Patents

Literature

58results about How to "Full play to enhance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

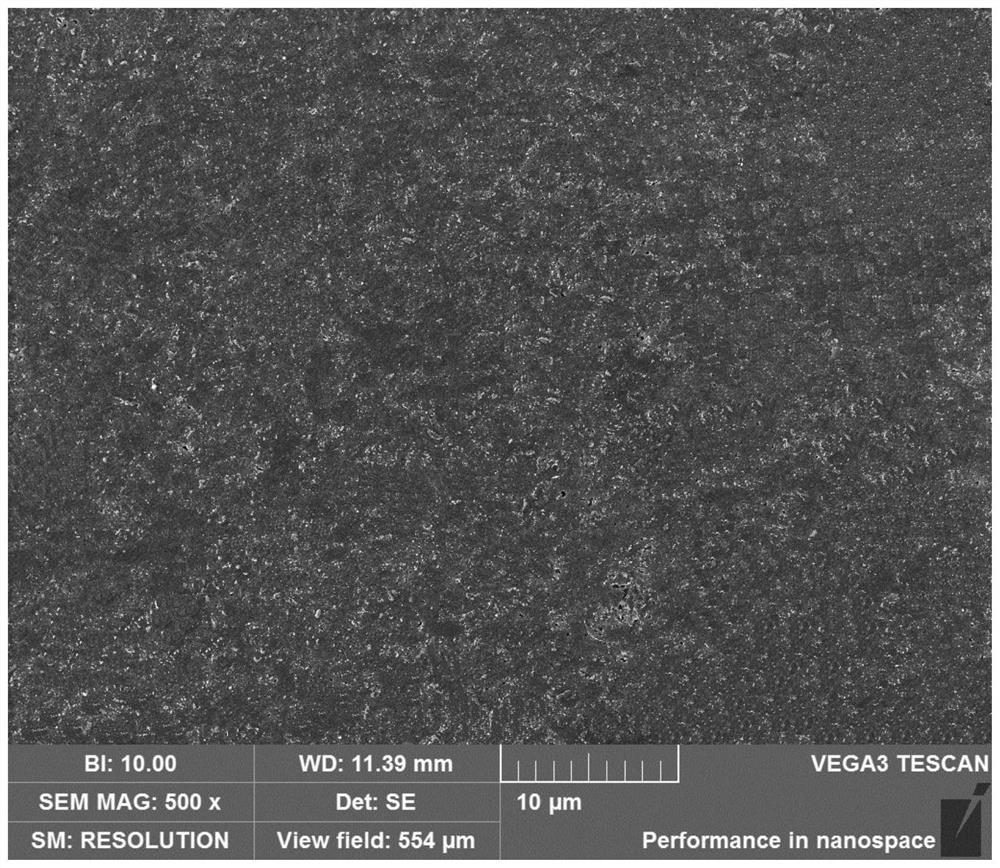

Preparation method of layered ternary ceramic reinforced copper composite material

The invention belongs to the technical field of powder metallurgy, and in particular relates to a preparation method of a layered ternary ceramic reinforced copper composite material. According to the preparation method, the reinforced effect of a strengthening phase can be fully exerted and the synergistic effect of a substrate and the strengthening phase are also fully exerted, so that the conductivity of the material is well matched with the strength of the substrate. The preparation method comprises the following steps: (1) carrying out ball-milling and mixing on 2wt%-45wt% of layered ternary metal ceramic powder and remained copper powder in a ball mill; (2) carrying out mould pressing on the mixed powder obtained in the step (1) so as to form a blocky green body; and (3) at the hydrogen or noble gas atmosphere, warming up the blocky green body to 800 DEG C-1250 DEG C at the warming speed rate of 20-40 DEG C / min, insulating for 0.5-3 hours, and cooling so as to obtain the layered ternary ceramic reinforced copper composite material.

Owner:CENT IRON & STEEL RES INST

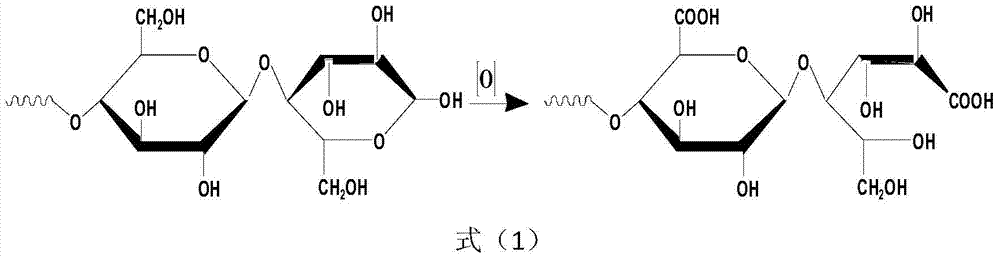

Starch adhesive with nanometer oxidized cellulose size as matrix and preparation method of starch adhesive

ActiveCN105542676AAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesPolymer scienceSlurry

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

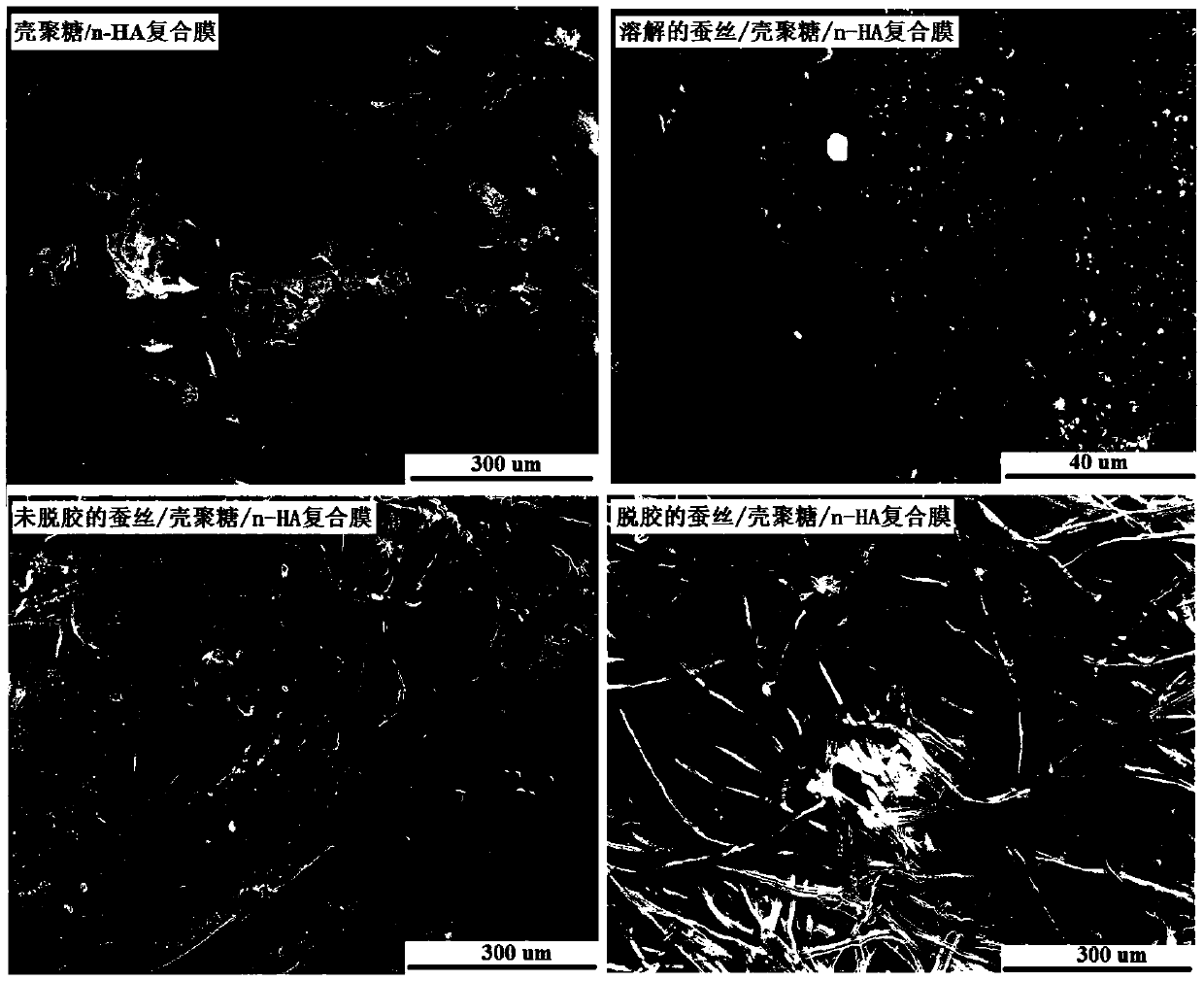

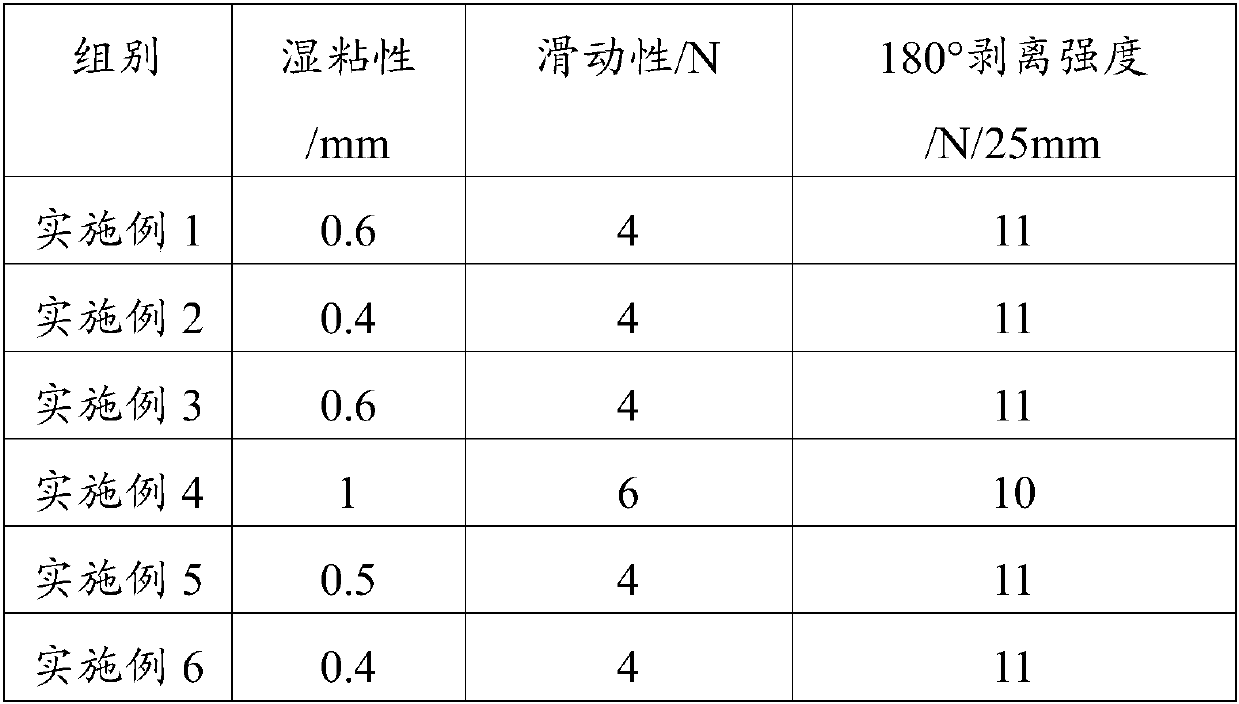

Starch adhesive and preparation method thereof

ActiveCN107779122AImprove water resistanceGood storage stabilityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveSolvent

