for being arranged in an inlet of an external chimney inner cavity, a first collecting part and a second collecting part, wherein the left and right sides of the flow-guiding part are used for being connected with inner cavity wall surfaces of the external chimney inlet respectively, and match the external chimney inner cavity or an adjacent flow-guiding part to form a smoke circulation channel; the flow-guiding part comprises a first flow-guiding cambered surface and a second flow-guiding cambered surface at the front and rear sides, circle centers of the first flow-guiding cambered surface and the second flow-guiding cambered surface are located at the same side, and the radius of the first flow-guiding cambered surface is larger than that of the second flow-guiding cambered surface; the first collecting part is arranged on the first flow-guiding cambered surface, and is used for collecting liquid, which flows upwards or downwards along the lower portion of the first flow-guiding cambered surface, in smoke; and the second collecting part is arranged at the top end of the flow-guiding part, and is used for intercepting and collecting the liquid in the smoke. After the smoke enters a chimney from a flue, change of a flow direction is made to be slower, a flow field of the smoke is made to be evener, and spaces for installation of the collecting parts are provided, so that a liquid-collecting function is achieved.

Owner:SHANGHAI DEFOG ENVIRONMENTAL SCI & TECH

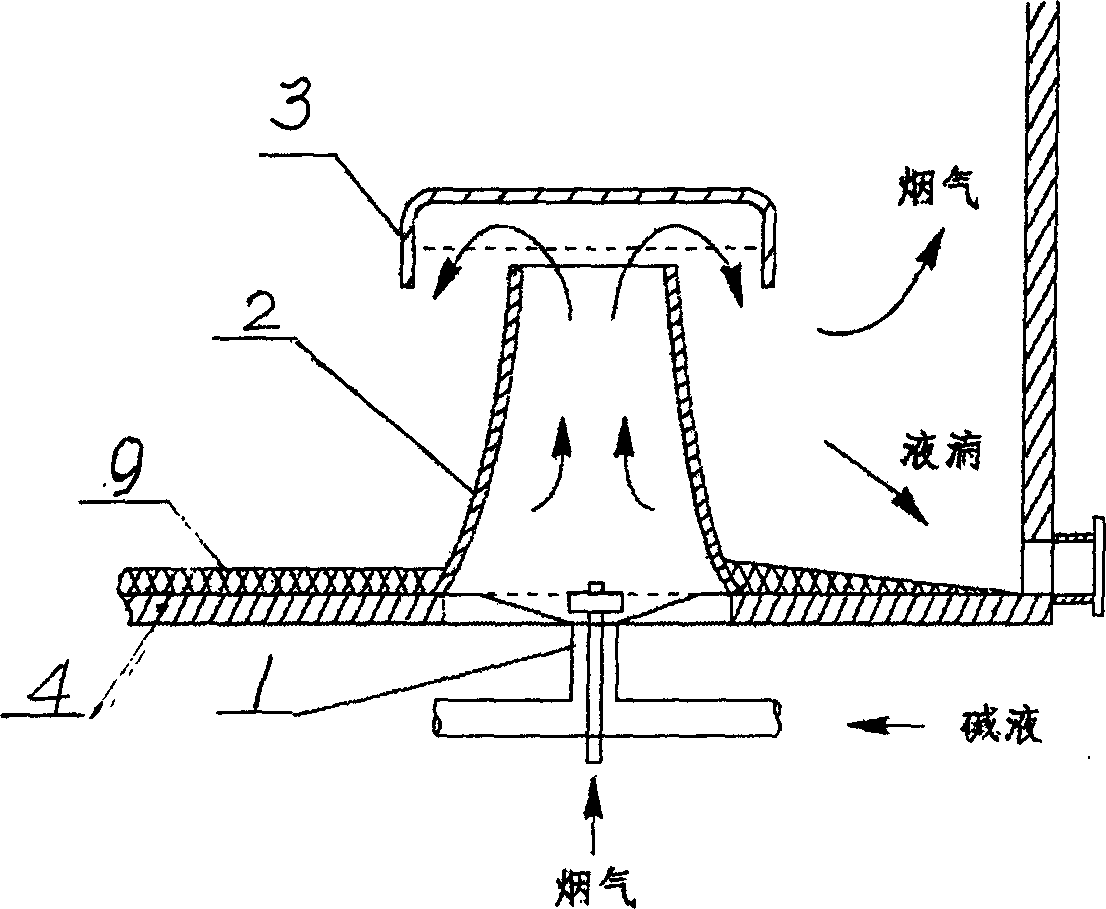

Double stage desulfurizing and dedusting apparatus

InactiveCN1259119CMake sure you don't bring waterAvoid secondary entrainmentUsing liquid separation agentLow speedFlue gas

