Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

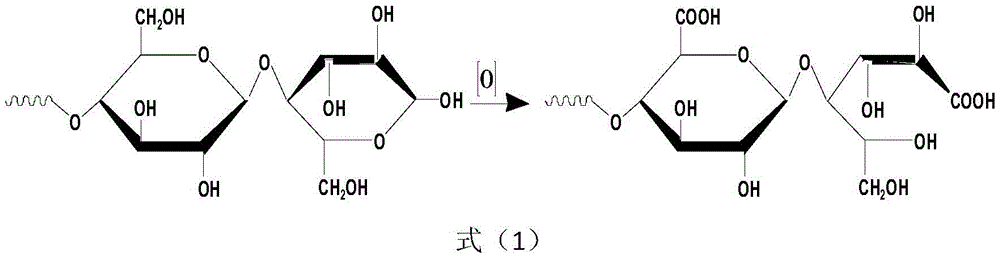

A technology of starch adhesives and oxidized cellulose, which is applied in the direction of cellulose adhesives, starch-derived adhesives, adhesives, etc., which can solve the problems of large energy consumption, reduced quantum size effect, and limited enhancement of adhesive strength, etc. problems, achieve the effects of reducing energy consumption, preventing agglomeration and coagulation, and improving compatibility and bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]A starch adhesive based on nano-oxidized cellulose slurry of the present invention, comprising the raw materials of the following components: 100 grams of oxidized cellulose slurry (solid content 8%) with an oxidation rate of 10%, 10 grams of starch, 2 The gram mass concentration is 30% oxidant H 2 o 2 , 0.2 gram of stabilizer polyvinyl alcohol, 0.1 gram of antiseptic ammonium pentaborate and 1 gram of emulsified paraffin; the nanofiber length in the nano-oxidized cellulose is 40% for a length of 1 to 100 nm; the length of a nanofiber for a content of 100 to 1000 nm 45%; fiber length 1μm ~ 10mm content is 15%.

[0034] The preparation method of the starch adhesive based on the nano-oxidized cellulose slurry of the present embodiment comprises the following steps:

[0035] (1) Take 8 grams of pulp board, add 80 grams of mass concentration to 20% sulfuric acid solution, shear and stir for 1h at a temperature of 50°C (shear rate is 2000rpm), and then add 1 gram of mass co...

Embodiment 2

[0040] A starch adhesive based on nano-oxidized cellulose slurry of the present invention, comprising the raw materials of the following components: 100 grams of oxidized cellulose slurry (solid content 10%) with an oxidation rate of 15%, 20 grams of starch, 5 Gram oxidant NaClO, 0.5 gram stabilizer polyvinyl alcohol, 0.2 gram preservative ammonium pentaborate and 0.5 gram emulsified paraffin; The nanofiber length in the nano-oxidized cellulose is 47% for the nanofiber length of 1~100nm; The nanofiber length is 100~ The content of 1000nm is 40%; the content of fiber length of 1 μm ~ 10mm is 13%.

[0041] The preparation method of the starch adhesive based on the nano-oxidized cellulose slurry of the present embodiment comprises the following steps:

[0042] (1) Take 10 grams of pulp board, add 90 grams of mass concentration to 40% sulfuric acid solution, shear and stir for 1 h (shear rate is 2000 rpm) at a temperature of 55 ° C, then add 1 gram of oxidant NaClO to continue she...

Embodiment 3

[0047] A starch adhesive based on nano-oxidized cellulose slurry of the present invention, comprising the raw materials of the following components: 100 grams of oxidized cellulose slurry (solid content 12%) with an oxidation rate of 20%, 30 grams of starch, 5 The gram mass concentration is 30% oxidant H 2 o 2 , 1 gram of stabilizer polyvinyl alcohol, 1 gram of antiseptic ammonium pentaborate and 1 gram of emulsified paraffin; the nanofiber length in the nano-oxidized cellulose is 60%; the nanofiber length is 100~1000nm 35%; fiber length 1μm ~ 10mm content is 10%.

[0048] The preparation method of the starch adhesive based on the nano-oxidized cellulose slurry of the present embodiment comprises the following steps:

[0049] (1) Take 10 grams of pulp board, add 90 grams of concentration into 50% sulfuric acid solution, shear and stir for 2 hours at a temperature of 55°C (shear rate is 4000rpm), then add 2 grams of oxidant with a mass concentration of 30% h 2 o 2 Continue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com