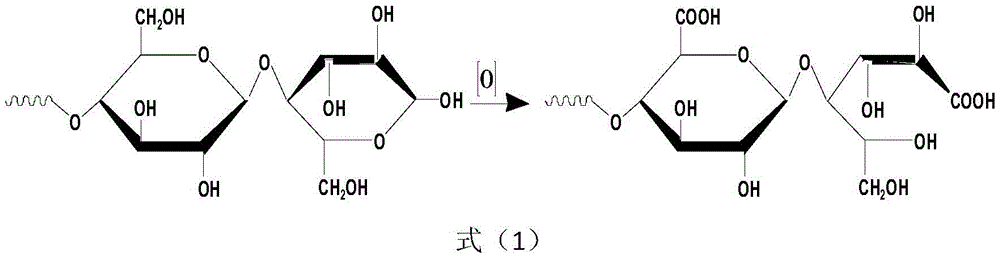

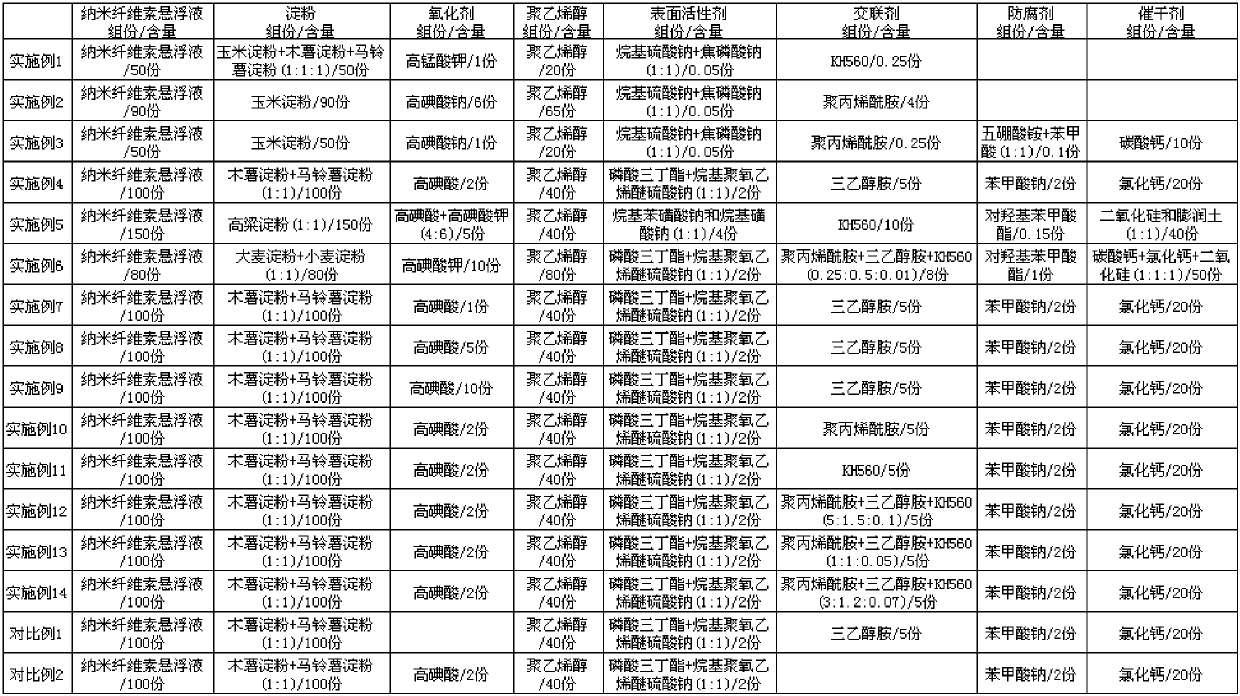

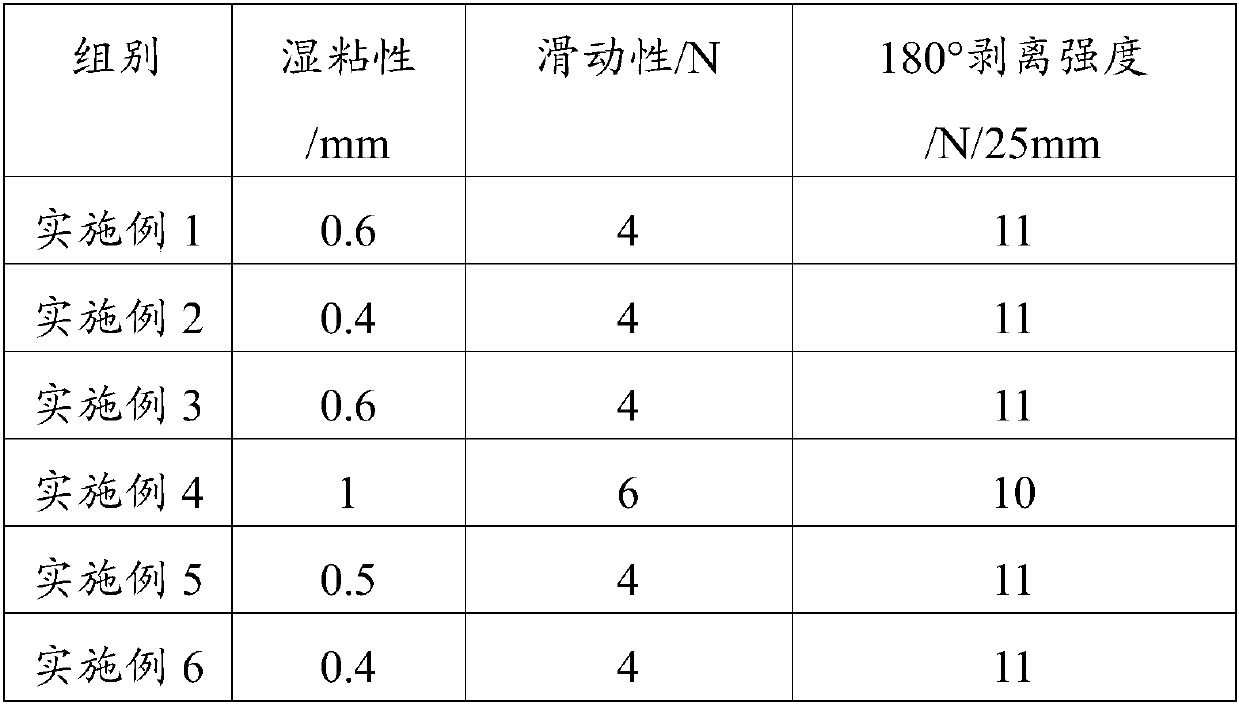

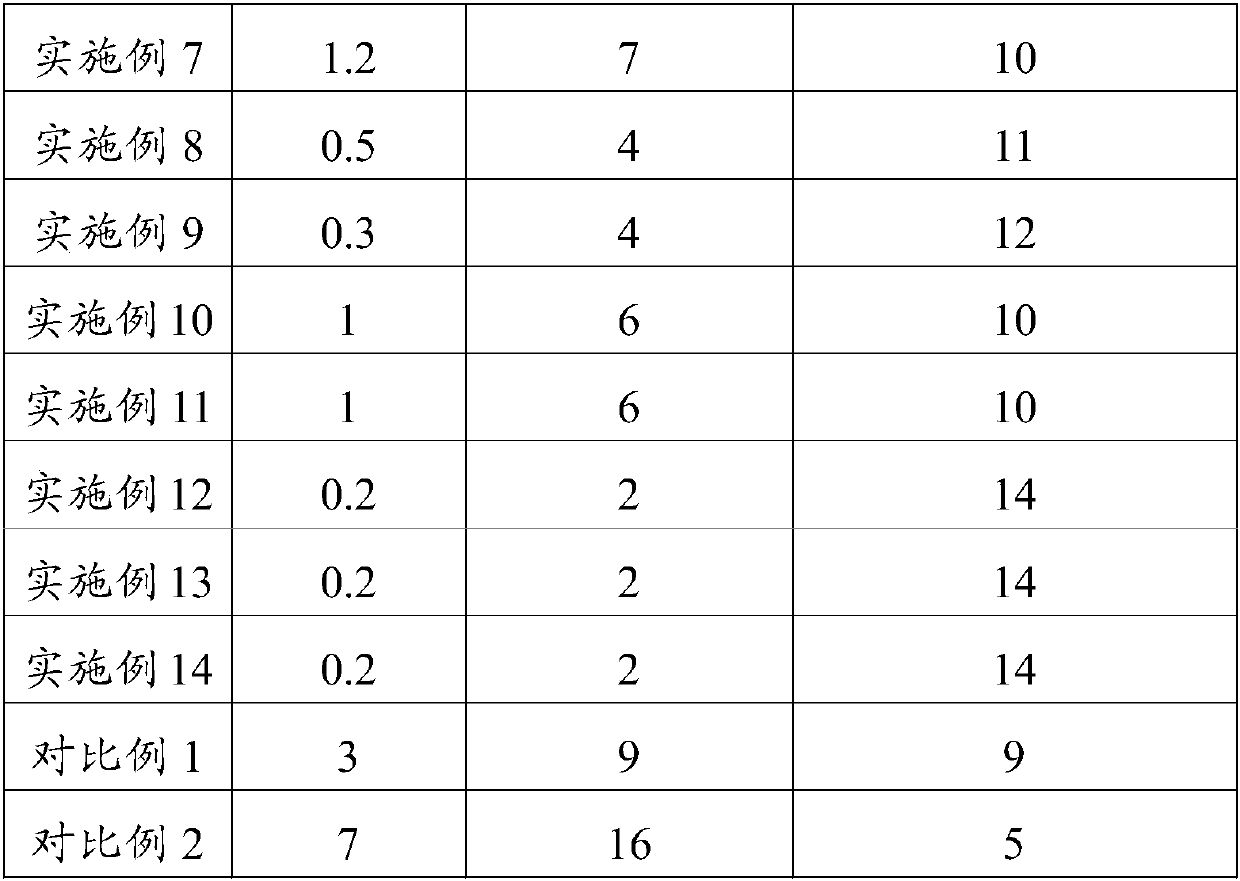

The application provides a starch adhesive. The starch adhesive is prepared from the following components in parts by weight: 50 to 150 parts of nanocellulose suspension, 50 to 150 parts of starch, 1to 10 parts of an oxidant, 20 to 80 parts of polyvinyl alcohol, 0.01 to 5 parts of a surfactant and 0.25 to 10 parts of a crosslinking agent. The starch adhesive has good properties including good waterproof performance, good storage stability, excellent initial adhesion, great adhesion, good flowability and good coagulation resistance. The application further provides a preparation method of thestarch adhesive. The preparation method comprises the following steps: (1) preparing the nanocellulose suspension, preparing a polyvinyl alcohol solution and preparing a dialdehyde starch solution; and (2) mixing the dialdehyde starch solution, the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent and stirring and reacting with certain pH value and temperature toprepare the starch adhesive. According to the method provided by the invention, starch and waste paper products are used as raw materials, aldehyde substances are not added in a reaction process and water is used as a solvent; and a production technology and a product have an environment-friendly property and all the raw materials can react sufficiently.

Owner:GUANGDONG YULAN GRP

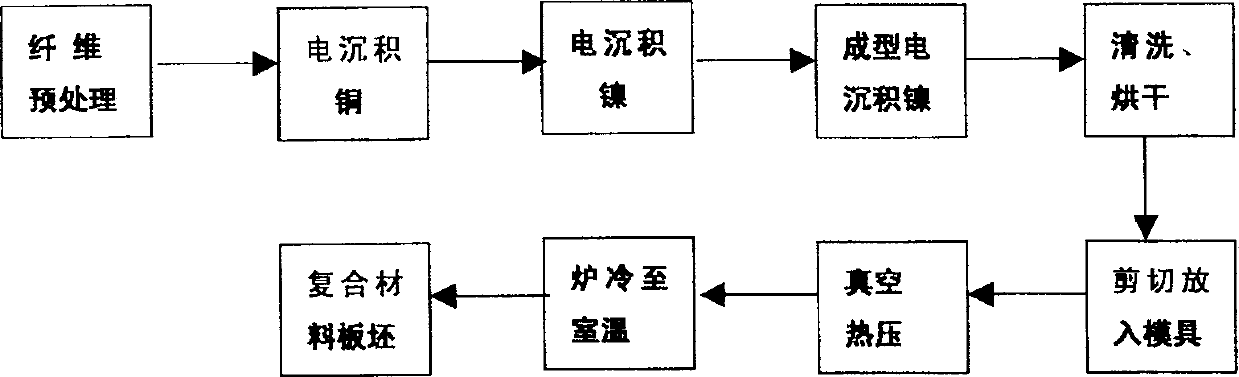

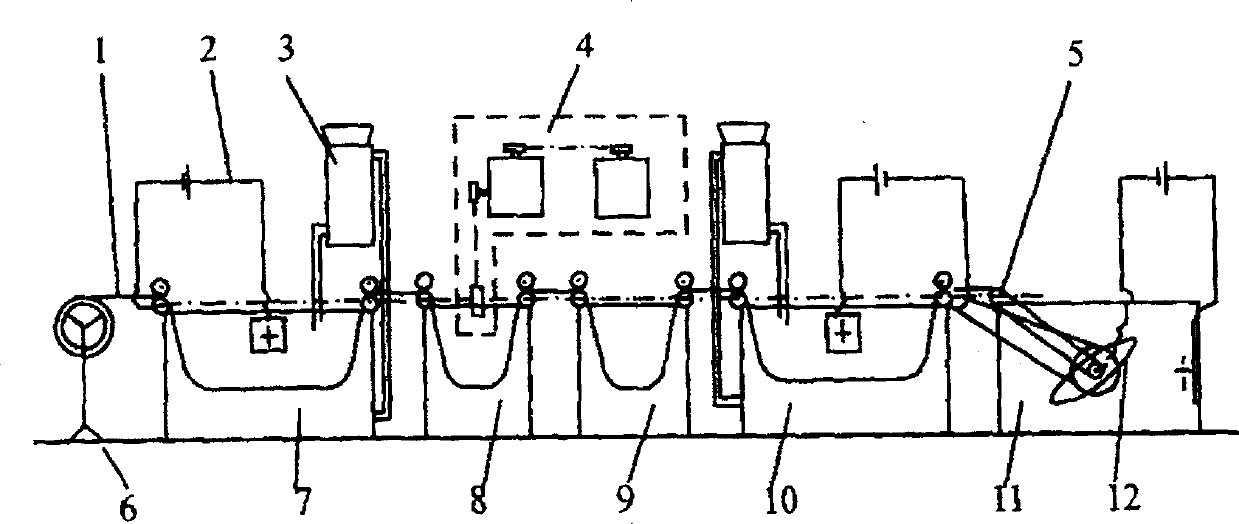

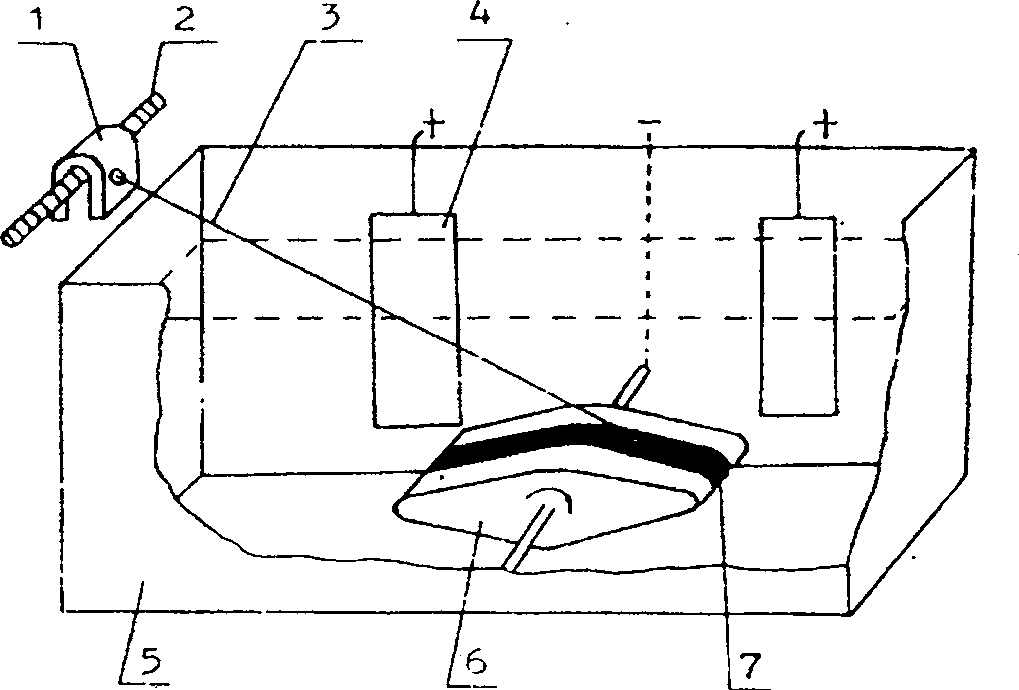

Carbon fiber reinforced nickel-based composite material and producing method thereof