The invention is a two-stage desulfurization and dust removal device. It includes a shell and a lye circulation system, and is characterized in that it is composed of low-resistance nozzles, low-speed Venturi tubes, impact baffles and circularly arranged baffle demisters that are installed sequentially from bottom to top. The beneficial effects of the present invention are: in the secondary desulfurization cycle, the structure of low-speed Venturi + impact baffle is adopted, so that the air resistance is low, the desulfurization efficiency is high, and it plays the role of primary dehydration; The device can completely remove the fine water droplets in the flue gas to ensure that the flue gas does not contain water. This structure has changed the plane layout of the traditional demister, and changed it to a unit structure. The perimeter of the dehydration flap is increased per unit area, which is more convenient for installation and maintenance, and the dehydration is more thorough due to the vertical installation of the deflector. , avoiding the secondary entrainment of flue gas, allowing a higher flow rate than flat installation, making the equipment more compact and saving space.

Owner:北京德厚朴化工技术股份有限公司

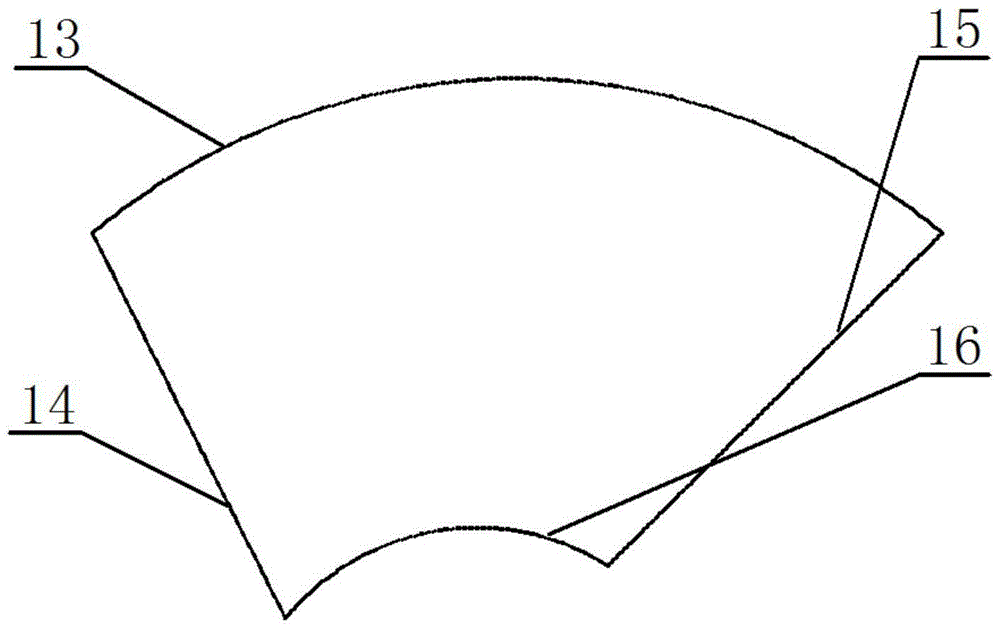

Cyclone separation water absorbing device used for flue gas dehydration

ActiveCN109621650AAvoid secondary entrainmentImprove the water absorption efficiency of the mediumGas treatmentDispersed particle separationCycloneComing out

The invention belongs to the technical field of wet method desulfurized tail gas dehydration, and provides a cyclone separation water absorbing device used for flue gas dehydration. On the basis of anoriginal flue gas dehydration device, cyclone separation water absorbing filling is additionally arranged, is of a hollowed cone frustum structure with a variable diameter, and is fixedly installed in a flue gas dehydrating device body and located on a cyclone separation blade; from a flue gas inlet end to a flue gas outlet end, the diameter of the cyclone separation water absorbing filling gradually becomes smaller; the angle formed by the section of the cyclone separation water absorbing filling and a horizontal plane is determined by the angle where flue gas comes out of the cyclone separation blade, and in other words, the flue gas which comes out of the cyclone separation blade perpendicularly makes contact with the cyclone separation water absorbing filling. In actual work, the water absorbing efficiency of media can be effectively improved, the actual proportion of flue gas with water removal can be increased, and after the media absorb water, secondary carrying of gas can be avoided.

Owner:中国石油集团东北炼化工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com