Multichannel-type composite demister and demisting method

A mist eliminator, multi-channel technology, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of large pressure drop, low space utilization, low mist removal efficiency, etc., to reduce equipment investment and operation. Great elasticity, solve the effect of chimney rain or gypsum rain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

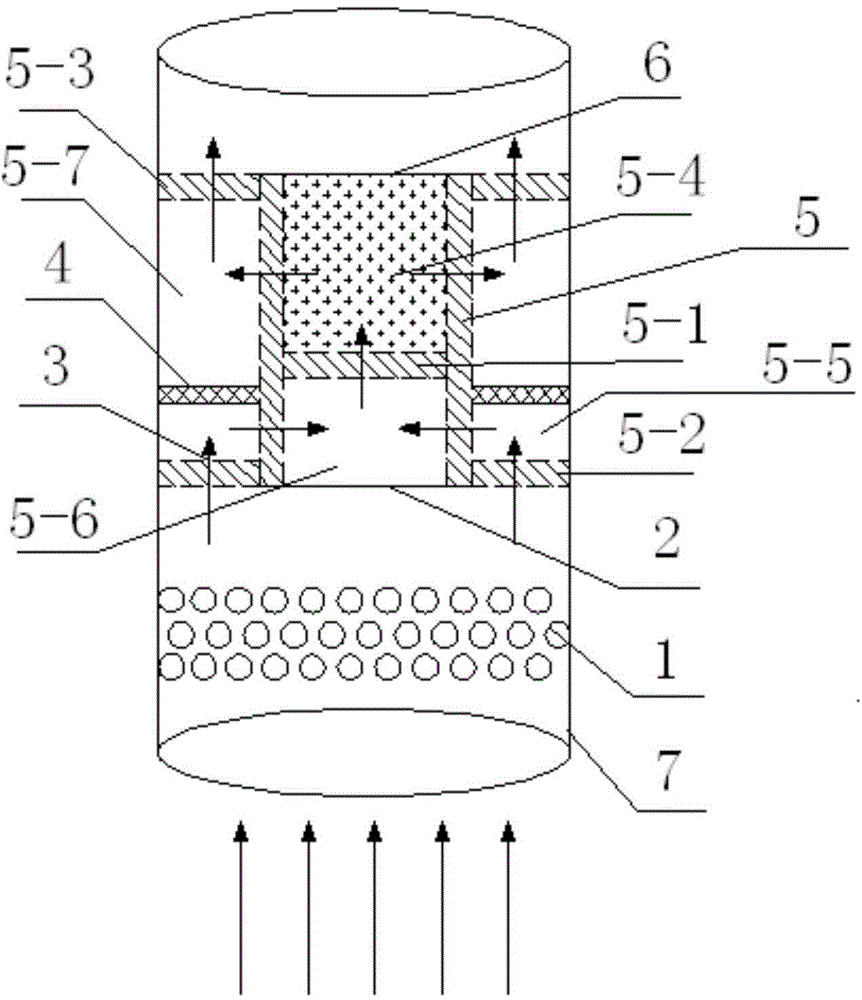

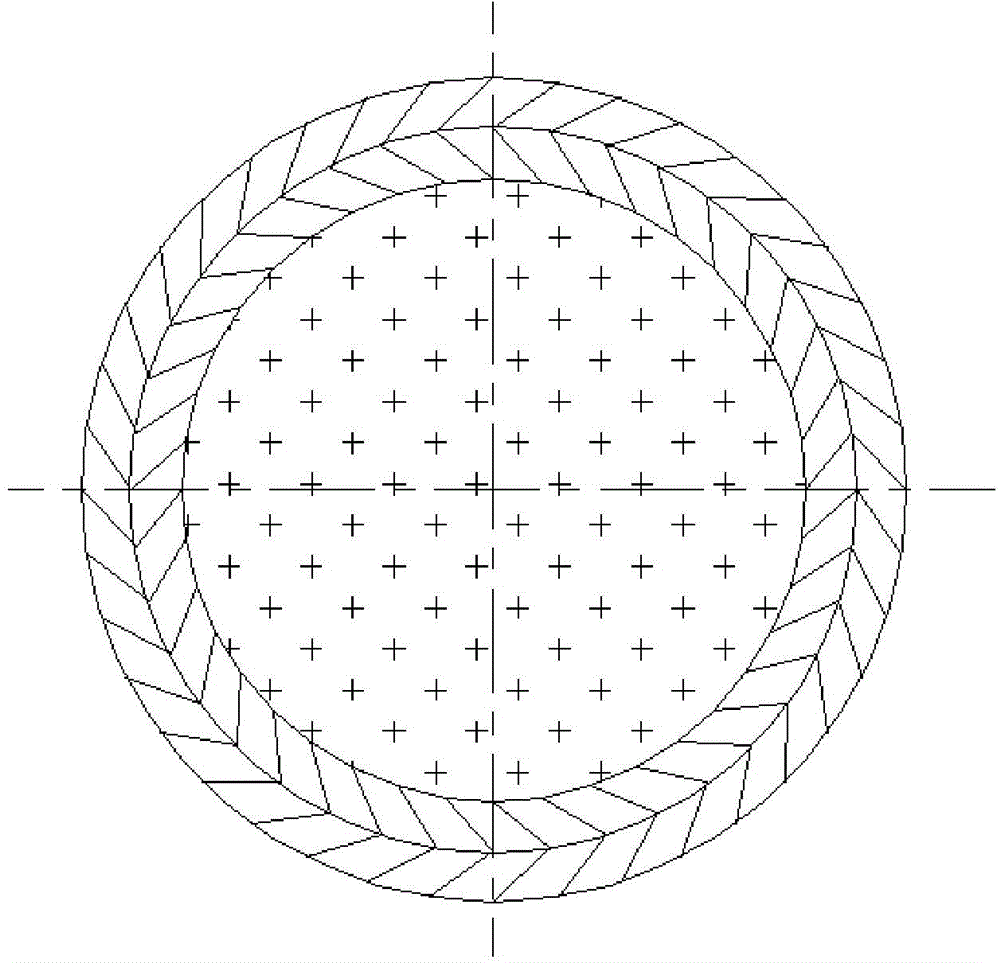

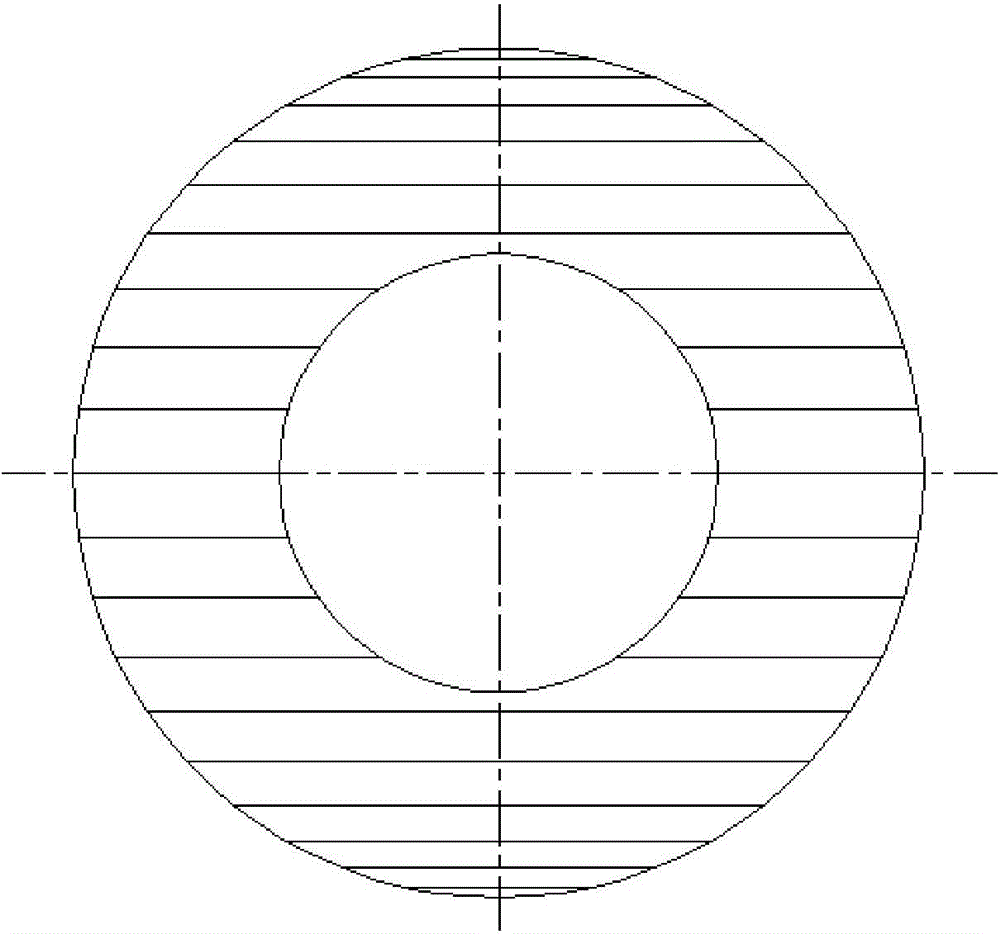

[0031] Such as Figures 1 to 5 shown. A multi-channel composite demister according to the present invention comprises: a demister housing 7, a cylindrical structure 5 surrounded by baffles arranged axially in the demister housing 7, the cylindrical structure The upper port of the 5 is provided with an upper baffle 6, and the lower port is provided with a lower baffle 2; the upper baffle 6 and the lower baffle 2 are non-porous plates.

[0032] The cylindrical structure 5 is radially provided with a first baffle 5-1, and the cylindrical structure 5 is divided into a stuffing chamber 5-4 and an intermediate rectifying chamber 5 with the first baffle 5-1 as a boundary. -6;

[0033] A second baffle 5-2 is provided between the lower end of the cylindrical structure 5 and the demister housing 7, and a third baffle is provided between the upper end of the cylindrical structure 5 and the demister housing 7 5-3;

[0034] A support plate 4 is provided between the middle part of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com