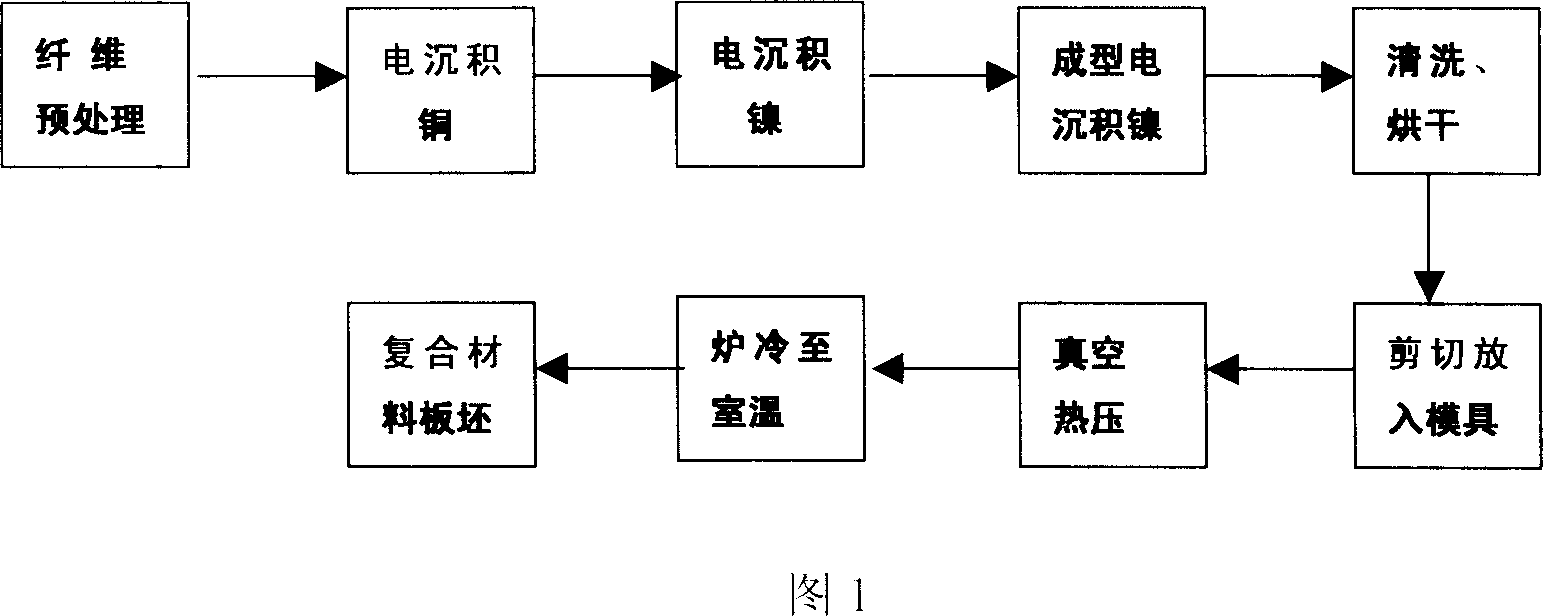

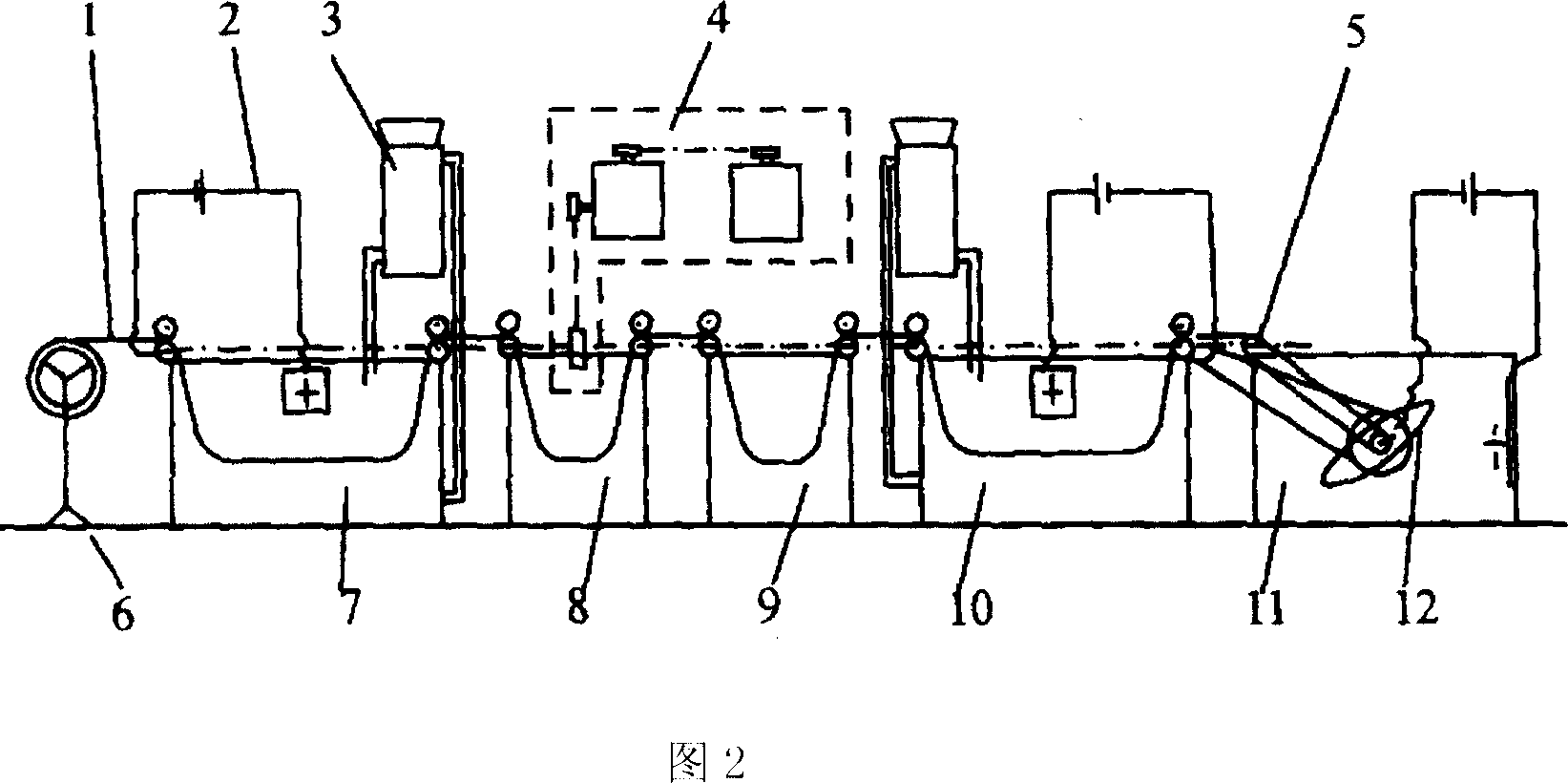

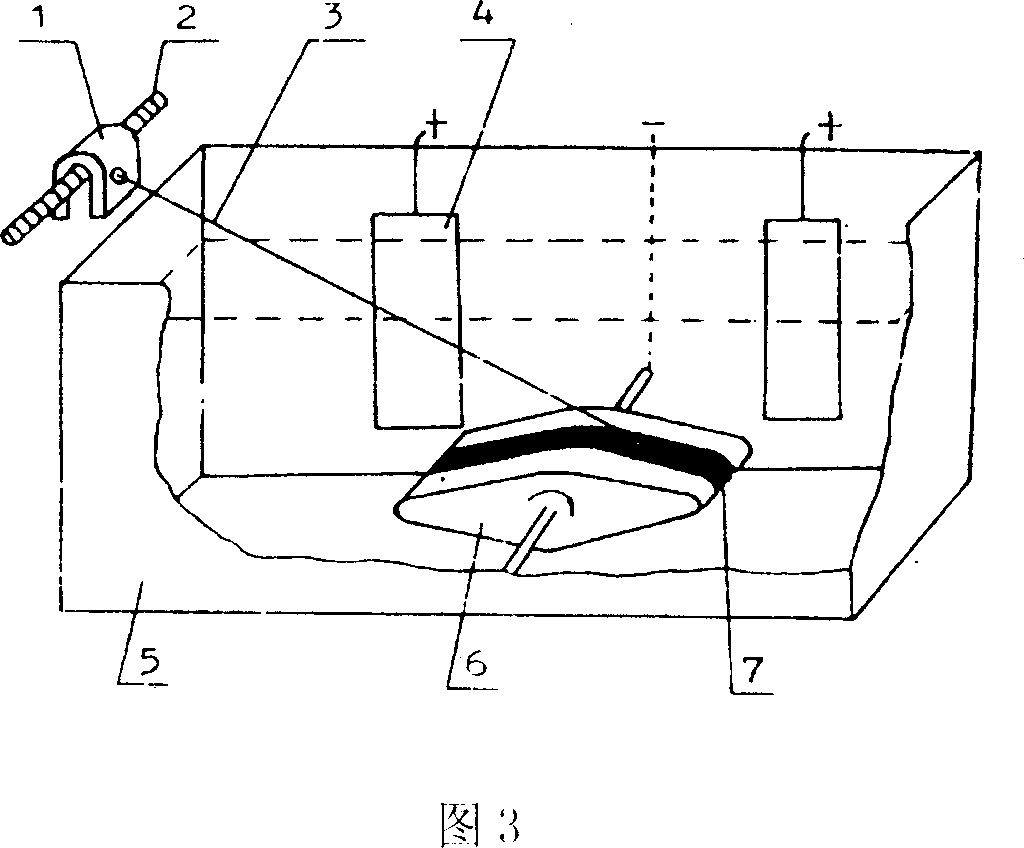

The present invention discloses one kind of carbon fiber reinforced Ni-base composite material and its preparation process, and relates to metal-base composite material. The carbon fiber reinforced Ni-base composite material consists of carbon fiber 30-35 vol%, Cu 6-8 vol %, and Ni 57-64 vol %. The technological process of preparing the composite material includes the steps of: pre-treatment of carbon fiber, electrodepositing Cu, washing, neutralizing, electrodepositing Ni, electrodepositing Ni to form, washing, stoving, cutting, vacuum hot pressing in mold, and cooling in the furnace. The present invention prepares the composite material in a three-step electrodepositing process, and the composite material has high heat strength, high elastic modulus, low density, high smelting point and other advantages, and may be used in the vane of gas-burning turbine engine, etc.

Owner:ZHONGBEI UNIV

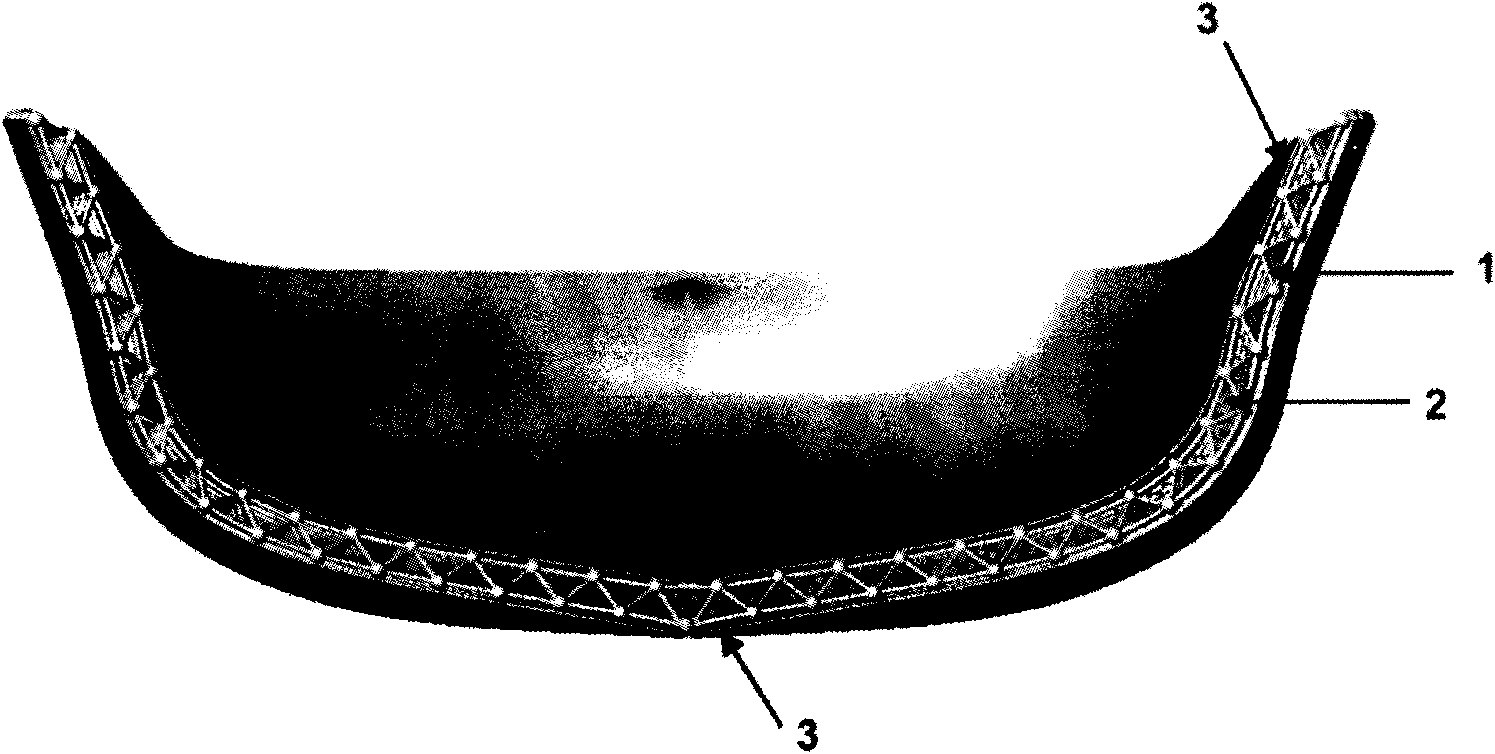

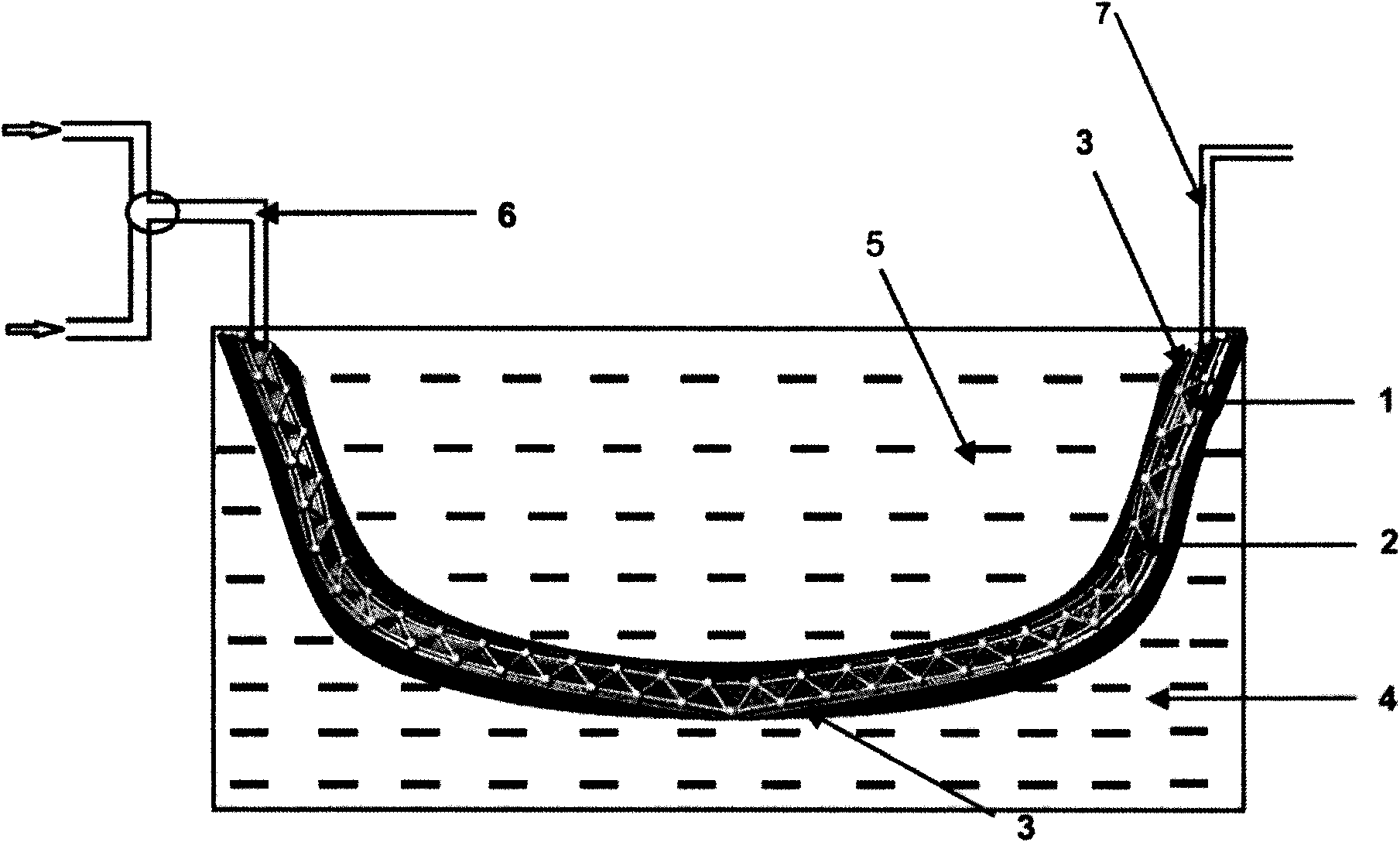

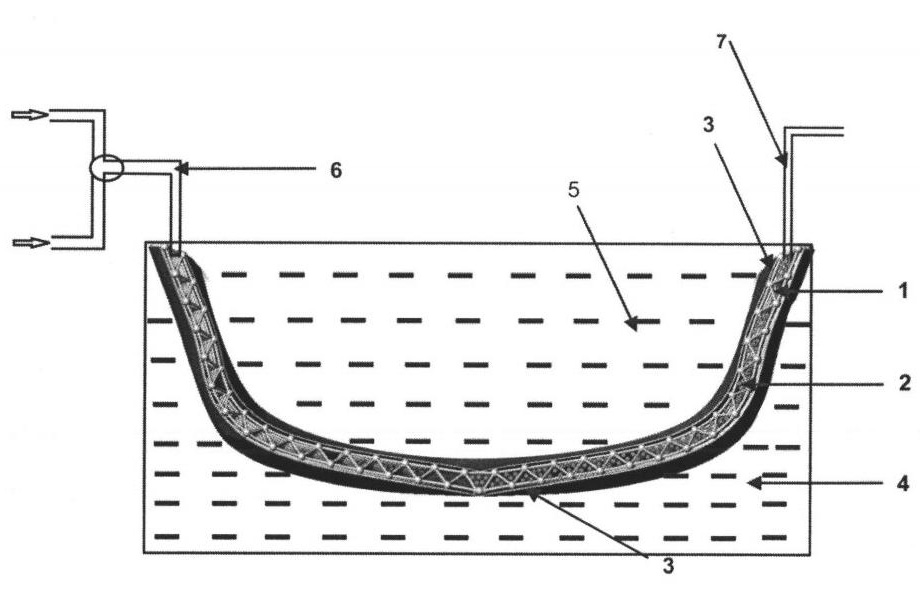

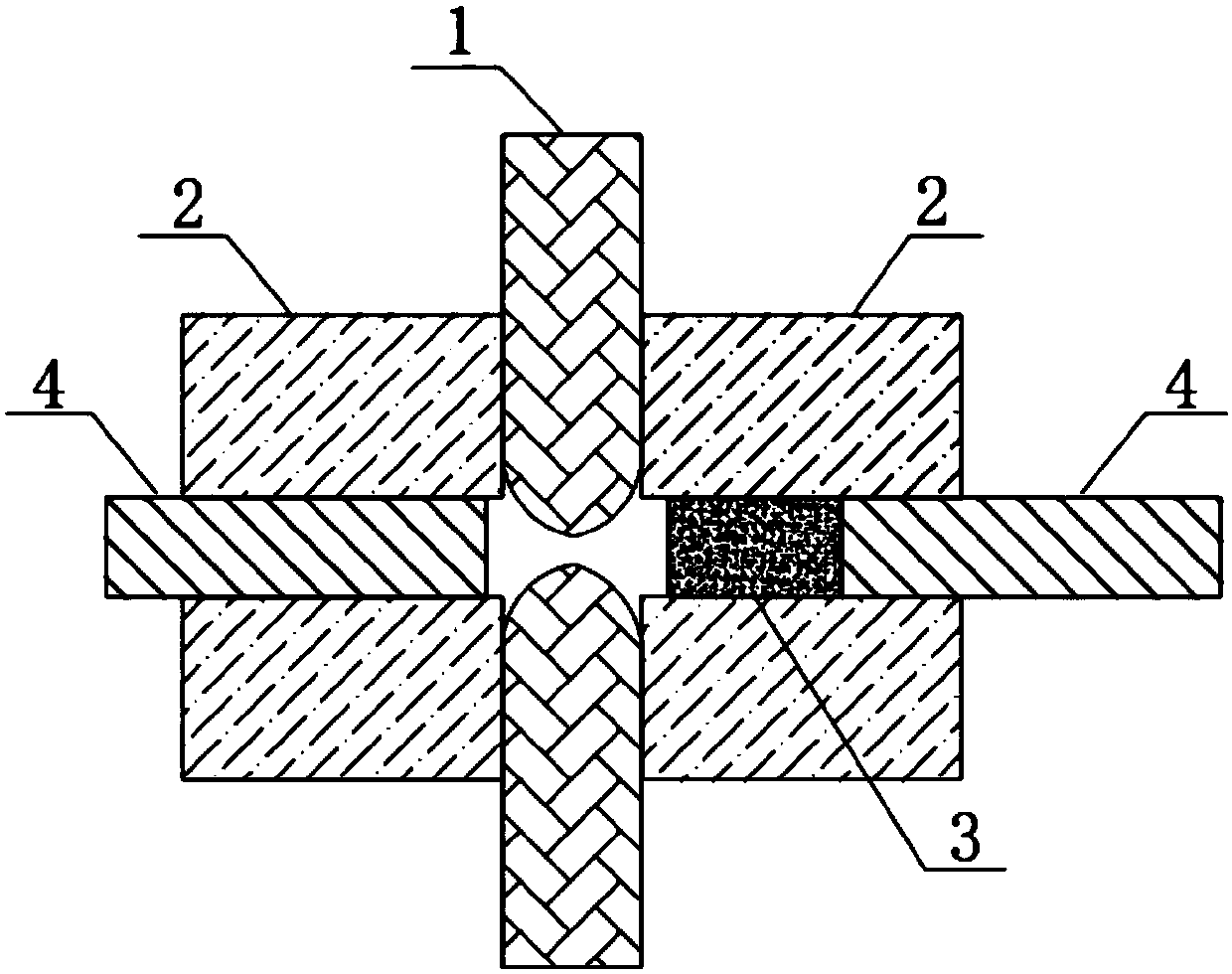

Truss framework composite material product, and flowing medium forming mould and forming method thereof

The invention discloses a truss framework composite material product, and a flowing medium forming mould and a forming method thereof. The truss framework composite material product consists of a framework reinforcing material, a skin material and a filling material, wherein the framework reinforcing material is formed by fixedly connecting rods and has the profile of the product; the skin material is attached to nodes of the framework reinforcing material, which serve as an outer profile; the filling material is embedded between the rods of the framework reinforcing material in the skin material; the flowing medium forming mould of the truss framework composite material product comprises a container, a cavity, a potting device and a flowing medium; and the forming method of the truss framework composite material product comprises the steps of potting the filling material into the cavity and curing the filling material to obtain the product. In the invention, the step of manufacturingthe mould cavity is saved, so that the manufacturing cost can be greatly reduced and the reinforcement function of the framework material can be fully exerted. The size of the product can be very large and is not limited to the conventional machining equipment, the length and the number of the rods of the reinforcing material are changed, and the skin material and the reinforcing material can very easily form the new cavity, so that the upgrading speed of the product is increased.

