Processing method and device for decoction pieces of dried roots of Changium smyrnioides Wolff

A technology for sheet processing and medicinal drink, applied in the field of processing method and equipment of ginseng medicinal pieces, can solve the problems of long time for moistening medicine, low yield of first-class product, serious material stratification, etc., and achieves better medicinal effect and molding. High rate, better quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

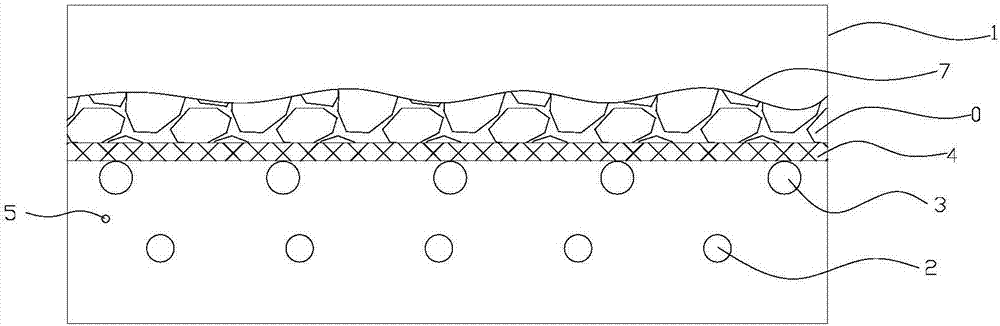

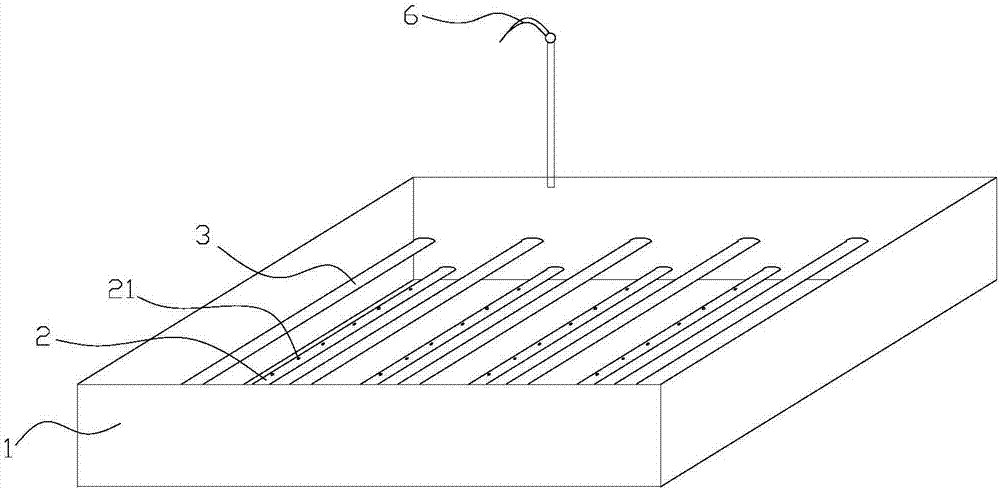

Image

Examples

Embodiment 1

[0047] A method for processing ginseng decoction pieces, comprising the following steps:

[0048] Cleaning: wash the silt and dust on the surface of the ginseng medicinal materials with water;

[0049] Drenching: put the ginseng medicinal material on a partition with mesh, sprinkle water once, and the amount of watering is 15 times of the mass of the ginseng medicinal material;

[0050] Steaming: cover a layer of cotton cloth on the ginseng treated in the step of soaking, and steam at 45°C for 3 hours;

[0051] Slicing: slice the material while it is hot;

[0052] Drying: hot air drying until the moisture content is less than 13%.

[0053] The schematic diagram of Mingdangshen decoction pieces that the present embodiment obtains is as follows: image 3 As shown, the yield of the first-class product reaches 94.55%.

Embodiment 2

[0055] A method for processing ginseng decoction pieces, comprising the following steps:

[0056] Cleaning: wash the silt and dust on the surface of the ginseng medicinal materials with water;

[0057] Drenching: put the ginseng medicinal material on a partition with a mesh, sprinkle water to moisten it, and the amount of water sprinkled is 15 times the mass of the ginseng medicinal material;

[0058] Steaming: cover a layer of cotton cloth on the ginseng treated by the step of soaking, and steam at 65°C for 3 hours;

[0059] Slicing: slice the material while it is hot;

[0060] Drying: hot air drying until the moisture content is less than 13%.

[0061] The first-class yield of Mingdangshen decoction pieces obtained in this example reaches 91.69%.

Embodiment 3

[0063] A method for processing ginseng decoction pieces, comprising the following steps:

[0064] Cleaning: wash the silt and dust on the surface of the ginseng medicinal materials with water;

[0065] Drenching: put the ginseng medicinal material on a partition with mesh, sprinkle water to moisten it, and the amount of water sprinkled is 20 times the mass of the ginseng medicinal material;

[0066] Evaporation: steam the ginseng medicinal materials treated by the dehydration step at 50°C for 3 hours;

[0067] Slicing: slice the material while it is hot;

[0068] Drying: hot air drying until the moisture content is less than 13%.

[0069] The first-class yield of Mingdangshen decoction pieces obtained in this example reaches 84.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com