Reduced air-dried coal briquette adhesive and production process thereof

A technology of binder and reducing agent, applied in the field of briquette binder, can solve the problems of lack of high temperature resistance, large energy loss, low ash melting point, etc., to improve the performance of high temperature resistance, reduce energy loss, increase The effect of forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

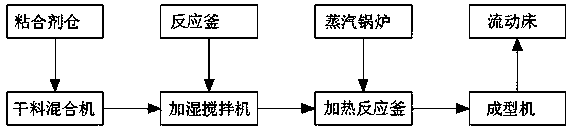

Image

Examples

Embodiment 1

[0036] The present invention has also developed a kind of production technology of reduction air-dried briquette binder, specifically comprises the following steps:

[0037] Step 1: Main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, 40% of lignite) and auxiliary raw materials (20% of reducing agent, 0.4% of decomposer, 4% of binder, Curing agent 0.004%) The materials involved in the interior are purchased and tested by the staff. After passing the test, they are stored in the warehouse for future use;

[0038] Step 2: For the main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, and 40% of lignite), mix various fuels in different proportions according to different purposes through different technical means;

[0039] Step 3: Proportioning the auxiliary raw materials reducing agent, decomposing agent, adhesive and curing agent according to the specified internal components;

[0040] S...

Embodiment 2

[0047] The present invention has also developed a kind of production technology of reduction air-dried briquette binder, specifically comprises the following steps:

[0048] Step 1: Main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, 40% of lignite) and auxiliary raw materials (17% of reducing agent, 0.45% of decomposer, 5% of binder, Curing agent 0.005%) The materials involved in the interior are purchased and tested by the staff. After passing the test, they are stored in the warehouse for use;

[0049] Step 2: For the main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, and 40% of lignite), mix various fuels in different proportions according to different purposes through different technical means;

[0050] Step 3: Proportioning the auxiliary raw materials reducing agent, decomposing agent, adhesive and curing agent according to the specified internal components;

[0051] Step 4:...

Embodiment 3

[0058] The present invention has also developed a kind of production technology of reduction air-dried briquette binder, specifically comprises the following steps:

[0059] Step 1: Main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, 40% of lignite) and auxiliary raw materials (15% of reducing agent, 0.5% of decomposer, 6% of binder, Curing agent 0.006%) The materials involved in the interior are purchased and tested by the staff. After passing the test, they are stored in the warehouse for future use;

[0060] Step 2: For the main raw materials (30% of anthracite, 20% of blue carbon powder or coke powder, 10% of coal slime, and 40% of lignite), mix various fuels in different proportions according to different purposes through different technical means;

[0061] Step 3: Proportioning the auxiliary raw materials reducing agent, decomposing agent, adhesive and curing agent according to the specified internal components;

[0062] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com