Owner:QINGDAO UNIV OF SCI & TECH +1

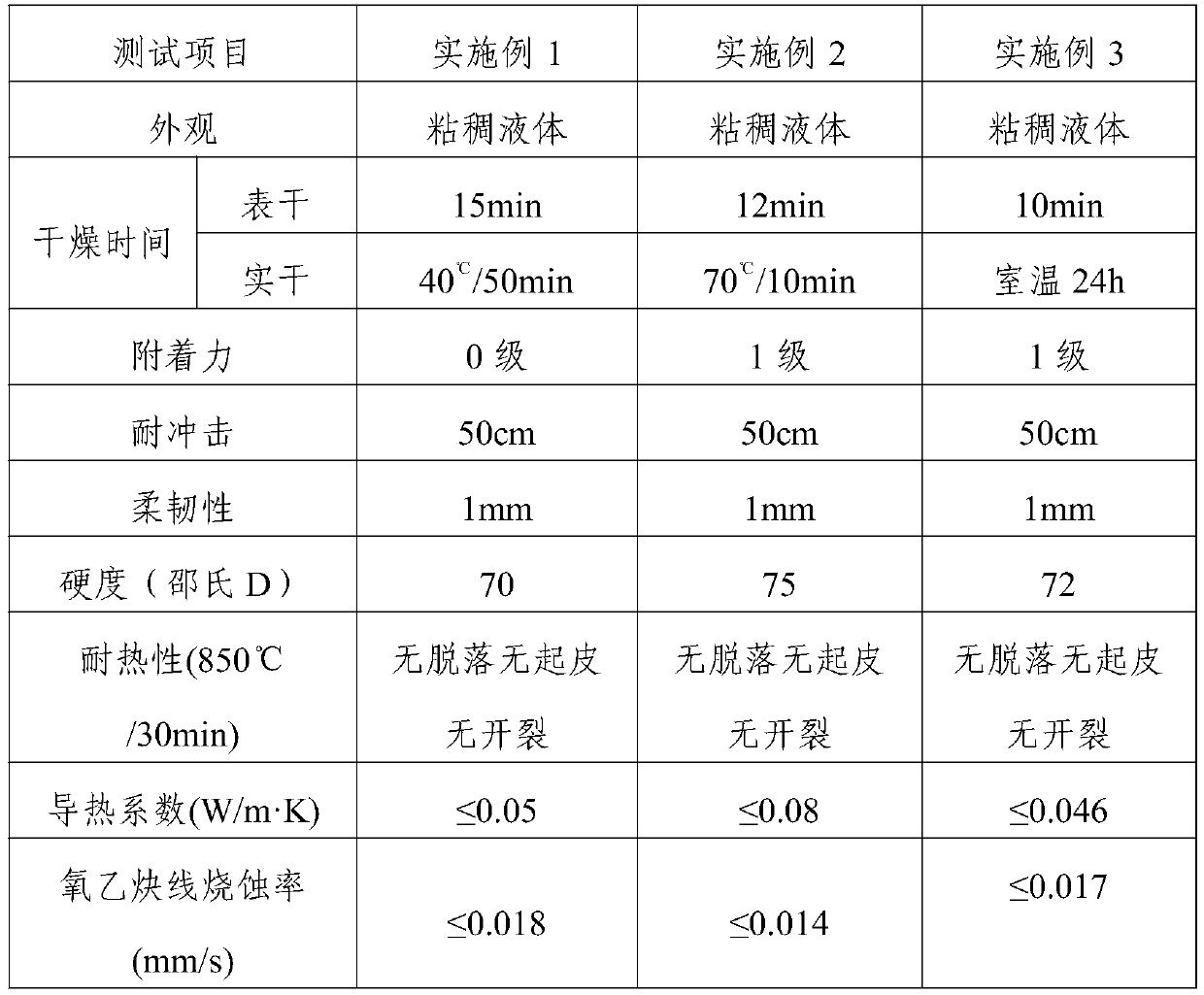

Porcelainizing ablation-resistant coating and preparation method thereof

ActiveCN111171721ALow thermal conductivityReduce wire ablation rateFireproof paintsFlight vehicleUltimate tensile strength

According to the porcelainizing ablation-resistant coating and the preparation method thereof provided by the invention, the porcelainizing ablation-resistant coating is obtained by optimizing the composition and proportion of the coating, and the coating formed by the prepared coating is high in bonding strength, can bear instantaneous high temperature of 1500 DEG C or above, and has a more excellent flame-retardant effect and mechanical strength. A ablation-resistant coating prepared by the method has the advantages of low heat conductivity coefficient, low linear ablation rate, high mechanical property, excellent manufacturability and the like. The preparation method disclosed by the invention is simple, and an effective way is provided for industrially preparing the ablation-resistantcoating on a large scale. The ablation-resistant coating can be cured at room temperature, the heat conductivity coefficient is lower than 0.1 W / (m.k), the linear ablation rate is lower than 0.02 mm / s, and the ablation-resistant coating has a very wide application prospect in an aircraft surface thermal protection system.

Owner:XIAN MODERN CHEM RES INST

Short carbon fiber reinforced phenol formaldehyde resin-based composite material and preparation method thereof

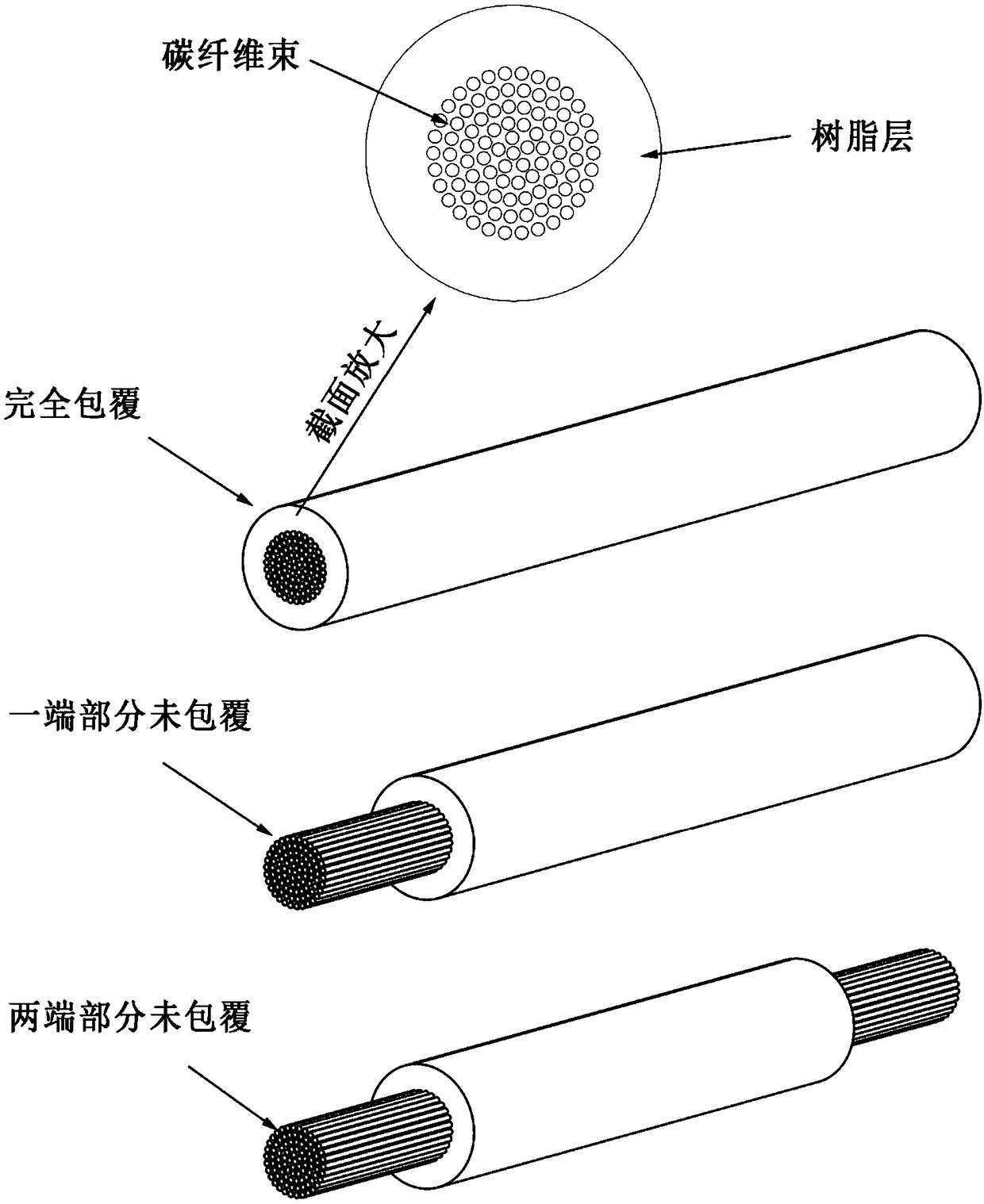

The invention discloses a short carbon fiber reinforced phenol formaldehyde resin-based composite material and a preparation method thereof. The preparation method comprises: carrying out high-temperature heat treatment on a continuous carbon fiber bundle to remove surface metal ions and impurities, washing until the surface is free of glue, and drying to obtain a pre-treated continuous carbon fiber bundle; preparing a short carbon fiber bundle coated with a phenol formaldehyde resin layer on the surface from the pre-treated continuous carbon fiber bundle by using equipment for preparing a short carbon fiber bundle coated with a phenol formaldehyde resin layer on the surface; mixing the short carbon fiber bundle coated with the phenol formaldehyde resin layer on the surface and phenol formaldehyde resin powder according to a certain ratio to obtain a mixture; pre-treating the mixture, and carrying out cold pressing pre-molding to prepare a pre-molded plate material; and loading the pre-molded plate material in a hot pressing mold, carrying out curing molding, and carrying out post-treatment to obtain the short carbon fiber reinforced phenol formaldehyde resin-based composite material.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

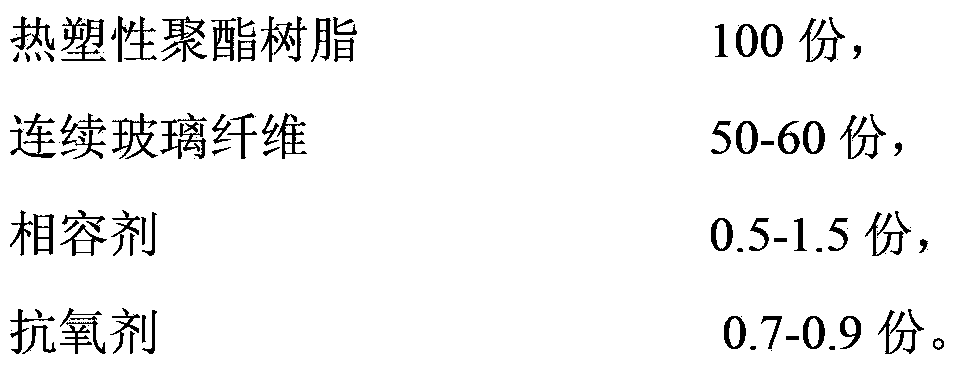

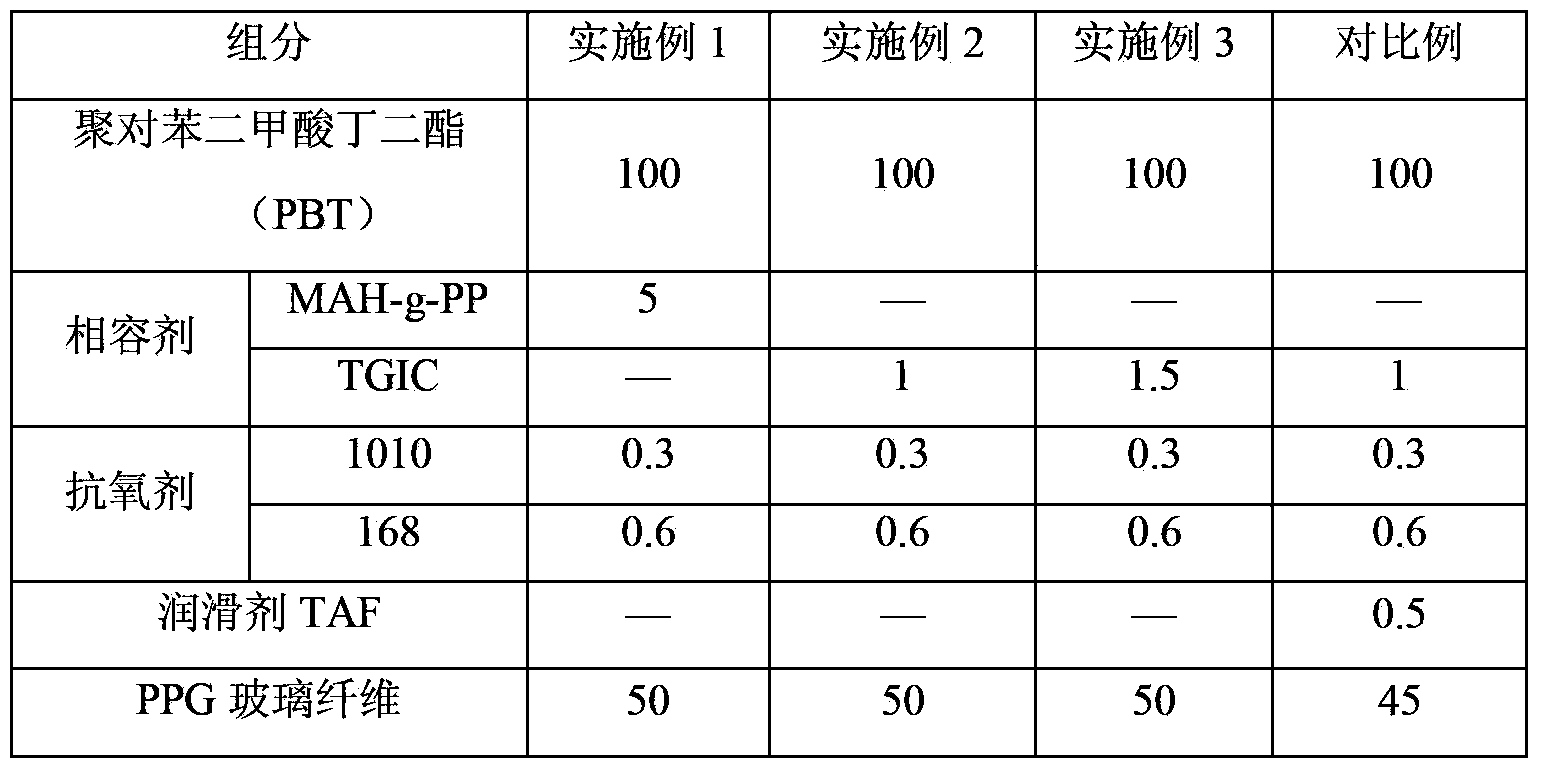

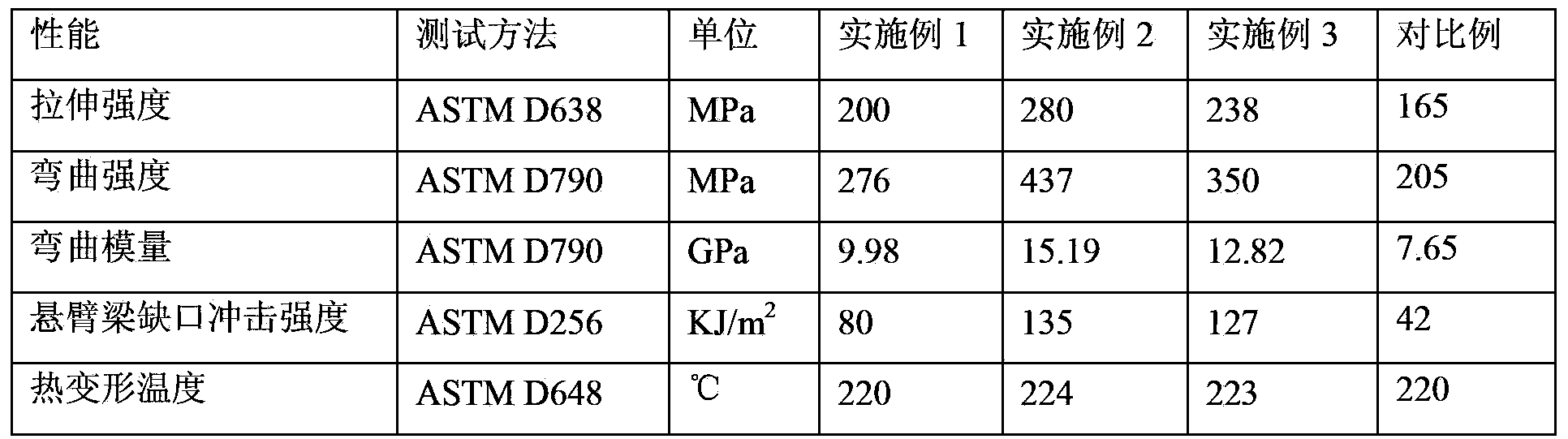

High-performance thermoplastic polyester composite material and preparation method thereof

The invention belongs to the technical field of composite materials and relates to a thermoplastic polyester composite material and a preparation method thereof. The composite material consists of the following components in parts by mass: 50-60 parts of continuous glass fiber, 100 parts of thermoplastic polyester resin, 0.5-1.5 parts of a compatilizer and 0.7-0.9 part of an antioxidant. The composite material disclosed by the invention has the advantages that the composite board is light in weight, has high heat resistance and high mechanical property, particularly, has obvious bending performance, is environmental friendly and has recyclability.

Owner:LIAONING LIAOJIE SCI & TECH

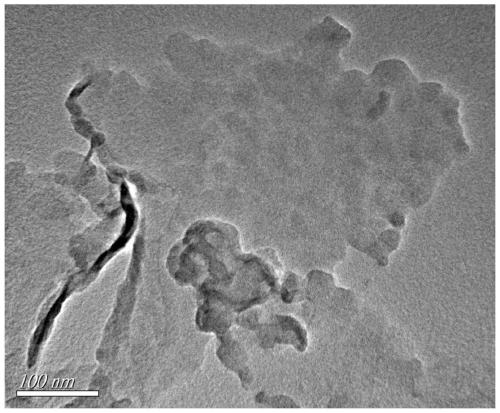

G-C3N4/CNT nanohybrid material modified PPESK lubricating film and preparation method thereof

ActiveCN111218113AStrong corrosion resistanceImprove anti-friction performanceFilm materialPolymer chemistry

The invention provides a g-C3N4 / CNT nanohybrid material modified PPESK lubricating film and a preparation method thereof, and belongs to the technical field of film material preparation. Urea and CNTare calcined to prepare g-C3N4 / CNT nanohybrid material modified PPESK resin, and then the modified PPESK lubricating film with high performances is prepared. The prepared film has high strength and toughness and outstanding tribological properties, and the preparation method is mild in reaction conditions, simple in preparation process, easy to operate, low in cost and suitable for large-scale production of polymer self-lubricating composite films.

