Biomass fuel particle and processing device and method thereof

A biomass fuel and fuel processing technology, applied in the direction of biofuel, waste fuel, raw material extrusion granulation, etc., can solve the problem of inability to control the size of biomass fuel particles, achieve good pressing effect, high molding rate, smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

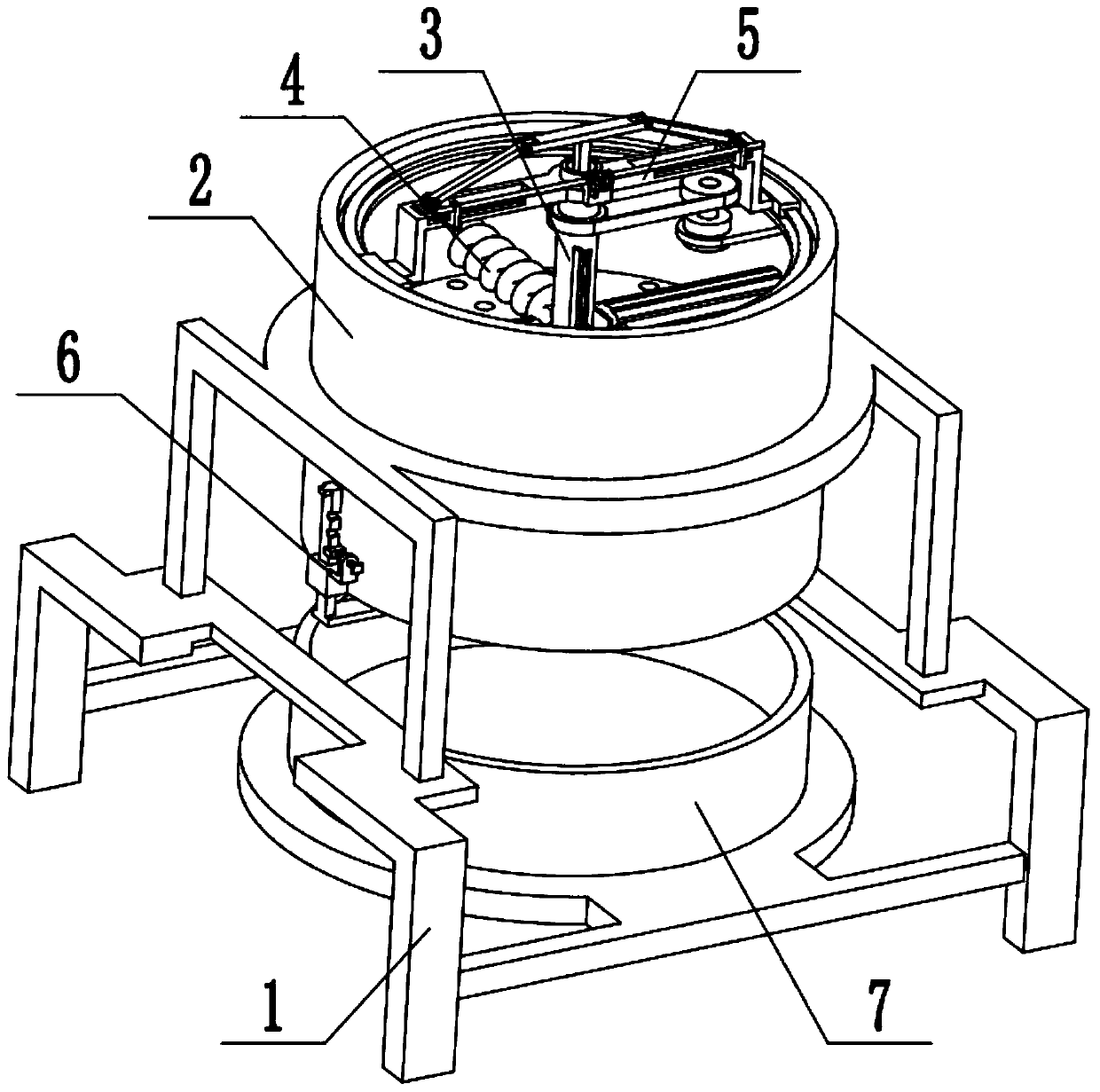

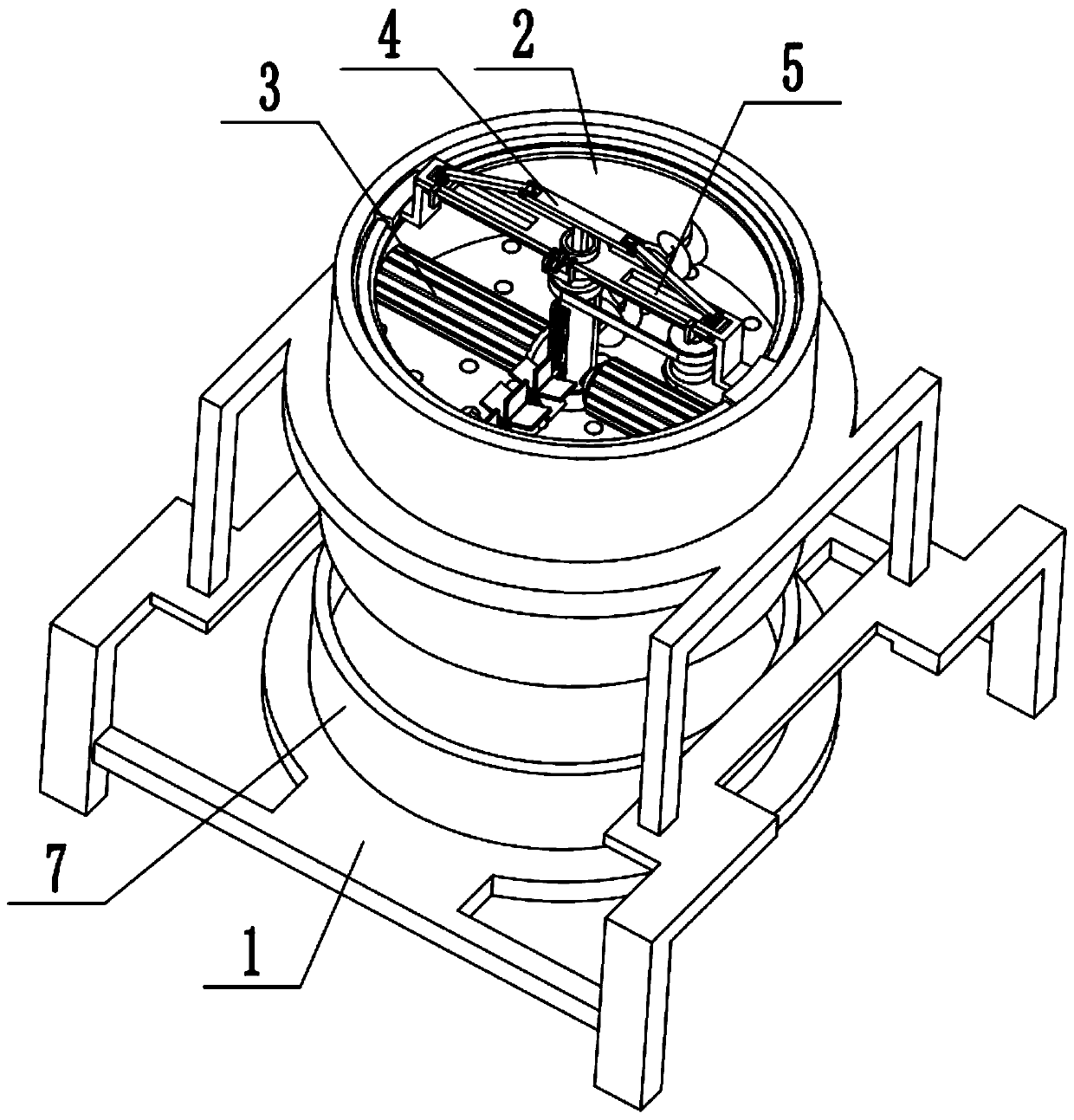

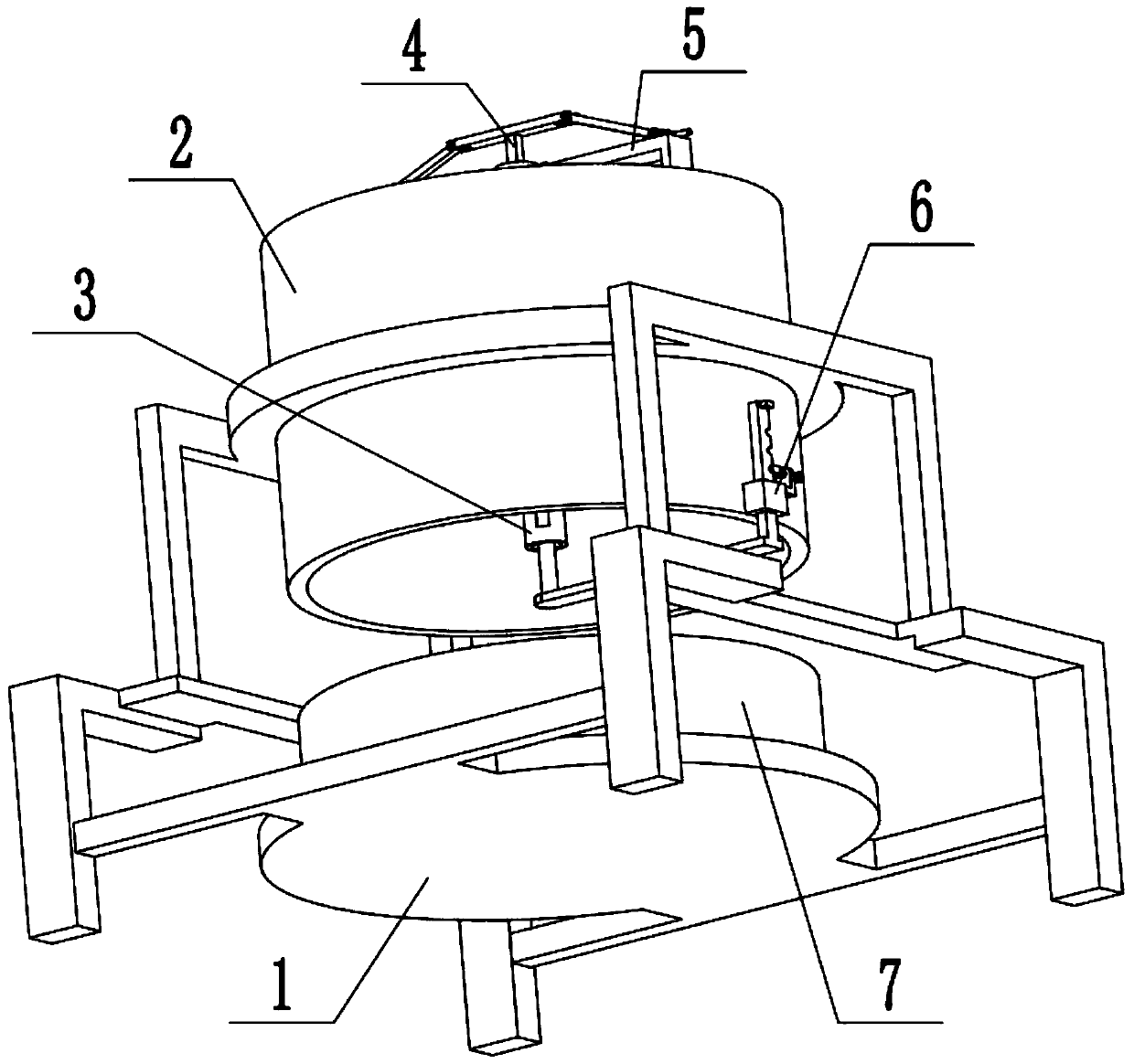

[0035] Combine below Figure 1-9 Describe this embodiment, a processing device for biomass fuel particles, including a support frame 1, a fuel processing cylinder 2, a particle processing driver 3, a fuel stirring and crushing mechanism 4, a reciprocating drive assembly 5, a cutting knife mechanism 6 and a receiving box 7. The fuel processing cylinder 2 is set on the support frame 1, the material receiving box 7 is placed on the support frame 1, the material receiving box 7 is located at the lower end of the fuel processing cylinder 