Owner:JIANGSU UNIV

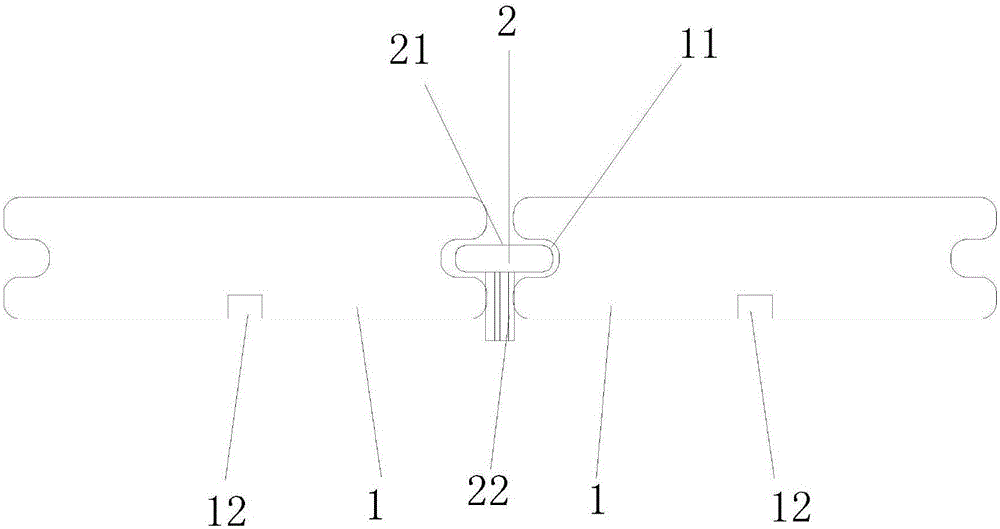

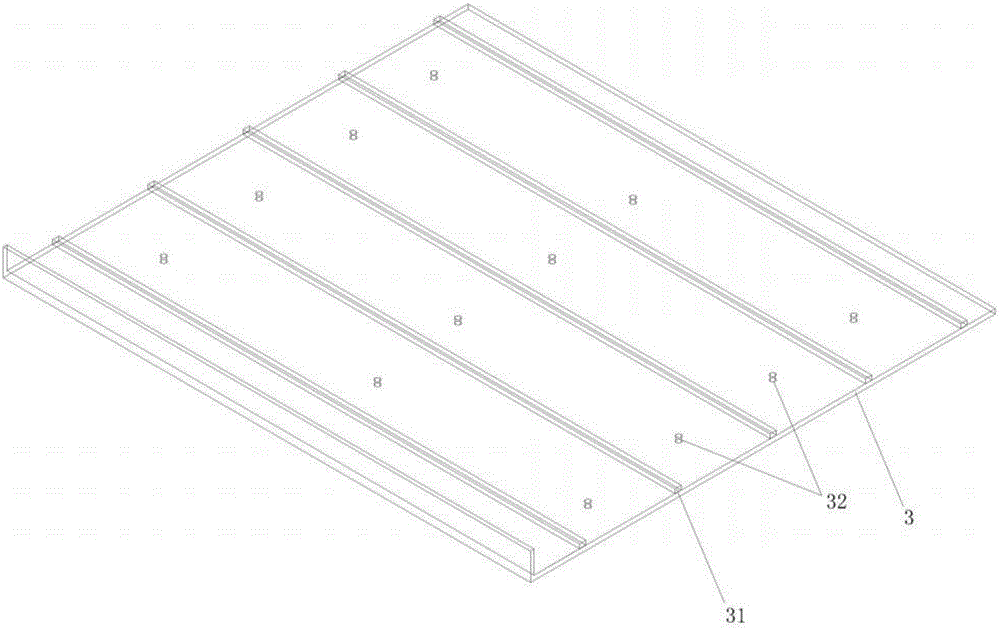

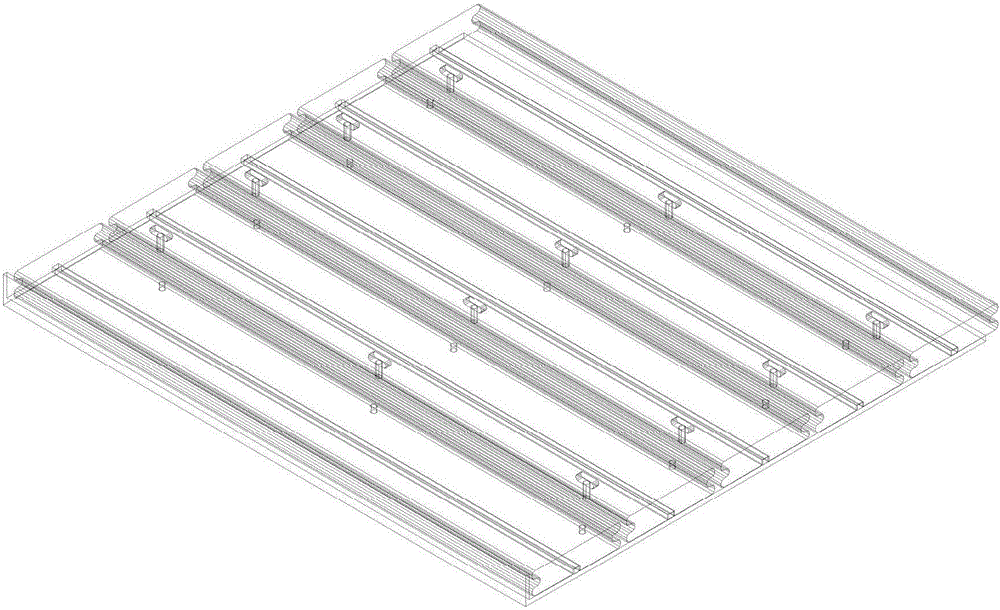

Wood-plastic flooring structure convenient and quick to install

InactiveCN106049807AEffective moisture-proofEasy to installFlooring insulationsEngineeringMechanical engineering

Owner:ANHUI GUOFENG WOOD PLASTIC COMPOSITE

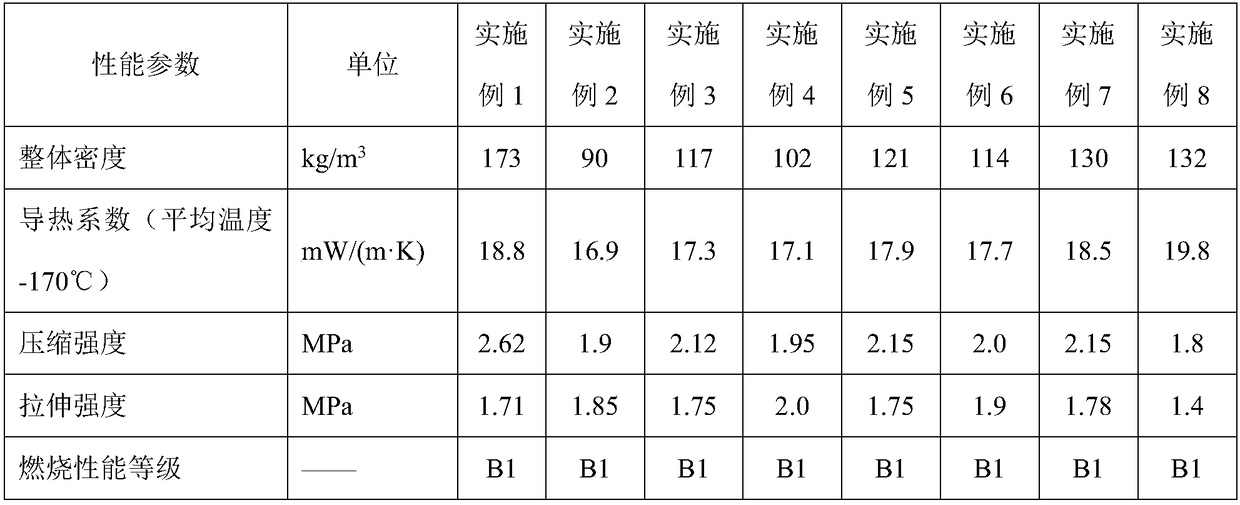

Cryogenic insulation material for low-temperature storage, transportation and application equipment, and preparation method thereof

The invention discloses a cryogenic insulation material for low-temperature storage, transportation and application equipment, and a preparation method thereof. The cryogenic insulation material is prepared by reacting a reinforced fiber, a filler and a rigid polyurethane foam foaming material, and is prepared from the components in parts by weight: 50 to 60 parts of reinforced fiber, 0.1 to 20 parts of filler, and 20 to 49.9 parts of rigid polyurethane foam foaming material. The preparation method of the cryogenic insulation material comprises the steps of blending the reinforced fiber and the filler according to the proportion so as to obtain a mixture; adding the rigid polyurethane foam foaming material into the mixture, fully mixing, and then pouring; and curing and forming to obtain the cryogenic insulation material. The cryogenic insulation material has the overall density being 80 to 200kg / m<3>, the heat conductivity coefficient being less than or equal to 22.0mW / (m.K) at the average temperature of minus 170 DEG C, the compression strength being larger than or equal to 1.5MPa at the temperature of minus 170 DEG C, the tensile strength being larger than or equal to 0.6MPa, and the combustion performance level being not lower than the B1 level in GB8624-2012 'building material and product combustion performance classification'.

Owner:南京红宝丽新材料有限公司

Method for preparing nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion

ActiveCN107774732AReduce defectsNo ruptureExtrusion containersExtrusion control devicesUltimate tensile strengthThermal treatment

The invention discloses a method for preparing a nano quasi-crystal reinforced Mg-Zn-Y alloy through reciprocation extrusion. The method comprises the following steps: A, preparing cast Mg-Zn-Y alloyaccording to atom percentages of set component elements as follows: 0.5-6% of Zn, 0.08-1.2% of Y and the balance of Mg, and the content ratio of atoms of Zn and Y is (5-7):1; B, annealing the cast Mg-Zn-Y alloy for 8-20 hours at 380-420 DEG C, and performing furnace cooling; C, keeping the temperature of the annealed Mg-Zn-Y alloy at 300-400 DEG C for 2-4 hours, and performing thermal extrusion, wherein the extrusion temperature is 300-400 DEG C, and the extrusion ratio is (9-60):1; D, putting the Mg-Zn-Y alloy after thermal extrusion processing in the step C into a thermal treatment furnace,heating to 540-600 DEG C, keeping the temperature for 5-20 minutes, and performing quenching; and E, keeping the temperature of the Mg-Zn-Y alloy obtained in the step D at 200-380 DEG C for 2-4 hours,and performing reciprocation extrusion, thereby obtaining the alloy. By adopting the method, a magnesium alloy which is excellent in yield strength, tension strength and ductility can be prepared.

Owner:SOUTHWEST JIAOTONG UNIV

Polypropylene composite cable material and preparation method thereof

InactiveCN106479056AImprove compatibilityHigh bonding strengthPlastic/resin/waxes insulatorsFire retardantPolypropylene composites

The invention provides a polypropylene composite cable material and a preparation method thereof. The polypropylene composite cable material is prepared by, by weight, 100 parts of polypropylene resin, 0.5-1 part of nucleating agent, 0.4-0.9 part of antioxidant, 1-2 parts of lubricating agent, 3-4 parts of impact modifier, 10-15 parts of flame retardant, 5-10 parts of compatibilizer, 0.6-1.1 part of anti-ultraviolet agent and 14-19 parts of modified pottery clay. The polypropylene composite cable material is high in mechanical performance.

Owner:佛山慧创正元新材料科技有限公司

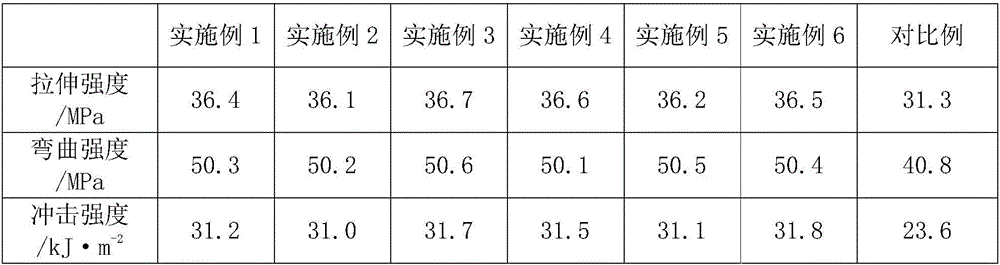

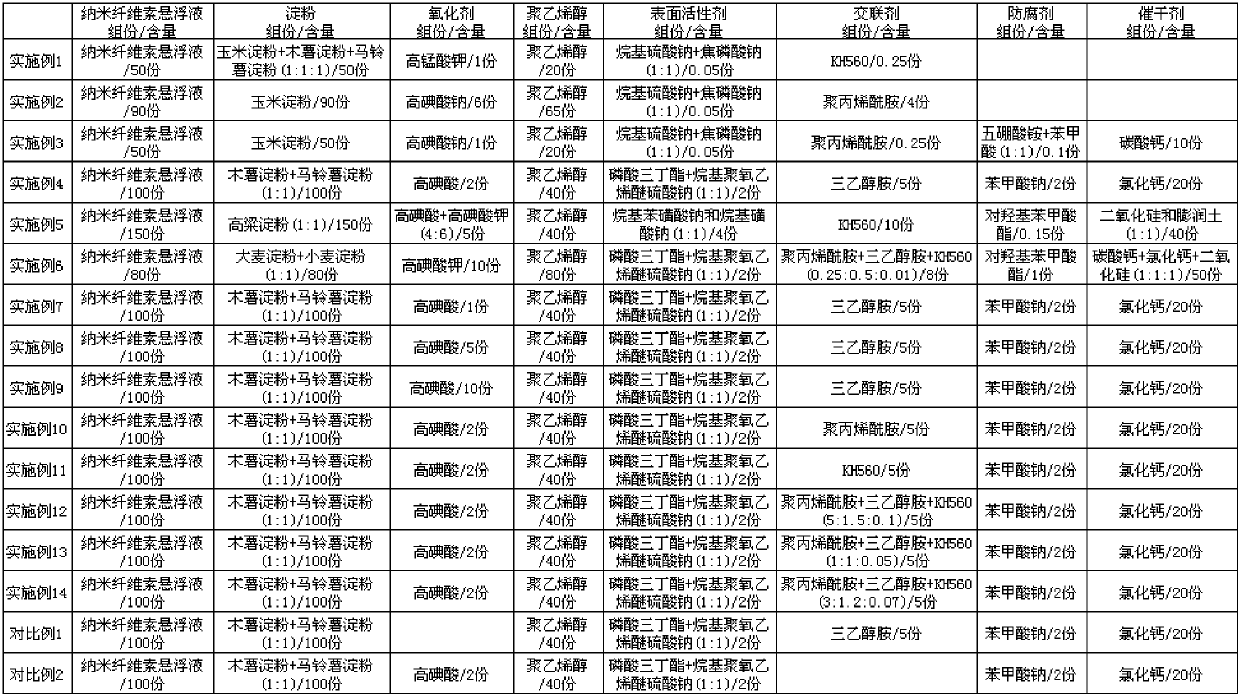

Natural silk-reinforced hydroxyapatite/chitosan composite film and preparation method thereof

ActiveCN110721348AGood biocompatibilityPrevent wound infectionSurgeryPharmaceutical delivery mechanismPolymer chemistryHydroxyapatites

The invention discloses a natural silk-reinforced hydroxyapatite / chitosan composite film and a preparation method thereof. The composite film is obtained by a method of combining solution-casting andfiber in-situ reinforcement. The preparation method of the composite film comprises the following steps: firstly preparing a uniform composite liquid from nano-hydroxyapatite and chitosan; then casting a half of the nano-hydroxyapatite / chitosan composite solution into a film; thirdly laying natural silk on the film; and finally casting the remaining half of the nano-hydroxyapatite / chitosan composite solution on the silk and naturally drying to obtain the composite film. The novel composite film has rich sources of the raw materials, and the preparation method is simple. In addition, mechanicalproperties, degradation performance, osteoconductivity and antibacterial properties of the composite film can be regulated and controlled by component contents of the composite film, and the composite film with excellent performance is expected to be obtained for guiding bone tissue regeneration membranes.

Owner:HUNAN NORMAL UNIVERSITY

A kind of starch adhesive and preparation method thereof

ActiveCN107779122BImprove water resistanceGood storage stabilityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveSolvent

The application provides a starch adhesive. The starch adhesive is prepared from the following components in parts by weight: 50 to 150 parts of nanocellulose suspension, 50 to 150 parts of starch, 1to 10 parts of an oxidant, 20 to 80 parts of polyvinyl alcohol, 0.01 to 5 parts of a surfactant and 0.25 to 10 parts of a crosslinking agent. The starch adhesive has good properties including good waterproof performance, good storage stability, excellent initial adhesion, great adhesion, good flowability and good coagulation resistance. The application further provides a preparation method of thestarch adhesive. The preparation method comprises the following steps: (1) preparing the nanocellulose suspension, preparing a polyvinyl alcohol solution and preparing a dialdehyde starch solution; and (2) mixing the dialdehyde starch solution, the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent and stirring and reacting with certain pH value and temperature toprepare the starch adhesive. According to the method provided by the invention, starch and waste paper products are used as raw materials, aldehyde substances are not added in a reaction process and water is used as a solvent; and a production technology and a product have an environment-friendly property and all the raw materials can react sufficiently.

Owner:GUANGDONG YULAN GRP

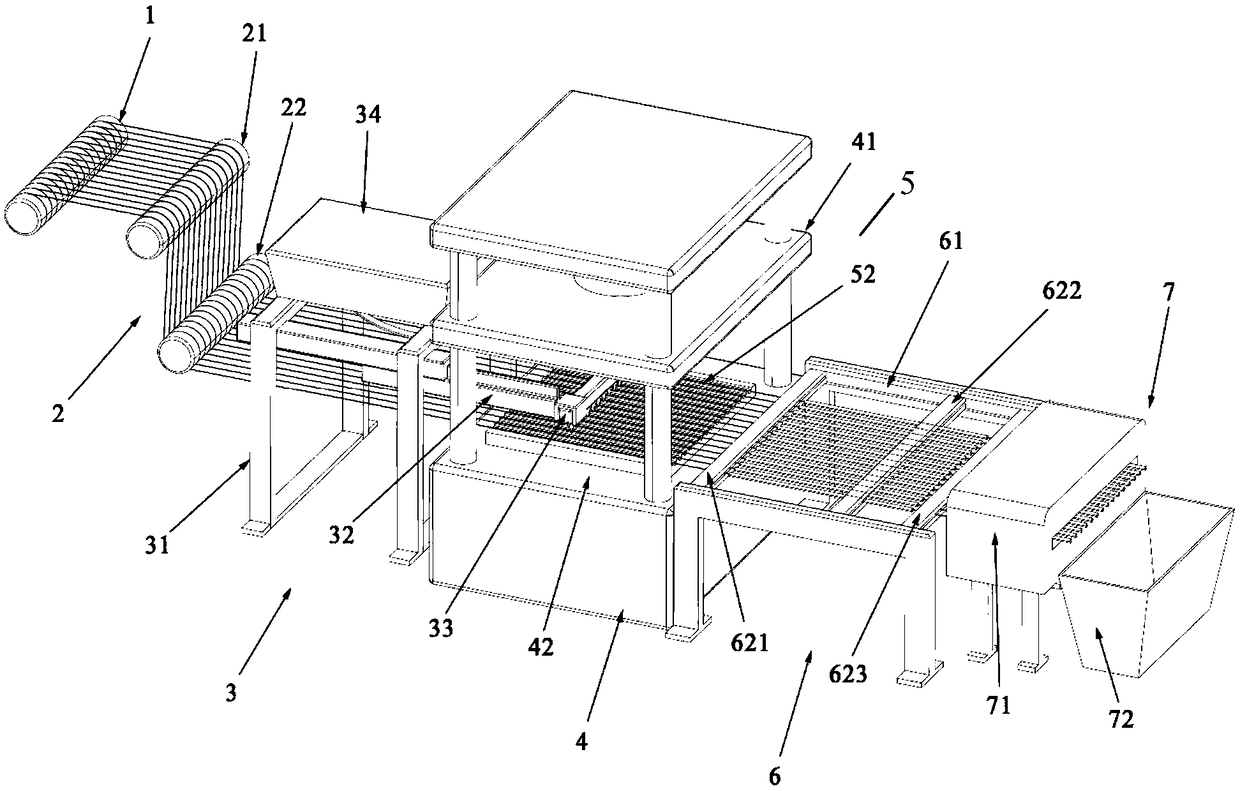

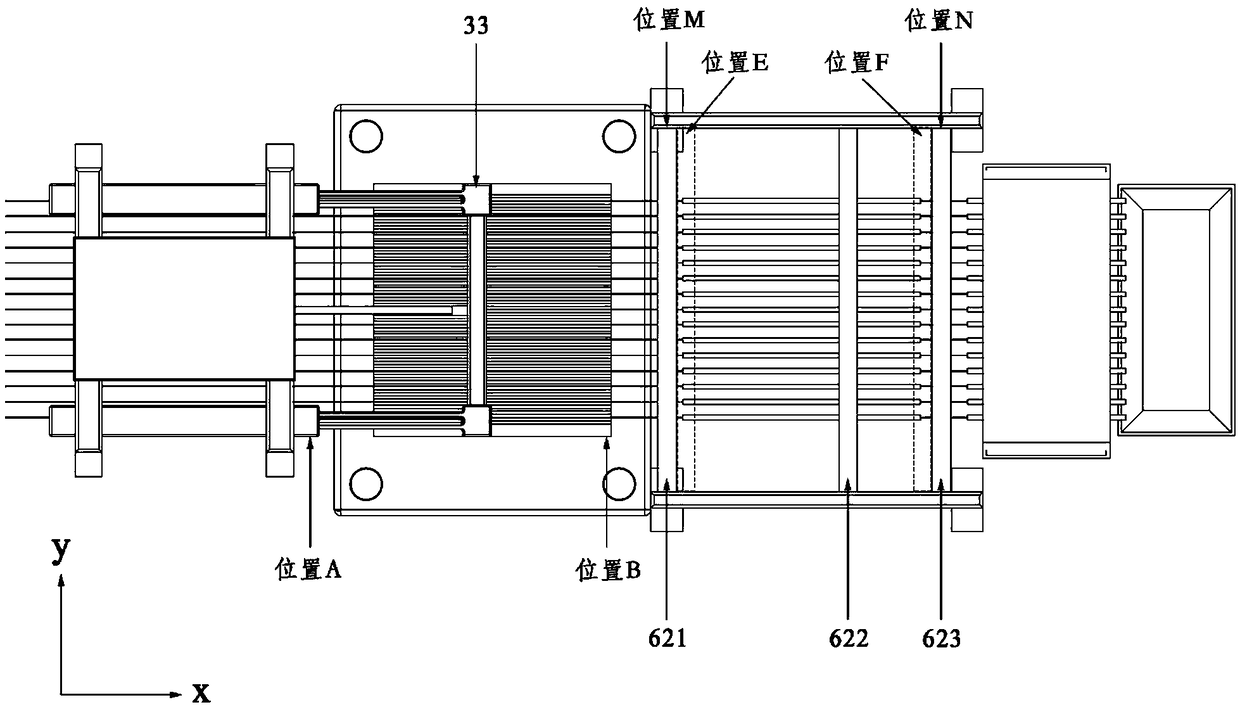

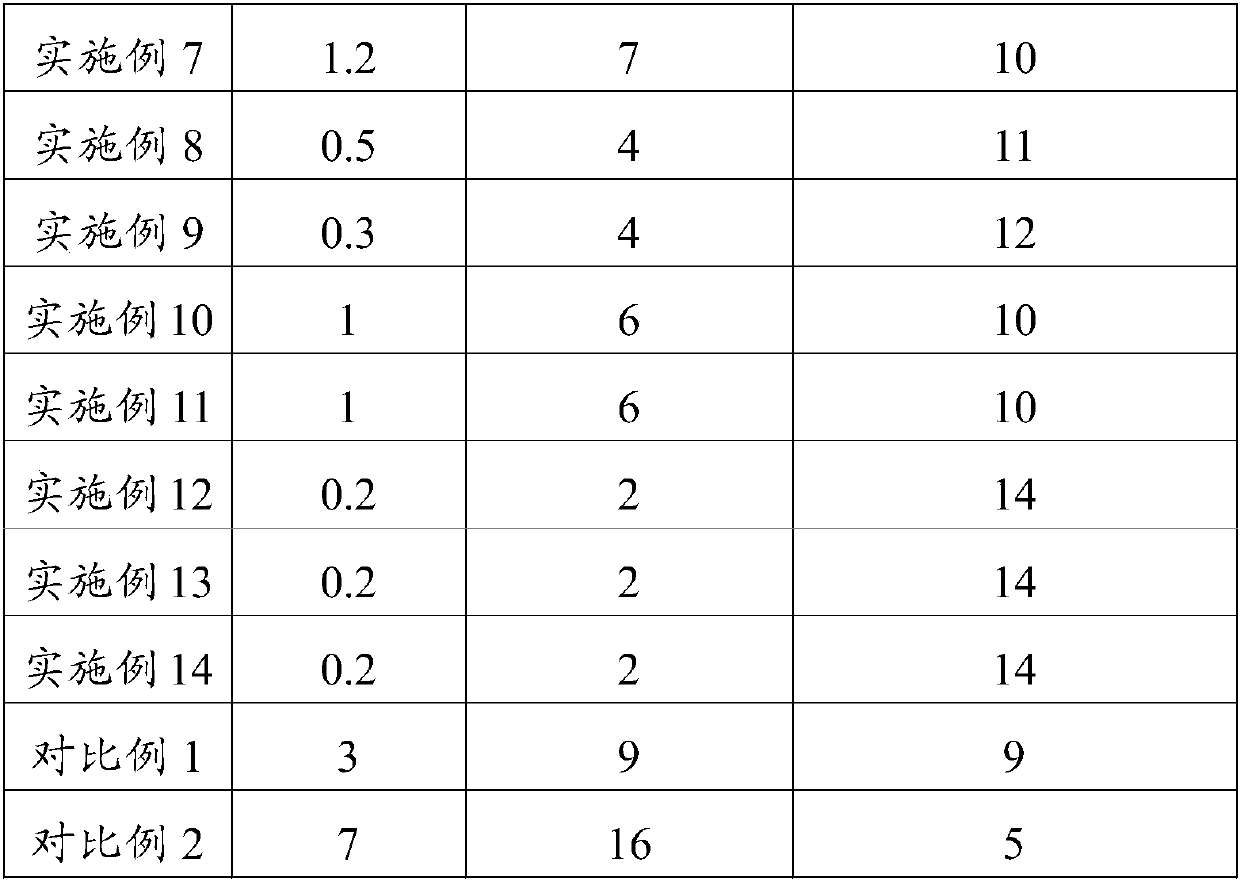

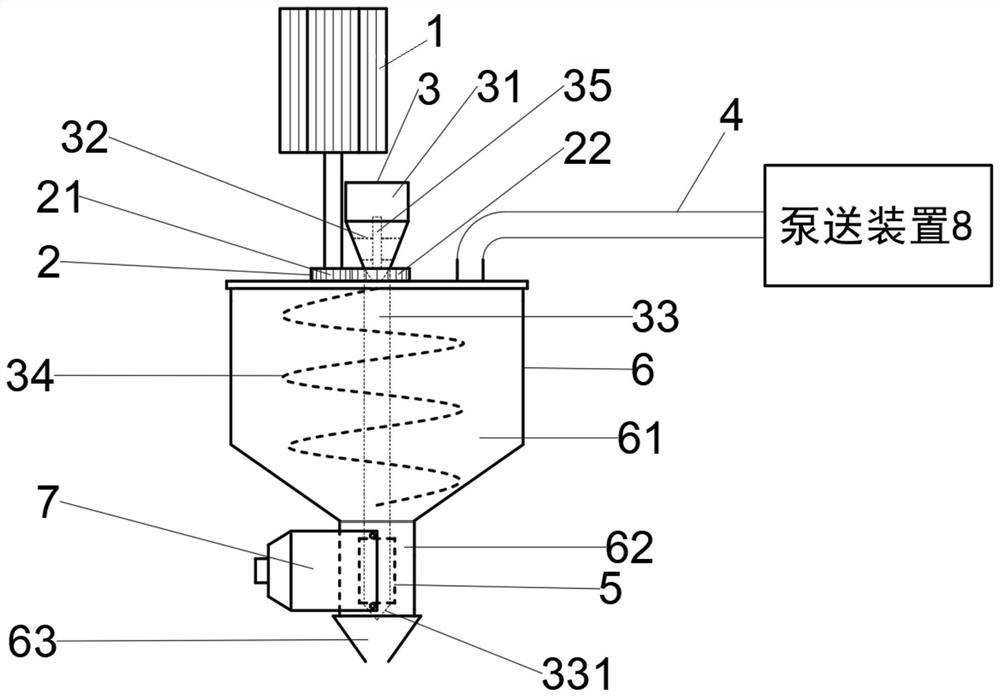

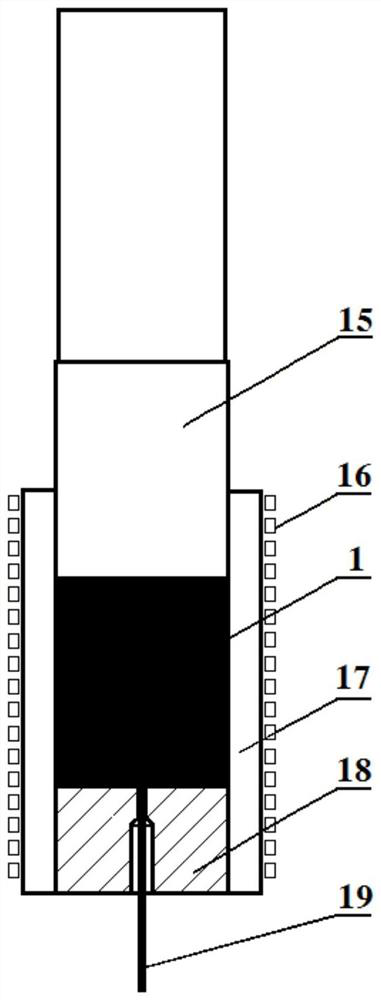

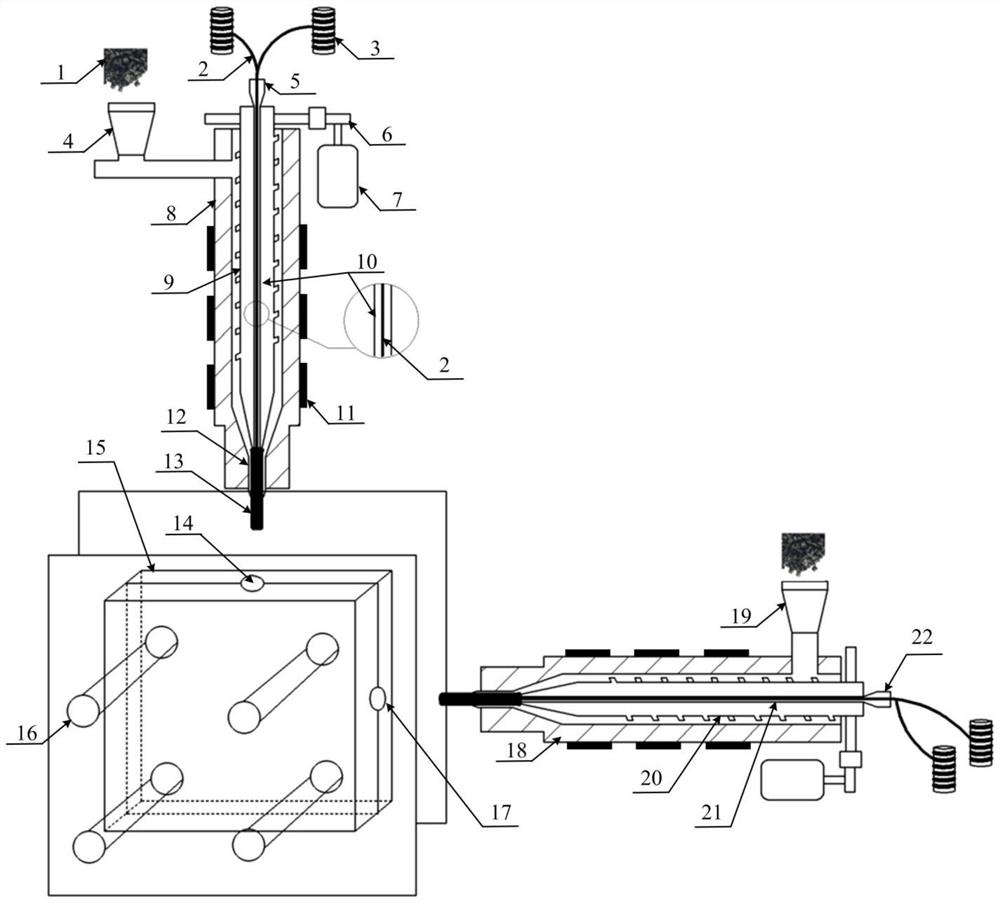

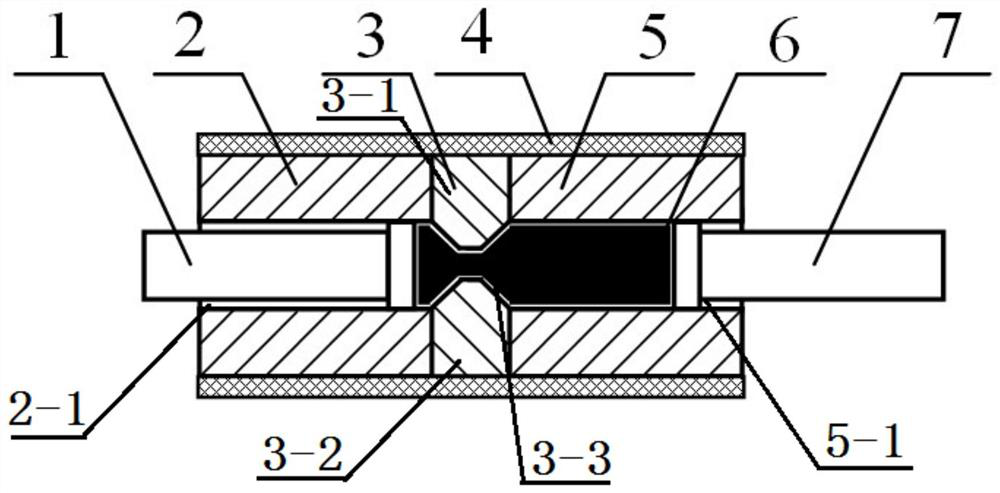

Device for preparing 3D printing oriented steel fiber reinforced cement-based composite material

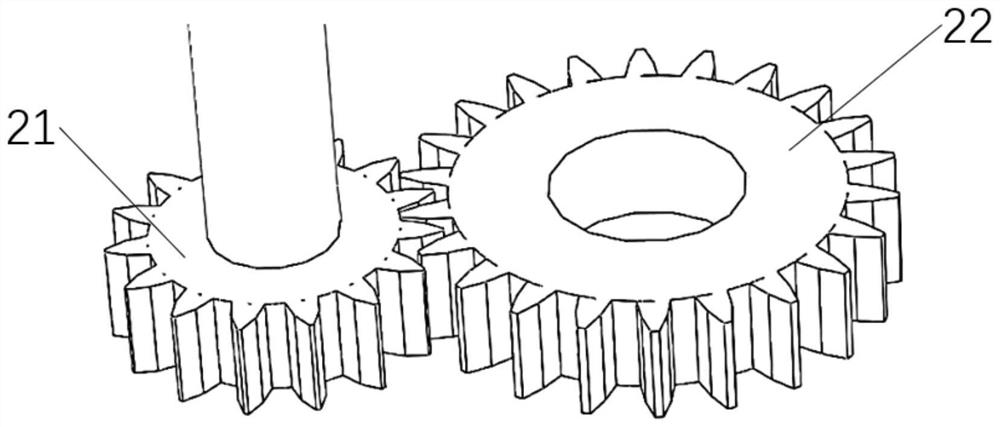

ActiveCN113547607AEvenly distributedFull play to enhanceAdditive manufacturing apparatusAuxillary shaping apparatusCement MaterialCement based composites

The invention discloses a device for preparing a 3D printing oriented steel fiber reinforced cement-based composite material. The device comprises a motor, a linkage gear set, a primary steel fiber orientation unit, a secondary steel fiber orientation unit, a material conveying hopper and an auxiliary vibrator, wherein the linkage gear set comprises a driving gear and a driven gear; the primary steel fiber orientation unit comprises a steel fiber hopper, push type stirring blades, a rotating vertical shaft, propeller blades and a vertical rod; the material conveying hopper comprises a material storage bin, an extrusion pipe and an extrusion opening; and the secondary steel fiber orientation unit is a cylindrical permanent magnet. According to the device, directional distribution of steel fibers in the 3D printing steel fiber reinforced cement-based composite material in the printing direction is achieved, the steel fibers are distributed more evenly, the reinforcing effect of the steel fibers is fully achieved, the technical problems of material extrusion smoothness, printing material compactness, fiber protrusion on the surface of a printing test piece and the like during 3D printing of the composite material are solved, and the structural mechanical property of the composite material is improved.