2, and the particle processing drive member 3 is arranged on the fuel processing cylinder 2 Above, the particle processing drive part 3 is in transmission connection with the fuel processing cylinder 2, the lower end of the fuel stirring and crushing mechanism 4 is connected with the particle processing drive part 3, the upper end of the fuel stirring and crushing mechanism 4 is movably connected with the reciprocating drive assembly 5, and the reci...

specific Embodiment approach 2

[0037] Combine below Figure 1-10 To illustrate this embodiment, the support frame 1 includes a base plate 1-1, a side frame 1-2, a door frame 1-3 and a ring seat 1-4; the receiving box 7 is placed on the base plate 1- 1, the two ends of the base plate 1-1 are respectively fixedly connected to a side frame 1-2, and the two side frames 1-2 are respectively fixedly connected to a door frame 1-3, and the ring seat 1-4 is fixed Connected between the two gate frames 1-3, the fuel processing cylinder 2 is fixedly connected to the ring seat 1-4.

specific Embodiment approach 3

[0039] Combine below Figure 1-10 To illustrate this embodiment, the fuel processing cylinder 2 is provided with a trapezoidal ring seat 2-1, a ring frame 2-2, a circular hole seat plate 2-3, and a driving bevel gear 2-4; The upper end is fixedly connected to the ring frame 2-2, and the ring frame 2-2 is provided with a trapezoidal ring seat 2-1, and the circular hole seat plate 2-3 is fixedly connected to the middle end of the fuel processing cylinder 2, and the driving bevel gear 2-4 Fixedly connected on the round hole seat plate 2-3, the particle processing driving part 3 is arranged on the round hole seat plate 2-3, a plurality of circular through holes are uniformly distributed on the round hole seat plate 2-3, the particle processing driving part 3 is connected with the drive bevel gear 2-4, and the reciprocating drive assembly 5 is movably connected with the trapezoidal ring seat 2-1, and the reciprocating drive assembly 5 can rotate on the trapezoidal ring seat 2-1. P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com