Owner:HEBEI UNIV OF TECH

HIPS modified master batch and preparation method thereof

The invention discloses HIPS modified master batch, comprising the following components in parts by weight: 55-75 parts of super-fine powder, 1-2 parts of an activated powder treatment agent, 12-17 parts of a dispersant, 4-5 parts of a master batch carrier and 16-19 parts of a compatibilizing toughener. By adopting the HIPS modified master batch, the cost of the HIPS product can be significantly reduced while the impact strength of the HIPS is not reduced, but is significantly improved. The invention also discloses a preparation method of the HIPS modified master batch. The method comprises the following steps: firstly, putting stearic acid and super-fine calcium carbonate powder into a high-speed mixer to be activated; adding other materials to be mixed evenly, and then putting the mixed materials into a twin-screw pelletizer to be pelletized, so as to form the product, namely the master batch.

Owner:SHANGHAI YUCHENG POLYMER MATERIAL CO LTD

Fully biodegradable composite material with excellent mechanical properties and preparation method thereof

ActiveCN111057350AFull play to enhanceImprove mechanical propertiesBio-packagingPolymer sciencePolybutylene

The invention discloses a fully biodegradable composite material with excellent mechanical properties and a preparation method thereof, and belongs to the technical field of biodegradable composite materials. The composite material is prepared from the following components in percentage by weight: 15%-75% of a polybutylene adipate-polybutylene terephthalate copolymer (PBAT), 10%-60% of starch, 5%-25% of glycerol, 0%-5% of nano silicon dioxide, and 0%-20% of a compatibilizer. The full-biodegradable composite material is safe, non-toxic, excellent in mechanical properties and capable of being completely biodegraded. The preparation method is simple, easy to control and implement, high in operability and low in production cost, and can be applied to various fields.

Owner:HUNAN UNIV OF TECH

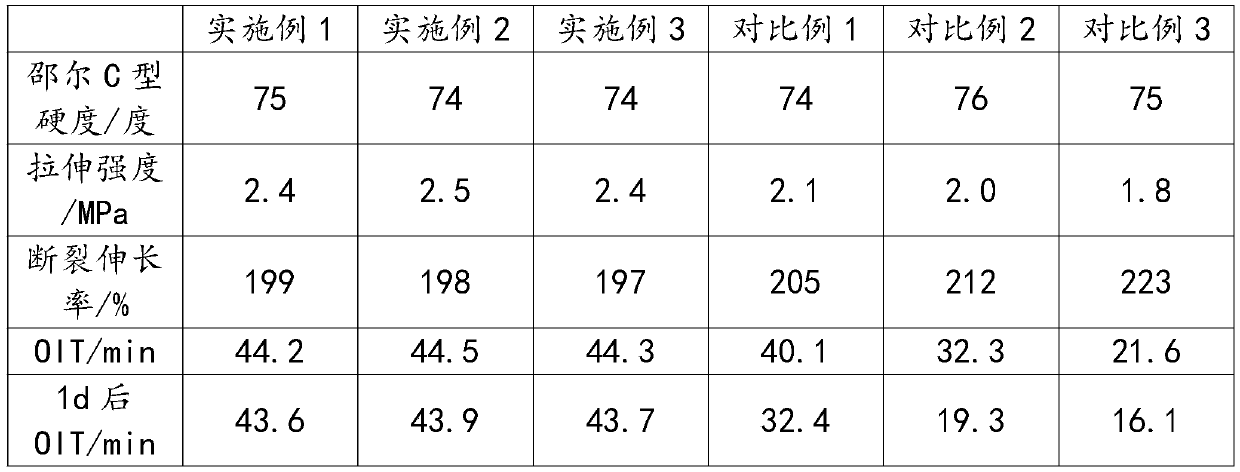

Preparation method of anti-aging foamed styrene-butadiene rubber

InactiveCN111533973AIncrease electron densityGood anti-aging performancePolymer scienceVulcanization

A preparation method of anti-aging foamed styrene-butadiene rubber is disclosed. The preparation method comprises the following steps: step 1, preparing materials comprising 90-100 parts of styrene butadiene rubber, 45-50 parts of modified white carbon black, 8-10 parts of carbon black, 1.6-2 parts of zinc oxide, 12-15 parts of a coupling agent, 3-4 parts of an accelerant, 1.8-2 parts of sulfur and 2.7-3 parts of a foaming agent; step 2, internal mixing; 3, mixing; 4, vulcanizing and foaming. According to the invention, the modified white carbon black is adopted to reinforce the foamed rubber;the surface of the white carbon black is grafted with a modified anti-aging agent through the silane coupling agent, a non-polar silane molecular chain and a modified anti-aging agent molecular chainare attached to the surfaces of white carbon black particles to form an organic layer, so that the compatibility with a rubber matrix can be improved, the agglomeration between the white carbon blackcan be weakened, and the white carbon black is uniformly distributed in the rubber matrix; besides, the modified anti-aging agent molecules have excellent anti-aging performance and are uniformly distributed in the rubber matrix along with the white carbon black, so that the anti-aging performance is fully exerted.

Owner:陈胜男

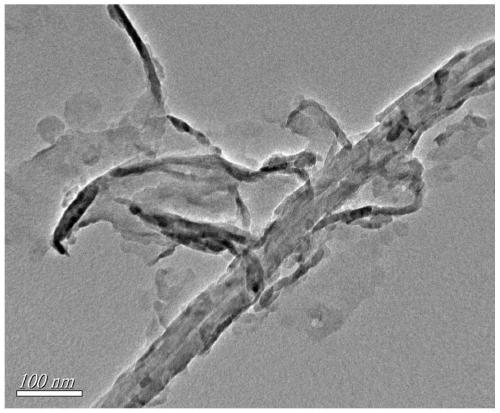

sw-cnts fiber reinforced magnesium alloy matrix composite material and method

ActiveCN111020417BSolve the inability to eliminate SW-CNTs windingSolving Reunions in BunchesAdditive manufacturing apparatusIncreasing energy efficiencySemi solidUltimate tensile strength

The invention discloses SW-CNTs fiber-reinforced magnesium alloy-based composite wire material, which is composed of the following raw material components by weight percentage: 0.5-1.5% of SW-CNTs short fibers, the balance is magnesium alloy powder, and the weight percentages of the above components The sum is 100%. The wire avoids the problem of weak interfacial bonding strength caused by poor wettability between SW‑CNTs fibers and magnesium alloy matrix, and gives full play to the comprehensive mechanical properties and physical and chemical properties of SW‑CNTs reinforced magnesium alloy matrix composites. The preparation method is as follows: step 1, high-energy ball milling; step 2, preparation of billet by semi-solid injection pressing; step 3, extrusion preparation of ultra-fine diameter wire.

Owner:西安优弧智熔增材制造有限公司

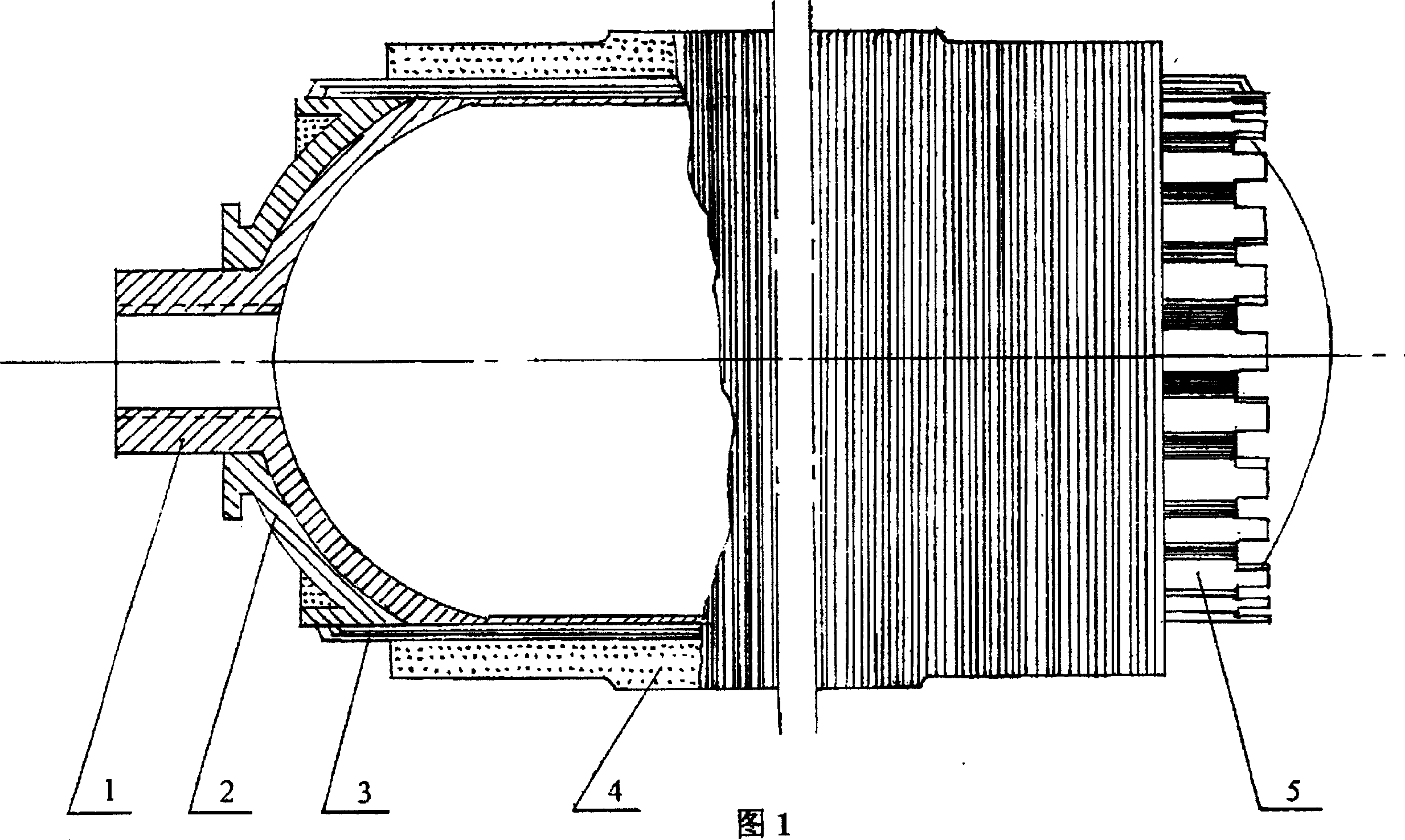

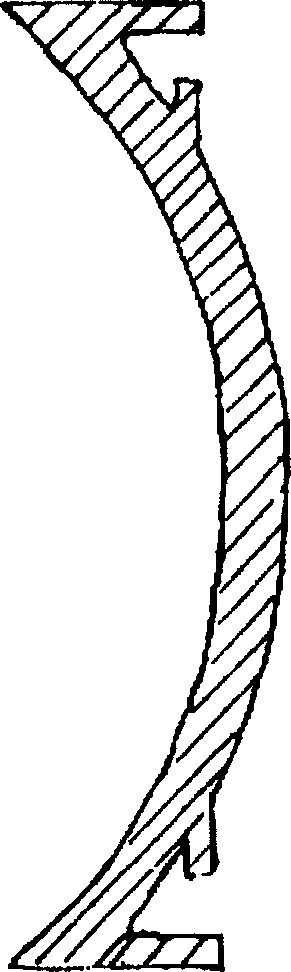

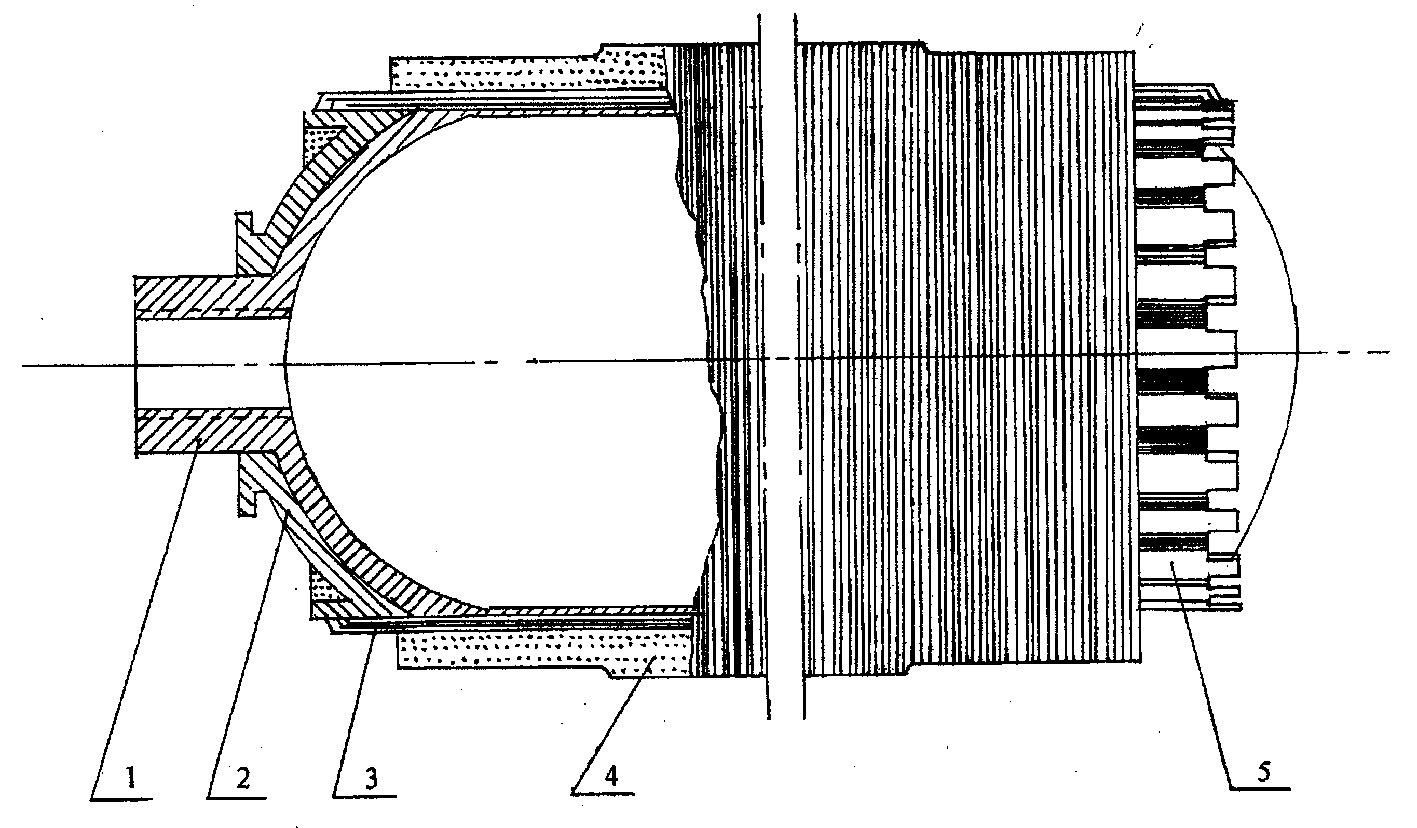

Orthogonal wound composite high pressure gas cylinder

The orthogonal wound composite high-pressure gas cylinder has inner lining and reinforcing fiber wound to the outer surface of the lining. The reinforcing fiber is first wound axially to constitute axial reinforcing layer and then circumferential to constitute circumferential reinforcing layer with the two reinforcing layers being orthogonal. Onto the two semi-spherical end covers of the lining, there are upper and lower outer covers contacting with the end covers closely and the outer covers have notches with hooks for the reinforcing fiber to be wound axially. The cylinder is light and highpressure resistant.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

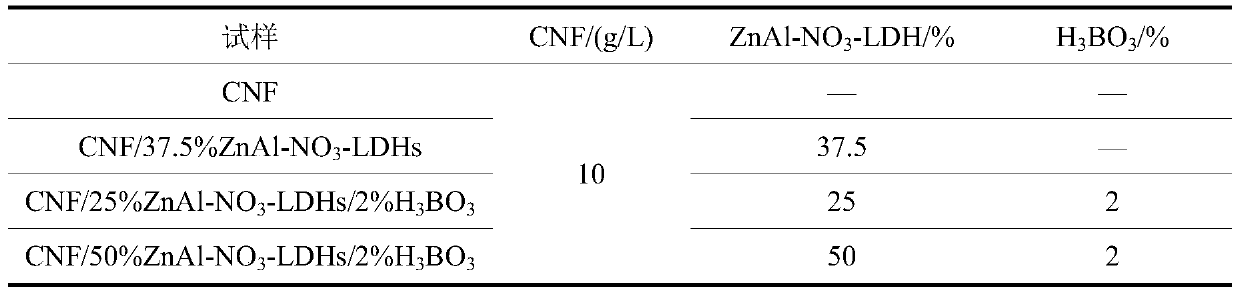

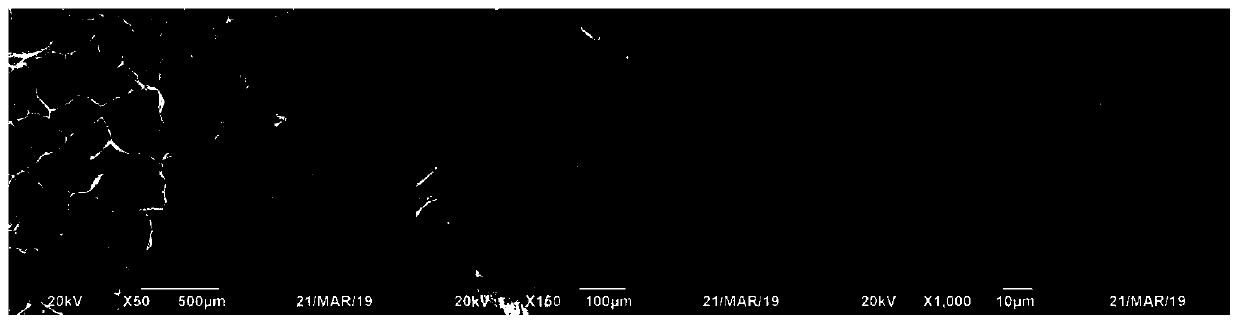

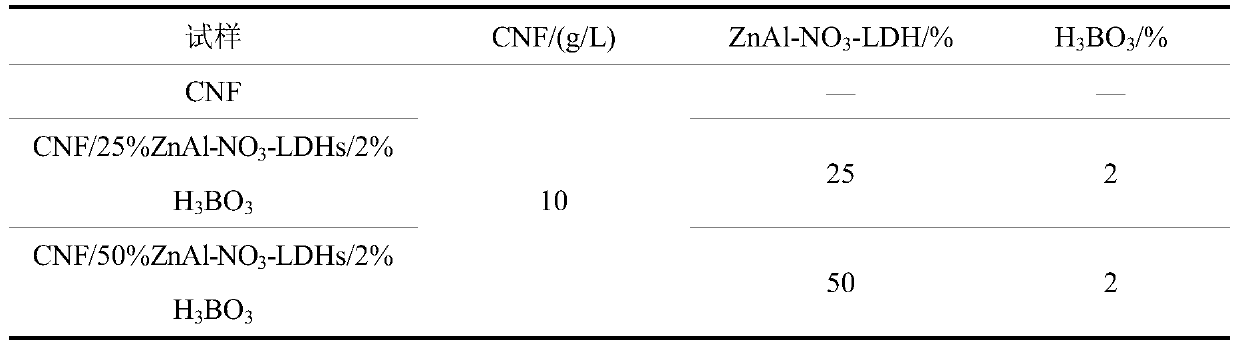

Phosphotungstic acid intercalated hydrotalcite light foam thermal insulating material and preparation method thereof

The invention discloses a phosphotungstic intercalated hydrotalcite type light foam thermal insulating material and a preparation method thereof. The preparation method comprises the following steps:preparing a Zn / Al hydrotalcite precursor by using a coprecipitation method; dropping a phosphotungstate solution into the slurry of the Zn / Al hydrotalcite precursor by using an ion exchange method, performing modification on the Zn / Al hydrotalcite precursor so as to obtain phosphotungstic acid-Zn / Al hydrotalcite; and mixing the phosphotungstic acid-Zn / Al hydrotalcite with a nano cellulose adhesiveand an adhesive, and performing freeze-drying, so as to obtain the phosphotungstic intercalated hydrotalcite type light foam thermal insulating material. By adopting heteropolyphosphotungstic acid intercalation modified ZnAl-LDHs, problems that as a flame retardant, single ZnAl-LDHs is large in addition amount, low in flame retardant efficiency, and the like, can be solved, and meanwhile, with the characteristics of light weight, high Young's modulus, high strength and renewability of the nano cellulose, the foam material has the characteristics of low density, high strength, green environmental protection, and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

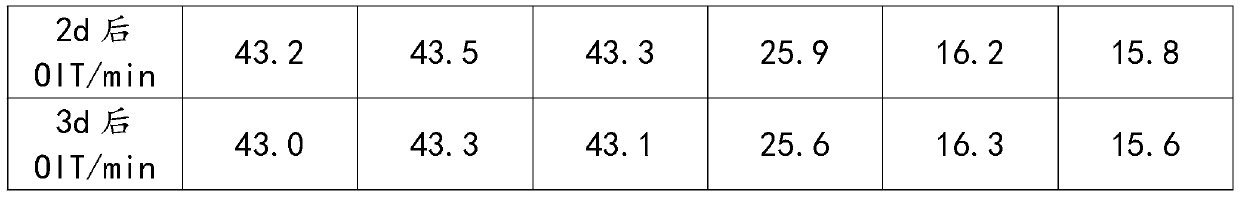

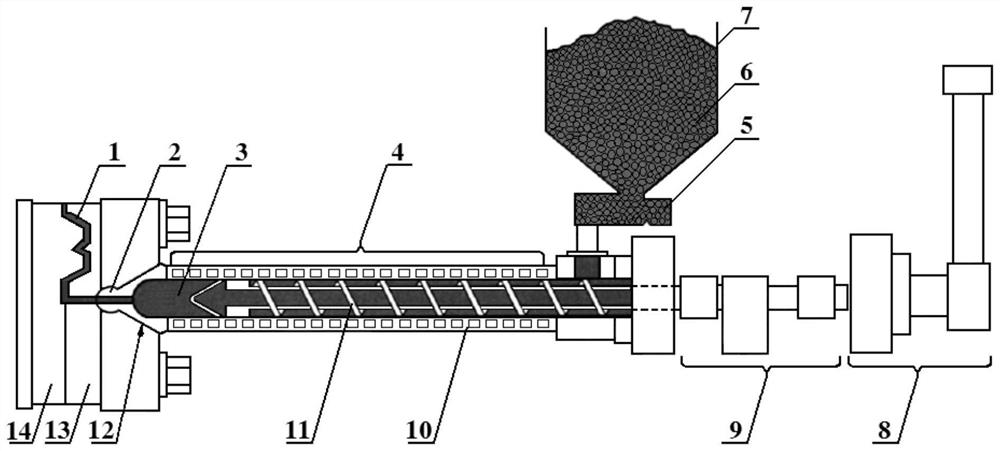

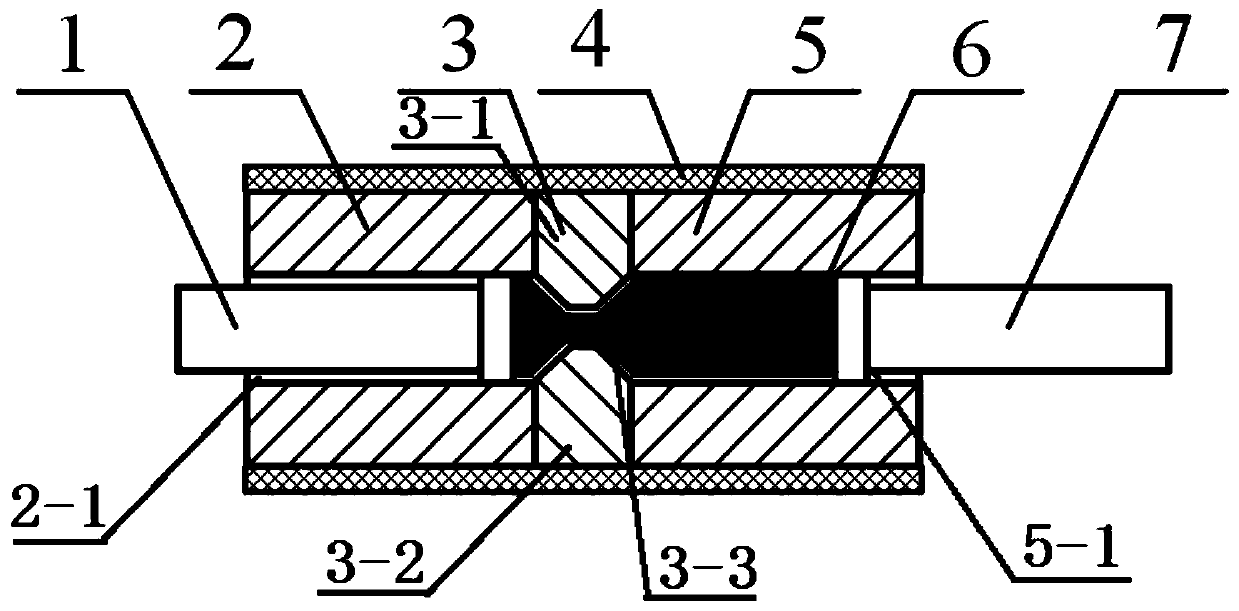

Injection molding process for continuous fiber composite material

The invention discloses a fiber-reinforced thermoplastic polymermatrix composite material. The fiber-reinforced thermoplastic polymer matrix composite material has the advantages of low density, high designability, easiness in molding, good recyclability, corrosion resistance and the like, and is widely applied to the fields of aviation, high-speed rails, ships, automobiles and the like. Along with the increase of the fiber length, the mechanical property of the composite material is further improved. The problems that an existing composite material injection molding process aims at discontinuous fiber composite materials (short or long fibers), the mechanical property of a formed component is poor, and the formed component is difficult to serve as a bearing component are solved. The invention relates to an injection molding process for a continuous fiber composite material. Injection molding of the continuous fiber-reinforced thermoplastic polymer matrix composite material is realized through ingenious structural design and innovative manufacturing thinking, resource waste caused by fiber cutting is avoided, and the injection molding process has the advantages of high production speed, capability of molding complex geometry, high manufacturing flexibility, and wide application range, and has wide application prospect in the manufacturing of thermoplastic composite material parts.

Owner:BEIHANG UNIV

Silicotungstic acid intercalated multi-component hydrotalcite-like lightweight thermal insulation material and preparation method thereof

ActiveCN110577380AReduce thermal conductivityImproved thermal stability and flame retardancyCeramicwareIon exchangeHydrotalcite

The invention discloses a silicotungstic acid intercalated multi-component hydrotalcite-like lightweight thermal insulation material and a preparation method thereof. The preparation method comprisesthe steps: preparing a multi-component hydrotalcite-like precursor by a coprecipitation method; dropwise adding a silicotungstate solution into the multi-component hydrotalcite-like precursor slurry by an ion exchange method, and modifying the multi-component hydrotalcite-like precursor to obtain silicotungstic acid-multi-component hydrotalcite; and mixing the obtained silicotungstic acid-multi-element hydrotalcite, nano cellulose and an adhesive, and carrying out freeze drying to obtain the silicotungstic acid intercalated multi-element hydrotalcite lightweight thermal insulation material. The environment-friendly lightweight foam refractory material lightweight in weight, highly porous, low in heat conductivity coefficient and excellent in flame retardant effect is obtained; the nano-crystalline cellulose lightweight foam is endowed with excellent heat-conducting property and flame-retardant and heat-insulating effects by utilizing the synergistic flame retardancy of multi-componentmetal elements of the multi-component layered metal hydroxide and causing guest silicotungstic acid anions with a flame-retardant effect between layers of layered metal hydroxide.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

sw-cnts and n-sicp reinforced magnesium alloy workpiece and method

The invention discloses SW-CNTs and N-SiCp reinforced magnesium alloy workpiece, which is composed of the following raw material components by weight percentage: 0.5-1.5% of SW-CNTs short fibers, 1-15% of N-SiCp particles, and the balance is magnesium alloy Powder, the sum of the weight percentages of the above components is 100%. The workpiece gives full play to the role of SW-CNTs short fibers and N-SiCp particles in strengthening the magnesium alloy matrix, and improves the comprehensive mechanical properties and physical and chemical properties of the composite material. The preparation method of the workpiece with the above-mentioned material is as follows: step 1: take the raw materials according to the above-mentioned proportion; step 2: put the SW-CNTs short fibers, N-SiCp particles and magnesium alloy powder that are completely mixed uniformly after the ball milling in step 1 into the semi-solid injection molding device to directly form composite material blanks or workpieces.

Owner:西咸新区镁高镁诺奖科技有限公司

gr/n-sic p Composite reinforced magnesium matrix composite material and preparation method thereof

ActiveCN111057923BAvoid burnsFull play to enhanceTransportation and packagingMetal-working apparatusMagnesium matrix compositePowder mixture

The present invention discloses GR / N‑SiC P Composite reinforced magnesium-based composite material, composed of the following raw material components by weight percentage: GR powder 0.5-1.5%, N-SiC P Powder 0.5-10%, the balance is magnesium powder, the sum of the weight percentages of the above components is 100%. Also disclosed is a preparation method for the above-mentioned material, including the following steps: Step 1, high-energy ball milling: Weigh the raw materials according to the above-mentioned weight percentages: take the above-mentioned GR powder, N-SiC P Powder and magnesium powder are placed in a high-energy ball mill at 30-60 rpm and mixed for 12-24 hours under the protection of argon; step 2, extrusion molding: the GR powder and N-SiC after ball milling in step 1 P The powder and magnesium powder mixture is extruded in two steps, first reciprocating extrusion, and then ordinary forward extrusion. This preparation method addresses the N‑SiC P The problem of agglomeration, and can ensure that the composite material has a certain elongation.

Owner:西安诺高镁防务技术有限公司

A starch adhesive based on nano-oxidized cellulose slurry and its preparation method

ActiveCN105542676BAvoid replacementPrevent drynessNon-macromolecular adhesive additivesStarch derivtive adhesivesSlurrySolvent

The invention discloses a starch adhesive with nanometer oxidized cellulose size as the matrix. The starch adhesive is prepared from, by weight, 100 parts of nanometer oxidized cellulose size with the oxidation rate of 5-30%, 10-40 parts of starch, 2-5 parts of oxidizing agent, 0.1-2 parts of stabilizer, 0.1-2 parts of preservative and 0.1-2 parts of emulsified paraffin. The preparation method includes the steps of preparing nanometer oxidized cellulose size the with oxidation rate of 5-30%, adding starch and 2-5 parts of oxidizing agent to the prepared nanometer oxidized cellulose size in batches, adding stabilizer, preservative and emulsified paraffin after sufficient stirring, and sufficiently stirring the components at a temperature of 50-70 DEG C till all the components are evenly dispersed to obtain the starch adhesive. The starch adhesive is high in bonding strength and high in water resistance. By means of the preparation method, the solvent replacement and drying process is avoided, energy consumption is greatly lowered, and labor intensity is reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Manufacture method of high-performance recyclable airscrew for unmanned aerial vehicles

The invention relates to a manufacture method of a high-performance recyclable airscrew for unmanned aerial vehicles. The manufacture method includes: making a core with 15-30% by weight of cork wood,evenly and tightly wrapping the surface of the core with 30% by mass of carbon fiber cloth, adding carbon fiber PA66 modified material, and performing high pressure resin transfer molding. The manufacture method has the advantages that the cord wood is used herein as a base, giving the advantages of light weight and easy attraction for other materials; carbon fiber is used as a basic reinforcingmaterial; the carbon fiber PA66 modified material is used as a filling dispersive material; the three materials provide an interface of certain binding strength; load that a resin base bears is transferred to reinforcing fibers through the interface so that the reinforcing effect of the reinforcing fibers is given to full play and the overall strength of the composite herein is improved; an airscrew manufactured herein has integrated structure made by one-off mold pressing and features high strength, light specific weight, recyclability and the like.

Owner:ANHUI XUSHENG NEW CONCEPT MATERIAL CO LTD

GR reinforced magnesium alloy-based composite material wire and preparation method

The invention discloses a GR reinforced magnesium alloy-based composite material wire. The GR reinforced magnesium alloy-based composite material wire comprises the following raw materials in percentage by weight: 0.5-1.5% of GR powder and the balance magnesium alloy powder, and the sum of the weight percentages of the components is 100%. The problems of multiple stratification and burning loss ofGR are avoided, the problem of the interface between single-layer graphene GR and magnesium alloy grains is solved, the reinforcing effect of the GR on a matrix is fully exerted, and interface microcracks are avoided. The invention also provides a preparation method of the composite material wire. The method comprises the following steps: 1, high-energy ball milling; and 2, extrusion forming, specifically, extrusion forming is carried out on the GR powder and the magnesium alloy powder subjected to ball milling in the step 1 in two steps, firstly reciprocating extrusion is carried out, and then normal forward extrusion is carried out, so that the graphene-reinforced magnesium alloy-based composite material wire is prepared.

Owner:西安诺高镁新材料科技有限公司

Carbon fiber reinforced nickel-based composite material and producing method thereof

The invention discloses a carbon fiber reinforced nickel-based composite material and a preparation method thereof, and relates to a metal-based composite material. The metal matrix composite materials prepared by the prior art are not suitable for parts such as steam turbines used at high temperatures. The composition and volume percentage of the composite material of the present invention are: carbon fiber: 30-35%, copper: 6-8%, nickel: 57-64%. The process steps are: carbon fiber pretreatment, copper electrodeposition, cleaning, neutralization, nickel electrodeposition, forming electrodeposited nickel, billet cleaning, drying, cutting billets into molds, vacuum hot pressing, and furnace cooling. The Cf / Ni composite material prepared by the three-step electrodeposition method in the present invention can not only meet the use requirements of gas turbine engine blades, but also has the advantages of good high temperature strength, high elastic modulus, low density, high melting point, and creep resistance. .

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com